Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1649 results about "Aircraft landing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Landing gear method and apparatus for braking and maneuvering

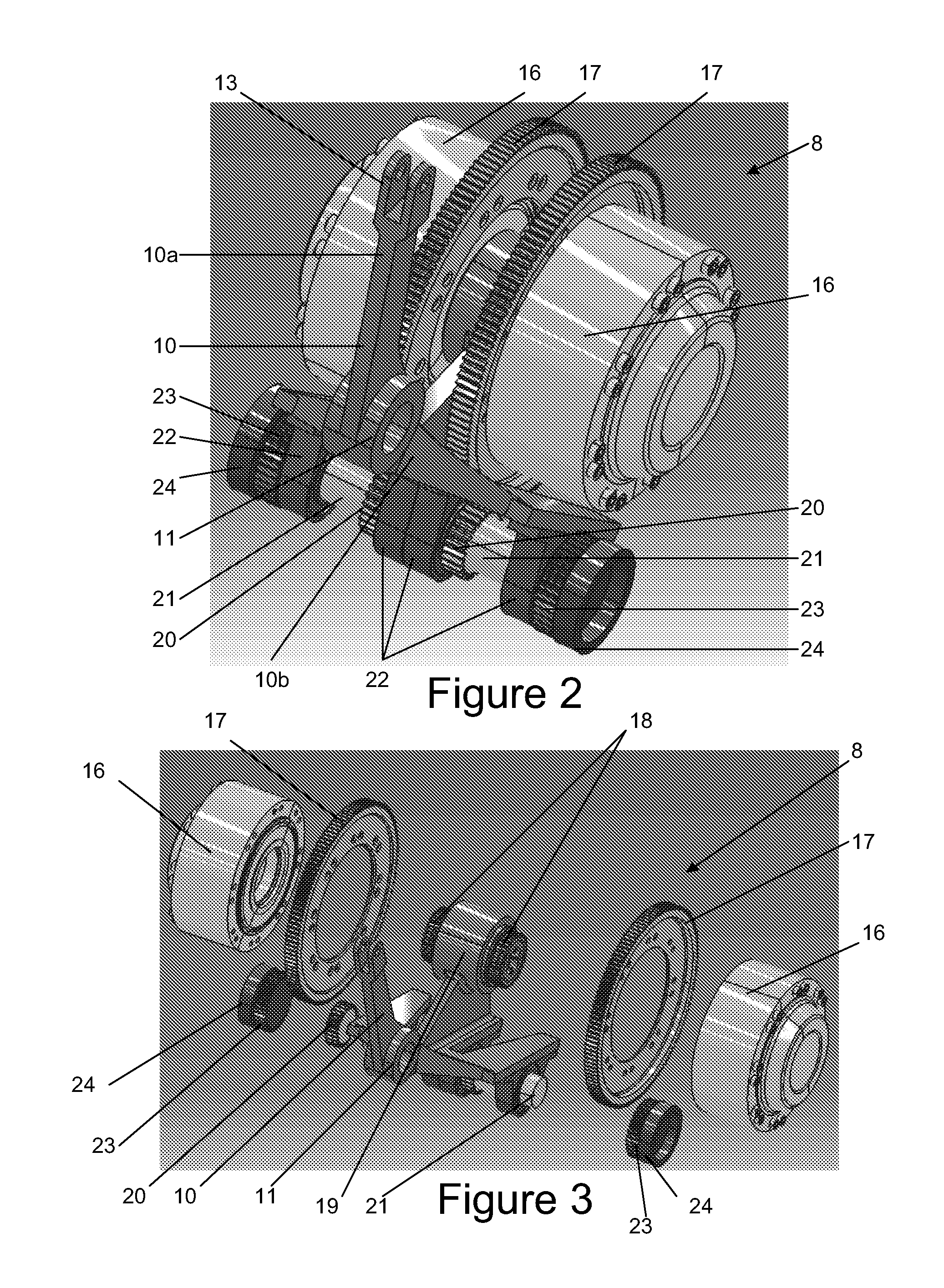

ActiveUS20050224642A1Improve braking effectIncrease flexibilityEnergy efficient operational measuresElectric devicesEngineeringElectric power

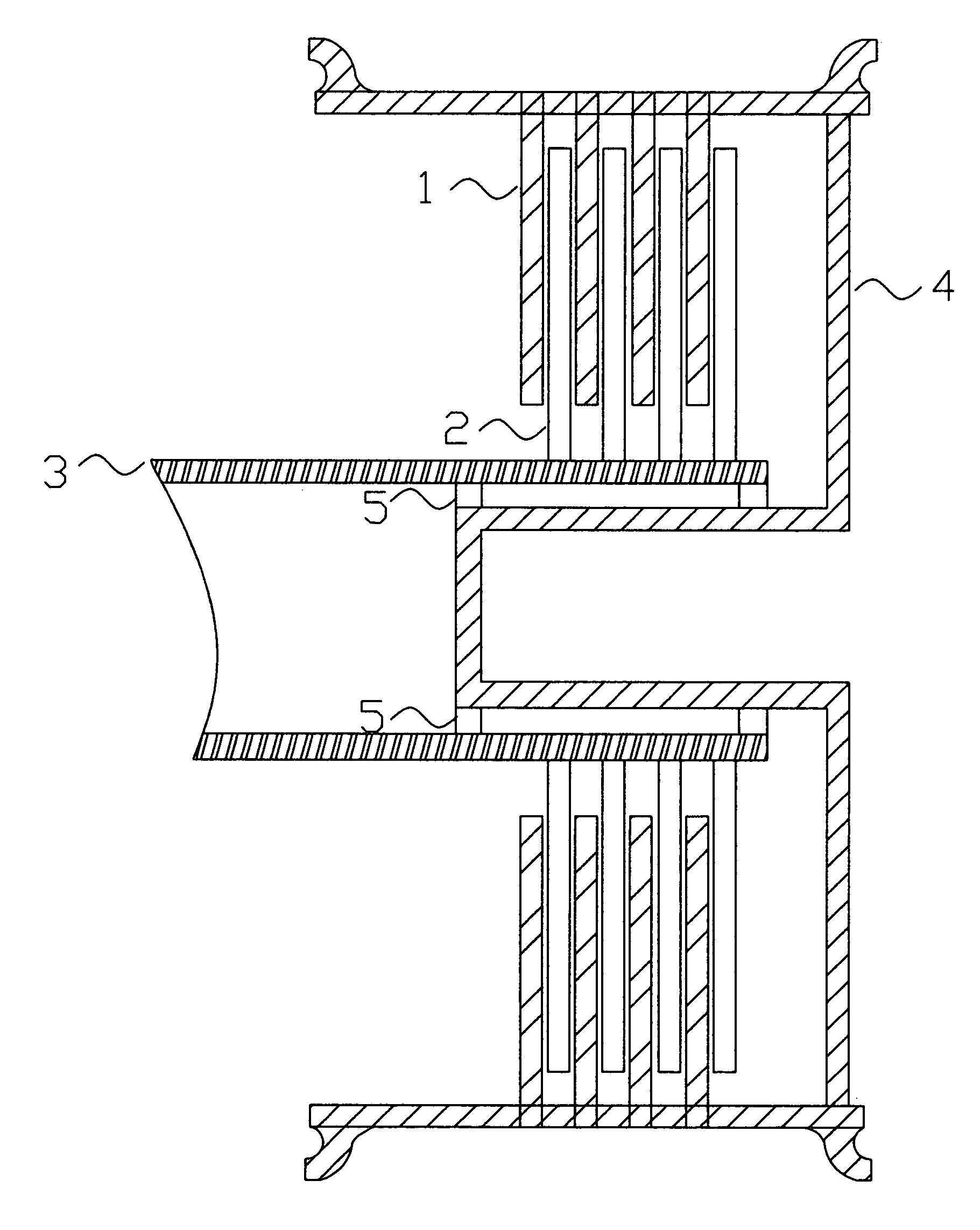

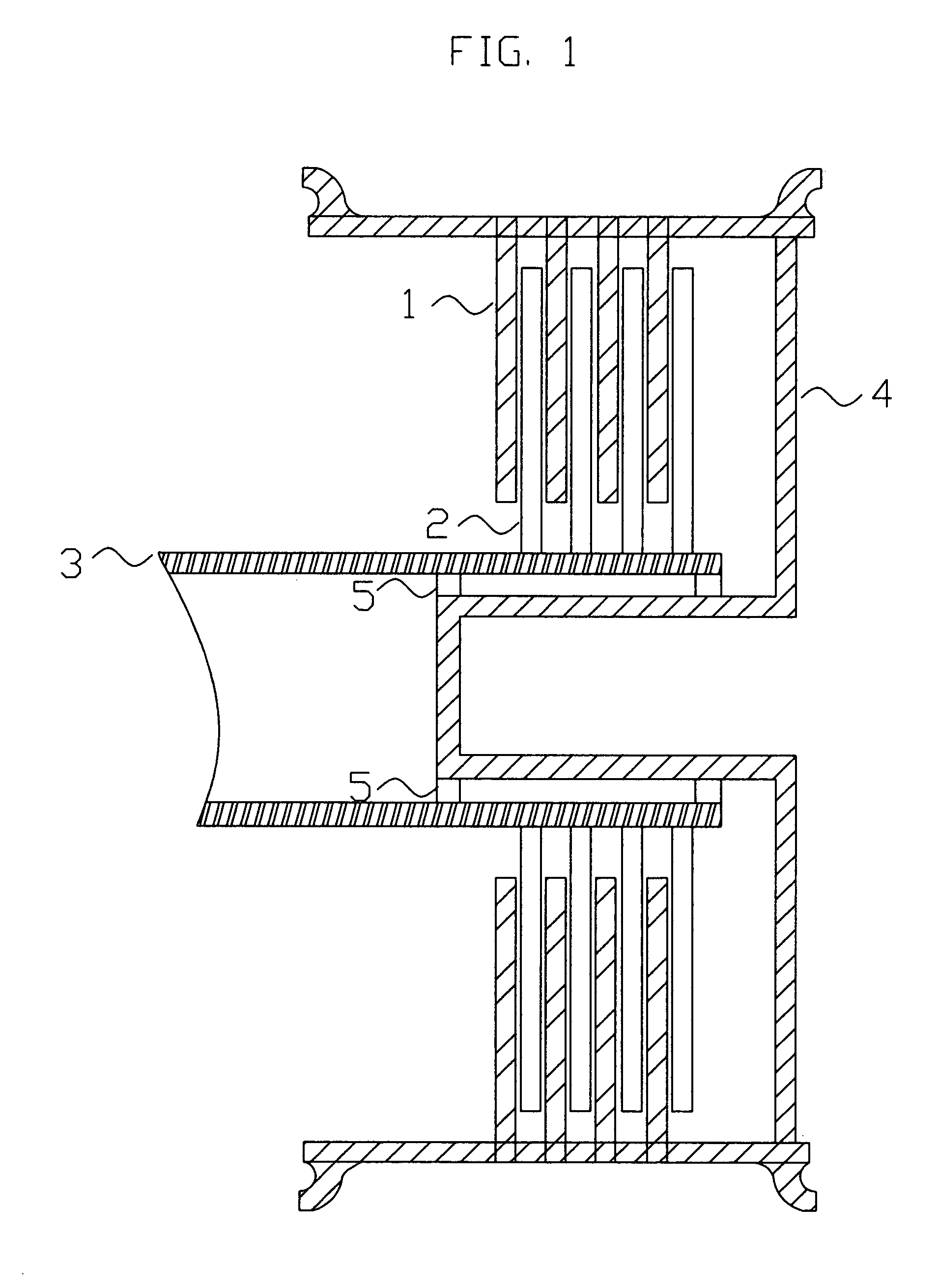

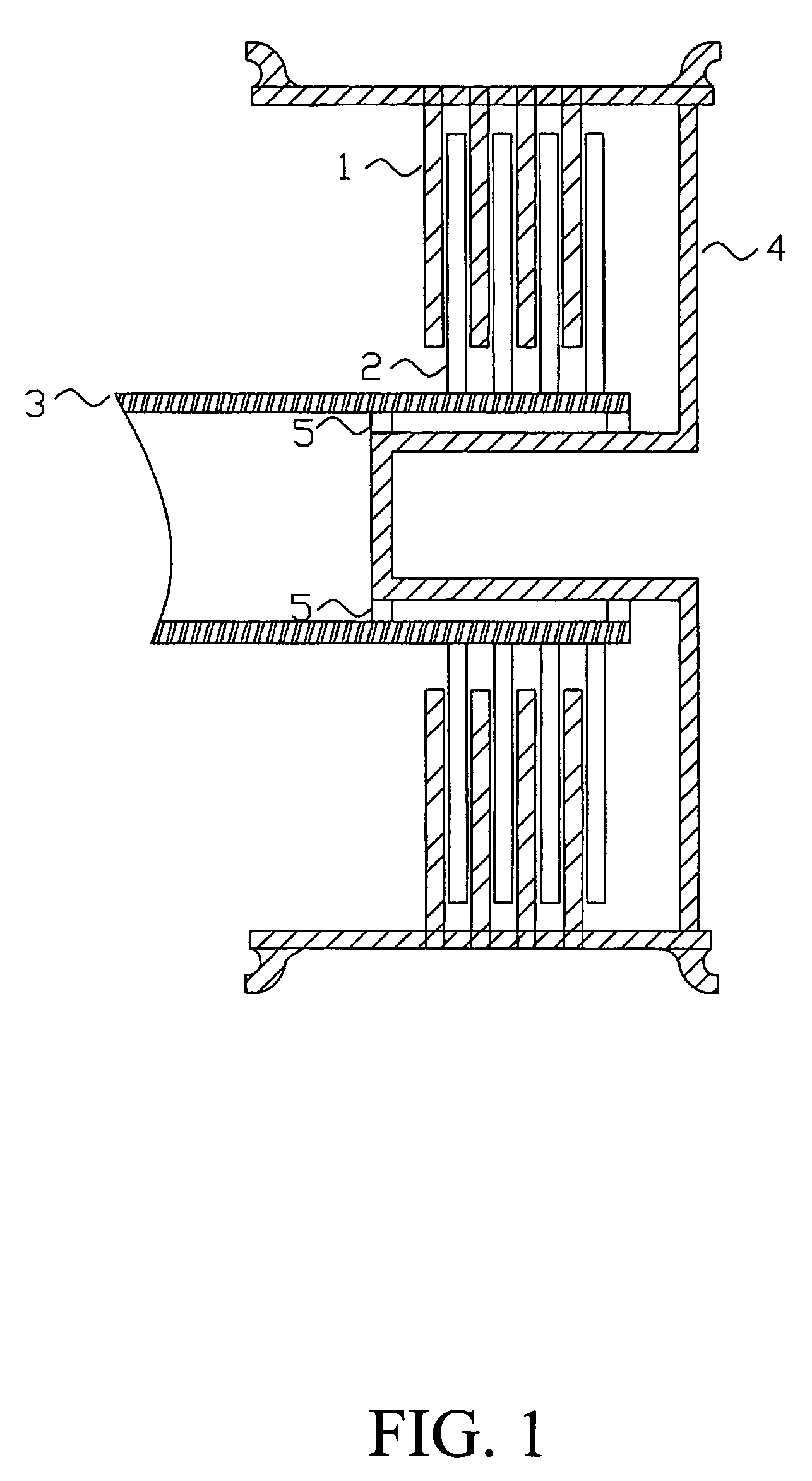

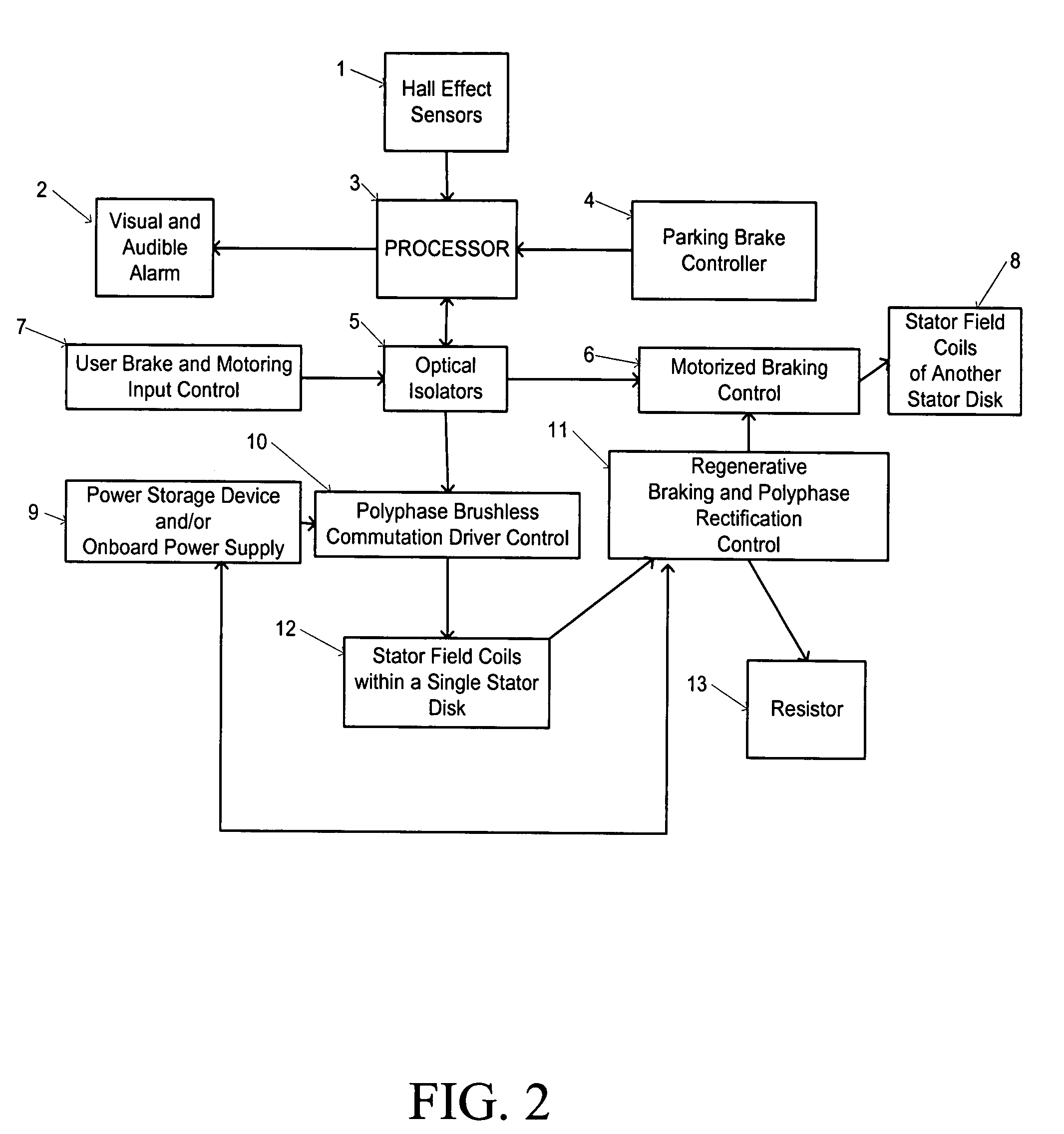

Aircraft landing gear comprised of a wheel hub motor / generator disks stack, includes alternating rotor and stator disks mounted with respect to the wheel support and wheel. The wheel hub motor / generator can provide motive force to the wheel when electrical power is applied, which may be applied prior to touch-down thus decreasing the difference in relative velocities of the tire radial velocity with that of the relative velocity of the runway thus greatly reducing the sliding friction wear of said tire. After touchdown the wheel hub motor / generator may be used as a generator thus applying a regenerative braking force and / or a motorized braking action to the wheel. The energy generated upon landing maybe dissipated through a resistor and / or stored for later use in providing a source for motive power to the aircraft wheels for the purpose of taxiing and ground maneuvers of said aircraft.

Owner:DELOS AEROSPACE

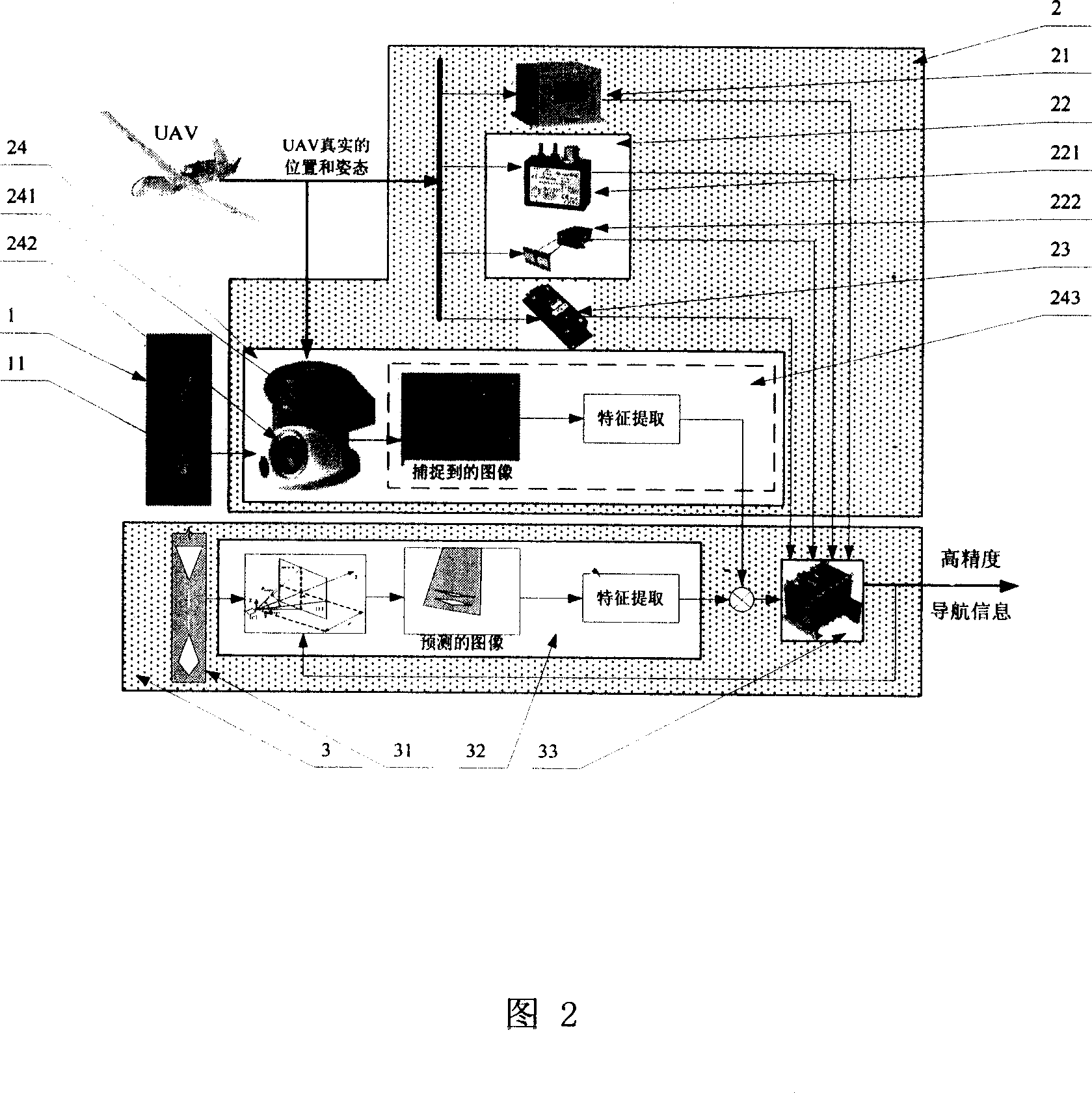

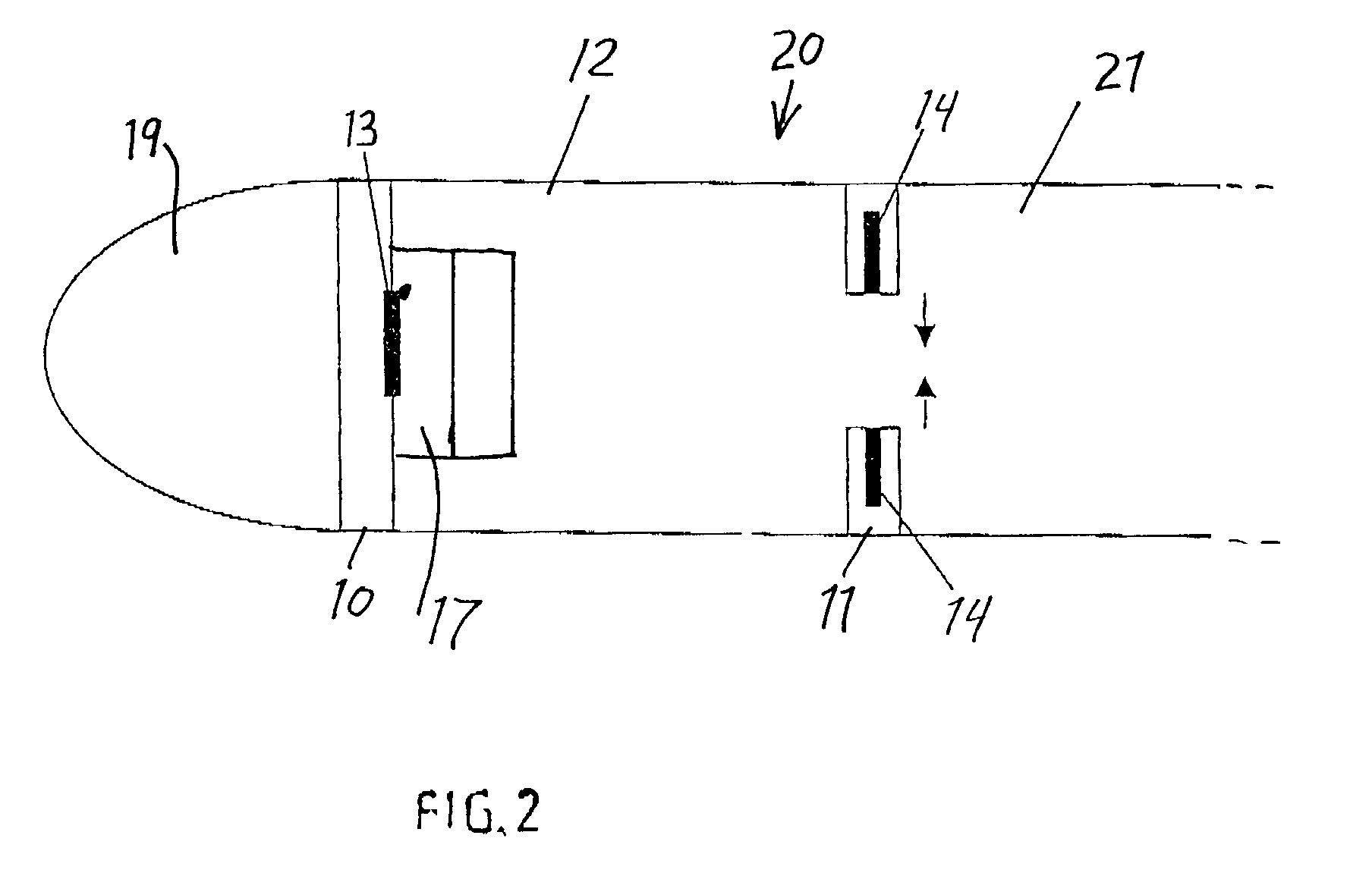

Unmanned aircraft landing navigation system based on vision

InactiveCN101109640AImprove survivabilityNavigational calculation instrumentsVehicle position/course/altitude controlJet aeroplaneOn board

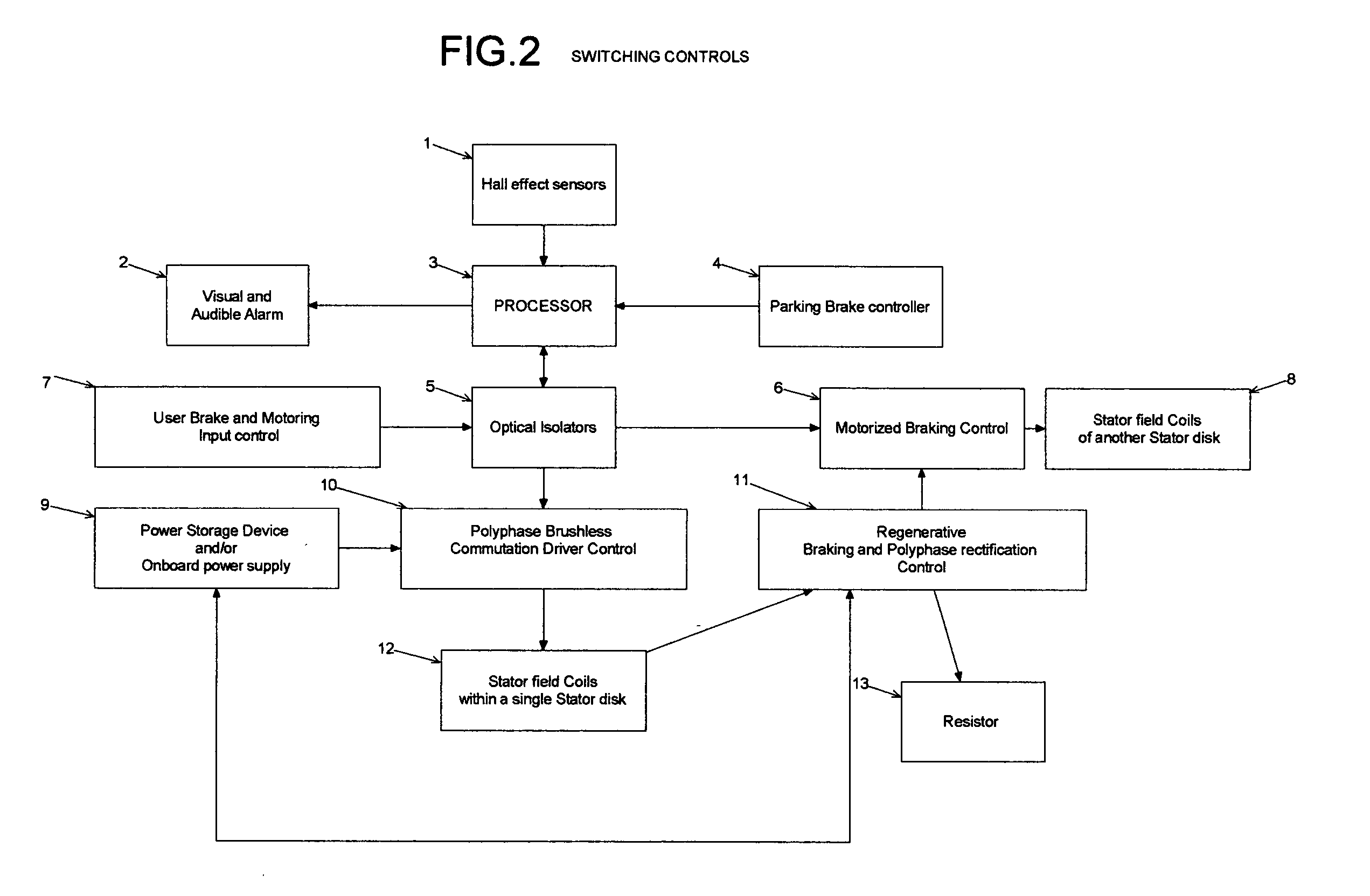

The invention provides a vision-based self-aid landing navigation system for an unattended air plane, which comprises a software arithmetic and a hardware arrangement. The software arithmetic comprises a computer vision arithmetic and an information merging and state estimation arithmetic; the hardware arrangement comprises a runway feature, on-board sensor subsystem and an information merging subsystem. The on-board sensor subsystem comprises an on-board camera system, an on-board inertial navigation system, a height meter system and a magnetic compass, measures the real UAV state, traces and analyzes the runway features by the on-board camera system, gets the measurements of the runway feature points, and sends the measurements to the information merging subsystem. The information merging subsystem gets the estimated value of the runway feature points through the runway model and the camera system model based on the estimated value of the airplane state at previous period as well as the measurement on the airplane state at current period by the on-board sensor subsystem, and compares with the measurements, merges other measurement information, and gets navigation information of high accuracy through calculation by the data processing module.

