Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "Sma actuator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

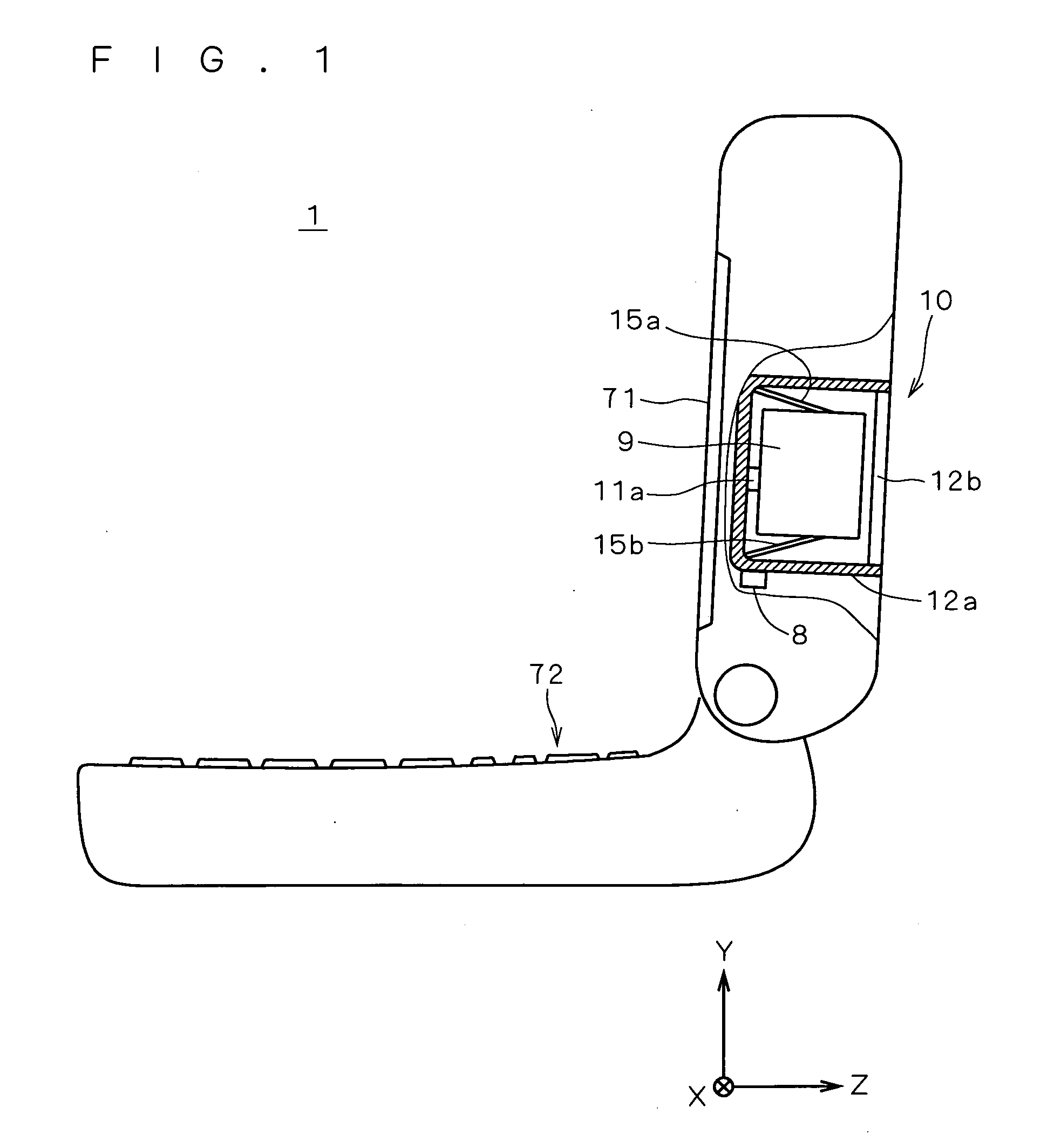

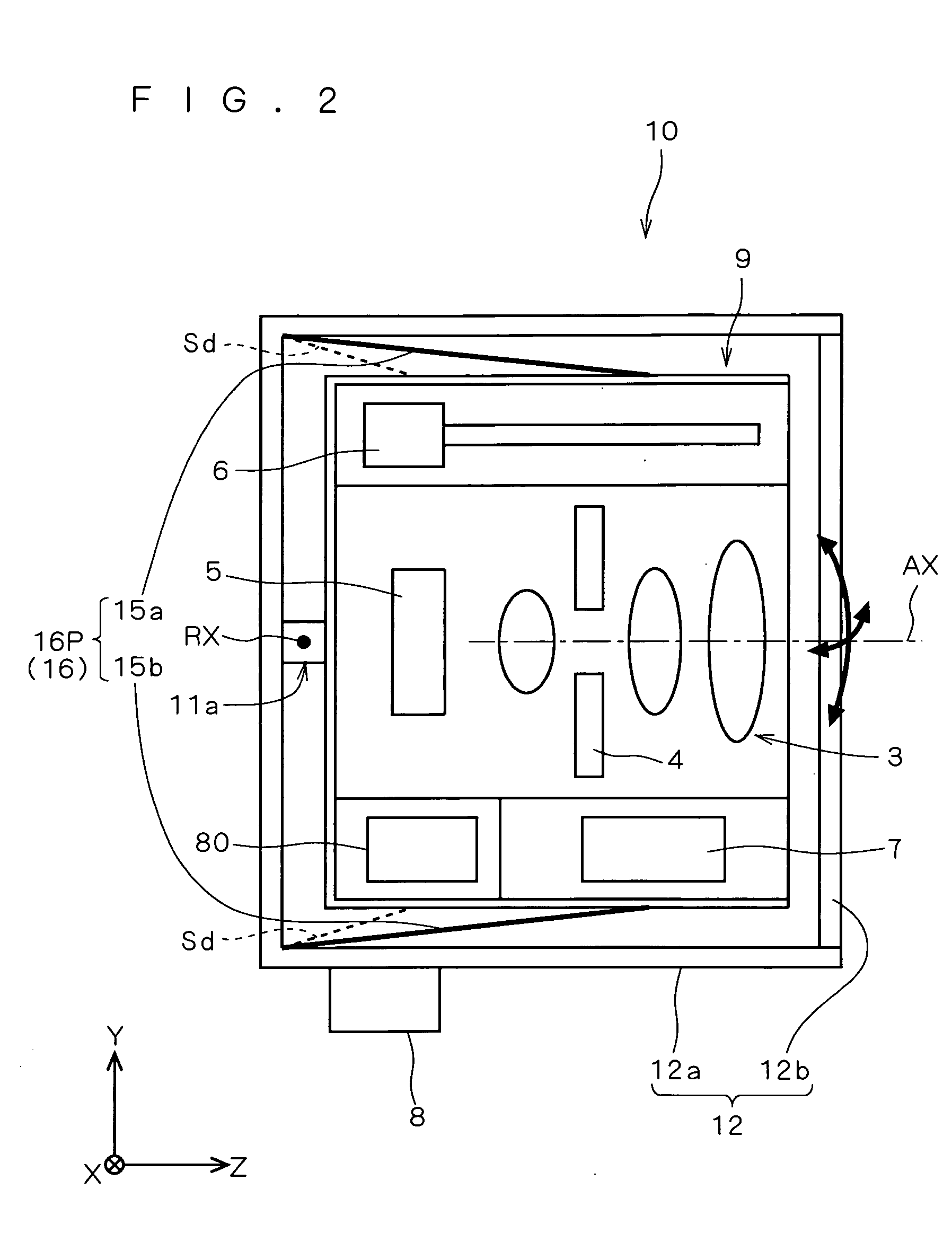

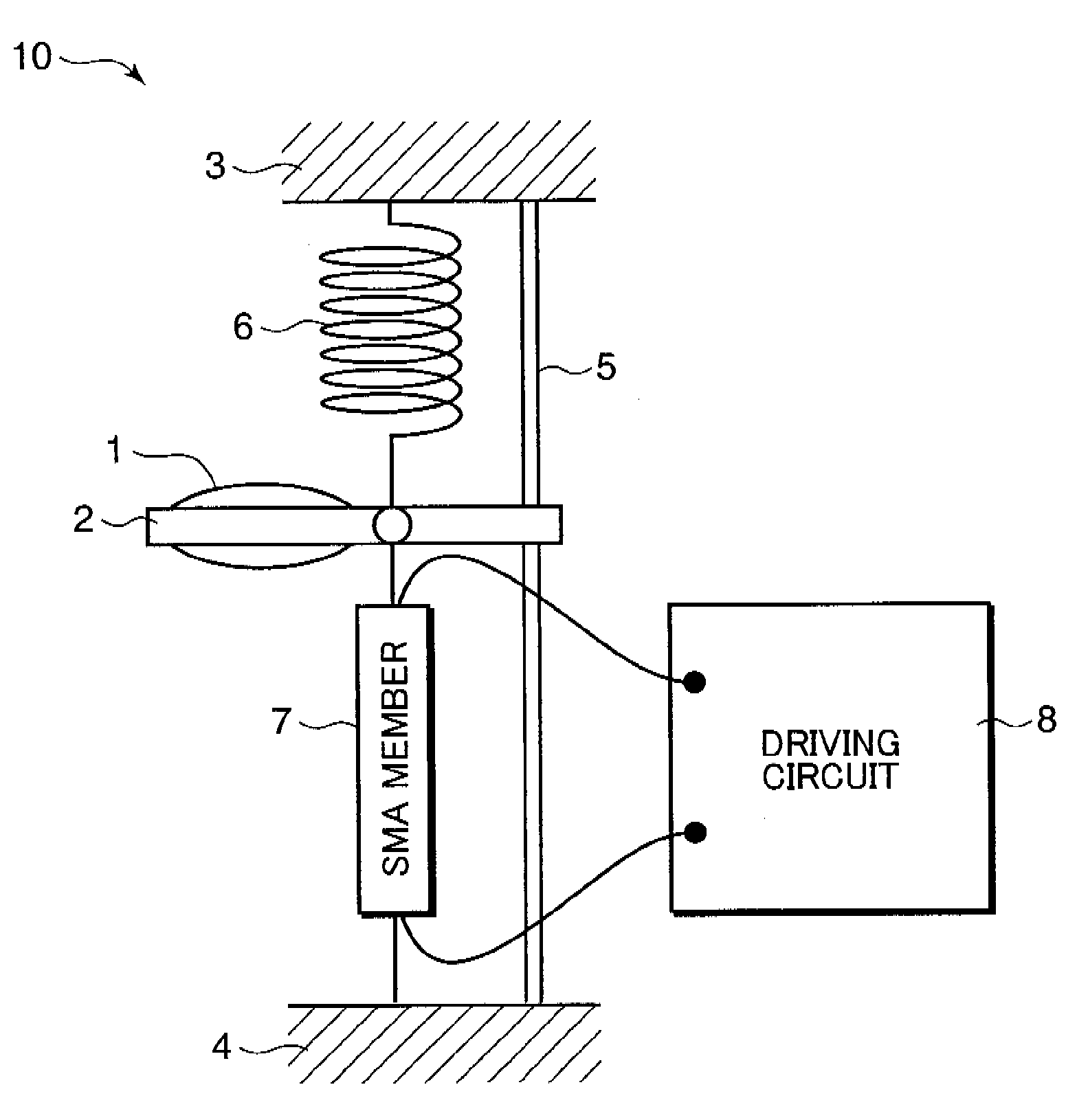

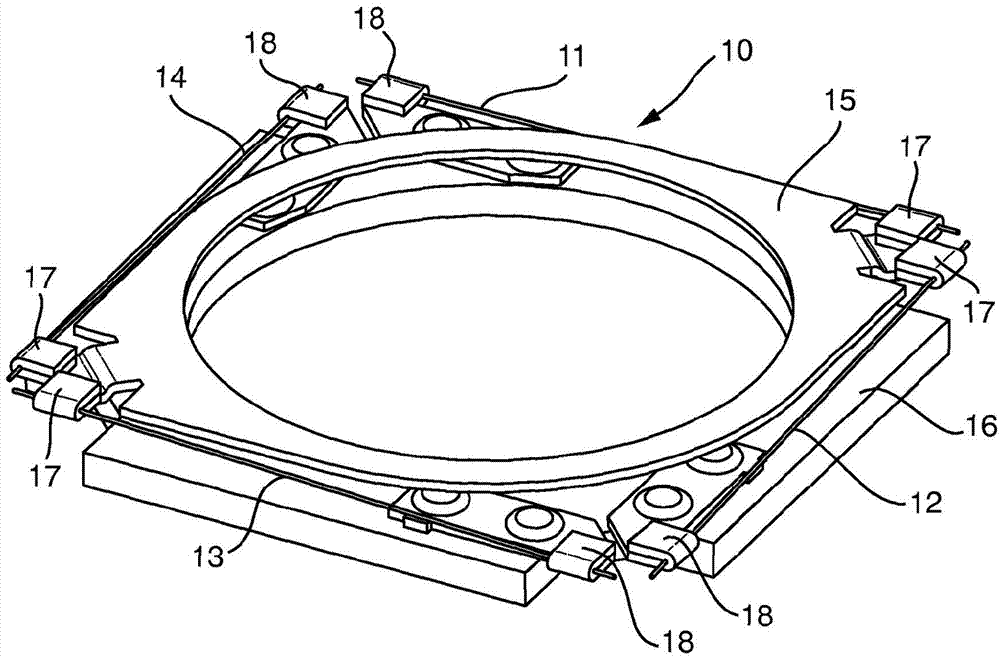

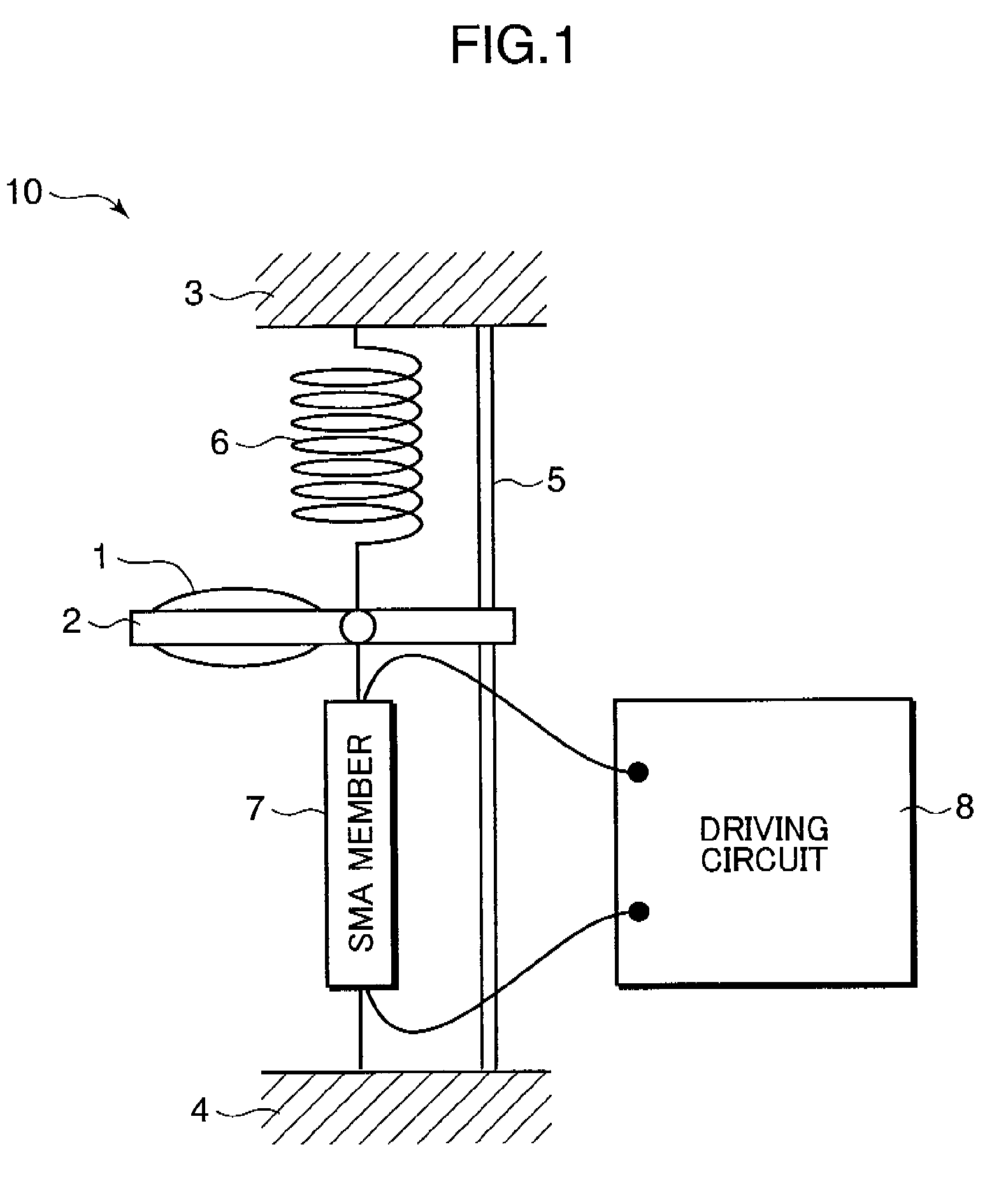

Driving apparatus

InactiveUS20070109412A1Improve responseImprove cooling effectTelevision system detailsOpticsEllipseImage stabilization

In an auto image stabilization system, a driving member formed as a wire of shape memory alloy (SMA) is retained by a projection of an image capturing unit. A distance Lb from the rotation center of an elastic deforming part to center of gravity (point of application) of the image capturing unit is longer than a distance La from the rotation center of the elastic deforming part to the projection (power point). In the configuration, equivalent mass (apparent mass) of the image capturing unit becomes (Lb / La) times, and it causes deterioration in response. Consequently, the driving member having an ellipse-shaped section in which a value obtained by dividing the width in the longer direction of the section by the width in the shorter direction is 1.3 or larger is employed. As a result, heat dissipation of the driving member increases, so that response in the SMA actuator can be properly improved.

Owner:KONICA MINOLTA INC

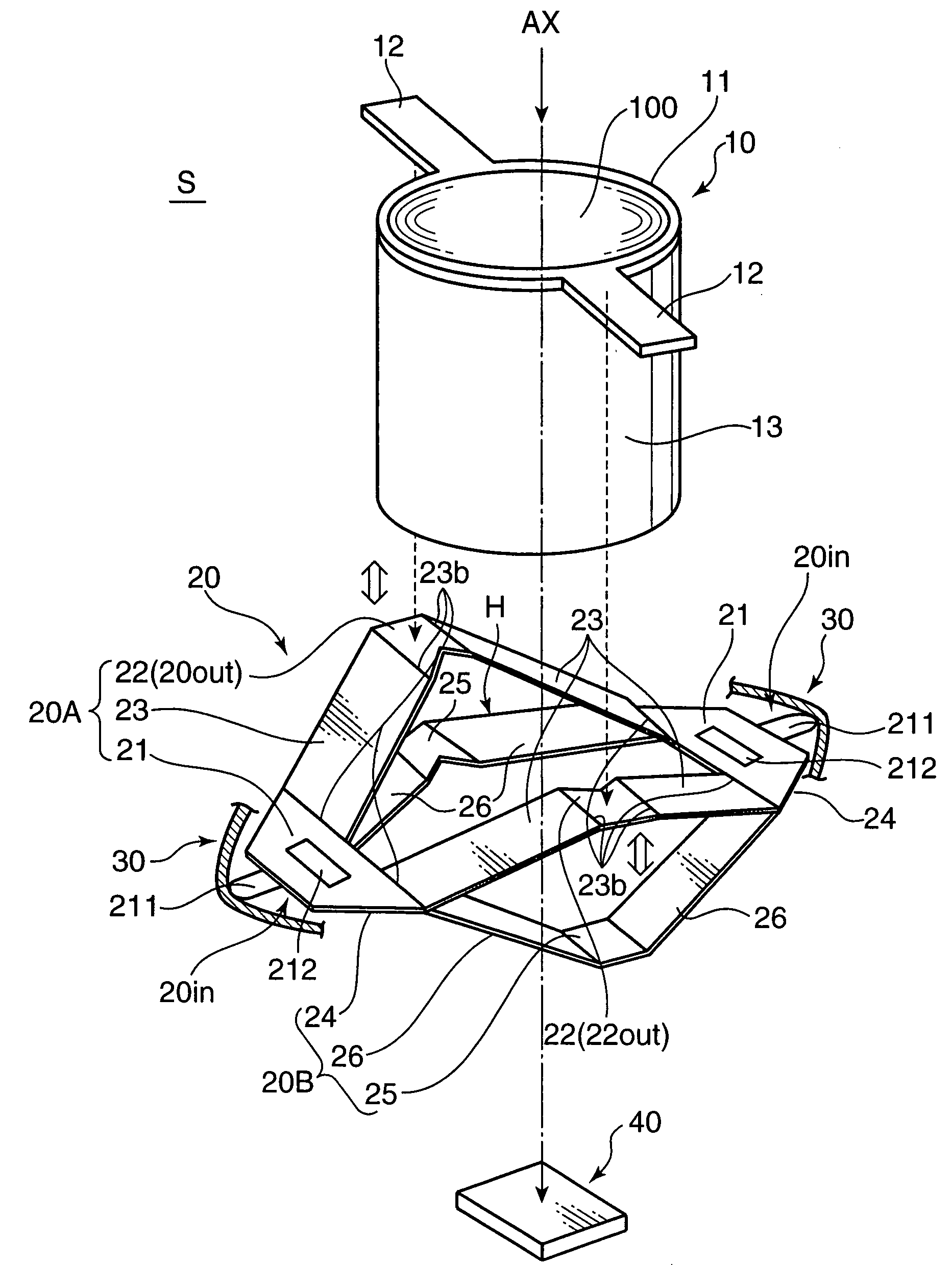

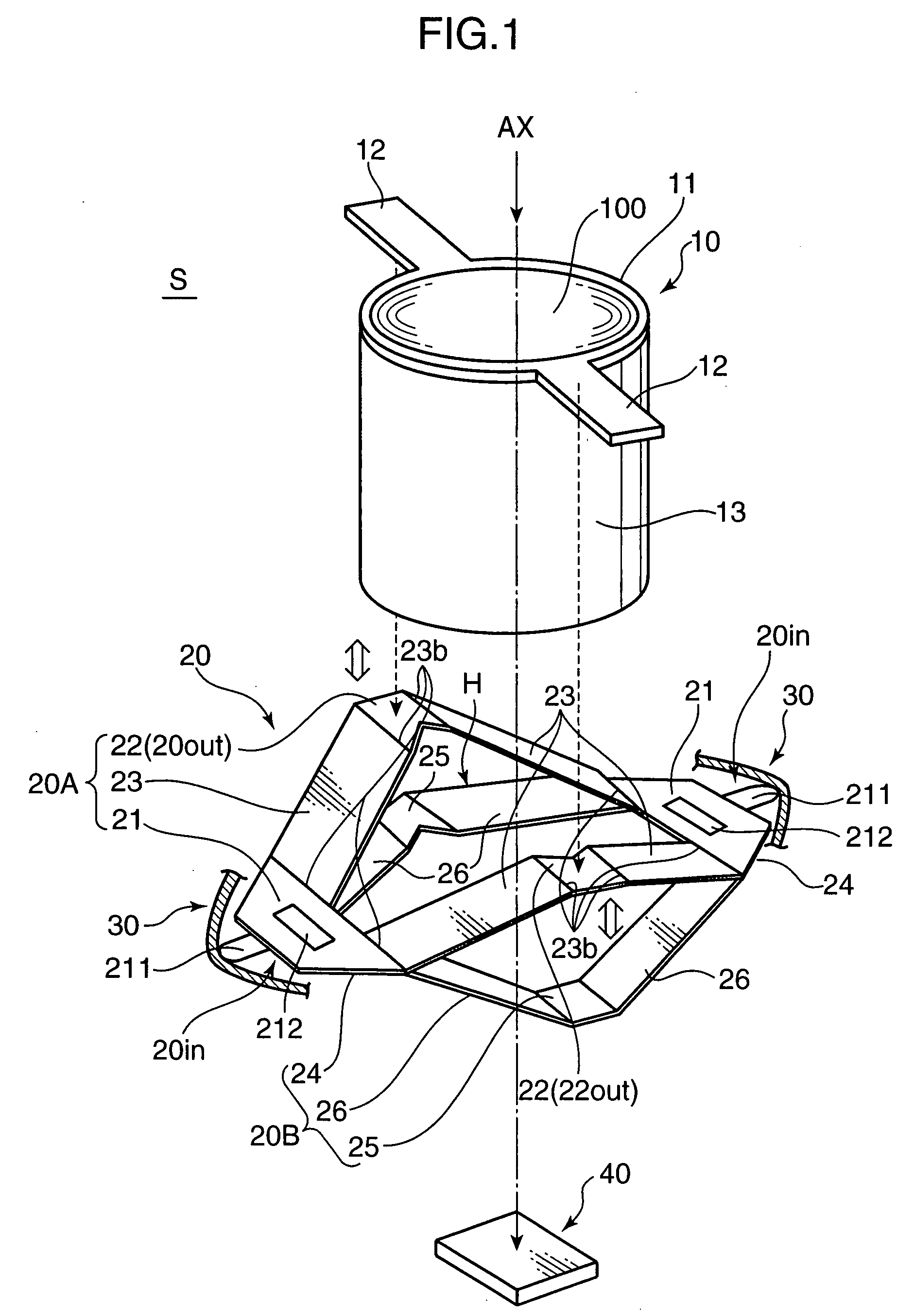

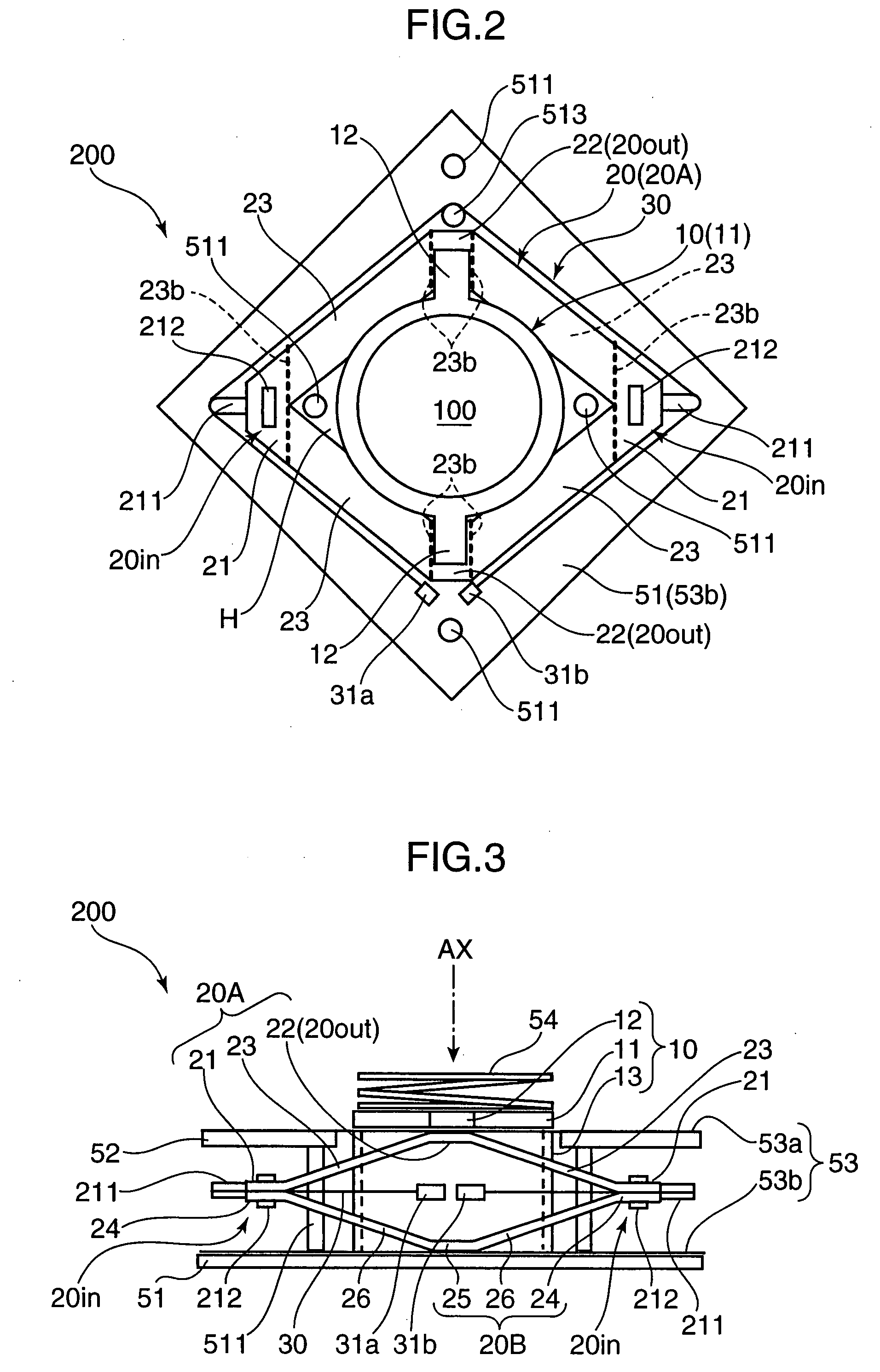

Driving device, driving mechanism, and image sensing apparatus

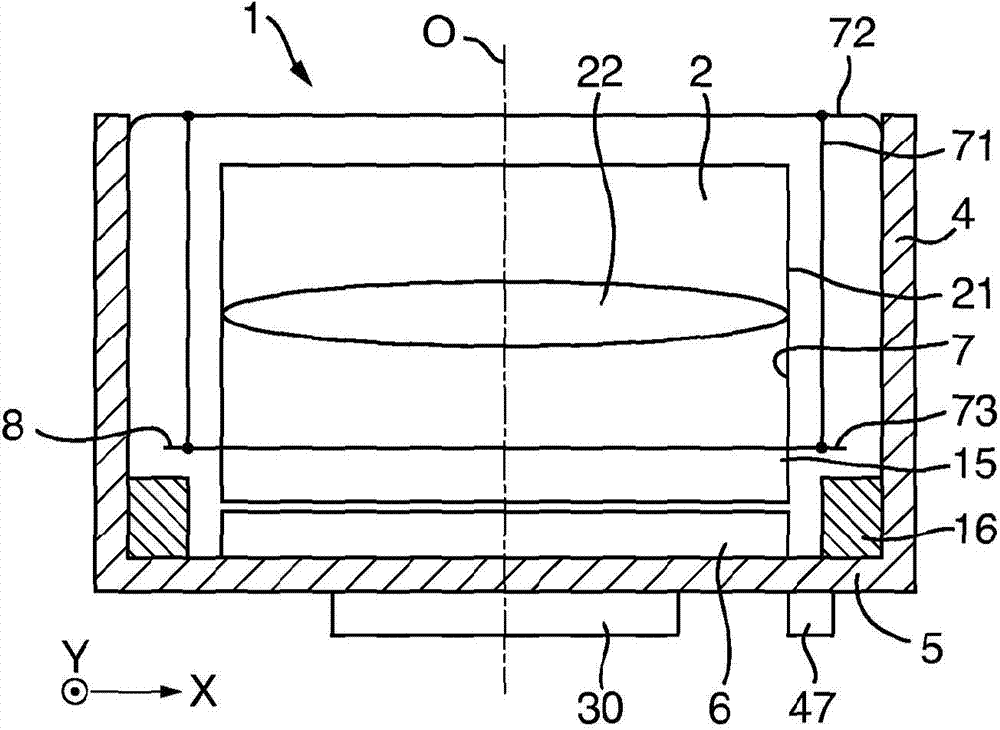

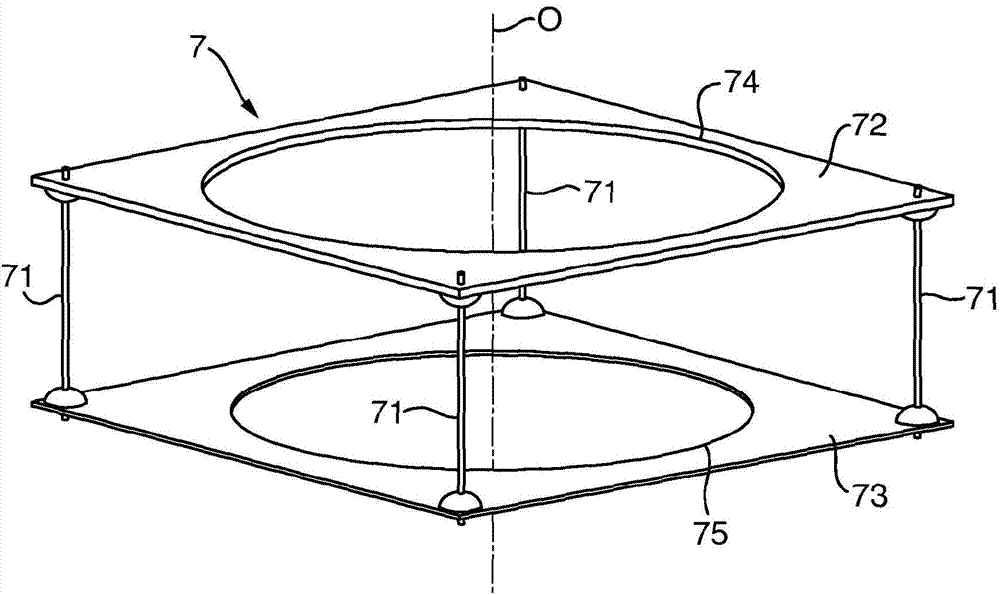

InactiveUS20070280668A1Small sizeReduce weightProjector focusing arrangementCamera focusing arrangementEngineeringSma actuator

A driving device is adapted to drive a driven member, and includes a driving member, and a linear shape memory alloy (SMA) actuator. The driving member has a displacement output portion which is movable in a first axis direction, and a displacement input portion for moving the displacement output portion in the first axis direction in response to an application of a moving force in a second axis direction orthogonal to the first axis direction. The driving member is engaged with the driven member at the displacement output portion. The SMA actuator is disposed in contact with the driving member at least at the displacement input portion to apply the moving force to the displacement input portion.

