Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1277results about How to "Reduce rolling resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

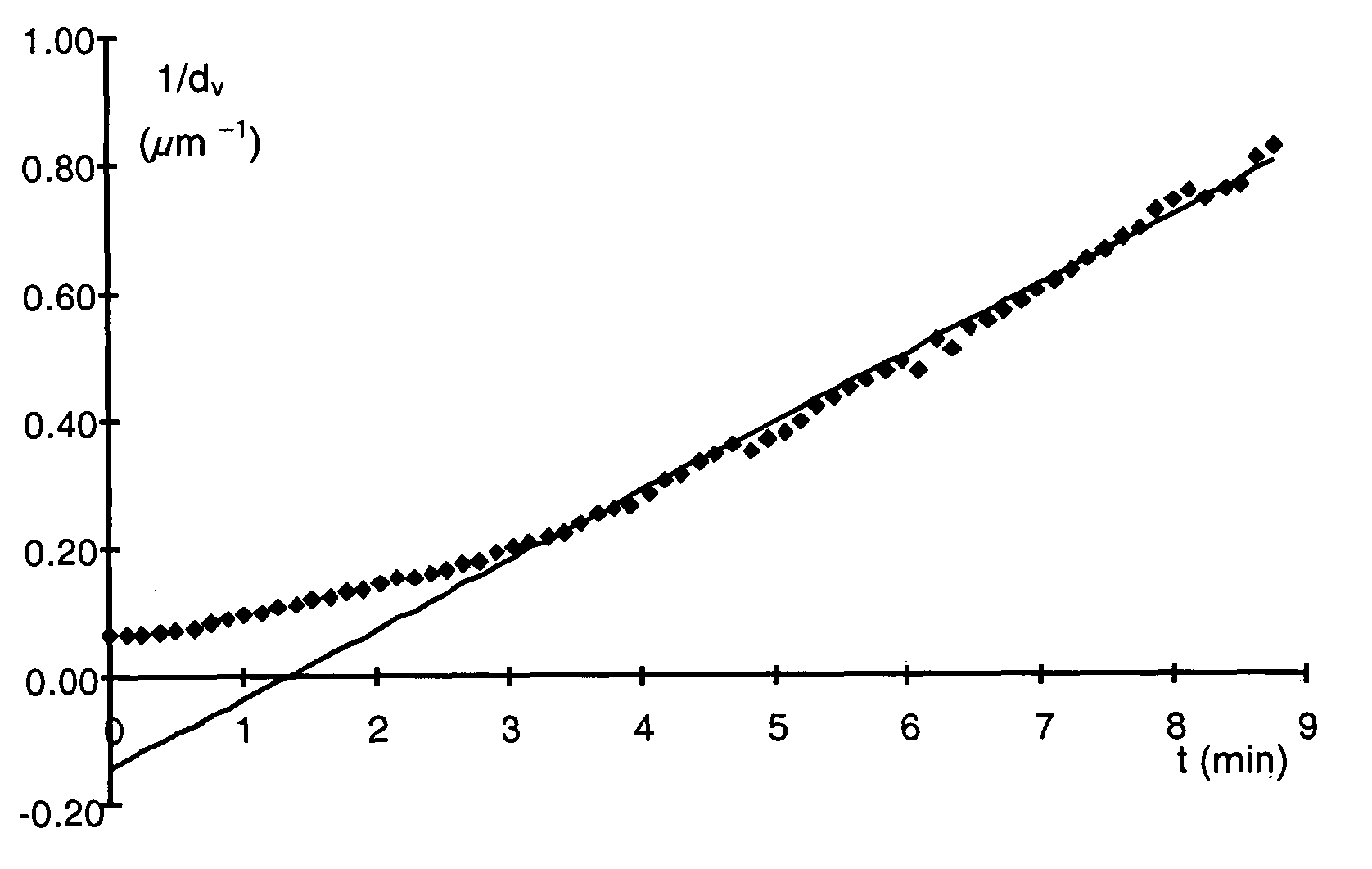

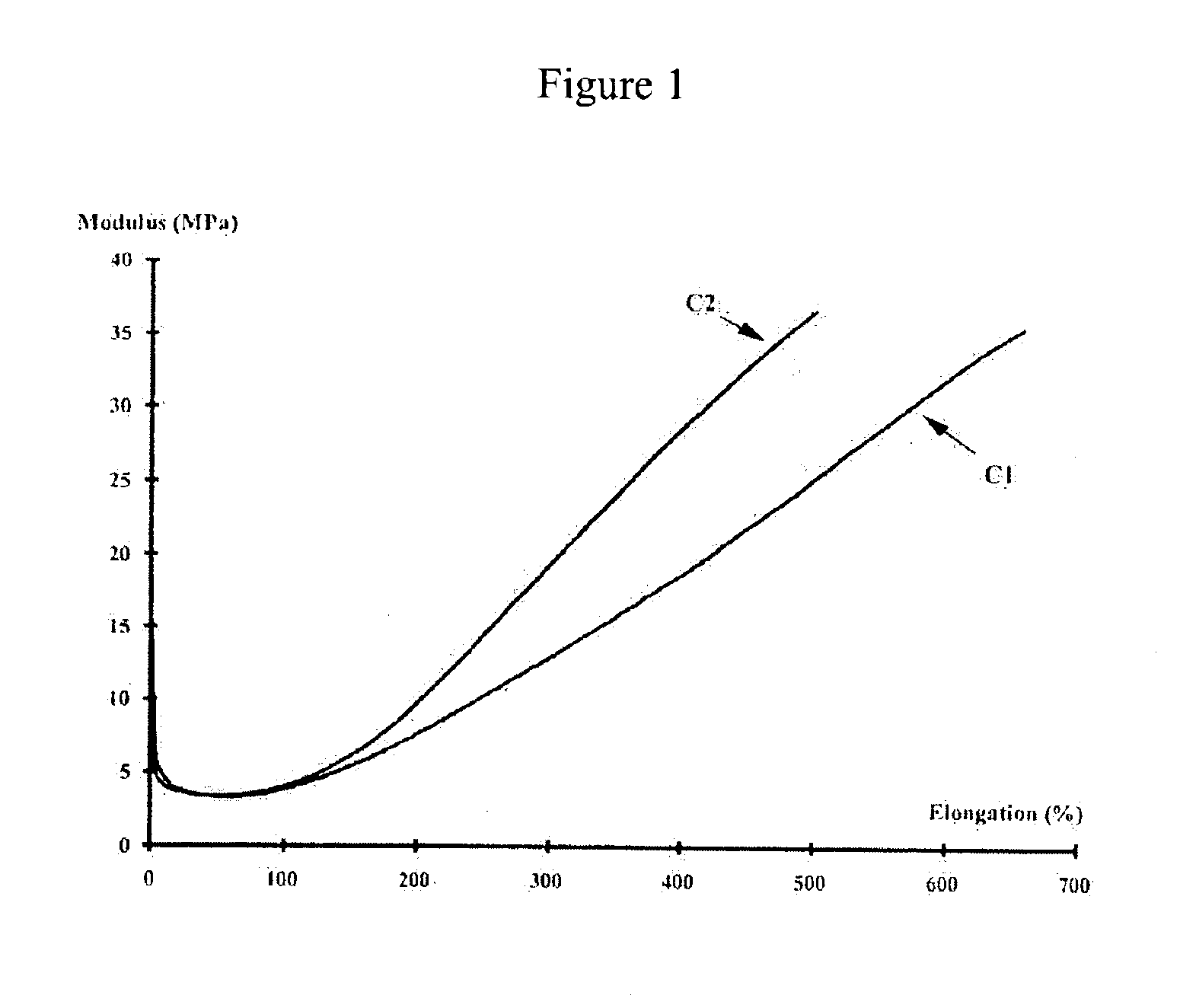

Diene rubber composition for tire comprising a specific silica as reinforcing filler

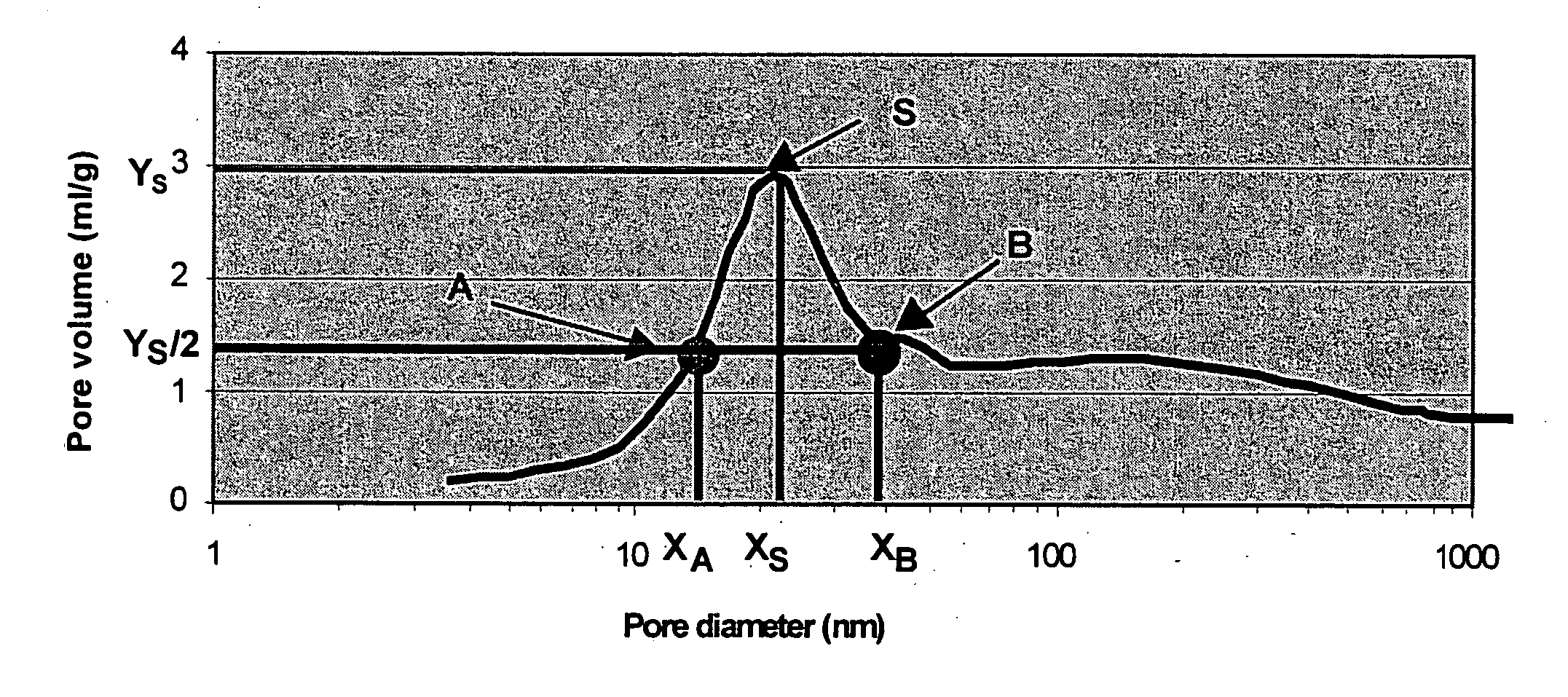

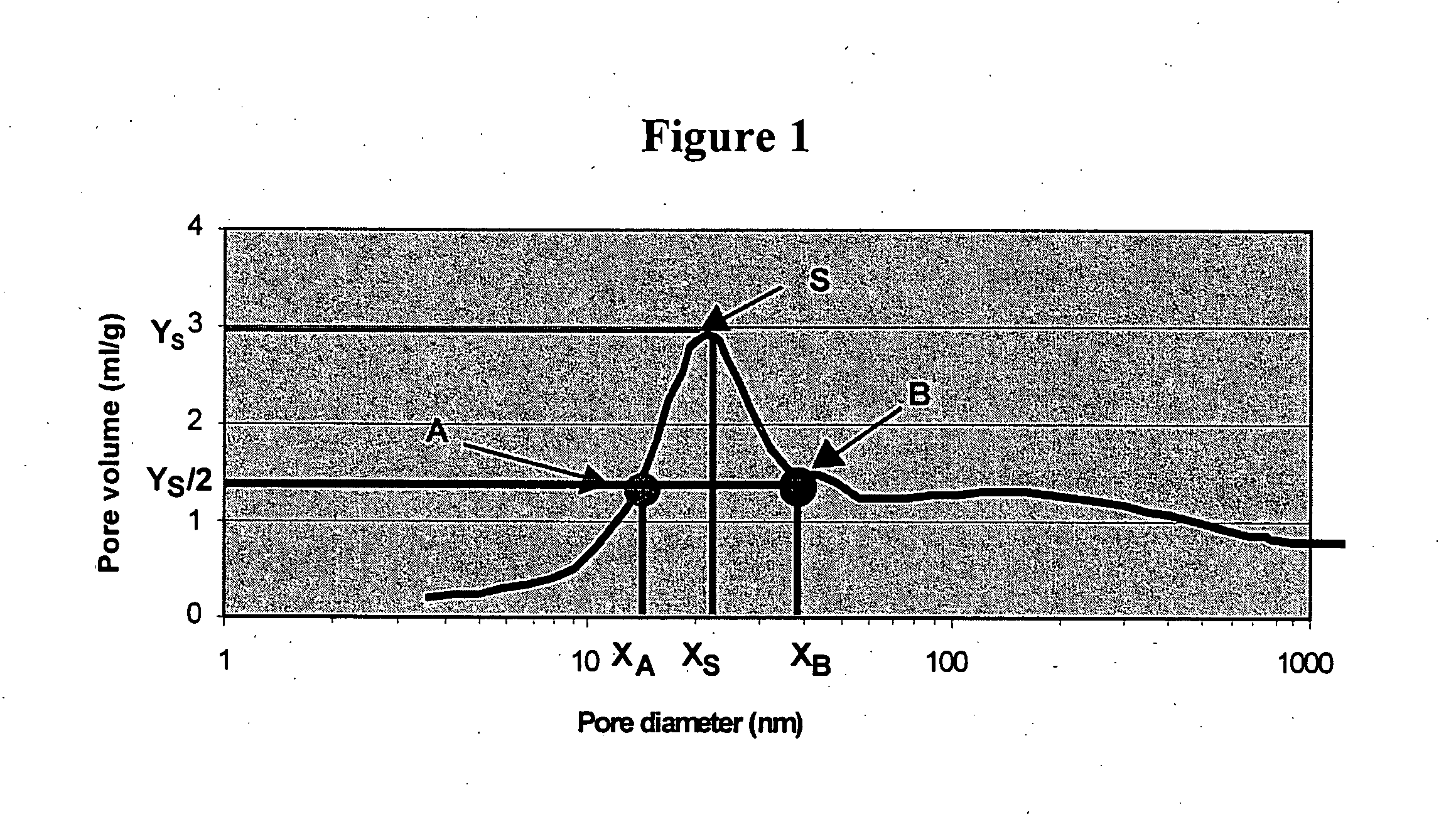

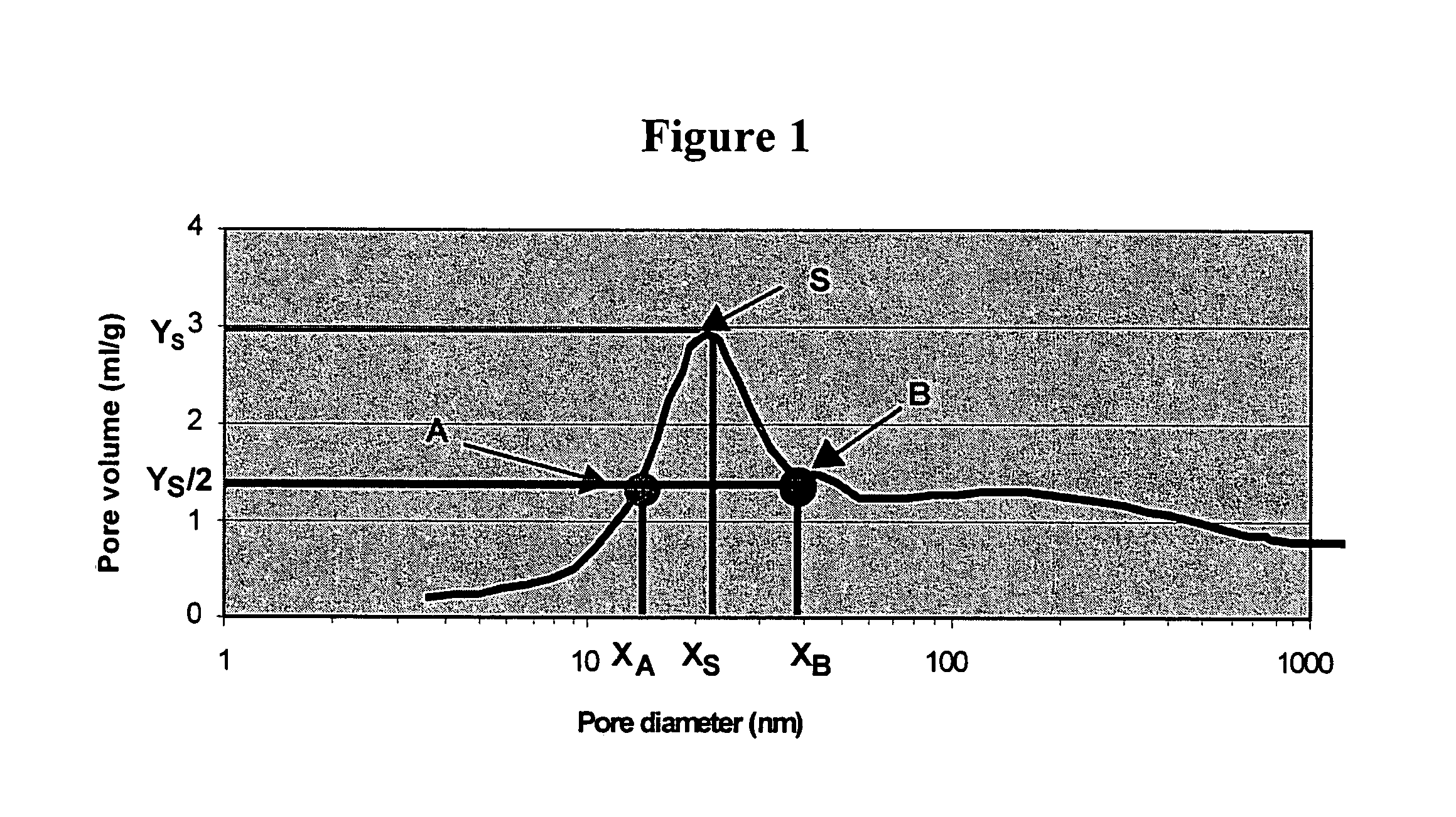

InactiveUS20050004297A1Less-difficult to processReduce hysteresisMaterial nanotechnologySpecial tyresElastomerPorosity

