Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

236results about How to "Eliminate chatter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

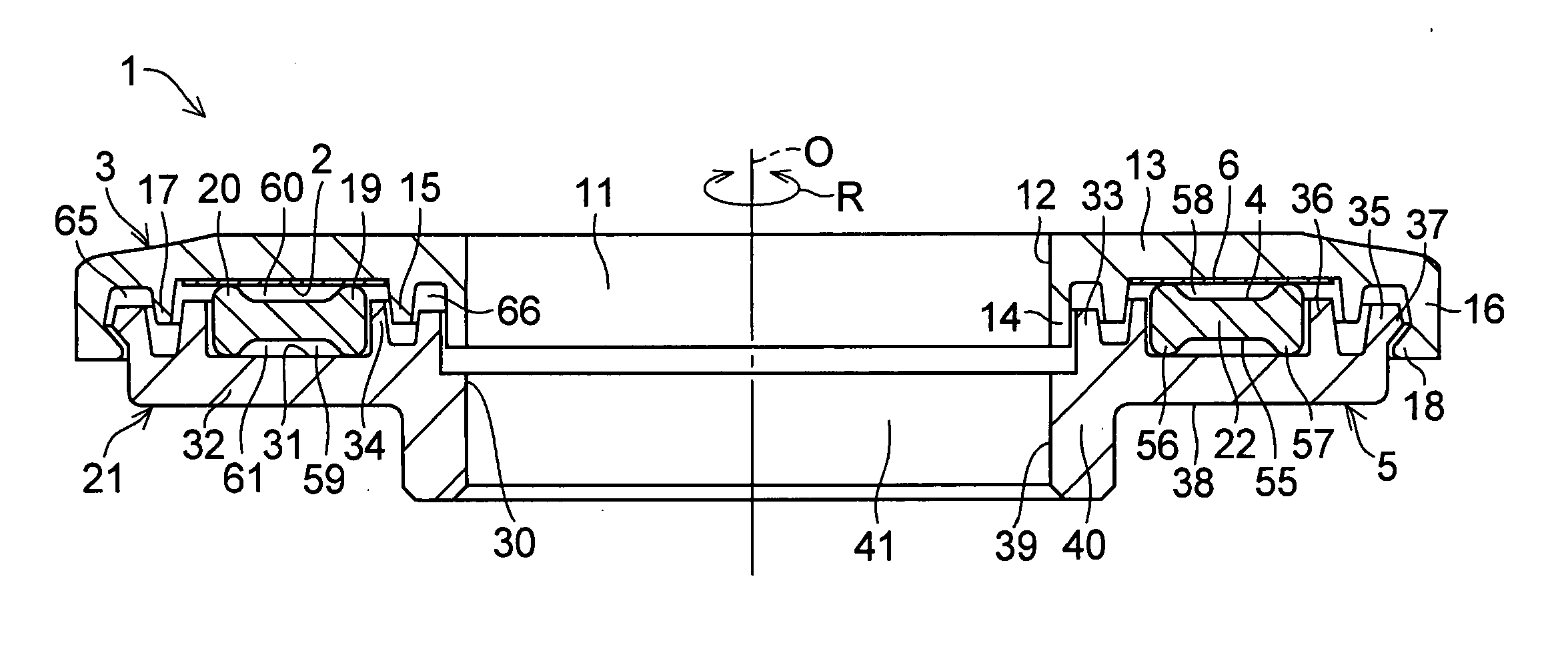

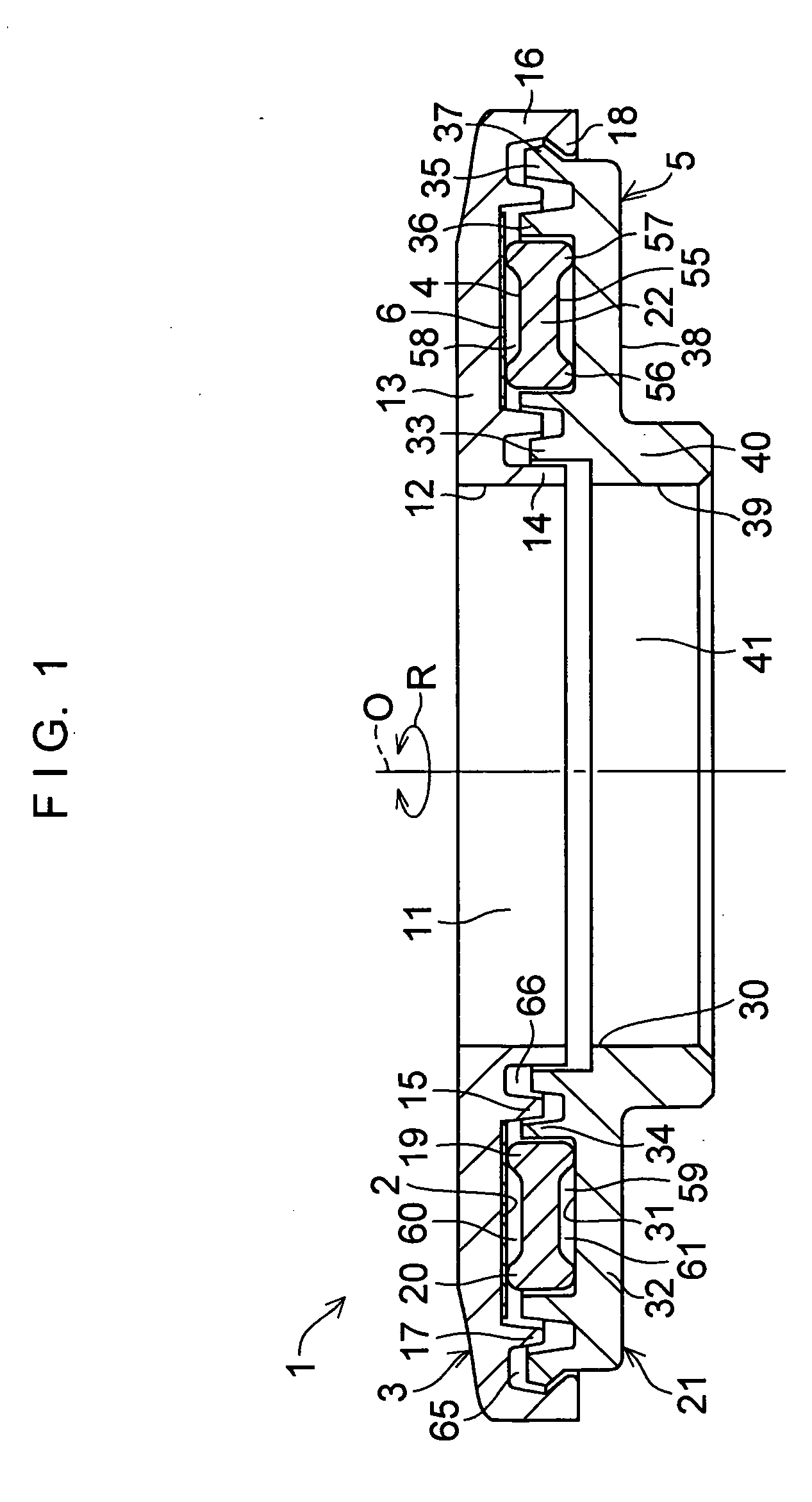

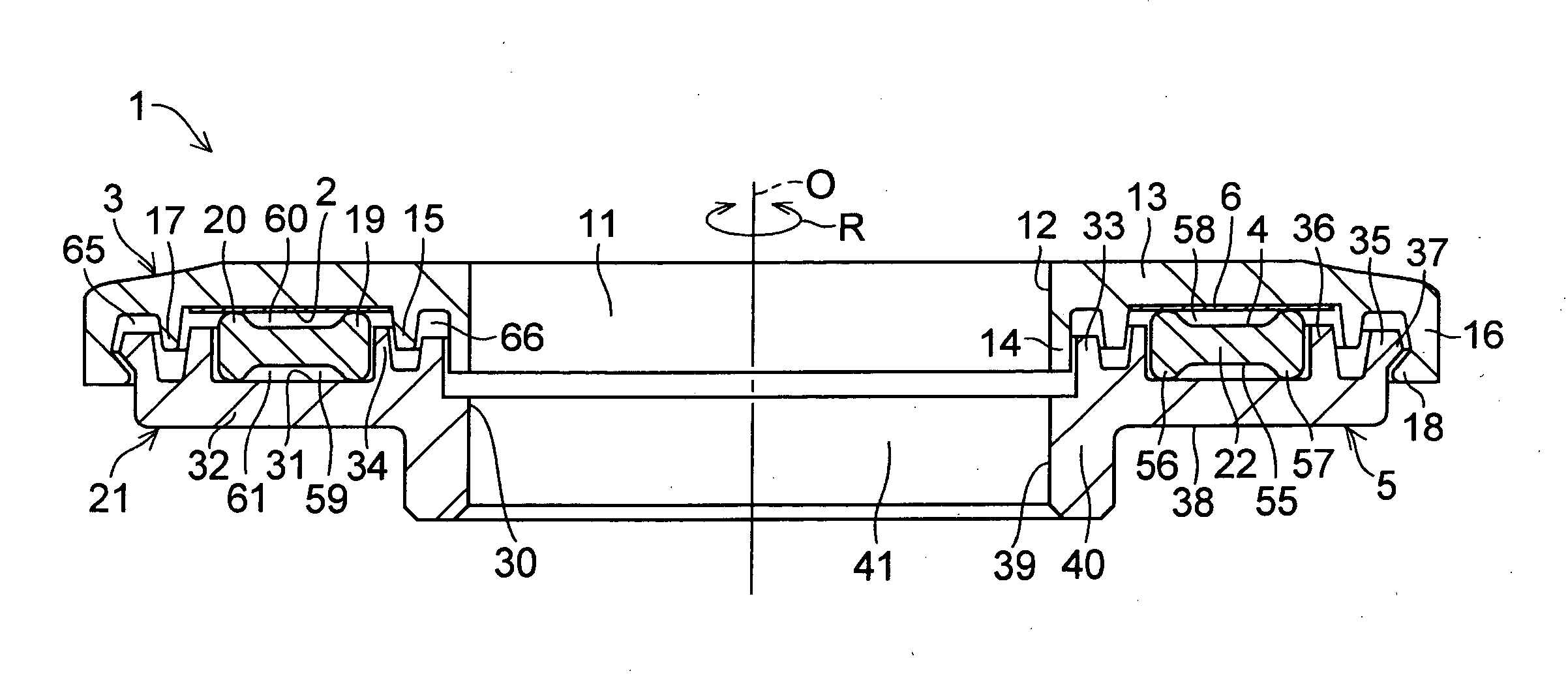

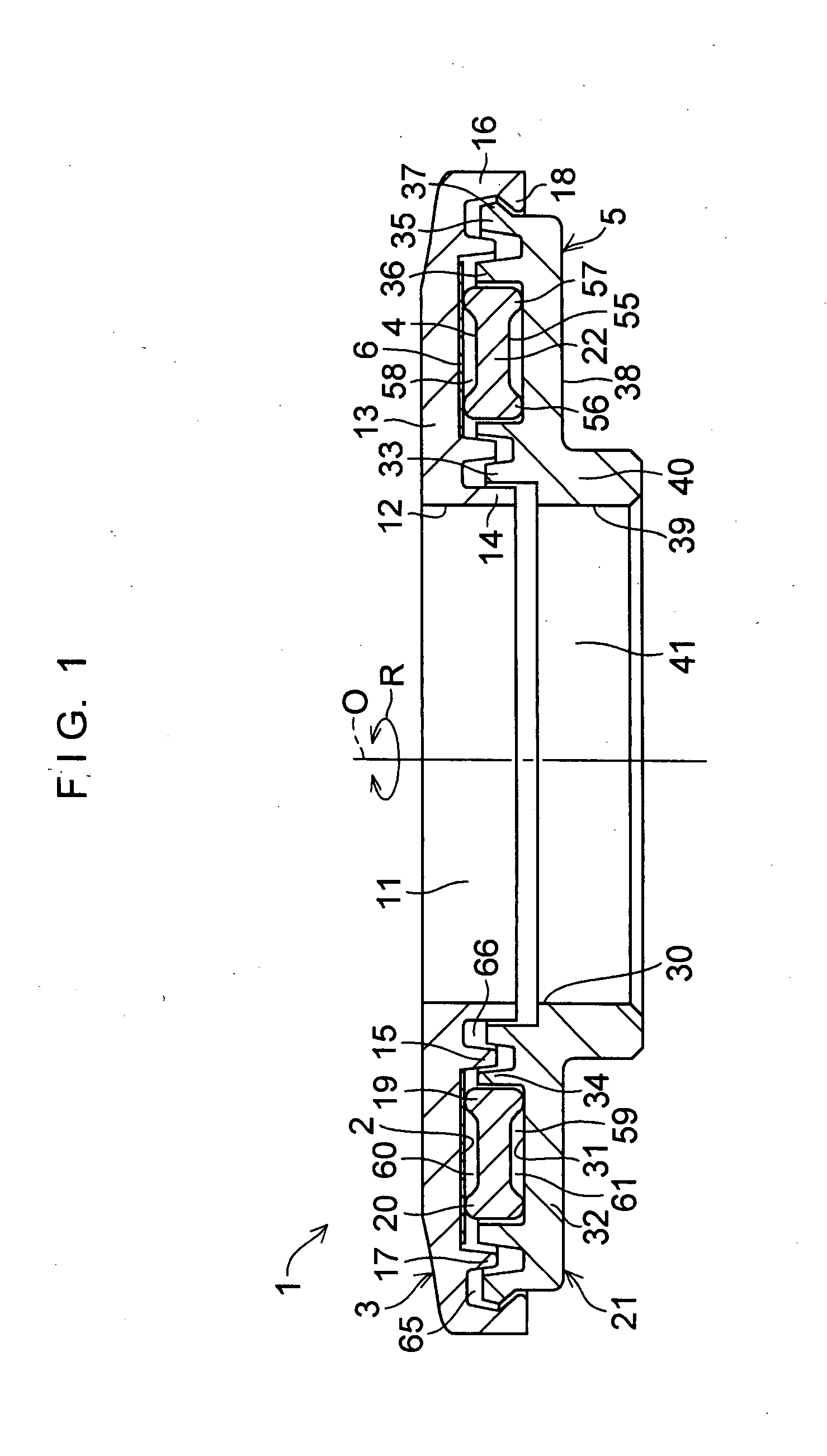

Sliding bearing

ActiveUS20080310780A1Easy to adjustReduce coefficient of frictionShaftsBearing componentsEngineeringSynthetic resin

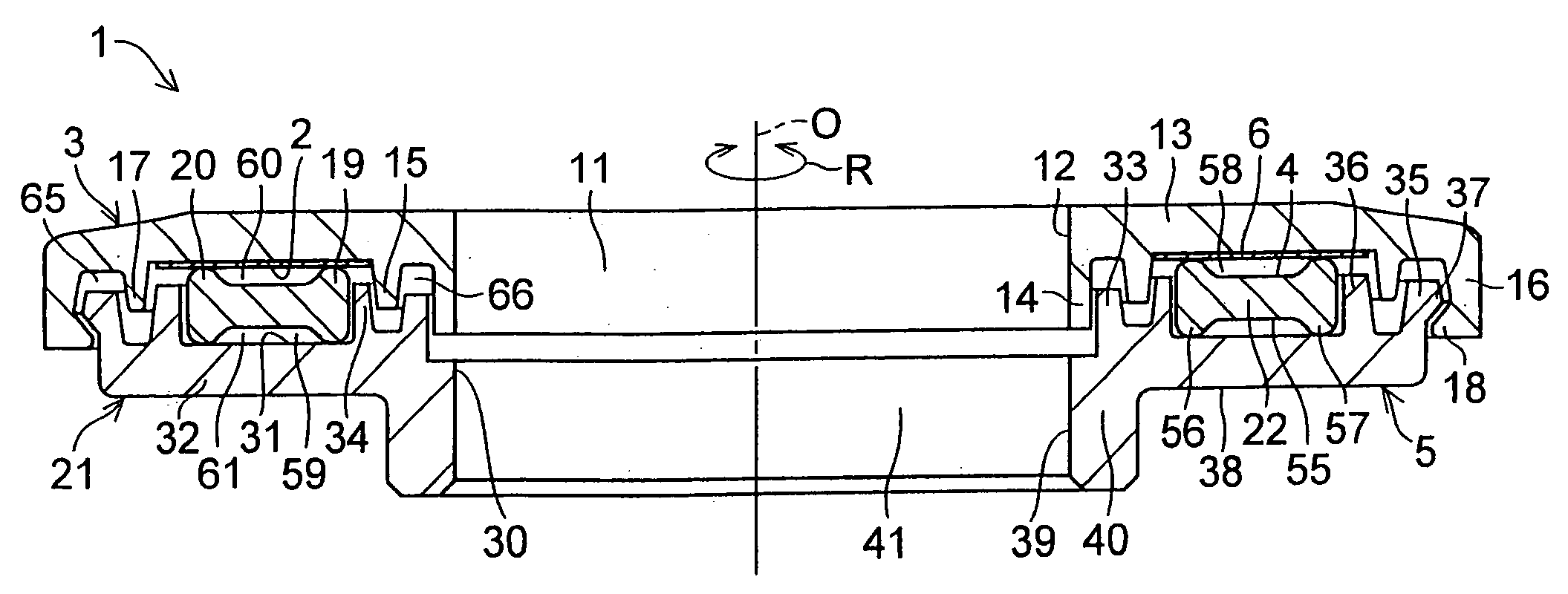

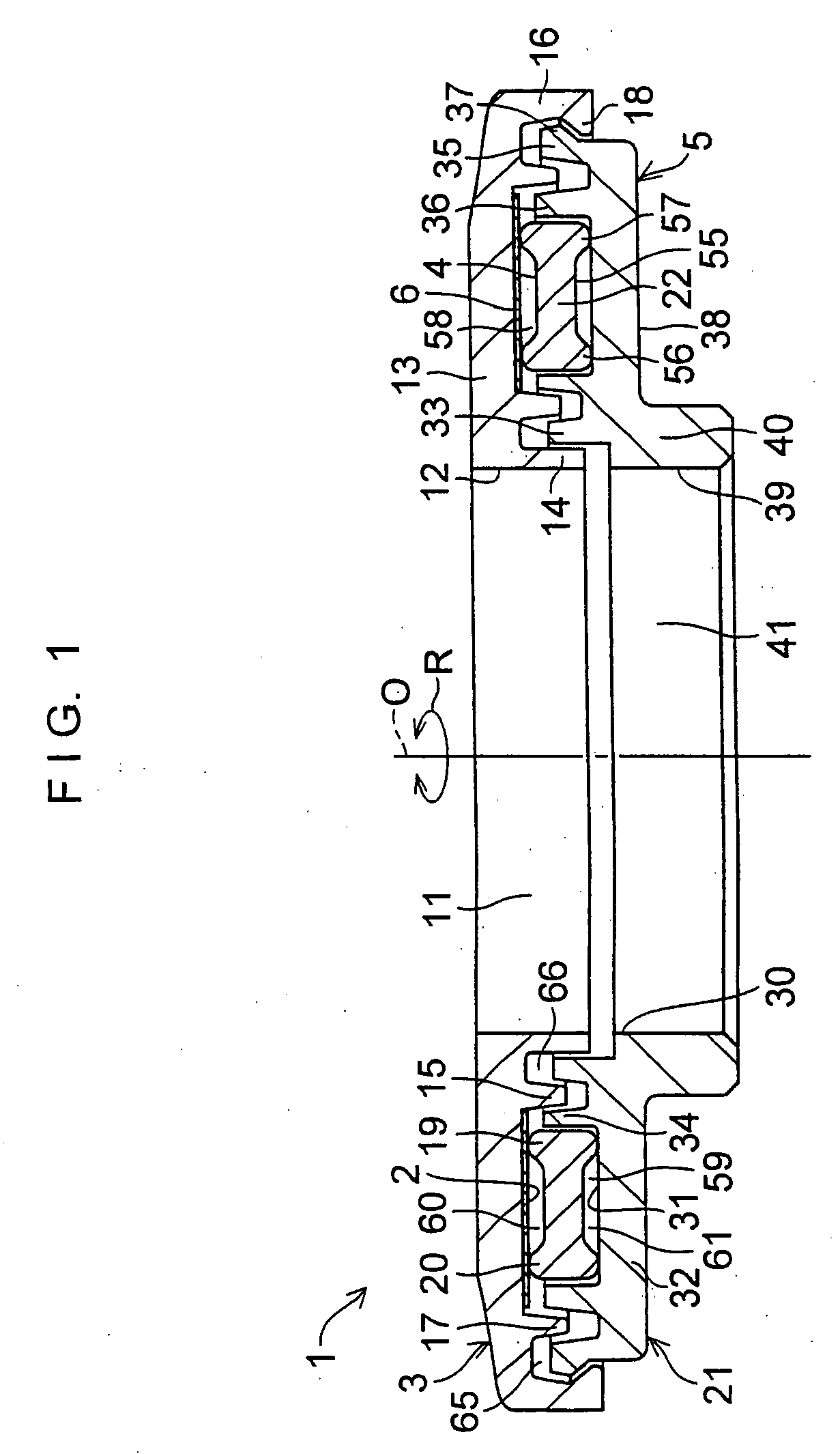

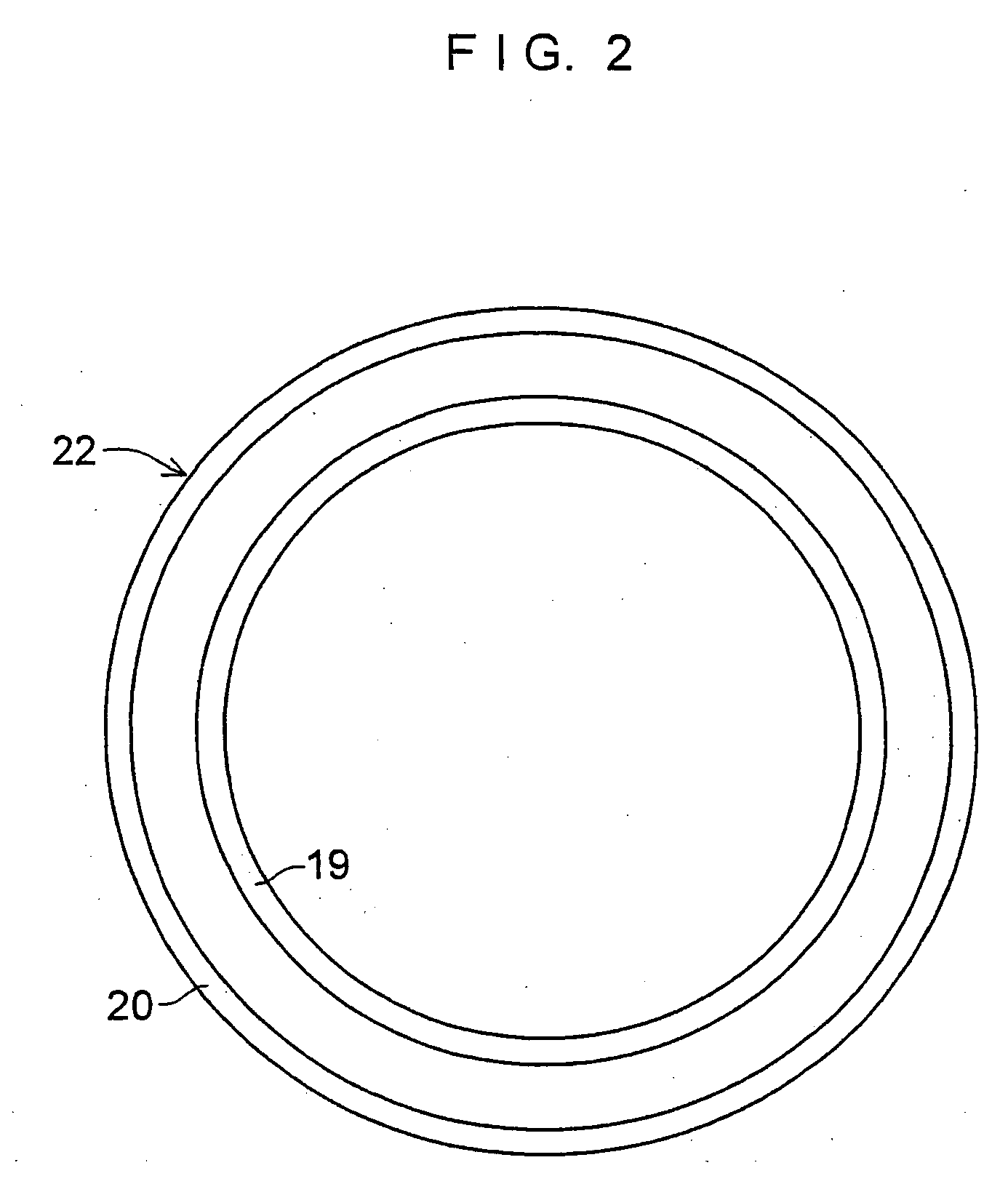

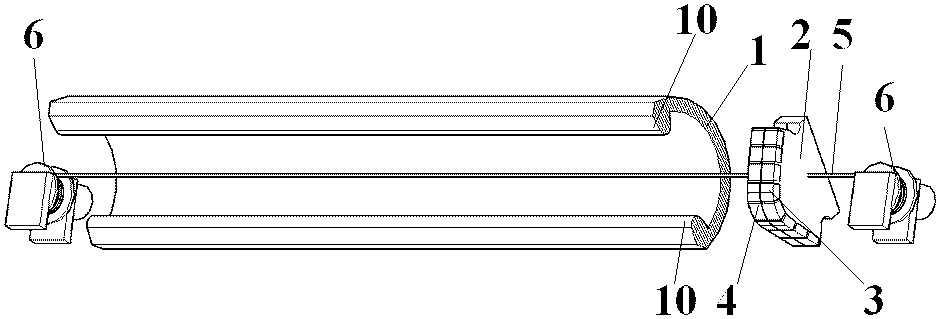

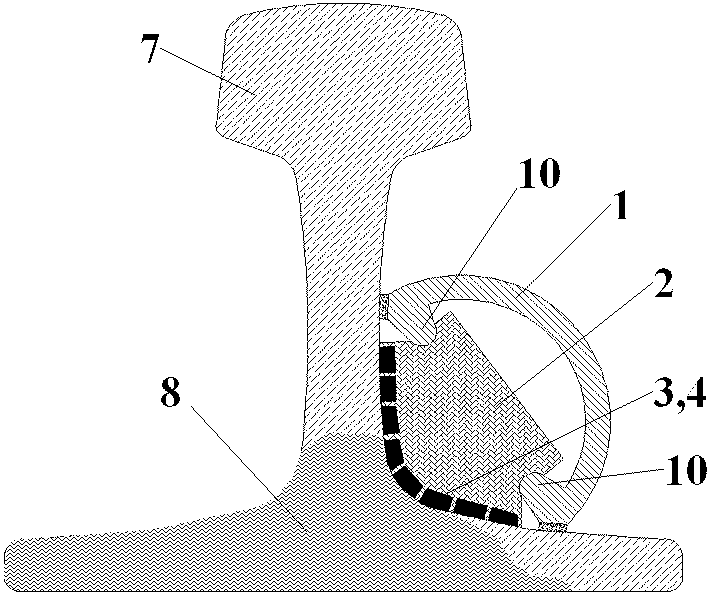

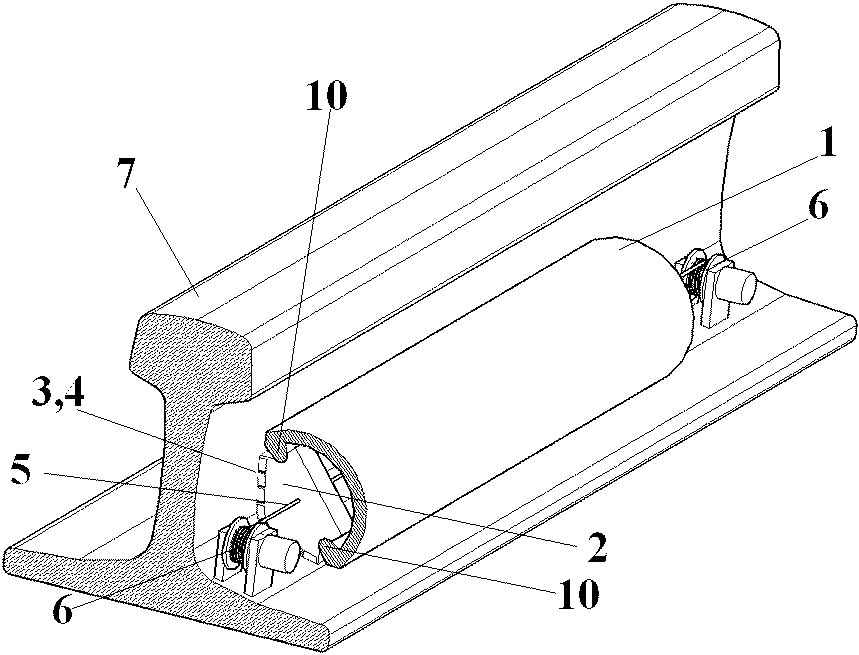

A sliding bearing (1) includes an upper casing (3) which is made of polyacetal resin as a synthetic resin, has an annular surface (2), and serves as a first bearing body; a second bearing body (5) which is made of a synthetic resin, is superposed on the upper casing (3) so as to be rotatable about an axis (O), and has an synthetic resin-made annular surface (4) opposed to the annular surface (2); and a synthetic resin-made annular sheet (6) which is interposed between the annular surfaces (2) and (4) and slidably abuts against at least one of the upper casing (3) and the bearing body (5).