Owner:KONICA MINOLTA OPTO

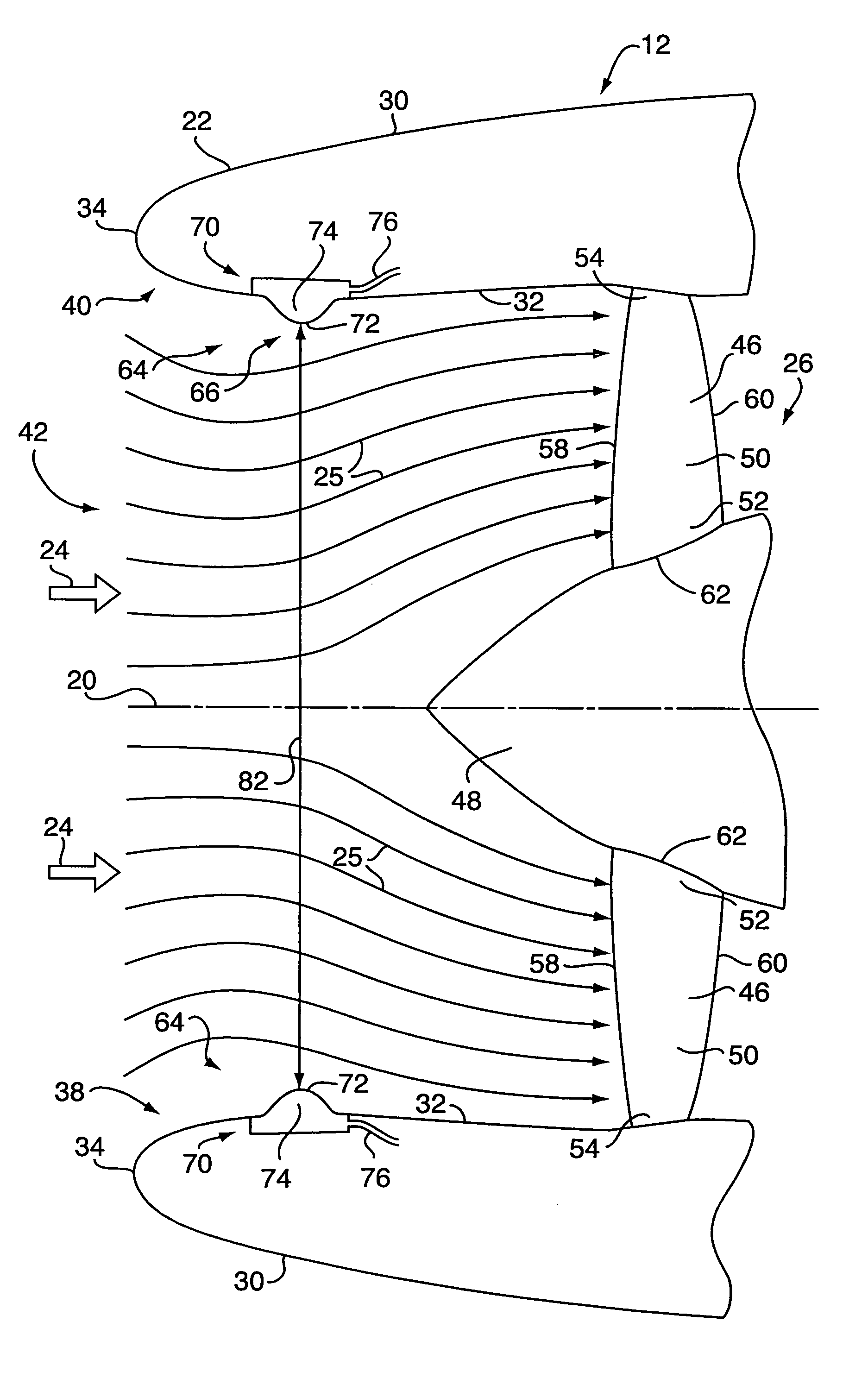

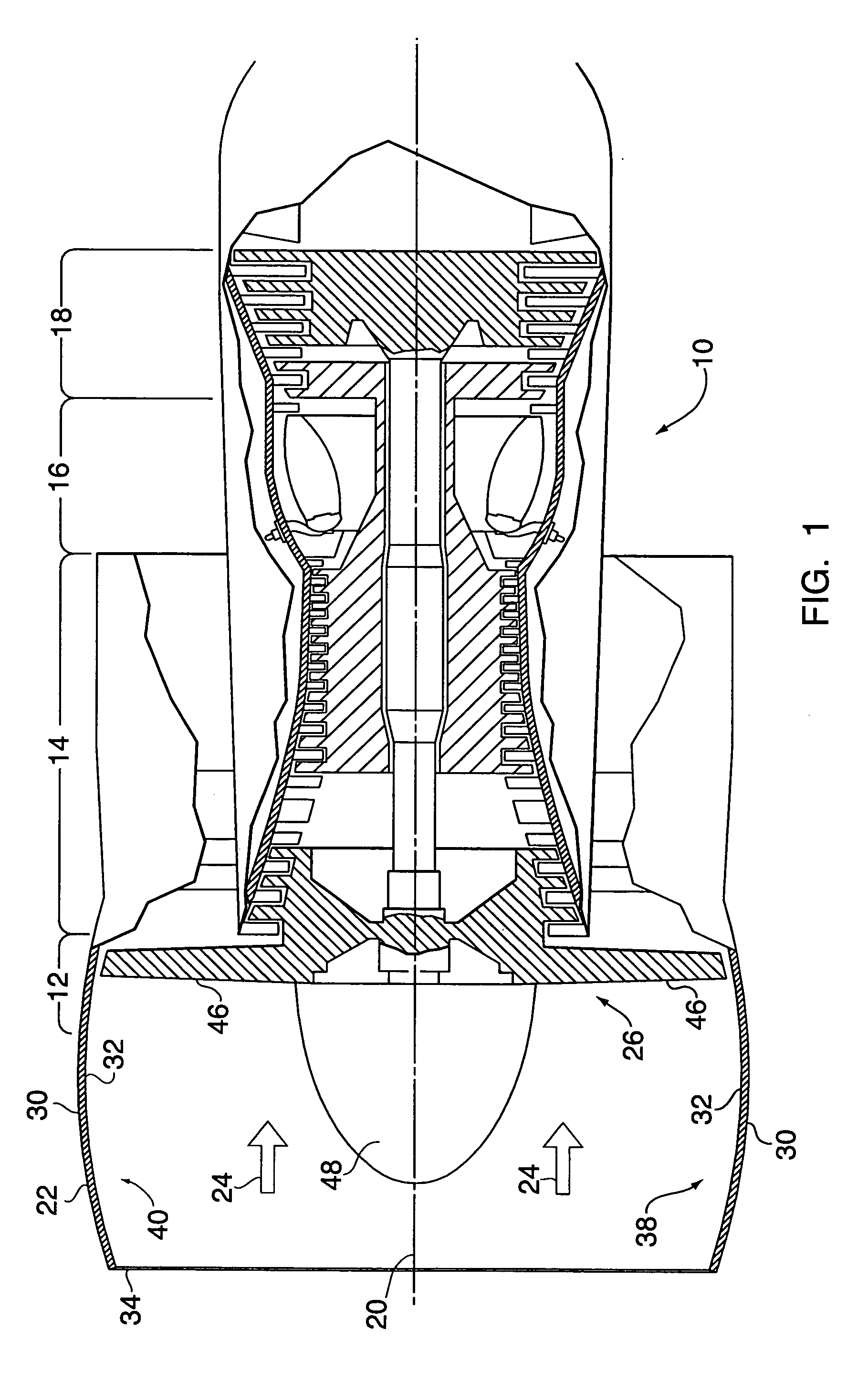

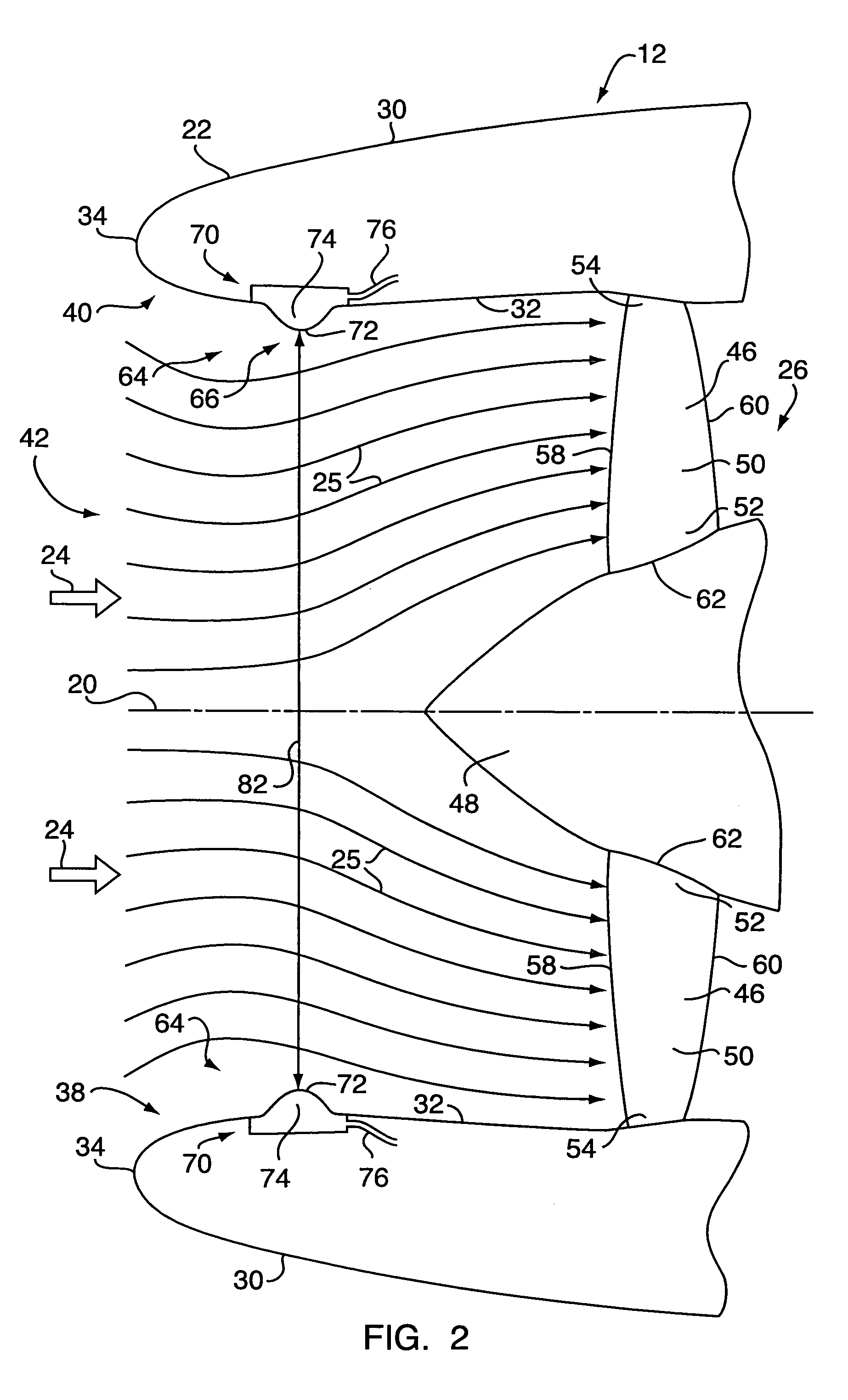

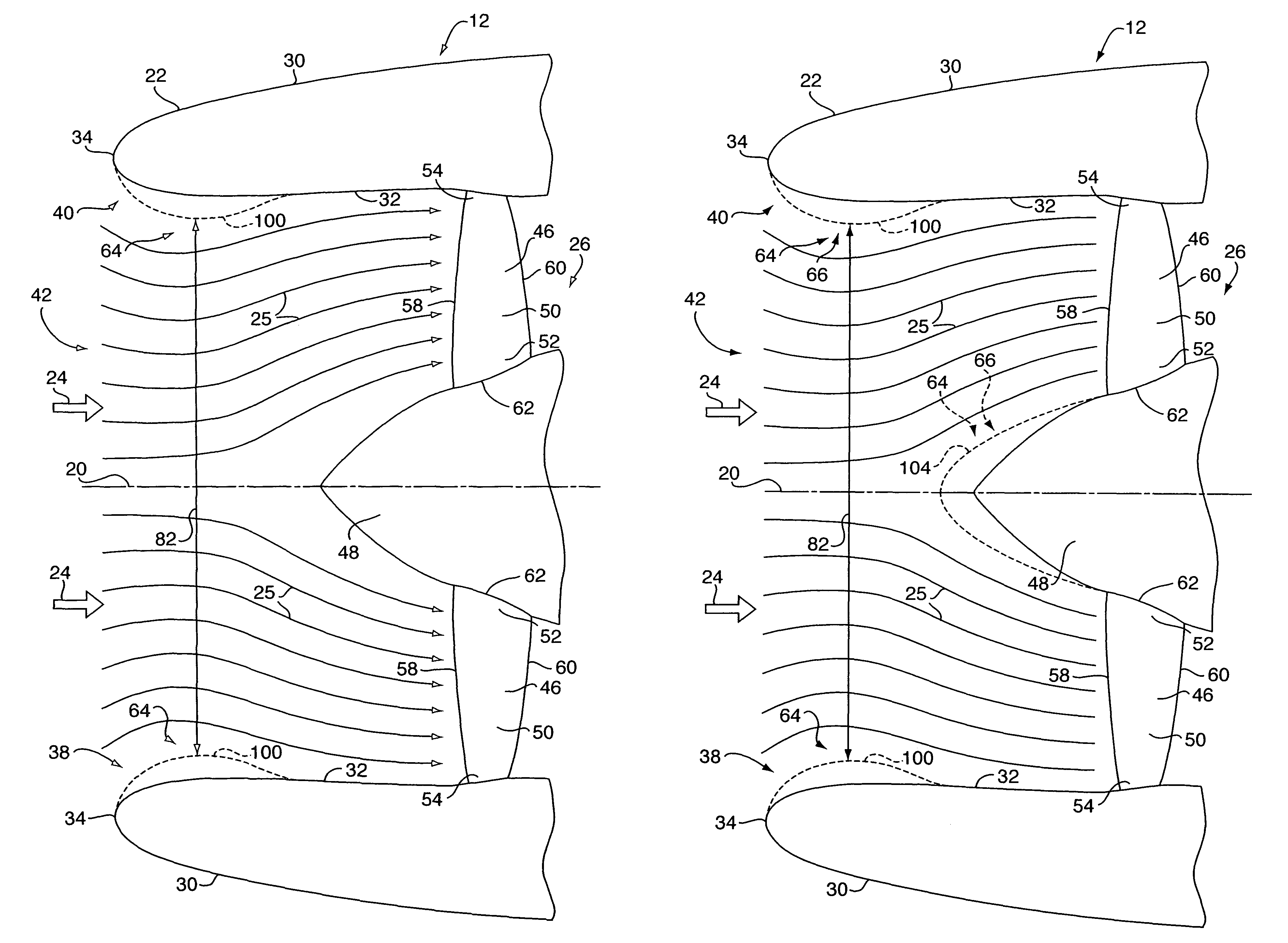

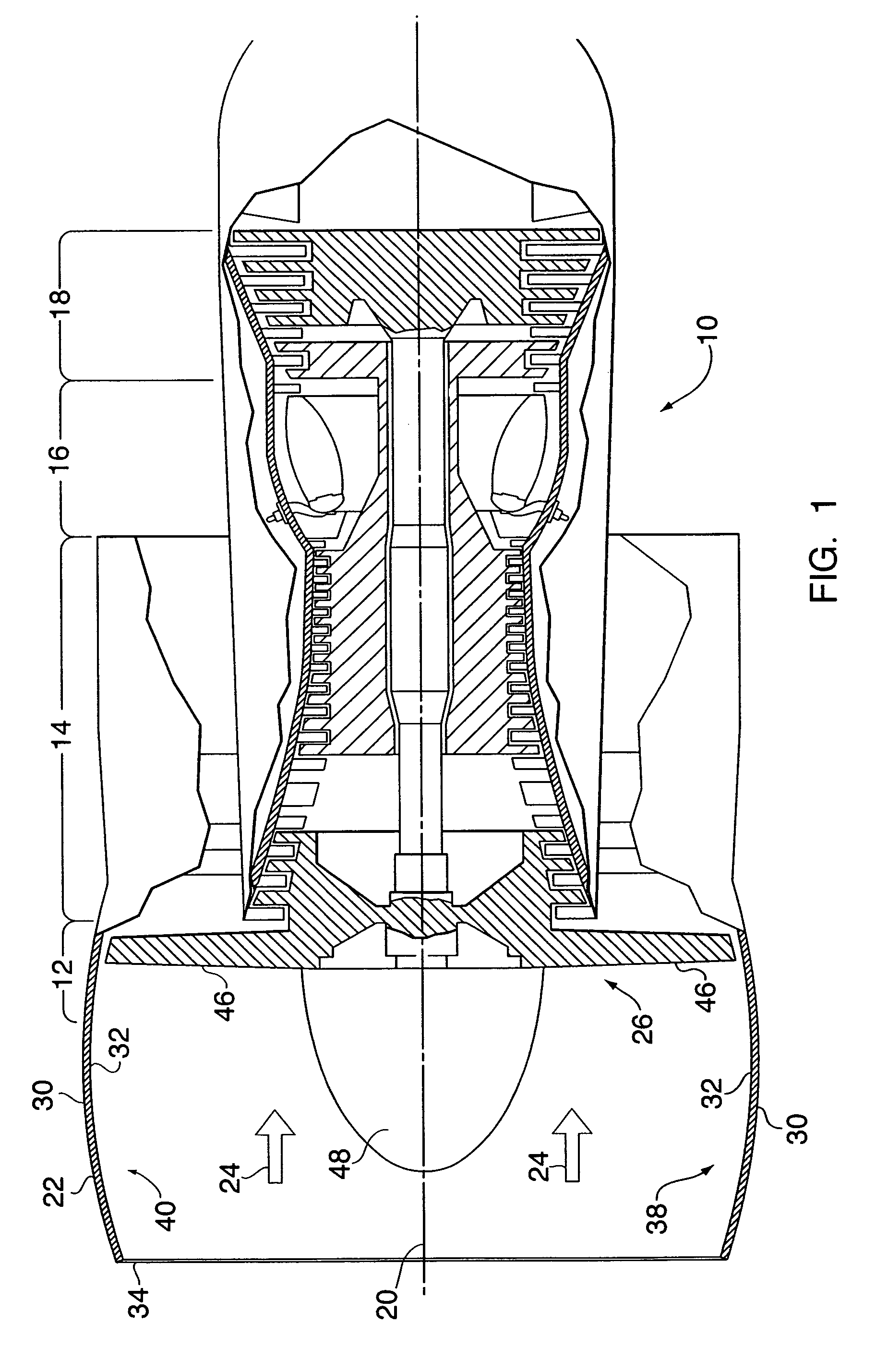

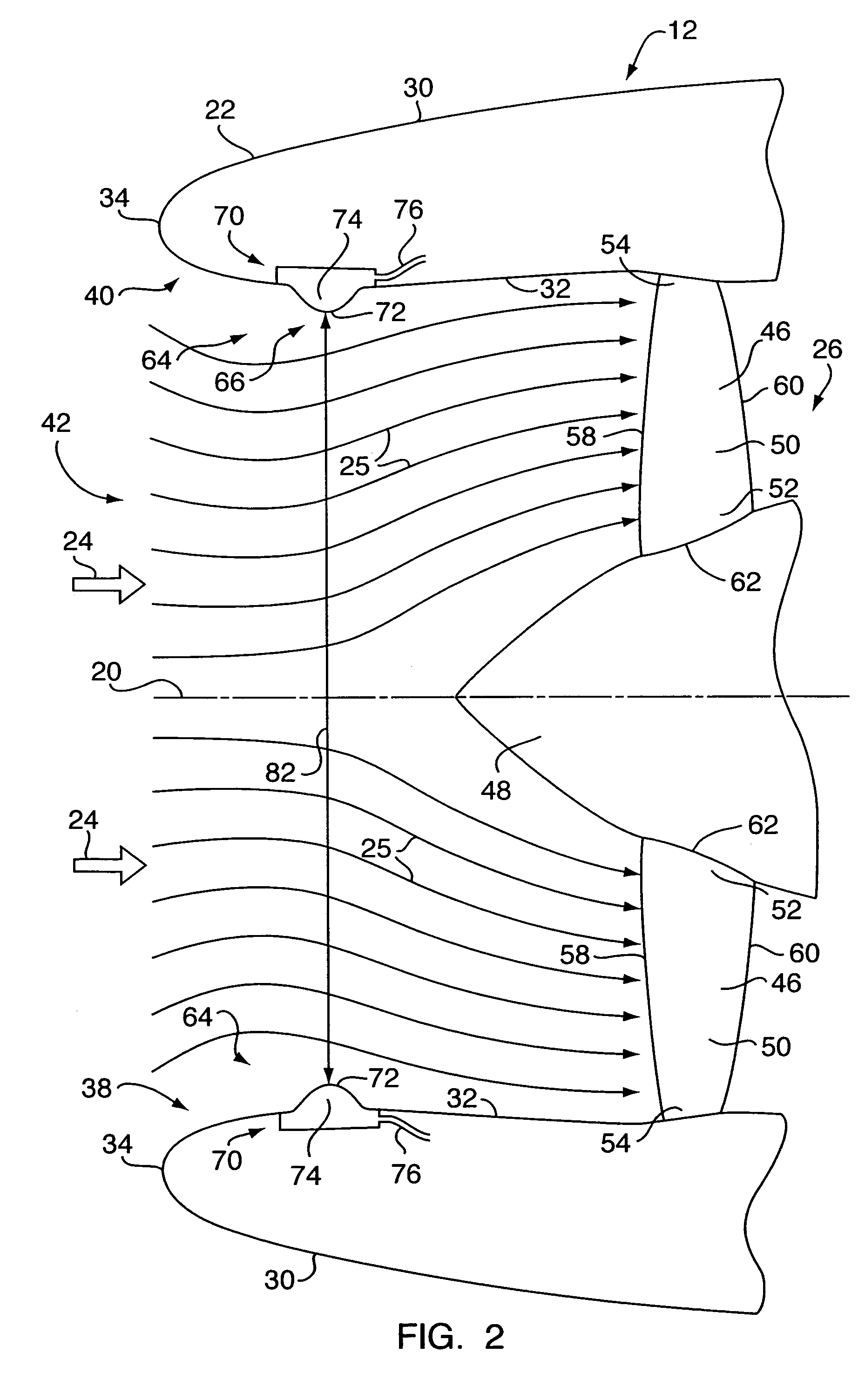

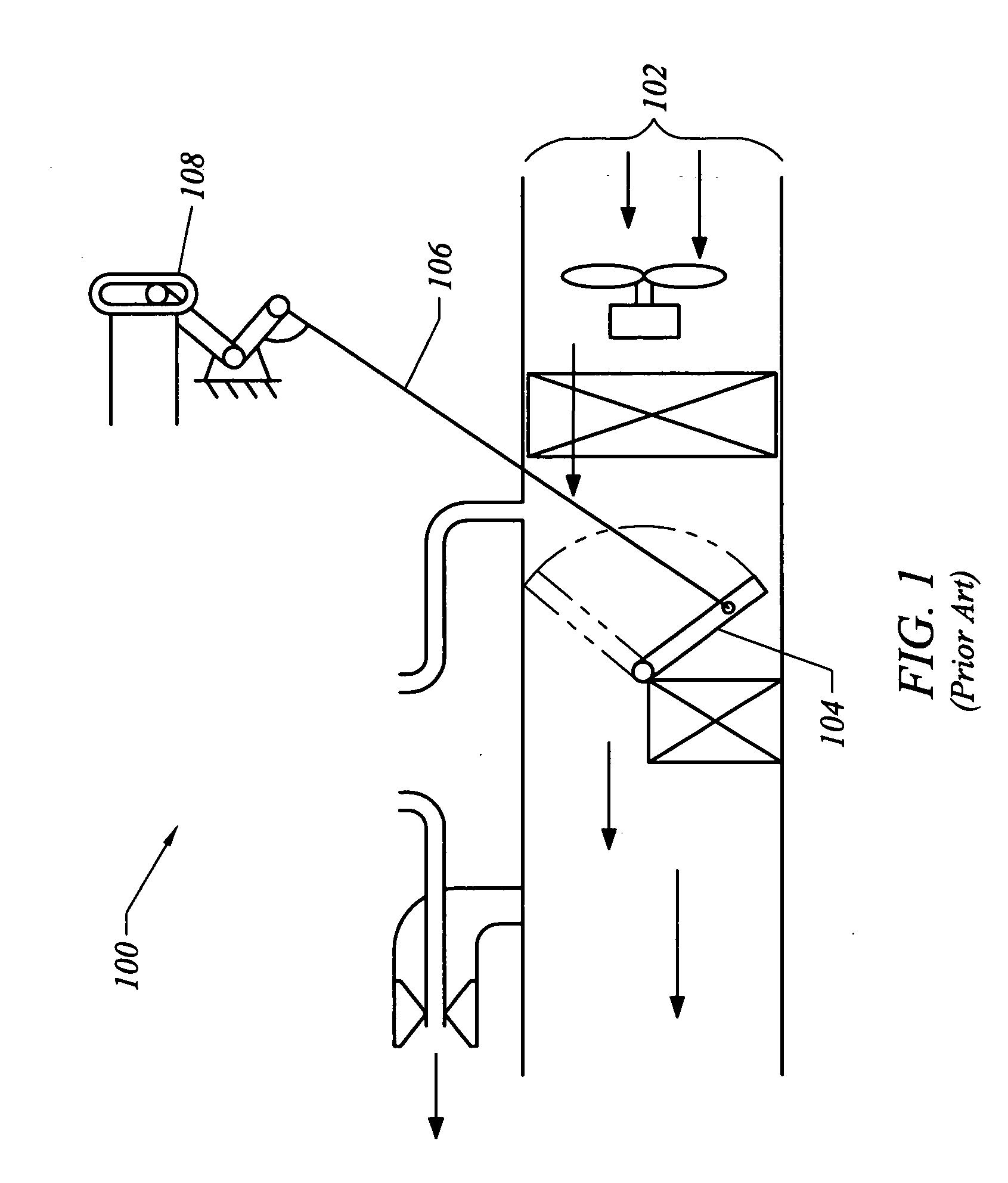

Gas turbine engine inlet with noise reduction features

InactiveUS20050274103A1Increase acoustic attenuationReducing inlet areaCombustion enginesGas turbine plantsNacelleCombustor

A gas turbine engine comprising a fan section, a compressor, a combustor and a turbine, includes a nacelle having an inner nacelle surface defining an inlet duct designed to reduce an inlet duct area of the inlet duct to increase acoustic attenuation. The gas turbine engine also includes a spinner, disposed forward of the fan section, that includes features to increase acoustic attenuation. In one embodiment of the present invention, the nacelle includes a nacelle contoured surface protruding radially inward from the inner nacelle surface to reduce the inlet duct area. In a further embodiment of the present invention, the spinner includes a spinner contoured surface for reducing the inlet duct area. In other embodiments, the nacelle and / or the spinner include an inflatable bladder, a SMA actuator, a fluidic actuator, or a combination thereof, selectively activated to increase acoustic attenuation during certain conditions of an aircraft.

