Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

214 results about "Pick-up truck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

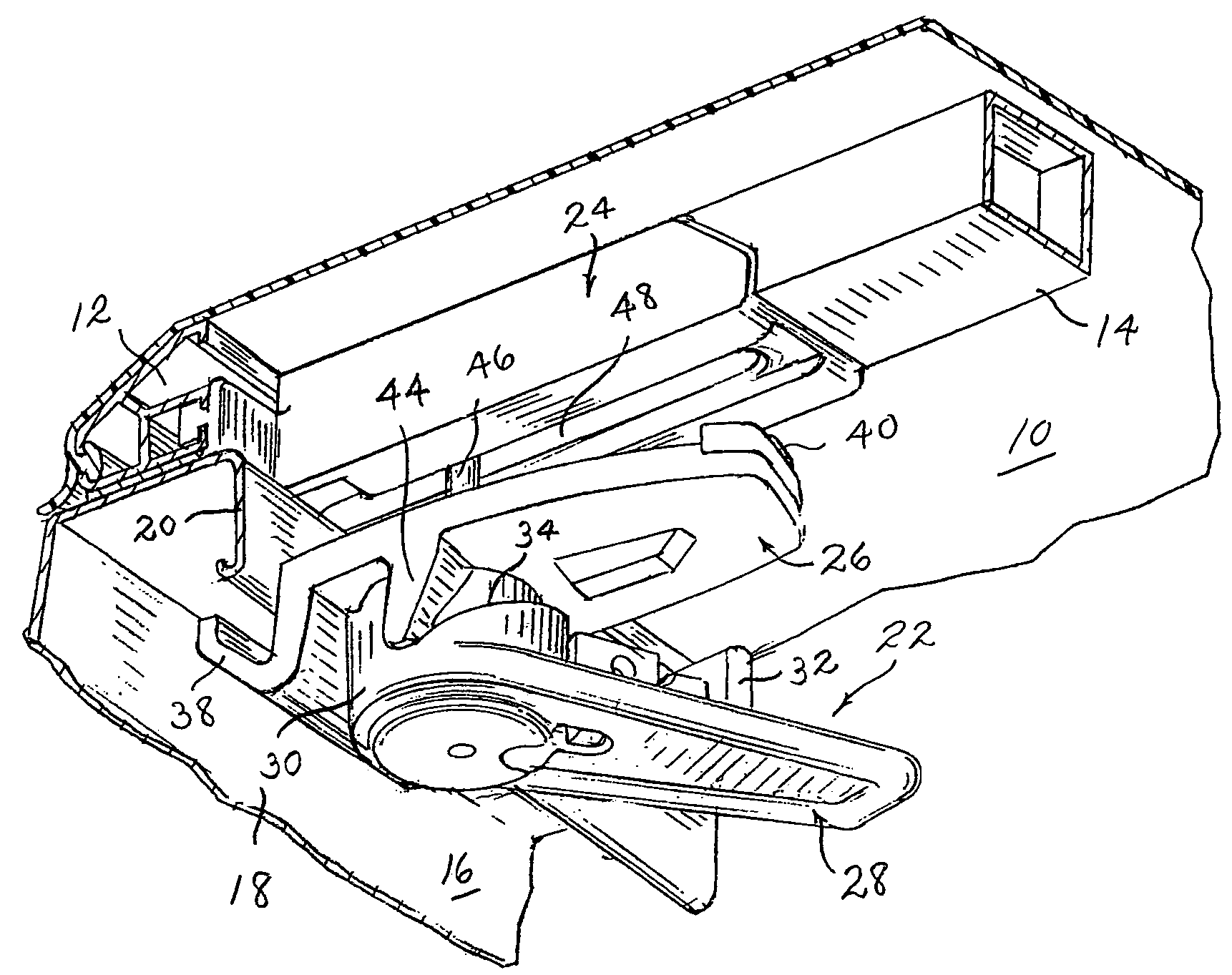

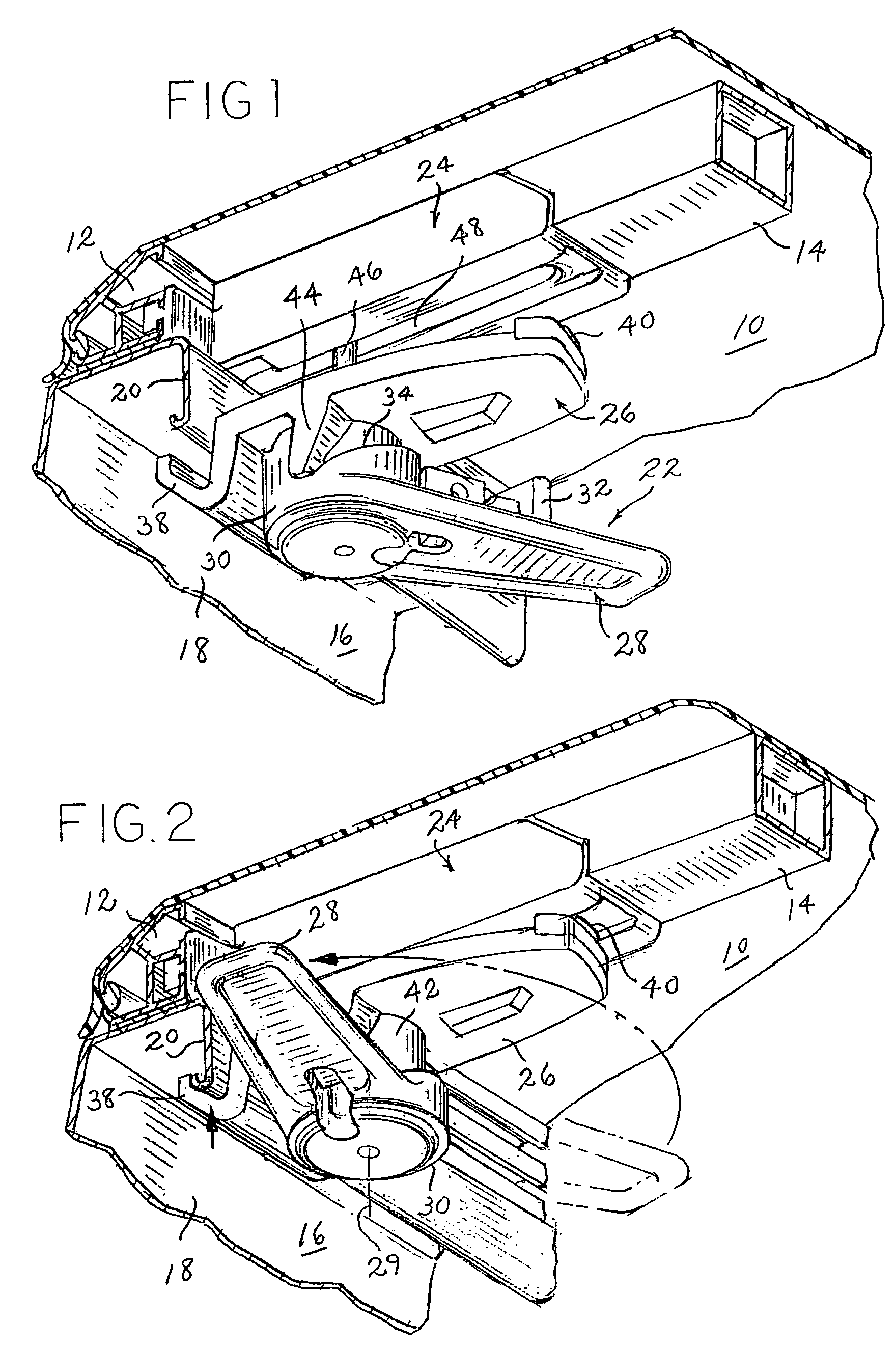

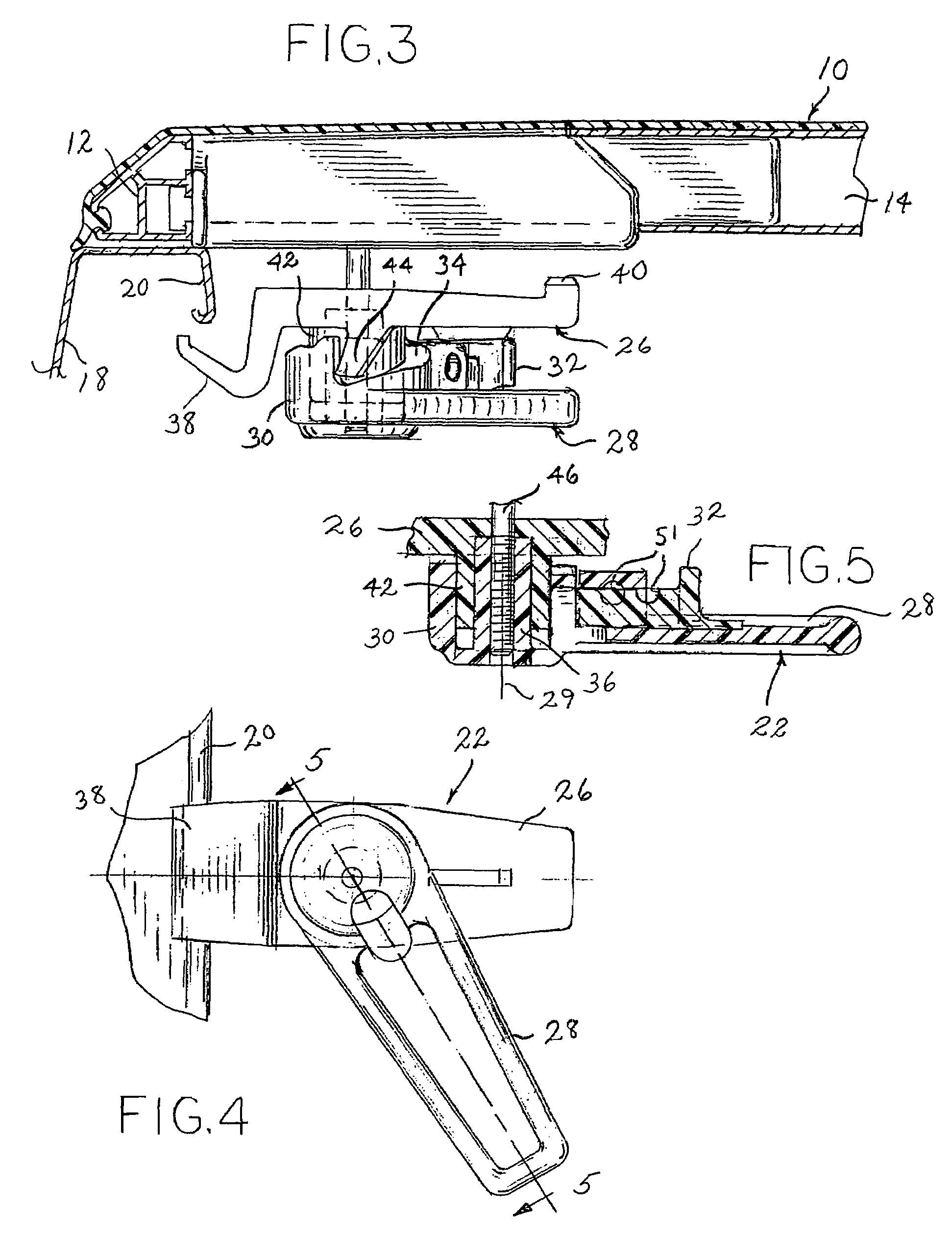

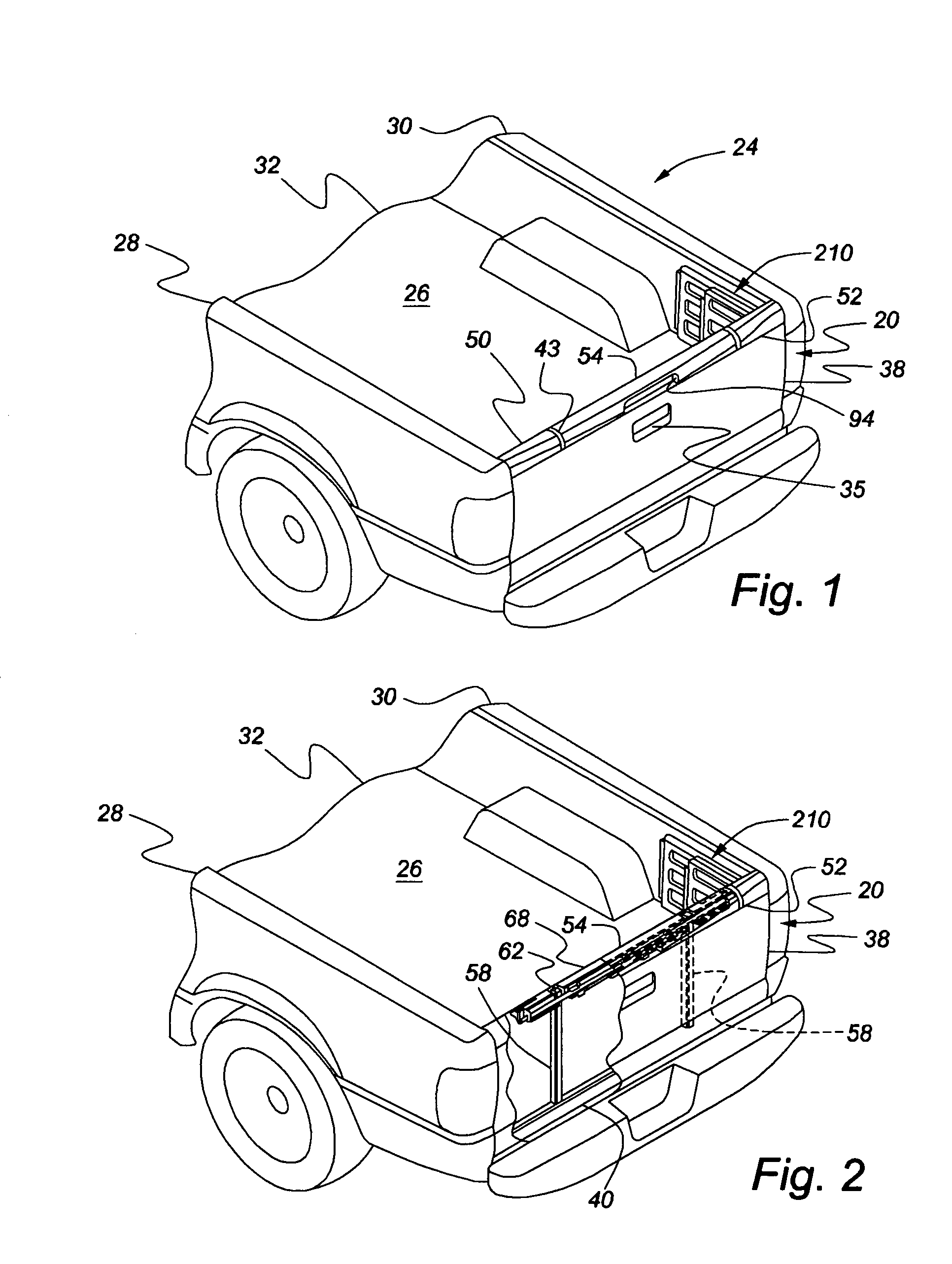

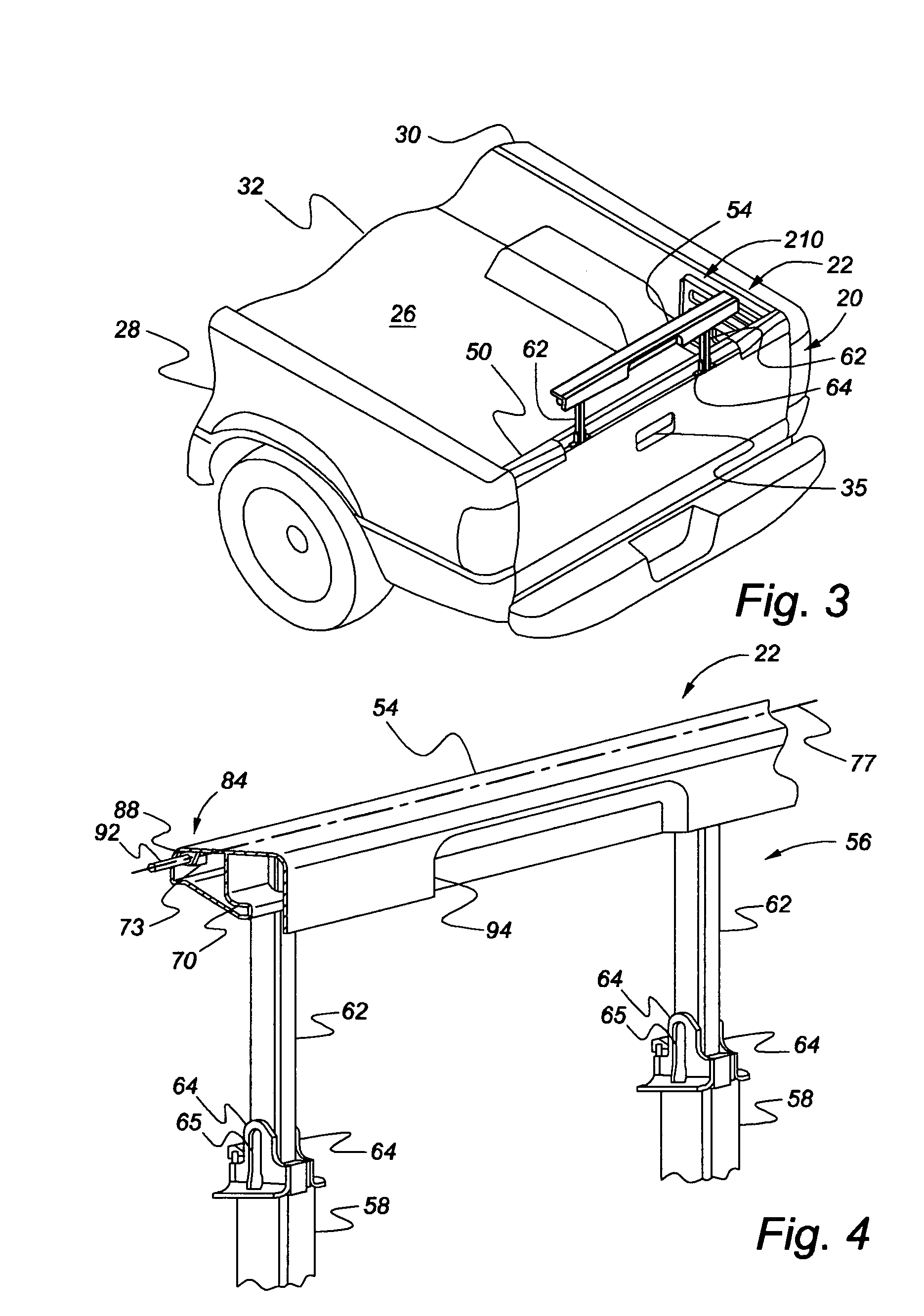

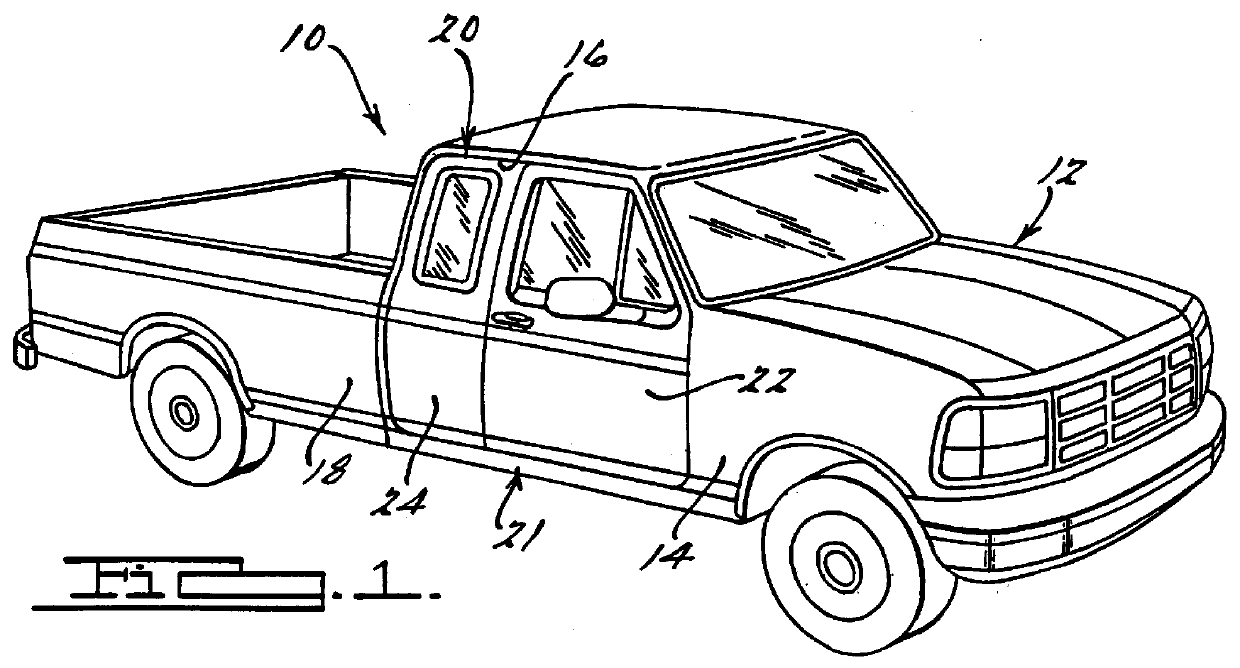

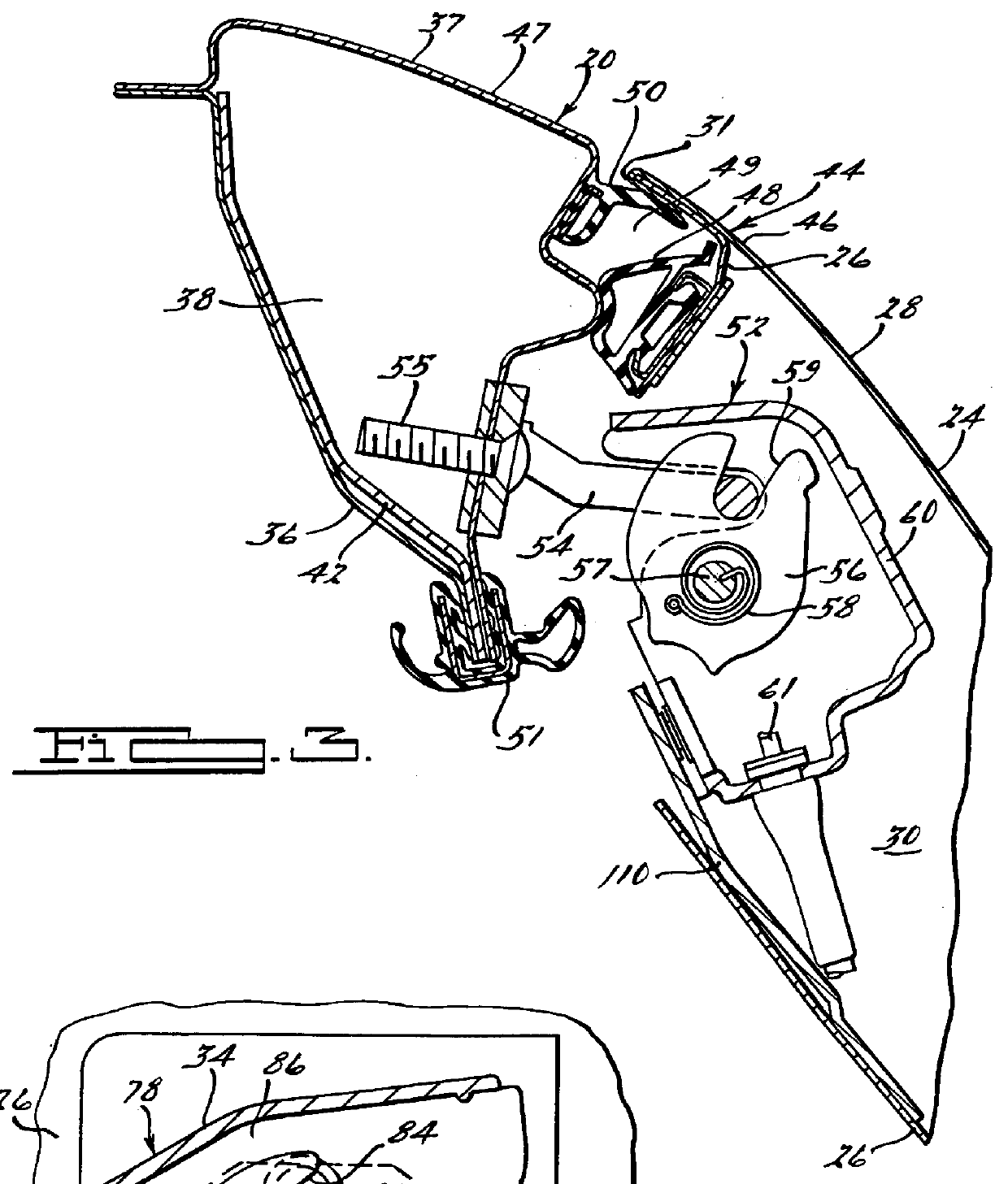

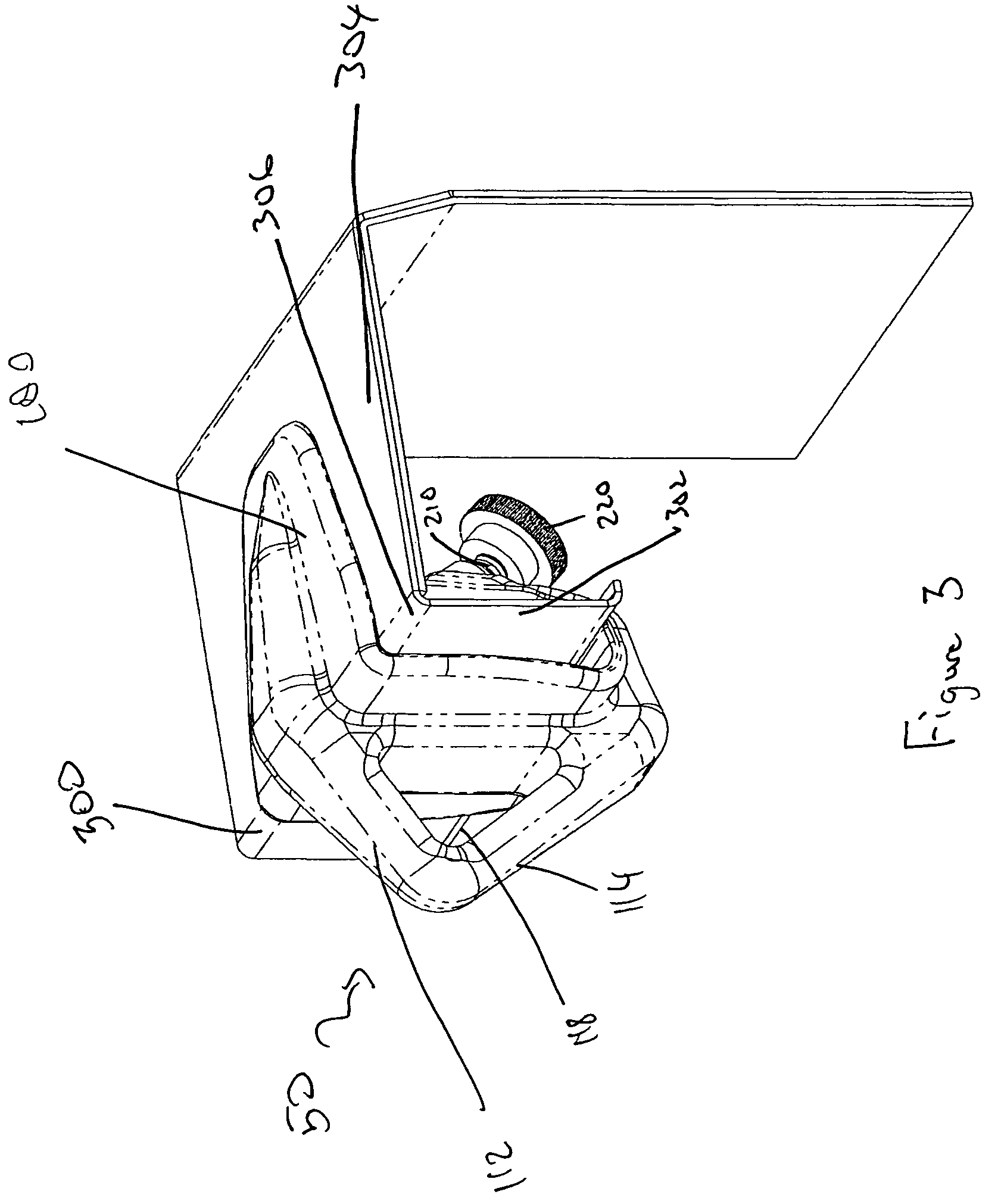

Grab handle for use with supplemental tailgate on pick-up trucks

ActiveUS7090276B1Large heightEfficient use ofVehicle with living accommodationSuperstructure subunitsPick-up truckMechanical engineering

A pivotable grab handle device is movable between a stowed position, which is positioned within a mating cavity formed in the main tailgate structure, and a deployed position that projects upwardly above the top surface of a lowered main tailgate structure. The grab handle device is mounted on a retainer bracket that is affixed to a pivot bracket mounted to the top surface of the lowered main tailgate structure. When pivotally raised into the deployed position, the grab handle allows a person using a supplemental tailgate assembly configured into a step function extending below the plane of the lowered main tailgate structure to be stabilized while climbing onto the cross member of the supplemental tailgate assembly and onto the top surface of the lowered main tailgate structure.

Owner:FORD GLOBAL TECH LLC +1

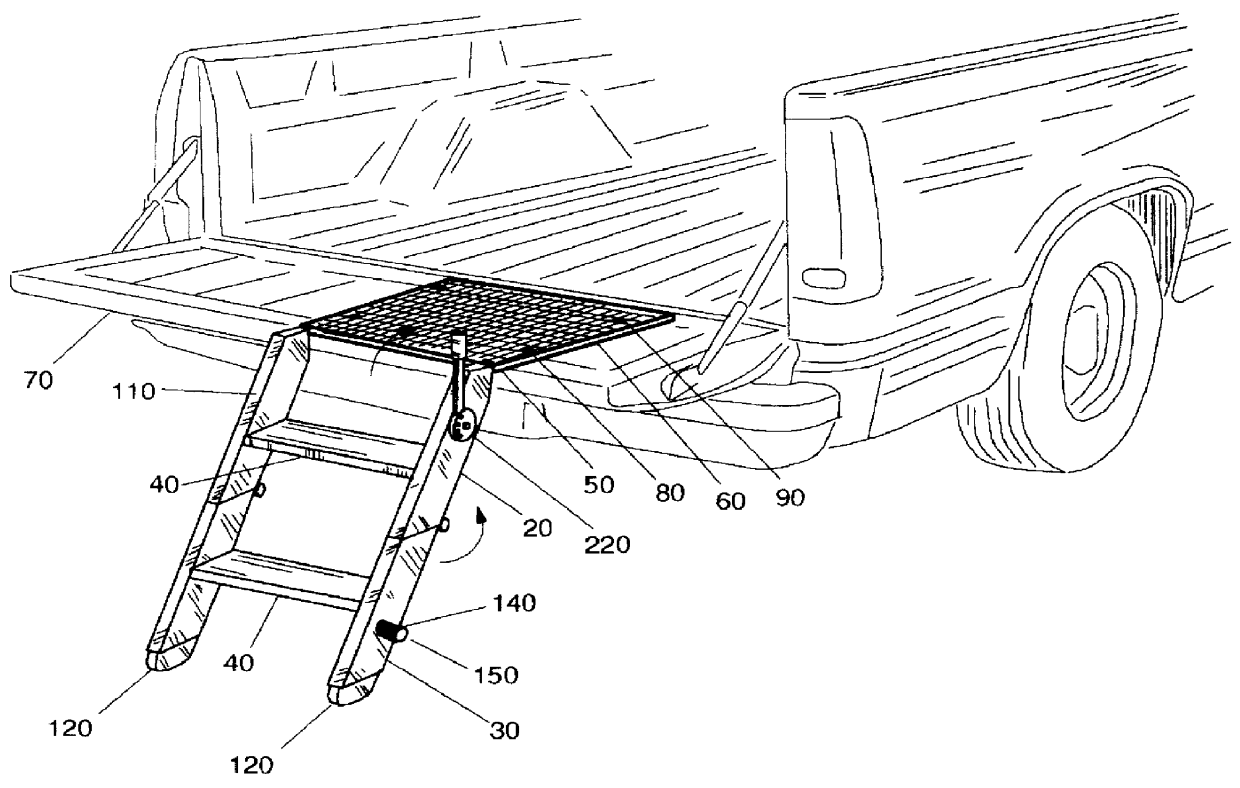

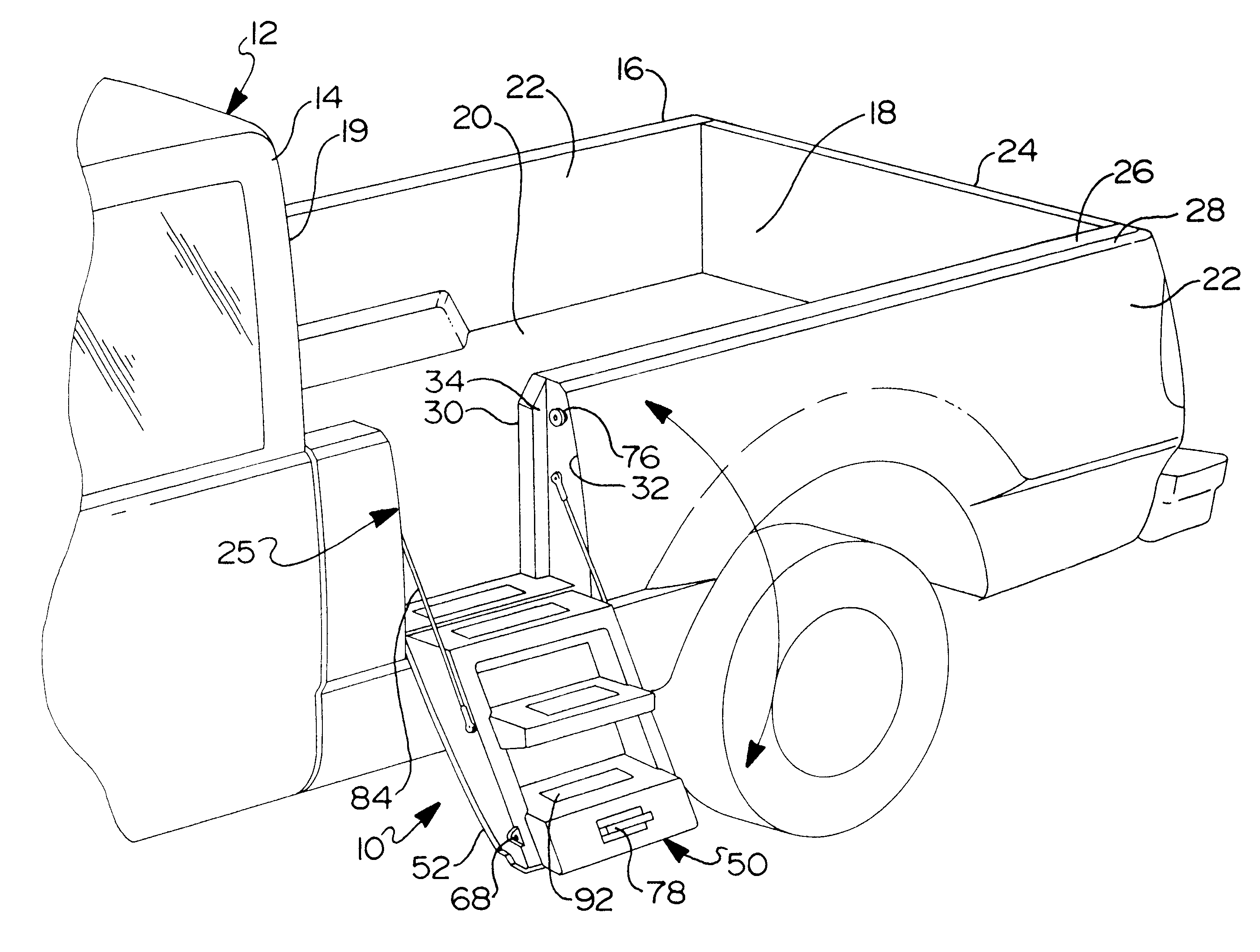

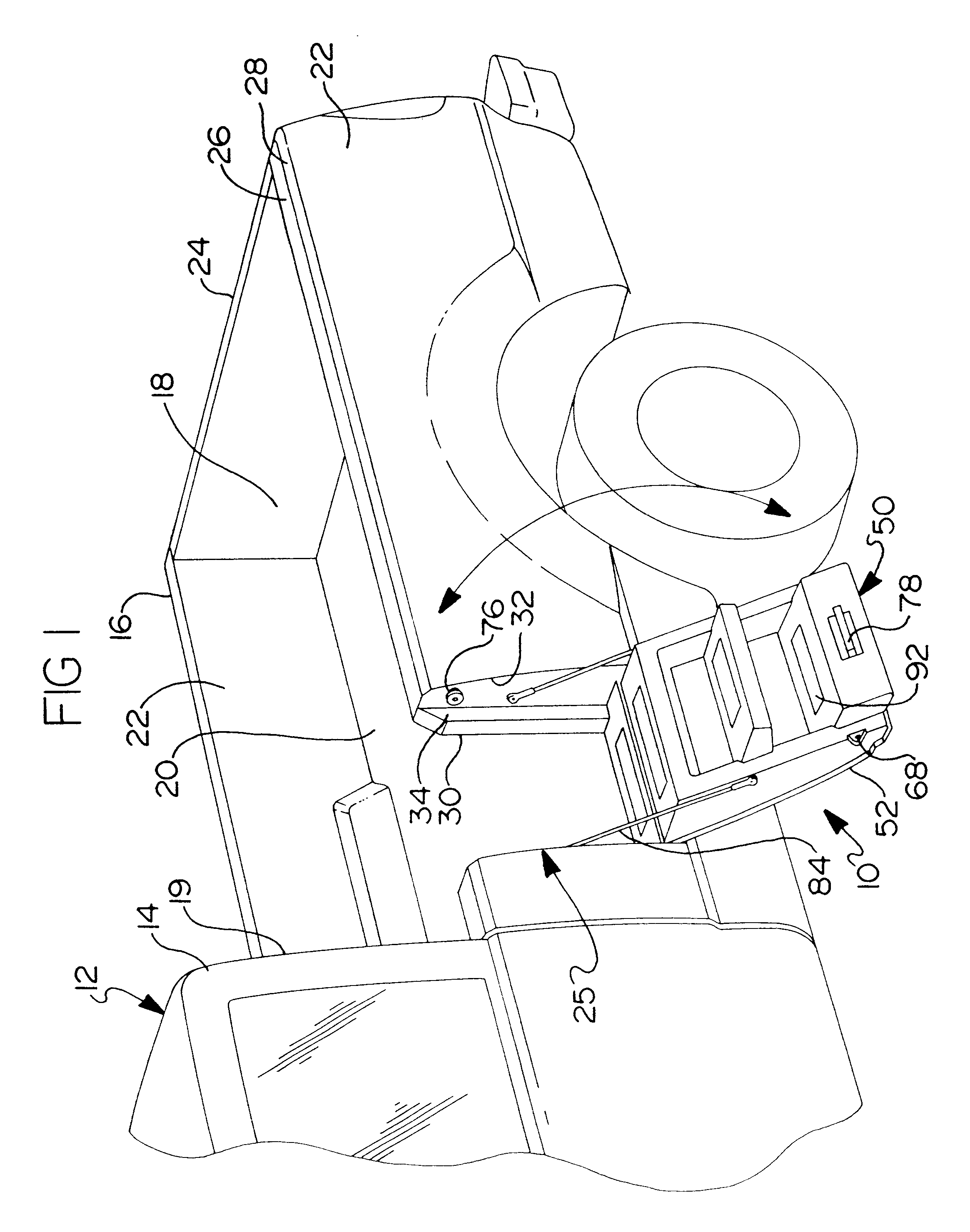

Universal, compact, truck tailgate ladder with support arms

InactiveUS6116378AEasy to adjustEasy to useSuperstructure subunitsSteps arrangementPick-up truckEngineering

A universal, compact, truck tailgate ladder with support arms is disclosed, comprised of a folding ladder of otherwise conventional design, with upper leg members and lower leg members, and a series of parallel steps connecting each set of upper leg members and lower leg members. The present invention is designed to attach to the interior surface of a pick-up truck tailgate via a fastening means, such as bolts.

Owner:BARROW SHERMAN DEAN

Integrated bed side step assembly for vehicles

An integrated bed side step assembly is provided for a pick-up truck having a bed. The integrated bed side step assembly includes a body opening assembly forming one side of the bed and having an opening extending therethrough above a floor of the bed to allow access to an interior of the bed. The integrated bed side step assembly also includes a door assembly operatively cooperating with the body opening assembly to open and close the opening and having at least one step to allow an operator to step up into and access the interior of the bed.

