Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

381 results about "Position loop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modular multi-axis motion control and driving system and method thereof

InactiveUS20060100723A1Improve performanceReduced dimensionSynchronous motors startersAC motor controlMOSFETNetwork service

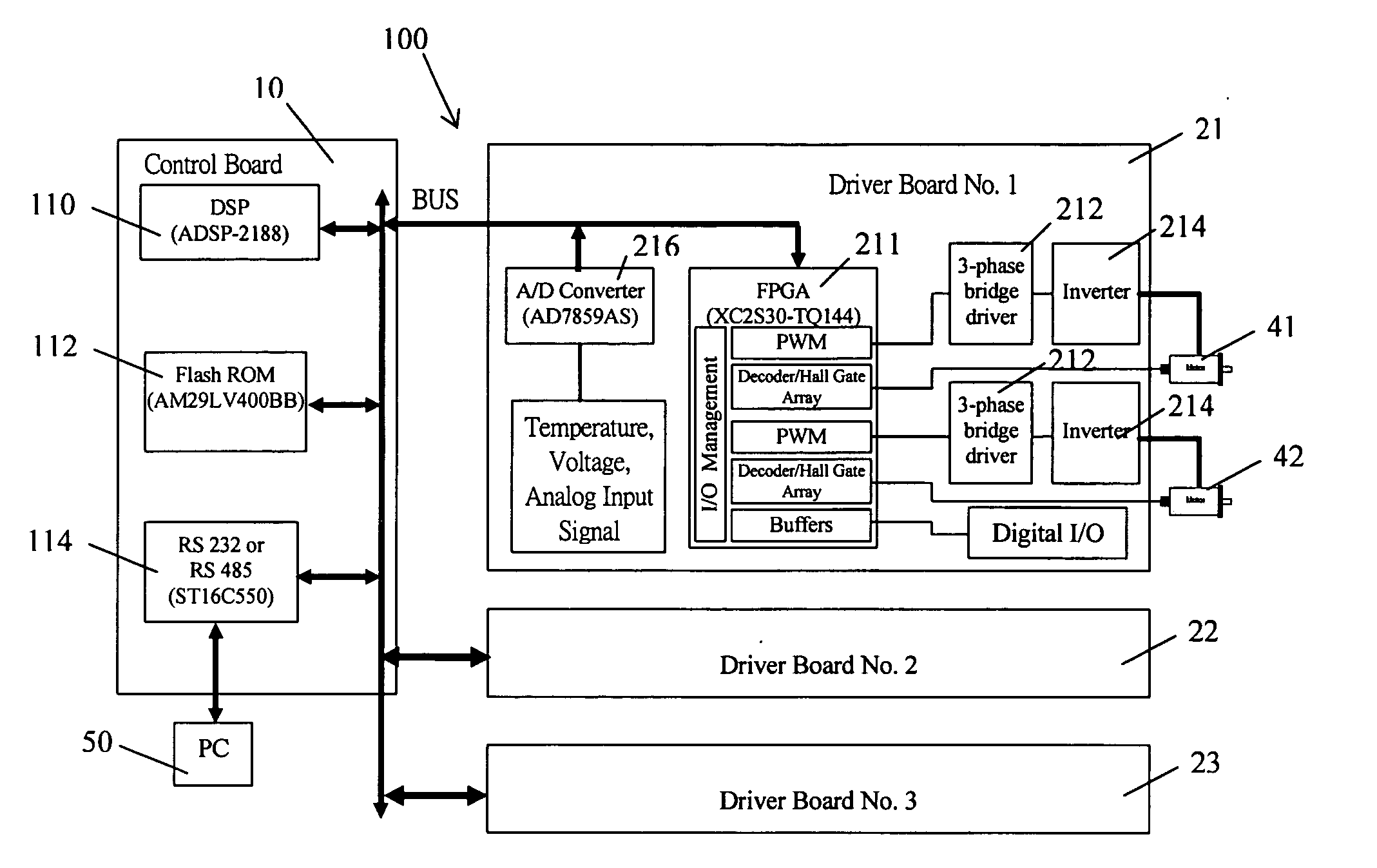

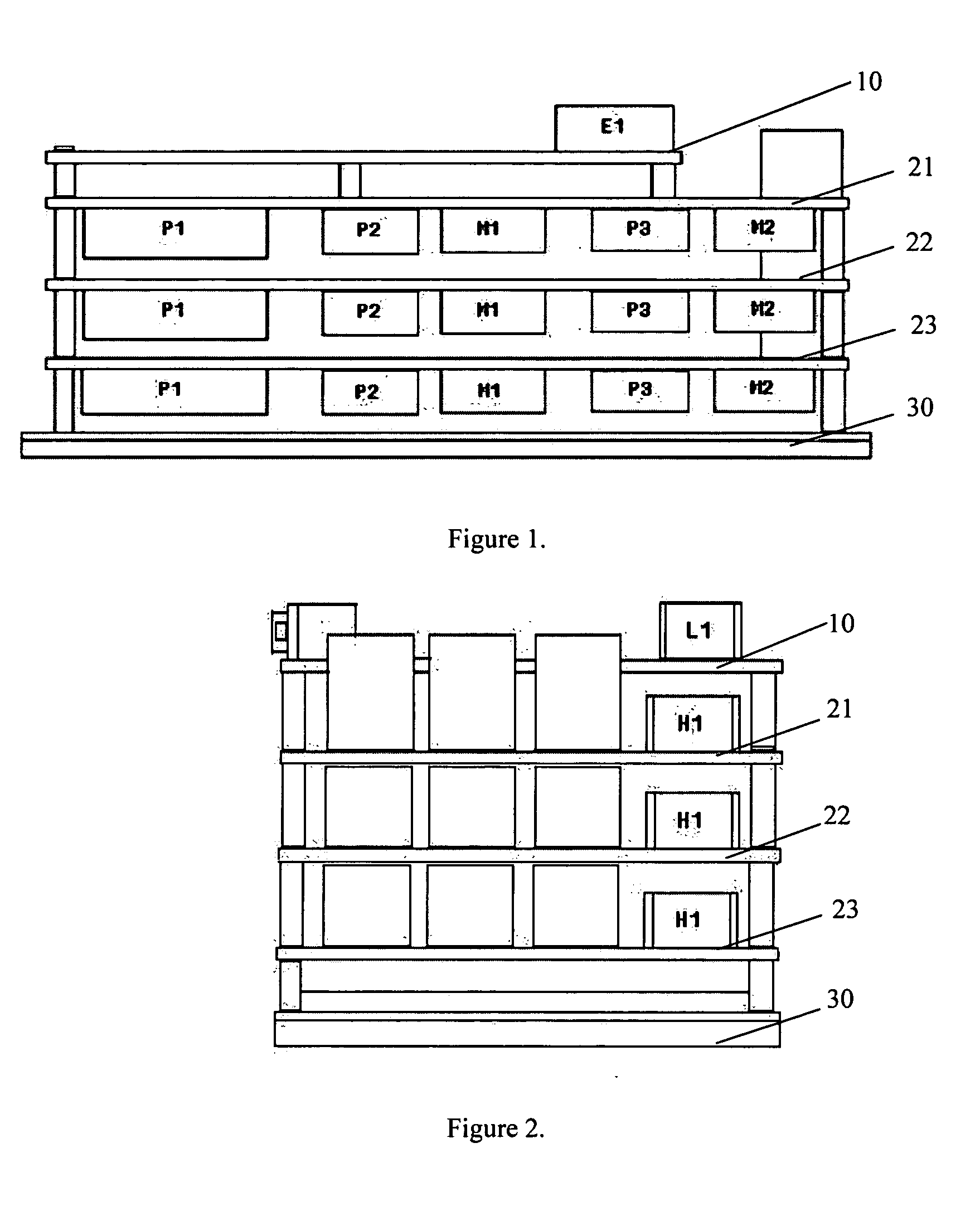

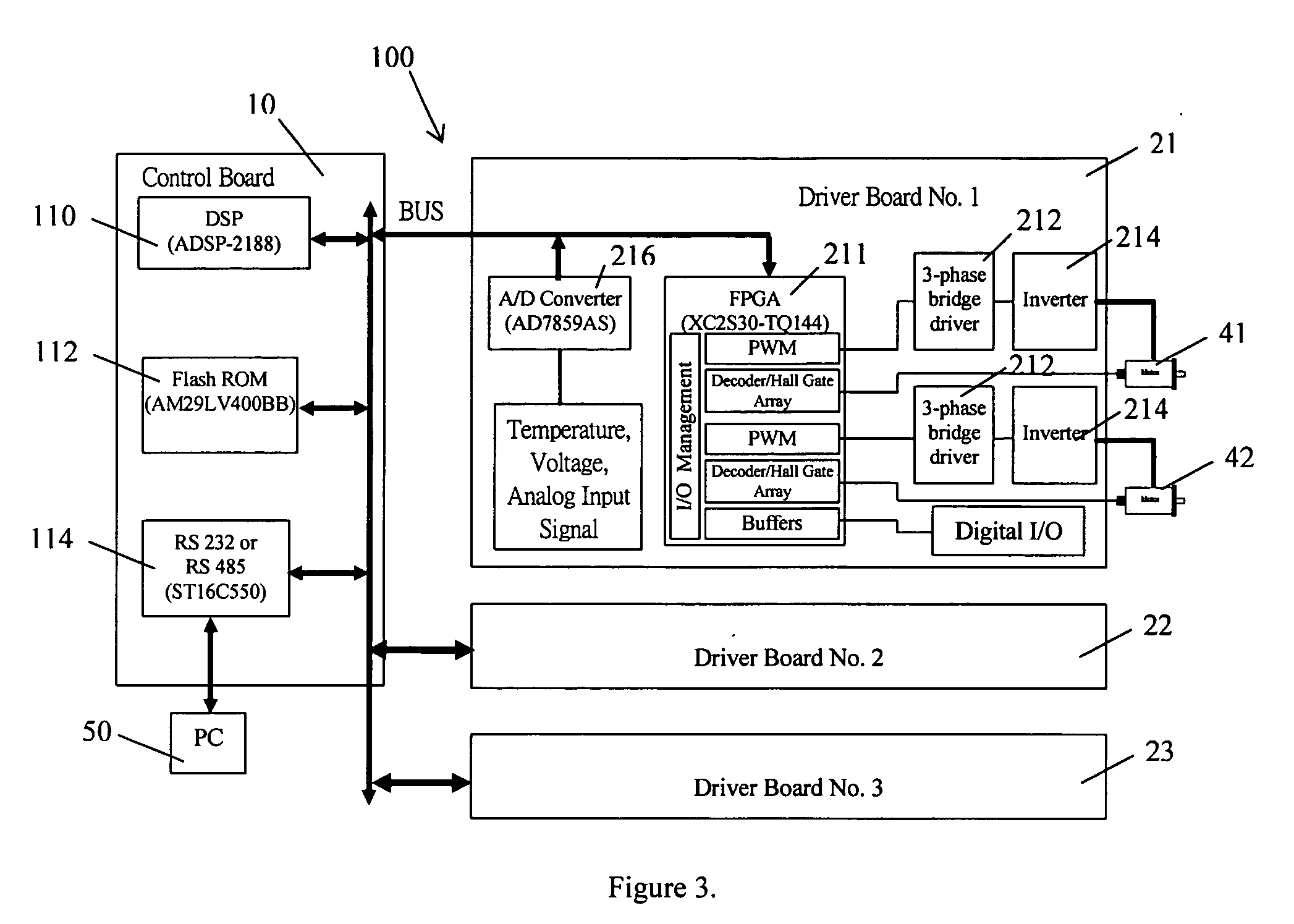

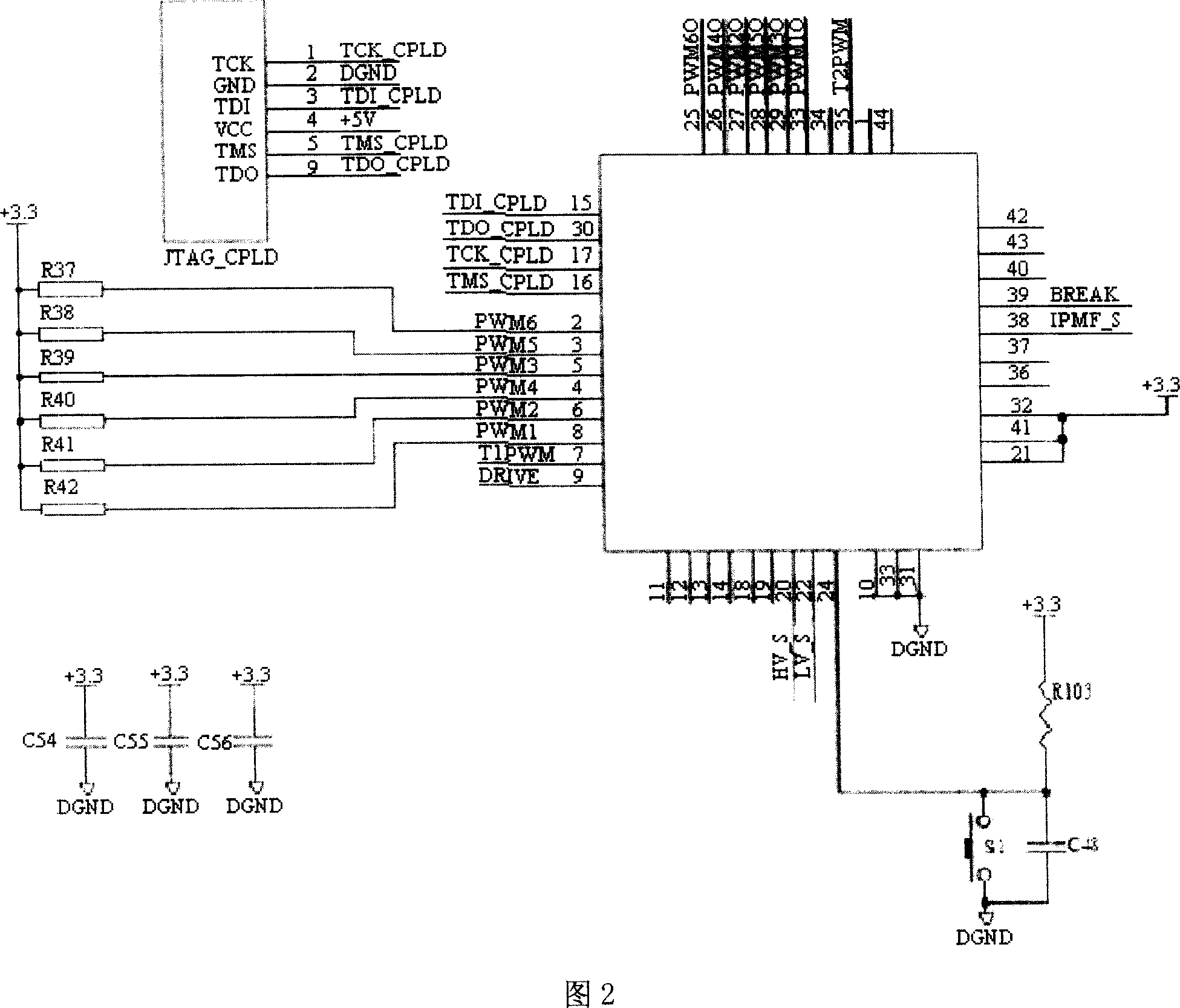

A modular multi-axis motion control and driving system is developed by using advanced Digital Signal Processor (DSP) and Field Programmable Gate Array (FPGA) technologies. A modular multi-axis motion control and driving system comprises: a control board comprising a DSP and Flash ROM connected to each other, for performing position control and current control of said system; a plurality of driver boards, connected to the control board through a bus, each of which comprise a FPGA device and a plurality of MOSFET power amplifier, for driving a plurality of servo motors; a computer, connected to said control board, for providing graphic user interface, through which motor setting, current and position loop tuning and diagnostic can be performed; Wherein, a control program, system parameters and FPGA configuration file are stored in said Flash ROM, when the system power is on, the DSP automatically executes an loader firmware to transfer the control program from said Flash ROM to the memory of DSP for execution, then the DSP reads the FPGA configuration file from the Flash ROM and configure the FPGA in the driver board, after that, the control program runs into a circulation loop to do system diagnose, network service and check command queue, while the current and position controls are implemented in an interrupt service.

Owner:DYNACITY TECH HK

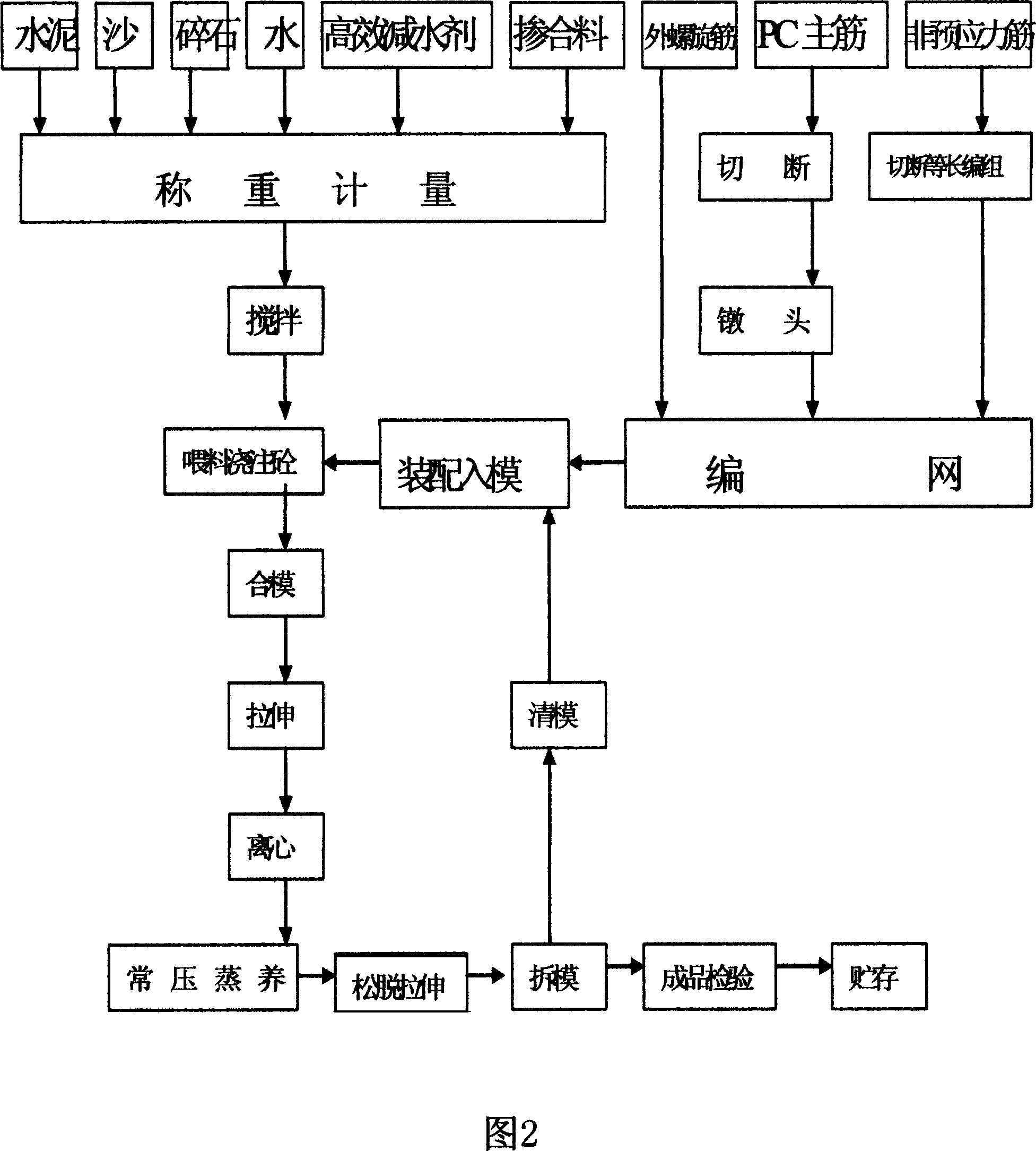

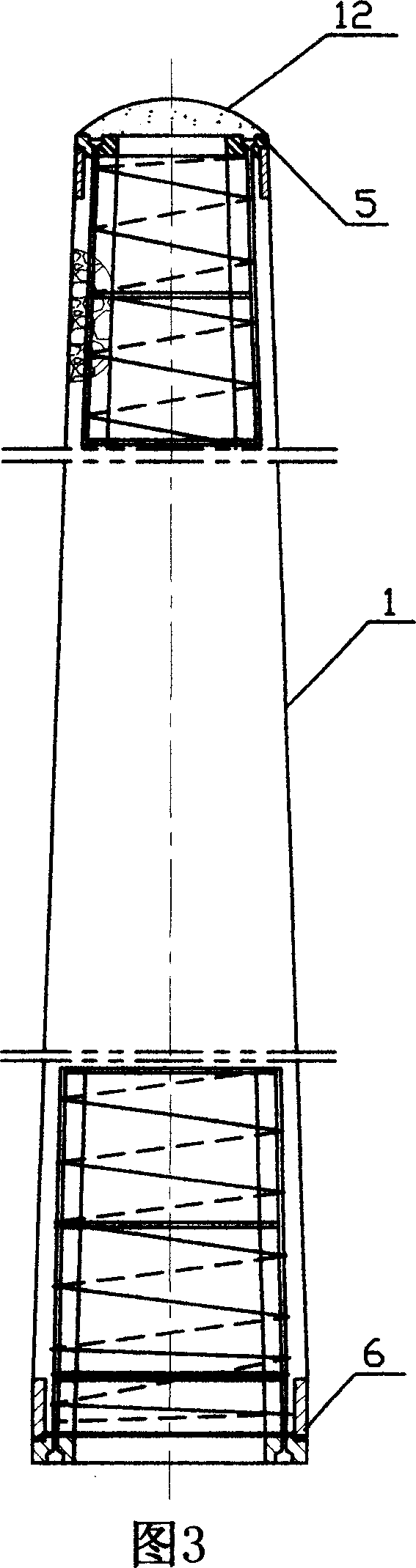

Prestressed concrete electrical pole and its production

InactiveCN101029540AImprove carrying capacityAvoid breakingCeramic shaping apparatusTowersReinforced concretePre stress

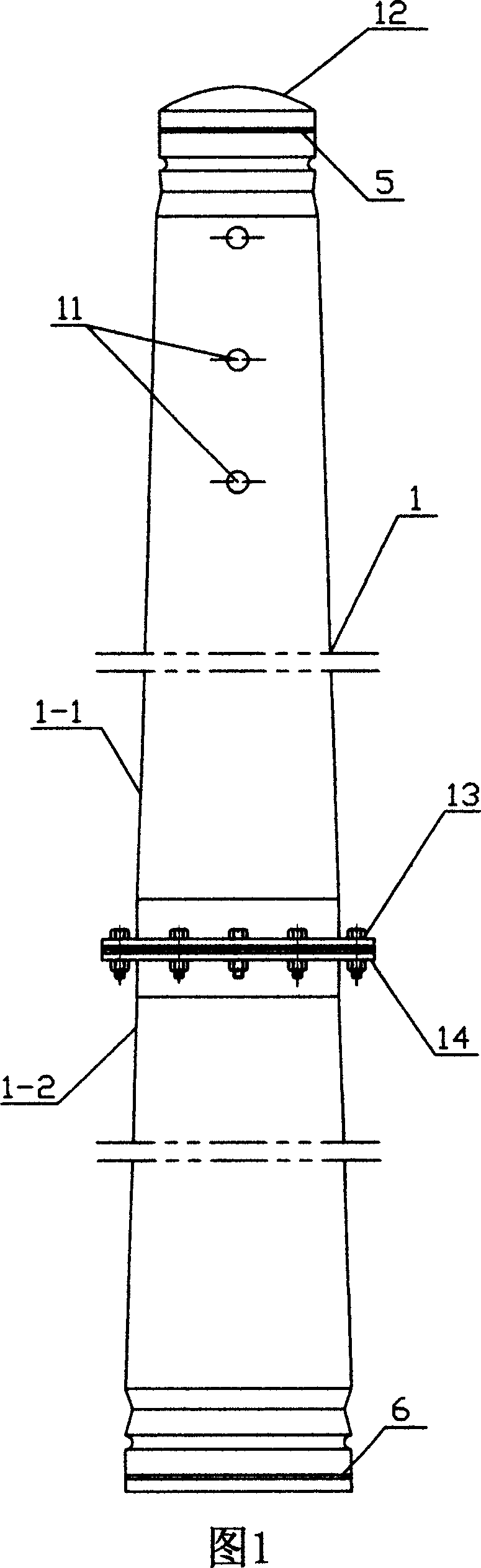

This invention is a prestressed concrete pole and its construction method. The pole is of a conicity at 1:75, with holes for cables. It can be a single pole or sectional fabricated. The pole is made by reinforce bar cage centrifugal casting. The reinforce bar cage is composed by vertical main bars and normal bars fixed on supporting and positioning loops, and binding outside by helix wire. Two end plates are installed to the pole ends to fix the mail bars. After installed the end plates and before centrifugal casting, pull the plates with 1000-1900KN power, and steaming the concrete to grade over C60, then loose the power. In case of sectional fabricated, the sections are connected to each other through bolts.