Owner:BEIHANG UNIV

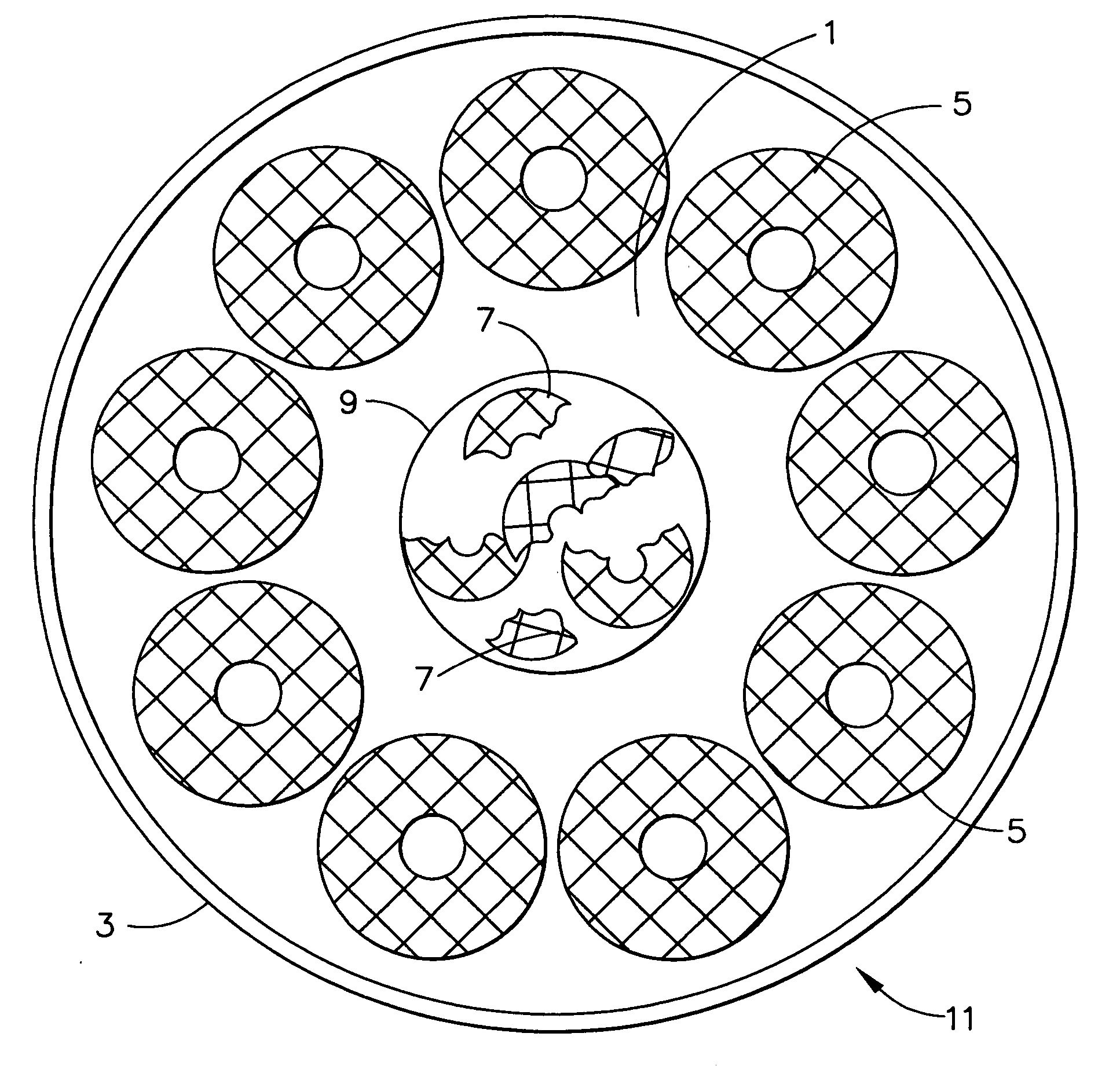

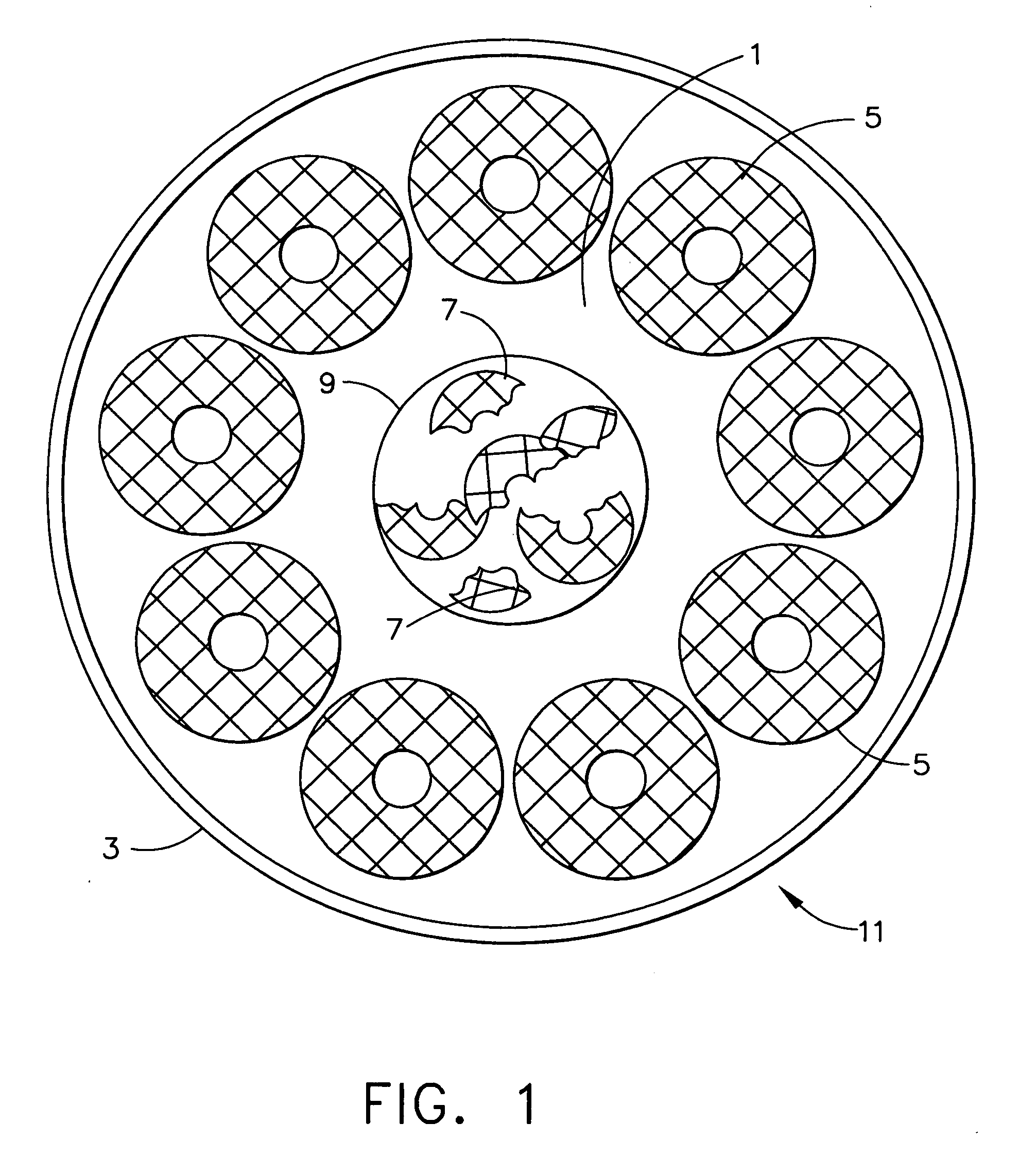

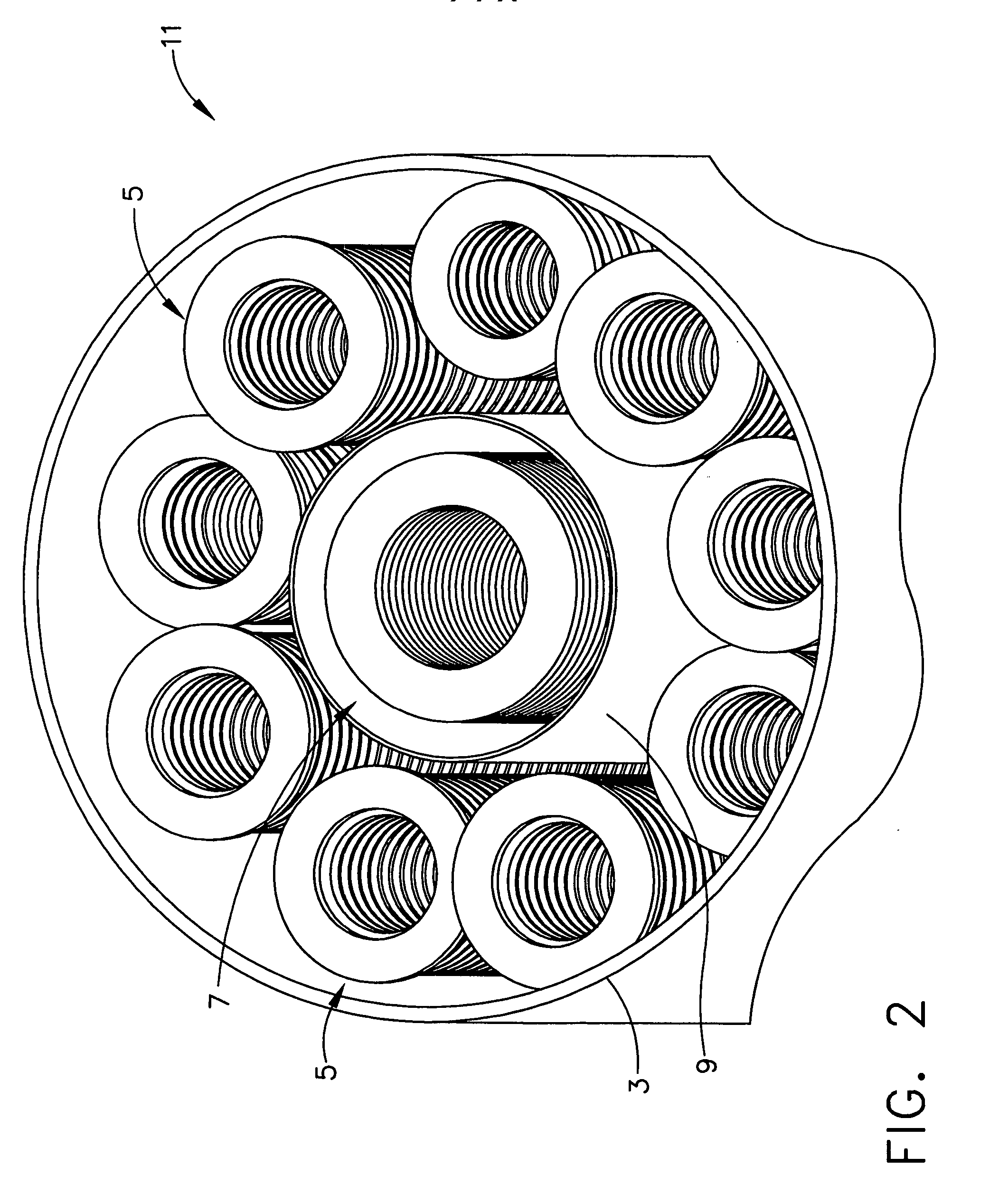

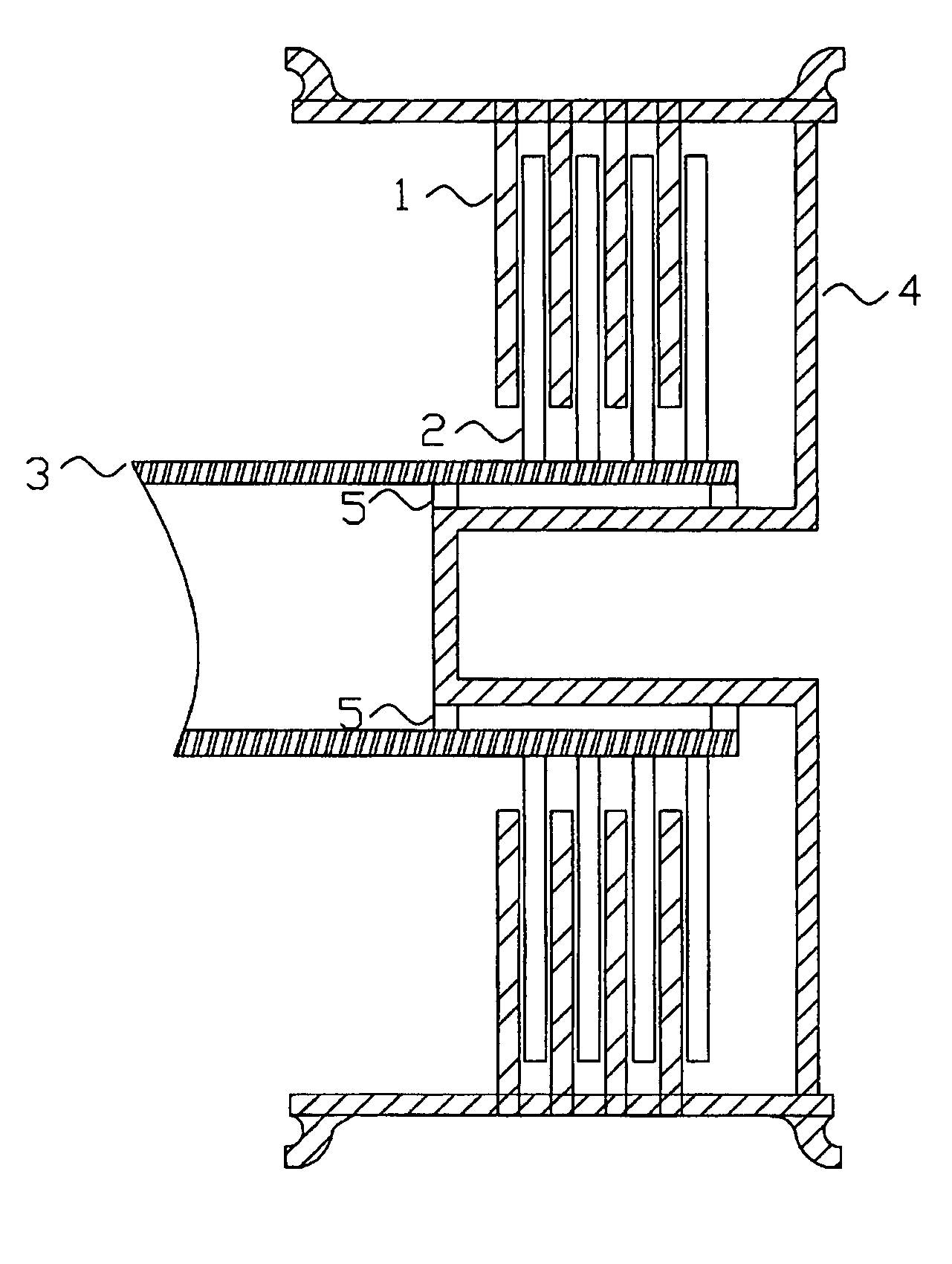

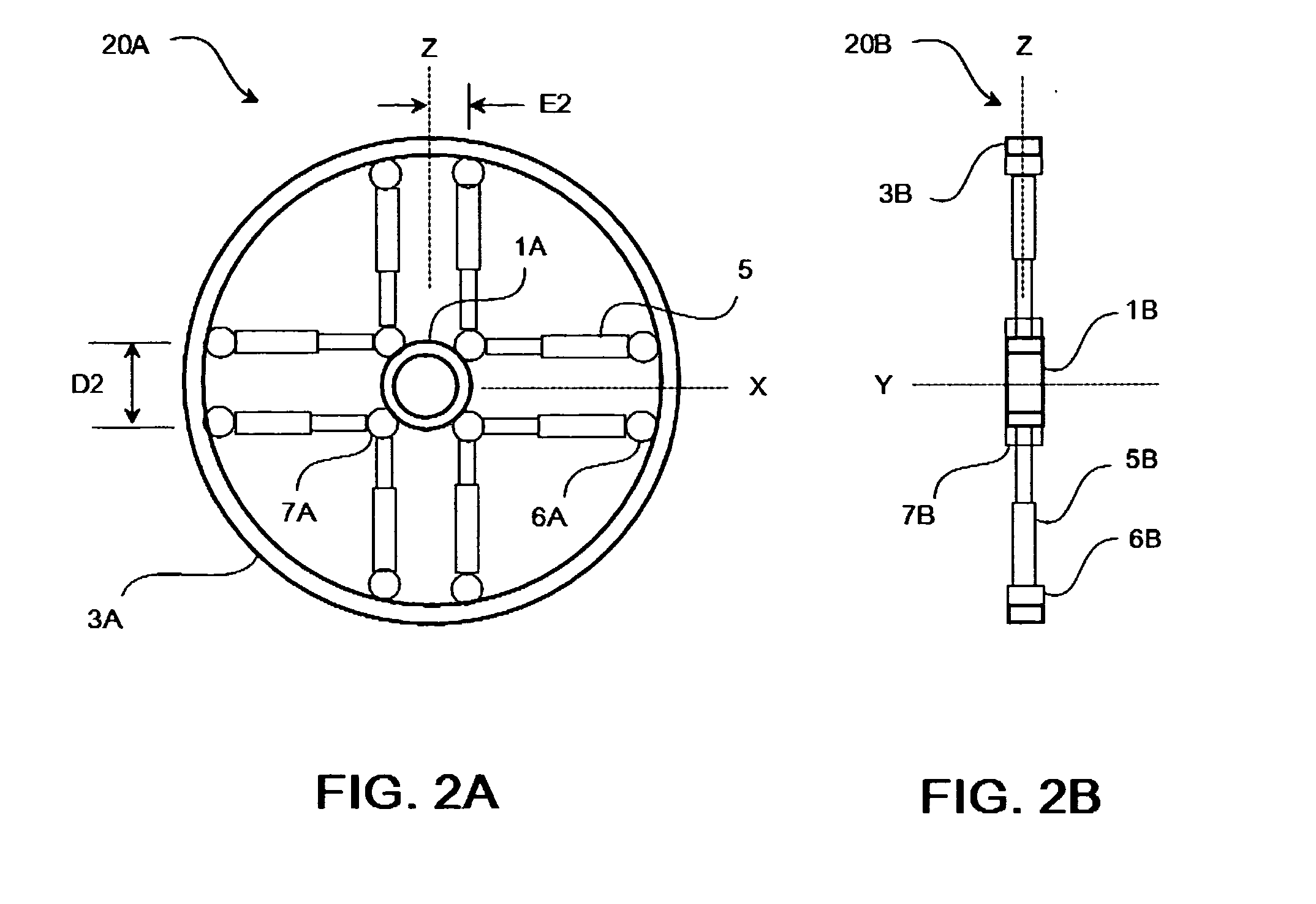

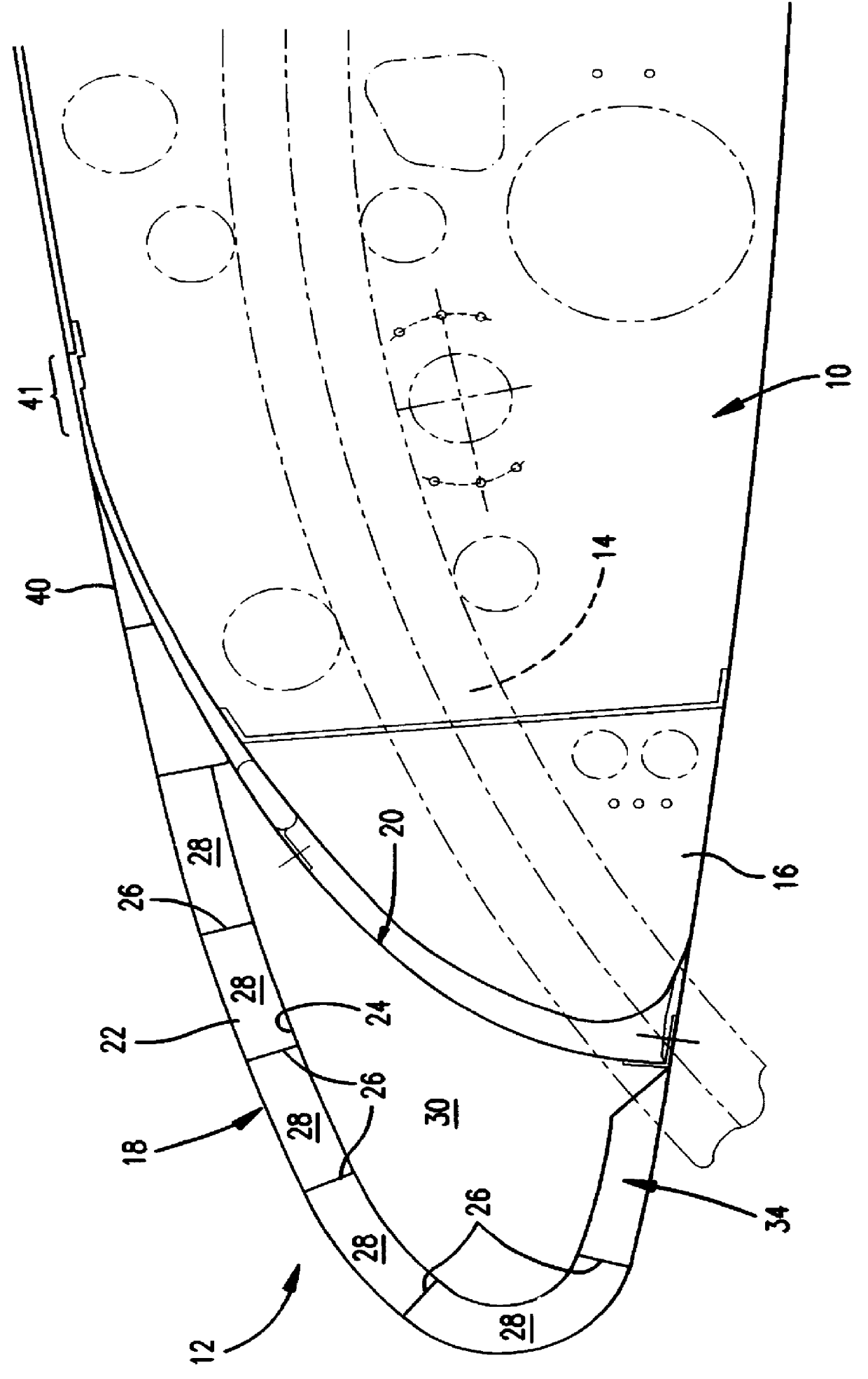

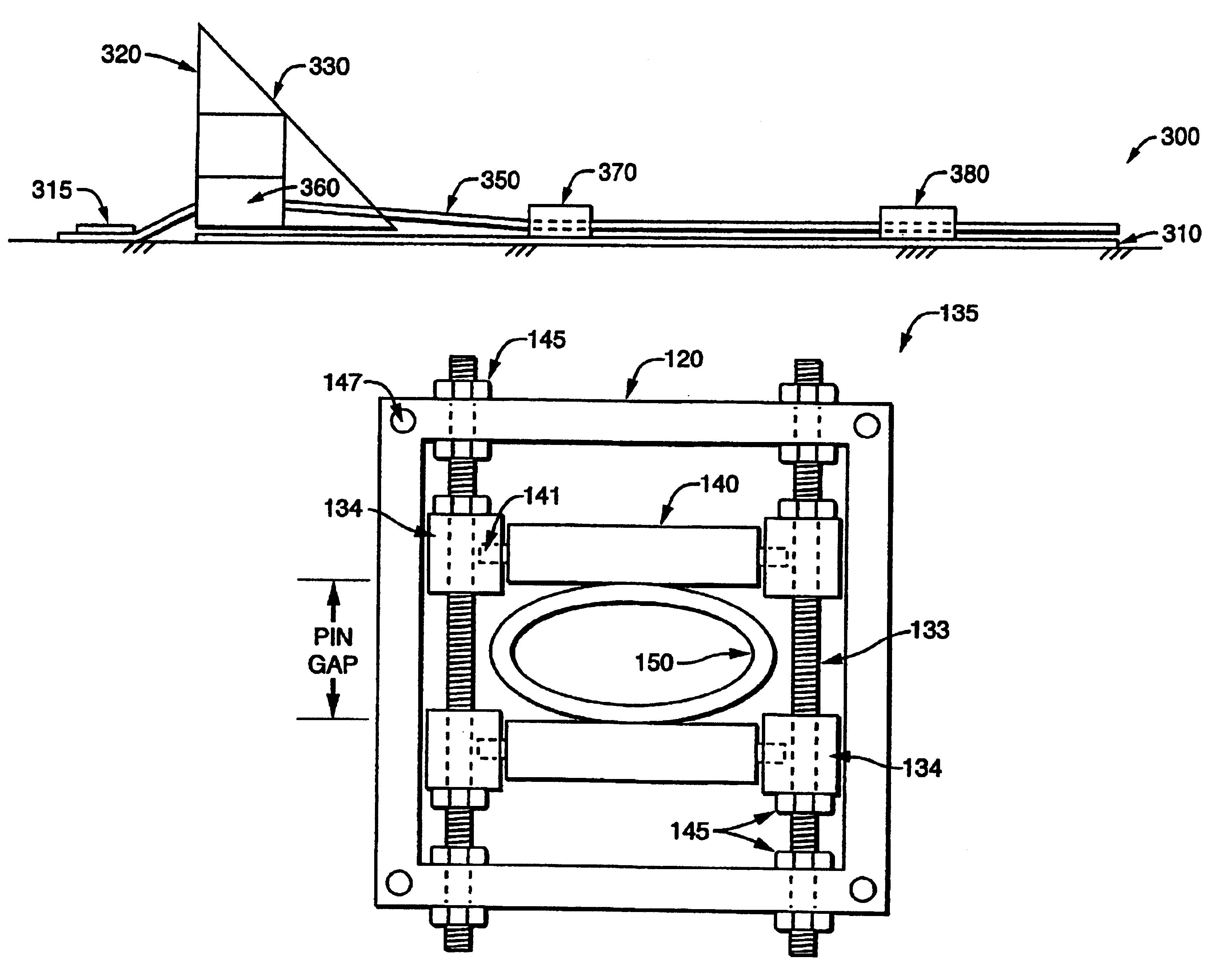

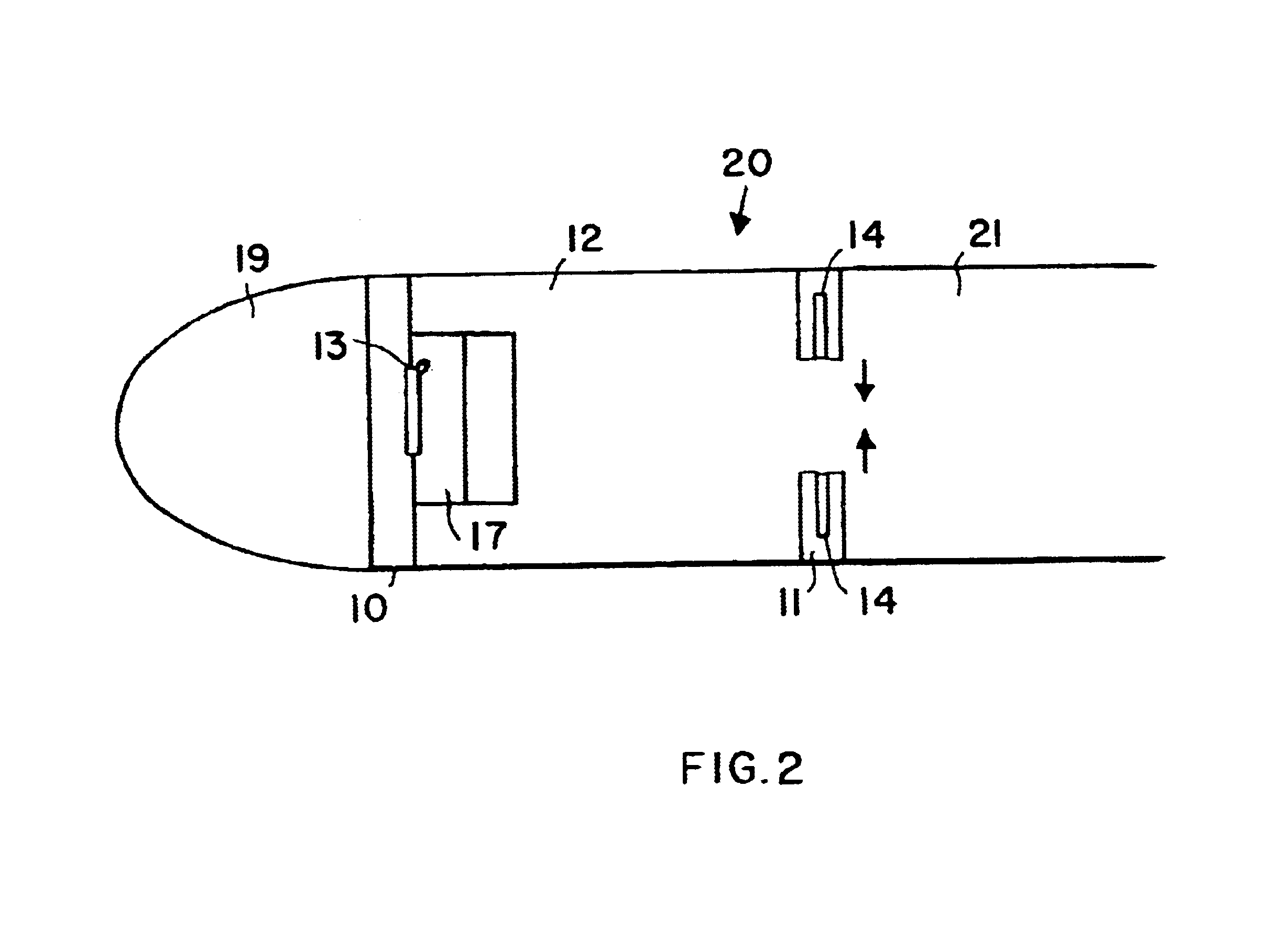

Chemical vapor deposition apparatus and method

InactiveUS20060046059A1High densityGreat and uniform weightLayered productsChemical vapor deposition coatingCarbon compositesCircular disc

Apparatus such as a furnace muffle (11) for use in a CVI / CVD furnace. The apparatus includes a bottom (12), a top (13), and an outer wall (3) defining an interior space (1) in the apparatus, and a passive heat distribution element (7, 9) located within the interior space (1) and apart from the outer wall (3). Preferably, the bottom (12) and top (12) include perforated plates and the outer wall (3) is cylindrical in shape and all are made of graphite or carbon-carbon composite material and the passive heat distribution element (7, 9) is cylindrical in shape and includes graphite or carbon-carbon composite discs having no spacers therebetween. Also, a method for densifying a porous carbon preform (5), which method includes the steps of: (a) providing the apparatus (11); (b) charging the apparatus (11) with a plurality of stacks of annular porous carbon preforms (5), the preforms being separated from one another by spacers (15); (c) locating the charged apparatus (11) in a furnace at a temperature in the range of 950-1100° C. and a pressure in the range of 5-40 torr; and (d) circulating a natural gas reactant blended with up to 15% propane through the apparatus for 150-900 hours. Also, a batch of carbon-carbon composite preforms made by the method, wherein the density of the batch of preforms is at least 0.5 g / cc higher than the density of a batch of preforms made by an otherwise identical process in which the apparatus does not contain a passive heat distribution element located within its interior. The preforms may be configured as aircraft landing system brake discs or racing car brake discs.

Owner:HONEYWELL INT INC

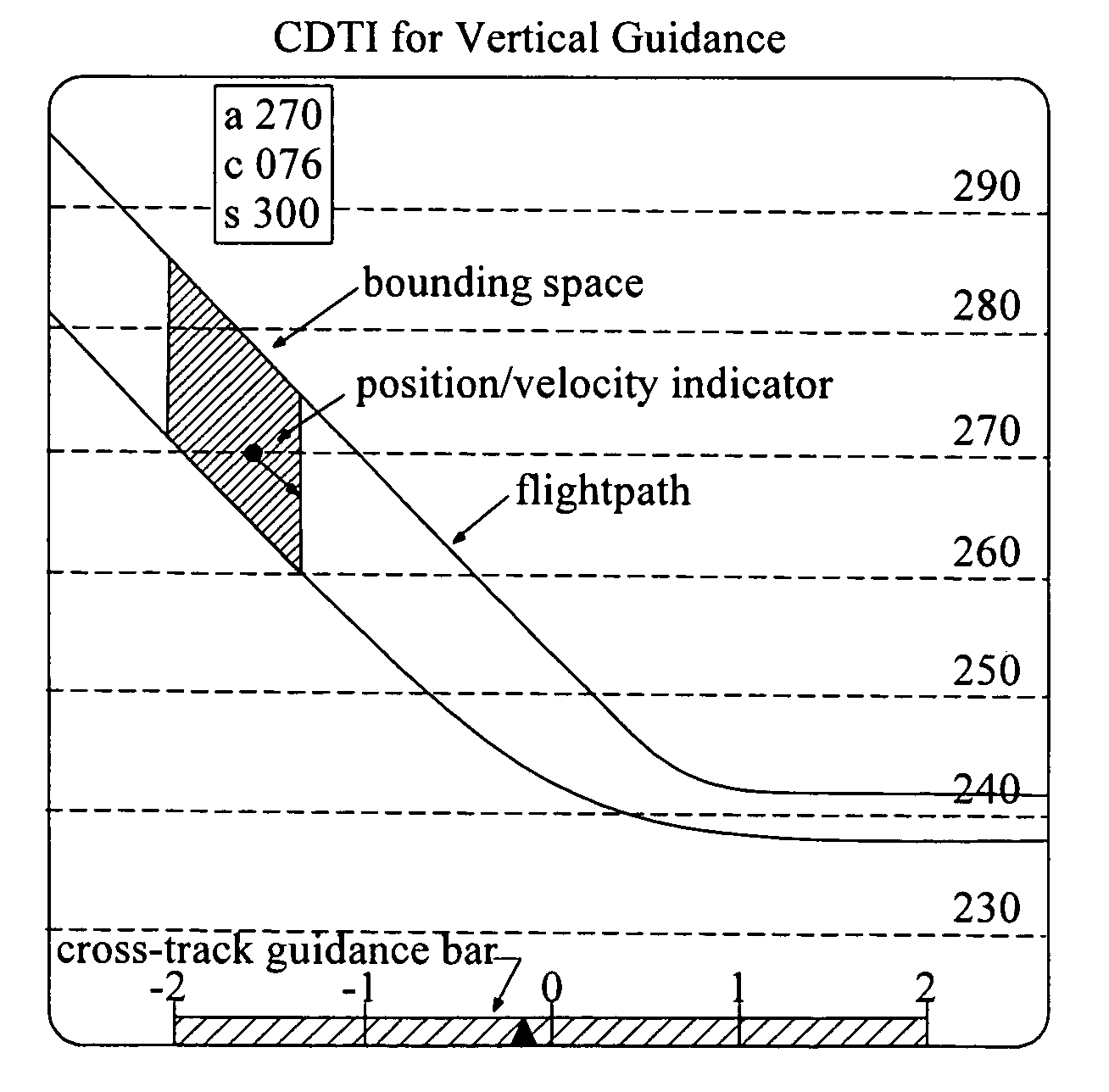

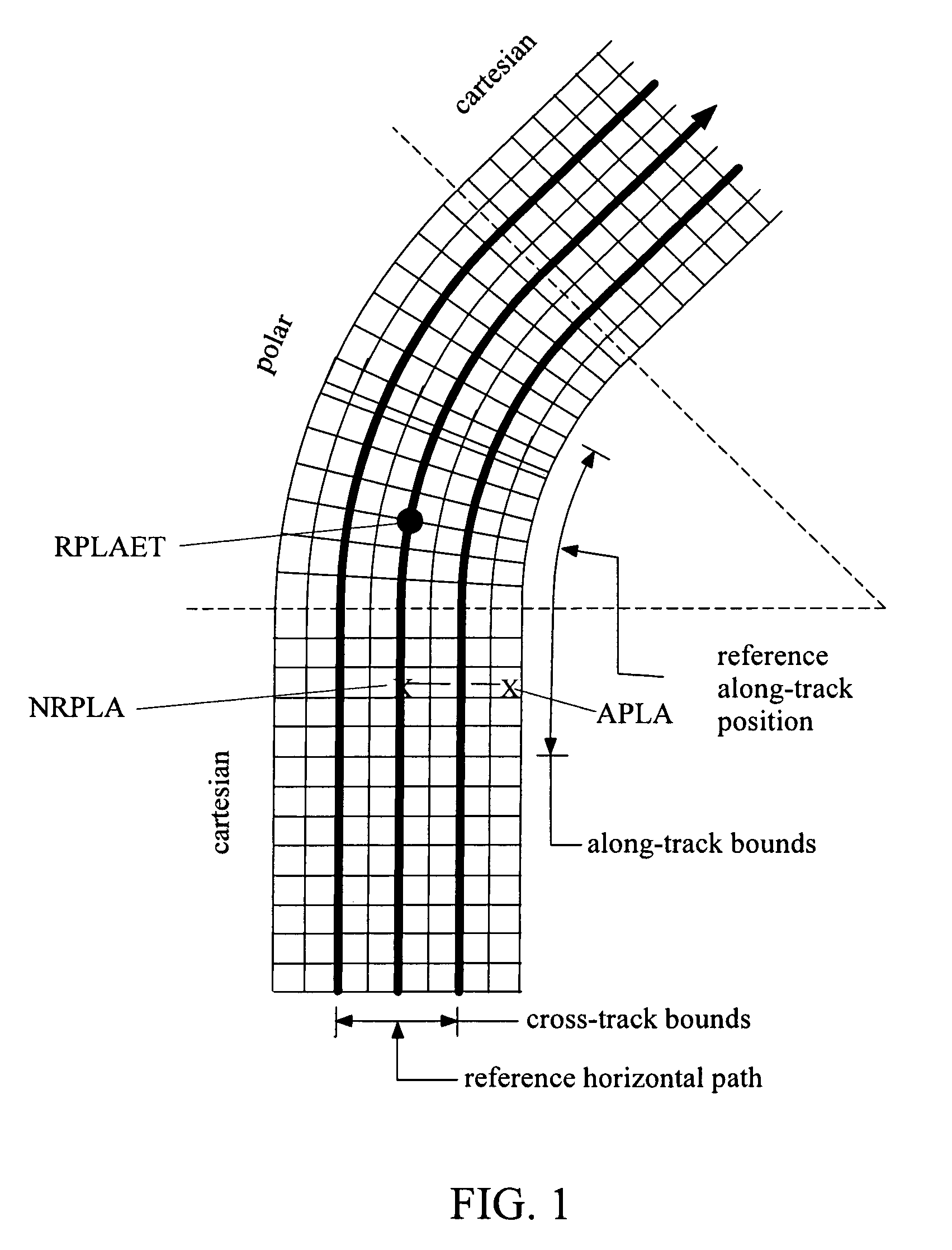

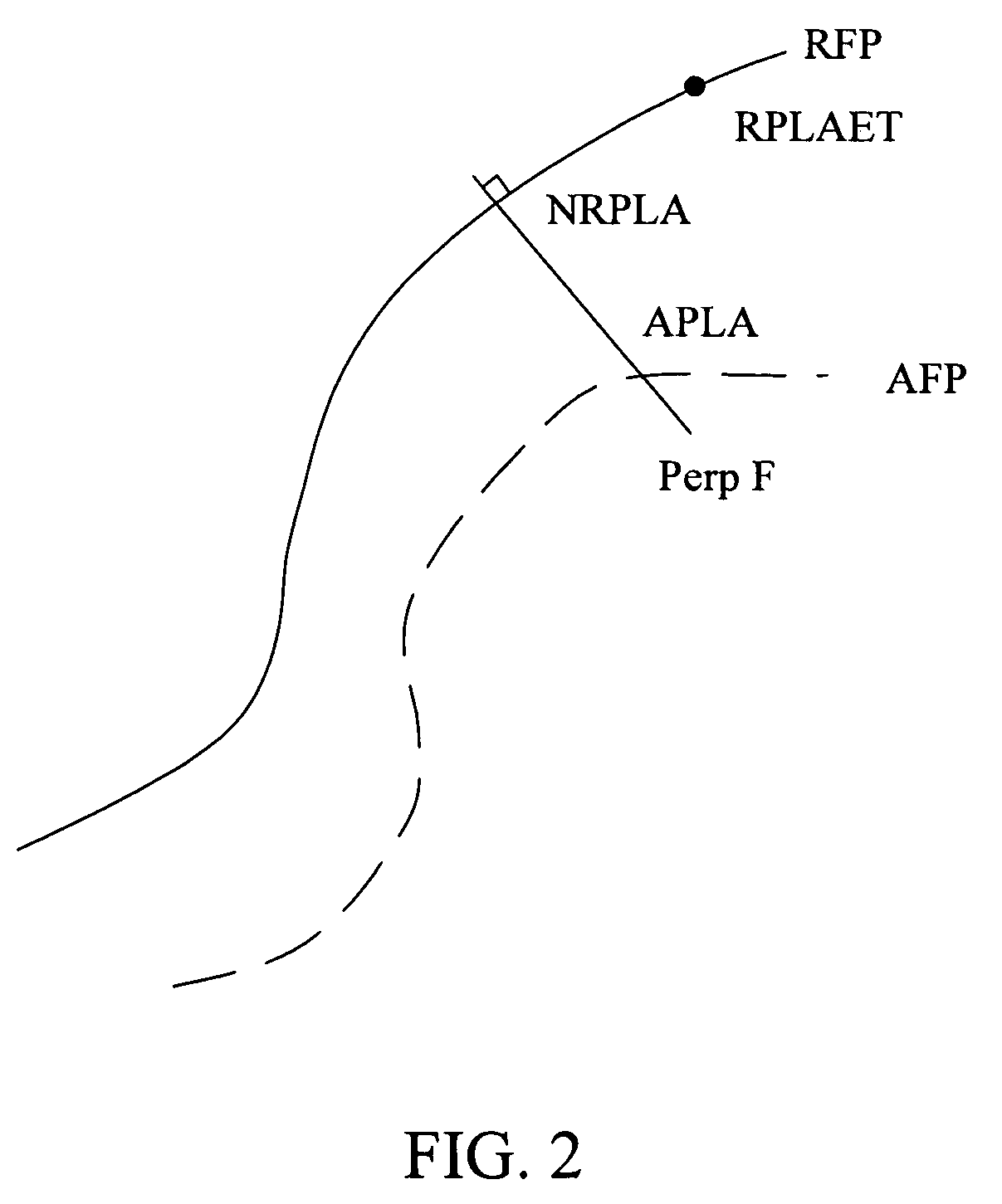

Trajectory specification for high capacity air traffic control

InactiveUS7650232B1Navigation instrumentsMultiple aircraft traffic managementSystems analysisAir traffic control

Method and system for analyzing and processing information on one or more aircraft flight paths, using a four-dimensional coordinate system including three Cartesian or equivalent coordinates (x, y, z) and a fourth coordinate δ that corresponds to a distance estimated along a reference flight path to a nearest reference path location corresponding to a present location of the aircraft. Use of the coordinate δ, rather than elapsed time t, avoids coupling of along-track error into aircraft altitude and reduces effects of errors on an aircraft landing site. Along-track, cross-track and / or altitude errors are estimated and compared with a permitted error bounding space surrounding the reference flight path.