Owner:UNITED TECH CORP

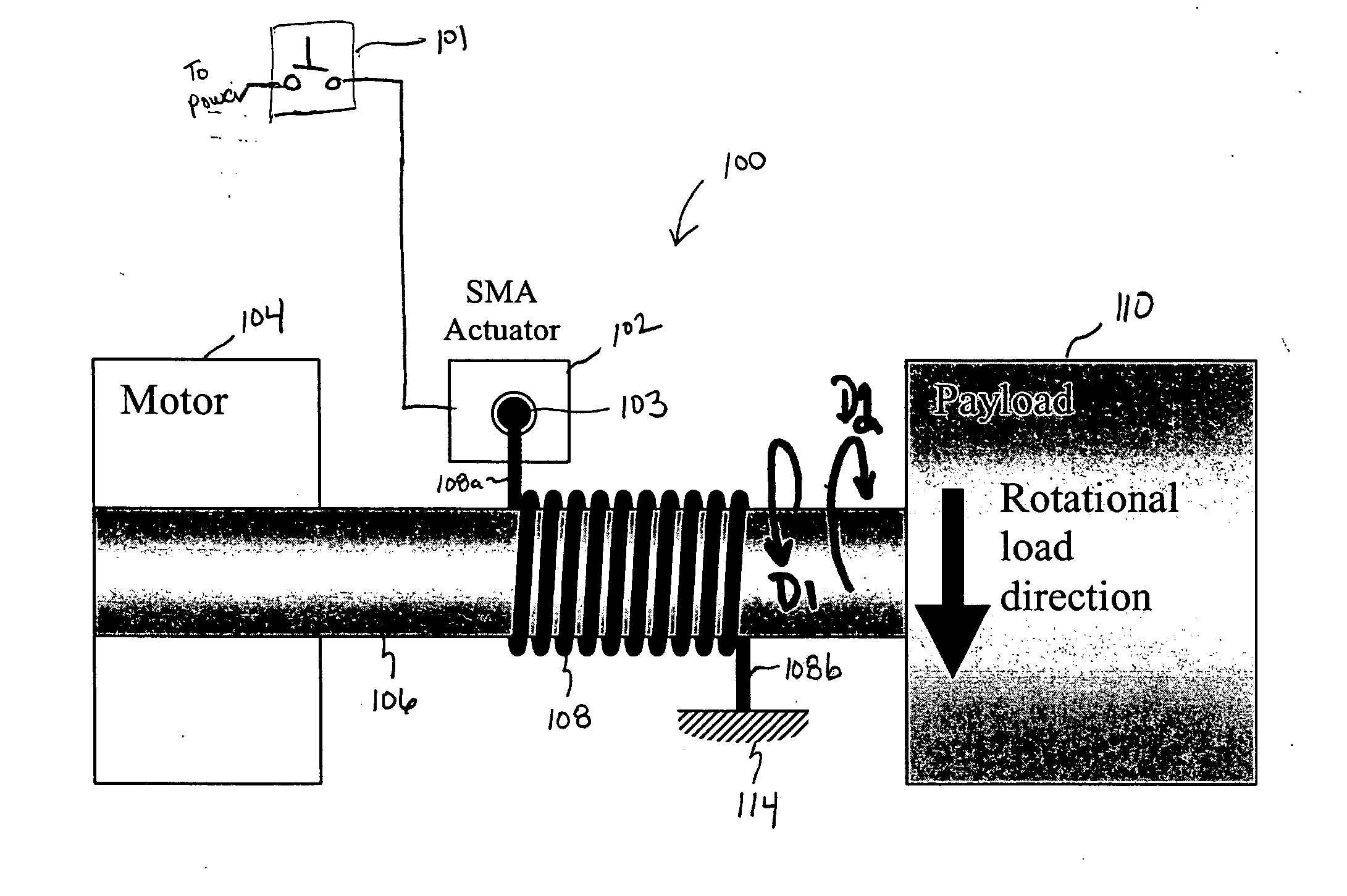

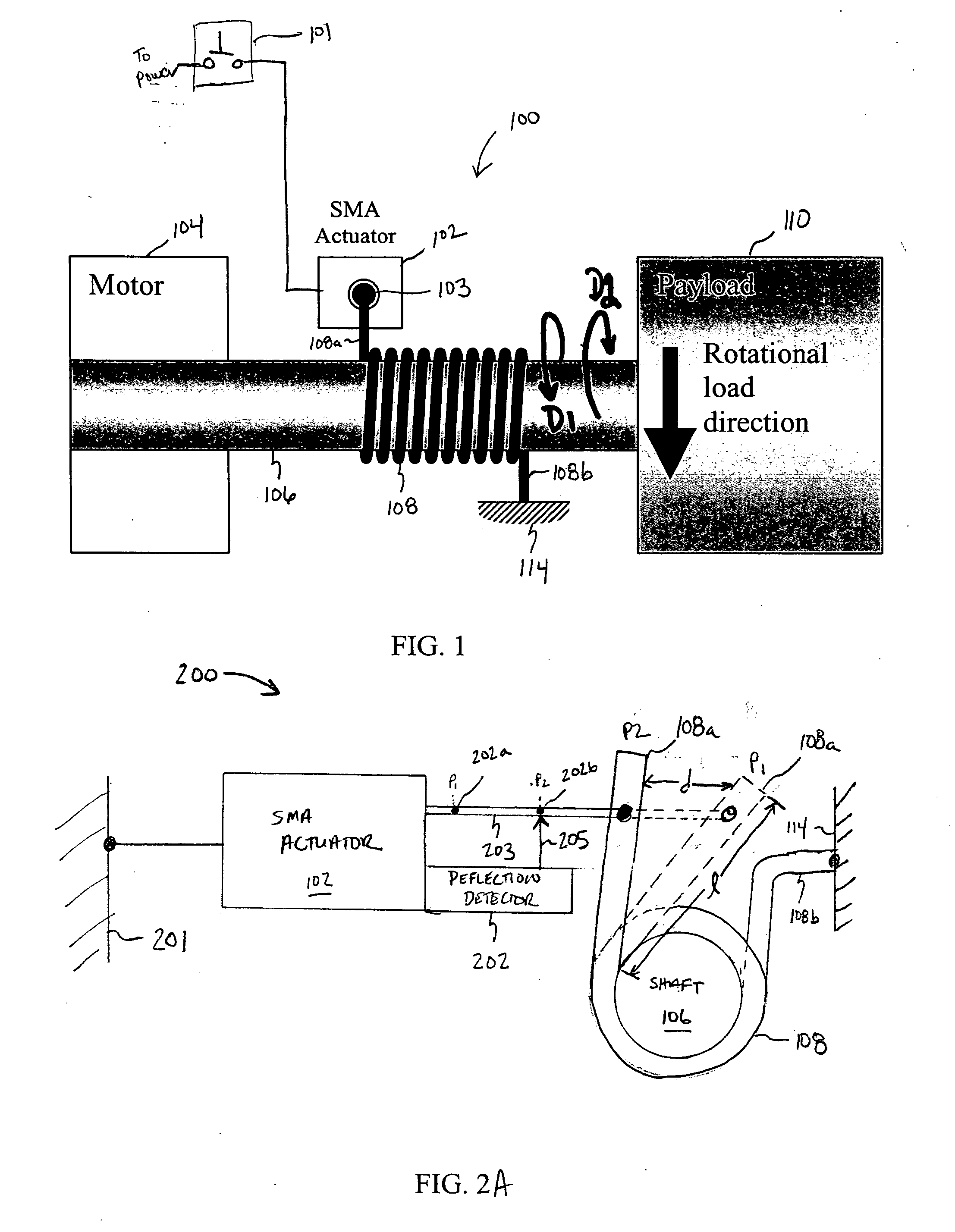

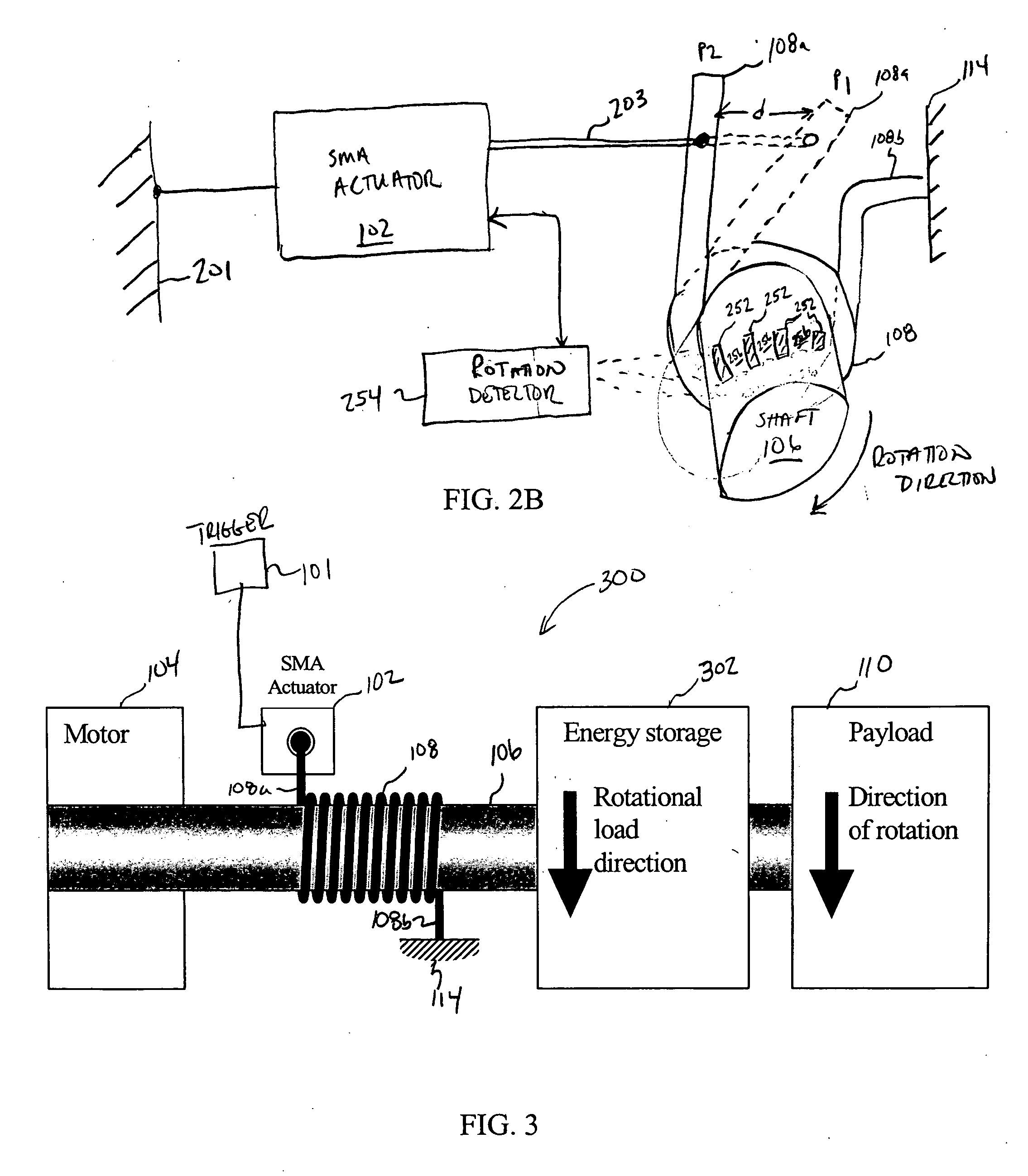

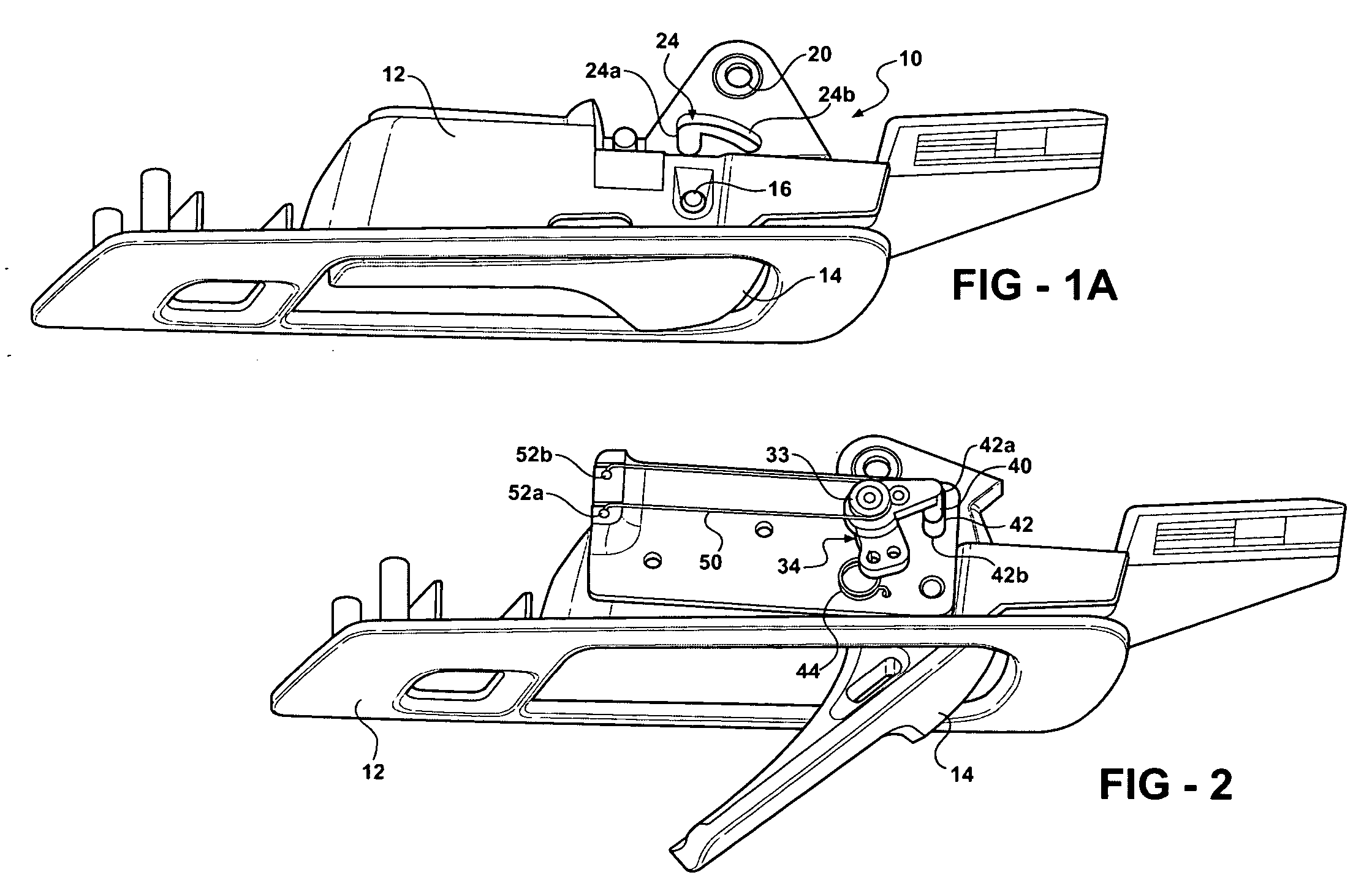

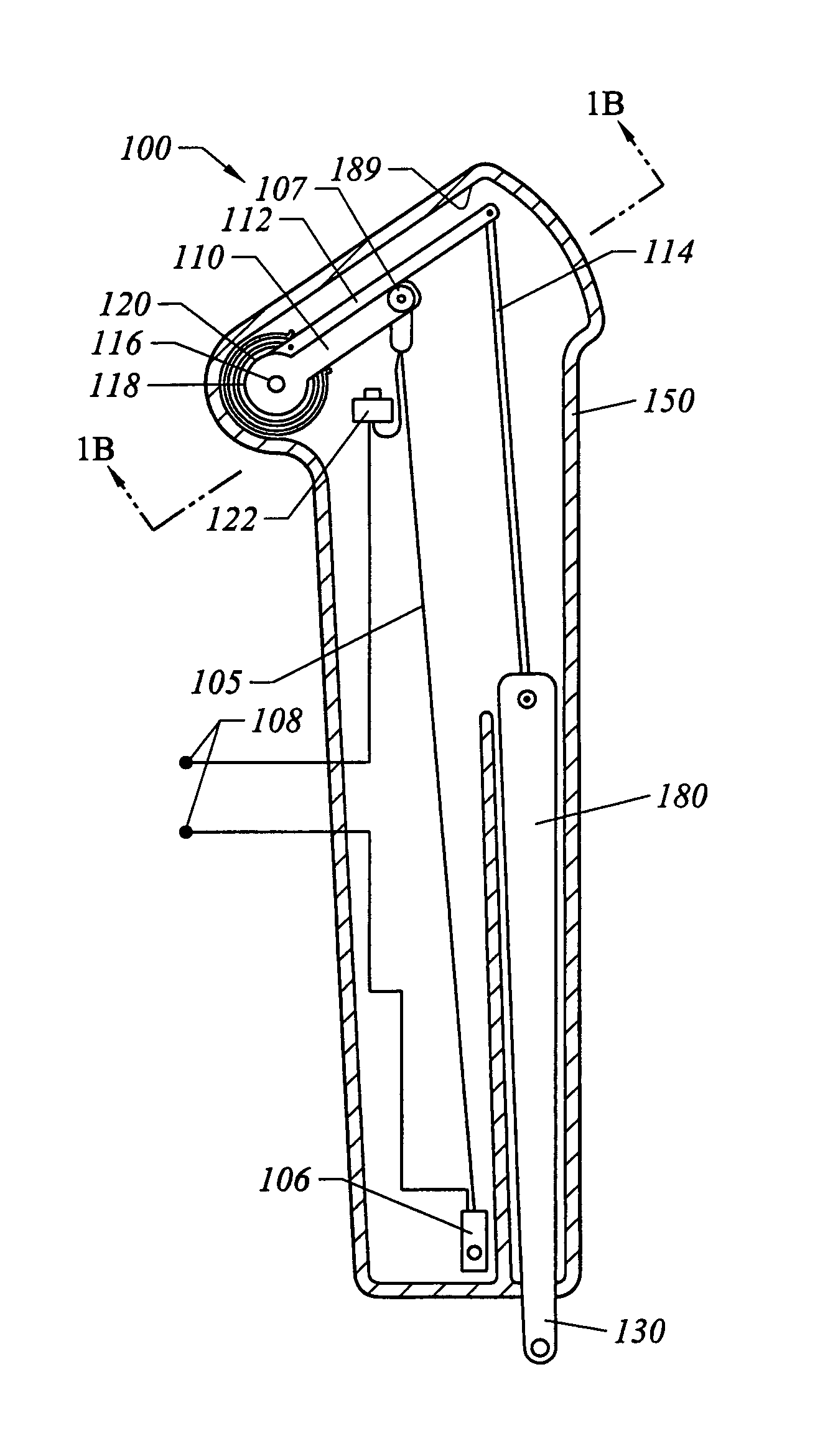

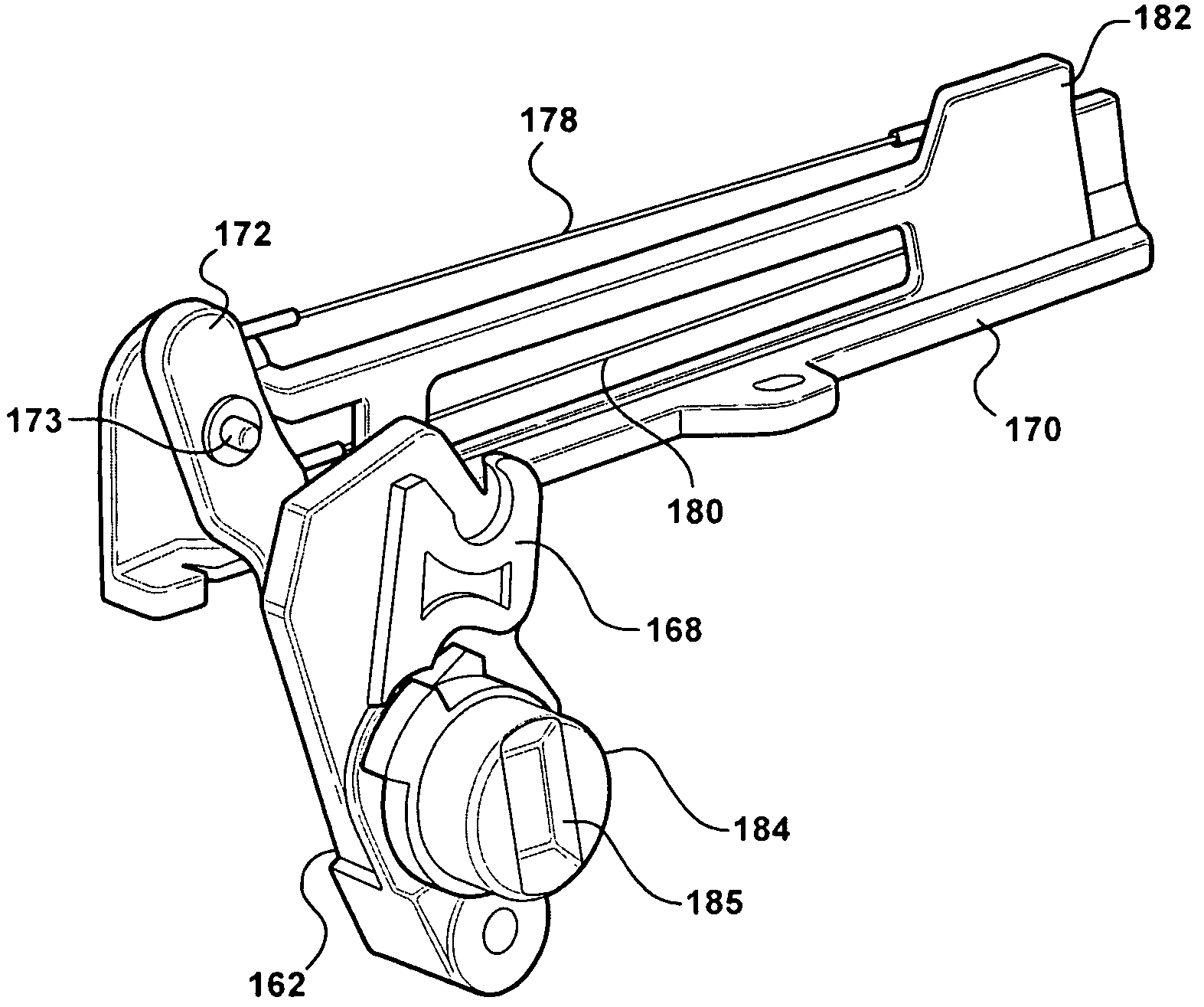

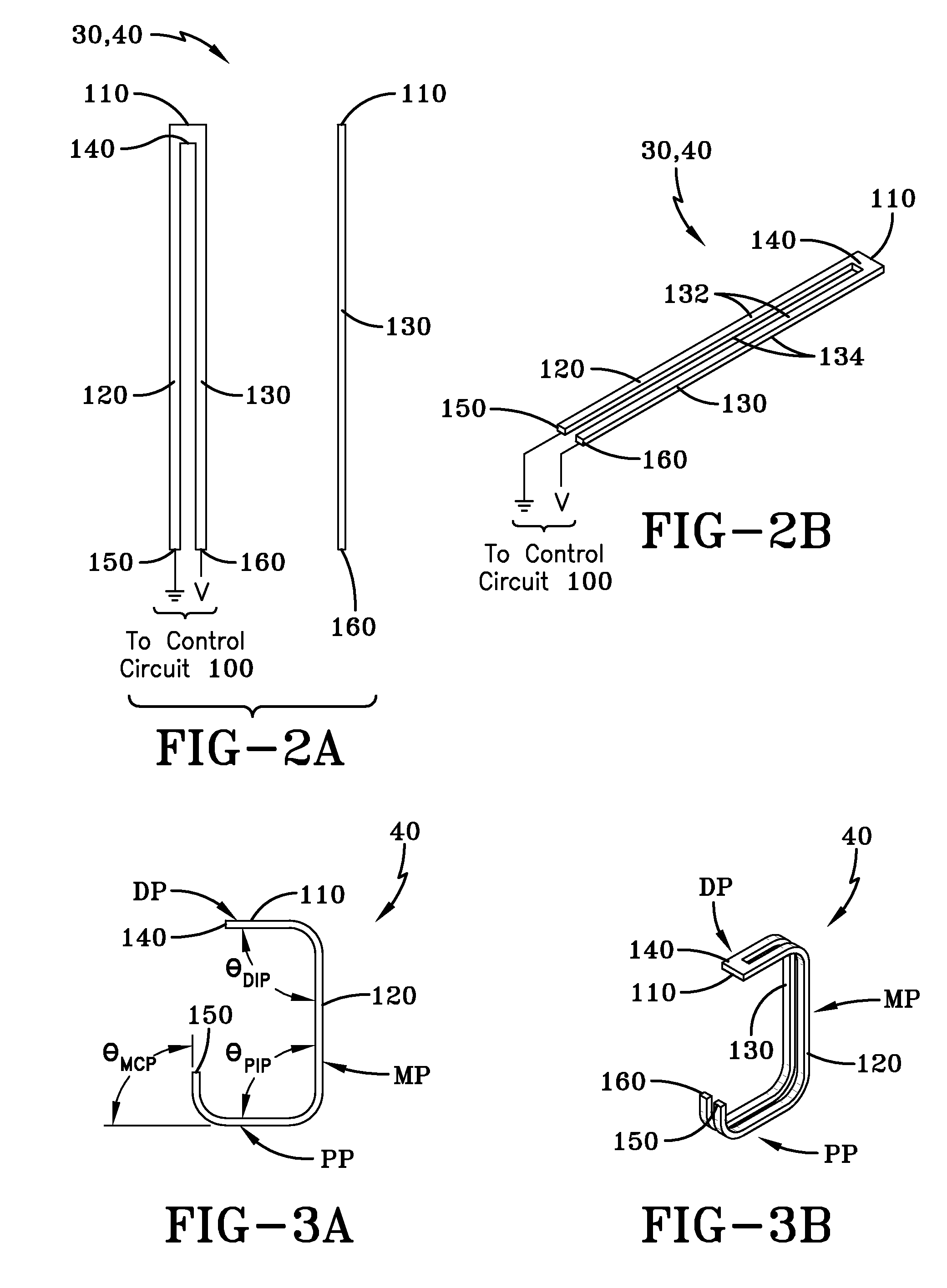

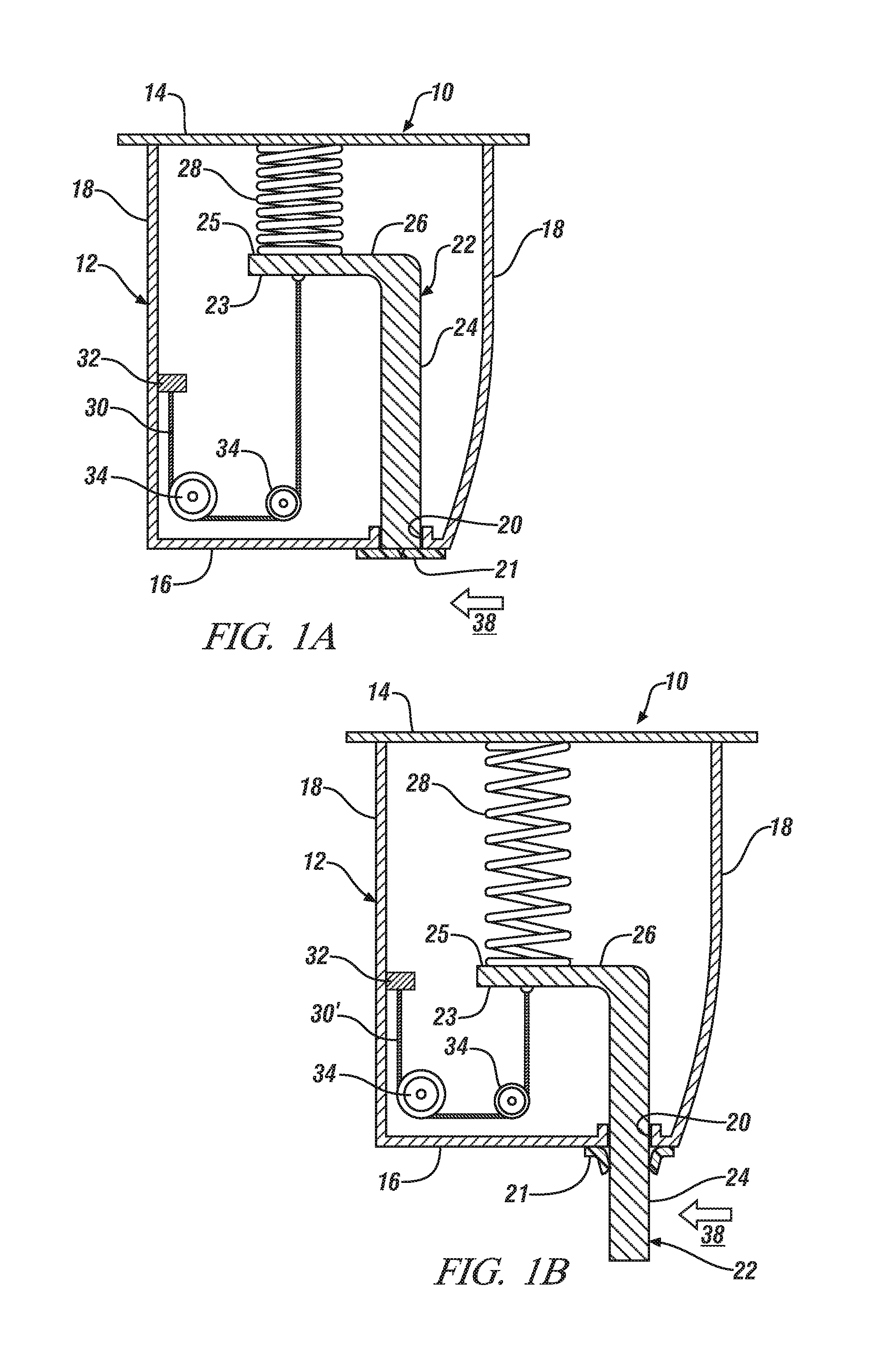

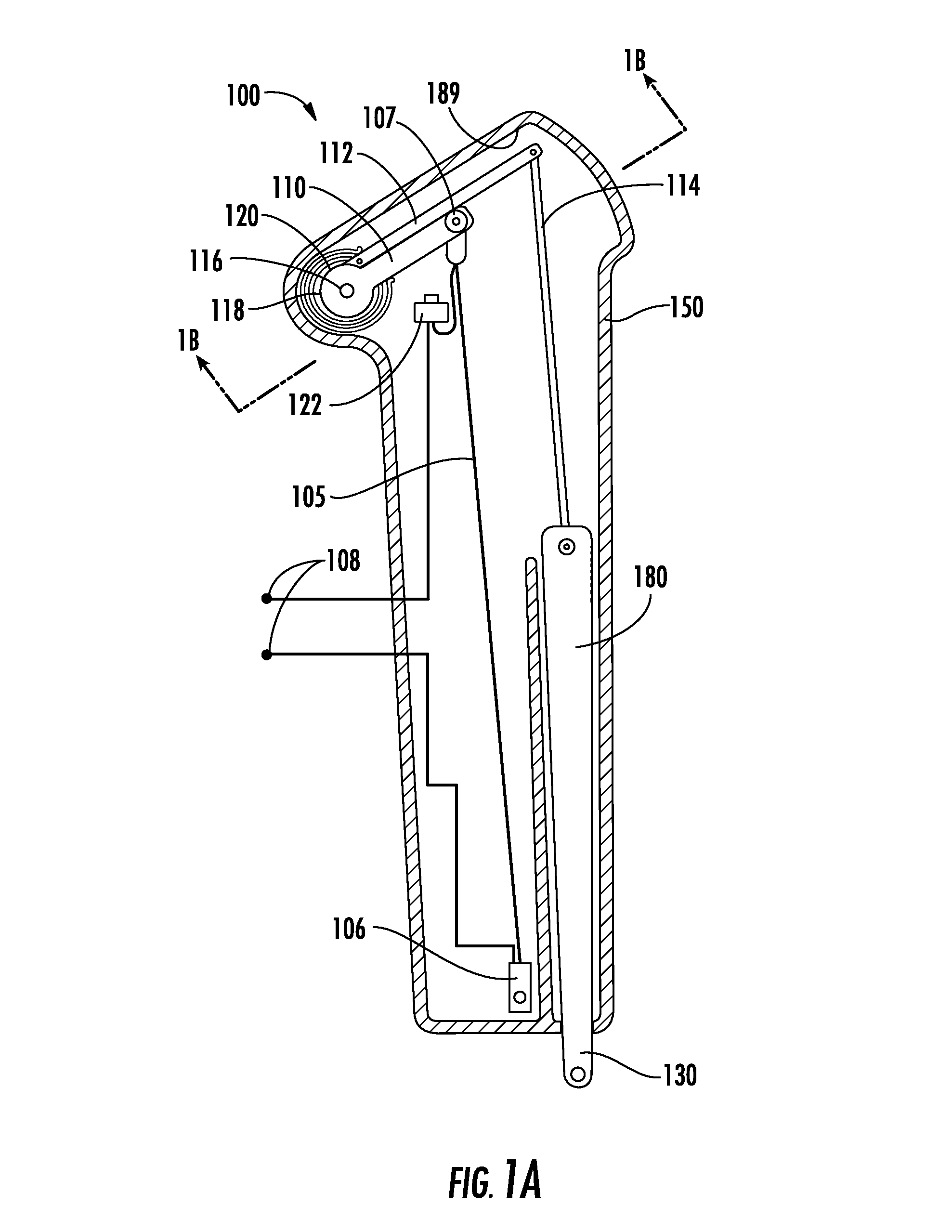

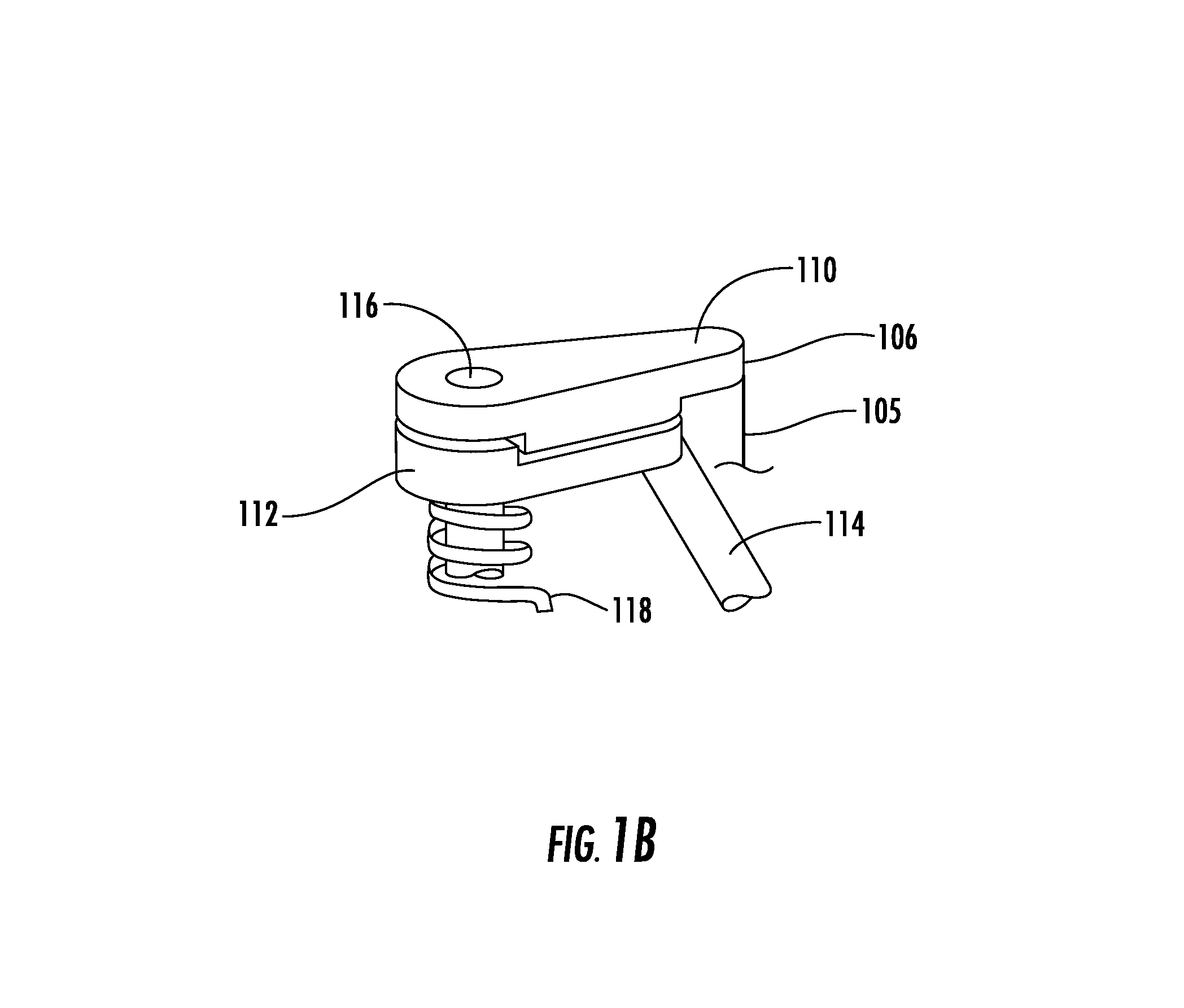

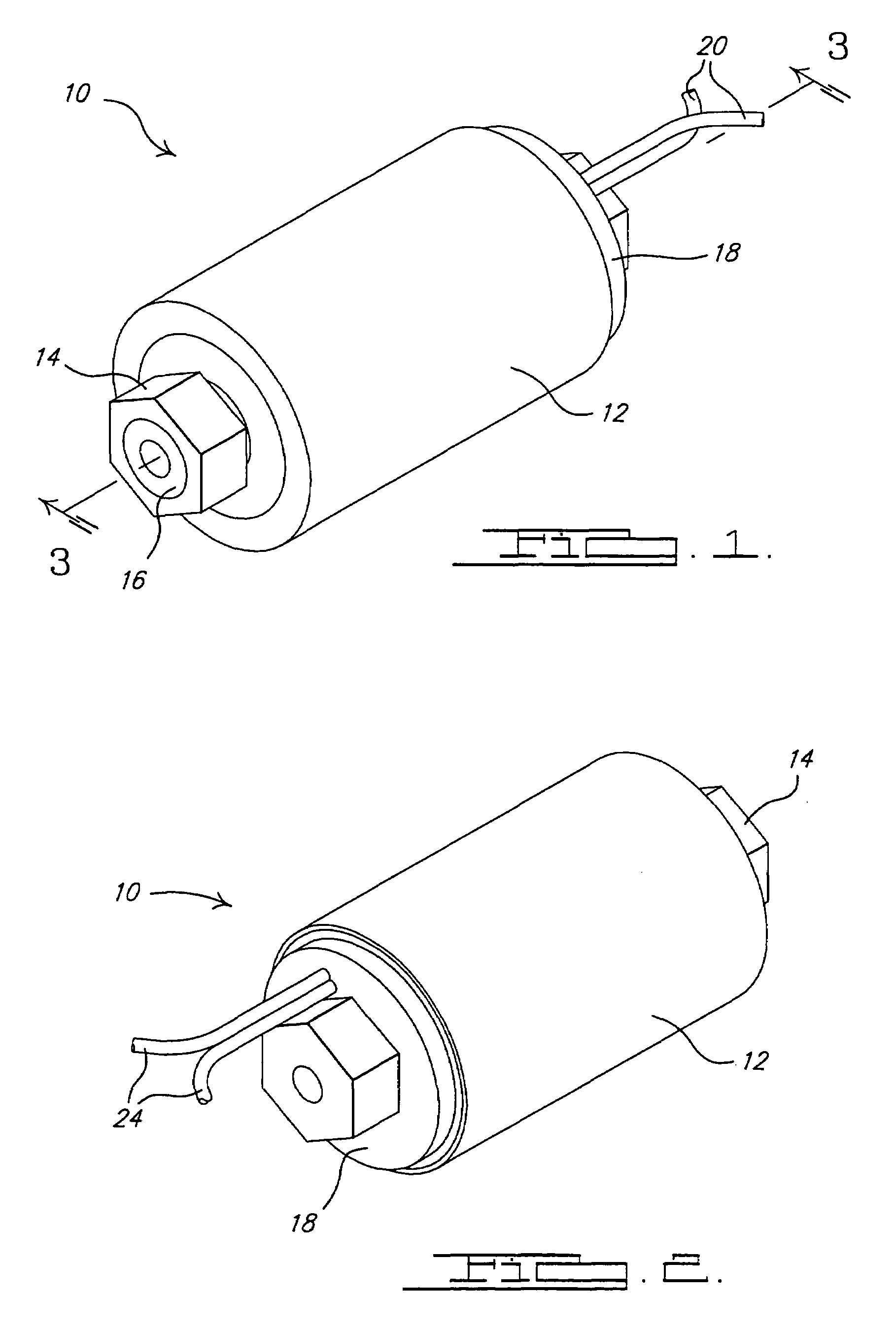

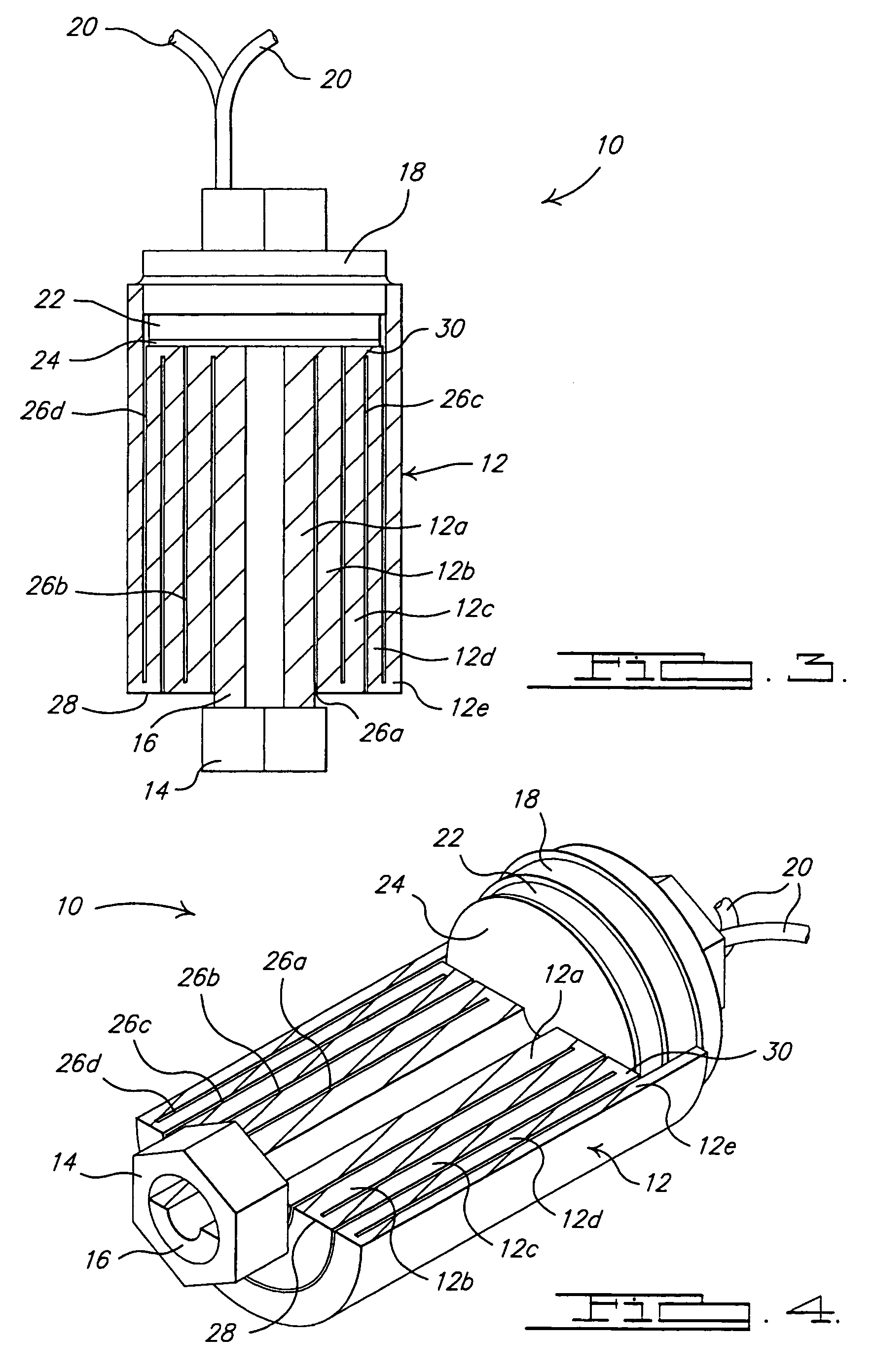

Shape memory alloy-actuated and bender-actuated helical spring brakes

In one embodiment of the present invention, a shape memory alloy (“SMA”)-actuated helical spring brake comprises a rotatable member and a helical wrap spring arranged concentrically about the rotatable member. The spring has a first spring end and a second spring end and includes a number of turns that are based radially inward and are configured to frictionally engage the rotatable member. The turns permit rotation of the rotatable member in a first direction and inhabit rotation in a second direction. The SMA-actuate helical spring brake also include an anchor point coupled to the second spring end, and an SMA actuator having an output drive member coupled to the first spring end. The SMA actuator is configured to, for example, deflect the first spring end to permit the rotatable member to rotate.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN

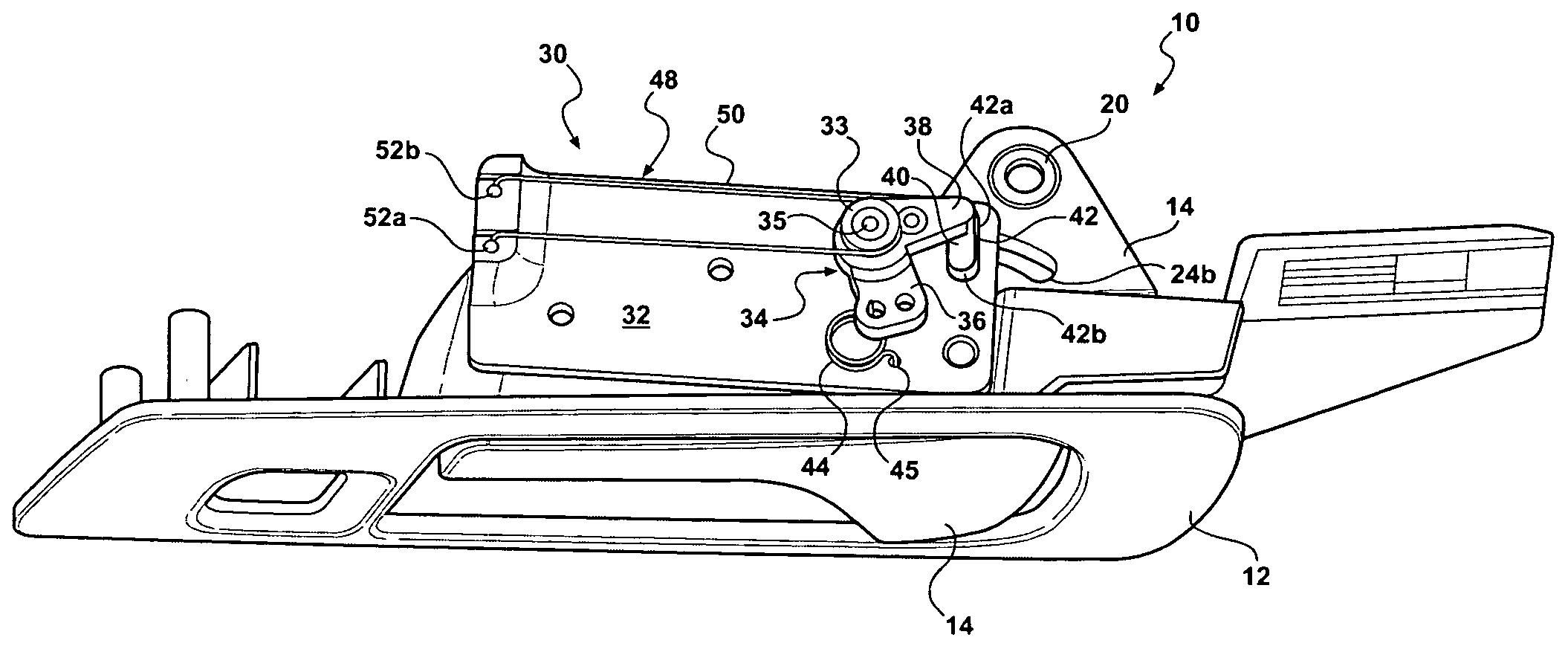

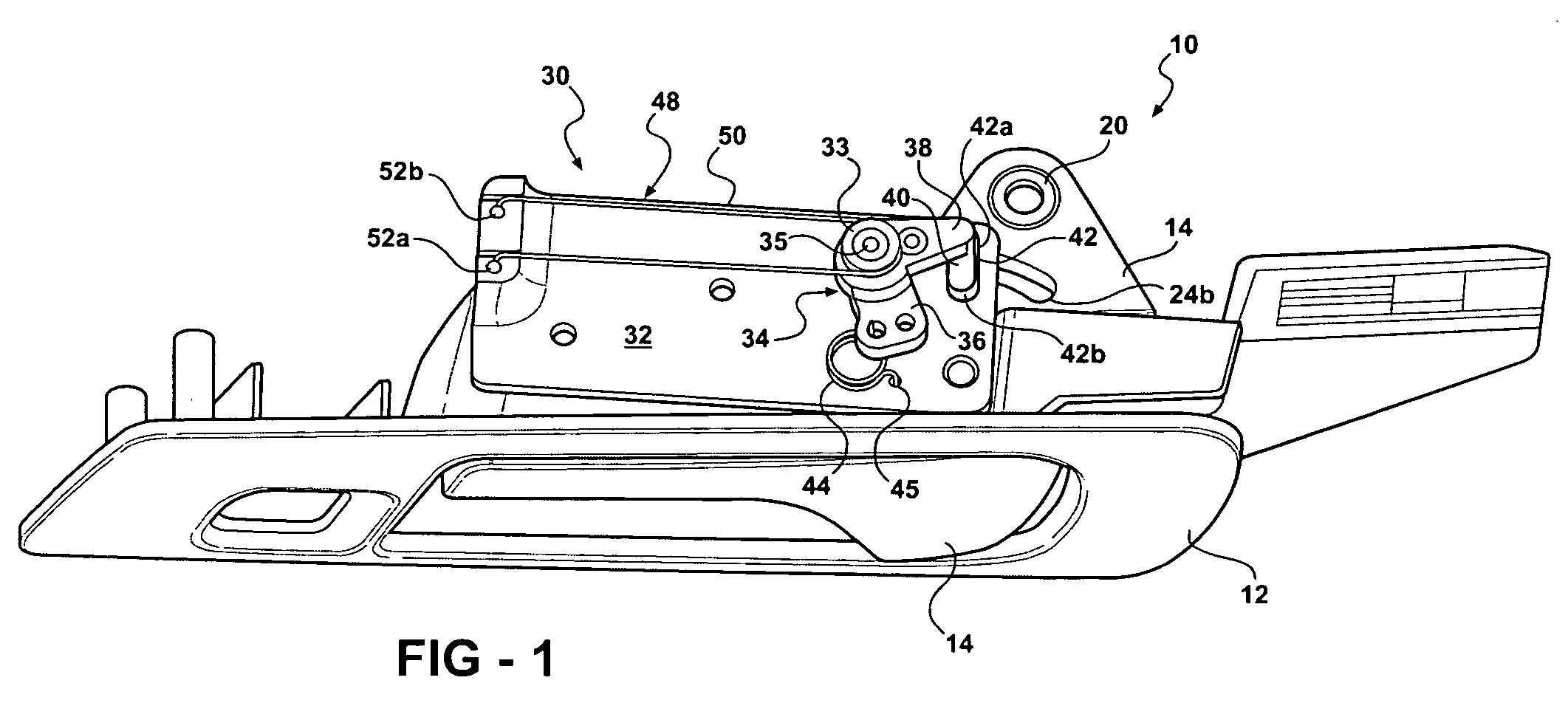

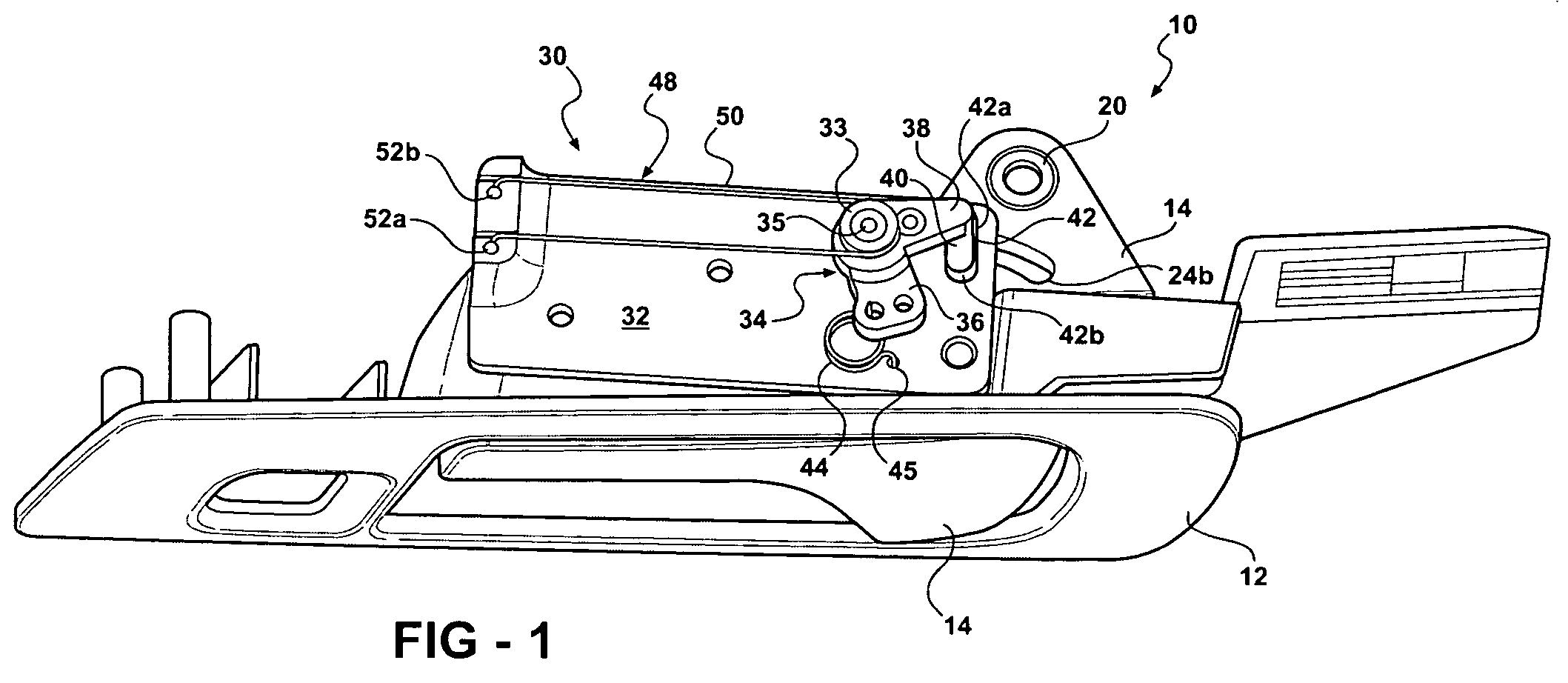

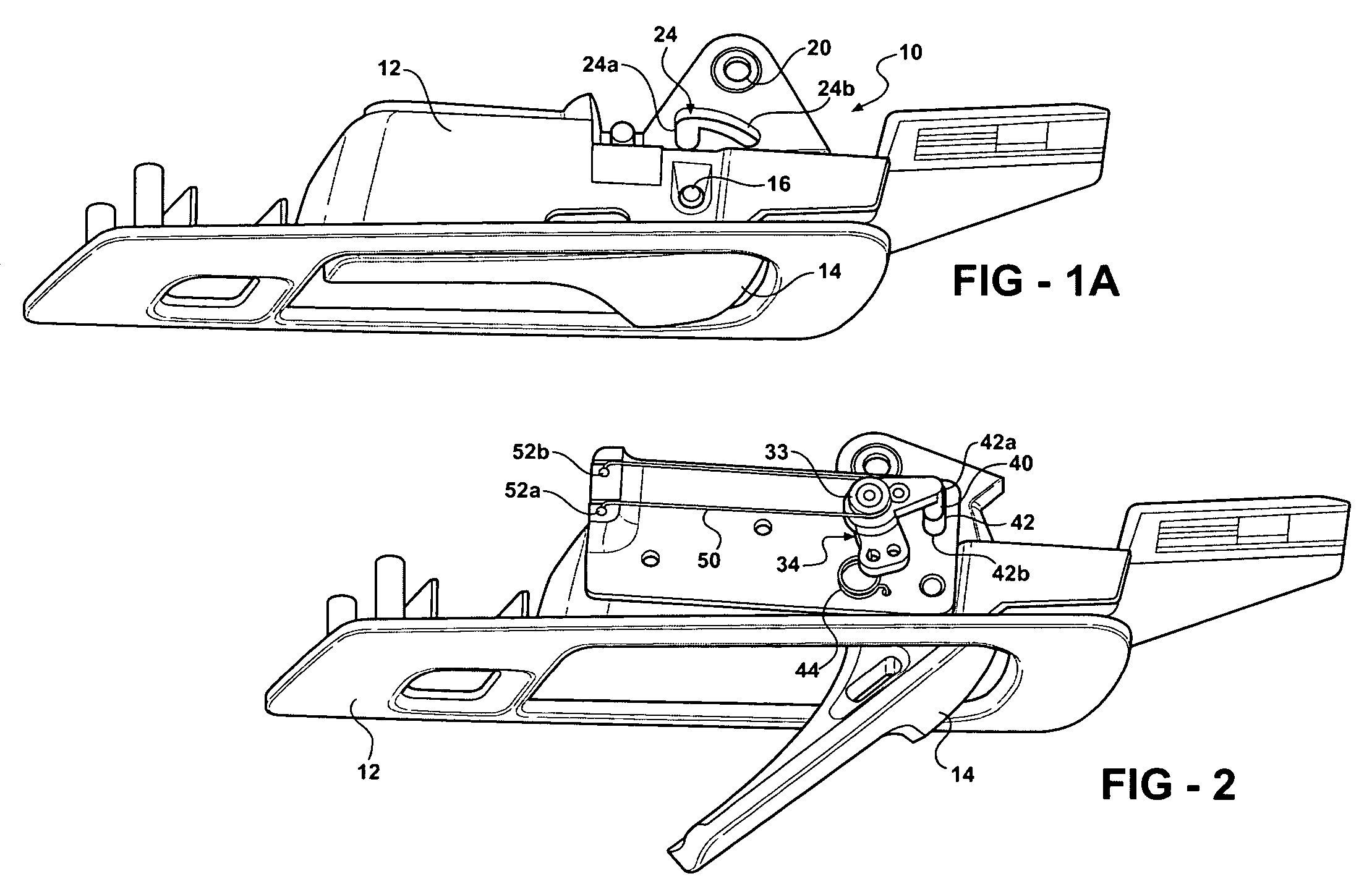

Vehicle lock controlled by a shape memory alloy actuator

InactiveUS20050146147A1Reduced packaging requirementsLow costNon-mechanical controlsConstruction fastening devicesControl theorySma actuator

A contractible shape memory alloy (SMA) wire is used to throw a lever in a latch. The SMA actuator provides weight and space savings. In one embodiment, the SMA actuator is incorporated in the handle of the latch in order to provide a child lock or double lock function. The handle has a lever which includes a relatively short slot leg and a relatively long slot leg. A toggle sits in the slot. At least one SMA wire is connected to the toggle to move it between the relatively short slot leg, wherein the lever is prevented from pivoting, and the relatively long slot leg, where the lever is enabled to pivot. In another embodiment, the SMA actuator is embedded in the latch itself, and used to throw a lever that controls the child lock function.

