Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5532results about How to "Fast heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

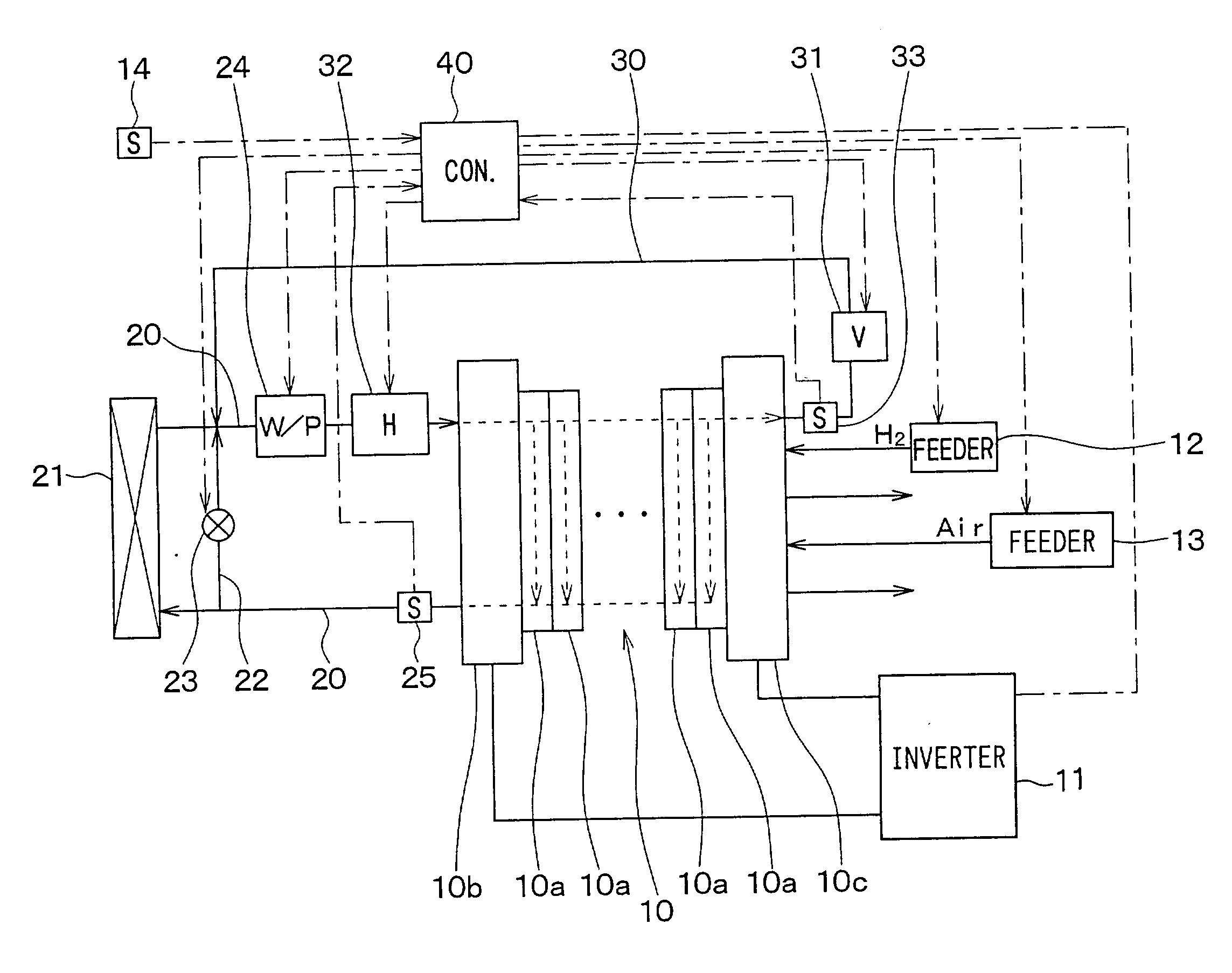

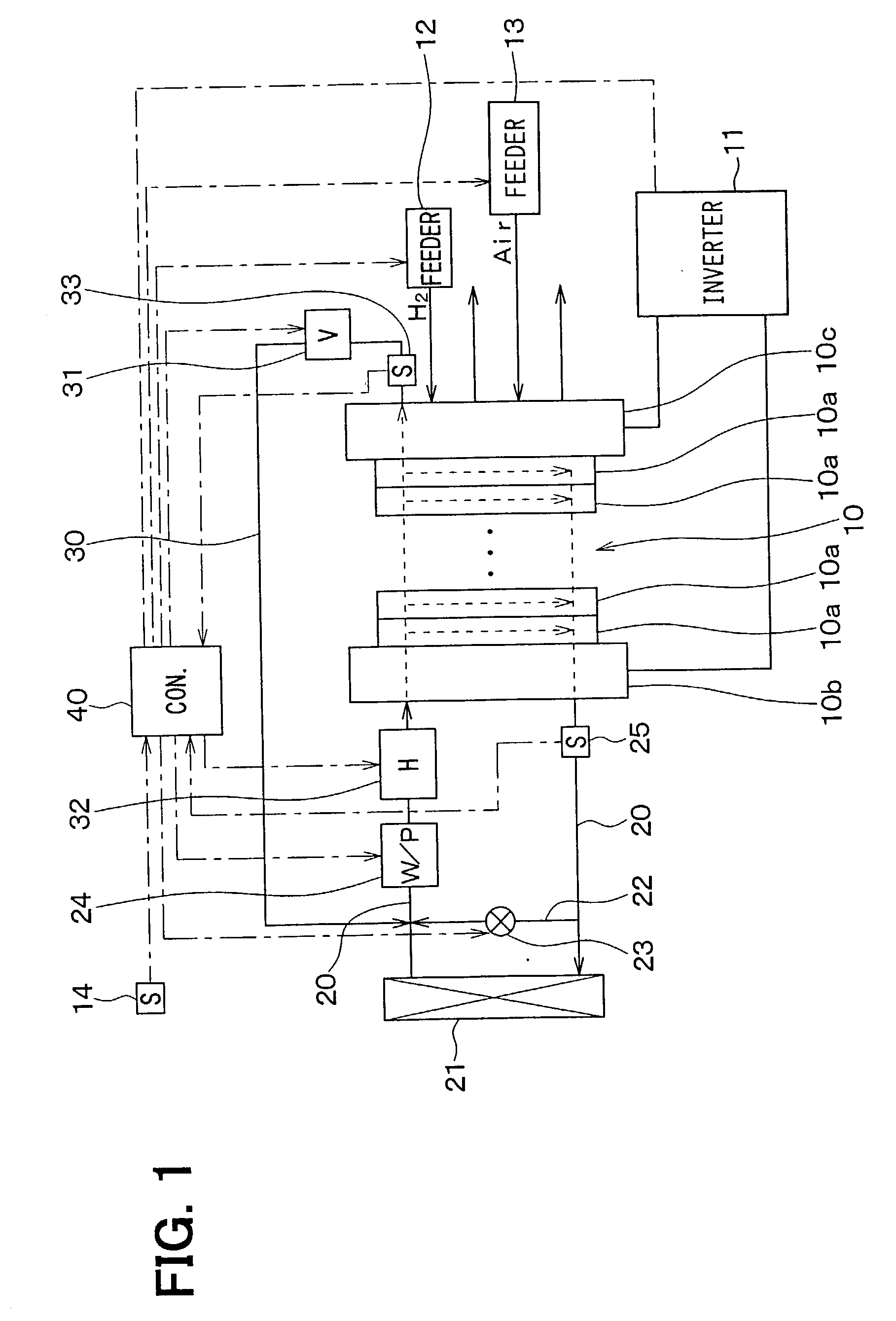

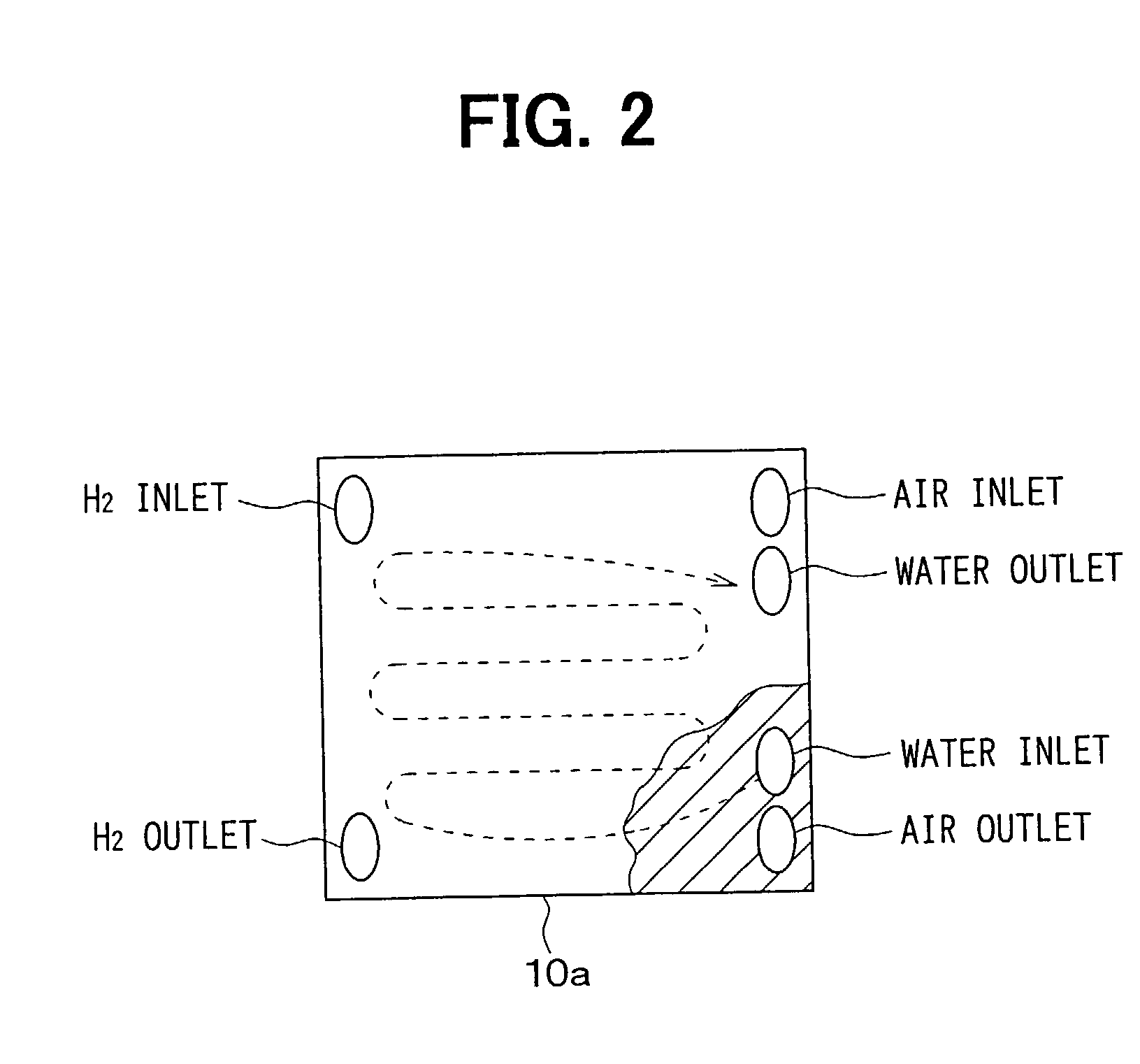

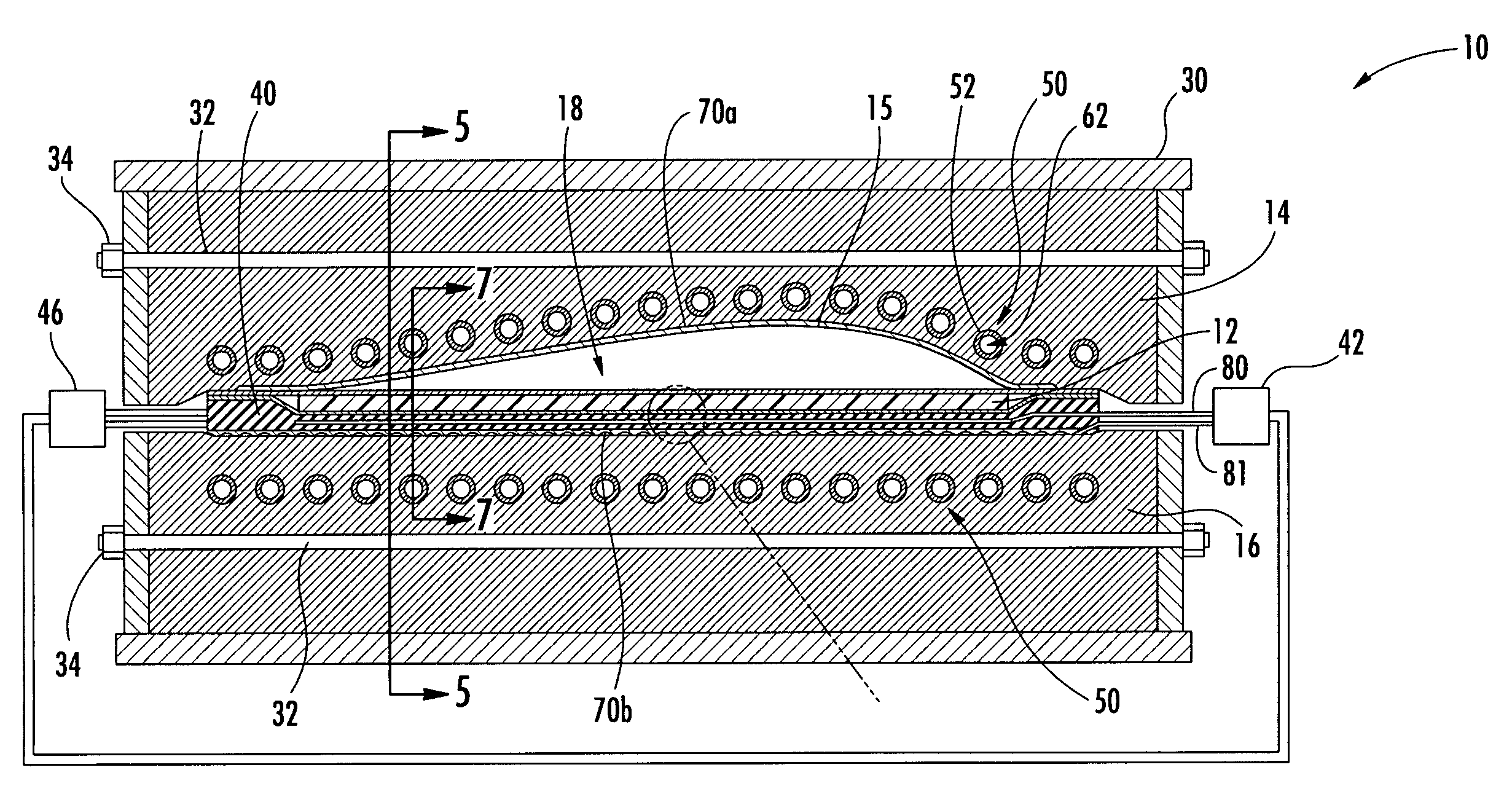

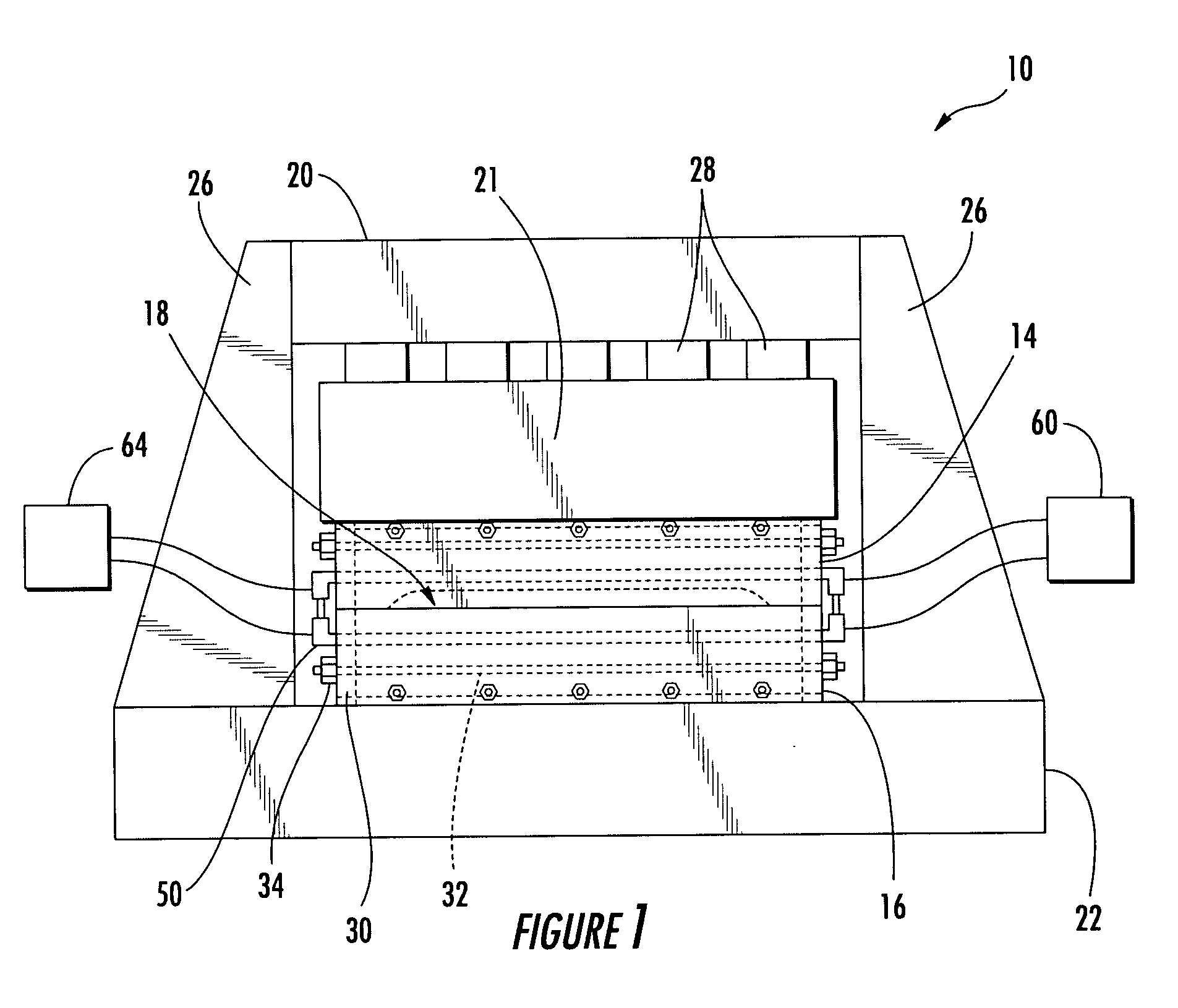

Fuel cell system

InactiveUS20030031905A1Small sizeHeating up fastFuel cell heat exchangeFuel cells groupingFuel cellsEngineering

A fuel cell system includes a fuel cell constructed by plural stacked cells, a circulation path through which a thermal medium is circulated into each cell, a heater for heating the thermal medium, a bypass path through which the thermal medium is circulated into a part of each cell while bypassing the other part thereof, and a flow control valve for controlling a flow amount of the thermal medium circulated in the bypass path. The thermal medium can be circulated into only the part of each cell in a warm-up operation, so that the part of each cell is collectively heated. An amount of the thermal medium circulated into the other part of each cell is controlled, so that all of each cell is finally warmed up in the warm-up operation.

Owner:DENSO CORP

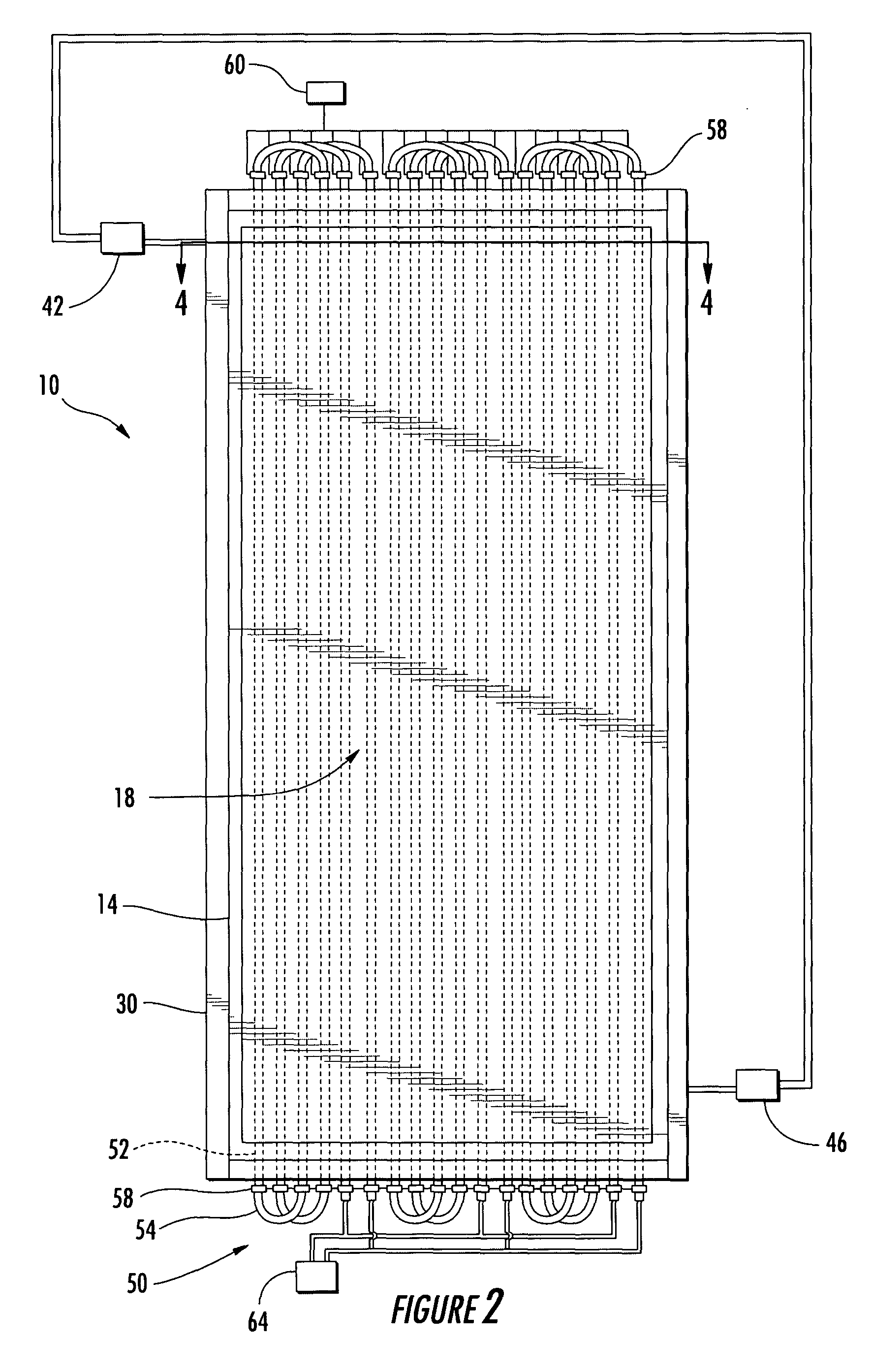

Forming apparatus and method

ActiveUS20050035115A1Reduce time and energyFast heatingMechanical working/deformationLaminationElectromagnetic fieldEngineering

An apparatus and method for forming a composite workpiece are provided. An electromagnetic field generator induces a current in a susceptor, thereby heating the workpiece in a die cavity. An elastomeric bladder in the cavity is inflated and urges the workpiece against a contour surface corresponding to a desired configuration of the workpiece. Coolant fluid can also be circulated through the die cavity to cool the workpiece. Thus, the workpiece can be heated, formed, and cooled quickly and without substantial heating of other components, thereby reducing the time and energy relative to conventional forming methods.

Owner:THE BOEING CO

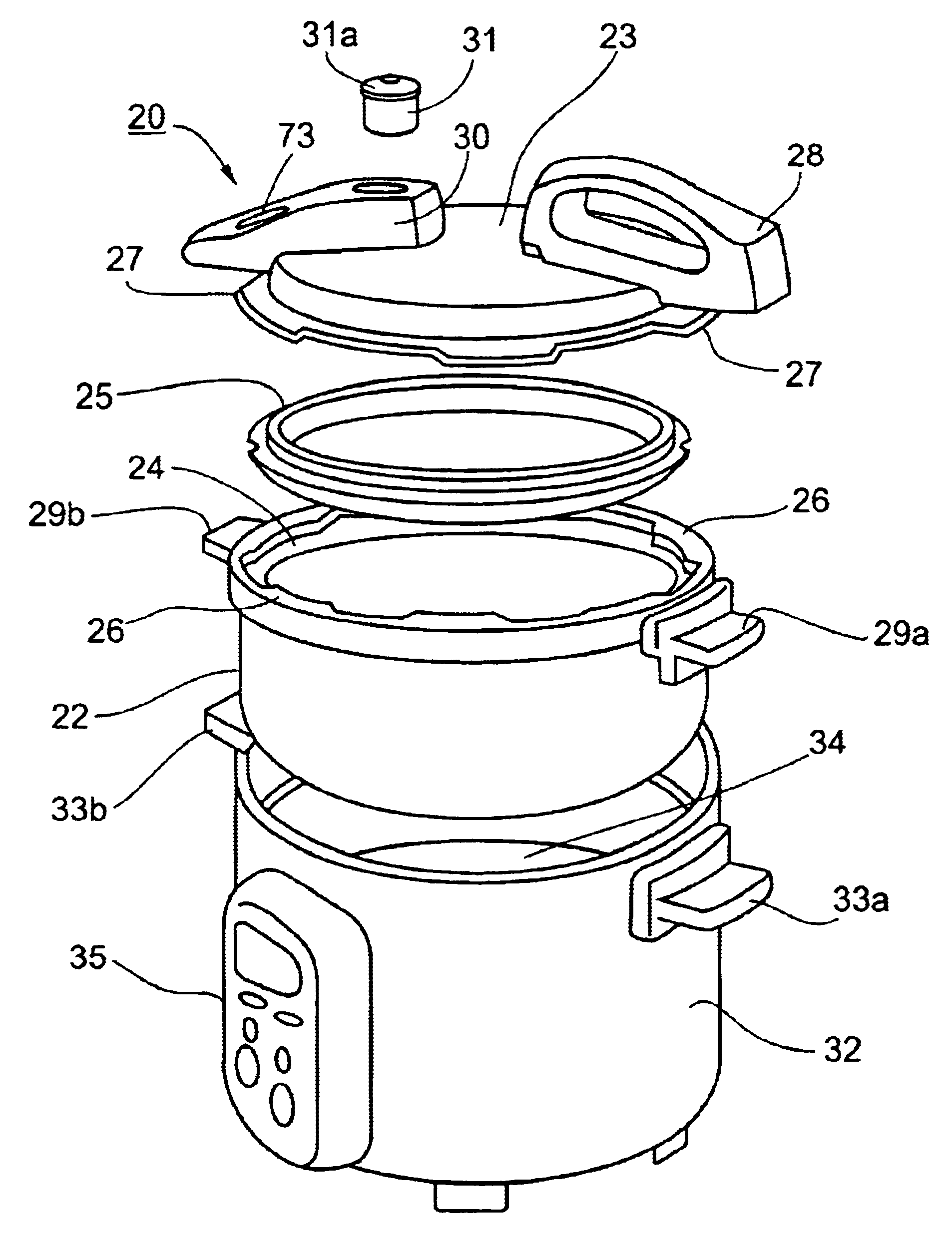

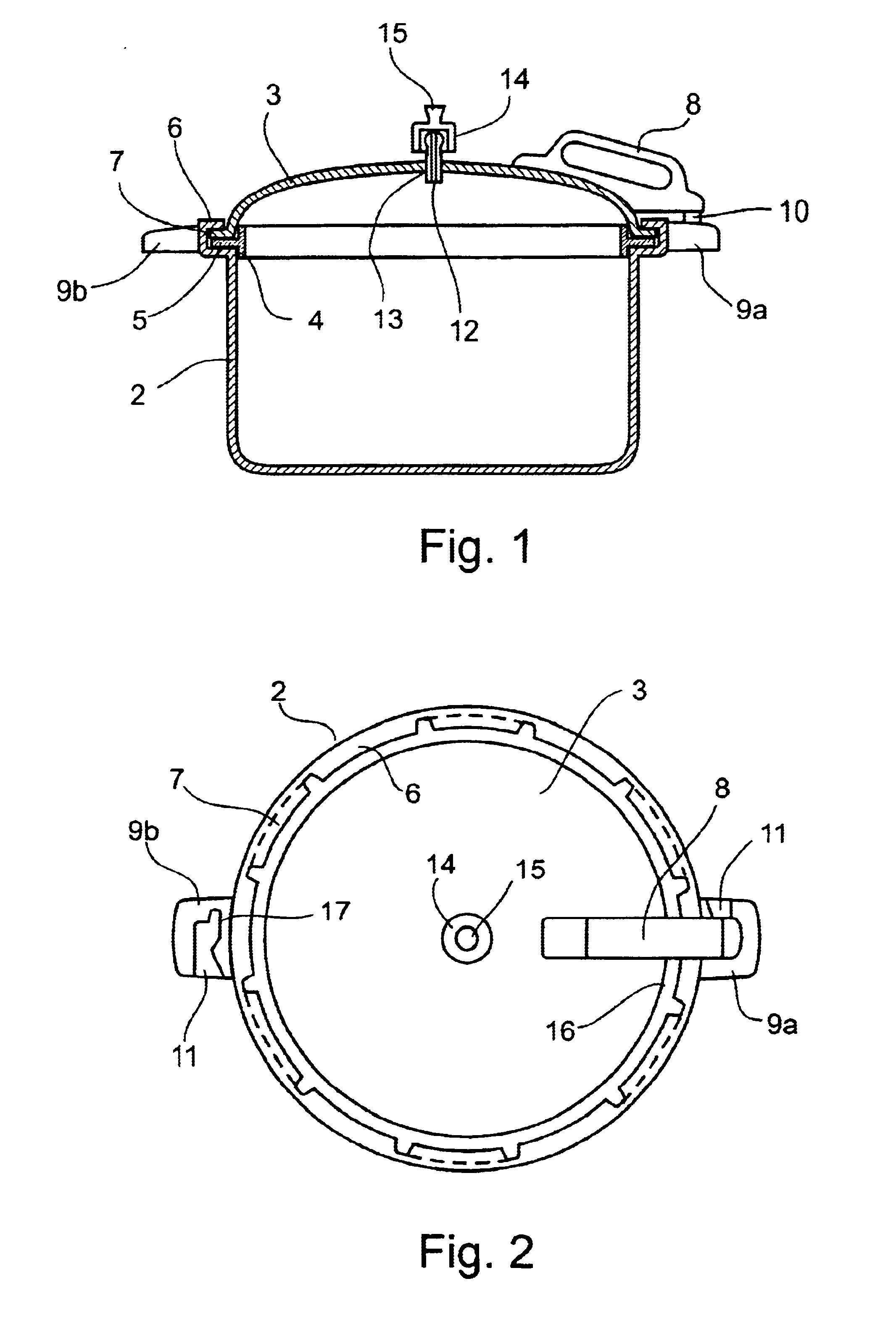

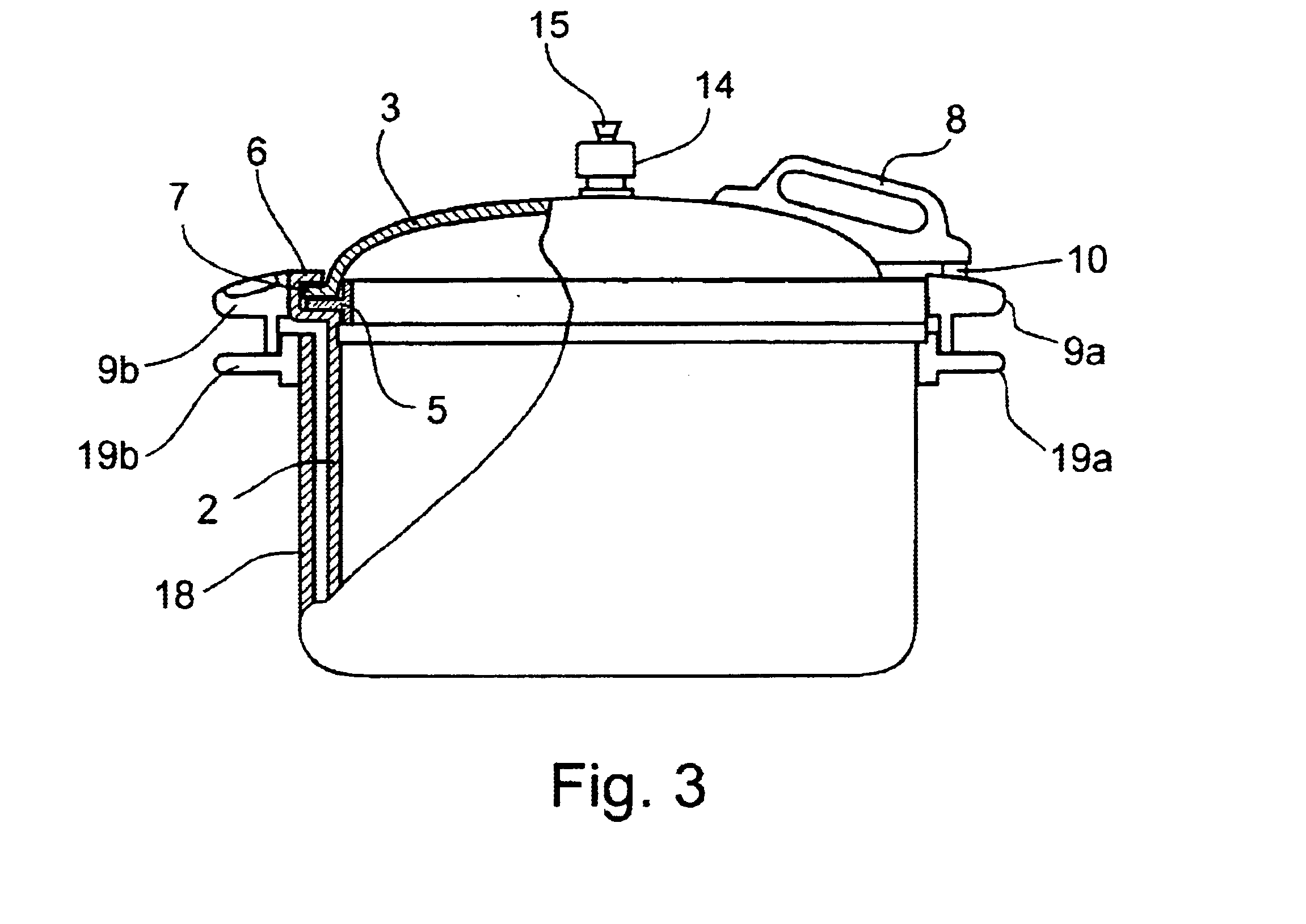

Pressure cooker

InactiveUS6705209B2Conveniently attachedEasy to useWater-bath cooking vesselsPressure-cookersEngineeringSafety Interlock

