Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4306results about "Induction heating apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

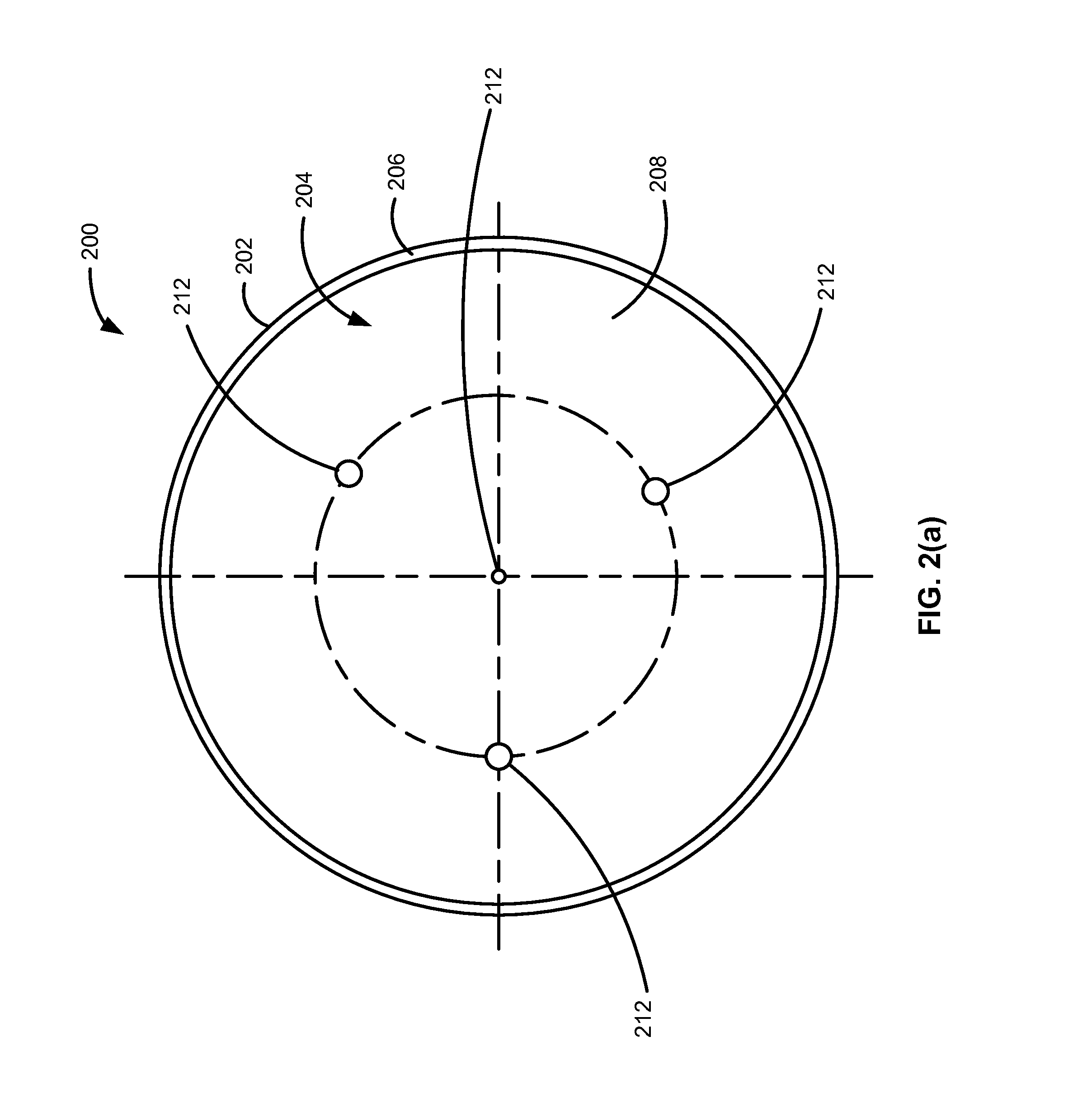

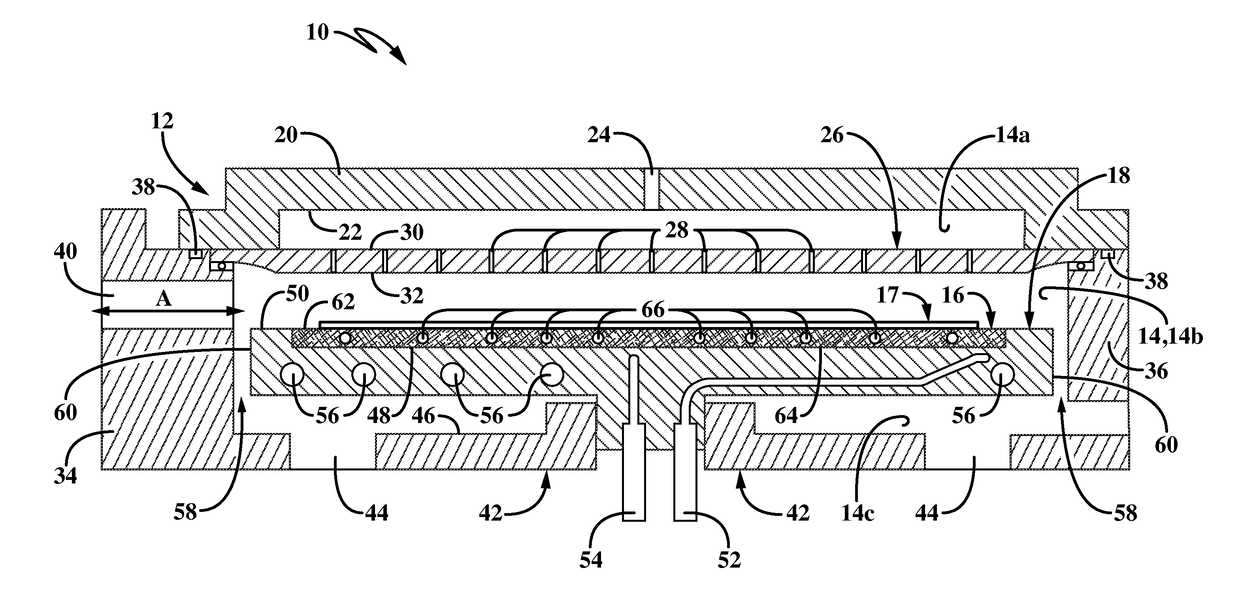

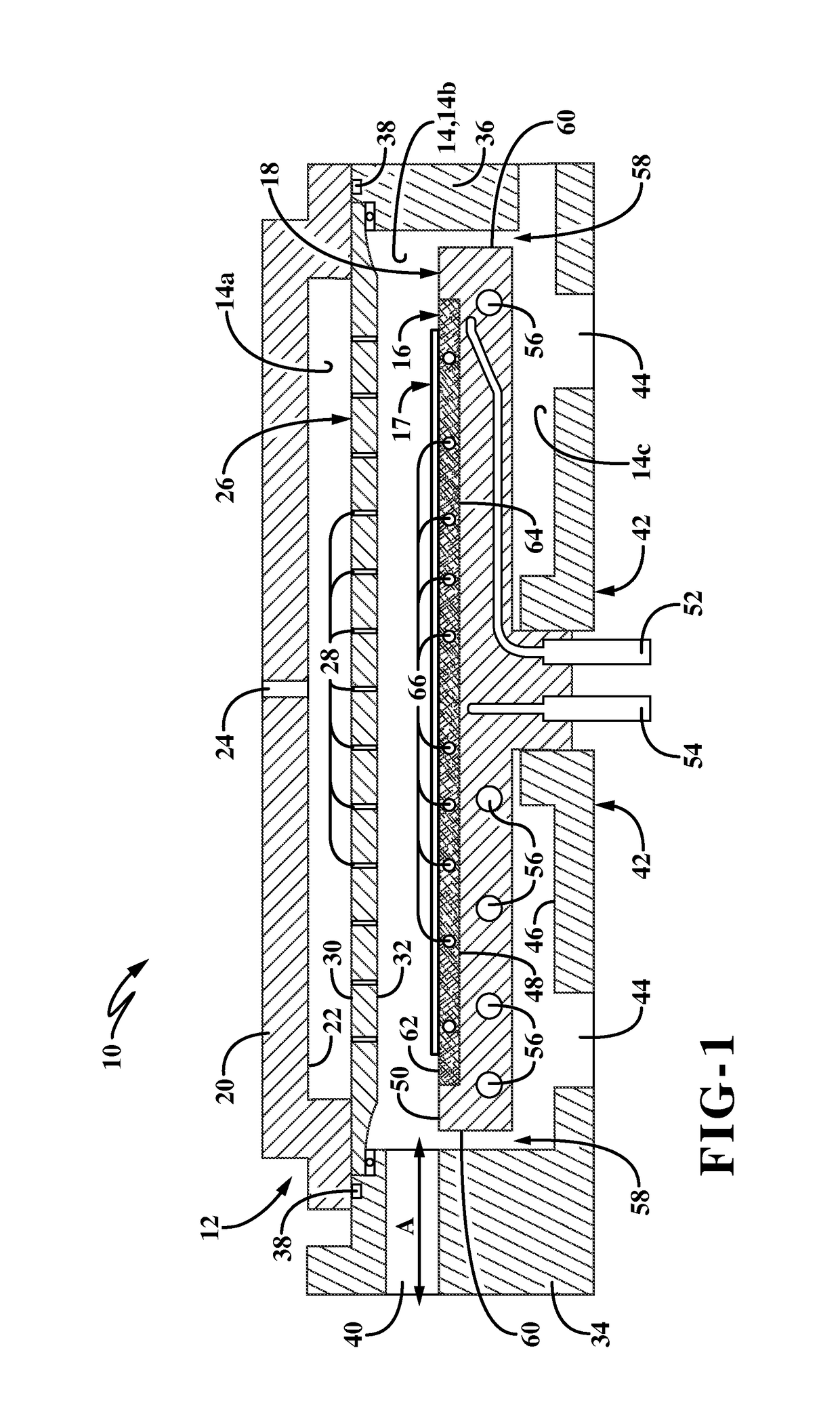

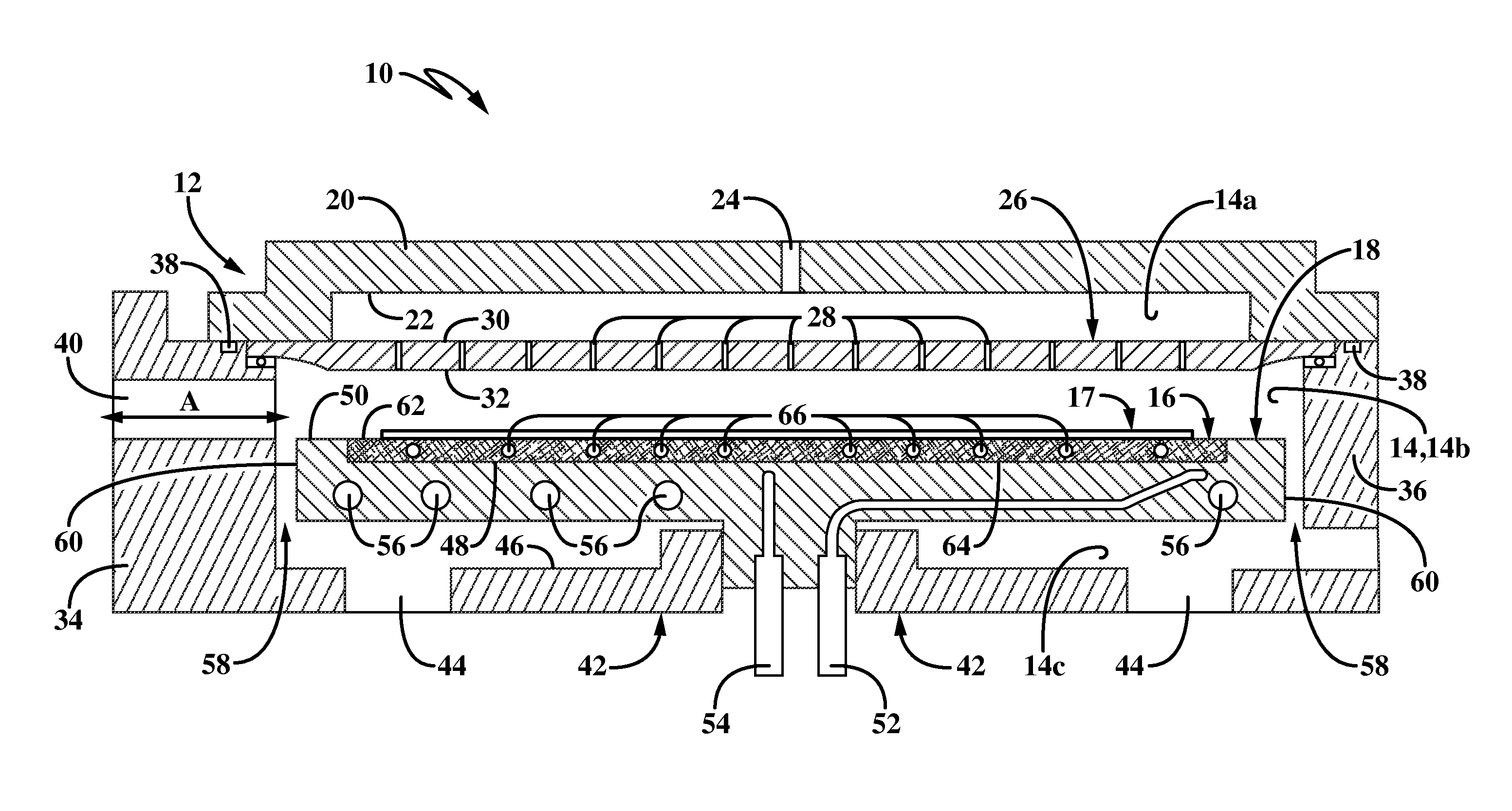

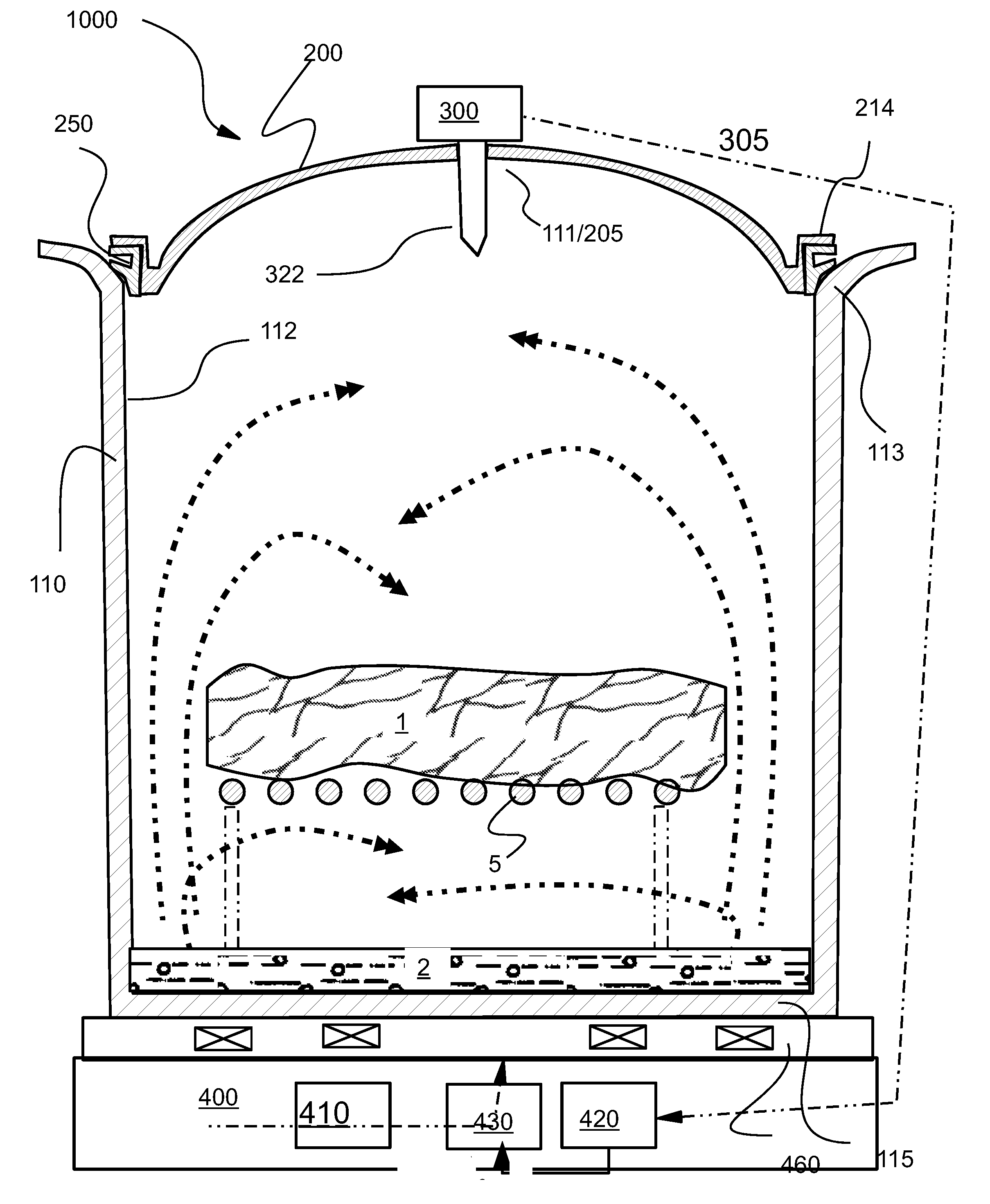

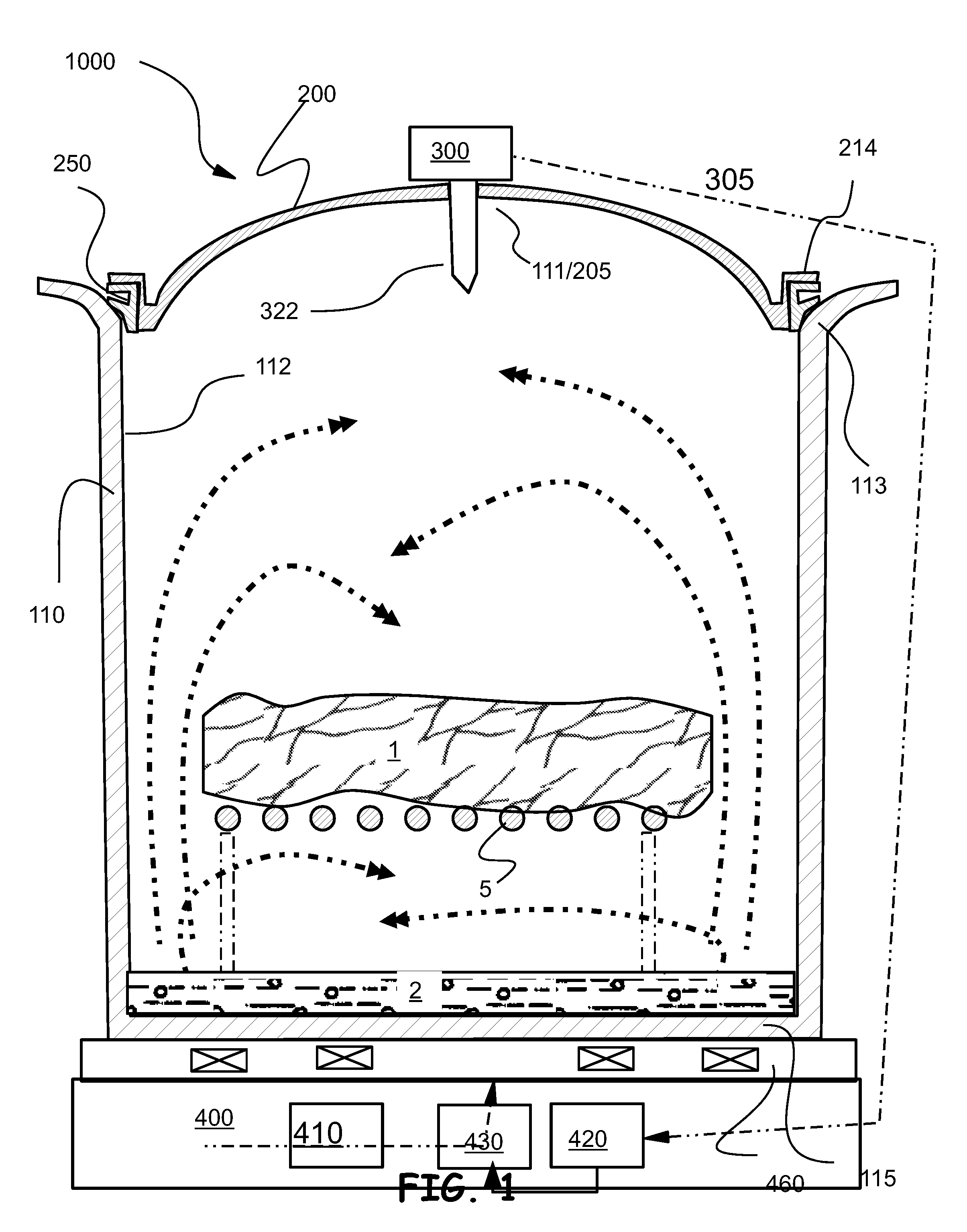

Removable substrate tray and assembly and reactor including same

InactiveUS20150267295A1Easy to replaceReduce manufacturing costFurnaces without endless coreSemiconductor/solid-state device manufacturingReactive materialBiomedical engineering

A substrate tray, a susceptor assembly including a substrate tray, and a reactor including a substrate tray and / or susceptor assembly are disclosed. The substrate tray is configured to retain a substrate during processing and can be formed of a substantially non-reactive material. The substrate tray can be received by a susceptor, formed of another material, to form the susceptor assembly.

Owner:ASM IP HLDG BV

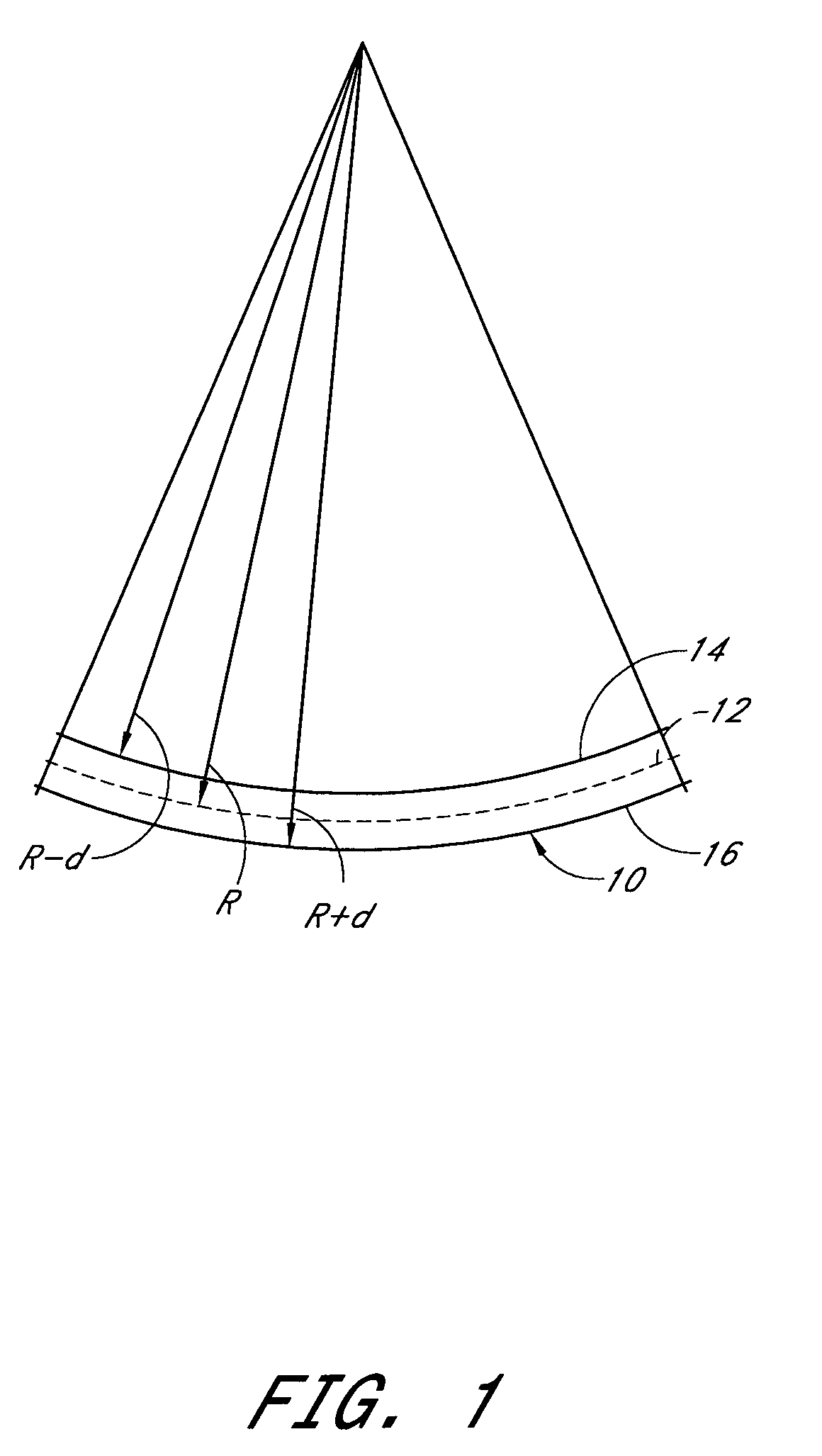

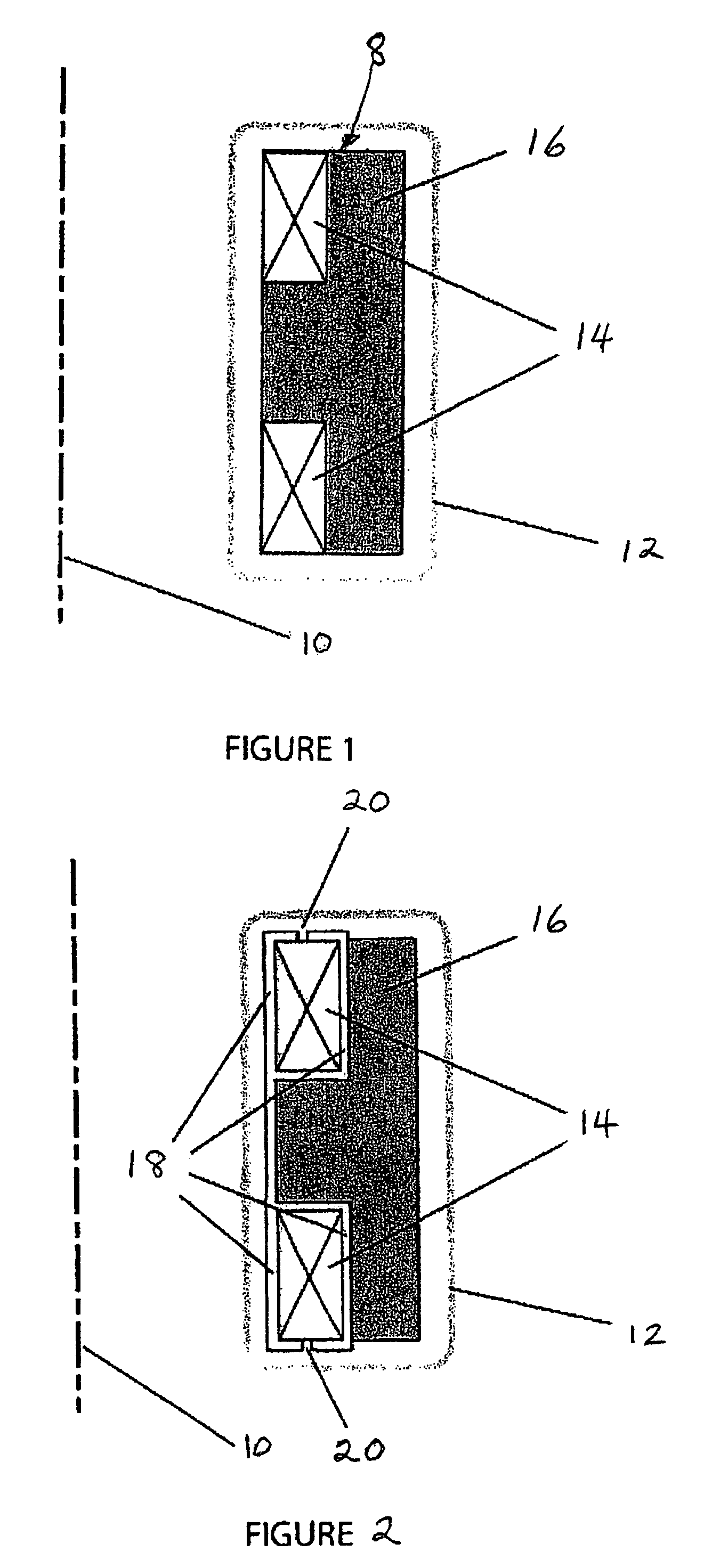

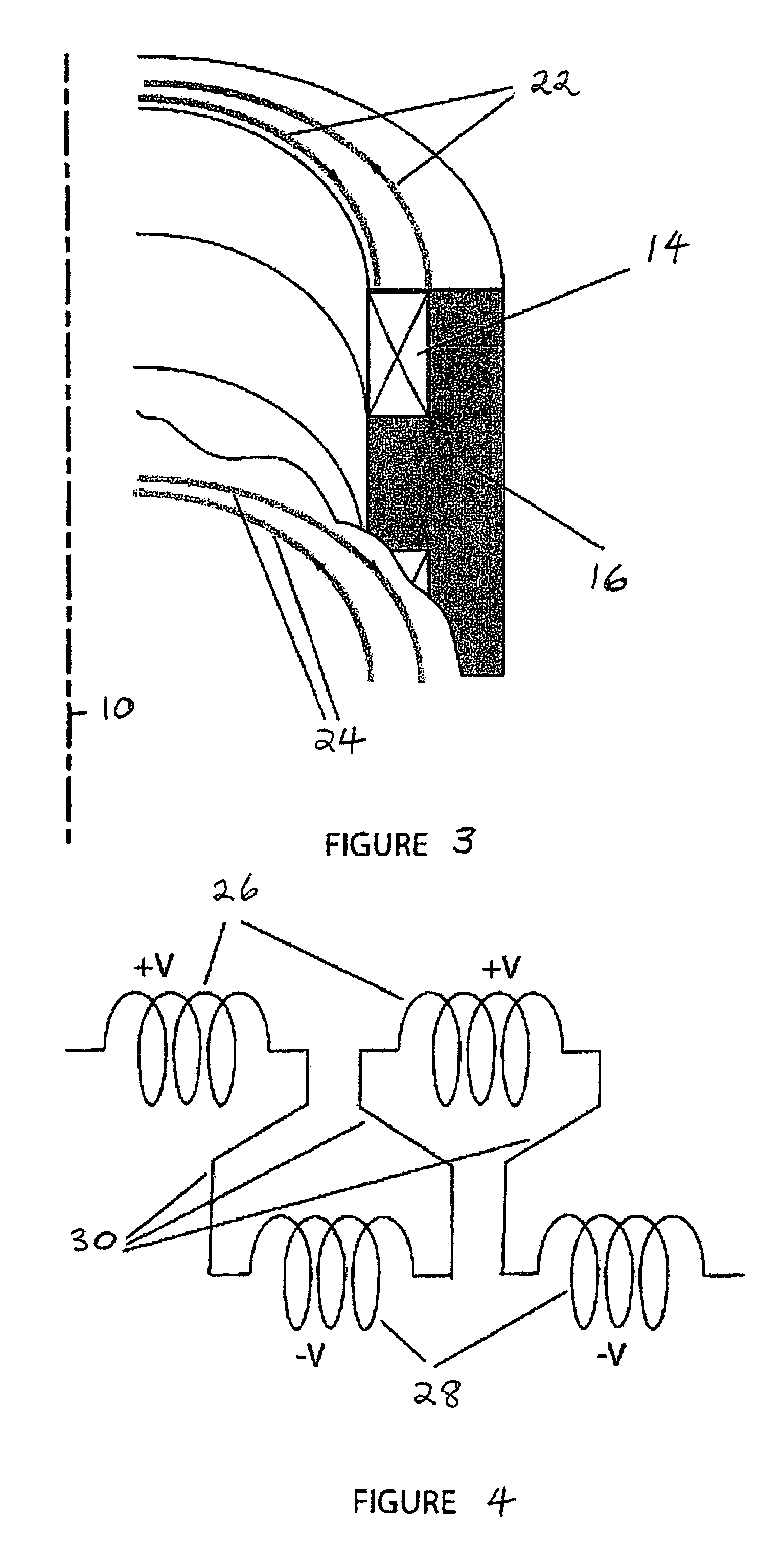

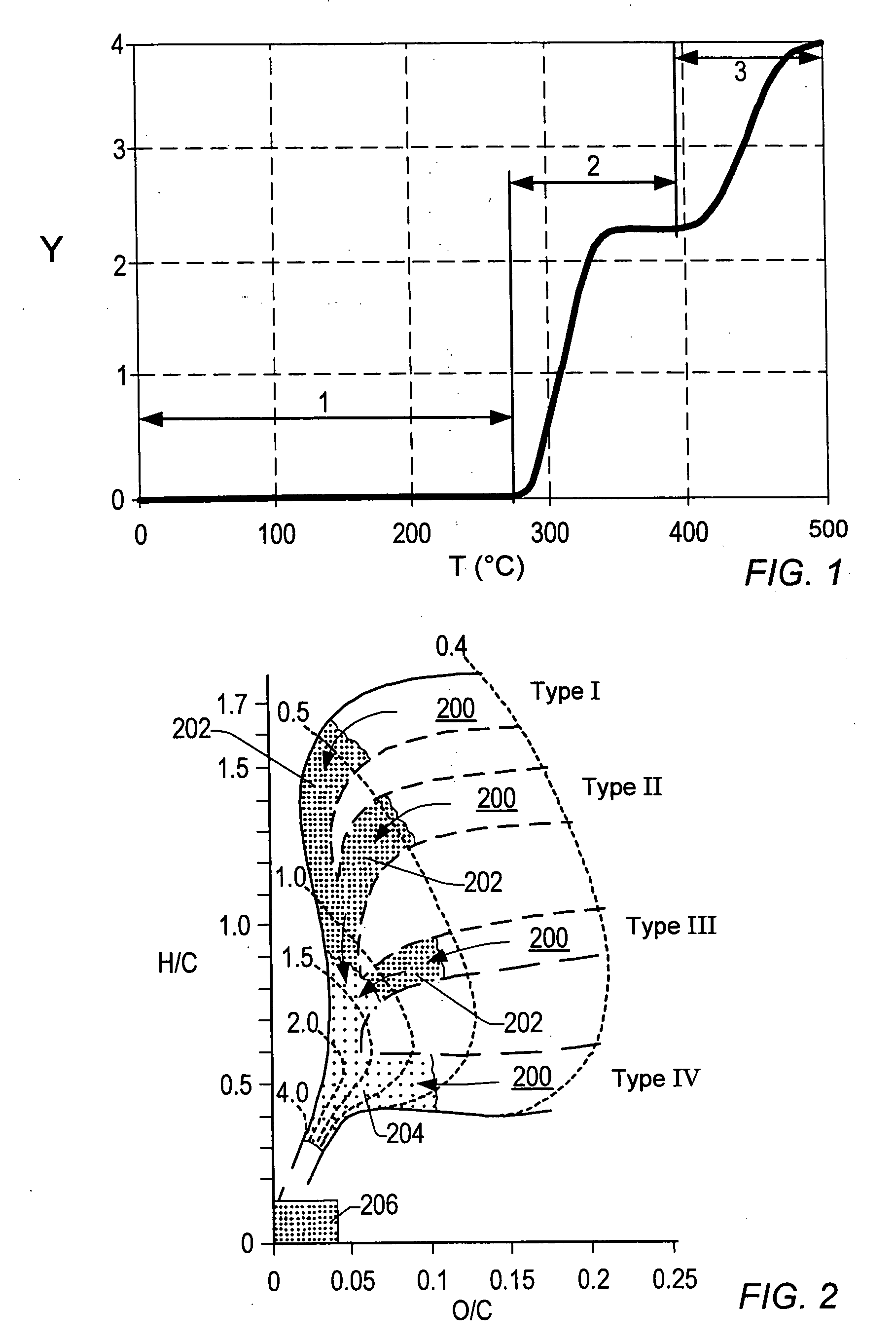

Electromagnetic susceptors with coatings for artificial dielectric systems and devices

InactiveUS20030226840A1Enhanced radiationLow dielectric constantGas treatmentMethane captureChemical treatmentSusceptor

A coated susceptor of electromagnetic energy for chemical processing made of a matrix material that surrounds a non-matrix material that is made from a material that is different from the matrix material, in which the matrix material is constructed of material having lower dielectric losses compared to the non-matrix material, the non-matrix material initially absorbs electromagnetic energy applied to the electromagnetic susceptor to a greater extent than the matrix material, the non-matrix material produces subsequent heat in the matrix material, and the surface of the susceptor is coated with a material that interacts with applied electromagnetic energy of at least one frequency and initially absorbs electromagnetic energy and produces heat.