Owner:INTIER AUTOMATIVE CLOSURES INC

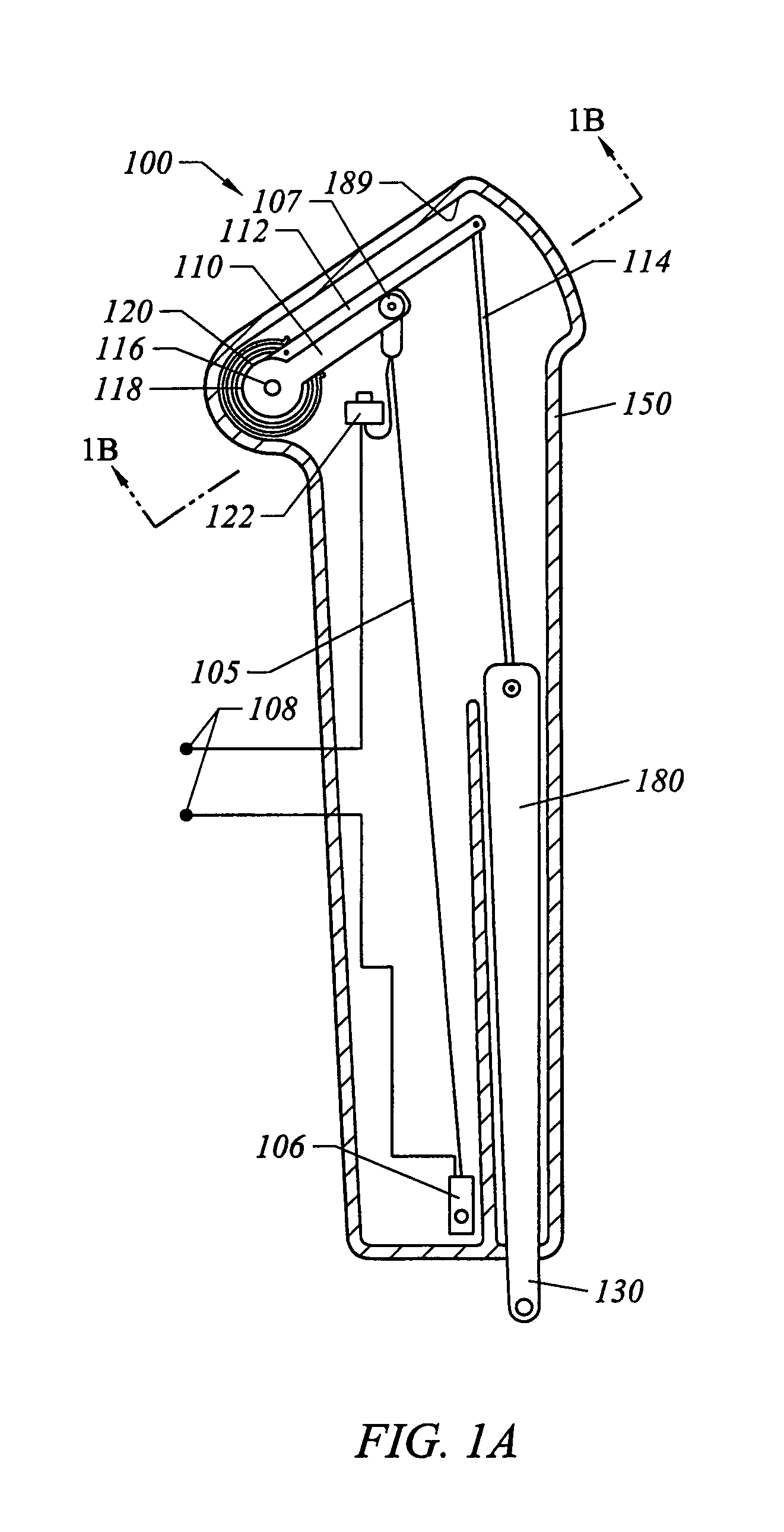

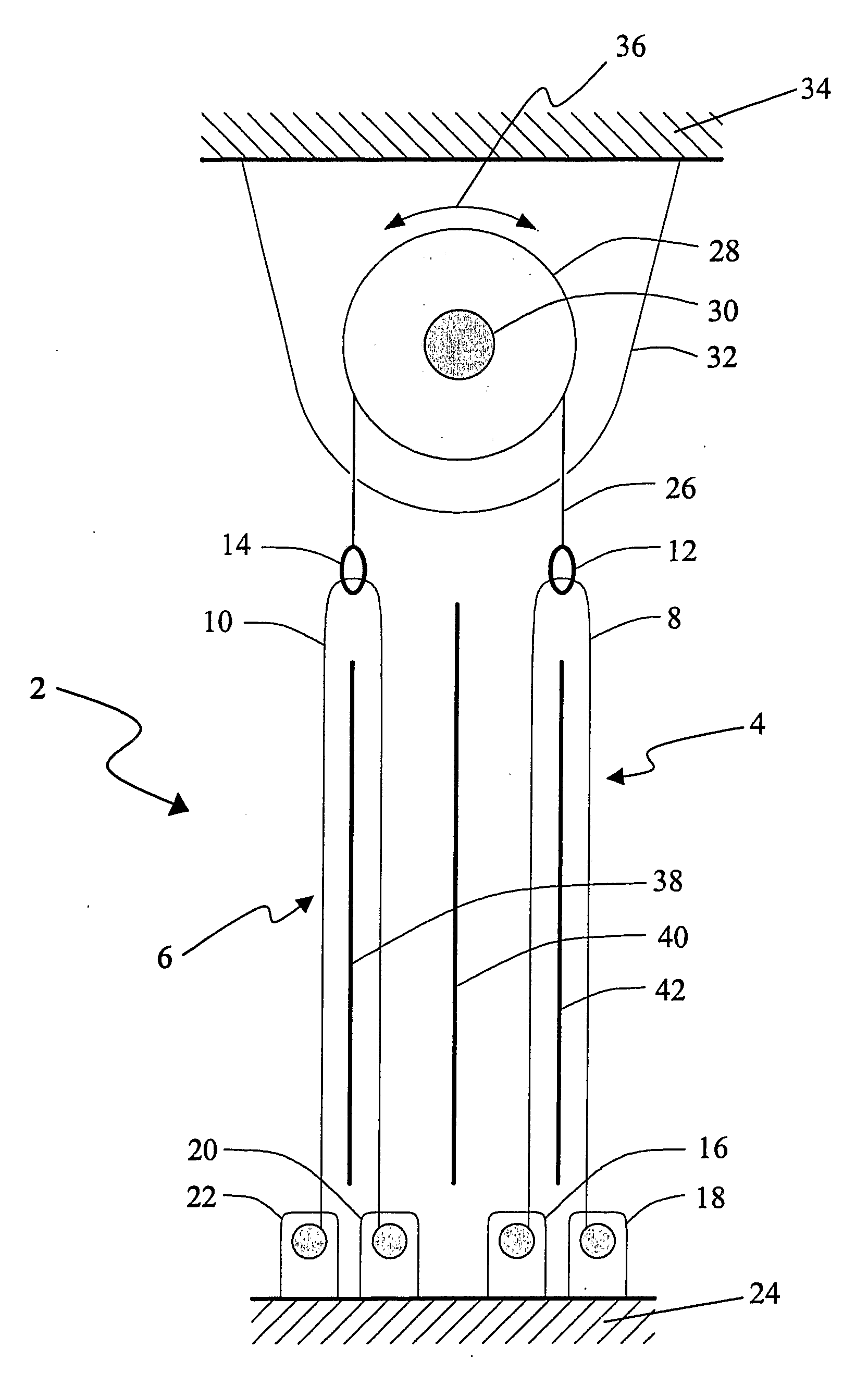

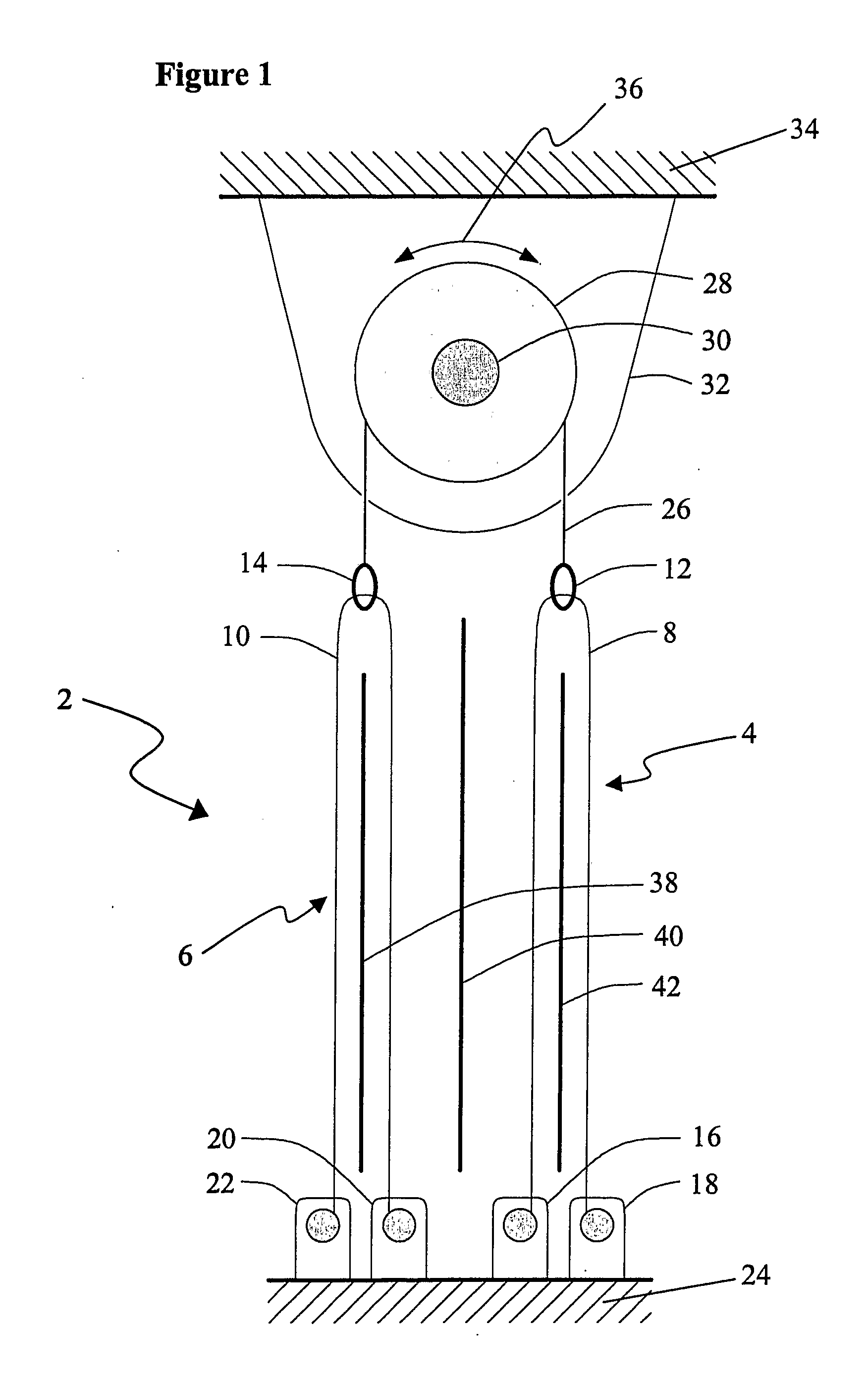

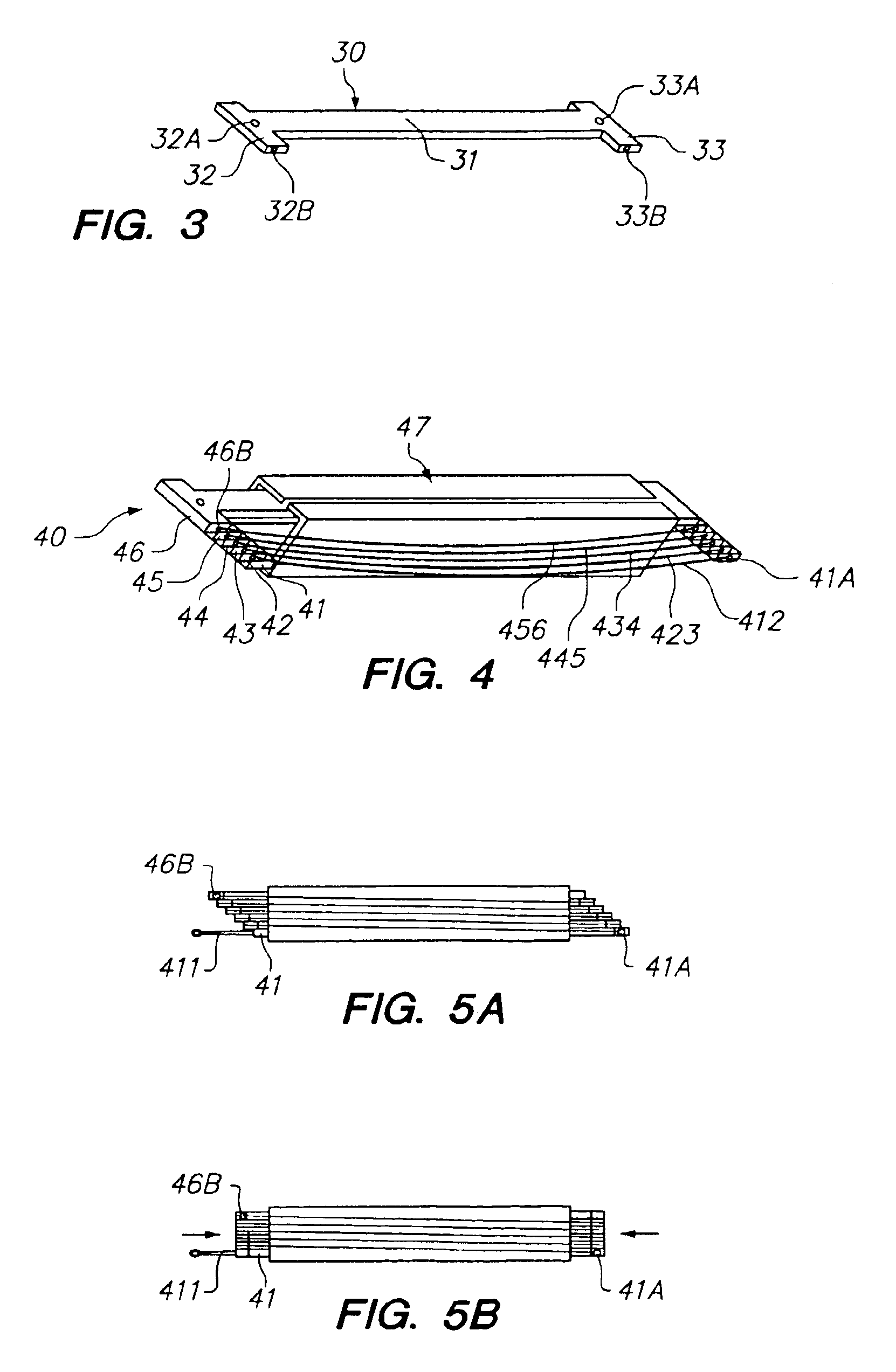

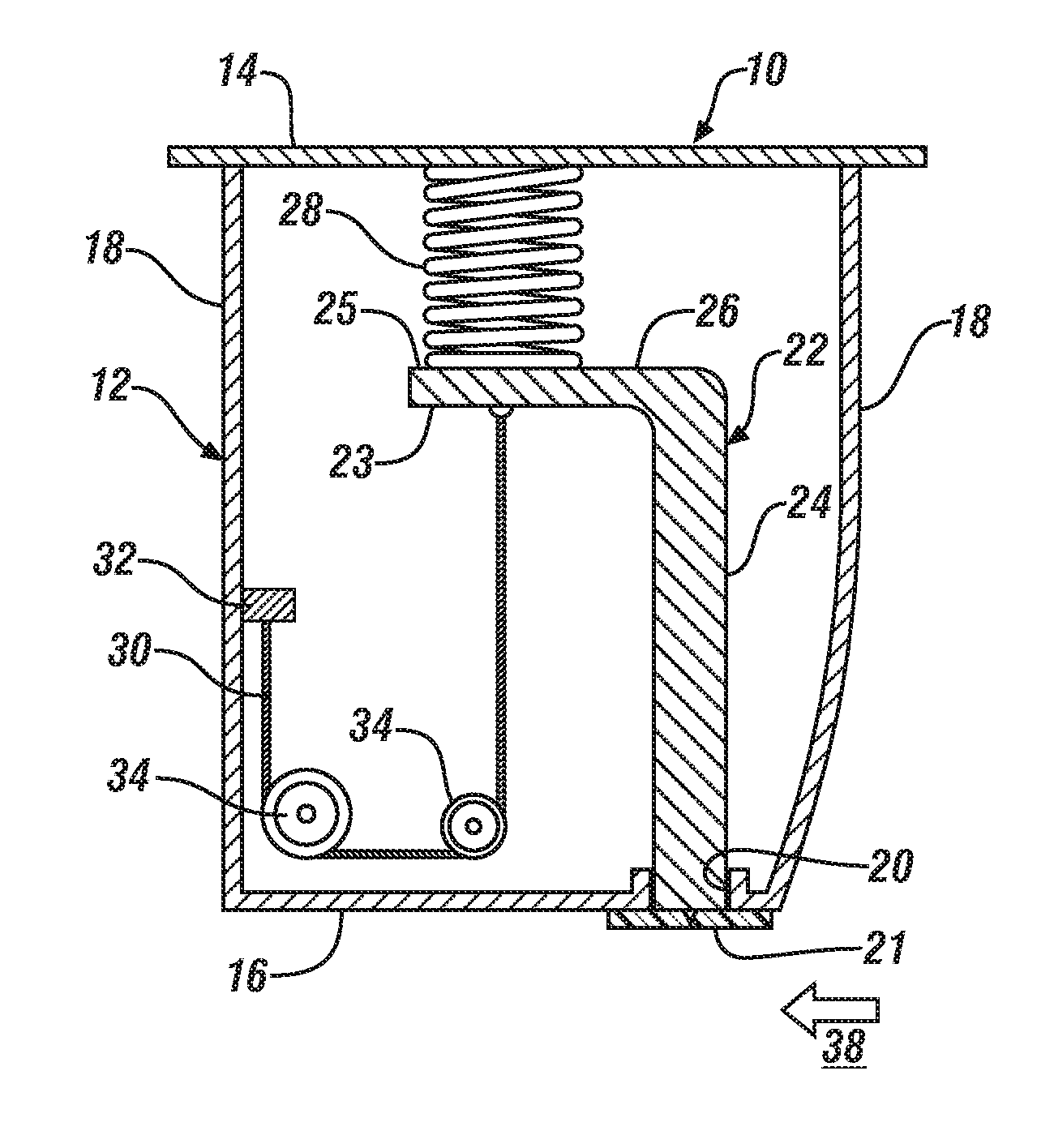

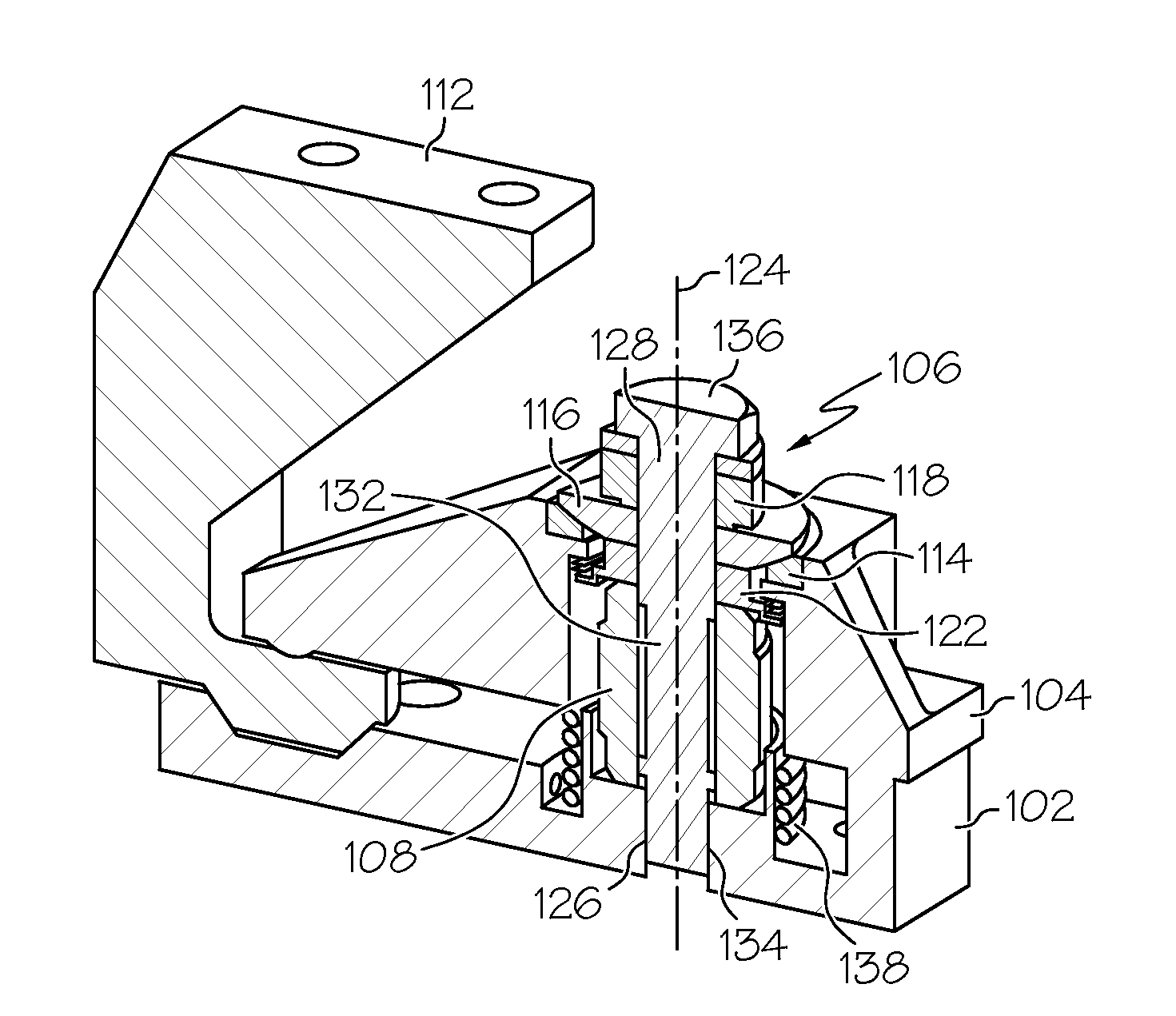

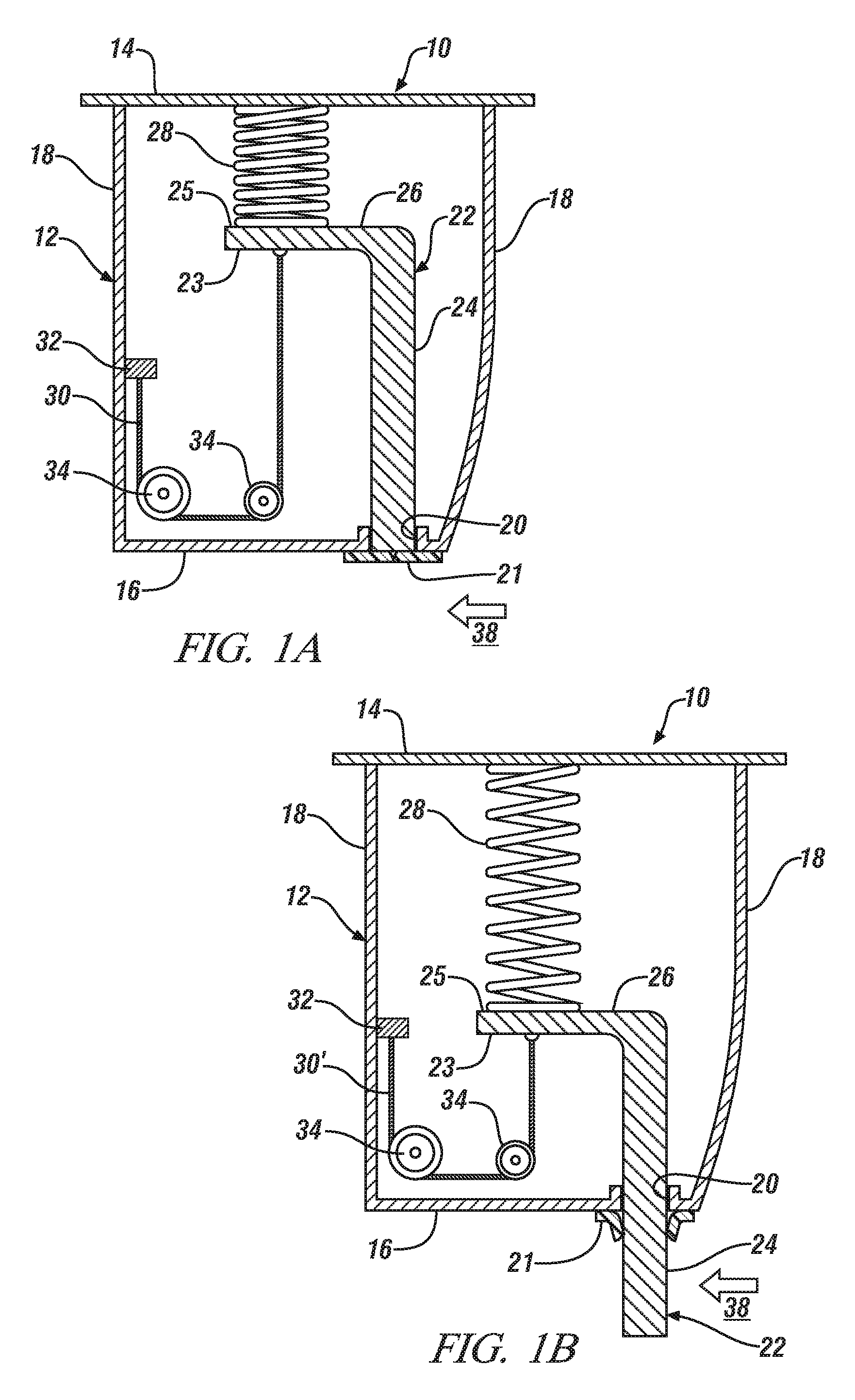

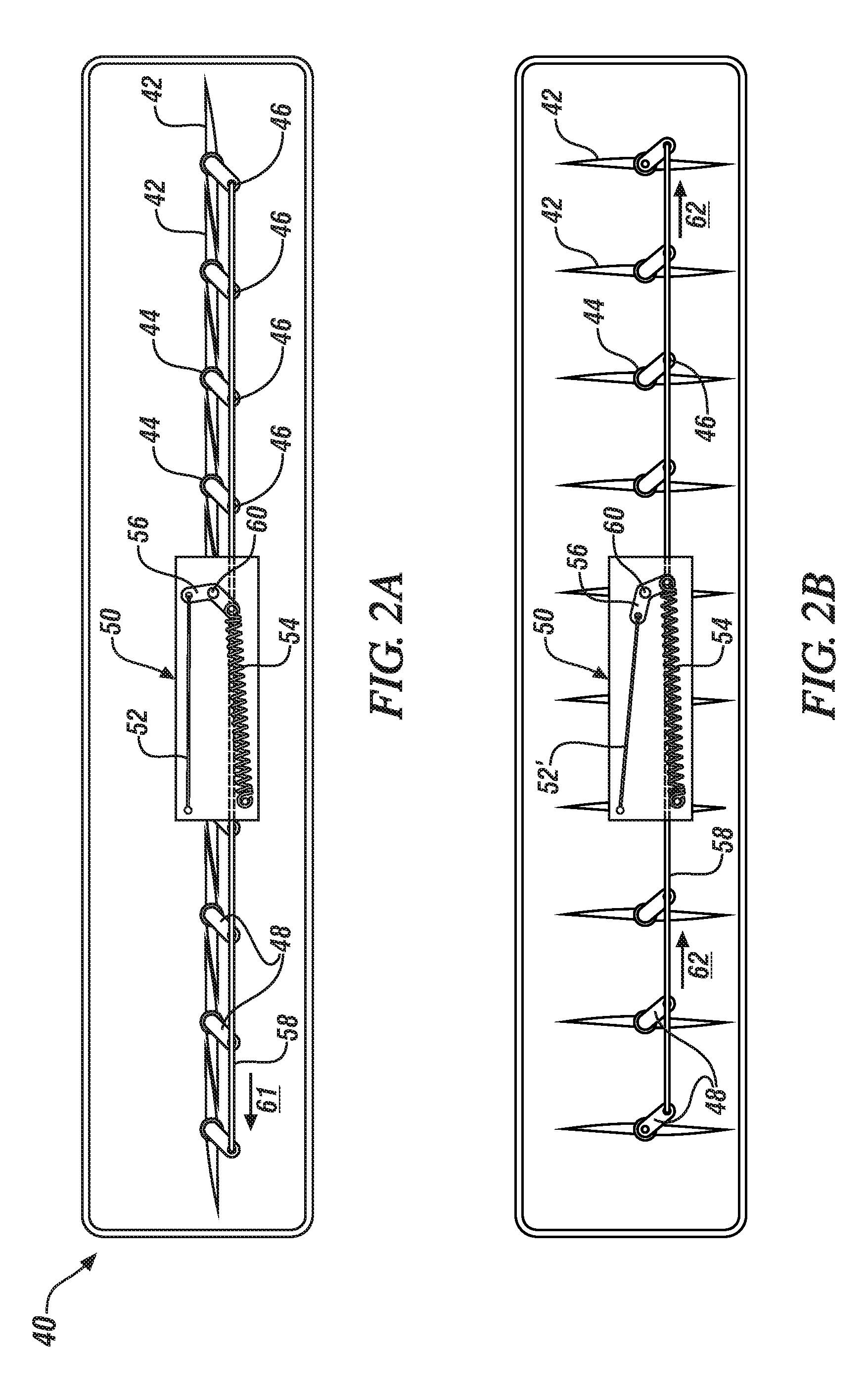

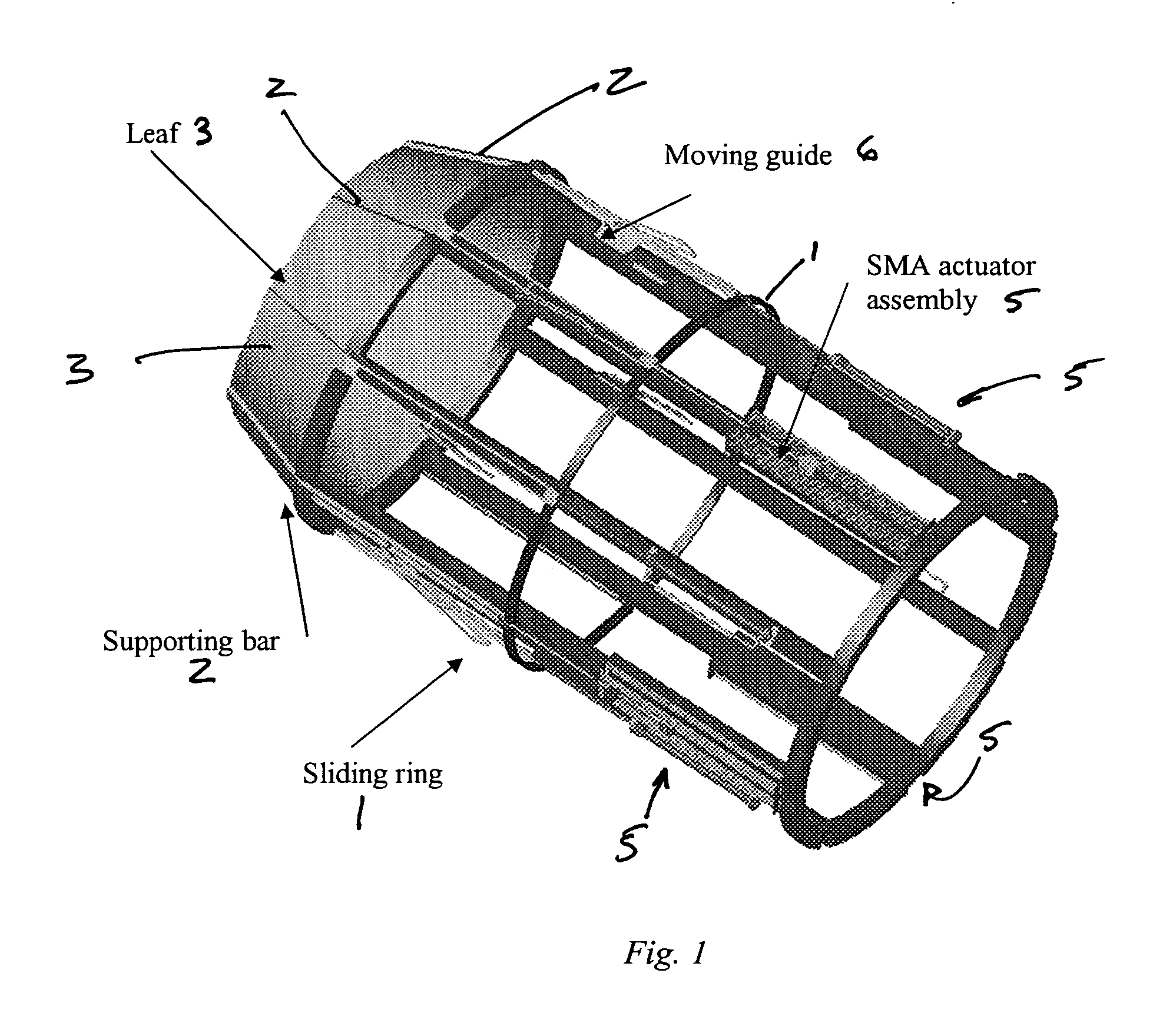

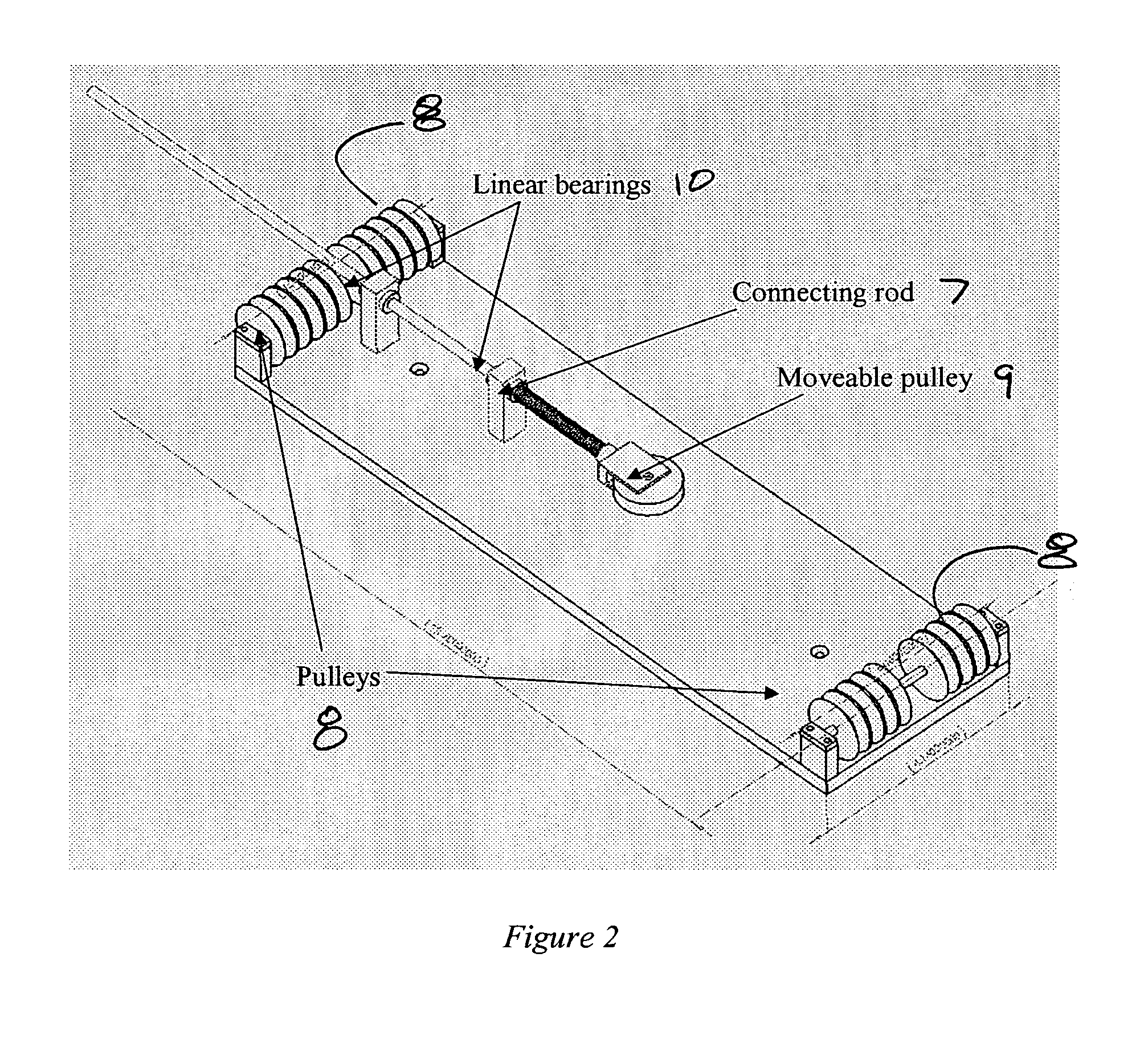

High stroke, highly integrated SMA actuators

InactiveUS7017345B2Avoid damageWing lift eficiencyMechanical power devicesControl theorySma actuator

A shape memory alloy (SMA) actuator assembly is provided that includes an SMA component. The SMA component is used to impart motion in an output shaft. Also provided is a return force component that provides a variable, tailored return force to the SMA component. Additionally, a variety of protective mechanisms are disclosed and utilized to prevent damage to the internal workings and components within the SMA actuator assembly as well as provide protection and safety for external workings.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN

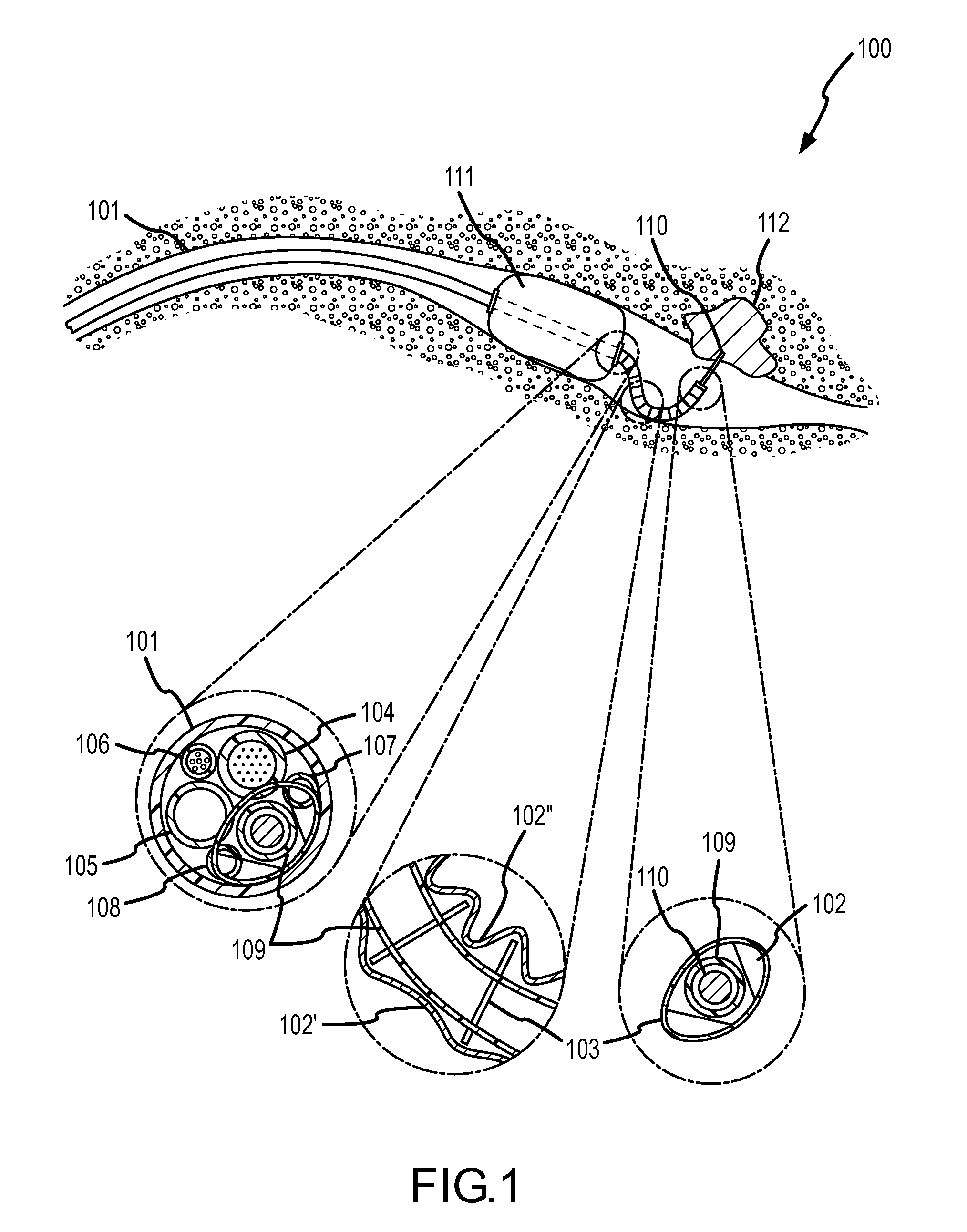

Endoscope apparatus, actuators, and methods therefor

InactiveUS20070239138A1Improve curing speedAccurate diagnosisBronchoscopesSurgeryMultiplexingPower flow

The present invention provides, in part, a dexterous endoscope apparatus, referred to herein as a MicroFlex Scope (MFS). The MFS is an novel, small diameter, e.g., less about 1 mm to about 4 mm, about 1 mm to about 3 mm, etc., dexterous endoscope that allows for access, direct visualization, tissue sampling, treatment, etc. of body lumens. In one embodiment, the distal end of the MFS of the invention is an ultra-flexible tip that comprises a plurality of thin, curved shape memory alloy (SMA) actuator elements attached to at least one structural skeleton, e.g., a coil spring skeleton or hinge structure. The SMA actuator elements in each structural skeleton segment are indirectly heated by a heater element and produce force in response to their temperature relative to specific thresholds. In certain embodiments, the heater element may include an integrated heater / sensor element adapted to heat the actuator element and to sense the temperature and bend state of the actuator element. In configurations comprising a plurality of actuator elements, multiplexing / demultiplexing of heating currents and sensor voltages may be accomplished via a parallel bus and demulitplexing circuit. In this regard, a demultiplexing circuit using standard microelectronic fabrication techniques may be designed to achieve individual sensing and control over each actuator element.

