Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6784results about "Output power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

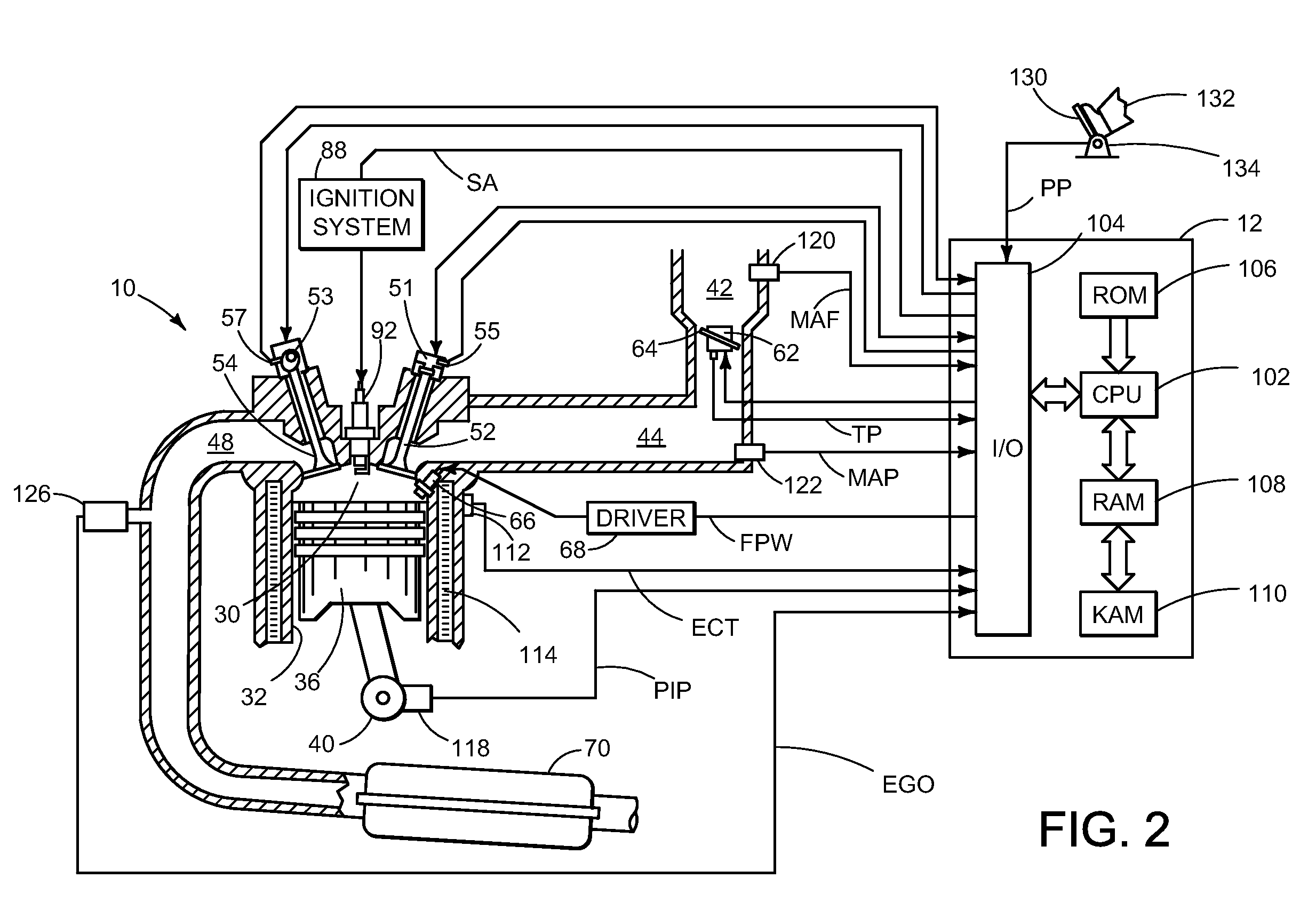

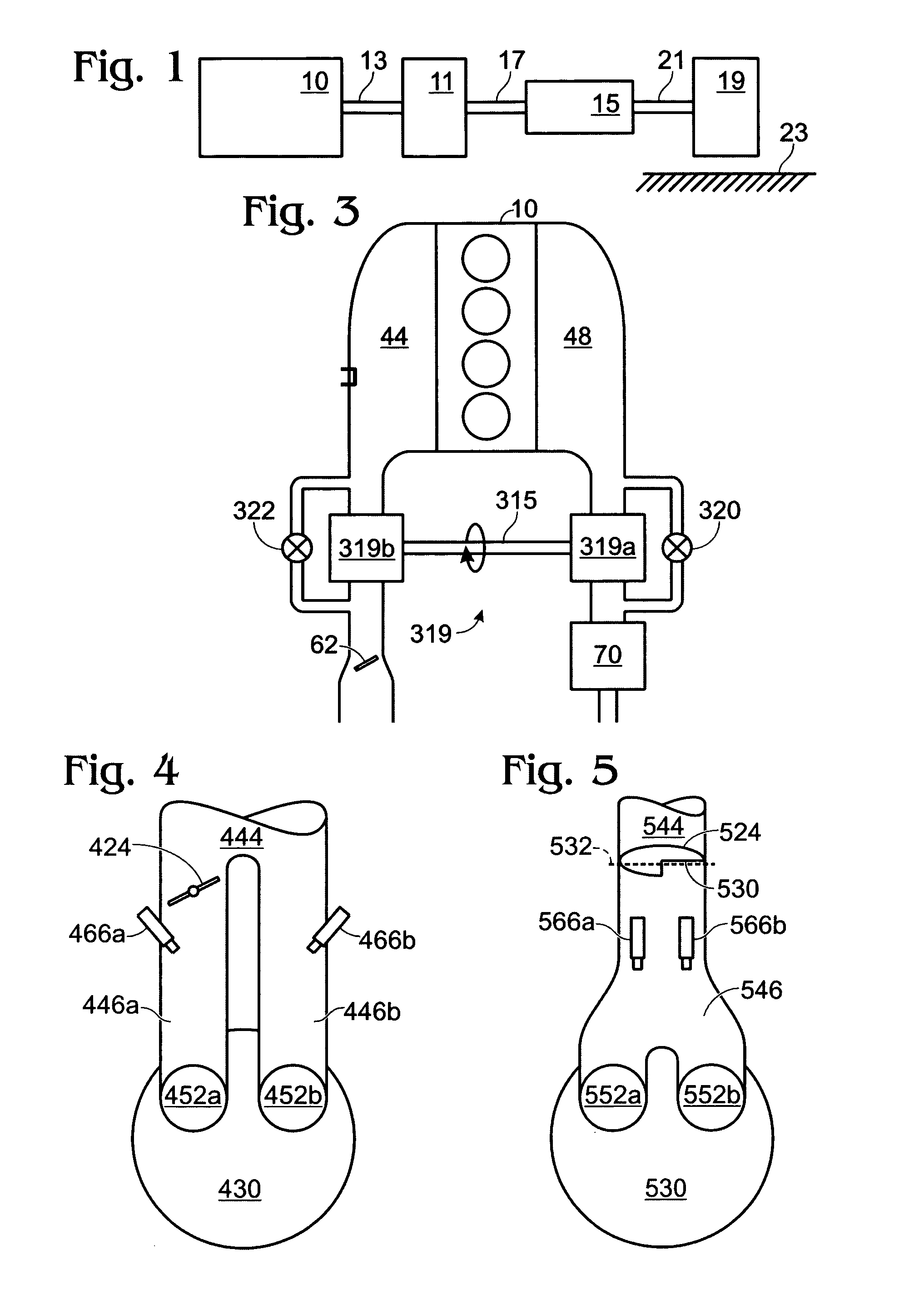

Internal combustion engine control for improved fuel efficiency

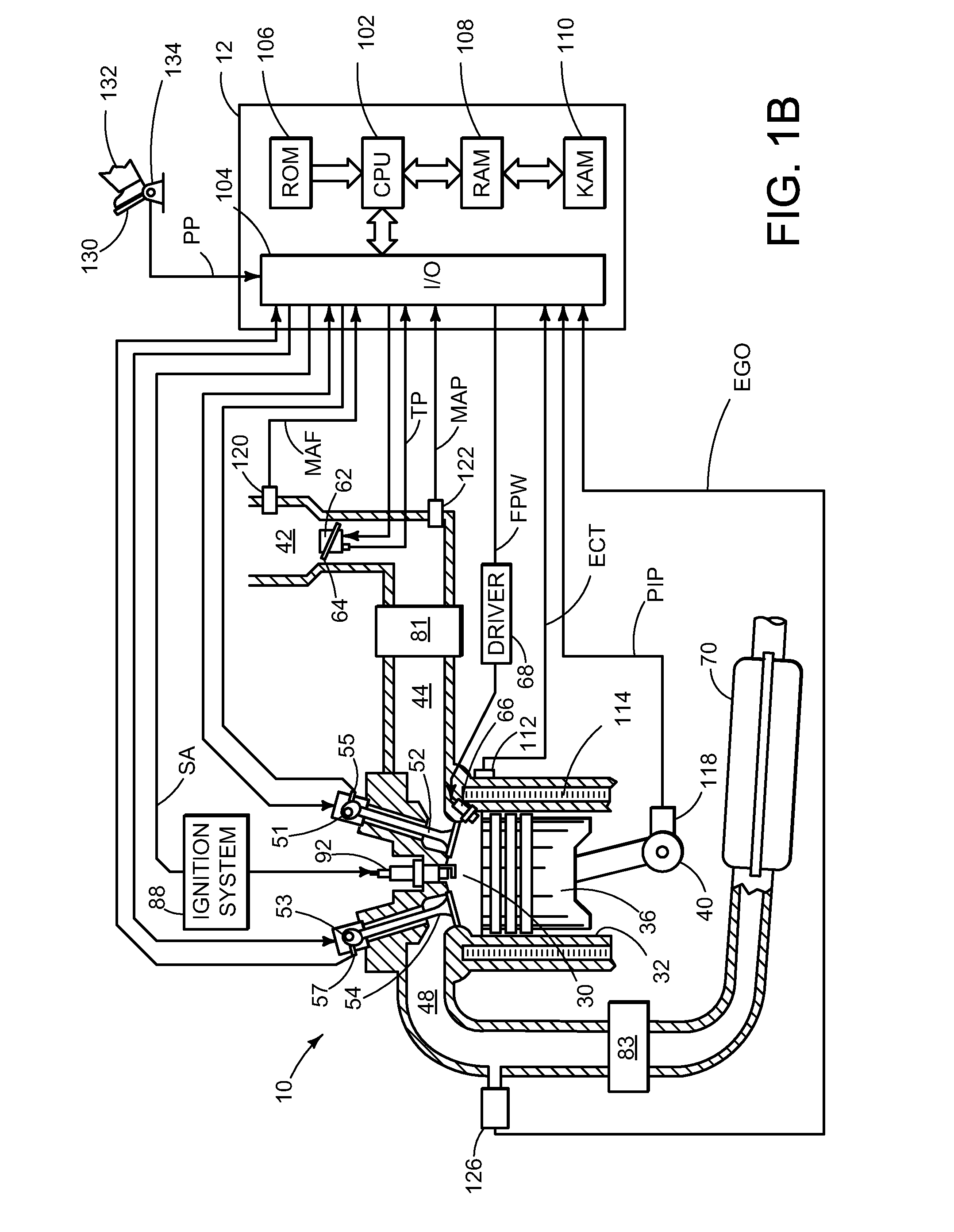

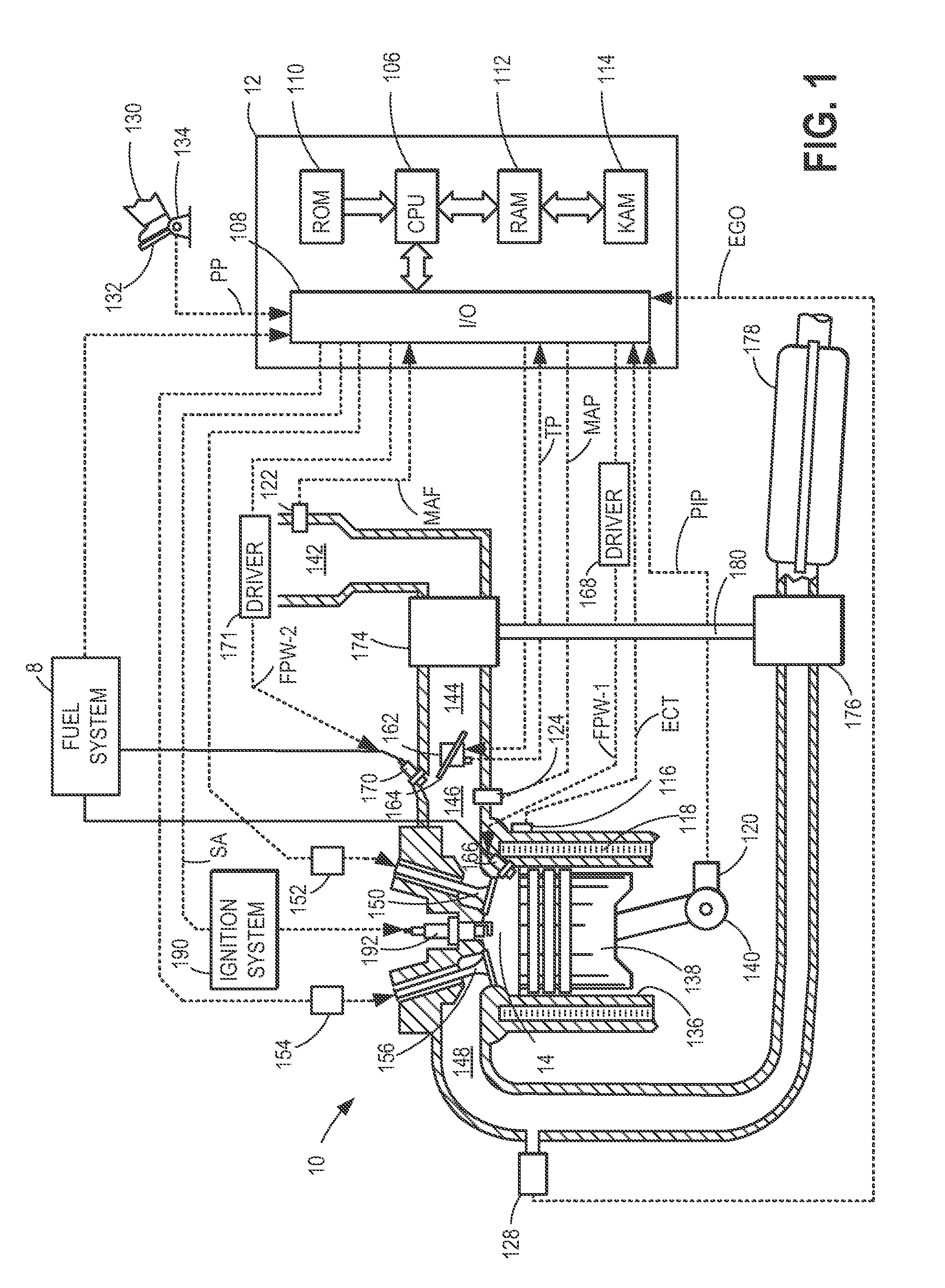

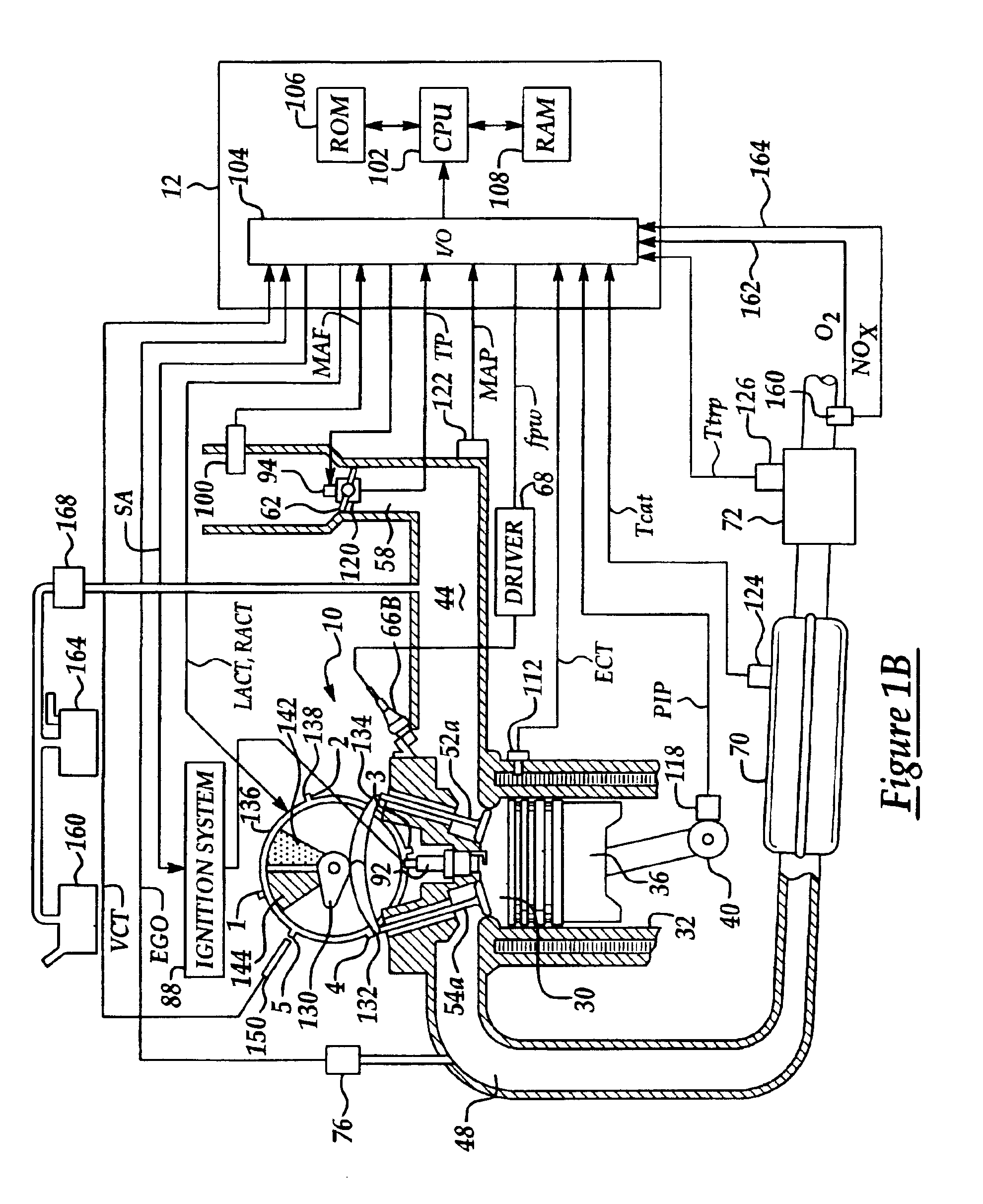

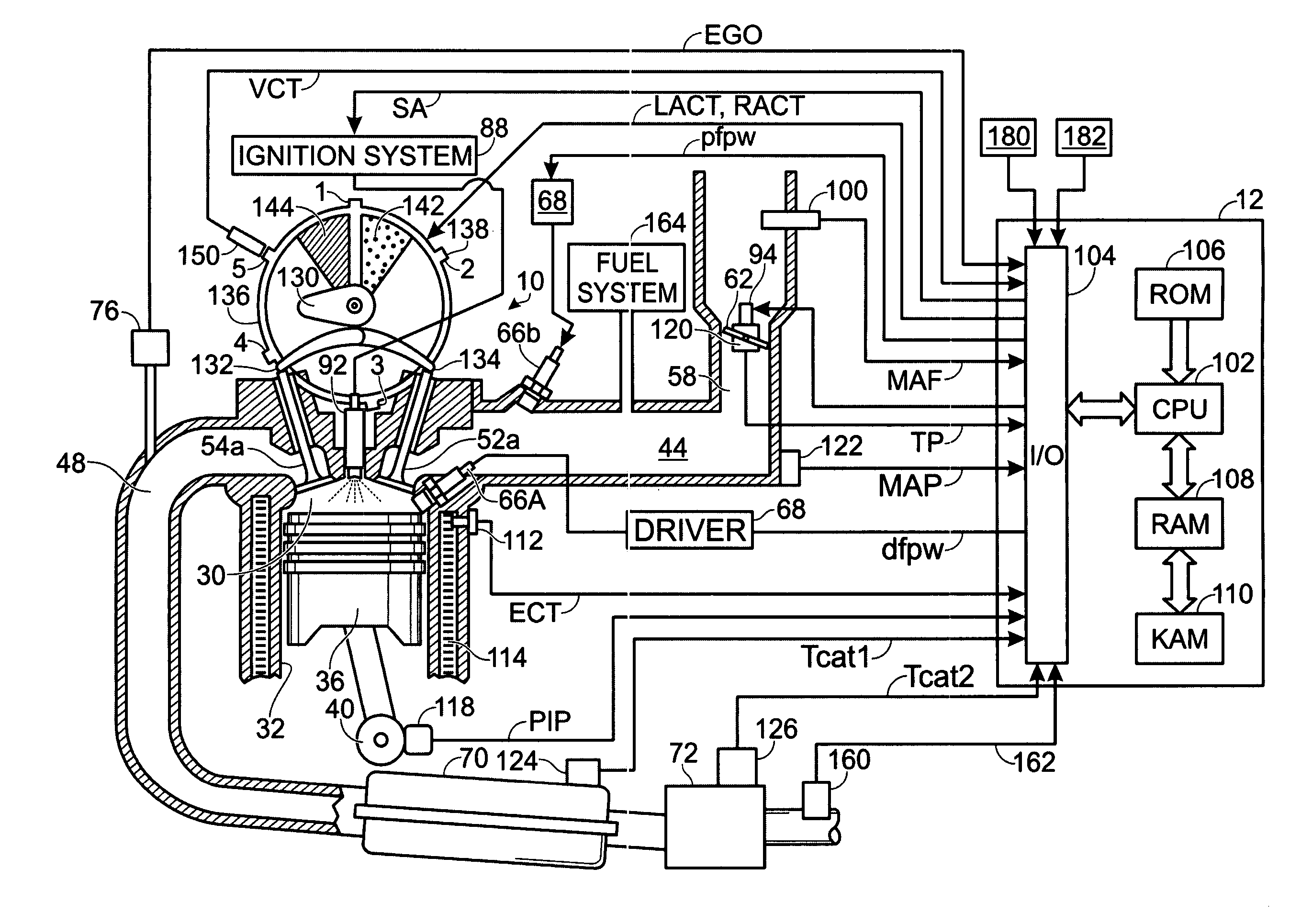

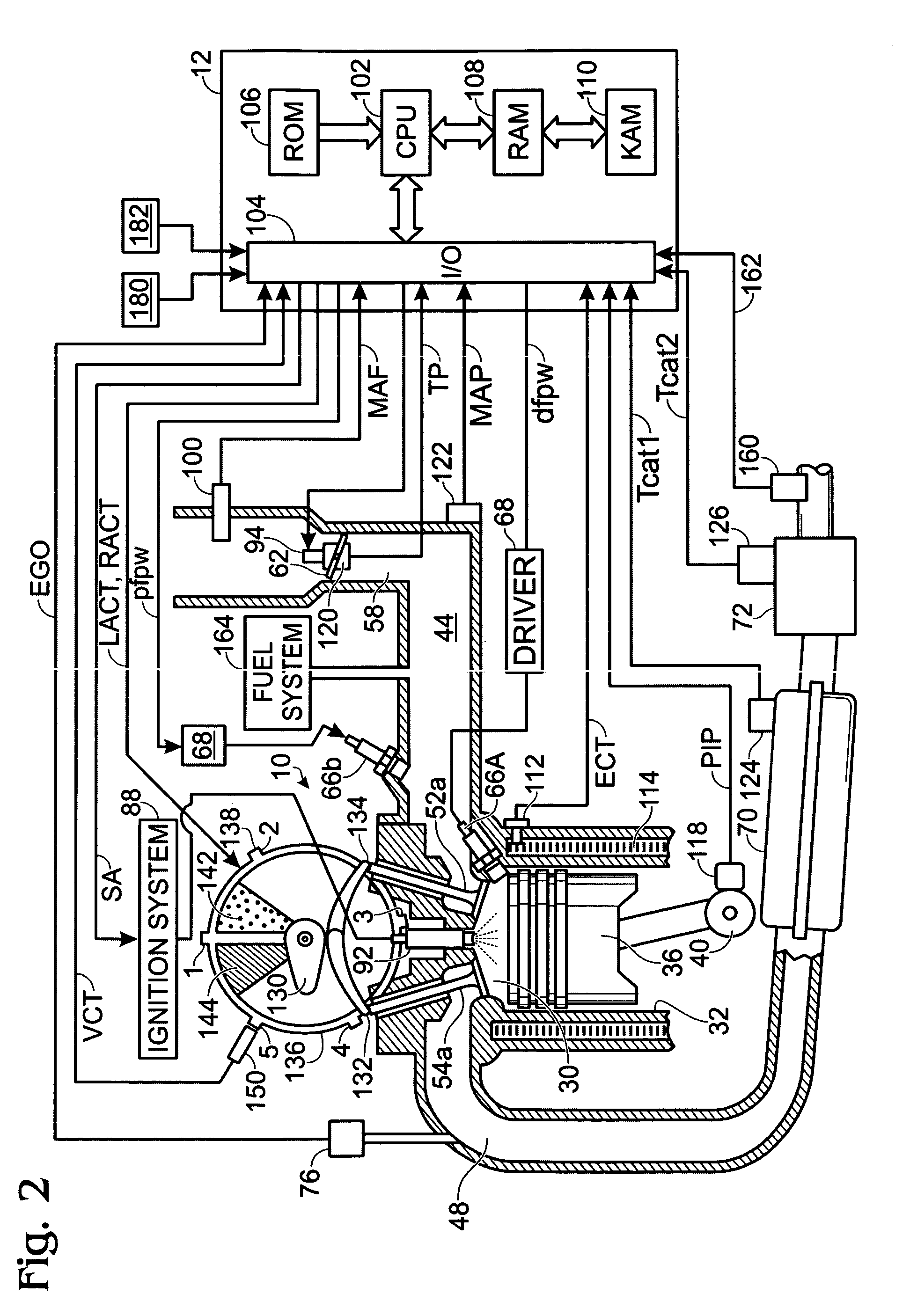

ActiveUS8131447B2Undesirable vibration reductionConvenient amountElectrical controlInternal combustion piston enginesCombustion chamberWork cycle

