Butt clamp swing tray piston swing driver

A driving machine and tray technology, which is applied to swing piston engines, swing piston engines, rotary or swing piston engines, etc. It can solve the problems of high manufacturing cost, low corrosion resistance of metal materials, and large parts and components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

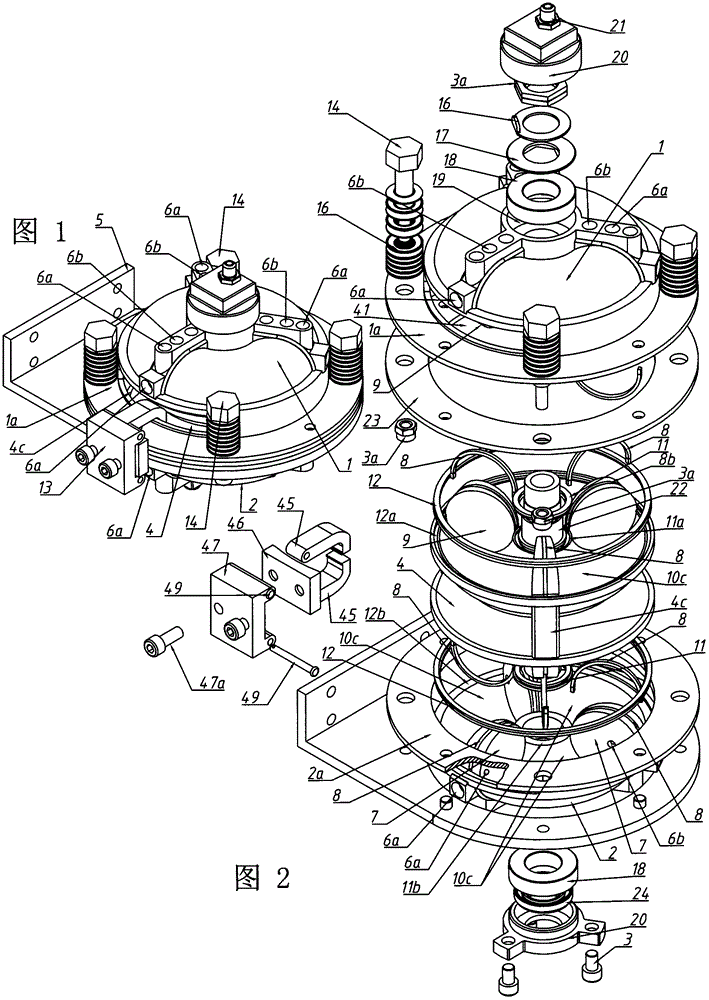

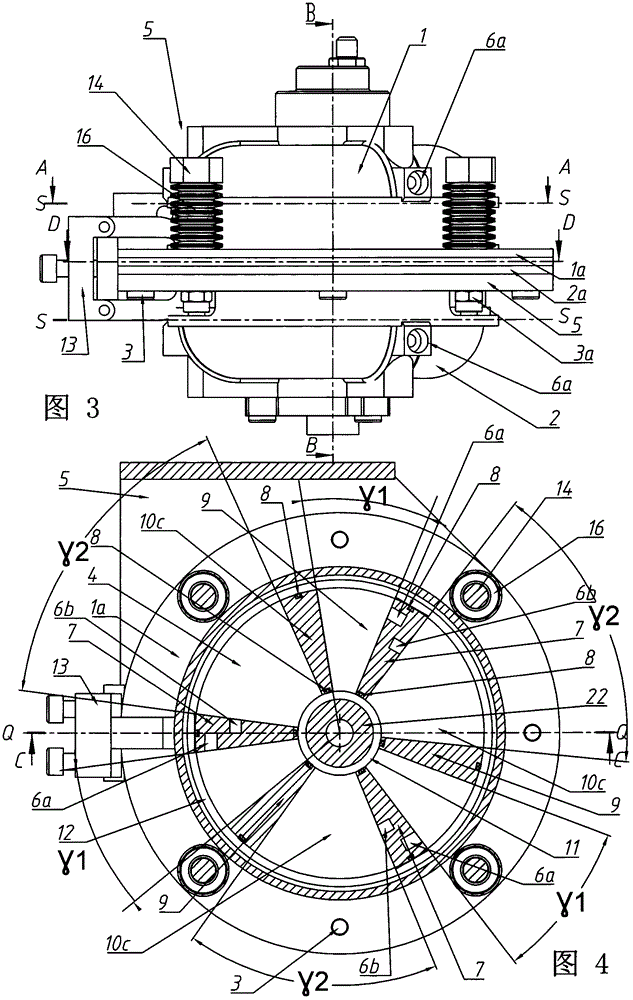

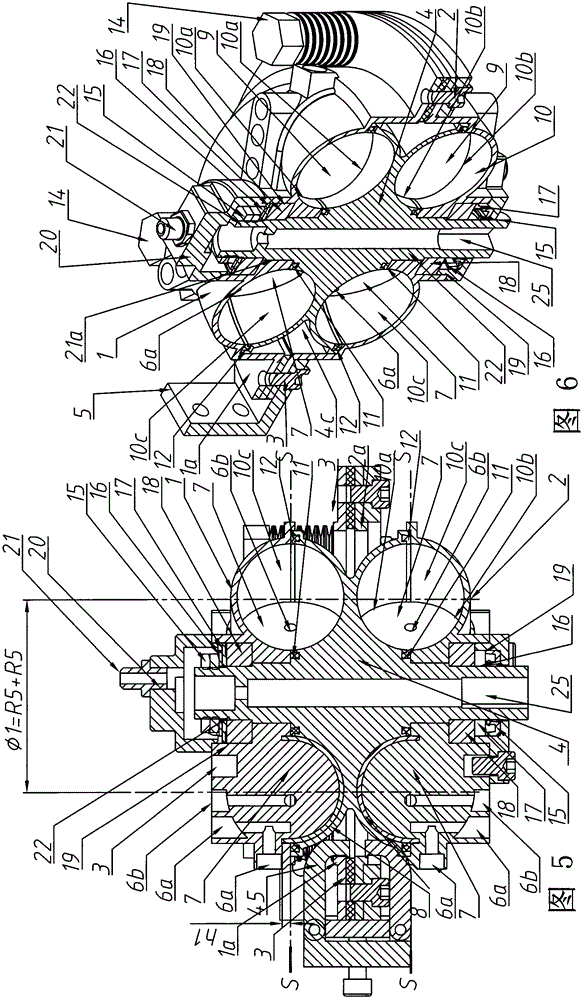

Method used

Image

Examples

Embodiment 3

[0083] refer to Figure 30 and 31 , as the partial structure embodiment 3 of the detachable piston sheet combined with the tray groove;

[0084] exist Figure 30 and 31 In , a part of the detachable piston sheet with circular outline 36b is fixedly inserted into the groove of the tray to form a detachable combined structure, and the joint part of the detachable piston sheet is inserted into the groove of the tray and the hole is used to use fasteners 37 is fixed; a static seal structure is provided between the joint surface of the detachable piston plate and the groove of the tray, the static seal structure includes a static seal and a static seal half-ring groove, and the static seal of the detachable piston plate is two band-pass The static seal half ring 39b of the hole is also provided with two static seal half ring grooves 39a that are provided with depressions along the tangent direction of the center circle of rotation on the detachable piston plate. The static seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com