Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

619results about "Wing lift eficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

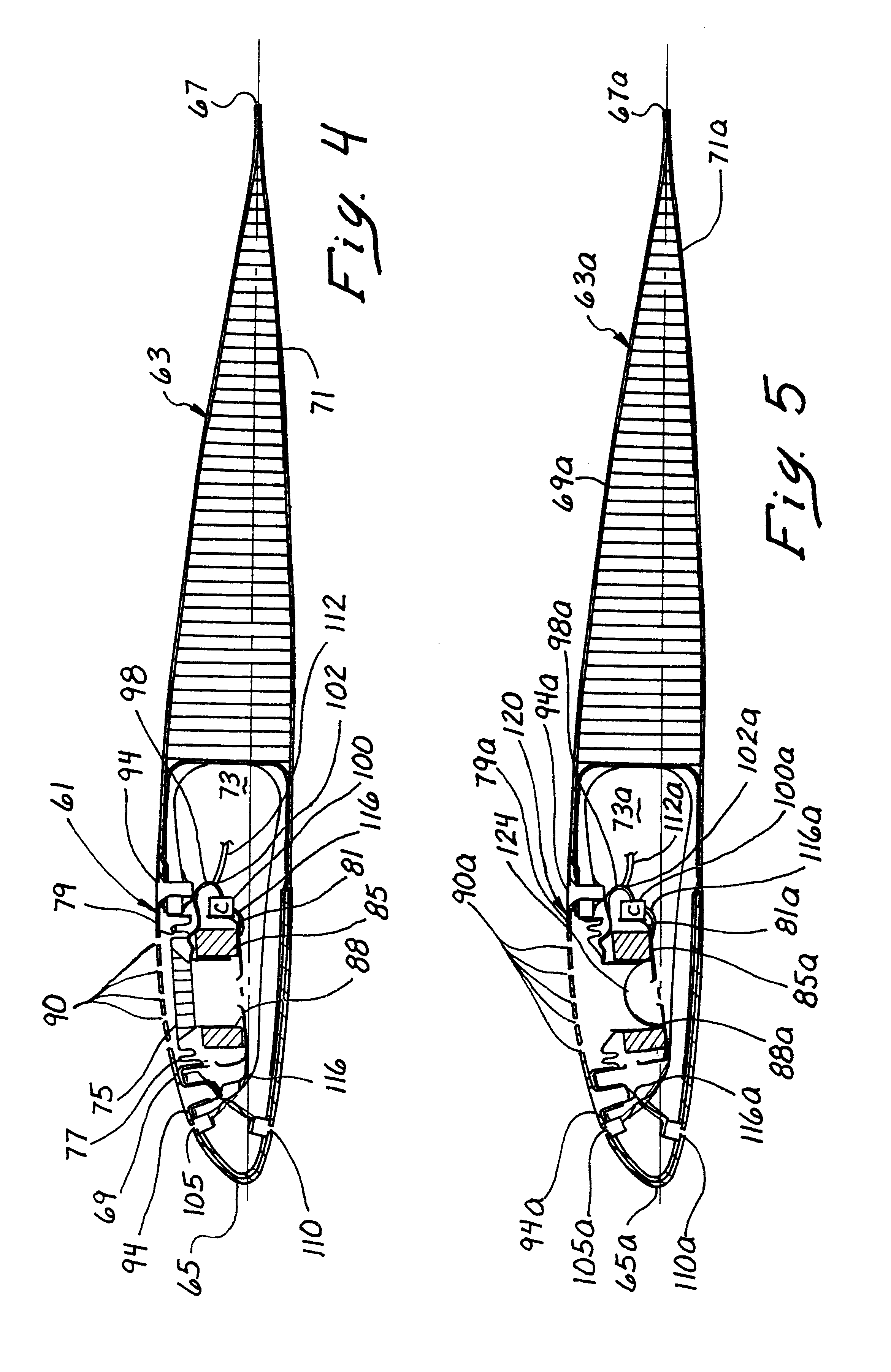

Rotorcraft having coaxial counter-rotating rotors which produce both vertical and horizontal thrust and method of controlled flight in all six degrees of freedom

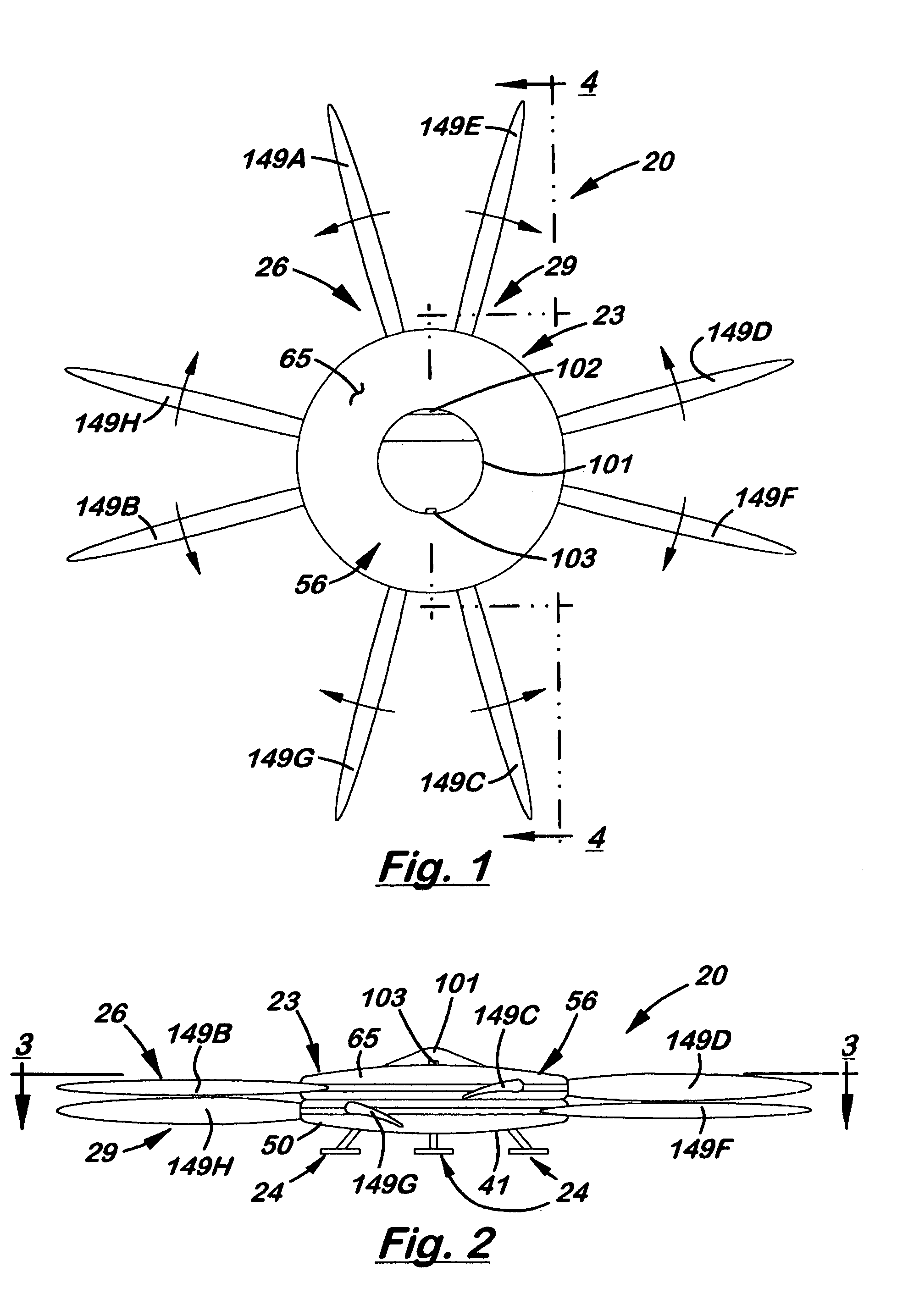

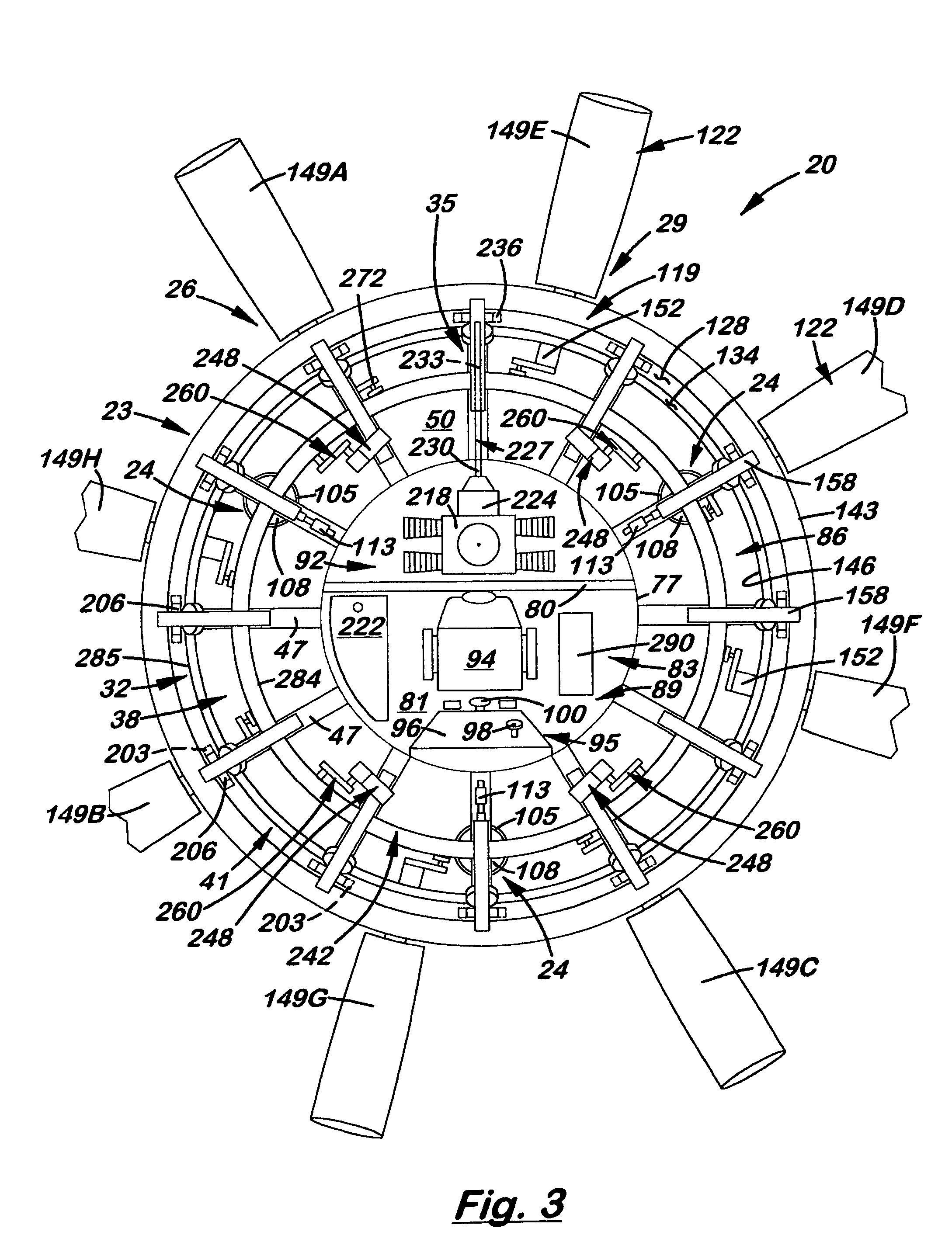

A rotorcraft and method for providing controlled flight which provides flight in all six degrees of freedom of pitch, roll, yaw, up / down, forward / rear, and left / right. The rotorcraft includes a fuselage with a pair of counter-rotating rotor blade assemblies each having a plurality of radially-extending airfoil shaped blades about a vertically disposed central axis. A rotor drive system mounted to the fuselage includes a motor or engine for rotationally driving the rotor blade assemblies. A rotor blade control system monitors the rotational location of each blade relative to the fuselage and allows a pilot to control respective vertical and horizontal thrust components of the blades corresponding to lift versus drag characteristics of the airfoils during rotation about the fuselage. This is done by changing the pitch angles of the blades and / or by utilizing respective flaps pivotally mounted to the blades to change the effective pitch angle of the blades.

Owner:PETERSEN BRUCE L

Load carrying structure having variable flexibility

InactiveUS6182929B1Simple wayReduce stiffnessPropellersPump componentsShape-memory alloyOperating temperature range

A load carrying structure having a selectively rigid or flexible characteristic includes a thermoplastic material (7) having a softening temperature above the operating temperature range of the load carrying structure, and a heating arrangement (8) provided to selectively heat the thermoplastic material to above its softening temperature. During normal operation, the thermoplastic material is in a rigid state and the overall load carrying structure is rigid to the prevailing loads. By activating the heating arrangement to heat the thermoplastic material to at least its softening temperature, the thermoplastic material and therewith the load carrying structure becomes flexible so that it may be deformed to a different configuration by applying a deforming load. Once the desired deformed configuration is achieved, the heating arrangement is deactivated, and the thermoplastic material is allowed to cool below its softening temperature so that it once again becomes rigid and rigidly fixes the new deformed configuration. The deforming force may be applied by any actuating mechanism, or for example by arranging shape memory alloys in connection with the thermoplastic material.

Owner:INST FUER VERBUNDWERKSTOFFE GMBH +1

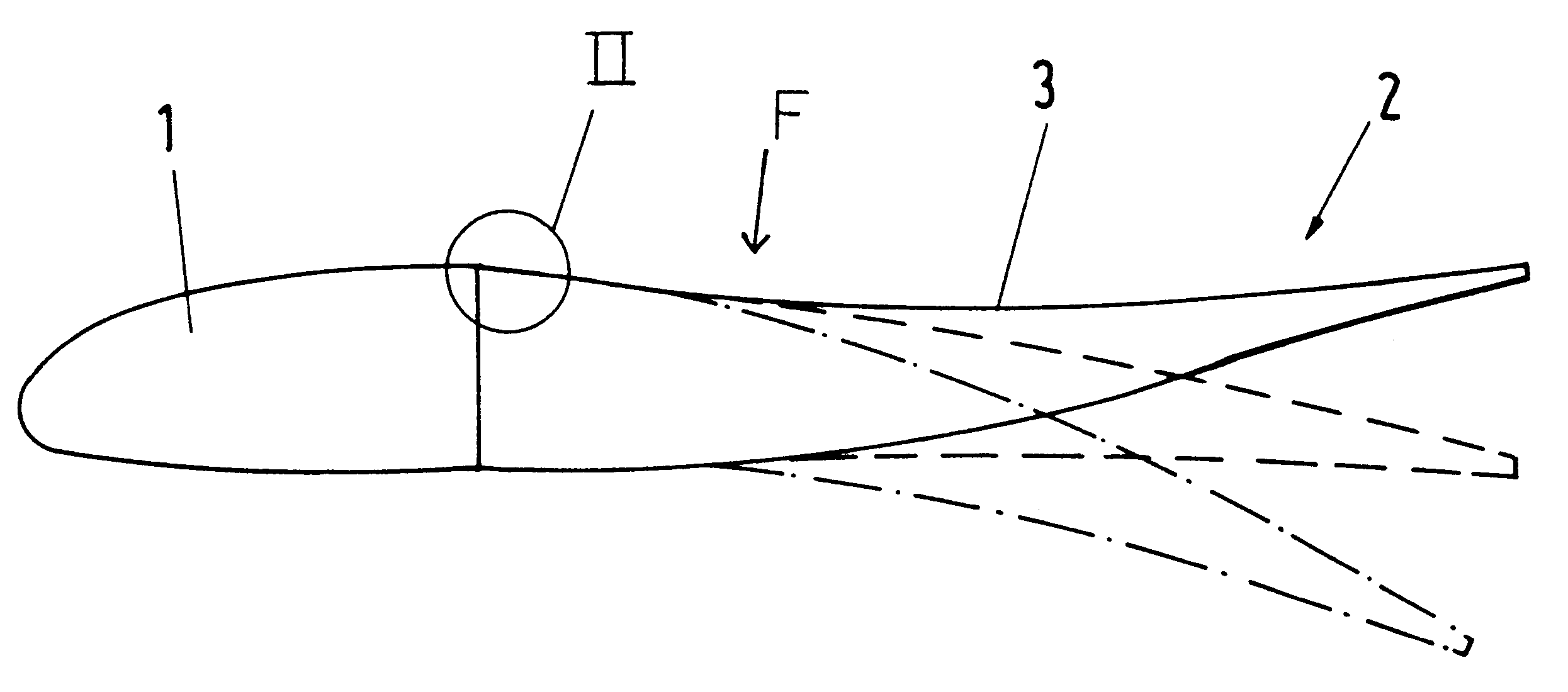

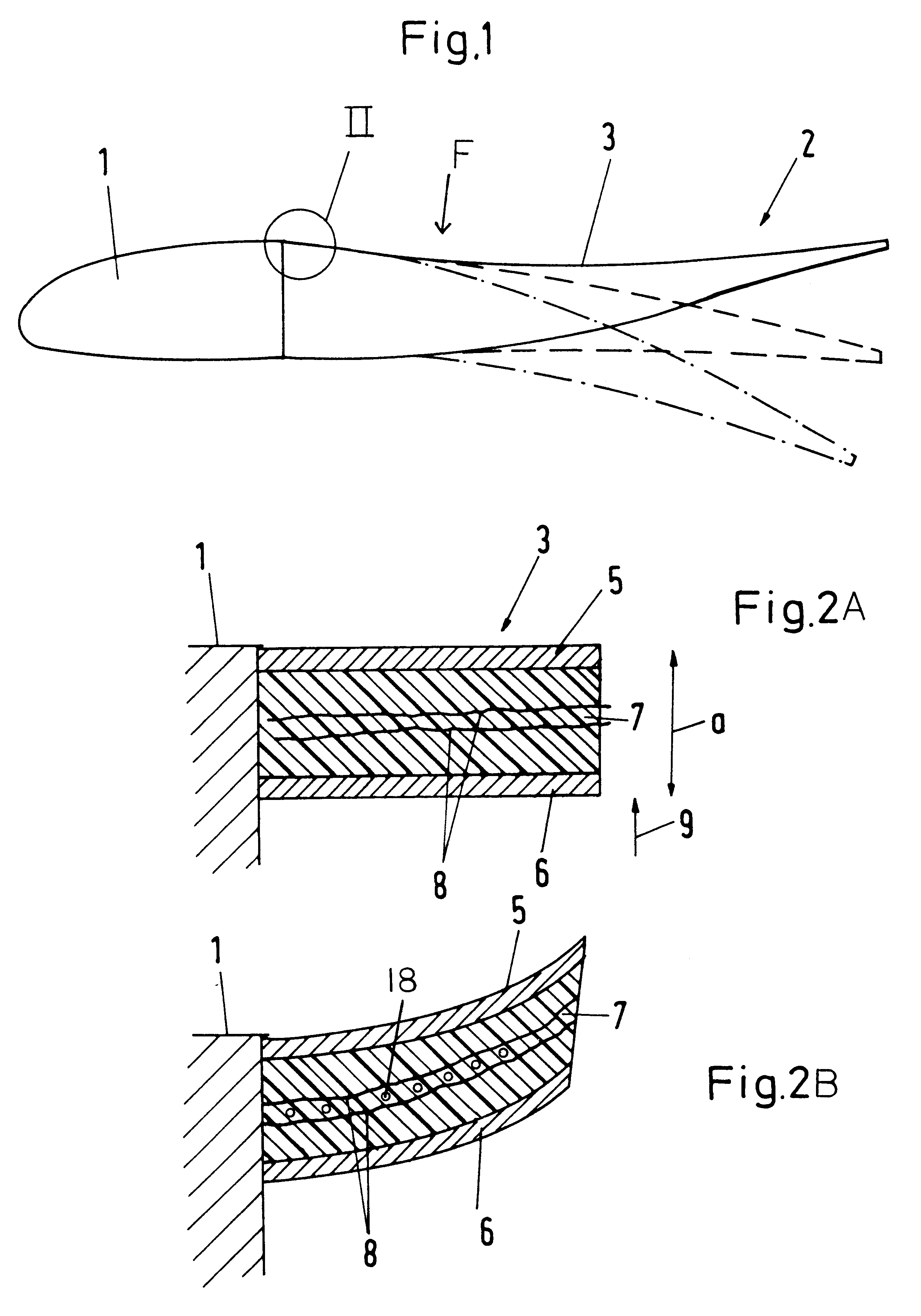

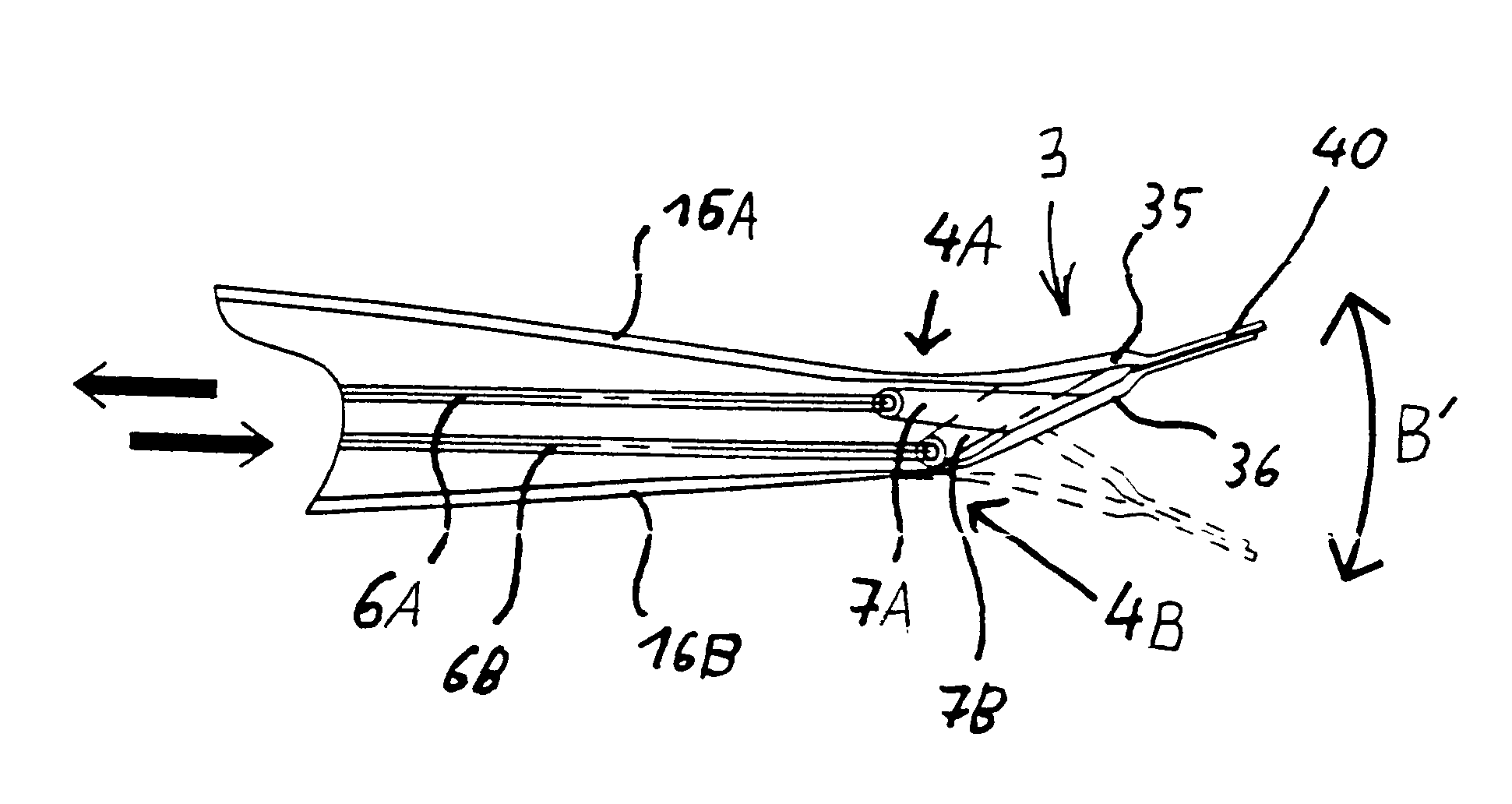

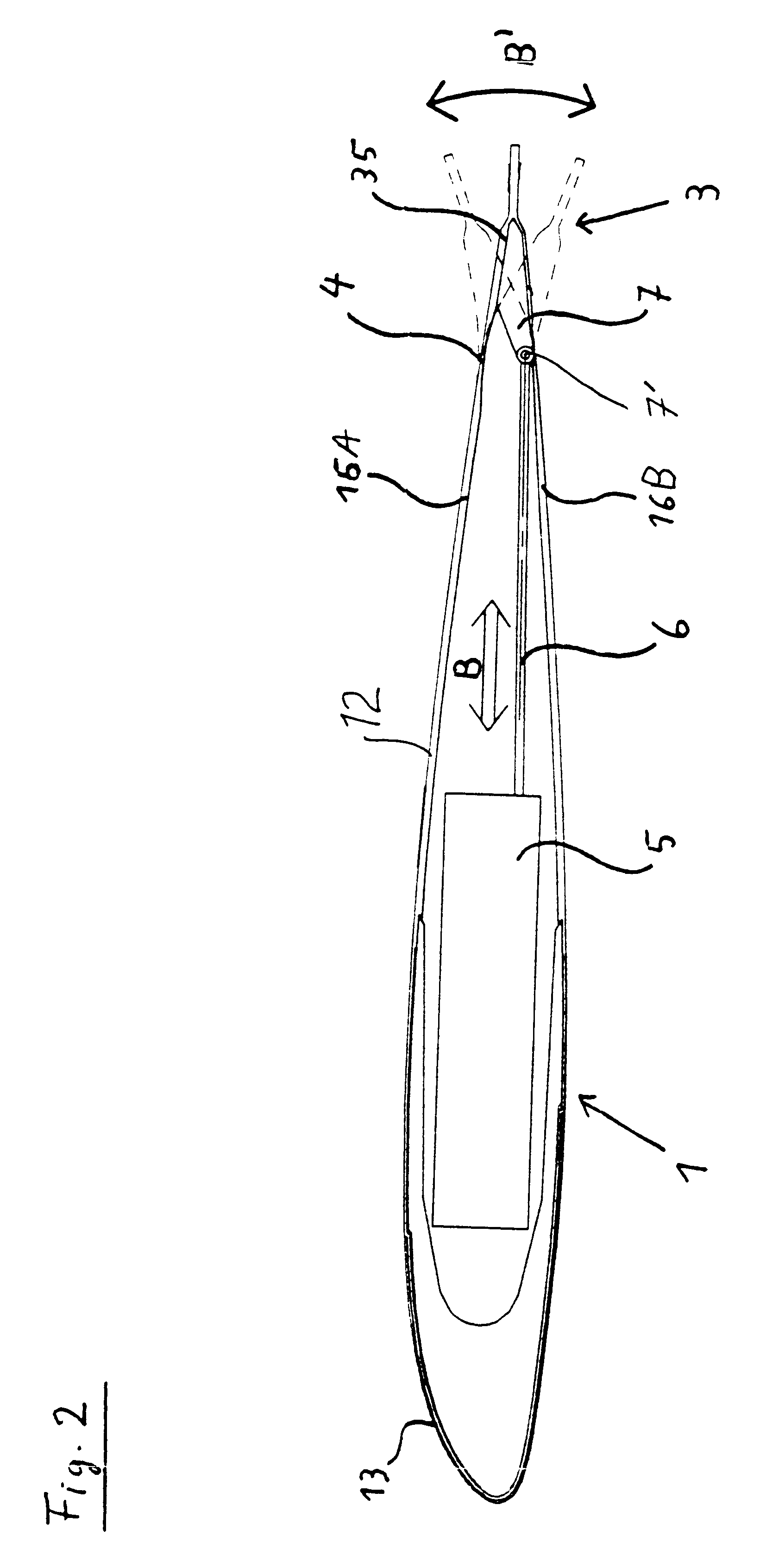

Helicopter rotor blade with a movable flap

InactiveUS6168379B1Durable and wear-resistant flexiblyImprove inspectionPropellersAircraft stabilisationPiezoelectric actuatorsFiber-reinforced composite

A helicopter rotor blade includes a main airfoil body (12) and a movable control flap (3) incorporated in the trailing edge profile of the airfoil body. The flap (3) is movably connected to the main airfoil body (12) by a flexibly bendable junction element (4), and is actuated by a piezoelectric actuator unit (5) via a push / pull rod (6) and a lever arm (7), whereby the control flap is deflected relative to the main airfoil body. The junction element (4) is preferably a continuous integral fiber-reinforced composite component having a flexible bending portion (42) with a reduced thickness in comparison to the adjoining portions, whereby the reinforcing fibers extend continuously through the joint in the direction of the connection between the main airfoil body and the flap.