Owner:UNIV OF COLORADO THE REGENTS OF

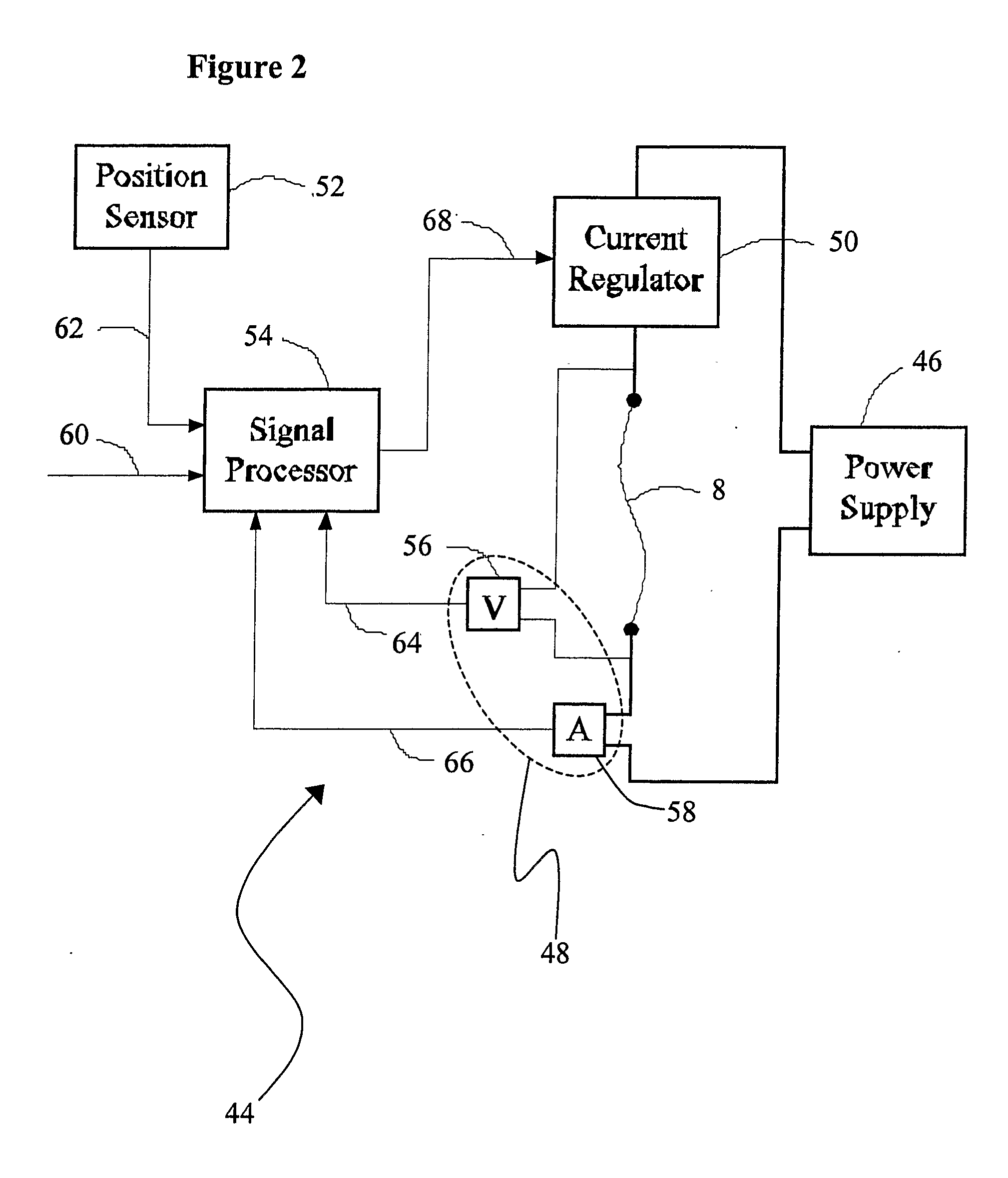

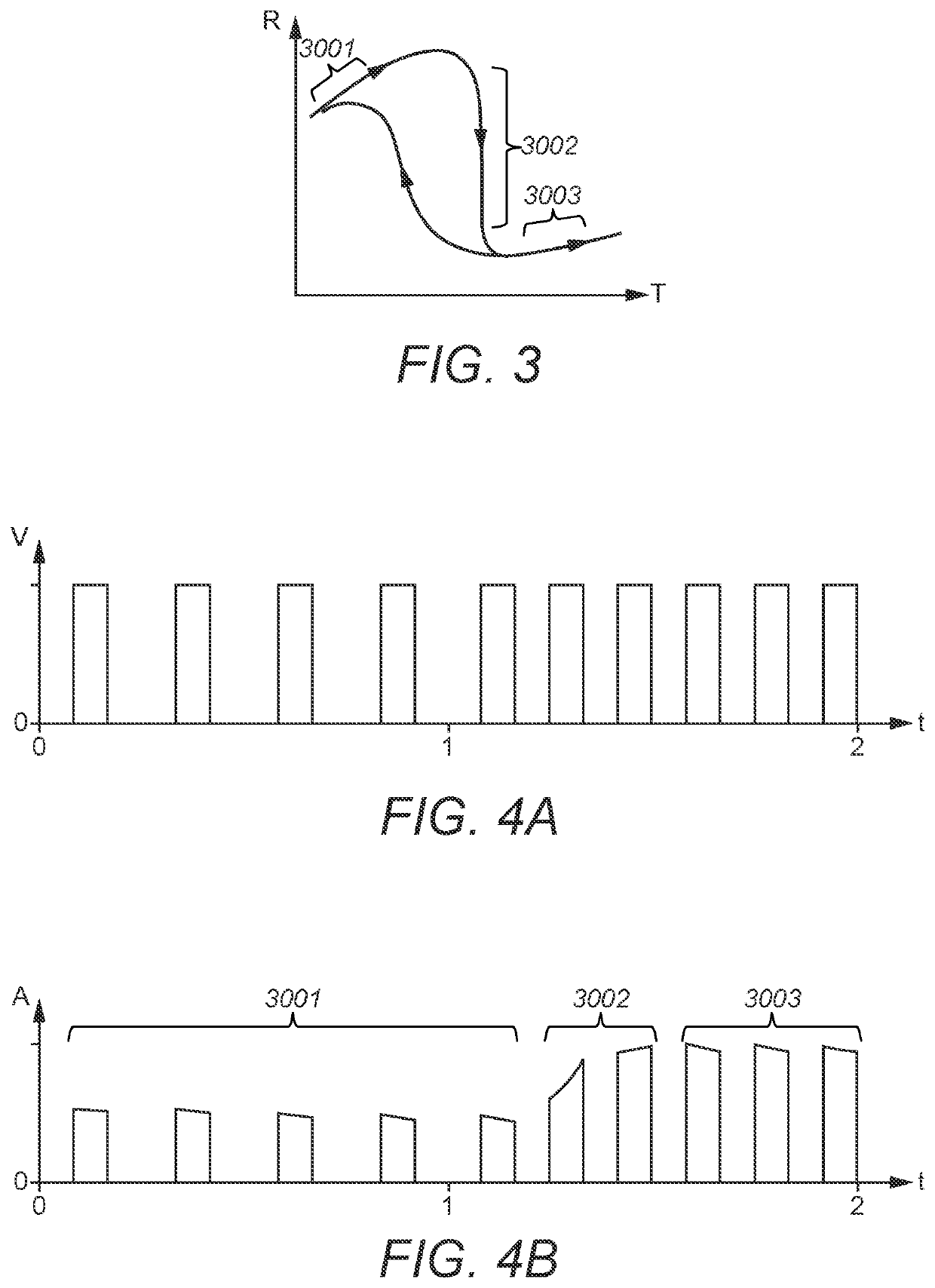

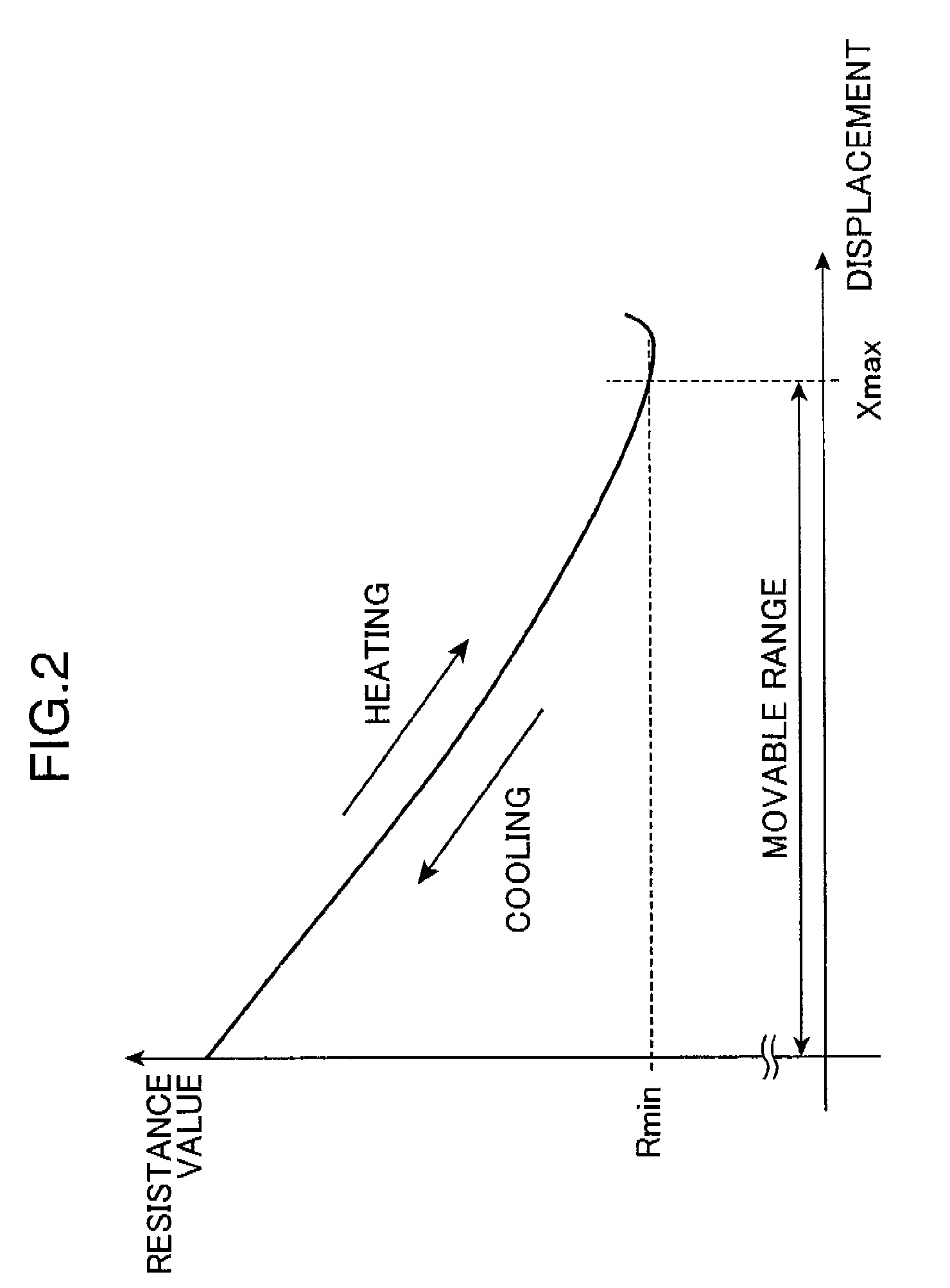

Shape memory alloy actuator

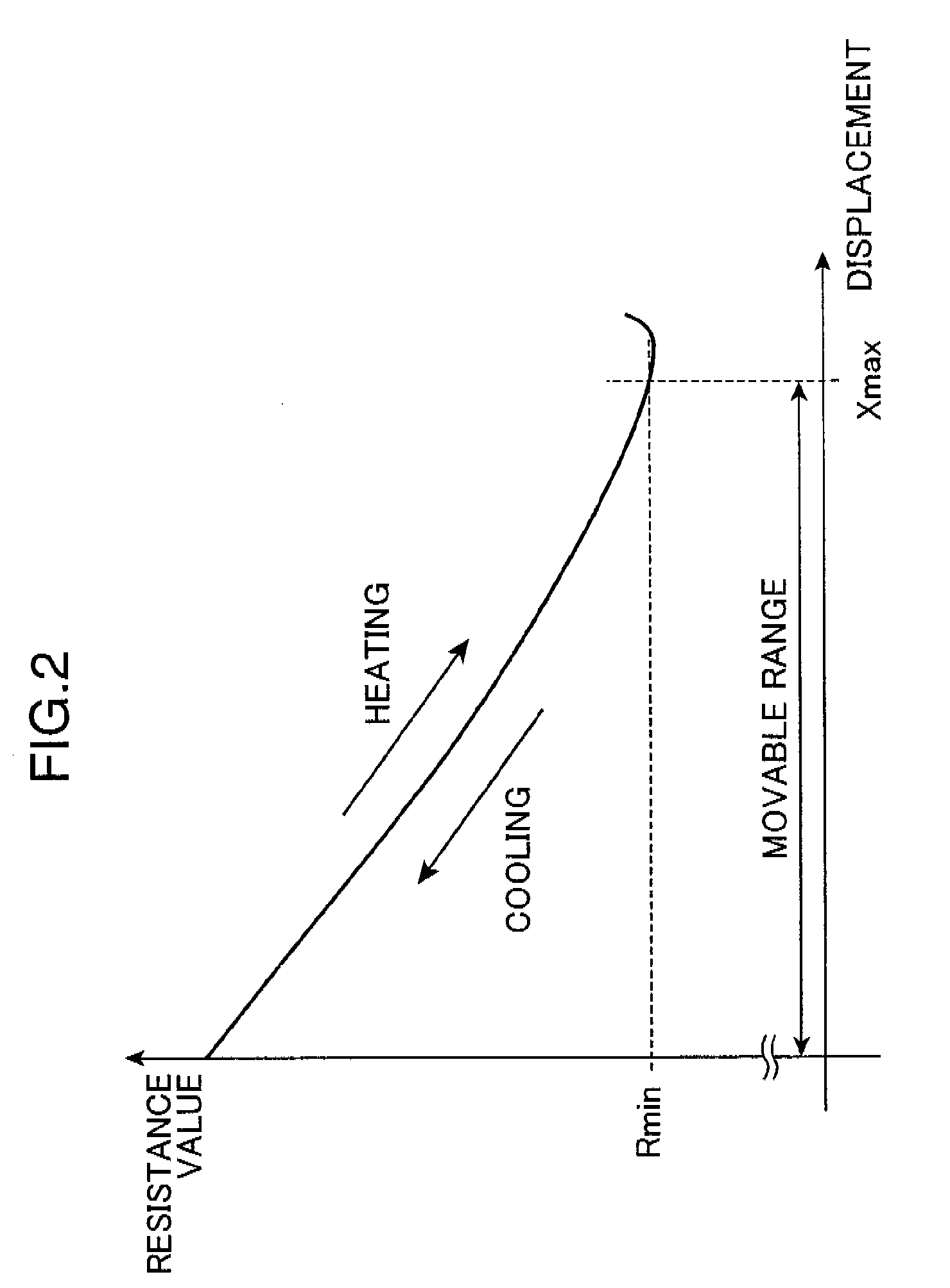

InactiveUS20070175213A1Increase movement speedIncrease ratingsMechanical power devicesClosed-cycle gas positive displacement engine plantElectrical resistance and conductanceControl theory

A controller (44) for a SMA actuator (2) includes an electgric power source (46) for applying an electric current through an SMA element (8), a sensor (48) to detect change in an electric resistance of the element (8); and a regulator (50) for controlling the magnitude of the applied electric current. The regulator (50) applies a first current above a safe limit current for the element (8) until a selected change in the electric resistance is detected and applies a second current less than the first current after the change is detected.

Owner:AUSTRALIEN NAT UNIV

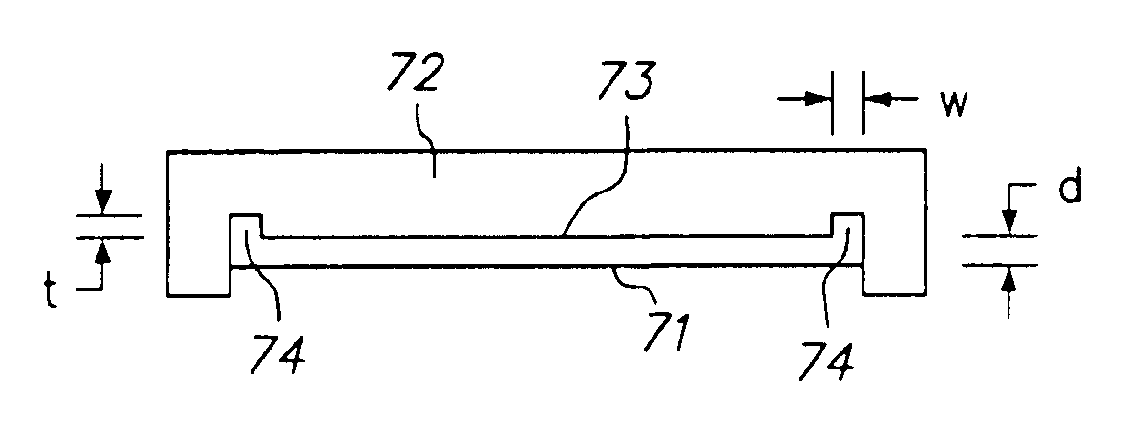

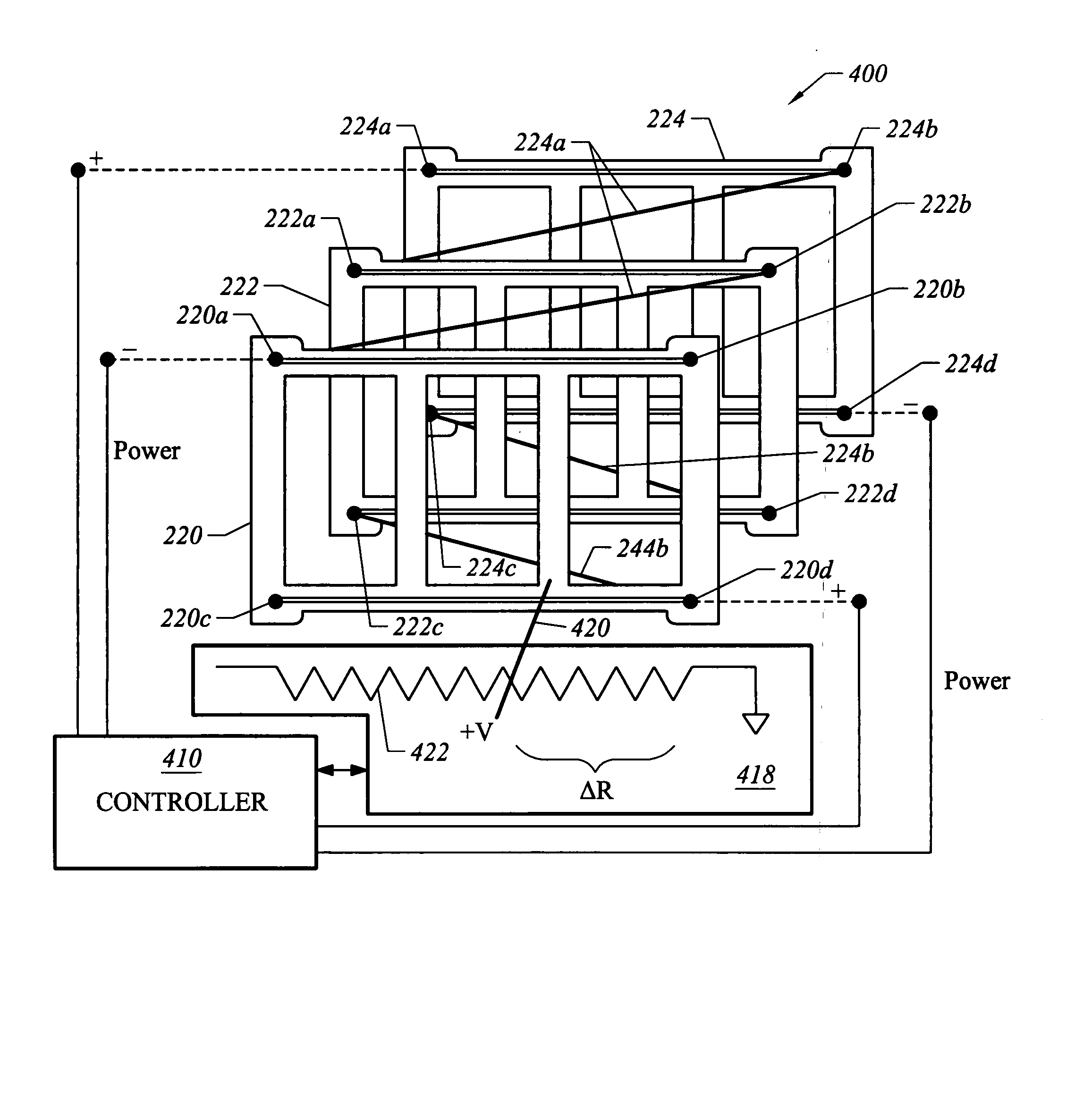

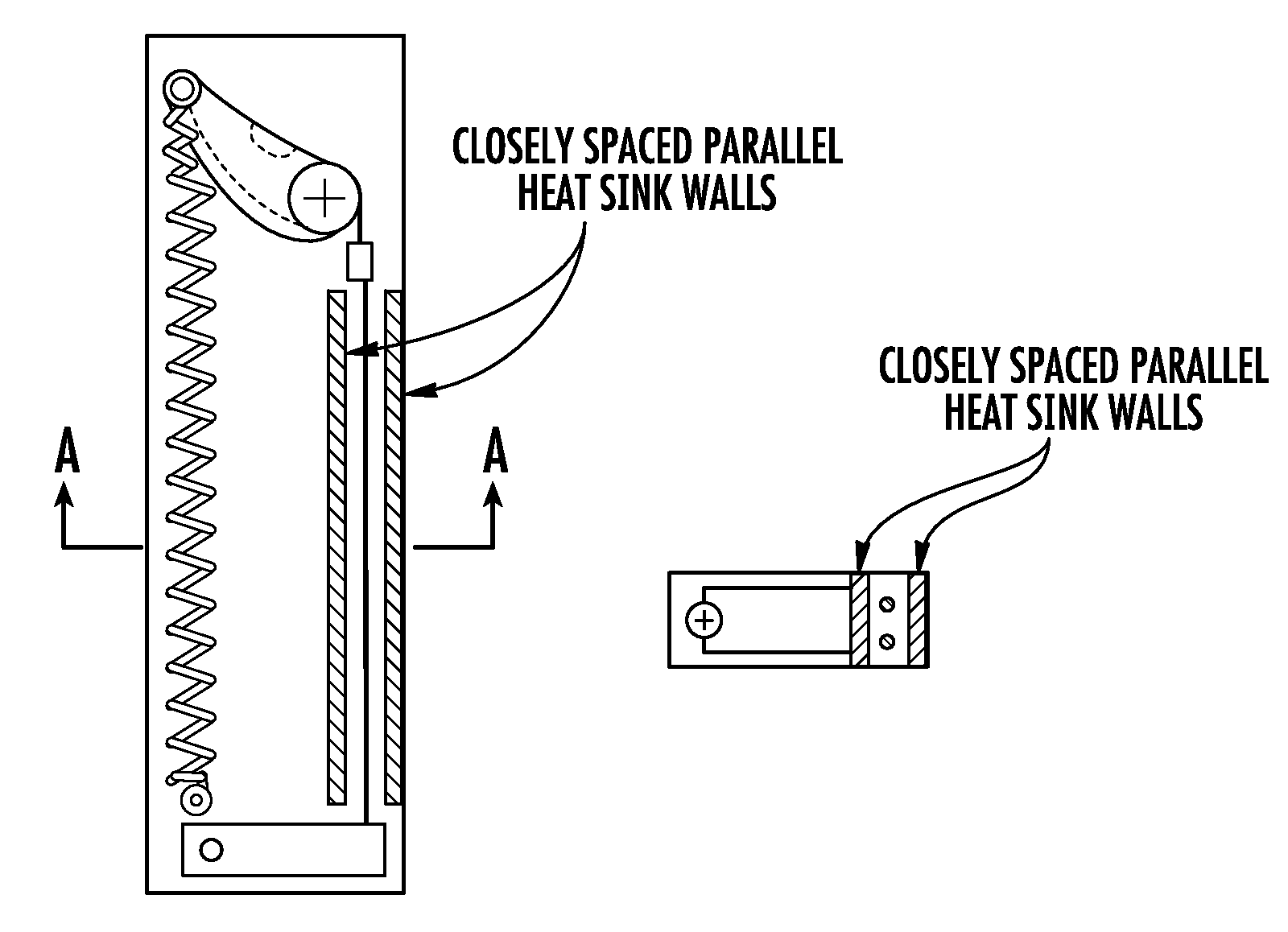

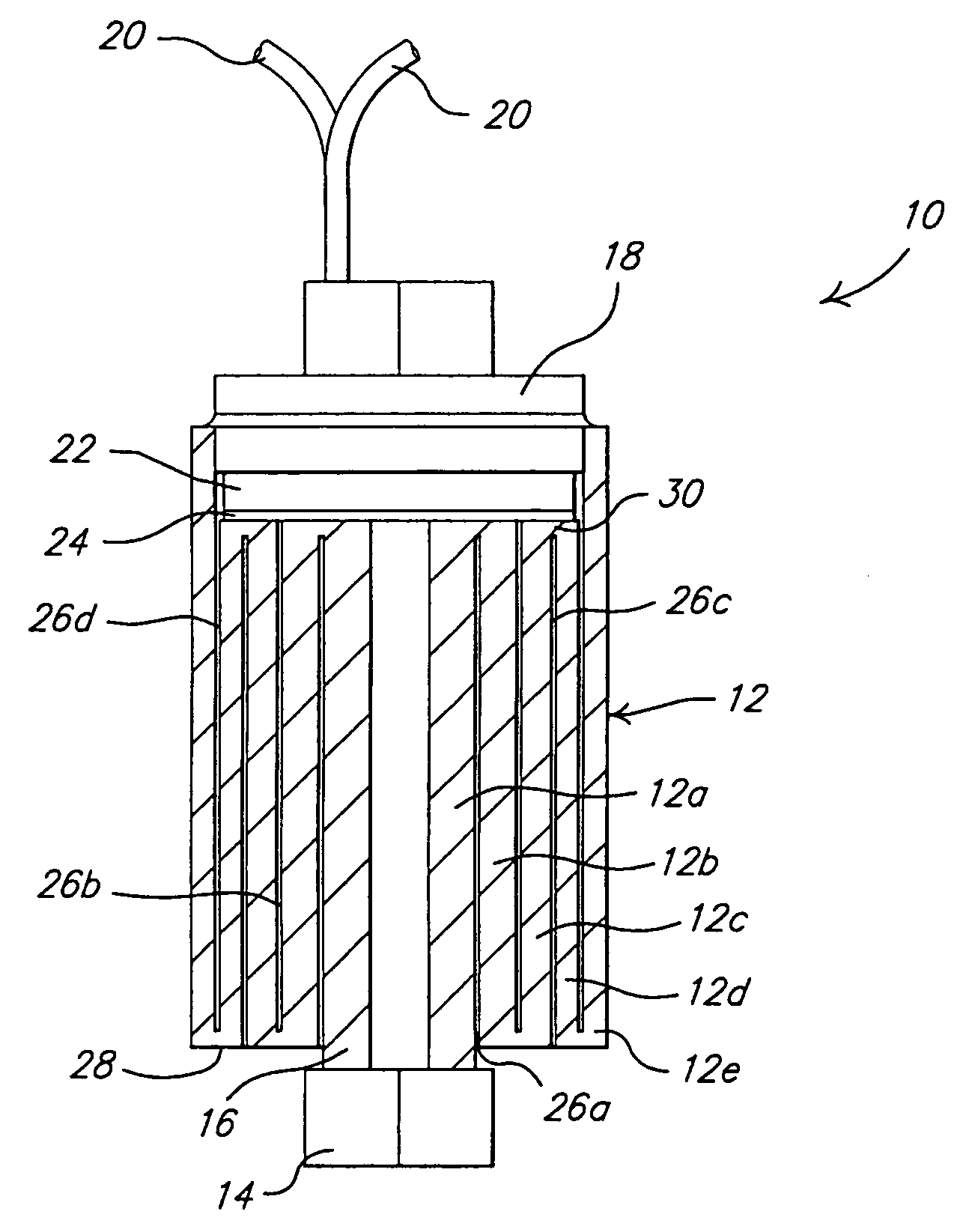

SMA actuator with improved temperature control

InactiveUS6981374B2Improve cooling effectRapid responseEngine componentsMechanical power devicesTemperature controlActive cooling

A SMA actuator having rigid members and SMA wires, in which improved temperature control of the SMA wires of the actuator is provided by a heat sink, which may be the rigid members themselves, in close proximity to at least a central portion of the wires. Optionally, the heat sink is sized and placed such that the end portions of the wires where they are attached to the rigid members are not in close proximity to the heat sink. Where the heat sink is external, it optionally has a cooling element that acts passively as a heat sink during the heating cycle of the actuator and that acts as an active cooling element during the cooling cycle of the actuator. An SMA actuator having a desired contraction limit and a power supply circuit has a switch in the power supply circuit that is normally closed when the actuator is contracted to less than the desired contraction limit and is opened by the actuator reaching the desired contraction limit. This improved temperature control provides greater cooling of the SMA wires for a faster response and an extended working life of the actuator.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN

Vehicle lock controlled by a shape memory alloy actuator

InactiveUS7364211B2Lower requirementLow costNon-mechanical controlsConstruction fastening devicesControl theorySma actuator

A contractible shape memory alloy (SMA) wire is used to throw a lever in a latch. The SMA actuator provides weight and space savings. In one embodiment, the SMA actuator is incorporated in the handle of the latch in order to provide a child lock or double lock function. The handle has a lever which includes a relatively short slot leg and a relatively long slot leg. A toggle sits in the slot. At least one SMA wire is connected to the toggle to move it between the relatively short slot leg, wherein the lever is prevented from pivoting, and the relatively long slot leg, where the lever is enabled to pivot. In another embodiment, the SMA actuator is embedded in the latch itself, and used to throw a lever that controls the child lock function.