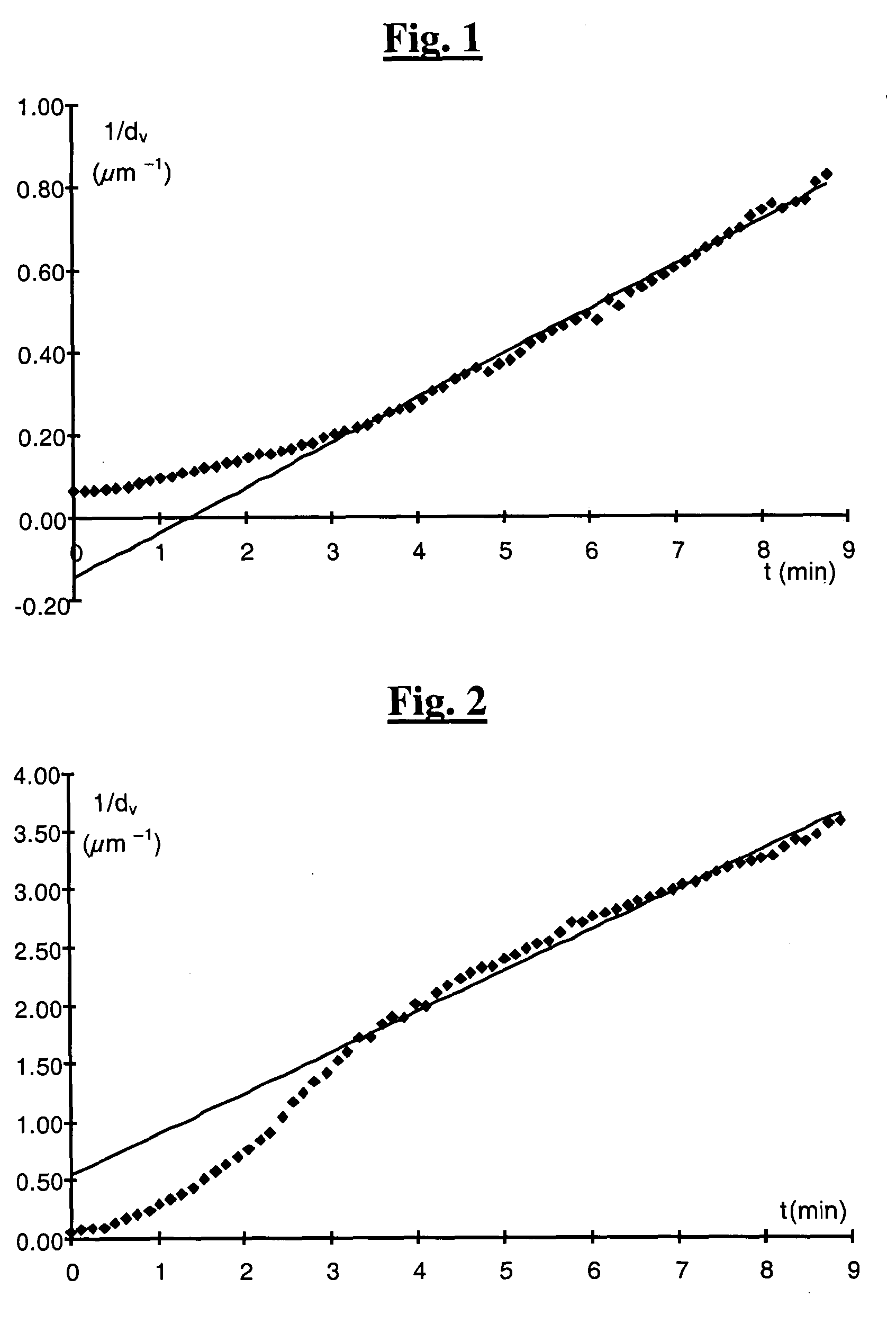

Diene rubber compositions are described containing a diene elastomer, a reinforcing inorganic filler, and a coupling agent wherein the inorganic filler includes a silica having the following characteristics: (a) a BET specific surface area between 45 and 400 m2 / g; (b) a CTAB specific surface area between 40 and 380 m2 / g; (c) an average particle size (by mass), dw, of 20 to 300 nm; and at least one of the following characteristics, preferably two and more preferably all three: (d) a particle size distribution such that dw≧ / CTAB)−30; (e) a porosity which meets the criterion L / FI≧−0.0025 CTAB+0.85; (f) an amount of silanols per unit of surface area, NSiOH / nm2; NSiOH / nm2≦−0.027 CTAB+10.5. These diene rubber compositions can be used for the manufacture of tires or of semi-finished products intended for tires.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

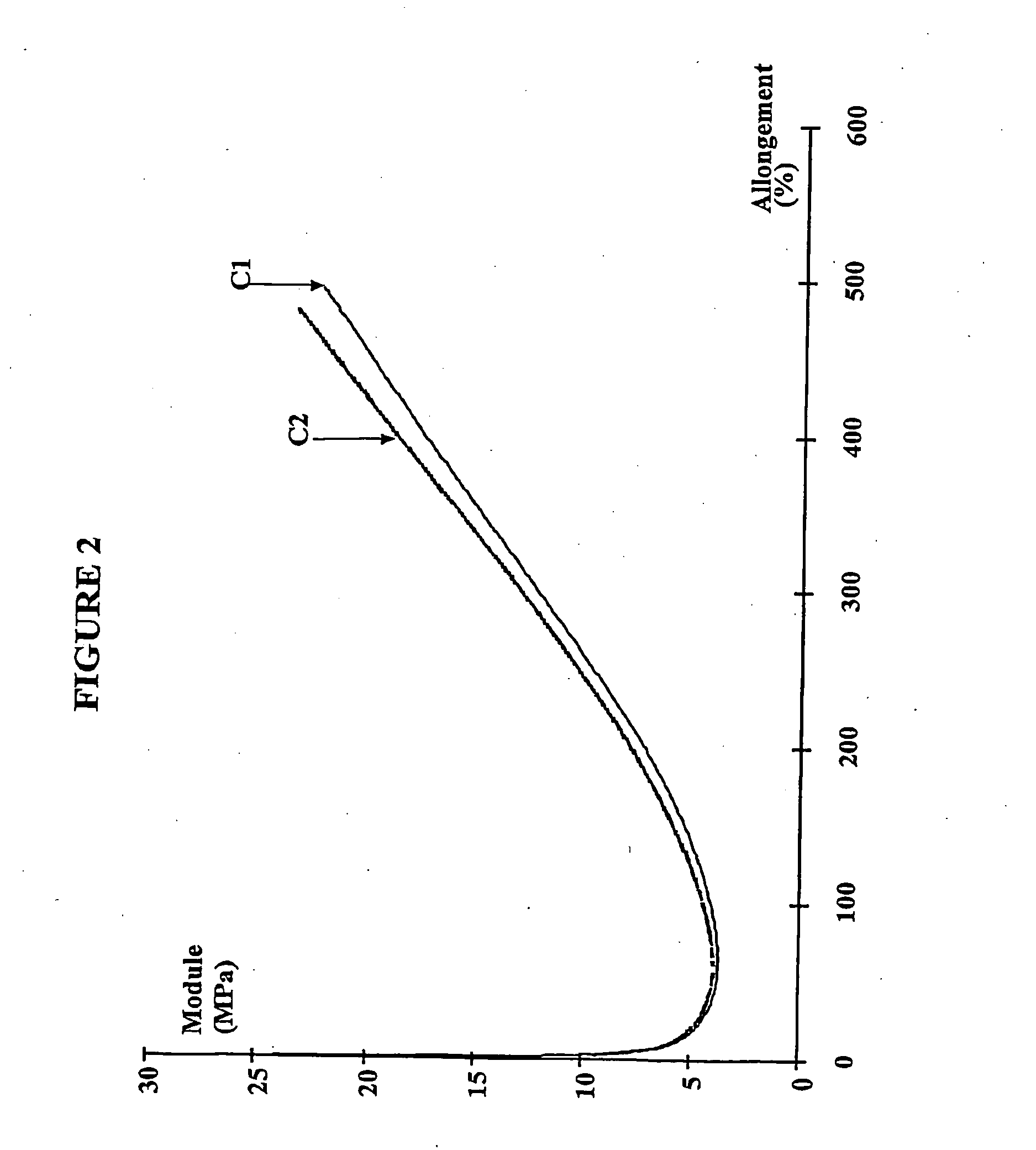

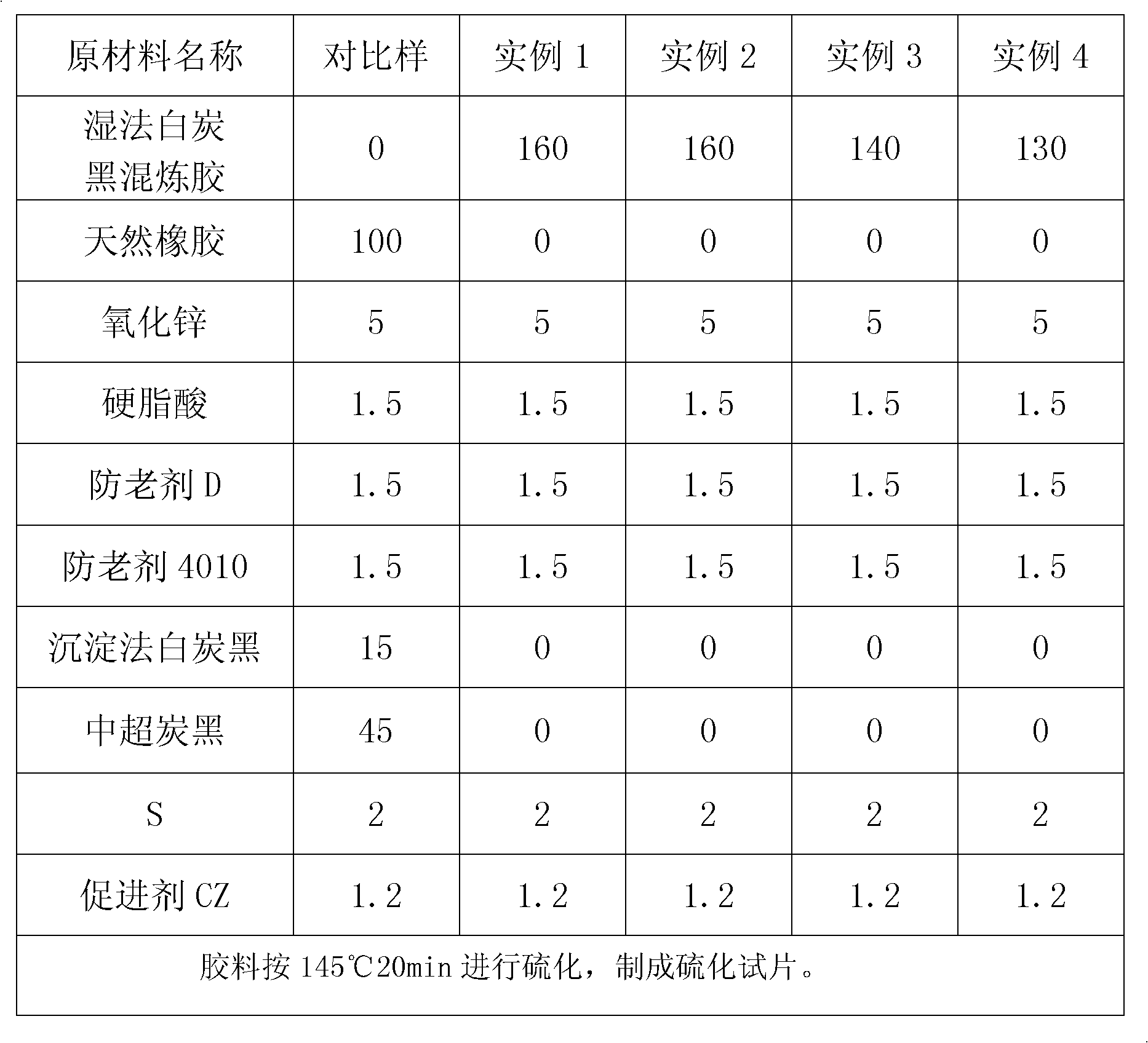

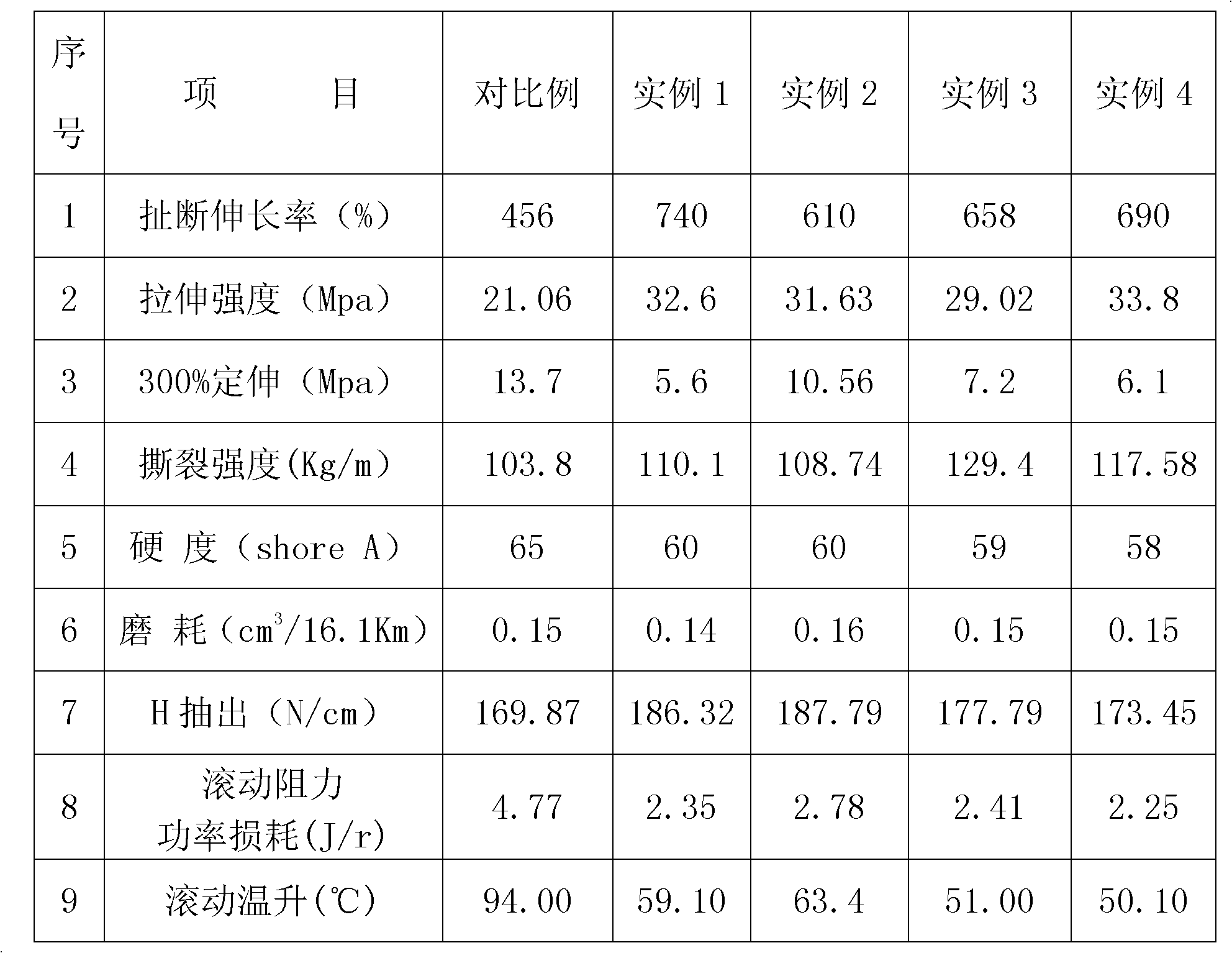

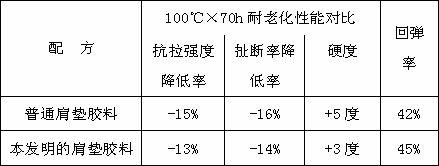

Preparation method of wet process mixed natural rubber material

ActiveCN102153792AGood dispersionImprove uniformityRolling resistance optimizationRubber materialPolymer science