Owner:AIRBUS HELICOPTERS DEUT GMBH

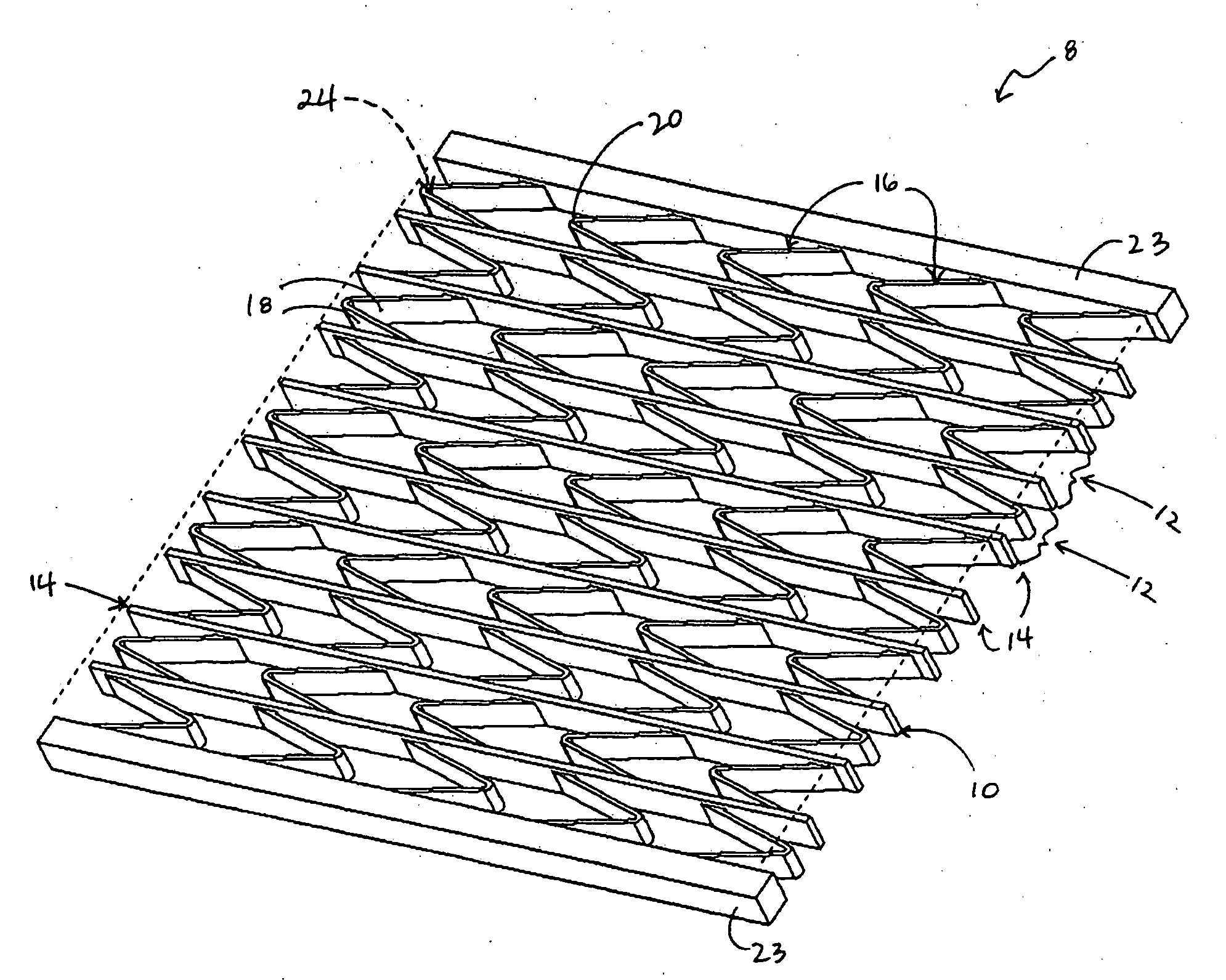

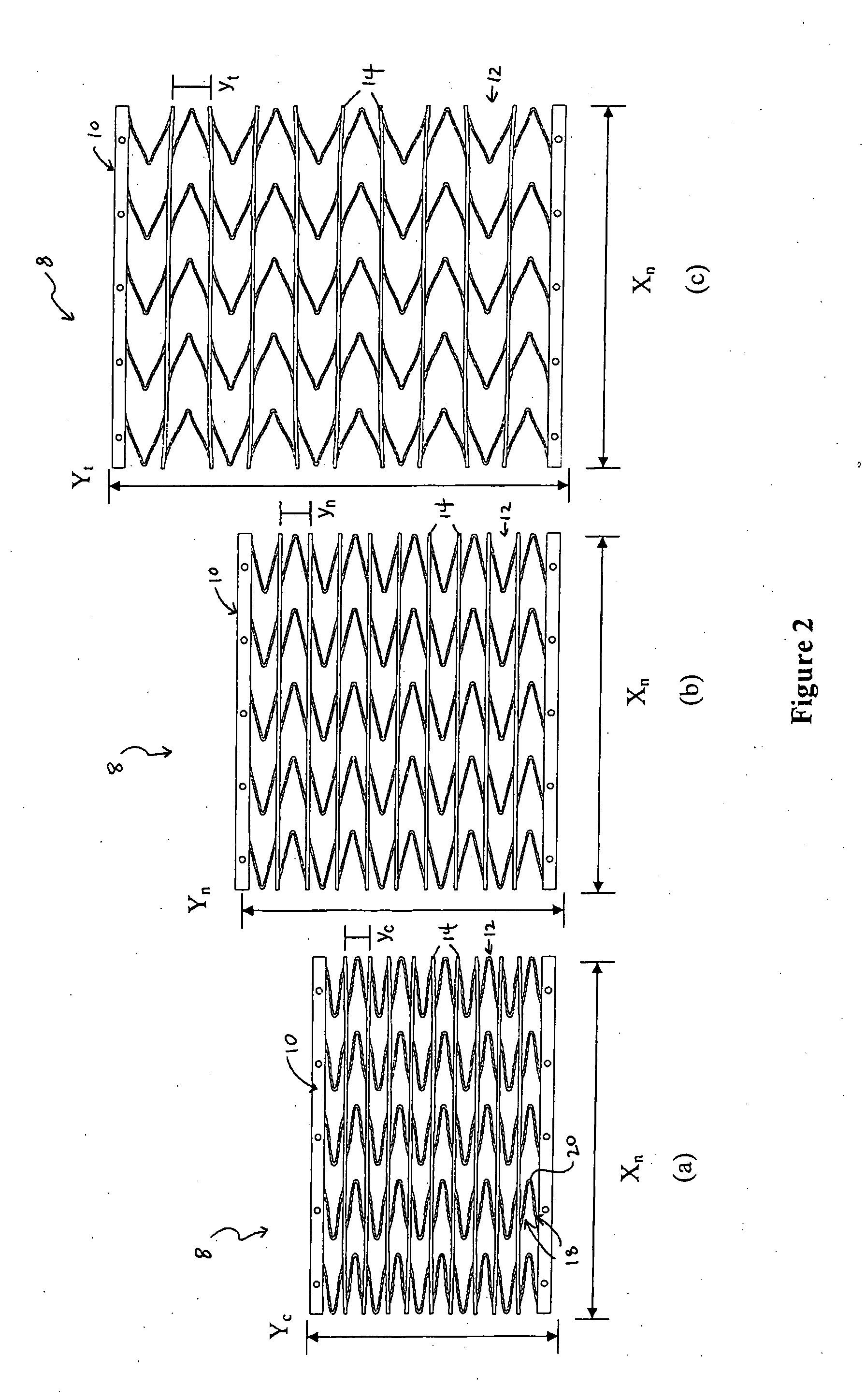

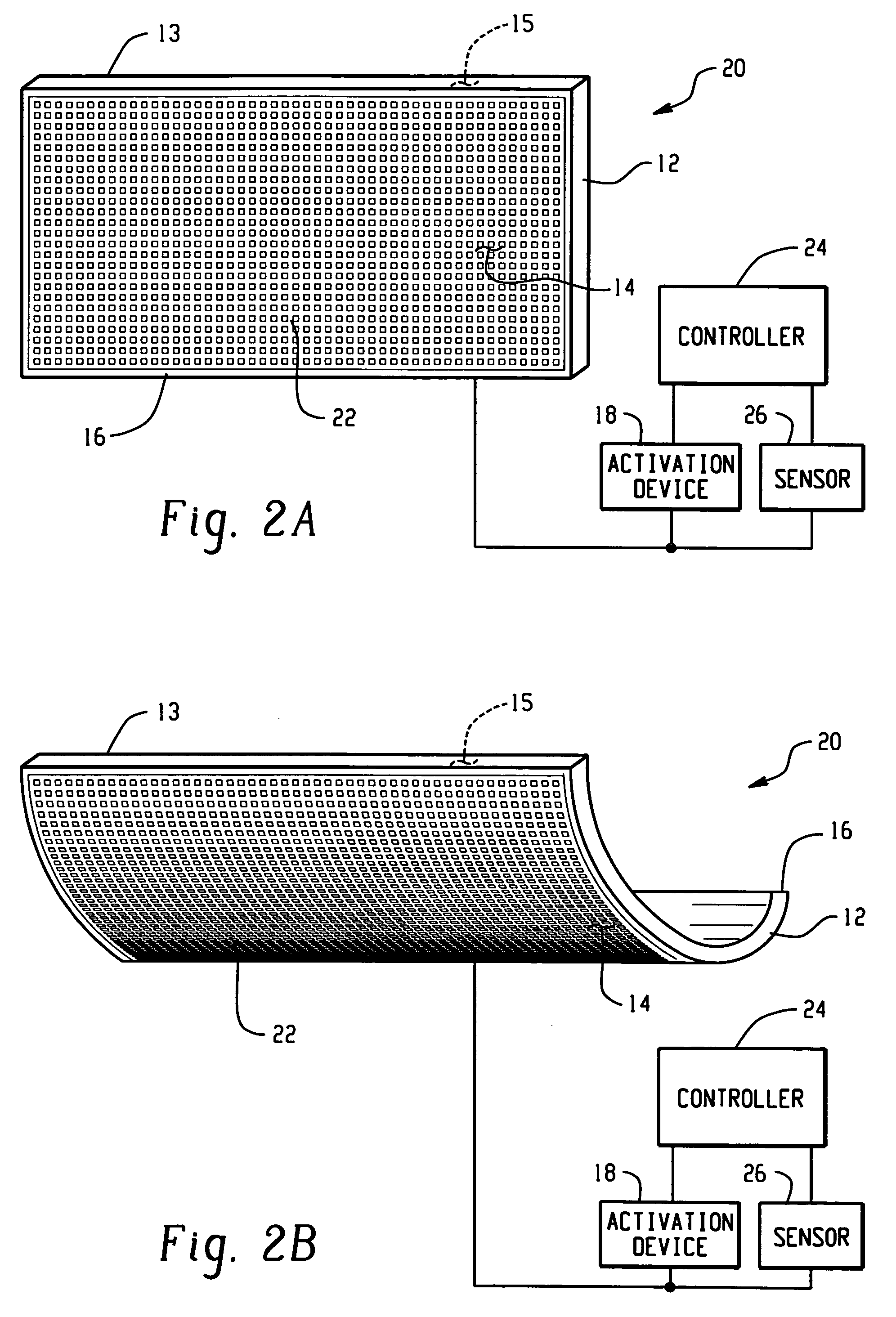

Cellular support structures used for controlled actuation of fluid contact surfaces

InactiveUS20080035788A1Aircraft stabilisationWithout power ampliicationHoneycomb likeBiomedical engineering

An assembly for controlling a vehicle, including a fluid contact surface constructed and arranged to act against a fluid passing over the fluid contact surface; and a support structure coupled to the fluid contact surface. The support structure is constructed and arranged to expand or contract between a first position and a second position, such that a first dimension of the support structure changes during movement of the support structure between the first position and the second position, while a second dimension of the support structure remains substantially constant during the movement of the support structure between the first position and the second position.

Owner:INNOVITAL LLC +2

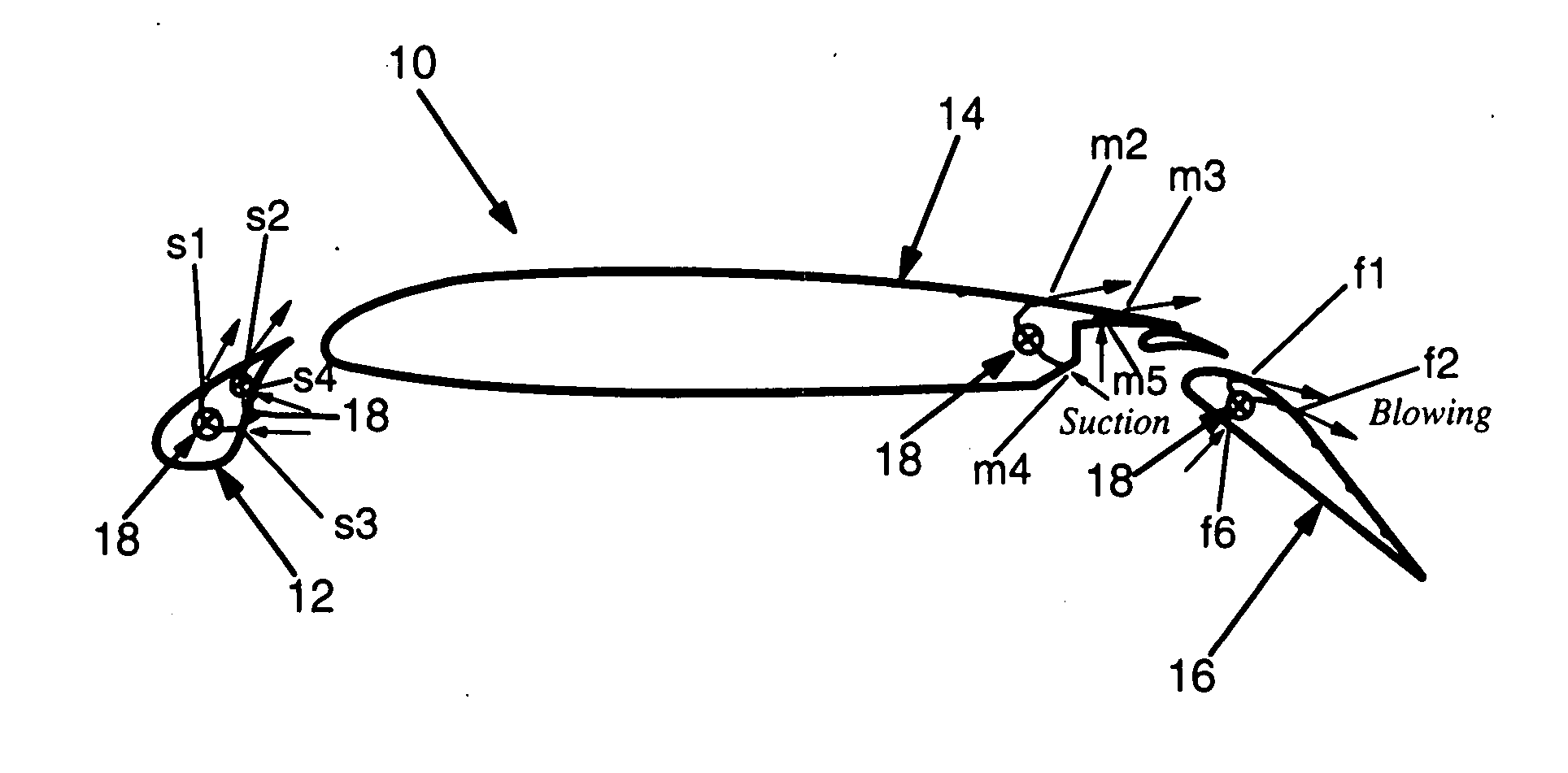

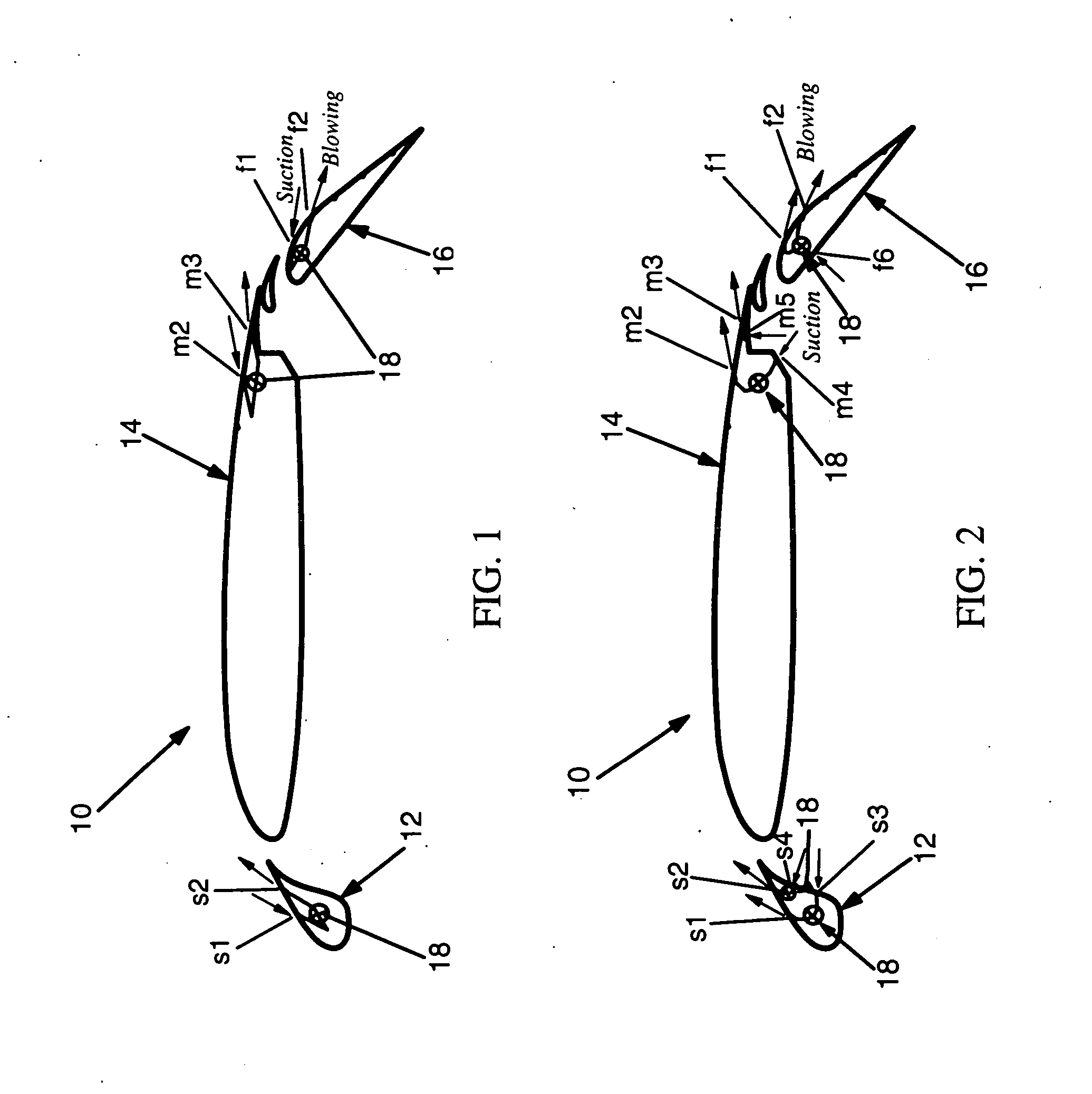

System for aerodynamic flows and associated method

ActiveUS20070034746A1Reduce viscositySpeed up circulationBoundary layer controlsWingsAirplaneAerodynamics

A system and method for controlling boundary layer flow over an aircraft wing are provided. The system includes at least one wing element, and a plurality of ports defined in the wing element and in fluid communication with one another. The system also includes at least one fluidic device operable to continuously ingest the fluid through at least one of the ports and eject the fluid out of at least one other port to control boundary layer flow of the fluid over the wing element.

Owner:THE BOEING CO

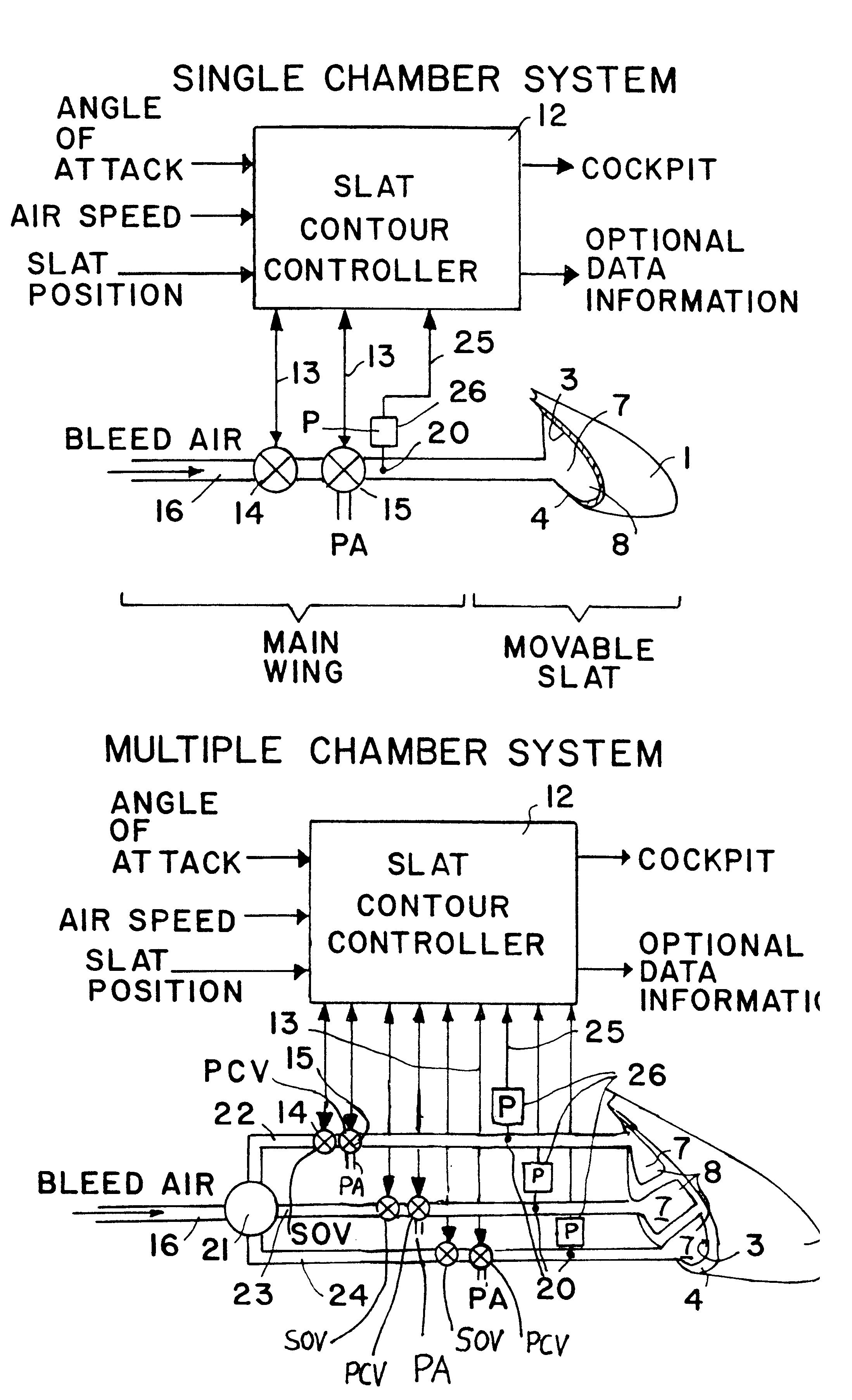

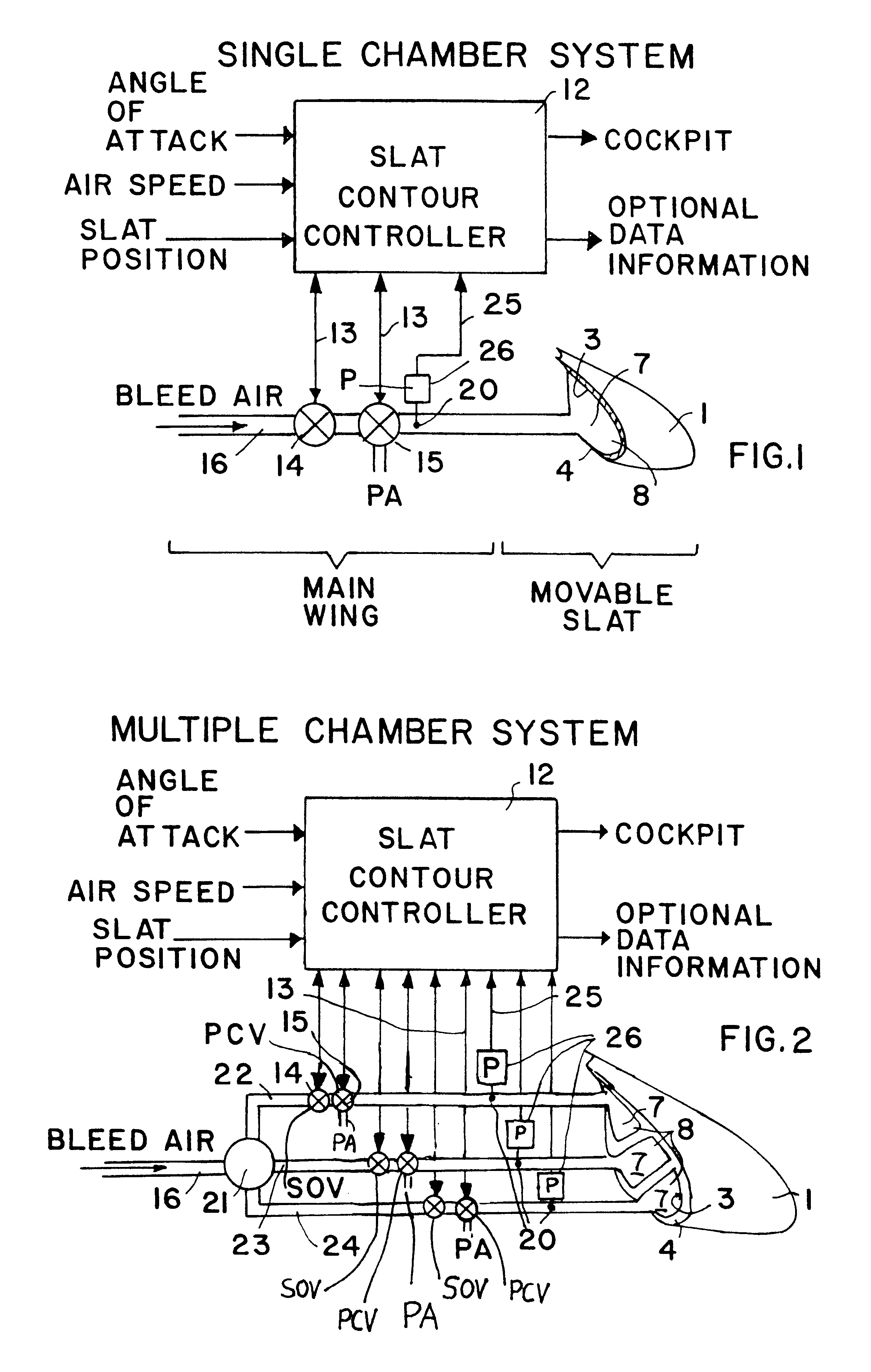

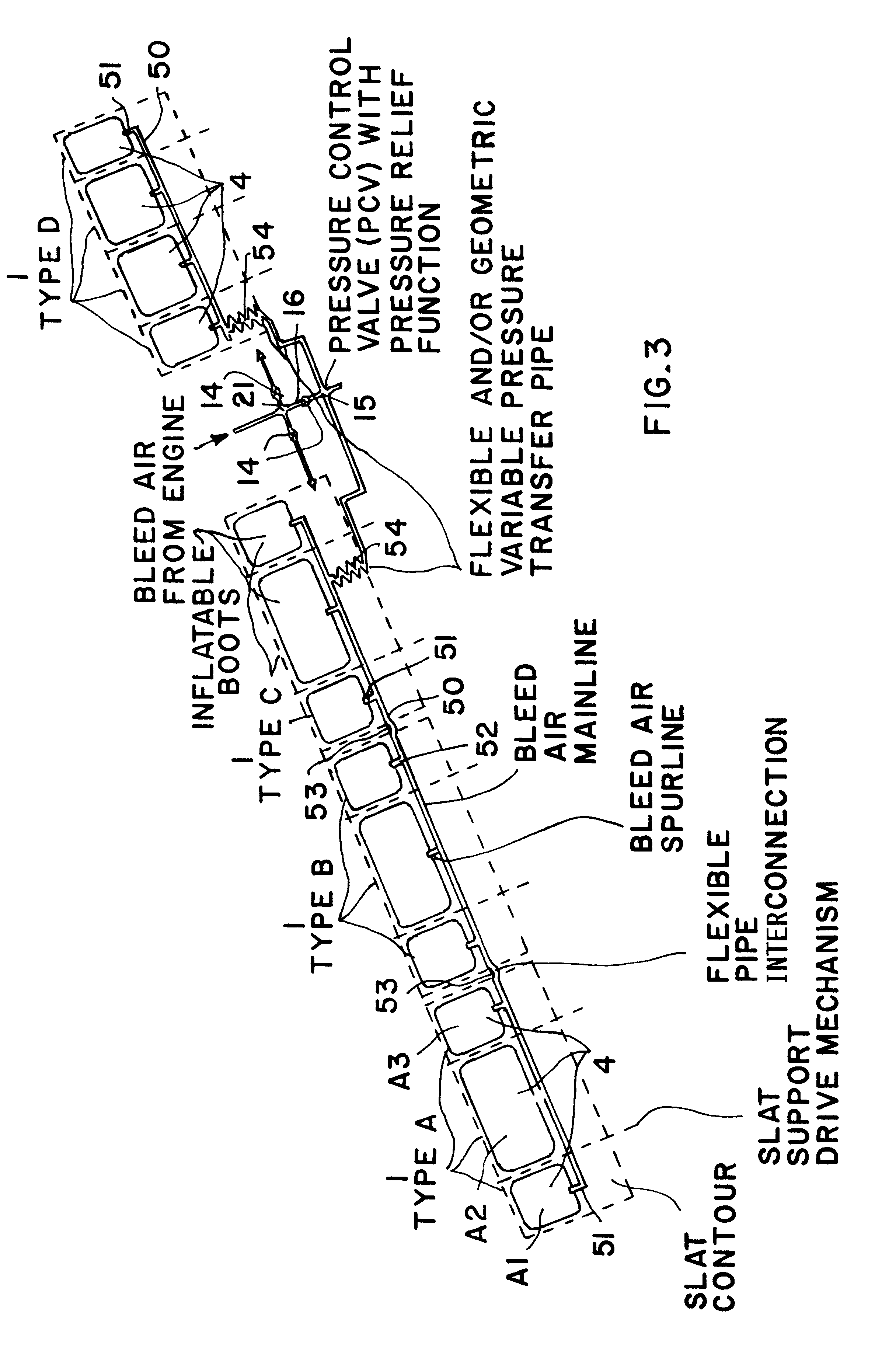

Pressure control system for a pressure-expandable displacement element

An elastically expandable hollow displacement element is secured to the rear surface of an aircraft wing slat. When the displacement element is contracted, the slat may be retracted onto the wing's leading edge. When the slat is extended, the displacement element is expanded to protrude convexly from the slat, thereby preventing vortex formation in the slat air gap and reducing aero-acoustic noise. A pressure control system for inflating and deflating the displacement element includes a bleed air line connected from the aircraft engine bleed air system to the displacement element, a shut-off valve and a pressure control valve interposed in series in the bleed air line, and a slat contour controller connected by respective signal lines to the valves, which control the quantity and the pressure of the bleed air supplied into the displacement element, for properly inflating the same.

Owner:AIRBUS OPERATIONS GMBH

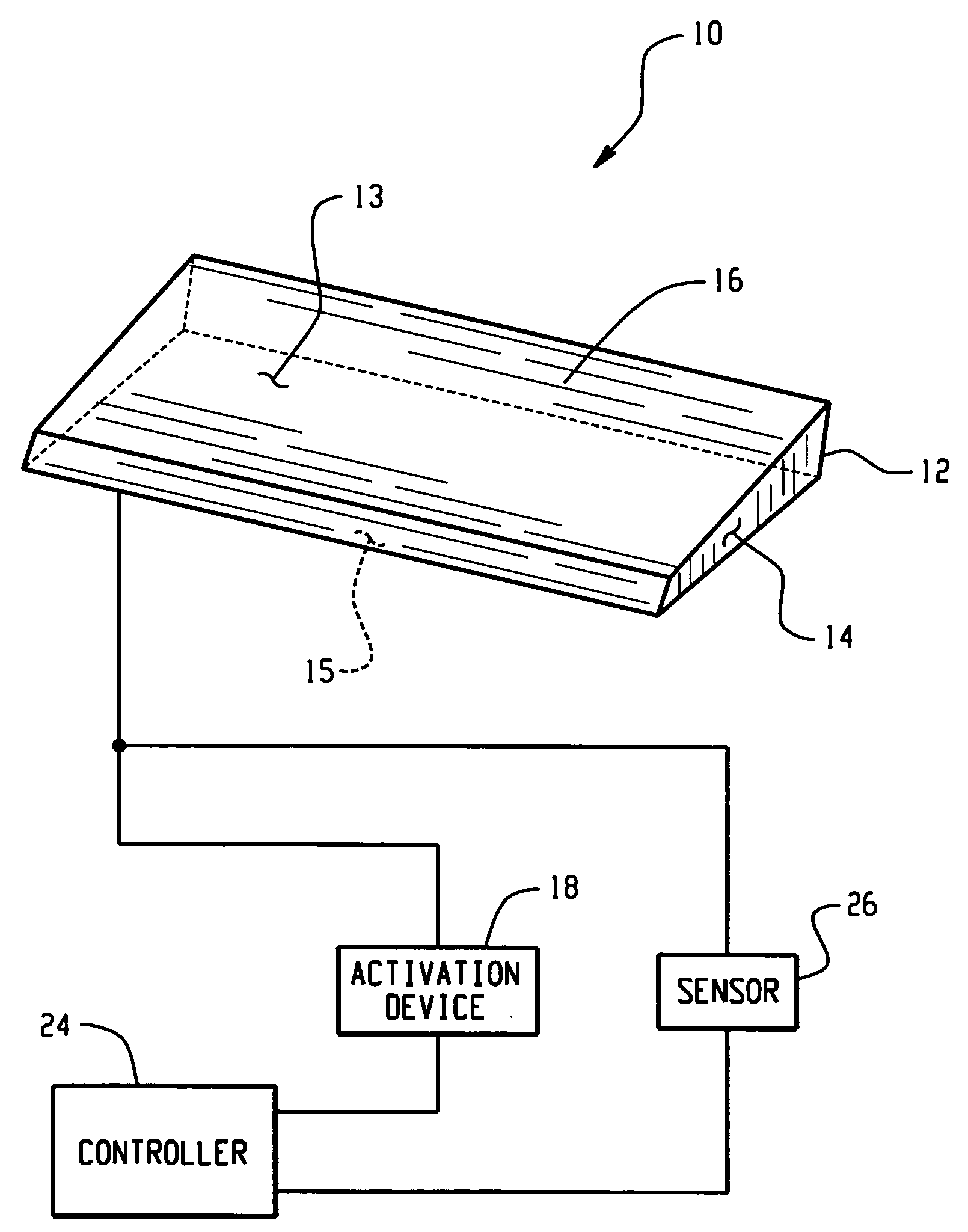

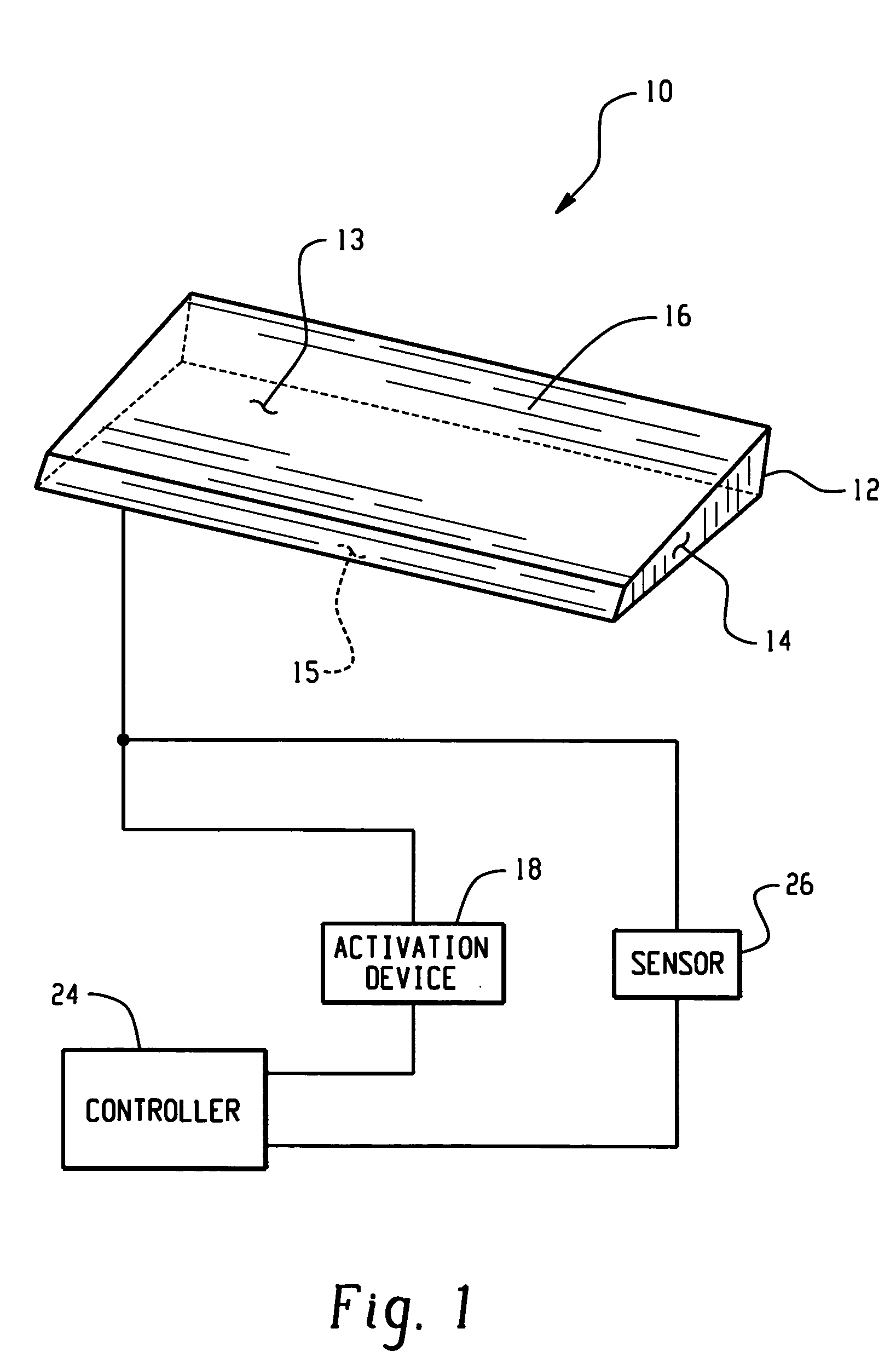

Airflow control devices based on active materials

ActiveUS20050121240A1Vehicle seatsVehicle body stabilisationBiological activationCoolant temperature

An airflow control device comprises a body and an active material in operative communication with the body. The active material, such as a shape memory material, is operative to change at least one attribute in response to an activation signal. The active material can change its shape, dimensions and / or stiffness producing a change in at least one feature of the airflow control device such as shape, dimension, location, orientation, and / or stiffness to control vehicle airflow to better suit changes in driving conditions such as the need for increased airflow through the radiator due to increases in engine coolant temperature. As such, the device improves vehicle fuel economy while maintaining proper engine cooling. An activation device, controller and sensors may be employed to further control the change in at least one feature of the airflow control device such as shape, dimension, location, orientation, and / or stiffness of the device. A method for controlling vehicle airflow selectively introduces an activation signal to initiate a change of at least one feature of the device that can be reversed upon discontinuation of the activation signal.

