Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7641 results about "Polyethylene terephthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

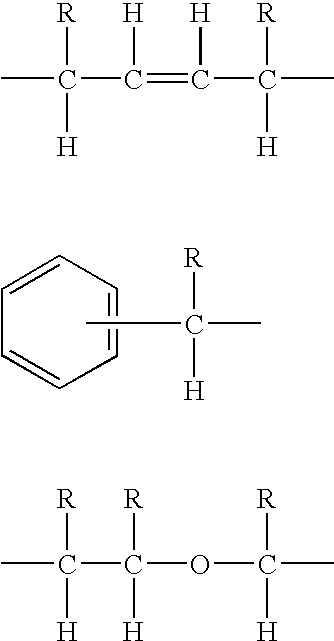

Polyethylene terephthalate (sometimes written poly(ethylene terephthalate)), commonly abbreviated PET, PETE, or the obsolete PETP or PET-P, is the most common thermoplastic polymer resin of the polyester family and is used in fibres for clothing, containers for liquids and foods, thermoforming for manufacturing, and in combination with glass fibre for engineering resins.

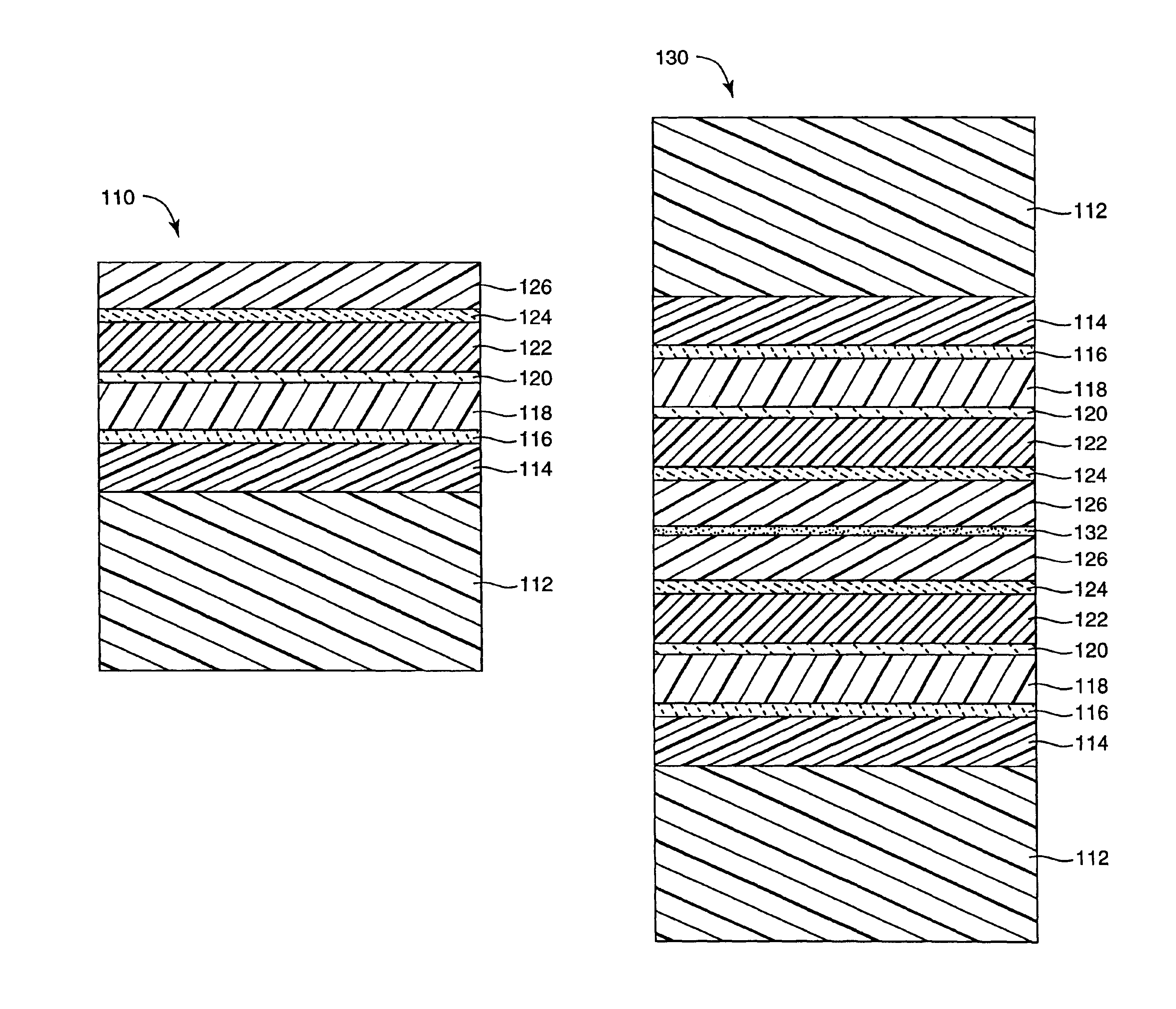

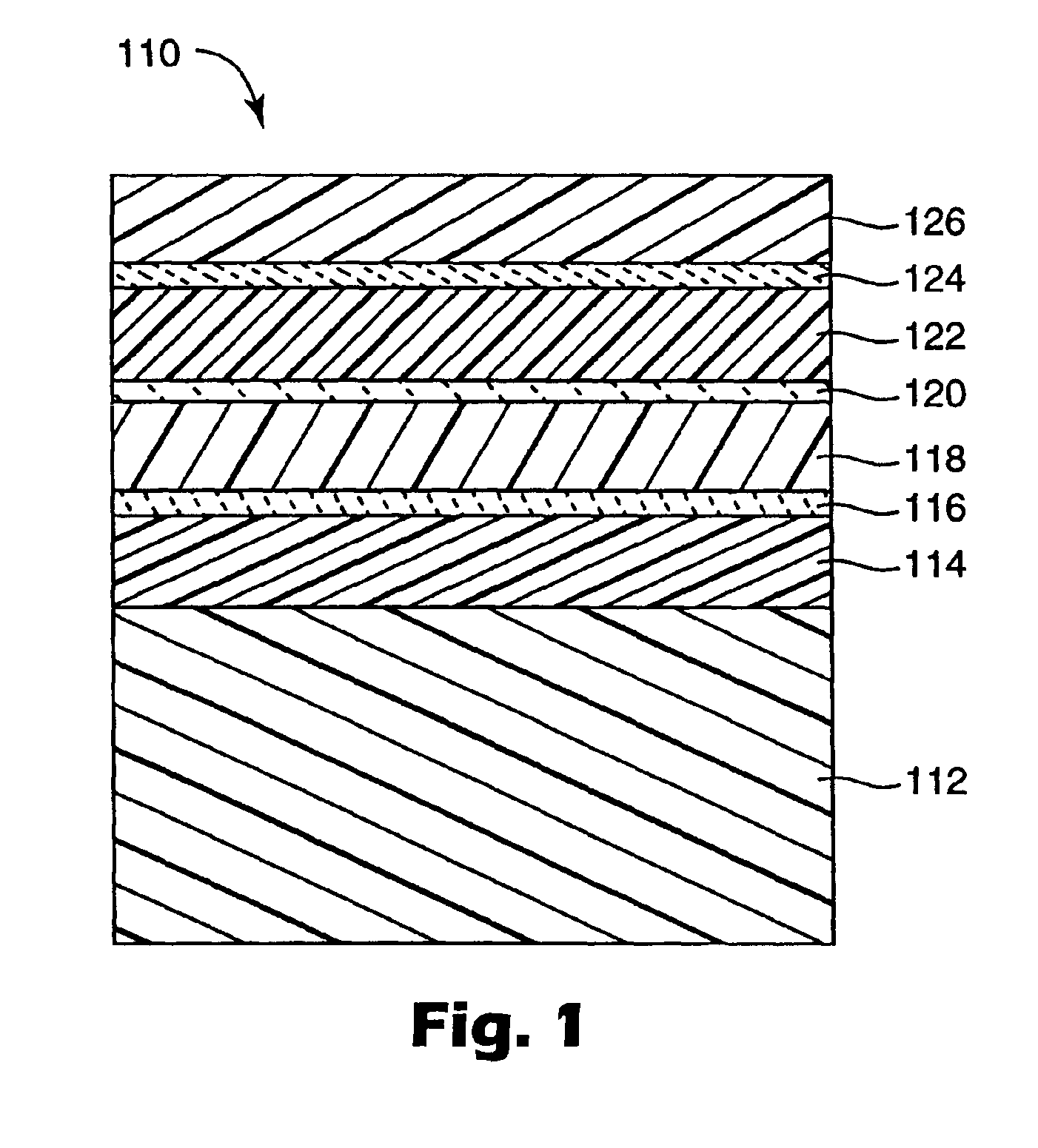

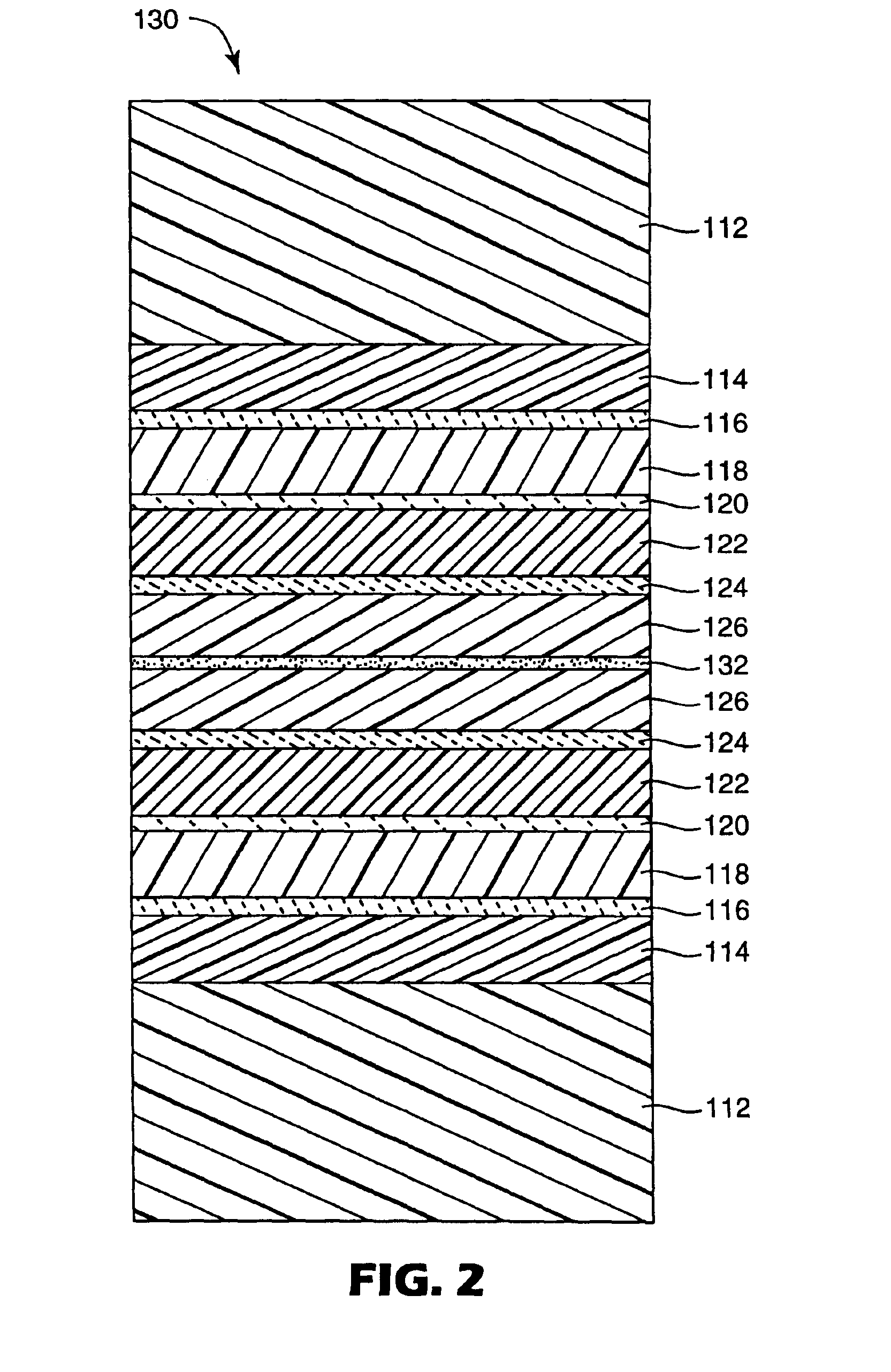

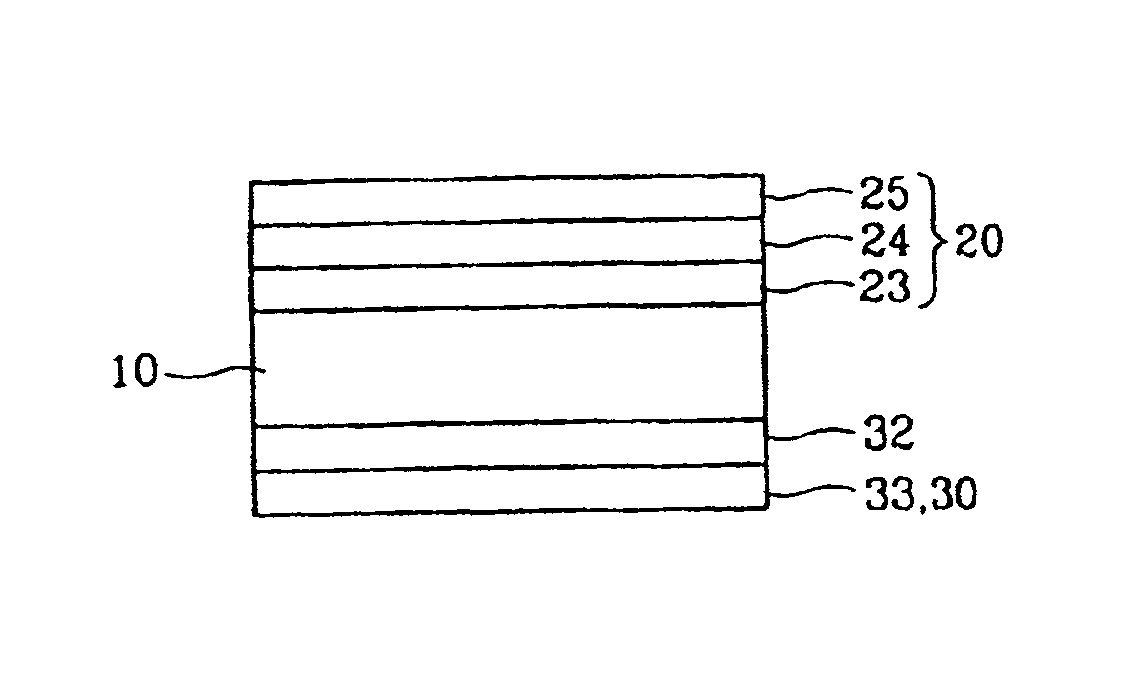

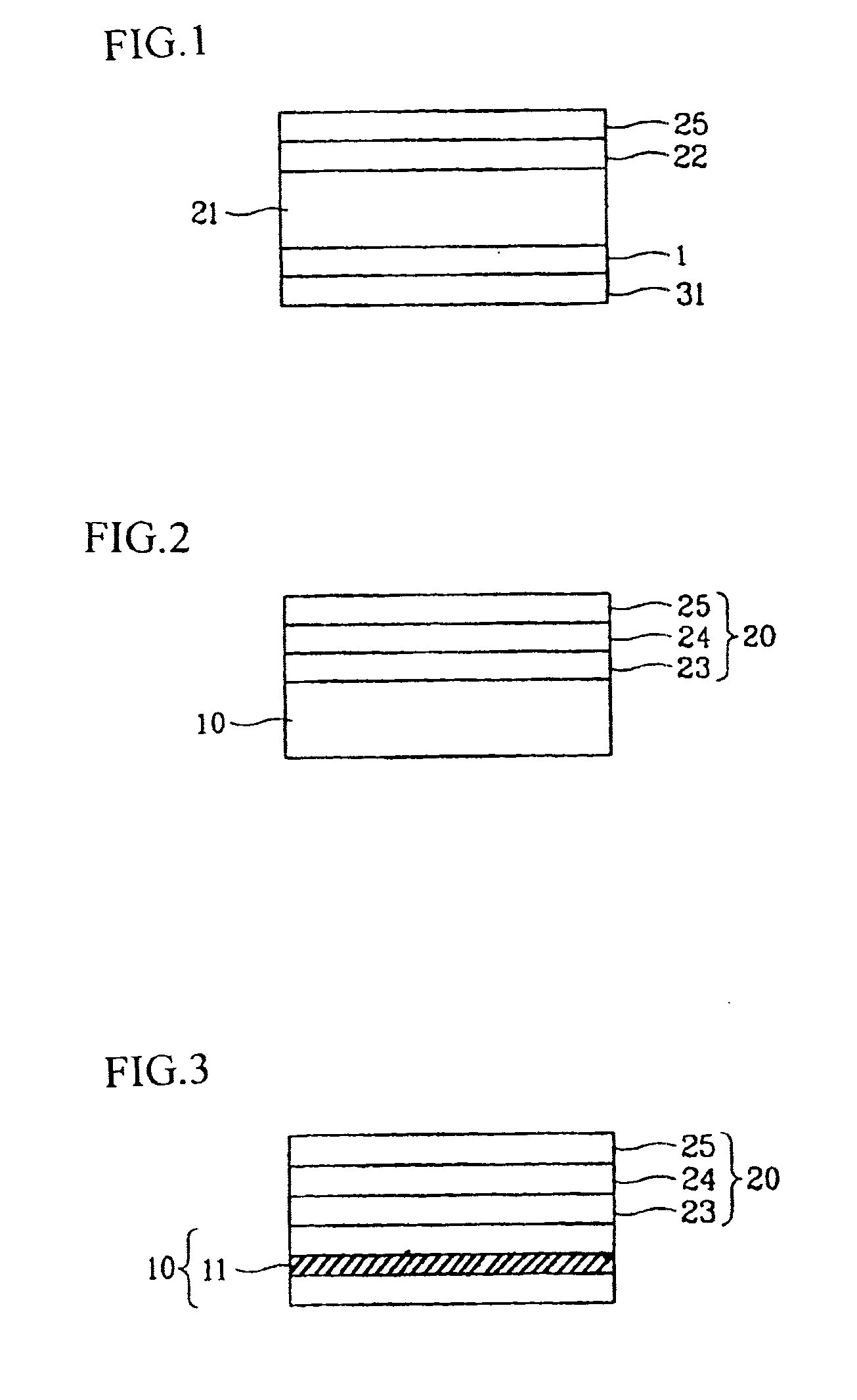

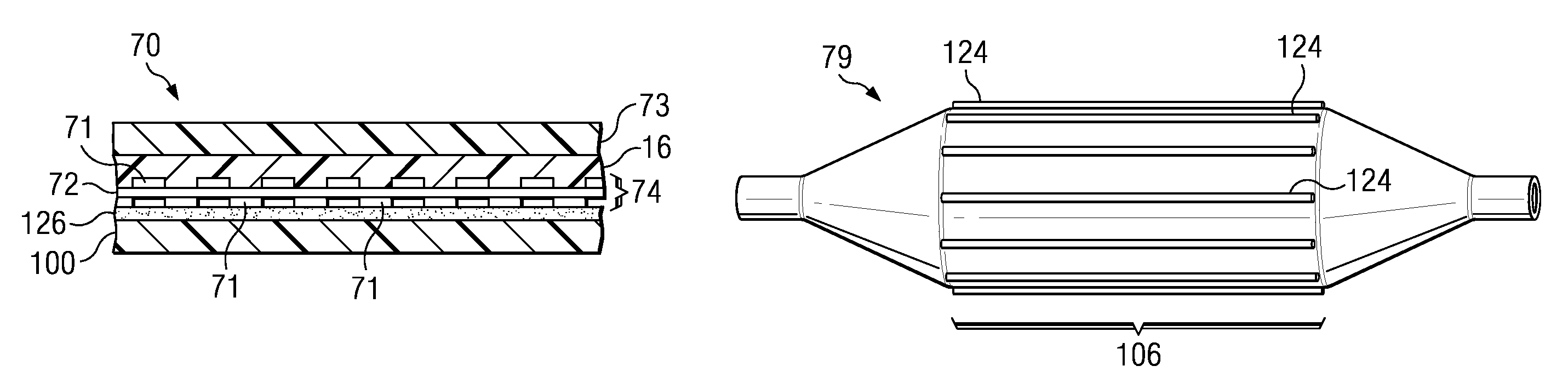

Flexible high-temperature ultrabarrier

InactiveUS7018713B2Final product manufactureSynthetic resin layered productsPolyethylene terephthalateOrganic light emitting device

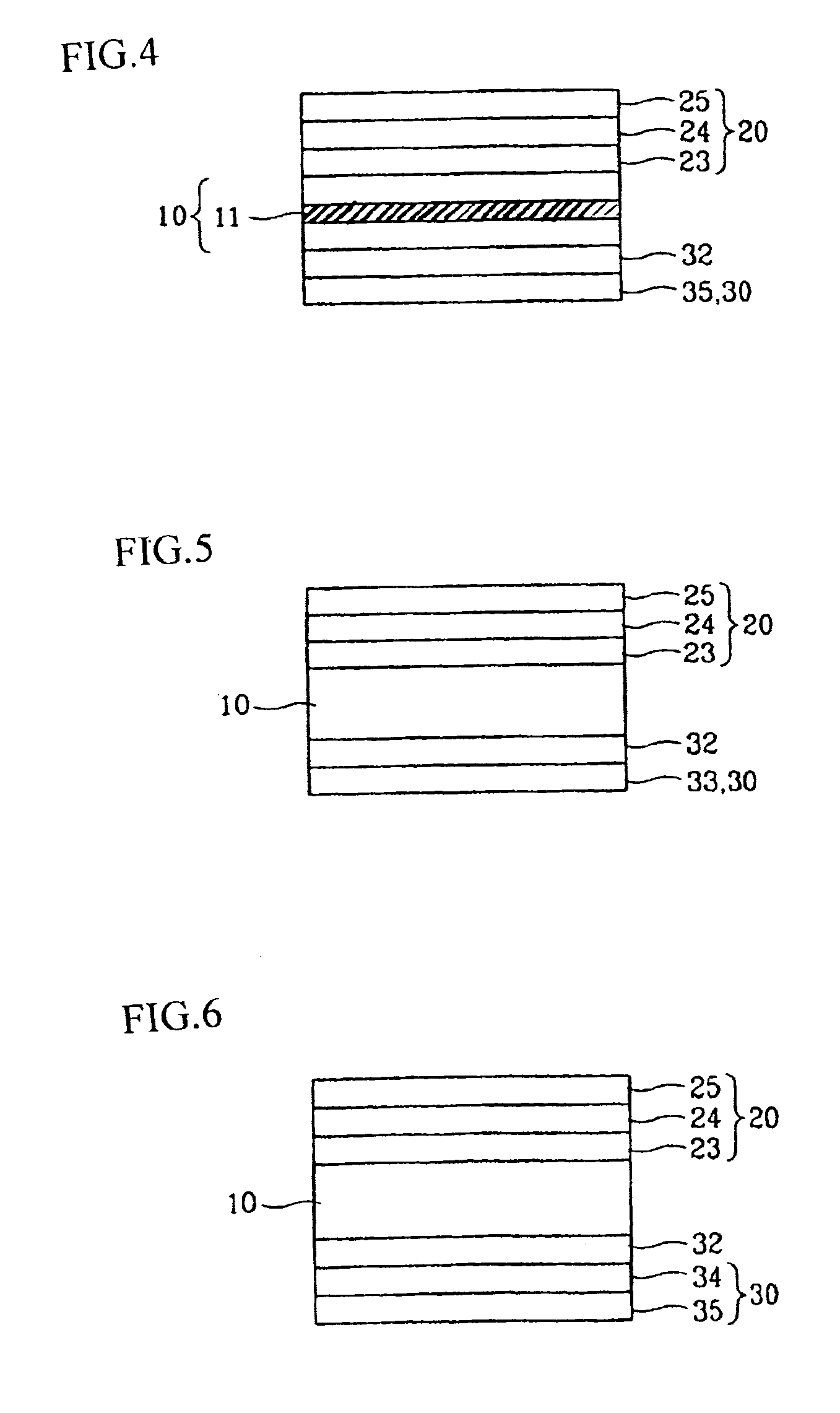

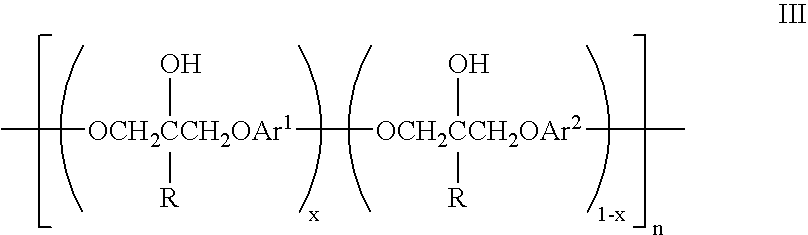

A flexible barrier assembly having a flexible visible light-transmissive substrate having a Tg greater than or equal to that of heat-stabilized polyethylene terephthalate (“HSPET”) overcoated with a first polymer layer having a Tg greater than or equal to that of HSPET and further overcoated with at least two visible light-transmissive inorganic barrier layers separated by at least one second polymer layer having a Tg greater than or equal to that of HSPET can be used to mount, cover, encapsulate or form moisture- and oxygen-sensitive articles such as organic light emitting devices and light valves.