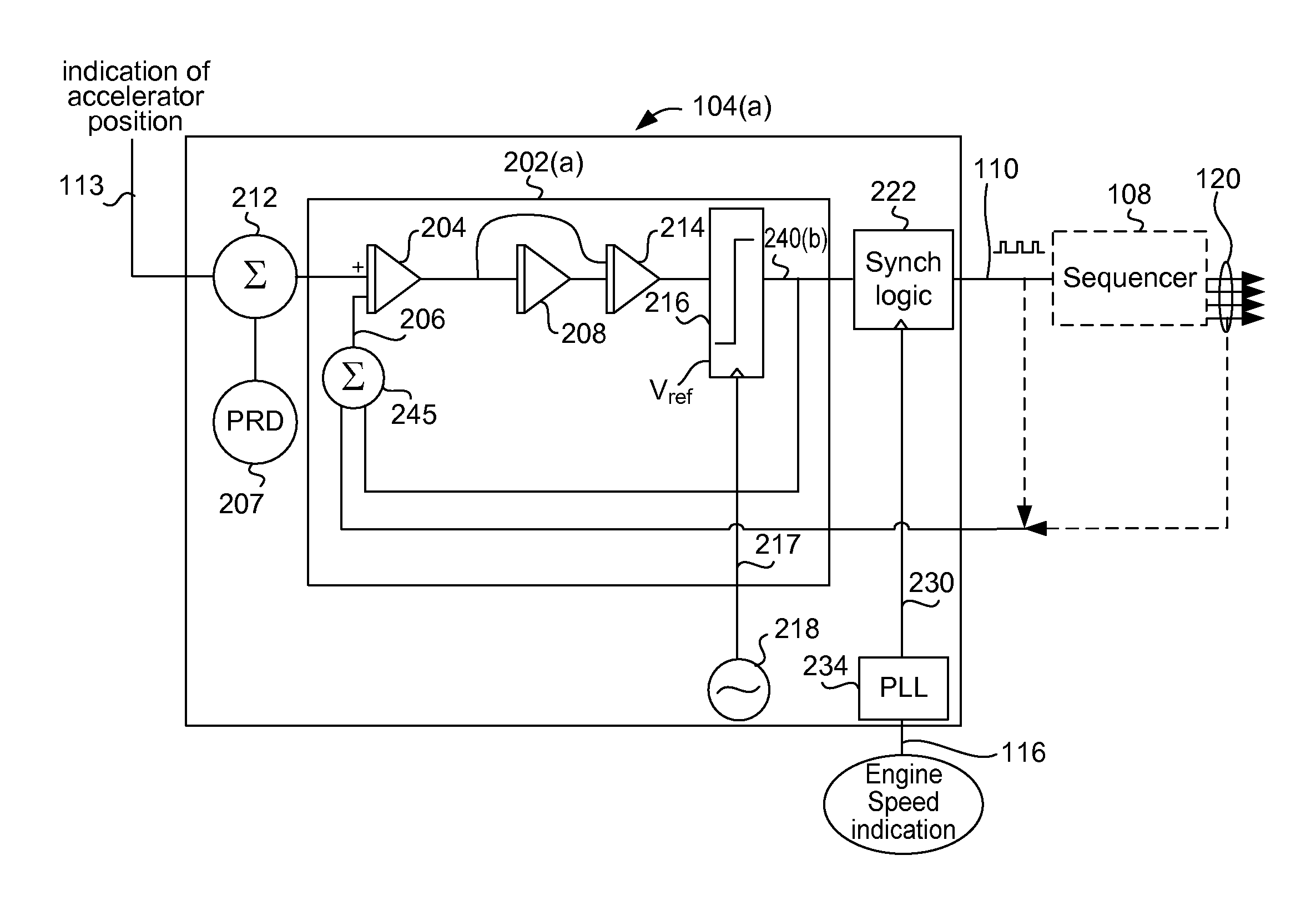

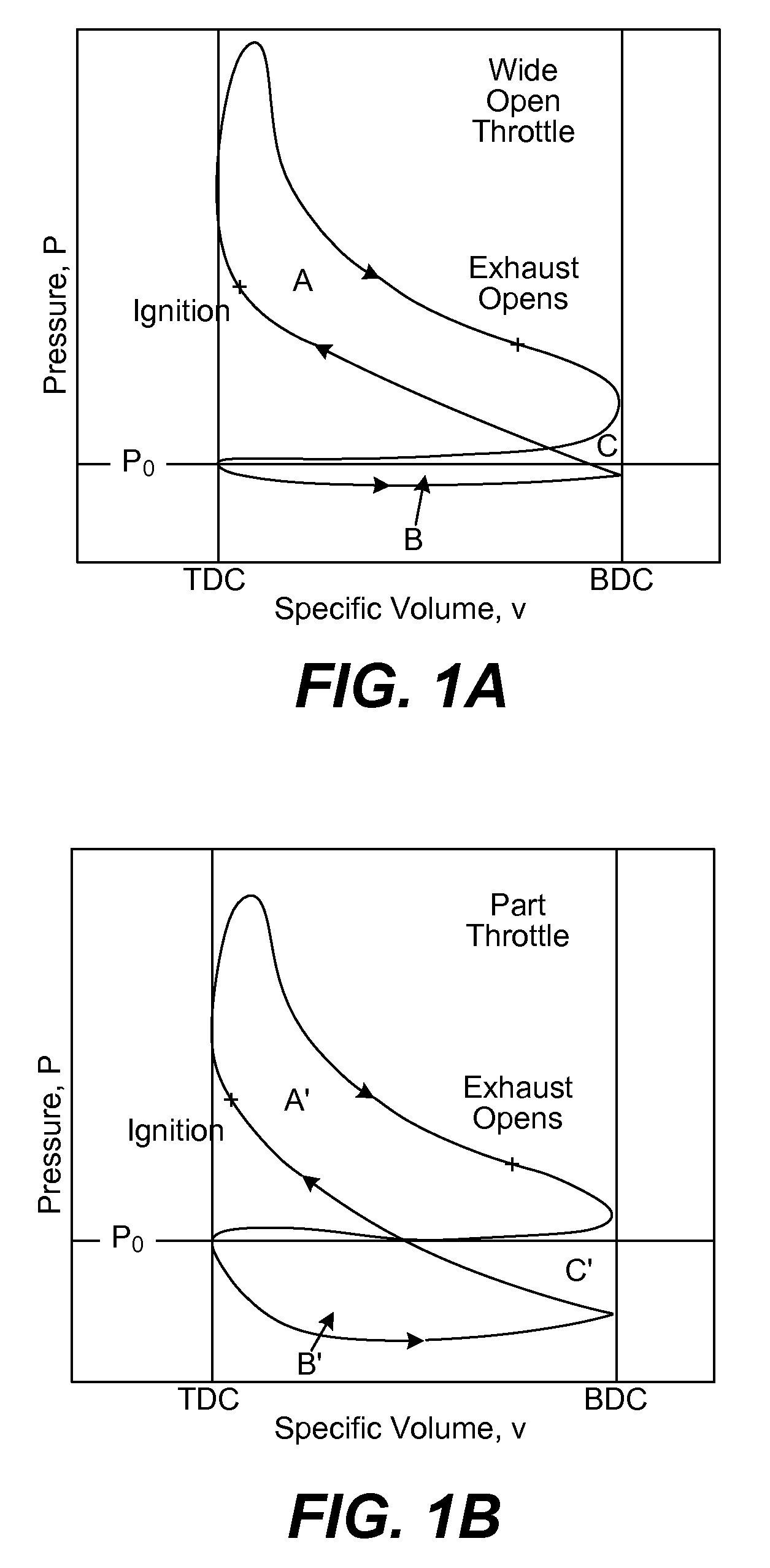

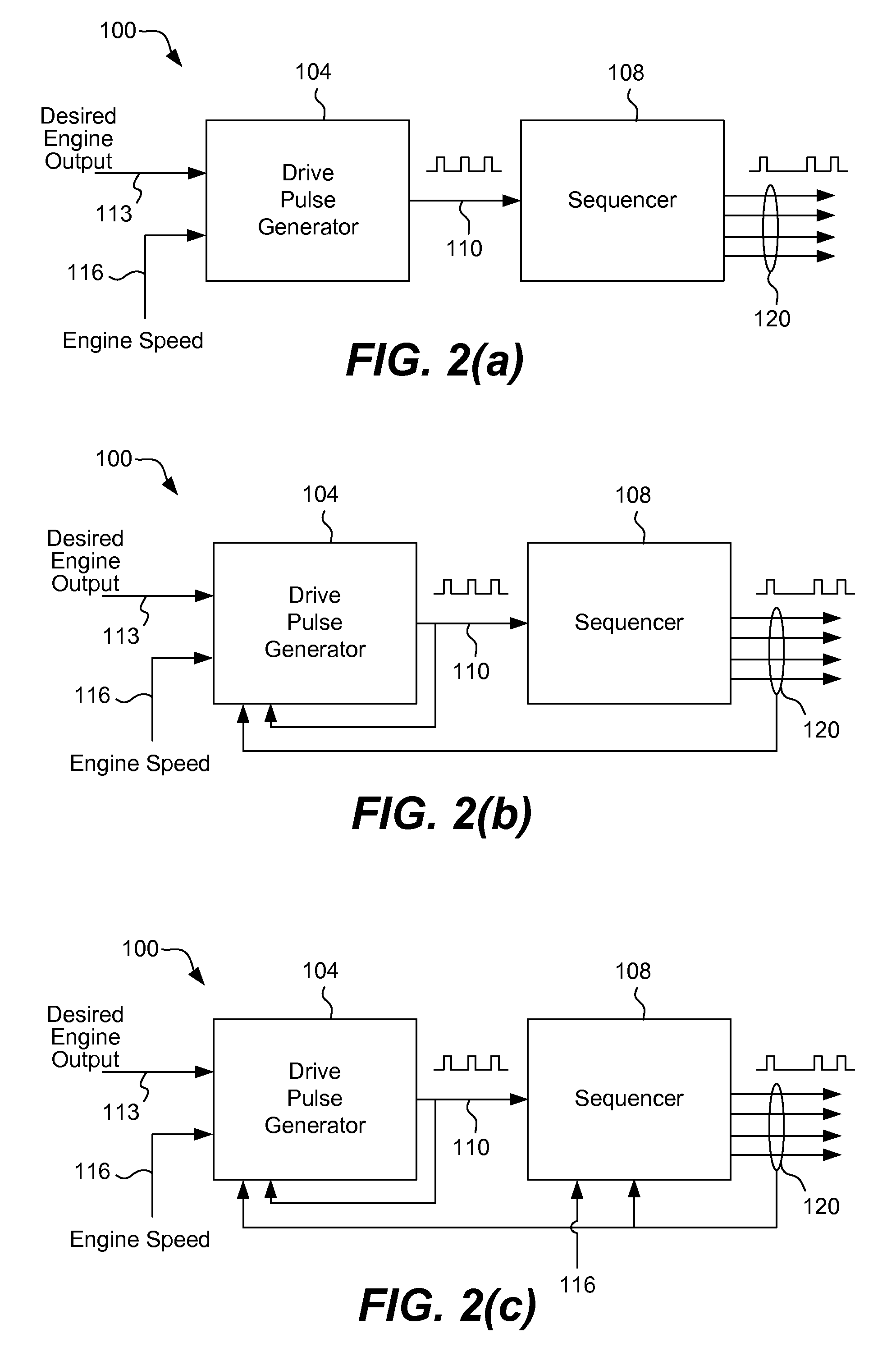

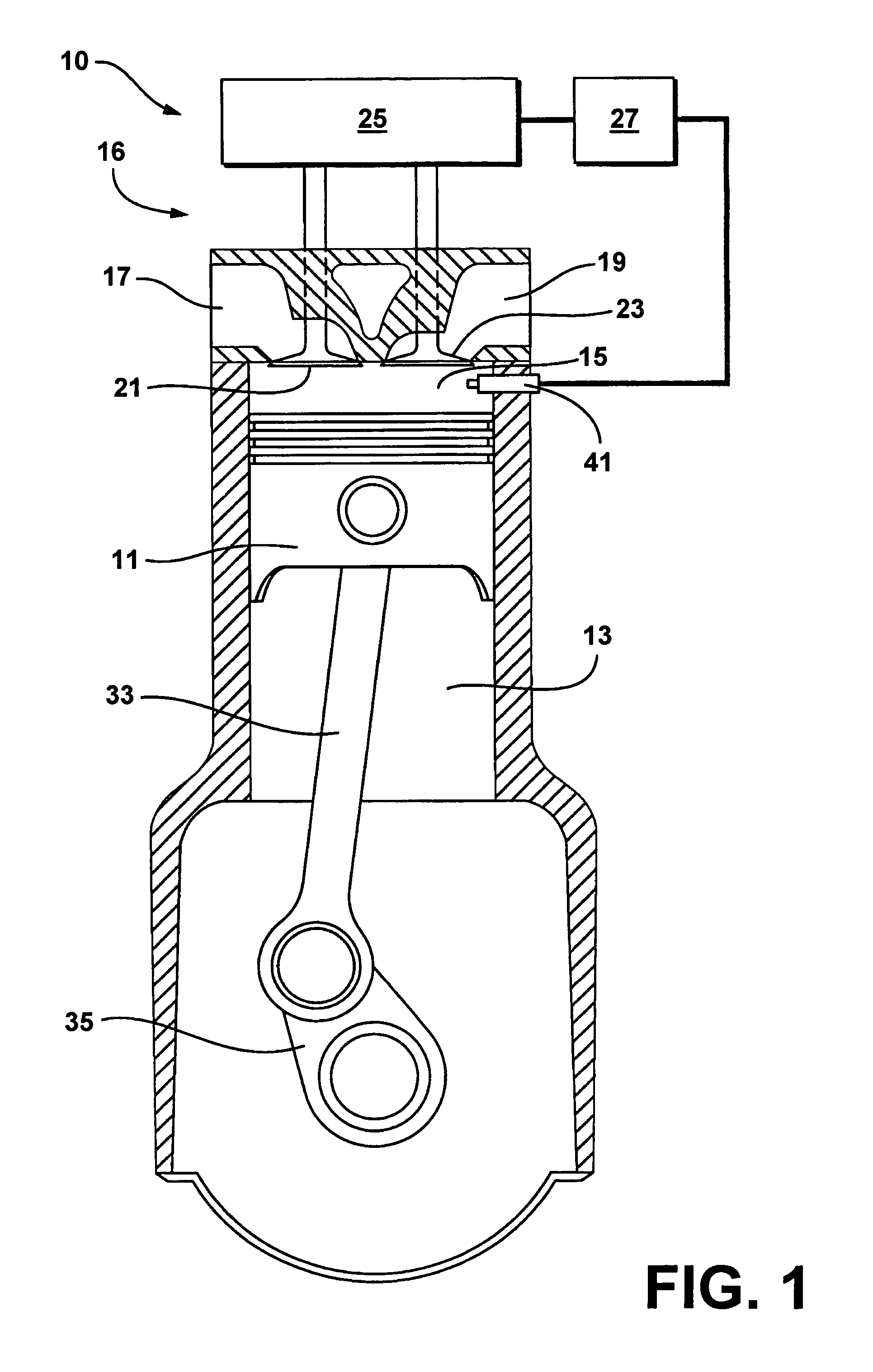

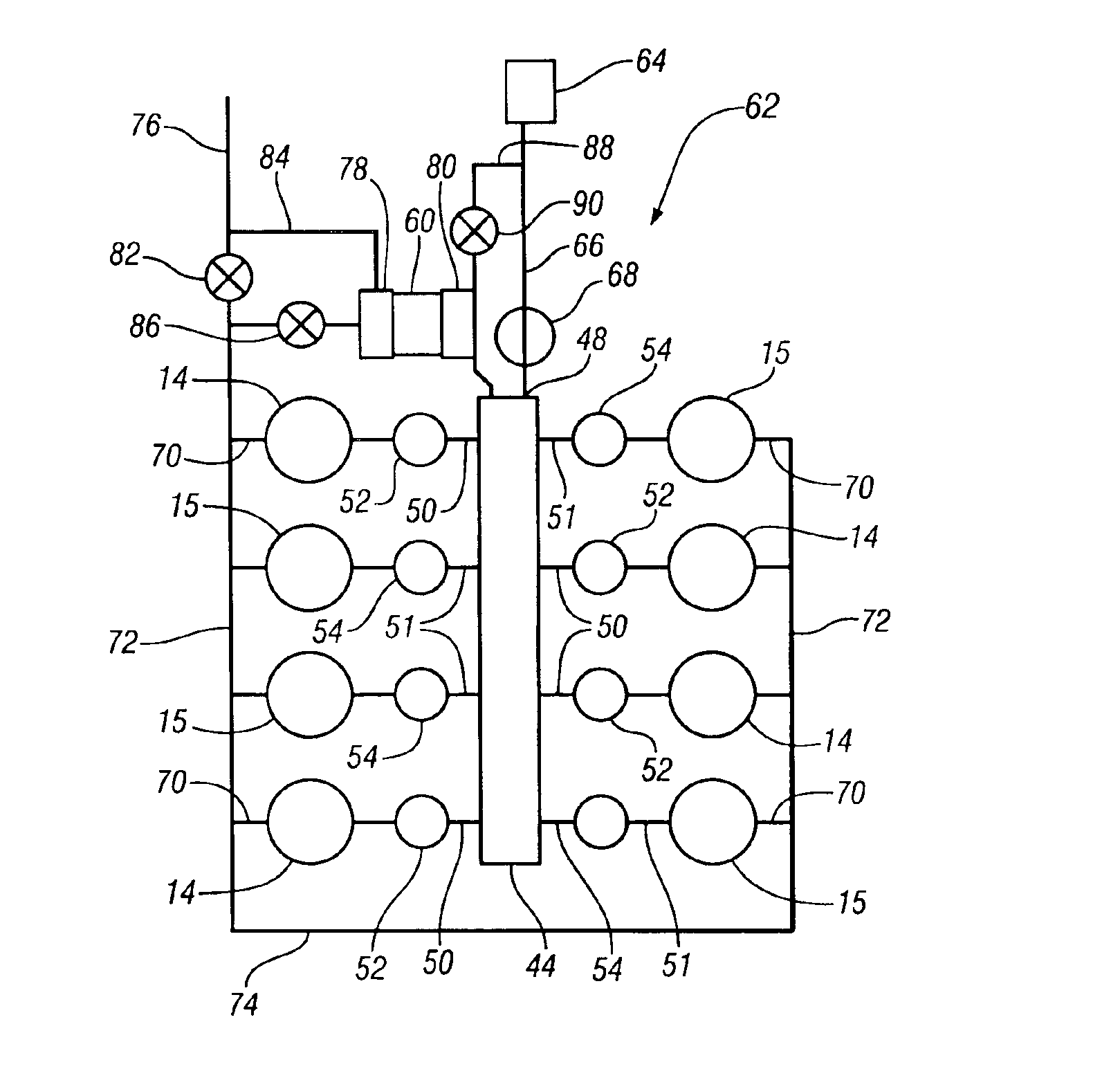

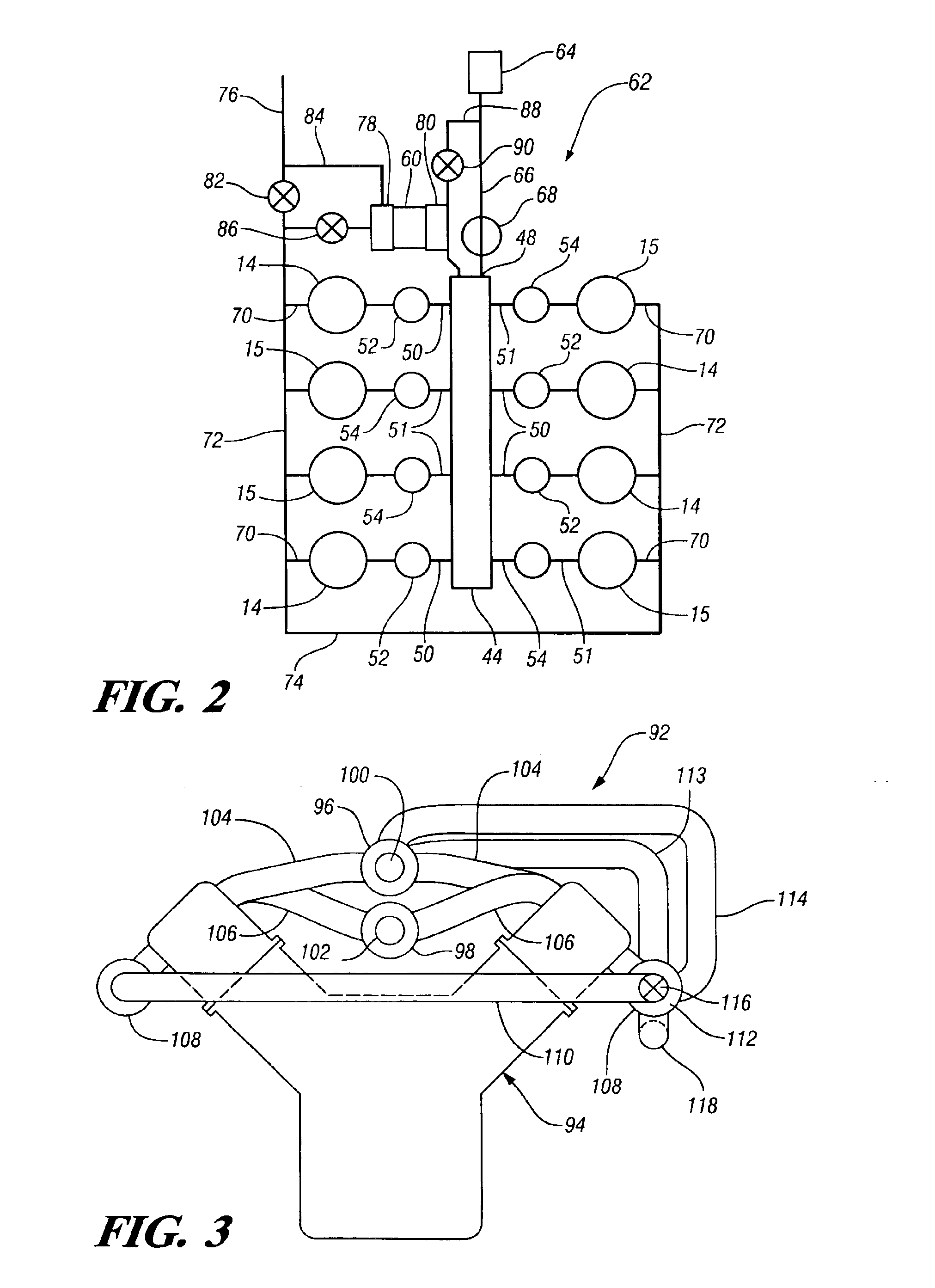

A variety of methods and arrangements for improving the fuel efficiency of internal combustion engines are described. Generally, selected combustion events are skipped during operation of the internal combustion engine so that other working cycles can operate at a better thermodynamic efficiency. In one aspect of the invention, an engine is controlled to operate in a variable displacement mode. In the variable displacement mode, fuel is not delivered to the working chambers (e.g. cylinders) during selected “skipped” working cycles. During active (“non-skipped”) working cycles, a maximum (e.g., unthrottled) amount of air and an optimized amount of fuel is delivered to the relevant working chambers so that the fired working chambers can operate at efficiencies closer to their optimal efficiency. A controller is used to dynamically determine the chamber firings required to provide the engine torque based on the engine's current operational state and conditions. The chamber firings may be sequenced in real time or in near real time in a manner that helps reduce undesirable vibrations of the engine.

Owner:TULA TECH INC

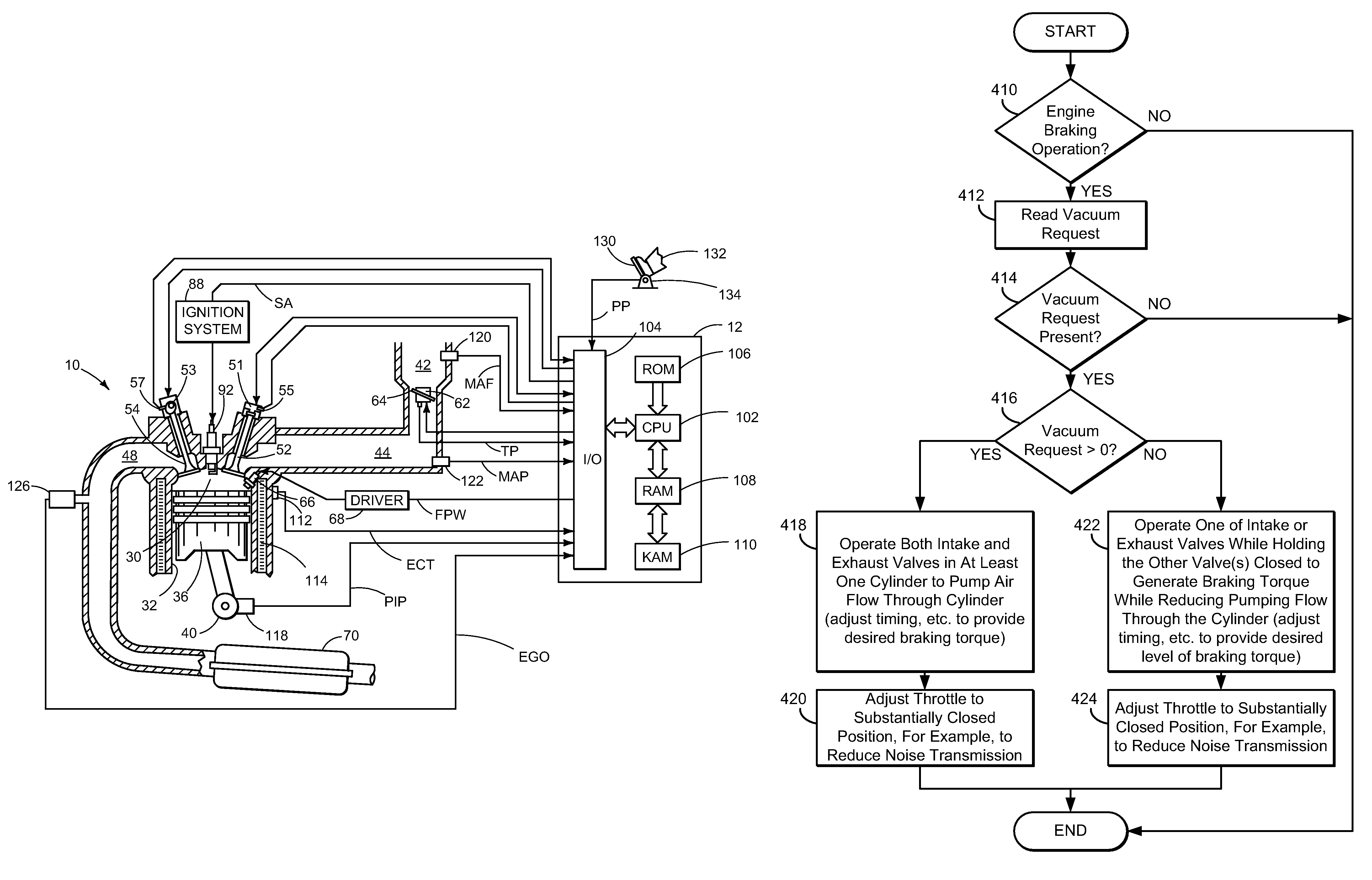

Vehicle braking control

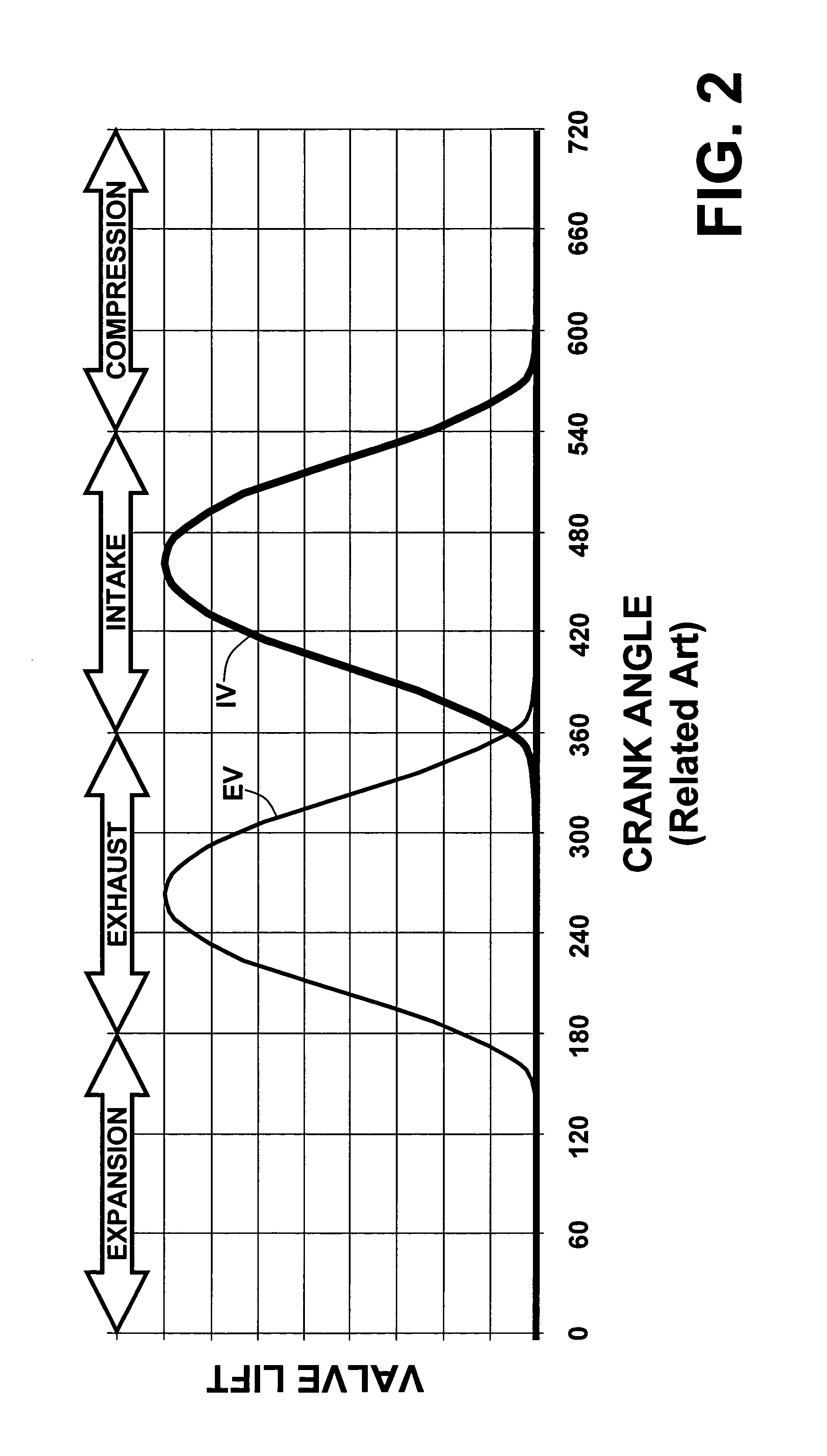

ActiveUS7930087B2Reduced effectivenessImprove fuel economyElectrical controlInternal combustion piston enginesExhaust valveInlet valve

A method of operating an engine for a vehicle having at least a first cylinder, the method comprising of operating the first cylinder to provide at least one of compression braking and expansion braking by holding one of an intake valve and an exhaust valve of the first cylinder closed while opening, closing, and opening the other of the intake valve and the exhaust valve during a cycle of the first cylinder and during a first vacuum level of an intake manifold upstream of the first cylinder; and operating the first cylinder to provide at least one of compression braking and expansion braking by operating both the intake valve and the exhaust valve of the first cylinder during a cycle of the first cylinder to allow at least some air to flow through the first cylinder during a second vacuum level of the intake manifold.

Owner:FORD GLOBAL TECH LLC

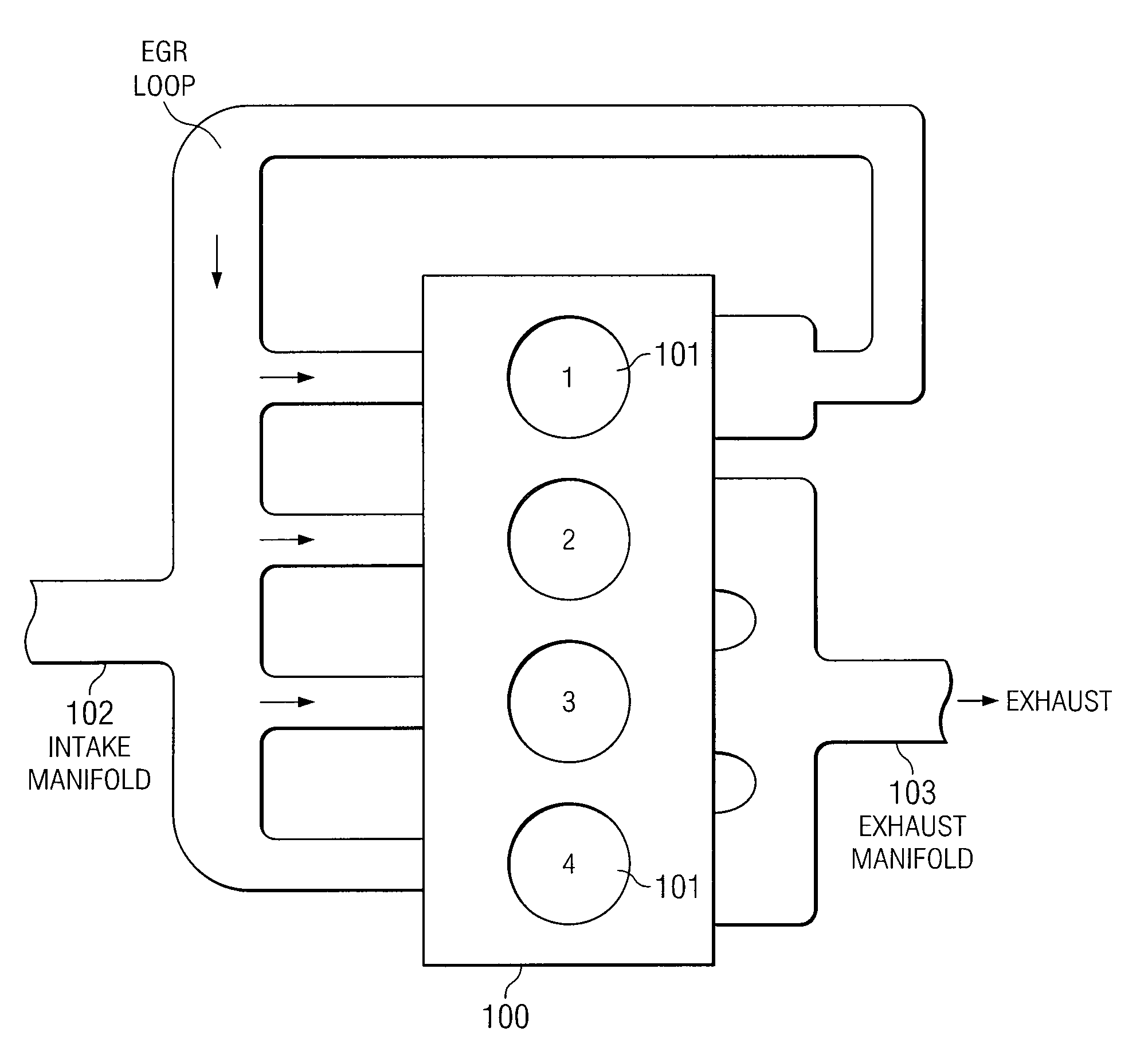

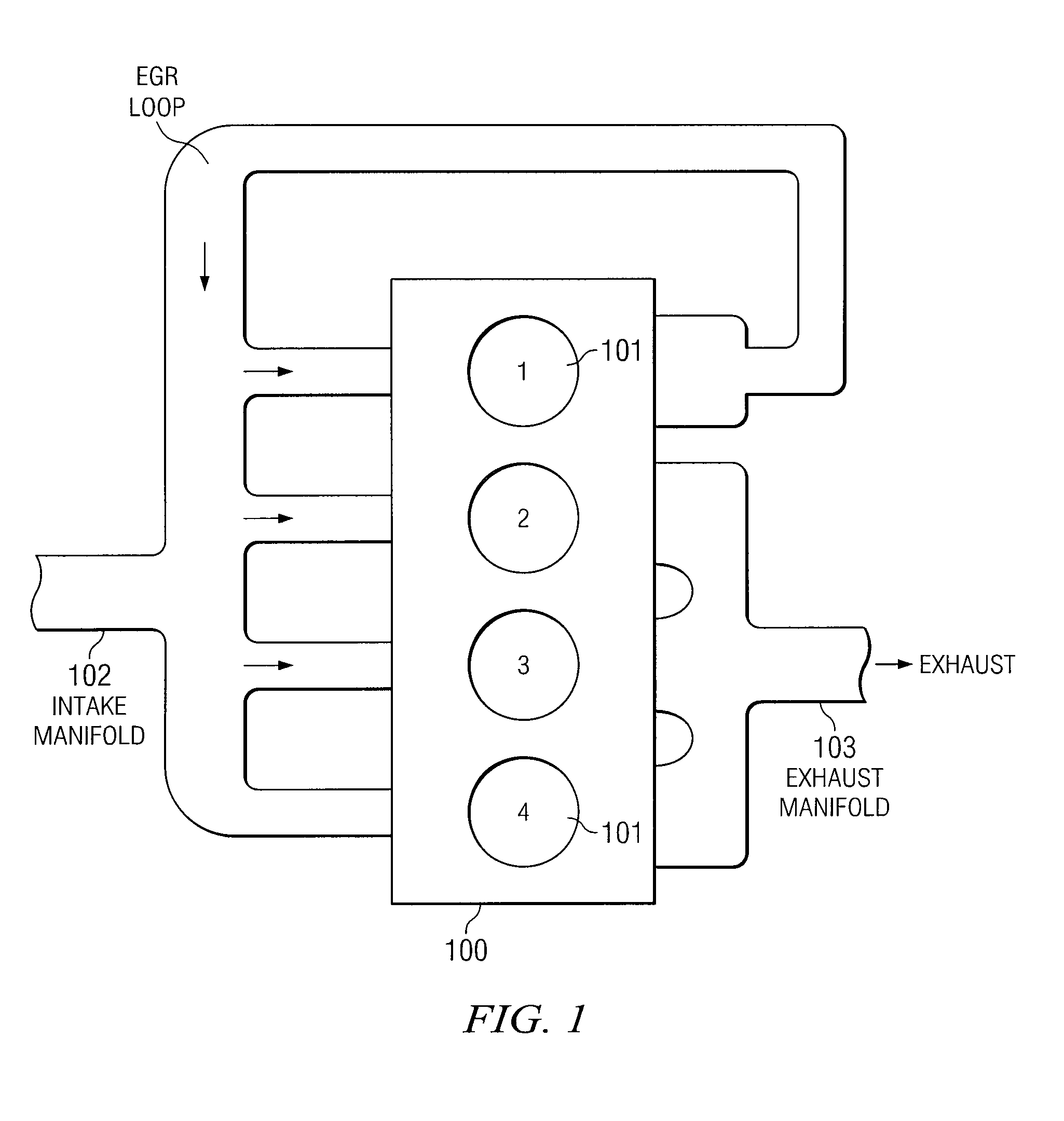

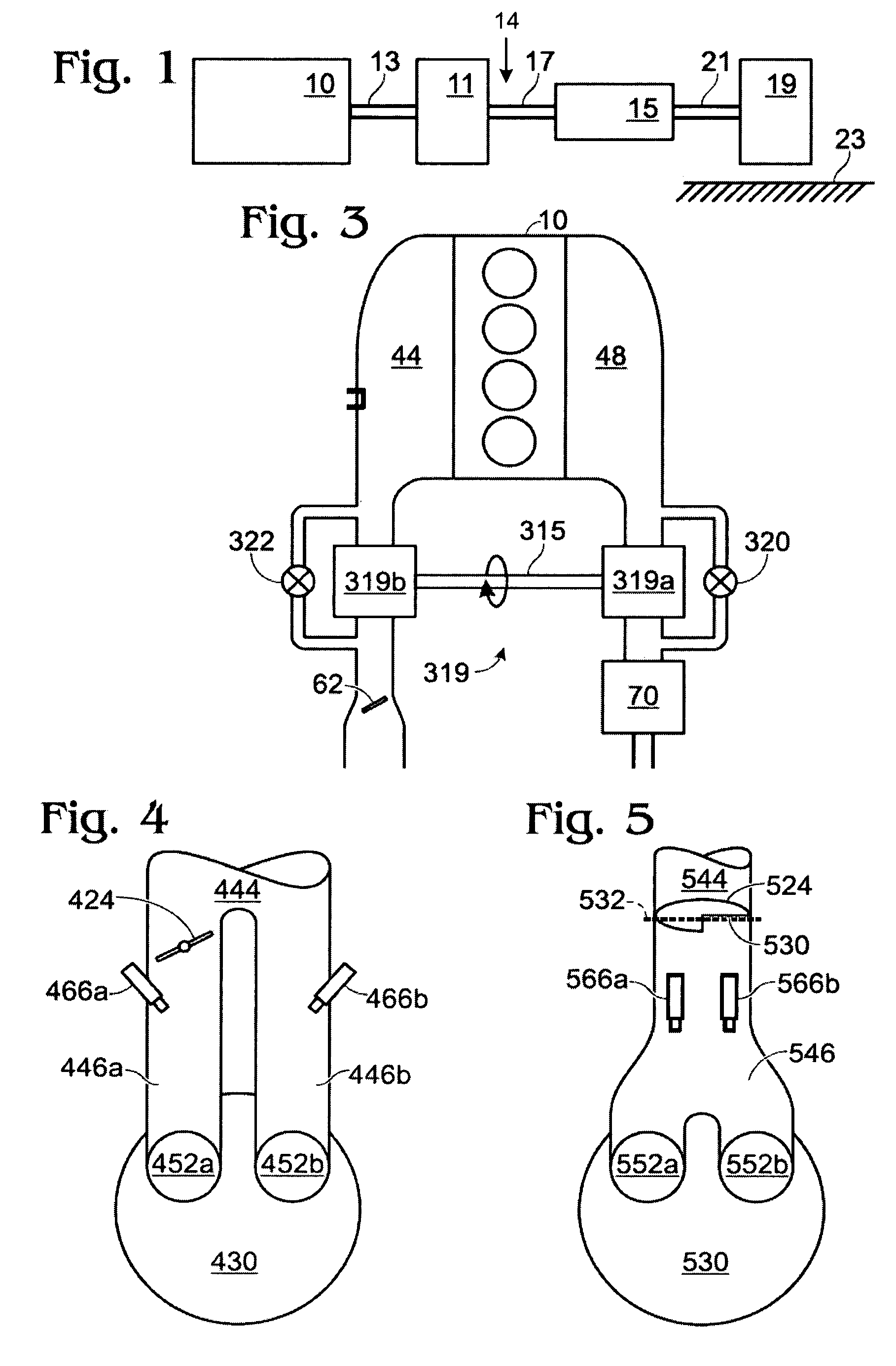

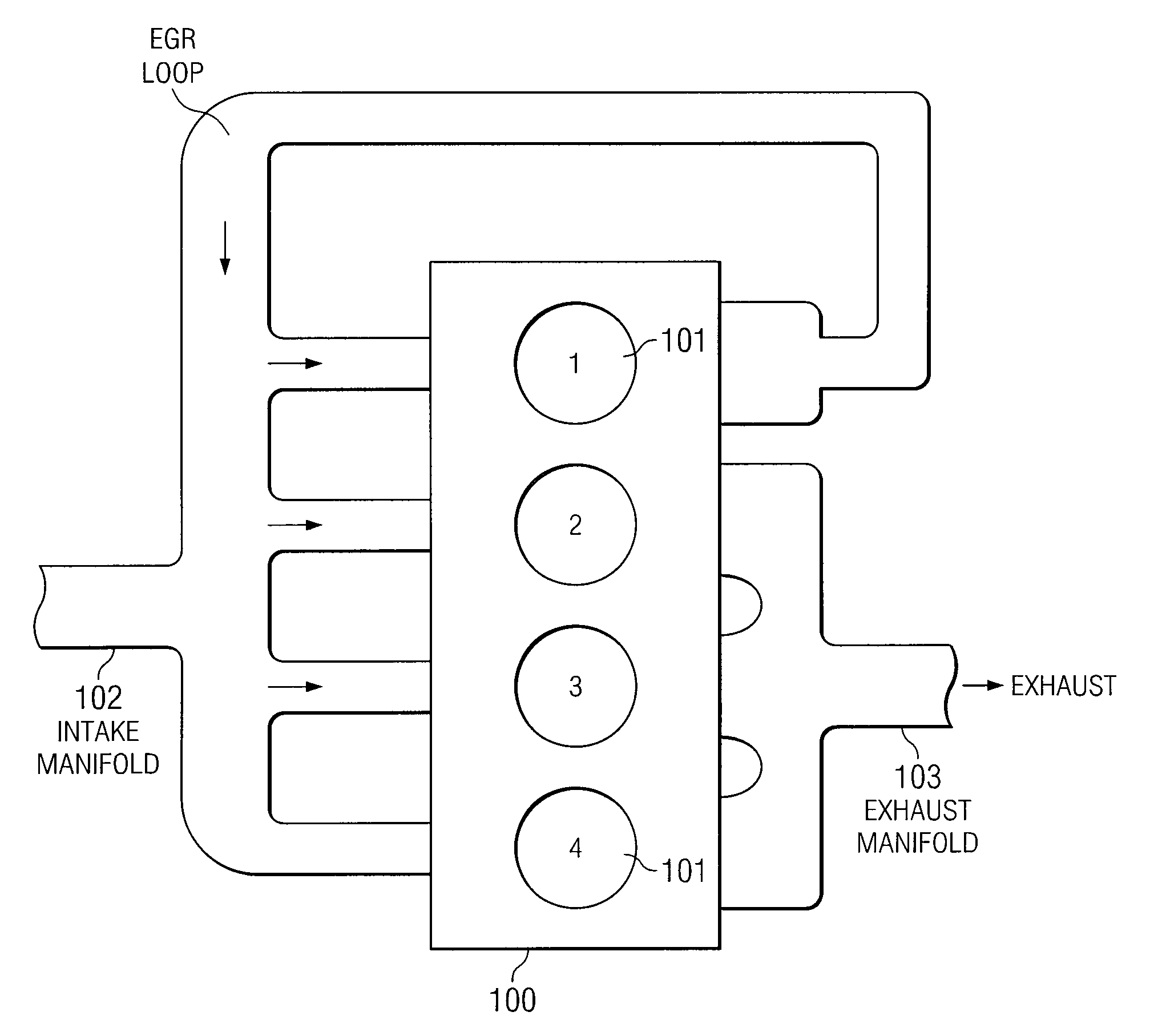

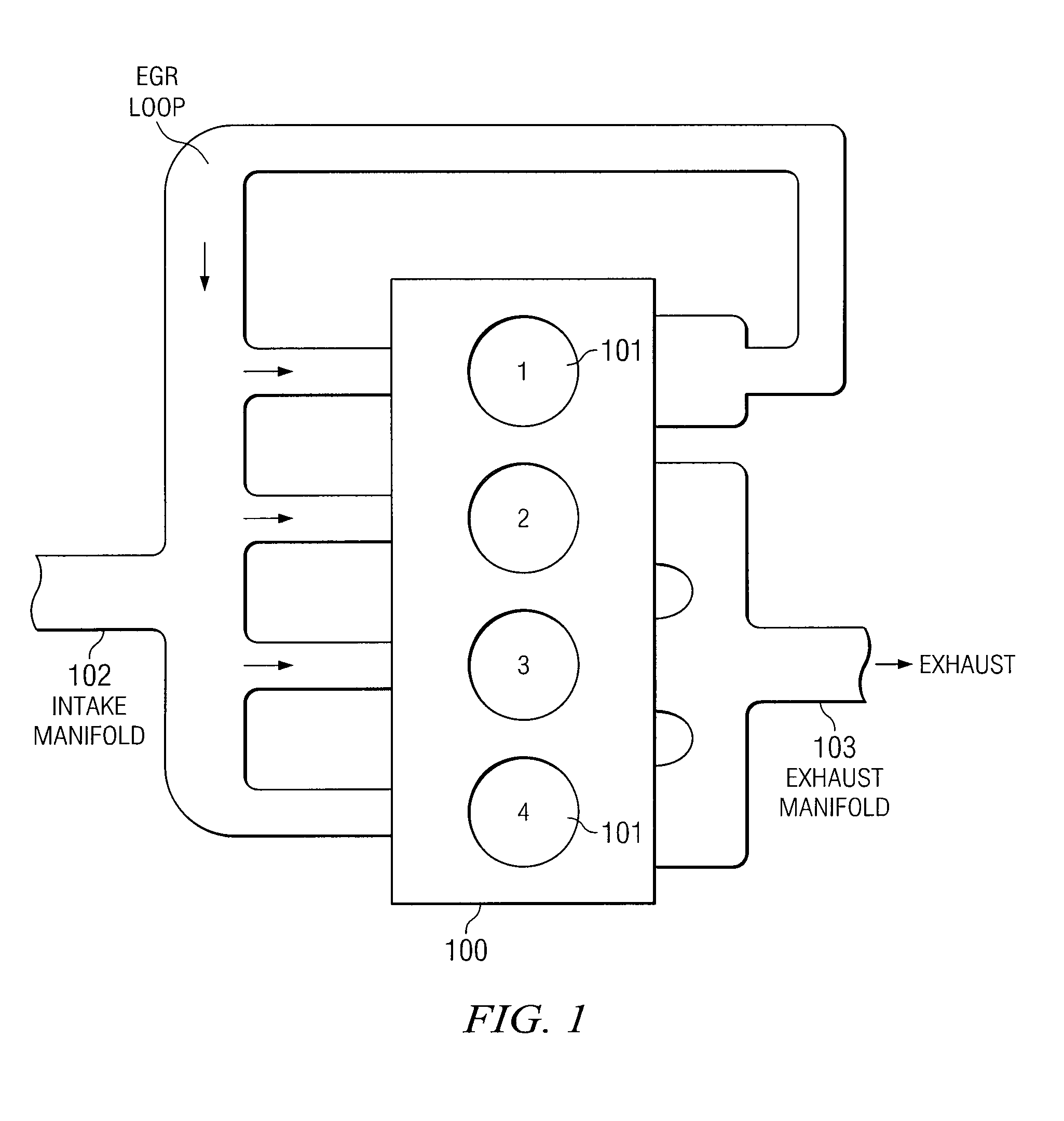

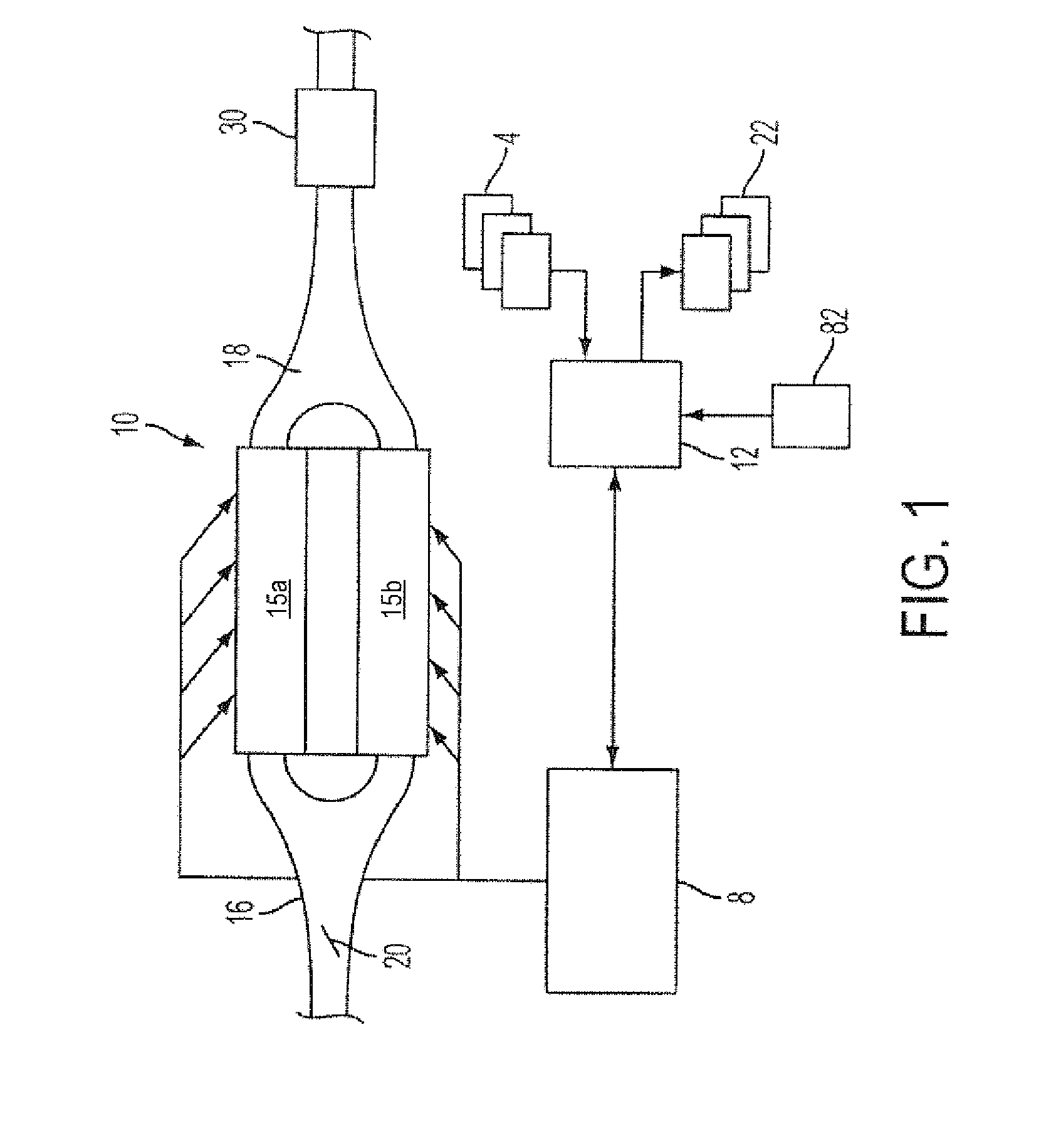

Egr system with dedicated egr cylinders

Improved exhaust gas recirculation system and methods that use one or more of the engine's cylinders as dedicated EGR cylinders. All of the exhaust from the dedicated EGR cylinders is recirculated back to the engine intake. Thus, the EGR rate is constant, but the EGR mass flow may be controlled by adjusting the air-fuel ratio of the dedicated EGR cylinders or by using various variable valve timing techniques.