Owner:NASA

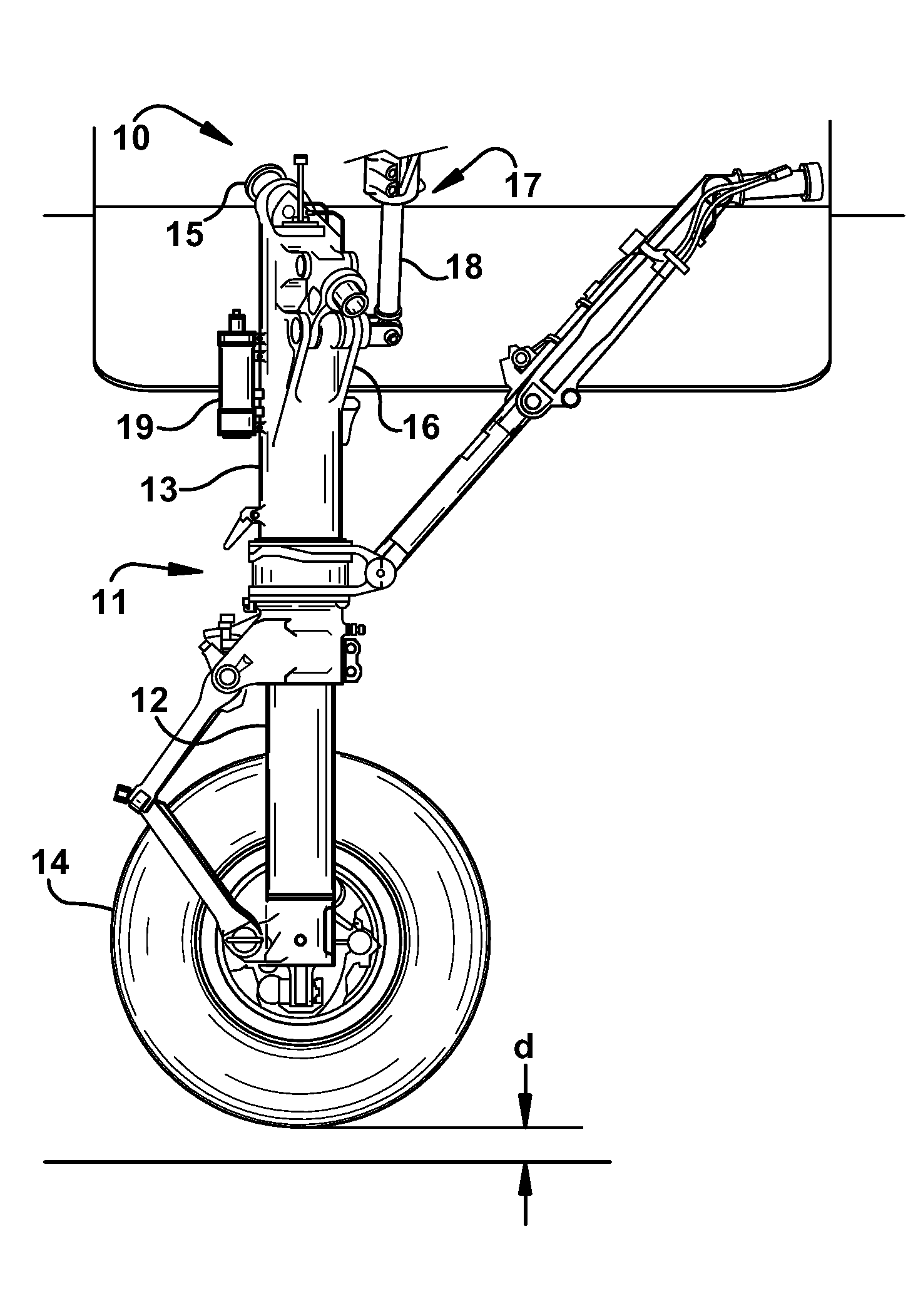

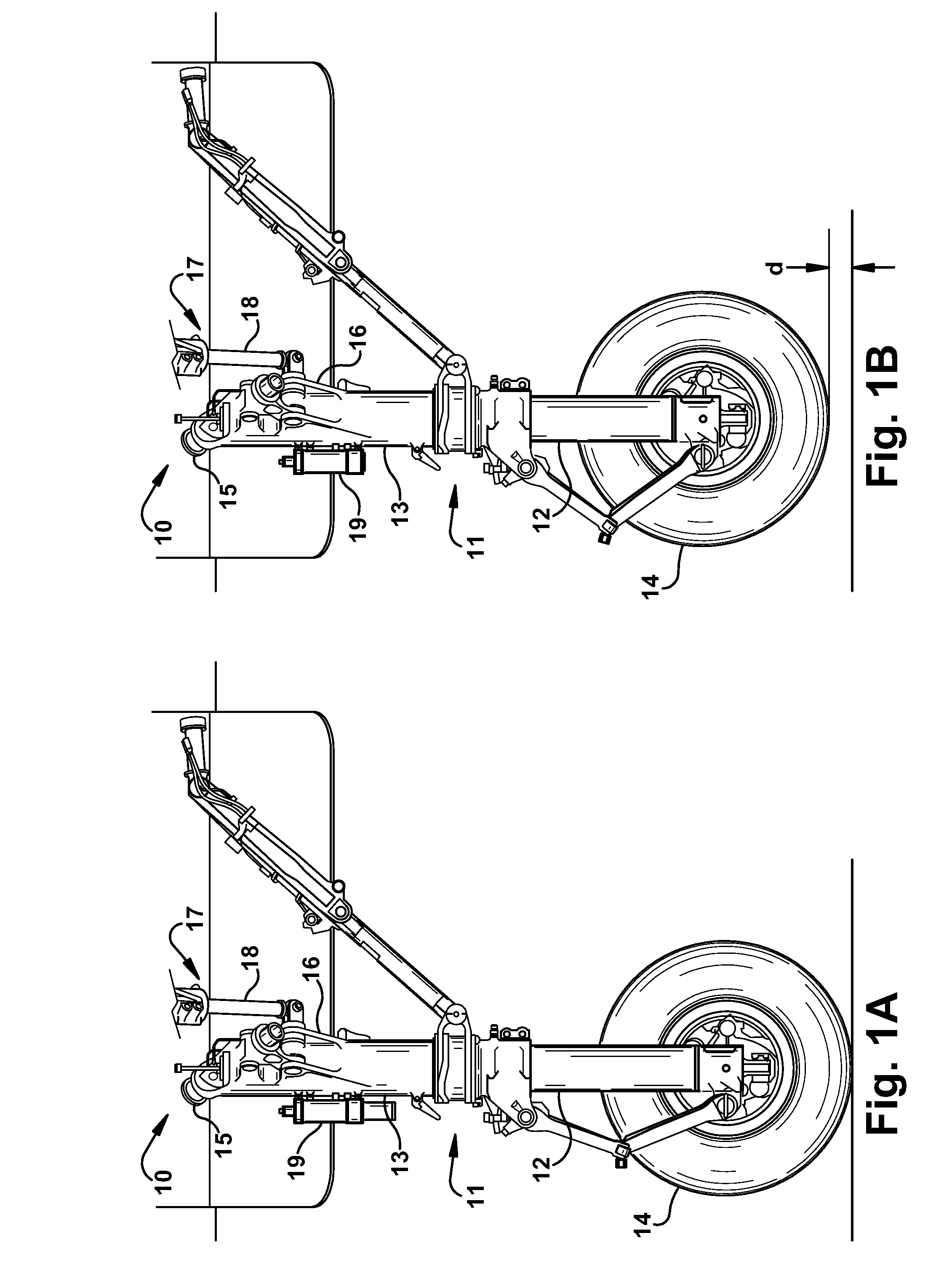

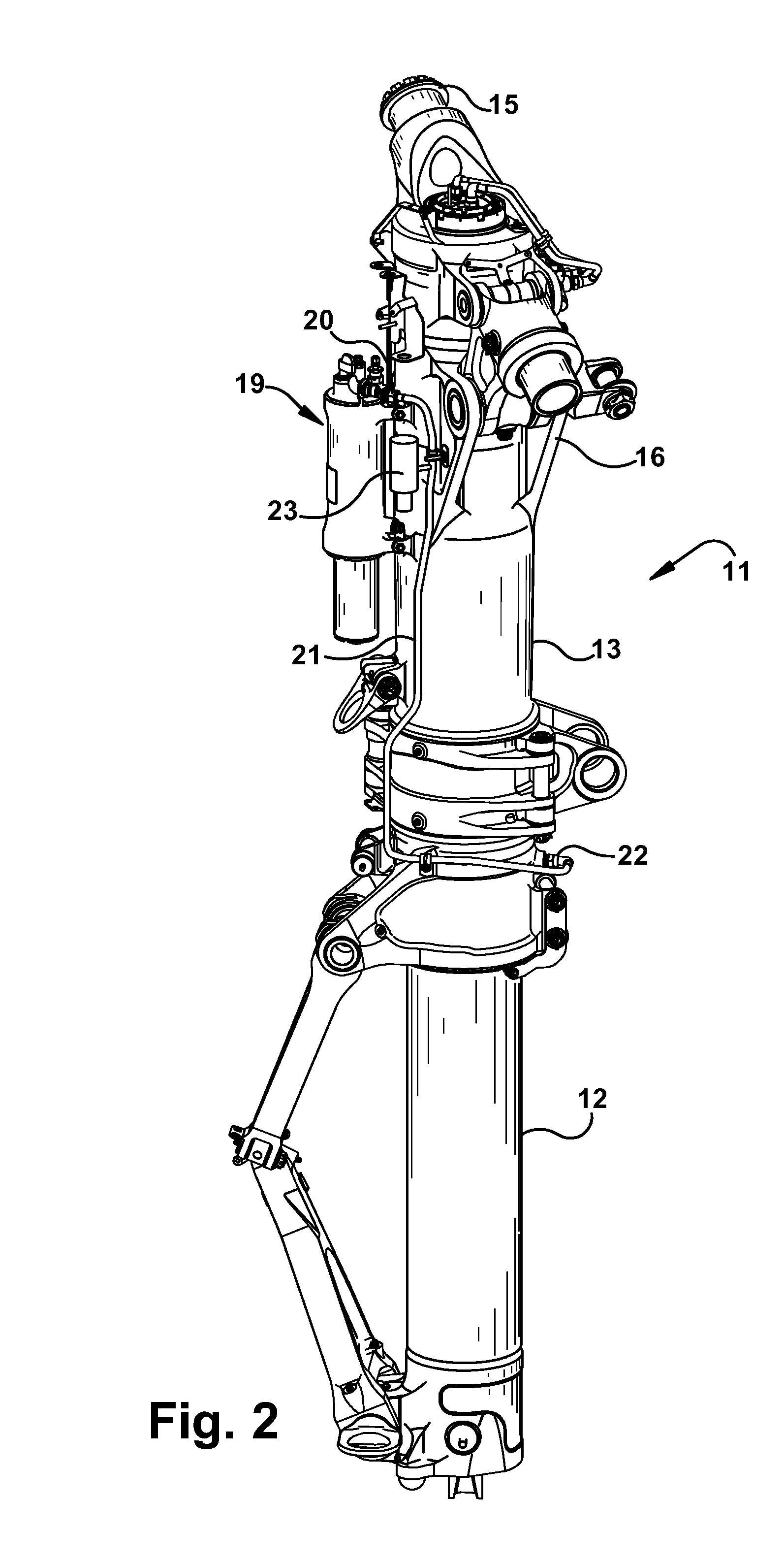

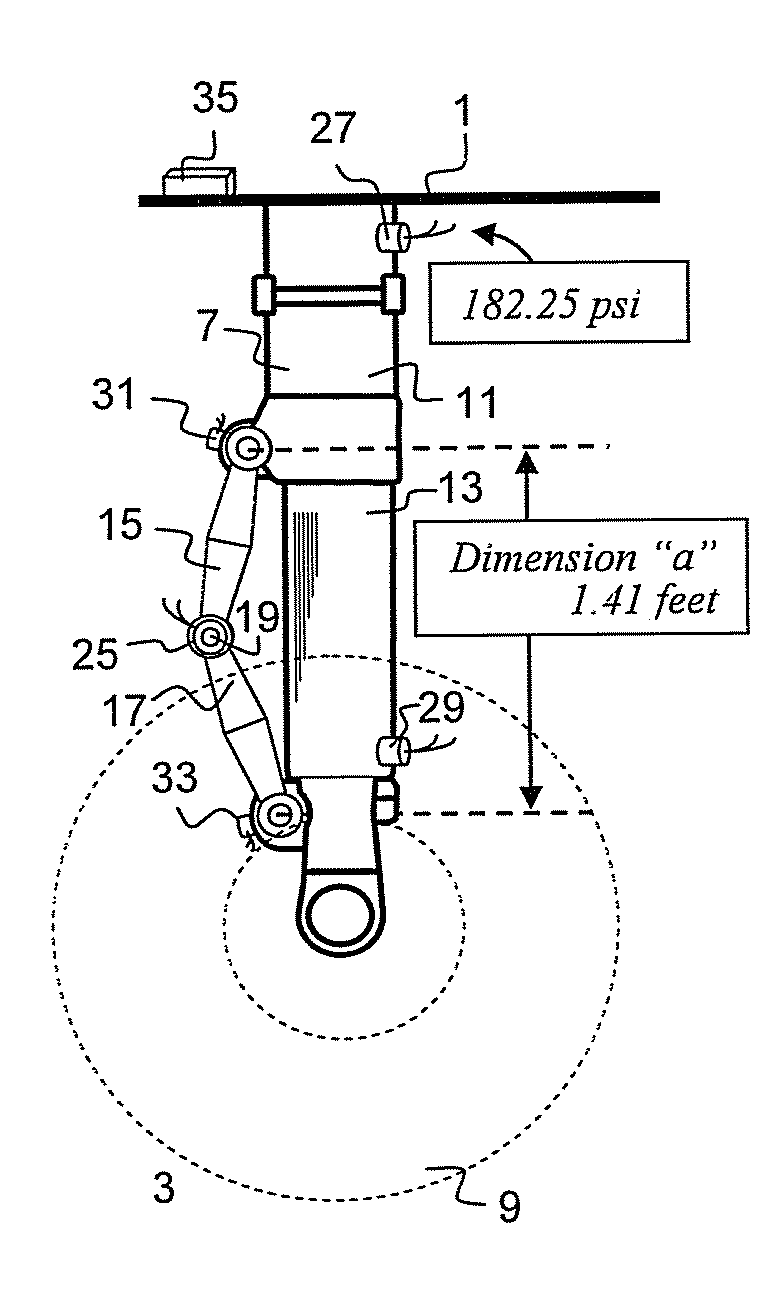

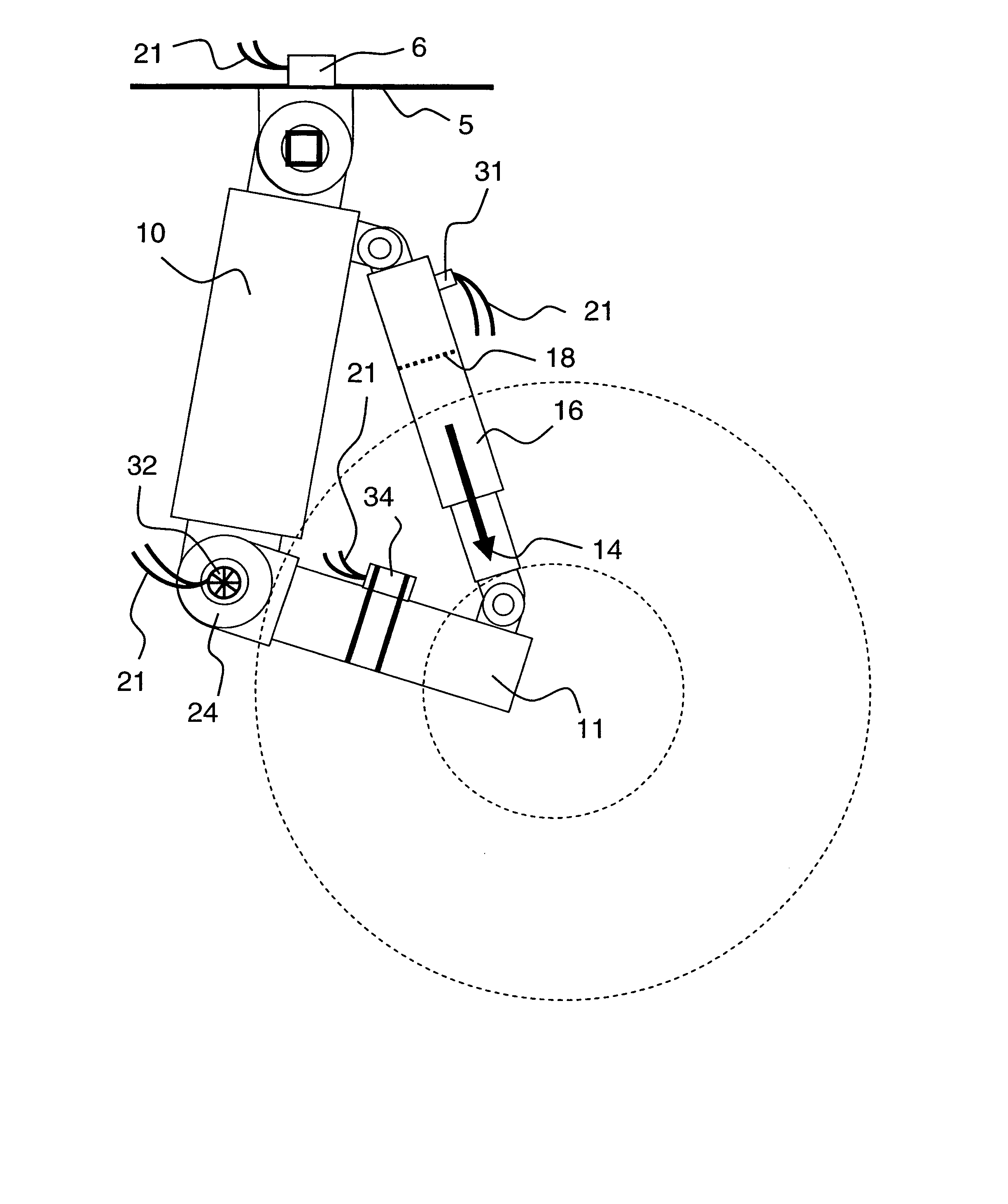

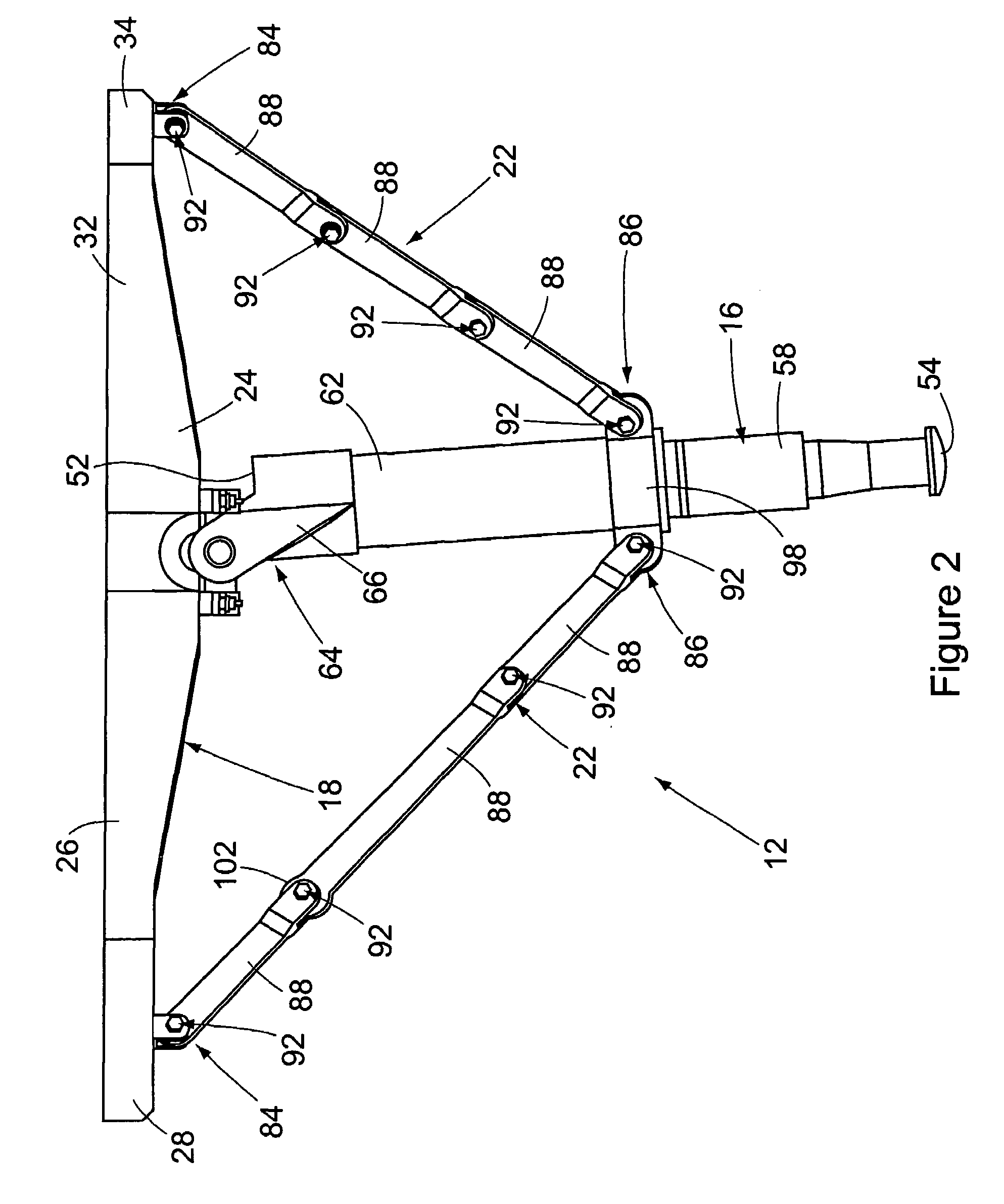

Electric-powered transfer cylinder for landing gear system

ActiveUS20100219290A1High hydraulic fluid flow rateSufficiently compactSpringsShock absorbersGear systemAircraft landing

A shock strut for an aircraft landing gear having a retract actuator that is moveable in length to deploy or retract the landing gear, that includes a shrink strut and a transfer device. The shrink strut may be compressed in length for stowage in the fuselage. The transfer device may be in closed fluid communication with the strut shrink for transferring and receiving hydraulic fluid to and from the strut shrink. When actuated by an aircraft hydraulic or electric system independent of any motion of the retract actuator, the transfer device may drive hydraulic fluid to the strut shrink thereby compressing or shrinking the shrink strut to a partially compressed length.

