Method for milling and vibration-damping blisk

An integral blisk and milling technology, applied in milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problems of blade cross-section position, contour and twist tolerance, small tool diameter, and knife yielding. , to achieve the effect of increasing the milling feed rate, saving processing time and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

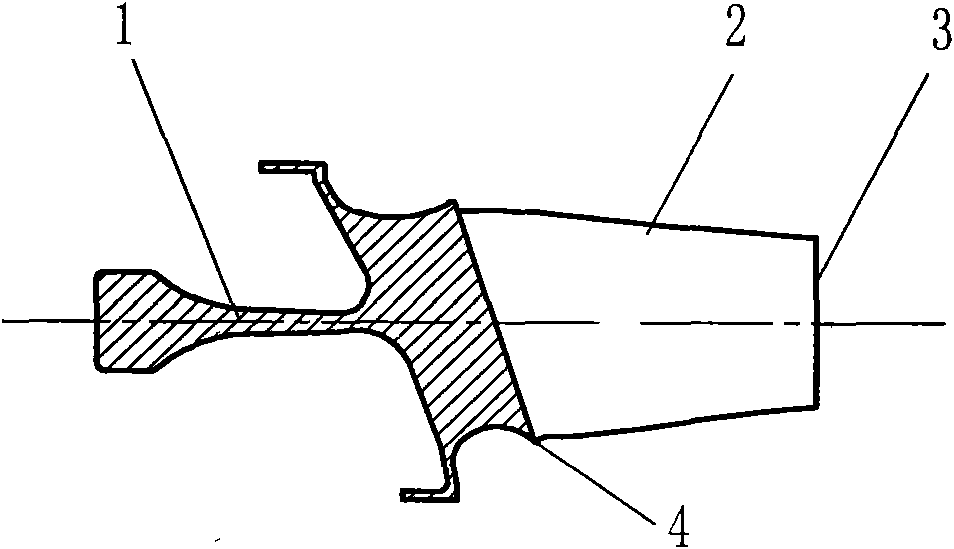

[0032] Embodiment: process a compressor integral blisk, the integral blisk is made up of disc 1 and blade 2, as figure 1 As shown, the material is titanium alloy.

[0033] Its processing steps are as follows:

[0034] 1. Filling materials are prepared according to a fixed ratio;

[0035] The mass ratio is: crystalline paraffin wax 65%, liquid wax 25%, rosin resin 9.9%, hindered phenolic antioxidant-2,6-tertiary butyl 4 methylphenol 0.1%;

[0036] 2. Melting filling material;

[0037] Fully mix the above filling materials in a metal container, heat on an electric furnace until the solid wax is completely melted, and then stir evenly to become a liquid filling agent.

[0038] 3. Install the pouring fixture;

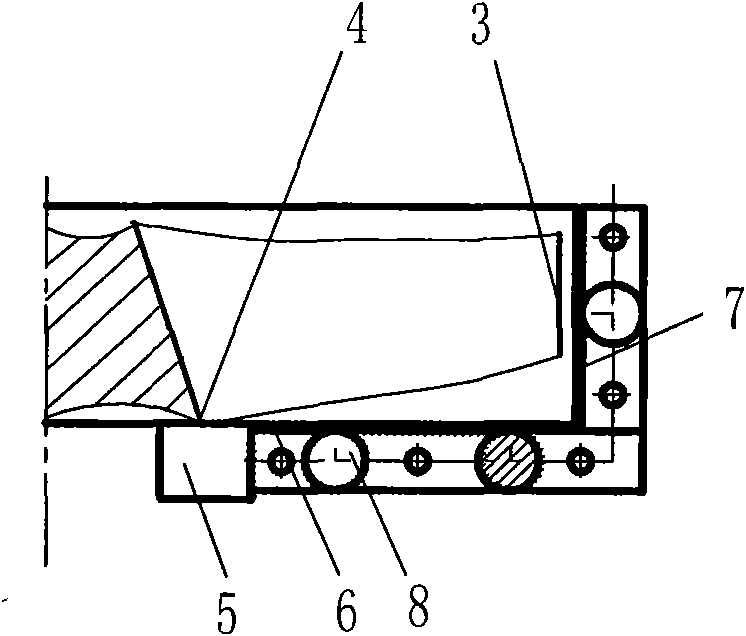

[0039] Such as figure 2 As shown, the semi-closed annular casting fixture is placed on the overall compressor blisk from bottom to top, so that the metal support ring 5 is in contact with the edge plate 4 to ensure positioning and sealing, and the side steel plate 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com