Owner:FORD GLOBAL TECH LLC

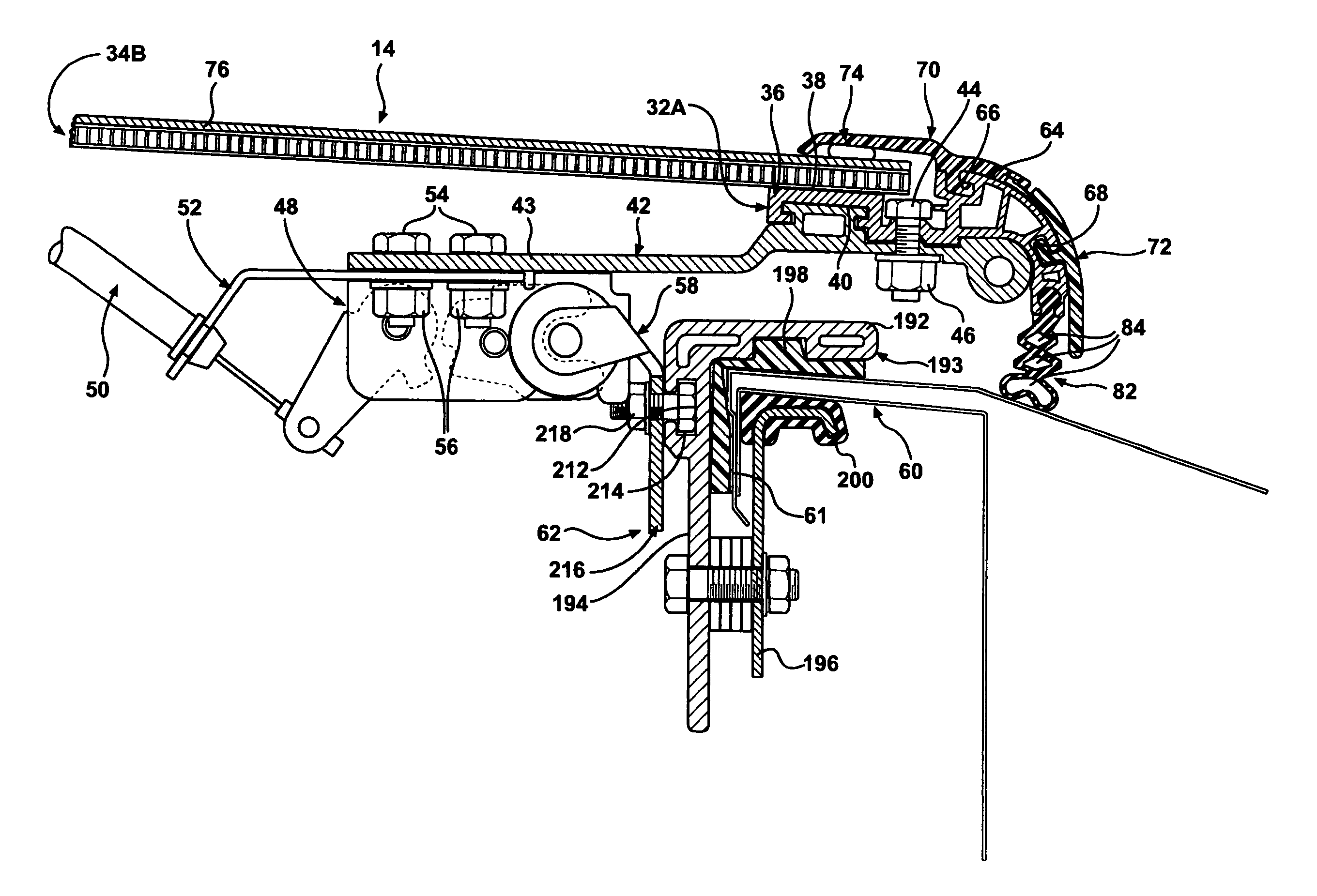

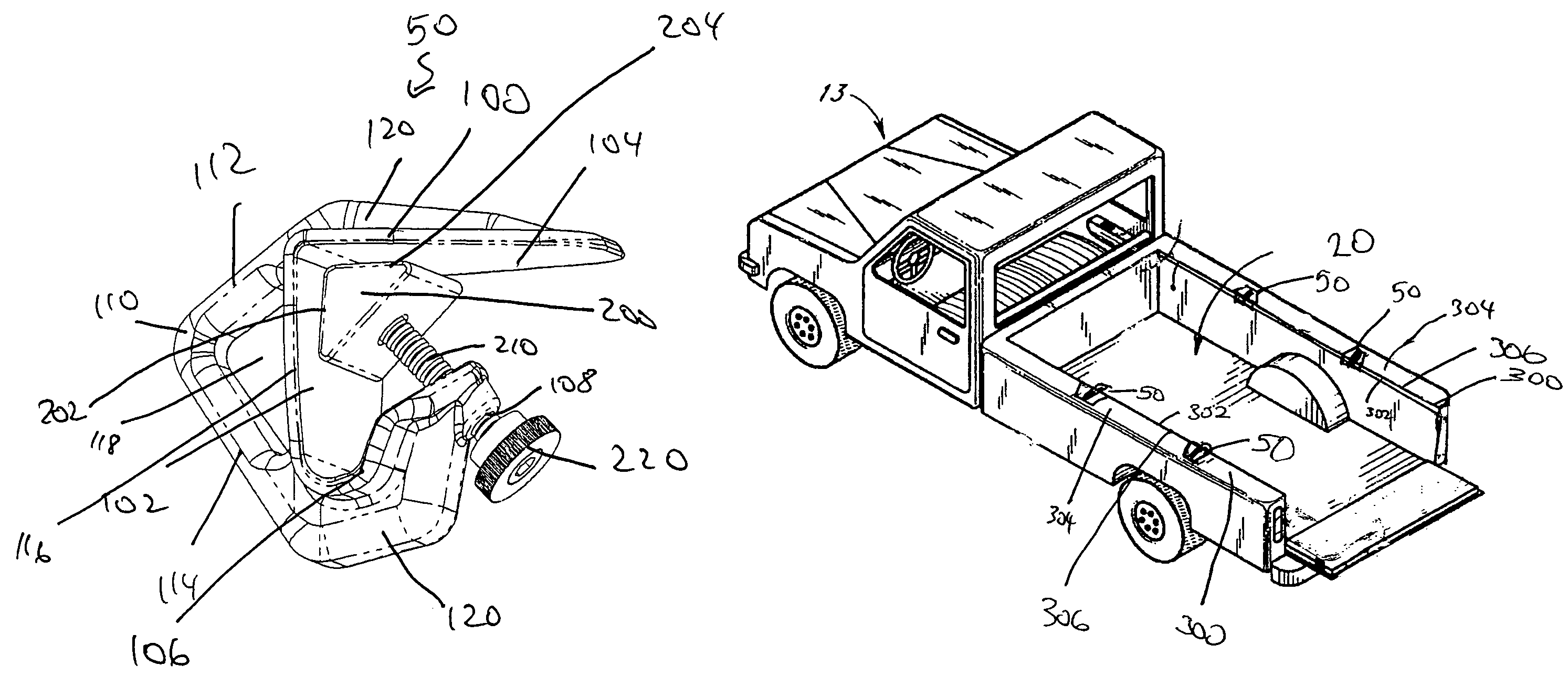

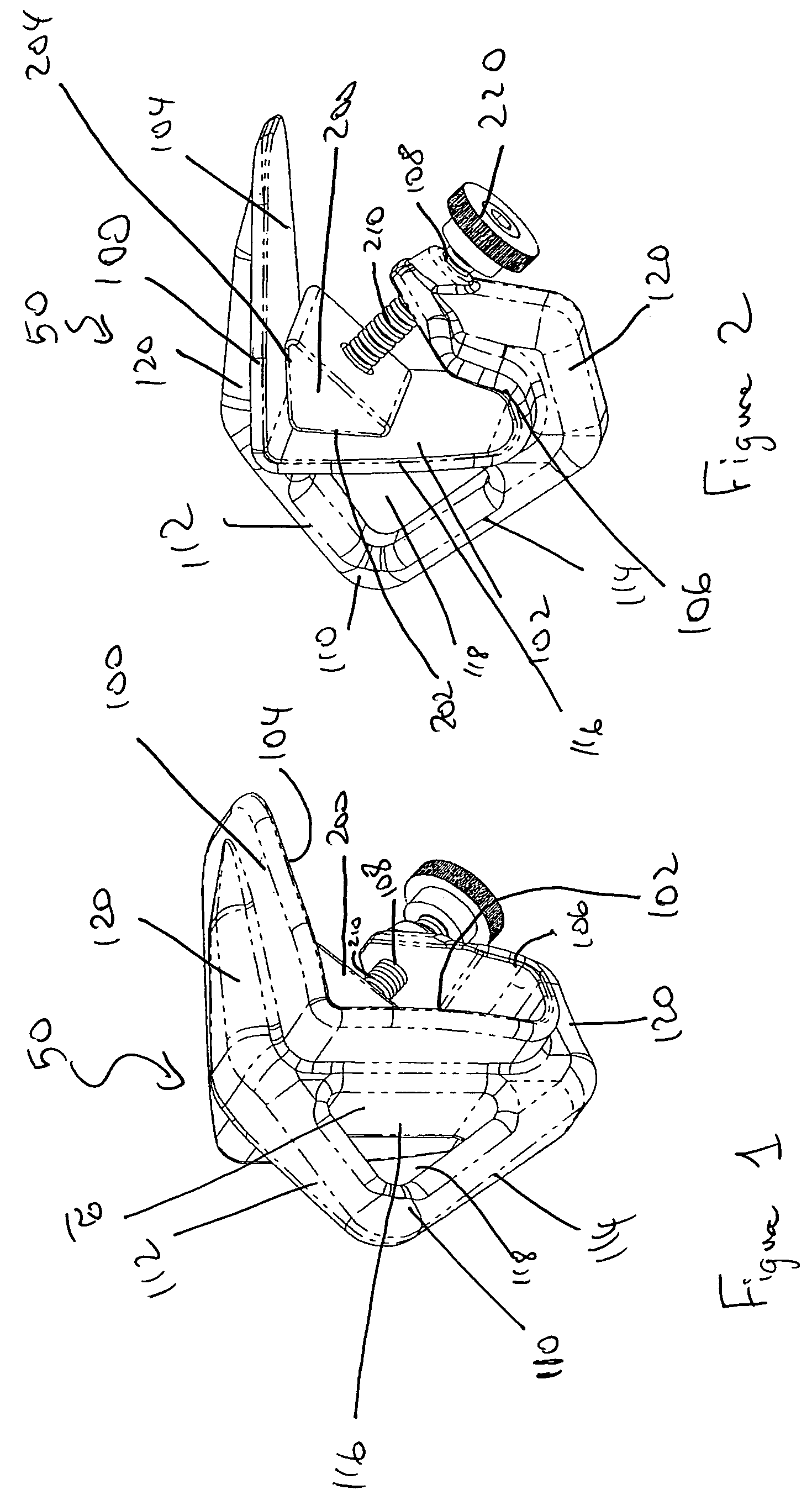

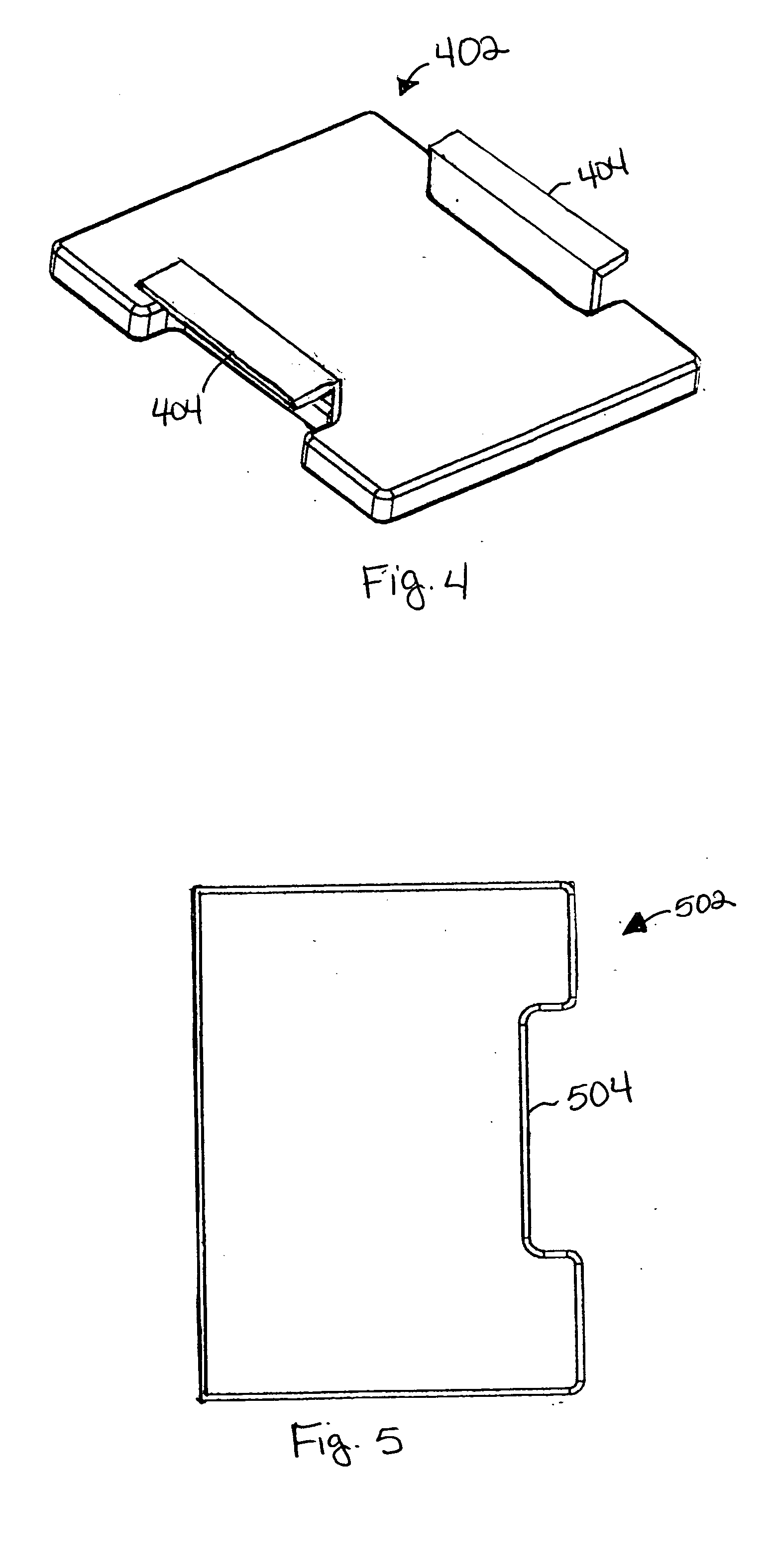

Clamp for a tonneau cover

A clamp for securing a tonneau cover to the bed of pick-up truck in which the clamp includes a base secured to the cover and a handle rotatably connected to the base. A cam part is located between the handle and the base, which upon rotation of the handle in a general horizontal plane causes the cam part to shift upwardly toward the base into engagement with the truck bed, securing the cover to the truck bed.

Owner:ADVANTAGE TRUCK ACCESSORIES

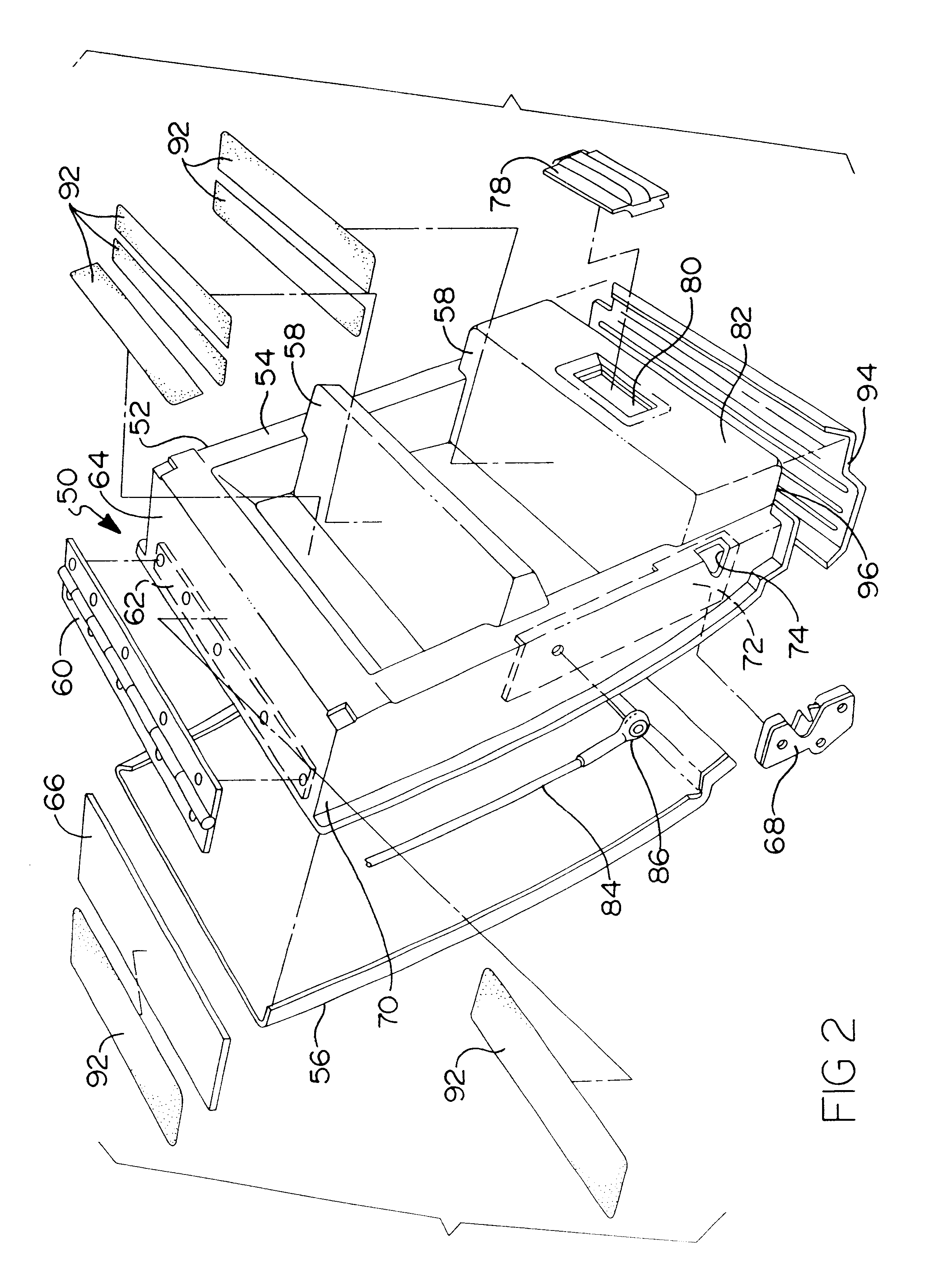

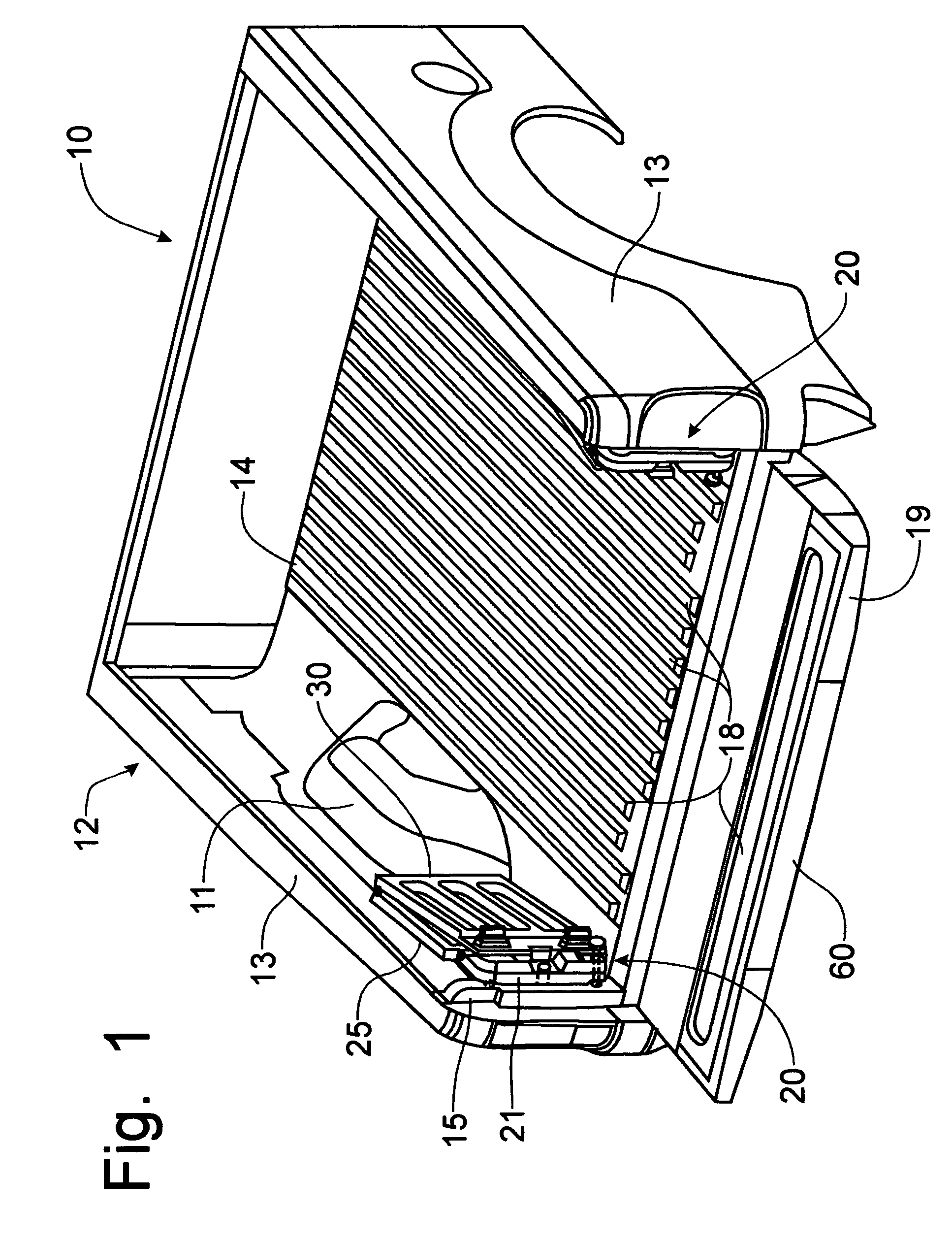

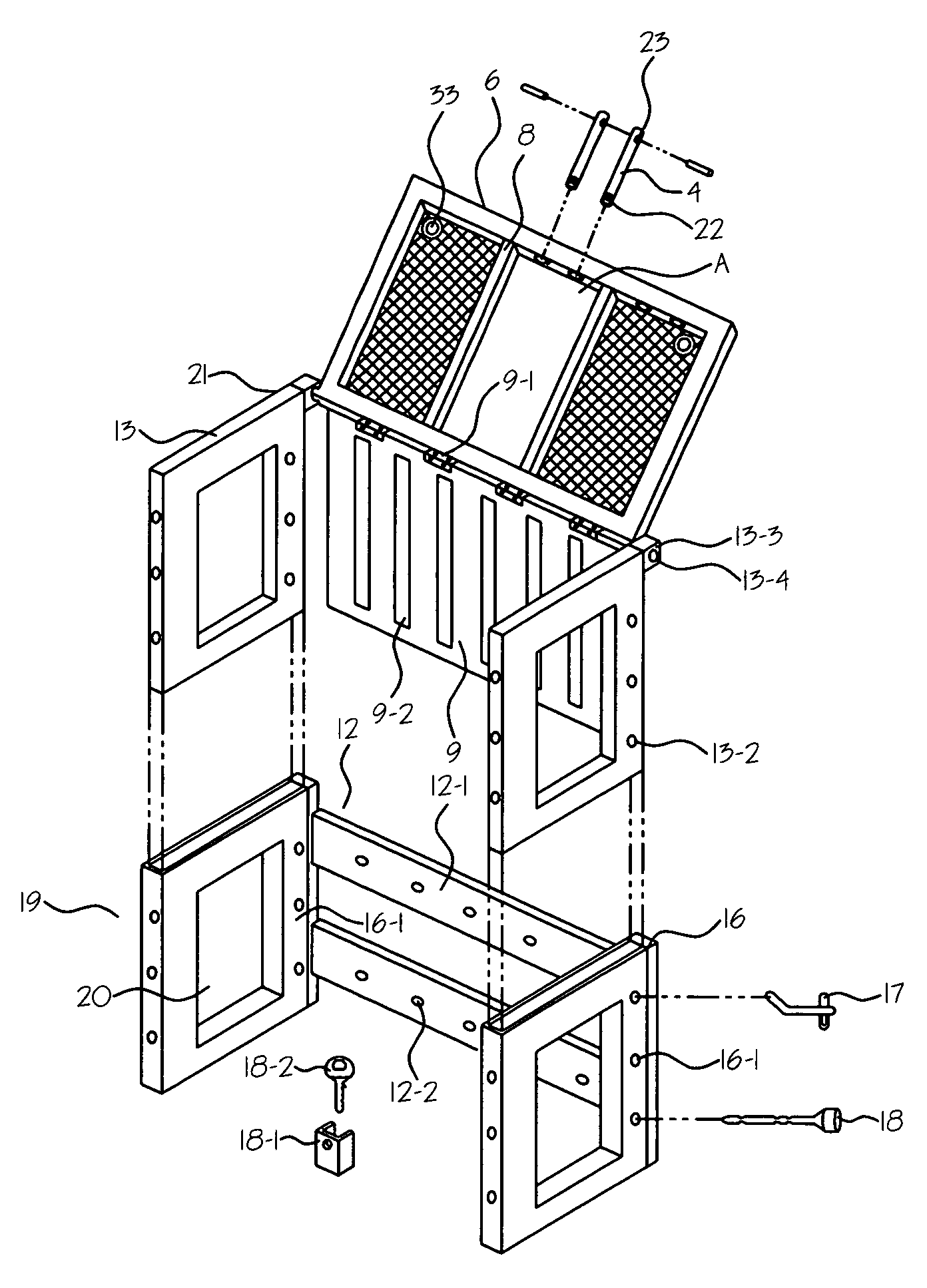

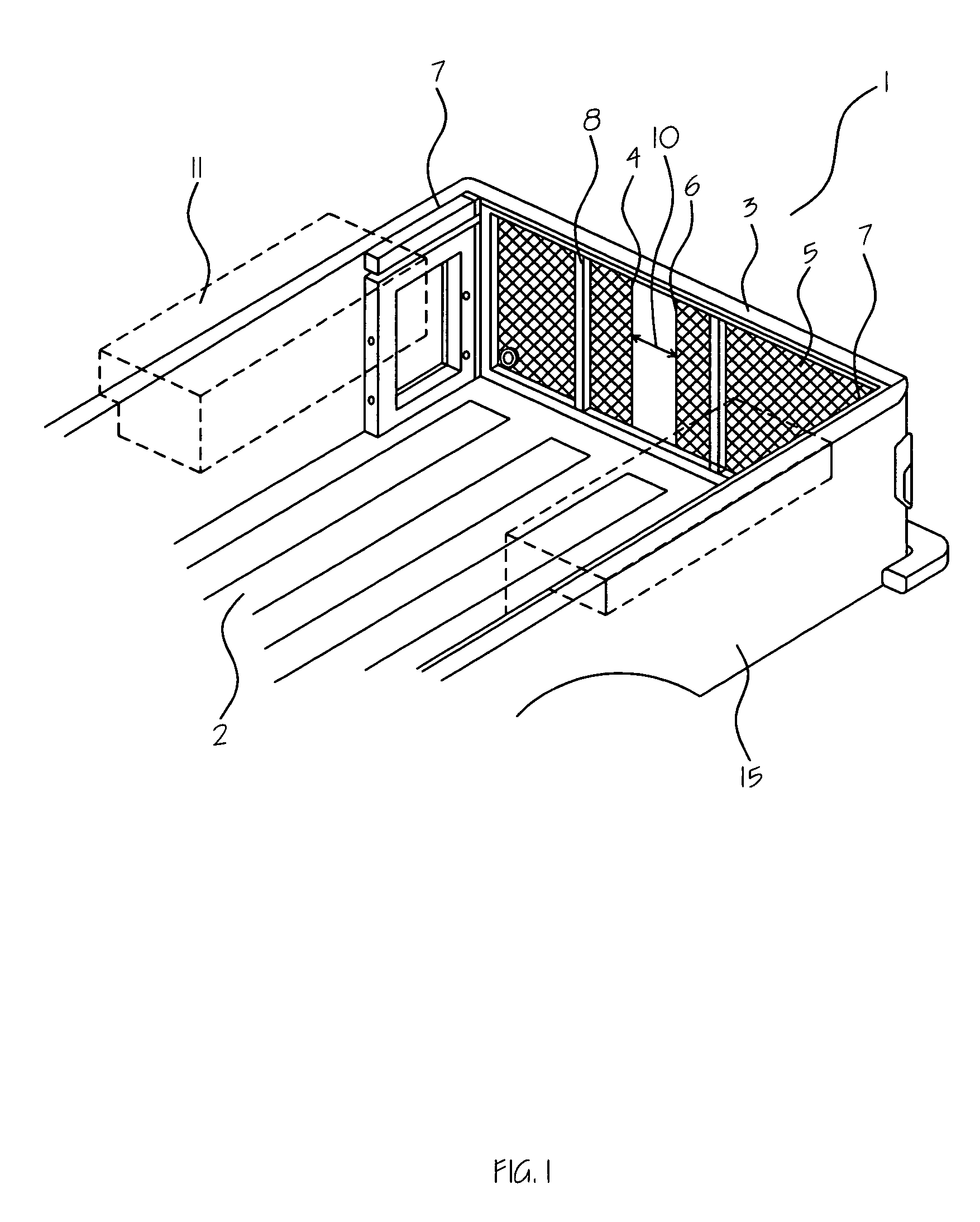

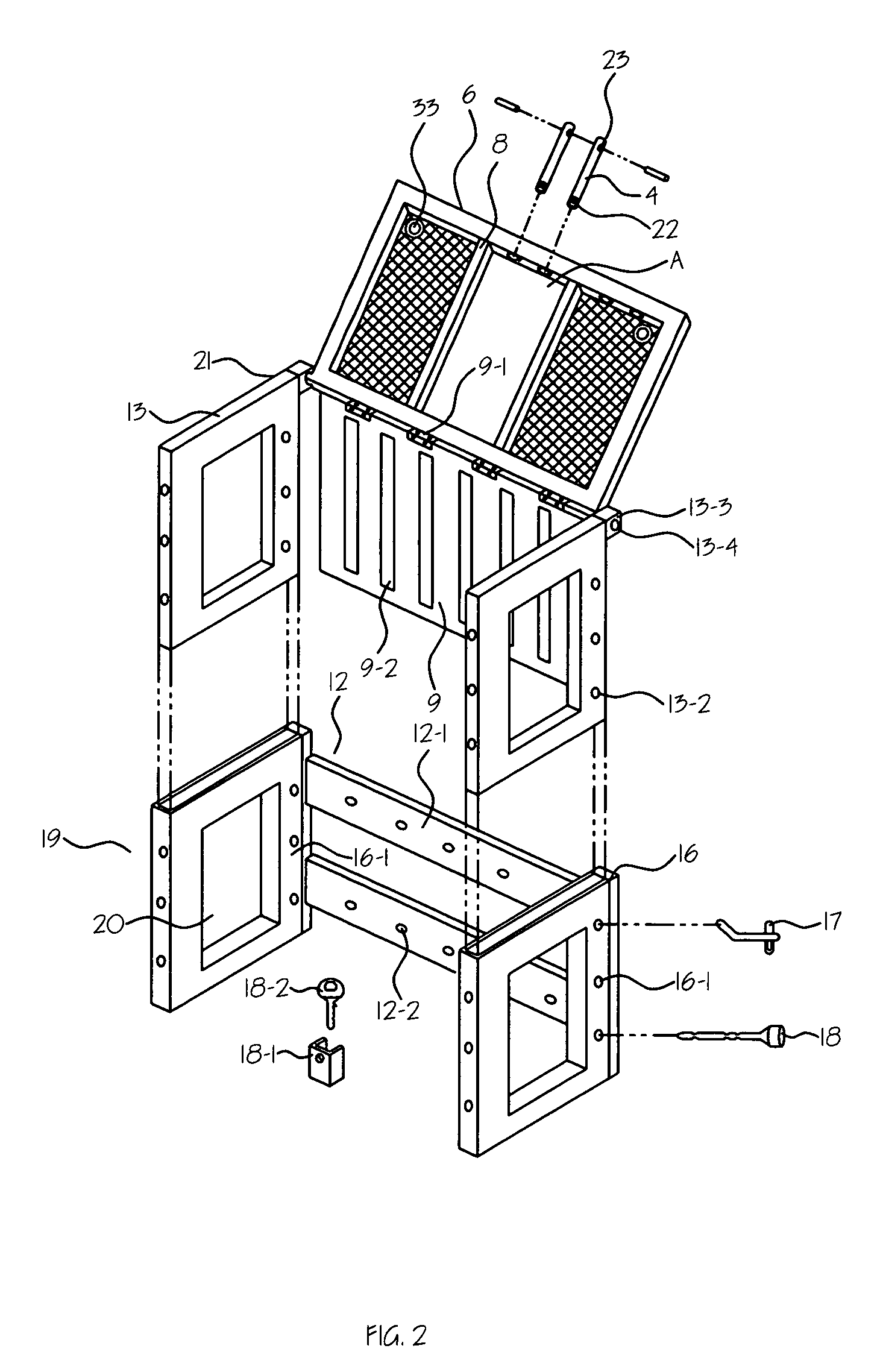

Configurable pivoting cage cargo retainer

ActiveUS7488021B1Simple and ergonomic to operateRestrain cargoVehicle to carry long loadsVehicle with living accommodationPick-up truckBed extension

A pivoting cage cargo is formed of opposing gate assemblies mounted on the rearwardmost D-pillar of a pick-up truck and movable from a folded, collapsed storage position against the respective side walls of the cargo box into multiple selectable operative configurations. The pivoting cage cargo retainer can be positioned in two different transversely extending positions that span the cargo bed when the gate assemblies are connected together. In one transverse position, the coupled gate assemblies cooperate with a lowered tailgate to provide a bed extension function. The other transverse position spans across the cargo bed to provide a divider function. Each gate assembly is also positionable into a storage container configuration that defines a small cargo retention area adjacent the side wall for the retention of small objects, such as grocery bags. A latching mechanism retains the gate assembly next to the side wall.