Owner:吕森金

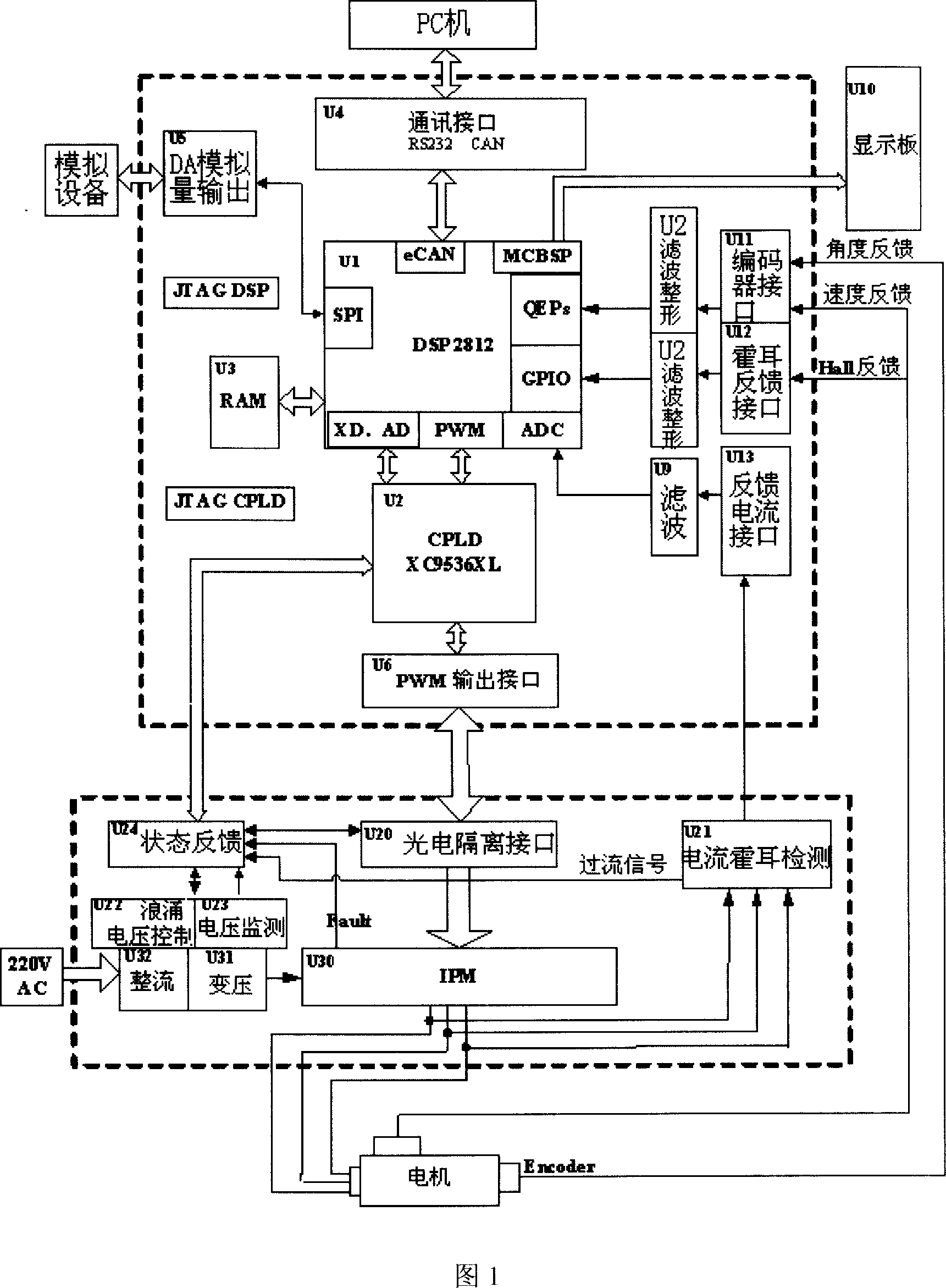

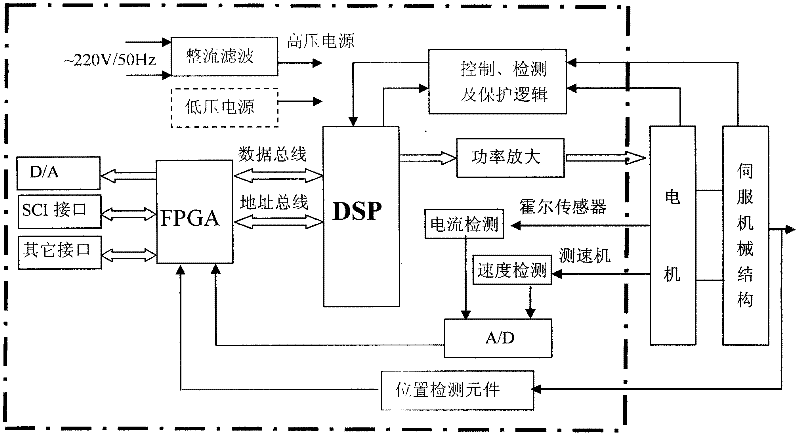

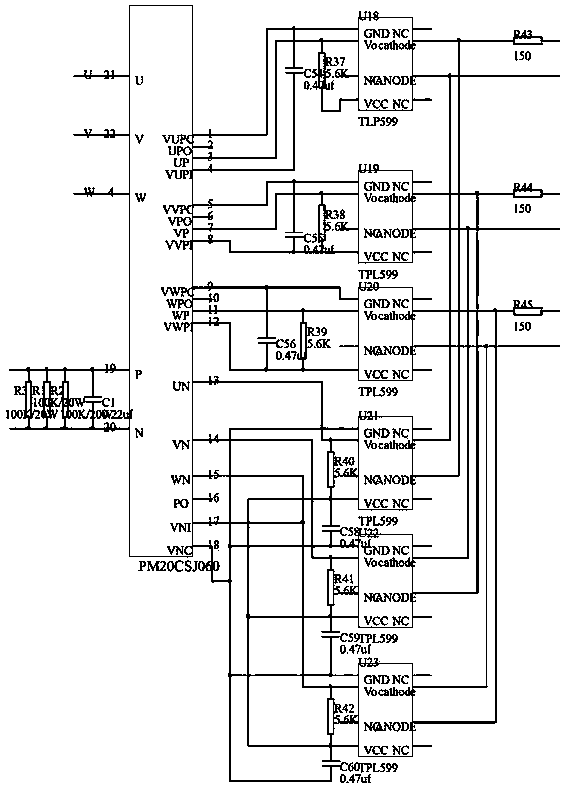

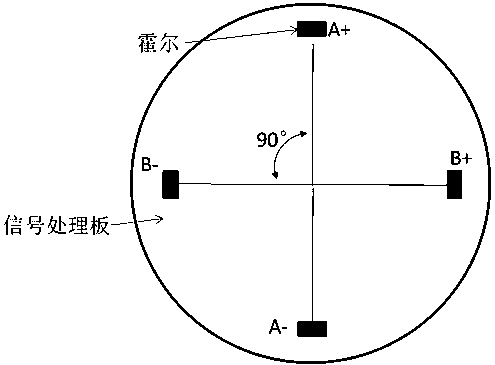

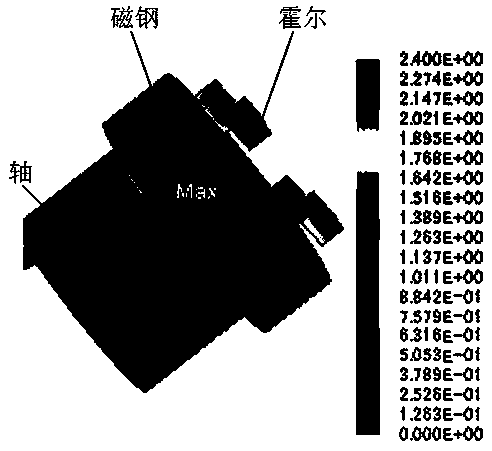

Brushless servo control system and driving apparatus based on permanent magnet brushless DC motor

InactiveCN101499753AHighly integratedReduce power consumptionVector control systemsSingle motor speed/torque controlMagnetic polesField-programmable gate array

The invention provides a driving device of a permanent magnetic brushless direct current (DC) servo motor, comprising a control unit, an interface unit and a driving unit; the control unit is connected with the driving unit by the interface unit; the control unit adopts a field programmable gate array (FPGA) and has high integration, low power dissipation and good operation real-time performance; the key point of the design of the control system is the control to three loops: a current loop, a speed loop and a position loop and the integral matching of the three loops so that three control modes of moment, speed and location can be realized; the control system can be used for simple speed regulation and also can be applied to high-precision positioning control situations; and when the brushless servo control system of the driving device is adopted, the current detection feedback signal and the magnetic pole detection feedback signal are directly obtained from the feedback element of the permanent magnetic brushless DC motor, thus being different from the traditional sampling method of the feedback signal of the servo system, thereby ensuring the signal sampling precision and reducing the cost.

Owner:常州合泰电机电器股份有限公司

DSP-based electric machine position servo device

InactiveCN1955868ARealize closed-loop servo controlImprove reliabilitySingle motor speed/torque controlControl using feedbackProgrammable logic deviceElectric machine

A servo device of motor position based on DSP consists of brushless DC motor being used as servo motor as its servo device being suitably set on digital control system requiring position control response quickly, control circuit being designed independently by DSP and programming logic component for realizing closed loop servo control of current loop and speed loop as well as position loop.

Owner:HARBIN ENG UNIV

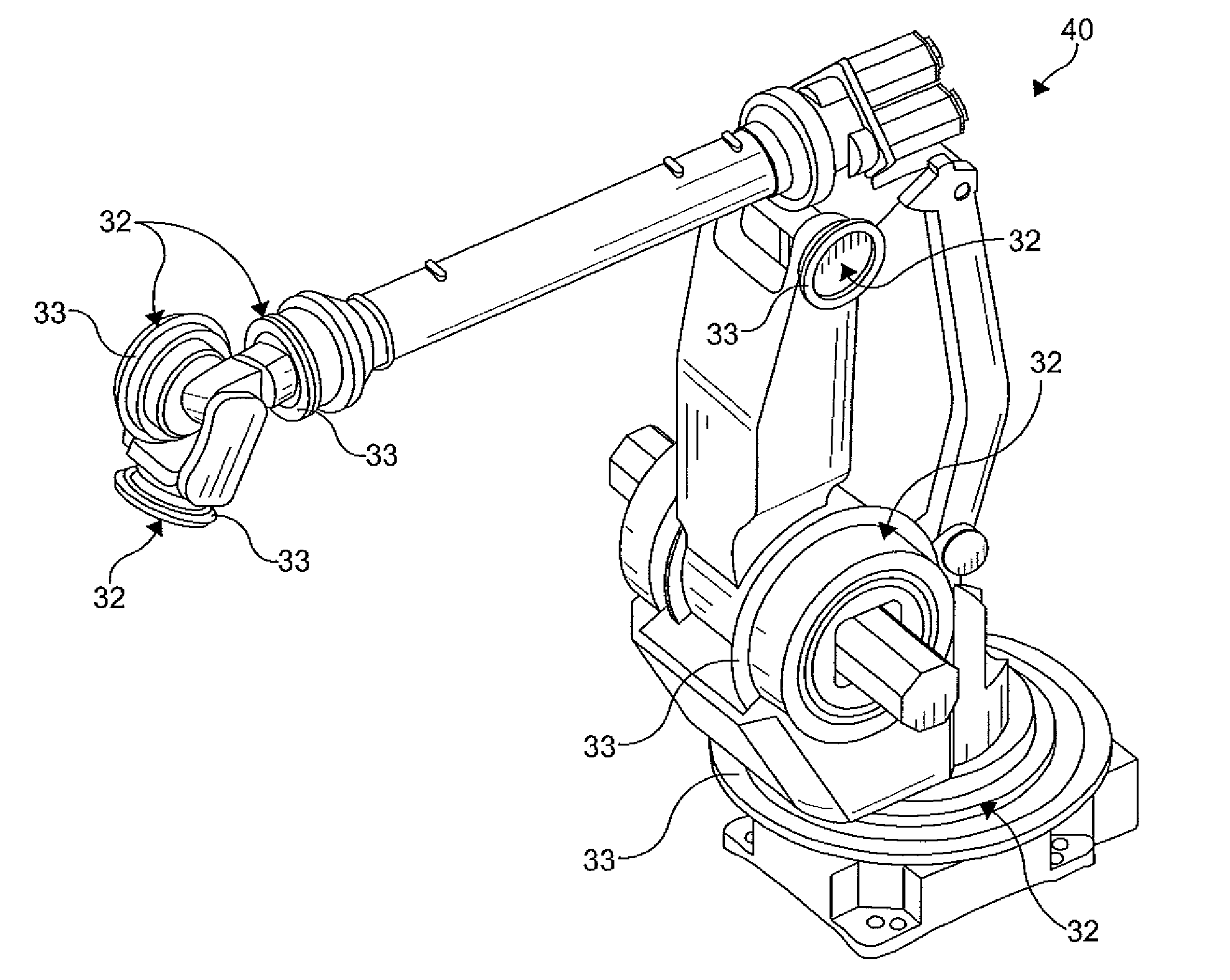

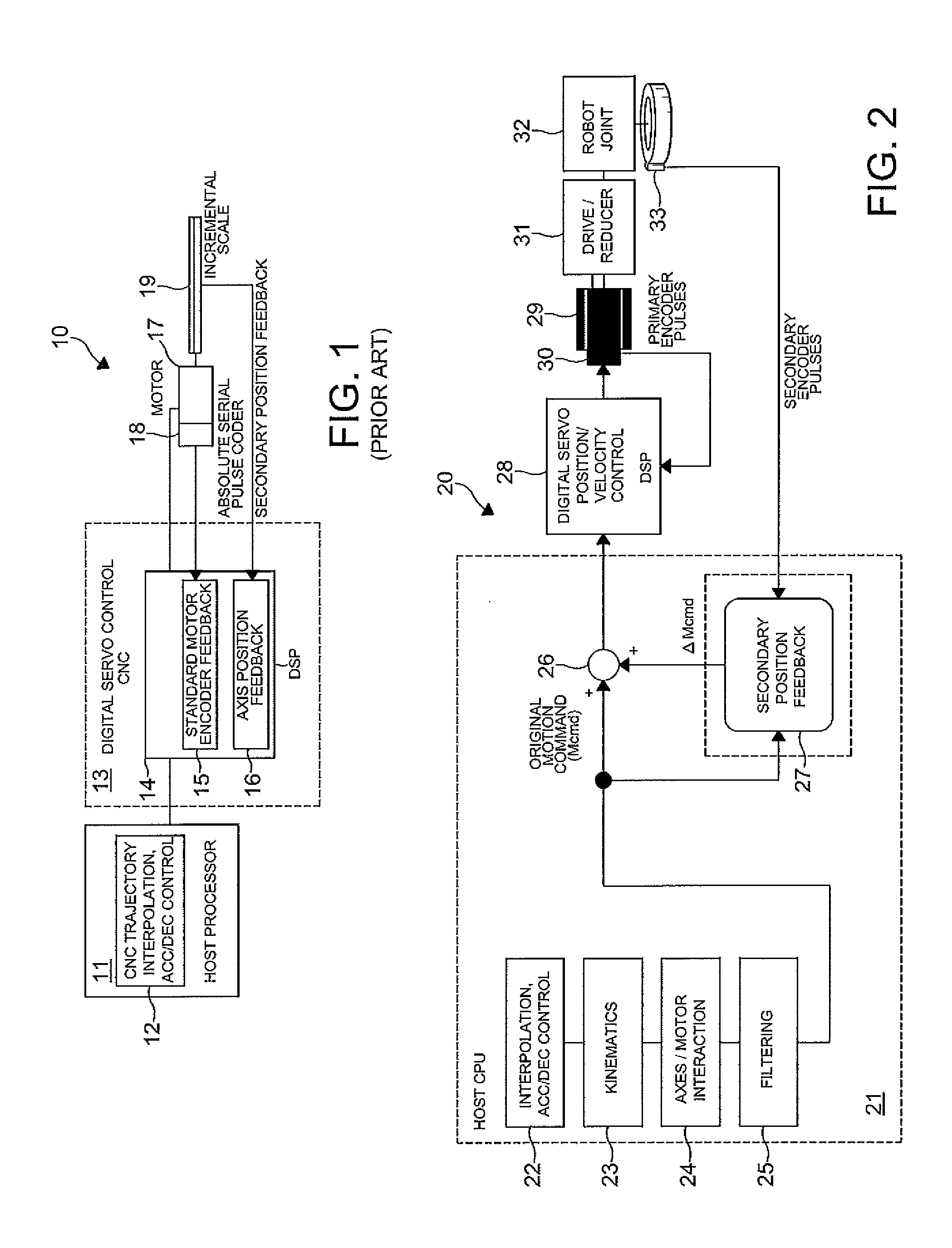

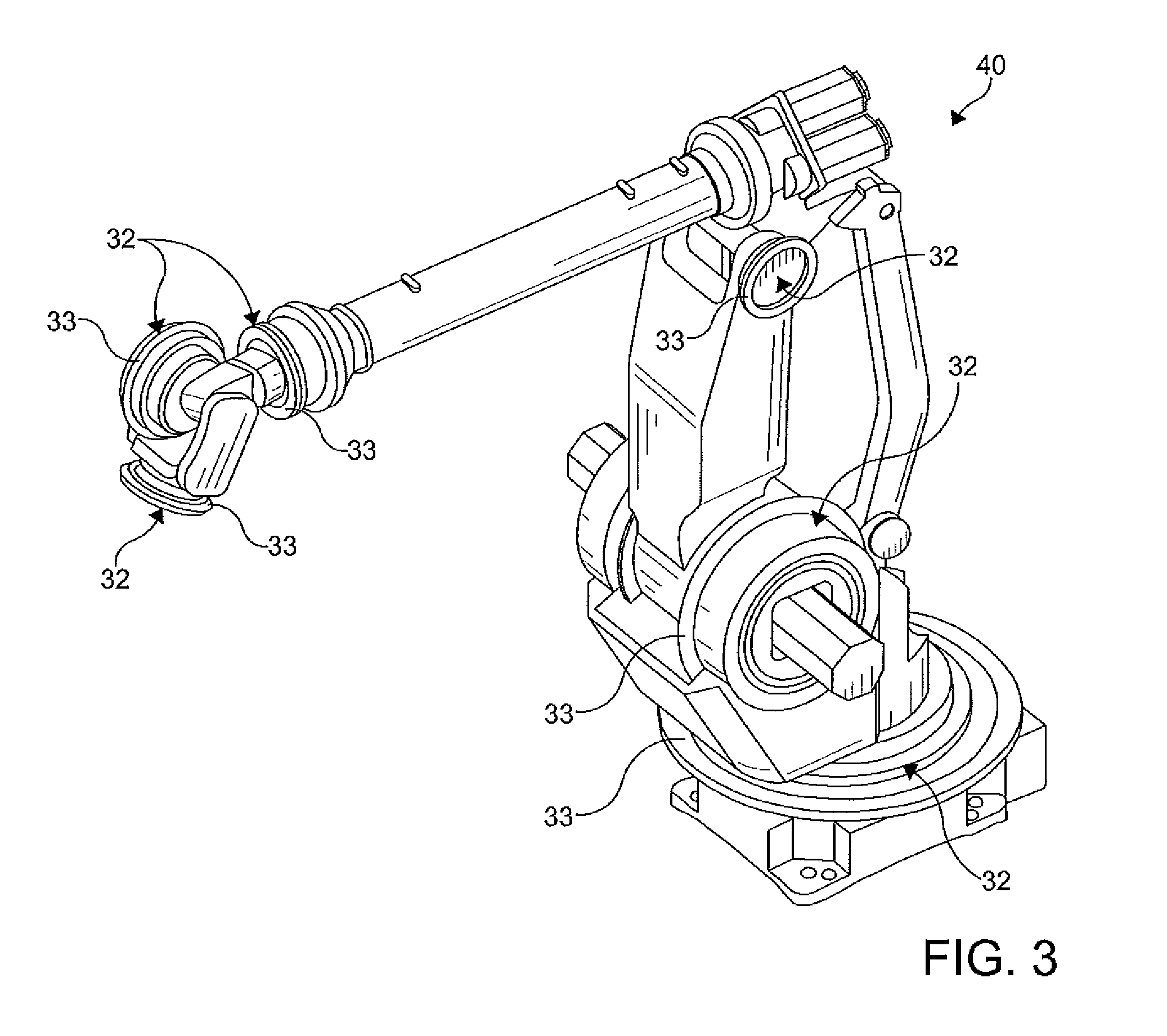

Secondary position feedback control of a robot

ActiveUS20100191374A1Remove complexityMaintain abilityComputer controlSimulator controlDual loop controlGear train

A method of and apparatus for achieving dynamic robot accuracy includes a control system utilizing a dual position loop control. An outer position loop uses secondary encoders on the output side of the gear train of a robot joint axis, while the inner position loop uses the primary encoder attached to the motor. Both single and dual loop control can be used on the same robot and tooling axes.