The invention relates to a preparation method of a wet process mixed natural rubber material. The method comprises the following steps of: preparing slurry and soaking 15-40 percent of dry white carbon black in 60-85 percent of deionized water; adding a coupling agent and a surfactant, uniformly mixing, grinding, preparing latex mixed liquor, extracting natural latex and adding white carbon black water dispersoid into the latex; stirring and mixing to obtain a latex mixed liquor, flocculating and adding acetic acid into the mixed liquor; performing rubber washing and dehydration by using a rubber washing machine and feeding to a rubber pelletizer for pelletizing; and feeding rubber particles into a box drying cabinet for drying. The preparation method has the advantages of simple machining process, small equipment investment, realization of various ideal performances with the most ordinary white carbon black, low dust pollution in the entire production process and energy saving. A tire manufactured with the method has small rolling resistance, low heat generation, high tensile strength, high tearing strength and high rubber material ageing resistance. Mixing of the white carbon black is performed in a liquid phase, so that the dispersivity and uniformity are enhanced.

Owner:ZHUZHOU ANBAOLINFENG NEW MATERIALS

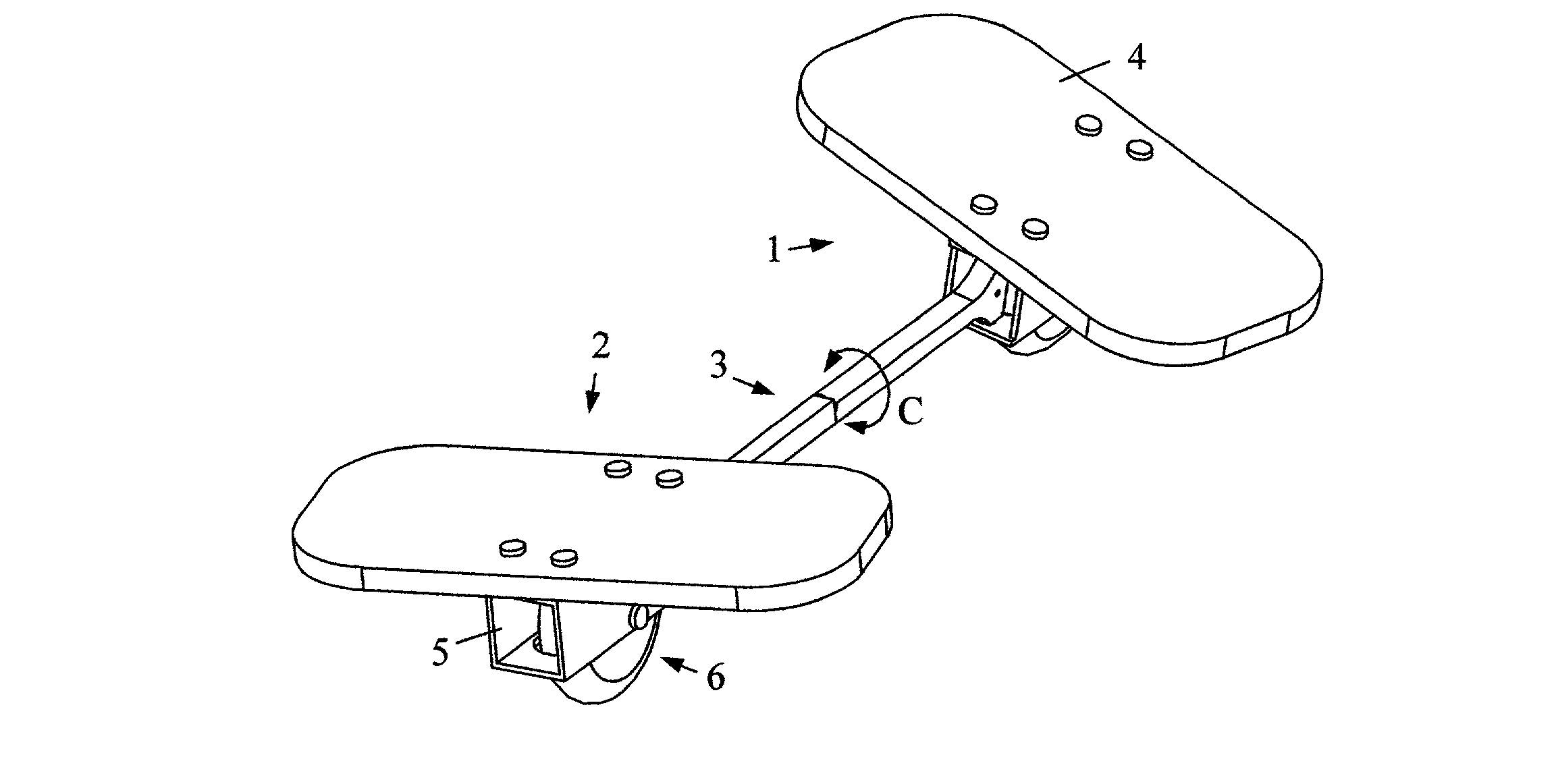

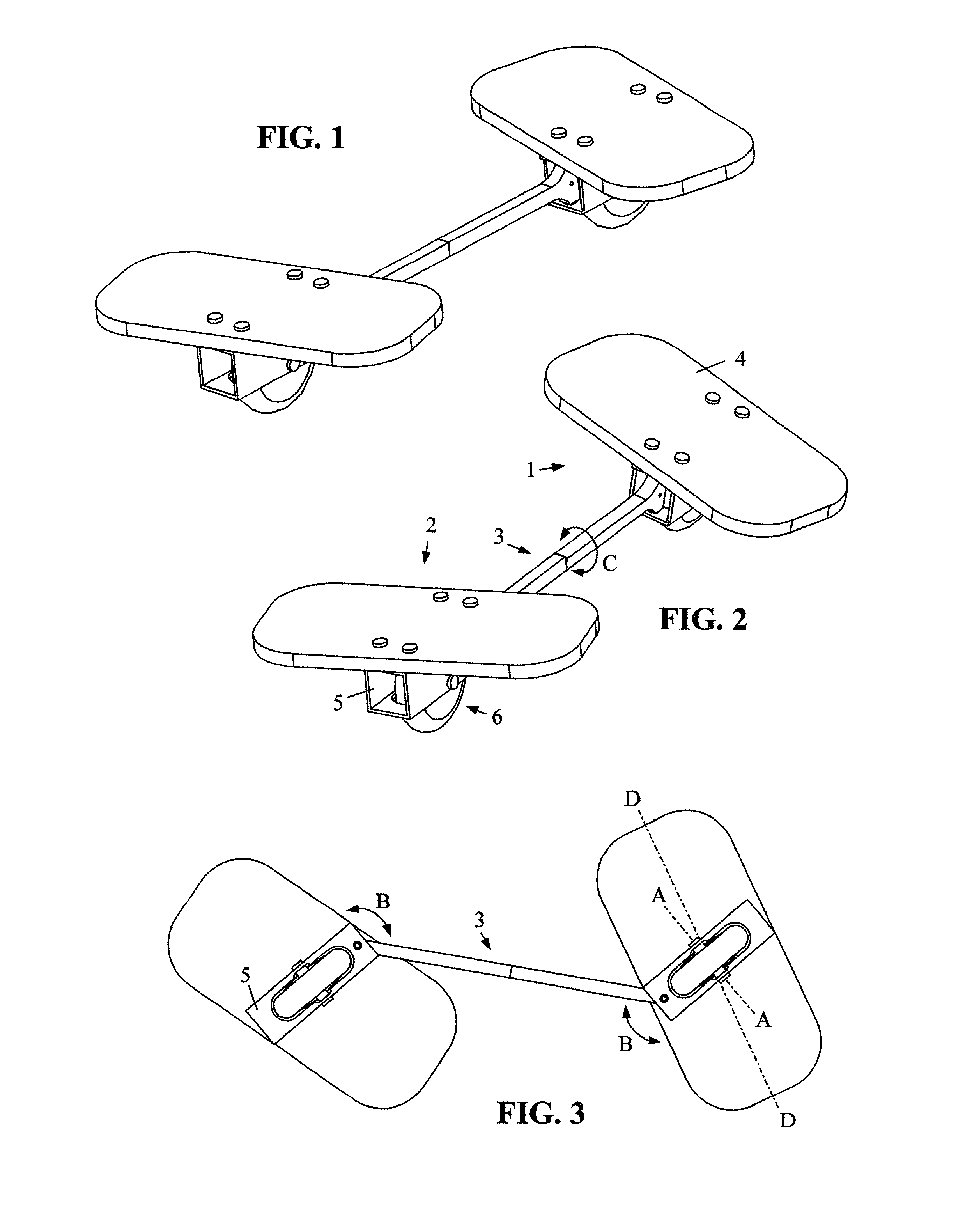

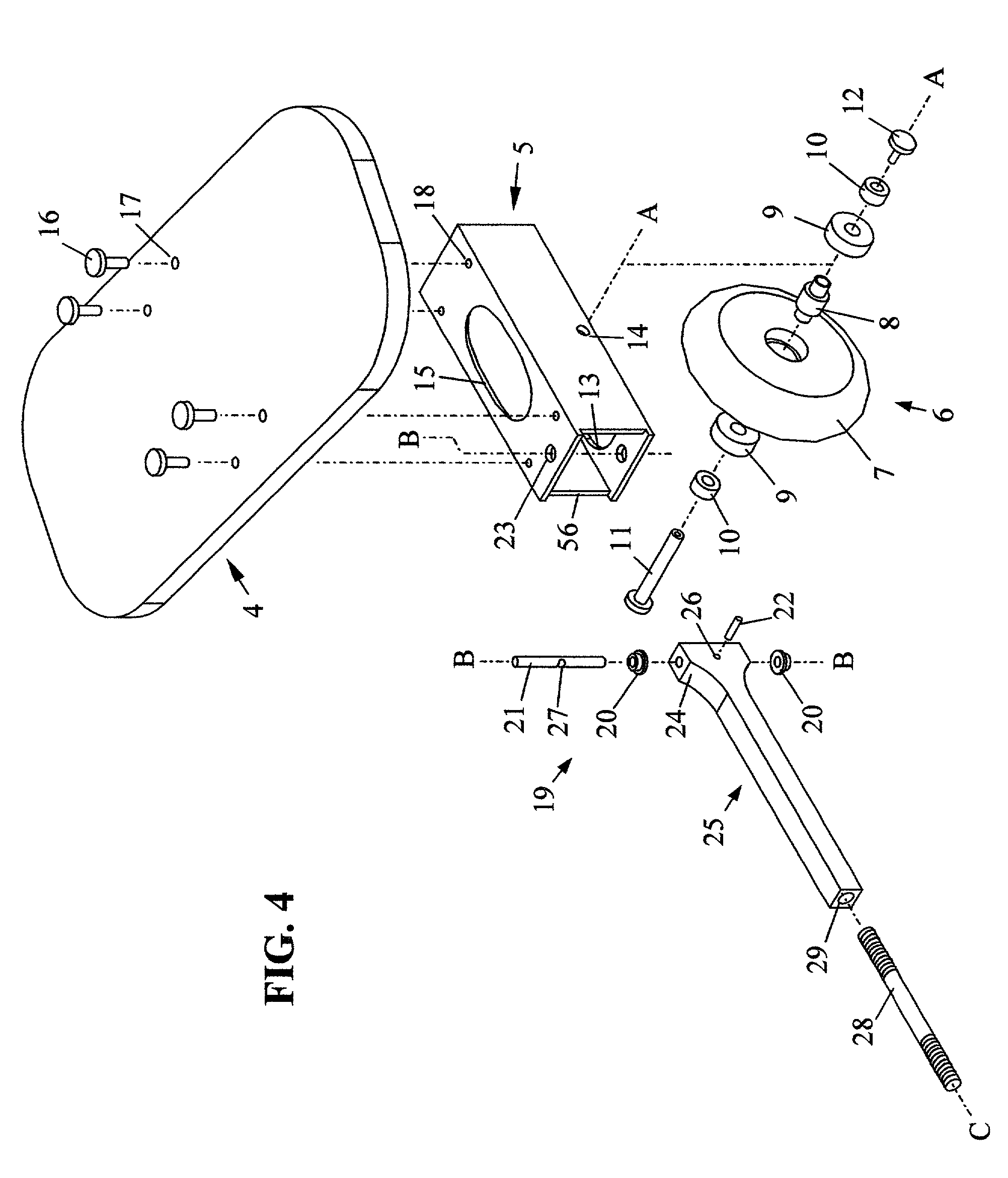

Balancing skateboard

InactiveUS7083178B2Reduce frictional resistanceInsensitivity to surface roughnessRider propulsionSkate-boardsRoad surfaceEngineering

A skateboard for use on pavement, ice or snow using a single narrow-footprint wheel, ice-blade or ski-runner attached to each foot, thus requiring the rider to dynamically balance the board. The skateboard is capable of self-propulsion at considerable speed on the flat or uphill by using an undulating motion. It can also lean up to 30 degrees and has a steering circle of only two feet. The board's construction comprises a front footboard, a rear footboard, and a strut which connects the two footboards and resists bending and extension. Each footboard includes a footpad, an attachment (i.e. a wheel, blade or ski), and a pivot joint connecting to the strut. The axis of this joint is aligned perpendicular to the footpad which allows the rider to steer each footboard independently by torsionally rotating the lower leg.

