Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3587 results about "Injection air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Secondary air injection (commonly known as air injection) is a vehicle emissions control strategy introduced in 1966, wherein fresh air is injected into the exhaust stream to allow for a fuller combustion of exhaust gases.

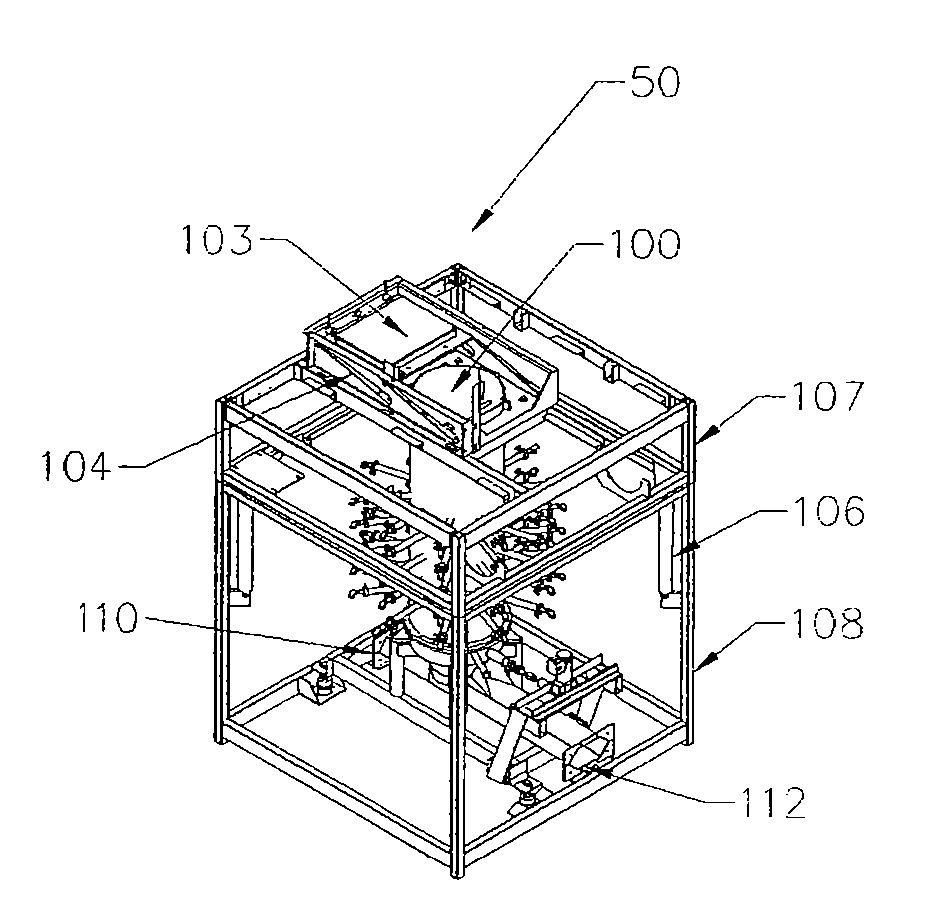

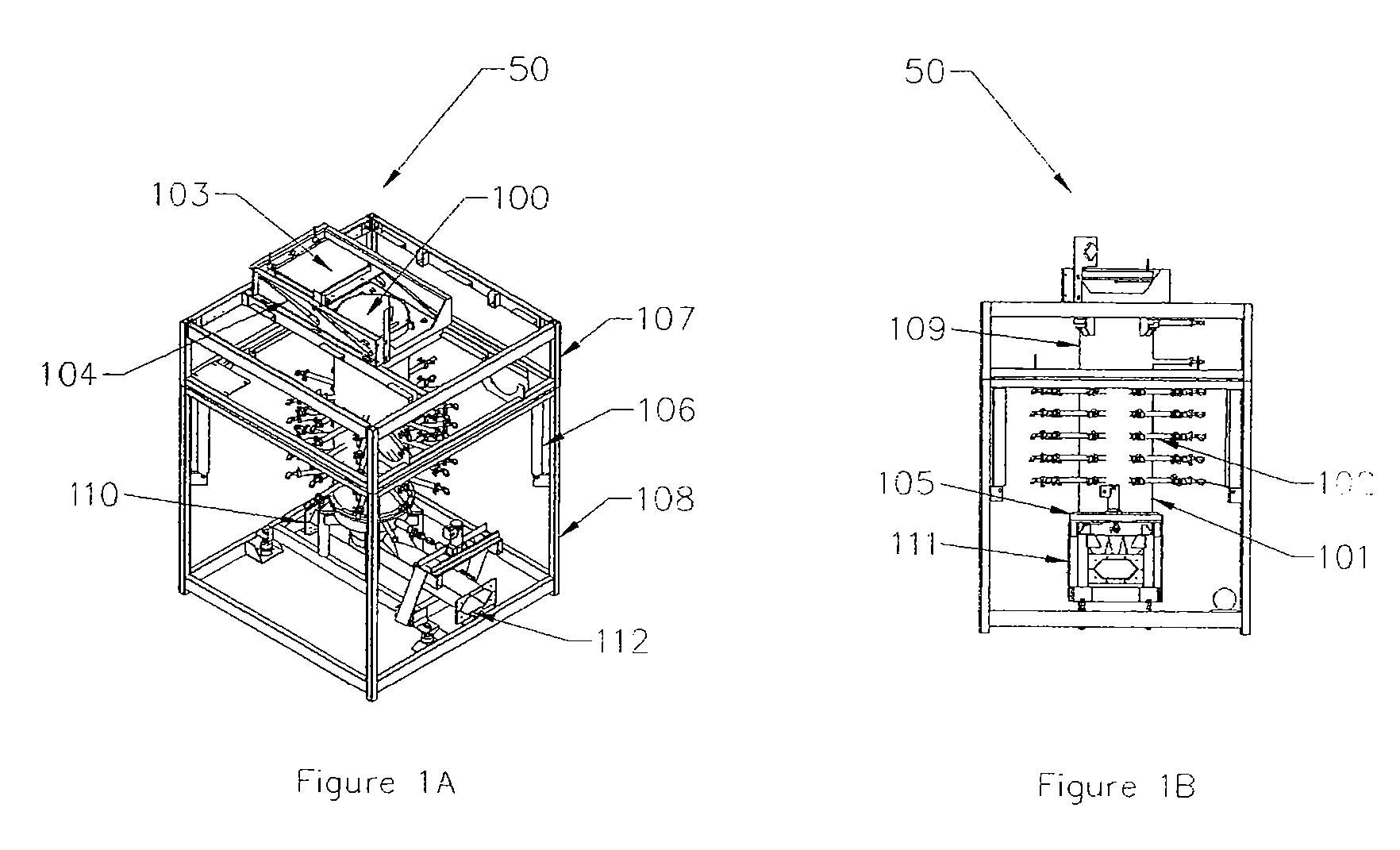

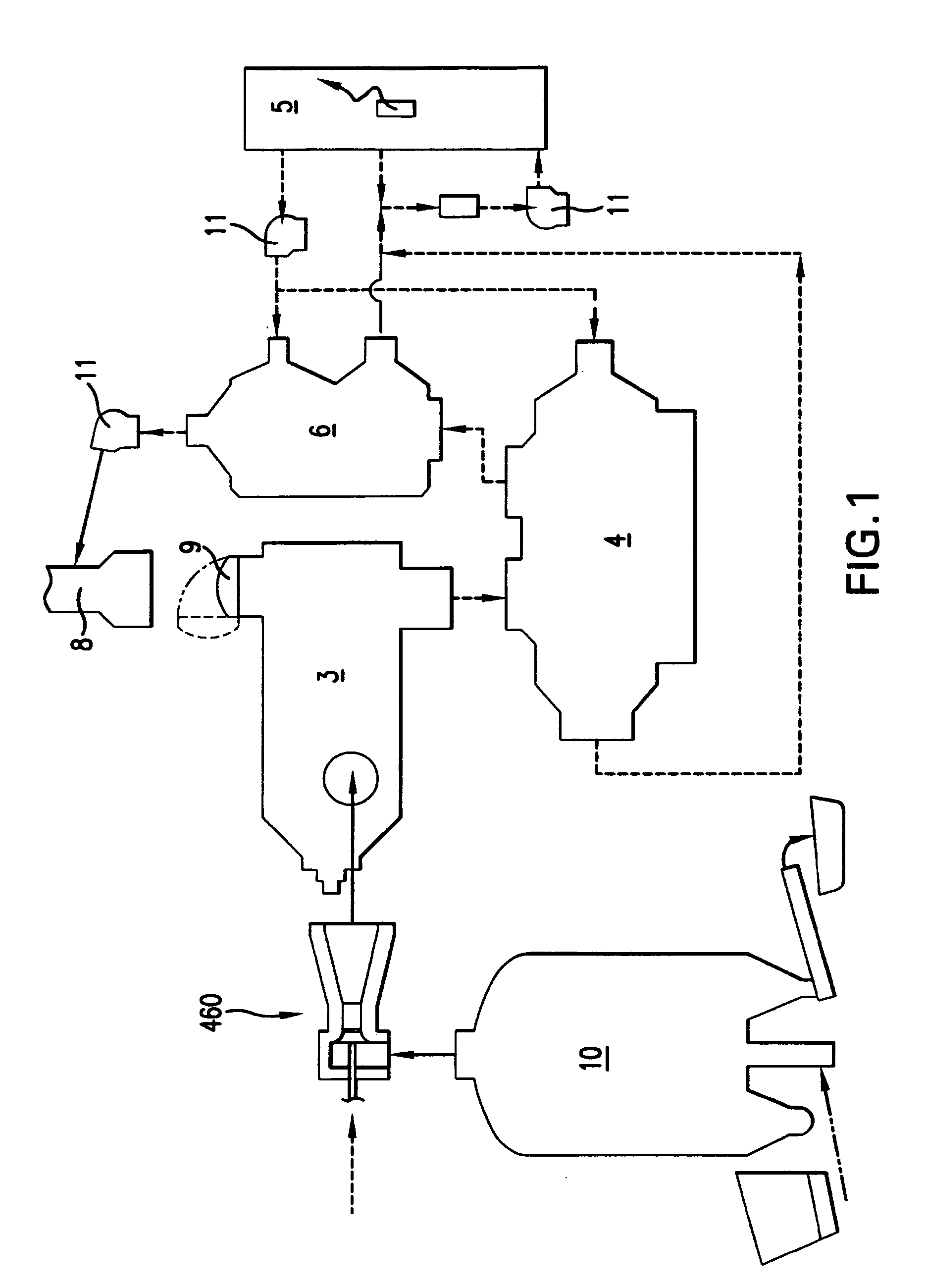

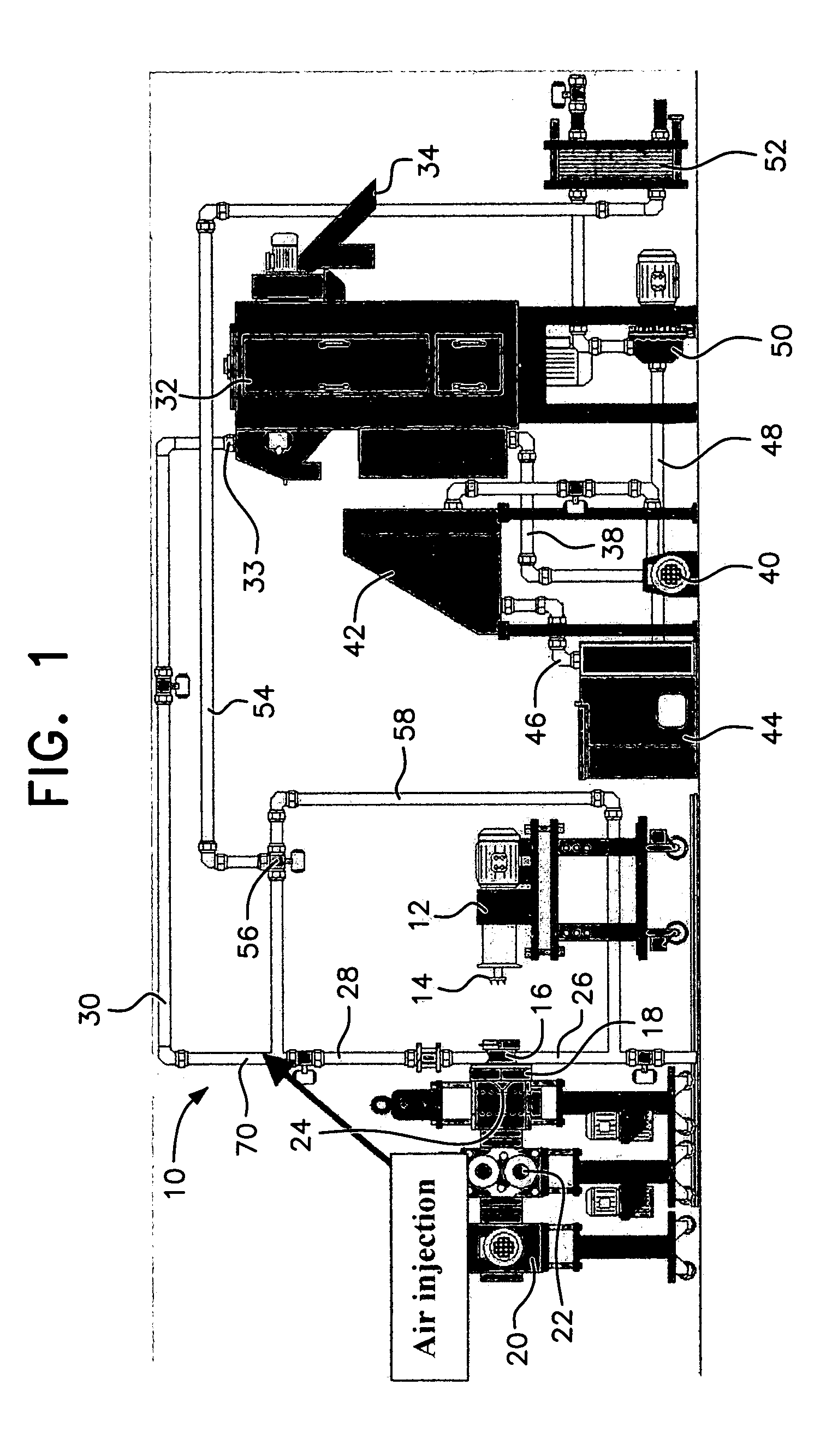

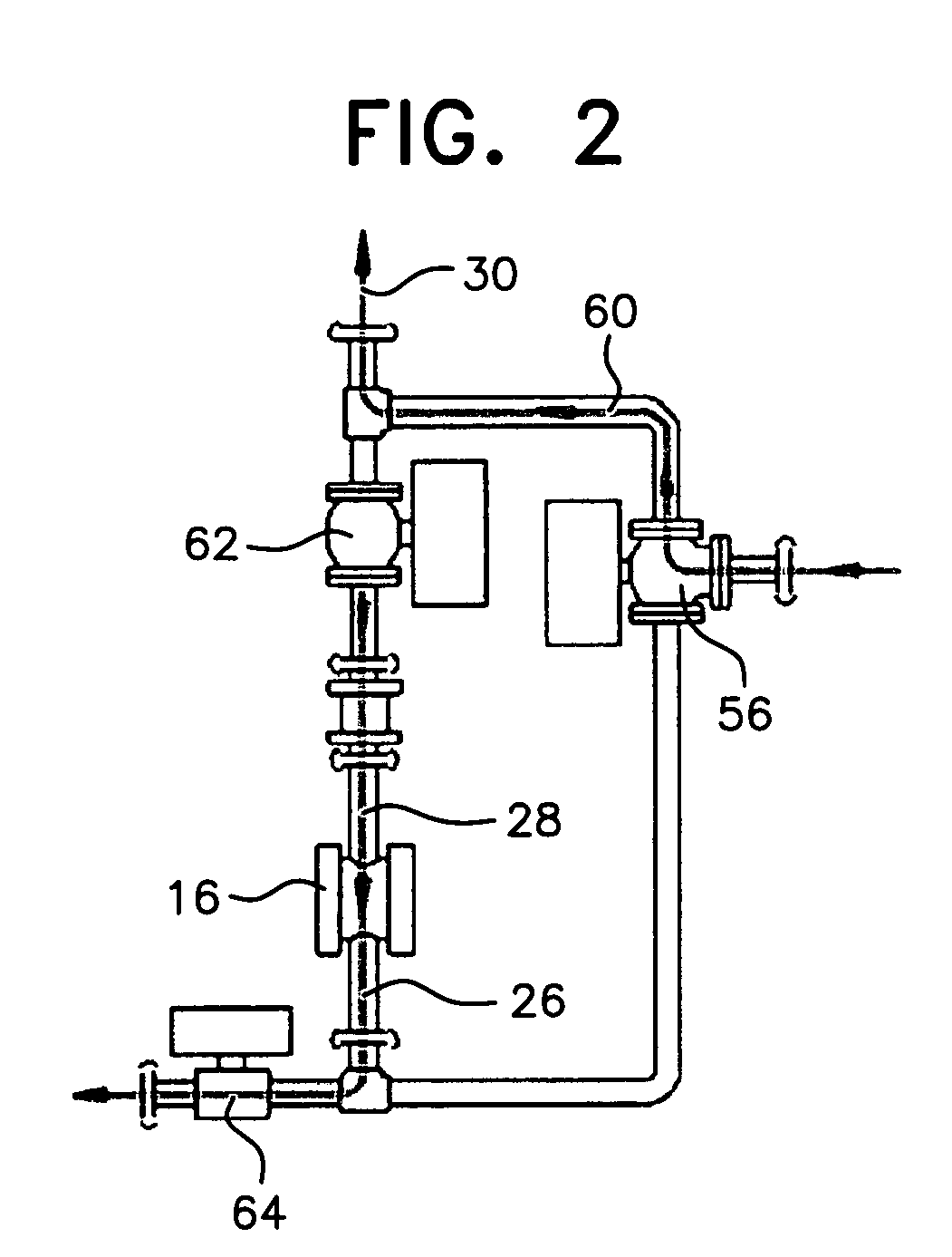

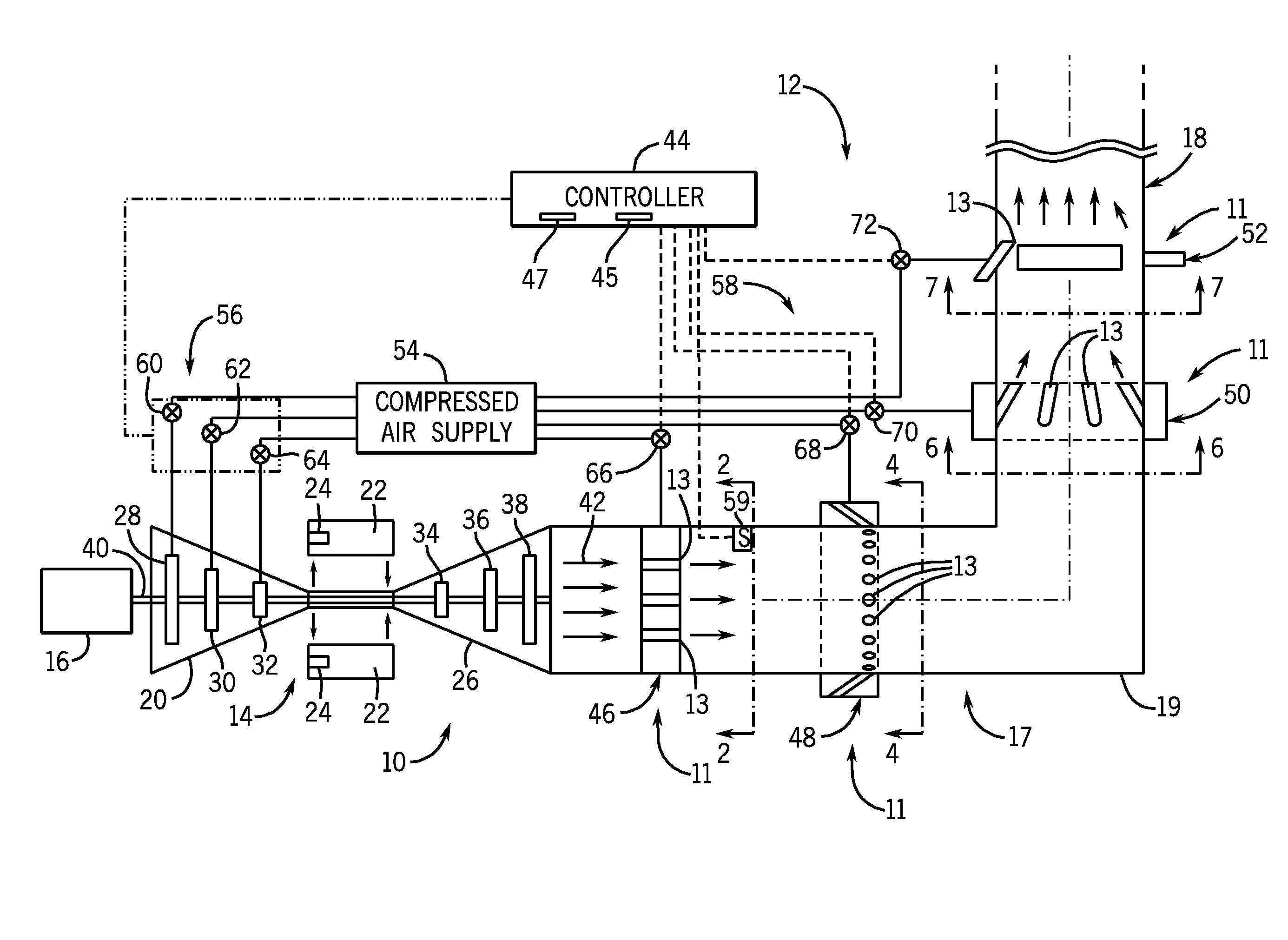

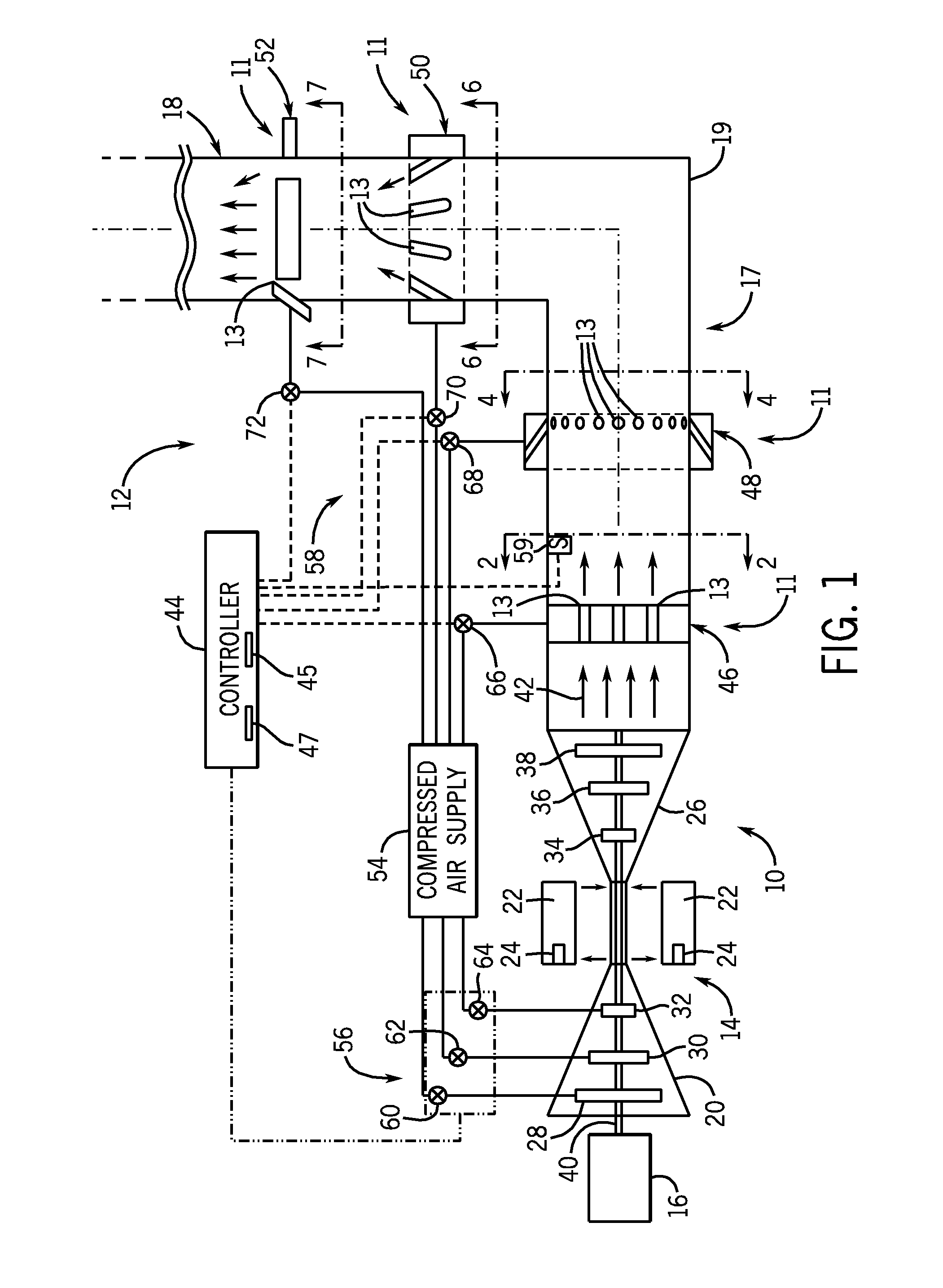

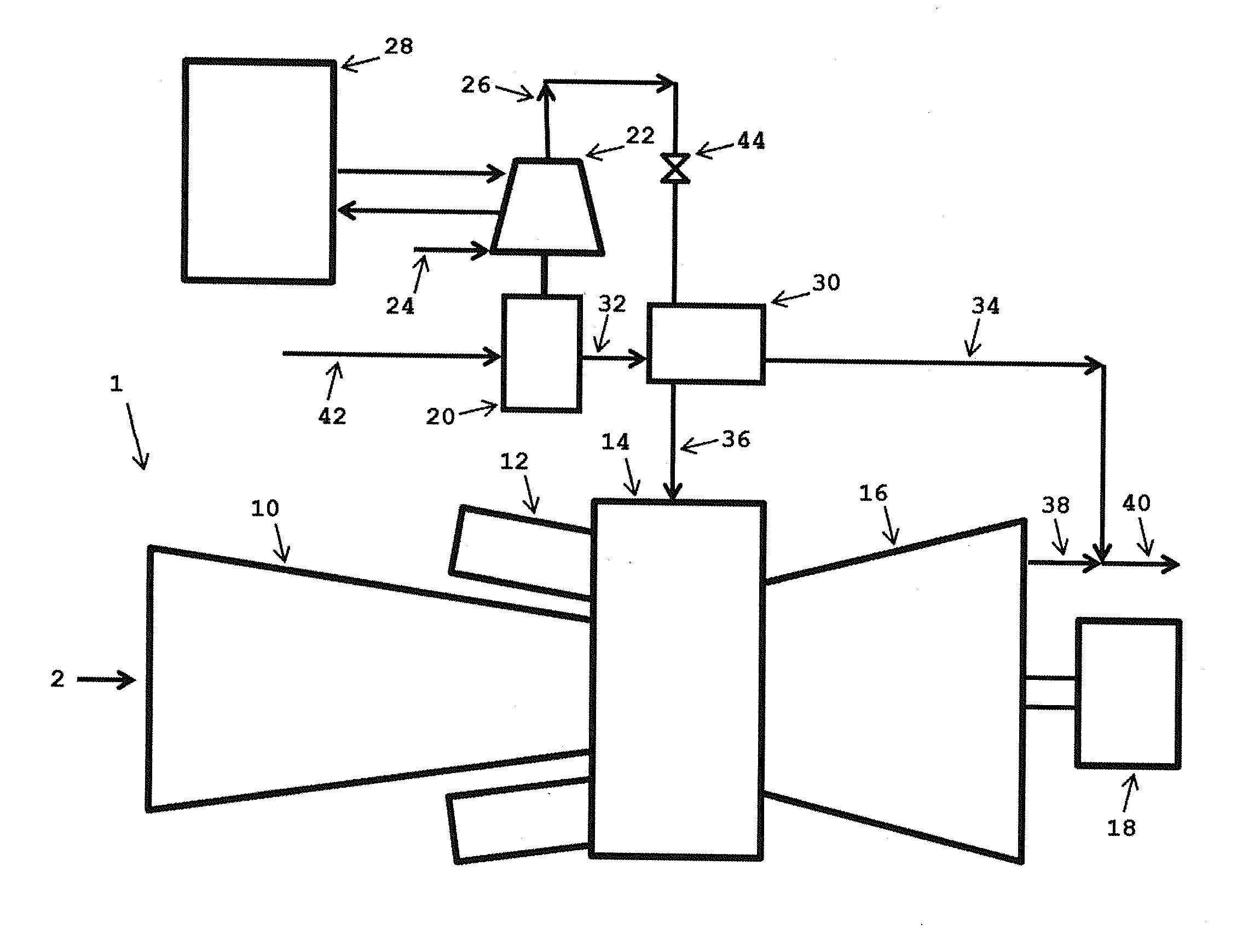

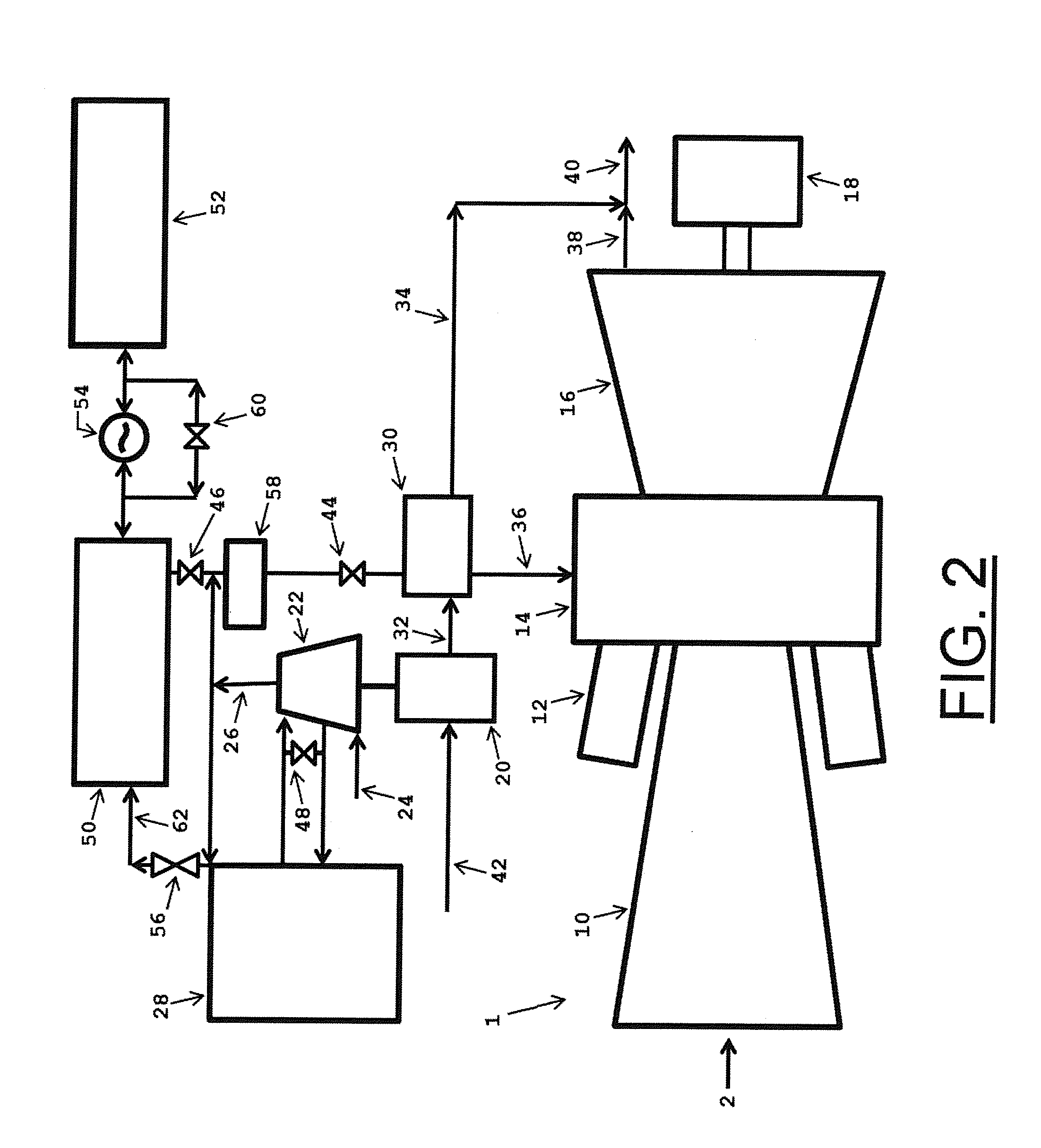

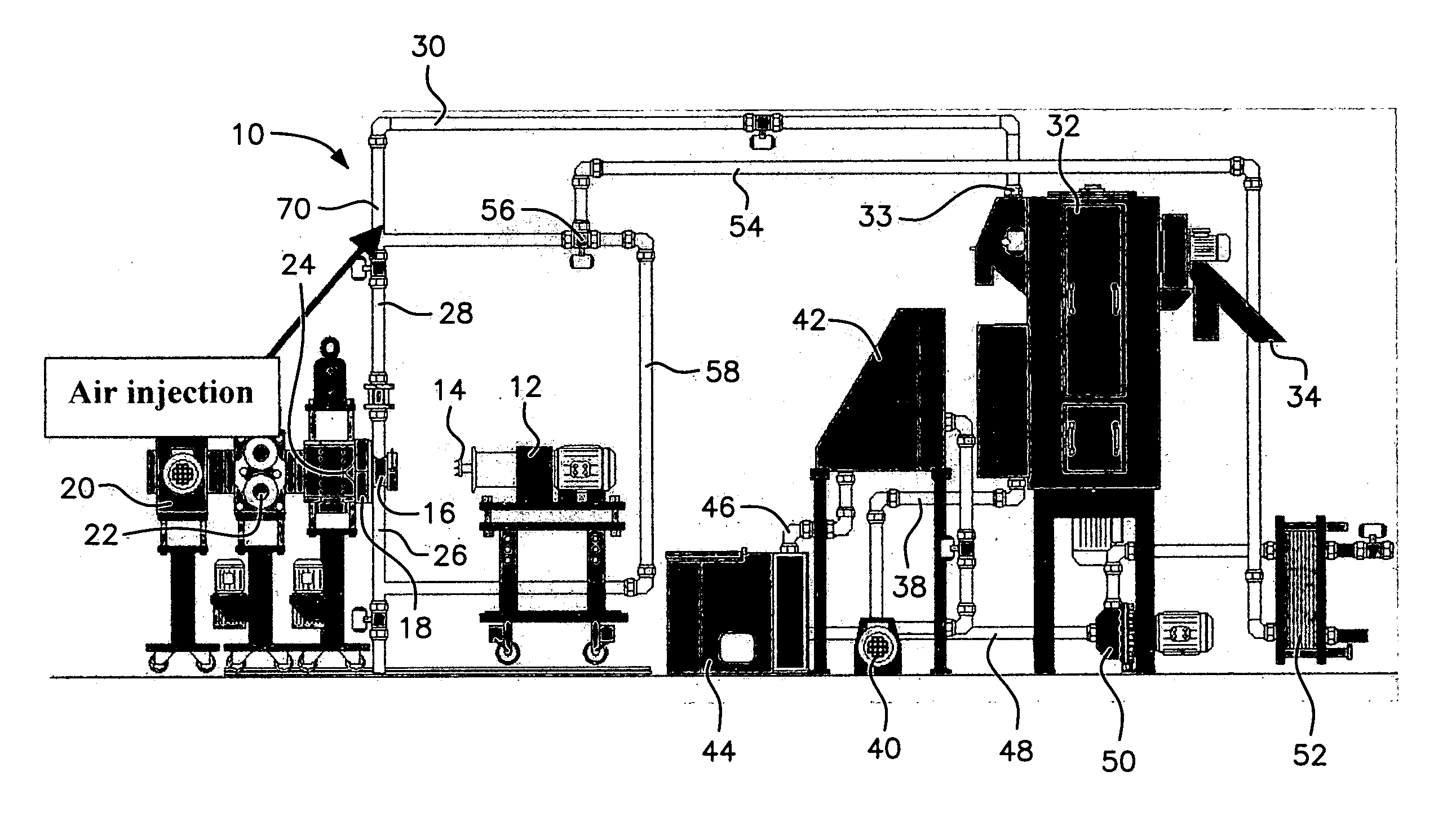

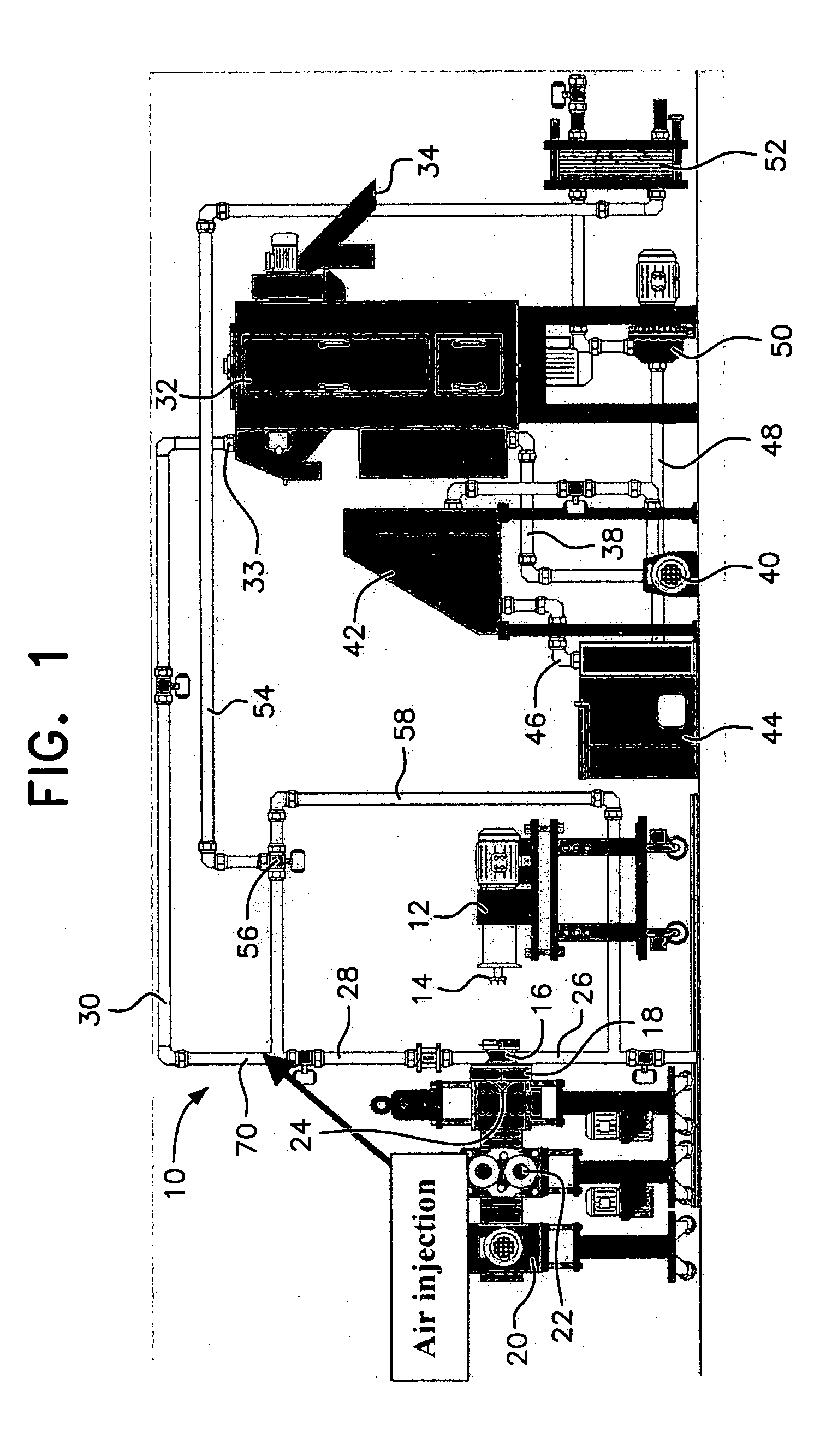

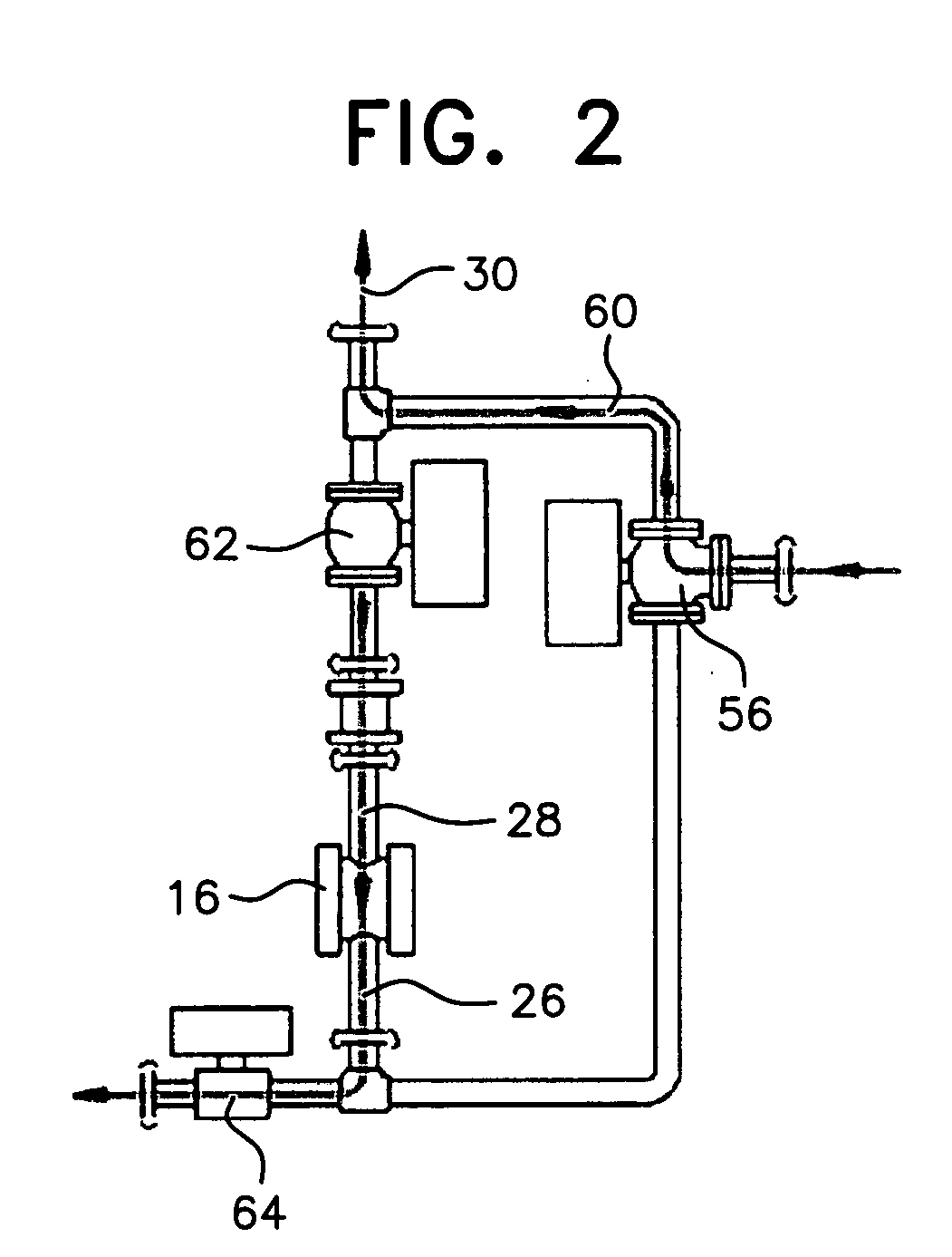

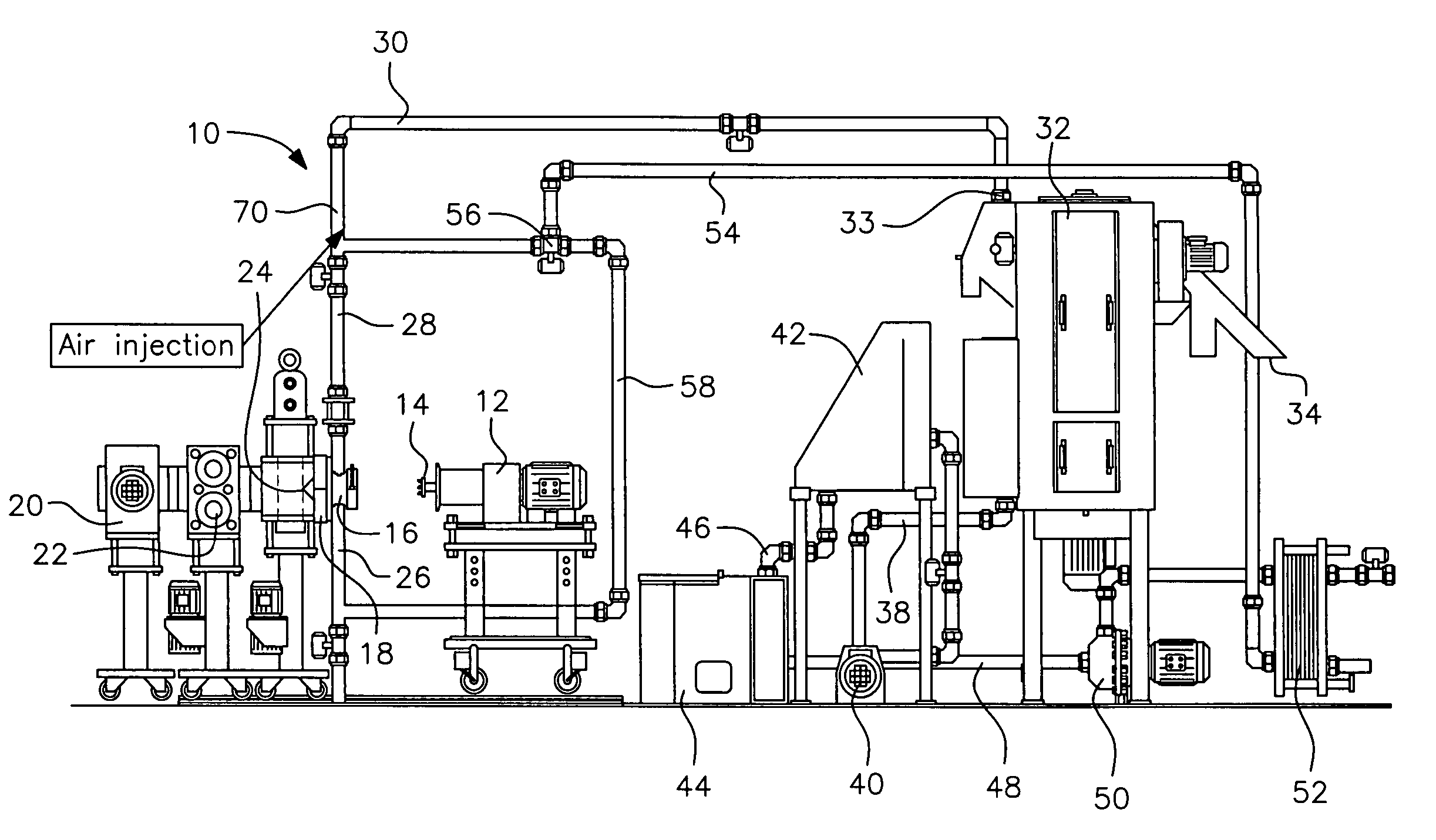

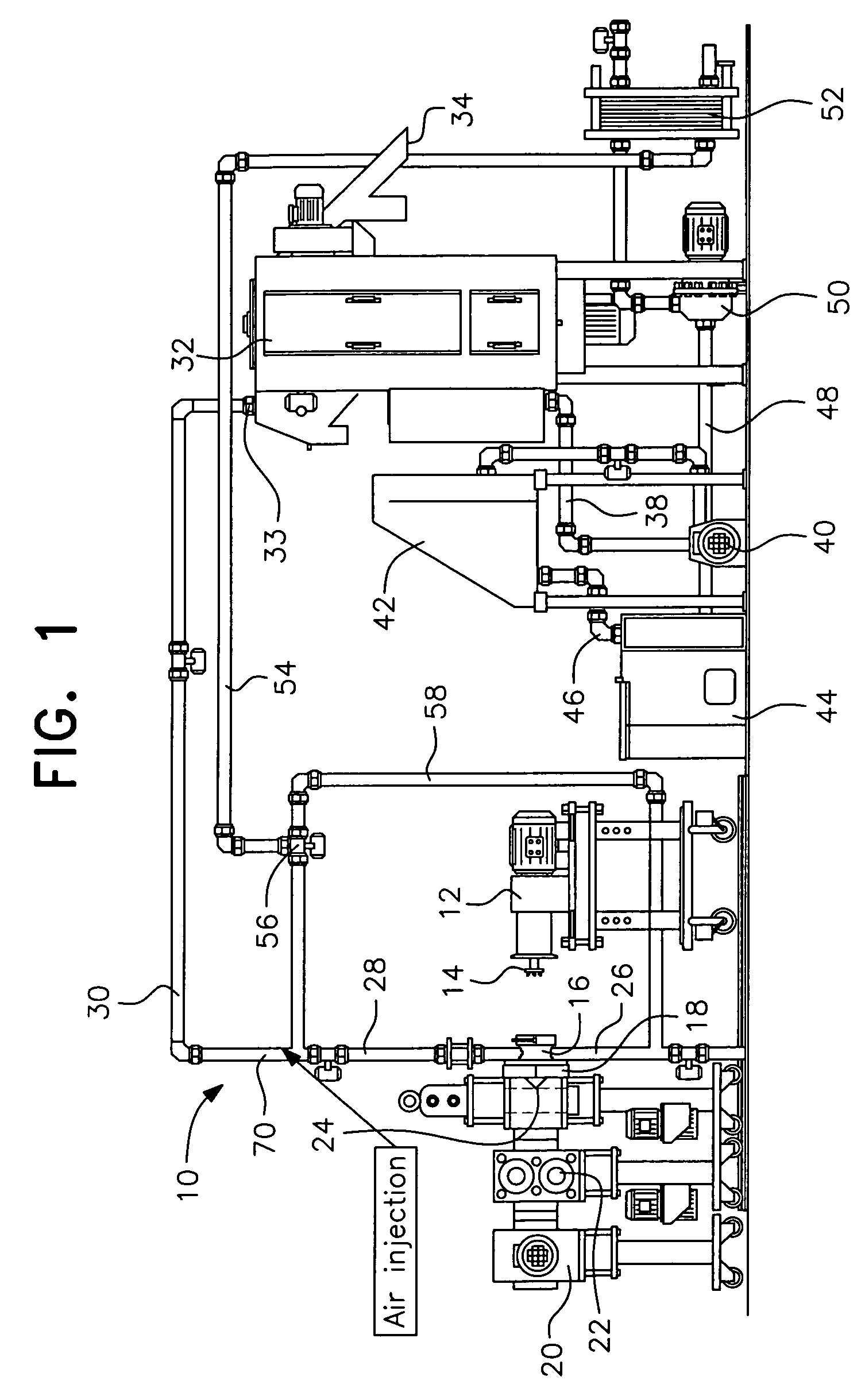

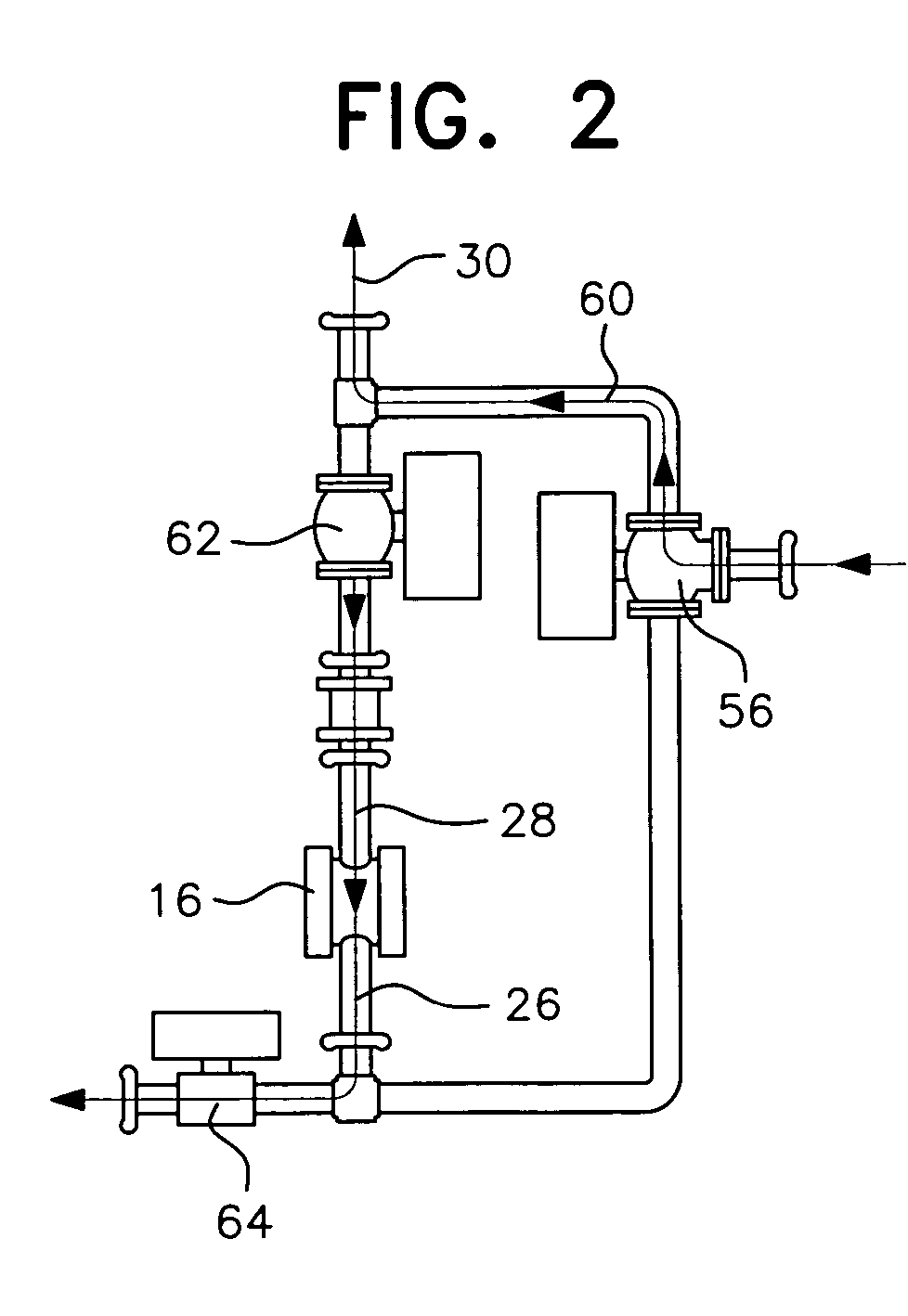

Method and Apparatus for Automated, Modular, Biomass Power Generation

ActiveUS20070006528A1Increasing fuel-bed bulk densityRestrict movementHydrogenDispersed particle filtrationElectric power systemFossil fuel

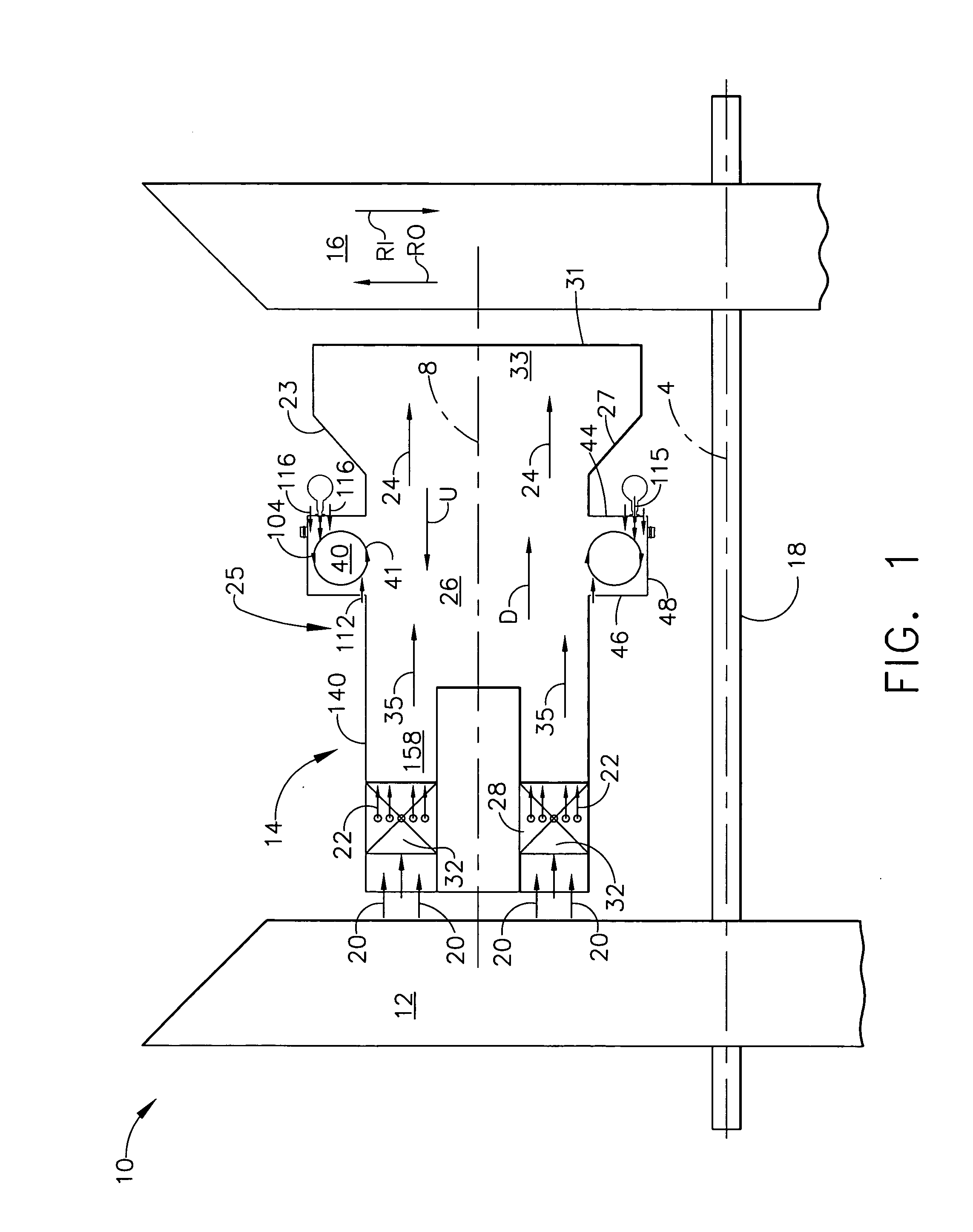

Method and apparatus for generating a low tar, renewable fuel gas from biomass and using it in other energy conversion devices, many of which were designed for use with gaseous and liquid fossil fuels. An automated, downdraft gasifier