Owner:DALTON ROBERT C

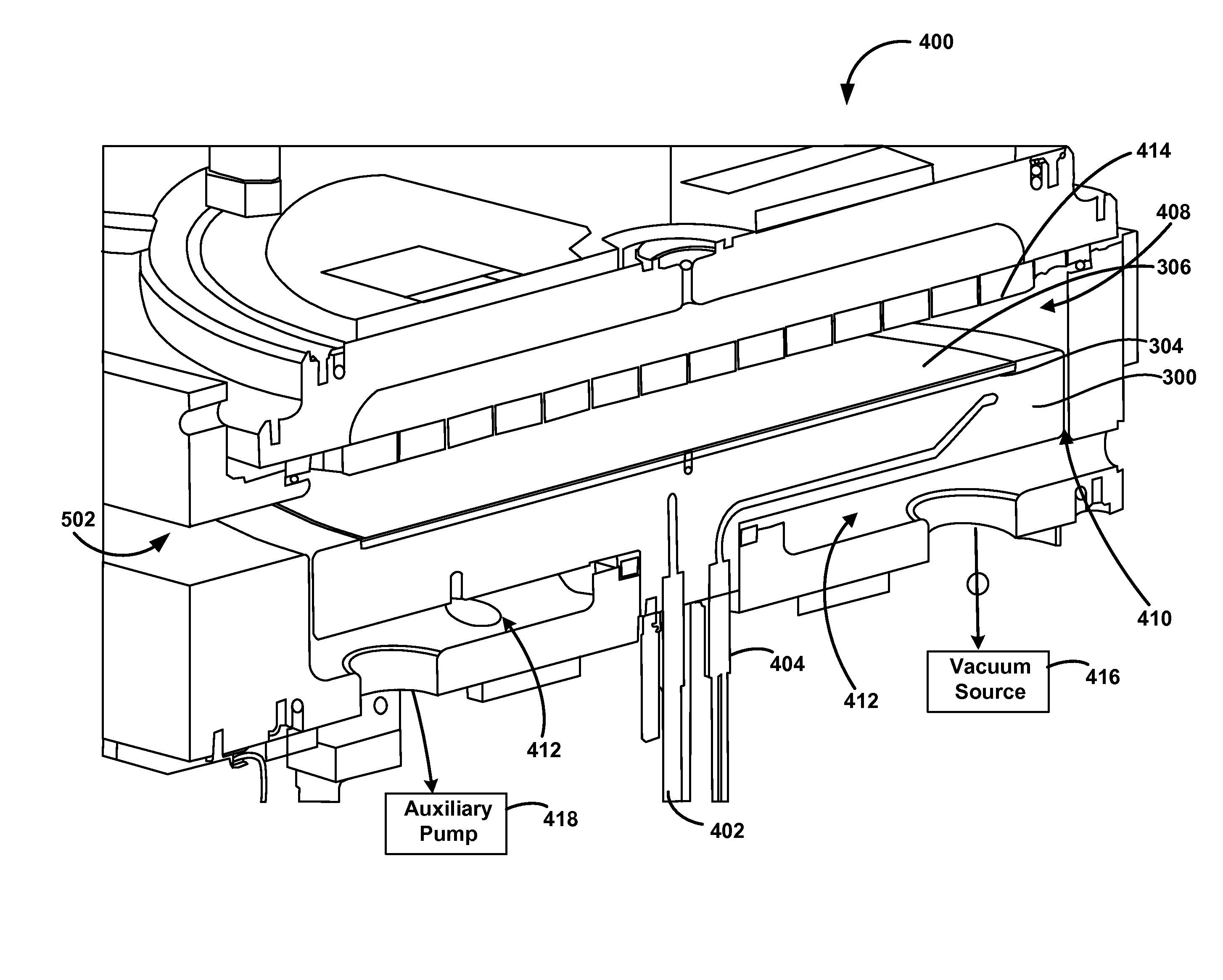

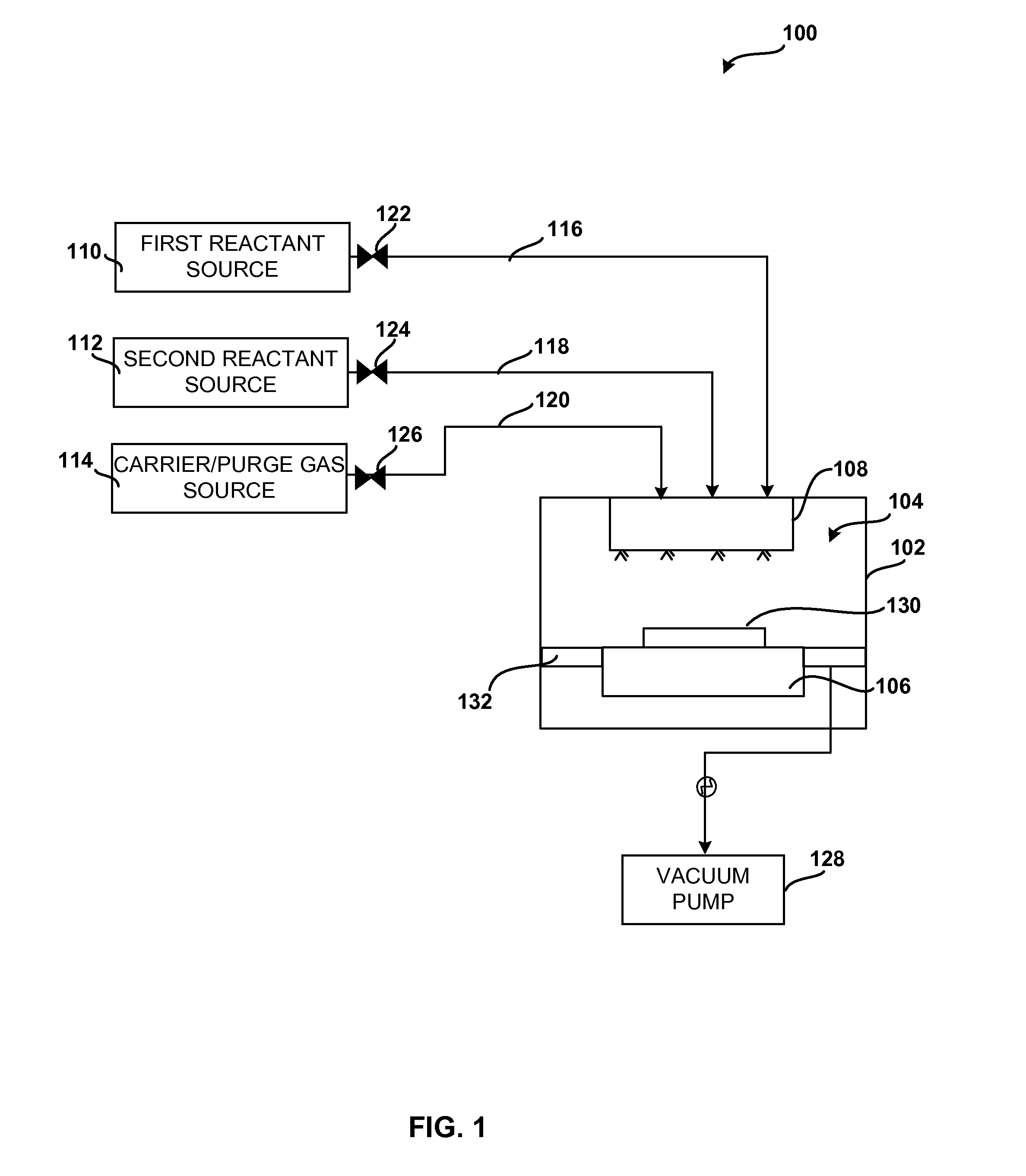

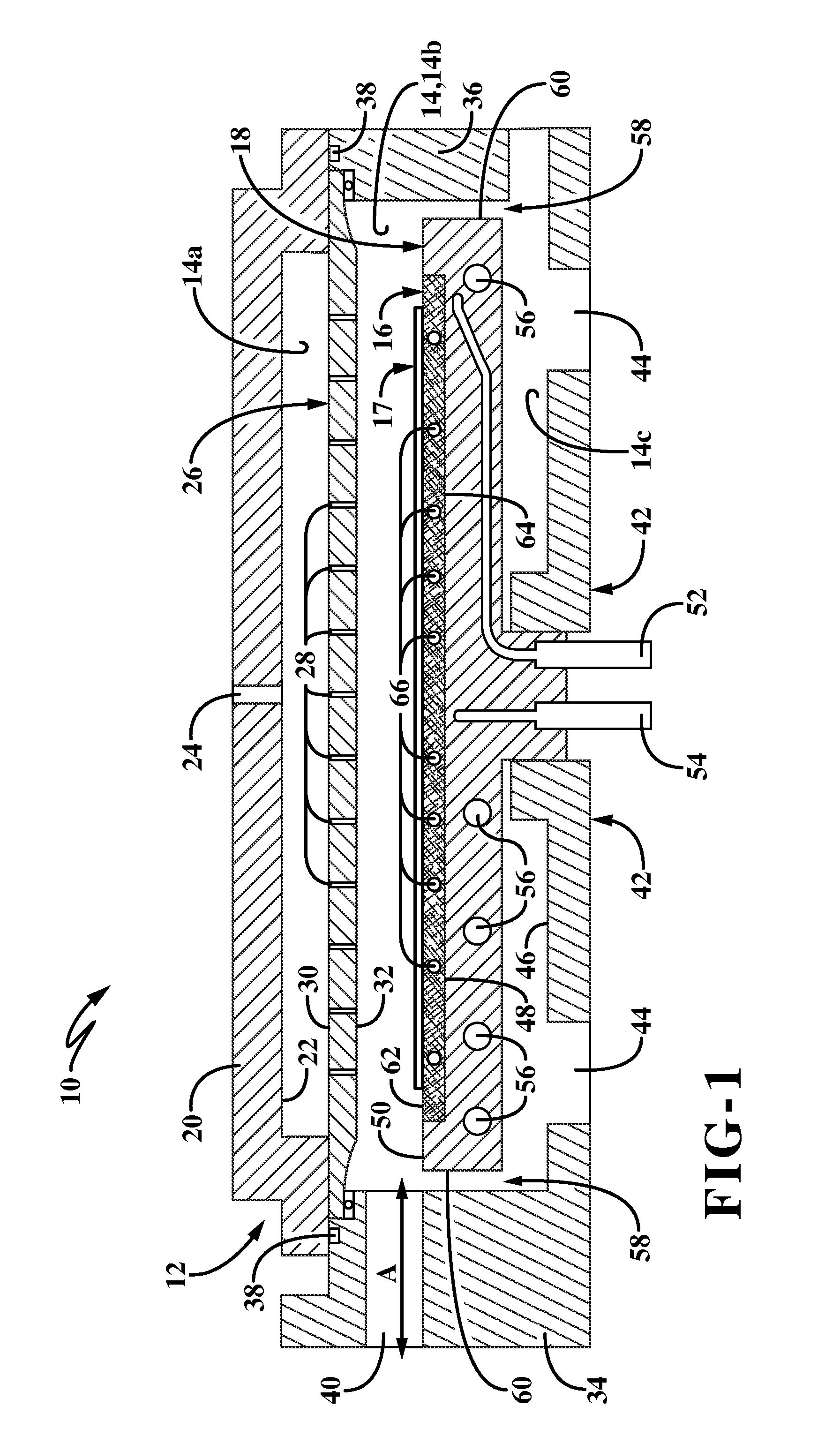

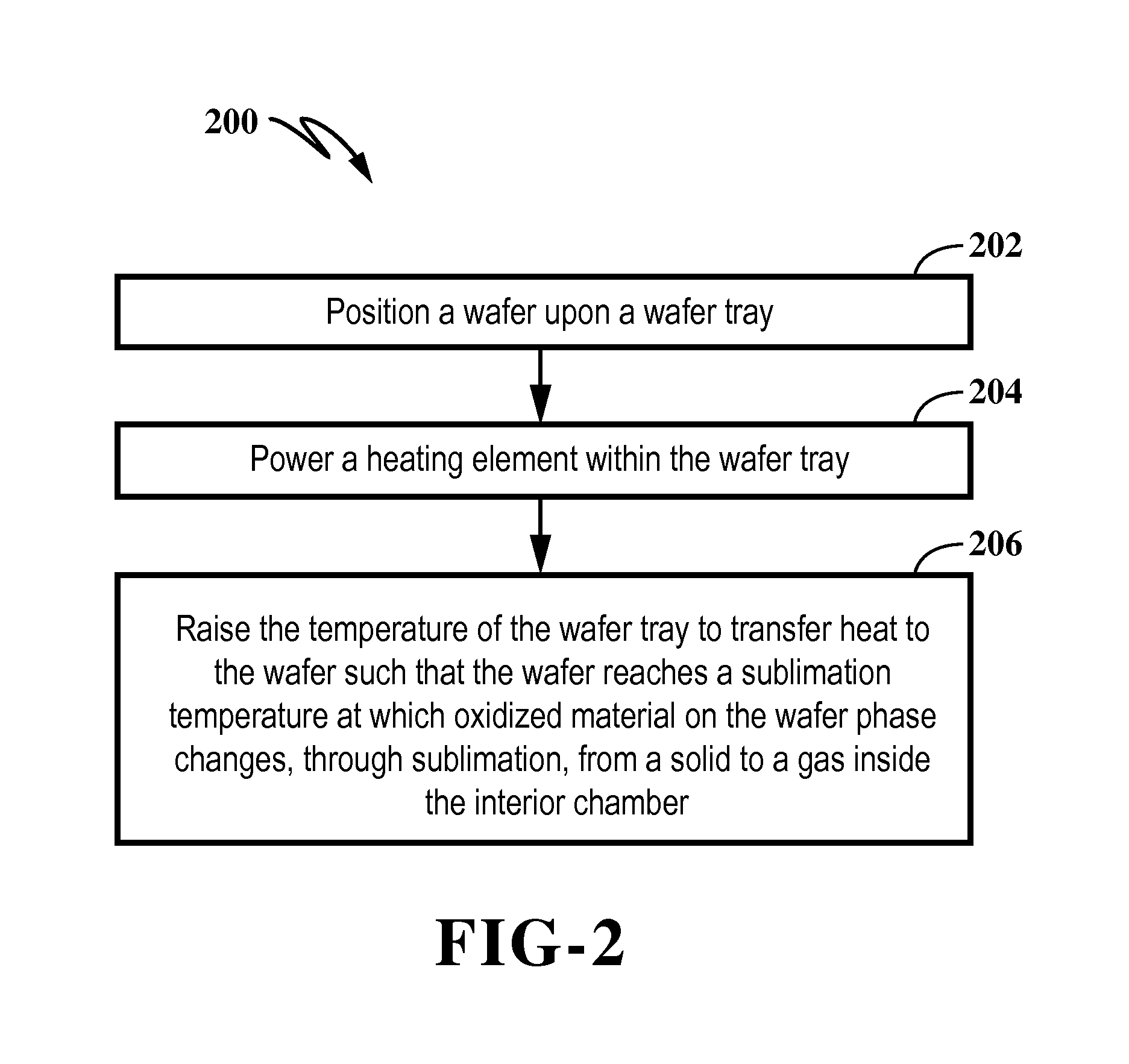

Reactor system for sublimation of pre-clean byproducts and method thereof

Owner:ASM IP HLDG BV

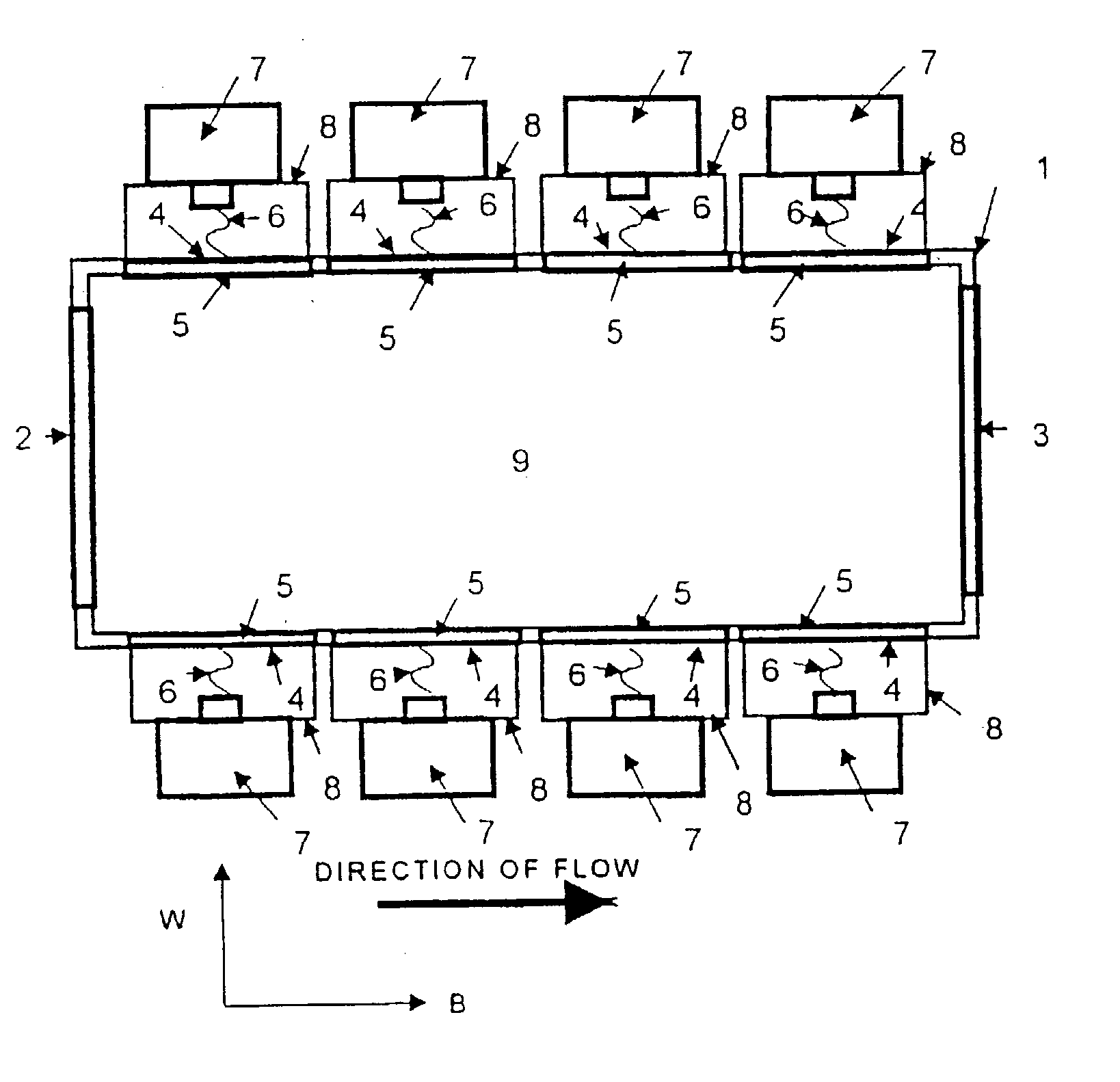

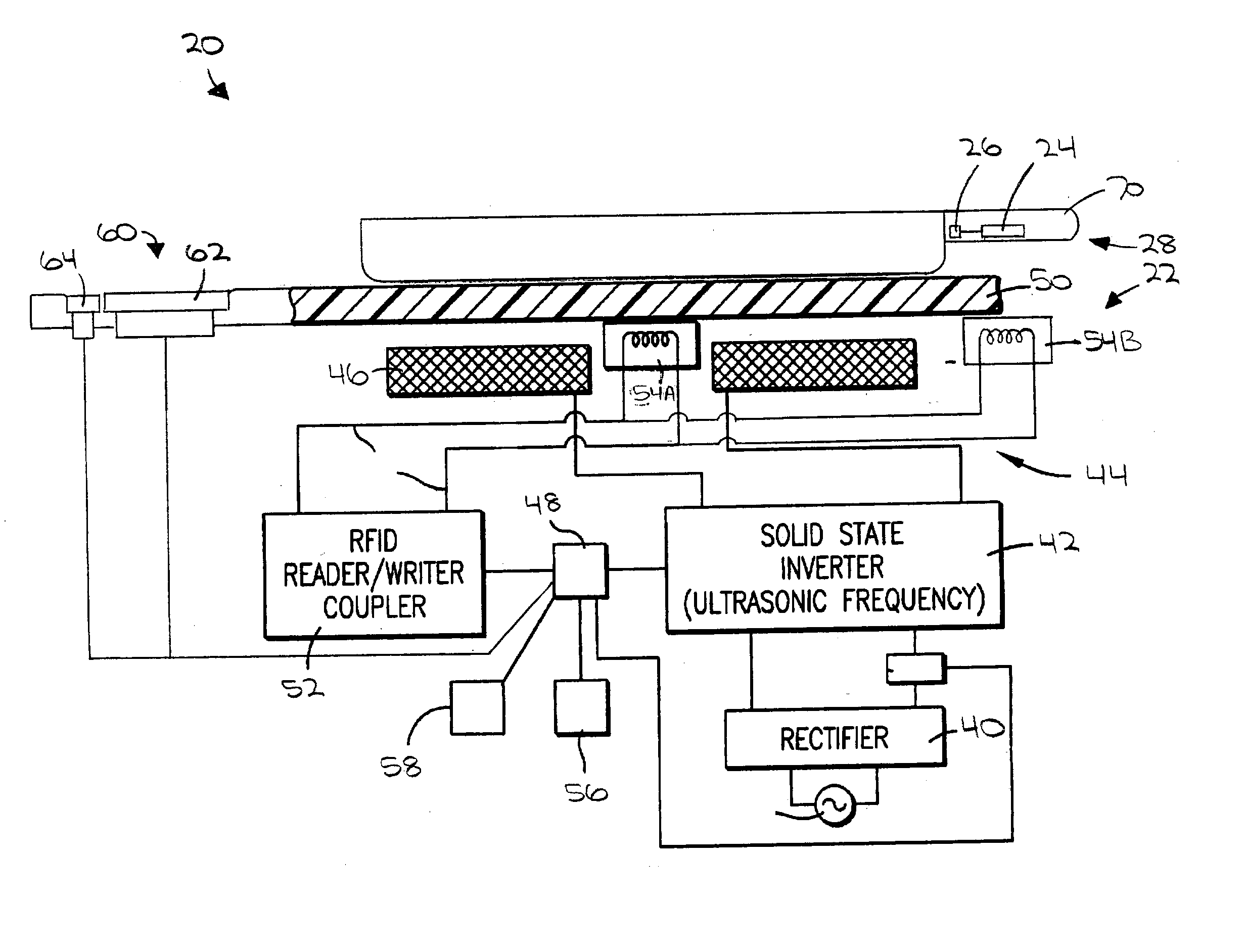

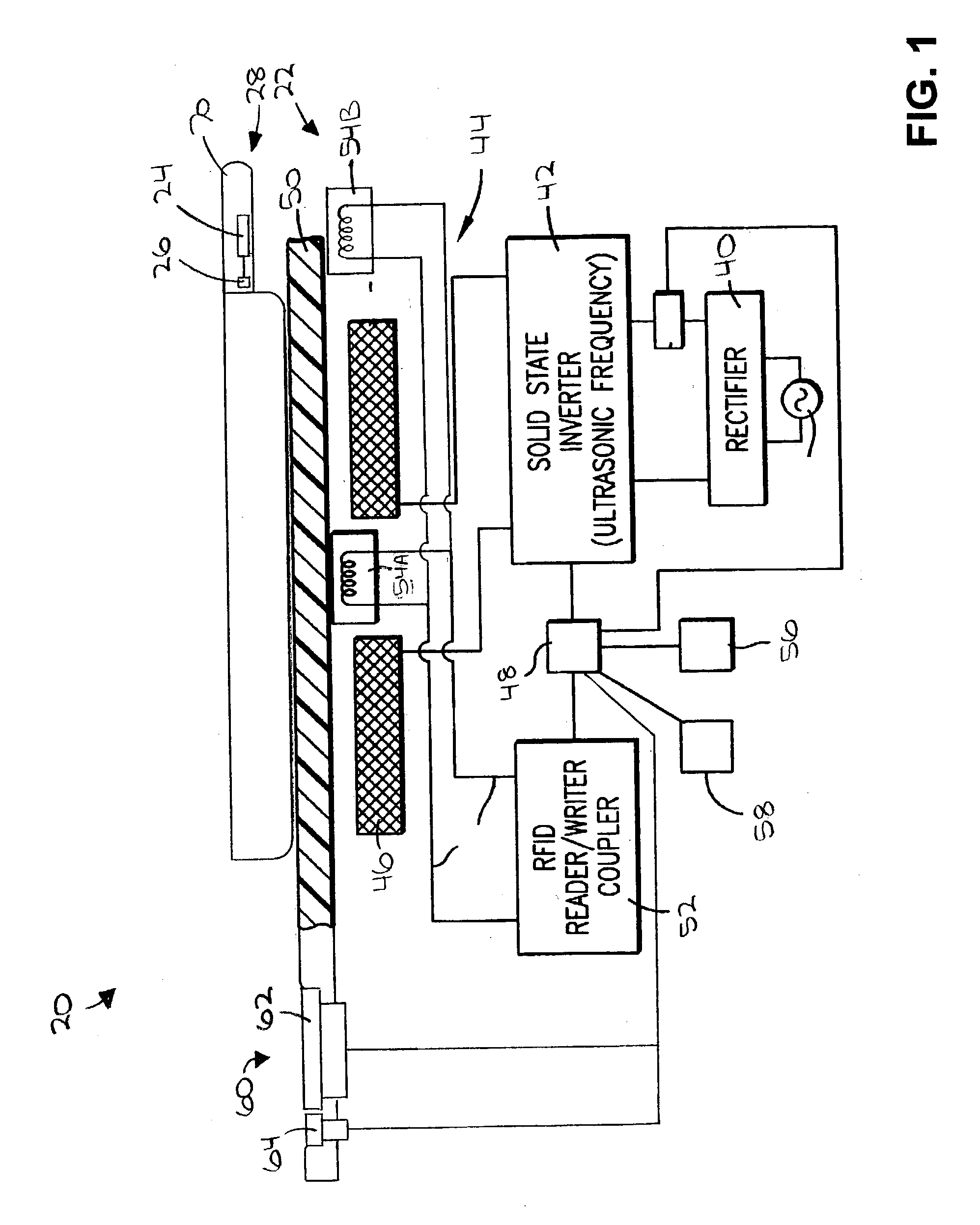

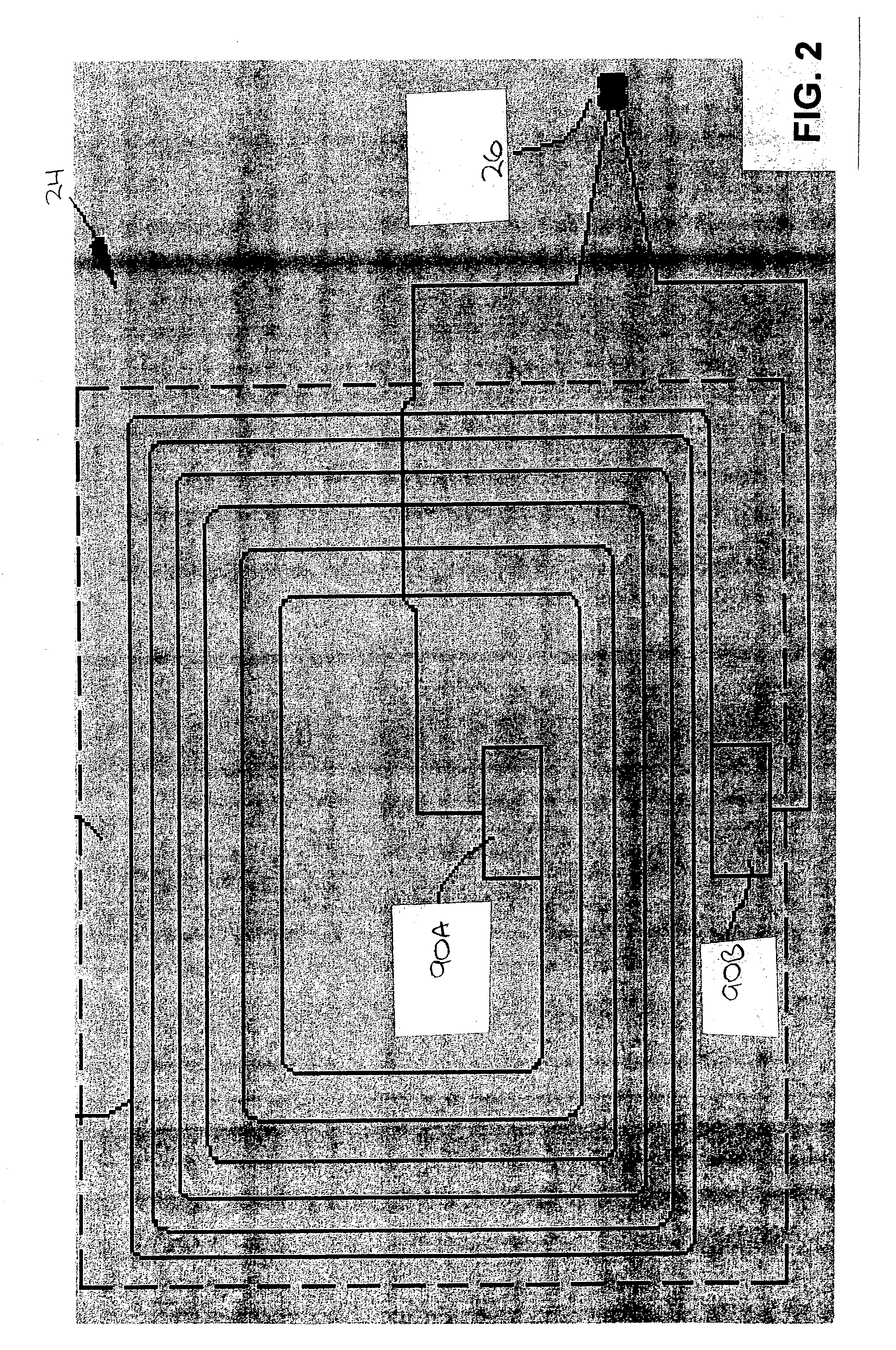

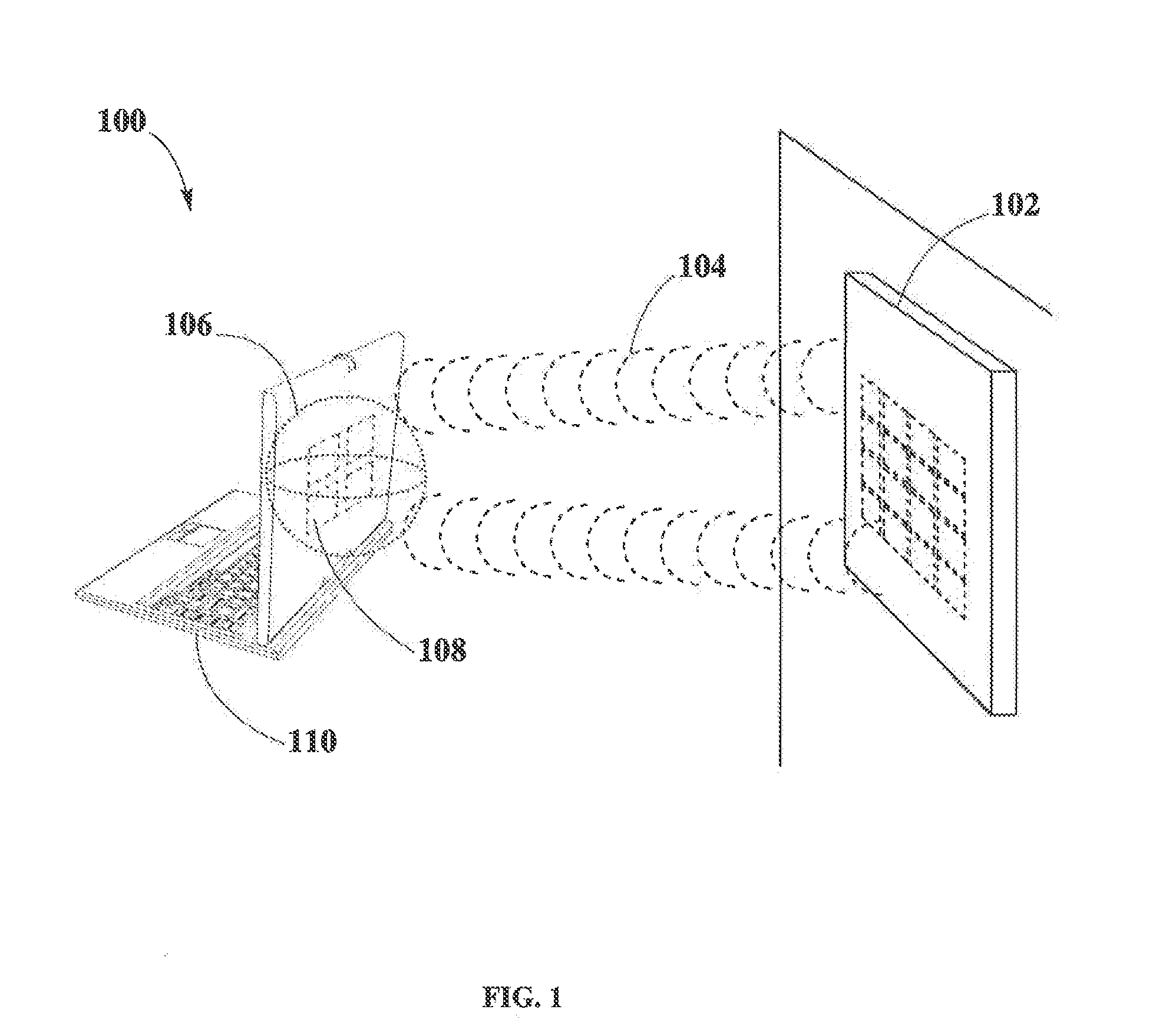

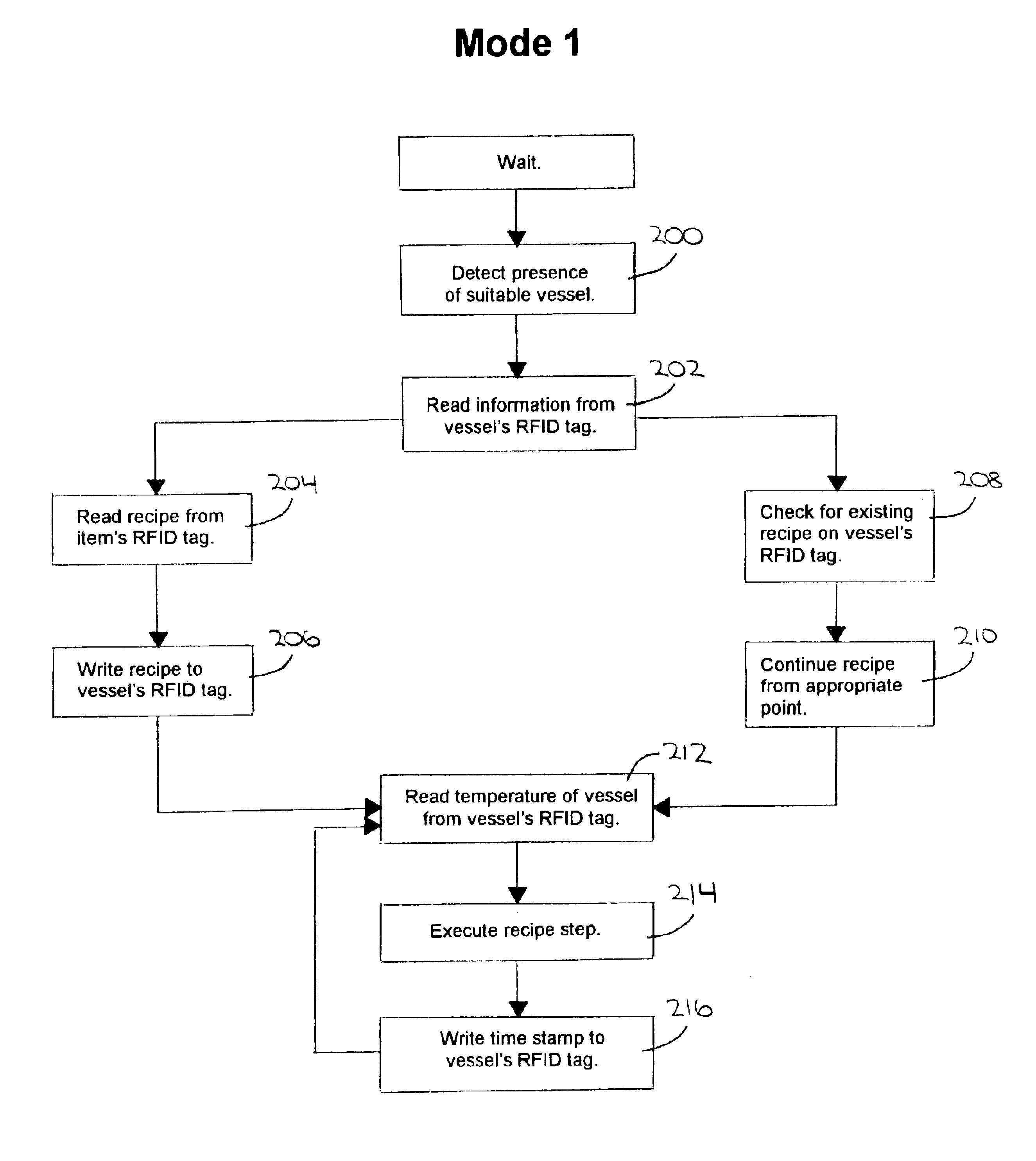

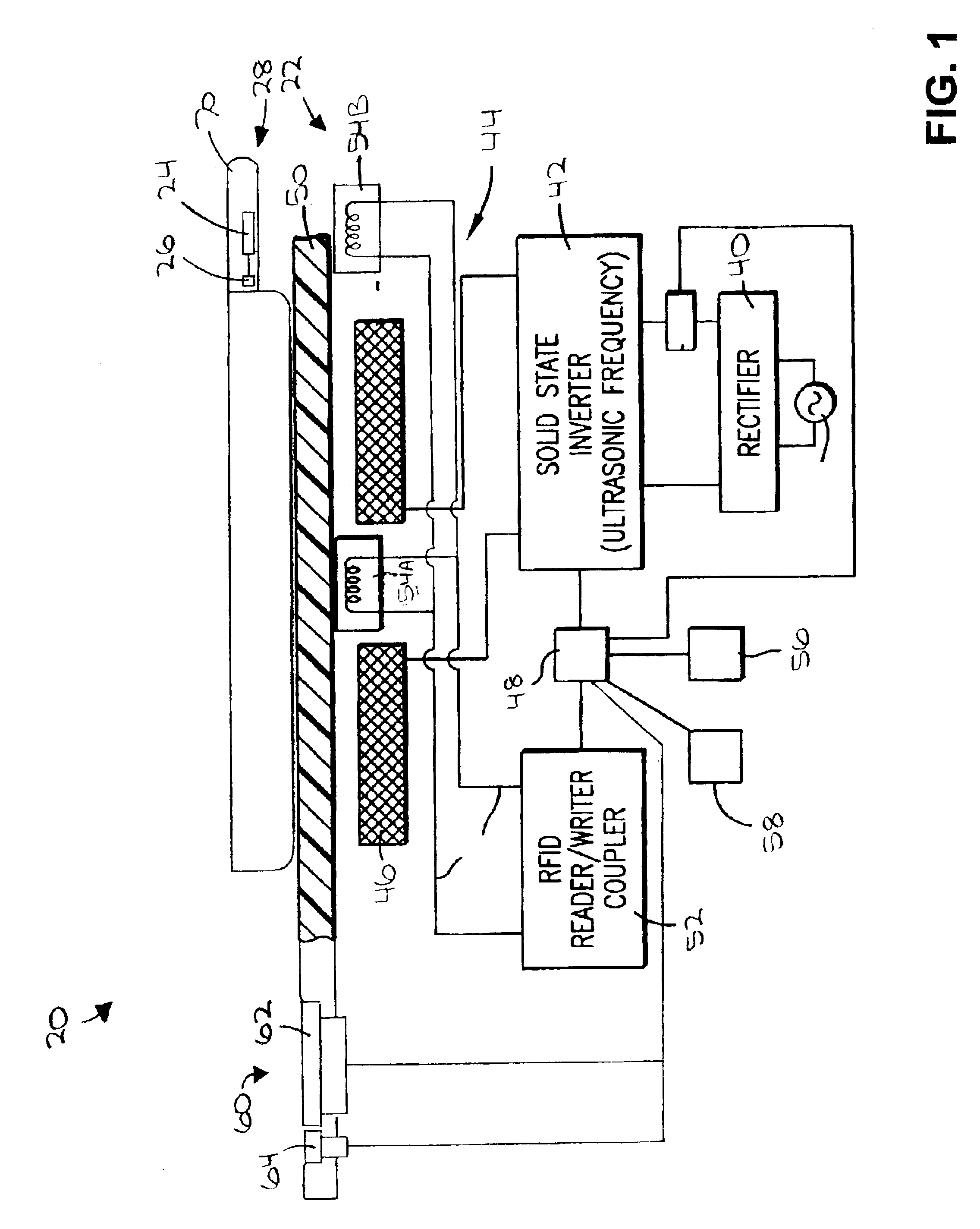

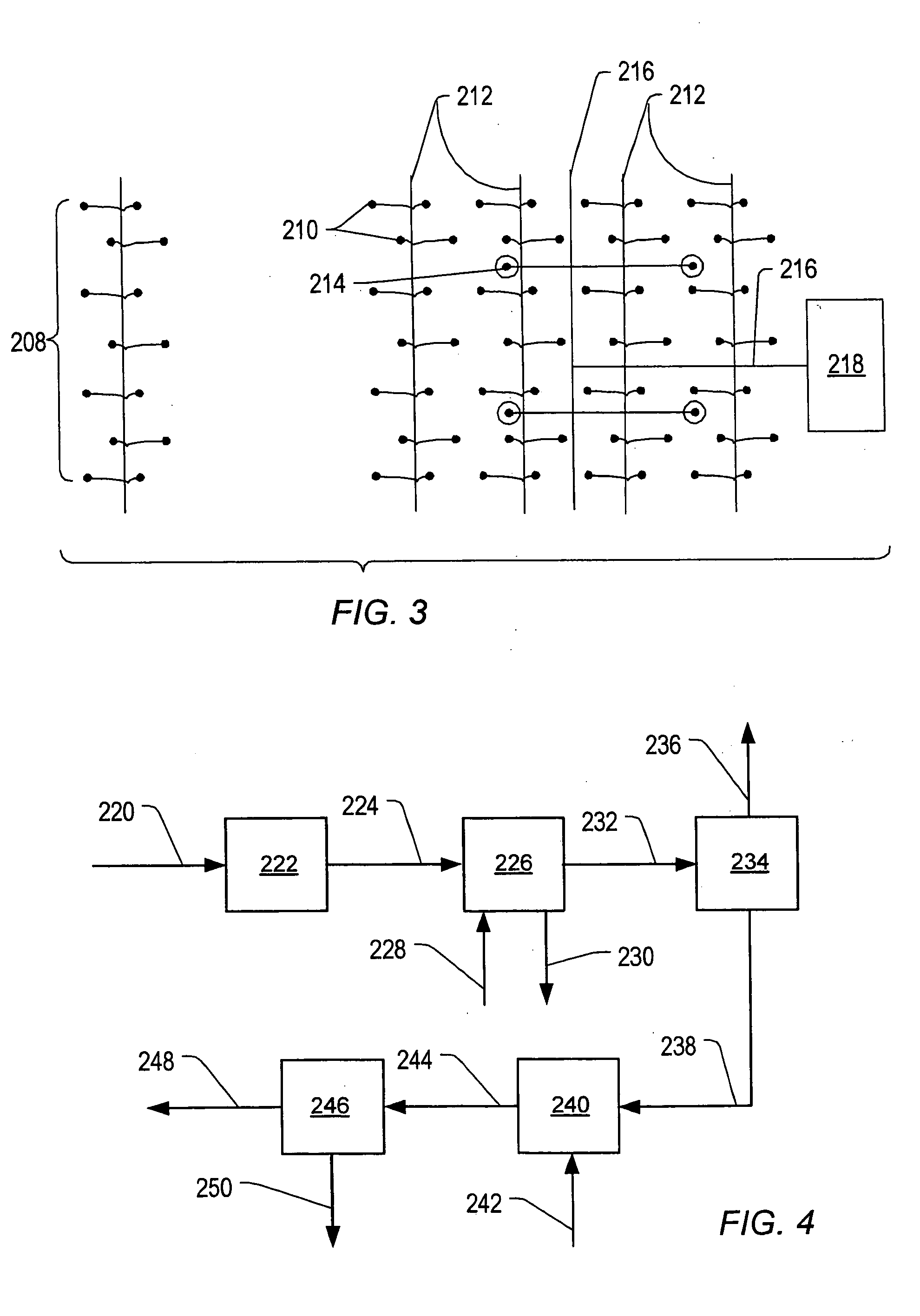

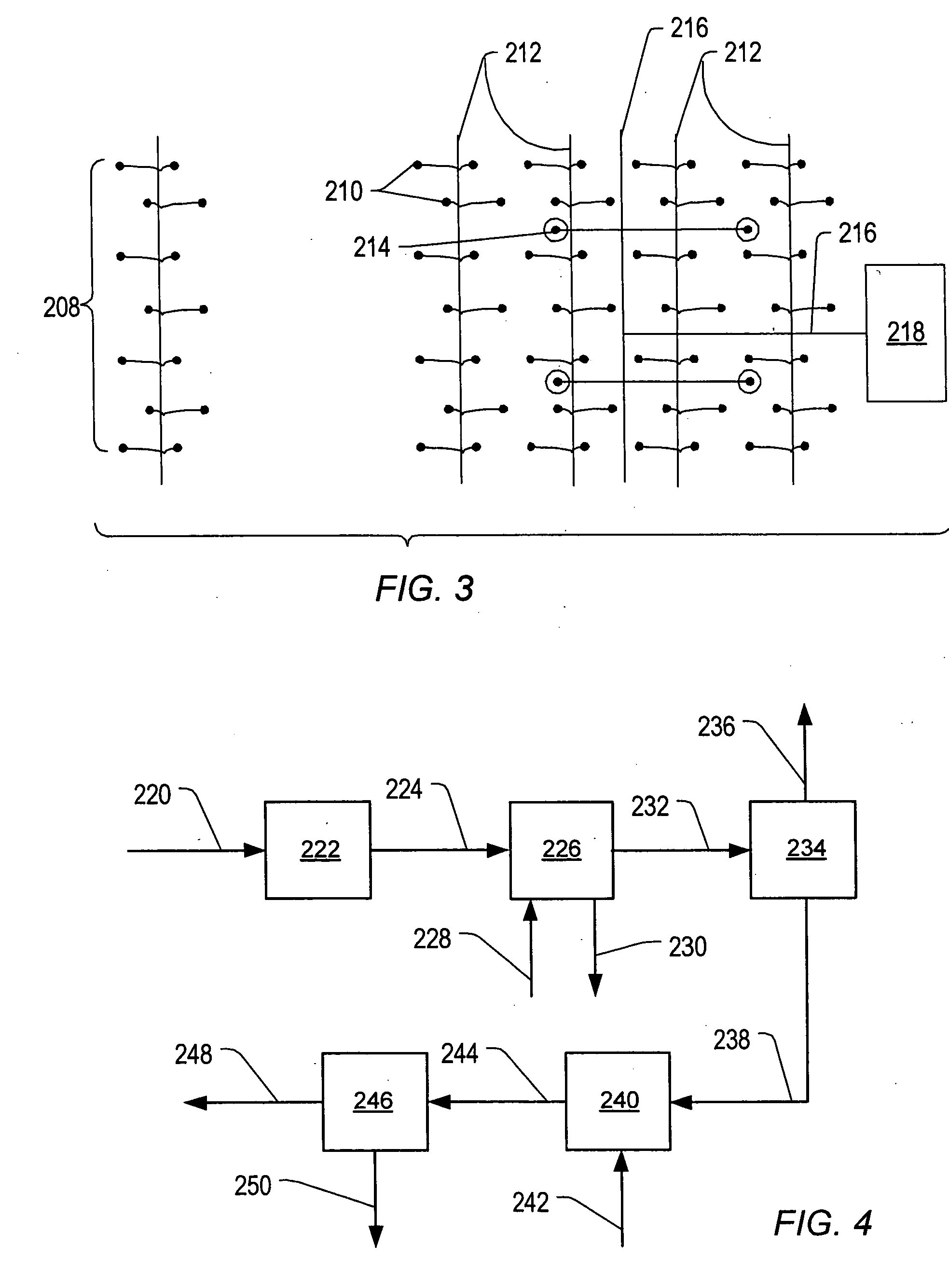

RFID-controlled smart induction range and method of cooking and heating

A system and method for providing multiple cooking modes and an ability to automatically heat cooking vessels and other objects using RFID technology, and an ability to read and write heating instructions and to interactively assist in their execution. An induction heating range is provided with two antennas per hob, and includes a user interface display and input mechanism. The vessel includes an RFID tag and a temperature sensor. In a first cooking mode, a recipe is read by the range and the range assists a user in executing the recipe by automatically heating the vessel to specified temperatures and by prompting the user to add ingredients. The recipe is written to the RFID tag so that if the vessel is moved to another hob, into which the recipe has not been read, the new hob can read the recipe from the RFID tag and continue in its execution.

Owner:HR TECH

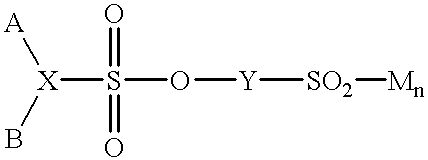

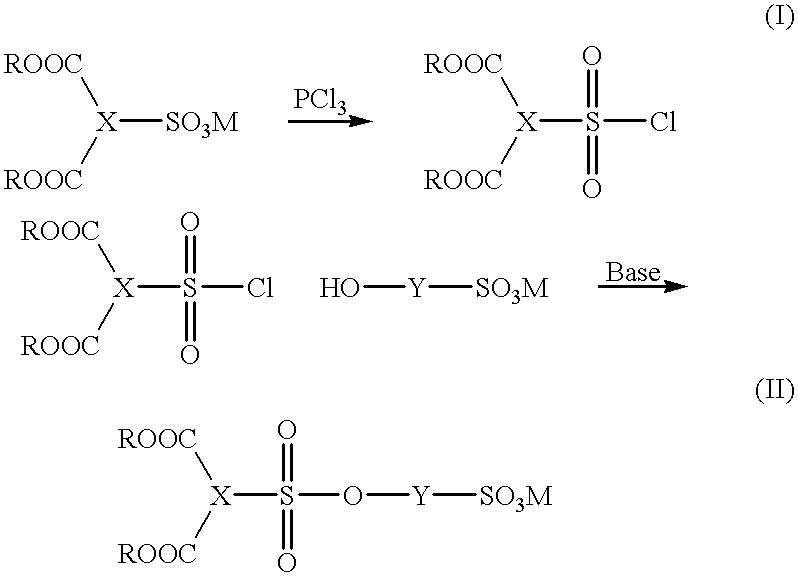

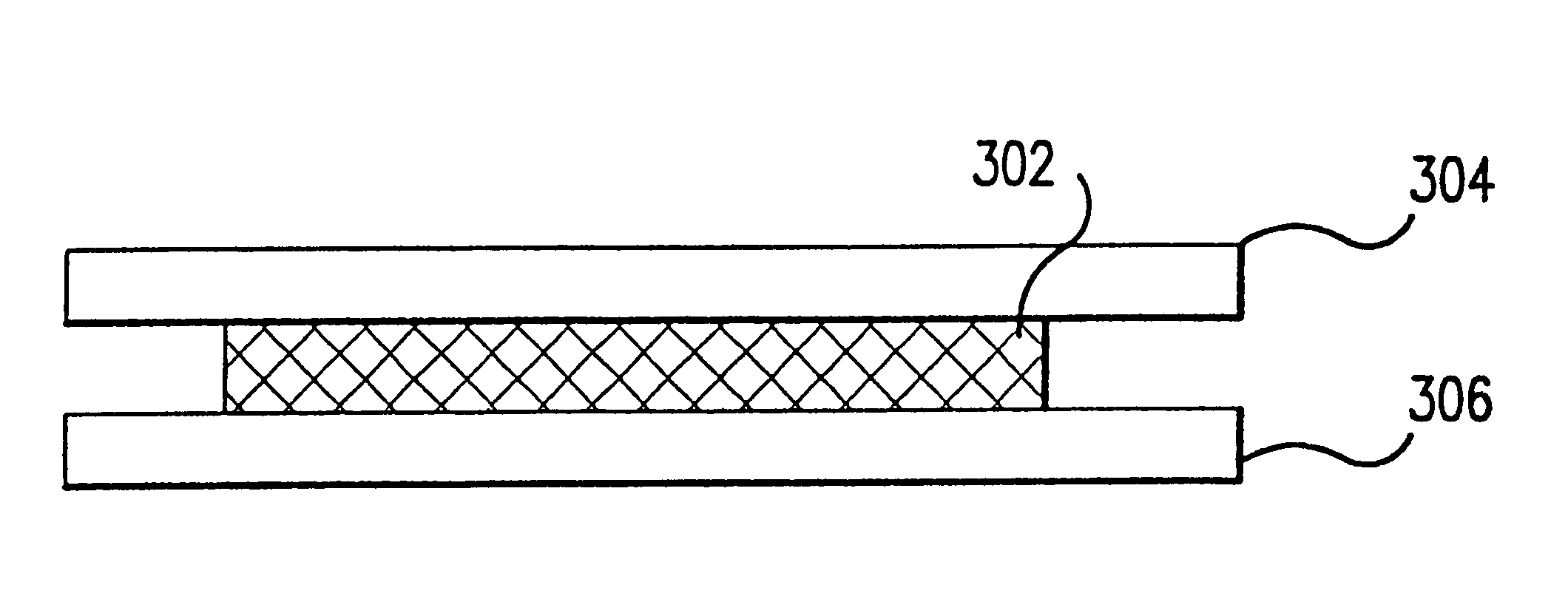

RF active compositions for use in adhesion, bonding and coating

A susceptor composition that can bond two or more layers or substrates to one another and that can be used to coat or cut a substrate. The susceptor composition is activated in the presence of radio frequency (RF) energy. In one embodiment, the susceptor composition of the present invention comprises a susceptor and a carrier. The carrier and susceptor are blended with one another and form a mixture, preferably a uniform mixture. The susceptor is present in an amount effective to allow the susceptor composition to be heated by RF energy. In a preferred embodiment, the susceptor also functions as an adhesive. The susceptor is an ionic or polar compound and acts as either a charge-carrying or an oscillating / vibrating component of the susceptor composition. The susceptor generates thermal energy in the presence of an RF electromagnetic or electrical field (hereafter RF field).