Owner:POTTER STEVEN DICKINSON

Diene rubber composition for tire comprising a specific silica as reinforcing filler

InactiveUS7250463B2Less-difficult to processReduce hysteresisMaterial nanotechnologySpecial tyresPorosityElastomer

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

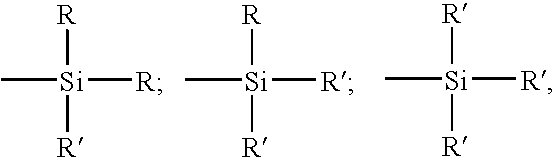

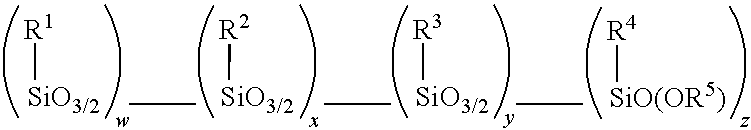

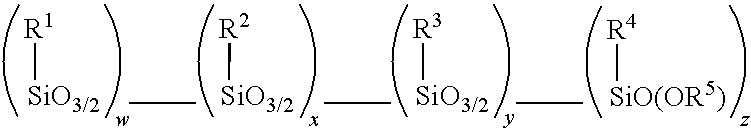

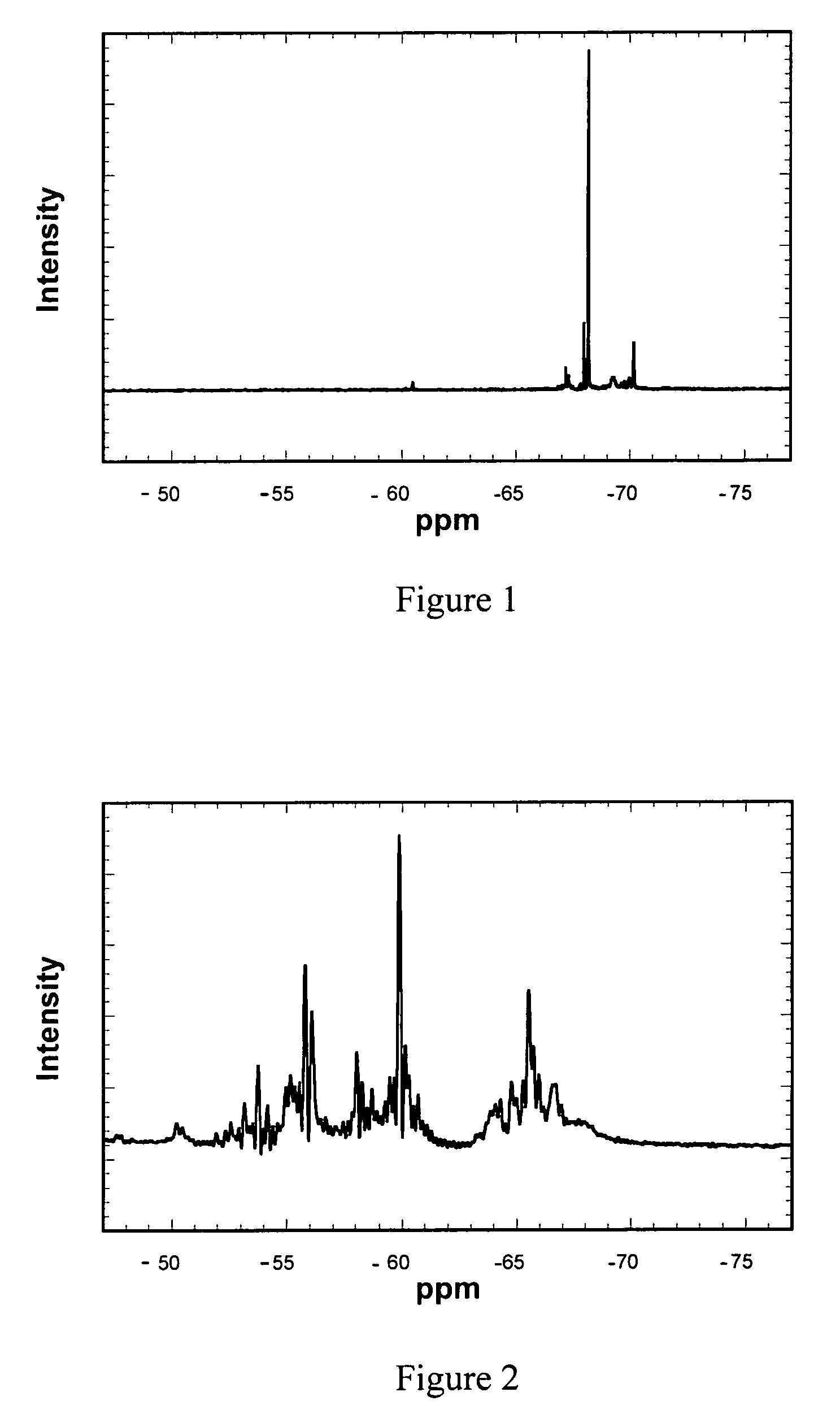

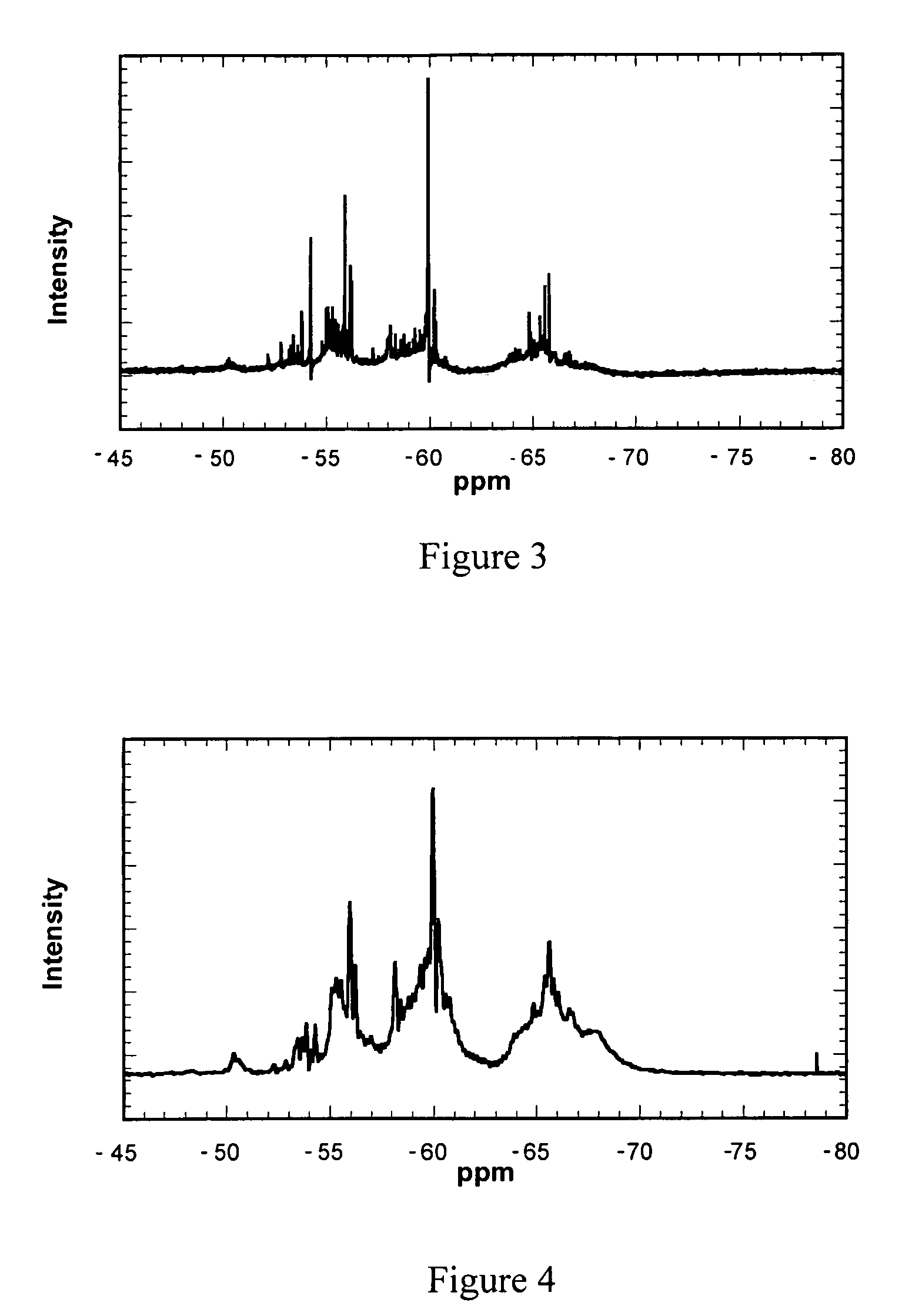

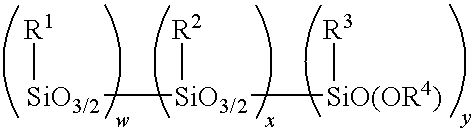

Compounding silica-reinforced rubber with low volatile organic compound (VOC) emission

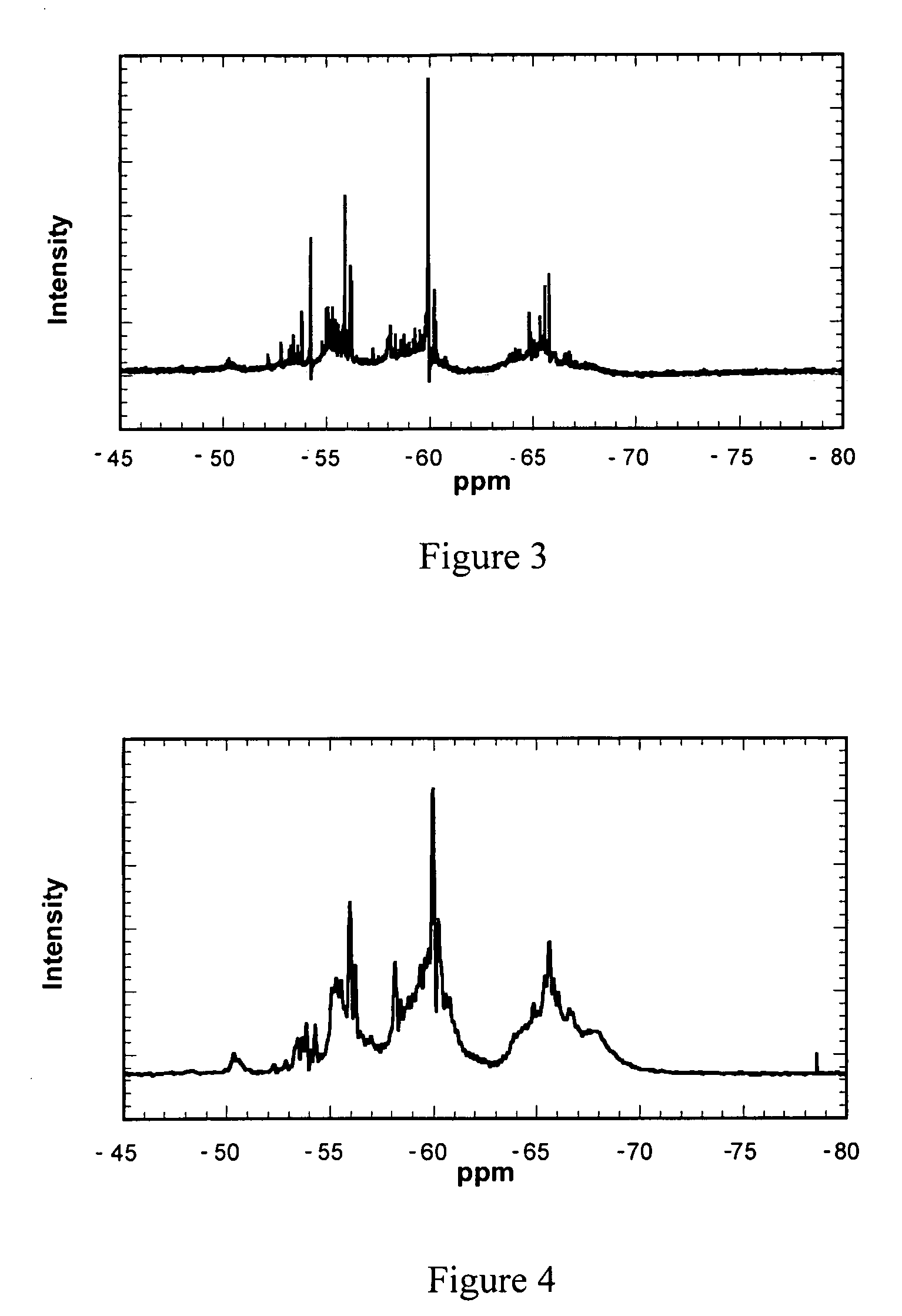

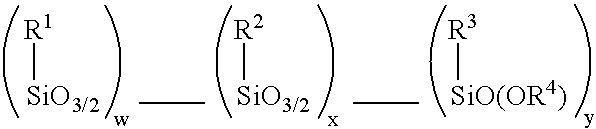

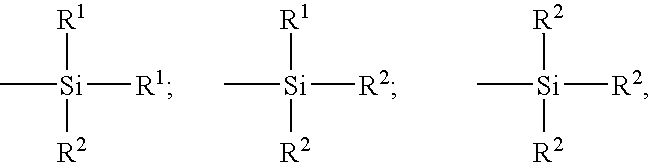

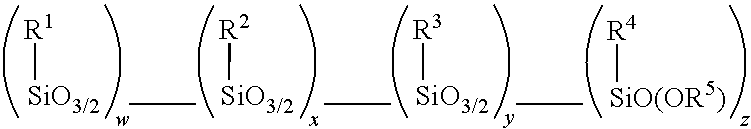

ActiveUS20060217473A1Enhanced rubber reinforcementEnhanced interactionSilicon organic compoundsSynthetic resin layered productsAlcoholReinforced rubber

Alkoxy-modified silsesquioxane compounds are described. The alkoxy-modified silsesquioxane compounds contain an alkoxysilane group that participates in an alkoxysilane-silica reaction as a silica dispersing agent in rubber, with the release of zero to about 0.1% by weight of the rubber of volatile organic compounds (VOC), especially alcohol, during compounding and further processing. Further described are methods for making alkoxy-modified silsesquioxanes, methods for making vulcanizable rubber compounds containing alkoxy-modified silsesquioxanes, vulcanizable rubber compounds containing alkoxy-modified silsesquioxanes, and pneumatic tires comprising a component that contains alkoxy-modified silsesquioxanes.

Owner:BRIDGESTONE CORP

Rubber composition based on diene elastomer and a reinforcing silicon carbide

InactiveUS20040030017A1Improve homogeneityReduce consumptionSpecial tyresTyre beadsElastomerPolymer science

A rubber composition usable for the manufacture of tires, based on at least one diene elastomer, a reinforcing inorganic filler and a coupling agent providing the bond between the inorganic filler and the elastomer, wherein said inorganic filler comprises a silicon carbide having the following characteristics: (a) a BET specific surface area of between 20 and 200 m<2> / g; (b) an average particle size (by mass), dw, of between 10 and 350 nm. Tires or semi-finished products for tires such as treads comprising said rubber composition.