Owner:FANUC ROBOTICS NORTH AMERICA

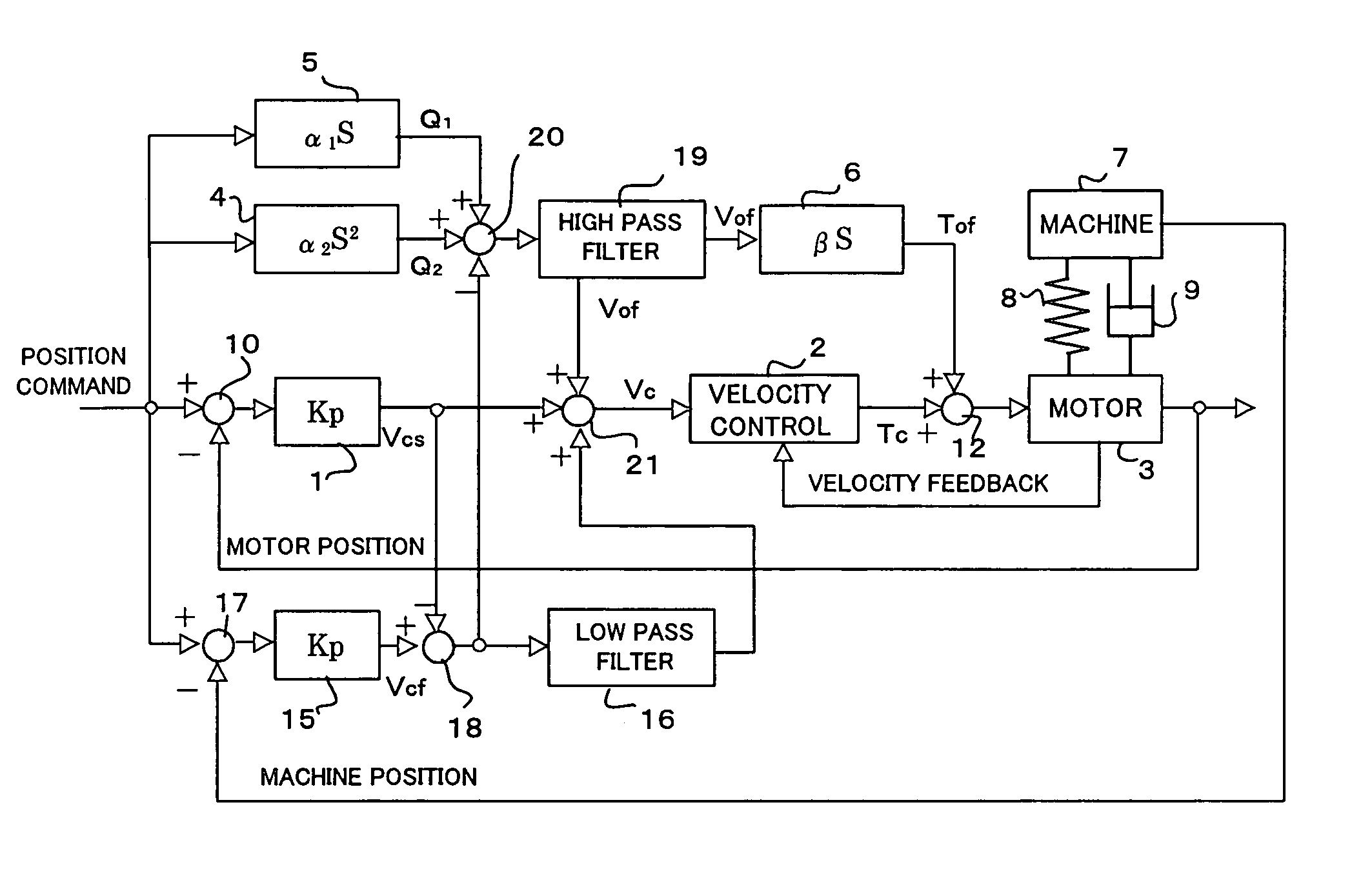

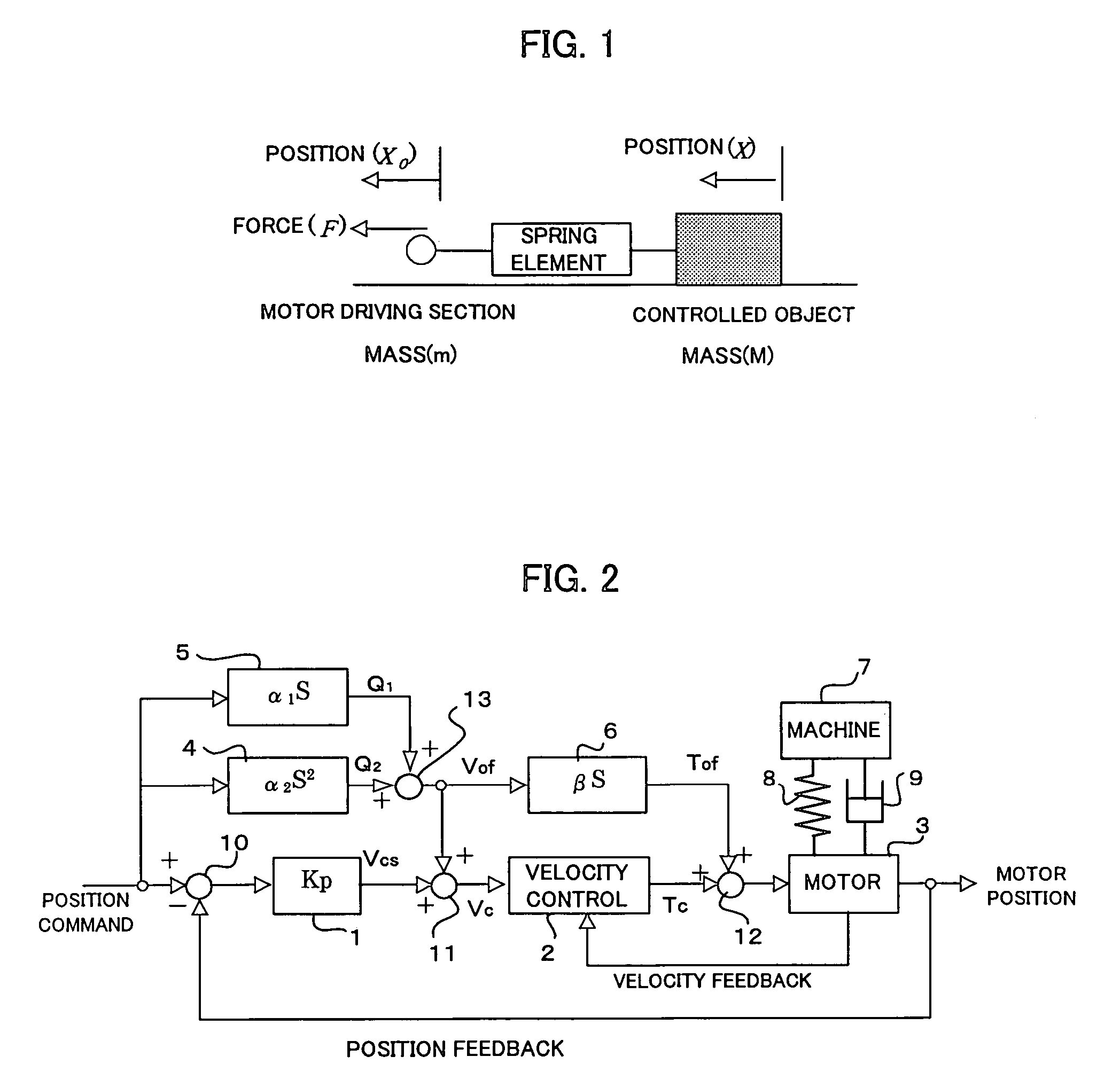

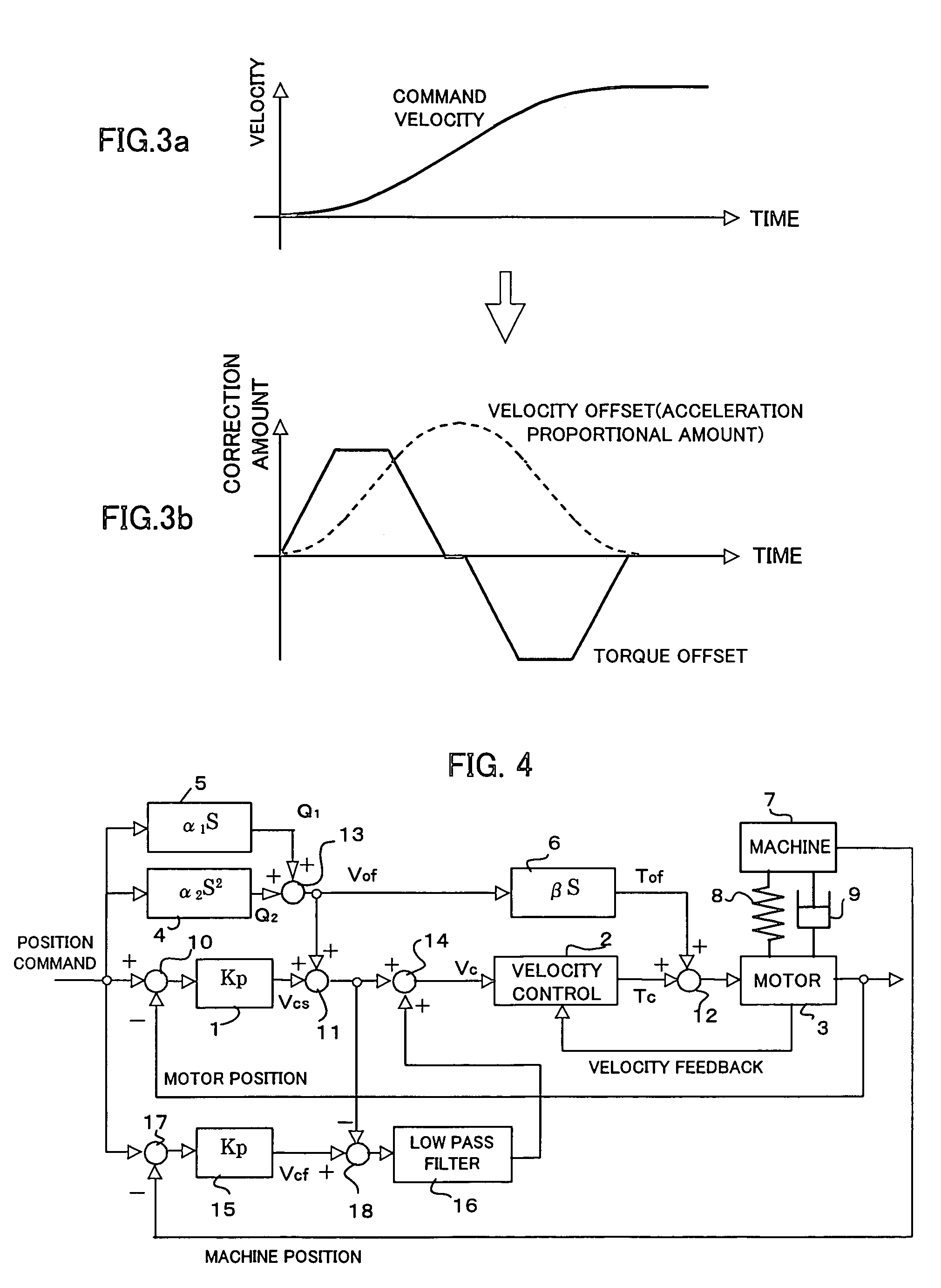

Controller

ActiveUS7030585B2Suppression delayReduce delaysElement comparisonFeeding apparatusLoop controlResponse delay

A controller capable of preventing response delay and generation of vibrations attributable thereto during position control of a movable part of a machine having low rigidity. A motor for driving a machine having low rigidity is subjected to position and velocity loop control. Compensation amount Q1 proportional to command velocity obtained by differentiating a position command and compensation amount Q2 proportional to second-order differentiated command acceleration are obtained. Compensation amounts Q1 and Q2 are added together, thus obtaining a velocity offset amount Vof corresponding to a estimated torsion amount. A differentiated value of the velocity offset amount is multiplied by coefficient β to obtain a torque offset amount Tof. The velocity offset amount Vof is added to a velocity command Vcs obtained by position loop control 1. The torque offset amount Tof is added to a torque command Tc outputted in velocity loop control 2, and the result is used as a drive command to the motor. Based on the velocity and the torque offset amount Vof and Tof, a torsion amount between motor 3 and the machine is controlled. The machine position and velocity are controlled with accuracy by regular position and velocity loop control.

Owner:FANUC LTD

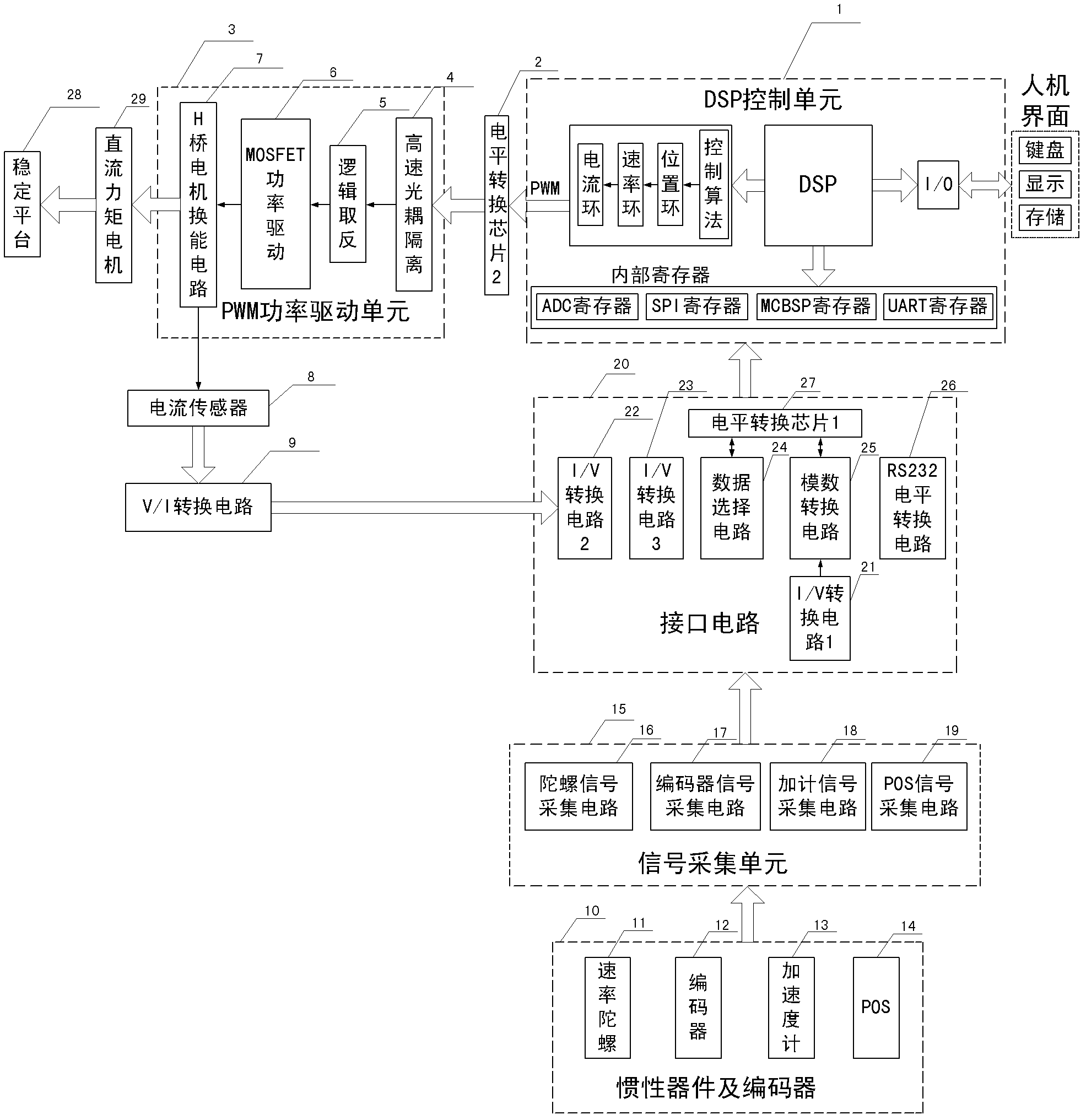

High-precision and large-load control system and method of three-axis inertially stabilized platform for airborne remote sensing

InactiveCN102436262AInhibition effectEnhanced inhibitory effectAttitude controlPosition/course control in three dimensionsDigital signal processingTorque motor

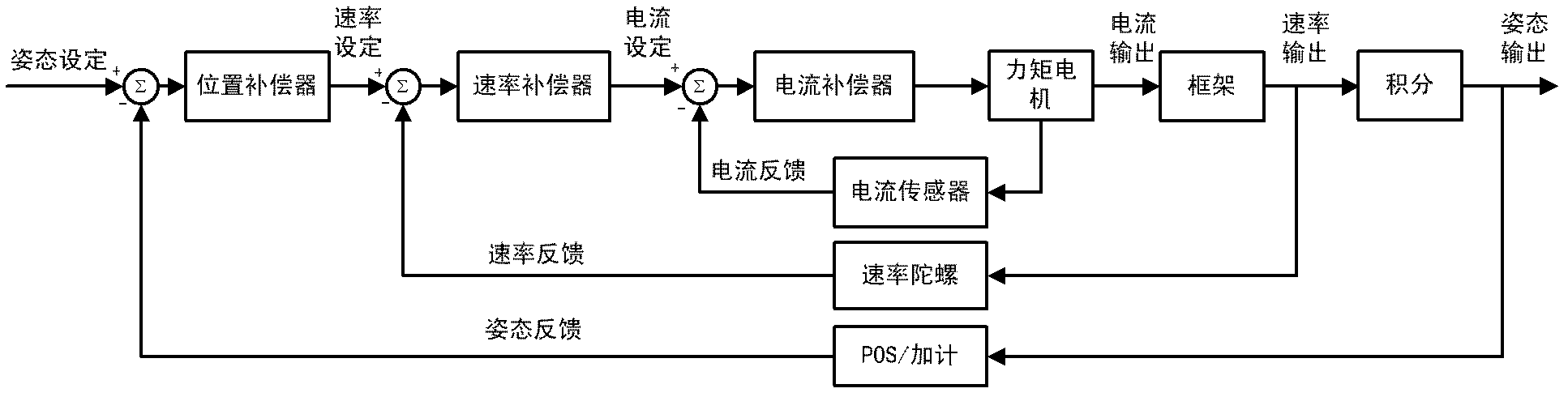

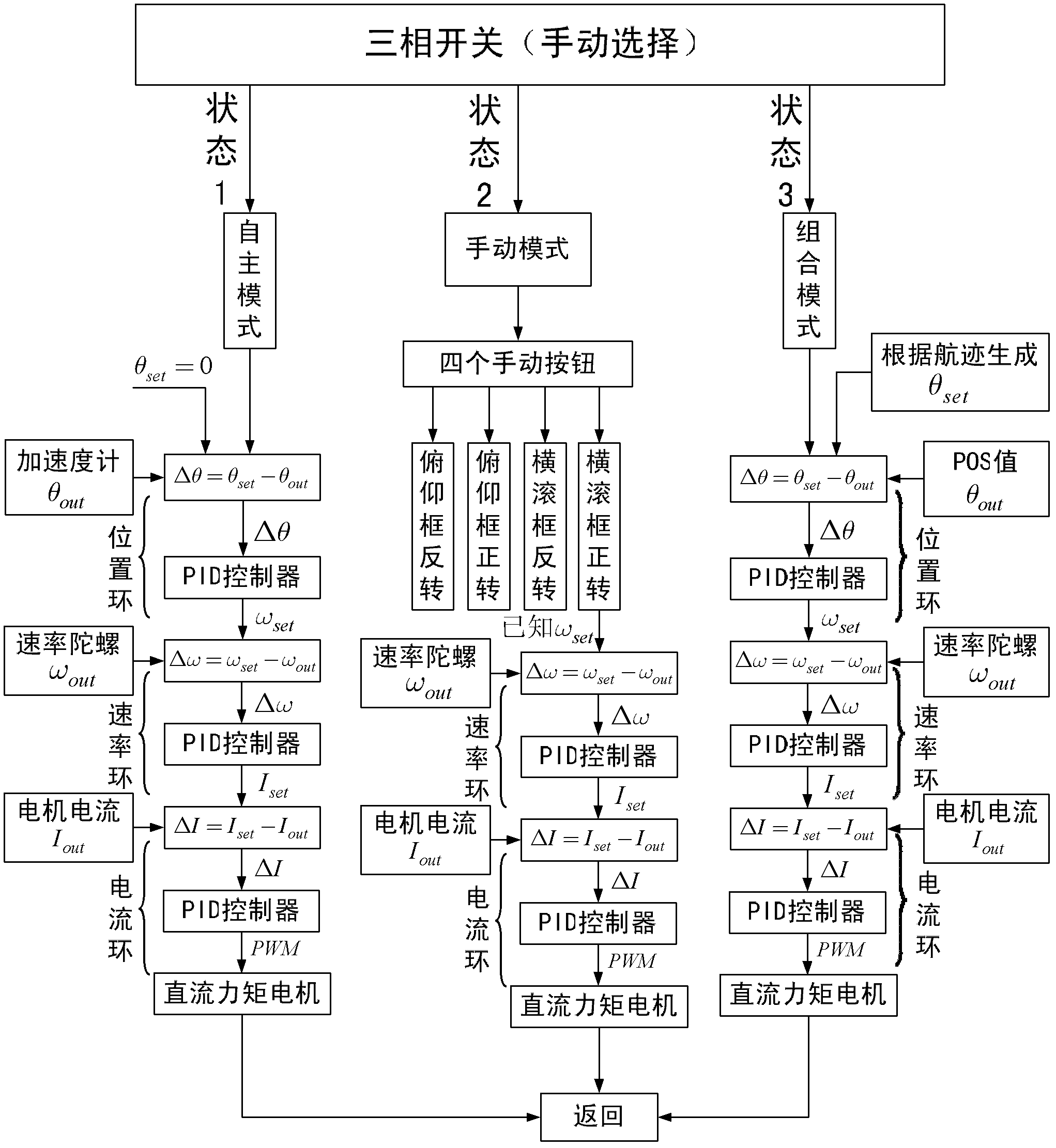

The invention provides a high-precision and large-load control system and method of a three-axis inertially stabilized platform for airborne remote sensing. The system comprises a DSP (digital signal processing) control unit, a PWM (pulse-width modulation) power drive unit, an interface circuit, a signal acquisition unit, an inertial device, an encoder and a direct current (DC) torque motor. The method comprises the following steps: acquiring data such as the attitude angle and angular speed of frameworks relative to an inertial space, coil current and relative corners among the frameworks through the signal acquisition unit; transferring the data into an internal register of the DSP control unit through the interface circuit so that the data is read by the DSP control unit; taking the data as signals to be input into the DSP control unit, and generating PWM controlled quantity by adopting a three-loop (a current loop, a speed loop and a position loop) compound control algorithm; and transferring PWM signals into an energy conversion circuit of an H-bridge DC motor through the power drive unit so as to drive the DC torque motor to change with reference instructions, and finally realizing active control of the inertially stabilized platform. The high-precision and large-load control system and method provided by the invention have the advantages that control precision and loading capability of the system are improved, the control algorithm is completed, and diversity and intellectualization of a platform operating mode are improved.