incorporates extensive air injection into the char bed to maintain the conditions that promote the destruction of residual tars. The resulting fuel gas and entrained char and ash are cooled in a special heat exchanger, and then continuously cleaned in a filter prior to usage in standalone as well as networked power systems.

Owner:COMMUNITY POWER CORP

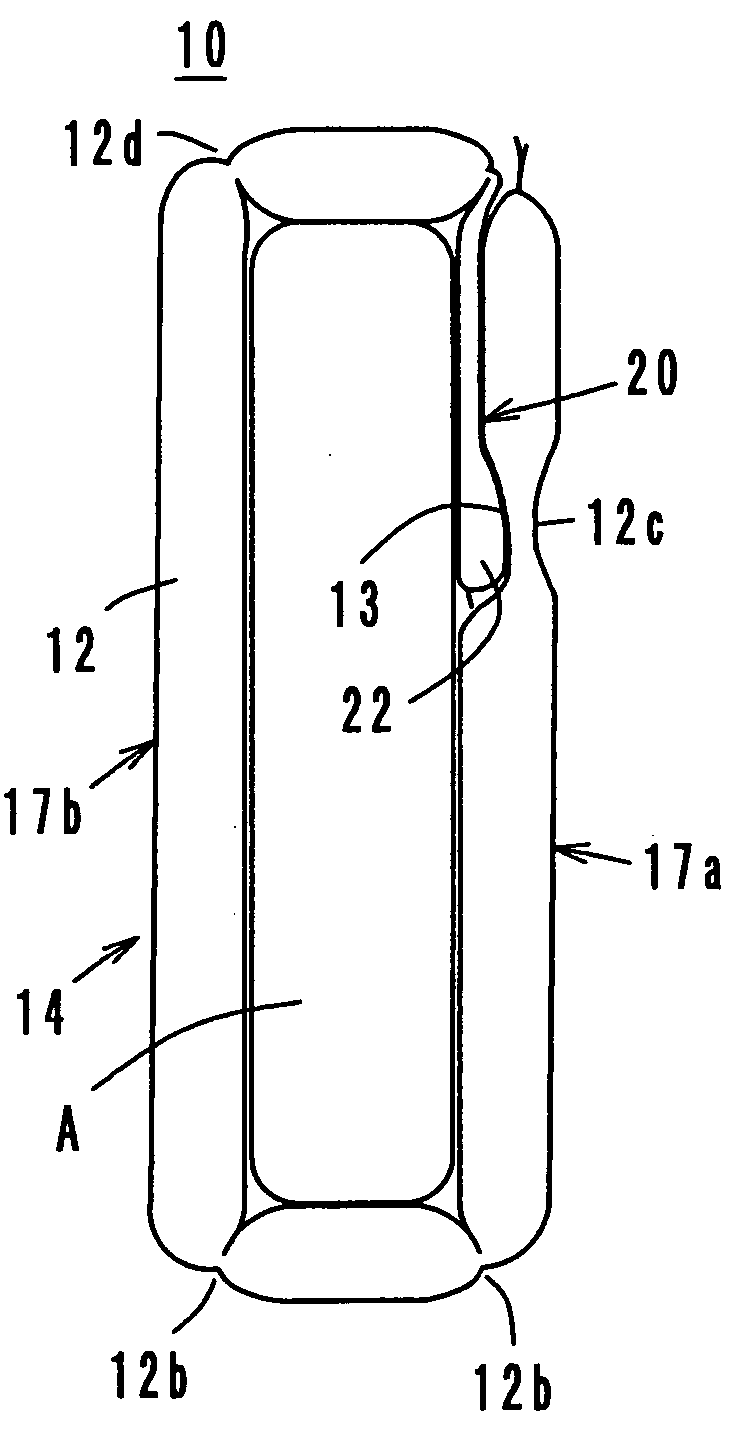

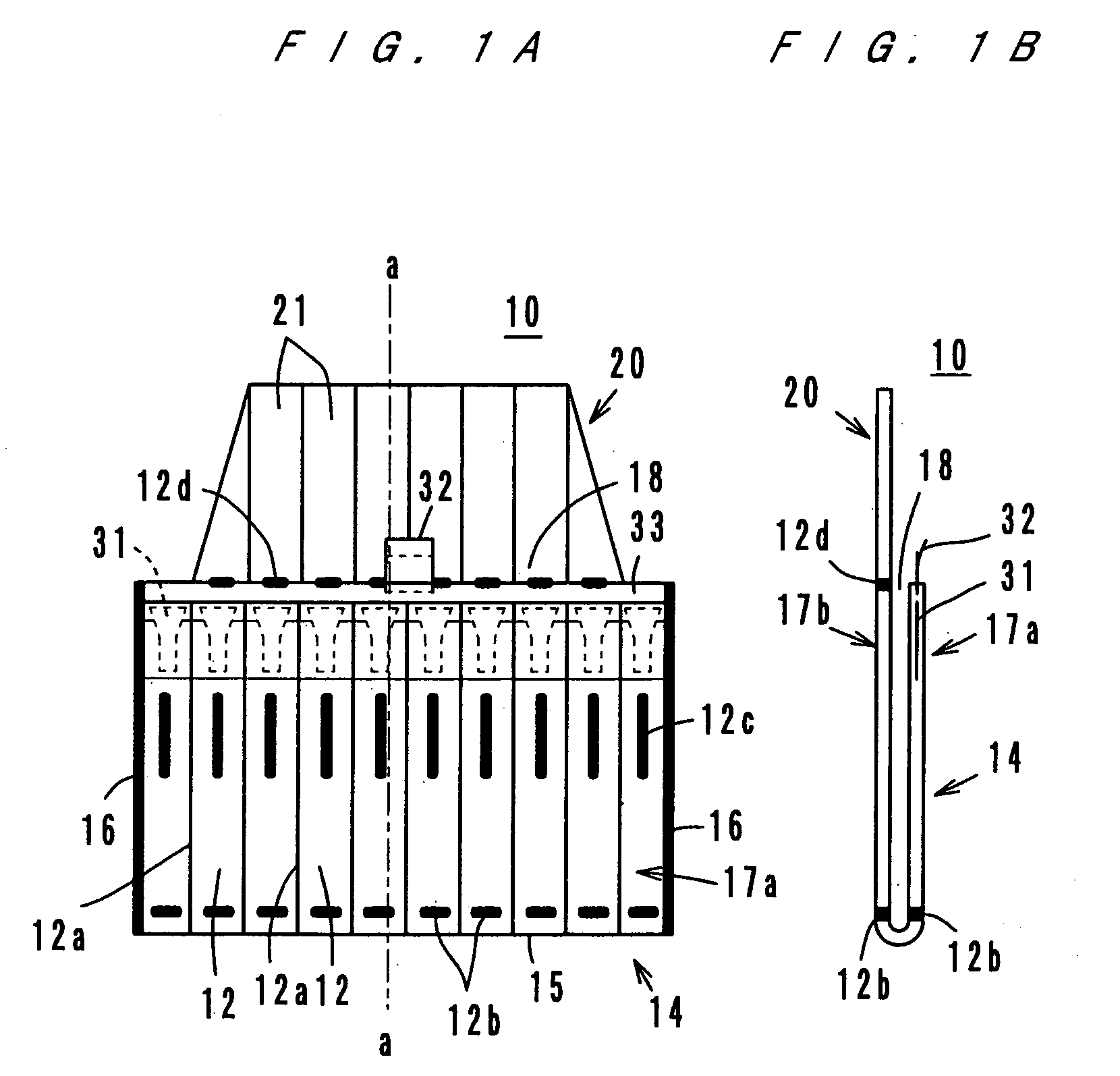

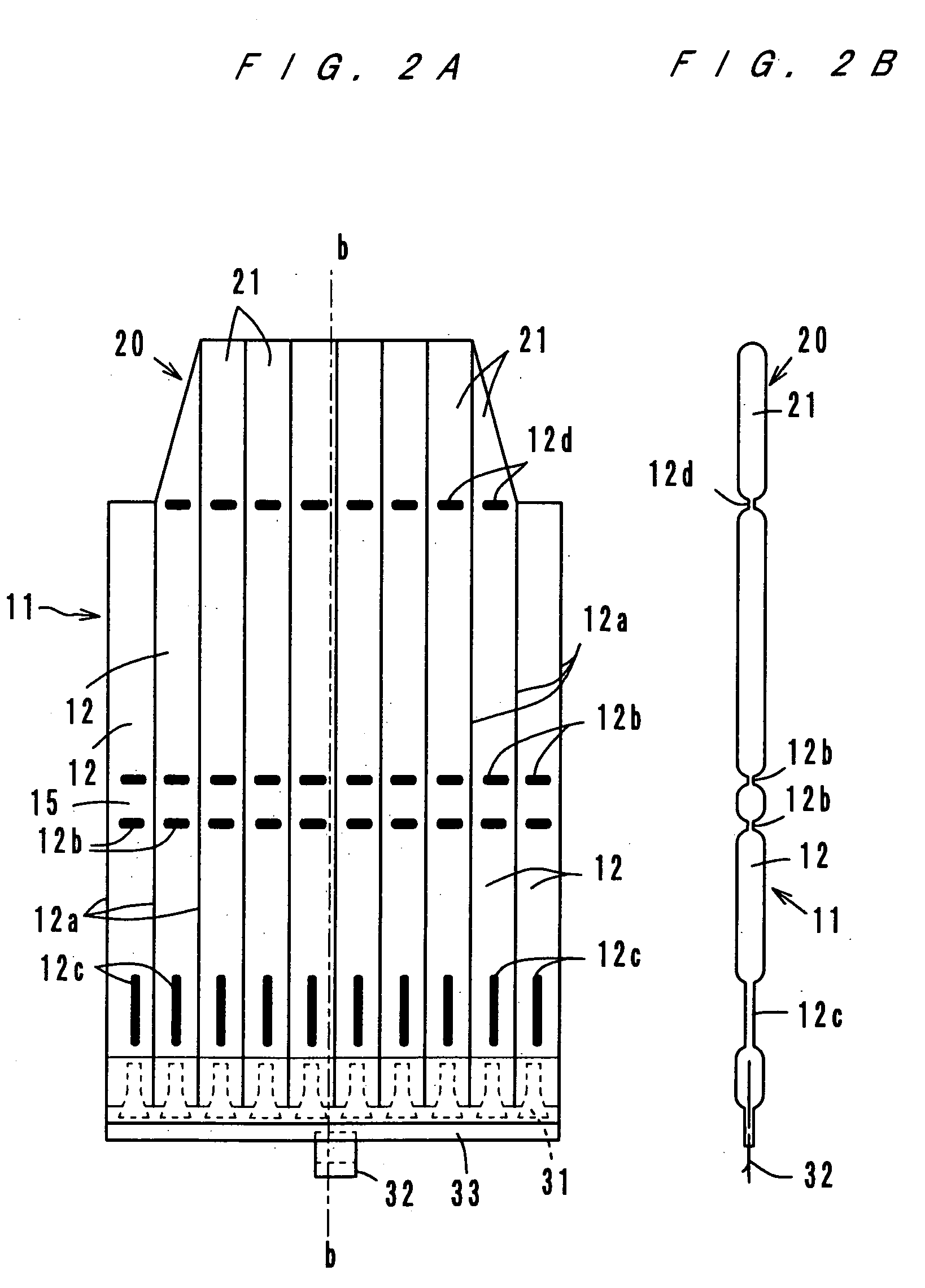

Plastic film bag with air cushioning function

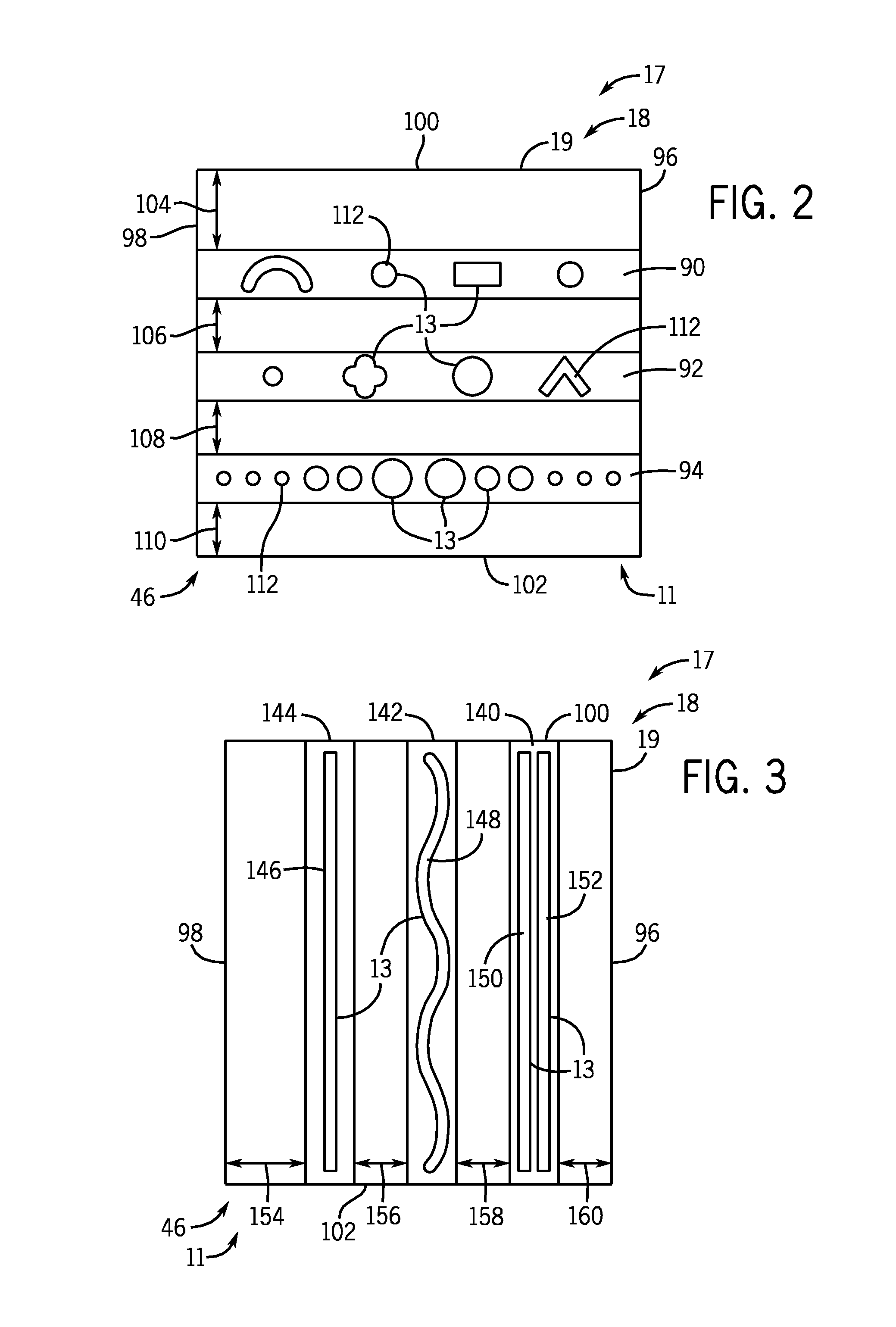

A plastic film bag with an air cushion has a bag body (14) composed of a front side (17a) and a back side (17b) made by folding a tubular material (11) which has a plurality of plastic film long cells (12) which are arranged and connected in parallel at substantially a center with respect to a direction of longer dimensions of the cells (12) and by fusing the folded portion at both sides (16), a flap (20) which is extended from an open end (18) of the back side of the bag body and which comprises a plurality of cells (21) which communicate with the cells (12) formed in the bag body, and air injection means (31, 32, 33) which is provided for the bag body to inject air into the cells (12, 21). When the cells are filled with air after an item (A) is contained in the bag body, the flap is pressed between the item contained in the bag body and the front side swollen with air, and the flap does not come out easily.

