High-precision permanent magnetic servo motor three-closed-loop control system and method

A permanent magnet servo motor and control system technology, applied in control systems, vector control systems, motor generator control, etc. Maintain performance indicators and other issues to save computing time, improve response speed and control accuracy, and avoid trigonometric functions and root-finding operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in combination with principle diagrams and specific operation examples.

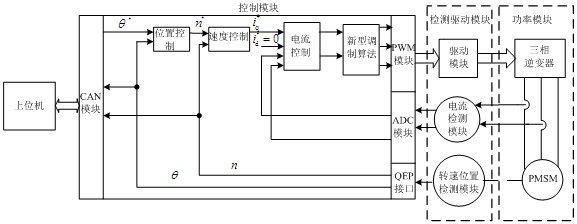

[0036] figure 1 It is a schematic diagram of the structure of a three-closed-loop control system controlled by a high-precision permanent magnet servo motor, as shown in figure 1As shown, the three-closed-loop control system of the high-precision permanent magnet servo motor of the present invention includes a power module, a detection and driving module, a control module and a host computer. The power module includes a three-phase inverter and a motor connected to it, and the detection drive module includes a drive module, a current detection module and a position and speed detection module. The control module includes a DSP hardware platform and a software part placed on the DSP hardware platform, and the software part includes a position control module, a speed control module, a current control module and a voltage vector modulation module....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com