Owner:OILES CORP

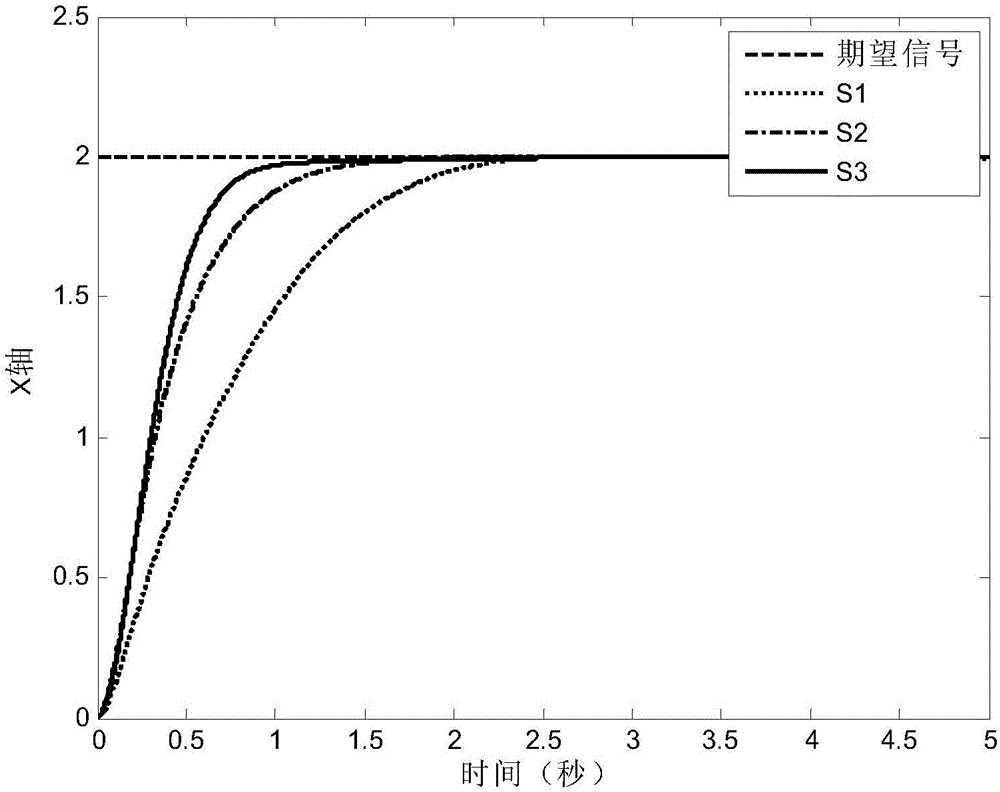

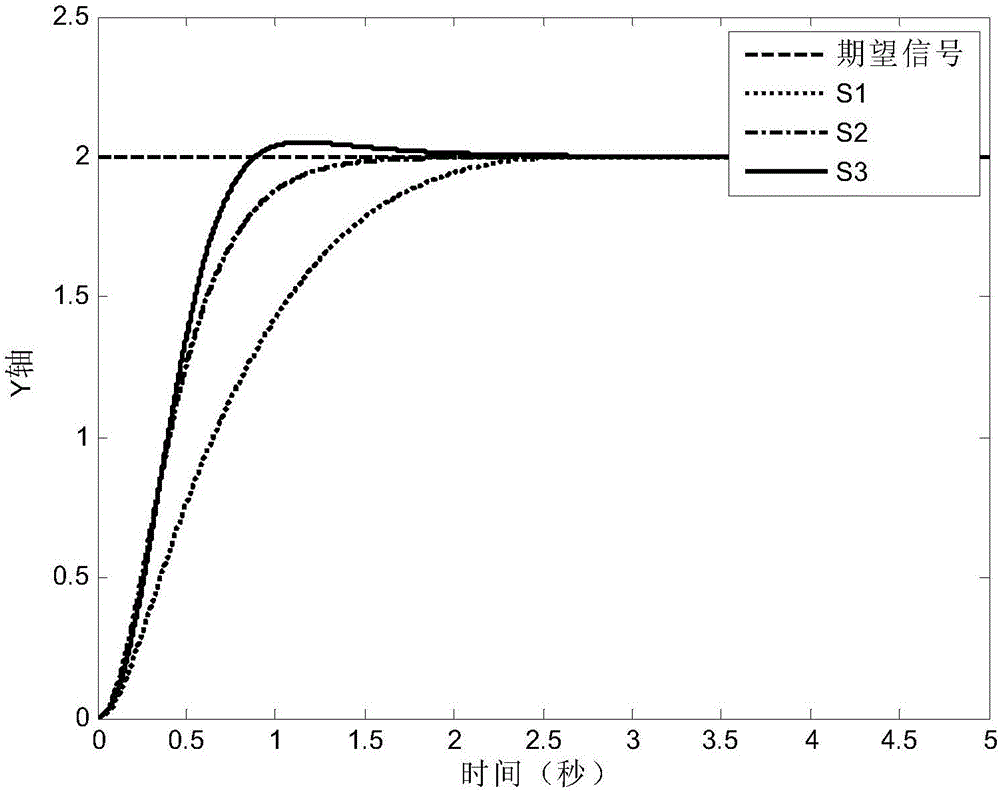

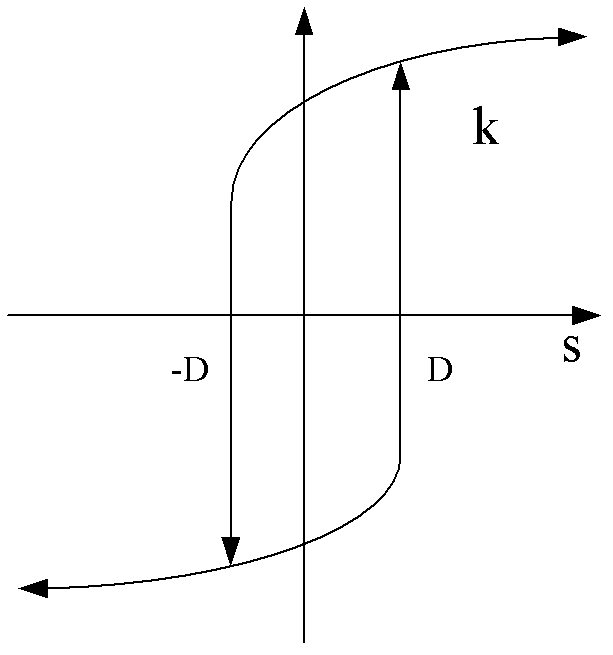

Sliding-mode control method of permanent magnet synchronous motor based on reaching law and disturbance observation compensation

ActiveCN109450320AEliminate chatterImprove anti-interference abilityElectronic commutation motor controlVector control systemsControl systemPermanent magnet synchronous motor

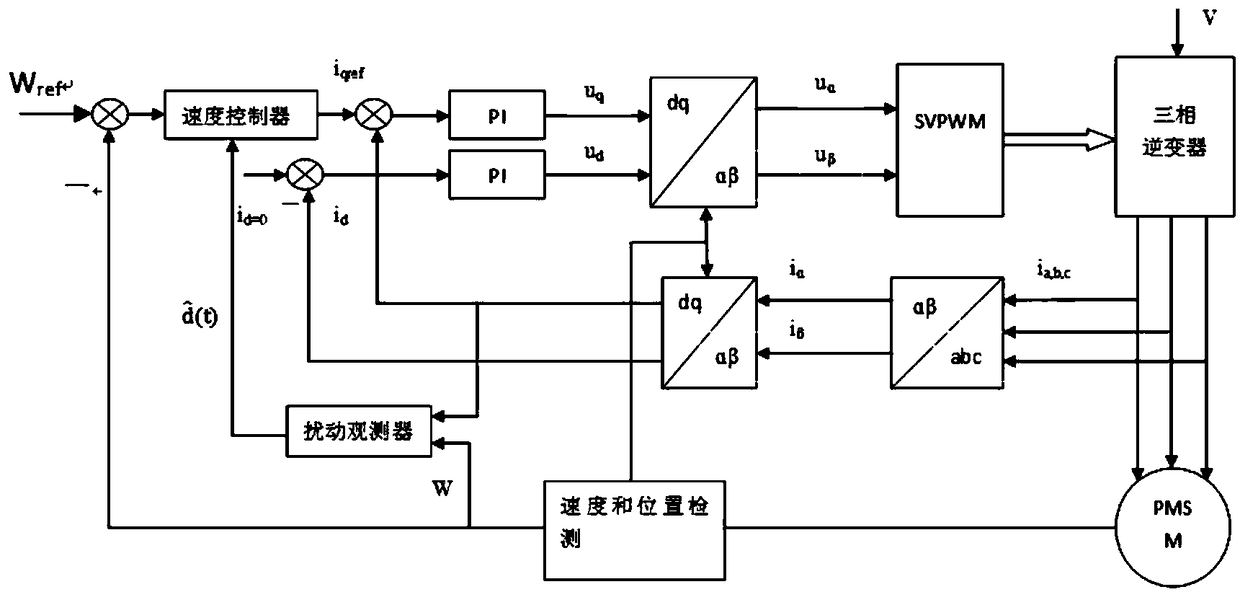

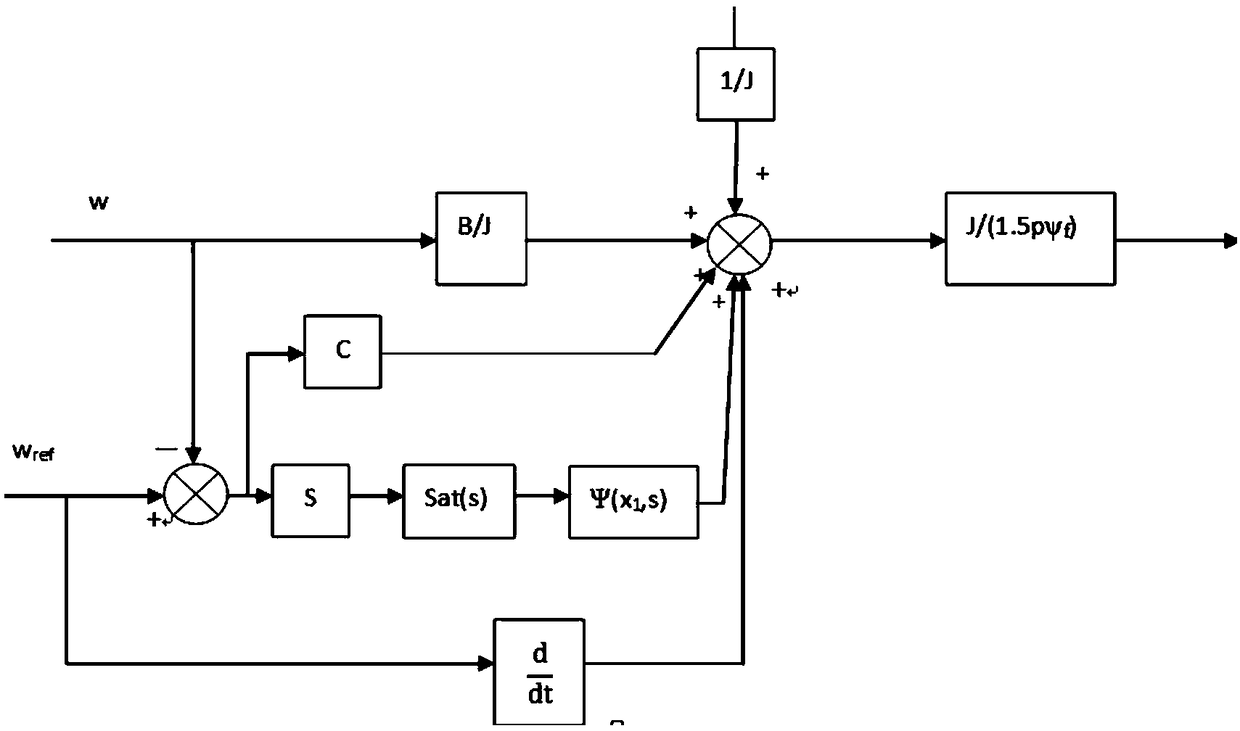

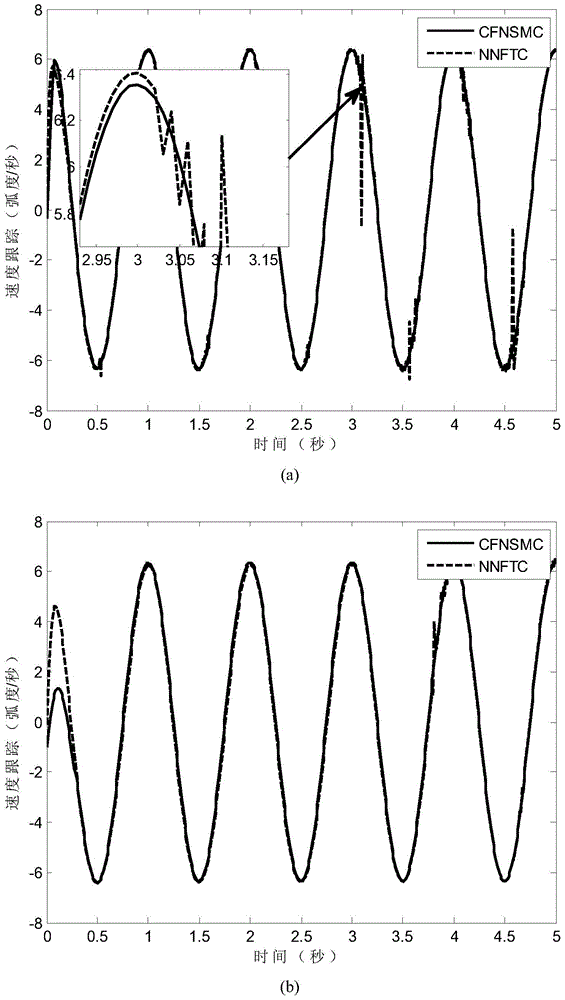

The invention provides a sliding-mode control method of a permanent magnet synchronous motor based on reaching law and disturbance observation compensation. A new reaching law algorithm is designed, and applicable in design of a speed controller in a sliding-mode variable structure; simultaneously, a saturation function is used in a disturbance observer control law, and used for improving a disturbance observer; a value observed by the disturbance observer is compensated in the speed controller; and therefore, a new control strategy is formed. The new control method is applicable in a vector control system of the permanent magnet synchronous motor; a current-speed double-closed-ring control structure is adopted; for buffeting and anti-interference problems in the sliding-mode control, an integral sliding-mode surface and a new reaching law are added based on the conventional sliding-mode speed controller; simultaneously, the disturbance observer is added; disturbance due to load changeis effectively inhibited; the responsiveness of the system is improved; buffeting of the system is reduced; and the anti-interference performance and the robustness of the system in a complex environment are obviously improved.

Owner:ZHEJIANG SCI-TECH UNIV

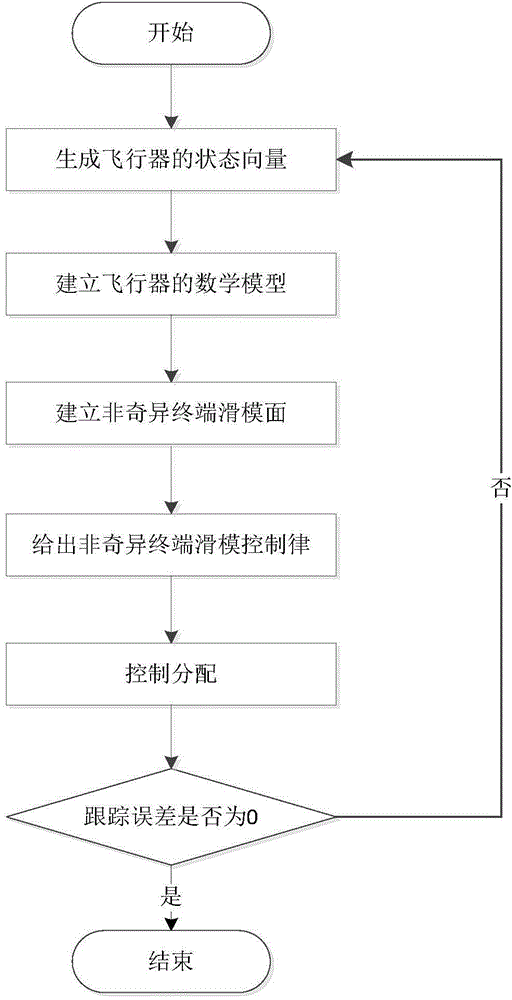

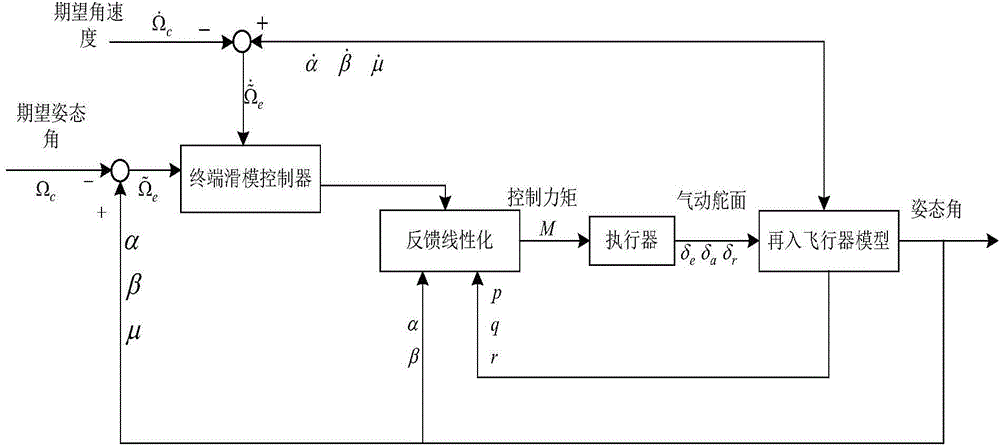

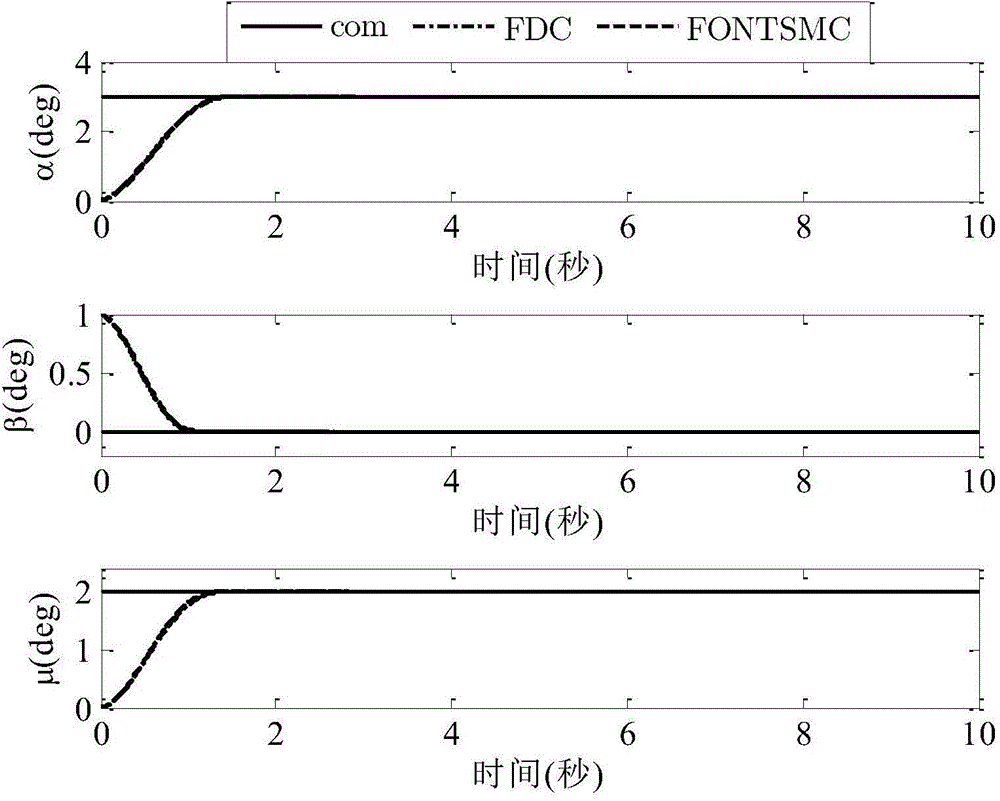

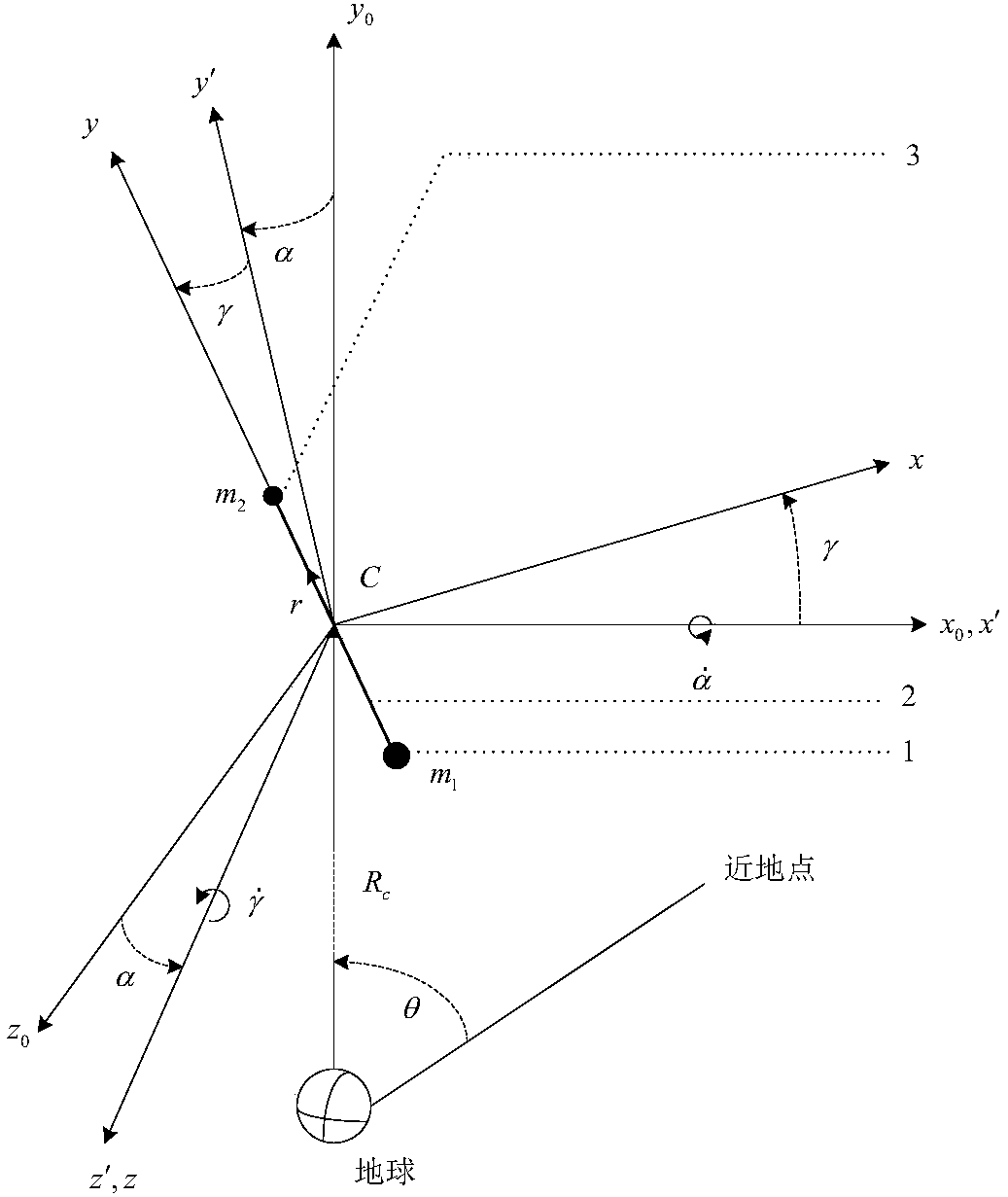

Reentry vehicle full-order non-singular terminal sliding mode posture control method

InactiveCN104950898AImprove performanceFast convergenceAttitude controlDifferentiatorAttitude control

The invention discloses a reentry vehicle full-order non-singular terminal sliding mode posture control method, relates to a reentry vehicle full-order non-singular terminal sliding mode posture control method based on a robust differentiator, and belongs to the technical field of vehicle control. The method includes the steps: generating the state vector of a vehicle; building a mathematical model of a reentry vehicle; simplifying the model of the reentry vehicle by feedback linearization; giving command information yc=(alpha c, beta c and mu c) T of a progressive tracking system for posture angles alpha, beta and mu of the vehicle when external interference exists in the system and parameters are uncertain; controlling allocation to obtain a rudder reflection angle command delta=(delta e, delta a and delta r) T; inputting the obtained rudder reflection angle command to the vehicle and controlling the posture of the vehicle. Tracking errors can be converged into zero within limited time, singular problems of controller output can be avoided, measuring noise generated by a traditional differentiator is suppressed by estimating error second-order derivatives, and buffeting of control quantity is eliminated by boundary layer and low-pass filtering techniques.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Sliding bearing

InactiveUS20060215944A1Easy to adjustReduce coefficient of frictionShaftsRotary machine partsEngineeringSynthetic resin

A sliding bearing (1) includes an upper casing (3) which is made of polyacetal resin as a synthetic resin, has an annular surface (2), and serves as a first bearing body; a second bearing body (5) which is made of a synthetic resin, is superposed on the upper casing (3) so as to be rotatable about an axis (O), and has an synthetic resin-made annular surface (4) opposed to the annular surface (2); and a synthetic resin-made annular sheet (6) which is interposed between the annular surfaces (2) and (4) and slidably abuts against at least one of the upper casing (3) and the bearing body (5).

Owner:OILES CORP

Sliding bearing

InactiveUS20070237439A1Easy to adjustEliminate chatterShaftsRotary machine partsEngineeringSynthetic resin

A sliding bearing (1) includes an upper casing (3) which is made of polyacetal resin as a synthetic resin, has an annular surface (2), and serves as a first bearing body; a second bearing body (5) which is made of a synthetic resin, is superposed on the upper casing (3) so as to be rotatable about an axis (0), and has an synthetic resin-made annular surface (4) opposed to the annular surface (2); and a synthetic resin-made annular sheet (6) which is interposed between the annular surfaces (2) and (4) and slidably abuts against at least one of the upper casing (3) and the bearing body (5).

Owner:OILES CORP

Terminal cooperative control method of four-rotor unmanned aerial vehicle

ActiveCN106094855AEliminate chatterFast dynamic responseAttitude controlPosition/course control in three dimensionsInner loopDynamic models

The invention relates to a terminal cooperative control method of a four-rotor unmanned aerial vehicle. The method includes the following steps that: the dynamic model of the four-rotor unmanned aerial vehicle is established based on Newton-Euler formula; the coupling relation of the position and attitude of the four-rotor unmanned aerial vehicle is decoupled, so that respective control can be carried out; a position terminal manifold and an attitude terminal manifold are constructed in a system state space, so that system error convergence speed can be accelerated; a position terminal cooperative controller and an attitude terminal cooperative controller are designed according to the dynamic characteristics of the corresponding manifolds, so that a control input buffeting phenomenon can be eliminated; and the two controllers are connected in series through a decoupling result, and an inner loop and an outer loop can be constructed so as to realize the flight control of the four-rotor unmanned aerial vehicle. The terminal cooperative control method of the four-rotor unmanned aerial vehicle provided by the invention can eliminate the control input buffeting phenomenon, improve the system response speed and realize the buffeting-free quick control of the four-rotor unmanned aerial vehicle.