Owner:DEA GENERAL AVIATION HLDG CO LTD

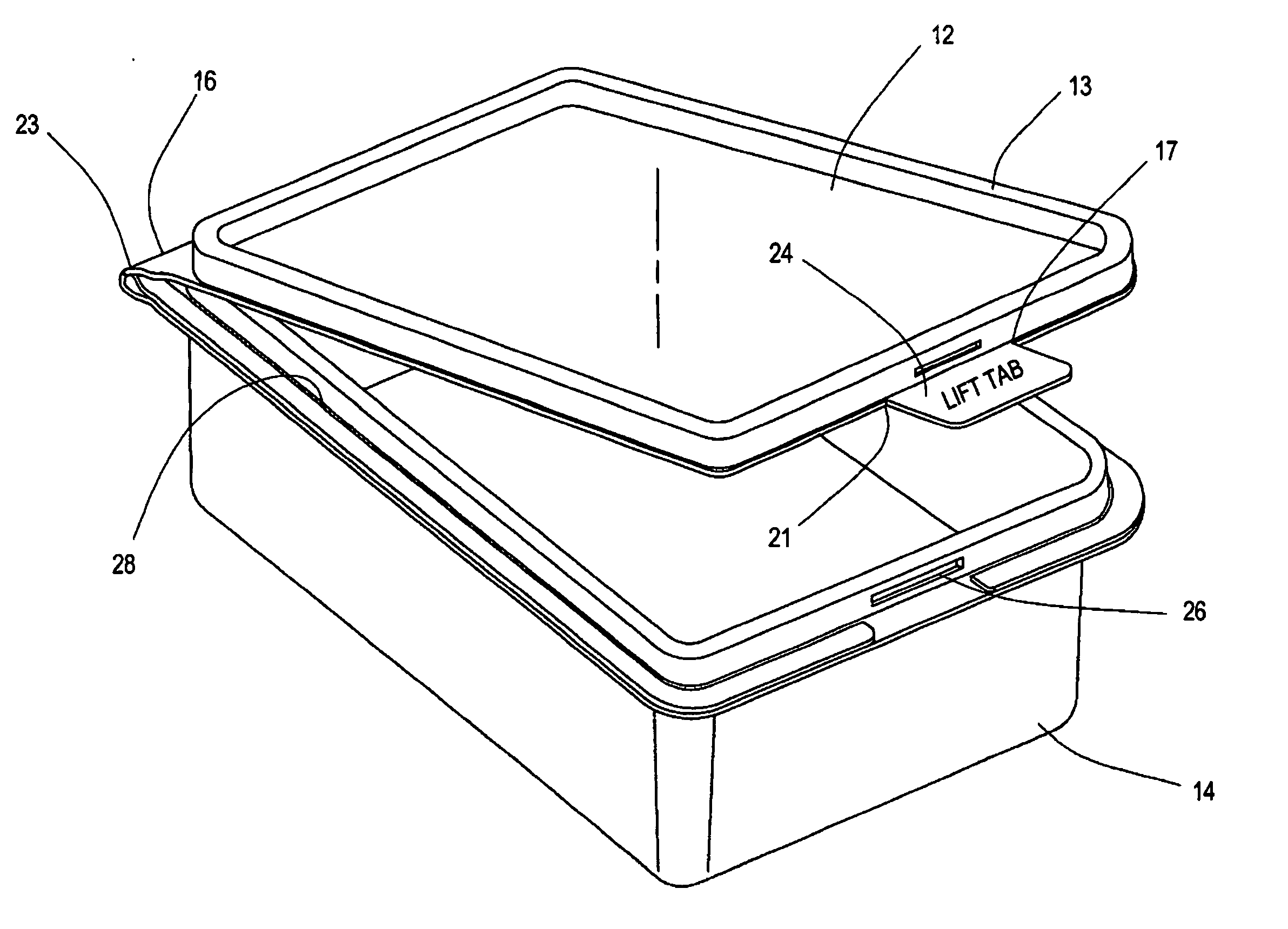

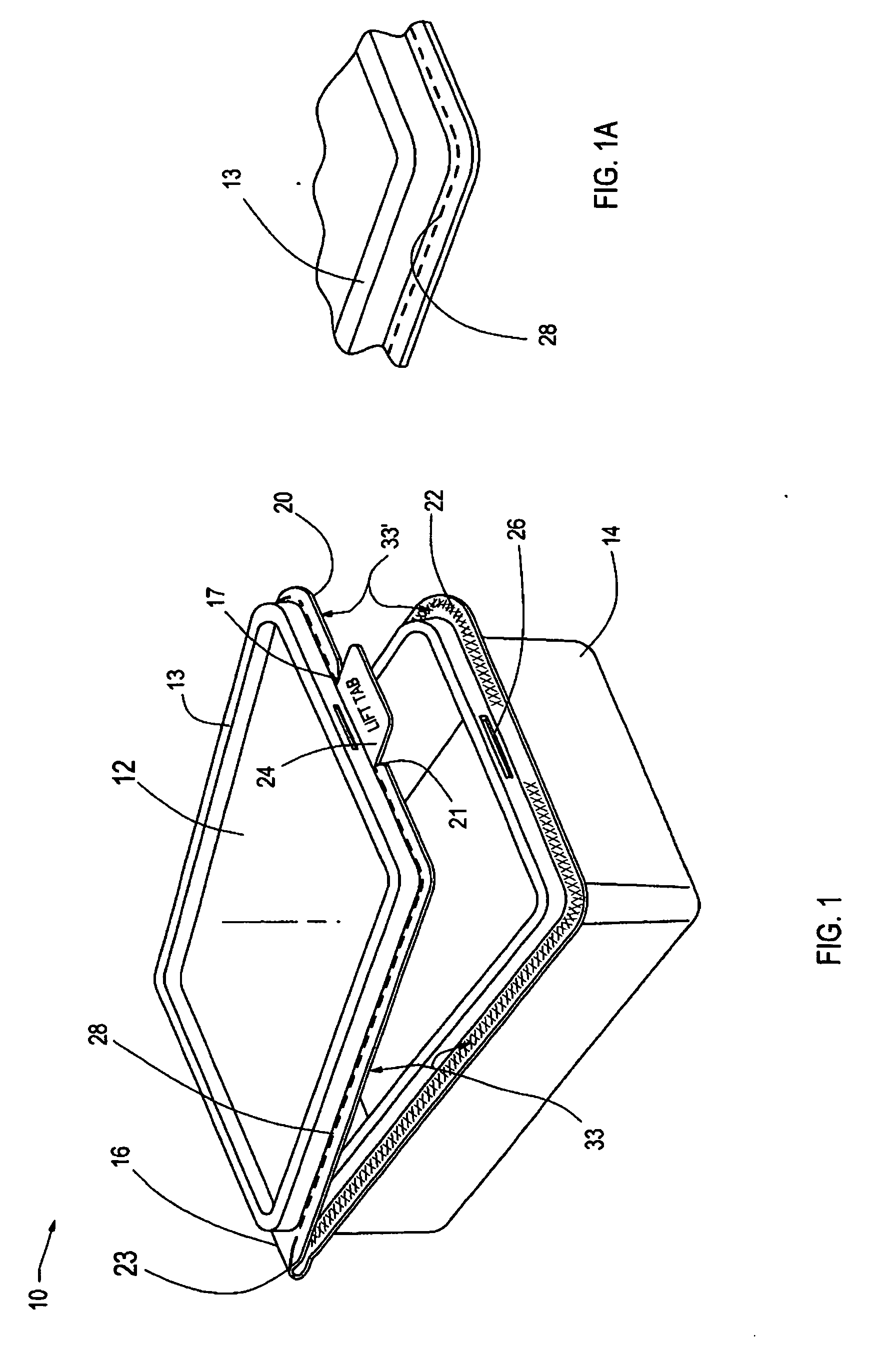

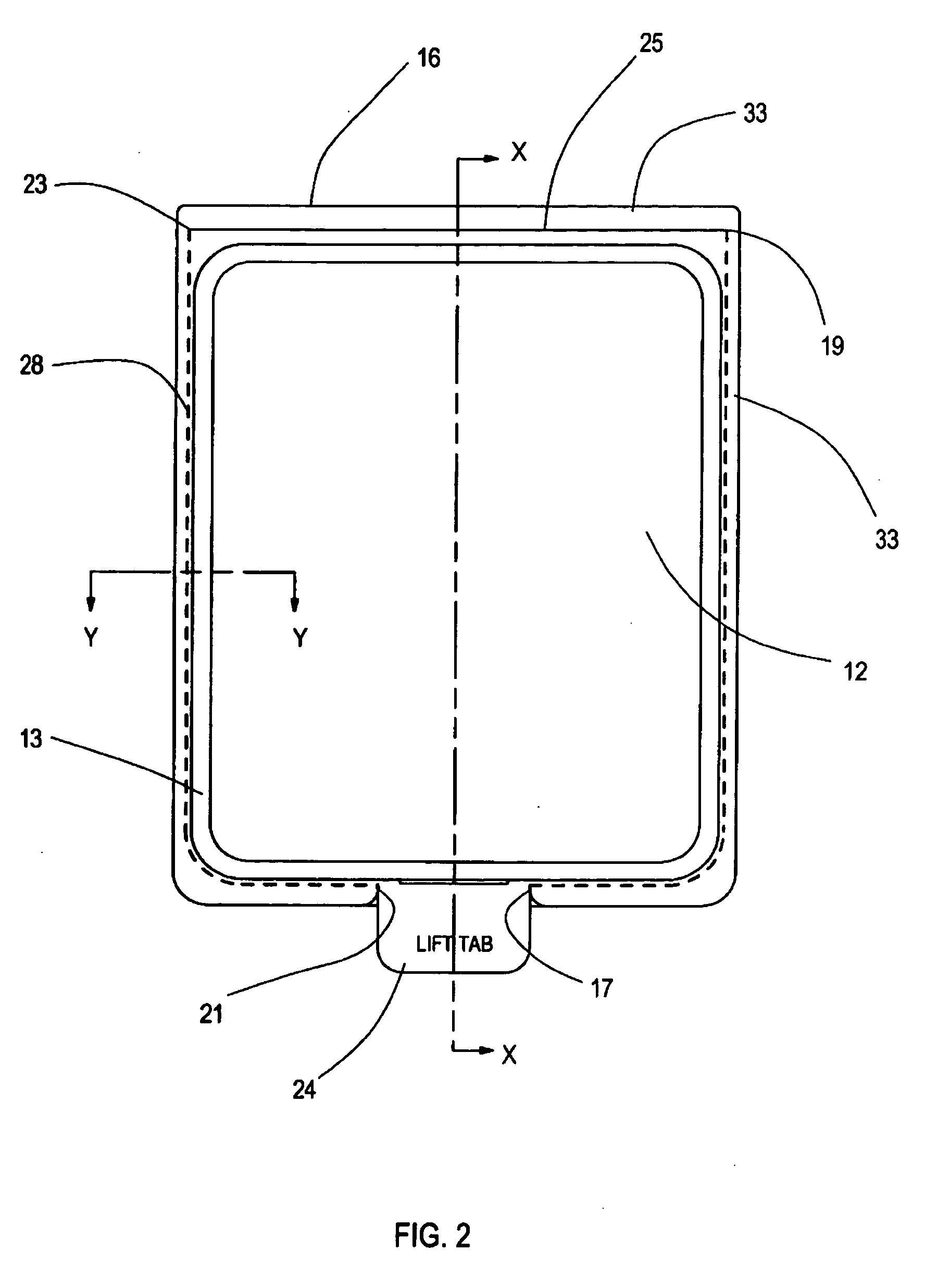

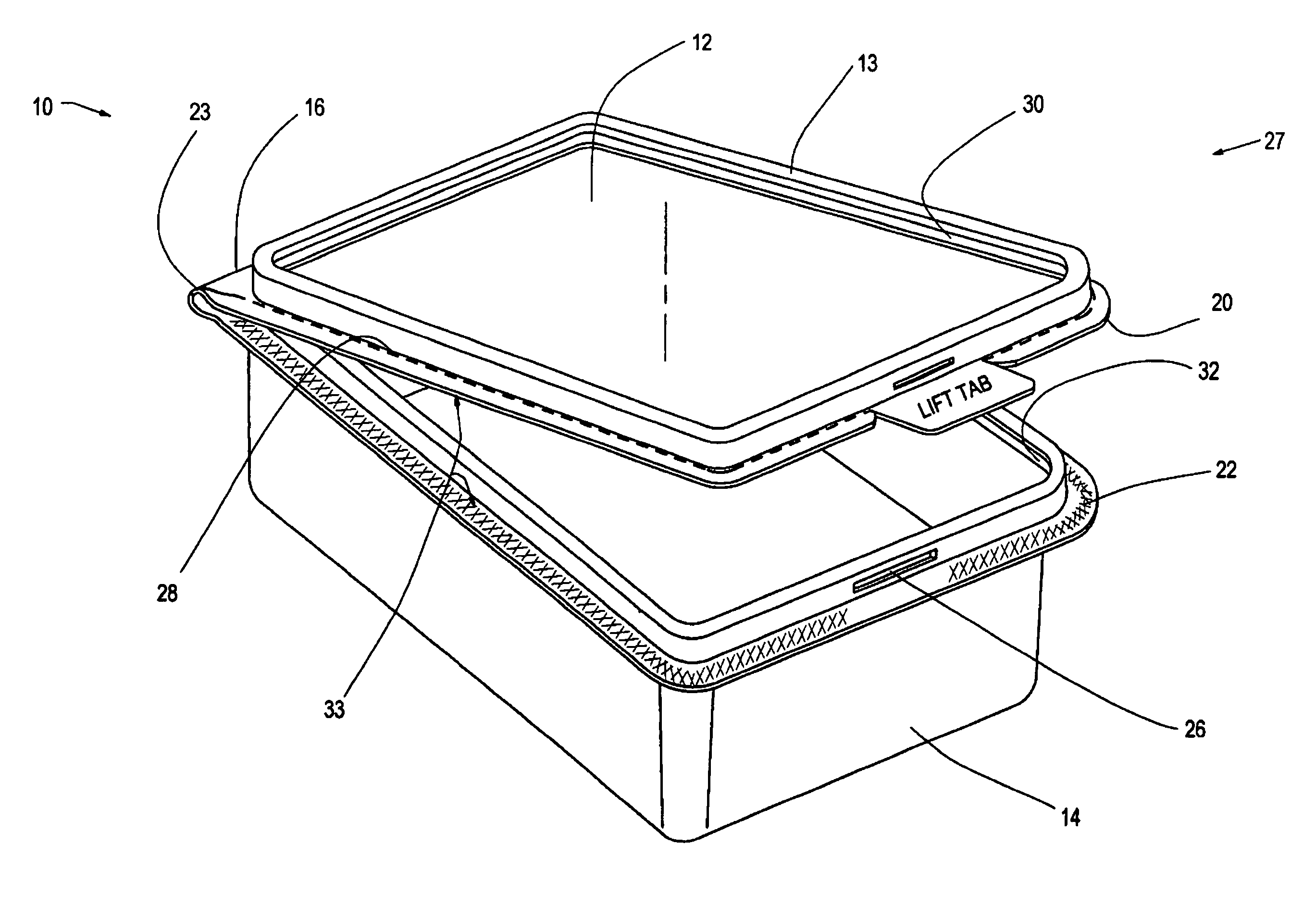

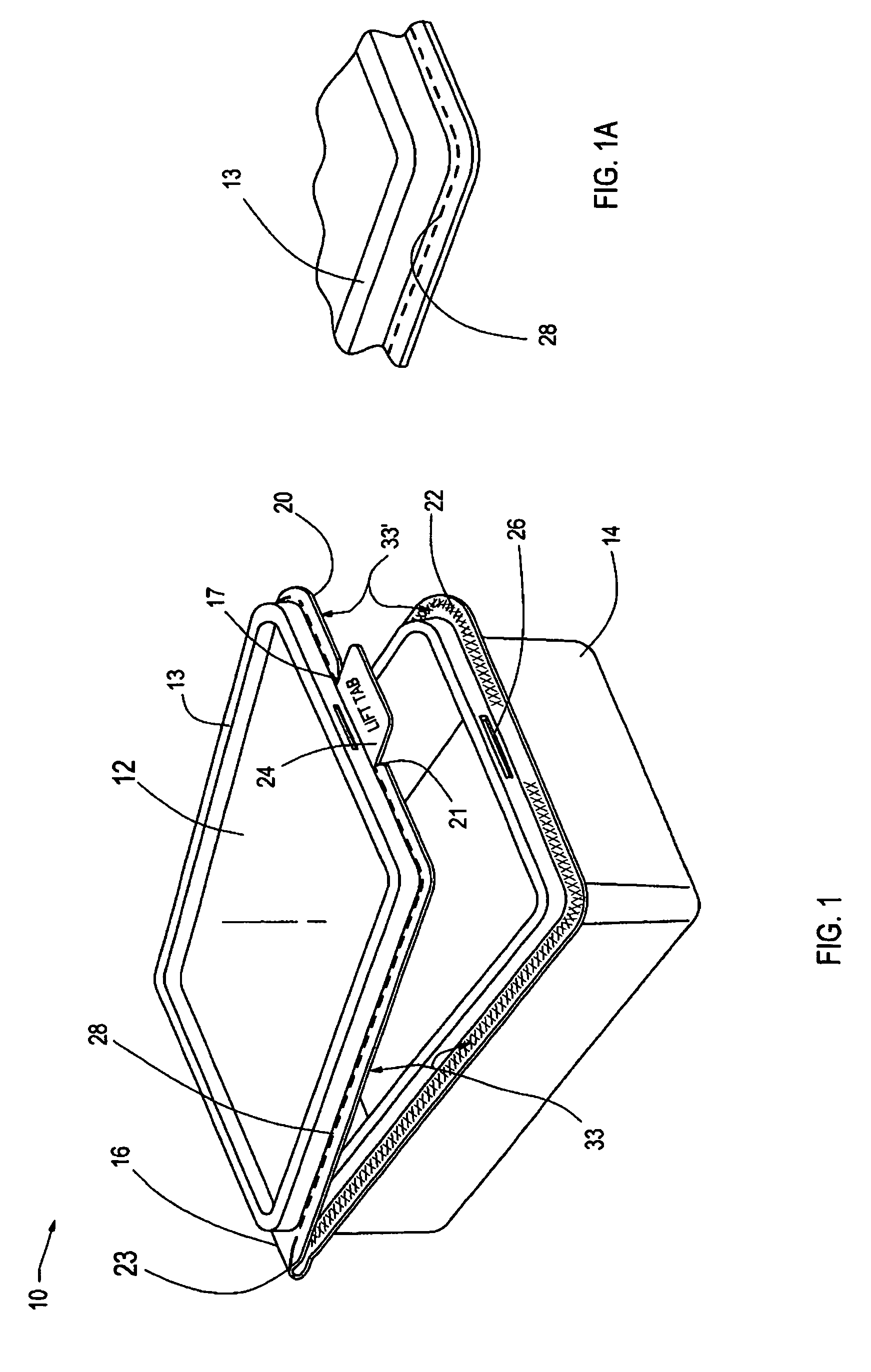

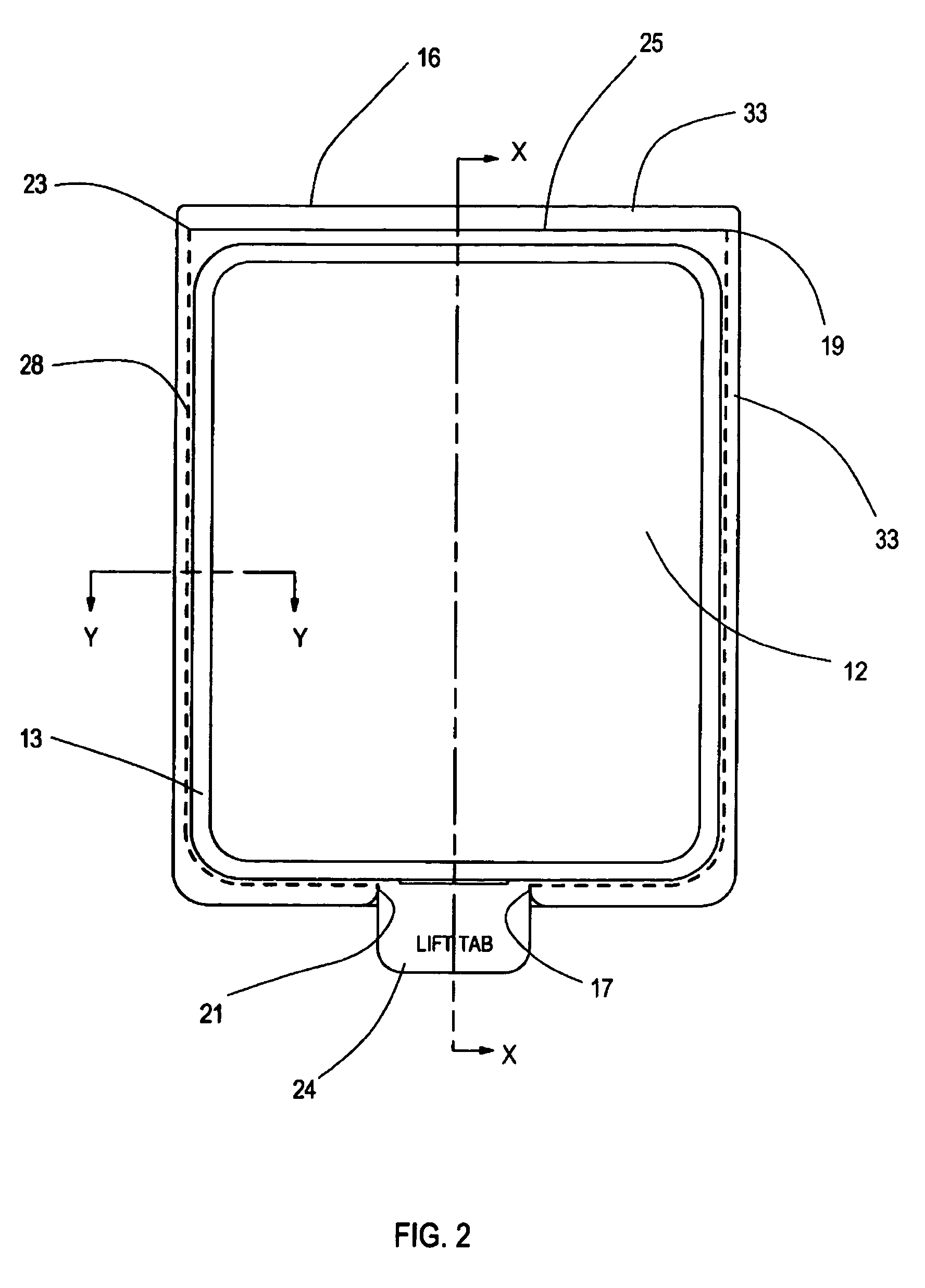

Versatile tamper-evident food container

ActiveUS20070012710A1Improved tamper-evident product packagingWithout riskCapsClosure capsInterference fitMaterial Perforation

A tamper-evident rigid plastic food container system wherein the outer periphery of the mating surfaces of the lid and tray are permanently bonded together after the food product has been placed in the tray, a set of perforated rows at an inner periphery, the interconnect of which needs to be torn into order to open the lid. Intentional, inadvertent or malicious ingress into the container can only be made by tearing at the perforations thereby evidencing the potential tampering and contamination of the packaging contents. The lid and tray edges may further include mechanical interference fits, including snap-fit grips that may be of the releaseably lockable kind to permit sealing, release and re-sealing multiple times without deterioration in reliability, and which can further prevent or minimize leakage of liquid food product.

Owner:PACTIV PACKAGING

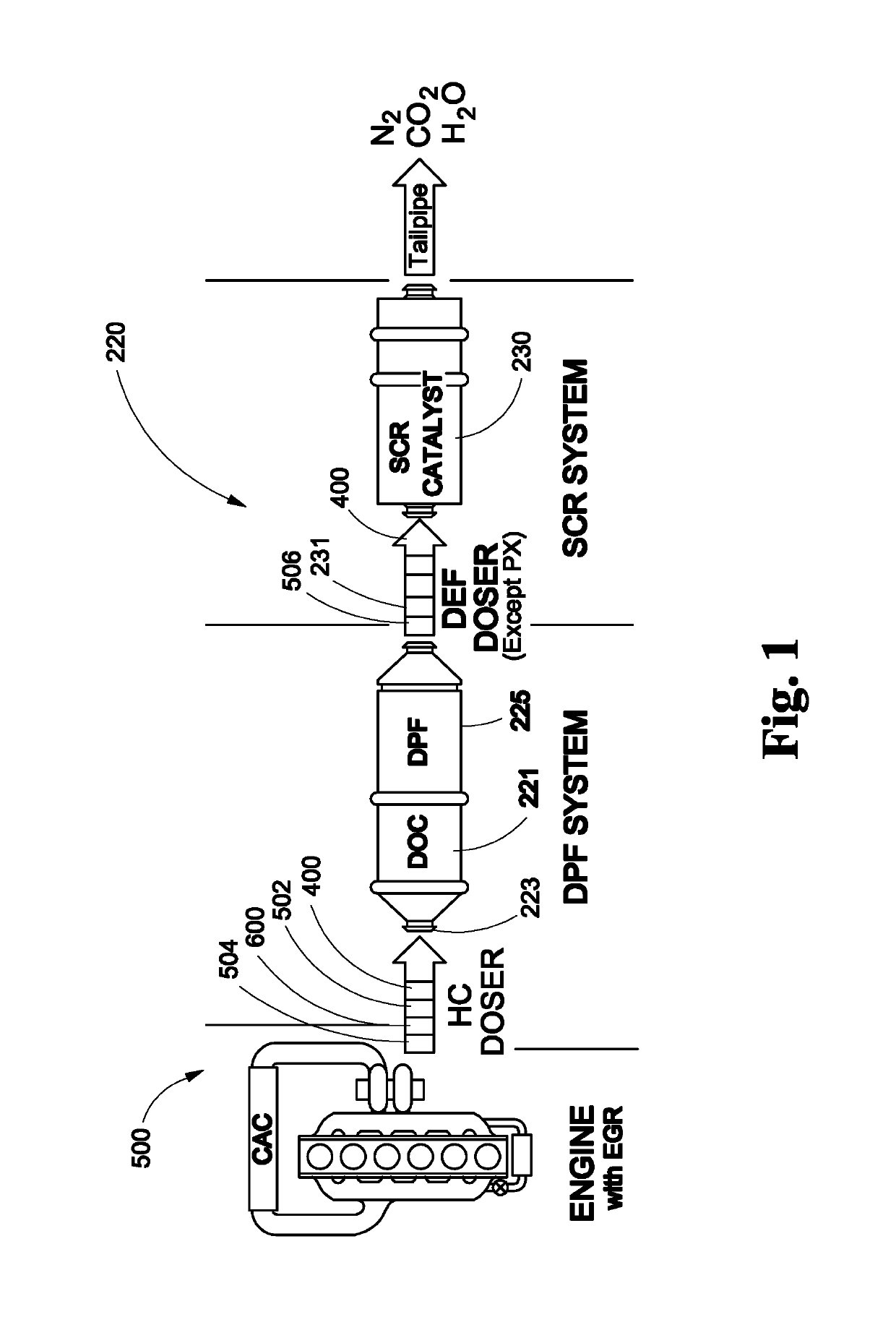

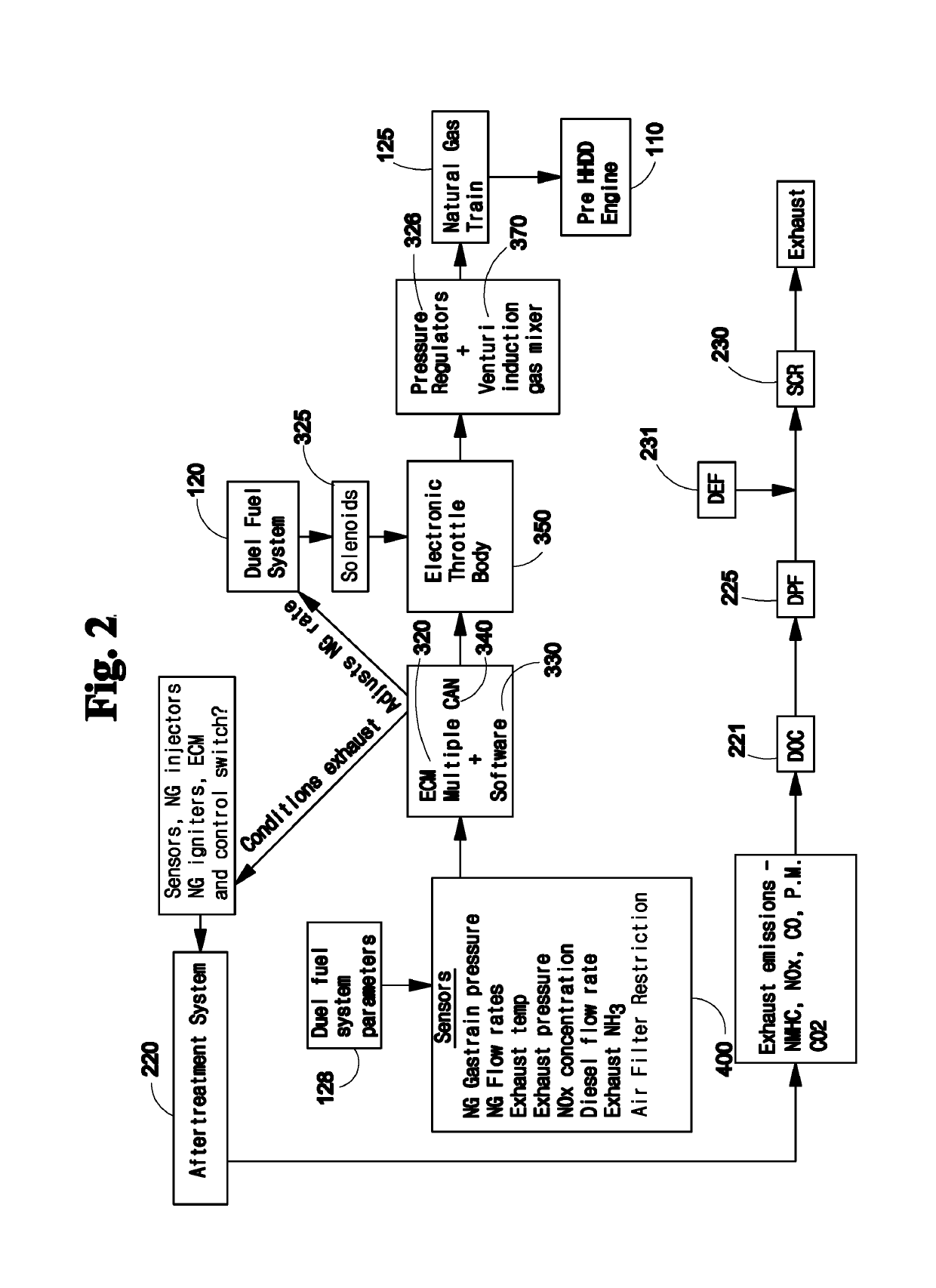

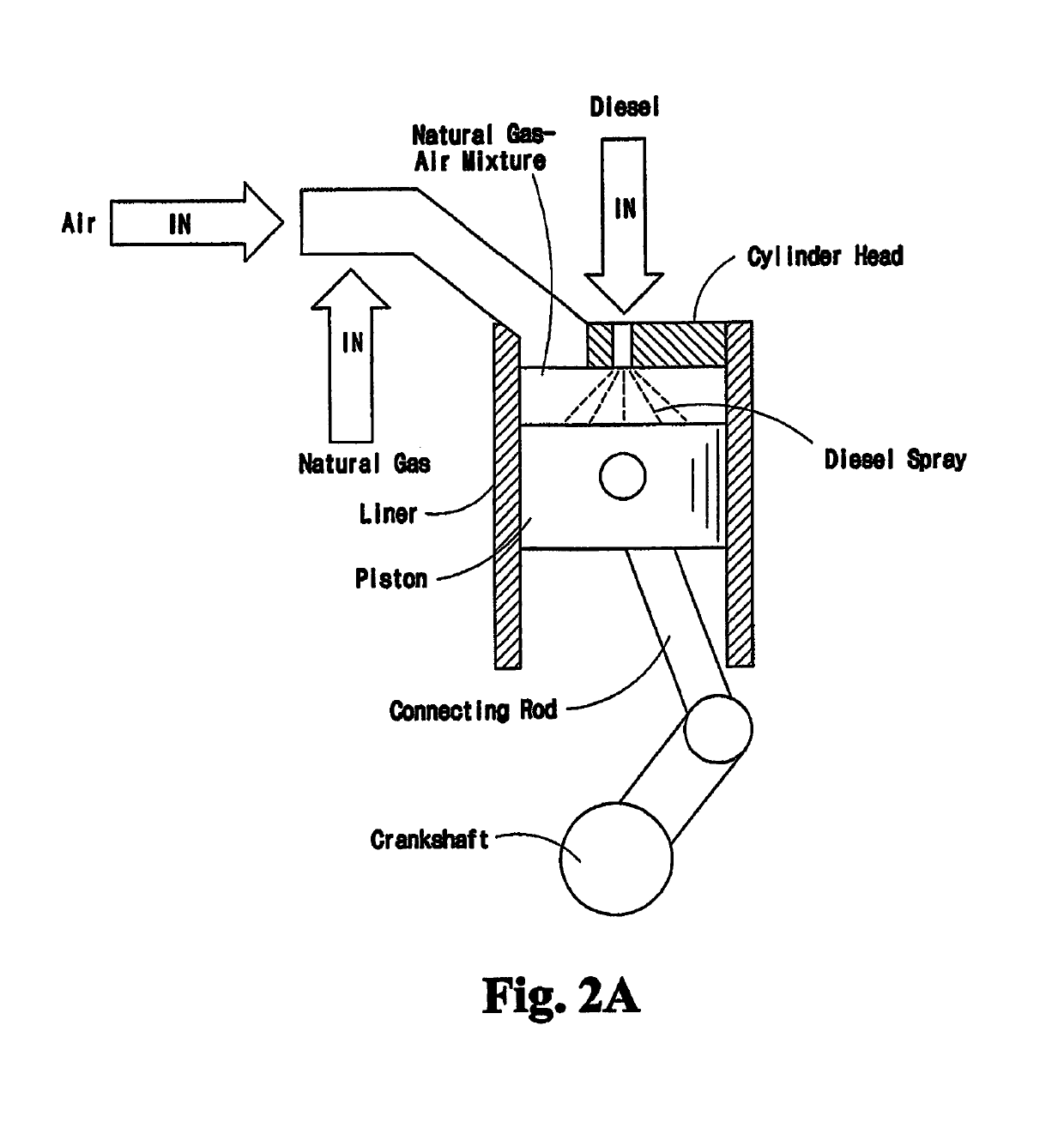

System comprising duel-fuel and after treatment for heavy-heavy duty diesel (HHDD) engines

ActiveUS10287943B1Eliminating of time lapseFast heatingInternal combustion piston enginesFuel supply apparatusDecreased carbon dioxideExhaust emission

The present invention provides up-fit after treatment technology for bringing Heavy-Heavy Duty Diesel (HHDD) engine powered vehicles into compliance with the Title 13 CCR, Part 2025 mandate (meeting 2010 criteria emission standards). It also includes a Dual Fuel system, Exhaust Thermal Management System further reducing: NOx constituents, consumption of diesel fuel, particulate matter and CO2 emissions. The invention further comprises multiple sensors that provide data to electronic control module(s). The APGV6000 enables rapid after-treatment thermal activation, compares “real-time” sensor data with target data, and adjusts the after treatment system and / or dual fuel system and / or Exhaust Thermal Management system to produce exhaust emissions well below 2010 exhaust emission standards. For 2010 and newer HHDD engine applications, the V6000 comprises the Dual Fuel and exhaust thermal management system to affect rapid after-treatment activation, reduced NOx emissions well below, 2010 (current) standards, reduce diesel fuel usage and reduce CO2 emission.

Owner:CLEAN POWER TECH LLC

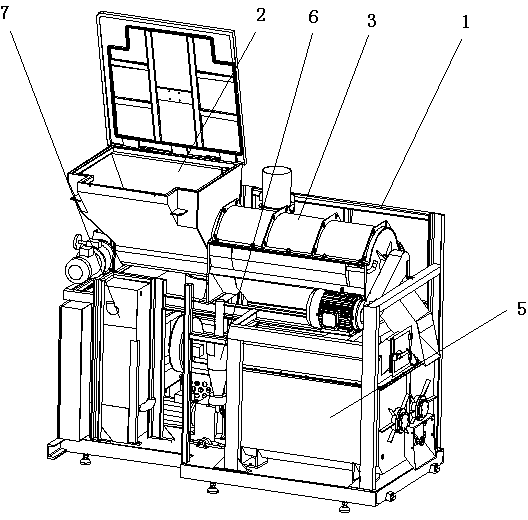

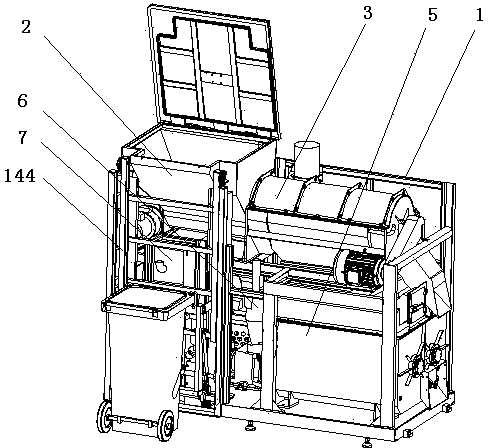

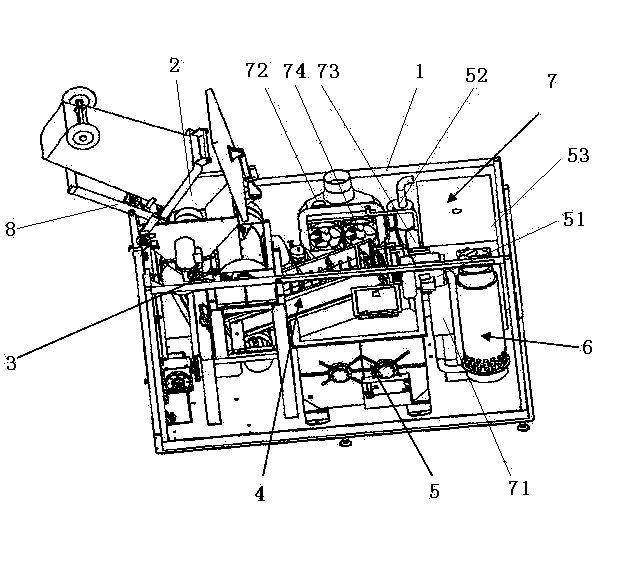

Kitchen waste pretreatment device

ActiveCN103464449ADeodorization up to standardWith automatic sortingSolid waste disposalControl systemOil water

The invention discloses a kitchen waste pretreatment device. The kitchen waste pretreatment device comprises a closed shell and a control system. The kitchen waste pretreatment device is characterized in that the upper end of the shell is provided with a feeding funnel and a feeding motor; the shell is internally provided with an automatic sorting device, a biological fermentation drying device, an oil-water separation device, an ionization deodorization device and a gas condensation device; the feeding funnel is communicated with a kitchen waste charge hole of the automatic sorting device through a discharge hole; the automatic sorting device is communicated with a charge hole of the biological fermentation drying device through a kitchen waste outlet; the automatic sorting device is communicated with the oil-water separation device through a liquid outlet; the biological fermentation drying device is communicated with the gas condensation device through a gas exhaust opening; the gas condensation device is communicated with the ionization deodorization device, so that the effects of automatic sorting, rapid fermentation treatment speed, uniform fermentation, rapid heating speed, capability of oxygenating in fermentation, standard gas deodorization and environment protection and no pollution are achieved.