Owner:THE BF GOODRICH CO

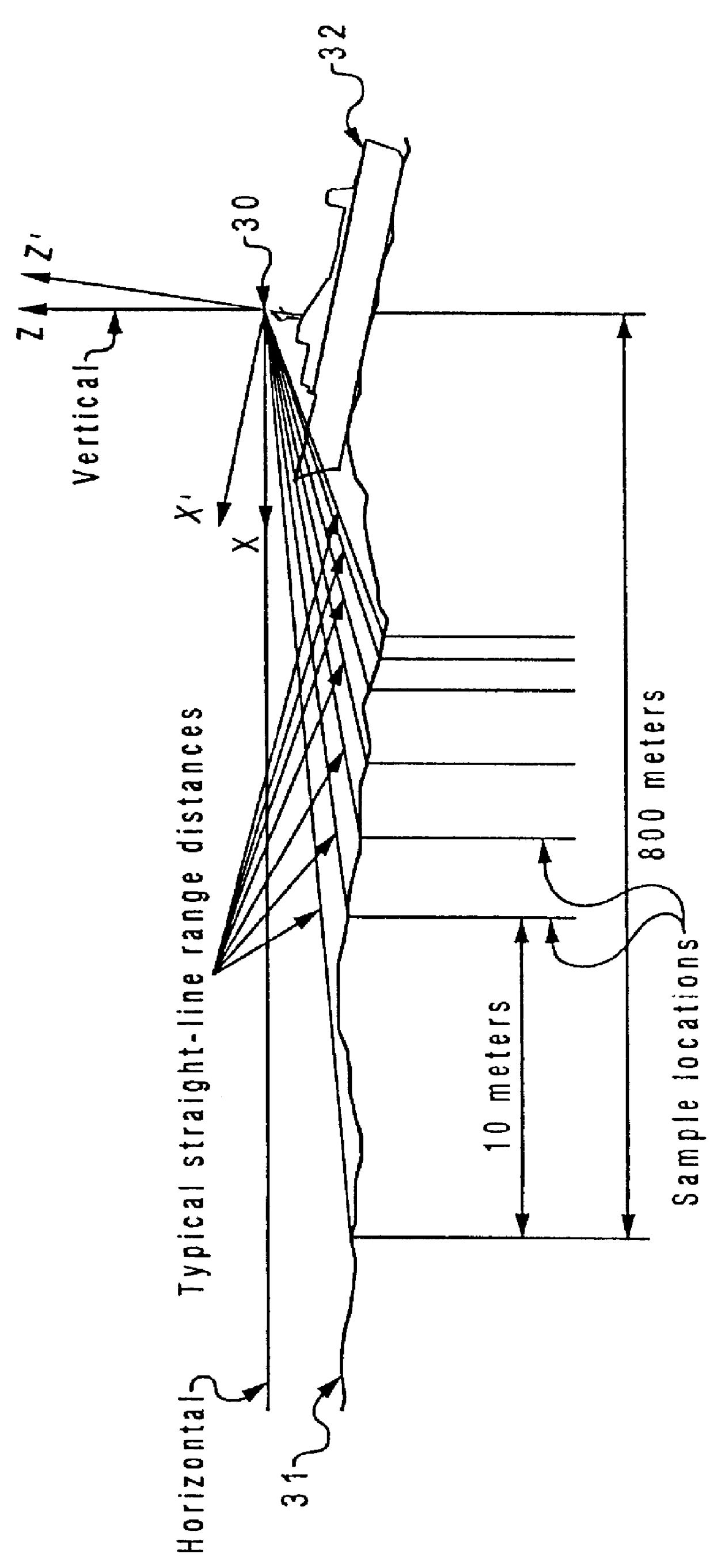

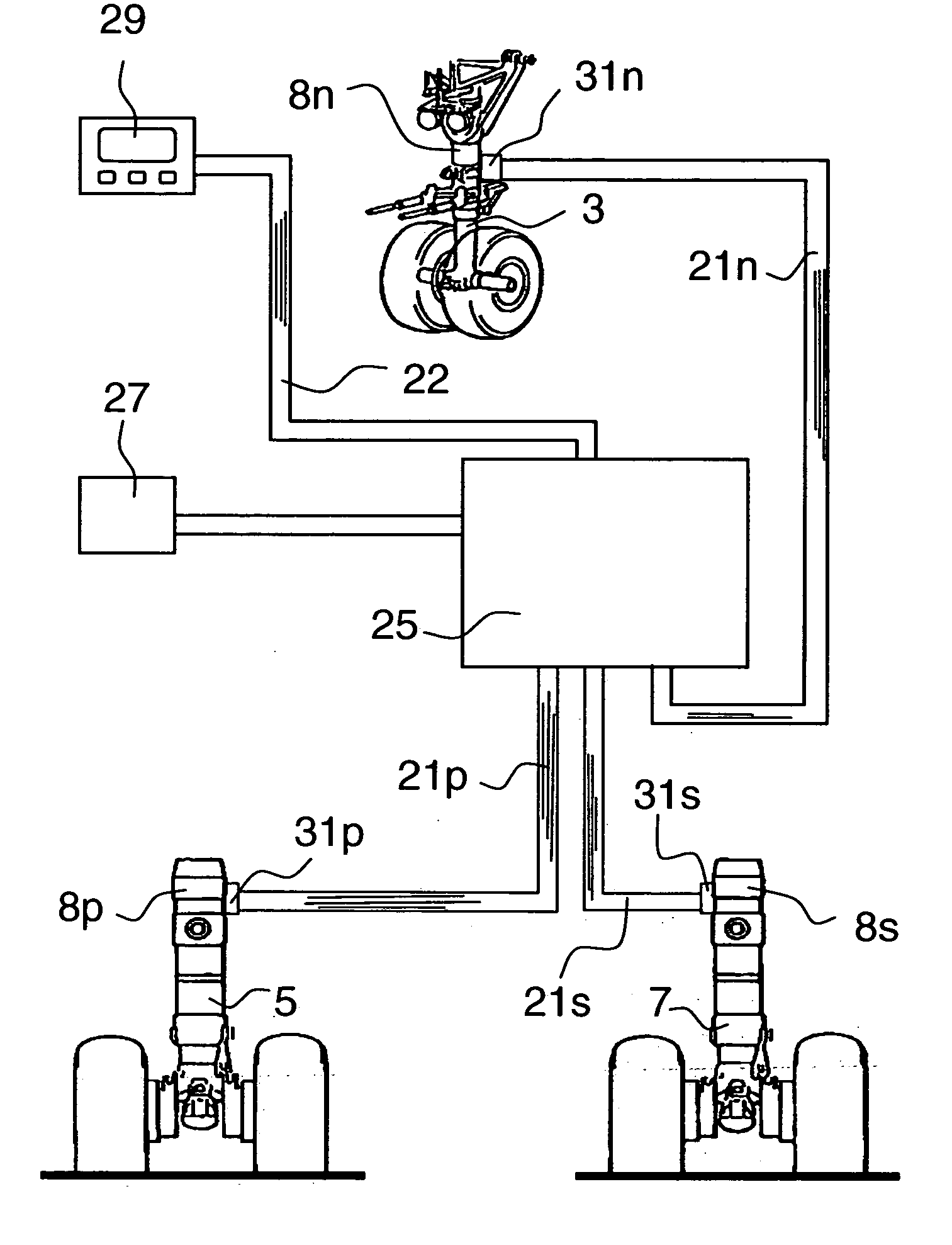

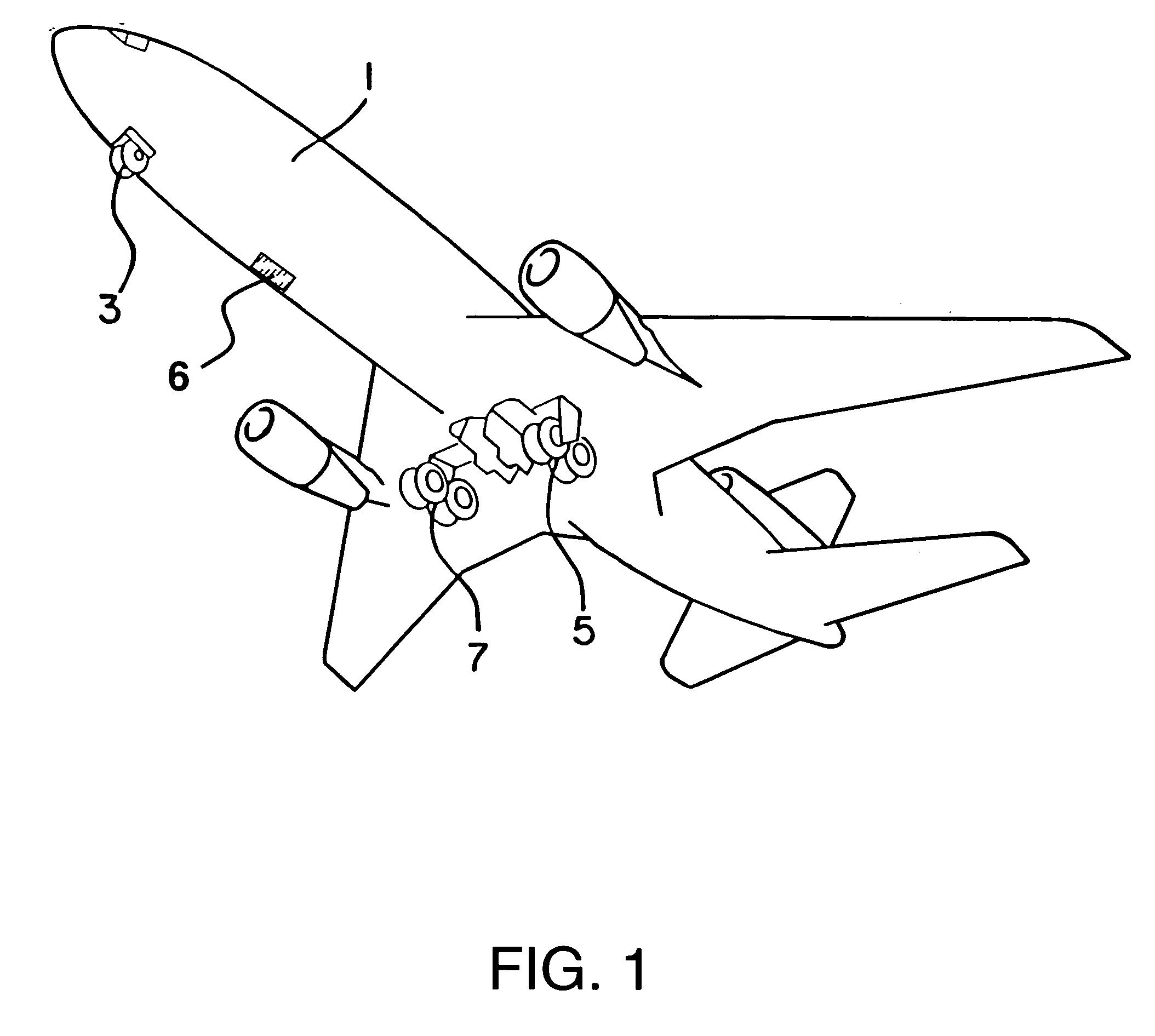

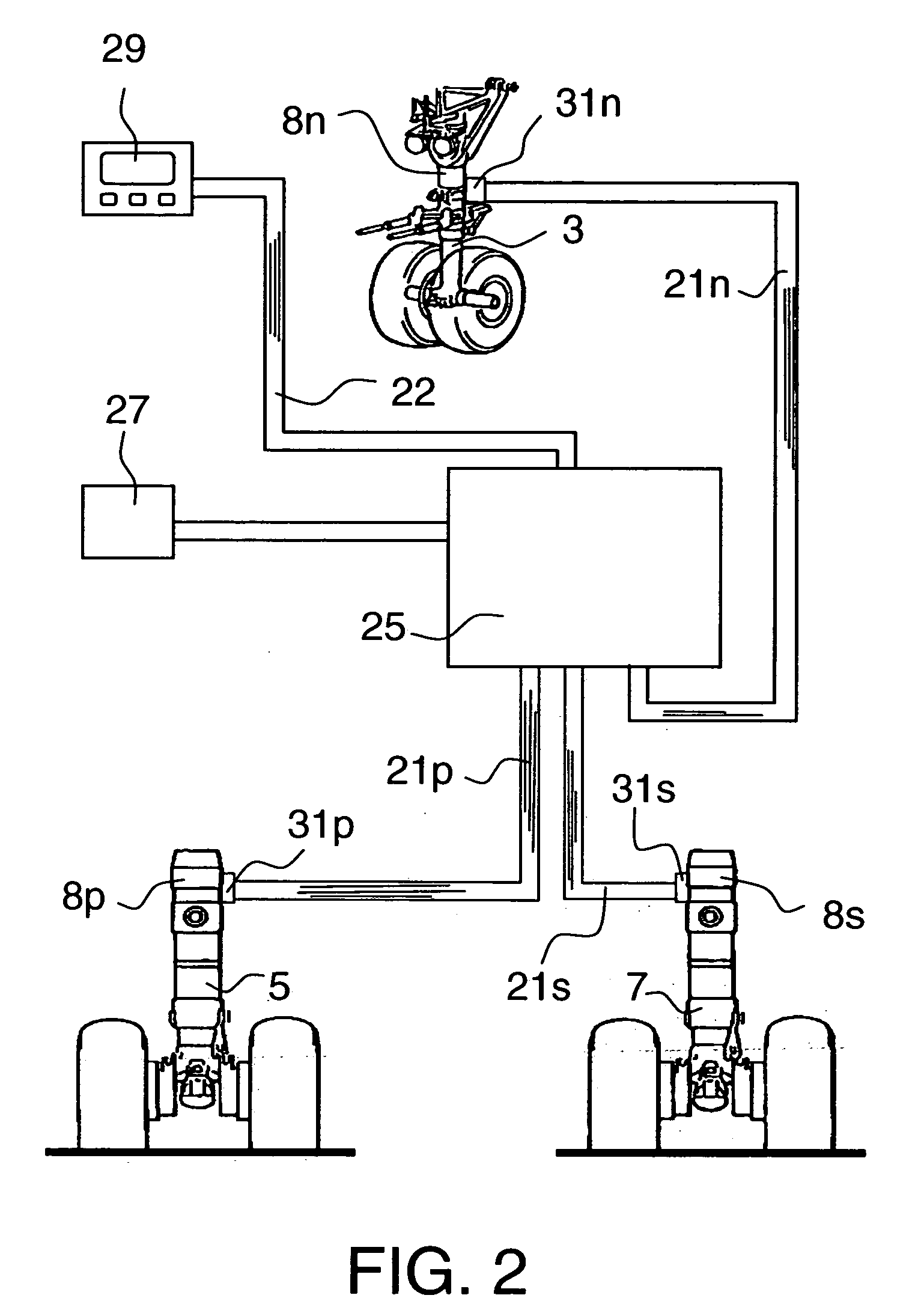

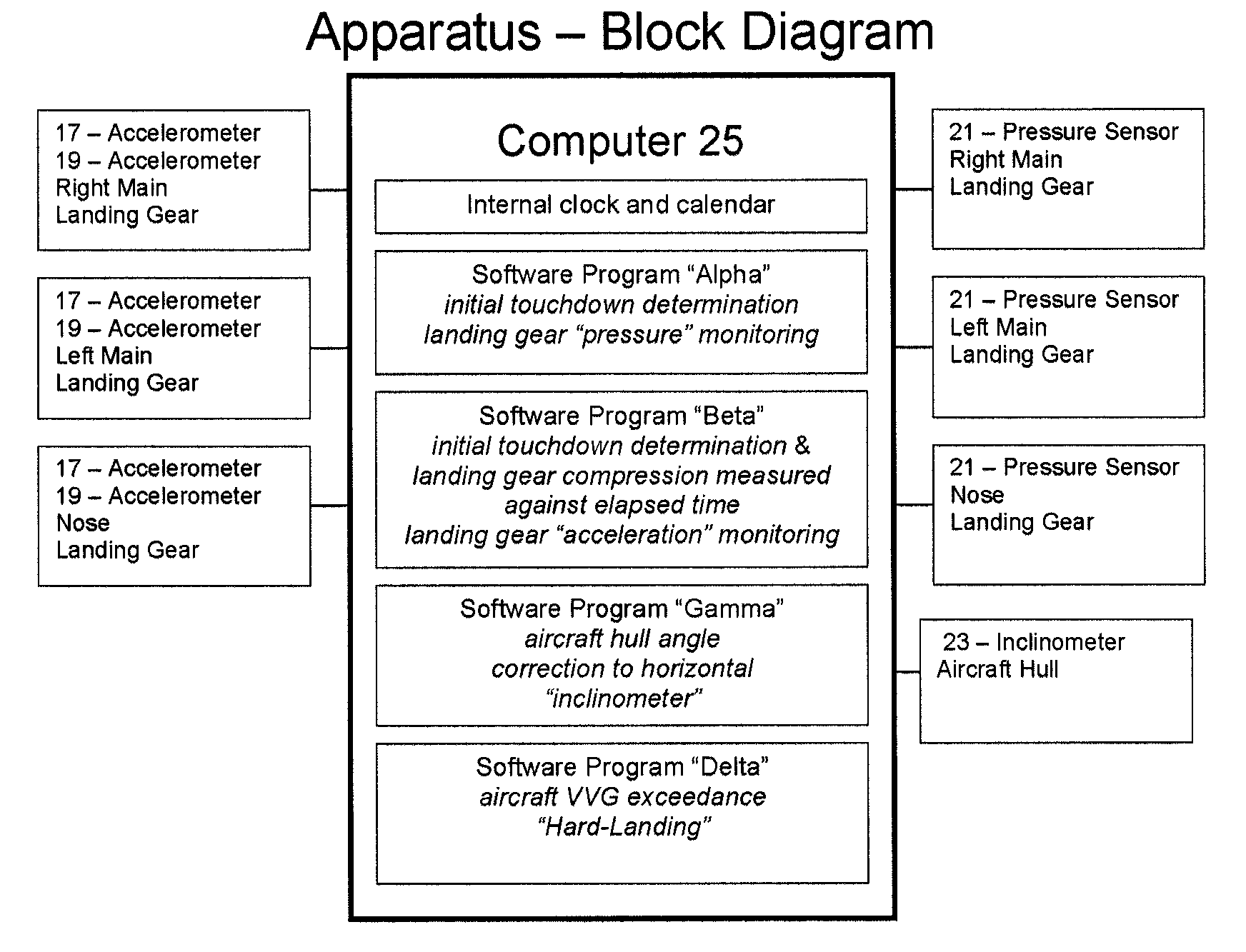

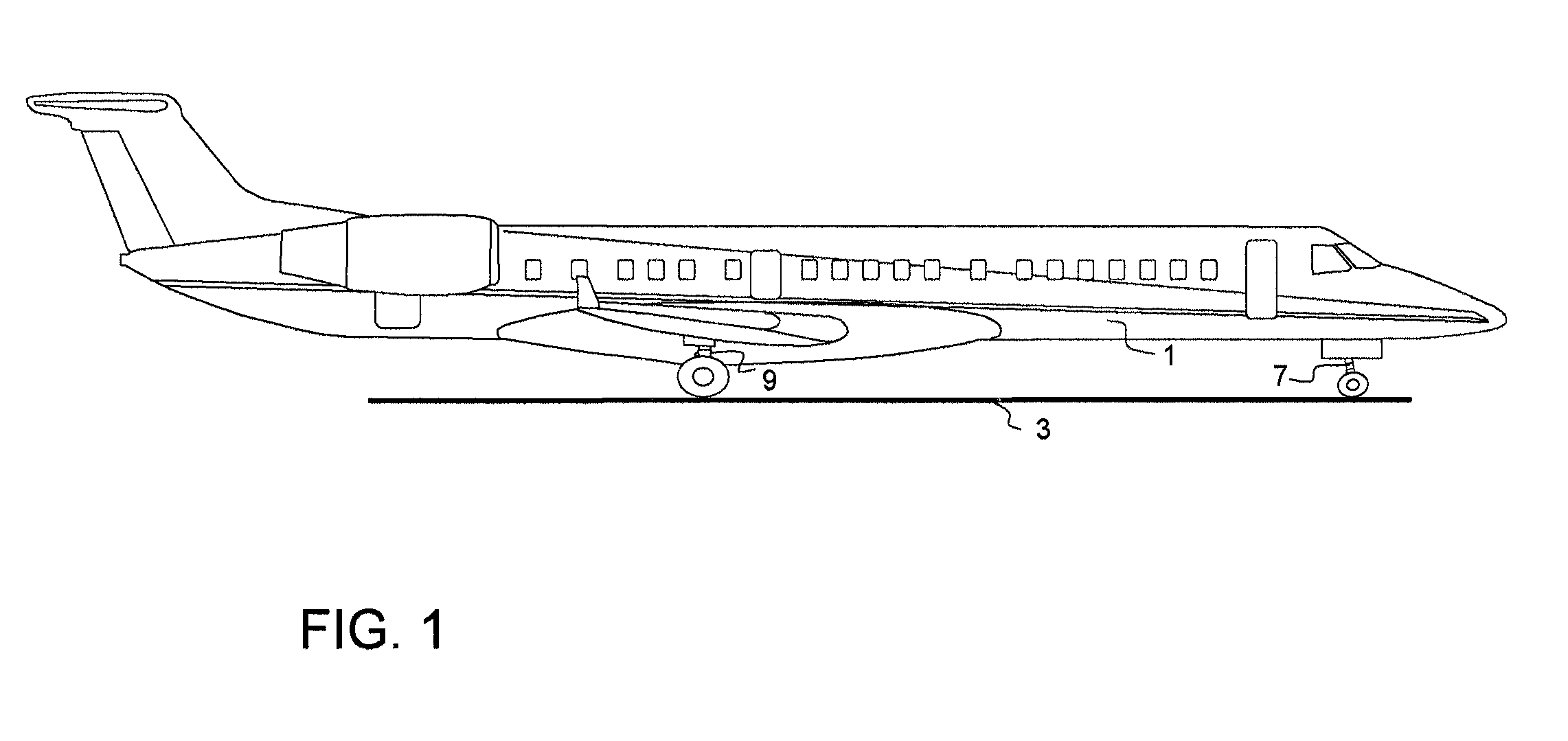

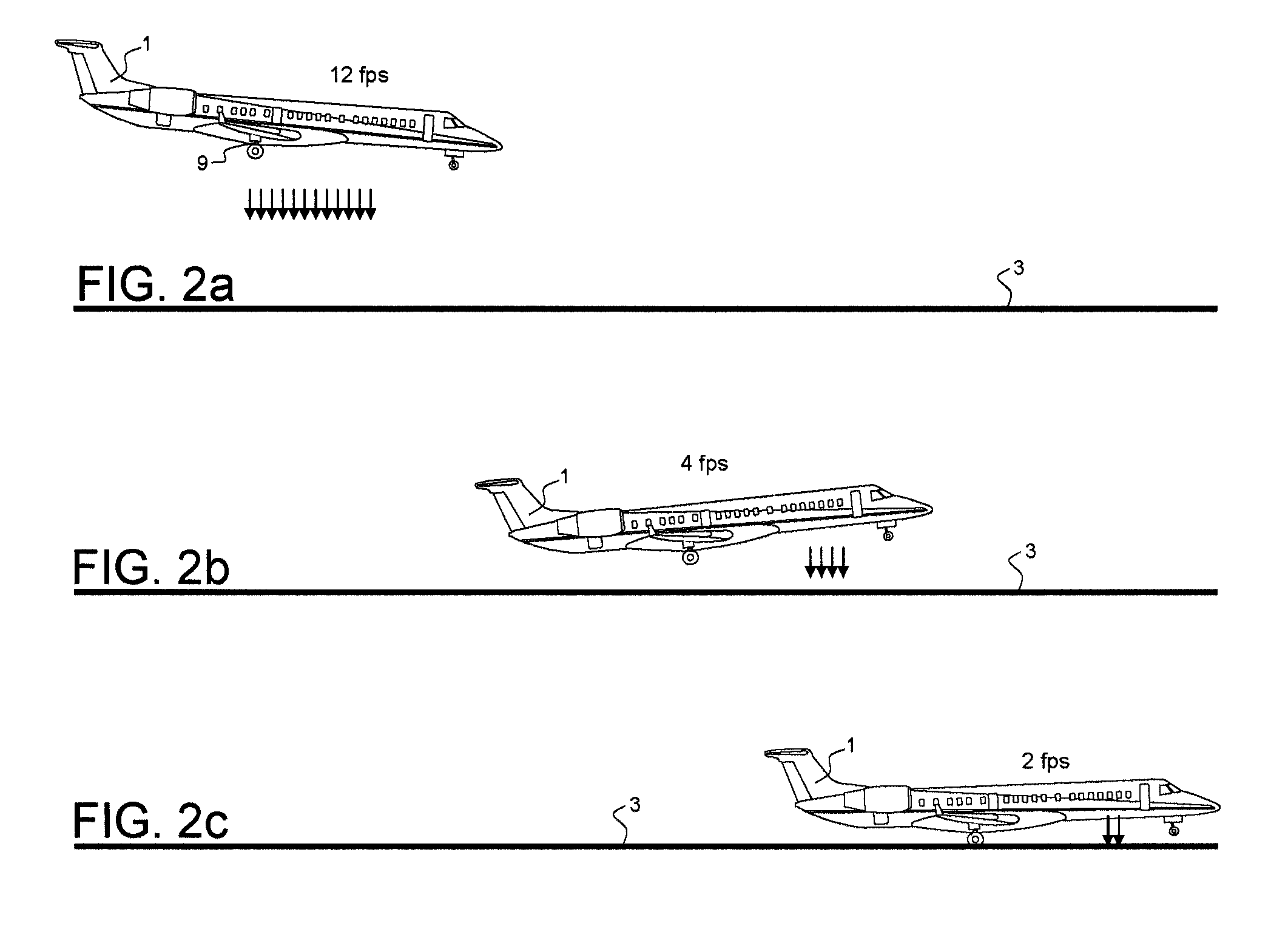

Aircraft landing gear compression rate monitor

ActiveUS8042765B1Aircraft health monitoring devicesSpeed measurement using gyroscopic effectsAircraft landingAirplane

A system for use in monitoring, measuring, computing and displaying the rate of compression of aircraft landing gear struts experienced while aircraft are executing either normal or hard landing events. A high speed computer attached to high speed cameras, or range-finders, mounted in relation to each of the landing gear struts are used to monitor, measure and record the landing gear compression rates and aircraft touch-down vertical velocities experienced by landing gear struts, as the aircraft landing gear initially comes into contact with the ground. The system also determines through landing gear strut compression rates if aircraft landing limitations have been exceeded.

Owner:NANCE C KIRK

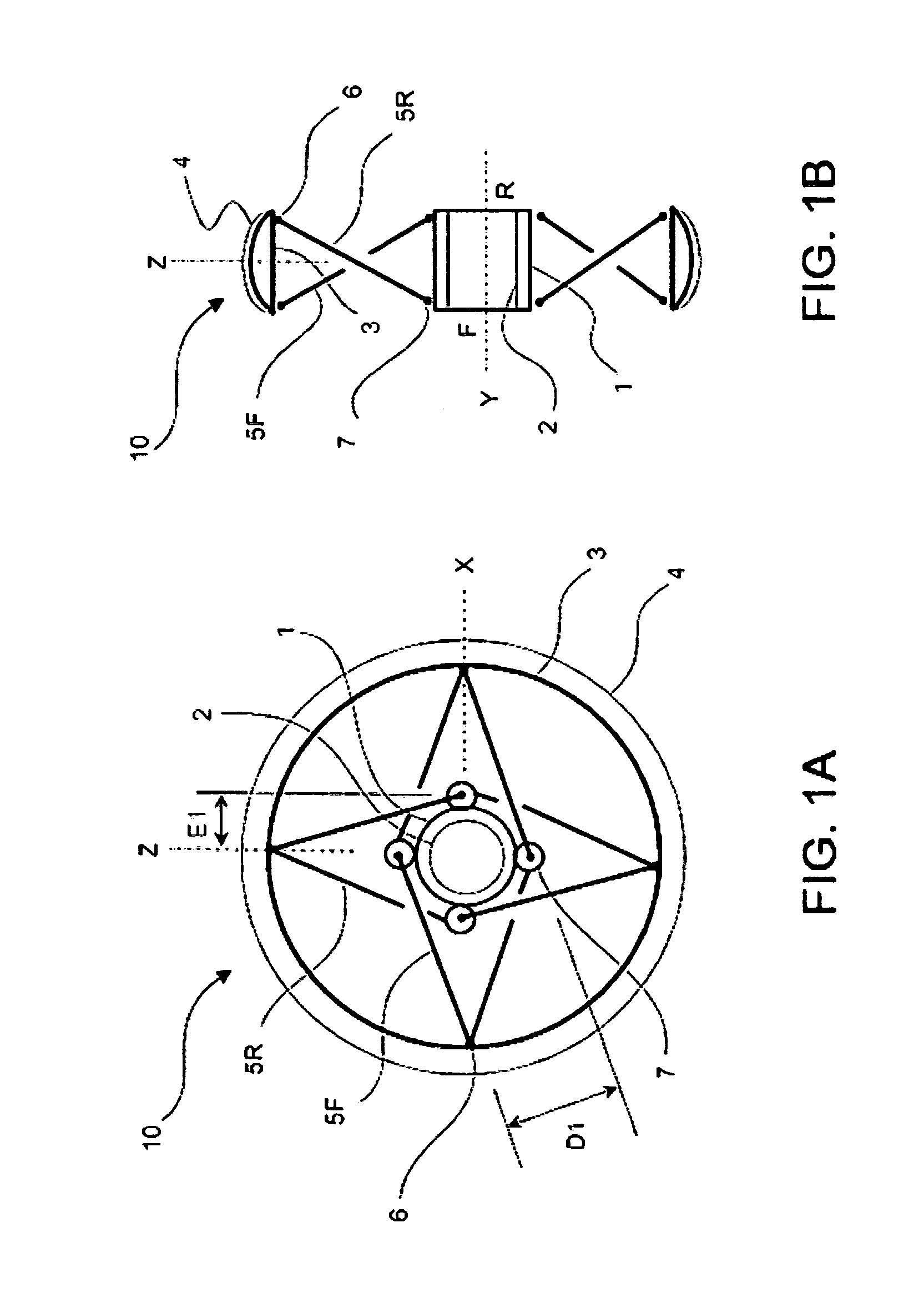

Landing gear method and apparatus for braking and maneuvering

InactiveUS7226018B2Reduce wearImprove stabilityElectric devicesEnergy efficient operational measuresElectric generatorAirplane

Aircraft landing gear comprised of a wheel hub motor / generator disks stack, includes alternating rotor and stator disks mounted with respect to the wheel support and wheel. The invention can provide motive force to the wheel when electrical power is applied, e.g. prior to touch-down, thus decreasing the difference in relative velocities of the tire radial velocity with that of the relative velocity of the runway and reducing the sliding friction wear of the tire. After touchdown the wheel hub motor / generator may be used as a generator thus applying a regenerative braking force and / or a motorized braking action to the wheel. The energy generated upon landing maybe dissipated through a resistor and / or stored for later use in providing a source for motive power to the aircraft wheels for taxiing and ground maneuvers of the aircraft. Methods and apparatuses for nose gear steering and ABS braking using the disclosed invention are described.

Owner:DELOS AEROSPACE

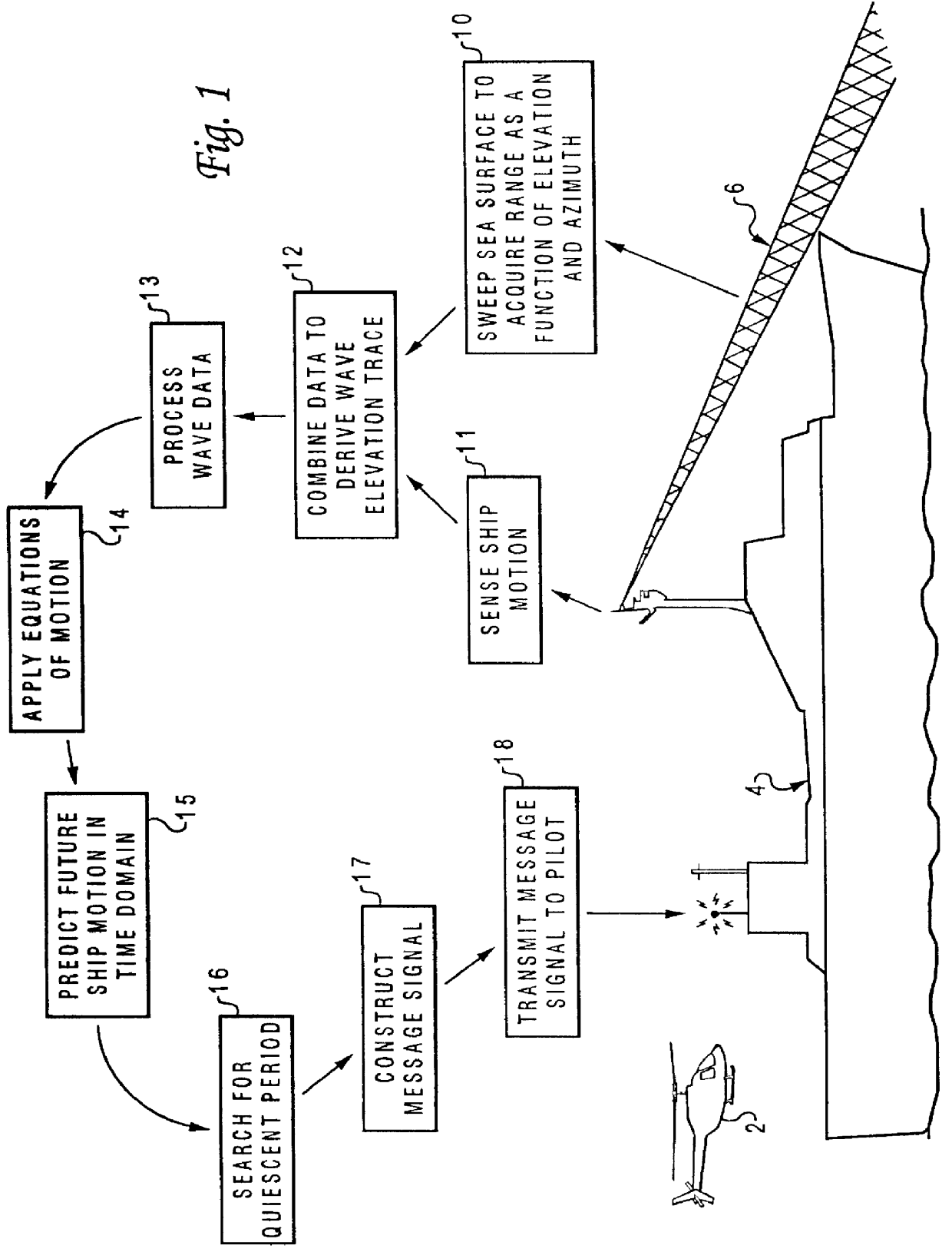

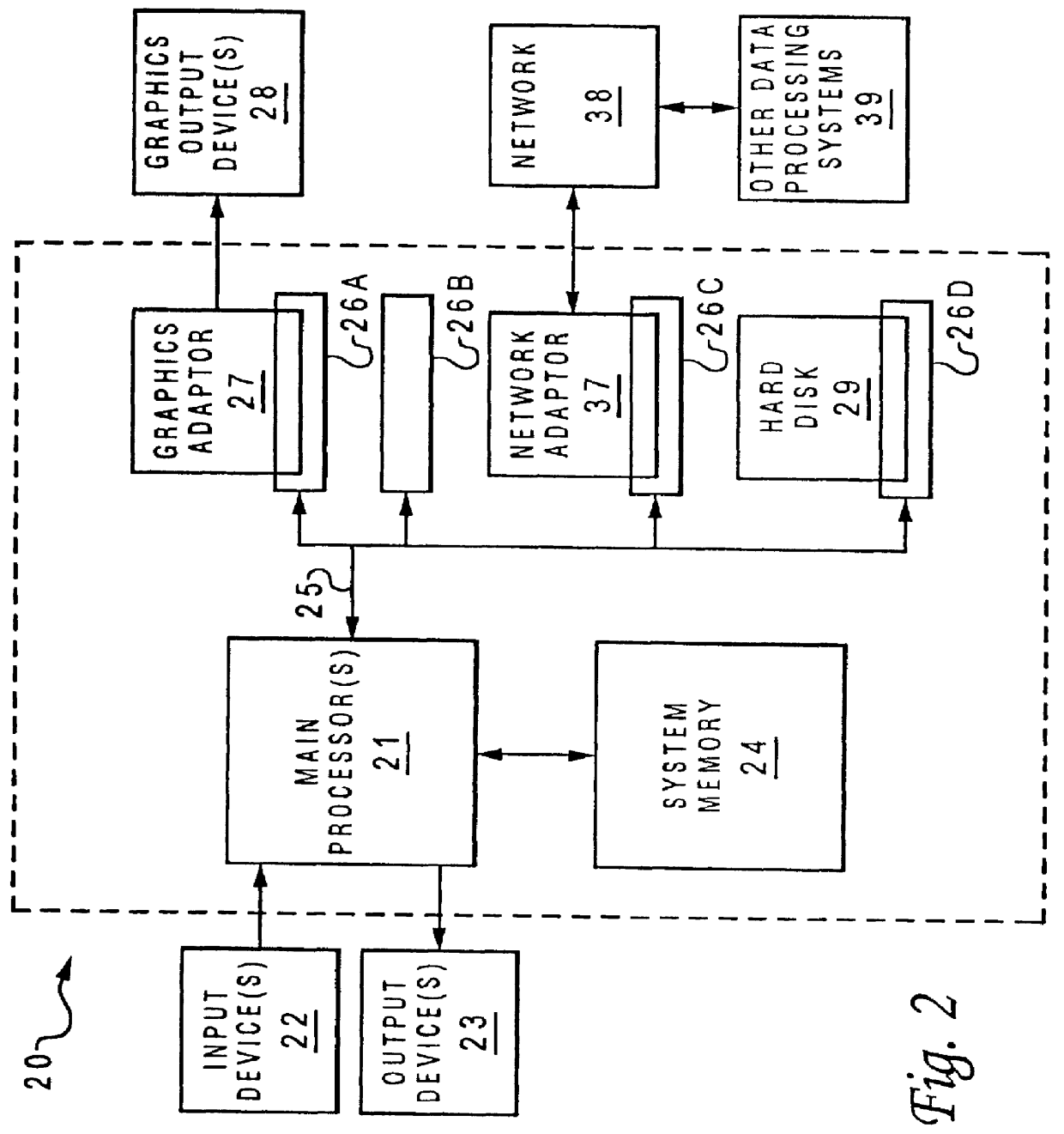

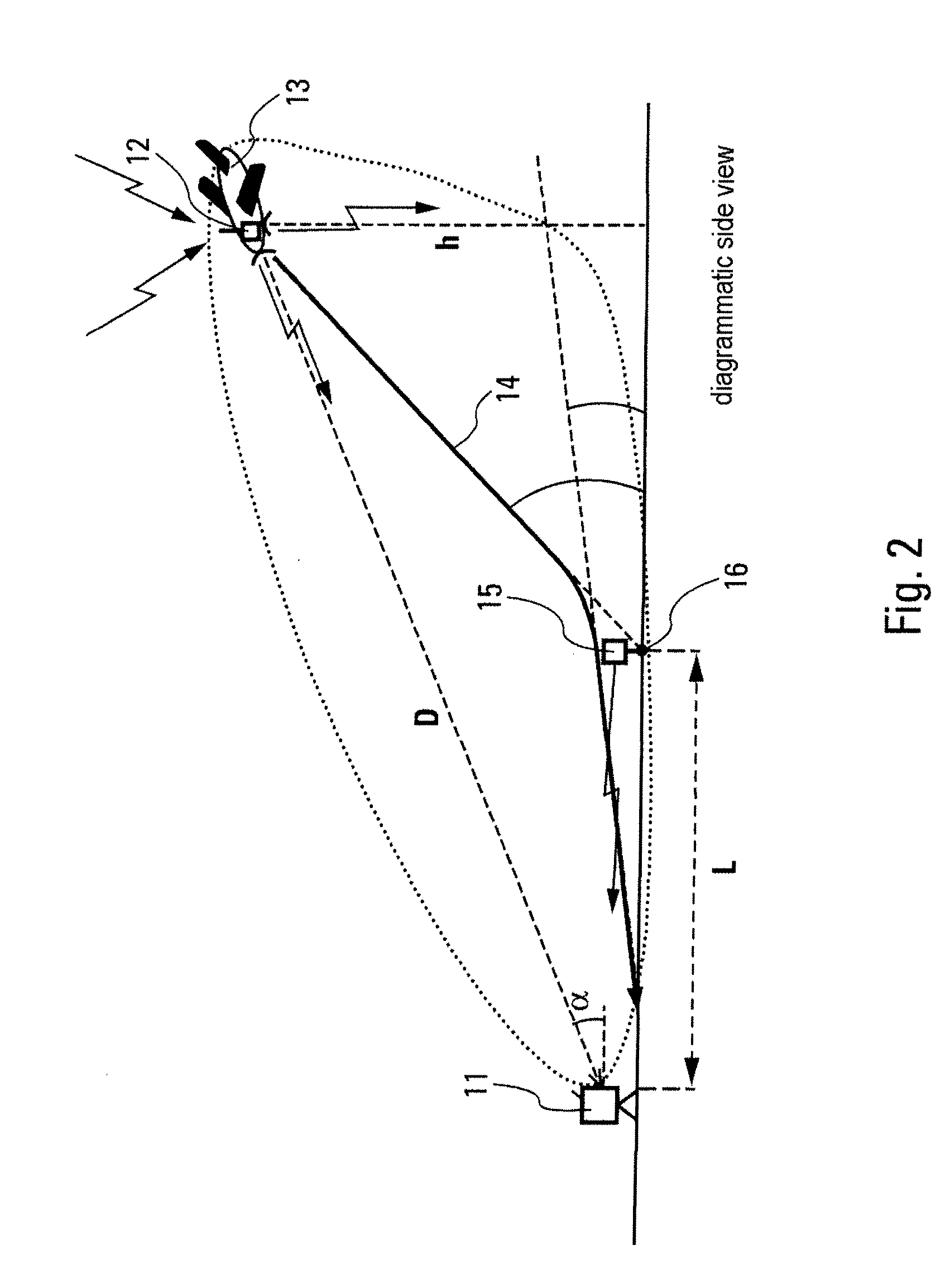

Method and system for predicting ship motion or the like to assist in helicopter landing

InactiveUS6064924AAnalogue computers for vehiclesAnchoring installationsShort termsVisual perception

A method for a short-term prediction of future ship motion in open water to furnish visual cueing information that can be remotely presented to a pilot during an aircraft landing is described. Two sets of samples of the sea surface geometry along a radial azimuth line from a ship as a function of elevation of a sensor are first acquired. These are compensated to remove the components due to the ship's motion. Two wave traces are then separately derived in Cartesian format from the two sets of acquired samples. These wave traces are subjected to a Fast Fourier Transform to detect the amplitudes and phases of the individual wavelength components. The direction of the wavelength components is determined using a measure of their phase change in the scan direction during the time interval between the two scans together with their measured wavelength. The amplitude, direction and phase of each component is utilized together with the known motion characteristics of the moving ship in order to derive a short-term prediction of future ship motion in the time domain. A quiescent period of the ship motion is located by comparing the short-term prediction with the pre-defined operating limit criteria. Finally, a message signal is transmitted to the pilot of the aircraft indicating Time-to-Land and the duration of the quiescent period.