Owner:3M INNOVATIVE PROPERTIES CO

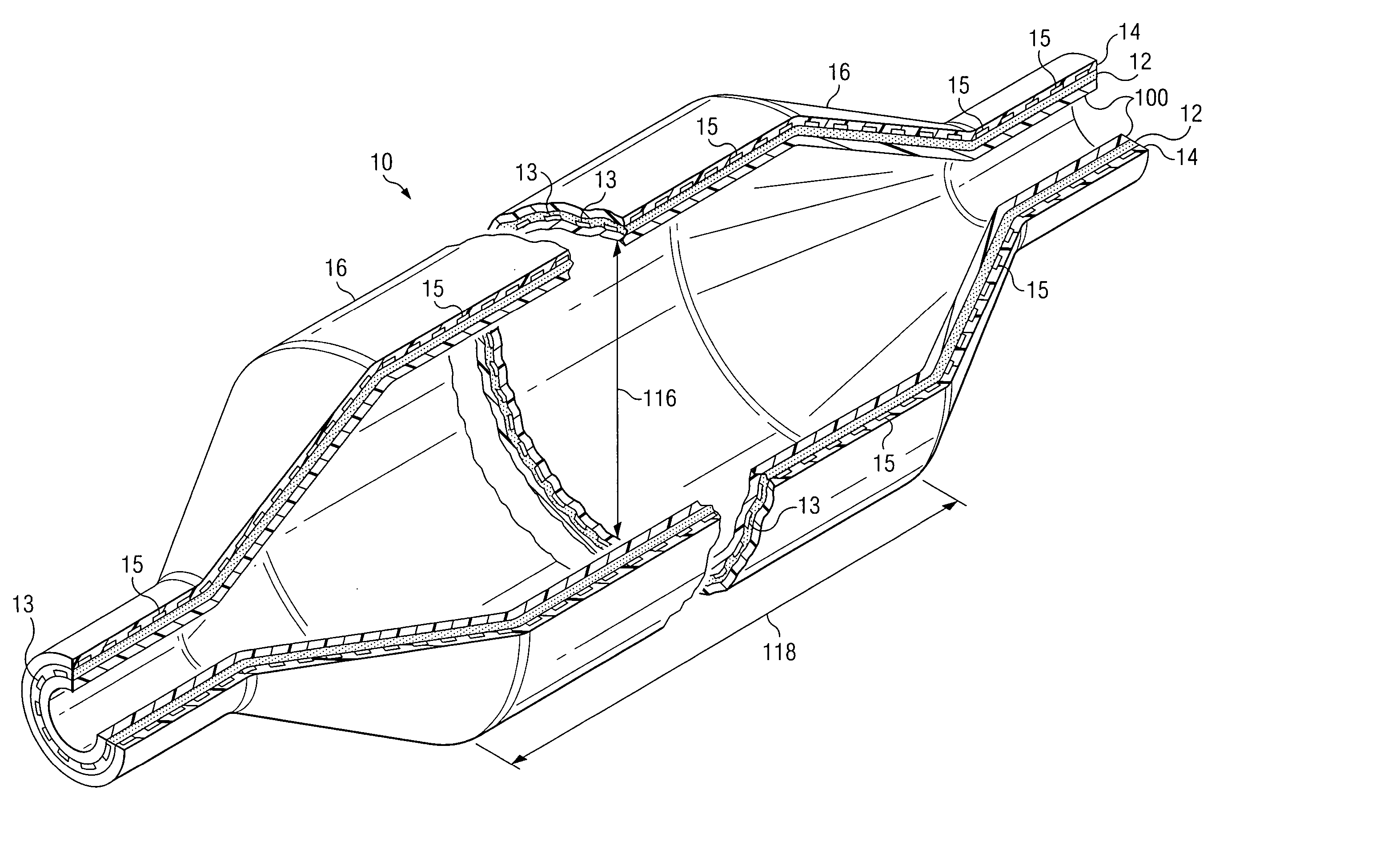

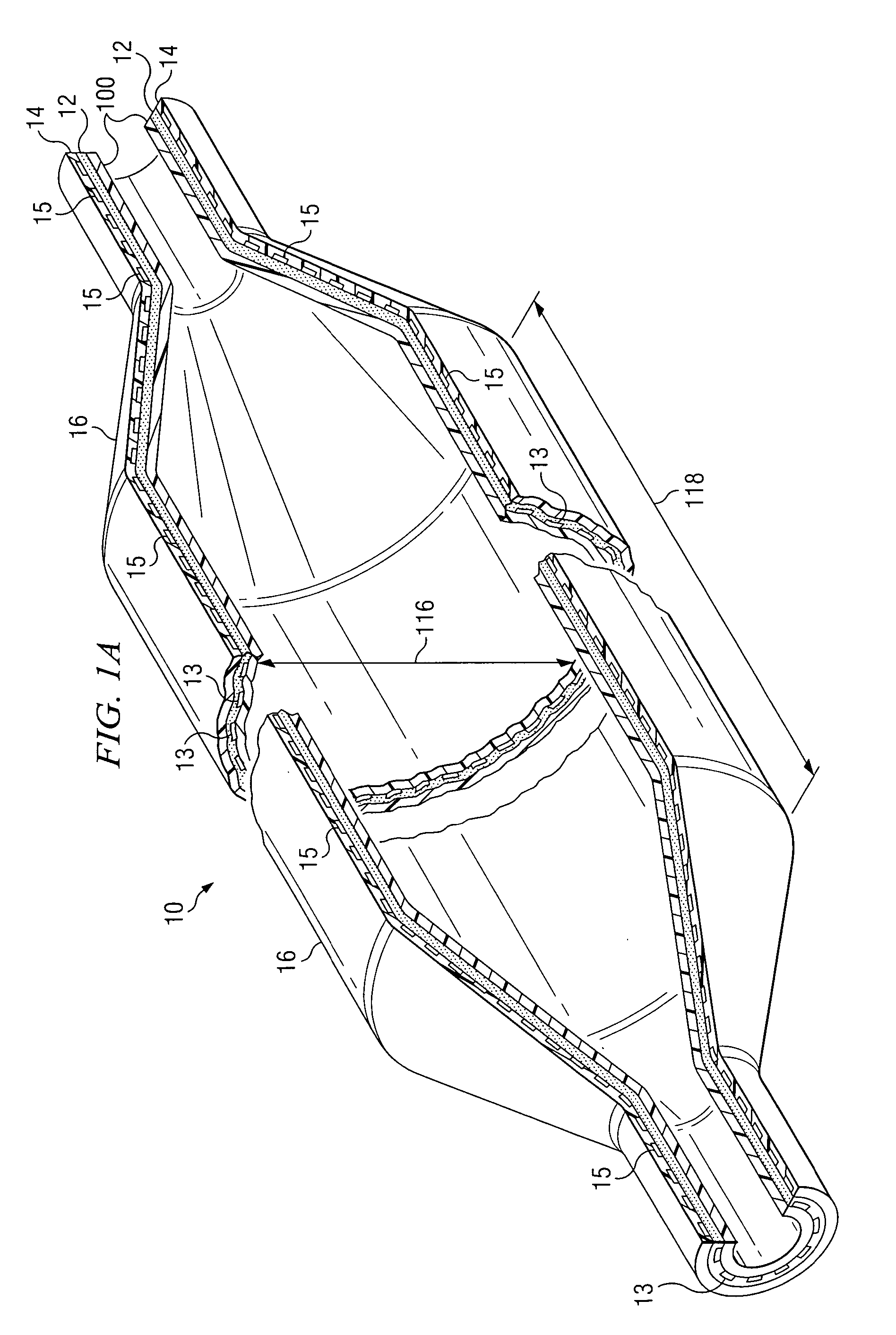

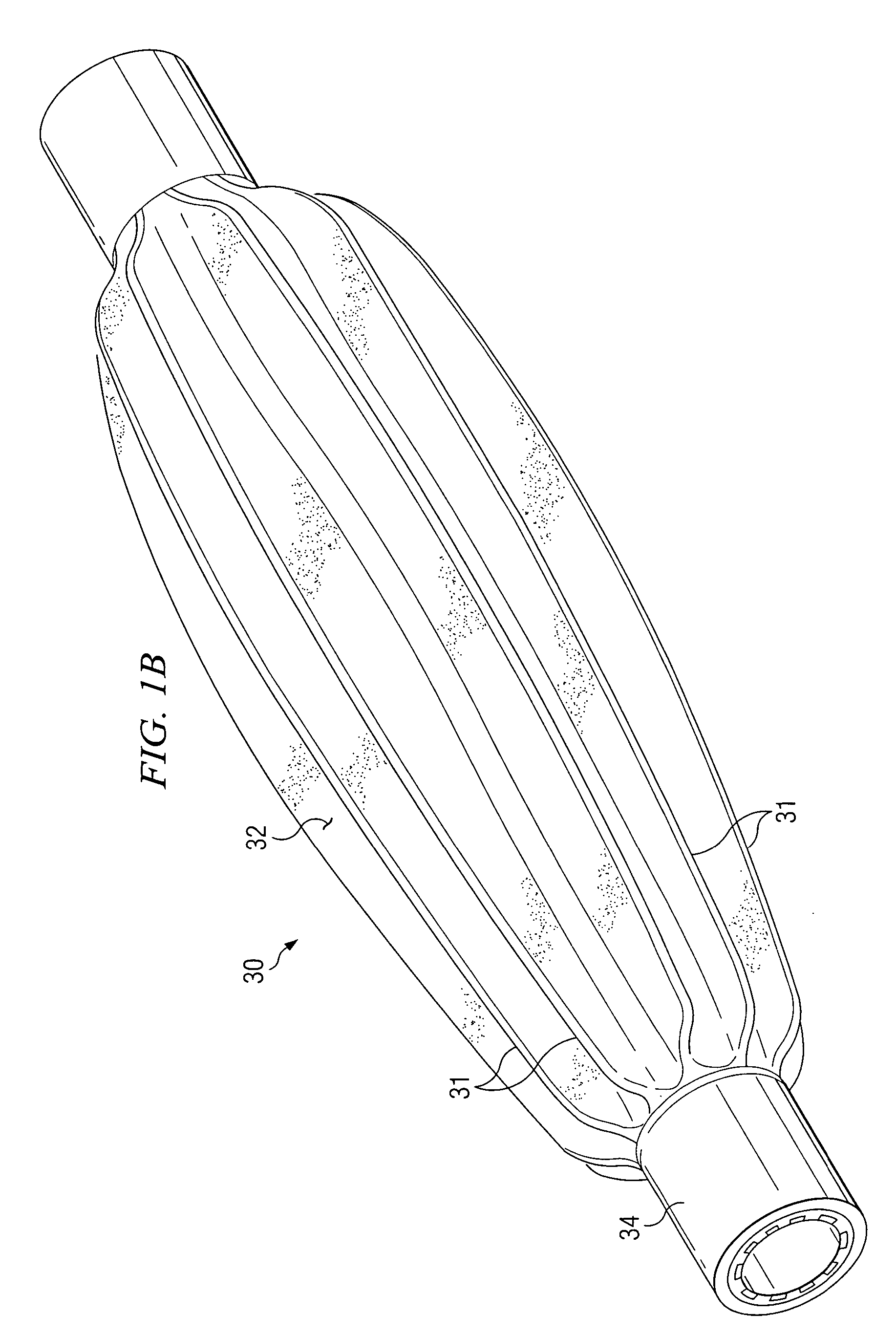

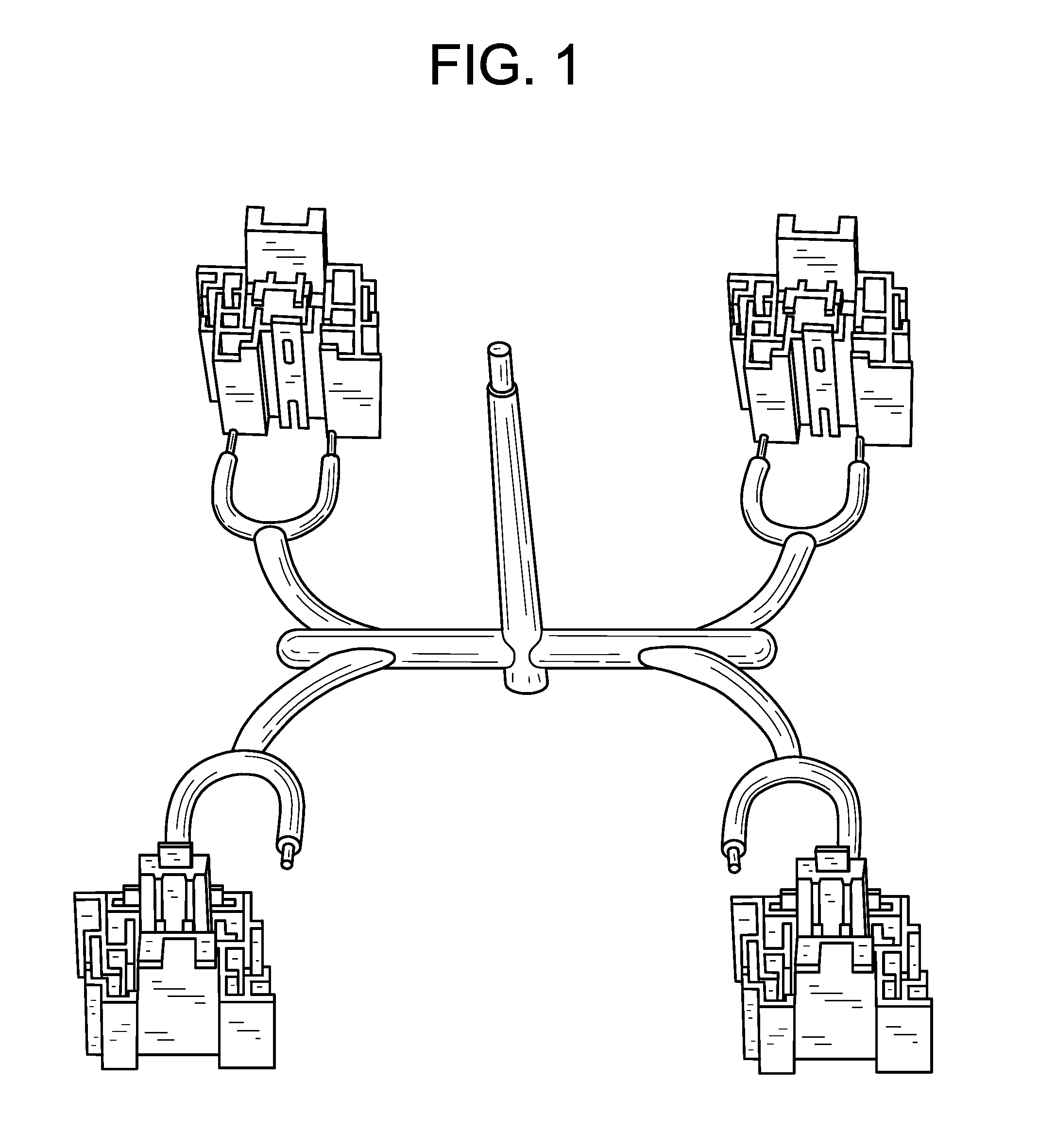

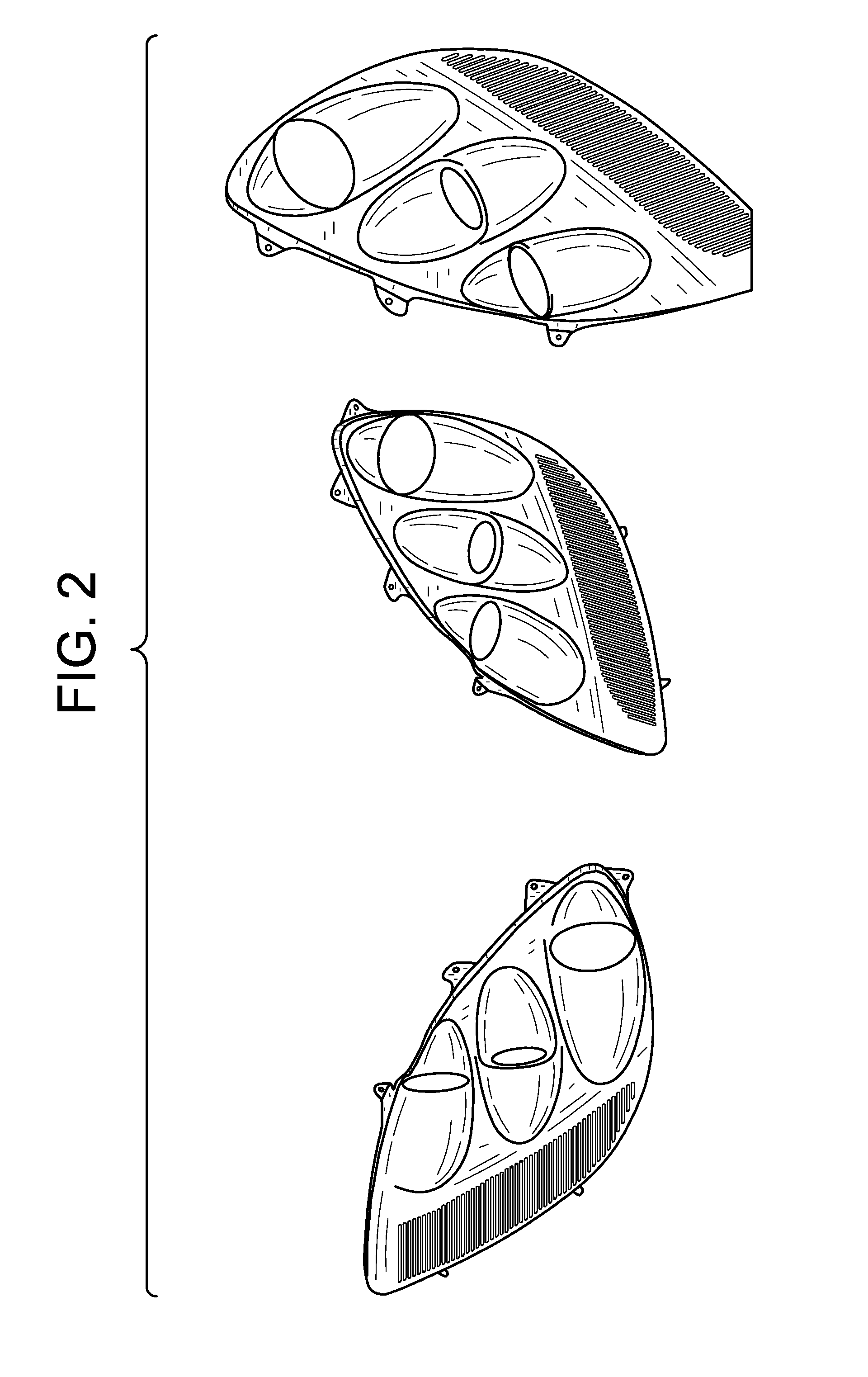

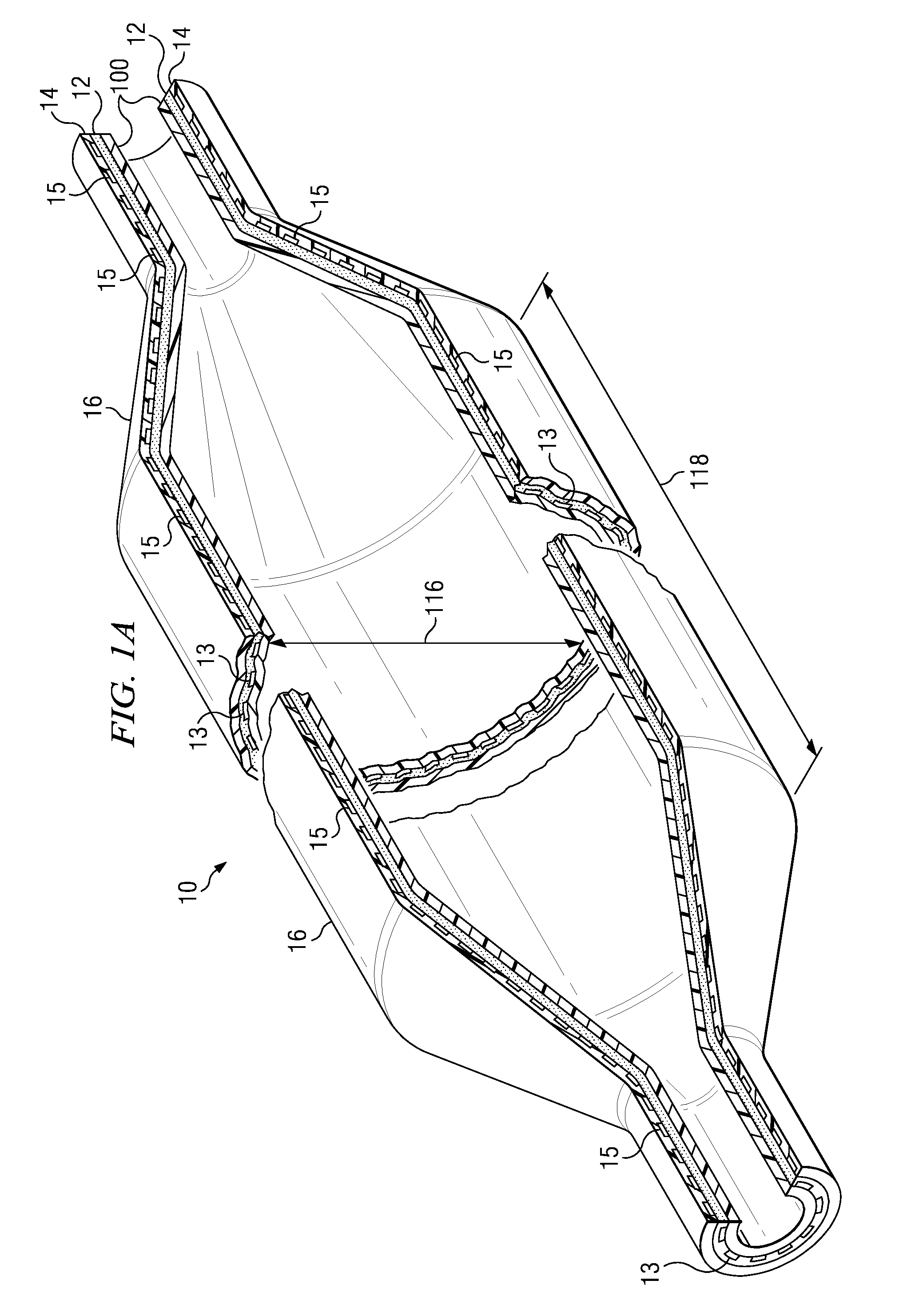

Medical balloon having strengthening rods

ActiveUS20060085023A1Increase pressureStentsBalloon catheterPolyethylene terephthalateMedical treatment

A non-compliant medical balloon includes a balloon layer having an outer surface and a strengthening rod connected to the outer surface of the balloon layer. The strengthening rod may be connected longitudinally on the outer surface fo the balloon layer. Typically, the balloon is formed of a polymer like polyethylene terephthalate.

Owner:BARD PERIPHERAL VASCULAR

Decorative floor covering comprising polyethylene terephthalate film layer in surface layer and manufacturing method of the same

InactiveUS6933043B1Superior surface printing sharpness and realismEasy to installSynthetic resin layered productsPaper/cardboard layered productsSurface layerPolyethylene terephthalate

The present invention provides a decorative floor covering comprising a surface layer and a substrate layer underneath, wherein the surface layer comprises a polyethylene terephthalate film layer, and a method for preparing the same. Furthermore, the present invention provides a decorative floor covering comprising a surface layer and a substrate layer underneath, wherein a light weight back layer is further comprised under the substrate layer, and a method for preparing the same. A decorative floor covering of the present invention is a decorative floor covering which has superior surface heat resistance, printing sharpness and realism, and it can be installed conveniently since not only can non-foamed polyvinyl chloride resin be used as a substrate layer, but also the weight of a floor covering is light when a light weight back layer is comprised under the substrate layer.

Owner:LG CHEM LTD

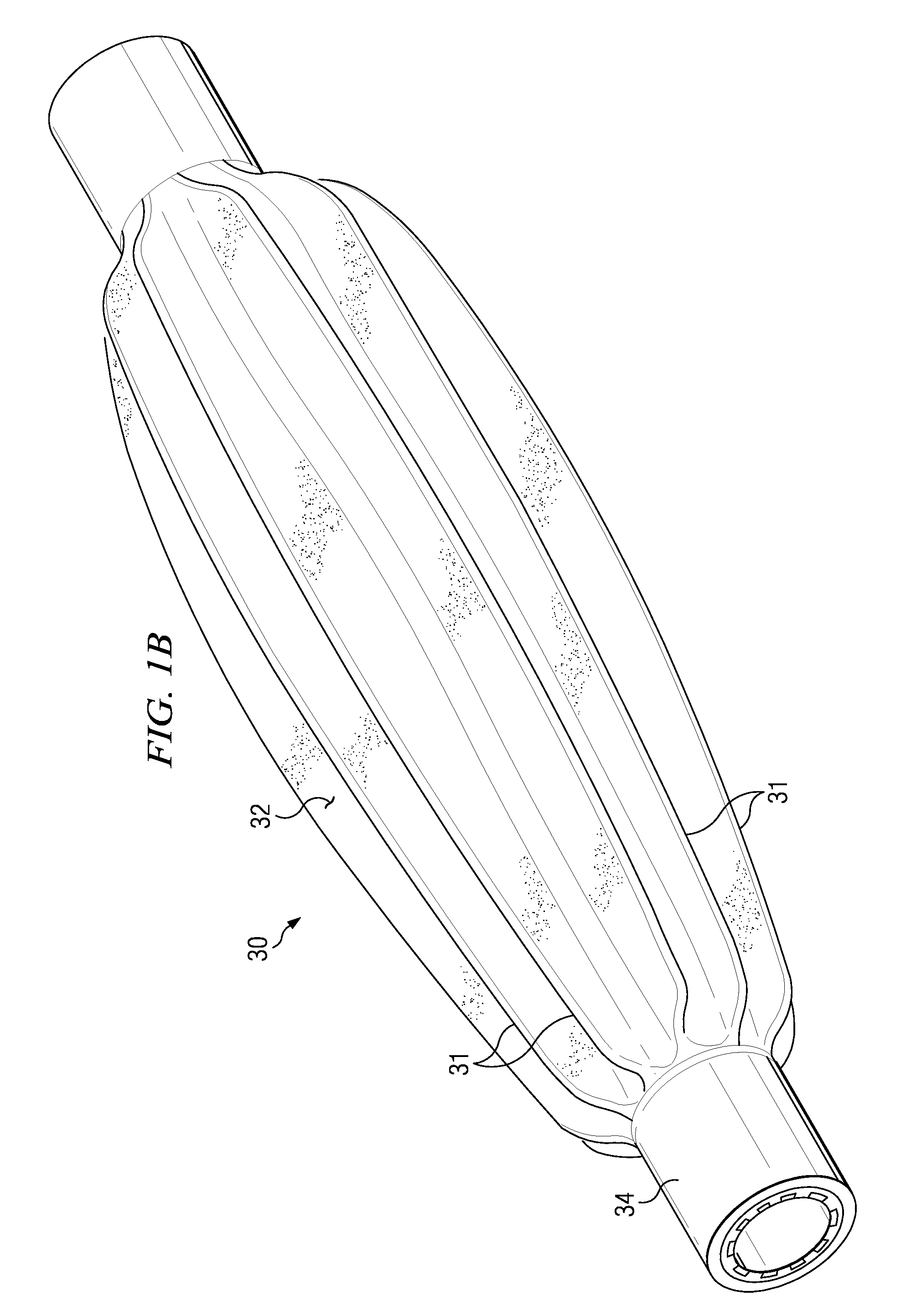

Oxygen-scavenging polymer blends suitable for use in packaging

InactiveUS20110045222A1Group 4/14 element organic compoundsSynthetic resin layered productsPolyethylene terephthalate glycolPolyethylene terephthalate