Owner:SHANDONG MINGLIU KITCHEN WASTE TREATMENT EQUIP CO LTD

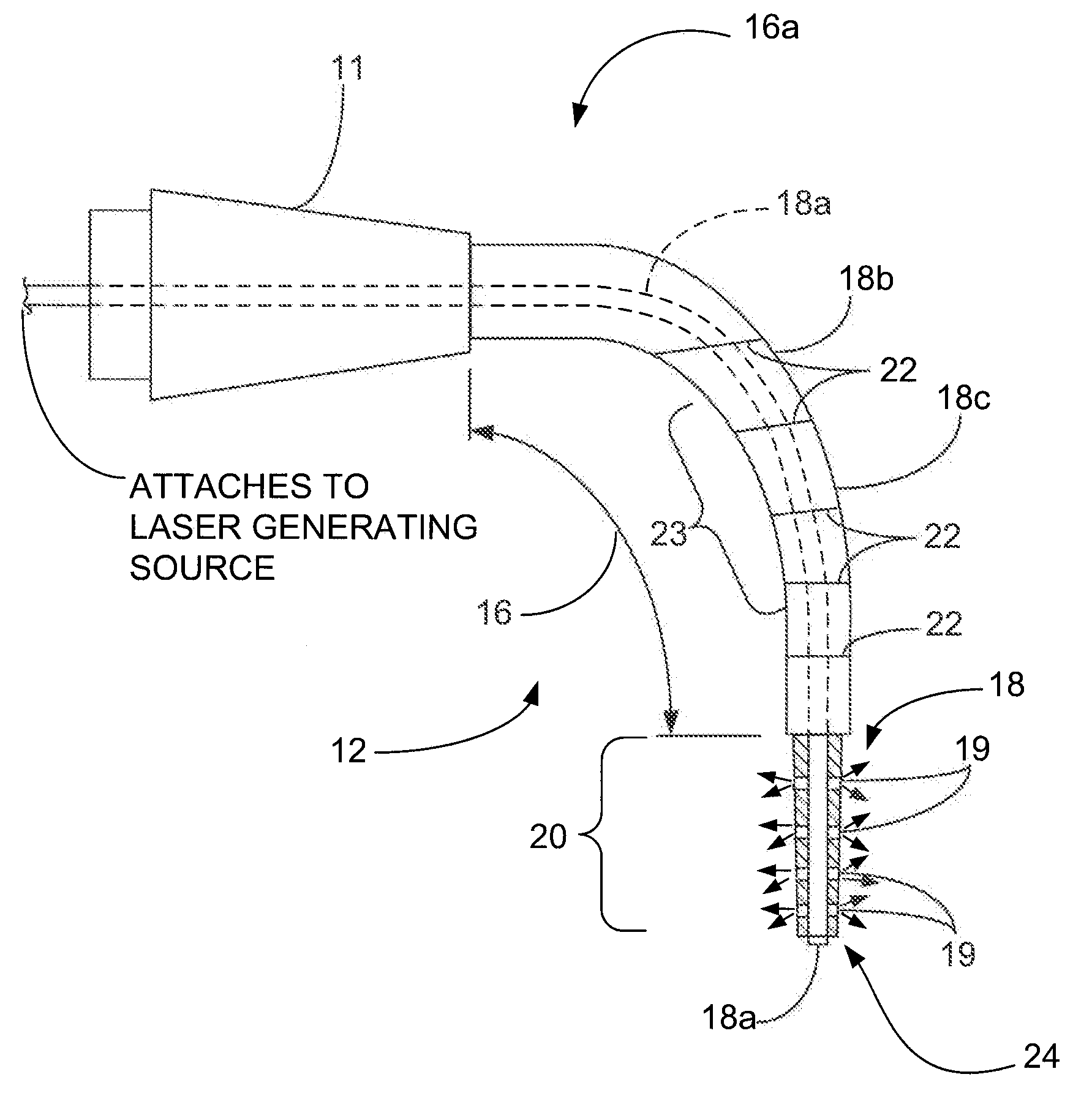

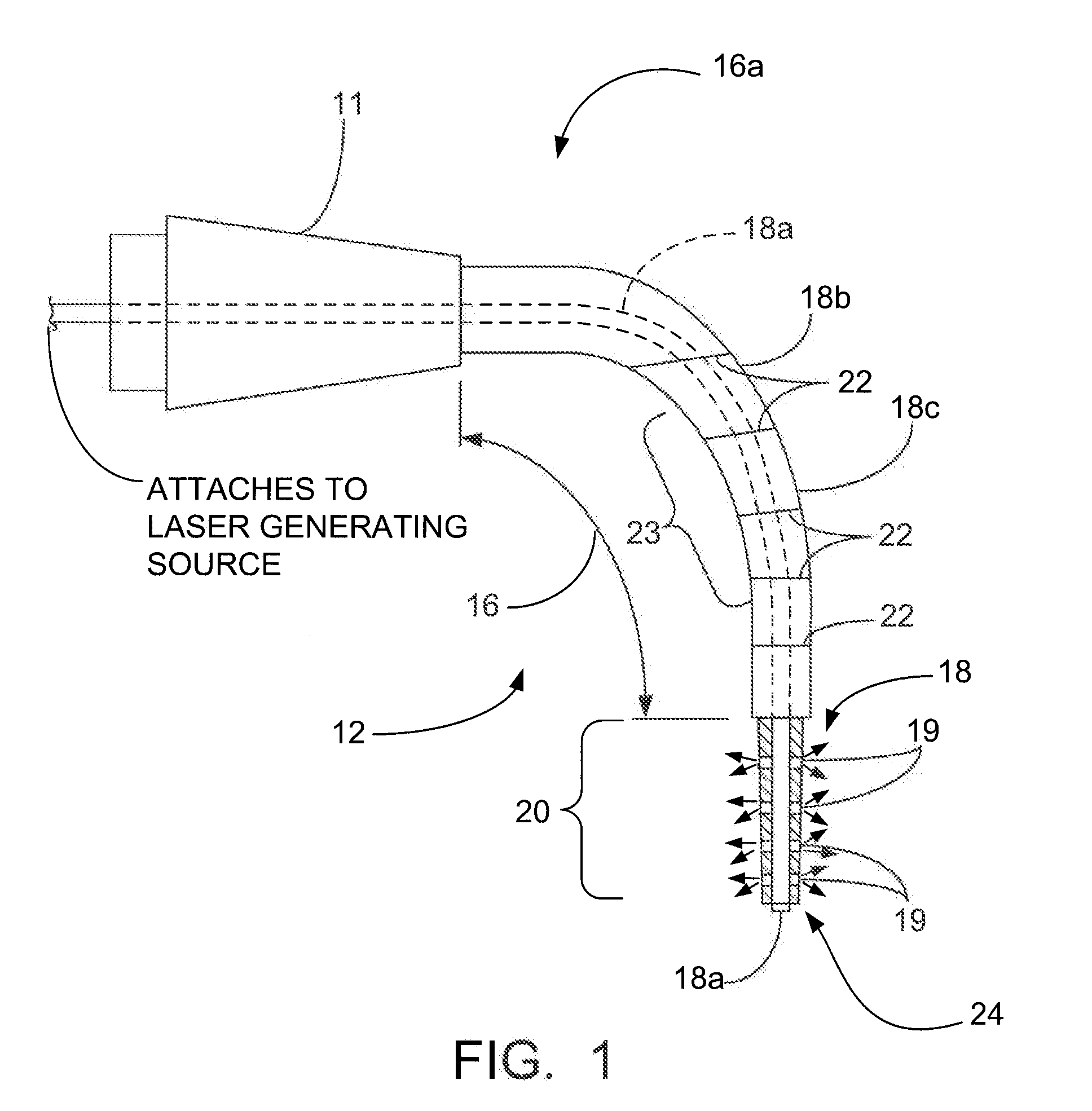

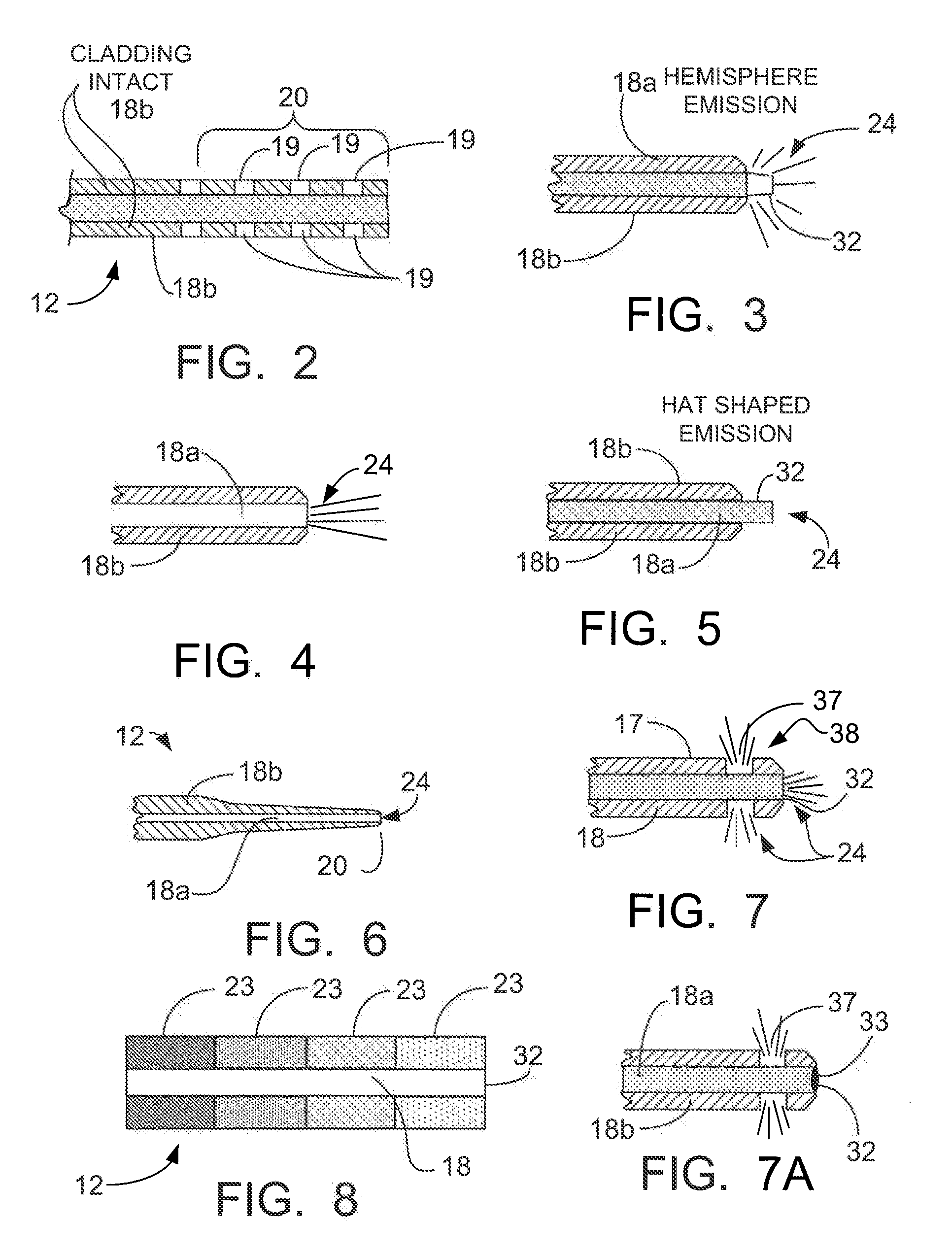

Method and Apparatus for Disinfecting or Sterilizing a Root Canal System Using Lasers Targeting Water

InactiveUS20090130622A1Sufficient deliveryEnhanced light absorptionSurgical instrument detailsDental toolsDiseaseEnergy absorption

Method and apparatus for disinfecting and / or sterilizing a root canal system by targeting the water content of disease and debris in the canals. The laser technique of employs a frequency of the wavelength emissions between about 930 to about 1065 nanometers with an optimum of 980 nm. This range of wavelengths targets the water content of tissue cells and pathogens as well as any residual organic debris in water within the root canal system after its preparation while being poorly absorbed by the surrounding dentin. The selection of the optimum wavelength produces significant effects generating and advancing treatment to the targeted aqueous environments. This is due to the rapid energy absorption by the water and the subsequent creation of gas bubbles, liberation of heat and subsequent propulsion of waves of heat and gas that impact along the canal walls and ramifications resulting in an enhanced bacterial kill and cleaning of the canal walls and ramifications. No dyes or other additives are necessary to enhance the effectiveness of the laser kill of bacteria, etc.

Owner:BOLLINGER JAMES EDWIN +2

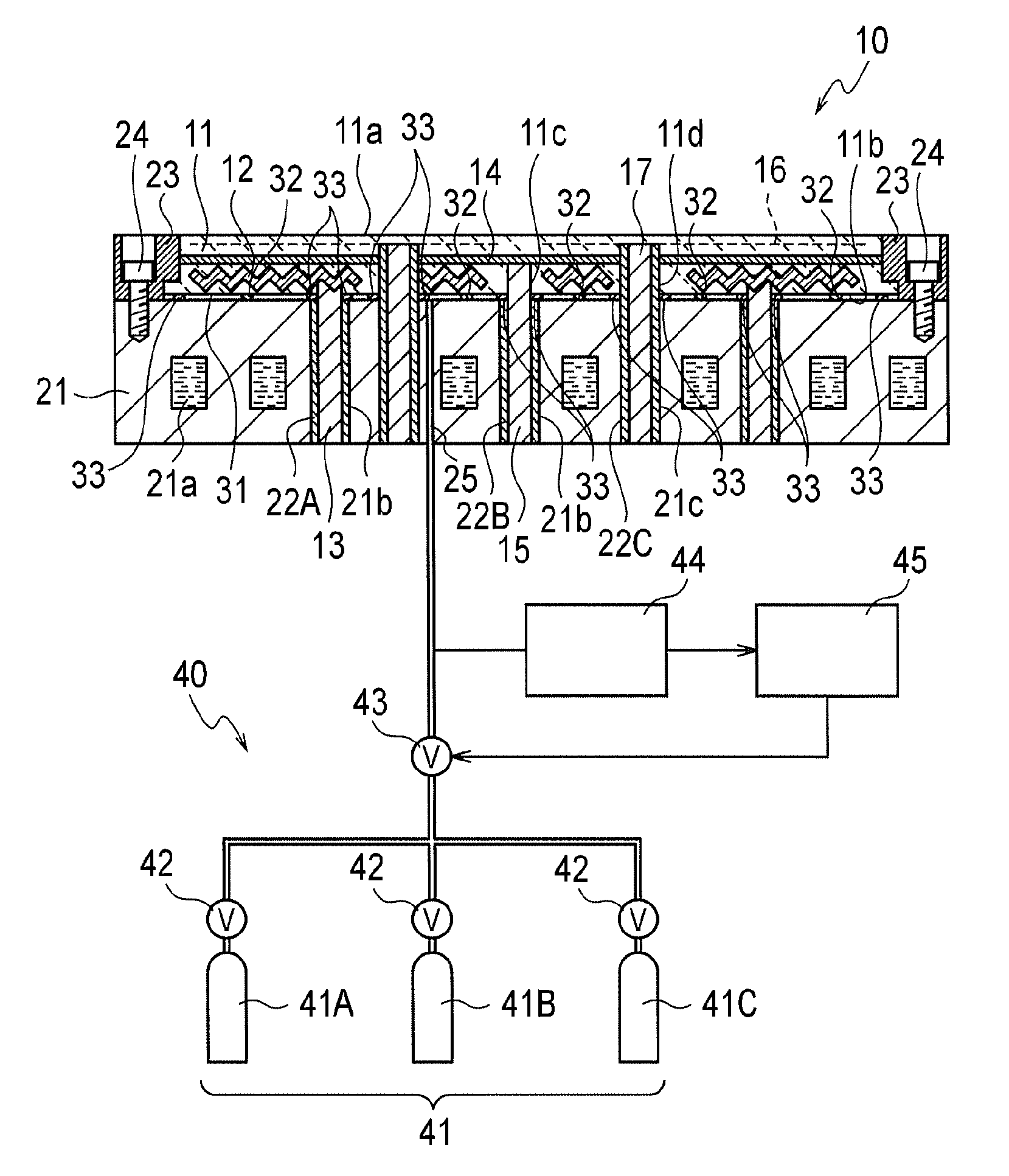

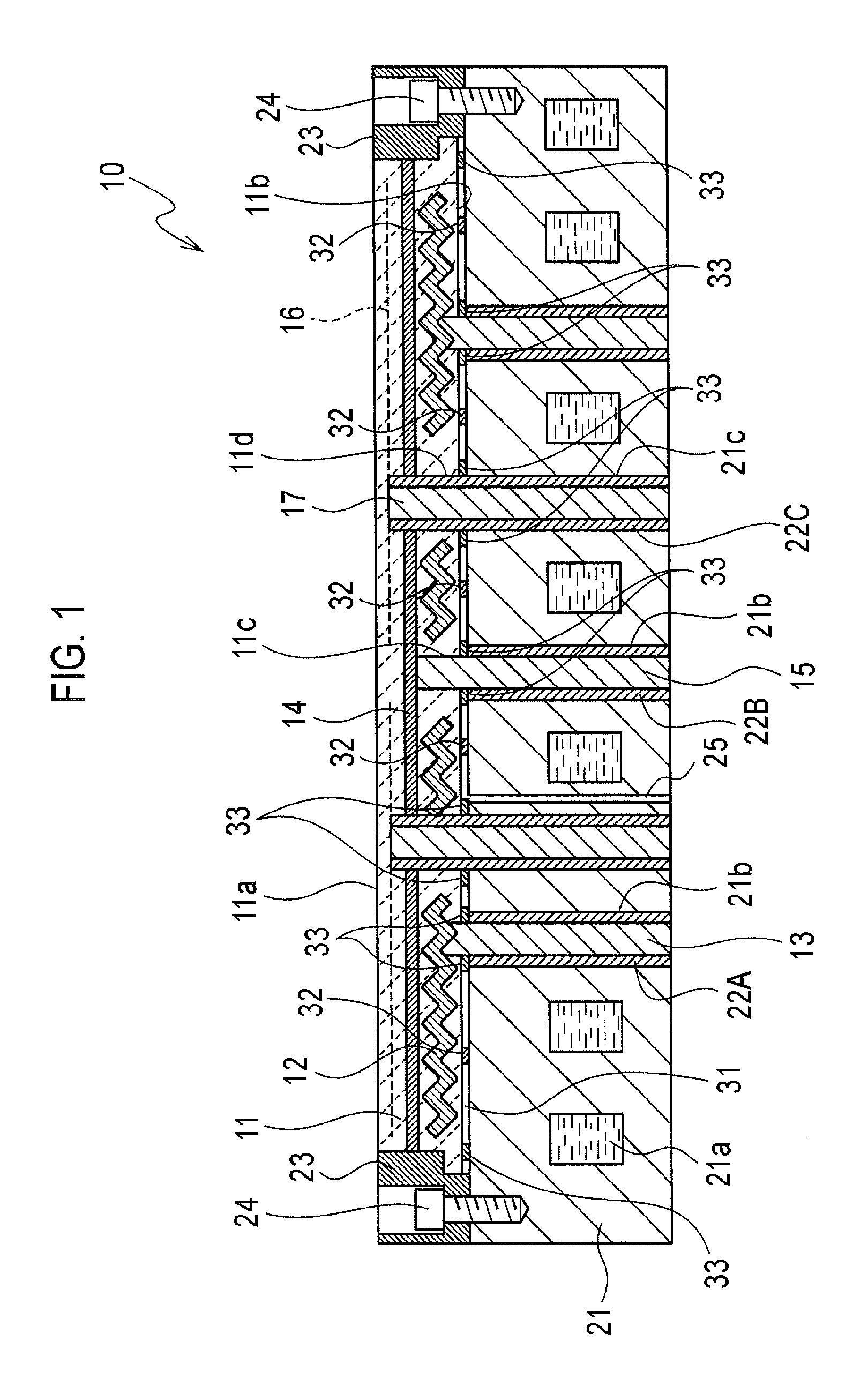

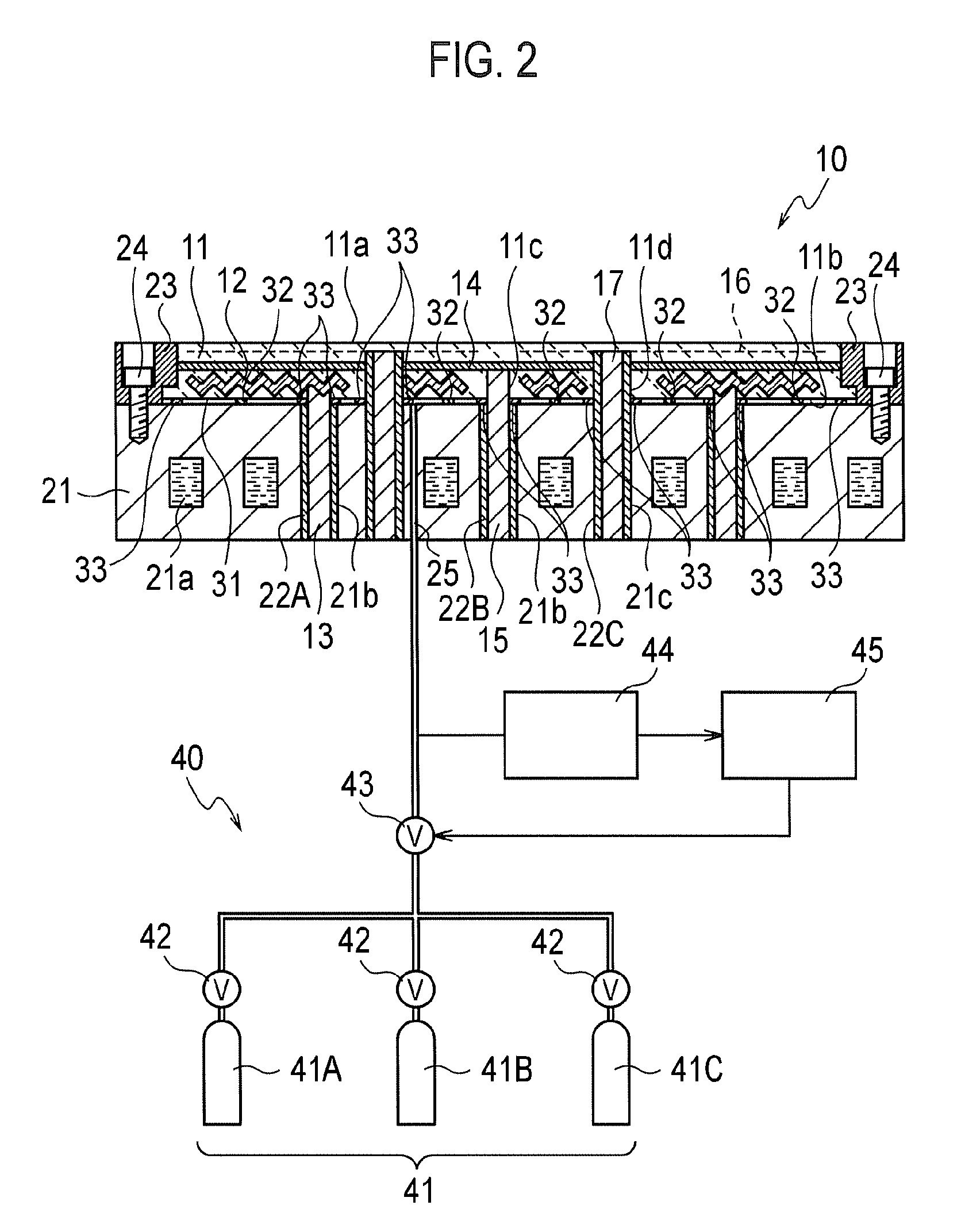

Heating apparatus

InactiveUS20090159588A1Improve thermal conductivityFast heatingSemiconductor/solid-state device manufacturingHot plates heating arrangementsMetallurgyMaterials science

A heating apparatus 10 includes a ceramic base 11 having a heating surface 11a and provided with a resistance heating body 12 embedded therein, and a temperature adjusting member 21 fixedly fastened proximal to a back surface of the ceramic base 11. A heat conductive member 14 having a thermal conductivity higher than the ceramic base 11 is provided between the heating surface of the ceramic base 11 and the resistance heating body 12. A gas is introduced to an air gap 31 between the ceramic base 11 and the temperature adjusting member 21 while controlling the gas pressure.

Owner:NGK INSULATORS LTD

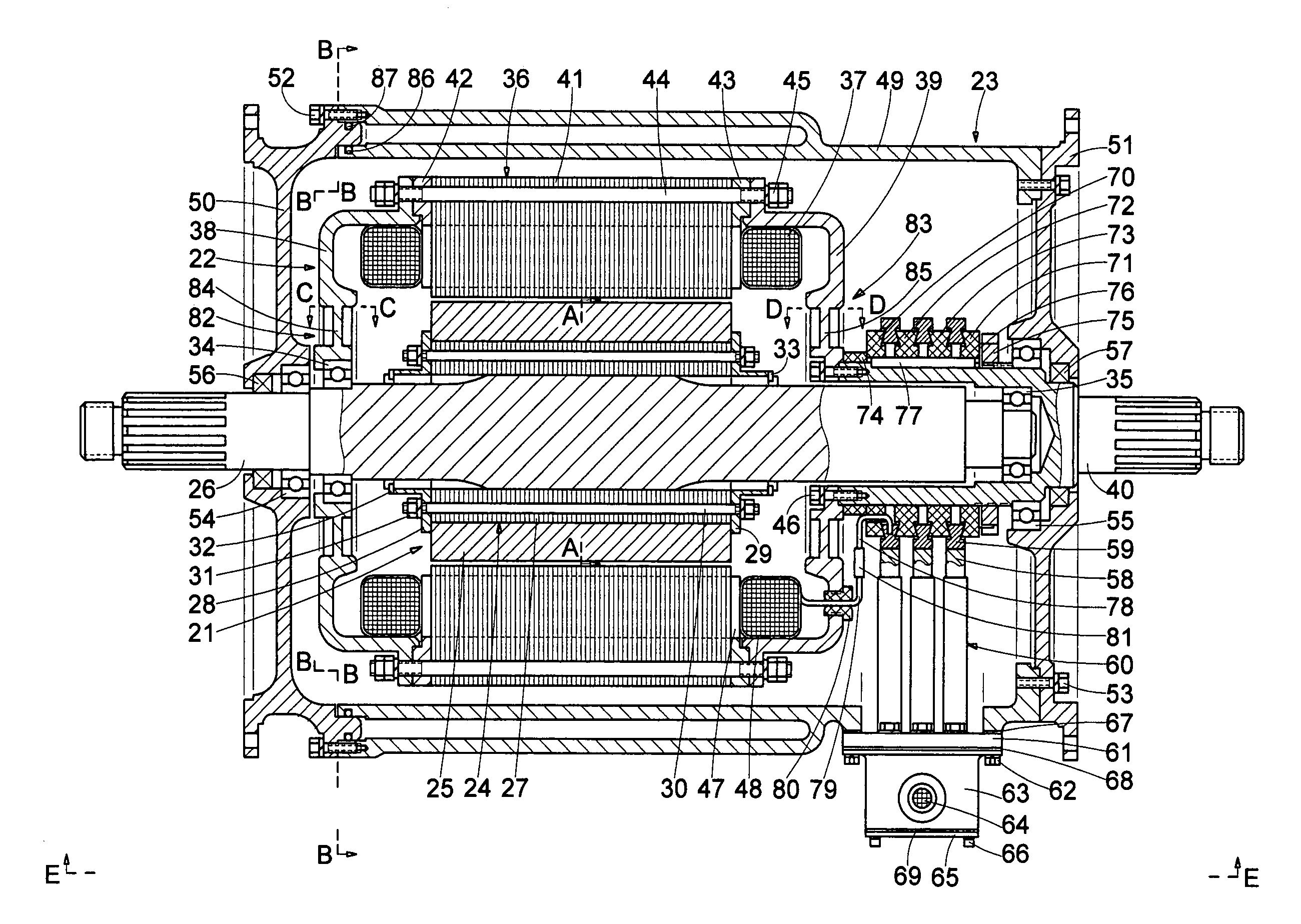

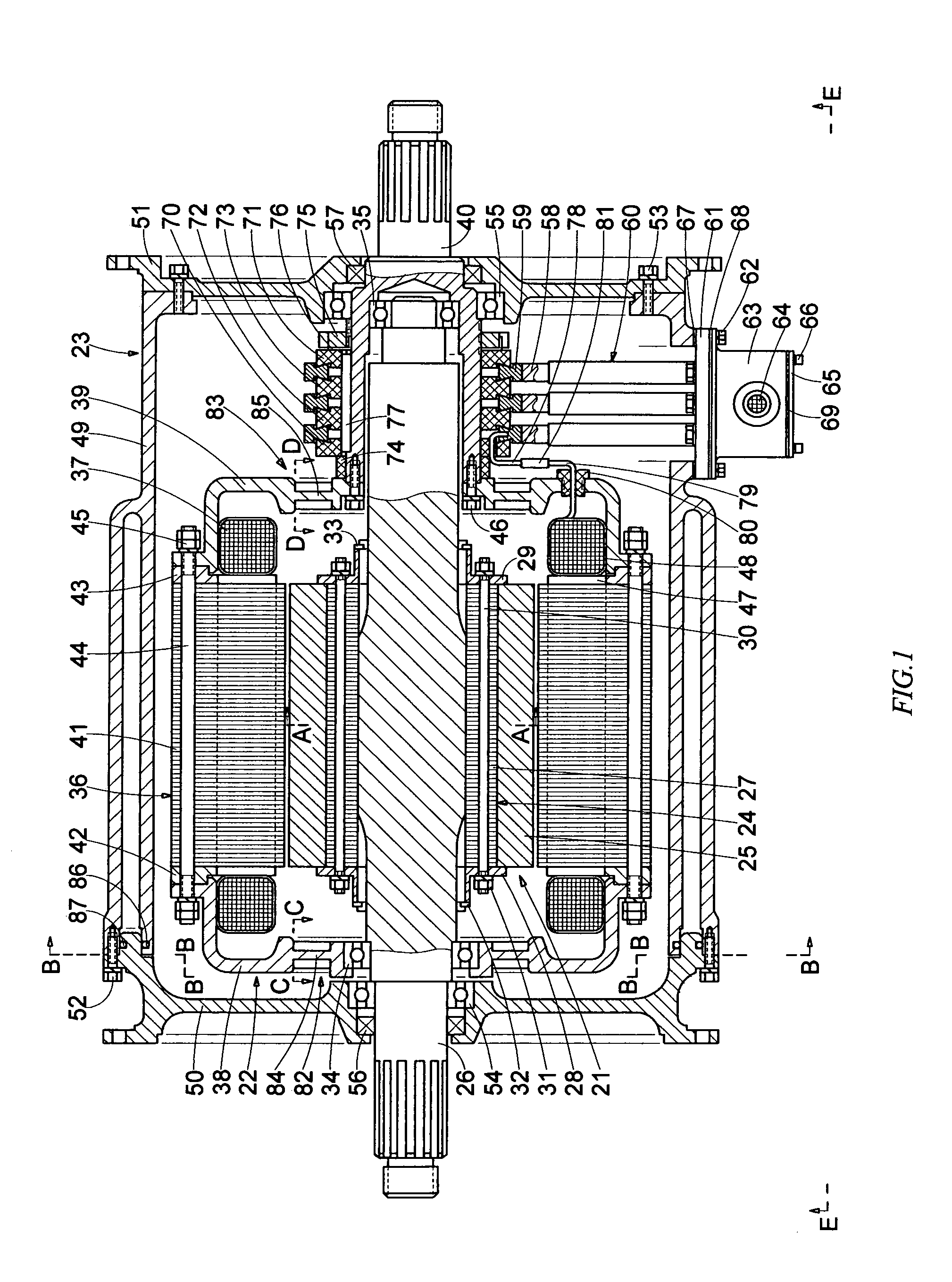

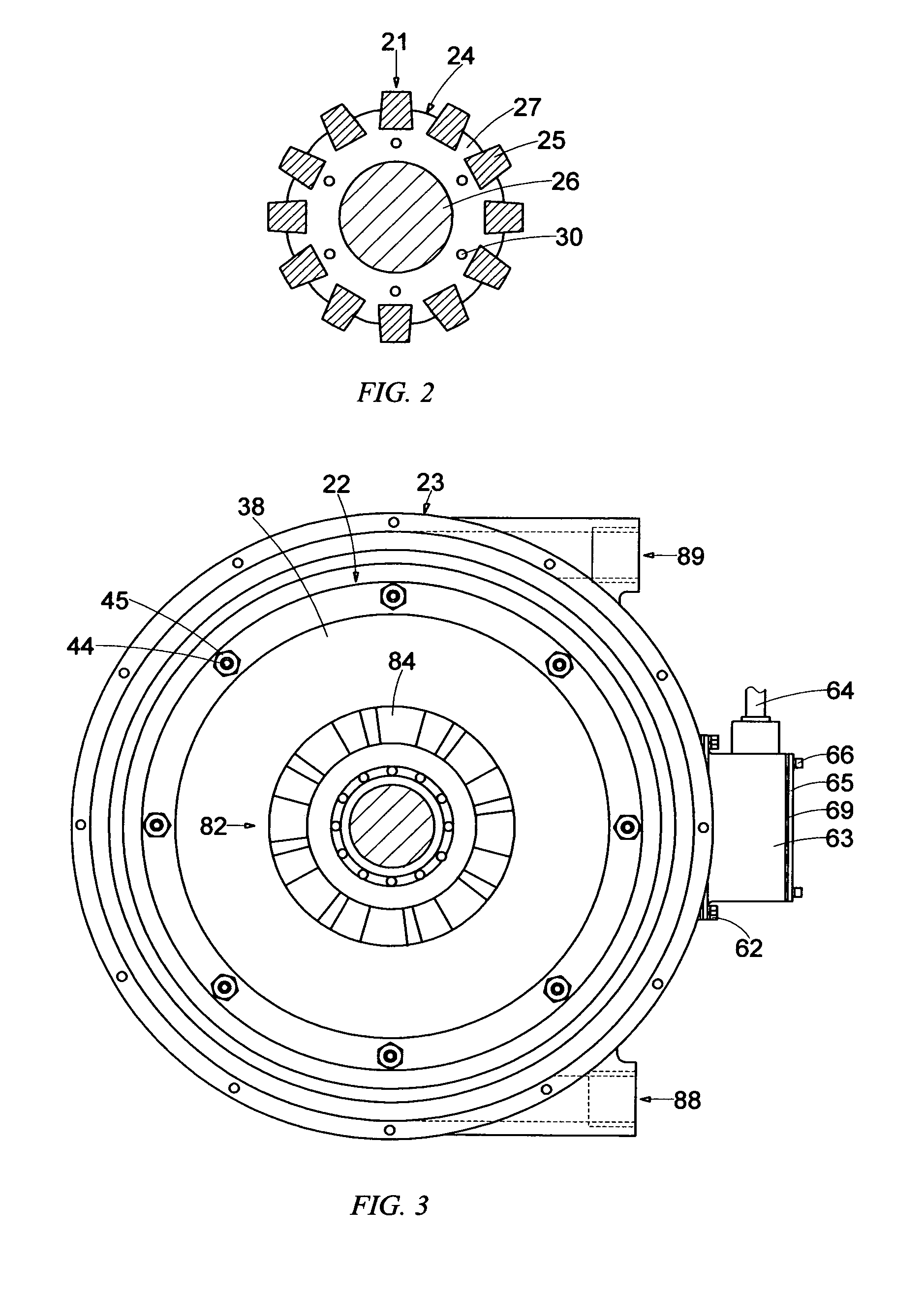

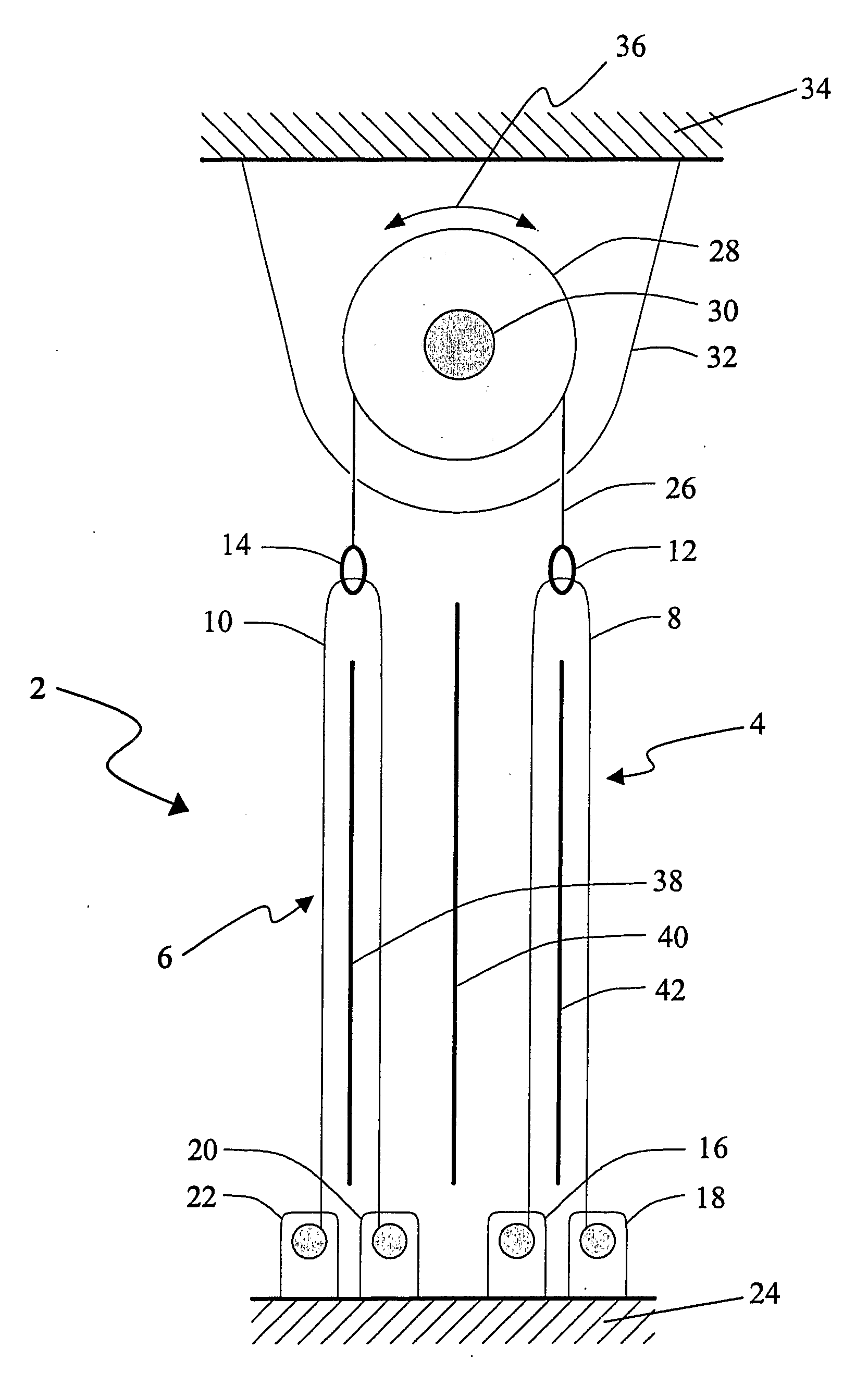

Dual-rotor electric traction motor

InactiveUS7466053B1Simple , reliable and easily accessibleSimple and reliable and easily accessibleMagnetic circuit rotating partsDC commutatorTraction motorMagnet

An inner rotor (21) is arranged as a motor field, including permanent magnets (25) embedded in an inner rotor core (24) and an inner rotor shaft (26) coupled with the inner rotor core. An outer rotor (22) is arranged as a motor armature, including a hollow armature core (36), plurality of windings (37), two side flanges (38, 39), and an outer rotor shaft (40) coupled with one of the side flanges. The inner rotor is rotatably supported inside the outer rotor, and both rotors are rotatably supported inside a stationary motor enclosure (23). Electric current is conducted to the windings of the armature via brushes (58) and sliprings (59). The interaction between a revolving electromagnetic field of the outer rotor and the permanent magnetic field of the inner rotor propels both rotors to rotate in opposite directions. Two axial fans (82, 83) integrated with the outer rotor side flanges and two axial fans (95, 96) coupled with the inner rotor shaft work in series and produce continuous internal close-loop air circulation between both rotors and between the outer rotor and the motor enclosure, for improving the rate of heat transmission from the rotors to the motor enclosure. If the outer rotor is selectively immobilized, the two inner rotor axial fans produce the internal close-loop air circulation.