Owner:MICHELIN RECH & TECH SA

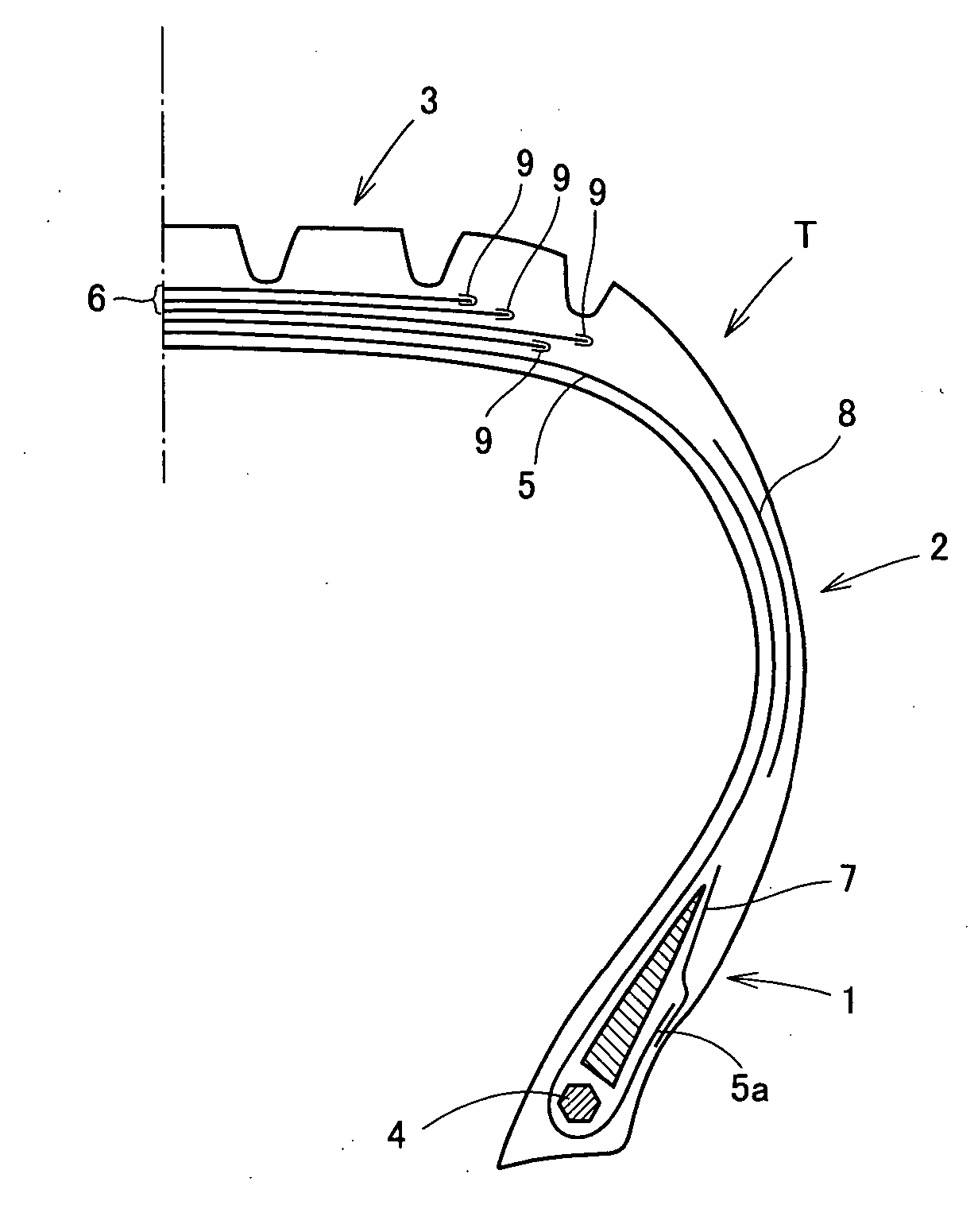

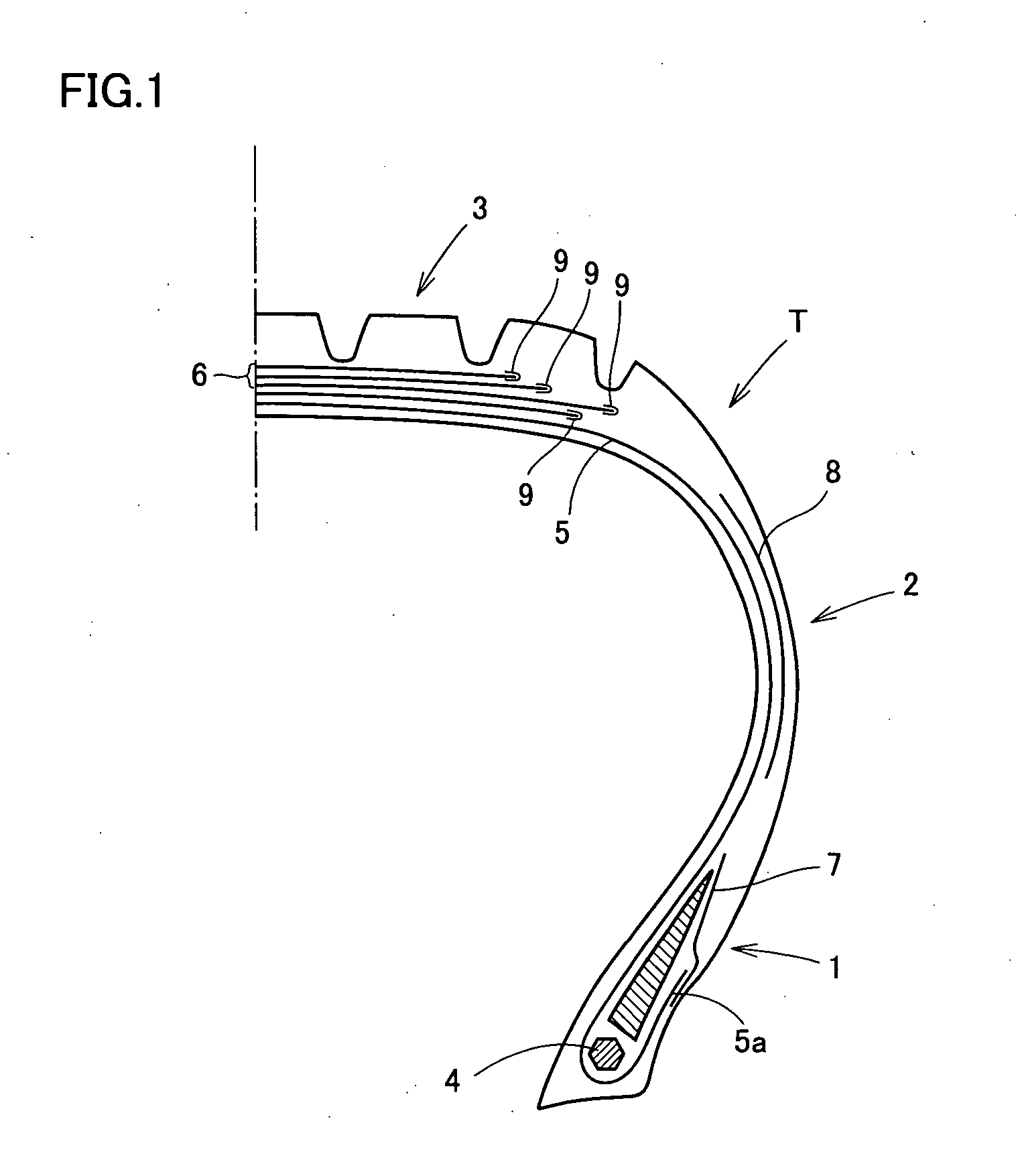

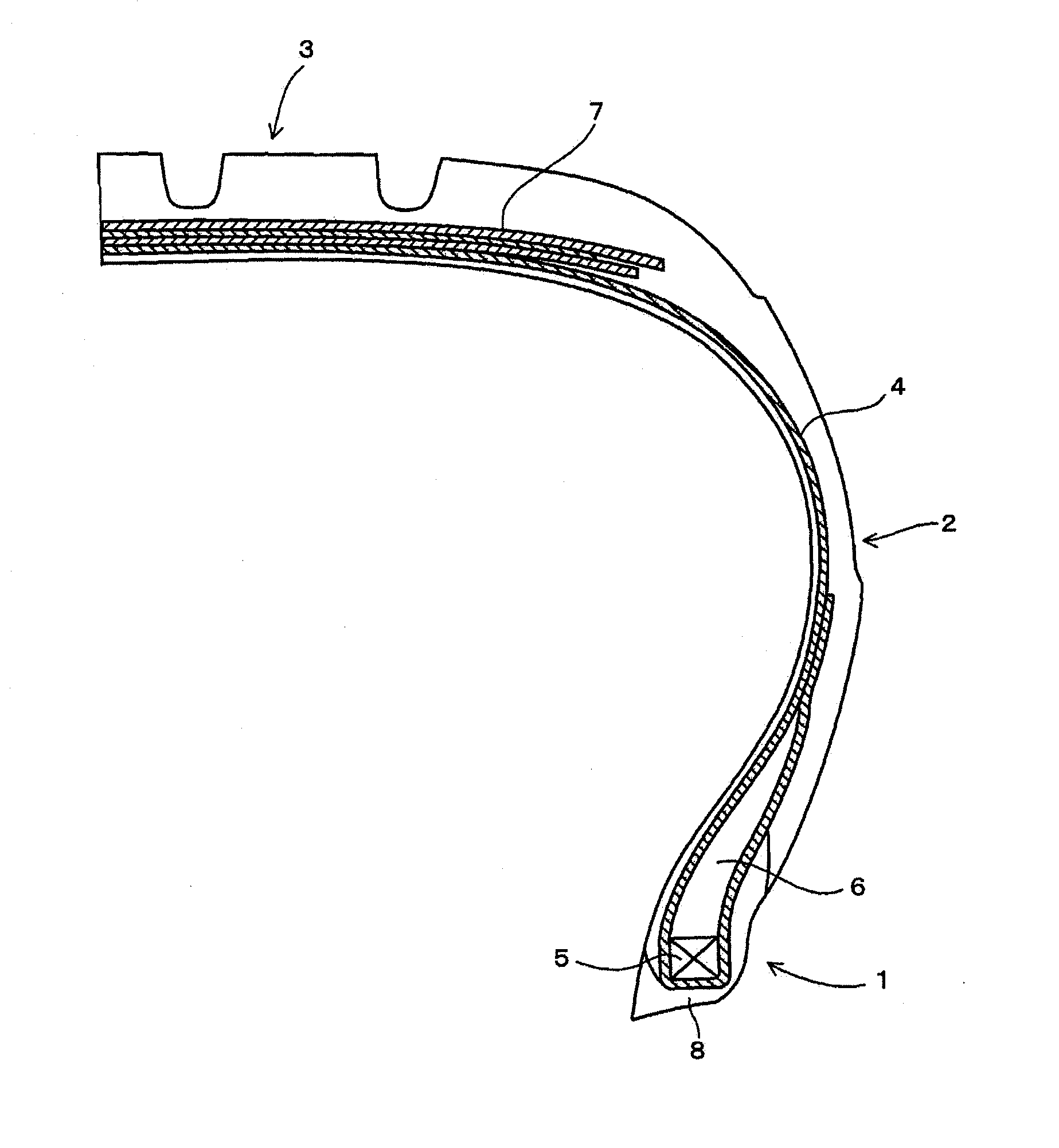

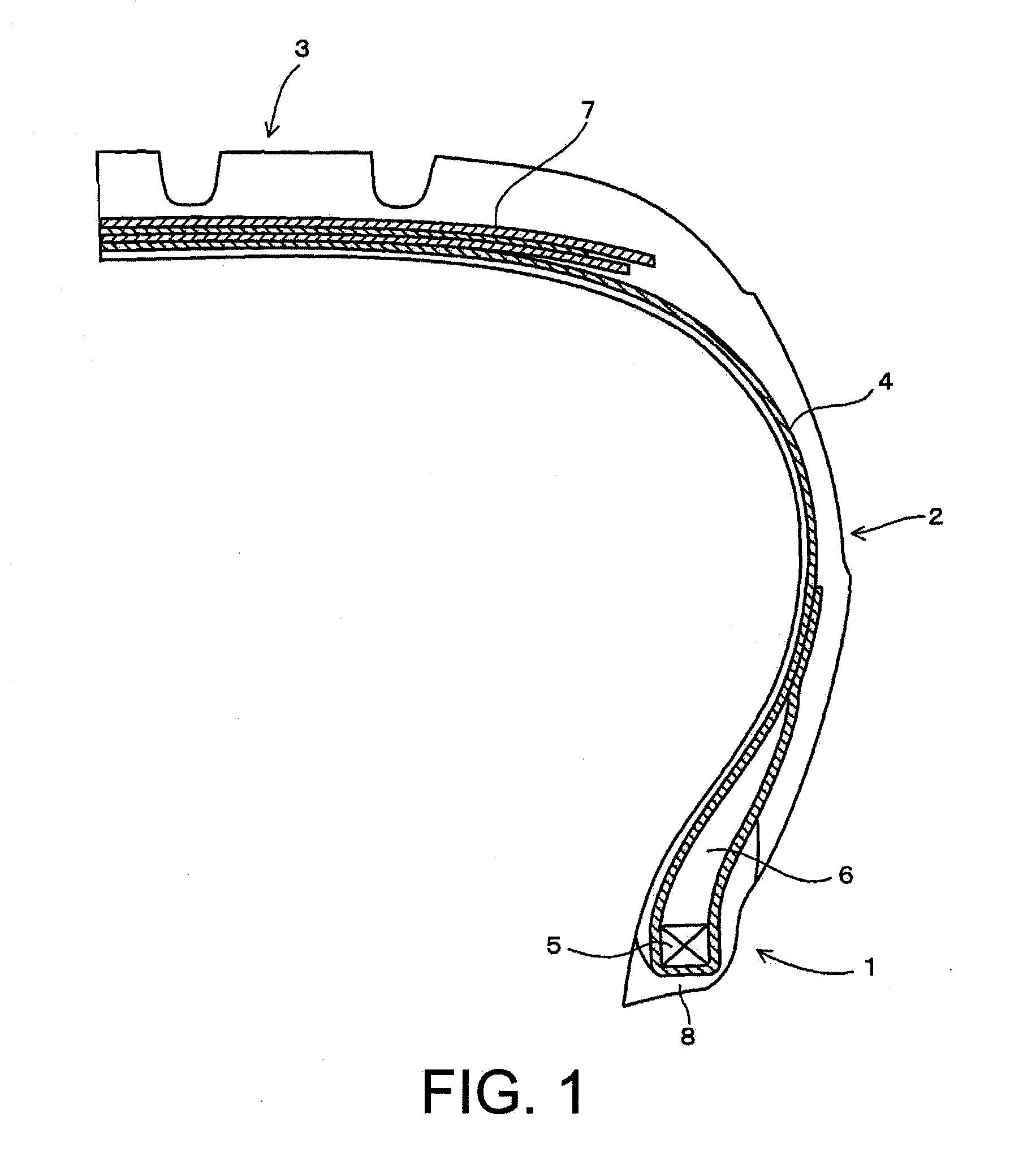

Pneumatic tire and method of producing the same

InactiveUS20060102269A1Increased durabilityReduce rolling resistanceSpecial tyresPneumatic tyre reinforcementsRolling resistanceCobalt salt

There is provided a pneumatic tire capable of achieving both reduced rolling resistance and enhanced durability and a method of producing the same. The pneumatic tire includes a reinforcement layer, formed of a steel cord coated with coating rubber, including at least one of a carcass, a bead reinforcement layer, a side reinforcement layer and a belt, with said coating rubber formed of a rubber compound containing 100 parts by mass of diene rubber, 30 to 80 parts by mass of silica having a nitrogen surface area of at least 70 m2 / g and at most 150 m2 / g, 1 to 15 parts by mass of a silane coupling agent, and organic acid cobalt salt. Preferably the steel cord has a cut edge of a breaker coated with an edge strip of rubber.