Owner:FORD GLOBAL TECH LLC

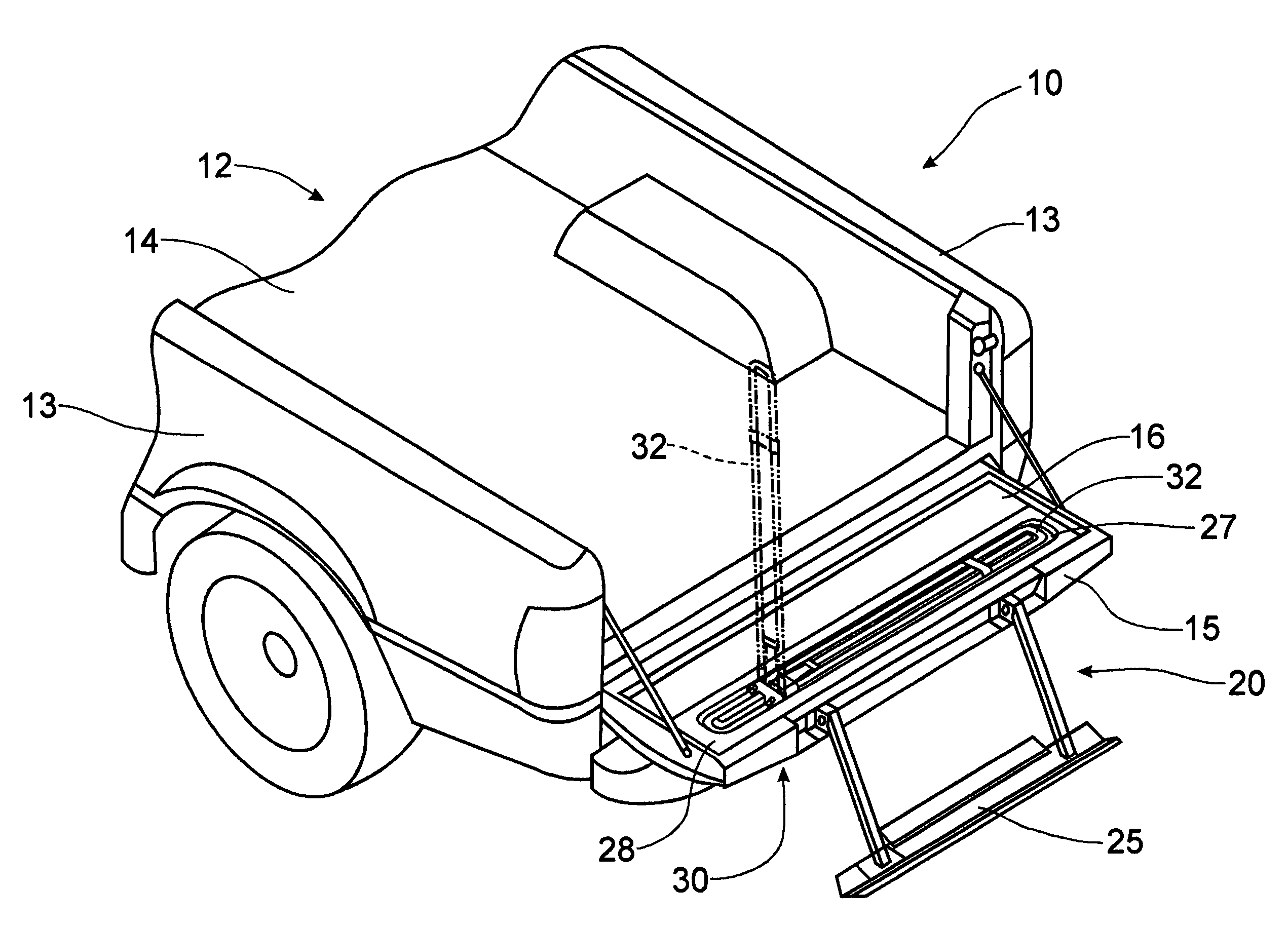

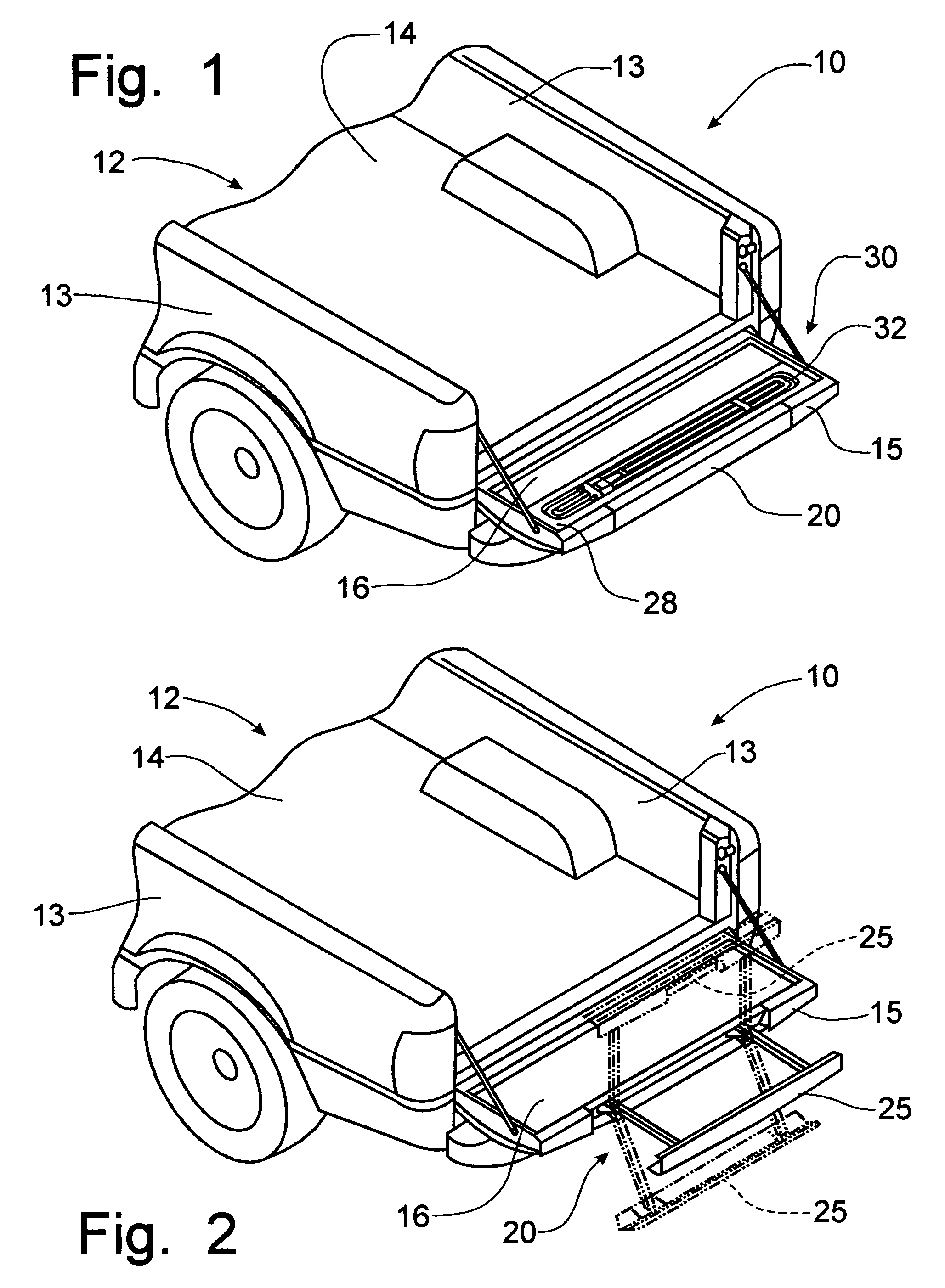

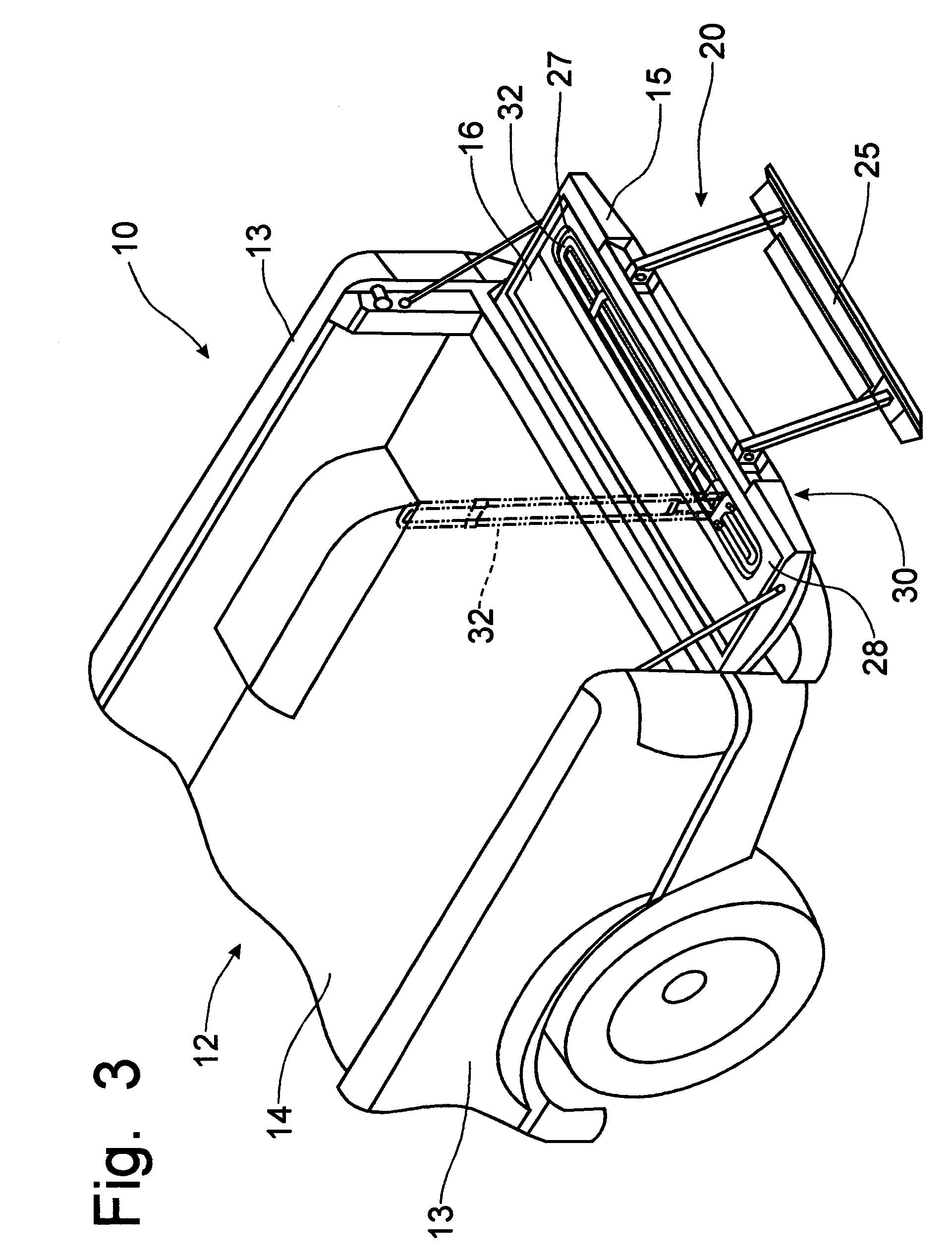

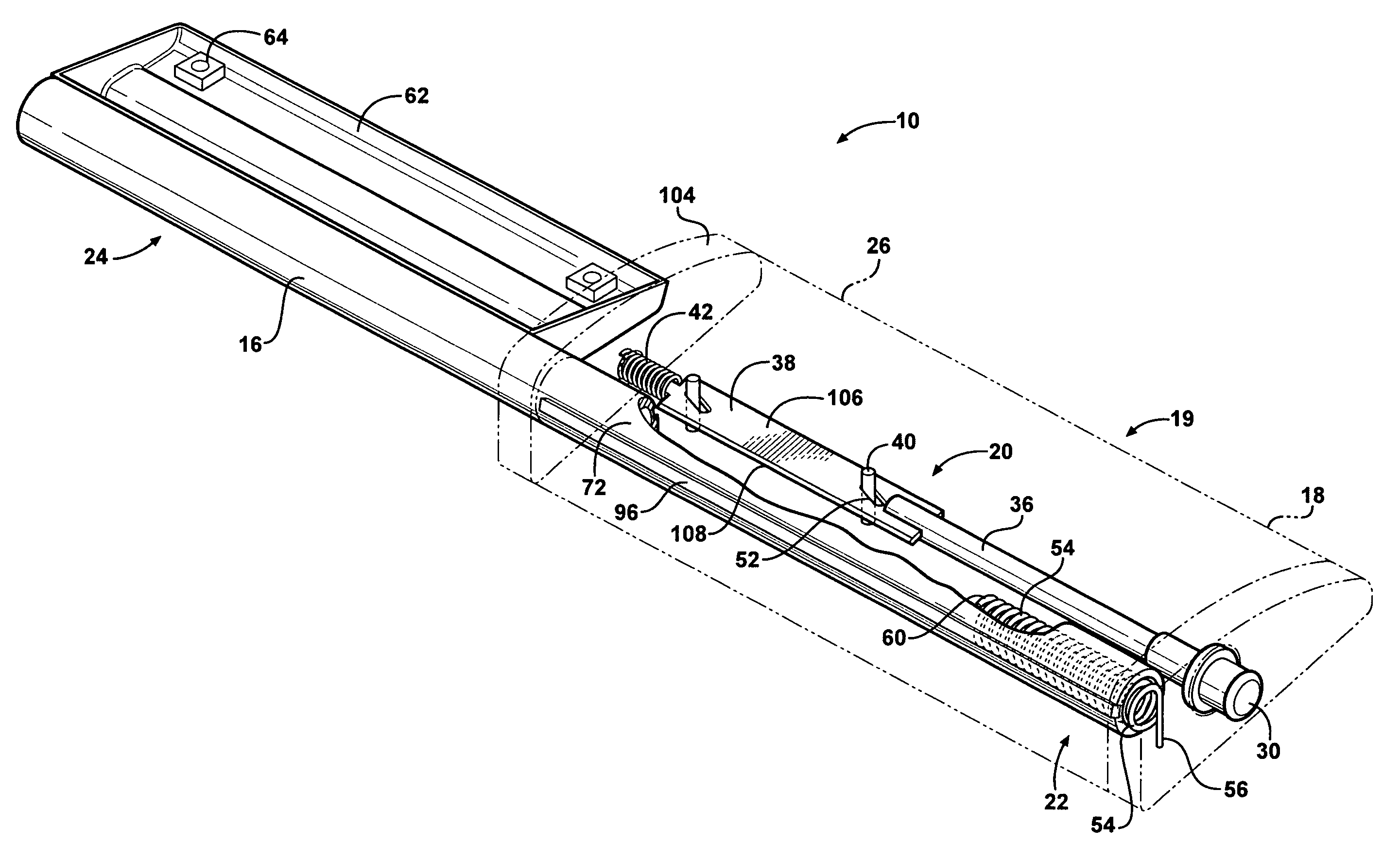

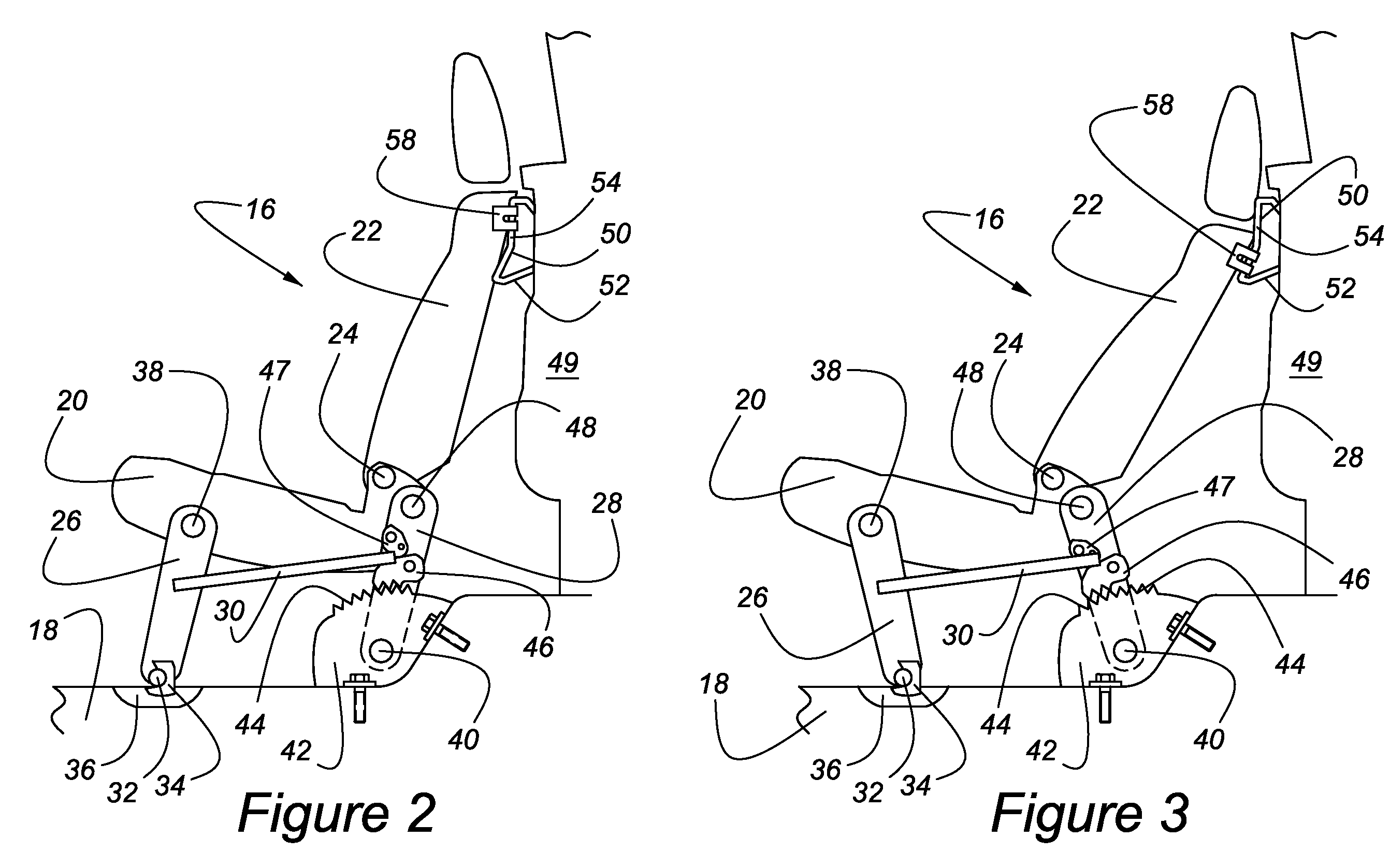

Pivoting cage cargo retainer for pick-up trucks

ActiveUS7111886B1Reduce wind resistanceIncrease capacityVehicle to carry long loadsVehicle with living accommodationPick-up truckEngineering

A pivoting cage cargo bed extender is pivotally mounted to the D-pillars of a pick-up truck to be pivotally movable between a forward position and a rearward position. In the rearward position, the pivoting cage serves as a supplemental tailgate structure that rests on the open tailgate to extend the operative area of the cargo bed. The pivoting cage is formed of individual segments that are hinged together and separable at the center into two halves that are each collapsible into a stowed position adjacent the respective side wall of the cargo bed. The two halves of the cargo bed are connectable with a latching mechanism at the center to form a pivoting cage structure that spans transversely across the floor of the cargo bed. The latching mechanism compresses an internal O-ring to provide a tight connection between the two halves.

Owner:FORD GLOBAL TECH LLC

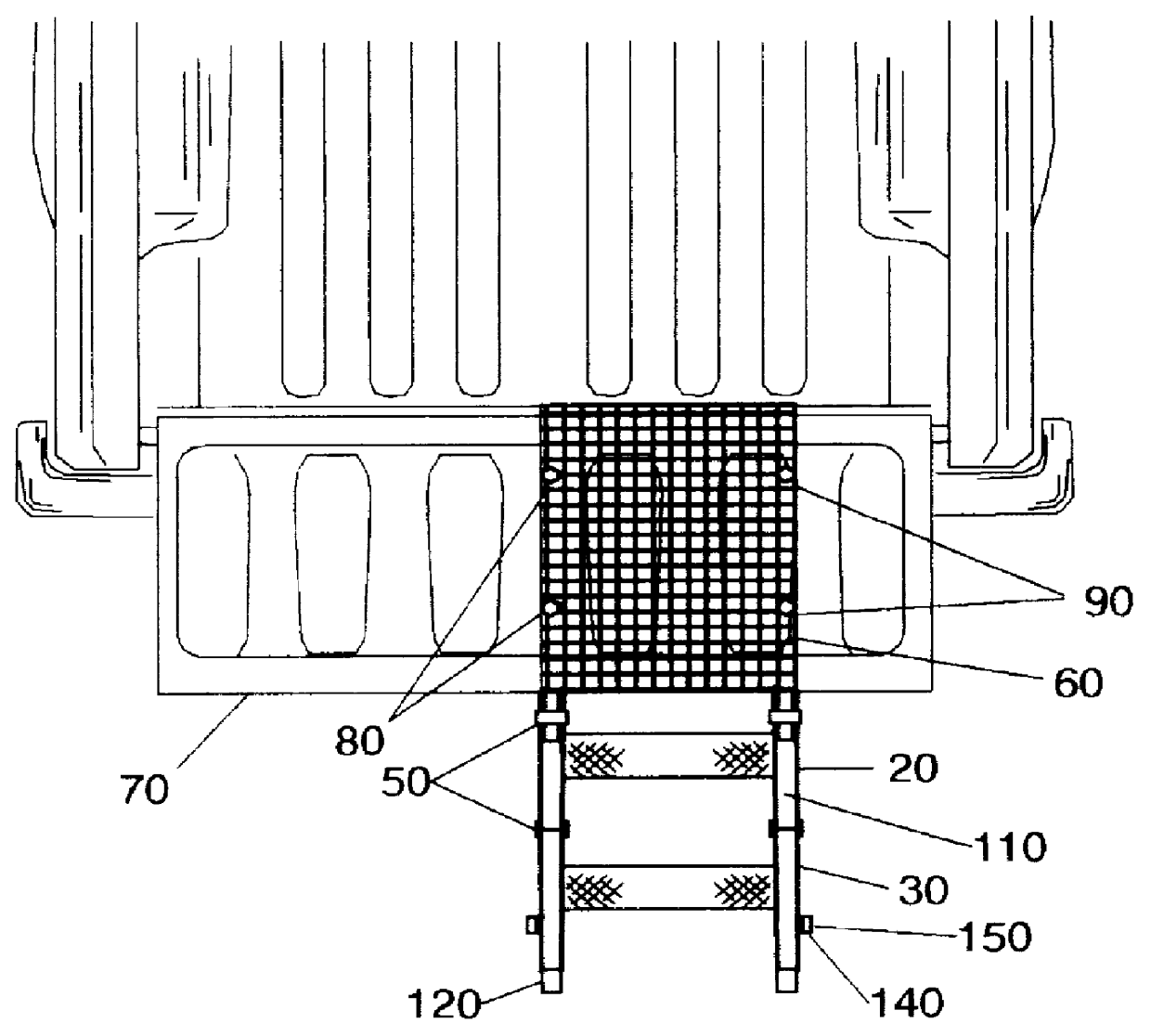

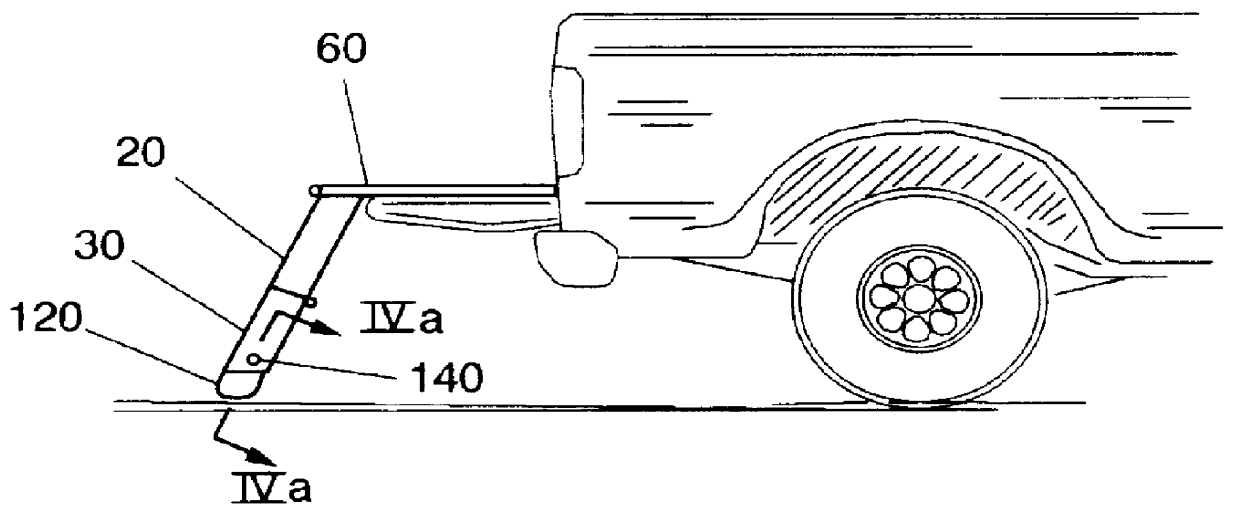

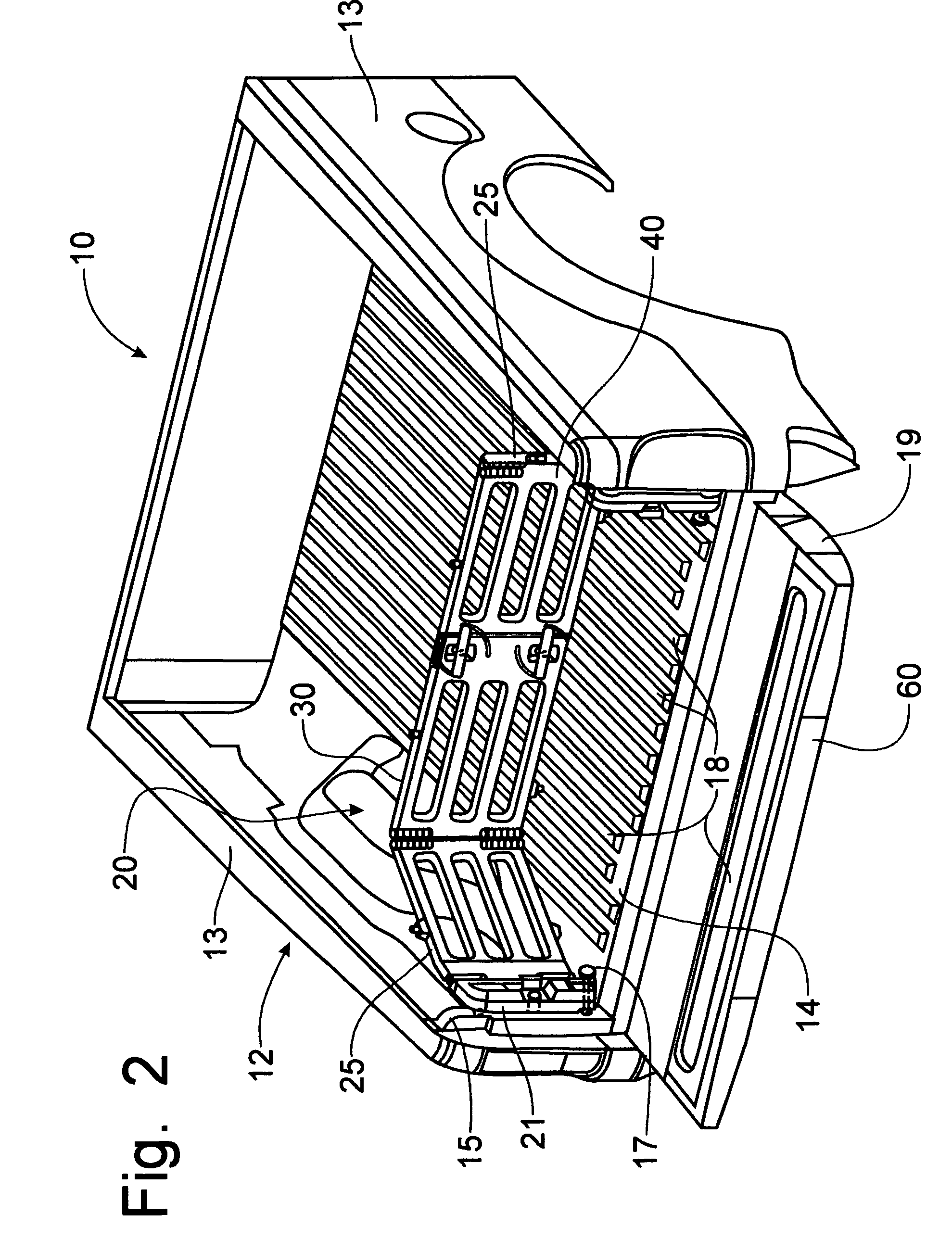

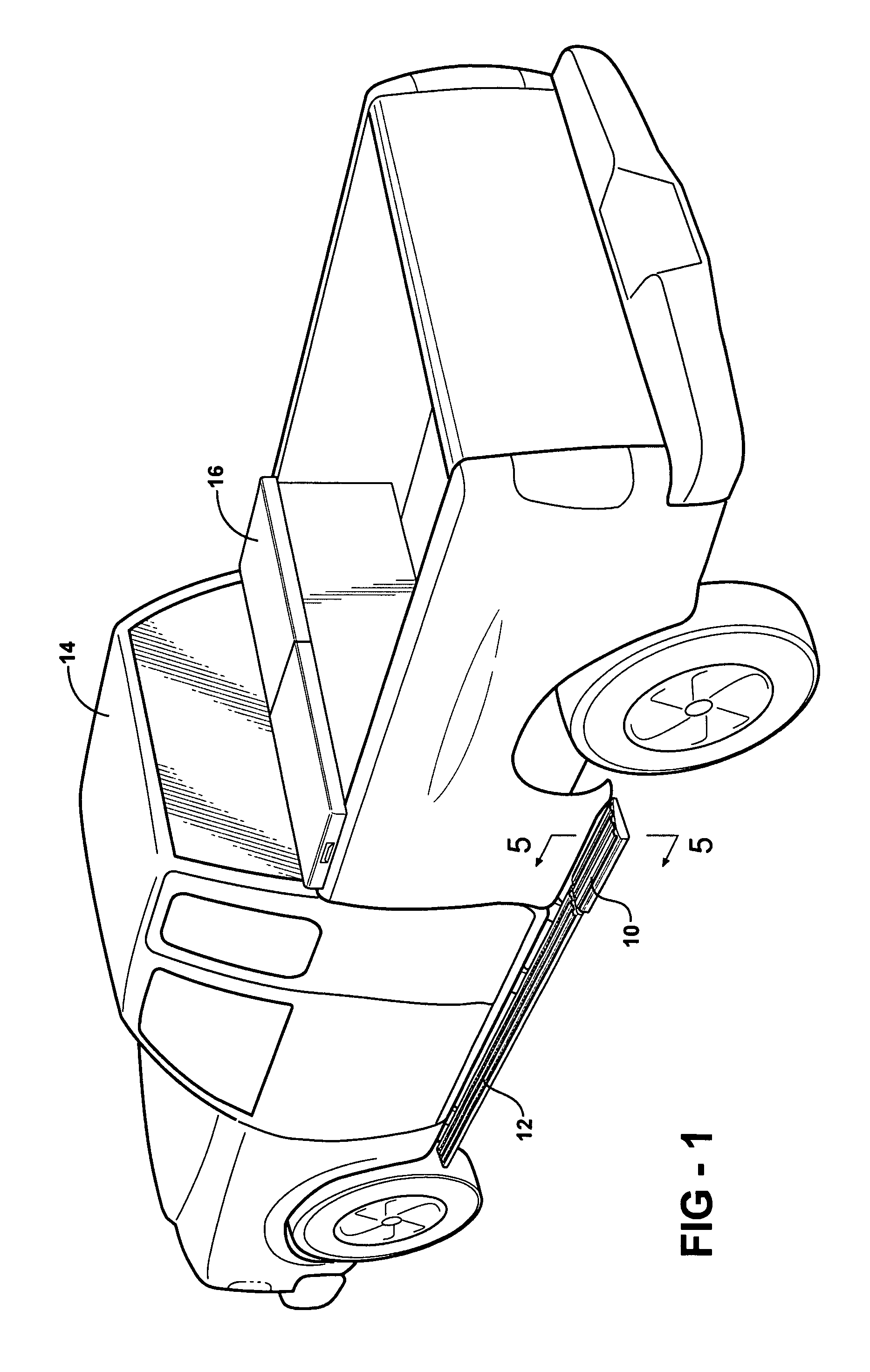

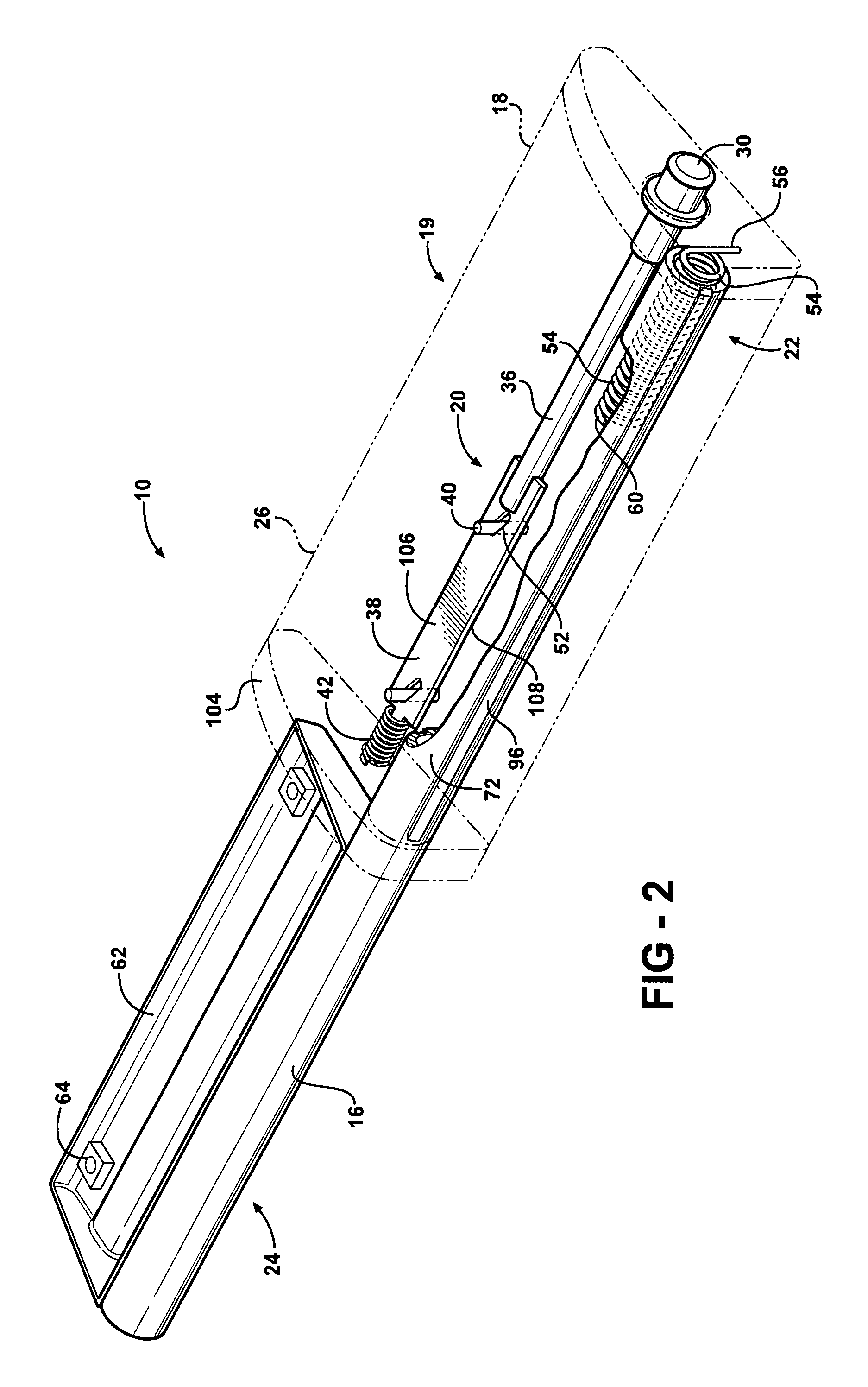

Retractable sidestep

A manually retractable side step assembly for a vehicle includes a rotatable step having a latch mechanism and a spring system that work in concert to rotate the step from a stowed position to a deployed position. In a stowed position, the step is in line with the running board of the vehicle. However, depressing a release button automatically rotates the step 180°, thus exposing an enlarged step area for providing ease of access to a roof rack on a minivan, SUV, or sport wagon, or if used with a pick-up truck, ease of access to a toolbox that is located in the rear of the truck.

Owner:MAGNA INTERNATIONAL INC

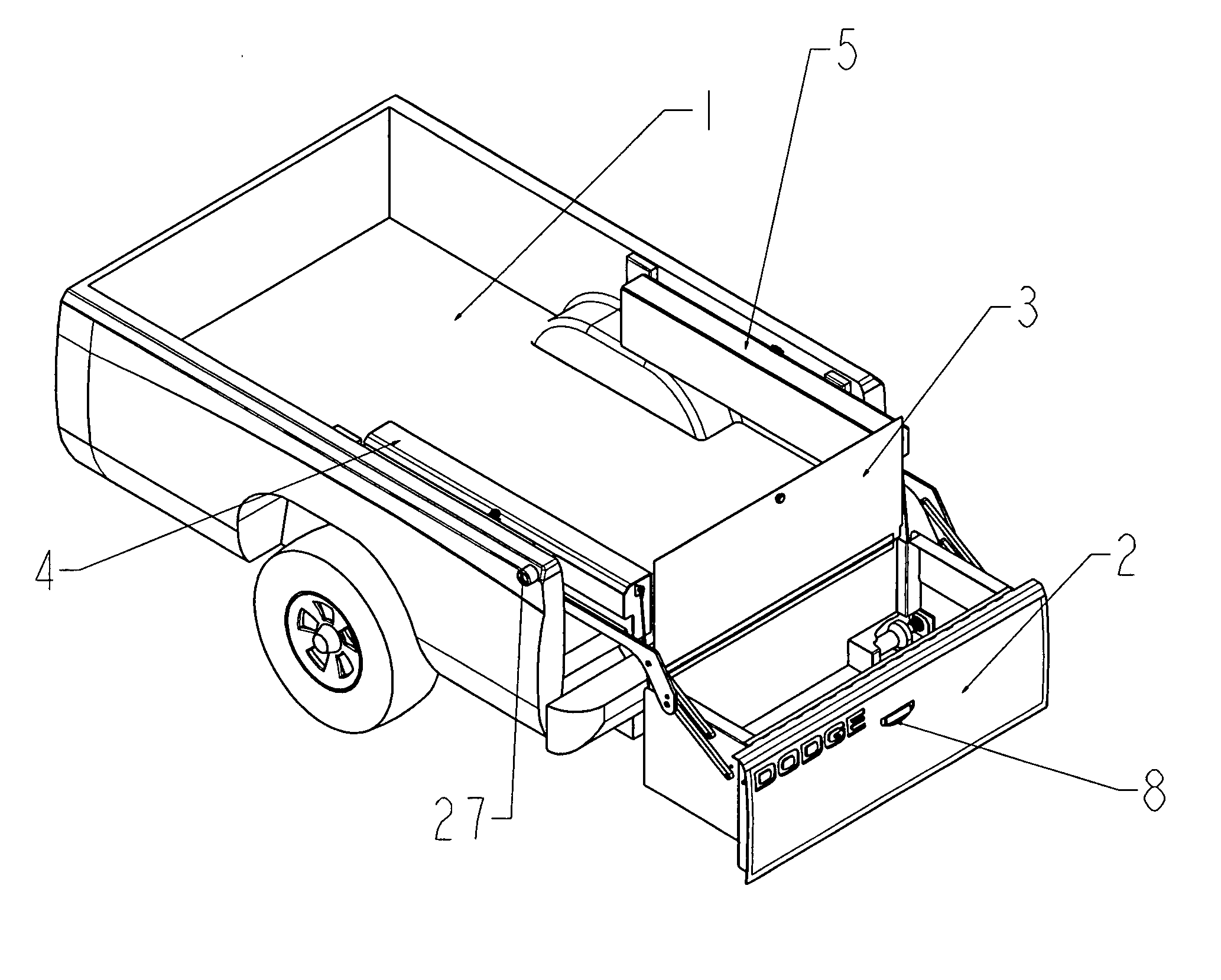

Storage compartment and step for pick-up trucks

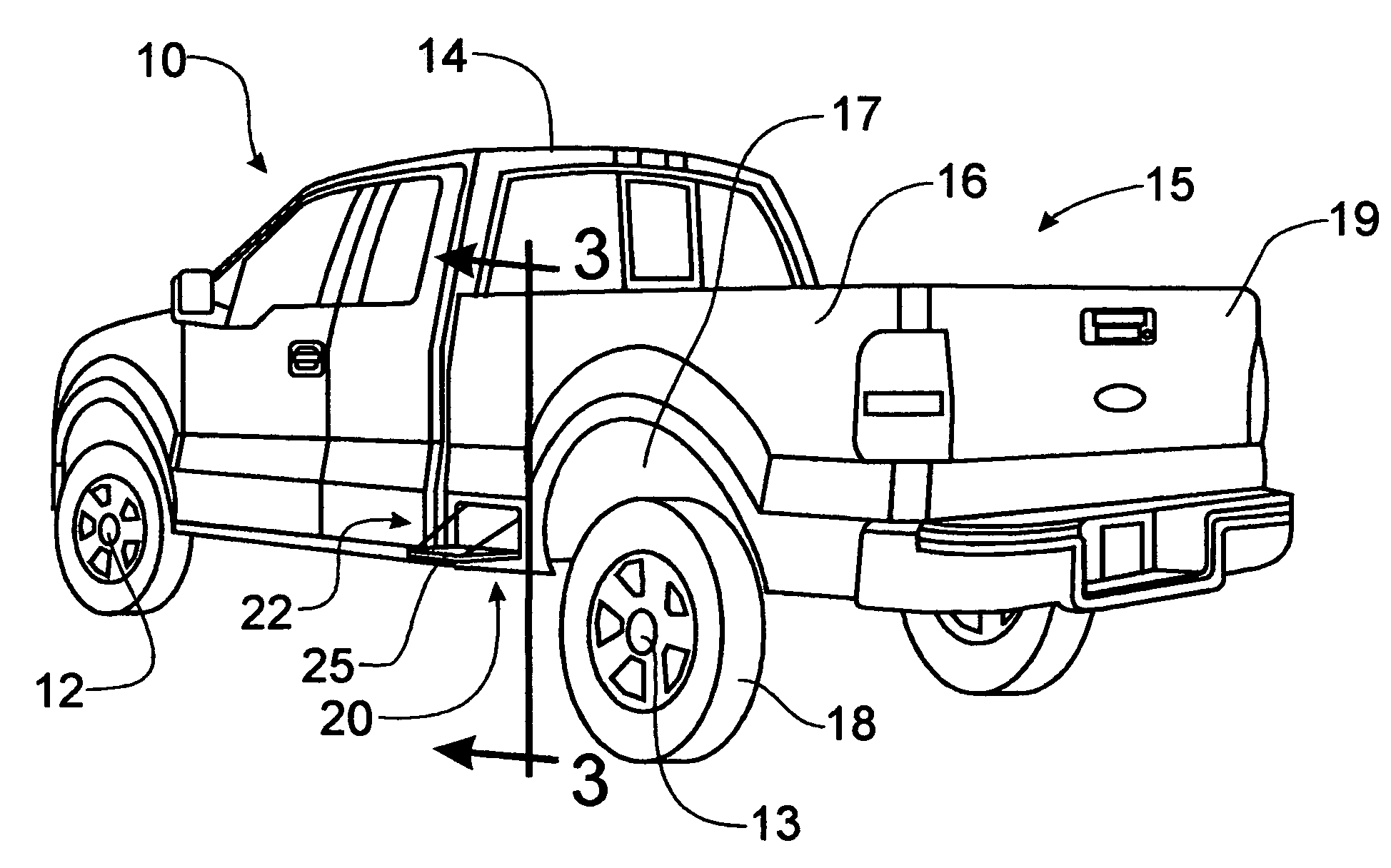

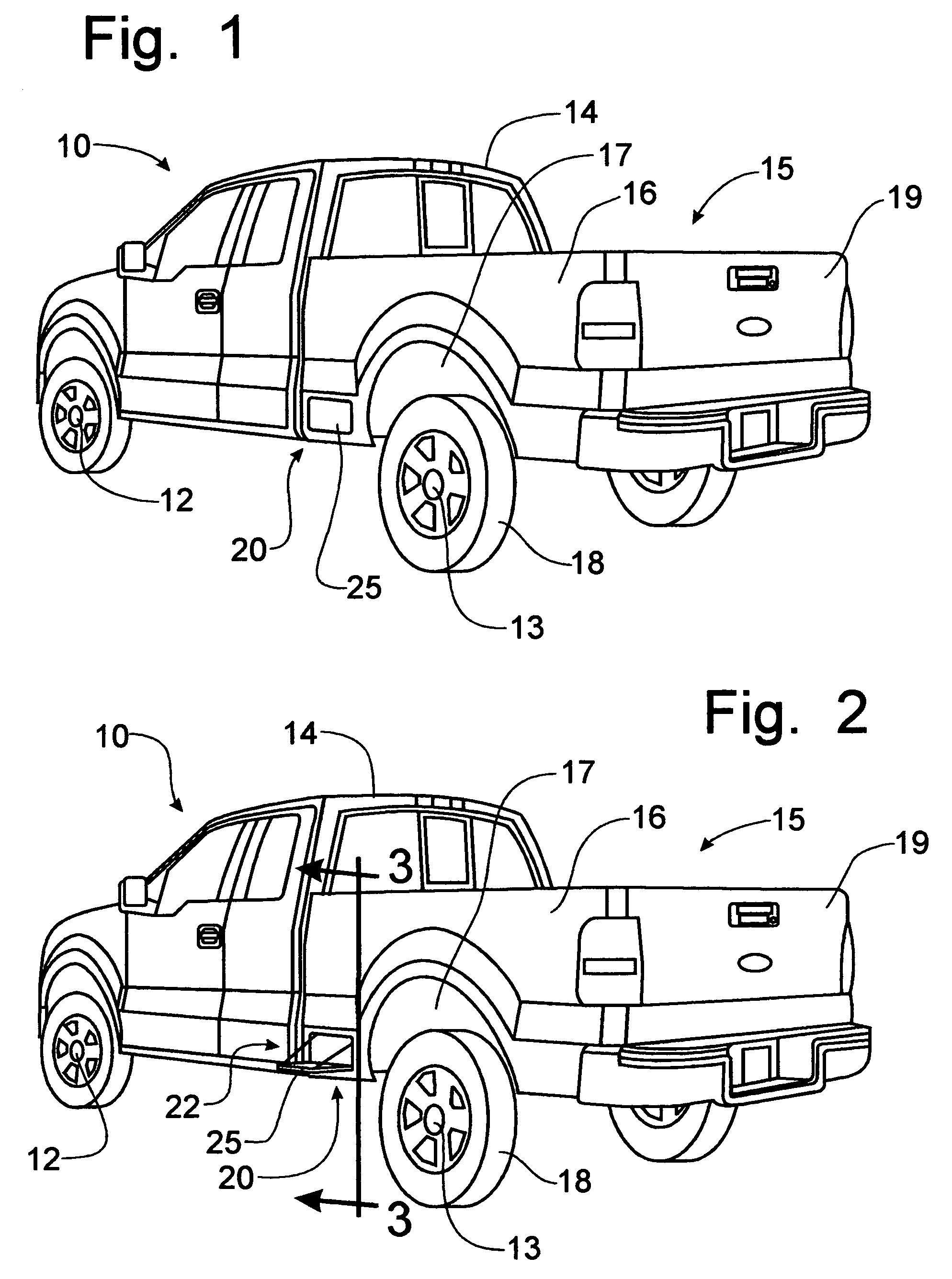

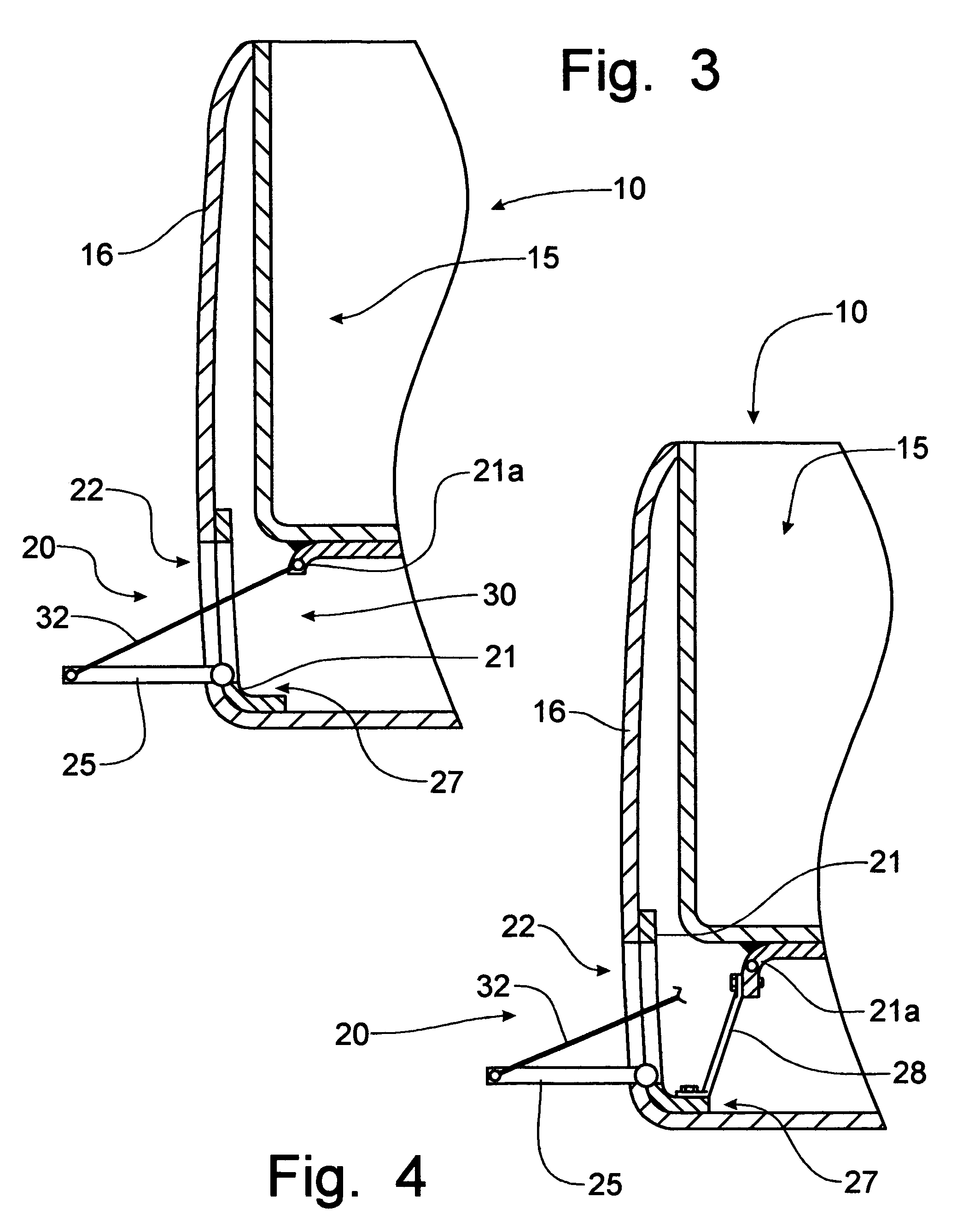

ActiveUS7118150B2Easy accessReliable constructionSuperstructure subunitsSteps arrangementPick-up truckEngineering

A storage compartment is formed on the lateral side of a pick-up truck to have a door that will open to a generally horizontal position to permit use thereof as a step to facilitate access to the interior of the cargo bed. The storage compartment door is pivotally supported by a pivot mechanism that is supported from the underside of the pick up box to provide sufficient support thereof to withstand the weight of a person utilizing the door as a step. The door is also provided with supplemental support members interconnecting the door and the underside of the pick up box. When closed, the door conceals the pivot mechanism to provide a smooth, clean line on the exterior surface of the truck. The opened door allows access to a storage compartment that preferably extends beneath a portion of the cargo bed to allow storage of small items in a contained compartment.