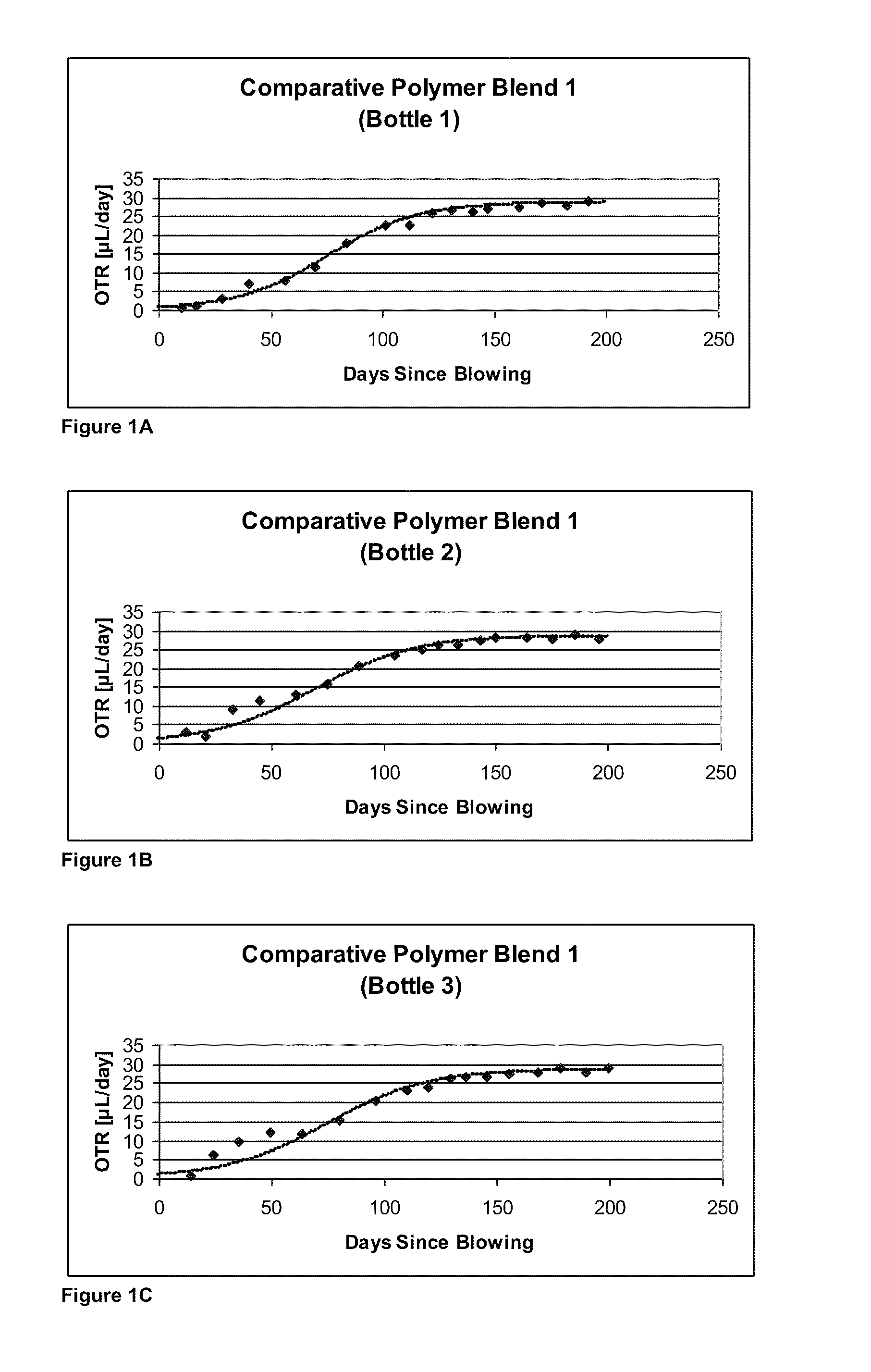

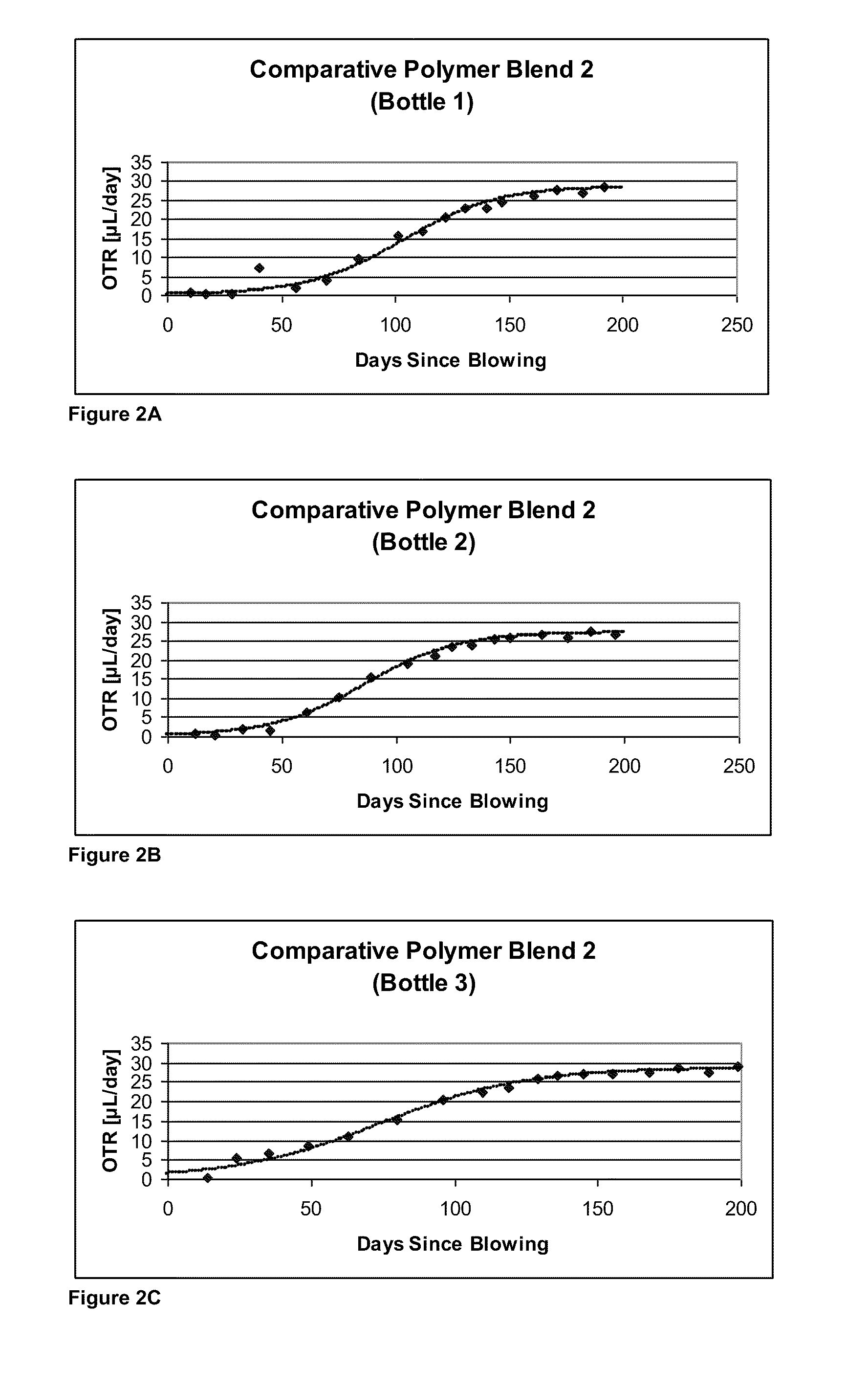

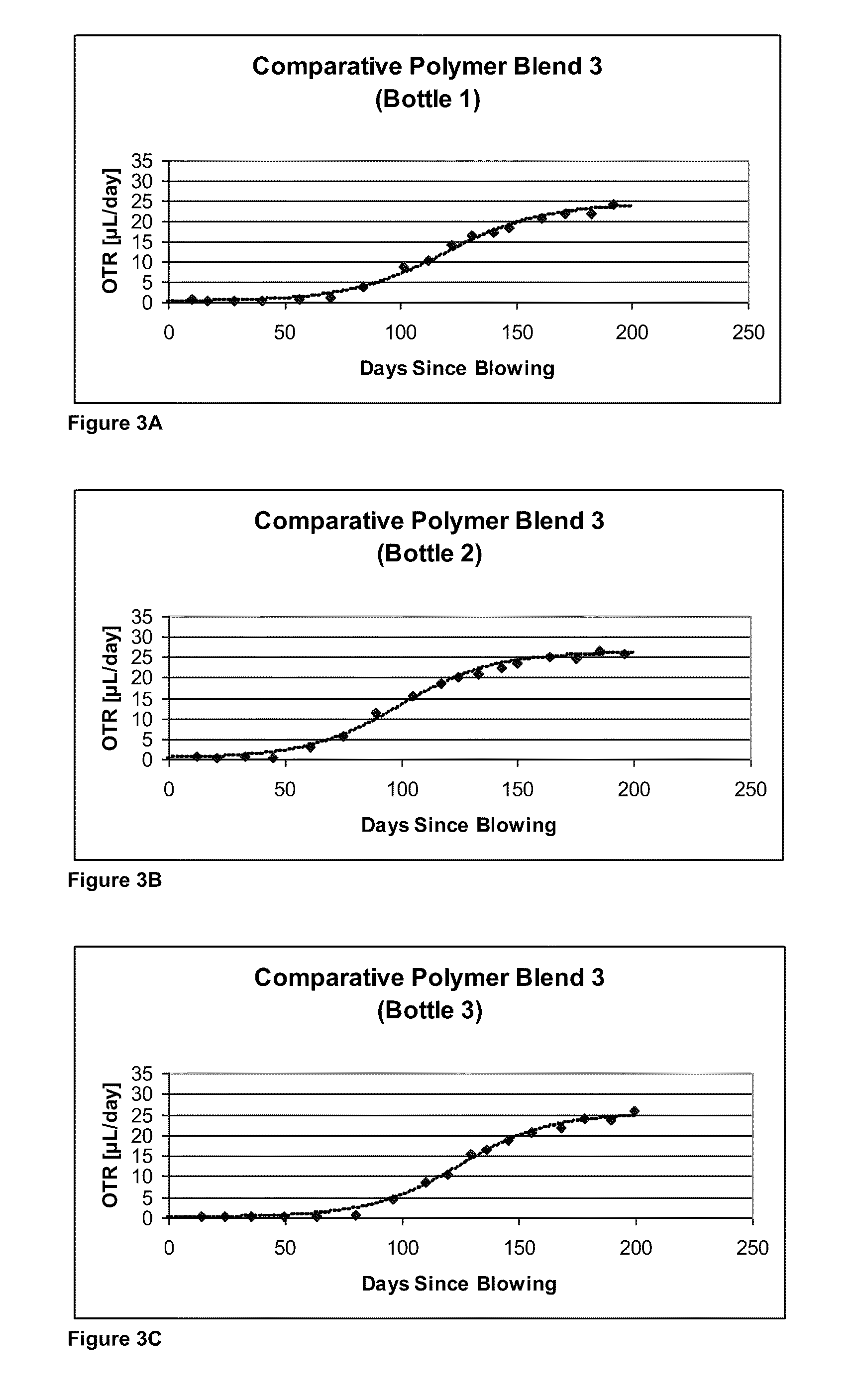

Polymer blends are disclosed that comprise one or more unsaturated olefinic homopolymers or copolymers having at least one functionality capable of entering into condensation reactions; one or more polyamide homopolymers or copolymers; one or more polyethylene terephthalate homopolymers or copolymers obtained using a catalyst system comprising antimony atoms; and one or more transition metal atoms. The inventive blends are useful for packaging, and exhibit improved oxygen-scavenging activity and lower haze compared with blends made using polyethylene terephthalate polymers prepared with antimony catalyst and either the olefinic or the polyamide homopolymers or copolymers, individually.

Owner:EASTMAN CHEM CO

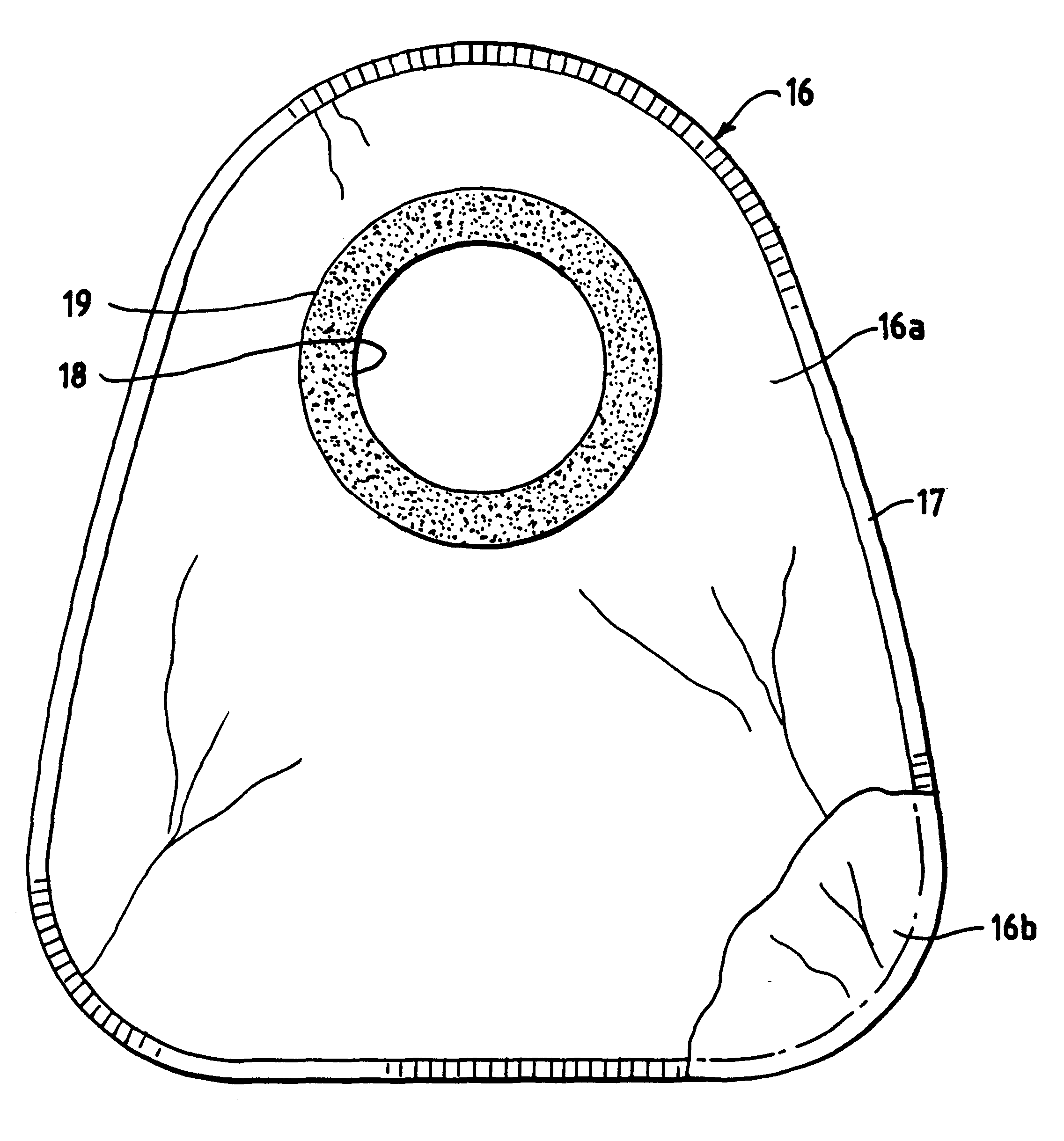

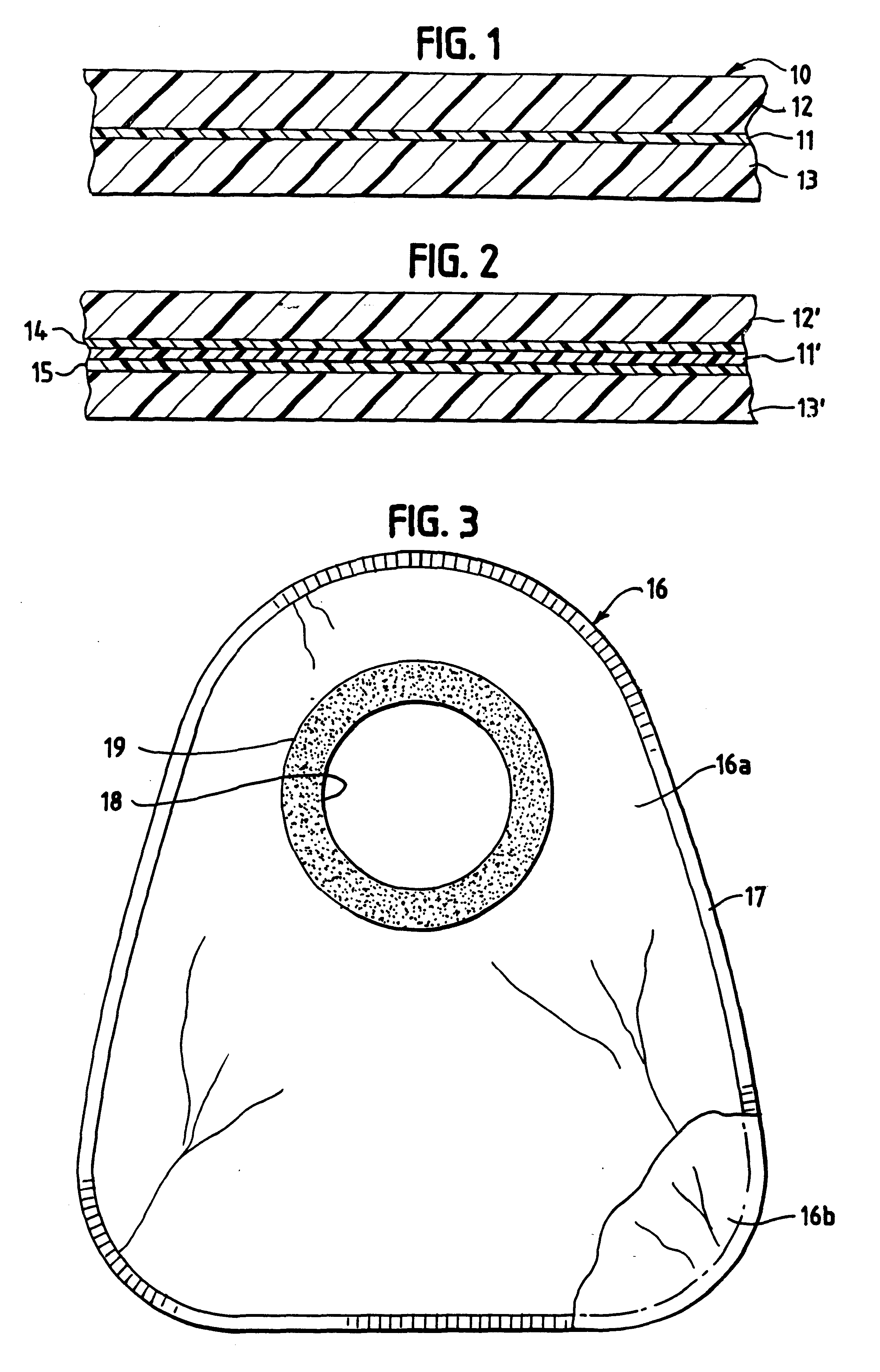

Multilayer chlorine-free film with polyester barrier layer and ostomy pouches formed therefrom

InactiveUS6258423B1Good odor barrier propertyMinimal noiseSynthetic resin layered productsColostomyLow noisePolyethylene terephthalate glycol

A multilayer heat-sealable chlorine-free film of relatively low modulus, high interlaminar strength, and low noise upon flexing is provided. The film comprises an odor barrier layer of polyester resin and at least one heat-sealable skin layer, preferably two such skin layers on opposite sides of said odor barrier layer, composed of a homopolymer of ethylene or a copolymer of ethylene and an alpha-olefin or an ester-containing monomer. In a preferred embodiment, the odor barrier layer is formed of polyethylene terephthalate and adhesive tie layers are interposed between the odor barrier layer and the skin layers, resulting in a multilayer film of five layers. Pouches formed of such multilayer films are also disclosed.

Owner:HOLLISTER INCORPORAED

Preparation of poly(trimethylene terephthalate)

In one embodiment, the invention is a process for the preparation of poly(trimethylene terephthalate) comprising (a) contacting terephthalic acid with 1,3-propanediol in the presence of an organic tin catalyst to form a bis(3-hydroxypropyl)terephthalate monomer; and (b) polymerizing said monomer in the presence of organic titanate polycondensation catalyst to obtain the poly(trimethylene terephthalate). In another embodiment, the invention is a process for the preparation of poly(trimethylene terephthalate) containing less than 1.6 mol % of DPG said process comprising contacting terephthalic acid with a 1.6 to 1 to 2:1 molar amount of 1,3-propanediol in the presence of 20 to 120 ppm (as tin), by weight of the poly(trimethylene terephthalate), of a organic tin catalyst, to form a bis(3-hydroxypropyl)terephthalate monomer and polymerizing said monomer to obtain the poly(trimethylene terephthalate). The invention is also directed to poly(trimethylene terephthalate) produced by the processes.

Owner:DUPONT IND BIOSCIENCES USA LLC

Polyester/polyamide blend having improved flavor retaining property and clarity

InactiveUS7375154B2High oxygen barrierImprove performanceConductive materialSpecial tyresPolyesterPolymer science

This invention relates to a polyester / polyamide blend having an excellent gas barrier property. More particularly, the present invention relates to combinations of a polyethylene terephthalate polymer and a polyamide polymer having an excellent gas barrier property and short oxygen scavenging induction periods, where the polyamide polymer has a C:A terminal group concentration ratio of 2:1 or more and a C+A terminal group concentration of at least 0.17 meq / g of polyamide polymer, wherein C represents a cumulative total of a terminal carboxyl group concentration and a terminal hydrocarbyl group concentration expressed in meq / g of polyamide, and A represents a terminal amine group concentration expressed in meq / g of polyamide.