Owner:SUMITOMO RUBBER IND LTD

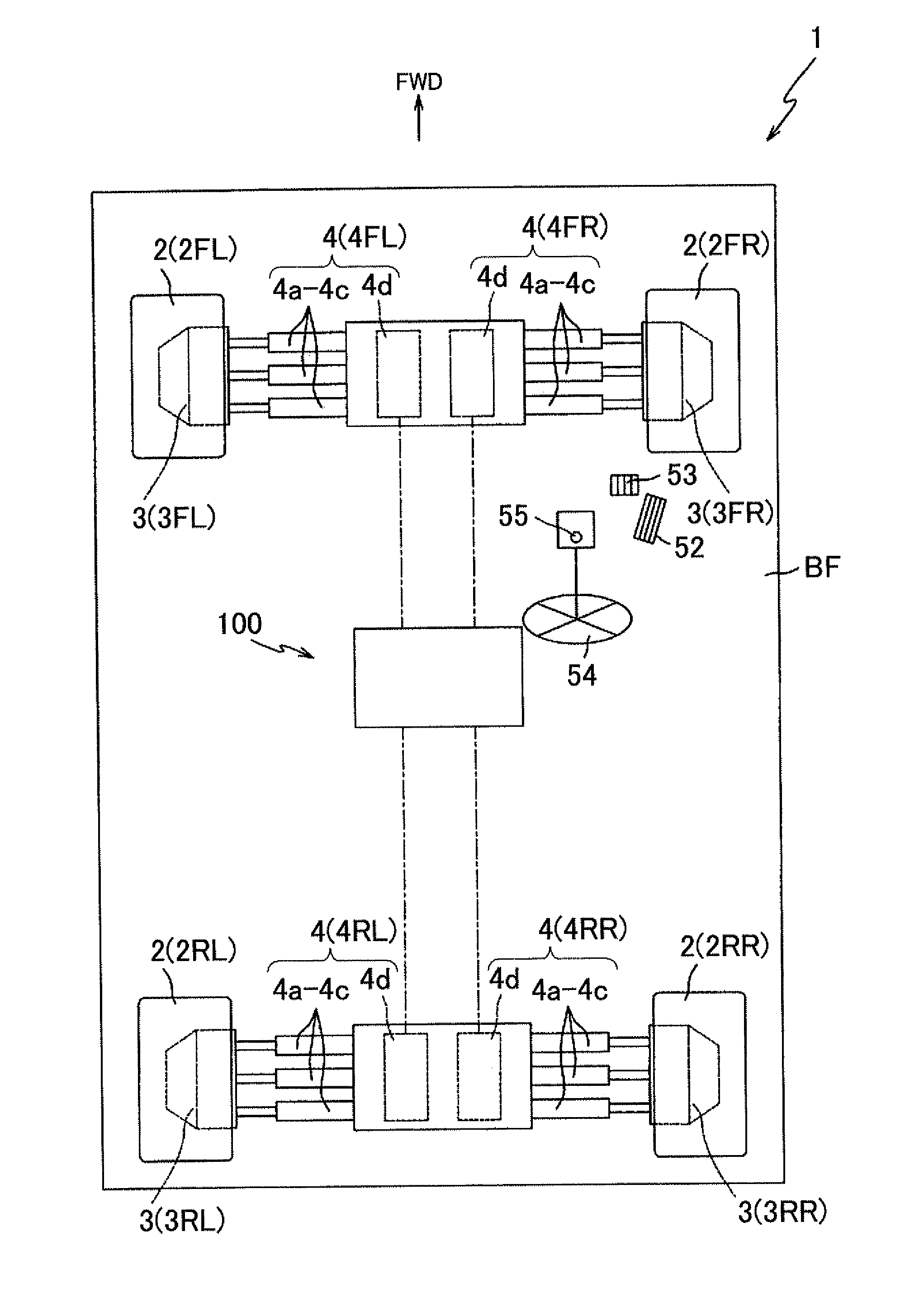

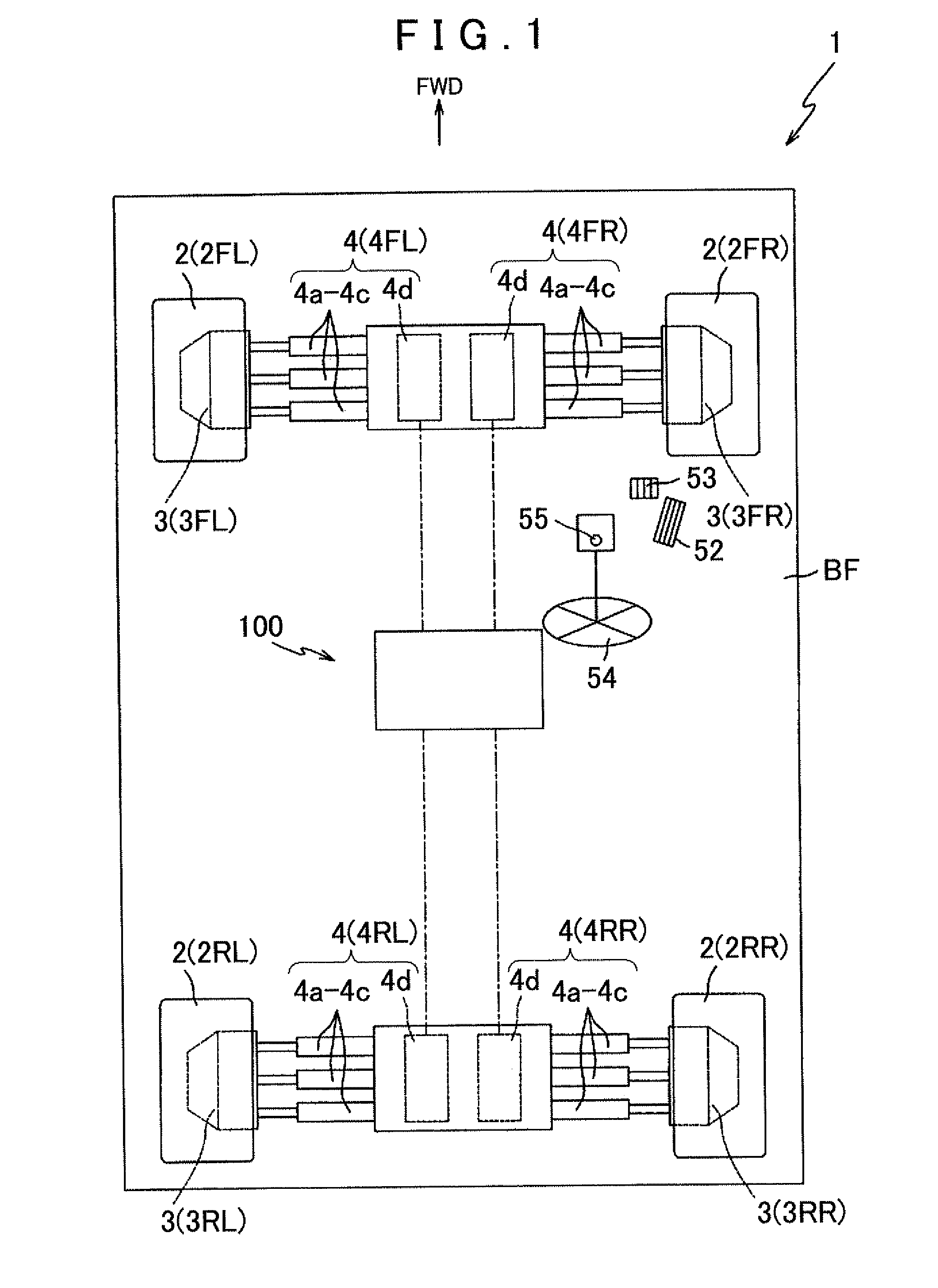

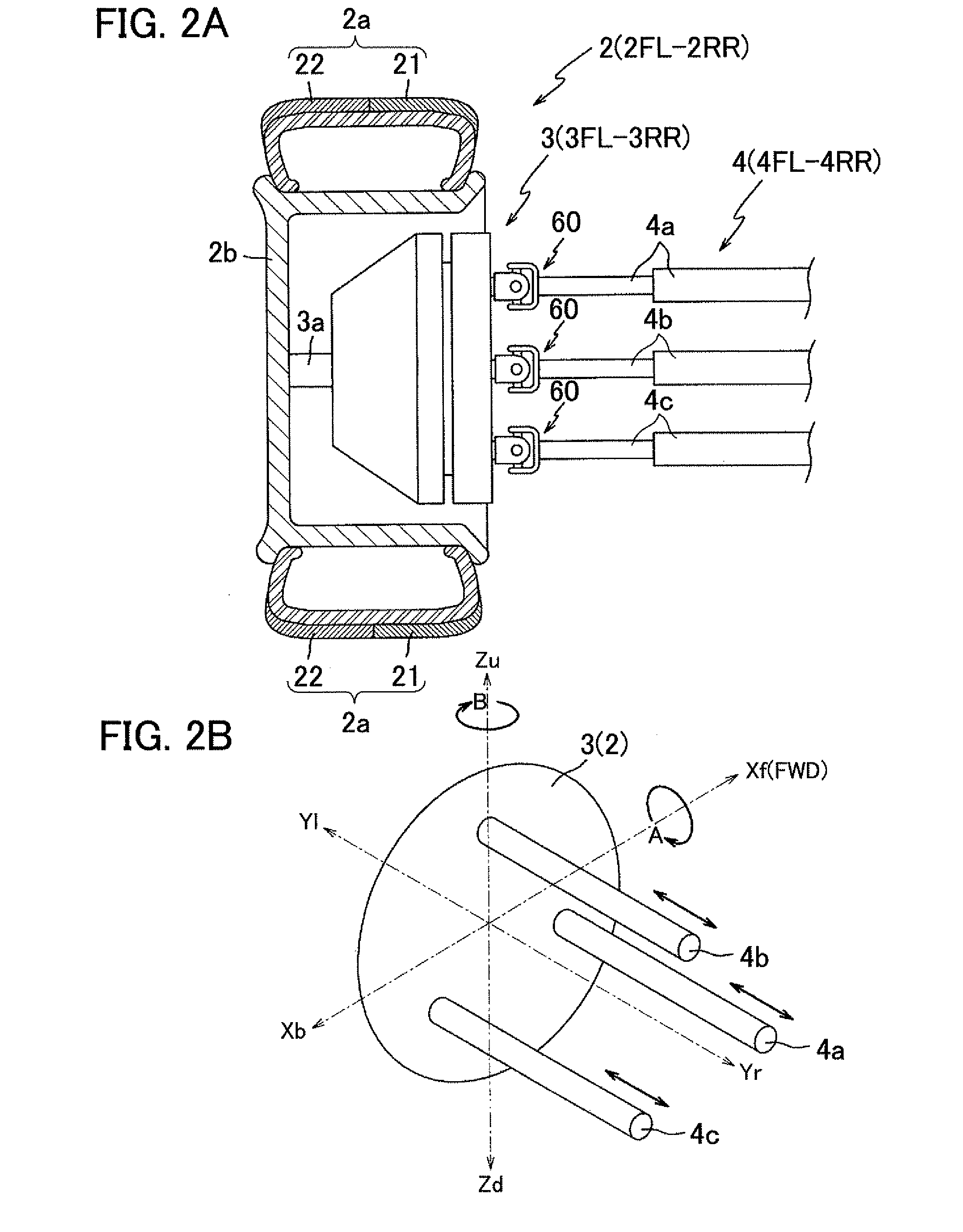

Camber angle controlling device

InactiveUS20100217491A1Improve gripIncrease clamping forceDigital data processing detailsSpecial tyresRolling resistanceCamber angle

A camber angle applying device is controlled to adjust the camber angle of wheels to a predetermined value. Therefore, the characteristics (or a high gripping property) of a high gripping force and the characteristic (or a low rolling resistance) of a small rolling resistance can be separately used as the performance of the wheels. By utilizing the high gripping property of the wheels, therefore, a vehicle is enabled to reduce its energy consumption, while retaining its running characteristics (such as a turning performance, an accelerating performance or a braking performance), by utilizing the rolling resistance of the wheels. Moreover, the camber angle applying device is controlled to reduce the rolling resistance of the wheels, so that the energy loss to occur in the wheels during running can be reduced to further reduce the energy consumption of the vehicle.

Owner:EQUOS RES

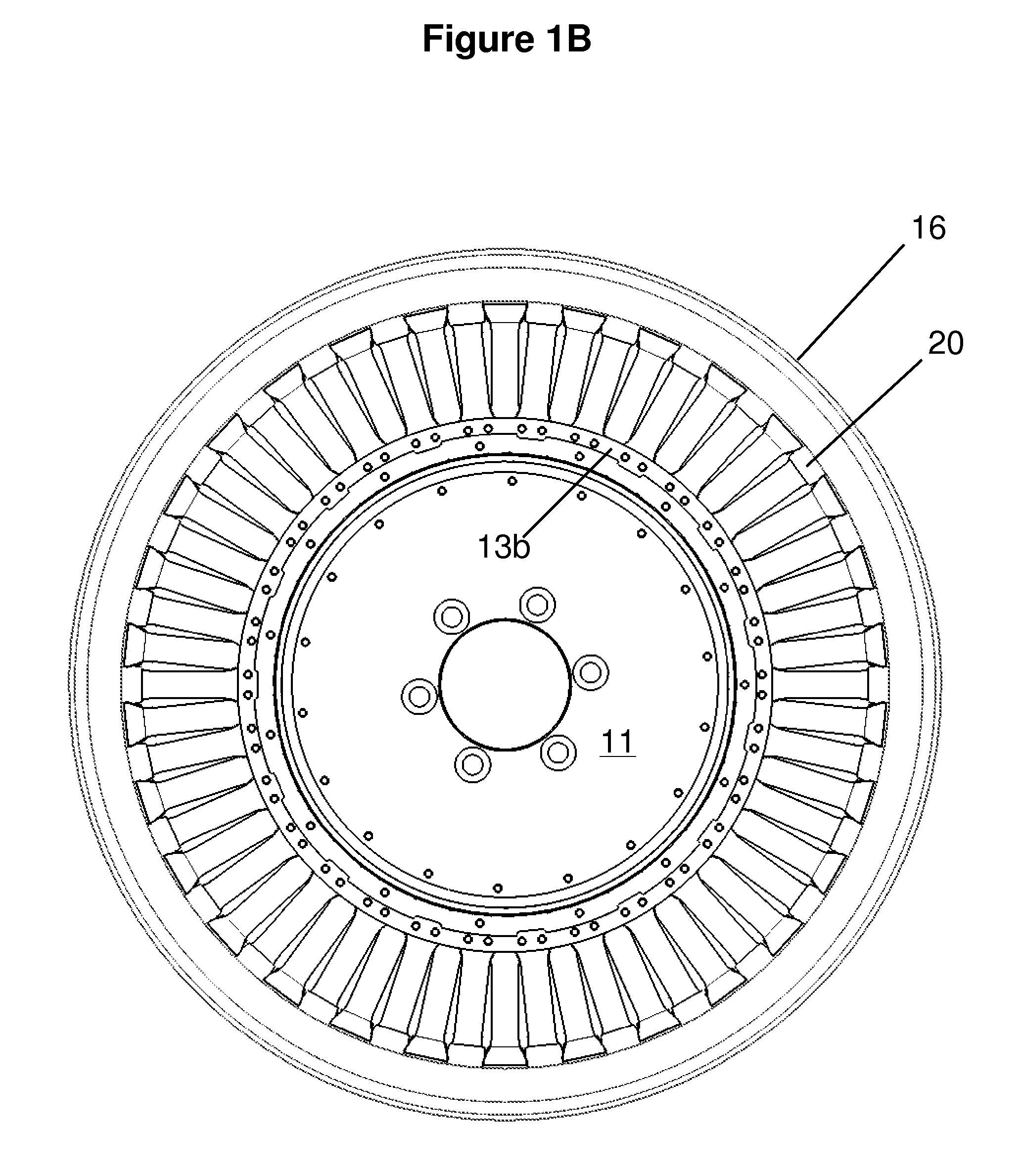

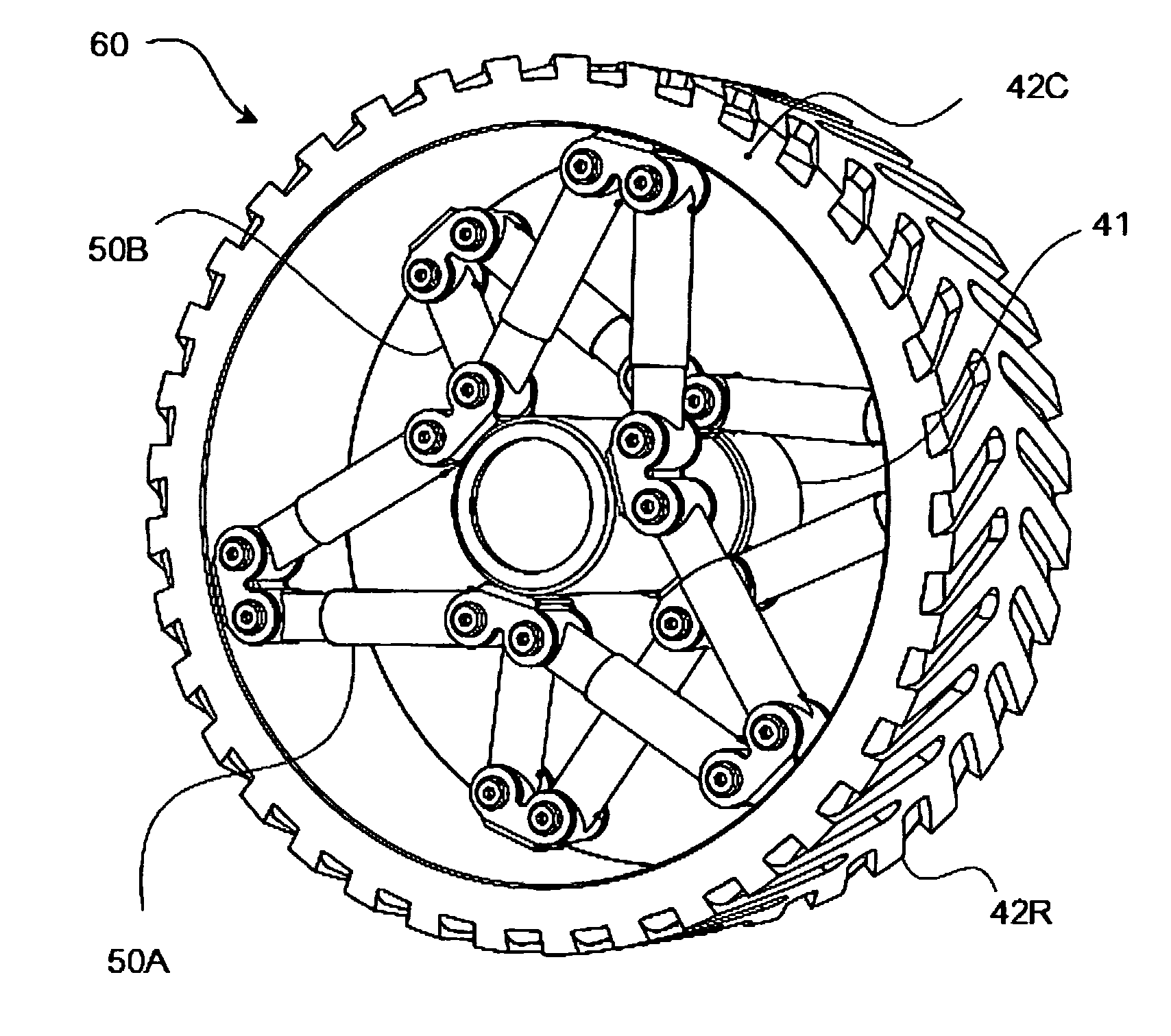

Variable Compliance Wheel

ActiveUS20110272254A1Improve lateral performanceReduce wasteShaft and bearingsNon-inflatable tyresEngineeringMechanical engineering

A system for adjusting the compliance of a wheel is provided. In one embodiment, wheel segments are adjusted, causing the stiffness of the wheel to change. Such adjustments can be made while the wheel is rotating, allowing the wheel compliance to be changed while a vehicle is in motion.