Owner:RADEV VLADIMIR

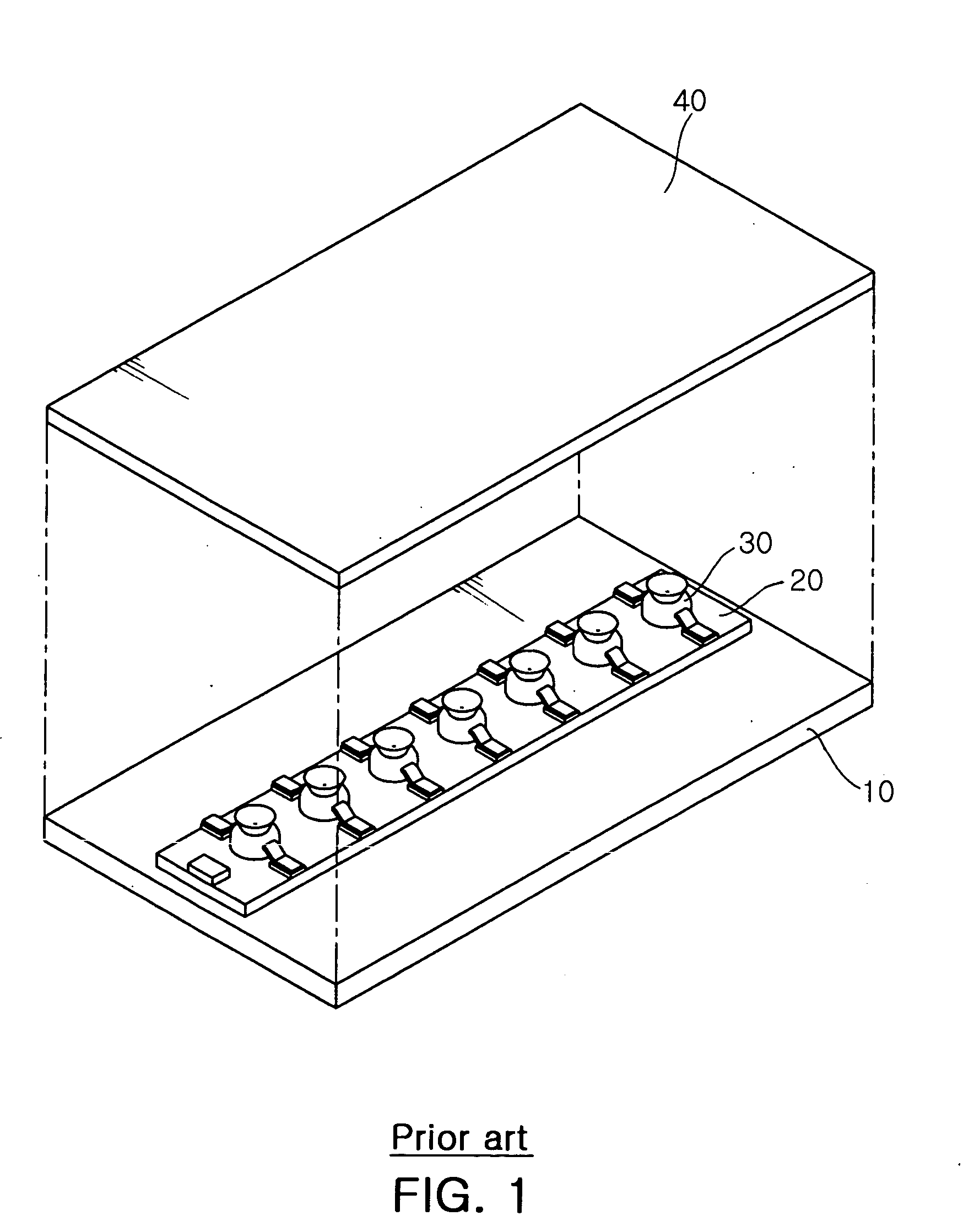

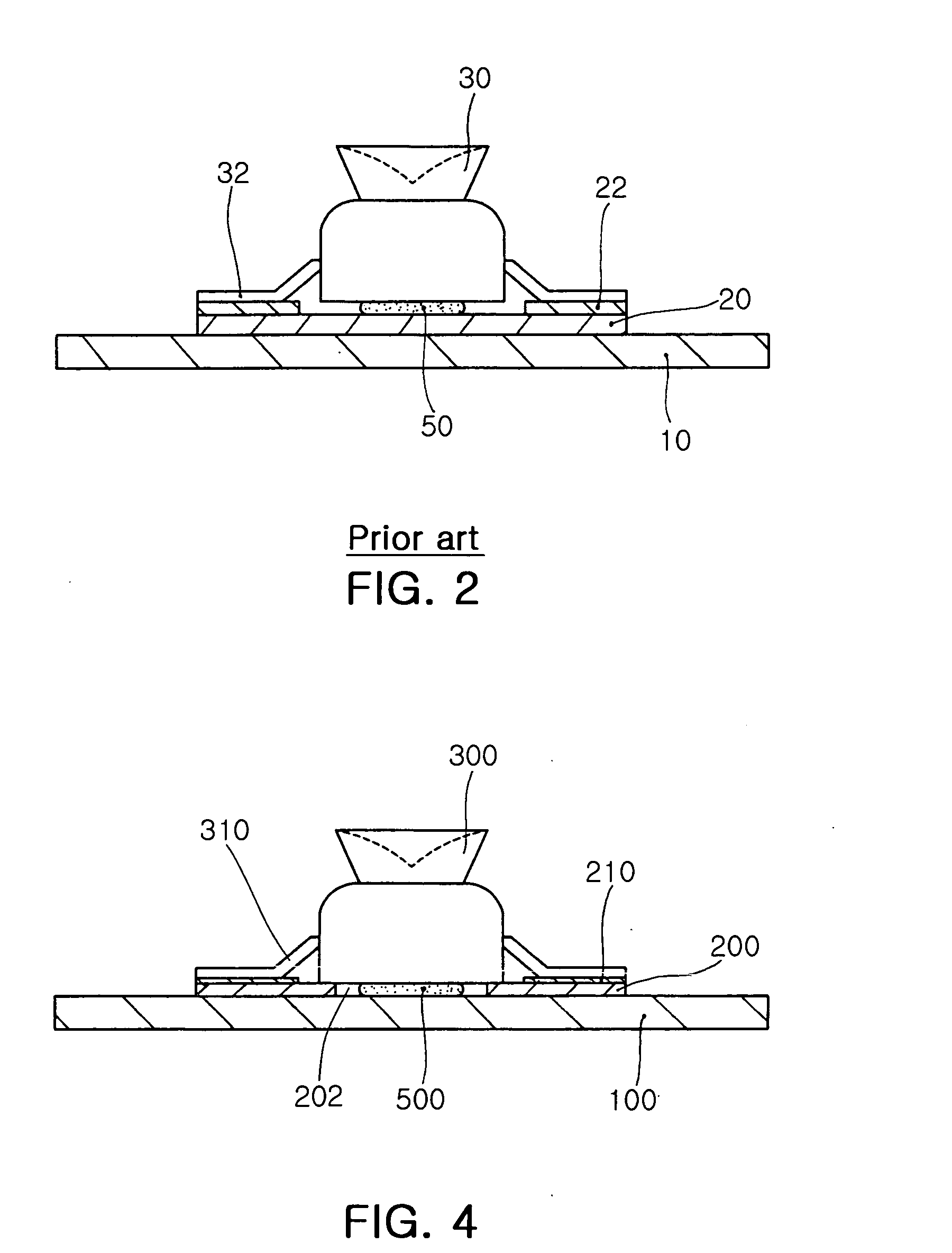

Slim type backlight unit

InactiveUS20070139929A1Less thickness and weightLight weightPoint-like light sourceLighting support devicesHeat conductingEngineering

A backlight unit of the invention is reduced in thickness, weight and manufacturing costs but improved in heat releasing efficiency. In the backlight unit, a flexible printed circuit board has at least one through hole perforated therein. An LED package is disposed on a top portion of the flexible printed circuit board corresponding to the through hole. The backlight unit of the invention employs the flexible printed circuit board in place of a metal printed circuit board as a means to conduct current to the LED package. This produces a slimmer and lighter backlight unit and also saves manufacturing costs. In addition, the LED package is directly bonded onto a bottom plate by a heat conducting adhesive, thereby ensuring heat generated from the LED package to be released more quickly.

Owner:SAMSUNG ELECTRONICS CO LTD

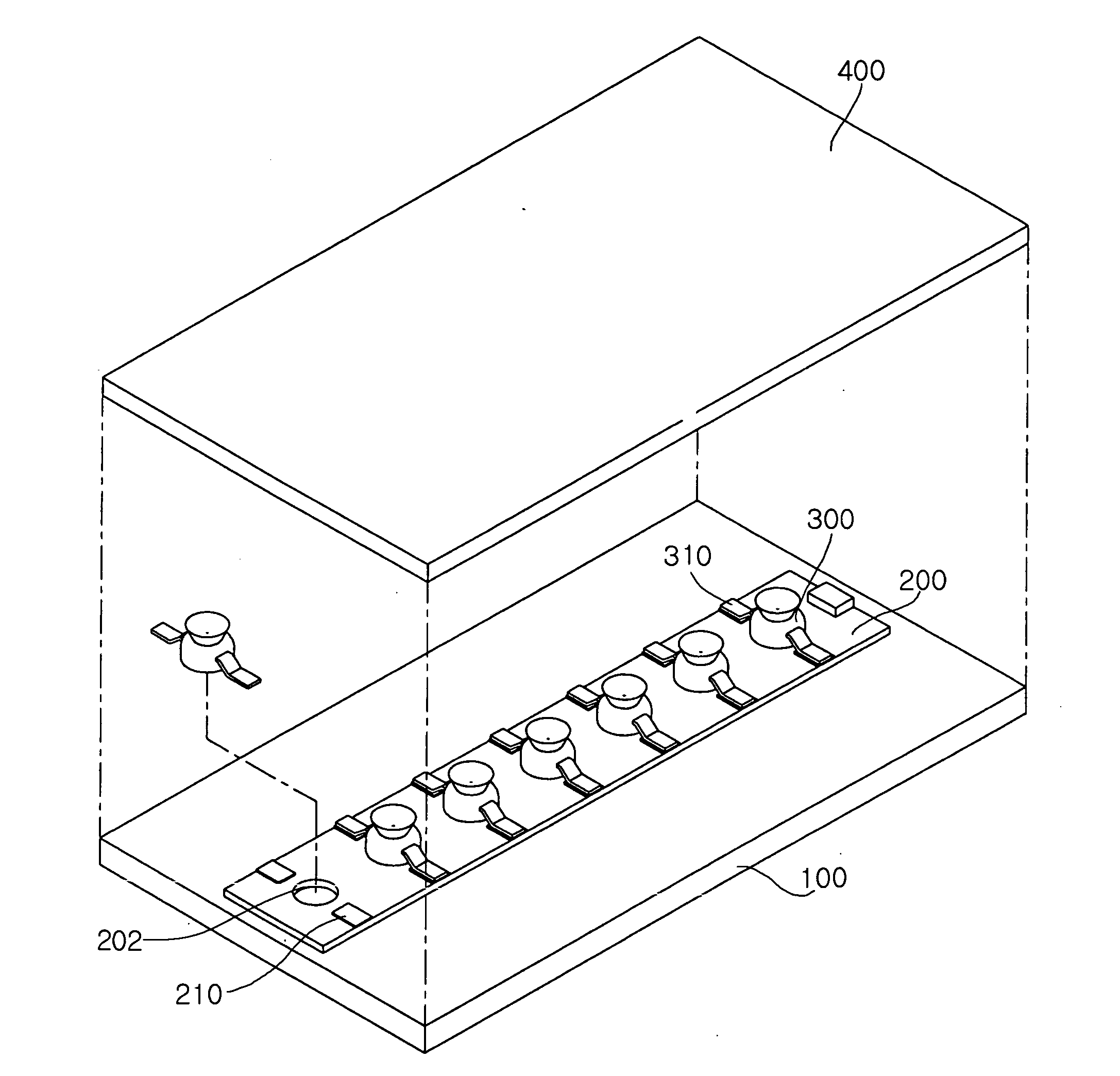

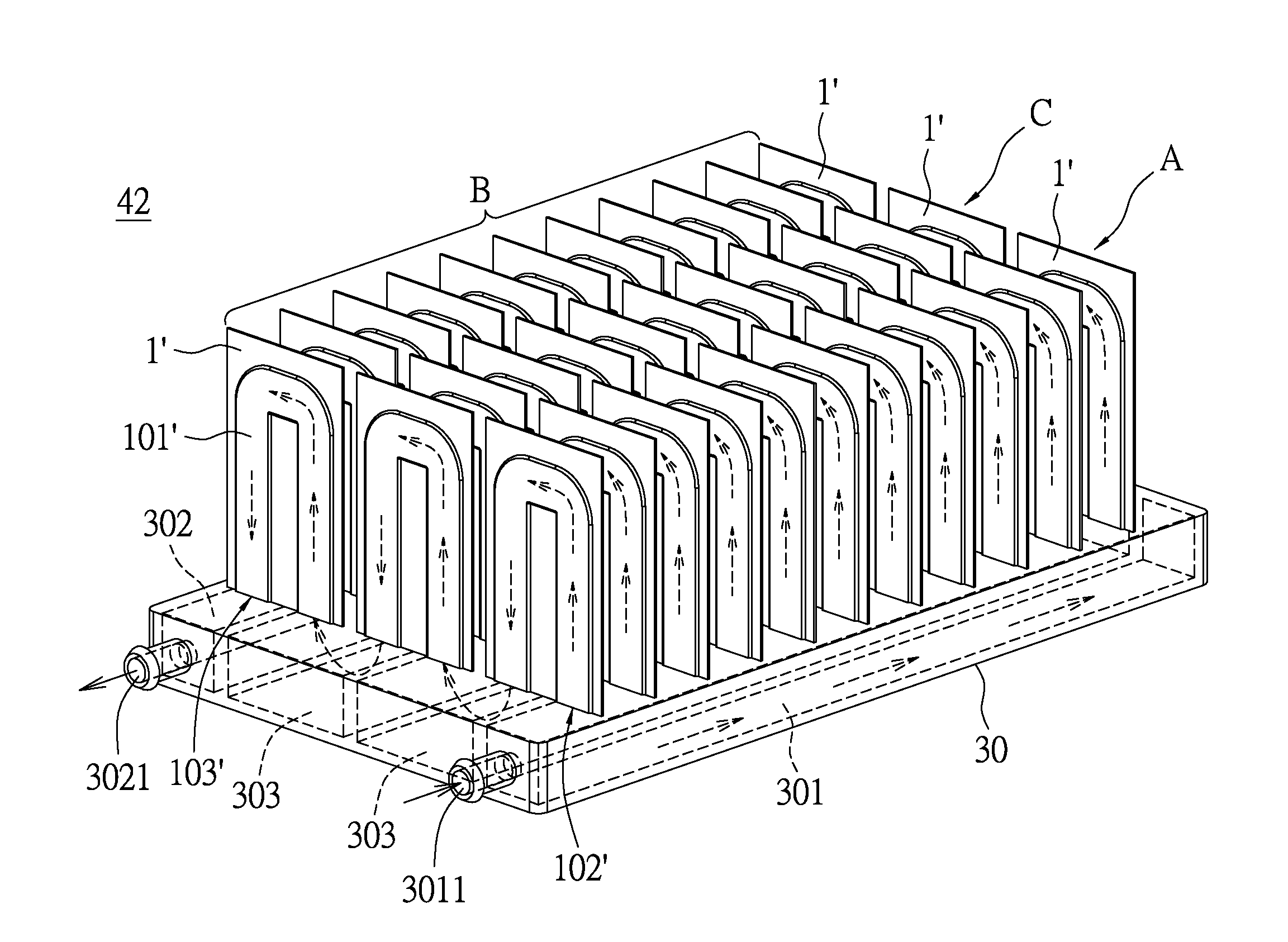

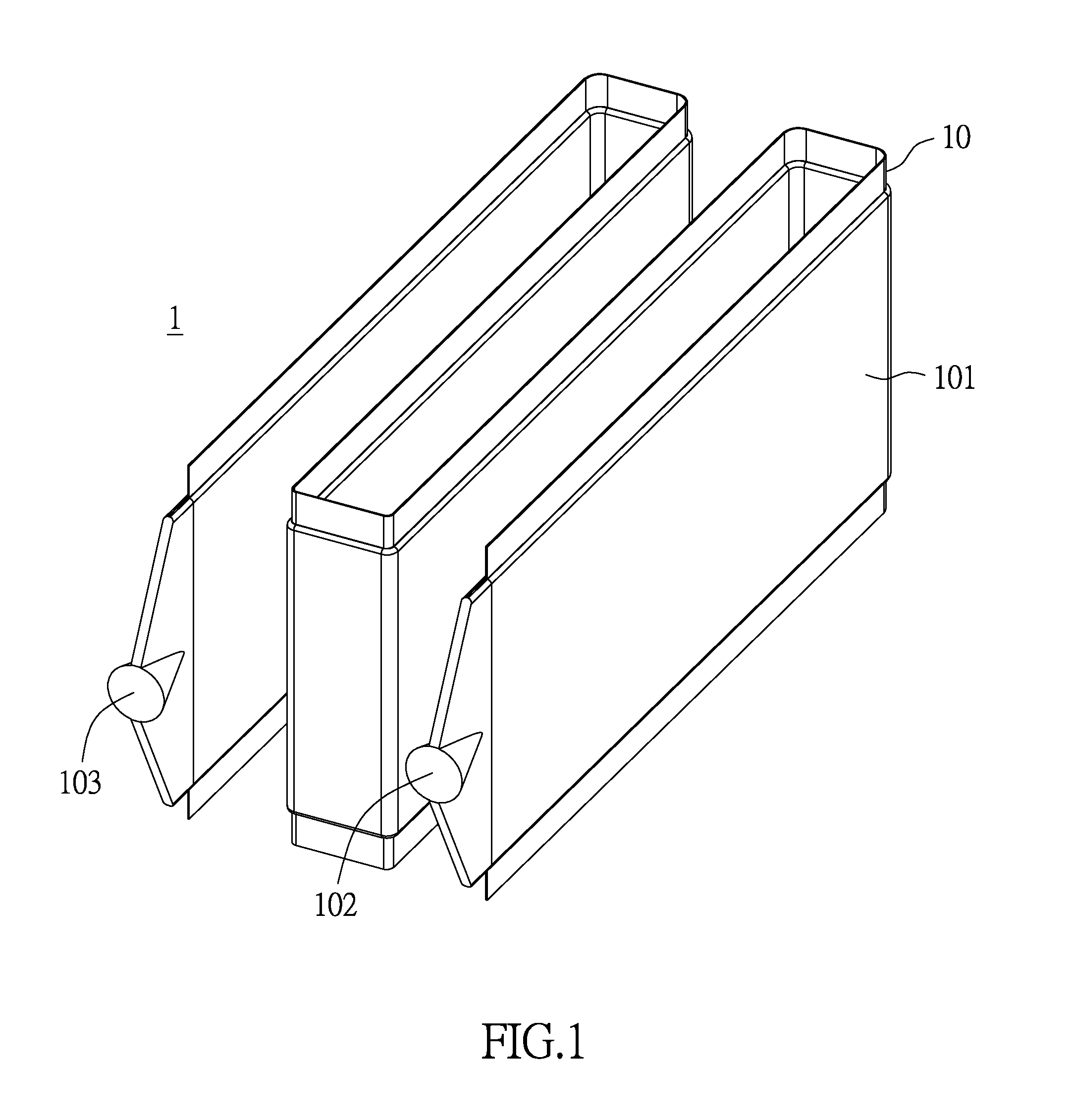

Battery module and heat dissipating unit thereof

InactiveUS20150200429A1Poor rate of heat dissipationPoor rate of heatSafety devices for heat exchange apparatusCell temperature controlBiomedical engineeringCoolant flow

A battery module comprises a base, a set of battery cells and a plurality of heat dissipating units. The base comprises an input opening, an output opening and a plurality of fluid channels. A set of battery cells is disposed on the base and comprises a plurality of battery cells. A channel is formed between neighboring battery cells and the heat dissipating units are respectively disposed in the channels. Each heat dissipating unit has a main body having an expandable fluid channel, a fluid inlet and a fluid outlet. Each expandable fluid channel is communicated with the respective fluid inlet and the respective fluid outlet, and the expandable fluid channels are communicated with the fluid channels of the base. When a coolant flows into the expandable fluid channel, at least one side wall expands with the pressure of the coolant and contacts the surface of the battery cell.

Owner:SIMPLO TECH COMPANY

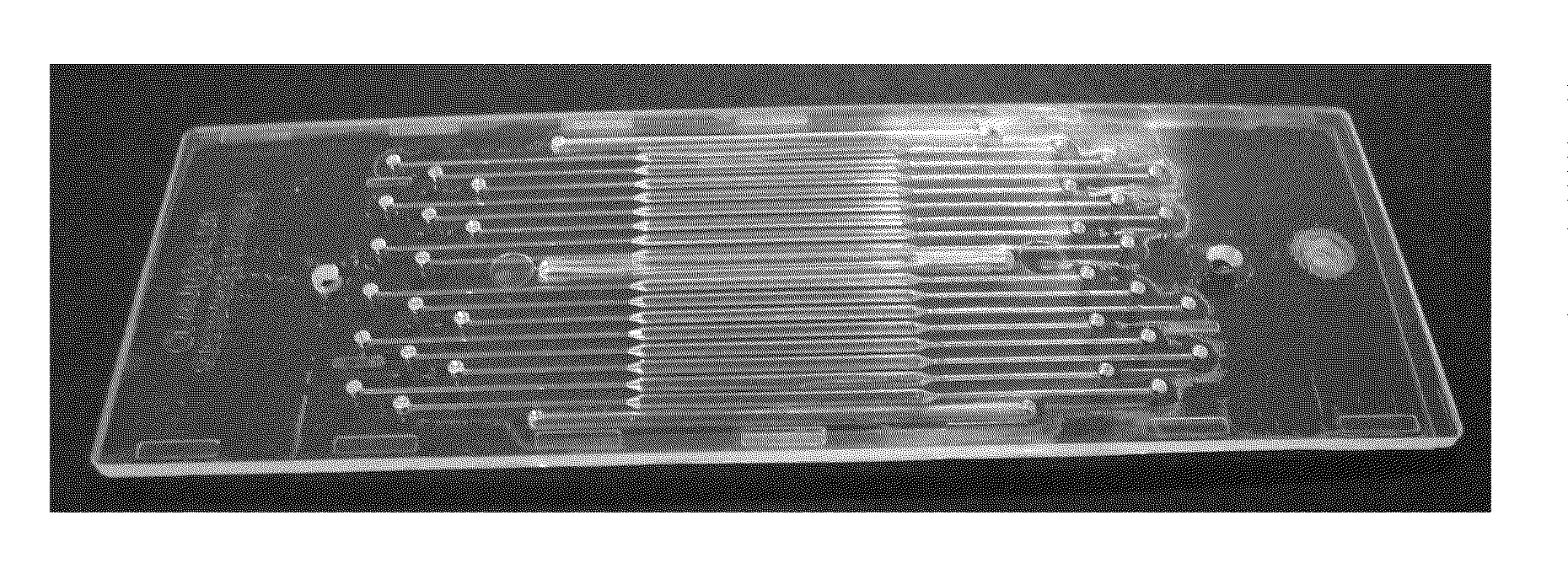

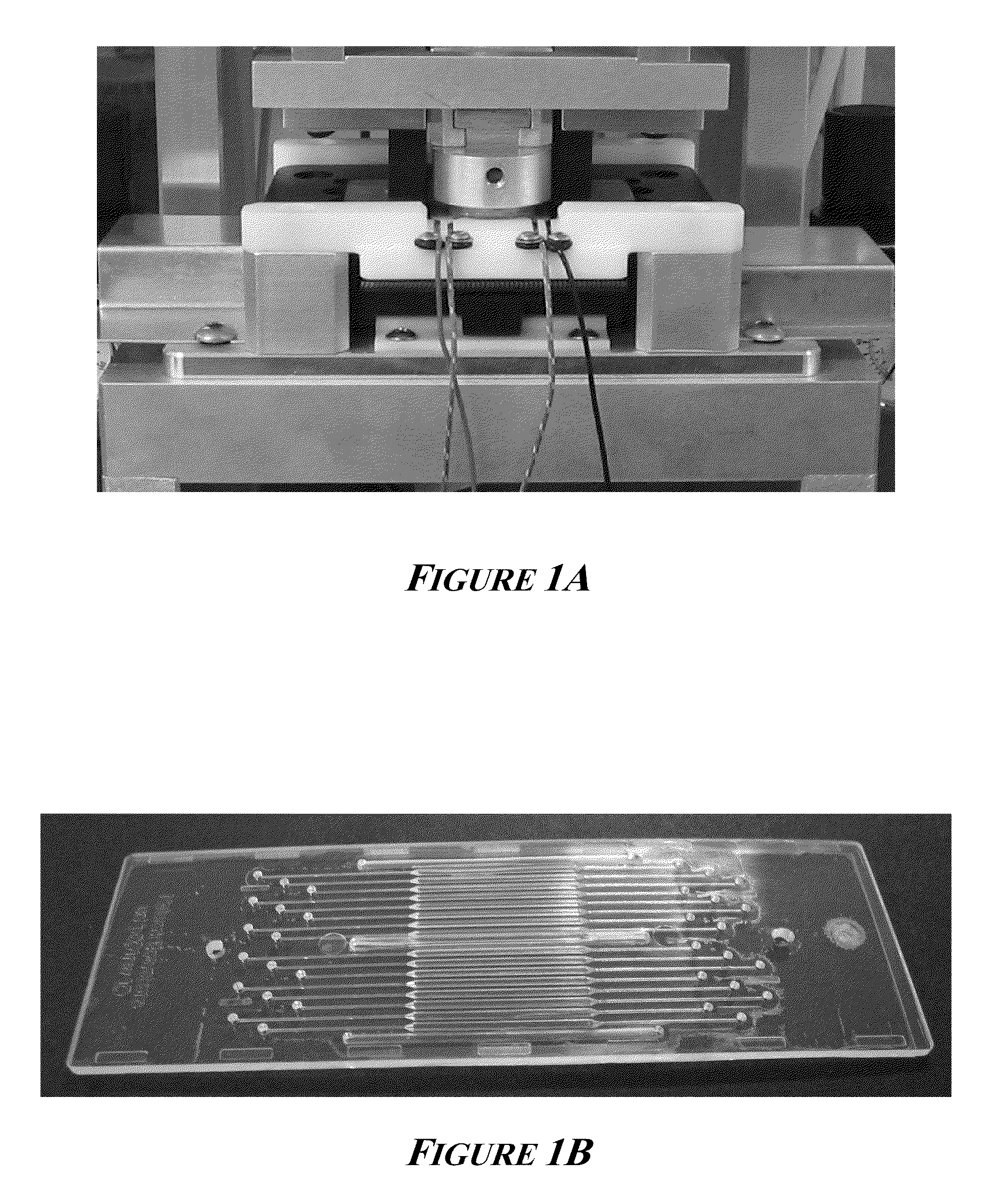

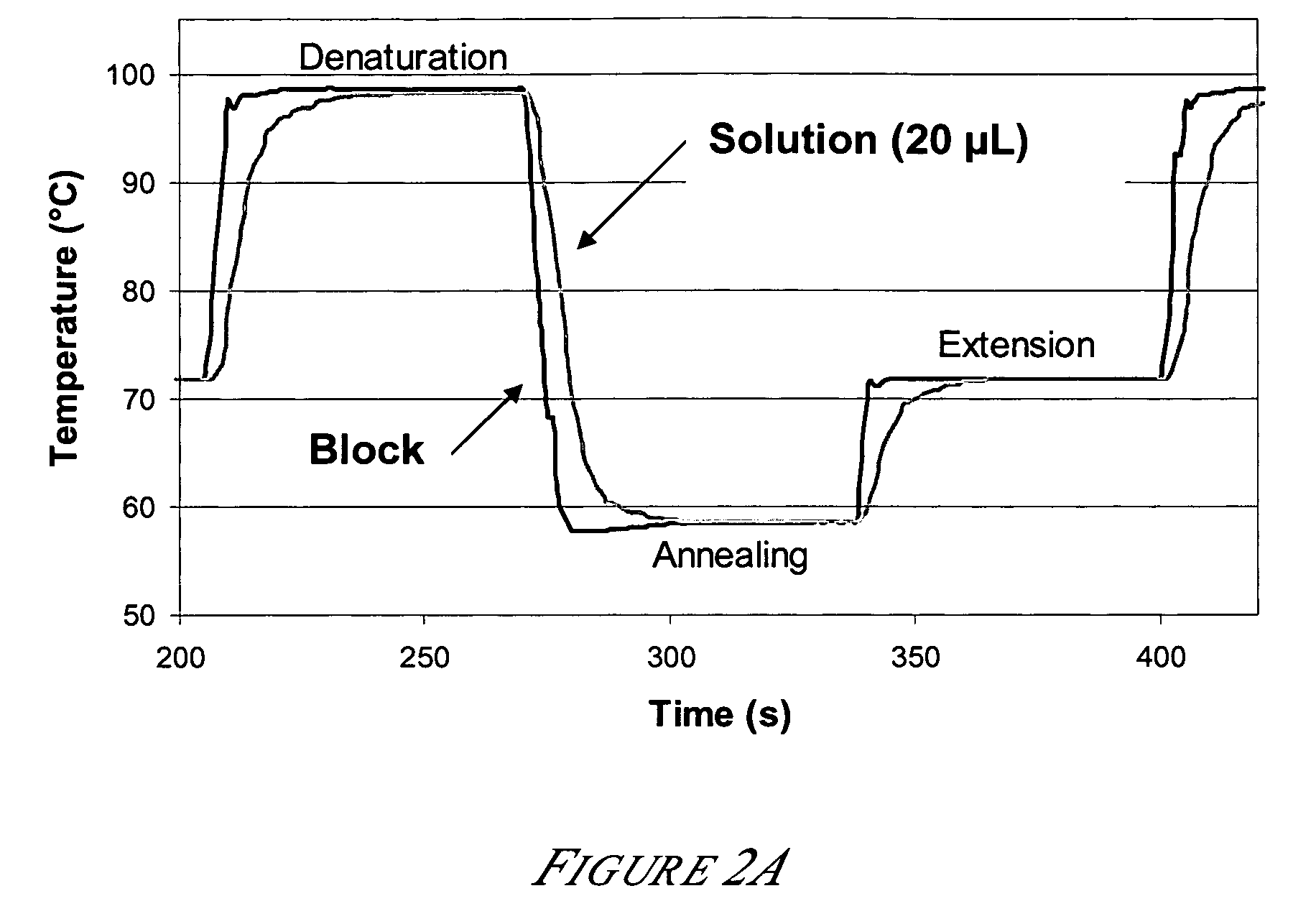

Methods for rapid multiplexed amplification of target nucleic acids

ActiveUS20090023603A1Monitor and accurately controlHigh speedBioreactor/fermenter combinationsHeating or cooling apparatusPrimary stutteringGuideline

A fast, multiplexed PCR system is described that can rapidly generate amplified nucleic acid products, for example, a full STR profile, from a target nucleic acid. Such systems include, for example, microfluidic biochips and a custom built thermal cycler, which are also described. The resulting STR profiles can satisfy forensic guidelines for signal strength, inter-loci peak height balance, heterozygous peak height ratio, incomplete non-template nucleotide addition, and stutter.

Owner:ANDE CORP

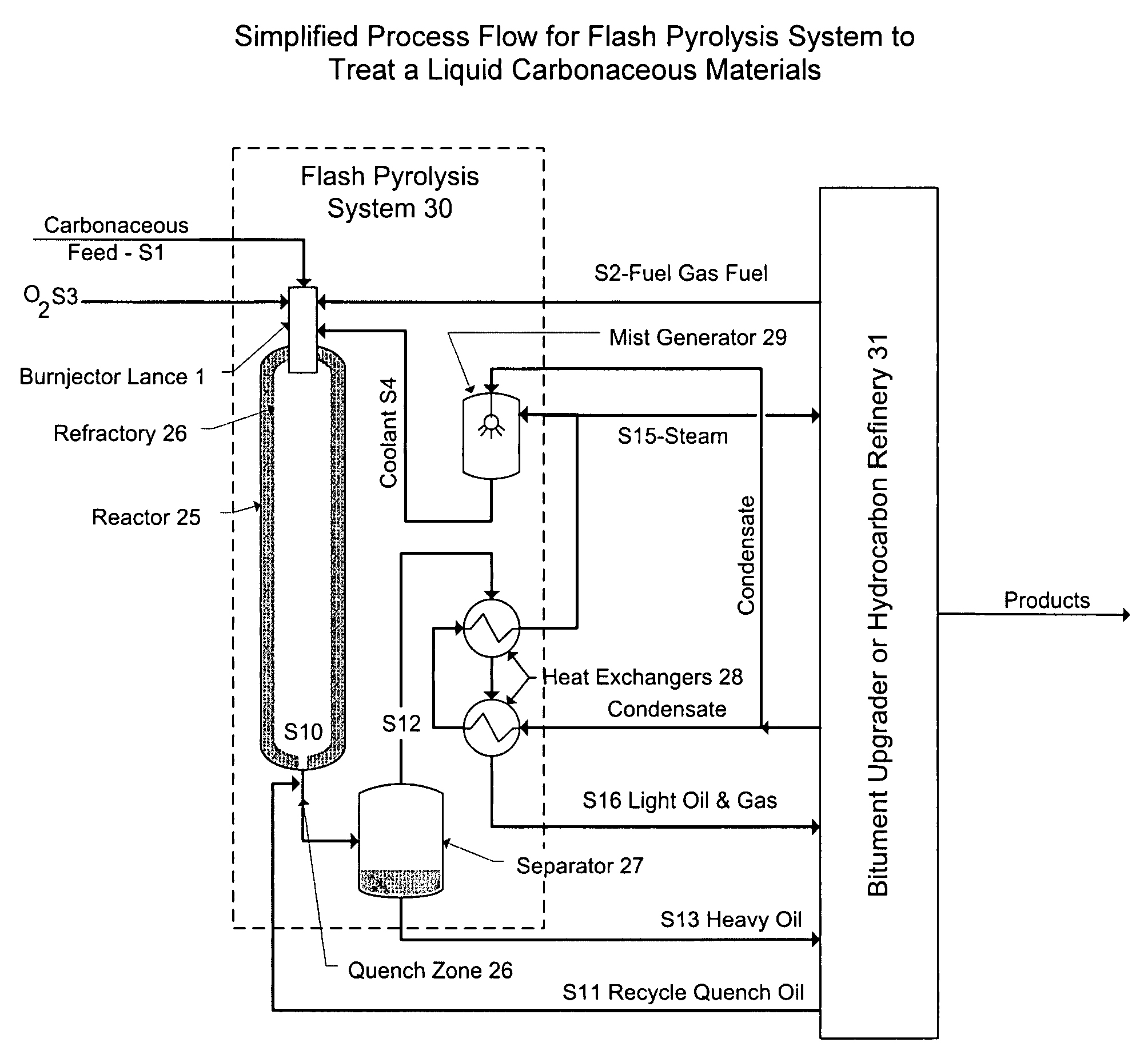

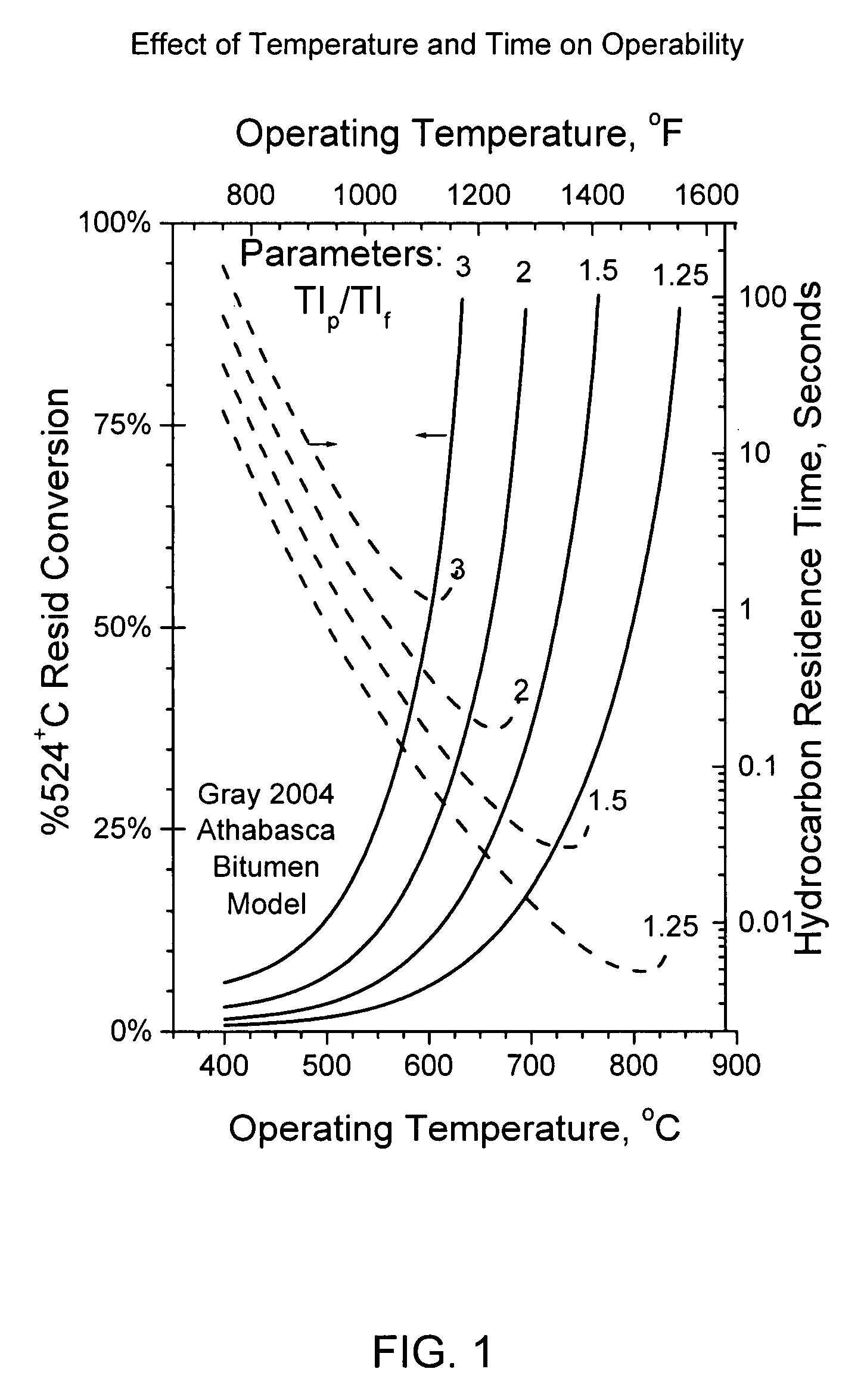

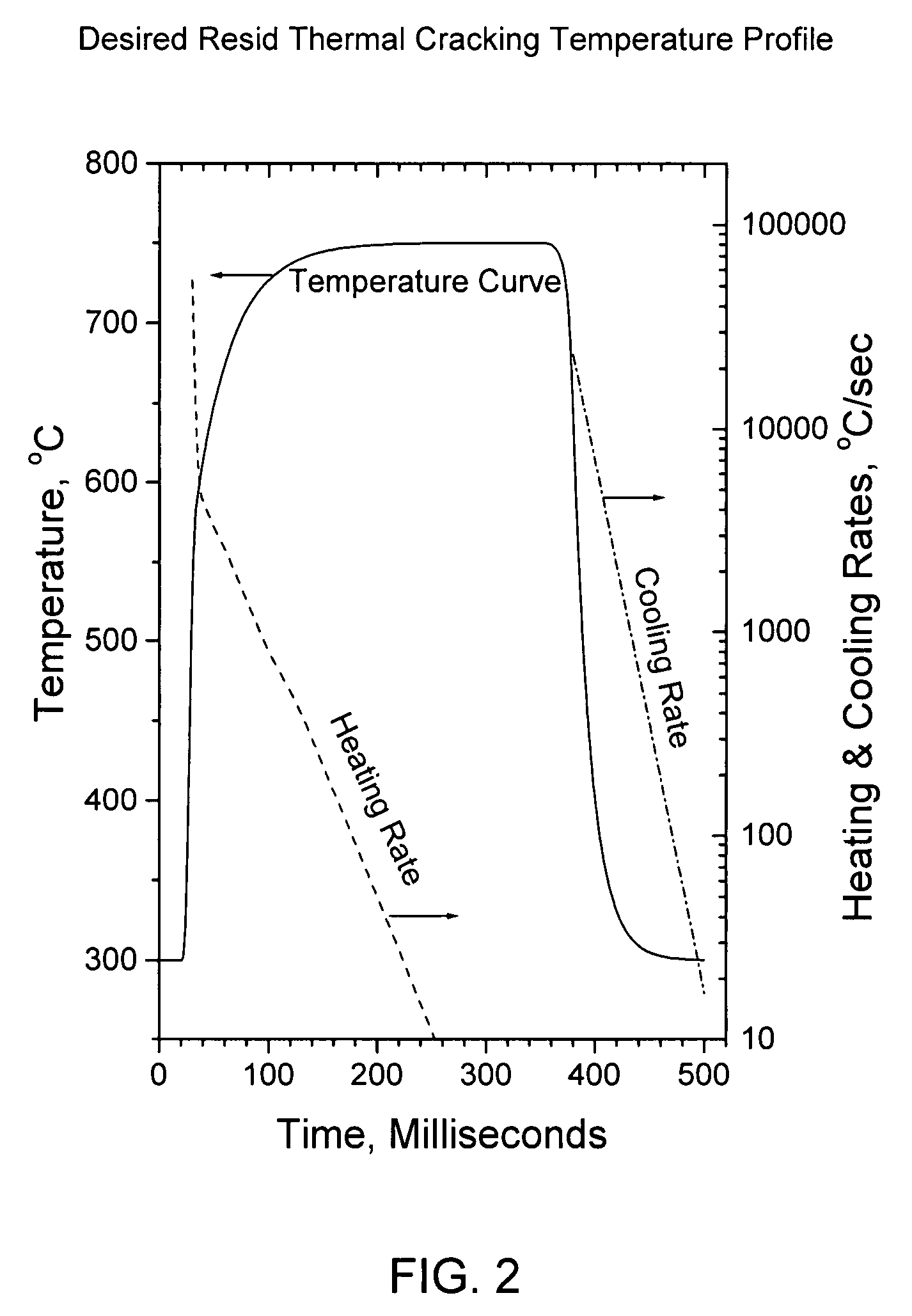

Flash pyrolosis method for carbonaceous materials

InactiveUS20070272538A1Efficient transferFast heatingThermal non-catalytic crackingDirect heating destructive distillationSufficient timeBoiling point

Methods are disclosed for pyrolizing carbonaceous materials to carbonaceous materials having lower boiling points by heating the carbonaceous material to a desired reaction temperature and holding the carbonaceous material in contact with the heat for a sufficient time to achieve the desired reaction to a lower boiling point carbonaceous materials, then rapidly cooling the desired reaction products. The heating source is a jet which will provide hot and high velocity gas streams to the carbonaceous material to be heated.

