DSP-based electric machine position servo device

A servo device, motor position technology, applied in position/direction control, single motor speed/torque control, electronic commutator and other directions, can solve the problems of electromagnetic interference maintenance, small output torque, short life, etc. Spark interference, high reliability, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention is further described as follows:

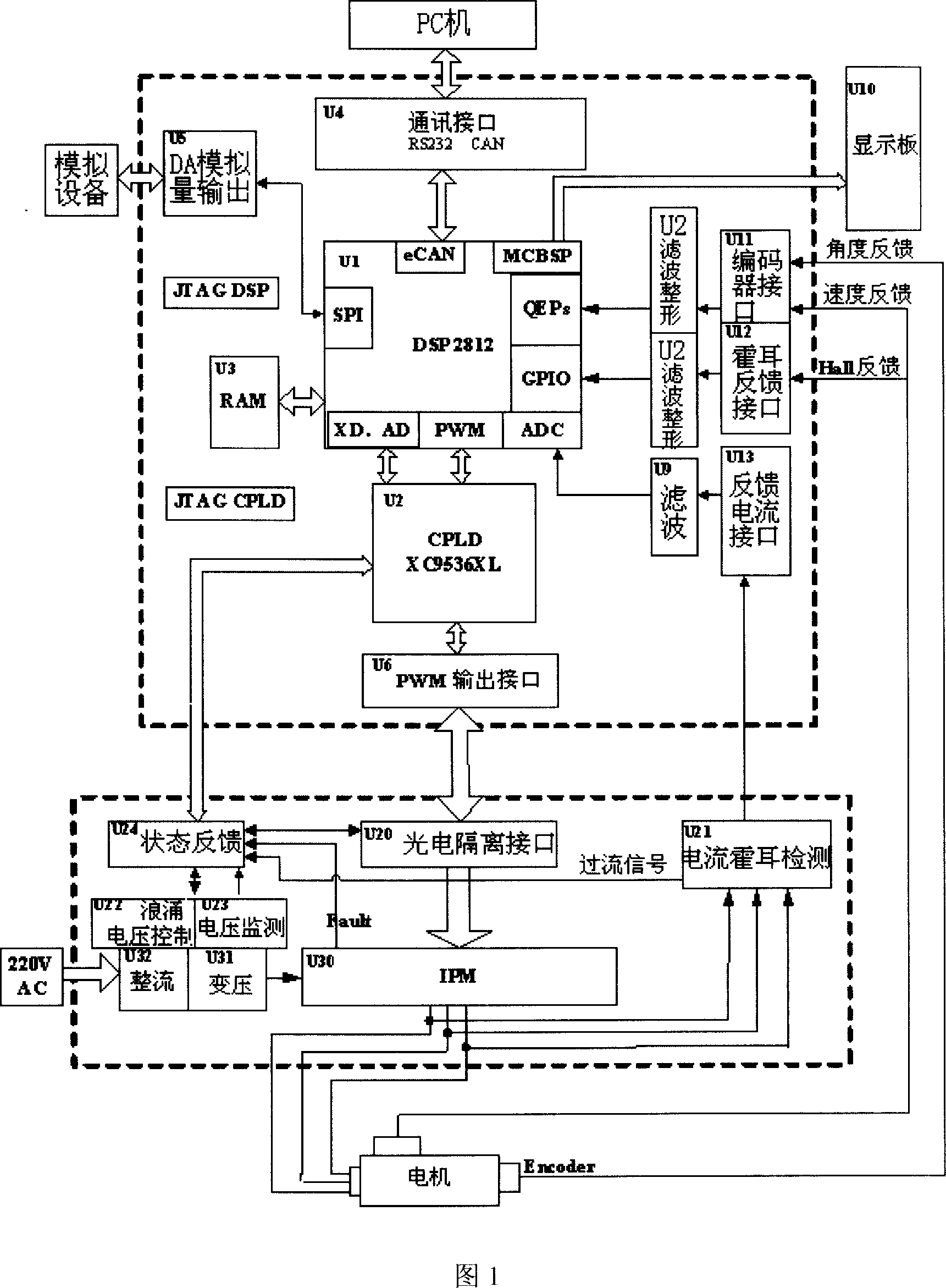

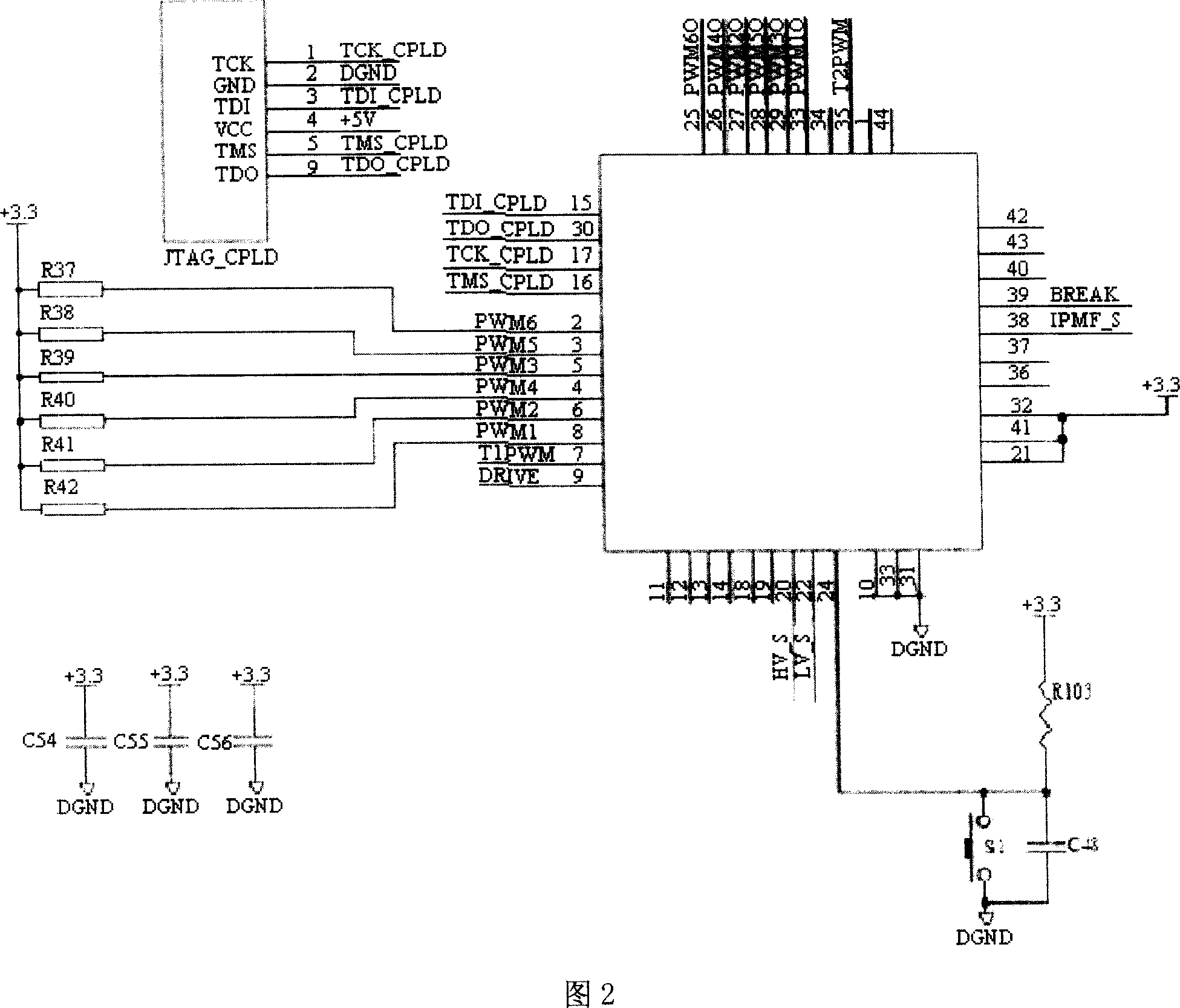

[0032] 1, the present invention includes a brushless DC motor and a control circuit, the control circuit includes a digital signal processor U1, a programmable logic device U2, a memory U3, a communication interface U4, an analog output U5, a PWM output U6, a filter U9, Display board U10, encoder interface U11, Hall feedback interface U12, feedback current interface U13, photoelectric isolation interface U20, current Hall detection U21, surge voltage control U22, voltage detection U23, status feedback U24, IPM intelligent power module U30 , rectifier module U31 and transformer module U32, digital signal processor U1 is connected to programmable logic device U2, memory U3, communication interface U4, analog output U5, filter U9 and display board U10, analog output U5 is connected to external analog equipment , the communication interface U4 is connected to an external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com