Owner:LOCKHEED MARTIN CORP

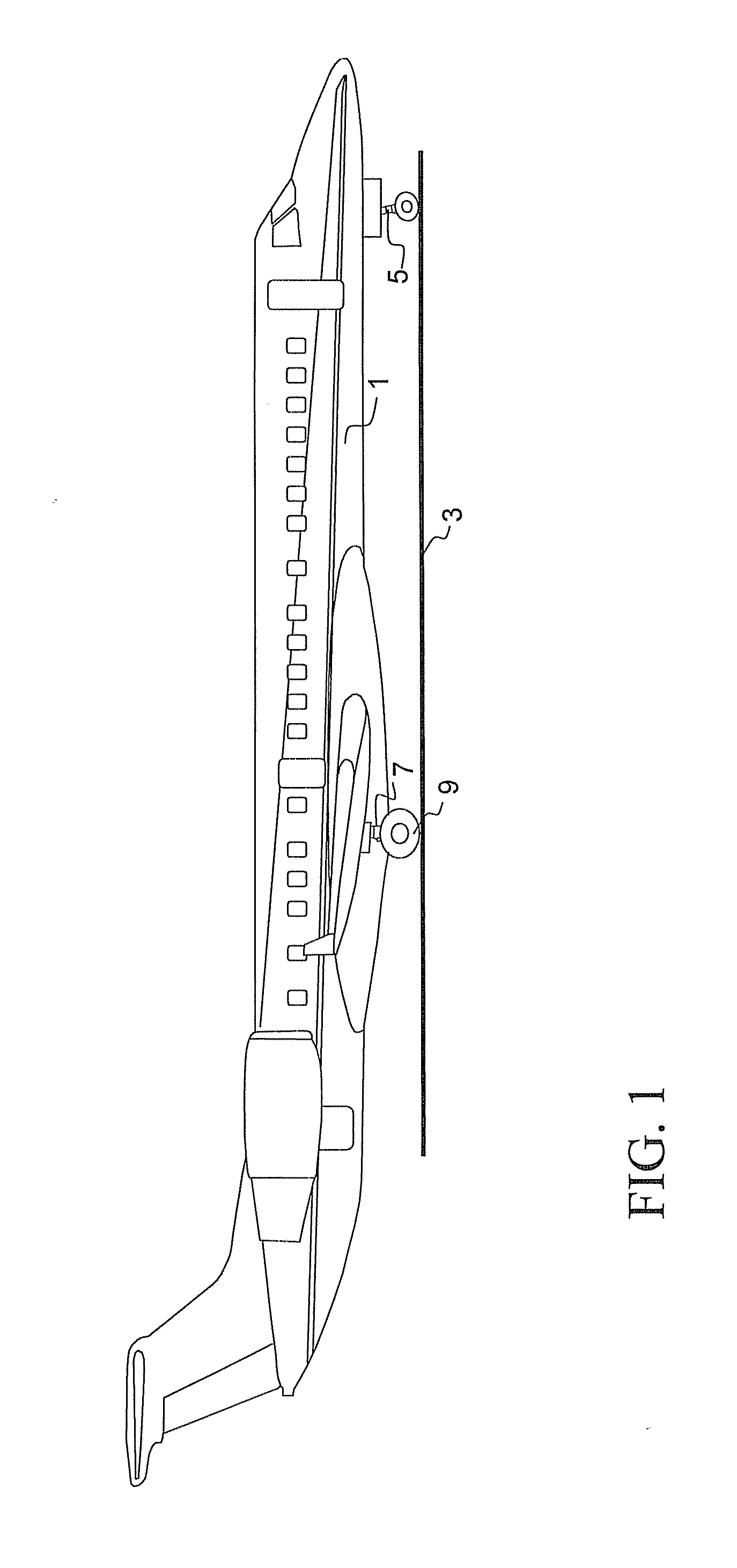

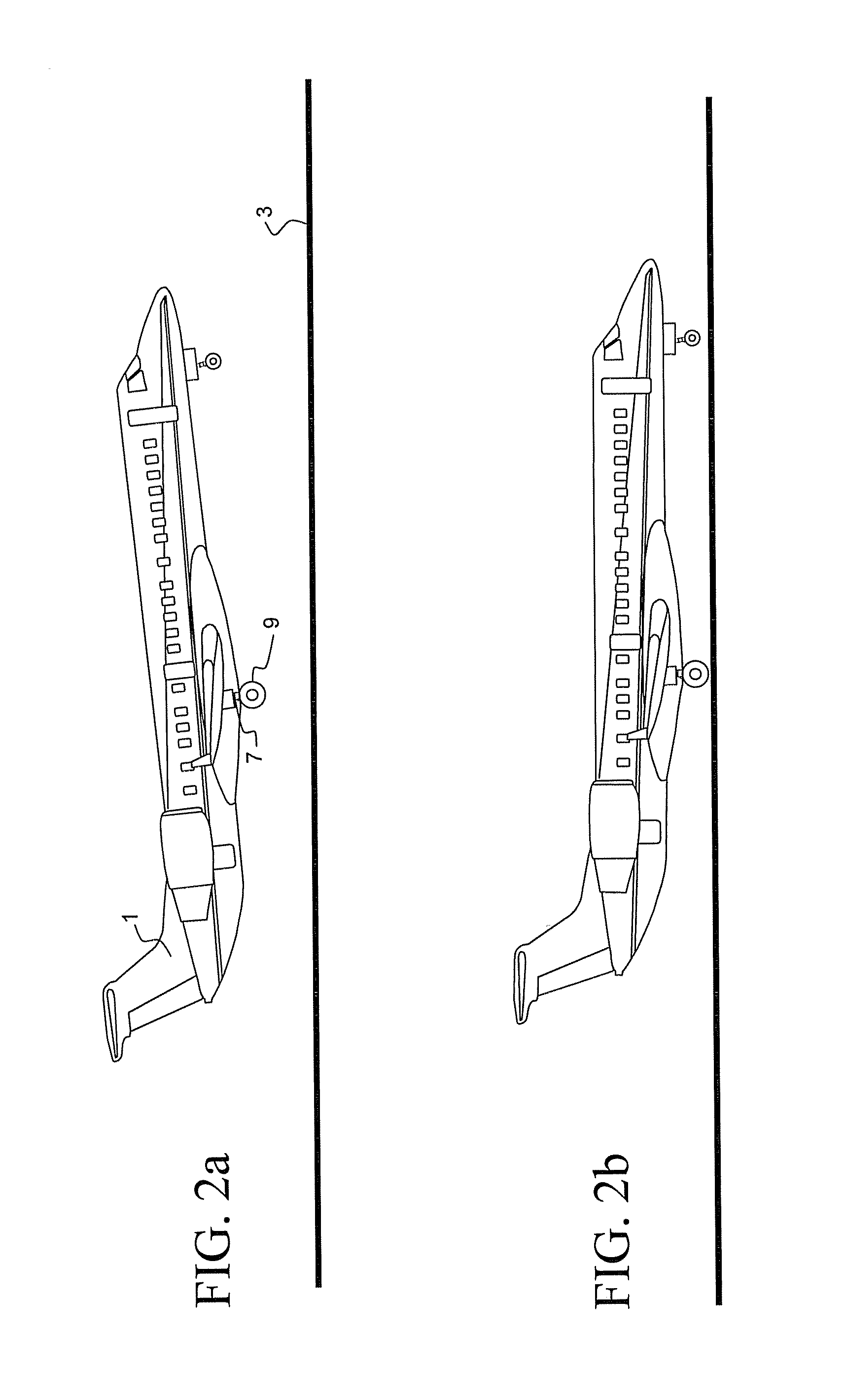

Autonomous and automatic landing system for drones

ActiveUS20090055038A1Improve robustnessSimple designAnalogue computers for vehiclesVehicle position/course/altitude controlGuidance systemFlight vehicle

The invention relates to an automatic aircraft landing guidance system having an electromagnetic detecting and locating device, positioned on the ground and a first multifunction transmitting / receiving radiofrequency beacon, on board each guided aircraft and transmitting in particular a continuous wave. The detecting and locating device uses the continuous wave transmitted by the beacon to perform a passive locating intended to improve the accuracy of the measurement of the angular position of the aircraft. It also comprises means for generating and periodically transmitting to the aircraft, via the beacon, information enabling said aircraft to rejoin an optimum landing path from its position. The invention applies more particularly to the guidance of autonomous and automatic aircraft such as drones in the approach and landing phase.

Owner:THALES SA

Unmanned aircraft system and operation method thereof

An unmanned aircraft system includes a manned aircraft and an unmanned aircraft. The manned aircraft includes a manned aircraft main wing, a manned aircraft fuselage, a manned aircraft landing system, and a manned aircraft joining mechanism provided at a bottom portion of the manned aircraft fuselage. The unmanned aircraft includes an unmanned aircraft main wing, an unmanned aircraft fuselage, an unmanned aircraft landing system, and an unmanned aircraft joining mechanism provided at a roof portion of the unmanned aircraft fuselage. The manned aircraft joining mechanism and the unmanned aircraft joining mechanism are detachably joined. The unmanned aircraft system can take off or land in a state that the unmanned aircraft and the manned aircraft are joined.

Owner:MITSUBISHI HEAVY IND LTD

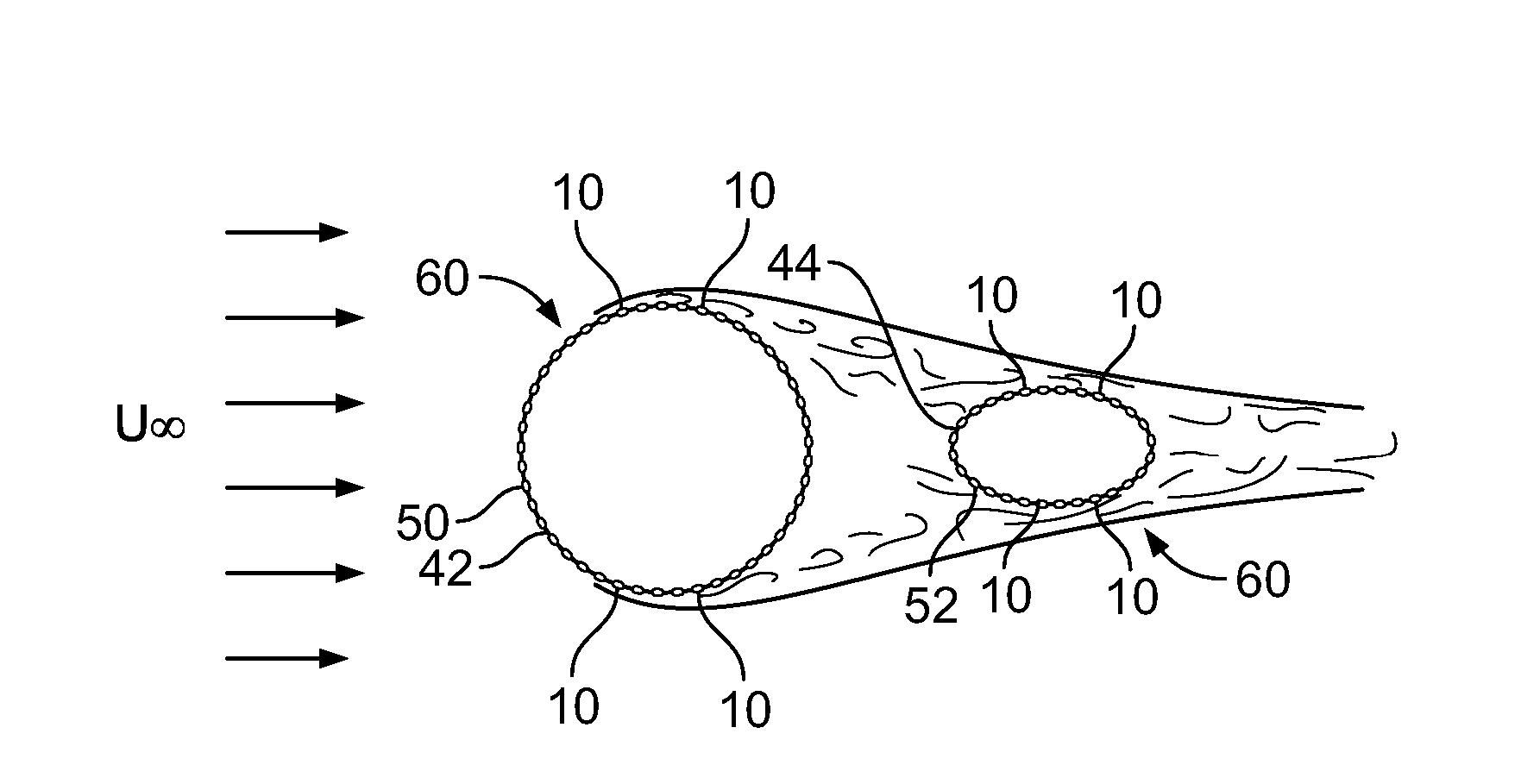

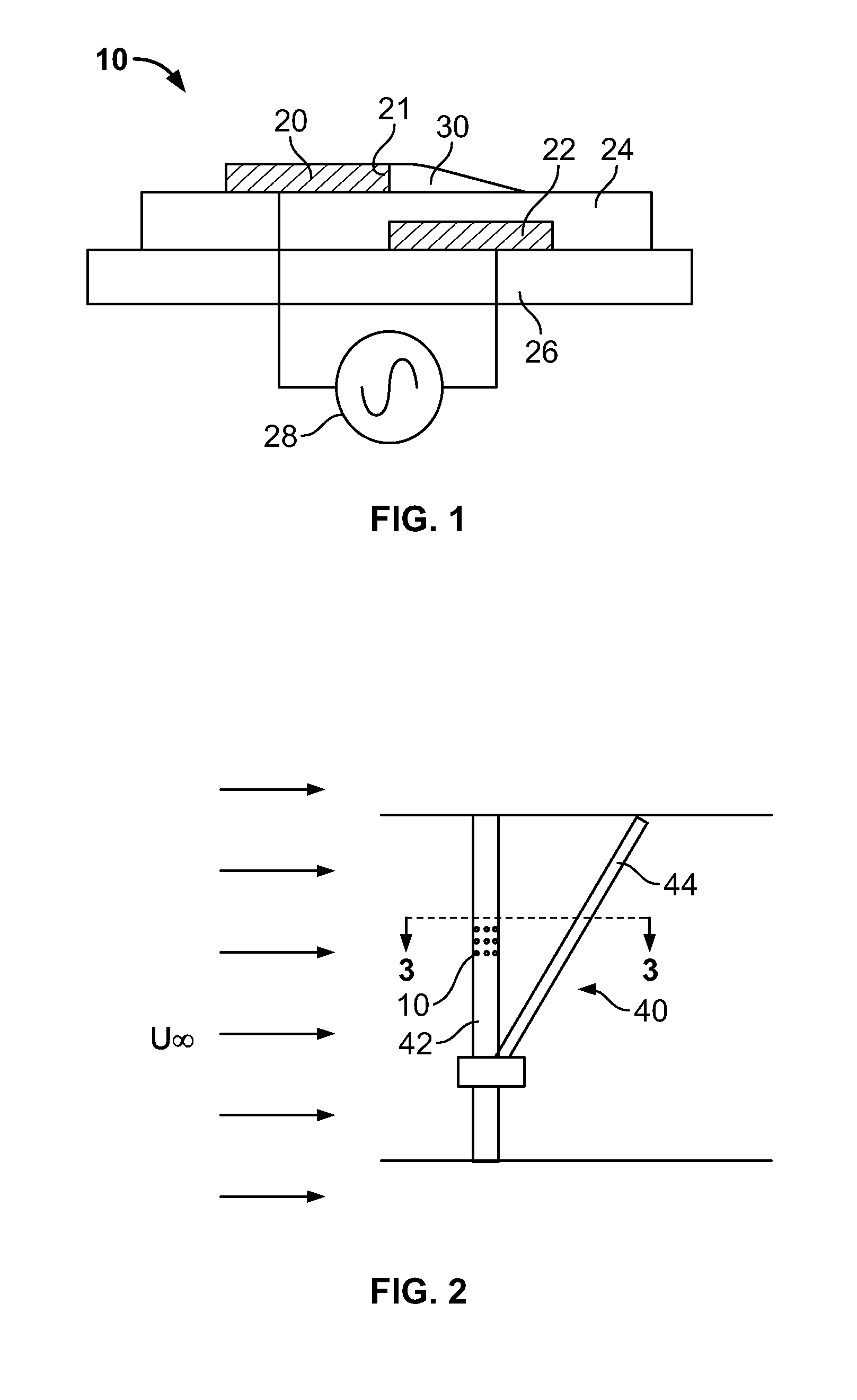

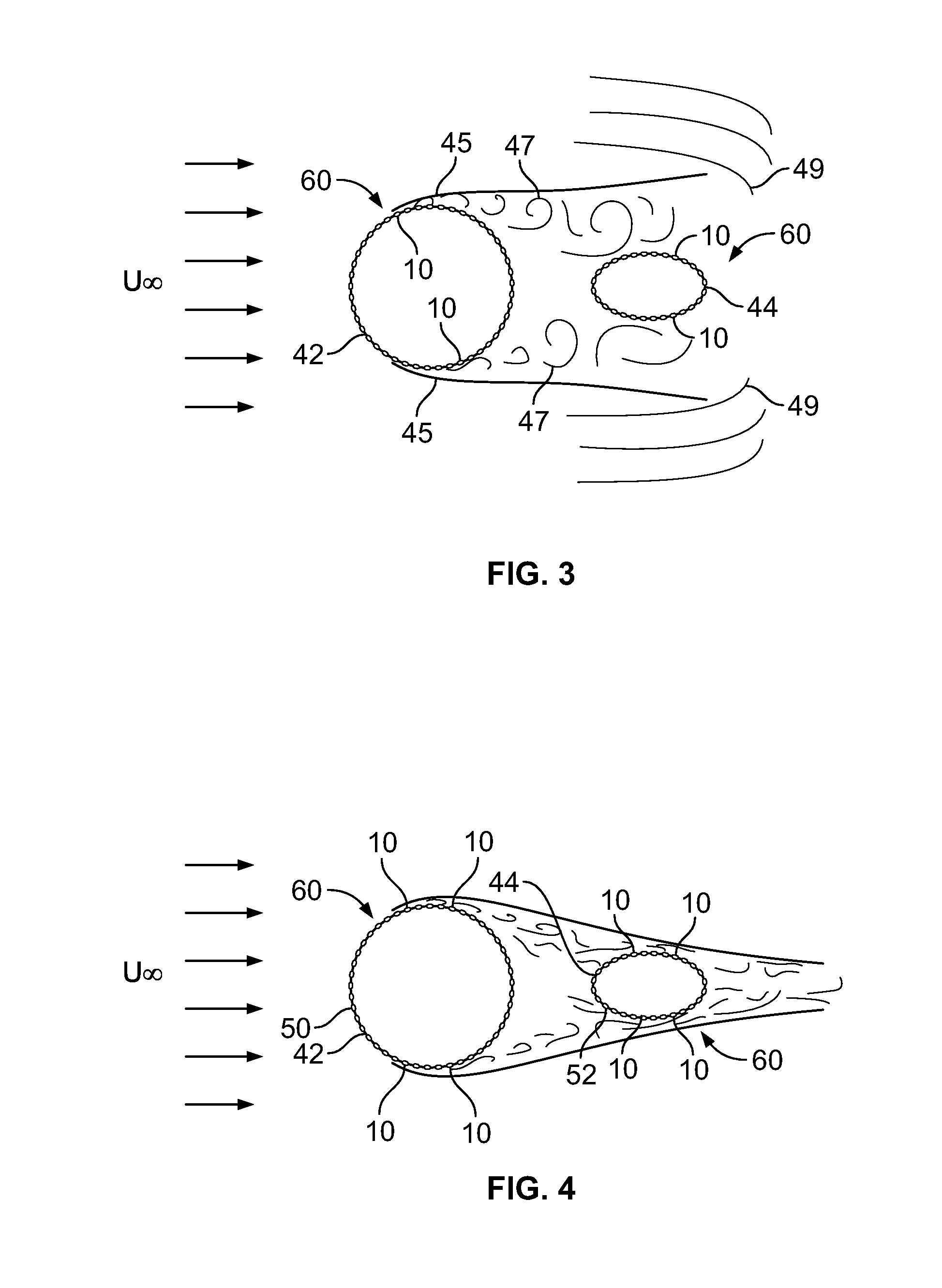

Methods and apparatus for reducing noise via a plasma fairing

A plasma fairing for reducing noise generated by, for example, an aircraft landing gear is disclosed. The plasma fairing includes at least one plasma generating device, such as a single dielectric barrier discharge plasma actuator, coupled to a body, such as an aircraft landing gear, and a power supply electrically coupled to the plasma generating device. When energized, the plasma generating device generates a plasma within a fluid flow and reduces body flow separation of the fluid flow over the surface of the body. In another example, the body includes a plurality of plasma generating devices mounted to the surface the body to further aid in noise reduction.

Owner:NOTRE DAME DU LAC THE UNIV OF

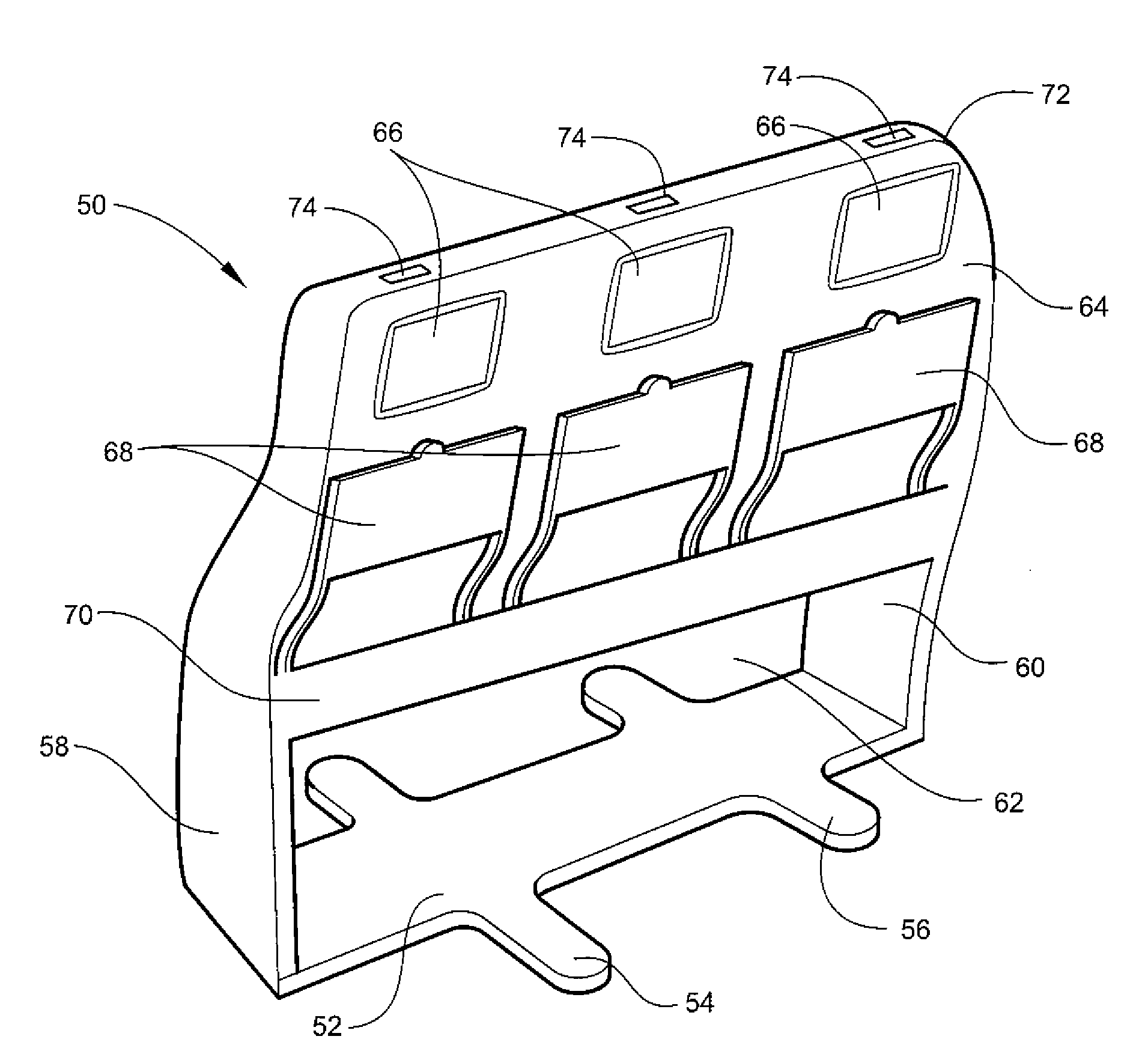

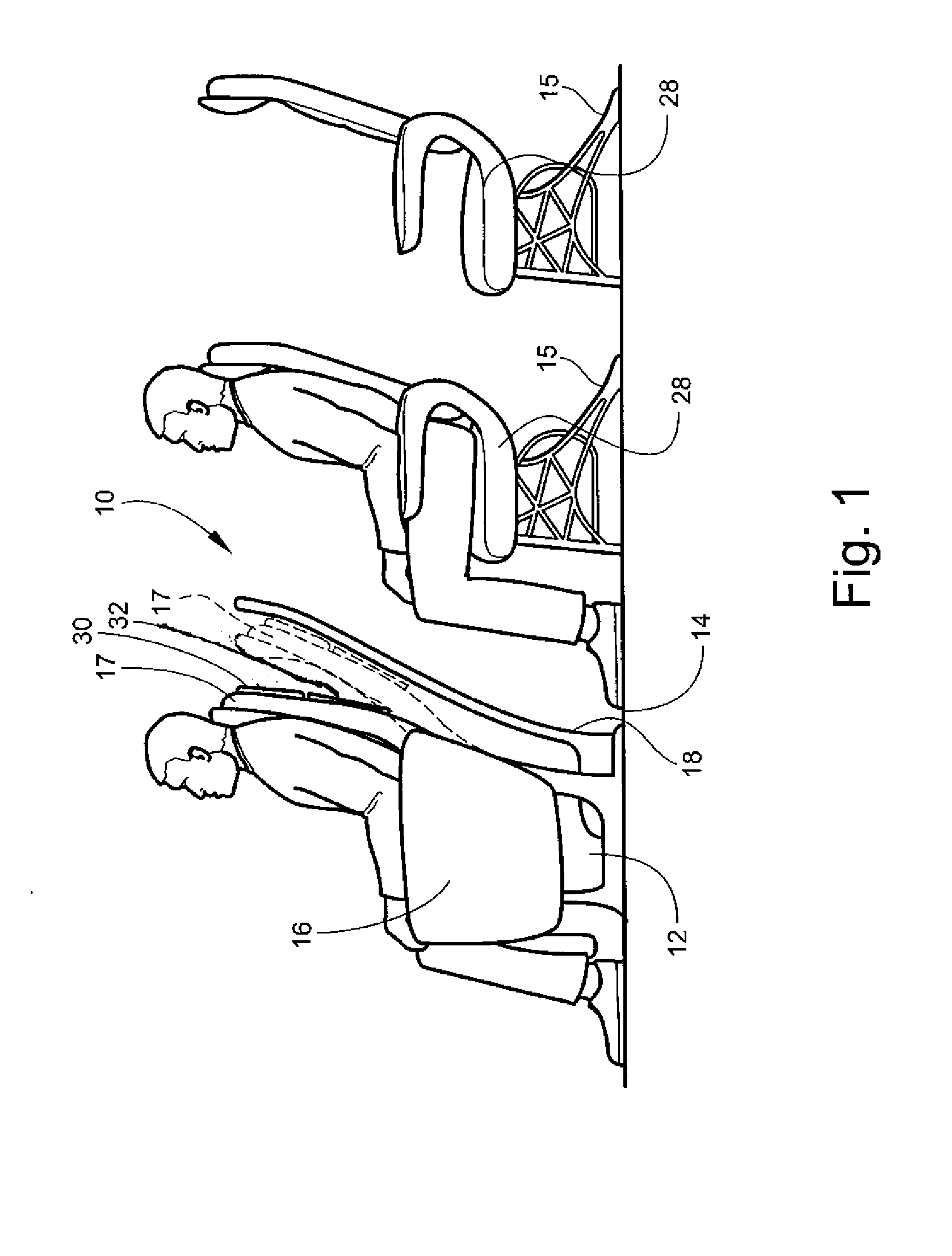

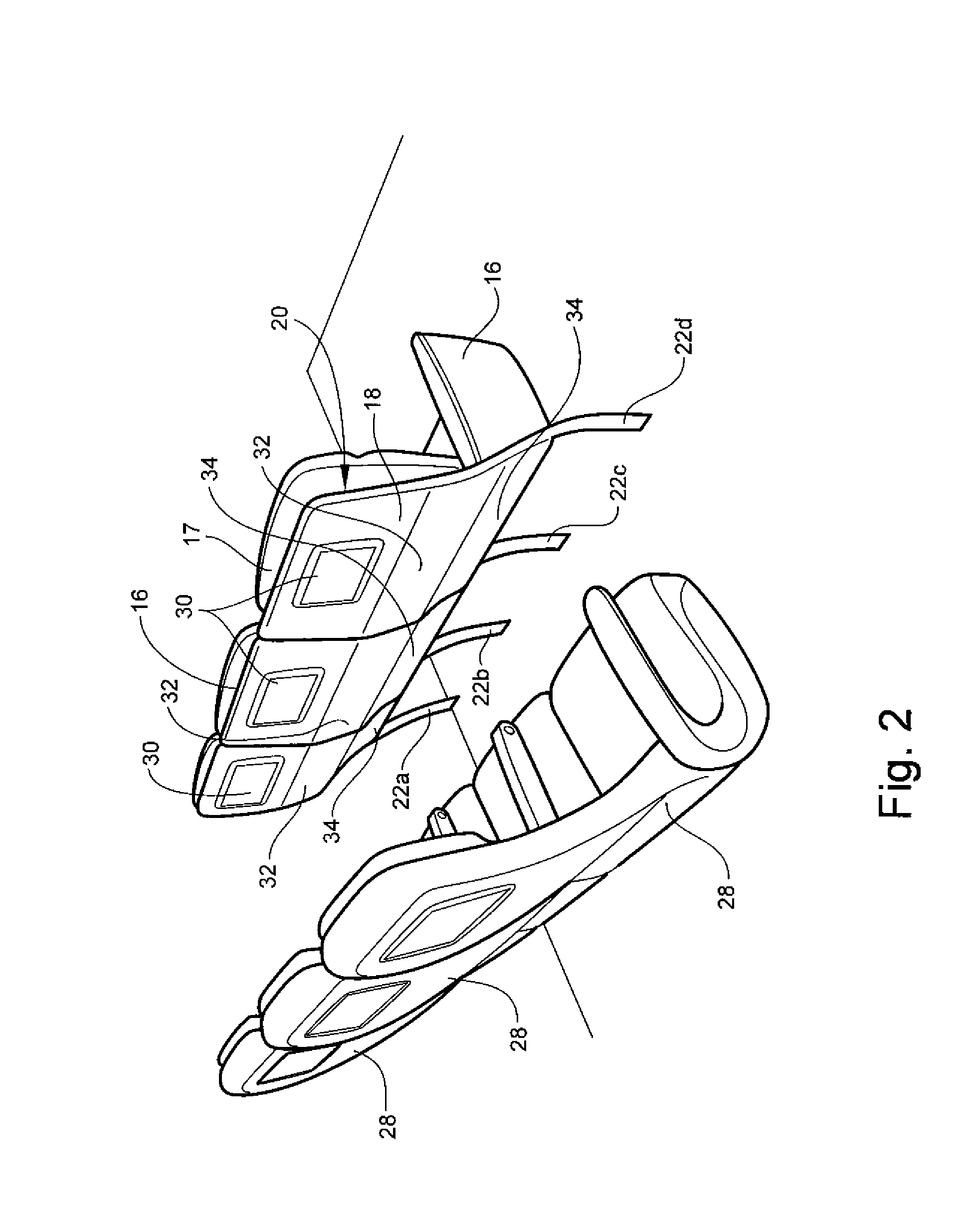

Class divider for aircraft cabin

ActiveUS20090200422A1Increased rollover momentIncreased rollover moment of the panelVehicle arrangementsBuilding constructionsNacelleAircraft landing

A class divider for an aircraft passenger cabin is provided. The class divider includes a partition positioned immediately aft of a rear row of seats in a first predetermined class area of the aircraft cabin and an aft-facing panel having a width and height generally corresponding to a width and height of the rear row of seats. One or more passenger convenience features selected from the group of video monitors, tray tables, and magazine storage pockets are provided on the aft-facing panel for use by passengers seated immediately aft of the partition in a front row of a second predetermined class area of the aircraft cabin.

Owner:BE AEROSPACE INCORPORATED

Aircraft anti-terrorism security system

InactiveUS20030058112A1Air-treatment apparatus arrangementsBank protection deviceMotion detectorAir steward

In an aircraft cabin floor adjacent to the cockpit, a trap door opens downwardly into a security cell, to trap a terrorist trying to enter the cockpit. Two walls with lockable airtight doors bound a safety buffer cabin between the cockpit and the passenger cabin. Sensors like seat occupancy sensors, motion detectors, video cameras and microphones provide data regarding the location, movement and activities of passengers to a system that evaluates the data to recognize unusual data situations indicating one or more escalation levels of suspicious or aggressive actions by passengers. Alarm signals and terrorist countermeasure devices such as fogging or tranquilizer gas generators, noise generators, high intensity blinding / glaring lights, a cabin lighting master shut-off, window darkening devices, and tranquilizer dart guns are actuated automatically by the evaluation system, or manually by a cockpit input device or a portable signaling device carried by a flight attendant.

Owner:AIRBUS OPERATIONS GMBH

Drone aircraft landing and docking systems

A docking station for an aircraft includes a base portion and an alignment system disposed on the base portion configured to orient the aircraft relative to the base portion. The alignment system can include a plurality of protrusions extending away from the base portion in a vertical direction. The plurality of protrusions can extend away from the base portion in both the vertical direction and a horizontal direction such that the protrusions can extend from the base portion at an angle.

Owner:AMERICAN ROBOTICS INC

Automated inspection of aircraft landing gear internal fluid levels

ActiveUS20140046533A1Reduce system complexityRegistering/indicating working of vehiclesDigital data processing detailsJet aeroplaneAircraft landing

A system for use in monitoring, measuring, computing and displaying the volumes of internal gas within a telescopic aircraft landing gear strut. Pressure sensors and temperature sensors and motion sensors are mounted in relation to each of the landing gear struts to monitor, measure and record the impact movement and rates of internal landing gear strut fluids; experienced by landing gear struts, as the aircraft landing gear initially come into contact with the ground. The computer of this system measures the compression experienced by each landing gear strut and determines if the landing gear strut is improperly serviced with either excess or deficient volumes of nitrogen gas. Additional features include automating the inspections required to aircraft landing gear, prior to flight, during flight and during landing events.

Owner:NANCE C KIRK

Shweel

InactiveUS20130340902A1Quiet and comfortable rideReduce rolling resistanceHigh resiliency wheelsMetalworkingRolling resistance

Shock-absorbers used as wheel-spokes between wheel-hub and rigid rim, which may be lined with threaded rubber or having gripping features otherwise. It reduces rolling resistance, saving fuel. It improves drivability. The compliance of the shocks is commensurate with that of a comparable inflated tire, but optimized passively or actively circumferentially, vertically and laterally. Rubber-bushing or spoke-inclination enhances driving stability. Giant field assembled mining-truck-wheels may be produced and deployed and field-assembled quickly by common metalworking shops at fractional cost and weight. It is environmentally friendly, for hardly using or not using rubber. The gas or liquid of the shock spokes may be interconnected and cooled. Soft and hard driving may be controlled manually or by computer on the fly. It is suitable for applications ranging from bicycle wheels to aircraft landing gears. It is fireproof, bulletproof, airless and silent. It cannot bounce or skid at jumpstart or braking and on ice.

Owner:KEMENY ZOLTAN A

Aircraft landing gear kinetic energy monitor

A system for use in monitoring, measuring, computing and displaying the Kinetic Energy generated and experienced while aircraft are executing either normal, overweight or hard landing events. Pressure sensors and motion sensors are mounted in relation to each of the landing gear struts to monitor, measure and record the impact loads and aircraft touch-down vertical velocities experienced by landing gear struts, as the aircraft landing gear initially comes into contact with the ground. Velocity adjustments are made to correct for errors caused by landing gear per-charge pressure and landing gear strut seal friction. The system also measures the landing loads experienced by each landing gear strut during the landing event and determines if aircraft limitations have been exceeded.

Owner:NANCE C KIRK

Landing assist apparatus interface bulkhead and method of installation

ActiveUS7344108B2Avoid areaAvoid damageArrester hooksAnchoring installationsControl mannerAircraft landing

An aircraft landing assist apparatus is designed to be retrofit to existing aircraft having internal constructions that have been modified to support the apparatus. The apparatus is designed so that on rough landings of the aircraft on a ship deck, the apparatus will collapse in a controlled manner to avoid any damage to ammunition and / or fuel storage areas of the aircraft.

