Peripherally pivoted oscillating vane machine

a technology of oscillating vane and rotating shaft, which is applied in the direction of machines/engines, oscillating piston pumps, liquid fuel engines, etc., can solve the problems of insufficient high pressure, single oscillating vane at high speed producing excessive vibration, and over-running clutches not providing reliable synchronized motion, etc., to achieve high flow and high pressure, improve efficiency and flexibility, and reduce the effect of over-running clutches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091]A description of the preferred embodiments of the invention follows.

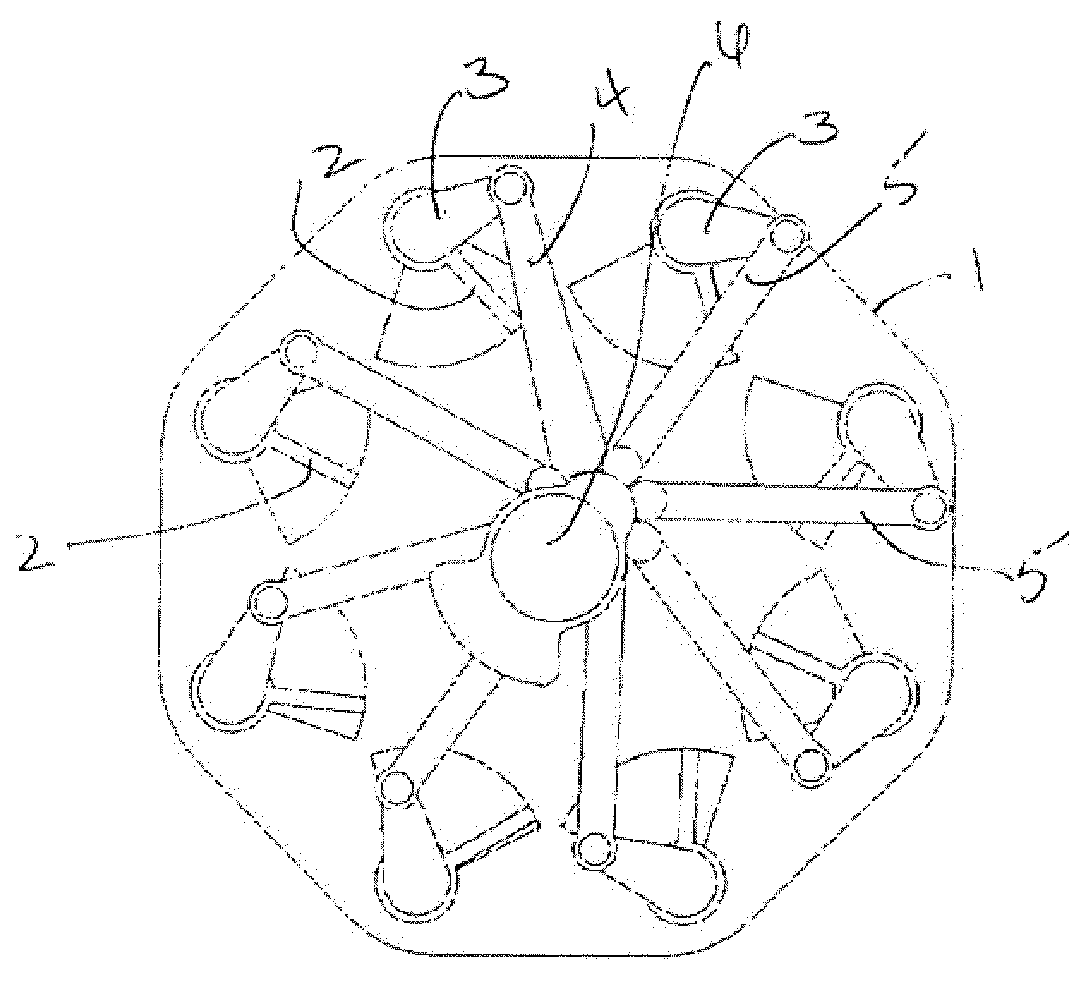

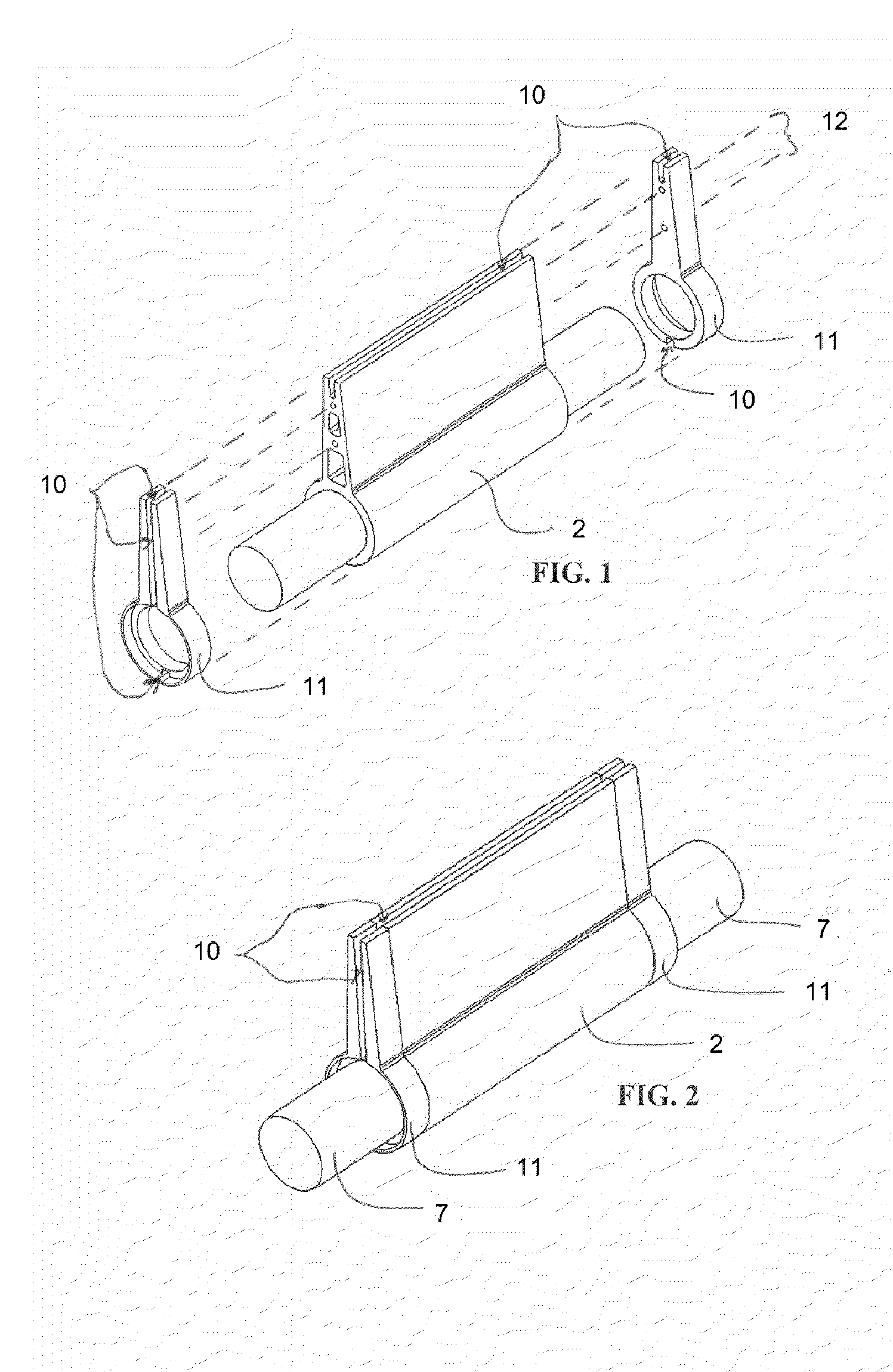

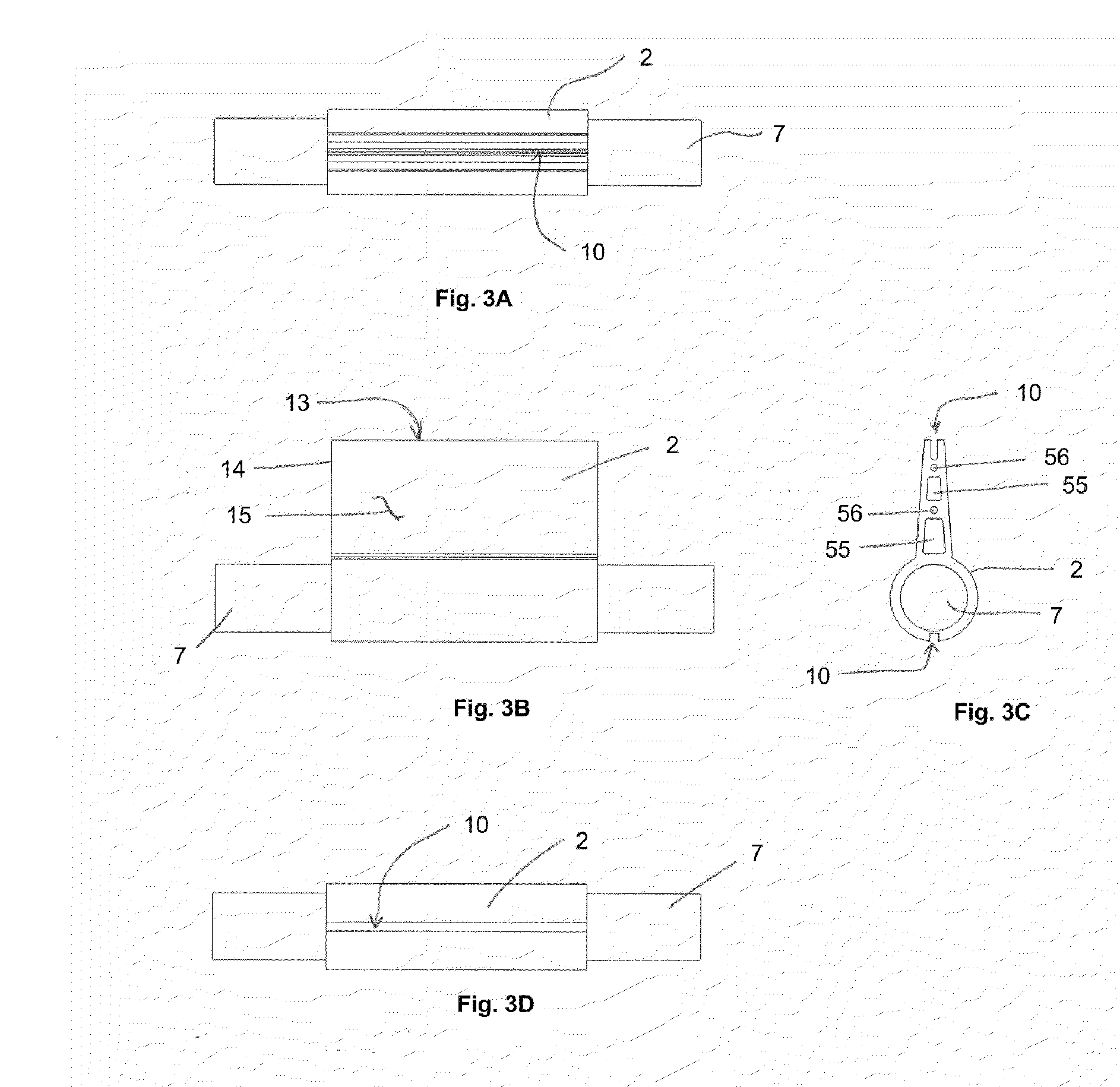

[0092]As has been appreciated in the prior art, and in earlier work performed by Chomyszak, the OVM provides a remarkable ratio of capacity to compress or expand fluid compared to its size and weight. Applicants have discovered that what limits the OVM from achieving its potential is that the loads imparted onto the drive mechanisms which interface with the oscillating vanes 2 can be extremely high.

[0093]For a given power level, there are four ways to improve the drive mechanism such that it is capable of withstanding the power being transmitted through it: 1) use stronger materials, 2) use larger components, 3) reduce the loads or 4) modify component geometry. The work performed thus far in designing, analyzing, building, and testing a working OVM has shown that the loads on the components are created by three sources: friction, inertia and pressure differential.

[0094]The frictional component is relatively sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com