Owner:ISHIZAKI SHIZAI +1

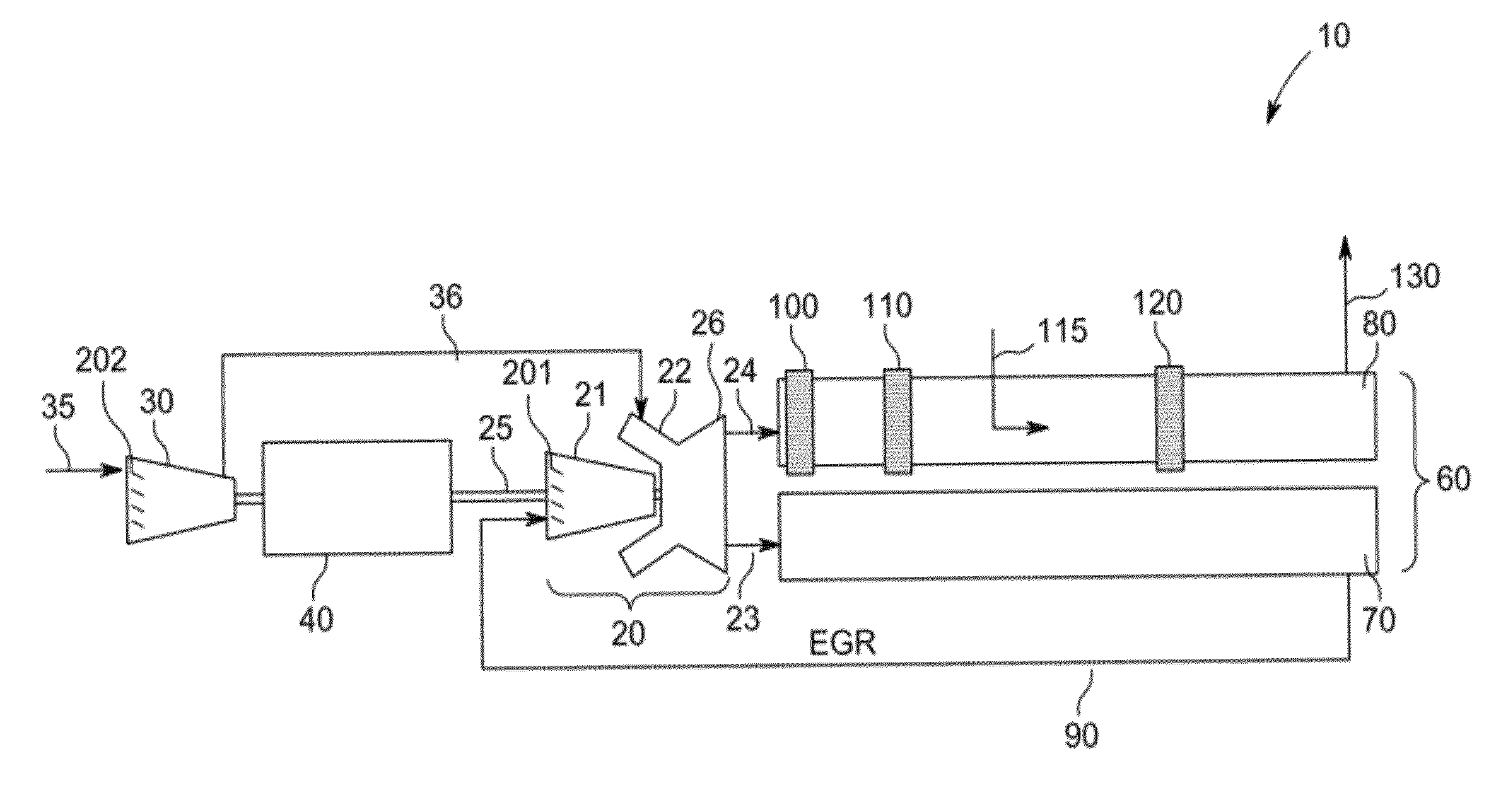

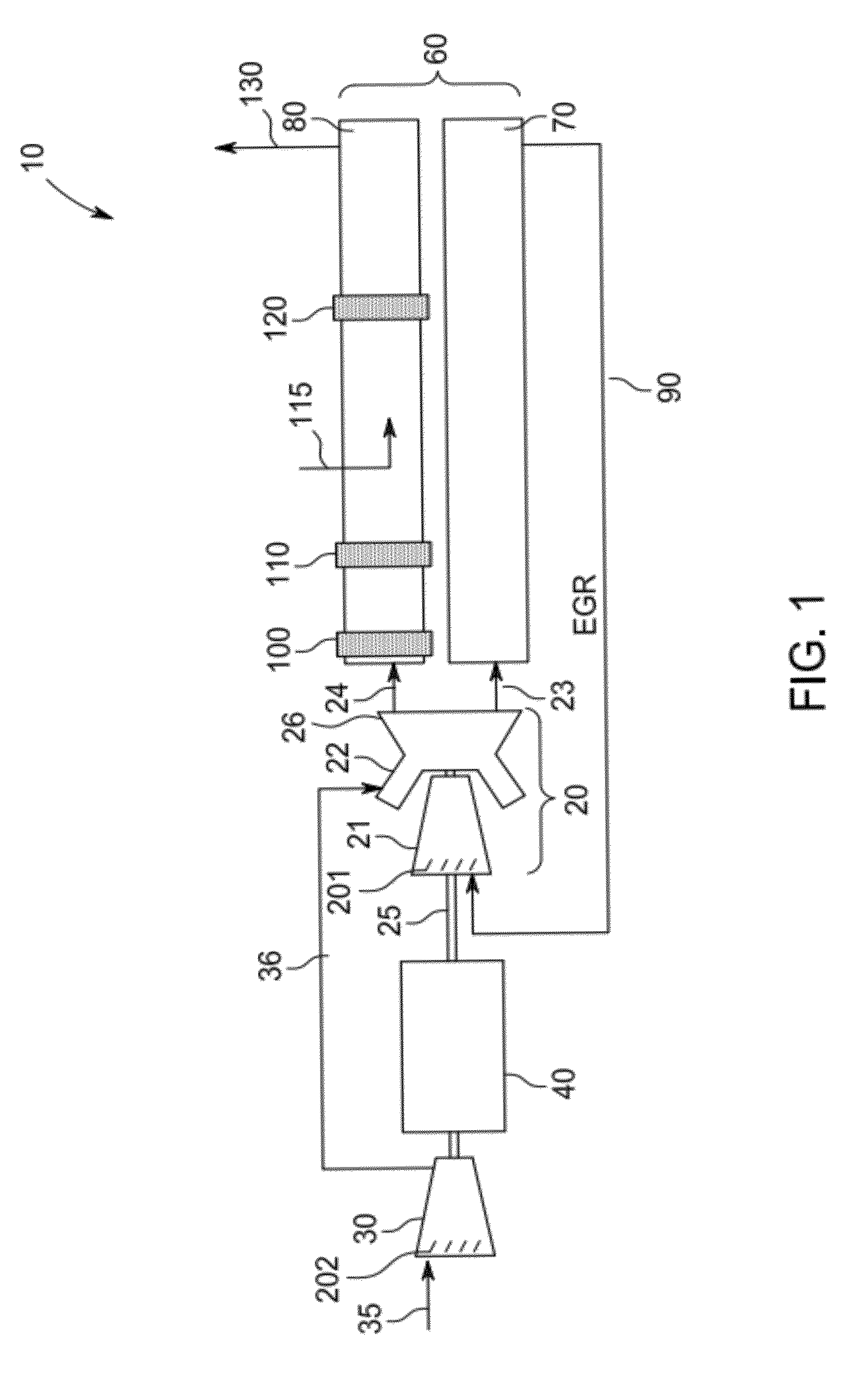

System and method to generate electricity

InactiveUS8166766B2Emission reductionReduce consumptionGas turbine plantsEngine controlElectricityProcess engineering

A split heat recovery steam generator (HRSG) arrangement including a first HRSG coupled to a turbine and thereby receptive of a portion of the exhaust gases to deliver the portion of the exhaust gases to a compressor, a second HRSG coupled to the turbine and thereby receptive of a remaining portion of the exhaust gases, which includes an NOx catalyst and a CO catalyst sequentially disposed therein to remove NOx and CO from the exhaust gases and an air injection apparatus to inject air into the second HRSG between the NOx catalyst and the CO catalyst to facilitate CO consumption at the CO catalyst.

Owner:GENERAL ELECTRIC CO

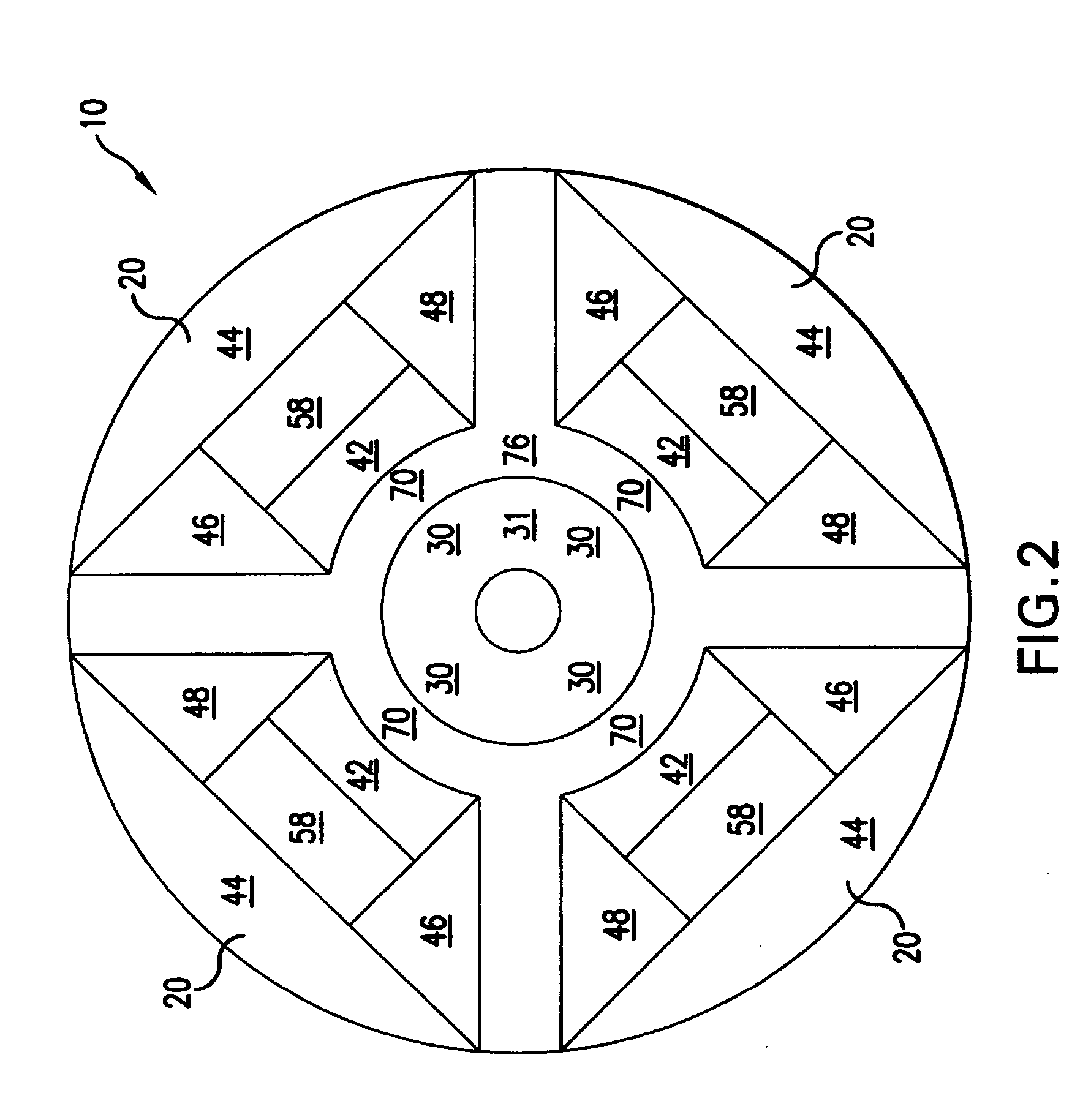

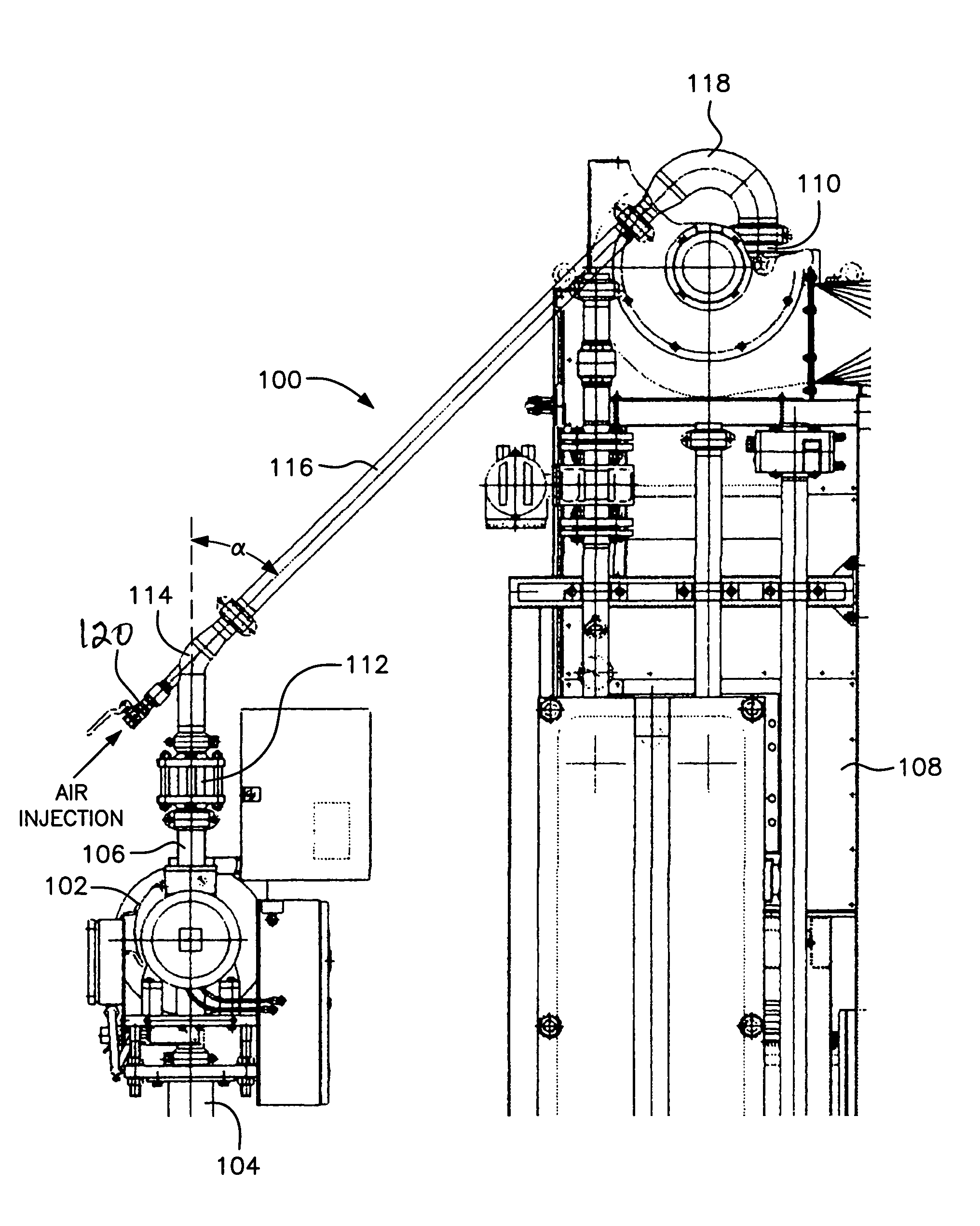

Pyrolyzing gasification system and method of use

InactiveUS20050109603A1High gasifier discharge temperatureEfficient processGasifier mechanical detailsBiofuelsHydrocotyle bowlesioidesExternal combustion engine

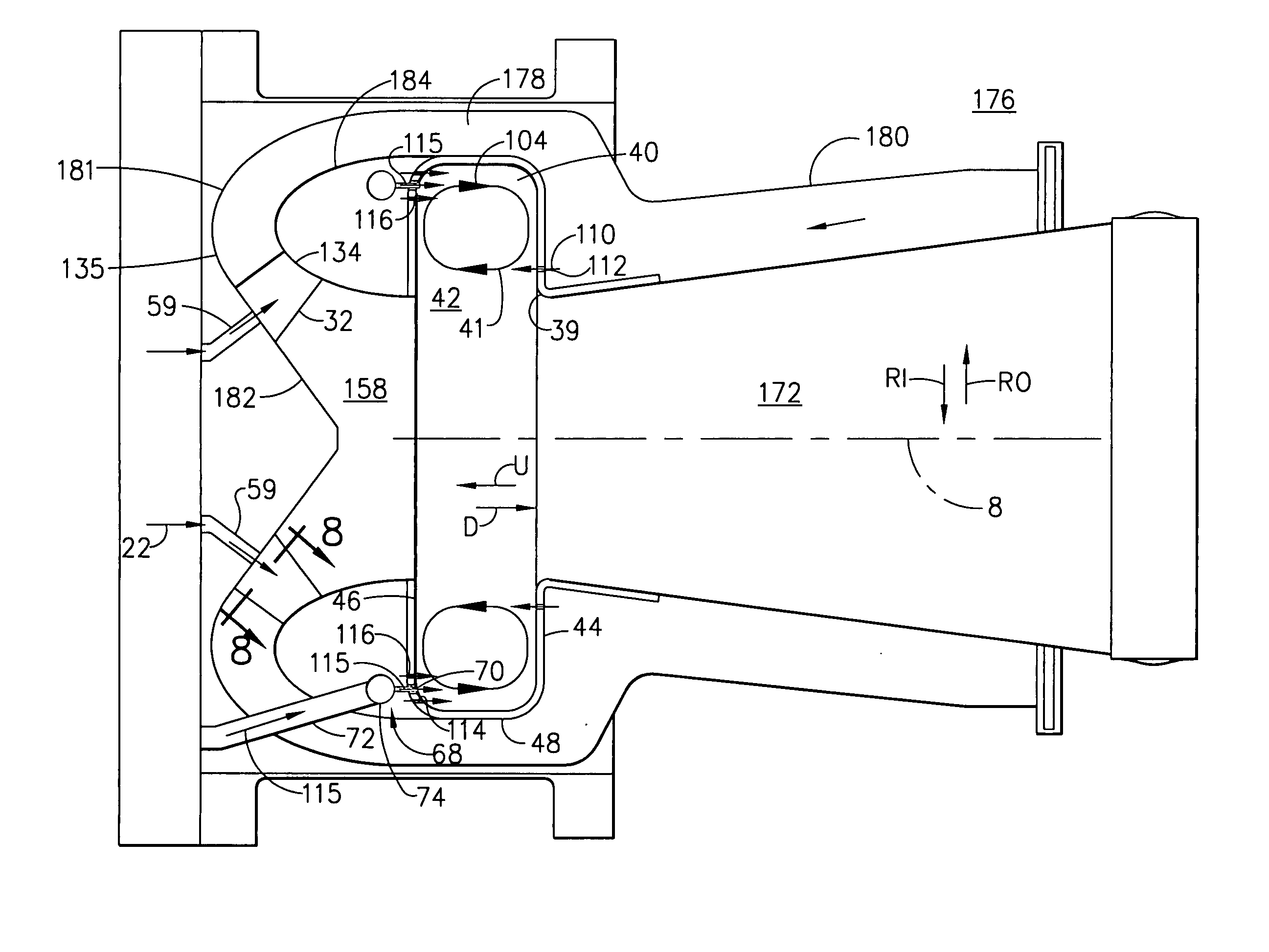

Pyrolyzing gasification system and method of use including primary combustion of non-uniform solid fuels such as biomass and solid wastes within a refractory lined gasifier, secondary combustion of primary combustion gas within a staged, cyclonic, refractory lined oxidizer, and heat energy recovery from the oxidized flue gas within an indirect air-to-air all-ceramic heat exchanger or external combustion engine. Primary combustion occurs at low substoichoimetric air percentages of 10-30 percent and at temperatures below 1000 degrees F. Secondary combustion is staged and controlled for low NOx formation and prevention of formation of CO, hydrocarbons, and VOCs. The gasifier includes a furnace bed segmented into individual cells, each cell is independently monitored using a ramp temperature probe, and provided with controlled air injection. Gasifier air injection includes tuyere arrays, lances, or both. The oxidizer includes three serially aligned stages separated by air injecting baffles, and ability to adjust the exit air temperature.

Owner:HEAT TRANSFER INT

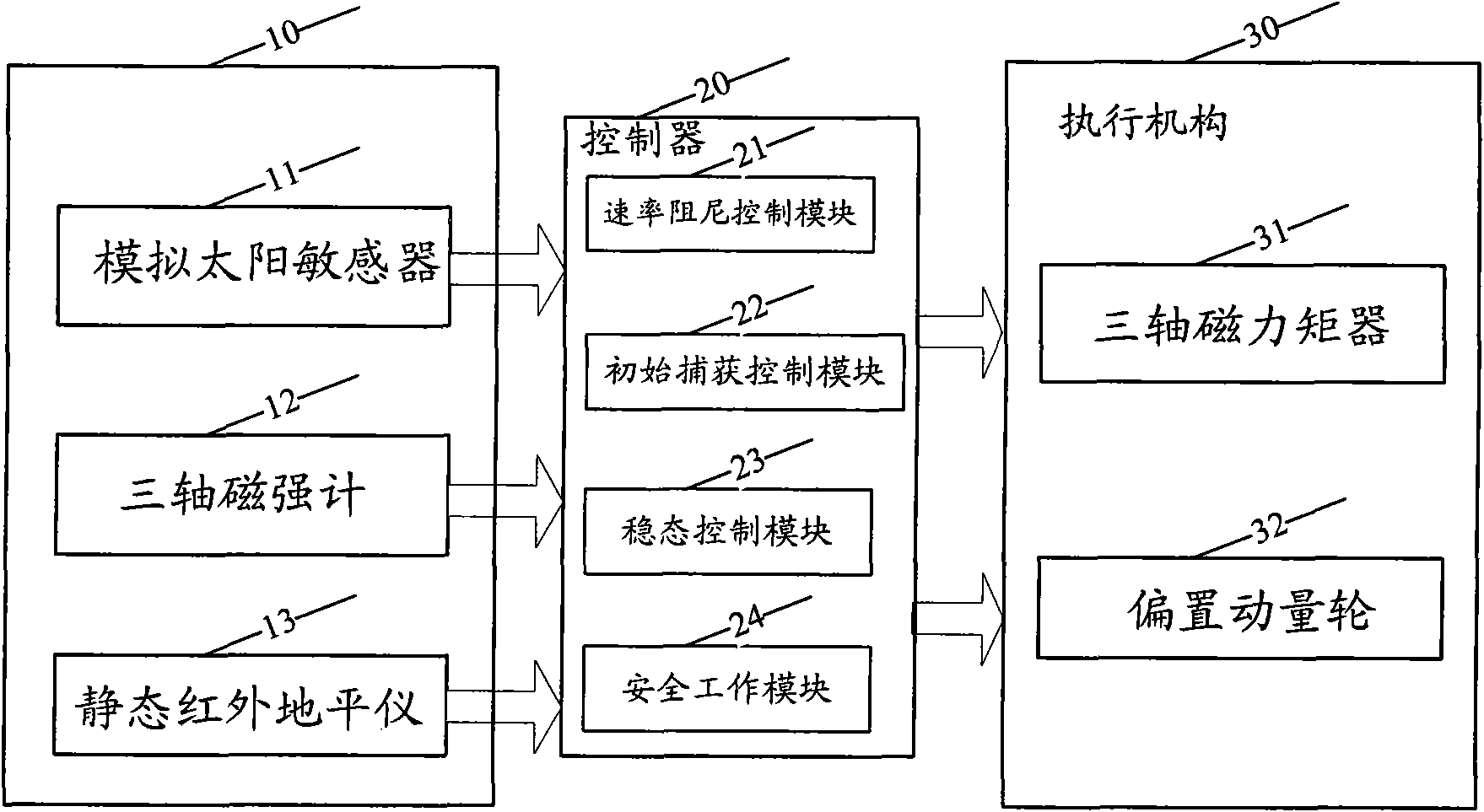

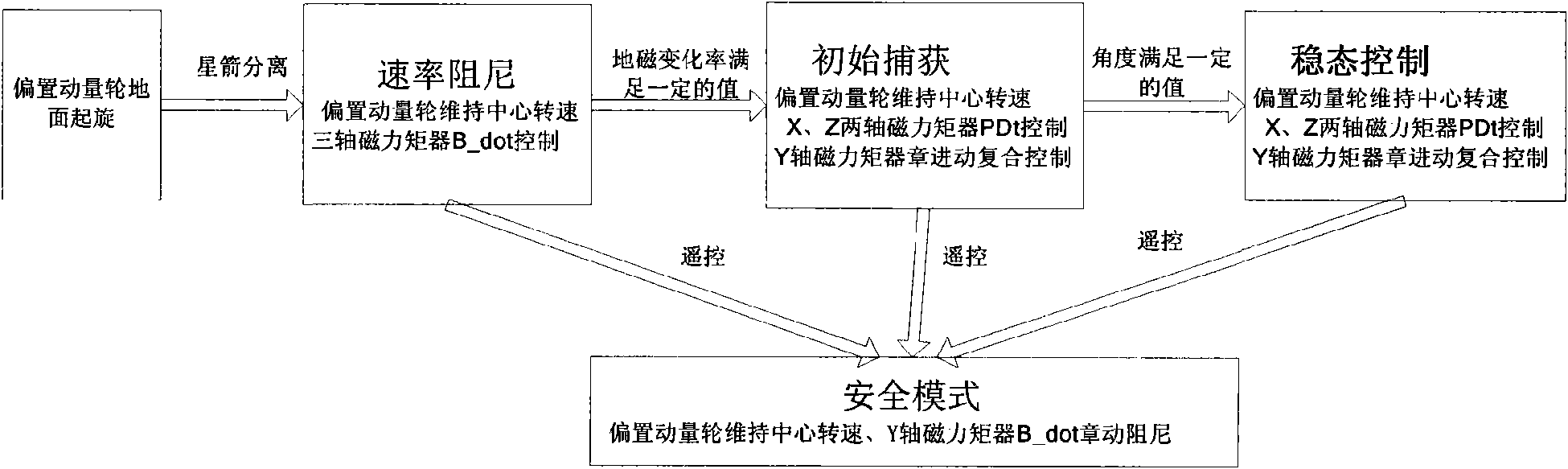

Attitude control system for space vehicle and method thereof

InactiveCN101554926AStable separationStable Initial Rate DampingSpacecraft guiding apparatusMagnetic tension forceNutation

The invention discloses an attitude control system for space vehicle and a method thereof. The control system has only one biased momentum wheel, one set of tri-axial magnetic torquer and one attitude controller loaded with algorithm. The method comprises a step of rate damping controlling, a step of initially capturing controlling and a step of stationarity controlling. At the rate damping stage, geomagnetism change is used to control the magnetic control of three passages of a satellite by B-dot; at the initially capturing stage, the magnetic control is realized, PD control is performed by pitching and the passages are rolled and yawed to carry out nutation and precession composite control; at the stationarity controlling stage, the magnetic control is realized, PD control is performed by pitching and the passages are rolled and yawed to carry out nutation and precession composite control. The capturing stage and the stationarity controlling stage fully depend on magnetic torquer to perform positive magnetic control, thereby changing which a satellite only uses a magnetic torquer to carry out unload of the momentum wheel or auxiliary magnetic control, so as to refine system configuration to further improve reliability of the system. Momentum of a satellite is biased to rotate on the ground, so as to ensure stable separation of the satellite without performing air injection control. Therefore, the magnetic torquer can be used for realizing fast and stable initial rate damping.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

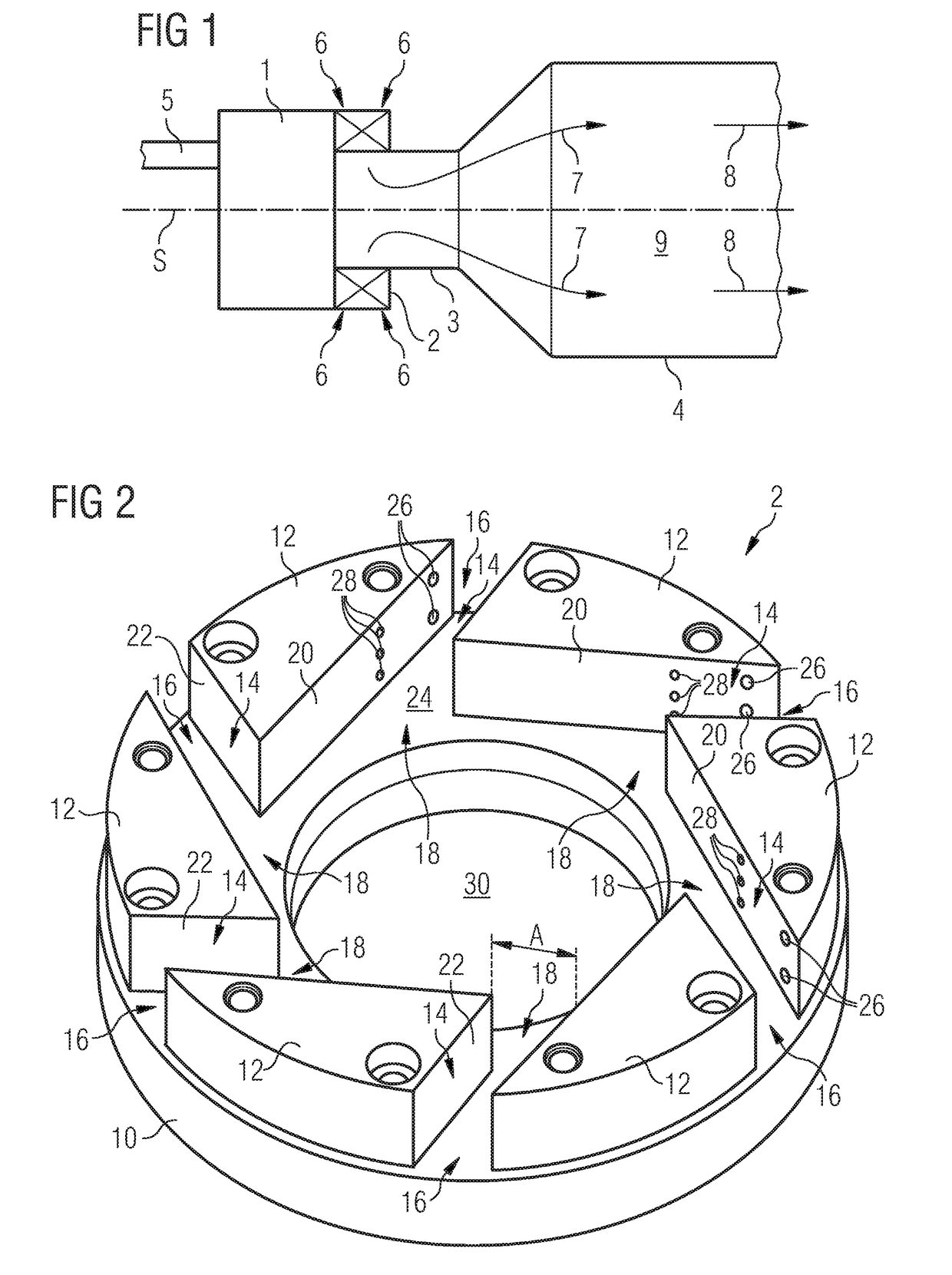

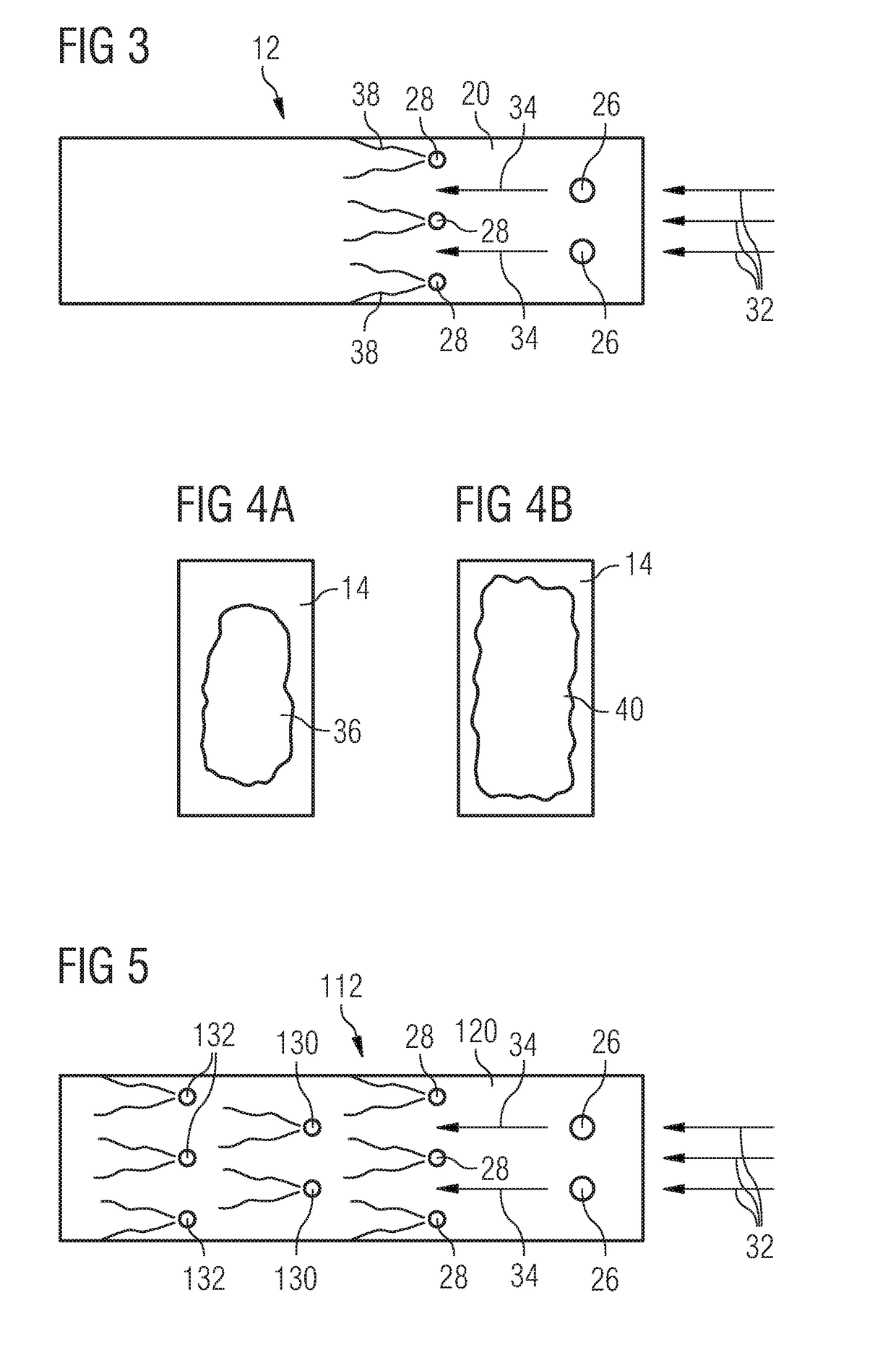

Gas turbine burner and method of mixing fuel and air in a swirling area of a gas turbine burner

InactiveUS8117846B2Increase ratingsImprove distributionBurnersContinuous combustion chamberCombustorInjection air

A gas turbine burner, comprising at least one swirler, the swirler having at least one air inlet opening, at least one air outlet opening positioned downstream to the air inlet opening and at least one swirler air passage extending from the at least one air inlet opening to the at least one air outlet opening which is delimited by swirler air passage walls; a fuel injection system which comprises fuel injection openings arranged in at least one swirler air passage wall so as to inject fuel into the swirler air passage; and an air injection system which comprises air injection openings arranged in at least one swirler air passage wall and positioned downstream of the fuel injection openings for injecting air into the swirler air passage.

Owner:SIEMENS AG

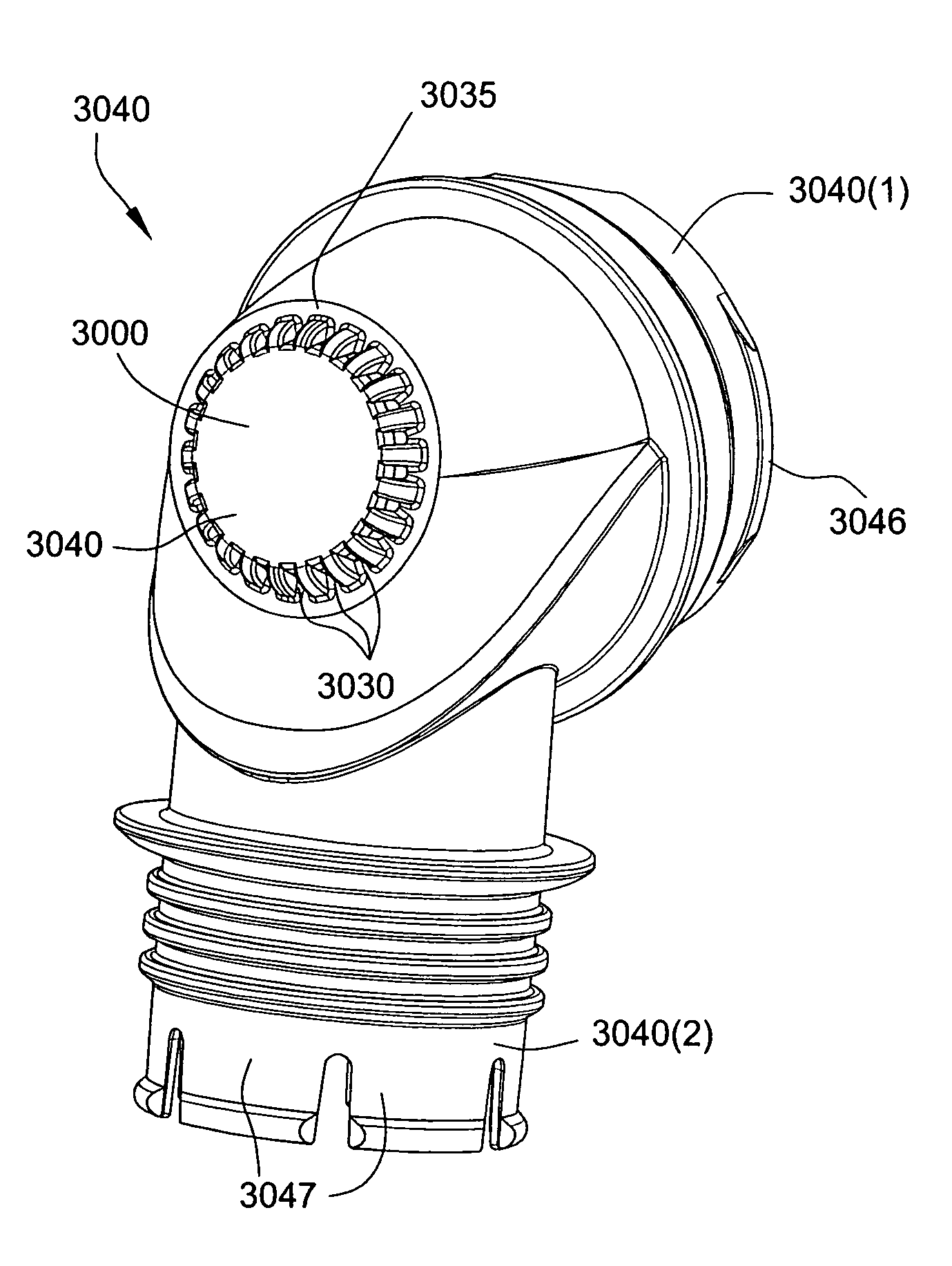

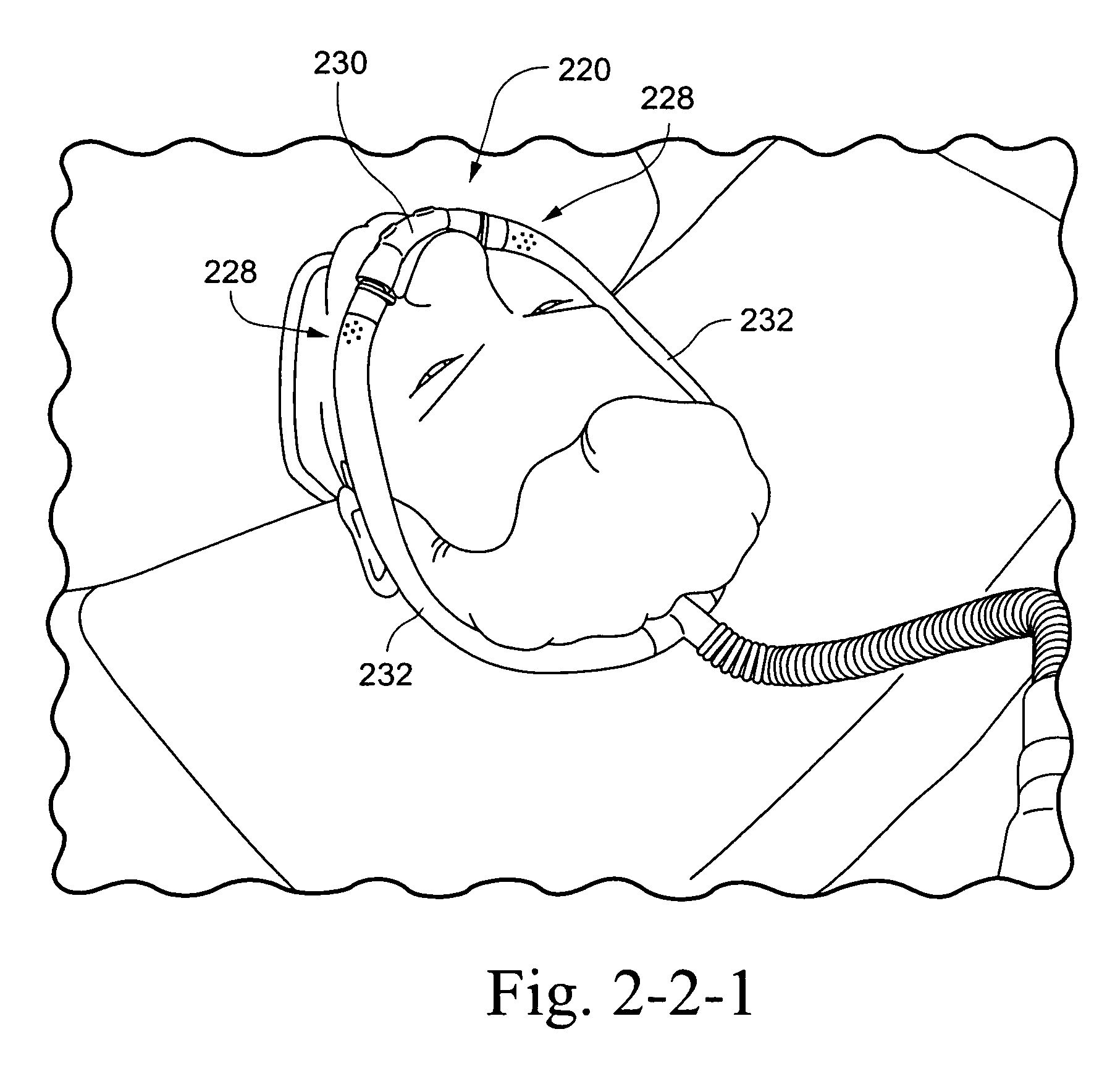

Mask vent

A vent arrangement is provided to a mask or associated conduit to discharge exhaled gas from the mask to atmosphere. The vent arrangement is structured to diffuse the exhaust vent flow to produce less air jetting, thereby increasing the comfort of the patient and their bed partner. For example, the vent arrangement may include one or more grill components and / or media constructed and arranged to diffuse vent flow.