Owner:BOC GRP INC

Techniques for Controlling Vapor Pressure in an Immersion Cooling Tank

ActiveUS20150060009A1Eliminate increase in pressureMaximize the effectAir-treating devicesTemperatue controlDifferential pressureTransducer

A method that controls pressure within an immersion cooling tank having condensation fluid flowing through a condenser, includes: a controller receiving a signal that indicates a current level of vapor pressure within the tank; determining from the signal when the current level of vapor pressure exceeds or is below a first preset threshold pressure level; and in response to the current level of vapor pressure exceeding or being below the first preset threshold pressure level, signaling a flow control mechanism that modulates a flow rate of the condensation fluid through the condenser to increase or decrease the rate of flow from a current rate of flow. The controller receives the signal by a pressure sensor within the immersion cooling tank detecting the current vapor pressure, generating the signal and forwarding the signal to the controller. The pressure sensor can be a differential pressure transducer that measures a differential pressure internal to and outside of the immersion tank.

Owner:DELL PROD LP

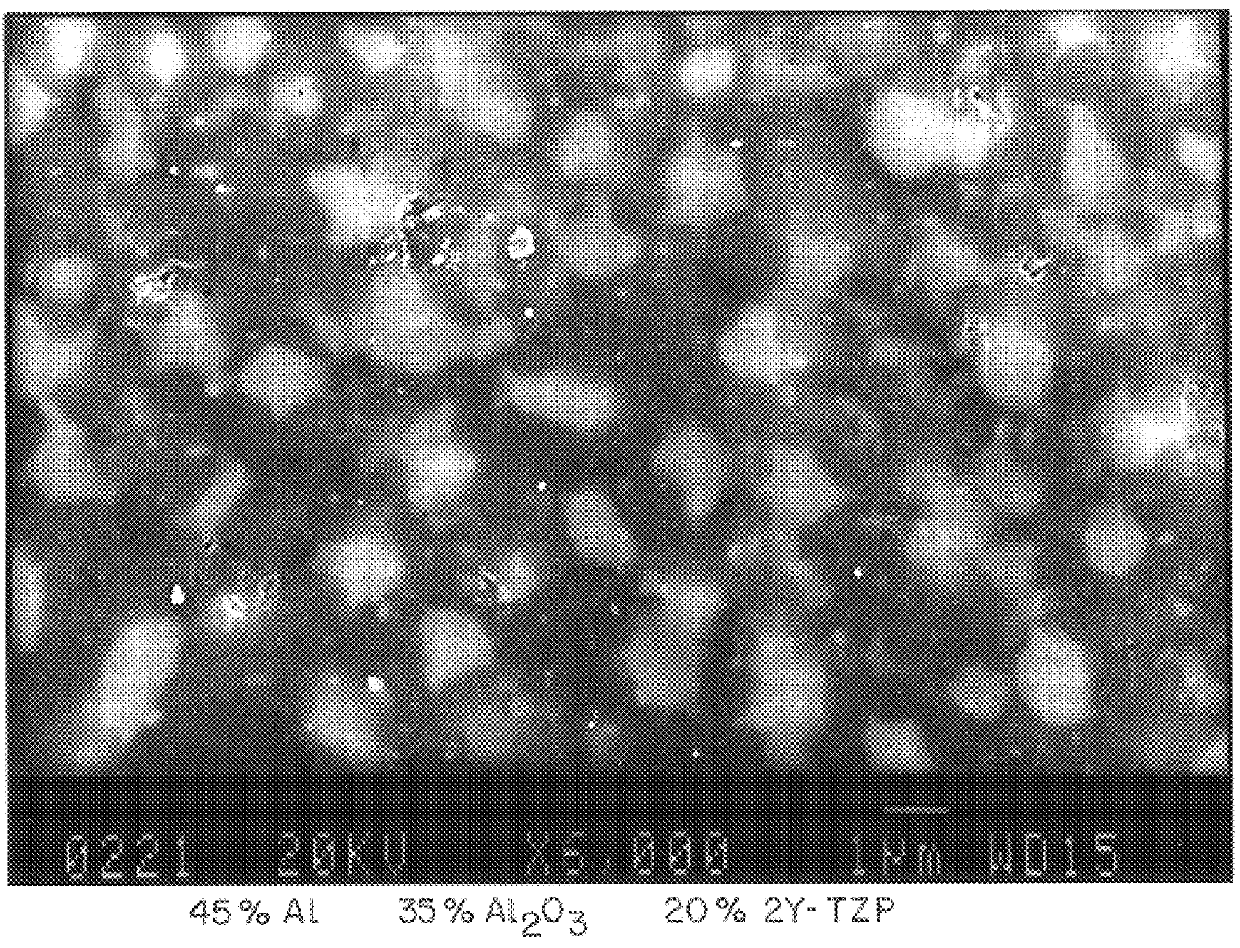

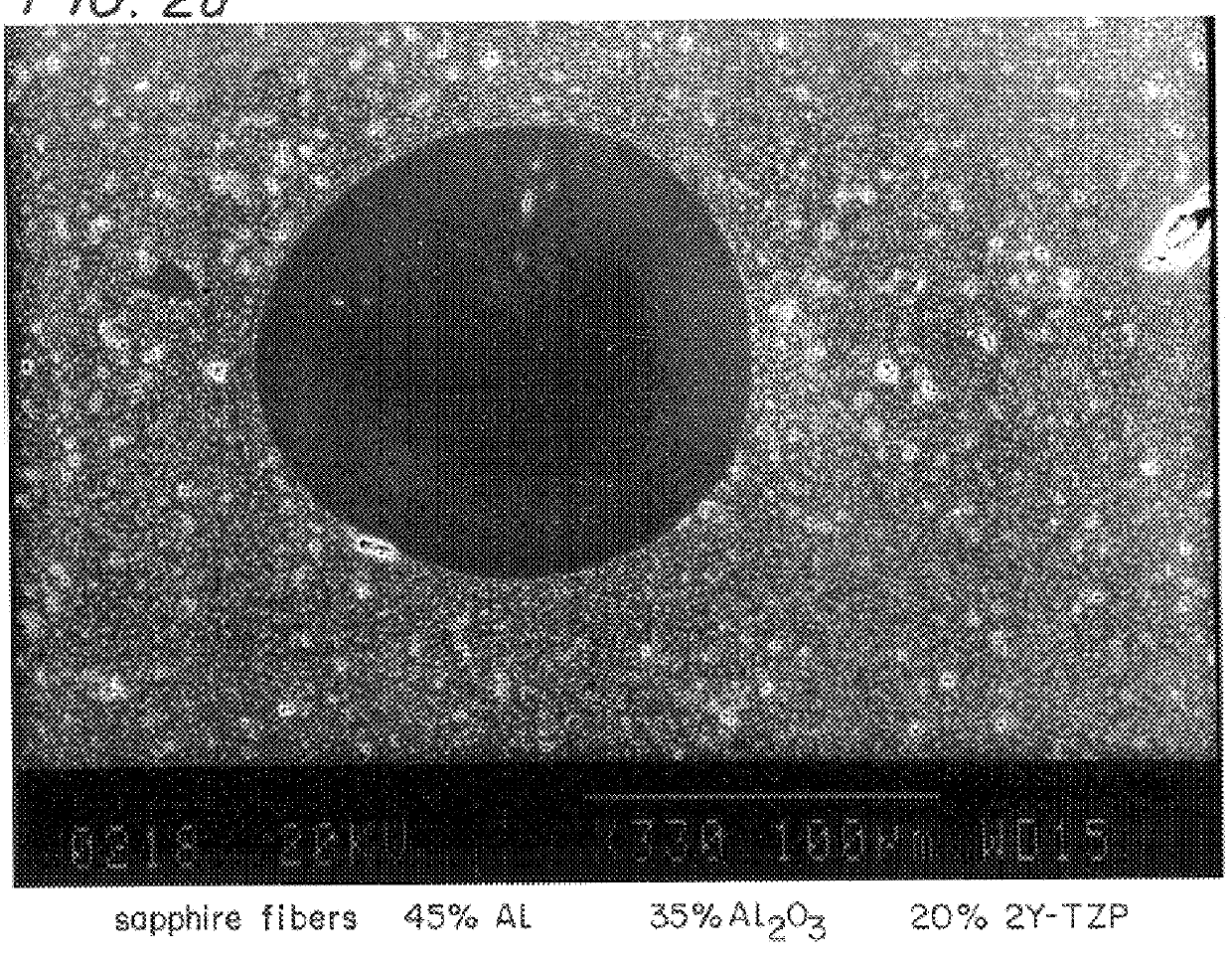

Production of an aluminide containing ceramic moulding

InactiveUS6025065AFast heatingLow heating rateSynthetic resin layered productsCeramic layered productsOxide ceramicMetal powder

PCT No. PCT / EP95 / 03347 Sec. 371 Date Nov. 19, 1997 Sec. 102(e) Date Nov. 19, 1997 PCT Filed Aug. 23, 1995 PCT Pub. No. WO96 / 20902 PCT Pub. Date Jul. 11, 1996A ceramic formed body containing a) 5 to 70 vol % of at least on intermetallic aluminide phase which additionally may contain aluminum or / and aluminum alloy, and b) 30 to 95 vol % of one or more ceramic phases which form a solid interconnecting skeleton and wherein the intermetallic phase or phases consist of predominantly interconnected areas with average sizes of 0.1 to 10 mu m, is obtained by sintering, in a non-oxidizing atmosphere, of a powder metallurgically green body which consists of a mixture of finely dispersed powder of aluminum, one or more ceramic substances and maybe further metals such that the mixture contains at least one oxide ceramic or / and metallic powder which, during sintering, reacts with aluminum thereby forming an aluminide and maybe Al2O3.

Owner:CLAUSSEN NILS

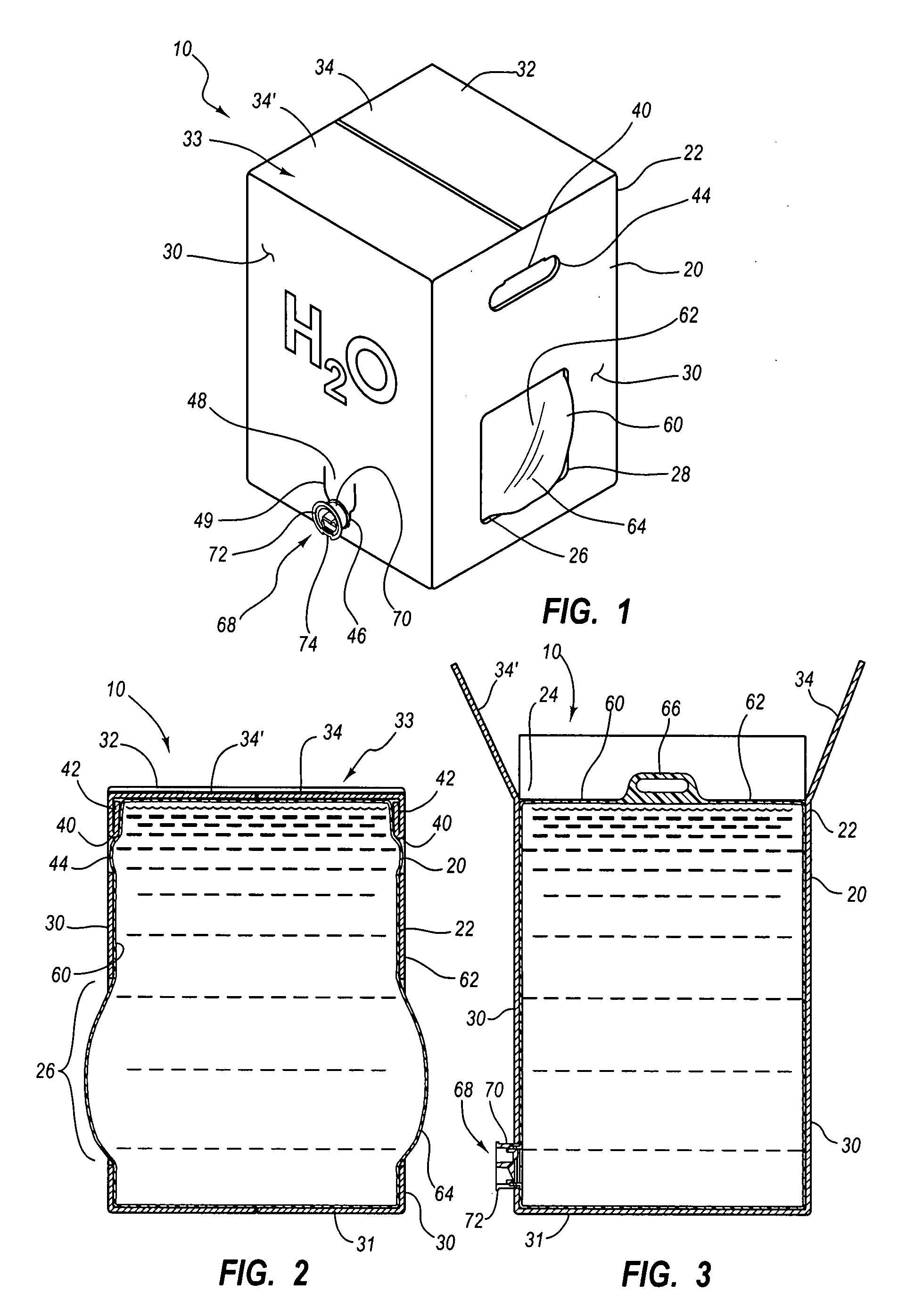

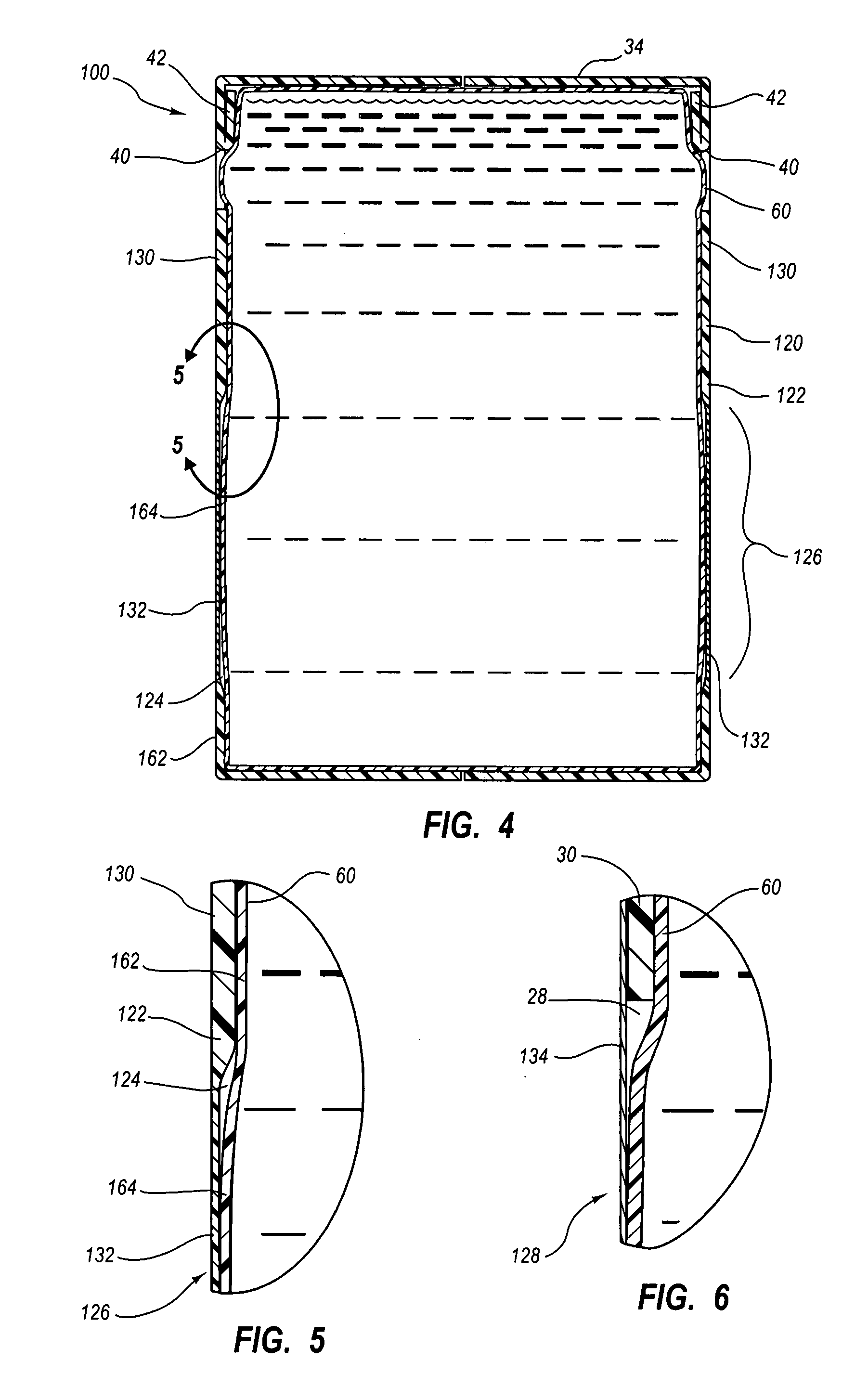

Temperature controlled liquid dispenser, containers therefore, and bag-in-box container construction

InactiveUS20080277417A1Improve thermal conductivityThermal energy is effectively and efficiently transferredDomestic cooling apparatusLiquid flow controllersTemperature controlThermal energy

A dispenser for relative rapid cooling or heating of the contents of a liquid storage container provides a receptacle for receiving the liquid storage container therein and positioning a thermal transfer portion of the liquid storage container in thermal conductive relationship with a thermal conduction pad associated with the receptacle. Thermal energy is effectively and efficiently transferred from the thermal conduction pad to the liquid in the liquid storage container. The thermal conduction pad is controlled to provide and maintain the desired temperature to the liquid. The liquid is dispensed directly from the container. Various types of containers can be used in the dispenser, with a special bag-in-box container having a inner container and outer box with thermal conduction windows in the box to provide good heat transfer between the thermal conduction pads and the inner container constituting an aspect of the invention. A special rigid container can also be used.

Owner:GROESBECK R CLAY

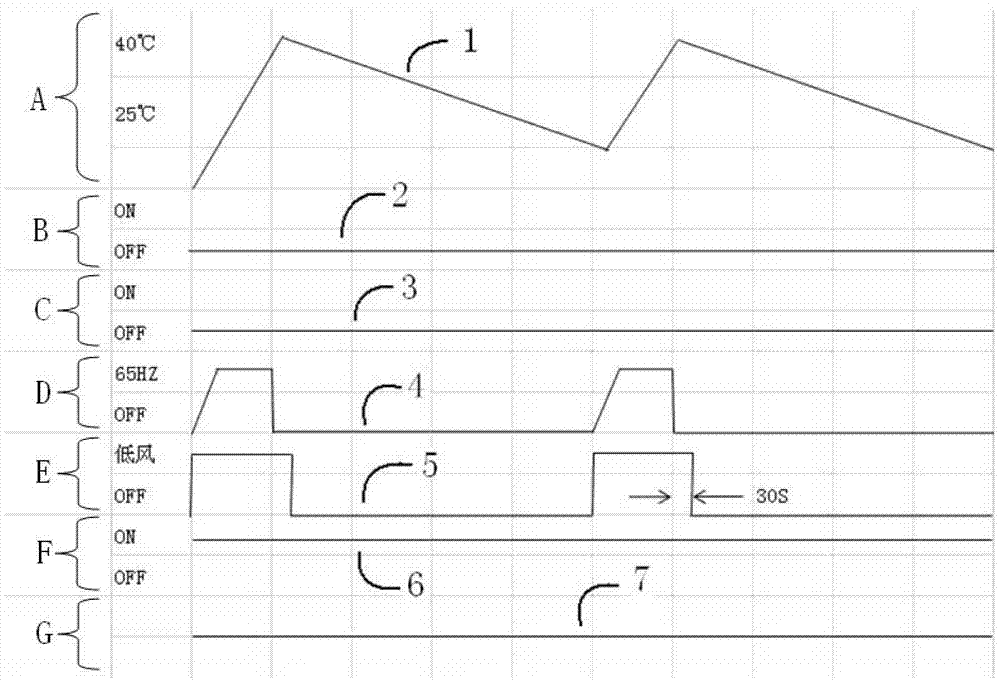

Control method and device for improving heating speed of air conditioner

ActiveCN102734898AFast heatingSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringOutdoor temperature

The invention provides a control method and device for improving heating speed of an air conditioner. The method comprises the following steps of: collecting the temperature of an indoor coil pipe when the air conditioner is at a standby state and an outdoor air temperature is less than or equal to a first outdoor temperature and an indoor temperature is less than or equal to the first indoor temperature; preheating the indoor coil pipe when the indoor coil pipe temperature is less than the first set temperature: starting up a compressor for preheating the indoor coil pipe, and stopping the compressor until the indoor coil pipe temperature is greater than or equal to a first set temperature, and delaying to stop an outdoor fan; and preheating the indoor coil pipe repeatedly when the indoor coil pipe temperature is less than a second set temperature. The control device comprises a starting module, a determination module and a preheating module, wherein the determination module is used for comparing the indoor coil pipe temperature and the preset temperature; and the preheating module controls the starting and stopping of the compressor according to the determined result so as to preheat the indoor coil pipe repeatedly. According to the invention, the heating speed of the air conditioner can be improved, and the effect that heating can be carried out once the air conditioner is started up is realized.

Owner:QINGDAO HAIER JIAOZHOU AIR CONDITIONER

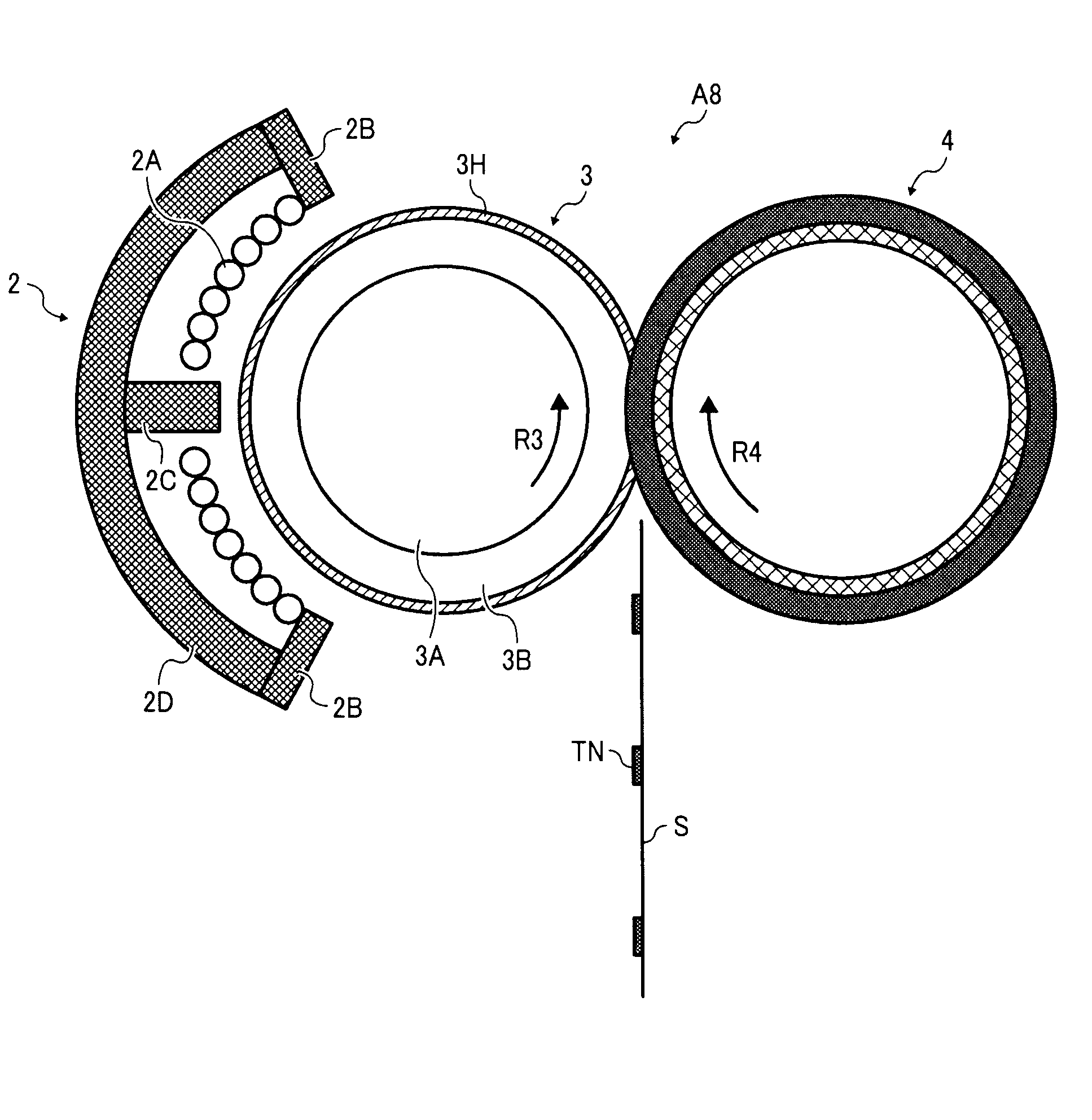

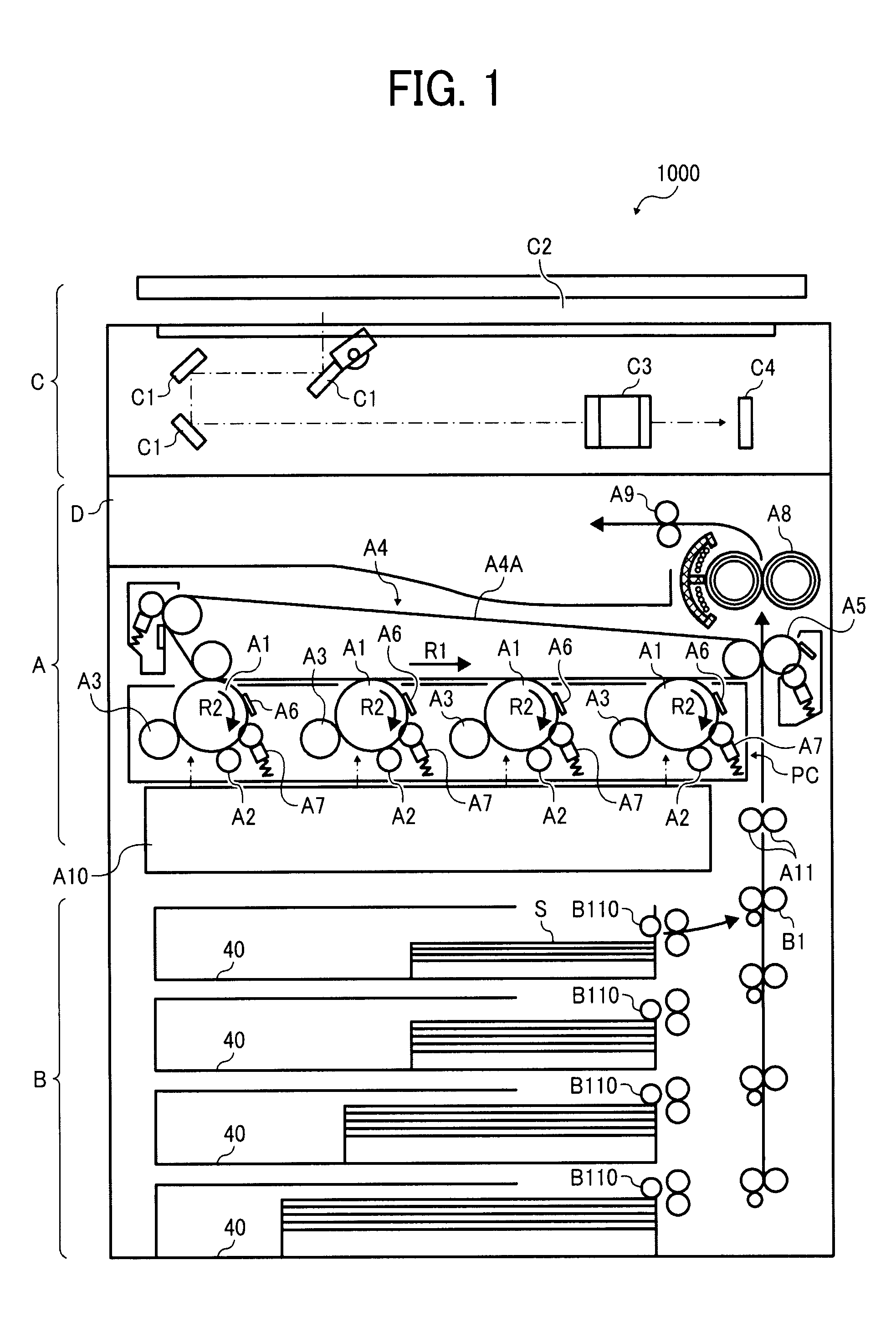

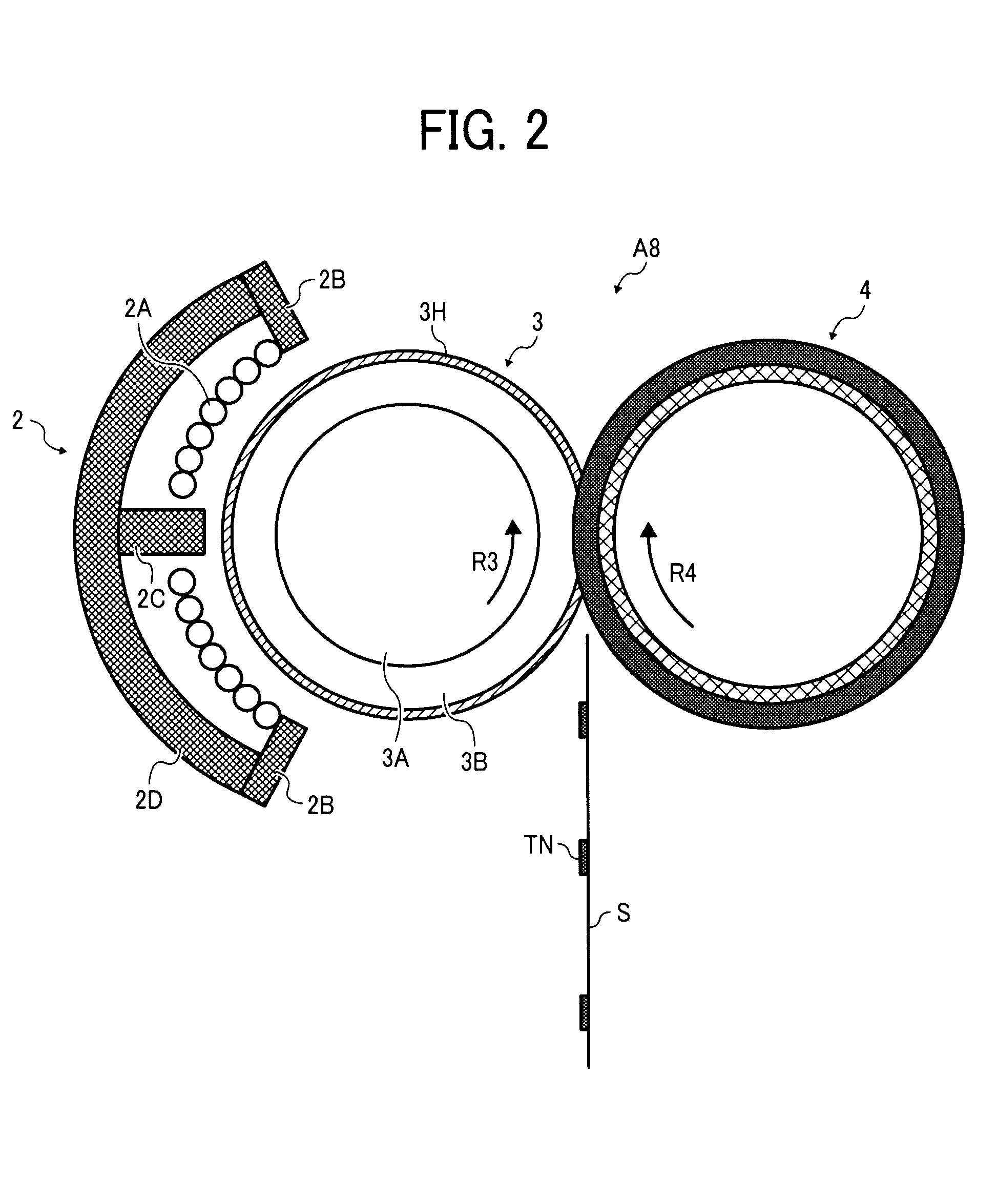

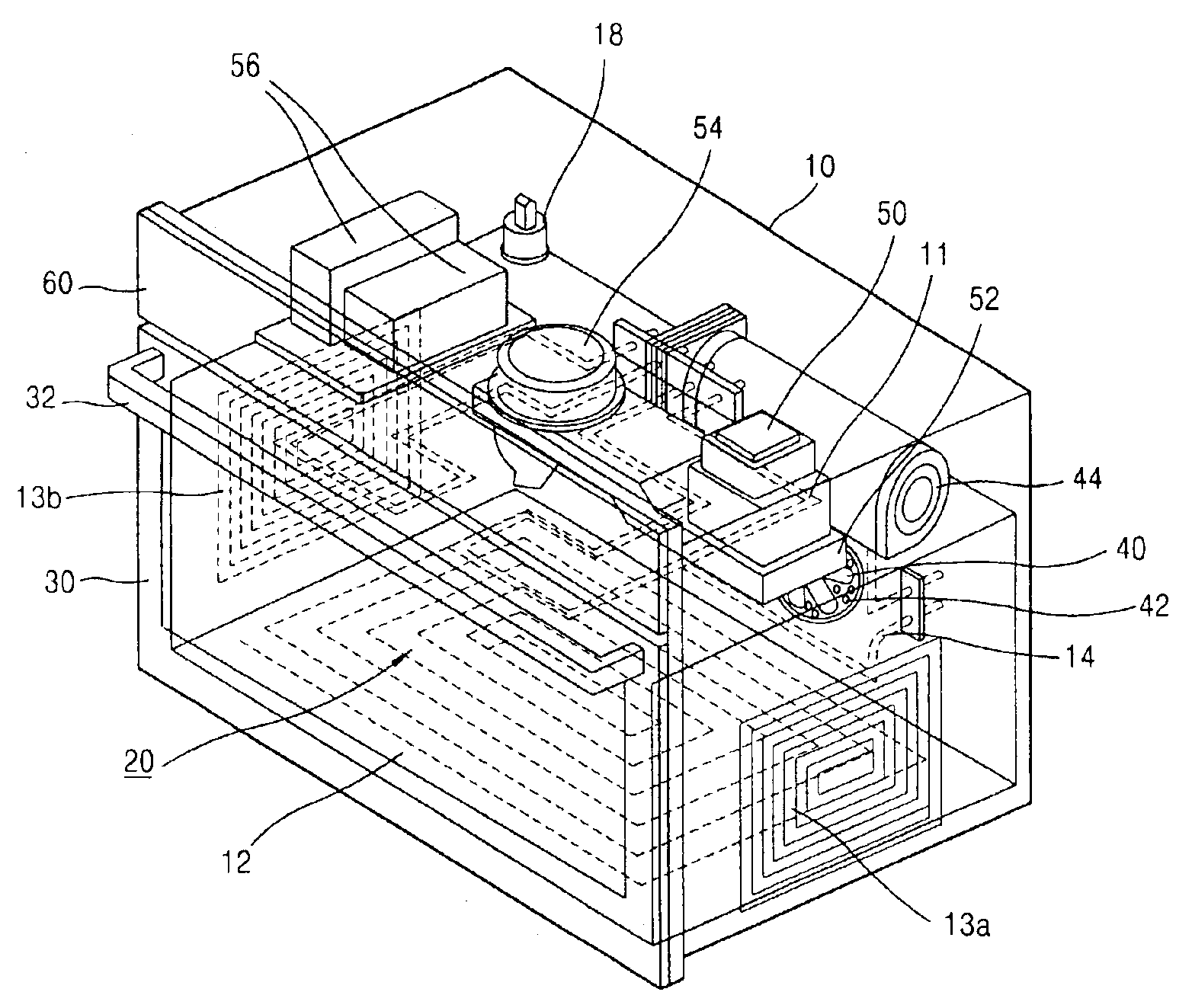

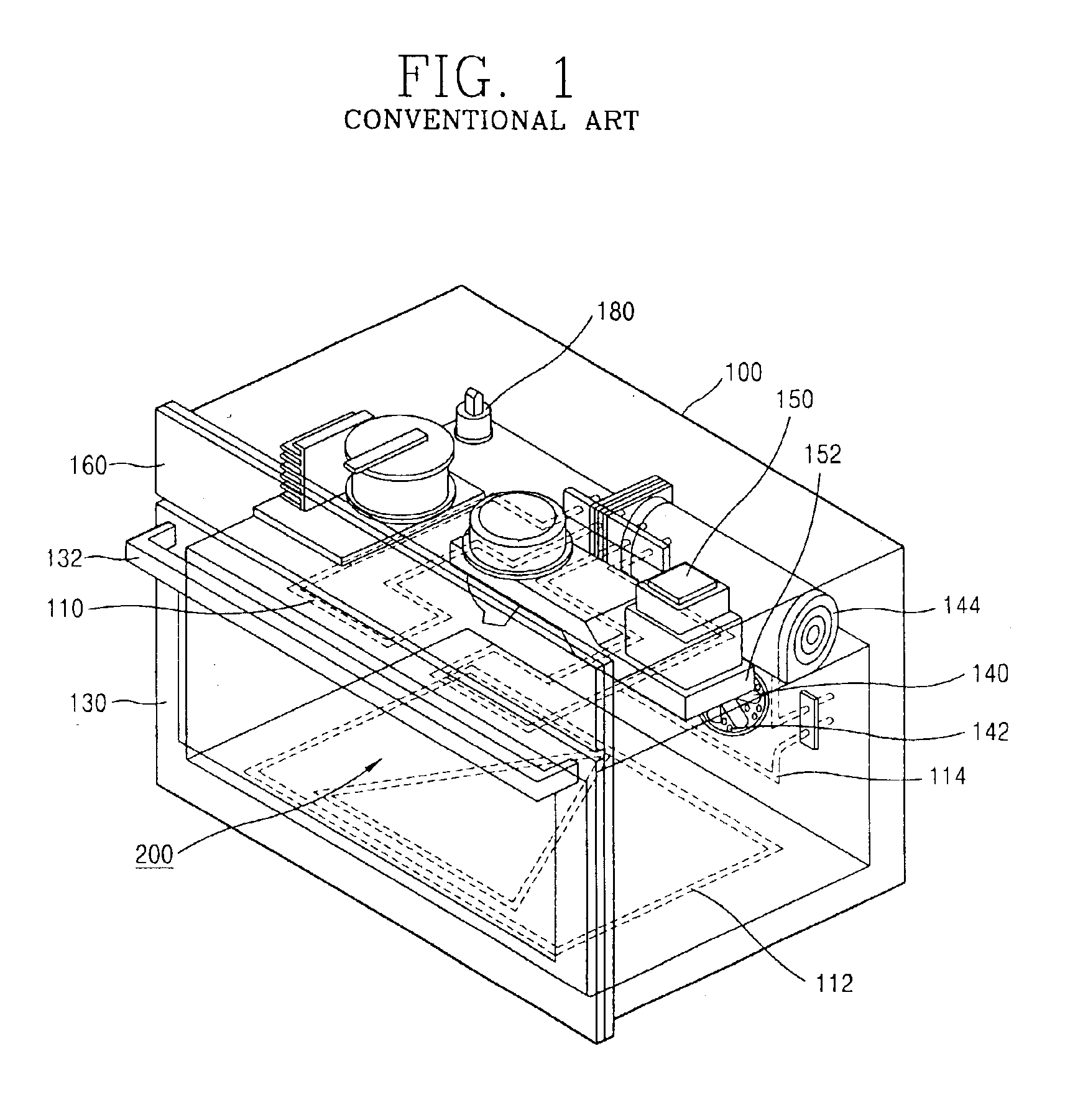

Image forming apparatus, fixing device, and heat-generating rotary member using induction heating

InactiveUS20090060550A1Fast heatingElectrographic process apparatusInduction heating apparatusTemperature controlImage formation

An image forming apparatus includes a fixing device for fixing a toner image on a sheet by applying heat, and including an exciting coil and a heat-generating rotary member. The exciting coil generates a magnetic flux. The heat-generating rotary member performs self-temperature control using a repulsive magnetic flux, and includes a degaussing member, a heat-generating layer, a magnetic shunt alloy layer, and a magnetic flux adjuster. The degaussing member generates the repulsive magnetic flux using the magnetic flux generated by the exciting coil. The heat-generating layer generates heat using the magnetic flux generated by the exciting coil. The magnetic shunt alloy layer is disposed between the exciting coil and the degaussing member, and receives heat generated by the heat-generating layer. The magnetic flux adjuster adjusts an amount of the repulsive magnetic flux generated by the degaussing member.