Owner:BEIHANG UNIV

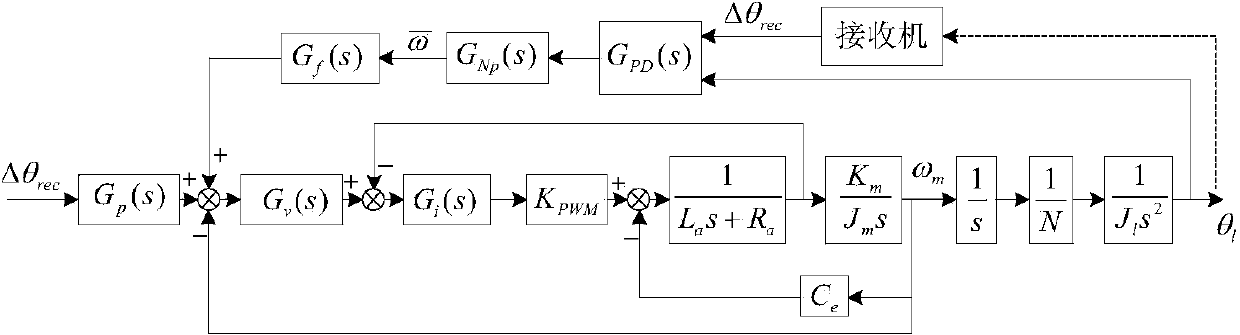

Self-tracking servo control system for flat plate with high integration and high precision

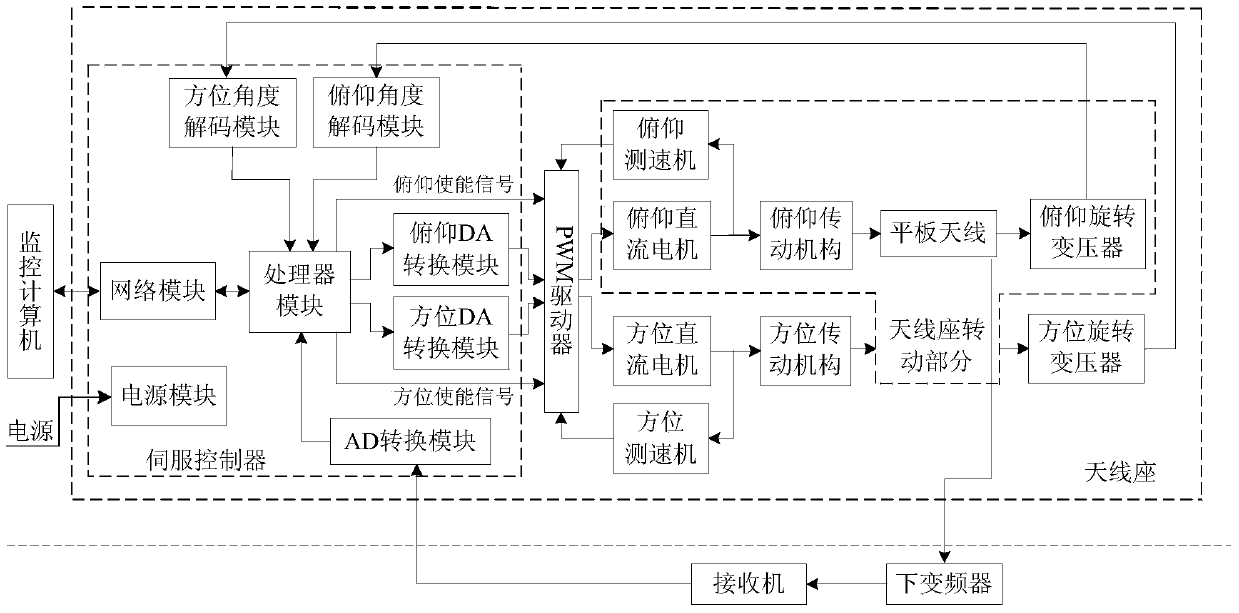

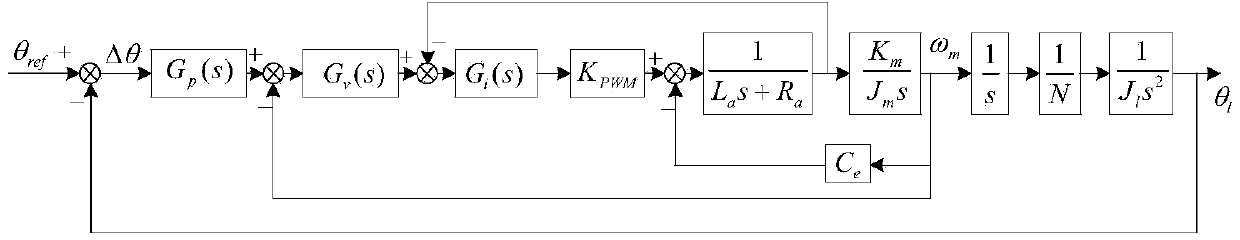

ActiveCN104199465AClear functionMeet the tracking accuracyAntennasPosition/direction controlClosed loopPosition loop

The invention discloses a self-tracking servo control system for a flat plate with high integration and high precision. The self-tracking servo control system comprises a monitoring computer, a servo controller, a PWM driver, a direct current motor, a speed measurer, a transmission mechanism, a rotary transformer, a flat plate antenna and a support rotating mechanism, wherein the monitoring computer receives working conditions and issues control commands; the servo controller receives the control commands issued by the monitoring computer, reads antenna angle position information and receiver angle error information, closes a position loop, tracks the closed loop, and outputs analog controlled quantity to the PWM driver; the PWM driver closes a speed lop and a current loop to drive the direct current motor to further drive the flat plate antenna by the transmission mechanism to rotate; the flat plate antenna receives high frequency telemetry signals; the transmission mechanism, the flat plate antenna and the support rotating mechanism jointly constitute an antenna pedestal; the servo controller, the PWM driver, the direct current motor, the speed measurer, and the rotary transformer are installed on the antenna pedestal; the self-tracking servo control system has the advantages of small volume, light weight, low energy consumption and high integration level.

Owner:BEIJING RES INST OF TELEMETRY +1

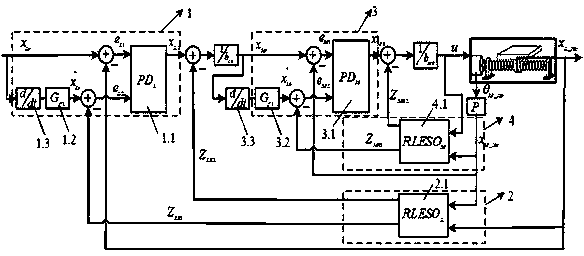

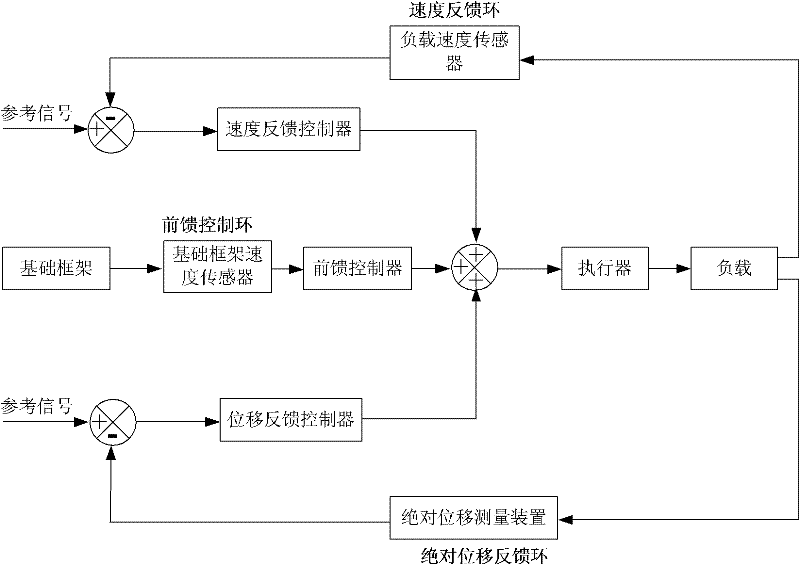

Anti-disturbance controller with double position loop feedback for feeding system

The invention discloses an anti-disturbance controller with double position loop feedback for a feeding system. The anti-disturbance controller is mainly used for high-speed and high-precision control over the feeding system. The double position loop feedback, namely the motor rotating angle position thetaM_list feedback and the load position xL_list feedback, is adopted in the controller. Two loops for the feedback are respectively provided with a position controller and a state observer. The state observers assess the total disturbance of the feeding system online in real time and conduct compensation so as to obtain the high anti-disturbance capability. On the basis of compensating for the total disturbance in real time, errors of input signals and feedback measurement signals and differential design linear feedback rates of the input signals and the feedback measurement signals are used to obtain high control bandwidths. In addition, the control performance of the controller can be further improved through speed and acceleration feedforward. Thus, the anti-disturbance controller has the high control bandwidth, the high anti-disturbance capability and the high robustness and further has the advantages of being simple in algorithm, clear in control parameter physical significance, easy to debug and the like.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU +1

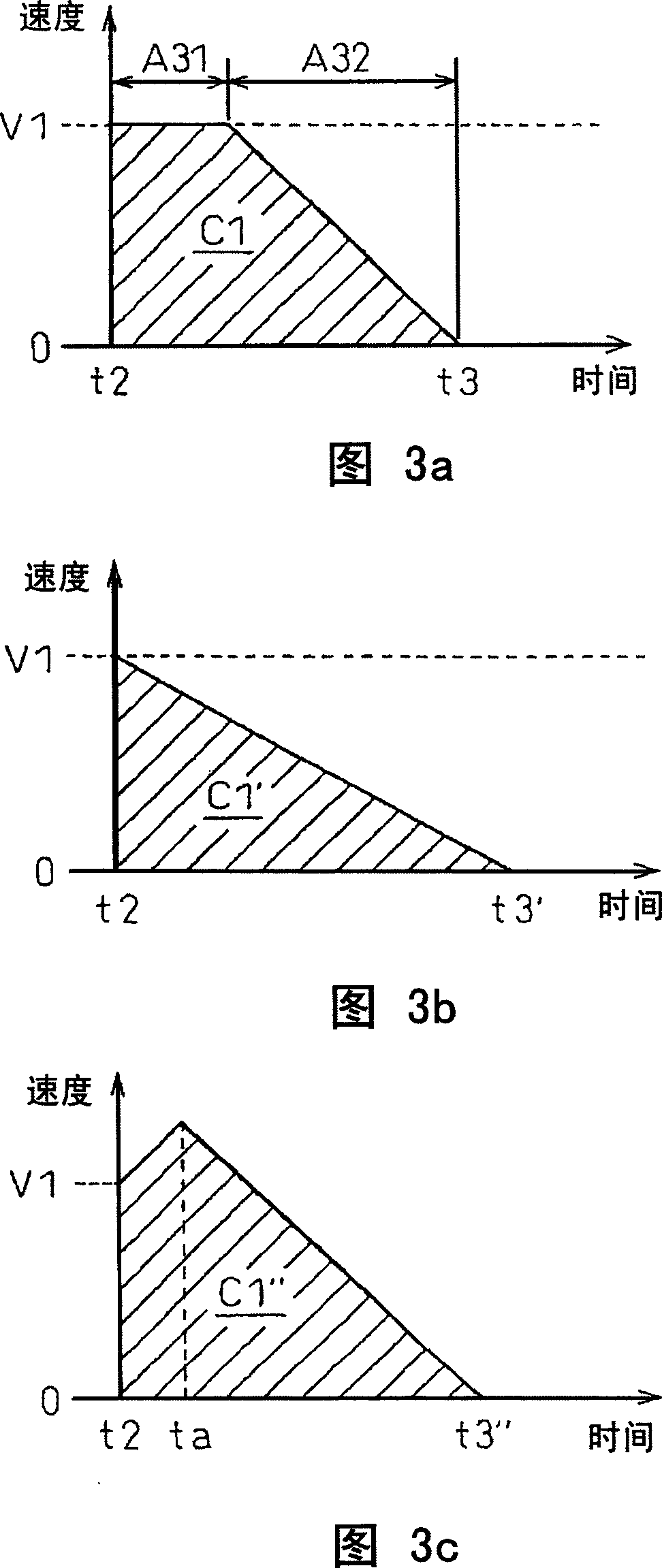

Fixed-position stop control apparatus for rotation shaft

A fixed-position stop control apparatus ( 10 ) includes: a move-instruction generating means ( 22 ) for generating a move instruction for each control cycle; a position loop control means ( 25 ) for position controlling a rotation shaft ( 61 ) for each control cycle according to the move instruction generated by the move-instruction generating means; and a speed loop control means ( 35 ) for speed controlling the rotation shaft according to one of a speed instruction generated by a higher level control apparatus ( 45 ) and a predetermined speed instruction, thereby switching the speed control of the rotation shaft by the speed loop control means to the position control of the rotation shaft by the position loop control means. In this fixed-position stop control apparatus, the move instruction generated by the move-instruction generating means has acceleration smaller than the acceleration corresponding to the acceleration and deceleration ability of the rotation shaft. With this arrangement, time required for the rotation shaft to stop at a fixed position can be decreased.

Owner:FANUC LTD

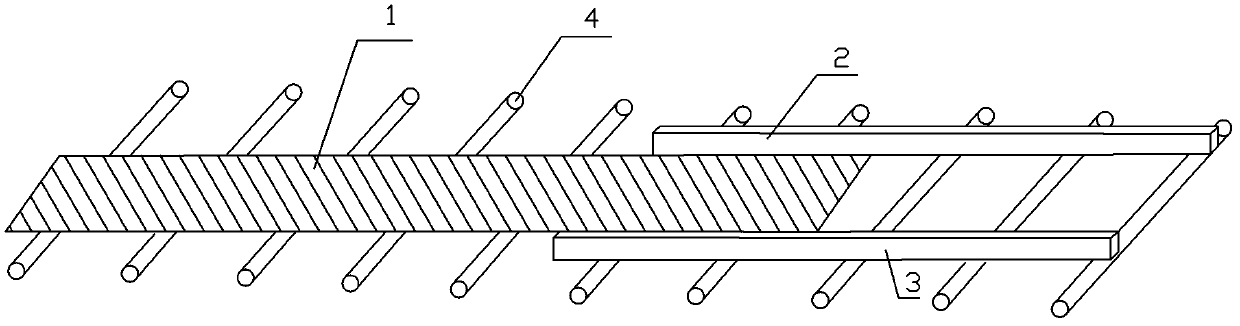

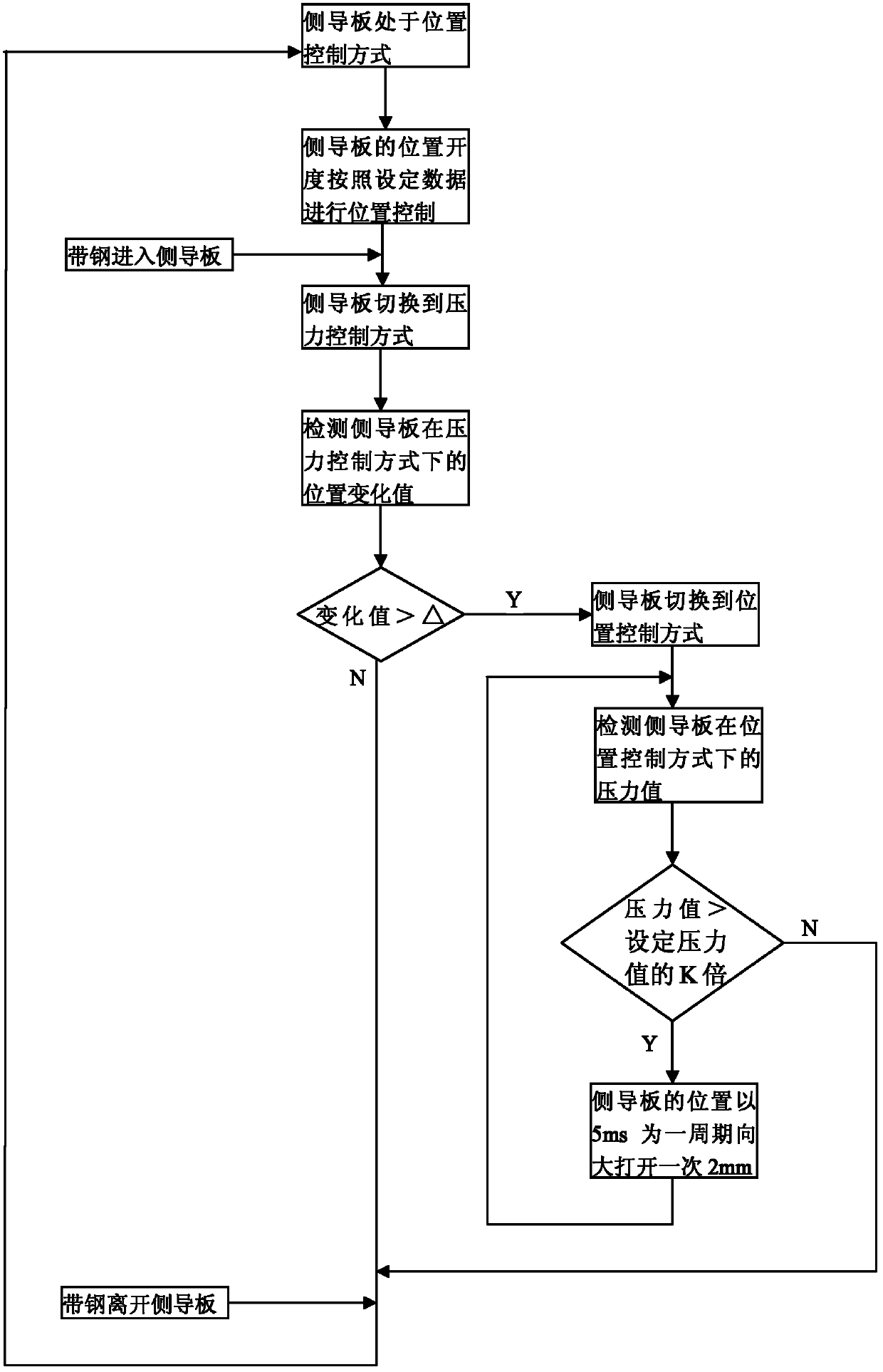

Control method of hot-rolling rolled side guide plate for improving hot-rolling roll shape quality

ActiveCN102896180AReduce the amount of reworkReduce manufacturing costControl mannerPressure feedback

The invention relates to a control method of a hot-rolling side guide plate in the metallurgy field, and relates to a control method of a hot-rolling rolled side guide plate for improving hot-rolling roll shape quality. The side guide plate is in a position ring control mode before the band steel enters into the rolling side guide plate; the control mode of side guide plate is switched to a pressure control mode from the position control mode after the band steel enters into the side guide plate; during the pressure control process, when the detected position change of the side guide plate exceeds [Delta]X mm, the control mode of side guide plate is switched to the position control mode from the pressure control mode; and if the position change does not exceed [Delta]X mm, the side guide plate is at the pressure control mode all the time; after the control mode of side guide plate is switched to the position control mode from the pressure control mode, a pressure feedback value of the side guide plate is detected; if the pressure feedback value exceeds K times of a pressure setting value in the pressure control mode, the position of the side guide plate is opened 2 mm with 5 s as a period, until the pressure feedback value of the side guide plate is lower than K times of a pressure setting value in the pressure control mode; and when the band steel leaves the side guide plate; the side guide plate enters into the position control mode. The method effectively solves the problems of quality defects such as layer offset, edge protrusions and edge cracks of roll shapes when rolling supplied material of the band steel swims or has cambers.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