Owner:ZHEJIANG UNIV OF TECH

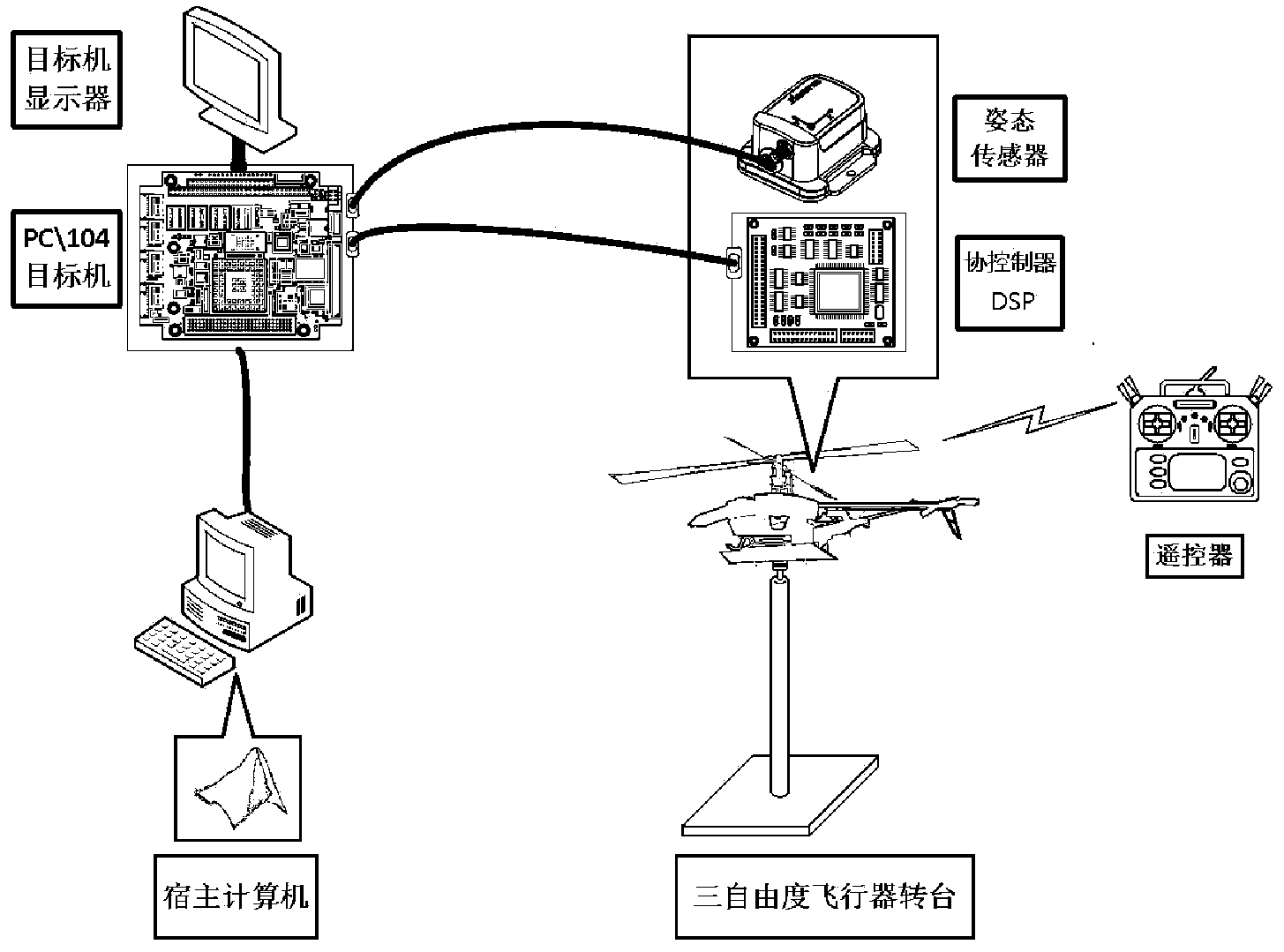

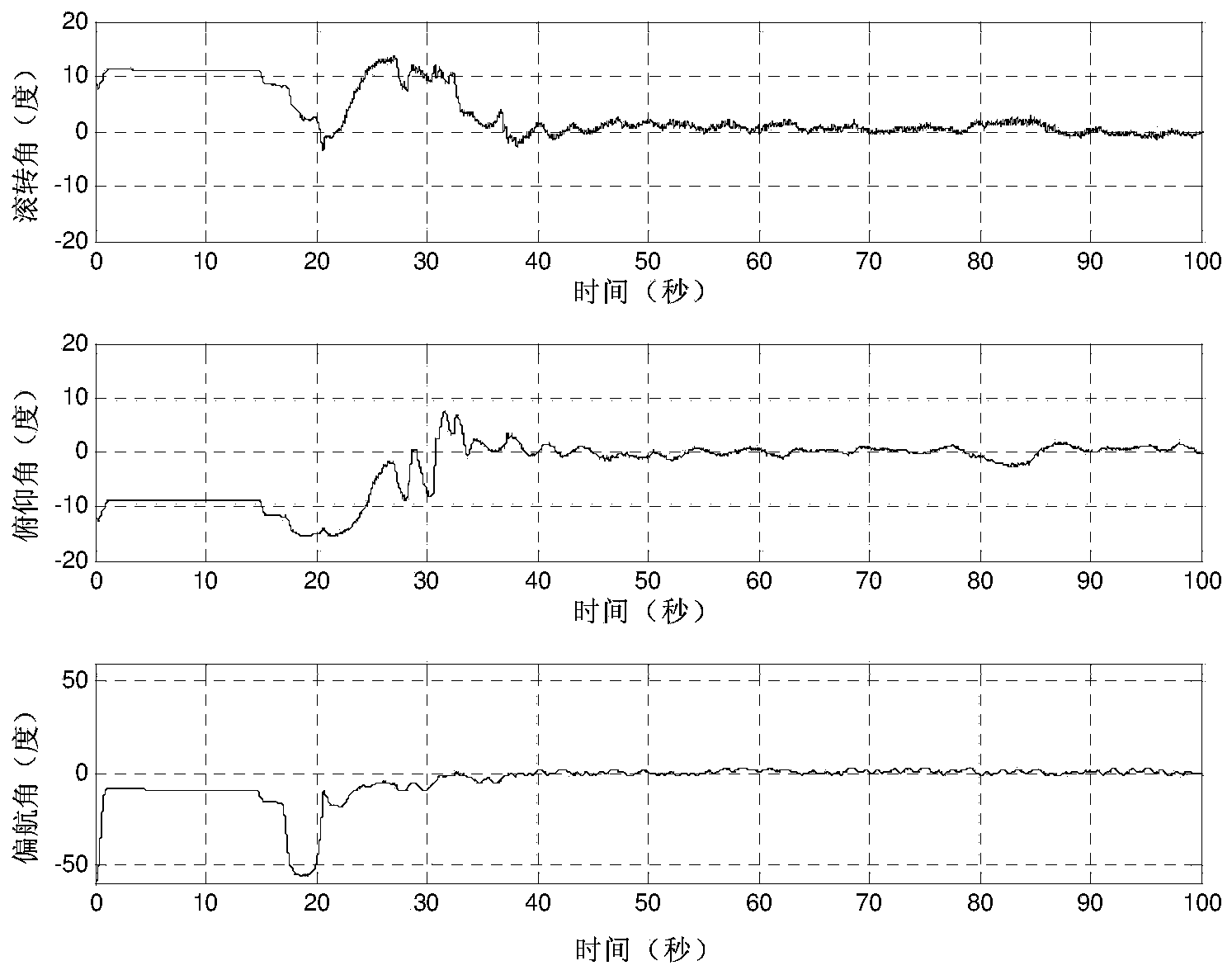

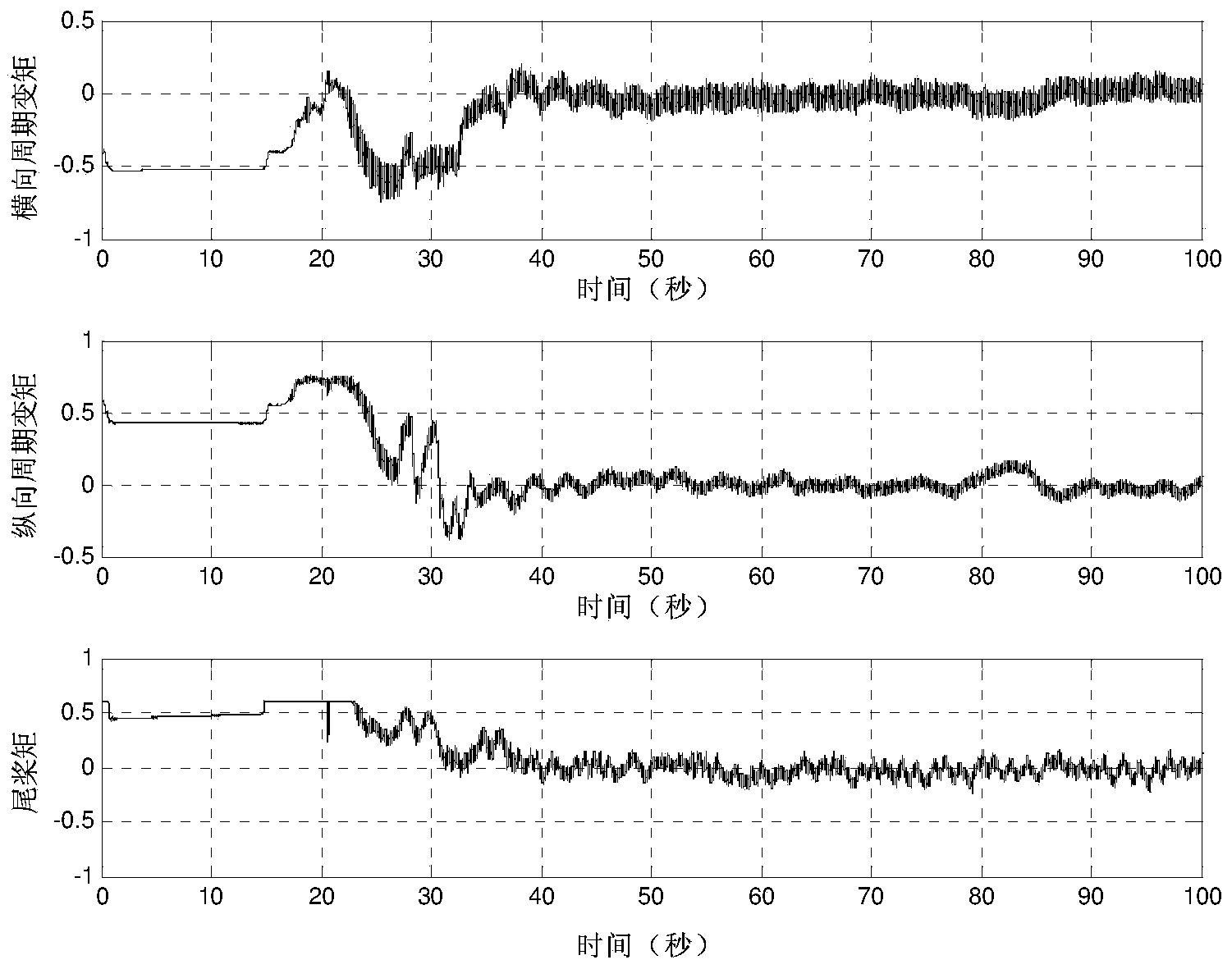

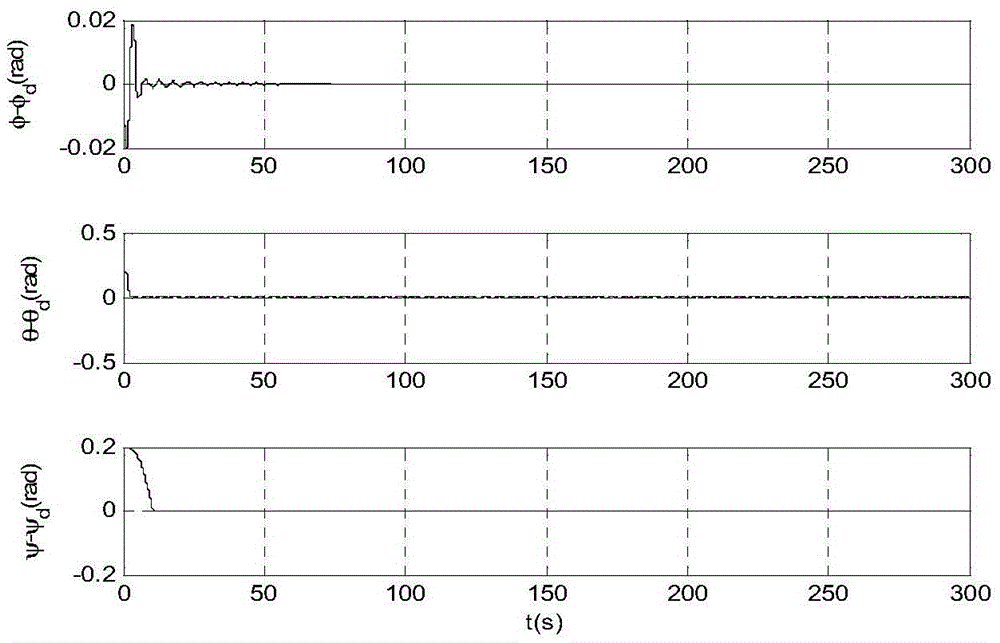

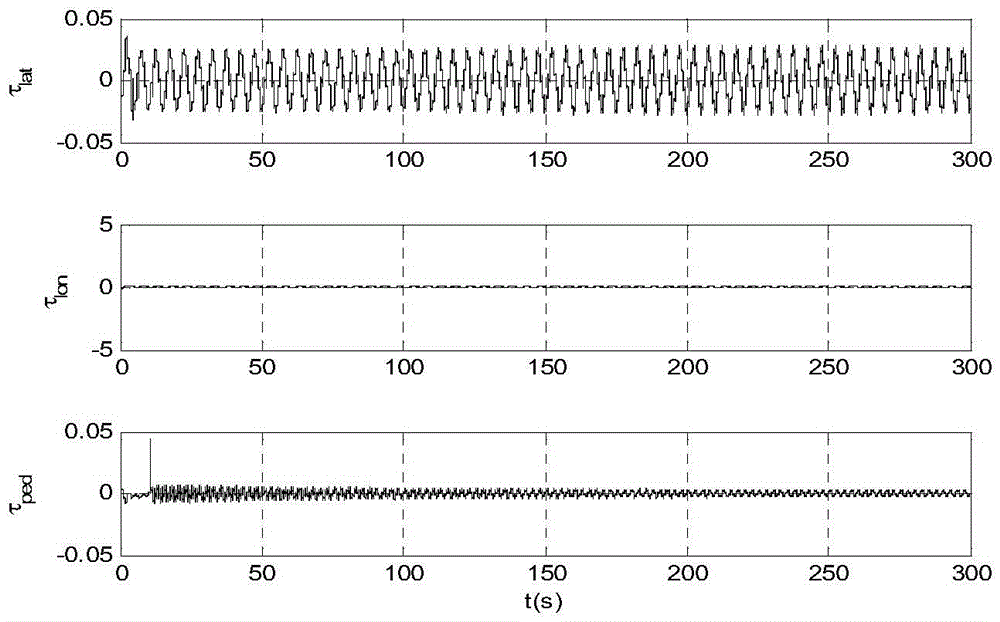

Nonlinear robust control method of posture of single-rotor unmanned helicopter based on fuzzy feedforward

The invention belongs to the field of miniature rotor type unmanned aerial vehicle autonomous flight control and research, and provides a method for controlling an unmanned aerial vehicle and for making an unmanned helicopter quickly and accurately stabilized and controlled. A controller less depends on prior knowledge of models and has good robustness on uncertainty of a system. According to the technical scheme, a nonlinear robust control method of the posture of the single-rotor unmanned helicopter based on fuzzy feedforward includes the following steps that firstly, the form of a single-rotor unmanned helicopter dynamical model and the form of a single-rotor unmanned helicopter posture dynamical model are as follows; secondly, the nonlinear semicontinuous robust controller based on fuzzy feedforward is designed (img file=' DDA0000463767750000011.TIF' wi=' 754' he=' 72' / ) ( / maths). The method is mainly applied to the design and manufacture of the miniature rotor type unmanned aerial vehicle.

Owner:TIANJIN UNIV

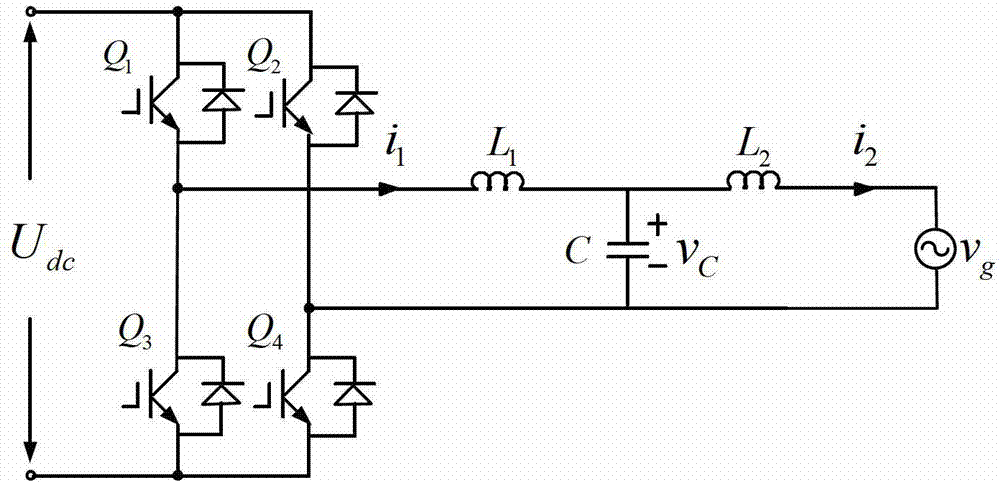

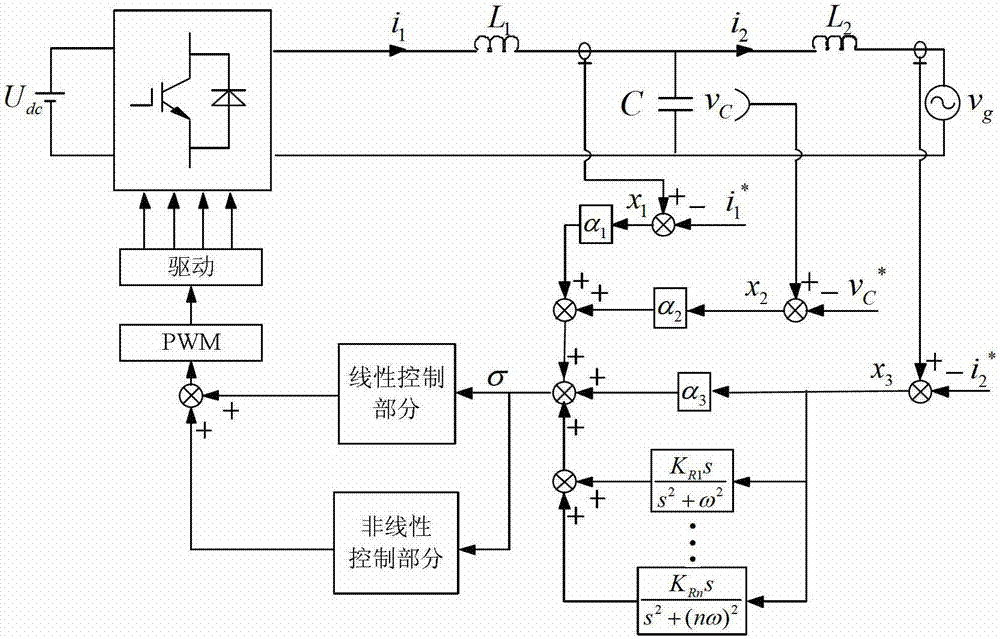

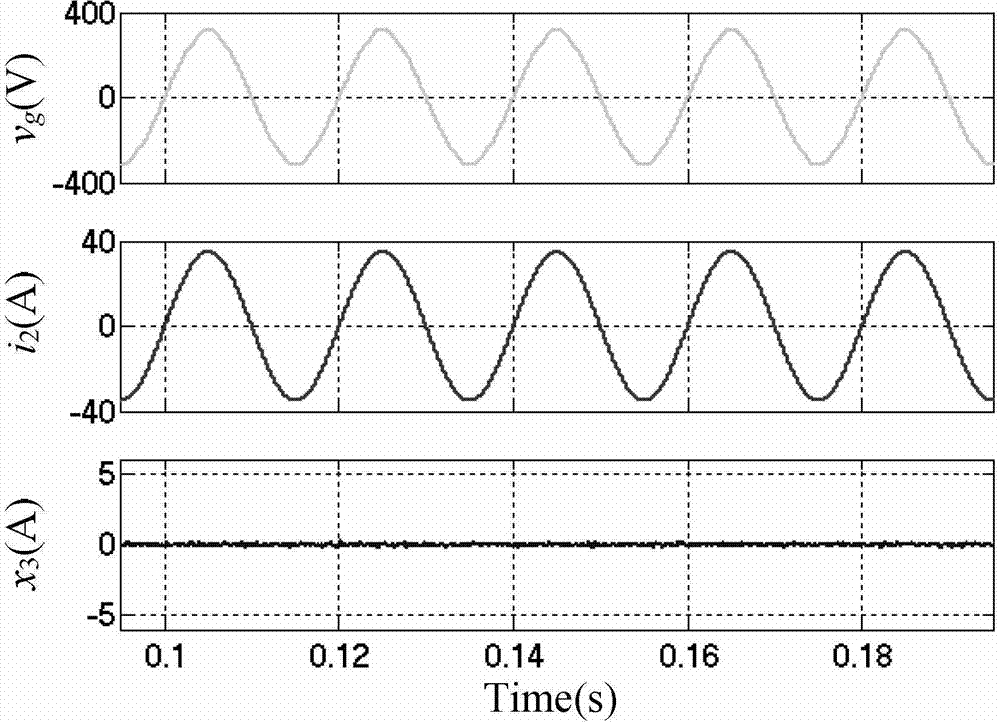

Sliding-mode variable structure control method of single phase grid-connected inverter based on multi-resonant sliding mode surface

ActiveCN102868183AImprove robustnessImprove dynamic response performanceSingle network parallel feeding arrangementsHarmonic reduction arrangementLinear state feedbackCarrier signal

The invention discloses a sliding-mode variable structure control method of a single phase grid-connected inverter based on a multi-resonant sliding mode surface. The method comprises the steps of: firstly, building a linear sliding mode surface according to detected current i1 of an inverter side filter inductor of the single phase grid-connected inverter, the voltage vc of a filter capacitor, the current i2 of a network side filter inductor, and the target output current i1* of a grid-connected inverter system, the target voltage vC* of the filter capacitor and the grid-connected target current i2*; adding a resonant item into the linear sliding mode surface so as to obtain the multi-resonant sliding mode surface; designing a sliding-mode variable structure controller by the multi-resonant sliding mode surface, leading a linear state feedback controller to an original nonlinear controller to obtain a final control quantity modulation wave d(s), and finally comparing the modulation wave with a carrier wave to generate a driving signal for driving a switch tube to act. According to the control method disclosed by the invention, the robustness and dynamic response ability of the grid-connected inverter system are improved; the tracking accuracy of grid-connected current is also improved; the harmonic content is removed, and the control method is simple and easy to achieve.

Owner:XI AN JIAOTONG UNIV

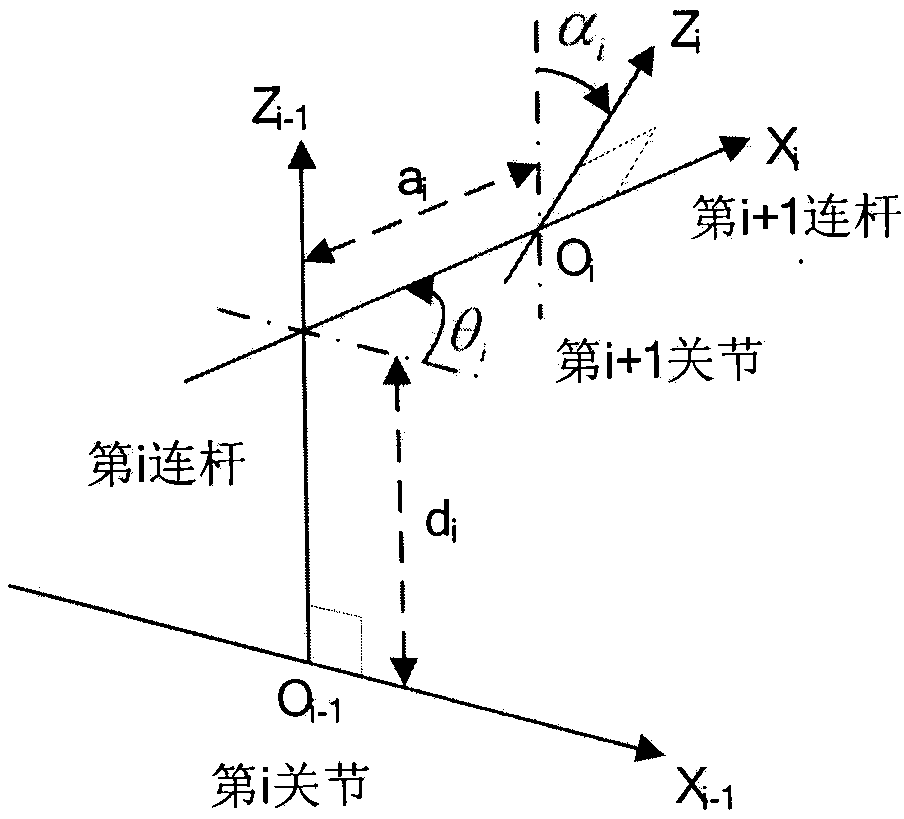

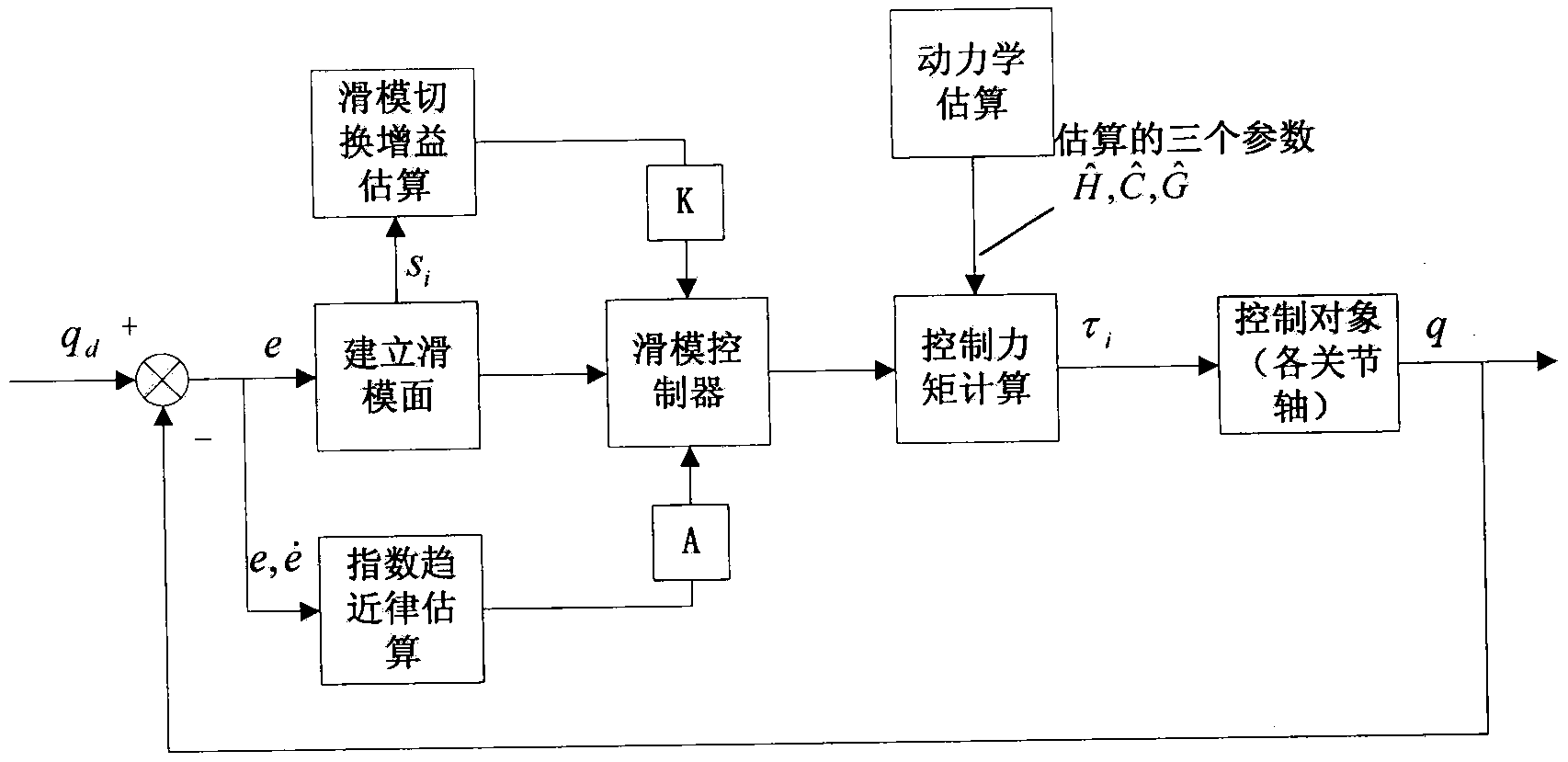

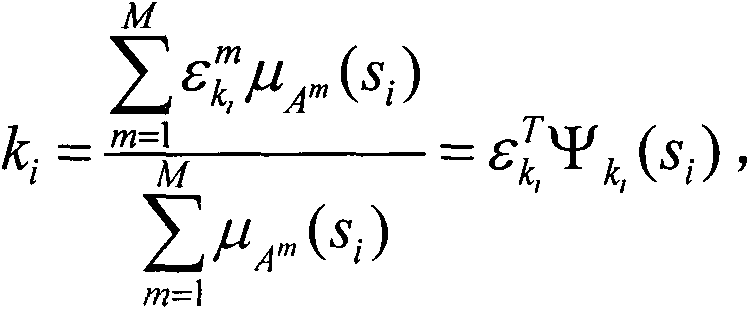

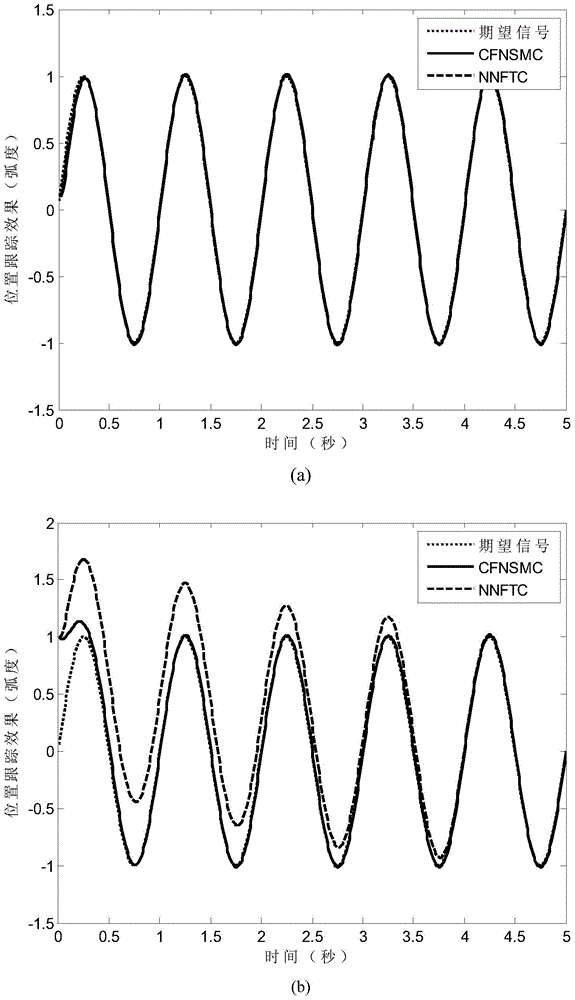

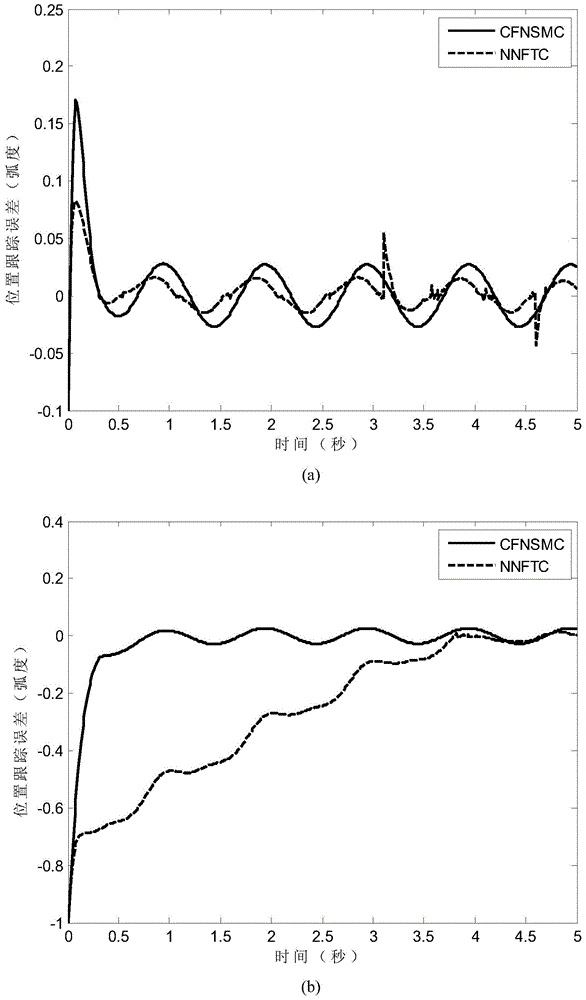

High-accuracy position control method for serial robot

InactiveCN103433924AImprove tracking accuracyImprove chatteringProgramme-controlled manipulatorMathematical modelRobot control

The invention provides an improved serial robot control method. According to the improved serial robot control method, a specific mathematical model of a controlled object does not need to be known; the improved serial robot control method has strong robustness and high tracking precision; and moreover, the problems of moment jump and velocity jump, which are caused by deviation of an original pose in a large range, are improved. Strong robustness in the control is ensured by adopting a slip form method on the basis of a torque calculation method; the buffeting problem in the slip form control is eliminated by introducing an exponential approach law; a self-adaptive fuzzy controller is adopted to carry out estimation on a slip form switching gain according to slip form arrival conditions so as to reinforce adaptive capacity of the controlled object for uncertain factors and eliminate the buffeting phenomenon of output torque in the slip form control; and another fuzzy self-adaptive controller is adopted to correct a coefficient of the exponential approach law so as to improve the problems of large moment and velocity jumps, which are caused by deviation of the original pose in a large range.