Owner:AMBRELL CORP

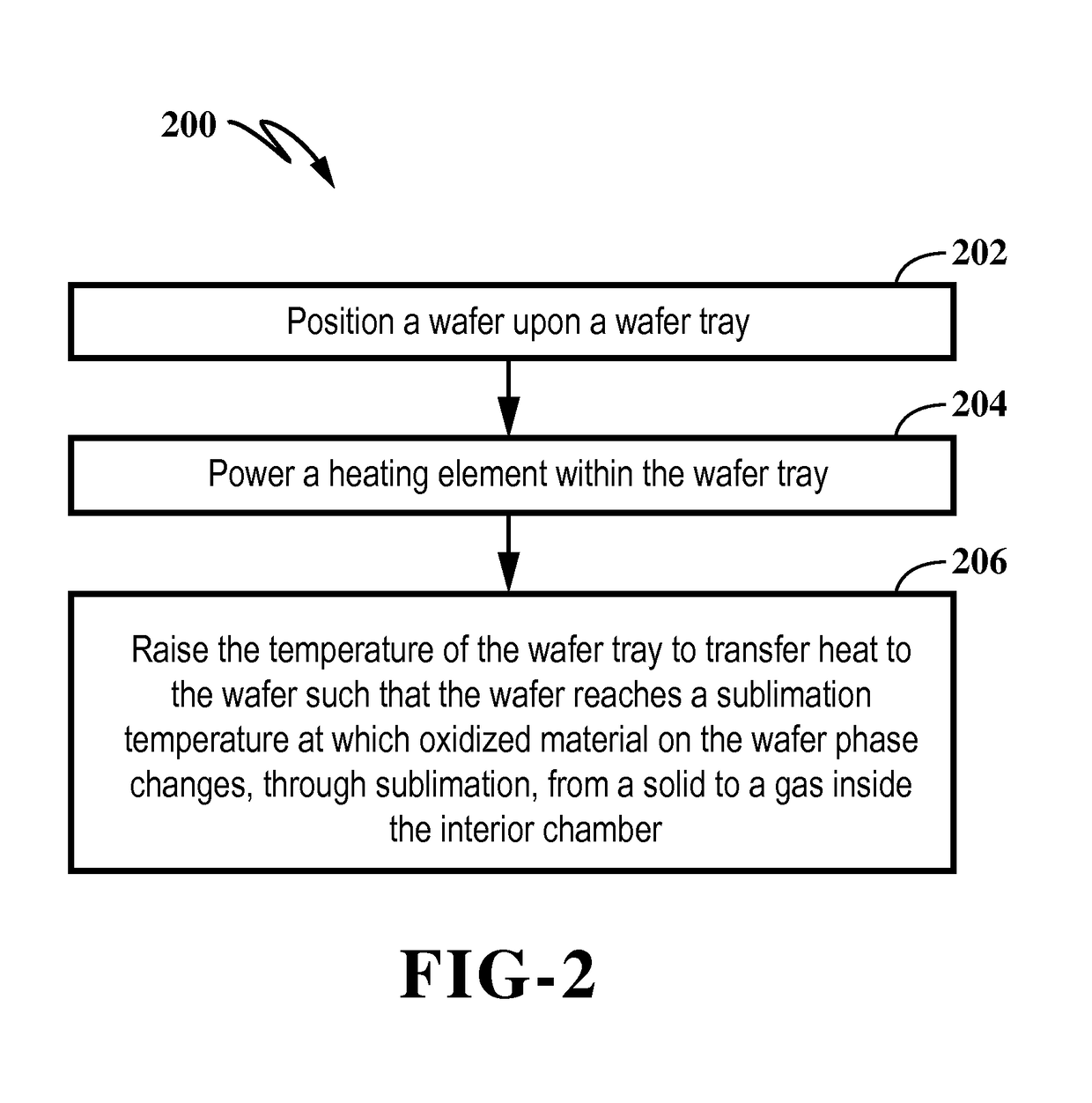

Reactor system for sublimation of pre-clean byproducts and method thereof

A reactor system and related methods are provided which may include a heating element in a wafer tray. The heating element may be used to heat the wafer tray and a substrate or wafer seated on the wafer tray within a reaction chamber assembly, and may be used to cause sublimation of a native oxide of the wafer.

Owner:ASM IP HLDG BV

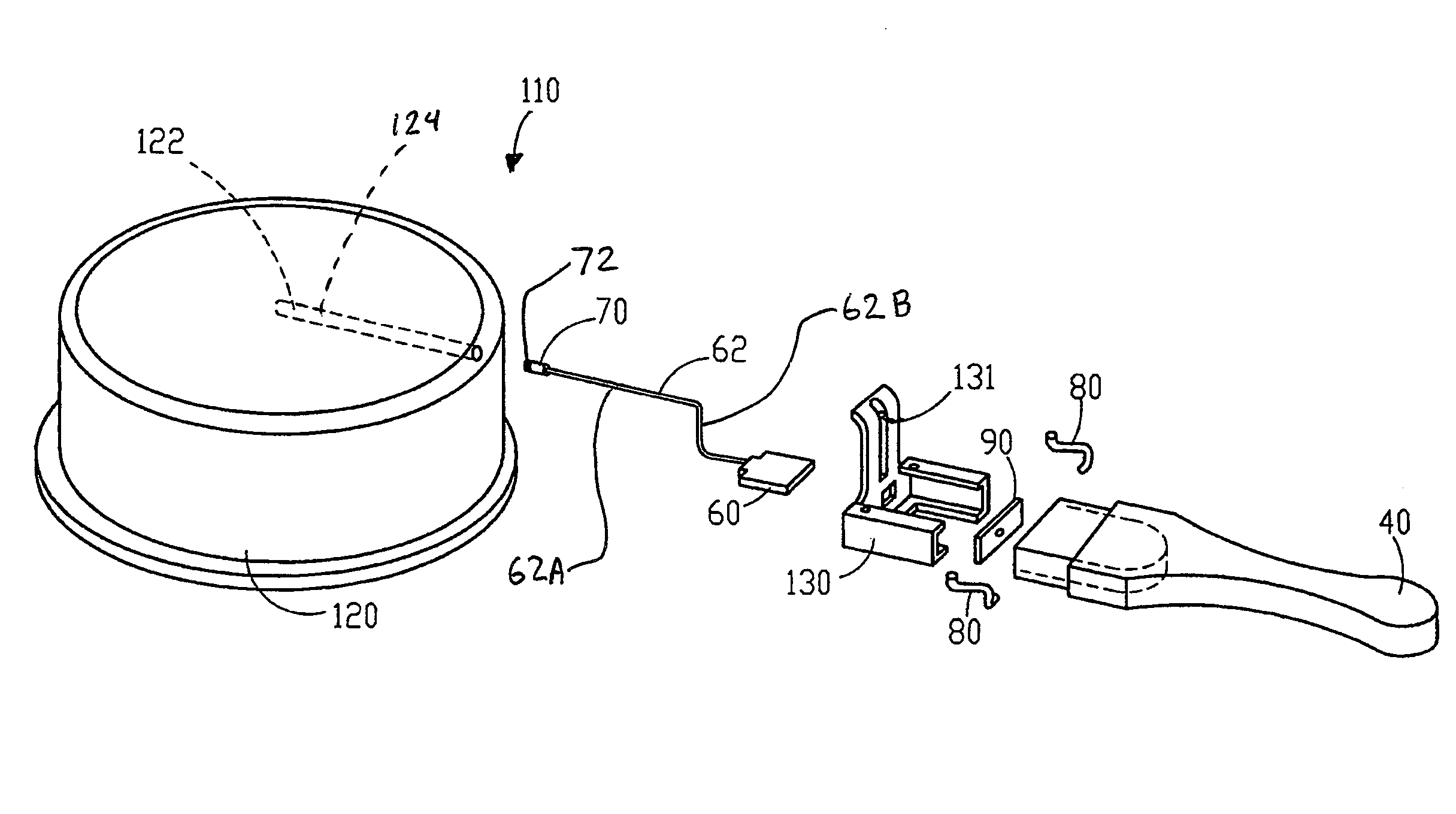

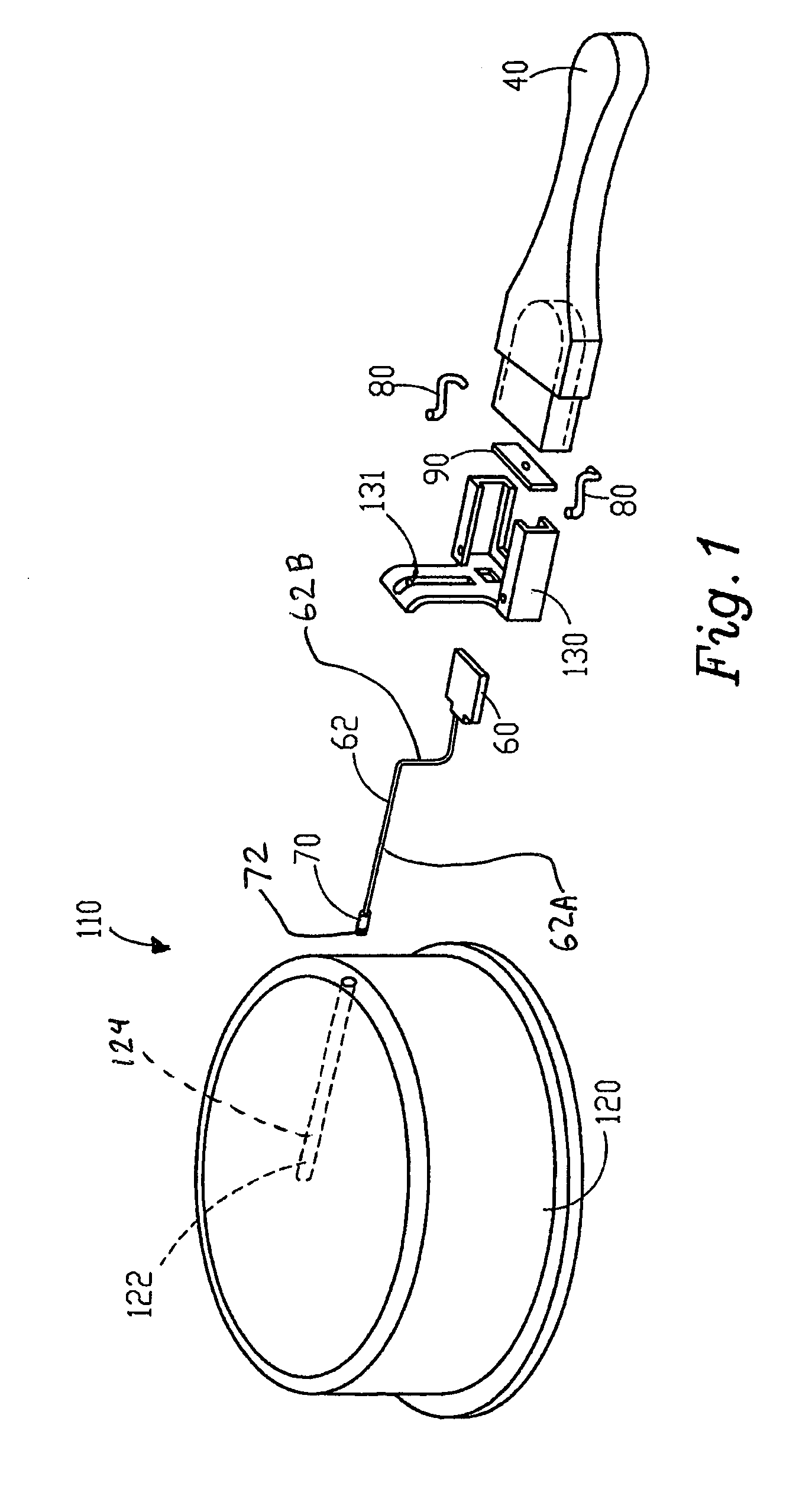

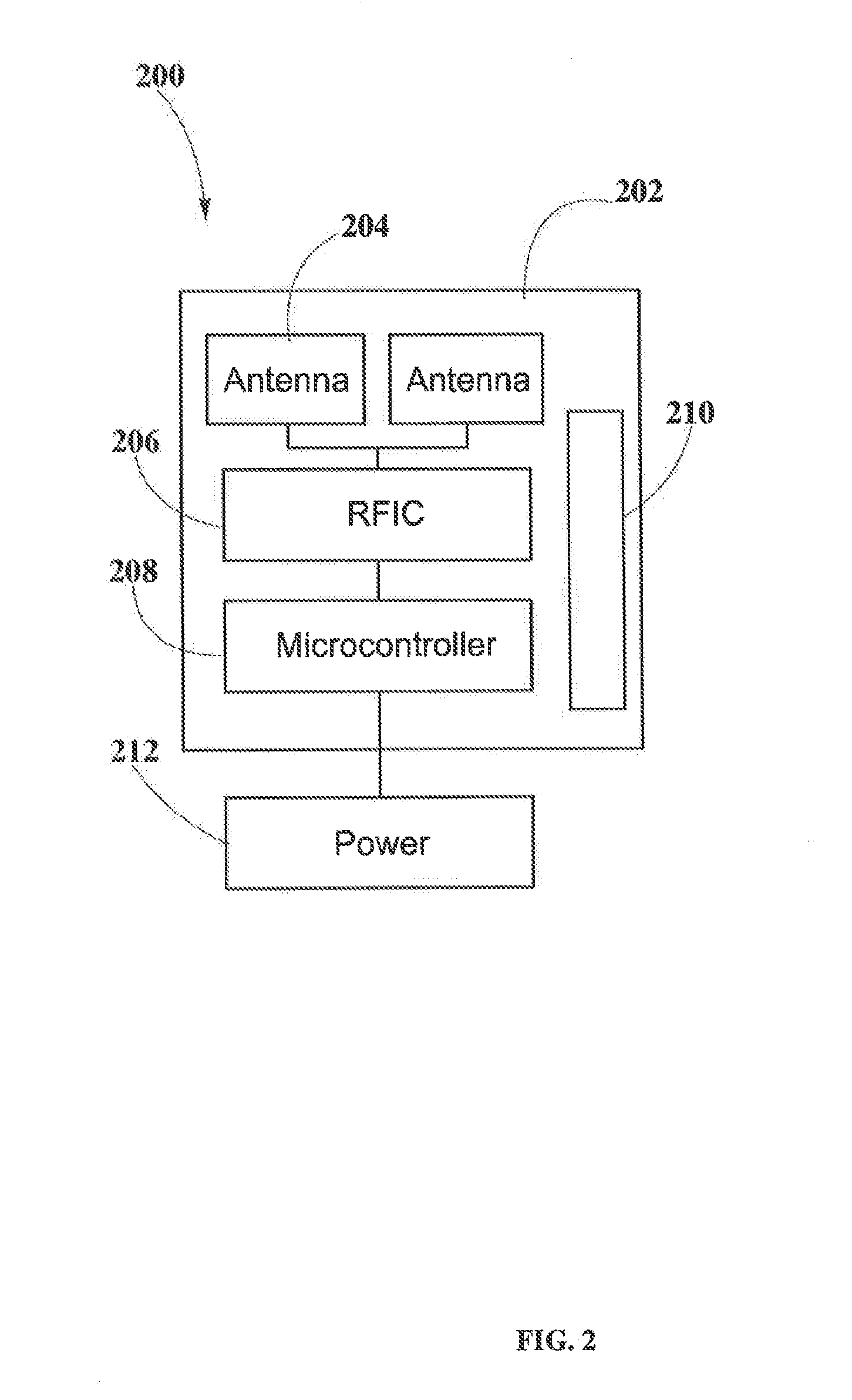

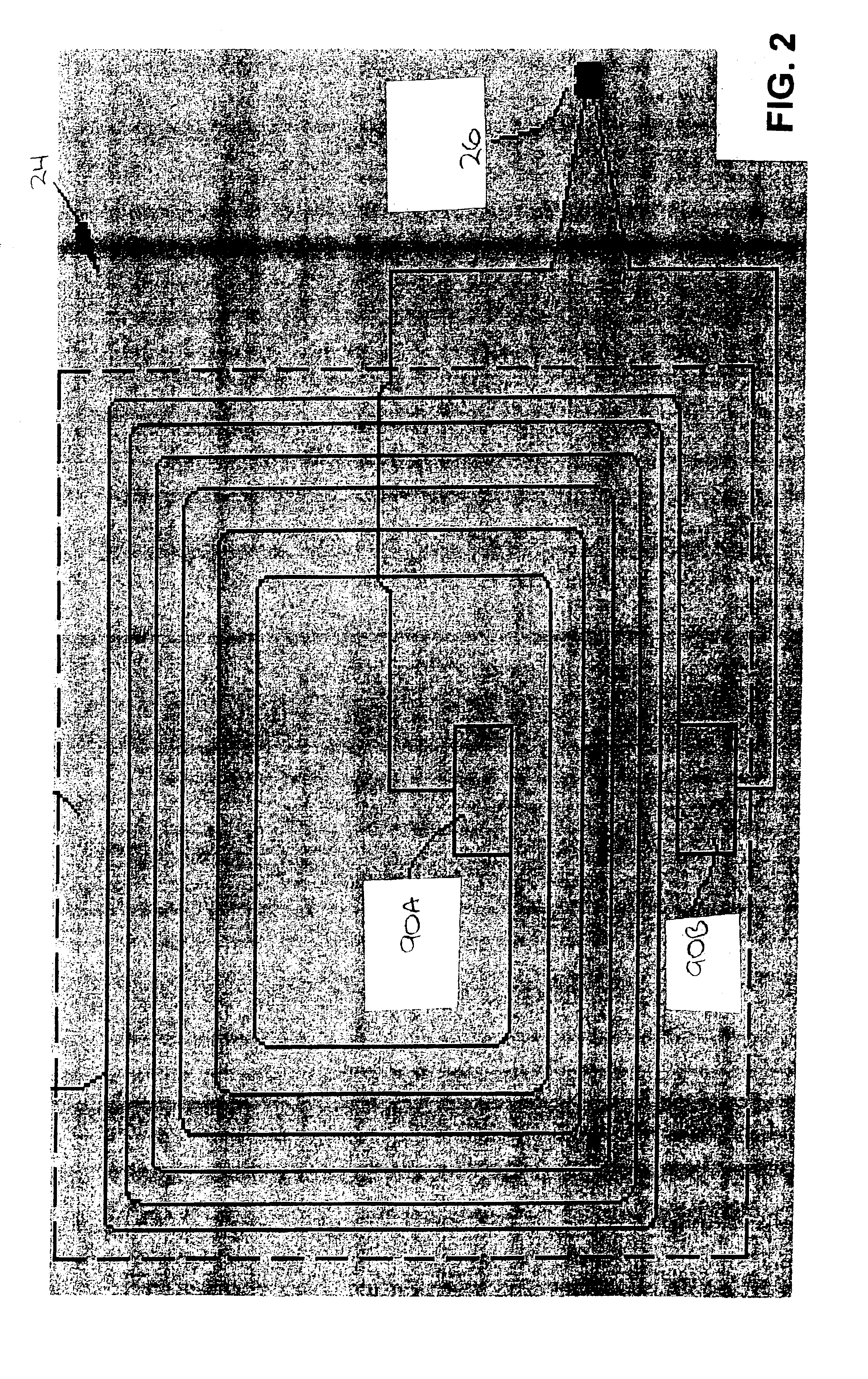

Tag assembly for radio frequency identification controlled heatable objects

ActiveUS7875836B2Improved operation/functionalityAdditional componentBoiling over preventionNear-field systems using receiversEngineeringRadio frequency

Components for use in a temperature controlled heatable object are provided in which a temperature sensor is connected to a transmitter such as a Radio Frequency Identification (RFID) tag. The RFID tag is encased in a protective overmolding and connected to the temperature sensor via a mineral insulated cable. An end cap containing a potting material (such as silicone or ceramic) is placed over the temperature sensor and laser welded to a sheathing of the mineral insulated cable. A potting material for use in a heatable object is also provided comprising a silicone-based material that is modified by adding bauxite to increase thermal conductivity.

Owner:IMURA INT USA

Contactlessly chargeable heater

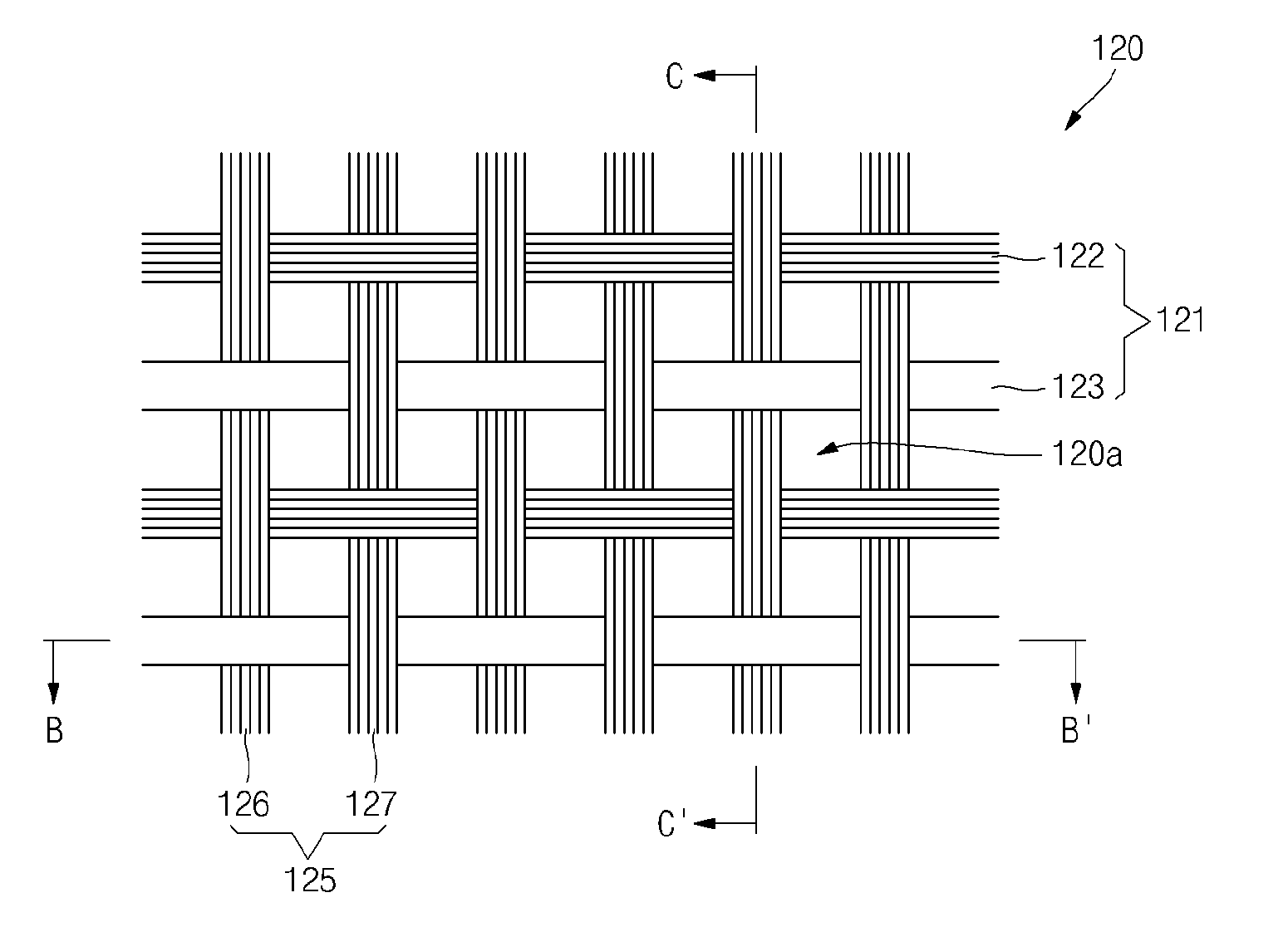

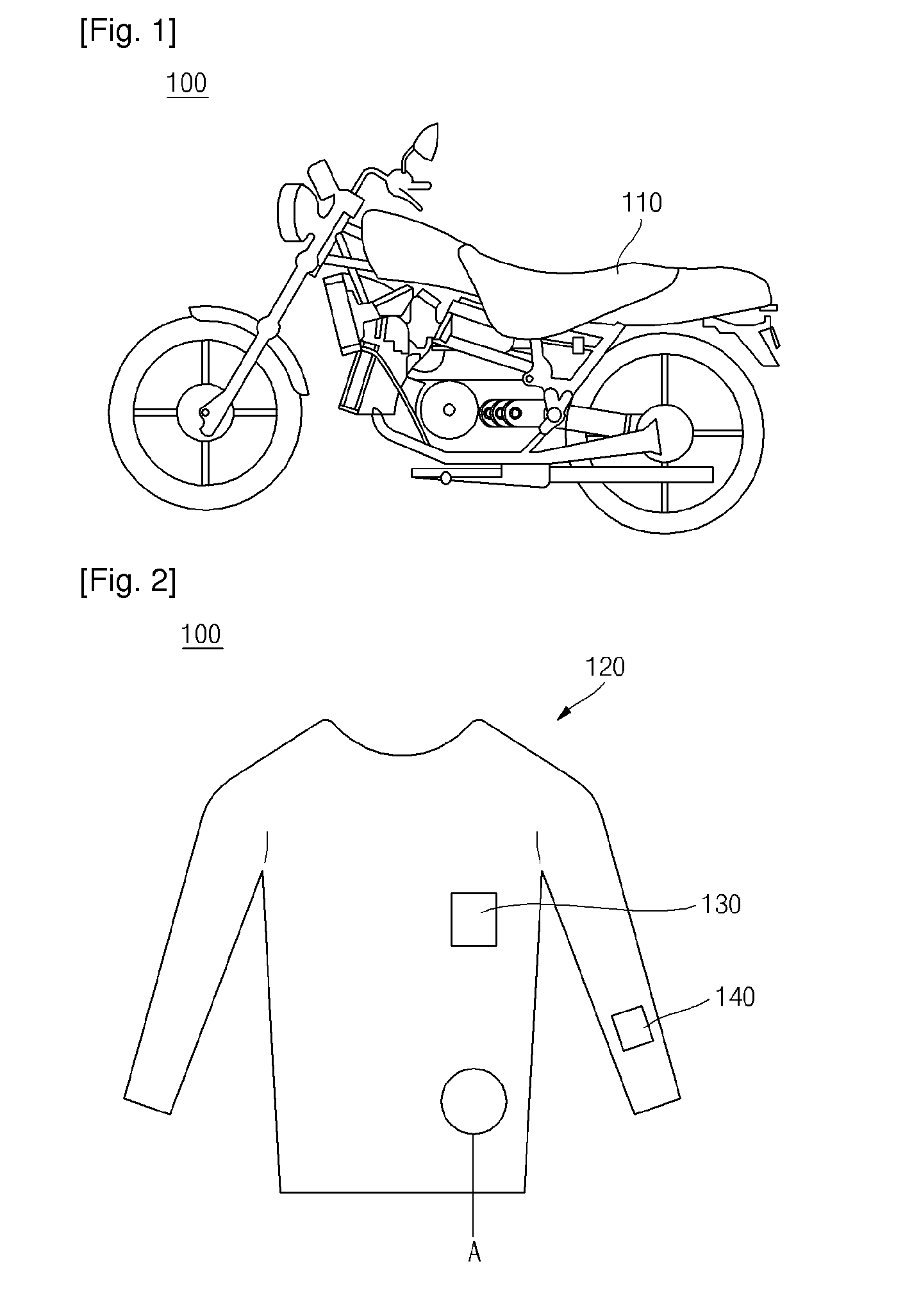

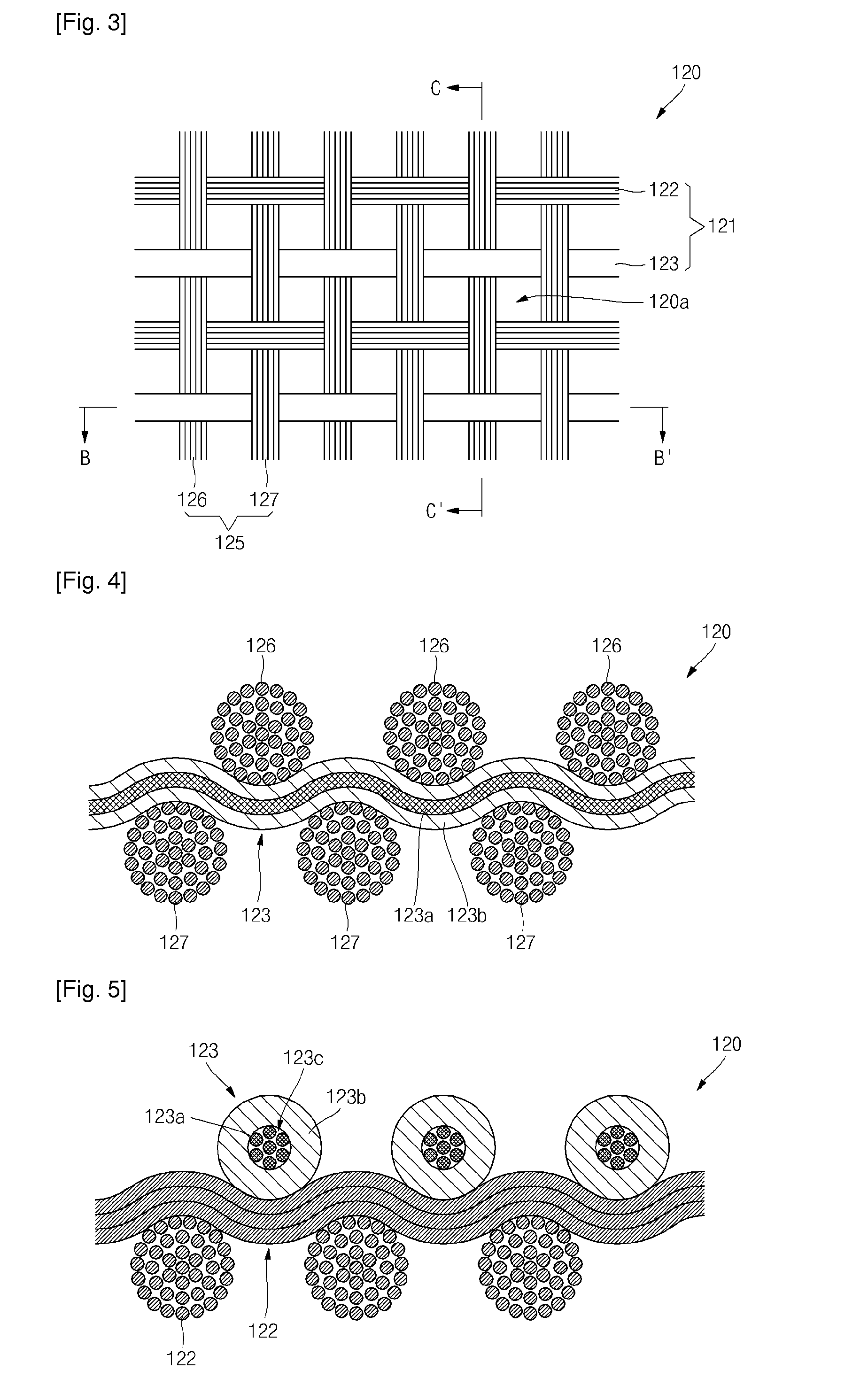

ActiveUS20130032589A1Increasing user 's convenienceEasily transfers heatTransformersOhmic-resistance heatingYarnEngineering

The present invention relates to a contactlessly chargeable heater. In one example, the contactles sly chargeable heater includes: a charging patch emitting magnetic force by means of current applied to an inner coil; and a heating body, receiving the magnetic force from the charging patch to perform a contactless charging operation, and including a digital yarn for emitting heat via the power generated through the contactless charging operation. The digital yarn is woven together using threads within the heating body.