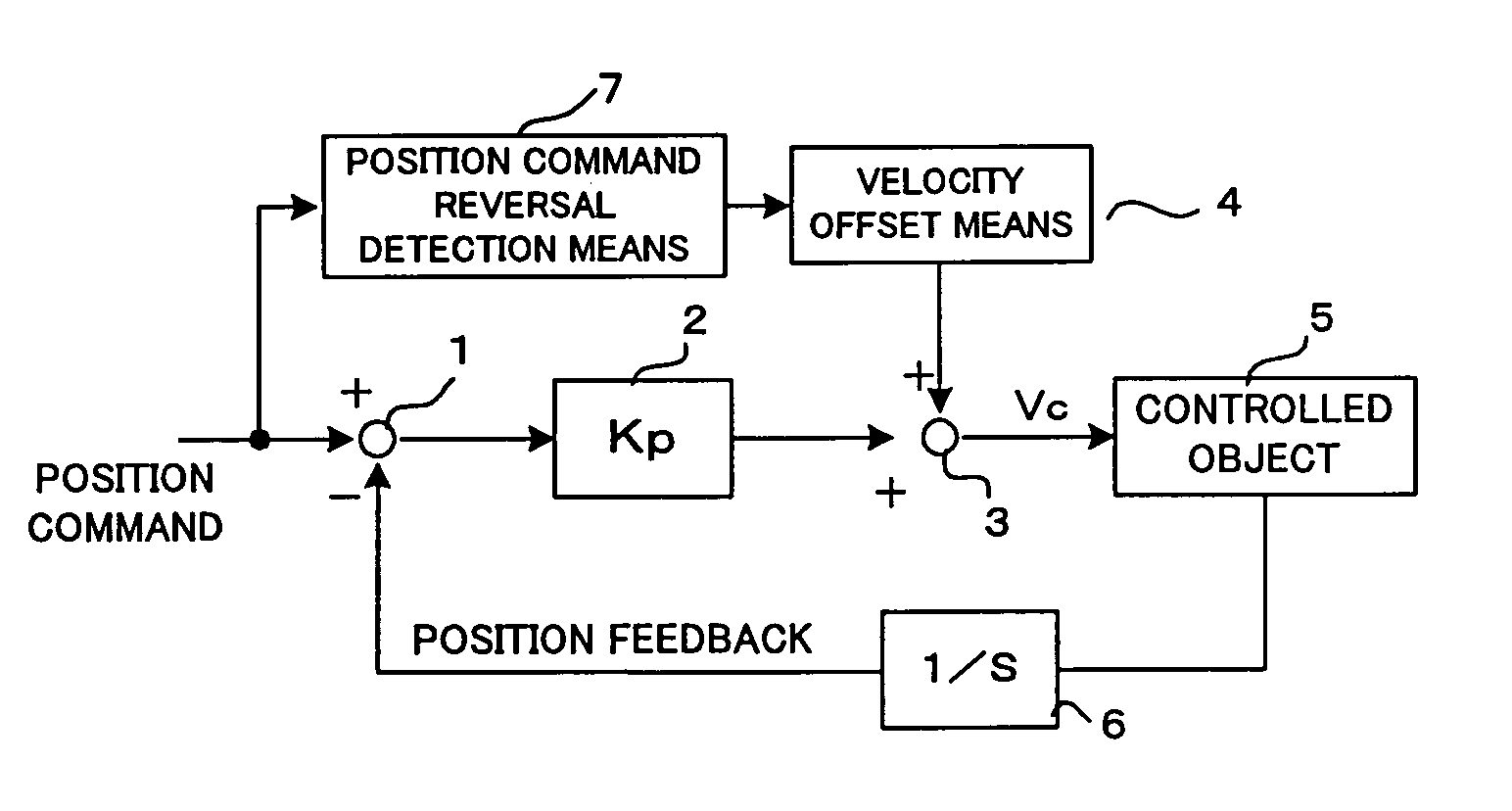

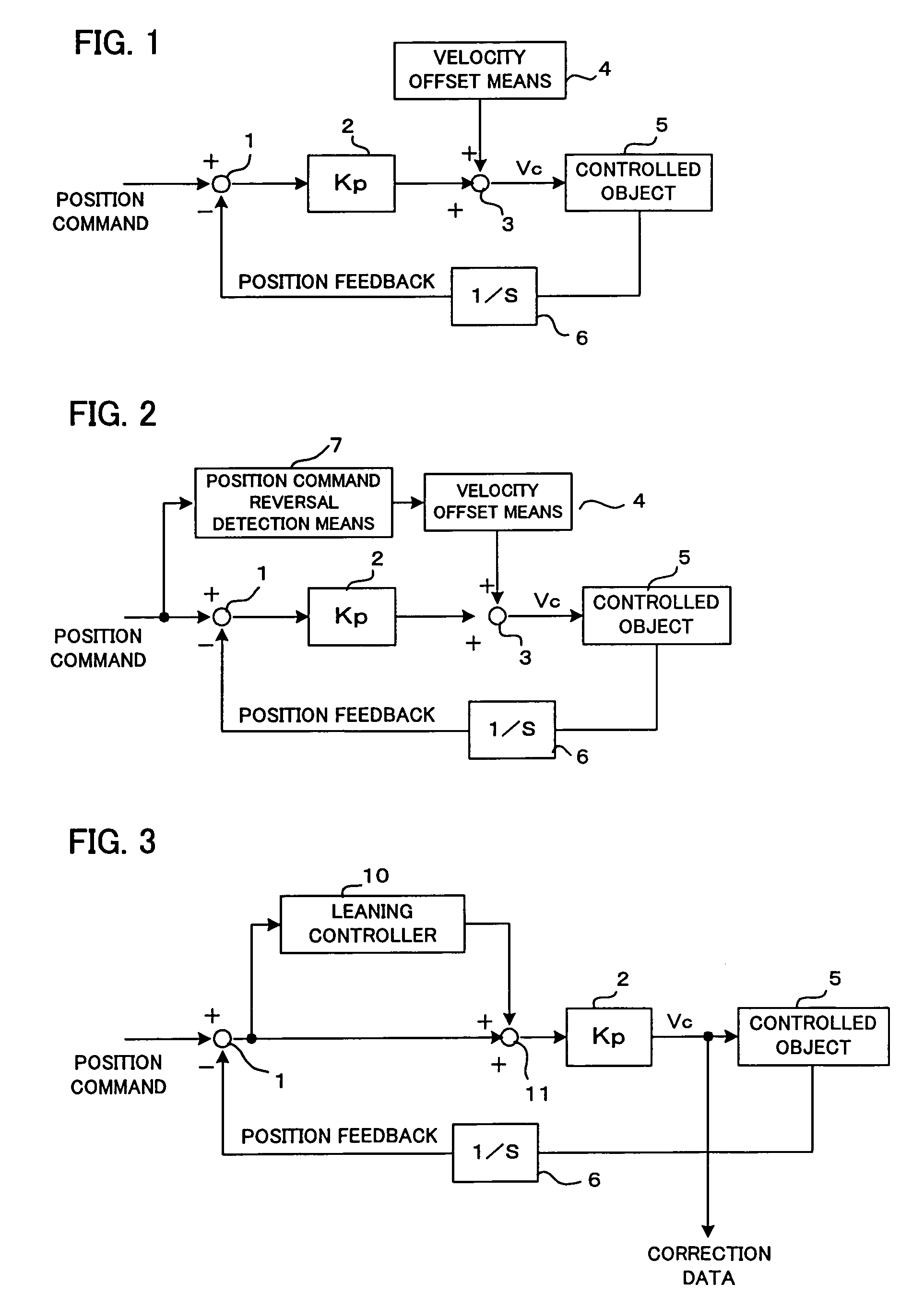

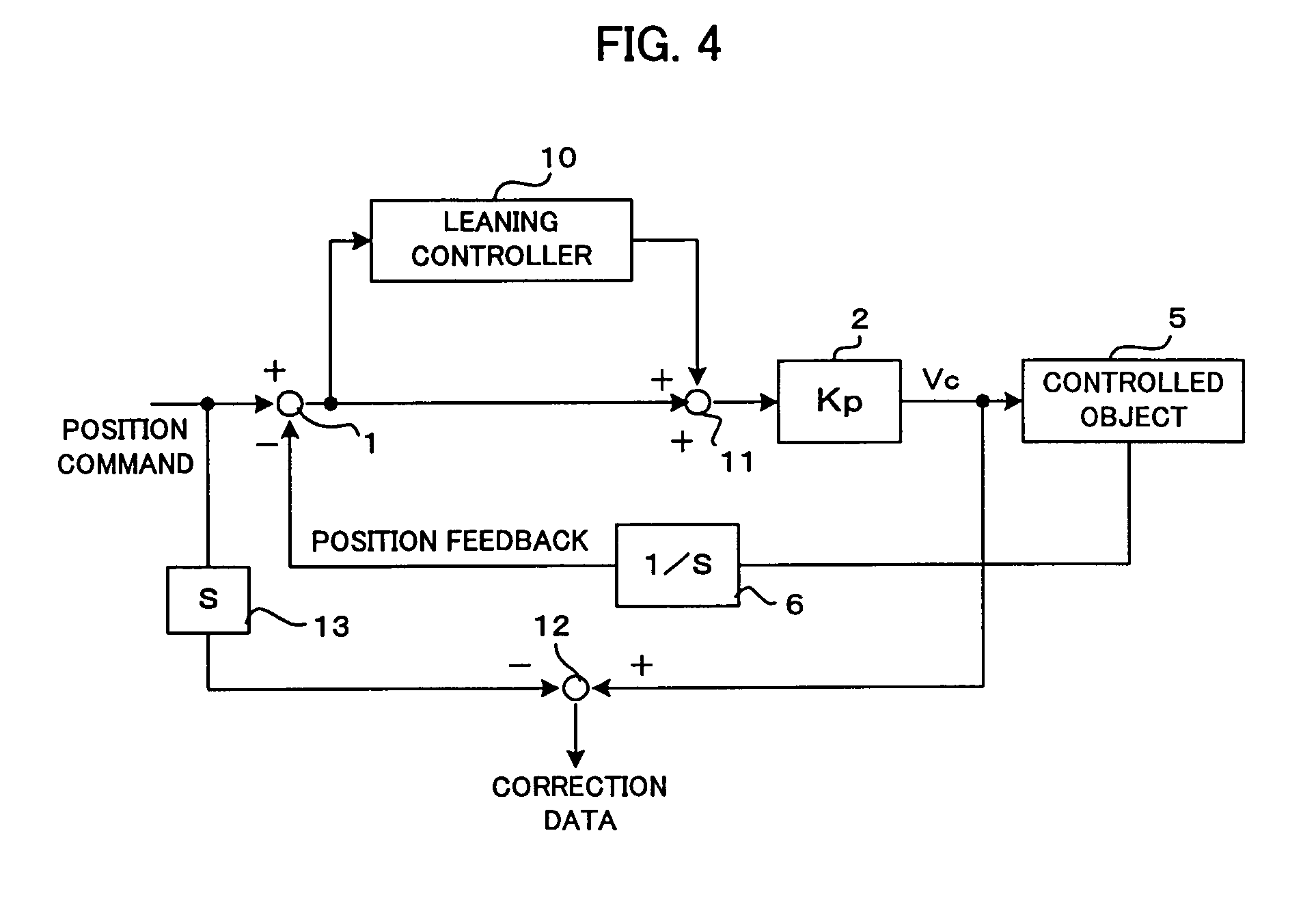

Servomotor driving controller

ActiveUS7084596B2Project delayImprove machining accuracyProgramme-controlled manipulatorComputer controlServomotorMachining

A servomotor driving controller capable of highly accurate machining, which prevents a quadrant projection upon change in the quadrant where machining is made. After the position deviation converges to zero by means of learning control, the velocity command or a difference between the velocity command and the commanded velocity which is the derivative of the position command is stored as velocity correction data. Until a predetermined time period elapses from when the sign of the position command is reversed, an amount of correction for each period of position loop processing is determined based on the correction data, and used to correct the velocity command.

Owner:FANUC LTD

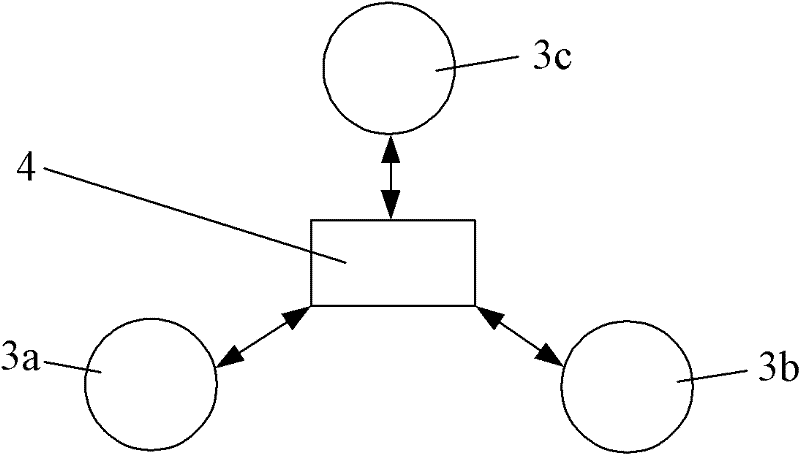

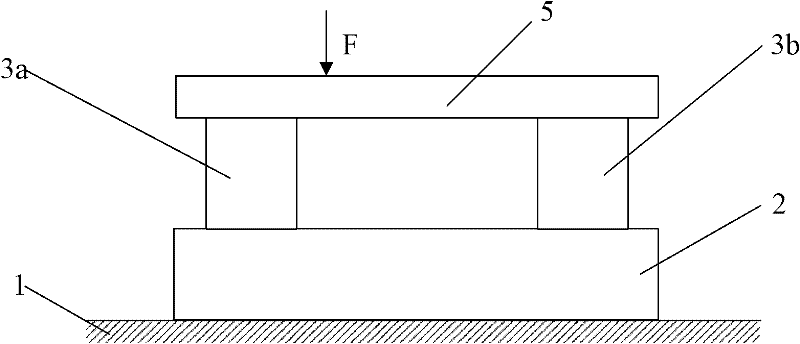

Active vibration damping system as well as vibration damping unit and absolute displacement measuring device thereof

ActiveCN102537196AImprove vibration damping effectIncrease position loop bandwidthNon-rotating vibration suppressionUsing electrical meansActive feedbackMeasurement device

The invention provides an active vibration damping system based on absolute displacement feedback and used for realizing active vibration damping on a load. The active vibration damping system comprises at least three vibration damping units used for realizing six degree-of-freedom active vibration damping on the load, wherein each vibration damping unit is provided with an absolute displacement measuring device, and the absolute displacement measuring device is used for detecting the absolute displacement of the load in real time; and a vibration damping control unit is respectively connected with the at least three vibration damping units, and the vibration damping control unit realizes active feedback control according to the absolute displacement. The vibration damping system based on the absolute displacement feedback has the following advantages: an air spring and a linear actuator work together to carry out active vibration damping, and the absolute displacement feedback technique is adopted to effectively improve the vibration damping performance of the vibration damping system, effectively increase position loop bandwidth of the vibration damping system and enhance the positional stability of the vibration damping system; and the active vibration damping system is convenient to use, small in size and lower in cost.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

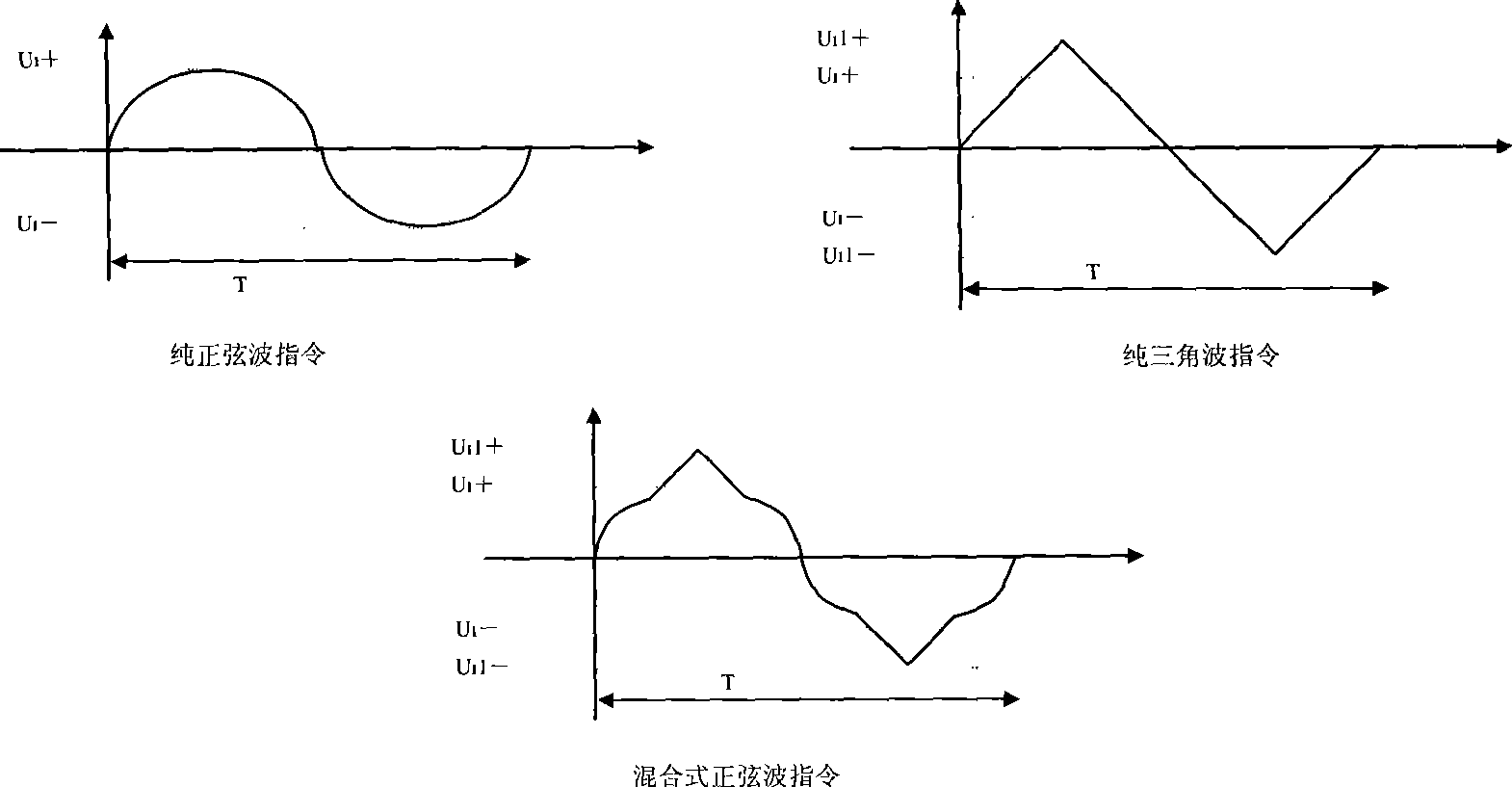

On-line rotational inertia identification device for alternate current permanent magnet servo system and identification method

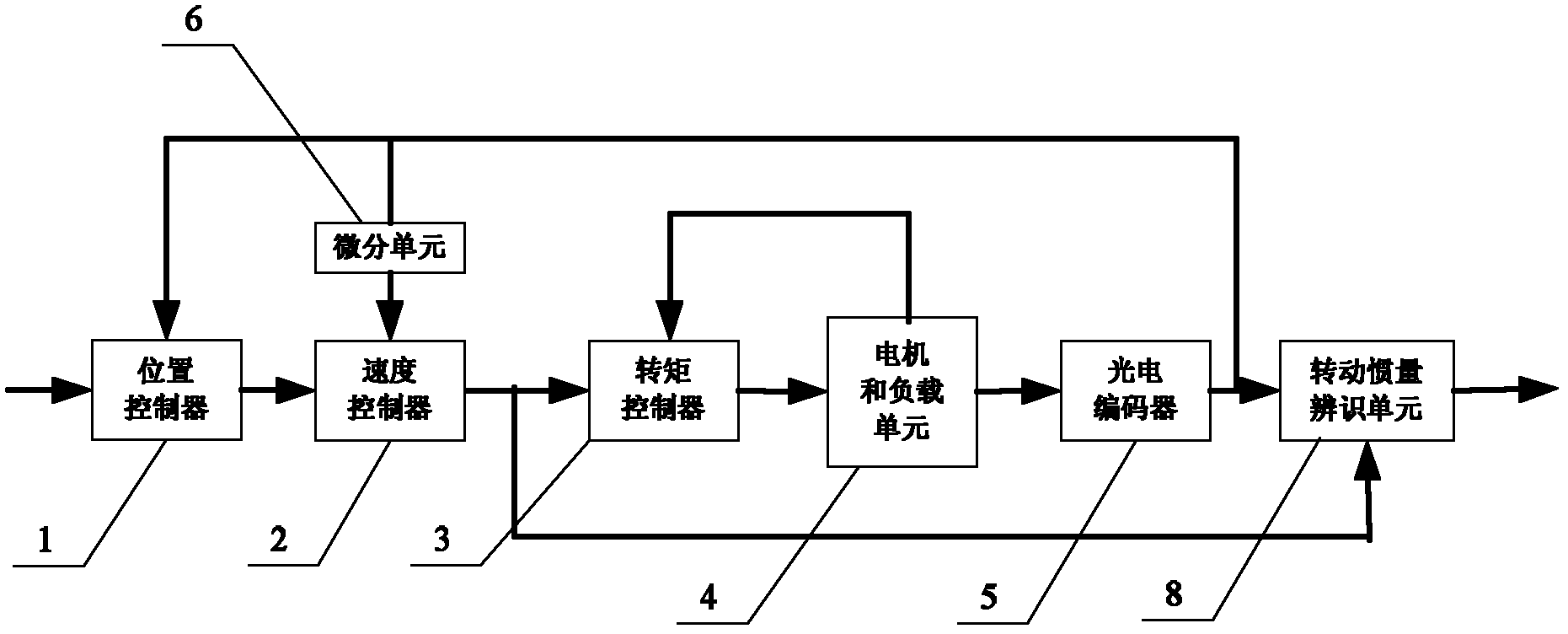

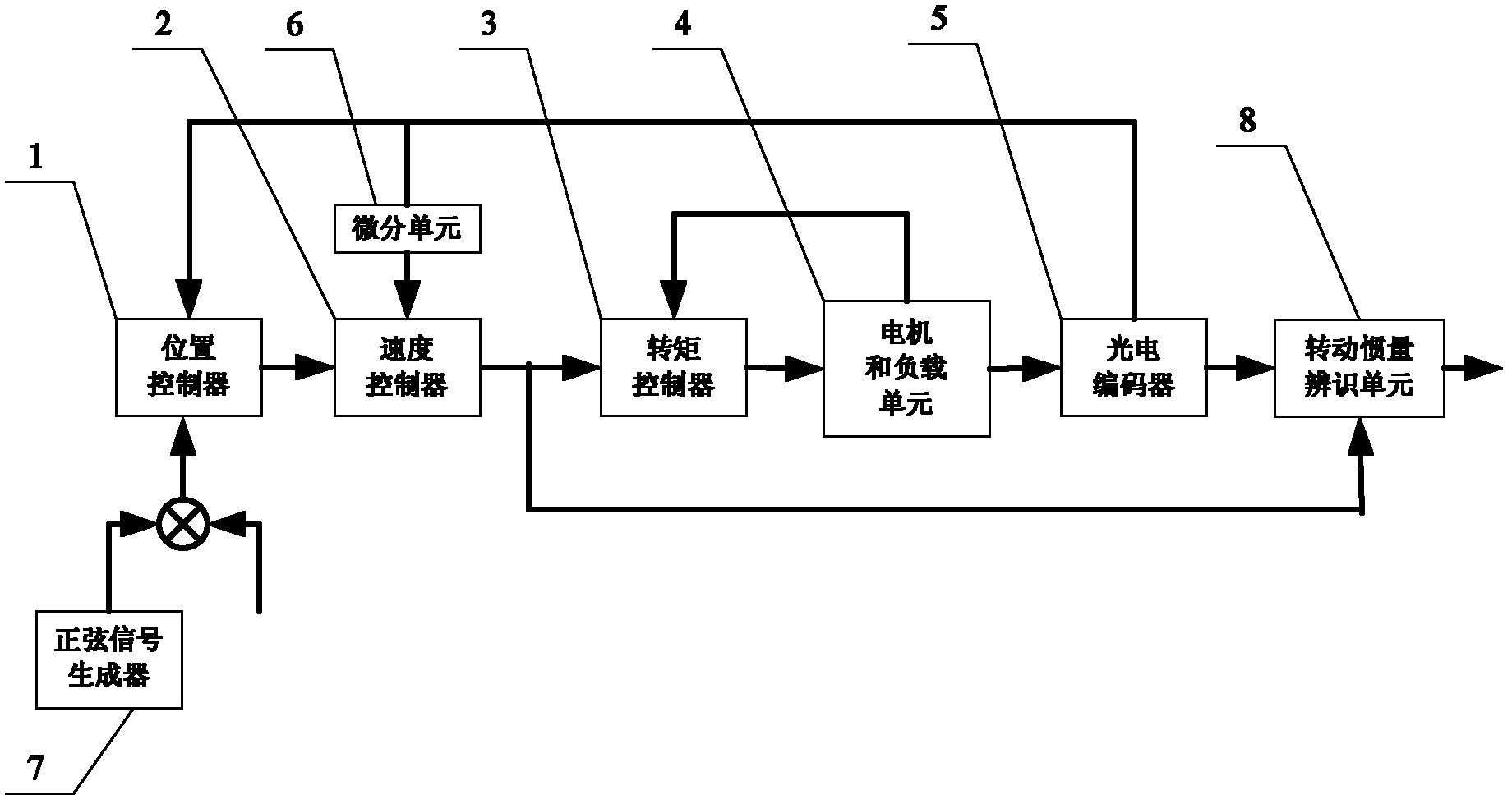

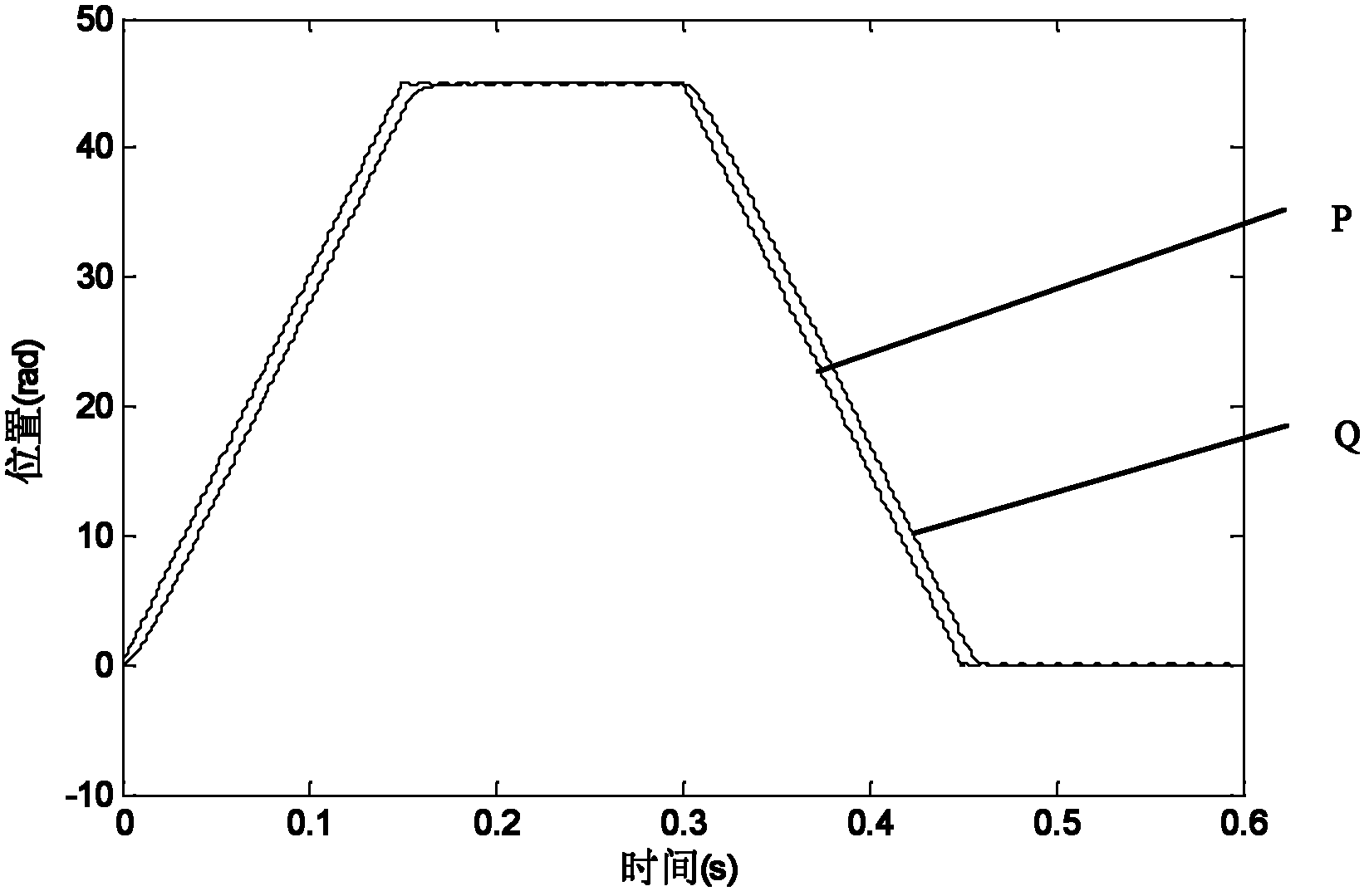

InactiveCN102355193ARealize online identificationImprove recognition accuracyElectronic commutation motor controlVector control systemsControl signalPosition angle

The invention discloses an on-line rotational inertia identification device for an alternate current permanent magnet servo system and an identification method, belongs to the technical field of servo motor control, and solves the problem that the conventional identification of rotational inertia of all motors is identification of rotational inertia of load mechanical systems in an off state so as not to adjust system control parameters according to current conditions of a system in real time. The device consists of a position controller, a speed controller, a torque controller, a motor and load unit, a photoelectric encoder, a differential unit, a sinusoidal signal generator and a rotational inertia identification unit; and the method comprises the following steps of: injecting a harmonic command with a lower amplitude value to a given position of a position loop motor during production run of a motor system; and extracting a motor position angle and torque control signal of a corresponding frequency component to realize on-line identification of the rotational inertia. The device and the method are suitable for on-line rotational inertia identification of the alternate current permanent magnet servo system.