Owner:GM GLOBAL TECH OPERATIONS LLC

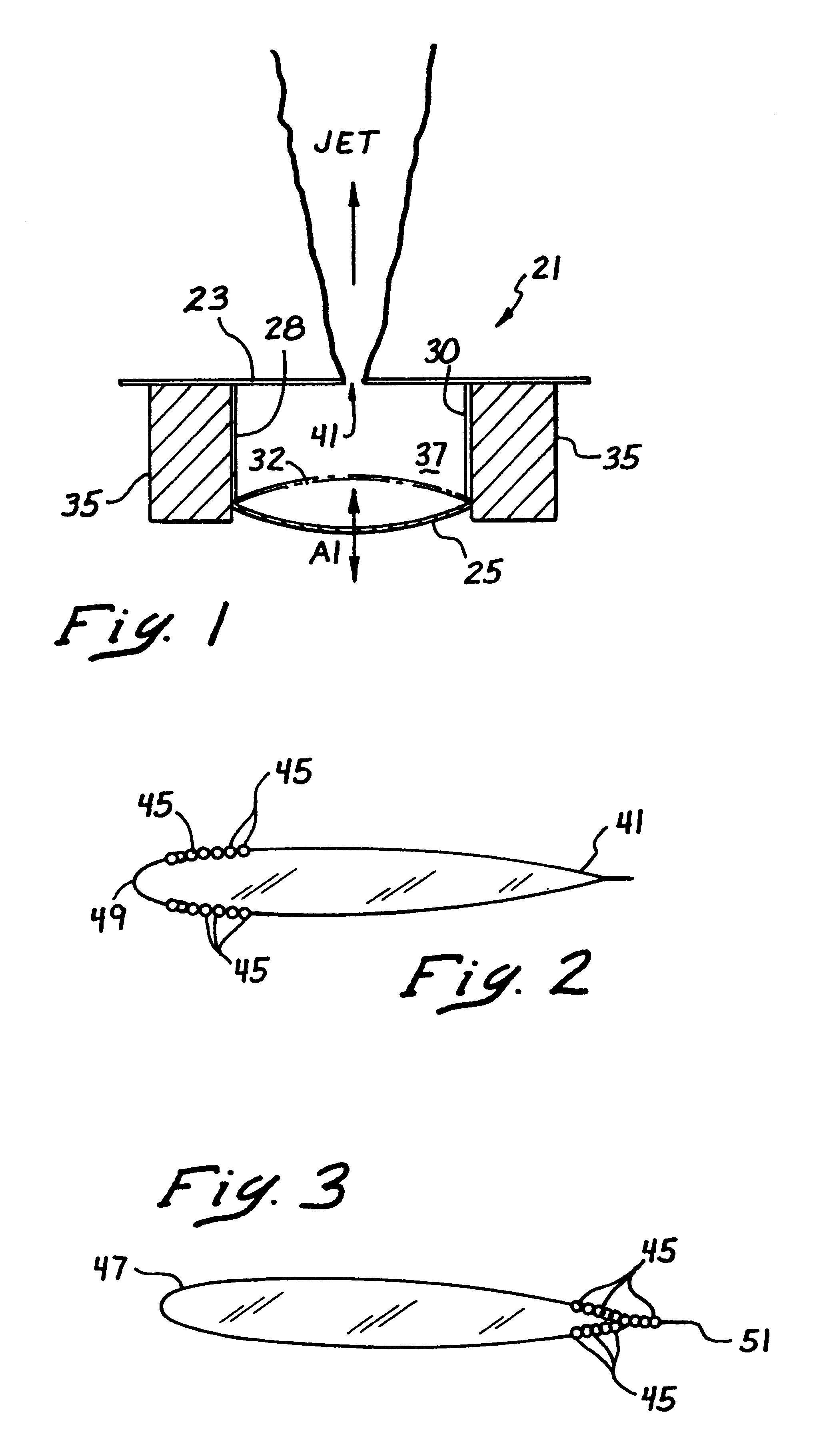

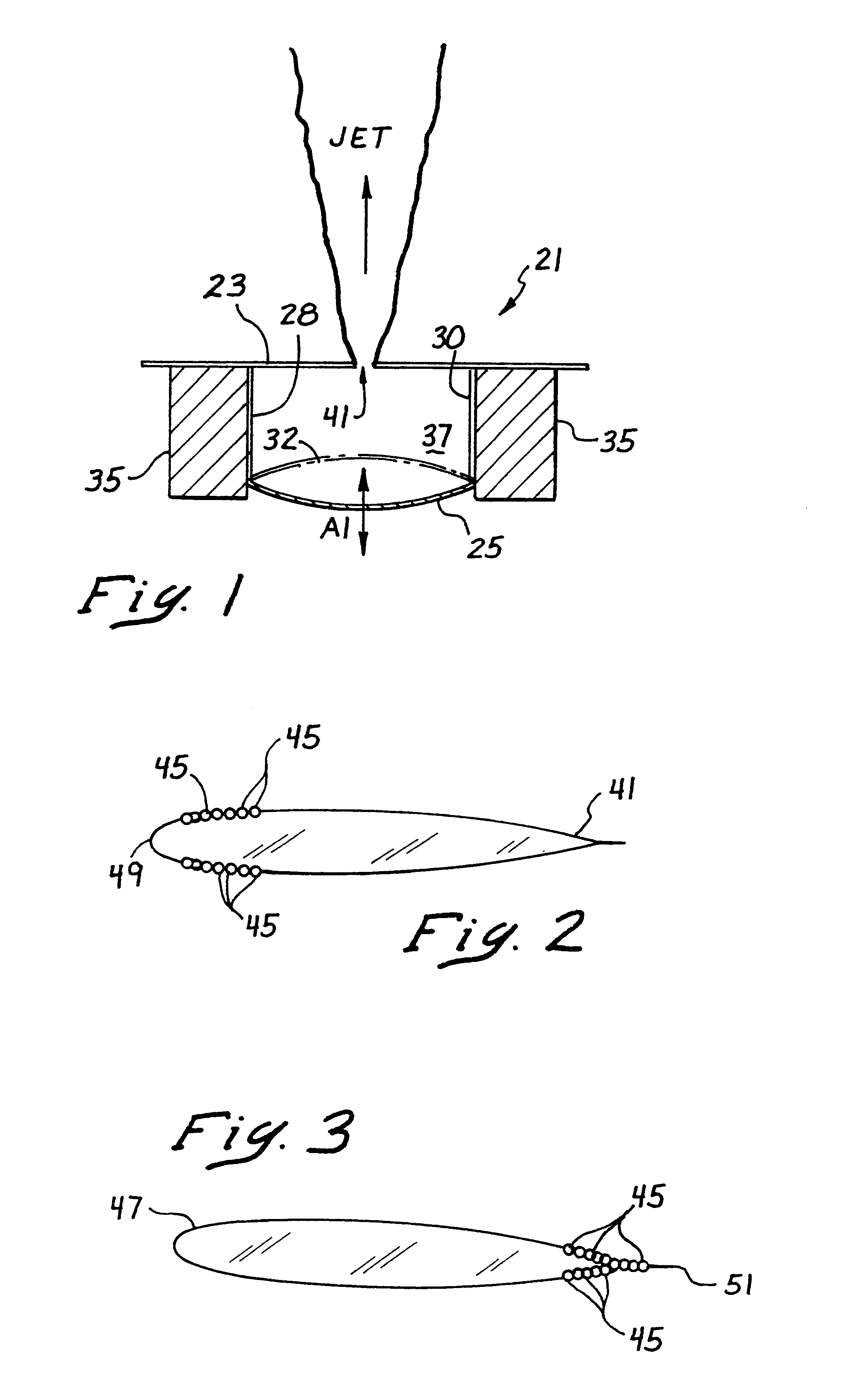

Oscillating air jets for reducing HSI noise

Porous surfaces on an aerodynamic structure driven with positive and negative pressures are used in an active control system for attenuating shock waves responsible for high-speed impulsive (HSI) noise. The control system includes an array of apertures in the outer skin of the structure providing fluid communication between the exterior flow stream and an interior volume of the structure. A movable diaphragm within the structure pushes air out of and pulls air in through the apertures under the action of a drive mechanism within the structure, thus creating oscillating air jets. The drive mechanism may be actuated by a controller based on information supplied by a sensor in the leading edge of the aerodynamic structure. The array of apertures may be spaced apart along the outer skin of the aerodynamic structure so as to span a distance of about 15% of the chord length. The oscillating airjets may be provided on multiple surfaces of the aerodynamic structure, including the upper and lower surfaces.

