Gas turbine combustion chambers

a combustion chamber and gas turbine technology, applied in the direction of machines/engines, efficient propulsion technologies, lighting and heating apparatus, etc., can solve the problems of dilution, undesirable orifices, and inability to reduce, so as to improve the temperature behavior of the combustion chamber walls, reduce the drawbacks, and prolong the life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

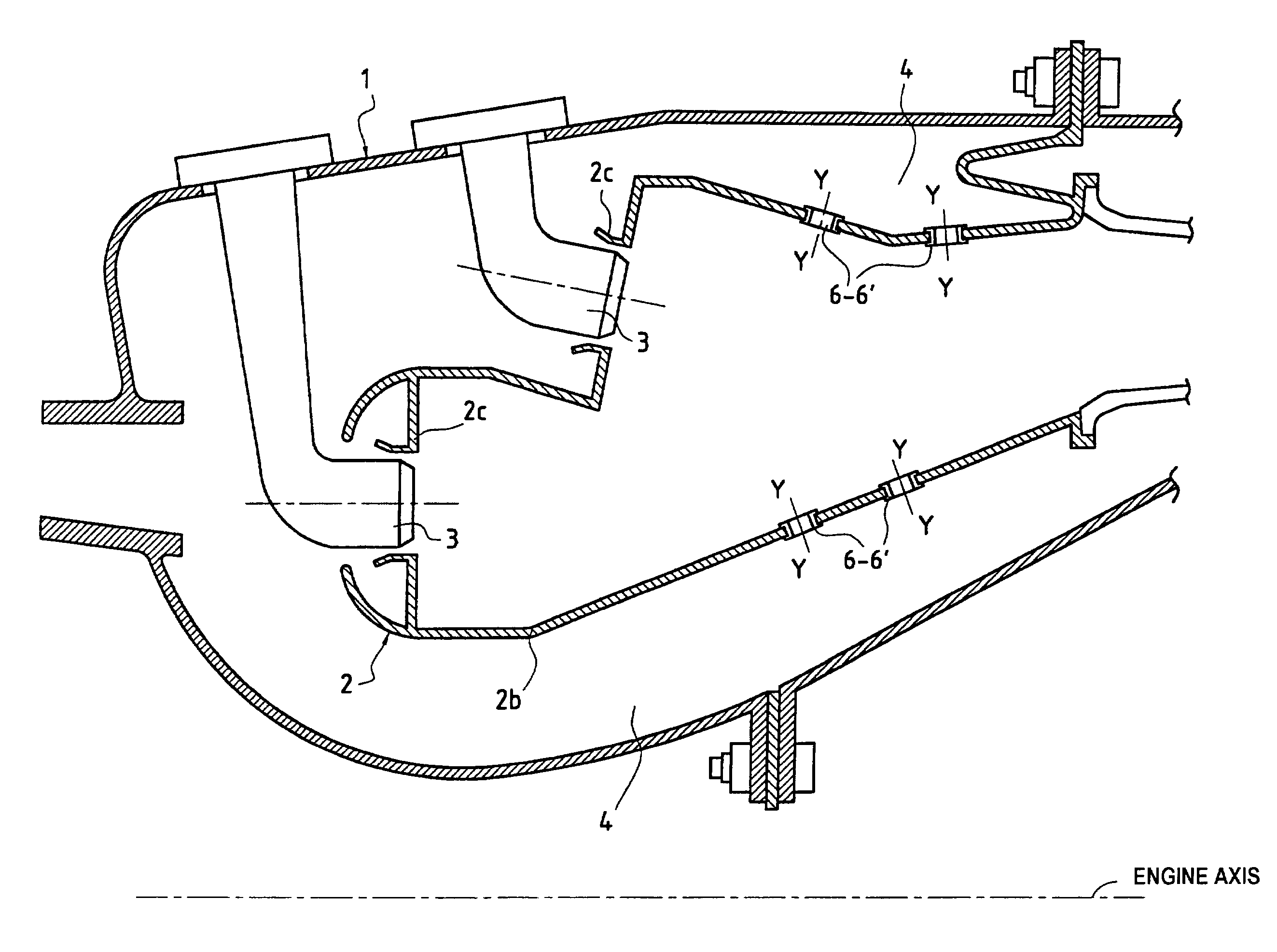

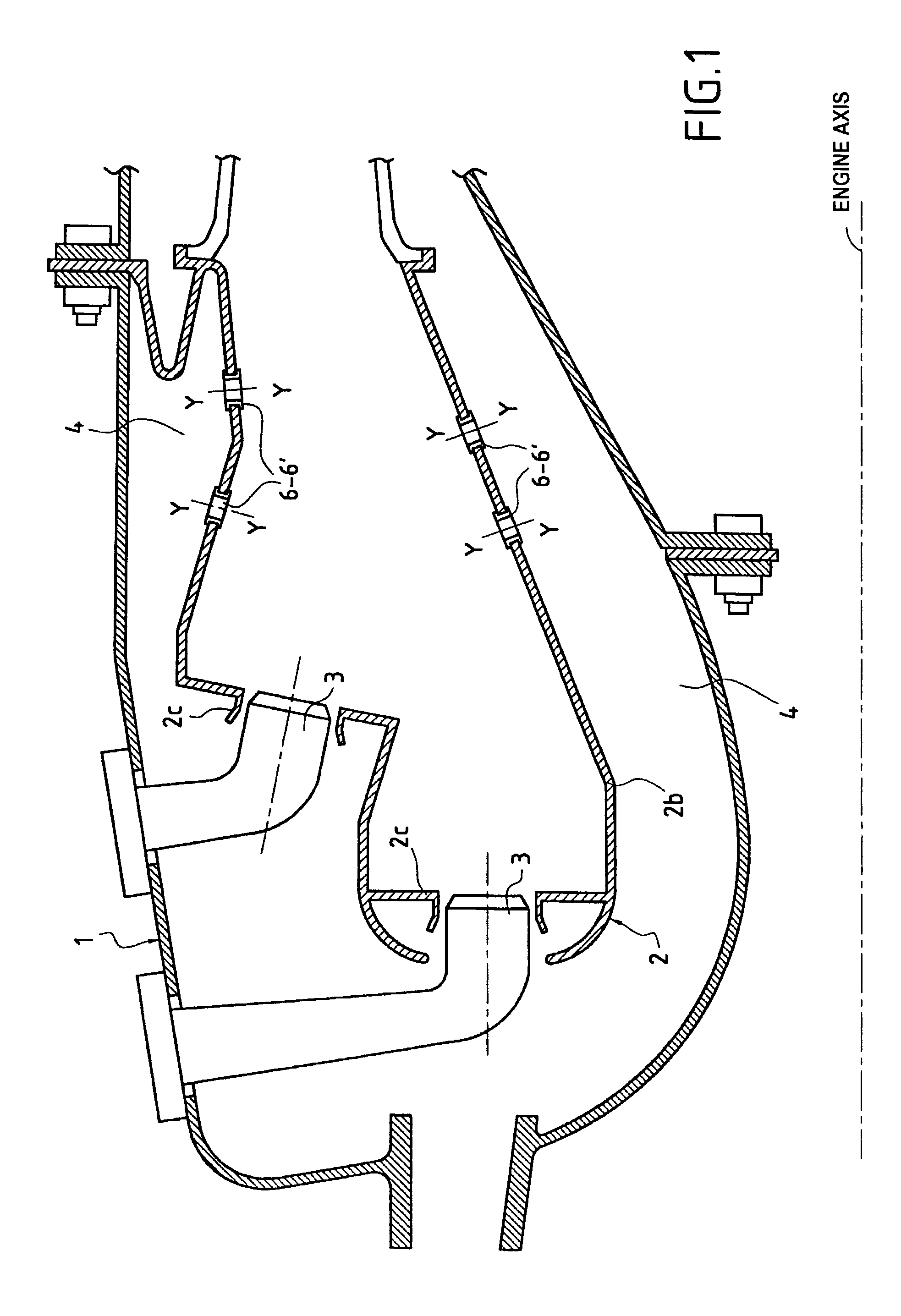

[0019] Reference is made initially to FIG. 1 which is an axial section view of a combustion chamber for an aircraft engine gas turbine.

[0020] Typically, a gas turbine possesses a compression section (not shown) in which air is compressed prior to being introduced into a combustion chamber casing 1, and then into a combustion chamber 2 situated therein. Thereafter the air is mixed with fuel injected into the combustion chamber prior to being burnt therein. The gas generated by this combustion is then directed towards a high pressure turbine (not shown), prior to being exhausted.