Owner:THE BOEING CO

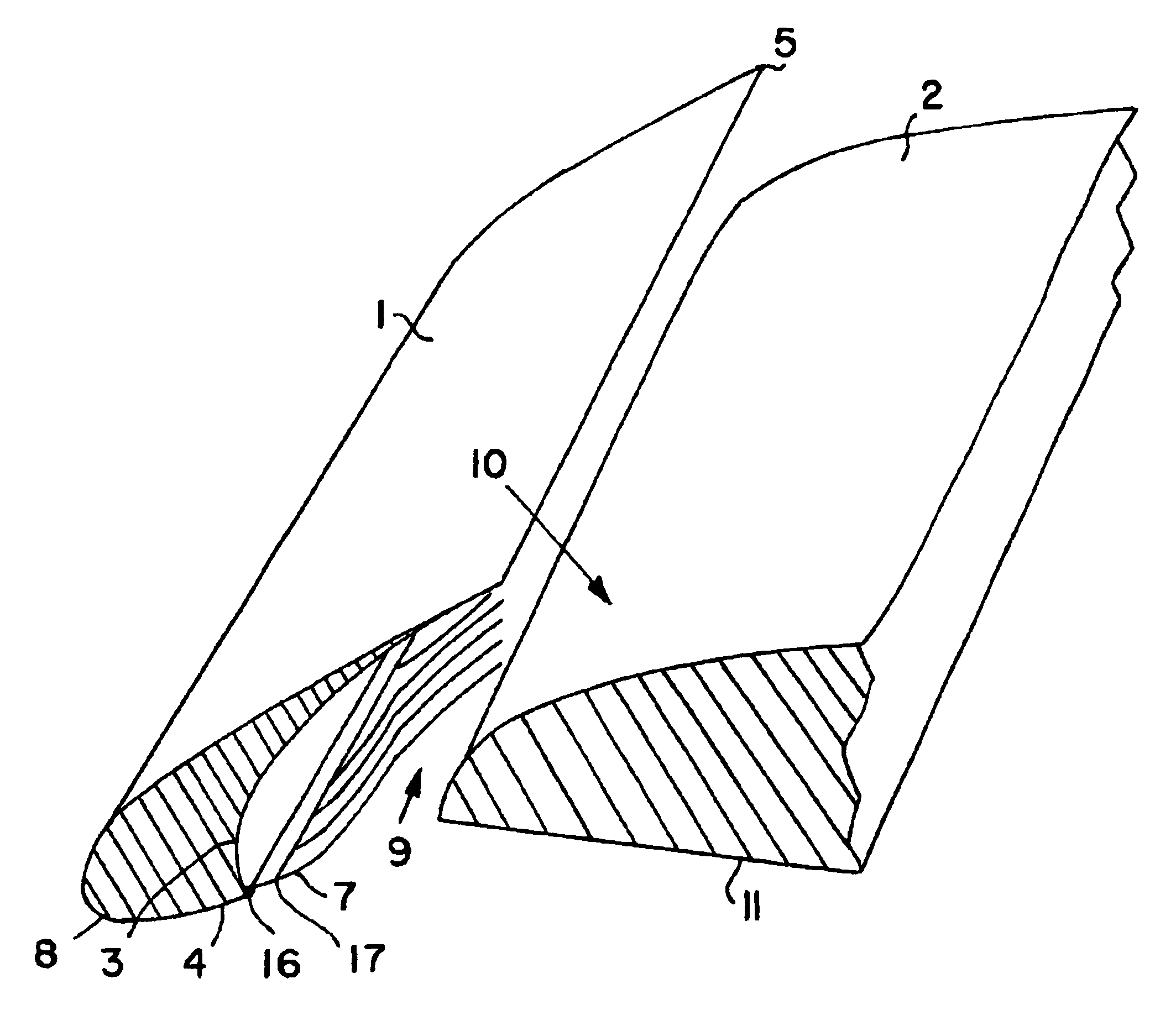

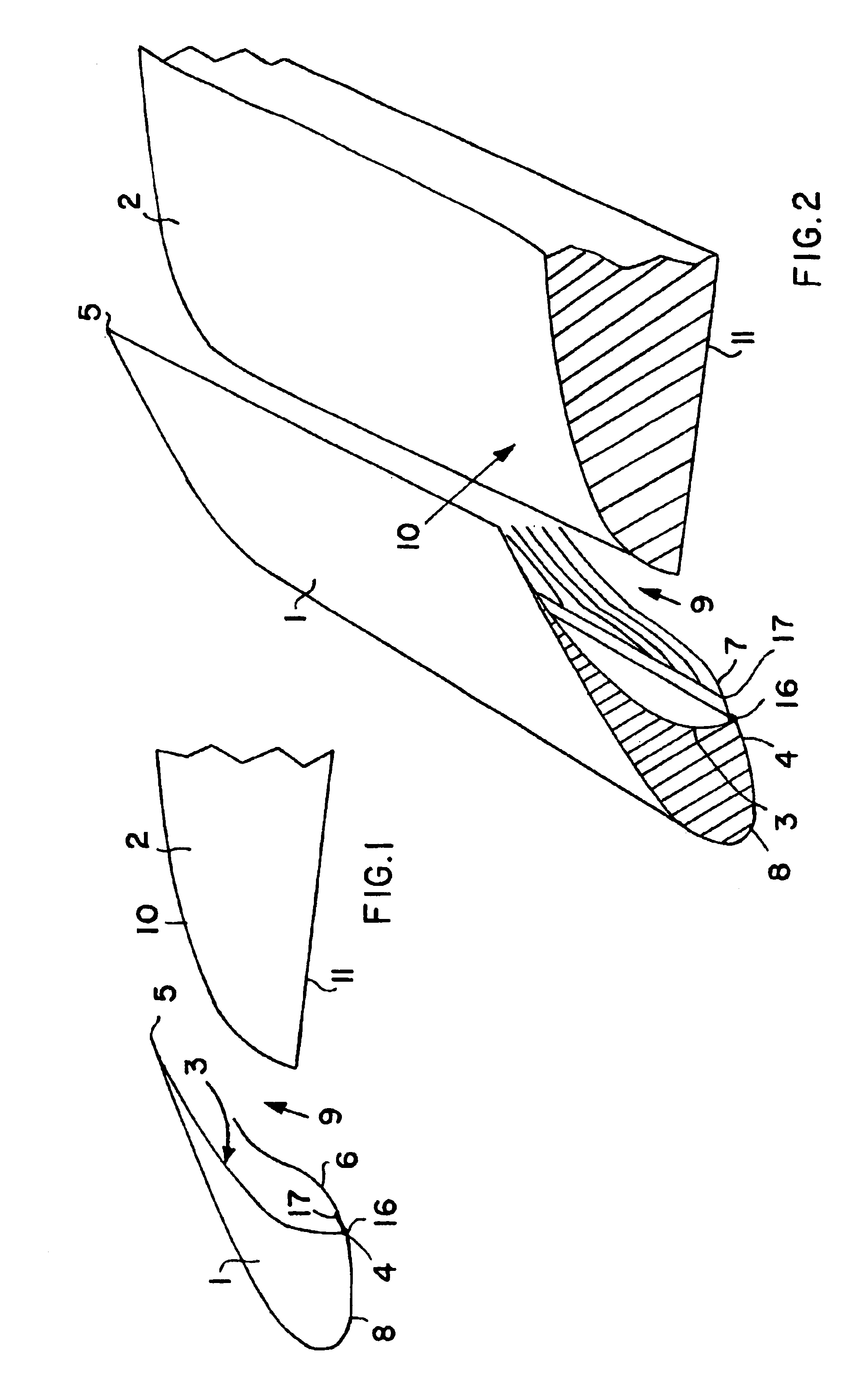

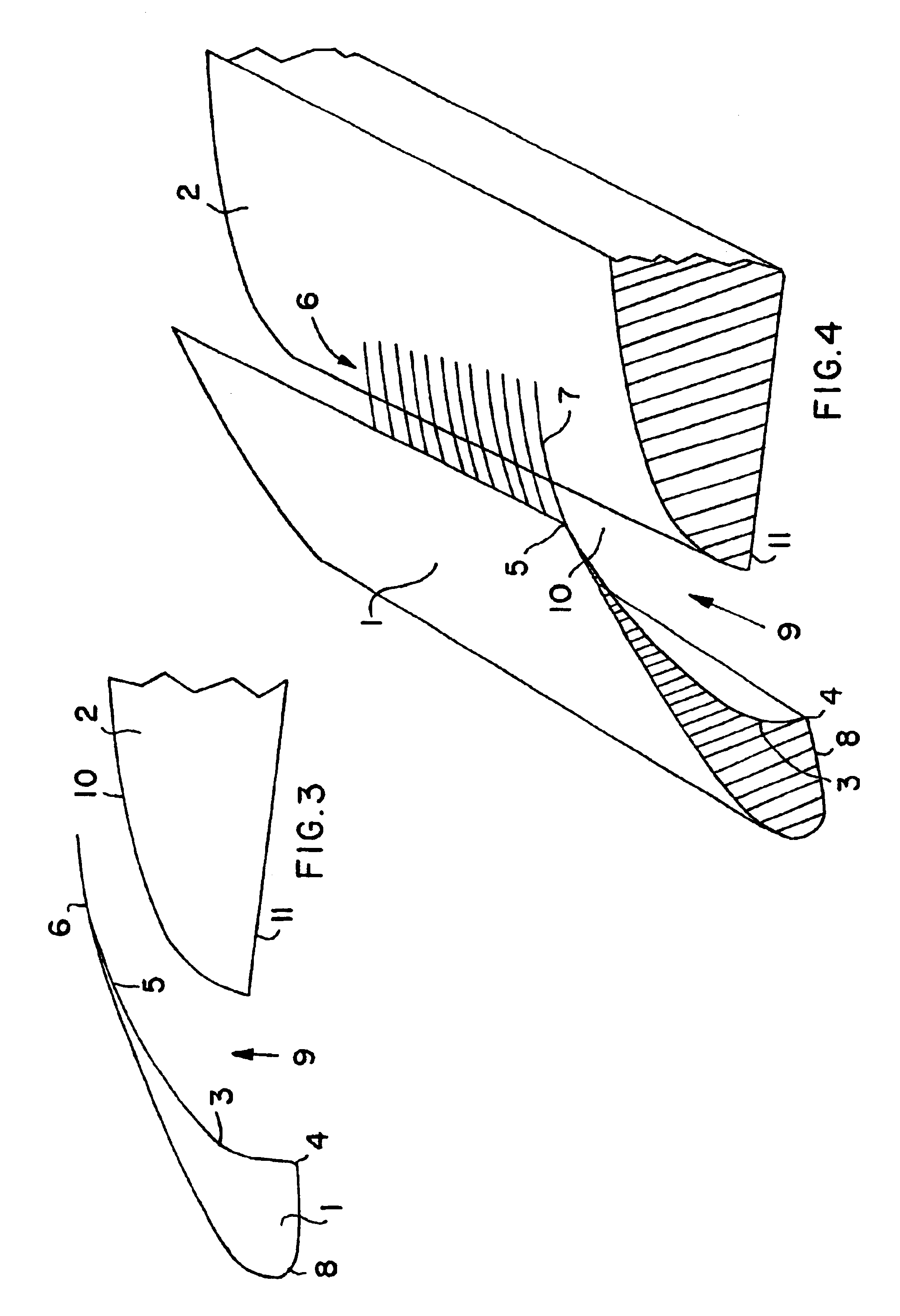

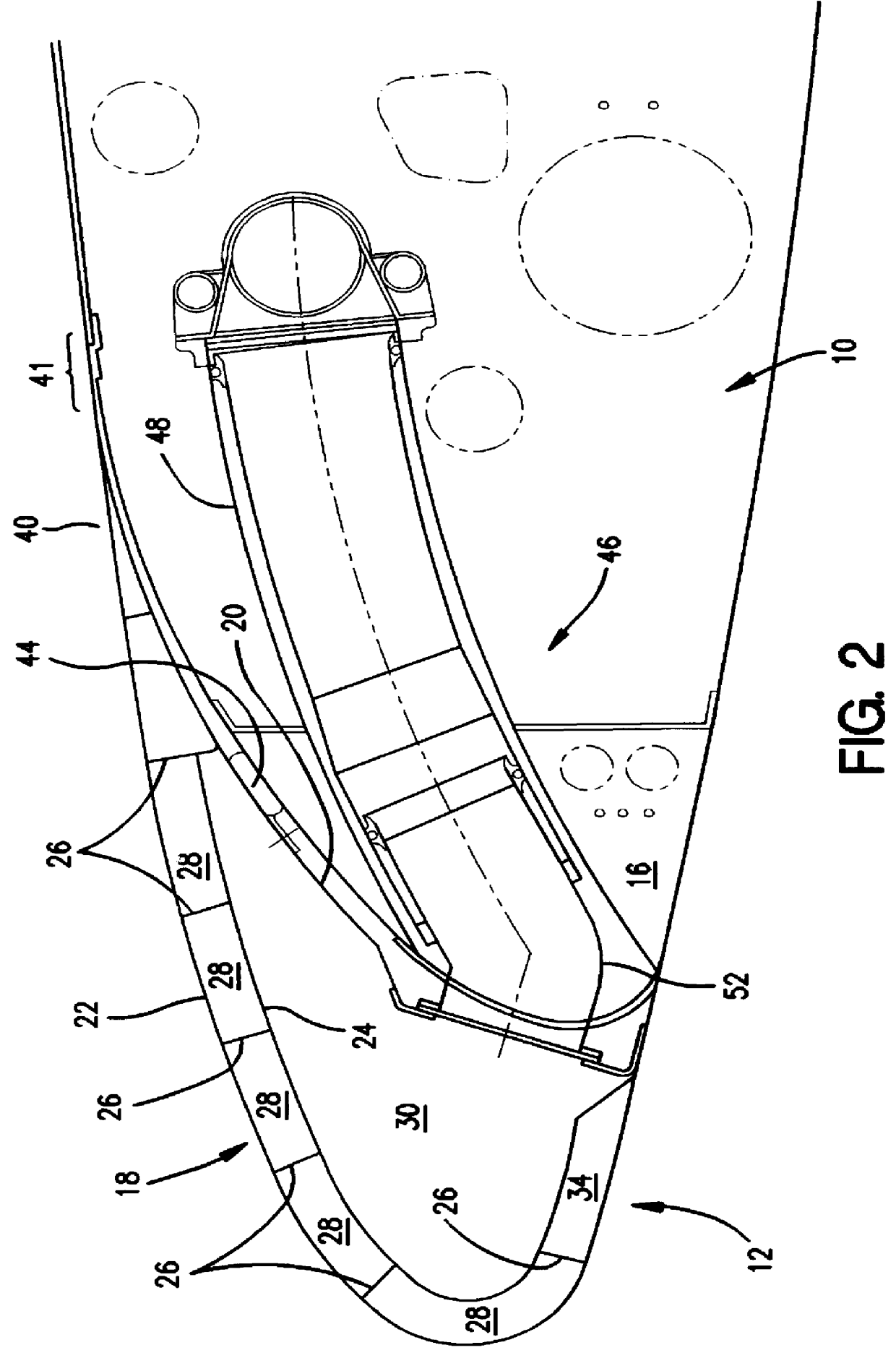

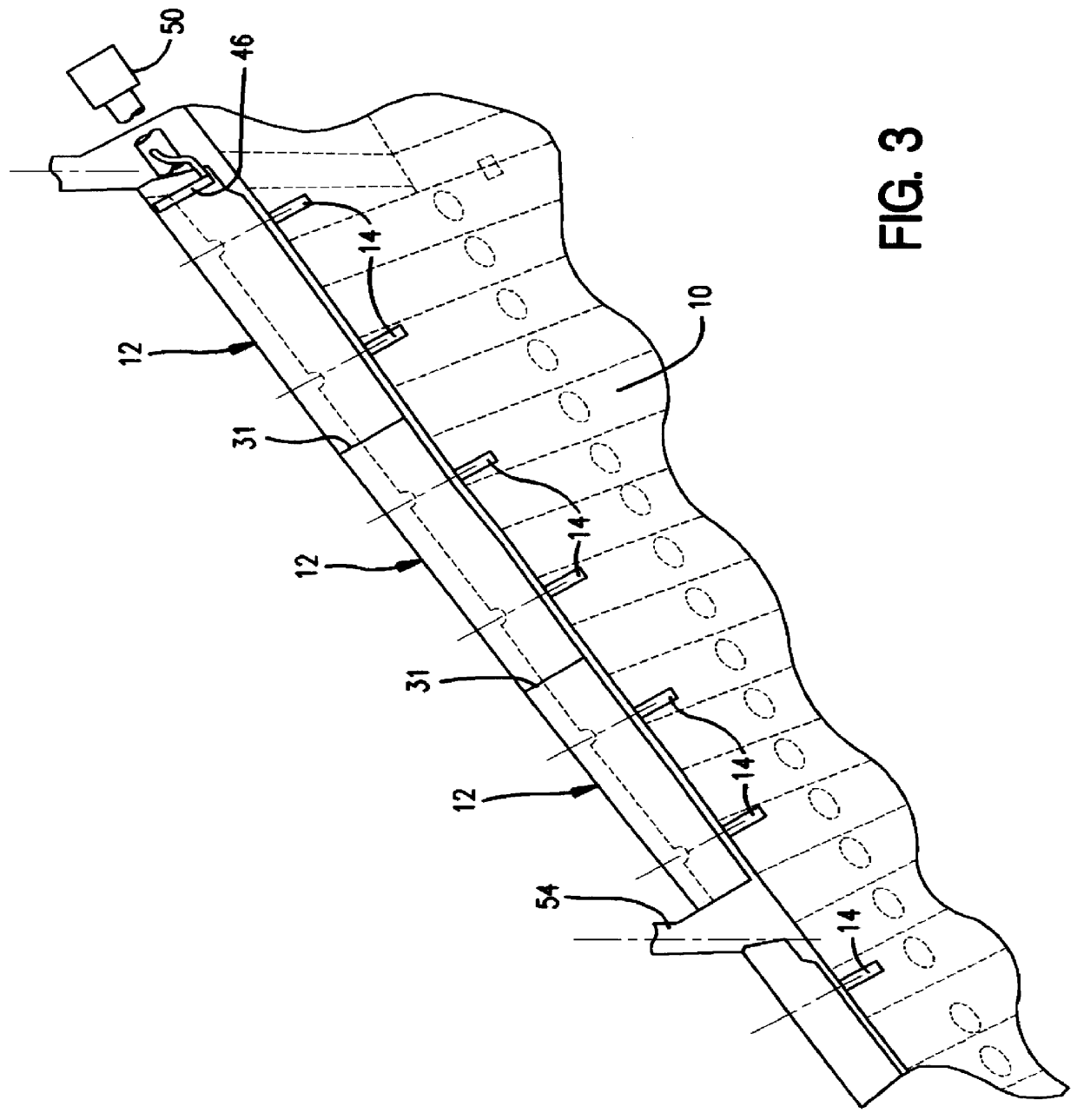

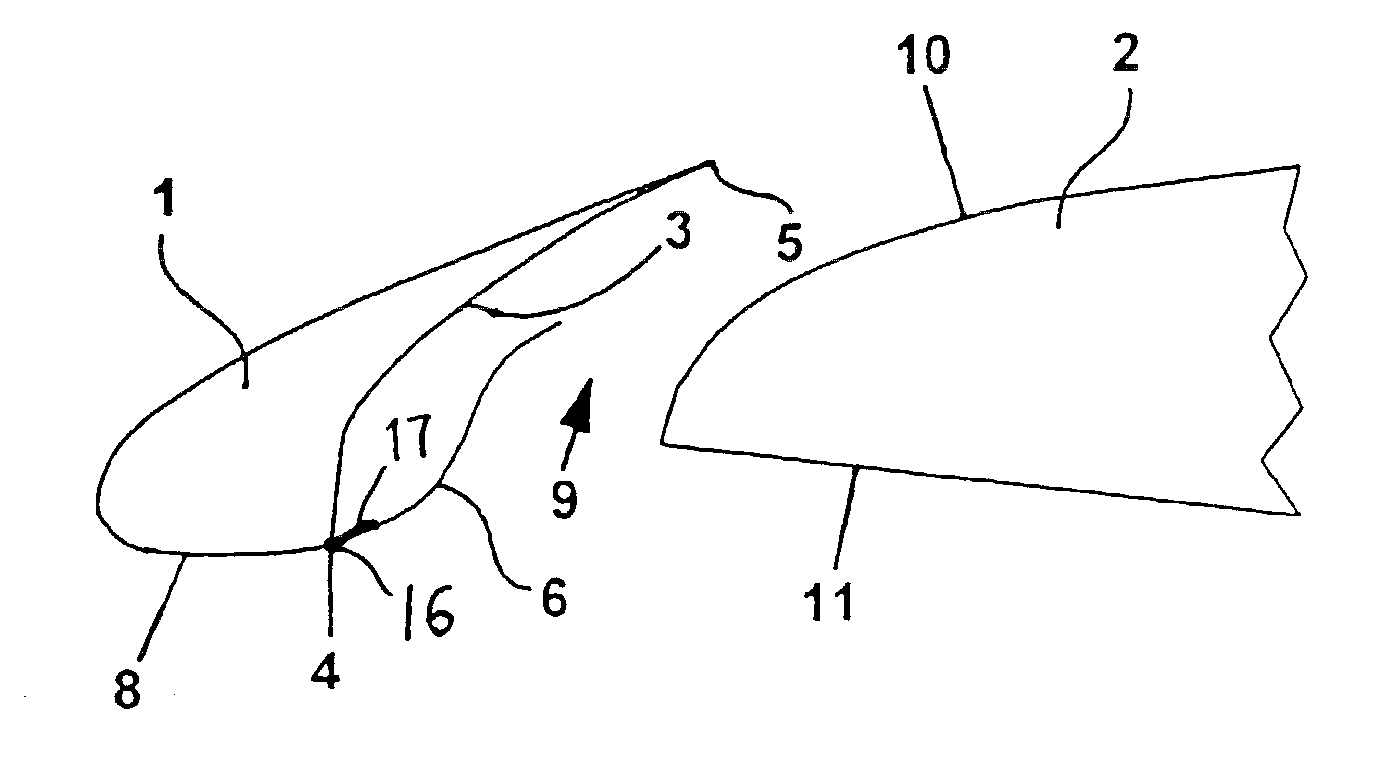

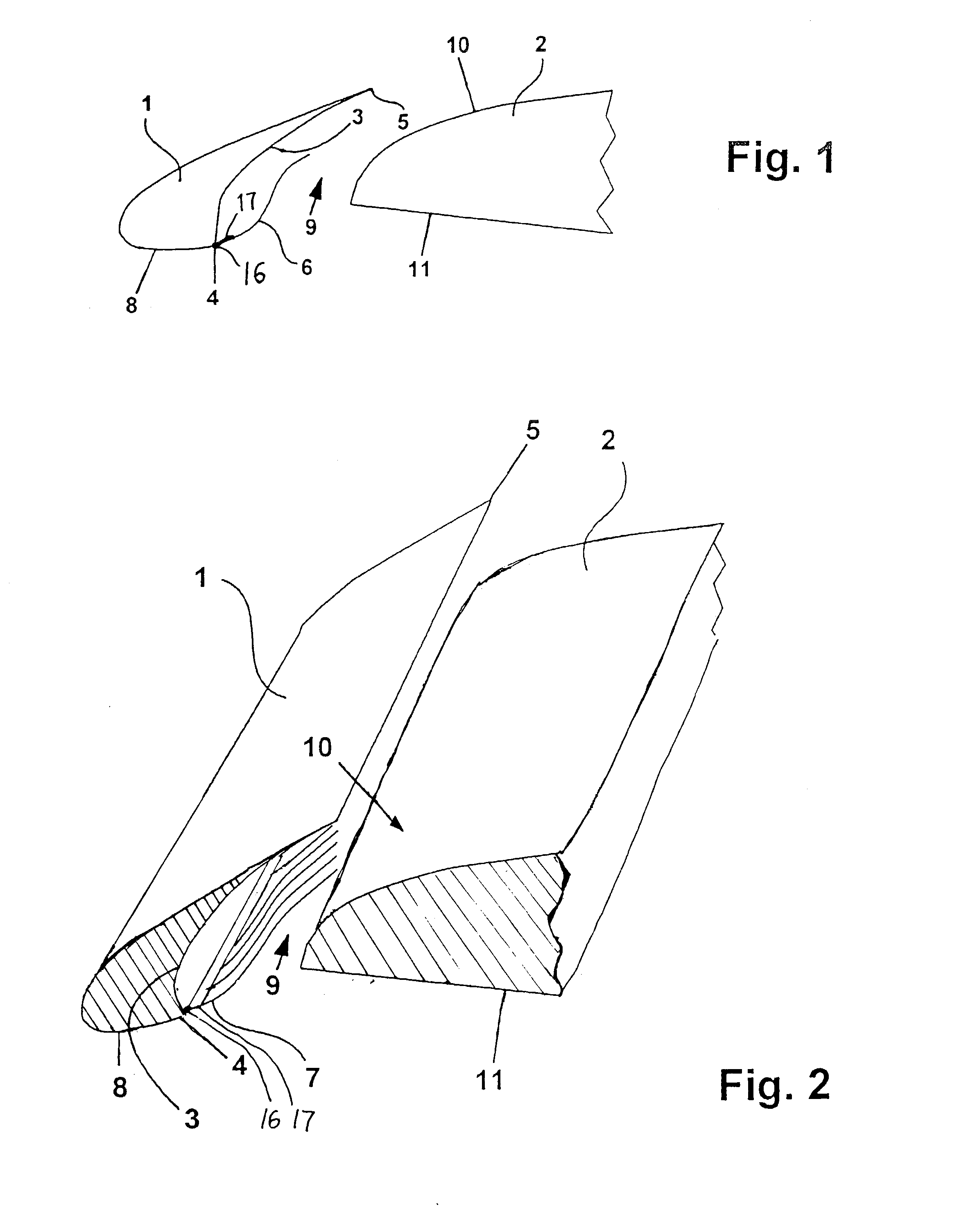

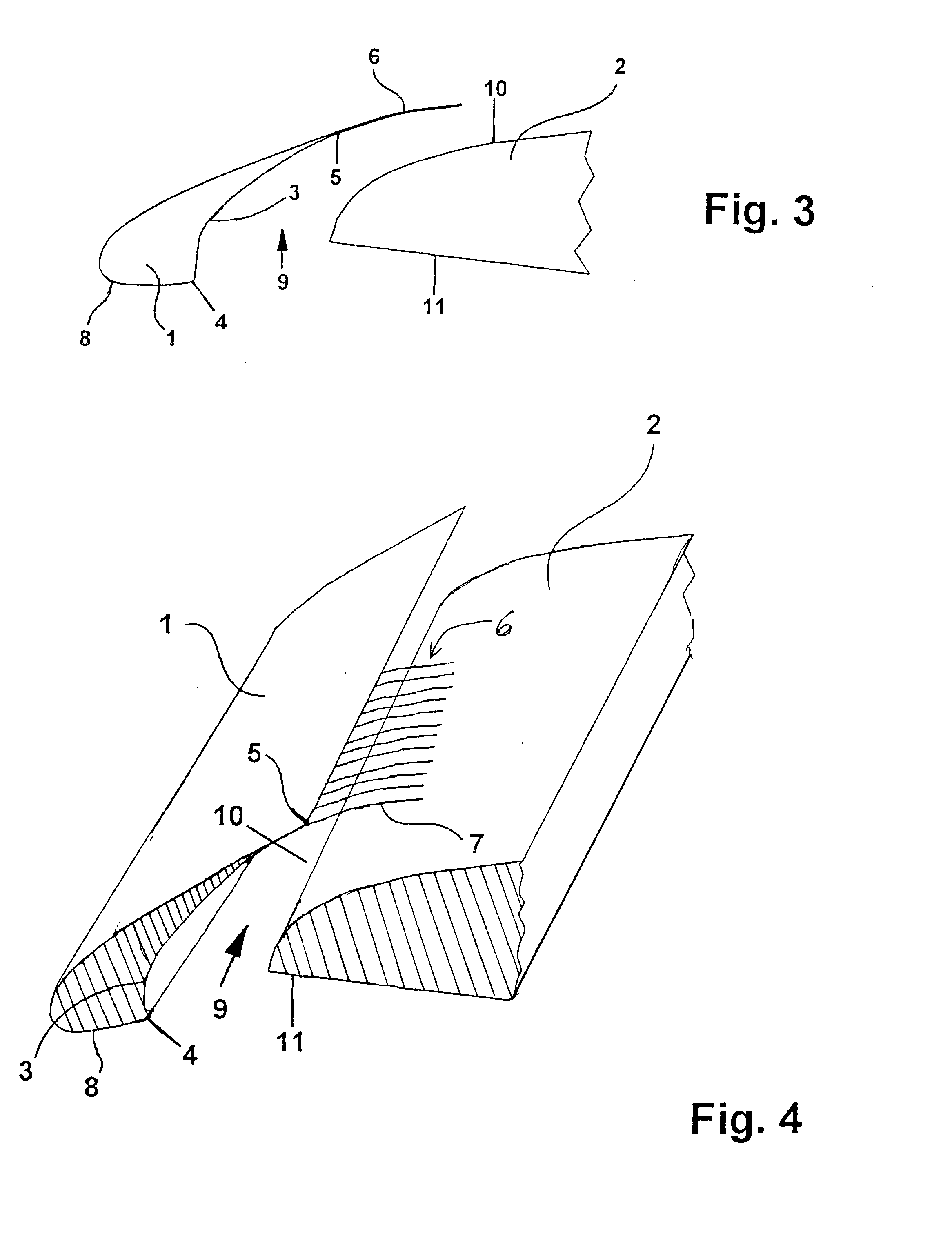

Flexible airflow separator to reduce aerodynamic noise generated by a leading edge slat of an aircraft wing

InactiveUS6789769B2Easy to transformStable separationInfluencers by generating vorticesDe-icing equipmentsLeading edgeBristle

A slat is selectively extended from a main wing body, with a concave rear surface of the slat facing a convex forward nose surface of the wing body, with a slat gap therebetween. At least one row of flexible bristles is movably arranged relative to the lower rear edge of the slat, to flexibly protrude up into the slat air gap. At least one row of flexible bristles is movably arranged along the upper rear edge of the slat to extend rearwardly over the slat air gap and the upper surface of the main wing body. The flexible bristles are flexibly self-positioning and self-contouring due to the aerodynamic forces acting thereon, to improve the air flow conditions through the slat gap, separate the slat gap airflow from an entrapped eddy vortex on the concave rear surface of the slat, and thereby reduce the aerodynamic noise generated along the slat gap.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV +1