Owner:GAIA HEALTHCARE INC

Wireless electrical temperature regulator for food and beverages

InactiveUS20150041459A1Containers for heating foodMachines using electric/magnetic effectsEngineeringIngested food

A cup or plate for heating food or beverages is disclosed. The cup / plate contains a heating component, which may keep consumable goods, such as food and beverages at a desired temperature. An insulated external layer may be placed between the heating component and the external portion of the cup / plate. A wireless power receiver may be coupled to the heater component to receive an electrical power source and transfer it to the heater component. A transmitter element may form pockets of energy at the location of the different receivers to be used as power sources.

Owner:ENERGOUS CORPORATION

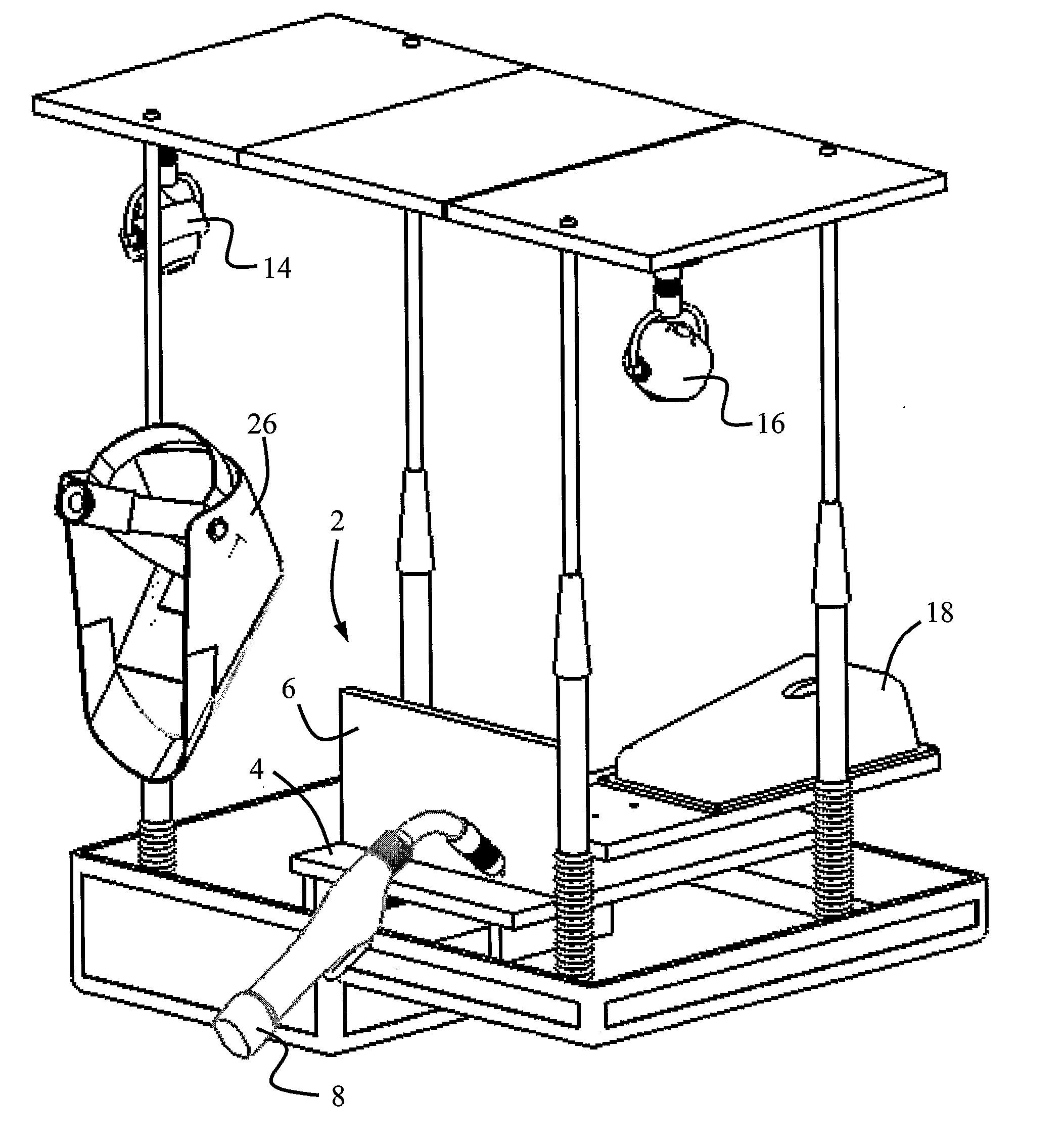

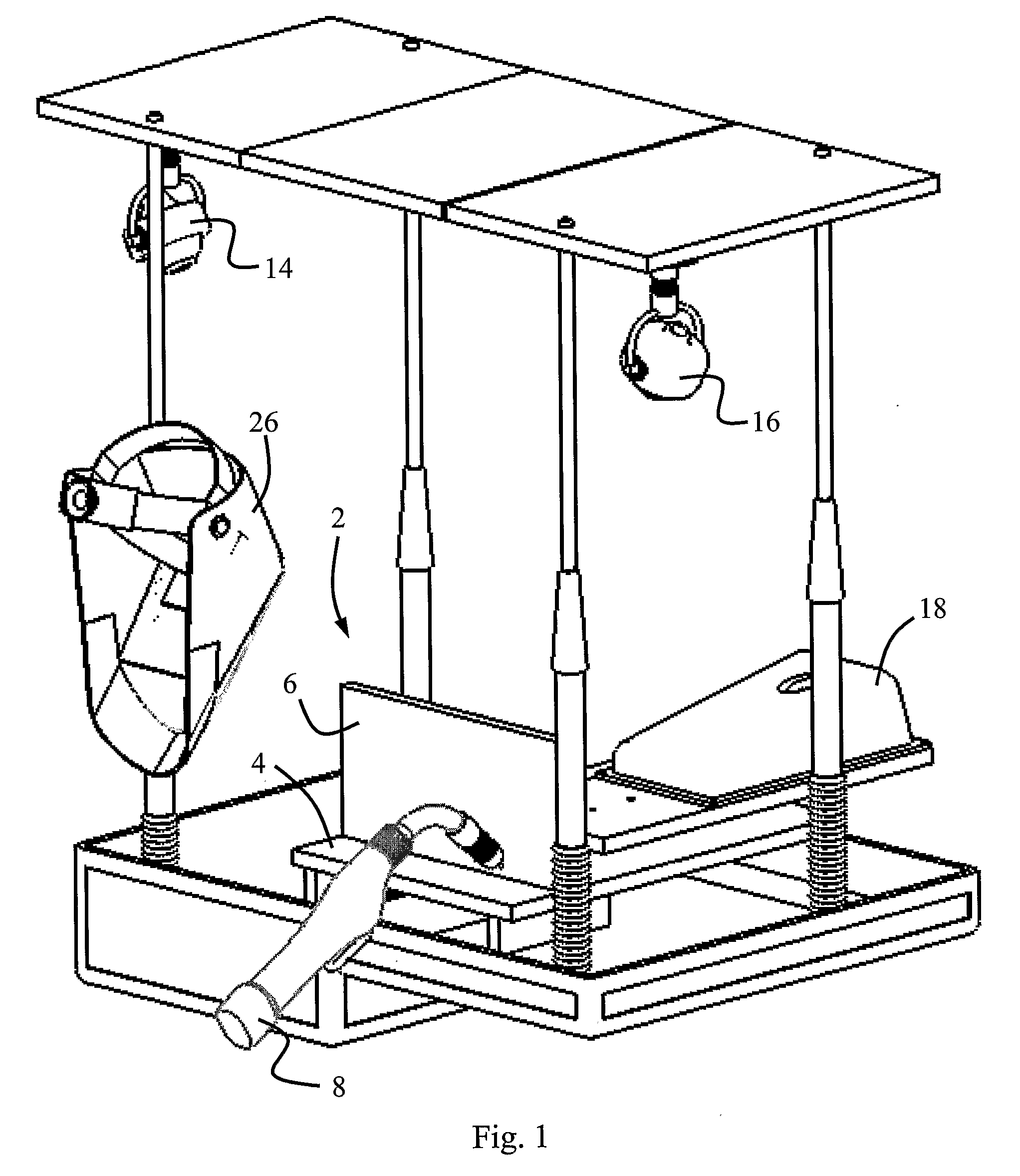

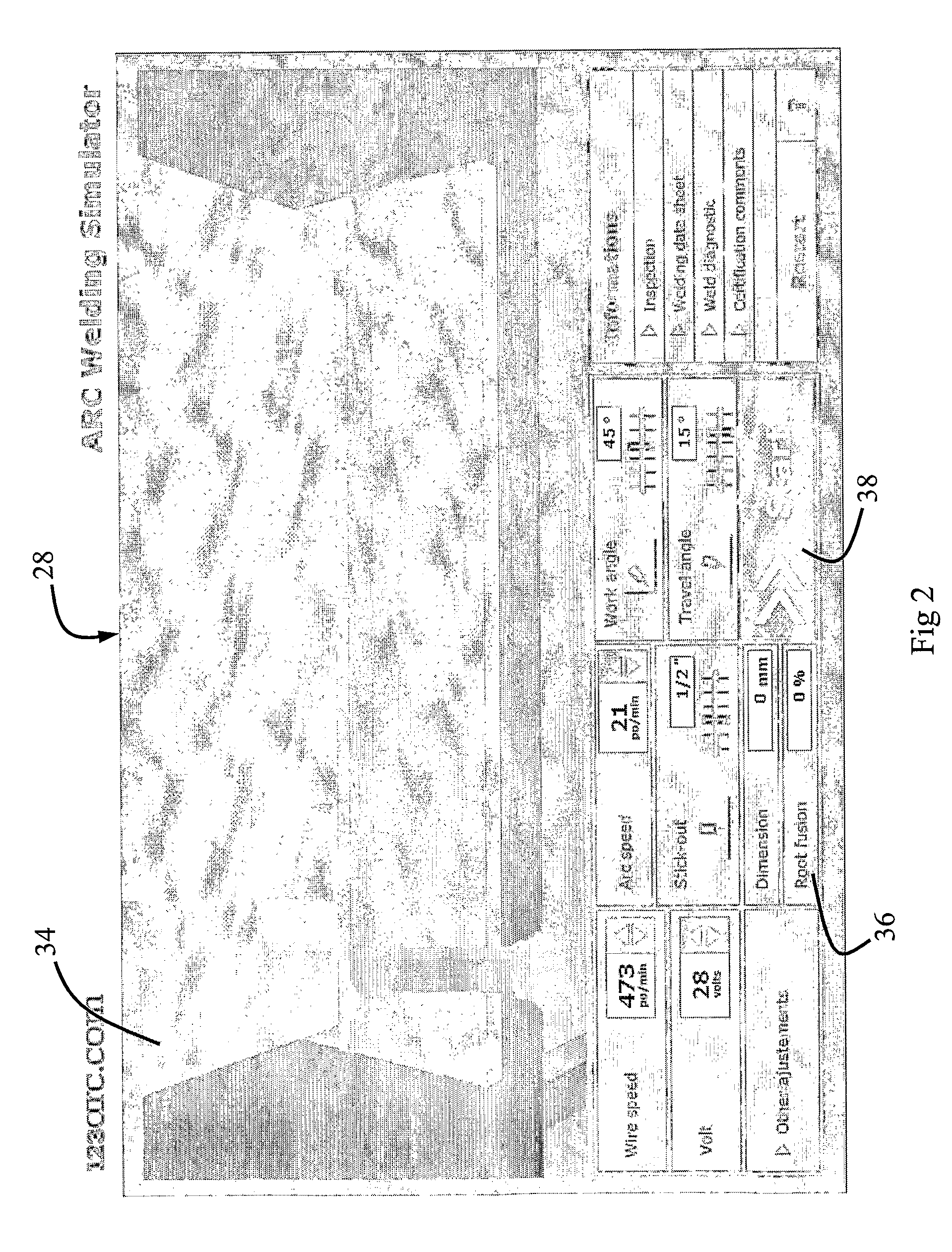

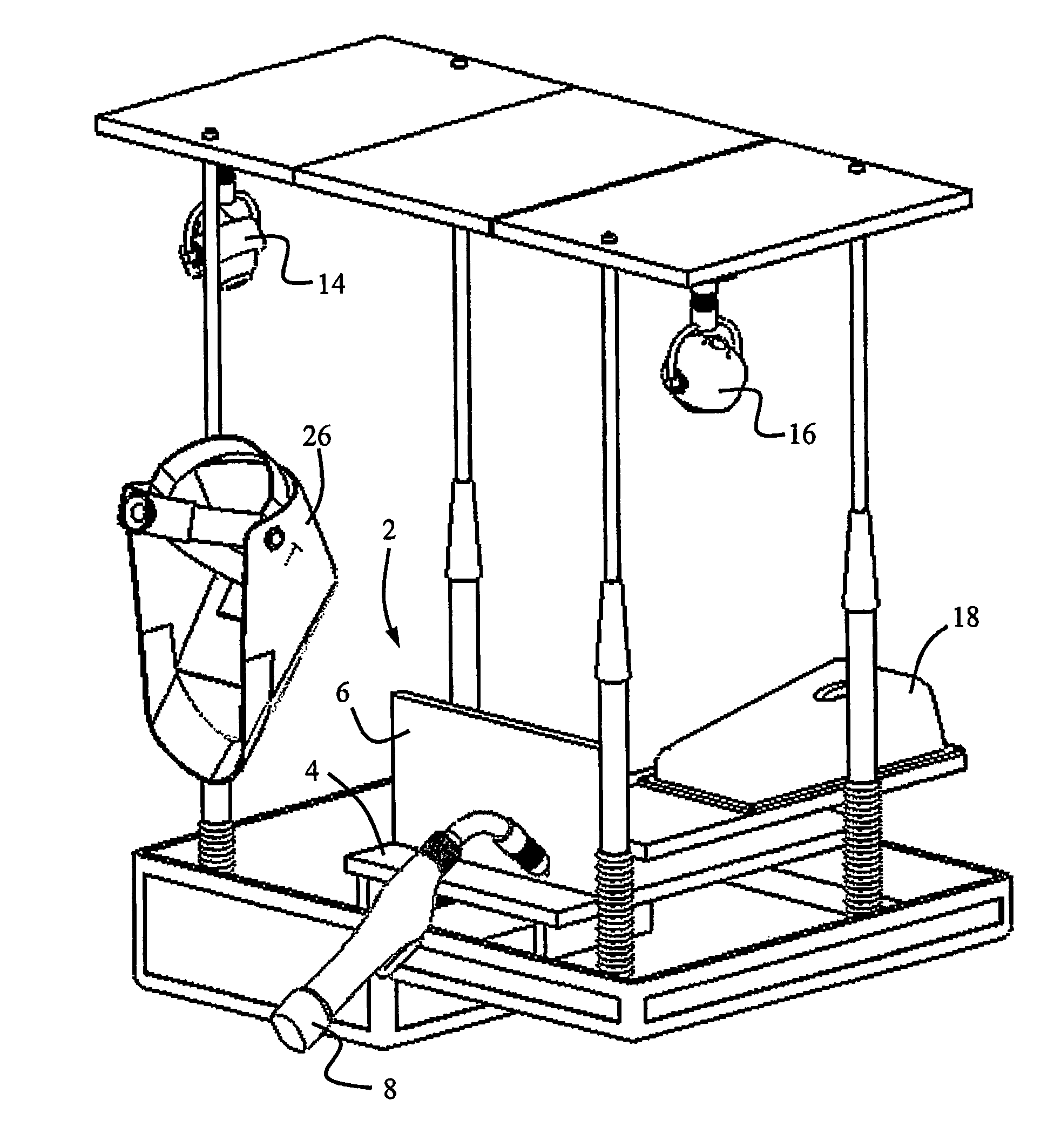

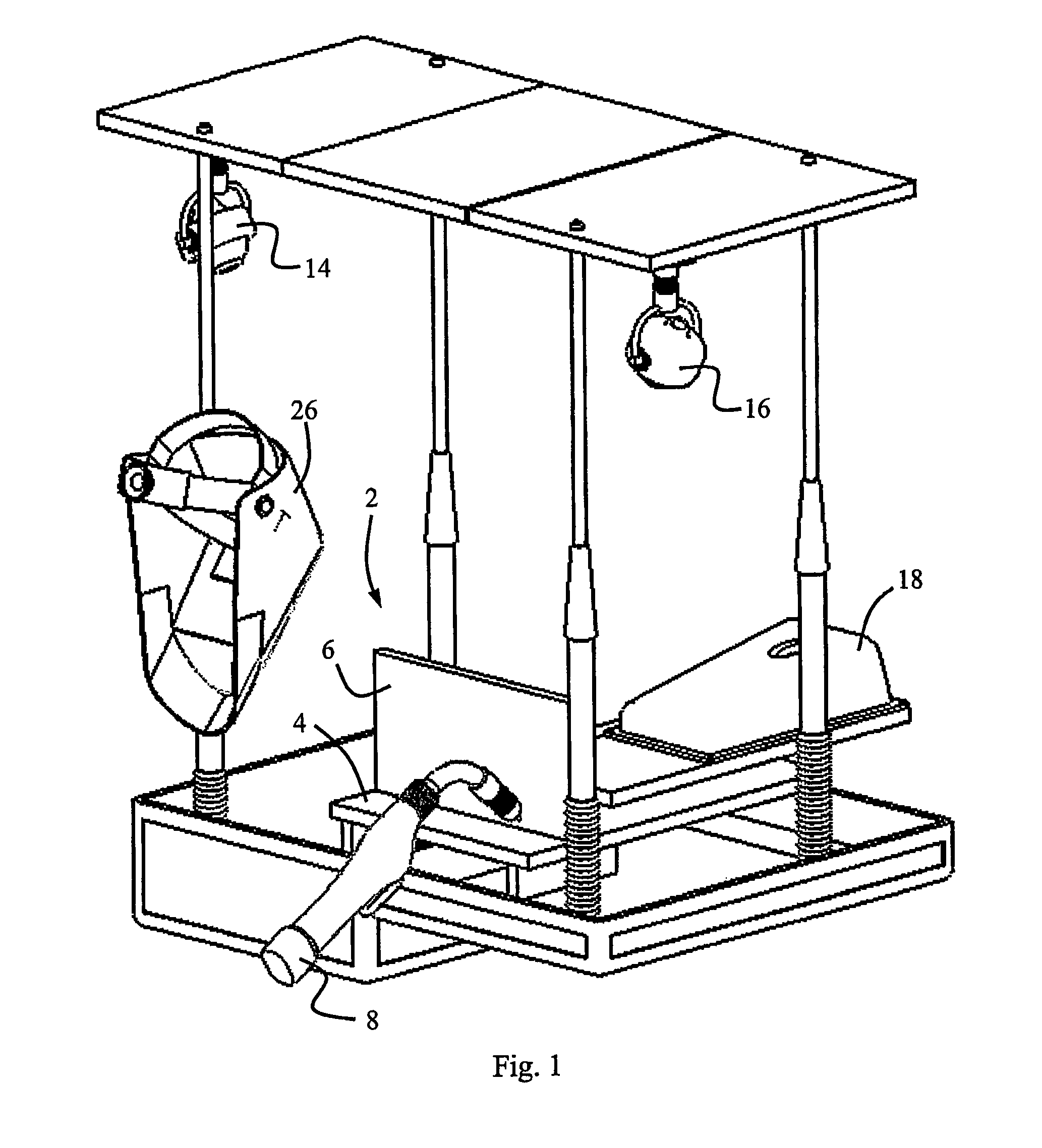

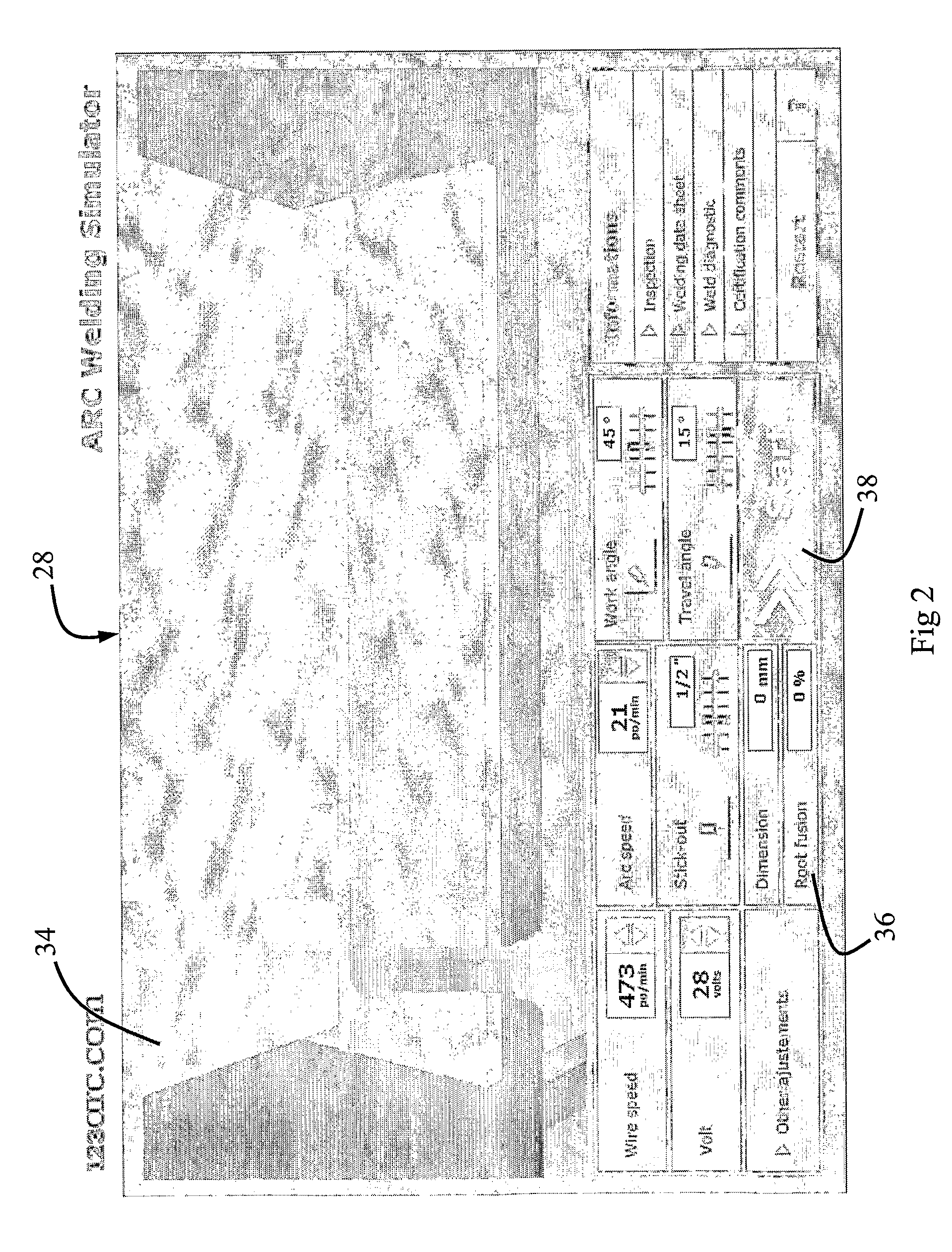

Body Motion Training and Qualification System and Method

InactiveUS20080038702A1Defective reproductionCosmonautic condition simulationsElectric discharge heatingSimulationDisplay device

The system allows training and qualification of a user performing a skill-related training exercise involving body motion in a workspace. A training environment is selected through a computer apparatus, and variables, parameters and controls of the training environment and the training exercise are adjusted. Use of an input device by the user is monitored. The 3D angles and spatial coordinates of reference points related to the input device are monitored through a detection device. A simulated 3D dynamic environment reflecting effects caused by actions performed by the user on objects is computed in real time as a function of the training environment selected. Images of the simulated 3D dynamic environment in real time are generated on a display device viewable by the user as a function of a computed organ of vision-object relation. Data indicative of the actions performed by the user and the effects of the actions are recorded and user qualification is set as a function of the recorded data.

Owner:123 CERTIFICATION

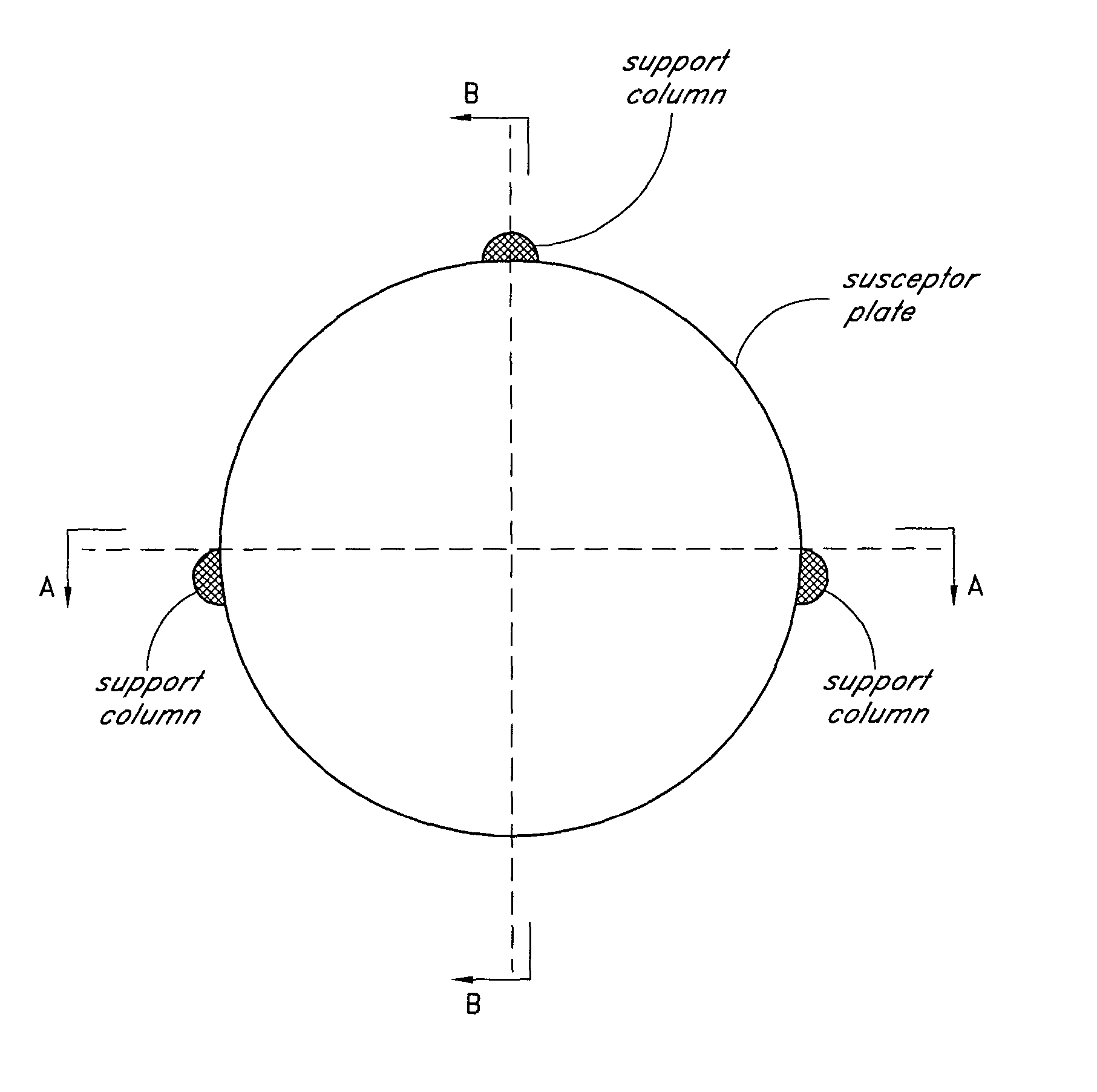

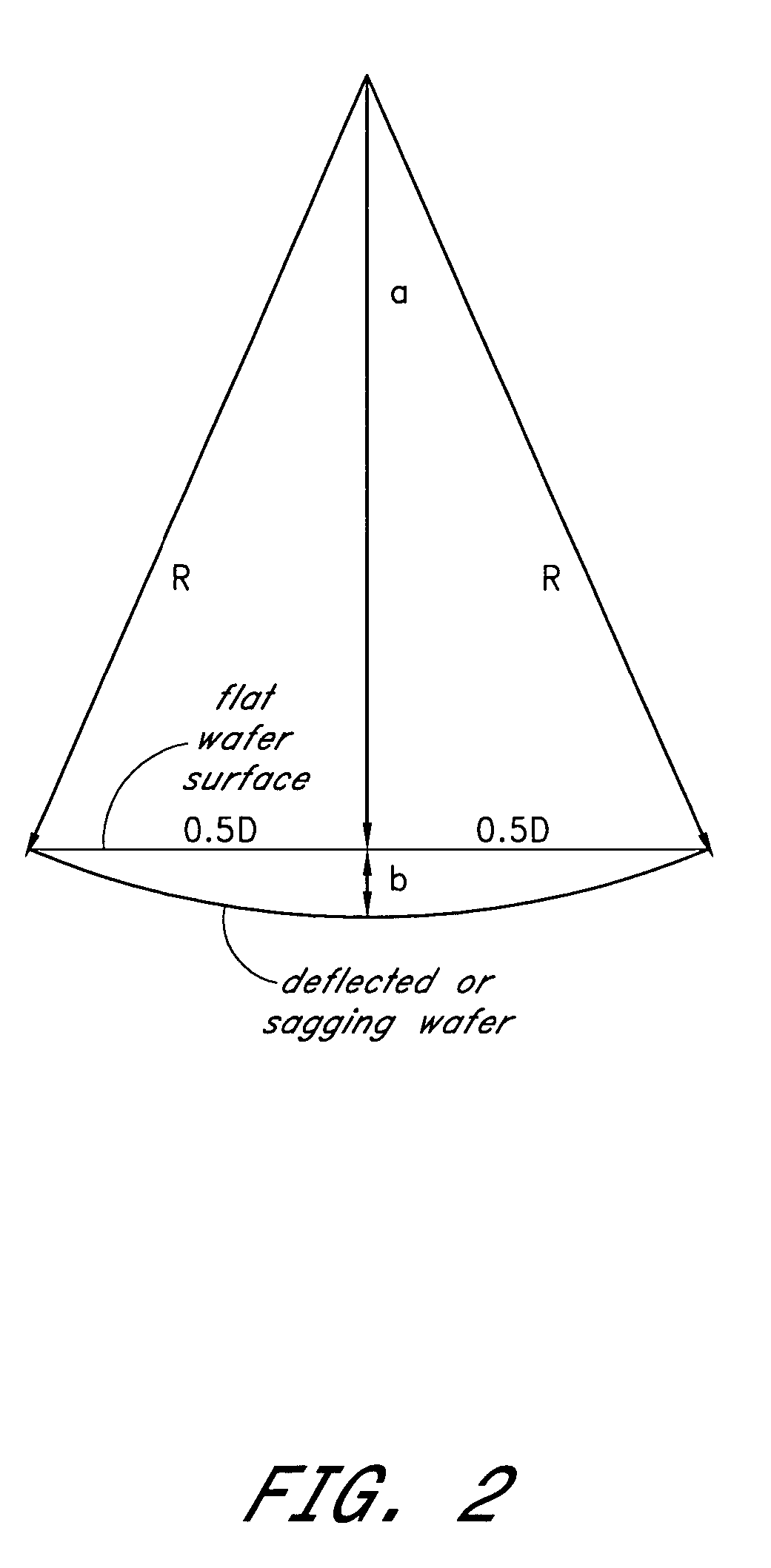

Susceptor plate for high temperature heat treatment

ActiveUS7256375B2Reduce slipFlatnessSemiconductor/solid-state device manufacturingInduction heating apparatusBatch processingSusceptor

Susceptor plates are provided for high temperature (e.g., greater than 1000° C.) batch processing of silicon wafers. The susceptor plates are designed to accommodate one wafer each, and a plurality of loaded susceptor plates are vertically spaced apart in a susceptor plate holder during batch or furnace processing. The susceptor plates provide “full” support beneath the wafers, with openings of at most 20 mm in diameter in the support surface. Protrusions are also kept to a minimum. The susceptor plates thus prevent the wafers from sagging beyond the point of plastic deformation. The support surface is also ground or polished to remove protrusions beyond a prescribed height. For a given treatment temperature, the susceptor plates permit higher ramp rates without wafer plastic deformation or sticking to the susceptor plate. In one embodiment, the susceptor plates are pre-bent in a direction opposing the direction of sag.

