Segmented-PI-control-based low-voltage direct-current servo driver

A servo drive, low-voltage DC technology, applied in control systems, AC motor control, electrical components, etc., can solve the problems of risk, single function, and high price in follow-up protection, and achieve high reliability, simple hardware design, and dynamic response. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, with reference to figure 1 , a low-voltage DC servo drive based on segmented PI control:

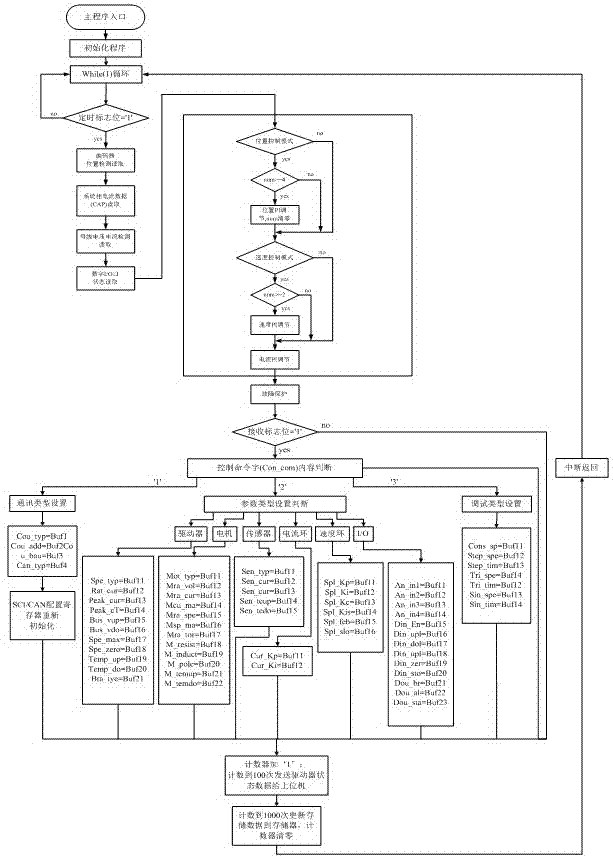

[0046] The control system of the servo drive includes three control loops: current loop, speed loop and position loop. After receiving the enable signal from the host computer, the servo drive enters the drive mode and is quantified by the A / D conversion circuit or communication interface. The position, speed or torque current signal of the host computer is used as the input signal of the position loop, speed loop or current loop to control the output of the MOSFET inverter circuit to drive the servo motor; at the same time, the incremental encoder and current sampling circuit detect the angle, speed, The current data is used as the feedback signal of the three loops, and the DSP processor controls the output of the MOSFET drive circuit to drive the servo motor according to the command data and the PI control algorithm of the feedback data; a logic processing circuit...

Embodiment 2

[0047] Embodiment 2, in a low-voltage DC servo driver based on segmental PI control described in Embodiment 1: the circuit of the servo driver mainly includes a power supply unit, a main control unit, an inverter unit, a signal conditioning unit, motor speed and angle Measuring unit, failsafe unit and communication unit.

Embodiment 3

[0048] Embodiment 3, in a low-voltage DC servo driver based on segmental PI control described in Embodiment 2, each unit circuit is specifically:

[0049] a) Power supply unit

[0050] Including main control 5V power supply and 12V drive power supply;

[0051] The main control 5V power supply circuit is used to generate the power supply required for the operation of the control circuit;

[0052] The 12V drive power supply circuit is used to generate the power supply required by the MOSFET drive circuit;

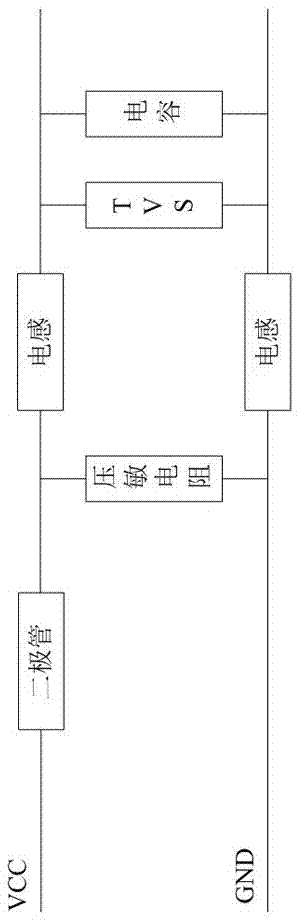

[0053] The input end of the power supply unit of the servo driver is equipped with a filter capacitor and a surge protection circuit composed of a one-way conductive diode, TVS, varistor, and inductor;

[0054] b) Main control unit

[0055] The main control unit mainly includes a DSP signal processor circuit;

[0056] The DSP signal processor circuit mainly completes the tasks of command acceptance, various signal acquisition, PWM signal generation, output torque control, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com