Owner:WUXI XINJIE ELECTRICAL +1

Neural network full order slip form control method for mechanical arm servo system

The invention discloses a neural network full order slip form control method for a mechanical arm servo system, which, aiming at the mechanical arm servo system containing a dynamic execution mechanism, is designed by utilizing the full-order slip form control method and combining with the neural network. The full order slip form is designed to guarantee the finite time convergence of the system and can eliminate buffeting and singular problems by avoiding the differential item in a practical control system. Besides, the neural network is used for approaching unknown non-linearity of the system and non-determinacy of internal-external disturbance. The neural network full order slip form control method for a mechanical arm servo system realizes provides a method to eliminate the buffeting and the singularity problem of the surface of the slip form, effectively complements the unknown linearity and the control method of the internal-external disturbance, and realizes fast and stable control of the system.

Owner:深圳市子庄智能科技有限公司

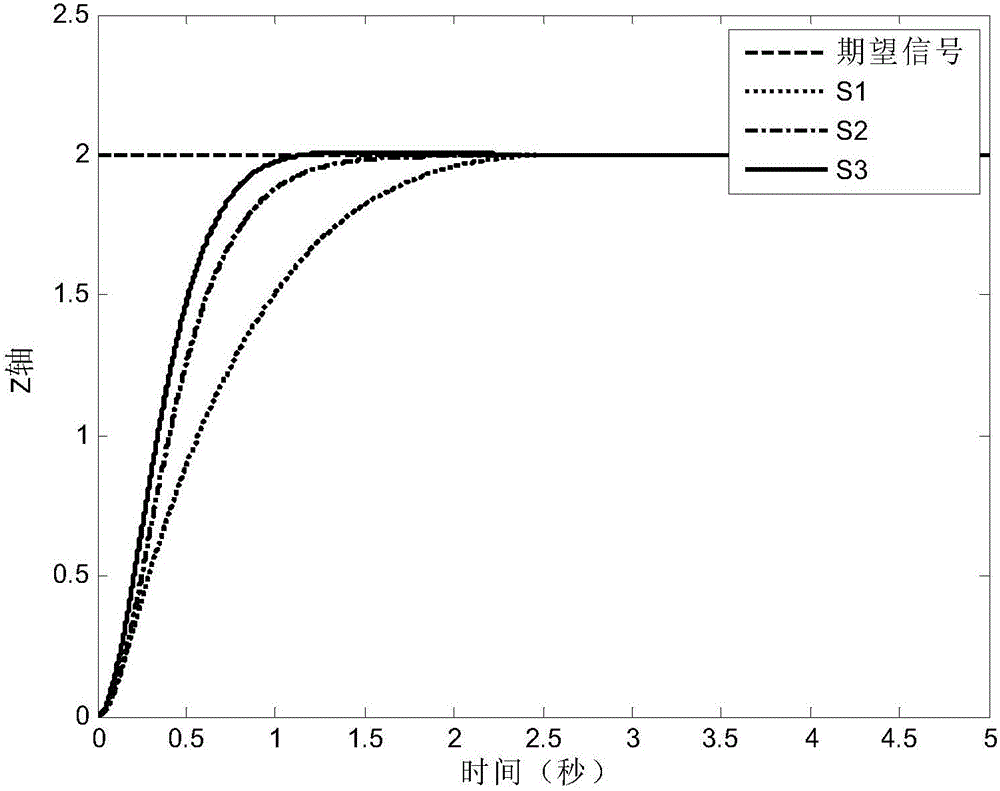

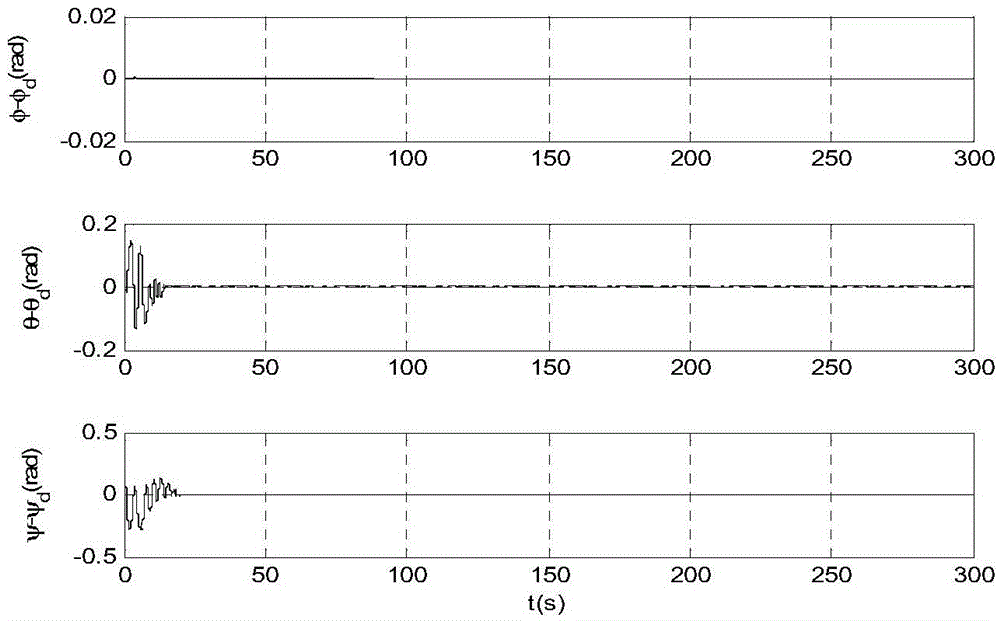

Self-adaptive control method of rapid attitude error convergence for small unmanned helicopter

InactiveCN105607473AGood attitude tracking controlEliminate chatterAttitude controlAdaptive controlDynamic modelsAttitude control

The invention relates to a nonlinear control method for a small unmanned helicopter, especially to an attitude control method for the small unmanned helicopter based on a second-order self-adaptive terminal sliding mode controller, and realizes rapid attitude error convergence and maintains relatively accurate attitude tracking control effect and relatively high system robustness under the condition that external interference of the small unmanned helicopter exists. According to the technical scheme of the invention, a second-order self-adaptive terminal sliding-mode method is applied to attitude system control of the small unmanned helicopter under the condition that the small unmanned helicopter has external interference. The method comprises the following steps that 1) an attitude dynamics model of the small unmanned helicopter is determined; 2) an attitude angle tracking error is defined, and a dynamics error model is arranged; 3) a control law is designed; and 4) self-adaptive control gain is designed. The method of the invention is mainly used for nonlinear control of the helicopter.

Owner:TIANJIN UNIV

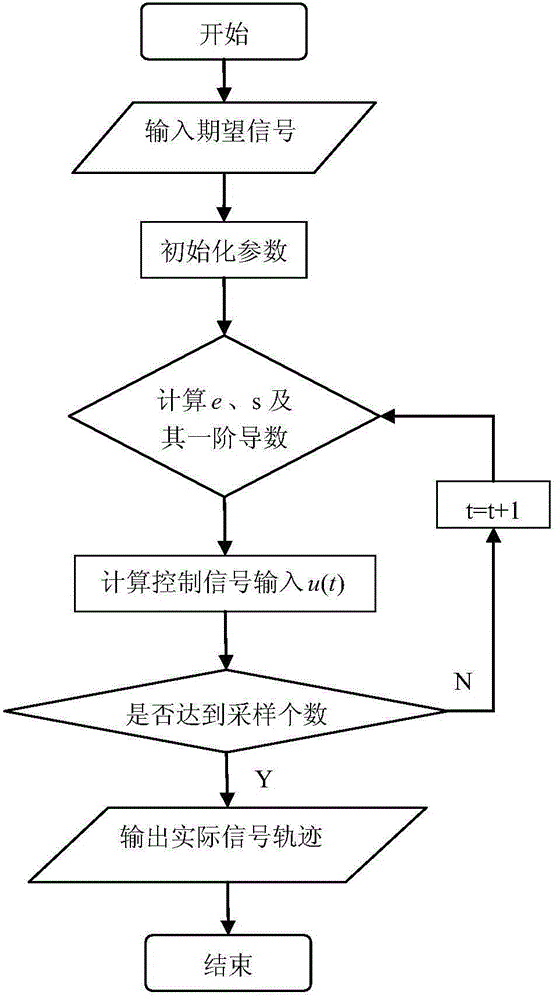

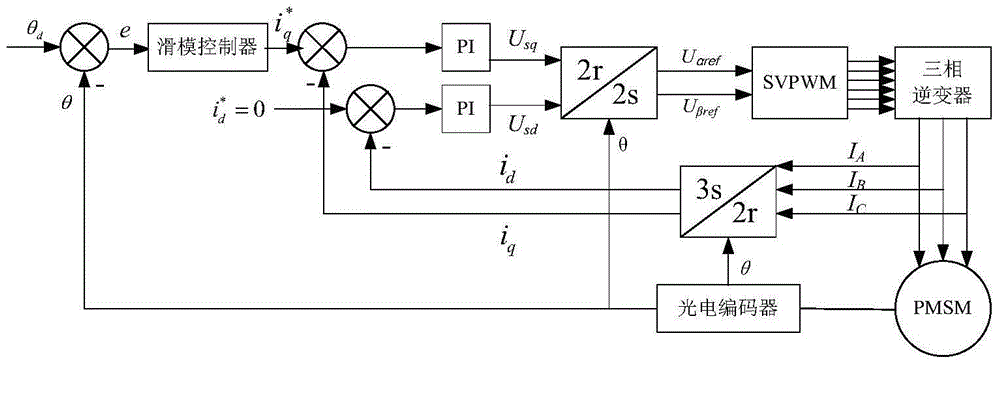

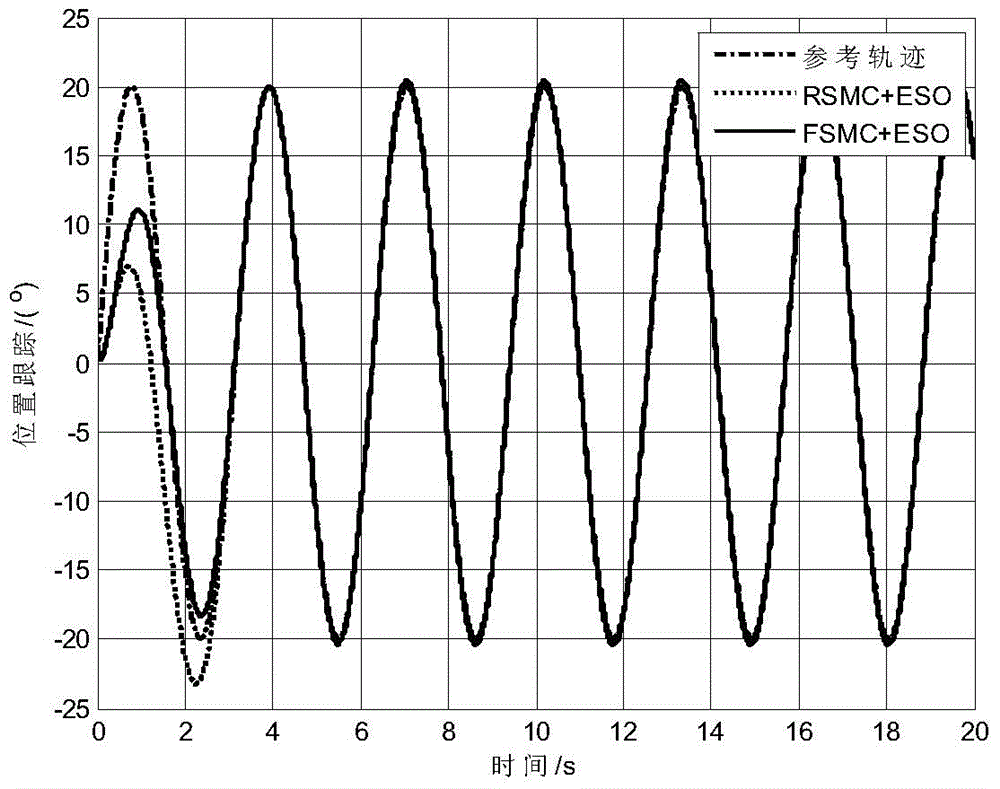

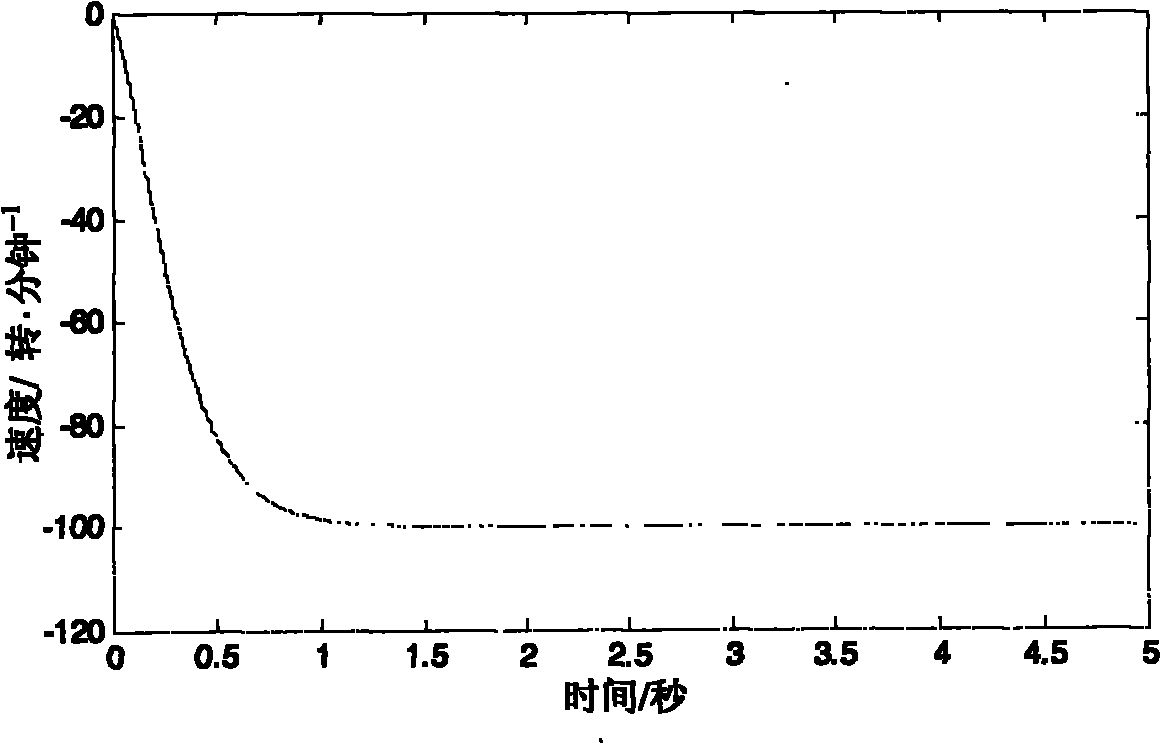

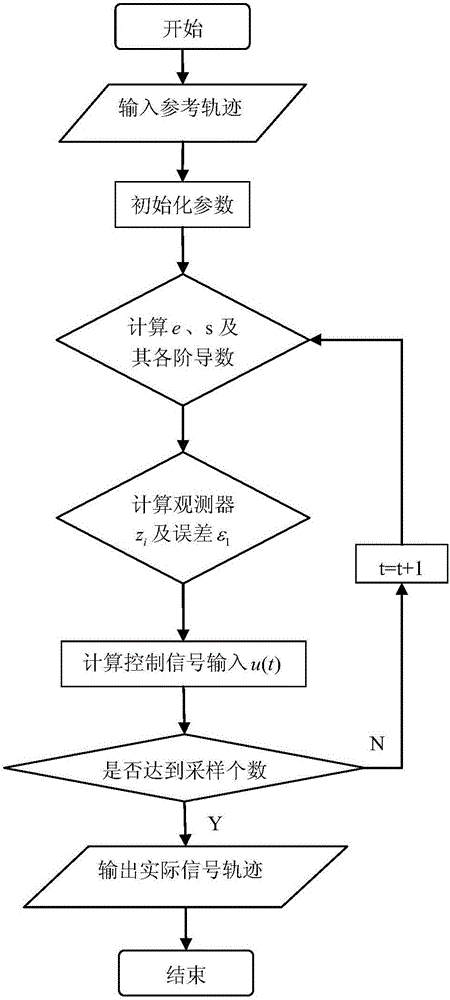

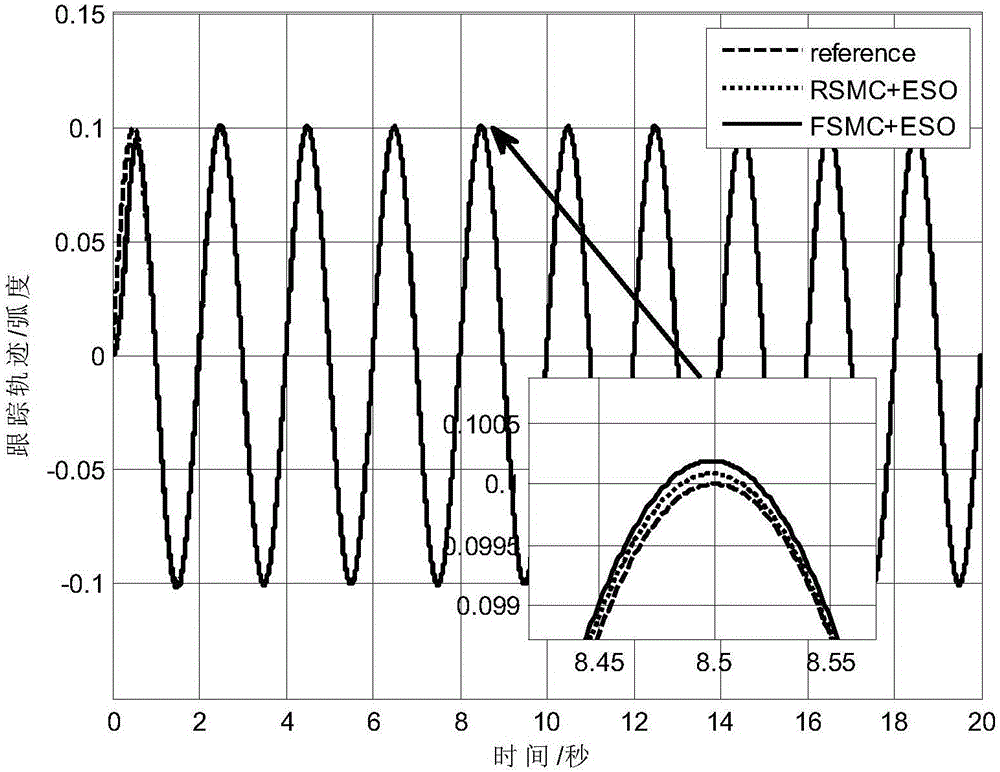

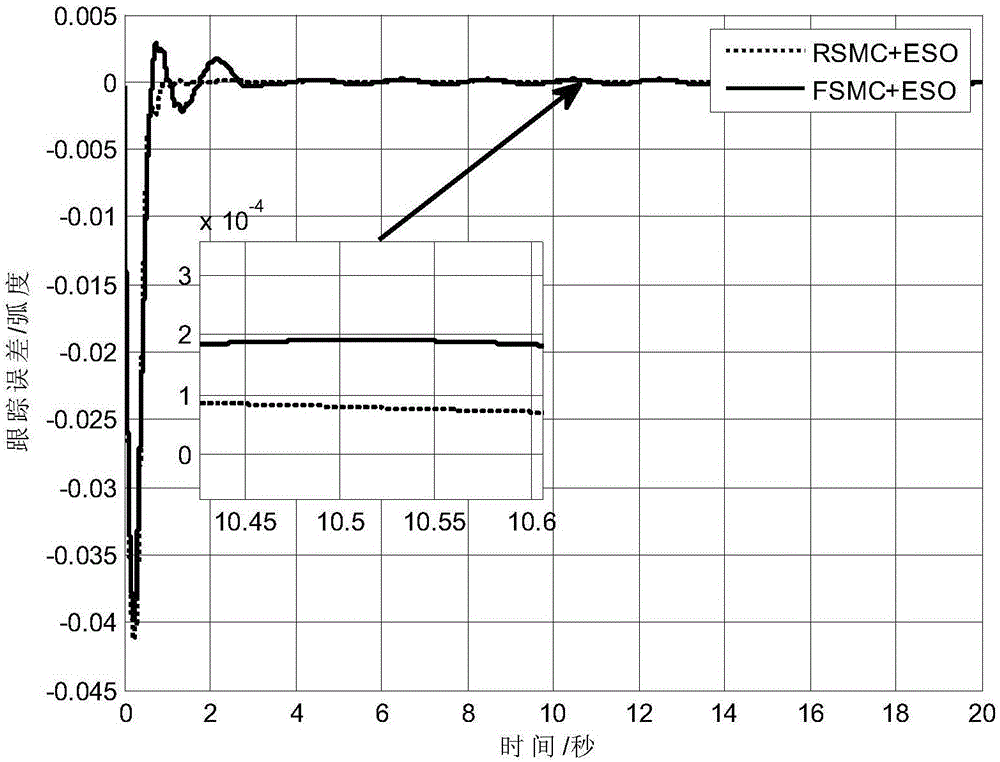

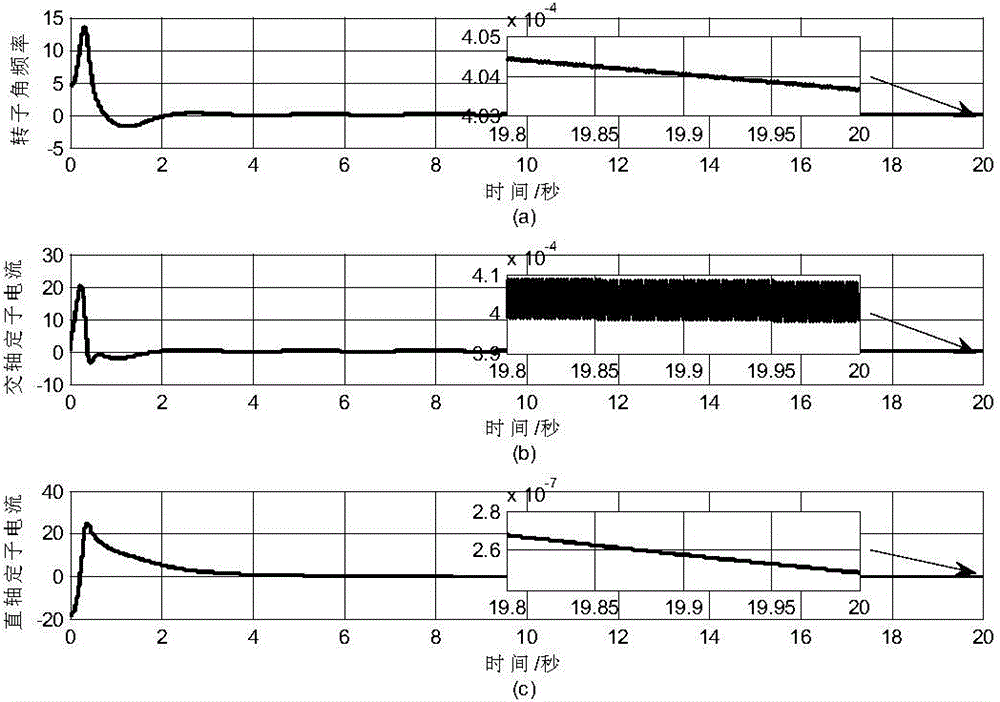

Permanent magnet synchronous motor full-order sliding mode variable structure position servo control method based on extended state observer

ActiveCN104682805AAccurate trackingEliminate chatterElectronic commutation motor controlVector control systemsState observerElectric machinery

The invention provides a permanent magnet synchronous motor full-order sliding mode variable structure position servo control method based on an extended state observer. The permanent magnet synchronous motor full-order sliding mode variable structure position servo control method comprises the following steps of establishing a permanent magnet synchronous motor system, and initializing system state and related control parameters; designing the extended state observer; based on the extended state observer, designing a full-order sliding mode controller, eliminating the chattering problem in sliding mode control, and guaranteeing that the system state can be quickly and stably converged to be zero. According to the full-order sliding mode variable structure position servo control method provided by the invention, the chattering problem of sliding mode control can be improved, the control precision of the system is improved, and the implementation for quick and accurate tracking on desired trajectories of motor output position is guaranteed.

Owner:TSINGYAN HUAKE INST OF NEW ENERGY

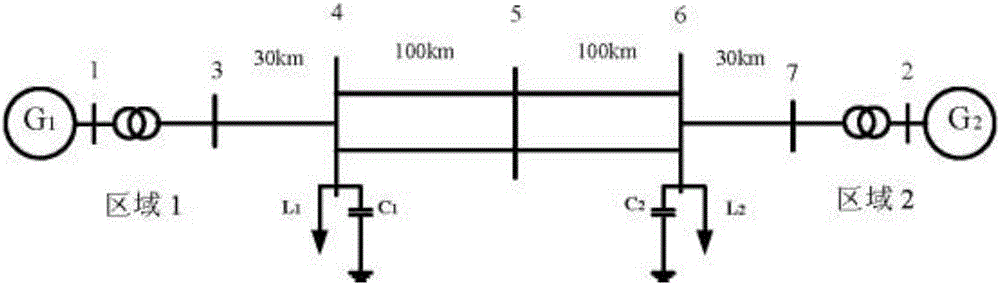

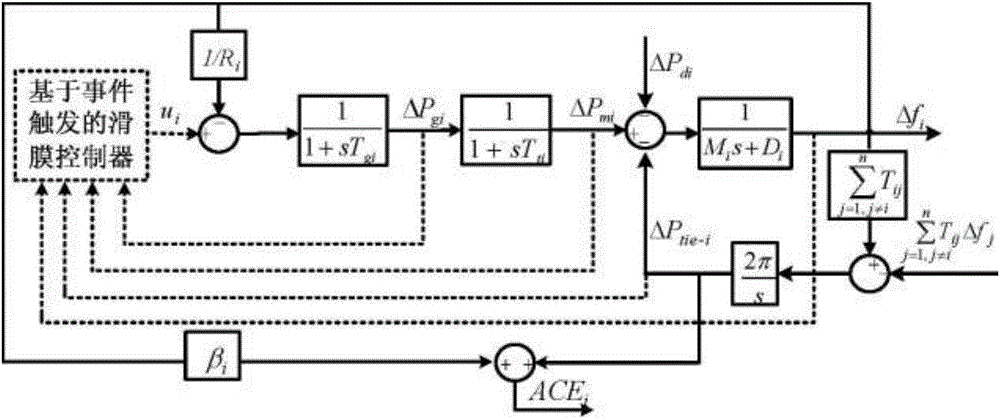

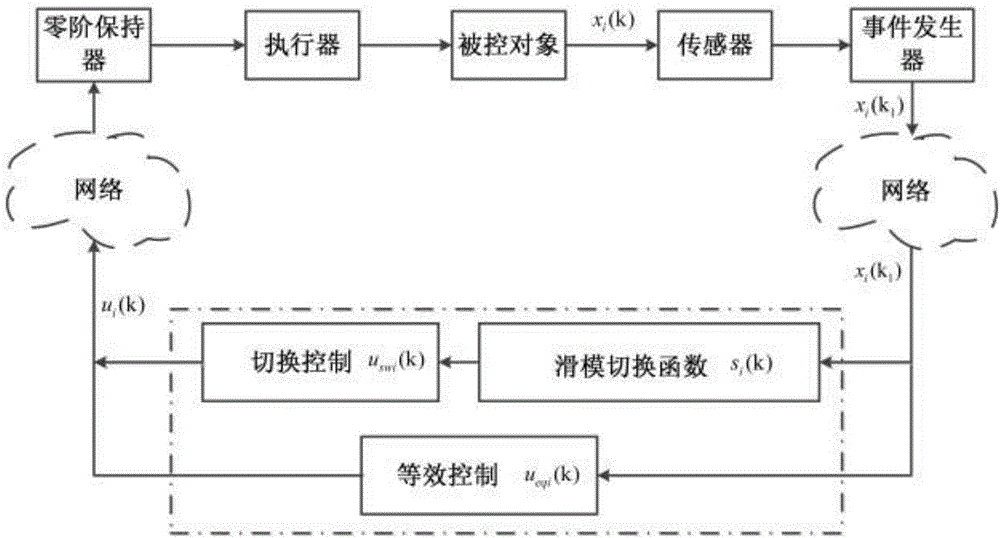

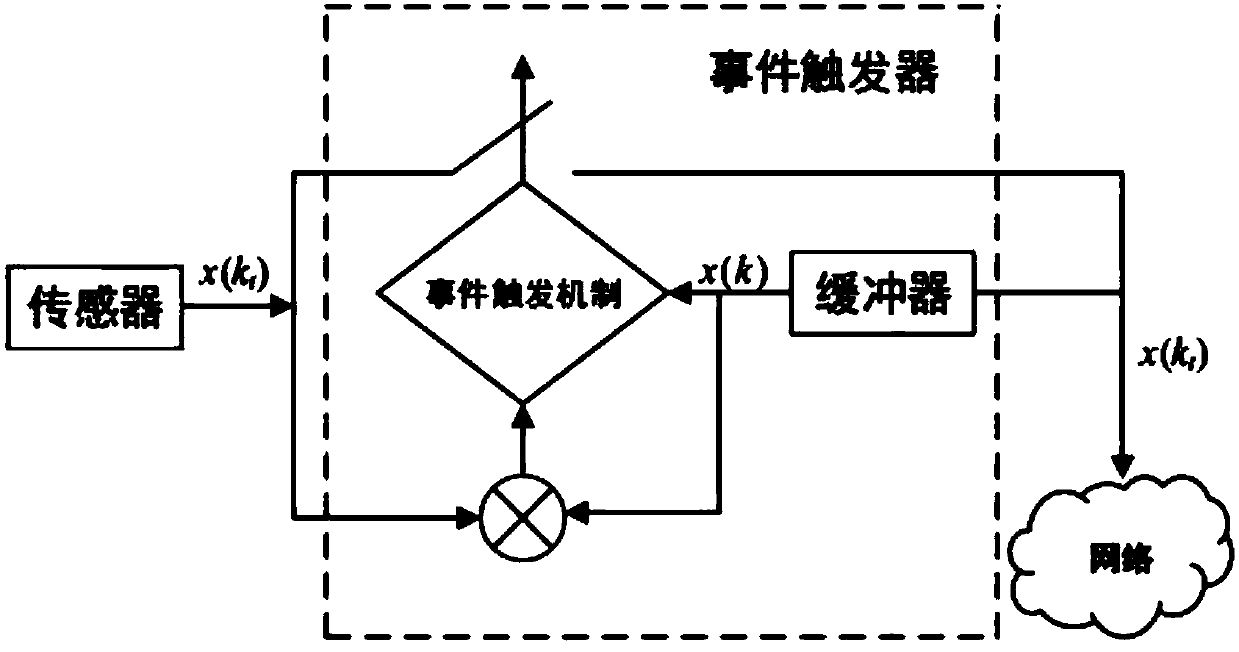

Event trigger load frequency control-based method of multi-zone interconnected power system

InactiveCN106374461ASuppress power dynamic deviationReduce occupancyPower oscillations reduction/preventionControl systemMathematical model

The invention discloses an event trigger load frequency control-based method of a multi-zone interconnected power system. The method comprises the steps of (1) building a mathematical model for load frequency control of a multi-energy power system; (2) researching an even trigger condition design of the load frequency control of the multi-zone interconnected power system on the basis of an event trigger mechanism; and (3) designing an event trigger-based controller. The system directly enters a sliding mode state from the beginning and a sliding mode exists in the overall control system; and for a sliding mode control system, after the system enters the sliding mode state, the dynamic property of the system is completely determined by the sliding mode state. The control method has the desired dynamic characteristic and has complete robustness on change of system parameters and external disturbance; and buffeting is eliminated. Due to use of the event trigger mechanism, the multi-energy power system can effectively inhibit dynamic frequency deviation and dynamic deviation of tie-line power and effectively reduce the network bandwidth occupancy.