Owner:SOUTHWEST RES INST

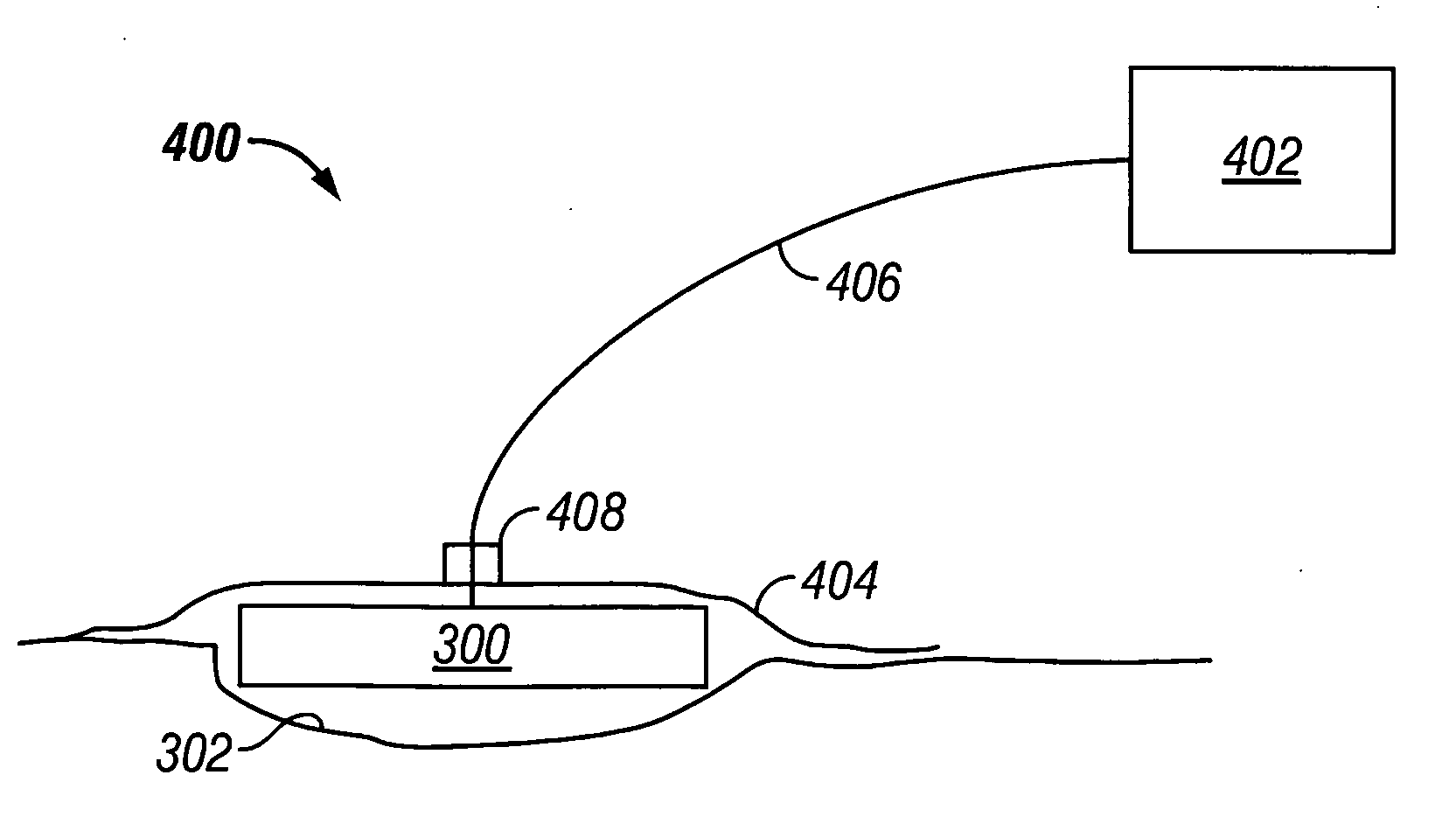

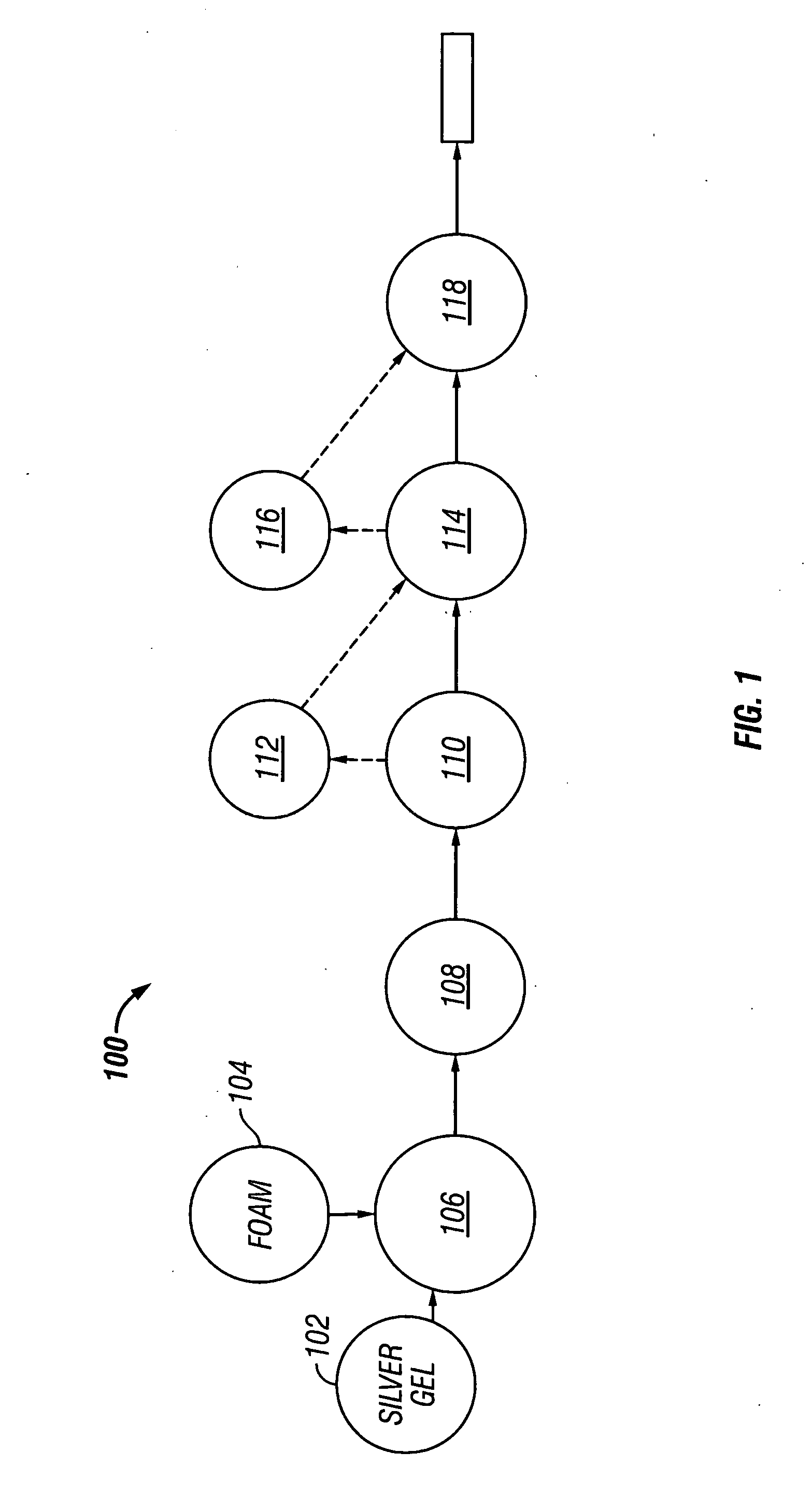

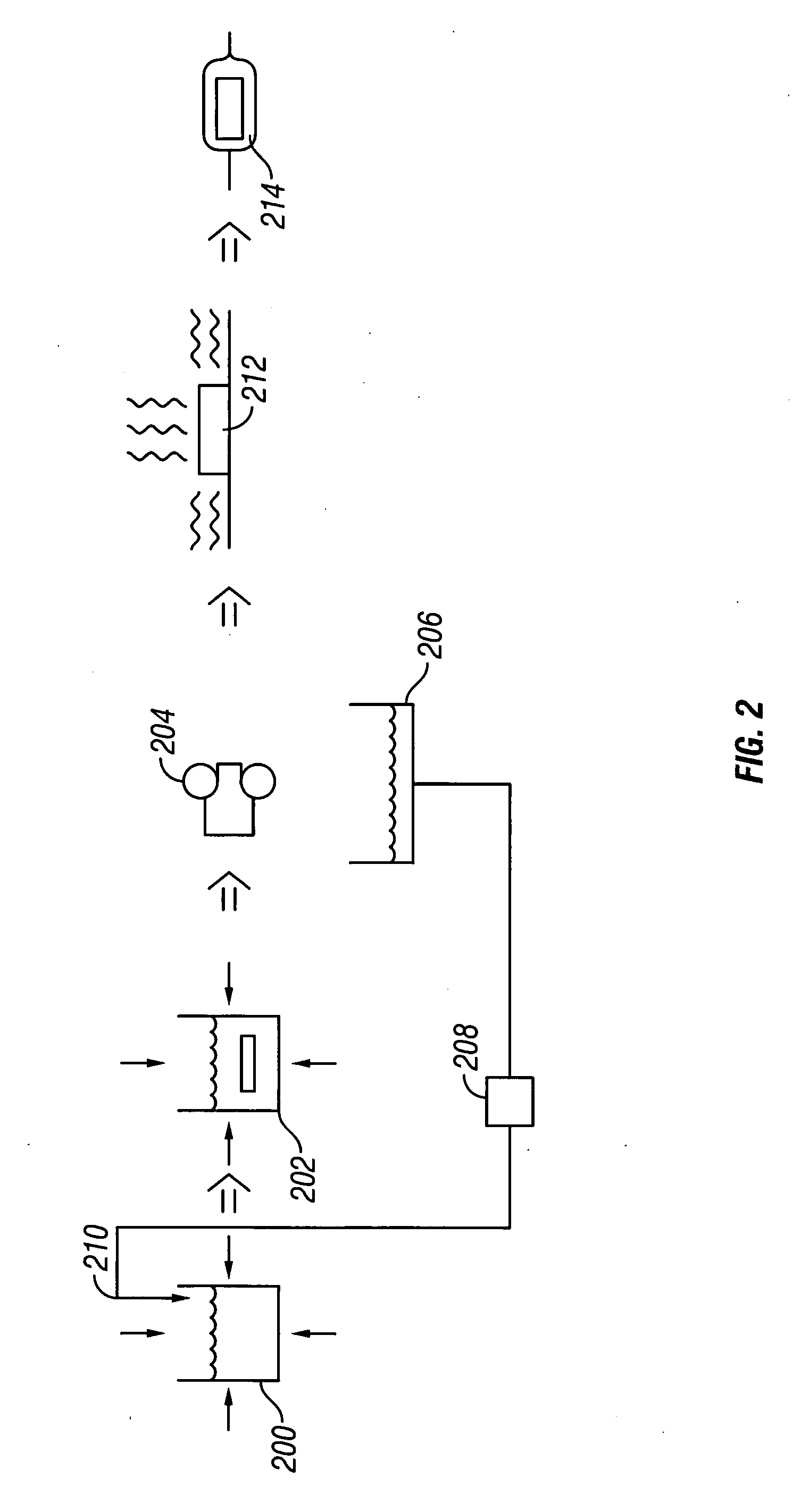

Method for coating substrate with antimicrobial agent and product formed thereby

A method for uniformly coating a foam or dressing with antimicrobial polymer incorporating agents, such as silver, and a foam or dressing formed by this process. Such foam or dressing is particularly useful in combination with negative pressure wound therapy.

Owner:KCI LICENSING INC

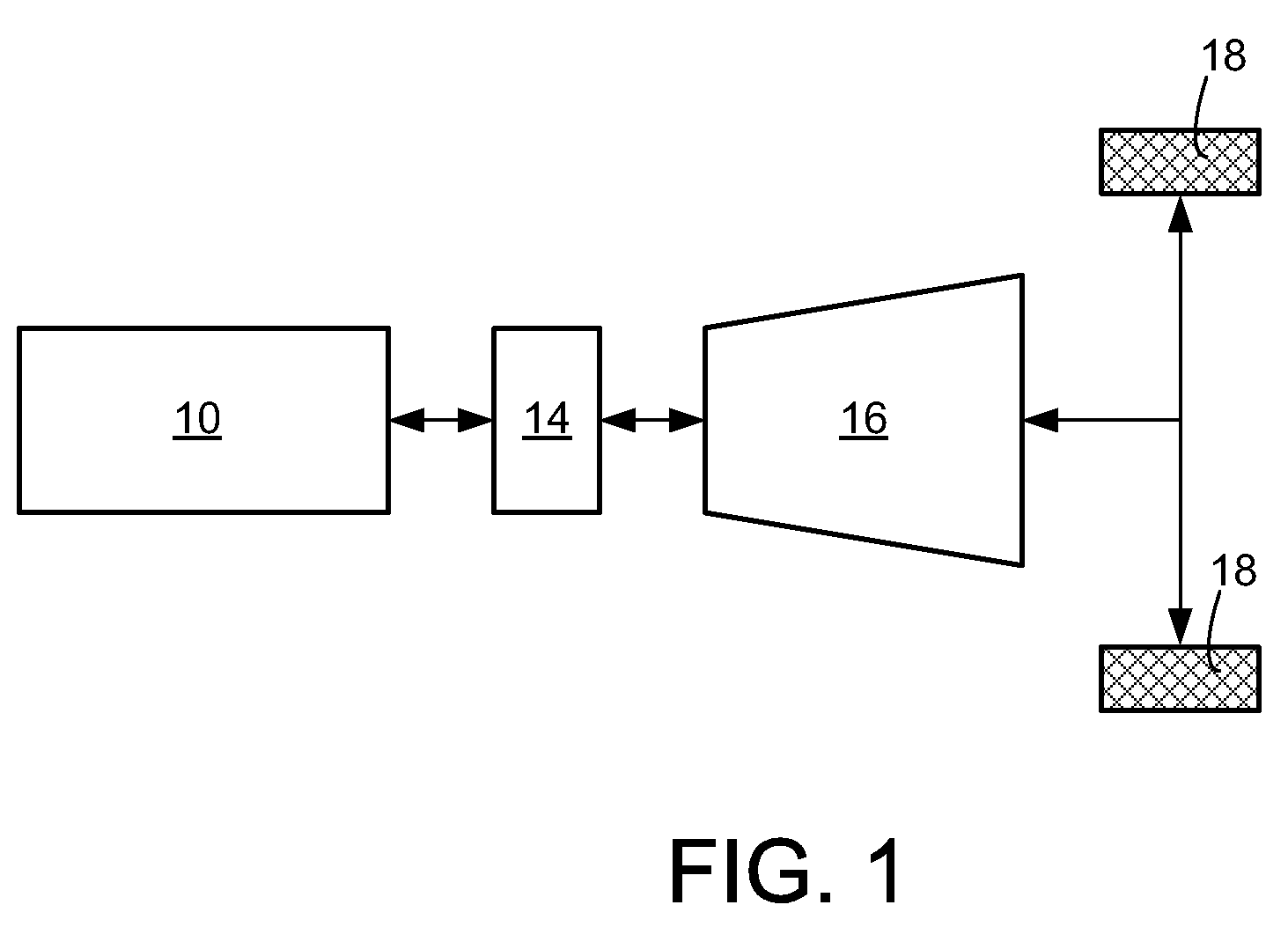

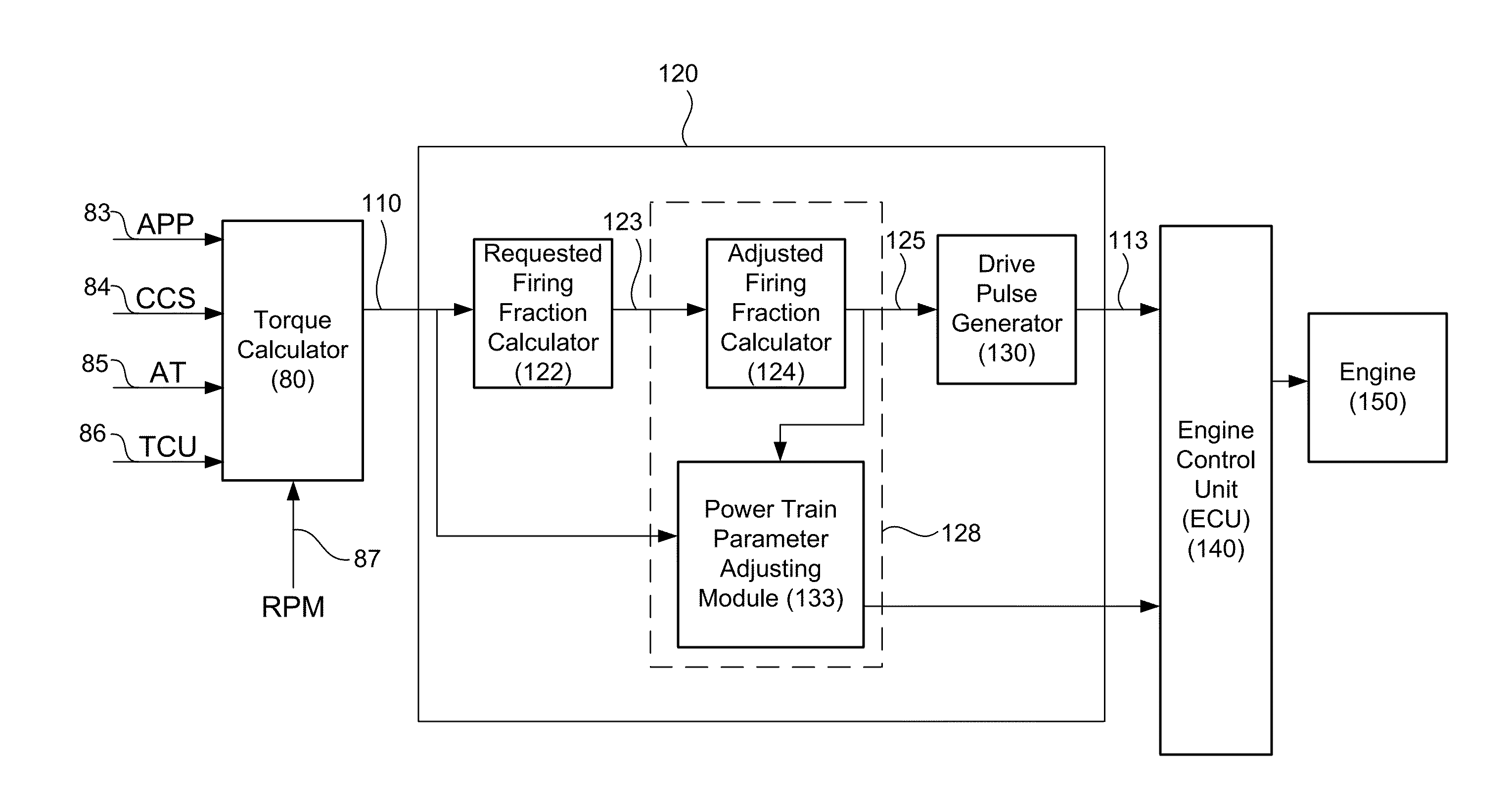

Firing fraction management in skip fire engine control

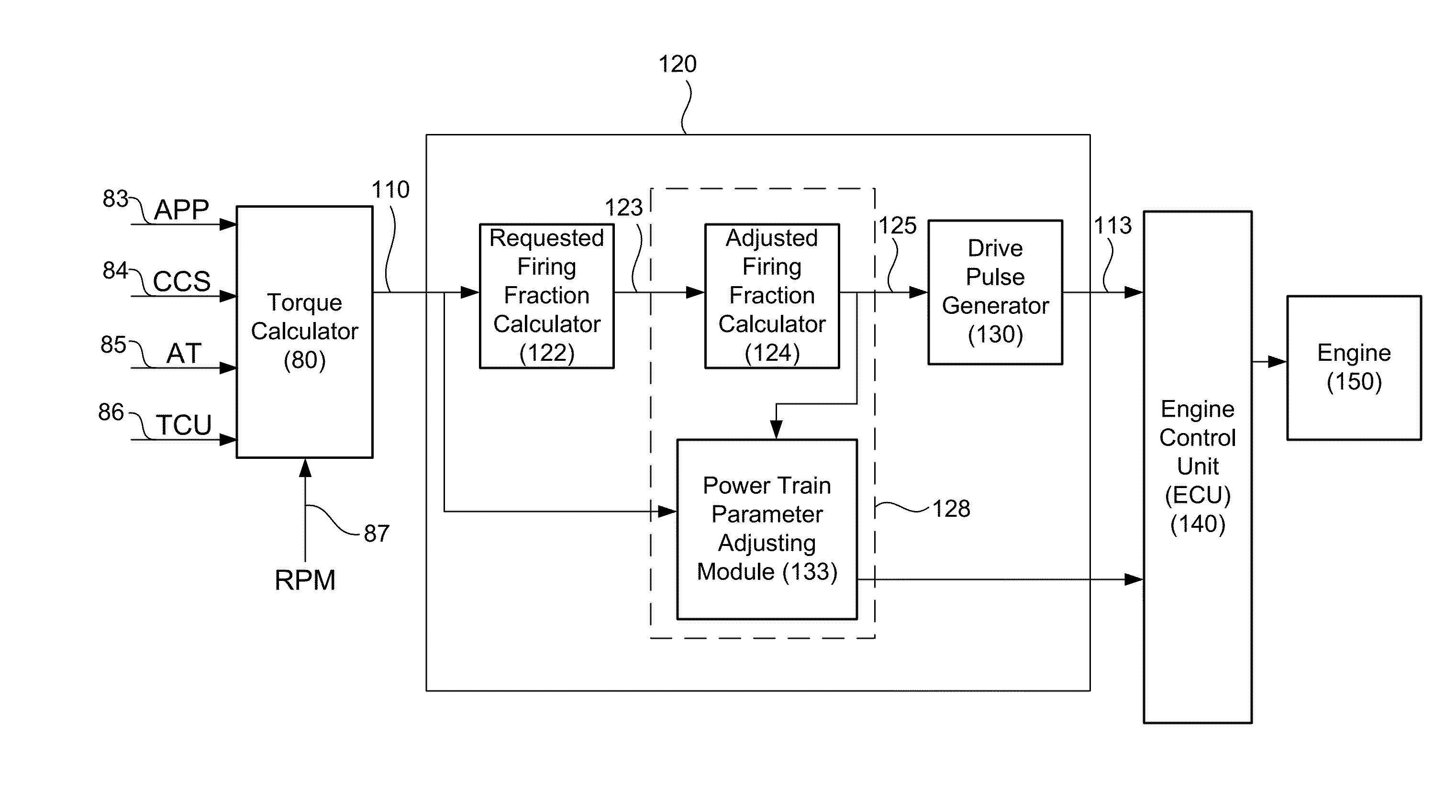

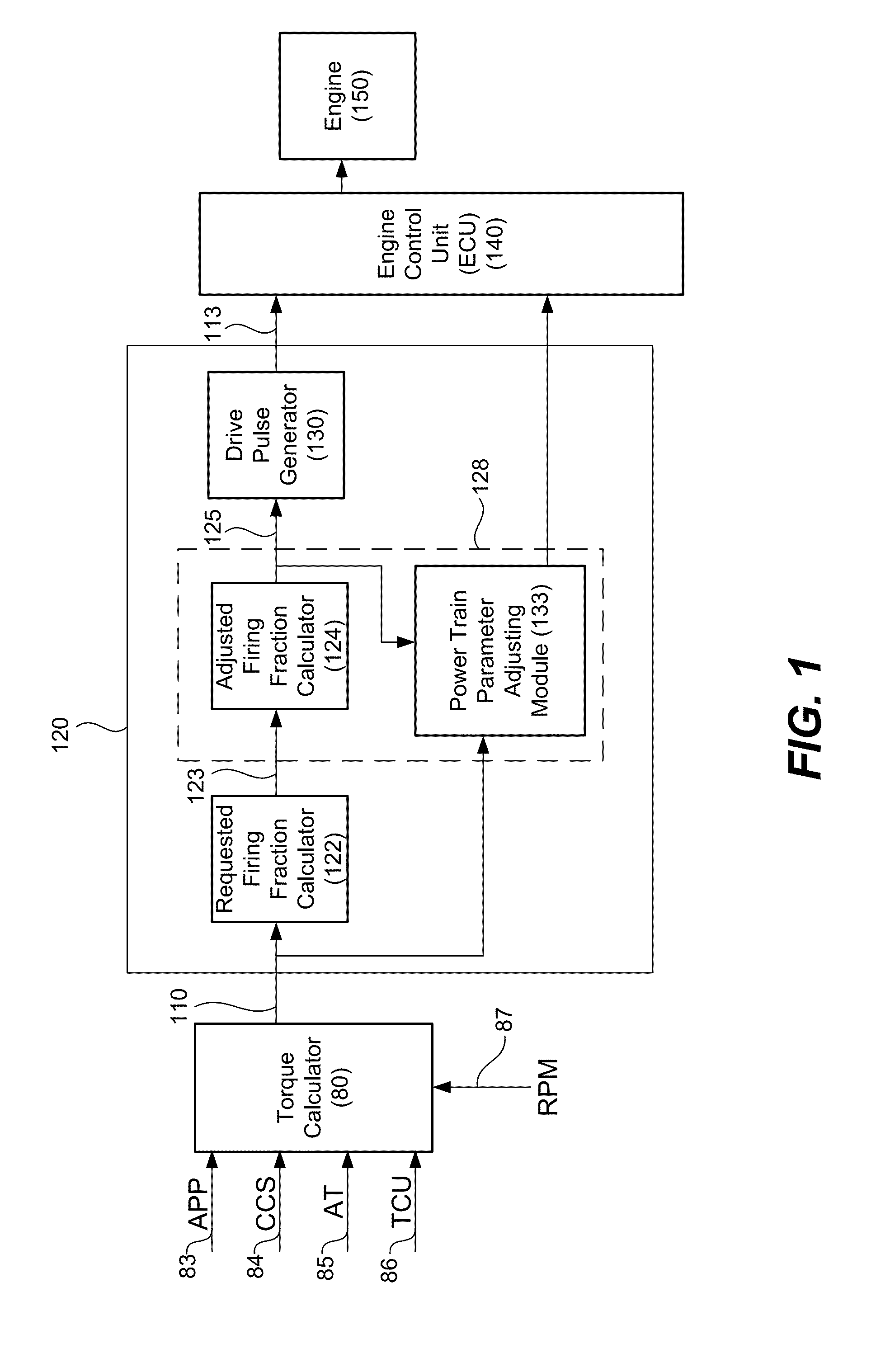

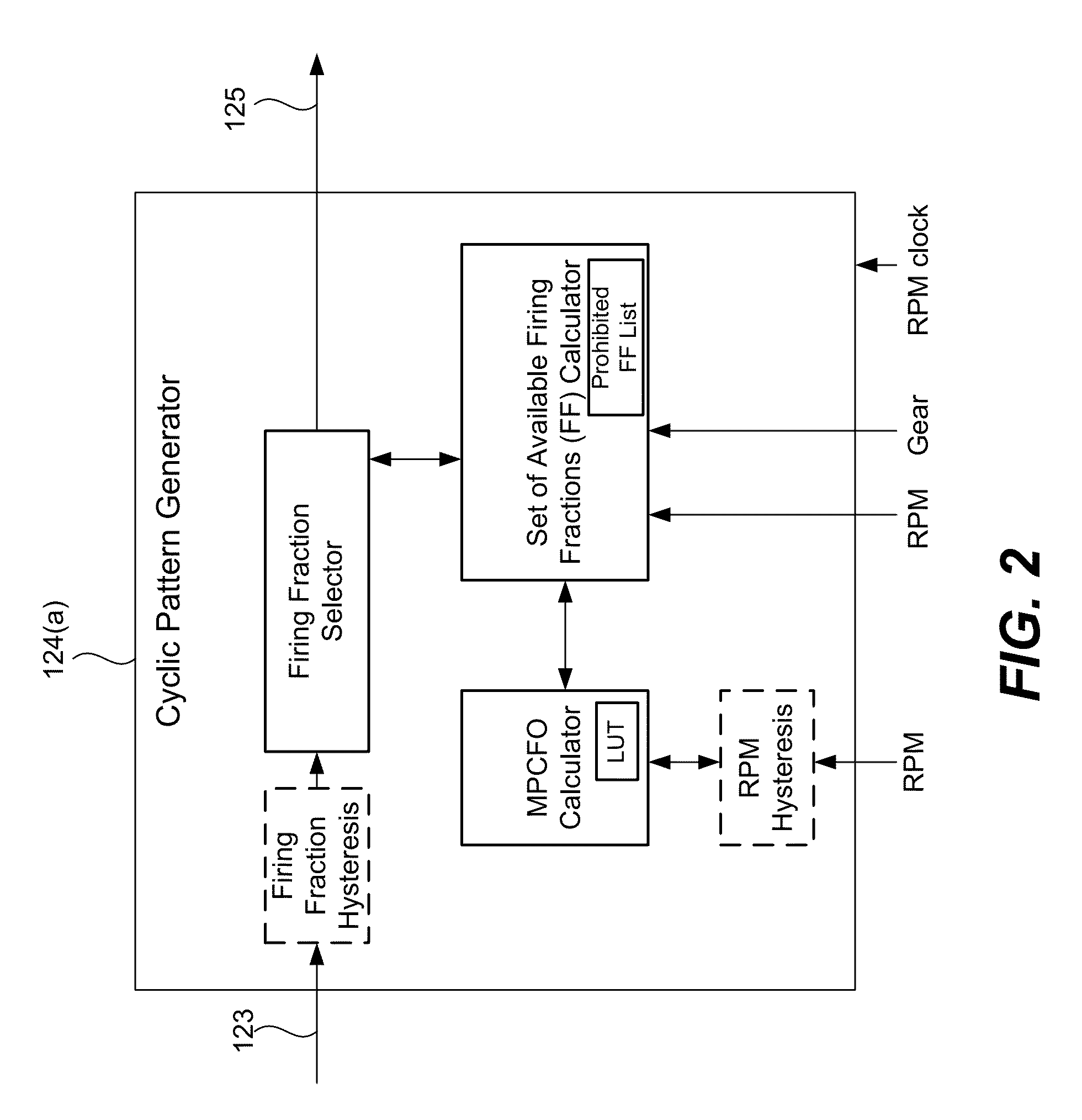

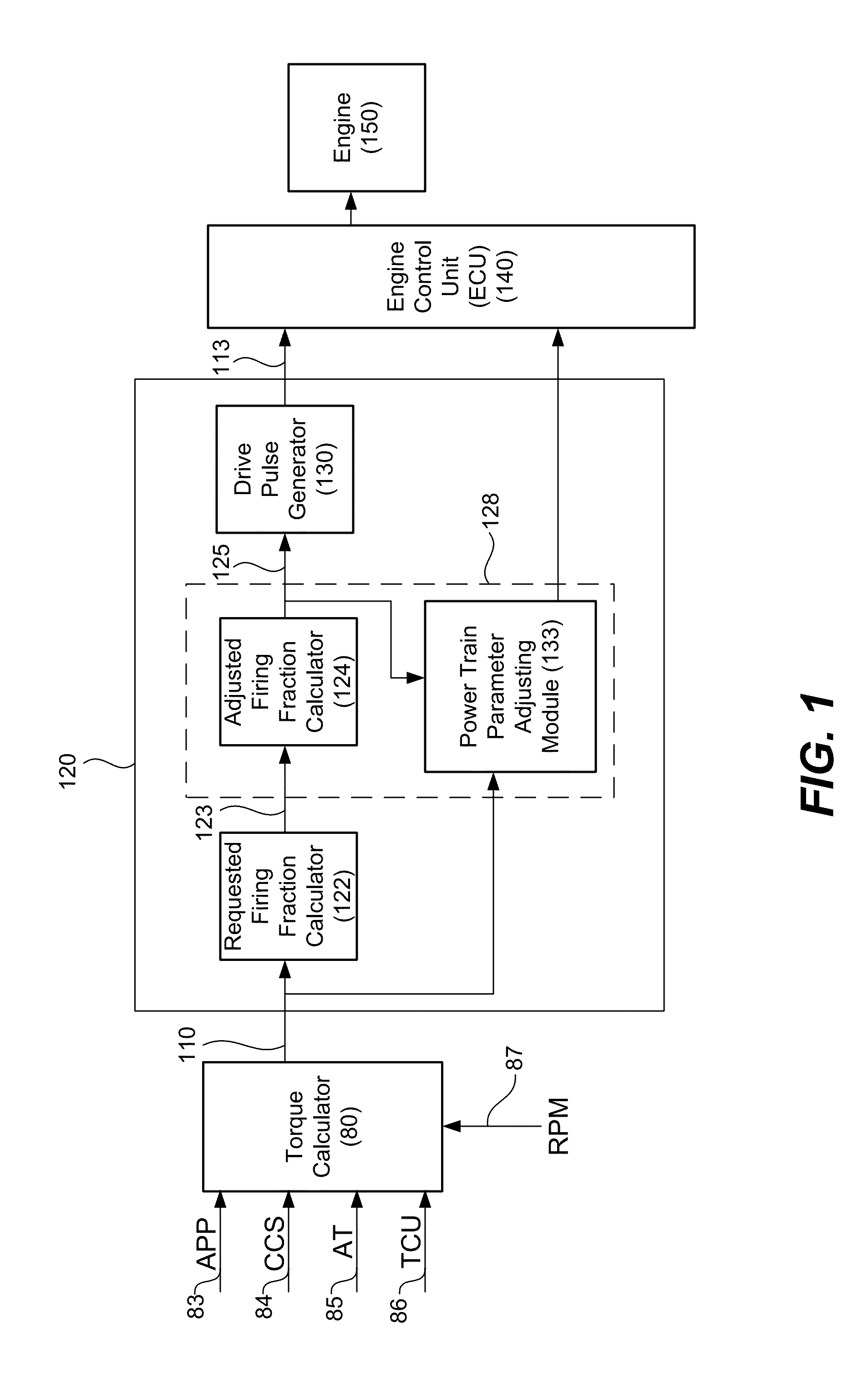

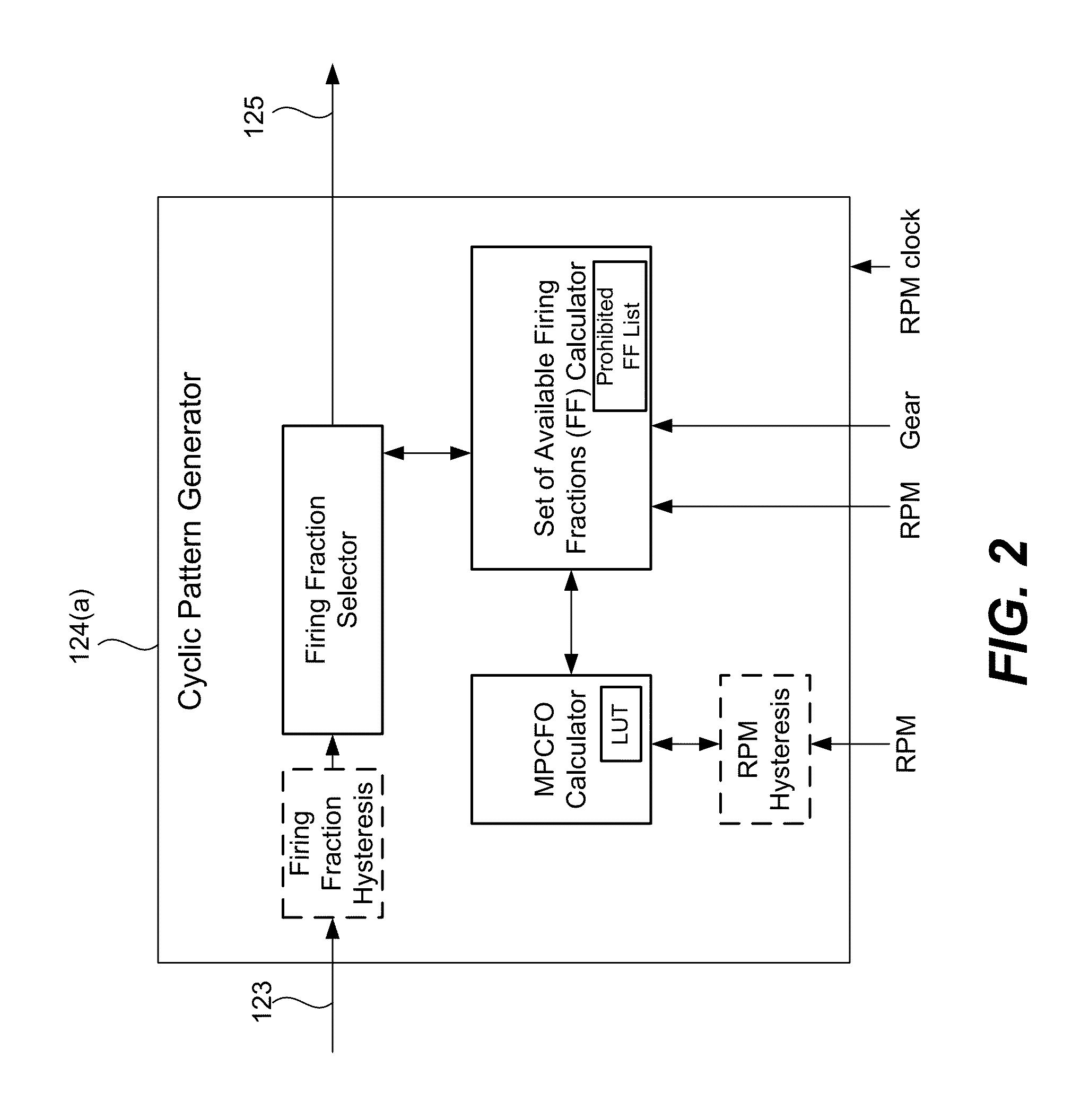

ActiveUS20130092127A1Reduce generationReduce probabilityElectrical controlOutput powerFire controlIgnition control

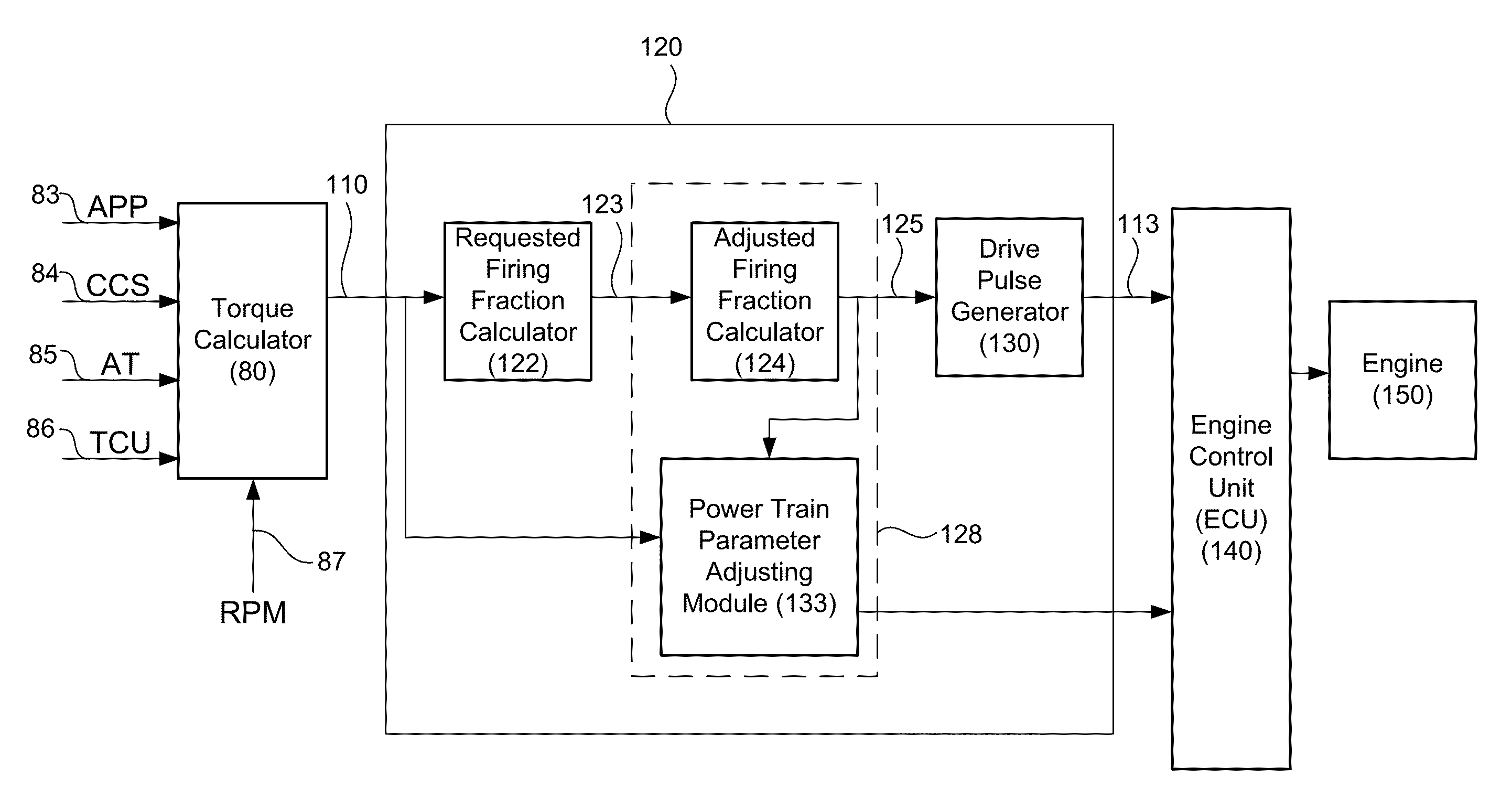

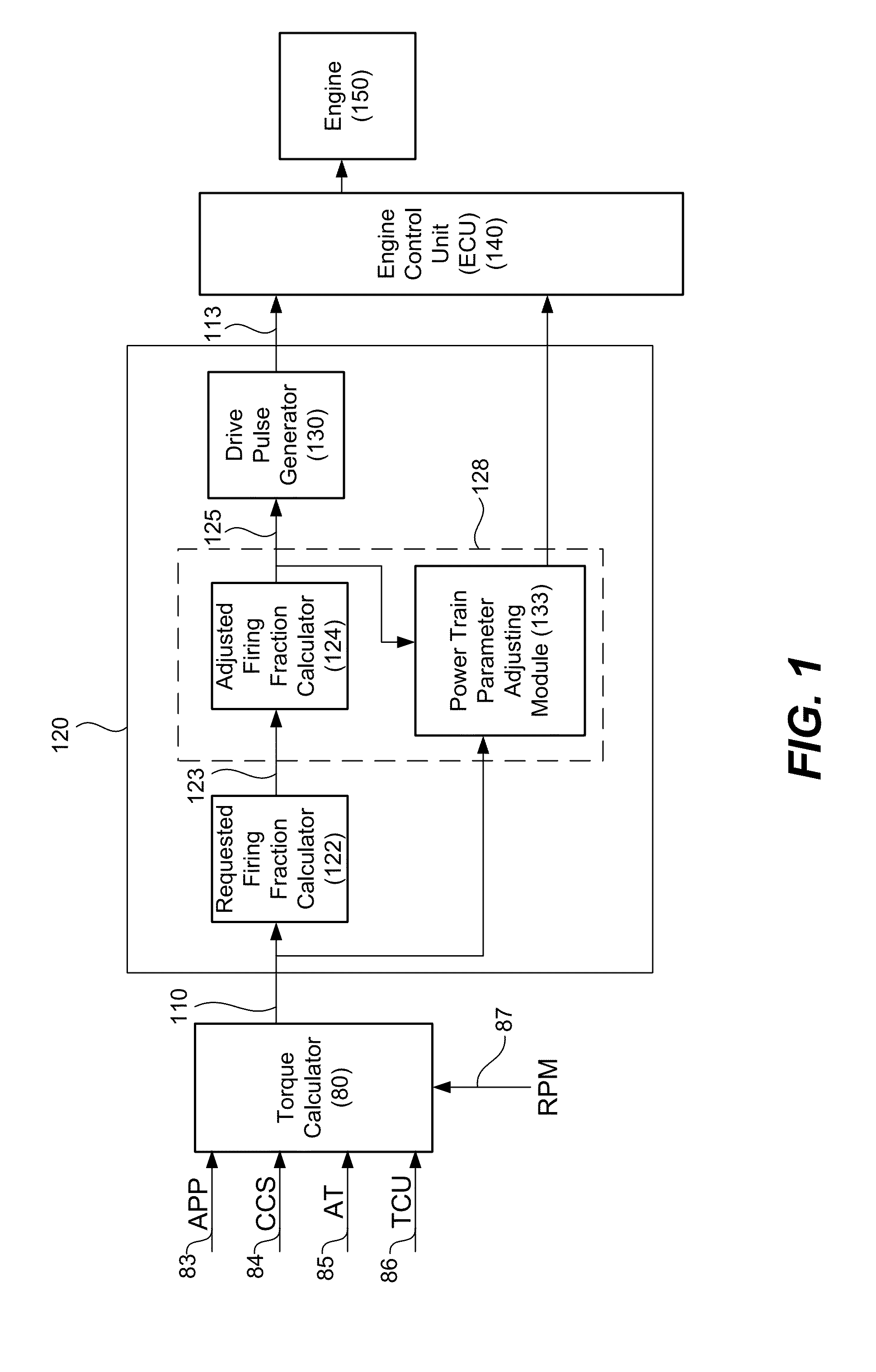

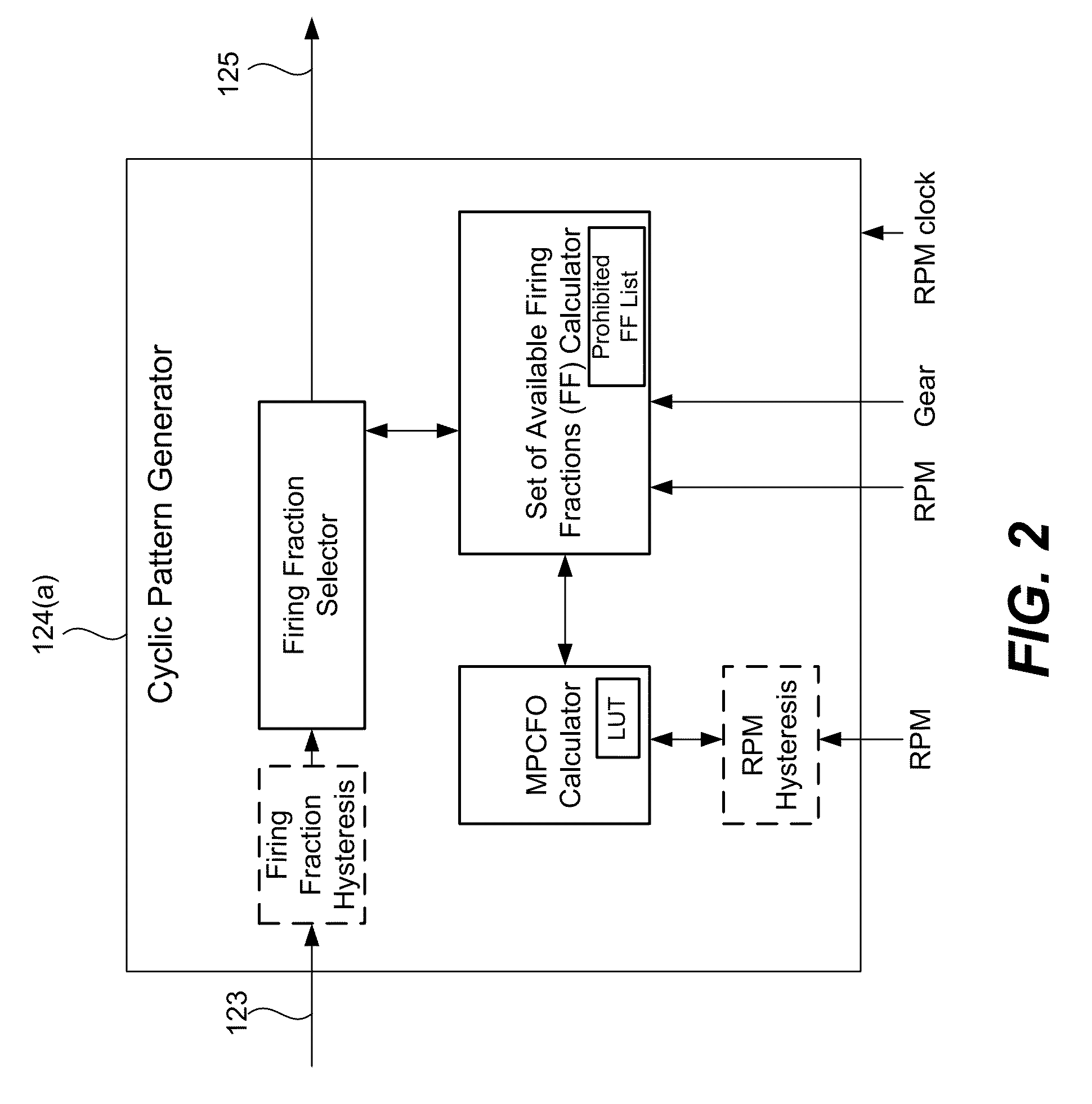

In various described embodiments skip fire control is used to deliver a desired engine output. A controller determines a skip fire firing fraction and (as appropriate) associated engine settings that are suitable for delivering a requested output. In one aspect, the firing fraction is selected from a set of available firing fractions, with the set of available firing fractions varying as a function of engine speed such that more firing fractions are available at higher engine speeds than at lower engine speeds. The controller then direct firings in a skip fire manner that delivers the selected fraction of firings.