Owner:EASTMAN CHEM CO

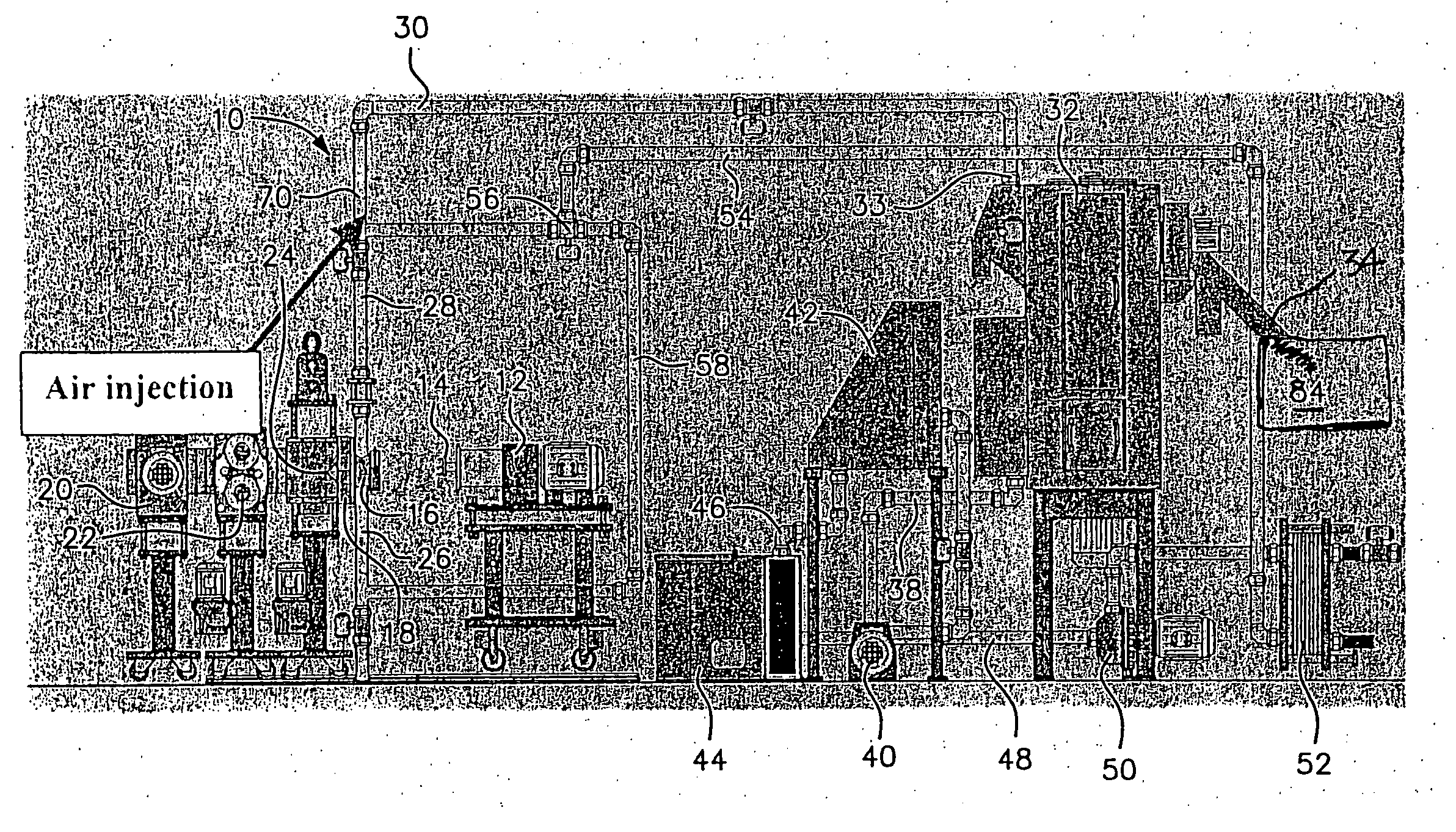

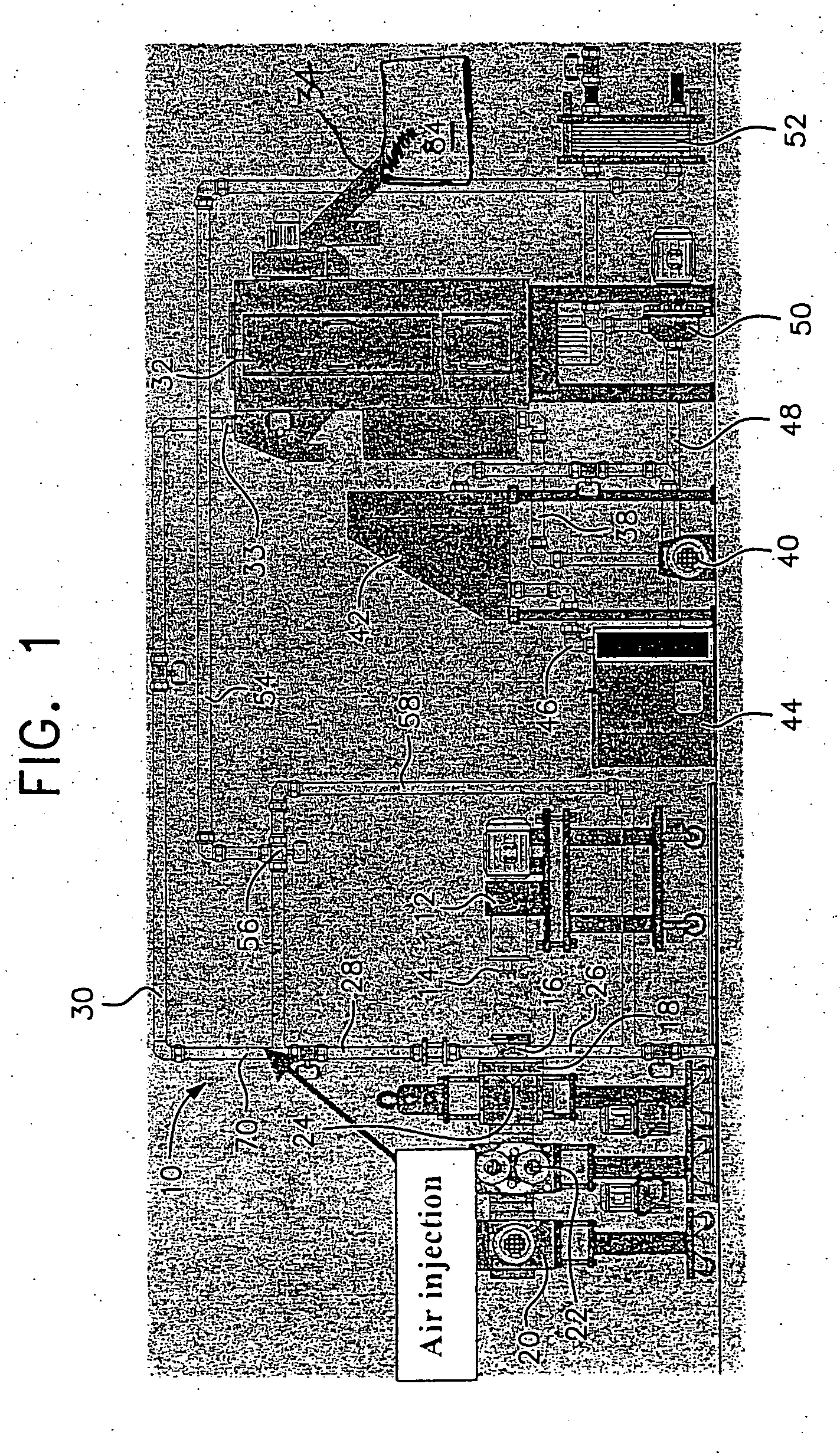

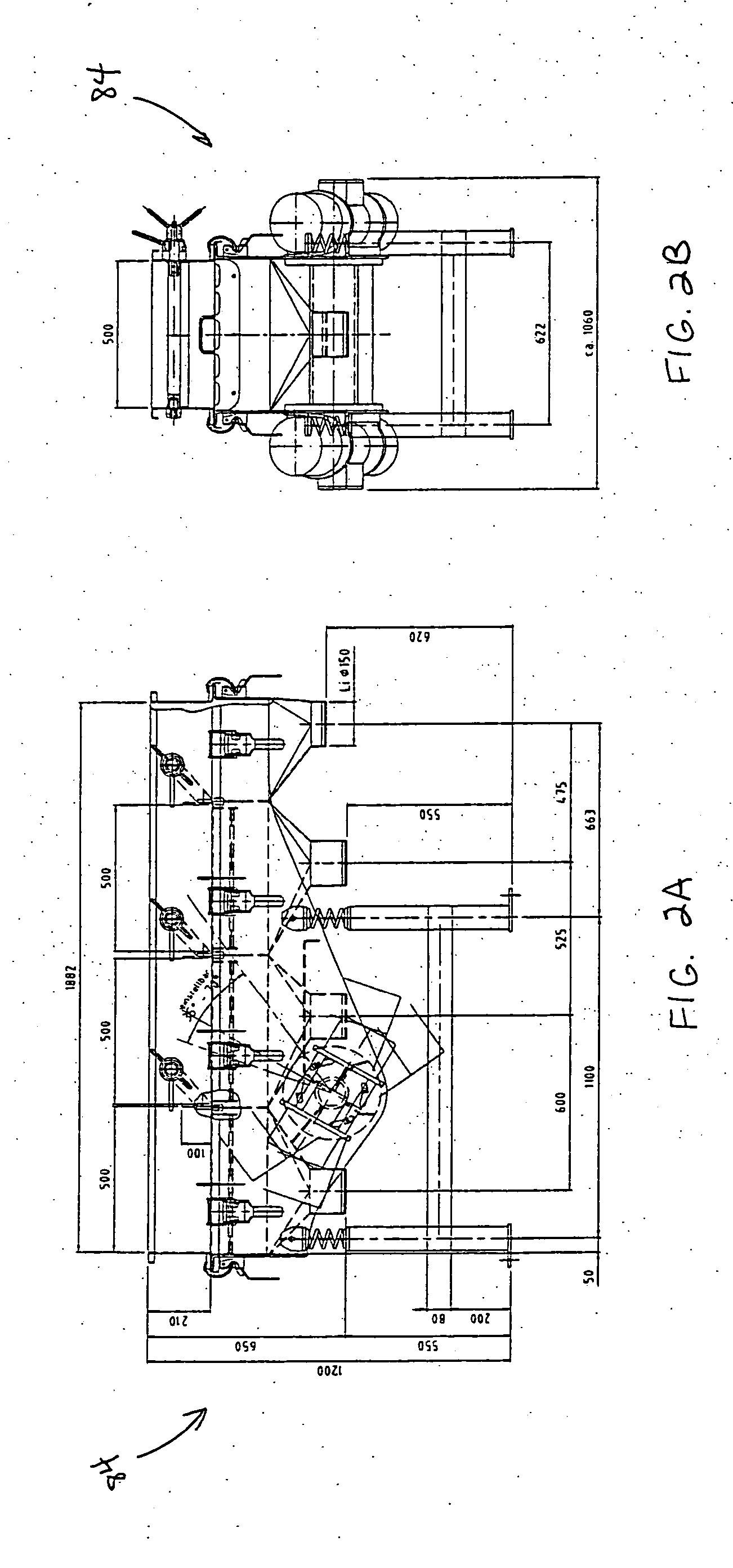

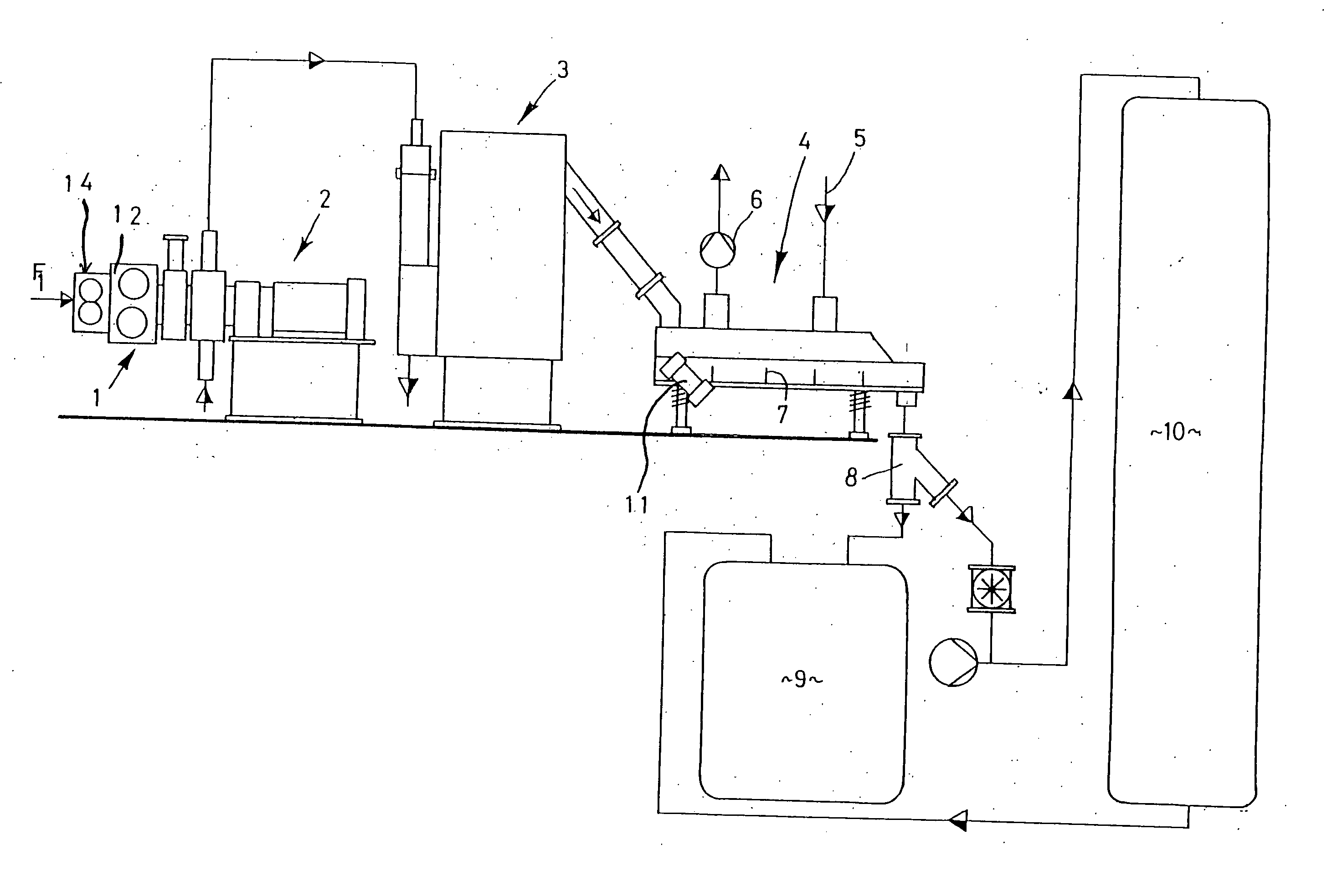

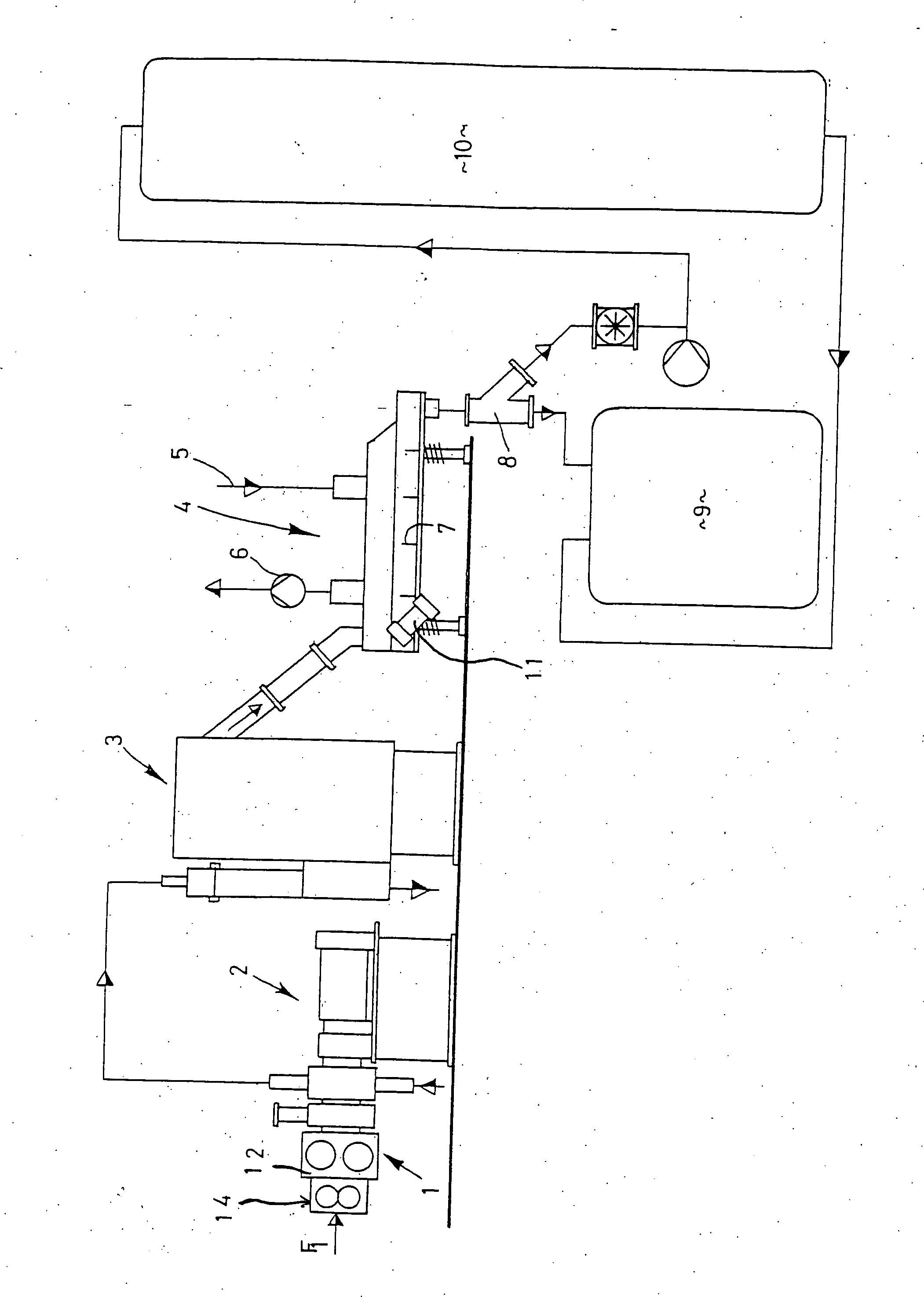

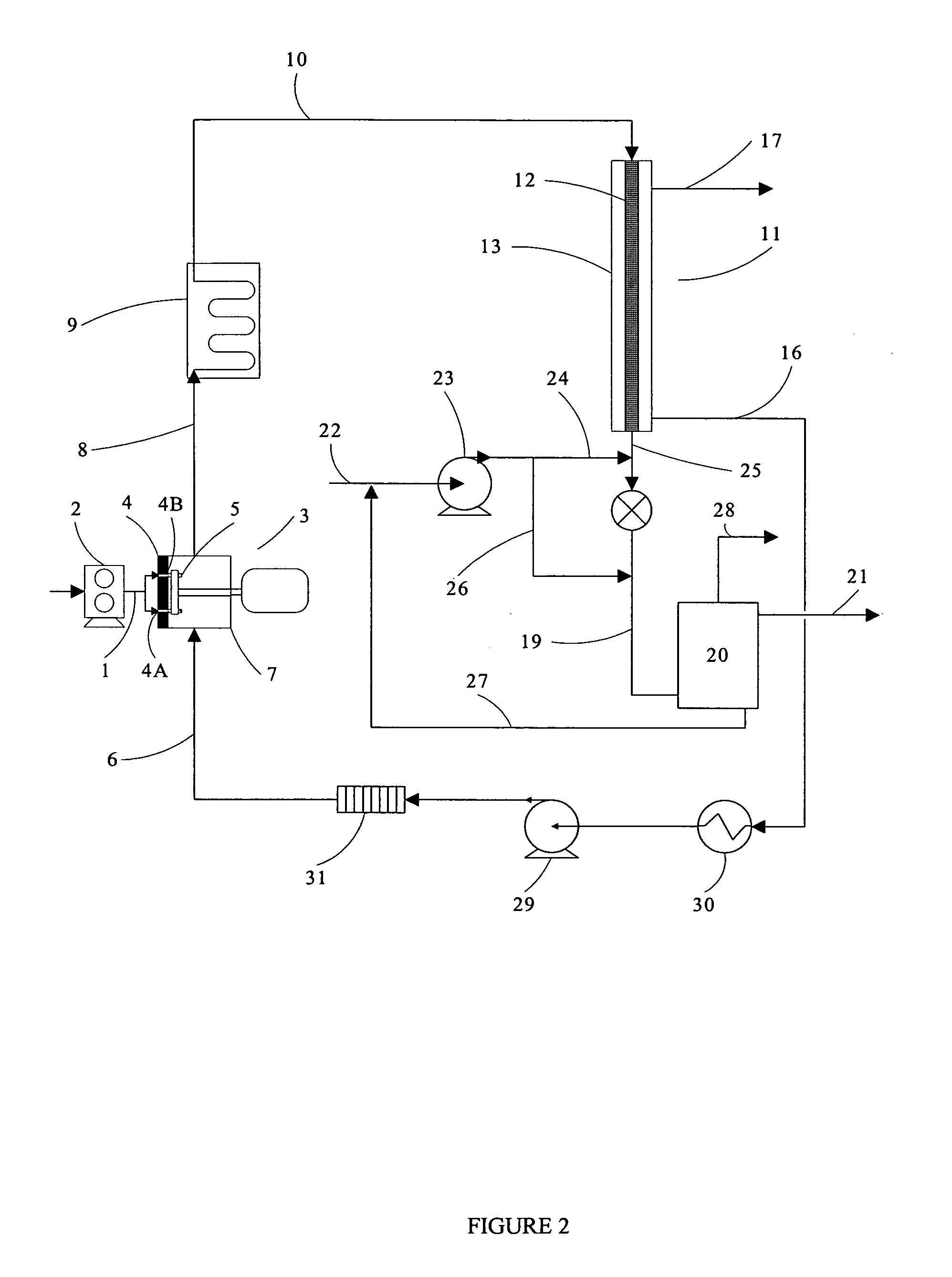

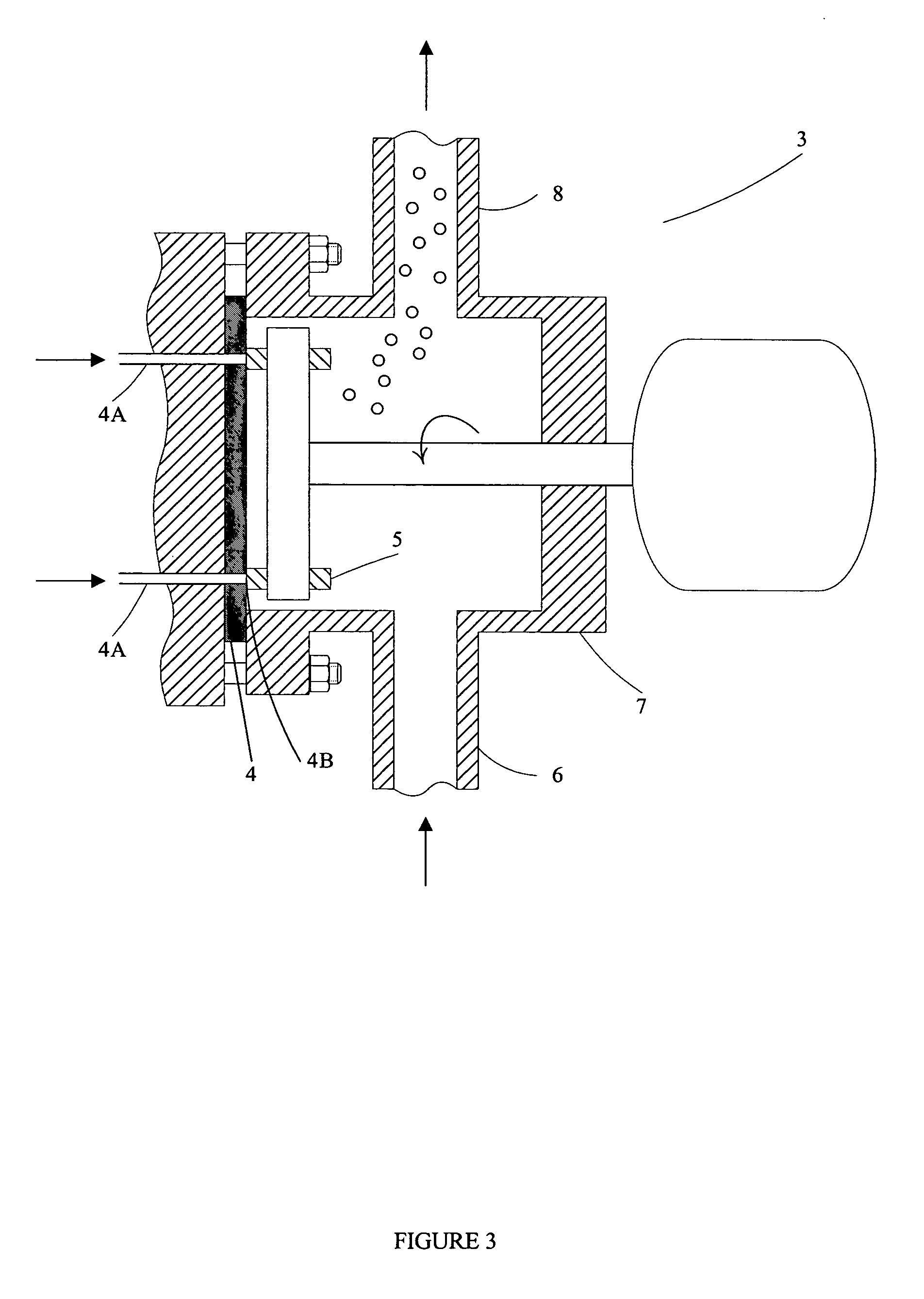

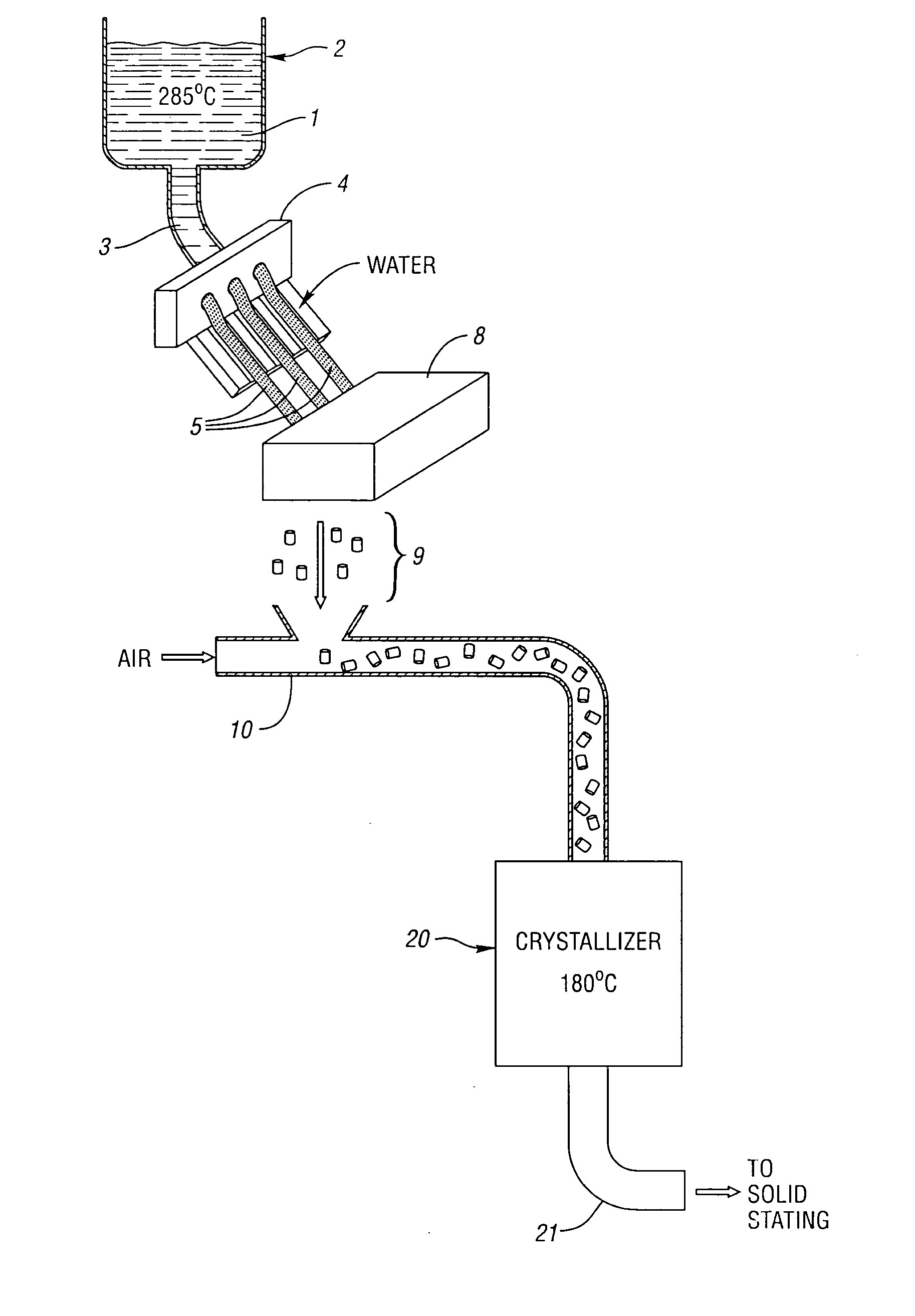

Method and apparatus for making crystalline PET pellets

InactiveUS20050110182A1Reduce dwell timeIncrease speedMouldsDrying solid materials without heatSlurryCrystallinity

A method and apparatus for underwater pelletizing and subsequent drying of polyethylene terephthalate (PET) polymers and other high temperature crystallizing polymeric materials to crystallize the polymer pellets without subsequent heating. High velocity air or other inert gas is injected into the water and pellet slurry line to the dryer near the pelletizer exit. Air is injected into the slurry line at a velocity of from about 100 to about 175 m3 / hour, or more. Such high-speed air movement forms a vapor mist with the water and significantly increases the speed of the pellets into and out of the dryer such that the PET polymer pellets leave the dryer at a temperature sufficient to self-initiate crystallization within the pellets. A valve mechanism in the slurry line after the gas injection further regulates the pellet residence time and a vibrating conveyor after the dryer helps the pellets to achieve the desired level of crystallinity and to avoid agglomeration.

Owner:GALA INDUSTRIES INC

Articles derived from compositions containing modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

ActiveUS20070275242A1Useful performance propertyPlastic recyclingSpecial tyresPolytetramethylene terephthalatePolyethylene terephthalate glycol

Compositions of matter including articles derived from (a) from 5 to 99.99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate and (2) contains a at least one residue derived from polyethylene terephthalate selected from the group consisting of antimony, germanium, diethylene glycol groups, isophthalic acid groups, cis isomer of cyclohexane dimethanol, trans isomer of cyclohexane dimethanol, sodium benzoate, alkali salts, napthalane dicarboxylic acids, 1,3-propane diols, cobalt, cobalt-containing compounds, and combinations thereof, and (b) from 0.01 to 95 wt. % of a member selected from the group consisting of (1) fillers, (2) a carboxy reactive component, (3) polyethyelene terephthalate, (4) a component including a polycarbonate and an impact modifier. The articles may be derived from various conversion processes, e.g., injection molding processes, extrusion processes, thermoforming processes, melt-blown process.

Owner:SHPP GLOBAL TECH BV

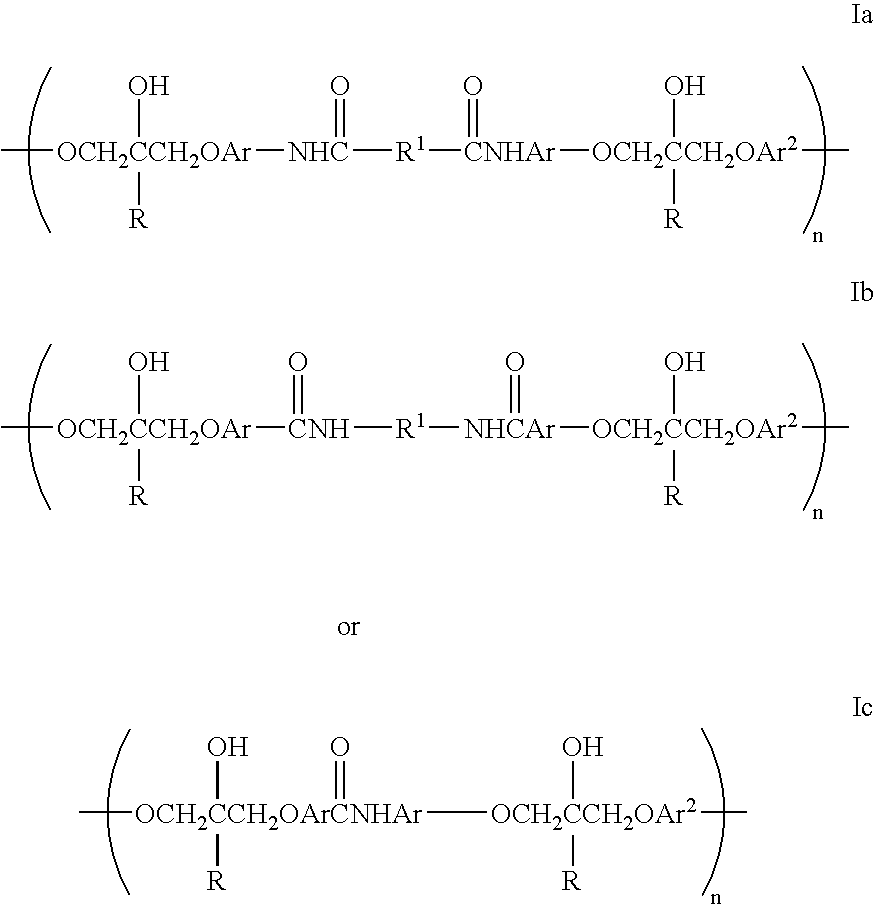

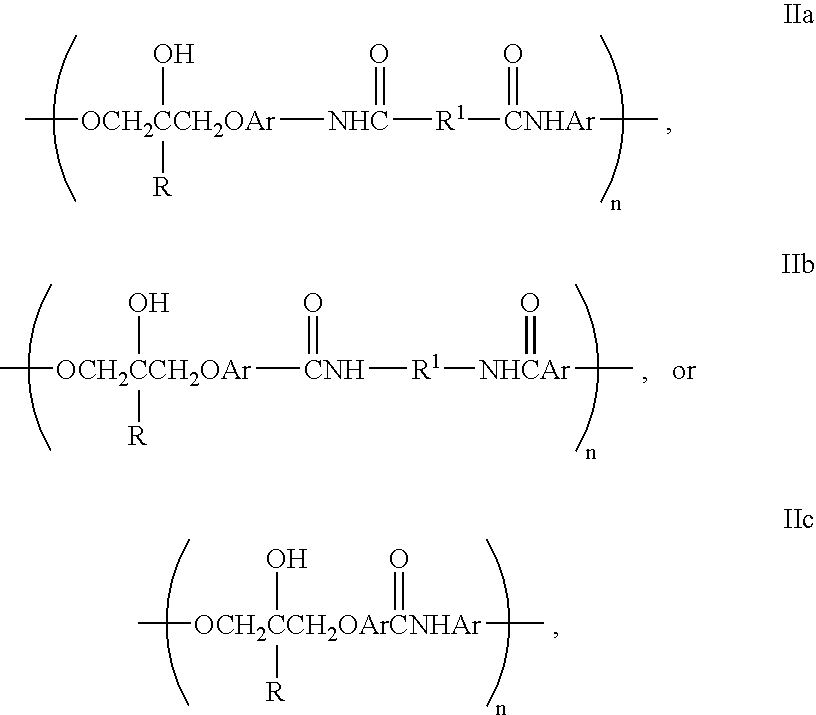

Polyamide-Polyester Polymer Blends and Methods of Making the Same

InactiveUS20080009574A1Superior polyamide-polyester barrier blendsEasy to recycleImpression capsDentistry preparationsPolyesterPolymer science

The present invention relates to polyamide-polyester barrier blends that possess improved gas barrier, clarity, and organoleptic properties, as well as containers (e.g., bottles), sheets, and films formed from such barrier resins. The invention further relates to polyamide-compatible polyethylene terephthalate resins that are useful in forming these improved polyamide-polyester polymer blends. The invention still further relates to cost-effective recycling of articles formed from polyamide-polyester polymer blends.