Owner:FORD GLOBAL TECH LLC

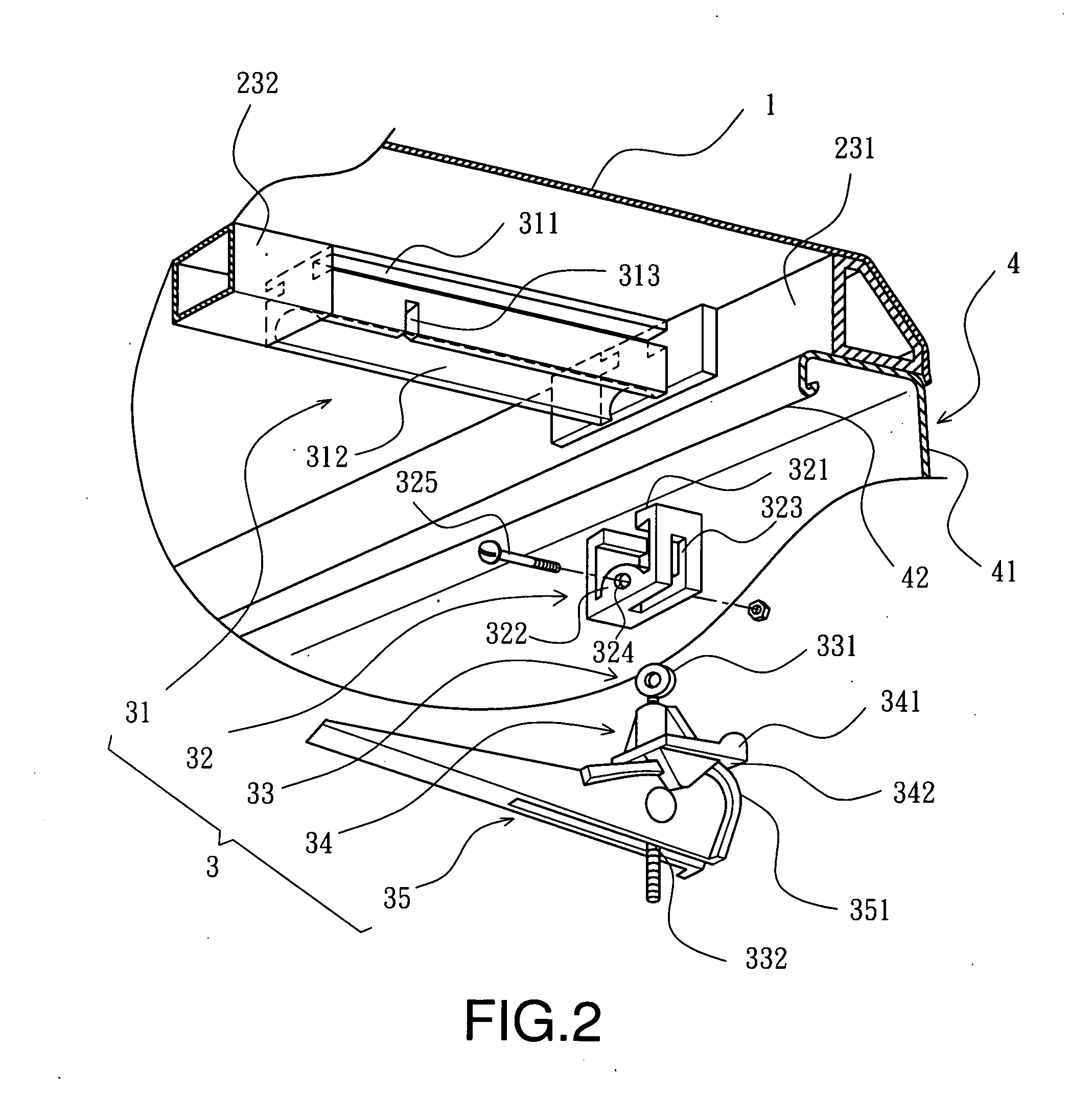

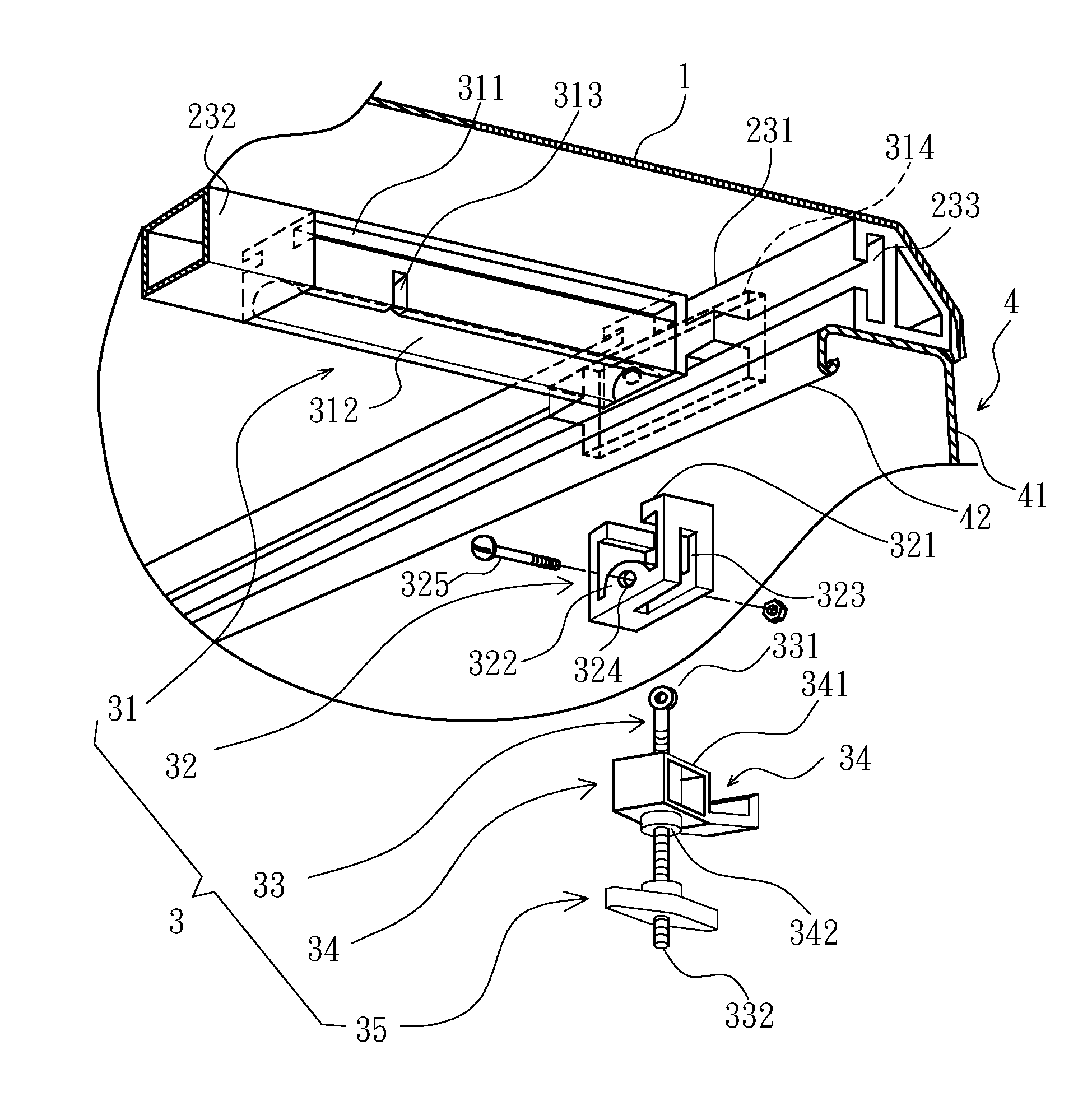

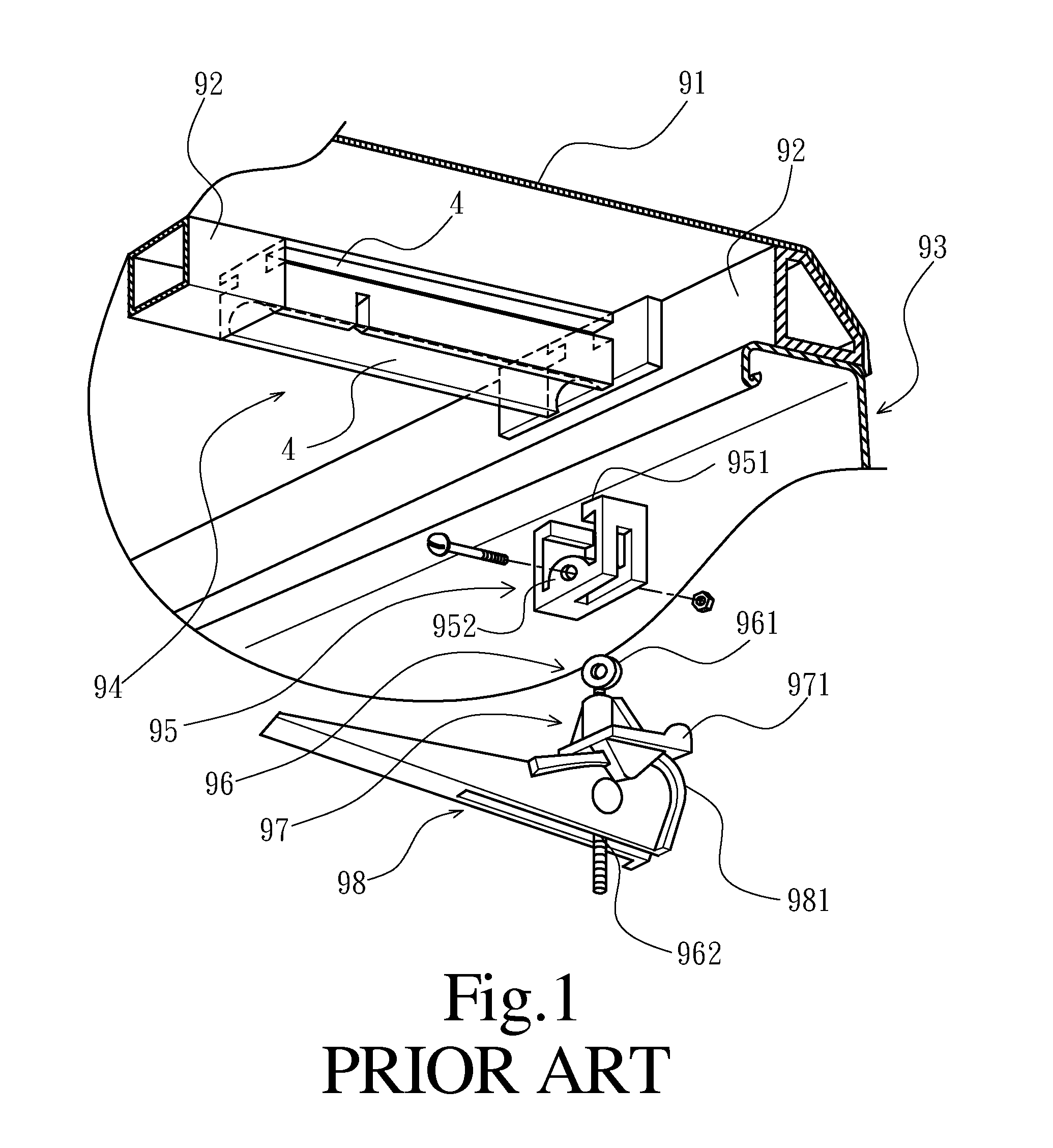

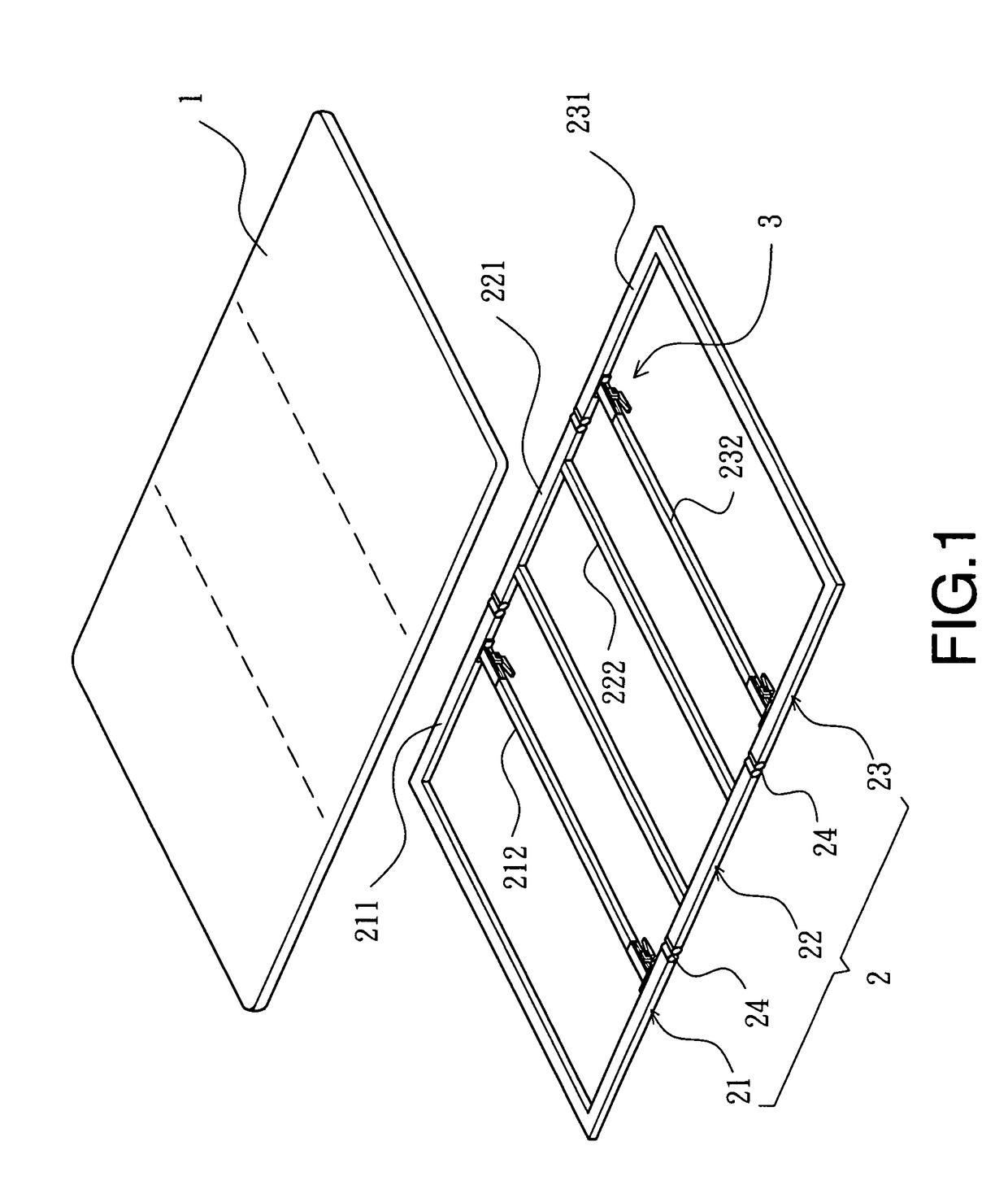

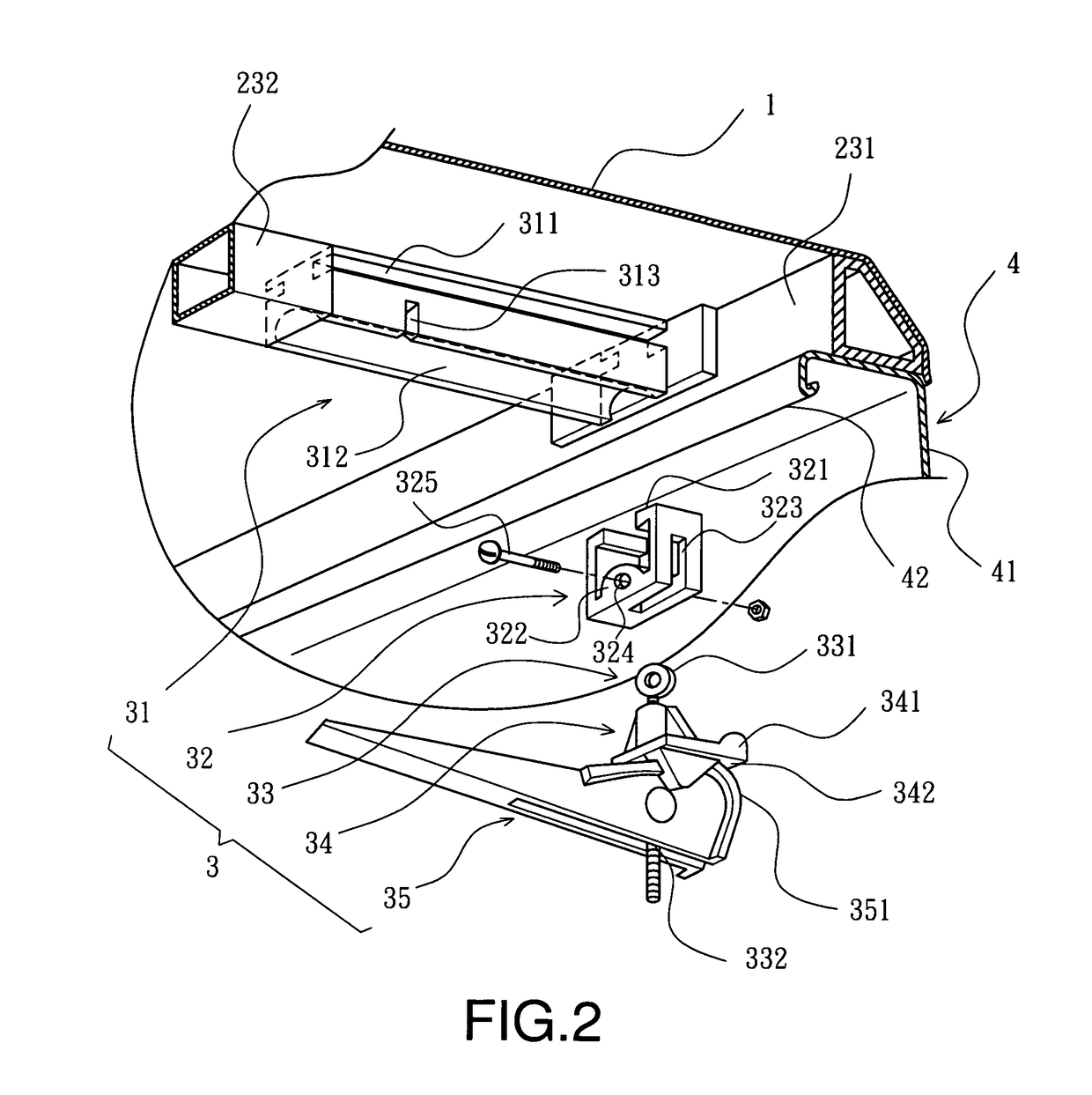

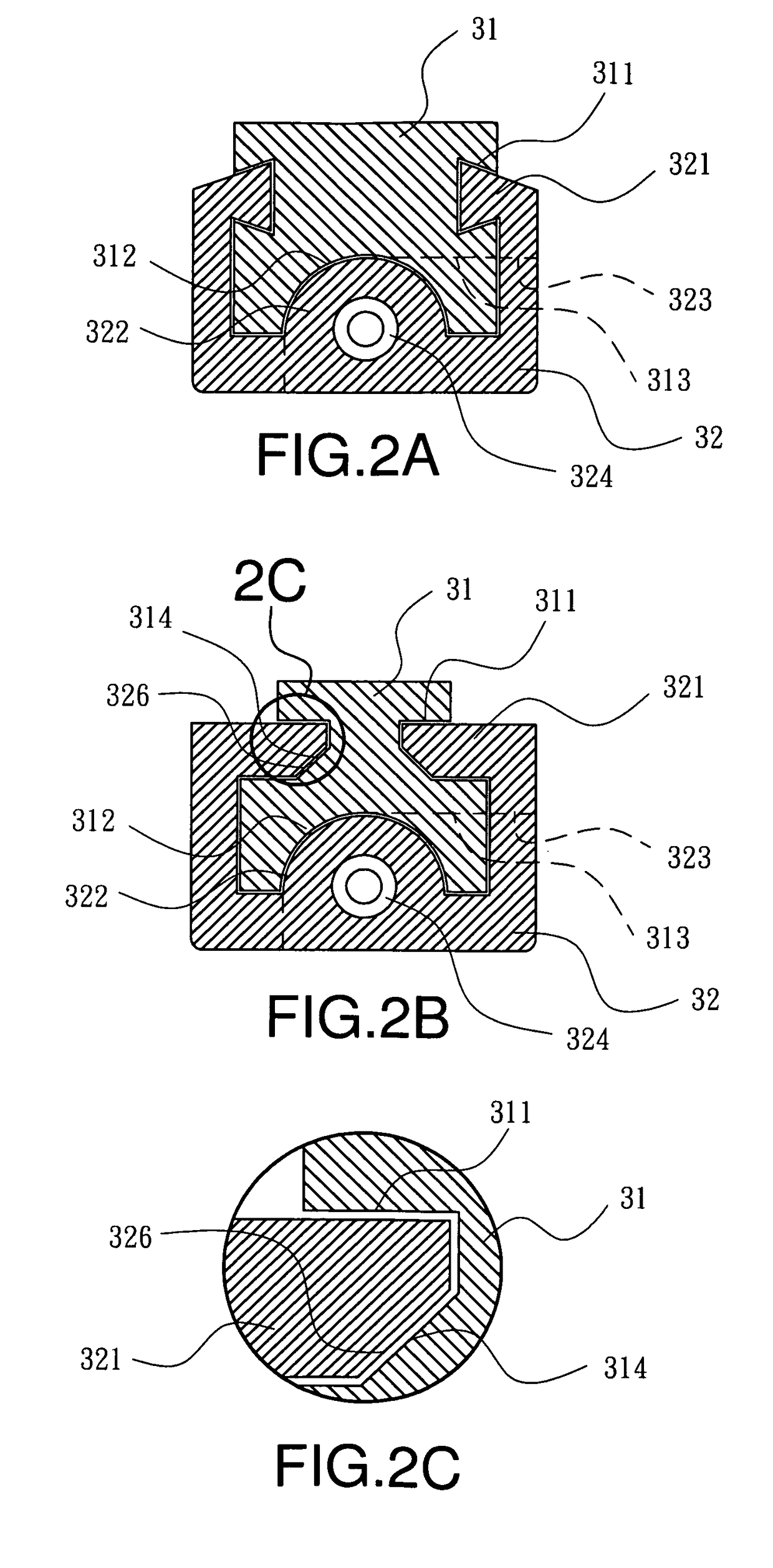

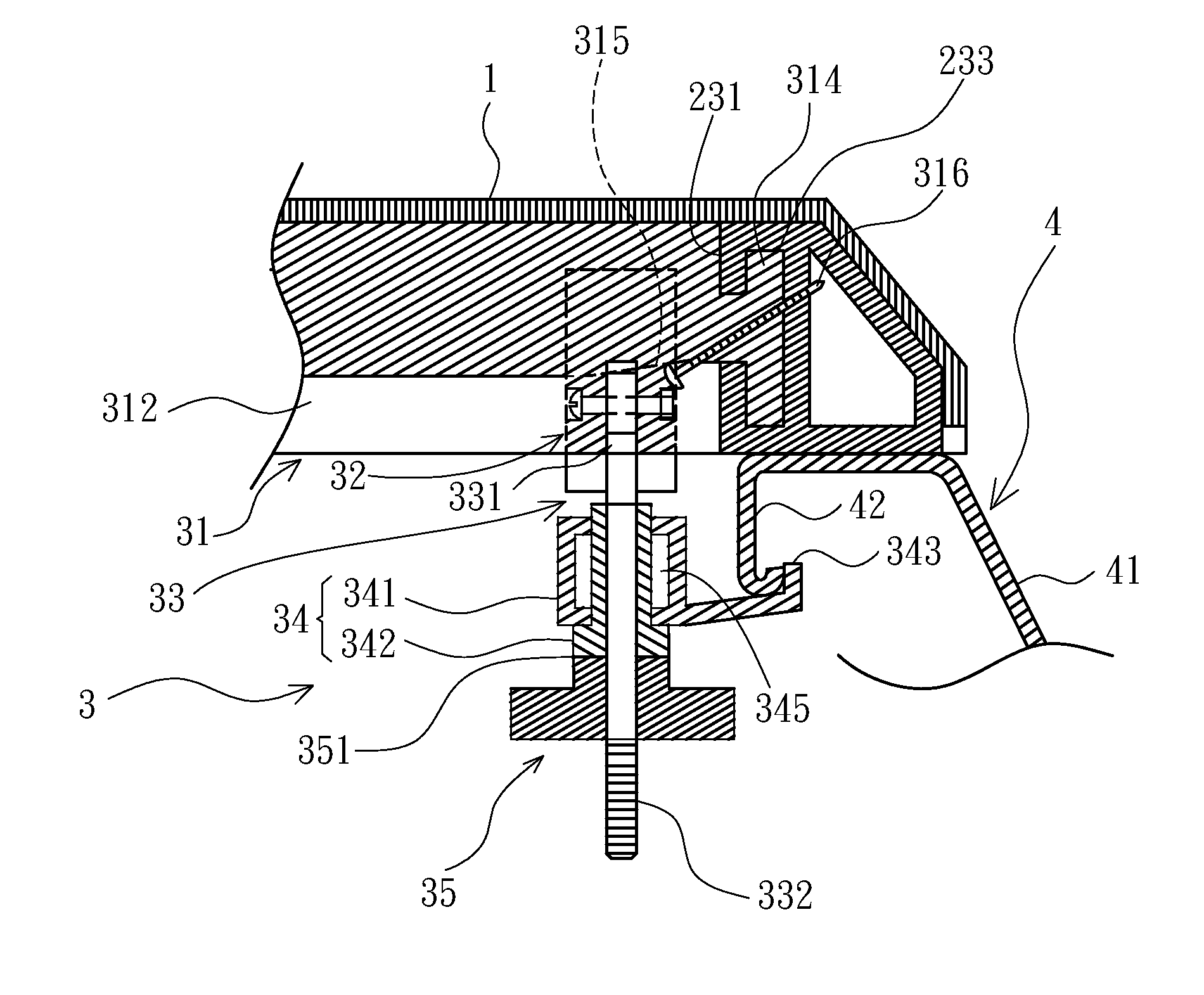

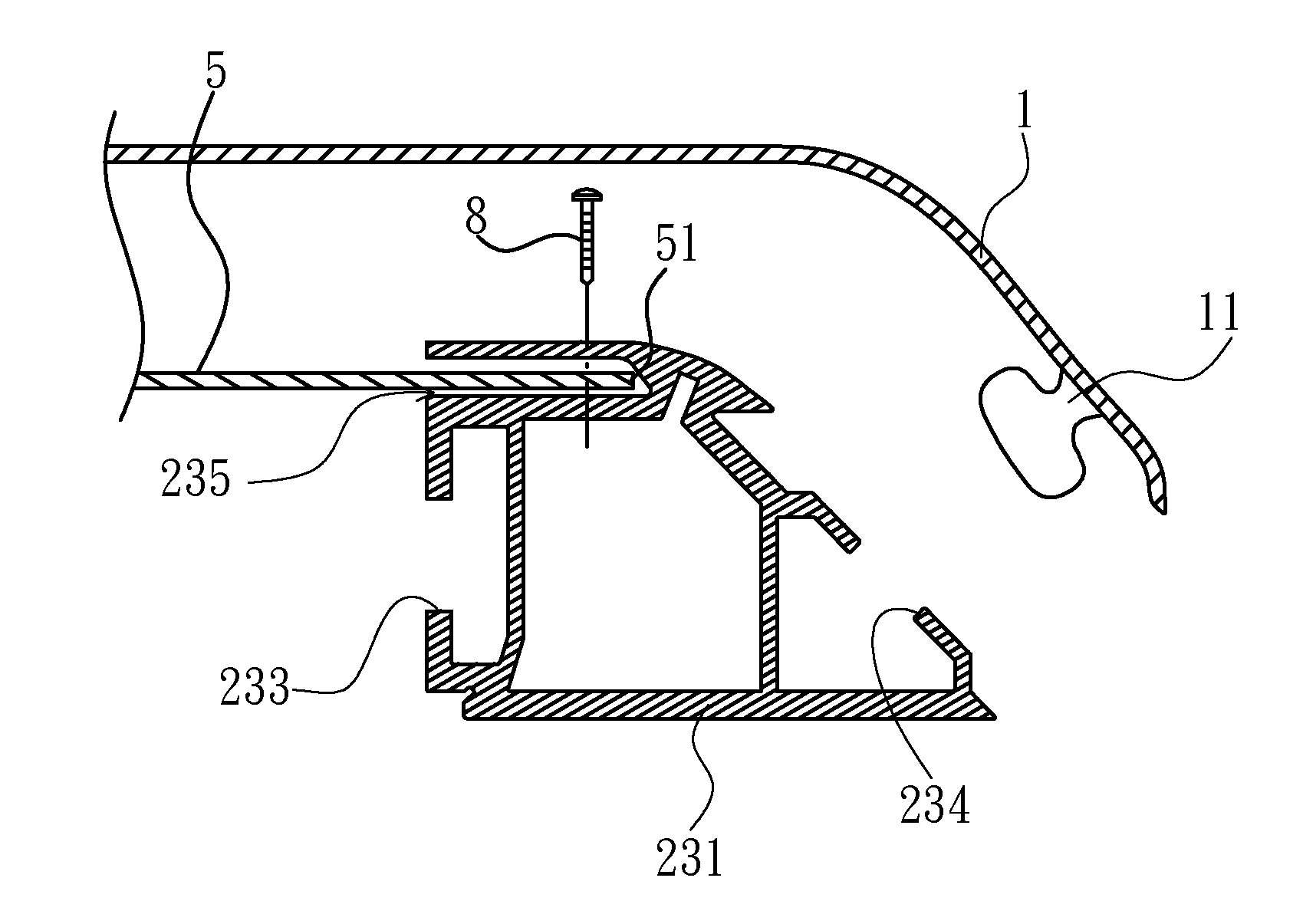

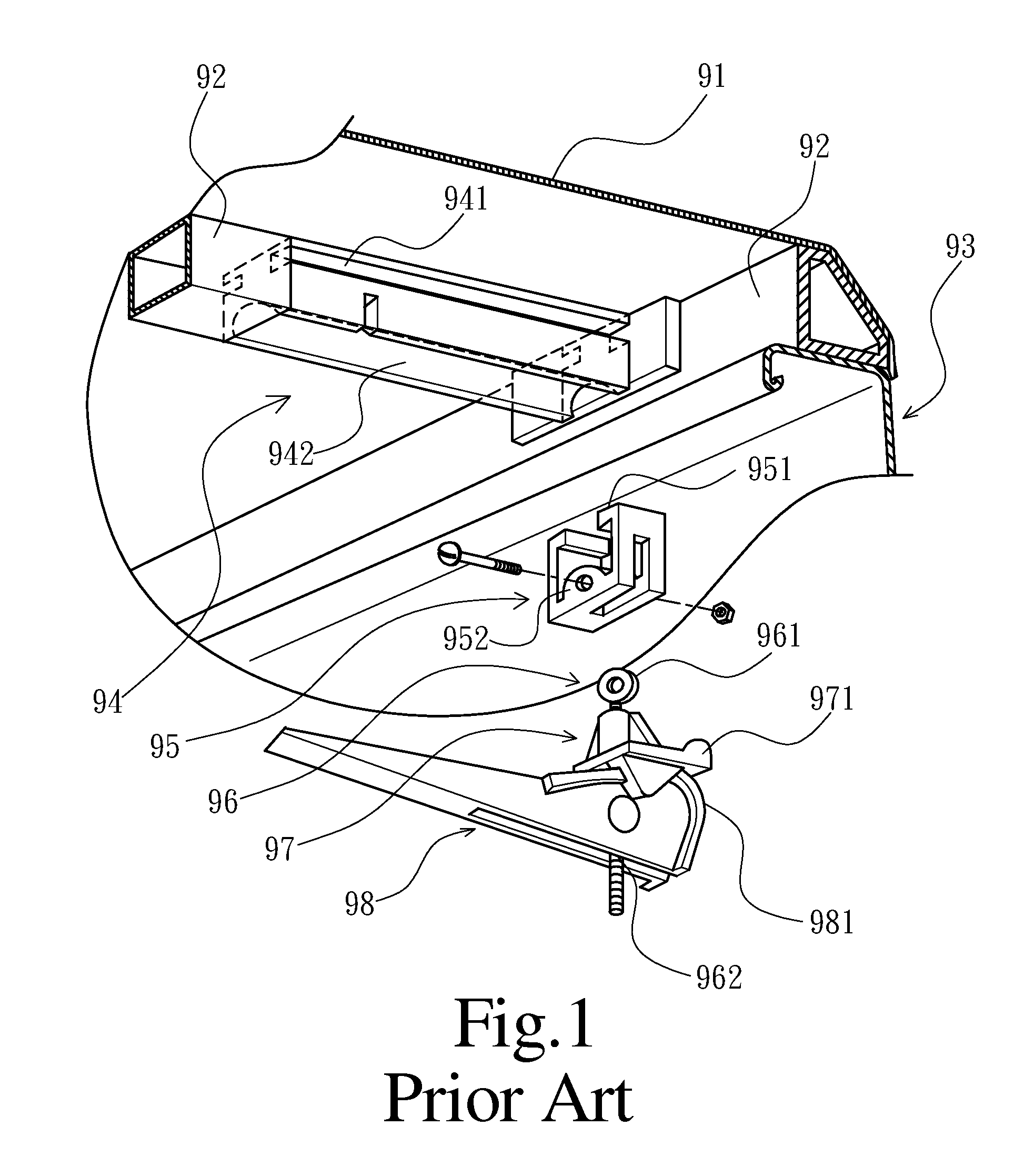

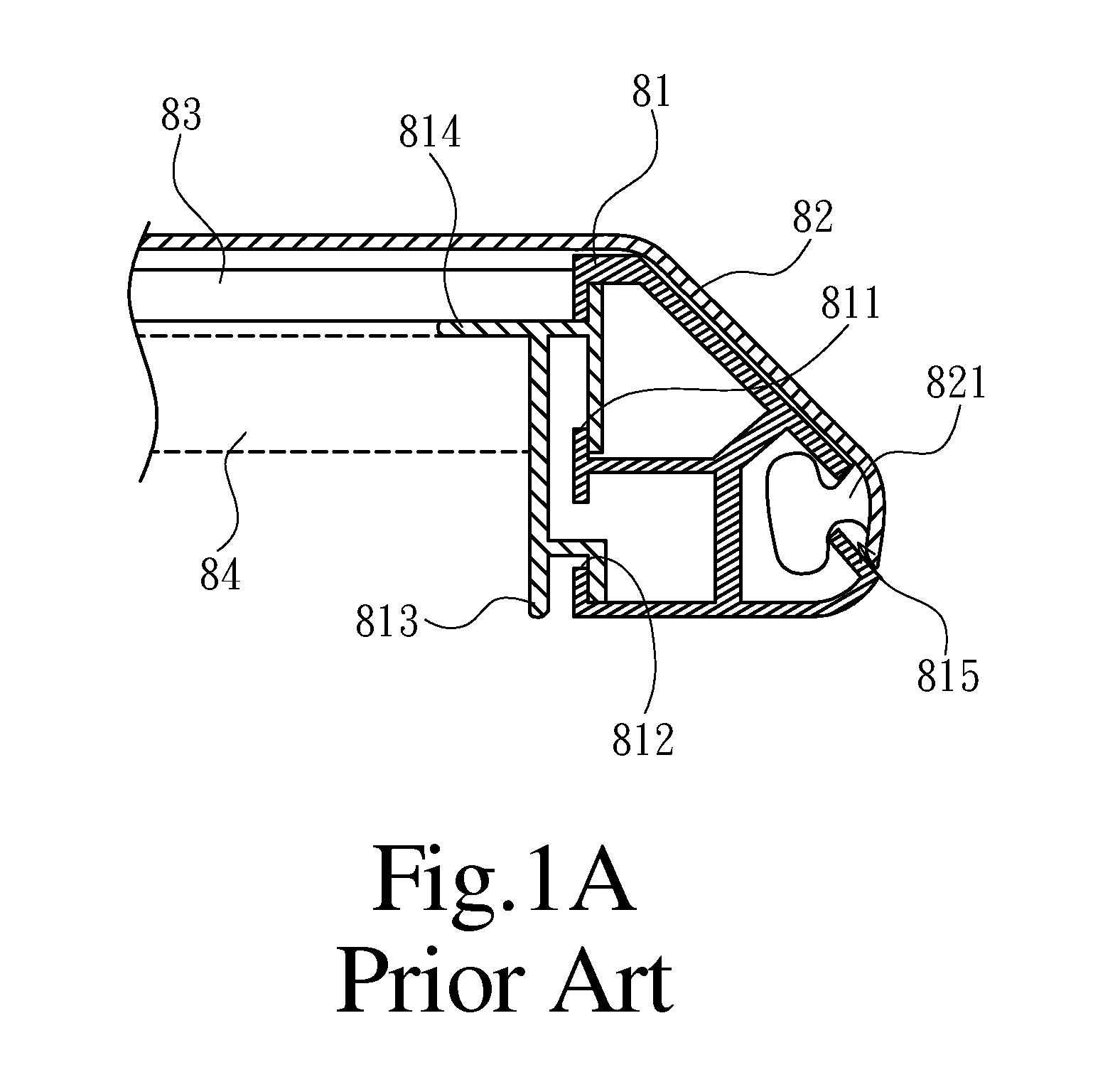

Clamp structure for tonneau cover

A clamp structure for a tonneau cover is disclosed and mounted to one frame section of a tonneau cover for releasably securing the frame section on a cargo bed of a pick-up truck. The clamp comprises: a foundation rail having two side grooves and a recess formed between the two side grooves; and a sliding block having two side hangers extended into and slidably moving along the two side grooves and a pivotal portion received in the recess; a clamp bolt; a grip element; and a handle. The side hangers of the sliding block is used to slidably move along the side grooves of the foundation rail, so that the sliding movement of the clamp structure pivotally connected to the sliding block in relation to the foundation rail is more stable and smooth based on two strong support points of the two side hangers in the two side grooves.