Owner:RICOH KK

Process for manufacturing alloy steel for rail frog

InactiveCN102409138AFast heatingExtended service lifeHeat treatment process controlProcess efficiency improvementAlloy steelSmelting

The invention discloses a process for manufacturing alloy steel for a rail frog. The process comprises the following steps of: smelting, pouring, forging, and performing heat treatment. The rail frog manufactured by the alloy steel which is manufactured by the manufacturing process has properties such as tensile strength, low-temperature impact properties and the like which are much higher than those of high manganese steel, the service life of the rail frog can be greatly prolonged, and the rail frog is not required to be frequently replaced, so that the operating cost of a rail can be greatly reduced.

Owner:WUHU SHANQIAO RAILWAY EQUIP

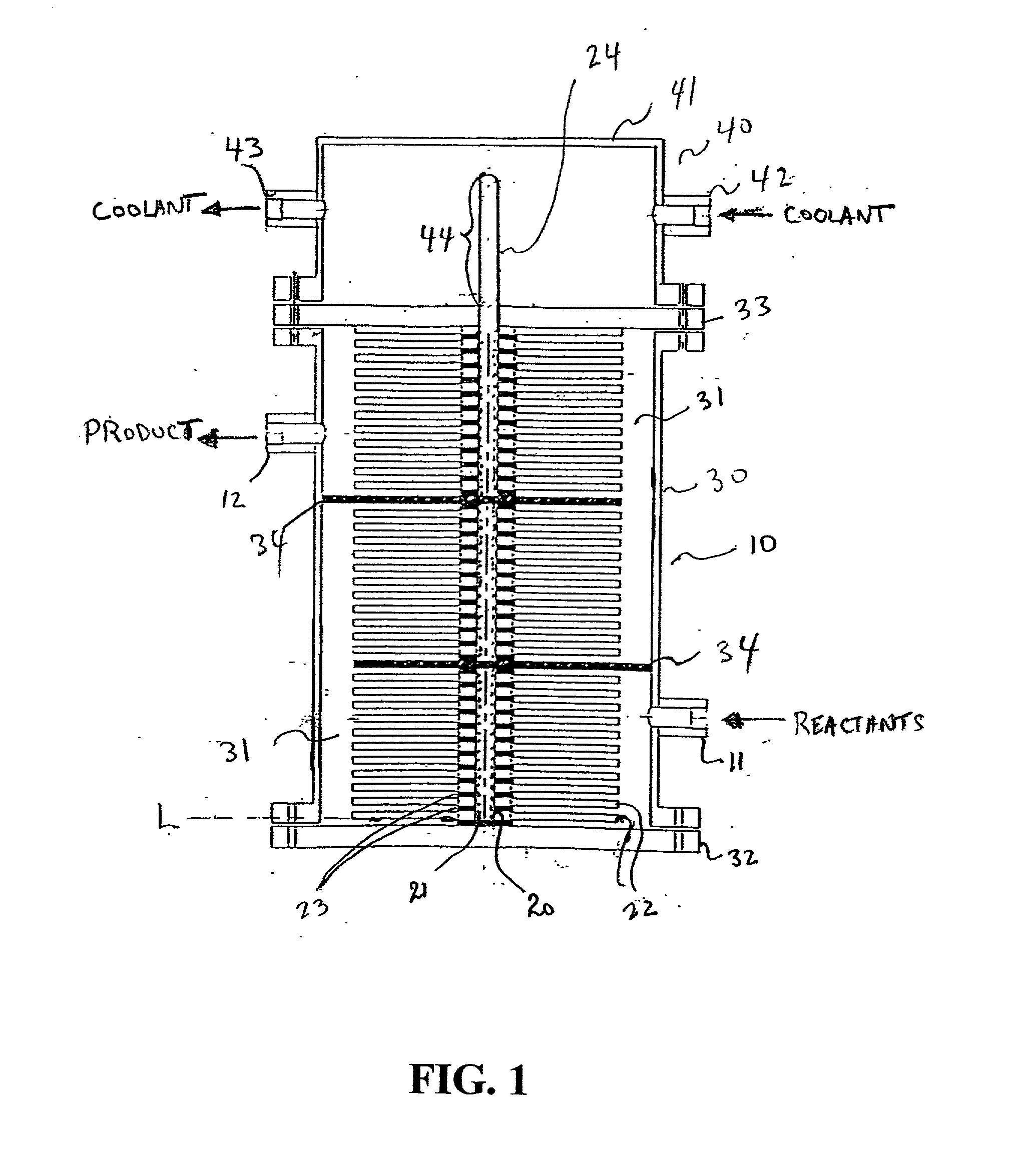

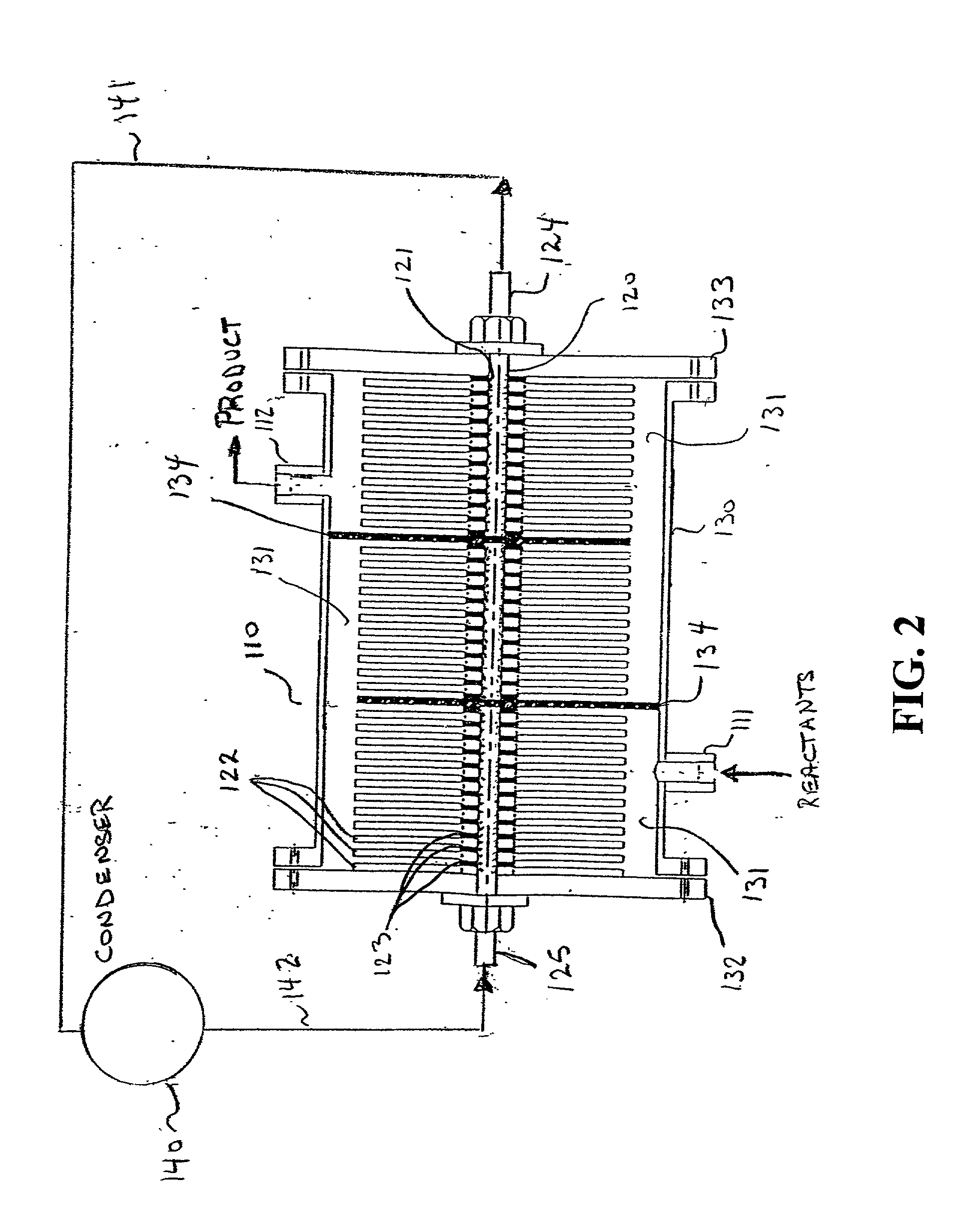

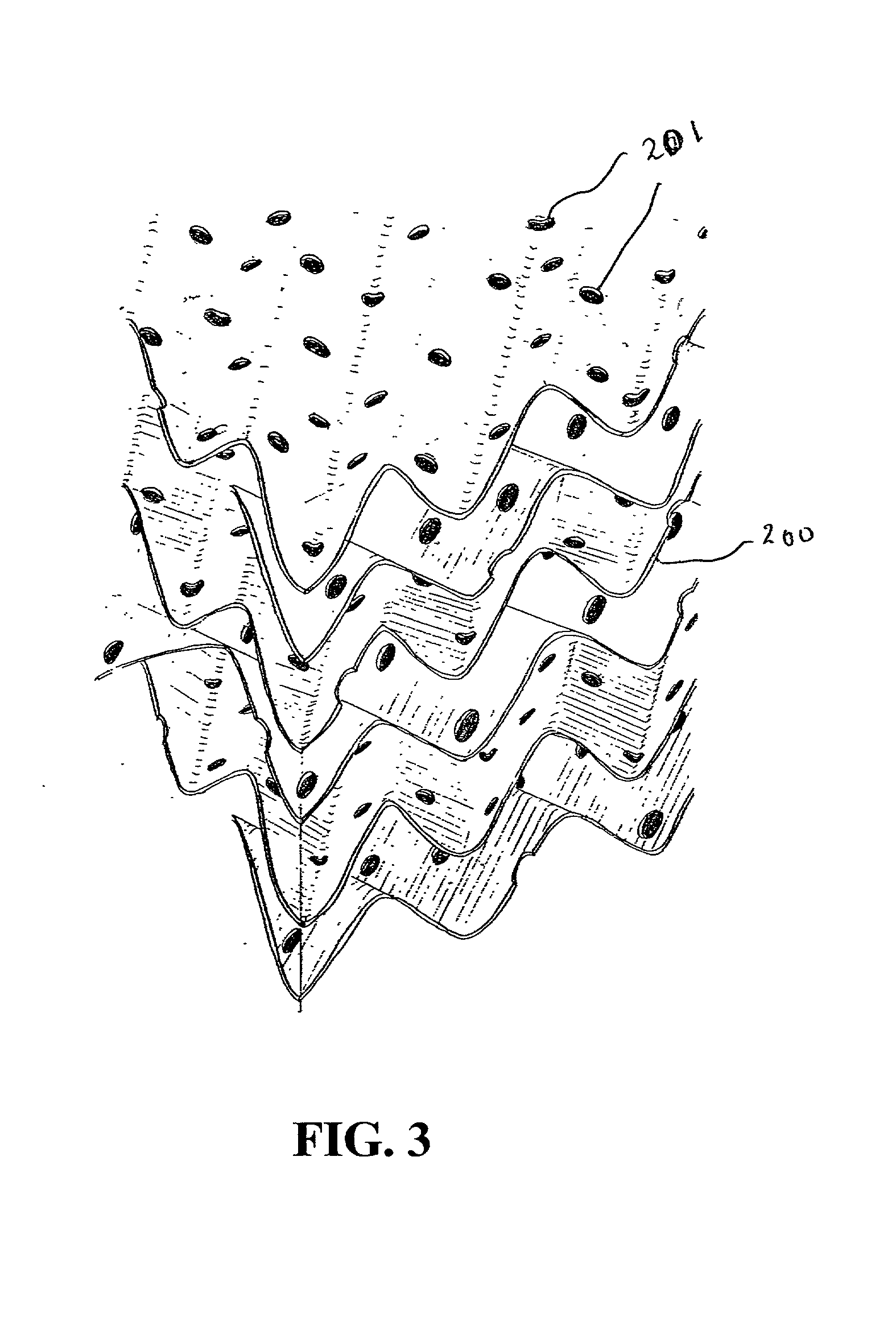

Stratified flow chemical reactor

InactiveUS20030133856A1Maximum effectivenessImprove thermal efficiencyFlow mixersTransportation and packagingReaction rateRates reactions

A polymerization reactor for exothermic liquid phase reactions comprises a reaction zone which is divided into a plurality of channels by thermally conductive heat transfer fins which are conductively mounted on one or more heat pipes for the removal of heat of reaction from reactants and reaction products flowing between the heat transfer fins. The reactor of the invention is capable of maintaining essentially isothermal conditions without the use of complicated and maintenance intensive agitators. The reactor is particularly useful when viscosity of the reactants and / or reaction products is high, when the reaction conducted has a fast reaction rate and when consistent polymer properties are desired.

Owner:SAUDI BASIC IND CORP SA

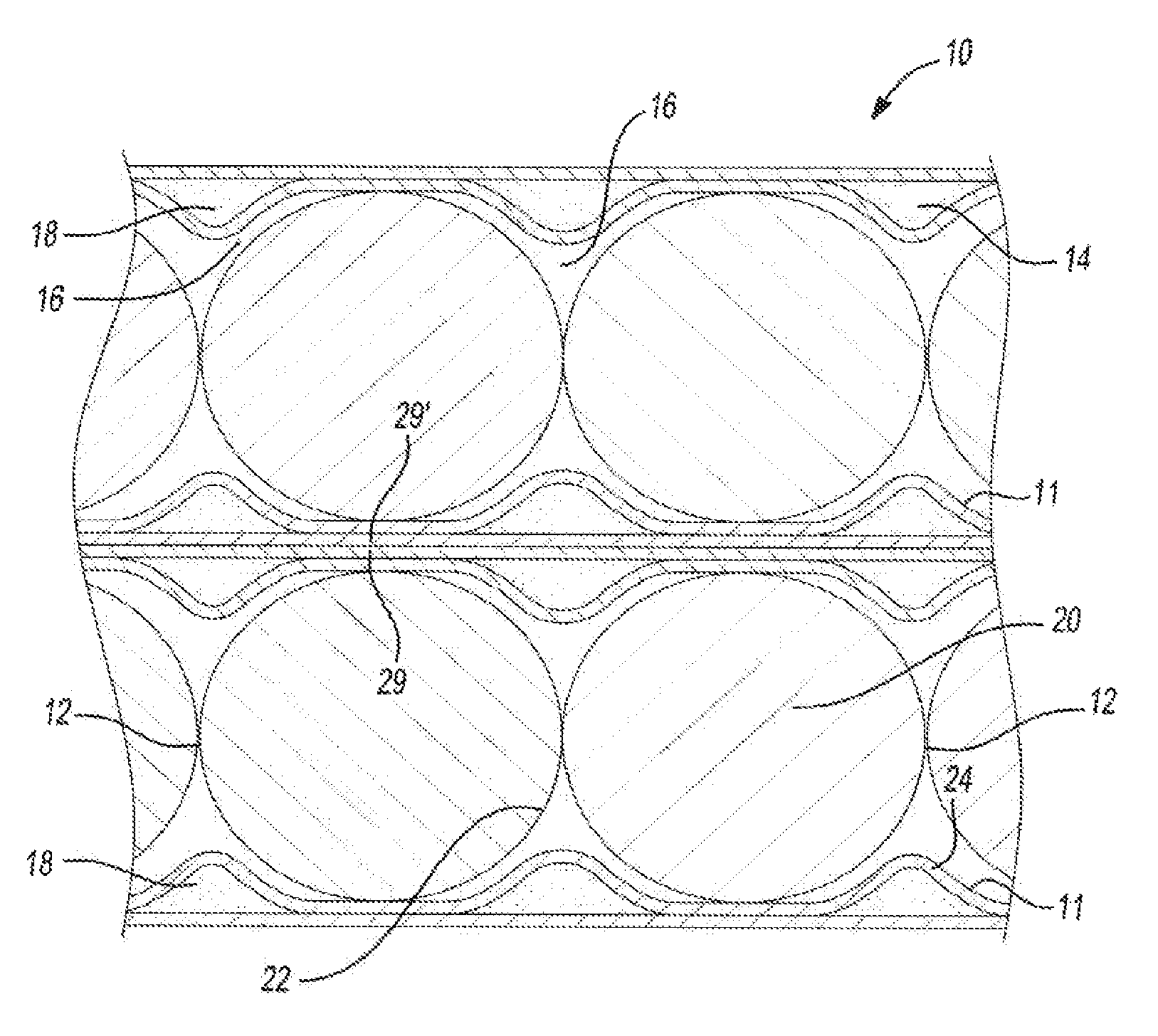

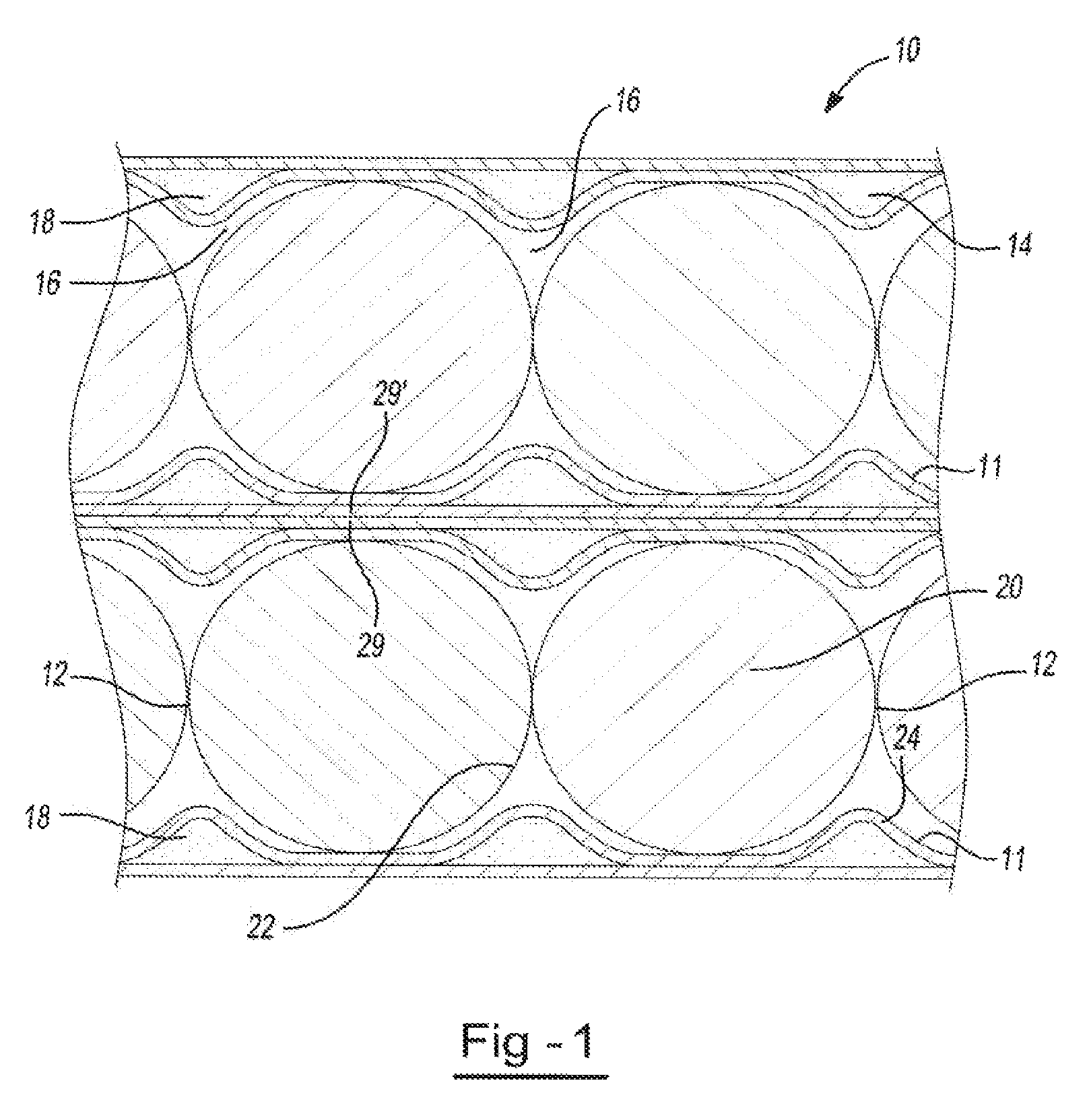

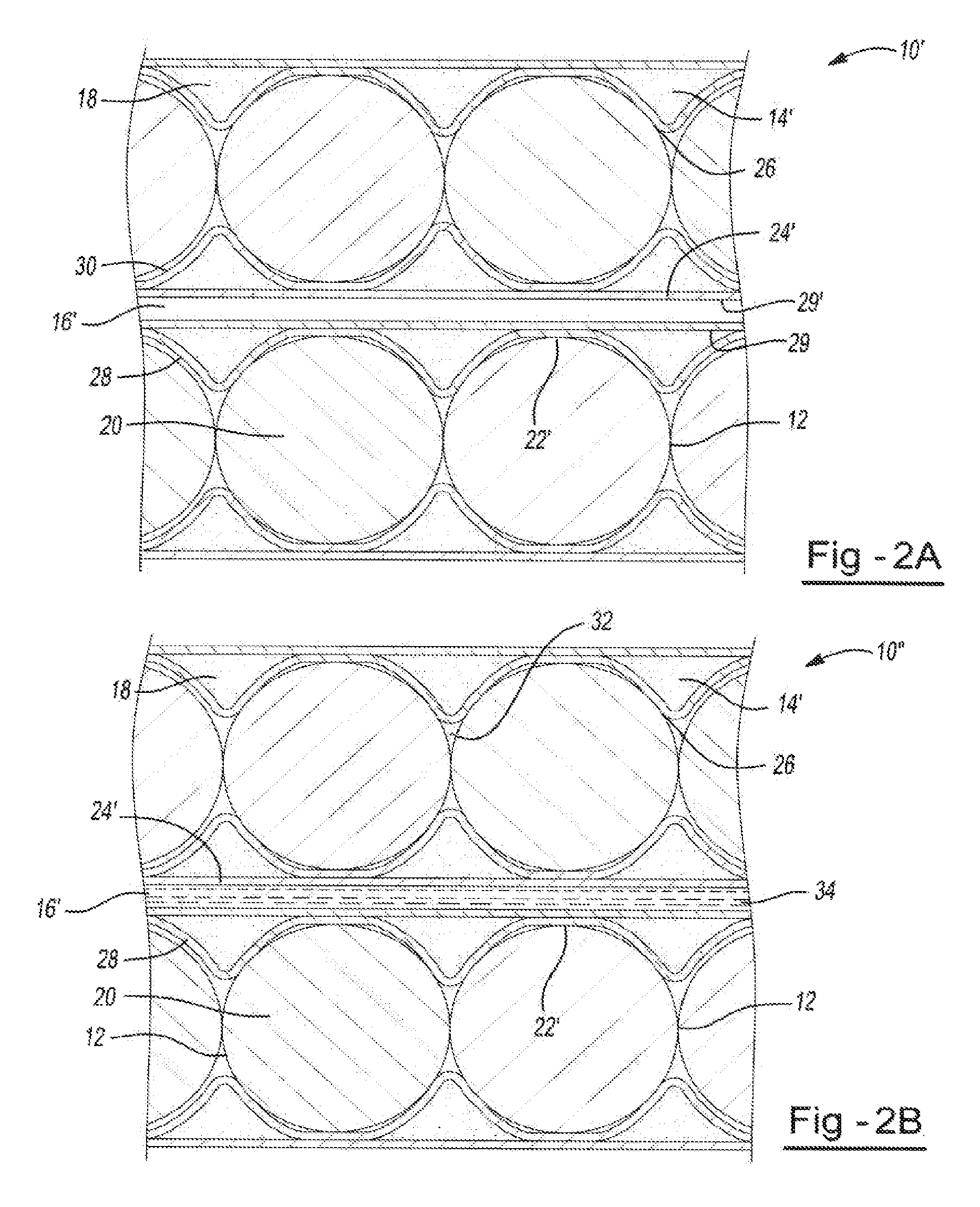

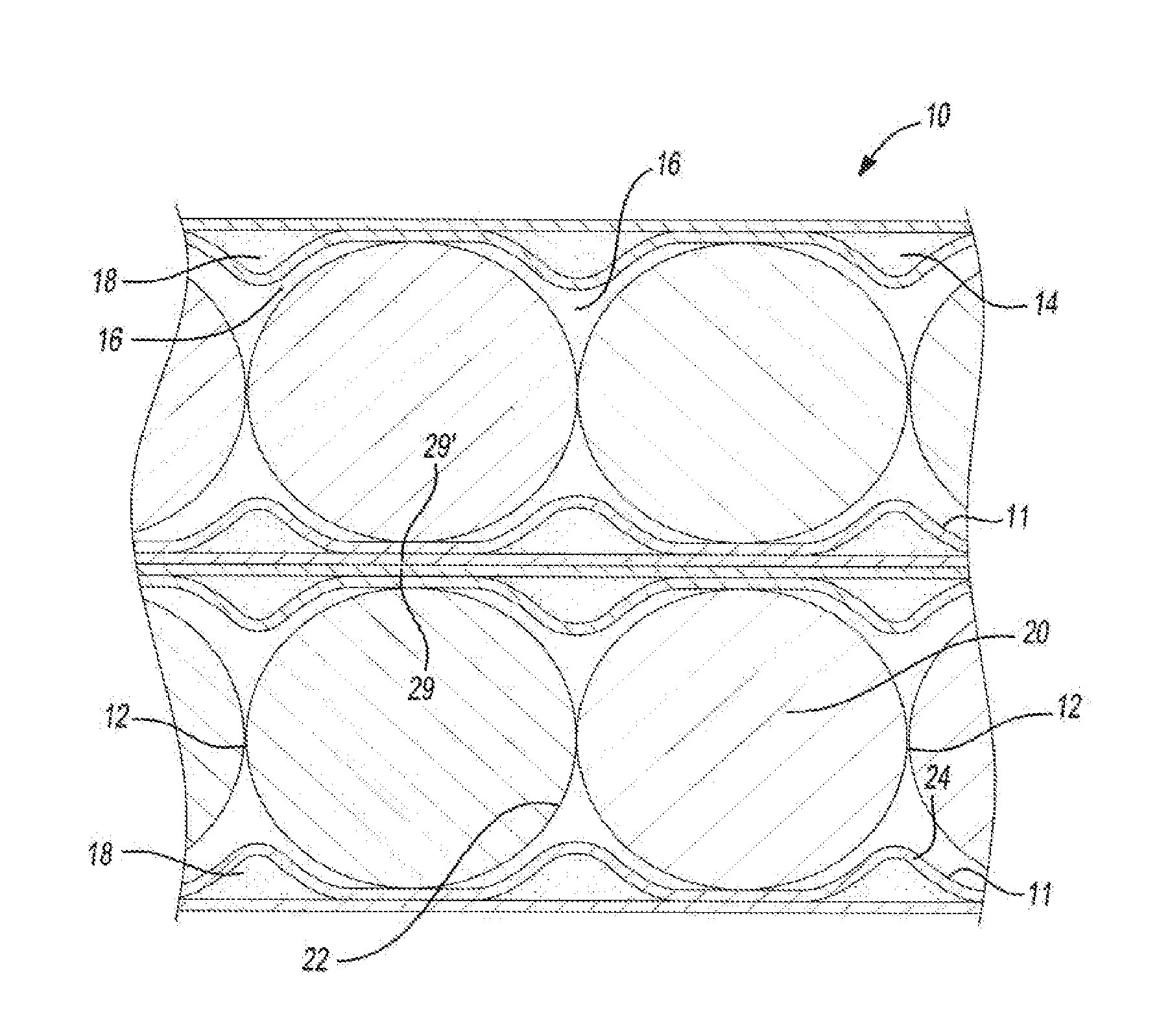

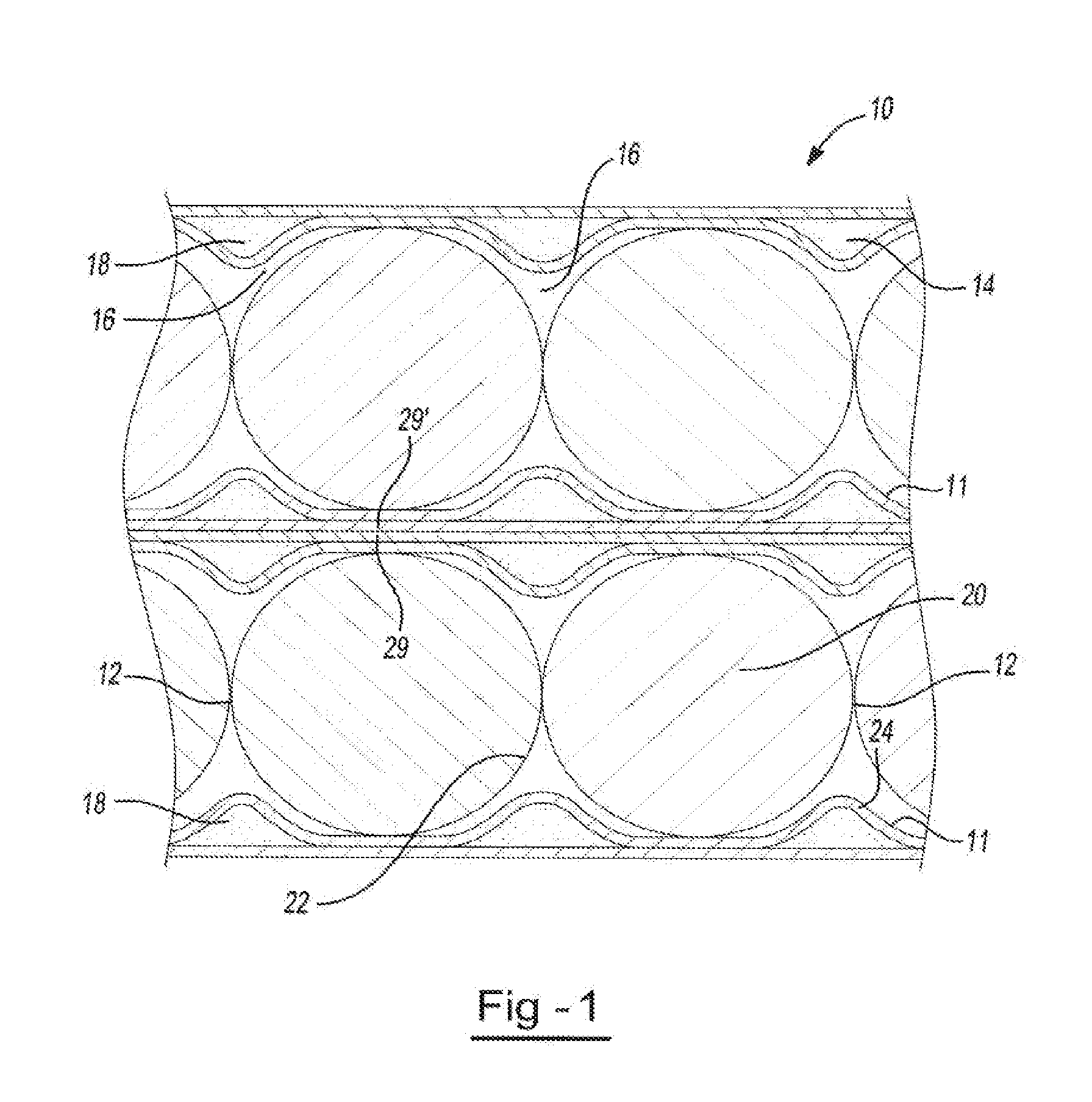

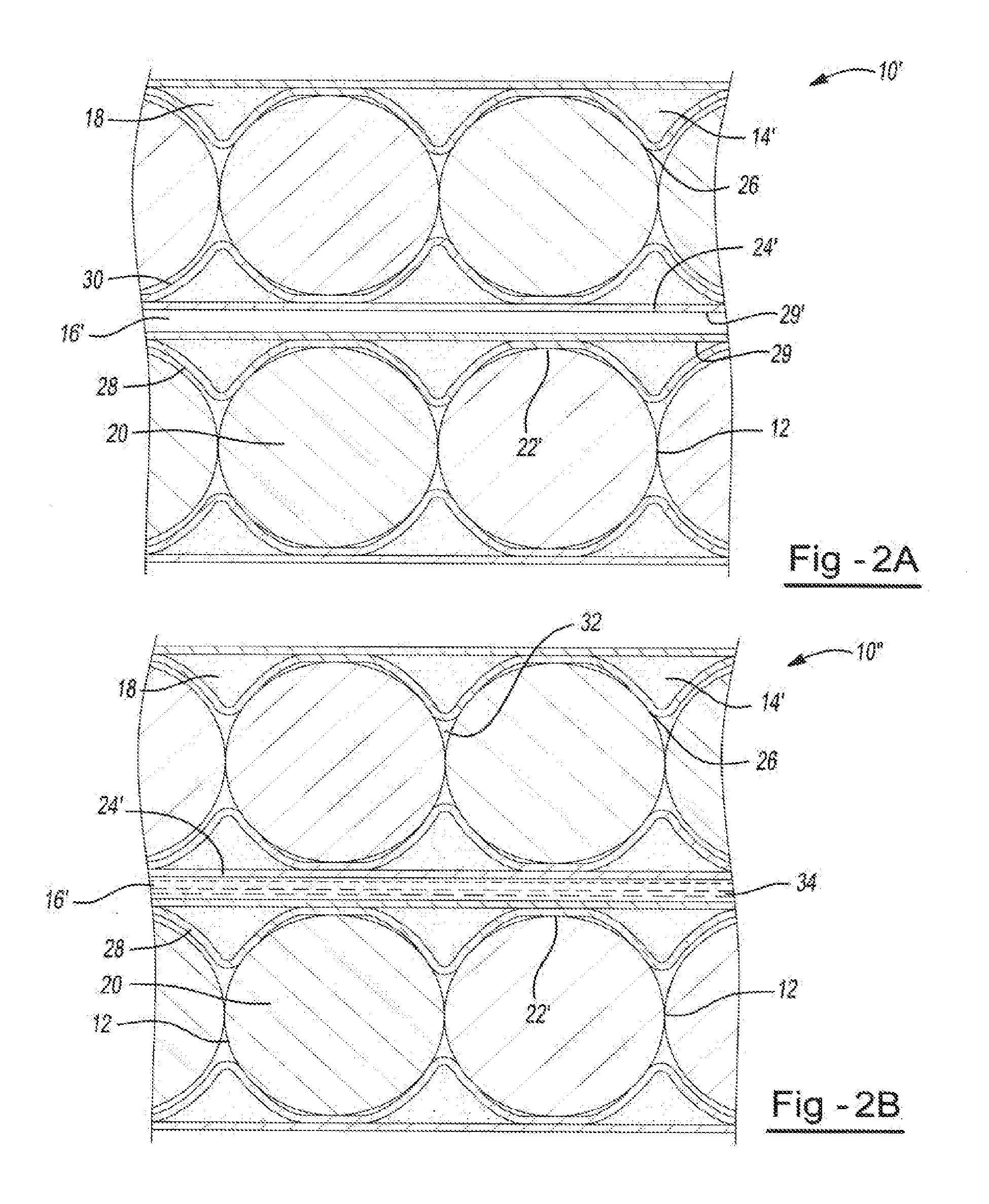

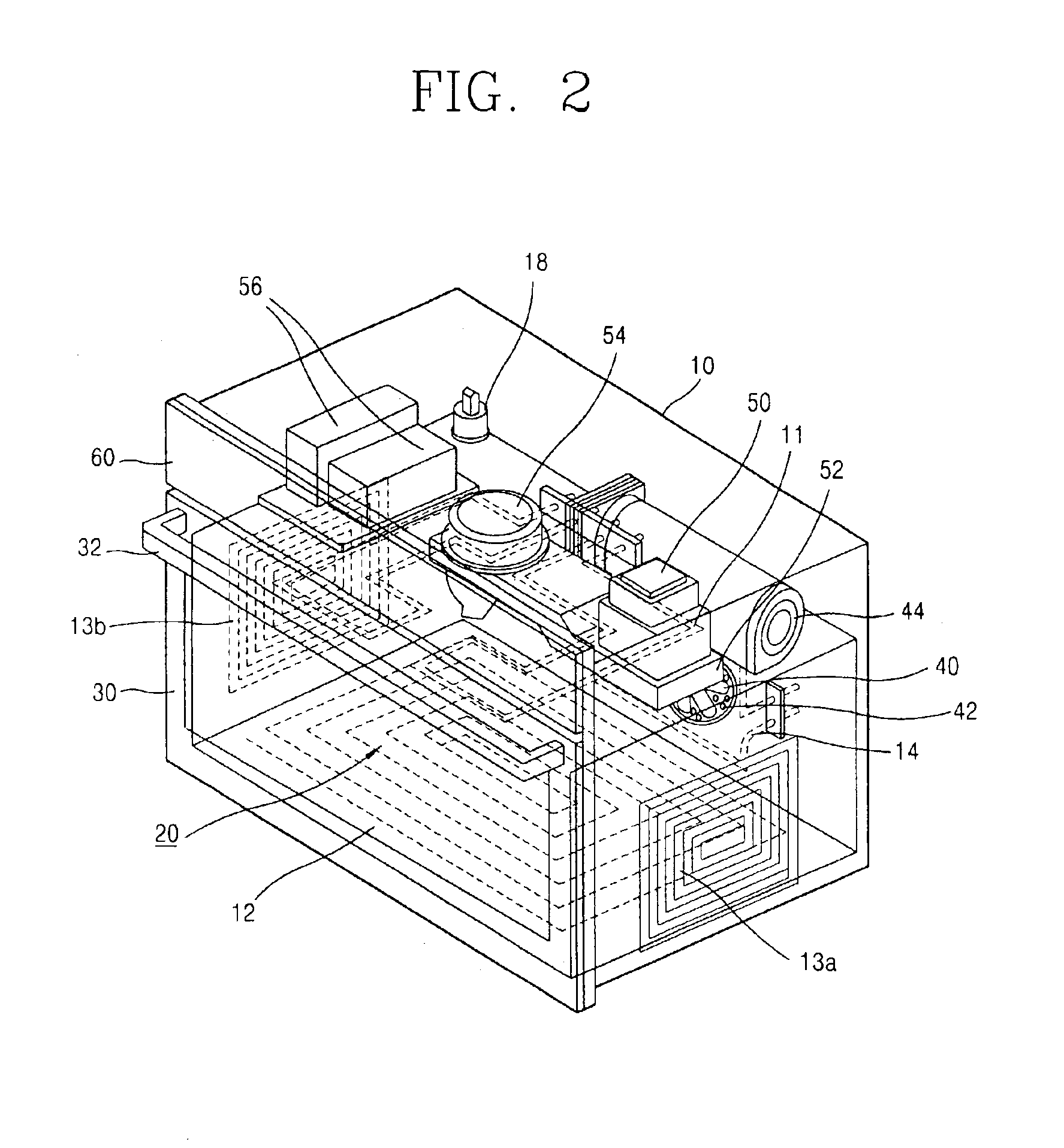

Thermal management of an electrochemical cell by a combination of heat transfer fluid and phase change material

InactiveUS9151545B2Heat dissipation fastEffective maintenanceHeat storage plantsCell temperature controlThermal energyThermal energy storage

The invention is directed at devices, systems, and processes for managing the temperature of an electrochemical call including a device 10 comprising an inlet for receiving a heat transfer fluid; one or more electrochemical cell compartments 12 for receiving one or more electrochemical calls 20; one or more thermal energy storage material compartments 14 containing one or more thermal energy storage materials 18; and one or more heat transfer fluid compartments 16 for flowing the heat transfer fluid through the device; wherein the space between the one or more heat transfer fluid compartments 16 and the one or more electrochemical cell compartments 12 preferably includes one or more first regions 22 (i.e. portion) that are substantially free of the thermal energy storage material 18; and the space between the one or more heat transfer fluid compartments 16 and the one or more thermal energy storage material compartments 14 preferably includes one or more second regions 24 (i.e. portion) that are substantially free of an electrochemical cell 20; so that the heat transfer fluid compartment 16 is in direct thermal communication with both the thermal energy storage material compartment 14 and the electrochemical cell compartment 12.