Owner:CHONGQING UNIV

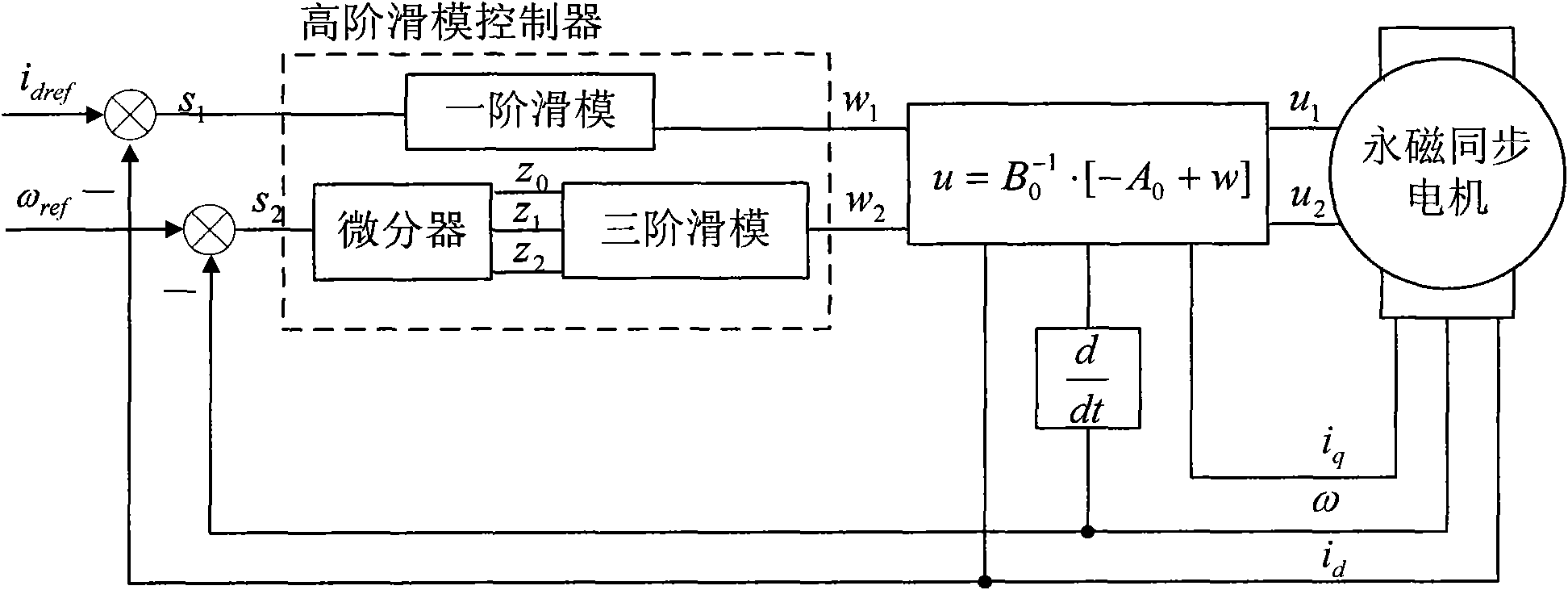

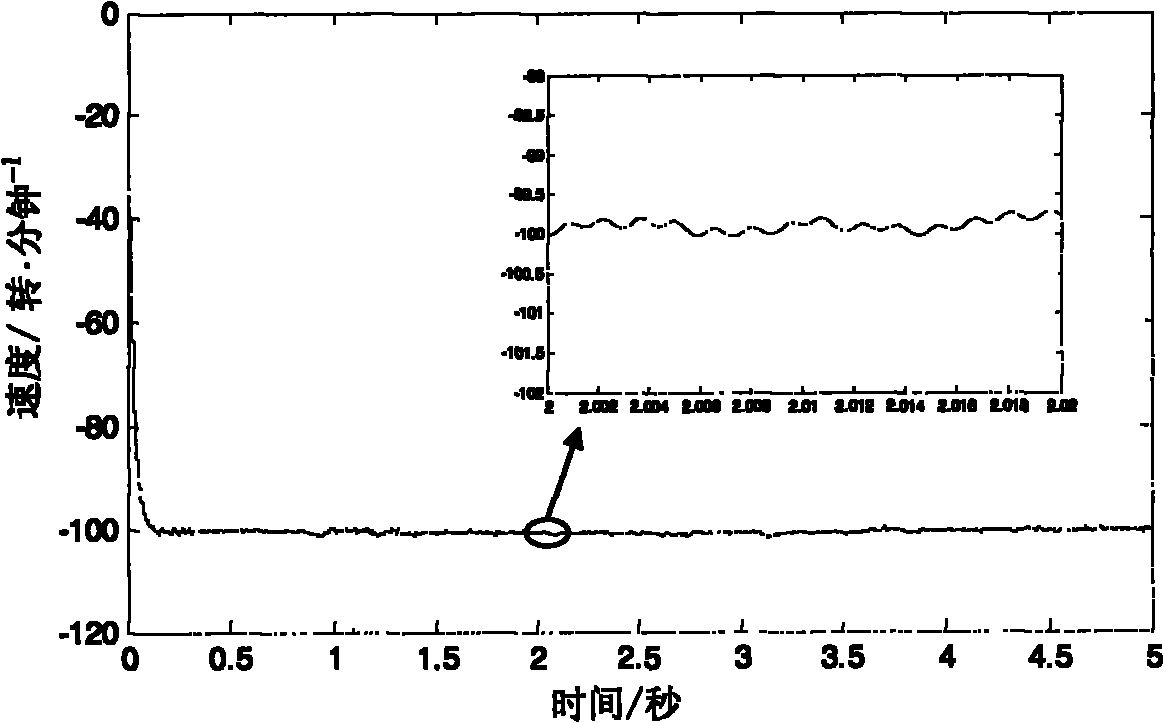

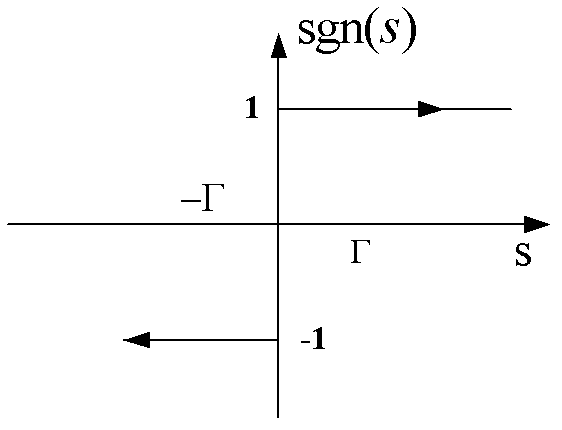

Method for removing chattering of sliding mode control of permanent magnet synchronous motor

InactiveCN101860294AEliminate chatterImprove control accuracyVector control systemsSingle motor speed/torque controlMulti inputDifferentiator

The invention relates to a method for removing chattering of sliding mode control of a permanent magnet synchronous motor, which can realize the removal of the chattering phenomenon of the sliding mode control of the permanent magnet synchronous motor. The method has the technical characteristics that: 1, a nonlinear mathematical model of the permanent magnet synchronous motor is established; 2, the nonlinear mathematical model is subjected to decoupling by adopting feedback linearization theory of a nonlinear system; and 3, a corresponding high-order sliding mode controller is designed on the basis of decoupling control respectively. By adopting a high-order sliding mode control algorithm with a differentiator, although indeterminate parameters, external interference, and other factors are present in the system, a robust controller aiming at a multi-input multi-output nonlinear permanent magnet synchronous motor is designed. The controller has the advantages of removing the chattering of the traditional sliding modes, having control accuracy and strong robustness of the traditional sliding modes, and making the control rules not limited by the degree of correlation of the system.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Mechanical arm servo system full-order slide mold control method based on extended state observer

ActiveCN105045101AAchieve precise tracking controlEliminate chatterAdaptive controlDynamic modelsState observer

The invention discloses a mechanical arm servo system full-order slide mold control method based on an extended state observer. The method comprises the following steps: establishing a dynamic model of a mechanical arm servo system, and initializing a system state and control parameters; designing the extended state observer; and based on the extended state observer, designing a full-order slide mold controller. The invention provided by the invention can effectively improve the problem of slide mold buffeting of conventional slide mold control in the mechanical arm servo system, improves the robustness of the system to a certain degree and enables the mechanical arm servo system to realize accurate tracking control.

Owner:ZHEJIANG UNIV OF TECH

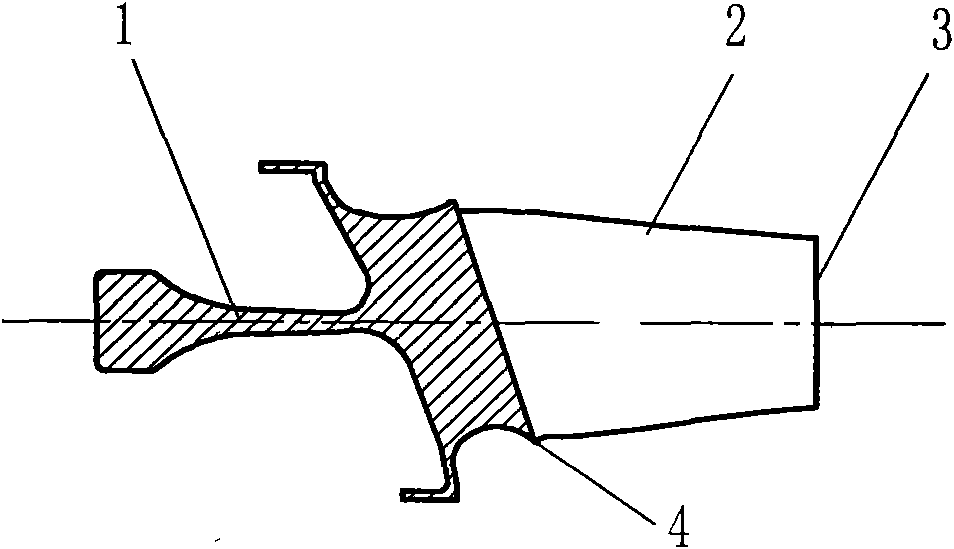

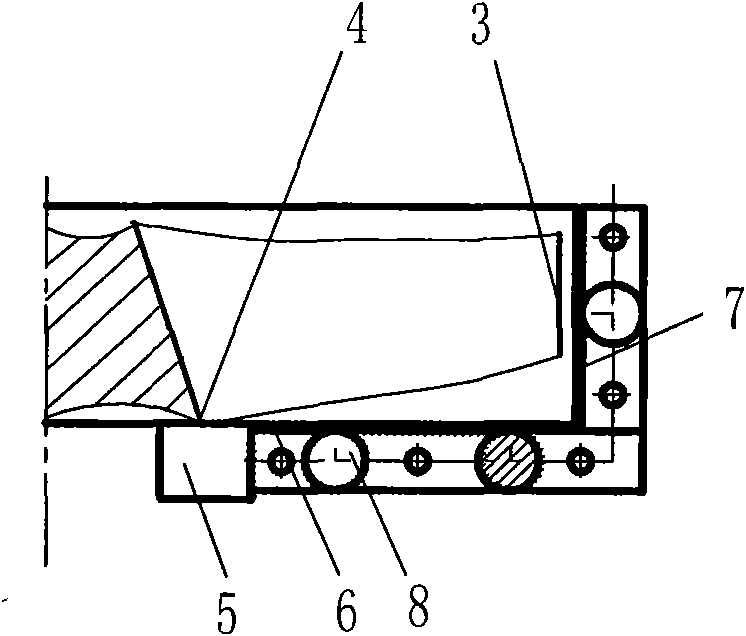

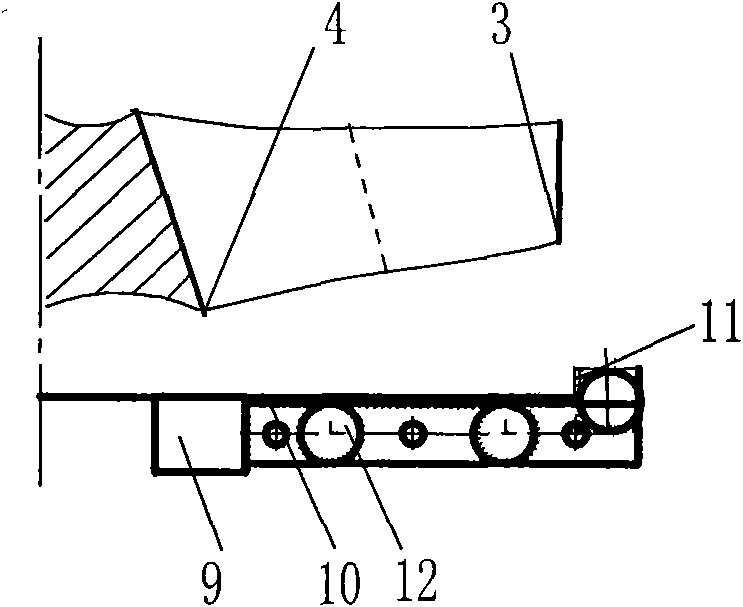

Method for milling and vibration-damping blisk

InactiveCN101912990AEliminate milling distortionEliminate ChatterMilling equipment detailsMaintainance and safety accessoriesEngineeringChatter mark

The invention belongs to the technical field of machining and discloses a method for milling and vibration-damping a blisk. The method comprises the following specific process steps of: (1) preparing a filling material according to the proportion; (2) melting the filling material; (3) mounting a pouring clamp; (4) pouring a filling agent; (5) condensing the filling agent at normal temperature, secondarily condensing the filling agent and checking the condensing state of the filling agent; (6) mounting a filtering clamp; and (7) carrying out the abutted milling processing and chip removal processing. By pouring the filling agent between the blisk and vanes in the milling processing of vane profile five coordinates of the blisk, the method enhances the rigidity of parts in the milling processing of the vanes, eliminates the chatter marks generated at the vent tip part of the vanes during milling and reduces the roughness of the surfaces of the vanes. Meanwhile, the rigidities of the parts and a clamping system thereof are enhanced, so that the milling feed rate is increased and the milling speed can be improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

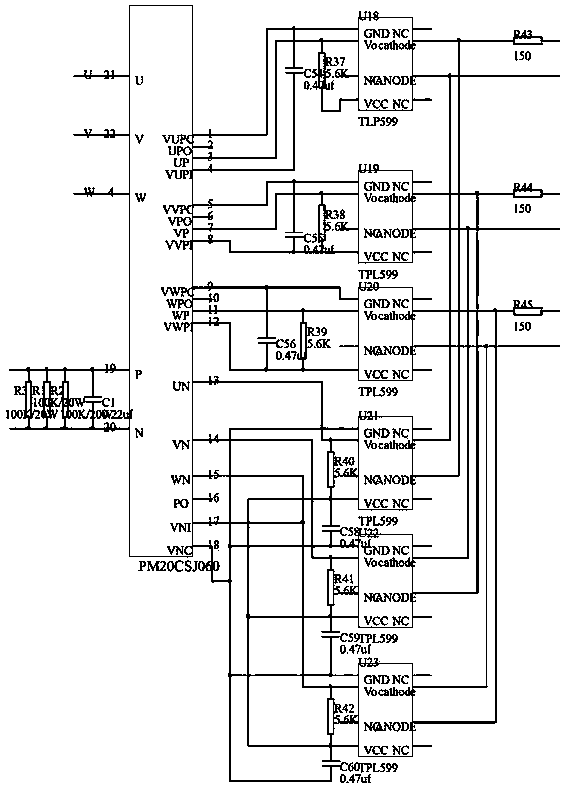

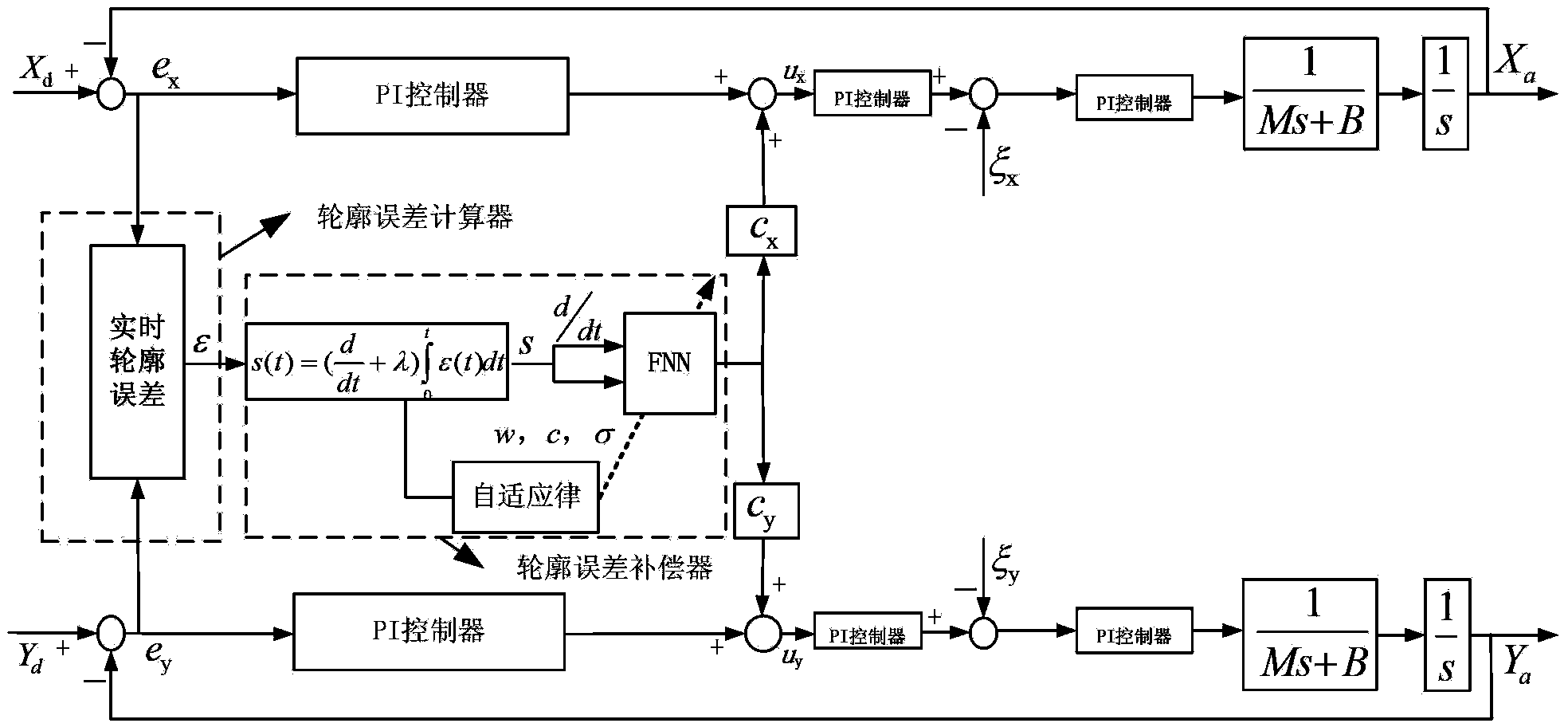

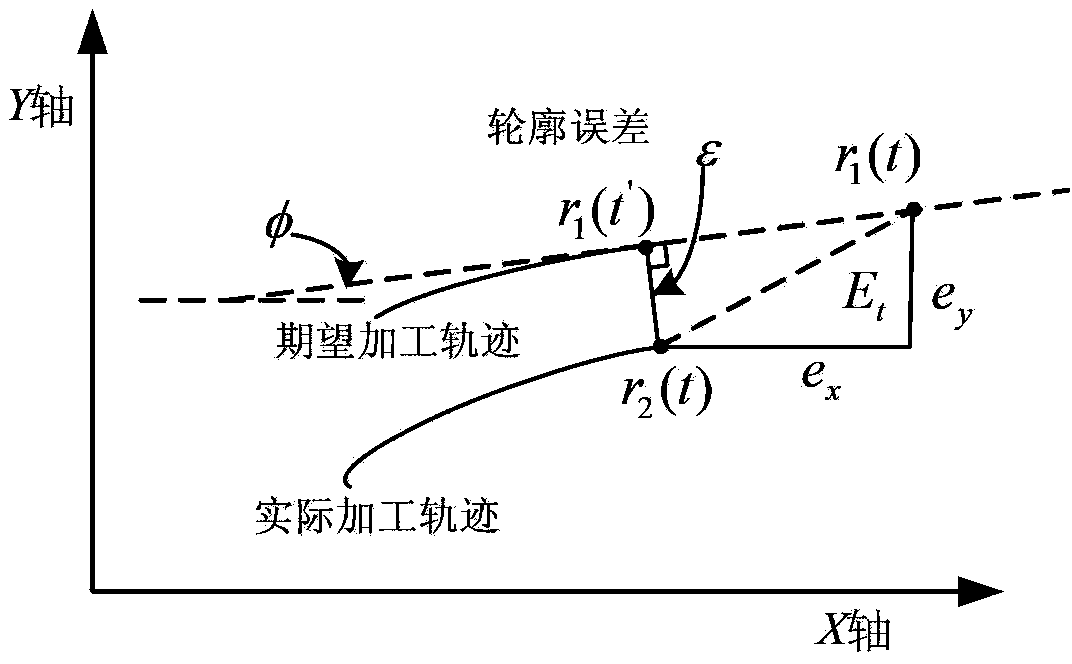

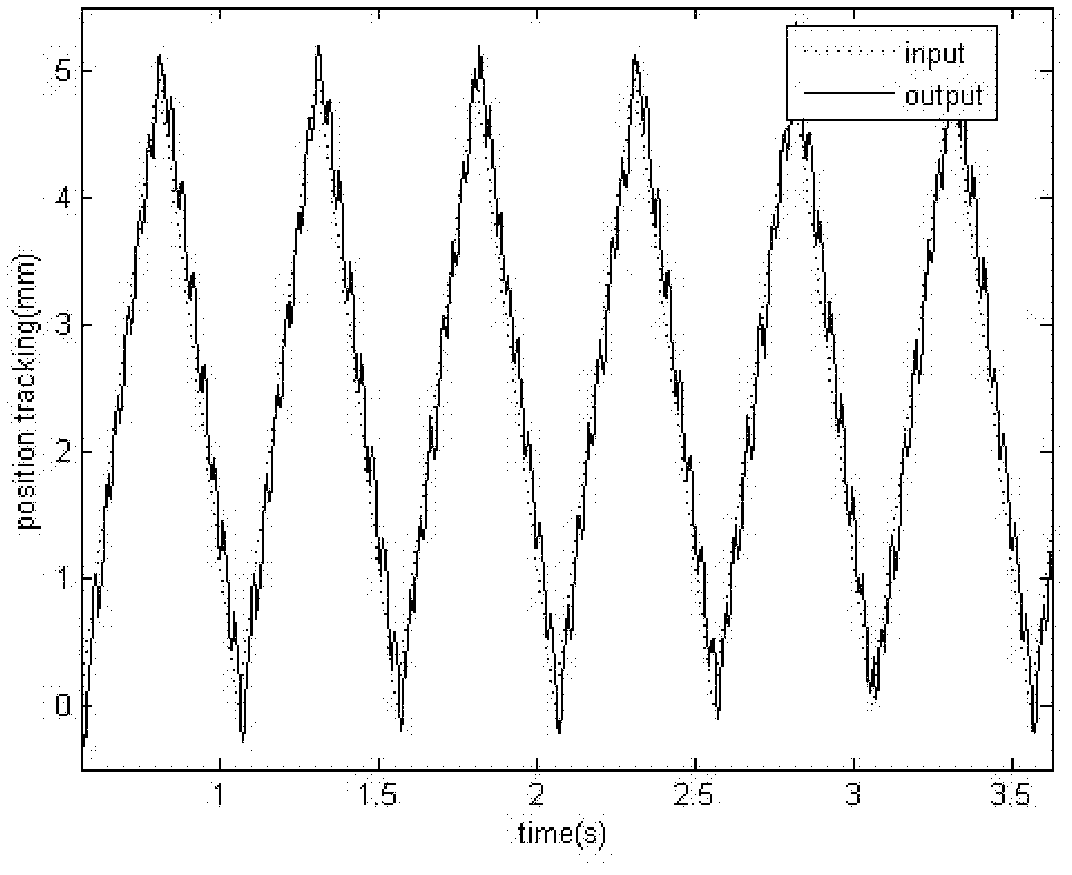

Double-linear-motor contour compensation device and method based on fuzzy RBF network sliding mode

InactiveCN103414419AEliminate chatterImprove profile accuracyElectronic commutation motor controlVector control systemsDigital signal processingGrating

The invention provides a double-linear-motor contour compensation device and method based on a fuzzy RBF network integral sliding mode with respect to a double-linear-motor numerical control feeding system with the axial direction being in mutual vertical movement. A real-time contour error is used as the input of a controller, the powerful self-learning ability of the controller enables the contour error to tend to zero within limited time, and thus contour machining precision is improved. The double-linear-motor contour compensation device comprises a commutating and voltage-stabilizing unit, an IPM inverter, a DSP, a Hall sensor, a grating ruler, a current detection unit, a position and speed detection unit, an optical coupling isolation circuit, a driving protection circuit and a fault detection and protection circuit. The DSP comprises a QEP circuit of an event manager EVA, an ADC module, a PWM unit, a Flash storage module, a program storage, a timer and a PDPINT pin. A PI controller of a position signal setter, a linear motor position loop, a speed loop and an electric current loop, a contour error calculator, a fuzzy RBF network integral sliding mode contour compensator and a driver device are further arranged inside the DSP. The double-linear-motor contour compensation device is good in robustness, suitable for contour machining tasks of any track and capable of achieving high-precision contour control.

Owner:SHENYANG POLYTECHNIC UNIV

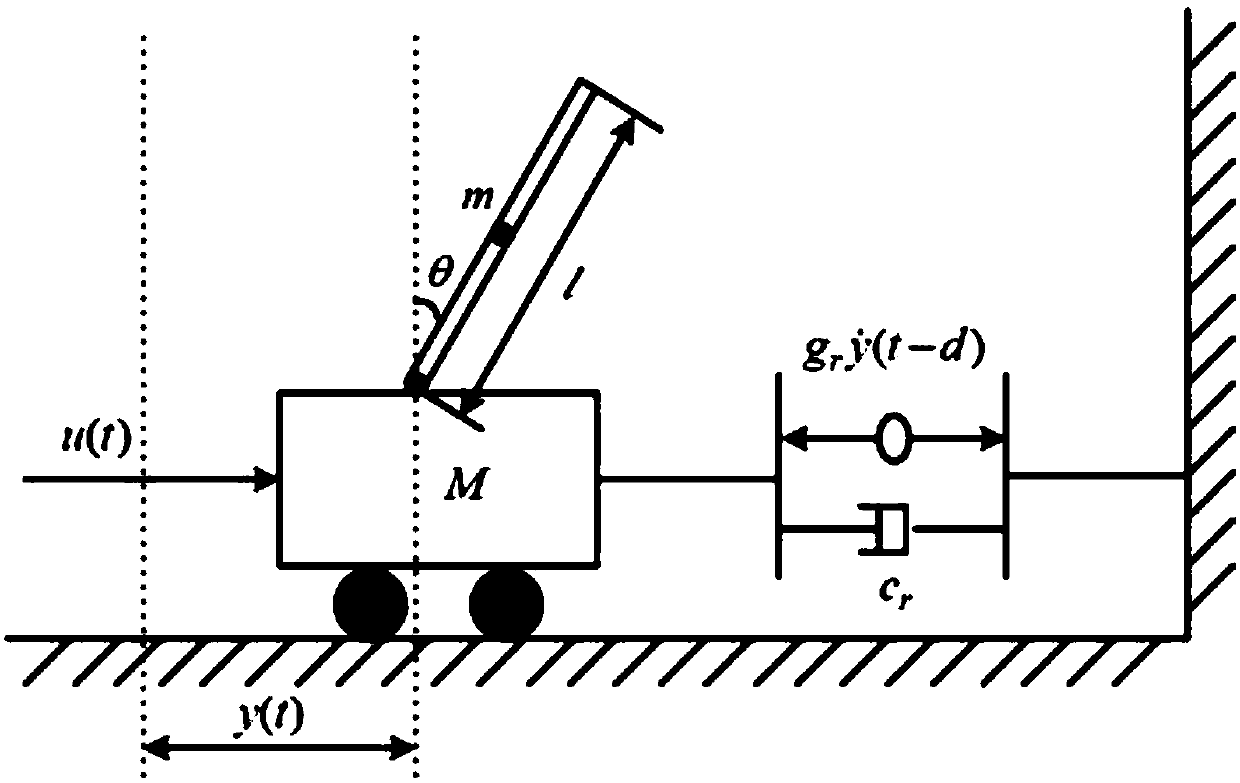

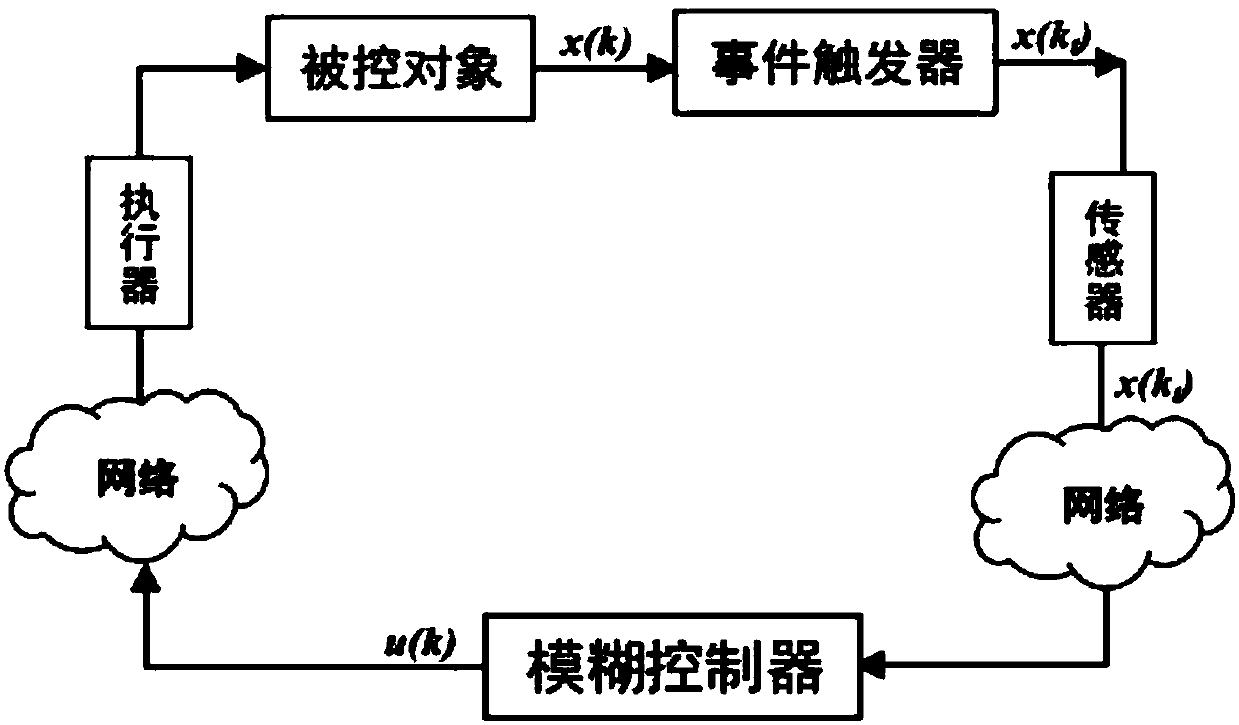

Fuzzy control method based on event trigger strategy for non-linear inverted pendulum system

InactiveCN107918284ASuppression of time-varying time-delay characteristicsFull robustnessAdaptive controlMathematical modelFuzzy control system

The invention discloses a fuzzy control method based on an event trigger strategy for a non-linear inverted pendulum system. The method comprises the following steps: 1, establishing a dynamic mathematical model of an inverted pendulum system with a delay resonator; 2, setting an event trigger strategy of the inverted pendulum system, and constructing a fuzzy controller for the inverted pendulum system with the delay resonator; and 3, transmitting a control instruction to an actuator of the inverted pendulum system by virtue of an event trigger mechanism by a fuzzy controller u(k), thereby realizing the objective of control. The fuzzy control method disclosed by the invention has complete robustness on changes of system parameters and external interference, buffeting is eliminated, and thesystem has excellent stability. Moreover, due to the use of the event trigger mechanism, the inverted pendulum system effectively suppresses time-varying delay characteristics, communication burdensare effectively alleviated, and bandwidth resources are saved.