Owner:TULA TECH INC

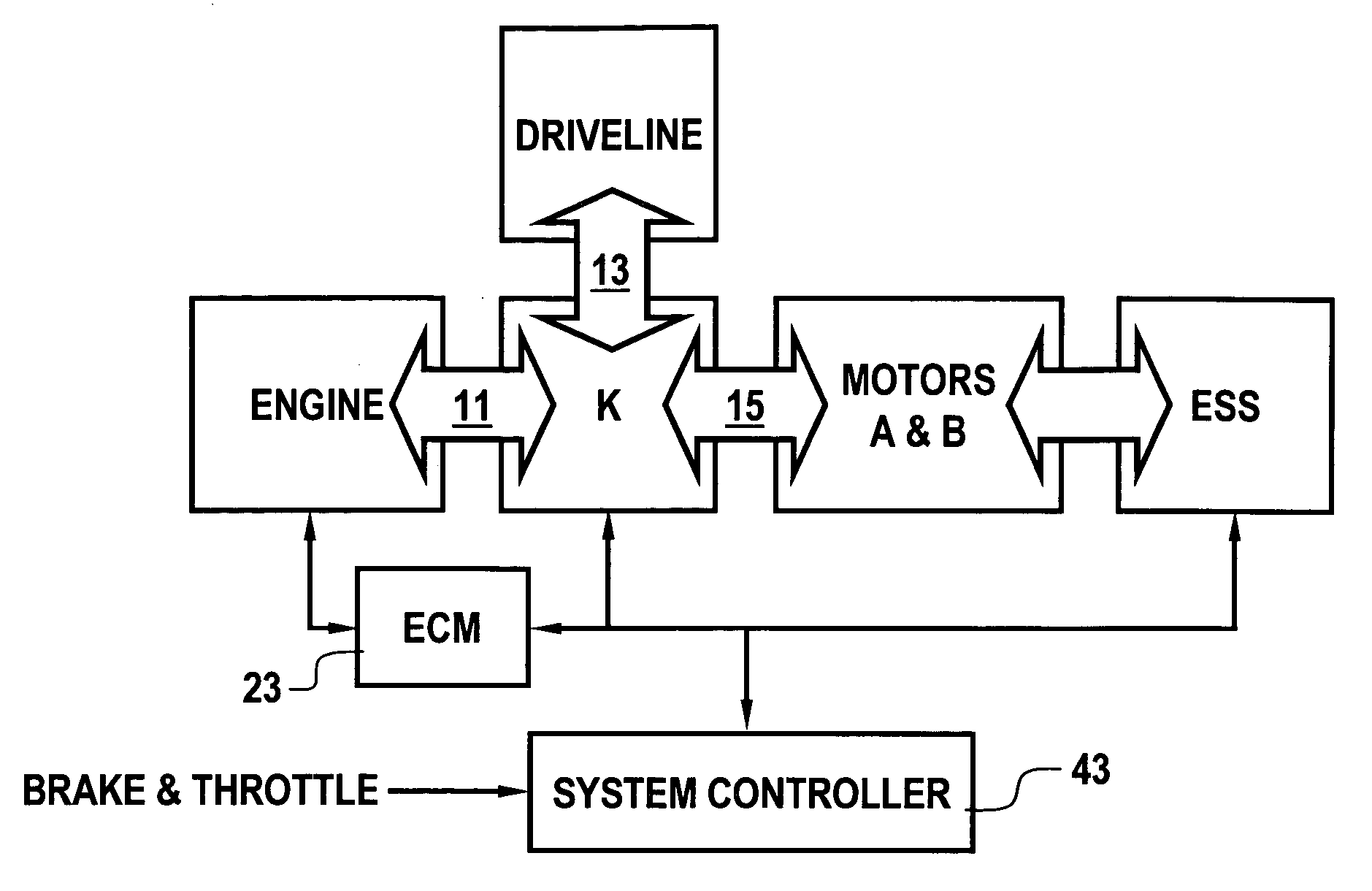

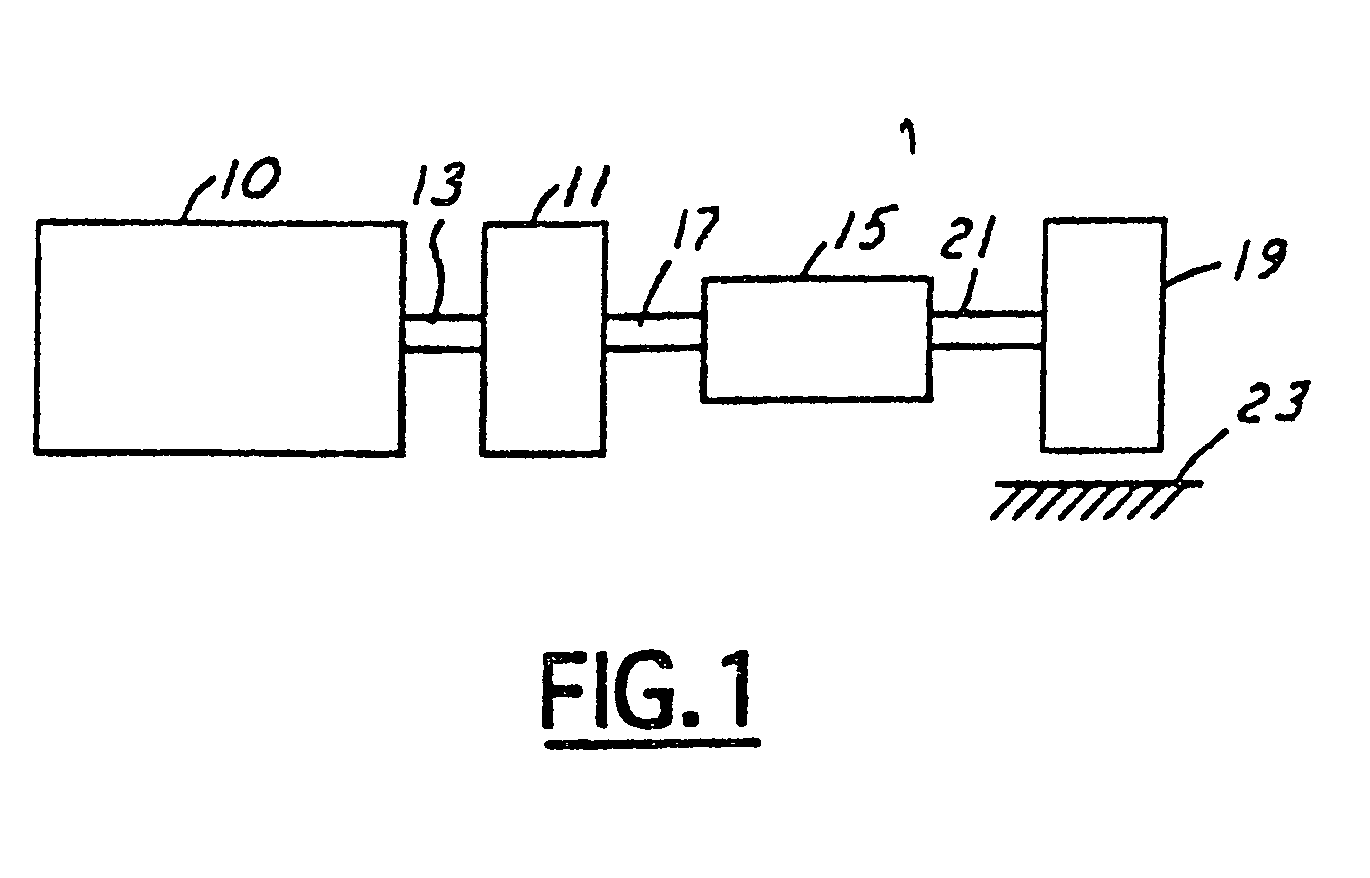

Coordinated regenerative and engine retard braking for a hybrid vehicle

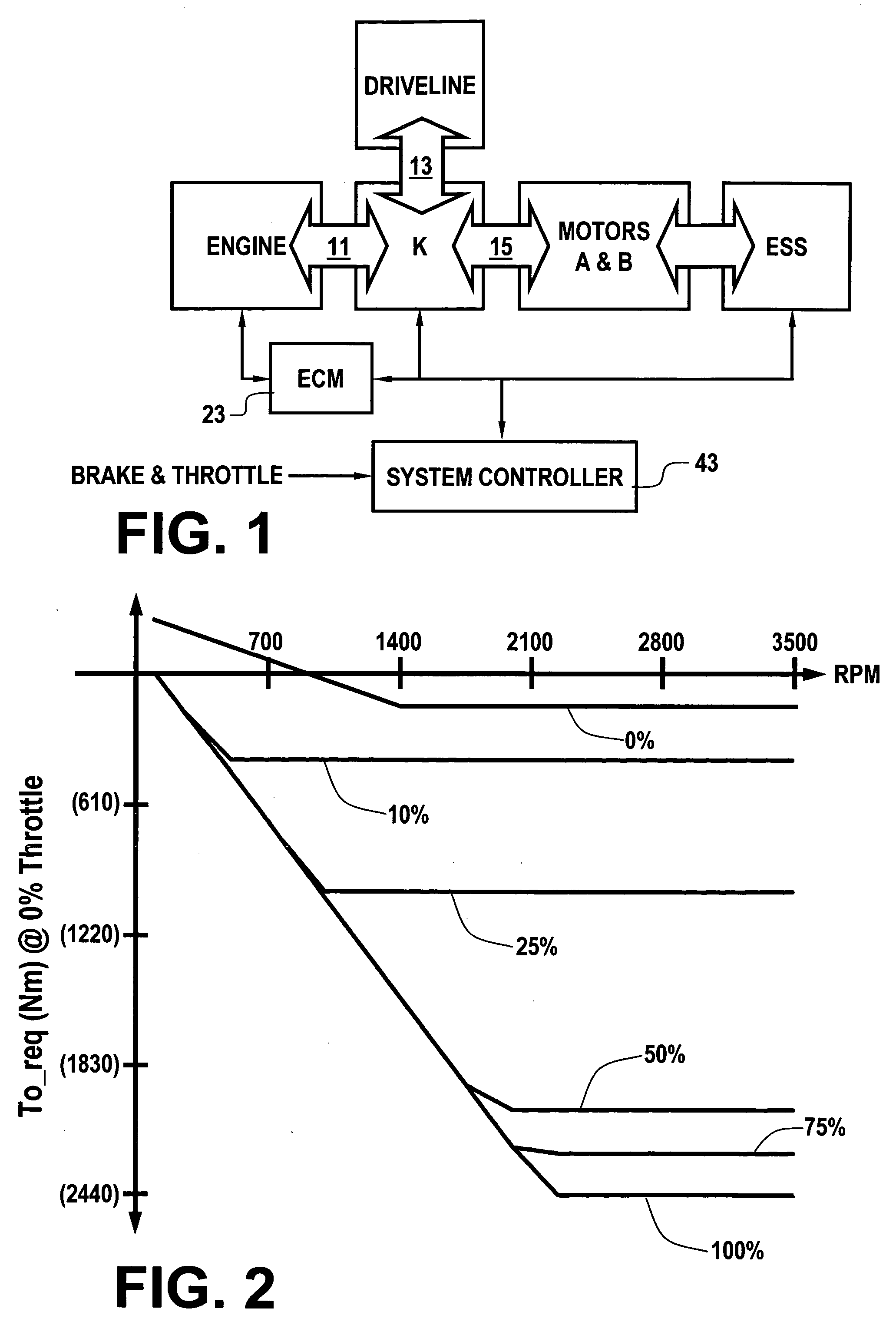

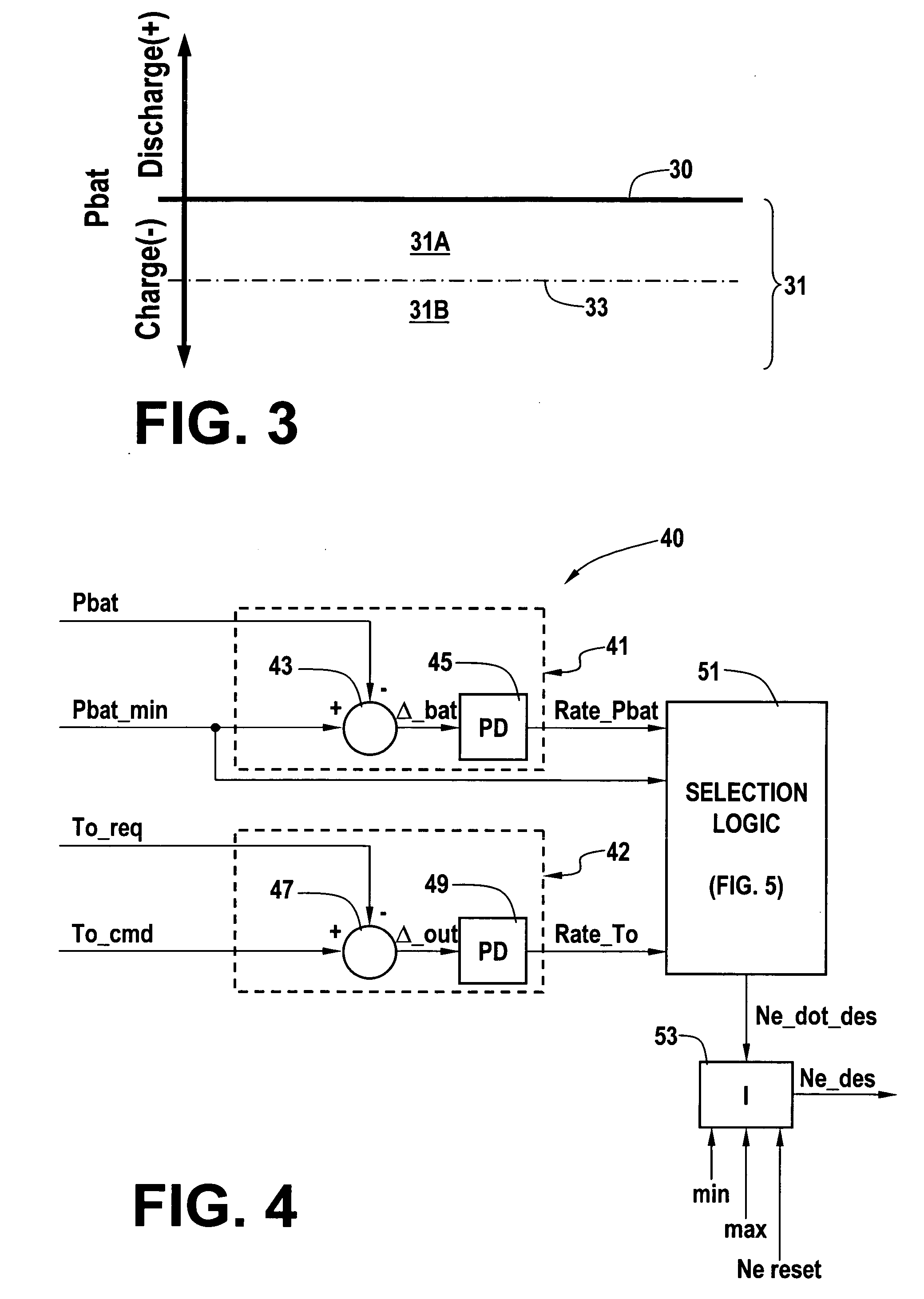

ActiveUS20050255965A1Increases the engine retard braking contributionReduce contributionHybrid vehiclesBraking element arrangementsPower flowGear wheel

A hybrid vehicle includes a powertrain having a retarded diesel engine, an electric machine and energy storage system. The engine and motor are operatively coupled through one or more planetary gearsets and selective coupling paths in accordance with application and release of various torque transfer devices to a drivetrain via an output. Regenerative and retarded engine braking are coordinated to provide priority to energy return to an energy storage system in accordance with predetermined power flow limits. Power flow in excess of the limits are handled by increased engine retard braking contributions via engine speed increases.

Owner:ALLISON TRANSMISSION INC

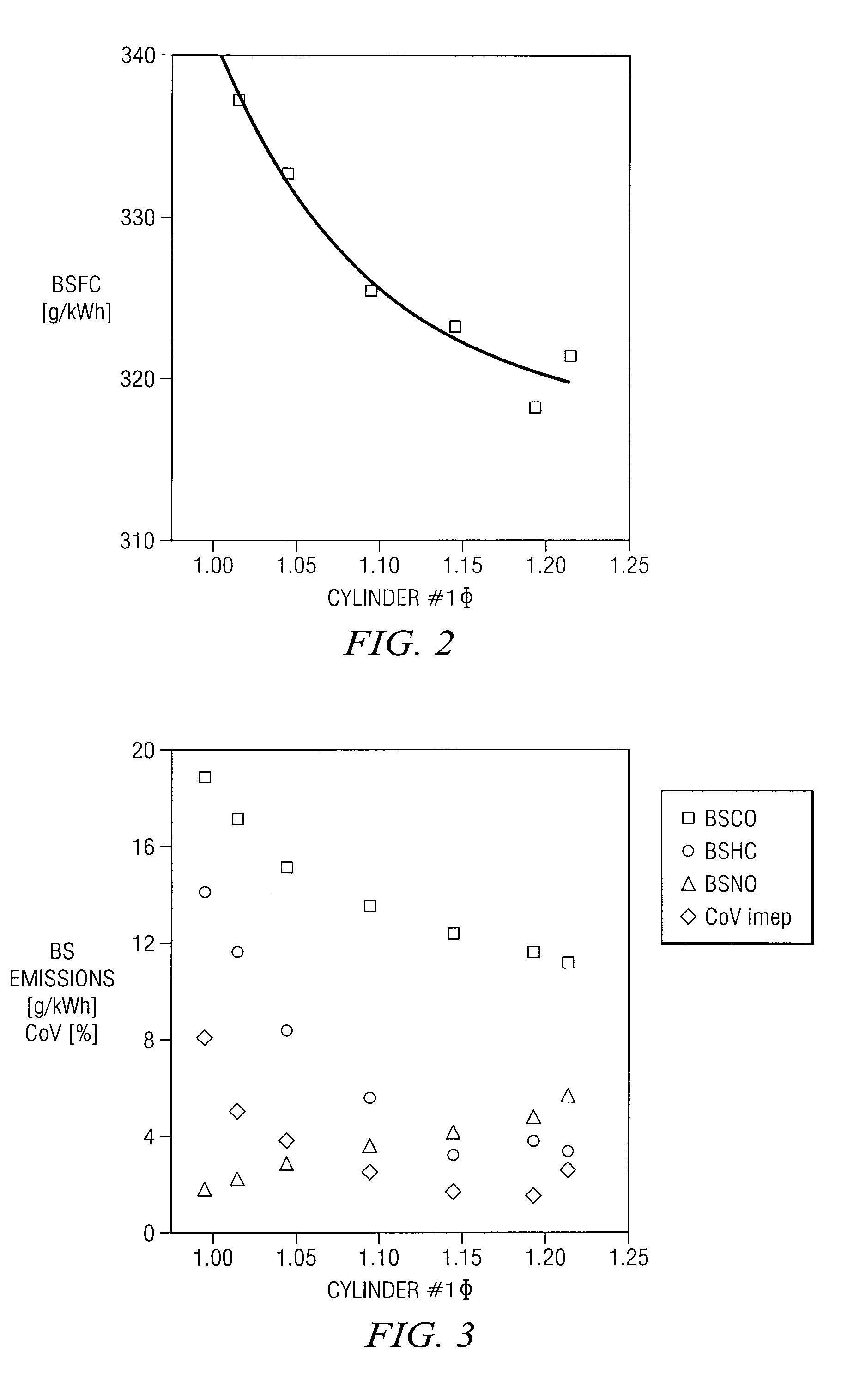

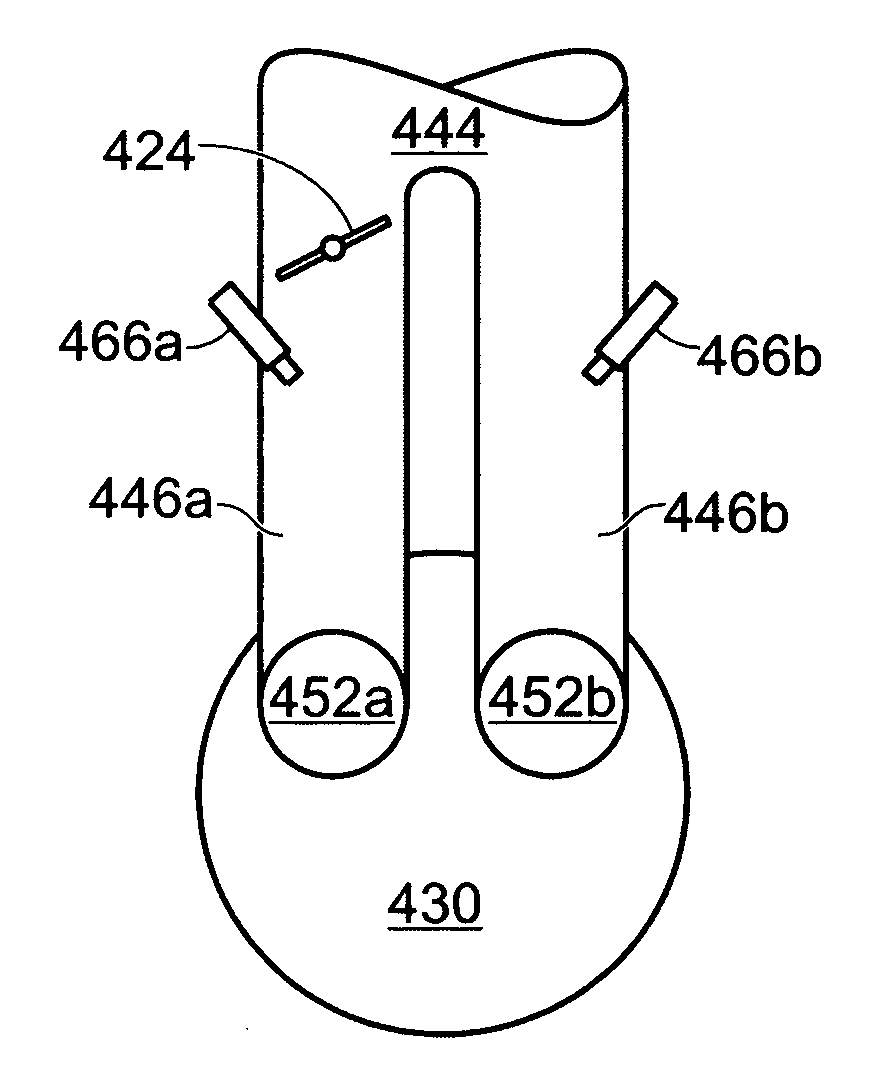

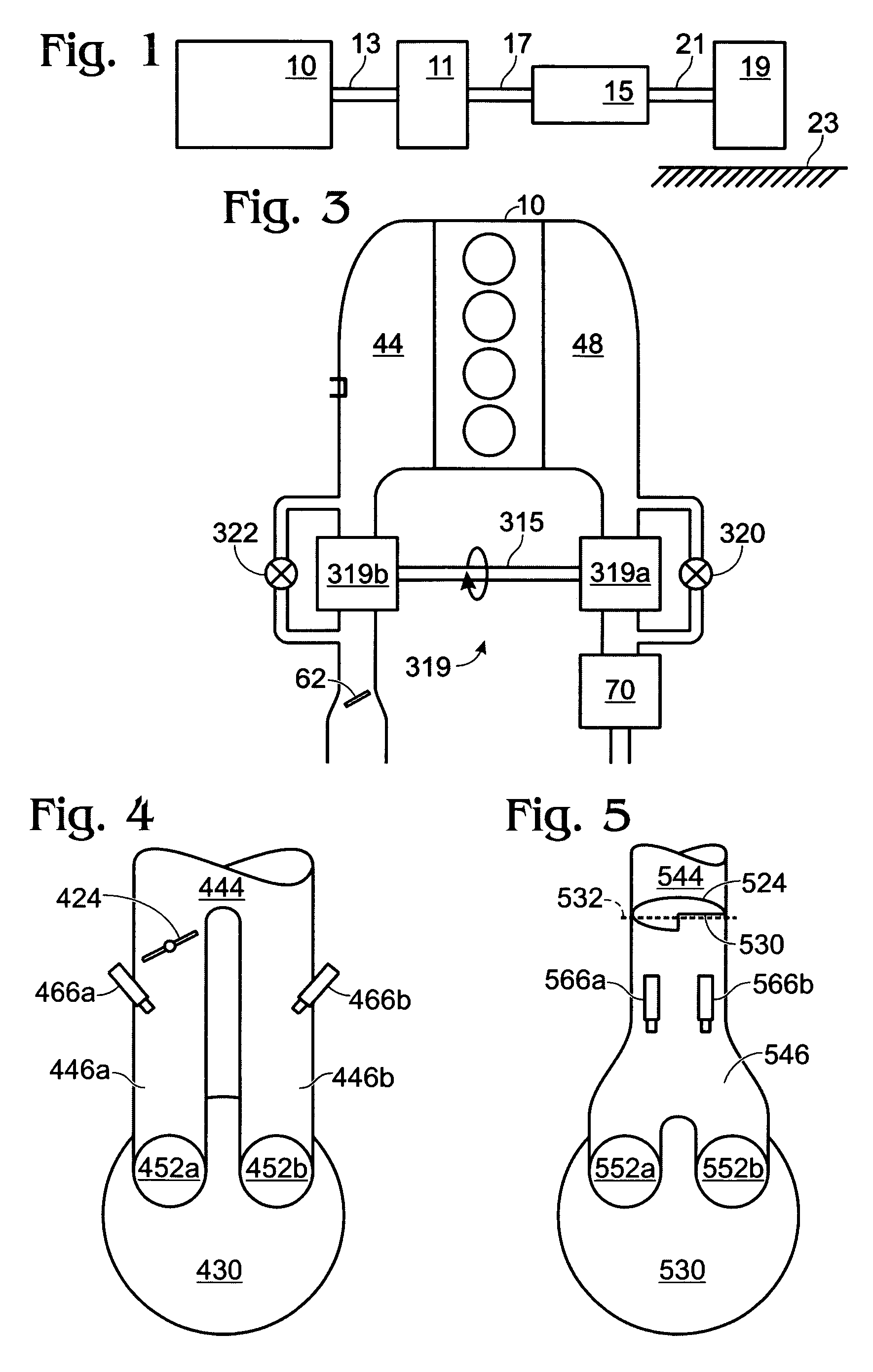

Differential torque operation for internal combustion engine

InactiveUS7503312B2Improve internal efficiencyImprove fuel efficiencyElectrical controlInternal combustion piston enginesInternal combustion engineControl theory

A method of operating an internal combustion engine having a plurality of cylinders including at least a first cylinder and a second cylinder, the method comprising firing the first cylinder and the second cylinder in an alternating sequence; during a first mode, adjusting an operating parameter of the engine to produce a first difference between an amount of torque produced by the firing of the first cylinder and an amount of torque produced by the firing of the second cylinder; during a second mode, adjusting the operating parameter of the engine to produce a second difference between an amount of torque produced by the firing of the first cylinder and an amount of torque produced by the firing of the second cylinder; and performing the first mode at a higher engine speed than the second mode; wherein the first difference is greater than the second difference.

Owner:FORD GLOBAL TECH LLC

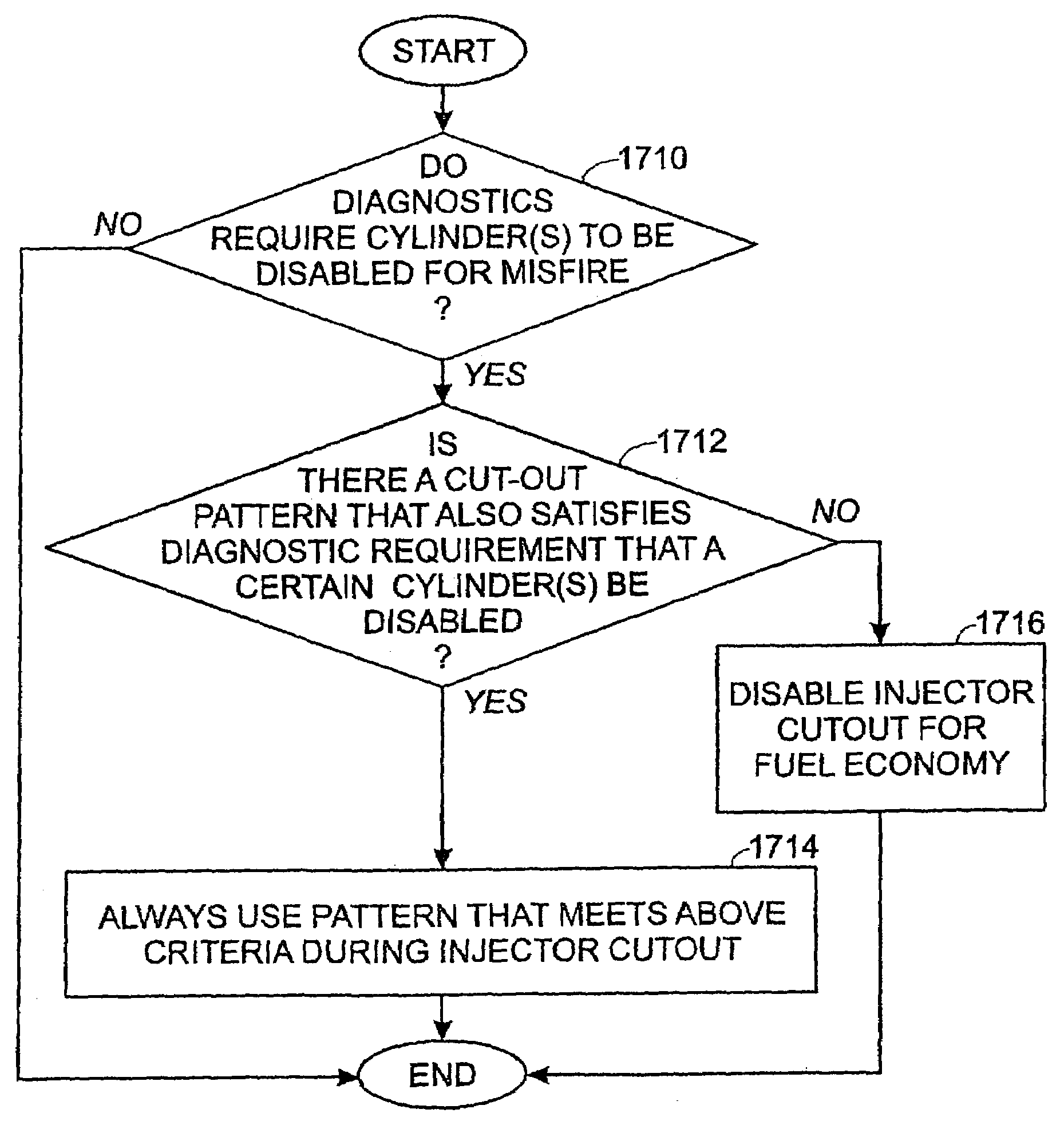

Engine system and method accounting for engine misfire

ActiveUS7086386B2Reducing engine pumping lossesMore efficientCombustion enginesOutput powerSystems designFuel vapor

Various systems and methods are disclosed for carrying out combustion in a fuel-cut operation in some or all of the engine cylinders of a vehicle. Further, various subsystems are considered, such as fuel vapor purging, air-fuel ratio control, engine torque control, catalyst design, and exhaust system design.

Owner:FORD GLOBAL TECH LLC

Firing fraction management in skip fire engine control

ActiveUS9086020B2Reduce generationReduce probabilityElectrical controlOutput powerFire controlIgnition control

In various described embodiments skip fire control is used to deliver a desired engine output. A controller determines a skip fire firing fraction and (as appropriate) associated engine settings that are suitable for delivering a requested output. In one aspect, the firing fraction is selected from a set of available firing fractions, with the set of available firing fractions varying as a function of engine speed such that more firing fractions are available at higher engine speeds than at lower engine speeds. The controller then direct firings in a skip fire manner that delivers the selected fraction of firings.

Owner:TULA TECH INC

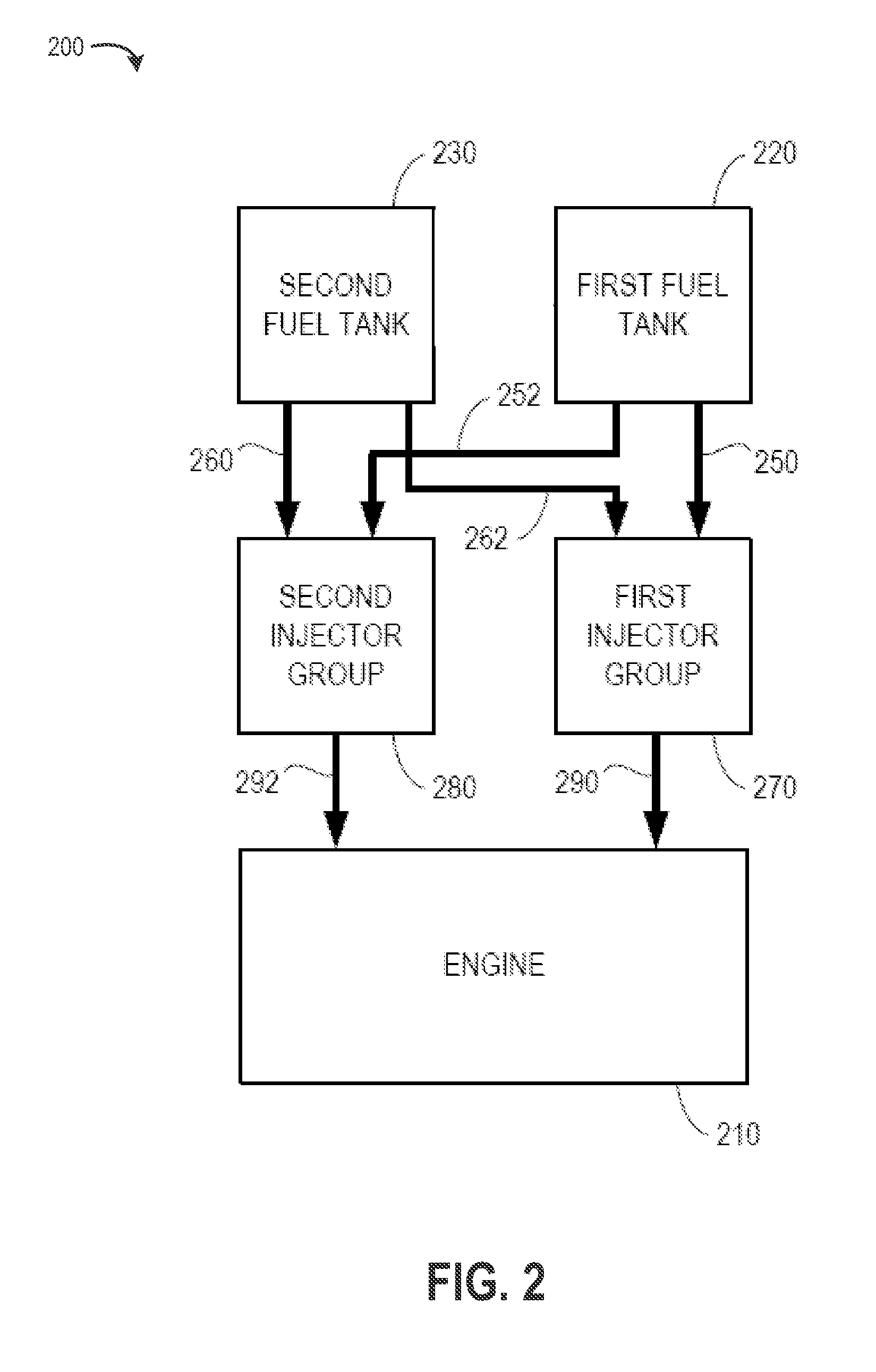

Fuel system for a multi-fuel engine

InactiveUS20120048242A1Reducing high pressure pump degradationReduce degradationElectrical controlInternal combustion piston enginesFuel typeHigh pressure

Methods and systems are provided for operating an engine fuel system including fuels of different fuel types. A first fuel type is delivered for port injection upon circulation through a high pressure pump when direct injection of a fuel is not requested to cool and / or lubricate the high pressure pump.