Owner:MCDONNELL DOUGLAS

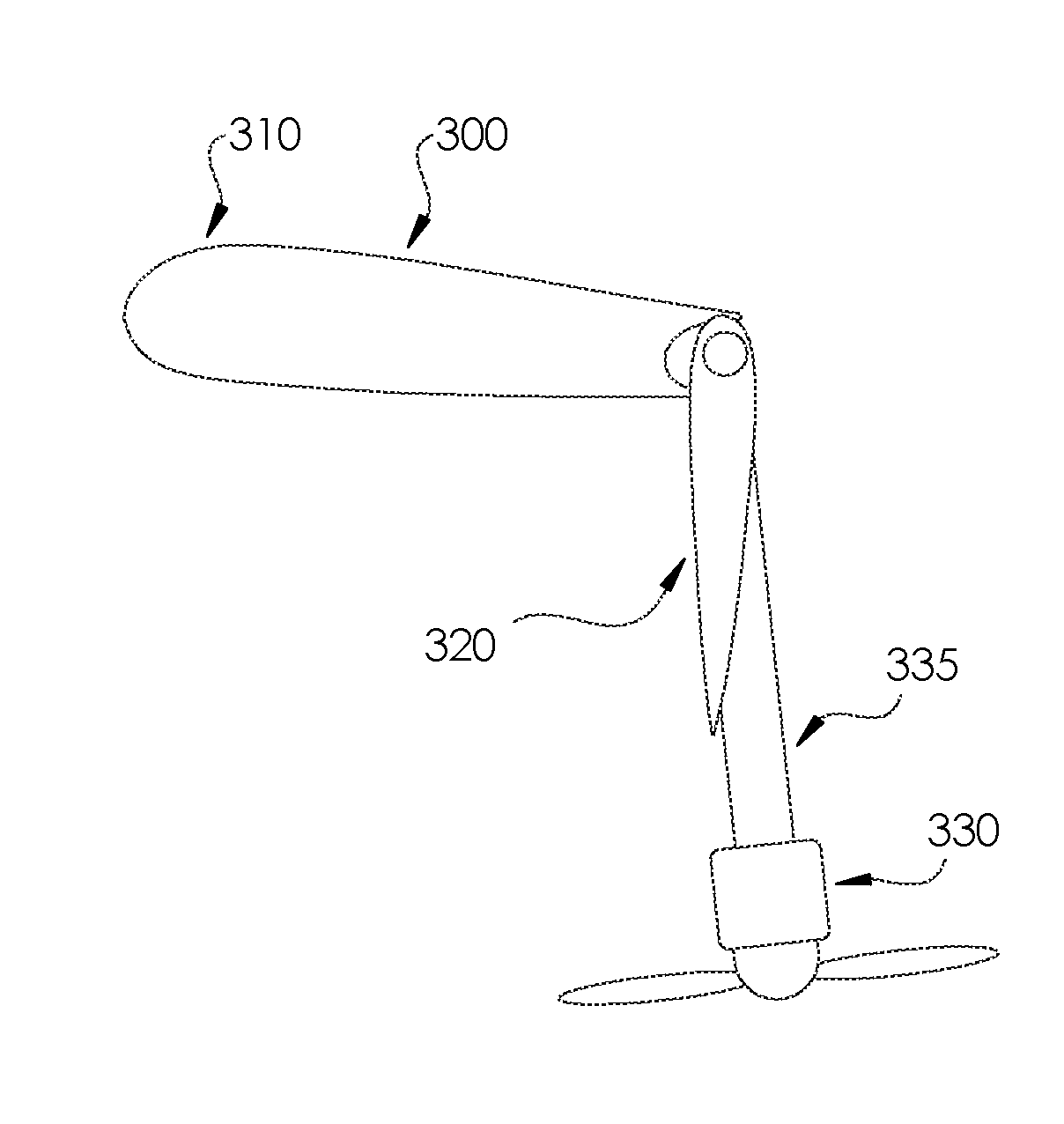

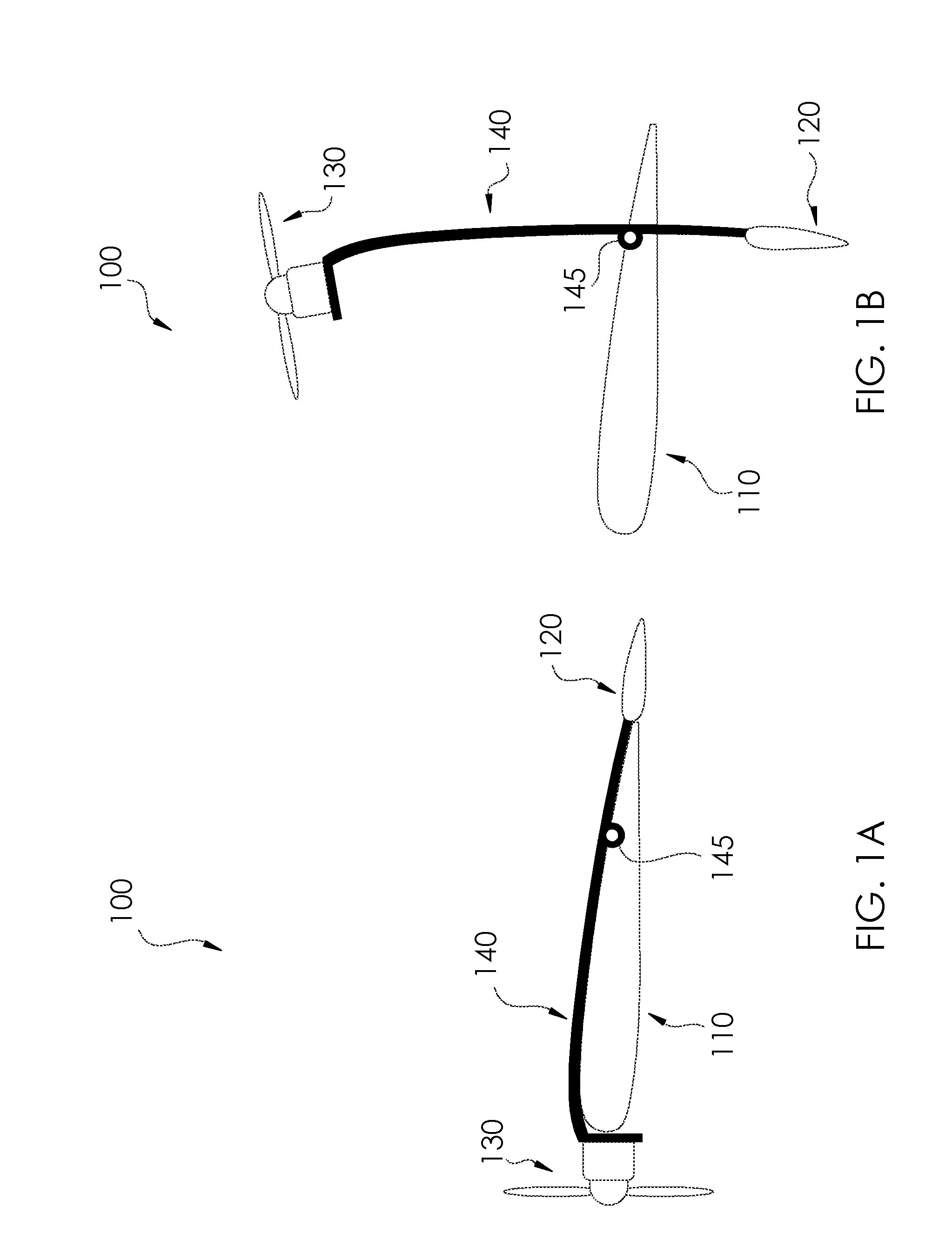

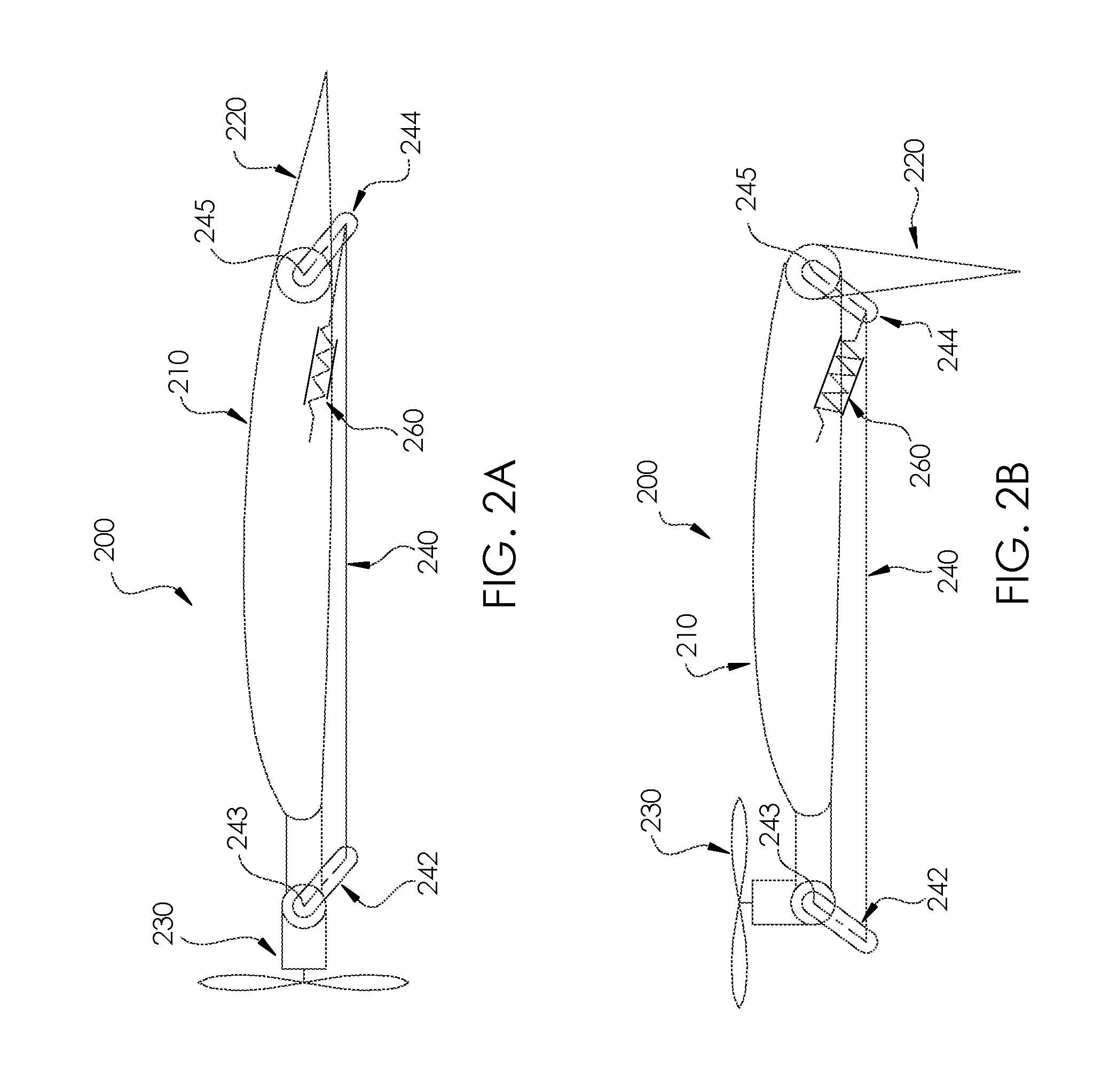

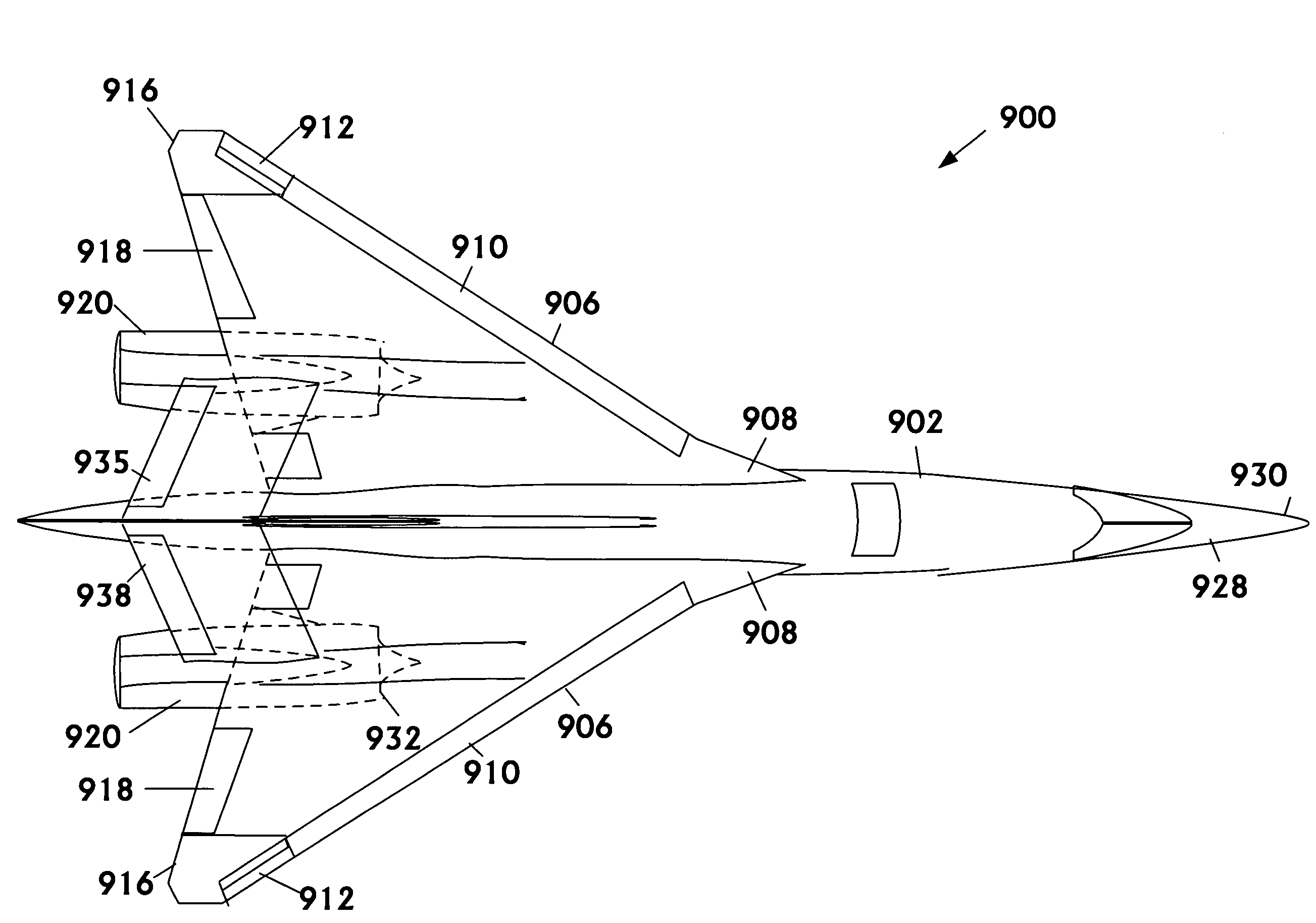

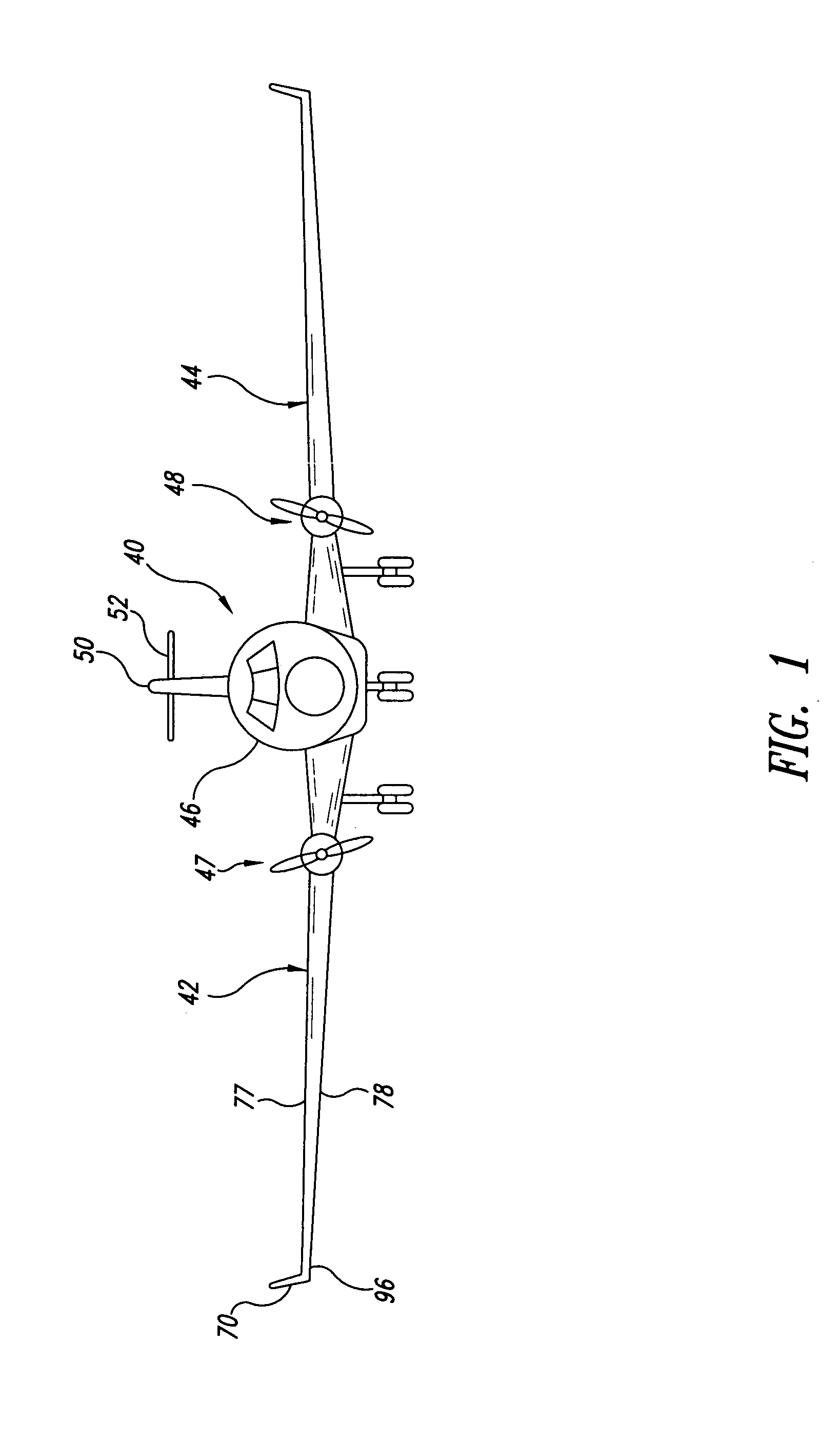

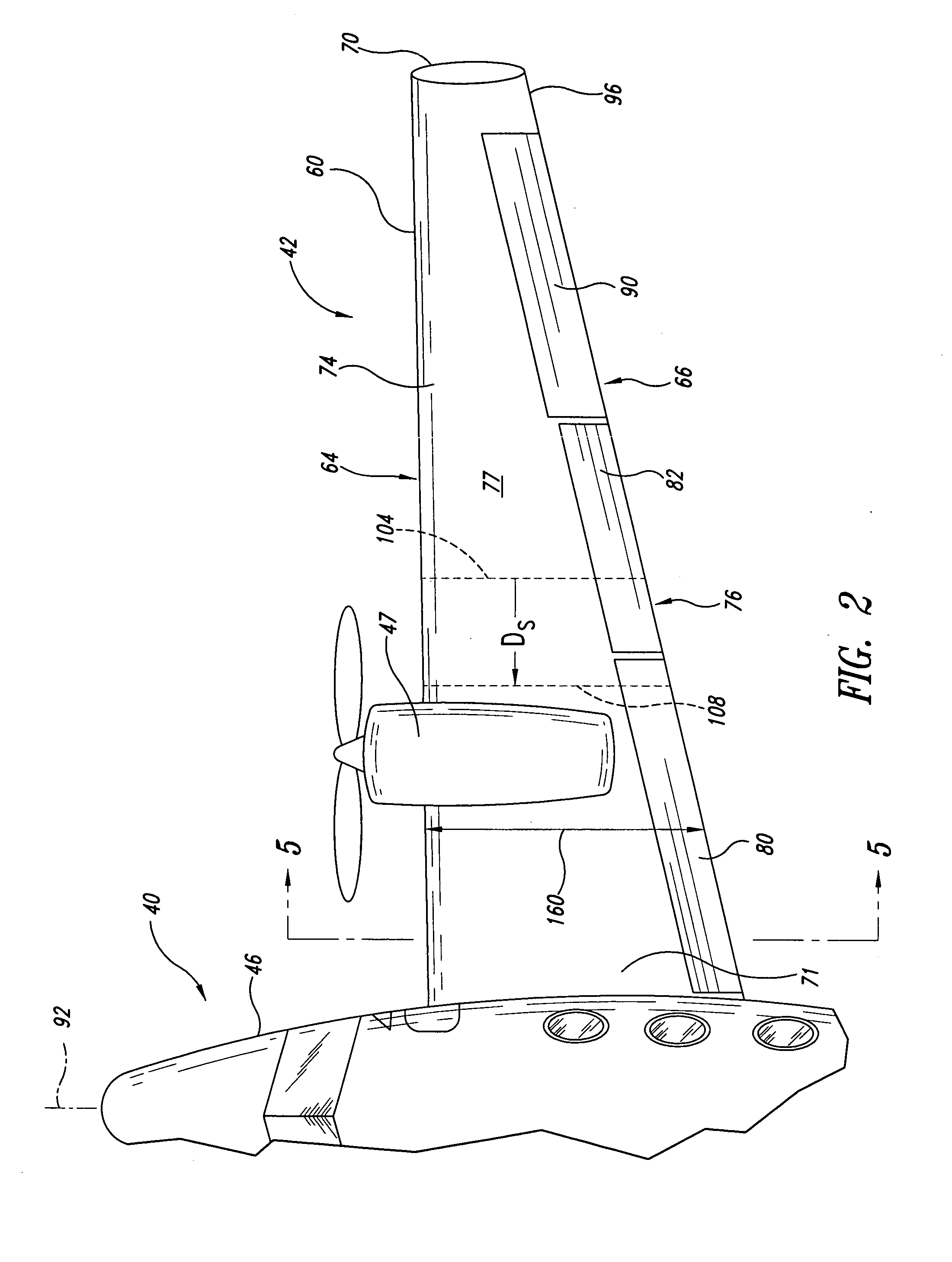

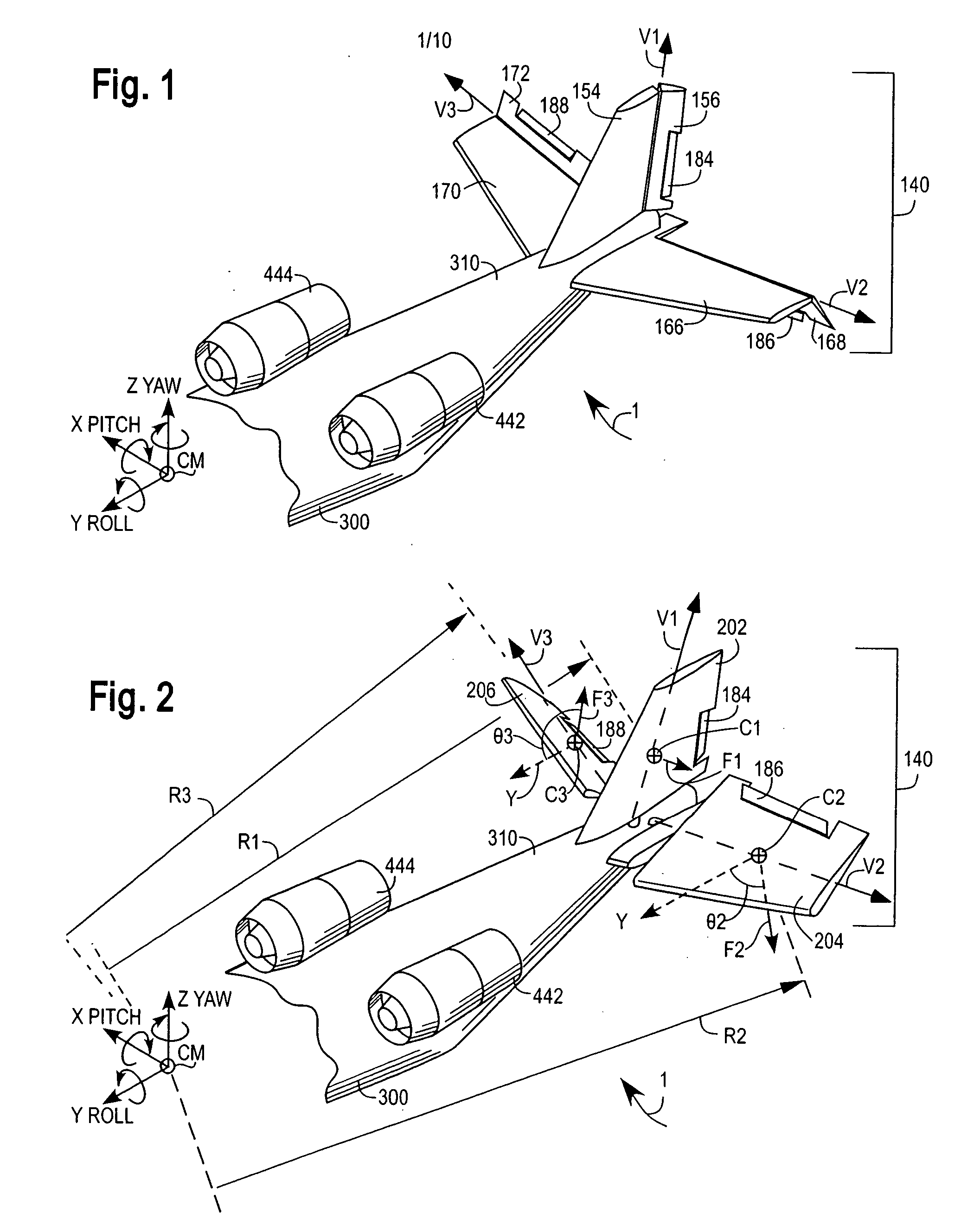

Aerodynamically Actuated Thrust Vectoring Devices

A vehicle includes a wing and a control surface pivotably coupled to the wing and configured to pivot about a range of motion. A propulsor is coupled to the control surface and configured to rotate between a first position associated with a hover flight mode and a second position associated with a forward flight mode. The propulsor is aerodynamically actuated between the first position and the second position due to aerodynamics about the wing. The propulsor may rotate from an initial flight mode, such as a takeoff mode, to a second flight mode, such as a forward flight mode.

Owner:NASA

Rotor system with pitch flap coupling

An articulated rotor system with a servo-flap rotor control system locates the focal point of a blade retention spherical elastomeric bearing inboard of a joint in the servo-flap pitch control tube which separates the flap hinge and supports the servo-flap pitch control tube on a single pivot bearing within a blade retention spindle. Rotor blade flapping produces relative movements between the servo-flap pitch control tube and the blade retention spindle which is converted through a servo-flap drive linkage into servo-flap pitch motions to provide flap / pitch coupling which reduces steady and transient blade flapping.

Owner:SIKORSKY AIRCRAFT CORP

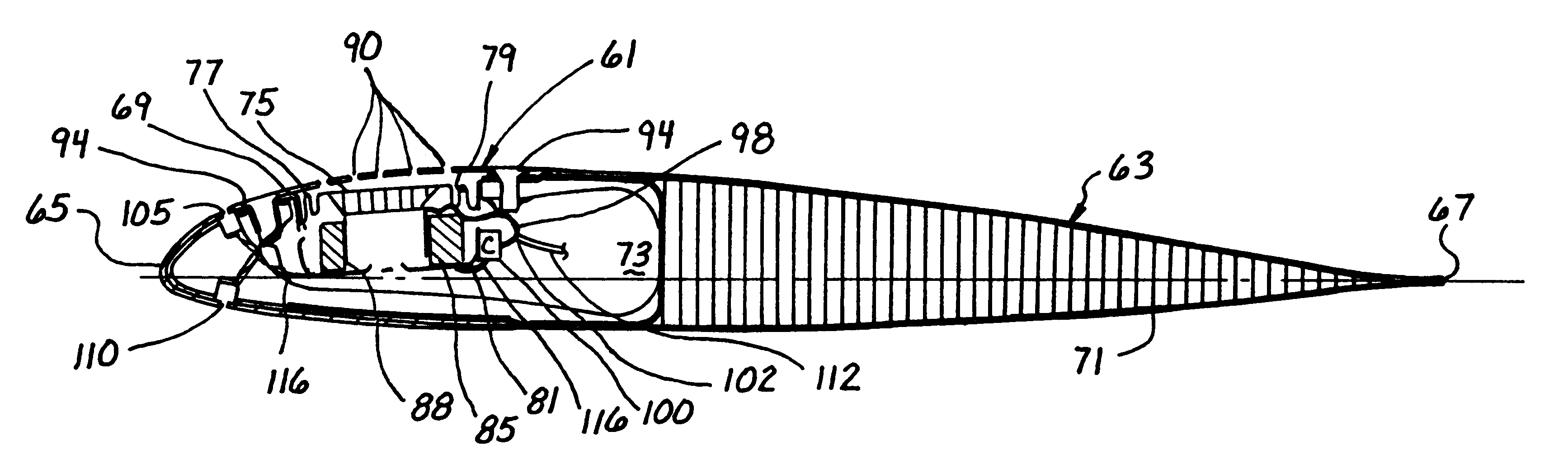

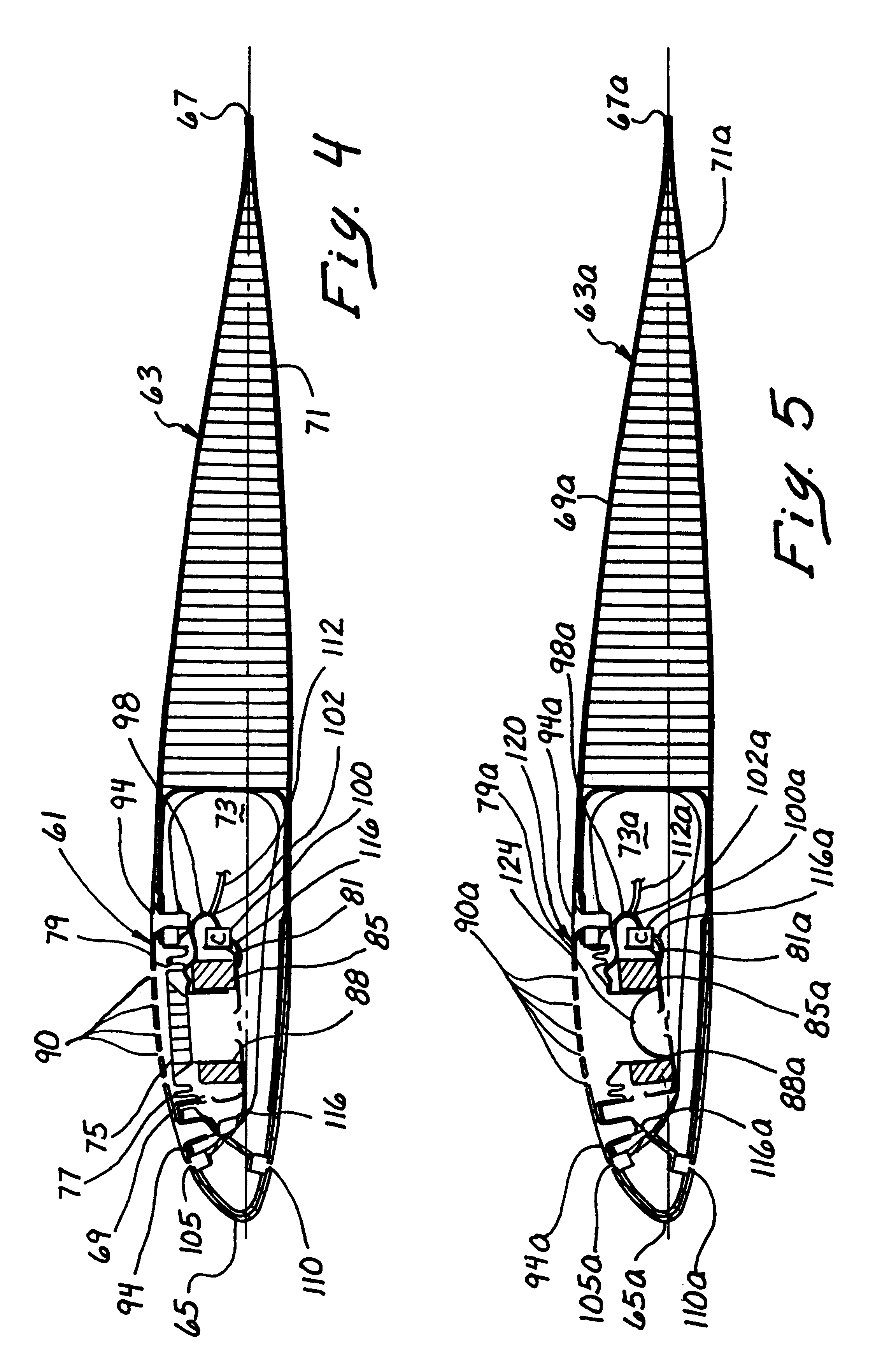

Oscillating air jets for implementing blade variable twist, enhancing engine and blade efficiency, and reducing drag, vibration, download and ir signature

A porous surface on an aircraft structure driven with oscillating positive and negative pressures is used as an active control device for attenuating negative aerodynamic interactions. The porous surfaces can be driven with positive and negative pressures either continuously or when predetermined flight conditions are present. The porous surfaces can be used on rotor blades to reduce BVI noise in descent flight conditions. The porous surfaces can be configured on rotor blades for affecting blade variable twist in accordance with various flight conditions, and can further be incorporated for reducing rotor hub vibrations as well. Porous surfaces placed on aerodynamic surfaces below the rotor blades of a tiltrotor aircraft can attenuate or eliminate download and fountain flow conditions. When placed on the trailing edges of a tip jet-exhaust driven rotor blade, the porous surfaces of the present invention can supplement the tip jet momentum of the exhaust to thereby reduce an amount of exhaust needed to drive the rotor blade.

Owner:MCDONNELL DOUGLAS

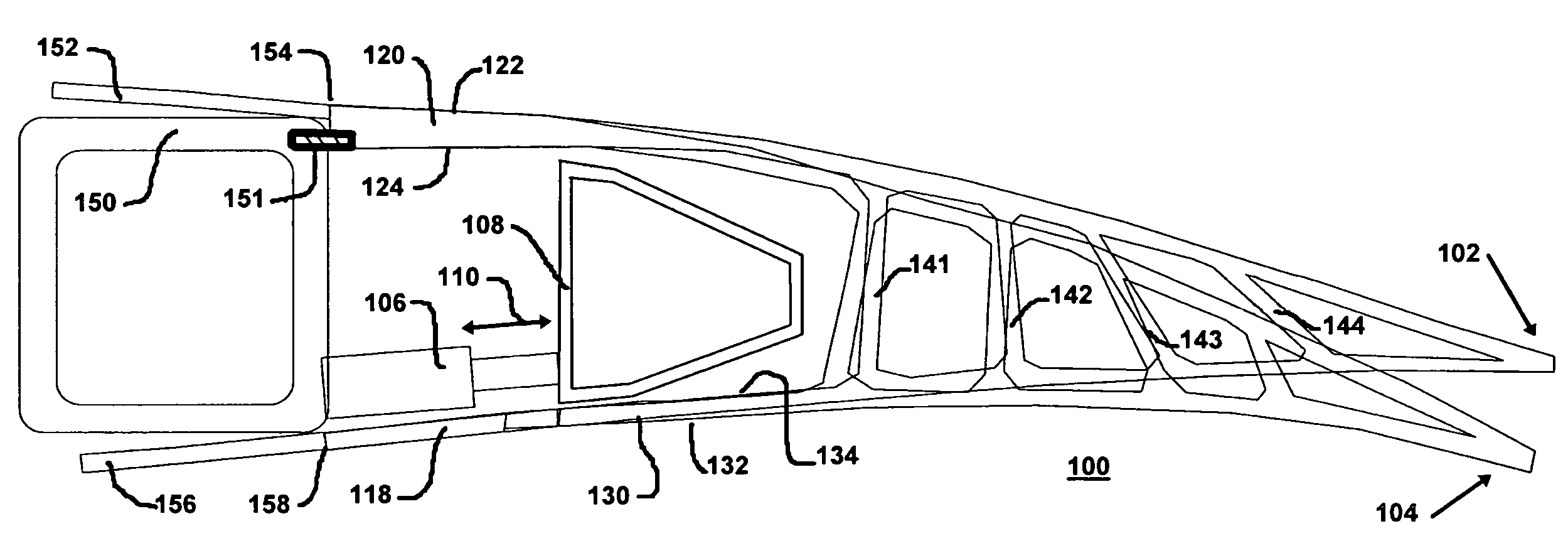

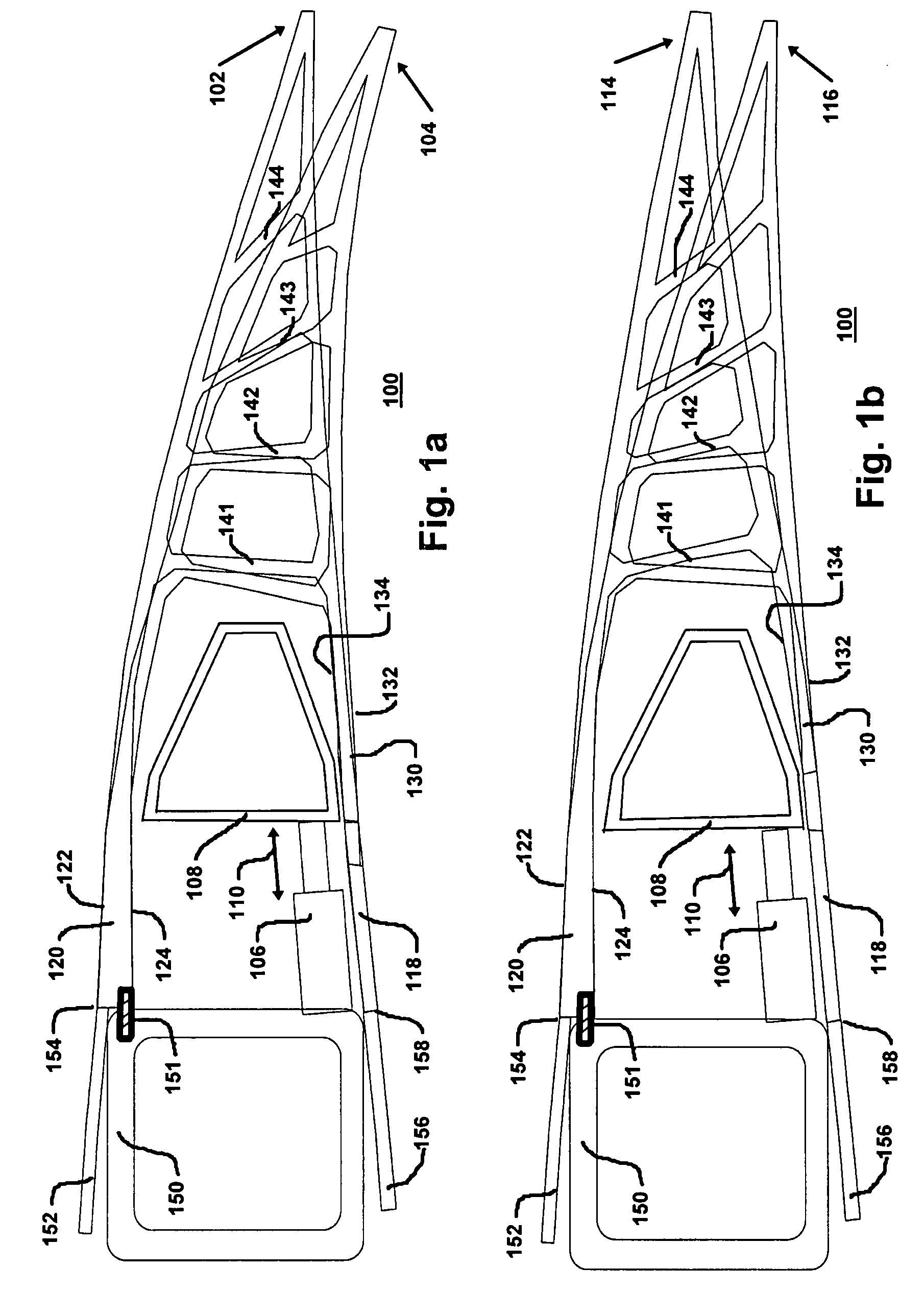

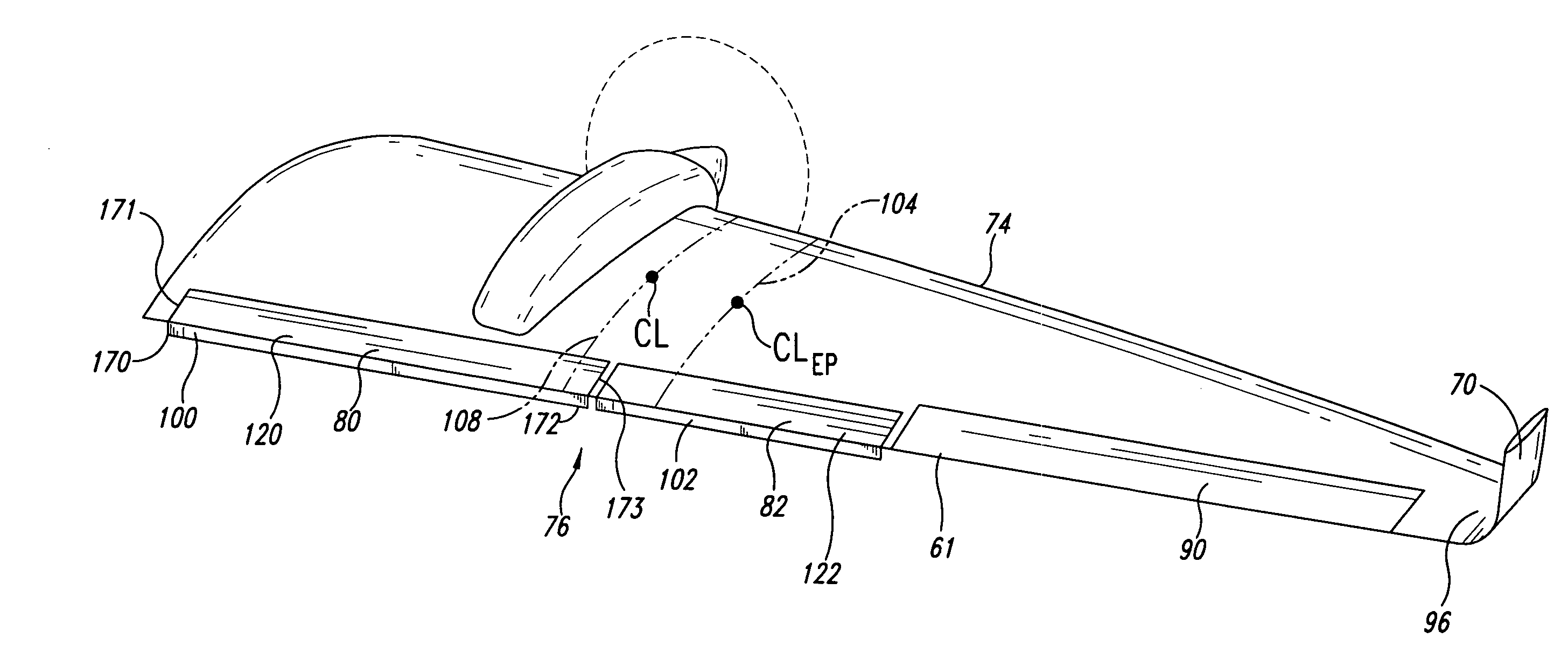

Adaptive compliant wing and rotor system

Variation in the contours of first and second compliant surfaces is produced by a compliant frame having a first resiliently variable frame element (120) having a corresponding first outer surface (122) and a first inner surface (124), and a second resiliently variable frame element (130) having a corresponding second outer surface (132) and a second inner surface (134). The first and second outer surfaces (122, 132) communicate with respective ones of the first and second compliant surfaces. A linkage element (141-144) having a predetermined resilience characteristic is coupled at a first end thereof to the first inner surface (124) and at a second end thereof to the second inner surface (134). A frame coupler (151) couples the first resiliently variable frame element (120) to a support element (150). An actuator (106) applies a force to the second resiliently variable frame element (130) with respect to the support element (150), resulting in a corresponding variation in the contour of the first and second compliant surfaces.

Owner:FLEXSYS

Airflow control devices based on active materials

An airflow control device comprises a body and an active material in operative communication with the body. The active material, such as shape memory material, is operative to change at least one attribute in response to an activation signal. The active material can change its shape, dimensions and / or stiffness producing a change in at least one feature of the airflow control device such as shape, dimension, location, orientation, and / or stiffness to control vehicle airflow to better suit changes in driving conditions such as weather, ground clearance and speed, while reducing maintenance and the level of failure modes. As such, the device reduces vehicle damage due to inadequate ground clearance, while increasing vehicle stability and fuel economy. An activation device, controller and sensors may be employed to further control the change in at least one feature of the airflow control device such as shape, dimension, location, orientation, and / or stiffness of the device. A method for controlling vehicle airflow selectively introduces an activation signal to initiate a change of at least one feature of the device that can be reversed upon discontinuation of the activation signal.