Owner:CHONGQING UNIV

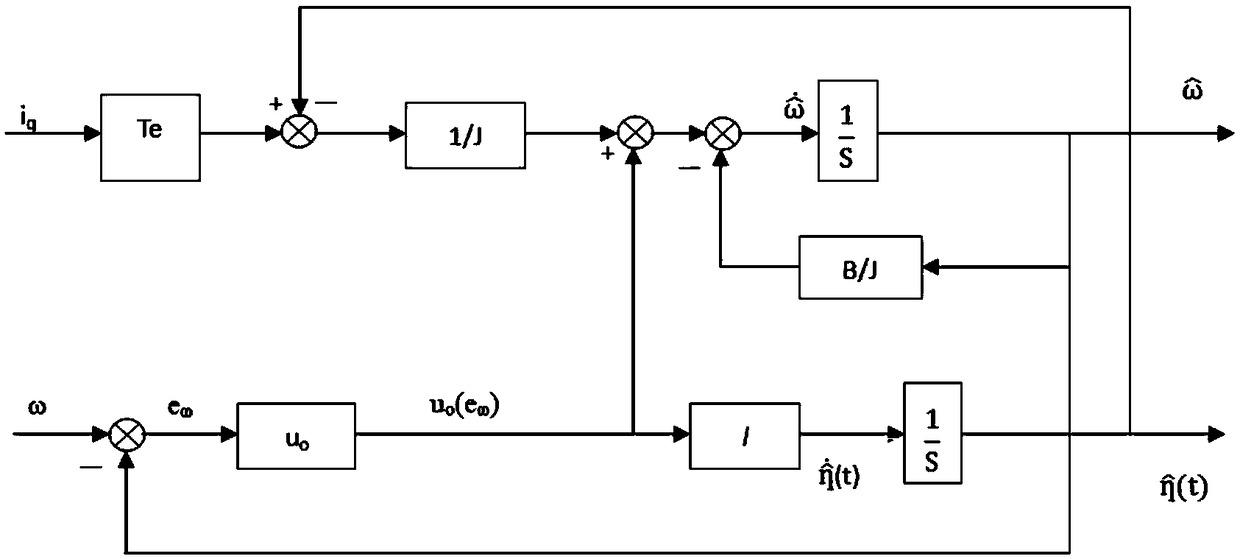

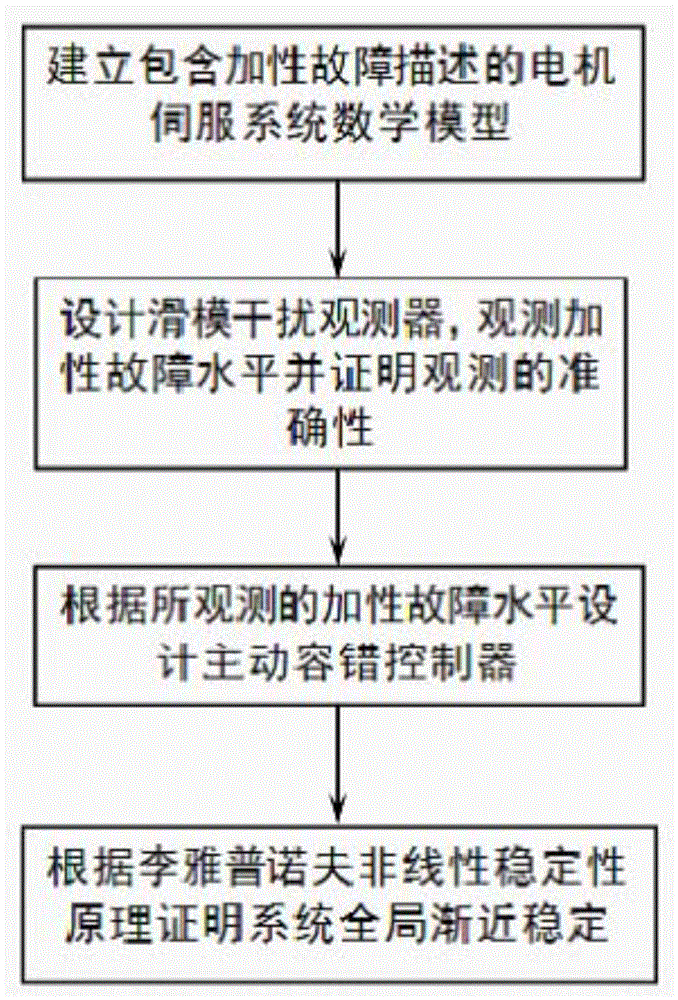

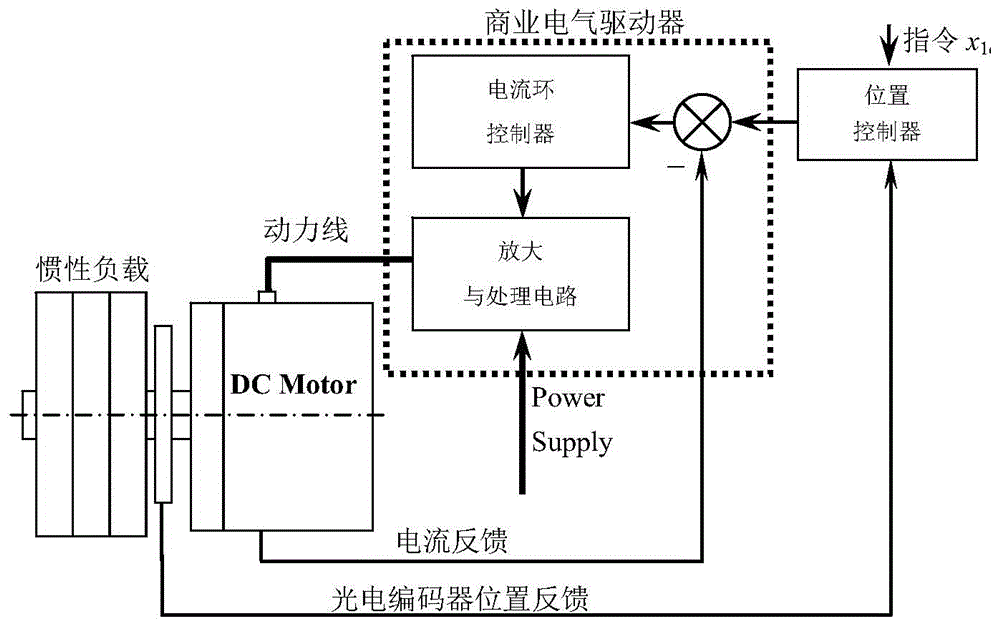

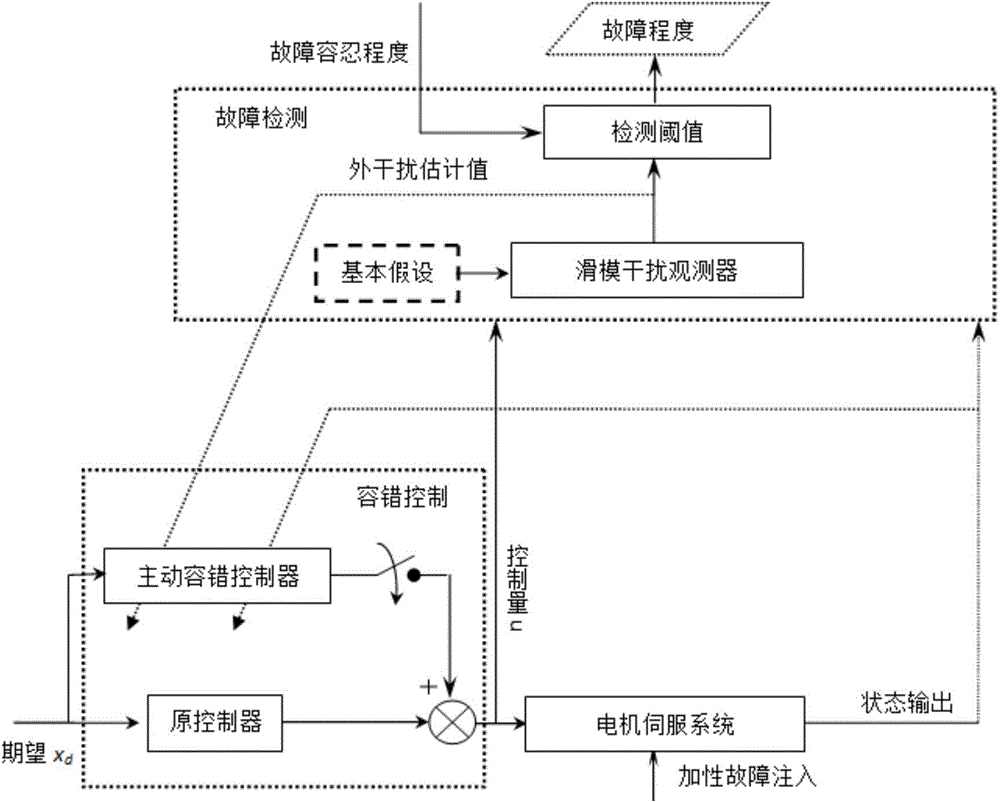

Motor servo system additivity fault detection and fault tolerant control method based on slip form

ActiveCN104808653AEliminate chatterGuaranteed real-timeElectric testing/monitoringMathematical modelNonlinear stability

The invention discloses a motor servo system additivity fault detection and fault tolerant control method based on a slip form. The method includes building a motor servo system mathematical model containing additivity fault description, designing a slip form disturbance observer to observe additivity fault level and demonstrate observation accuracy, designing an initiative fault tolerant controller according to the observed additivity fault, and demonstrating system overall gradual stability according to the Lyapunov nonlinear stability principle. By means of the control method, the reasonable fault tolerance degree can be set to ensure that effects caused by various model uncertainties are kept in the designed fault tolerance range all the time when the system has no fault, false alarming of the system is avoided, and fault detection robustness is improved. The additivity fault level of the system can be observed on line, real-time performance of additivity fault detection is guaranteed while system control performance is not affected, active detection missing and fault tolerant control of minor faults can be achieved, and timely warning of severe faults is also achieved.

Owner:NANJING UNIV OF SCI & TECH

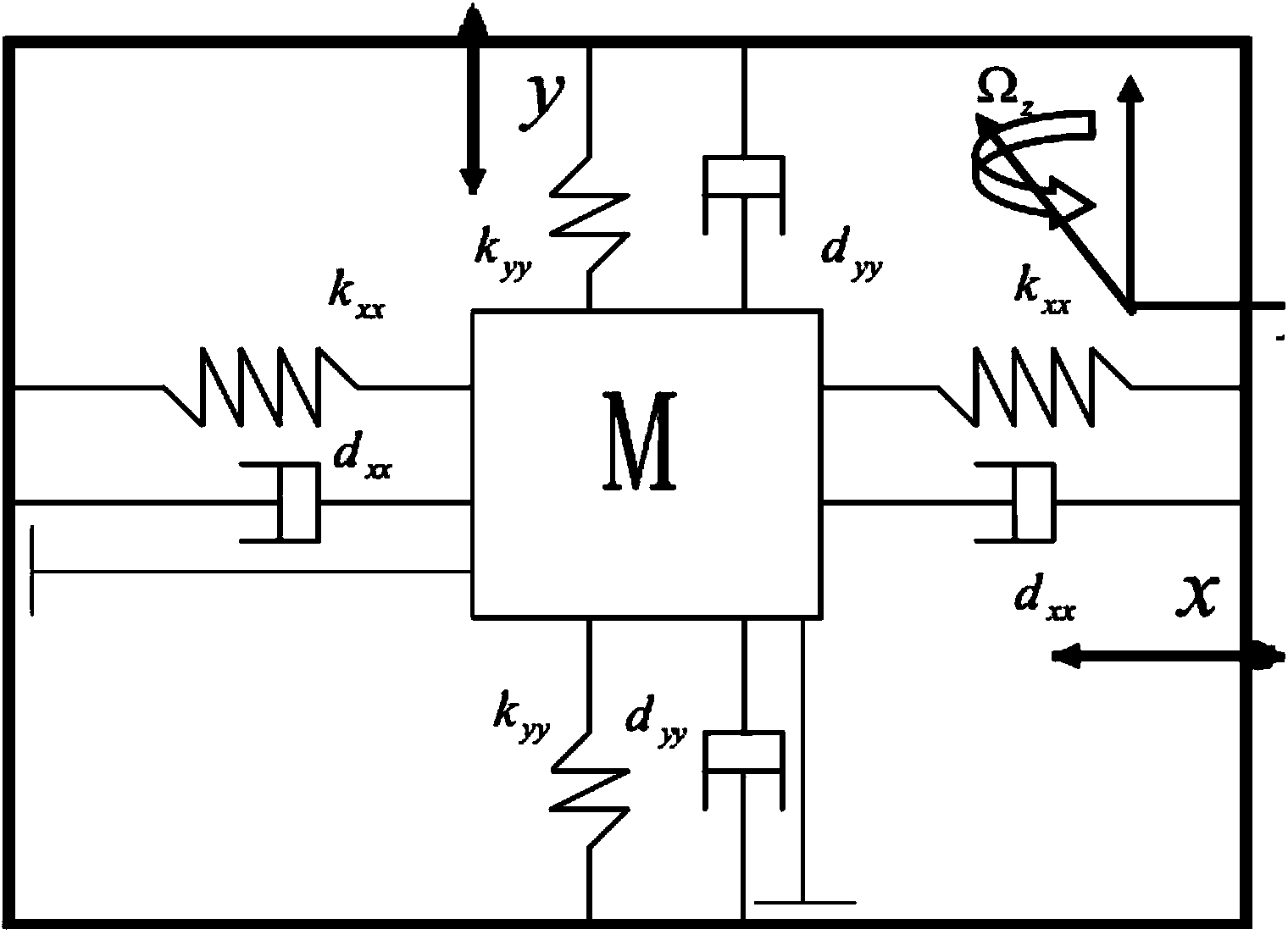

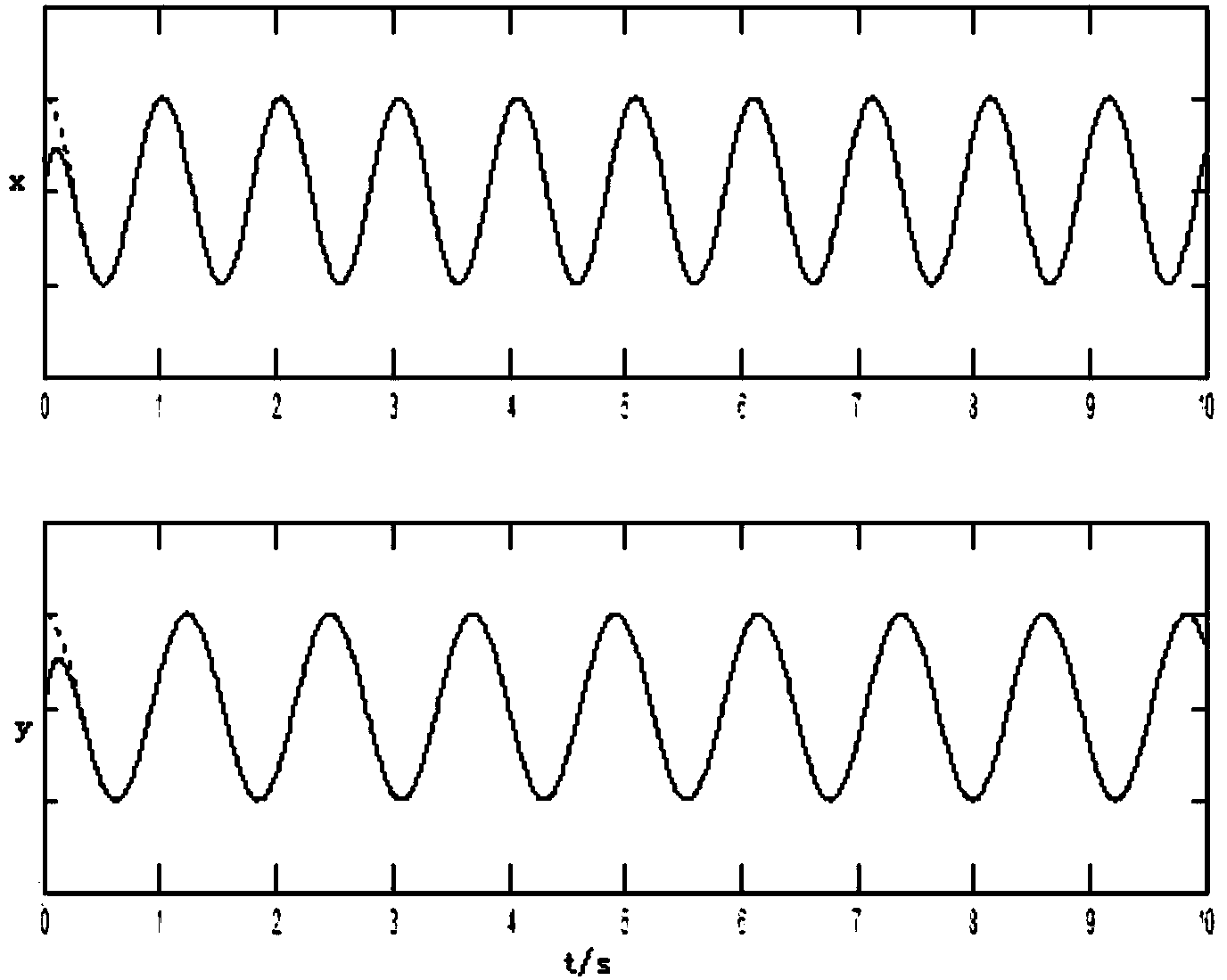

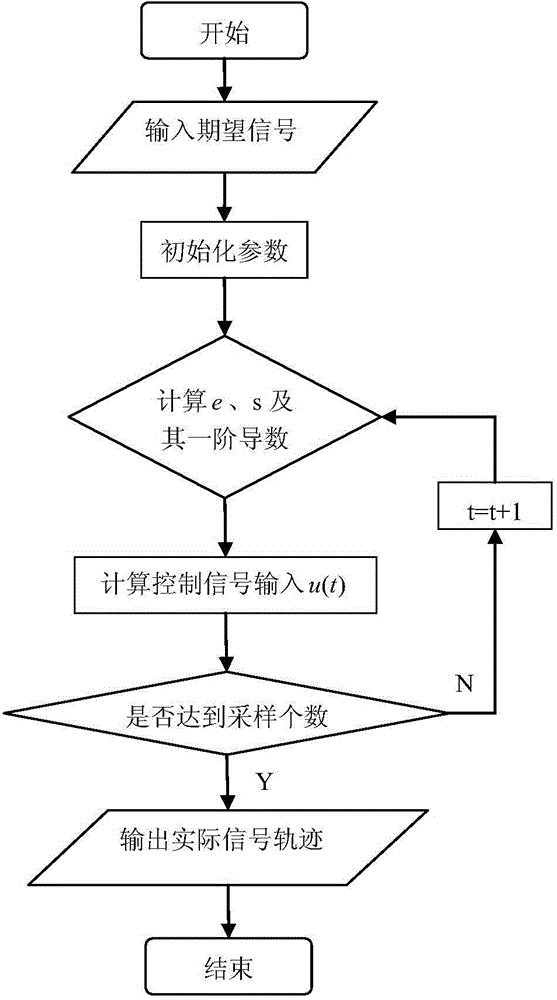

Method of global sliding mode control of neural network of micro-gyroscope

InactiveCN103529701ARealize online updateEliminate online updatesAdaptive controlRobustificationGyroscope

The invention discloses a method of a global sliding mode control of a neural network of a micro-gyroscope, which comprises the following steps of establishing a global sliding mode control system of the neural network, designing a control law and taking as a control input of the micro-gyroscope, designing a self-adaptive law based on an Lyapunov function theory, and verifying the stability of a closed-loop system. The global sliding mode control is realized by designing a dynamic nonlinear sliding mode surface, the defect of no robustness in a reach movement stage of the sliding mode control is eliminated, the system has robustness in the whole process of response, and the respective defects of the global sliding mode control and the neural network are reduced by utilizing the intelligent control function of global sliding mode and the neural network. According to the method, the selection of sliding mode coefficients is simplified, the transient performance and the robustness of the sliding mode control system are improved, so that the closed-loop control system has global robustness, buffeting in the sliding mode control is eliminated, and thus a powerful foundation is provided for expansion of an application range of the micro-gyroscope.

Owner:HOHAI UNIV CHANGZHOU

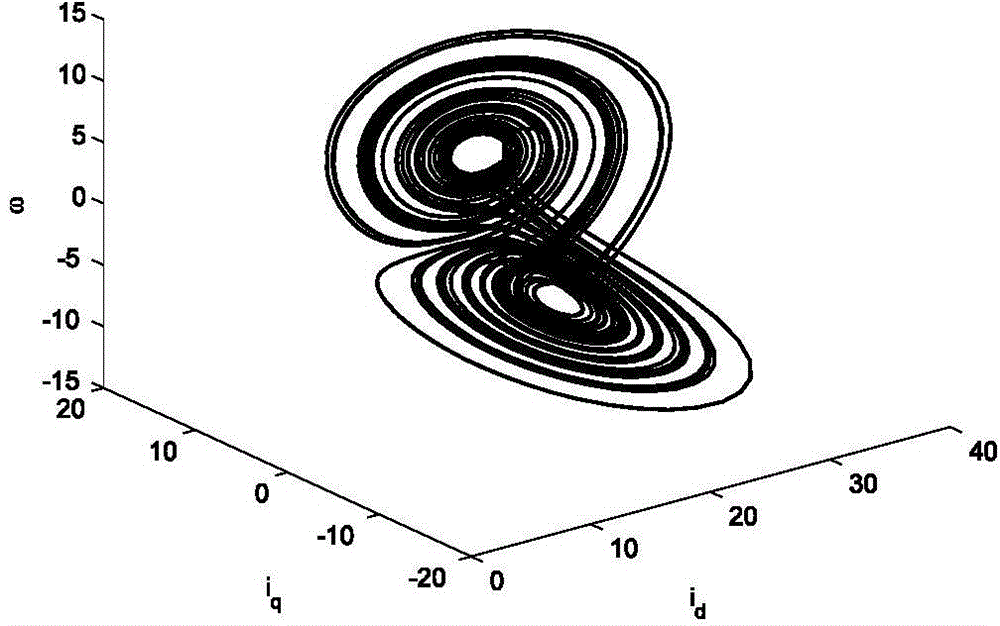

Extended-state-observer-based full-order sliding mode control method of chaotic system of permanent magnet synchronous motor

InactiveCN104901599AEliminate chatterConvergent stabilityElectronic commutation motor controlVector control systemsState observerPermanent magnet synchronous motor

The invention relates to an extended-state-observer-based full-order sliding mode control method of a chaotic system of permanent magnet synchronous motor. The method comprises: a chaotic model, an initialization system state, and correlated control parameters of a permanent magnet synchronous motor system are established; on the basis of coordinate conversion, the permanent magnet synchronous motor chaotic model is converted into one based on a standard extended state observer design suitable for a non-linear extended state observer design; a full-order sliding mode controller is designed based on the extended state observer to eliminate a buffeting phenomenon in the sliding mode control and guarantee that the system state can be convergent to a zero point rapidly and stably. According to the full-order sliding mode control method, the buffeting phenomenon in sliding mode control can be prevented and the chaotic state of the system can be guaranteed to be convergent to the zero point rapidly and stably.

Owner:ZHEJIANG UNIV OF TECH

Control method and device for eliminating system buffeting during sliding mode control of linear motor

InactiveCN102185558AReduce switching frequencyReduce buffeting amplitudeAC motor controlHysteresisSoft switching

The invention relates to a control method and device for eliminating system buffeting during sliding mode control of a linear motor. In the method, a sign function in the conventional sliding mode control formula is replaced by a diffusion hysteresis function, so that control voltage on a mover coil is evaluated. Due to the soft switching property of the diffusion hysteresis function, buffeting during sliding mode control is eliminated. Parameters in a formula are obtained by second-order approximation and an experiment. The device comprises a linear motor, a displacement sensor, a signal processor, a driving circuit and the like, wherein a control signal of the signal processor is connected to the driving circuit; the signal processor comprises a central processing unit, an A / D (Analog to Digital) circuit, a D / A (Digital to Analog) circuit, an ROM (Read Only Memory) module, an RAM (Random Access Memory) module, a pulse width modulation module and a signal receiving circuit, and is used for storing a formula and parameters of a sliding mode control method; and the central processing unit is used for obtaining a voltage signal of the mover coil according to the mover displacement data of the displacement sensor and regulating the voltage of the mover coil through the pulse width modulation module so as to realize stable linear movement of the mover. By adopting the method and the device, system buffeting is eliminated effectively, and the running reliability is enhanced; and the method and the device are easy to realize.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Inverted pendulum system integral sliding mode control method for dollies with unknown hysteresis loops

The invention discloses an inverted pendulum system integral sliding mode control method for dollies with unknown hysteresis loops. The method comprises the following steps: building a dynamic model for an inverted pendulum system; conducting equivalent transformation together with hysteresis loops; initializing the system, sampling time and controlling parameters; together with sliding mode control and an inverted method, introducing a virtual control variable into the design of every step, and finally inferring the input for a self-adaptive controller; at the same time, utilizing the characteristics of a Nussbaum function, which solves the problem with unknown control directions; and calculating the tracking errors of the control system, the integral sliding mode surface, errors in variables and differentiations. The control method provided by the invention can effectively improve the position of an inverted pendulum system, which ensures that the inverted pendulum system to quickly and stably converge to the zero point, thus effectively eliminating the buffeting problems in sliding mode control.