Owner:DOW GLOBAL TECH LLC

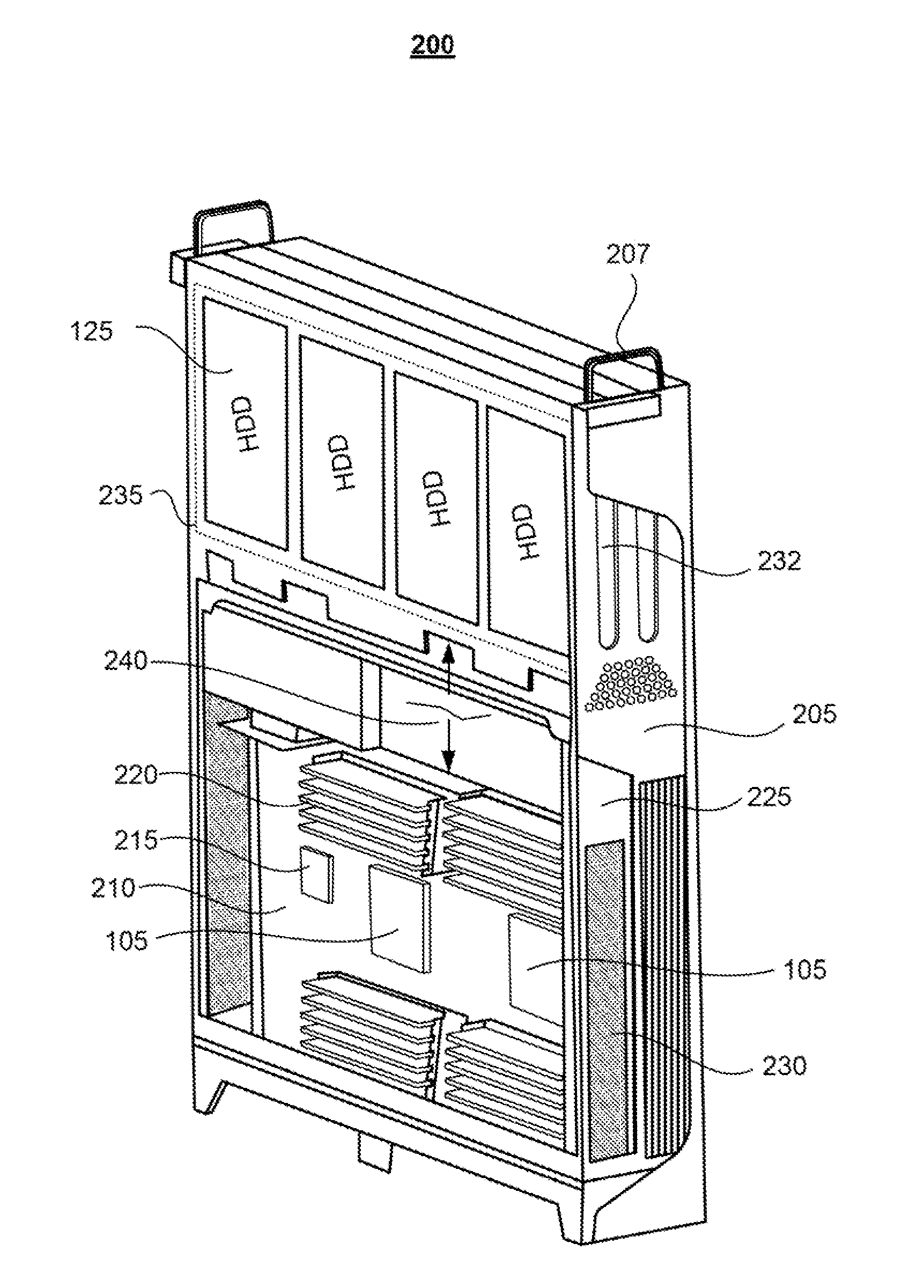

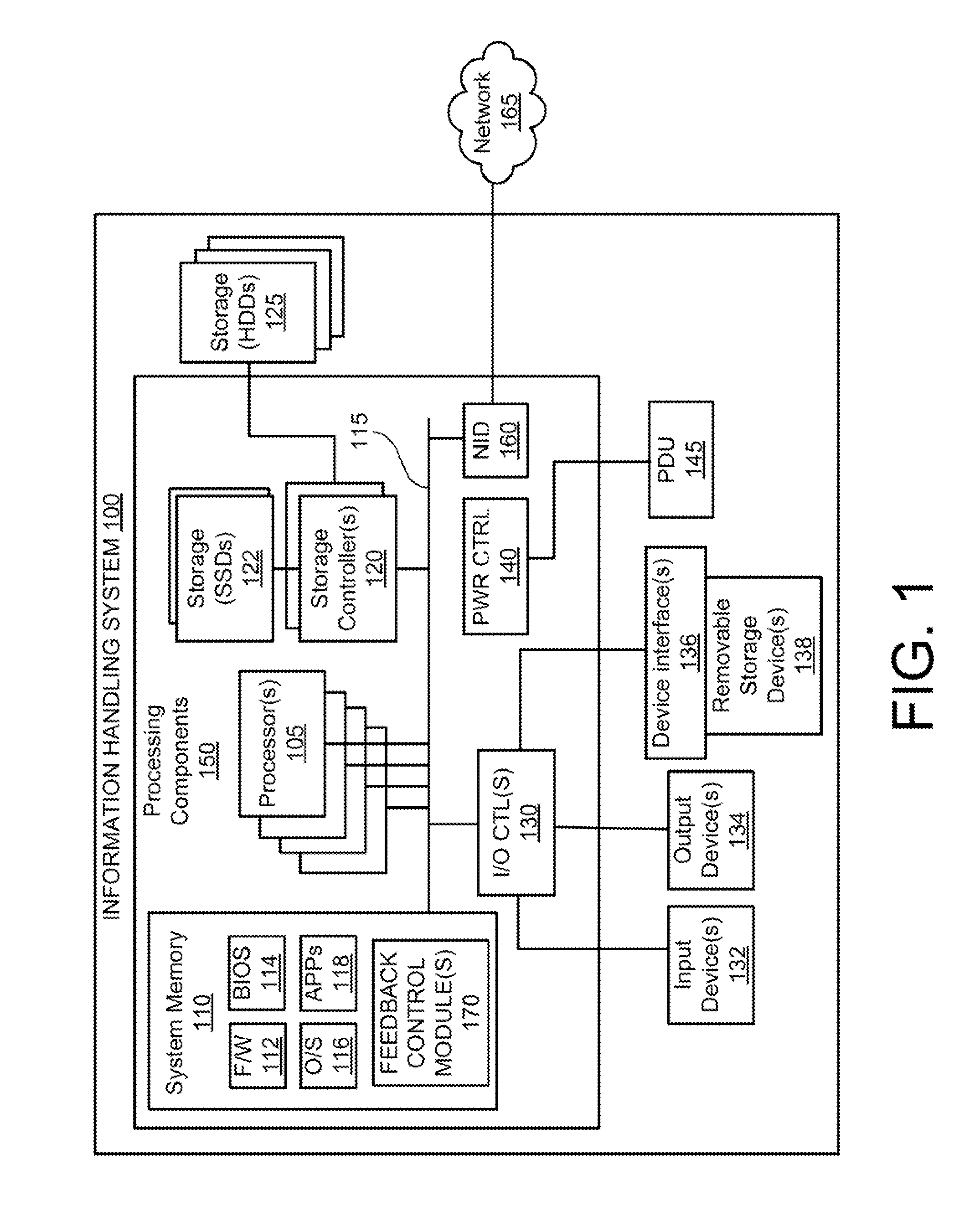

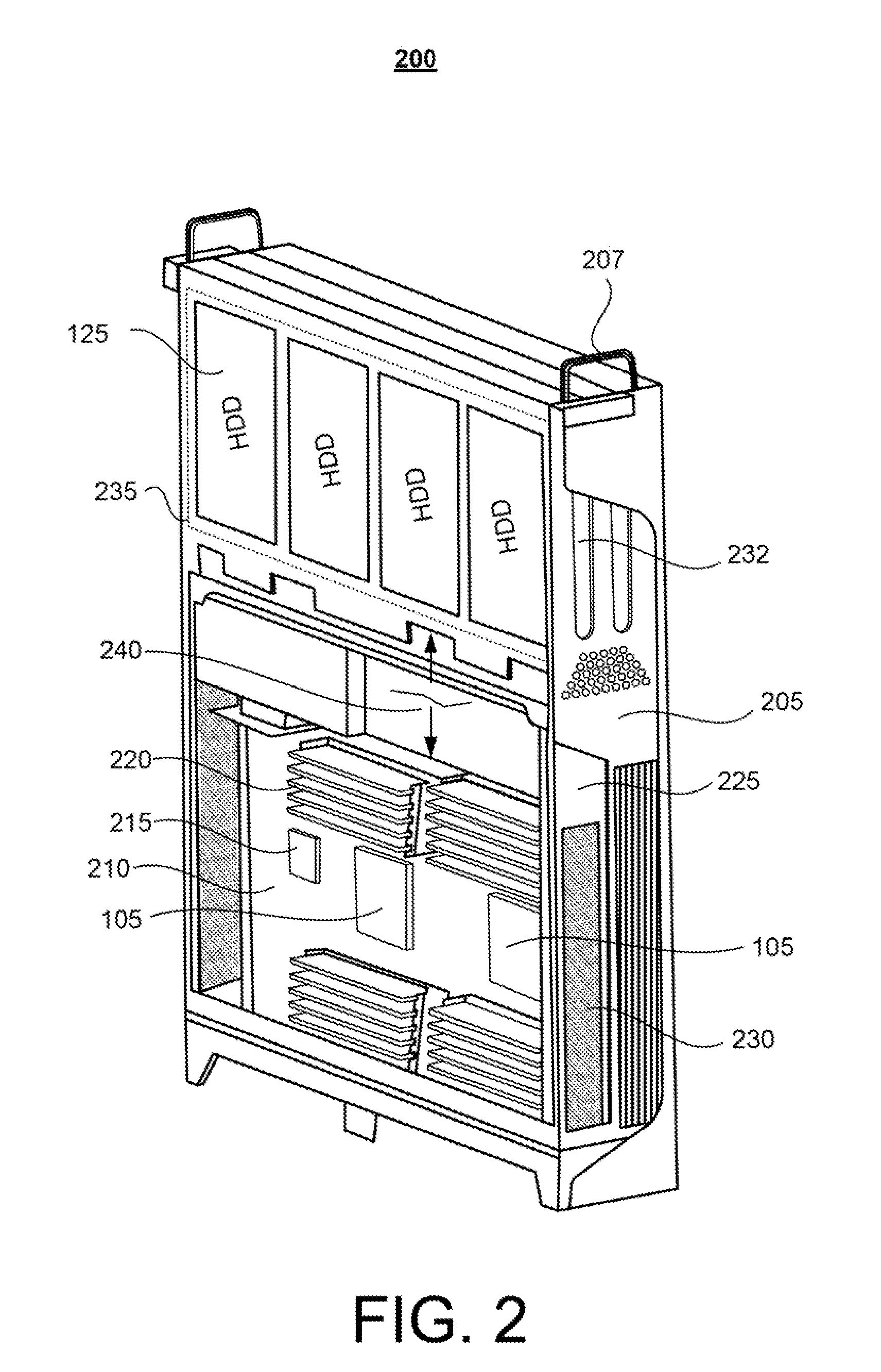

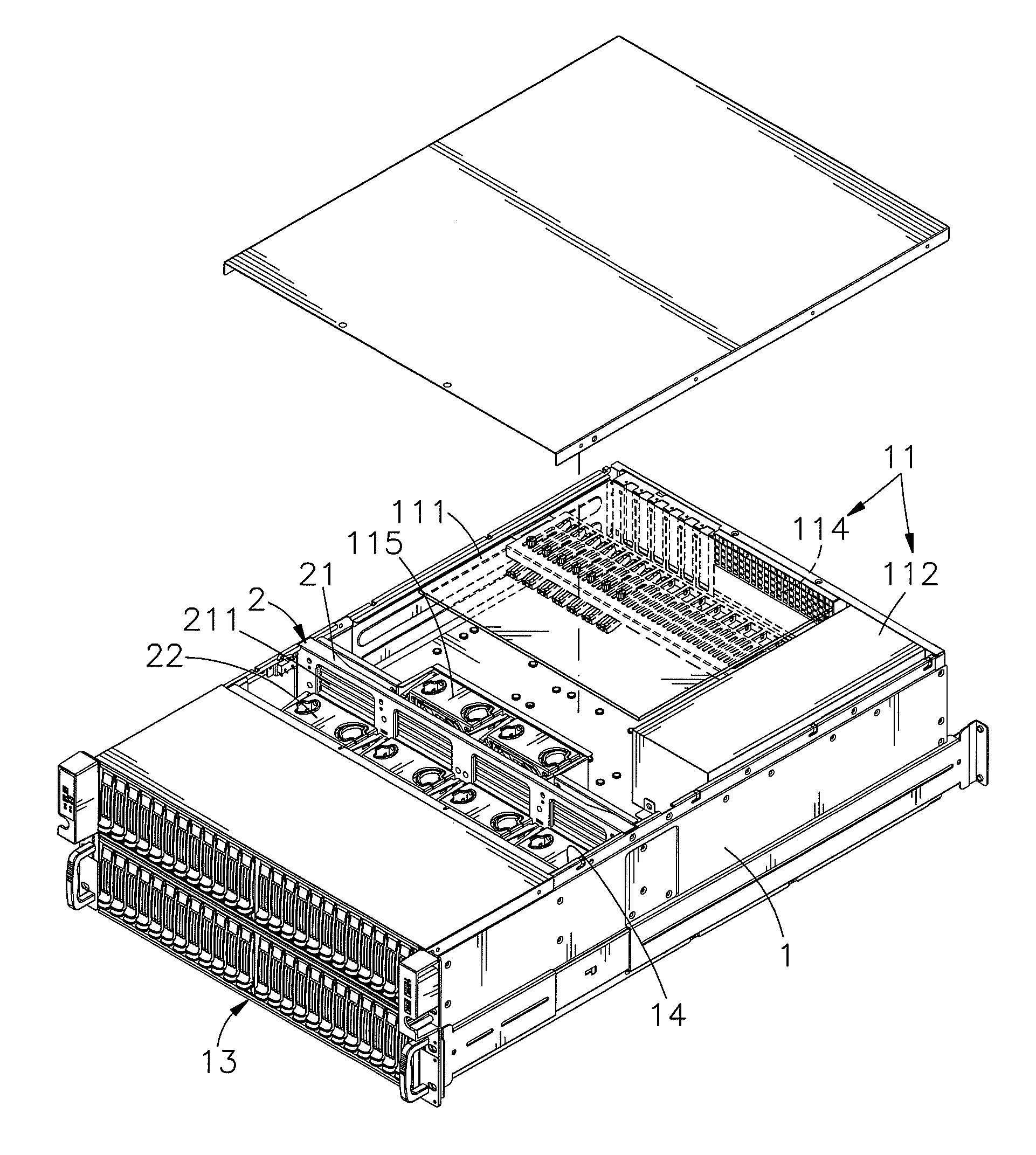

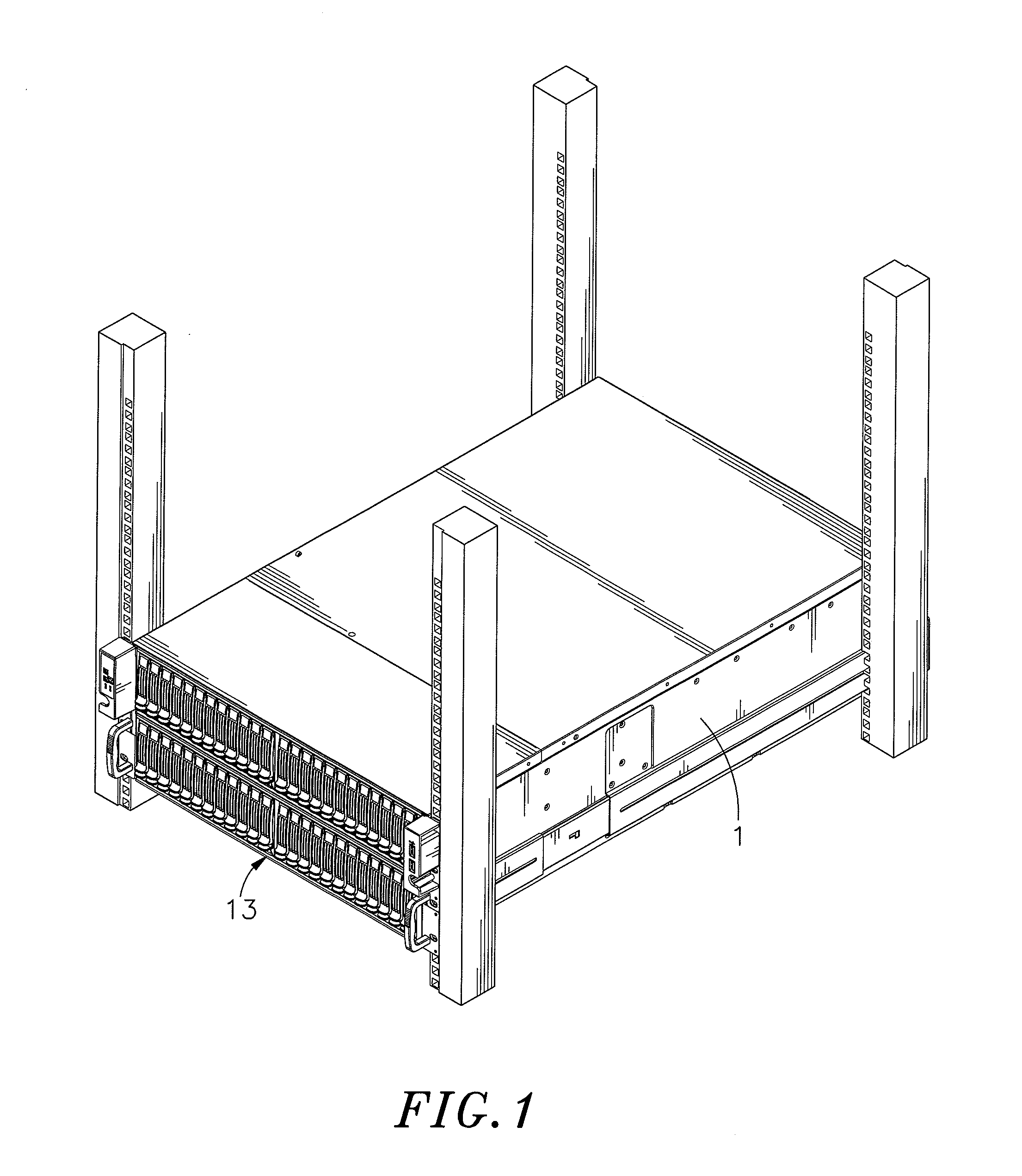

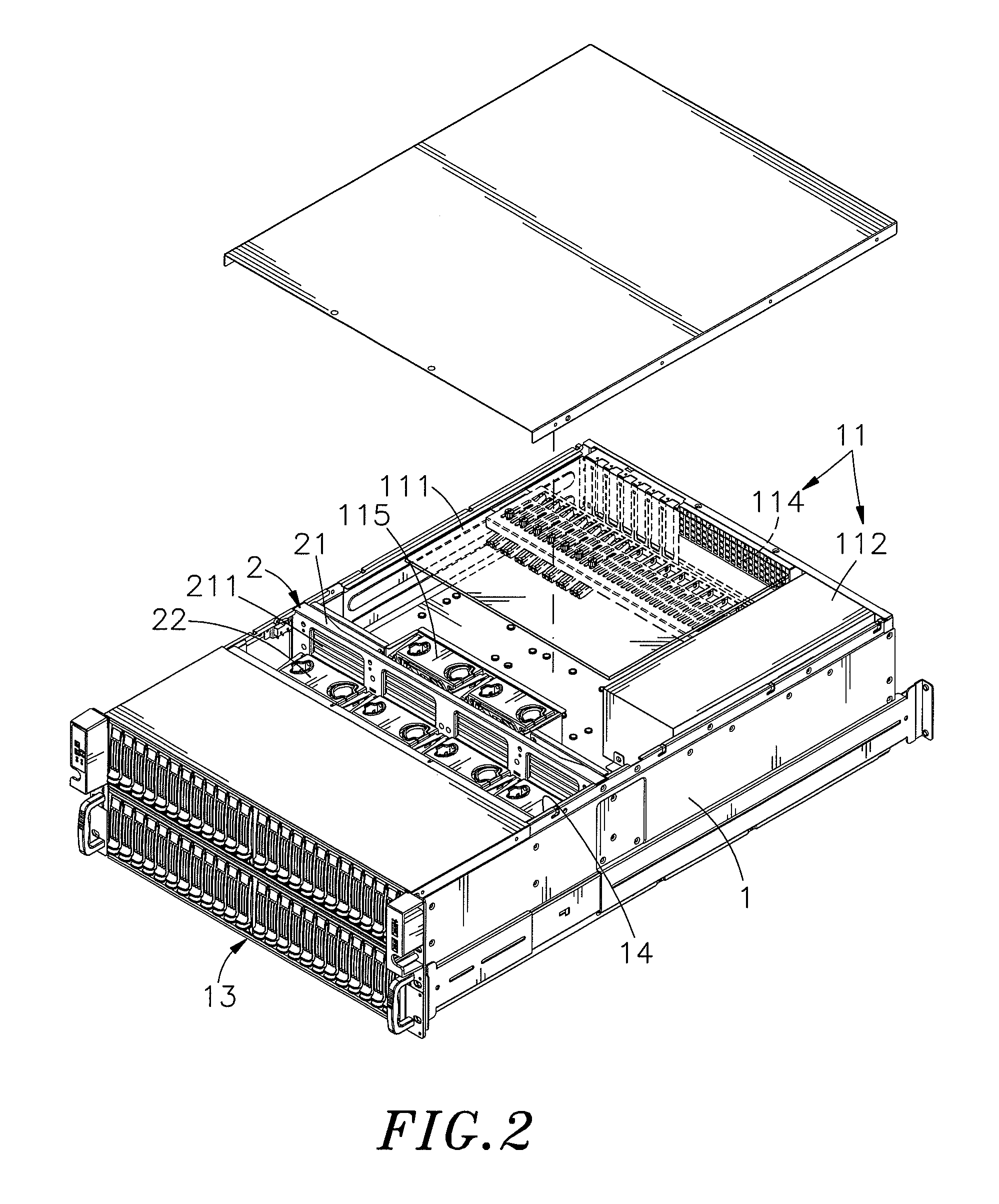

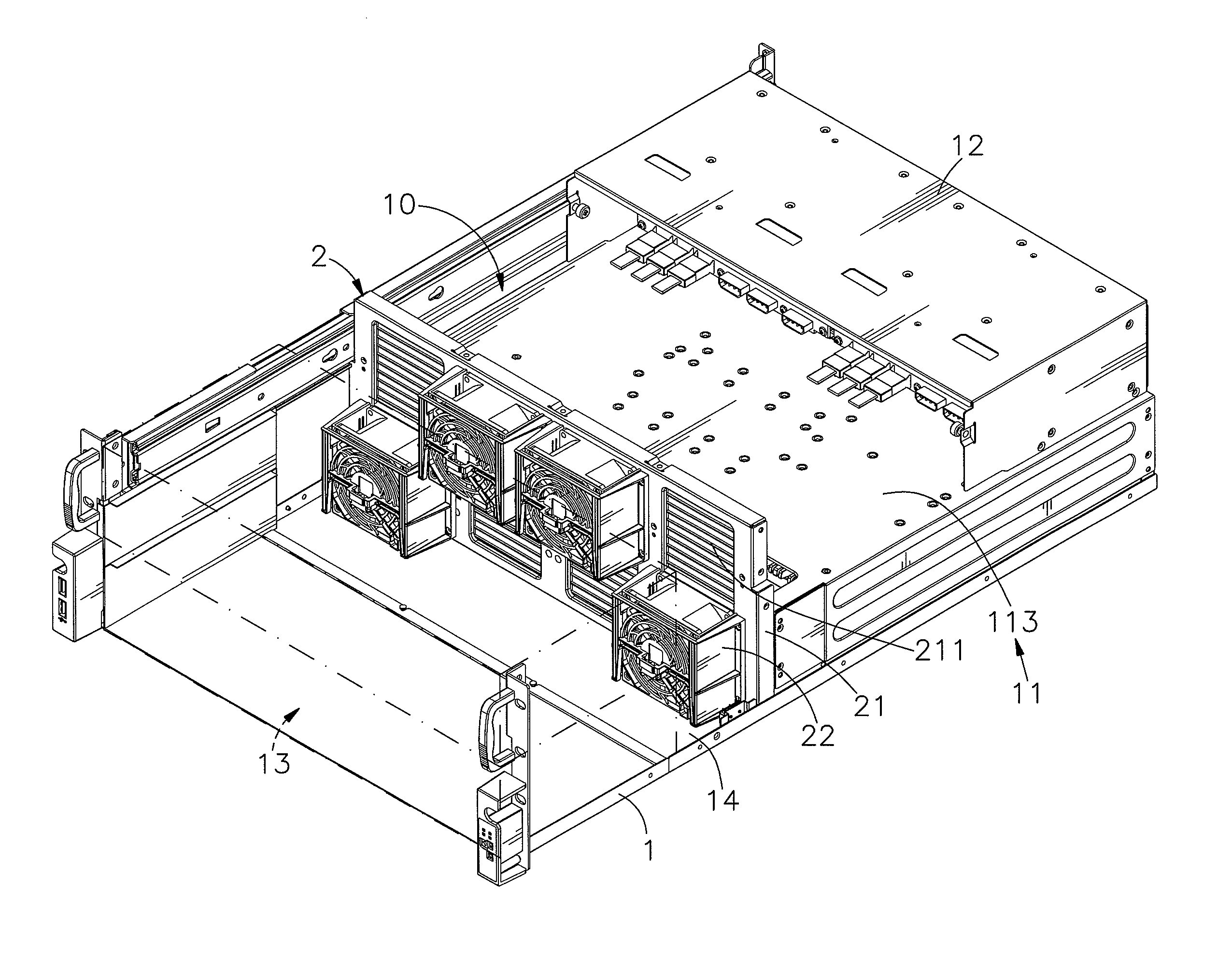

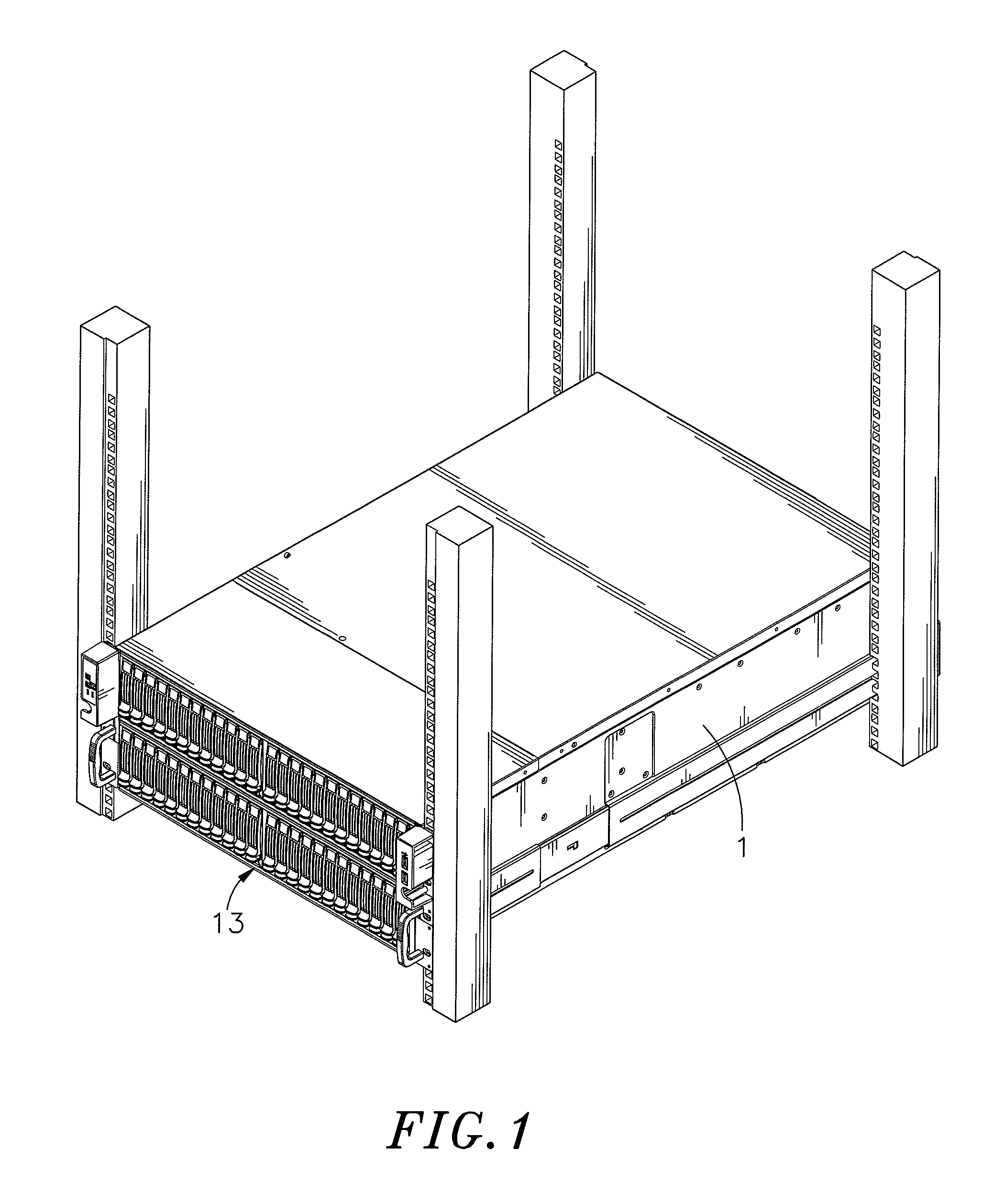

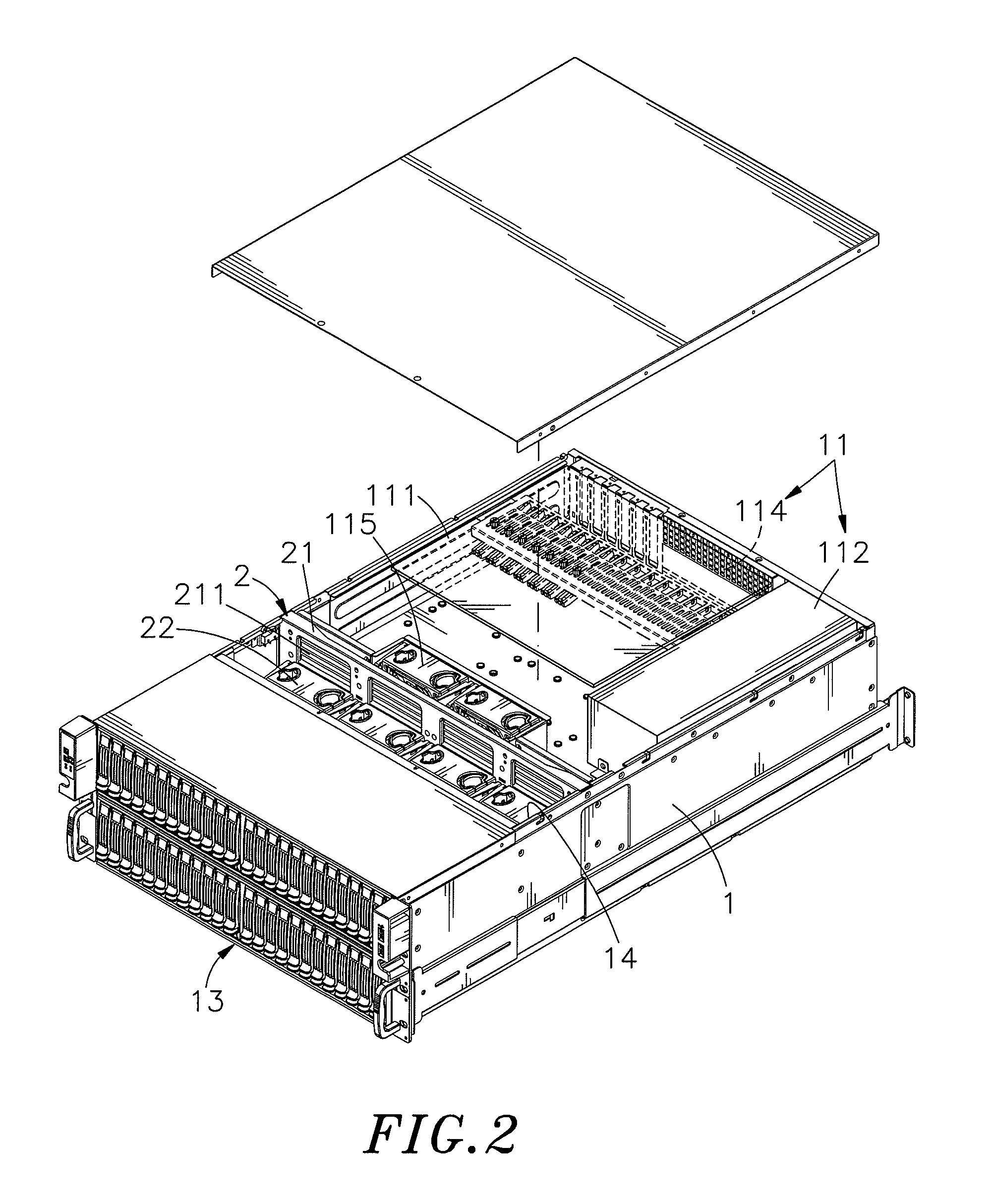

Server and cooler moduel arrangement

ActiveUS20110273840A1Fast heatingHeat dissipationPump componentsDigital data processing detailsOperational systemEngineering

A server and cooler module arrangement includes a server accommodating a stack of an operating system and an electronic device in an accommodation chamber therein at one side and an access device unit in the accommodation chamber at an opposite side, and a cooler module, which comprises a rack mounted in a partition way in the accommodation chamber between the stack of operating system and electronic device and the access device unit and a plurality of fans respectively adjustably mounted in respective open frames at different elevations and adapted for drawing air or sending air toward different heat sources in the operating system, the electronic device and the access device unit for quick dissipation of waste heat.