Owner:ASM INTERNATIONAL

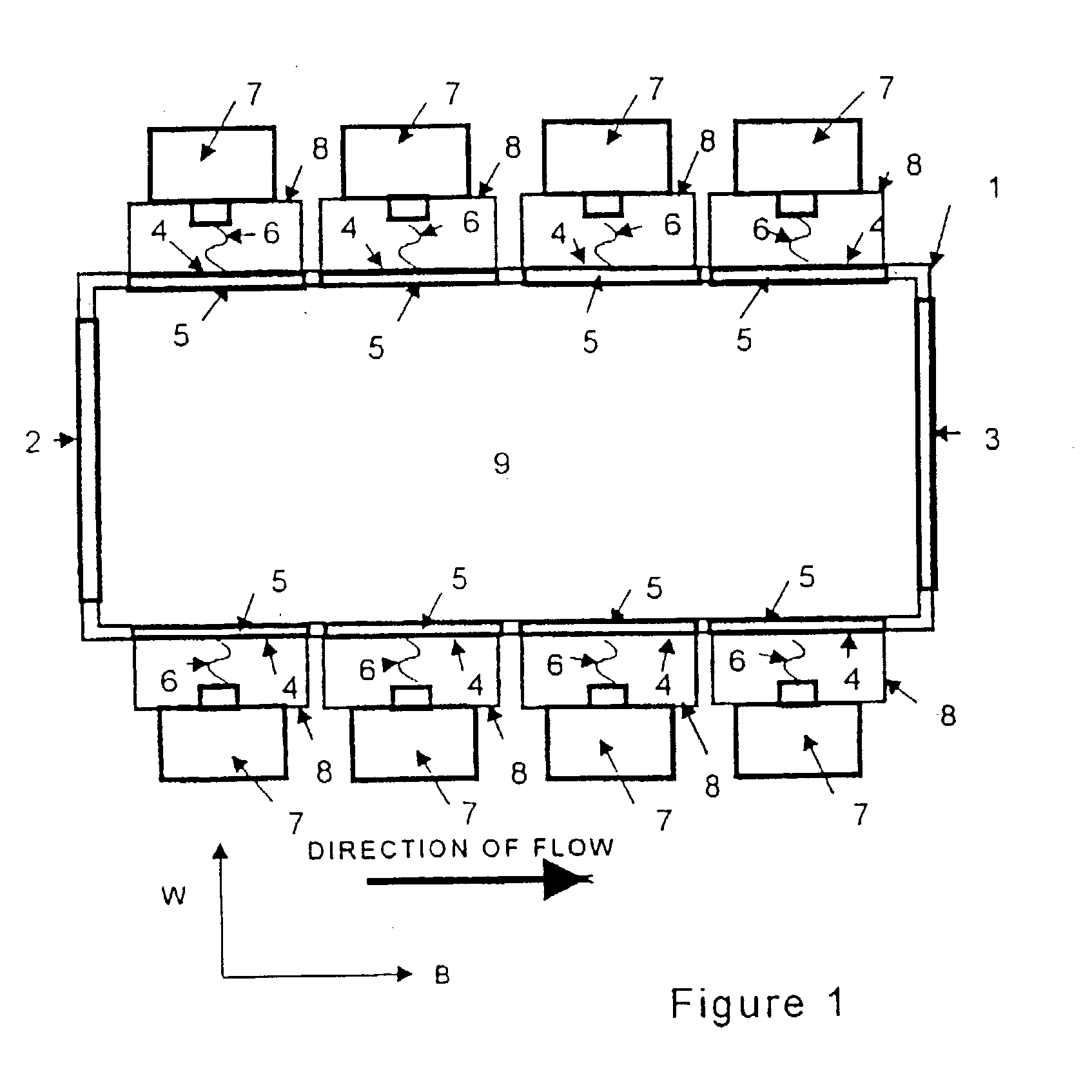

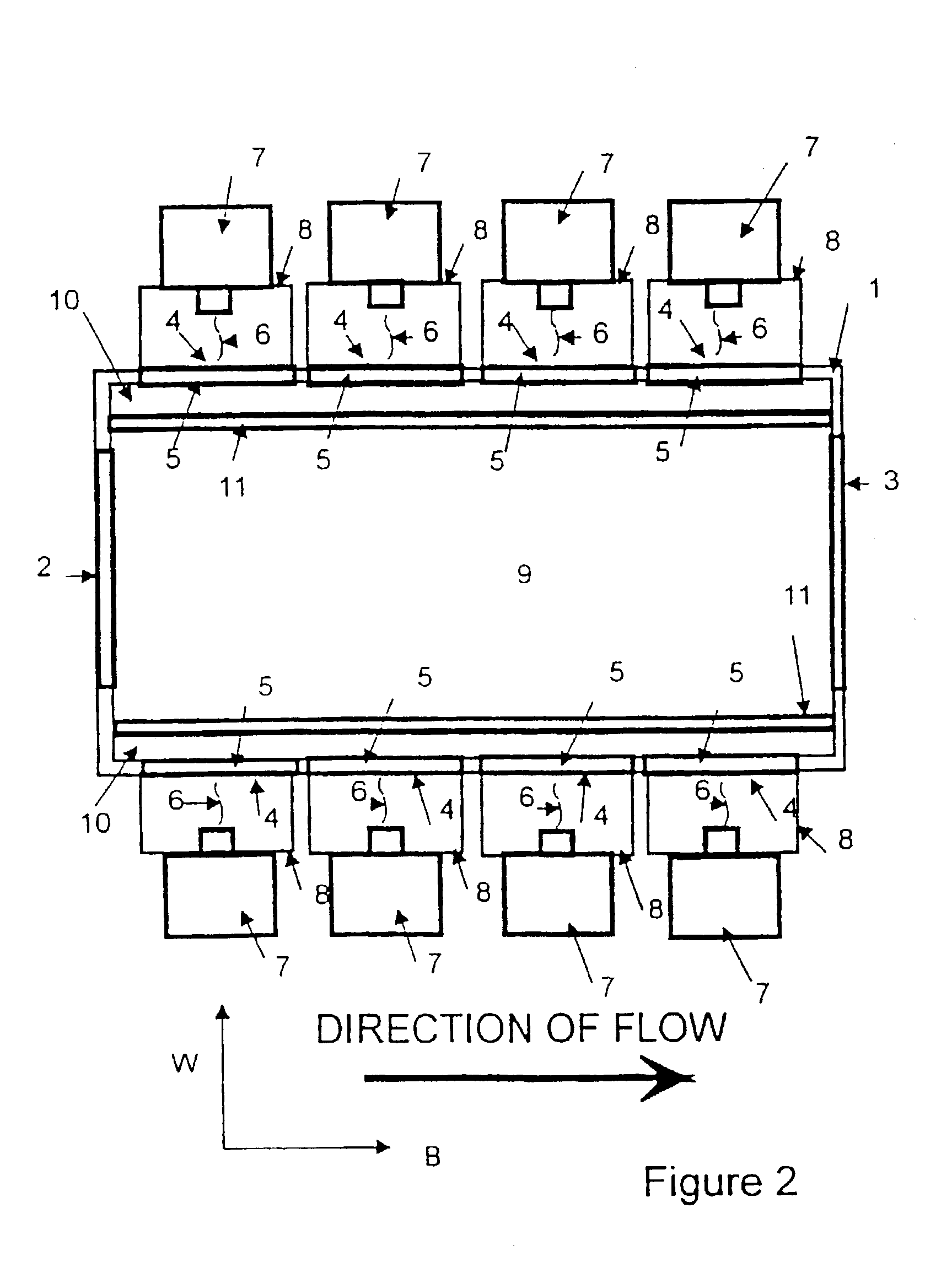

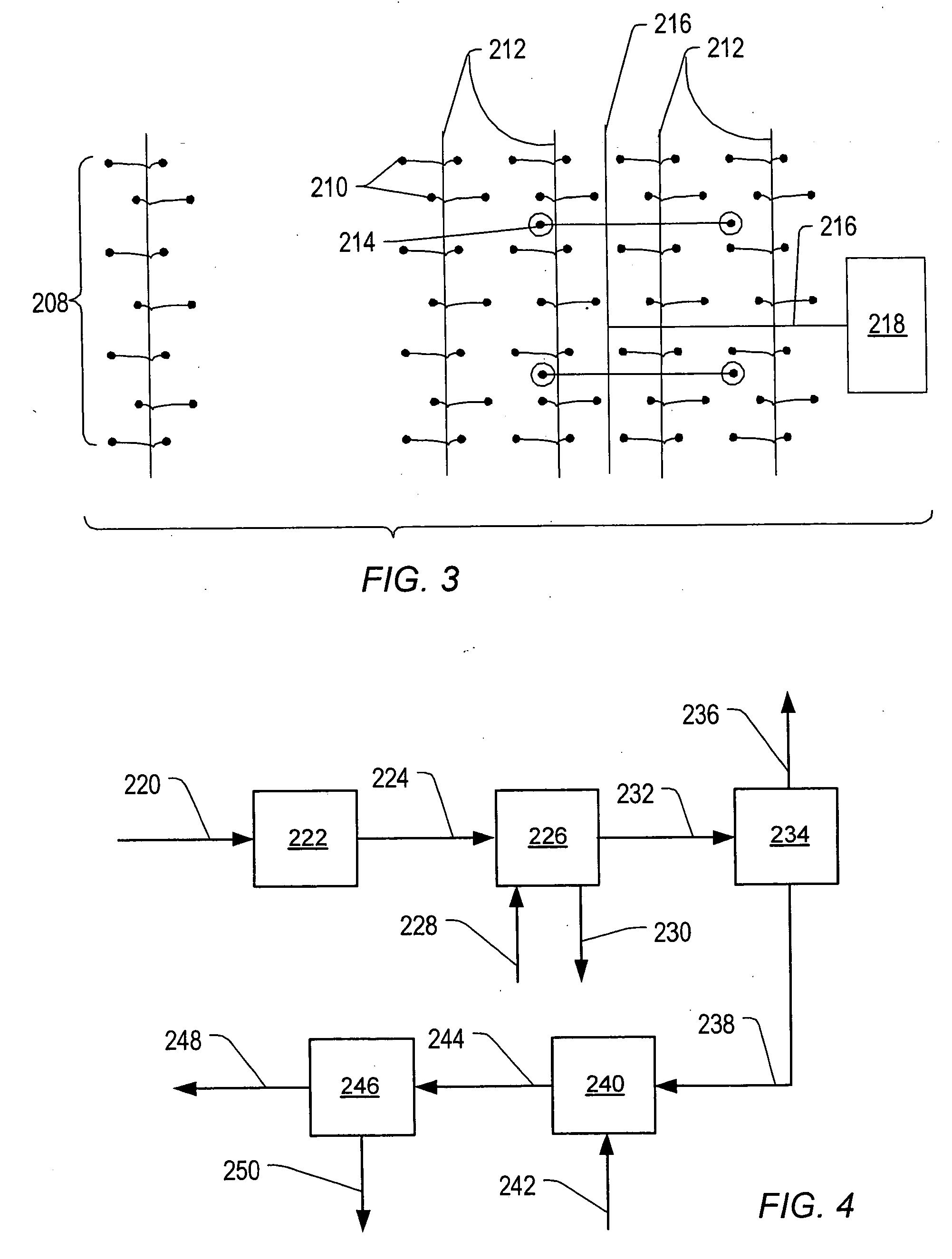

RFID-controlled smart range and method of cooking and heating

InactiveUS6953919B2Facilitate communicationFacilitates informationCooking vesselsDeep fat fryersAdditive ingredientEngineering

A system and method for providing multiple cooking modes and an ability to automatically heat cooking vessels and other objects using RFID technology, and an ability to read and write heating instructions and to interactively assist in their execution. An induction heating range is provided with two antennas per hob, and includes a user interface display and input mechanism. The vessel includes an RFID tag and a temperature sensor. In a first cooking mode, a recipe is read by the range and the range assists a user in executing the recipe by automatically heating the vessel to specified temperatures and by prompting the user to add ingredients. The recipe is written to the RFID tag so that if the vessel is moved to another hob, into which the recipe has not been read, the new hob can read the recipe from the RFID tag and continue in its execution.

Owner:HR TECH

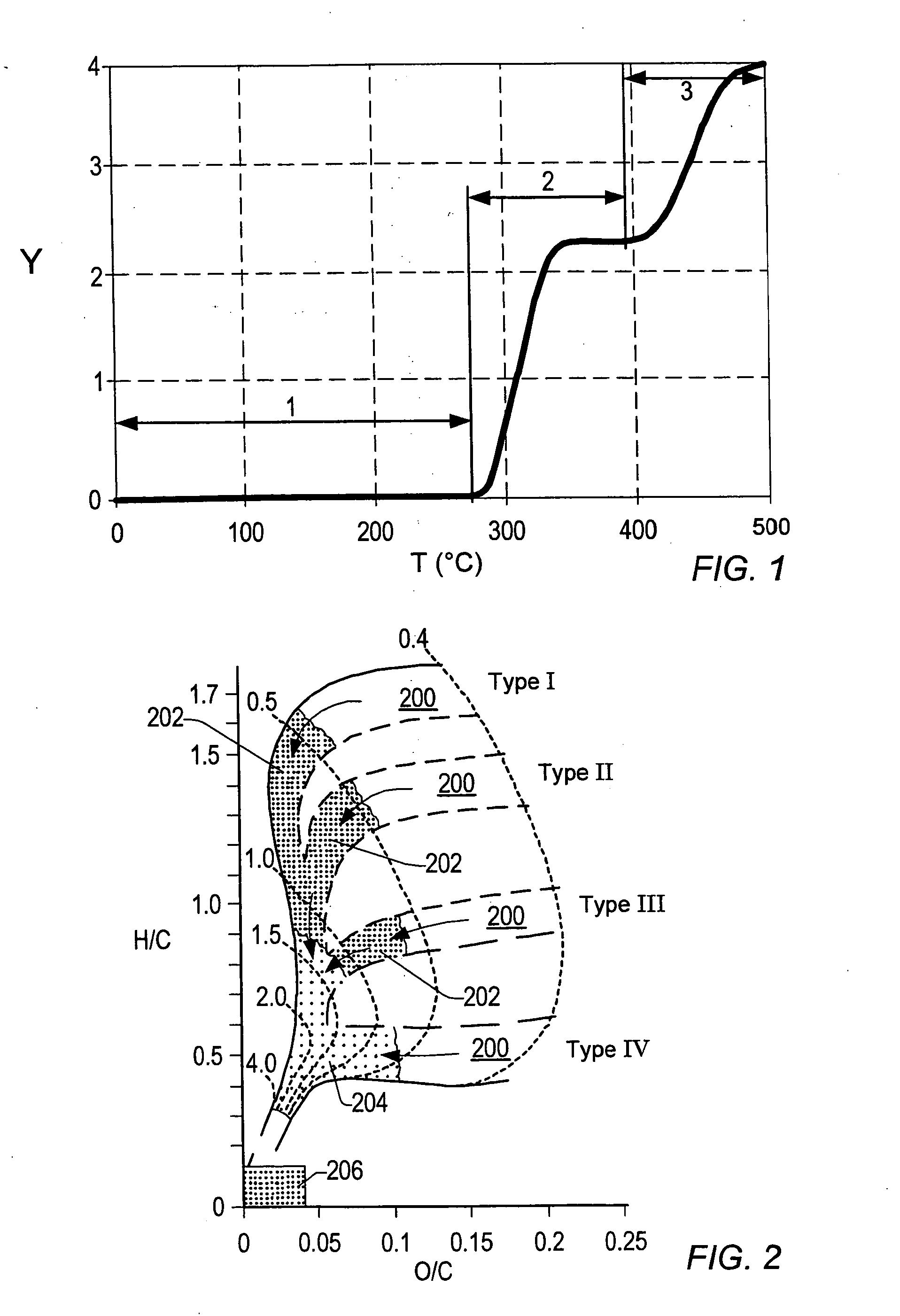

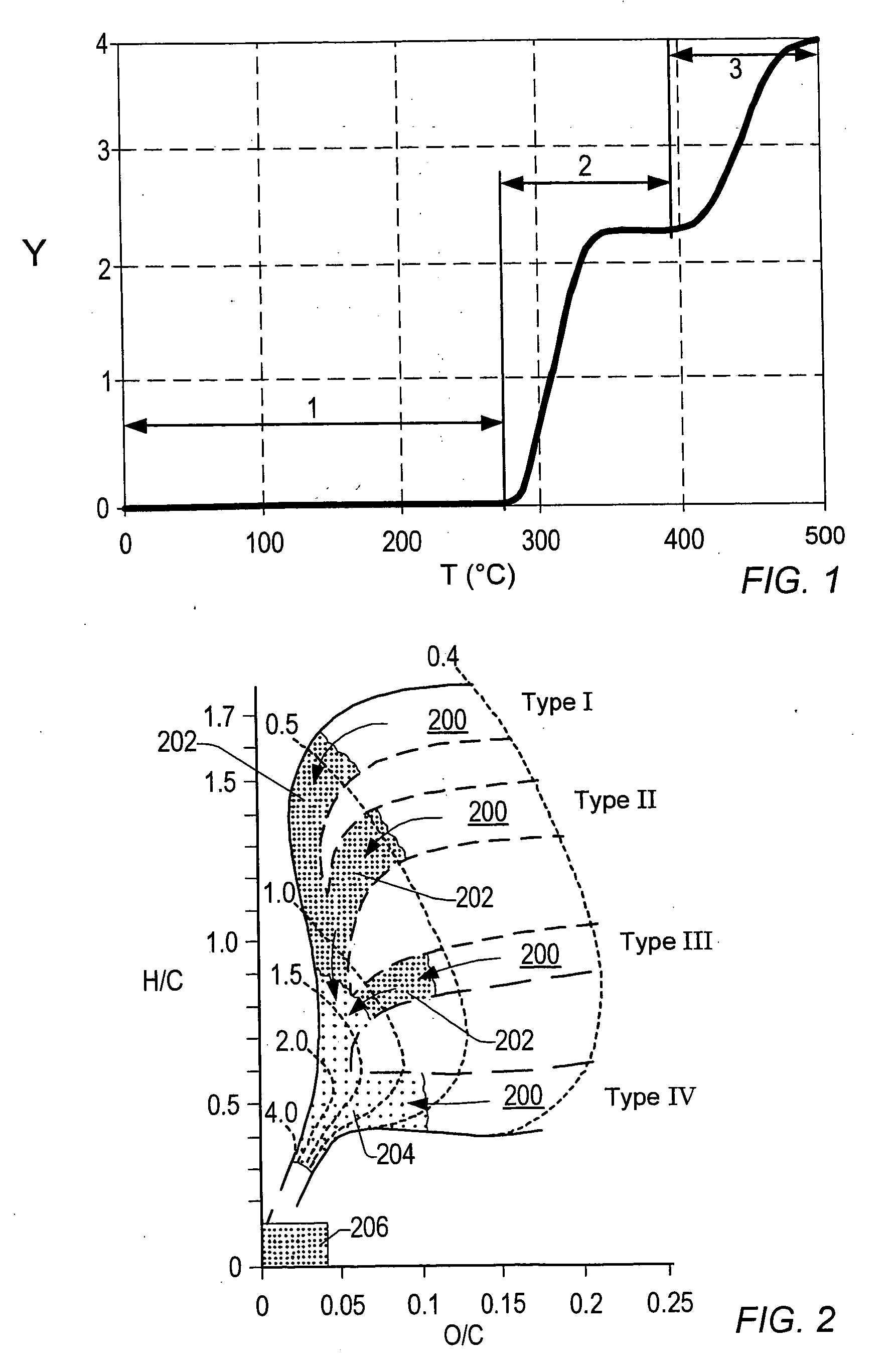

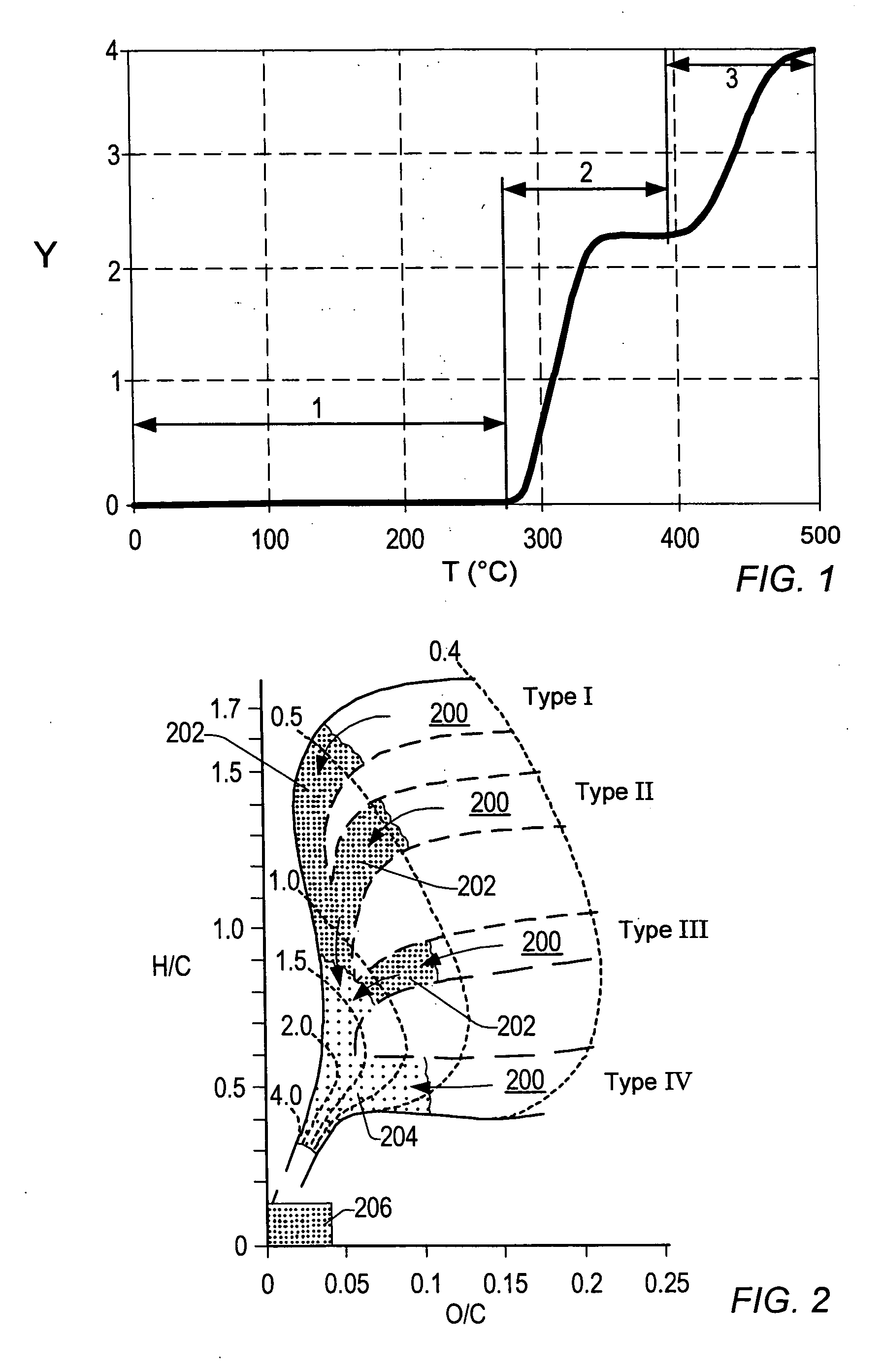

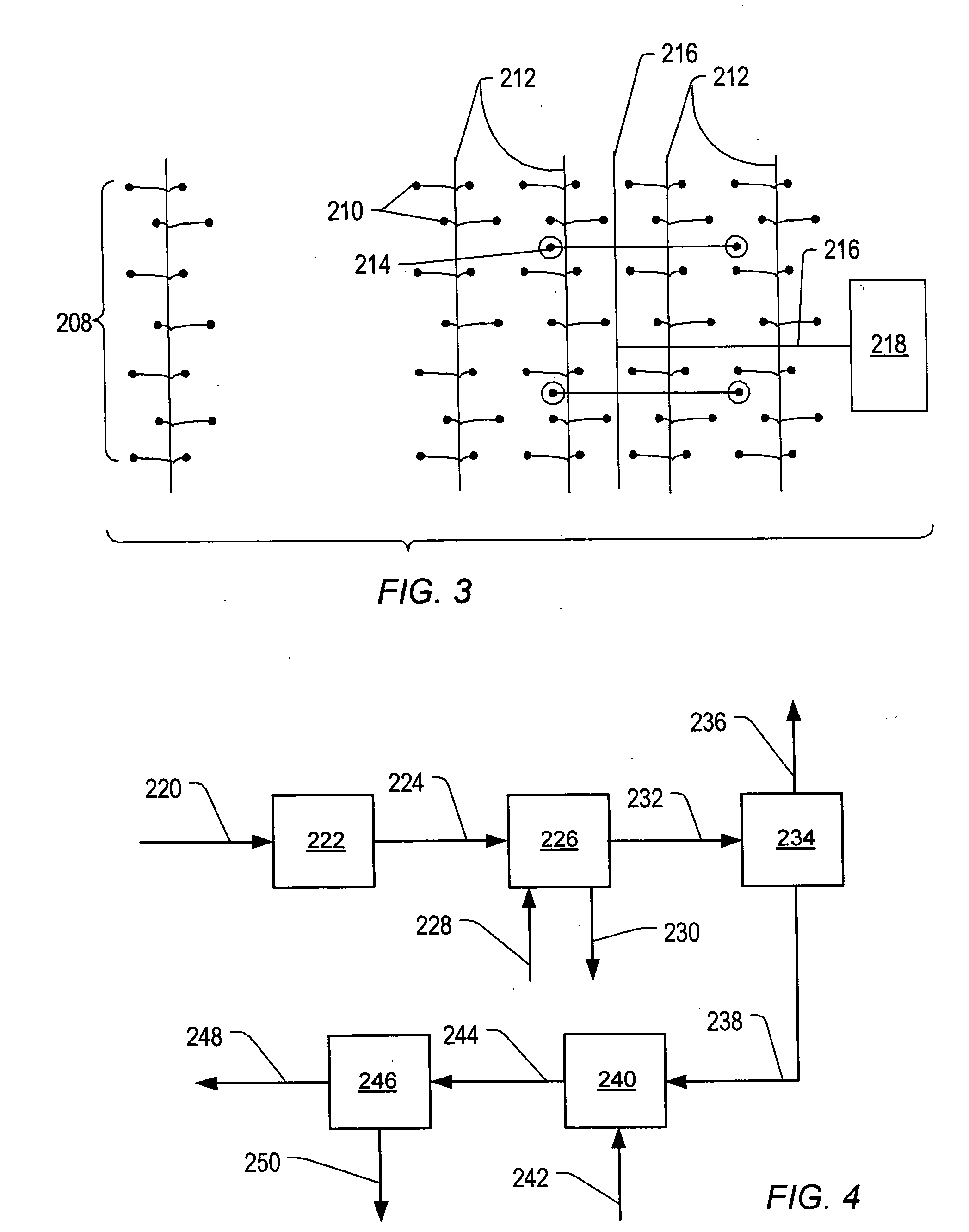

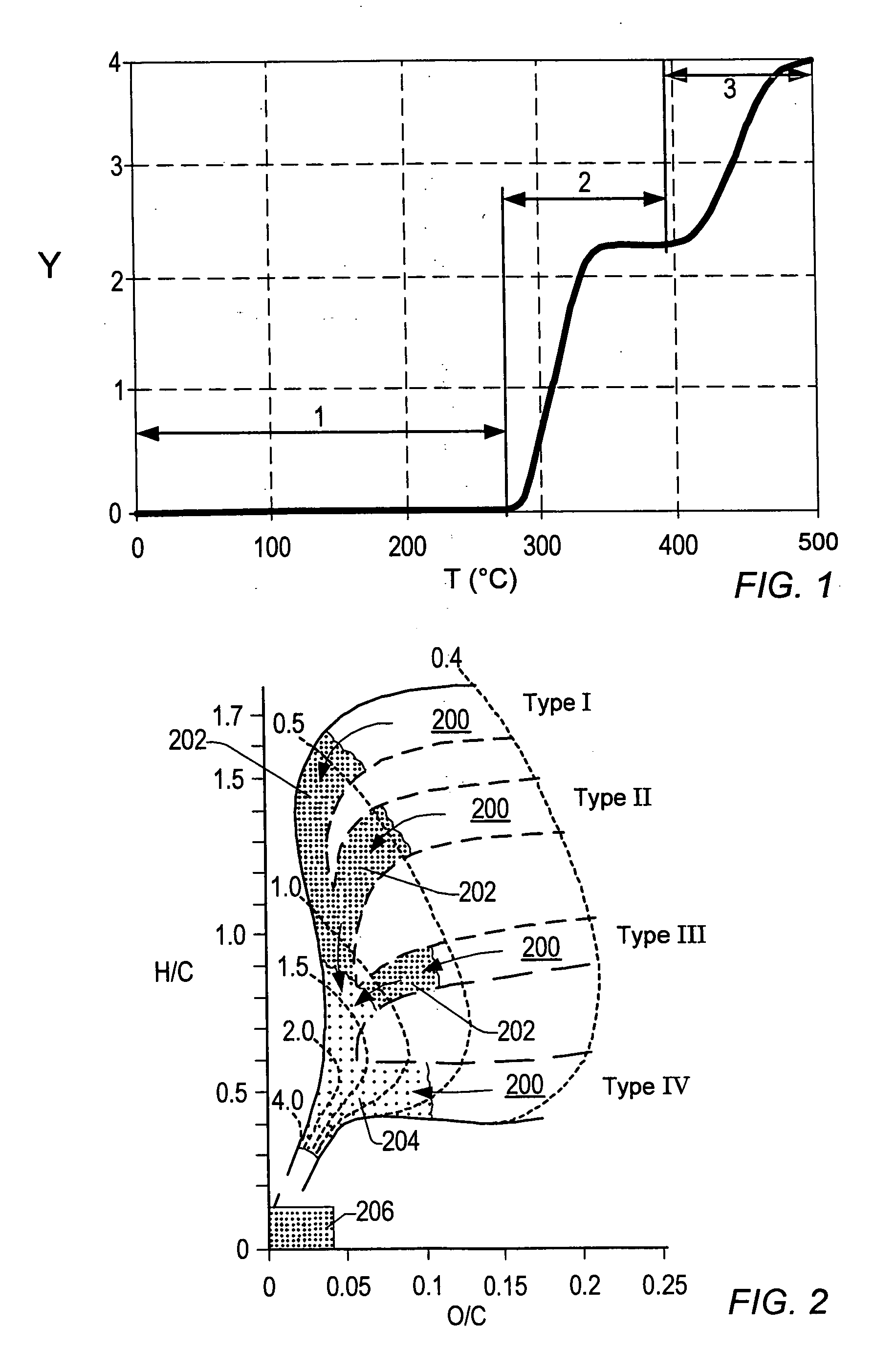

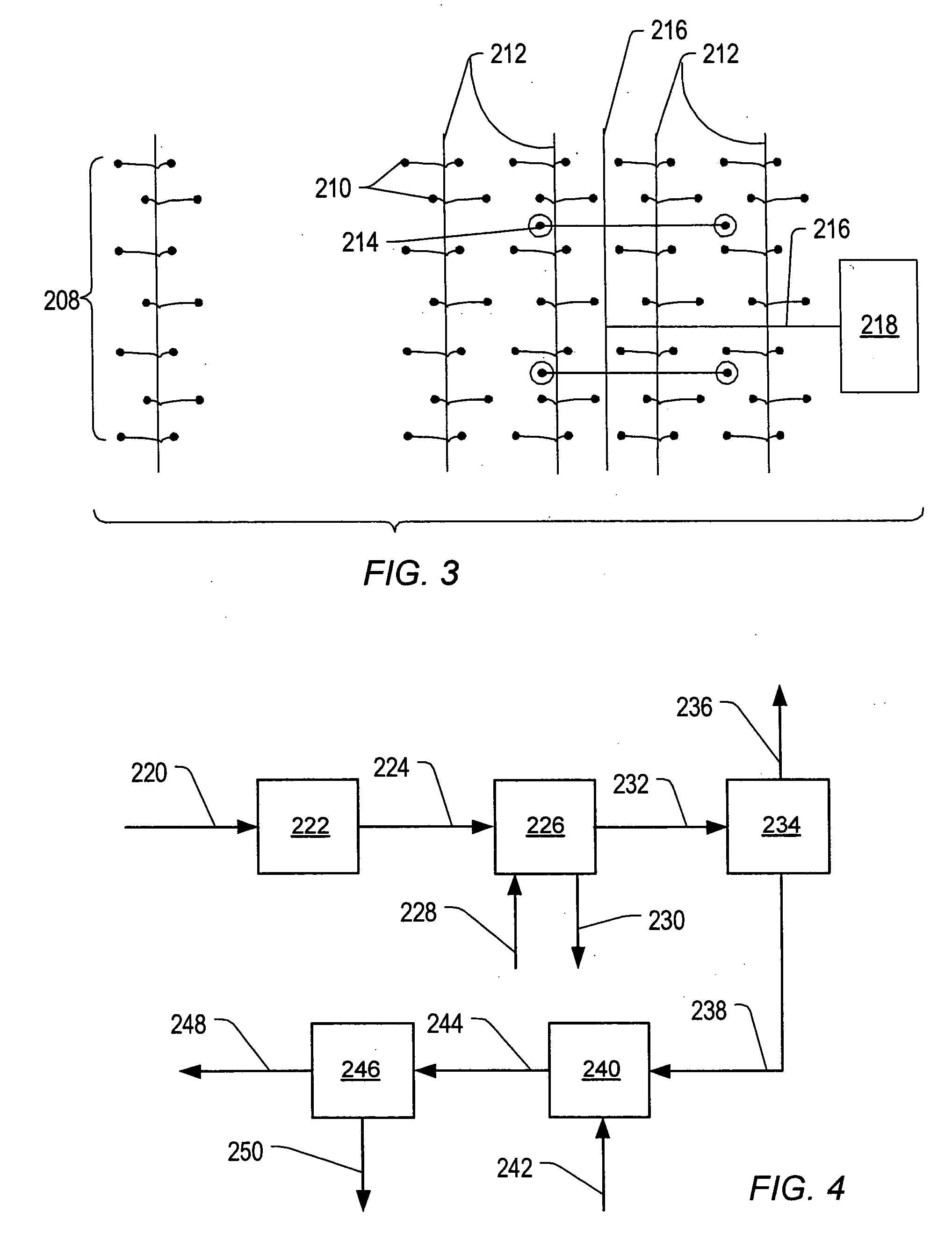

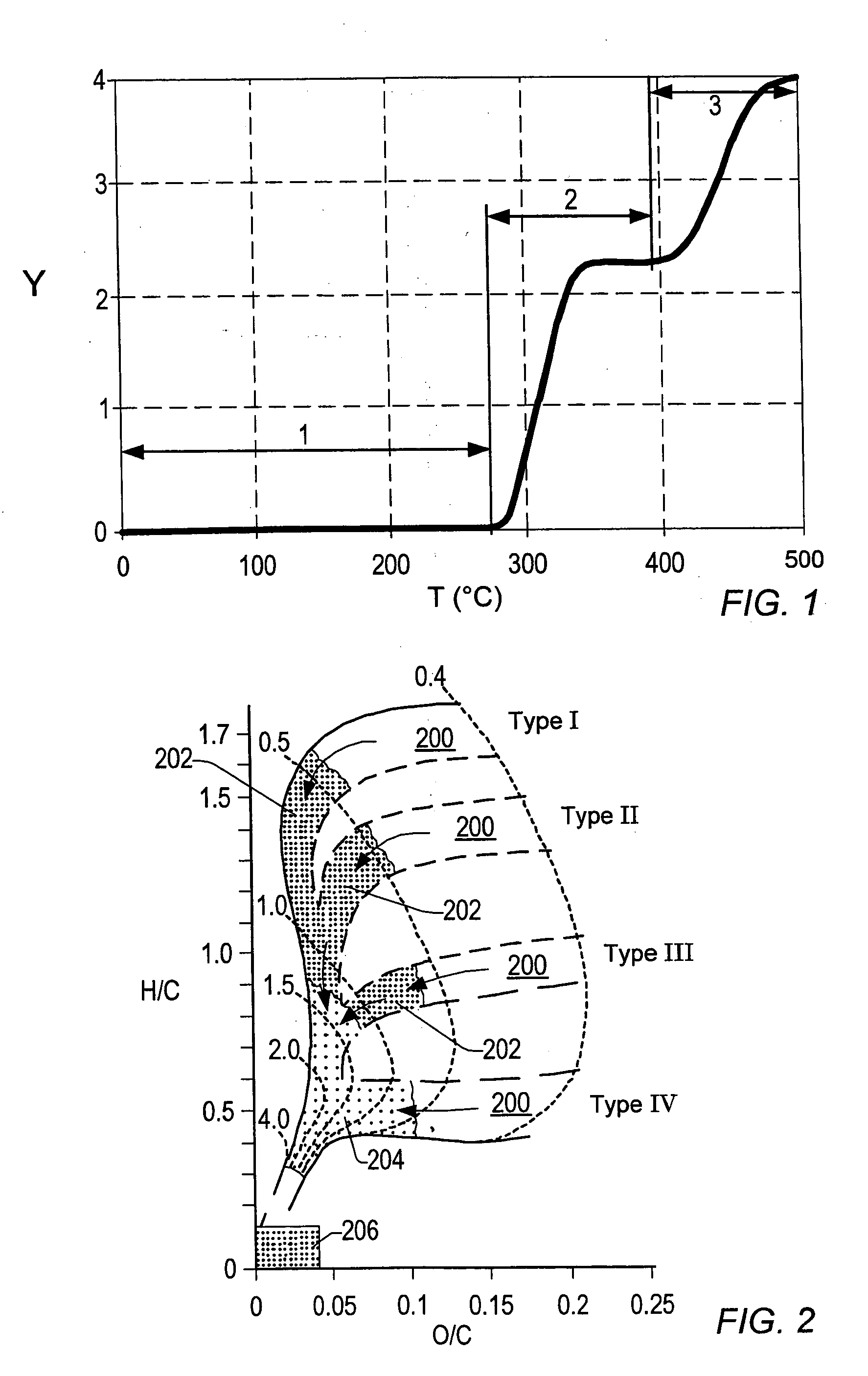

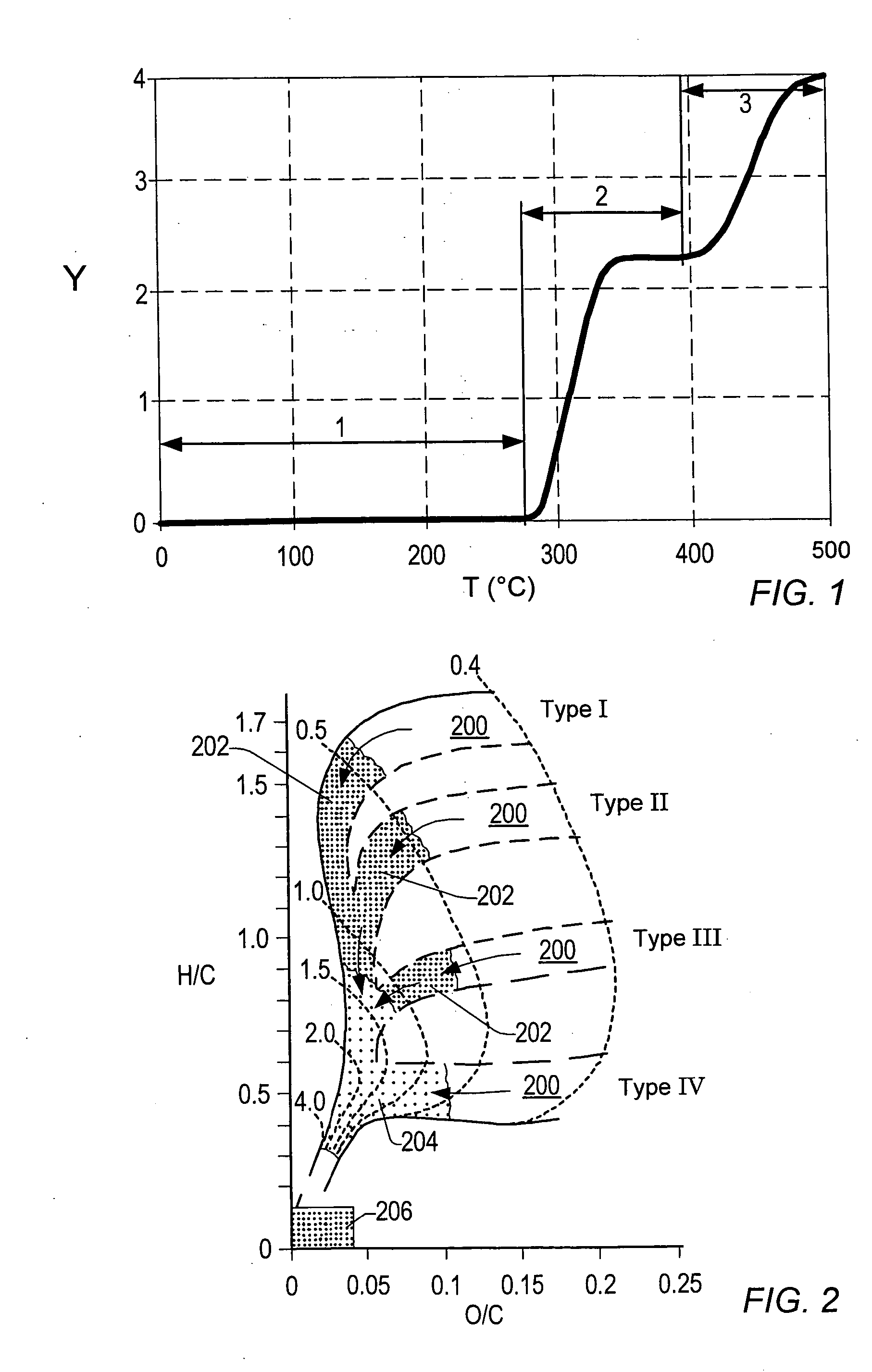

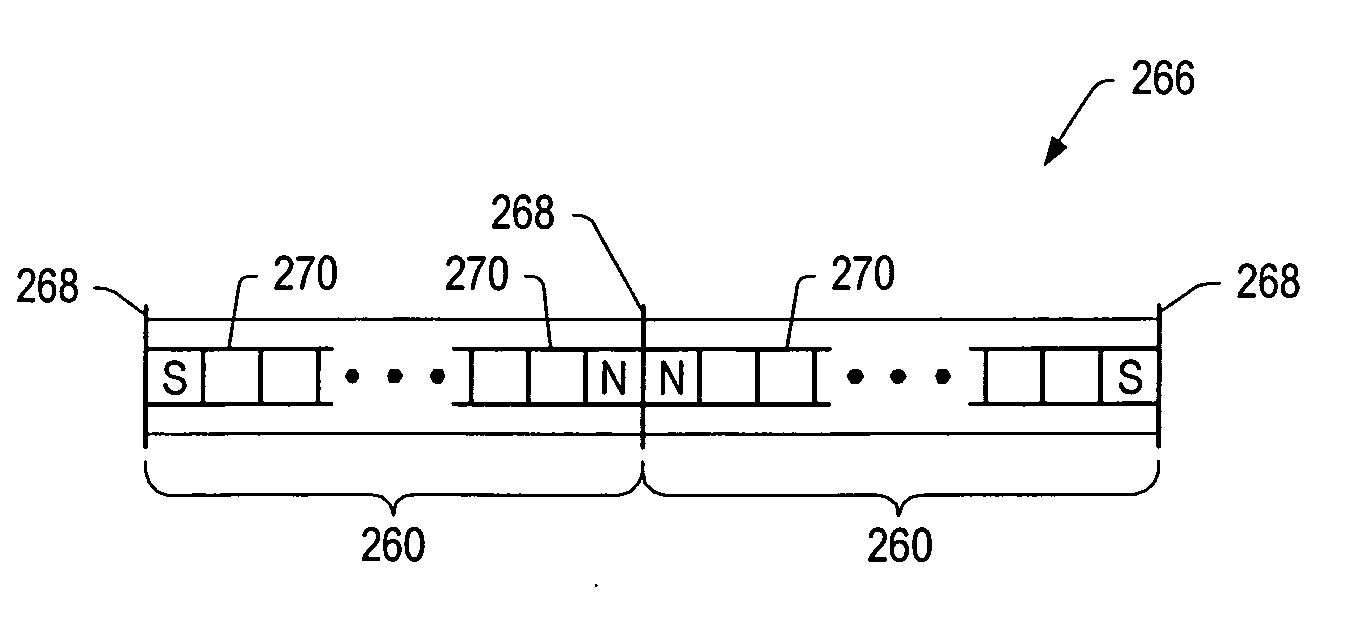

Temperature limited heaters with high power factors

Certain embodiments provide a heater. The heater includes a ferromagnetic member. The heater also includes an electrical conductor electrically coupled to the ferromagnetic member. The electrical conductor is configured to conduct a majority of time-varying electrical current passing through the heater at about 25° C. The heater is configured to provide a first heat output below the Curie temperature of the ferromagnetic member. The heater is configured to automatically provide a second heat output approximately at and above the Curie temperature of the ferromagnetic member. The second heat output is reduced compared to the first heat output.