Owner:CYC ENG

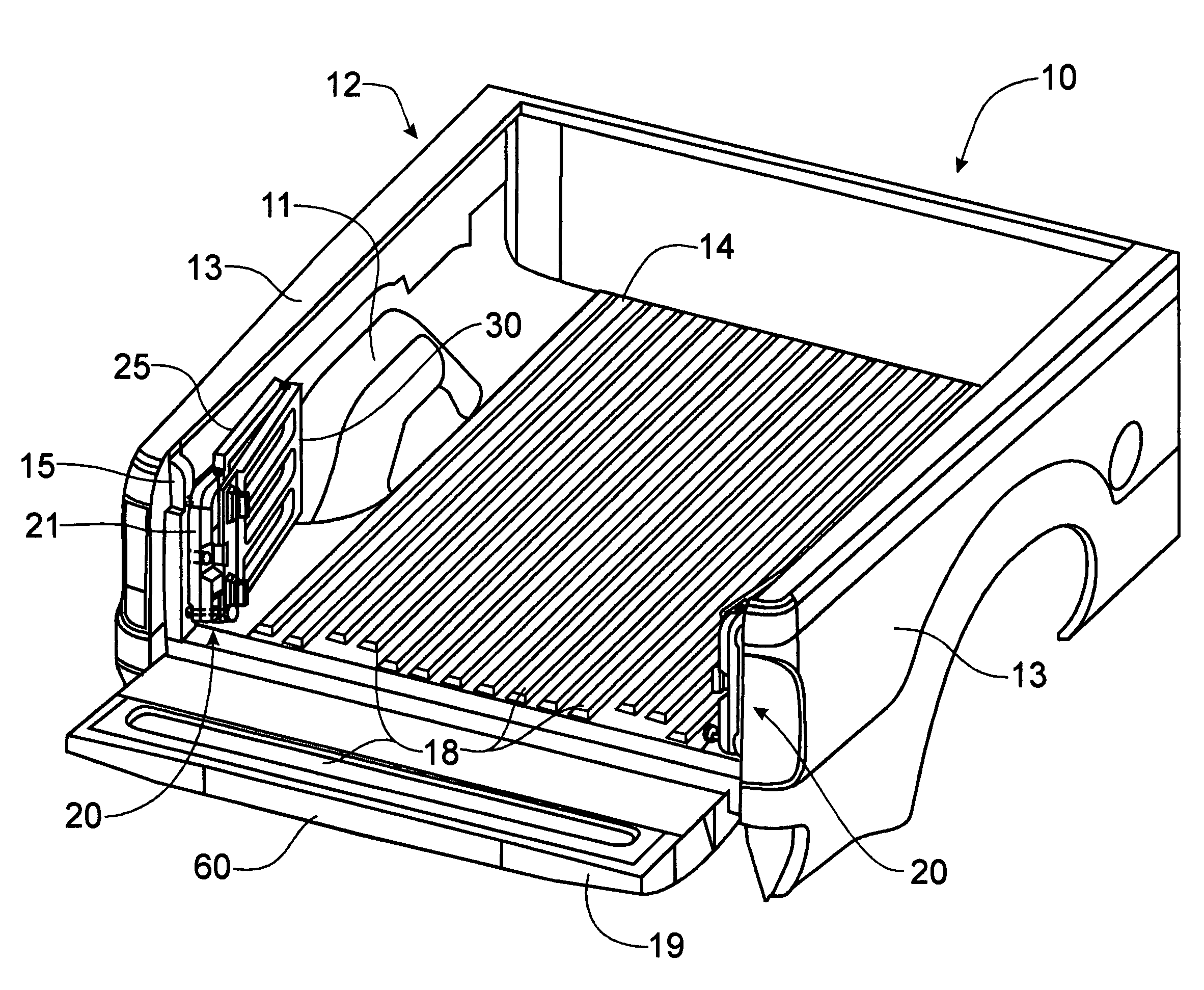

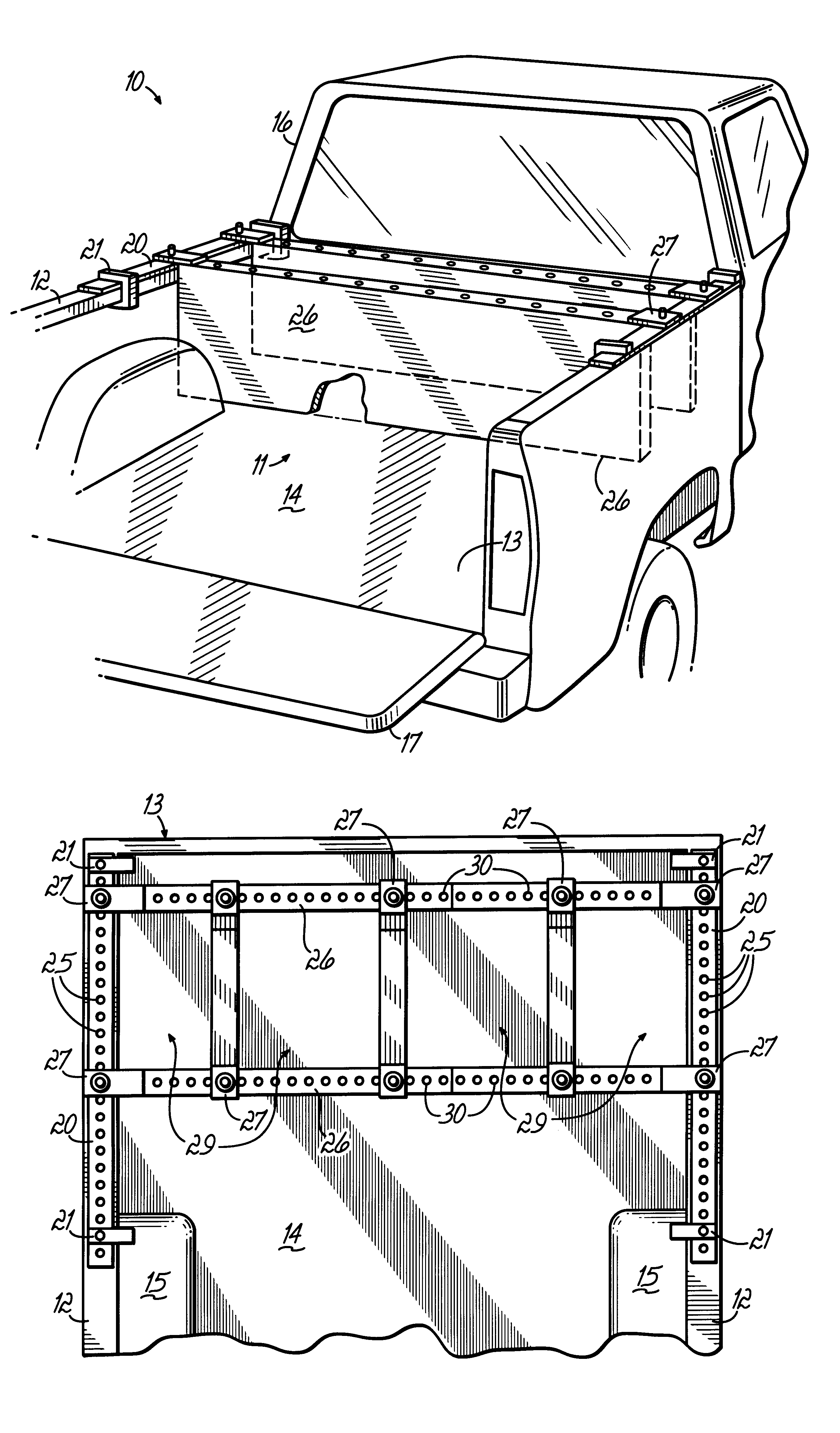

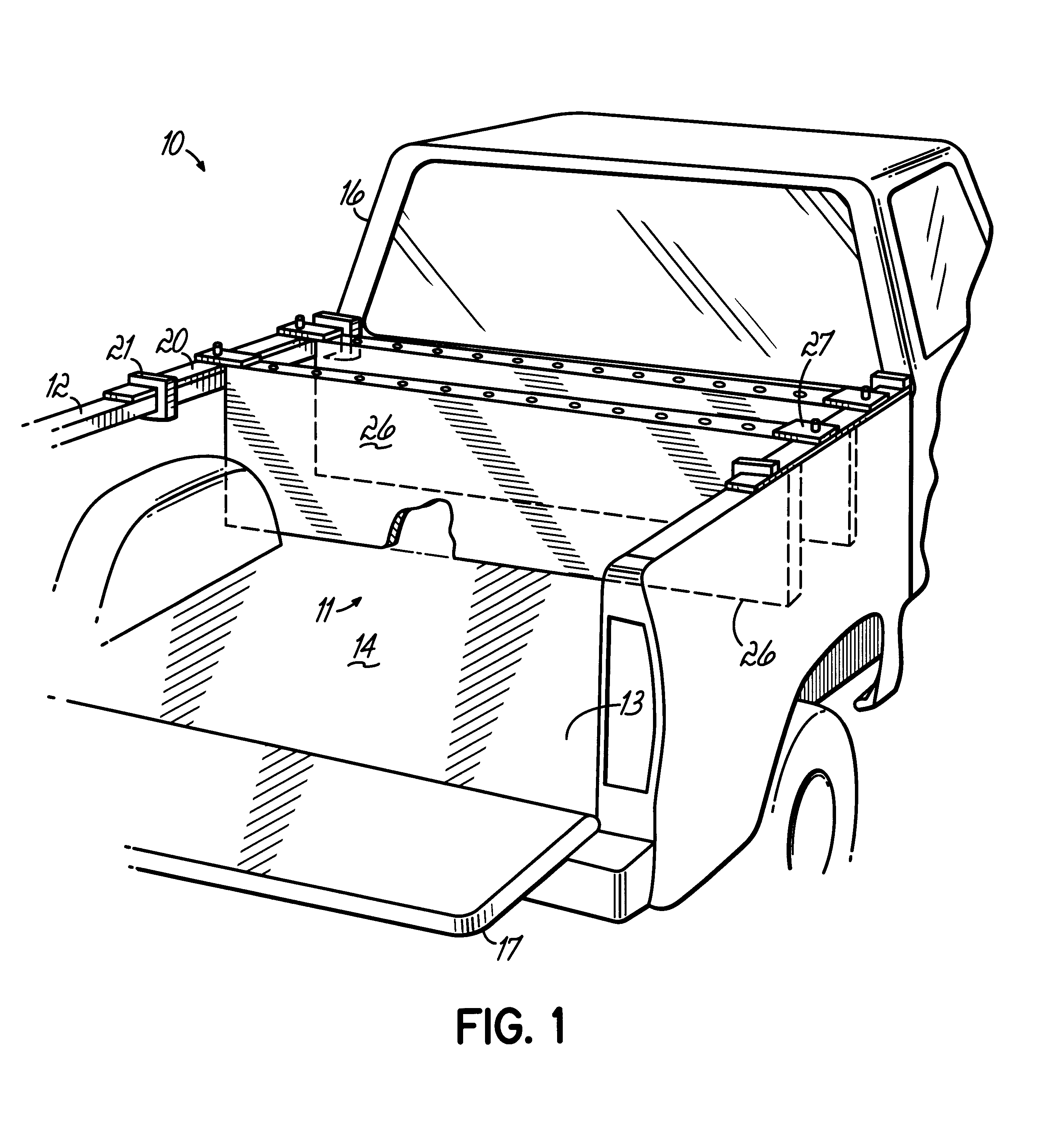

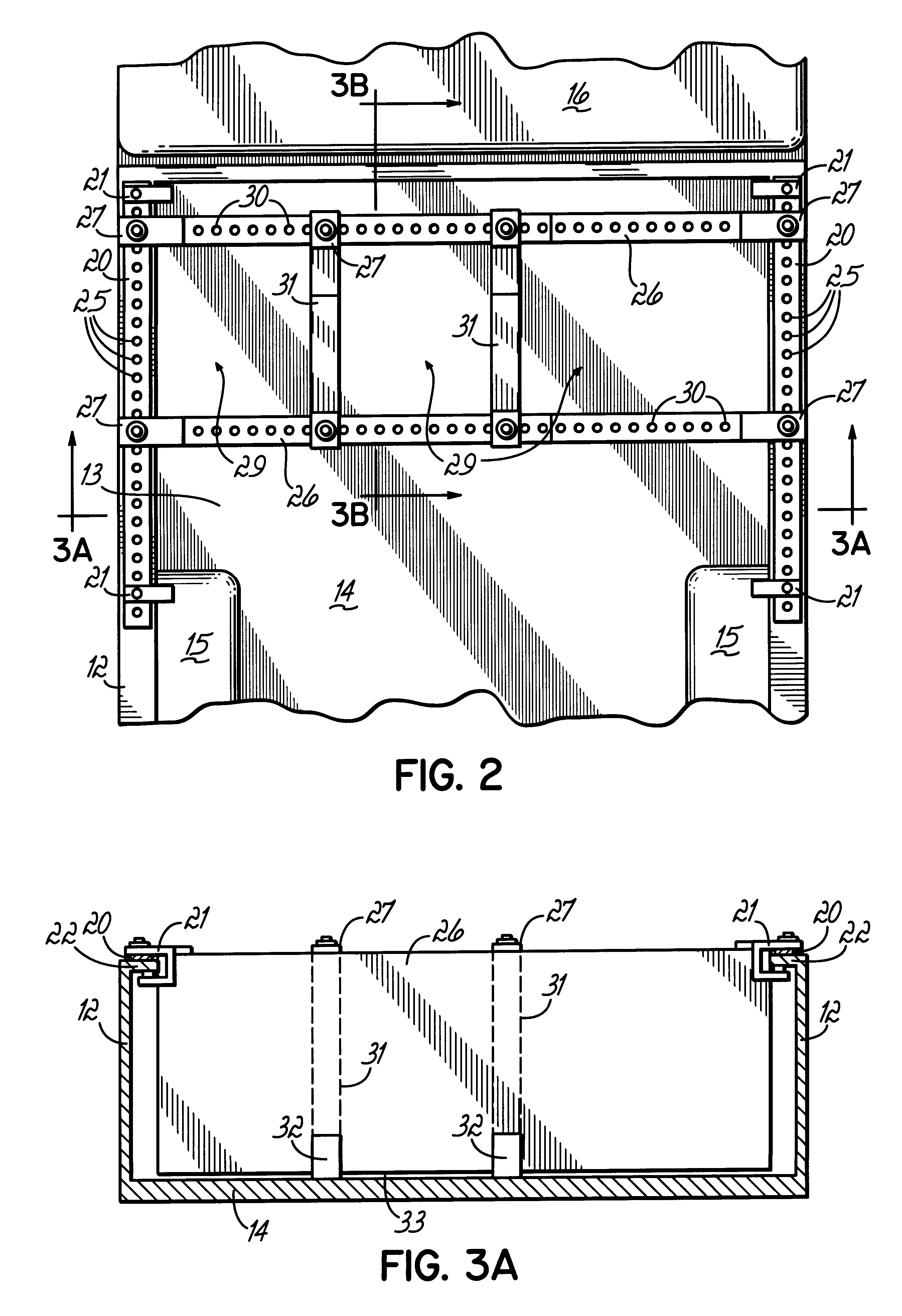

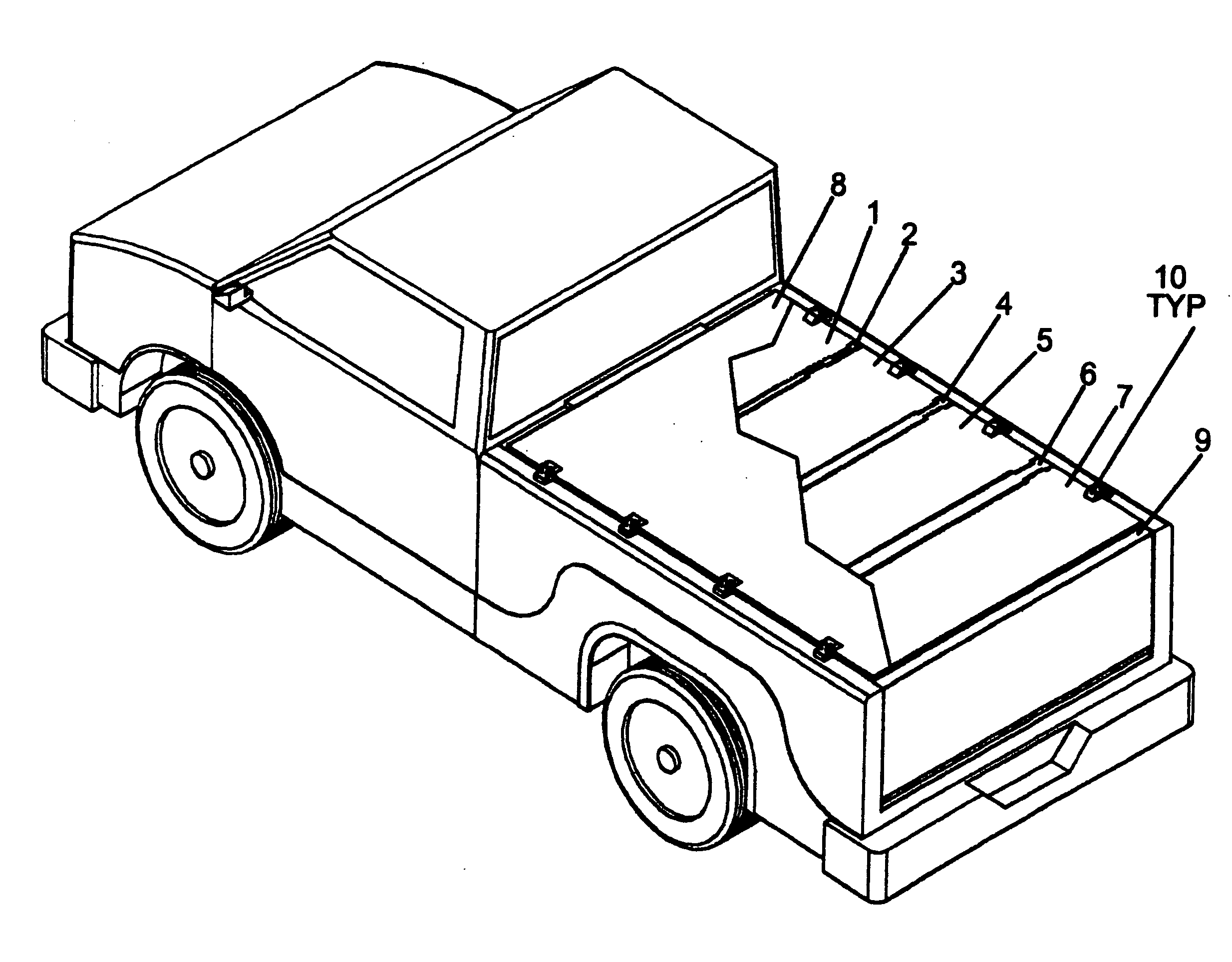

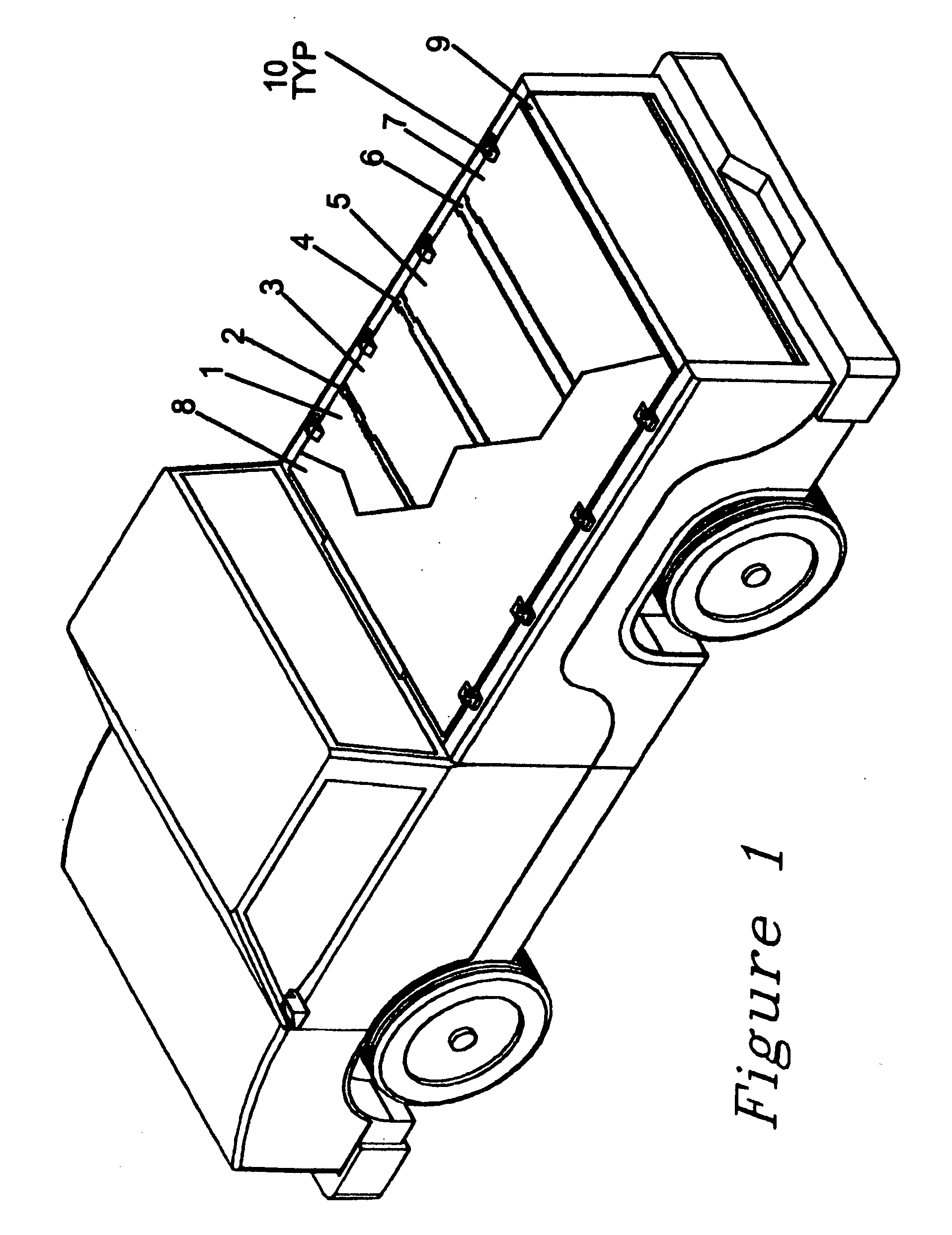

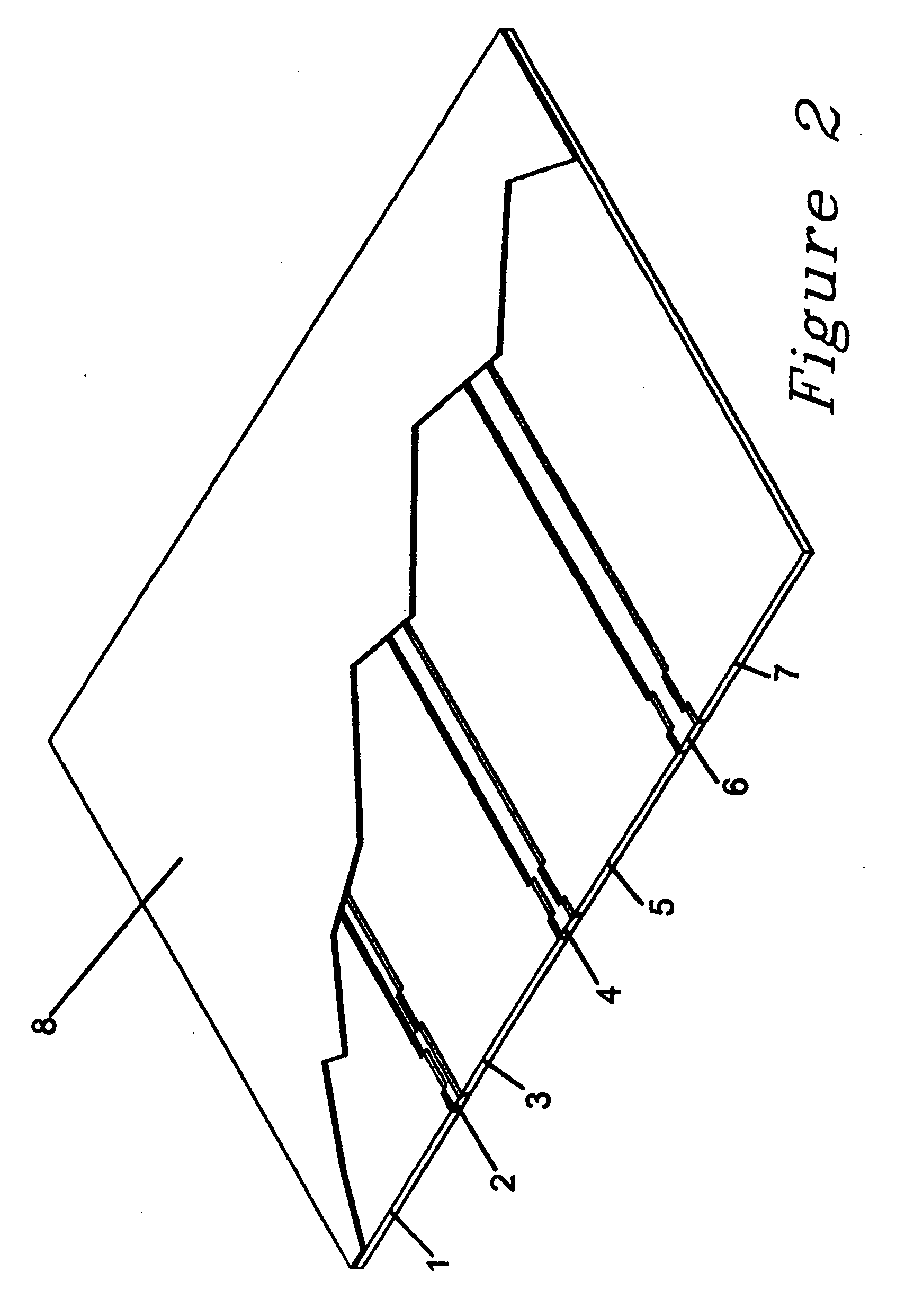

Cargo space divider

InactiveUS6206624B1Easy to installPreventing unwanted cargo movementLoad securingPick-up truckEngineering

Disclosed is a cargo space divider wherein a system of dividing walls allow a cargo space, preferably a pick-up truck bed, to be sectioned off into smaller, variably sized sections in order to prevent objects transported therein from rolling or sliding about the bed. The device consists of a pair of support rails that are installed along and clamped to the sidewalls of the truck bed above the wheel wells. Lateral sectioning walls span the width of the truck bed and longitudinal sectioning walls span between the lateral sectioning walls, both in adjustable positions, thus creating divided cargo spaces that are adjustable both in number and size.

Owner:BRANDENBURG RACHEL B

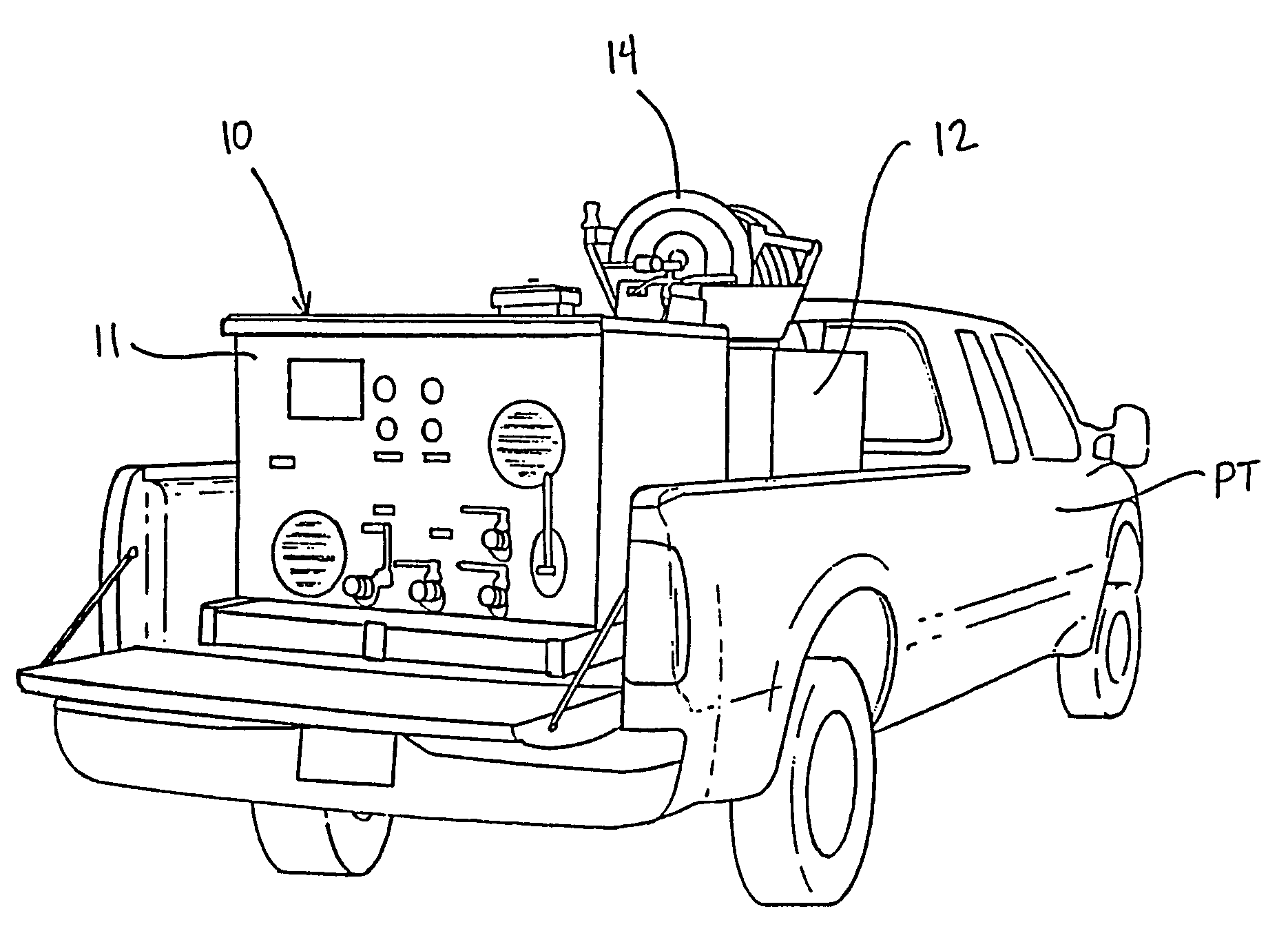

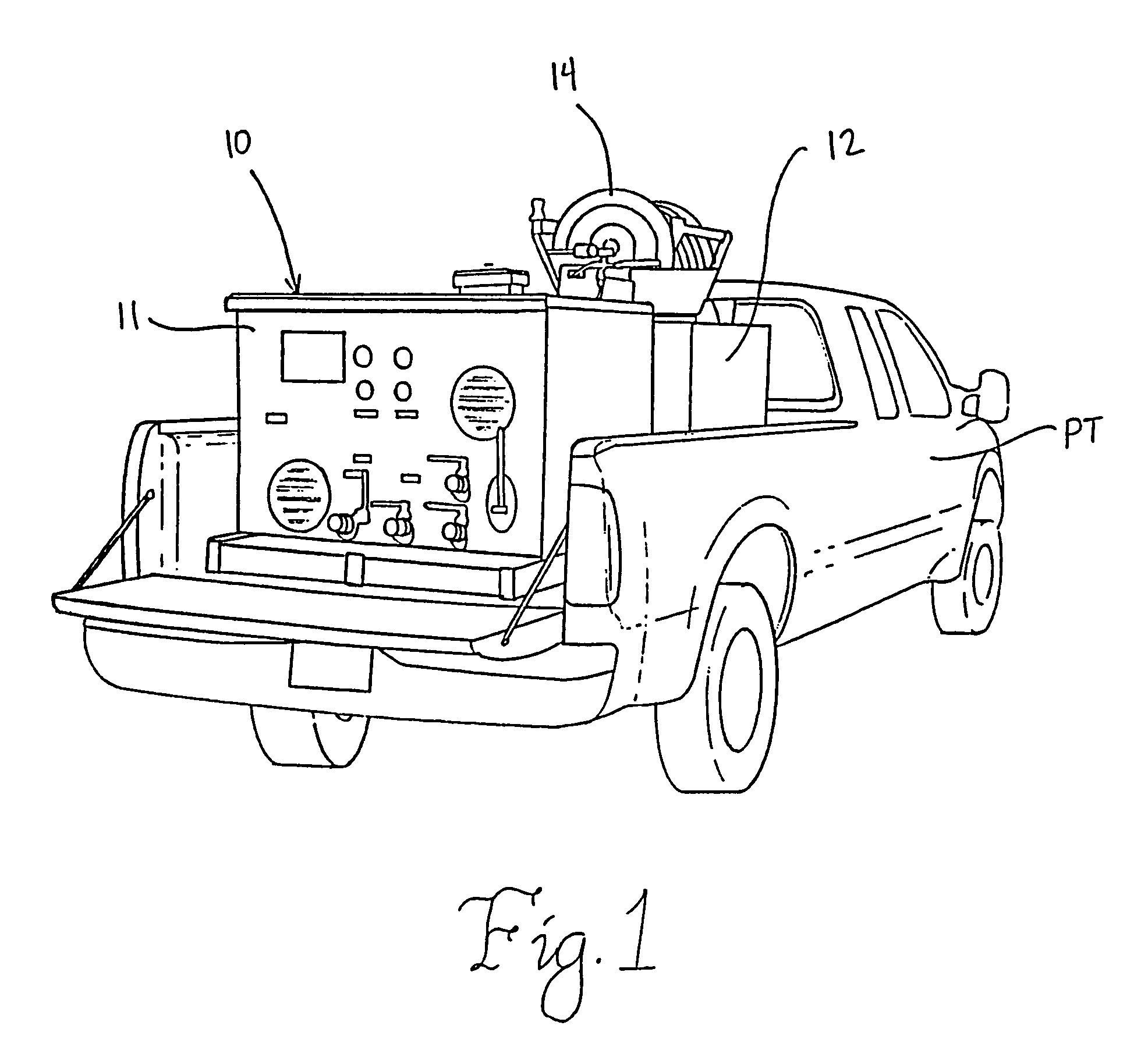

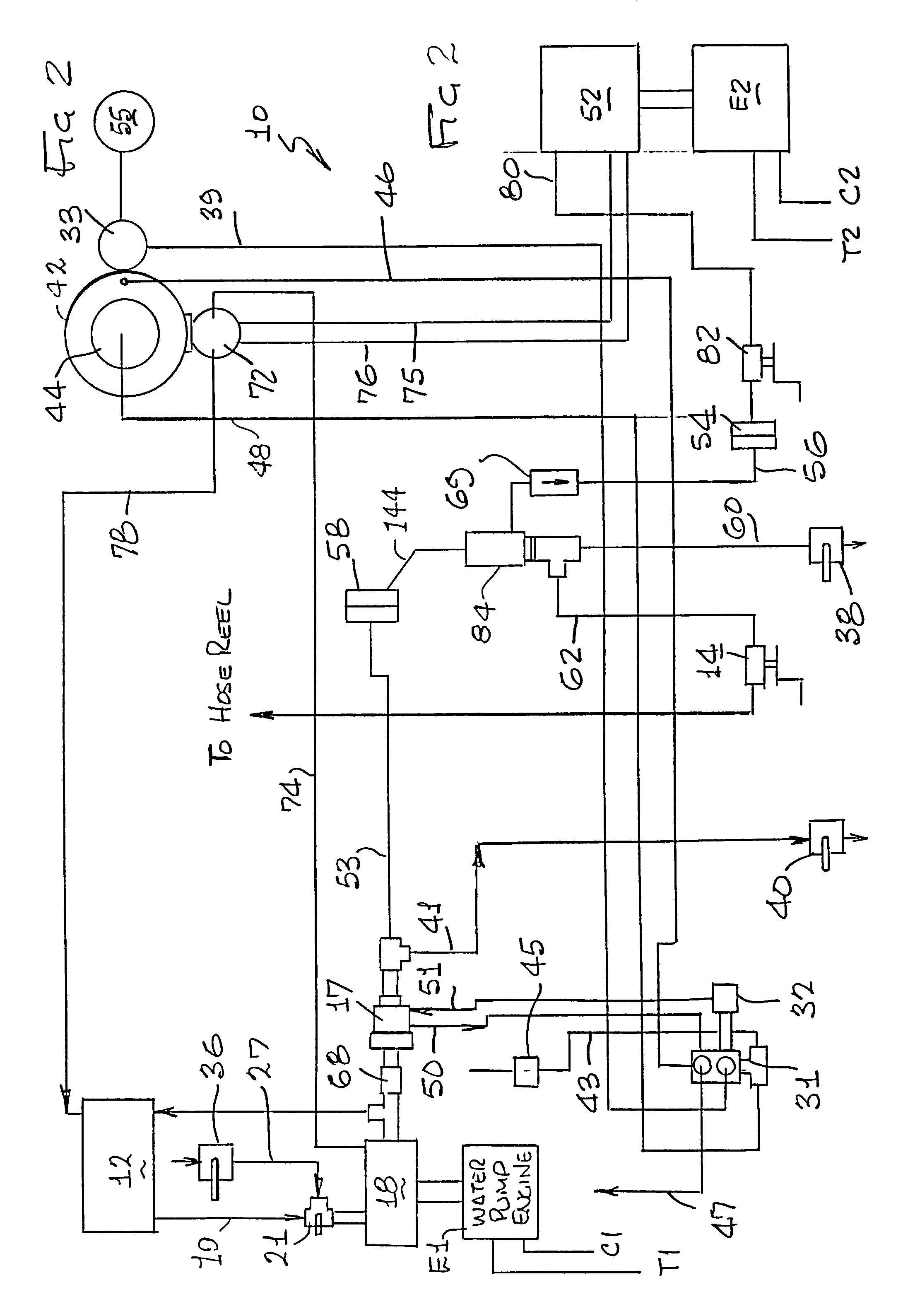

Universal transportable compressed air foam fire fighting system

A compressed air / foam fire fighting system which is sufficiently compact to be carried on the bed of a pick-up truck includes a water tank, a pump for providing water at substantial pressure to a water conduit, an engine for driving the pump, a foam reservoir including a bladder tank connected to the pump, an air compressor, an engine for driving the air compressor, a differential pressure valve connected in the water conduit, a metering valve adjustable to supply a desired proportion of foam concentrate to water connected across the differential pressure valve, an air valve for controlling the amount of air from said compressor, and an air injection venturi for mixing air into a water / foam concentrate. A two-way valve connected between the tank and the pump is movable between a first position where water is pumped from the water tank and a second or suction position where water is drawn from an outside tank or other source. The system can supply plain water, a water / foam mixture, a mixture of compressed air, water, and foam, or compressed air only.