Owner:GM GLOBAL TECH OPERATIONS LLC

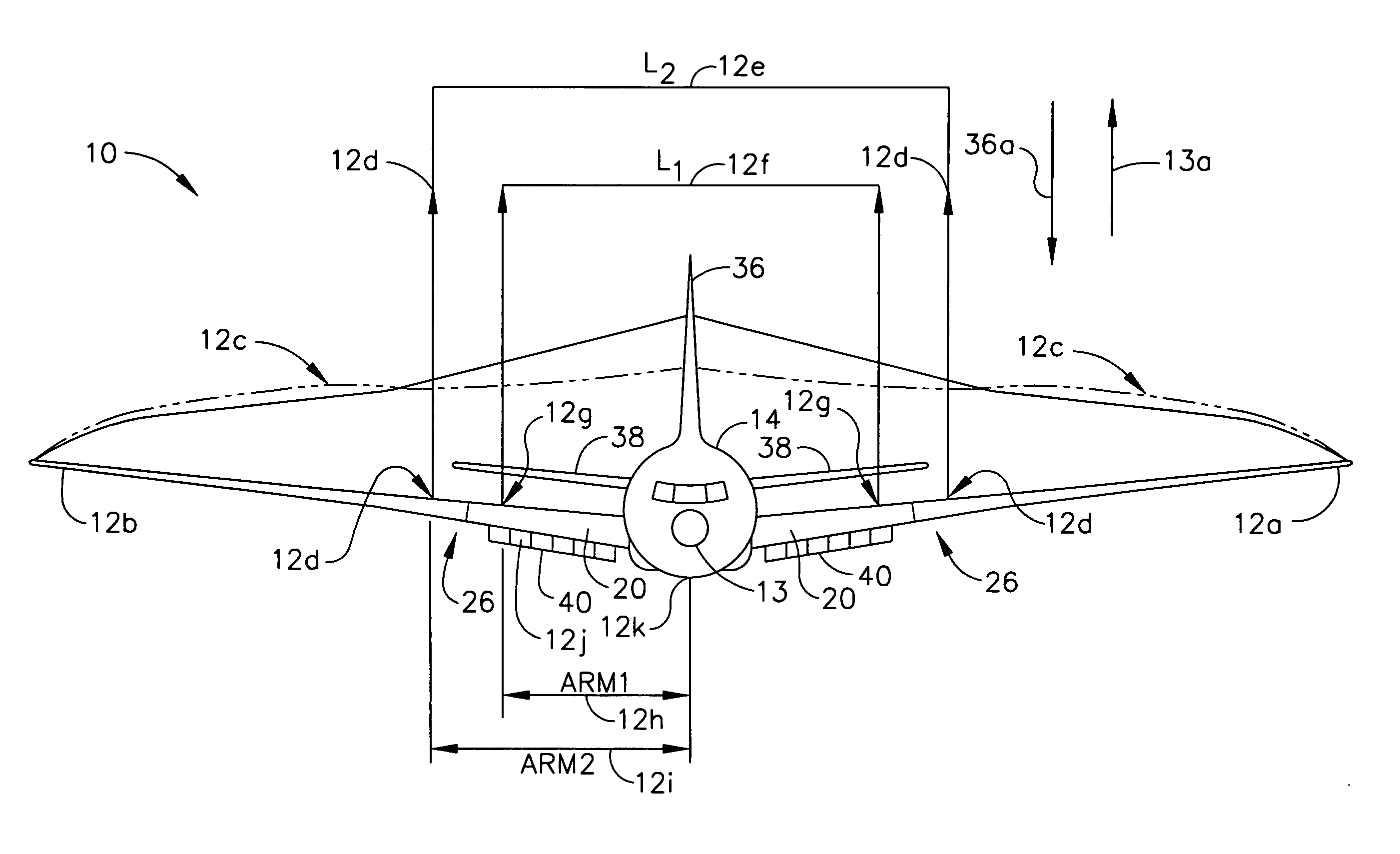

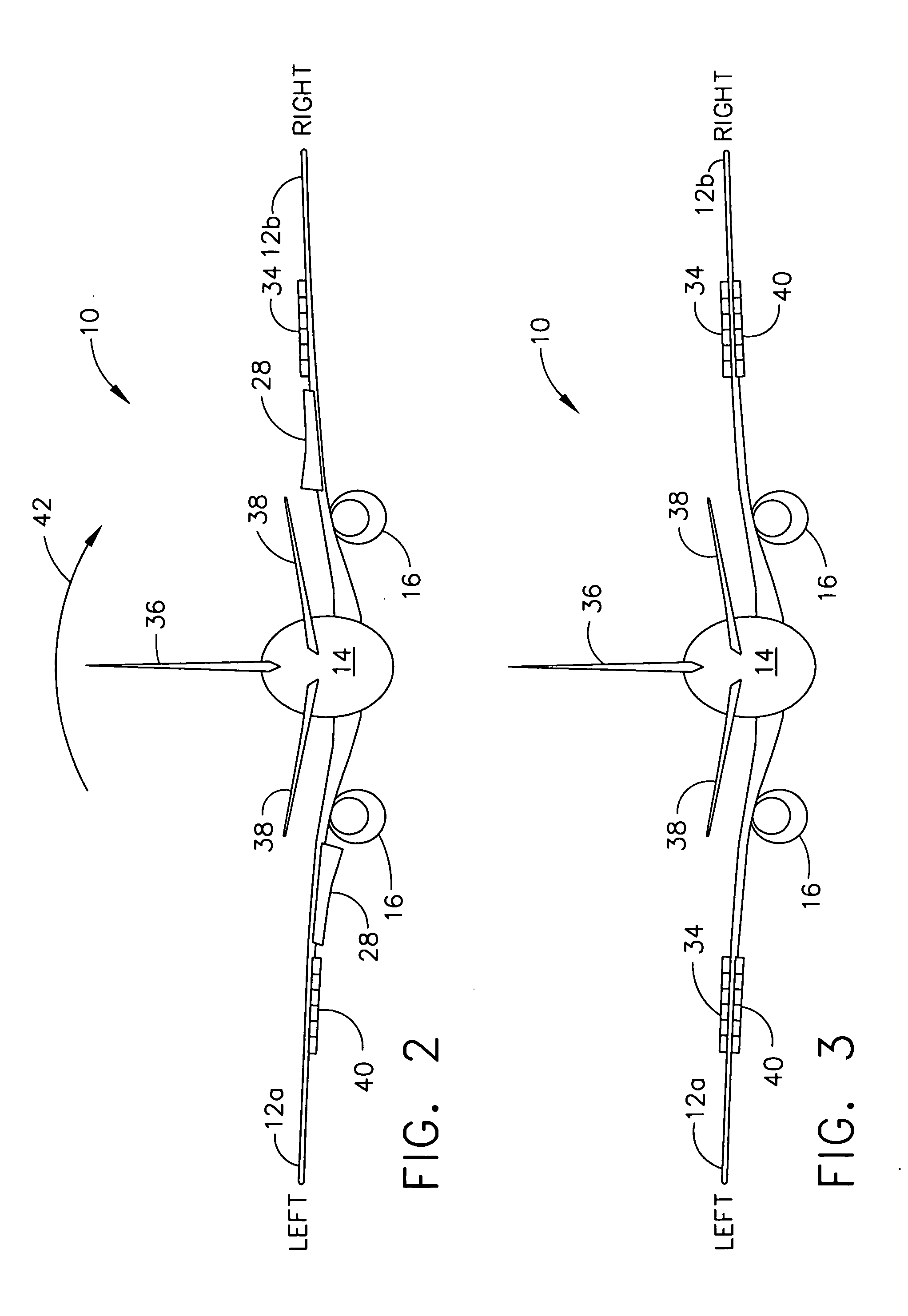

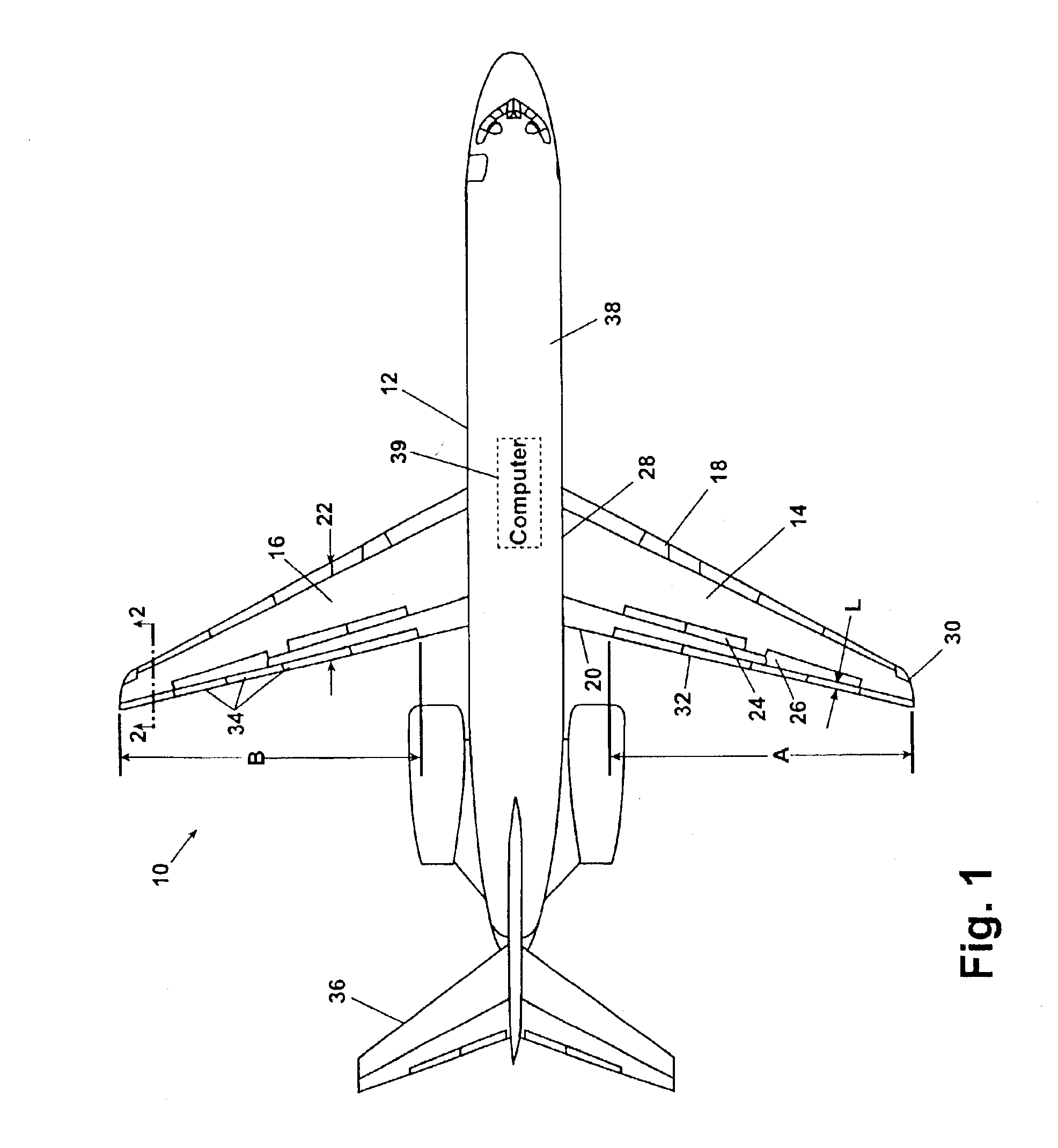

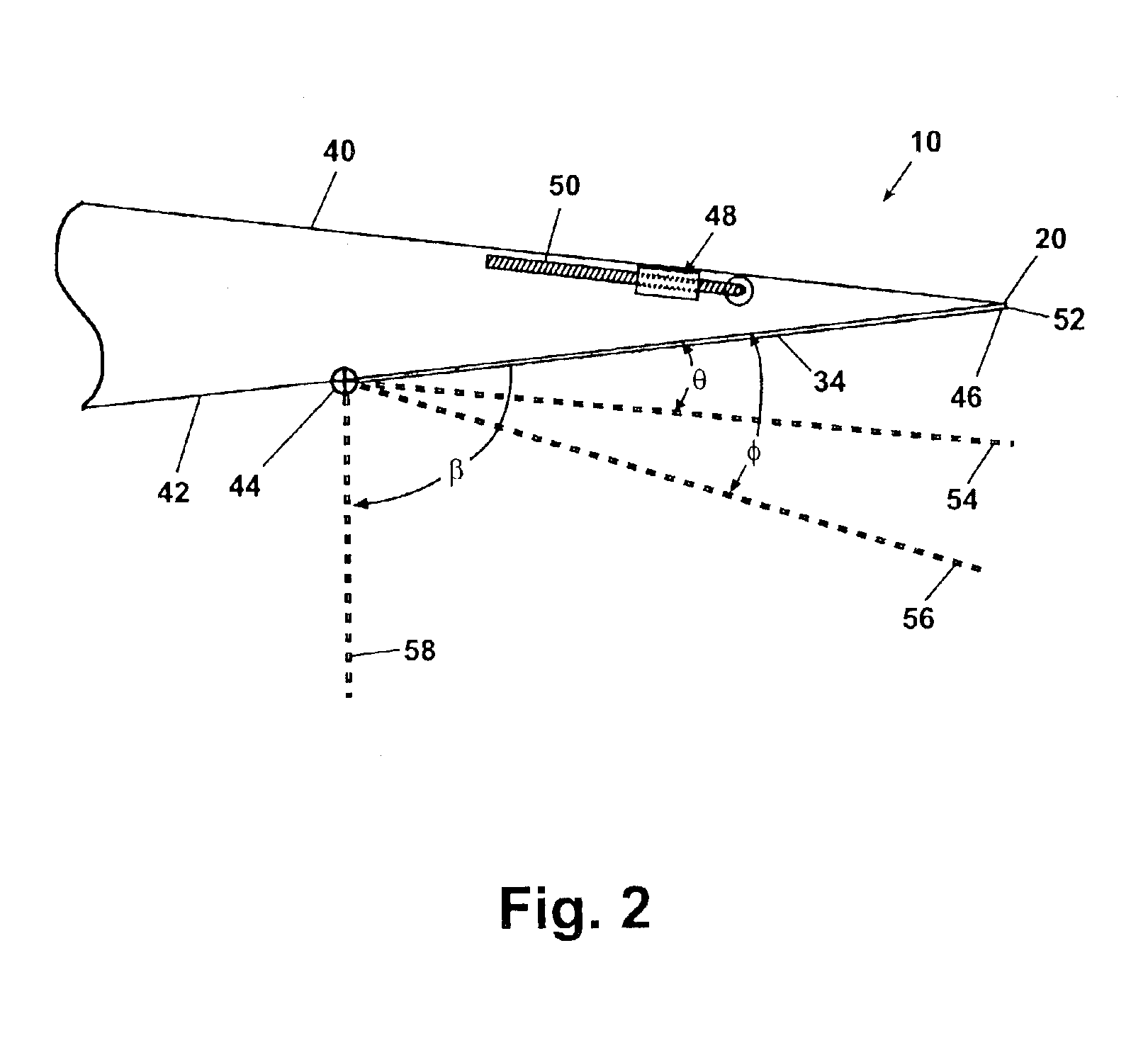

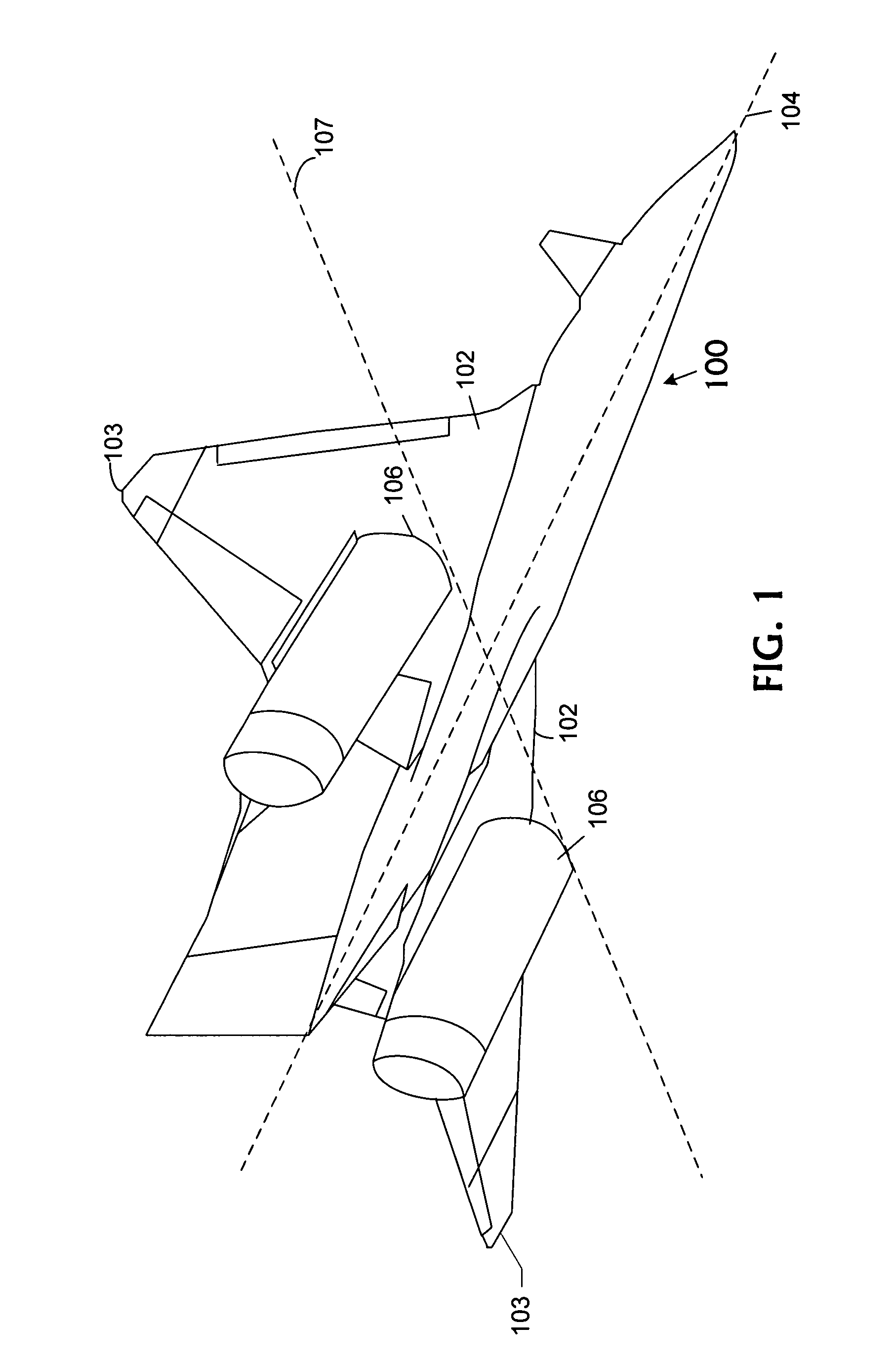

Lifters, methods of flight control and maneuver load alleviation

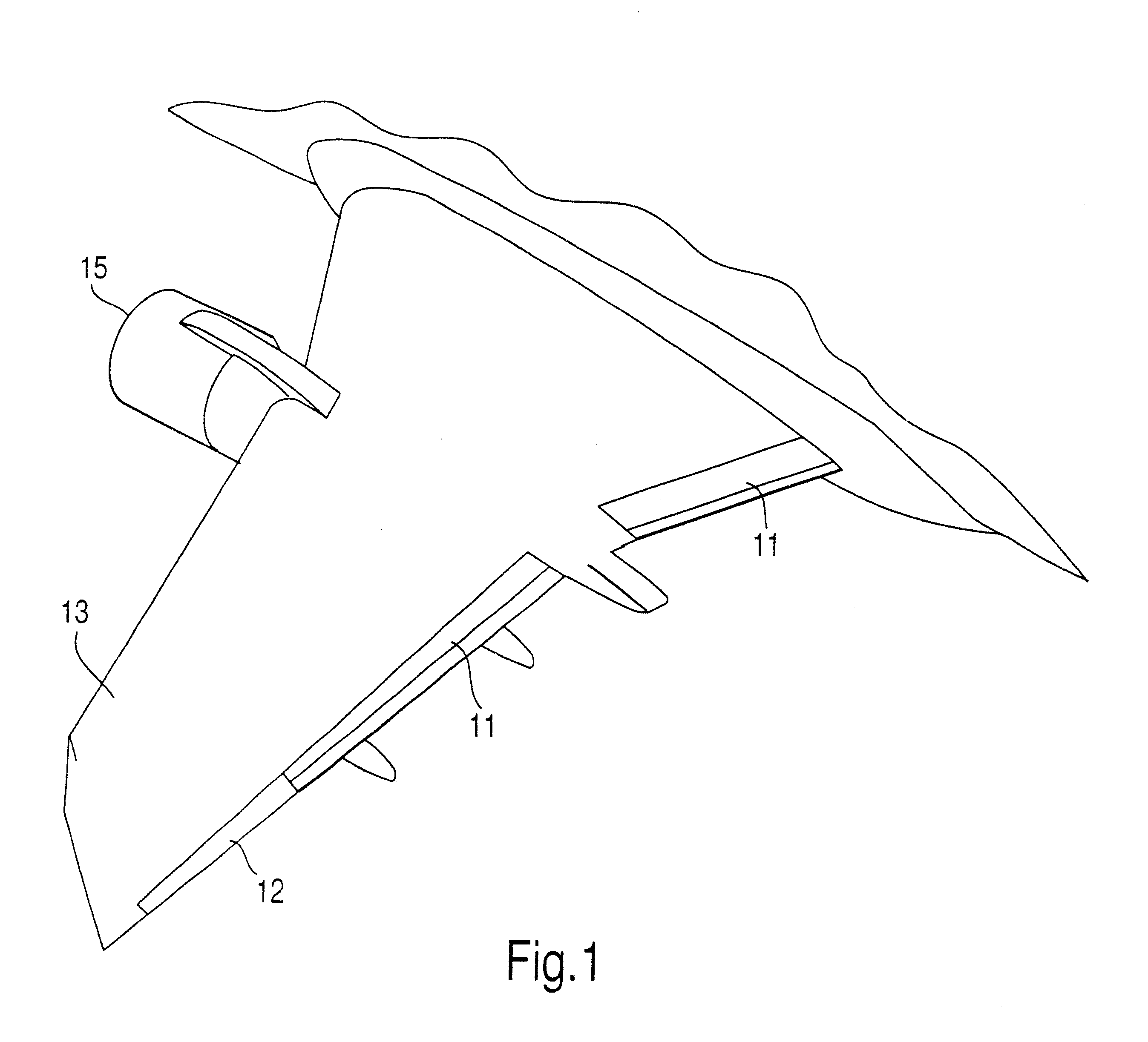

InactiveUS20050242234A1Shorten speedWith power amplificationAir braking surfacesSupersonic speedAirplane

The present invention provides a flight control system and method for various models of aircraft, including thin-winged, long range, transonic and low supersonic aircraft, and may be beneficial on supersonic and hypersonic aircraft as well. One embodiment of the flight control system comprises a plurality of lifters for generating lift or drag, the plurality of lifters mechanically associated with a lower surface of each wing in a pair of wings. During operation, the lifters may be selectively deployed alone or in combination with other flight control devices, such as ailerons and spoilers, to provide various operative benefits such as improved roll control, speed braking functionality, and maneuver load alleviation.

Owner:THE BOEING CO

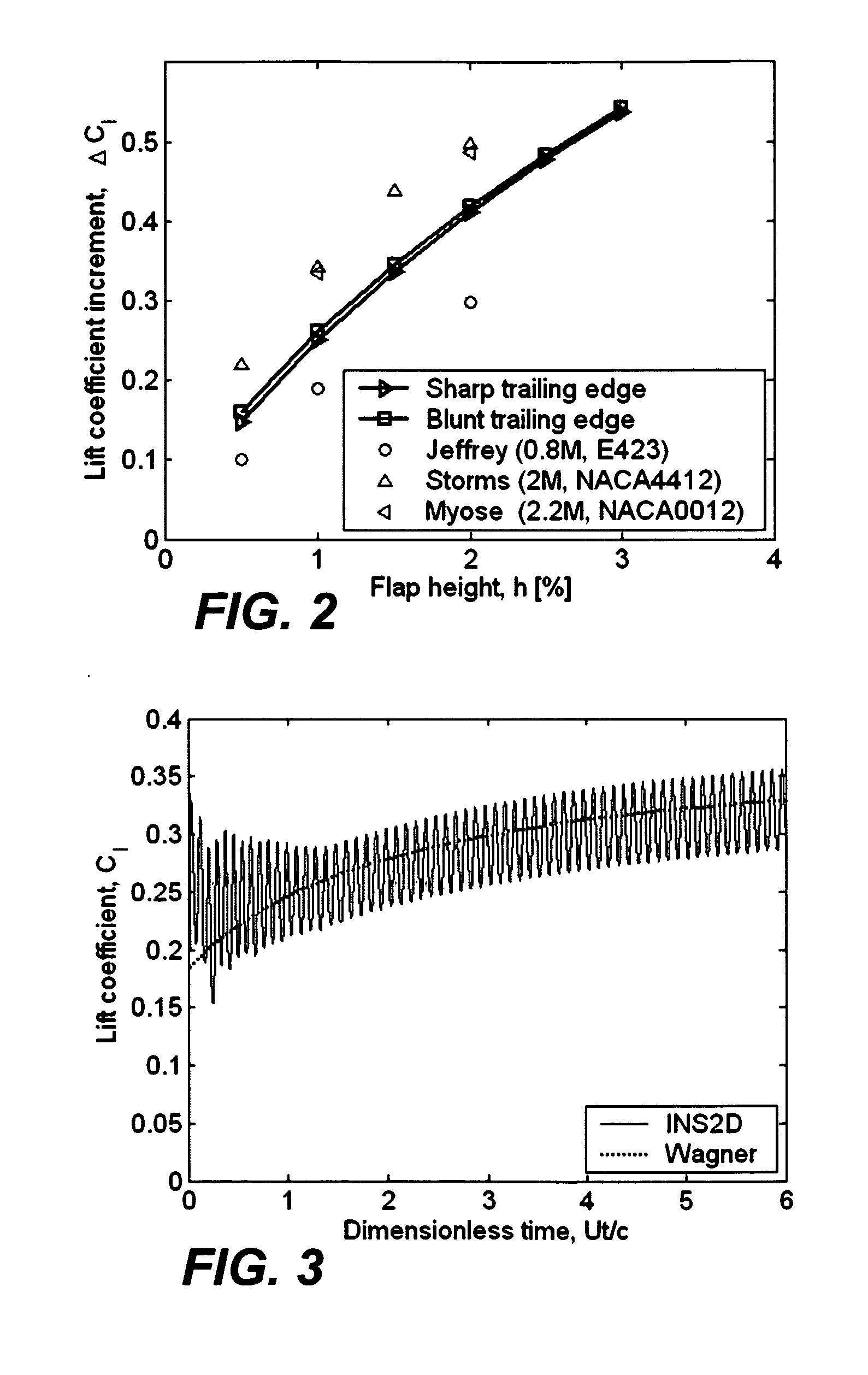

Variable trailing edge geometry and spanload control

A mobile platform lift increasing system includes at least one wing-shaped structure having a leading edge, a trailing edge and a chord length perpendicularly measurable between the leading and trailing edges. A rotatable control surface is located near a trailing edge undersurface. The control surface length is approximately one to five percent of the chord length. A deployment device is positioned between the wing shaped structure and the control surface. The deployment device operably rotates the control surface through a plurality of positions ranging between an initial position and a fully deployed position. Wing lift is increased at speeds up to approximately transonic speed by continuously rotating the control surface to accommodate variables including mobile platform weight change from fuel usage.

Owner:THE BOEING CO

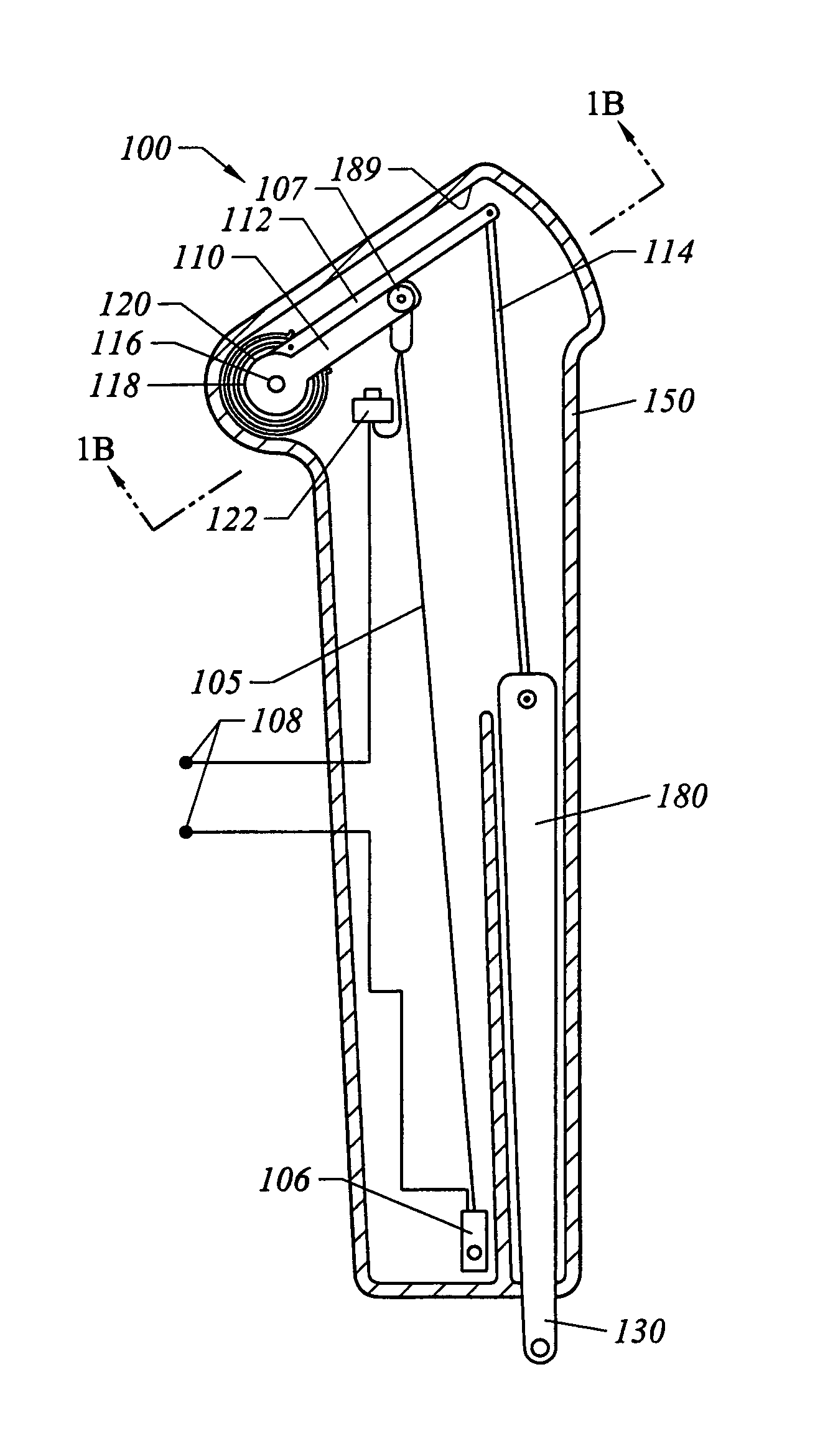

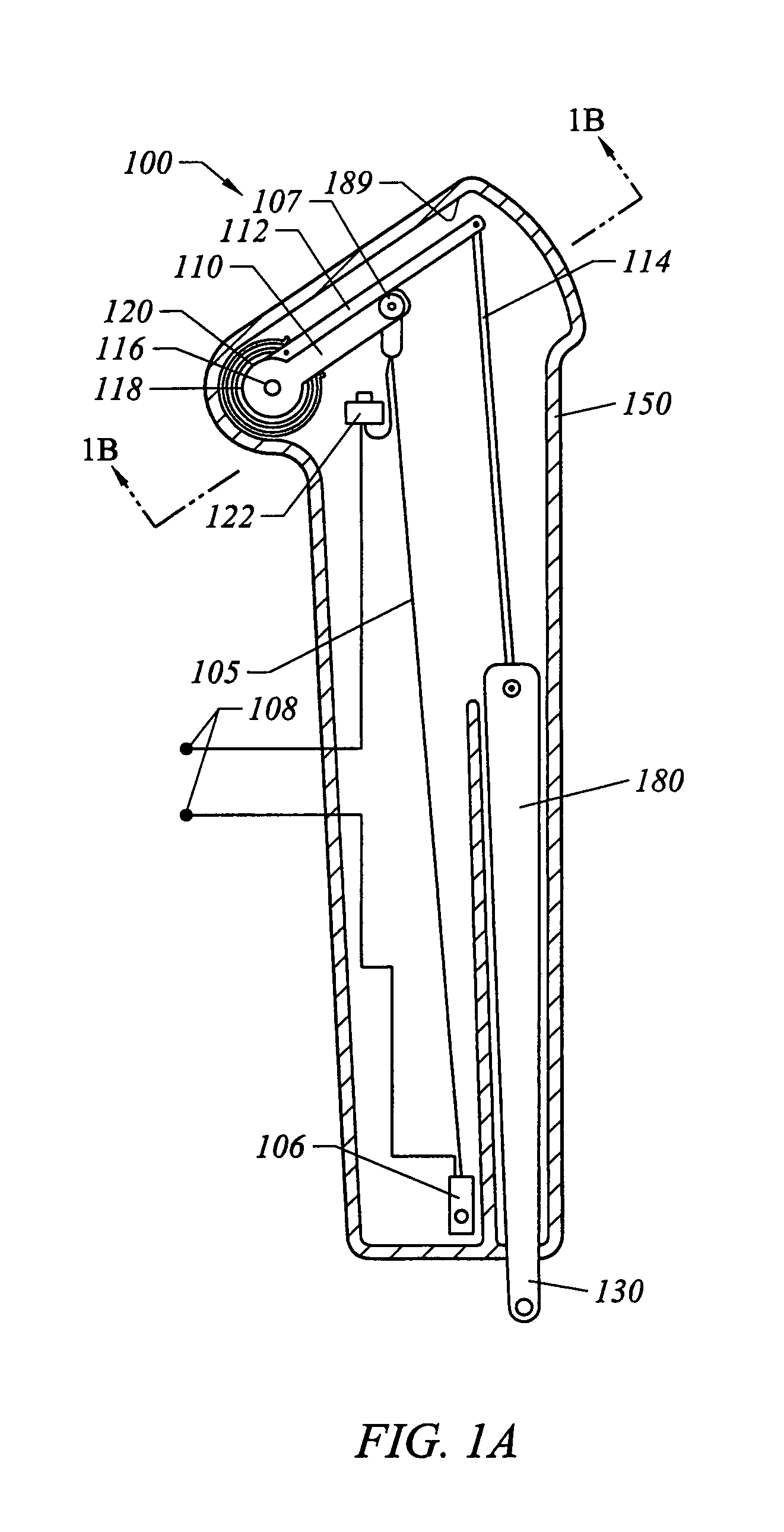

High stroke, highly integrated SMA actuators

InactiveUS7017345B2Avoid damageWing lift eficiencyMechanical power devicesControl theorySma actuator

A shape memory alloy (SMA) actuator assembly is provided that includes an SMA component. The SMA component is used to impart motion in an output shaft. Also provided is a return force component that provides a variable, tailored return force to the SMA component. Additionally, a variety of protective mechanisms are disclosed and utilized to prevent damage to the internal workings and components within the SMA actuator assembly as well as provide protection and safety for external workings.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN

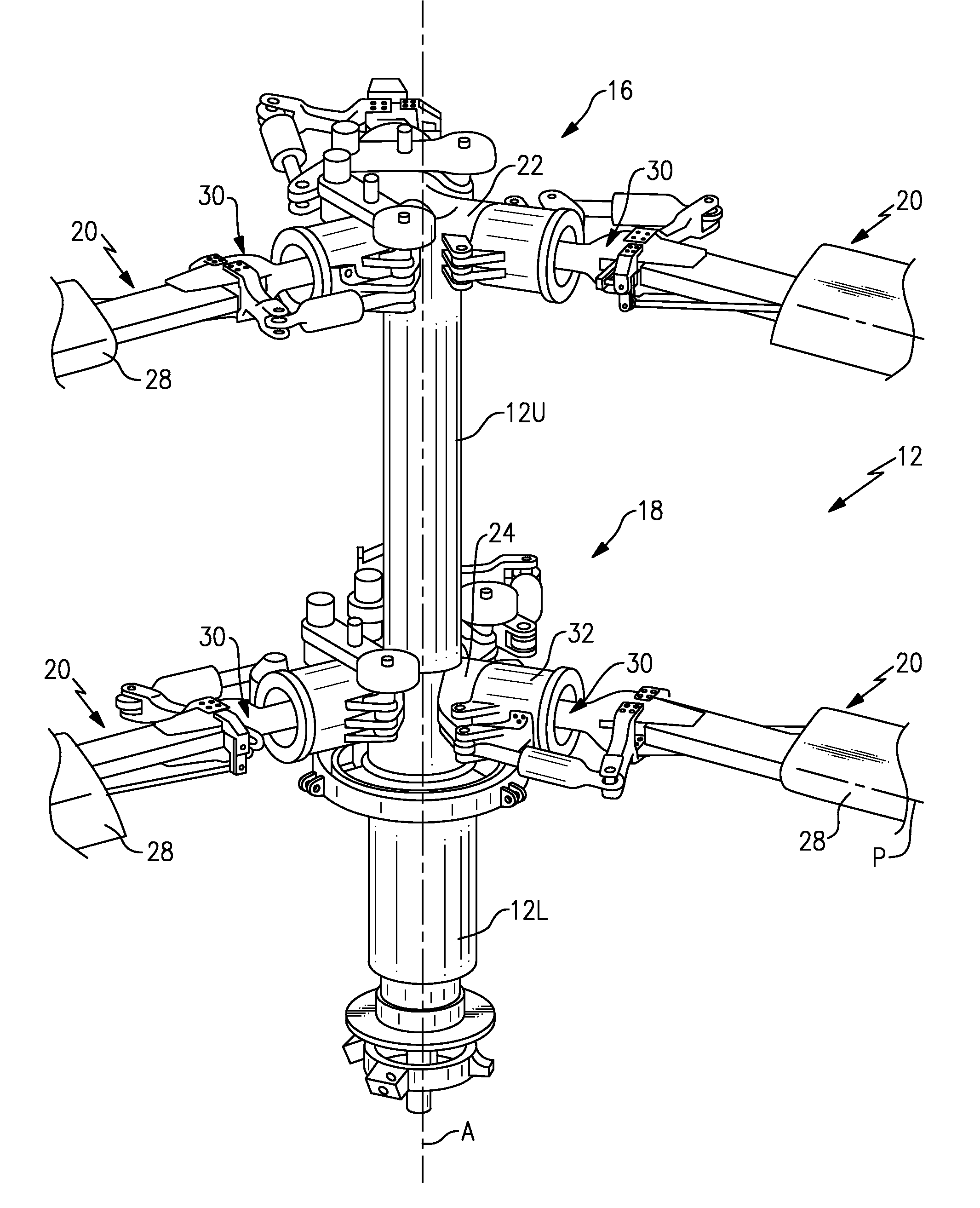

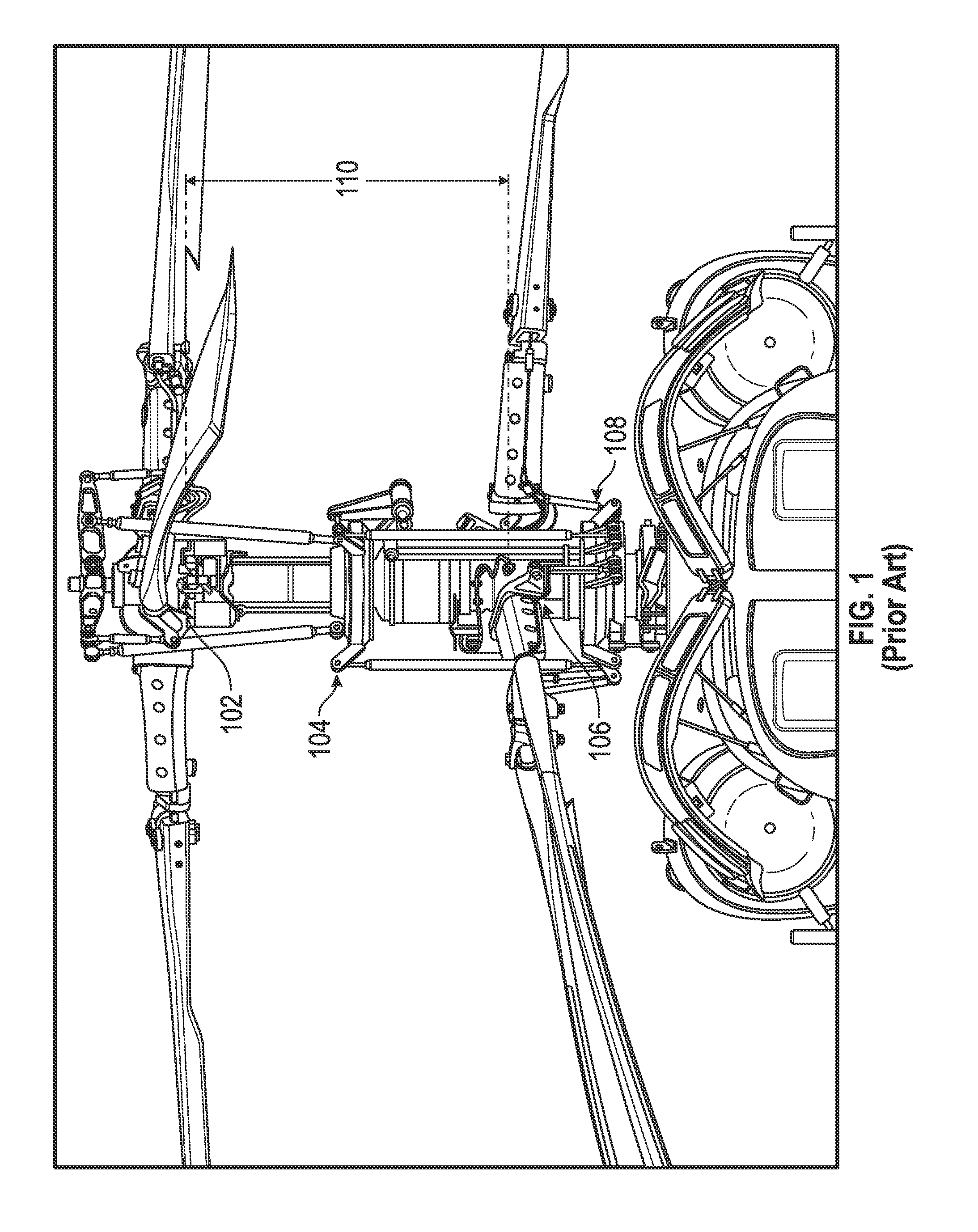

Compact co-axial rotor system for a rotary wing aircraft and a control system thereof

ActiveUS7083142B2Easy to separateReduce the overall heightPropellersPump componentsTip positionControl system

A dual, counter rotating, coaxial rotor system provides an upper and lower rotor system, with a reduced axial rotor separation distance along a common axis by way of rotor tip position sensing and rotor position controls to avoid tip contact.