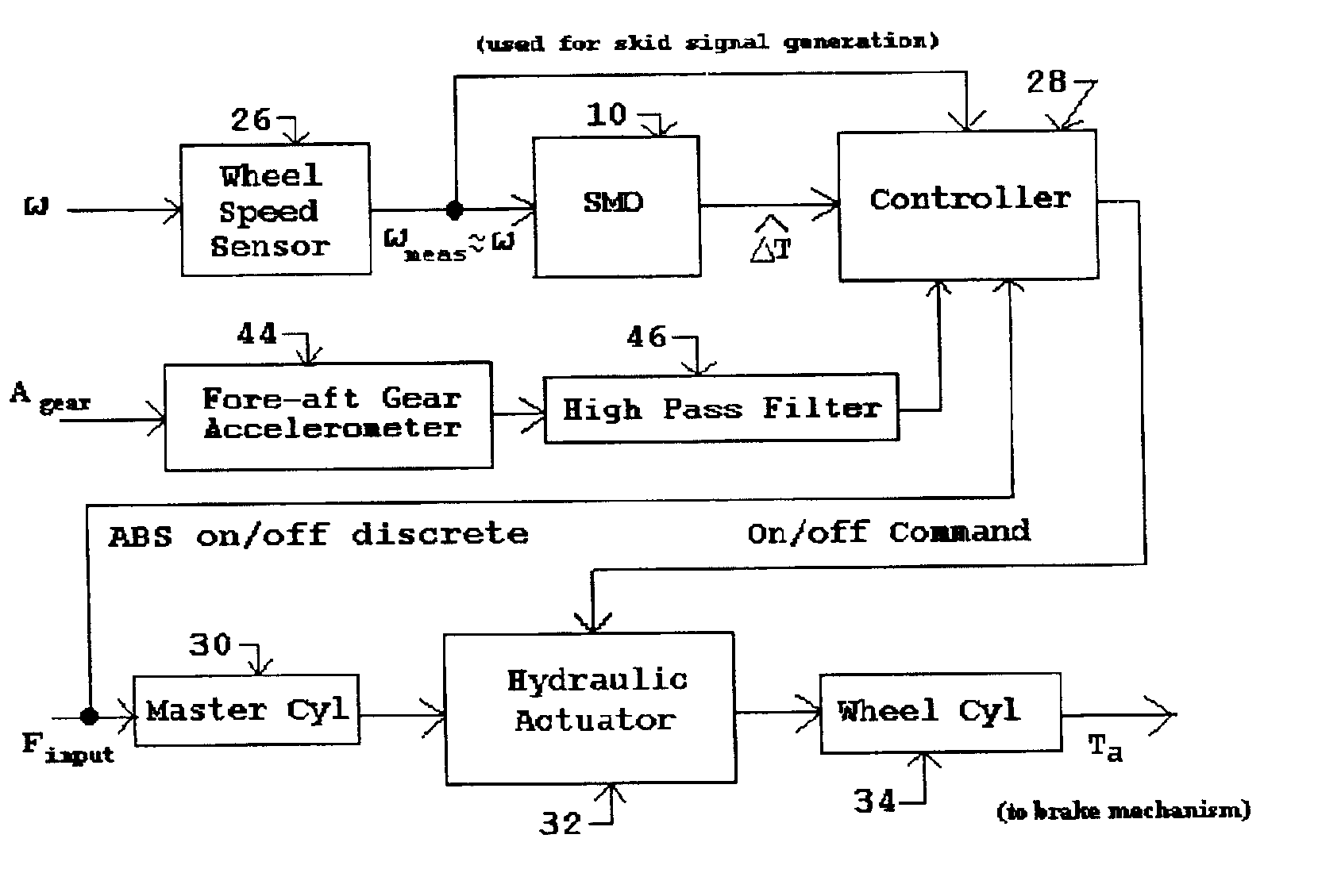

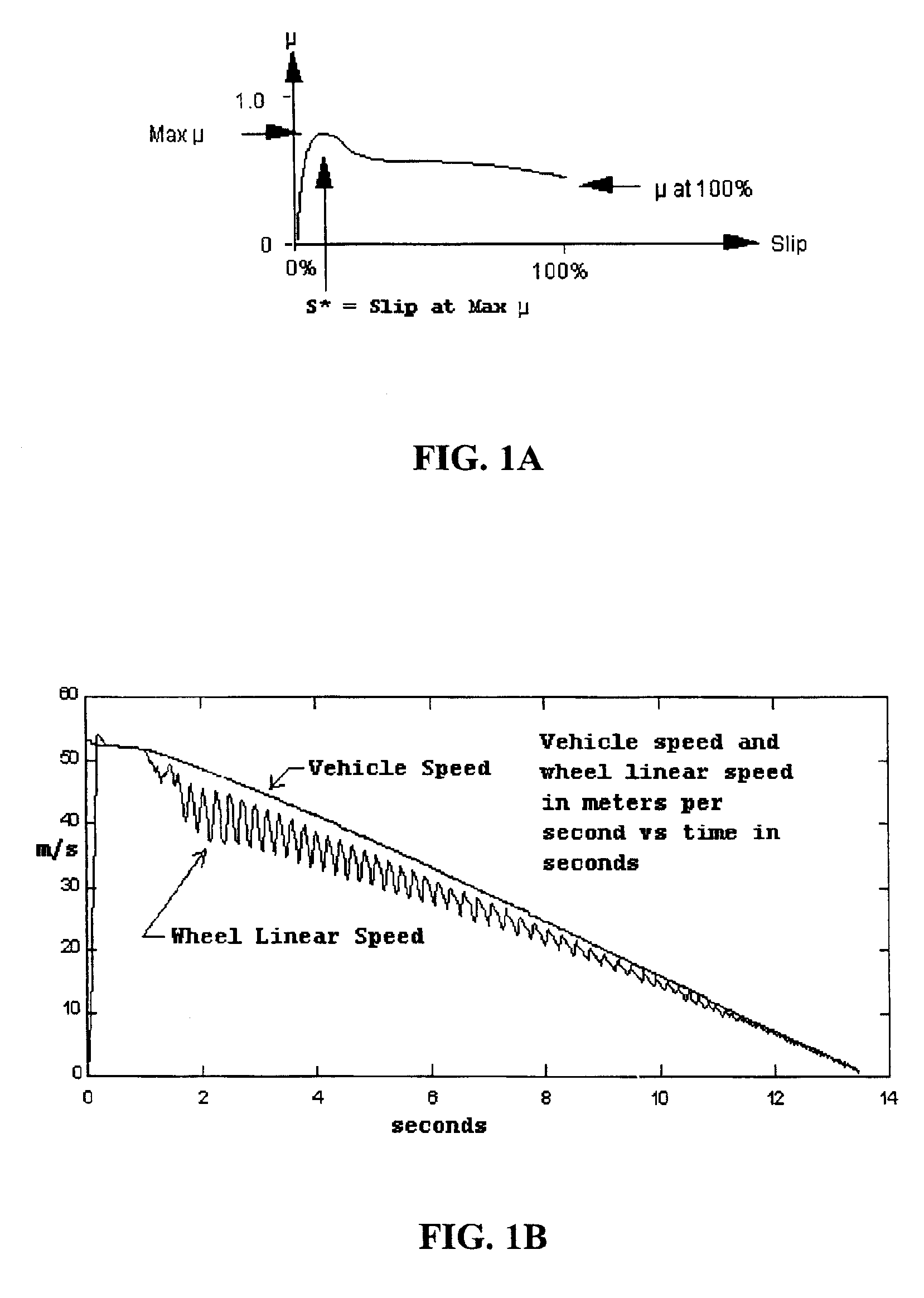

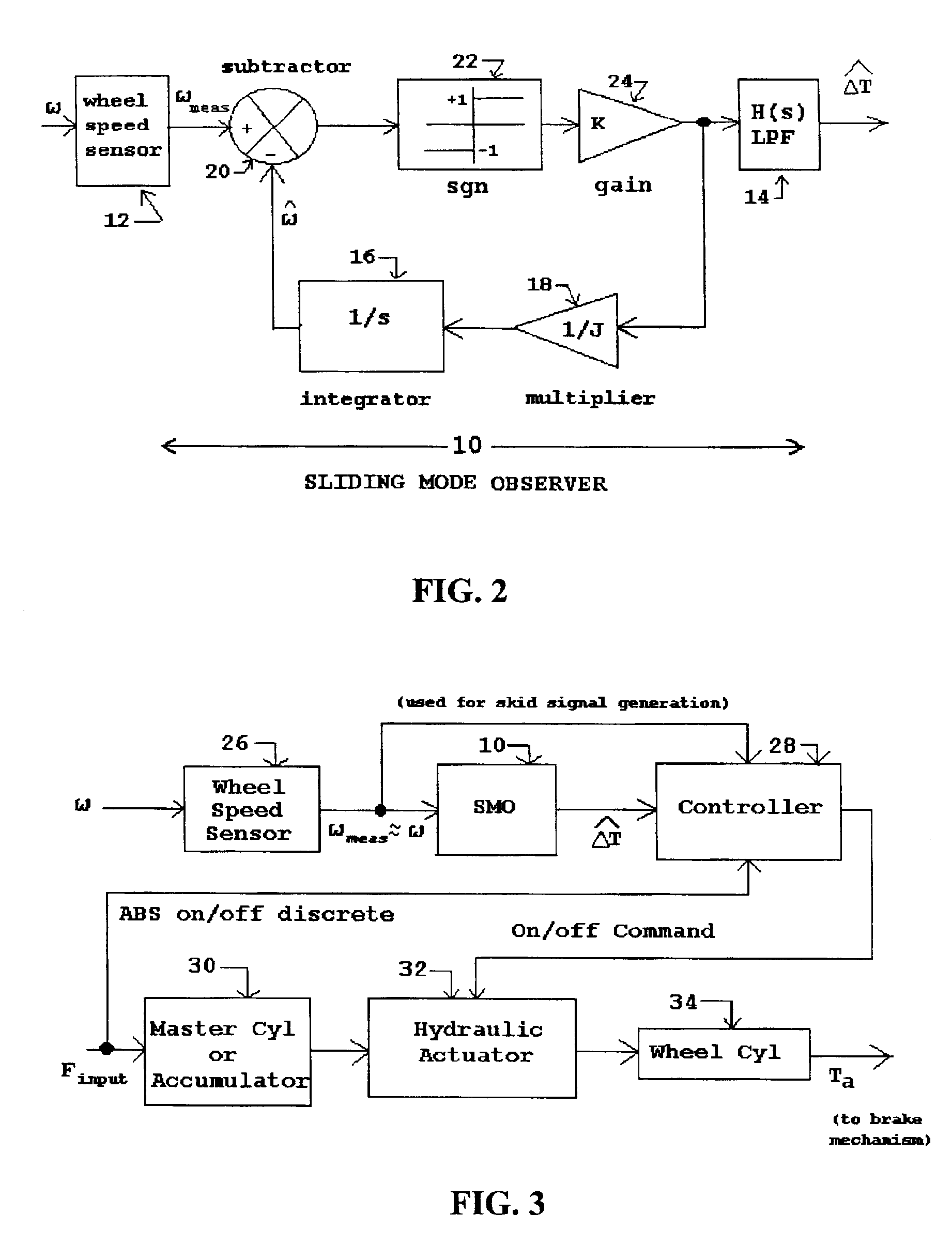

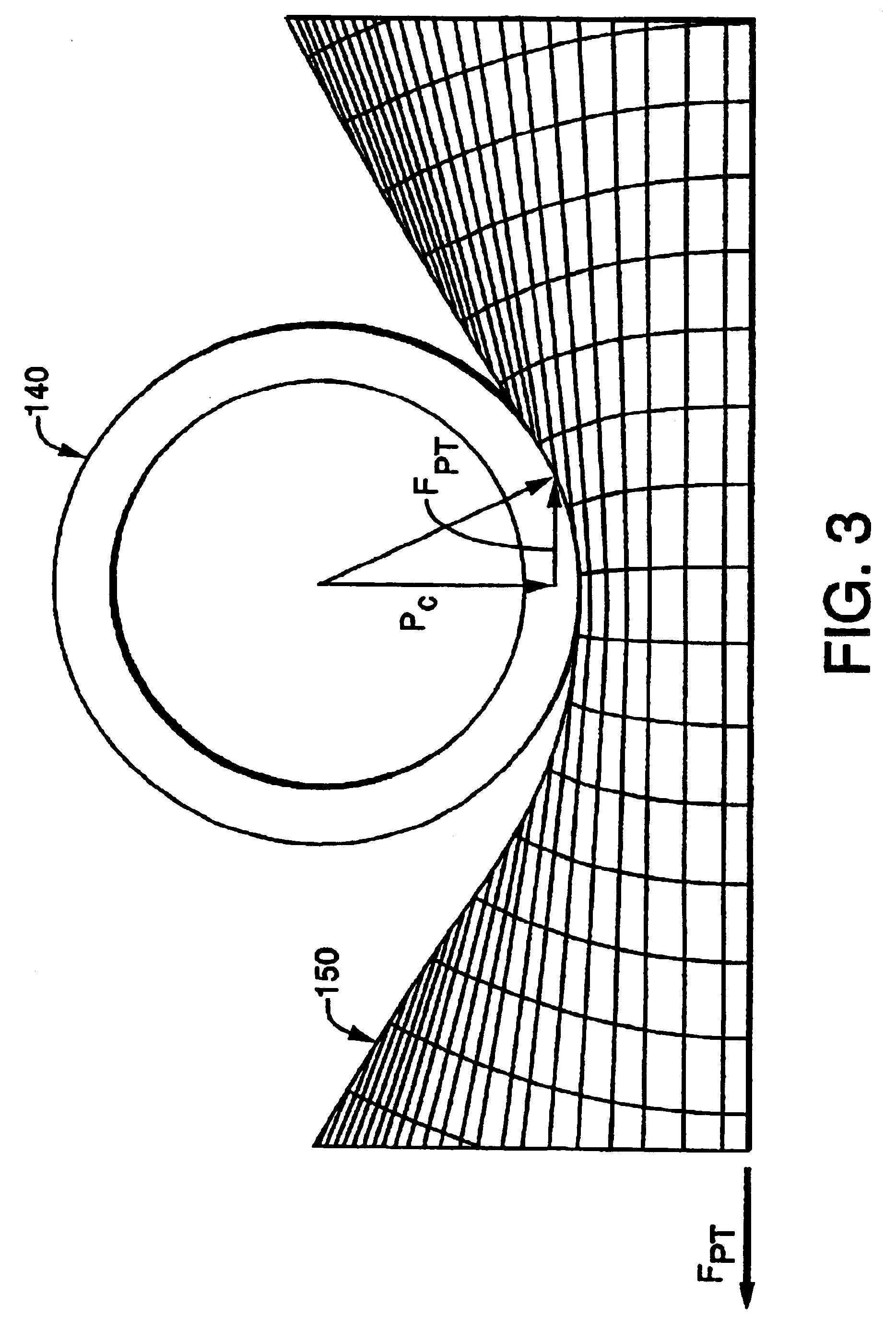

Antilock brake systems employing a sliding mode observer based estimation of differential wheel torque

InactiveUS6890041B1Easy to implementOptimize wheel slip during brakingBraking action transmissionBrake regulatorsAccelerometerControl signal

Improved methods and systems for controlling hydraulically or electrically actuated anti-lock brake systems (ABS) on air and land vehicles requiring only measurement of wheel angular speed although brake torque measurements can also be employed if available. A sliding mode observer (SMO) based estimate of net or different wheel torque (road / tire torque minus applied brake torque) derived from the measured wheel speed is compared to a threshold differential wheel torque derived as a function of a “skid signal” also based on wheel speed only to generate a braking control signal. The braking control signal can be employed to rapidly and fully applying and releasing the brakes in a binary on-off manner and, as an additional option, possibly modulating the maximum available brake hydraulic pressure or electrical current when the brakes are in the “on” state in a continuous manner. In the case of the basic on-off component of braking, the brakes are released when the estimate of differential wheel torque is less than the threshold differential wheel torque (i.e. for relatively high values of brake torque), and the brakes are applied fully when the estimate of differential wheel torque is greater than or equal to the threshold differential wheel torque. For aircraft landing gear applications, a fore-aft accelerometer mounted on the landing gear can be used to suppress nonlinear gear displacement oscillations commonly called gear walk in the direction of wheel roll.

Owner:SMO GRP

Aircraft wing leading edge high lift device with suction

InactiveUS6135395AReduce resistanceReduce layeringBoundary layer controlsFluid dynamicsLeading edgeAircraft landing

An aircraft wing, wing assembly and method of reducing drag are provided. The wing asembly includes a main wing portion (10) and a leading edge high lift portion (12). The high lift portion is movable between a retracted position in which it generally merges with the main wing portion and a deployed position forwardly thereof. At least a substantial part of an upper surface (22) of the high lift portion is air permeable or perforated and in flow communication with a suction passage (30) in it. In flight, suction may be applied to the suction passage to reduce the chordwise extent of the turbulent boundary layer over the upper or lower wing surface.

Owner:AIRBUS OPERATIONS LTD

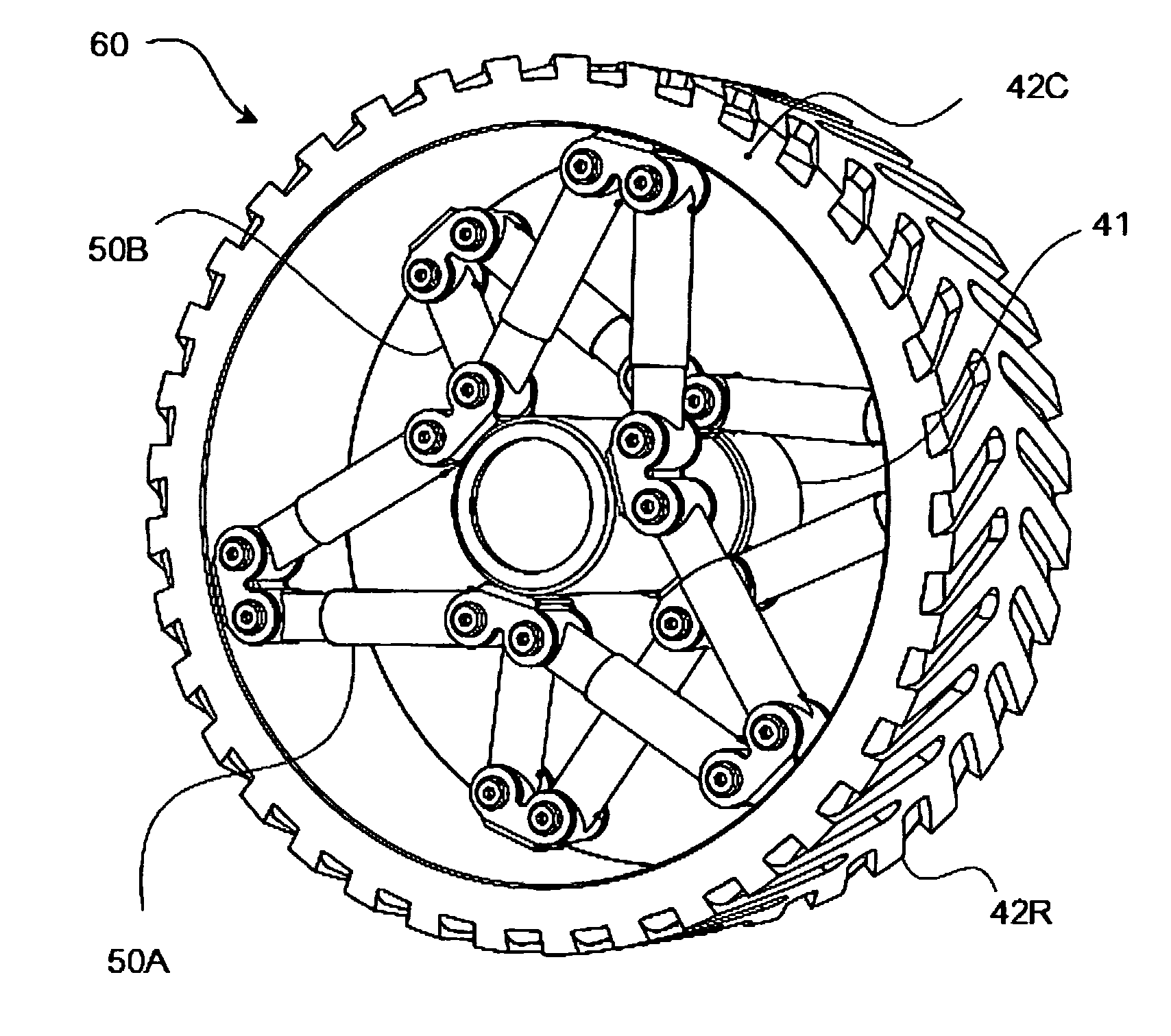

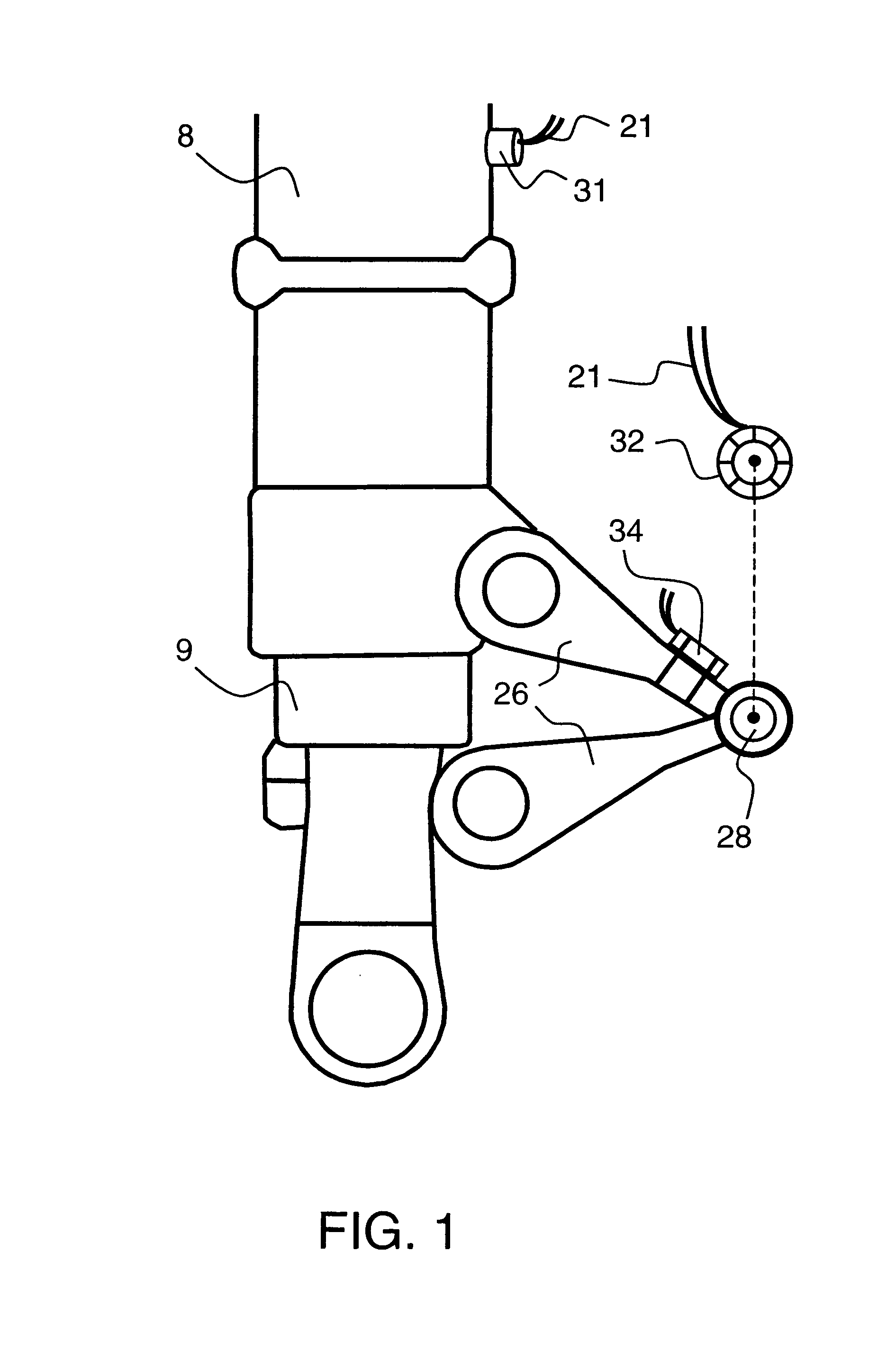

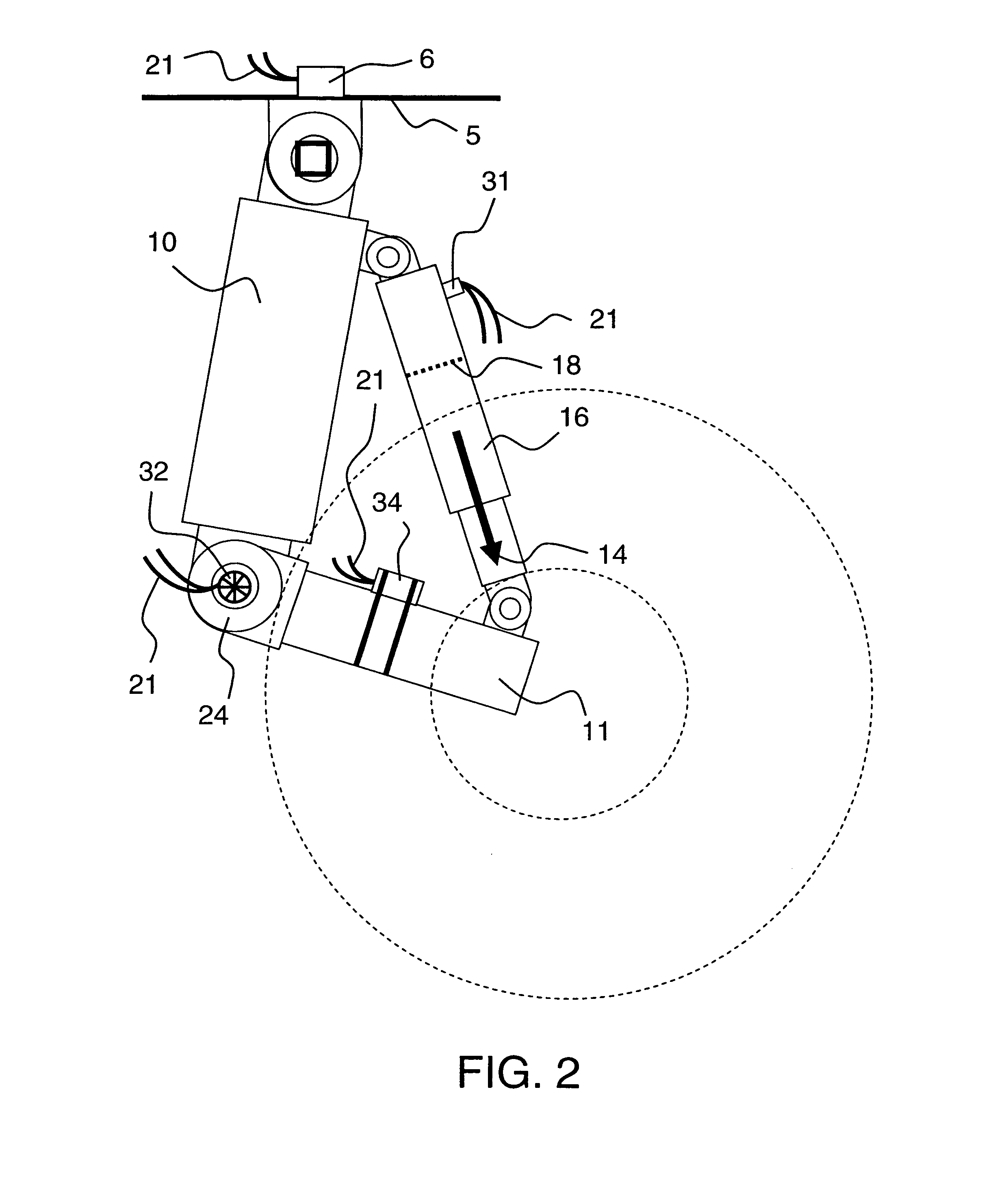

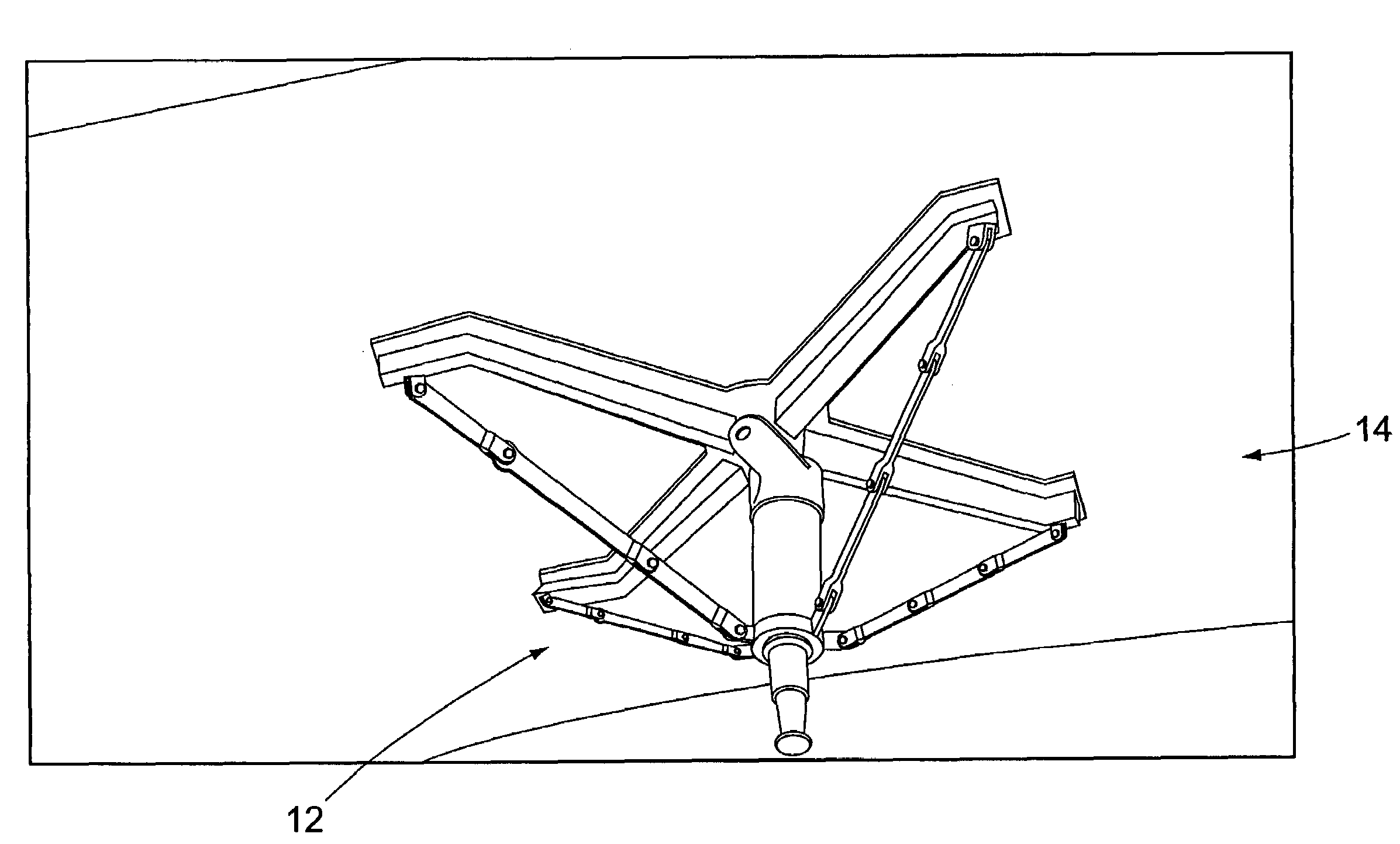

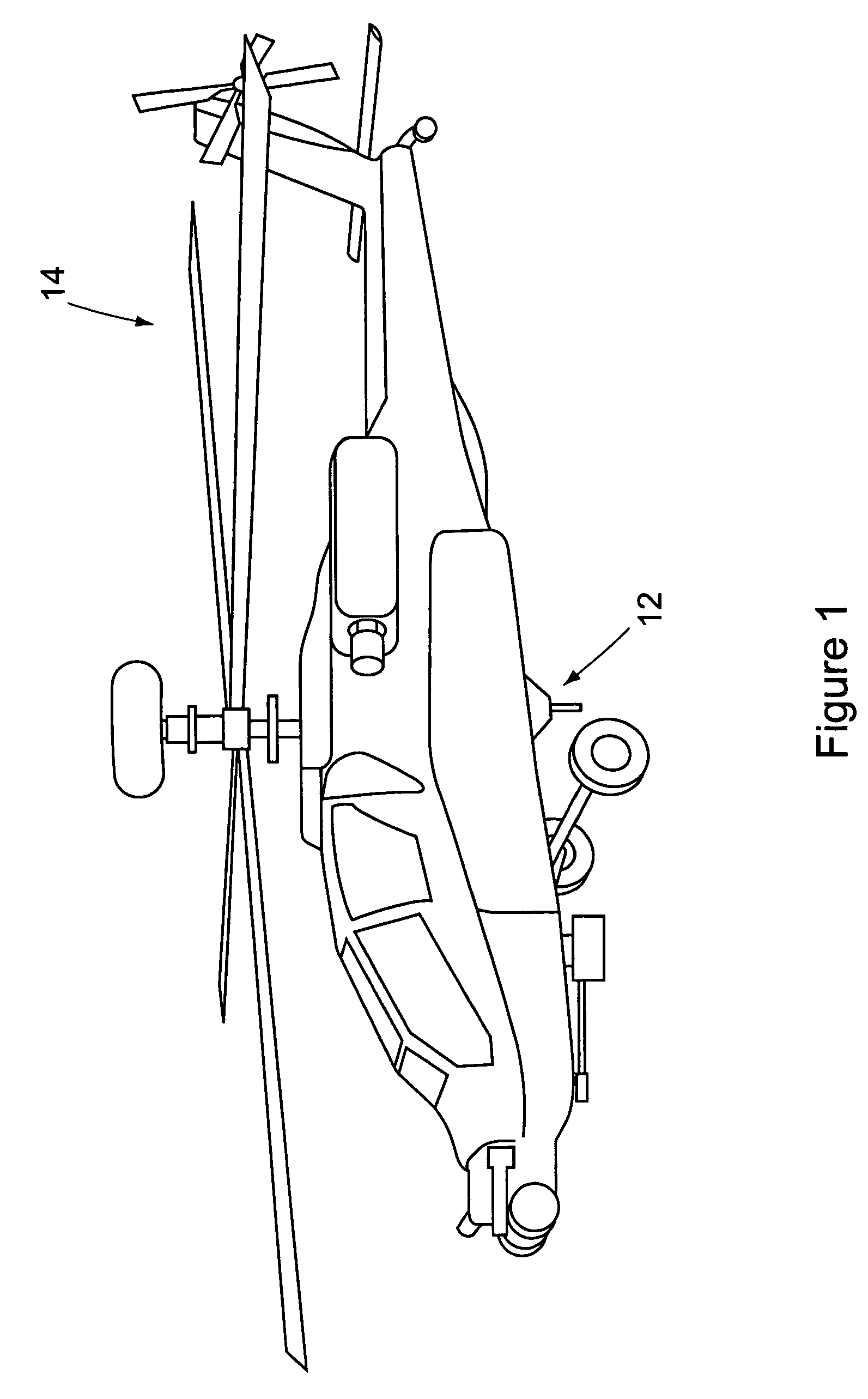

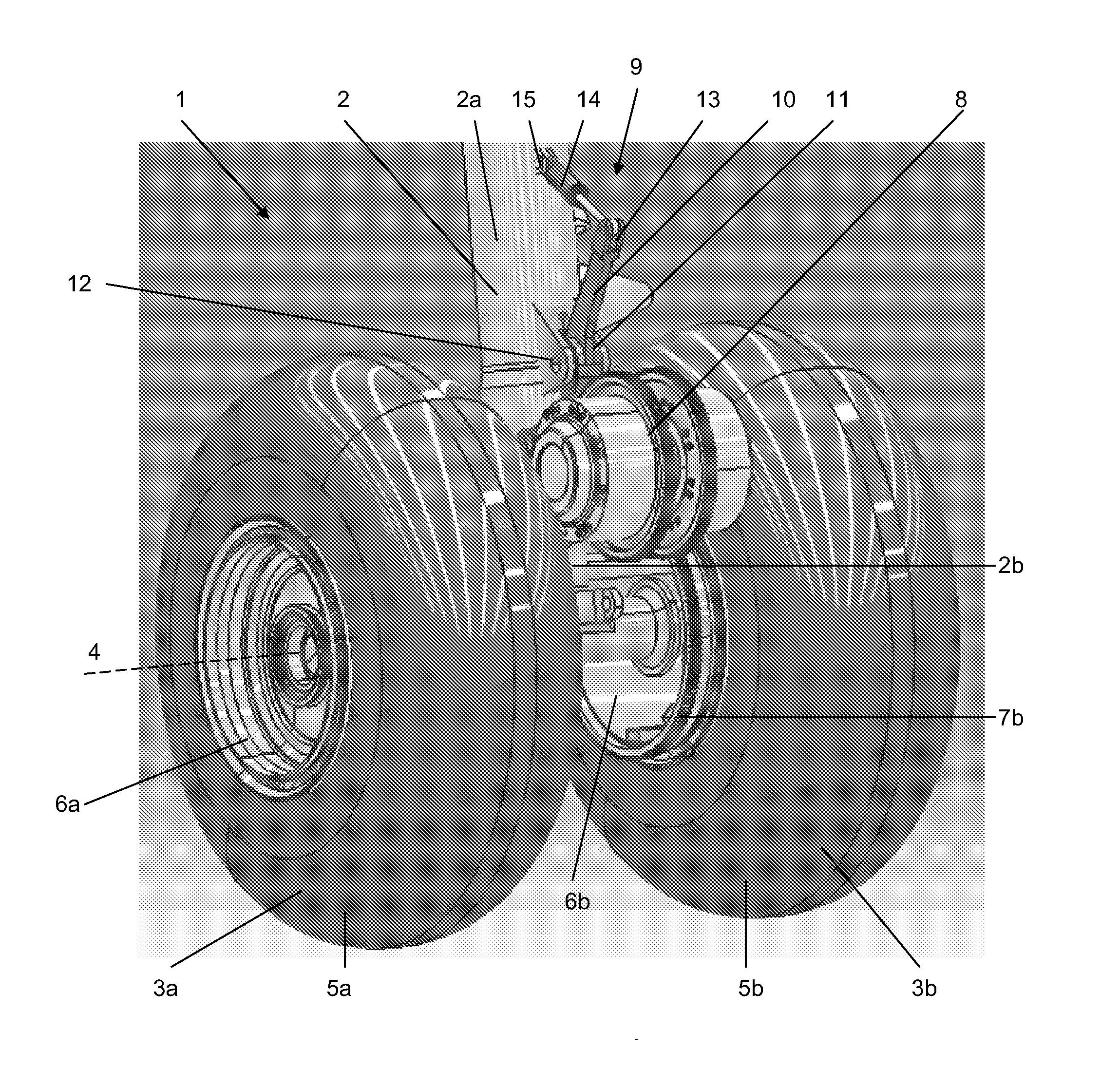

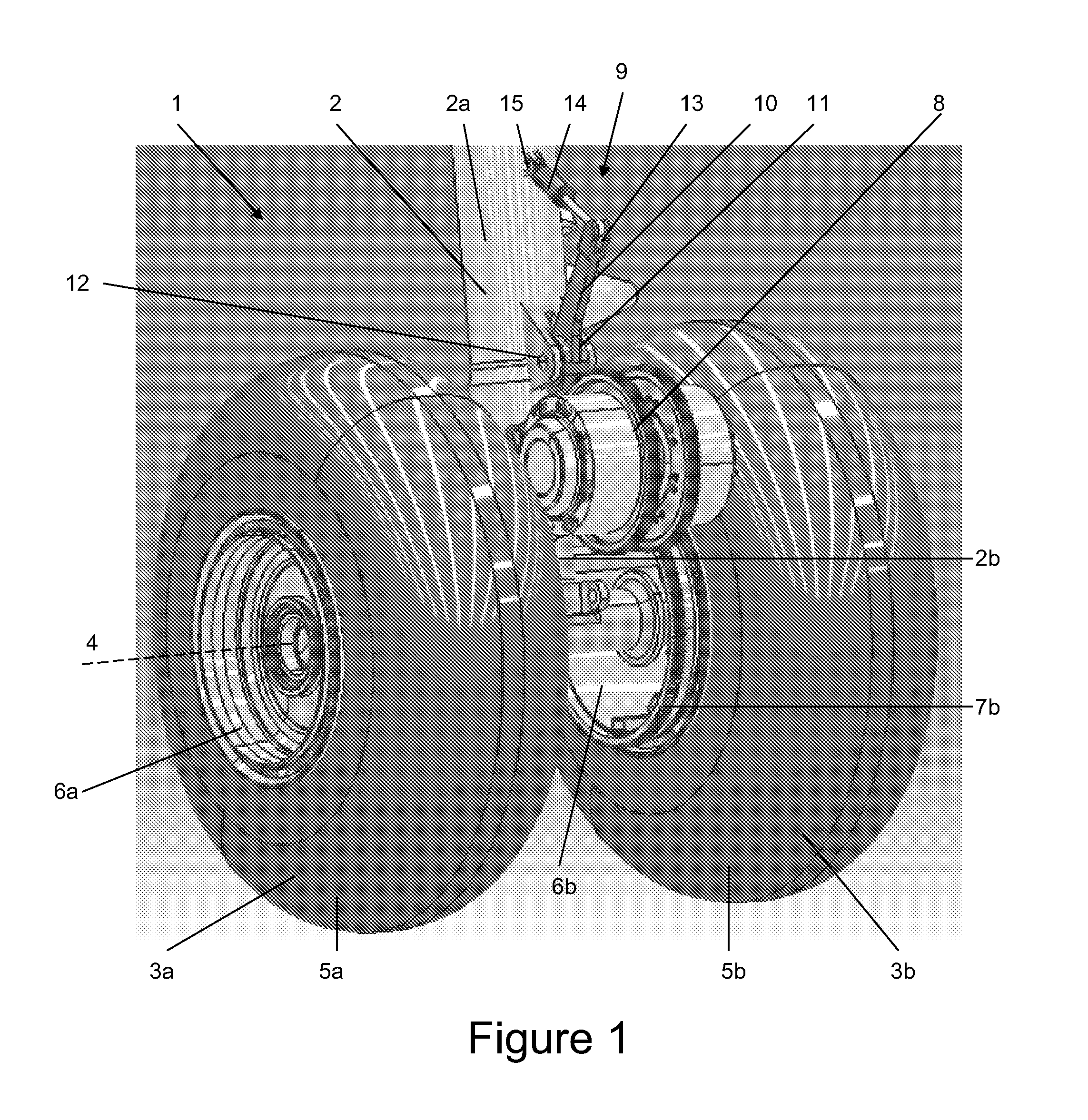

Aircraft landing gear

ActiveUS20120153075A1Large caliberSignificant torque magnifying gear ratioEnergy efficient operational measuresAlighting gearGear wheelFlight vehicle

An aircraft landing gear comprising: a shock-absorbing main leg having a sprung part for attachment to an aircraft and an un-sprung part including a slider and an axle carrying at least one wheel, the wheel having a toothed ring gear; a drive transmission mounted externally on the sprung part, or on the un-sprung part, of the main leg, the drive transmission having at least one motor and a drive pinion for meshing with the toothed ring of the wheel; and an actuator for lifting the drive transmission into and out of driving engagement with the toothed ring and for maintaining the driving engagement as the landing gear deflects during a ground taxiing operation. Also, a method of operating the aircraft landing gear.