Owner:ROBWEN

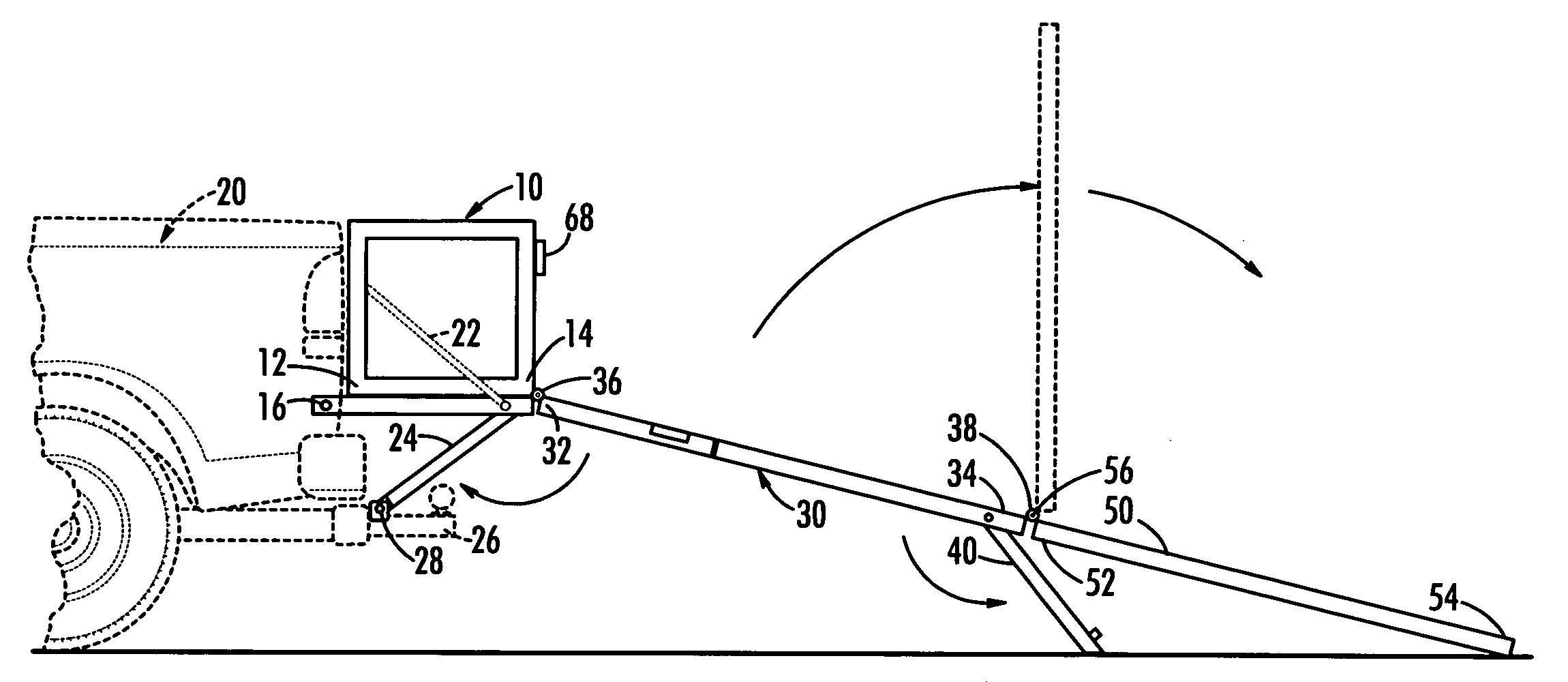

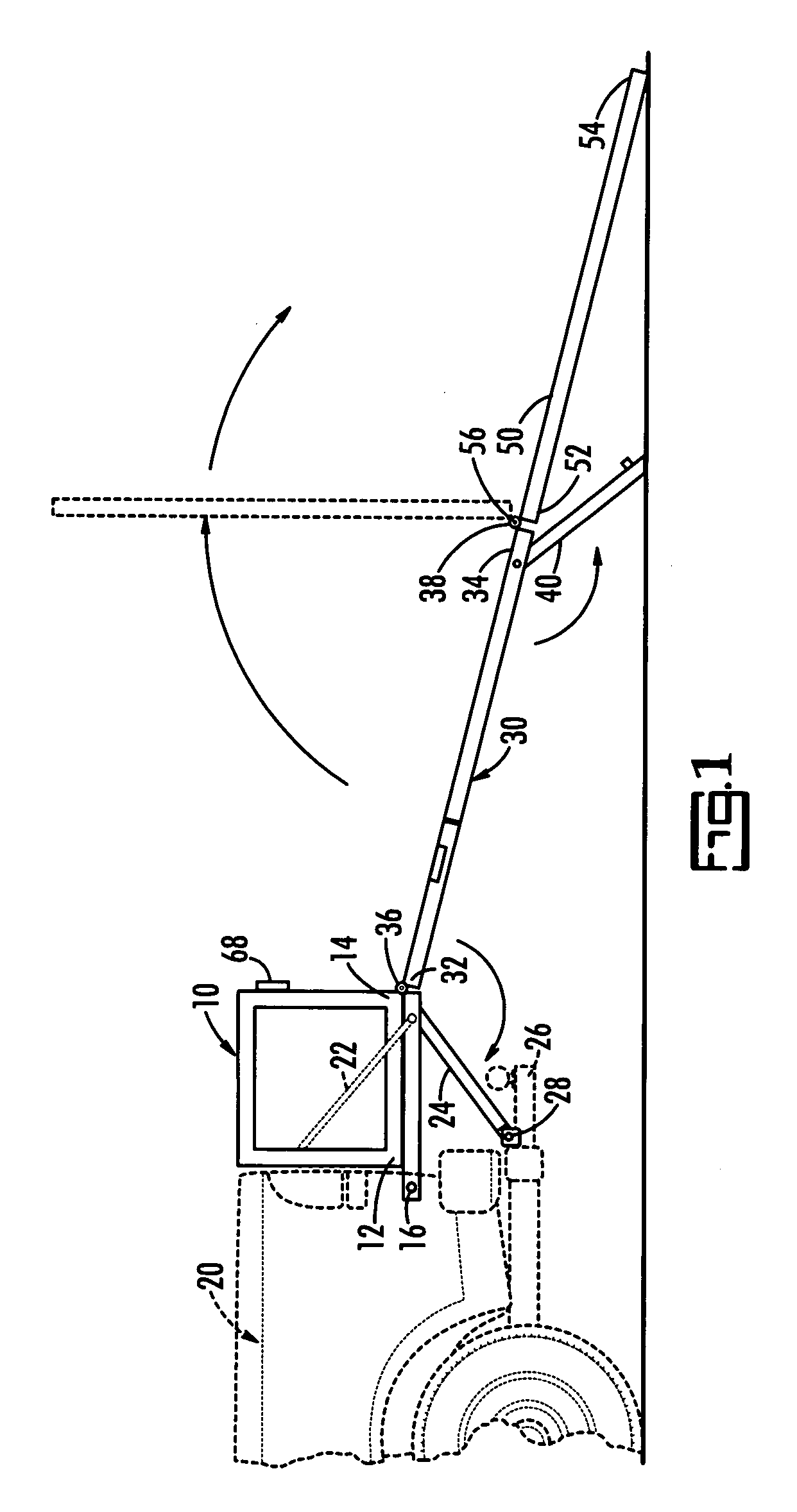

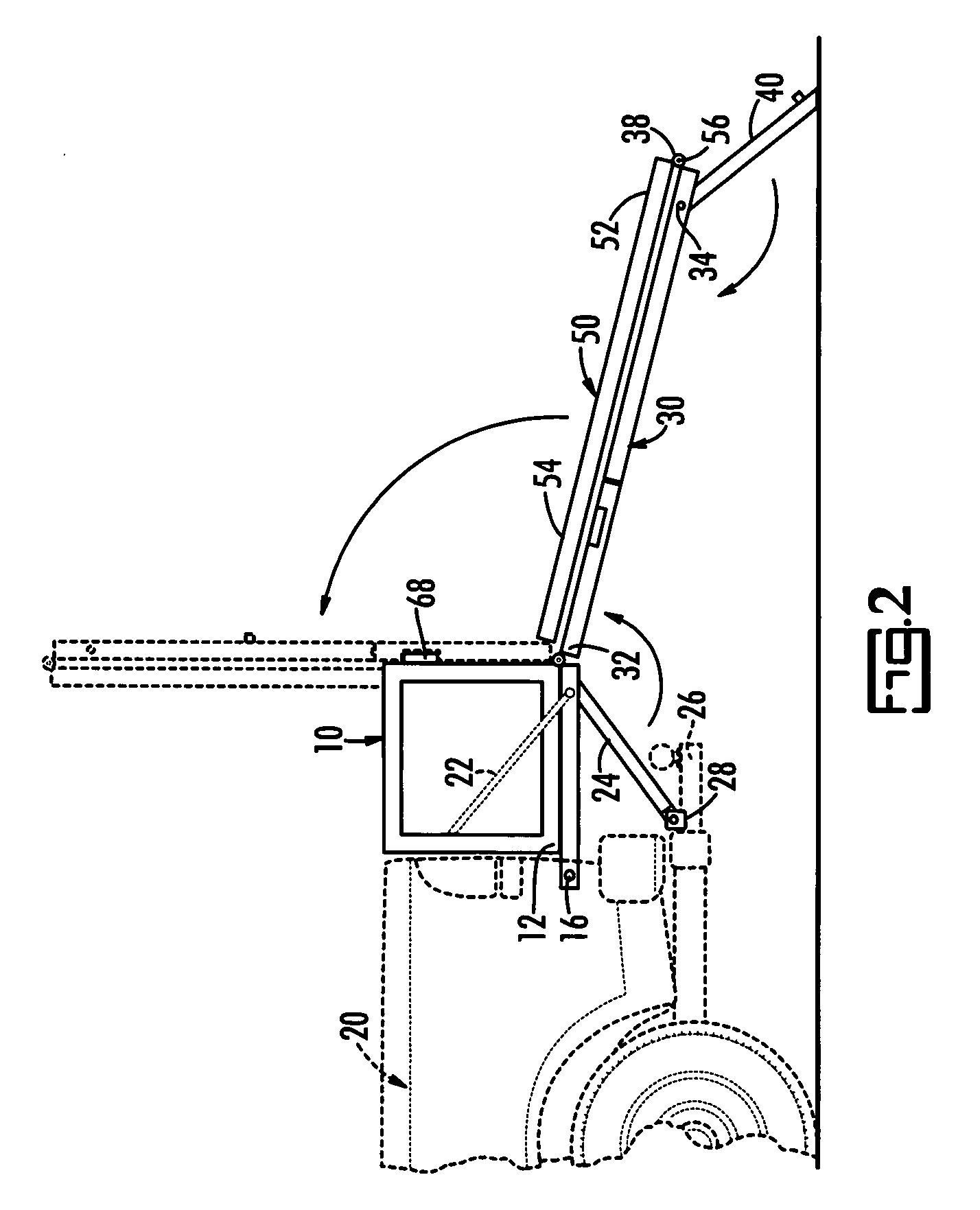

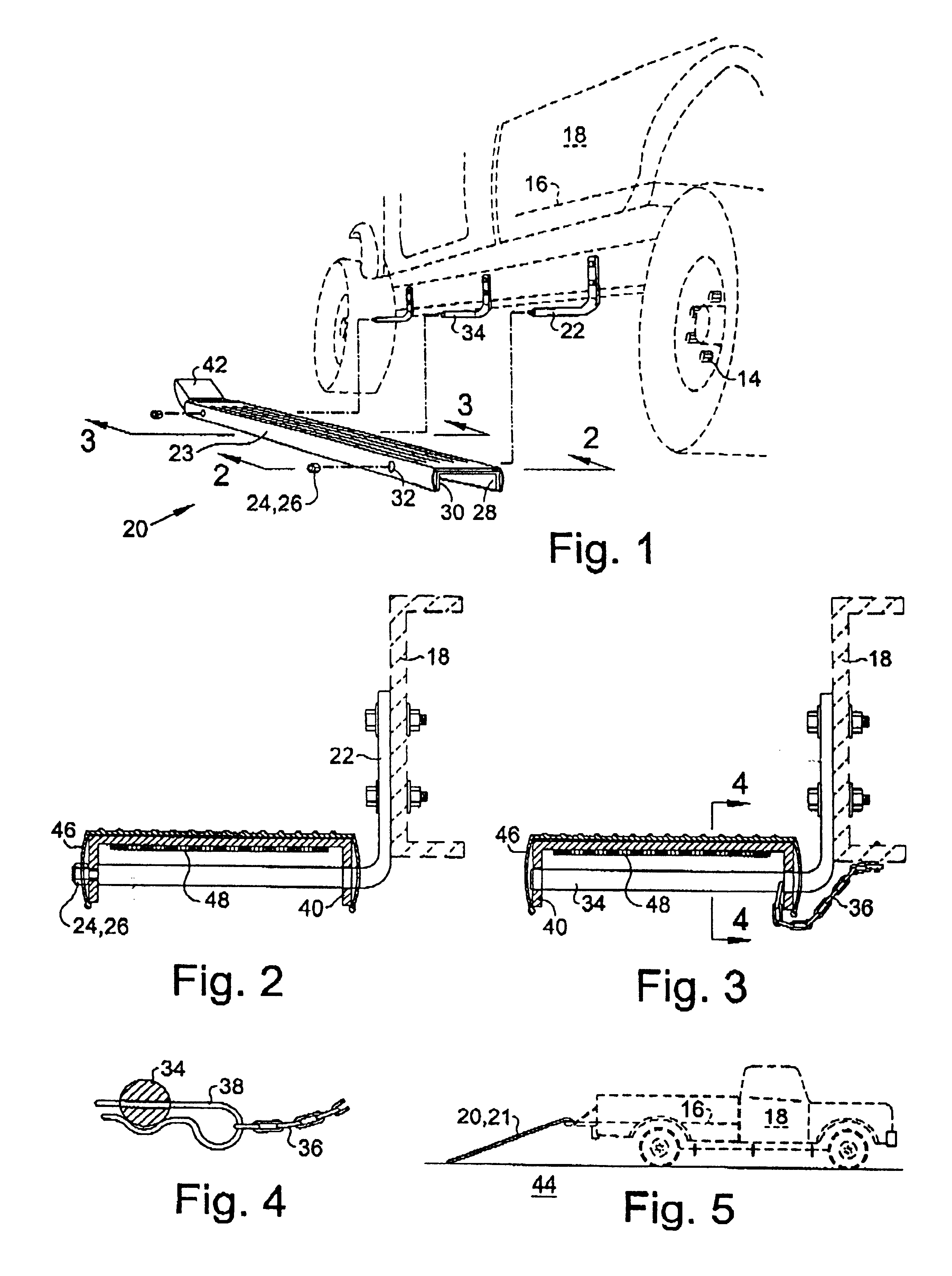

Cargo area extending foldable loading ramp

InactiveUS20080159838A1Easy to unfoldExtend usable cargo areaRefuse receptaclesLoading/unloading vehicle arrangmentVisibilityPick-up truck

A three-section foldable loading ramp extends a pick-up truck's cargo area to accommodate heavy and lengthy items. The first or frame section of the present loading ramp installs onto the existing tailgate slip hinges in place of the tailgate without tools or modification of the vehicle. Upper and lower ramp sections are pivotally connected to each other and to the frame section in a similar manner. An arm carried by the first frame section pivots down onto the vehicle's hitch for additional support for the ramp; two legs pivot down from the upper ramp to engage the ground provide further support. The surface of ramp is covered with expanded metal or metal mesh to provide traction in the loading configuration and rearward visibility for the drive in the loaded configuration, with reinforcing added where the load will engage the ramp surface.

Owner:REC RAMP

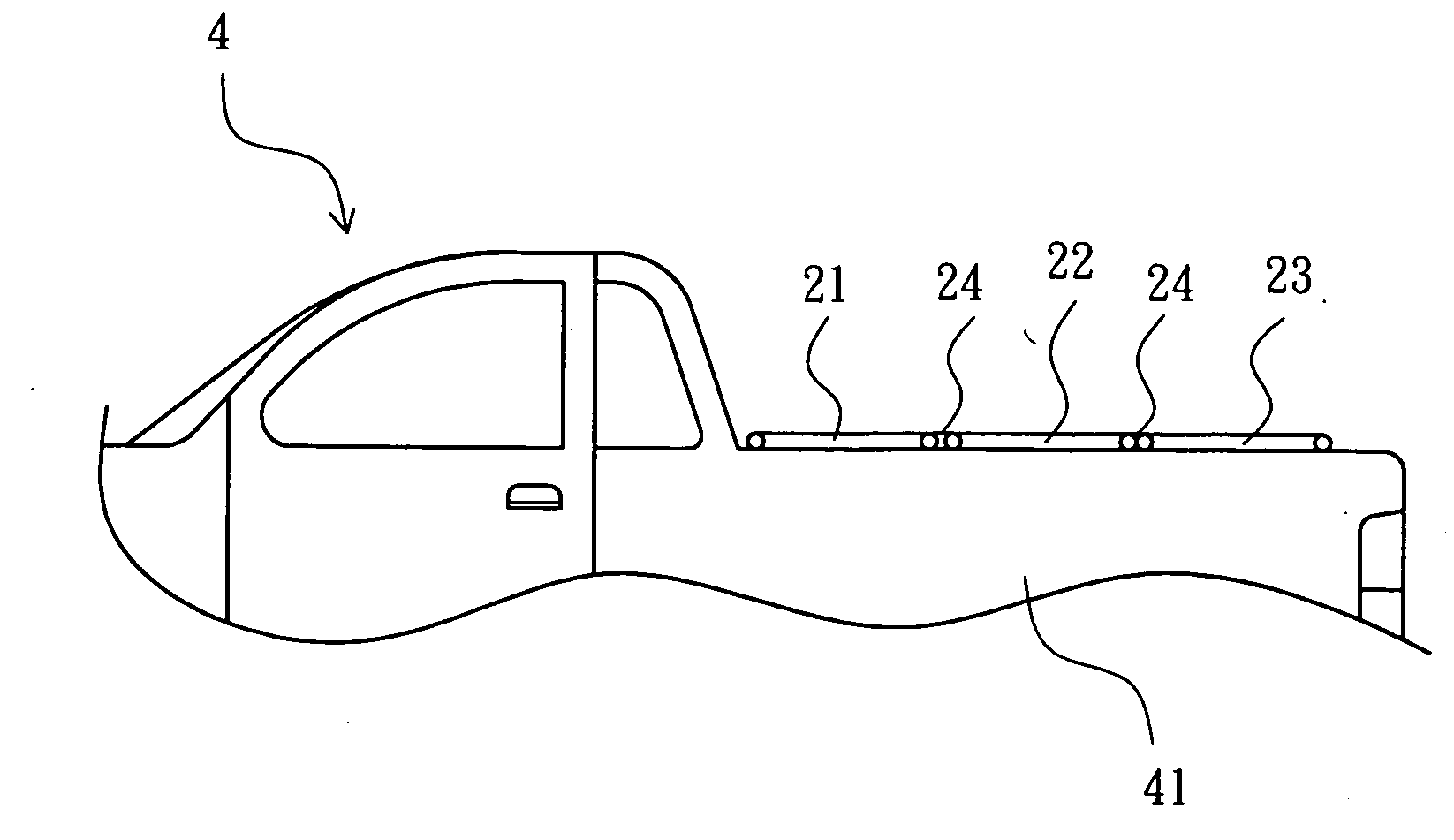

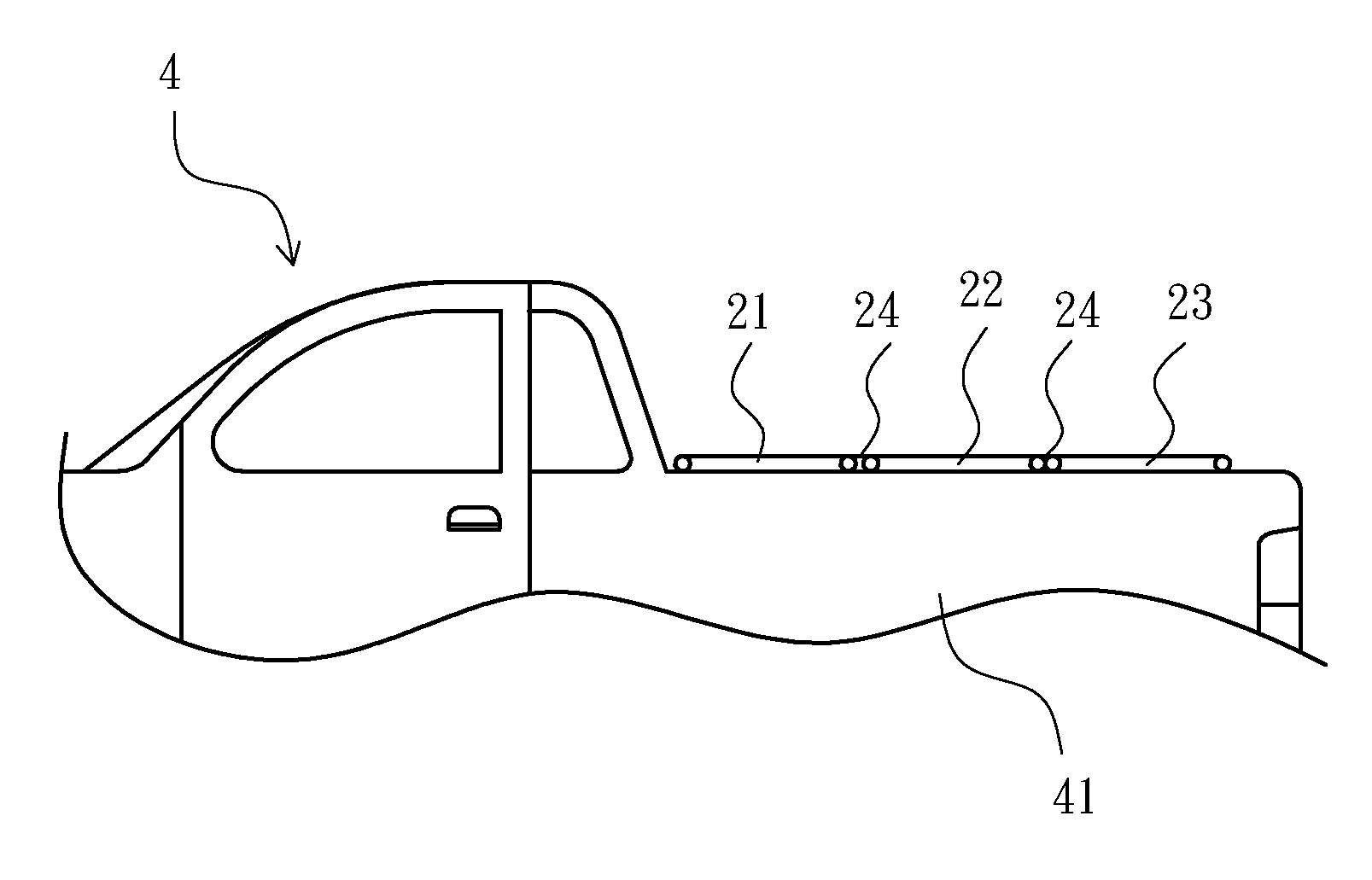

Clamp structure for tonneau cover of pick-up truck

ActiveUS20120274092A1Improve reliabilityImprove stabilityTransportation itemsRoofsPick-up truckPlastic materials

A clamp structure for a tonneau cover of a pick-up truck is disclosed and mounted to one frame section of a tonneau cover for releasably securing the frame section on a side wall of a cargo bed of the pick-up truck. The clamp structure has a composite grip element which has a metal grip body and a plastic sleeve. The metal grip body has an engaging portion to stably engage with the side wall of the pick-up truck. The plastic sleeve has a first abutment flange to smoothly abut against a turning handle, and a second abutment end facing a sliding block. Thus, the composite grip element can provide advantages of both of metal and plastic material, so that the operational stability and reliability of the clamp structure can be enhanced, and the lifetime thereof can be elongated.

Owner:CYC ENG

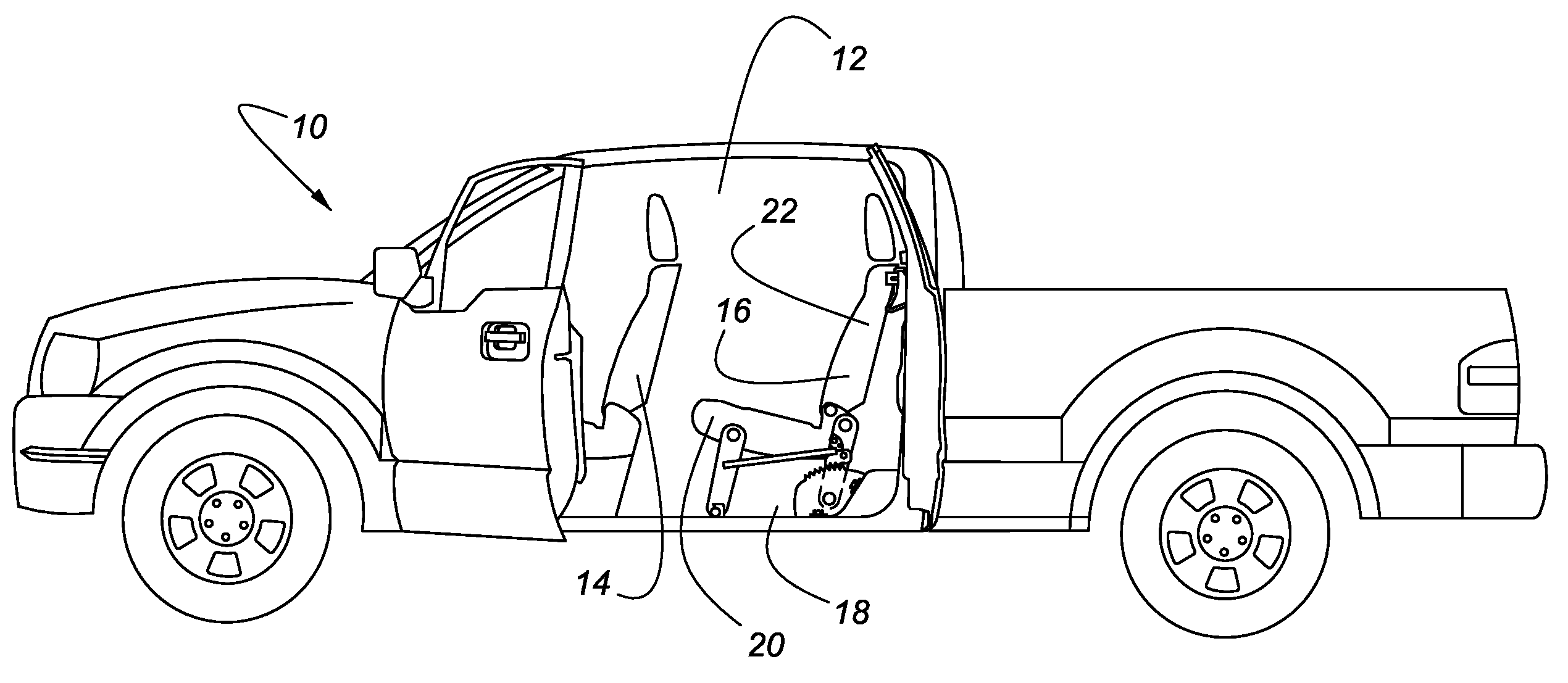

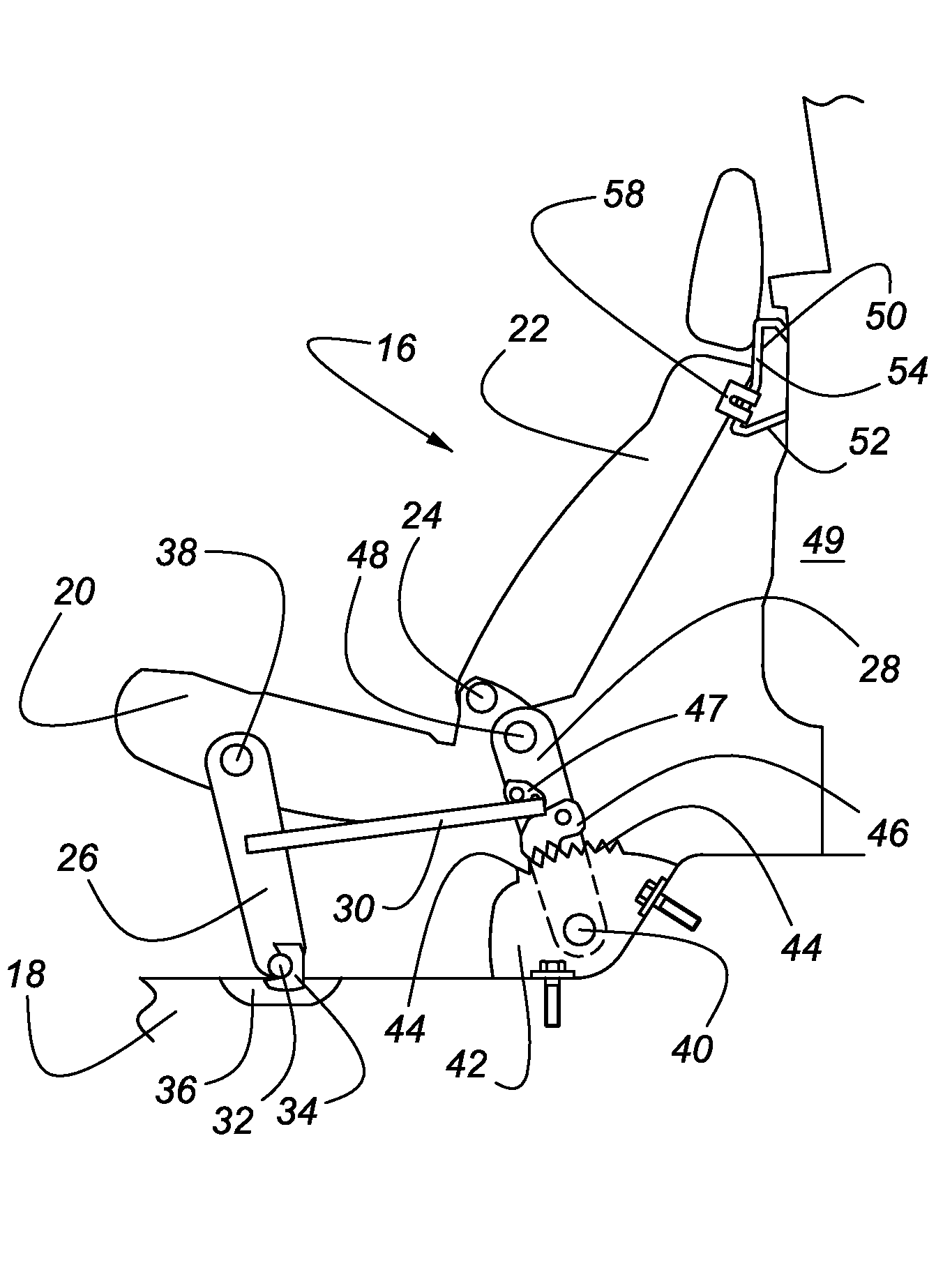

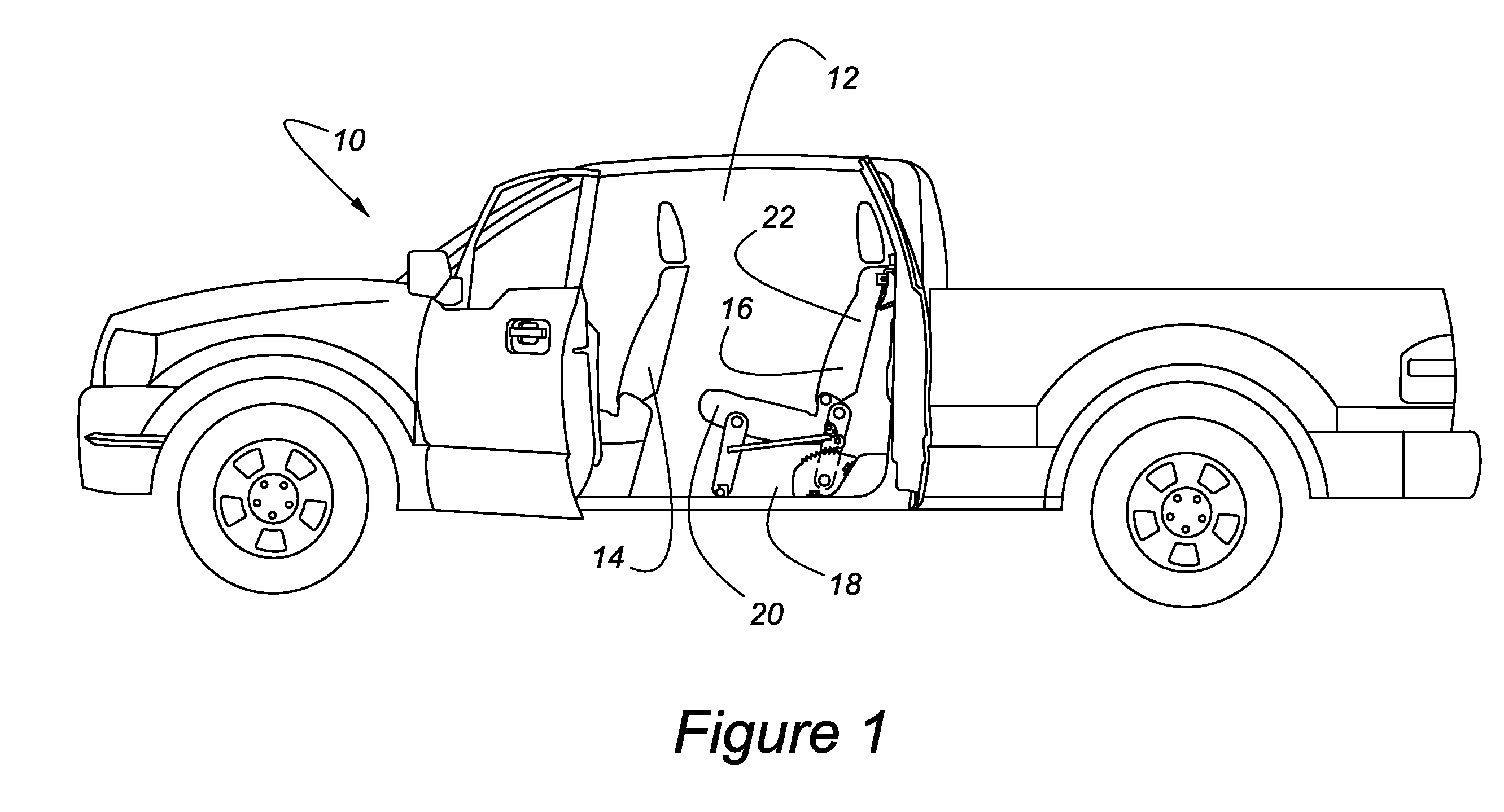

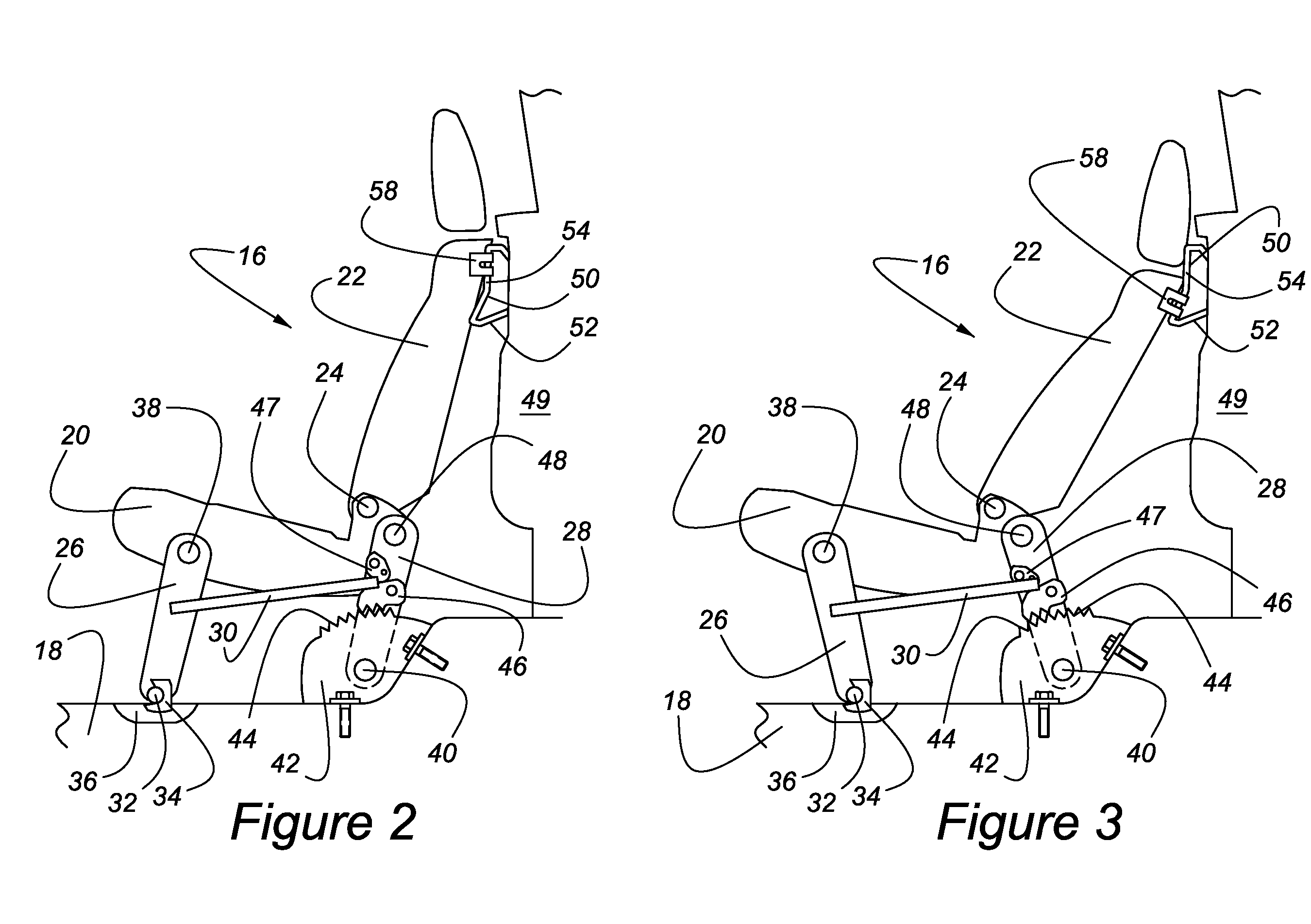

Reclining rear seat for vehicle having four-bar link

A reclining rear seat for a motor vehicle such as a pick-up truck is provided. The rear seat utilizes a pivoting, four-bar link arrangement between the underside of the seat bottom and the vehicle floor. The seat back is slidably and releasably attached to a striker fitted to the inside back wall of the vehicle. This arrangement permits the occupant to selectively move the seat between a reclining position and a non-reclining position without compromising storage space between the front seat and the rear seat. When not in use, the seat bottom may be released and moved to a substantially vertical position against the seat back to increase cargo space. Alternatively, the seat back may be released and moved to a substantially horizontal position against the seat bottom to increase cargo space.