Owner:RESMED LTD

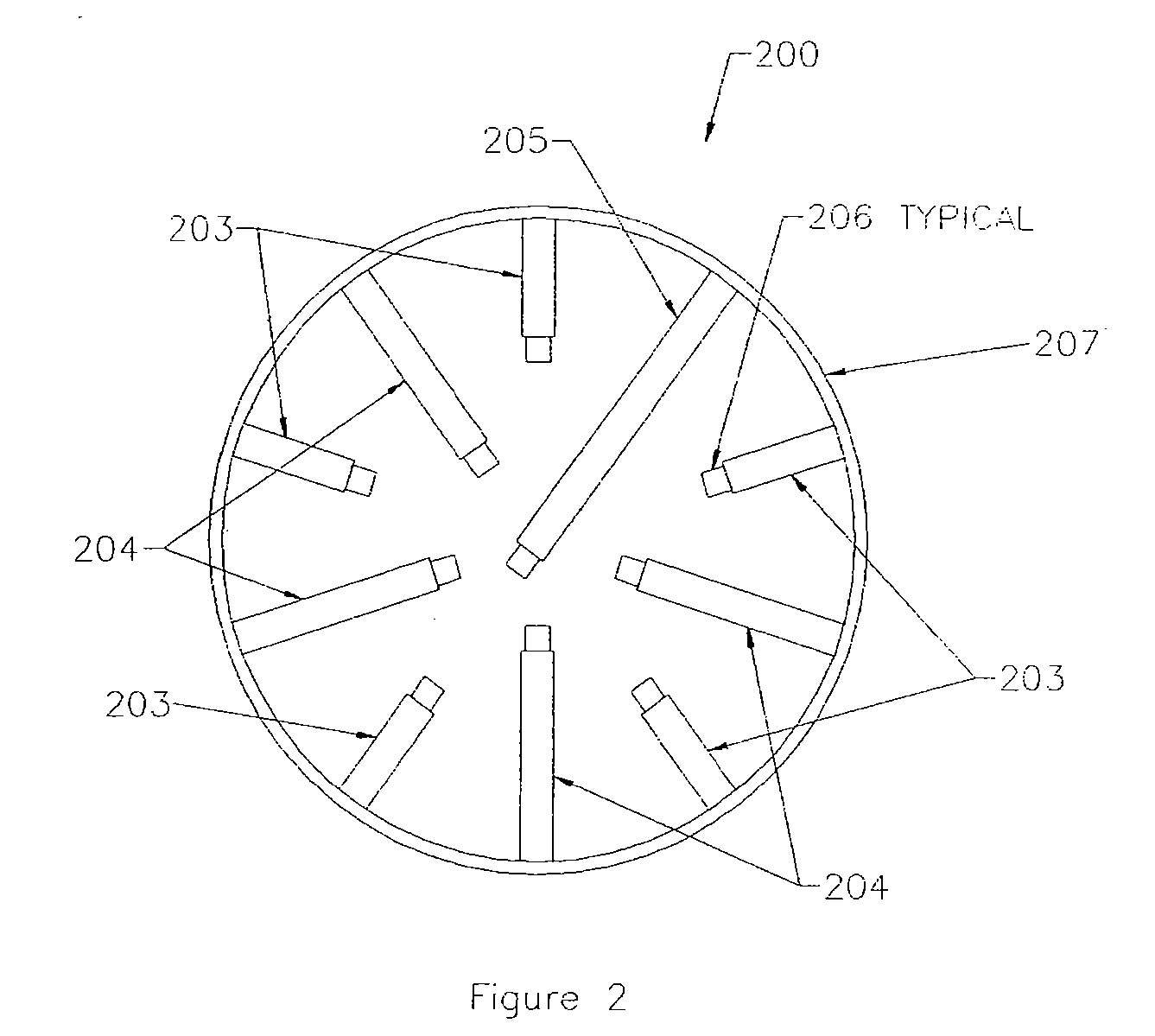

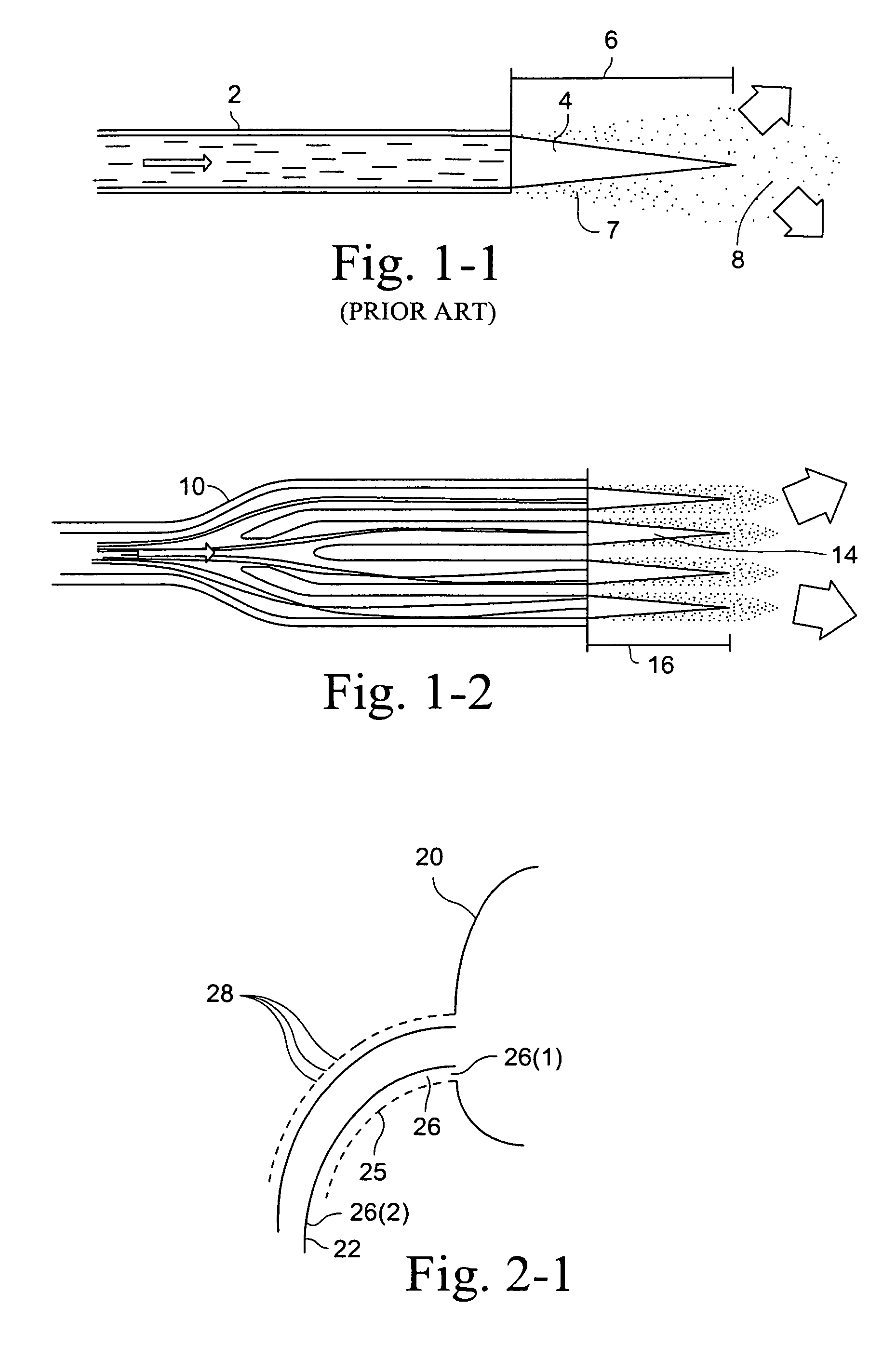

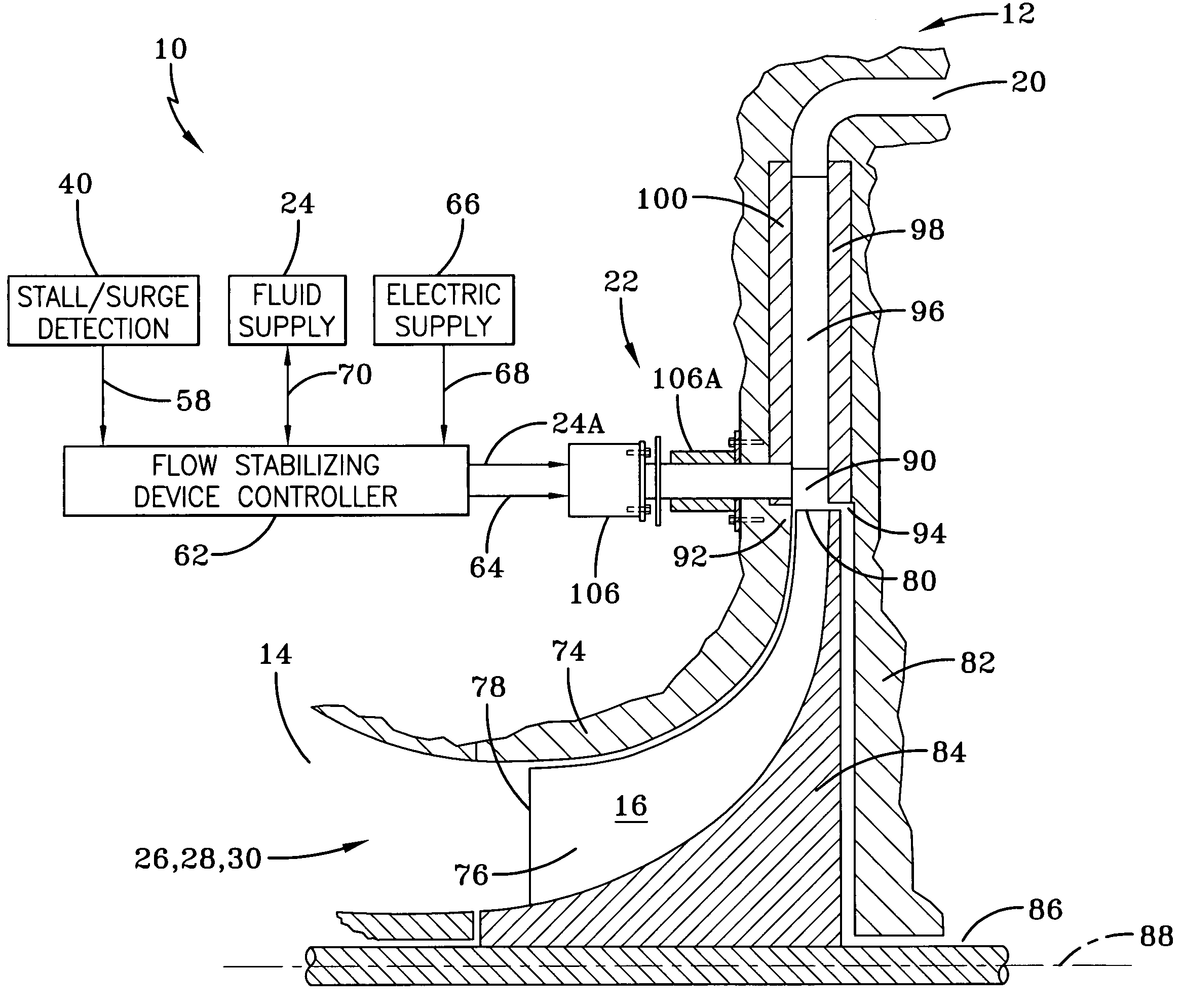

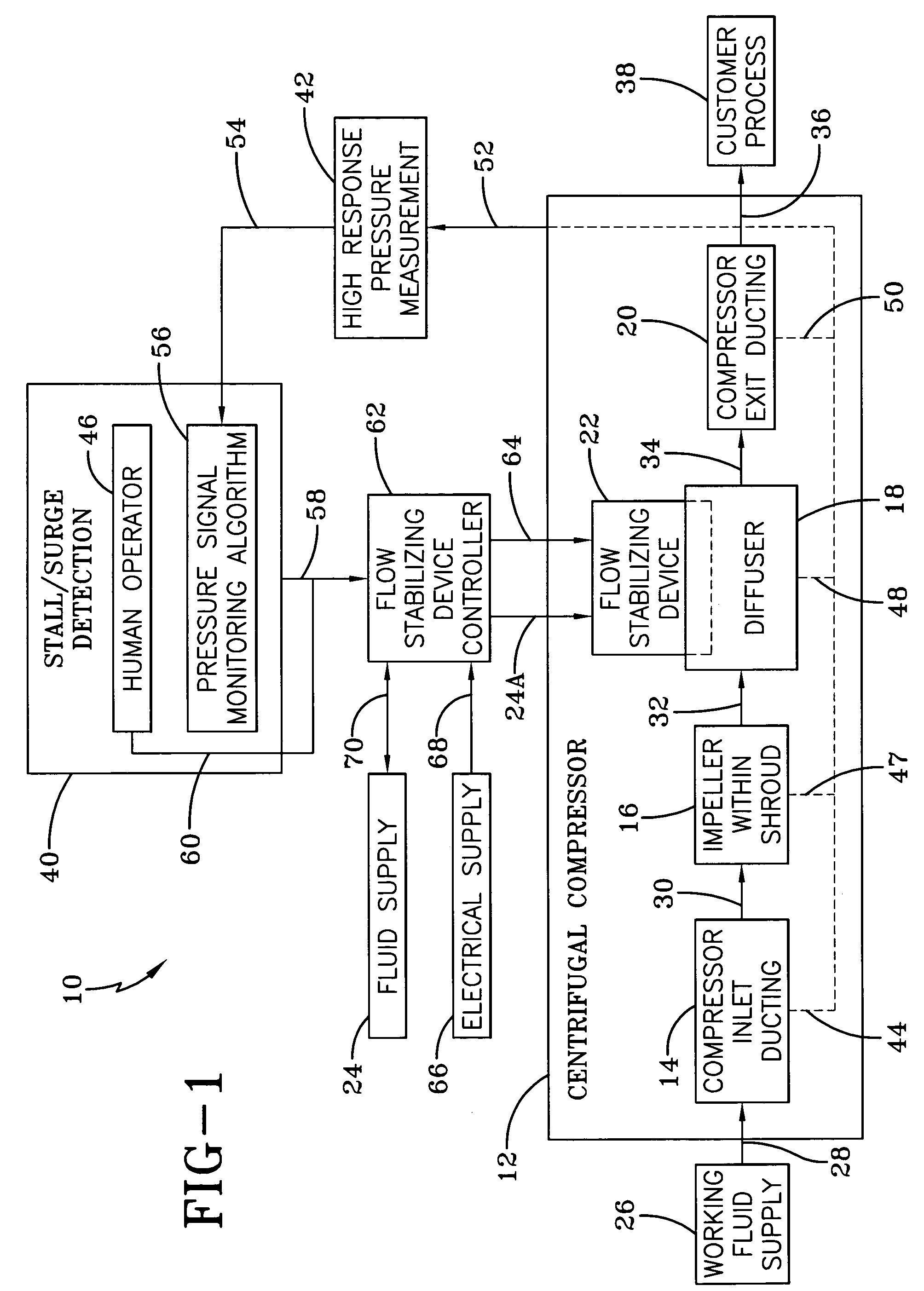

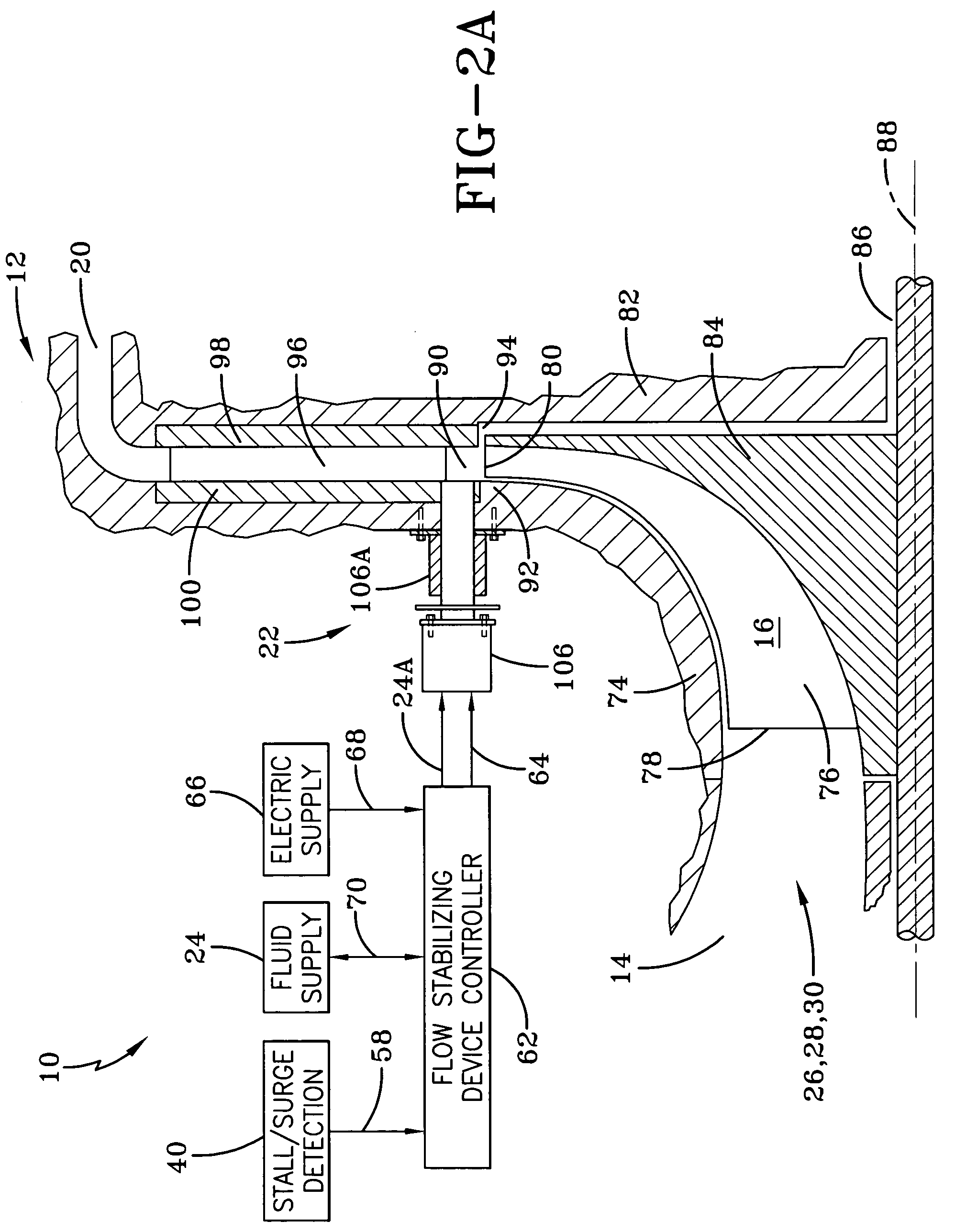

Devices and methods of operation thereof for providing stable flow for centrifugal compressors

InactiveUS7326027B1Process stabilityAvoid adjustmentEngine manufactureWind motor controlEngineeringInjection air

Centrifugal compressor flow stabilizing devices and methods of operation thereof are disclosed that act upon the flow field discharging from the impeller of a centrifugal compressor and modify the flow field ahead of the diffuser vanes such that flow conditions contributing to rotating stall and surge are reduced or even eliminated. In some embodiments, shaped rods and methods of operation thereof are disclosed, whereas in other embodiments reverse-tangent air injection devices and methods are disclosed.

Owner:NASA

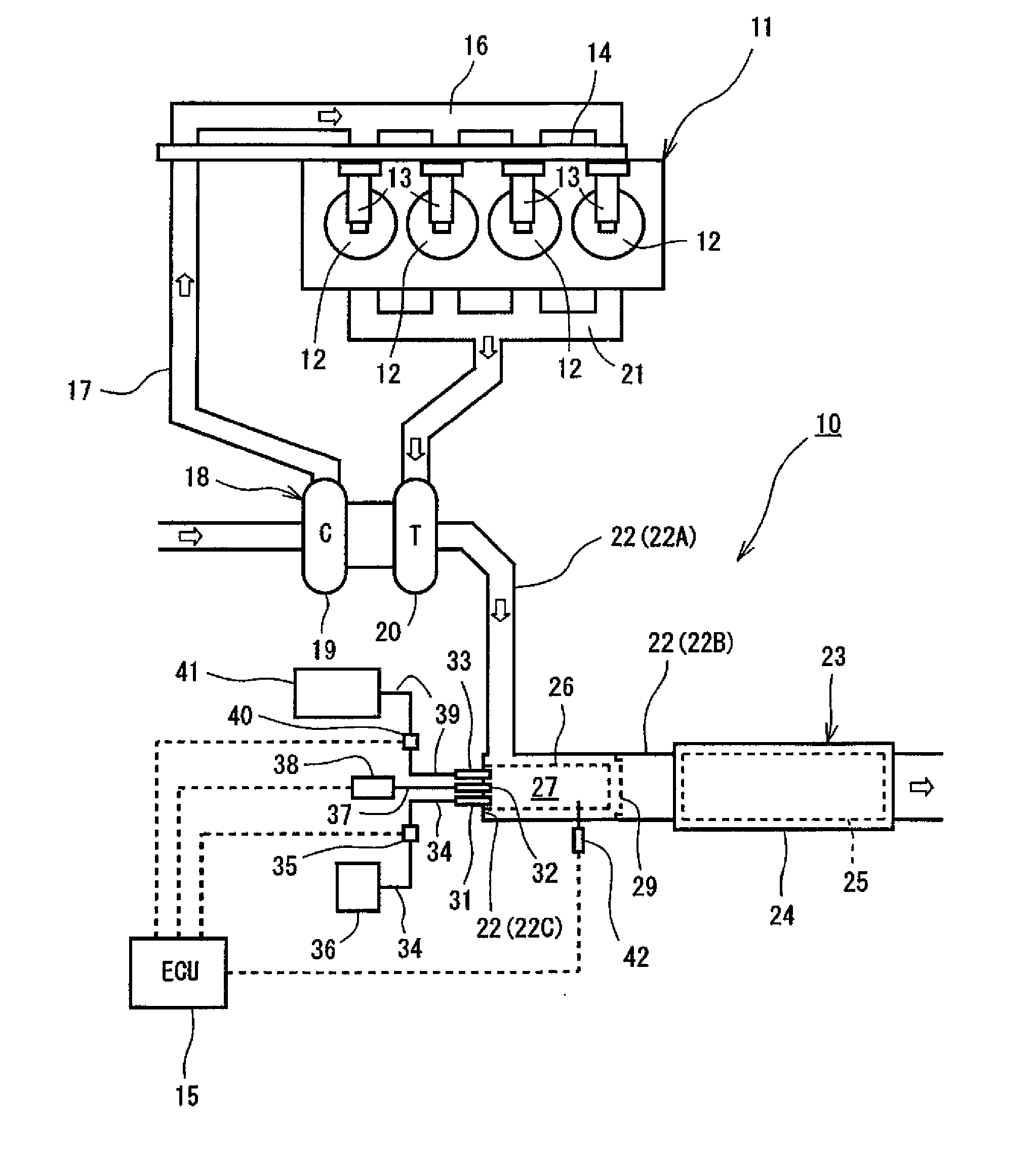

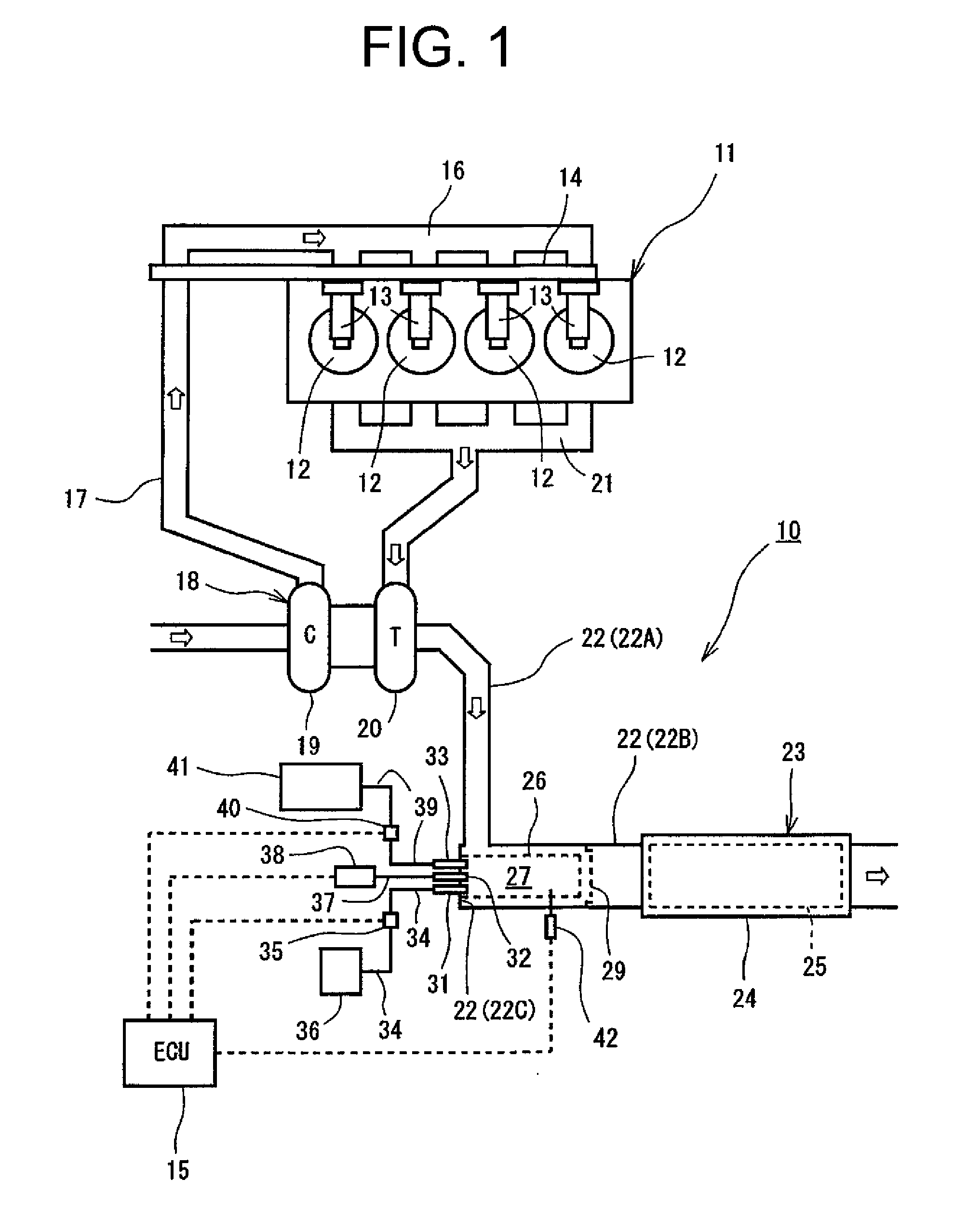

Exhaust gas treatment system

InactiveUS20110061374A1Internal combustion piston enginesSilencing apparatusInjection portExhaust fumes

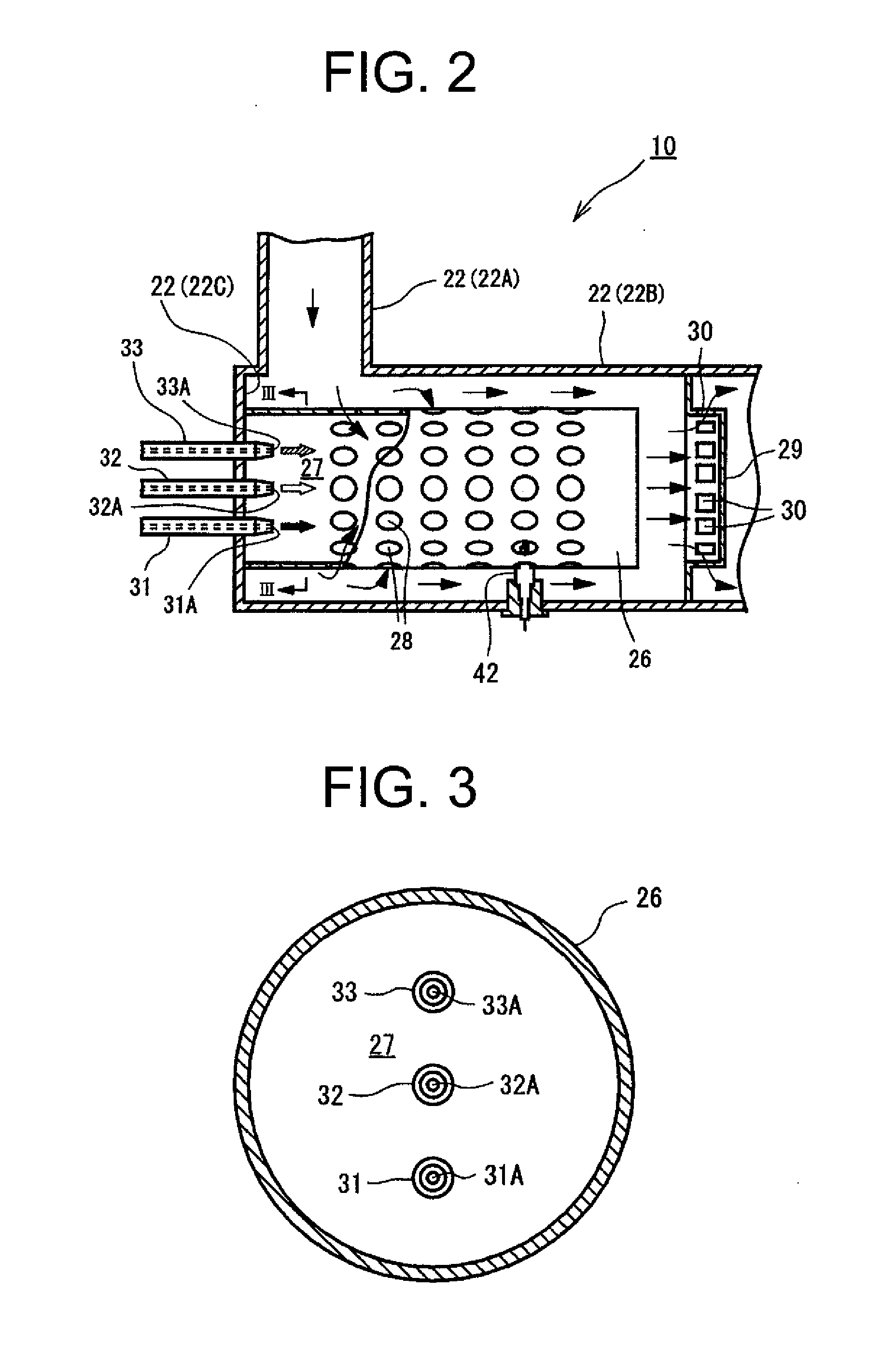

An exhaust gas treatment system includes an exhaust passage through which exhaust gas from an internal combustion engine is allowed to flow, a selective catalytic reduction catalyst provided in the exhaust passage, a mixing chamber provided upstream of the selective catalytic reduction catalyst in the exhaust passage as viewed in the direction of exhaust gas flow, a fuel injection valve for injection of fuel, an air injection valve for injection of air, and a urea water injection valve for injection of urea water. The fuel injection valve, the air injection valve and the urea water injection valve each has an injection port directed to the mixing chamber.

Owner:TOYOTA IND CORP

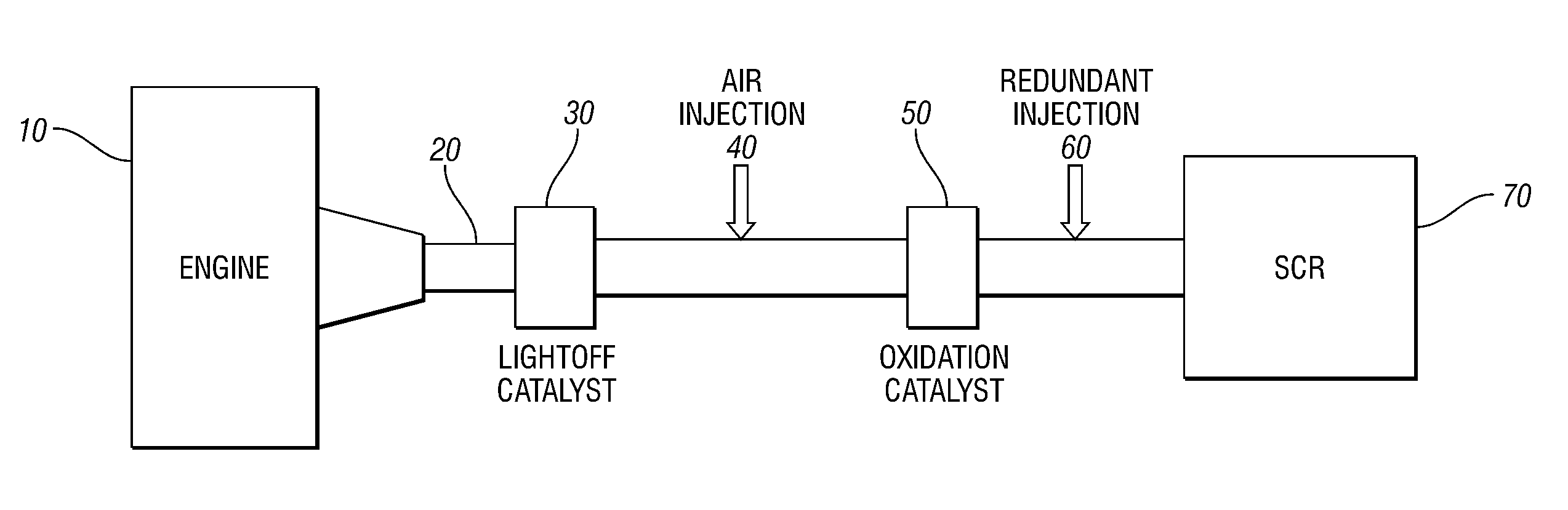

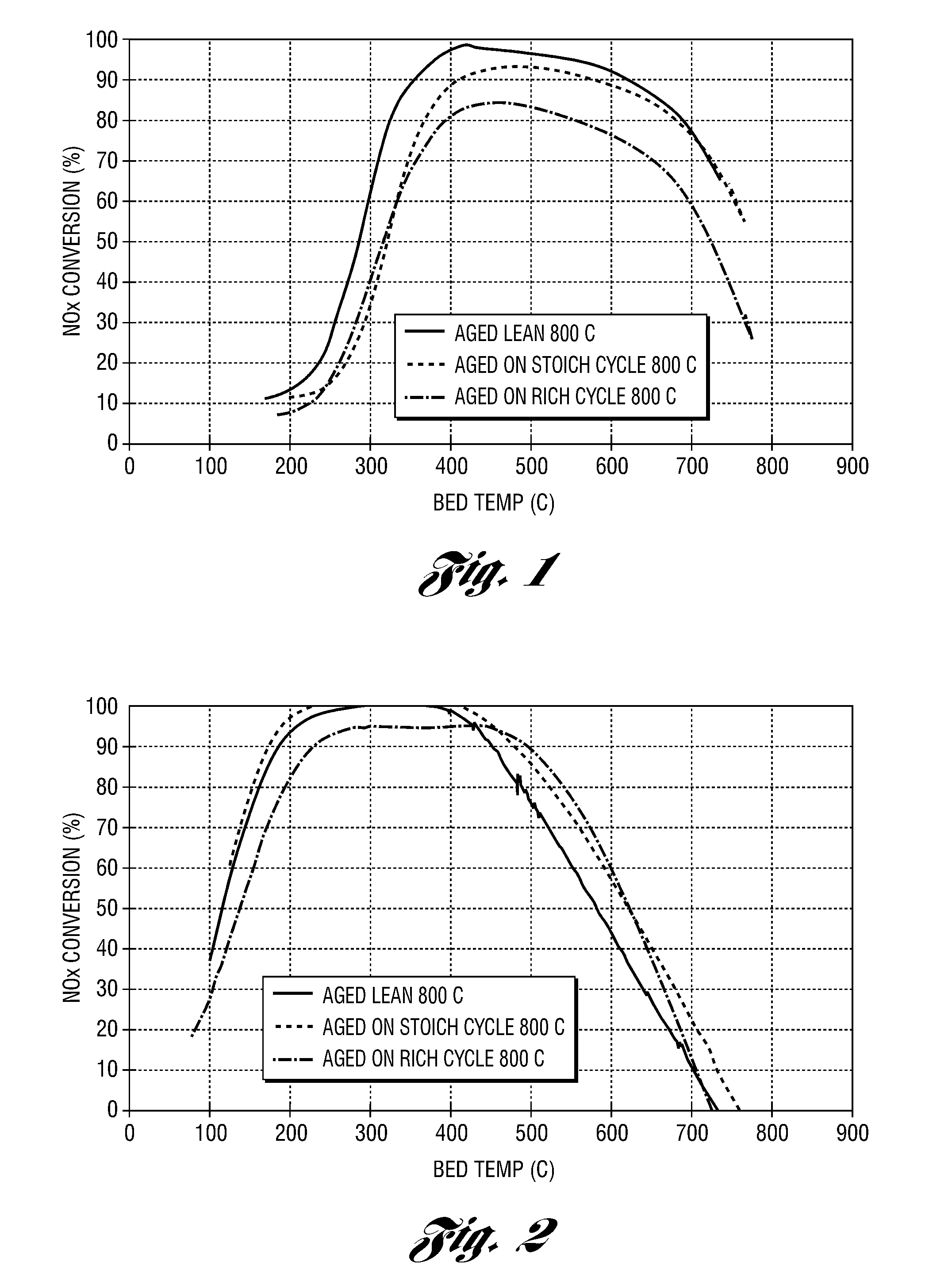

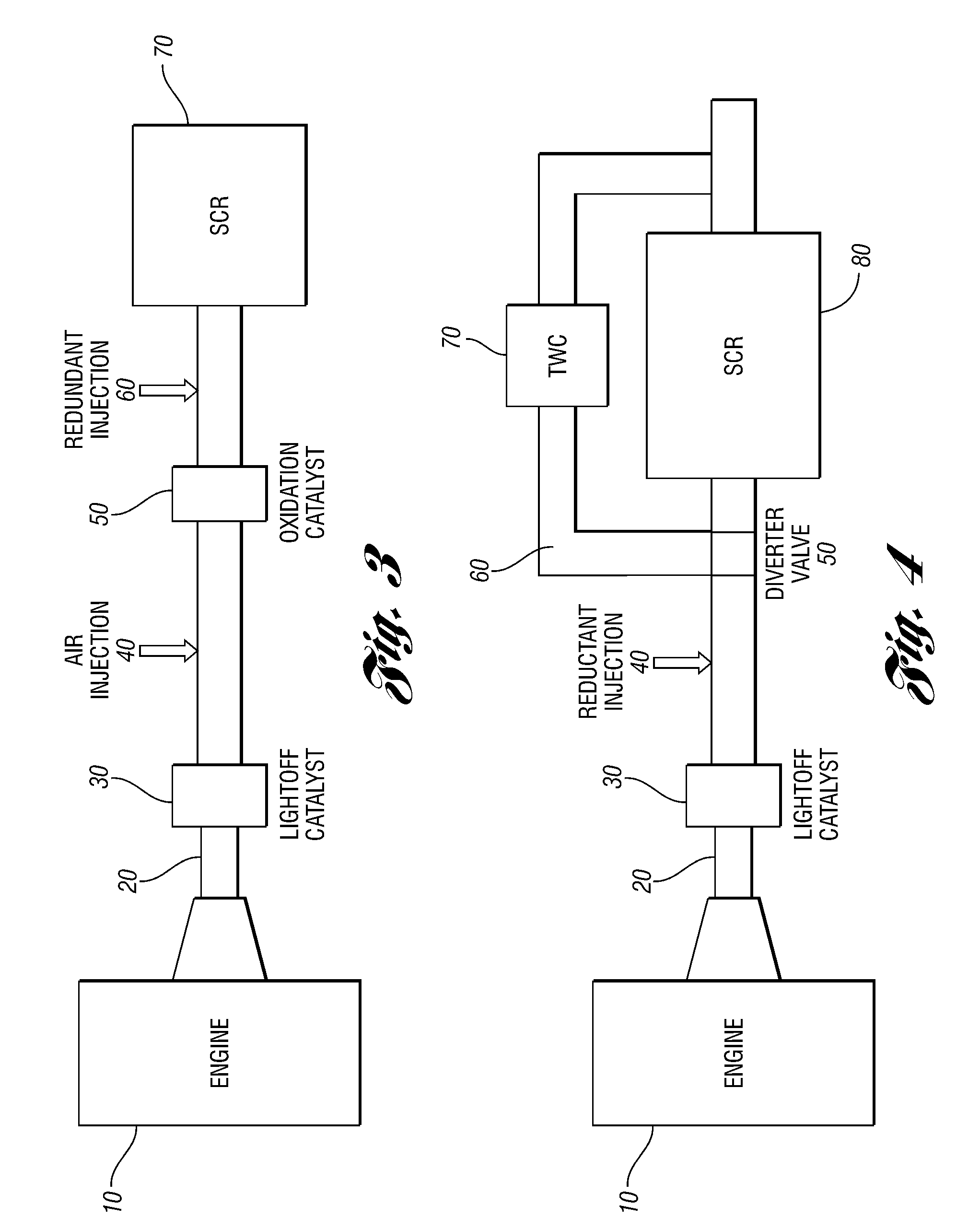

Air-injection system to improve effectiveness of selective catalytic reduction catalyst for gasoline engines

InactiveUS20090260349A1Increased durabilityHarmful emissionGas treatmentInternal combustion piston enginesGasolineEngineering

Embodiments are described to improve the durability of a lean NOx aftertreatment system. According to one embodiment of the present invention an air injection system is used to inject air continuously into the exhaust system between the upstream three-way catalyst and the downstream selective catalytic reduction (SCR) catalyst when the engine is operating at stoichiometric or rich air / fuel ratios and the exhaust temperatures are above a calibratible level (e.g., 700° C.). In another embodiment, an oxidation catalyst is positioned downstream of the air injection point to prevent exothermic reactions from occurring on the SCR. In another embodiment, the reductant for the SCR is generated in-situ. In yet another embodiment, a diverter valve with a reduction catalyst in a bypass arm is utilized to bypass the SCR during high load conditions.