Owner:SHELL OIL CO

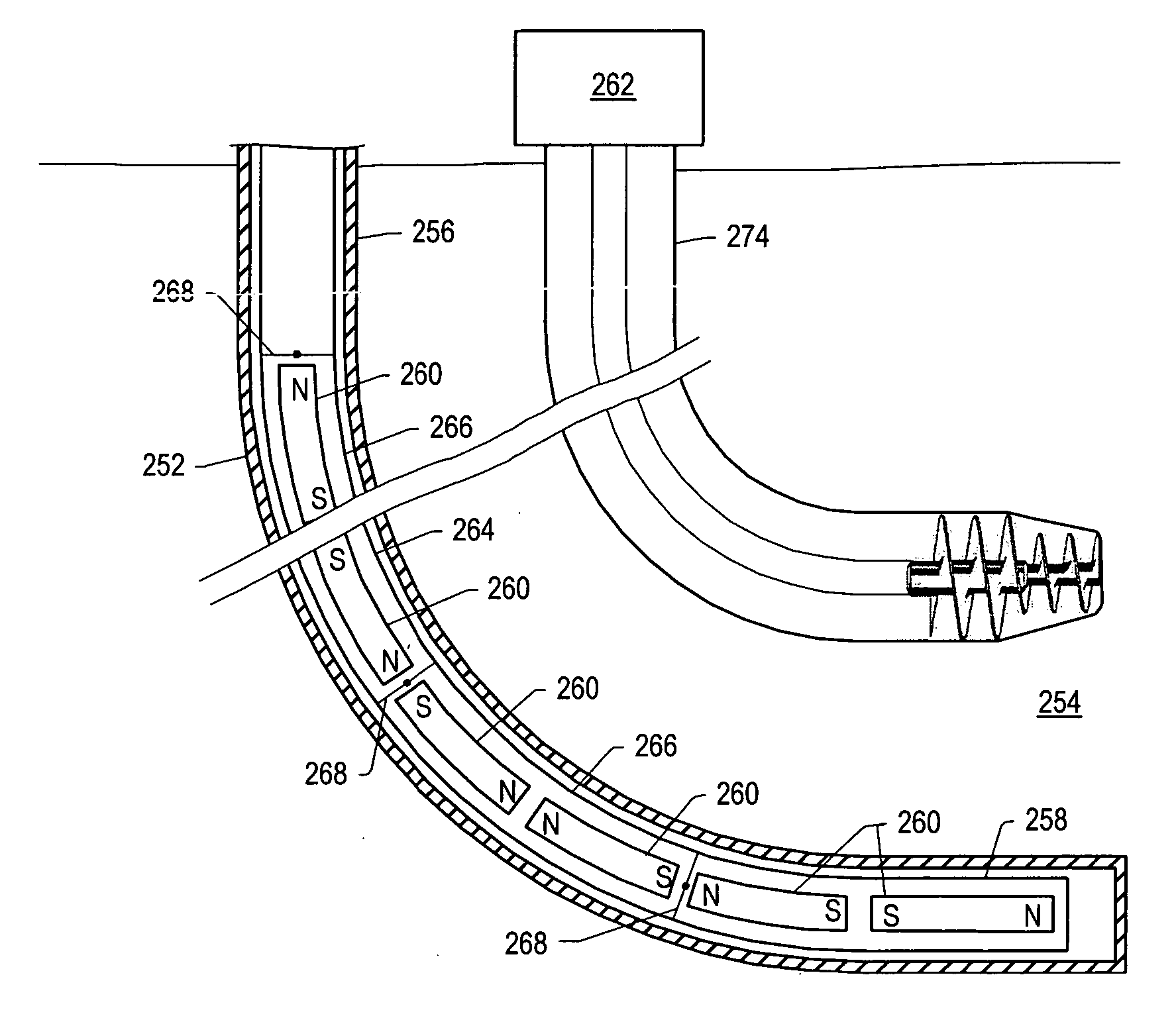

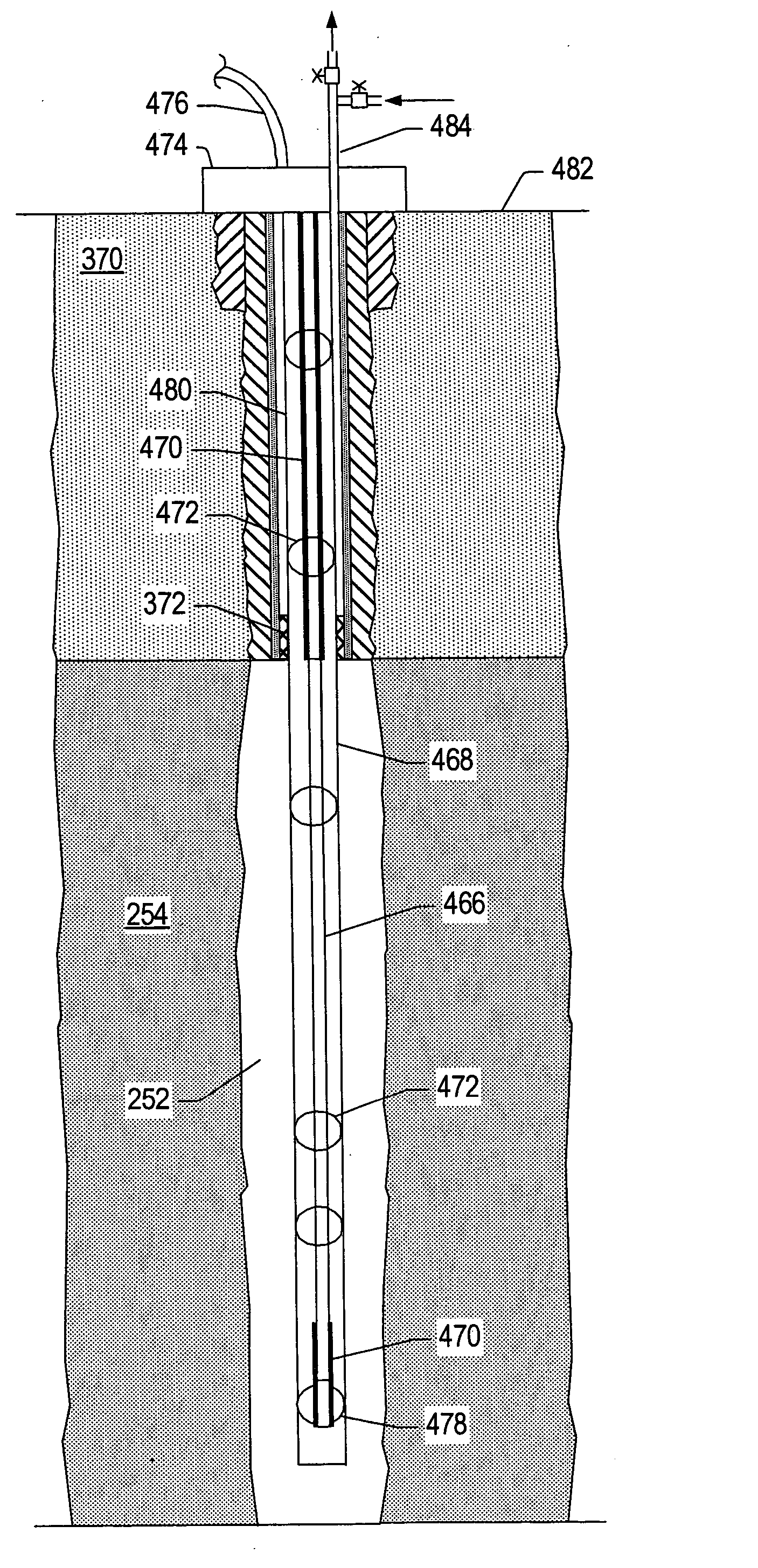

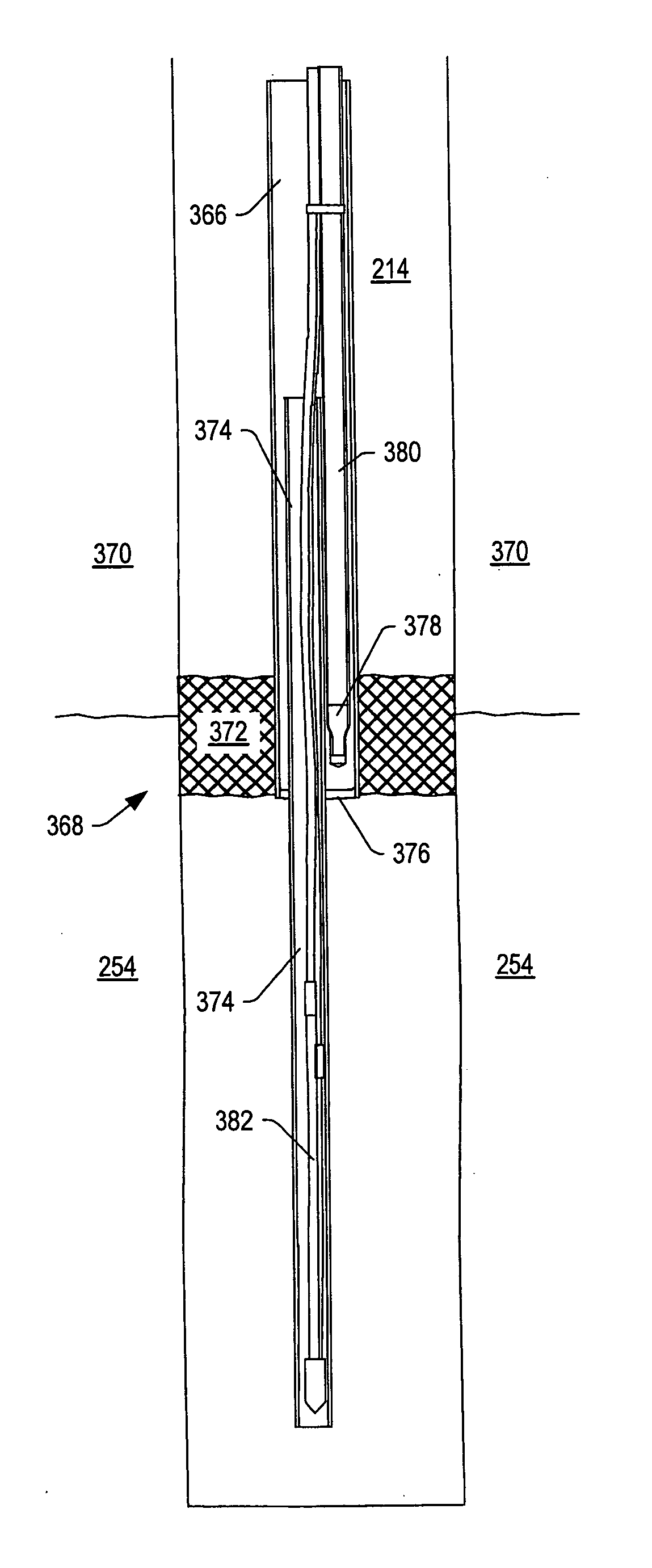

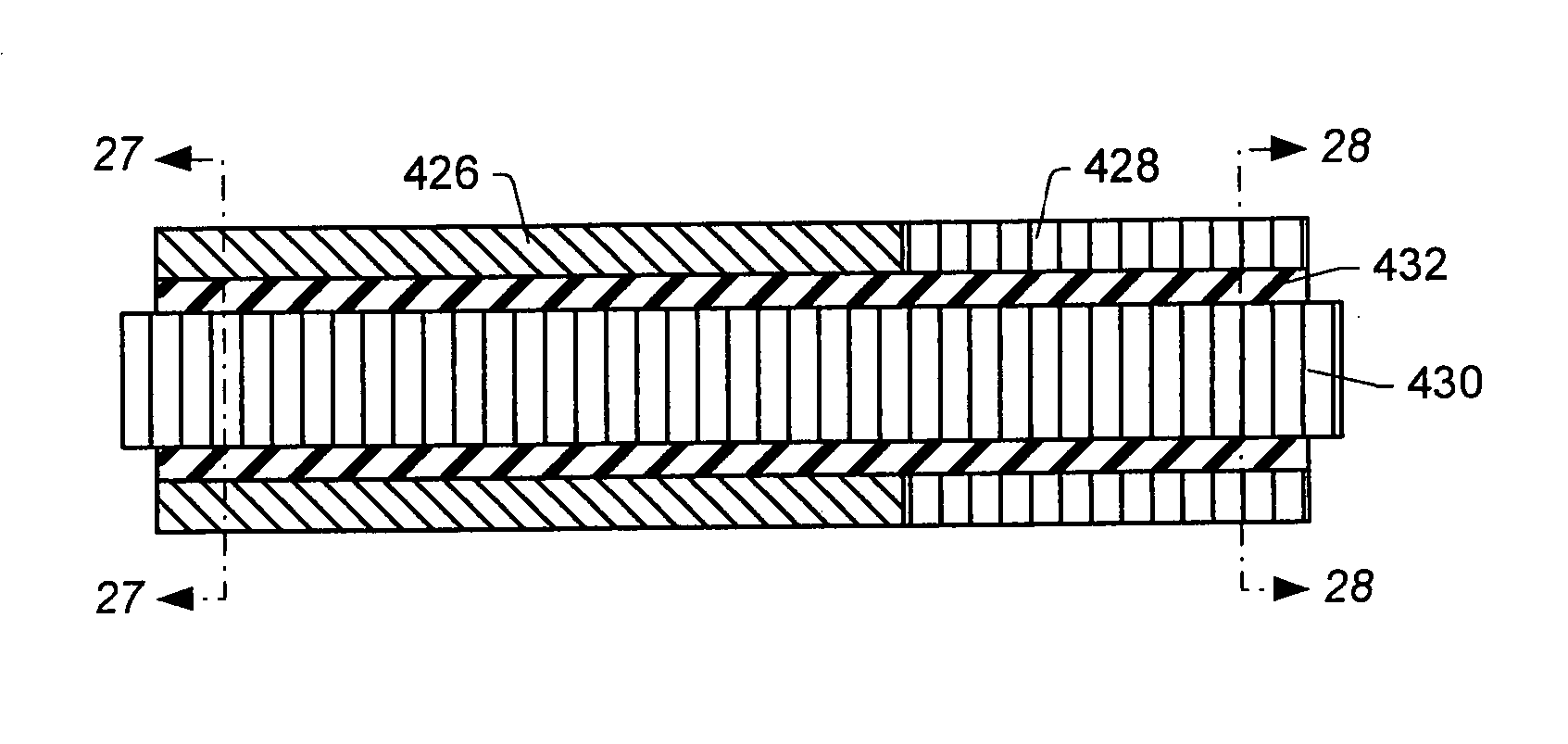

Subsurface electrical heaters using nitride insulation

Certain embodiments provide a heating system configurable to heat a subsurface formation. The system includes an electrical conductor configured to generate an electrically resistive heat output during application of electrical current to the electrical conductor. An electrical insulator at least partially surrounds the electrical conductor. The electrical insulator includes a nitride. A sheath at least partially surrounds the electrical insulator.

Owner:SHELL OIL CO

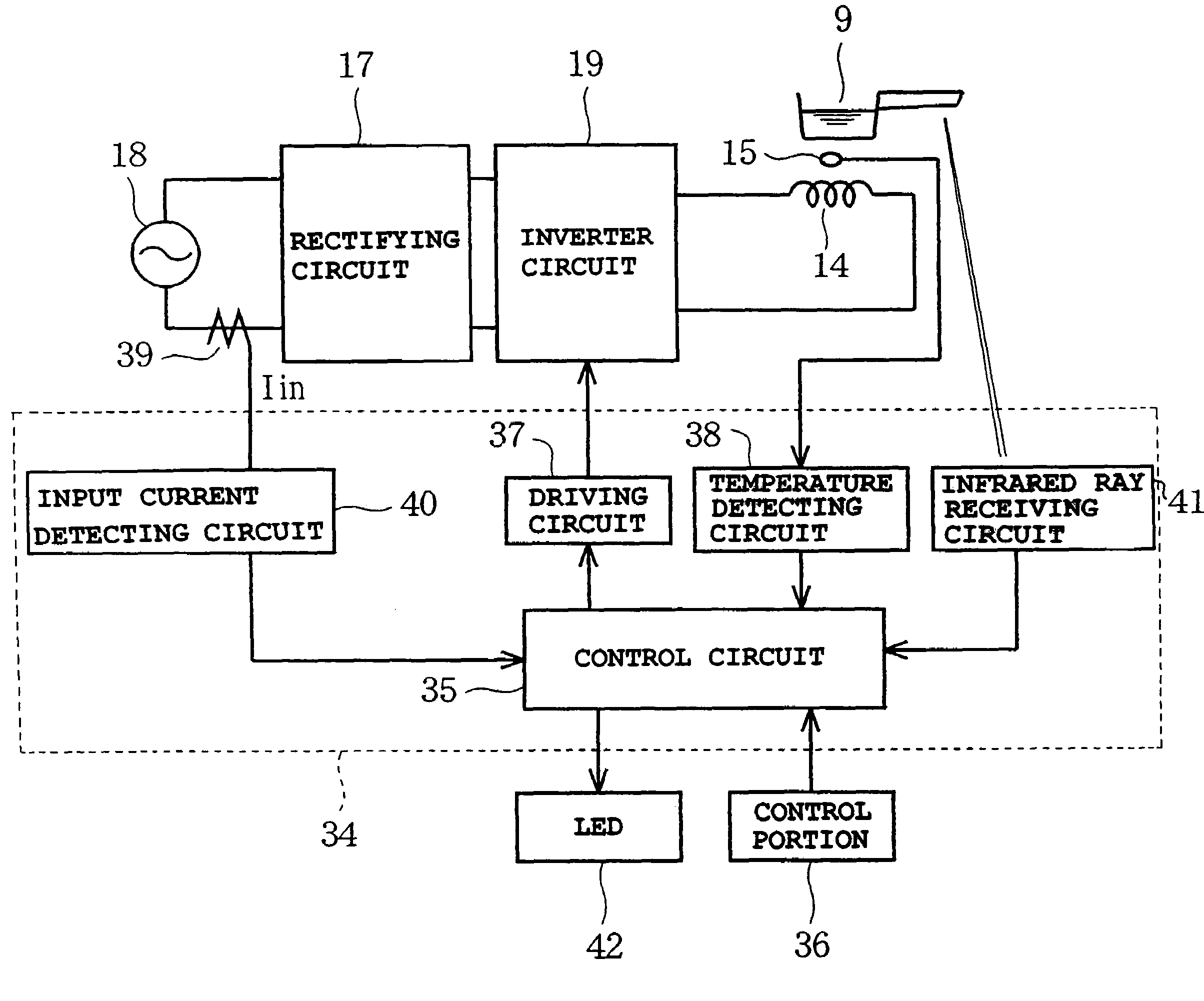

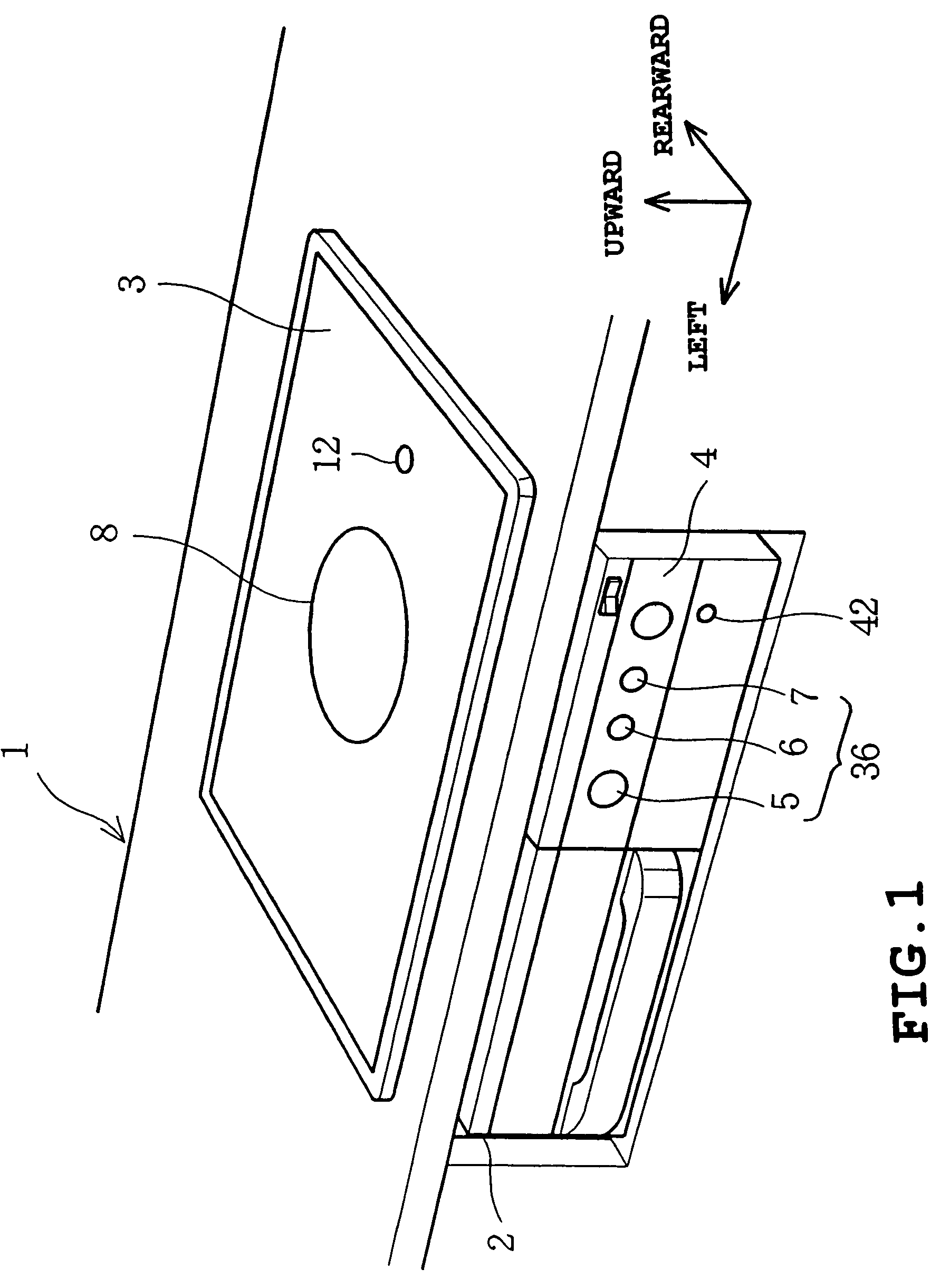

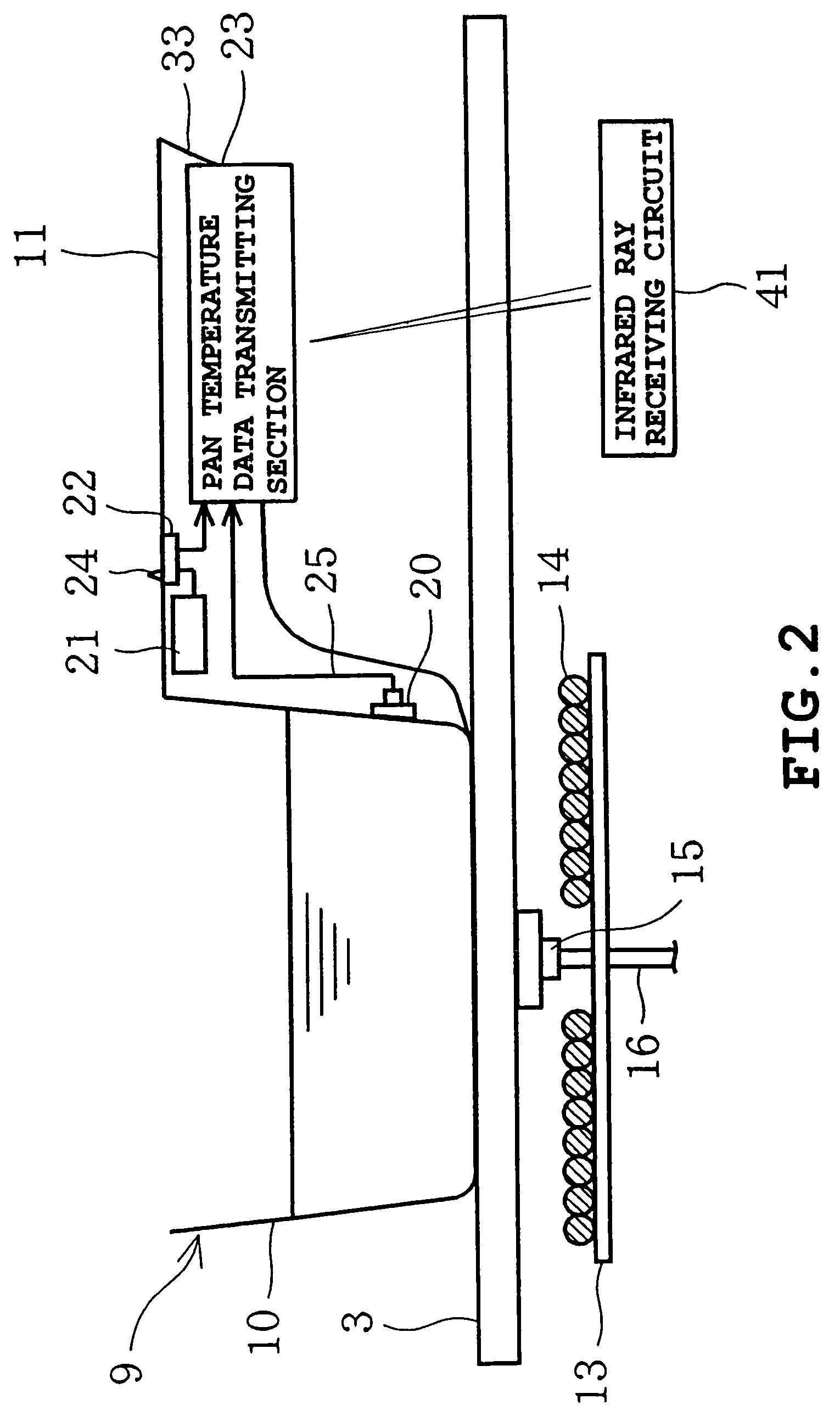

Cooking tool

InactiveUS7473872B2Little strengthAvoid it happening againCooking vesselsInduction heating controlInfraredData control

A heat cooking apparatus includes a supporting unit for supporting a cooking tool, a heating unit for heating the cooking tool, a receiving unit capable of receiving temperature data of the cooking tool transmitted in the form of infrared rays from the exterior, and a controlling unit for controlling the heating unit on the basis of temperature data received by the receiving unit.

Owner:IRIS OHYAMA

Radio frequency (RF) heating system

An RF heating system for bonding a first element to a second element. In one embodiment, the RF heating system includes: (a) a composition, which functions as an adhesive, interposed between the first and second elements, the composition including an ionomer and a polar carrier, wherein the ionomer and / or the carrier are present in amounts effective to allow the composition to be headed by a fringe RF field; and (b) a radio frequency (RF) heating apparatus for producing the fringe RF field.

Owner:AMBRELL CORP

Inductive quench for magnet protection

ActiveUS7701677B2Effective heat conductionMagnetic measurementsMagnetsSuperconducting CoilsInternal energy

A coil system for inductively heating a superconducting magnet in order to provide an internal energy dump by uniformly quenching a high performance superconducting magnet. The quench-inducing system uses AC magnetic fields that require negligible reactive power. The system is especially suited for inducing a relatively uniform quench in dry superconducting magnets.