Owner:AIRBUS OPERATIONS LTD

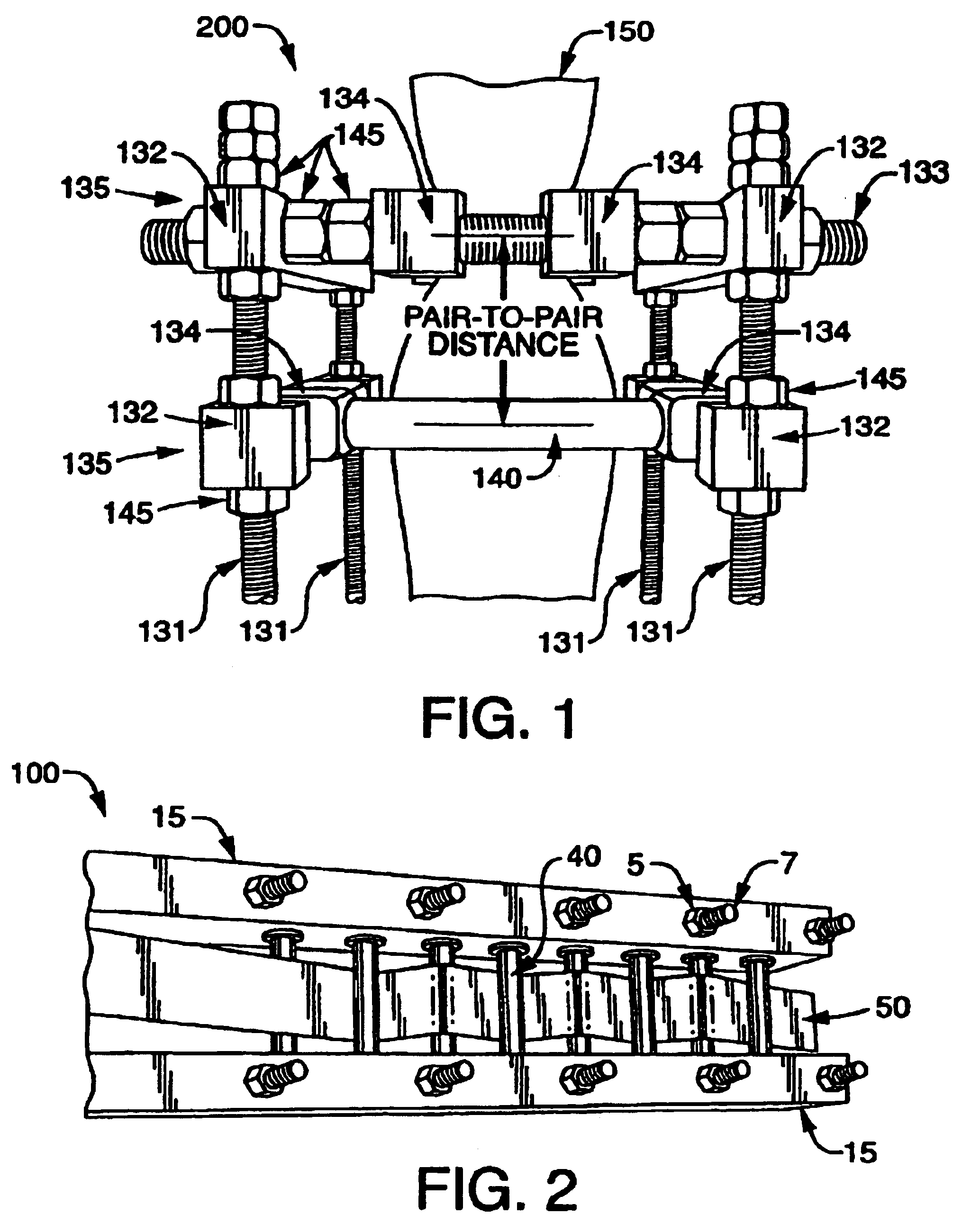

Variable force energy dissipater and decelerator

InactiveUS6962245B2Efficient and cost-effective managementMore kinetic energyTraffic signalsElastic dampersUltrasound attenuationSteering column

Tunable pull-through energy attenuator and decelerator devices is disclosed which provide for variable force-time profiles, deceleration and kinetic energy attenuation of moving objects so as to prevent damage or injury to impacting objects, vehicles or persons. The device employs either consumable inelastic or reusable, viscoelastic deforming elements, such as tubes, rods, plates or strips, which absorb substantial amounts of energy through repeated inelastic or viscoelastic deformation when the deforming element is pulled-through a tunable array of rigid pins having a variety of configurations and settings. The disclosed devices provide for variable force-time profiles which control the cumulative deformation and thereby the amount of energy absorbed and rate of deceleration of impacting objects. The device may be readily adapted and deployed as highway vehicle guardrails, road barriers or crash cushions for frontal and side impacts and as load attenuators for crash-resistant aircraft seats, spacecraft landing pods, crash-resistant aircraft landing gear, aircraft and vehicle passenger restraint harnesses, cargo tie-downs, vehicle bumpers and collapsible vehicle steering columns.

Owner:WORCESTER POLYTECHNIC INSTITUTE

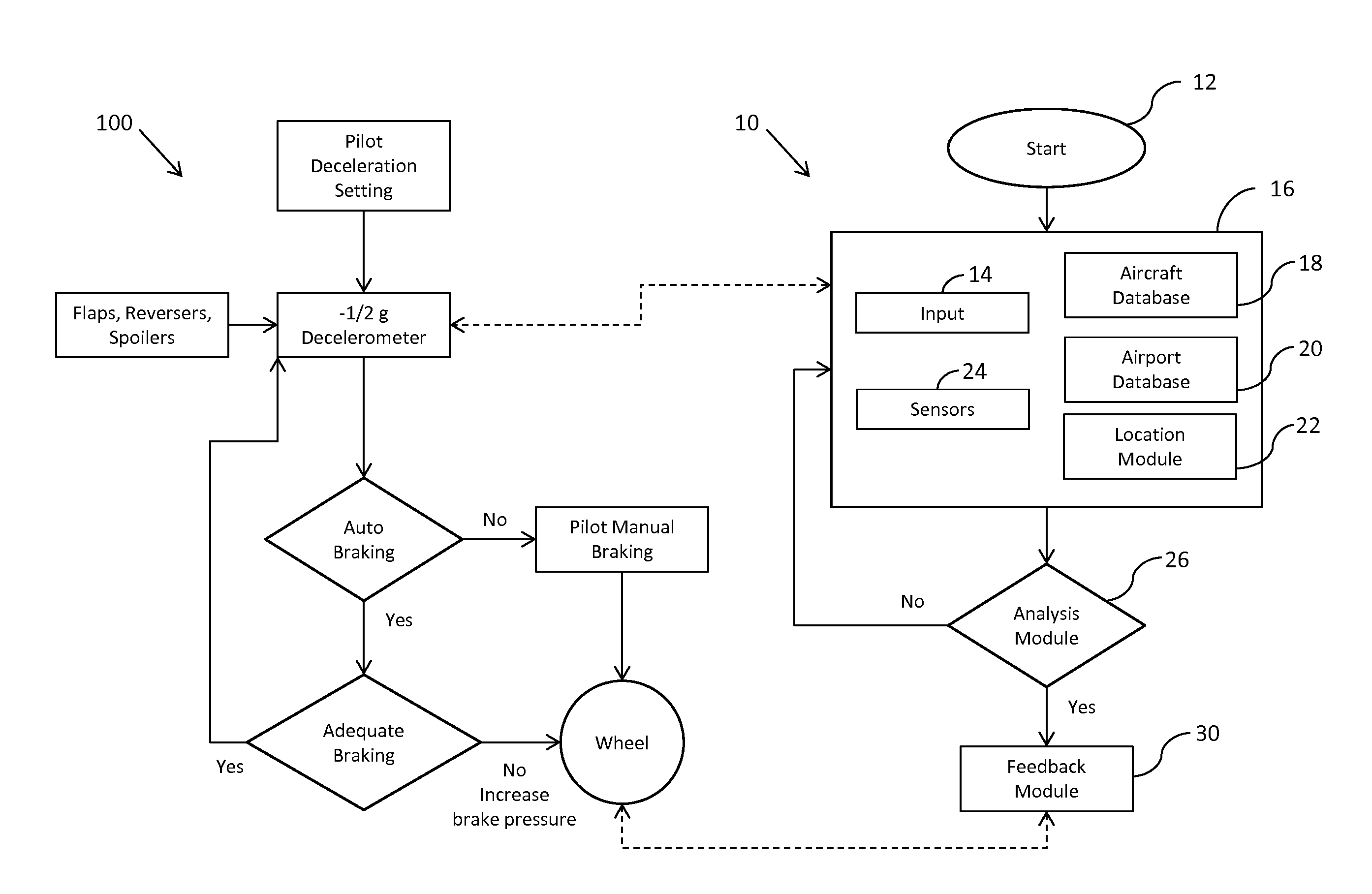

Aircraft braking early warning system

ActiveUS20140257603A1Well formedAnalogue computers for vehiclesAutomatic braking sequenceEarly warning systemFlight vehicle

A method provides alert information, regarding an aircraft wheel braking system, to an operator of an aircraft during an aircraft landing. An input of a target deceleration rate for the landing aircraft is received prior to the aircraft having landed on a ground surface. At least one sensor electronically collects information relevant to a real-time deceleration rate of the aircraft after the aircraft has landed on the ground surface, and the real-time deceleration rate of the aircraft is calculated. The target deceleration rate is compared to the calculated deceleration rate to determine an effectiveness of the aircraft wheel braking system. A visual, audible, or tactile alert is optionally provided to the operator of the aircraft, and data from this system could also be used as an input for various other aircraft safety systems. A system for performing the method is also provided.

Owner:3RD MILLENNIUM SOLUTIONS

Aircraft anti-terrorism security system

InactiveUS6844817B2Effectively counterEffectively suppressAir-treatment apparatus arrangementsBurglar alarmMotion detectorAir steward

In an aircraft cabin floor adjacent to the cockpit, a trap door opens downwardly into a security cell, to trap a terrorist trying to enter the cockpit. Two walls with lockable airtight doors bound a safety buffer cabin between the cockpit and the passenger cabin. Sensors like seat occupancy sensors, motion detectors, video cameras and microphones provide data regarding the location, movement and activities of passengers to a system that evaluates the data to recognize unusual data situations indicating one or more escalation levels of suspicious or aggressive actions by passengers. Alarm signals and terrorist countermeasure devices such as fogging or tranquilizer gas generators, noise generators, high intensity blinding / glaring lights, a cabin lighting master shut-off, window darkening devices, and tranquilizer dart guns are actuated automatically by the evaluation system, or manually by a cockpit input device or a portable signaling device carried by a flight attendant.

Owner:AIRBUS OPERATIONS GMBH

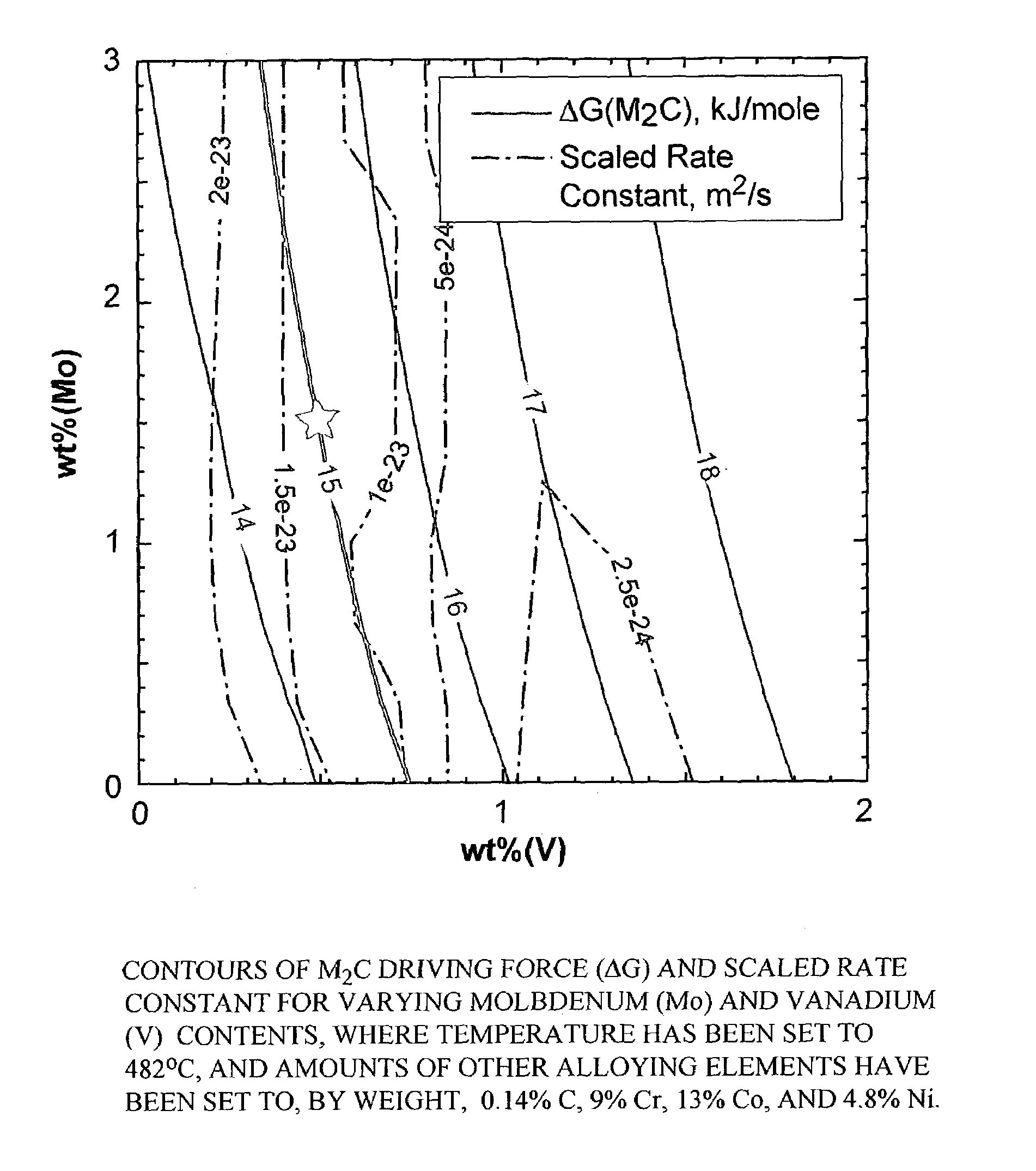

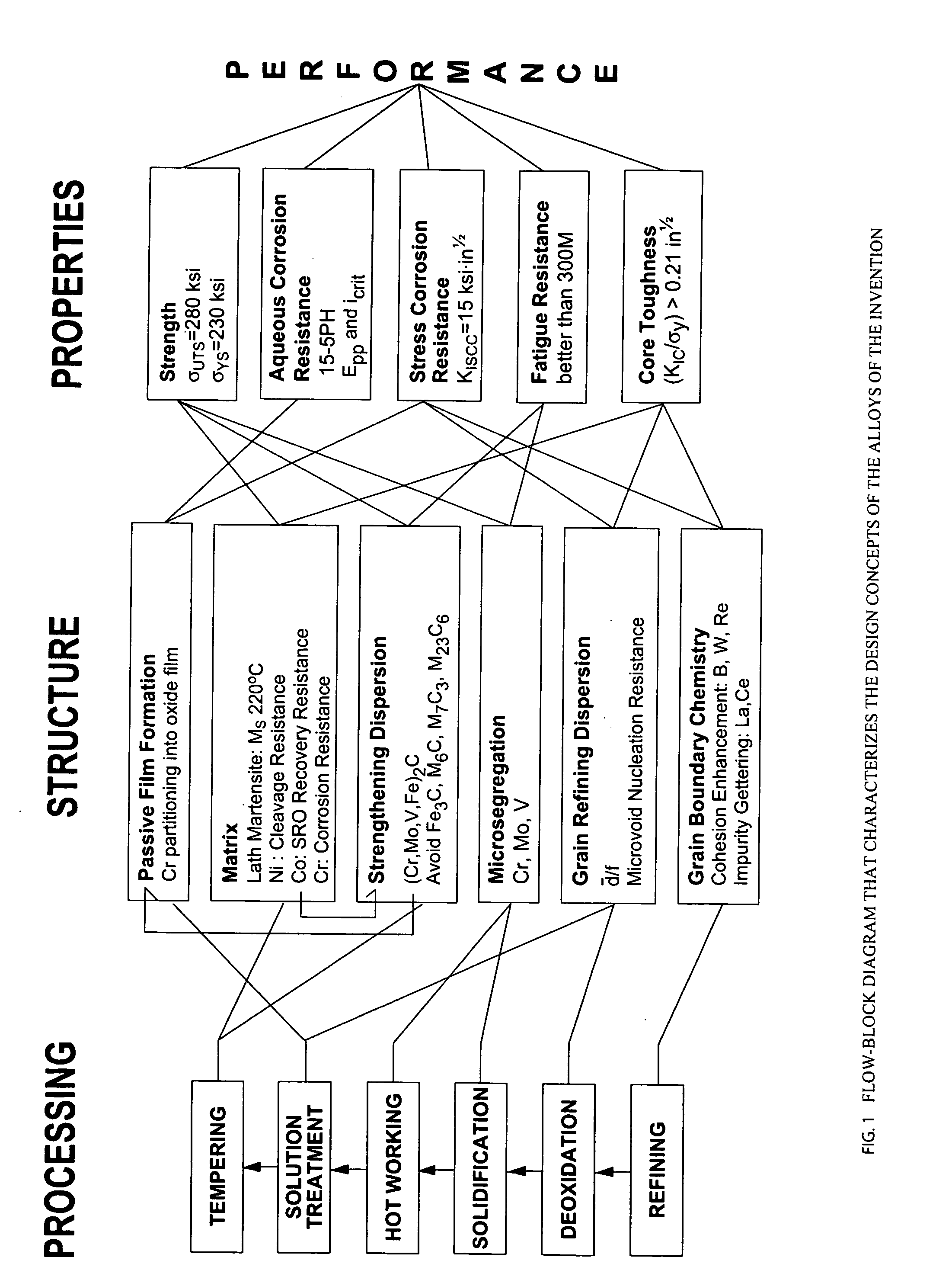

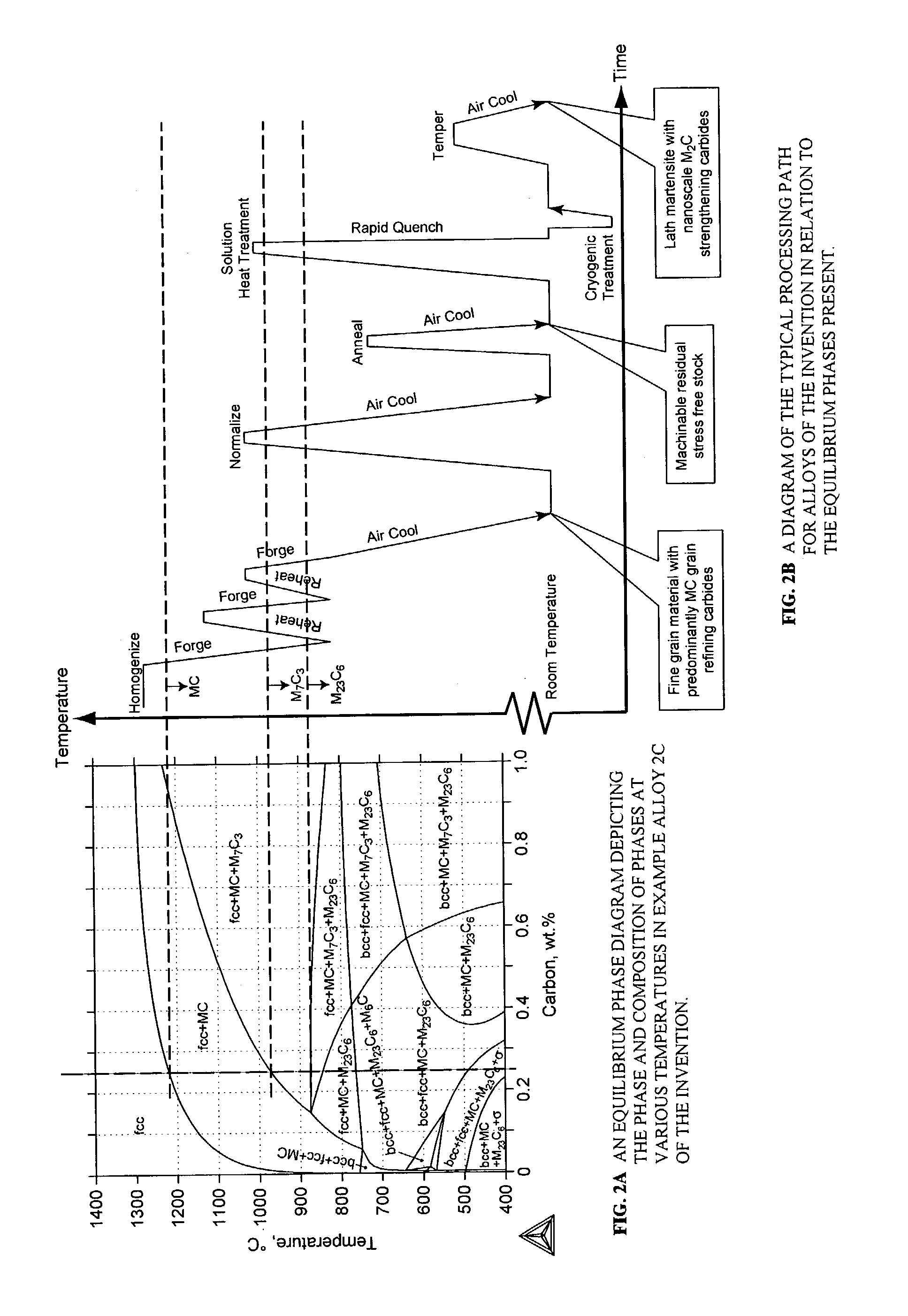

Nanocarbide precipitation strengthened ultrahigh-strength, corrosion resistant, structural steels

InactiveUS7160399B2Simple working processHigh strengthFurnace typesHeat treatment furnacesCobaltMaterials science

A nanocarbide precipitation strengthened ultrahigh-strength, corrosion resistant, structural steel possesses a combination of strength and corrosion resistance comprising in combination, by weight, about: 0.1 to 0.3% carbon (C), 8 to 17% cobalt (Co), 0 to 10% nickel (Ni), 6 to 12% chromium (Cr), less than 1% silicon (Si), less than 0.5% manganese (Mn), and less than 0.15% copper (Cu), with additives selected from the group comprising about: less than 3% molybdenum (Mo), less than 0.3% niobium (Nb), less than 0.8% vanadium (V), less than 0.2% tantalum (Ta), less than 3% tungsten (W), and combinations thereof, with additional additives selected from the group comprising about: less than 0.2% titanium (Ti), less than 0.2% lanthanum (La) or other rare earth elements, less than 0.15% zirconium (Zr), less than 0.005% boron (B), and combinations thereof, impurities of less than about: 0.02% sulfur (S), 0.012% phosphorus (P), 0.015% oxygen (O) and 0.015% nitrogen (N), the remainder substantially iron (Fe), incidental elements and other impurities. The alloy is strengthened by nanometer scale M2C carbides within a fine lath martensite matrix from which enhanced chemical partitioning of Cr to the surface provides a stable oxide passivating film for corrosion resistance. The alloy, with a UTS in excess of 280 ksi, is useful for applications such as aircraft landing gear, machinery and tools used in hostile environments, and other applications wherein ultrahigh-strength, corrosion resistant, structural steel alloys are desired.

Owner:QUESTEK INNOVATIONS LLC

Flexible airflow separator to reduce aerodynamic noise generated by a leading edge slat of an aircraft wing

InactiveUS20030226936A1Easy to transformStable separationInfluencers by generating vorticesDe-icing equipmentsLeading edgeBristle

A slat is selectively extended from a main wing body, with a concave rear surface of the slat facing a convex forward nose surface of the wing body, with a slat gap therebetween. At least one row of flexible bristles is movably arranged relative to the lower rear edge of the slat, to flexibly protrude up into the slat air gap. At least one row of flexible bristles is movably arranged along the upper rear edge of the slat to extend rearwardly over the slat air gap and the upper surface of the main wing body. The flexible bristles are flexibly self-positioning and self-contouring due to the aerodynamic forces acting thereon, to improve the air flow conditions through the slat gap, separate the slat gap airflow from an entrapped eddy vortex on the concave rear surface of the slat, and thereby reduce the aerodynamic noise generated along the slat gap.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV +1

Aircraft landing gear automated inspection and life limitation escalation system and method

A system for use in monitoring, measuring, computing and displaying the landing loads experienced while aircraft are executing either normal, overweight or hard landing events. Pressure sensors and motion sensors are mounted in relation to each of the landing gear struts to monitor, measure and record the impact loads and aircraft sink rates; experienced by landing gear struts, as the aircraft landing gear initially come into contact with the ground. The computer of this system measures the landing loads experienced by each landing gear strut and determines if a hard landing event has occurred. Additional features include automating the inspections required to aircraft components, after overweight or hard landing events.

Owner:NANCE C KIRK

Aircraft landing gear compression rate monitor and method to increase aircraft landing weight limitation

ActiveUS8180504B1Weight increaseAnalogue computers for vehiclesDigital data processing detailsAccelerometerData stream

A system for use in monitoring, measuring, computing and displaying the rate of compression of aircraft landing gear struts, experienced while aircraft are executing either normal or hard landing events. Further by measuring the vertical compression rate of the landing gear strut, thus with aircraft hull angle correction to horizontal, determining the vertical sink-rate of the aircraft, as it comes into initial contact with the ground. Accelerometers are attached to opposing sides of a compressible landing gear strut, monitoring and measuring parallel data streams; then identifying differential acceleration data streams, which computed through mathematical algorithms measure the collapse rate of the landing gear strut. Pressure sensors are attached to the working pressure within the landing gear strut, so to monitor in-flight landing gear strut pre-charge pressure, until such time as the pre-charge pressure suddenly increases, to detect the aircraft has come into initial contact with the ground. A method of operating an aircraft at an increased maximum landing weight limitation.

Owner:NANCE C KIRK

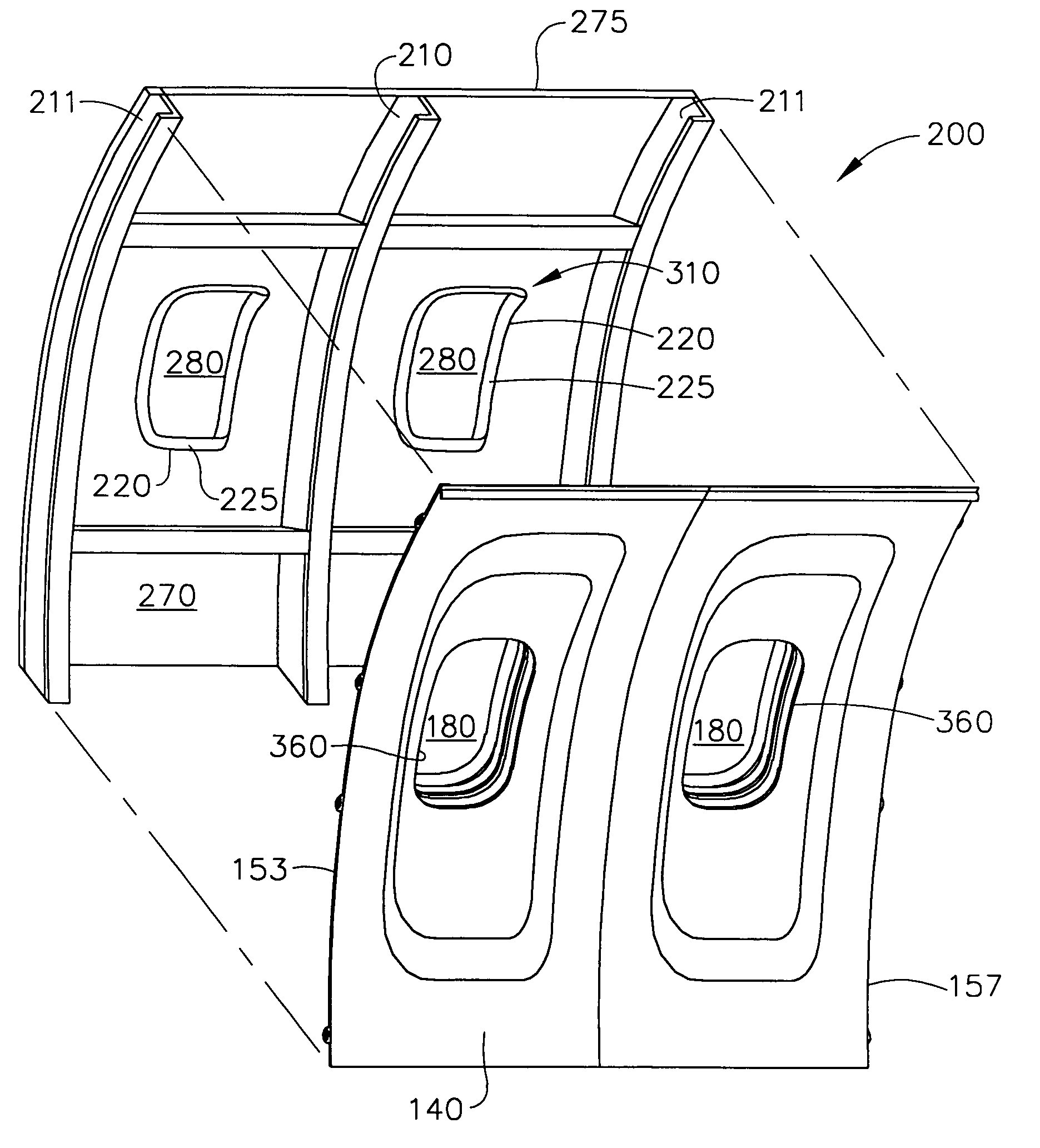

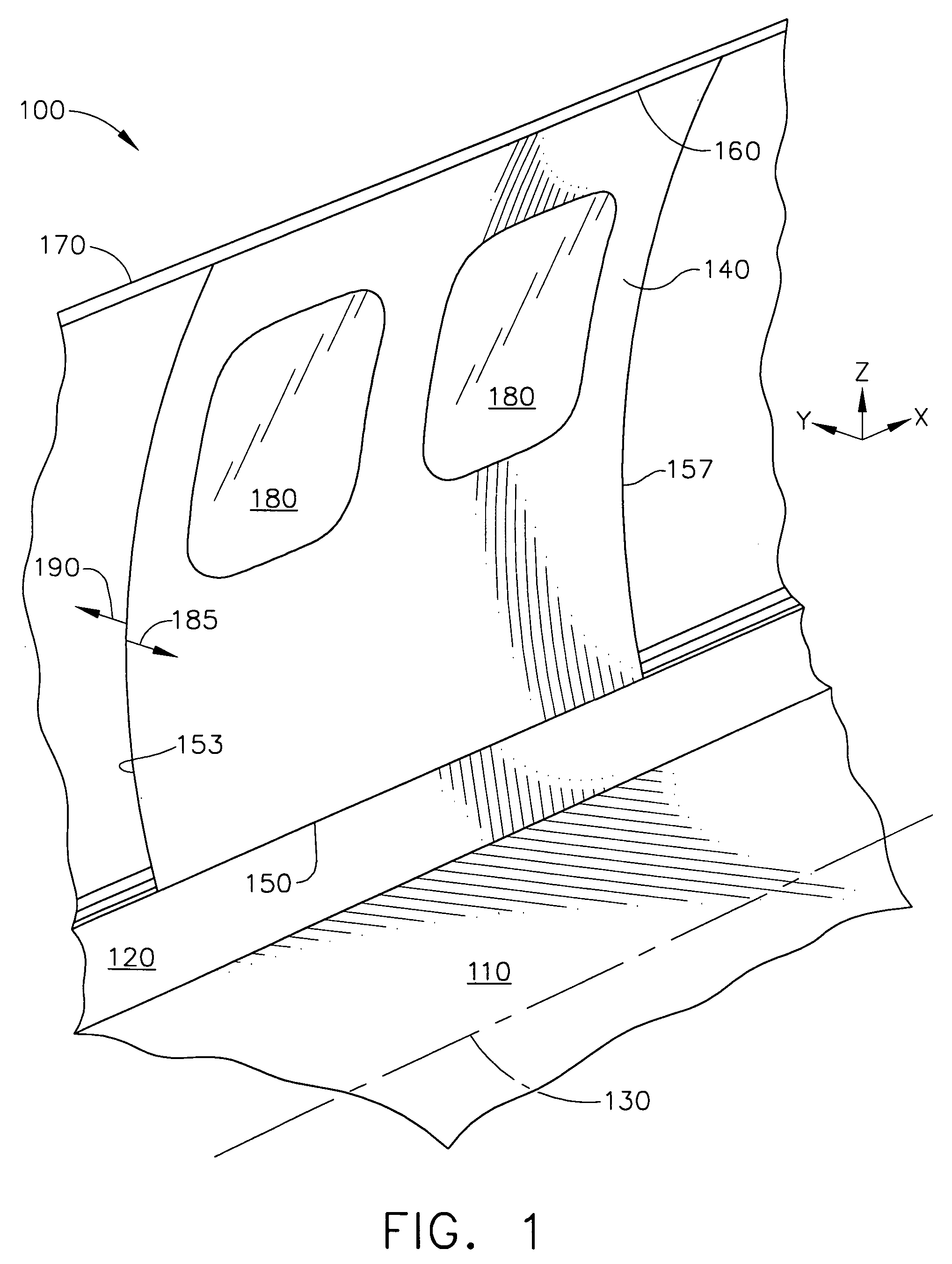

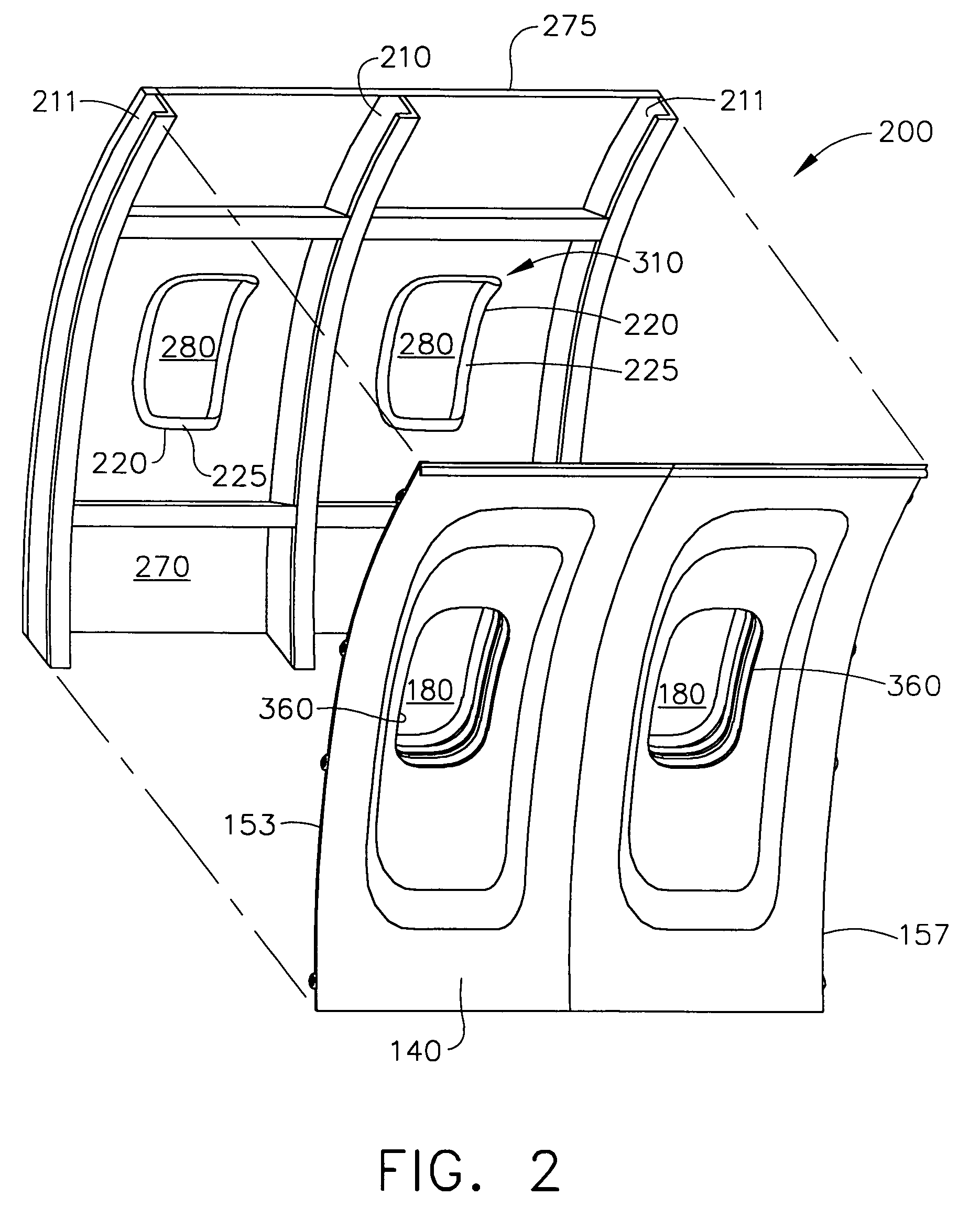

Integrated window belt system for aircraft cabins

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com