[0021] In the embodiment shown in FIG. 1, the combustion chamber 2 is of the annular type. Naturally, the present invention also applies to any other shape of combustion chamber.

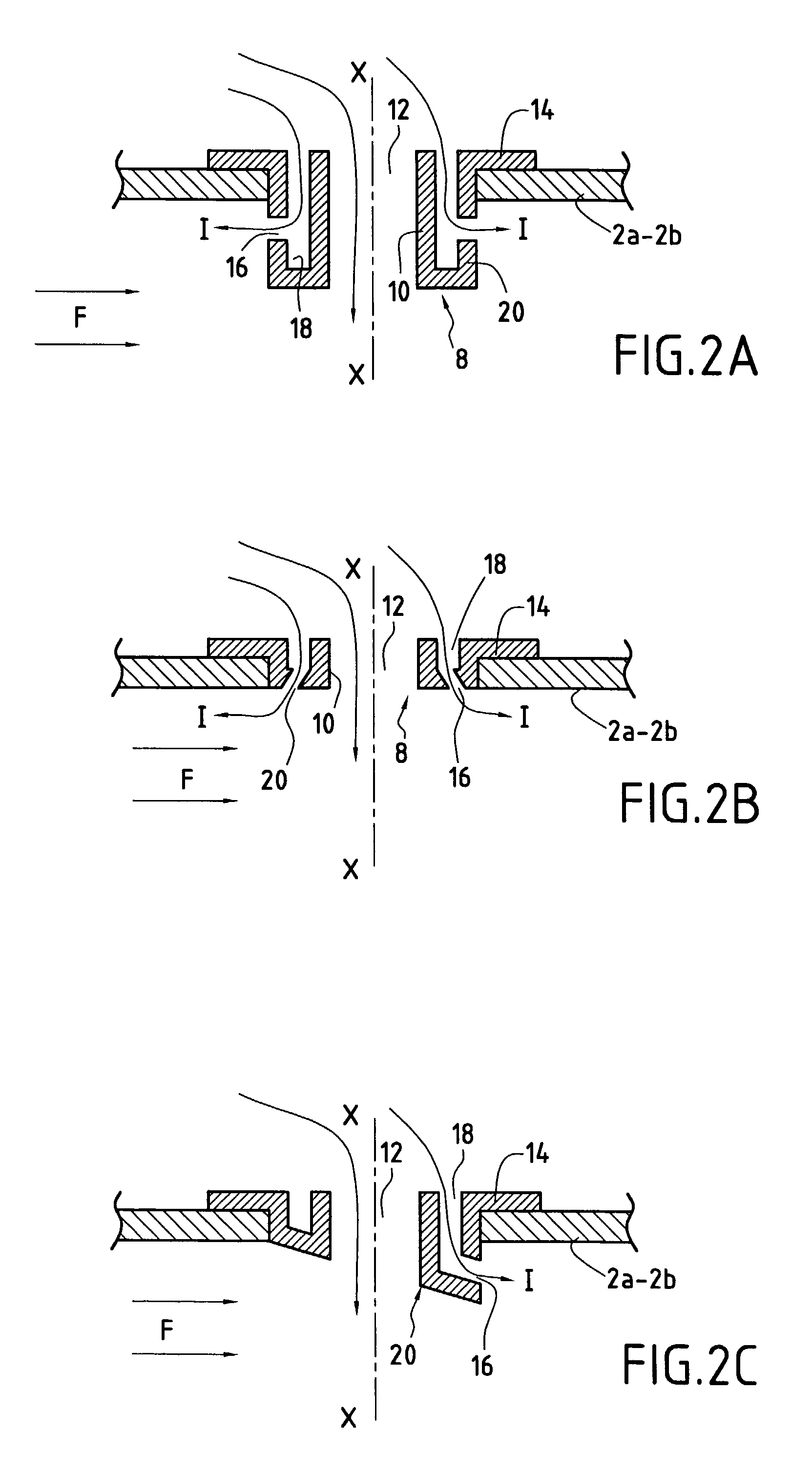

[0022] The combustion chamber 2 is defined by outer and inner side walls 2a and 2b interconnected by an end wall 2c fitted with injector systems 3 through which fuel is introduced into the combustion chamber. Conventionally, such injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com