Owner:FORD GLOBAL TECH LLC

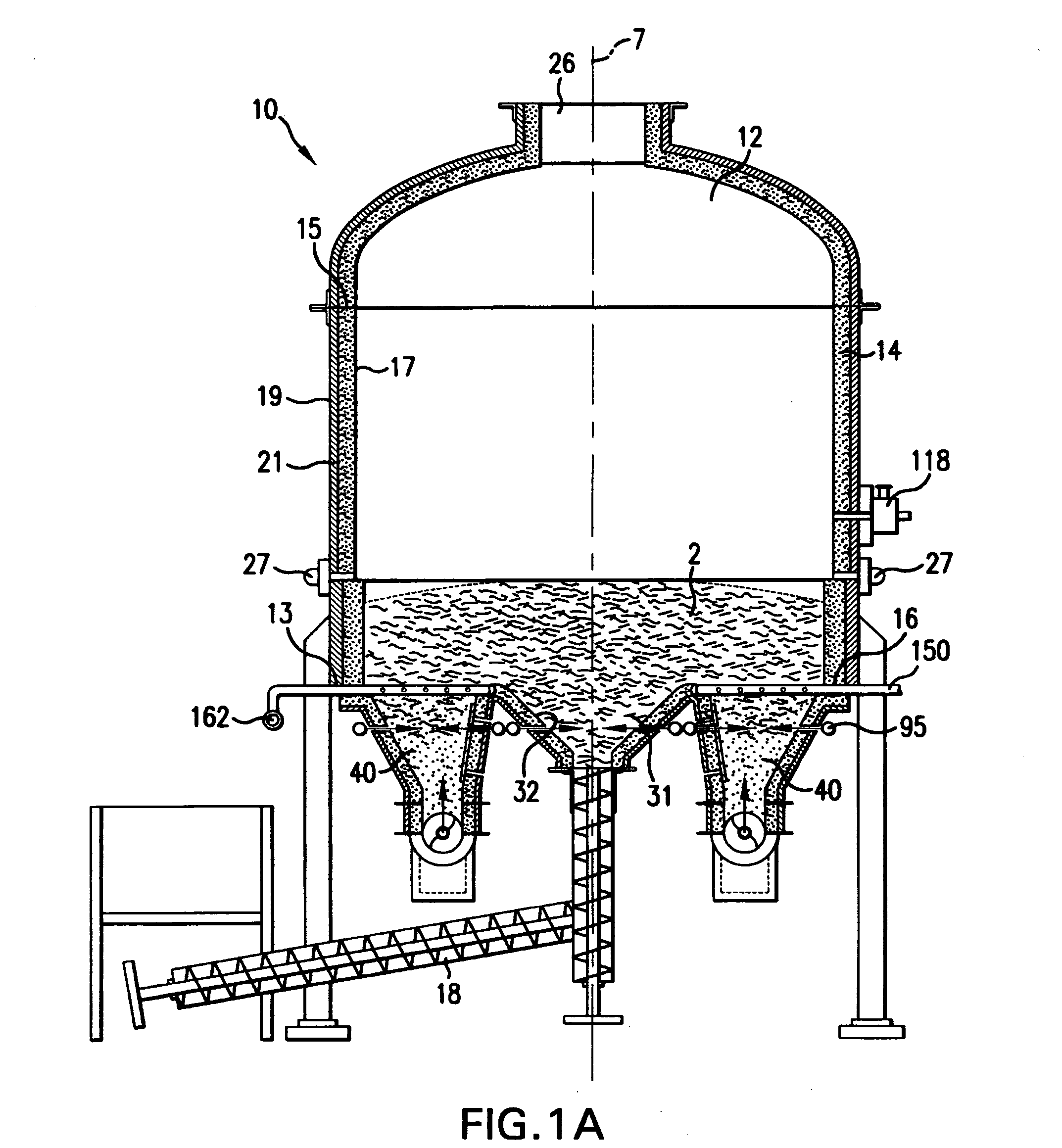

Method and apparatus for making crystalline PET pellets

InactiveUS7157032B2Reduce dwell timeImprove heating conditionsMouldsDrying solid materials without heatPolyethylene terephthalateSlurry

Owner:GALA INDUSTRIES INC

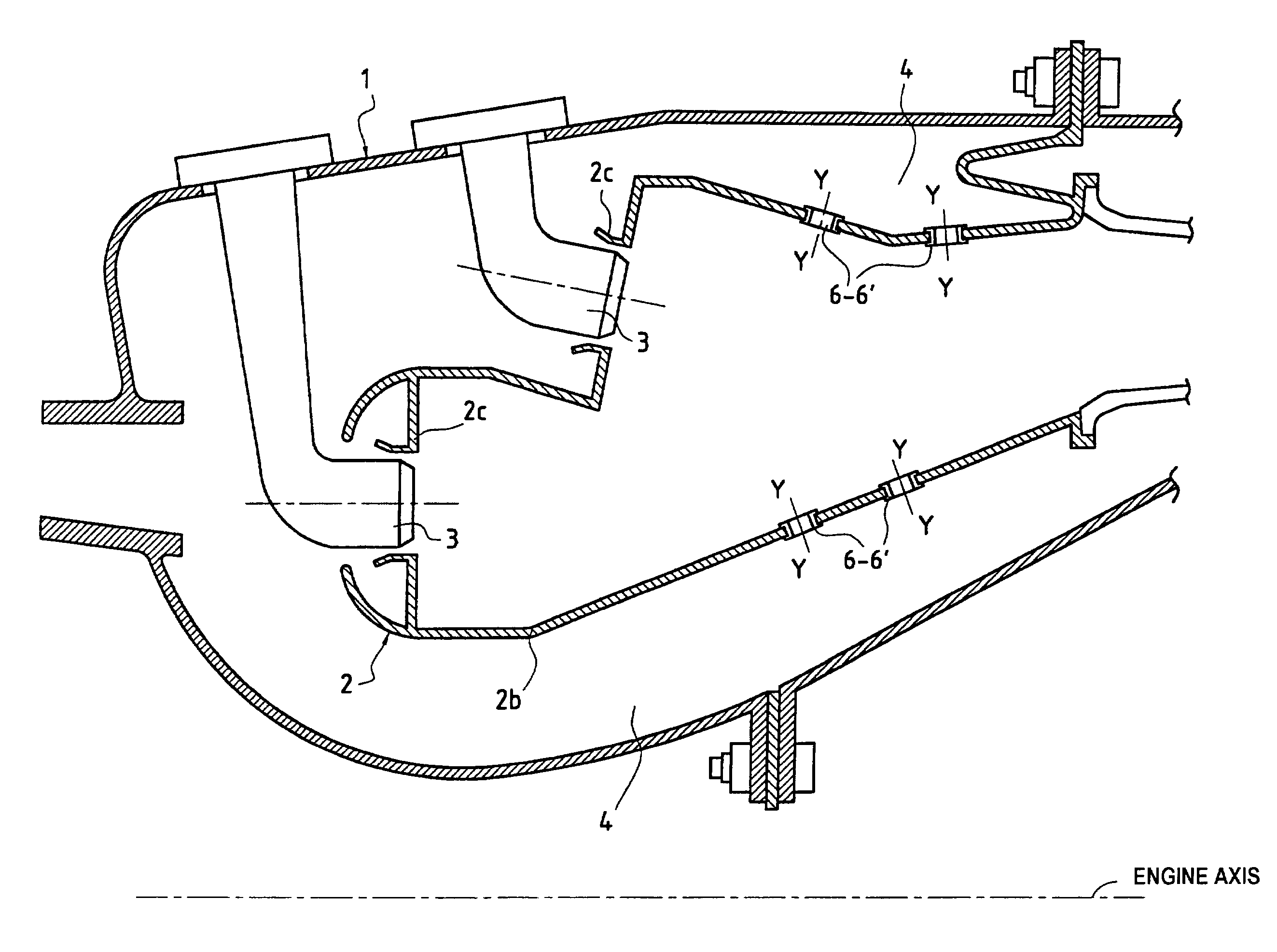

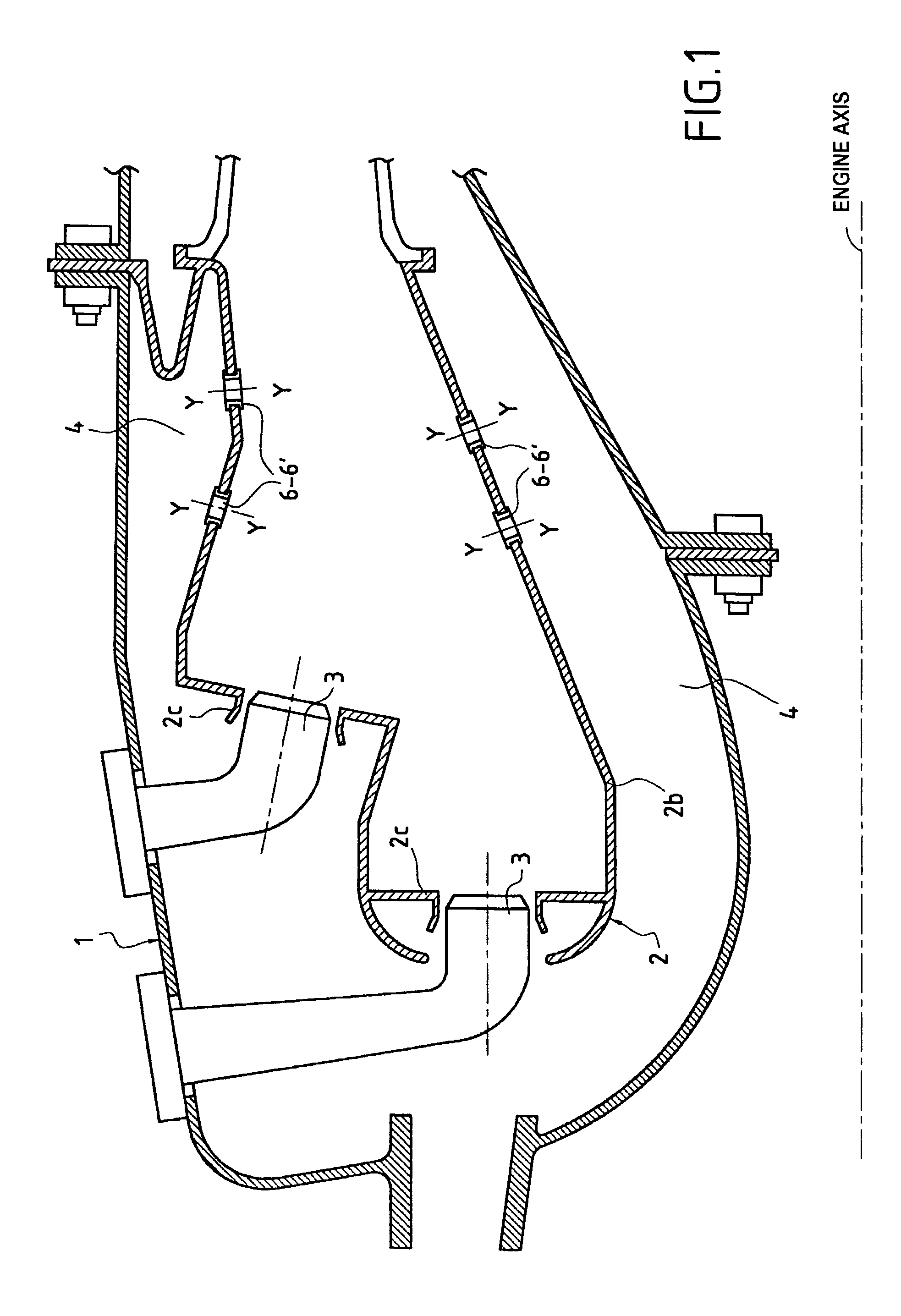

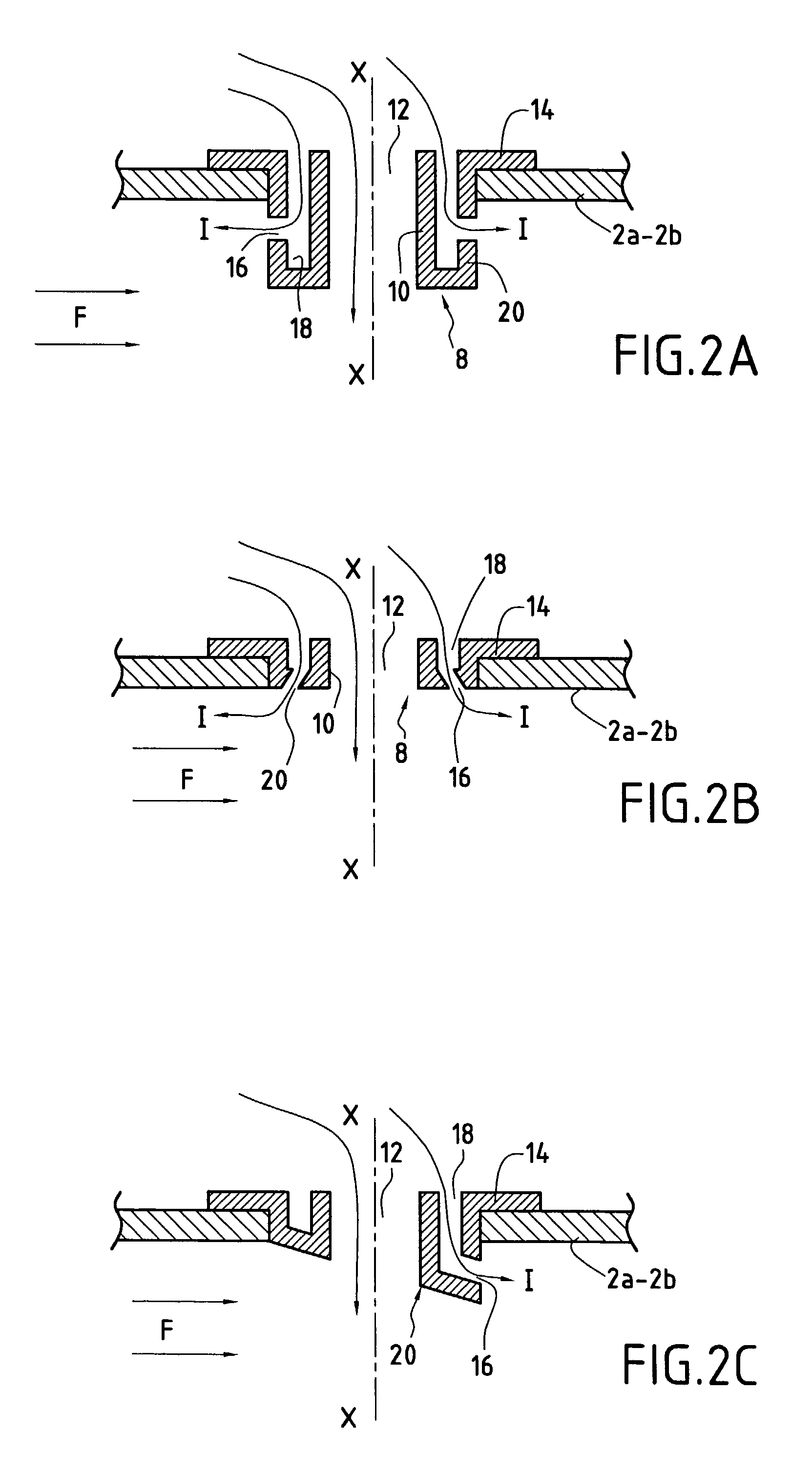

Gas turbine combustion chambers

InactiveUS20020189260A1Improve temperature behaviorMitigate such drawbackContinuous combustion chamberGas turbine plantsCombustion chamberInjection air

A combustion chamber for a gas turbine made up of outer and inner side walls, the combustion chamber being received in a casing so as to define an annular space between the combustion chamber and the casing in which there flows air for combustion, for dilution, and for cooling the combustion chamber, the side walls of the combustion chamber being pierced by a plurality of holes in which bushings of substantially elliptical right section are fixed to define air injection passages for injecting air into the combustion chamber, each bushing having a peripheral wall in which at least one additional orifice is formed opening out into the combustion chamber in the immediate vicinity of the side wall of the combustion chamber in which said bushing is fixed so that the air passing through said orifice flows substantially along said peripheral wall, the peripheral wall of each bushing having at least one groove opening out into the annular space and into which the or each orifice opens out so as to be fed with air and so as to cool the peripheral wall of the bushing.

Owner:SNECMA MOTEURS SA

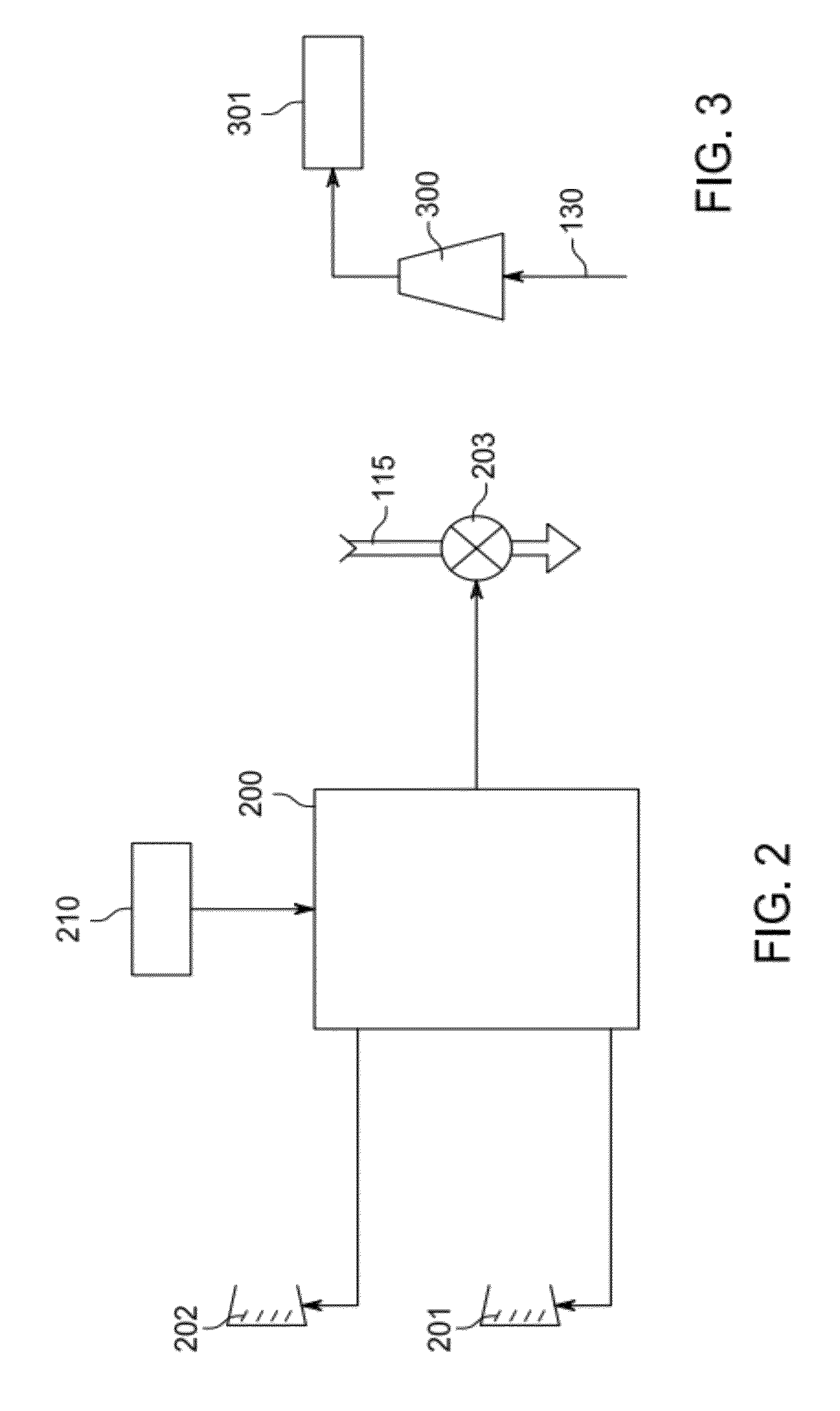

System and Method for Reducing Back Pressure in a Gas Turbine System

InactiveUS20140230444A1Reduce back pressureReduce airflowEngine manufactureTurbine/propulsion engine coolingExhaust fumesInjection air

In a first embodiment, a system, including an exhaust duct configured to flow an exhaust gas, and an air injection system coupled to the exhaust duct, wherein the air injection system comprises a first air injector configured to inject air into the exhaust duct to assist flow of the exhaust gas through the exhaust duct.

Owner:GENERAL ELECTRIC CO

Gas turbine engine combustor can with trapped vortex cavity

A gas turbine engine combustor can downstream of a pre-mixer has a pre-mixer flowpath therein and circumferentially spaced apart swirling vanes disposed across the pre-mixer flowpath. A primary fuel injector is positioned for injecting fuel into the pre-mixer flowpath. A combustion chamber surrounded by an annular combustor liner disposed in supply flow communication with the pre-mixer. An annular trapped dual vortex cavity located at an upstream end of the combustor liner is defined between an annular aft wall, an annular forward wall, and a circular radially outer wall formed therebetween. A cavity opening at a radially inner end of the cavity is spaced apart from the radially outer wall. Air injection first holes are disposed through the forward wall and air injection second holes are disposed through the aft wall. Fuel injection holes are disposed through at least one of the forward and aft walls.

Owner:GENERAL ELECTRIC CO

Gas turbine air injection system control and method of operation

ActiveUS20140373551A1Reliable generationIncrease ratingsEngine fuctionsGas turbine plantsPower stationInjection air

Owner:POWERPHASE

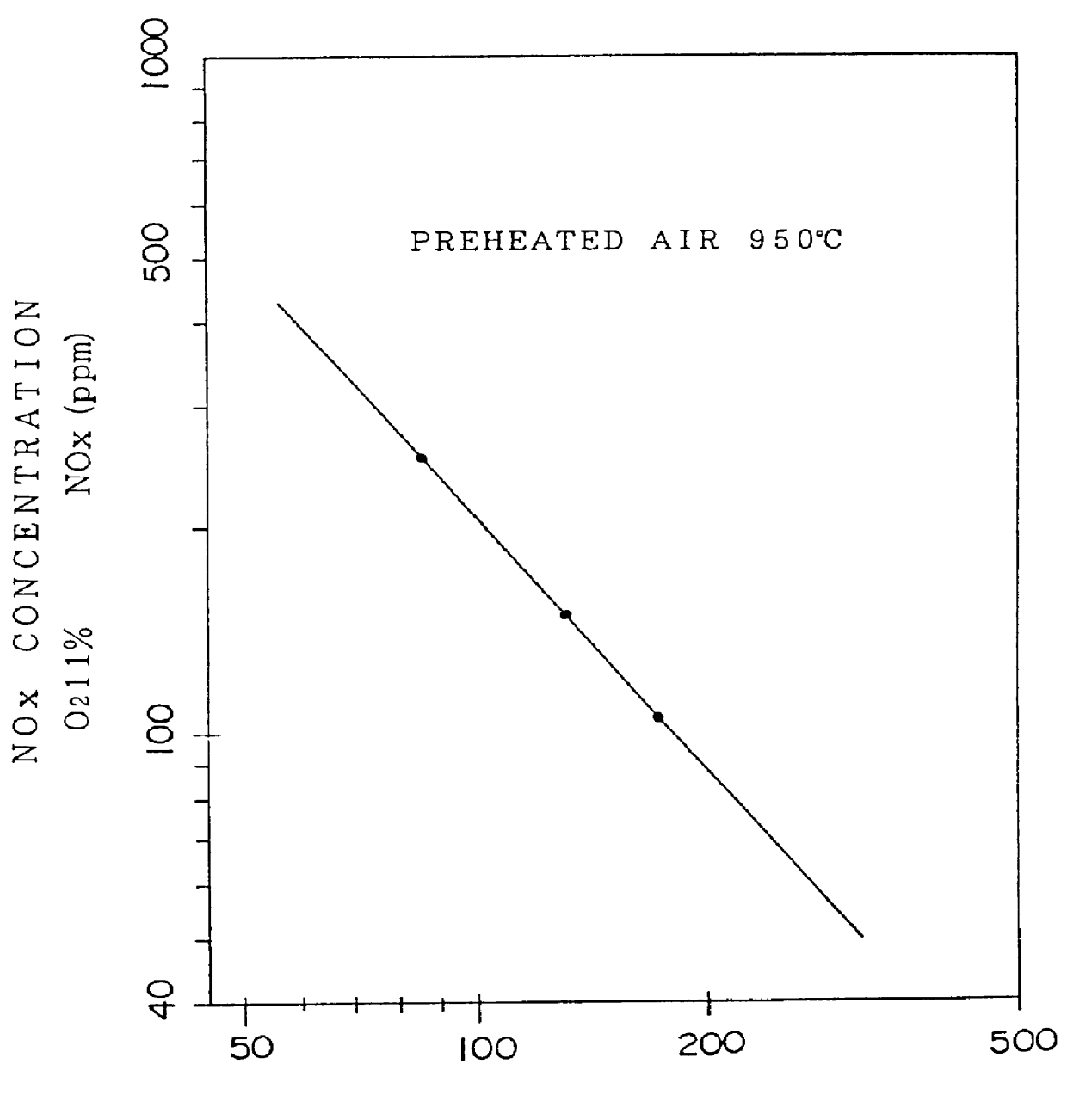

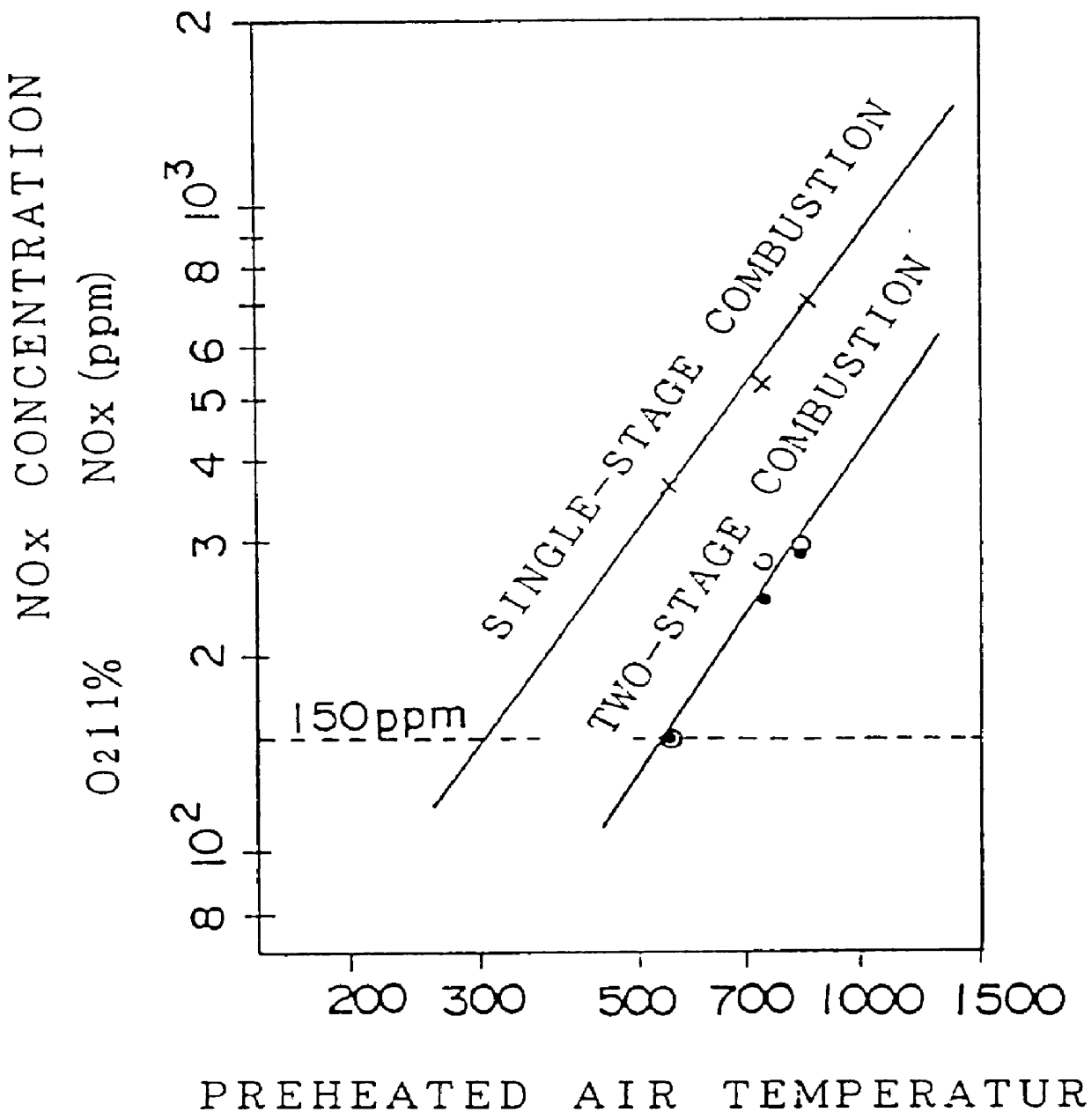

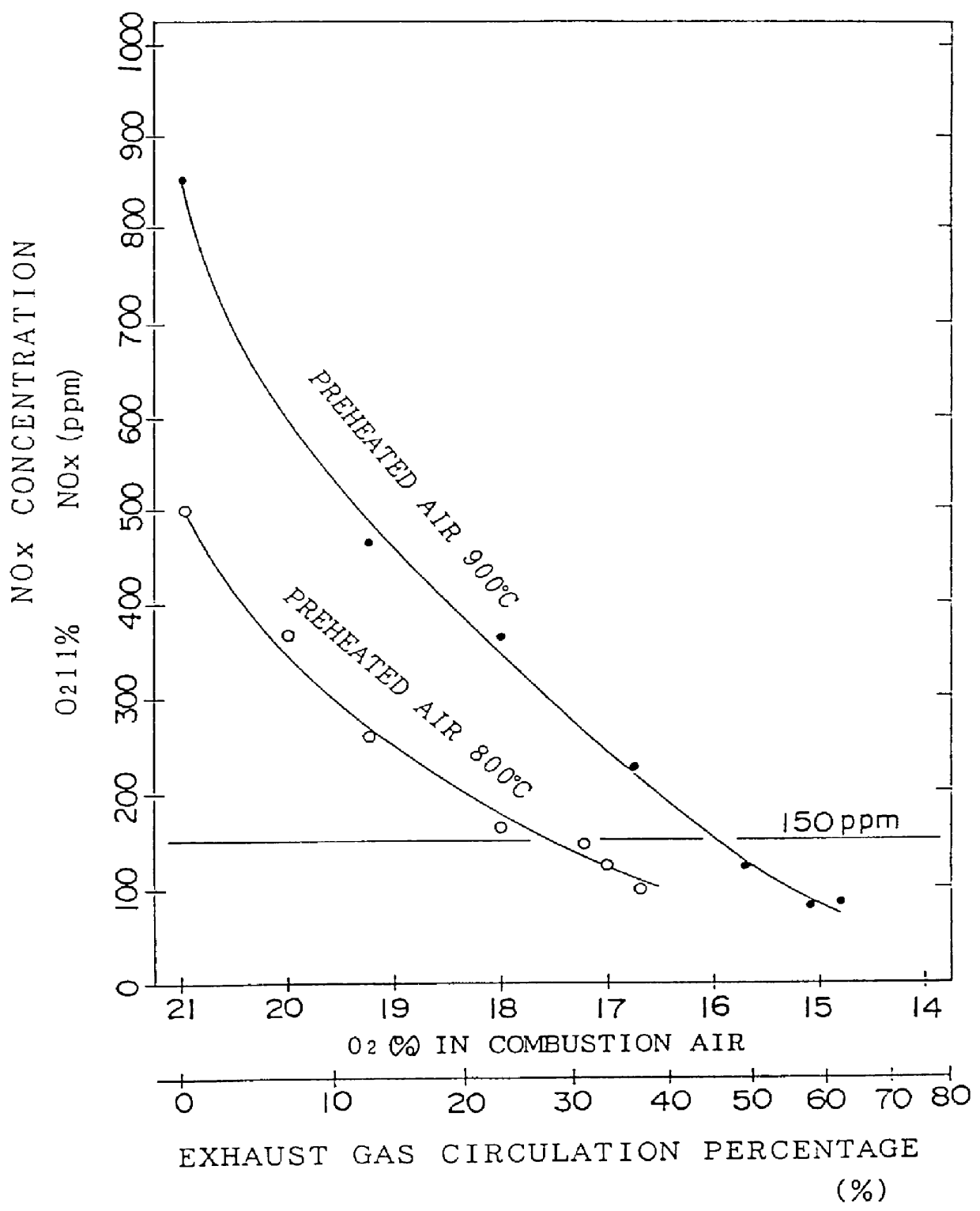

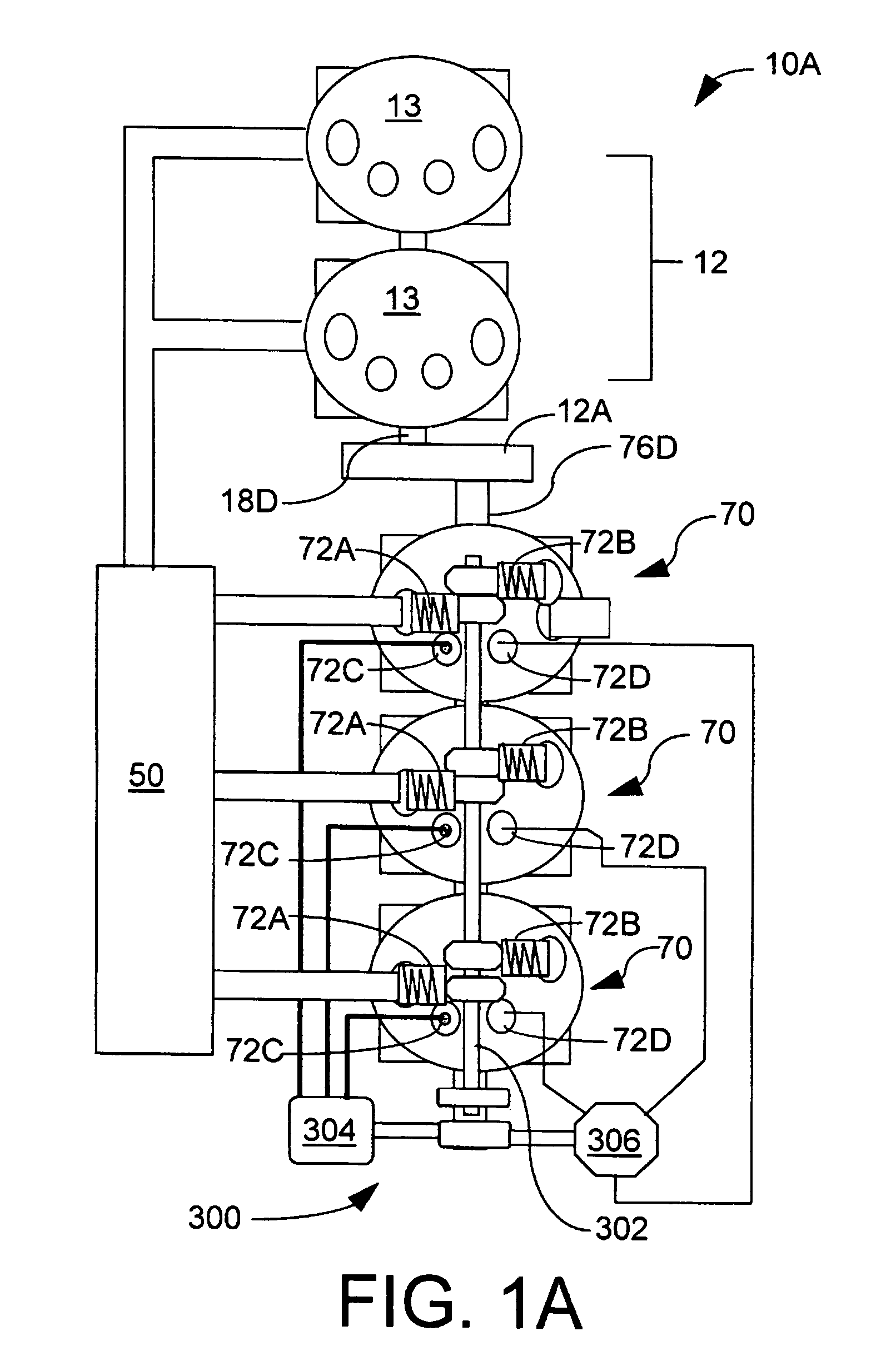

Radiant tube burner

PCT No. PCT / JP95 / 01916 Sec. 371 Date May 23, 1996 Sec. 102(e) Date May 23, 1996 PCT Filed Sep. 22, 1995 PCT Pub. No. WO96 / 09496 PCT Pub. Date Mar. 28, 1996With respect to a radiant tube burner to be used for heating a heating furnace or the like, to suppress the generation of NOx accompanying combustion, to make the structure thereof fit for a radiant tube burner equipment, to simplify the control of a fuel supply system and an air supply system, and to prevent the coking. Furthermore, to provide a combustion control scheme appropriate to a radiant tube burner. For these purposes, the present invention placed the respective tips of a fuel nozzle, e.g., pilot burner joint-use nozzle (11), and an air throat (13) in the end of a radiant tube (3) and moreover has a combustion air injection port (33) of the air throat (13) provided to be deviated in contact with or near to the inner circumferential wall surface of the radiant tube (3). In addition, a control device (307) for making a burner burn alternately.