Owner:FORD GLOBAL TECH LLC

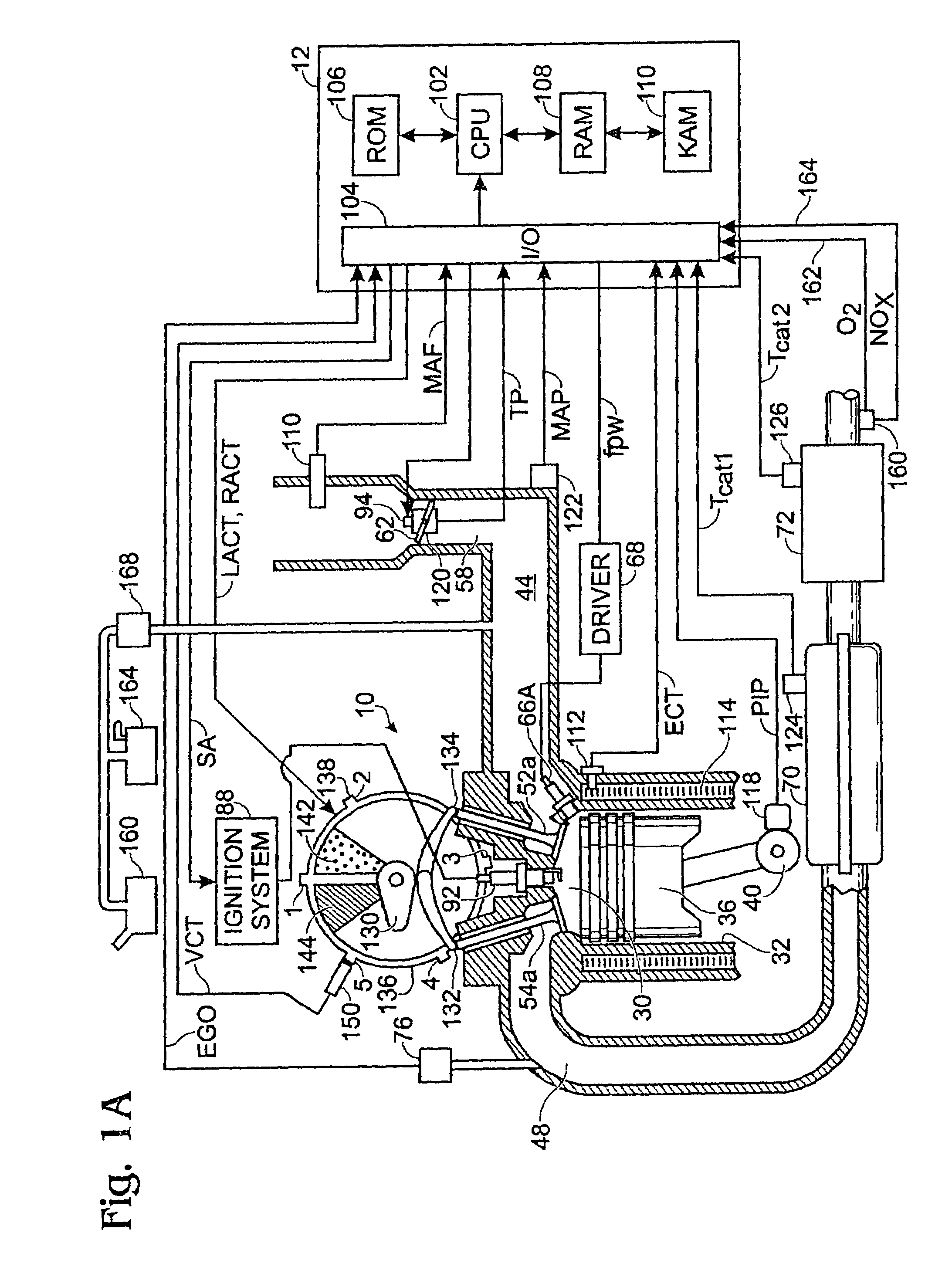

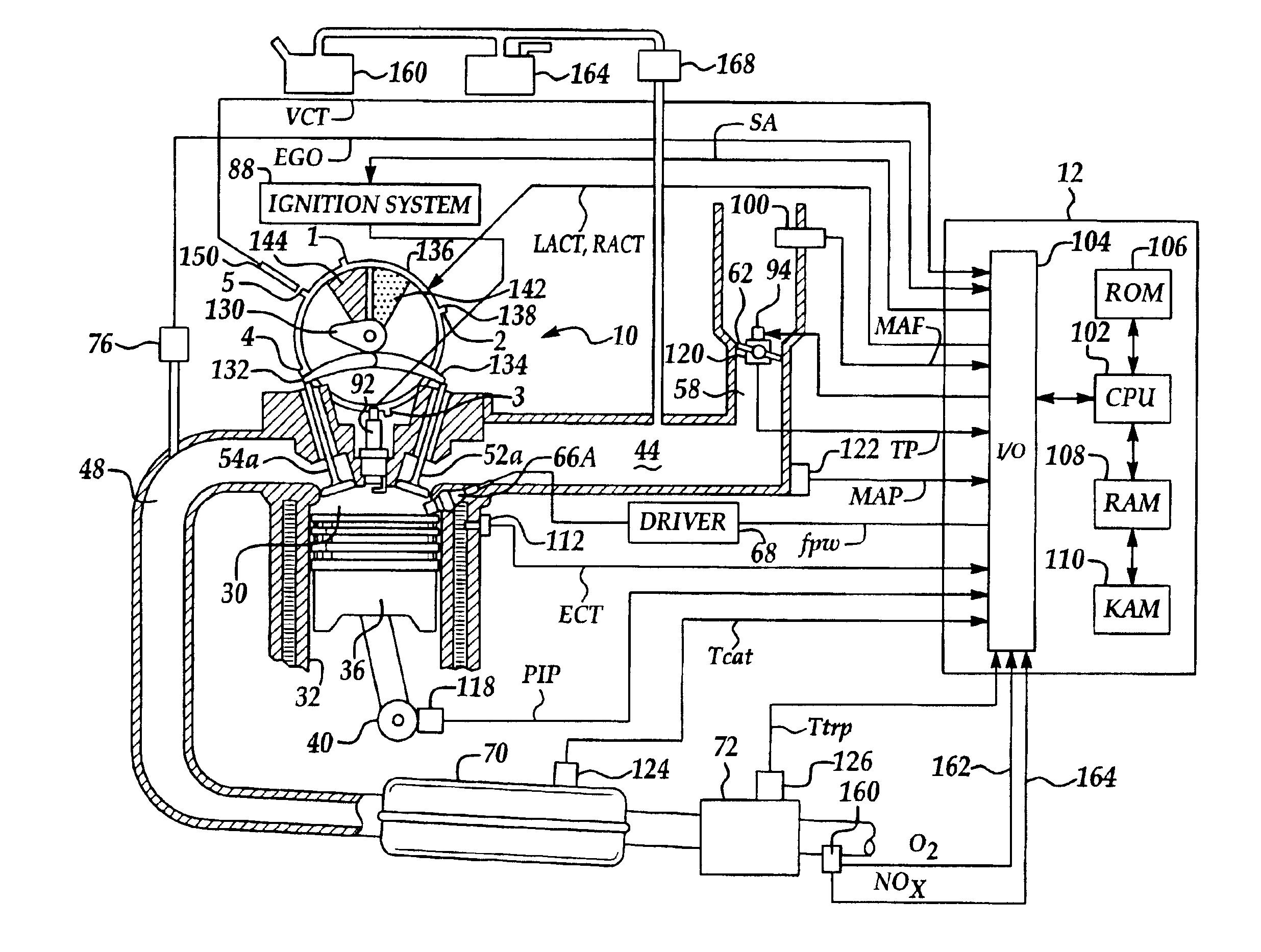

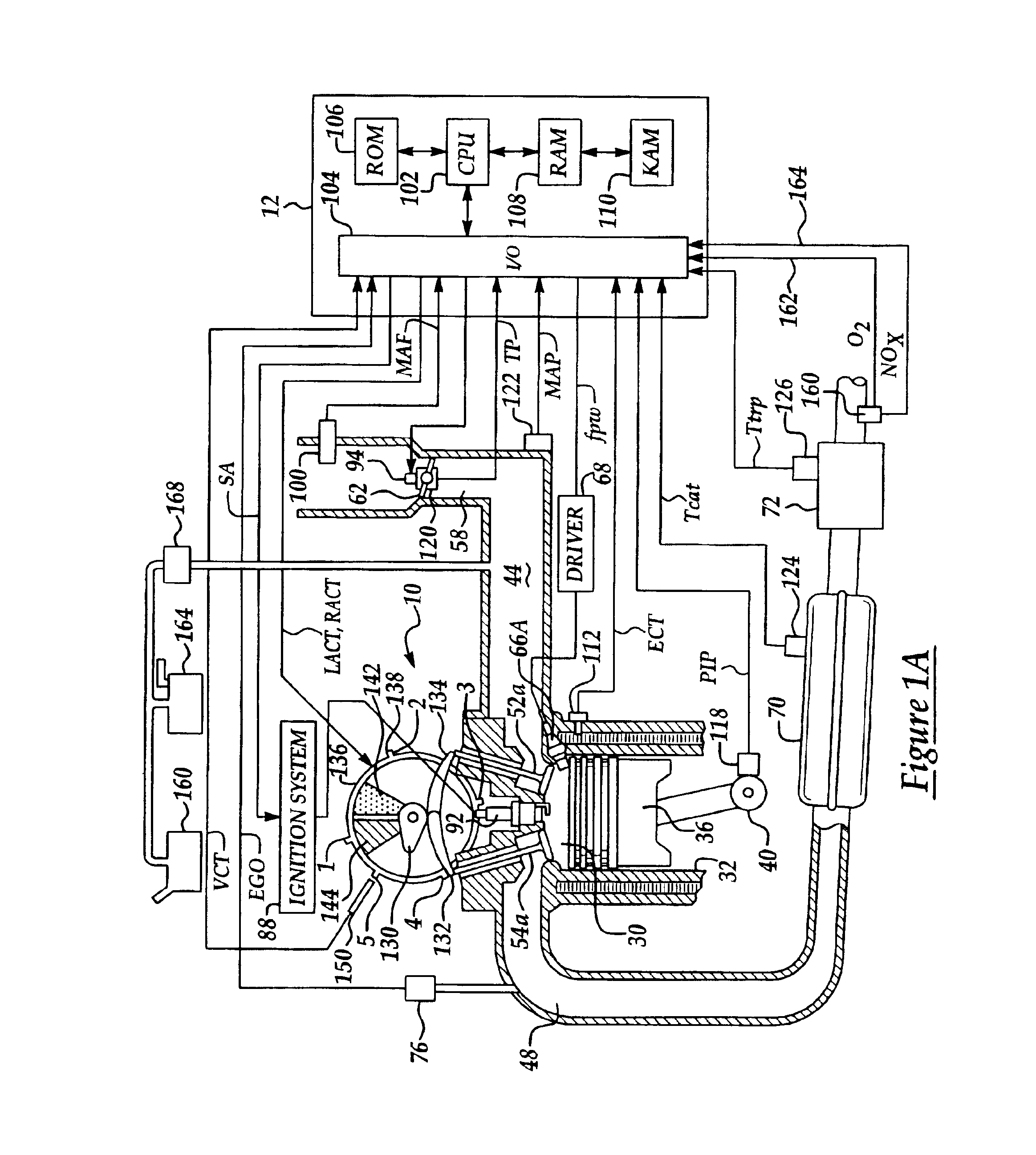

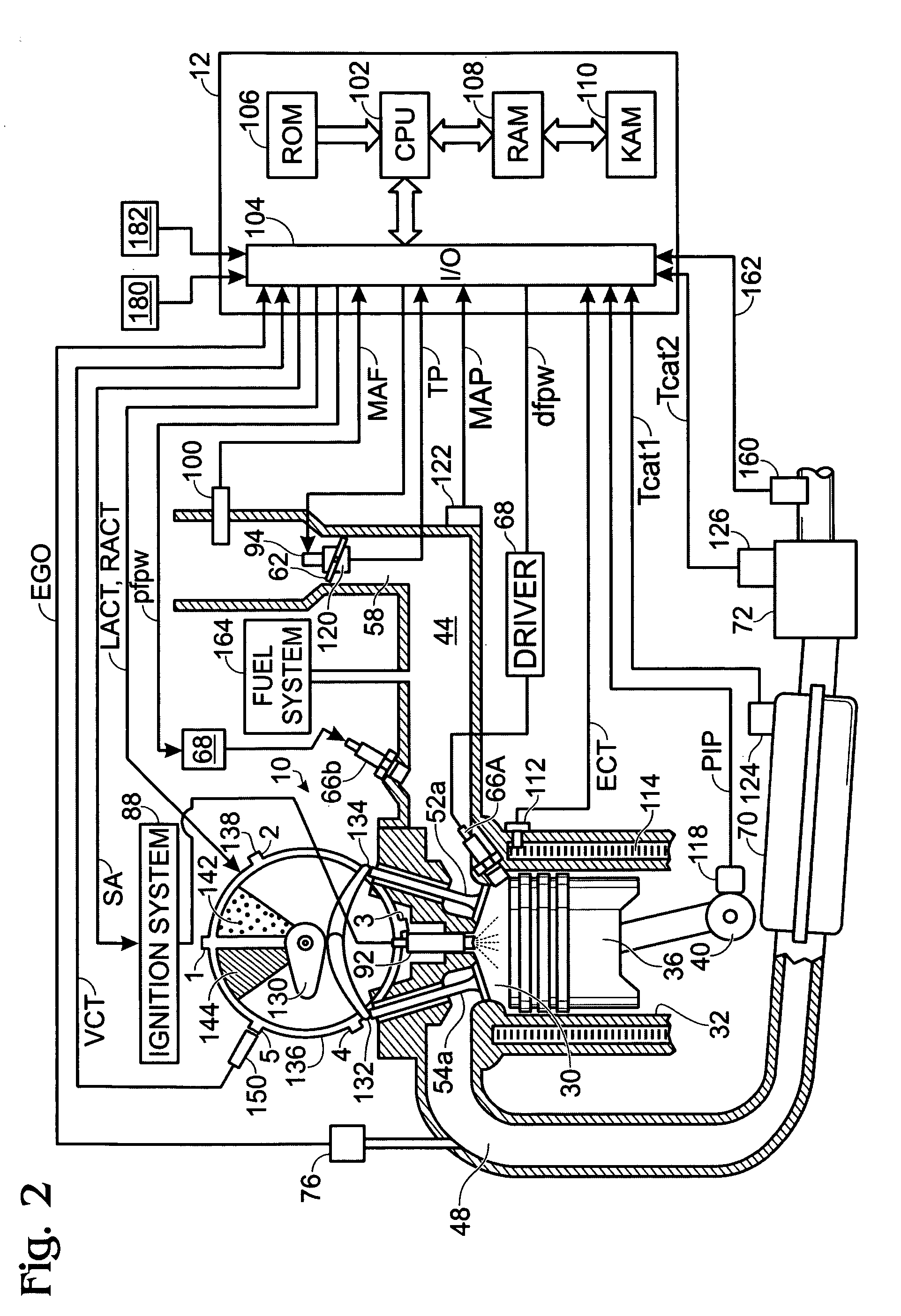

Method for rapid catalyst heating

InactiveUS6568177B1High load conditionMore ignition timingElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

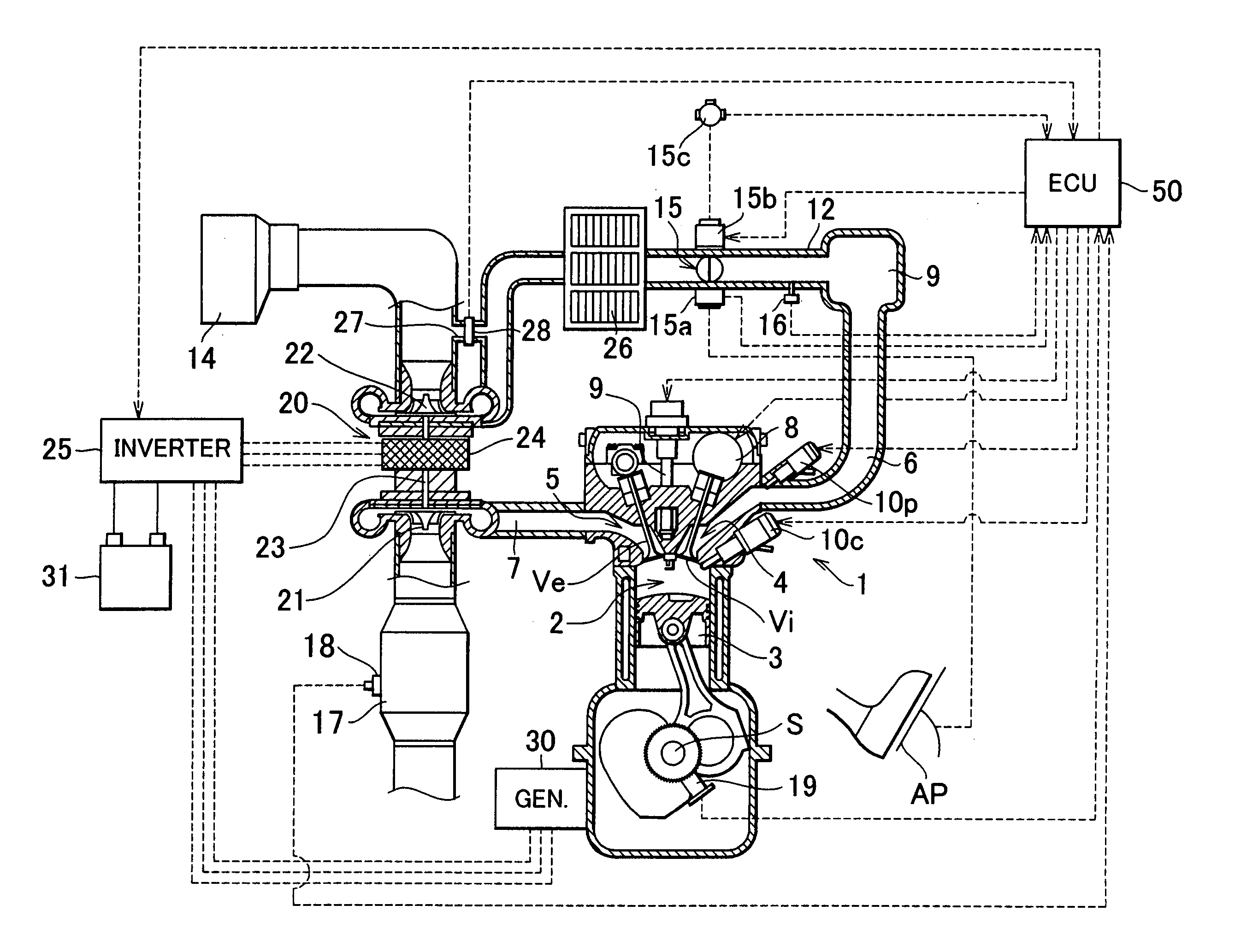

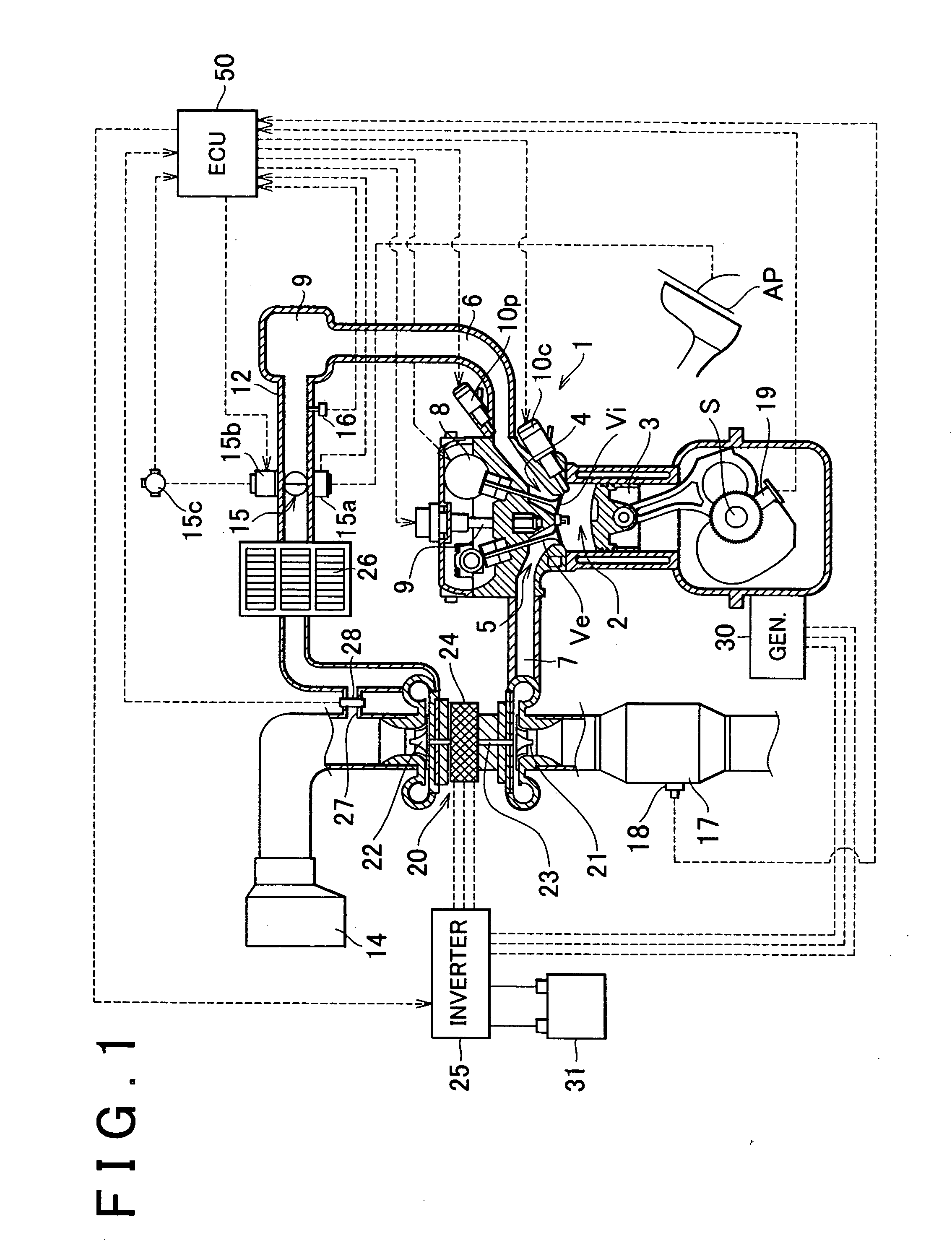

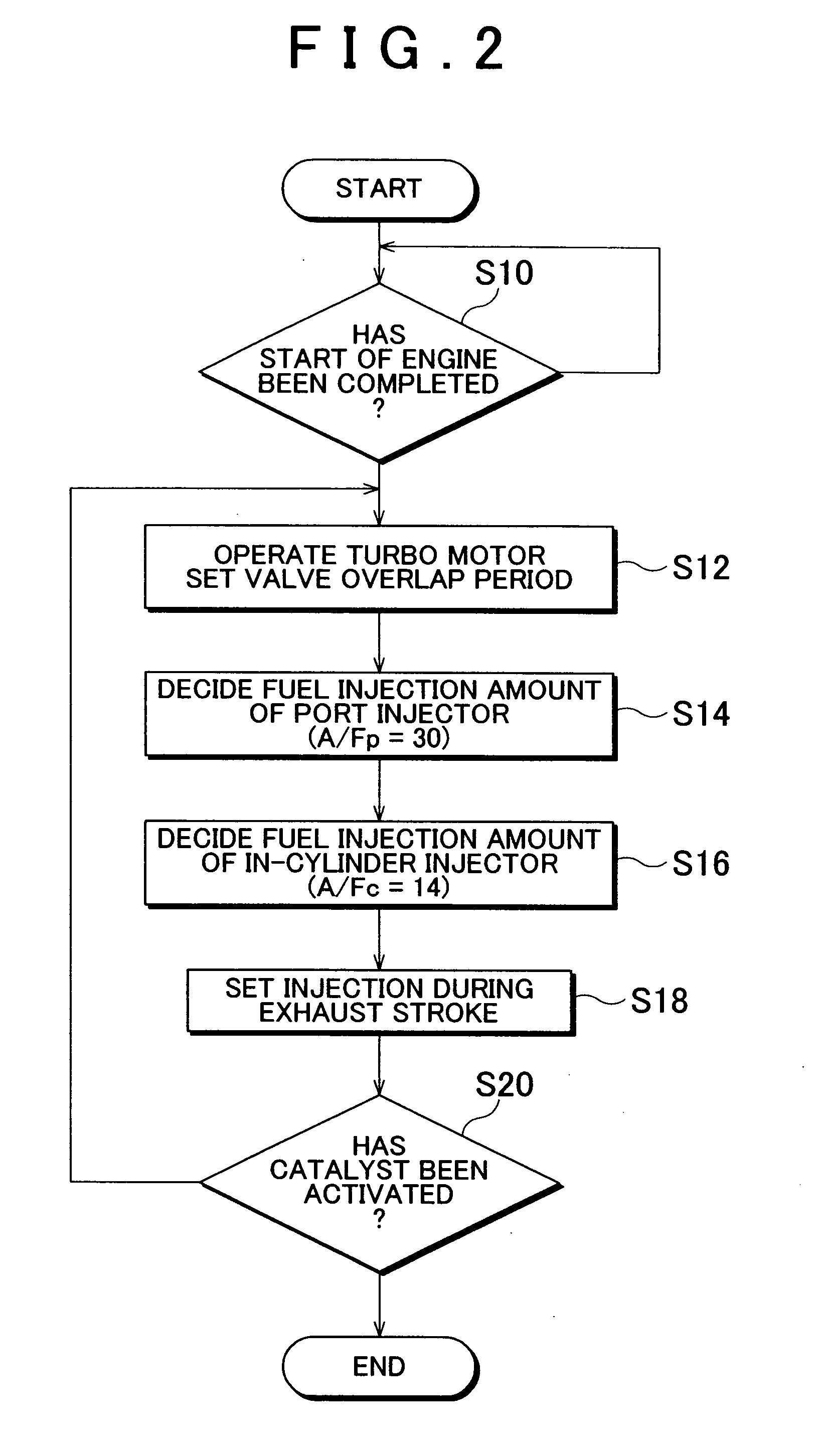

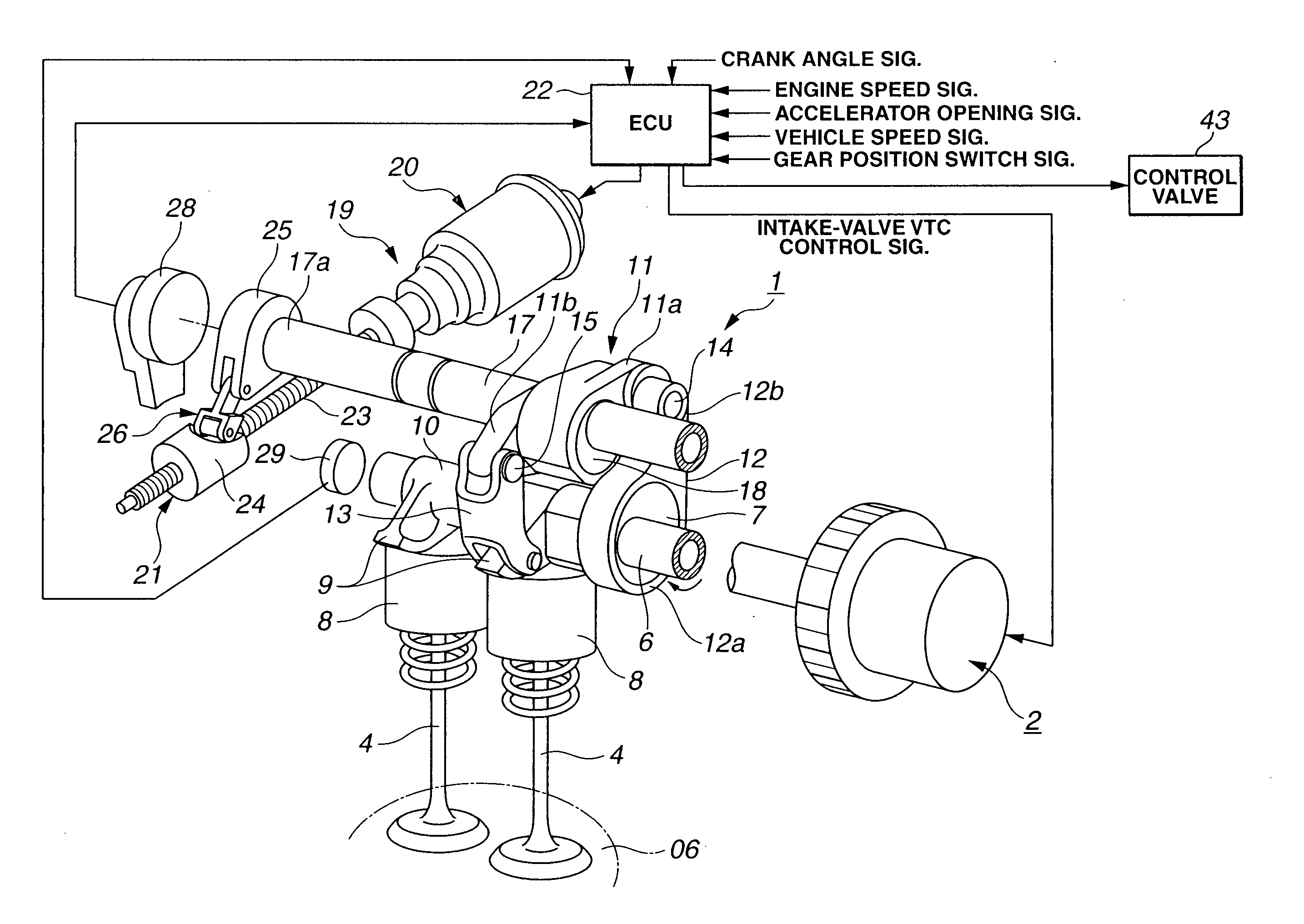

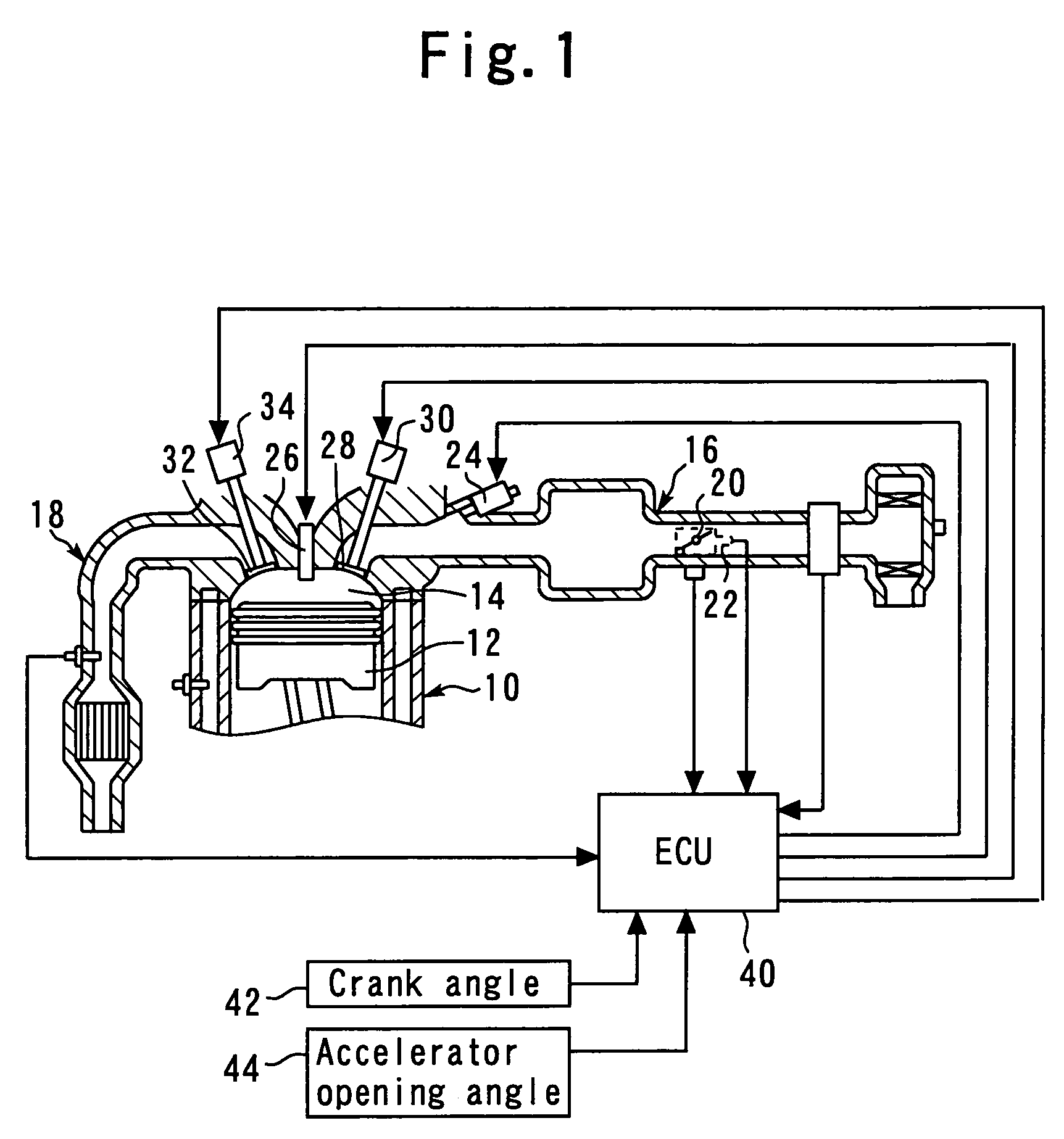

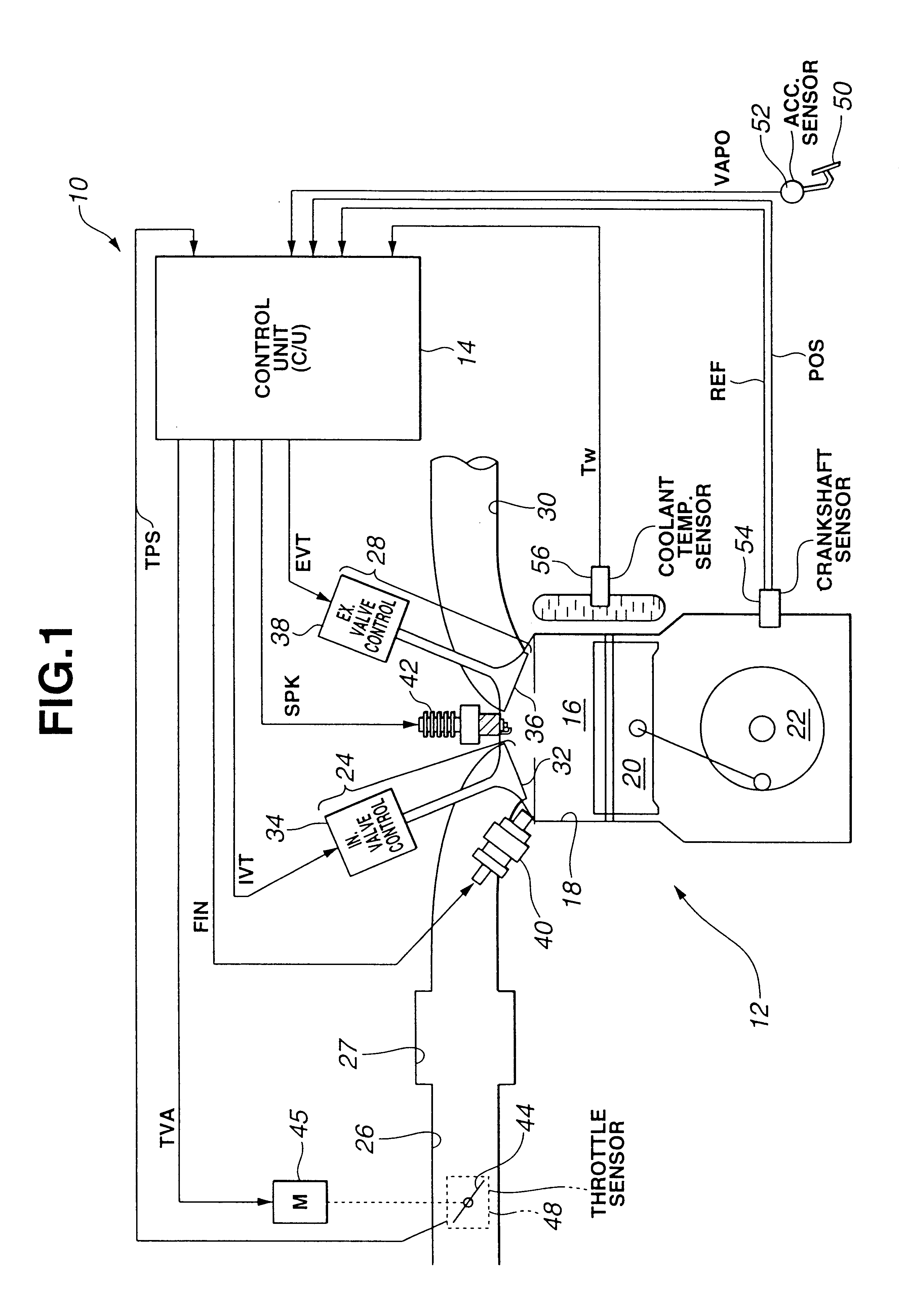

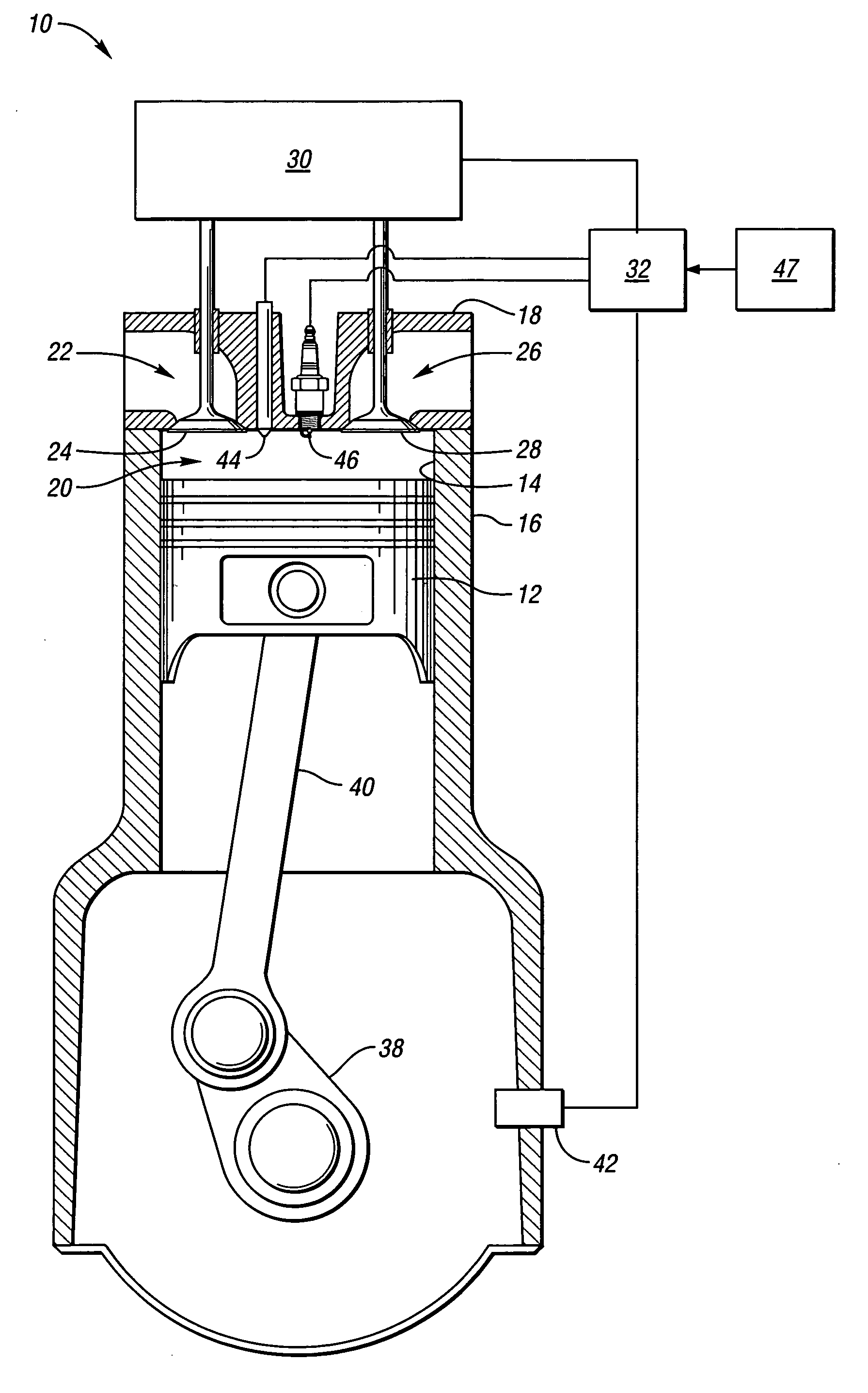

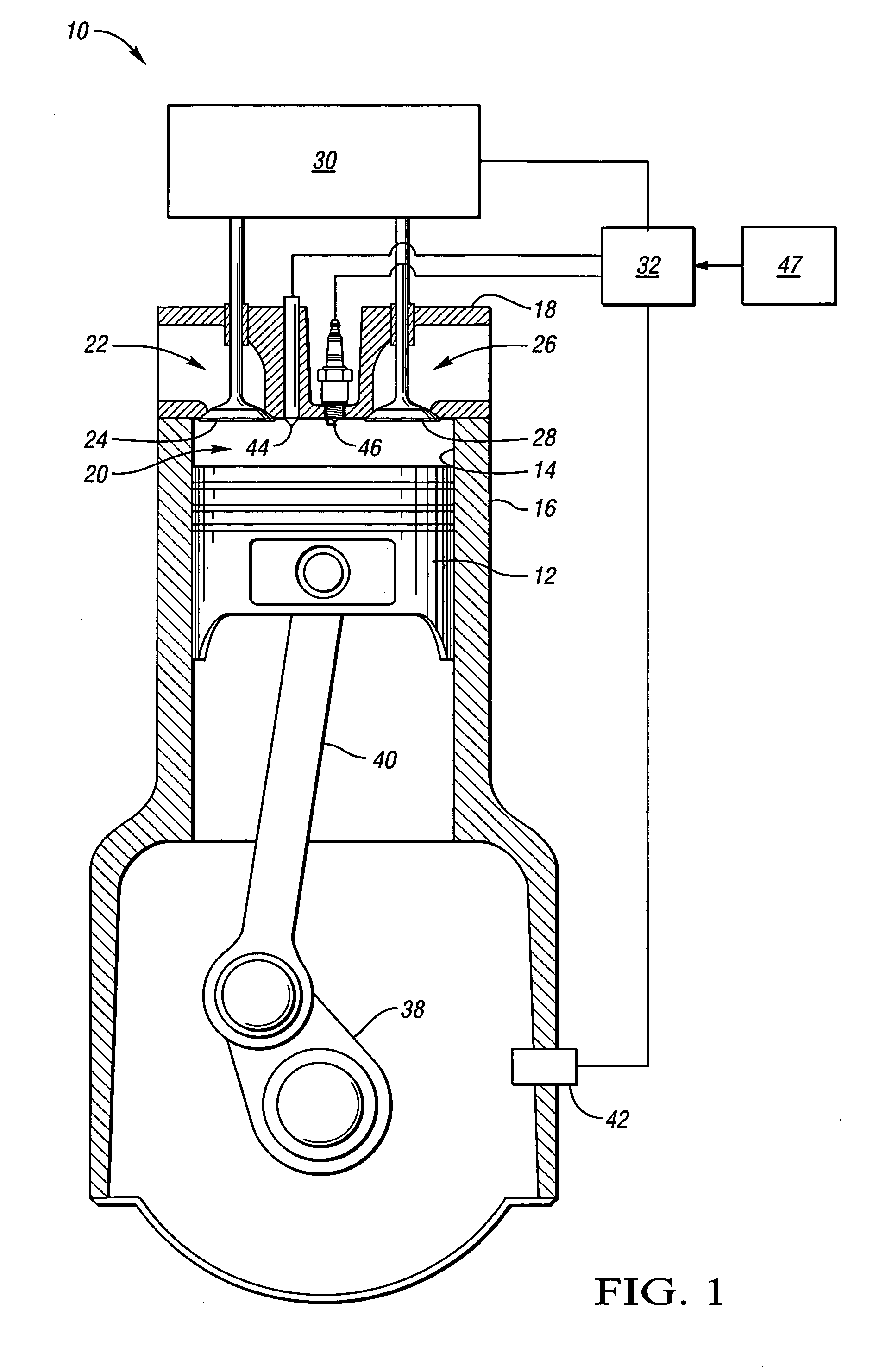

Internal combustion engine and control method thereof

InactiveUS20050097888A1Reliably activatedReduce exhaust emissionsElectrical controlInternal combustion piston enginesCombustion chamberExhaust valve

An internal combustion engine in which power is generated by burning a mixture of fuel supplied from a port injector and / or an in-cylinder injector and air in a combustion chamber, includes a valve drive mechanism which can change a valve opening characteristic of at least one of an intake valve and an exhaust valve; a turbocharger which supercharges air taken into the combustion chamber; a turbo motor which changes supercharging pressure generated by the turbocharger; a catalyst device including a catalyst which purifies exhaust gas discharged from the combustion chamber; and an ECU which controls the turbo motor such that pressure of the air taken into the combustion chamber becomes larger than back pressure until it is determined that the catalyst has been activated, and which sets a valve overlap period during which both of the intake valve and the exhaust valve are opened.

Owner:TOYOTA JIDOSHA KK

System and method for engine fuel blend control

A system for an engine, comprising of a cylinder located in the engine, a fuel delivery system for varying relative delivery amounts of a first and second injection type into said cylinder, and a controller configured to adjust a parameter affecting flow through the engine in response to said relative delivery amounts of said first and second injection type.