Owner:ZHEJIANG UNIV OF TECH

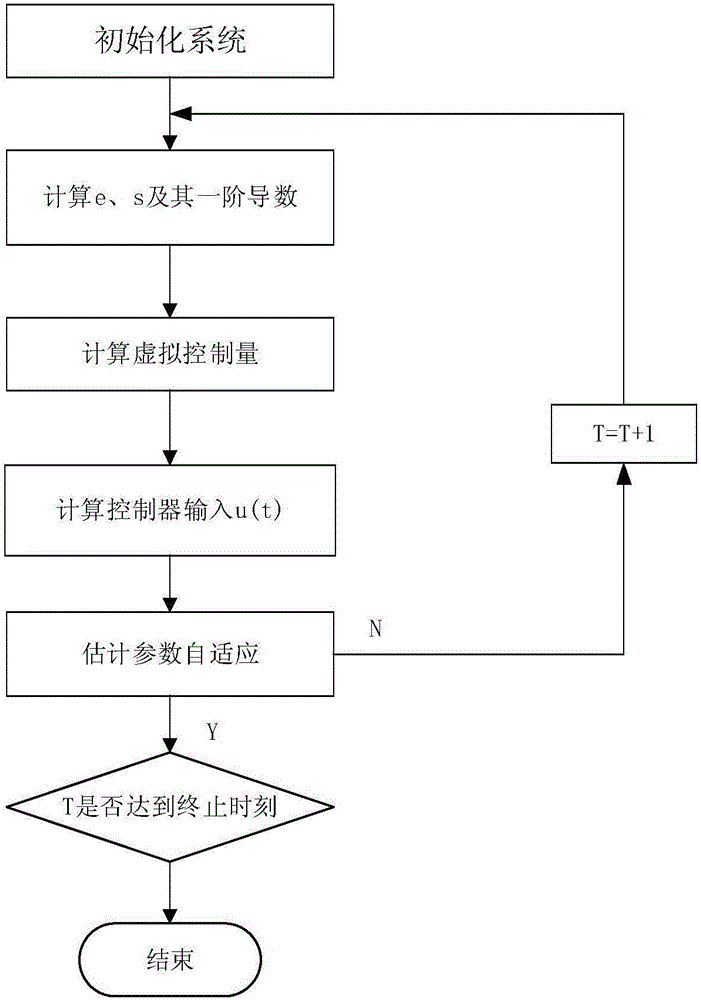

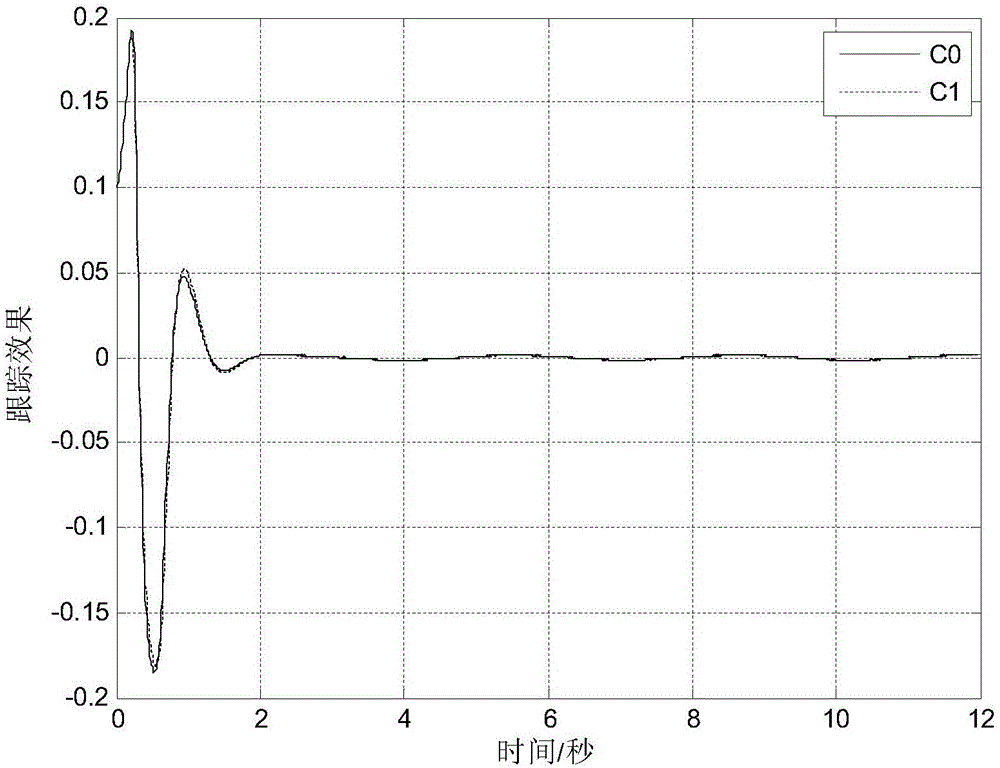

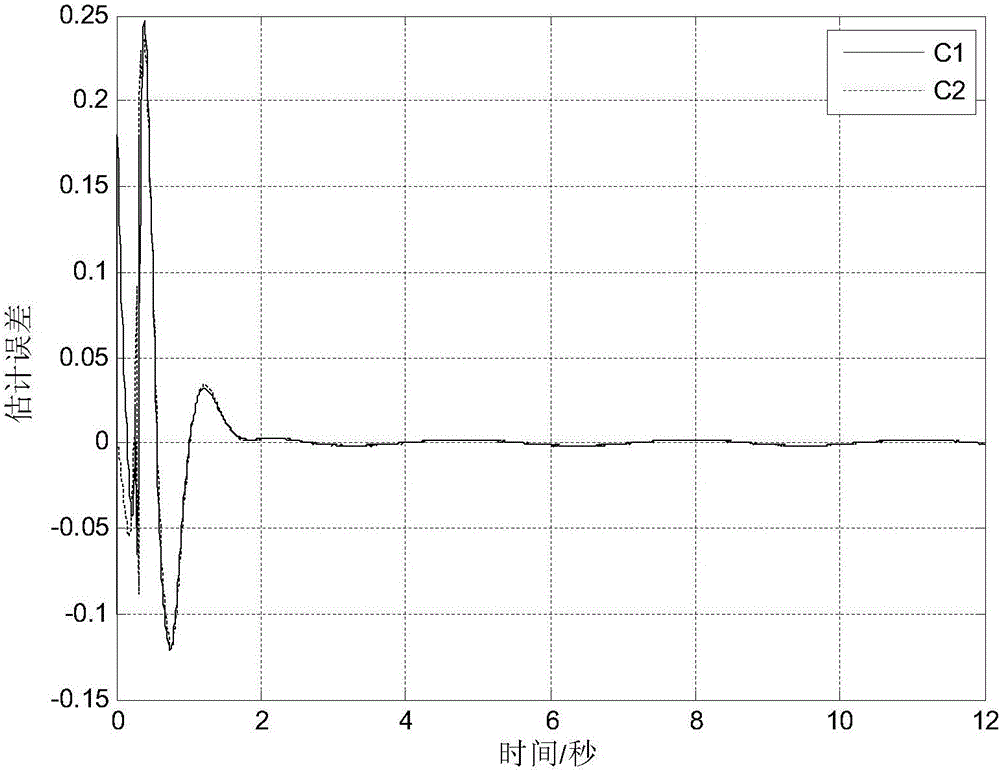

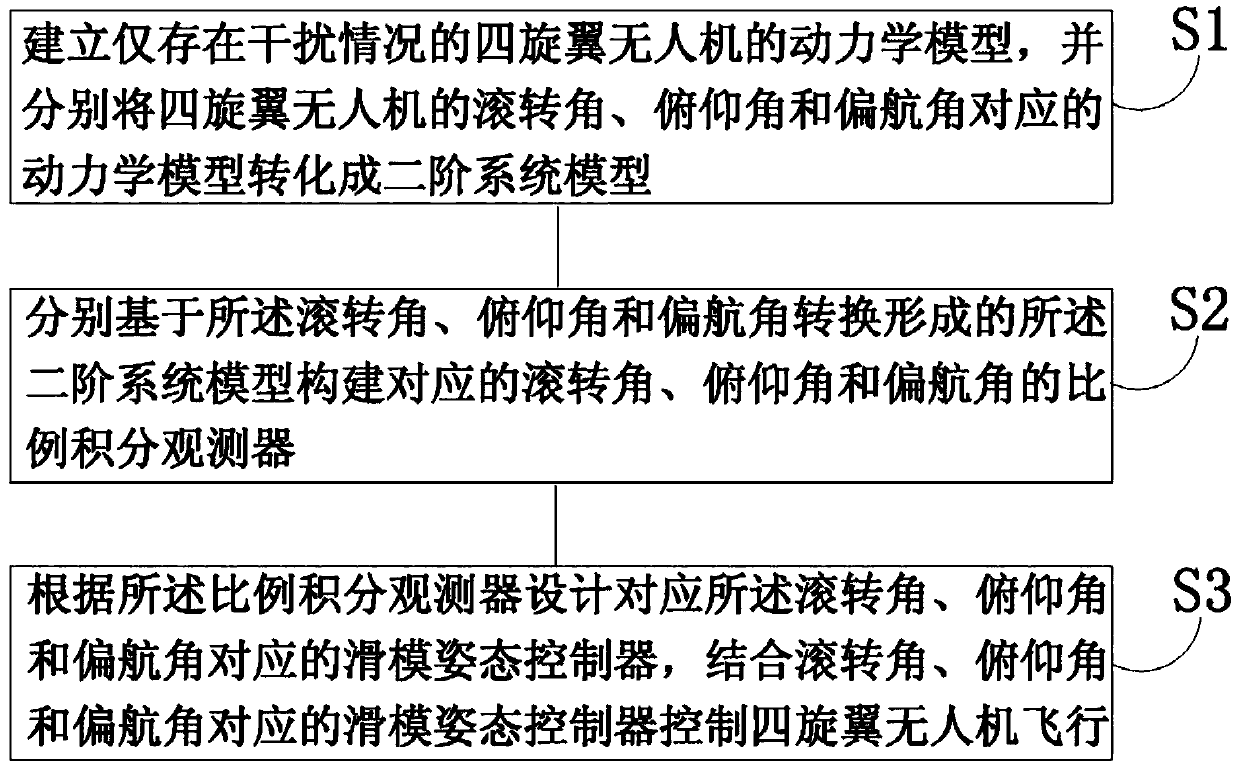

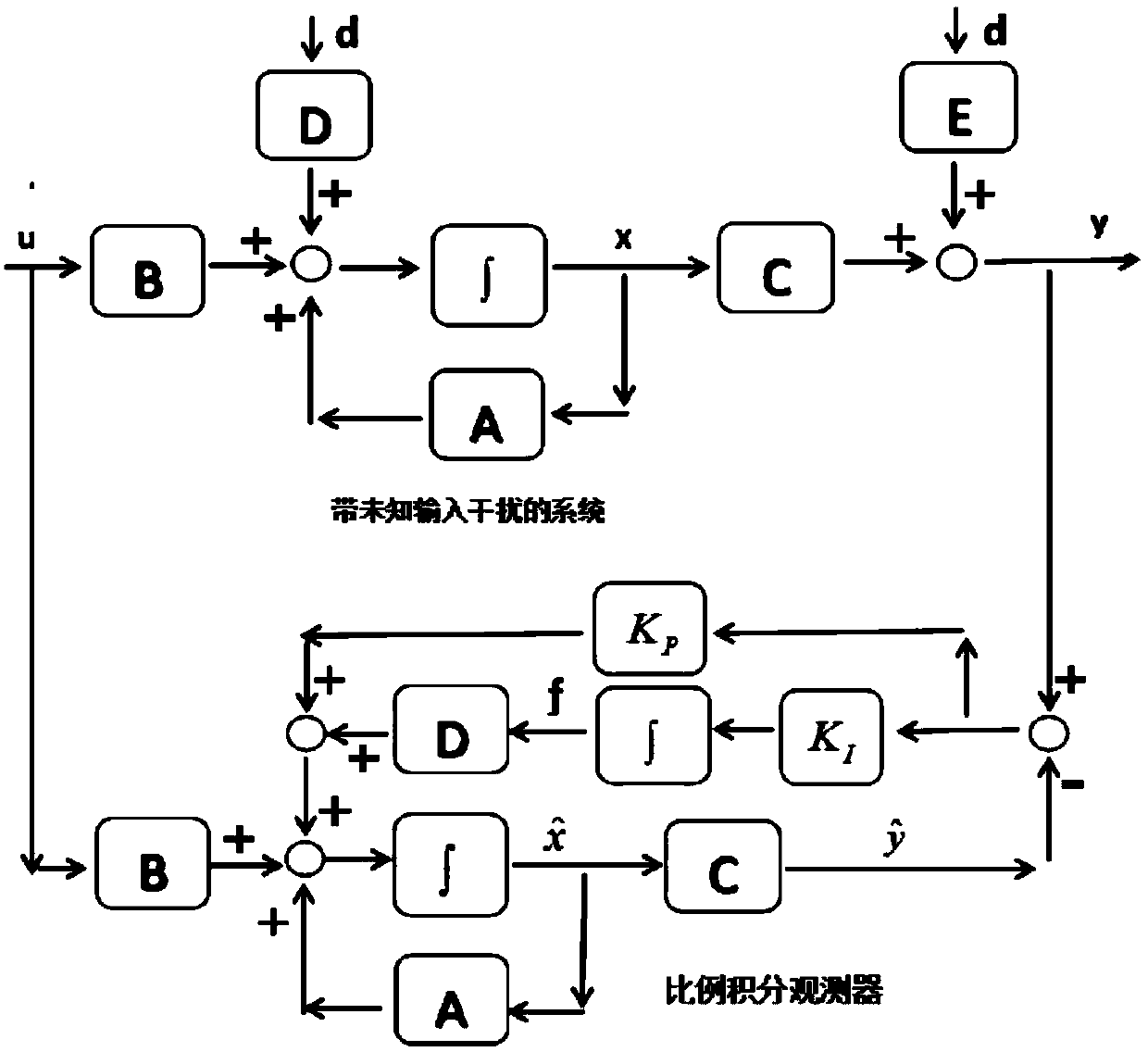

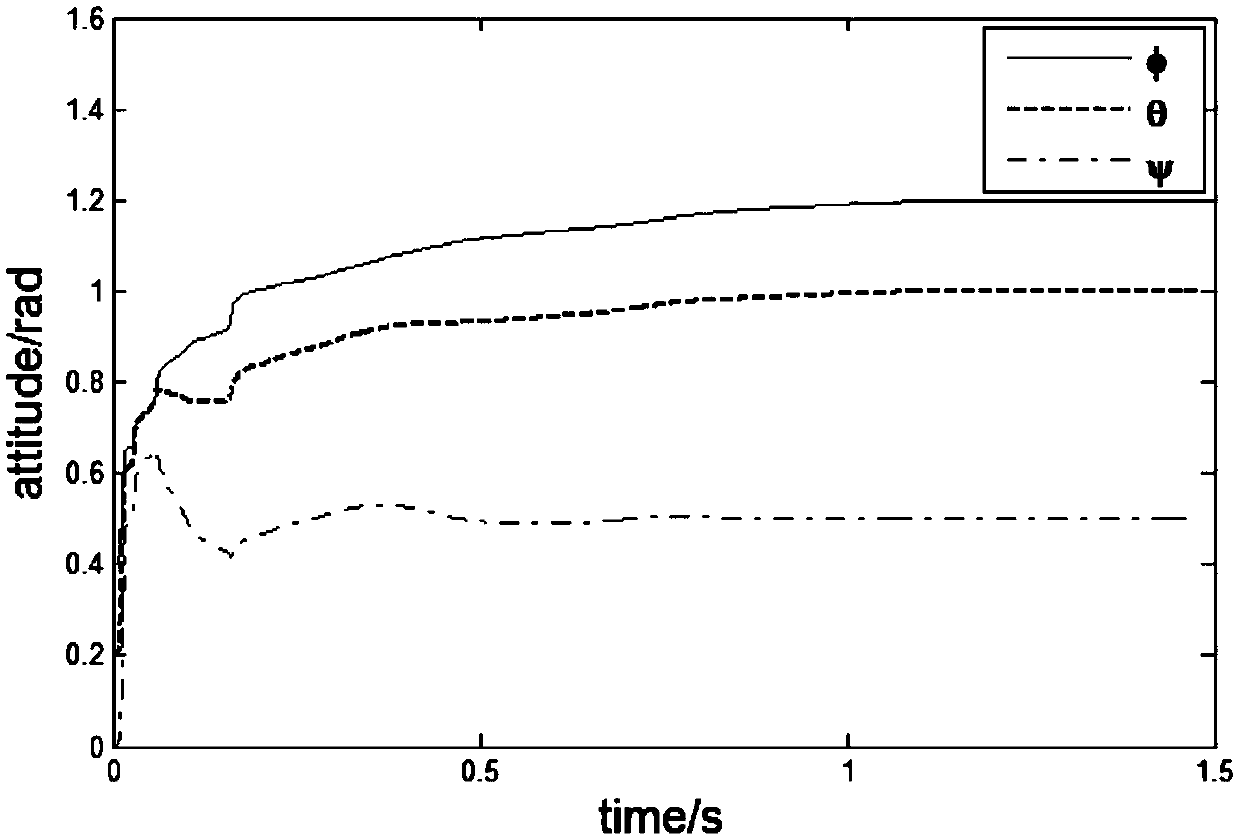

Sliding mode attitude control method for quadrotor UAV based on proportional integral observer

InactiveCN109521786AImproving Steady State Tracking AccuracyImprove robustnessAttitude controlAdaptive controlElevation angleDynamic models

The invention discloses a sliding mode attitude control method for a quadrotor UAV based on a proportional integral observer. The method comprises steps that a dynamic model of the quadrotor UAV withinterference only is established, and expressions of a rolling angle, an elevation angle and a yaw angle of the quadrotor UAV are transformed into second-order system models; the second-order system models are utilized to construct the corresponding proportional integral observer; a sliding mode attitude controller is designed according to the proportional integral observer, and the sliding mode attitude controller in combination with the rolling angle, the elevation angle and the yaw angle is utilized for flight control of the quadrotor UAV. The method is advantaged in that the proportional integral observer is combined with the sliding mode attitude controller, the partial feedback function of the proportional integral observer is utilized to estimate the shape and position input interference state of the quadrotor UAV, steady state tracking accuracy of the proportional integral state observer is improved, through the sliding mode attitude controller, relatively strong robustness andanti-interference to uncertain factors of the quadrotor UAV are achieved, and design and calculation are simple.

Owner:NANJING UNIV OF POSTS & TELECOMM

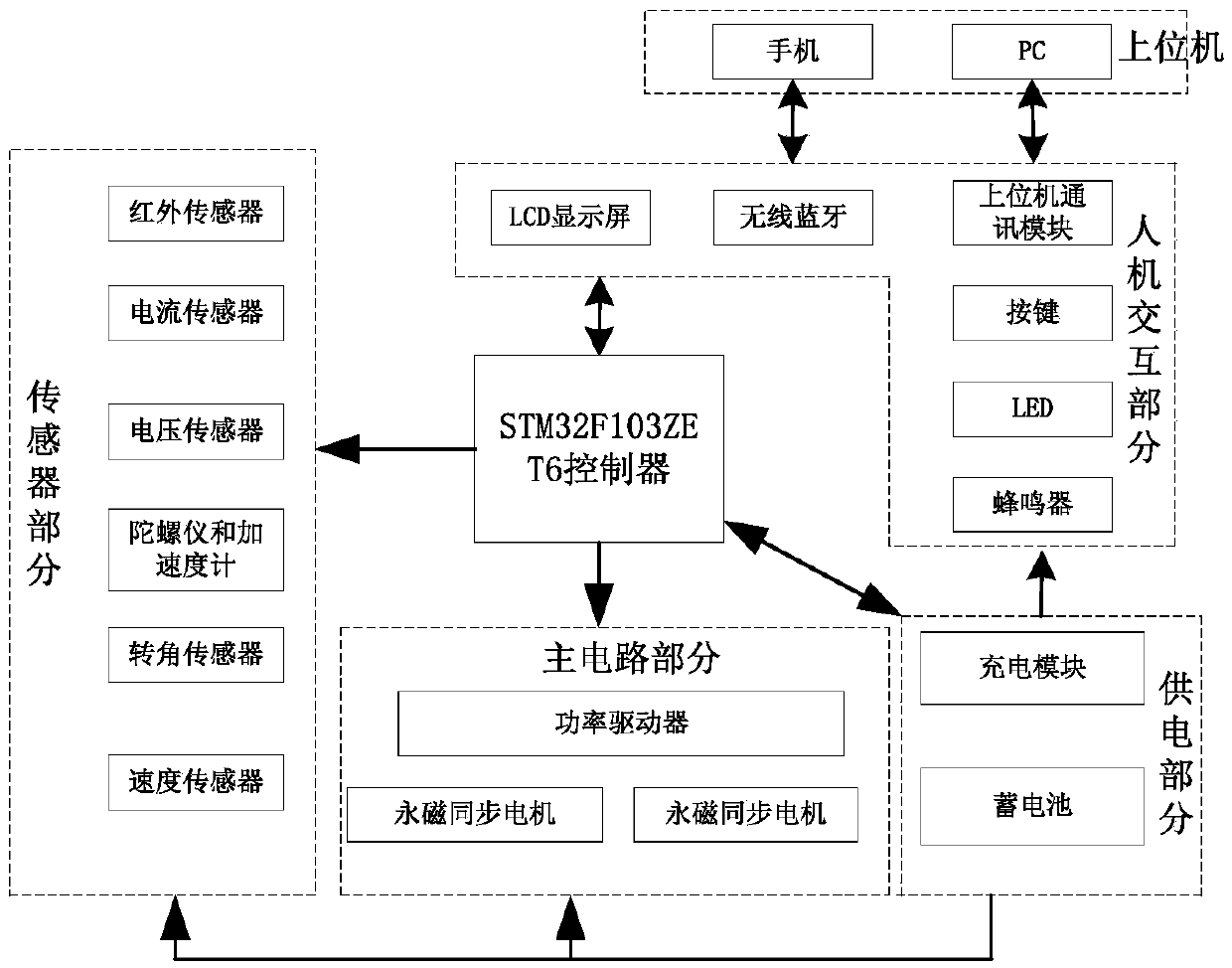

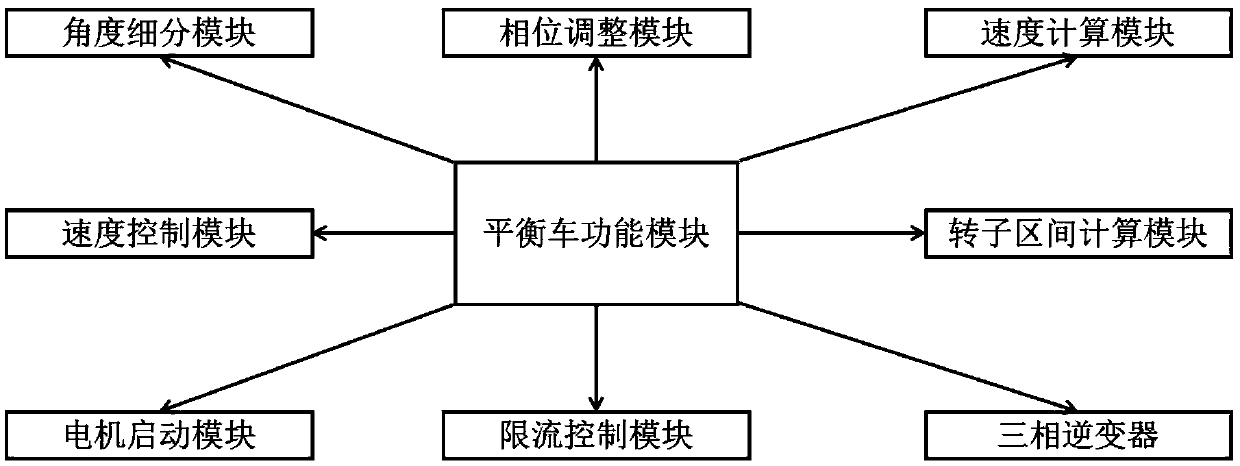

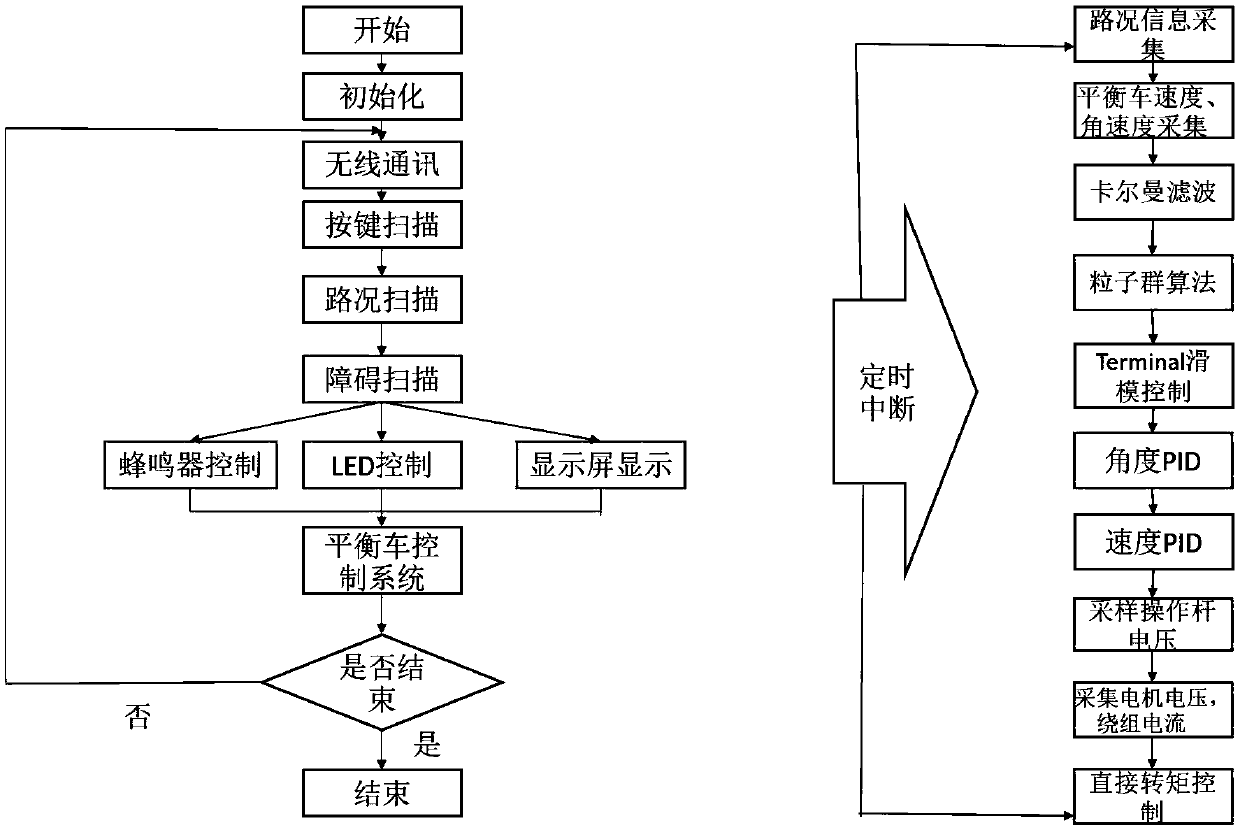

A system for balancing a vehicle and a control method thereof

ActiveCN109067264AStrong battery lifeReduce loss rateTorque ripple controlMultiple motor speed/torque controlMathematical modelParticle swarm algorithm

The invention discloses a balancing vehicle system and a control method thereof. According to a difference equation model and a drift error model of attitude signals of the balancing vehicle system, astate equation of an extended Kalman filter and a mathematical model of a permanent magnet linear motor are established. A second-order dynamic Terminal sliding film is used to drive permanent magnetsynchronous motor. Particle Swarm Optimization (PSO) is used to optimize the parameters of tracking controller, synchronization controller, clearance elimination controller and switching function ina two-motor system. The invention realizes that the signal collected by the sensor of the balancing vehicle has large noise and zero drift error, and solves the problem of poor robustness and the problem that the Brush motor structure is complex, fault, maintenance workload, short life, commutation spark easy to produce electromagnetic interference, as well as in the balance of the car in the process of running jitter, deviation is too large, and low security.