Owner:HARBIN INST OF TECH

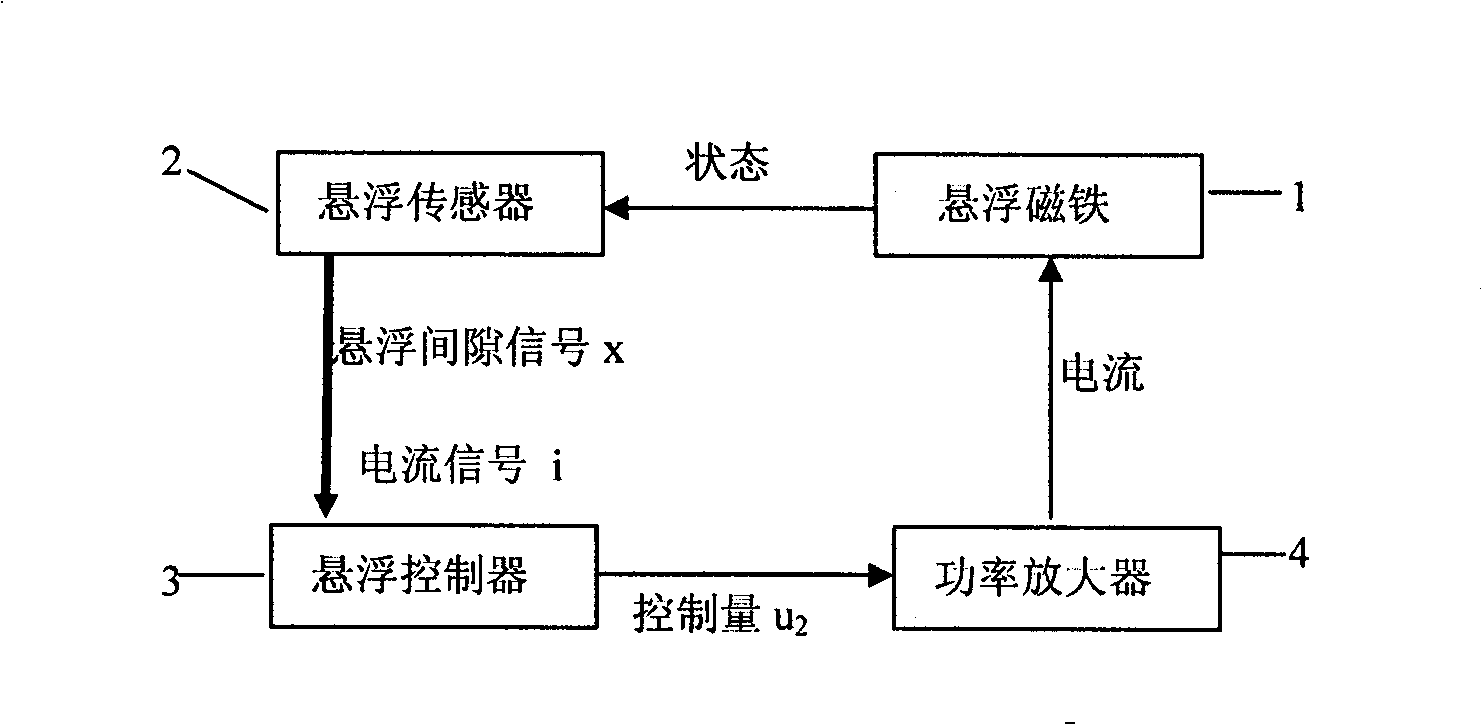

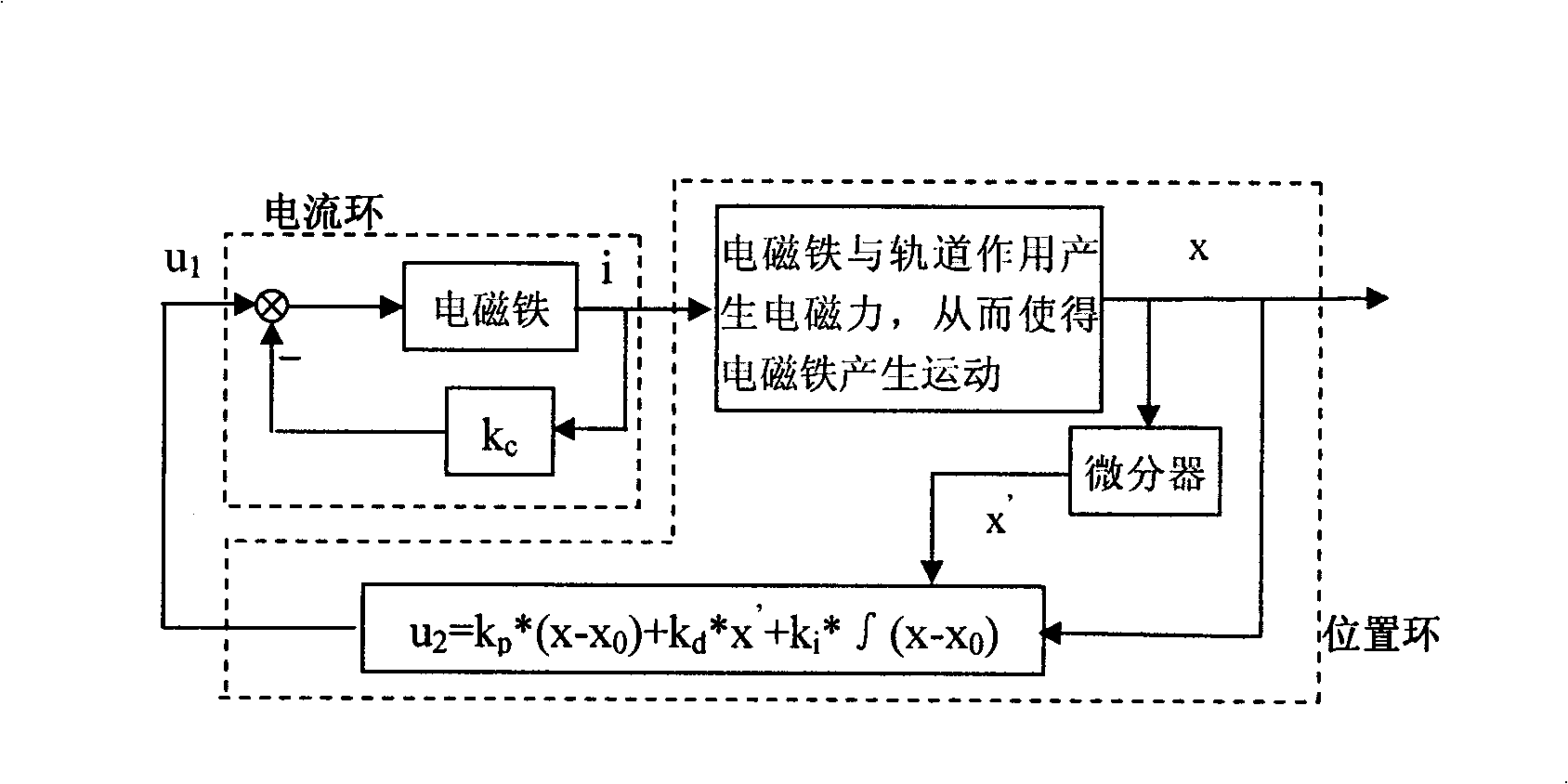

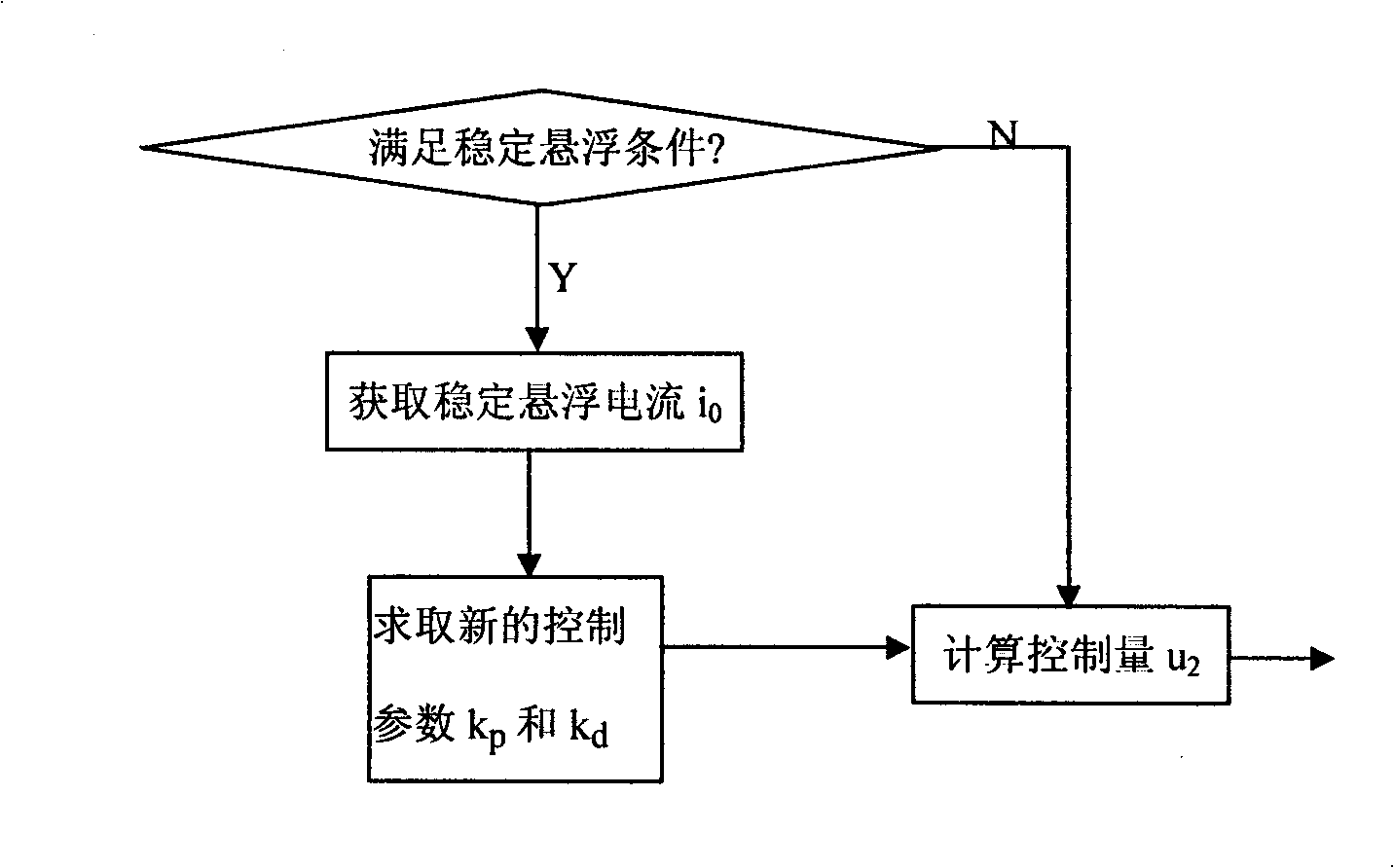

Maglev system suspension control method

InactiveCN101348083ASuspension stabilitySuspension unchangedElectric propulsionPerformance indexStatic error

The invention relates to a suspension control method for a magnetic suspension system, which comprises the steps: adopting a current loop to accelerate the rising velocity of the current i in an electromagnetic coil; adjusting a position loop to control the suspension performance in a set range; eliminating the static error during stable suspension by controlling the integral of a suspension clearance; selecting an integral control parameter ki so as to eliminate the influence of the suspension clearance integral on suspension performance; using a suspension performance index to adjust a suspension clearance control parameter kp and a suspension clearance differential control parameter kd; determining laden variable quantity according to the variation of stable suspension current i; corresponding changes the suspension control parameters kp and kd according to the variation of suspension current i0 so as to adjust the voltage control variable u2 at the both ends of an electromagnet in the suspension process and keeping the suspension performance unchanged all the time under the condition of variable load. By using the current of the magnetic suspension system when the suspension is stable to change the suspension control parameters, the method can not only overcome the disadvantages of the ordinary PID control method, but also has the advantage of easy realization of the ordinary PID control method.

Owner:NAT UNIV OF DEFENSE TECH

Portable batting practise cage and method of using the same

A portable batting practise cage and method of use of the same. The portable batting practise cage includes several support poles and a non-supporting mesh shell. The shell has a substantially planar end wall, depending anchor lines and several transversely extending rows of externally positioned loops. The shell is supported and held erect by inserting one of the several support poles through each of the several transversely positioned rows of externally positioned loops, and anchoring the mesh shell to a ground surface by means of the anchor lines. A pitching port is provided through the planar end wall of the shell, enabling a pitcher positioned outside of the structure to pitch to a batter positioned within the mesh shell.

Owner:BRUYER ROBERT WILLIAM +1

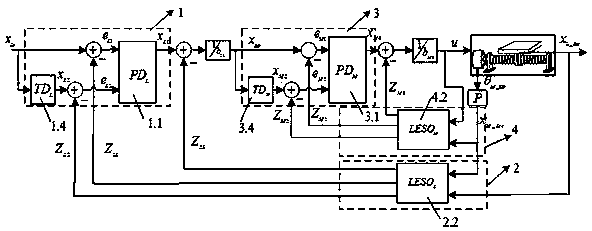

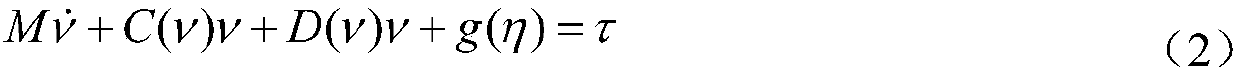

Underwater robot attitude and position control method based on double-closed-loop active disturbance rejection

The invention discloses an underwater robot attitude and position control method based on double-closed-loop active disturbance rejection. The method is characterized by firstly, for a underwater robot, using a momentum and moment theorem and using a conversion relation between a geodetic coordinate system and a body coordinate system to establish a dynamical model; designing the speed loop expansion state observer of the underwater robot to observe unmodeled and external disturbances and carrying out real-time compensation suppression so that the anti-disturbance performance of a speed loop is greatly increased and the robustness of a system is improved; aiming at the high frequency vibration characteristic of the speed loop, using a disturbance observation value to construct a speed loopactive disturbance rejection controller based on nonlinear function feedback; based on a non-linear function fhan, designing the tracking differentiator of a target position signal, giving the transition process and the target speed estimation value of a position signal, avoiding the sudden change of system response and solving the conflict of rapidity and overshoot; and designing a underwater robot position loop proportion-differential controller based on position deviation feedback, wherein the controller is suitable for engineering application.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

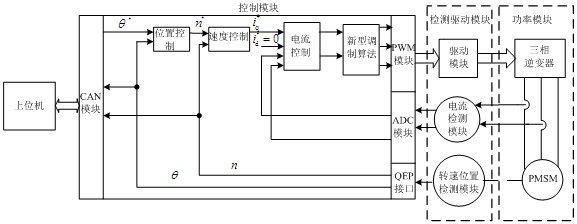

High-precision permanent magnetic servo motor three-closed-loop control system and method

InactiveCN102624315AImprove reliabilityImprove controllabilityVector control systemsSingle motor speed/torque controlVoltage vectorSynchronous motor

The invention discloses a high-precision permanent magnetic servo motor three-closed-loop control system and a high-precision permanent magnetic servo motor three-closed-loop control method. The system comprises an upper computer, a control module, a detection driving module and a power module; the power module comprises a three-phase inverter and a permanent magnetic synchronous motor; three phases of outputs of the three-phase inverter are connected to the interior of the permanent magnetic synchronous motor; a software part comprises a position control module, a speed control module, a current control module and a voltage vector modulation module and is controlled by adopting a three-closed loop system comprising a position loop, a speed loop and a current loop; a speed error signal is regulated by fuzzy PI compound control of the control module; the fuzzy PI (Proportion Integration) compound control comprises fuzzy control and PI control which are combined by adopting a fuzzy conversion mode; and the voltage vector modulation module is a voltage vector pulse width modulation module on the basis of a Kohonen neural network. According to the invention, the dynamic performance, the steady accuracy and the robustness of a permanent magnetic synchronous motor controller can be effectively improved and the control rapidness and strong load disturbance resistance are achieved.

Owner:SHANGHAI SANY PRECISION MACHINERY

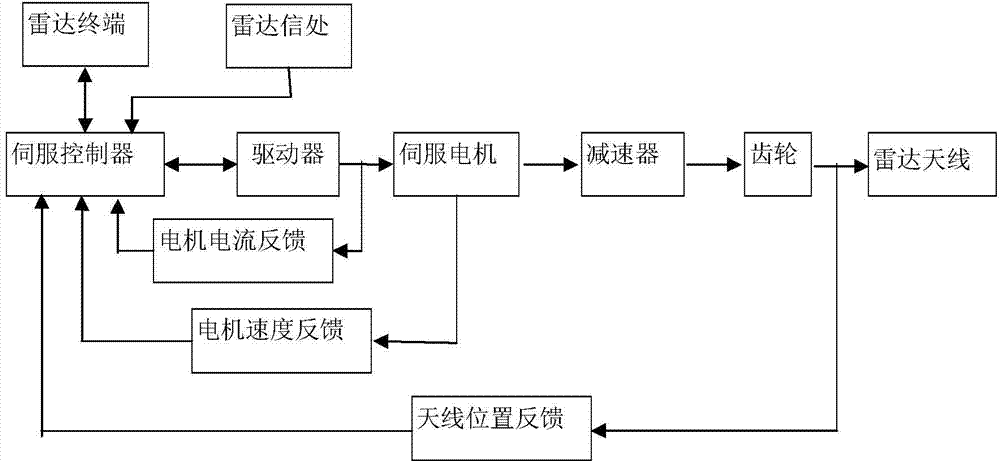

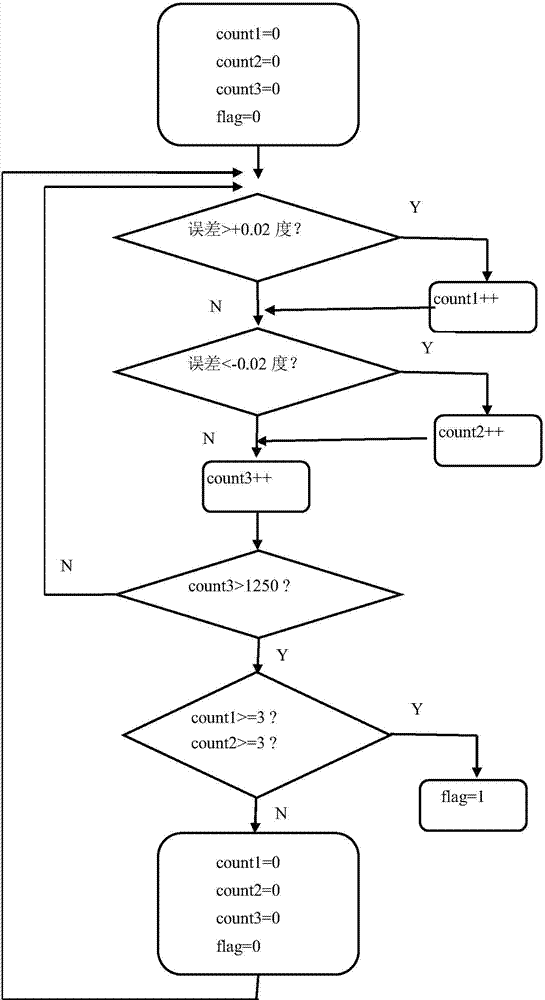

Self-adaptive radar antenna position oscillation treating method

ActiveCN104122531AEliminate residualEliminate Position OscillationWave based measurement systemsAntennasInformation processingNegative feedback

The invention provides a self-adaptive radar antenna position oscillation treating method and aims to provide a method capable of detecting characteristics of a radar antenna position automatically and eliminating position oscillation when the radar antenna position is found out. The technical scheme includes that in a tracking radar servo control system, motor current of a servo controller is taken as negative feedback of an electric current ring, motor speed is taken as negative feedback of a speed ring, a position ring is designed to be controlled proportionally and integrally, and the current ring and the speed ring are designed into servo system loops which are controlled proportionally, integrally and differentially; an operation processor arranged inside the servo controller is used for receiving and executing control commands transmitted by a radar terminal system and error information transmitted by a radar information processing system and regularly detecting errors of tracking positions of a radar antenna. When oscillation of the radar antenna position is detected, the proportionality coefficient and the integration coefficient of a servo control position loop are gradually decreased during every calculation period, and output voltage is lowered to eliminate the oscillation.