Owner:NIPPON KOKAN KK +1

Method and apparatus for making crystalline PET pellets

InactiveUS20050110184A1Reduce dwell timeImprove heating conditionsMouldsDrying solid materials without heatPolyethylene terephthalateSlurry

A method and apparatus for underwater pelletizing and subsequent drying of polyethylene terephthalate (PET) polymers and other high temperature crystallizing polymeric materials to crystallize the polymer pellets without subsequent heating. High velocity air or other inert gas is injected into the water and pellet slurry line to the dryer near the pelletizer exit. The slurry line has a substantially straight component, and air is preferably injected at the end of the straight component nearest the pelletizer exit and in a direction substantially coincident with the axis of the straight component. The air injection significantly increases the speed of the pellets into and out of the dryer such that the PET polymer pellets leave the dryer above at least 135° C., and preferably above 145° C., to self-initiate crystallization.

Owner:GALA INDUSTRIES INC

Air mattress

InactiveUS7254853B1Prevented from expandingAvoid expansionStuffed mattressesSpring mattressesFiberEngineering

An air mattress is disclosed, which comprises an upper raw material member which has a coating layer at an upper surface of the same; a lower raw material which is spaced and installed at a lower side of the upper raw material member and has a coating layer at a lower surface of the same; a plurality of fiber threads which vertically connect the upper and lower raw material members and react with respect to an external pressure; a coated side raw material which is fixedly engaged to seal a surrounding portion between the upper and lower raw material members; and an air injection valve engaged at one side of the side raw material. A force distribution function is excellently performed when an external impact is applied to the air mattress according to the present invention, so that a distortion phenomenon of the product is prevented. It is possible to prevent the sides of the air mattress from being abnormally expanded by the side raw material bonded to the upper raw material member and the lower raw material member.

Owner:KIM WORL SUNG

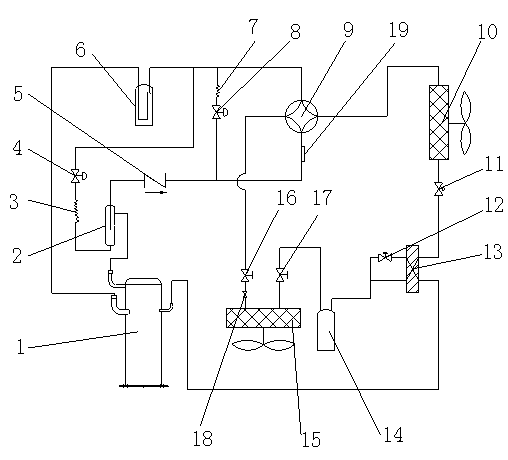

Enhanced vapor injection air-conditioning circulating system and control method thereof

ActiveCN103471275AImprove heating effectGuaranteed uptimeCompression machines with reversible cycleRefrigeration safety arrangementVapor–liquid separatorFour-way valve

The invention relates to a central air-conditioning system, in particular to a duct air conditioner, namely an enhanced vapor injection air-conditioning circulating system. A vapor injection side electronic expansion valve of the system is subject to discharge superheat control instead of vapor injection superheat control; high discharge superheat is guaranteed, and heating capacity of the system can be further improved by vapor injection; the system is especially applicable to variable frequency compressors; high heating capacity is kept even under different operating frequencies; the system operates stably and fluctuates little. The enhanced vapor injection air-conditioning circulating system comprises a controller, a compressor, a four-way valve, a vapor-liquid separator, an economizer, a solenoid valve and a coolant pipe. The compressor is a variable frequency compressor. The economizer is a plate economizer. The electronic expansion valve controls vapor injection. The vapor injection electronic expansion valve is subject to discharge superheat control instead of vapor injection superheat control; accordingly, high discharge superheat is guaranteed, and heating capacity of the system is further improved by vapor injection. The system is especially applicable to variable frequency compressors; the heating capacity is kept even under different operating frequencies; the system operates stably and fluctuates little.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

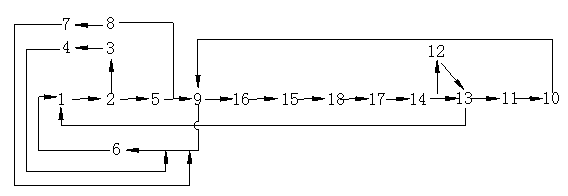

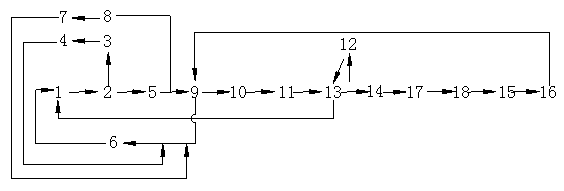

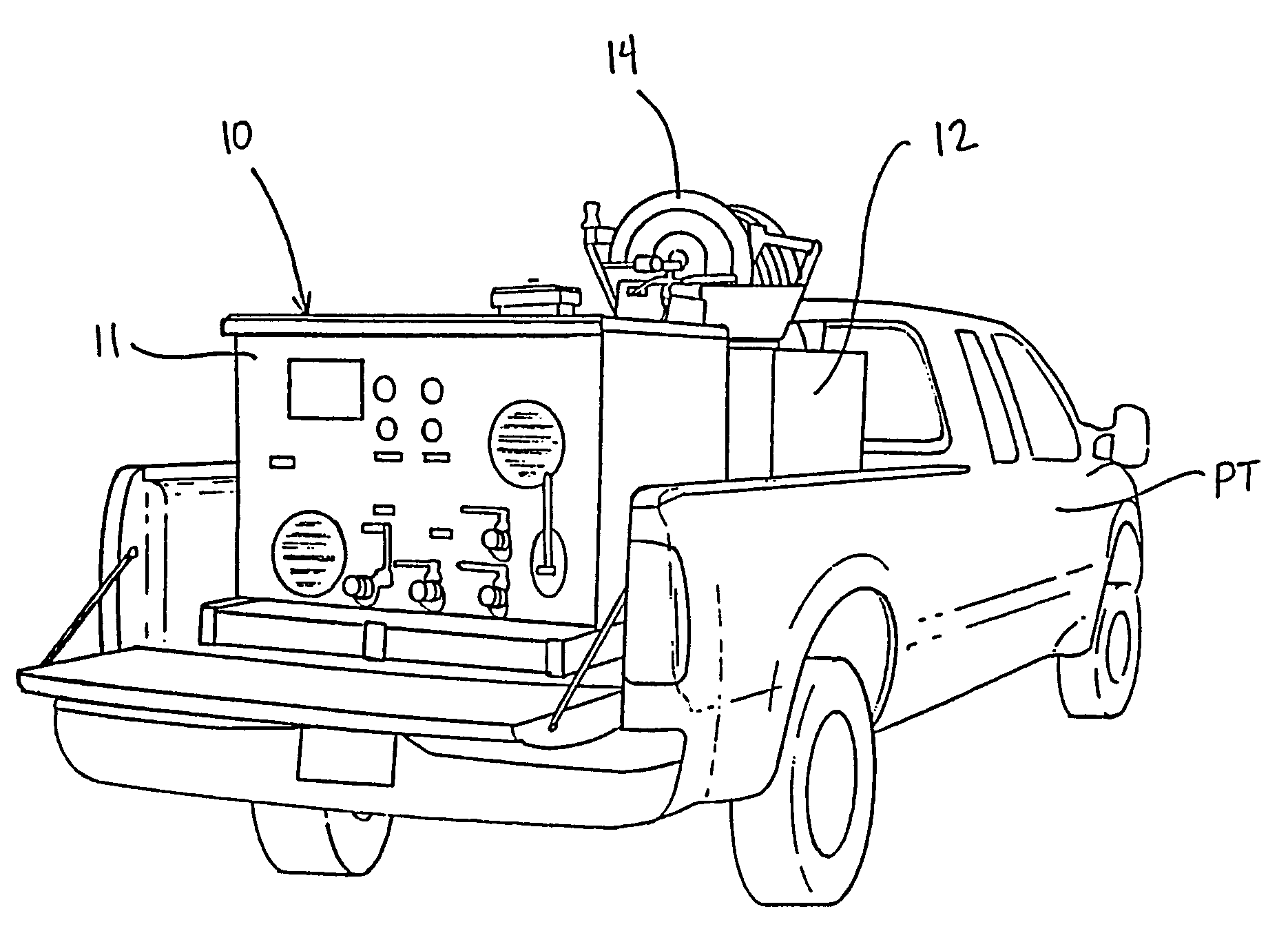

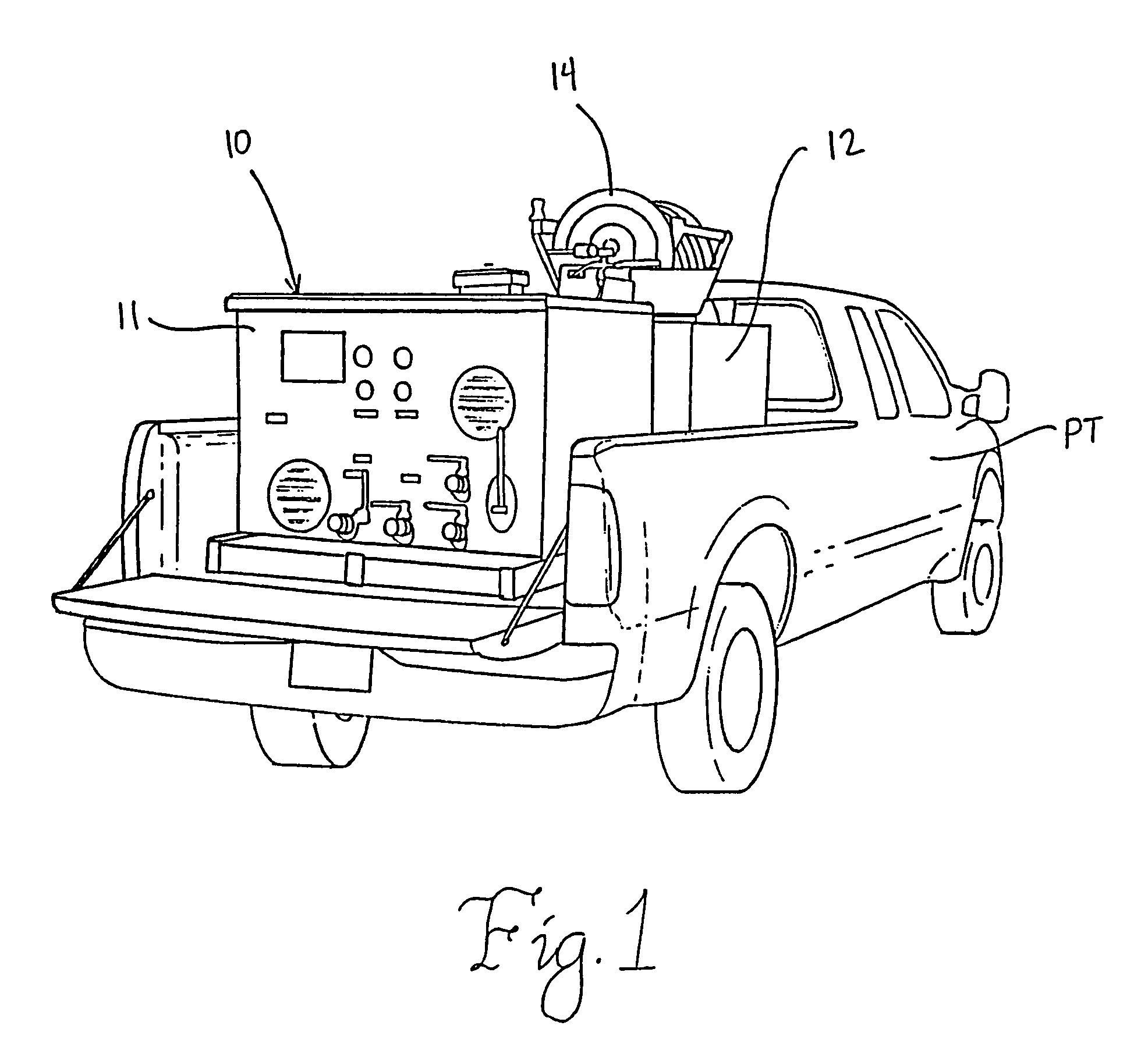

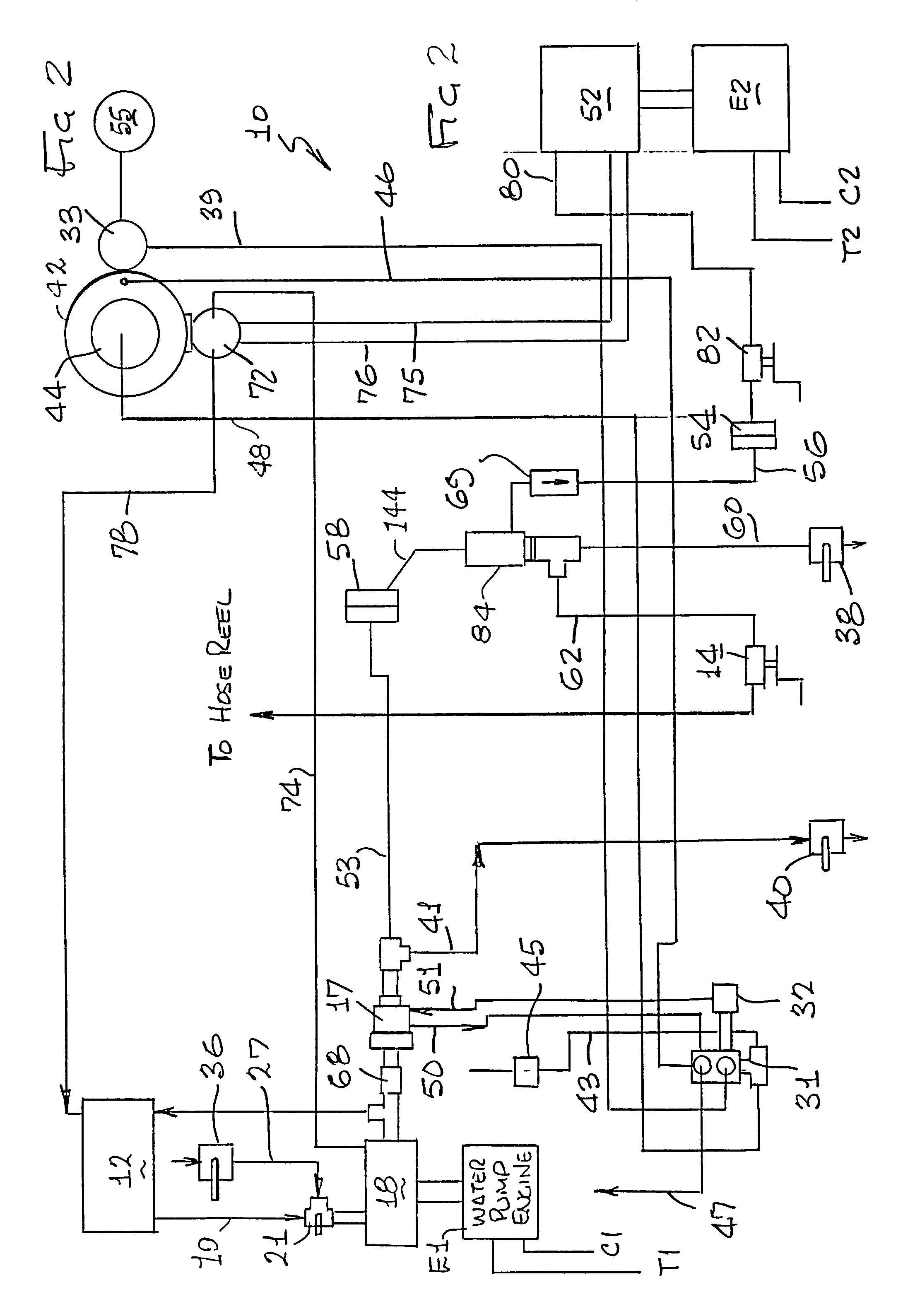

Universal transportable compressed air foam fire fighting system

A compressed air / foam fire fighting system which is sufficiently compact to be carried on the bed of a pick-up truck includes a water tank, a pump for providing water at substantial pressure to a water conduit, an engine for driving the pump, a foam reservoir including a bladder tank connected to the pump, an air compressor, an engine for driving the air compressor, a differential pressure valve connected in the water conduit, a metering valve adjustable to supply a desired proportion of foam concentrate to water connected across the differential pressure valve, an air valve for controlling the amount of air from said compressor, and an air injection venturi for mixing air into a water / foam concentrate. A two-way valve connected between the tank and the pump is movable between a first position where water is pumped from the water tank and a second or suction position where water is drawn from an outside tank or other source. The system can supply plain water, a water / foam mixture, a mixture of compressed air, water, and foam, or compressed air only.

Owner:ROBWEN

Air injection engine

InactiveUS7007639B1Improve power densityHigh expansion rateInternal combustion piston enginesOutput powerCombustionExternal combustion engine

An internal combustion engine of the present invention features separate compression and expansion cycles. The engine includes a separate compressor device which pressurizes air by a ratio greater than 15 to 1, at least one two stroke combustion cylinder and a compressed air conduit for transferring compressed air from the compressor to the at least one combustion cylinder. An air injection valve injects the compressed air into the combustion cylinder during the second half portion of the return stroke of the combustion cylinder. The compressed air is mixed with fuel and combusted for expansion during a power stroke. In this engine compression occurs only to a minor degree in the combustion cylinder. Accordingly, the compression ratio of the present engine may be significantly higher or lower than the volumetric expansion ratio of the combustion cylinder thus resulting in corresponding increases in either power density or thermodynamic efficiency respectively.

Owner:D J ENG

Method and apparatus for making crystalline pet pellets

InactiveUS20070132134A1Reduce dwell timeImprove heating conditionsMouldsDrying solid materials without heatPolyethylene terephthalateSlurry

Owner:GALA IND INC

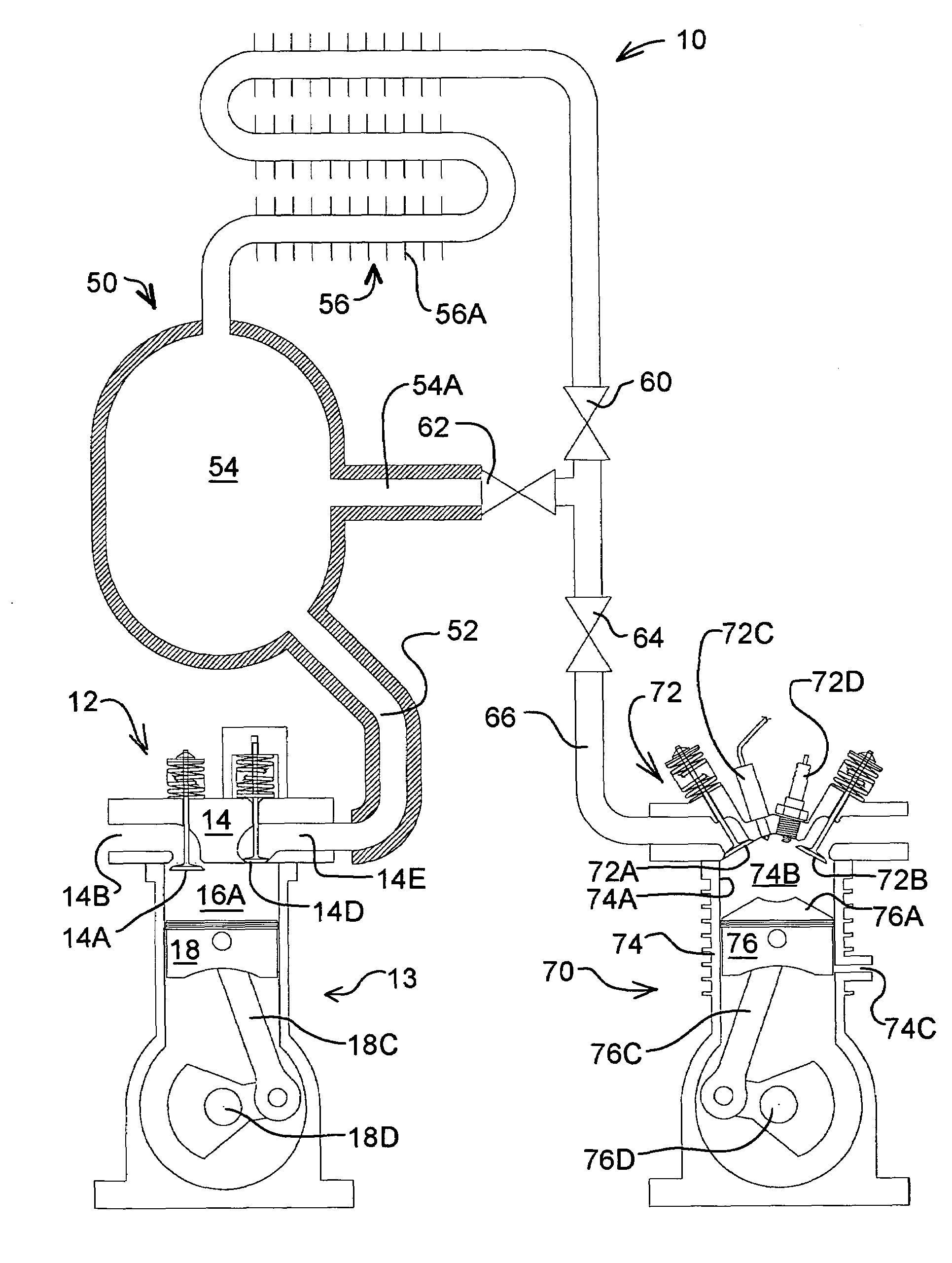

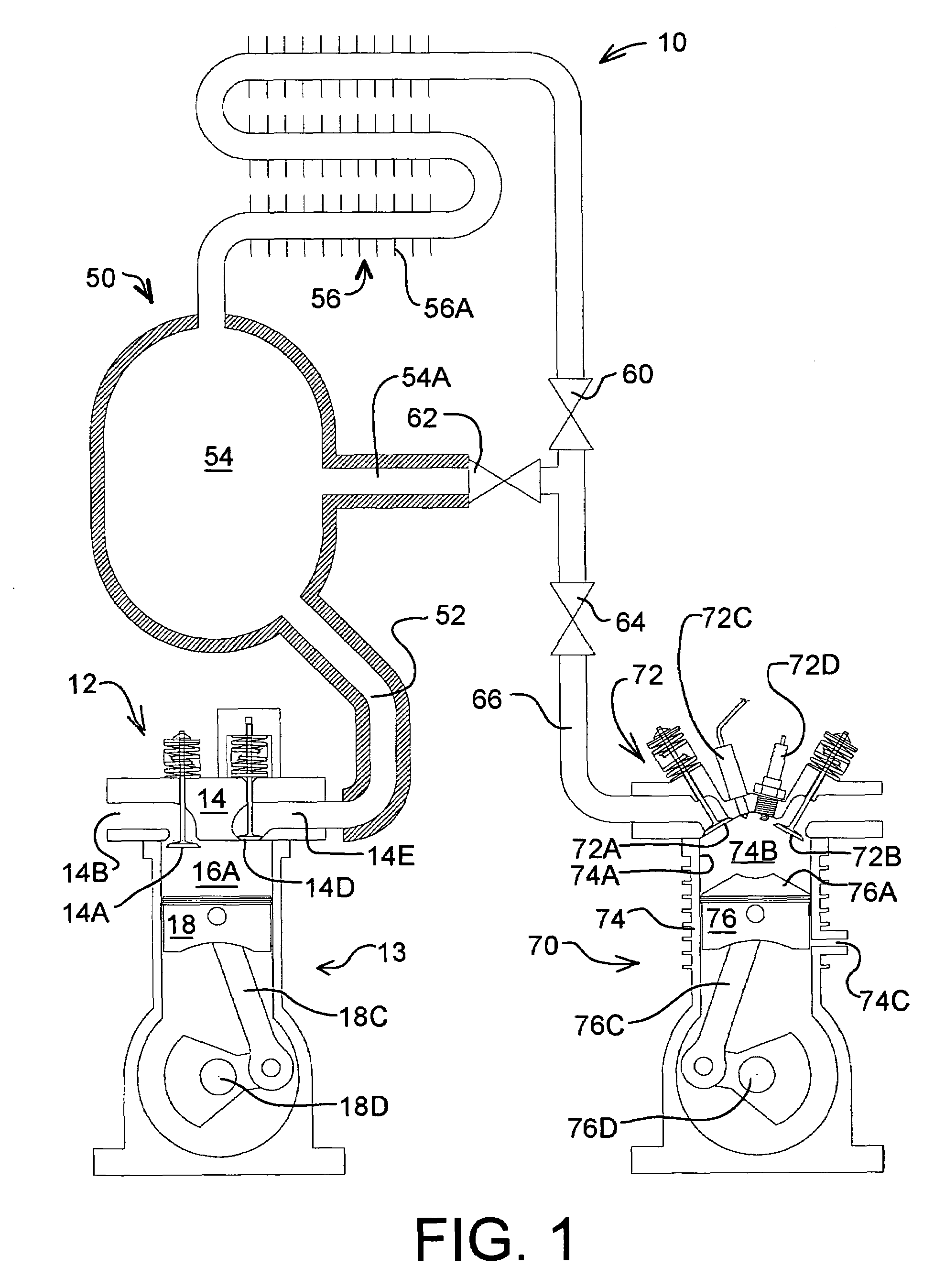

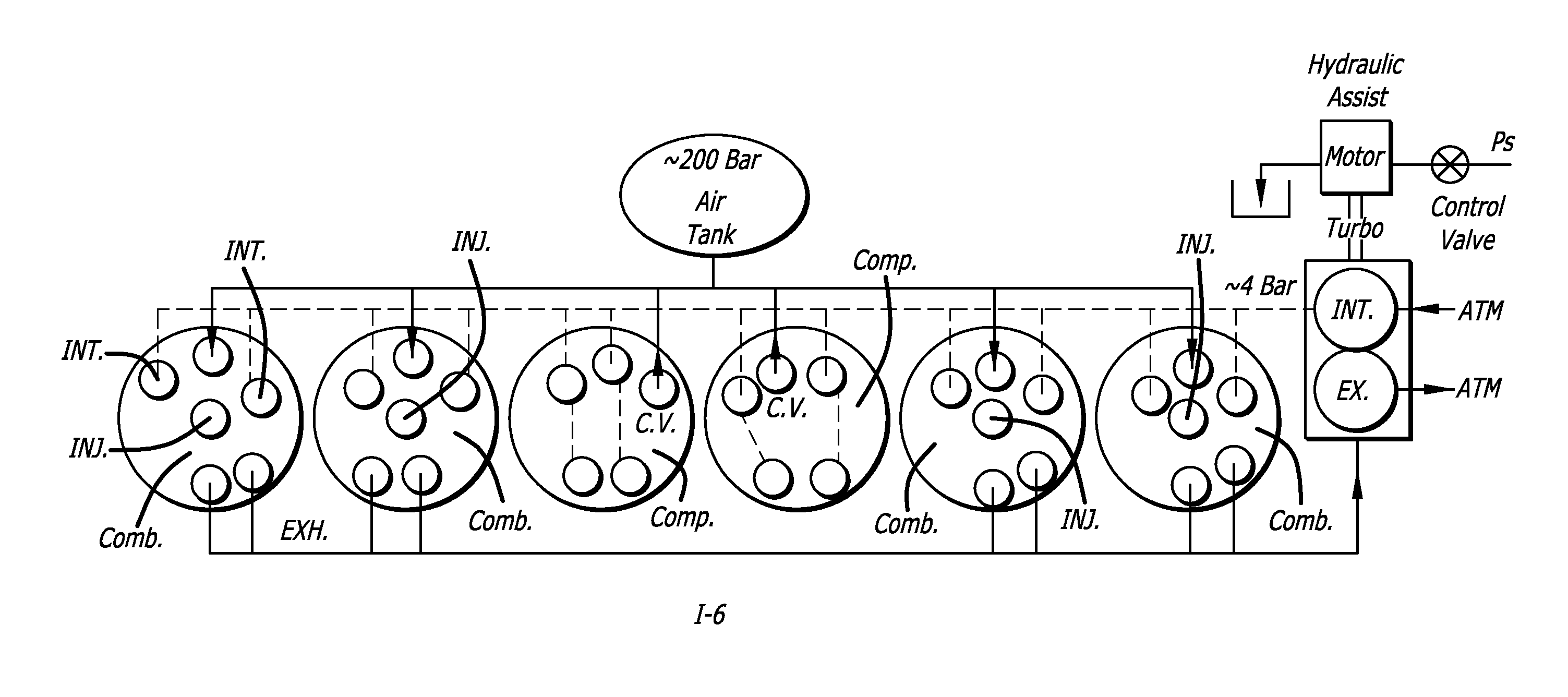

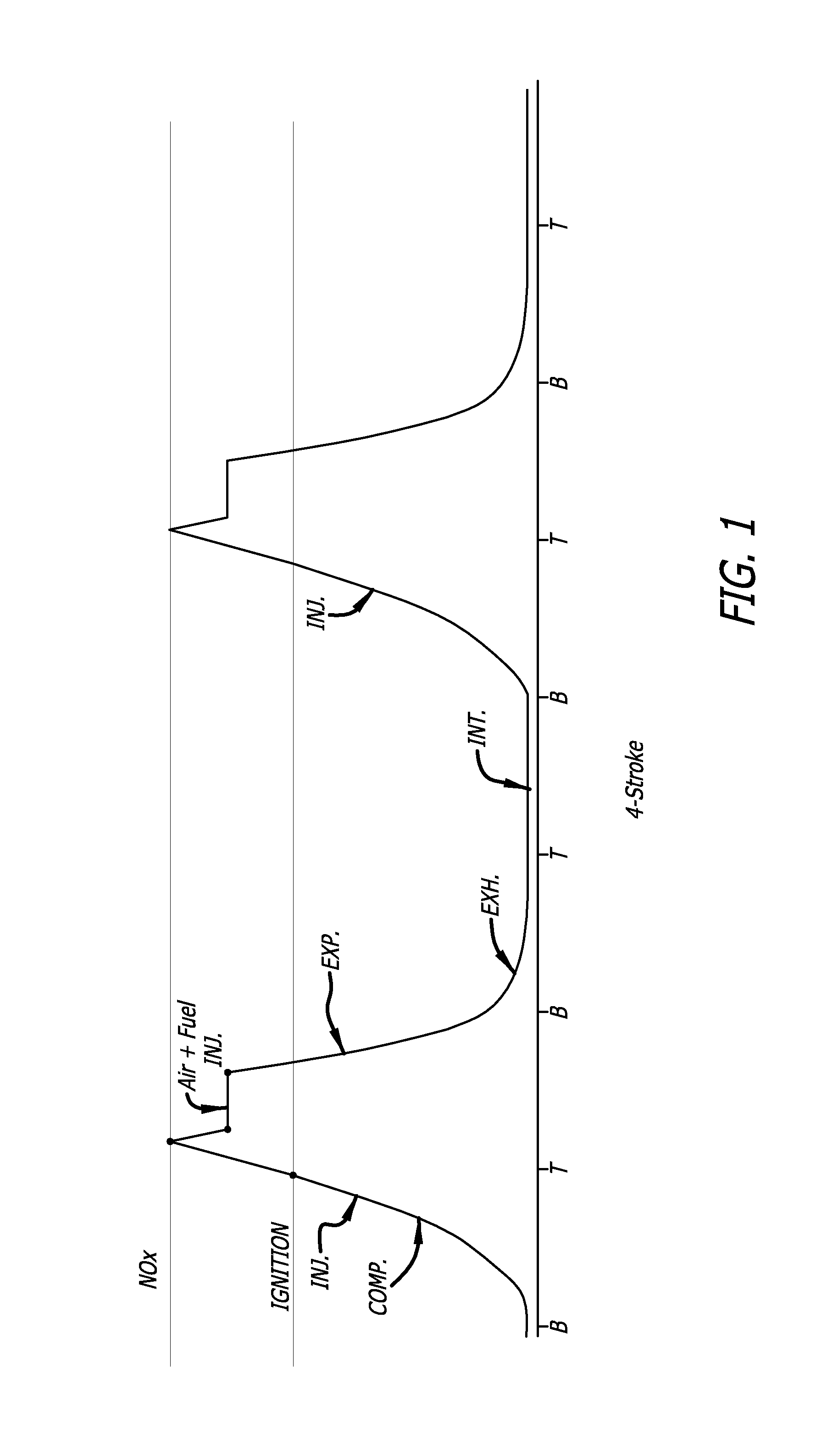

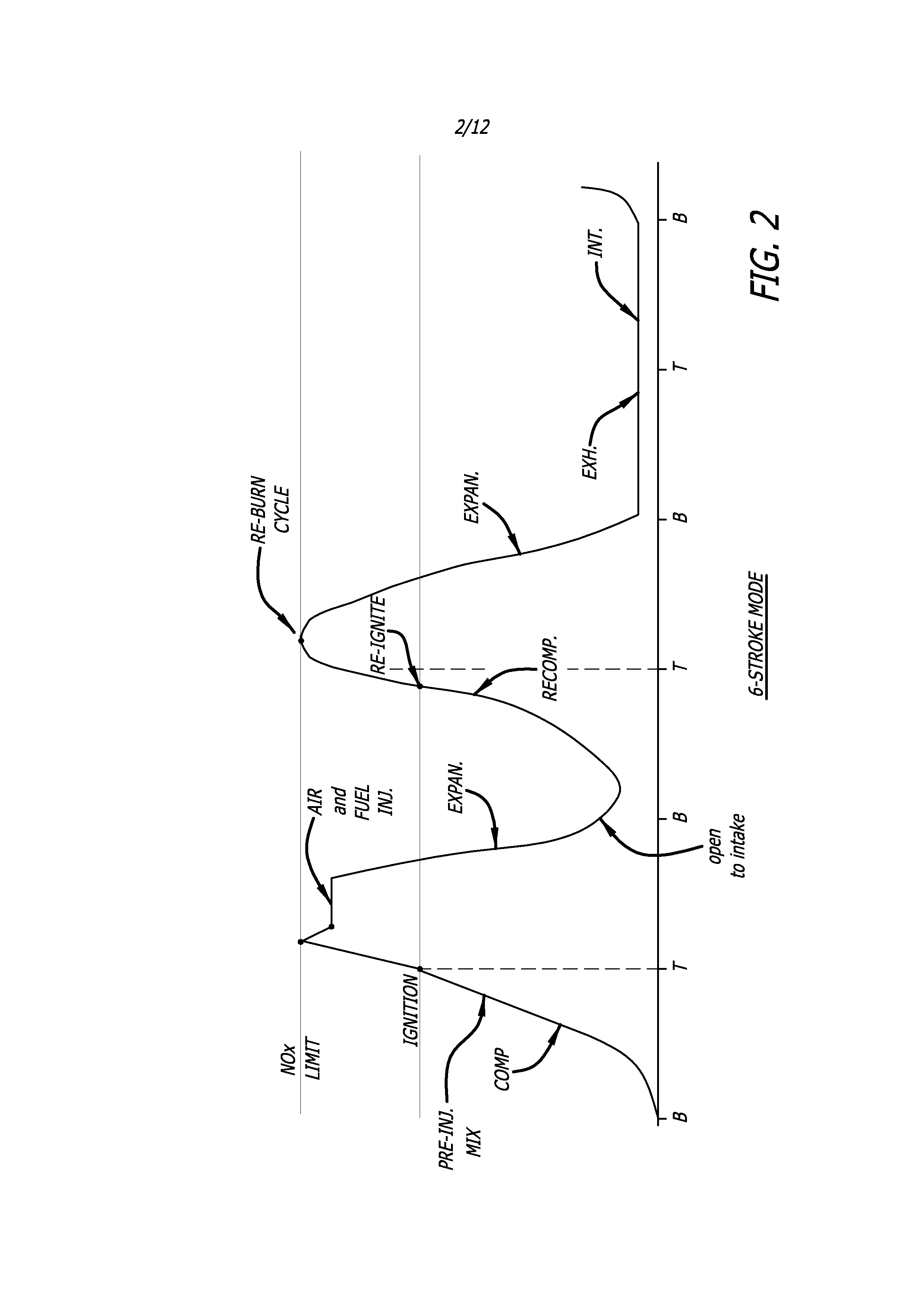

High performance, low emission engines, multiple cylinder engines and operating methods

ActiveUS7954472B1Electrical controlInternal combustion piston enginesCombustion chamberExhaust valve

High performance, low emission engines, multiple cylinder engines and operating methods based on compression ignition of a combustion chamber charge. In accordance with the methods, fuel is injected into the combustion chamber after the exhaust valve closes, and air is injected into the combustion cylinder before the end of the compression stroke in an amount to limit the temperature after ignition to less than the temperature at which NOX forms. After ignition and during the power stroke, more air is injected into the combustion chamber to sustain combustion until all fuel is consumed, the air being injected so as to again limit the combustion temperatures to less than the temperature at which NOX forms. The air injected during the compression stroke is injected at substantially the same combustion chamber pressure as the air injected during the power stroke, so that air may efficiently be injected from the same pressurized source. The fuel injected into the combustion chamber may be all the fuel needed, or additional fuel may be injected during the power stoke.