Owner:WELLMAN INC

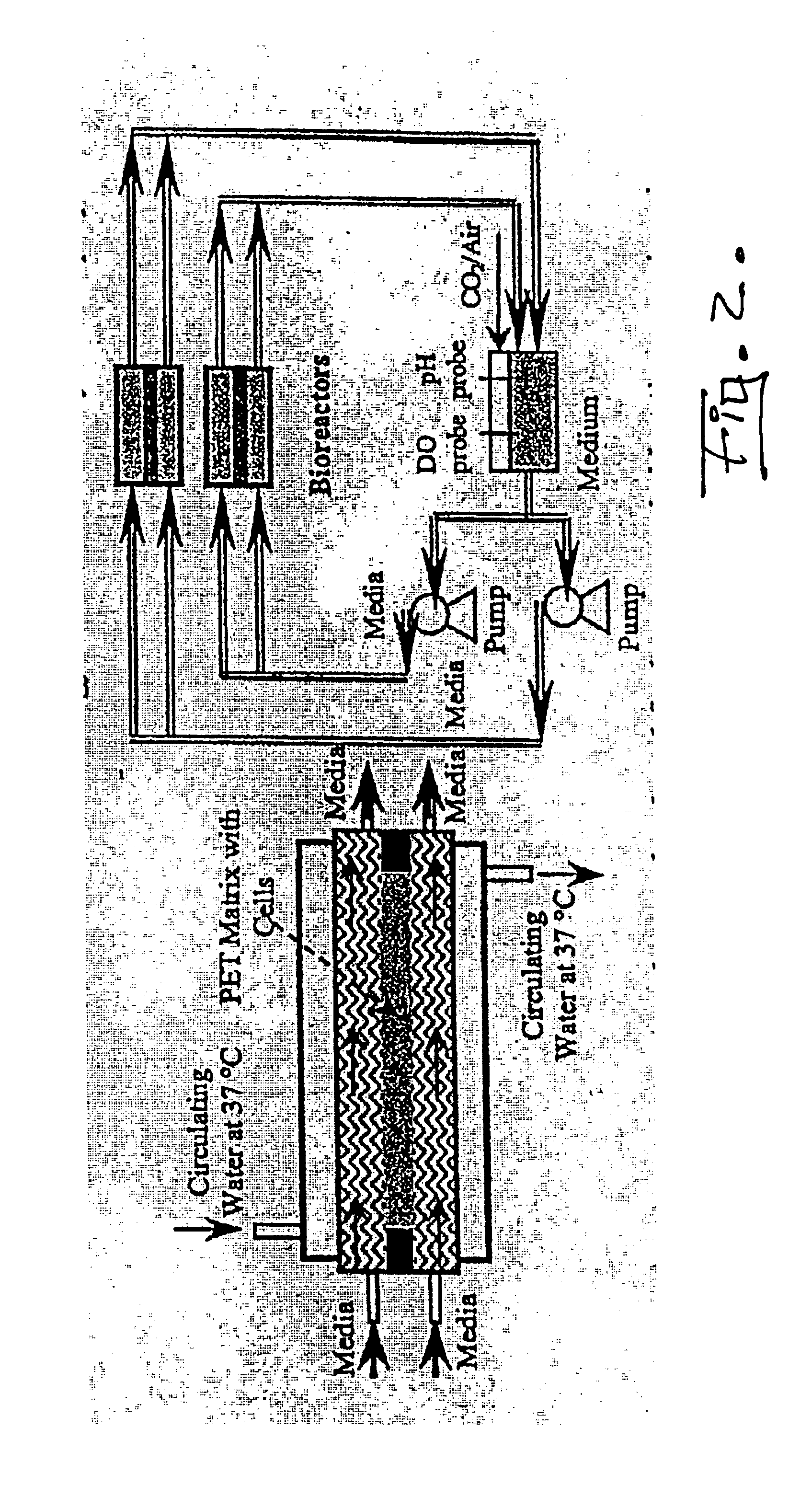

Modular cell culture bioreactor and associated methods

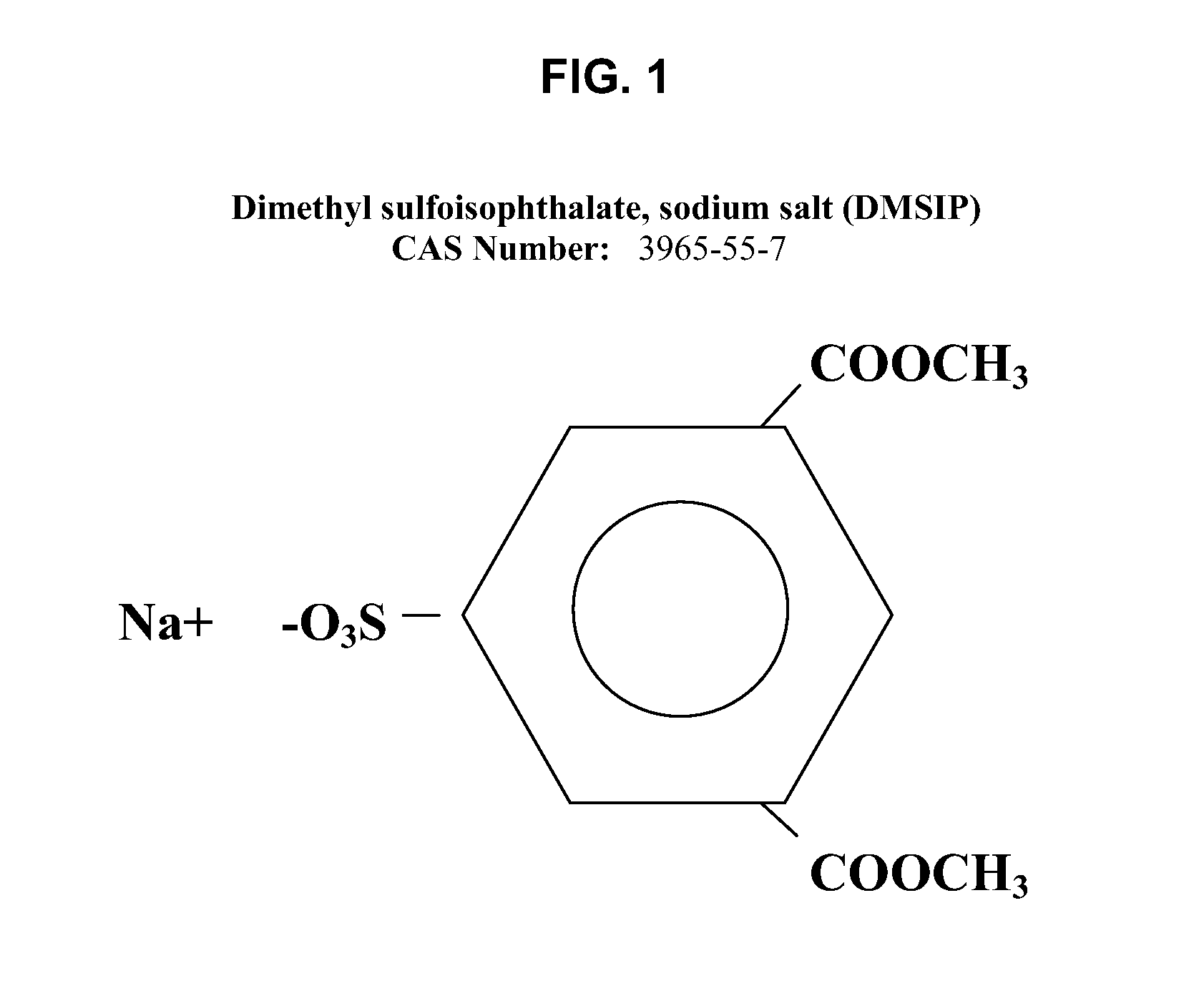

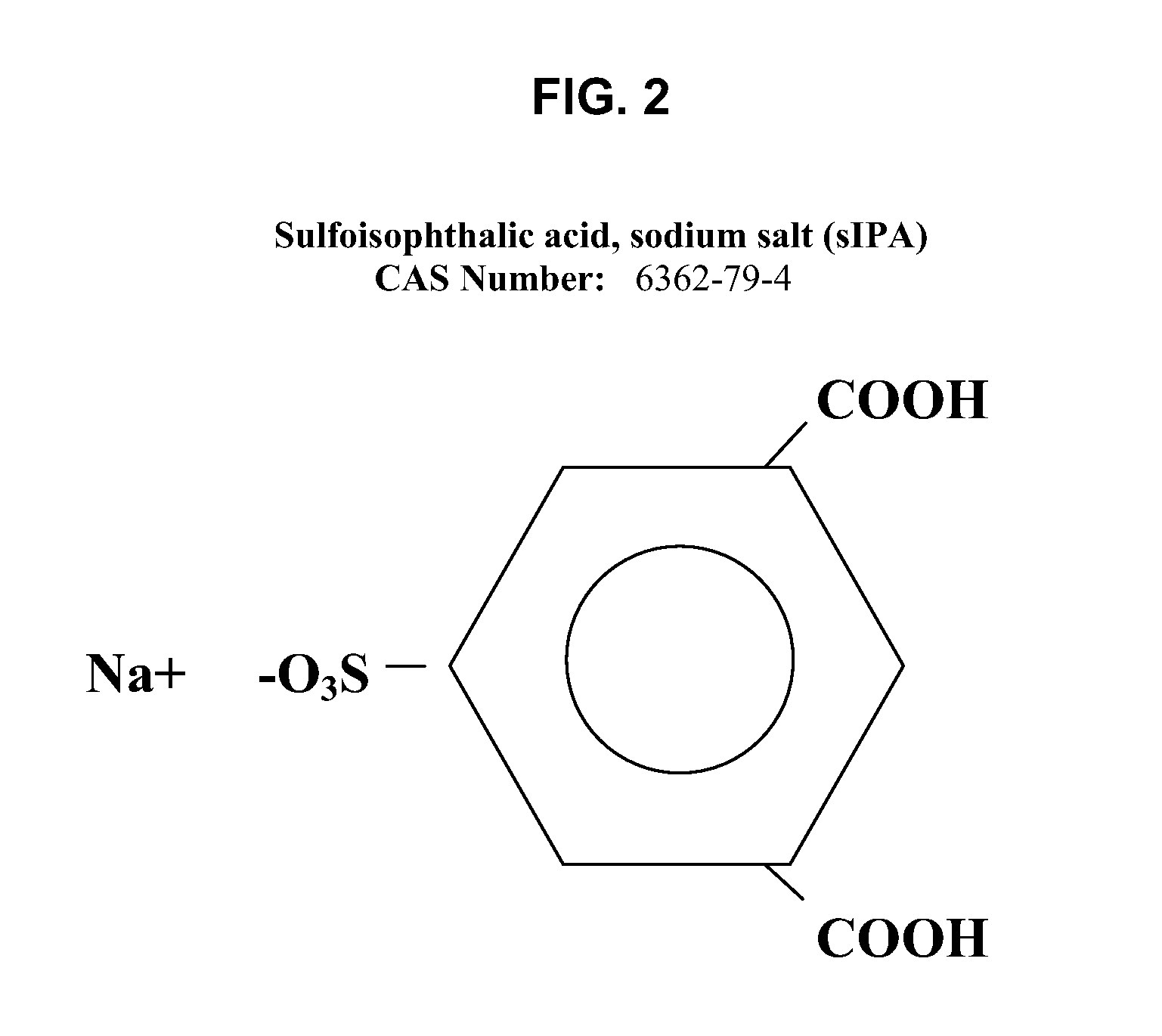

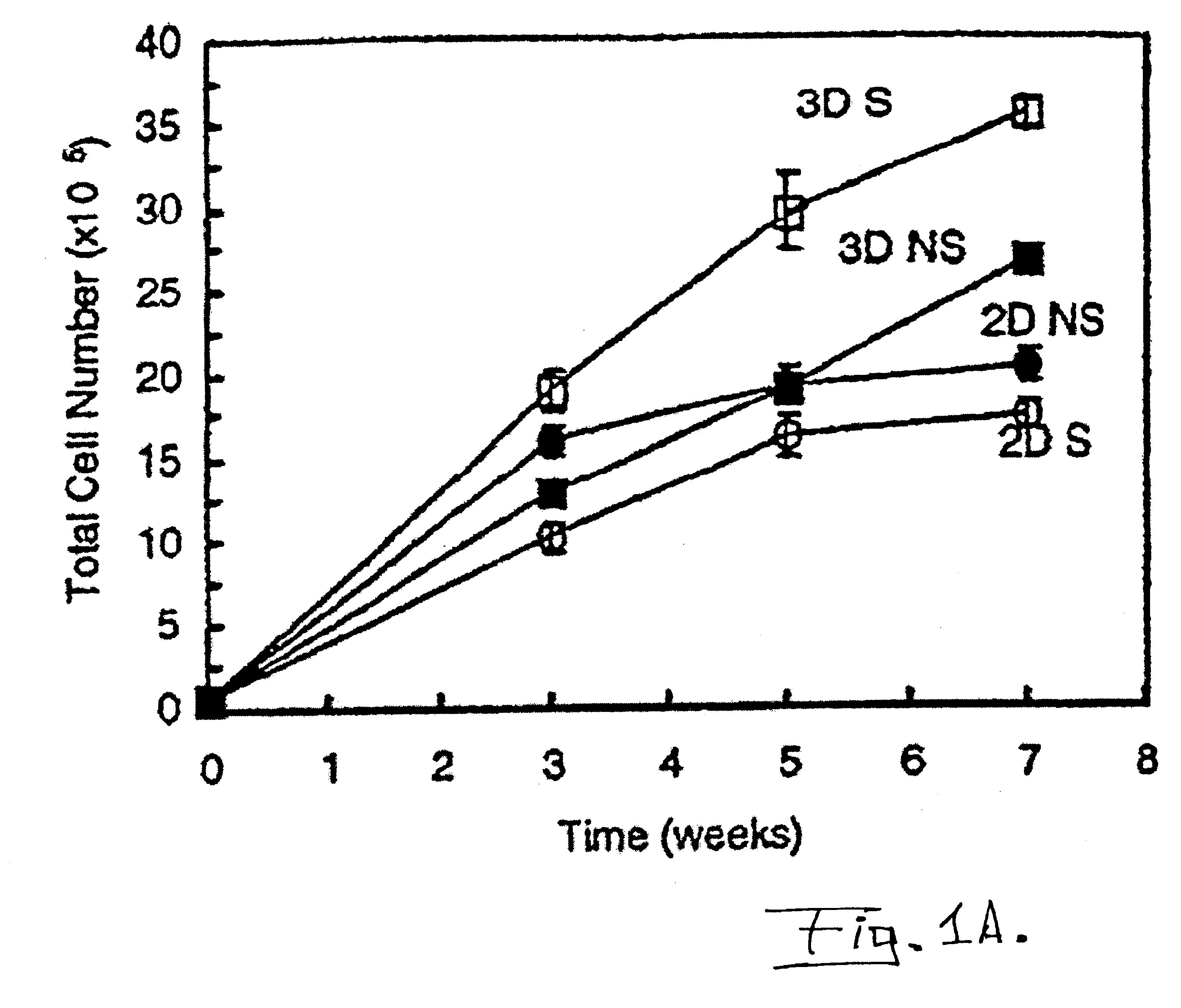

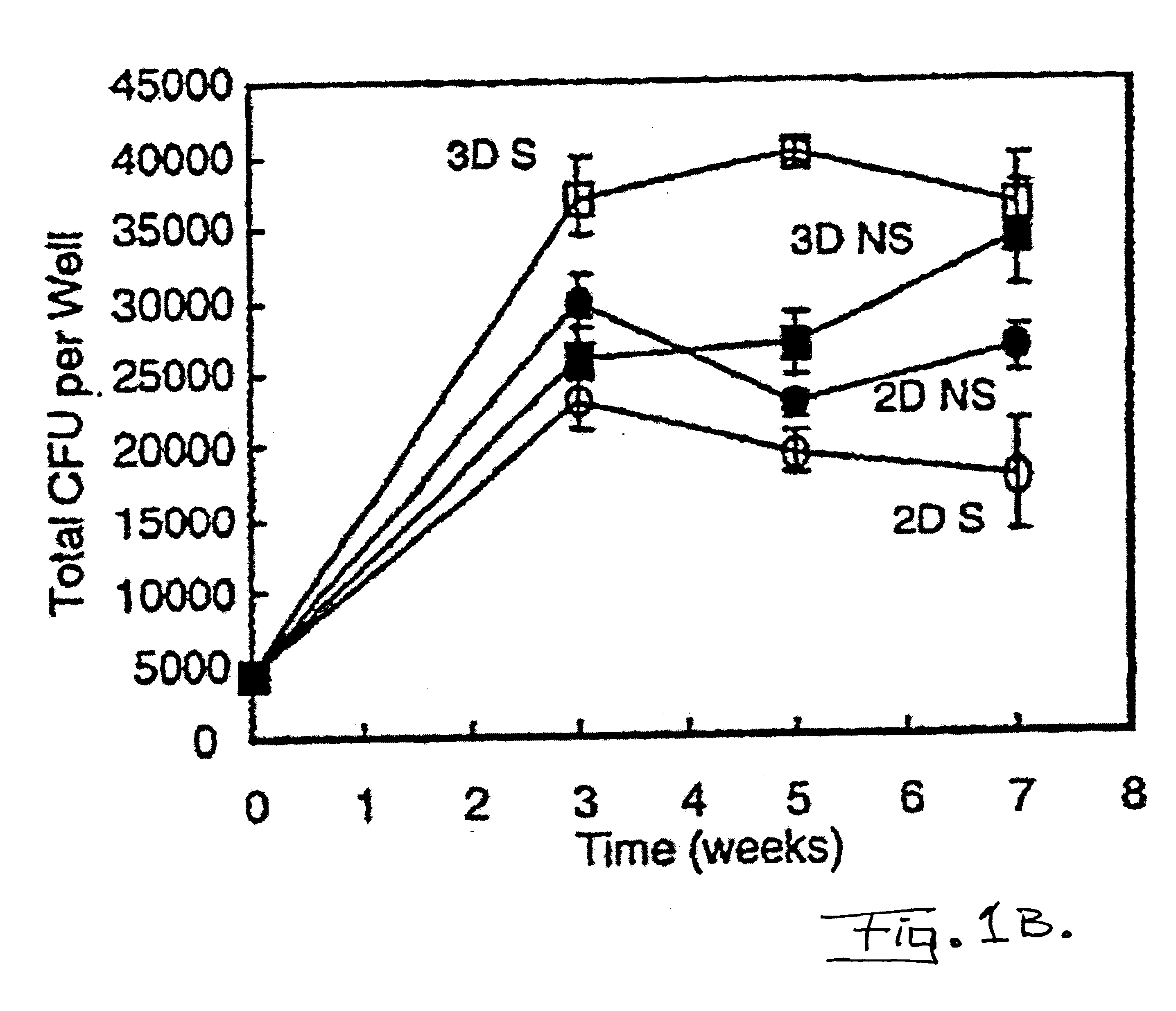

InactiveUS6875605B1Bioreactor/fermenter combinationsBiological substance pretreatmentsPolyethylene terephthalate3D cell culture

An apparatus and method for a modular cell culture bioreactor comprises a plurality of chambers for cell culture; at least one reservoir containing a cell support medium; a plurality of conduits fluidly connecting the at least one reservoir with the plurality of chambers; and at least one pump fluidly connected through the plurality of conduits with the at least one reservoir and with the plurality of chambers to pump cell support medium therethrough; wherein each individual chamber of the plurality of chambers includes at least one three-dimensional matrix comprising polyethylene terephthalate, a plurality of channels carrying the cell support medium and having the matrix positioned in fluid communication therebetween, and at least two openings into each the channel, wherein a first the opening is in fluid connection with the pump and a second the opening is in fluid connection with the reservoir.

Owner:FLORIDA STATE UNIV RES FOUND INC

Container having barrier properties and method of manufacturing the same

ActiveUS20050181155A1Improve structural strengthImprove barrier propertiesBottlesSynthetic resin layered productsPolymer sciencePolyethylene terephthalate

A method of manufacturing a multilayer or a monolayer plastic container is disclosed. The container has a barrier layer manufactured from (i) a polyester resin, preferably an aromatic polyester resin such as a polyethylene terephthalate, (ii) a polyamide material, preferably an aromatic polyamide material, and (iii) an oxygen scavenging material, preferably a transition method. The present invention also provides containers having a multilayer or a monolayer body. In the preparation of the barrier layer. a preform first is prepared by an injection-molding process wherein a preblend containing a diluent polyester, polyamide material, and an oxygen scavenging material is added to a base polyester during the injection molding process. The preform then is expanded to form a container.

Owner:SWIMC LLC

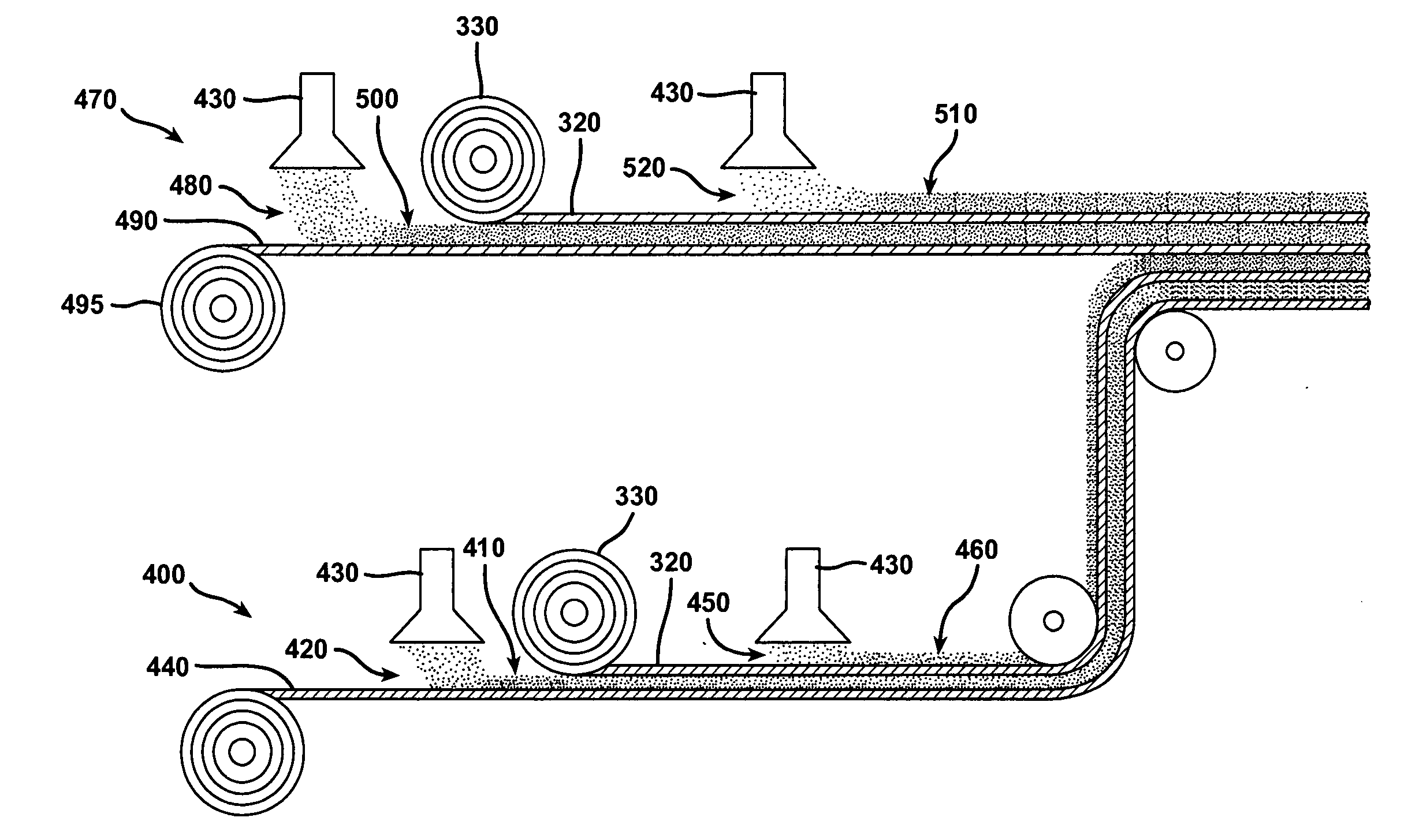

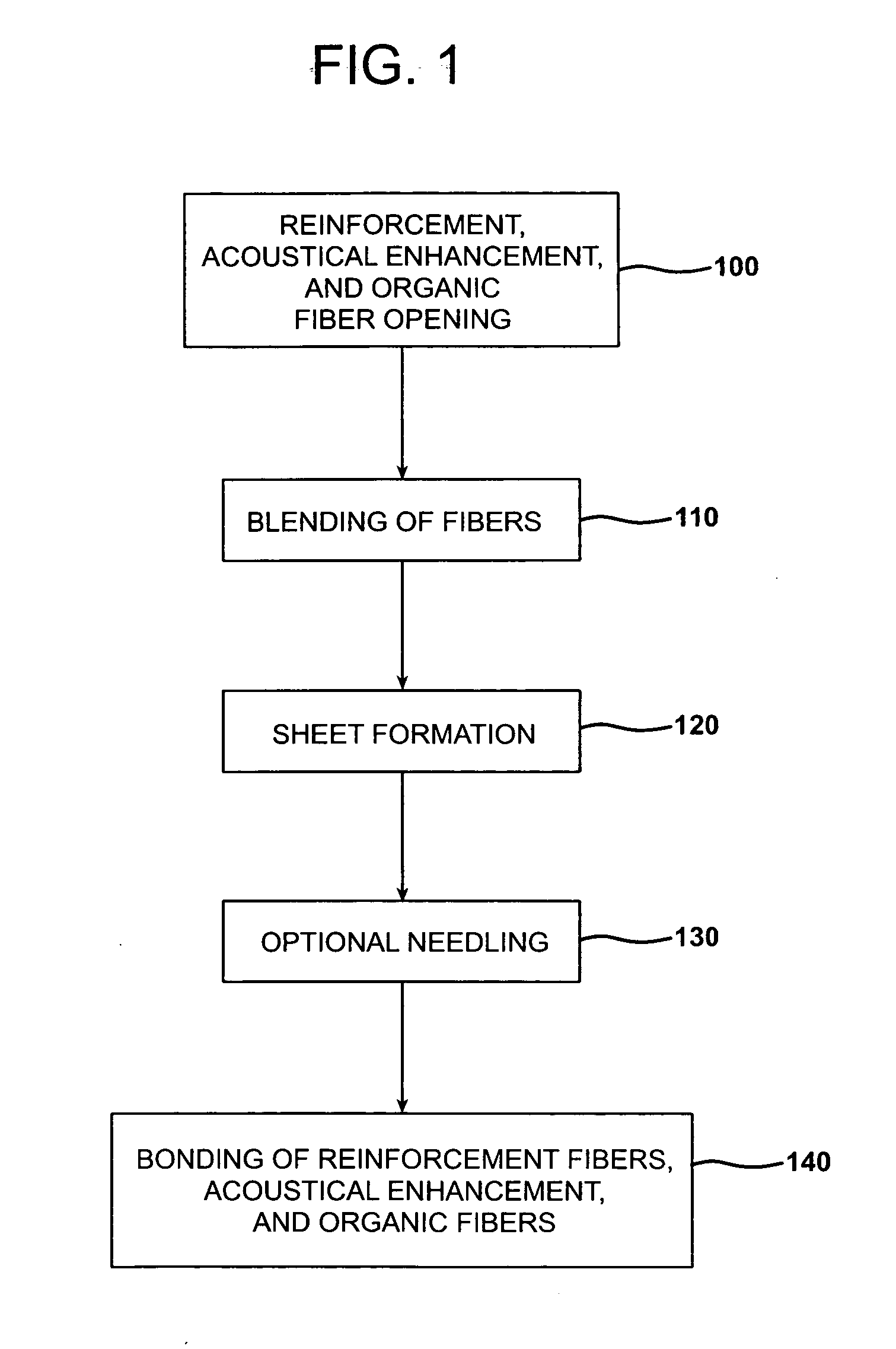

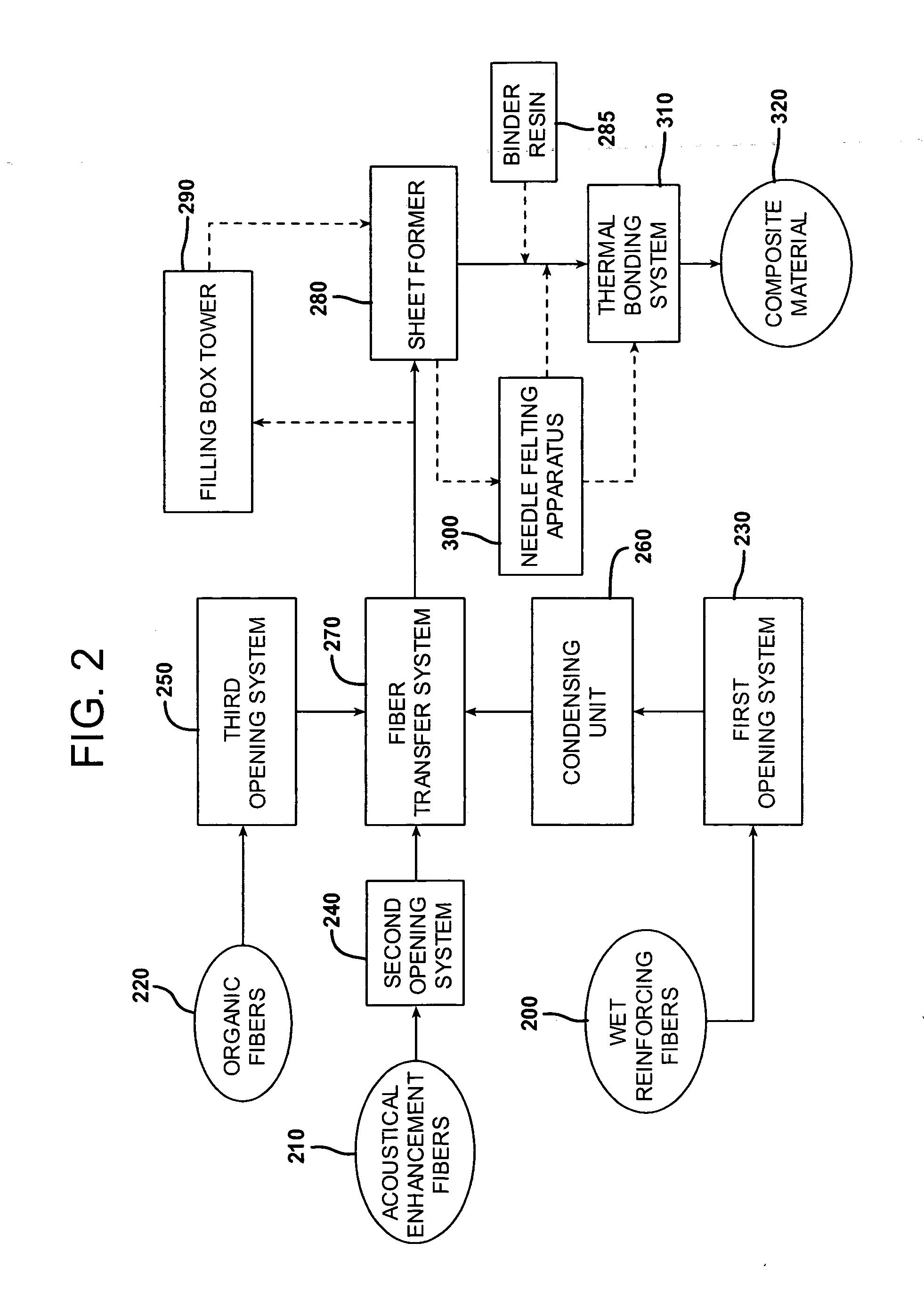

Thermoplastic composites with improved sound absorbing capabilities

InactiveUS20060137799A1Alter its performanceOptimization propertiesWood working apparatusBaby linensGlass fiberPolyethylene terephthalate

A composite material formed of reinforcement fibers, acoustical enhancing fibers such as polyethylene terephthalate (PET) fibers or modified polyethylene terephthalate fibers, and one or more organic fibers is provided. The acoustical enhancing fiber may be any fiber that provides increased or enhanced acoustical absorbance, particularly at low frequencies. The composite material may be formed by partially opening wet reinforcing fibers, acoustical enhancing fibers, and organic fibers, mixing the reinforcing, acoustical enhancement, and organic fibers, forming the fibers into a sheet, and bonding the fibers in the sheet. Preferably the reinforcing fibers are wet use chopped strand glass fibers. The composite material may be formed of a single layer of reinforcement, acoustical enhancement fibers, and organic fibers. Alternatively, the composite material may be a multi-layered composite in which the acoustical enhancement fibers are located in an acoustical layer laminated to a thermal layer formed of the organic fibers and reinforcement fibers.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Medical balloon having strengthening rods

Owner:BARD PERIPHERAL VASCULAR

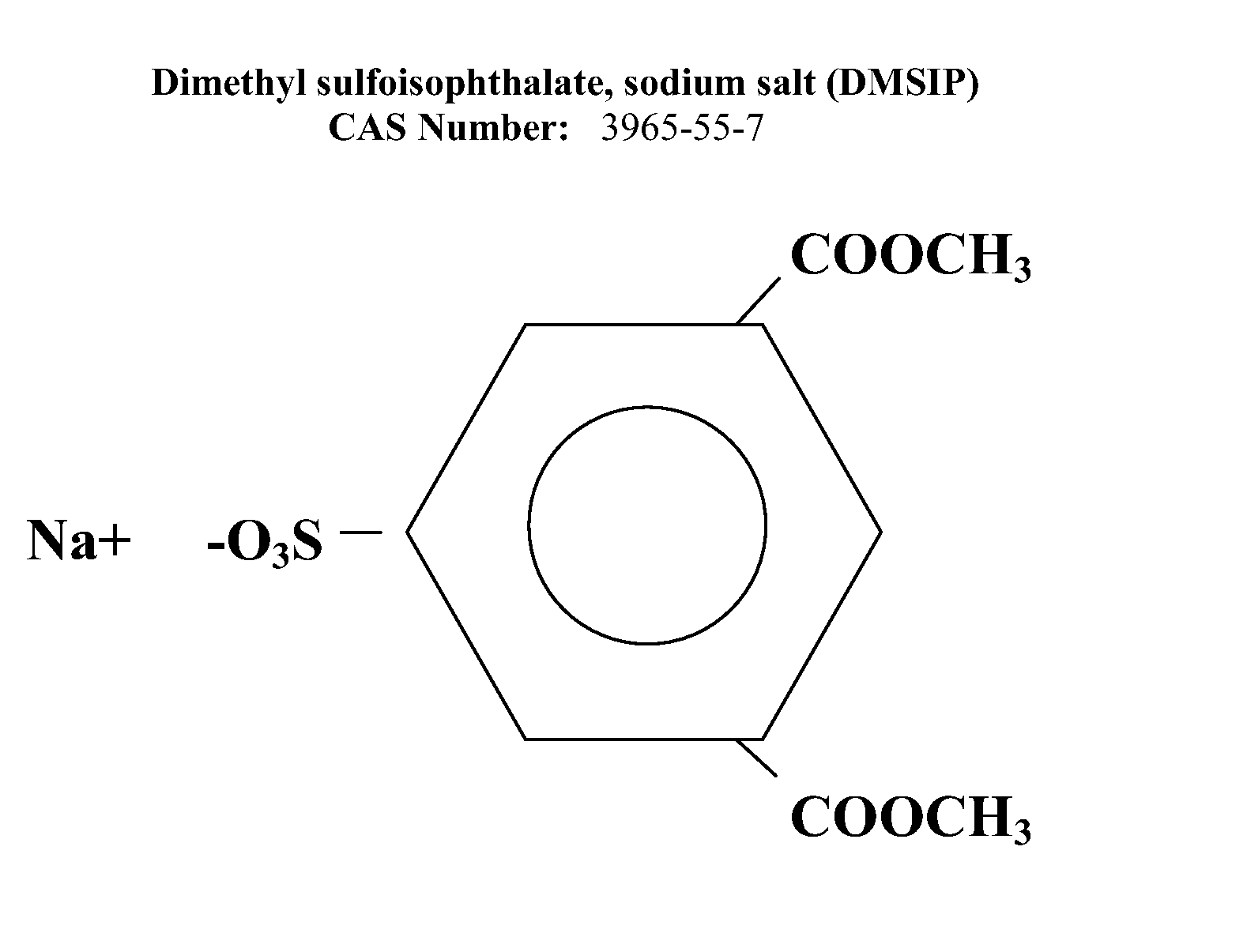

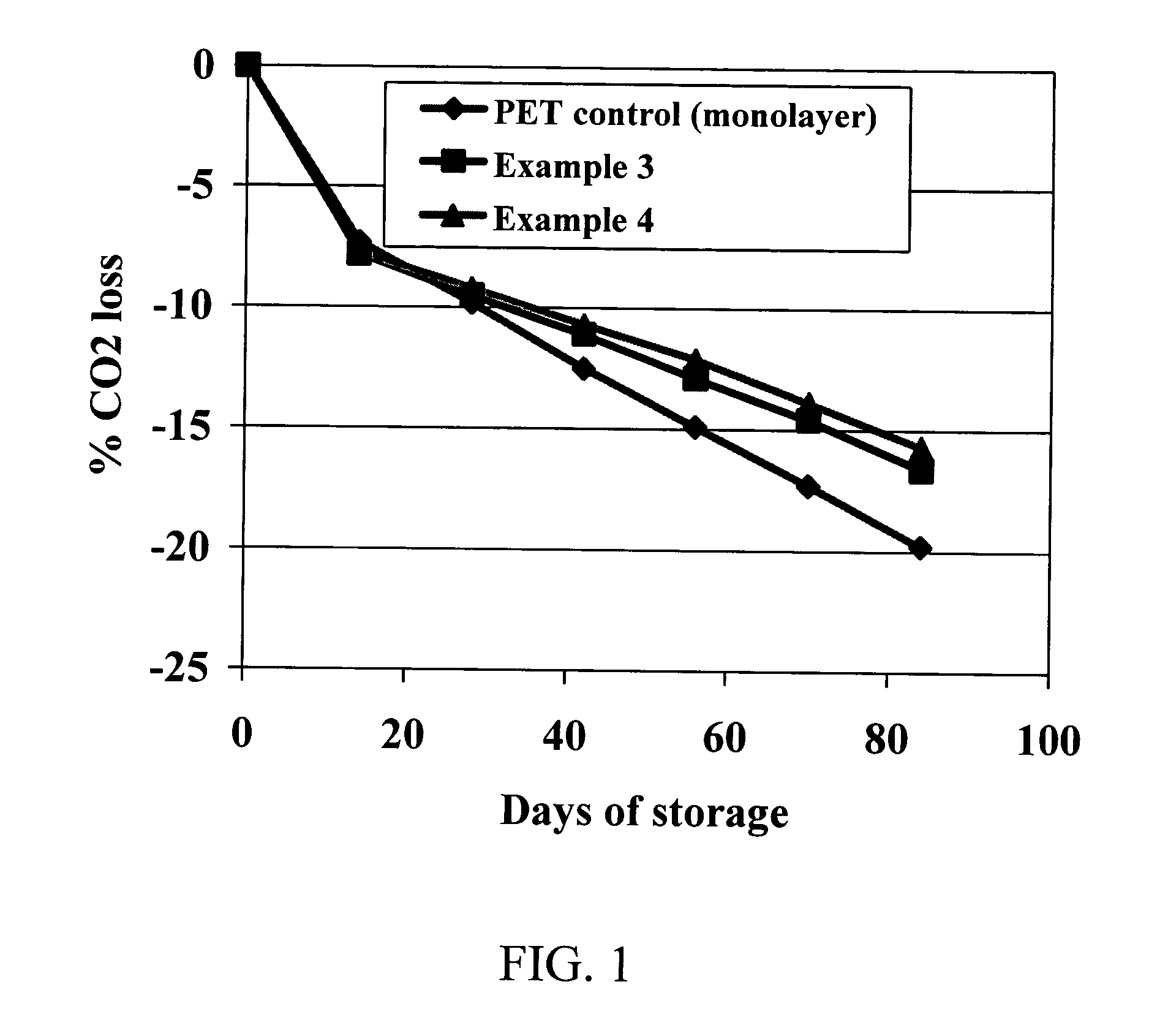

Delamination-resistant, barrier polyamide compositions for 3-layer pet beverage bottles

Gas barrier polyamide compositions exhibiting a low crystallization rate and good coinjection stretch blow moldability with polyethylene terephthalate (PET) to enable the fabrication of clear, high barrier multilayer PET bottles that have a long shelf life.