Owner:MASSACHUSETTS INST OF TECH

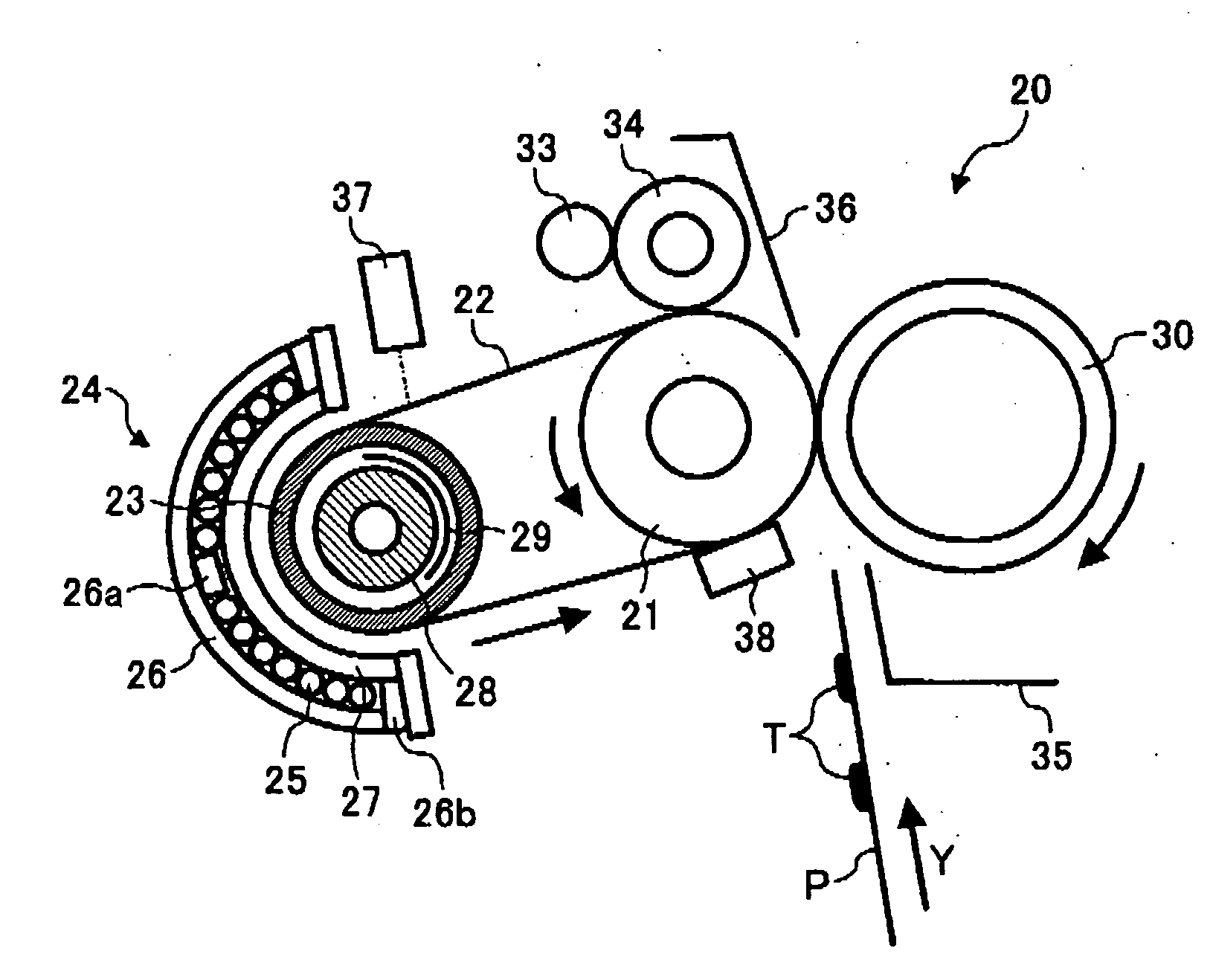

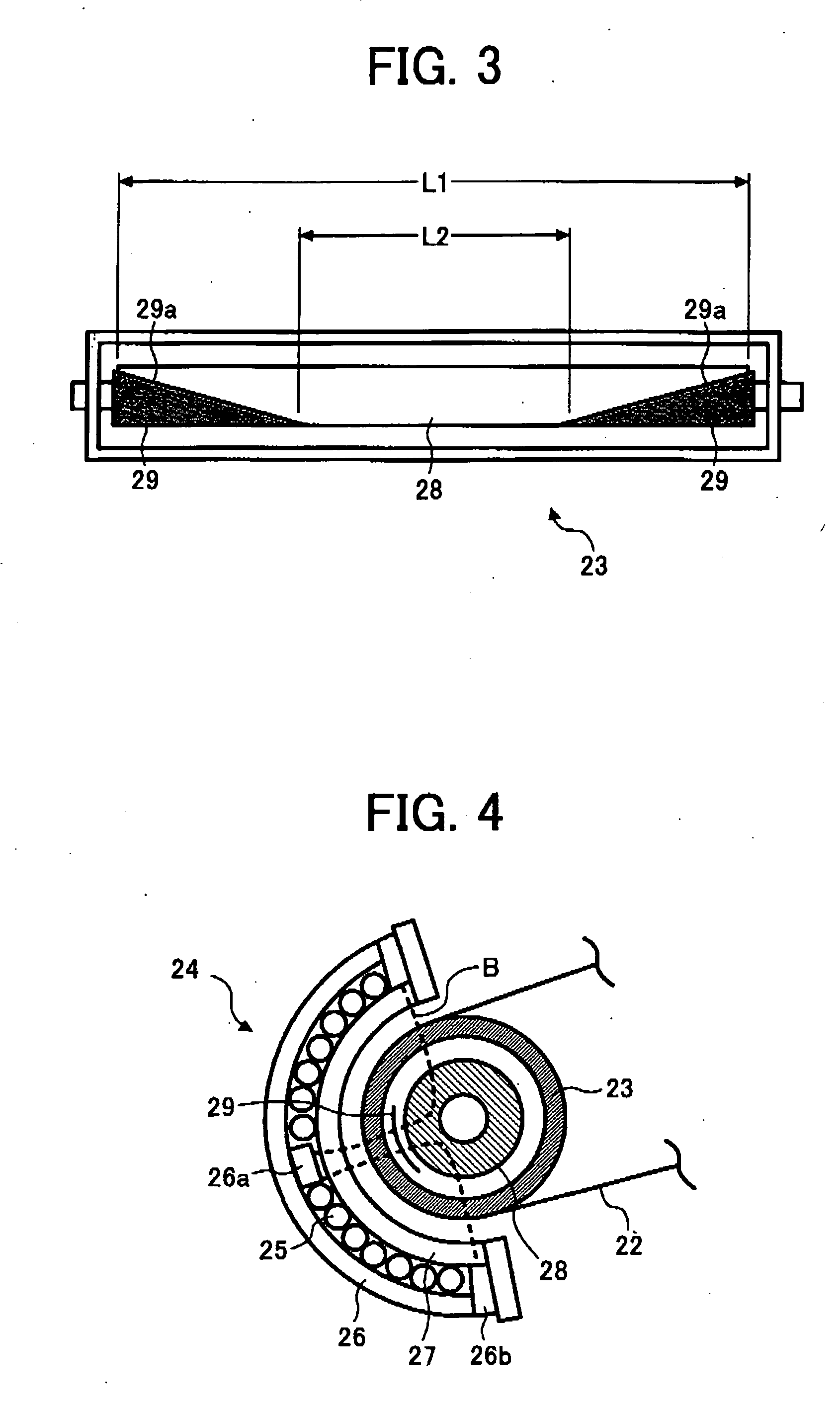

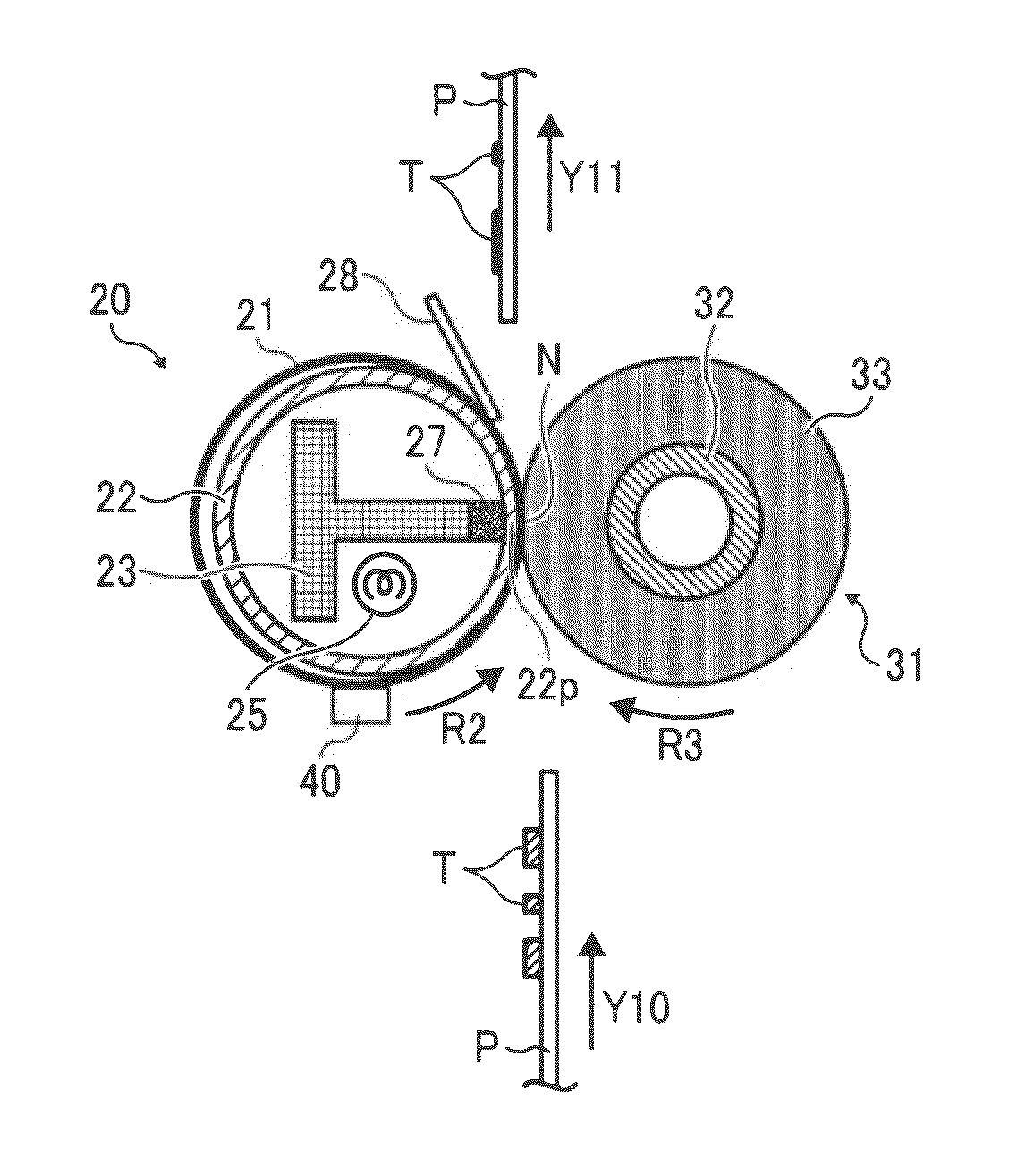

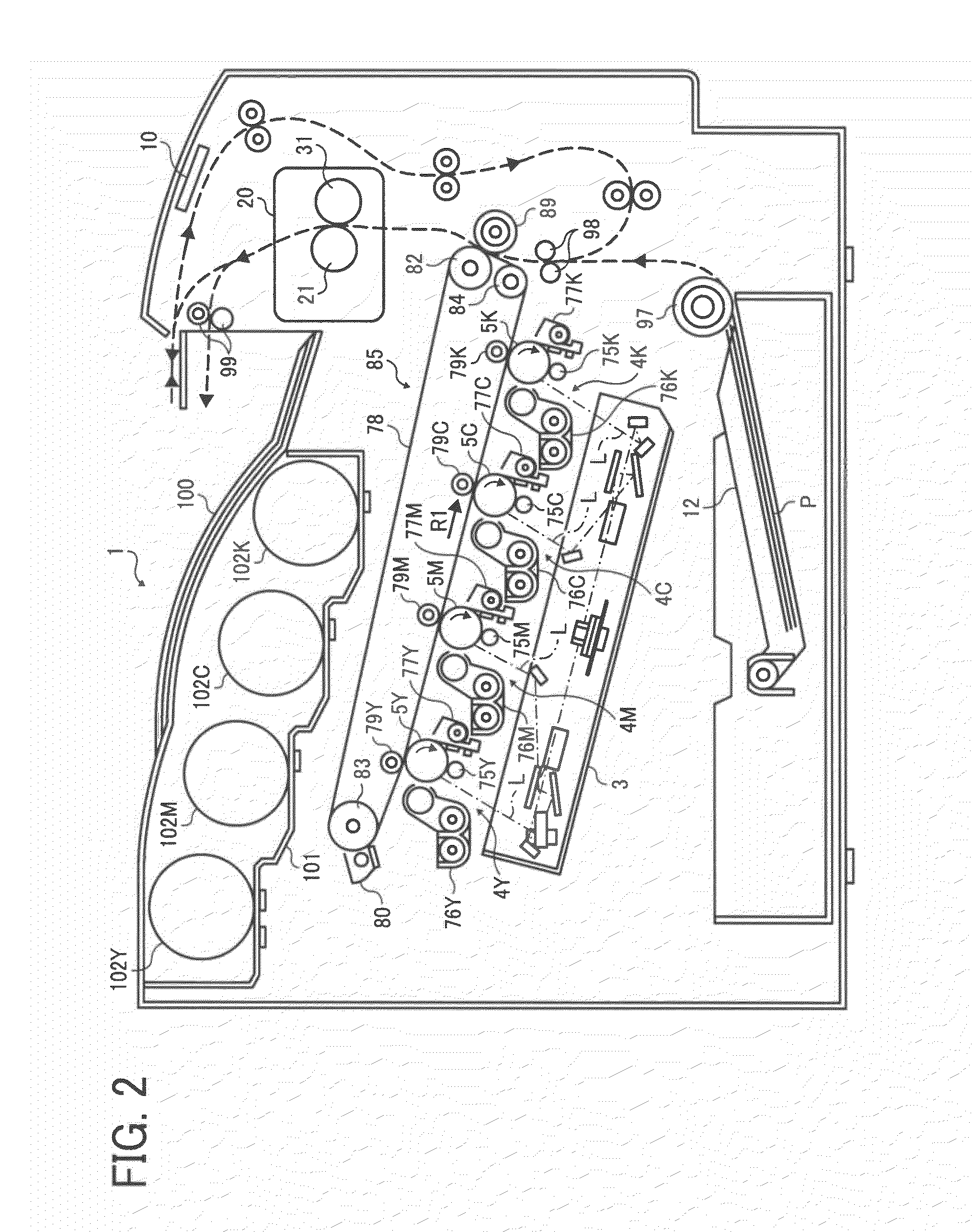

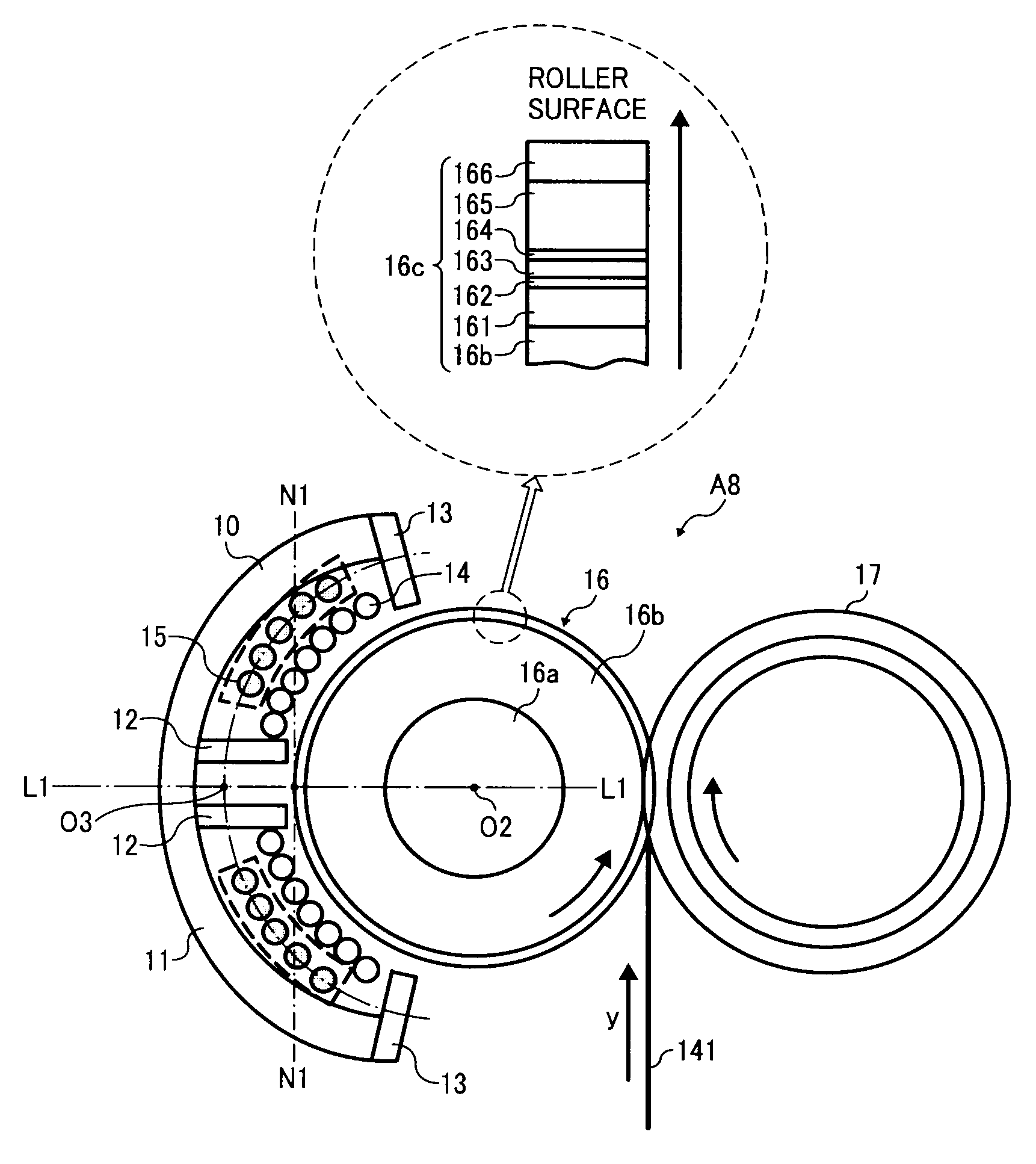

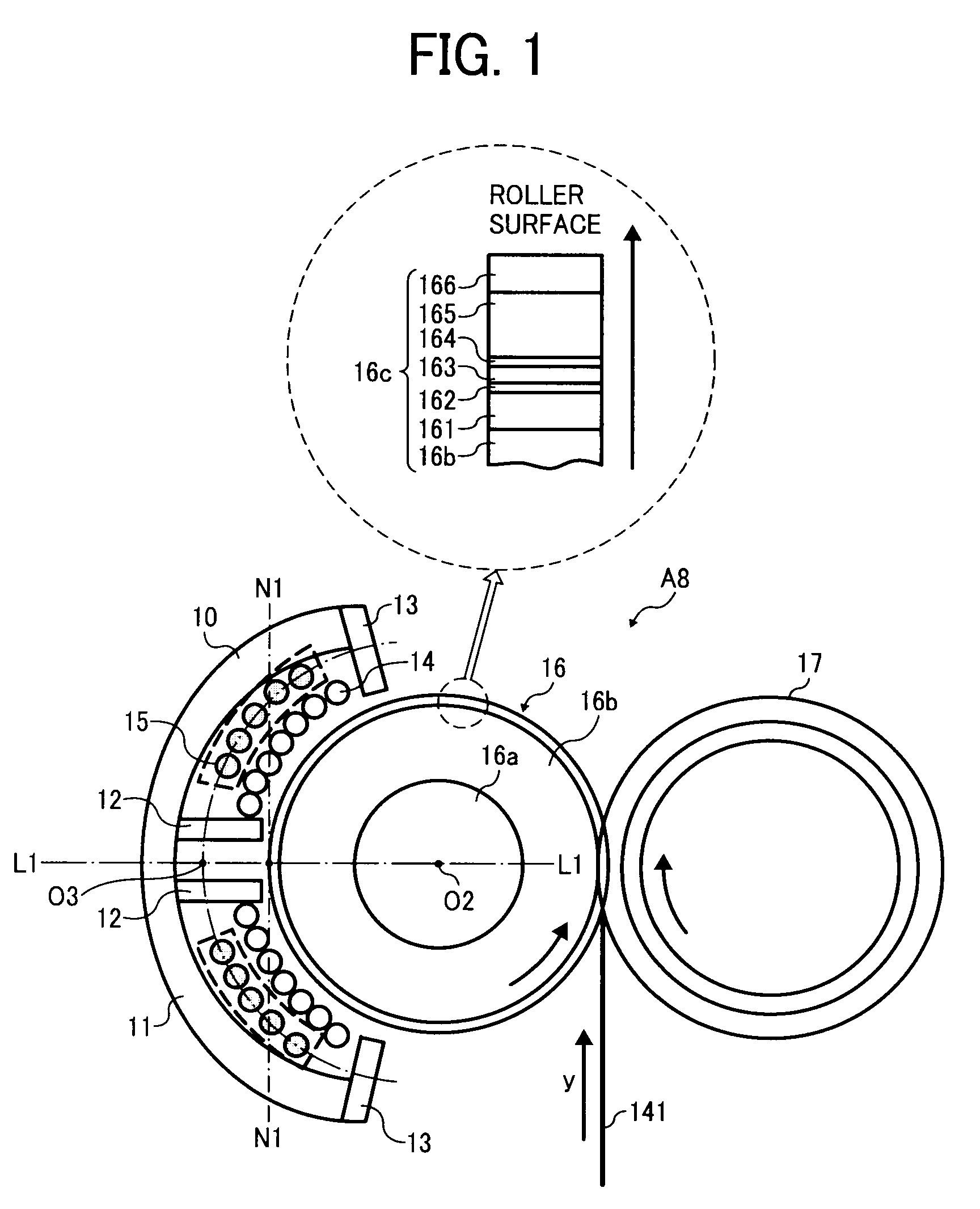

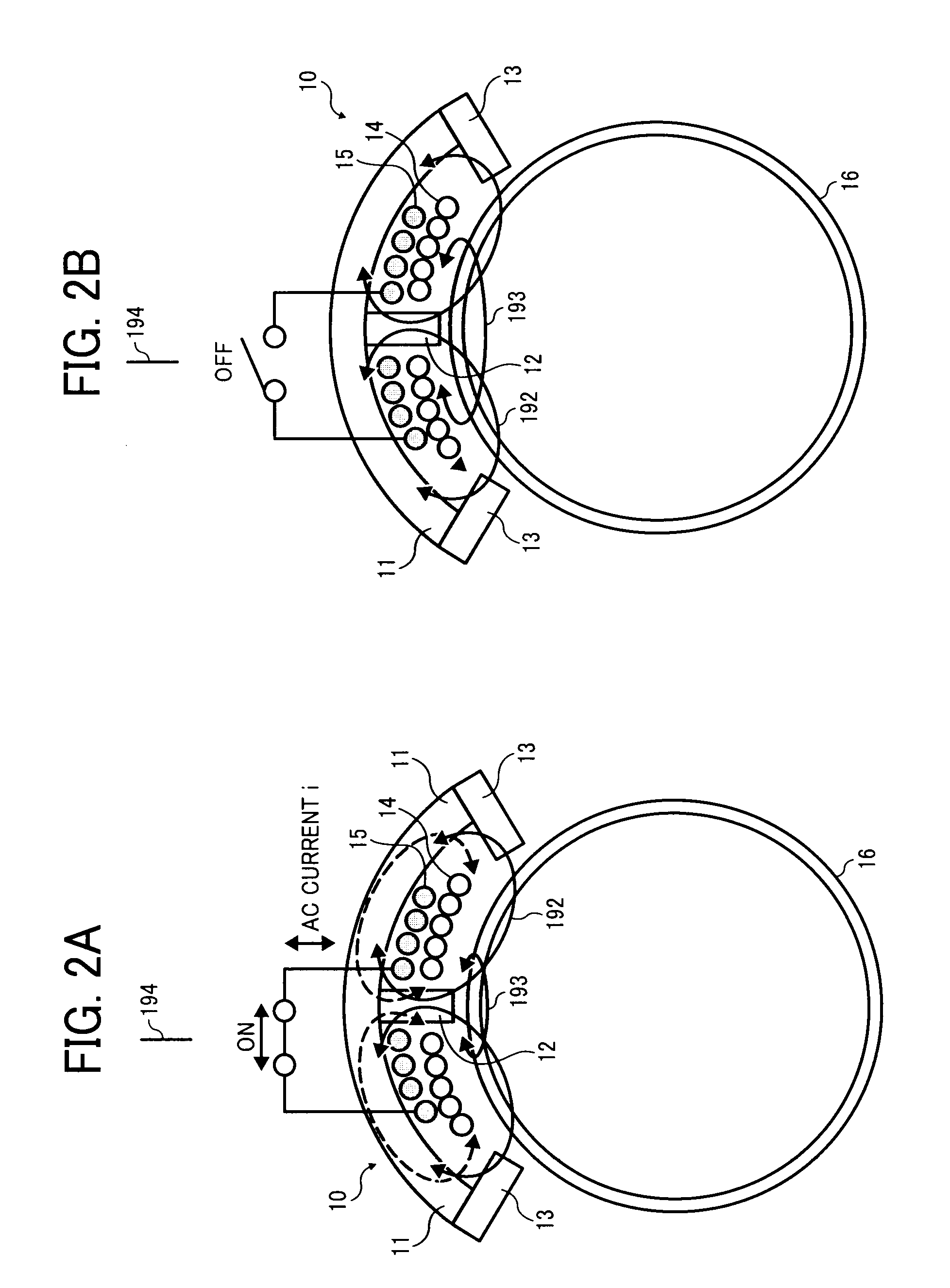

Image fixing apparatus stably controlling a fixing temperature, and image forming apparatus using the same

InactiveUS20060029411A1Electrographic process apparatusInduction heating apparatusImage formationEngineering

An image forming apparatus includes an image forming mechanism and an image fixing unit. The image forming mechanism forms a toner image on a recording sheet. The image fixing unit fixes the toner image onto the recording sheet. The image fixing unit includes a magnetic flux generator, a heat member, a magnetic flux adjuster, and a controlling member. The magnetic flux generator generates a magnetic flux. The heat member is heated inductively by the magnetic flux generated by the magnetic flux generator. The magnetic flux adjuster reduces the magnetic flux active on the heat member to form a heat reduction area in an outer circumferential surface of the heat member in a width direction thereof. The controlling member moves the magnetic flux adjuster to change the heat reduction area.

Owner:RICOH KK

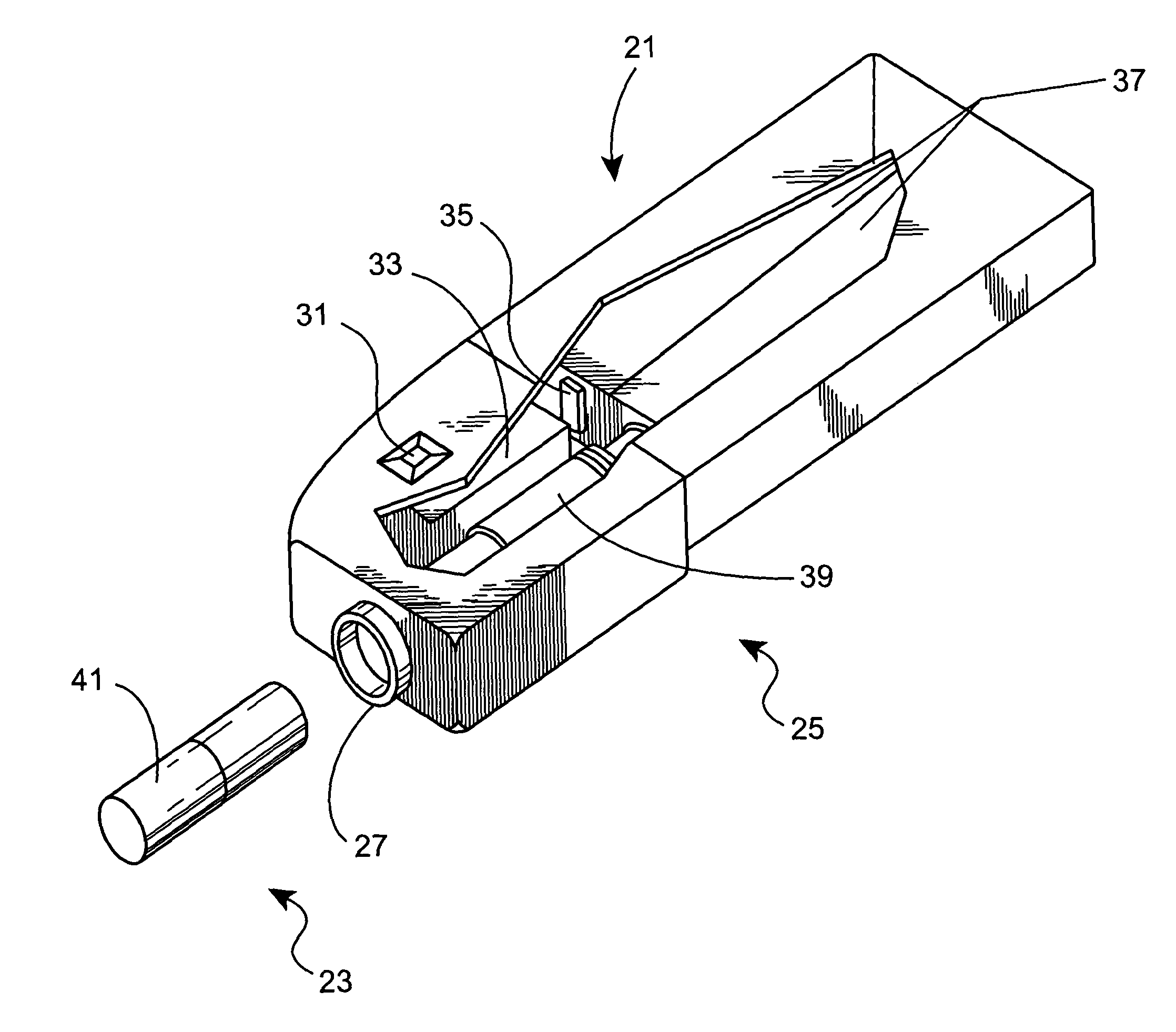

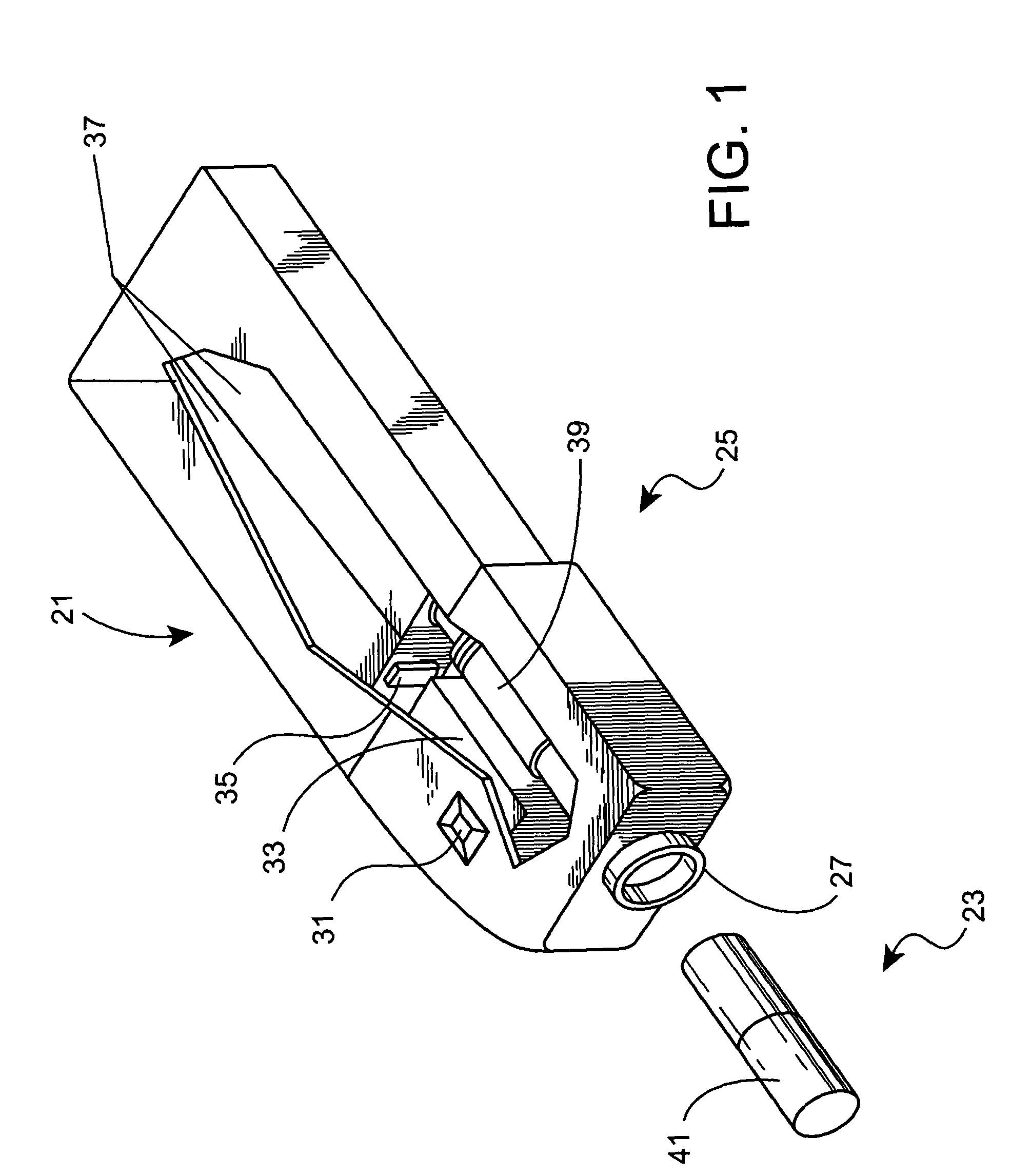

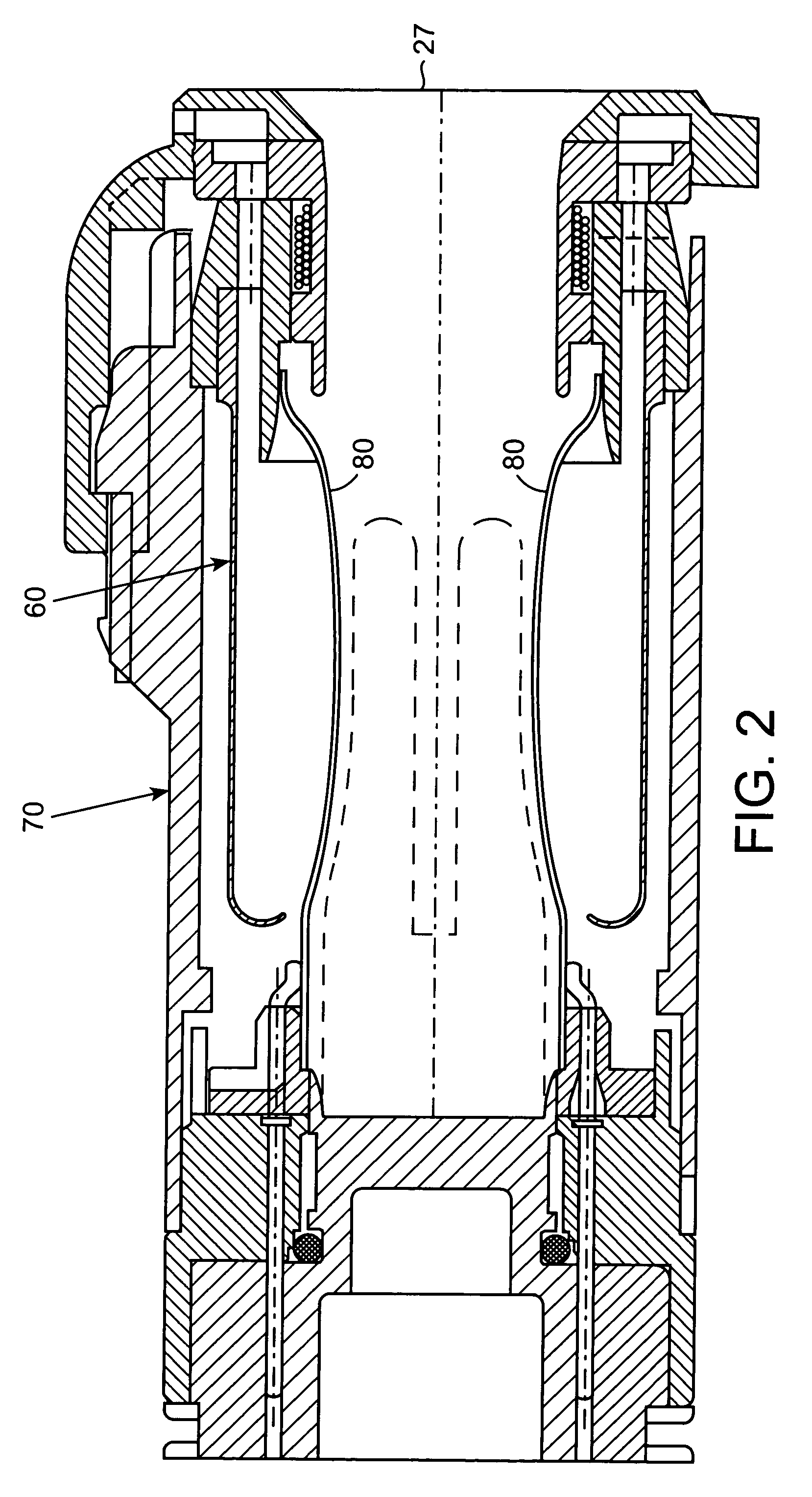

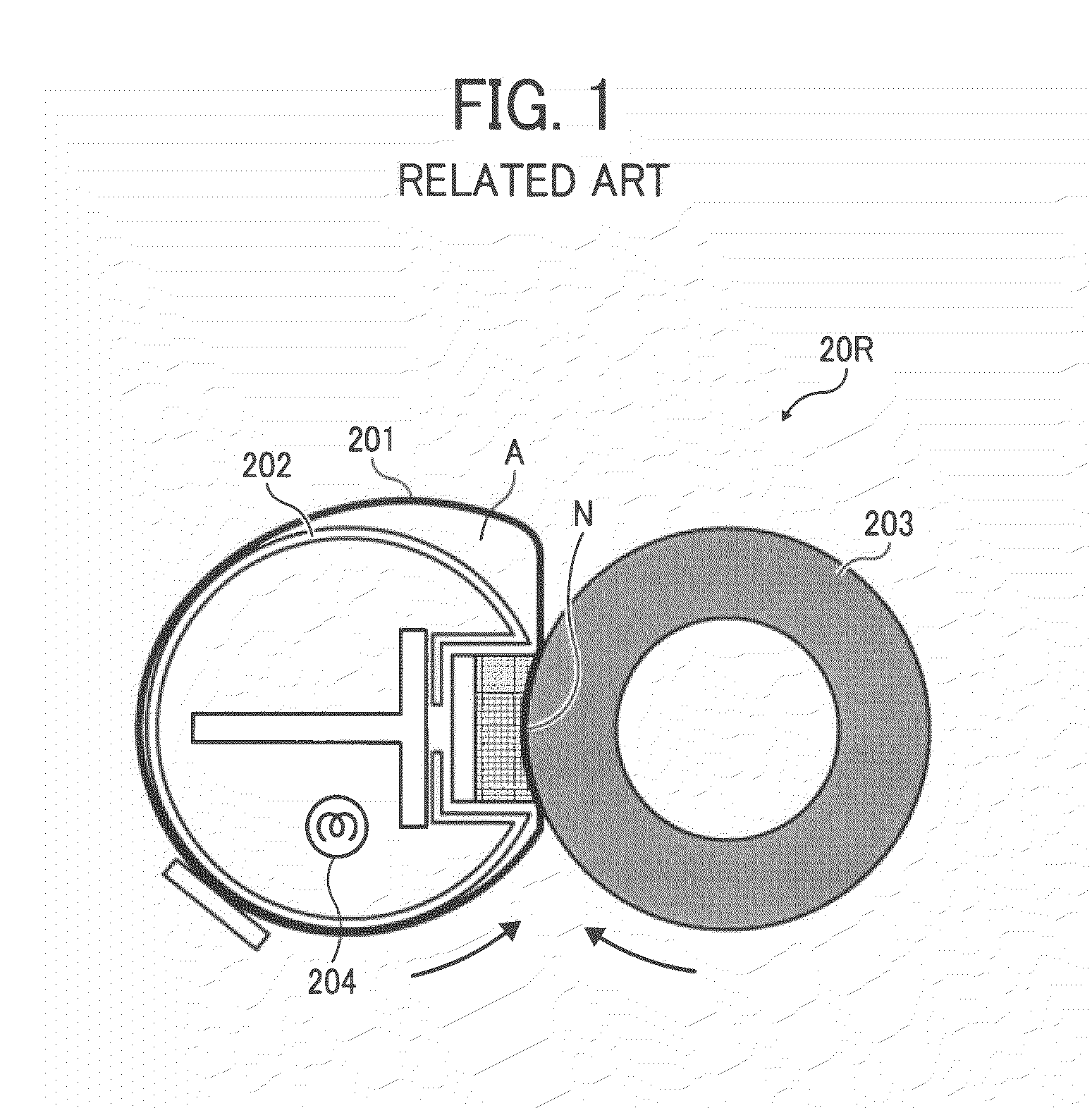

Inductive heating magnetic structure for removing condensates from electrical smoking device

ActiveUS7185659B2Enhance inductive heating techniqueReduce the required powerTobacco pipesTobacco devicesElectricityHeat power

Thermal cleaning of an electrically heated smoking device, and in particular the removal of condensates formed within the smoking device as a result of extended periods of use, is achieved with a cleaning system that utilizes inductive heating that provides efficient and intense localized heating in the cleaning process. The thermal power of the inductive heating process is increased or the power necessary to activate the inductive heating process is decreased by the addition of a magnetic shell by itself or in combination with a magnetic pin.

Owner:PHILIP MORRIS USA INC

Body motion training and qualification system and method

InactiveUS8512043B2Defective reproductionElectric discharge heatingGymnastic exercisingWorkspaceSimulation

The system allows training and qualification of a user performing a skill-related training exercise involving body motion in a workspace. A training environment is selected through a computer apparatus, and variables, parameters and controls of the training environment and the training exercise are adjusted. Use of an input device by the user is monitored. The 3D angles and spatial coordinates of reference points related to the input device are monitored through a detection device. A simulated 3D dynamic environment reflecting effects caused by actions performed by the user on objects is computed in real time as a function of the training environment selected. Images of the simulated 3D dynamic environment in real time are generated on a display device viewable by the user as a function of a computed organ of vision-object relation. Data indicative of the actions performed by the user and the effects of the actions are recorded and user qualification is set as a function of the recorded data.