Owner:FORD GLOBAL TECH LLC

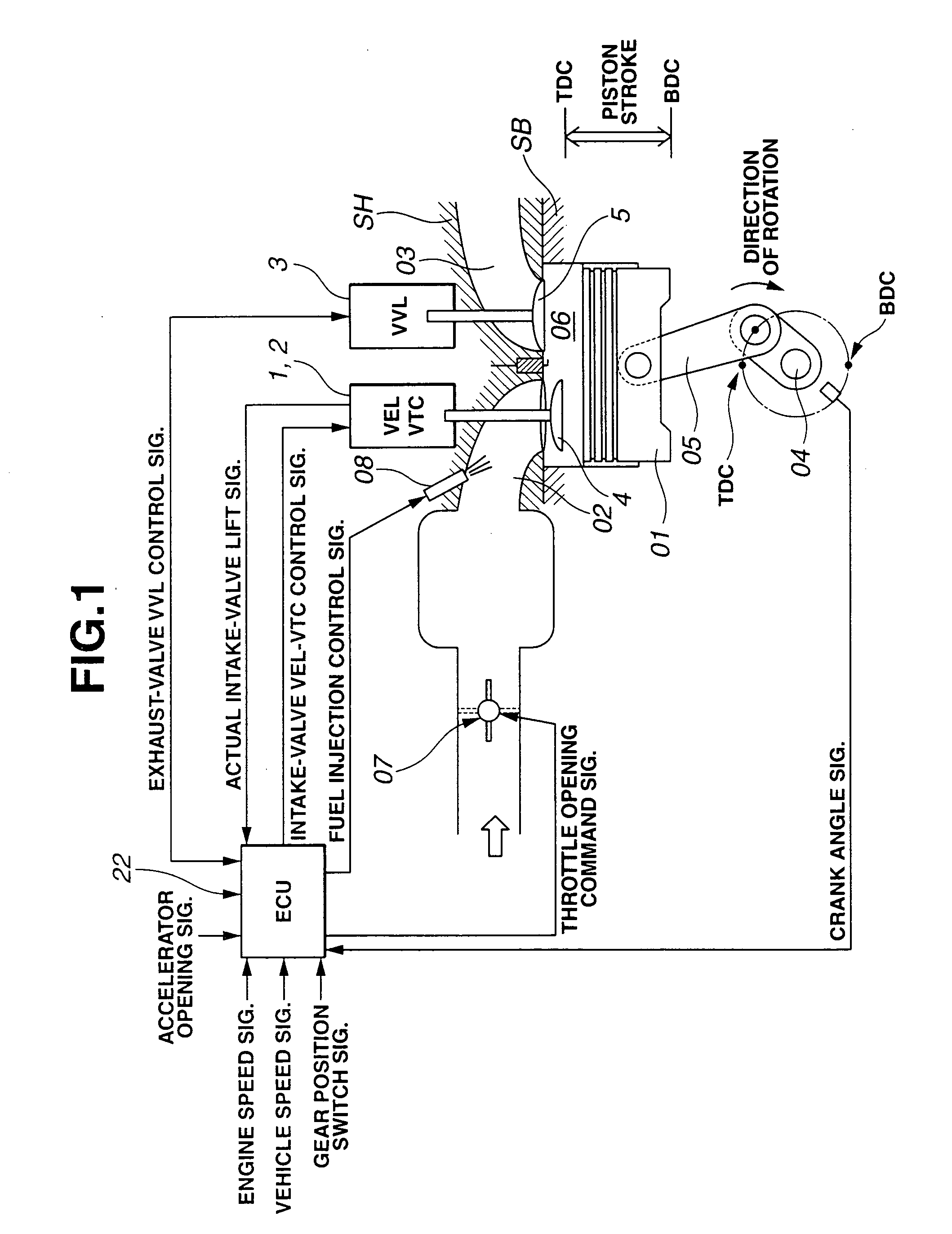

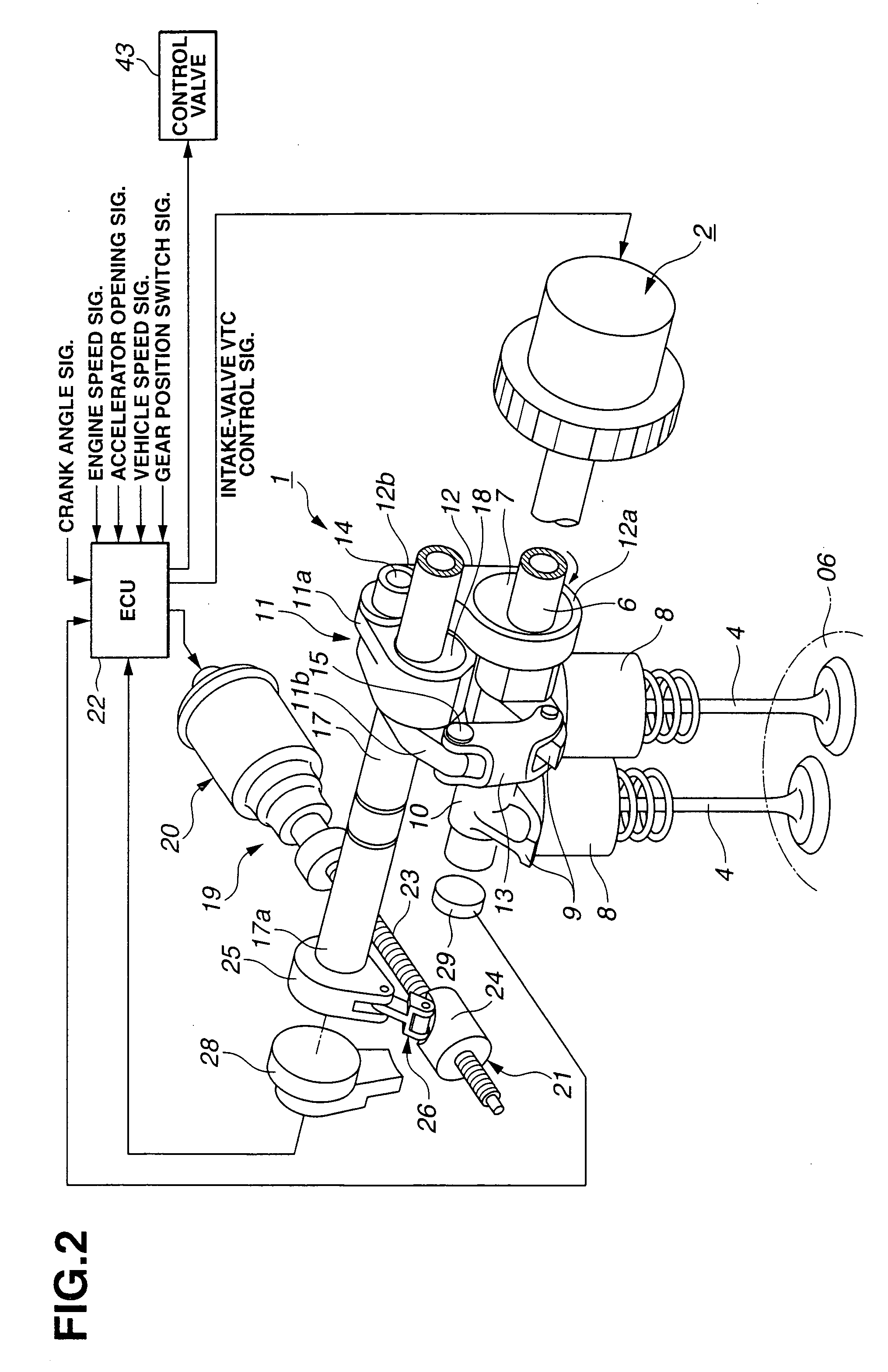

Cylinder cutoff control apparatus of internal combustion engine

InactiveUS20060037578A1Reduced engine braking effectTendency increaseValve arrangementsElectrical controlExhaust valveTop dead center

A cylinder cutoff control apparatus of an engine initiates a cylinder cutoff mode only when two conditions, namely a low load condition such as a vehicle cruising condition and an intake valve closure timing controlled to a given timing value before a bottom dead center, are both satisfied. A fuel cutoff mode is executed prior to the cylinder cutoff mode. During a transition to the cylinder cutoff mode, the control apparatus holds an intake valve open timing at a given timing value substantially corresponding to a top dead center, simultaneously with reducing an intake valve lift amount of each intake valve, subjected to cylinder cutoff control, to a zero lift. Immediately when the intake valve lift amount is reduced to below a lift threshold value, an exhaust valve lift amount of each exhaust valve, subjected to the cylinder cutoff control, is controlled to a zero lift.

Owner:HITACHI LTD

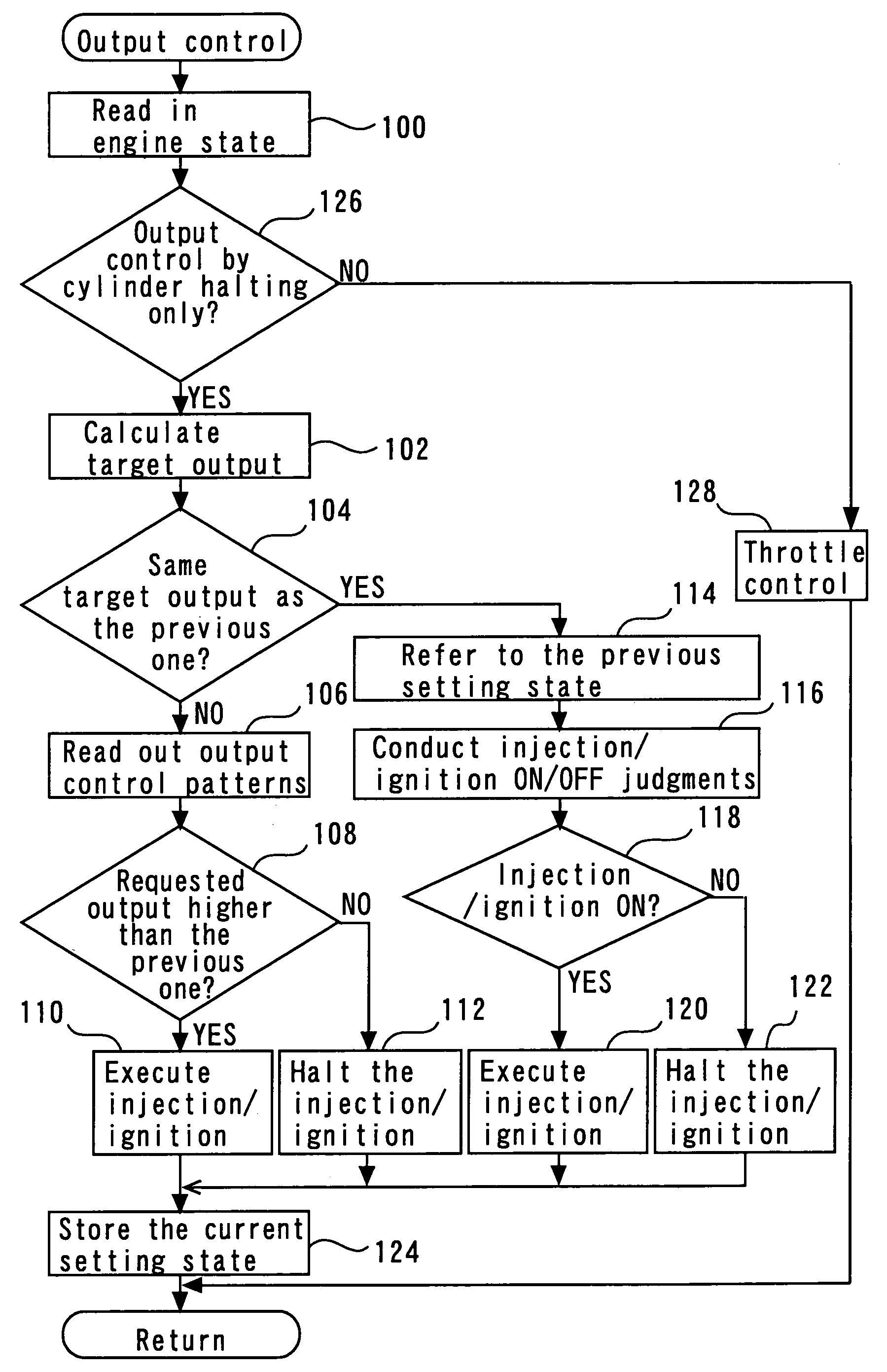

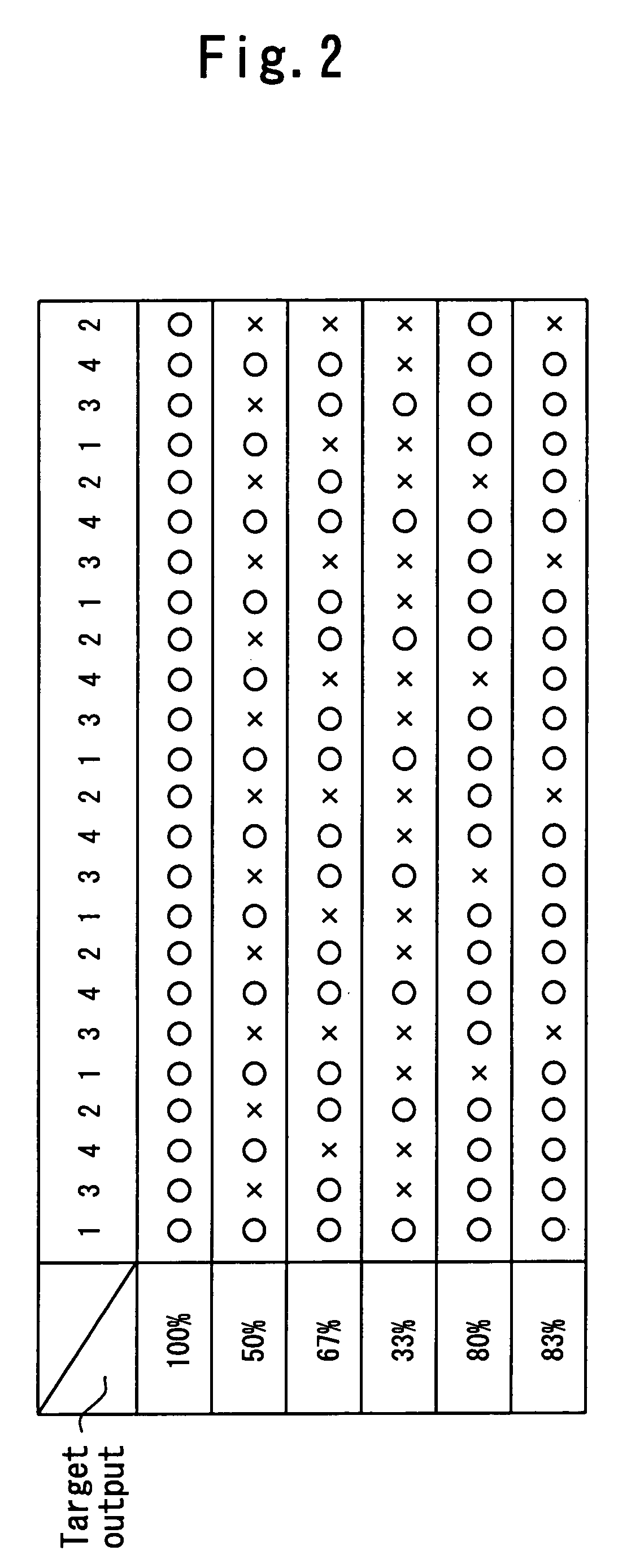

Output control system for internal combustion engine

InactiveUS7066136B2Easy to controlElectrical controlInternal combustion piston enginesCombustionExhaust valve

An intake electromagnetic driving valve and an exhaust electromagnetic driving valve are provided which use electromagnetic force to drive an intake valve and an exhaust valve, respectively. In step 102, the ratio between the number of combustion execution cycles and the number of combustion halts is set to obtain a desired target output value. Output control patterns that each consist of combustion execution timing equivalent to the required number of combustion execution cycles, and combustion halt timing equivalent to the required number of combustion halts are set in step 106, 114. In steps 108 to 112, or 118 to 122, in accordance with the output control patterns, whether combustion is to be executed is set with respect to the explosion timing that arrives in each cylinder in order.

Owner:TOYOTA JIDOSHA KK

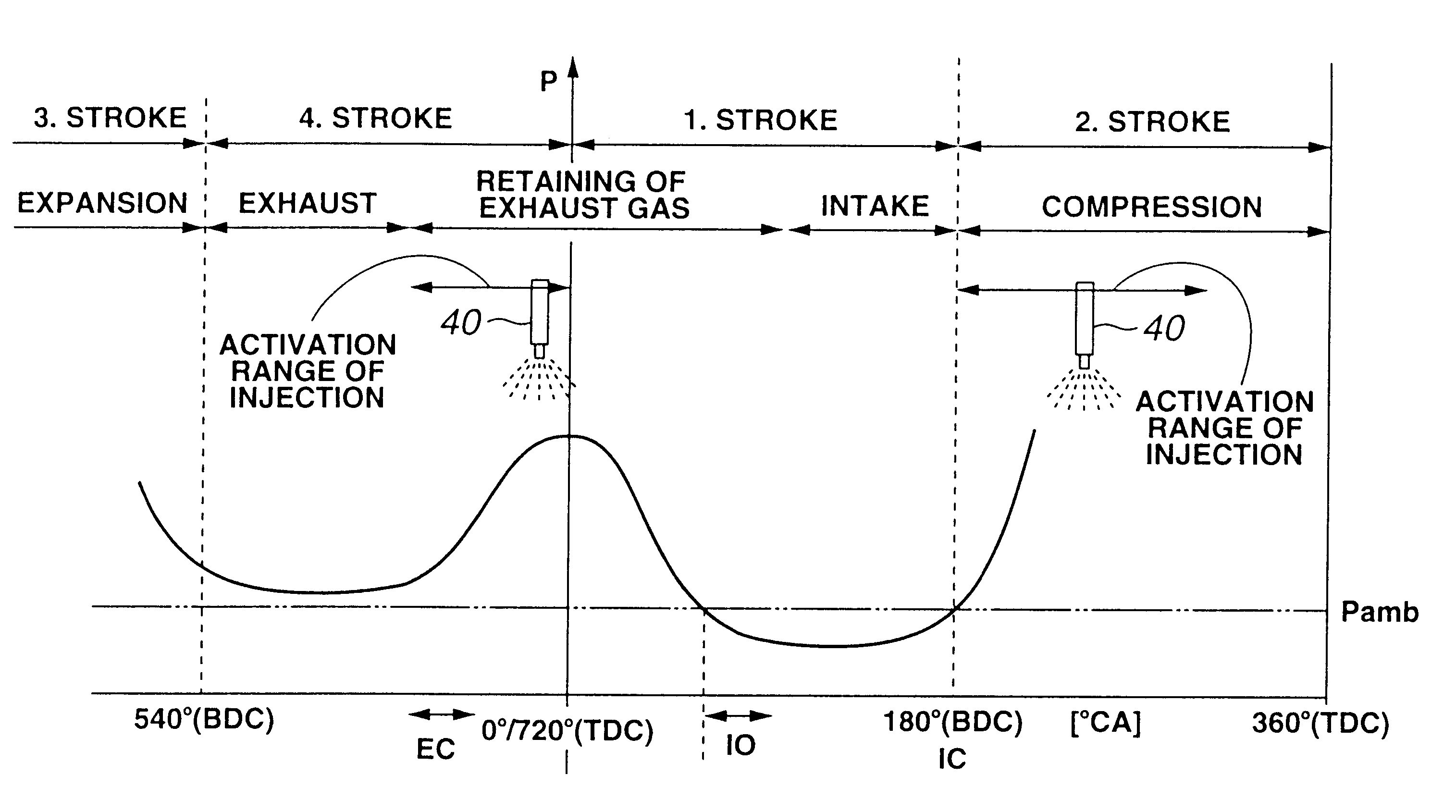

System and method for auto-ignition of gasoline internal combustion engine

During operation with part load, a gasoline internal combustion engine is operated with a lean air / fuel mixture by auto-ignition. During operation with full load, spark-ignition is used to operate the engine. The internal combustion engine is operated in three auto-ignition combustion modes depending upon magnitude of a predetermined operating parameter. The operating parameter is indicative of the engine load or the engine speed. The three auto-ignition combustion modes are a gasoline reform auto-ignition combustion mode, an auto-ignition stratified charge combustion mode, and an auto-ignition homogeneous charge combustion mode. In the gasoline reform auto-ignition combustion mode that may be selected during operation with low part load, a first fuel injection during an exhaust gas retaining phase produces sufficient amount of active fuel radicals for promotion of auto-ignition of air / fuel mixture produced by a second fuel injection during the subsequent compression phase. In the auto-ignition stratified charge combustion mode that may be selected during operation with intermediate part load, a fuel injection during compression phase supports auto-ignition. In the auto-ignition homogeneous charge combustion mode that may be selected during operation with high part load, a fuel injection during intake phase supports auto-ignition.

Owner:NISSAN MOTOR CO LTD

System and method for tip-in knock compensation

ActiveUS20070119425A1Improve the heating effectTrend downElectrical controlInternal combustion piston enginesHeat capacityOperant conditioning

A method of controlling an engine, the method comprising of providing fuel having a blend to a cylinder of the engine, actively varying said fuel blend in response to at least an operating condition, and where during a transient operating condition, said blend is adjusted to increase a heat capacity of said fuel to reduce a tendency for knock.

Owner:FORD GLOBAL TECH LLC

Firing fraction management in skip fire engine control

ActiveUS20130092128A1Reduce probabilityReduce generationElectrical controlOutput powerFire controlControl theory

In various described embodiments skip fire control is used to deliver a desired engine output. A controller determines a skip fire firing fraction and (as appropriate) associated engine settings that are suitable for delivering a requested output. In one aspect, the skip fire controller is arranged to select a base firing fraction that has a repeating firing cycle length that will repeat at least a designated number of times per second at the current engine speed. Such an arrangement can be helpful in reducing the occurrence of undesirable vibrations.

Owner:TULA TECH INC

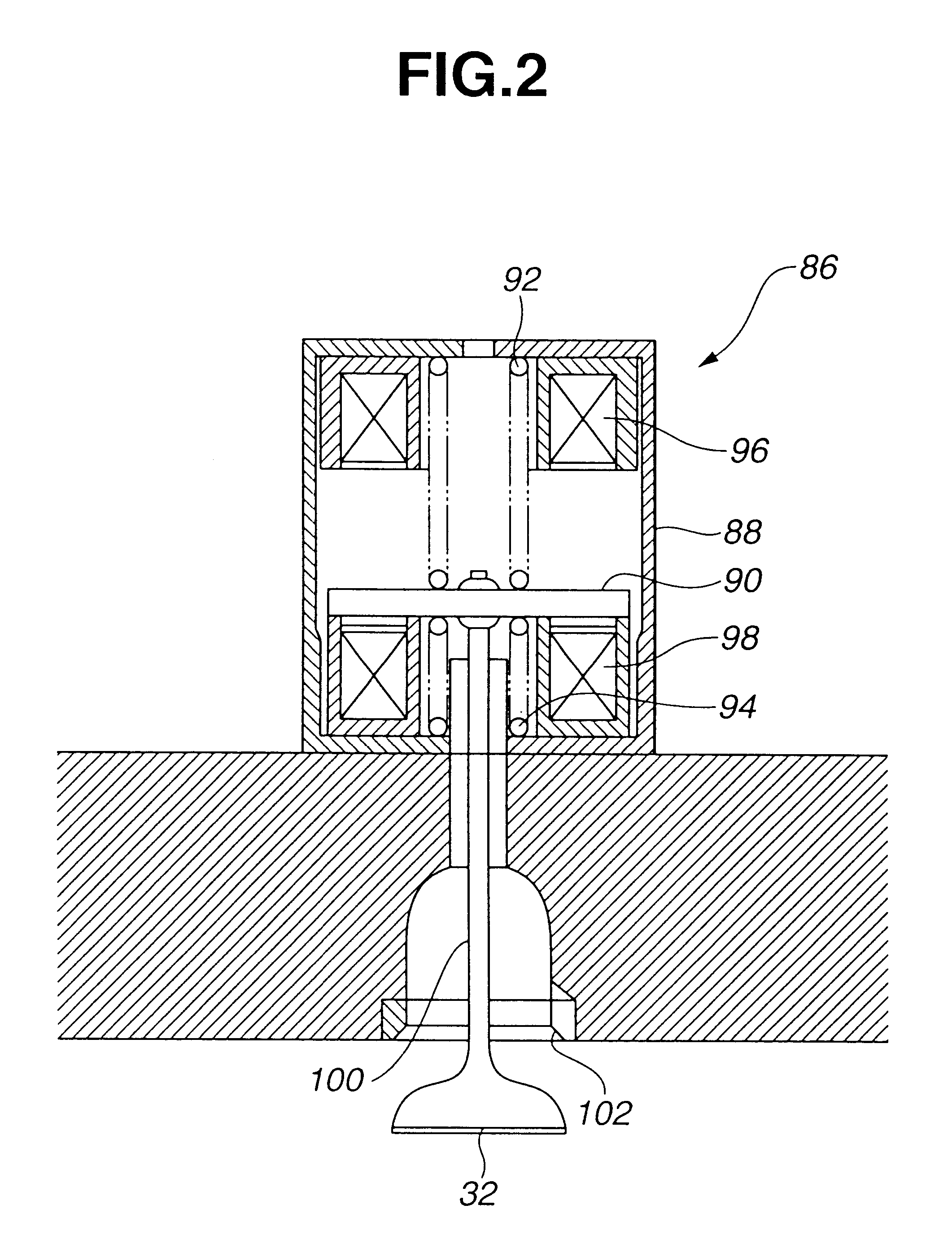

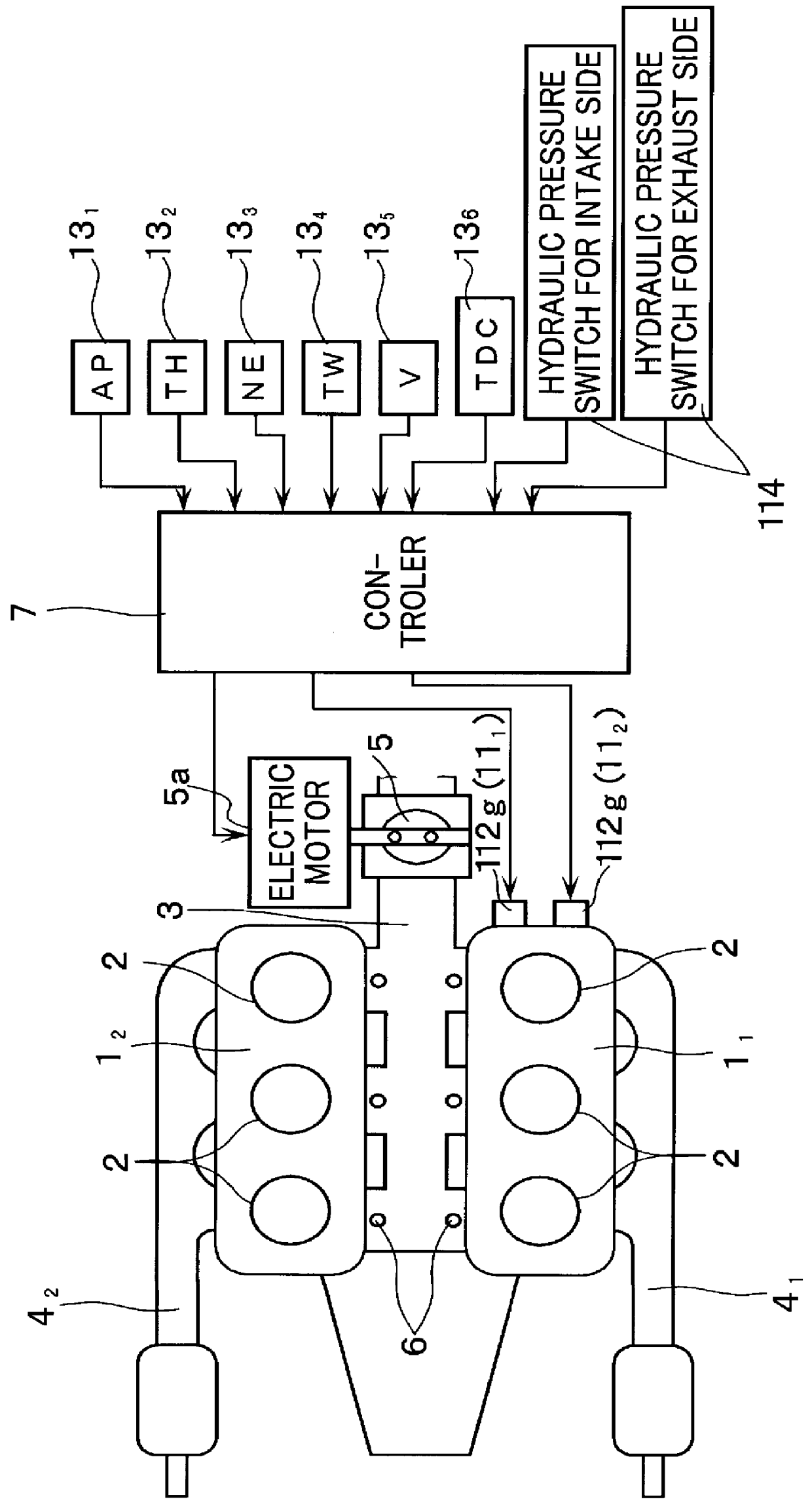

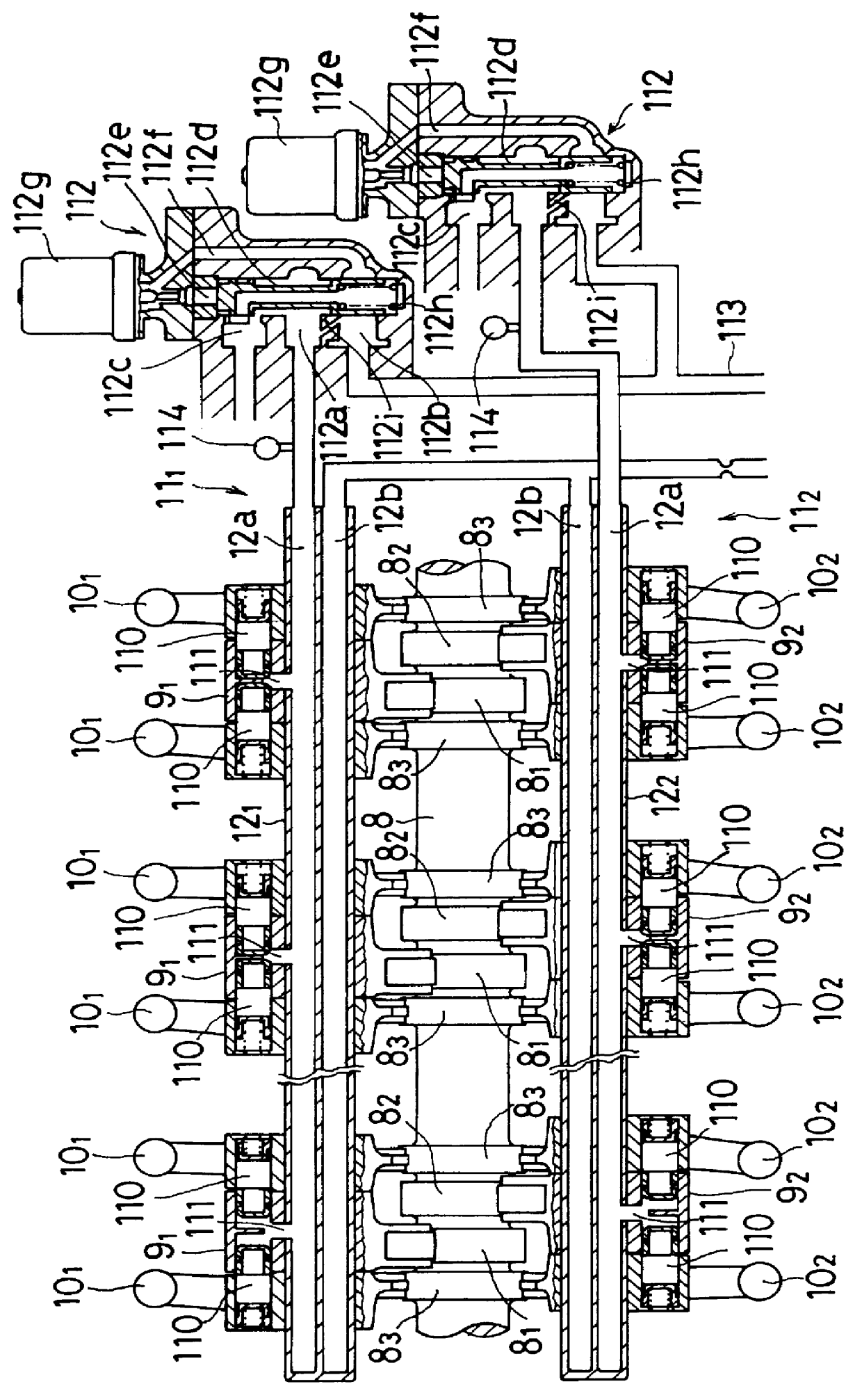

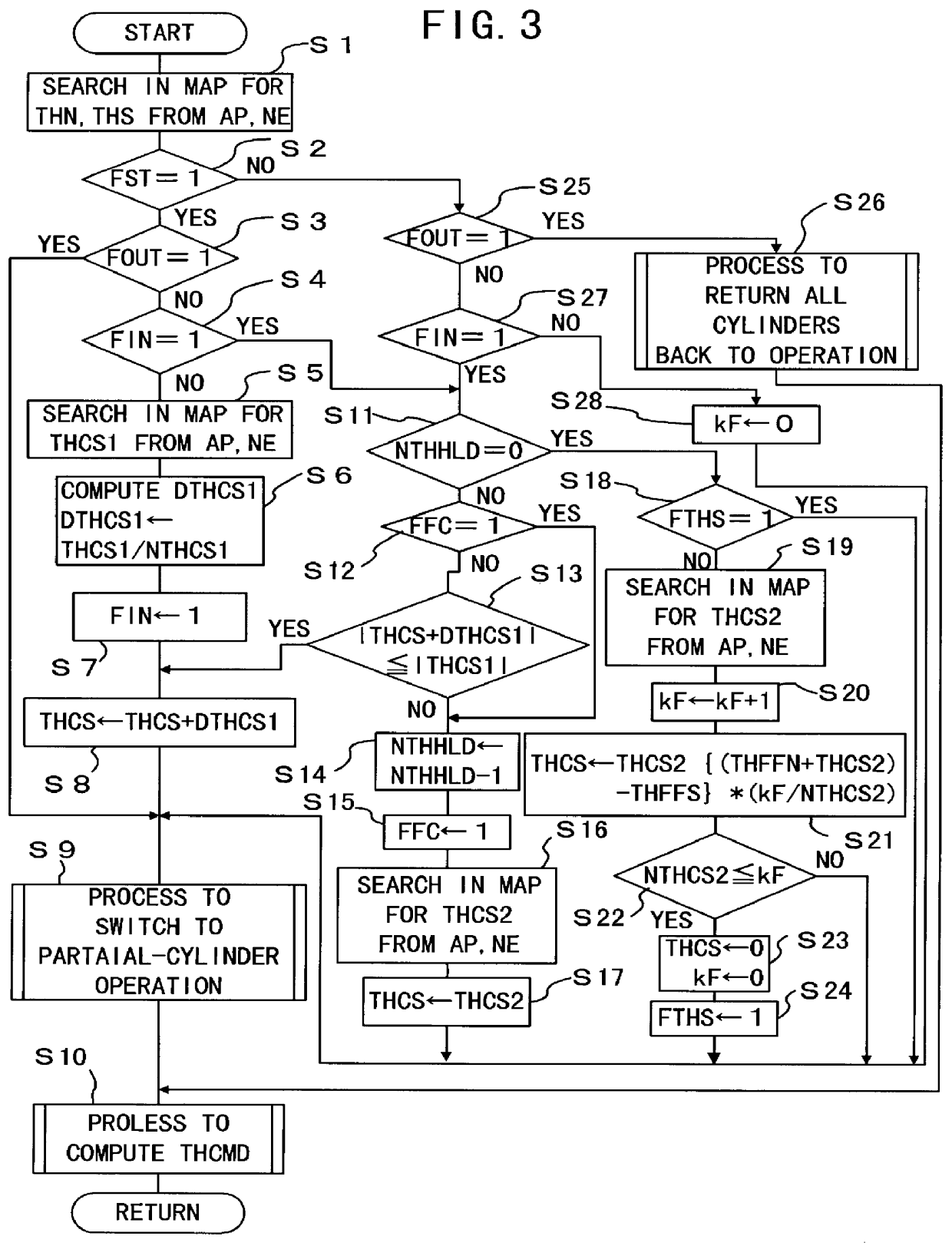

Apparatus for controlling multi-cylinder internal combustion engine with partial cylinder switching-off mechanism

In an apparatus for controlling a multi-cylinder internal combustion engine with partial cylinder switch-off mechanism which is switchable between an all-cylinder operation mode in which all cylinders are operated and a partial-cylinder operation mode in which operation of partial cylinders is suspended, the operation of intake valves and exhaust valves is suspended or resumed in a predetermined order with respect to all of the suspended cylinders irrespective of a rotational frequency of the engine. There are provided a solenoid valve on an intake side and a solenoid valve on an exhaust side for switching input hydraulic pressures for hydraulically operated switching devices respectively on the intake side and on the exhaust side between the driving state and the drive-free state. At the time of switching the operation, one of the solenoid valves on the intake side and the exhaust side is driven in advance. The subsequent number of rotations of a crankshaft is counted. When the number of this counting has reached a predetermined value, the solenoid valve on the other side is driven.