Owner:MILLENWORKS

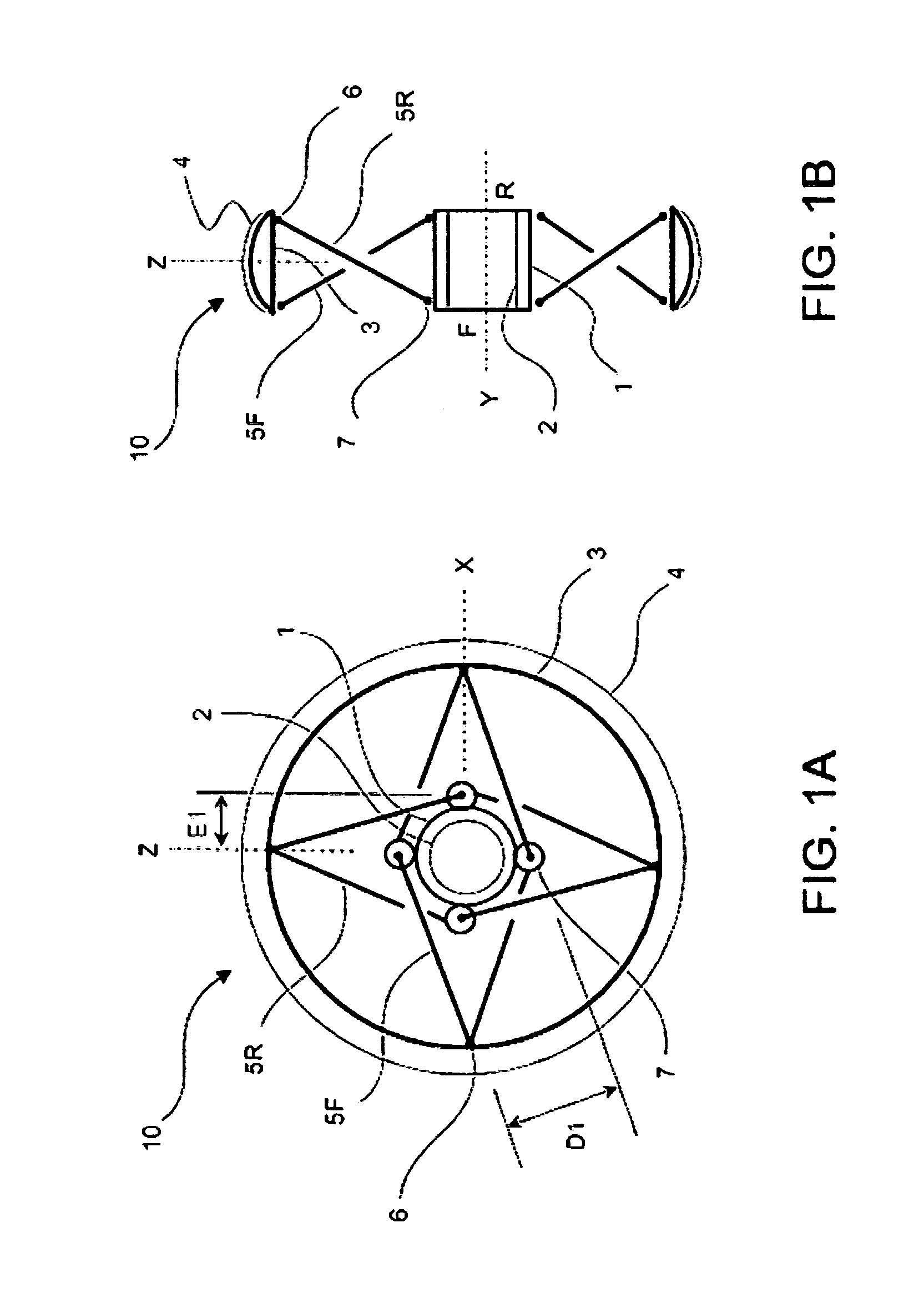

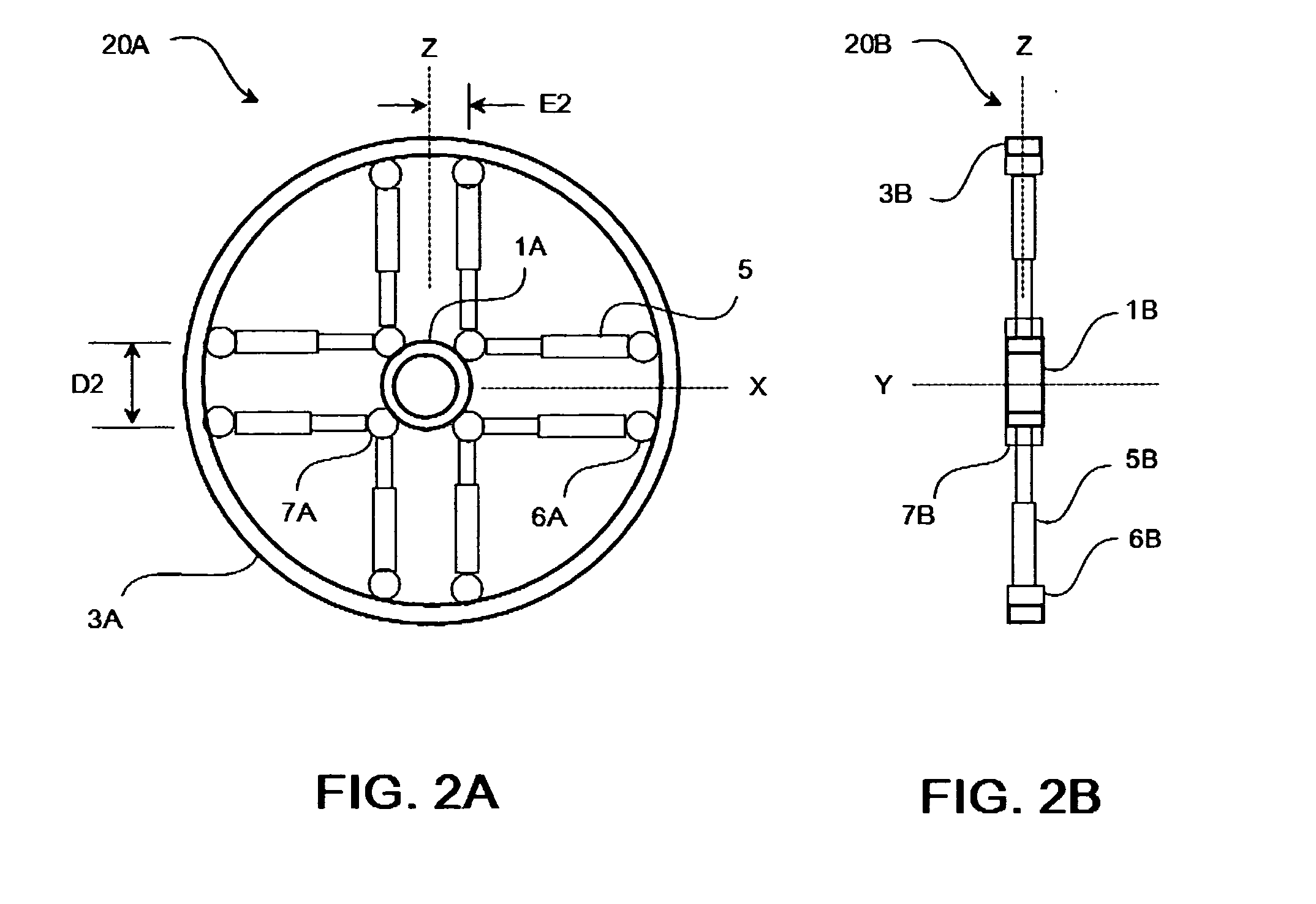

Shweel

InactiveUS20130340902A1Quiet and comfortable rideReduce rolling resistanceHigh resiliency wheelsMetalworkingRolling resistance

Shock-absorbers used as wheel-spokes between wheel-hub and rigid rim, which may be lined with threaded rubber or having gripping features otherwise. It reduces rolling resistance, saving fuel. It improves drivability. The compliance of the shocks is commensurate with that of a comparable inflated tire, but optimized passively or actively circumferentially, vertically and laterally. Rubber-bushing or spoke-inclination enhances driving stability. Giant field assembled mining-truck-wheels may be produced and deployed and field-assembled quickly by common metalworking shops at fractional cost and weight. It is environmentally friendly, for hardly using or not using rubber. The gas or liquid of the shock spokes may be interconnected and cooled. Soft and hard driving may be controlled manually or by computer on the fly. It is suitable for applications ranging from bicycle wheels to aircraft landing gears. It is fireproof, bulletproof, airless and silent. It cannot bounce or skid at jumpstart or braking and on ice.

Owner:KEMENY ZOLTAN A

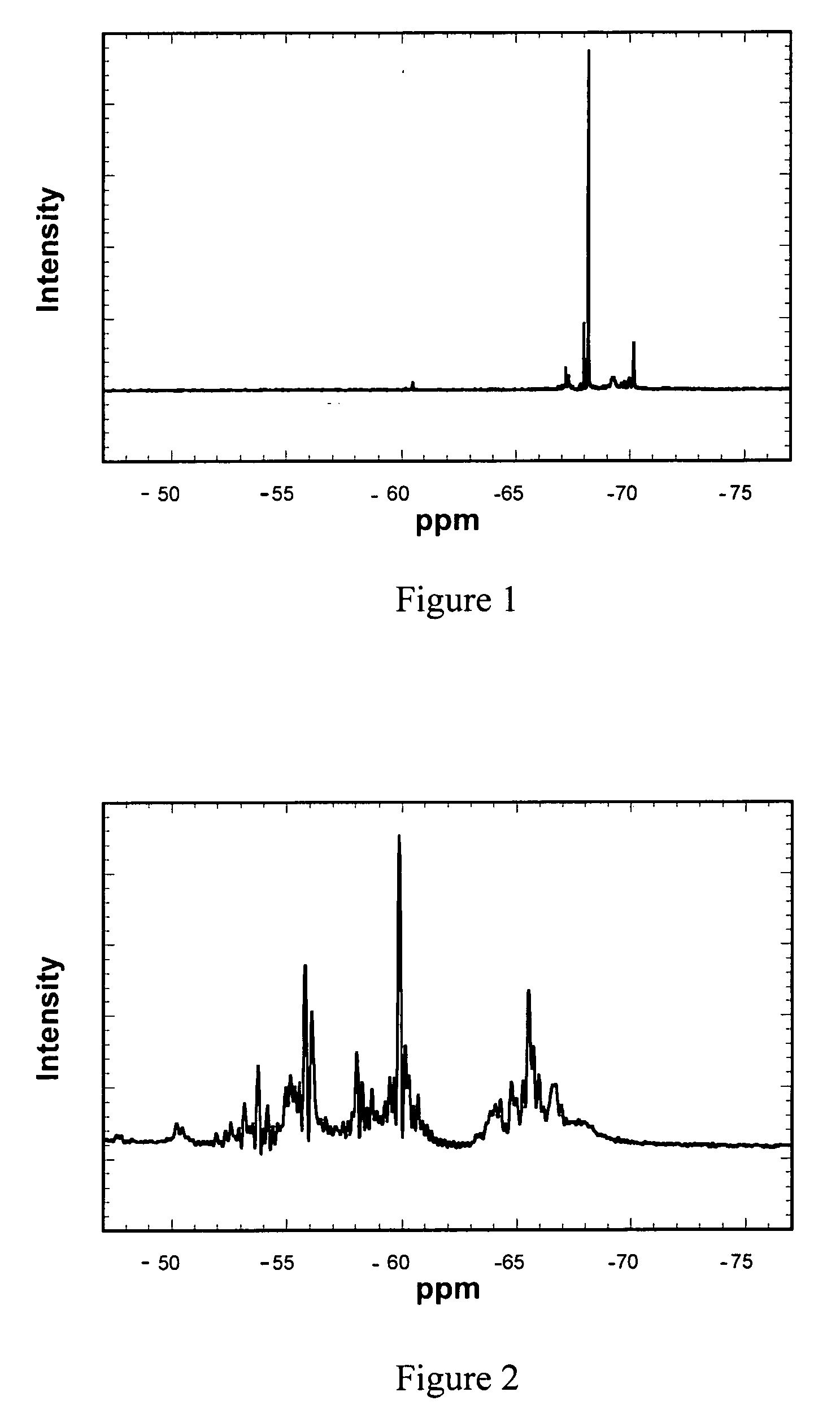

Silica containing rubber composition

InactiveUS7307121B2Great tractionReduce rolling resistanceSpecial tyresPretreated surfacesElastomerHysteresis