Owner:STURMAN DIGITAL SYST

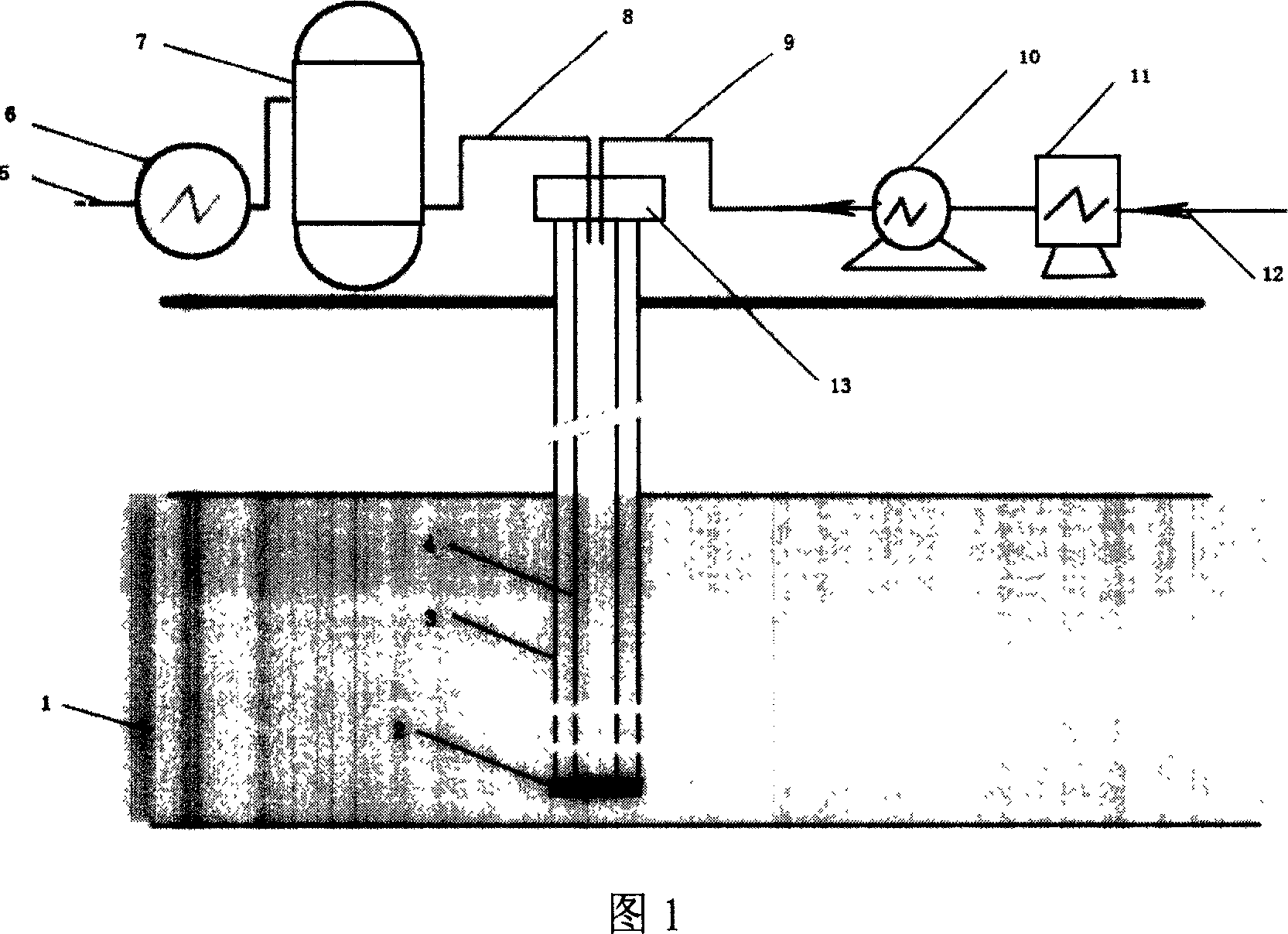

Exploitation technique for disgorging thick oil by pouring air to assistant steam

The present invention provides a method for production of heavy oil reservoir. It is technically characterized by that in the cyclic steam injection and steam-flooding process it utilizes air injection to raise recovery efficiency and engineering benefits. Said method includes the following steps: after the oil well is drilled, making casing sand control completion of heavy oil reservoir so as to inhibit sand inflow in after-production; constructing artificial bottom hole so as to resist high-pressure produced by injecting steam and high-pressure air; after well completion injecting hot steam (above 200 deg.C), and injecting air into same oil reservoir, reducing heavy oil viscosity, then closing well, making crude oil and oxygen gas produce oxidation reaction; after the wellhead pressure is stabilized, opening well and making production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

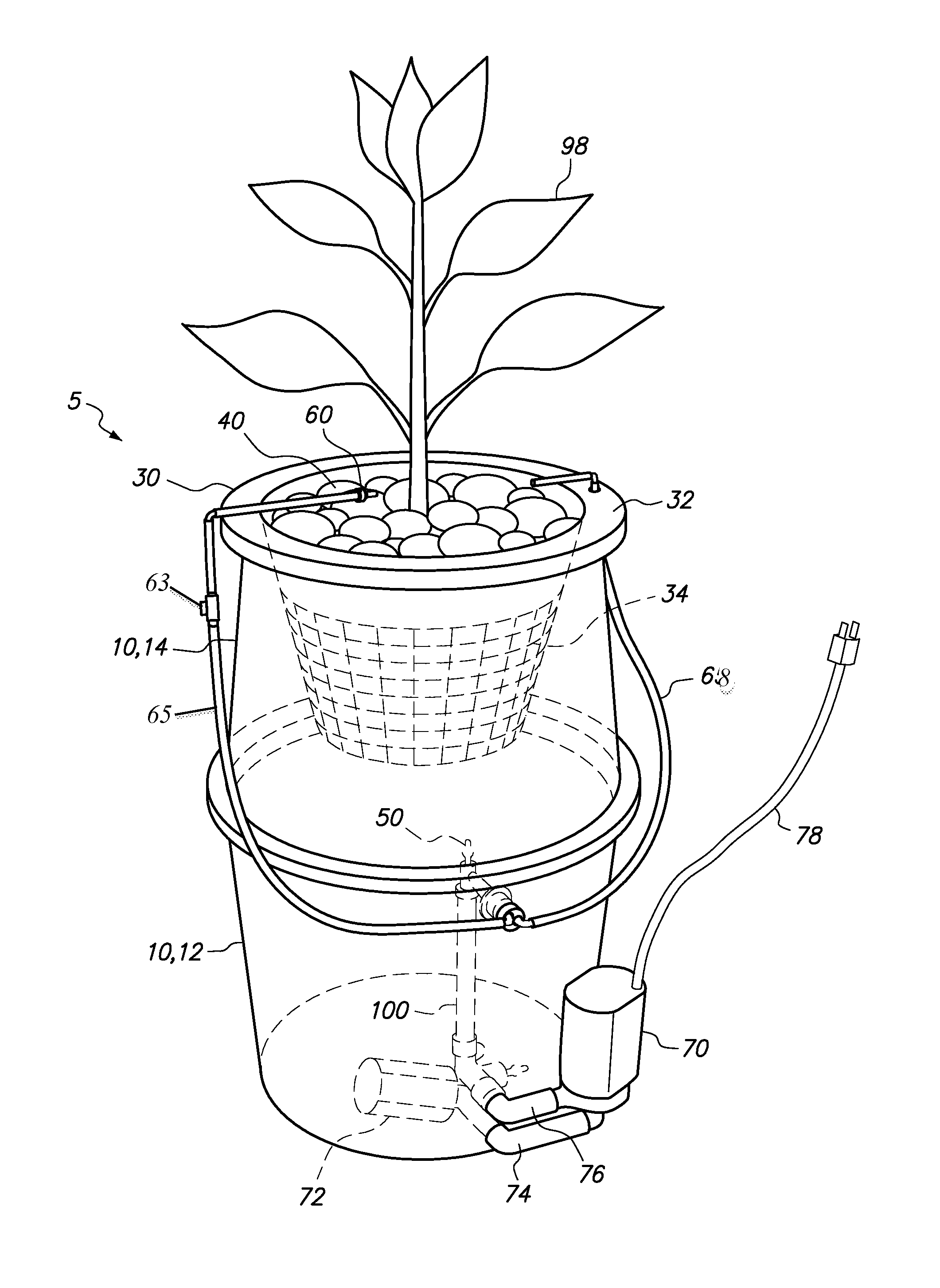

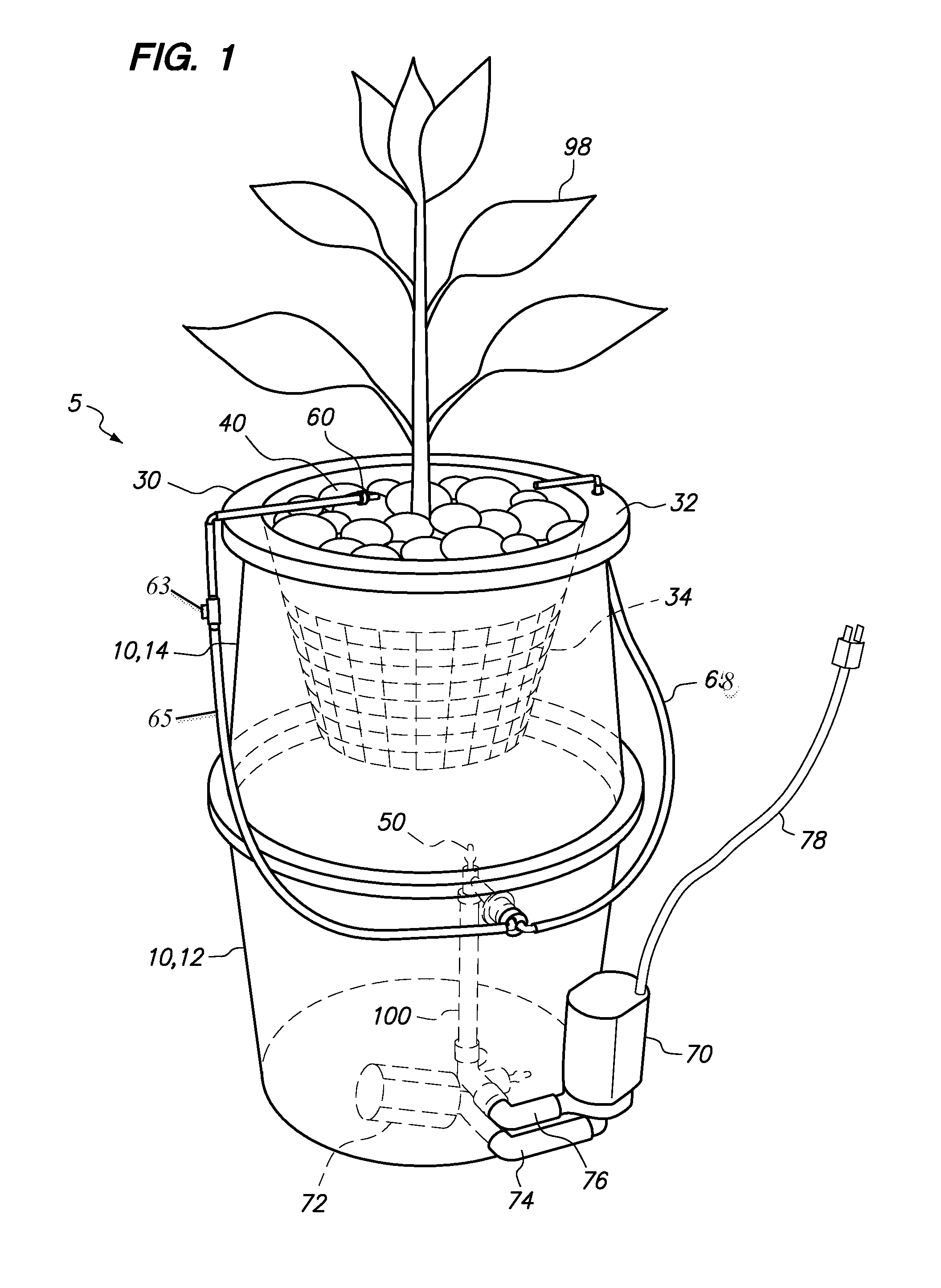

Hydroponic plant container with highly oxygenated nutrient solution using continuous air injection and continuous coriolis effect mixing

InactiveUS20130255152A1Increase dissolved oxygen levelsMaximize contactAgriculture gas emission reductionCultivating equipmentsPlant rootsNutrient solution

A hydroponic plant container with a reservoir of “highly oxygenated” nutrient solution that is the result of continuous direct air injection into the bottom of the reservoir, at a specific range of trajectories, along with continuous Coriolis effect mixing. The highly oxygenated nutrient solution is used to provide a deep water culture for the lower section of the plant roots, to saturate the middle section of the plant roots with fine droplets of the highly oxygenated nutrient solution, and to saturate the growing media and the upper section of the plants roots with a continuous drip of the highly oxygenated nutrient solution.

Owner:JOHNSON DAN +1

Hydrotherapy circulation and cleaning system

InactiveUS20050120473A1Reduce riskEasy to disassembleBathing devicesEnvironmental engineeringWater circulation

A spa, whirlpool or hot tub hydrotherapy system comprised of a unitized pump and motor assembly to provide a pipeless water circulation and air injection system that is easy to clean. The system can optionally provide an ionization device, which injects a stream of silver, copper and zinc ions into the water to kill bacteria, mold and algae, and solid-state lighting.

Owner:MCDOUGALL EUGENE MR

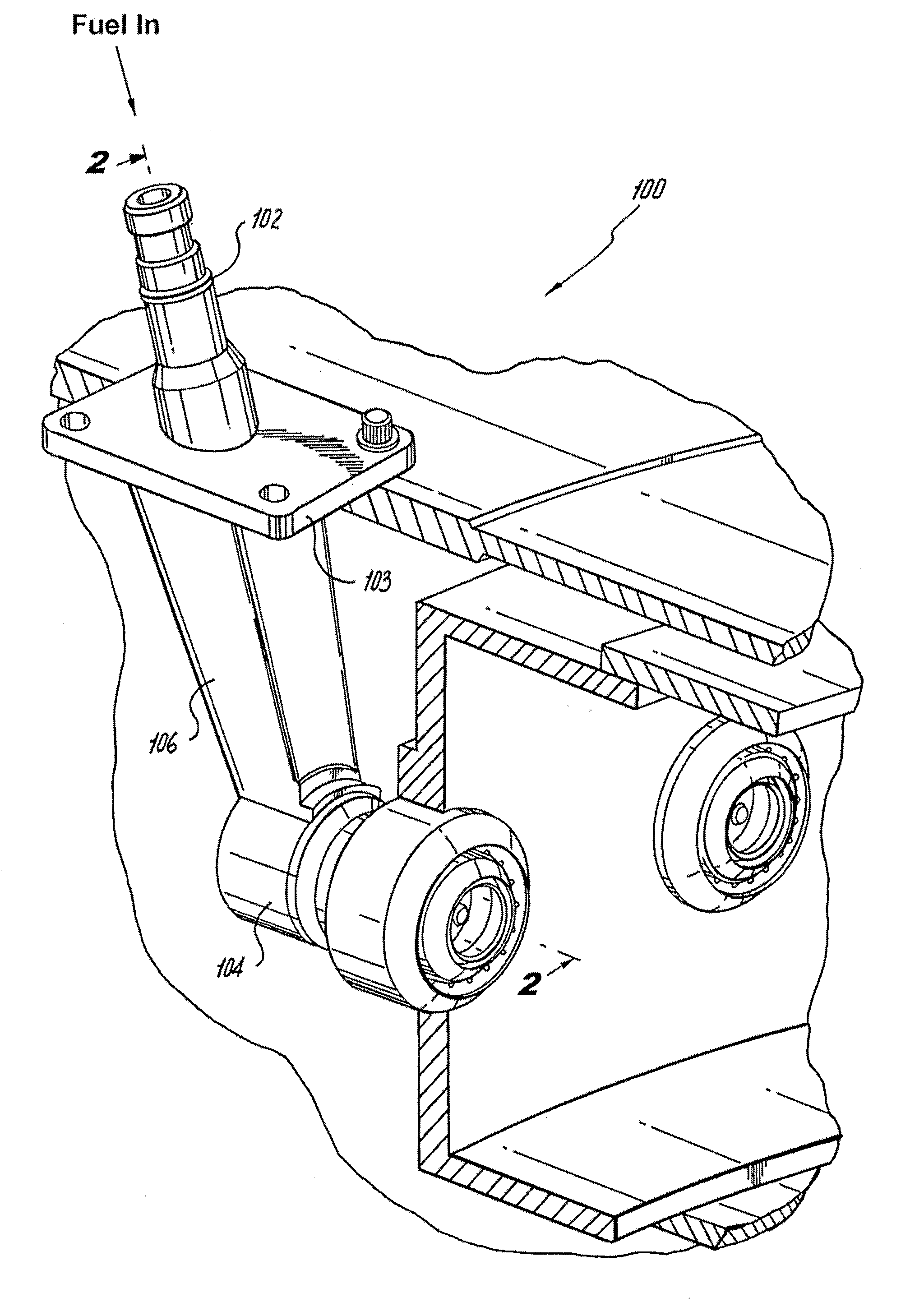

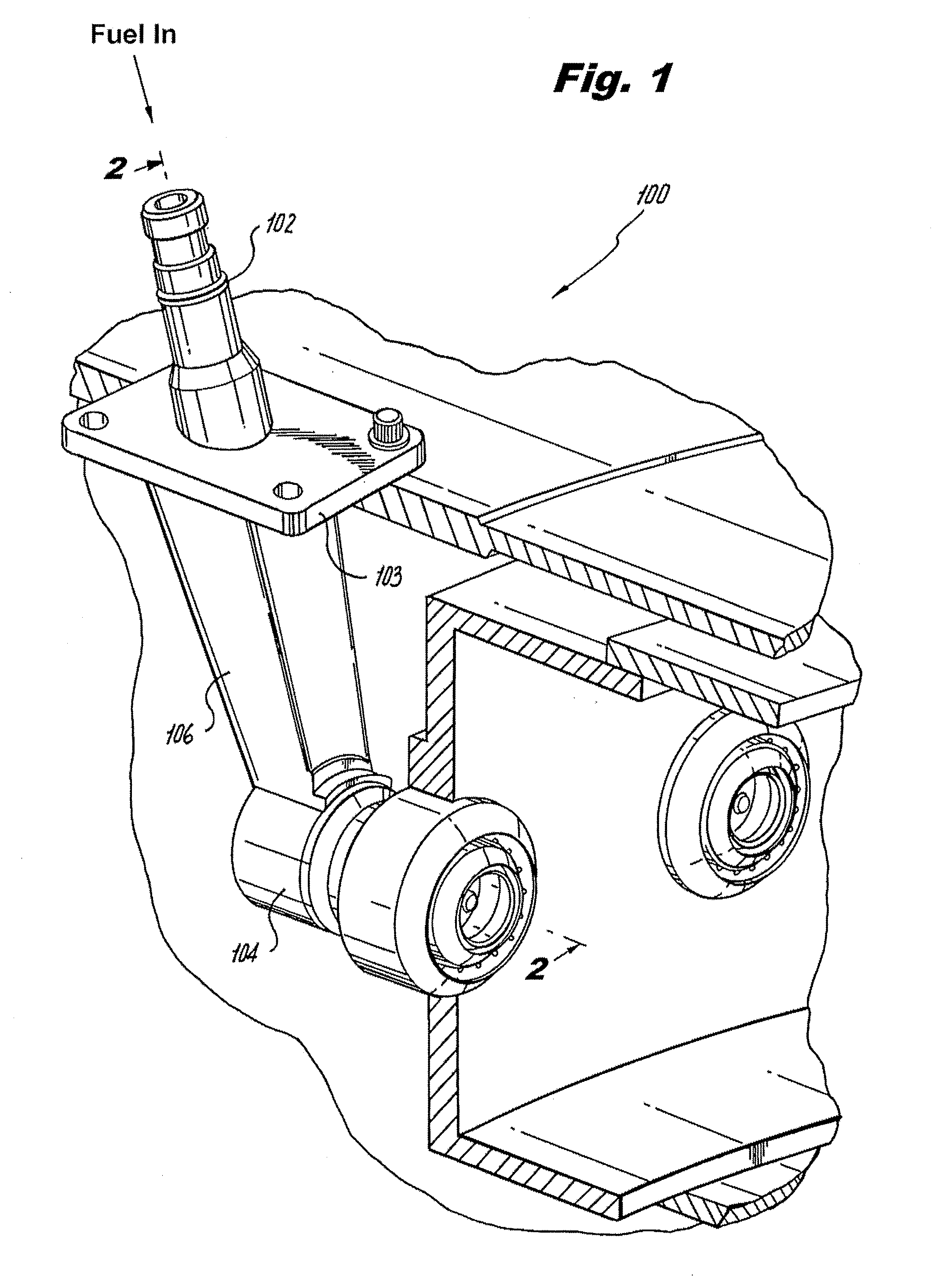

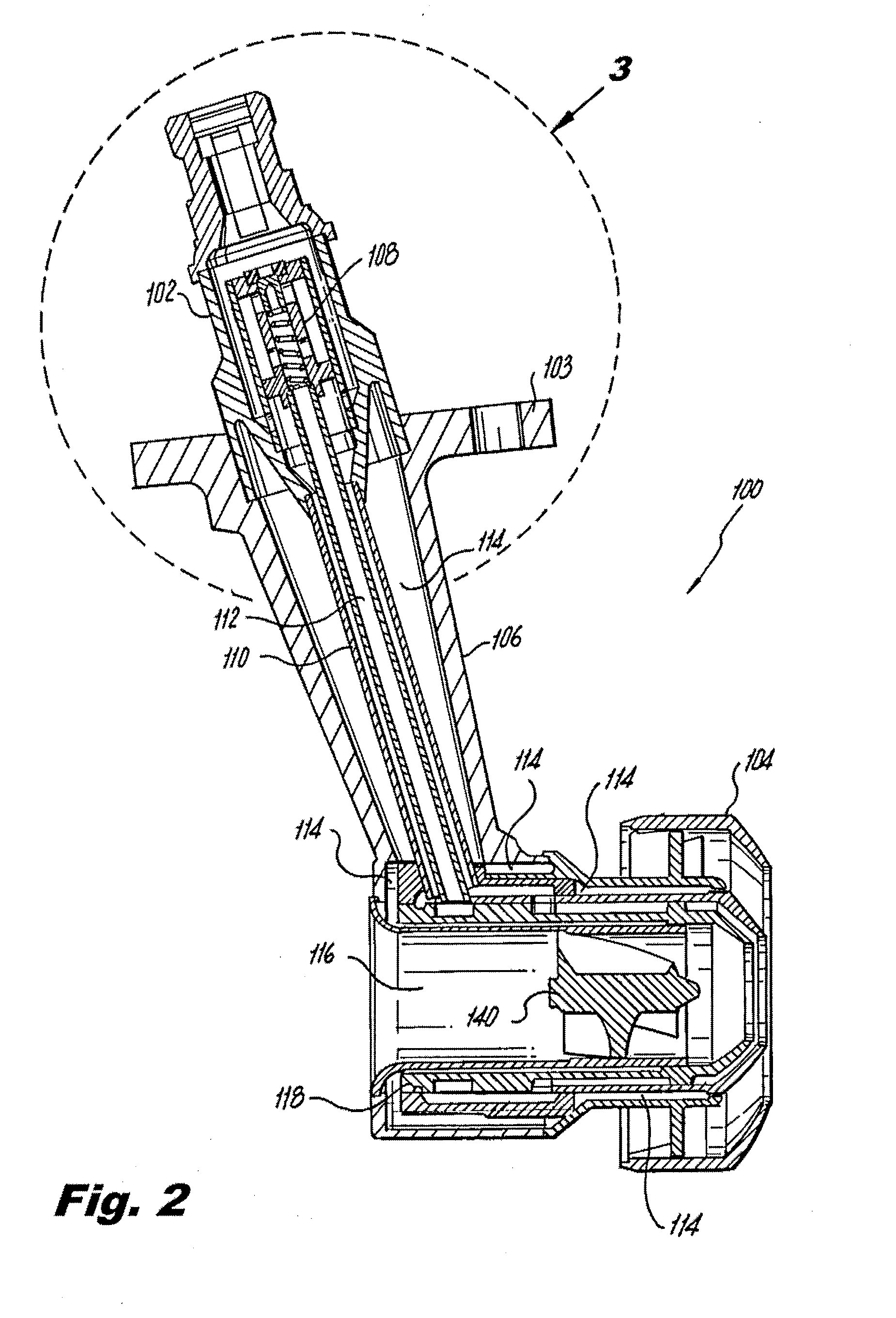

Pure air blast fuel injector

An air blast fuel injector for a gas turbine engine includes an elongate feed arm having an inlet fitting for receiving fuel and for distributing the fuel to first and second fuel delivery conduits extending through the feed arm. A nozzle body is operatively connected to the feed arm. The nozzle body includes an on-axis inner air circuit and fuel circuitry radially outboard of the inner air circuit for delivering fuel to a fuel swirler outboard of the inner air circuit. The fuel circuitry includes a first fuel circuit configured and adapted to deliver fuel to the fuel swirler from the first fuel conduit of the feed arm and a second fuel circuit configured and adapted to deliver fuel to the fuel swirler from the second fuel conduit of the feed arm.

Owner:ROLLS ROYCE PLC

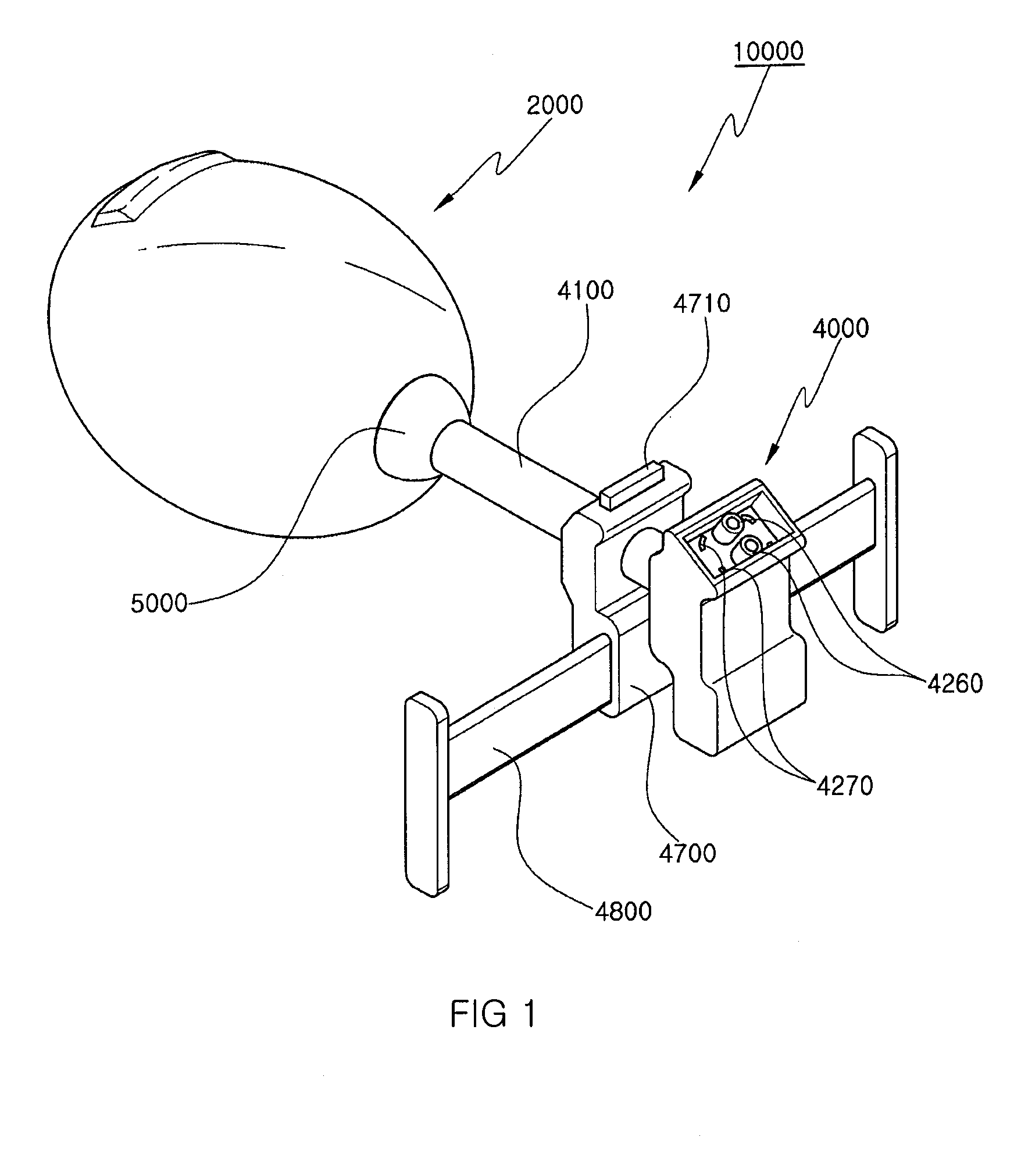

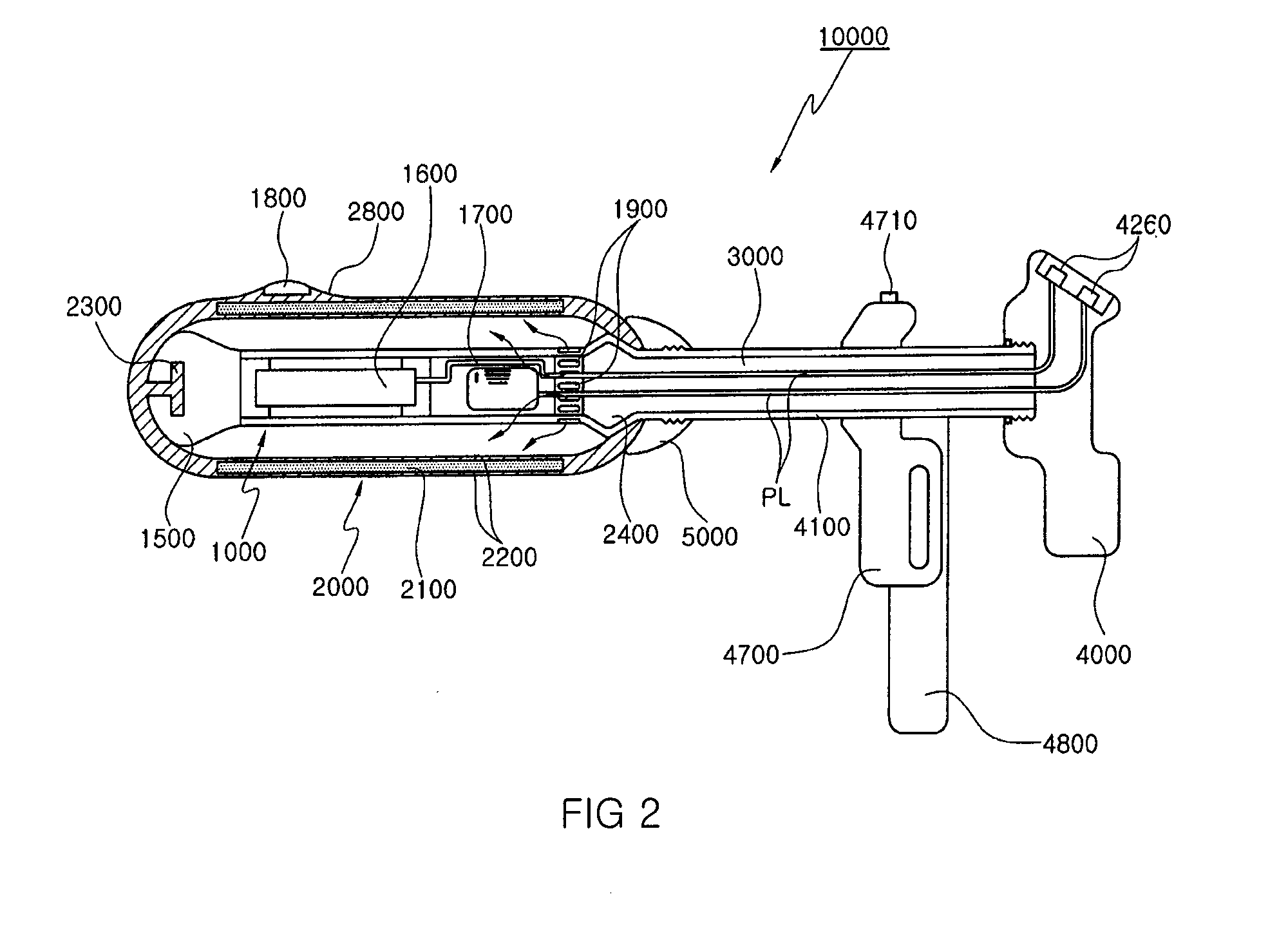

Apparatus For Examining and Curing Urinary Incontinence, and For Exercising Bio-Feedback of Women Vagina Muscles

ActiveUS20080139876A1Simple treatmentReadily treat urinaryPerson identificationGenitals massagePelvic diaphragm muscleAir pump

An apparatus for examining and curing urinary incontinence and exercising the pelvic floor muscles and vaginal muscles using bio-feedback including a controller main body, a probe, and a bio-feedback device. The probe includes: an insert frame extending in a longitudinal direction thereof, an insert expansion part surrounding adjacent to a front end of the insert frame and expandable therearound; an air supply path connected to the interior of the insert expansion part to supply air; a handle engaged with the insert frame; a fixing means for fixing the insert expansion part to the insert frame or the handle; a valve installed at the air supply path; and a PTC ceramic heater and a vibration motor installed at the insert frame. An elastic member includes a magnet, an insertion depth adjustment part, and leg support parts installed at the insertion depth adjustment part. The bio-feedback device includes a sound generating means, and an image display means. The main body includes a controller for controlling each component, a motorized air pump, an air flow detection sensor, a pressure detection sensor, a spring air cylinder, a solenoid air injection valve, an air tank, etc. Therefore, it is possible for a user to readily perform examination and treatment of urinary incontinence and pelvic floor muscle (vagina muscle) reinforcement exercise using bio-feedback.

Owner:APIMEDS

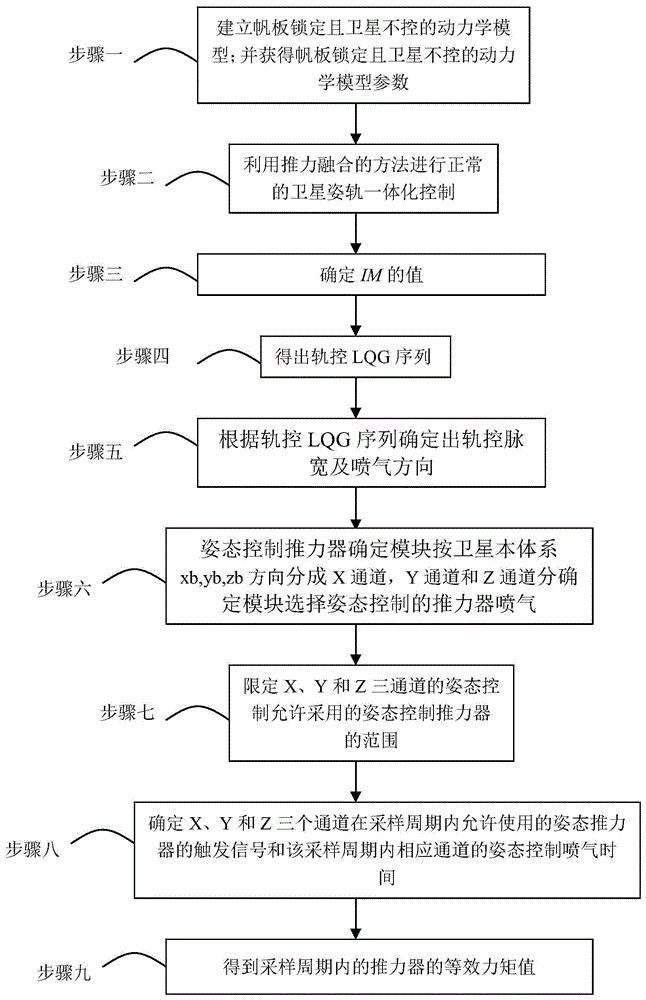

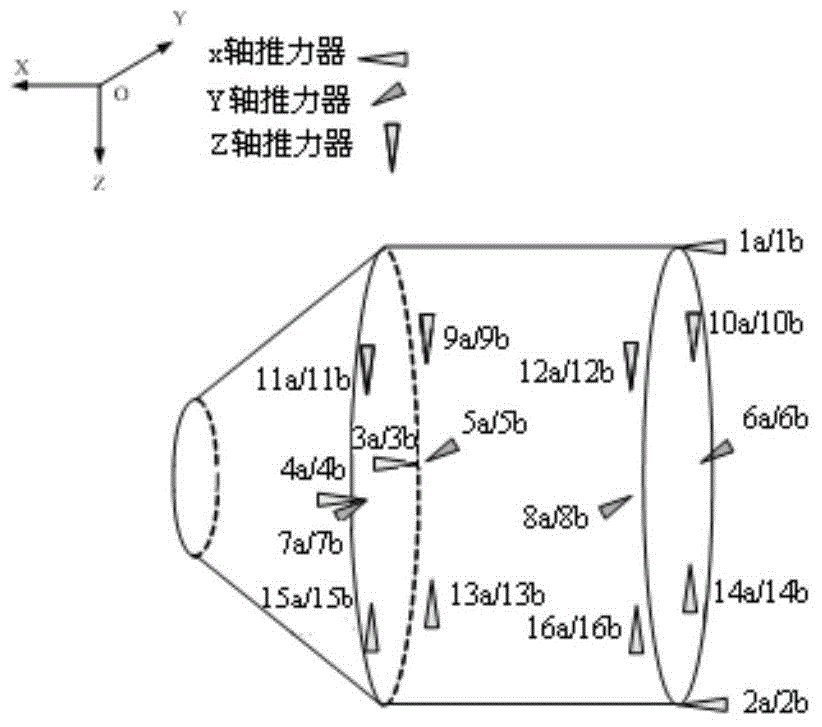

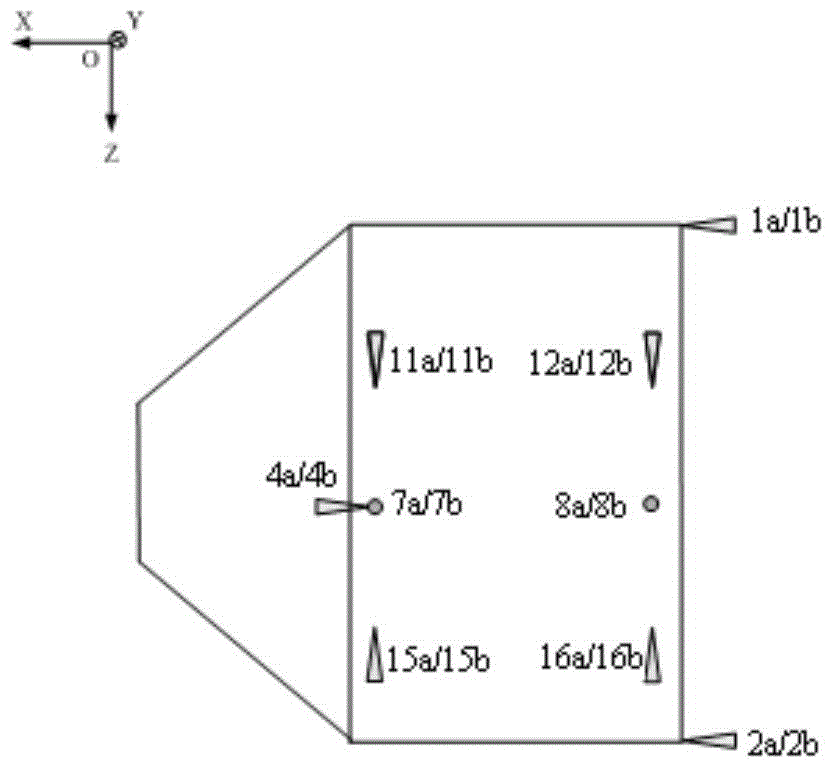

Flexible satellite attitude orbit coupling control method based on isolation allowance method and pulse width fusion strategy

The invention relates to the field of flexible satellite attitude orbit coupling control, in particular to a flexible satellite attitude orbit coupling control method based on an isolation allowance method and a pulse width fusion strategy. The method solves the problems that in the satellite in-orbit attitude and orbit control process, a flywheel cannot control that the corresponding thruster layout is not given, the plume influence and rotational inertia level bias are not considered, isolation allowance is not considered and the attitude does not meet the requirement. The method comprises the steps of 1, obtaining sailboard locking and satellite uncontrollable dynamical model parameters; 2, determining installation position coordinates of a thrust; 3, determining an IM value; 4, obtaining an orbit-control LQG sequence; 5, determining the orbit-control pulse width and the air injection direction; 6, selecting air injection of the attitude-controlled thrust; 7, determining the range of the attitude-controlled thrust; 8, determining the attitude-controlled air injection time; 9, obtaining an equivalent force moment value. The flexible satellite attitude orbit coupling control method is applied to the field of flexible satellite attitude orbit coupling control.