Owner:HONDA MOTOR CO LTD

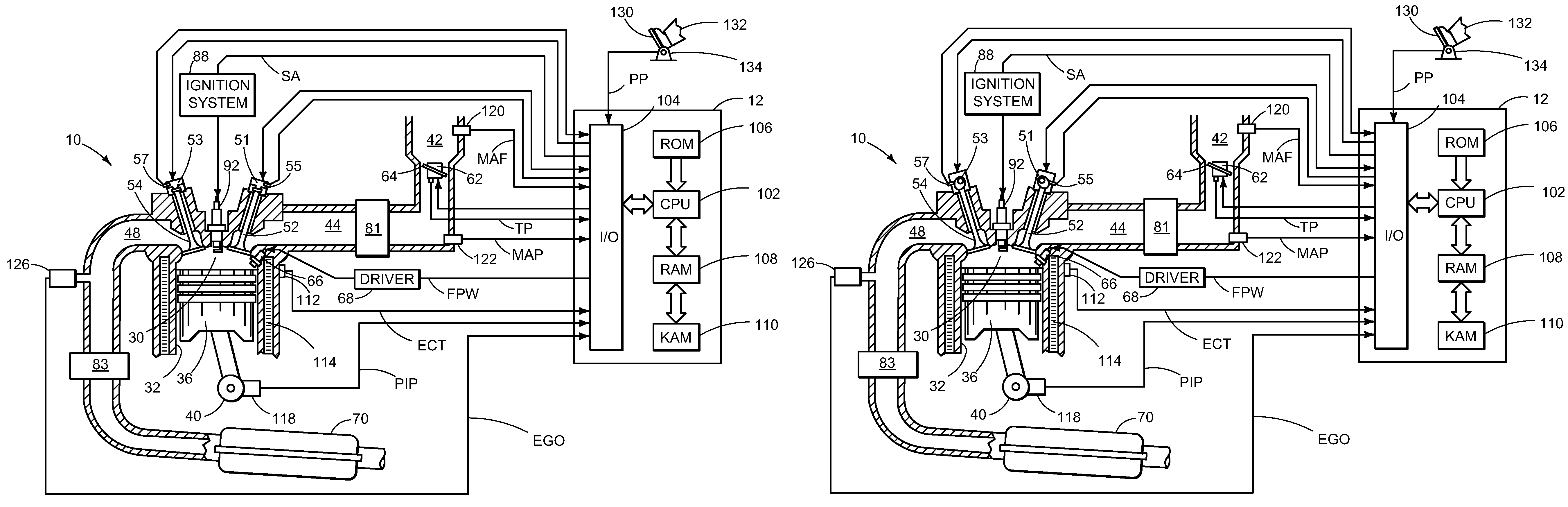

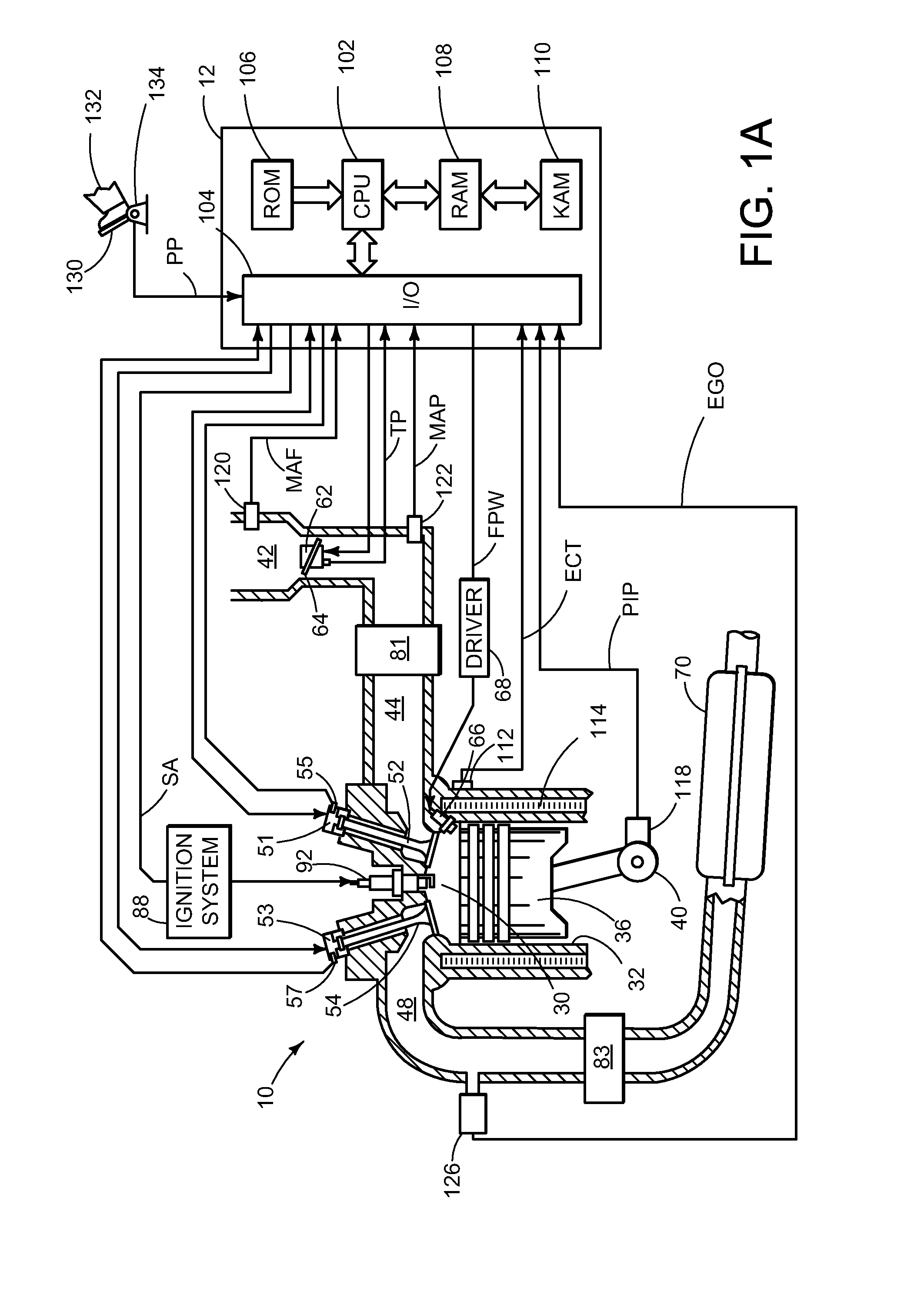

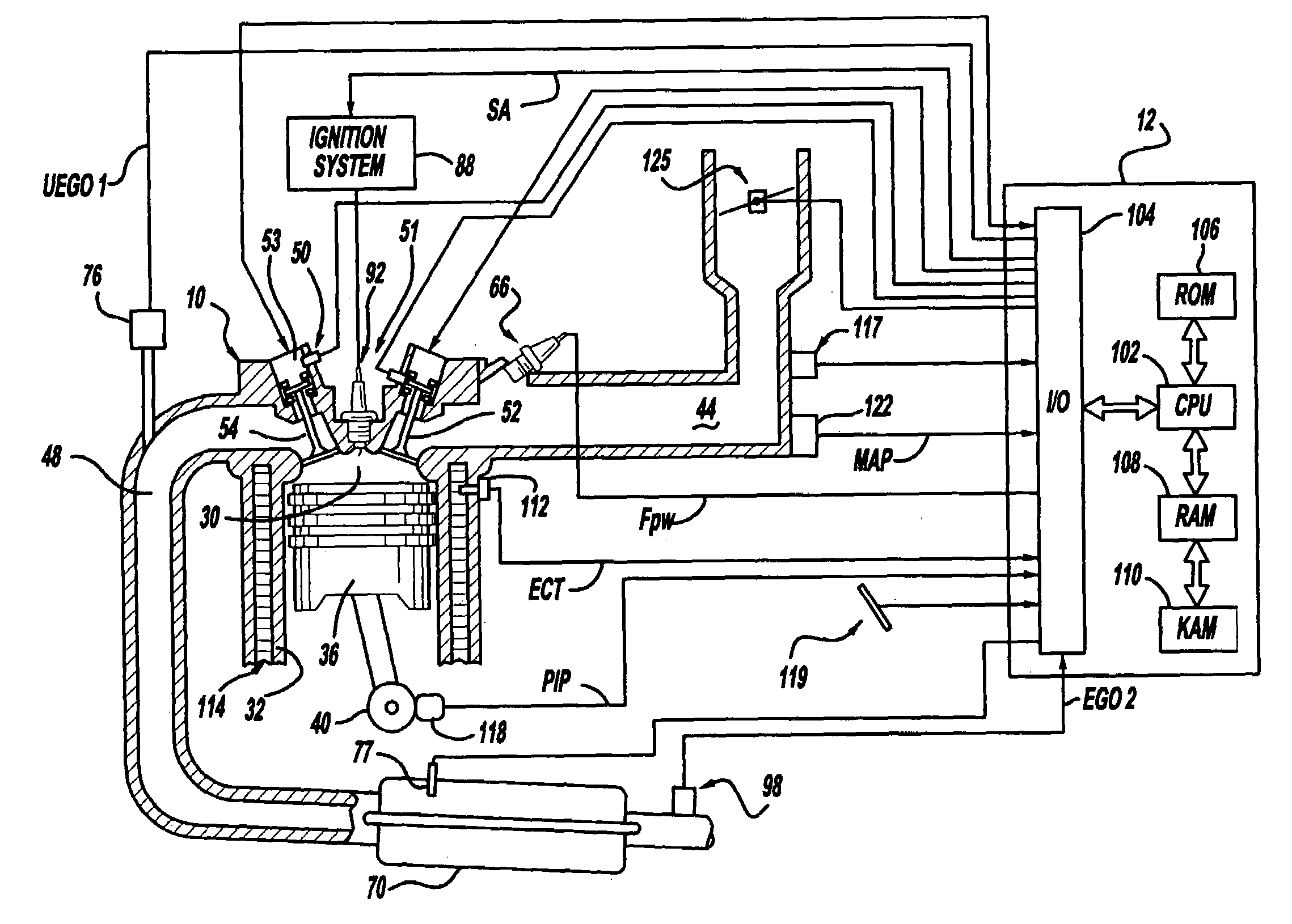

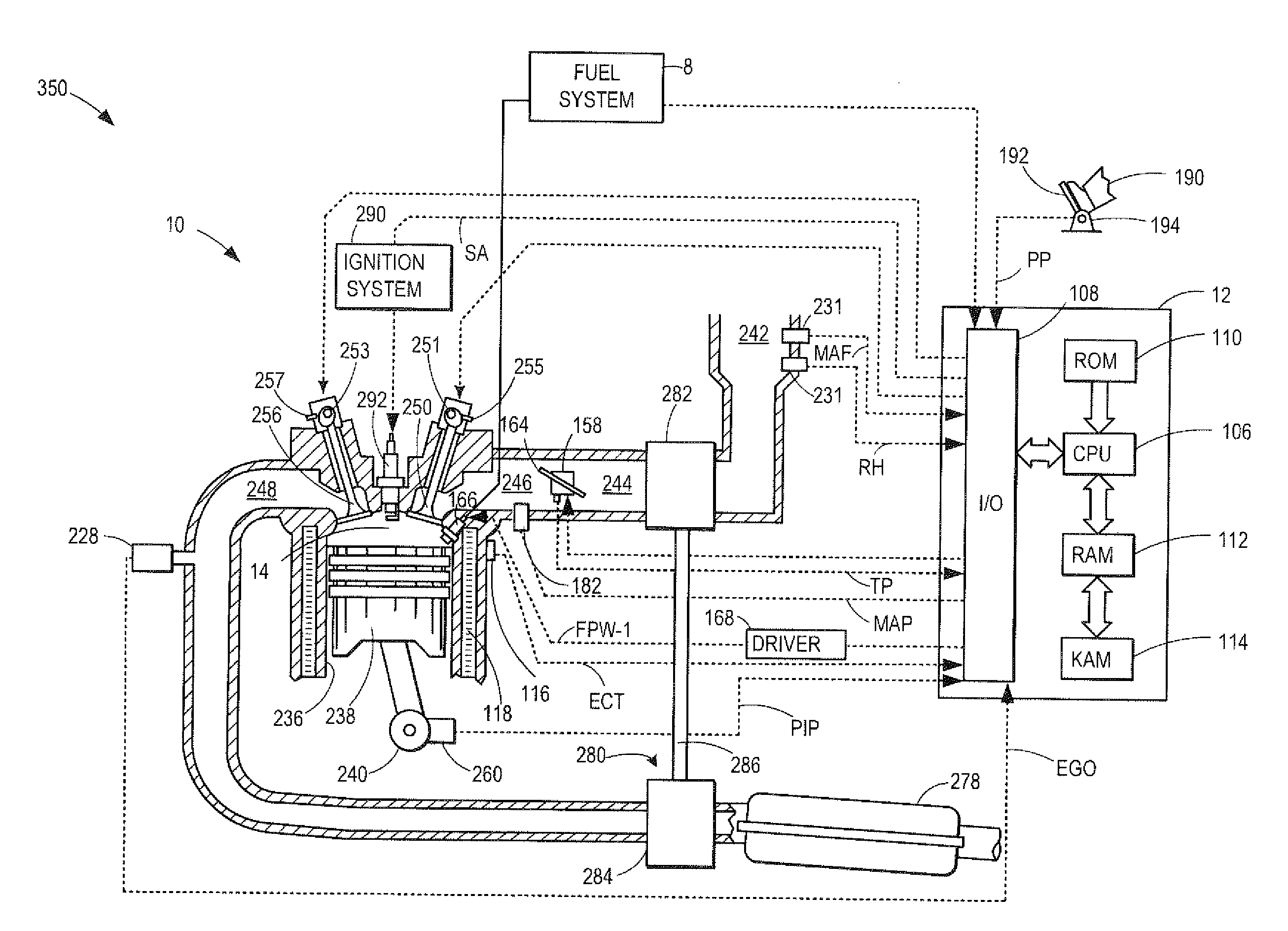

Engine air-fuel control for an engine with valves that may be deactivated

ActiveUS7032581B2Weaken influenceEasy to controlElectrical controlInternal combustion piston enginesEngine valveAir–fuel ratio

A system and method to control engine valve timing to improve air-fuel control in an engine with valves that may be deactivated. Valves that may be deactivated are controlled in a manner to improve detection of individual cylinder air-fuel ratios.

Owner:FORD GLOBAL TECH LLC

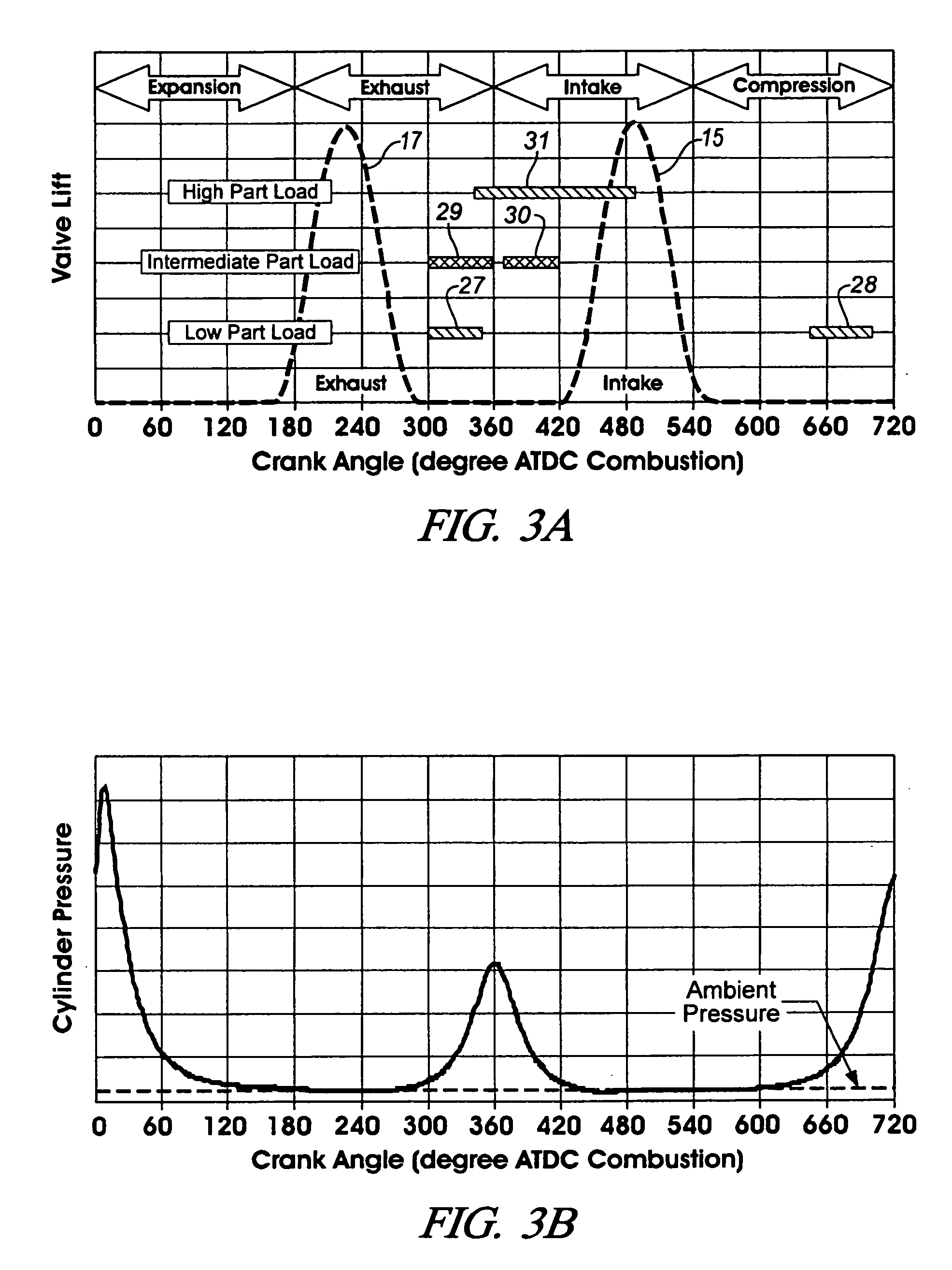

Valve and fueling strategy for operating a controlled auto-ignition four-stroke internal combustion engine

ActiveUS7021277B2Improve abilitiesReduce decreaseValve arrangementsElectrical controlCombustionOperating point

Part load operating point for a controlled auto-ignition four-stroke internal combustion engine is reduced without compromising combustion stability through load dependent valve controls and fueling strategies. Optimal fuel economy is achieved by employing negative valve overlap to trap and re-compress combusted gases below a predetermined engine load and employing exhaust gas re-breathing above the predetermined engine load. Split-injection fuel controls are implemented during low and intermediate part load operation whereas a single-injection fuel control is implemented during high part load operation. Split-injections are characterized by lean fuel / air ratios and single-injections are characterized by either lean or stoichiometric fuel / air ratios. Controlled autoignition is thereby enabled through an extended range of engine loads while maintaining acceptable combustion stability and emissions at optimal fuel economy.

Owner:GM GLOBAL TECH OPERATIONS LLC

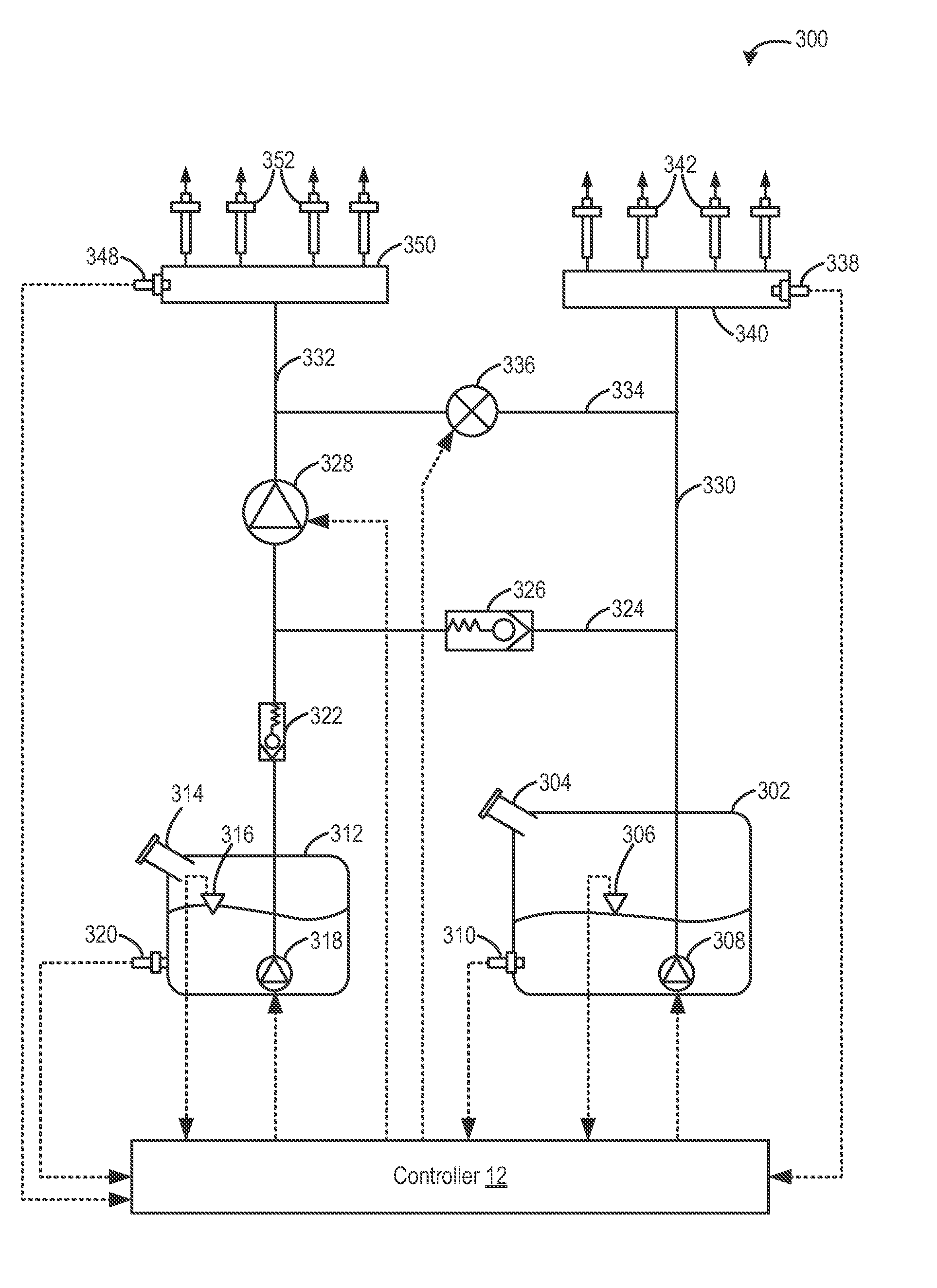

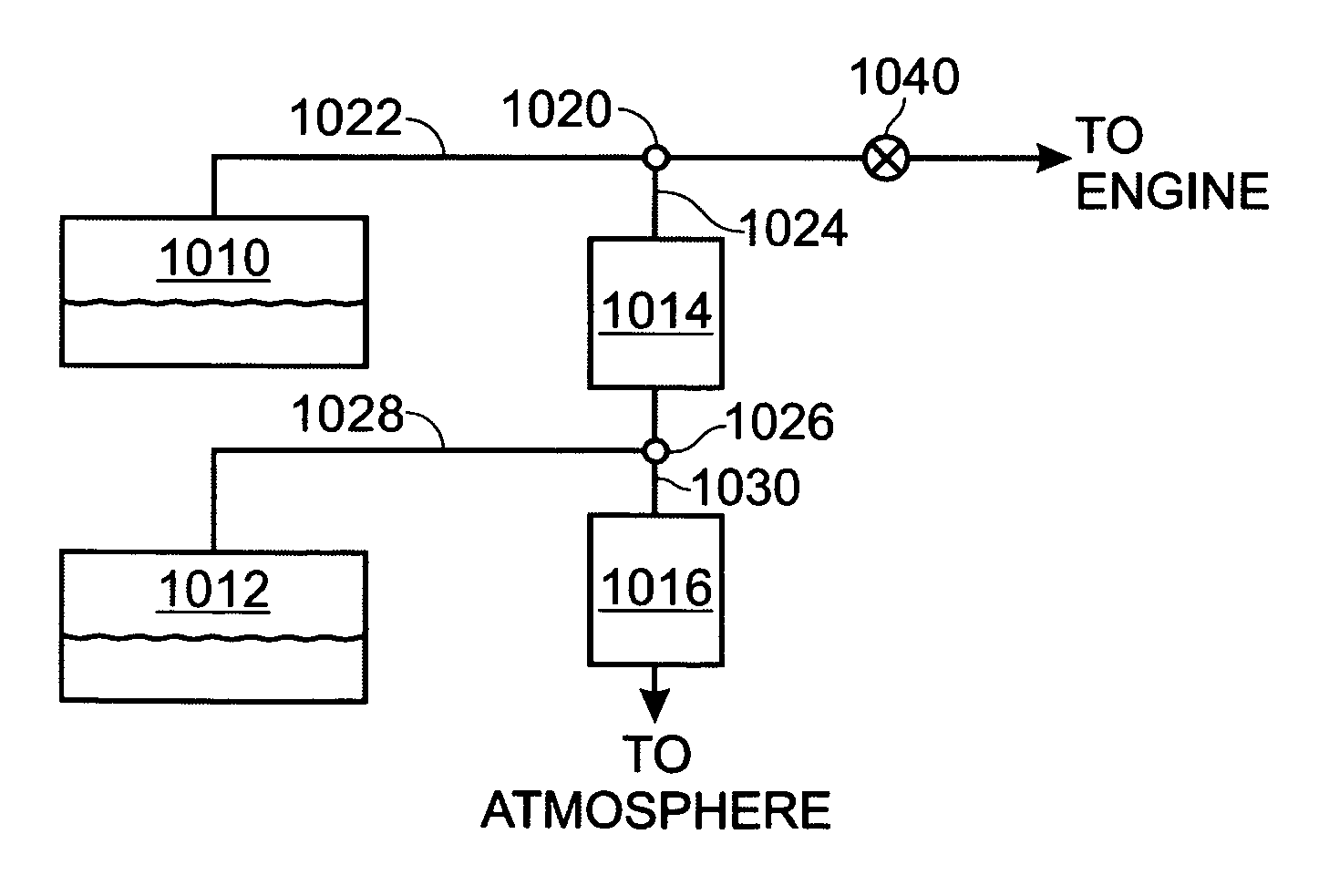

Purge system for ethanol direct injection plus gas port fuel injection

ActiveUS7293552B2Low costElectrical controlInternal combustion piston enginesPort fuel injectionEngineering

Owner:FORD GLOBAL TECH LLC

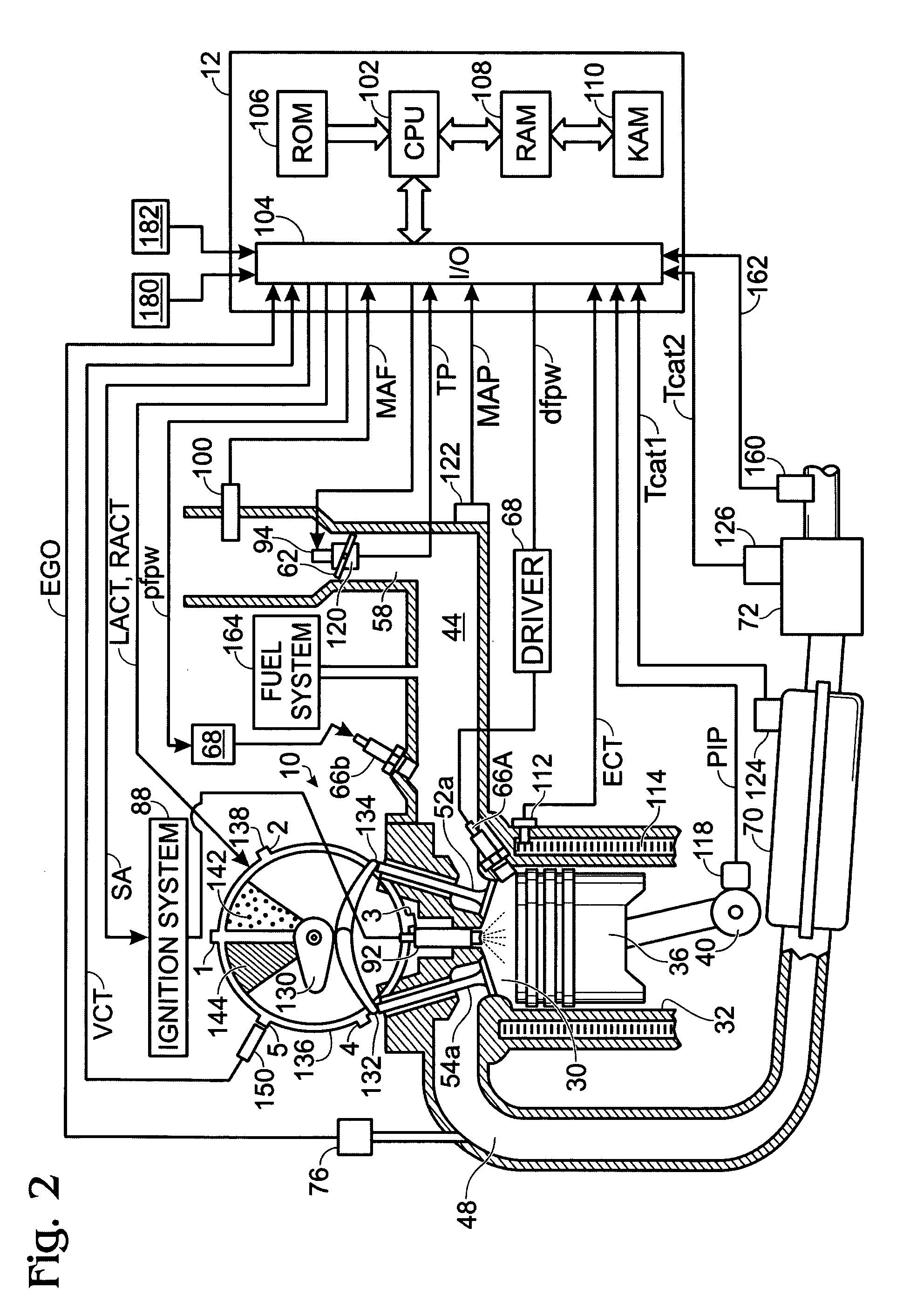

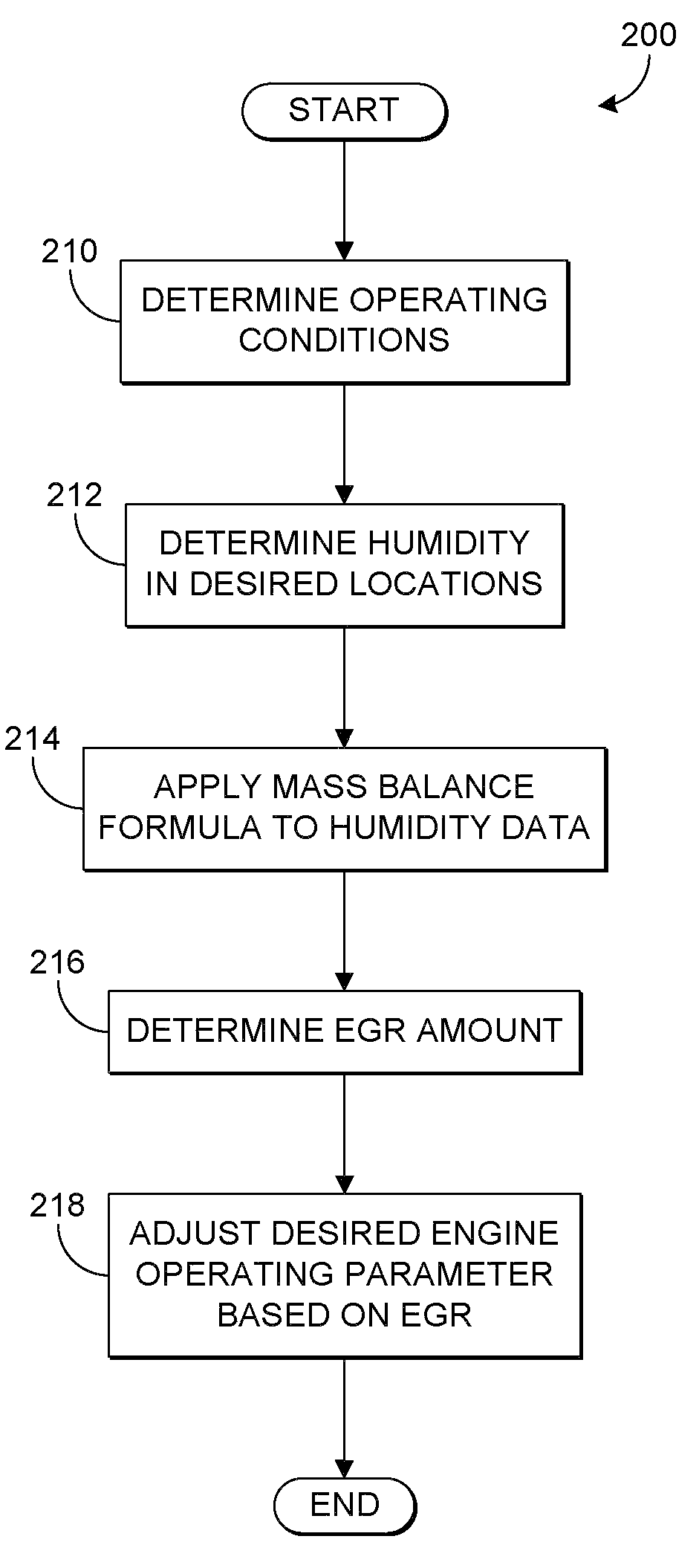

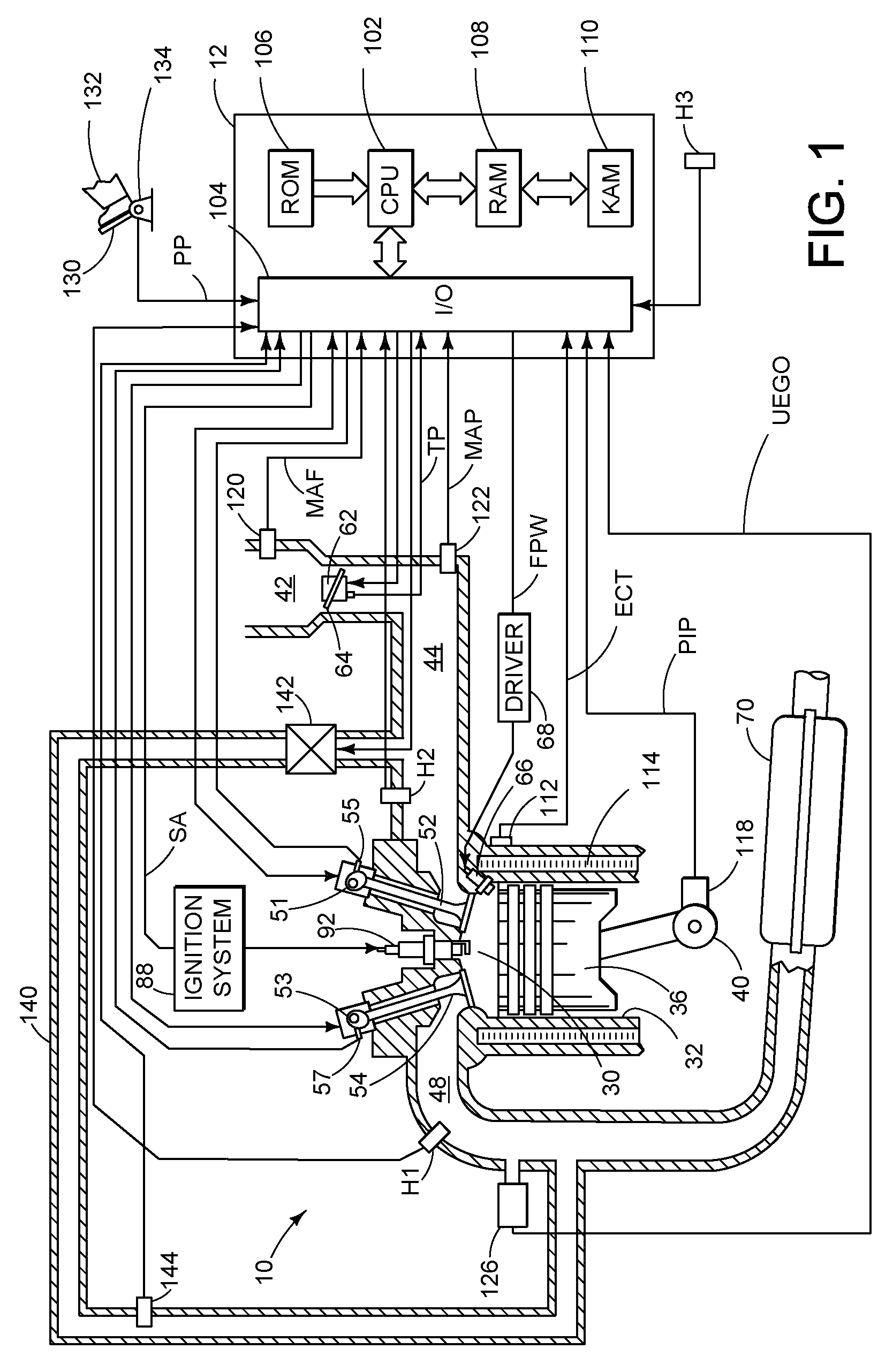

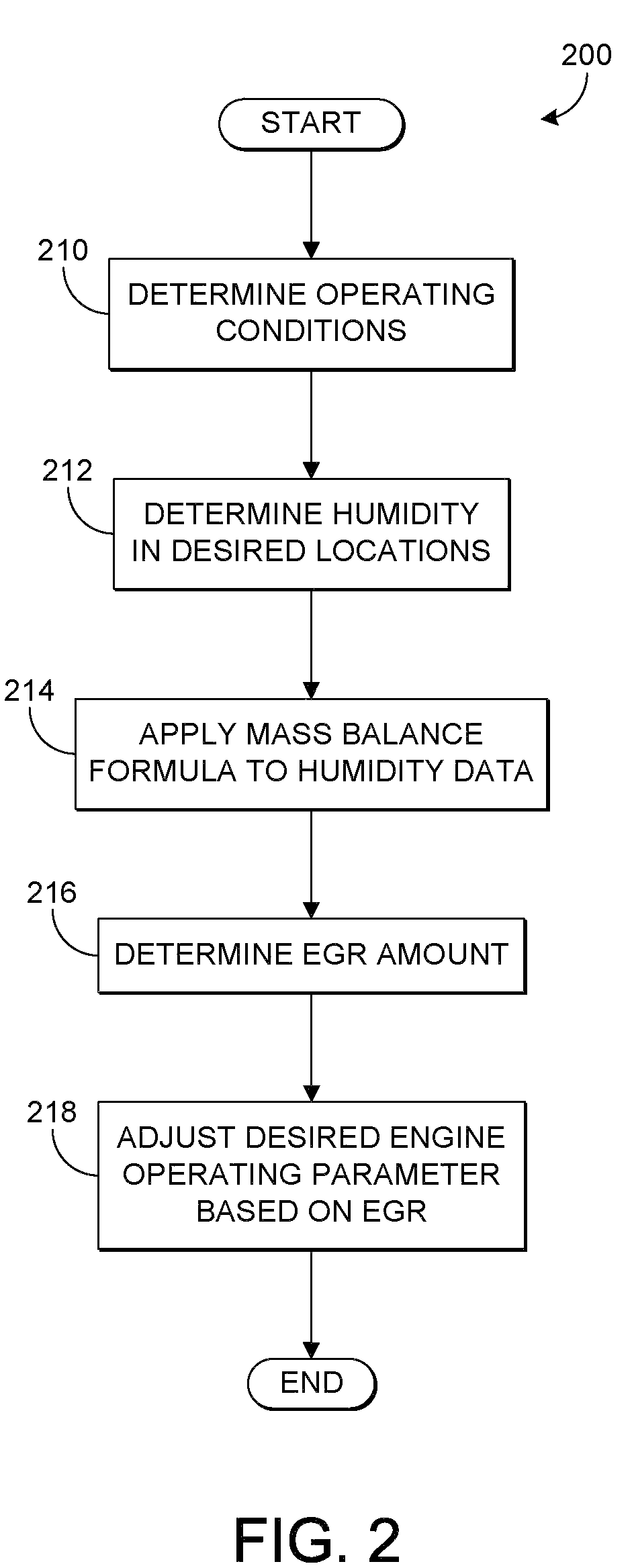

EGR detection via humidity detection

InactiveUS7715976B1Amount of EGRAccurately determineElectrical controlInternal combustion piston enginesExhaust gas recirculationMoisture sensor

Various systems and methods are described for controlling an engine in a vehicle which includes an exhaust passage and an exhaust gas recirculation system. One example method comprises adjusting an engine operating parameter based on an exhaust gas recirculation amount, the exhaust gas recirculation amount based on a first humidity and a second humidity, the first humidity generated from a first humidity sensor at a first location and the second humidity generated from a second humidity sensor located in the exhaust passage of the engine.

Owner:FORD GLOBAL TECH LLC

EGR system with dedicated EGR cylinders

Improved exhaust gas recirculation system and methods that use one or more of the engine's cylinders as dedicated EGR cylinders. All of the exhaust from the dedicated EGR cylinders is recirculated back to the engine intake. Thus, the EGR rate is constant, but the EGR mass flow may be controlled by adjusting the air-fuel ratio of the dedicated EGR cylinders or by using various variable valve timing techniques.

