Energy-efficient hydraulic servo cylinders with bi-directional cushioning and precise force control

A two-way buffering and hydraulic servo technology, applied in the field of hydraulic servo cylinders, can solve the problems that the interactive impact force cannot be completely eliminated, the internal pressure changes greatly, and the working life is shortened, so as to improve the load matching followability and flexibility, and good variable rigidity and elastic performance, reducing the effect of pressure difference inside and outside the oil port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

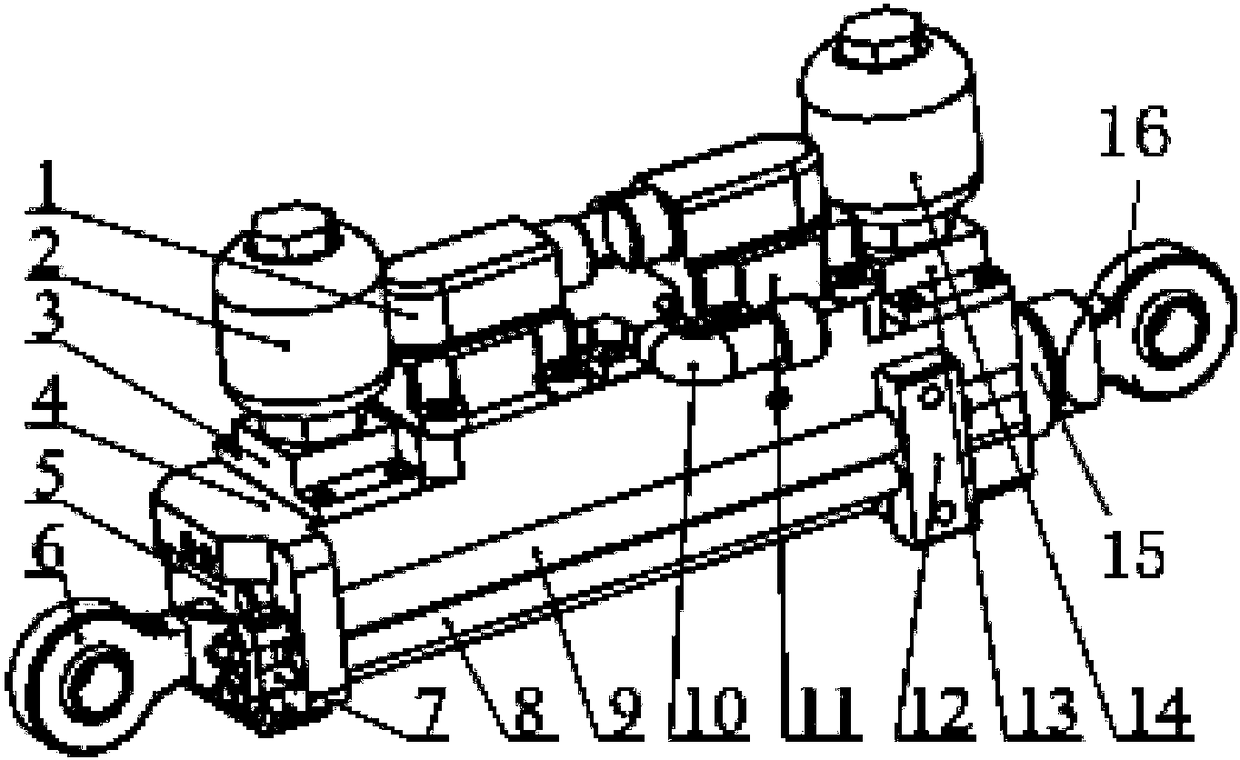

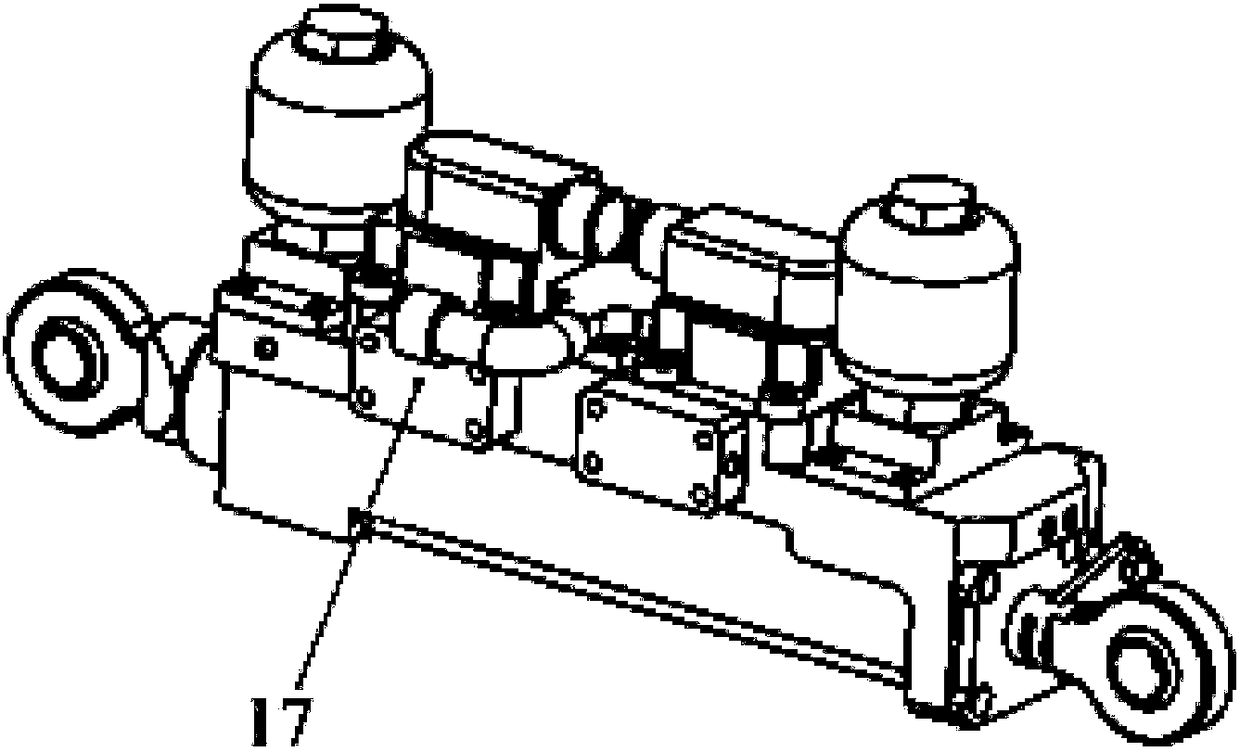

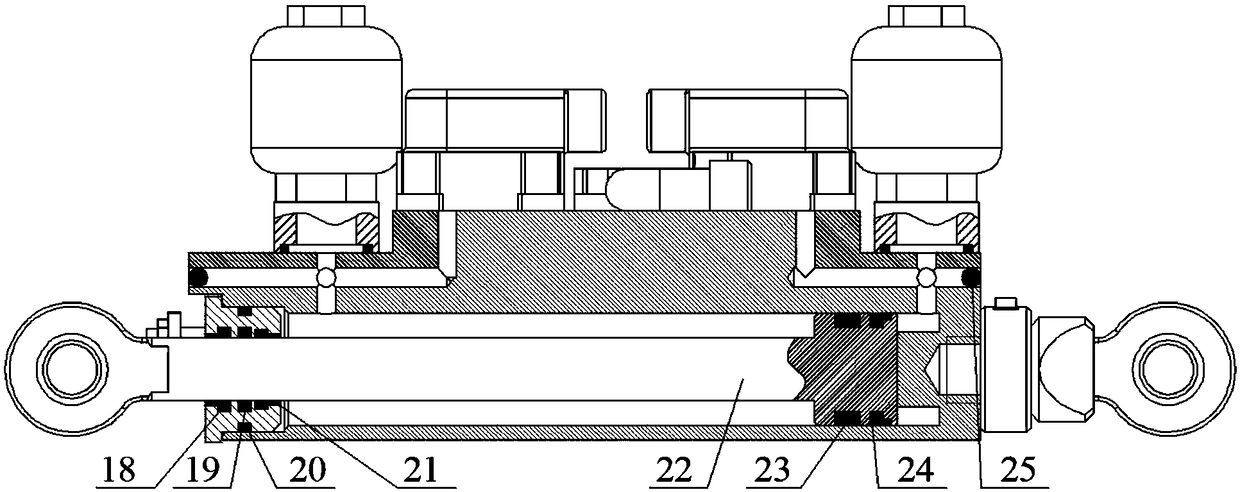

[0027] Such as figure 1 , figure 2 with image 3 As shown, the high-energy-efficiency hydraulic servo cylinder with two-way buffering and precise force control of the present invention includes a cylinder barrel 4, and a piston rod 22 is arranged in the cylinder barrel 4, see image 3 , the piston rod 22 is installed in the cylinder barrel 4 through the front cylinder cover 5, an O-ring 20 is arranged between the front cylinder cover 5 and the cylinder barrel 4, and a dustproof sealing ring 18 is arranged between the piston rod 22 and the front cylinder cover 5 , Combination gasket 9 and end cover end guide ring 21. One end of the piston rod 22 in the cylinder 4 is provided with a piston end guide ring 23 and a combined sealing gasket 24 , and the other end extends out of the cylinder 4 and is connected with a joint bearing 6 . Piston rod 22 separates cylinder barrel 4 into two parts, rod chamber 27 and rodless chamber 28 (see Image 6 ), the cylinder 4 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com