Owner:HONEYWELL INT INC

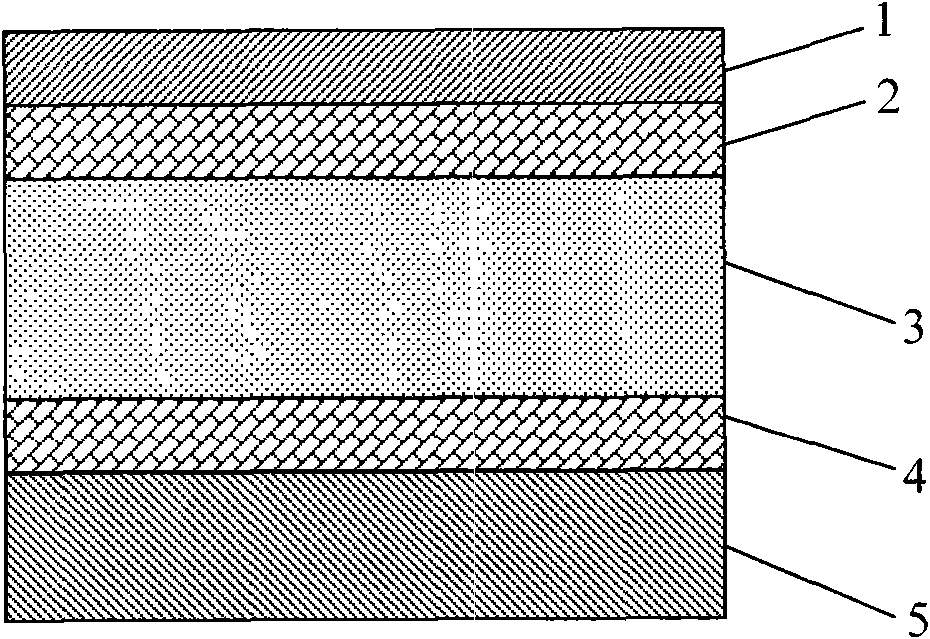

Multilayer containers and preforms having barrier properties utilizing recycled material

InactiveUS6808820B2Reduce the amount requiredMaintain good propertiesSynthetic resin layered productsDomestic articlesPolyesterPolyethylene terephthalate glycol

Preferred embodiments relate to methods and apparatus for making articles made of polyester, preferably virgin polyethylene terephthalate (PET), having coated directly to at least one of the surfaces thereof one or more layers of recycled or post-consumer PET and one or more layers of a material with good gas-barrier characteristics, preferably silicon oxide. Preferably, the recycled PET layer comprises about 25% to about 50% of the entire material content. Preferably the articles take the form of preforms and the containers are blow-molded therefrom and the barrier layer is subsequently applied. The preferred barrier materials have a lower permeability to oxygen and carbon dioxide than PET. In addition, the neck of the preforms and bottles is at least partially in the crystalline state and the body is primarily in the amorphous or semi-crystalline state. This structure in a preform enables the preform to be easily blow molded by virtue of the amorphous material in the body, while being able to have dimensional stability in hot-fill applications.

Owner:CONCENTRATE MFG OF IRELAND

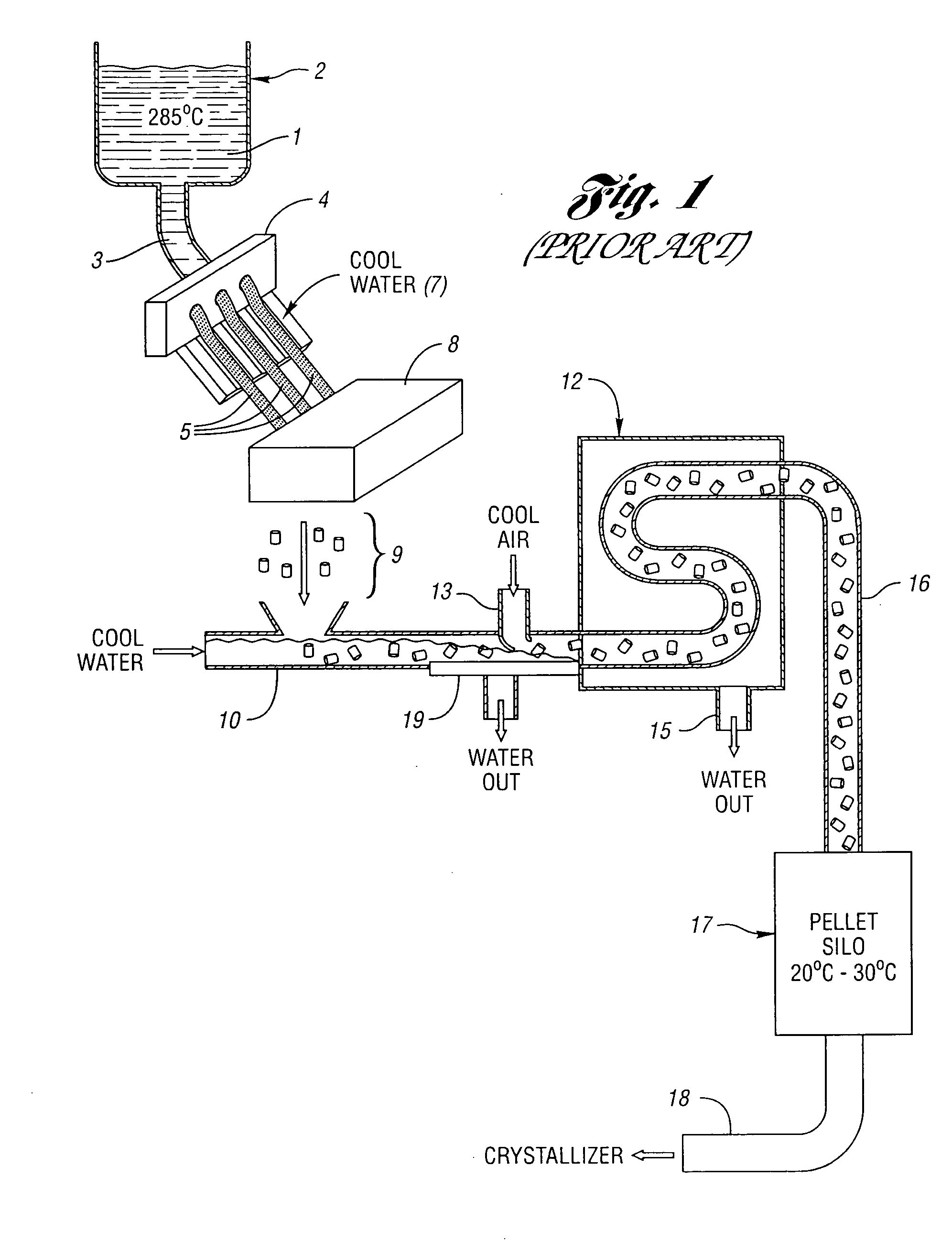

Method and apparatus for thermally processing polyester pellets

InactiveUS20050085620A1Long dwell timeSmall contact surfaceMouldsConfectioneryPolyesterPolyethylene terephthalate

Method and apparatus for thermally processing polyester pellets, e.g., polyethylene terephthalate pellets, in order to achieve a partial crystallization, whereby the polyester melt is fed to an underwater pelletizer and pelletized, the pellets obtained are fed to a water / solids separating device and the dried pellets are fed at a pellet temperature of greater than 100° C. to an agitation device that the pellets leave at a pellet temperature of over 100° C.

Owner:NORDSON CORP

Dip, spray, and flow coating process for forming coated articles

InactiveUS20040071885A1Easy to useSynthetic resin layered productsPretreated surfacesPolyethylene terephthalateMaterials science

This invention relates to methods and apparatus for making coated articles with one or more layers by dip, spray or flow coating. In one aspect, this invention relates to an apparatus and method for making coated containers, preferably comprising polyethylene terephthalate, from coated preforms. In preferred embodiments, the apparatus and method permit the coated container or preform to be made in an energy-efficient manner that reduces the danger of coating damage and thus increases the efficacy of the final container.

Owner:ADVANCED PLASTICS TECH LUXEMBOURG SA

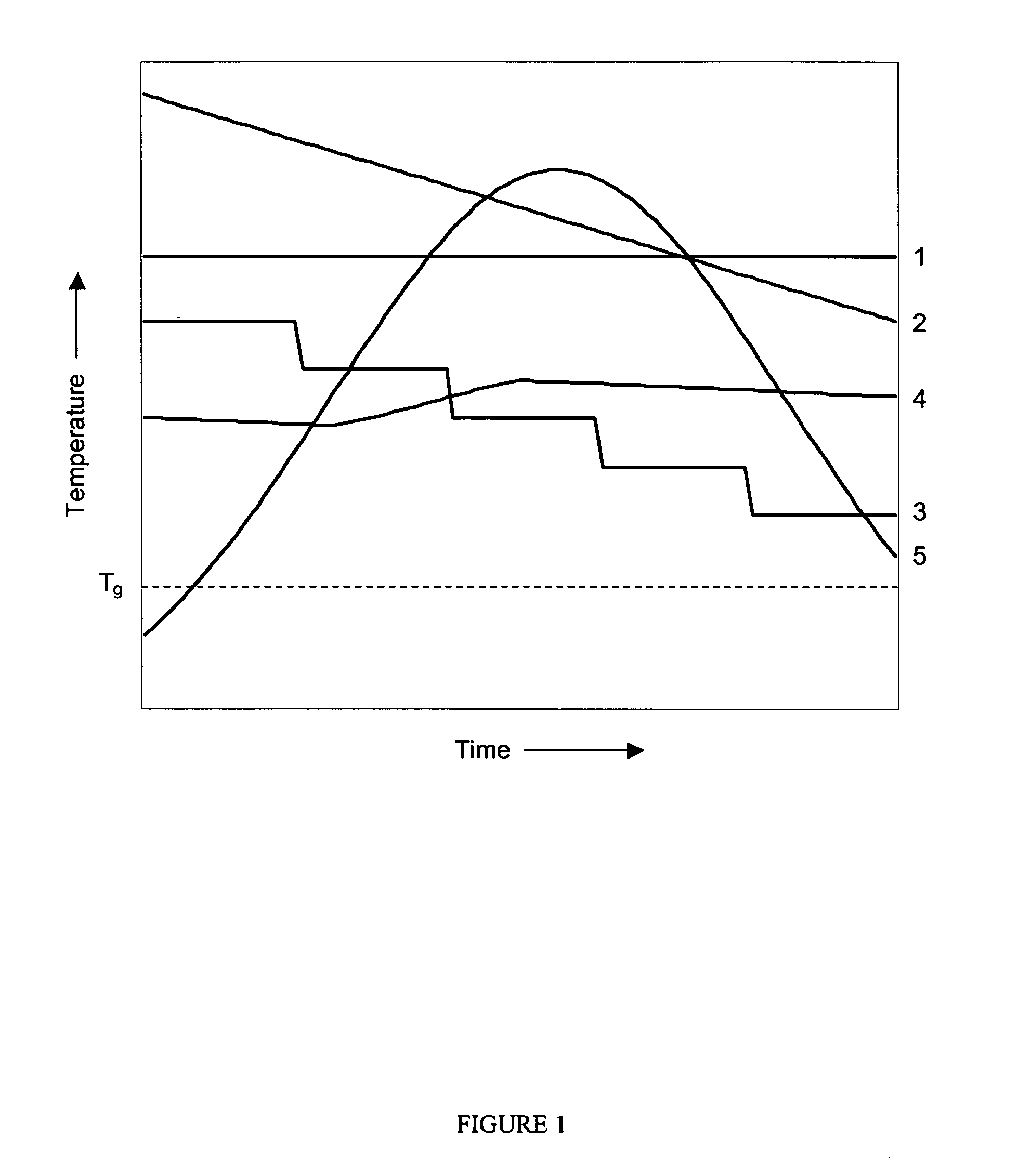

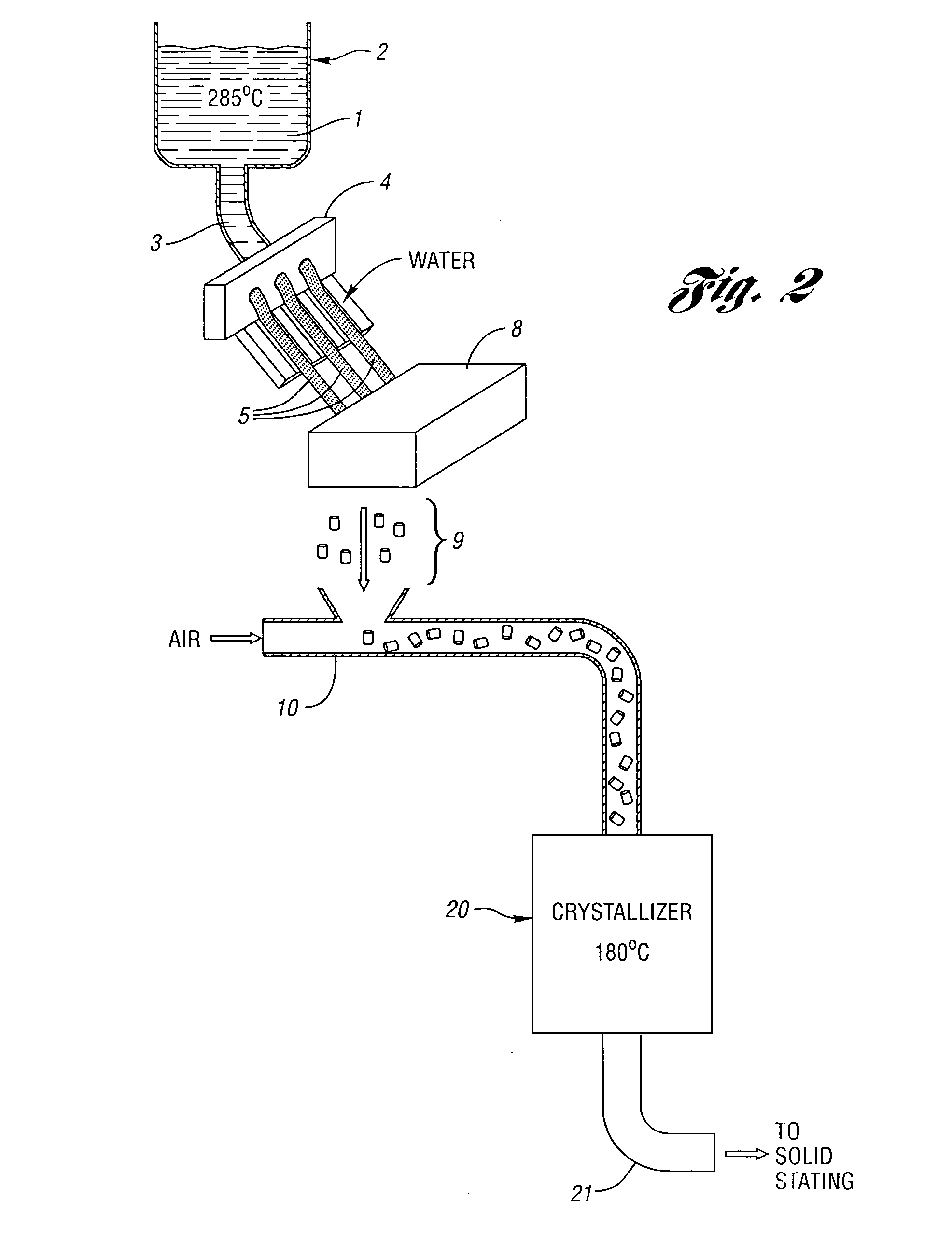

Thermal crystallization of a molten polyester polymer in a fluid

InactiveUS7192545B2Reduce molecular weightEnergy efficiencyDrying gas arrangementsCeramic shaping apparatusPolyesterLiquid medium

A process for crystallizing a polyester polymer by introducing a molten polyester polymer, such as a polyethylene terephthalate polymer, into a liquid medium at a liquid medium temperature greater than the Tg of the polyester polymer, such as at a temperature ranging from 100° C. to 190° C., and allowing the molten polyester polymer to reside in the liquid medium for a time sufficient to crystallize the polymer under a pressure equal to or greater than the vapor pressure of the liquid medium. A process flow, underwater cutting process, crystallization in a pipe, and a separator are also described.

Owner:ALPEK POLYESTER SA DE CV

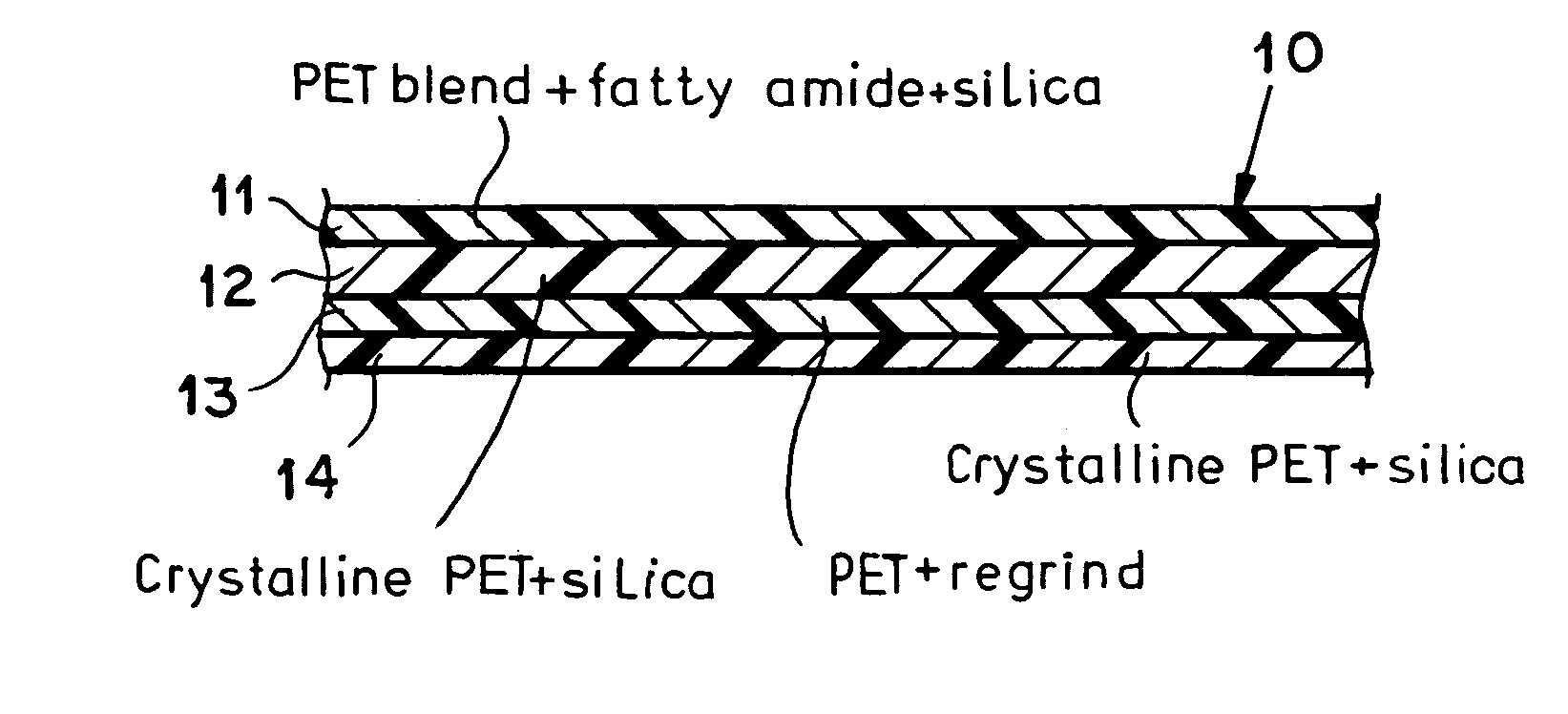

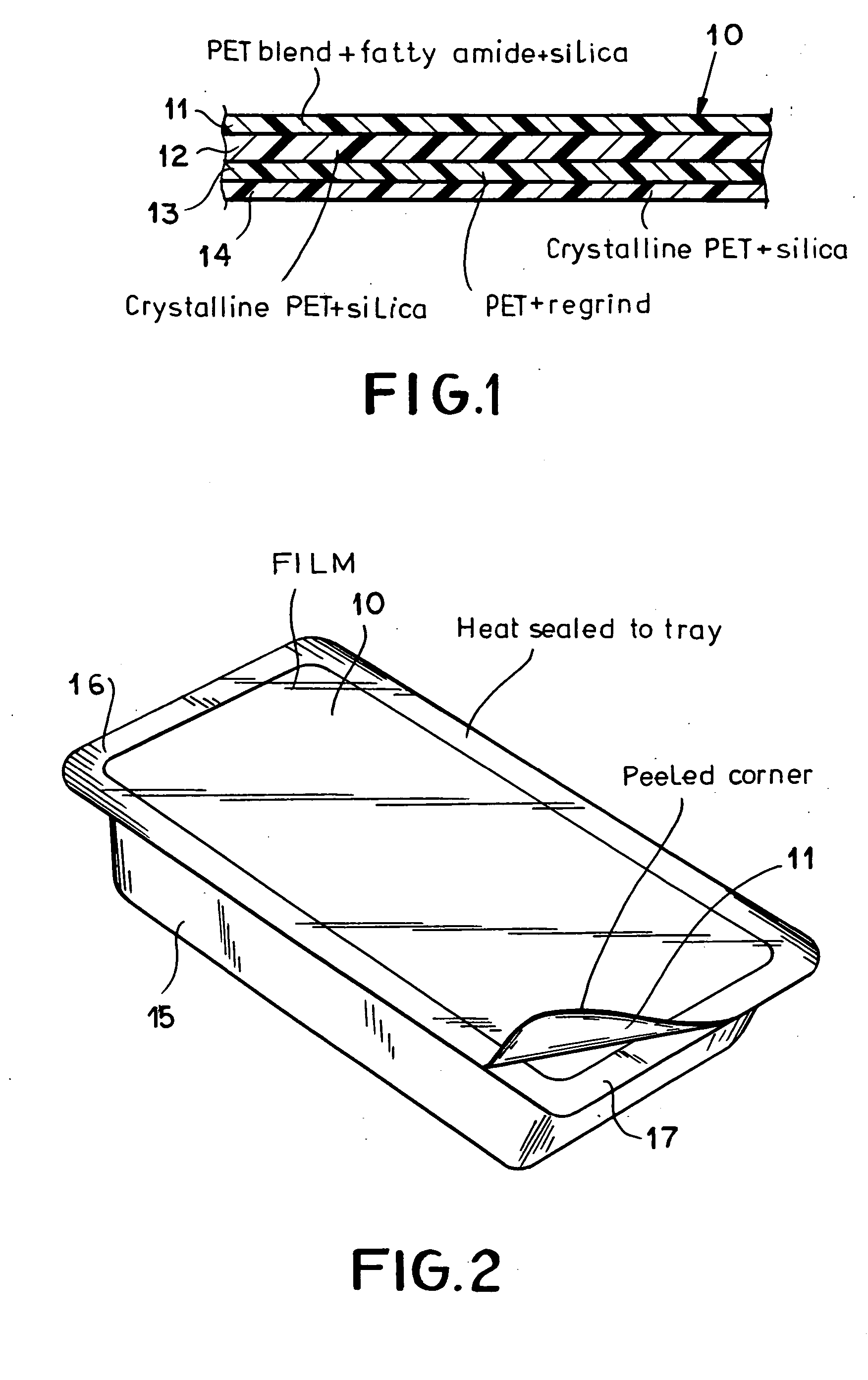

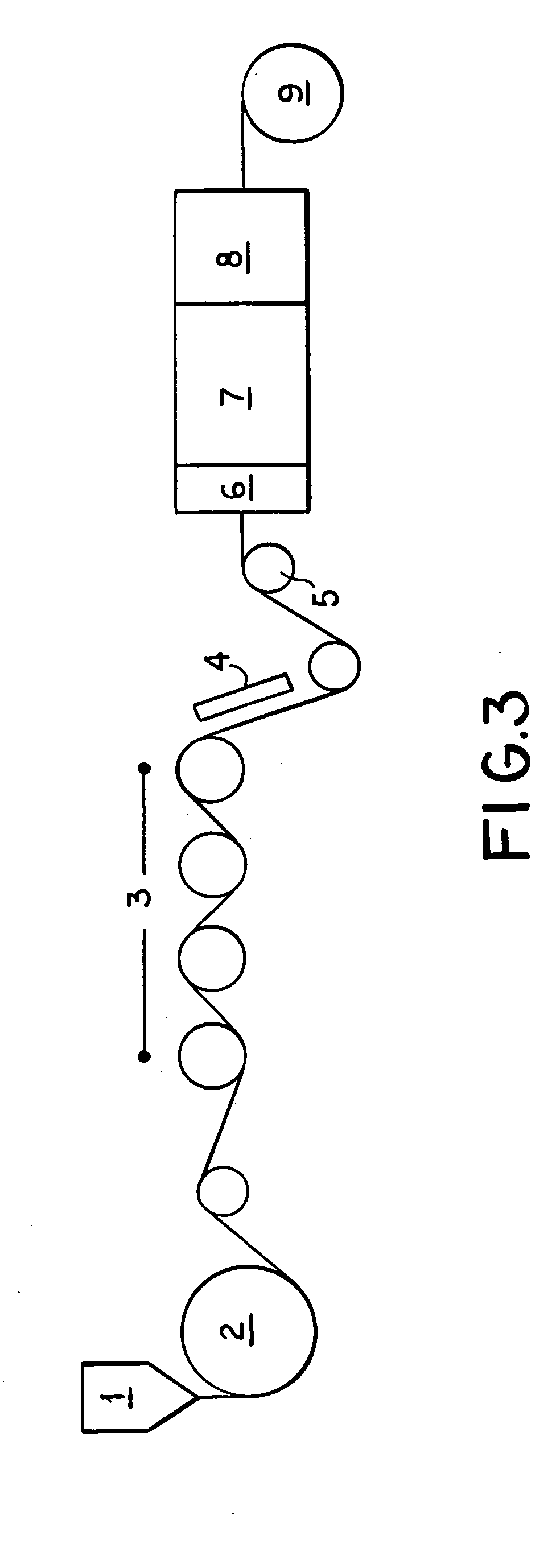

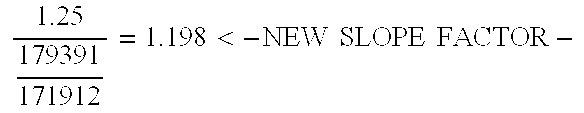

Co-extruded biaxially oriented sealable, peelable film and process for its production

ActiveUS20050208282A1Increase temperatureAvoid stickingLiquid surface applicatorsRecord information storagePolyethylene terephthalatePolyethylene terephthalate glycol

A peelable sealable co-extruded film, comprising: i. a skin layer capable of heat sealing against a rim of a container, to itself, or to another film and adapted to be peeled there from and comprising a hot melt adhesive resin; and ii. a core layer underlying said skin layer and comprising crystalline homopolymer polyethylene terephthalate; and a method for the preparation thereof.