Owner:INTIER AUTOMATIVE CLOSURES INC

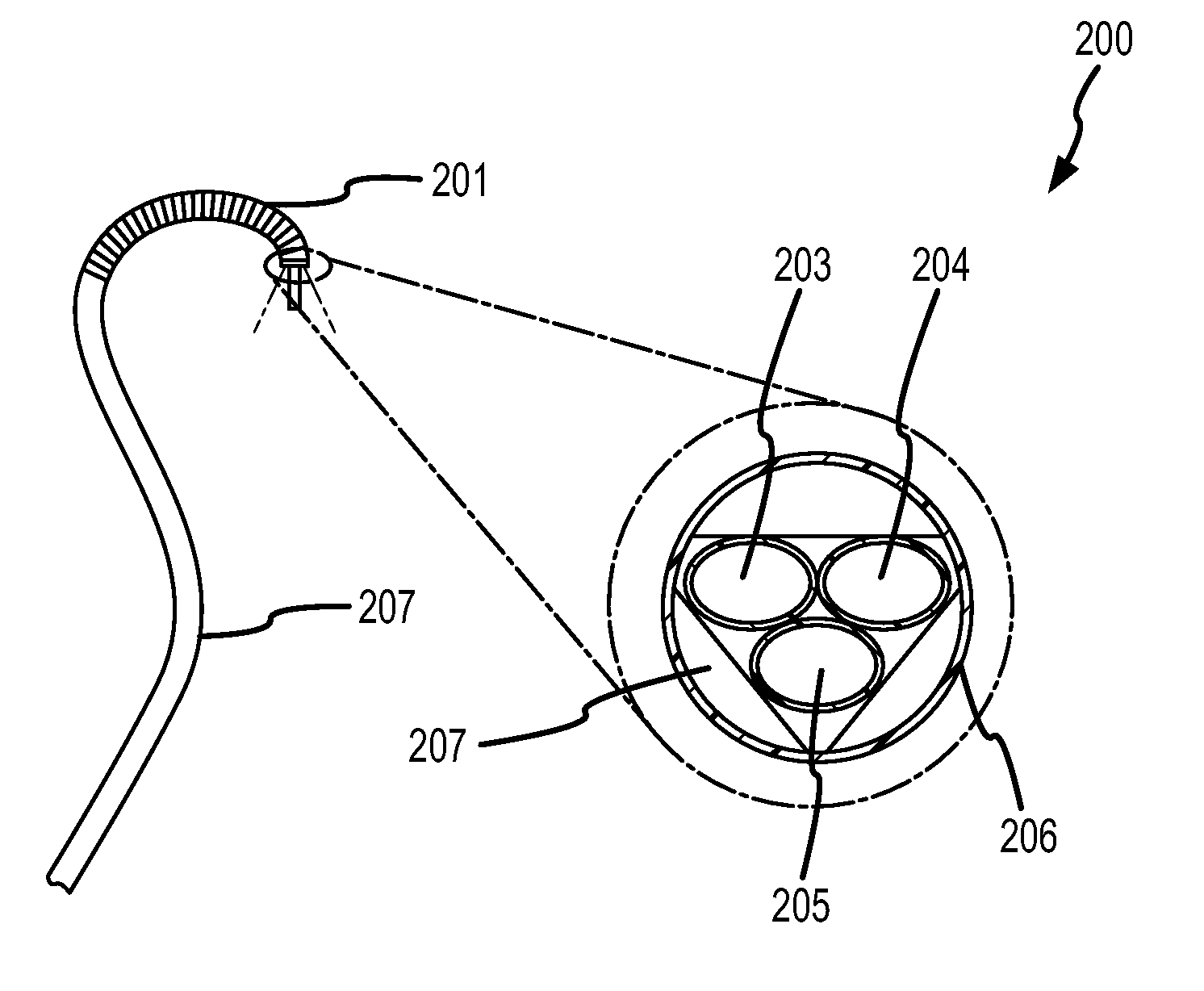

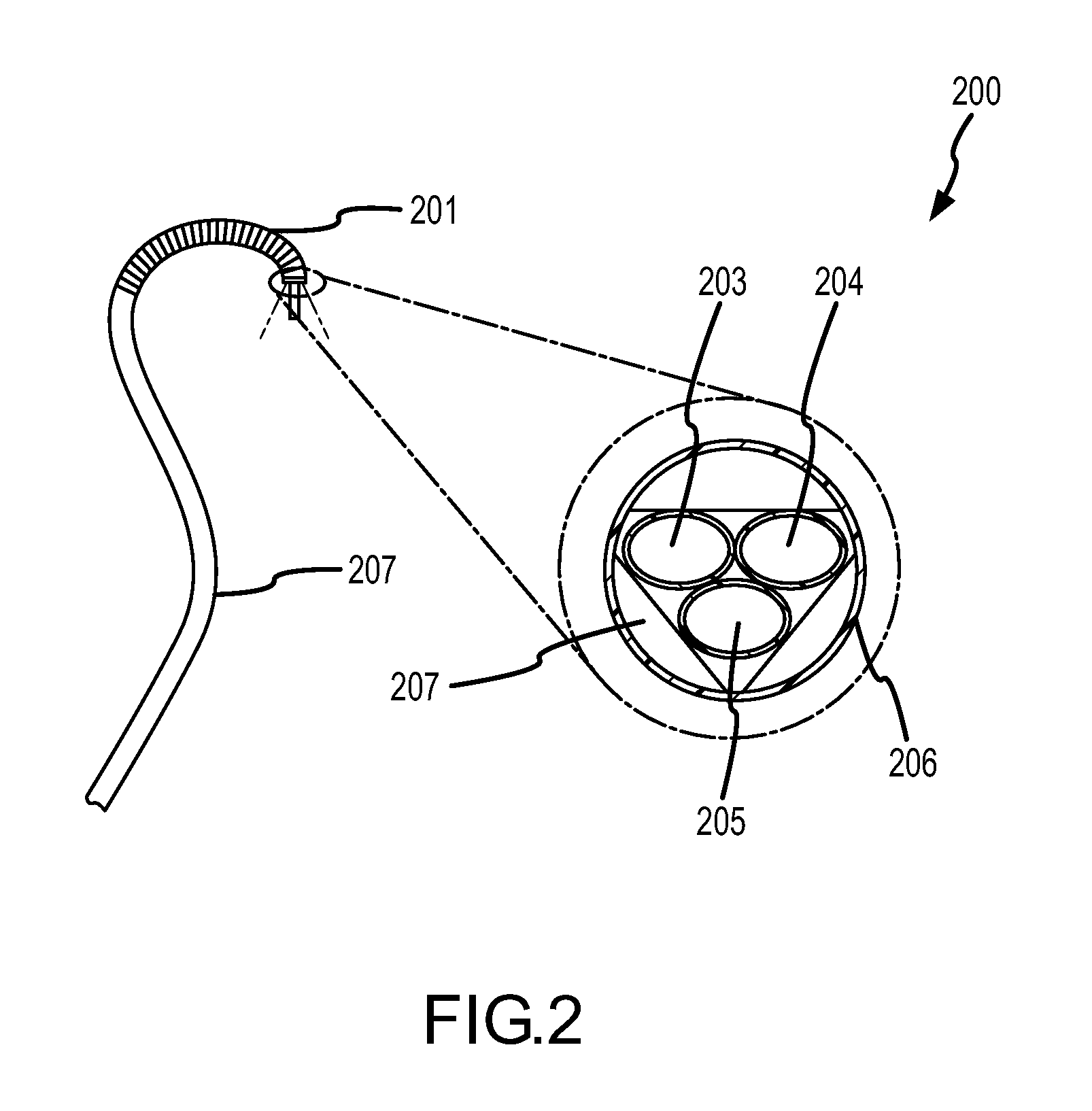

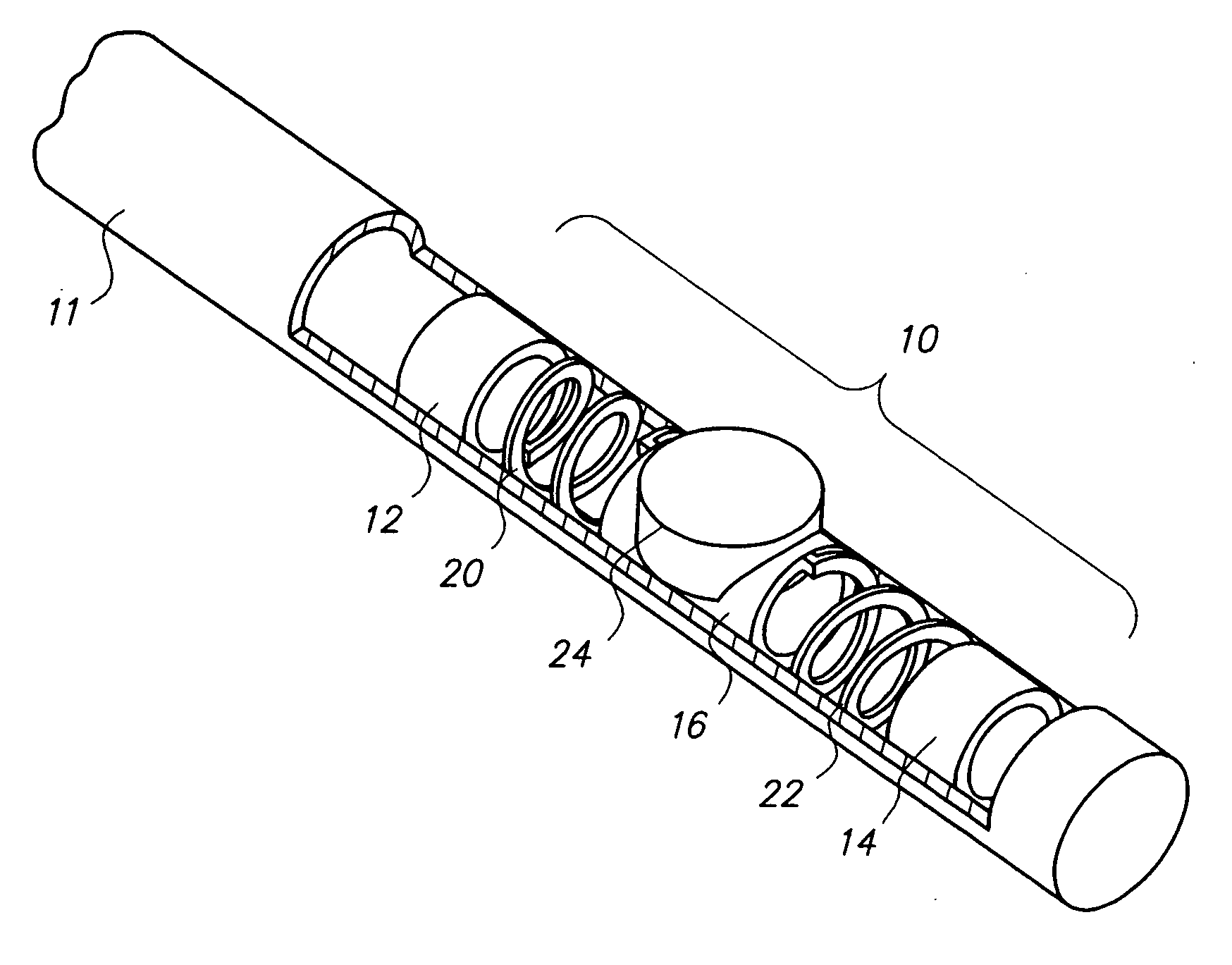

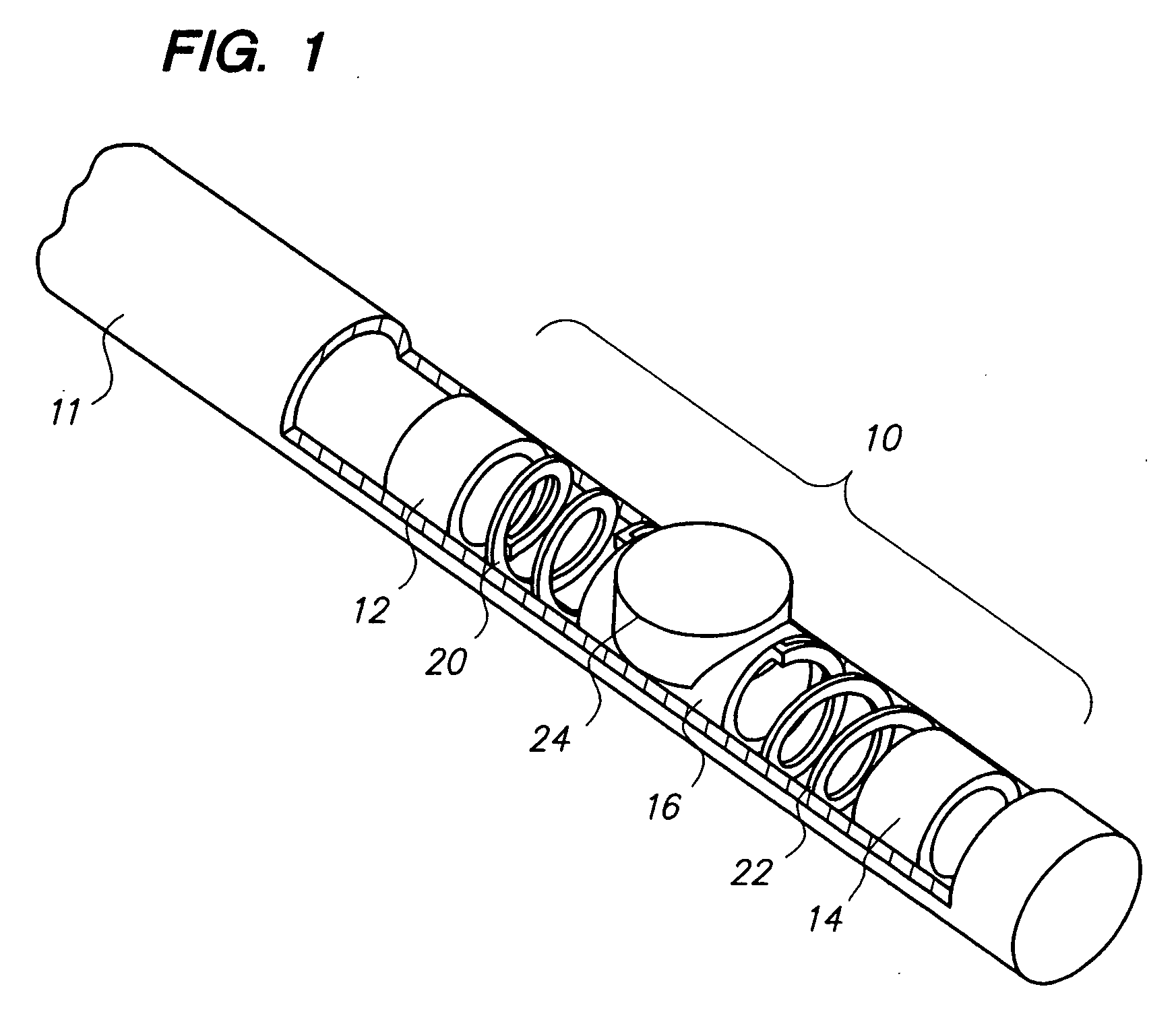

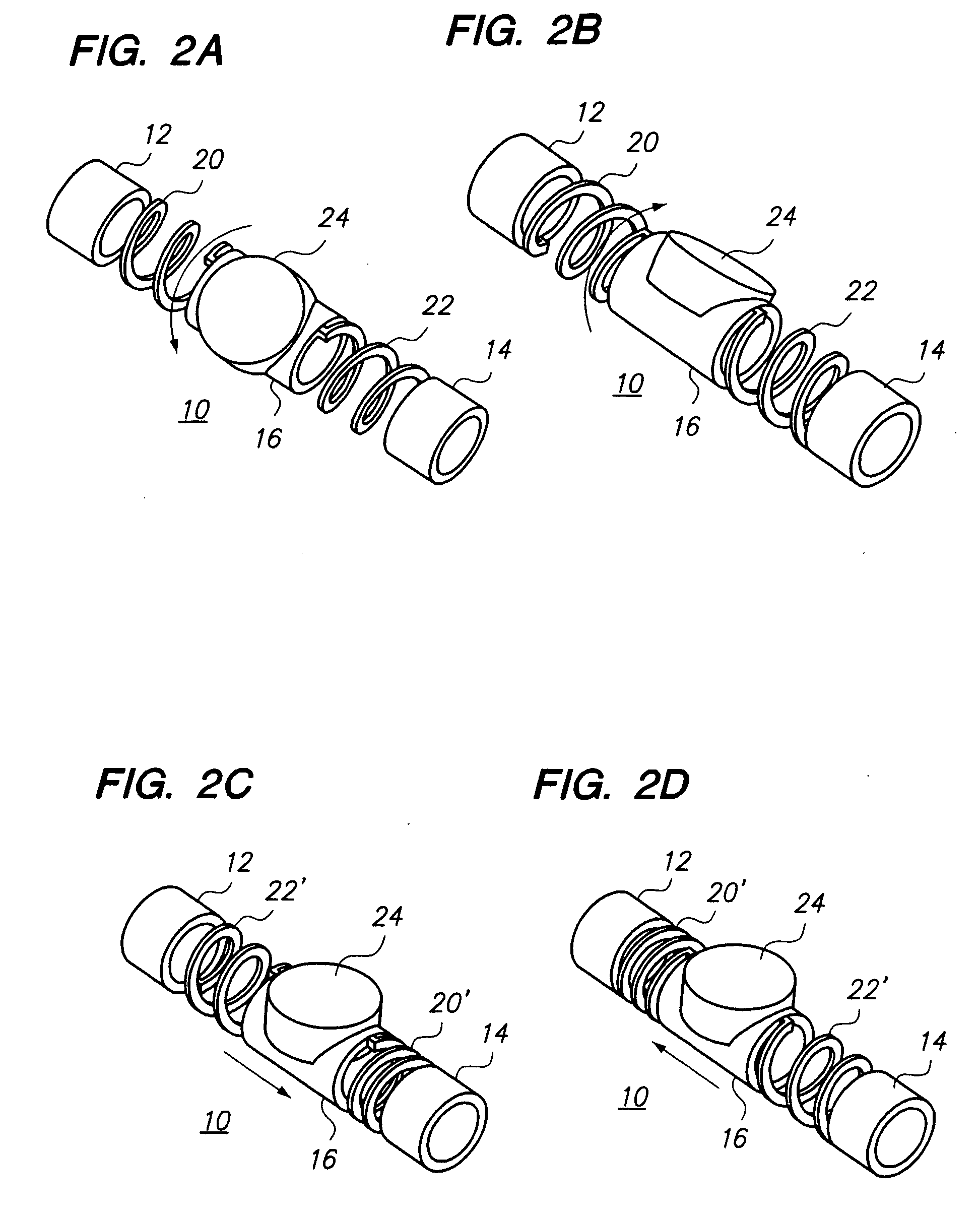

Miniature actuator mechanism for intravascular imaging

The present invention relates to a new intravascular imaging device based on a Shape Memory Alloy (SMA) actuator mechanism embedded inside an elongate member such as a guide wire or catheter. The present invention utilizes a novel SMA mechanism to provide side-looking imaging by providing movement for an ultrasound transducer element. This novel SMA actuator mechanism can be easily fabricated in micro-scale, providing an advantage over existing imaging devices because it offers the ability to miniaturize the overall size of the device, while the use of multiple transducer crystals maximizes field of view. Also disclosed are methods of using the same.

Owner:VOLCANO CORP

Gas turbine engine inlet with noise reduction features

A gas turbine engine comprising a fan section, a compressor, a combustor and a turbine, includes a nacelle having an inner nacelle surface defining an inlet duct designed to reduce an inlet duct area of the inlet duct to increase acoustic attenuation. The gas turbine engine also includes a spinner, disposed forward of the fan section, that includes features to increase acoustic attenuation. In one embodiment of the present invention, the nacelle includes a nacelle contoured surface protruding radially inward from the inner nacelle surface to reduce the inlet duct area. In a further embodiment of the present invention, the spinner includes a spinner contoured surface for reducing the inlet duct area. In other embodiments, the nacelle and / or the spinner include an inflatable bladder, a SMA actuator, a fluidic actuator, or a combination thereof, selectively activated to increase acoustic attenuation during certain conditions of an aircraft.

Owner:RTX CORP

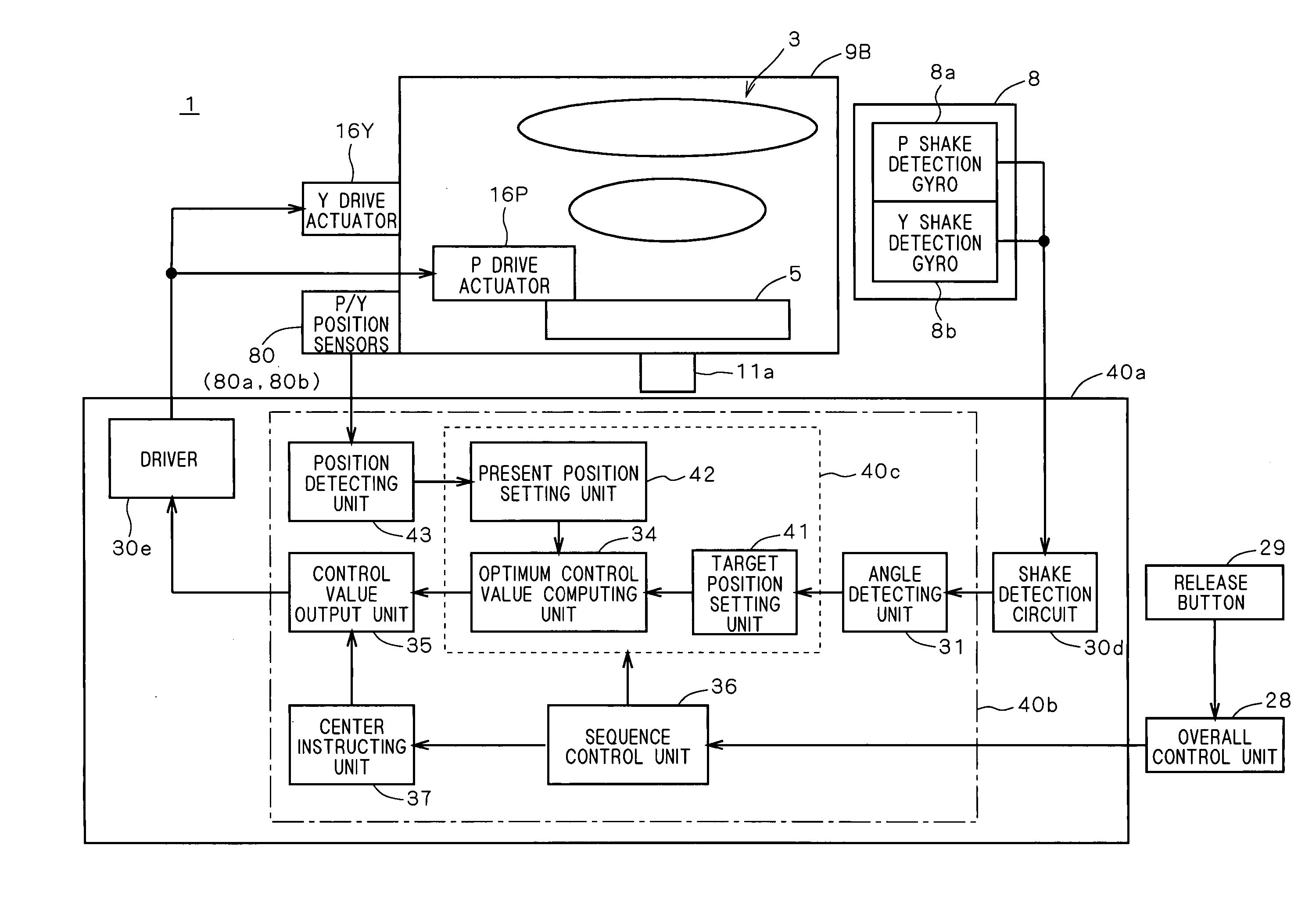

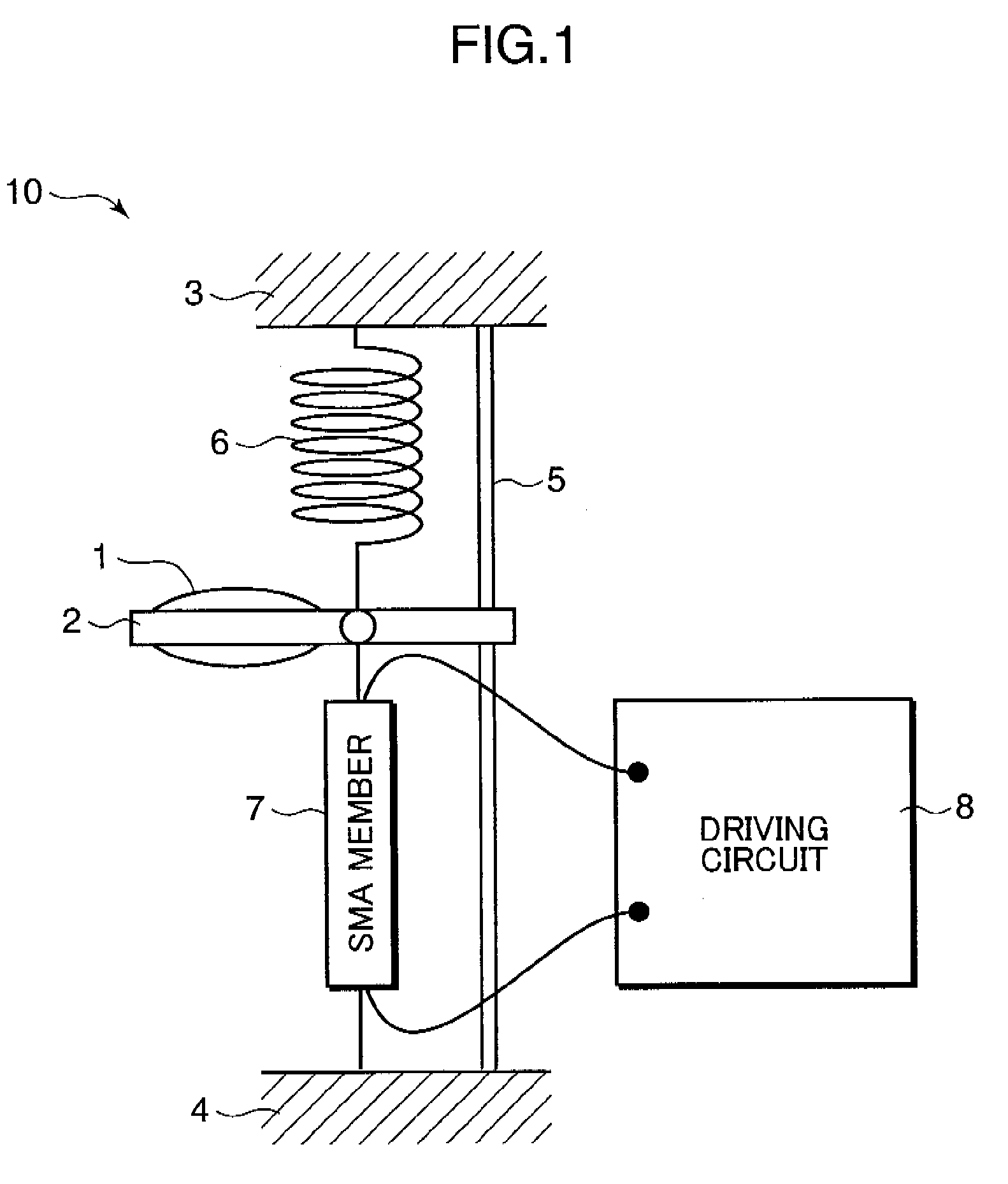

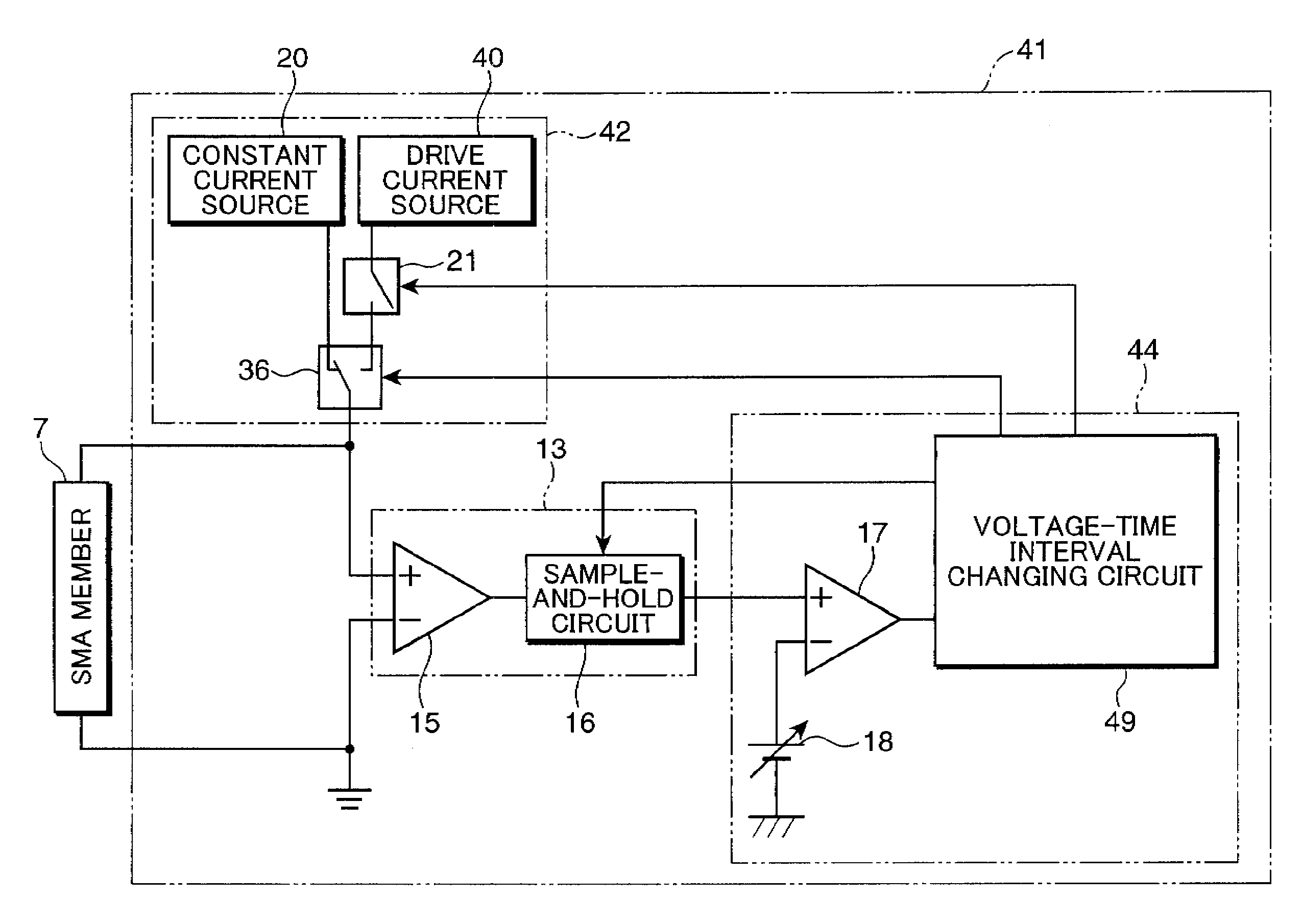

Sma actuator driving device, and image pickup device incorporated with the same

InactiveUS20090009656A1Suppress power lossGreat fabricationTelevision system detailsProjector focusing arrangementDriving currentElectrical resistance and conductance

In a shape memory alloy actuator driving device, a predetermined constant current is applied to a shape memory alloy member as a retrieval signal to detect a terminal voltage of the shape memory alloy member, and a detection result of the terminal voltage is compared with a target voltage value to be calculated based on a target resistance value of the shape memory alloy member and a value of the constant current to cause a driving circuit to output, to the shape memory alloy member, a drive current that makes the detection result substantially equal to the target voltage value.

Owner:KONICA MINOLTA OPTO

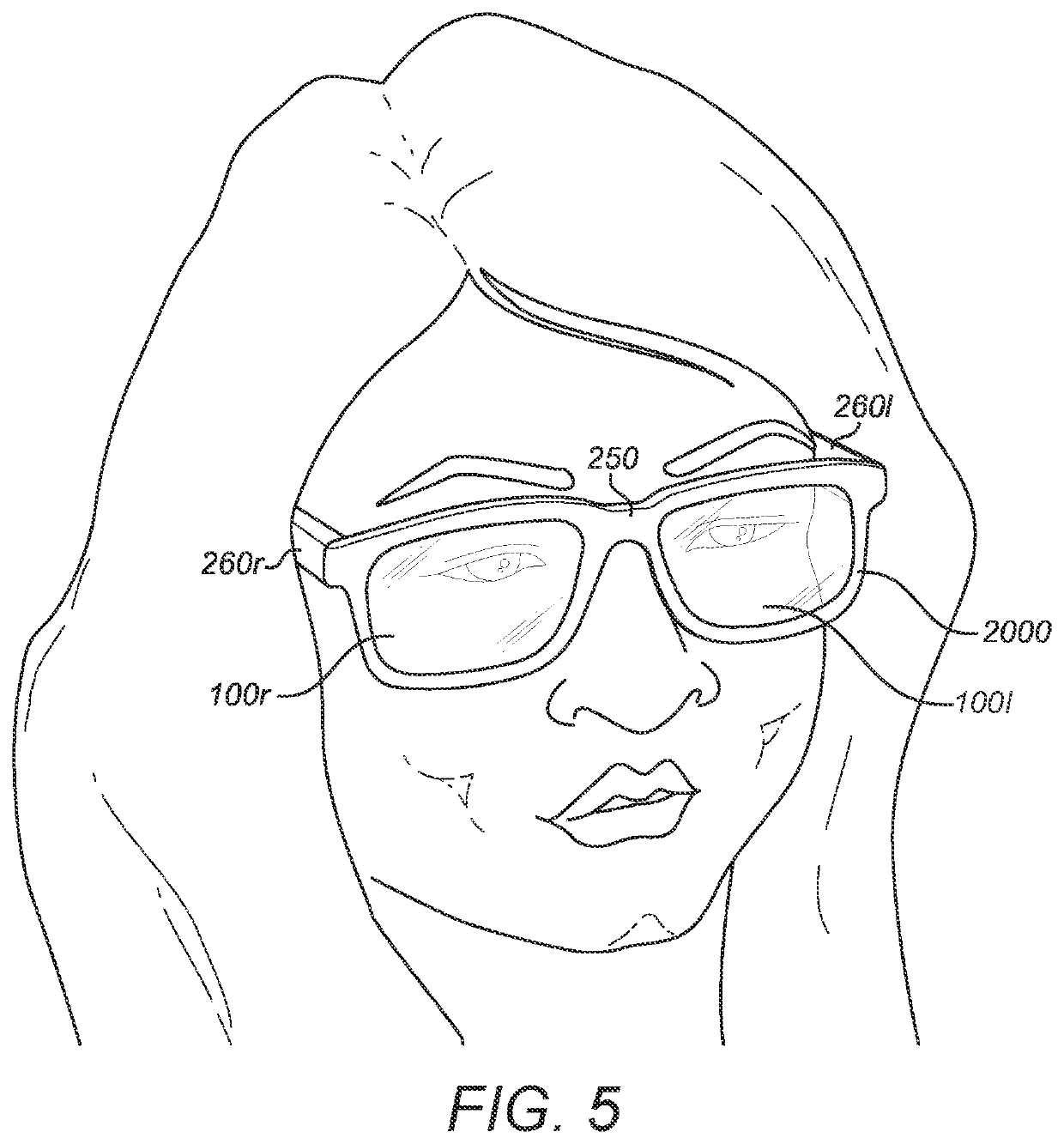

Shape memory alloy actuation apparatus

An SMA actuation apparatus moves a movable element relative to a support structure in two orthogonal directions using a total of four SMA actuator wires each connected at its ends between the movable element and the support structure and extending perpendicular to the primary axis. None of the SMA actuator wires are collinear, but the SMA actuator wires have an arrangement in which they are capable of being selectively driven to move the movable element relative to the support structure to any position in said range of movement without applying any net torque to the movable element in the plane of the two orthogonal directions around the primary axis. Accordingly, it is possible to drive movement whilst balancing the forces to limit torque around the primary axis.

Owner:CAMBRIDGE MECHATRONICS

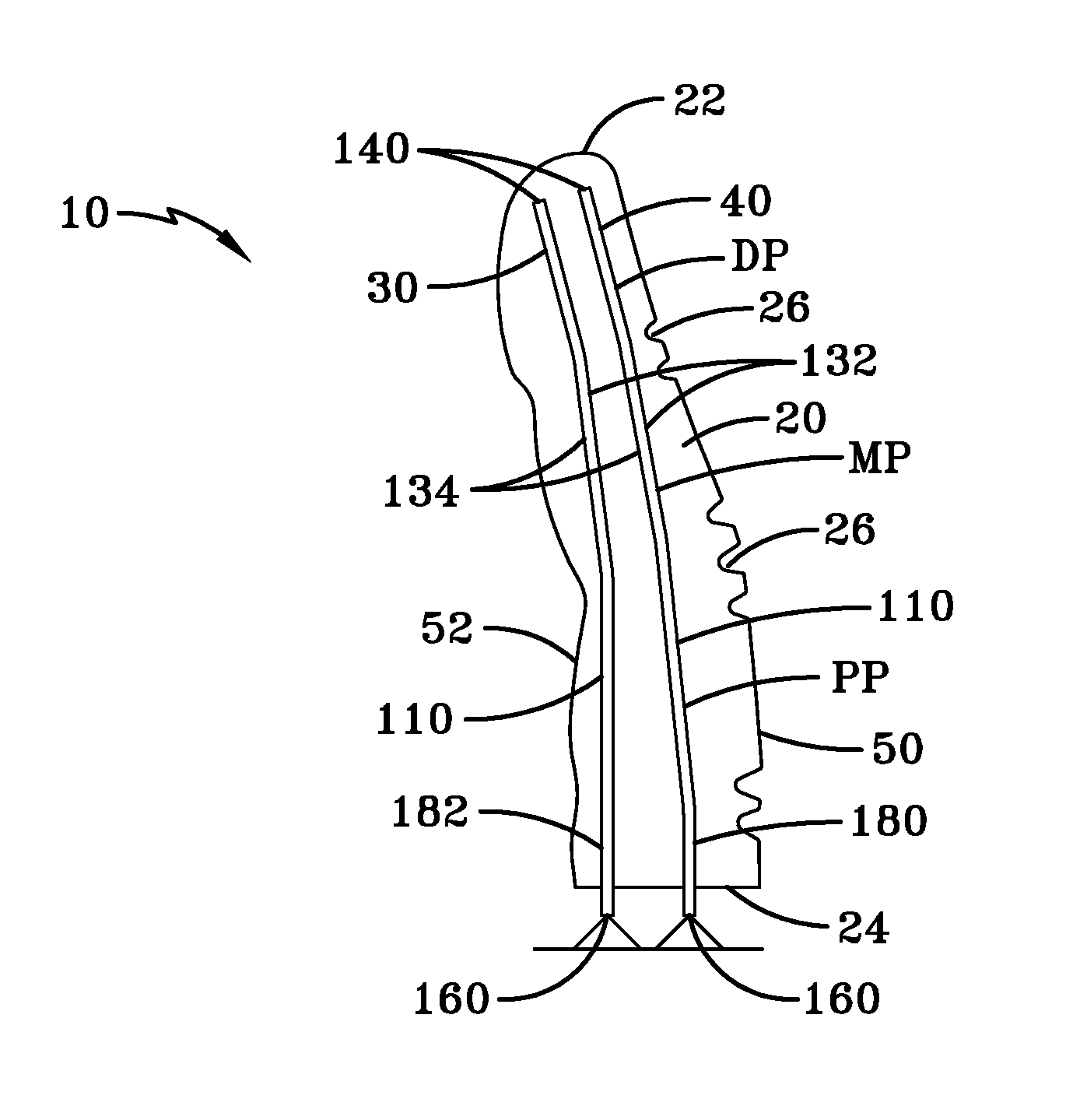

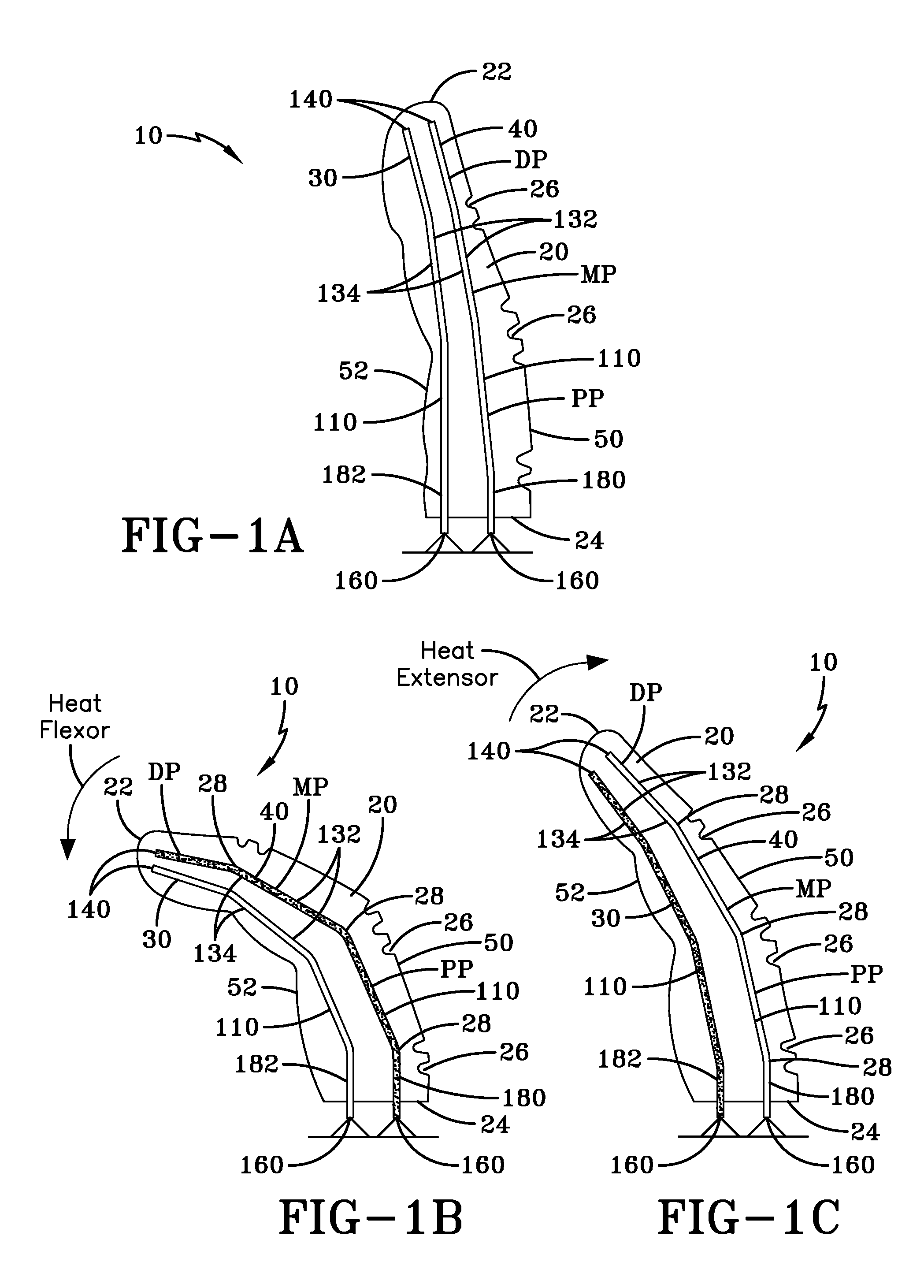

Antagonistically actuated shape memory alloy manipulator

An antagonistically actuated shape memory alloy (SMA) manipulator utilizes a pair of SMA actuators. The SMA actuators are configured, such that one actuator is trained to have a substantially linear or extended shape in its austenite phase, while the other actuator is trained to have a curved or flexed shape in its austenite phase. As such, the manipulator is operated, such that when one SMA actuator is heated and takes on its “trained” shape in the austenite phase, the other SMA actuator is permitted to cool and allowed to return to its original “untrained” shape in the martensite phase, and vice versa. This antagonistic operation of the SMA actuators allows the manipulator to achieve rapid flexion and extension movements.

Owner:THE UNIVERSITY OF AKRON

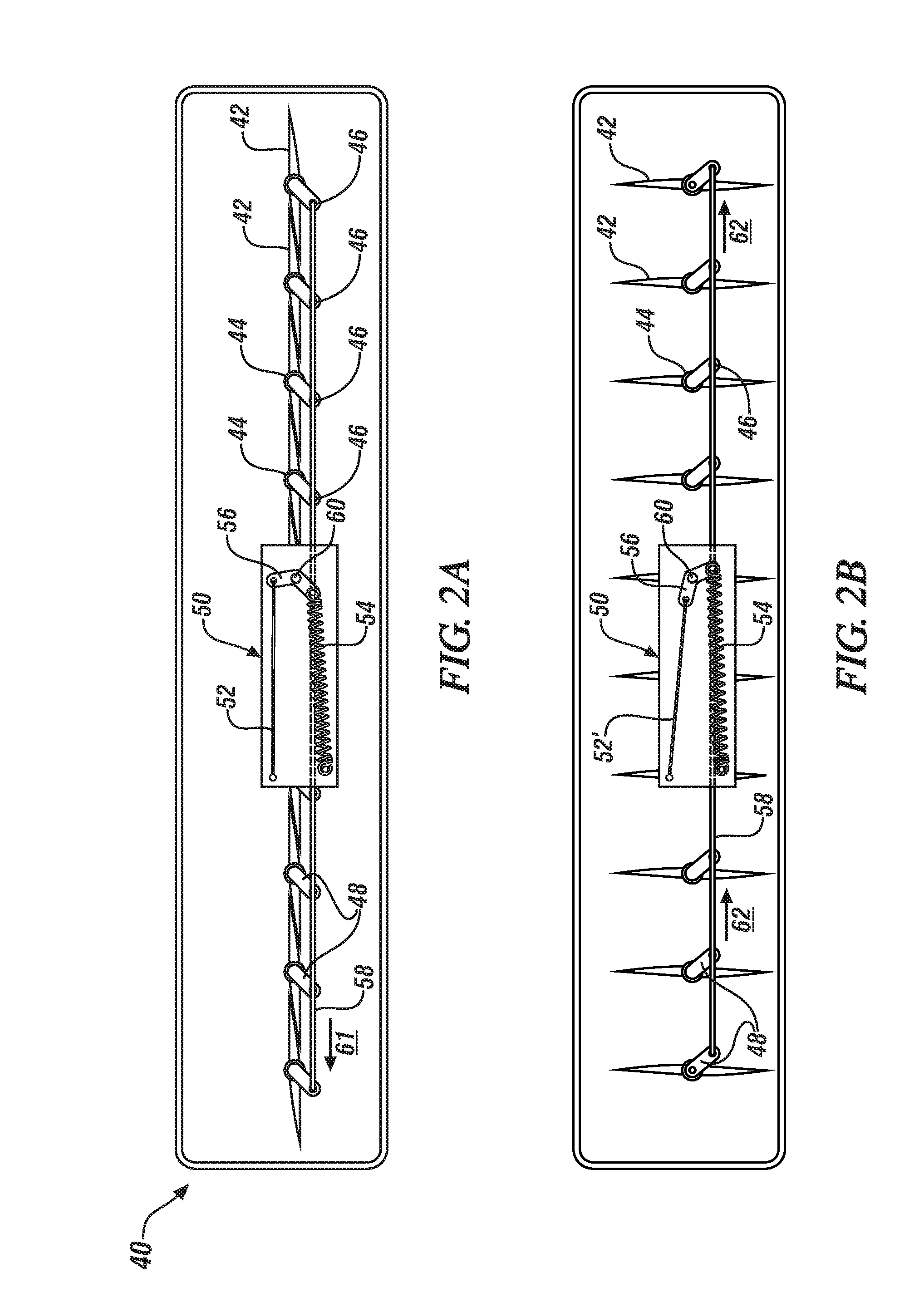

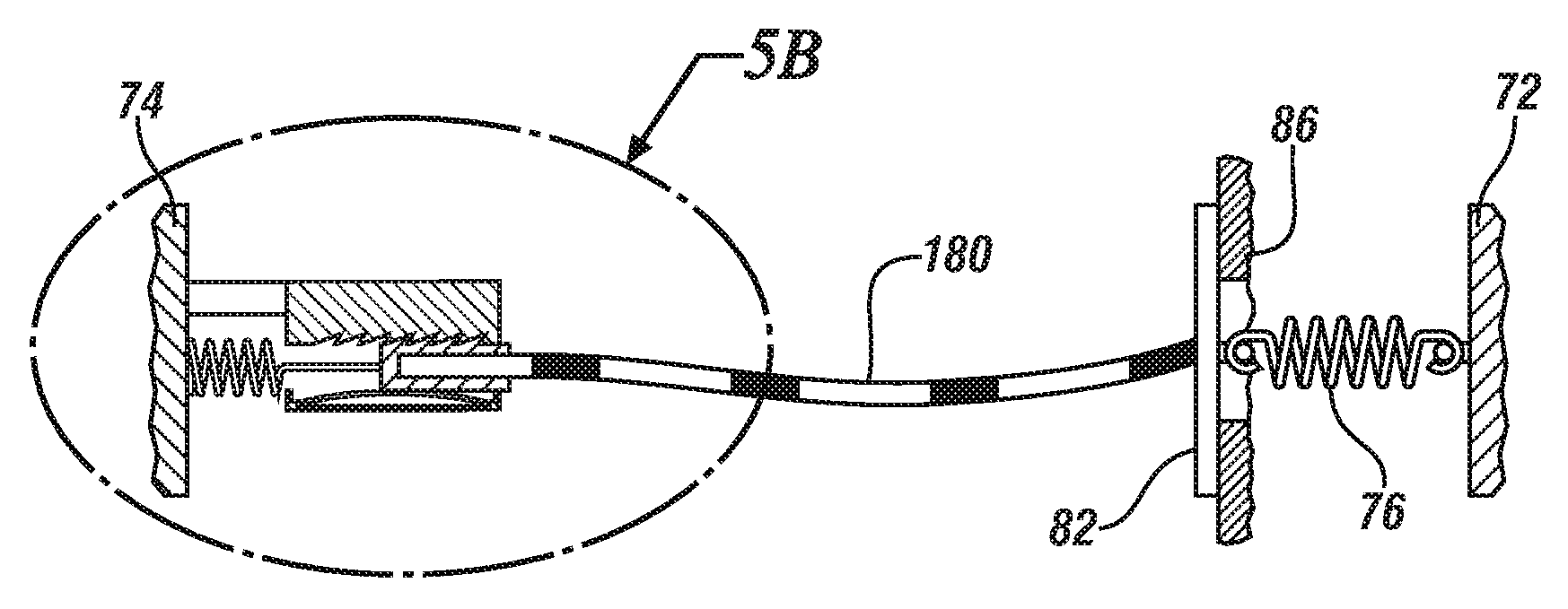

Compensating for incomplete reversal in mechanisms incorporating shape memory alloy wire

InactiveUS20140060036A1Engage with obstructionAvoid relative motionCoolant flow controlMechanical power devicesShape-memory alloyAlloy

Shape memory alloy (SMA) actuating elements are commonly simpler and of lower mass than alternative actuator designs and may find particular application in the transportation industry. Such SMA-powered devices are usually reliable and long-lived but the phase transformations which occur in the SMA alloy and are responsible for its utility are not totally reversible. This irreversibility, a consequence of irrecoverable strain, may progressively degrade the long-term actuator performance as the irrecoverable strain accumulates over many operating cycles. Methods and devices for compensating for these effects and extending the useful cycle life of SMA actuators are described.