Owner:123 CERTIFICATION

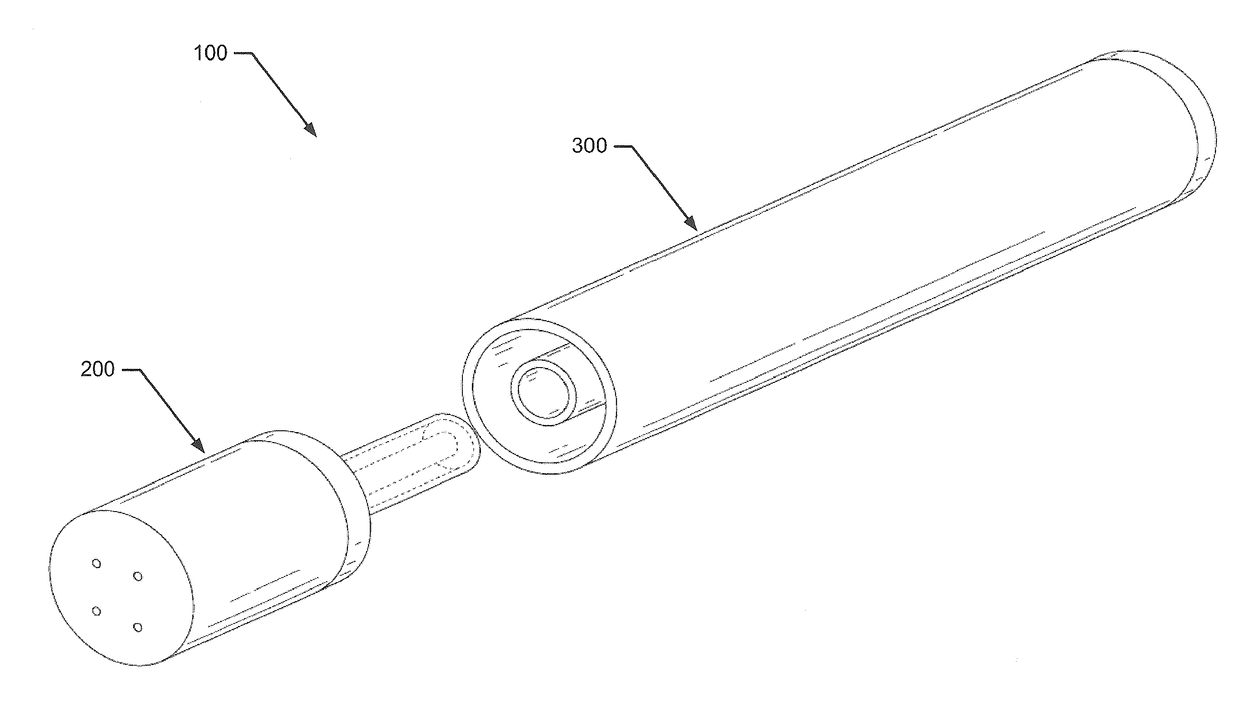

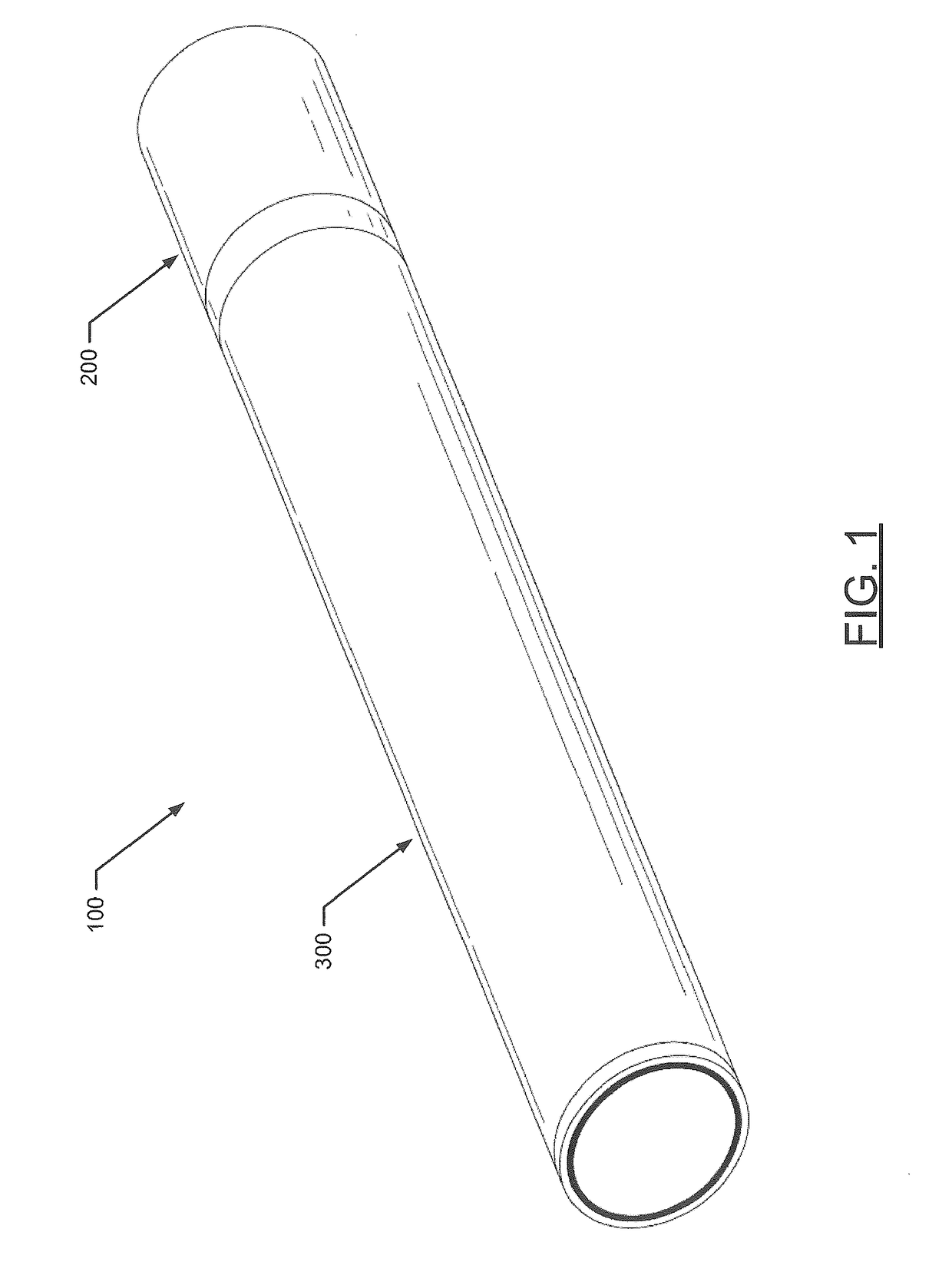

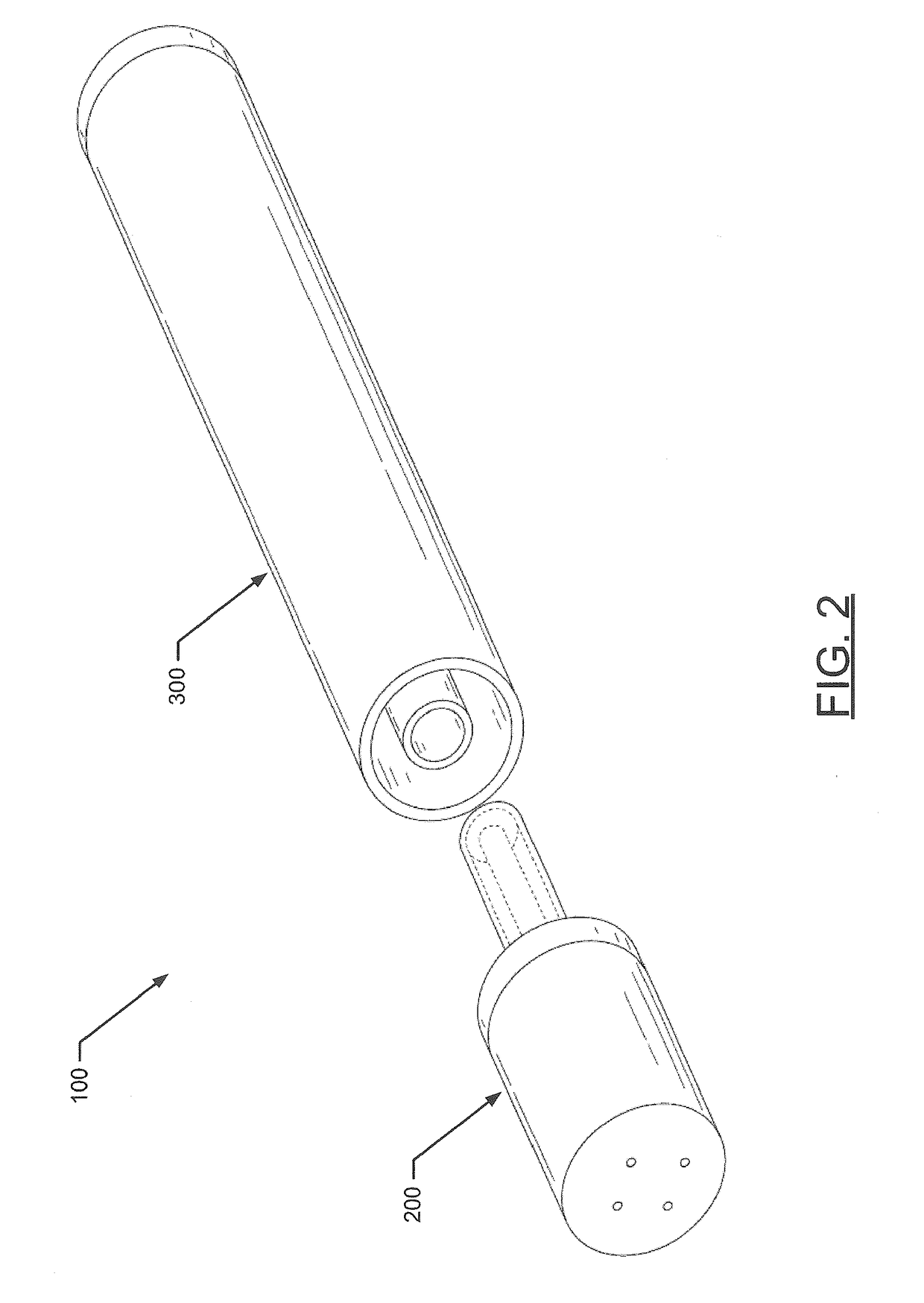

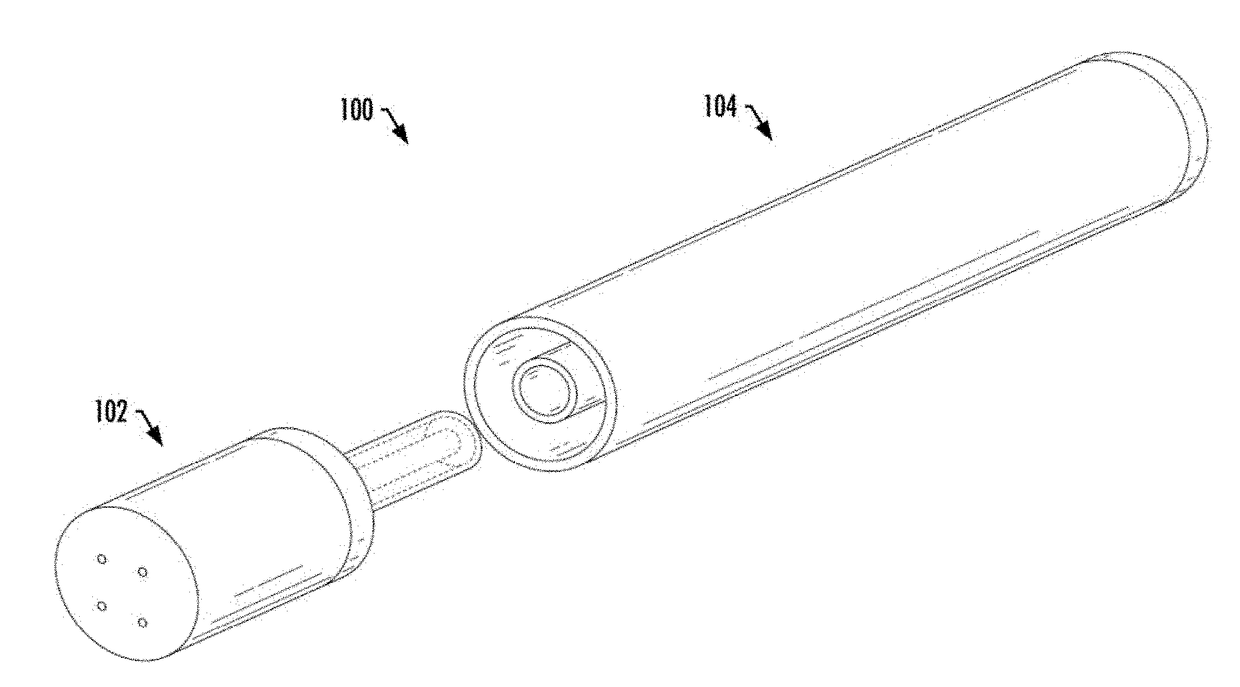

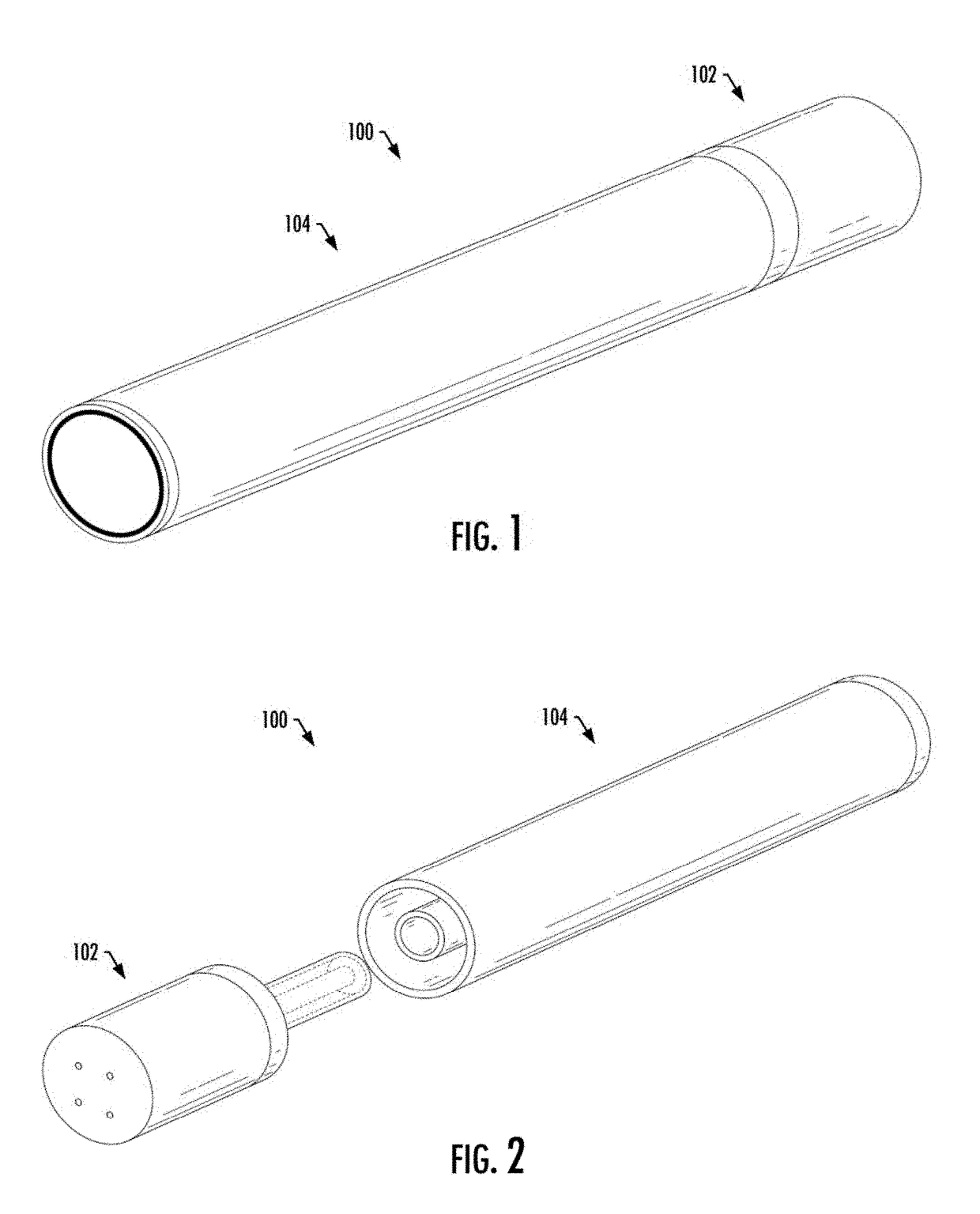

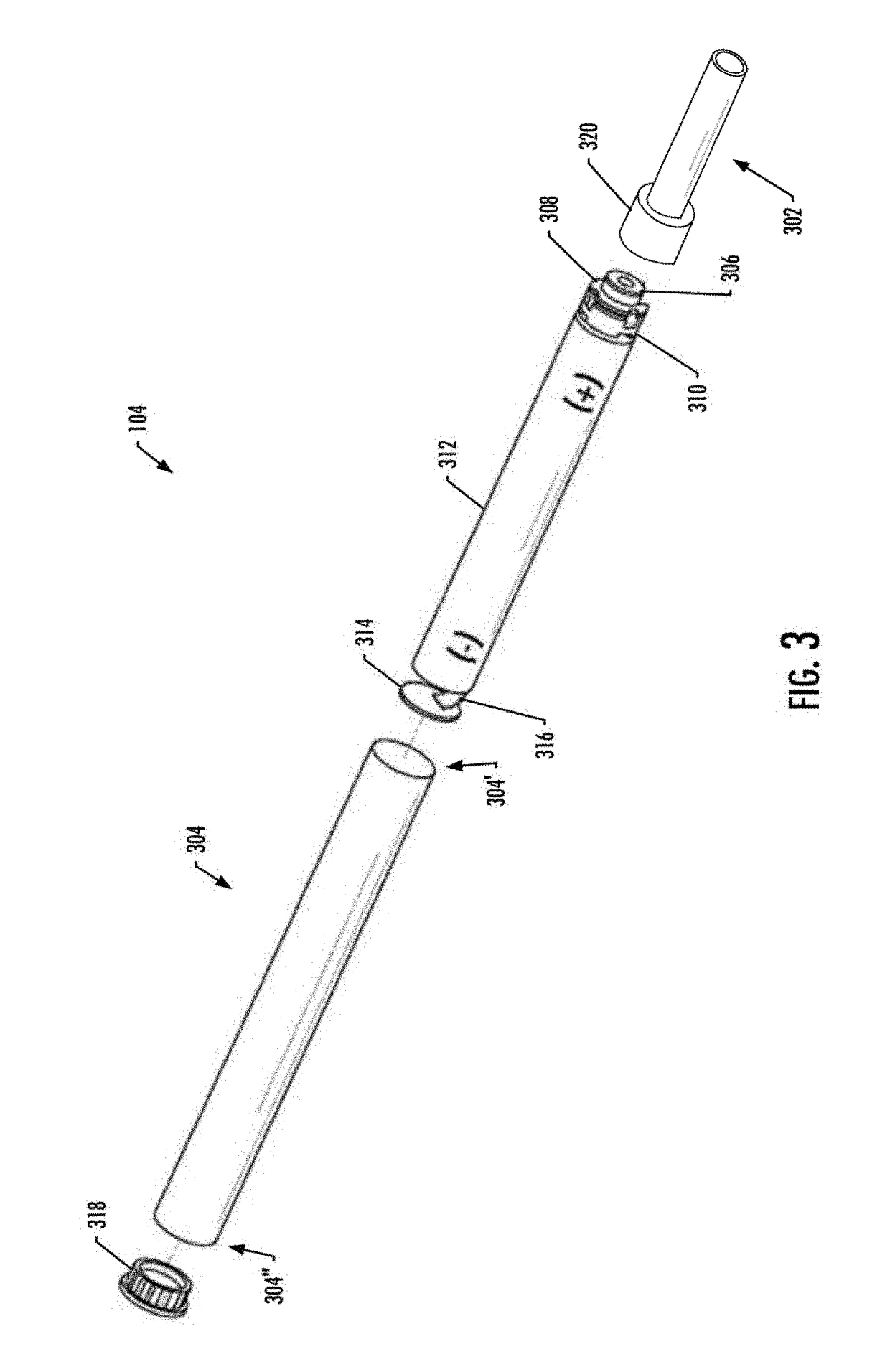

Aerosol delivery device including a wirelessly-heated atomizer and related method

The present disclosure relates to an aerosol delivery device configured to wirelessly heat an atomizer. The aerosol delivery device may include a control body and a cartridge. The control body may include an induction transmitter. The cartridge may include an induction receiver and an aerosol precursor composition. When electrical current is directed to the induction transmitter, the induction receiver may be inductively heated. The heat produced by the induction receiver may form an aerosol from the aerosol precursor composition at the substrate. Related methods are also provided.

Owner:RAI STRATEGIC HLDG INC

Temperature limited heaters with thermally conductive fluid used to heat subsurface formations

InactiveUS20050269090A1Improve thermal conductivityThermal drillingInsulationEngineeringElectrical current

Certain embodiments provide a system including a heater. The heater includes one or more electrical conductors. The heater is configured to generate a heat output during application of electrical current to the heater. The heater includes a ferromagnetic material. A conduit at least partially surrounds the heater. A fluid is located in a space between the heater and the conduit. The fluid has a higher thermal conductivity than air at standard temperature and pressure (STP) (0° C. and 101.325 kPa). The system is configured to provide (a) a first heat output below a selected temperature when time-varying electrical current is applied to the heater, and (b) a second heat output near or above the selected temperature when time-varying electrical current is applied to the heater.

Owner:SHELL OIL CO

Triaxial temperature limited heater

InactiveUS20050269094A1InsulationFluid removalElectrical resistance and conductanceElectrical conductor

Certain embodiments provide a heater. The heater includes an inner electrical conductor. A heater section at least partially surrounds the inner electrical conductor. The heater section is configured to generate an electrically resistive heat output during application of time-varying electrical current to the heater section. The heater section includes ferromagnetic material. An outer electrical conductor at least partially surrounds the heater section. An applied time-varying electrical current is configured to propagate through the inner electrical conductor and the outer electrical conductor in substantially the same direction. The applied time-varying electrical current is configured to propagate through the heater section in a substantially opposite direction. The heater provides a first heat output when time-varying electrical current is applied to the heater below a selected temperature, and a second heat output approximately at and above the selected temperature during use. The second heat output is reduced compared to the first heat output.

Owner:SHELL OIL CO

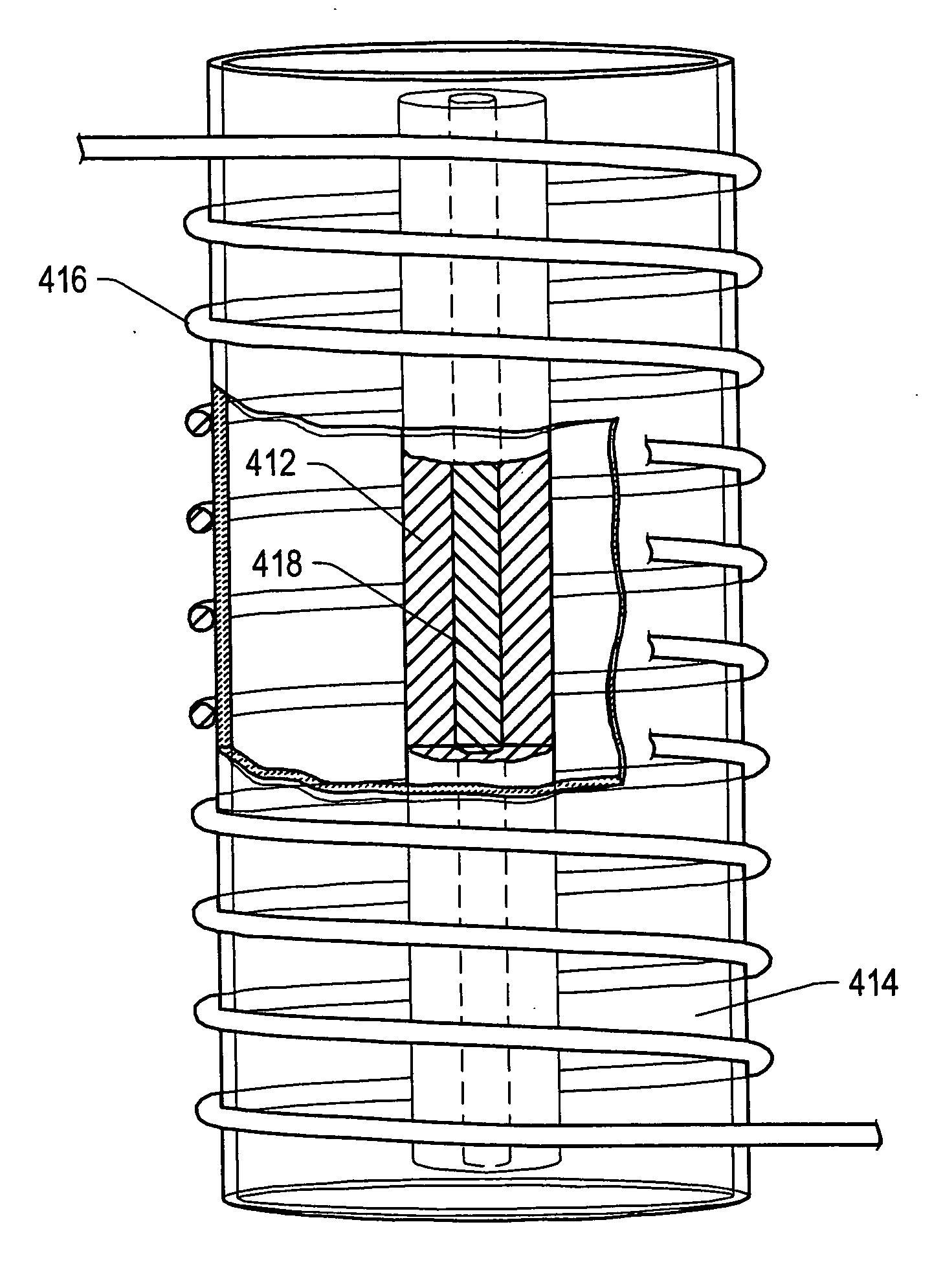

Control for an induction-based aerosol delivery device

An aerosol delivery device is provided that includes a substrate configured to carry an aerosol precursor composition, and includes an induction transmitter, induction receiver and control component. The induction transmitter is configured to generate an oscillating magnetic field. The induction receiver is positioned in proximity to the substrate, and configured to generate heat when exposed to the oscillating magnetic field and thereby vaporize components of the aerosol precursor composition. The control component is configured to direct current to the induction transmitter to drive the induction transmitter to generate the oscillating magnetic field, with the control component being configured to direct the current according to a zero voltage switching (ZVS) inverter topology.

Owner:RAI STRATEGIC HLDG INC

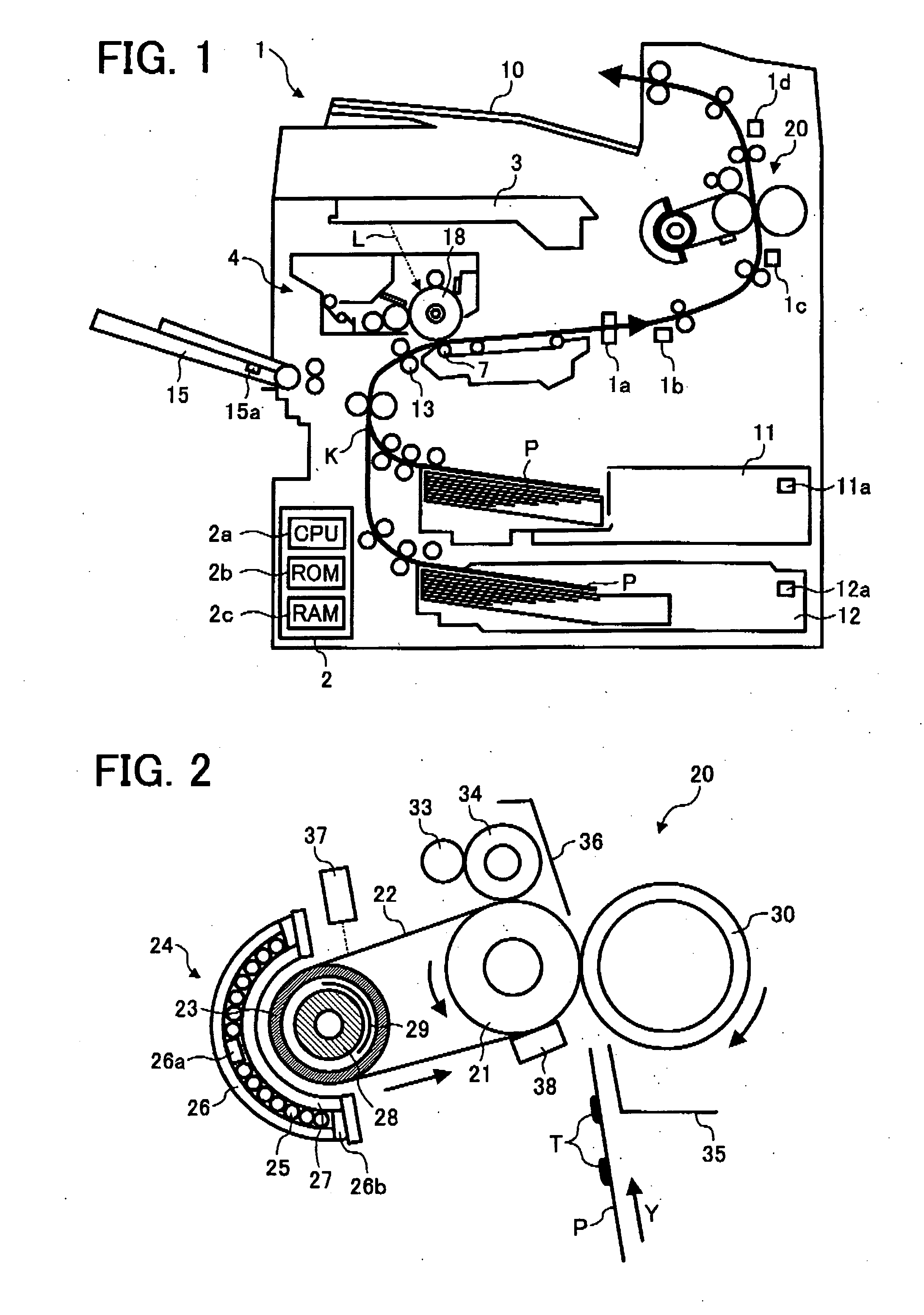

Fixing device and image forming apparatus incorporating same

InactiveUS20110044734A1Ohmic-resistance heatingElectrographic process apparatusEngineeringImaging equipment

Owner:RICOH KK

Temperature limited heaters with relatively constant current

Owner:SHELL OIL CO

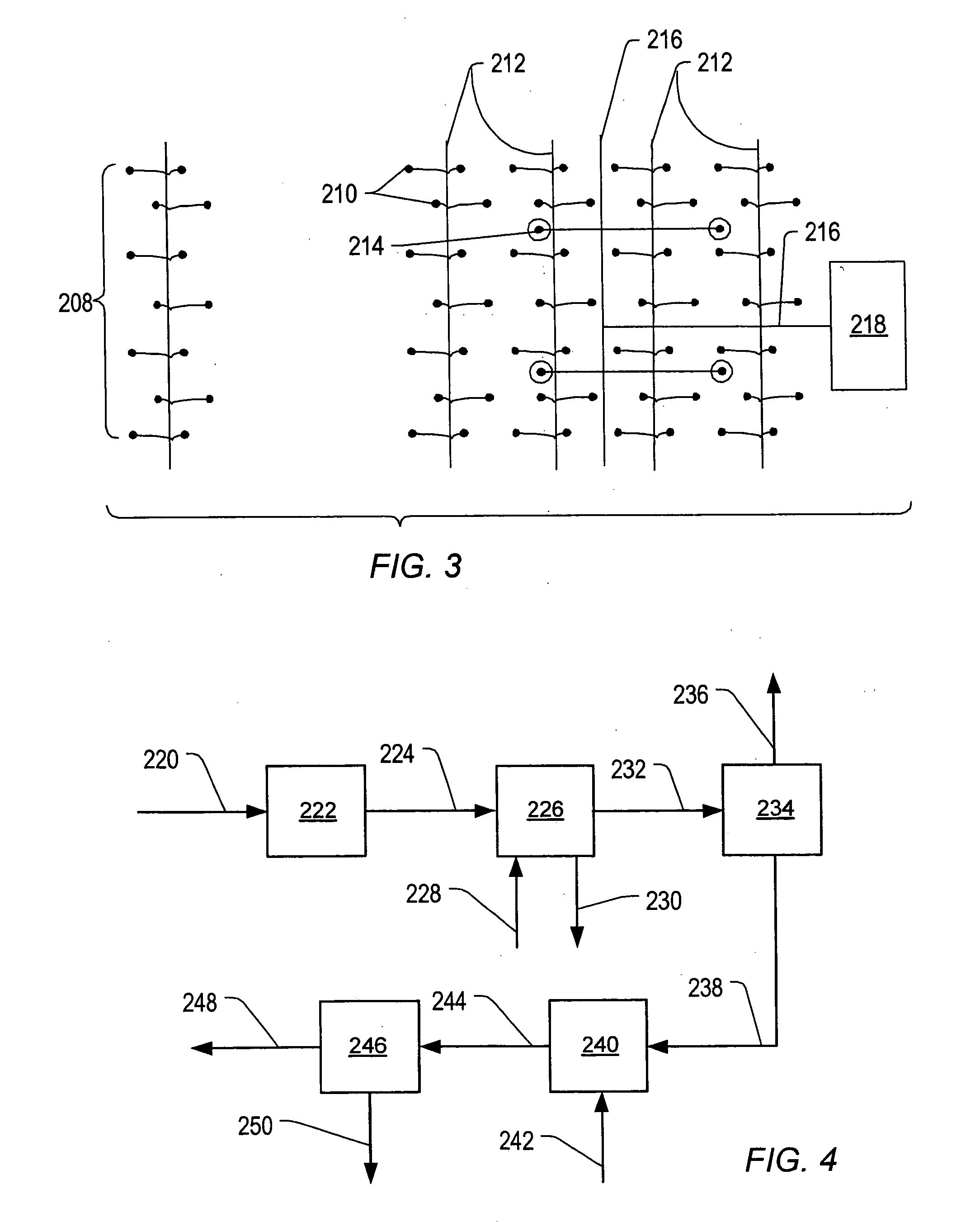

Reducing viscosity of oil for production from a hydrocarbon containing formation

ActiveUS20050269091A1Viscosity of fluidLow viscosityThermal drillingInsulationElectrical resistance and conductanceElectrical conductor

Certain embodiments provide a method for treating a hydrocarbon containing formation. The method includes applying electrical current to one or more electrical conductors located in an opening in the formation to provide an electrically resistive heat output. The heat is allowed to transfer from the electrical conductors to a part of the formation containing hydrocarbons so that a viscosity of fluids in the part and at or near the opening in the formation is reduced. Gas is provided at one or more locations in the opening such that the fluids are lifted in the opening towards the surface of the formation. The fluids are produced through the opening.

Owner:SHELL OIL CO

Fixer, image forming apparatus including same, and fixing method

ActiveUS20090245897A1Electrographic process apparatusInduction heating apparatusImage formationEngineering

A fixer includes a fixing member provided with a rotary heat generator, a pressure member to form a nip with the fixing member to sandwich the sheet, an excitation coil disposed facing a heat generation layer of the rotary heat generator to generate magnetic flux that inductively heats the heat generation layer, a loop-shaped demagnetization coil unit disposed facing the heat generation layer to generate magnetic flux that partly counteracts the magnetic flux generated by the excitation coil, a first magnetic core disposed in a first area that is enclosed by both the excitation coil and the demagnetization coil unit, and a second magnetic core disposed in a second area that is outside a loop of the demagnetization coil unit and enclosed by the excitation coil. The first magnetic core and the second magnetic core are magnetically continuous in a rotary axial direction of the rotary heat generator.

Owner:RICOH KK

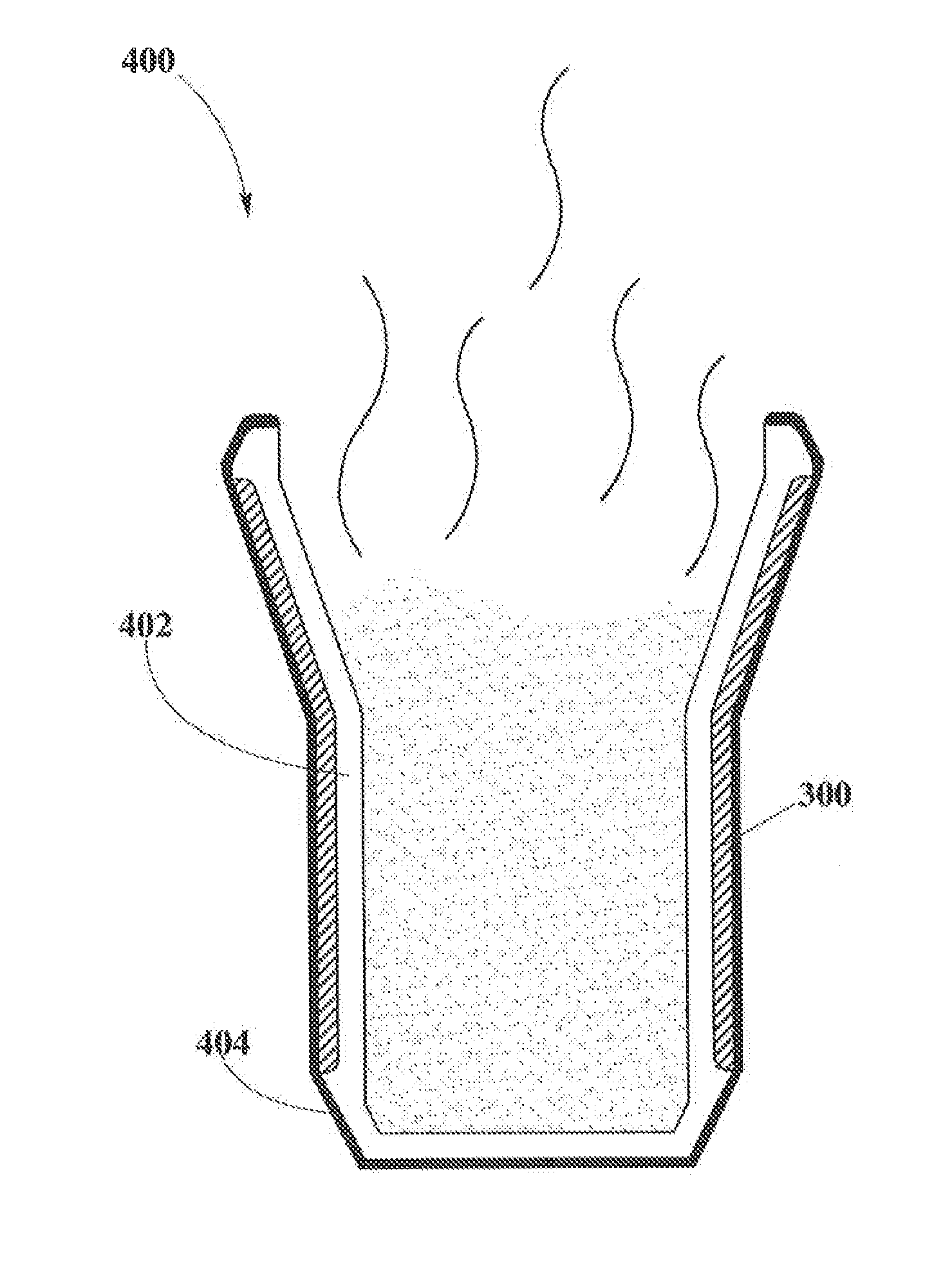

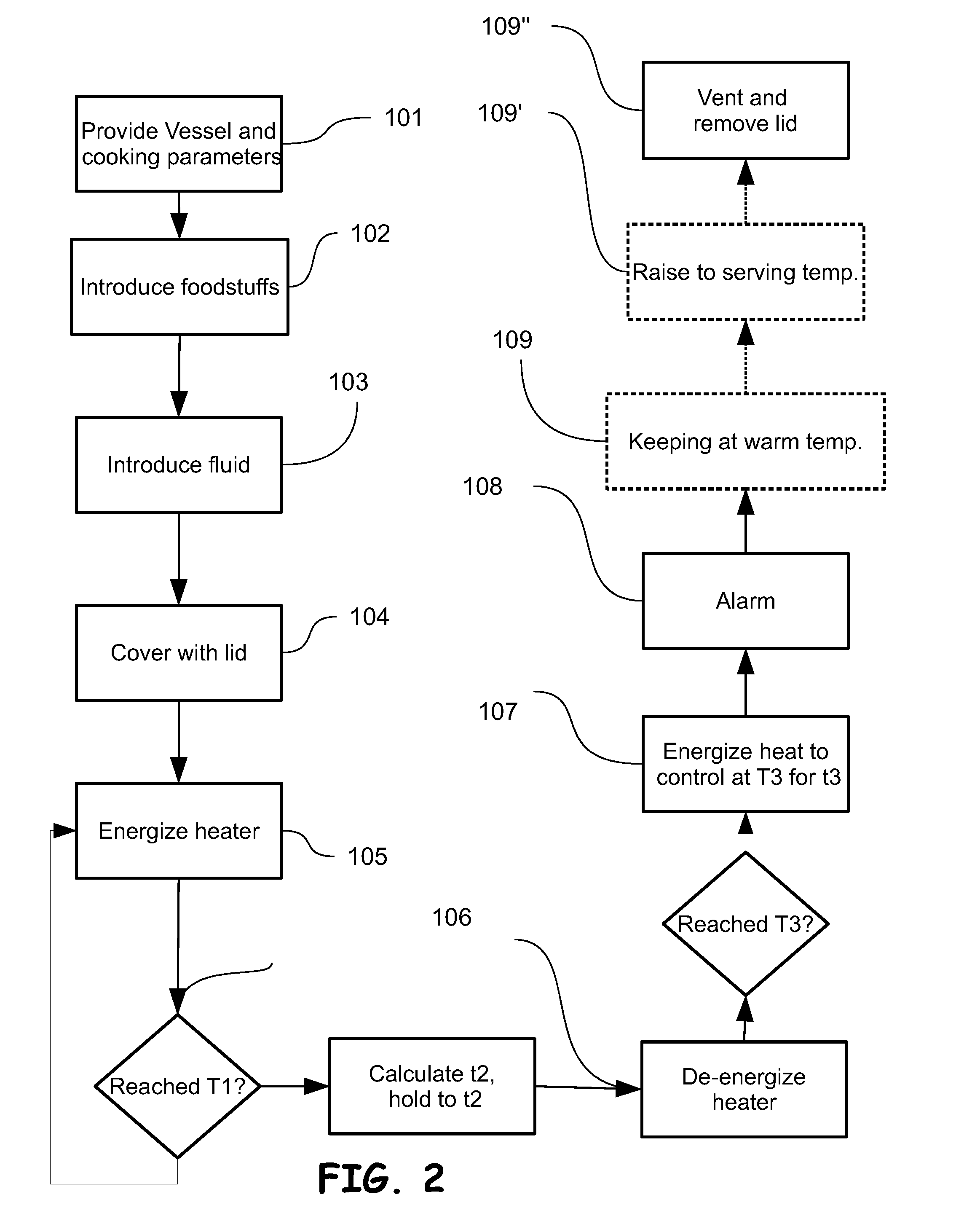

Low-pressure cooking method and cookware vessel adapted for the same

ActiveUS20140348987A1Long cooking timeReduce heating powerBoiling over preventionSteam cooking vesselsTemperature controlWater vapor

Food stuffs are cooked at precise temperatures, which are optionally below 100° C., in a vessel that is evacuated to exclude air, in which low pressure steam replaces the air. When a sufficient quantity of air is excluded and replaced with water vapor, the temperature of vapor is accurately measured inside the vessel below the lid to control the temperatures within about 1° C. Air is preferably excluded via a controlled heated process for a relatively short period of time at high temperature to generate steam, the temperature is lowered to condense water vapor upon which the lid will sealingly engage the rim of the vessel, forming a partial vacuum in the cooking vessel.

Owner:MEYER INTPROP

Inhibiting effects of sloughing in wellbores

Owner:SHELL OIL CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com