Owner:TERPHANE

Preparation of poly(trimethylene terephthalate) with low level of di(1,3-propylene glycol)

A process of preparing poly(trimethylene terephthalate) containing less than 2.0 mole % of DPG comprising:(a) providing a molar amount of 1,3-propanediol:C1 to C4 dialkyl ester of terephthalic acid of 1.2:1 to 1.9:1,(b) reacting the 1,3-propanediol with the C1 to C4 dialkyl ester of terephthalic, acid to form bis(3-hydroxypropyl)terephthalate monomer in the presence of 10-100 ppm (as titanium metal) of an organic titanate catalyst, by weight of the poly(trimethylene terephthalate), and(c) polymerizing the bis(3-hydroxypropyl)terephthalate monomer to obtain the poly(trimethylene terephthalate); andpoly(trimethylene terephthalate) produced by the process.

Owner:DUPONT IND BIOSCIENCES USA LLC

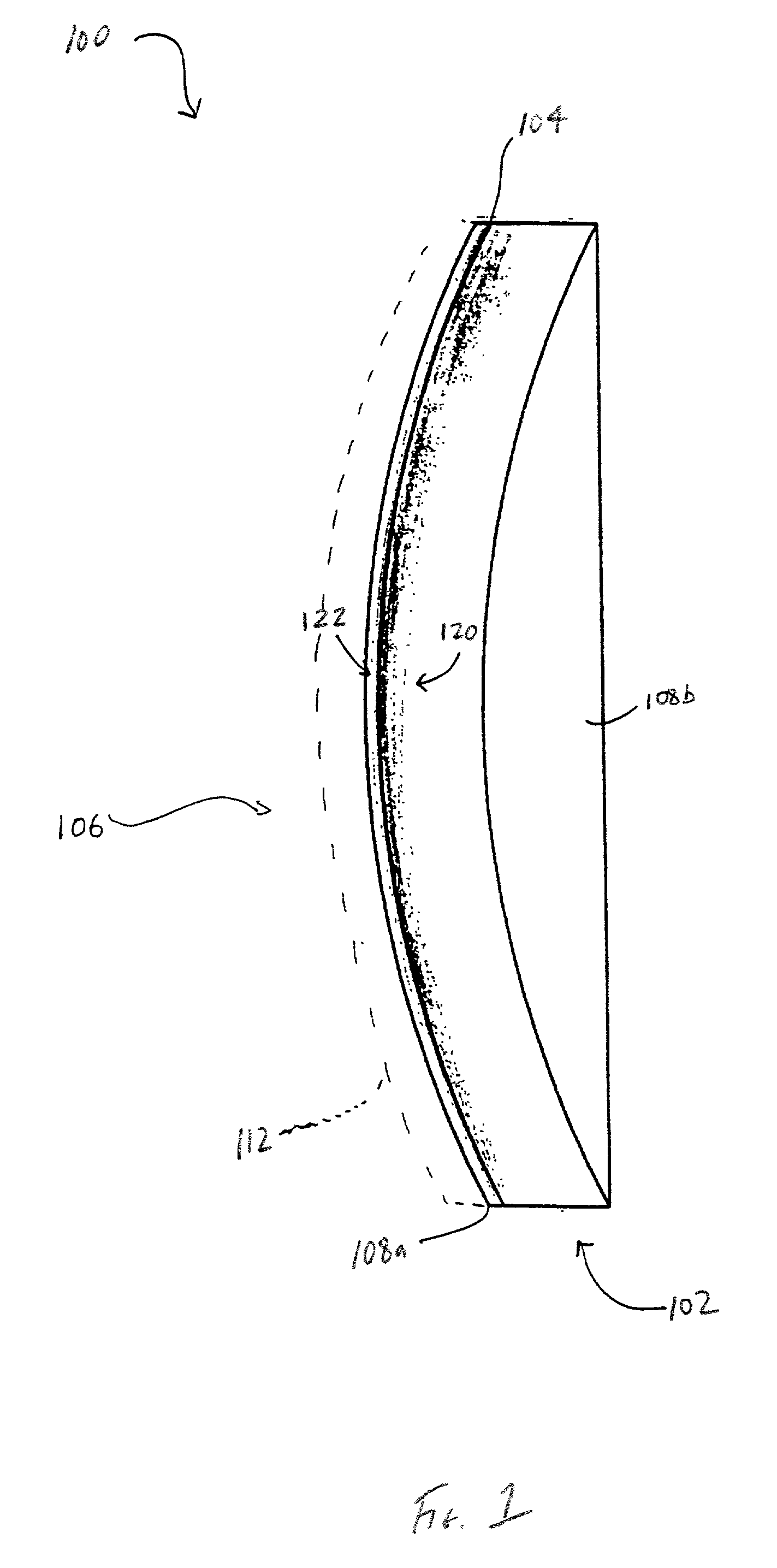

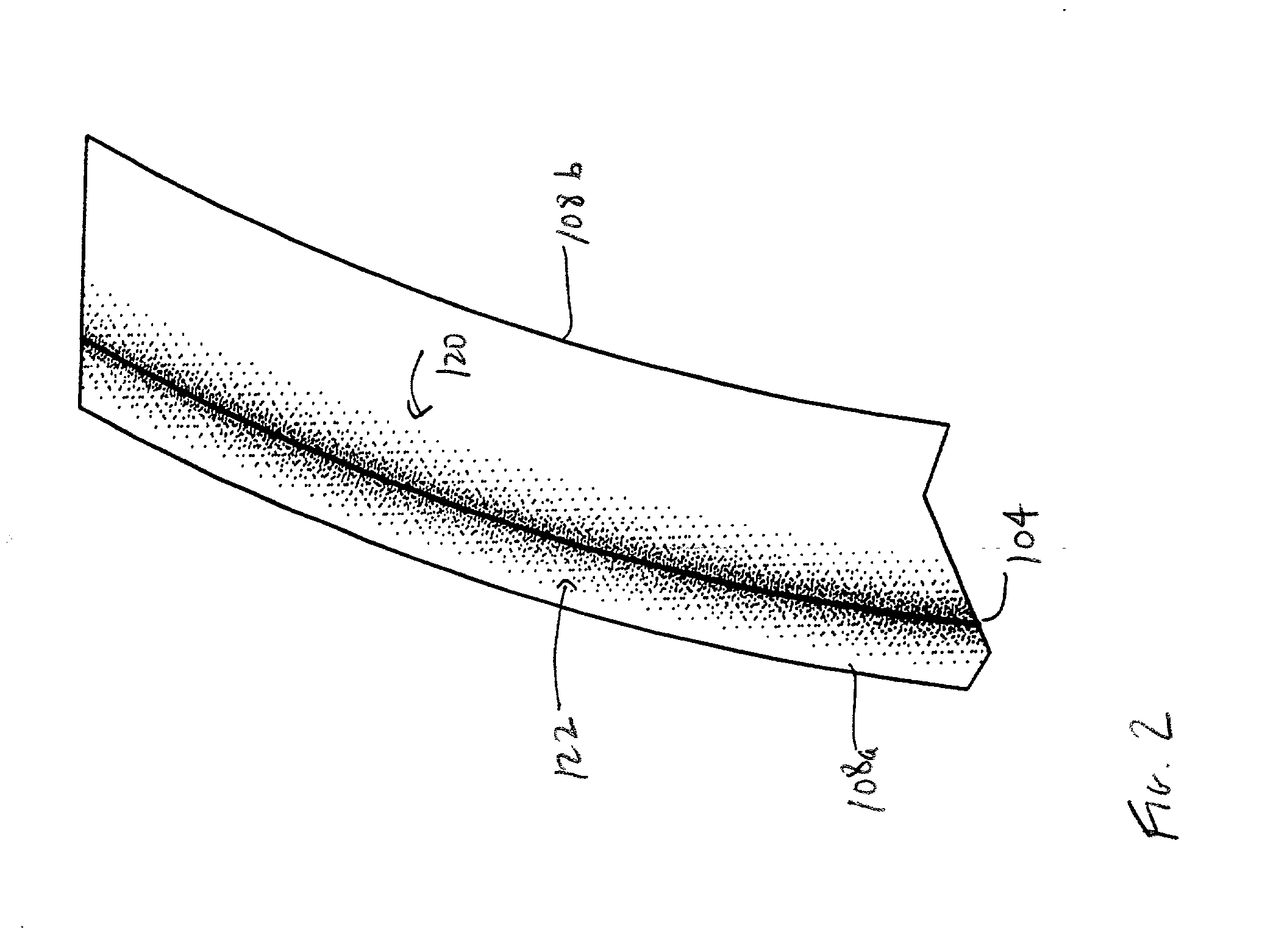

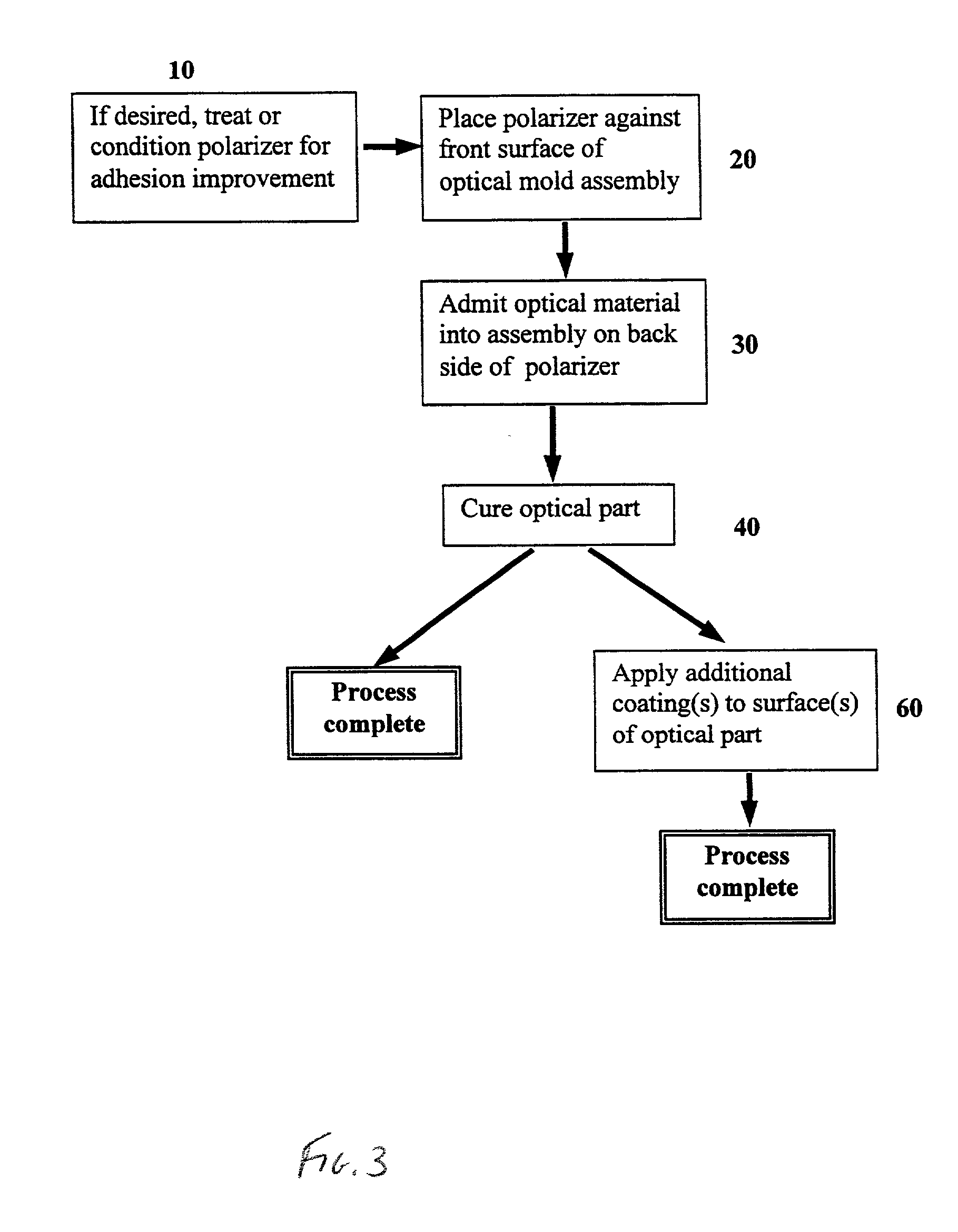

Polarized eyewear using high impact, high optical-quality polymeric material

InactiveUS20010028435A1Improve impact performanceImprove impact resistanceSpectales/gogglesSynthetic resin layered productsPolyvinyl alcoholPolarizer

Optical-quality polarized parts and methods for manufacturing the optical parts are disclosed. The optical-quality polarized parts comprise a high impact, lightweight, high optical quality polyurethane construct and a polarizer bonded to the construct. The construct may be a lens substrate wherein the polarizer is integrally bonded at or near the front surface of the lens substrate. A sidefill gasket may be used to support and position the polarizer within a mold cavity for reproducibly forming the optical part. The polarizer may comprise a polyethylene terephthalate film or a laminated polyvinyl alcohol film or wafer. The polarized optical part has improved impact resistance over conventional thermoset resin parts, as well as better optical properties than similarly impact-resistant polycarbonate constructs.

Owner:YOUNGER MFG

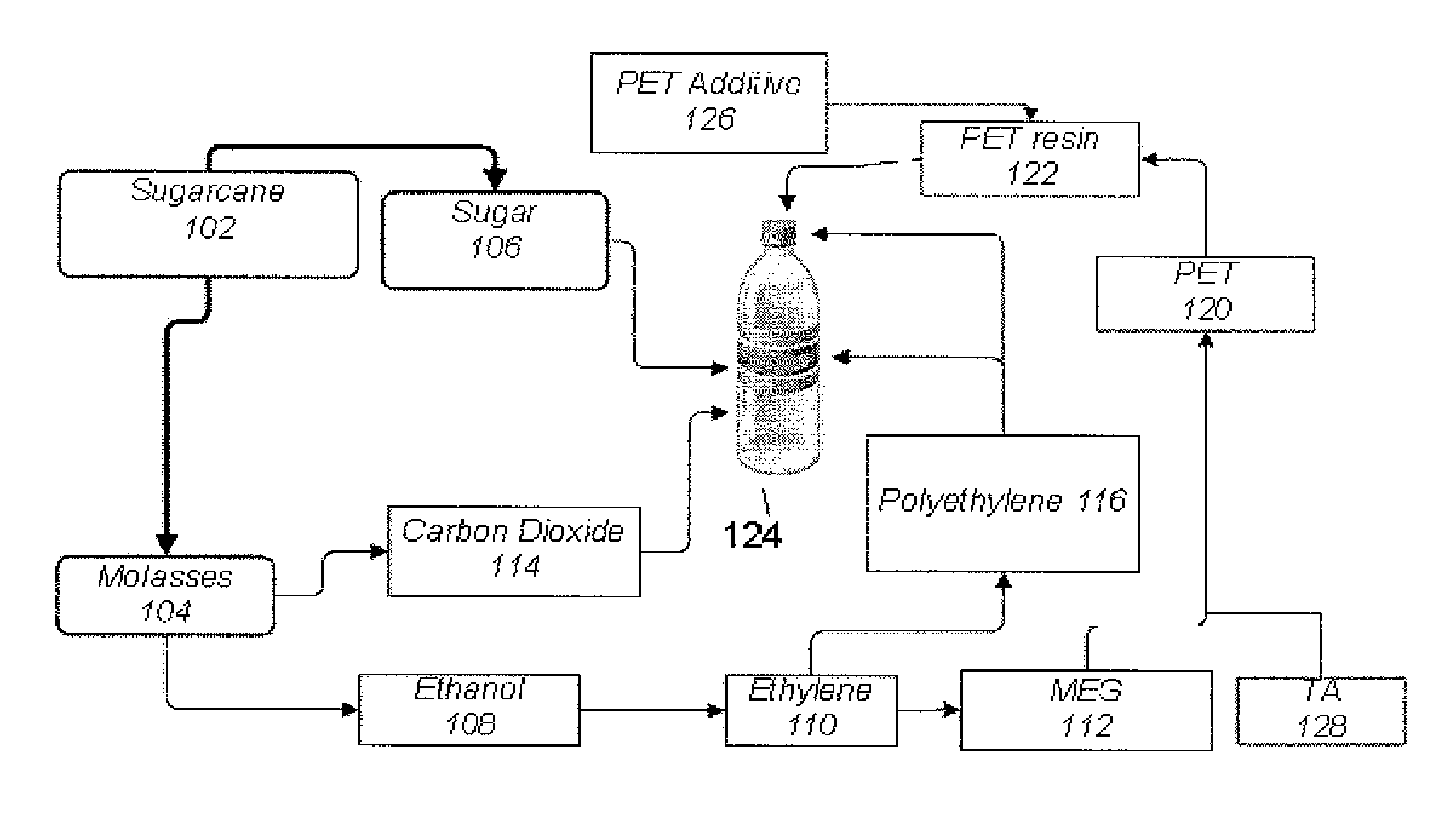

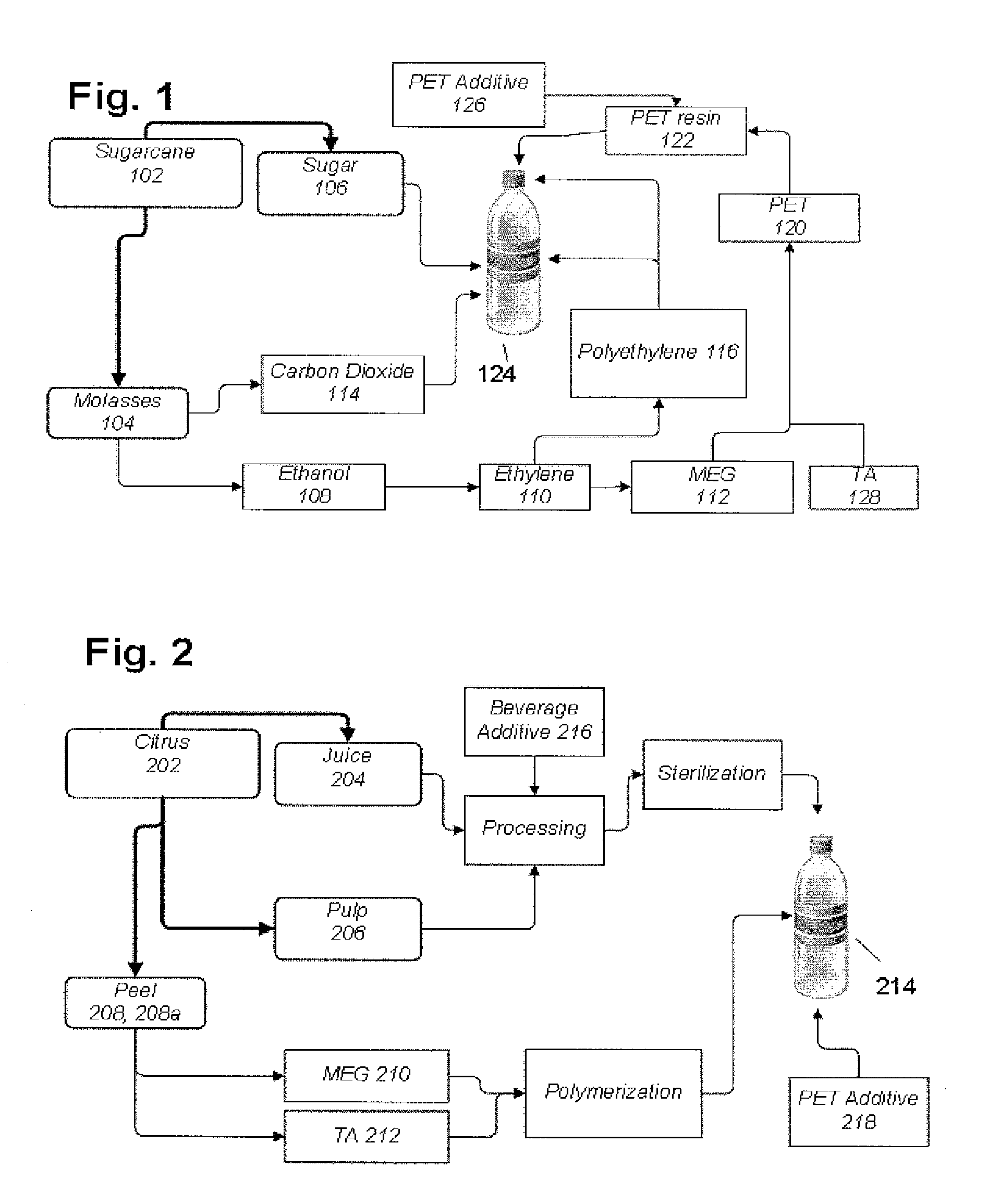

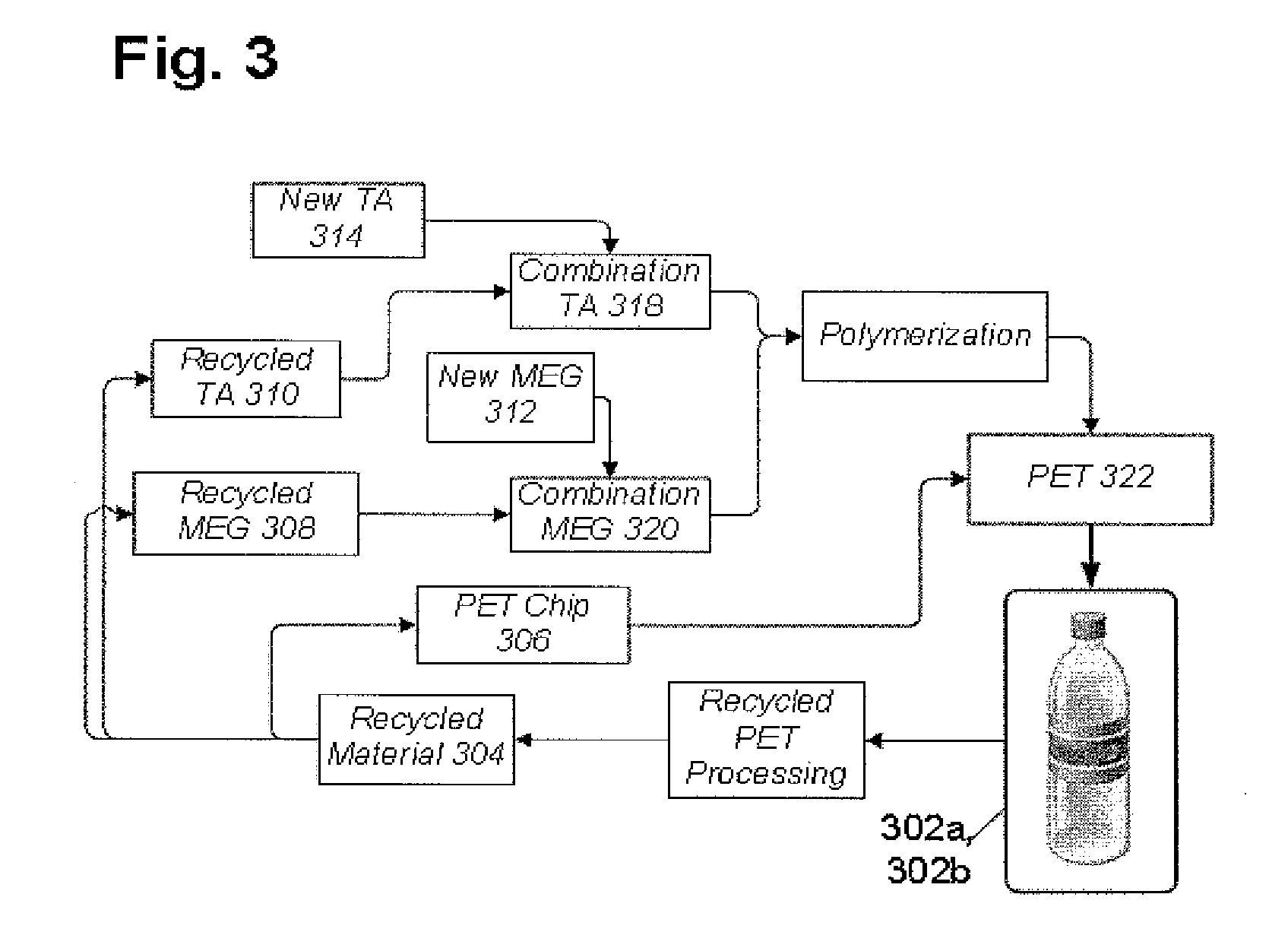

Bio-based polyethylene terephthalate packaging and method of making thereof

InactiveUS20100028512A1Flexible coversWrappersPolyethylene terephthalatePolyethylene terephthalate glycol

This invention relates to a method of making a bio-based PET packaging and particularly to a method of producing a bio-based PET from at least one bio-based material comprising: a) forming at least one PET component from at least one bio-based material, wherein the at least one PET component is selected from a monoethylene glycol (“MEG”), a terephthalic acid (“TA”), and combinations thereof; (b) processing said bio-based PET component into a bio-based PET.

Owner:THE COCA-COLA CO

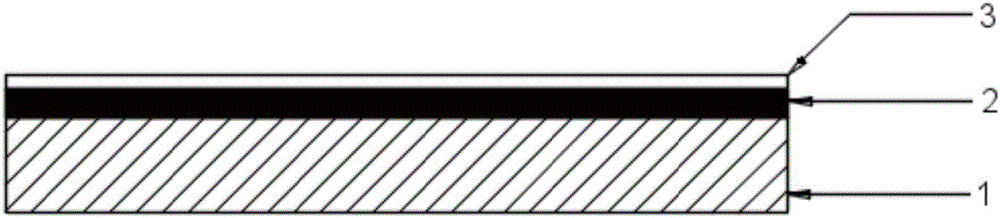

Novel solar battery backboard

ActiveCN101582458ANovel structureMaterials are readily availableSynthetic resin layered productsPhotovoltaic energy generationPolyurethane adhesiveAlloy

The invention relates to a novel solar battery backboard, which comprises the following components according to the adhesion in turn: a weathering layer, a first adhesive layer, a structure-enhancing layer, a second adhesive layer and an adhesive reflecting layer; wherein, the weathering layer is a polyvinylidene fluoride alloy layer modified by inorganic materials; the adhesive reflecting layer is a white polyethylene layer; preferably, the polyvinylidene fluoride alloy layer is a plastic alloy layer formed by the polyvinylidene fluoride and the inorganic materials with the thickness of 4-40 mum; the white polyethylene layer is a plastic alloy layer in which polyethylene is mixed with inorganic white pigment, anti-ultraviolet stabilizer and hot-oxygen ageing resistance stabilizer with the thickness of 10-300mum; the structure-enhancing layer is a polyethylene qlycol terephthalate layer; the first adhesive layer and the second adhesive layer can be one of the following three, namely, a polyurethane adhesive layer, an acrylic ester adhesive layer or an epoxy adhesive layer with the thickness of 1mum-30mum. The invention features novel structure, easily obtained materials, greatly reduced cost and good performance, conforms to the requirements of the backboard, and has important significance on solar energy industry.

Owner:SHANGHAI HIUV NEW MATERIALS

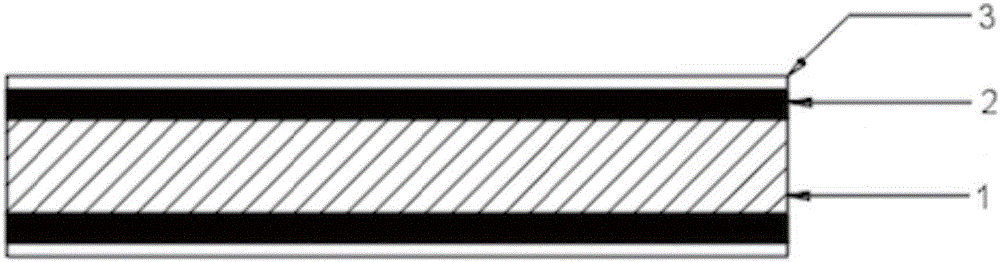

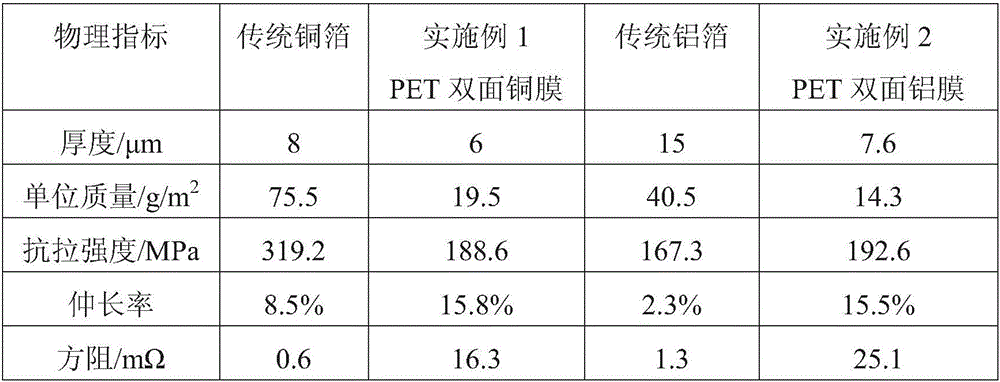

Flexible current collector for lithium battery and preparation method thereof

ActiveCN106654285AEnhanced machinabilityLow mass densityElectrode carriers/collectorsFiberPolyethylene terephthalate glycol

The invention discloses a flexible current collector for a lithium battery and a preparation method thereof. The flexible current collector comprises a flexible substrate layer, a metal conductive plated layer and a conductive anti-oxidization layer which are combined tightly in sequence, wherein the flexible substrate layer is one of polyvinyl chloride, polyethylene, polypropylene, polystyrene, polyethylene terephthalate, polydimethylsiloxane and polyimide; the thickness of the flexible substrate layer is 1-20 microns; the metal conductive plated layer is one of Cu, Al, Ni, Au and Ag and the thickness of the metal conductive plated layer is 0.1-5 microns; and the conductive anti-oxidization layer is at least one of conductive graphite, graphene, carbon nanotubes and carbon nano-fibers, and the thickness of the conductive anti-oxidization layer is more than 0 and smaller than 1 micron. The flexible current collector disclosed by the invention has high machinability and relatively high thermal stability and anti-oxidization energy; and the quality density of a whole body is small.