Owner:GM GLOBAL TECH OPERATIONS LLC

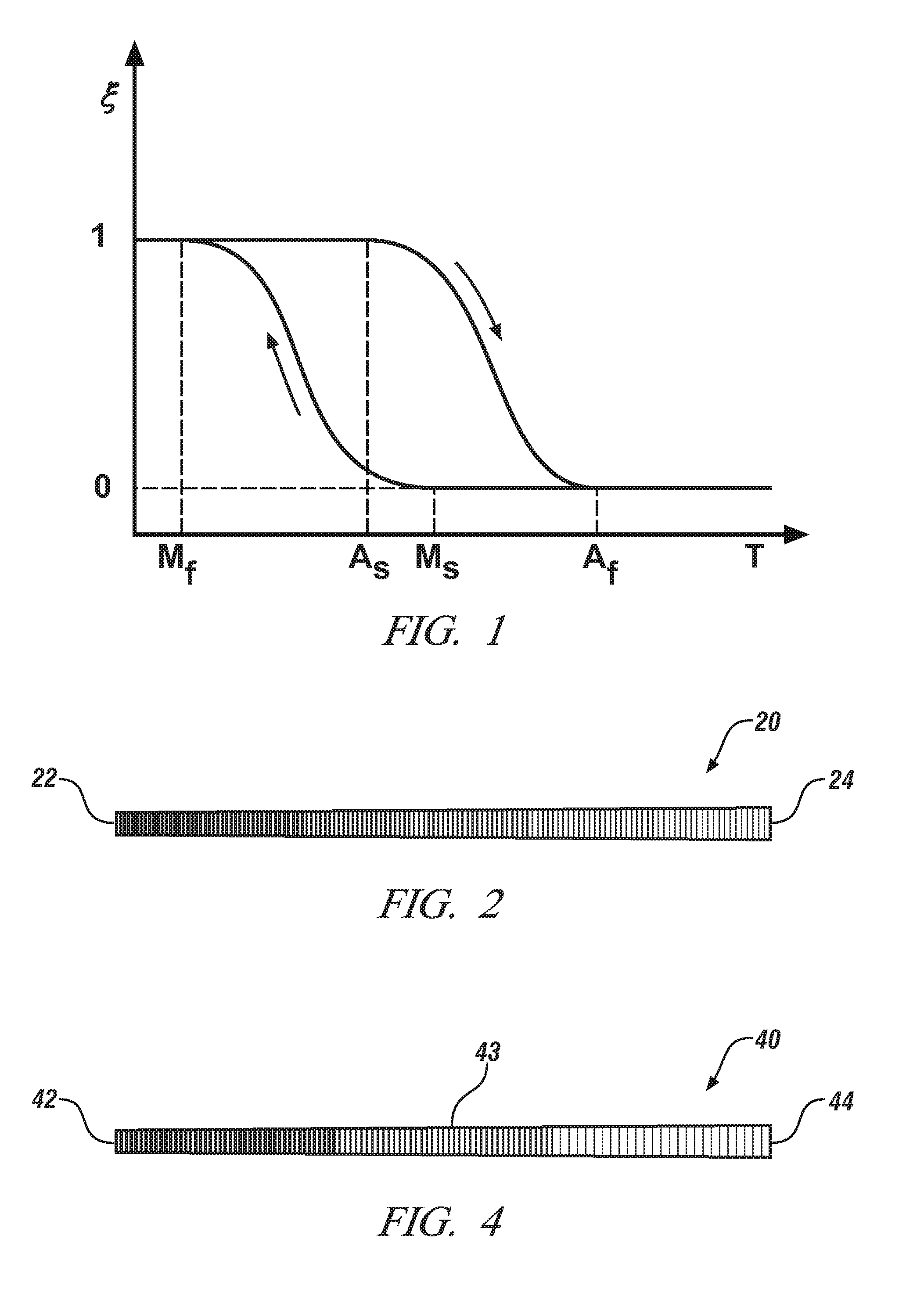

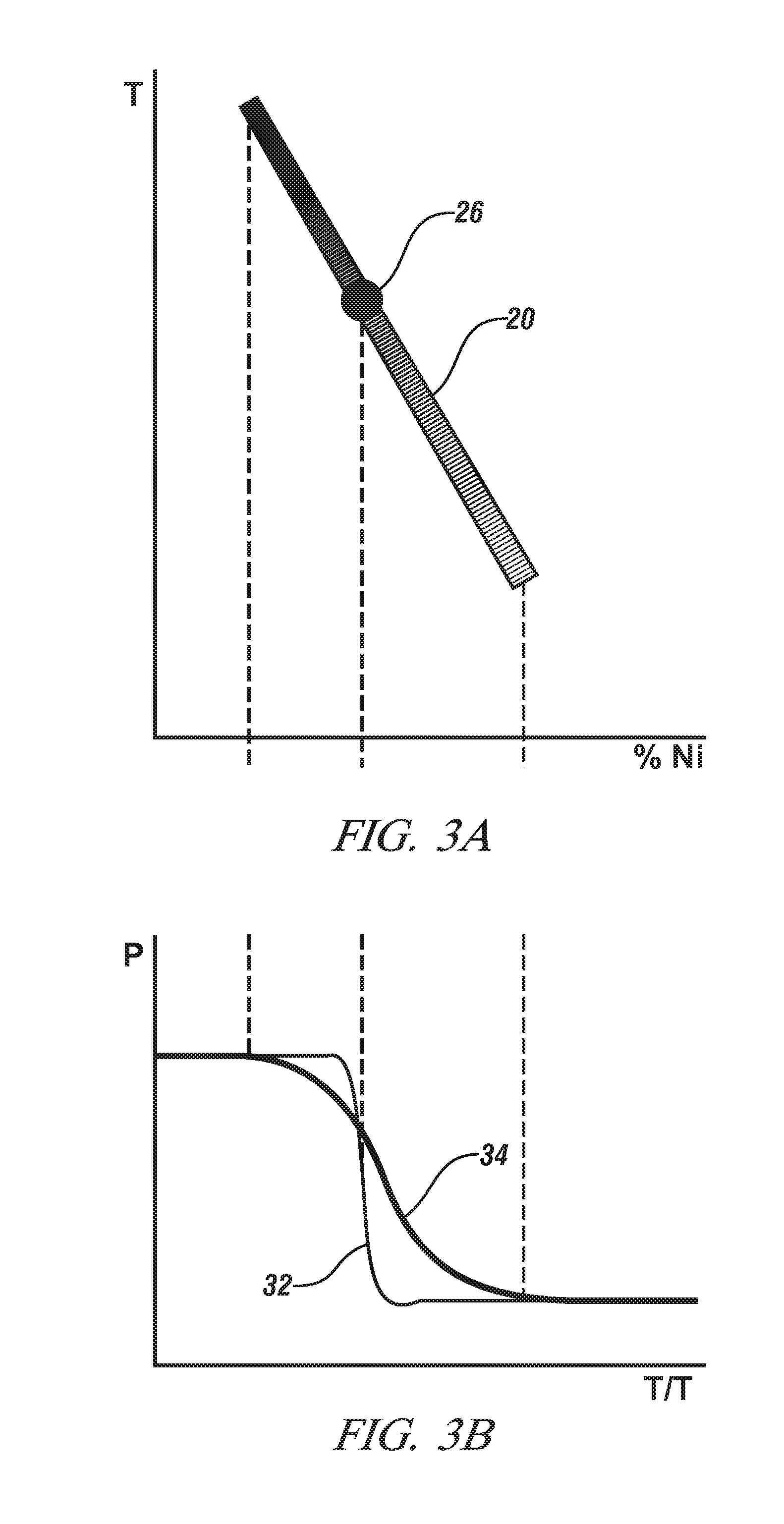

Phase change graded sma actuators

A shape memory alloy element is disclosed that is configured to undergo a graded phase change along a dimension of the shape memory alloy element in response to thermal stimulus. This graded phase change produces a graded displacement response of the shape memory element.

Owner:GM GLOBAL TECH OPERATIONS LLC

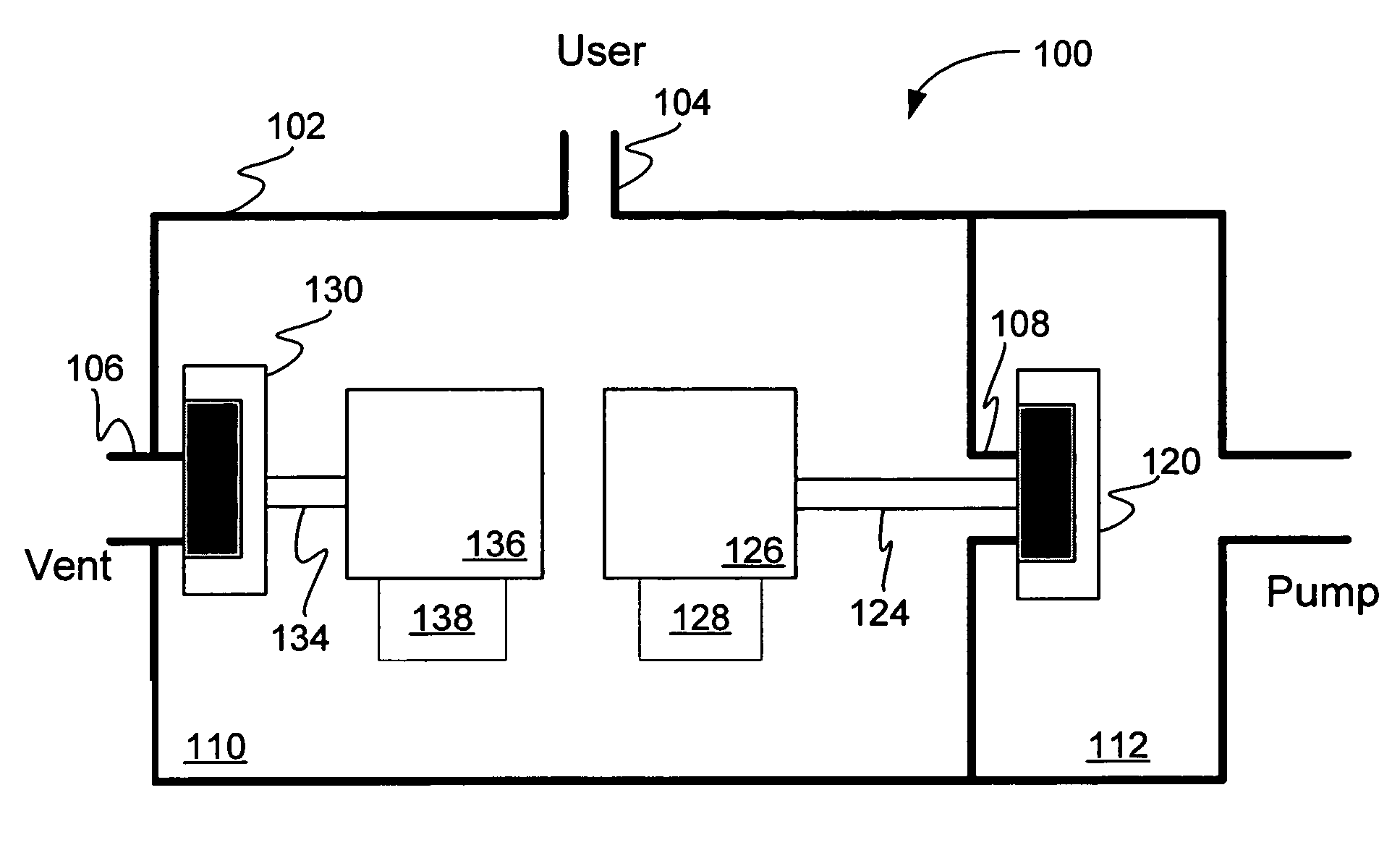

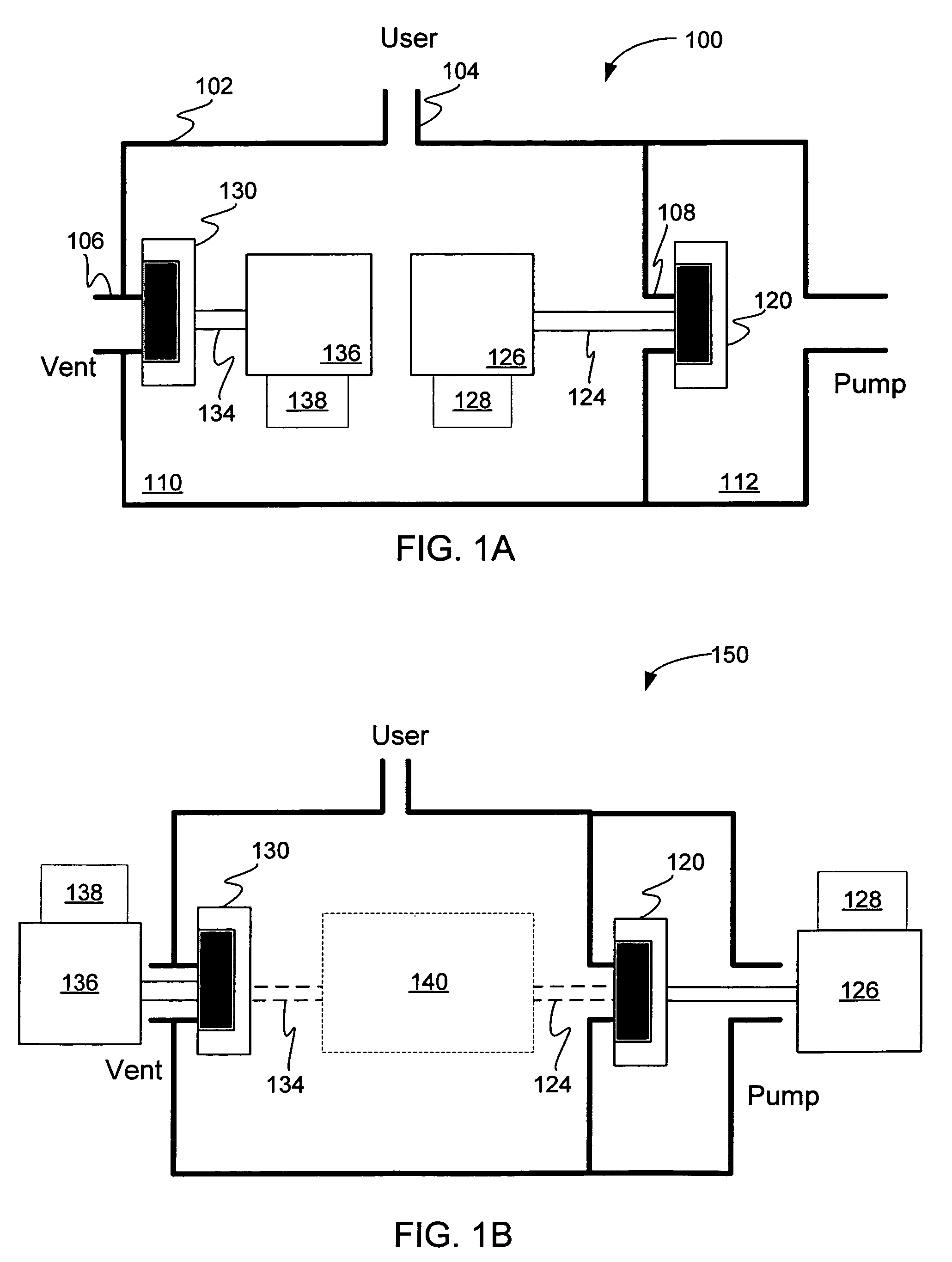

System, method and apparatus for reducing frictional forces and for compensating shape memory alloy-actuated valves and valve systems at high temperatures

ActiveUS7748405B2Temperature control without auxillary powerOperating means/releasing devices for valvesAlloyTemperature Compensator

A valve system including a number of shape memory alloy (“SMA”)-actuated valves for controlling the flow of fluids is disclosed as is a variety of types of SMA-actuated valves and methods of operation. In one embodiment, a valve system includes a housing having a substantially closed cavity as well as a second port for communicating a fluid. Further, the valve system includes a first SMA actuator configured to control the position of the first seal to vary fluid flow through the firs port, and a first temperature compensator for adjusting the position of the seal by an amount proportional to temperature. A second SMA-actuated valve, driven by either a unidirectional or a bidirectional SMA actuator, controls the position of the second seal to vary fluid flow through the second port, and a second temperature compensator for adjusting the position of the second seal by another amount proportional to temperature.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN +1

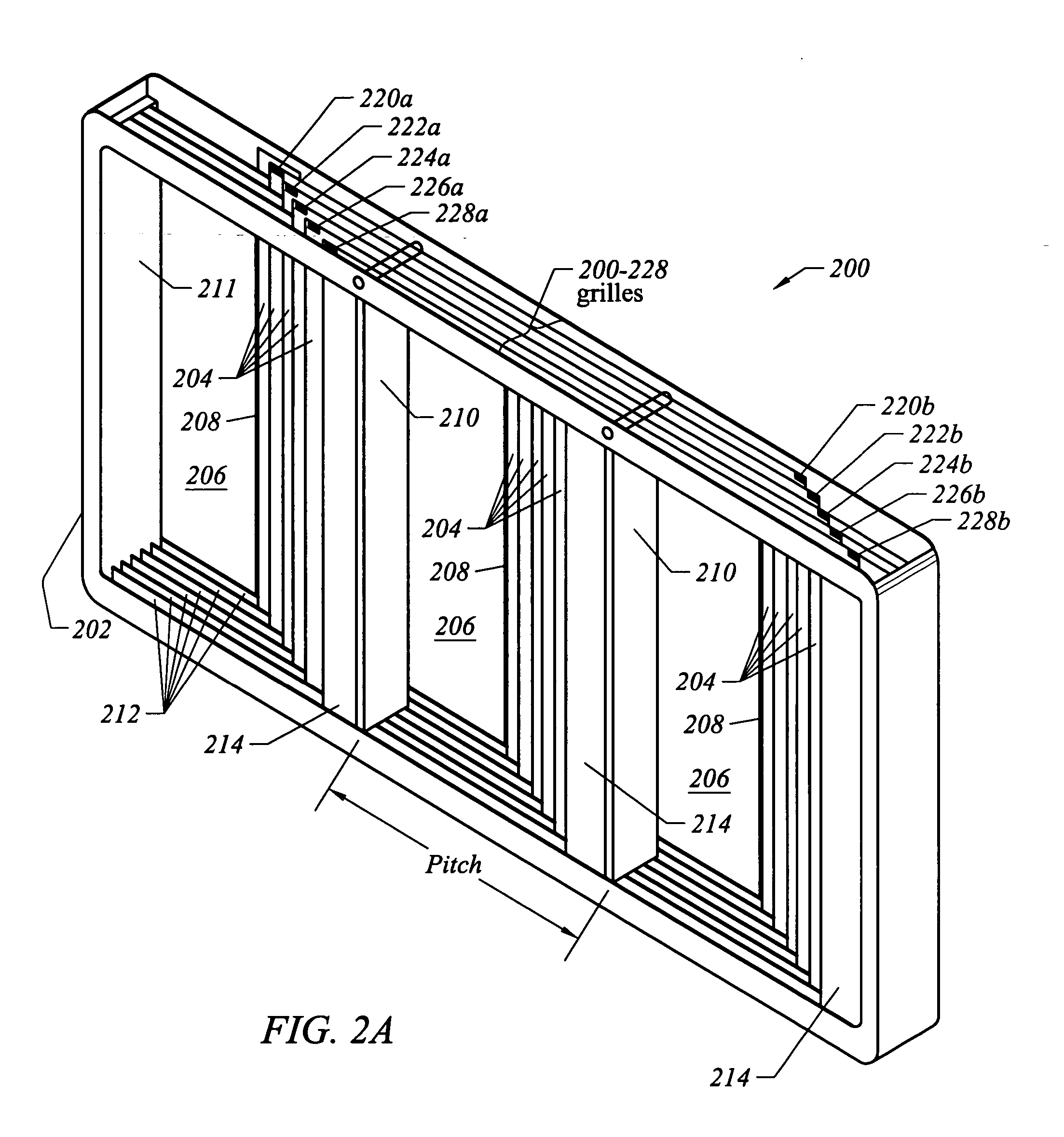

Flow control assemblies having integrally formed shape memory alloy actuators

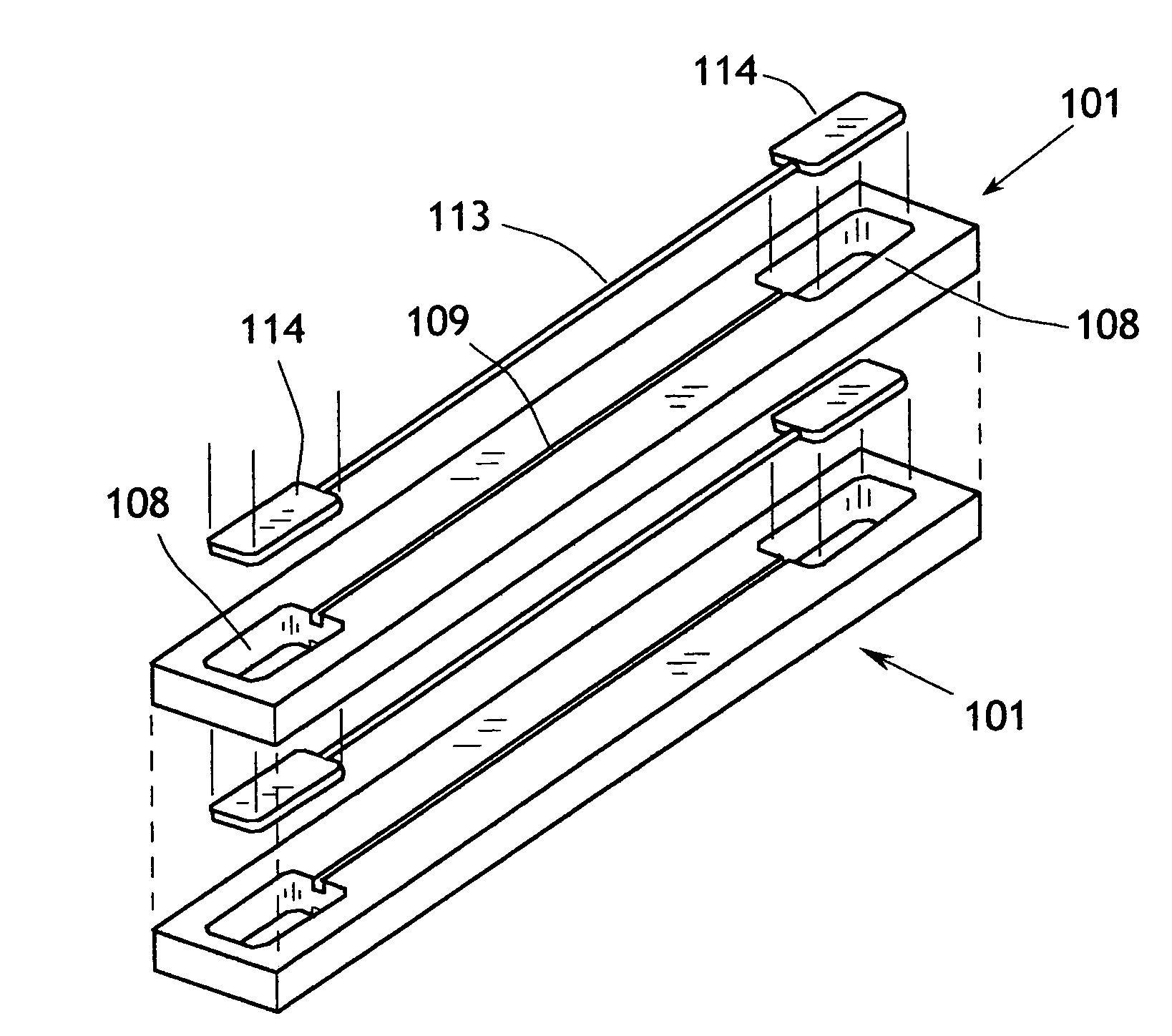

ActiveUS20050000574A1Easy to integrateSimple and inexpensivePlug valvesAir-treating devicesLong axisEngineering

In one embodiment of the present invention, a shape memory alloy (“SMA”)-actuated flow controller comprises a number of grille members, each having a long axis and being slideable relative to one another parallel to that long axis. The SMA-actuated flow controller also includes a frame configured to guide the number of grille members, and an actuator disposed within the frame to move at least one of the number of grille members for varying a size of an aperture. Further, the actuator includes an SMA actuator that includes a number of SMA elements each connecting one grille number to another.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN

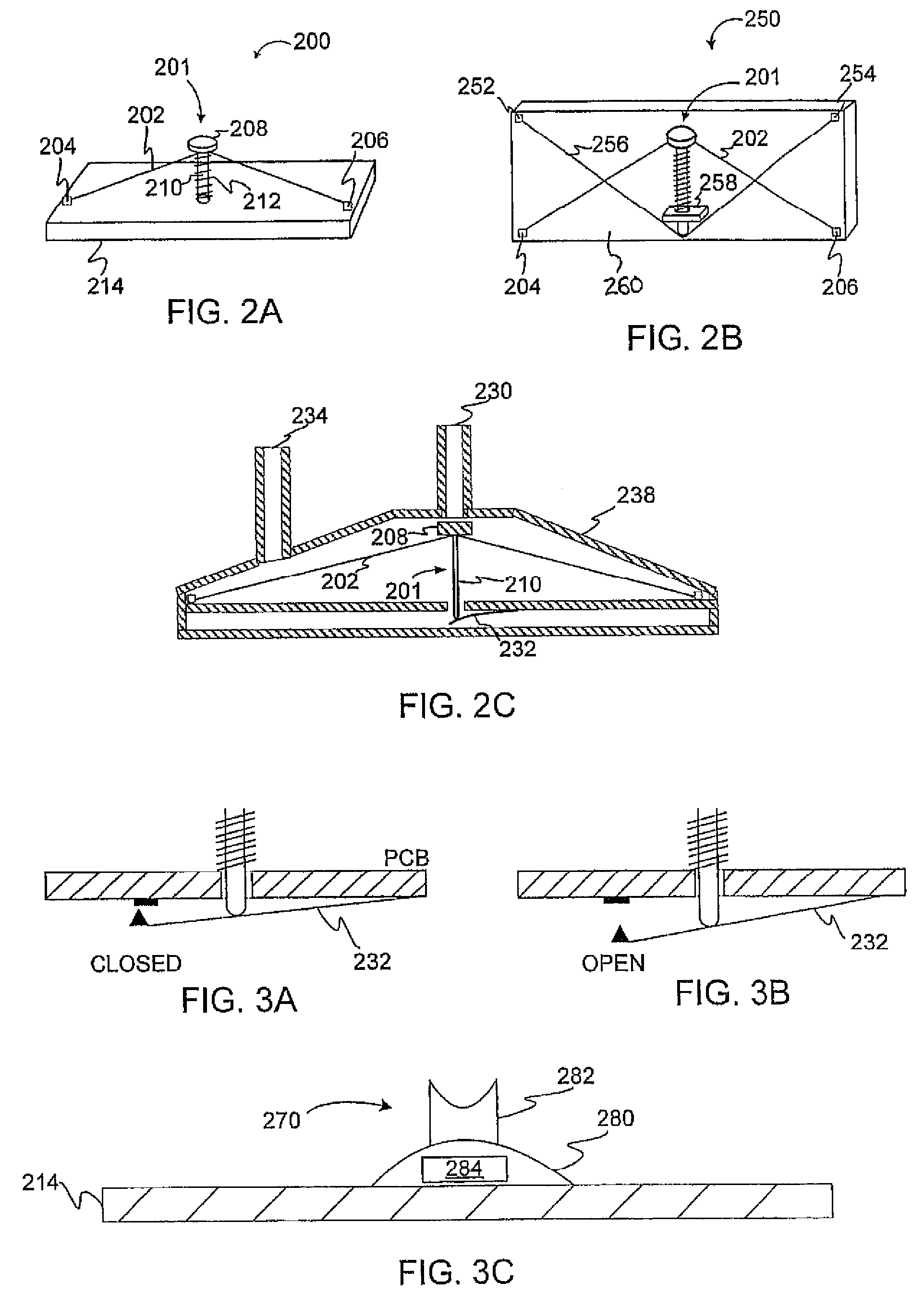

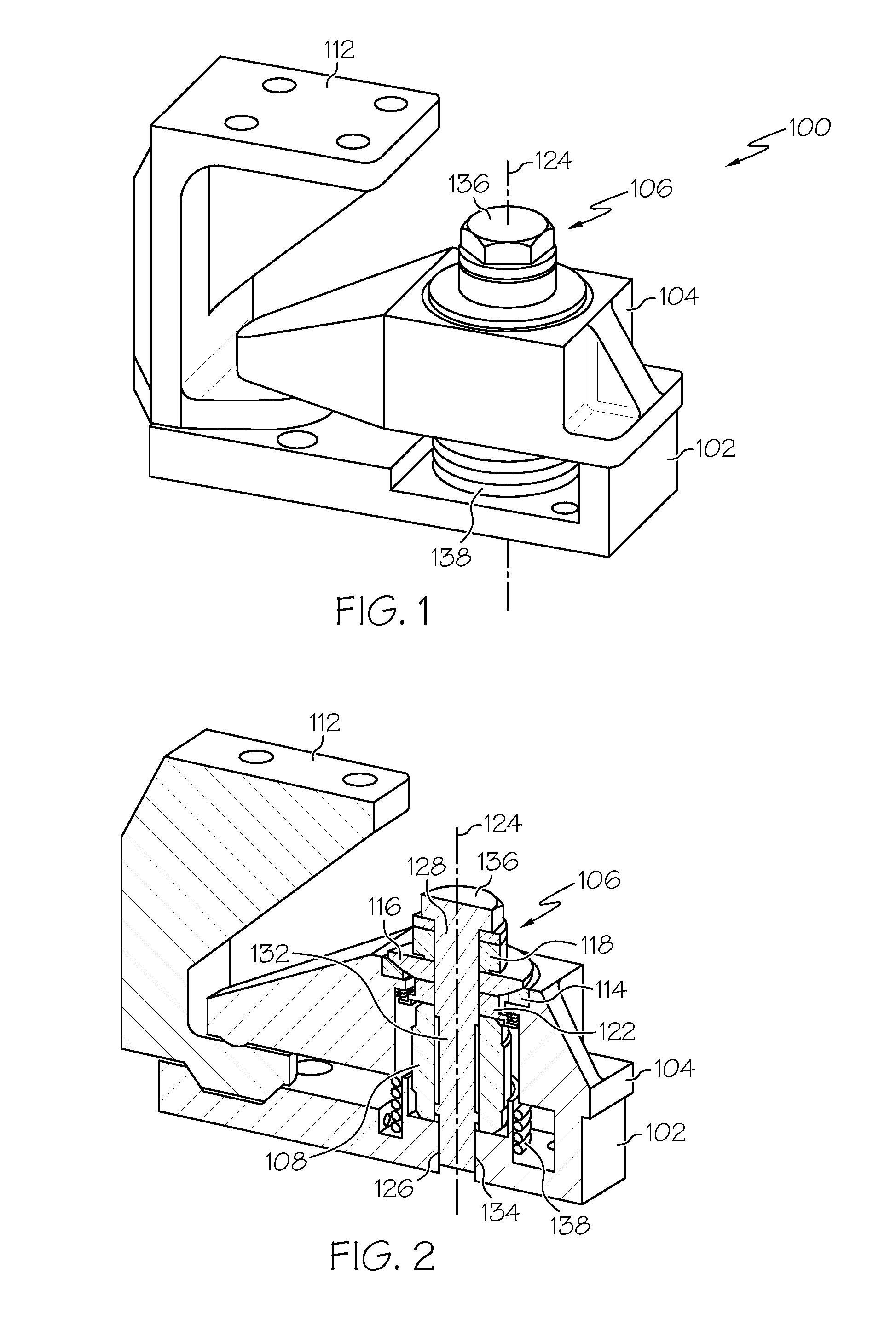

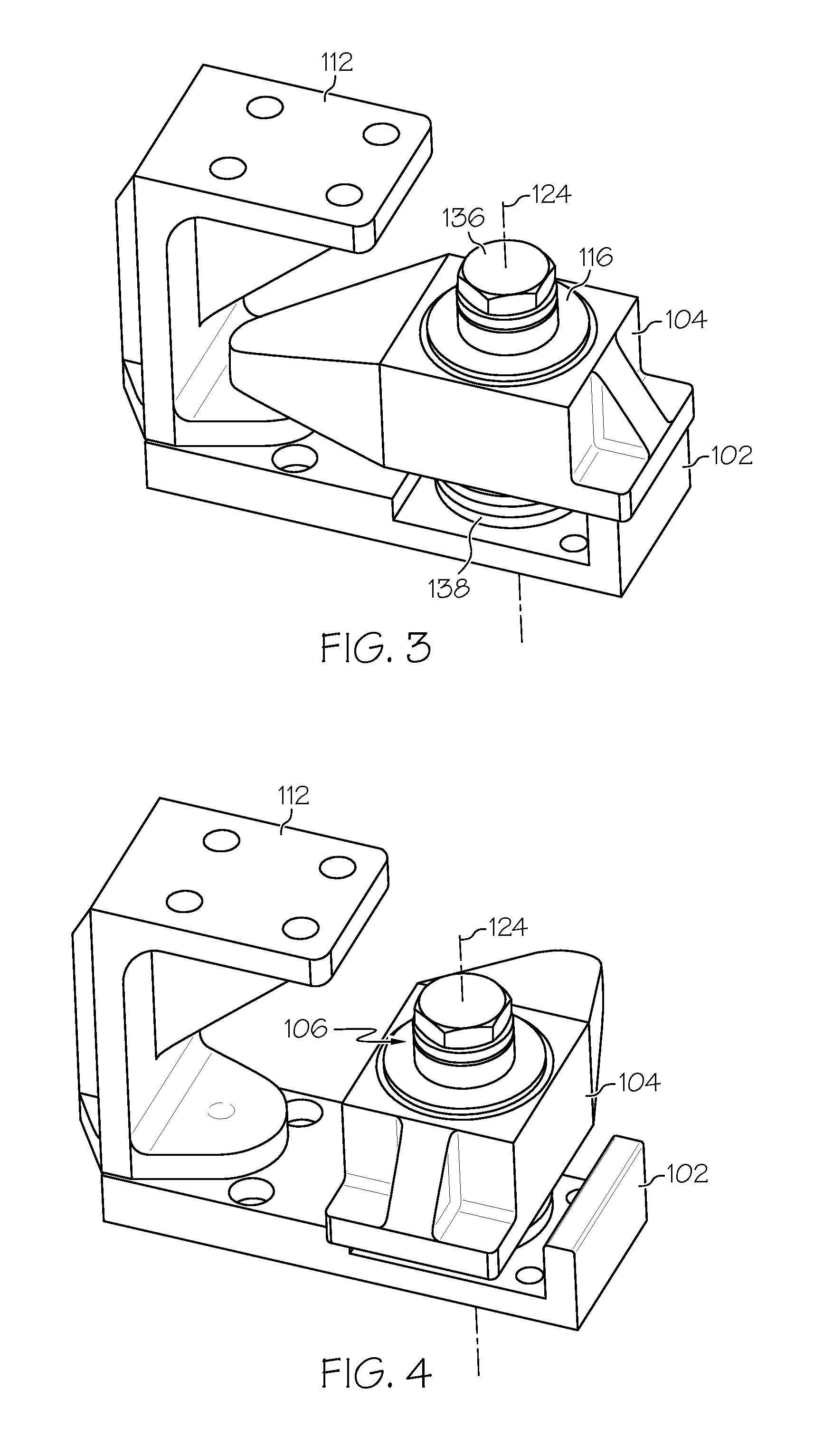

Payload launch lock mechanism

ActiveUS20120112010A1Large payload range of motionCosmonautic vehiclesCosmonautic partsPower flowLocking mechanism

A payload launch lock mechanism includes a base, a preload clamp, a fastener, and a shape memory alloy (SMA) actuator. The preload clamp is configured to releasibly restrain a payload. The fastener extends, along an axis, through the preload clamp and into the base, and supplies a force to the preload clamp sufficient to restrain the payload. The SMA actuator is disposed between the base and the clamp. The SMA actuator is adapted to receive electrical current and is configured, upon receipt of the electrical current, to supply a force that causes the fastener to elongate without fracturing. The preload clamp, in response to the fastener elongation, either rotates or pivots to thereby release the payload.

Owner:HONEYWELL INT INC

Compensating for incomplete reversal in mechanisms incorporating shape memory alloy wire

InactiveUS9021801B2Engage with obstructionMaintain tensionCoolant flow controlMechanical power devicesAlloySma actuator

Shape memory alloy (SMA) actuating elements are commonly simpler and of lower mass than alternative actuator designs and may find particular application in the transportation industry. Such SMA-powered devices are usually reliable and long-lived but the phase transformations which occur in the SMA alloy and are responsible for its utility are not totally reversible. This irreversibility, a consequence of irrecoverable strain, may progressively degrade the long-term actuator performance as the irrecoverable strain accumulates over many operating cycles. Methods and devices for compensating for these effects and extending the useful cycle life of SMA actuators are described.

Owner:GM GLOBAL TECH OPERATIONS LLC

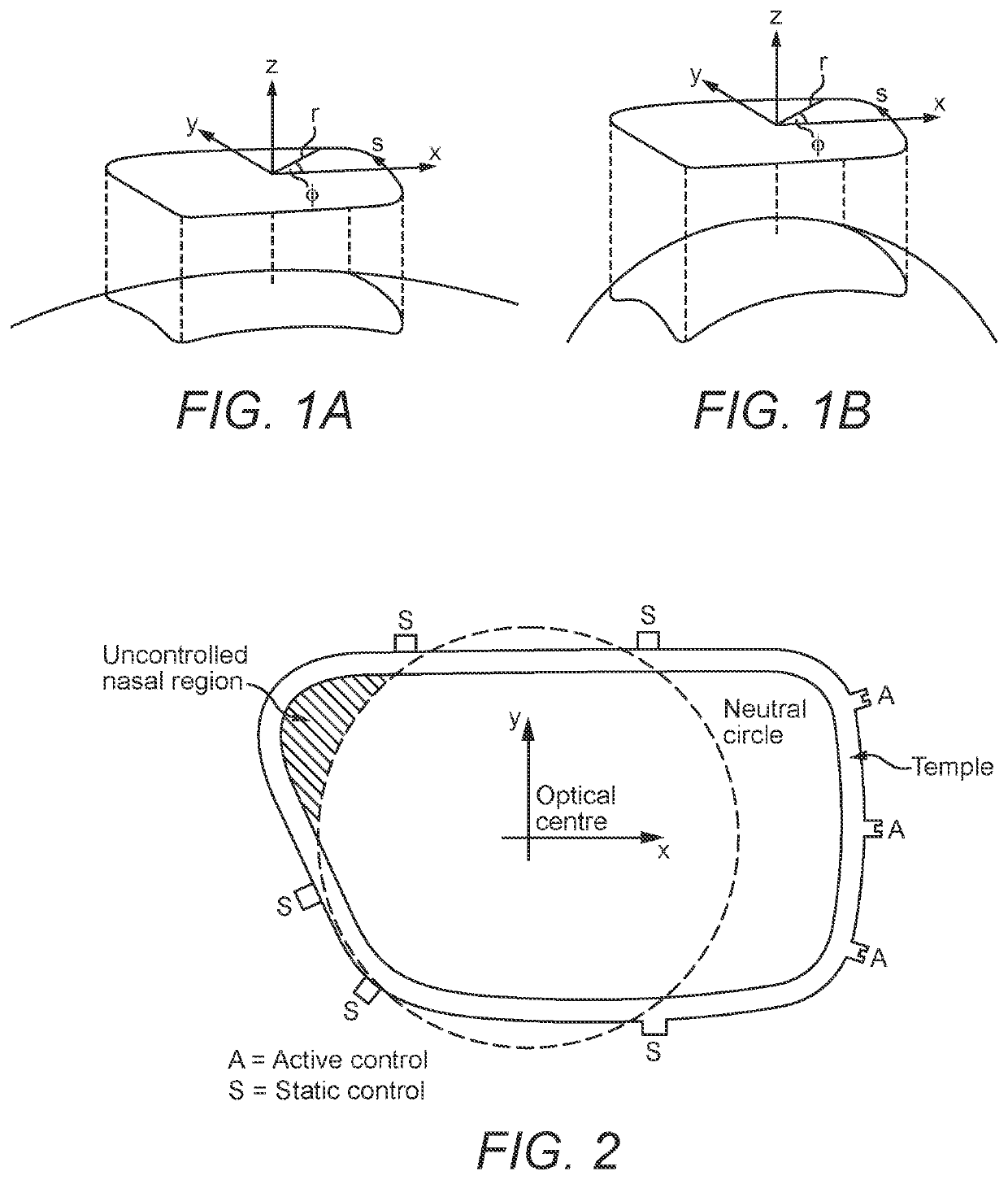

Improvements in or relating to variable focusing power optical devices

PendingUS20210033871A1High strengthGood opticsMachines/enginesMechanical power devicesEngineeringOptical surface

An adjustable fluid-filled lens or minor assembly 100 comprising a fluid-filled envelope and a supporting structure therefor; the fluid-filled envelope being constituted by a first wall that is formed of a distensible elastic membrane 15 having an exterior optical surface of variable focusing power, a second wall 18 that is spaced from the first wall on a z-axis, and a collapsible peripheral side wall 17 that extends between the first and second walls, and being filled with a substantially incompressible fluid 16; a membrane holding structure 14 that is attached to a peripheral edge of membrane 15 for holding the membrane under tension; and one or more selectively operable actuator assemblies r1, r2, r3 for moving one or more corresponding regions of the peripheral edge of the membrane on the z-axis towards and away from the second wall 18 for controlling the profile of the peripheral edge of the membrane; wherein the or each actuator assembly comprises a connecting member 91, 92, 93 that is attached to the membrane or membrane holding structure at a respective actuation point, a linear actuator 531, 532, 533 that is mounted to the supporting structure and a linkage 81, 82, 83 that is connected between the connecting member and an actuation point a1, a2, a3 on the linear actuator; wherein the linear actuator is a linear SMA actuator comprising an array of SMA wires 53 that are coupled together to work in parallel and which extend transversely of the z-axis, and the linkage is configured for converting linear motion of the actuation point of the SMA actuator in a direction transverse the z-axis to linear motion of the connecting member on the z-axis, thereby to move the corresponding region of the peripheral edge of the membrane 5 towards or away from the second wall 18.