Owner:CHENBRO MICOM

Versatile tamper-evident food container

ActiveUS8083089B2Improved tamper-evident product packagingWithout riskCapsClosure capsInterference fitEngineering

A tamper-evident rigid plastic food container system wherein the outer periphery of the mating surfaces of the lid and tray are permanently bonded together after the food product has been placed in the tray, a set of perforated rows at an inner periphery, the interconnect of which needs to be torn into order to open the lid. Intentional, inadvertent or malicious ingress into the container can only be made by tearing at the perforations thereby evidencing the potential tampering and contamination of the packaging contents. The lid and tray edges may further include mechanical interference fits, including snap-fit grips that may be of the releasably lockable kind to permit sealing, release and re-sealing multiple times without deterioration in reliability, and which can further prevent or minimize leakage of liquid food product.

Owner:PACTIV PACKAGING

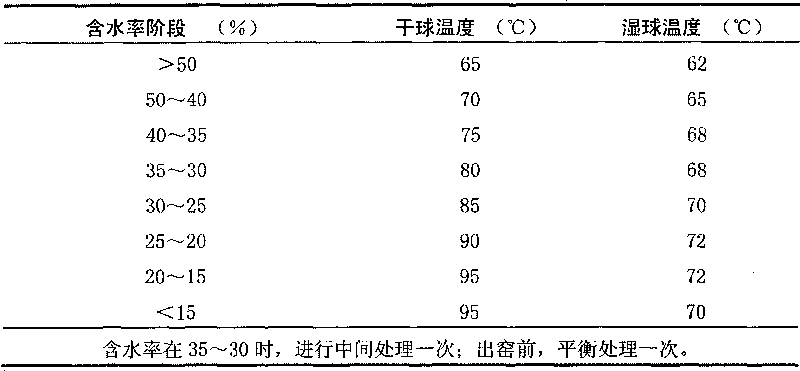

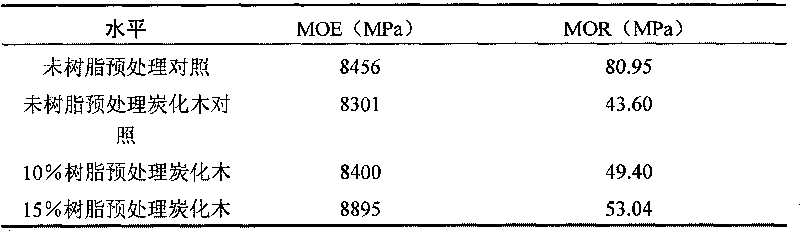

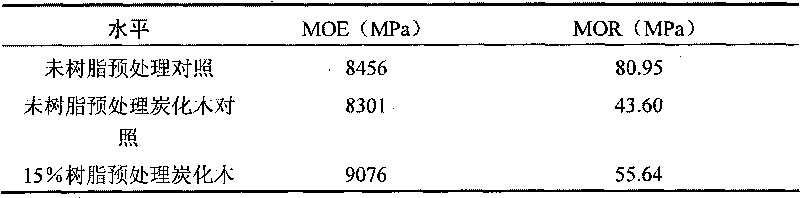

Method for producing rubber tree carbonized wood by resin pretreatment

ActiveCN101716790AHigh strengthIncrease added valuePressure impregnationWood impregnation detailsPulp and paper industryAdditional values

The invention belongs to the technical field of wood modification, in particular relating to a method for producing rubber tree carbonized wood by resin pretreatment. The method comprises the following steps: putting the rubber saw wood of which the water content is less than 15% in a vacuum treatment tank for impregnating; then, stacking and airing the wood, putting the wood in a kiln, routinely drying the wood in the kiln until the water content is less than 12%, and then, taking the wood out of the kiln; and putting the obtained wood in heat treatment equipment for high-temperature heat treatment, and taking the wood out of the kiln to obtain the rubber tree carbonized wood, wherein the water content of the wood is 4-6%. The invention has simple processes, high heating rate in the heat treatment process and high production efficiency, can increase the strength of the rubber tree carbonized wood by vacuum pressurization and impregnation of resin, and can effectively prevent the wood from deforming and cracking in the heat treatment process. The obtained rubber tree carbonized wood has the advantages of little loss of strength of the wood, elegant color, more excellent dimensional stability and durability and the like, and can be widely used for indoor and outdoor floors, landscapes, decorative materials and the like, thereby widening the application field of the rubber tree wood and increasing the additional value of the rubber tree wood.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Thermal management of an electrochemical cell by a combination of heat transfer fluid and phase change material

InactiveUS20120263980A1Heat dissipation fastEffective maintenanceHeat storage plantsCell temperature controlThermal energy storageElectrical battery

The invention is directed at devices, systems, and processes for managing the temperature of an electrochemical call including a device (10) comprising an inlet for receiving a heat transfer fluid; one or more electrochemical cell compartments (12) for receiving one or more electrochemical calls (20); one or more thermal energy storage material compartments (14) containing one or more thermal energy storage materials (18); and one or more heat transfer fluid compartments (16) for flowing the heat transfer fluid through the device; wherein the space between the one or more heat transfer fluid compartments (16) and the one or more electrochemical cell compartments (12) preferably includes one or more first regions (22) (i.e. portion) that are substantially free of the thermal energy storage material (18): and the space between the one or more heat transfer fluid compartments (18) and the one or more thermal energy storage material compartments (14) preferably includes one or more second regions (24) (i.e. portion) that are substantially free of an electrochemical cell (20); so that the heat transfer fluid compartment (16) is in direct thermal communication with both the thermal energy storage material compartment (14) and the electrochemical cell compartment (12).

Owner:DOW GLOBAL TECH LLC

Server and cooler moduel arrangement

ActiveUS8045328B1Fast heatingHeat dissipationPump componentsDigital data processing detailsComputer moduleElectric equipment

A server and cooler module arrangement includes a server accommodating a stack of an operating system and an electronic device in an accommodation chamber therein at one side and an access device unit in the accommodation chamber at an opposite side, and a cooler module, which comprises a rack mounted in a partition way in the accommodation chamber between the stack of operating system and electronic device and the access device unit and a plurality of fans respectively adjustably mounted in respective open frames at different elevations and adapted for drawing air or sending air toward different heat sources in the operating system, the electronic device and the access device unit for quick dissipation of waste heat.

Owner:CHENBRO MICOM

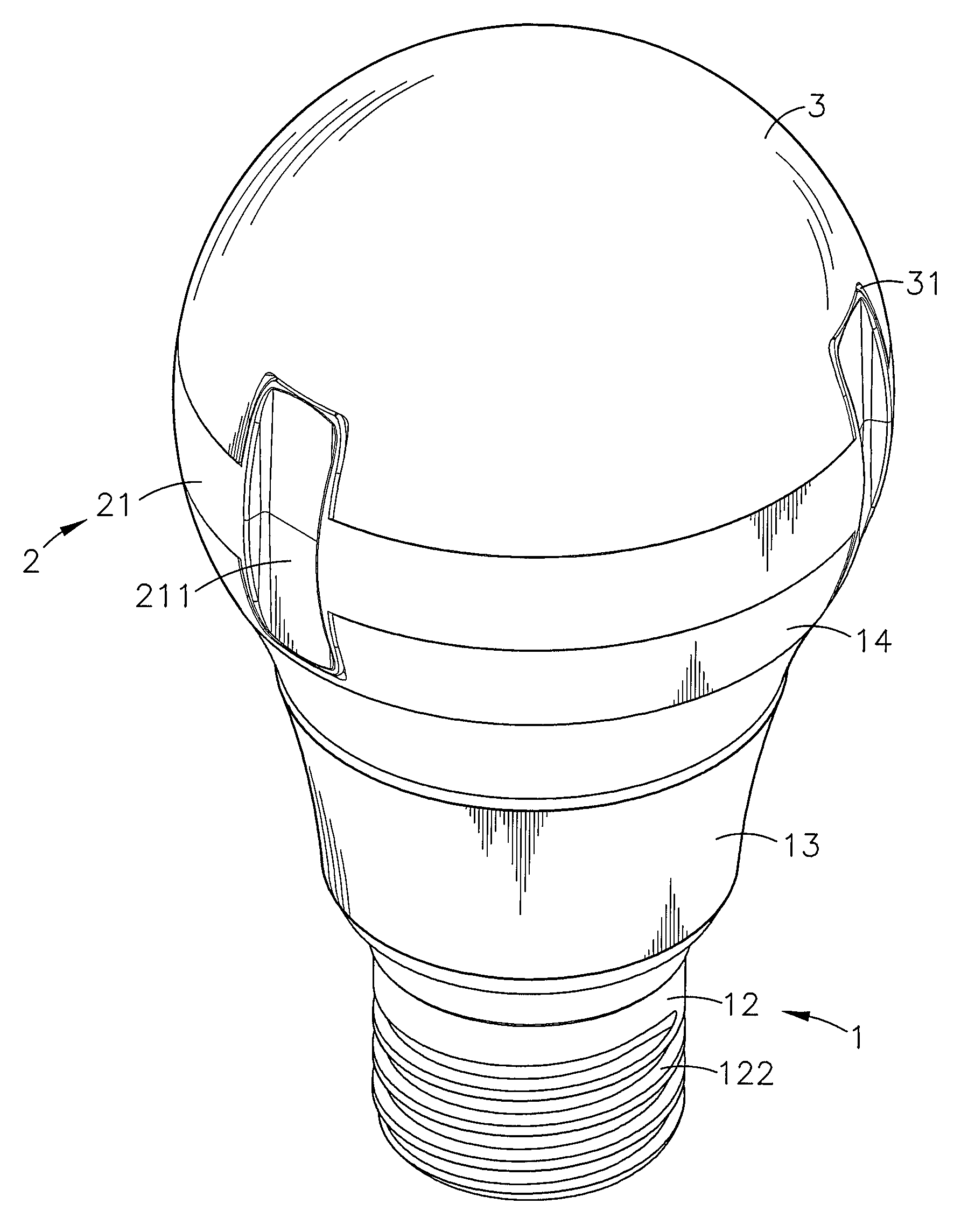

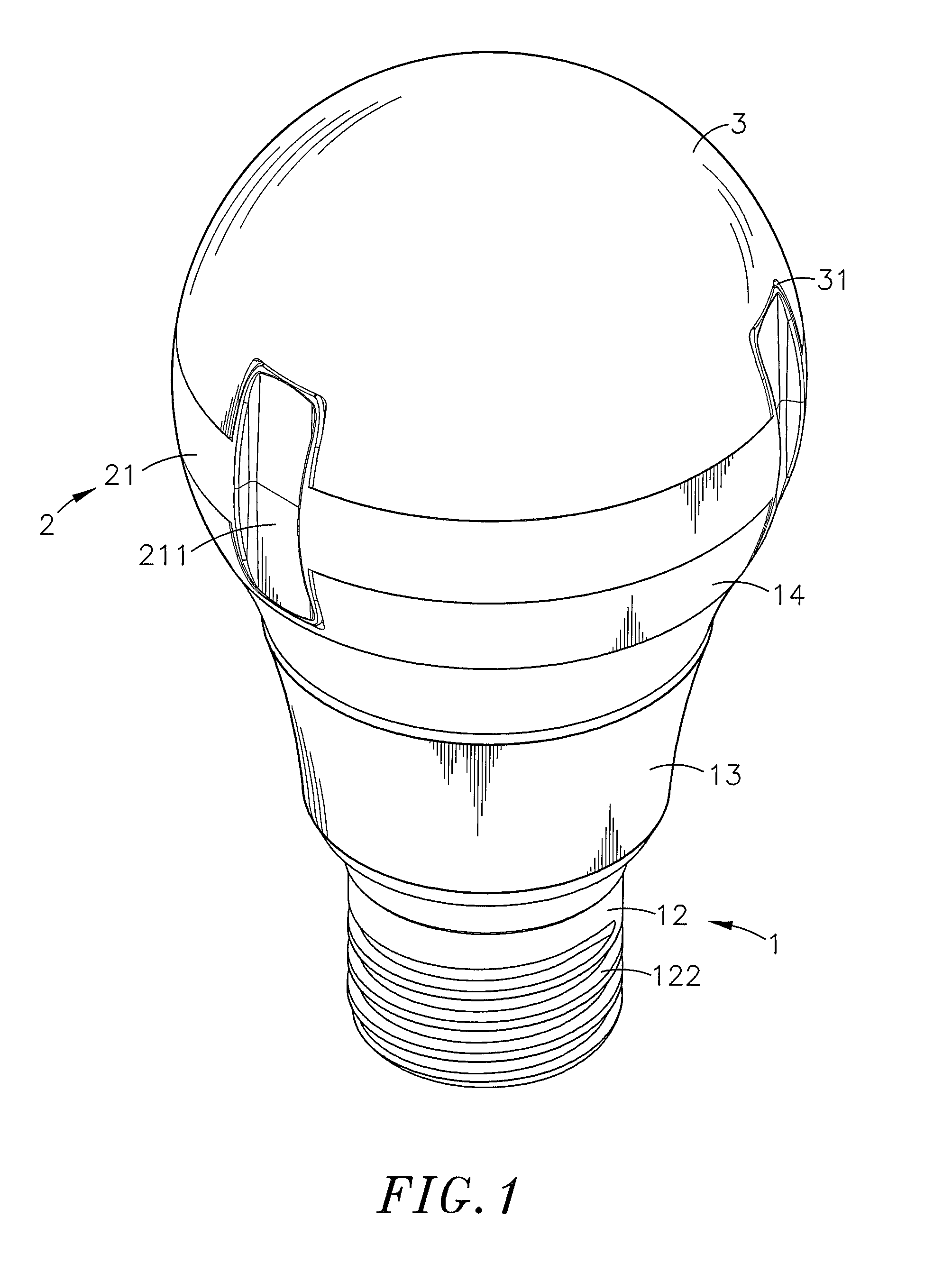

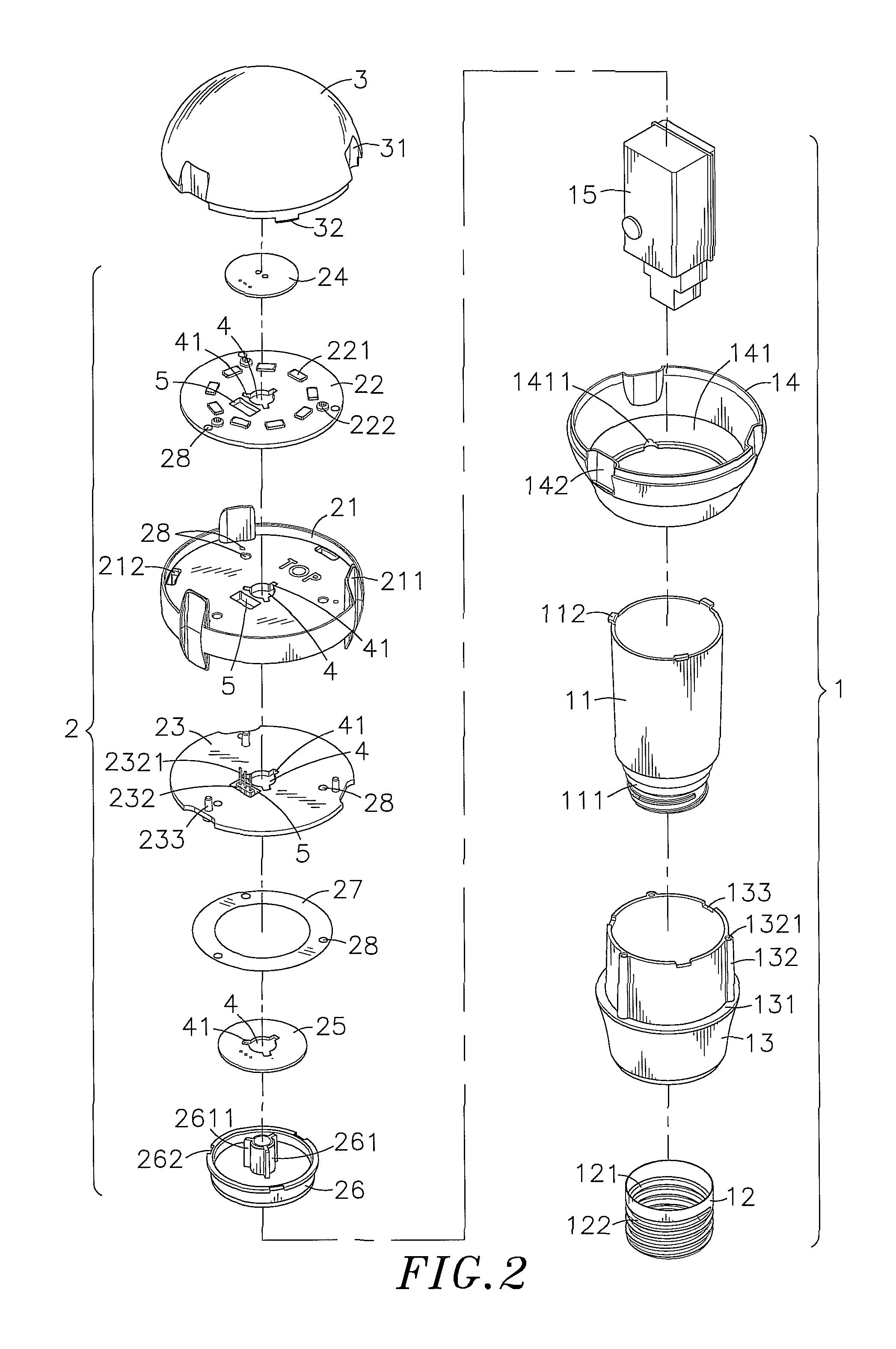

Light bulb with upward and downward facing LEDs having heat dissipation

InactiveUS8985815B2Fast heatingHigh component positioning stabilityCoupling device connectionsPoint-like light sourceComputer moduleLamp shell

A light bulb includes a lamp base unit including a base, an electrically insulative hollow column fastened to the base, a heat sink surrounding the electrically insulative hollow column, a light-transmissive shade surrounding the upper part of the metal cylindrical heat sink and a power supply module electrically connected to the base, a light source module including a metal holder plate, a first circuit board with upward-facing LEDs, a second circuit board with downward-facing LEDs, a first adapter board, a second adapter board, a positioning block and a heat transfer pad and supported on the heat sink in the light-transmissive shade, and a lamp shell fastened to the metal holder plate and capped on the light-transmissive shade. During operation of the LEDs, waste heat can be quickly dissipated into the outside open air through the mounting lugs of the metal holder plate, the heat transfer pad and the heat sink.

Owner:CHICONY POWER TECH CO LTD

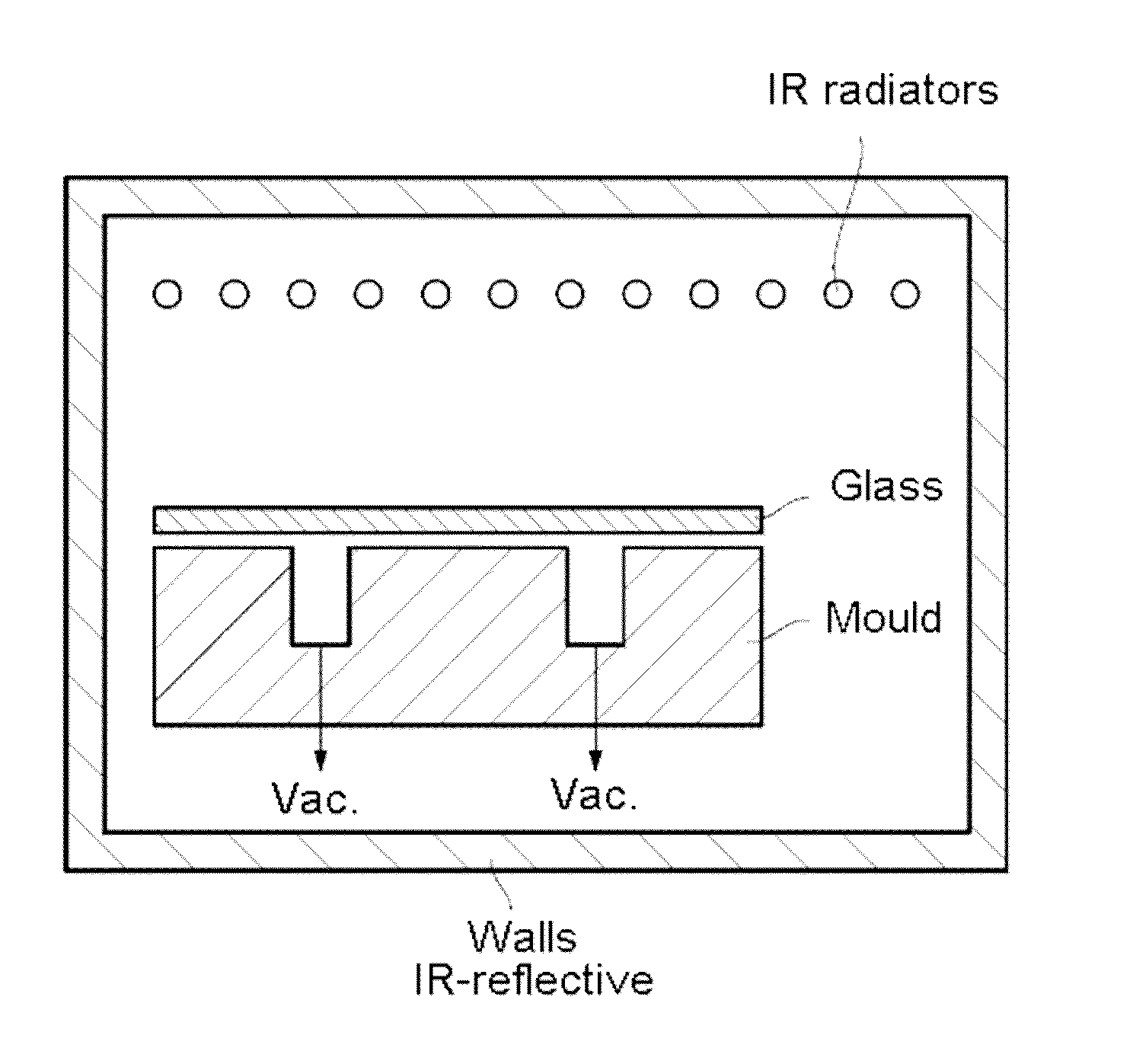

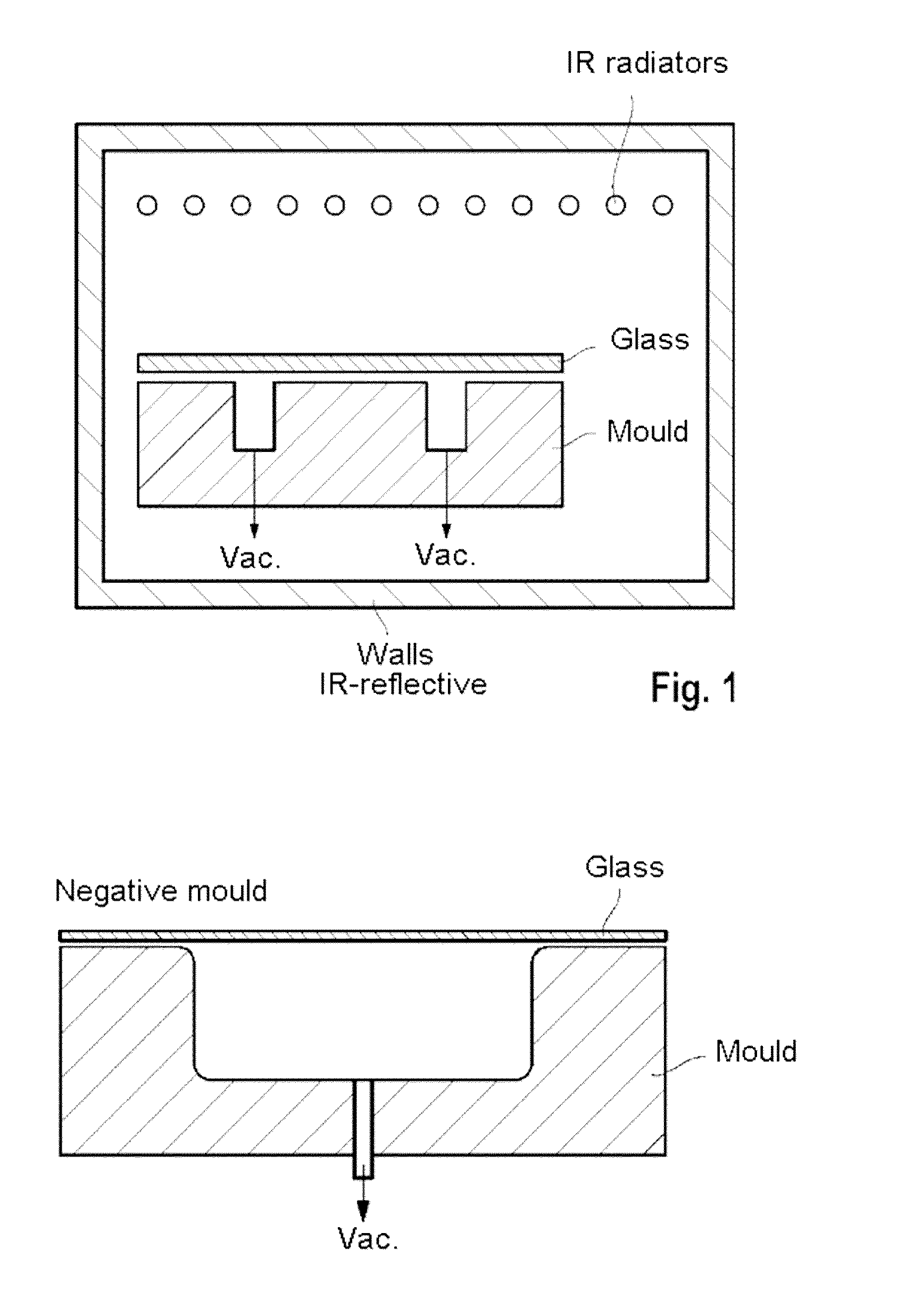

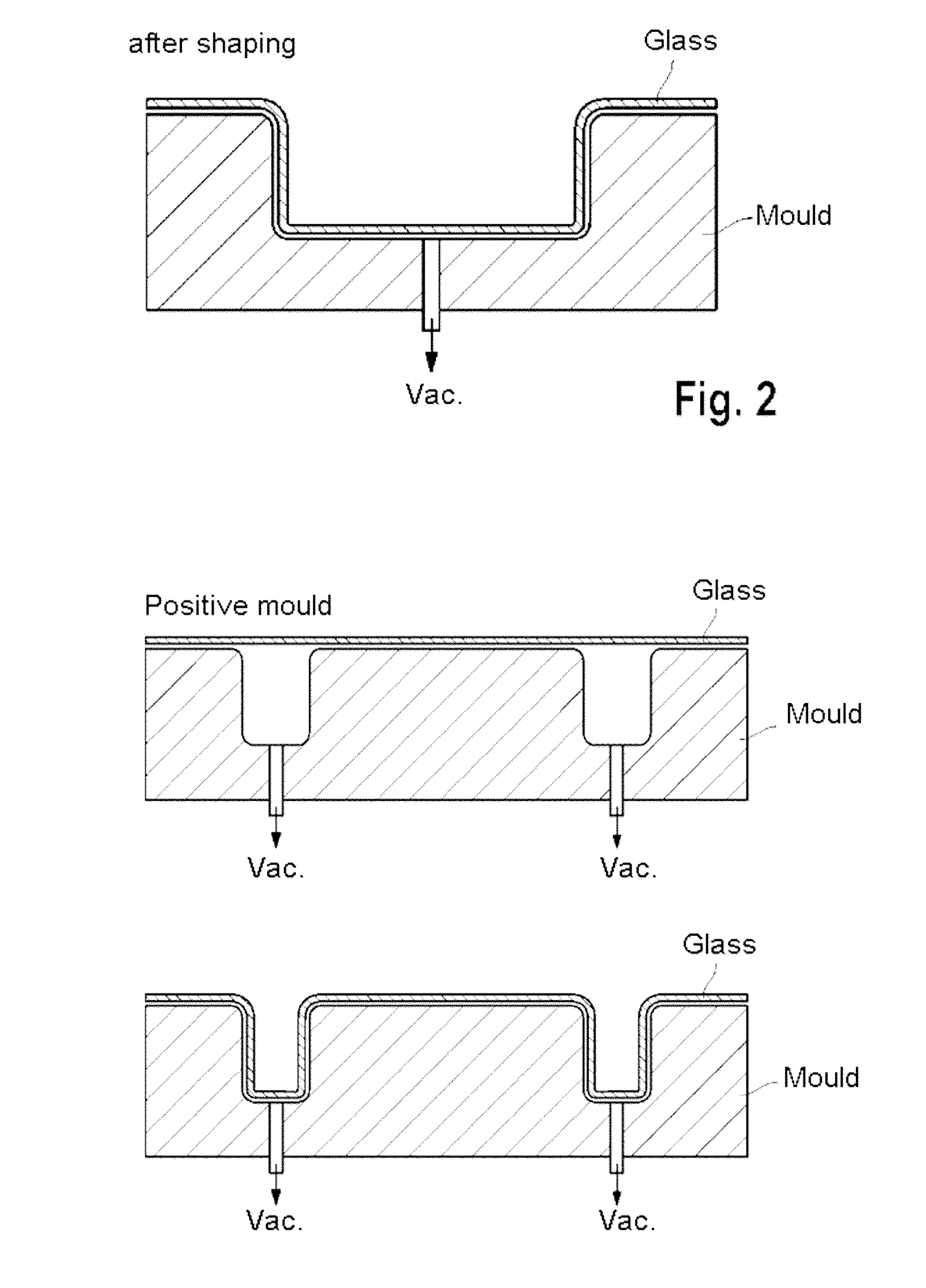

Method for manufacturing molded glass articles, and use of the glass articles manufactured according to the method

ActiveUS20130298608A1Fast heatingMaintain temperatureGlass reforming apparatusGlass severing apparatusMetallurgyPositive pressure

Processes for producing shaped glass articles with a defined geometry are provided. In some embodiment, the process includes arranging a glass pane on a mould, heating the glass pane by infrared radiation, deforming the heated glass pane over the mould by gravity, negative pressure, and / or positive pressure, and cooling the shaped glass pane to obtain the shaped glass article with a defined geometry.

Owner:SCHOTT AG

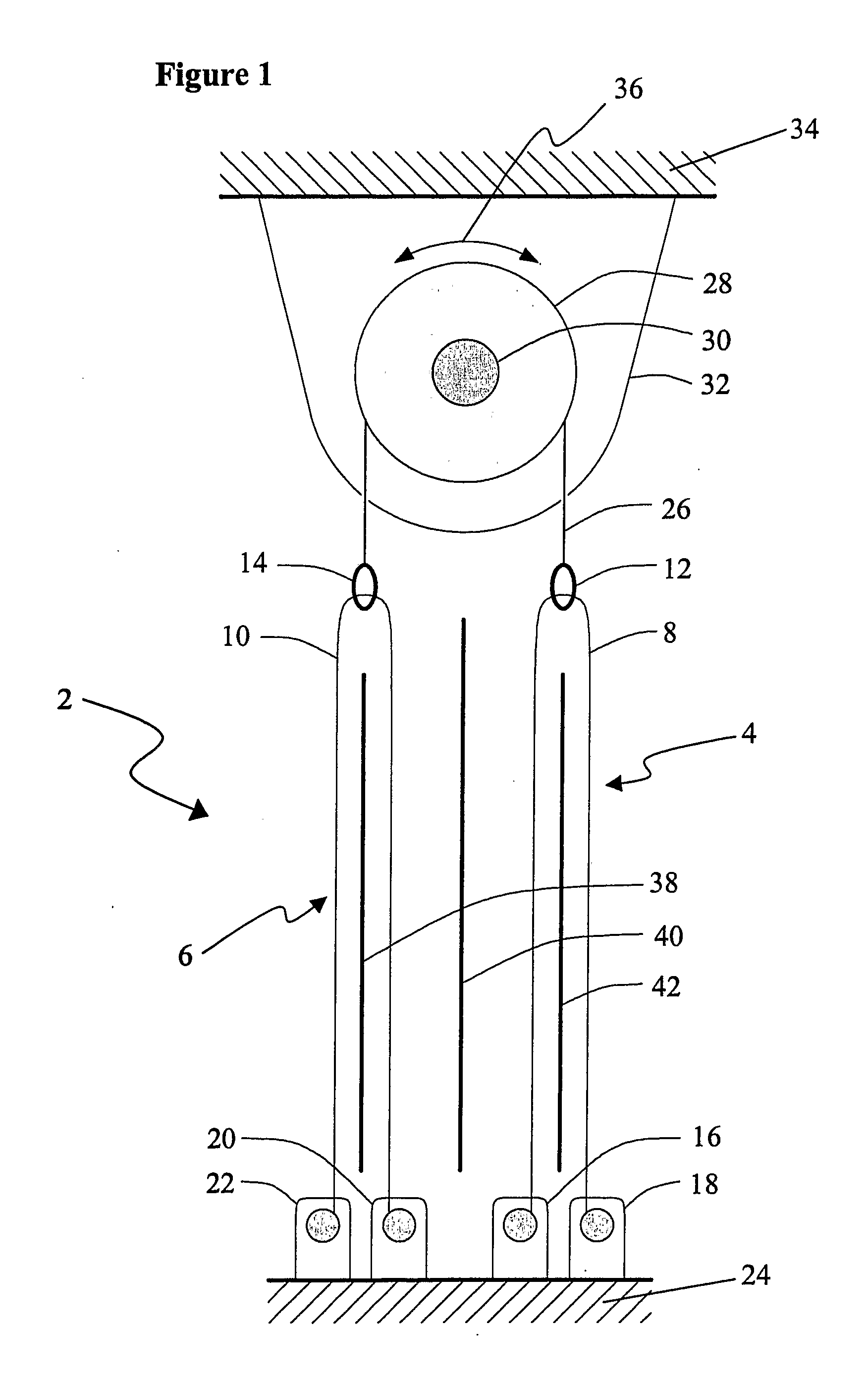

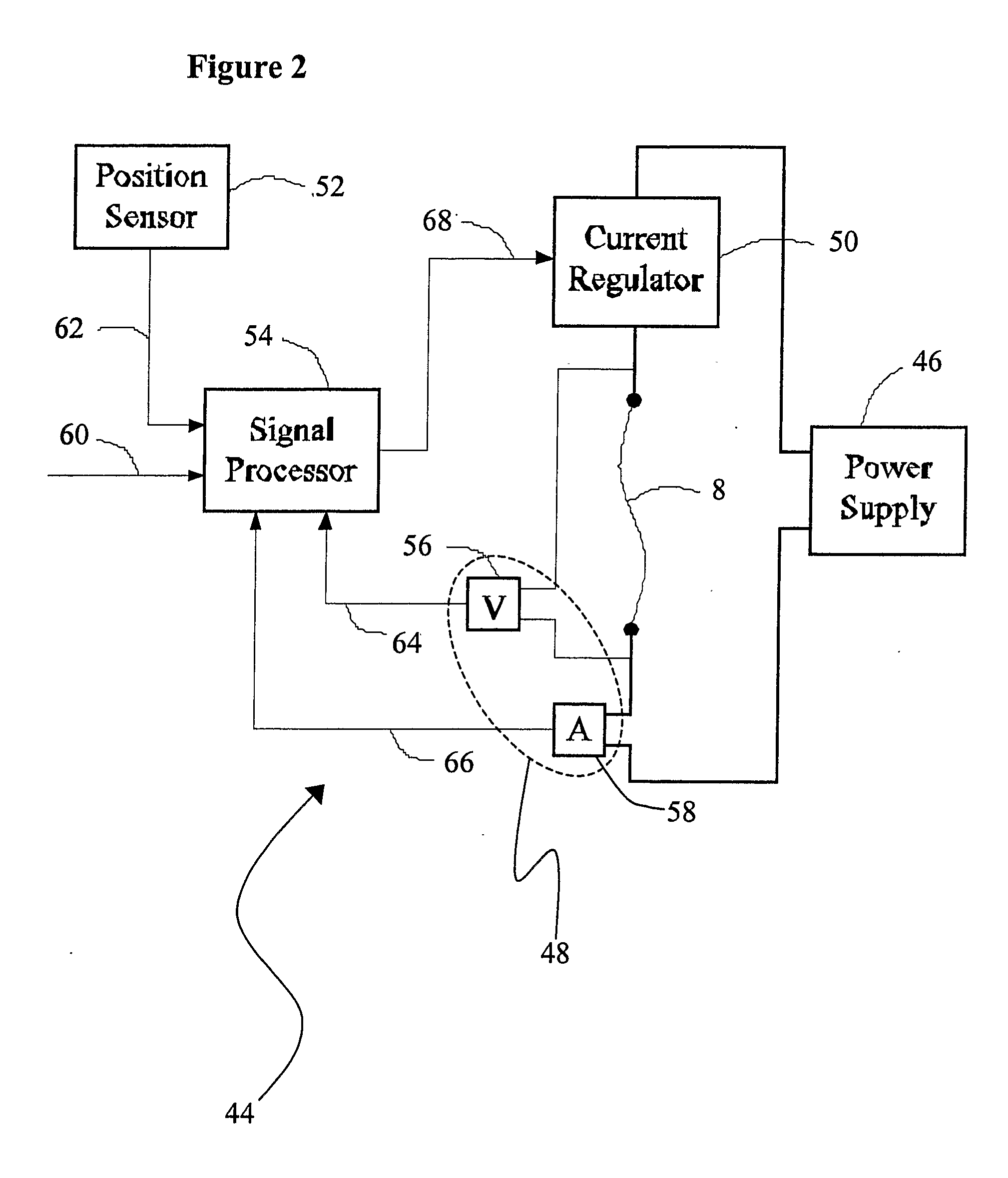

Shape memory alloy actuator

InactiveUS20070175213A1Increase movement speedIncrease ratingsMechanical power devicesClosed-cycle gas positive displacement engine plantElectrical resistance and conductanceControl theory

A controller (44) for a SMA actuator (2) includes an electgric power source (46) for applying an electric current through an SMA element (8), a sensor (48) to detect change in an electric resistance of the element (8); and a regulator (50) for controlling the magnitude of the applied electric current. The regulator (50) applies a first current above a safe limit current for the element (8) until a selected change in the electric resistance is detected and applies a second current less than the first current after the change is detected.

Owner:AUSTRALIEN NAT UNIV

Electric oven applying an induction heating at both sides of the cavity

InactiveUS6864468B2Fast heatingFast transferDomestic stoves or rangesCoil arrangementsPyrolysisInternal temperature

Disclosed is an electric oven which increases temperature fast and reduces heat loss in accordance with that a cavity surface generates its own heat by using an induction heating. The electric oven comprises: a case having a door at a front side and having a cavity for receiving food therein; a magnetron installed at one side of an upper portion of the cavity for generating microwave of high frequency and supplying heat to the cavity; an inverter for generating high frequency at a space between the case and the cavity; first, second, third, and fourth heating units installed each side of the cavity for supplying heat. Since temperature of a cooking chamber can be set as wanted uniformly and faster, preheating time and actual cooking time can be reduced. Also, since inner temperature of the cavity rises faster and simultaneously, an automatic cleaning in the cavity using pyrolysis can be performed faster and uniformly, thereby reducing power consumption.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com