Owner:SOUTHWEST RES INST

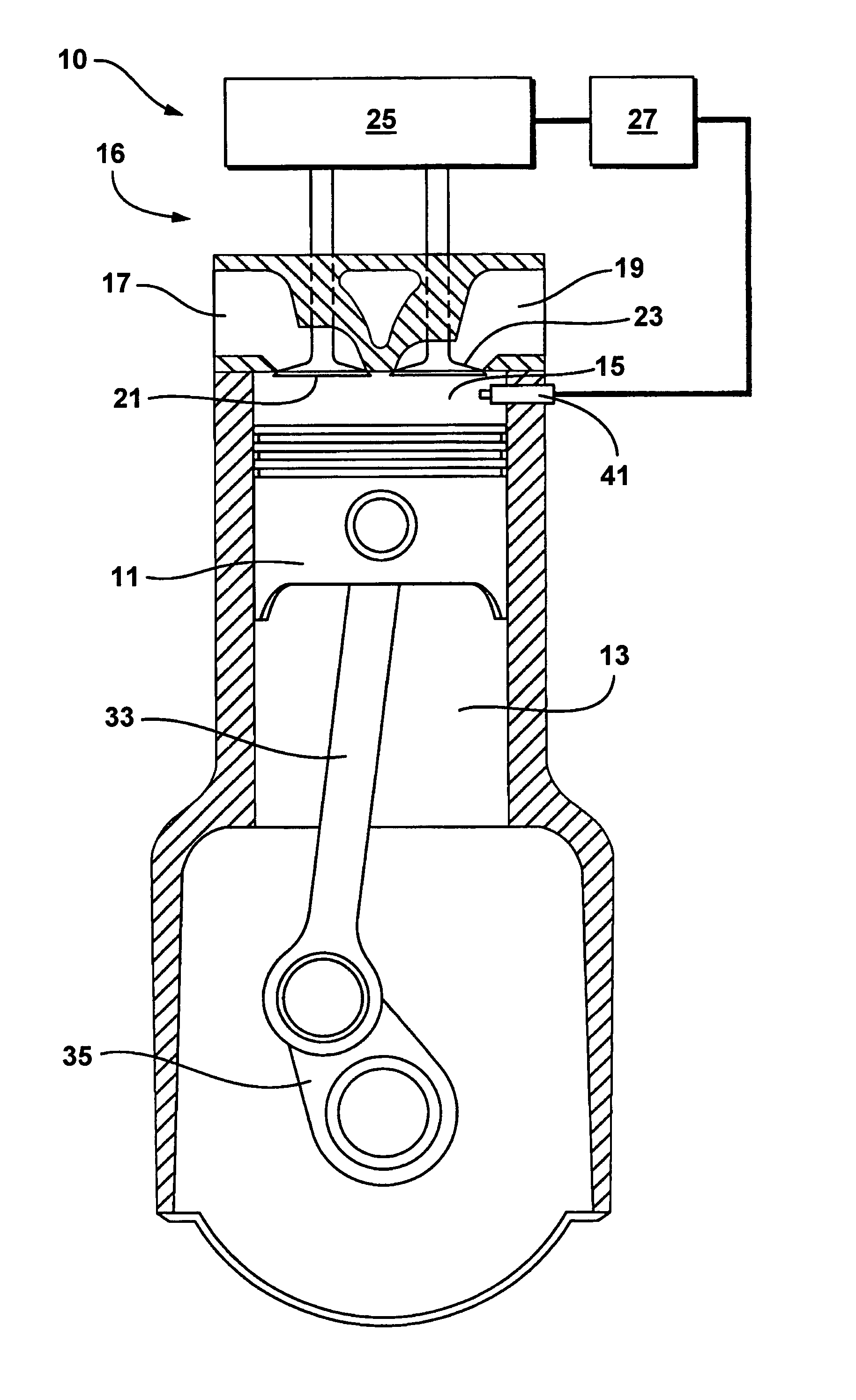

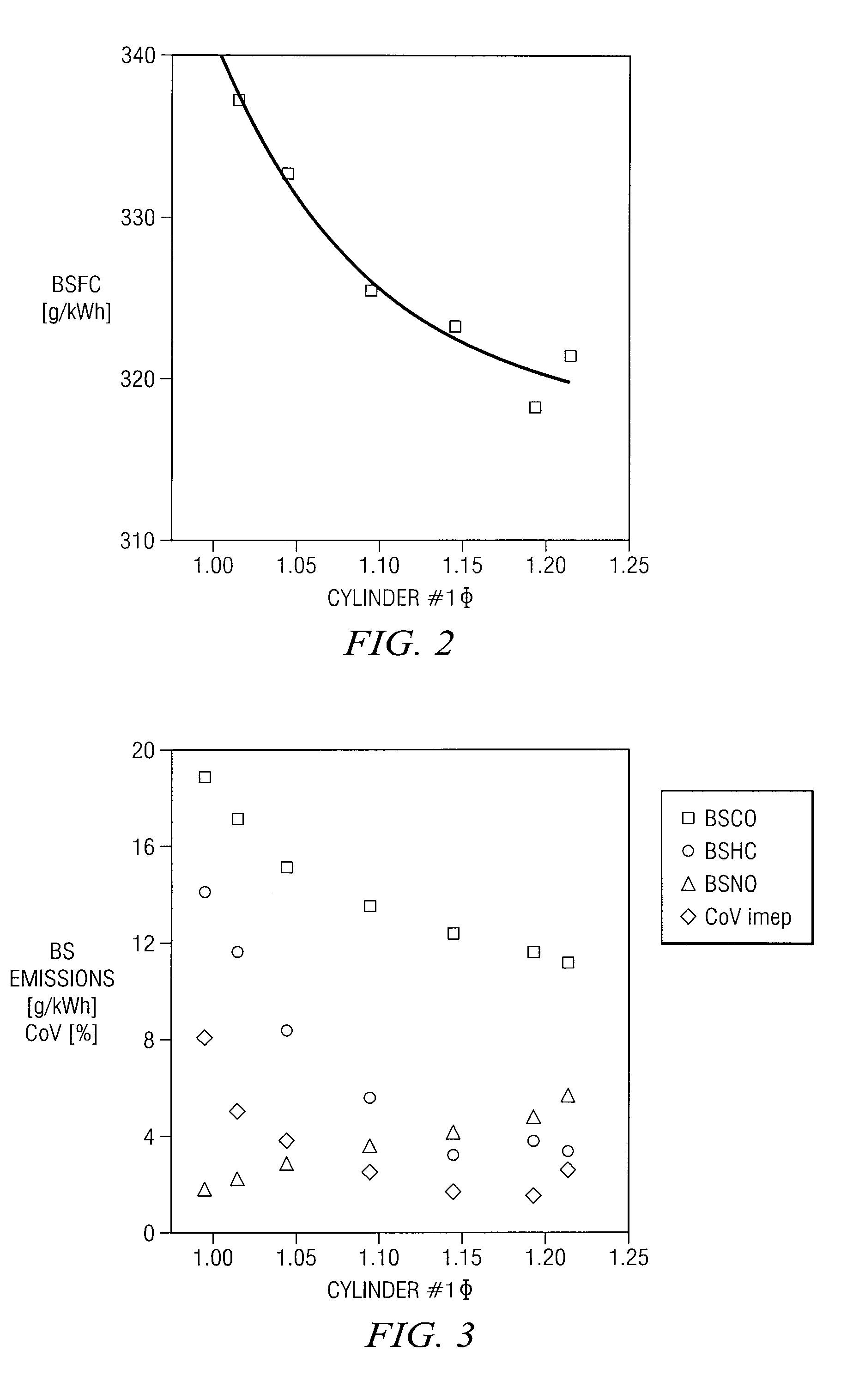

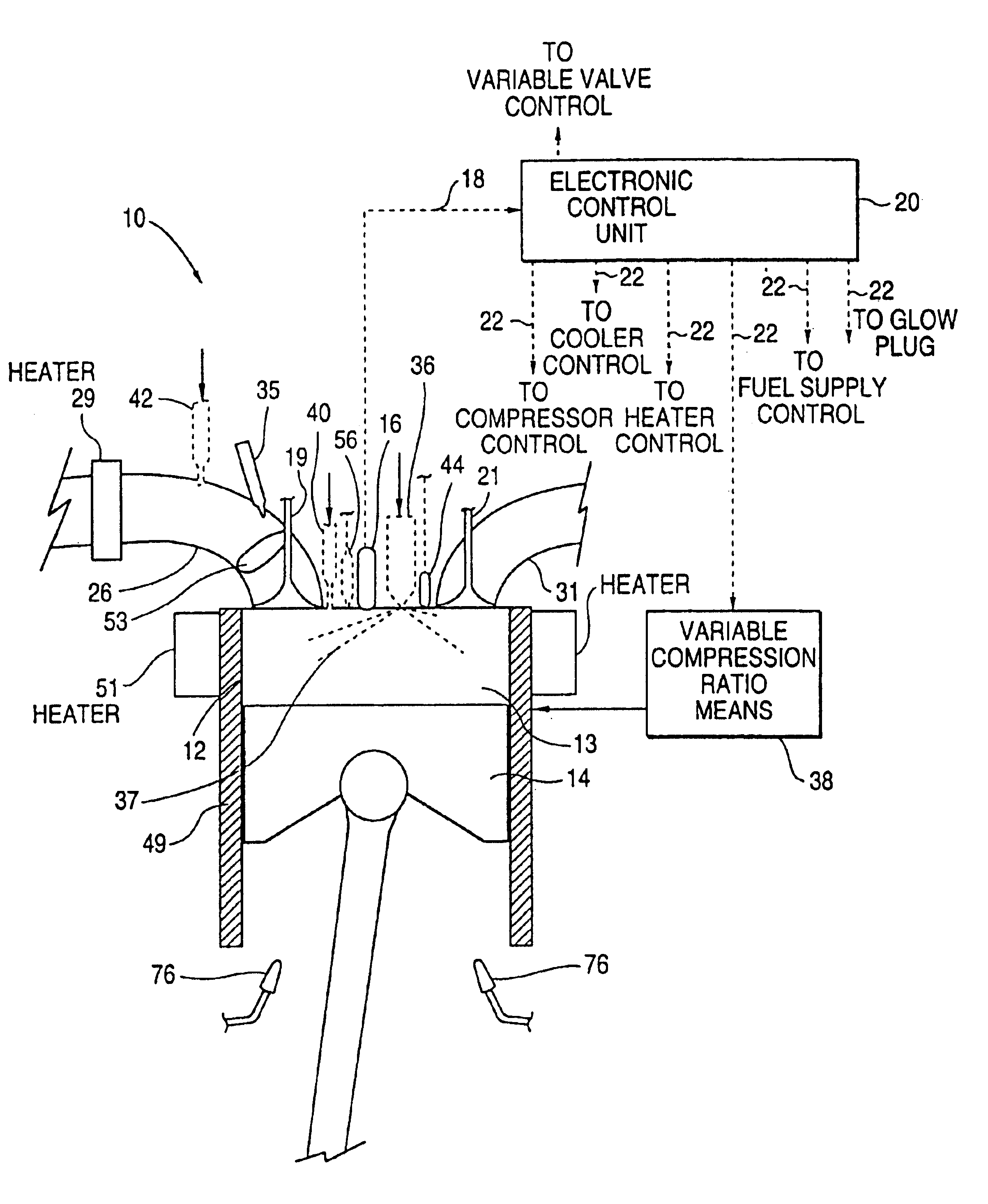

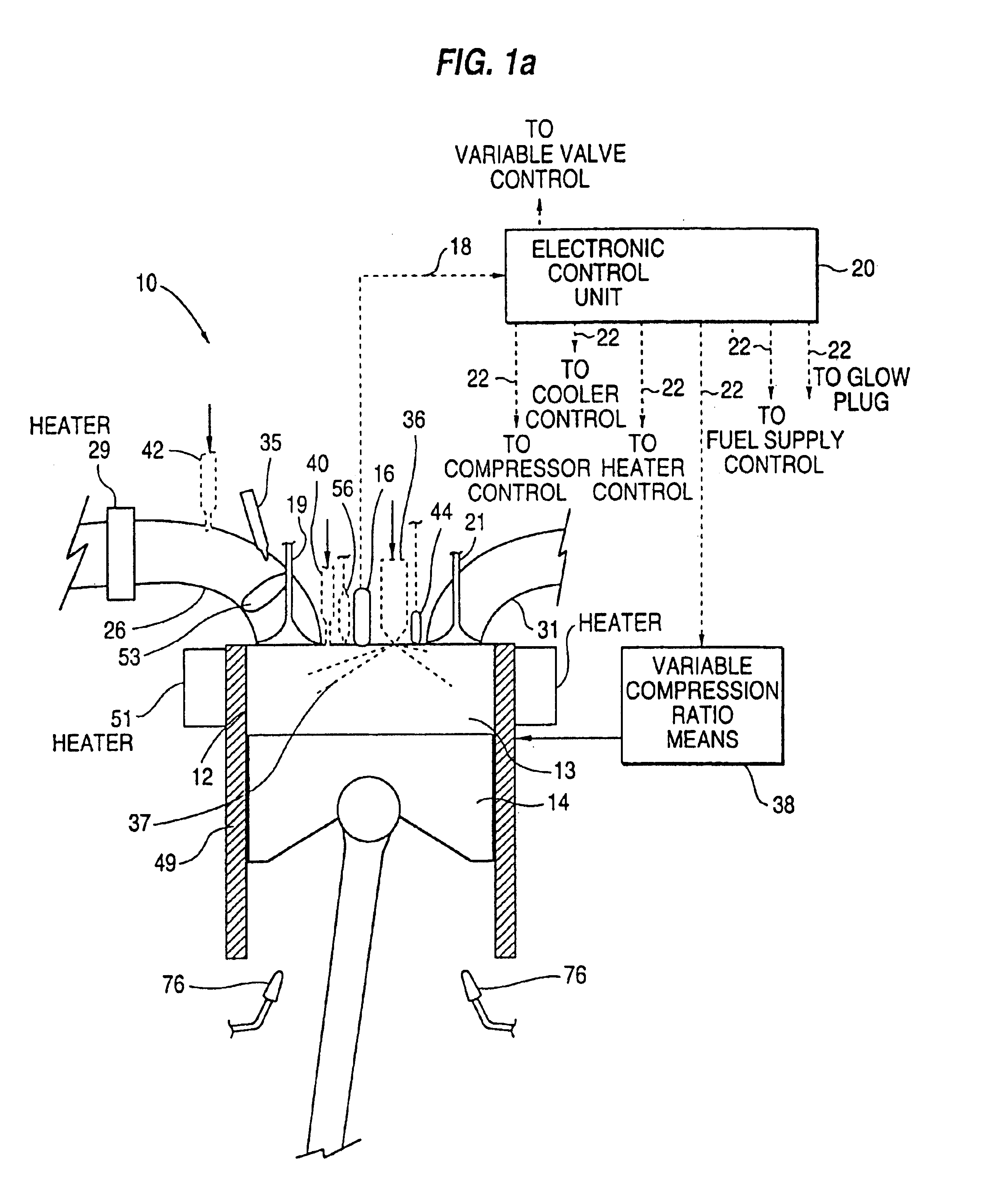

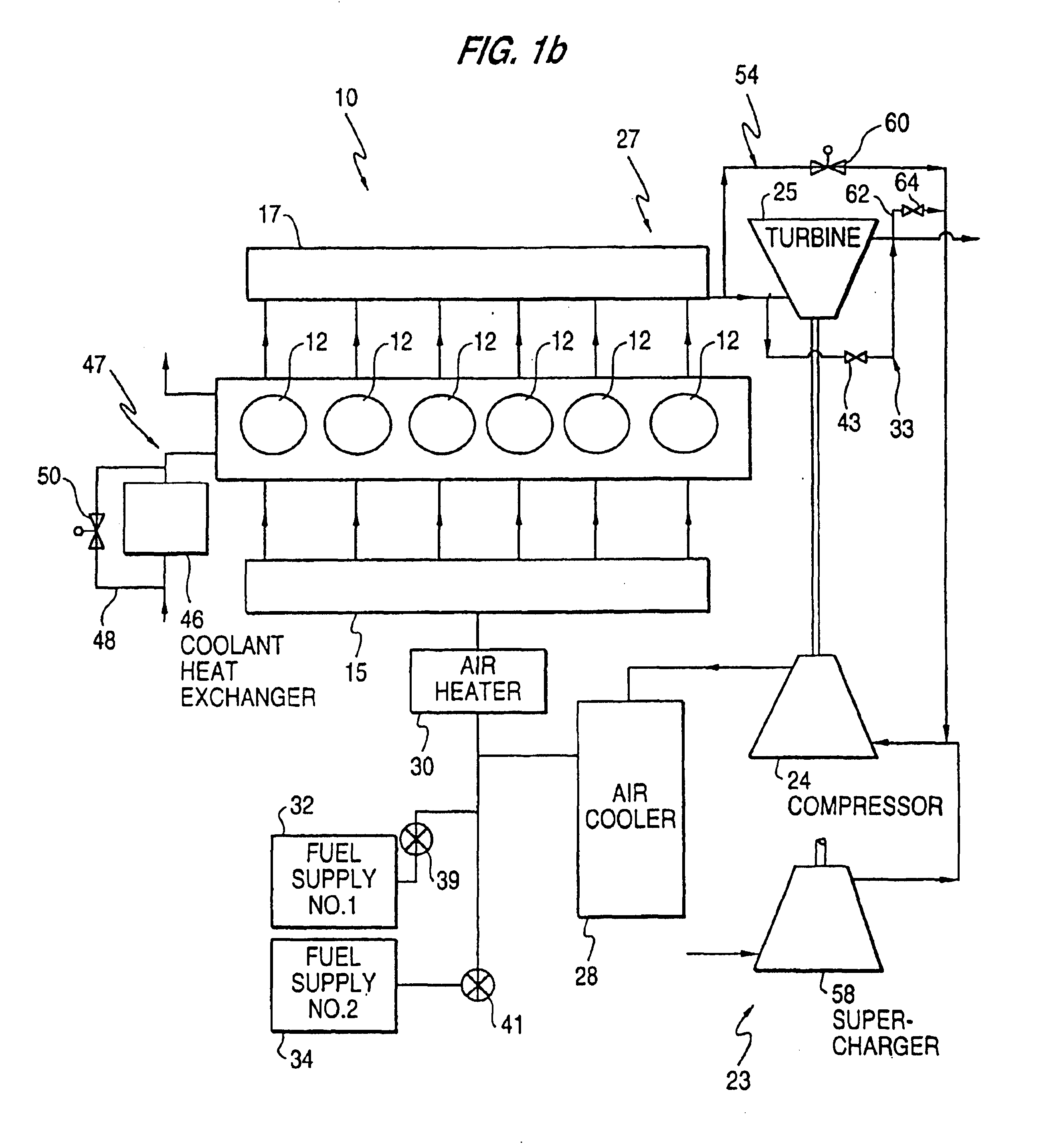

Premixed charge compression ignition engine with optimal combustion control

InactiveUS6915776B2Operate efficiently and effectivelyOvercome deficienciesElectrical controlNon-fuel substance addition to fuelCombustion noiseControl signal

A premixed charge compression ignition engine, and a control system, is provided which effectively initiates combustion by compression ignition and maintains stable combustion while achieving extremely low nitrous oxide emissions, good overall efficiency and acceptable combustion noise and cylinder pressures. The present engine and control system effectively controls the combustion history, that is, the time at which combustion occurs, the rate of combustion, the duration of combustion and / or the completeness of combustion, by controlling the operation of certain control variables providing temperature control, pressure control, control of the mixture's autoignition properties and equivalence ratio control. The combustion control system provides active feedback control of the combustion event and includes a sensor, e.g. pressure sensor, for detecting an engine operating condition indicative of the combustion history, e.g. the start of combustion, and generating an associated engine operating condition signal. A processor receives the signal and generates control signals based on the engine operating condition signal for controlling various engine components to control the temperature, pressure, equivalence ratio and / or autoignition properties so as to variably control the combustion history of future combustion events to achieve stable, low emission combustion in each cylinder and combustion balancing between the cylinders.

Owner:CUMMINS INC

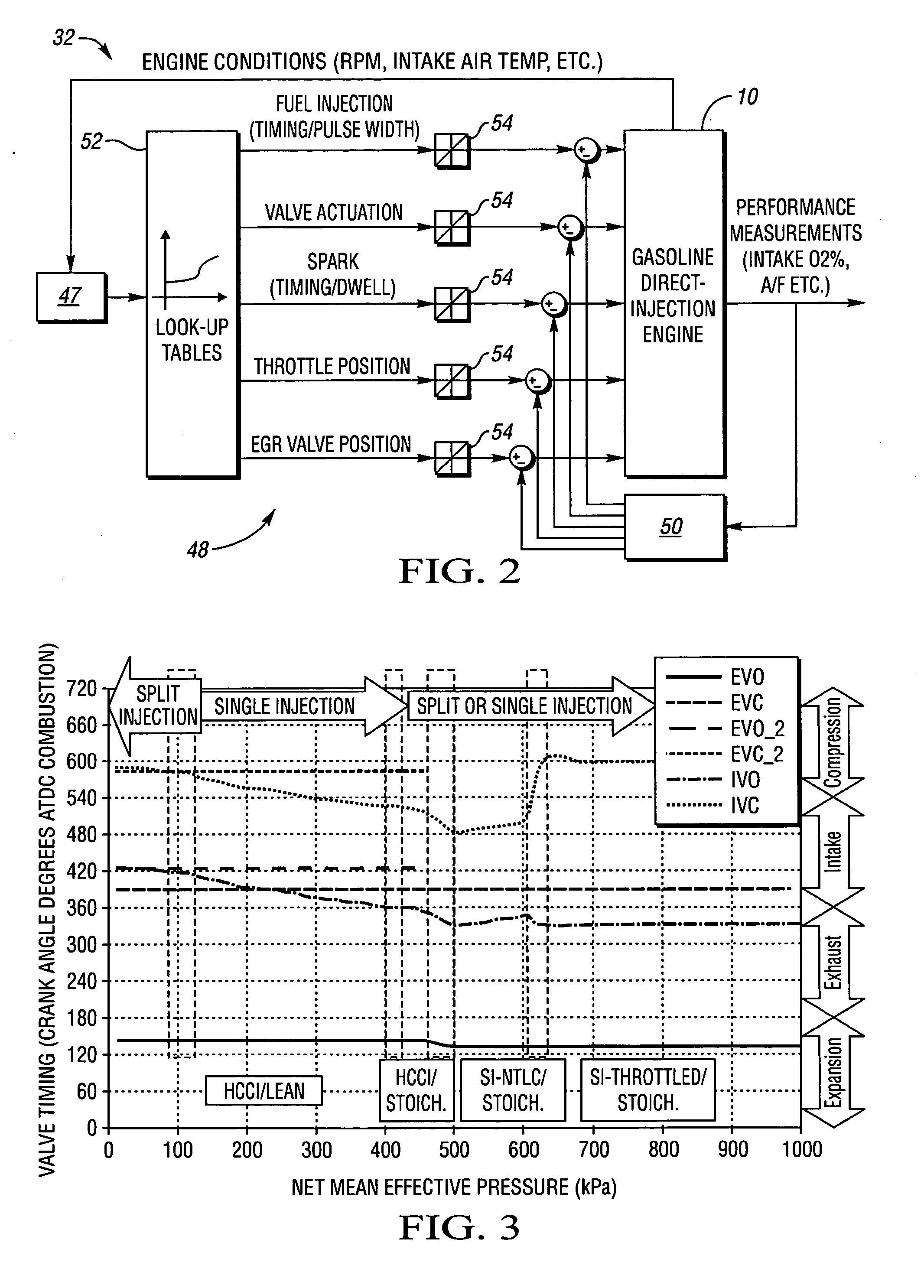

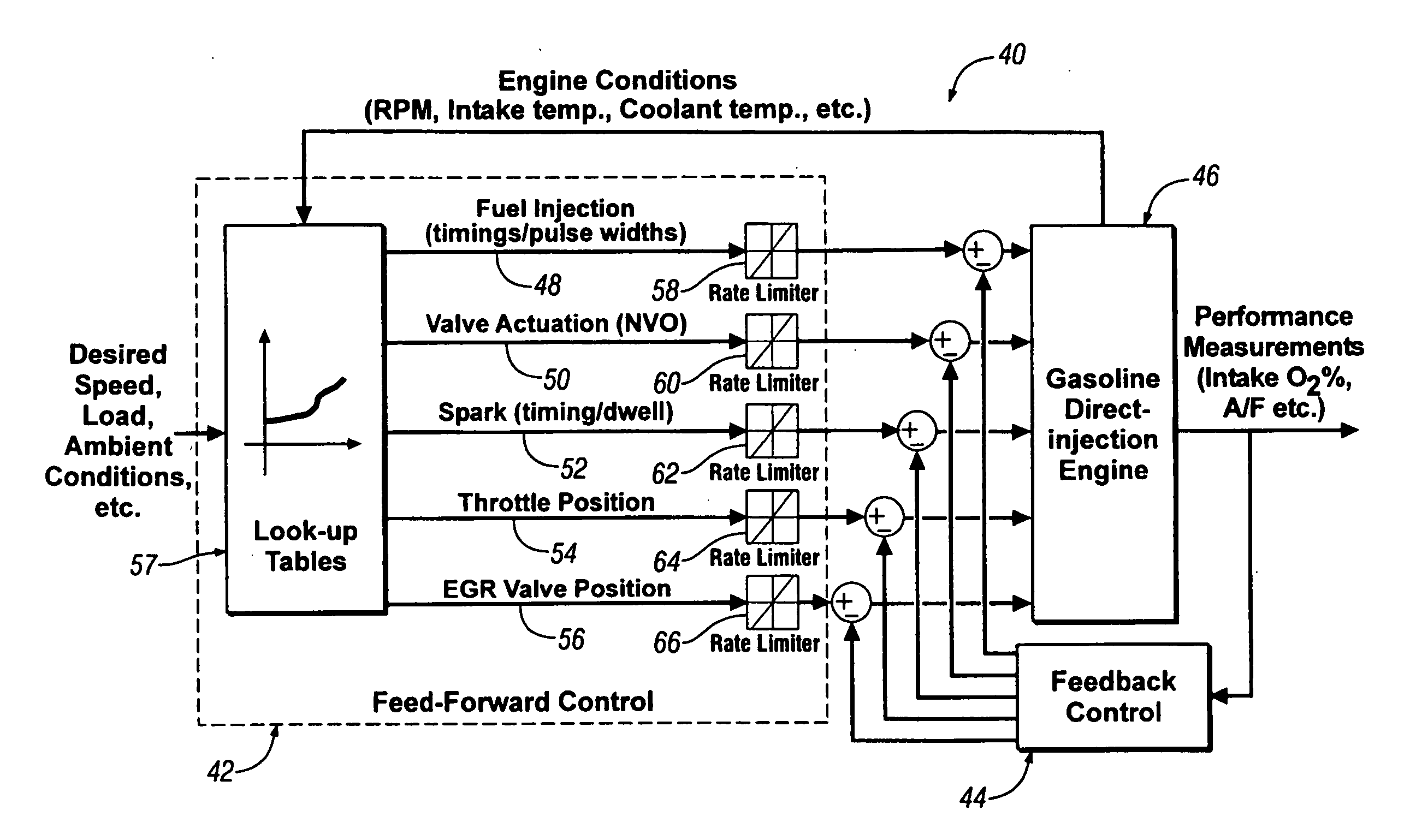

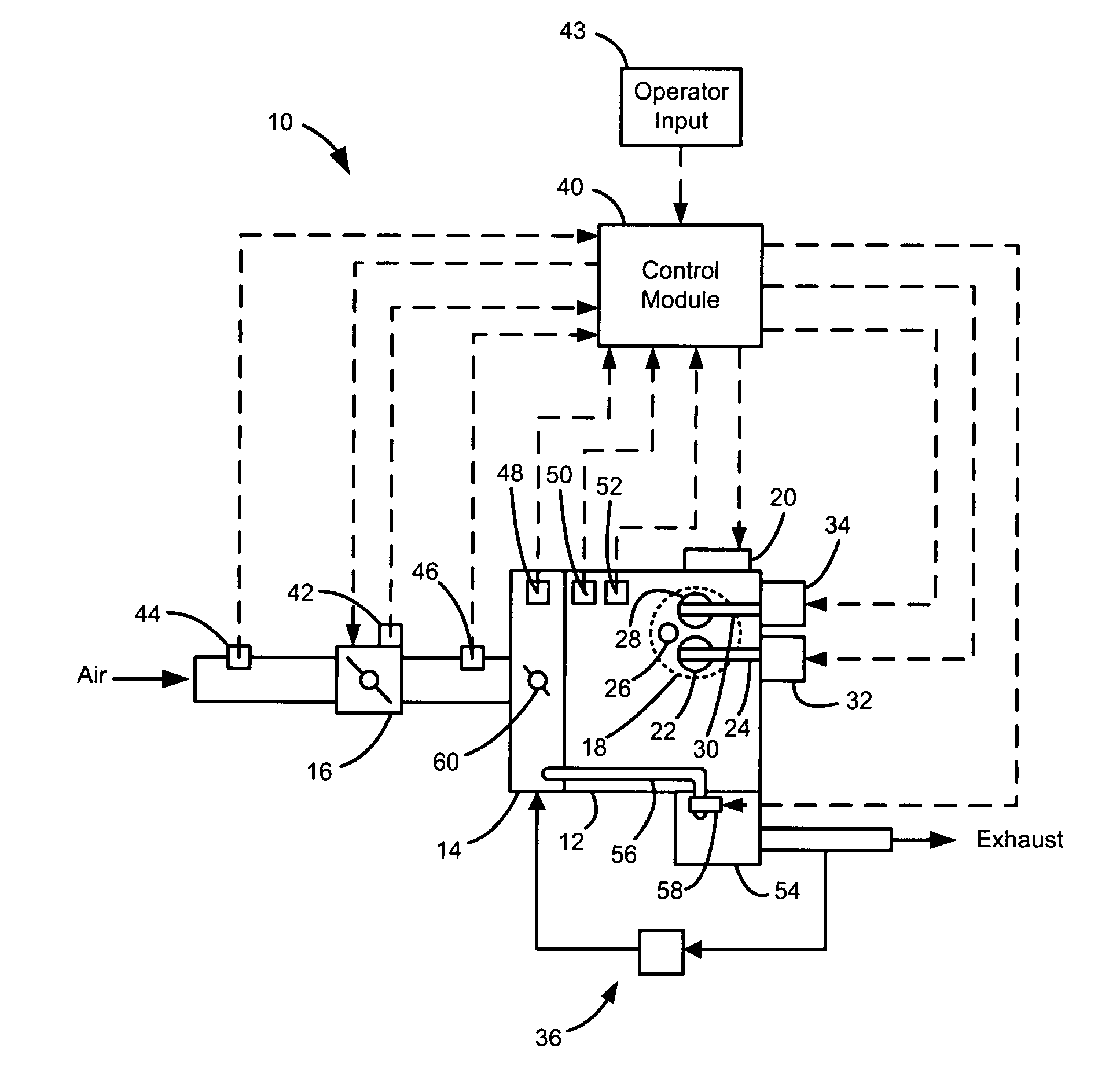

Method of HCCI and SI combustion control for a direct injection internal combustion engine

InactiveUS20060243241A1Improve fuel economyRobust controlValve arrangementsElectrical controlHomogeneous charge compression ignitionGasoline direct injection

The present invention relates to methods for robust controlled auto-ignition and spark ignited combustion controls in gasoline direct-injection engines, including transients, using either exhaust re-breathing or a combination of exhaust re-compression and re-breathing valve strategy. These methods are capable of enabling engine operation with either lean of stoichiometric or stoichiometric air / fuel ratio for oxides of nitrogen (NOx) control, with varying exhaust gas recirculation (EGR) rates and throttle valve positions for knock control, and with a combination of homogeneous charge compression ignition (HCCI) and spark ignition (SI) combustion modes to optimize fuel economy over a wide range of engine operating conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for load transient control between lean and stoichiometric combustion modes of direct-injection engines with controlled auto-ignition combustion

InactiveUS20060196469A1Electrical controlNon-fuel substance addition to fuelStable stateHomogeneous charge compression ignition

A method is provided for control of a direct-injection engine operated with controlled auto-ignition (HCCI) during load transient operations between modes of lean combustion low load (HCCI / Lean) and stiochiometric combustion medium load (HCCI / Stoich.). The method includes 1) operating the engine at steady state, within a homogeneous charge compression-ignition (HCCI) load range, with fuel-air-exhaust gas mixtures at predetermined conditions, for each speed and load, and controlling the engine during changes of operating mode between one to another of the HCCI / Stoich. medium load mode and the HCCI / Lean lower load mode by synchronizing change rates of predetermined controlled inputs to the current engine fueling change rate.

Owner:GM GLOBAL TECH OPERATIONS LLC

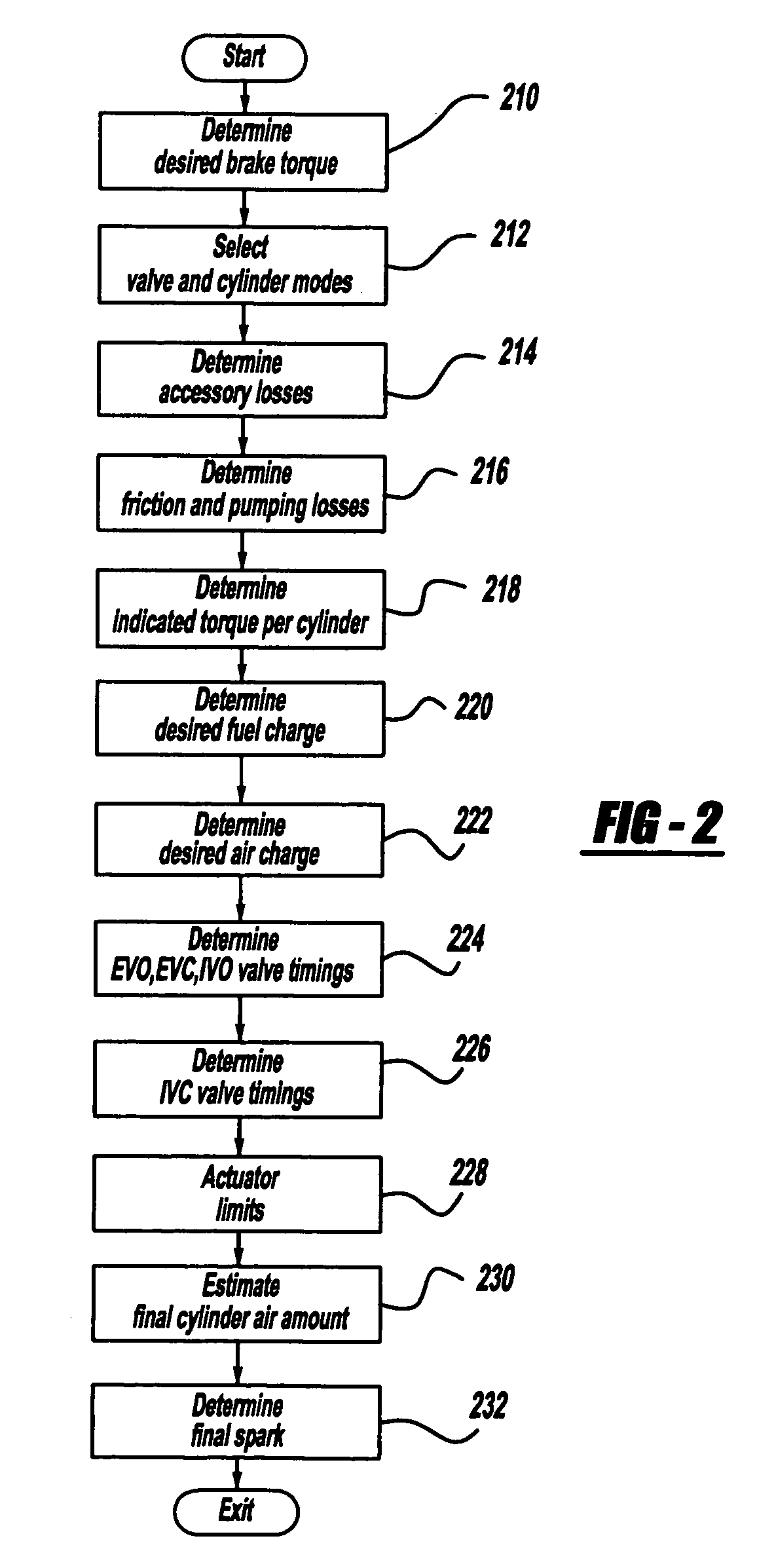

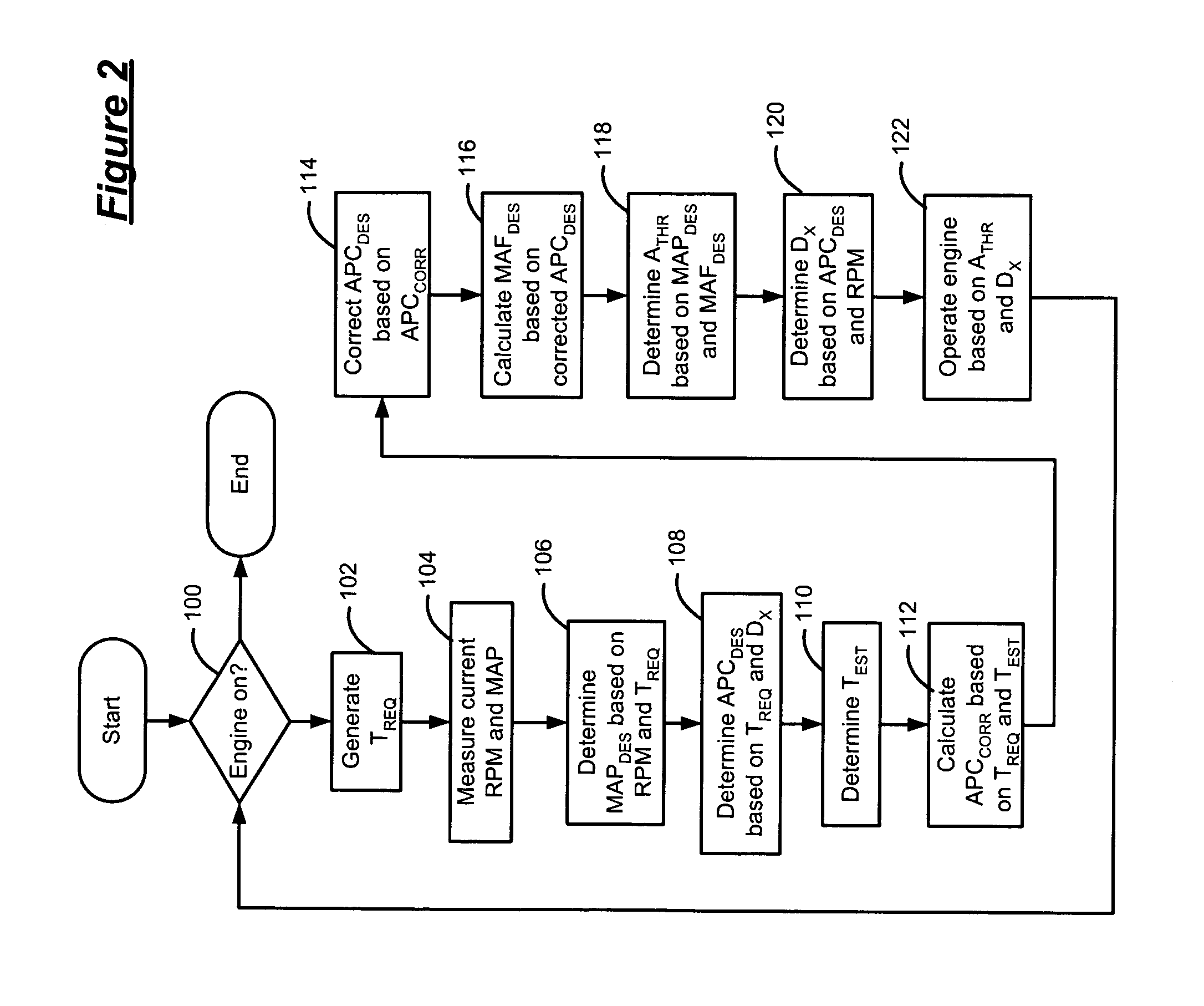

Coordinated engine torque control

ActiveUS7021282B1Electrical controlNon-fuel substance addition to fuelThrottle controlControl system

Owner:GM GLOBAL TECH OPERATIONS LLC

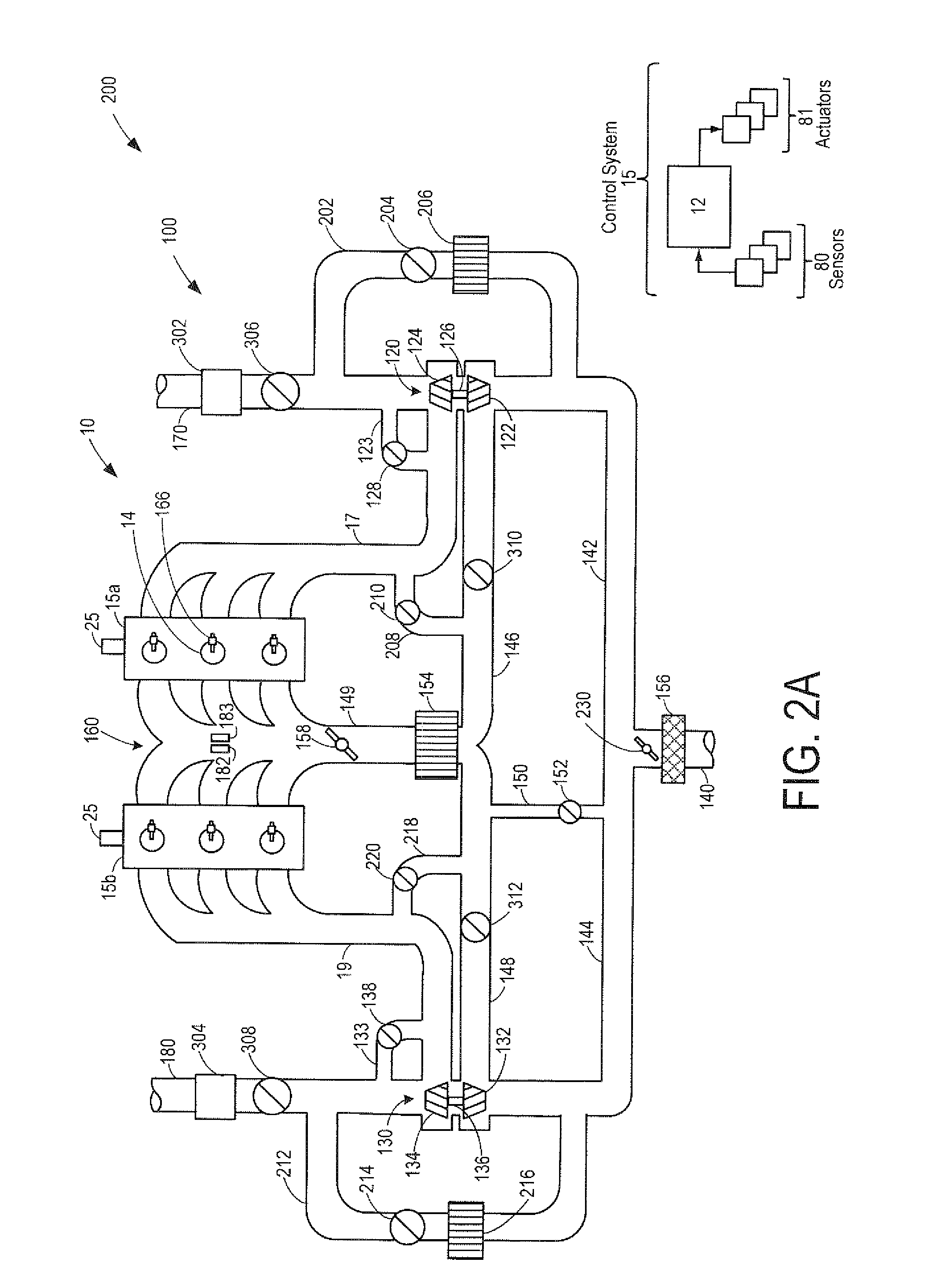

Methods and Systems for Variable Displacement Engine Control

ActiveUS20110265454A1Control flowHigh catalytic efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringThrottle

Methods and systems are provided for selecting a group of cylinders for selective deactivation, in a variable displacement engine system, based at least on a regeneration state of an exhaust catalyst. The position of one or more valves and throttles may be adjusted based on the selective deactivation to reduce back-flow through the disabled cylinders while also maintaining conditions of a downstream exhaust catalyst. Pre-ignition and knock detection windows and thresholds may also be adjusted based on the deactivation to improve the efficiency of knock and pre-ignition detection.

Owner:FORD GLOBAL TECH LLC

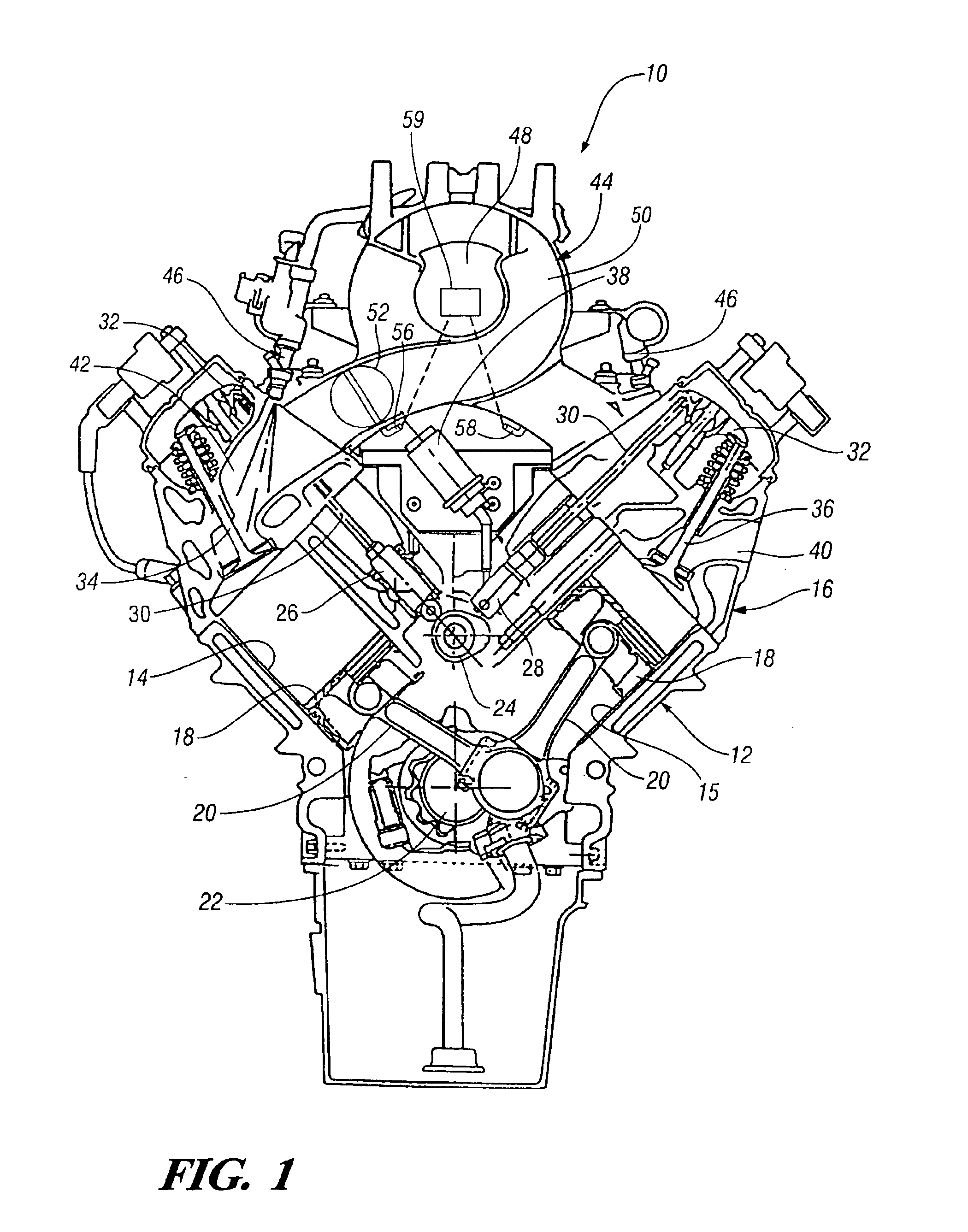

Engine and method of operation with cylinder deactivation

ActiveUS6874463B1Improvement in DOD operationEasy to operateElectrical controlInternal combustion piston enginesExhaust valveCylinder Valve

An engine with cylinder deactivation (Displacement on Demand or DOD™) includes standard (STD) cylinders which are not deactivated and DOD cylinders which can be deactivated by closing their intake and exhaust valves and shutting off their fuel supply. To provide smooth transitions, the STD and DOD cylinders form separate groups each supplied with charge air through one or more separate throttles. When switching to DOD operation, the throttles are oppositely actuated to cut out the DOD cylinders and maintain torque in the active cylinders prior to deactivation of the cylinder valves. When returning to STD operation, the valves are reactivated before oppositely actuating the throttles to enable full cylinder operation. In DOD operation, a small supercharger may be operated to boost torque of the operating STD cylinders and thus increase the DOD operating range.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com