Owner:ZHEJIANG UNIV

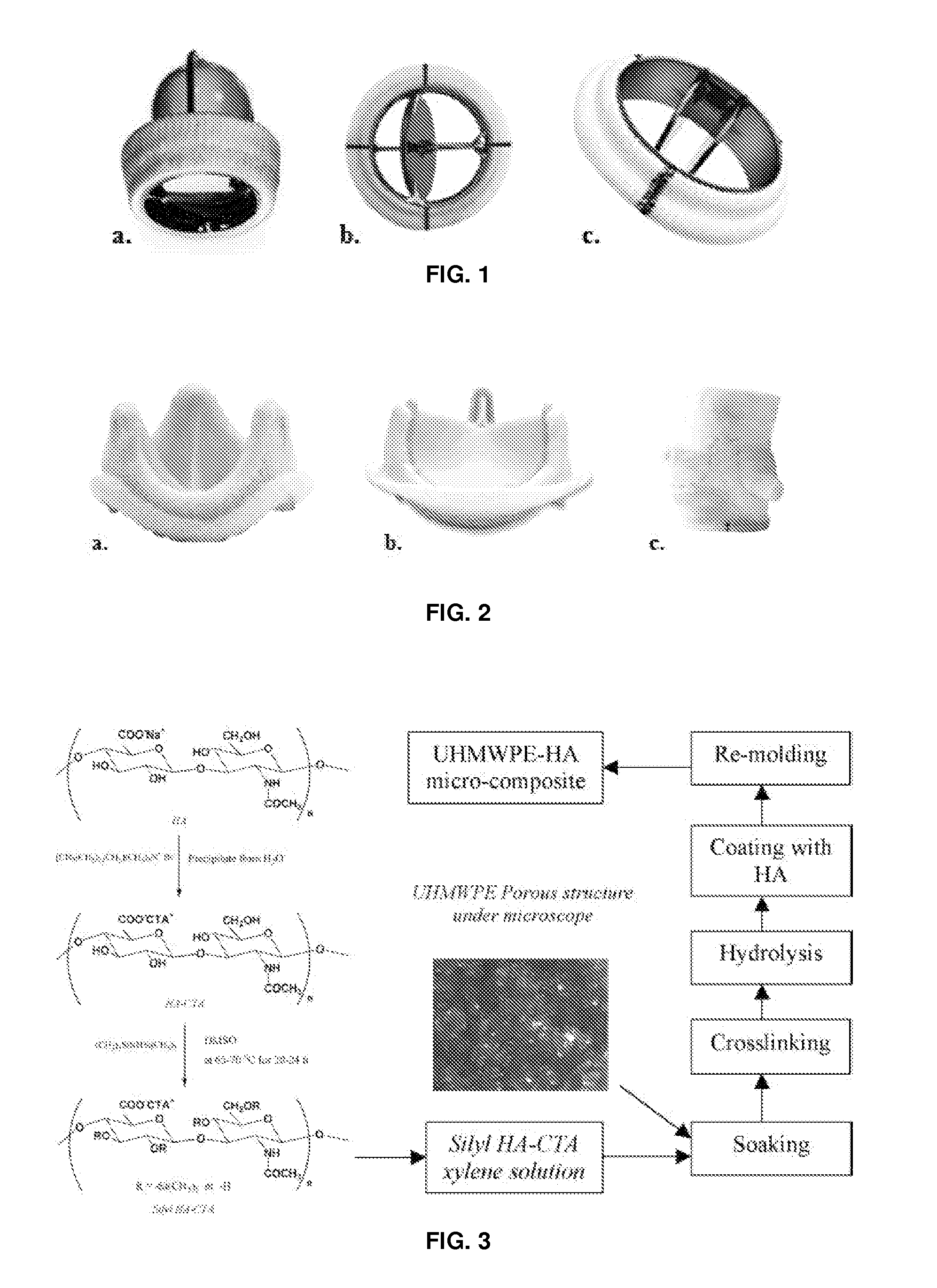

Glycosaminoglycan and Synthetic Polymer Material for Blood-Contacting Applications

ActiveUS20150196688A1Improve surface chemistryFeasible at commercial productionSuture equipmentsOrganic active ingredientsLow-density polyethyleneLinear low-density polyethylene

Provided herein is a composite, comprising: a polymer host selected from the group consisting of low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), polyethylene terephthalate (PET), polytetrafluoroethylene (PTFE), and polypropylene (PP), polyurethane, polycaprolactone (PCL), polydimethylsiloxane (PDMS), polymethylmethacrylate (PMMA), and polyoxymethylene (POM); and a guest molecule comprising hyaluronic acid; wherein the guest molecule is disposed within the polymer host, and wherein the guest molecule is covalently bonded to at least one other guest molecule. Also provided herein are methods for forming the composite, and blood-contracting devices made from the composite, such as heart valves and vascular grafts.

Owner:COLORADO STATE UNIVERSITY

Glassy carbon thermoplastic compositions

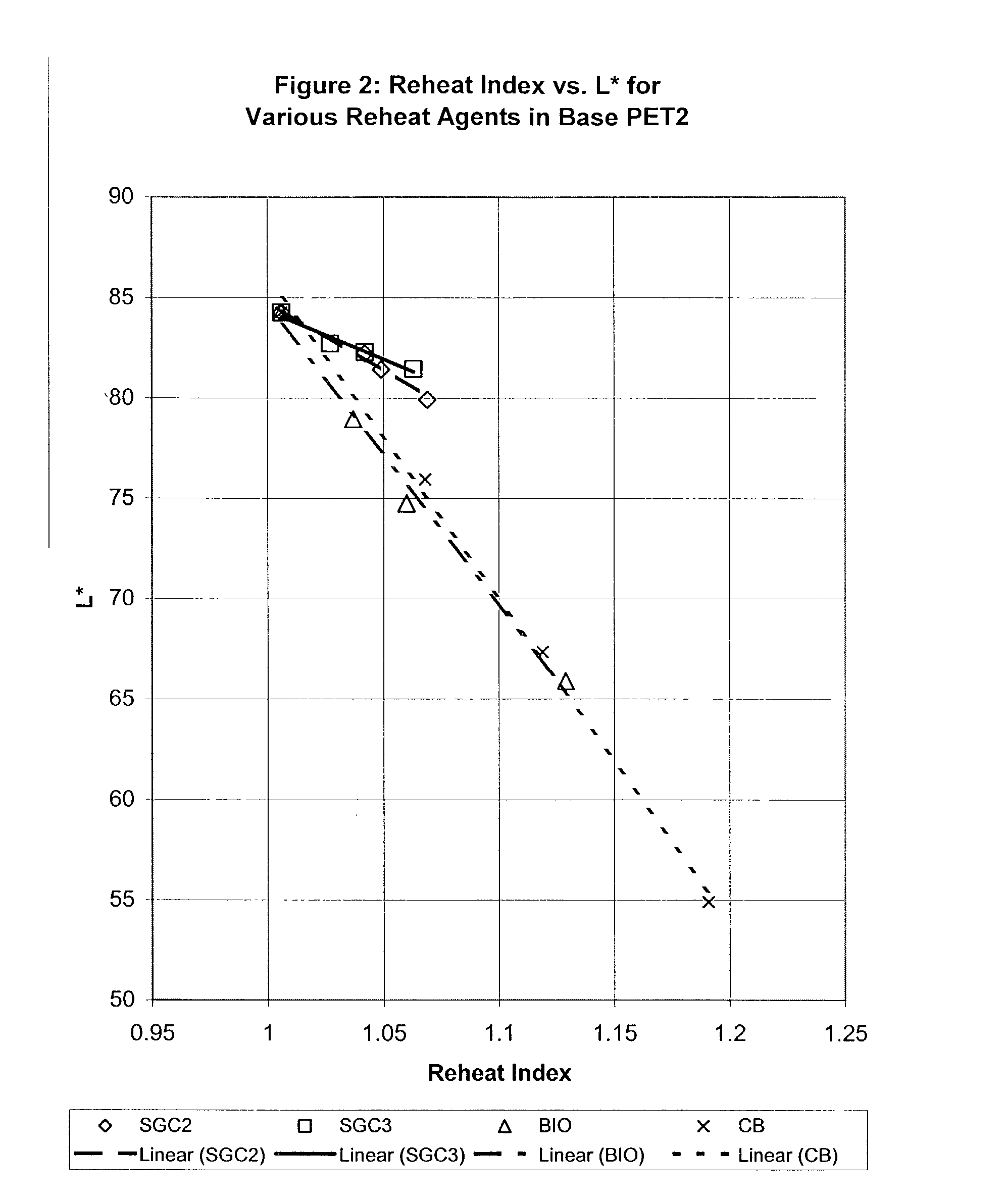

InactiveUS20040101642A1Good reheat rateImproved * b * ratingSynthetic resin layered productsThin material handlingPolyesterStatic friction coefficient

A thermoplastic composition such as a polyester composition including polyethylene terephthalate polymers containing glassy carbon, and the preforms, bottles, sheets, rods, tubes, films and other articles made from these compositions. Also, polyester compositions are provided which have a certain individual or combination of properties, including low coefficient of static friction, low coefficient of static friction and low haze or high L* or low positive b* or a combination thereof, and those having low L* and low positive b* at given reheat rates.

Owner:EASTMAN KODAK CO

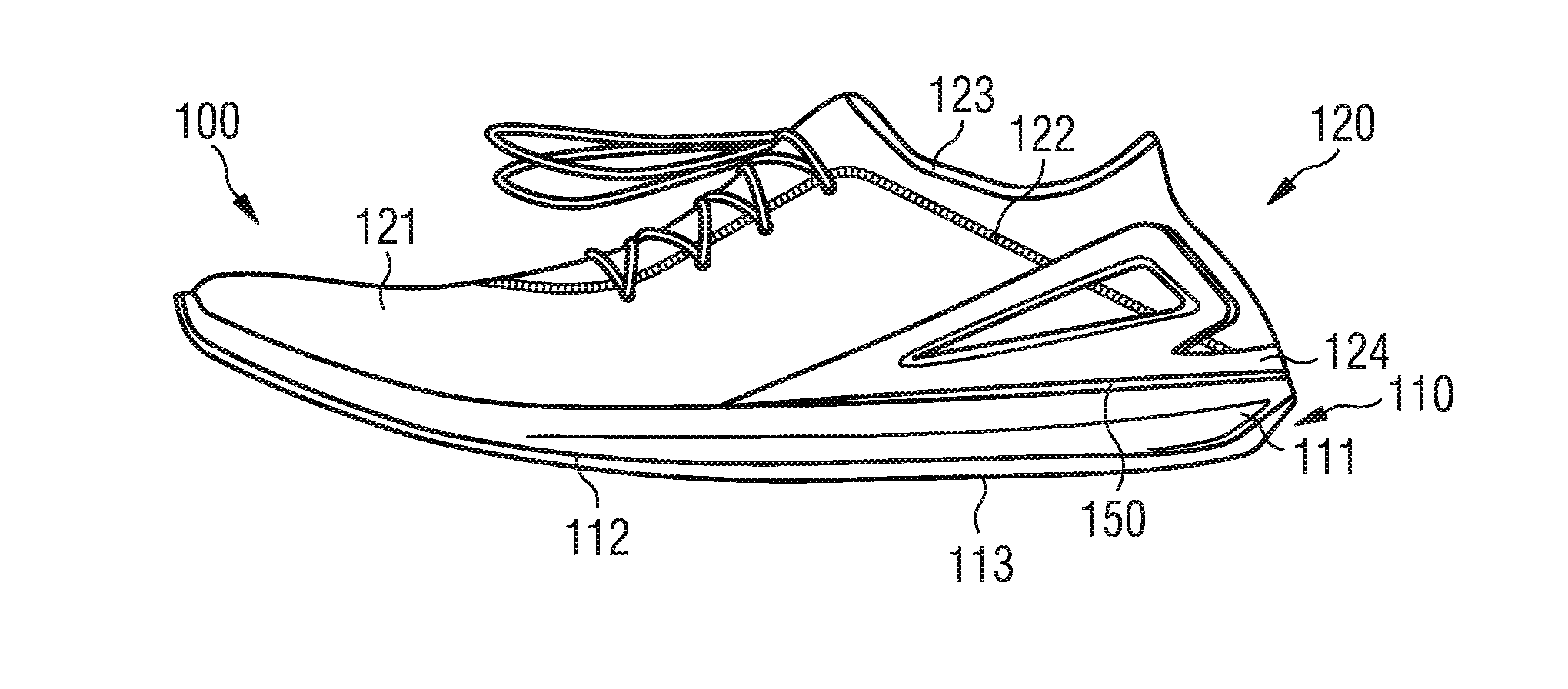

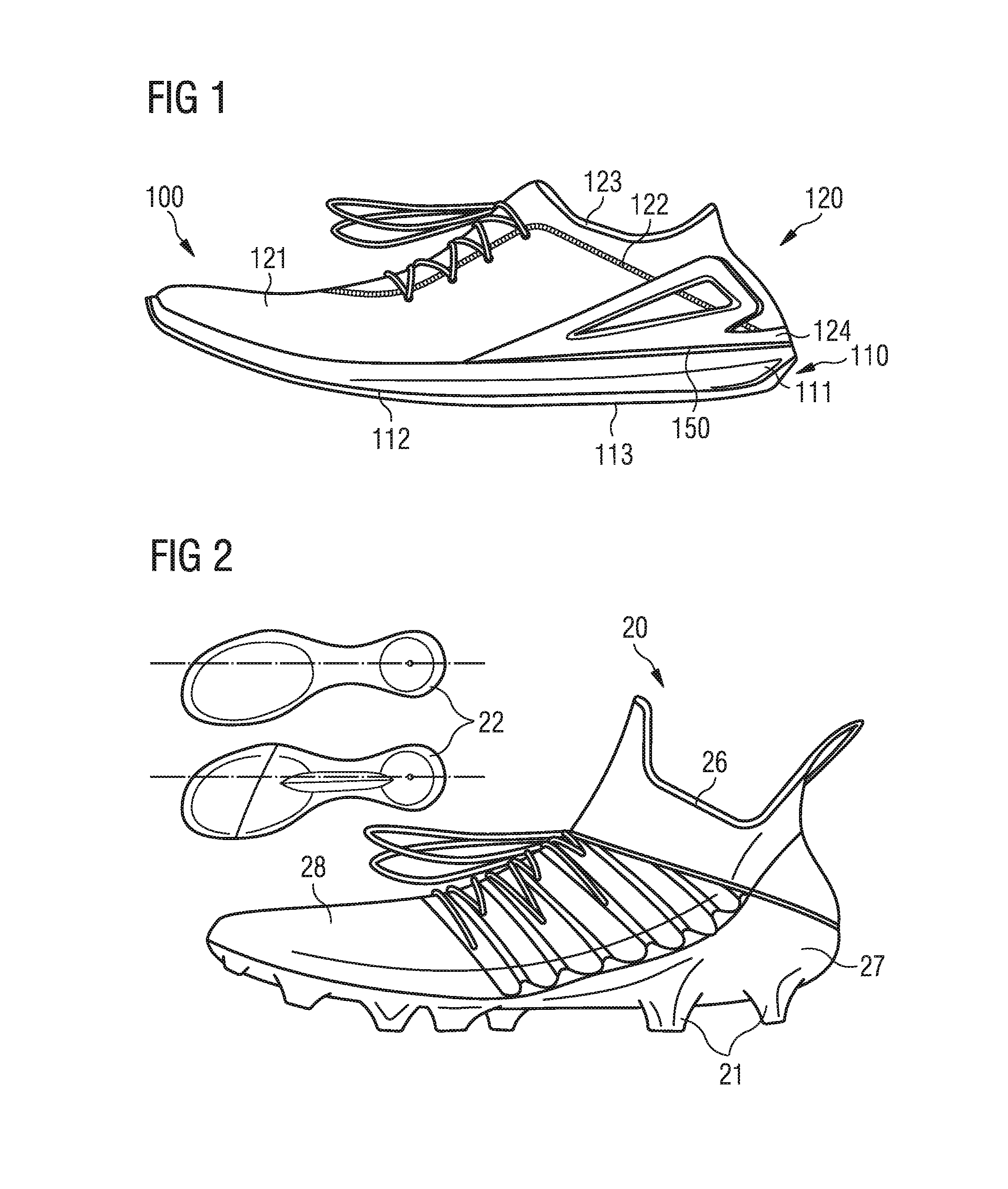

Sports Shoes and Methods for Manufacturing and Recycling of Sports Shoes

InactiveUS20160302508A1Easy to identifySolesInsolesPolyethylene terephthalatePolyethylene terephthalate glycol

A sports shoe includes an upper wherein a majority by weight of the upper is made from a thermoplastic base material and a sole wherein a majority by weight of the sole is made from the same thermoplastic base material. The sole and the upper are individually fabricated and joined to each other. The thermoplastic base material includes at least one of the following materials: thermoplastic polyurethane TPU, polyamide PA, polyethylene terephthalate PET, or polybutylene terephthalate PBT.

Owner:ADIDAS

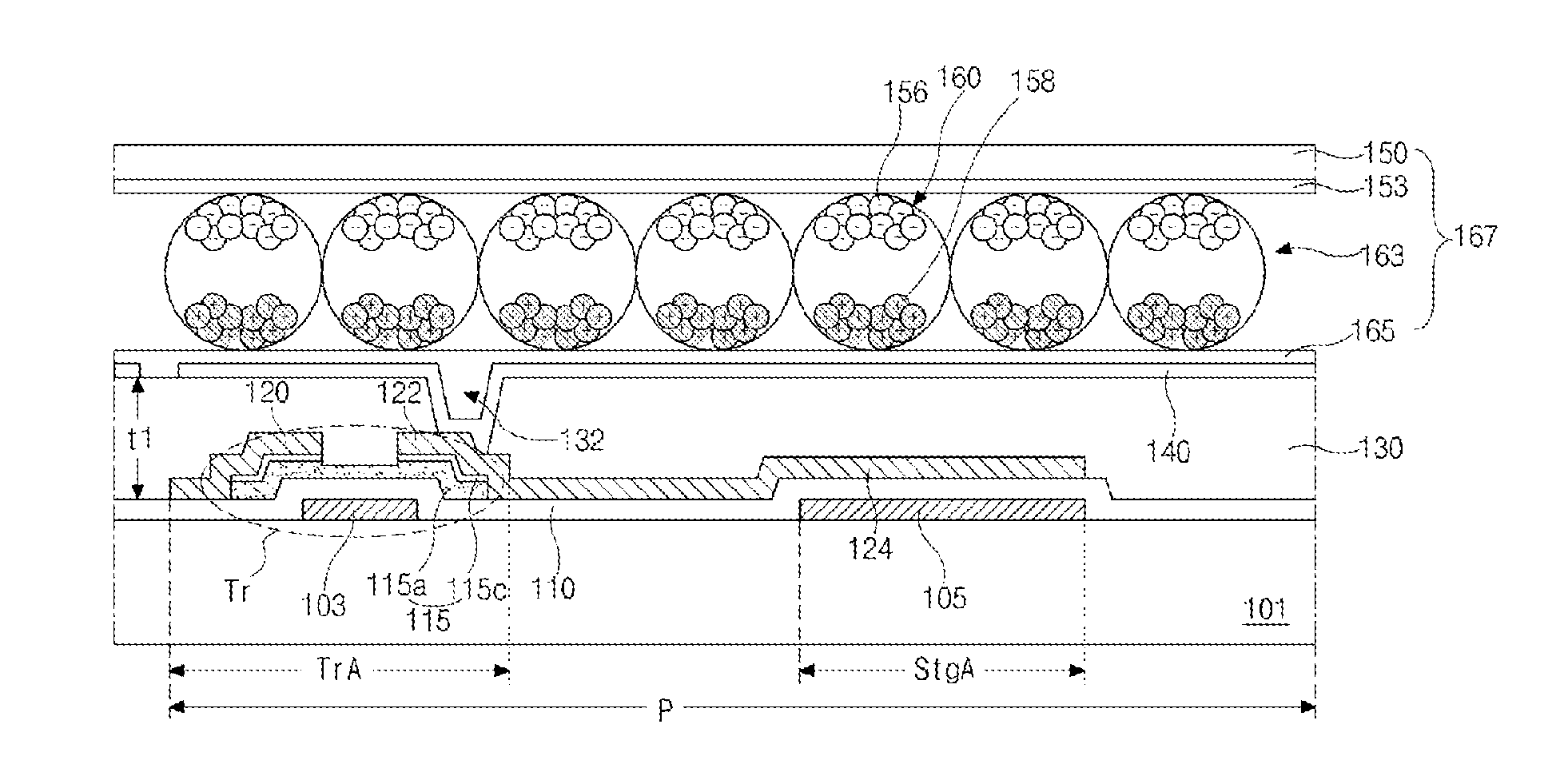

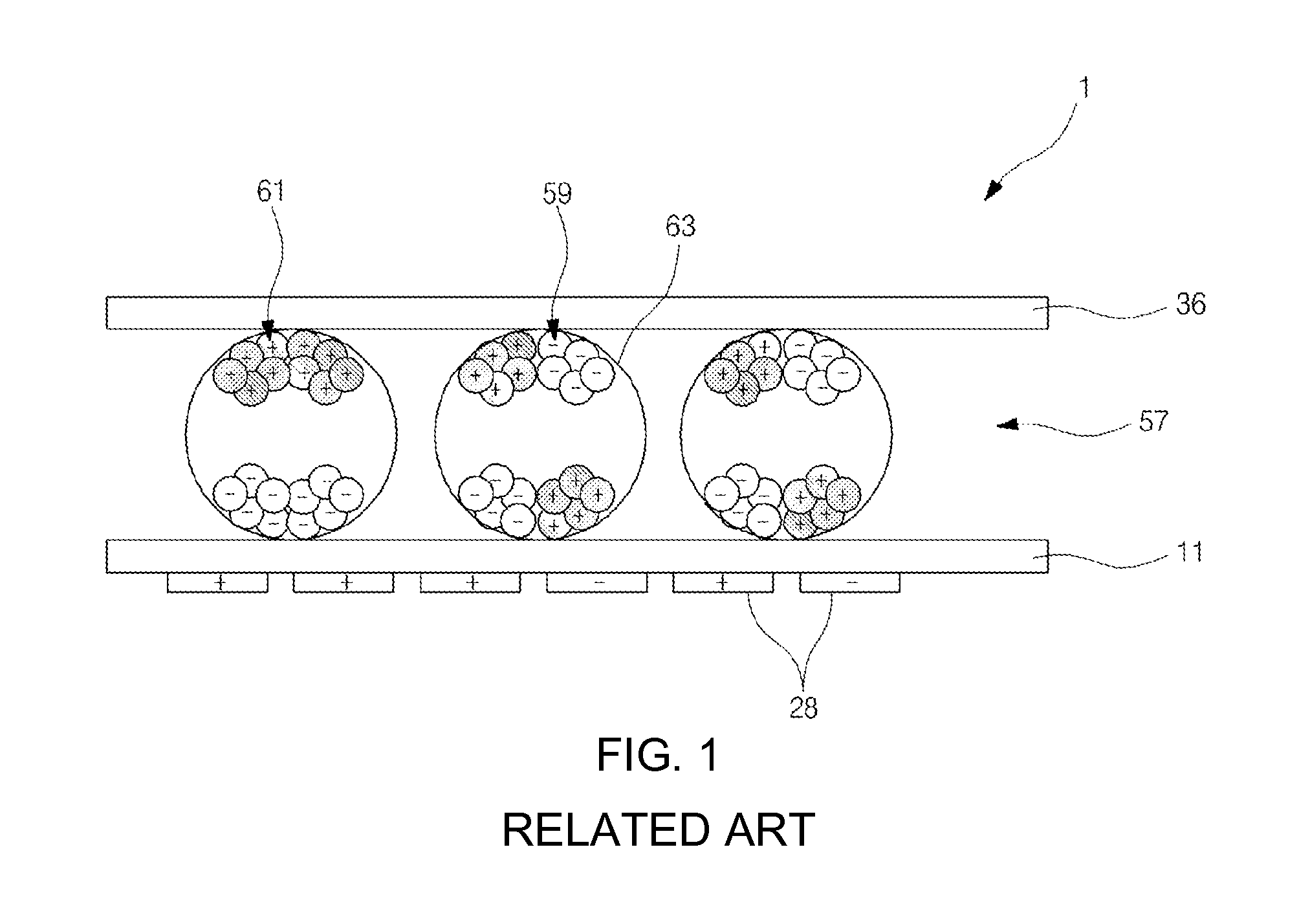

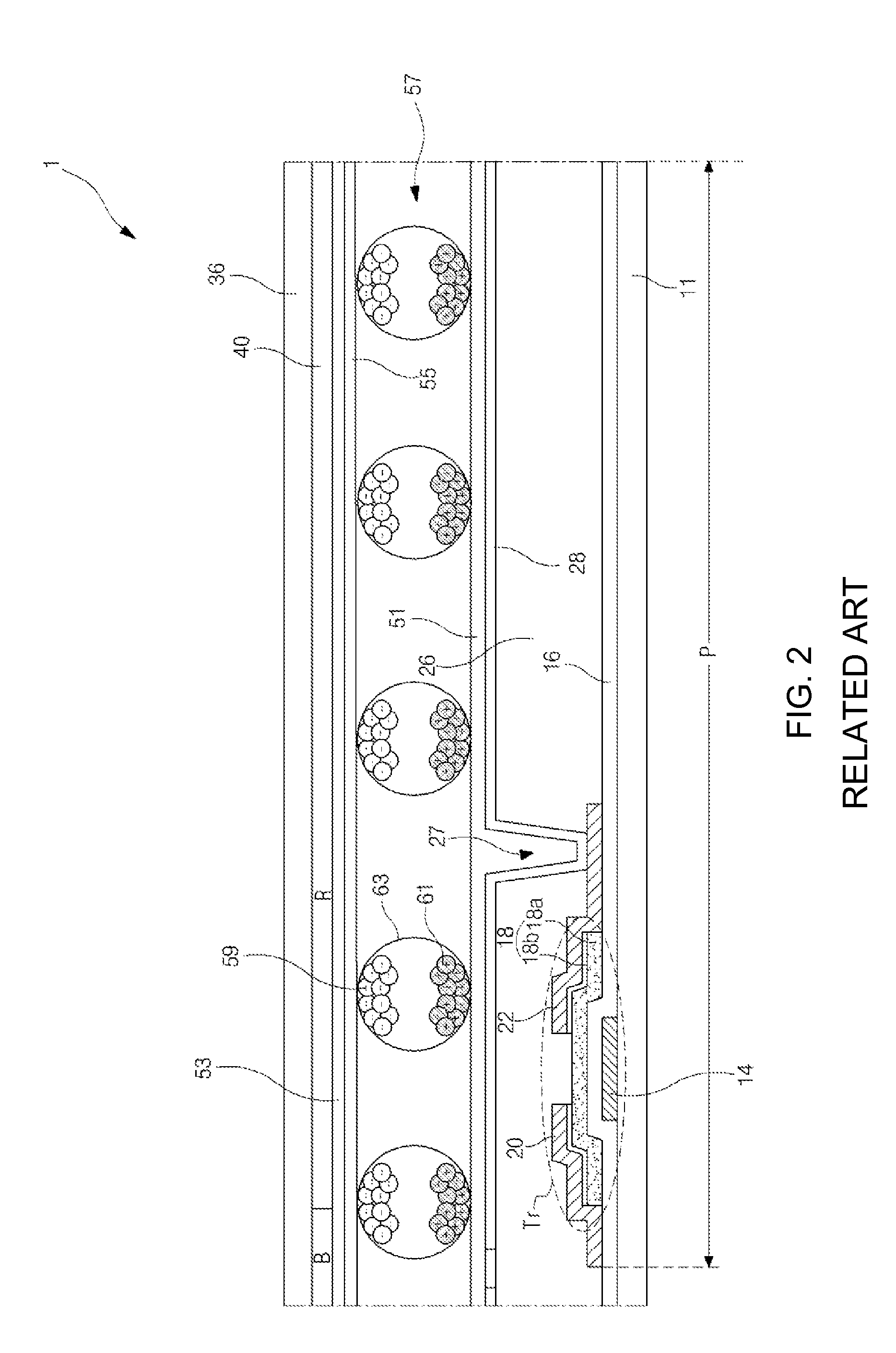

Electrophoretic display device and method of fabricating the same

InactiveUS20110026099A1Eliminate the problemVessels or leading-in conductors manufactureNon-linear opticsElectric fieldPolyethylene terephthalate

An electrophoretic display device includes a switching element on a substrate including a display area having a pixel region and a non-display area at a periphery of the display area, a passivation layer covering the switching element, a pixel electrode on the passivation layer and connected to the switching element, an electrophoresis film on the pixel electrode and including an ink layer and a base film, wherein the ink layer includes a plurality of charged particles, and the base film is formed of polyethylene terephthalate, a common electrode for generating an electric field with the pixel electrode to drive the electrophoresis film, and a color filter layer directly on the electrophoresis film, wherein the color filter layer is formed under temperatures of less than 100 degrees of Celsius.

Owner:LG DISPLAY CO LTD

Direct coupling of melt polymerization and solid state processing for PET

ActiveUS20050056961A1Increase temperatureReduce molecular weightWood working apparatusBuilding constructionsPolyethylene terephthalate glycolPolyethylene terephthalate

Strands of molten polyethylene terephthalate (PET) from a PET polycondensation reactor are solidified, pelletized, and cooled only to a temperature in the range of 50° C. to a temperature near the polymer Tg by contact with water. The still hot pellets are conveyed, optionally followed by drying to remove water, to a PET crystallizer. By avoiding cooling the amorphous pellets to room temperature with water and cool air, significant savings of energy are realized.

Owner:ALPEK POLYESTER SA DE CV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com