Owner:FORD GLOBAL TECH LLC

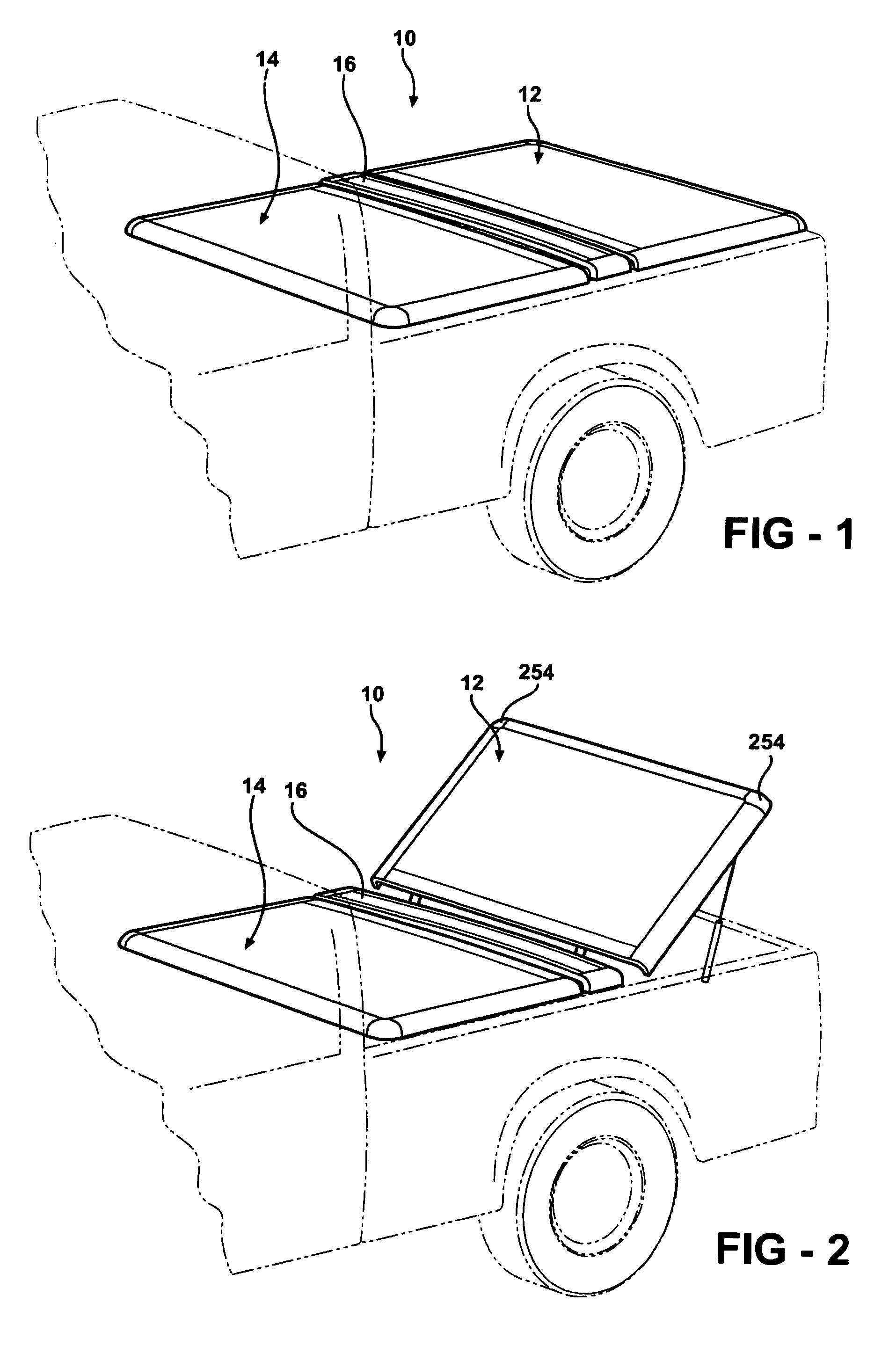

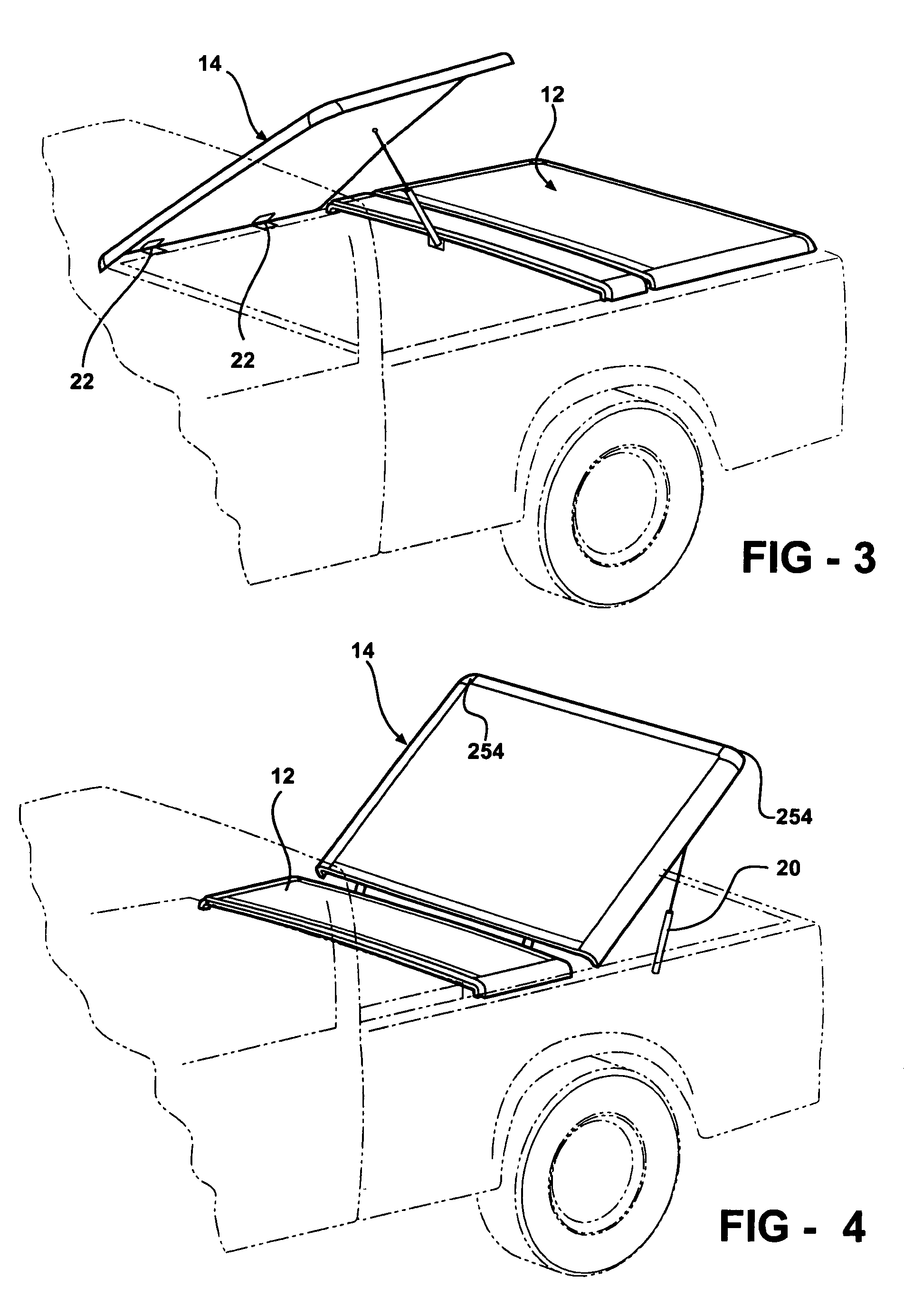

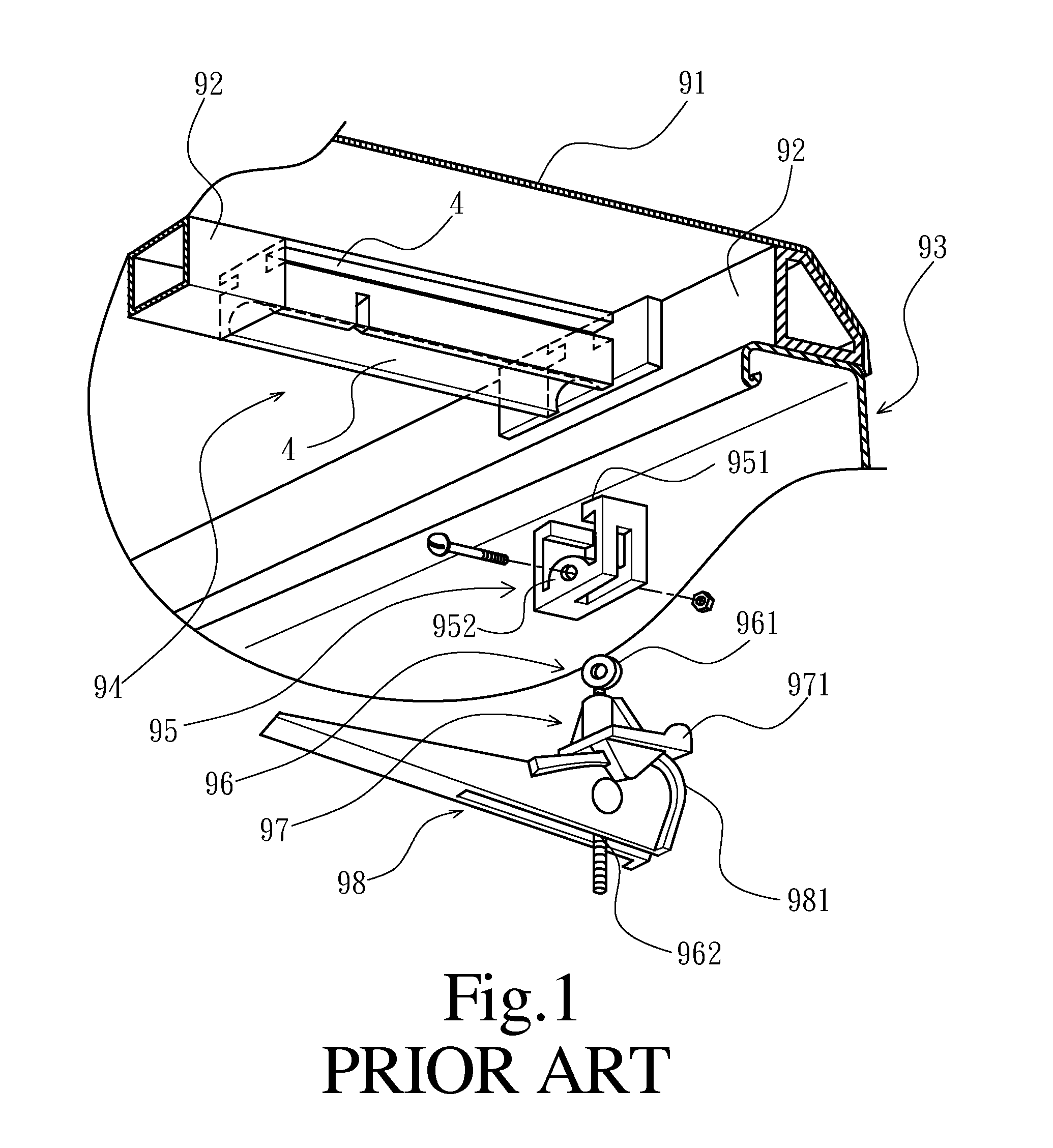

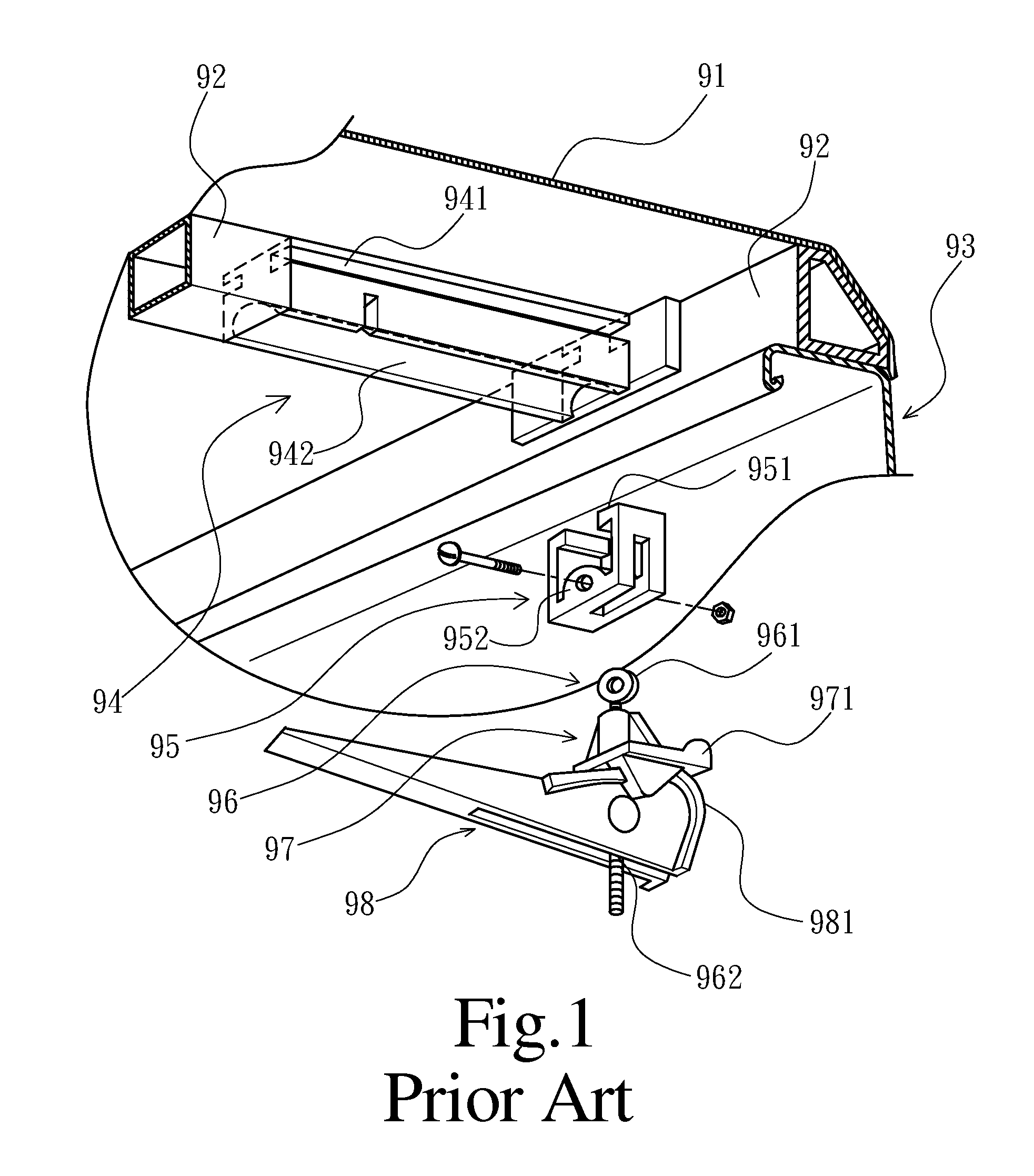

Hard tonneau cover

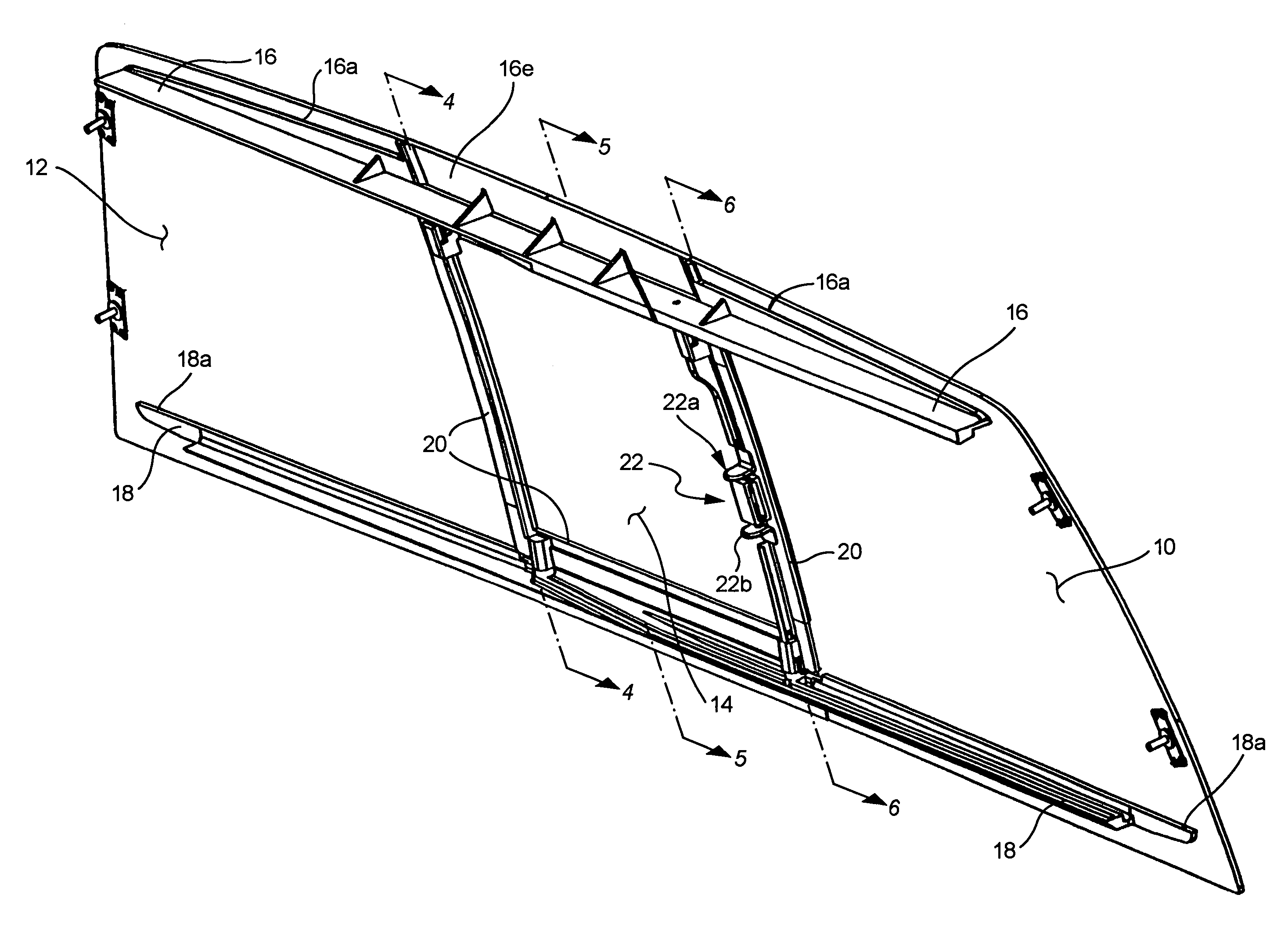

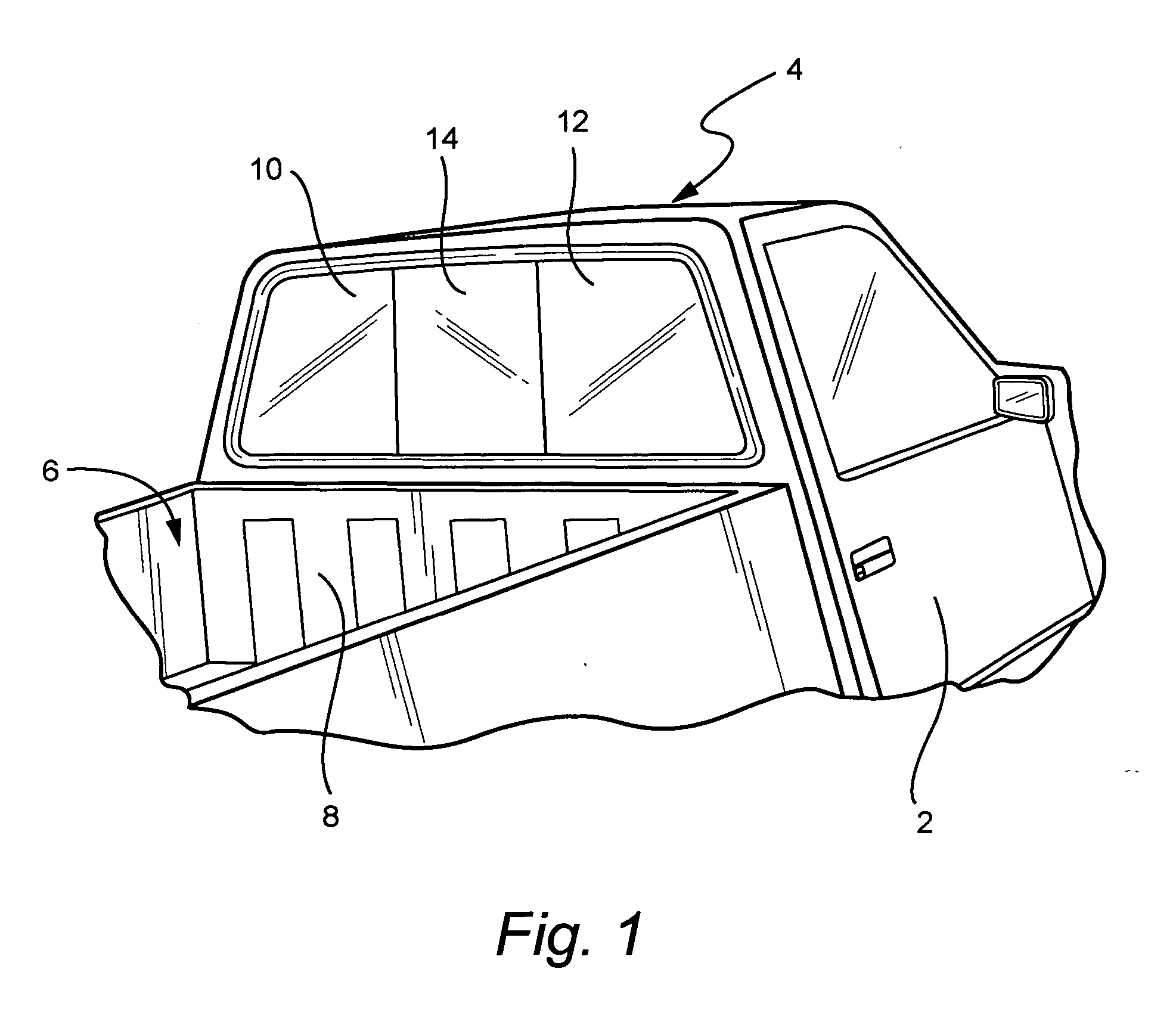

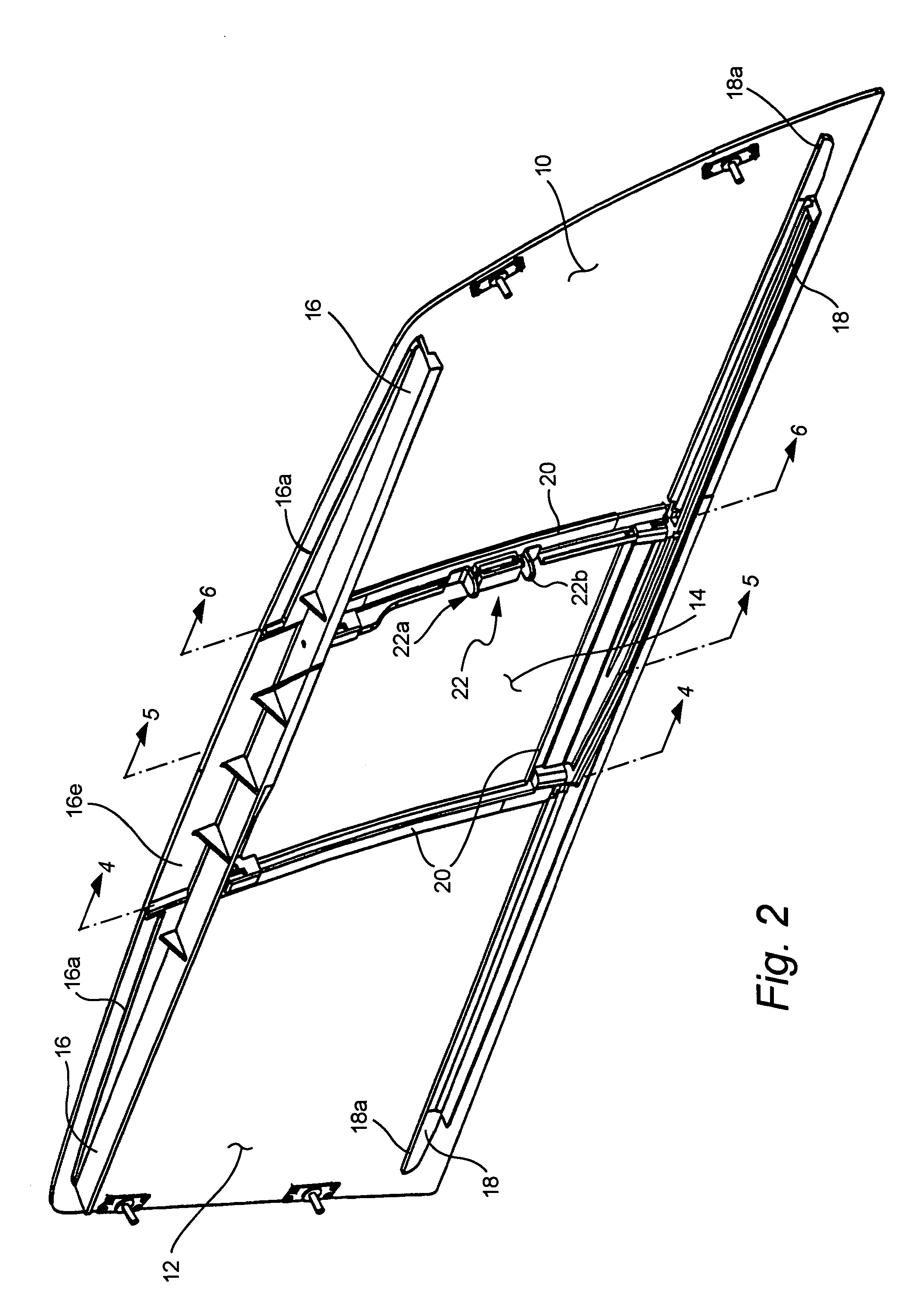

InactiveUS7252322B2Avoid enteringSufficiently compressibleLoad coveringRoofsPick-up truckEngineering

A hard tonneau cover having one or more sections is constructed of a framework of extruded rails with one or more section panels held by molded plastic trim strips installed on perimeter rails included in the framework. The cover is mounted above the cargo box of a pick-up truck by a plurality of striker-latch assemblies on one side of the cargo box, and hinge assemblies on the other side, each having components mounted to the cargo box side walls with universal clamp brackets. The panels are constructed of reinforced corrugated plastic which is covered by a color integrated film. A simplified connector plate is used to connect abutting ends of the rails in the framework. A peripheral seal extends down from the perimeter rails in which it is mounted to engage the top of the cargo box side walls and tailgate. Water drainage paths including drainage channels in the rails are provided to eliminate water from the panel surfaces.

Owner:RUSU WILLIAM

Reclining rear seat for vehicle having four-bar link

A reclining rear seat for a motor vehicle such as a pick-up truck is provided. The rear seat utilizes a pivoting, four-bar link arrangement between the underside of the seat bottom and the vehicle floor. The seat back is slidably and releasably attached to a striker fitted to the inside back wall of the vehicle. This arrangement permits the occupant to selectively move the seat between a reclining position and a non-reclining position without compromising storage space between the front seat and the rear seat. When not in use, the seat bottom may be released and moved to a substantially vertical position against the seat back to increase cargo space. Alternatively, the seat back may be released and moved to a substantially horizontal position against the seat bottom to increase cargo space.

Owner:FORD GLOBAL TECH LLC

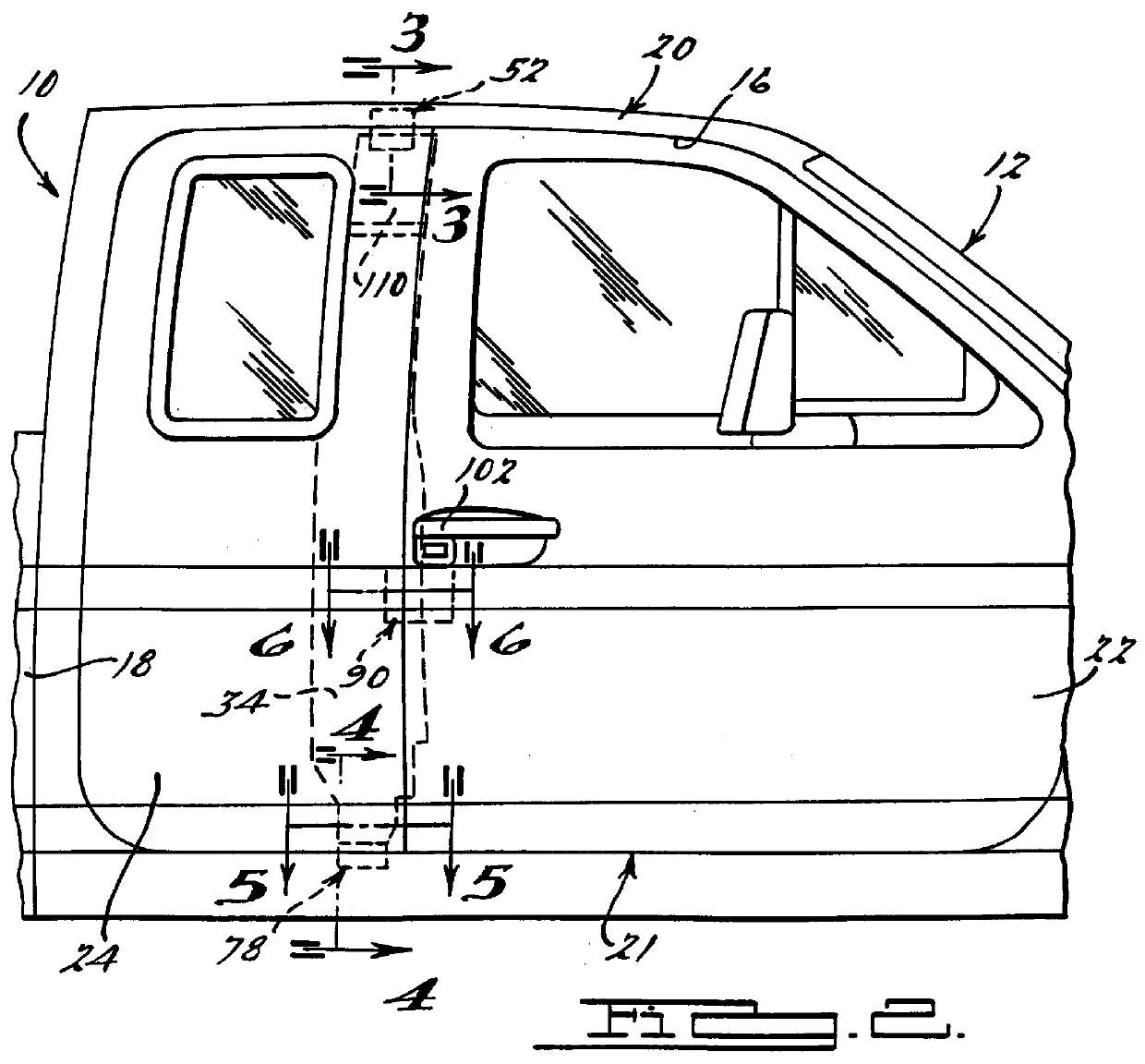

Door assembly for pick-up trucks

A door assembly for closing a door opening in a side of a body of a pick-up truck includes a rocker at a bottom portion of the door opening and a roof rail at a top portion of the door opening. The door assembly also includes a first door and second door pivotally connected to the body and joined pillarlessly between an open and closed position. The door assembly further includes a vertical reinforcement assembly disposed within either one of the first door and second door, an upper latch assembly interconnecting the vertical reinforcement assembly and the roof rail, and a lower latch assembly interconnecting the vertical reinforcement assembly and the rocker to resist inward movement of the first door and the second door from the closed position with respect to the body of the pick-up truck.

Owner:FORD GLOBAL TECH LLC

Clamp structure for tonneau cover

A clamp structure for a tonneau cover is disclosed and mounted to one frame section of a tonneau cover for releasably securing the frame section on a cargo bed of a pick-up truck. The clamp comprises: a foundation rail having two side grooves and a recess formed between the two side grooves; and a sliding block having two side hangers extended into and slidably moving along the two side grooves and a pivotal portion received in the recess; a clamp bolt; a grip element; and a handle. The side hangers of the sliding block is used to slidably move along the side grooves of the foundation rail, so that the sliding movement of the clamp structure pivotally connected to the sliding block in relation to the foundation rail is more stable and smooth based on two strong support points of the two side hangers in the two side grooves.

Owner:CYC ENG

Clamp structure for tonneau cover of pick-up truck

A clamp structure for a tonneau cover of a pick-up truck is disclosed and mounted to one frame section of a tonneau cover for releasably securing the frame section on a side wall of a cargo bed of the pick-up truck. The clamp structure has a composite grip element which has a metal grip body and a plastic sleeve. The metal grip body has an engaging portion to stably engage with the side wall of the pick-up truck. The plastic sleeve has a first abutment flange to smoothly abut against a turning handle, and a second abutment end facing a sliding block. Thus, the composite grip element can provide advantages of both of metal and plastic material, so that the operational stability and reliability of the clamp structure can be enhanced, and the lifetime thereof can be elongated.

Owner:CYC ENG

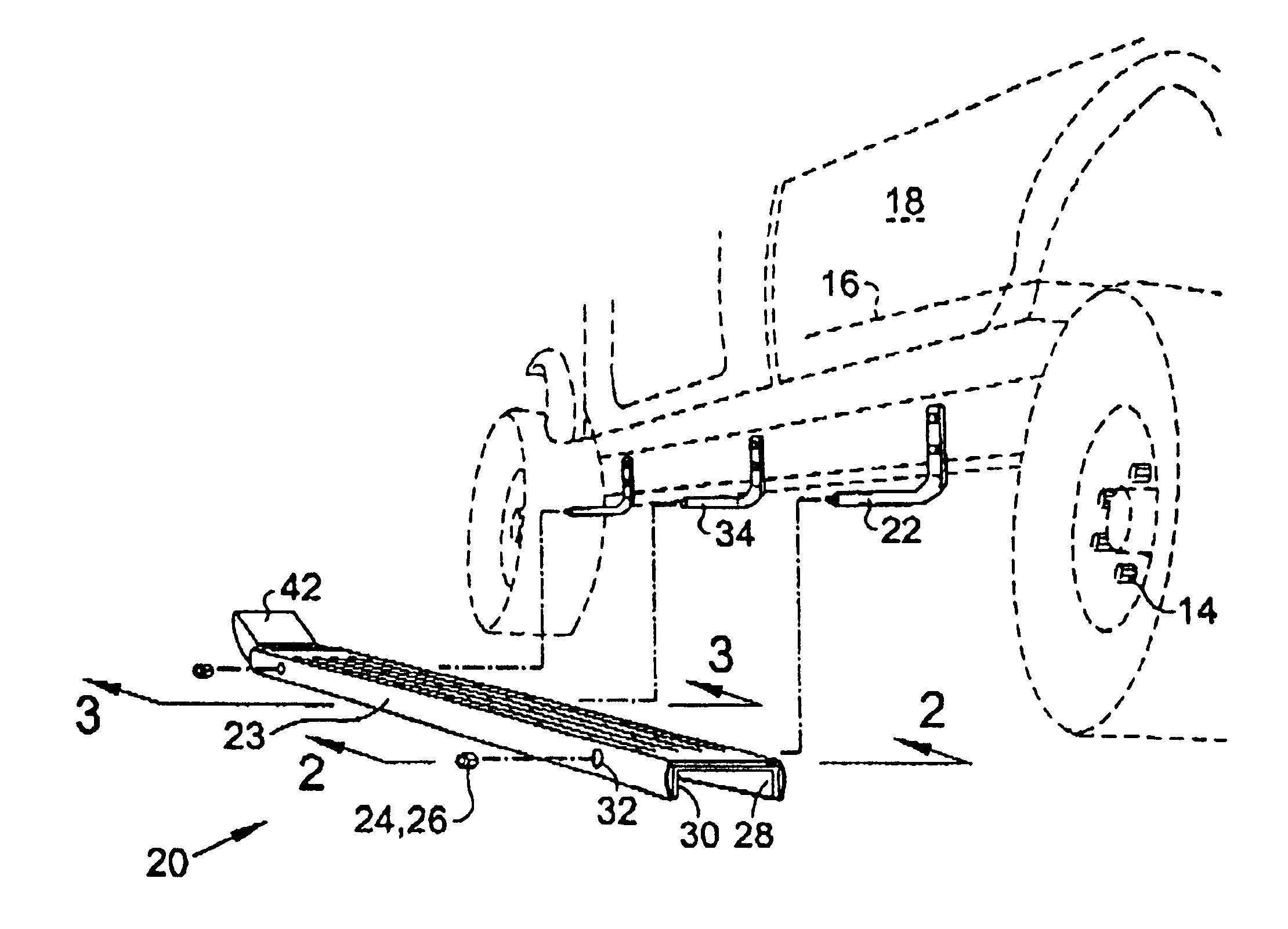

Vehicle running board detachable for use as loading ramp

InactiveUS6592135B2Convenient and inexpensive and reliableNeed can be availableVehicle arrangementsSuperstructure subunitsPick-up truckIn vehicle

A running board assembly for pick-up trucks, vans, and sport utility vehicles which has a detachable runner which used as a loading ramp when and wherever a loading ramp is needed to load the vehicle. The assembly not only provides the convenience of a running board which divides the long stretch when stepping into the vehicle; but additionally, it provides a convenient and unobtrusive means of carrying loading ramps in vehicles which typically lack the storage capacity, and particularly the length in their storage bed, to carry a loading ramp. The running board assembly comprises: a front and rear mounting bracket each secured to a lower central side portion of the vehicle; an elongate runner releasably engaging, and carried by the front and rear mounting brackets; and, releasable lock means to releasably lock the elongate runner board on the brackets.

Owner:HENDRIX THERON V

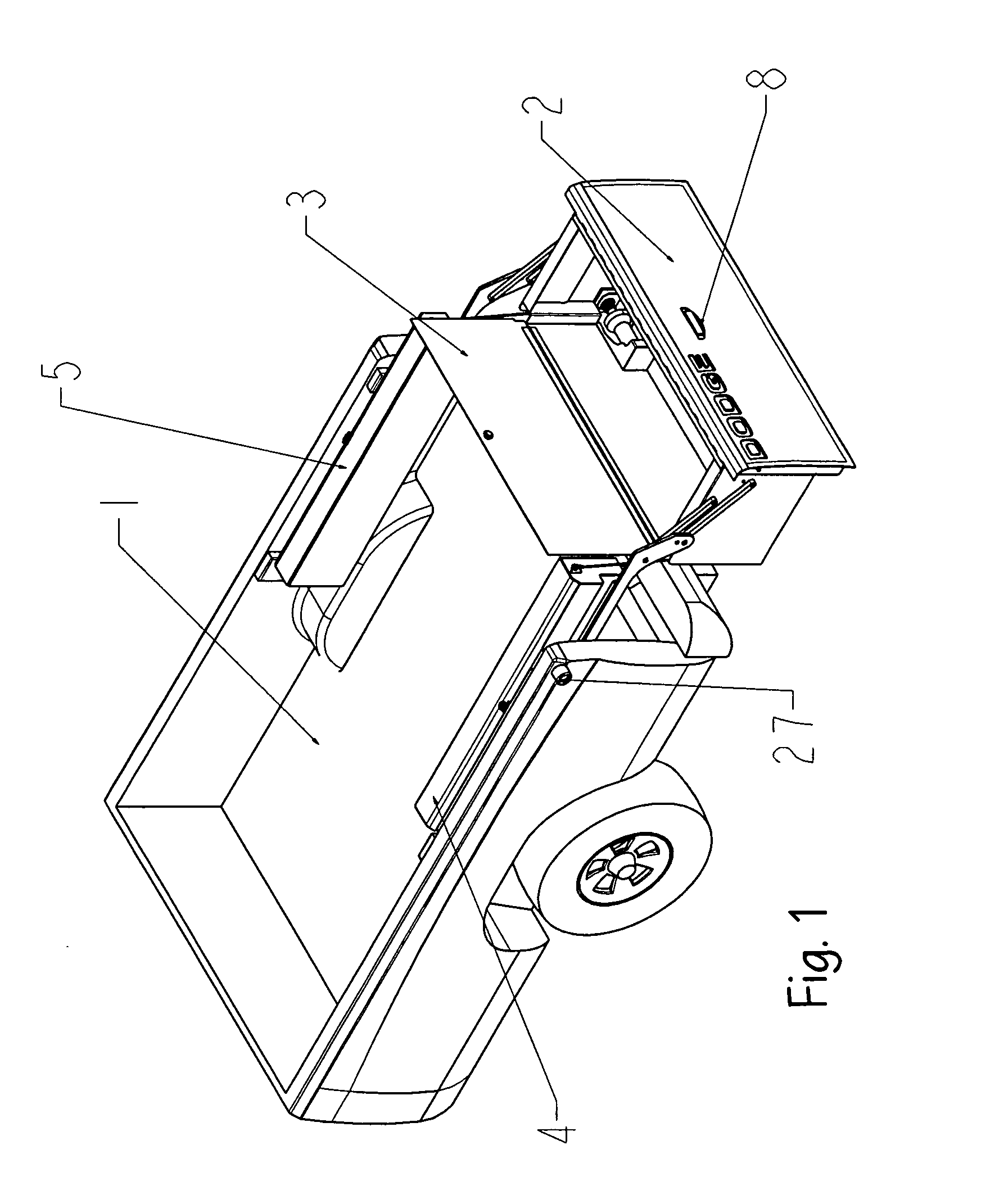

Truck storage and work surface tailgate

InactiveUS7111884B2The process is simple and convenientEasily retrofitted togetherRefuse receptaclesVehicle with living accommodationPick-up truckEngineering

A storage compartment and integrated tailgate worksurface is disclosed. The storage compartment is easily retrofitable to any standard or light duty pick-up truck bed. A parallel linkage mechanism and integrated power unit can raise and lower the storage compartment without rotation, thereby keeping objects in an initial desired orientation and placement within the compartment. The parallel linkage system also facilitates adjustment of the integrated tailgate work surface to convenient working heights.