Owner:汇佳网(天津)科技有限公司

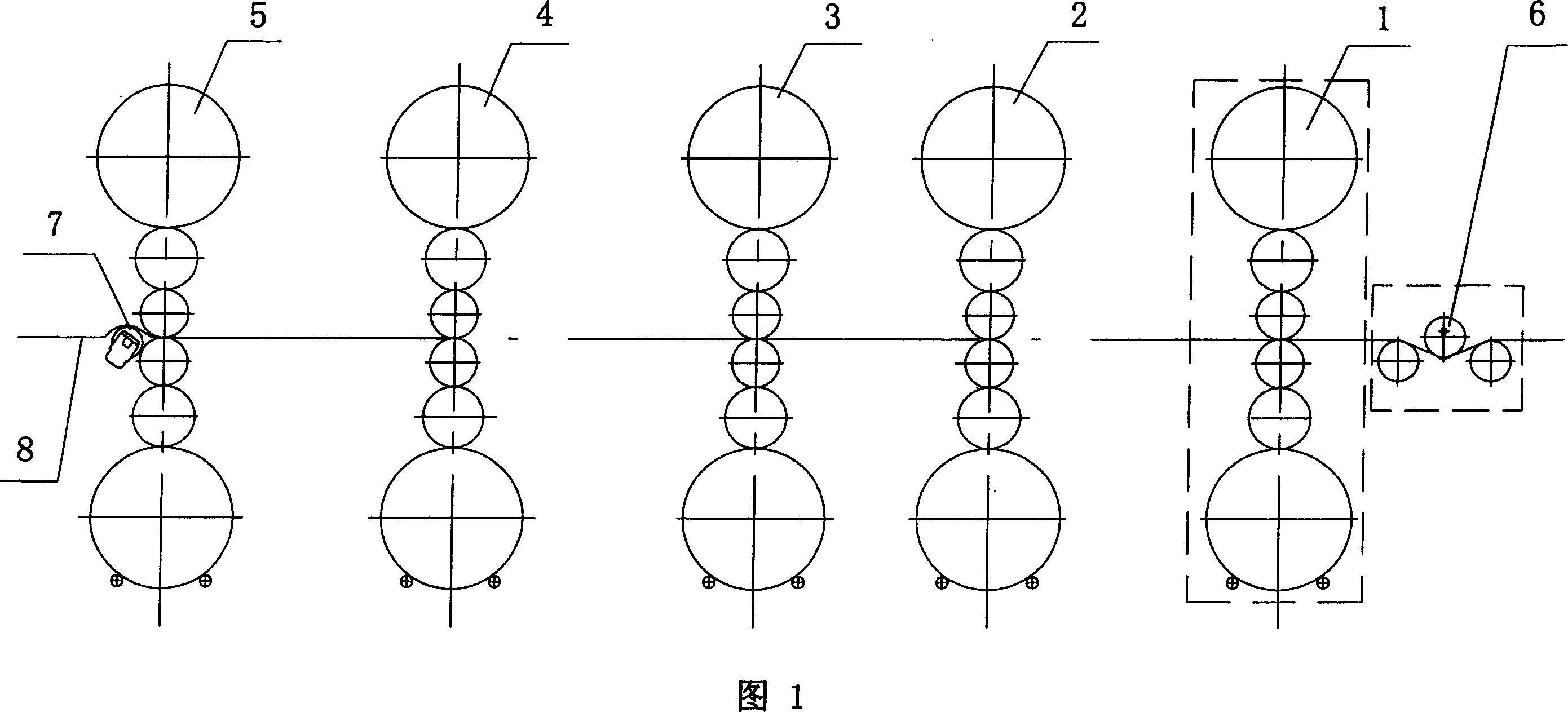

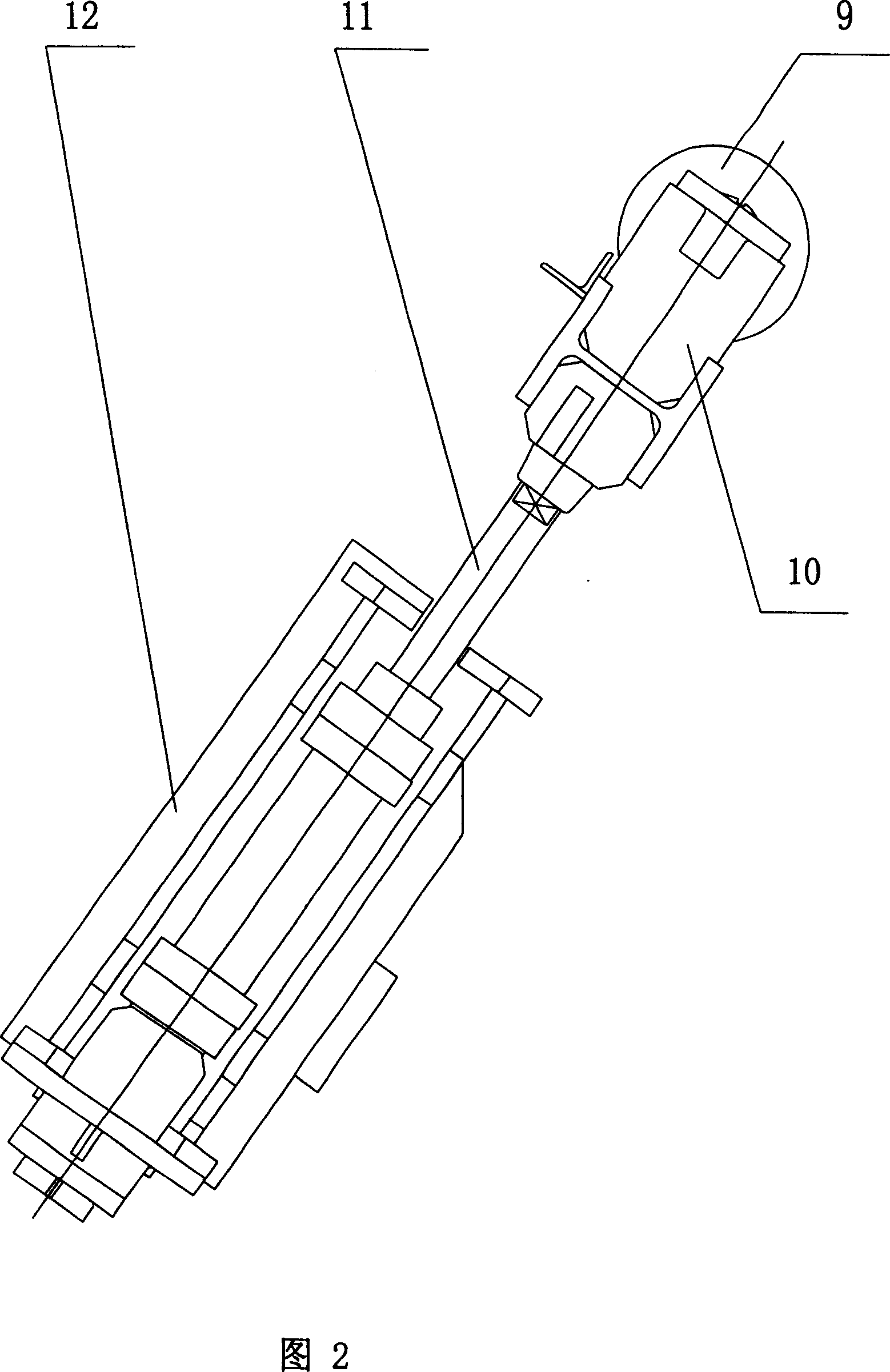

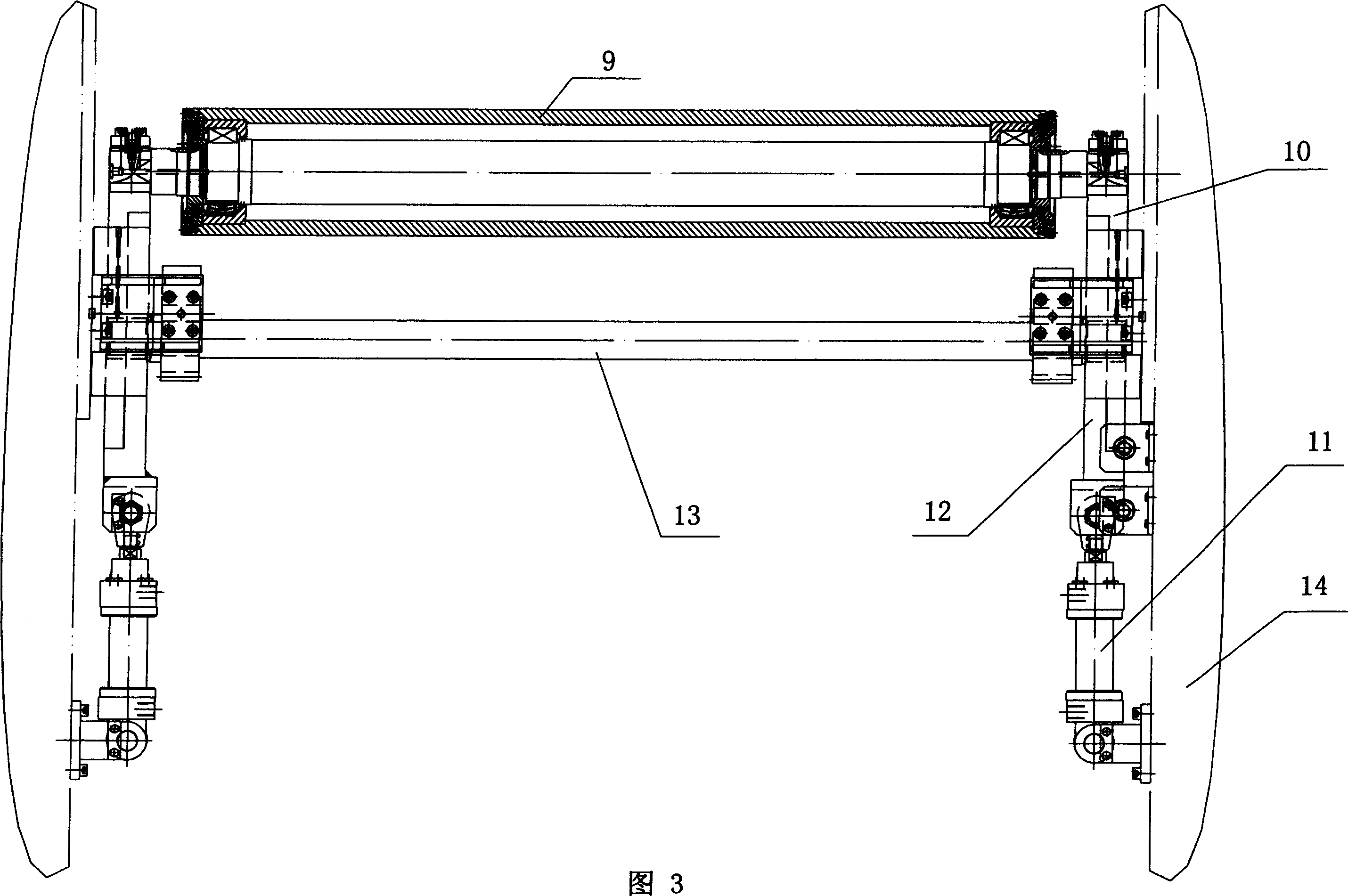

Method for preventing vibration of steel bar under high-speed rolling station of ultra-thin plate

ActiveCN1962103AReduce driveGood effectGuiding/positioning/aligning arrangementsRolling equipment maintainenceHydraulic cylinderStrip steel

The invention relates to a method for the vibration of band steel in high-speed rolling process, wherein said method is characterized in that: the first frame inlet of cold rolling machine is arranged with three-roller stabilizer which comprise left low roller, right low roller and upper middle roller; the upper middle roller is above the left and right low rollers, and above the rolling line; the left and right low rollers are under the rolling line; the band steel is through between the upper middle roller and left low roller and right low roller, the upper middle roller is lifted by hydraulic cylinder; when in normal rolling, the upper middle roller compresses the band steel; the last frame outlet of machine has single-roller vibration resistor; when in normal rolling, the vibration-resistant roller extends out driven by the hydraulic cylinder, to tension the bane steel.

Owner:WISDRI ENG & RES INC LTD

Automatic electromagnetic nondestructive testing method and device for in-use steel rail

ActiveCN103018324AEliminate chatterEliminate distractionsMaterial magnetic variablesAutomatic controlMagnetic memory

The invention discloses an automatic electromagnetic nondestructive testing method and device for an in-use steel rail. The device comprises a semi-circular tubular rail frame, a slide block, arrayed eddy current probes, arrayed metal magnetic memory probes, electronically-controlled wire take-up and pay-off racks and a steel wire rope. According to the method and the device, based on the principle of electromagnetic nondestructive testing, a rail slide testing method is adopted, the slide block is fixed outside a testing face of the steel rail, a probing face of the slide block is matched with the testing face of the steel rail to be tested, arrayed electromagnetic detection probes and arrayed metal magnetic memory detection probes are fixed on the probing face of the slide block, and the slide block is electromechanically and automatically controlled to slide along the testing face of the steel rail to be tested so as to carry out testing; various defects of the surface of the steel rail to be tested can be tested by adopting differential eddy current scanning rules and absolute eddy current scanning rules in an array eddy current testing method, and meanwhile, the interference and influence caused by vibration and lift-off are eliminated; the situations of early fatigue and stress concentration of the steel rail can be evaluated by an array metal magnetic memory testing method; and the device is high in testing efficiency and testing accuracy, facilities and equipment are not required for being in operation suspension, and the in-use testing can be carried out.

Owner:EDDYSUN (XIAMEN) ELECTRONICS CO LTD

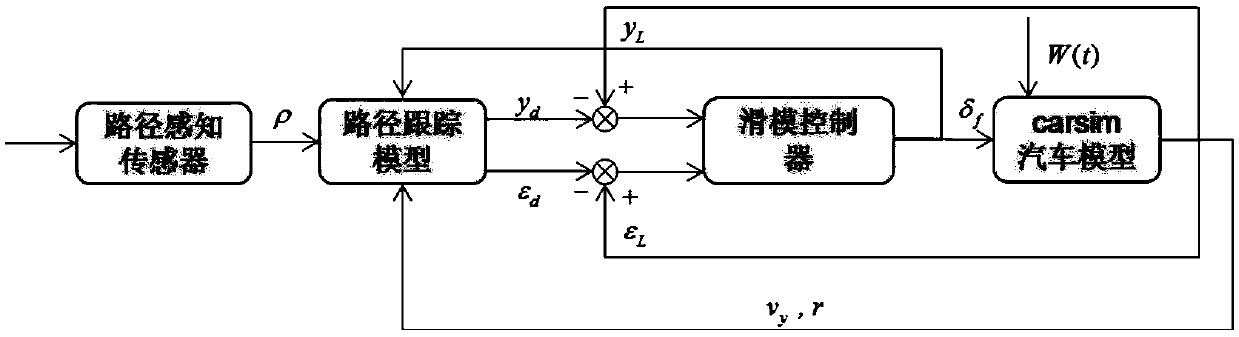

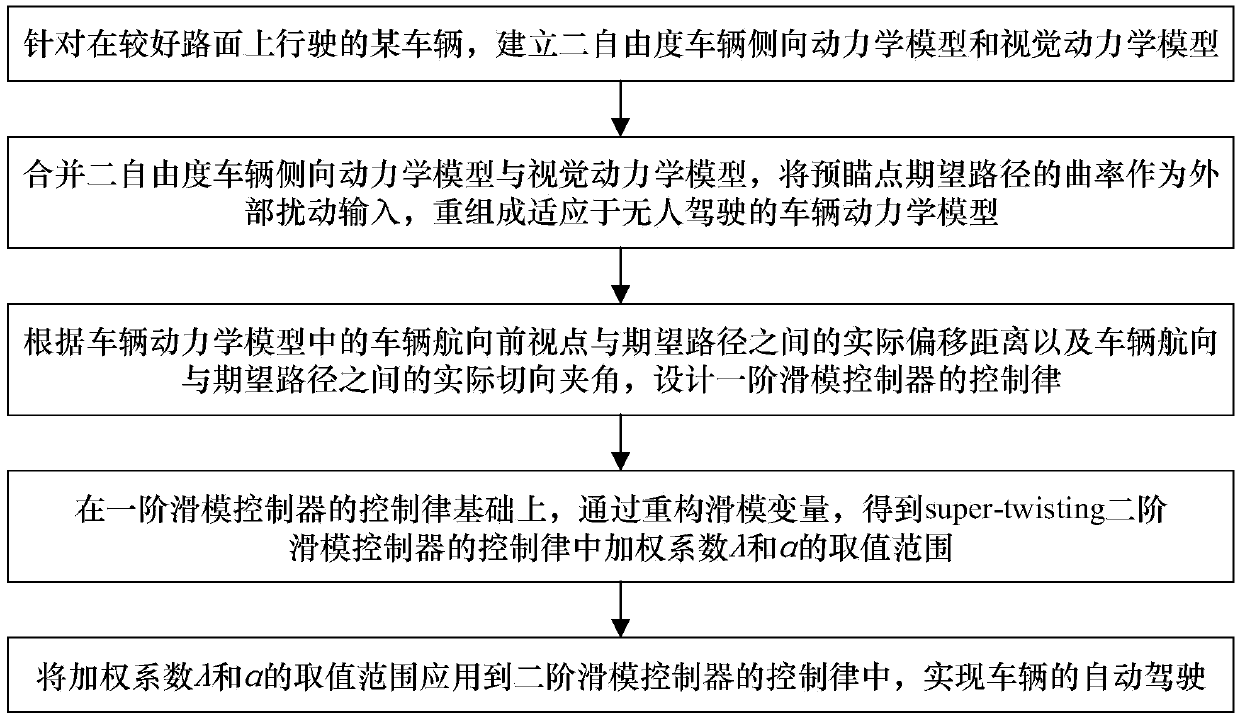

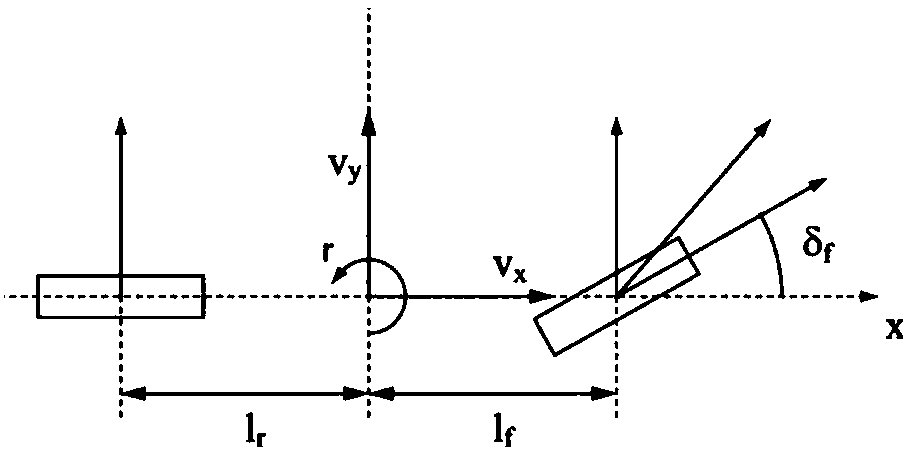

Second order sliding mode control method for autonomous vehicle based on visual dynamics

ActiveCN108919837AGood control effectEliminate chatterTarget-seeking controlOffset distanceSliding mode control

The invention discloses a second order sliding mode control method for an autonomous vehicle based on visual dynamics, and belongs to the field of intelligent vehicles. The method includes the steps that firstly, a two-freedom vehicle lateral dynamic model and a visual dynamic model are established and combined, and a curvature of rho of a desired path on a preview point is taken as the input of external disturbance, and a vehicle dynamic model is reconstituted; and according to an actual offset distance of y<L> between a front viewpoint of vehicle heading and the desired path and an actual tangential angle of epsilon<L> between the vehicle heading and the desired path, a control law of a first order sliding mode controller is designed; based on the control law of the first order sliding mode controller, by reconstructing a sliding mode variable of s, a value range of weighting coefficients of lambada and alpha in a control law u<s> of a second order sliding mode controller of super-twisting is obtained; the value range of weighting coefficients of lambada and alpha is applied to the control law u<s> of the second order sliding mode controller to achieve automatic driving of vehicles. According to the second order sliding mode control method for the autonomous vehicle based on the visual dynamics, a series of problems such as nonsequence of traditional sliding mode control andchattering in a nonlinear system control theory are solved, and strong robustness is achieved.

Owner:BEIHANG UNIV

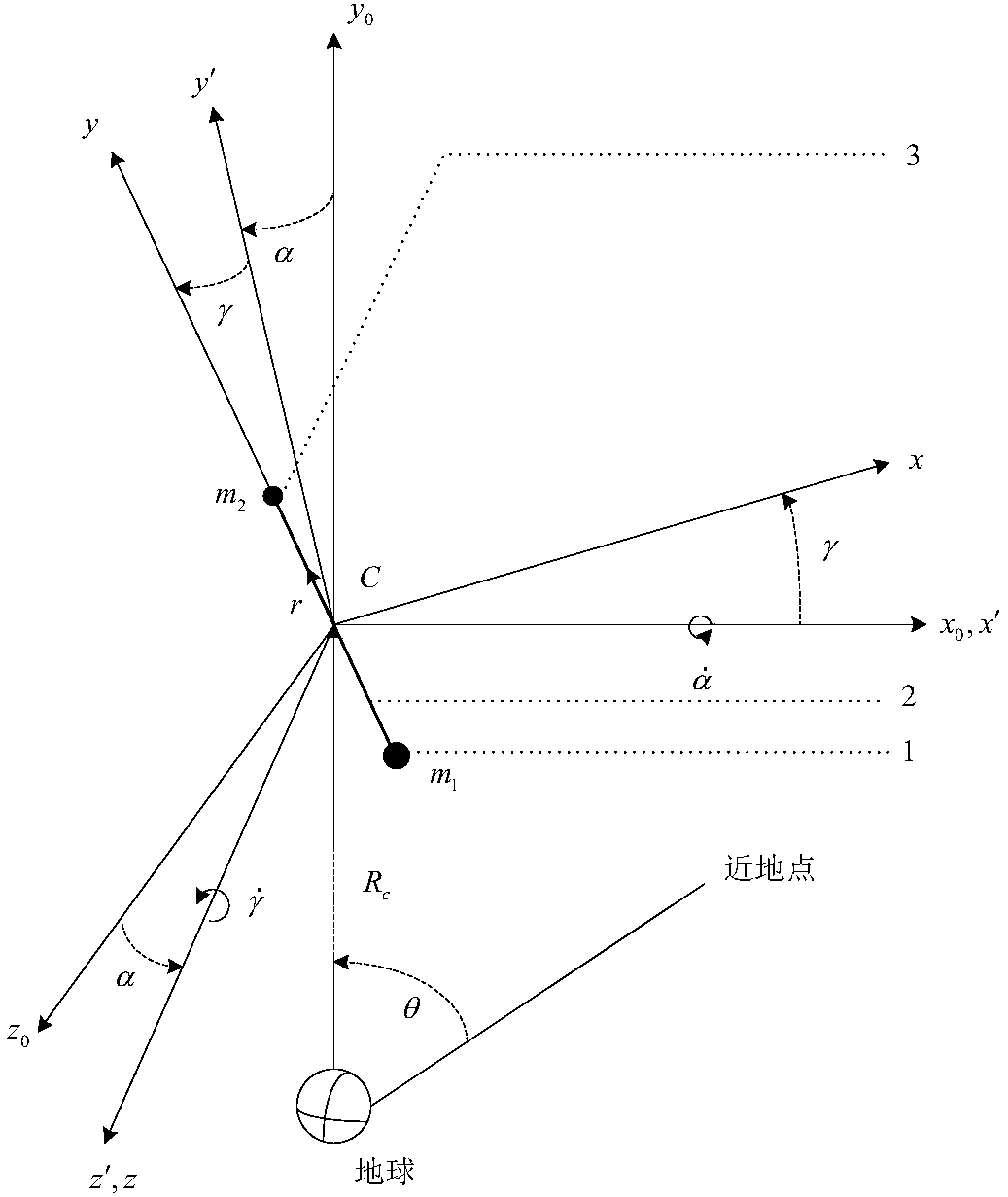

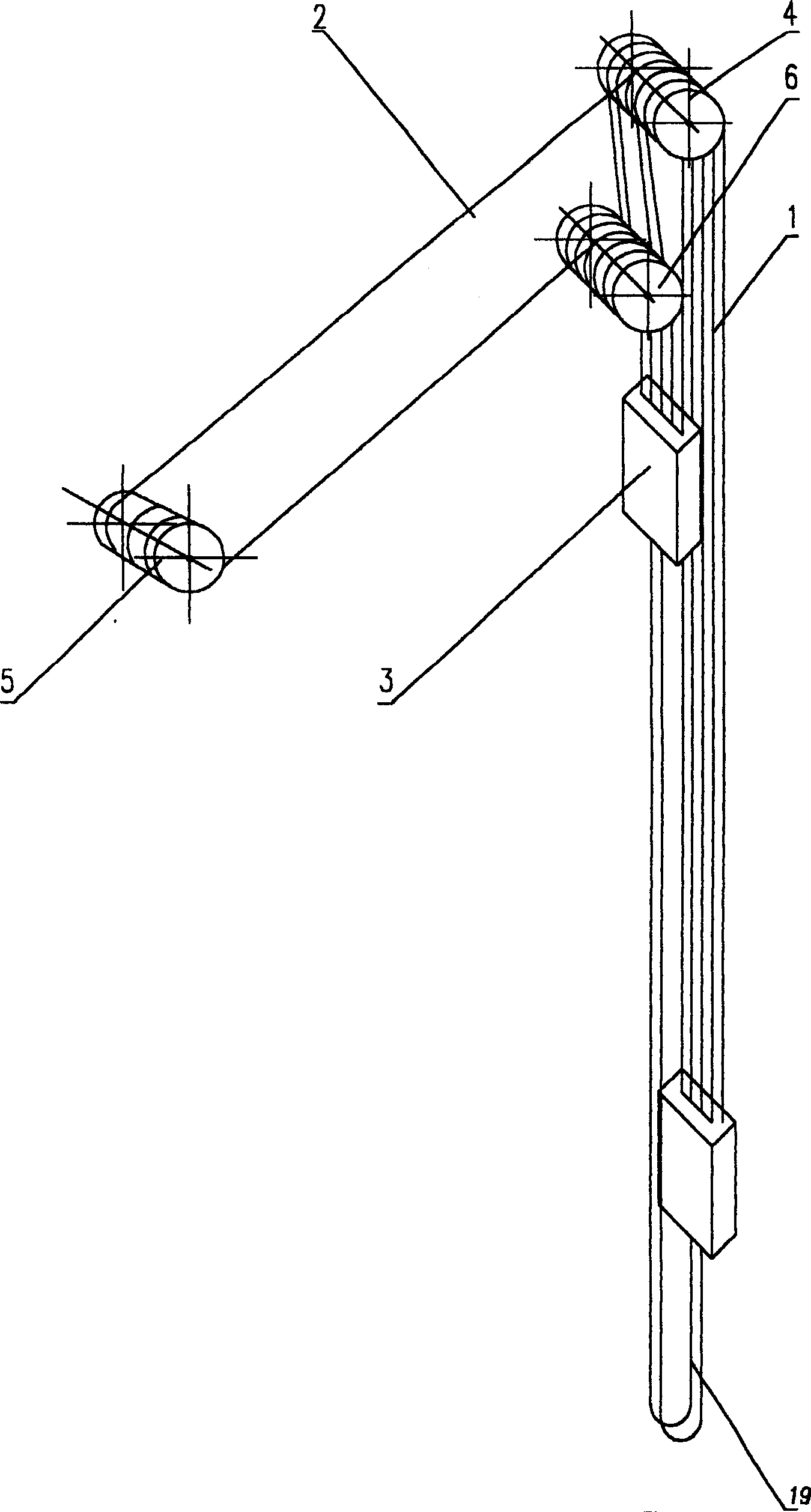

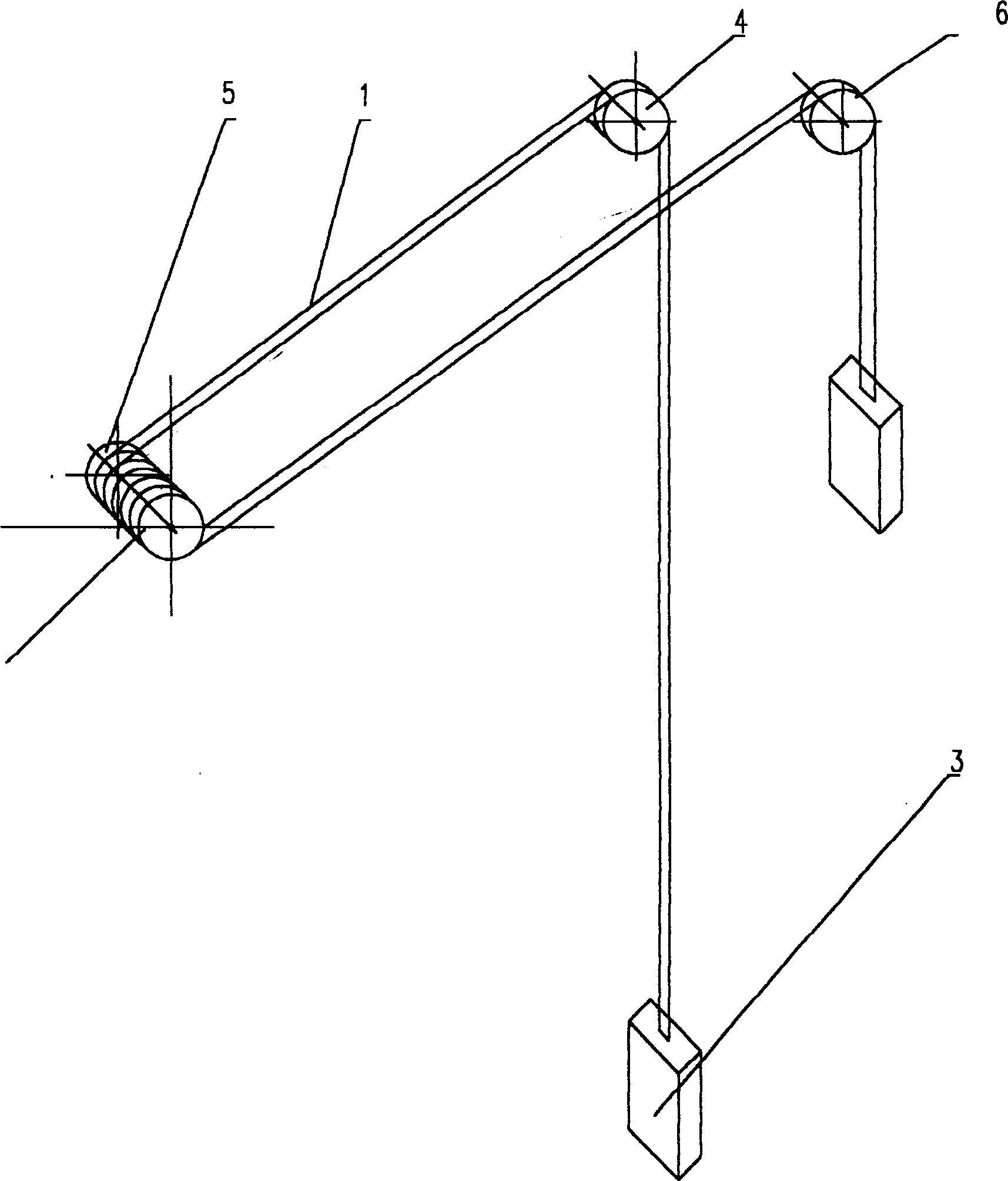

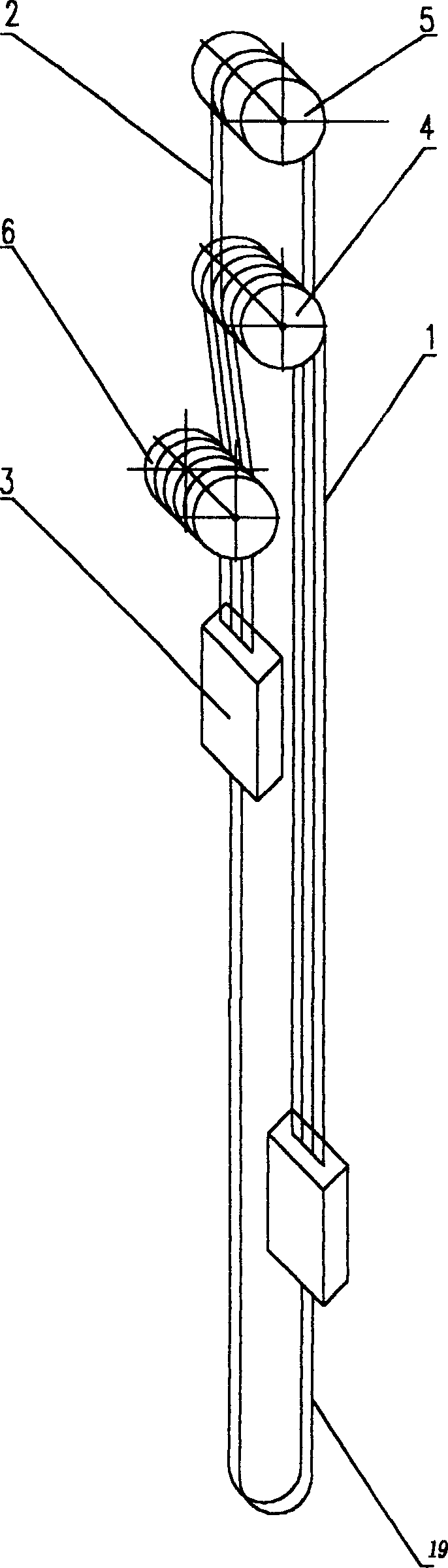

Space tether capturing system keeping stage tether in-plane and out-plane angle stable control method

The invention relates to a space tether capturing system keeping stage tether in-plane and out-plane angle stable control method. Firstly, a space tether capturing system keeping stage kinetic model is built; according to a sliding mode variable equation, a space tether capturing system keeping stage kinetic equation is sorted; a space tether capturing system keeping stage Super-Twisting control law is designed; and the magnitude of the space tether capturing system keeping stage tether in-plane and out-plane angle stable control torque is calculated. The method of the invention has the beneficial effects that the designed control law can quickly eliminate swing of in-plane and out-plane angles in an interference condition, and the tether in-plane and out-plane angles can be controlled to be expected values; and in comparison with the traditional sliding mode method, the designed control law can realize continuous control input and eliminate chattering.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Lifter suspended by multiple cables and balanced by tail cable

A multi-cable suspended lift with tail cable for balancing is composed of drive drum, overhead pulley set for bearing all load of suspending steel cable and lift container, driving steel cable, lift contain and tail cable. The active load of driving steel cable and lift container is borne by drive drum.

Owner:杨光良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com