Owner:SIKORSKY AIRCRAFT CORP

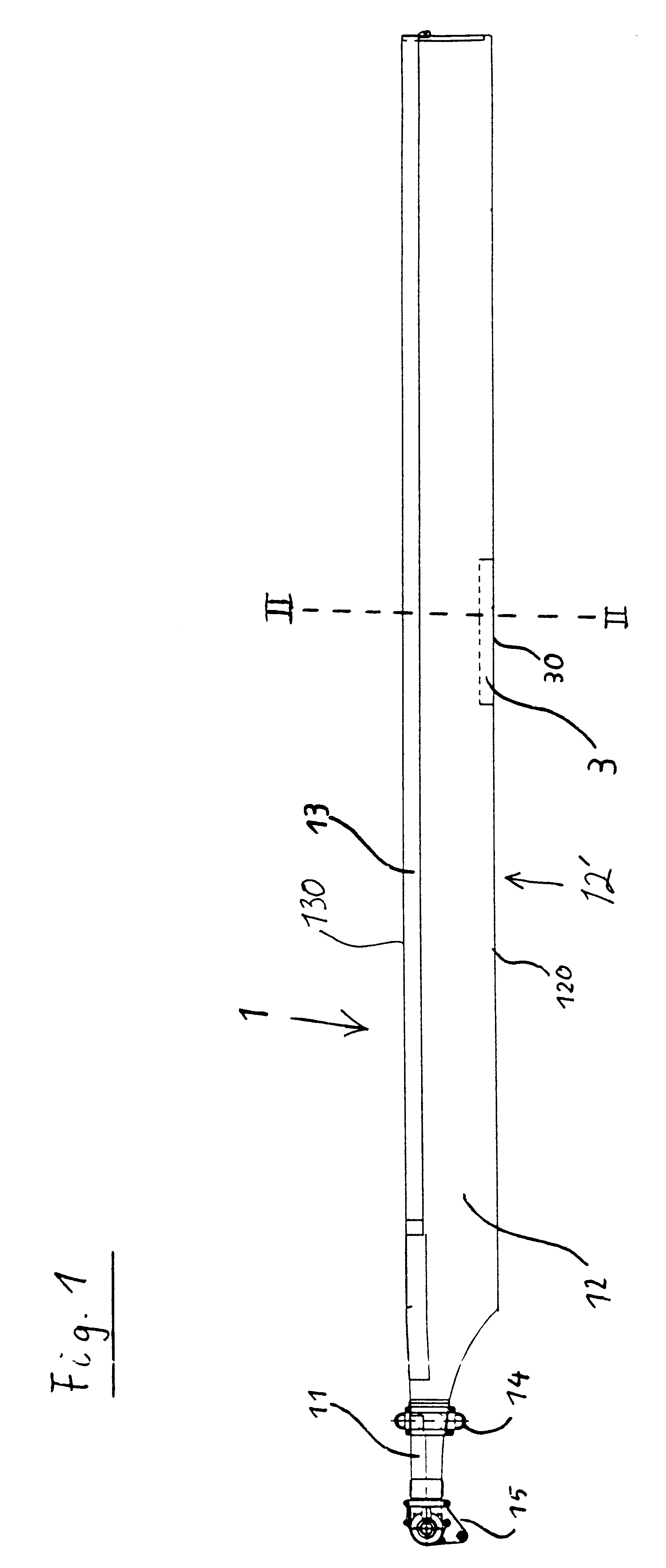

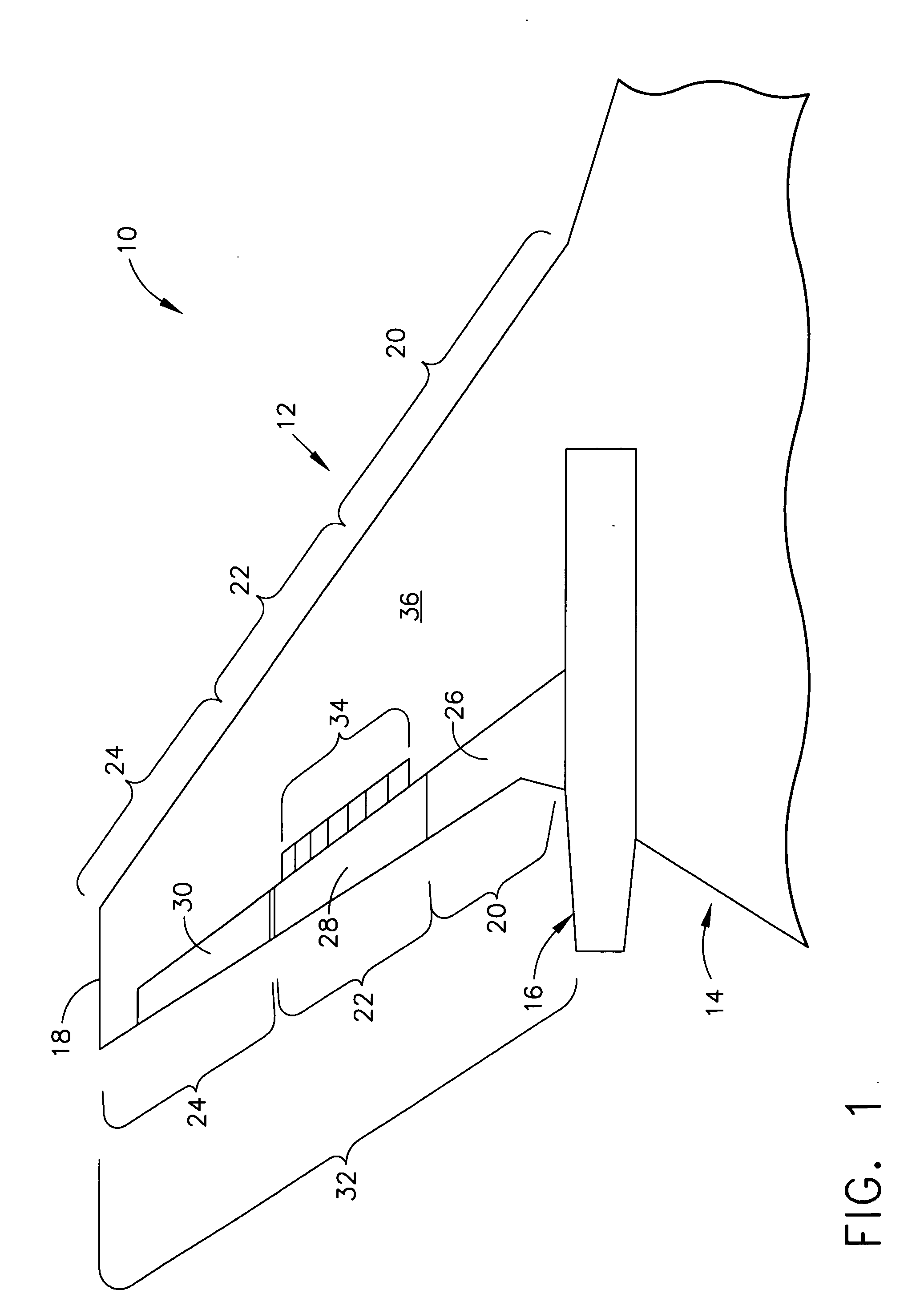

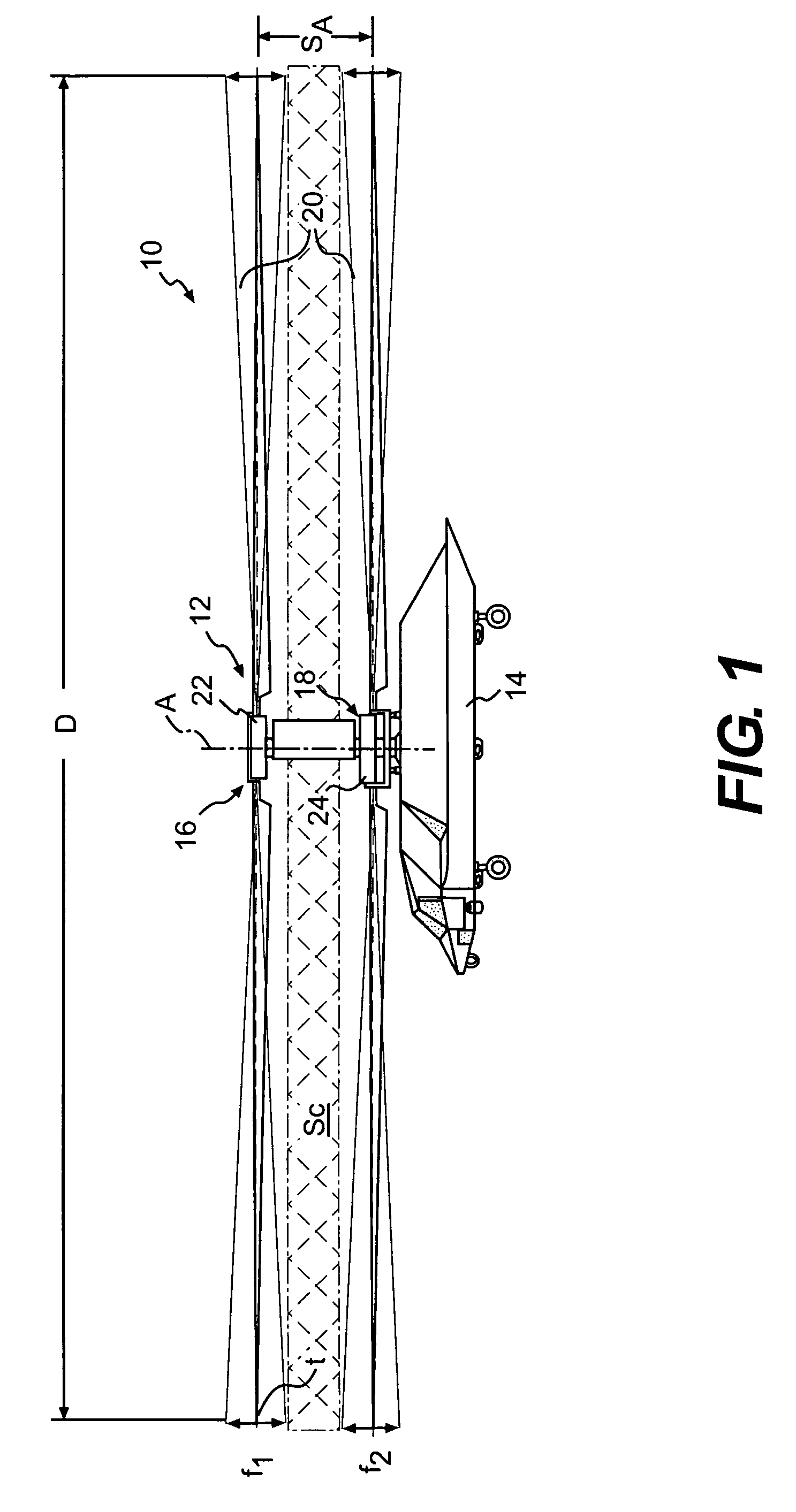

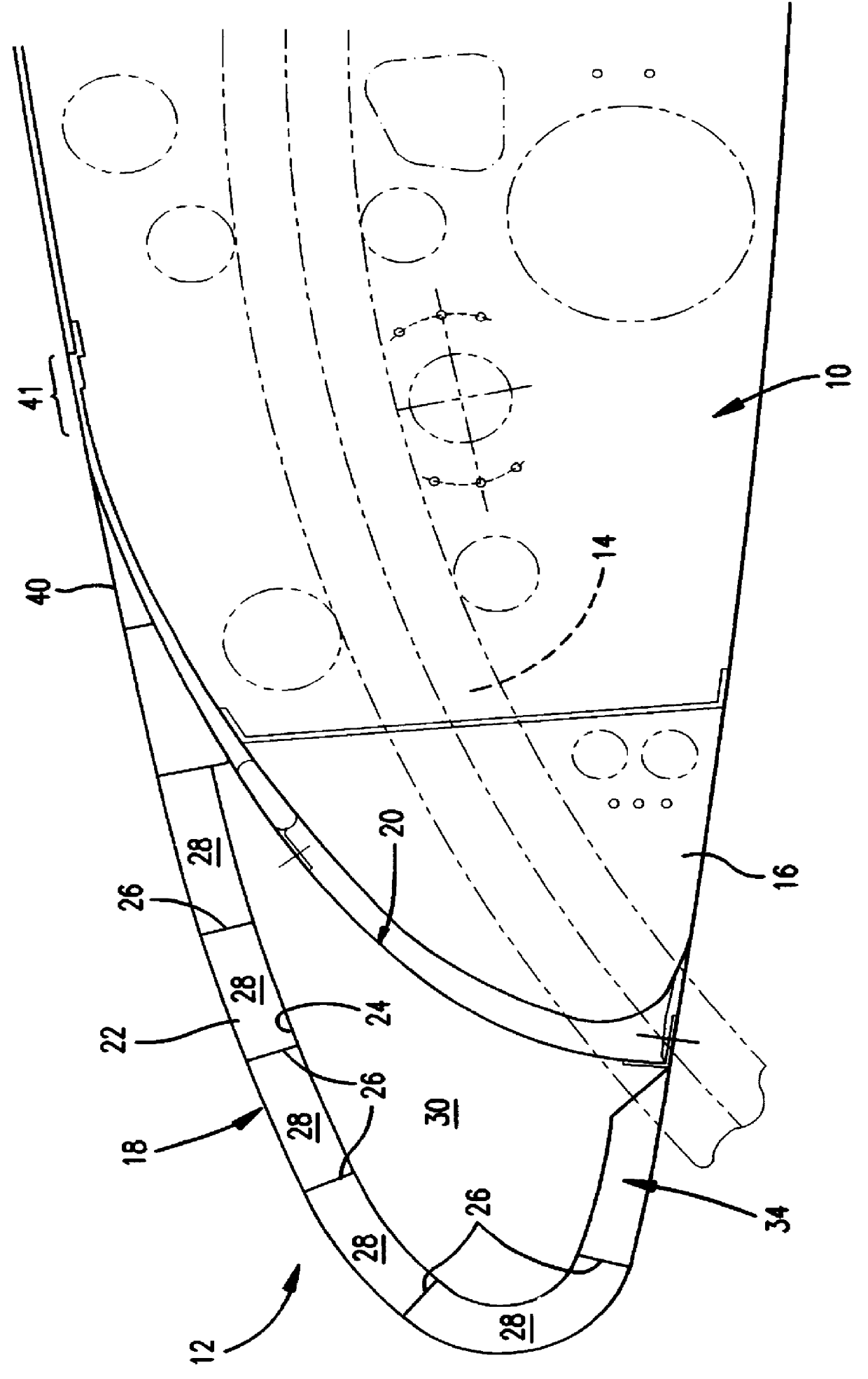

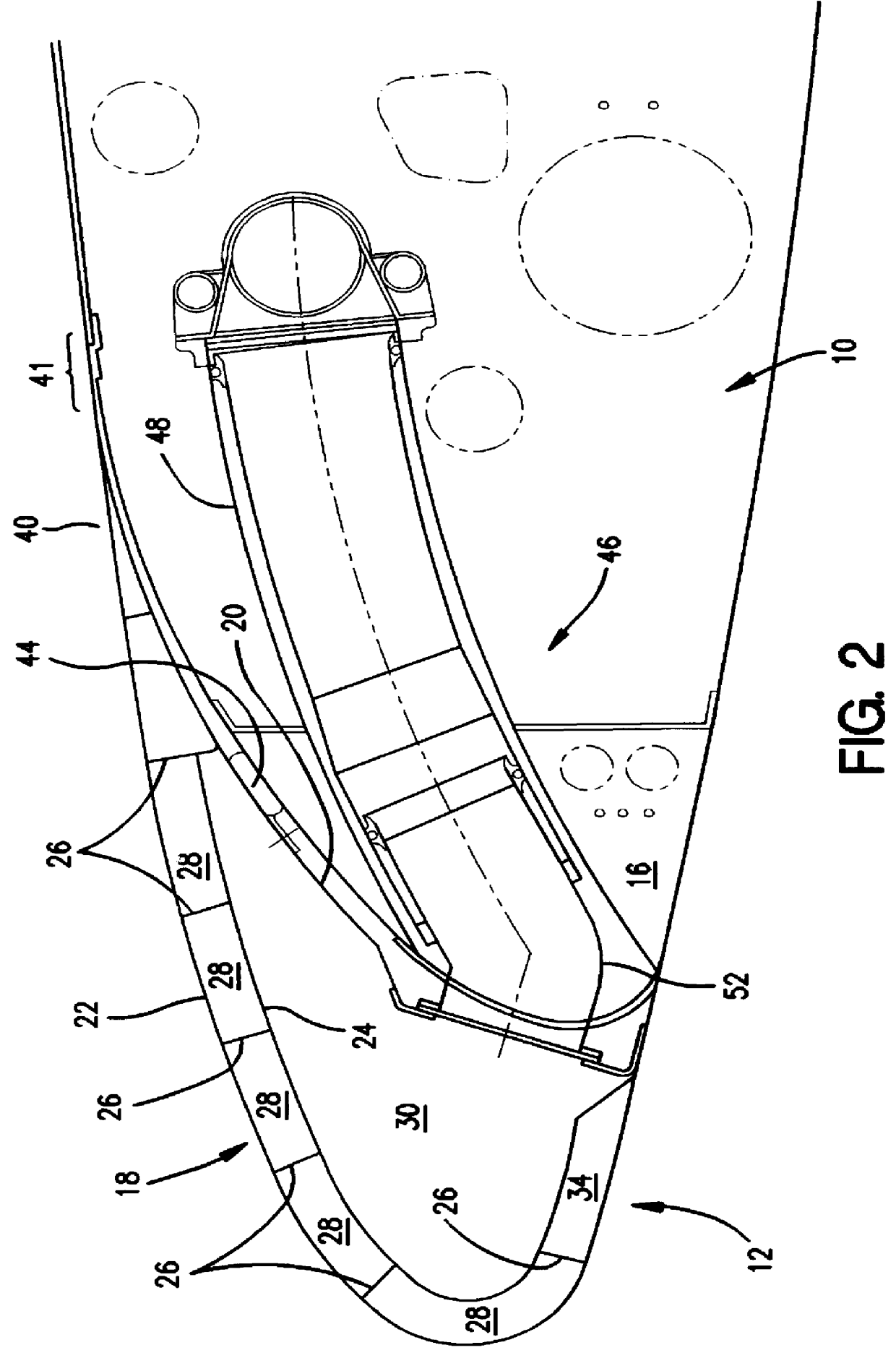

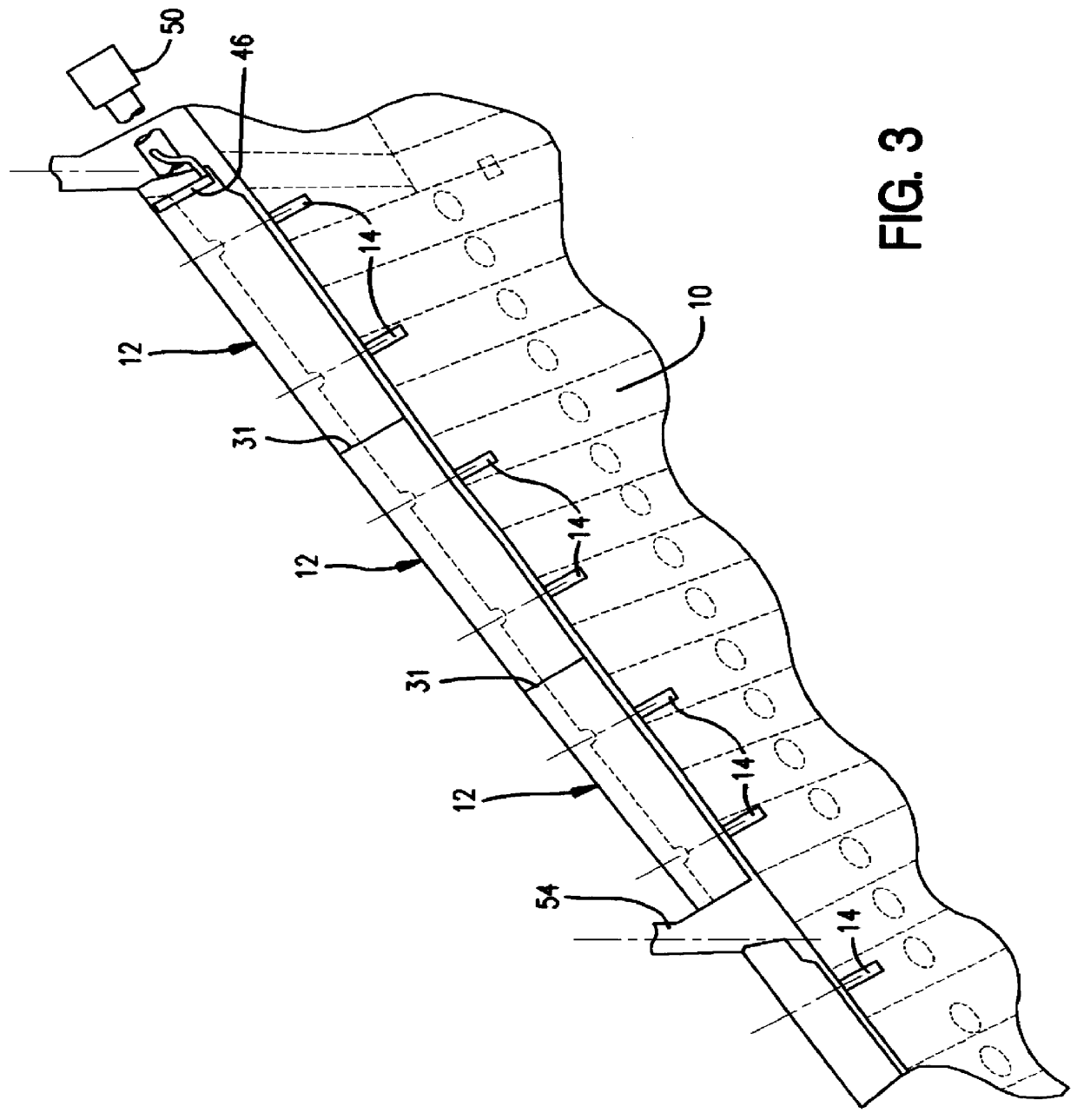

Aircraft wing leading edge high lift device with suction

InactiveUS6135395AReduce resistanceReduce layeringBoundary layer controlsFluid dynamicsLeading edgeAircraft landing

An aircraft wing, wing assembly and method of reducing drag are provided. The wing asembly includes a main wing portion (10) and a leading edge high lift portion (12). The high lift portion is movable between a retracted position in which it generally merges with the main wing portion and a deployed position forwardly thereof. At least a substantial part of an upper surface (22) of the high lift portion is air permeable or perforated and in flow communication with a suction passage (30) in it. In flight, suction may be applied to the suction passage to reduce the chordwise extent of the turbulent boundary layer over the upper or lower wing surface.

Owner:AIRBUS OPERATIONS LTD

Compact co-axial rotor system for a rotary wing aircraft and a control system therefor

ActiveUS20050236518A1Easy to separateReduce the overall heightPropellersPump componentsTip positionControl system

A dual, counter rotating, coaxial rotor system provides an upper and lower rotor system, with a reduced axial rotor separation distance along a common axis by means of rotor tip position sensing and rotor position controls to avoid tip contact.