Owner:KURION INC

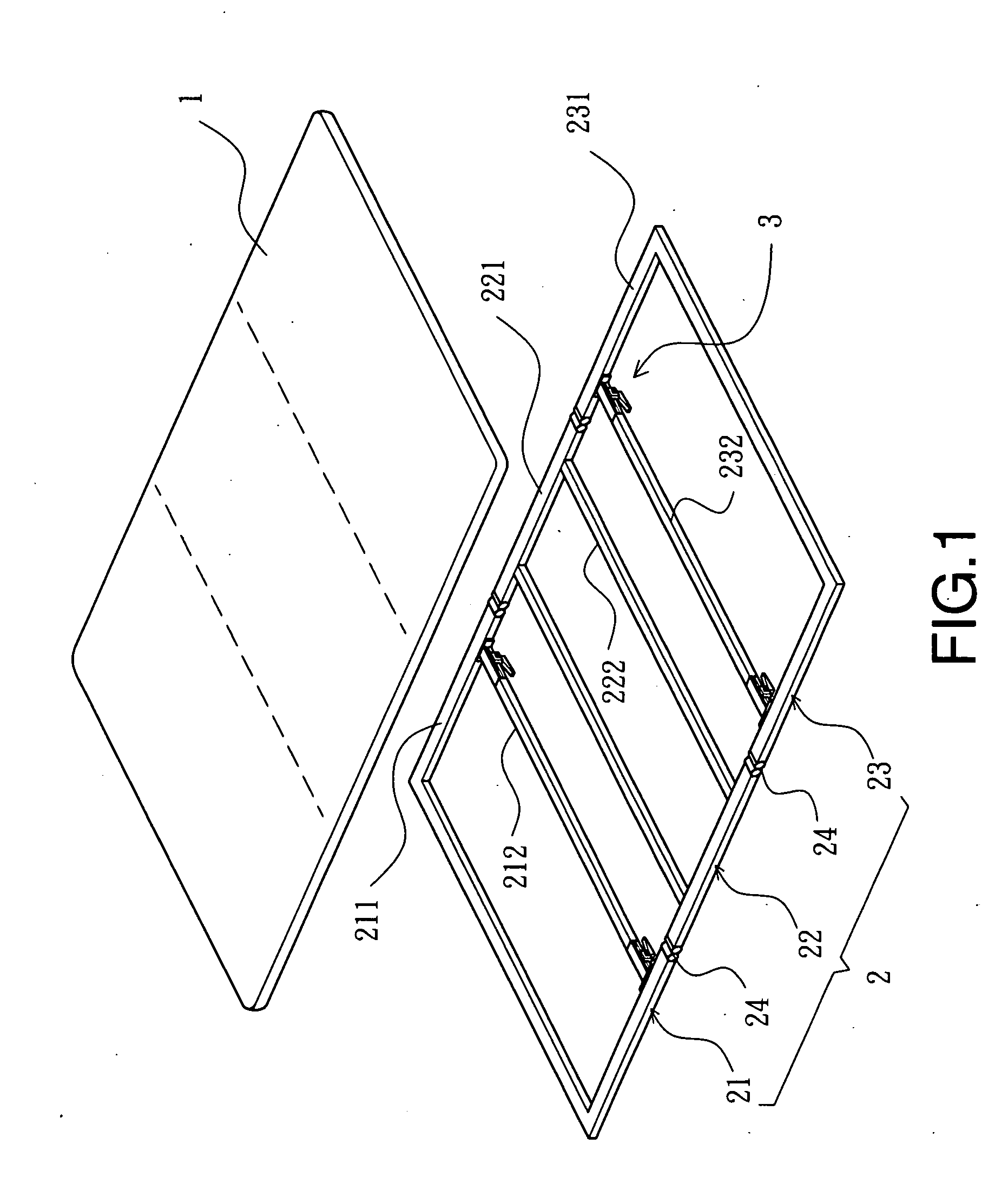

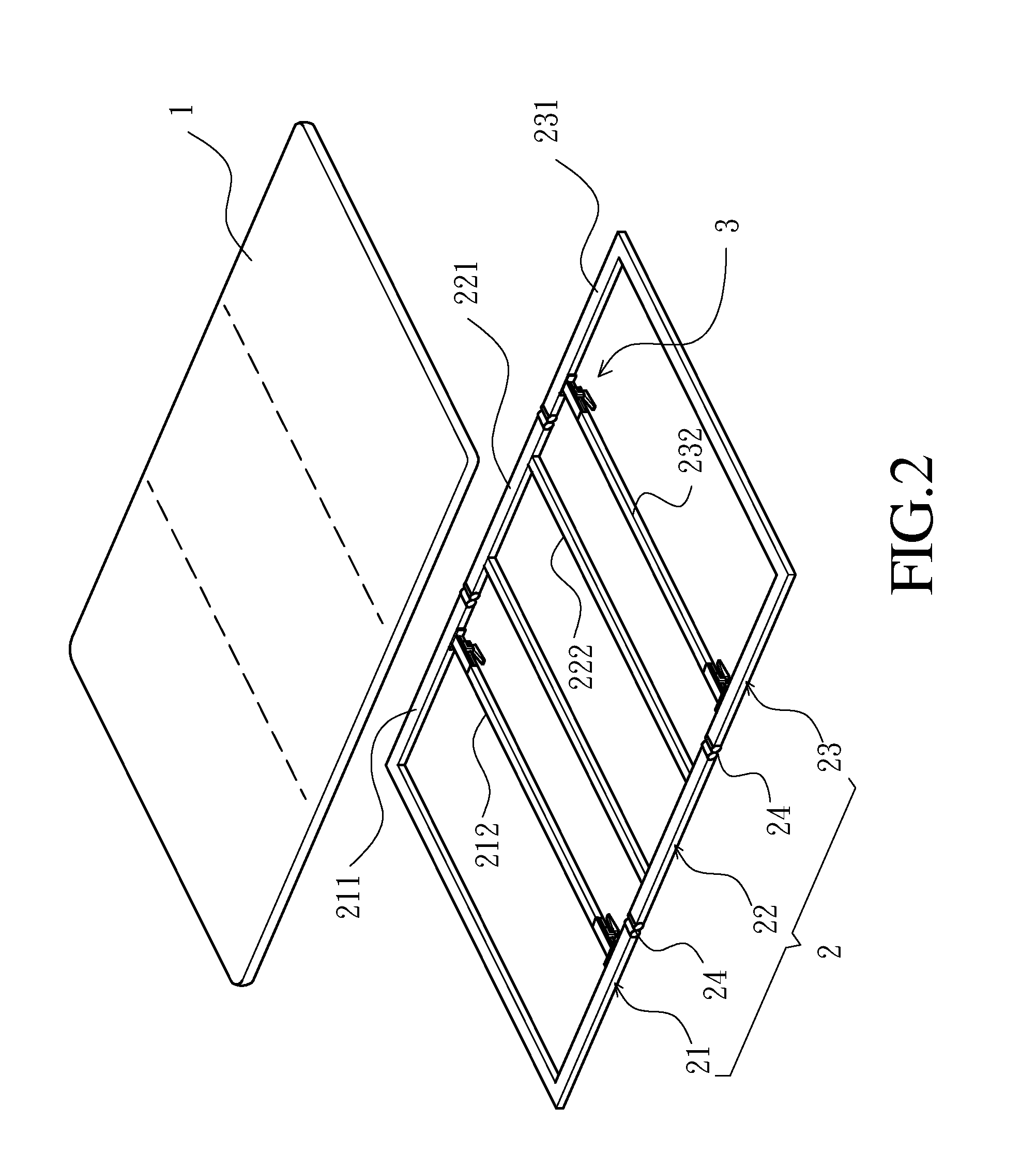

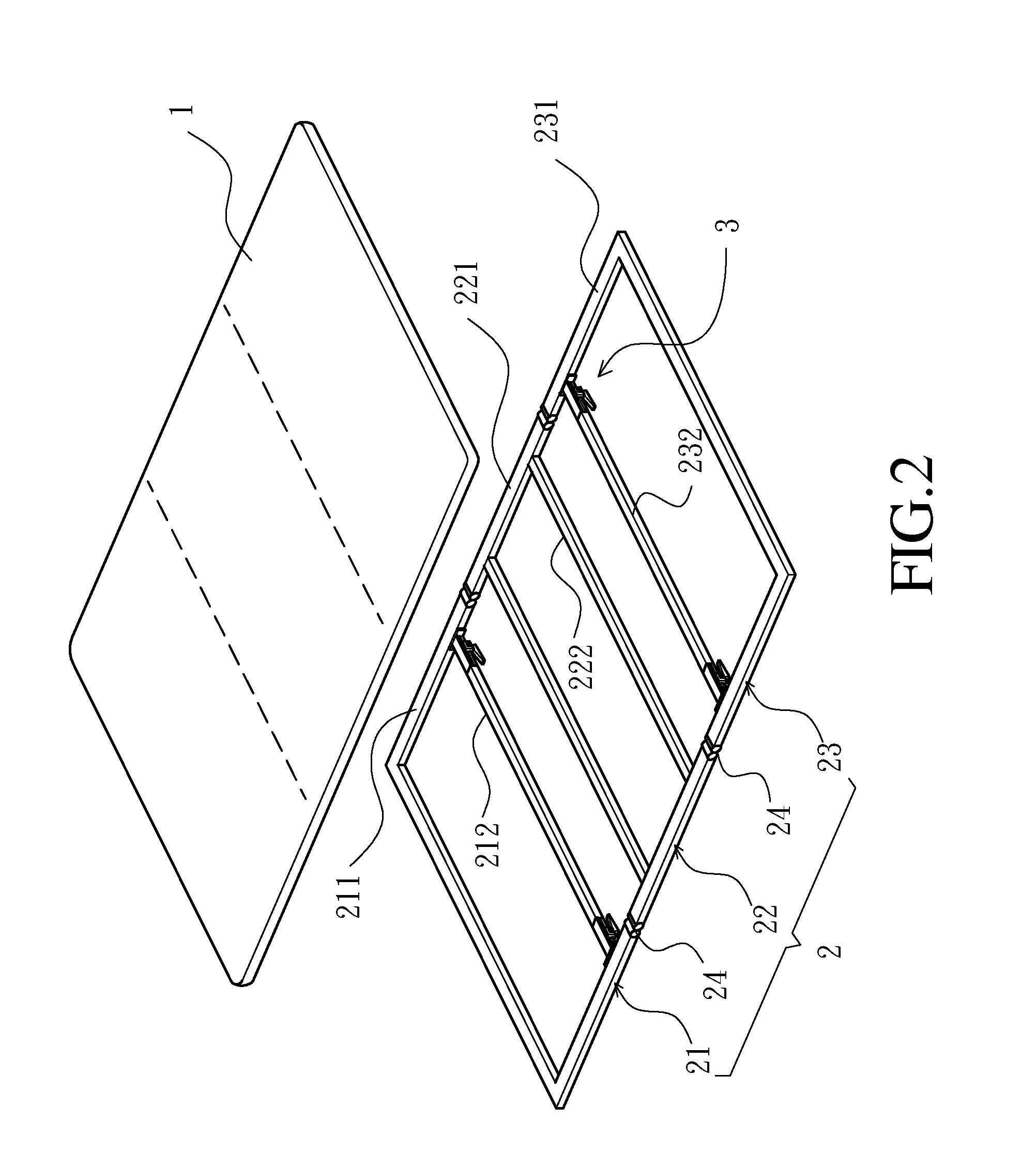

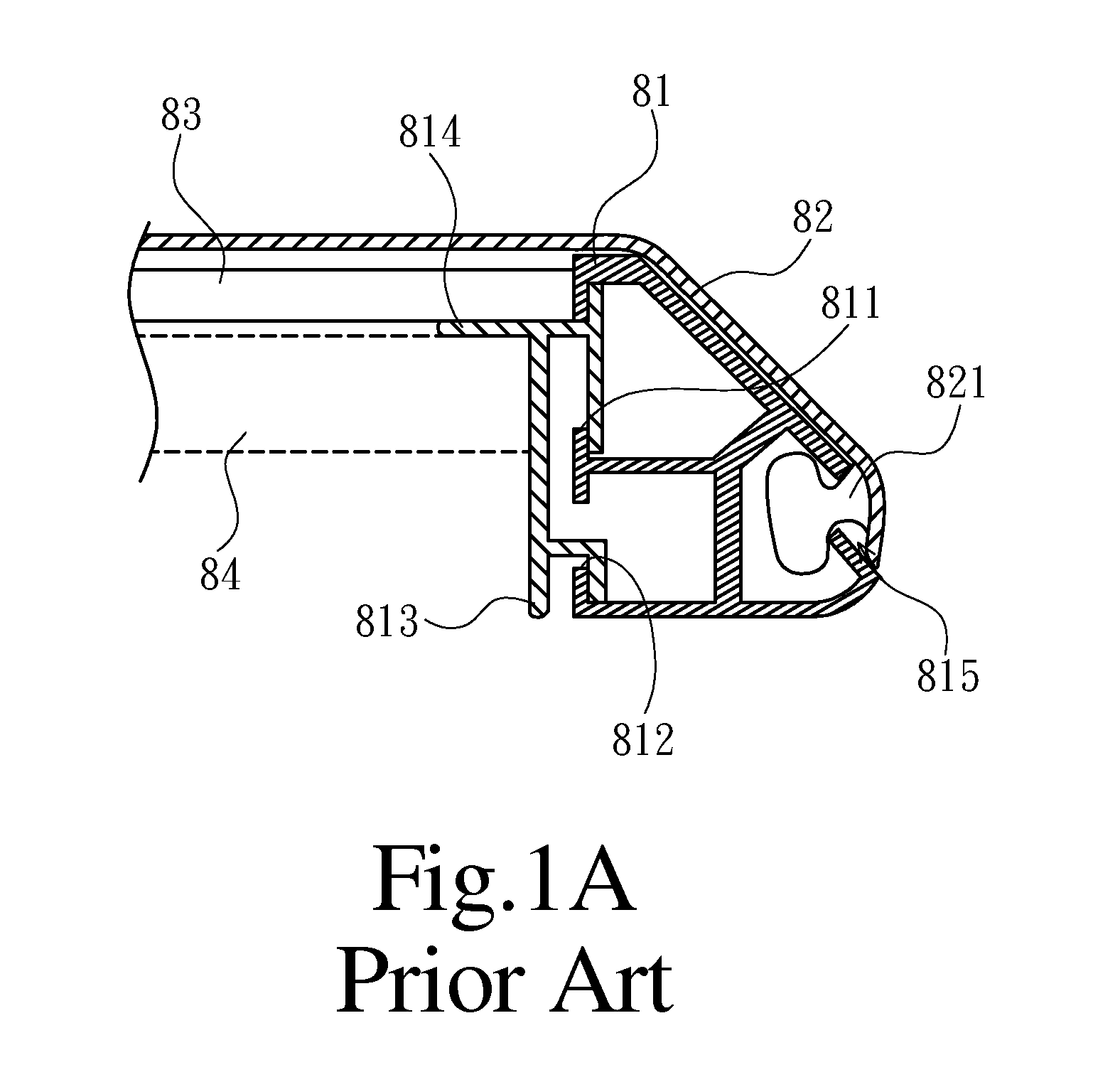

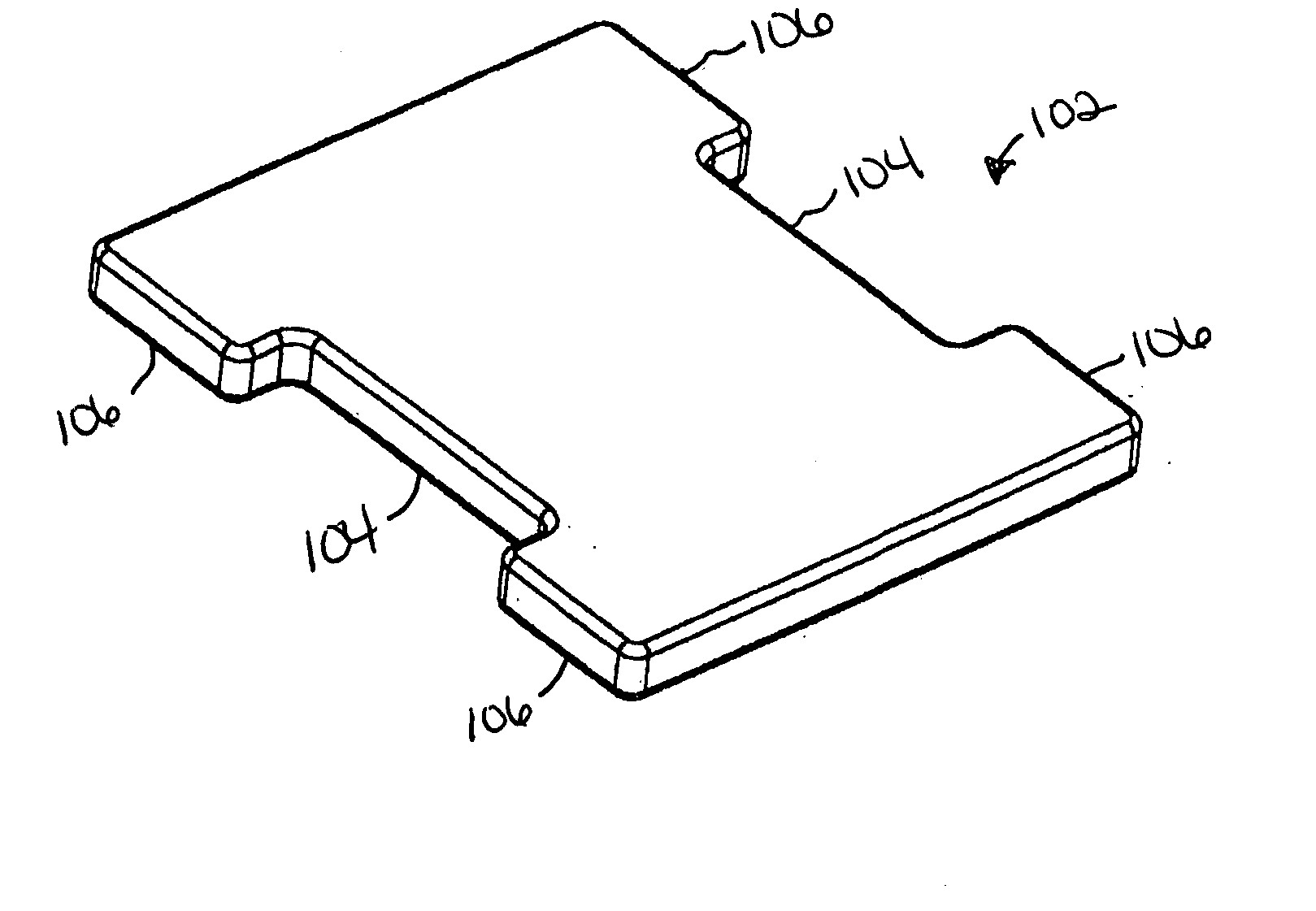

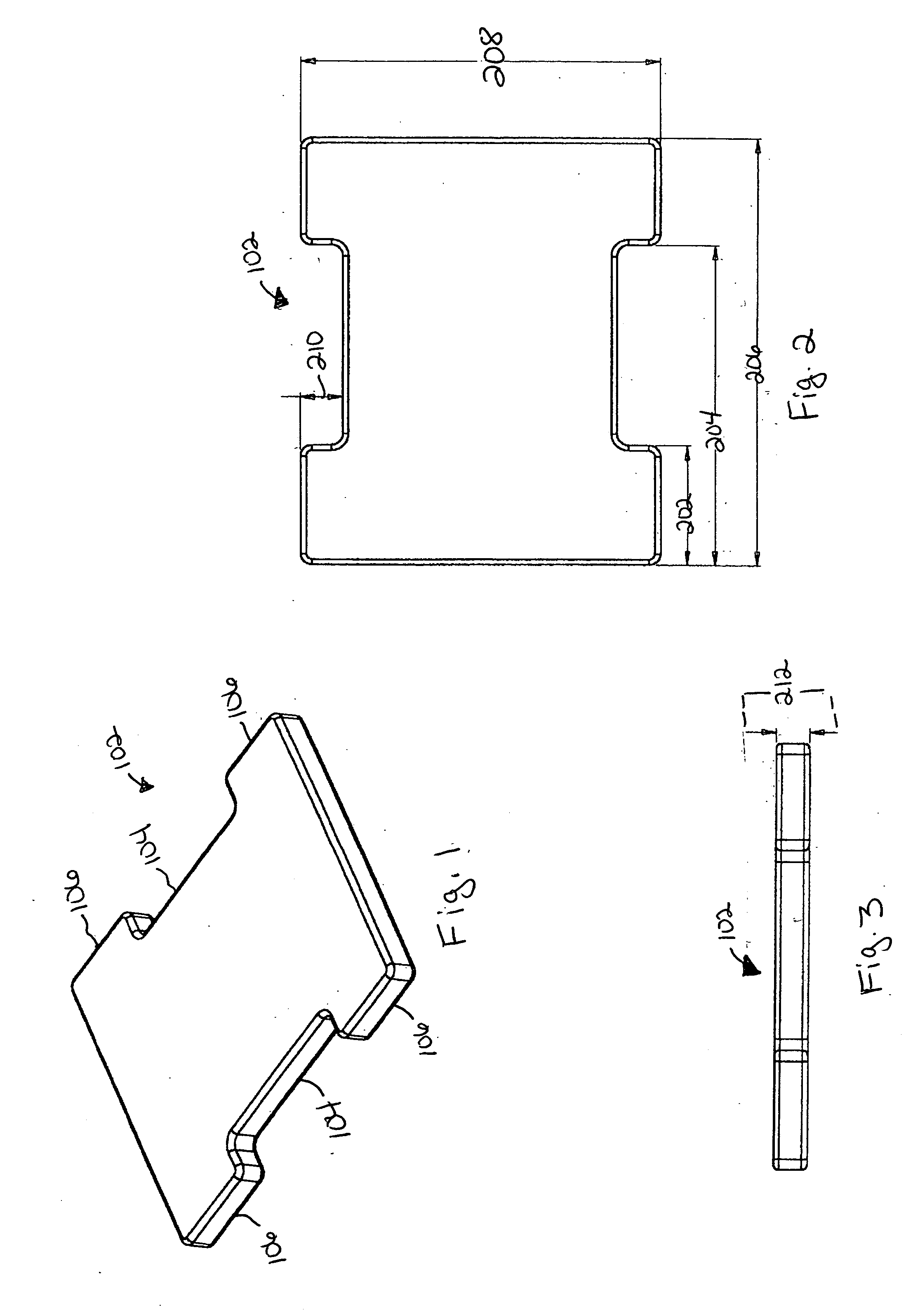

Composite tonneau cover of pick-up truck

A composite tonneau cover of a pick-up truck is disclosed. The composite tonneau cover has at least one frame section and is releasably secured on a side wall of a cargo bed of the pick-up truck. Each of the frame section comprises: a flexible cover material; a rigid metal panel covered by the flexible cover material and having at least two end edges; and a plurality of outer rails covered by the flexible cover material. Each of the outer rails has an inner side formed with an installation groove, and each of the end edges of the rigid metal panel is inserted into the installation groove of one of the outer rails. Thus, the composite tonneau cover can provide dual advantages of hard-top type tonneau cover and soft-top type tonneau cover.

Owner:CYC ENG

Pick up truck tonneau cover with tailgate storage

InactiveUS20100140973A1Avoid stretchingConveniently removedLoad coveringRoofsPick-up truckEngineering

A multi-section tonneau cover for a pickup cargo box which folds up to form a stack which is than stowable in a cavity in the pickup tailgate. Intermediate section panels and special hinged connections allow a roll-up type folding pattern so that a waterproof cover layer can be attaching extending over all of the section panels without interfering with the folding up of said main section panels.

Owner:DUNCAN ANTONIO

Vehicle bed tie down device

A removable vehicle bed tie down device comprises a clamp body and a gripper assembly that is securely advanceable relative to the clamp body. The clamp body and the gripper assembly are shaped and configured to apply a gripping force to two intersecting walls of a bed rail of a vehicle such as a pick up truck. The clamp body includes a mount point and a rib that may be formed as an integrated unitary structure with the clamp body, thus providing high strength and stiffness with low manufacturing costs. The rib extends over substantially the entire outer surface of the clamp body and distributes loads applied to the mount point over the entire clamp body and to the gripper assembly.

Owner:LUND MOTION PRODS

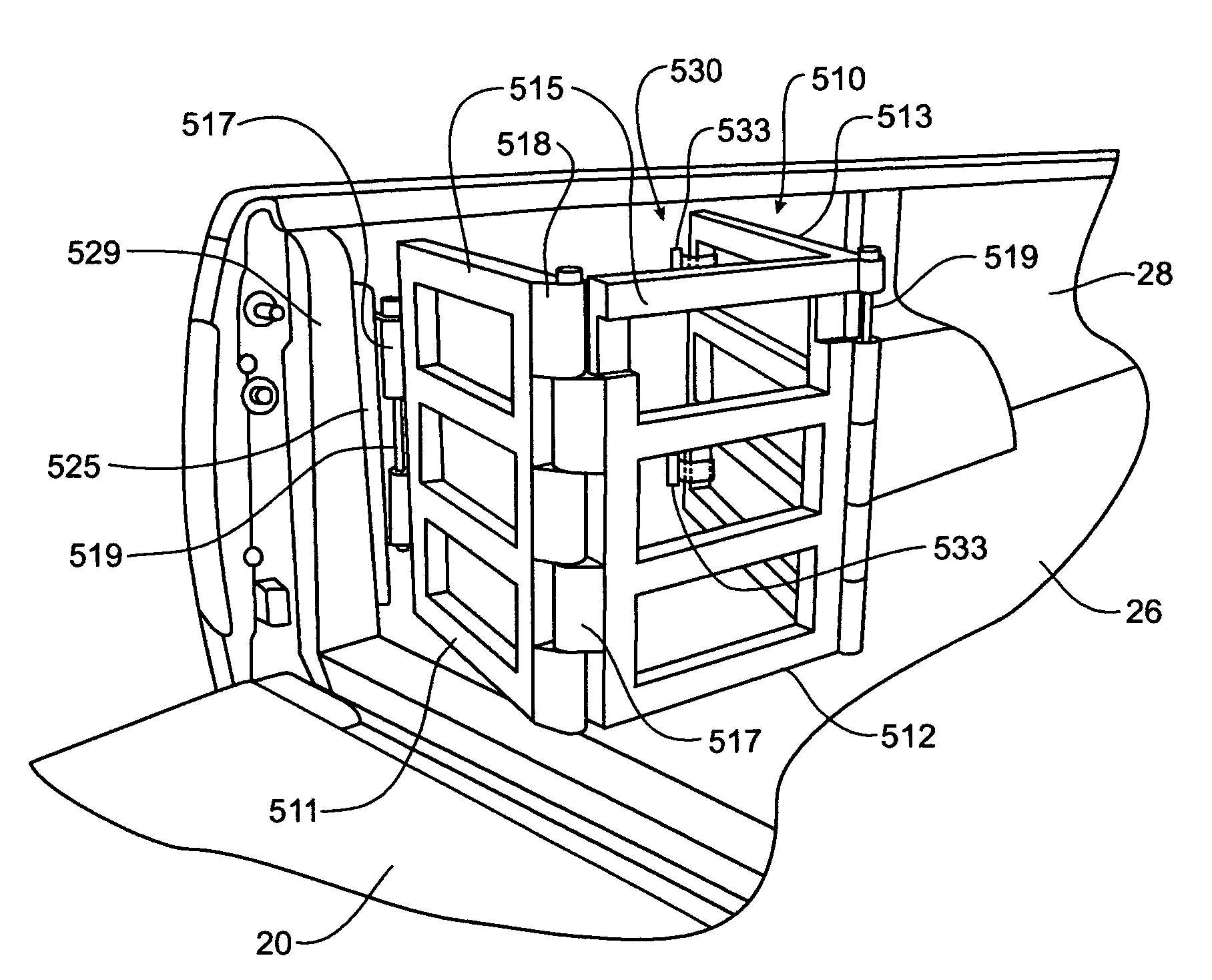

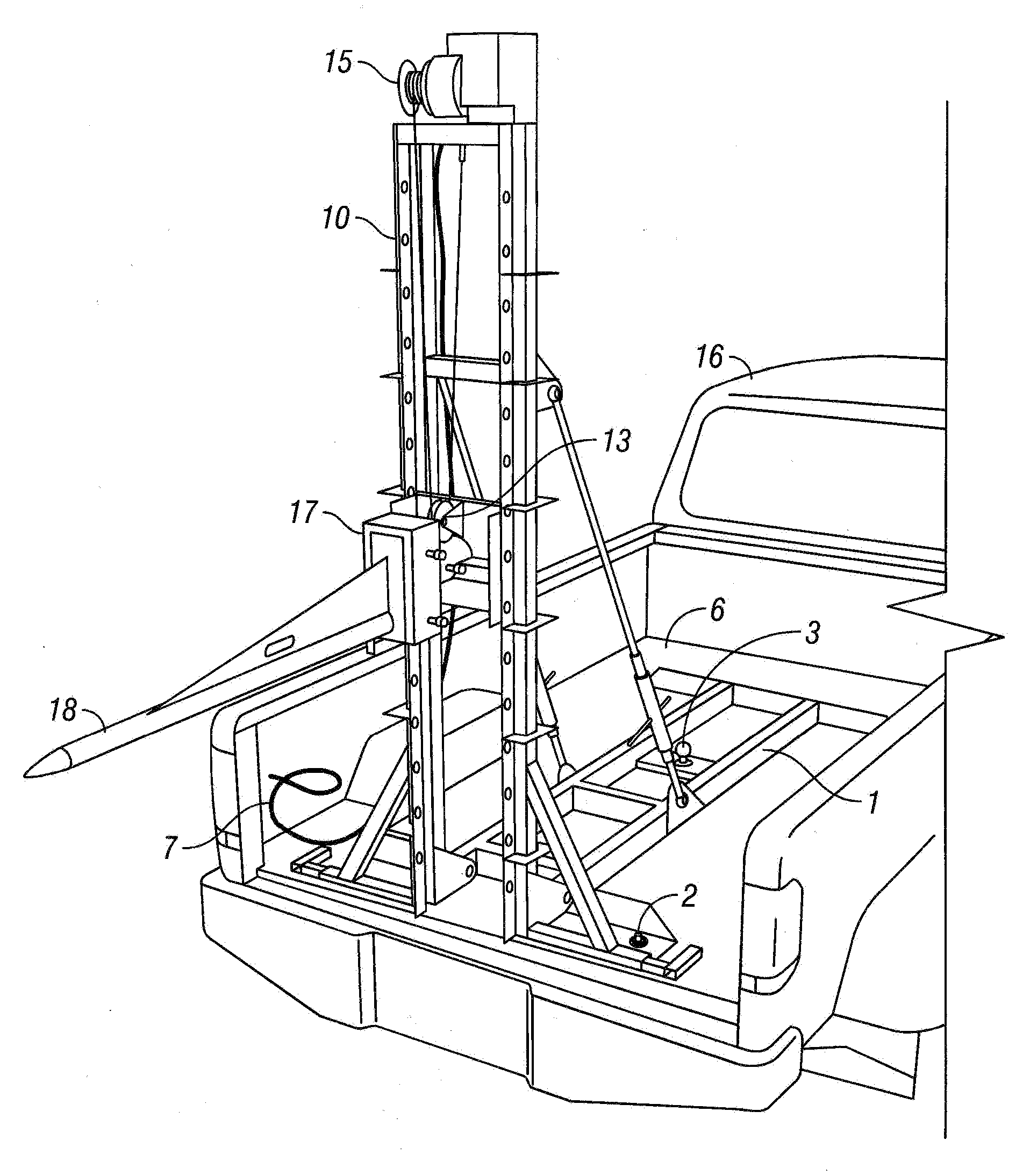

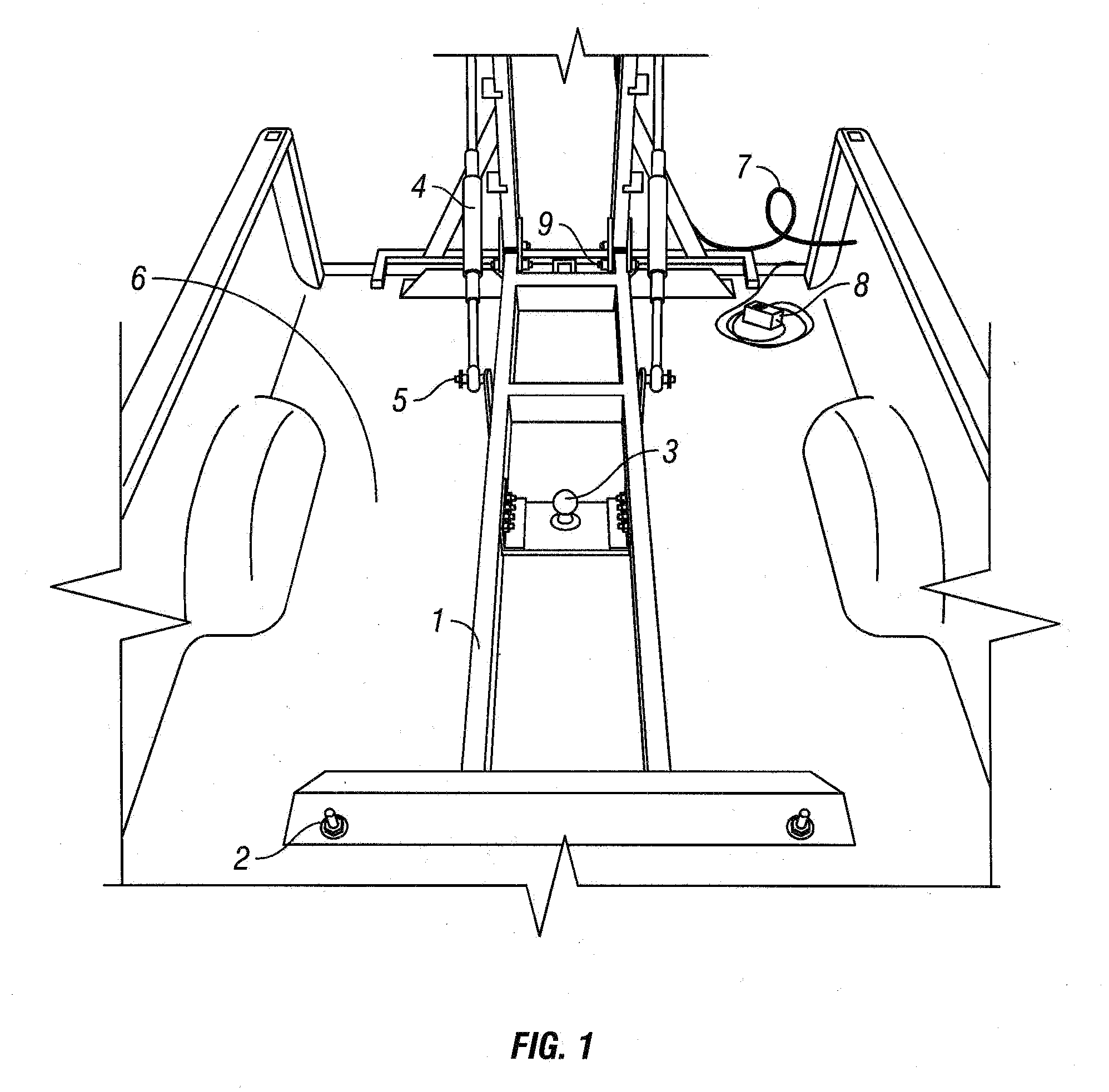

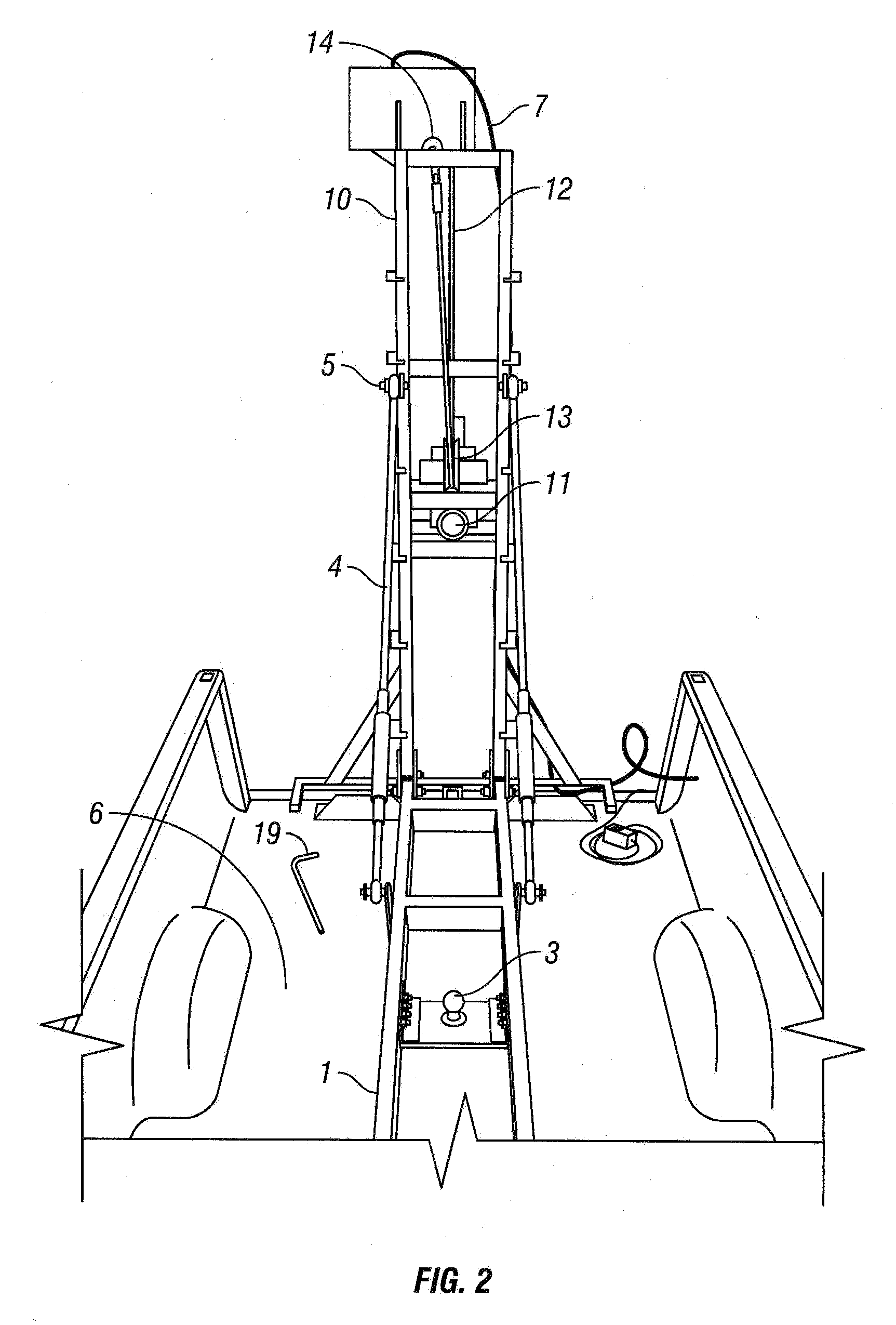

Truck Mounted Multifunction Lifting System and Method

A collapsible electrical or hydraulic system mountable in the rear of a truck for lifting and other functions. The system is compatible with other common uses of pick-up trucks. It is operated from within the cab of the truck, standing outside the pick-up truck bed, or remotely. The system operates in various modes and with various tools. The lifting system is collapsible to a low-profile and allows the use of the pick-up truck for towing a “gooseneck” trailer. Multiple attachments include, but are not limited to, a fork lift, hay bale spear, hay bale unroller, pallet forks, man-lift cages, dump bucket, drilling attachment, and / or a vehicle recovery platform, such as the towing / lifting functions of a tow truck.

Owner:BROOKS BRADY B

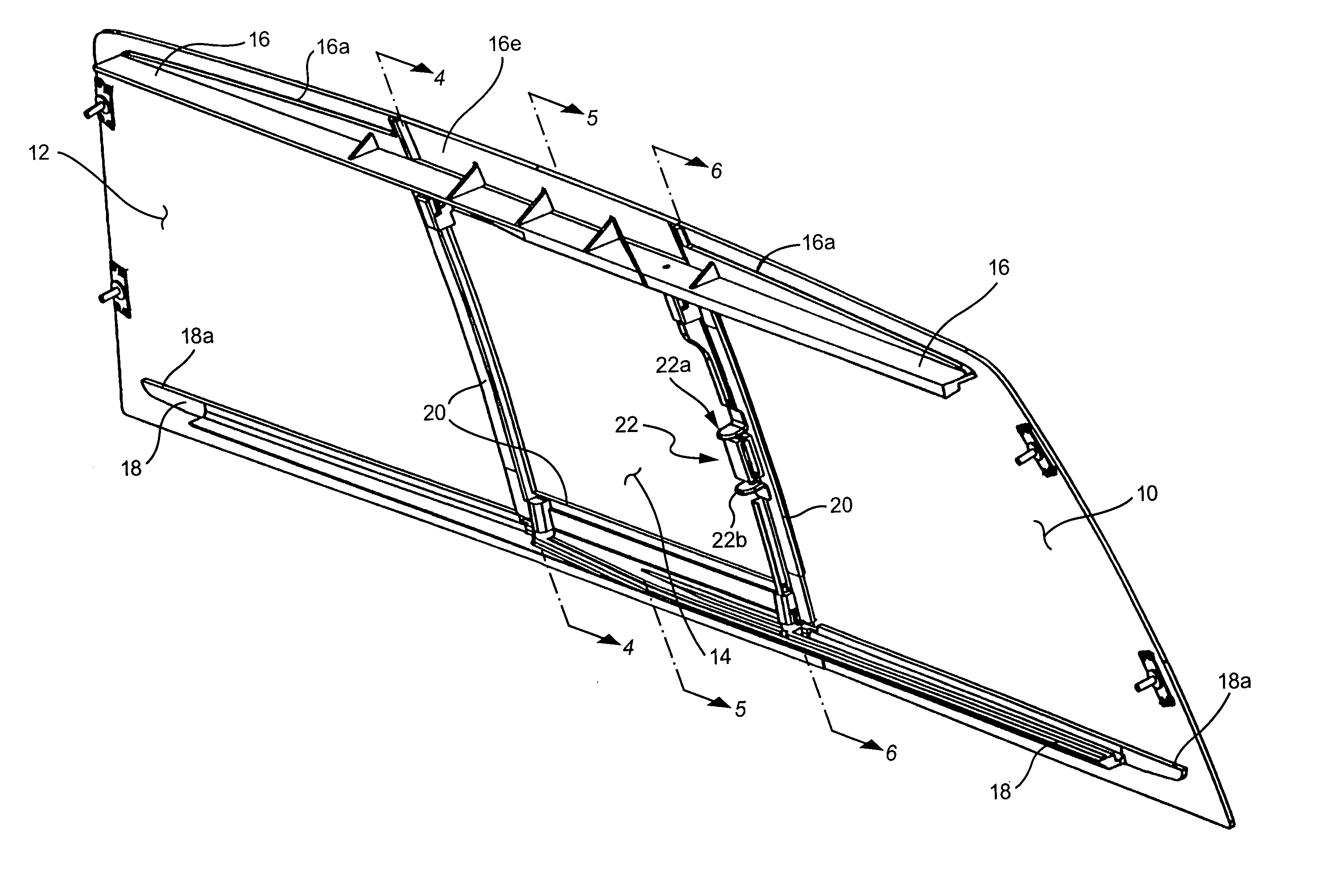

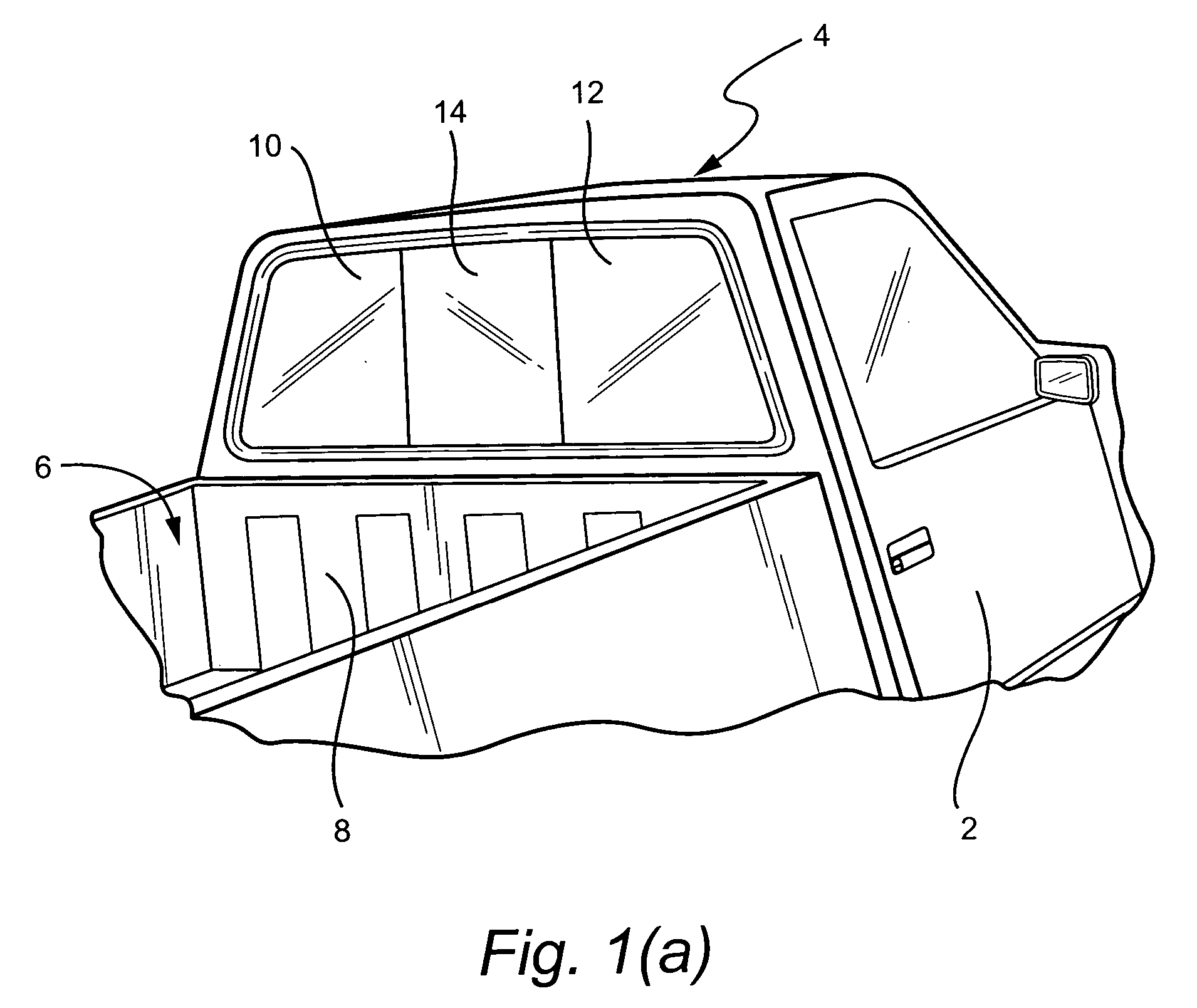

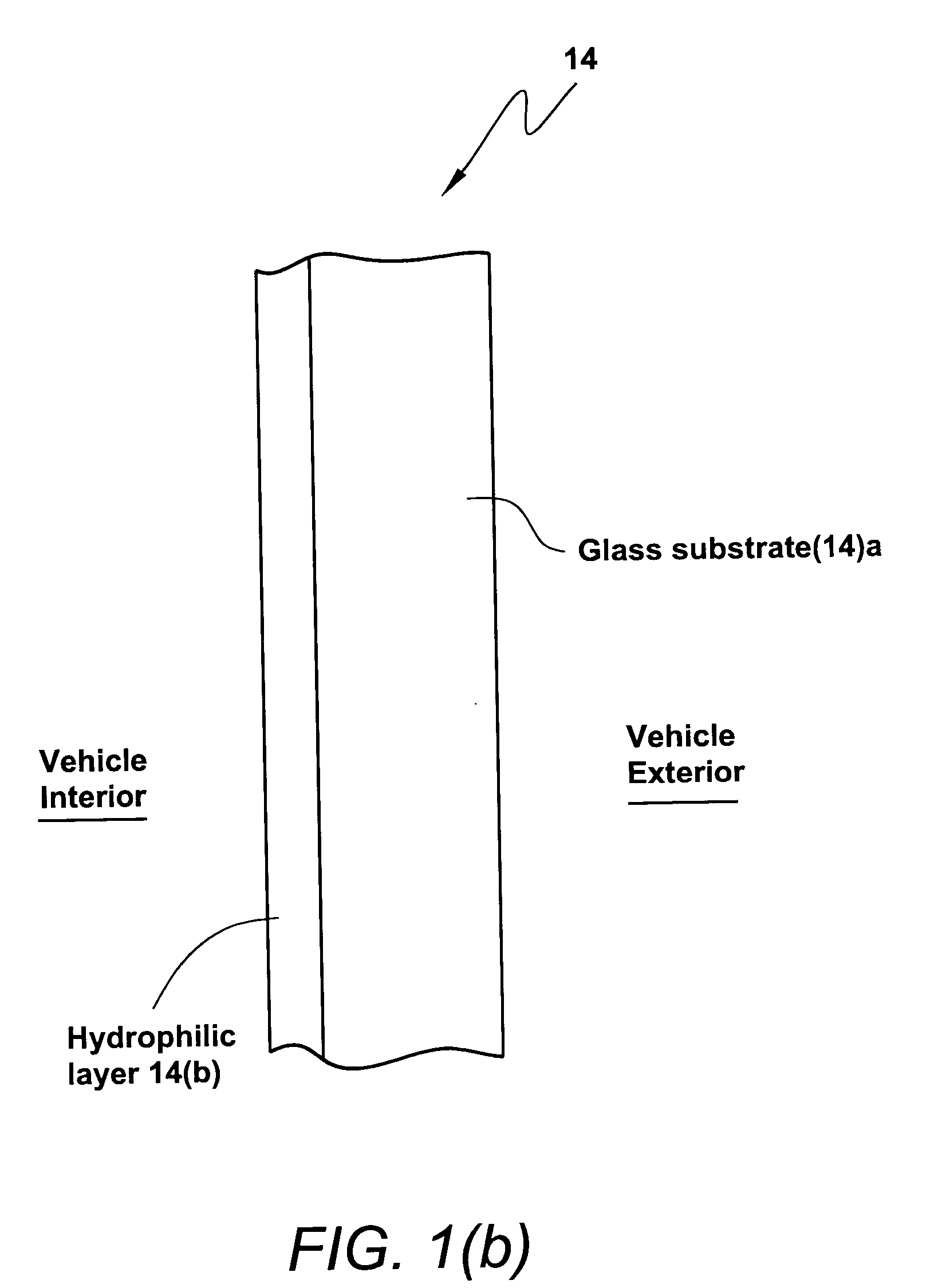

Flush-mounted slider window for pick-up truck with hydrophilic coating on interior surface thereof, and method of making same

InactiveUS20060107599A1Prevent and reduce tendencyWindowsWindscreensHydrophilic coatingPick-up truck

A window structure is provided which may be used as a rear window in a pick-up truck or the like. In certain example embodiments, the window structure includes a slidable window panel or sheet located between a pair of fixed window panels or sheets. The slidable window panel may have a hydrophilic coating on an interior major surface thereof for anti-fogging purposes.

Owner:GUARDIAN GLASS LLC

Composite tonneau cover of pick-up truck

A composite tonneau cover of a pick-up truck is disclosed. The composite tonneau cover has at least one frame section and is releasably secured on a side wall of a cargo bed of the pick-up truck. Each of the frame section comprises: a flexible cover material; a rigid metal panel covered by the flexible cover material and having at least two end edges; and a plurality of outer rails covered by the flexible cover material. Each of the outer rails has an inner side formed with an installation groove, and each of the end edges of the rigid metal panel is inserted into the installation groove of one of the outer rails. Thus, the composite tonneau cover can provide dual advantages of hard-top type tonneau cover and soft-top type tonneau cover.

Owner:CYC ENG

Truck-bed mattress

A mattress is disclosed having an overall size and shape that enable it to fit securely in the back of a pick-up truck, SUV, mini-SUV or some other vehicle. While the specifications and examples listed herein assume a full-size vehicle, a proportionally smaller mattress can be configured to accommodate mid-size or smaller vehicles.

Owner:KENNAN WILLIAM B

Adjustable truck box extender flip gate

InactiveUS7204537B1Unstable loadReduce usageVehicle to carry long loadsVehicle with living accommodationComing outPick-up truck

A pick-up truck box extender flip gate is provided. The truck box extender flip gate of the current application is comprised of; 1) a tail gate attaching frame, 2) two side faces, each of which is comprised of one guide and one metal frame. 3) a first front face that is rotatably connected to the two guides, and 4) a second front face that is rotatably connected to the first front face via hinges. When the pick-up truck box extender flip gate is in retracted position, the two guides are embedded in two rectangular metal frames which are welded to both ends of the tail gate frame. The first front face and the second front face are overlapped with the tailgate-attaching frame when the flip gate is retracted. In extended position, the first front face and second front faces come out of the attaching frame to extend the pick-up truck cargo box space. The first and second front faces have racks for holding bicycle wheel or long ladder's leg. The pick-up truck box extender flip gate of the current application occupies less space than previous truck box extenders and renders additional space to a pick-up truck.

Owner:OH KWANG - JIN +1

Flush-mounted slider window for pick-up truck

A window structure is provided which may be used as a rear window in a pick-up truck or the like. In certain example embodiments, the window structure includes a slidable window panel or sheet located between a pair of fixed window panels or sheets. The slidable window panel may be approximately flush with the fixed panels when in the closed position, but not in the opened position.

Owner:GUARDIAN GLASS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com