Owner:ADLENS

SMA actuator safety mechanism

InactiveUS6928812B2Guaranteed releaseImprove heat insulationMechanical power devicesClosed-cycle gas positive displacement engine plantCouplingBiological activation

A method and apparatus for preventing the unintended activation of SMA devices by ambient temperatures that exceed the phase transition temperature of the SMA material itself. In one embodiment a passive actuator is coupled to an active actuator, each having identical arrangements of SMA wire, but connected in opposite directions to compensate for temperature drift that is not due to powered heating. A second embodiment consists of a passive SMA wire connected to a latch / release mechanism allowing the actuator itself to move rather than moving the load. In a third embodiment the passive wire is connected to a load coupling, so that the load itself is disconnected from the actuator when the passive wire reaches the phase transition temperature. The passive wire may be made of a lower-temperature wire than the active wires, so that the release action occurs long before the active wire begins to be moved by ambient temperature.

Owner:PERIHELIAN

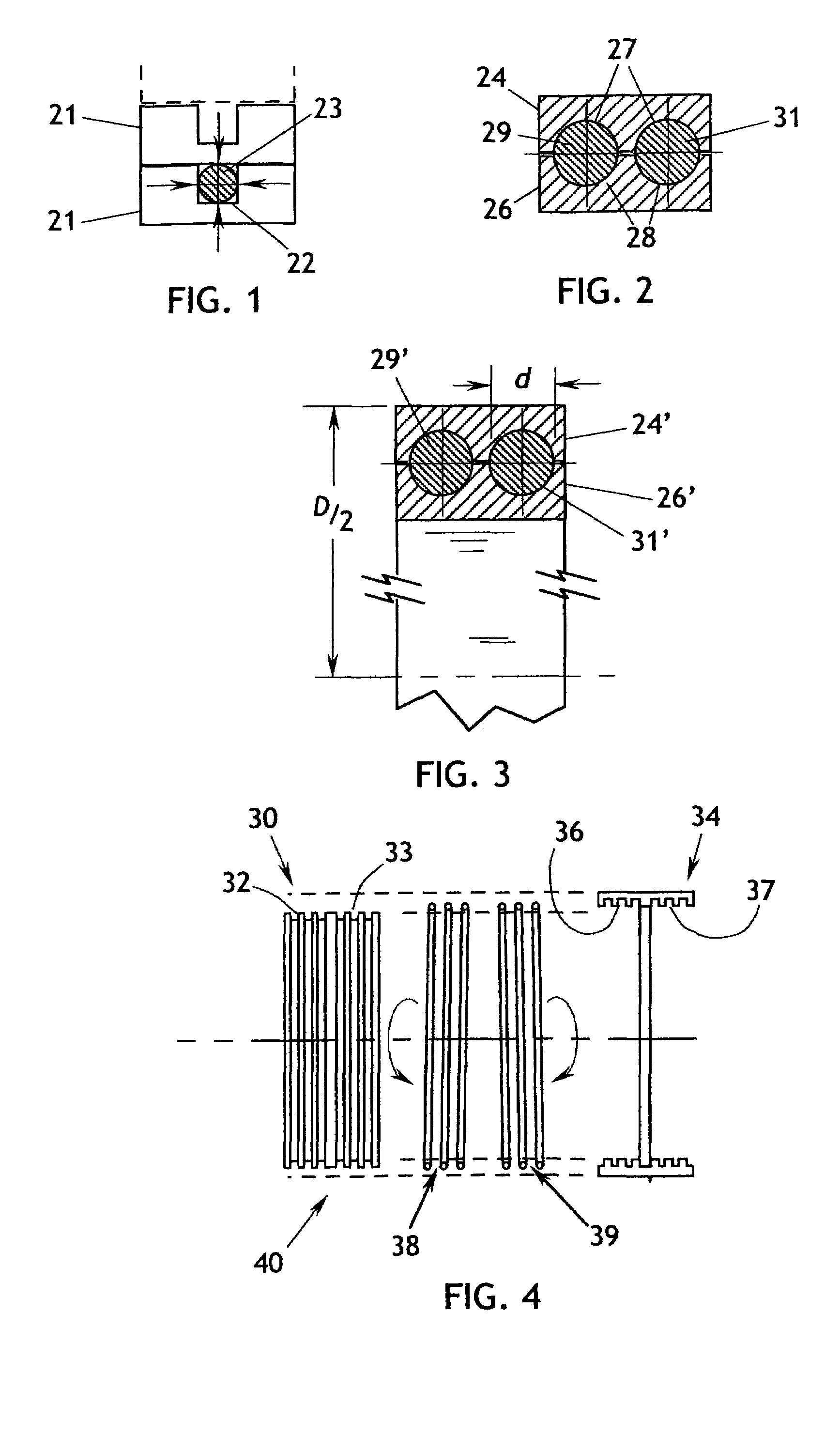

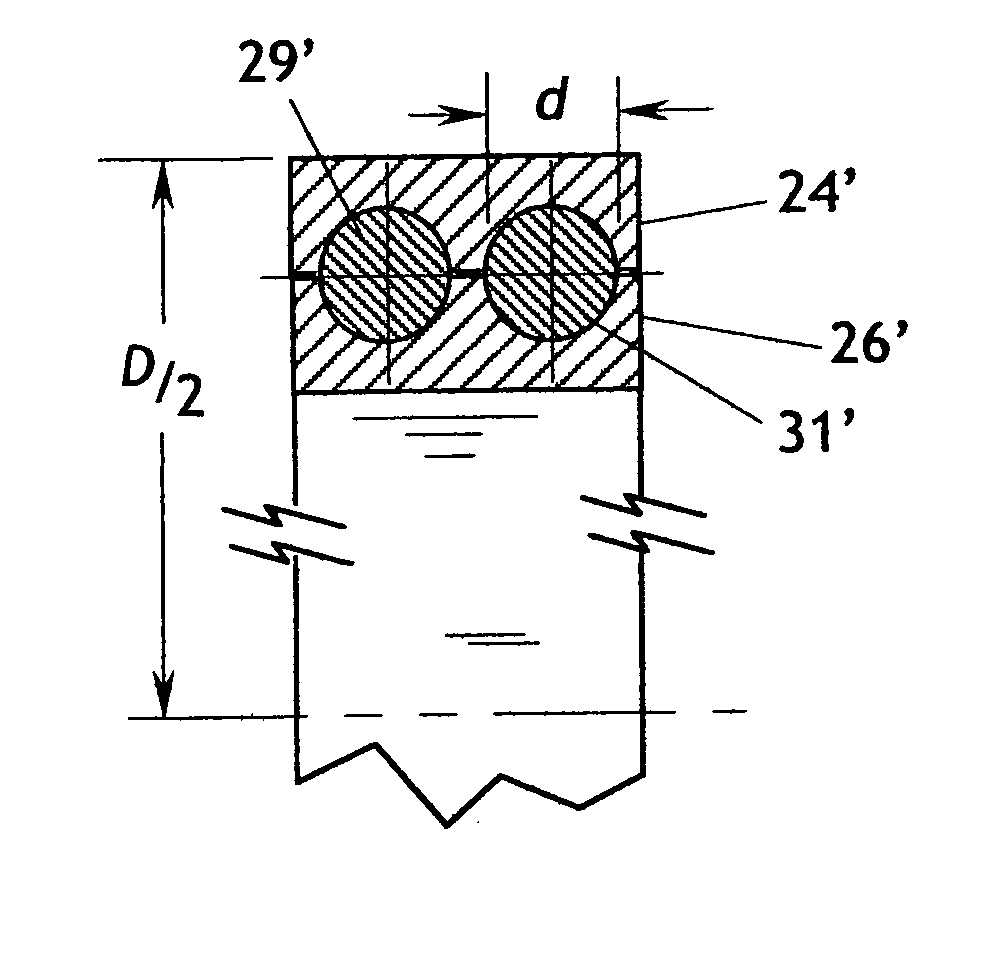

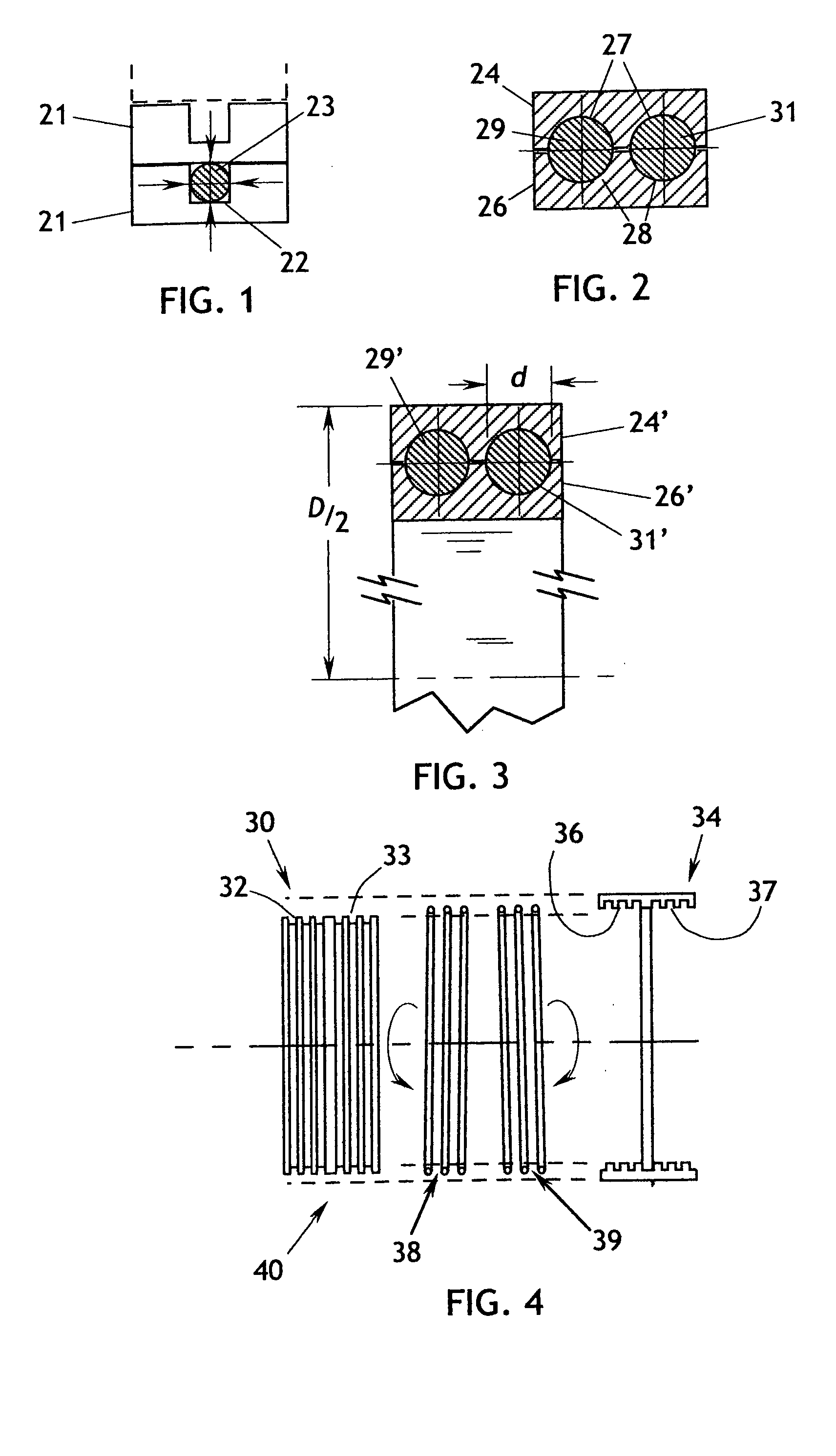

Shape memory alloy actuator

InactiveUS7021055B2Excursion can be increasedEasy to controlMechanical power devicesClosed-cycle gas positive displacement engine plantBobbinEngineering

Actuators that employs a shape memory alloy component as the driving element include linear and rotational devices. An Intrinsic Return Means (IRM) may be imparted to the SMA actuator, thereby reducing the use of a spring return mechanism. The rotational actuator may include a cylindrical bobbin with a helical groove to receive an SMA wire. A number of turns may be placed in a small length of bobbin to amplify the rotational excursion. In another rotational actuator, a plurality of narrow, coaxial rings are provided, the rings being nested in close concentric fit or stacked in side-by-side fashion. Each ring is provided with a groove extending thereabout to receive an SMA wire and contraction of the wire causes each ring to rotate with respect to the adjacent ring. In an embodiment for linear actuation, the invention provides a bar-like component having SMA wires joined between bars. The invention includes a lost motion coupling to join two counter-acting SMA stroke amplification devices, whether linear or rotational.

Owner:PERIHELIAN

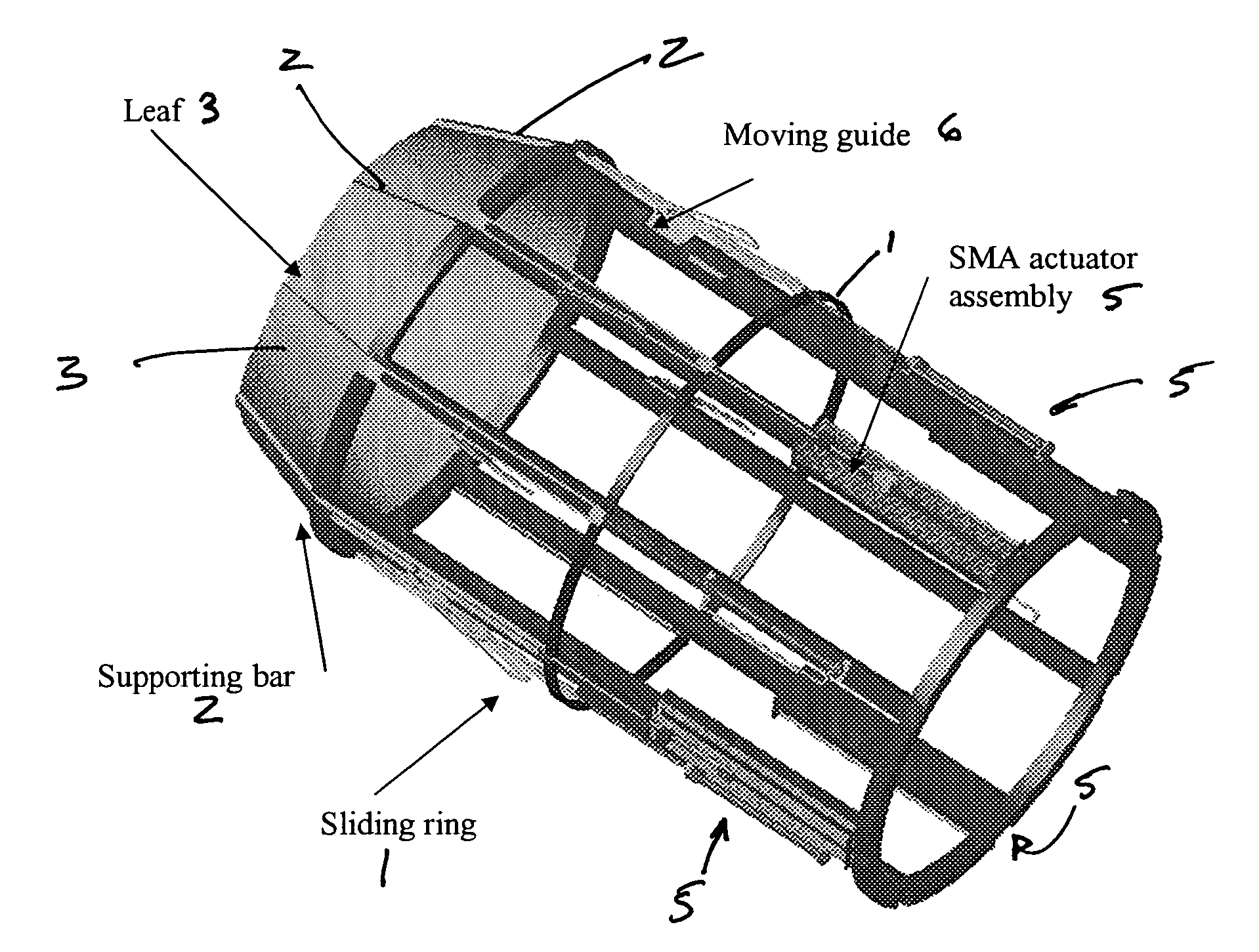

Shape memory alloy actuated adaptive exhaust nozzle for jet engine

ActiveUS20060191267A1Reduce weightEliminate chatterAircraft navigation controlSpraying apparatusJet engineAlloy

The proposed adaptive exhaust nozzle features an innovative use of the shape memory alloy (SMA) actuators for actively control of the opening area of the exhaust nozzle for jet engines. The SMA actuators remotely control the opening area of the exhaust nozzle through a set of mechanism. An important advantage of using SMA actuators is the reduction of weight of the actuator system for variable area exhaust nozzle. Another advantage is that the SMA actuator can be activated using the heat from the exhaust and eliminate the need of other energy source. A prototype has been designed and fabricated. The functionality of the proposed SMA actuated adaptive exhaust nozzle is verified in the open-loop tests.

Owner:HOUSTON UNIV OF THE

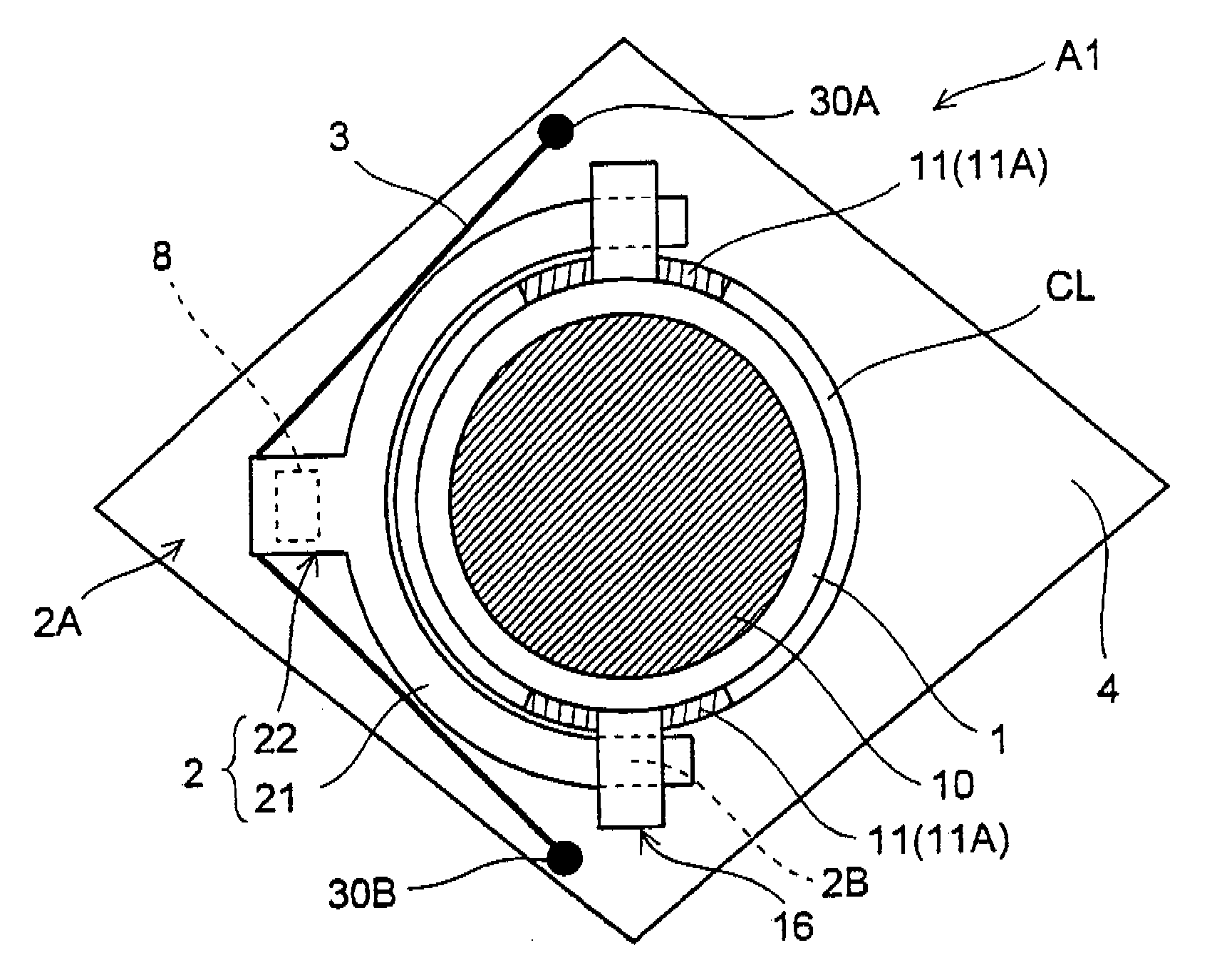

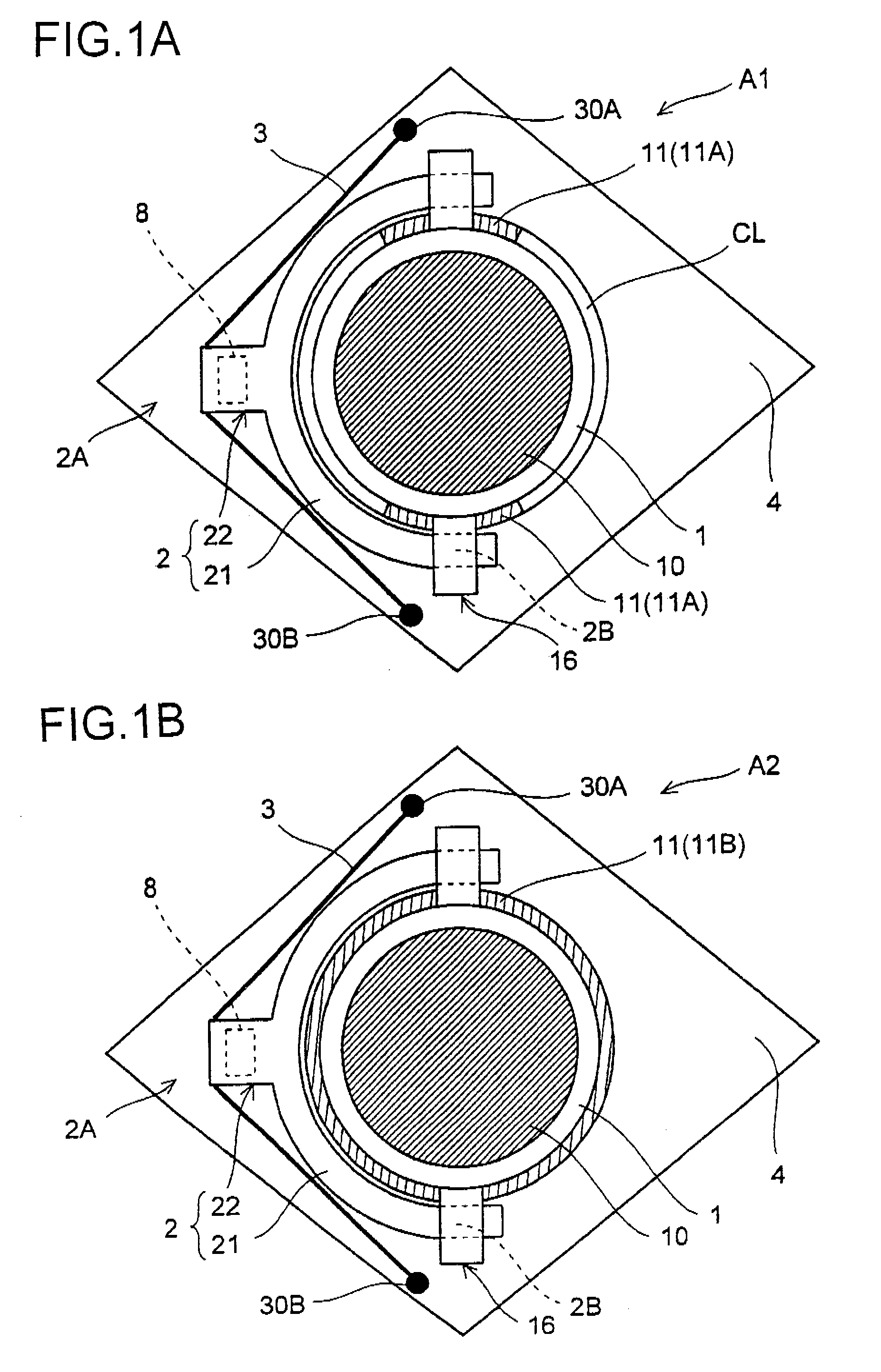

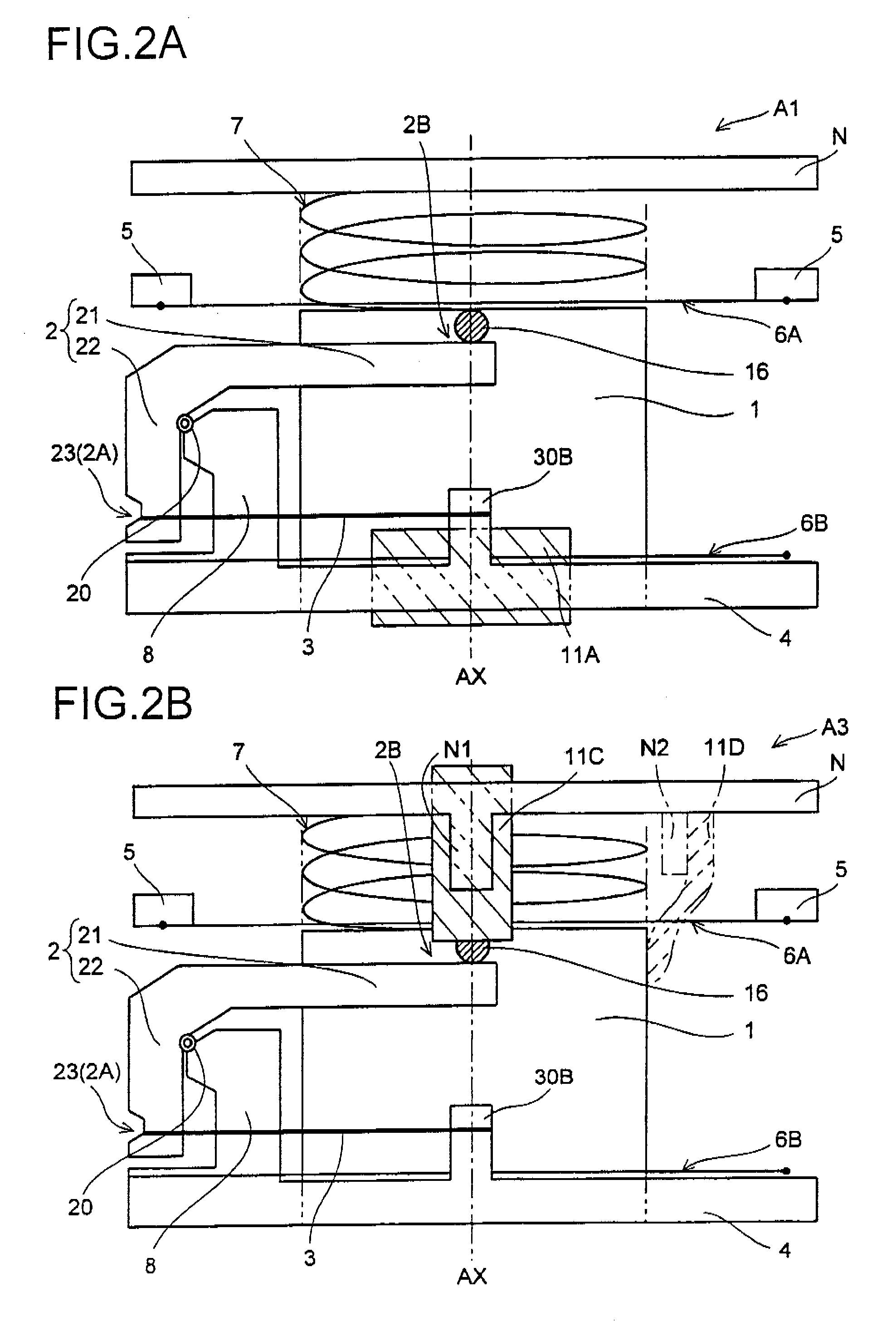

Drive mechanism and drive device

InactiveUS20100293940A1Inhibit deteriorationRelieve pressureMountingsMechanical power devicesSma actuatorHigh heat

A drive mechanism and a drive device each comprise a driven body (1), a displacement member (2), and an SMA actuator (3) for giving a displacement force. The driven body (1) is coupled to a fixed section through a viscoelastic member (11 (11A, 11B, 11C, 11D)). A displacement output section is engaged with the driven body, and thereby a predetermined portion of the displacement member (2) for displacing the driven body in a first-axis direction is connected to the fixed section through the viscoelastic member (11 (11E, 11F, 11G, 11H)). A shape-memory alloy (SMA) actuator is used. The position of the driven body is stably and quickly controlled. Even if a shock force is exerted or even if the drive mechanism and the drive device are left in a high-temperature environment for a long time, the SMA, the drive mechanism, and the drive device do not deteriorate, the sizes and weights thereof can be reduced, and they can be easily assembled.

Owner:KONICA MINOLTA OPTO

Methods of manufacturing highly integrated SMA actuators

ActiveUS8127543B2Avoid damageMechanical power devicesClosed-cycle gas positive displacement engine plantEngineeringControl theory

A shape memory alloy (SMA) actuator assembly is provided that includes an SMA component. The SMA component is used to impart motion in an output shaft. Also provided is a return force component that provides a variable, tailored return force to the SMA component. Additionally, a variety of protective mechanisms are disclosed and utilized to prevent damage to the internal workings and components within the SMA actuator assembly as well as provide protection and safety for external workings.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN

SMA actuator driving device, and image pickup device incorporated with the same

InactiveUS8068167B2Suppress power lossGreat fabricationTelevision system detailsProjector focusing arrangementDriving currentTerminal voltage

In a shape memory alloy actuator driving device, a predetermined constant current is applied to a shape memory alloy member as a retrieval signal to detect a terminal voltage of the shape memory alloy member, and a detection result of the terminal voltage is compared with a target voltage value to be calculated based on a target resistance value of the shape memory alloy member and a value of the constant current to cause a driving circuit to output, to the shape memory alloy member, a drive current that makes the detection result substantially equal to the target voltage value.

Owner:KONICA MINOLTA OPTO

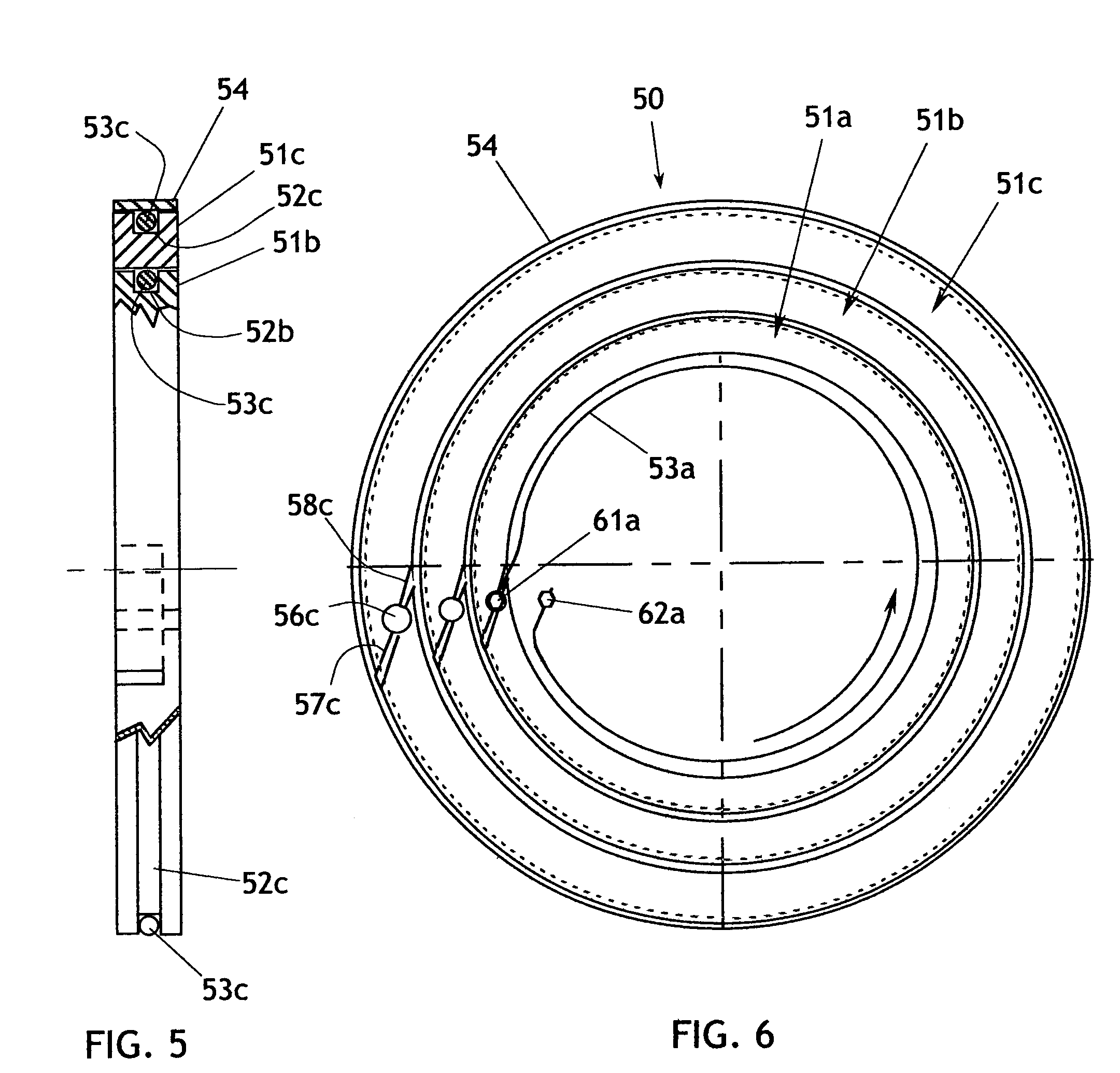

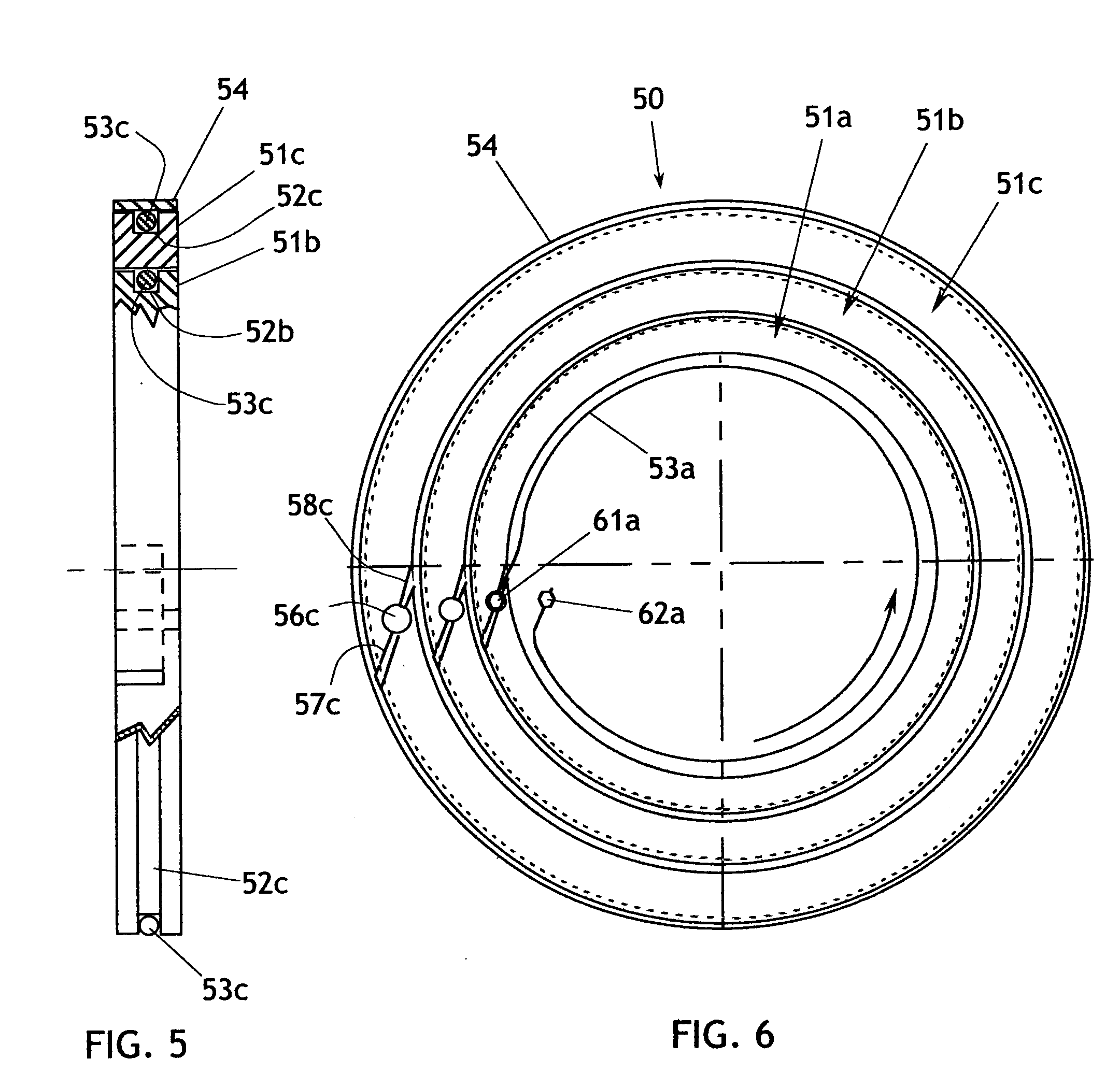

Concentric tube shape memory alloy actuator apparatus and method

ActiveUS7159398B1High torque outputIncreasing angular deflectionWing lift eficiencyMechanical power devicesPower flowAlloy

A rotary SMA actuator includes an SMA assembly having a plurality of grooves formed therein to form a plurality of concentrically arranged SMA tubes. A heater element is disposed against an input end of the SMA tubes and generates heat when electrical current is applied thereto. The heat is used to heat the SMA tubes, which causes an angular deflection of each of the tubes at an output end thereof. An innermost one of the SMA tubes is used as an output member and its angular deflection is the sum of the angular deflections of all of the SMA tubes. The actuator is of a smaller size and lighter weight than electrical, mechanical, hydraulic or pneumatic actuators of comparable torque output. The actuator also provides greater deflection capability than similarly sized SMA type actuators that do not employ concentric tubes.

Owner:THE BOEING CO

Shape memory alloy actuator

InactiveUS20050103008A1Reduce usageExcursion can be increasedMechanical power devicesClosed-cycle gas positive displacement engine plantBobbinEngineering

Actuators that employs a shape memory alloy component as the driving element include linear and rotational devices. An Intrinsic Return Means (IRM) may be imparted to the SMA actuator, thereby reducing the use of a spring return mechanism. The rotational actuator may include a cylindrical bobbin with a helical groove to receive an SMA wire. A number of turns may be placed in a small length of bobbin to amplify the rotational excursion. In another rotational actuator, a plurality of narrow, coaxial rings are provided, the rings being nested in close concentric fit or stacked in side-by-side fashion. Each ring is provided with a groove extending thereabout to receive an SMA wire and contraction of the wire causes each ring to rotate with respect to the adjacent ring. In an embodiment for linear actuation, the invention provides a bar-like component having SMA wires joined between bars. The invention includes a lost motion coupling to join two counter-acting SMA stroke amplification devices, whether linear or rotational.

Owner:PERIHELIAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com