Owner:SIKORSKY AIRCRAFT CORP

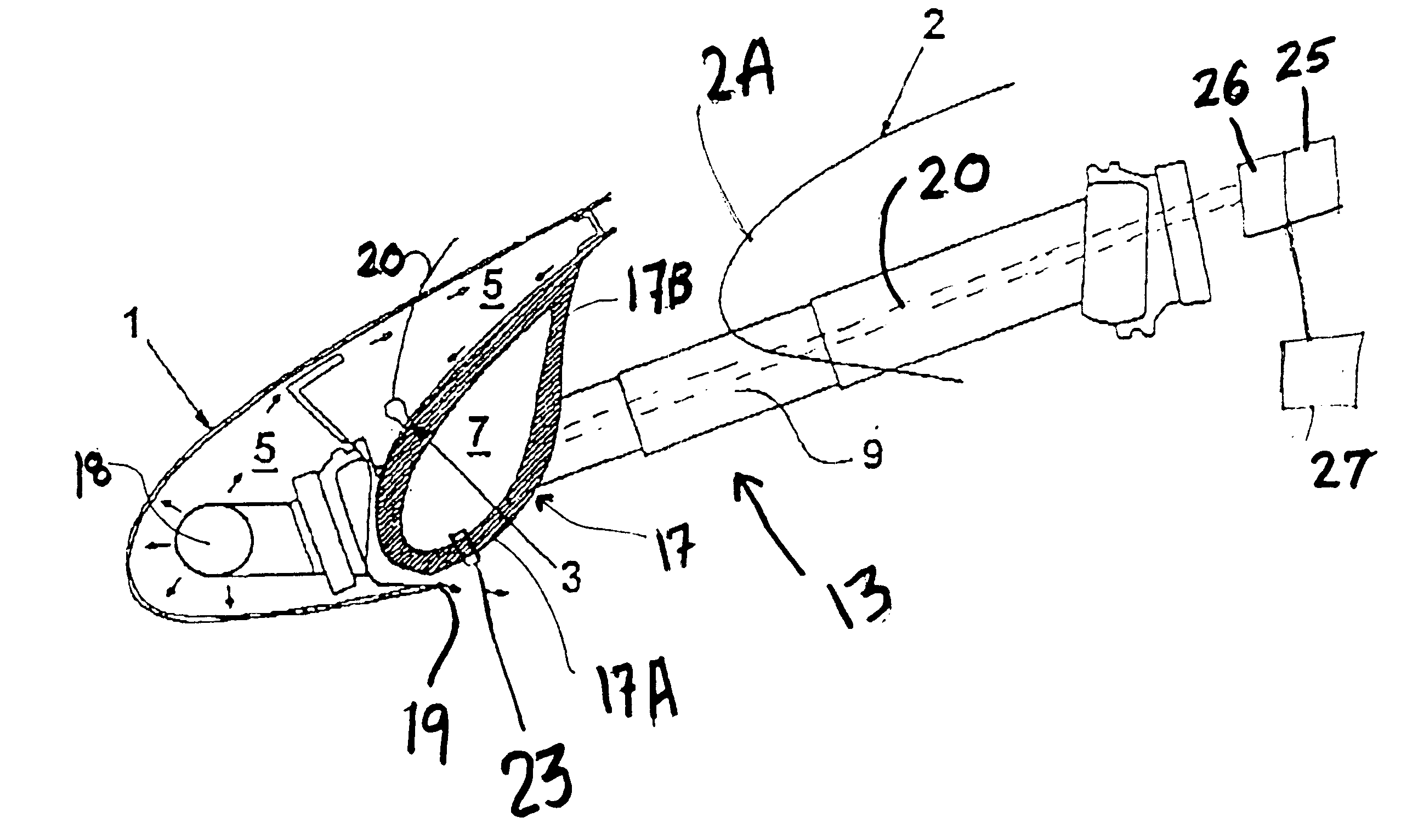

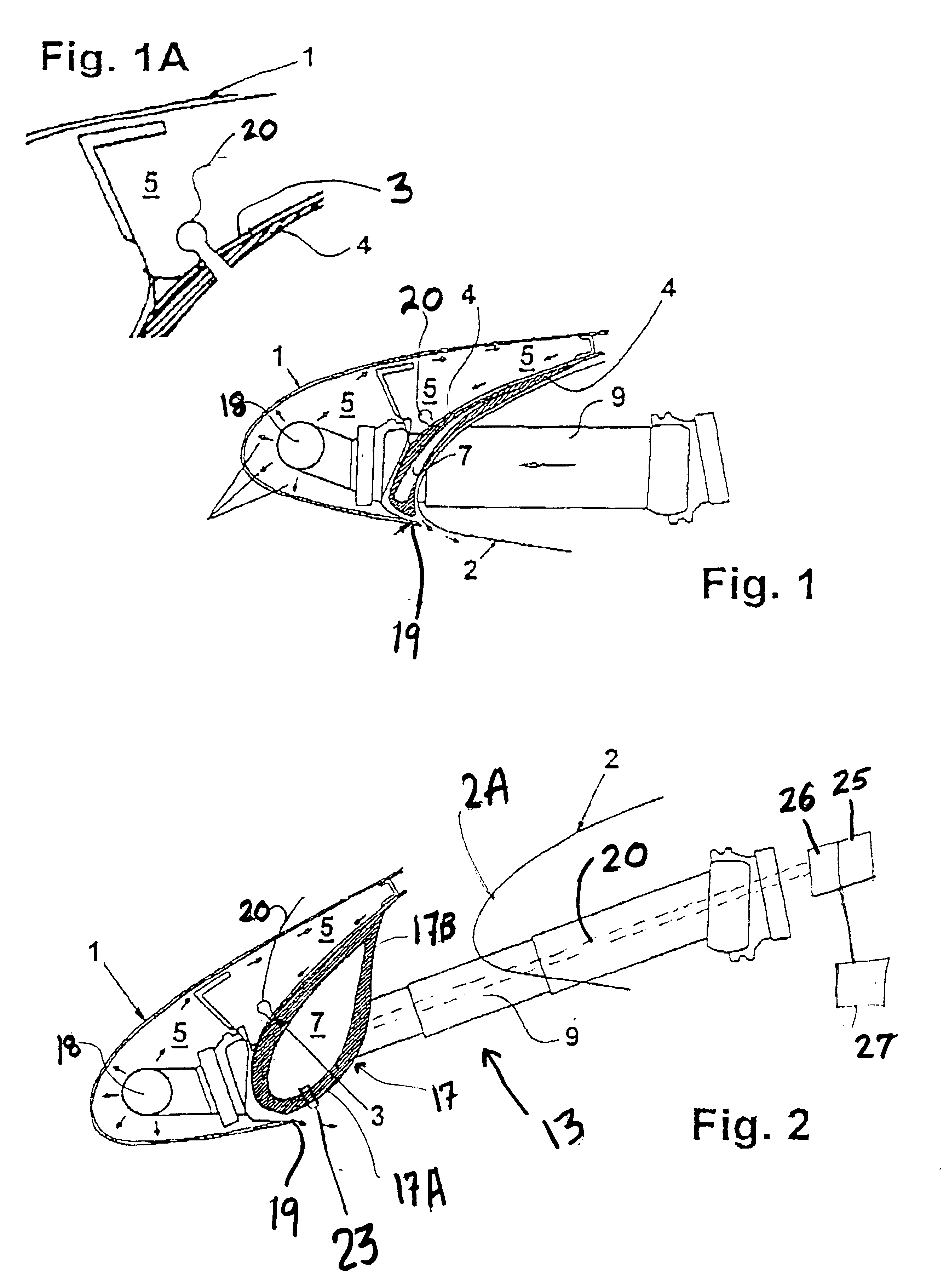

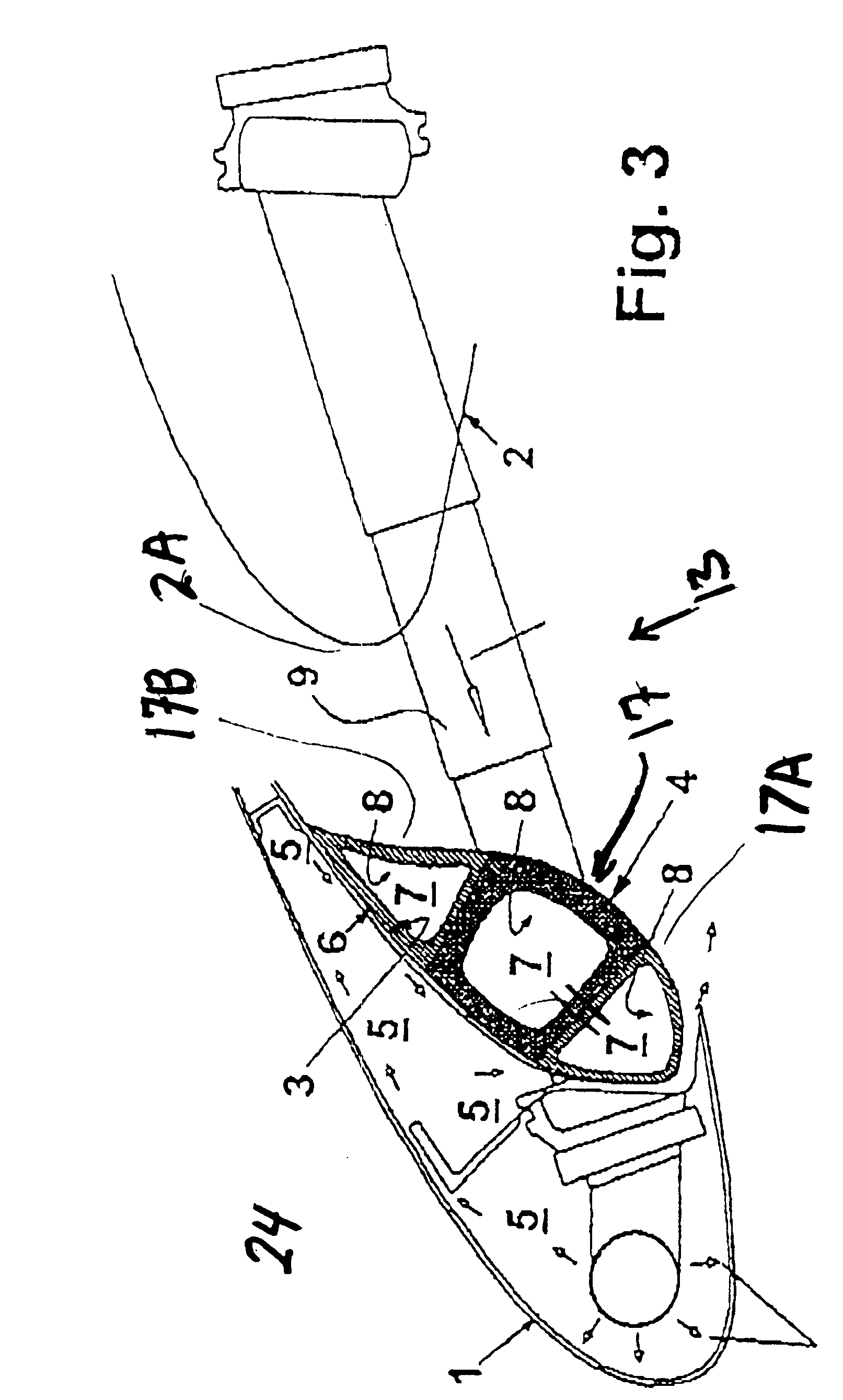

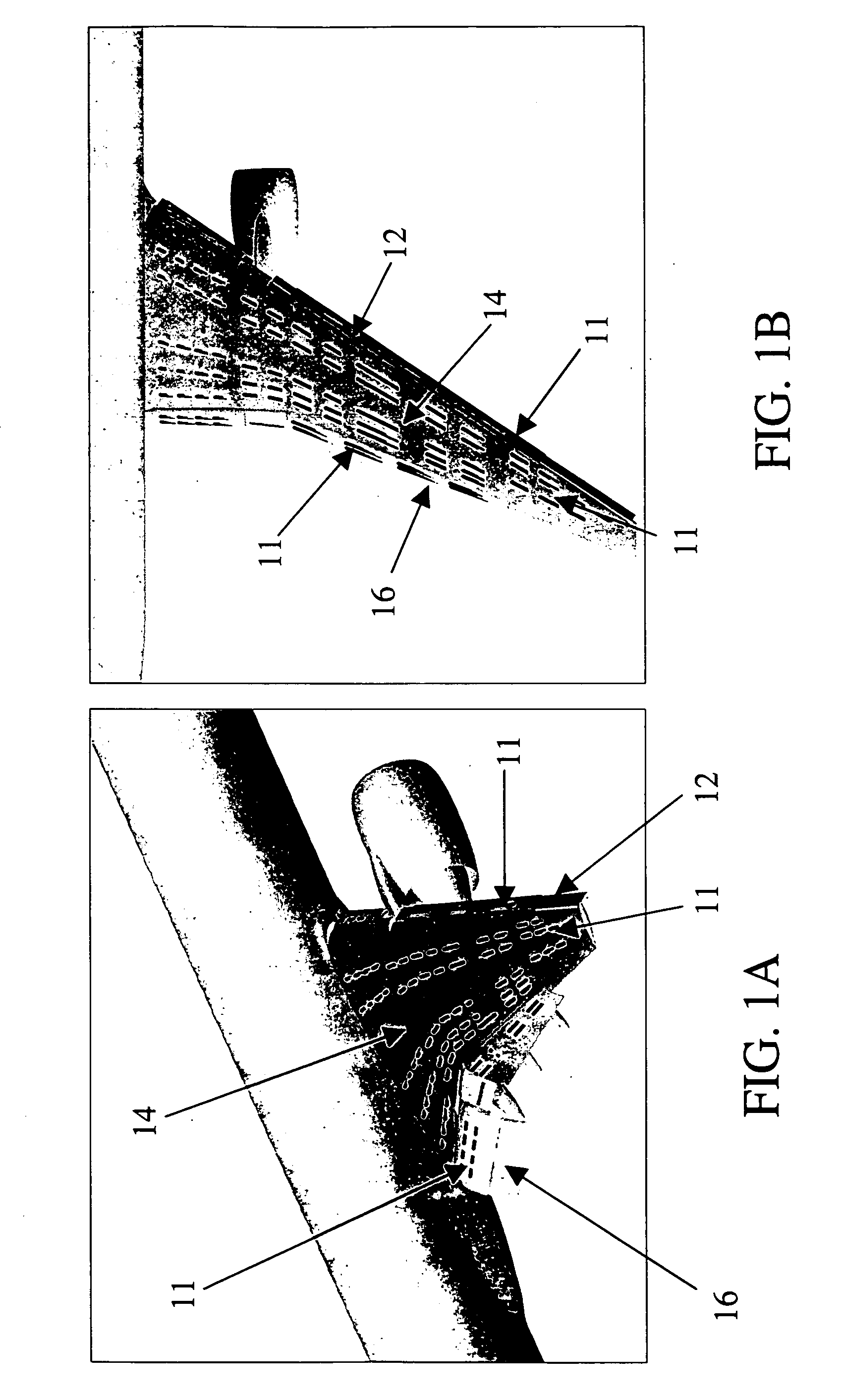

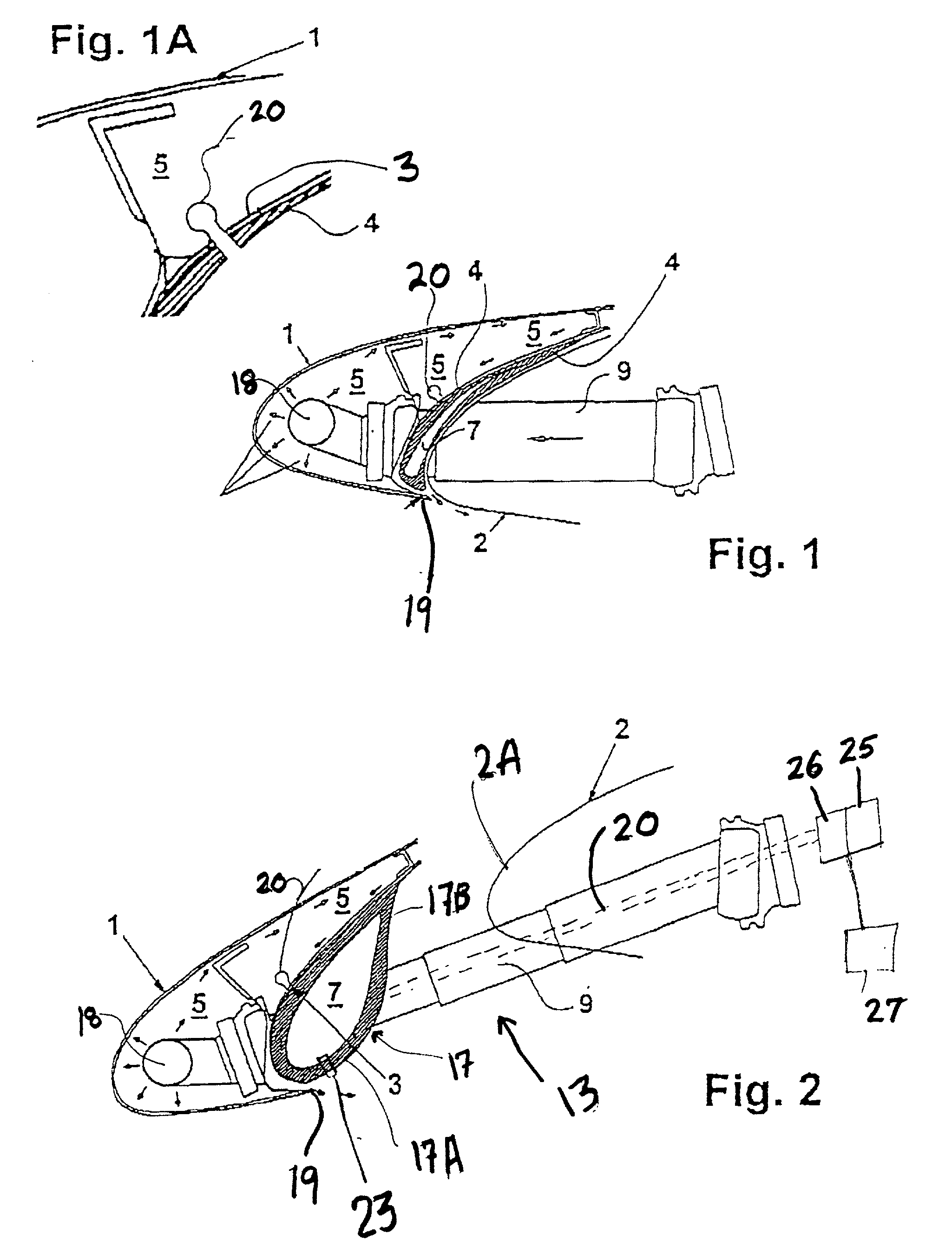

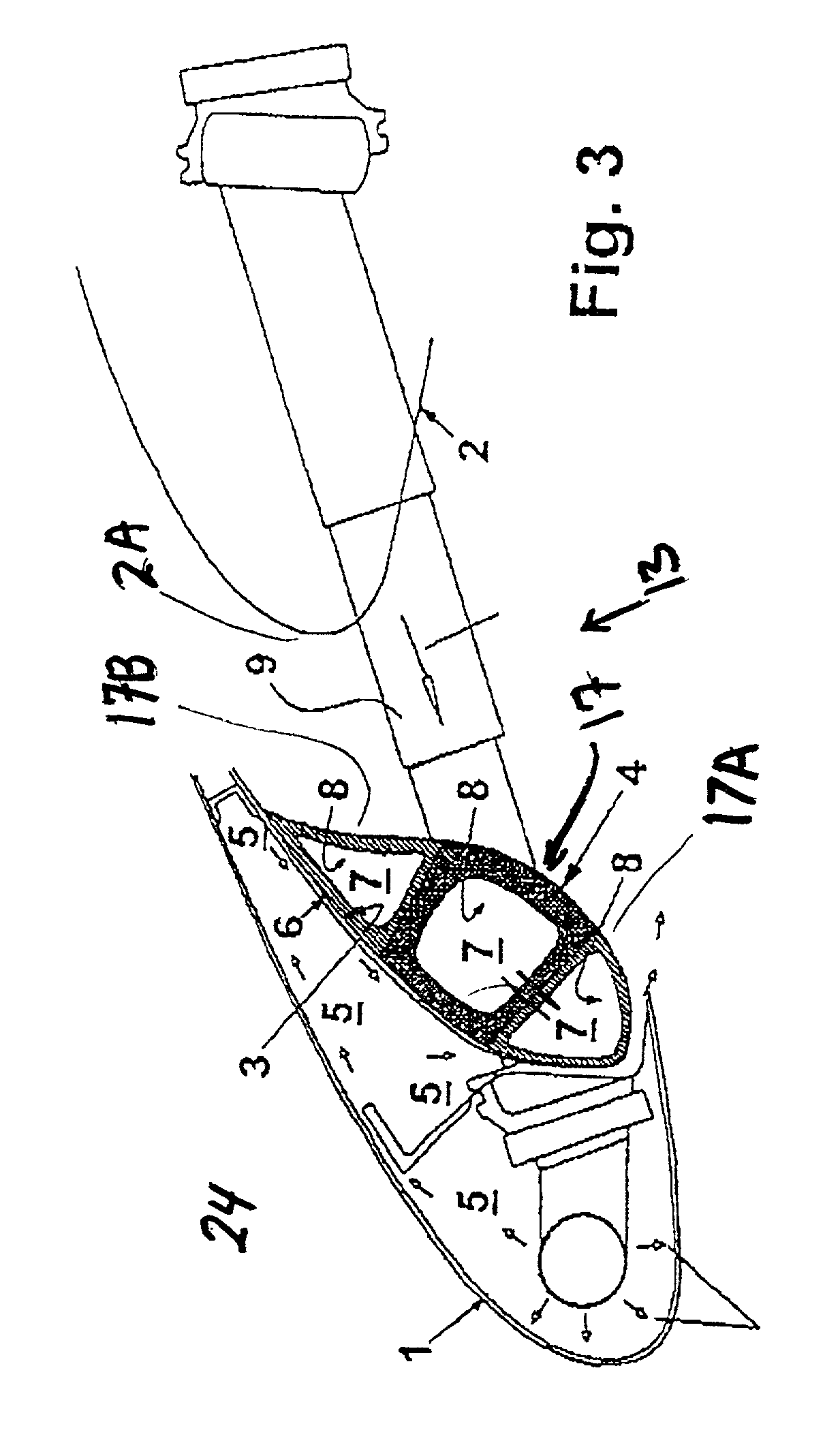

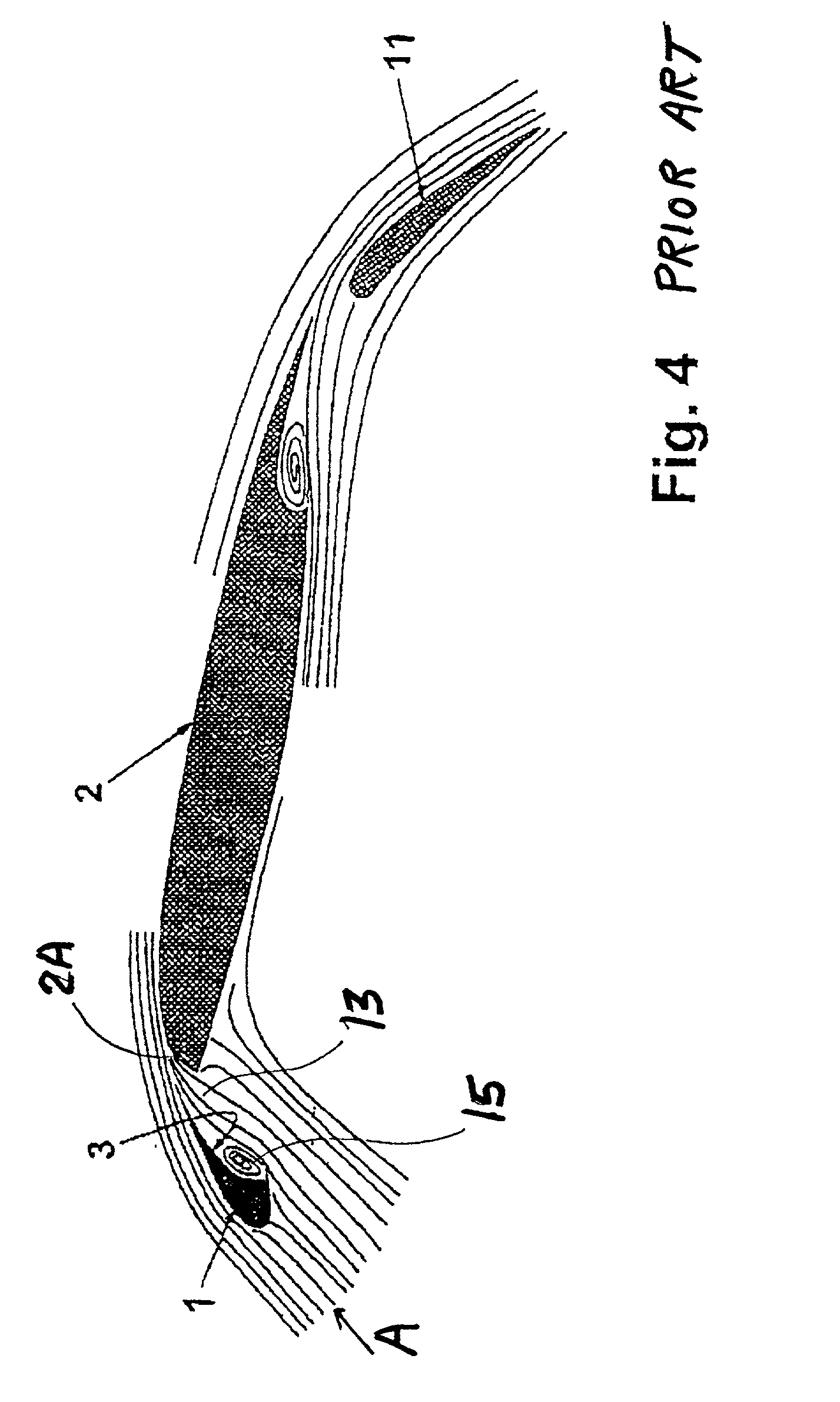

Method for reducing fuel consumption in aircraft

InactiveUS6598834B2Aircraft controlEfficient propulsion technologiesFlight control surfacesPush pull

A method and means are provided for increasing the aerodynamic efficiency of an airfoil employed by an aircraft. The method utilizes the primary flight control surfaces (11) (12) contiguous to the airfoil's trailing edge and relocates these devices to novel positions (21) (23) resulting in an expanded cord and enhanced camber for the aircraft wing (13). Self-adjusting push-pull rods (25) (60) replace conventional solid rods (24) where necessary in combination with a re-rigging of the flight control surfaces (11) (12) to predetermined positions (21) (23). Any voids created by this modification between the shared upper and lower fluid flow surfaces of the aircraft wing (13) and its flight control surfaces (11) (12) are eliminated through the installation of appropriate structure (40) or seal (43). Thus the aircraft wing (13) retains a unique geometric profile as a usual configuration.

Owner:AEROTECH SERVICES +1

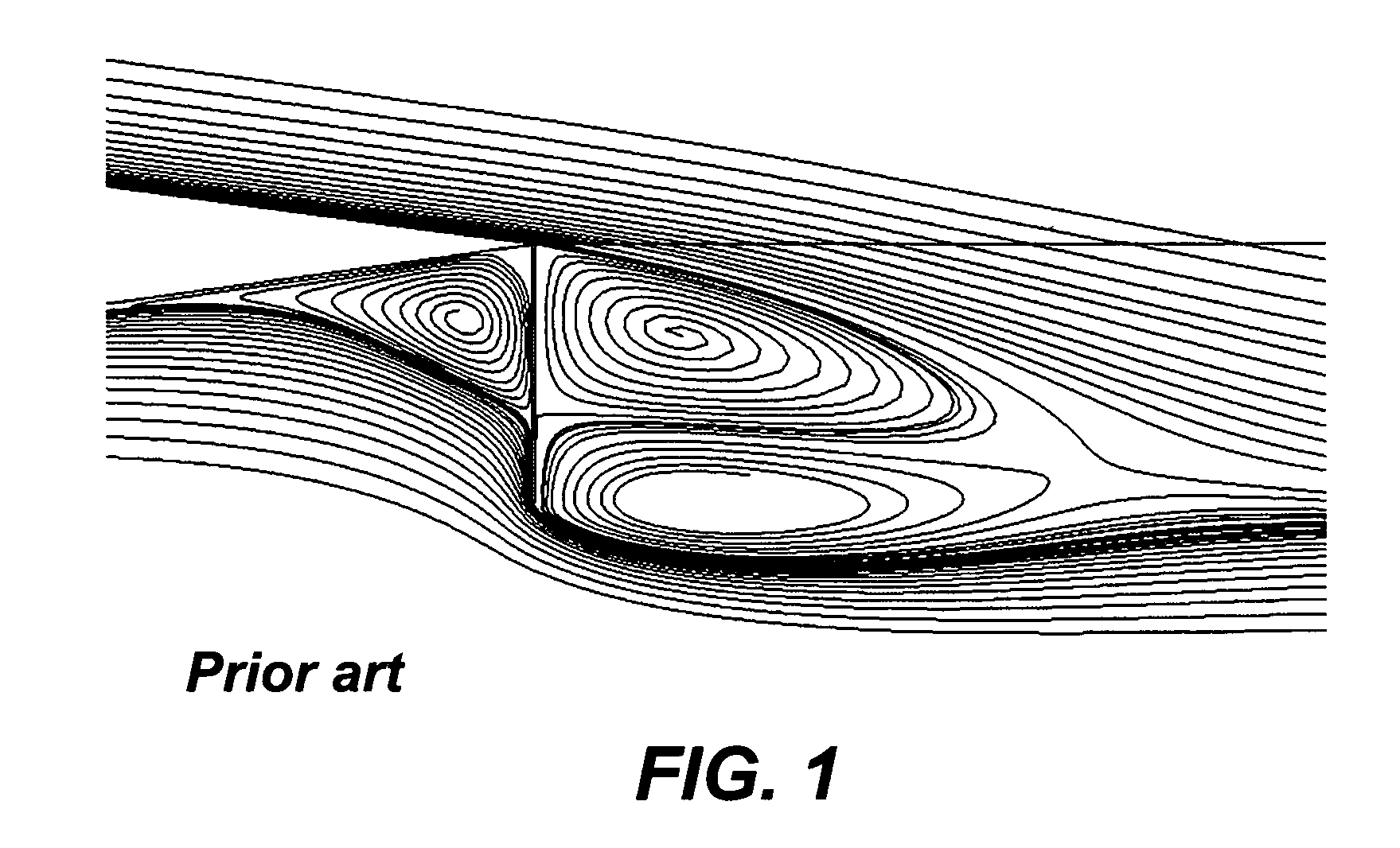

Aerodynamic noise reducing structure for aircraft wing slats

A hollow expandable and contractible displacement element is secured onto the concave rear surface of a slat facing the leading edge of an aircraft wing. A bleed air line supplies engine bleed air into the hollow displacement element to selectively expand or contract the displacement element, which is preferably elastically expandable. When the slat is extended, the displacement element is expanded to fill-out the concave cavity on the rear surface of the slat so as to prevent formation of a vortex in the slat air gap and thereby to reduce aero-acoustic noise. When the slat is retracted, the displacement element is contracted to be conformingly accommodated in the sickle-shaped space between the slat and the leading edge of the wing.

Owner:AIRBUS OPERATIONS GMBH

Rotorcraft having coaxial counter-rotating rotors which produce both vertical and horizontal thrust and method of controlled flight in all six degrees of freedom

A rotorcraft and method for providing controlled flight which provides flight in all six degrees of freedom of pitch, roll, yaw, up / down, forward / rear, and left / right. The rotorcraft includes a fuselage with a pair of counter-rotating rotor blade assemblies each having a plurality of radially-extending airfoil shaped blades about a vertically disposed central axis. A rotor drive system mounted to the fuselage includes a motor or engine for rotationally driving the rotor blade assemblies. A rotor blade control system monitors the rotational location of each blade relative to the fuselage and allows a pilot to control respective vertical and horizontal thrust components of the blades corresponding to lift versus drag characteristics of the airfoils during rotation about the fuselage. This is done by changing the pitch angles of the blades and / or by utilizing respective flaps pivotally mounted to the blades to change the effective pitch angle of the blades.

Owner:PETERSEN BRUCE L

Wing employing leading edge flaps and winglets to achieve improved aerodynamic performance

ActiveUS7475848B2Facilitate sonic boom reductionEasy to controlInfluencers by generating vorticesWith power amplificationLeading edgeControl system