Owner:LINGBAYI ELECTRONICS GRP

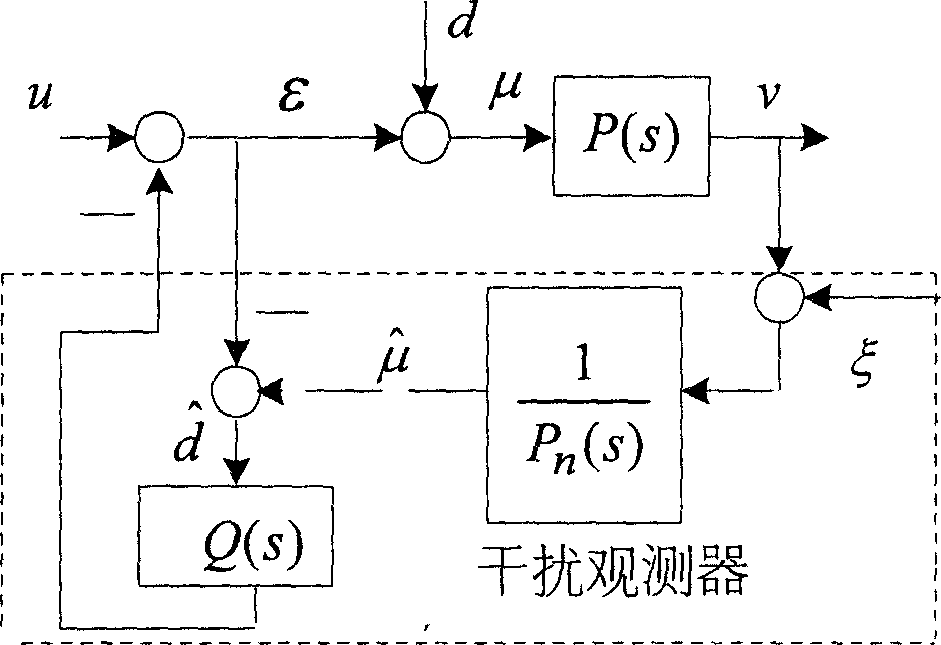

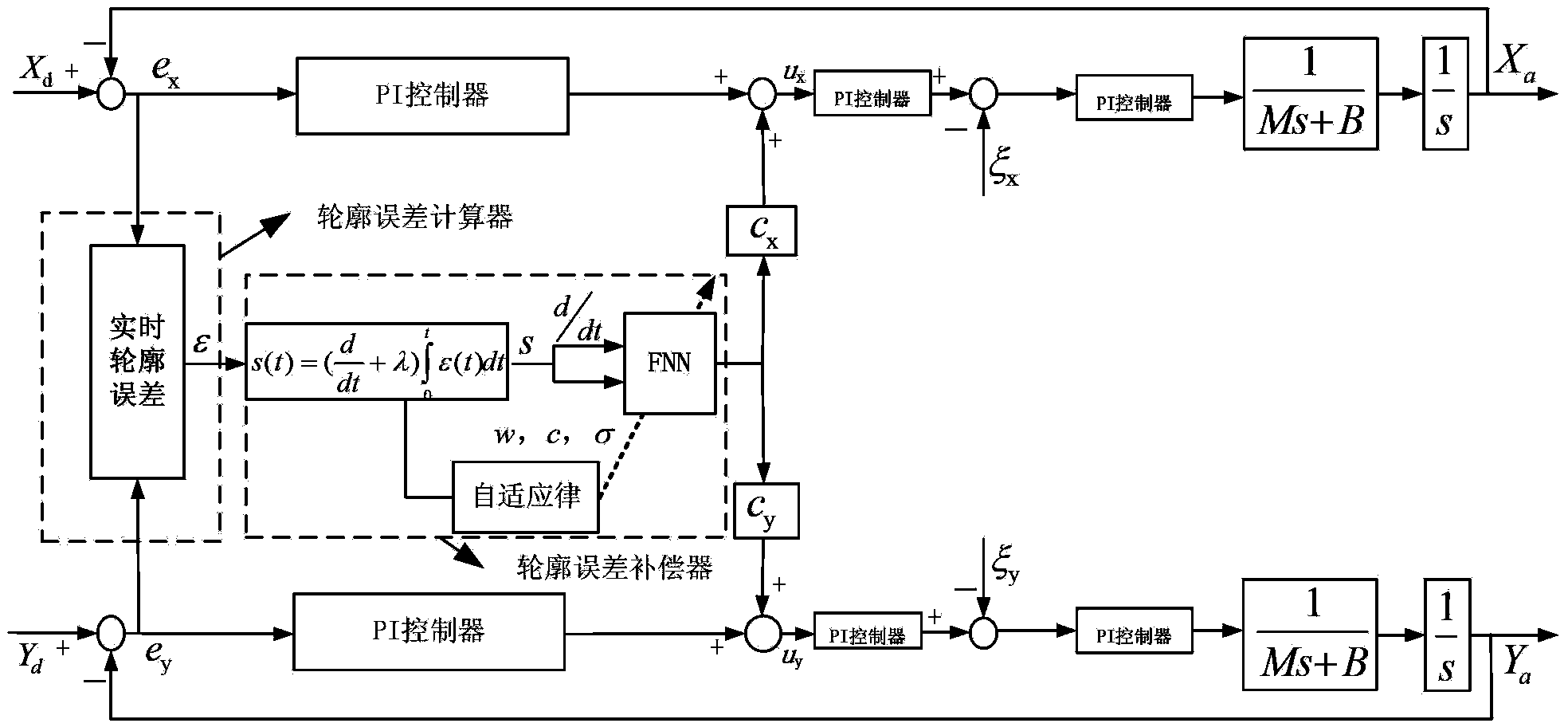

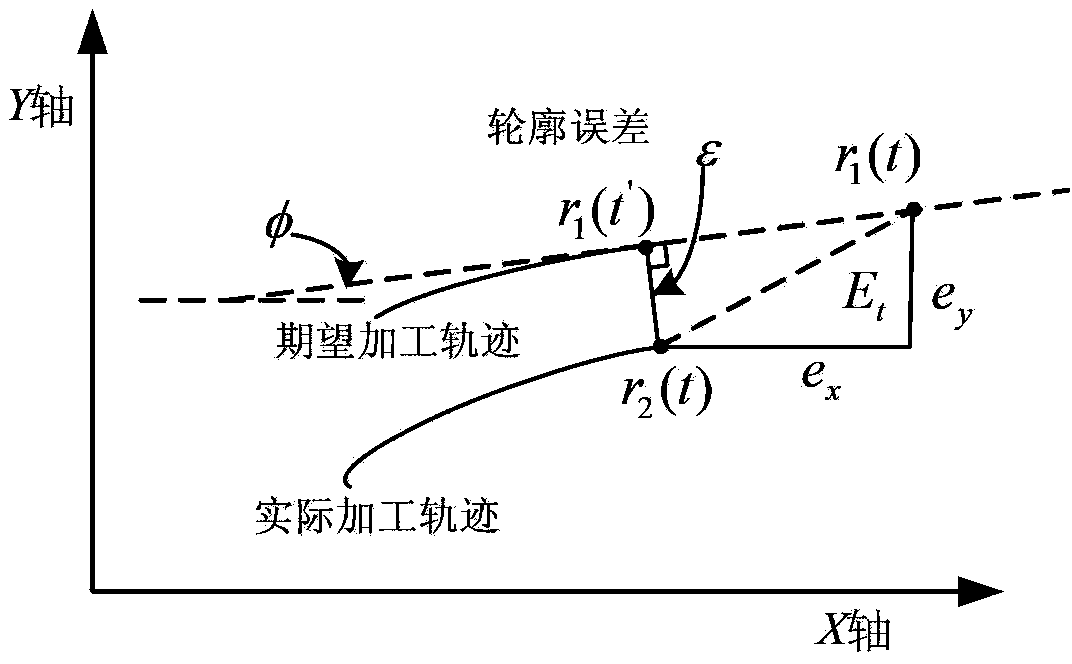

Method for improving contour machining precision by using zero phase error tracking controller and disturbance observer

InactiveCN1845025AIncrease speedImprove contour machining accuracyNumerical controlIntegratorPosition loop

The invention relates to a method for improving the profile processing accuracy by zero phase error track control and disturb-detection. It comprises: a ZPETC, PD position controller, a DOB, and a controlled object. Wherein, the ZPETC is used to eliminate the error generated by the phase delay of close-loop system; the PD controller is used to improve the response character of position loop; DOB is used to eliminate the disturbance of system and make the transmit function of speed loop into reference mode; the controlled object is formed by a motor, a speed ring, and a current ring; the input signal of ZPETC is a position reference instruction; the output position signal processed by ZPETC is compared with the feedback position signal to be fed to PD position feedback controller; the input of PD controller is the speed preset signal; after comparing the speed preset signal and the output signal of DOB, the error is fed into controlled object; the output of controlled object is the actual output speed signal, via integrator, to be actual position signal.

Owner:SHENYANG POLYTECHNIC UNIV

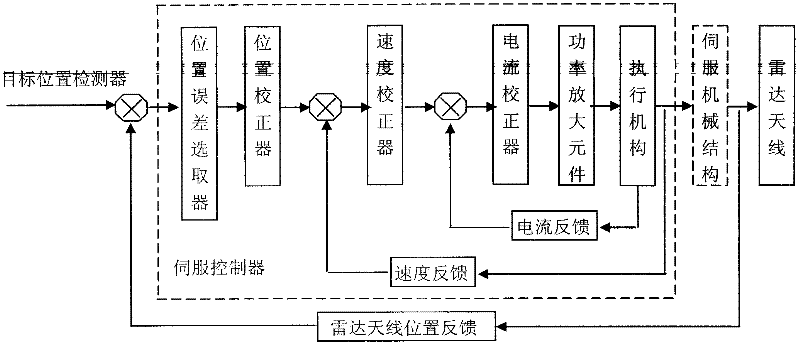

Servo system for tracking moving target by linear variable-coefficient servo driving radar antenna

The invention provides a servo system for tracking a moving target by a linear variable-coefficient servo driving radar antenna. A servo controller consists of a position error selector, a position corrector, a speed corrector, a current corrector, a power amplifying element and an execution mechanism which are connected in series with one another; current of a motor is fed back by a Hall sensor to form a current loop of the servo system, and speed of the motor is fed back by a speed measurer coaxial with the motor to form a speed loop of the servo system; an antenna position is fed back by a position detection element coaxial with the radar antenna to a target position detector to form a position loop of the servo system; a circuit of the servo controller comprises a digital signal processor (DSP) and a field programmable gate array (FPGA) which are connected with each other through an address bus and a data bus; the built-in linear equation variable-coefficient operation of the DSP and the operation treatment of the three loops controls the motor to drive the antenna to run; and the FPGA exchanges data with the DSP through a programmed decoding circuit, and transmits and receives serial communication interface (SCI) data. According to the servo system, the radar tracking error can be reduced quickly, and the radar tracking precision is improved.

Owner:国工科技集团有限公司

Segmented-PI-control-based low-voltage direct-current servo driver

The invention relates to a segmented-PI-control-based low-voltage direct-current servo driver. A control system consists of three control loops: an electric current loop, a speed loop, and a position loop. After receiving an enabling signal from an upper computer, the servo driver enters a driving working mode; quantization of a position, speed or torque current signal of the upper computer is carried out by an A / D conversion circuit or communication interface and thus an input signal of the position loop, speed loop, or the electric current loop is obtained; and the output of an MOSFET inverter circuit is controlled to drive the servo driver. Meanwhile, an incremental encoder and a current sampling circuit detect angle, speed, and current data serving as feedback signals of the three loops; and a DSP processor controls the output of the MOSFET inverter circuit based on a PI control algorithm of command data and feedback data so as to drive the servo driver. The provided servo driver has characteristics of simple hardware design, small size, convenient maintenance, wide speed regulation range, fast dynamic response speed, and high reliability and the like.

Owner:连云港杰瑞电子有限公司

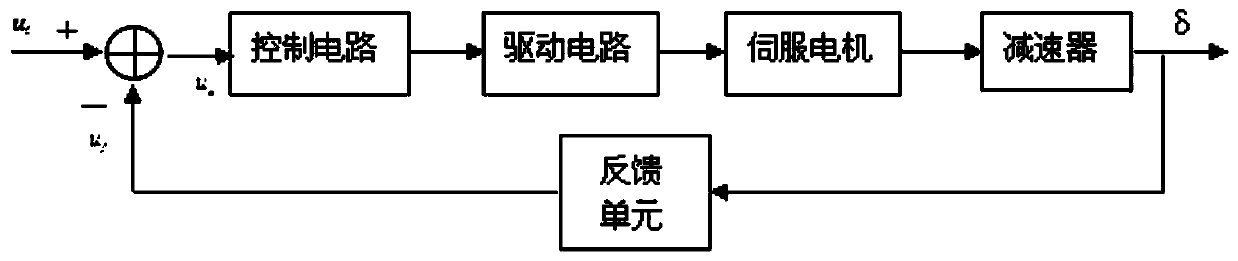

Position loop control-based electric steering engine system

InactiveCN103699134AOvercoming dispersionOvercome temperaturePosition/course control in three dimensionsLoop controlControl signal

The invention relates to an electric steering engine system, and particularly discloses a position loop control-based electric steering engine system, which is implemented in a way of combining hardware and software. A DC / DC (direct current / direct current) power supply with isolated output is adopted for a power circuit in a hardware design, and missile power is transformed to be supplied to each unit circuit; TMS320F2812 is adopted as a master control unit of a control circuit, and is used for acquiring a rudder control signal and a rudder deflection angle feedback signal, integrating and amplifying errors of the rudder control signal and the rudder deflection angle feedback signal, calculating an actually output PWM (pulse width modulation) signal by using a fuzzy PID (proportion integration differentiation) algorithm, and providing the PWM signal for a driving circuit; the driving circuit is used for performing power amplification on the signal, and driving a steering engine execution mechanism to rotate, thereby realizing closed-position loop control on the electric steering engine system.

Owner:陕西航天导航设备有限公司

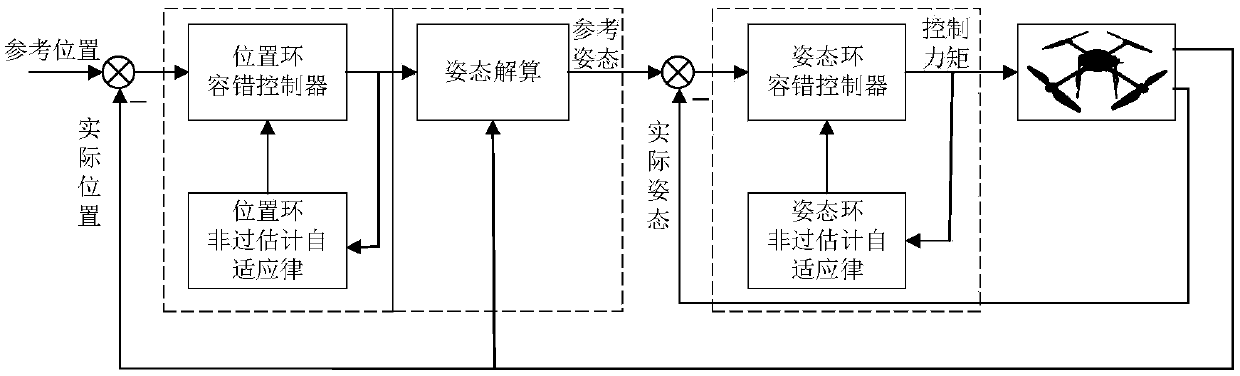

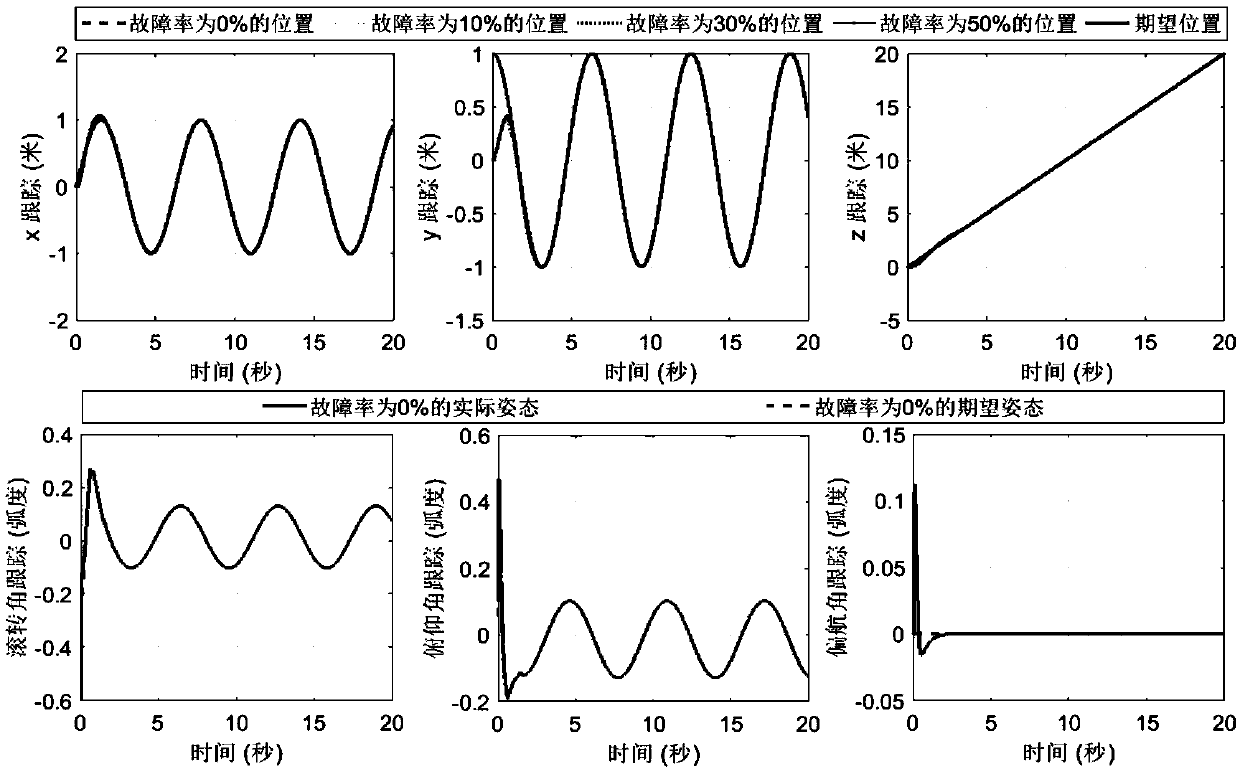

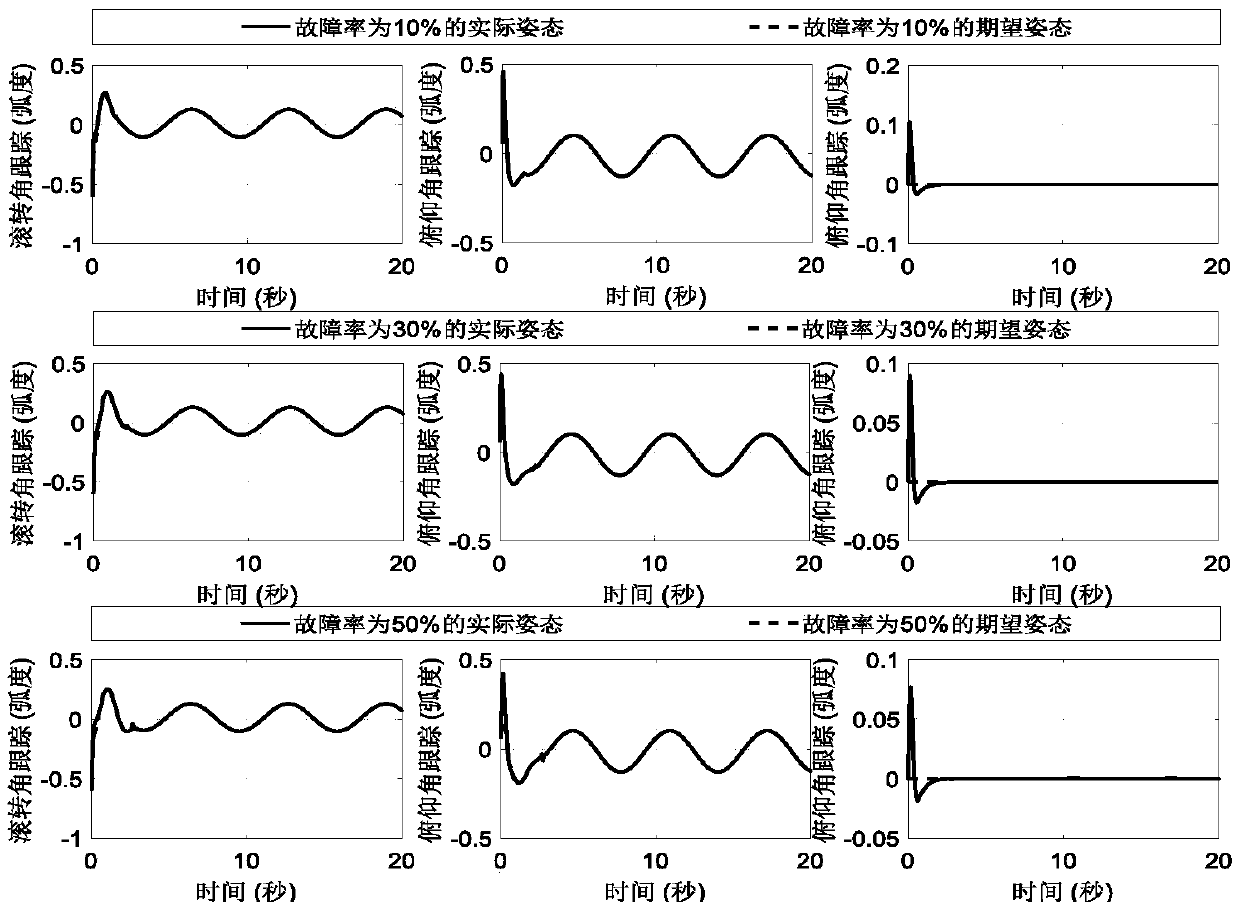

Adaptive multi-variable quad-rotor unmanned aerial vehicle finite-time fault-tolerant control method

ActiveCN108803317ASolve the problem of high-precision fast and stable tracking controlHigh precisionAdaptive controlSimulationVirtual control

The invention relates to the technical field of unmanned aerial vehicle control, and aims to solve a problem of high-precision fast and stable tracking control for a quad-rotor unmanned aerial vehicleunder the influences of a rotor fault and an unknown disturbance boundary so as to achieve the purposes of comprehensively improving the control performance of the quad-rotor unmanned aerial vehicleand enhancing the safety and reliability of the system. The invention relates to an adaptive multi-variable quad-rotor unmanned aerial vehicle finite-time fault-tolerant control method, which comprises the steps of first designing an adaptive finite-time position fault-tolerant controller; second, calculating the attitude, and establishing an analysis relation between a position loop virtual control instruction and an attitude loop reference attitude instruction based on flight characteristics of the quad-rotor unmanned aerial vehicle; and third, designing an adaptive finite-time attitude fault-tolerant controller. The method is mainly applied to unmanned aerial vehicle control occasions.

Owner:TIANJIN UNIV

Double-linear-motor contour compensation device and method based on fuzzy RBF network sliding mode

InactiveCN103414419AEliminate chatterImprove profile accuracyElectronic commutation motor controlVector control systemsDigital signal processingGrating

The invention provides a double-linear-motor contour compensation device and method based on a fuzzy RBF network integral sliding mode with respect to a double-linear-motor numerical control feeding system with the axial direction being in mutual vertical movement. A real-time contour error is used as the input of a controller, the powerful self-learning ability of the controller enables the contour error to tend to zero within limited time, and thus contour machining precision is improved. The double-linear-motor contour compensation device comprises a commutating and voltage-stabilizing unit, an IPM inverter, a DSP, a Hall sensor, a grating ruler, a current detection unit, a position and speed detection unit, an optical coupling isolation circuit, a driving protection circuit and a fault detection and protection circuit. The DSP comprises a QEP circuit of an event manager EVA, an ADC module, a PWM unit, a Flash storage module, a program storage, a timer and a PDPINT pin. A PI controller of a position signal setter, a linear motor position loop, a speed loop and an electric current loop, a contour error calculator, a fuzzy RBF network integral sliding mode contour compensator and a driver device are further arranged inside the DSP. The double-linear-motor contour compensation device is good in robustness, suitable for contour machining tasks of any track and capable of achieving high-precision contour control.