Owner:HARBIN INST OF TECH

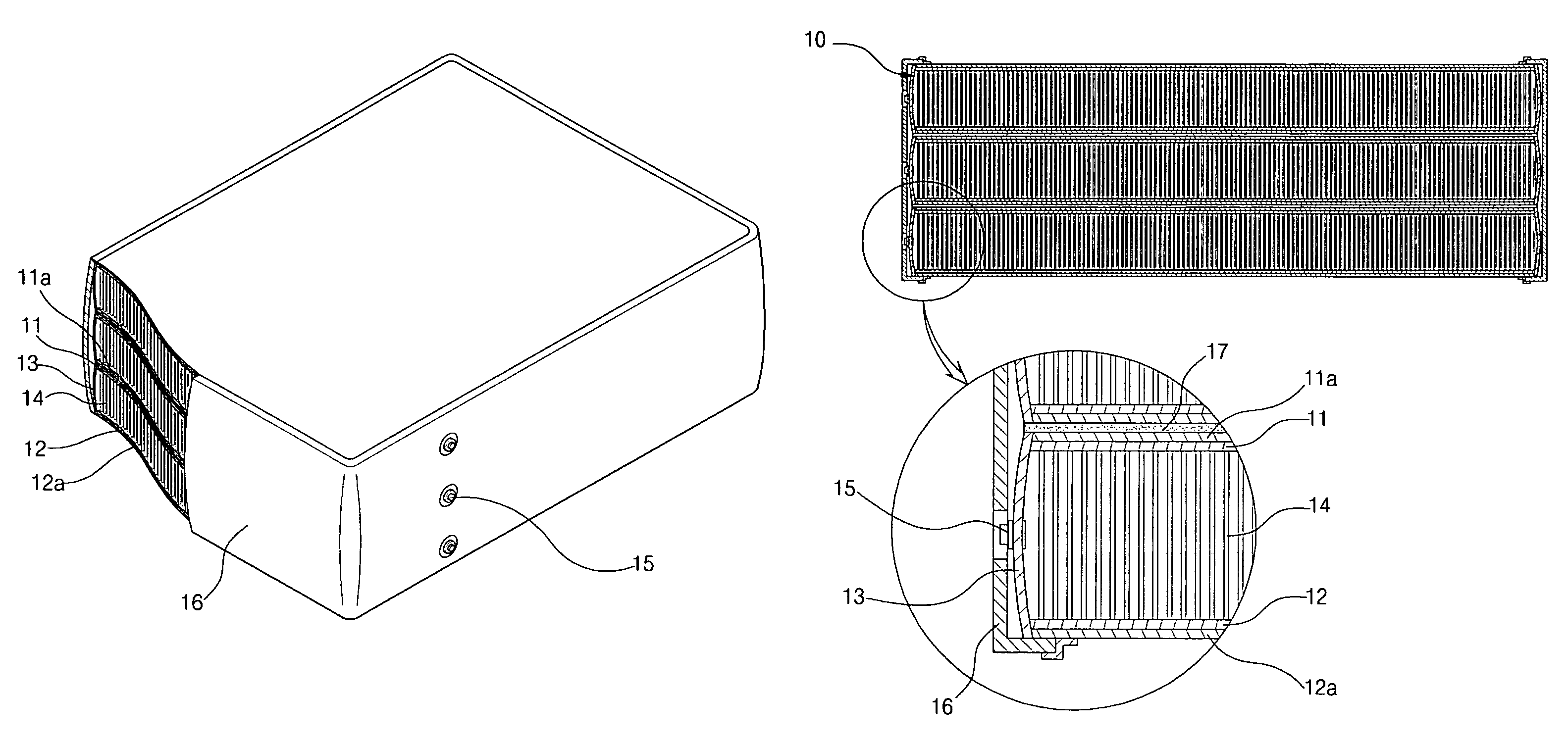

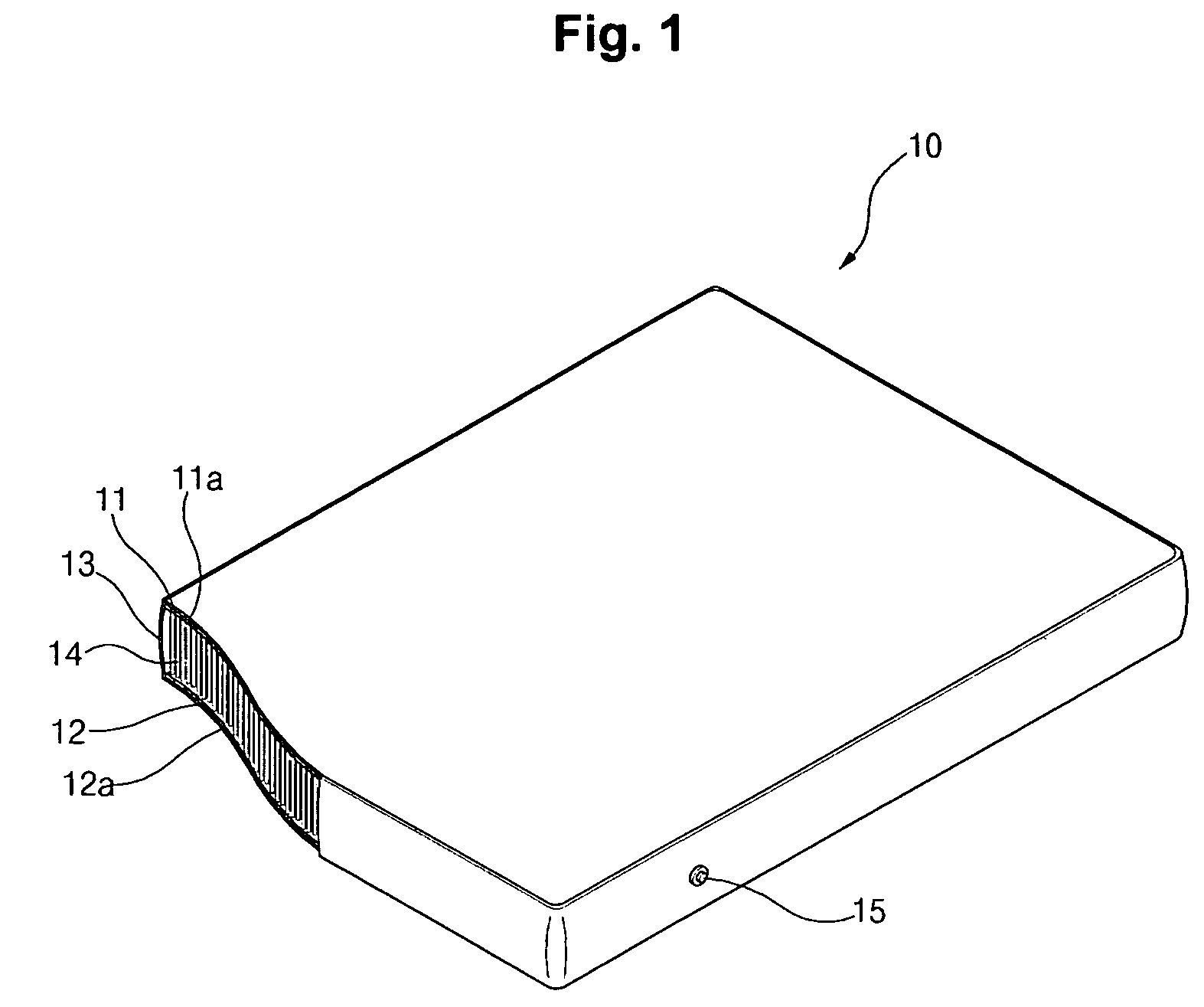

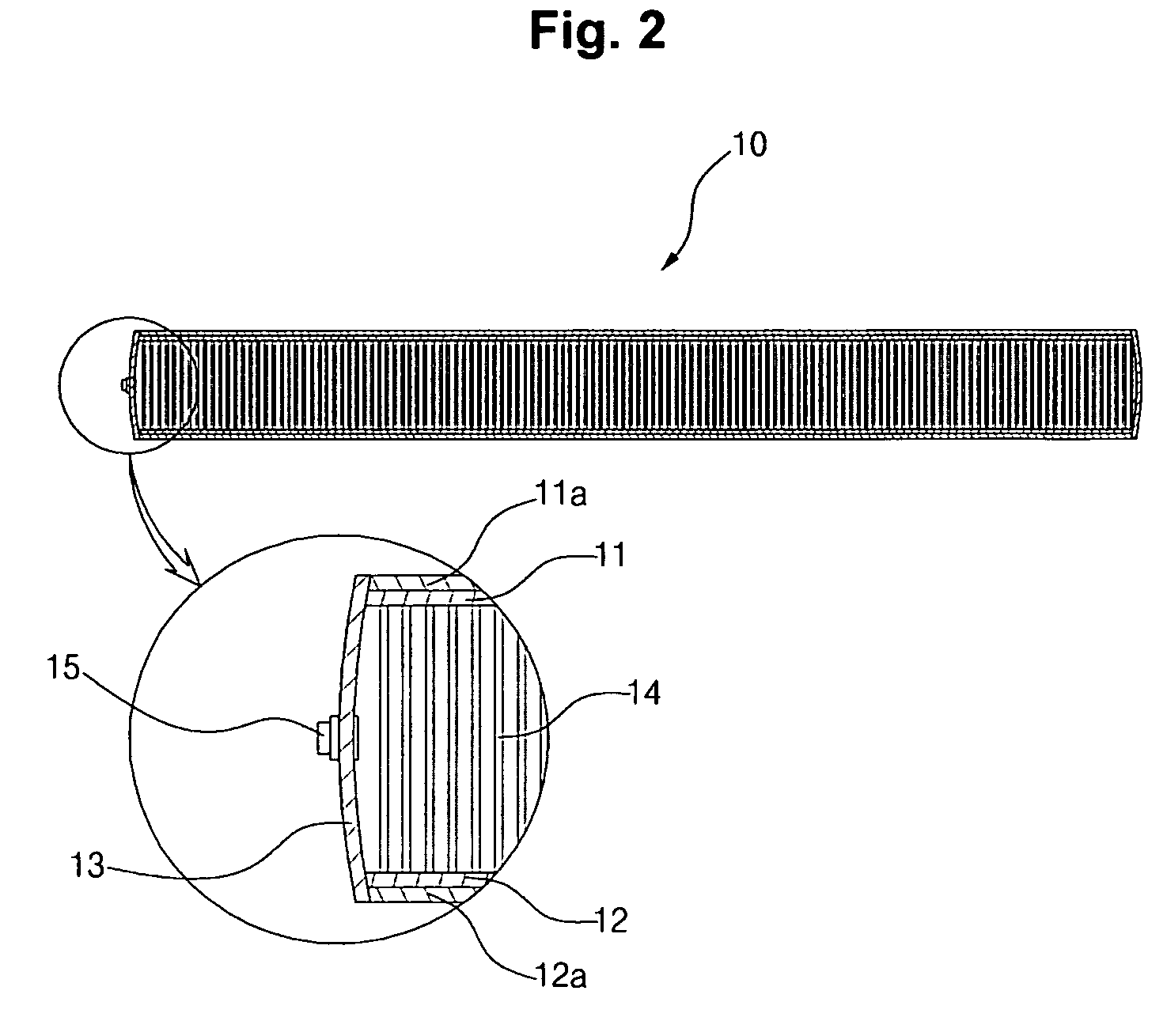

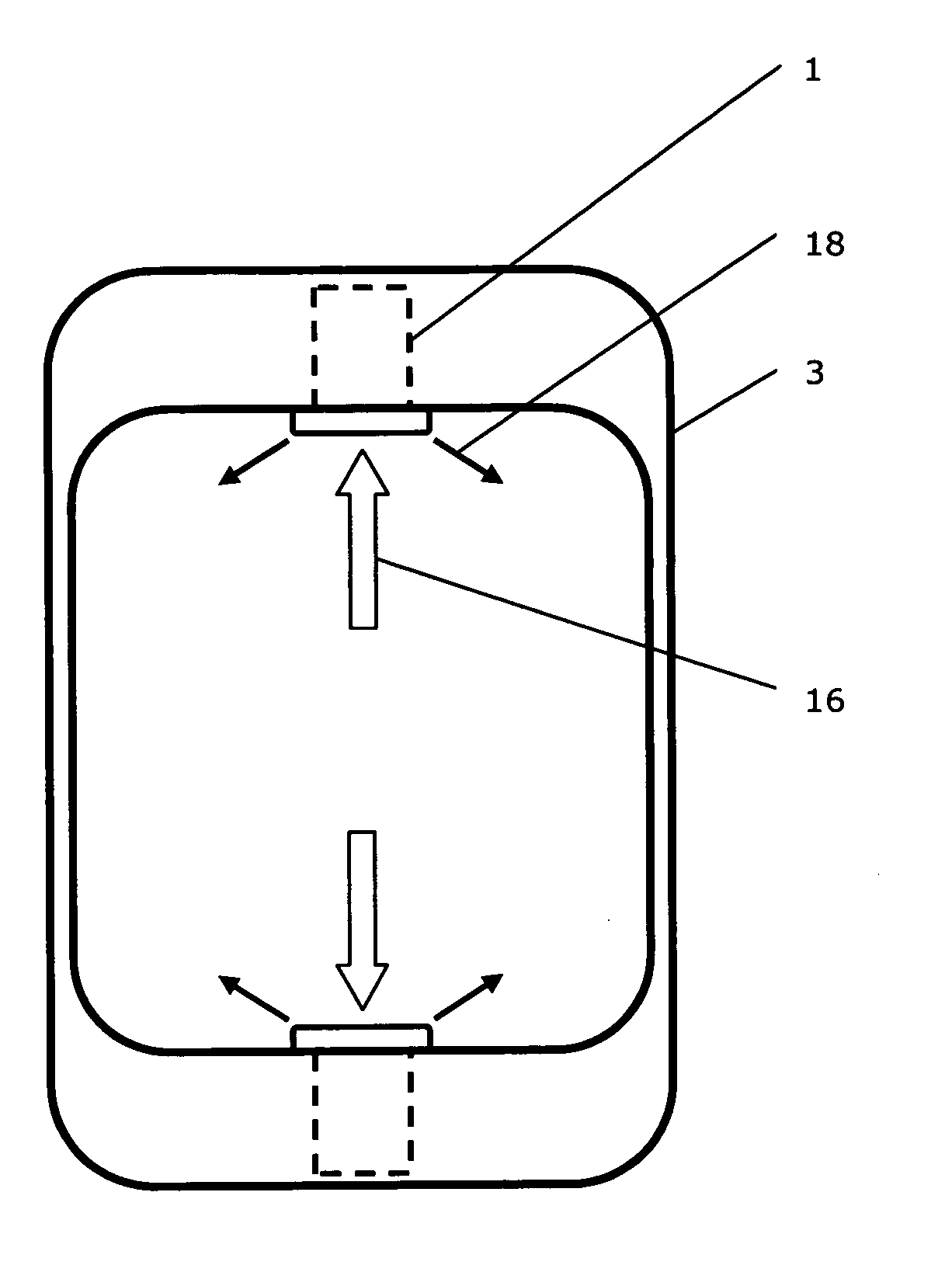

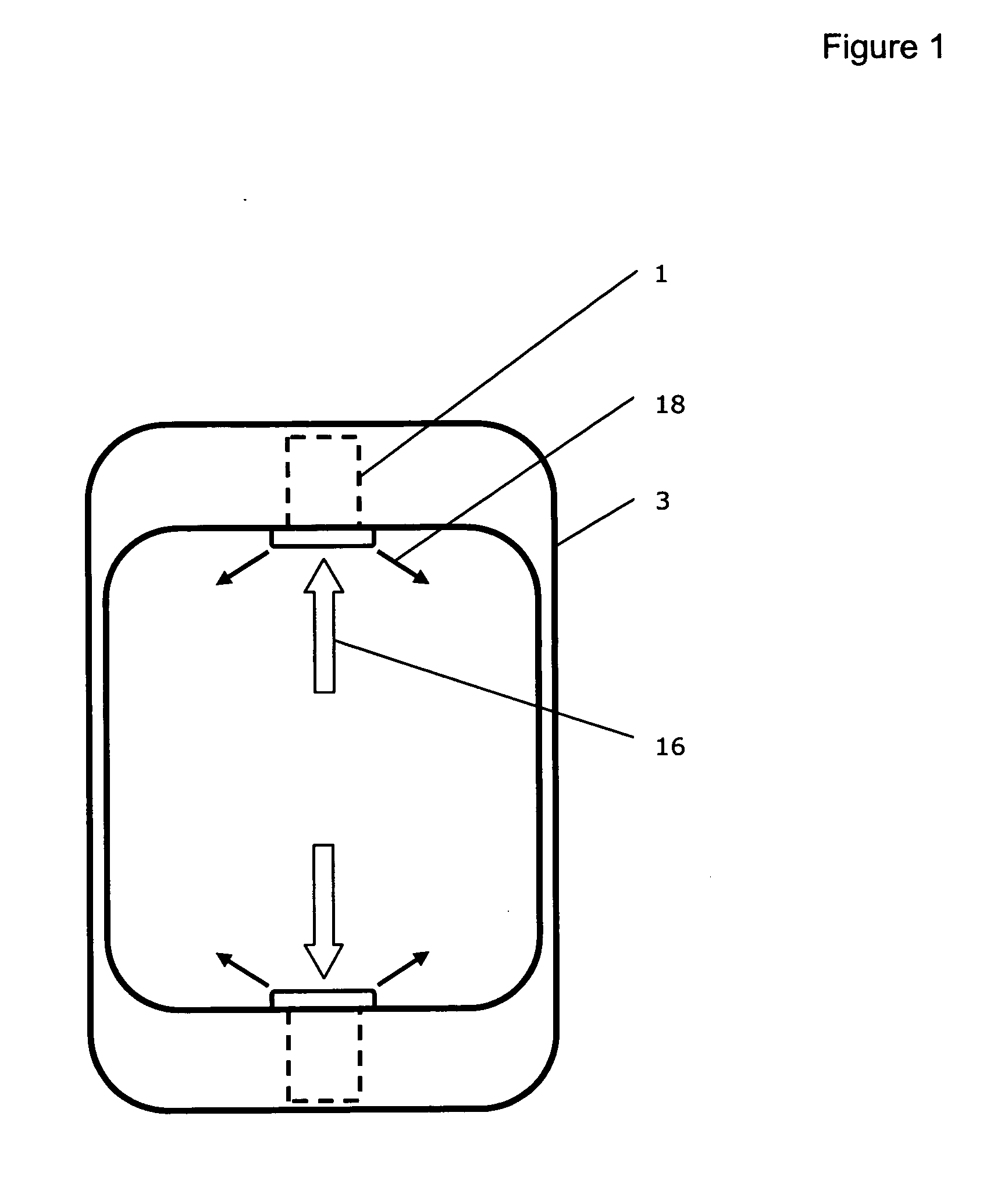

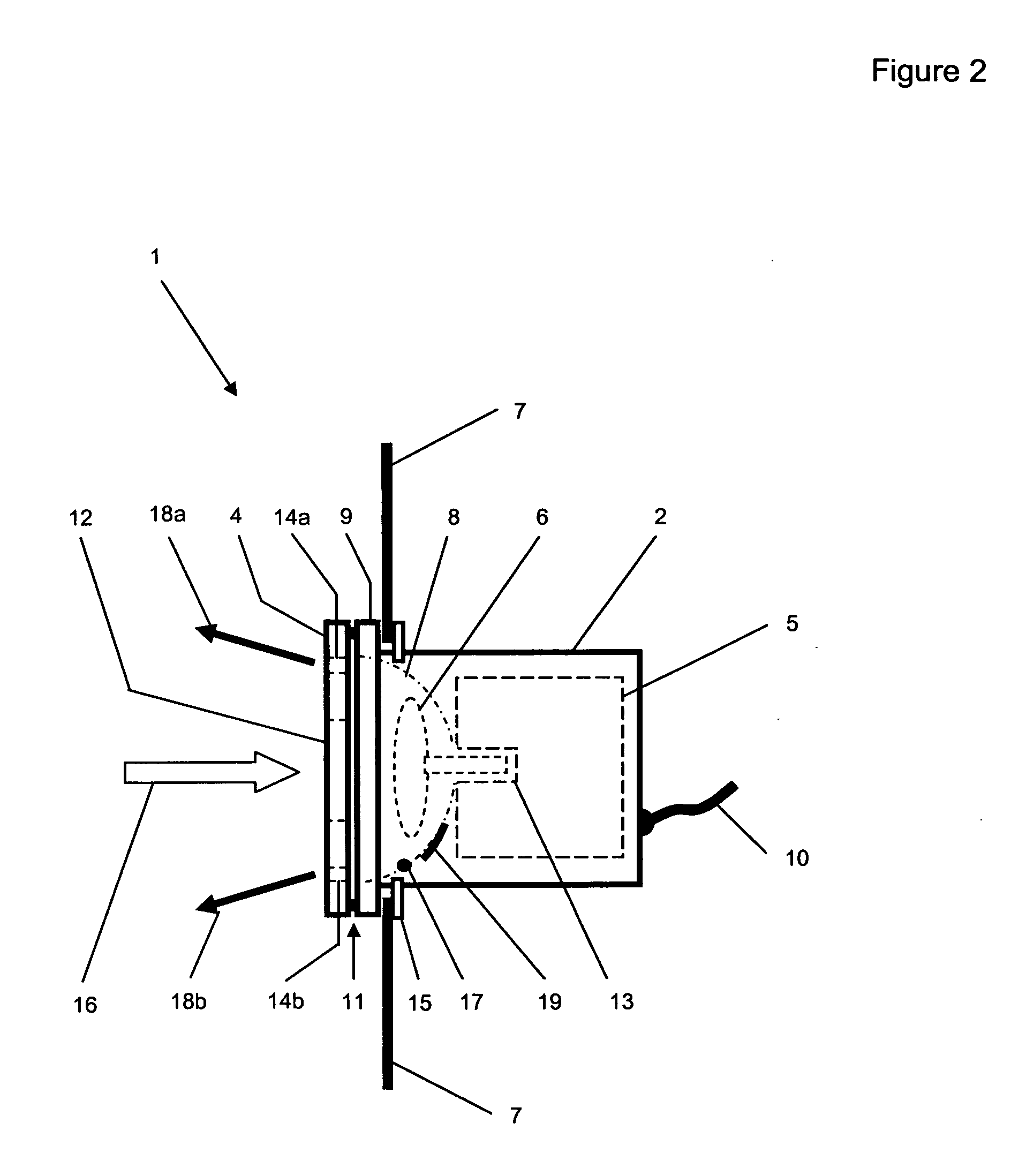

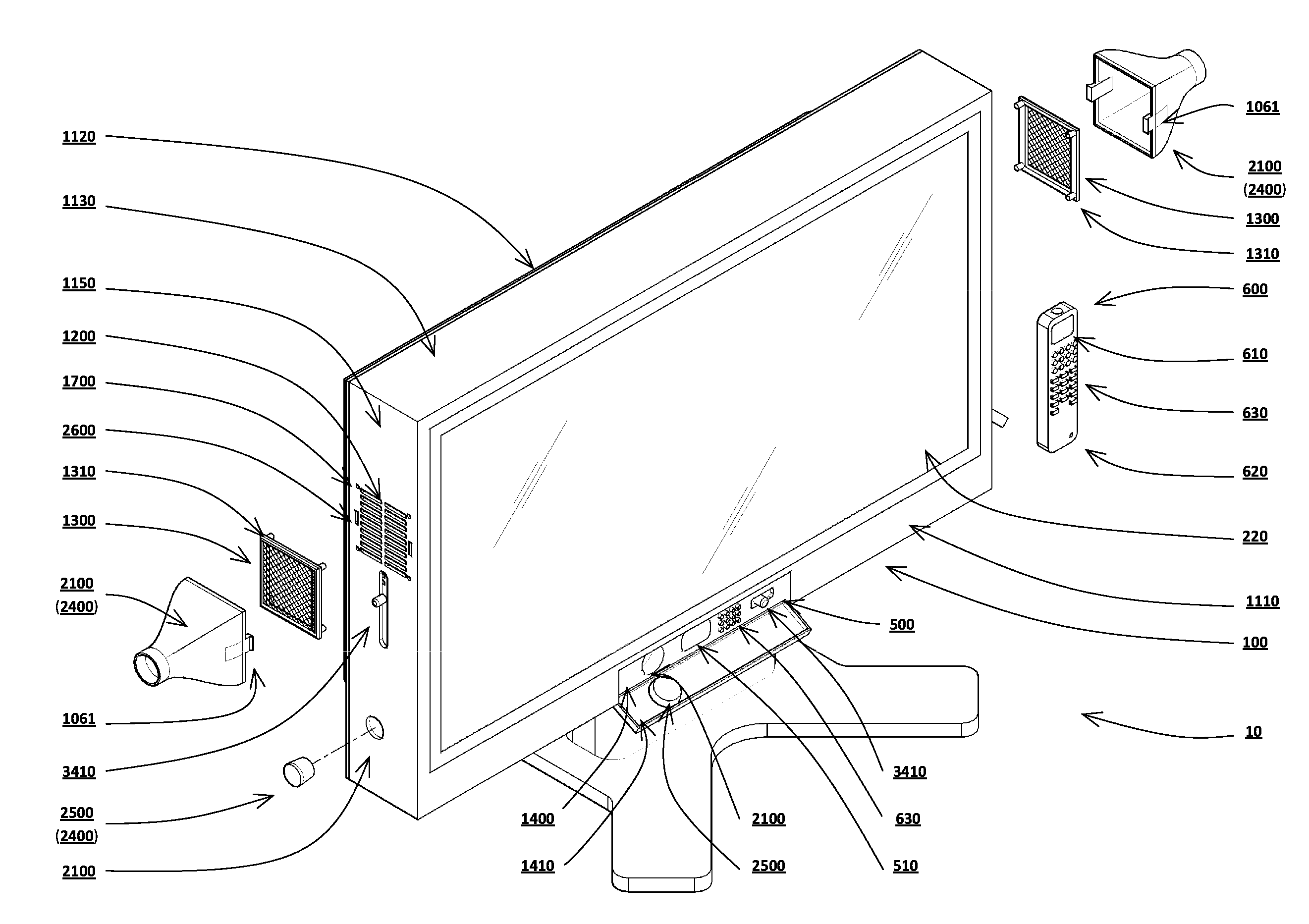

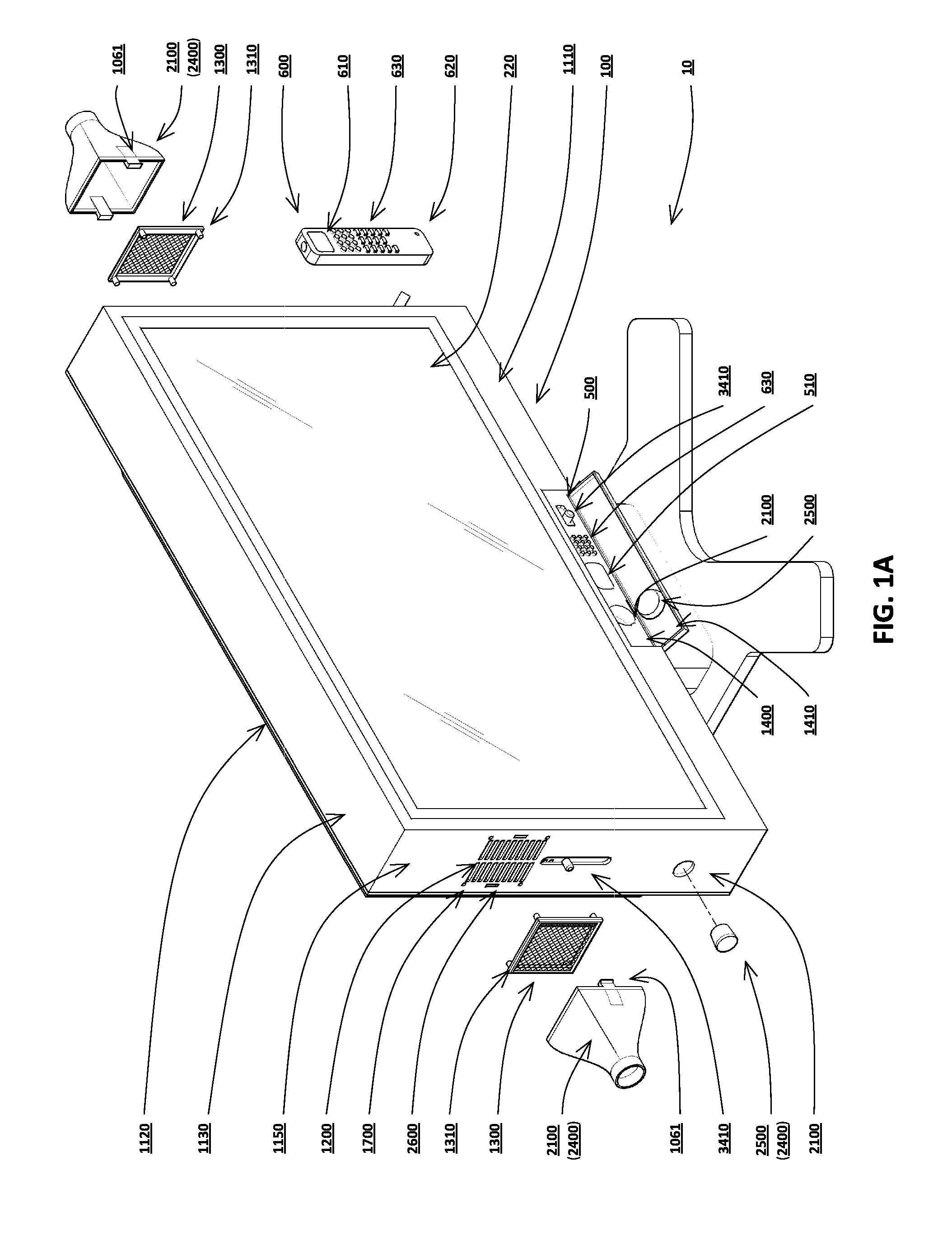

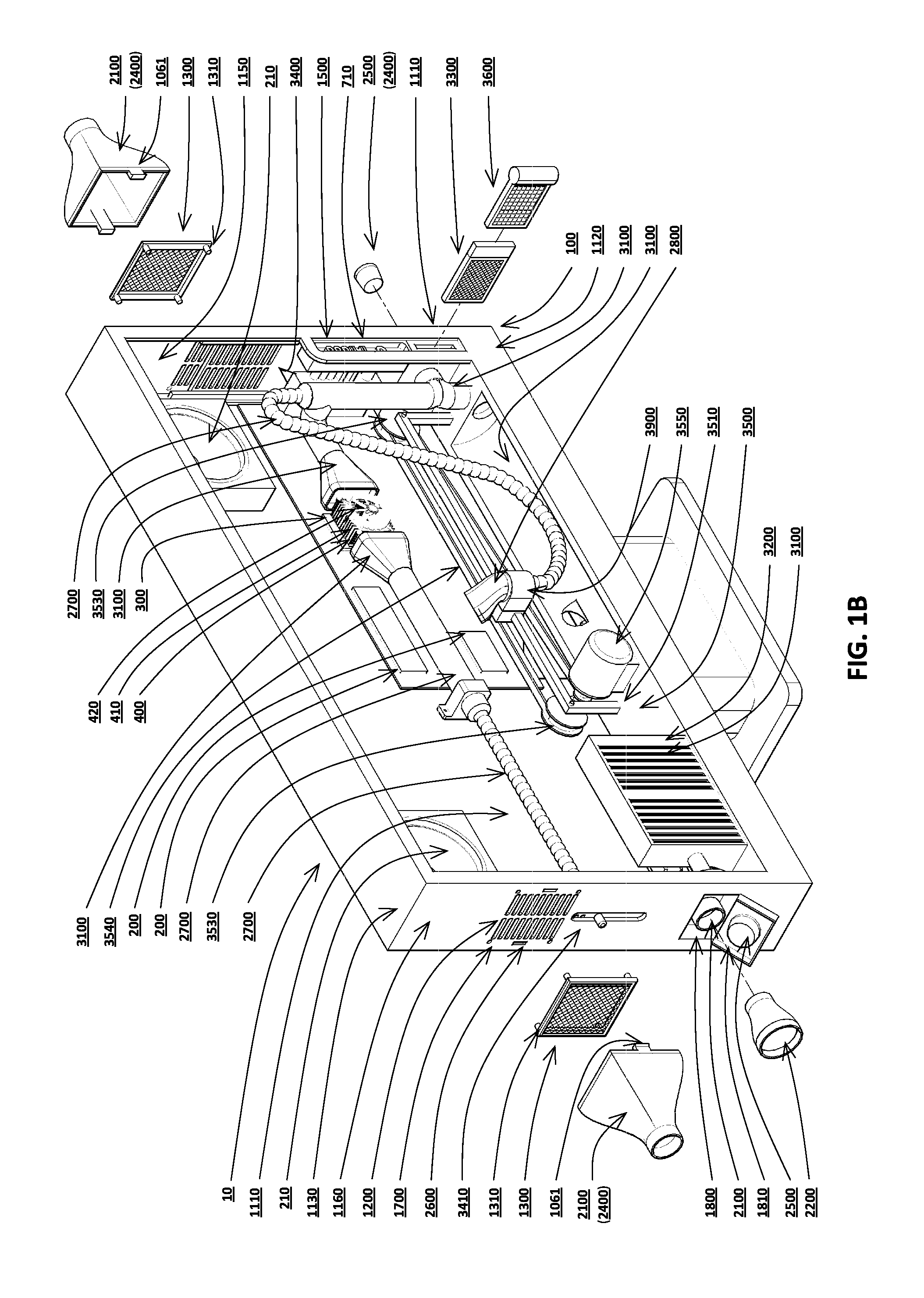

Dust Removal System for Electronic Devices

InactiveUS20120118327A1Timely and easily and safely dust removalImprove performanceMechanical cleaningPressure cleaningInjection airAmbient air

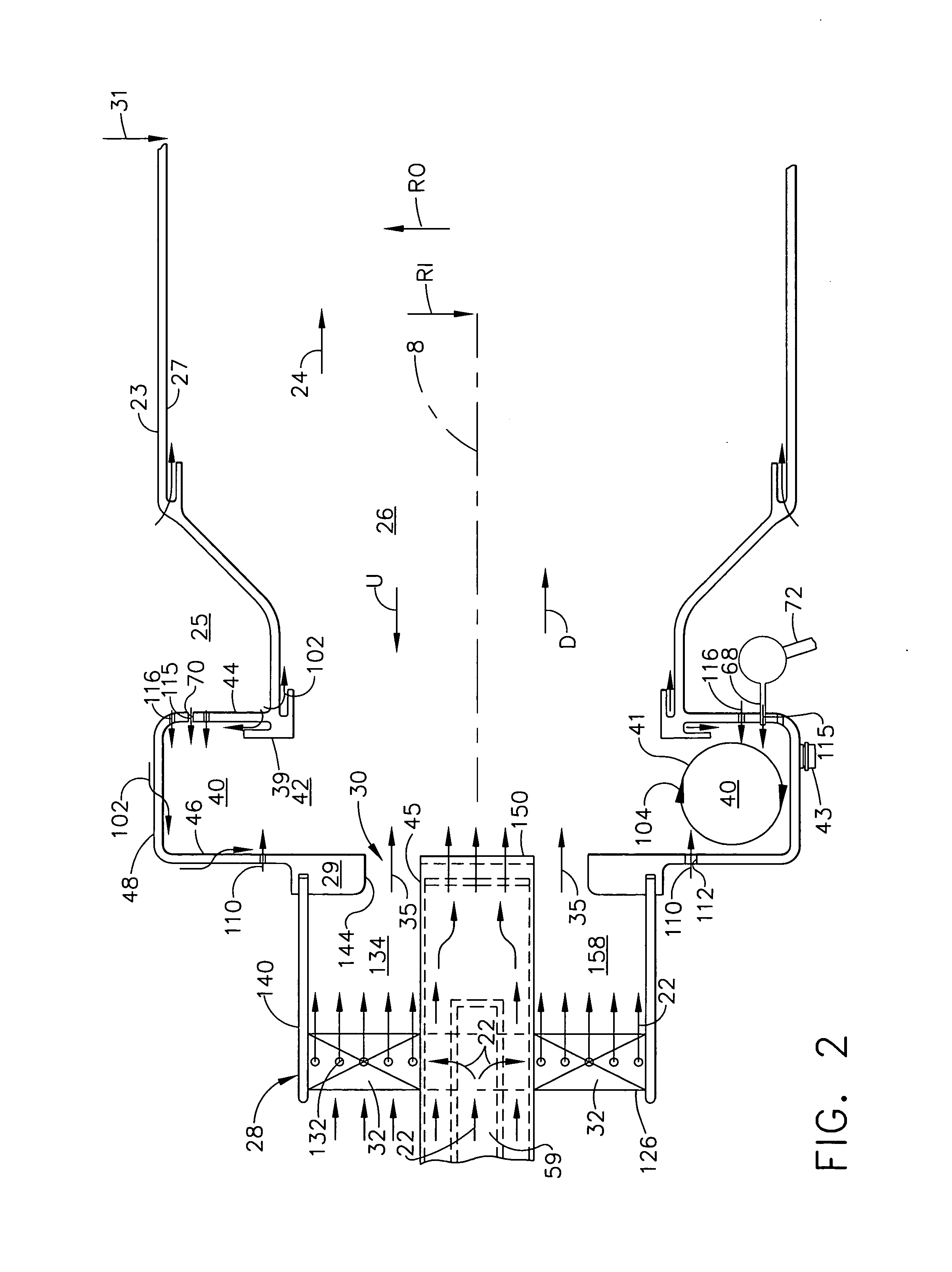

Several techniques are disclosed to prevent dust and other particles from building up inside housings of electronic devices. These allow timely, easy and safe dust removal from the entire volume of the housing of the device without its disassembly by creating directed airflows inside of the housing. Moreover, dust is carried from the enclosure to a dust trap without allowing escape of dust from the enclosure into the ambient air. Dust removal is carried out by creating one or more directed airflows by air injection, exhausting or both air injection and air exhausting to move the dust from the enclosure to the dust trap. In some cases a sealing member is supplied to close off apertures in the enclosure that are not used in the dust collection process.

Owner:MAZMANYAN ROUBEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com