Owner:SUPERSONIC AEROSPACE INT

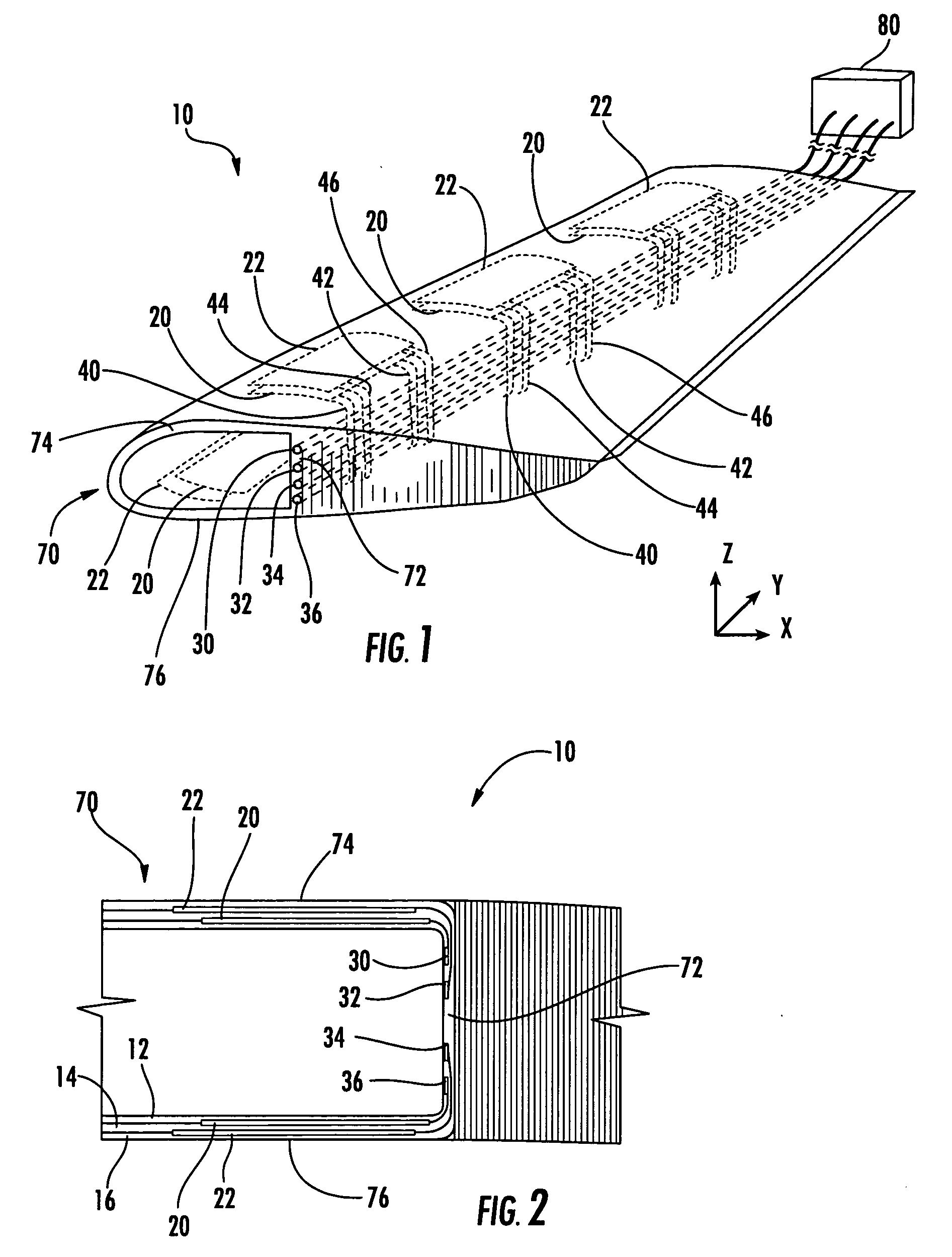

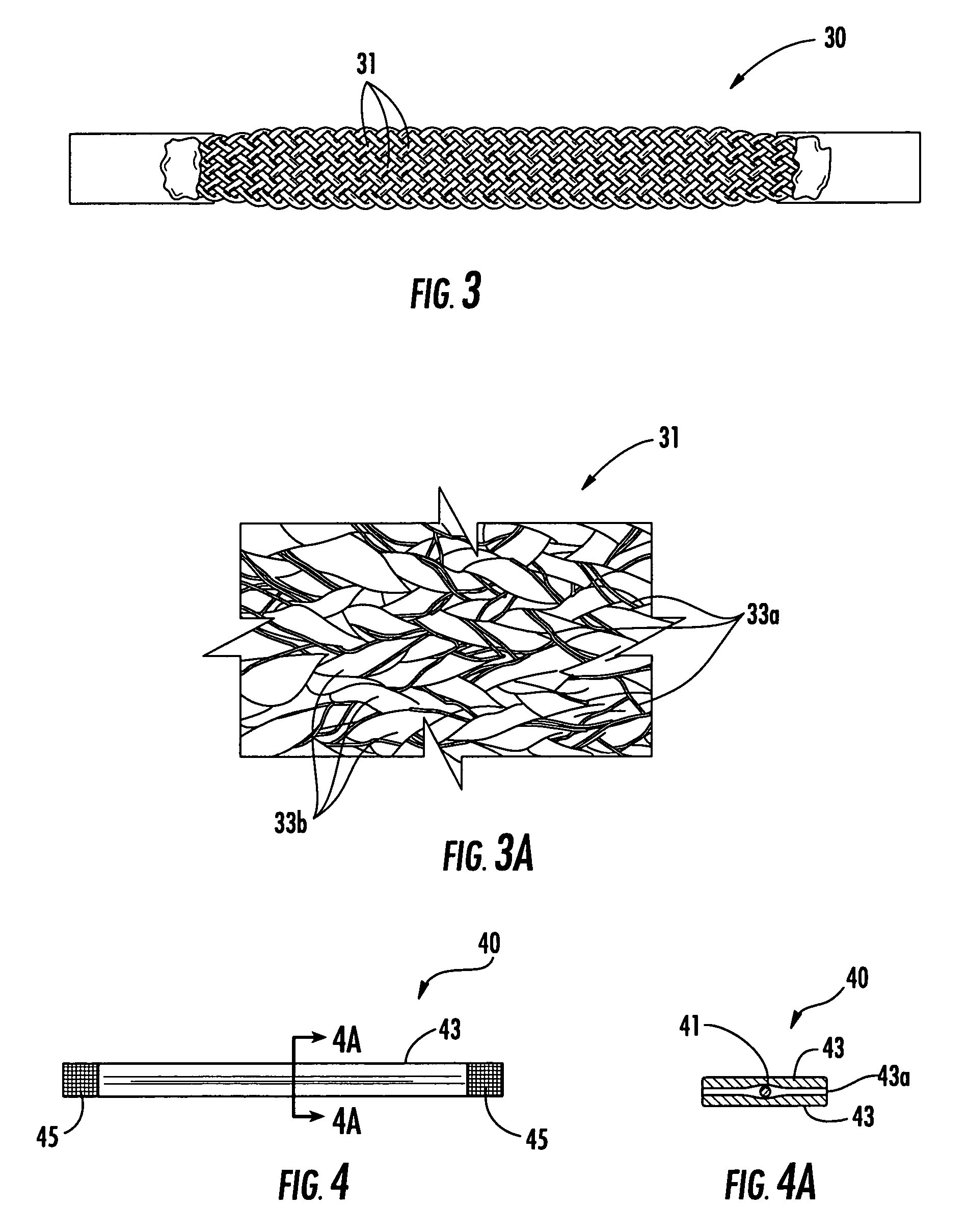

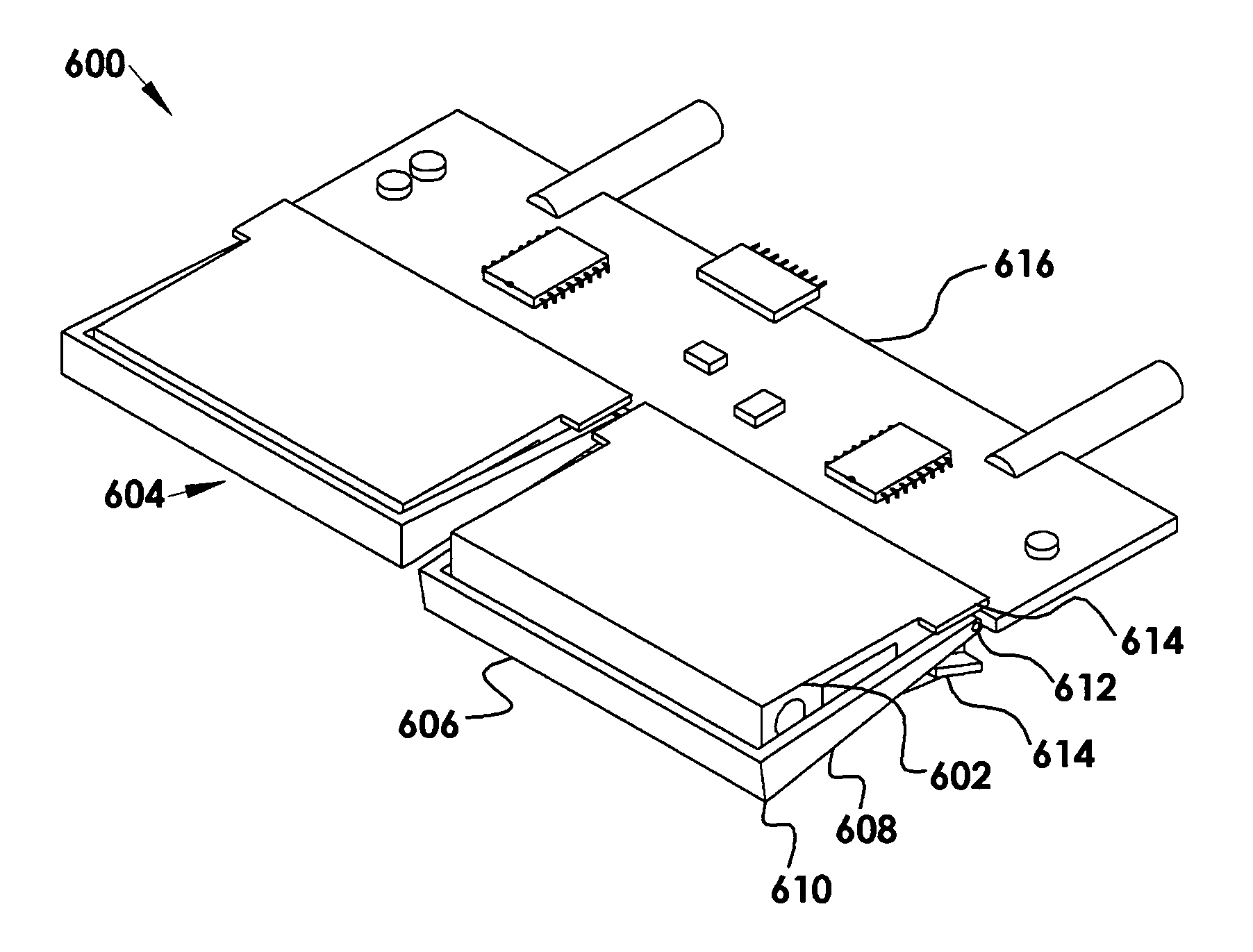

Structurally integrated circuit and associated method

ActiveUS20050257956A1Envelope/housing resistor manufactureLaminating printed circuit boardsElectrical devicesIntegrated circuit

A composite structural member with an integrated electrical circuit and an associated method of manufacture are provided. The structural member includes a plurality of layers of structural reinforcement material, and two or more electrical devices are disposed at least partially between the layers with an intermediate layer of the structural reinforcement material disposed between the electrical devices. At least one electrical bus is disposed in the structural member, and each electrical device is connected to the bus by a conductive electrode. Thus, the electrodes can extend through the intermediate layer of the structural reinforcement material to connect each of the electrical devices to one or more of the buses.

Owner:THE BOEING CO

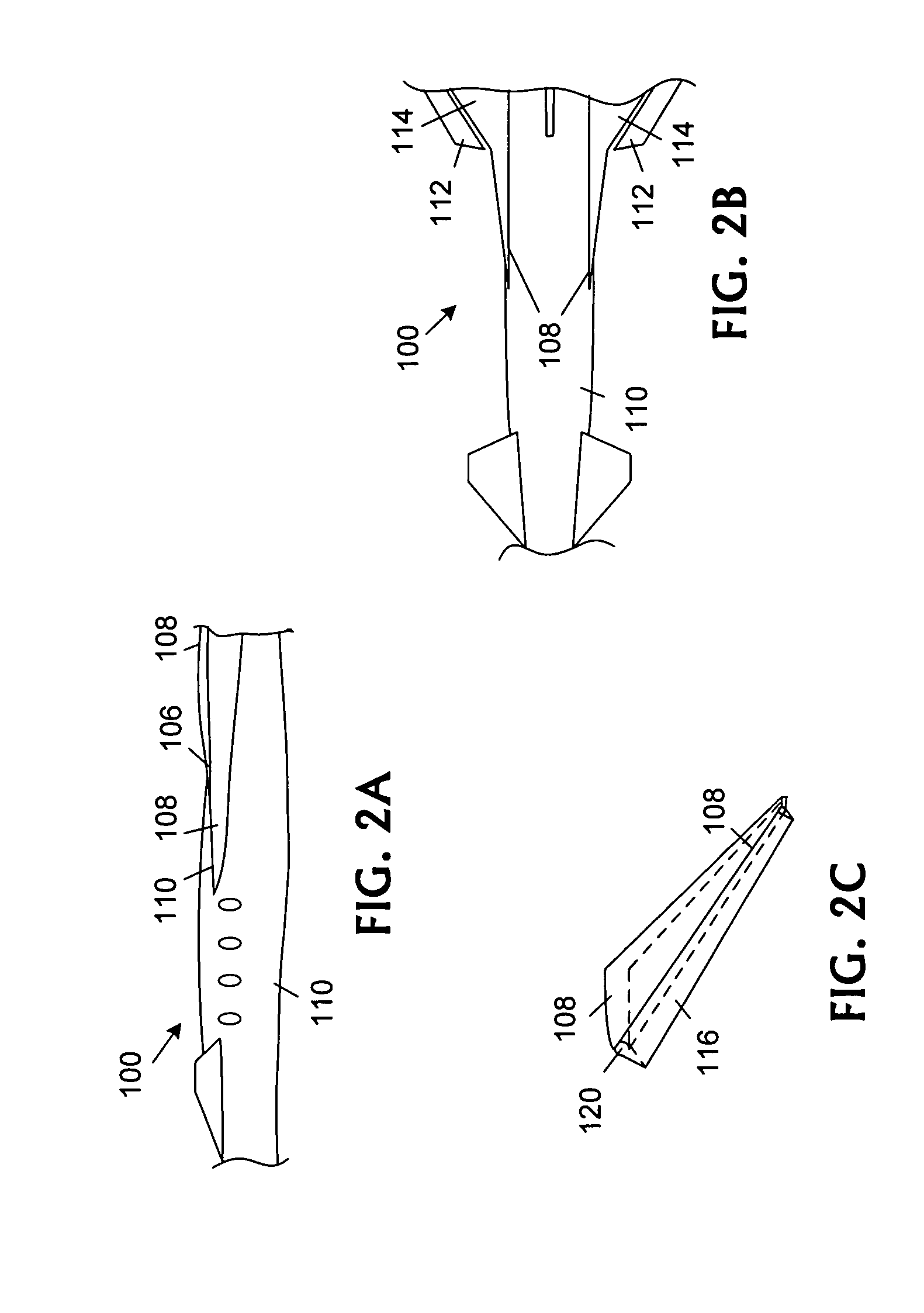

Apparatus and method for use on aircraft with spanwise flow inhibitors

InactiveUS20090302167A1Relieve pressureImprove fatigue performanceInfluencers by generating vorticesAircraft stabilisationLeading edgeTrailing edge

An aircraft can include a wing with a leading edge and a trailing edge. The wing has a main body and movable control surfaces coupled to the main body. The wing generates lifting forces when the aircraft is in flight. The movable control surfaces can be used to control the generated lifting forces. A spanwise flow inhibitor extends from the outer wingtip of the wing. At least one gurney flap extends generally downwardly from at least a portion of the trailing edge of the wing. The flap at least partially counteracts a change in center of lift attributable to the spanwise flow inhibitor.

Owner:DESROCHE ROBERT J

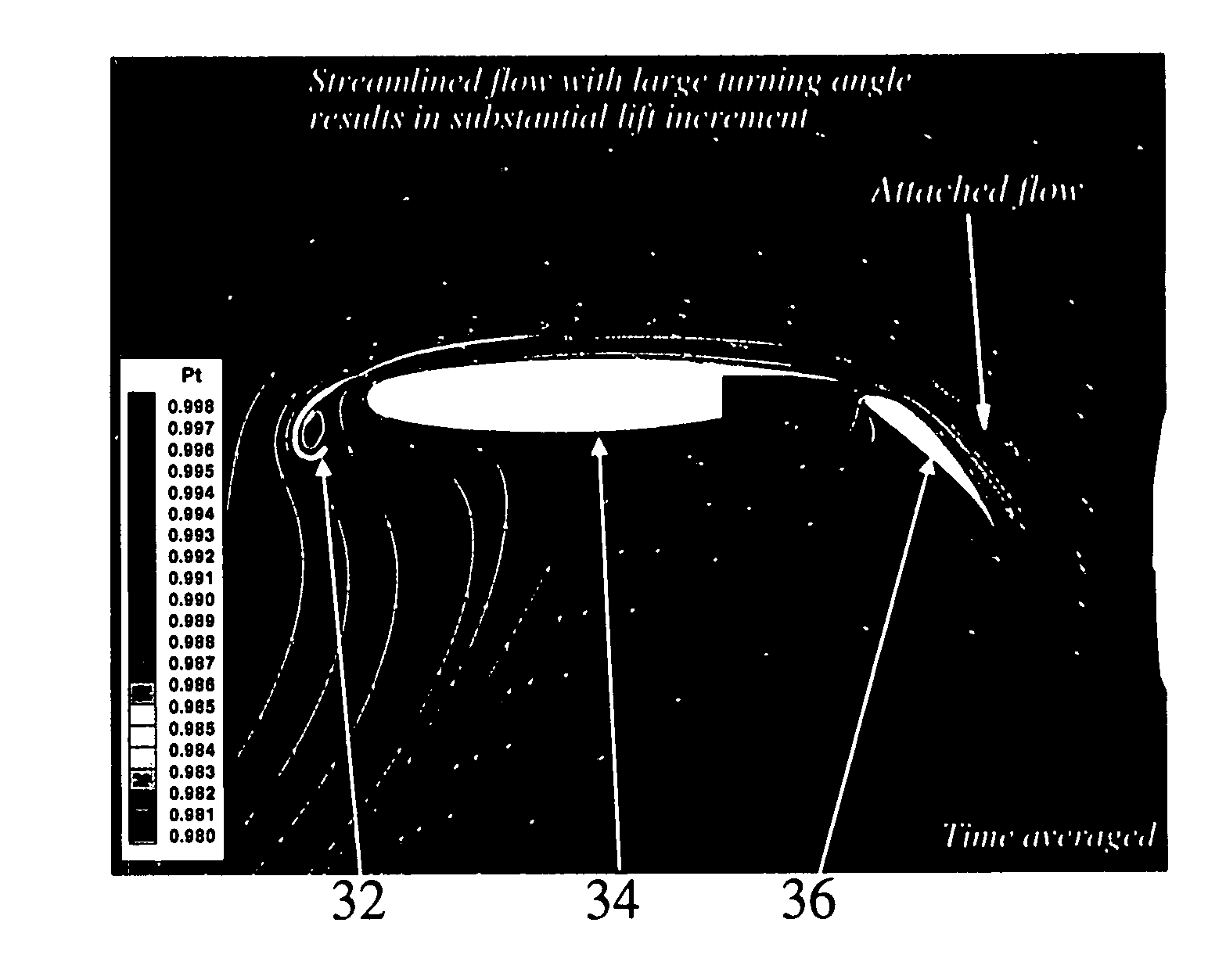

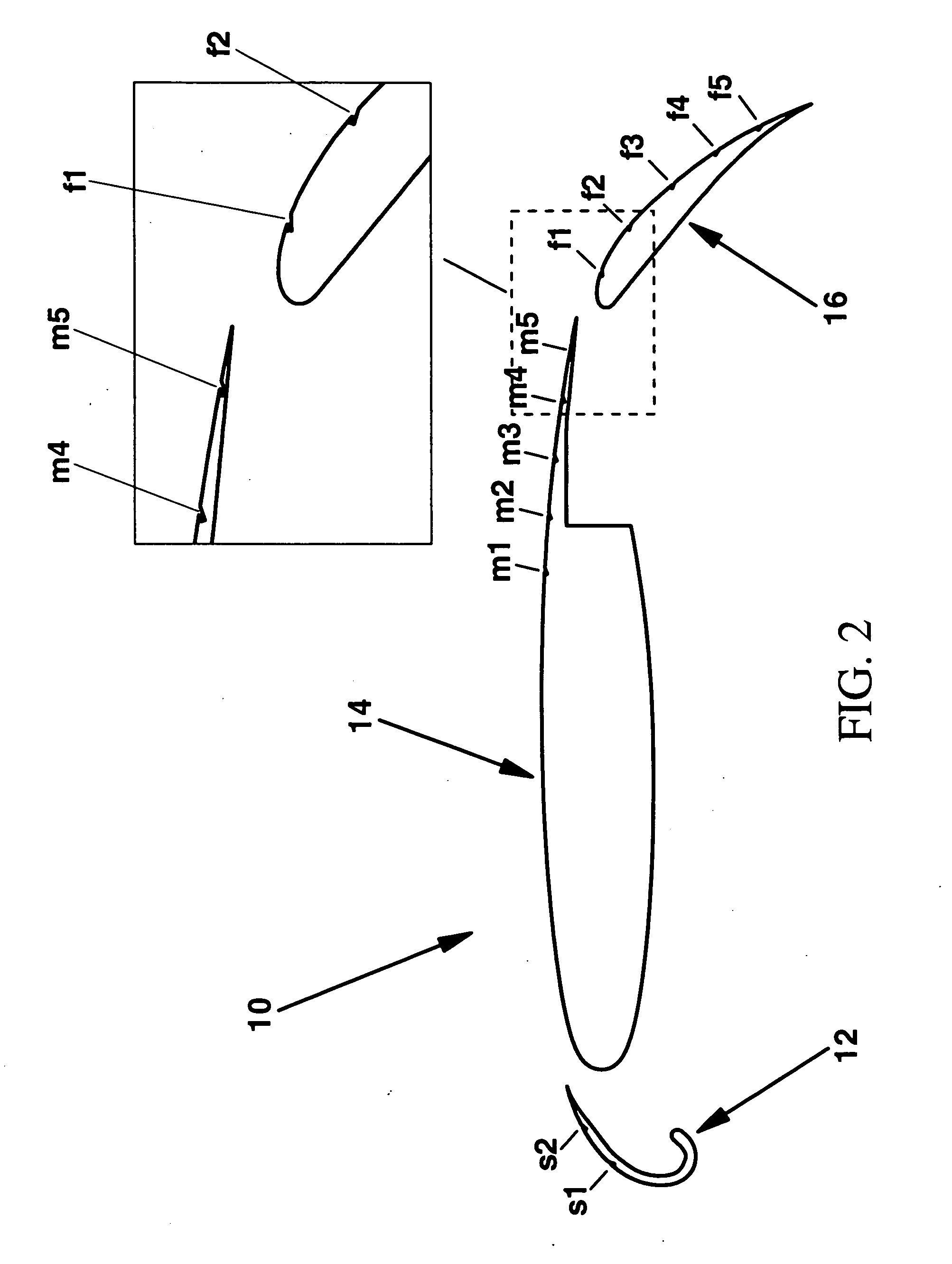

Miniature trailing edge effectors for aerodynamic control

InactiveUS20070221789A1Significant aeroelastic effectWeight increaseAircraft stabilisationActuated personallyTrailing edgeAerodynamics

Improved miniature trailing edge effectors for aerodynamic control are provided. Three types of devices having aerodynamic housings integrated to the trailing edge of an aerodynamic shape are presented, which vary in details of how the control surface can move. A bucket type device has a control surface which is the back part of a C-shaped member having two arms connected by the back section. The C-shaped section is attached to a housing at the ends of the arms, and is rotatable about an axis parallel to the wing trailing edge to provide up, down and neutral states. A flip-up type device has a control surface which rotates about an axis parallel to the wing trailing edge to provide up, down, neutral and brake states. A rotating type device has a control surface which rotates about an axis parallel to the chord line to provide up, down and neutral states.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

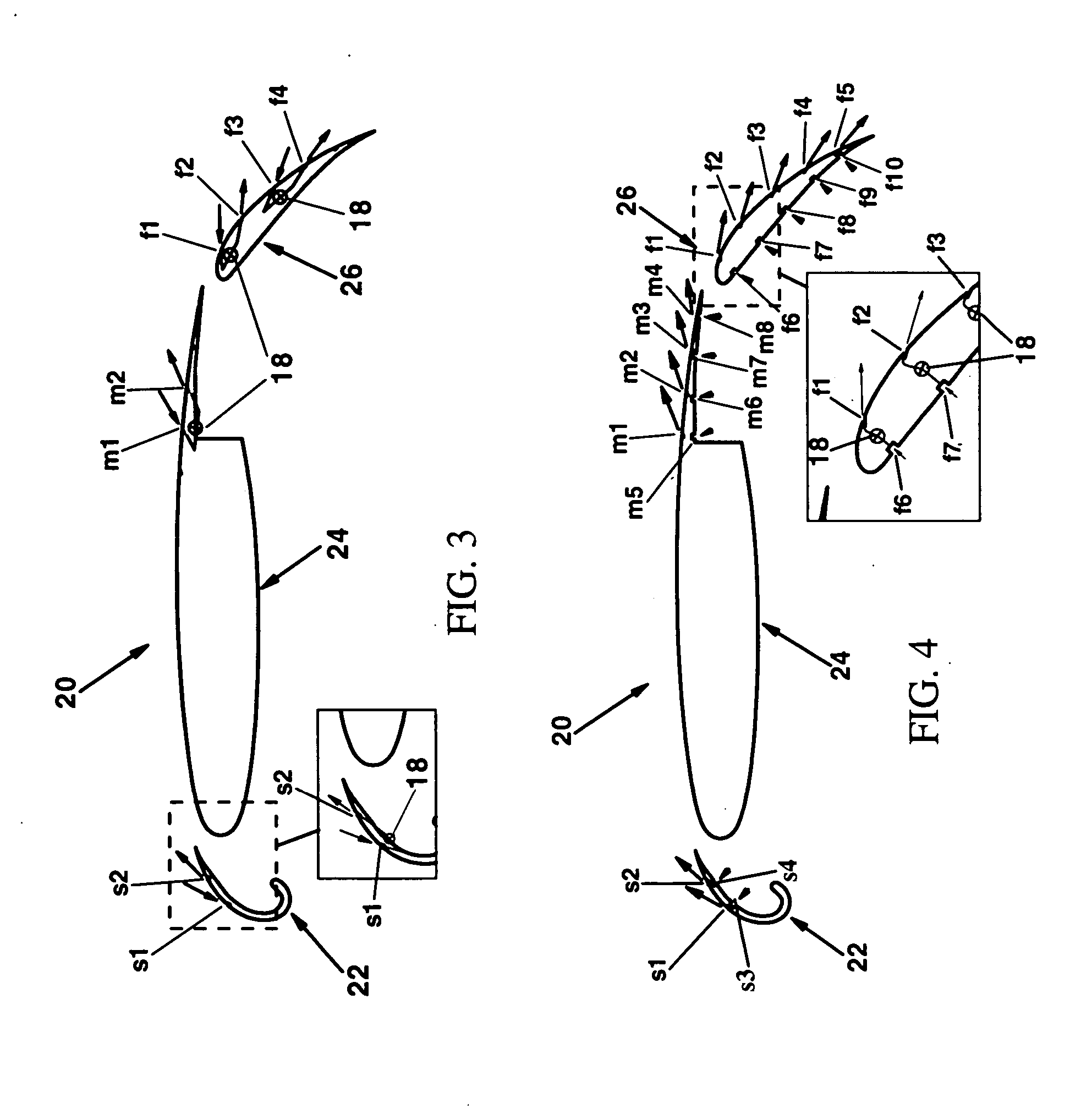

Lift augmentation system and associated method

ActiveUS20070051855A1Easy to liftReduce viscosityBoundary layer controlsWingsAugmentation systemMulti element

A system and method for generating lift provided by a multi-element aircraft wing are provided. The system includes a main wing element, a slat interconnected to the main wing element, and a flap interconnected to the main wing element. The system also includes at least one port defined in at least one of the slat, main wing element, and flap. In addition, the system includes at least one fluidic device operable to regulate fluid flow into and out of the at least one port to control boundary layer flow over at least one of the slat, main wing element, and flap.

Owner:THE BOEING CO

Helicopter rotor load reduction and tip clearance control

A method of controlling a helicopter having a rotor with blades is provided. The method includes receiving, by a computing device comprising a processor, at least one input associated with the helicopter; generating, by the computing device, control signals configured to counteract blade bending associated with the rotors based on the received at least one input; measuring, by the computing device, blade signals using sensors for the blades; extracting, by the computing device, harmonic loads from the measured blade signals; adapting, by the computing device, the control signals based on the harmonic loads; and controlling, by the computing device, servos connected to the blades to adjust the blades according to the adapted control signals to reduce vibratory loads on the blades.

Owner:SIKORSKY AIRCRAFT CORP

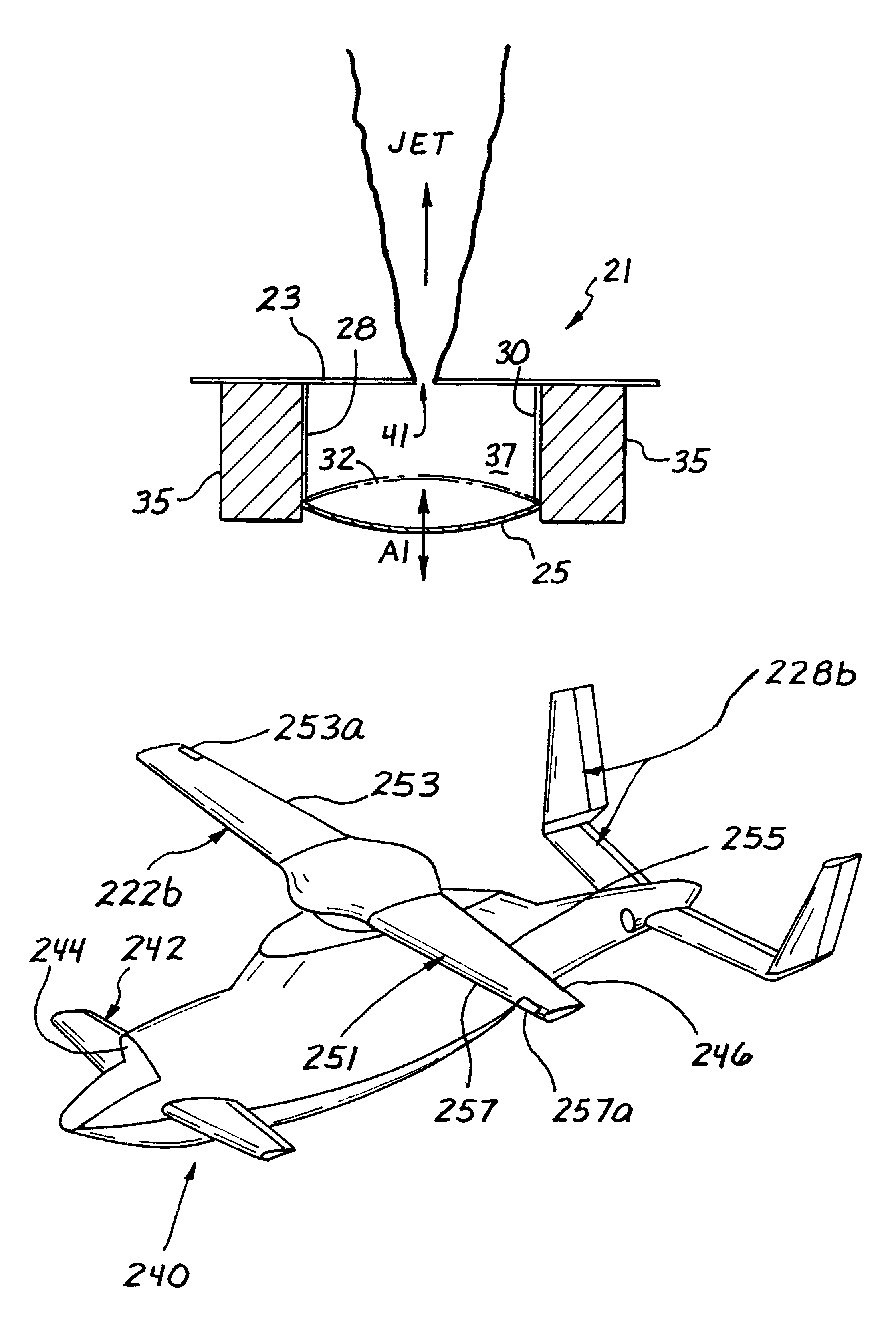

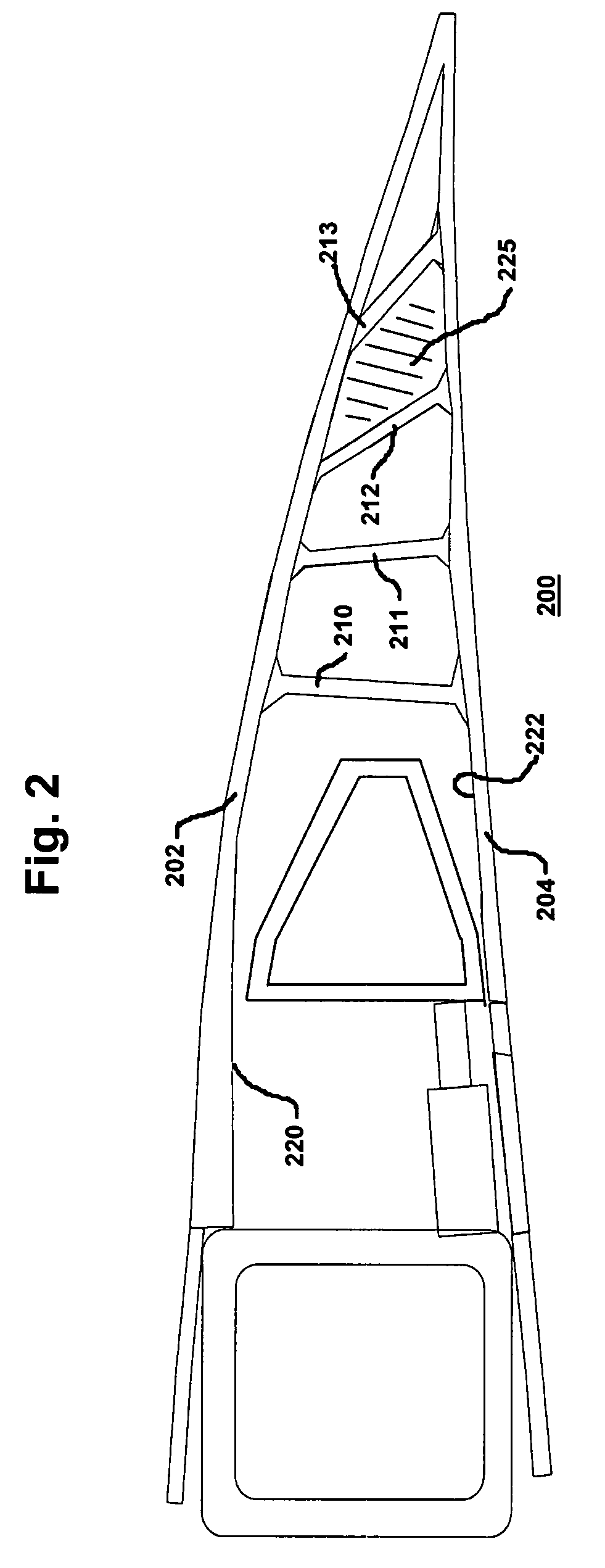

Aircraft attitude control configuration

An aircraft attitude control configuration enables control surfaces to provide attitude control for an aircraft at hover or low air speed conditions. The aircraft attitude control configuration includes a thruster mounted to an aircraft for thrusting air, a first control surface kinematically coupled to the aircraft at a position downstream of the thruster, and a second control surface kinematically coupled to the aircraft at a position downstream of the thruster, the second control surface being differentially movable with respect to the first control surface such that a portion of the thrusted air from the thruster generates a first vector force on the first control surface and another portion of the thrusted air generates a second vector force on the second control surface, so that the first and the second vector forces provide a net roll moment about the Y-Roll axis.

Owner:MORGAN AIRCRAFT LLC

Aerodynamic noise reducing structure for aircraft wing slats

InactiveUS20010038058A1Influencers by generating vorticesAircraft stabilisationLeading edgeLine tubing

A hollow expandable and contractible displacement element is secured onto the concave rear surface of a slat facing the leading edge of an aircraft wing. A bleed air line supplies engine bleed air into the hollow displacement element to selectively expand or contract the displacement element, which is preferably elastically expandable. When the slat is extended, the displacement element is expanded to fill-out the concave cavity on the rear surface of the slat so as to prevent formation of a vortex in the slat air gap and thereby to reduce aero-acoustic noise. When the slat is retracted, the displacement element is contracted to be conformingly accommodated in the sickle-shaped space between the slat and the leading edge of the wing.

Owner:AIRBUS OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com