Owner:SHENYANG POLYTECHNIC UNIV

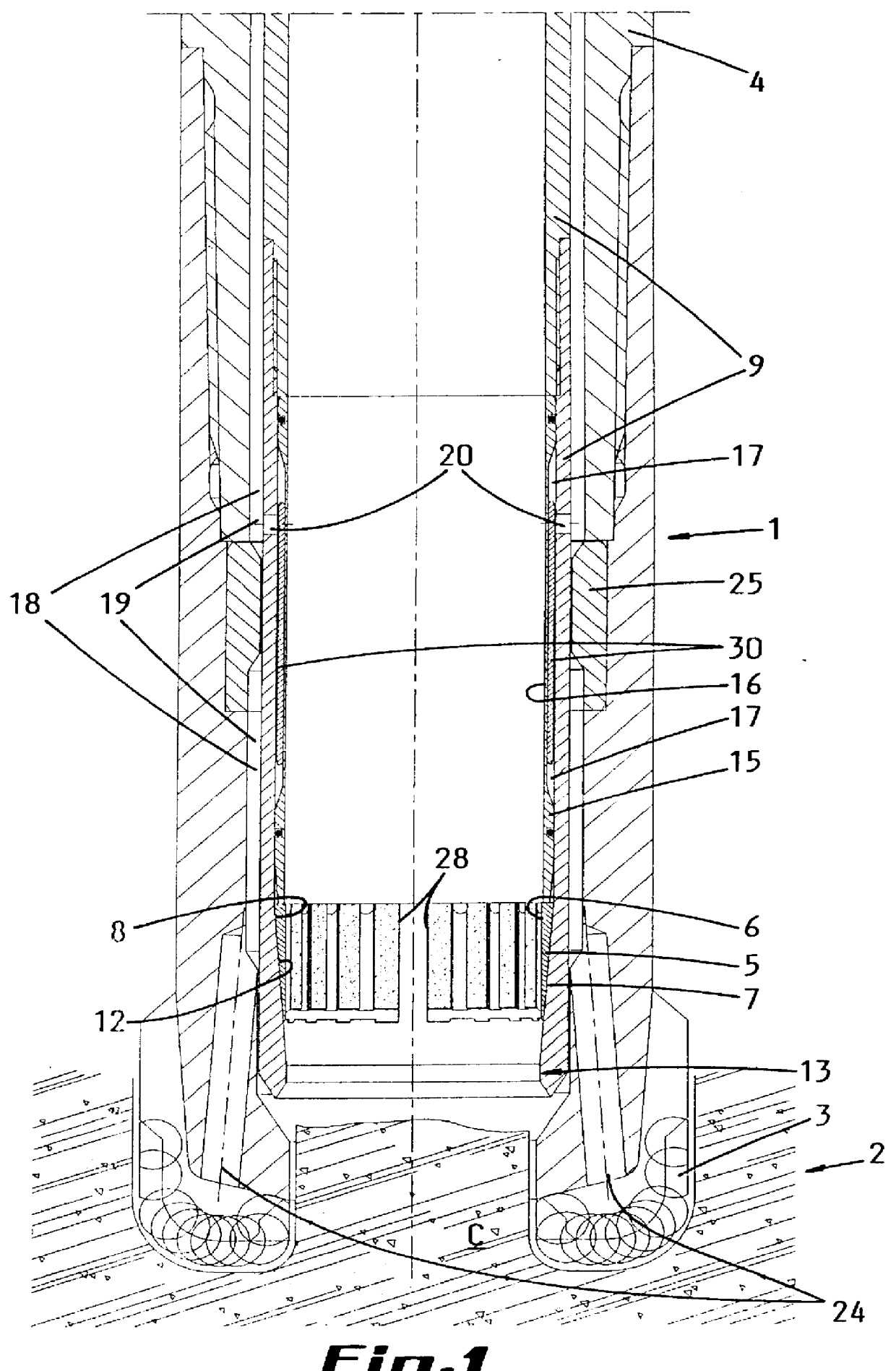

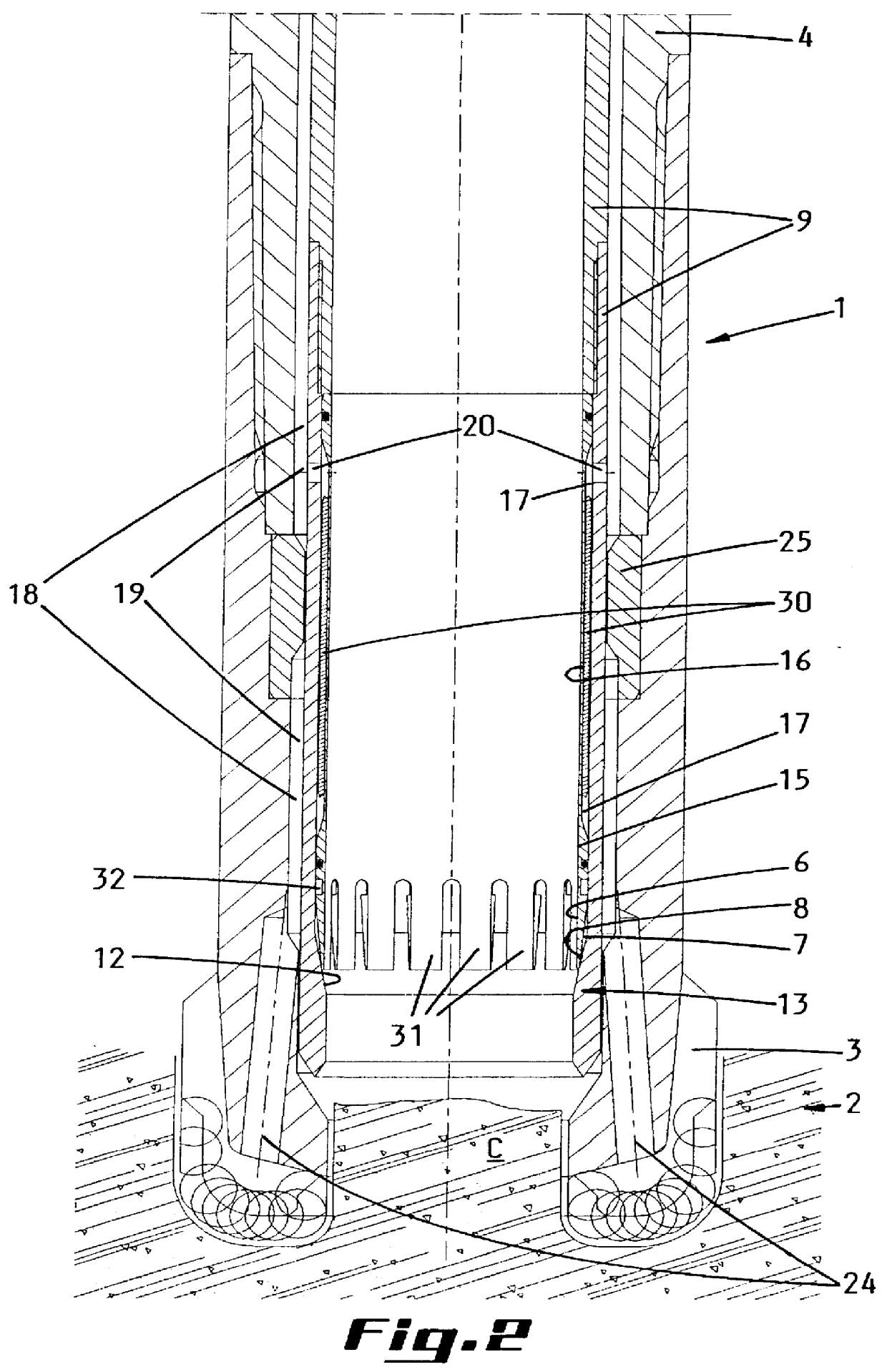

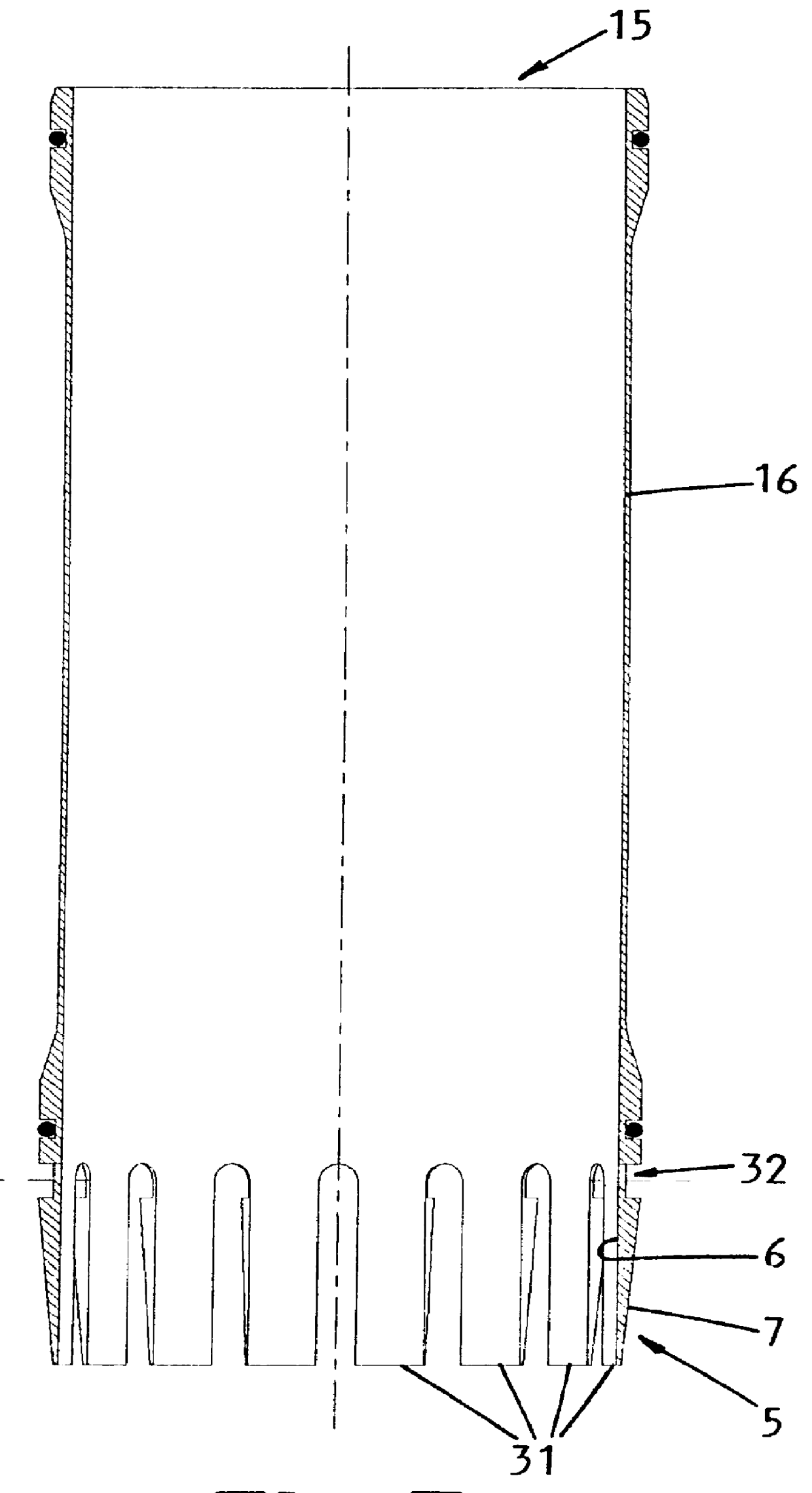

Core sampler

PCT No. PCT / BE97 / 00006 Sec. 371 Date Jul. 14, 1998 Sec. 102(e) Date Jul. 14, 1998 PCT Filed Jan. 15, 1997 PCT Pub. No. WO97 / 26440 PCT Pub. Date Jul. 24, 1997A core sampler, particularly for use in oil prospecting, including a flexible movable ring (5), provided in particular at the front end (2) of the core sampler, which end is connected to a coring bit (3), for grasping a core sample (C) to be brought to the surface. The ring has a cylindrical internal surface (6) to be clamped around the core sample (C), and a frustoconical external surface (7) tapering towards the front end (2). In the end or starting position, the ring (5) is exposed to zero or minimal strain from the bearing surface (12) and has an internal diameter no smaller than the outer diameter of the core sample (C) to be grasped. The core sampler (1) comprises control mechanism for longitudinally moving the movable ring (5) from the end starting position to an end clamping position. A flexible sleeve (15) is advantageously substantially coaxial with the movable ring (5) and engages the side thereof opposite the front end (2) of the core sampler (1).

Owner:HALLIBURTON ENERGY SERVICES INC

Active disturbance rejection controller and industrial robot

ActiveCN109676634AReduced error control power consumptionImprove robustnessManipulatorControl powerActive disturbance rejection control

The invention discloses an active disturbance rejection controller, and an industrial robot. The active disturbance rejection controller comprises a differential tracker, a position loop and a speed loop; the input end of the differential tracker is connected with the output end of a controlled object, and is used for estimating the position and the speed of the controlled object; the position loop is composed of a first controller and a first extended observer, the first controller is based on the position error feedback control rule to generate speed control amount, the speed observation value output by the second output end of the first extended observer is used for compensating the speed control amount, the speed loop is composed of a second controller and a second extended observer, the second controller is based on the speed error feedback control rule to generate the acceleration control amount, and the acceleration disturbance observed value output by the second end of the second extended observer is used for compensating the acceleration control amount. The error control power consumption can be effectively reduced, and the system robustness and the response speed are improved.

Owner:杭州君辰机器人有限公司 +1

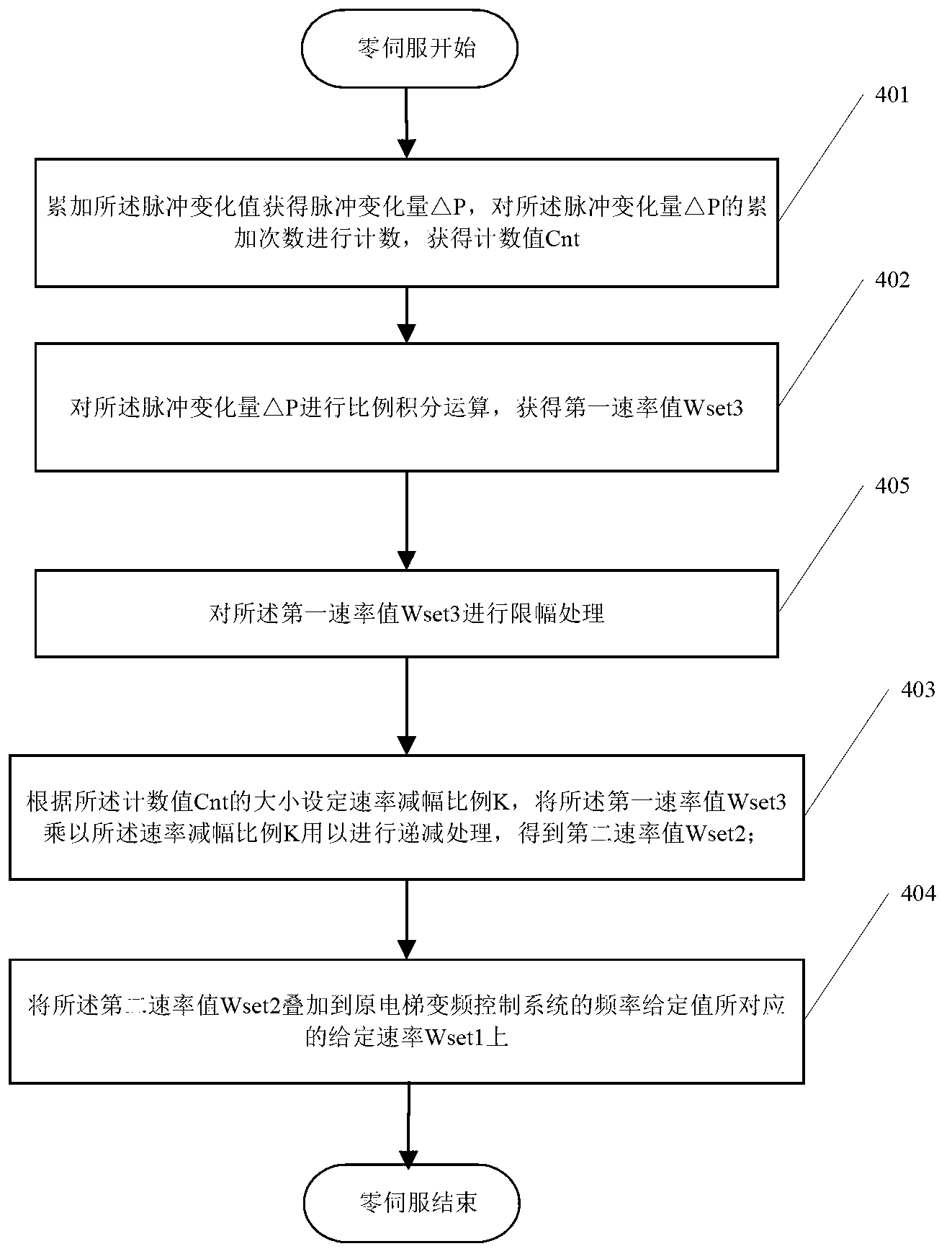

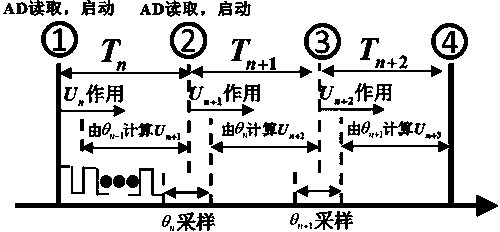

Automatic adjustment method and system of elevator starting torque

The invention discloses an automatic adjustment method and system of an elevator starting torque. The automatic adjustment system comprises a frequency setting module, a negative feedback adjustment processing module and a position loop operation control module. The frequency setting module is used for setting a given frequency, and acquires a given speed rate Wsetl according to the given frequency. The negative feedback adjustment processing module is used for subjecting a motor to negative feedback adjustment processing based on calculation of speed loop proportional integral according to the given speed rate Wsetl. The position loop operation control module is used for subjecting the given speed rate Wsetl to compensation processing according to pulse change values acquired from a traction machine shaft. By adopting the position loop operation control module in a conventional inverter vector control system in performing operation control processing on a position loop PI to compensate the given frequency, vectors of the motor are effectively controlled, sliding is avoided, and comfortability at an elevator starting moment is achieved under the condition of no weighing devices in the elevator.

Owner:SHENZHEN HPMONT TECH

Permanent magnet synchronous motor control method and device based on angular displacement time-delay-free observer

InactiveCN108880358AEliminate lagEliminate computational lag errorsAC motor controlElectric motor controlTime delaysPermanent magnet synchronous motor

Embodiments of the invention relate to a permanent magnet synchronous motor control method and device based on an angular displacement time-delay-free observer, and aims to improve the position loop response speed of a control system while the angular displacement feedback lag delay generated in a control system angular displacement sampling calculation process is eliminated. According to the angular displacement observation method, an angular displacement observation model is established according to a motion equation of the permanent magnet synchronous motor, and a time-delay-free angular displacement feedback signal is obtained, so that the angular displacement feedback speed of the control system is further improved, and the response capability of the control system is improved.

Owner:HARBIN UNIV OF SCI & TECH

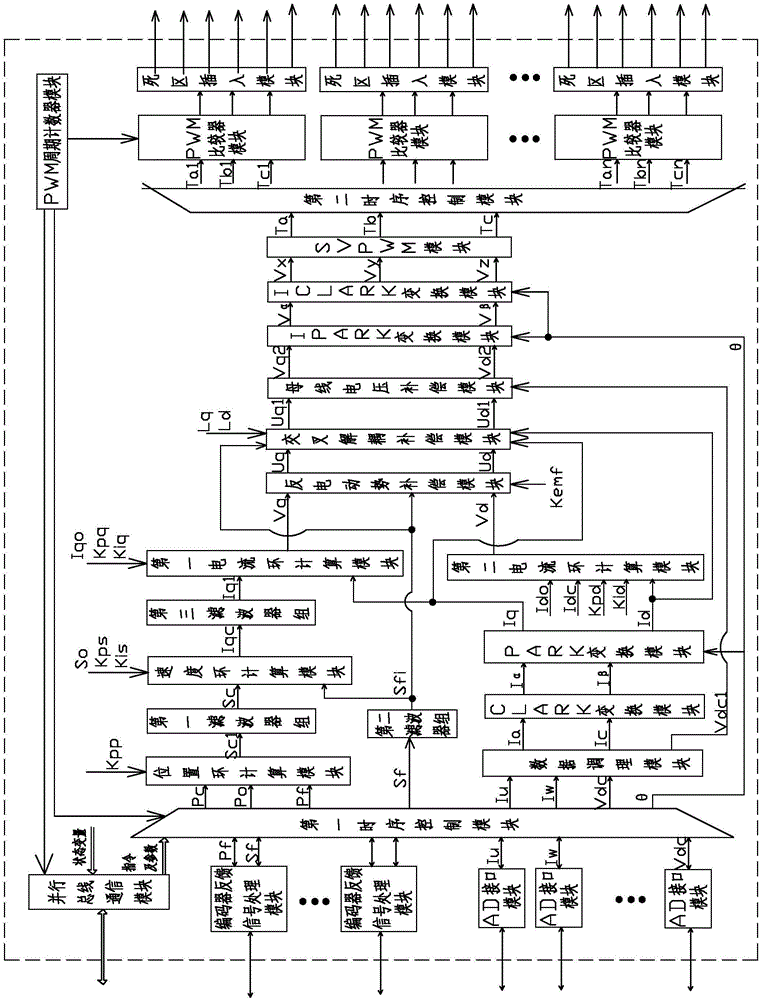

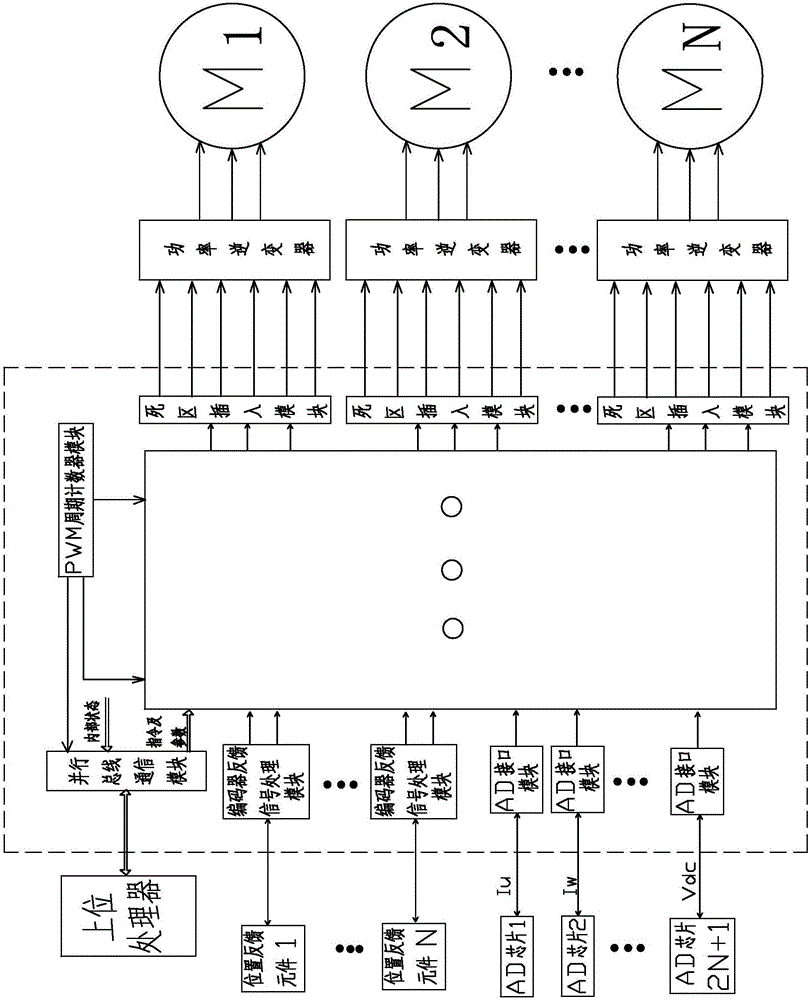

Multi-shaft AC servo motor control device

ActiveCN106208876AHigh control precisionGood real-time controlElectronic commutation motor controlAC motor controlHysteresisMotor shaft

The invention provides a multi-shaft AC servo motor control device, which comprises a parallel bus communication module, a PWM cycle counter module, an encoder feedback signal processing module, an AD interface module, a first sequential control module, a position loop computation module, a first filter group, a second filter group, a speed loop computation module, a third filter group, a data conditioning module, a CLARK transformation module, a PARK transformation module, first and second current loop computation modules, a counter electromotive force compensation module, a cross decoupling compensation module, a bus voltage compensation module, an IPARK transformation module, an ICLARK transformation module, an SVPWM module, a second sequential control module, a PWM comparator module and a dead zone insertion module. When the multi-shaft AC servo motor control device is used, the control hysteresis of a position loop, a speed loop and a current loop can be eliminated, the real-time property is good and the control precision is high; and through the global PWM cycle counter, the complete synchronization between multiple motor shafts can be realized.

Owner:广州金智为电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com