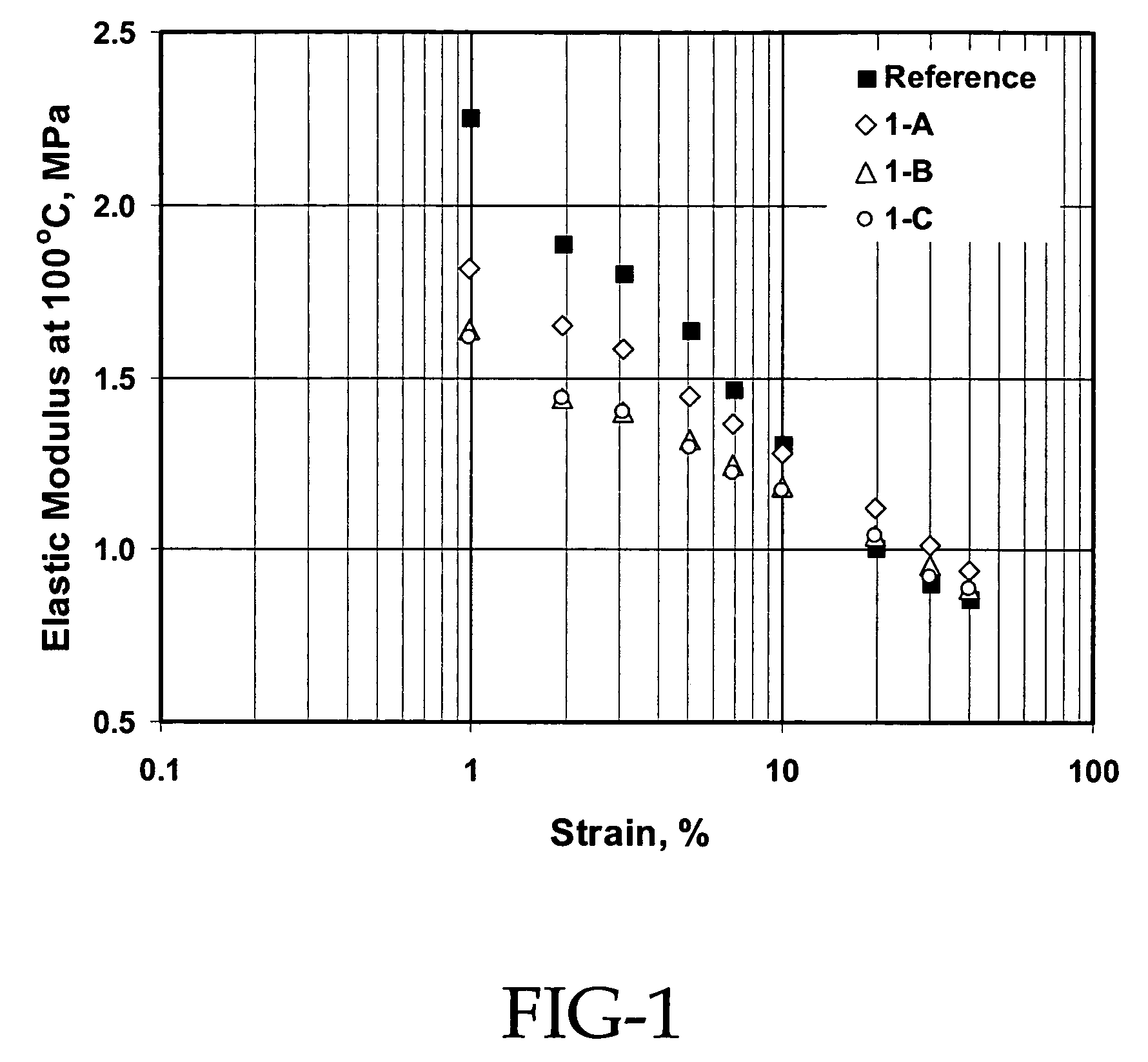

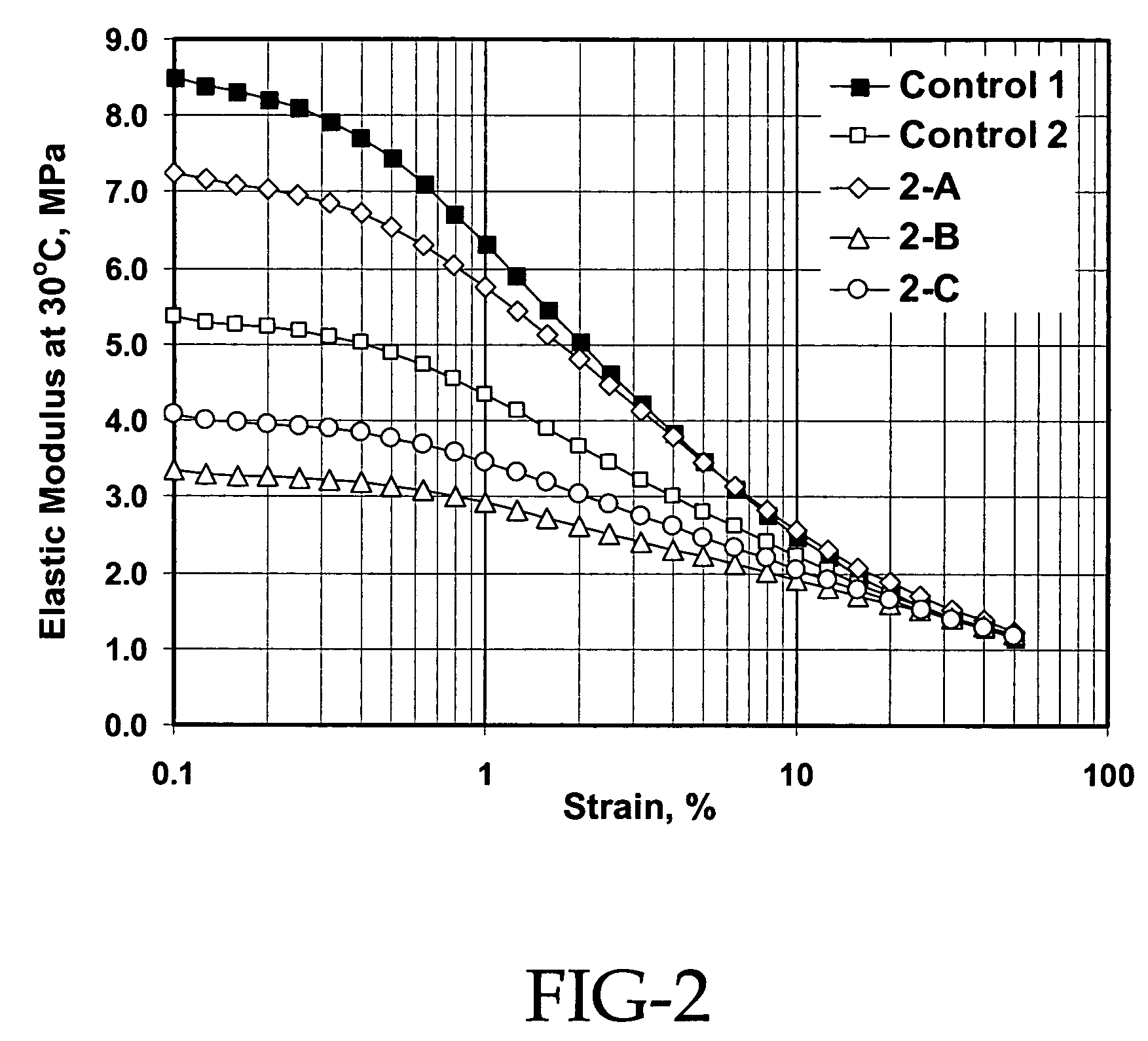

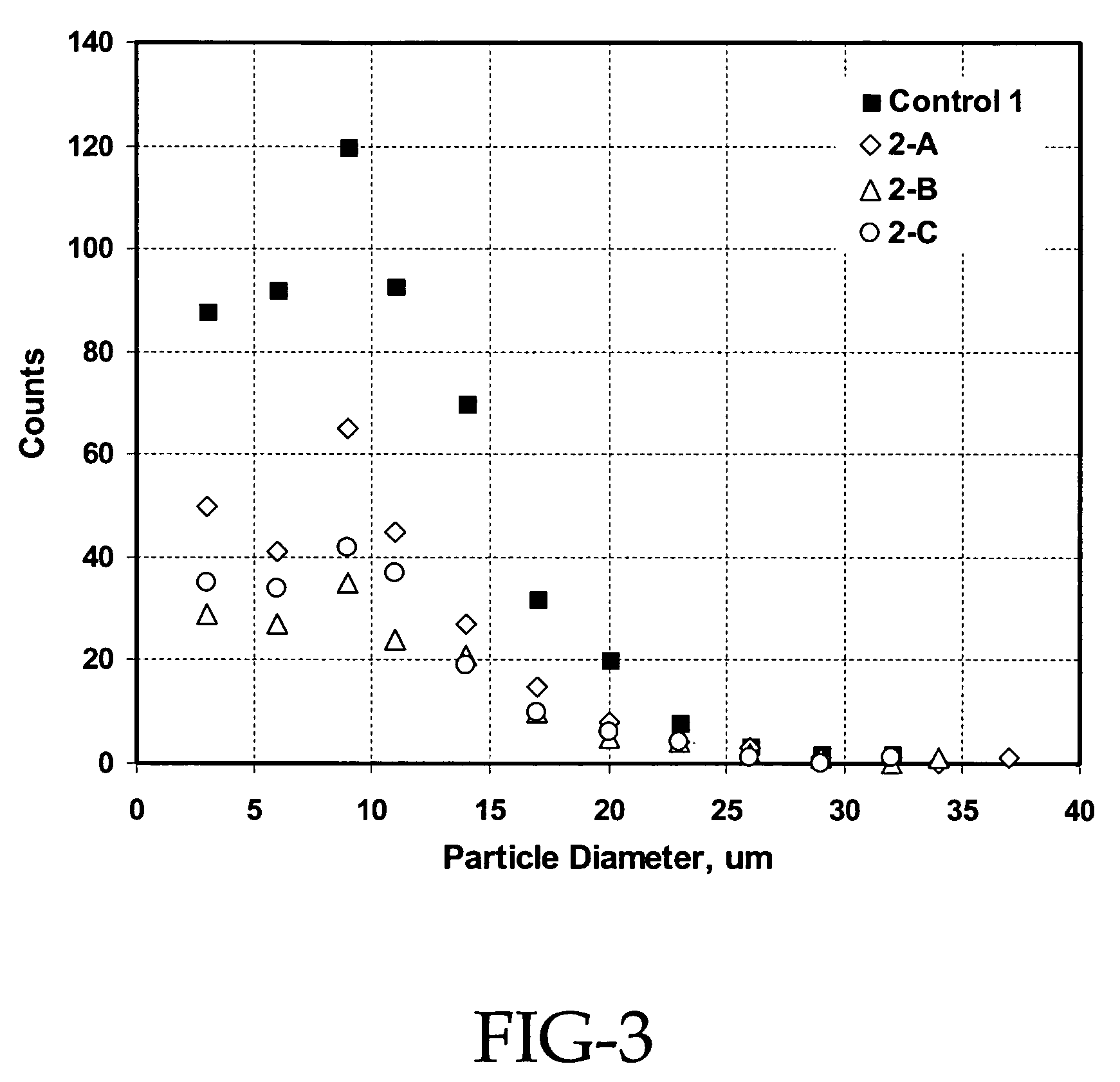

This invention discloses a method for preparing rubber compositions that exhibit unique combinations of properties that are desirable for tire tread applications for enhanced snow / ice and wet traction, low rolling resistance and increased treadwear performance in comparison with conventional silica compounds. Specifically, a high reactively silane coupling agent, such as a mercaptosilane, is used in combination with a silane coupling typically used for silica tread compounds such as bis(triethoxylsilylpropyl)disulfide to treat silica pellets in a hydrocarbon solvent at elevated temperatures. The treated silica is then blended with solution elastomer cement in a hydrocarbon solvent. The deposited reactive silanes partially react with the elastomer molecules forming a layer of polymer grafted on the silica surfaced. This structure significantly improves the silica retention during the steam stripping operation. Almost 100% (99+%) silica retention has been achieved by this invention. After solvent removal from steam stripping, the treated silica / elastomer mixer is dewatered and dried using conventional equipment such as shaker screens, expellers and expanders to form a well-dispersed silica masterbatch. This technique results in silica compounds with excellent silica dispersion and increased filler-polymer interaction, hence enhanced compound performance such as better physical properties, more desirable dynamic properties (low hysteresis at high temperatures and high hysteresis at low temperatures) and increased abrasion resistance.

Owner:THE GOODYEAR TIRE & RUBBER CO

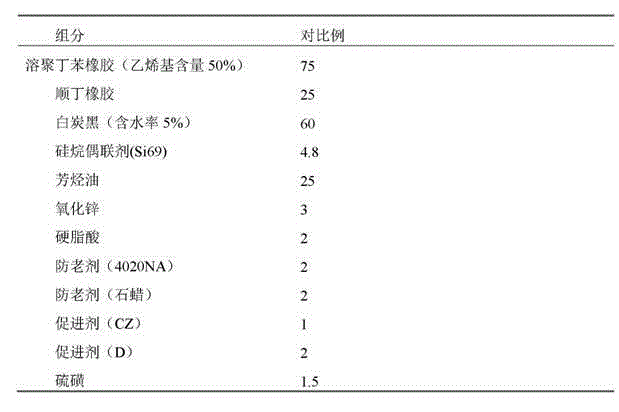

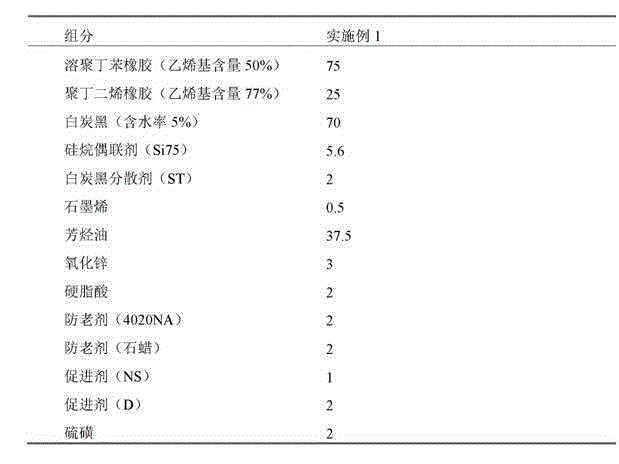

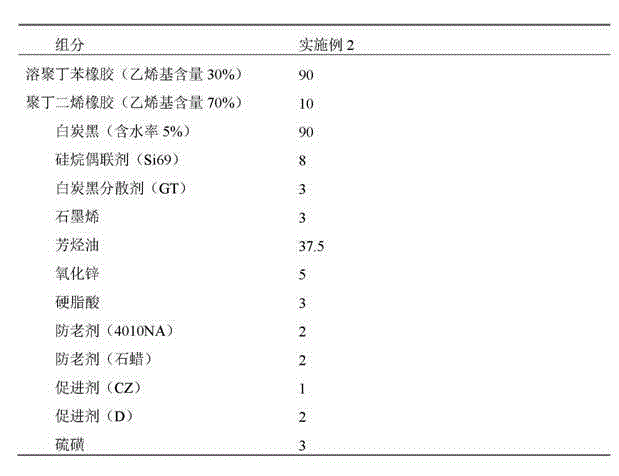

Antistatic low-rolling-resistance tyre tread material and preparation method thereof

ActiveCN102911411AReduce rolling resistanceSolve static electricity accumulationRolling resistance optimizationChemistryButadiene-styrene rubber

The invention relates to the technical field of rubber, in particular to an antistatic low-rolling-resistance tyre tread material and a preparation method thereof. The material is characterized by comprising the following constituents in parts by weight: 40-90 parts of solution polymerized styrene-butadiene rubber, 10-60 parts of polybutadiene rubber, 50-90 parts of white carbon black, 4-8 parts of silane coupling agent, 0.5-3 parts of graphene, 1-3 parts of white carbon black dispersing agent, 10-37.5 parts of aromatic oil, 2-5 parts of zinc oxide, 1-3 parts of stearic acid, 2-4 parts of anti-aging agent, 2-4 parts of accelerant and 1-3 parts of sulphur. Sizing materials are mixed by an internal mixer, the rotor speed, the sizing material mixing time and the temperature are controlled, and a composite material is prepared by the four-section mixing method. The rolling resistance of a tyre can be reduced; more importantly, the problem that the white carbon black filling tread composite material has static accumulation is solved by using the graphene; and the wet-skid resistance and the abrasion resistance of a tyre tread of a passenger vehicle can be improved.

Owner:BEIJING UNIV OF CHEM TECH

Amino alkoxy-modified silsesquioxane adhesives for improved metal adhesion and metal adhesion retention to cured rubber

InactiveUS20090165913A1Improve adhesion performanceImproved metal adhesion metal retention propertySpecial tyresTyresEndcappingPolymer science

Amino alkoxy-modified silsesquioxanes (amino AMS), and / or amino co-AMS compounds that also comprise a mercaptosilane or a blocked mercaptosilane, are excellent adhesives for coating plated or unplated metal wire for adherence of the wire to a rubber stock. The amino AMS and / or the amino / mercaptan co-AMS adhesives can be used with all types of rubber and there is no requirement for the use of special adhesive additives to the rubber vulcanizates, such as, but not limited to, cobalt, resins and high sulfur levels. In particular, the use of amino AMS and / or amino / mercaptan co-AMS compounds as adhesives for bonding wire to rubber also improves the adherence performance of the reinforcements to obtain sufficient bonding that is resistant to degradation over the course of time, especially resistance to thermal aging and / or thermo-oxidizing aging, in particular corrosion in the presence of water.

Owner:BRIDGESTONE CORP

Rubber composition for a tire comprising a reinforcing inorganic filler and an (inorganic filler/elastomer) coupling system

InactiveUS6984689B2Improve efficiencyReduce in quantityOther chemical processesSpecial tyresGuanidine derivativesElastomer

The present invention is directed to a rubber composition that is useful for the manufacture of tires, where the composition is based on a diene elastomer, a reinforcing inorganic filler, and a coupling system. The coupling system comprises a polysulfurized alkoxysilane (“PSAS”) coupling agent (inorganic filler / diene elastomer) associated with a 1,2-dihydropyridine and a guanidine derivative. The present invention is further directed to tires and semi-finished products for tires comprising a rubber composition according to the invention. The invention is also directed to a coupling system (inorganic filler / diene elastomer) for a rubber composition based on a diene elastomer reinforced by an inorganic filler, where the coupling system comprises a polysulfurized alkoxysilane (PSAS) coupling agent in association with a 1,2-dihydropyridine and a guanidine derivative.

Owner:MICHELIN RECH & TECH SA

Rubber composition for tire and pneumatic tire using the same

A rubber composition for a tire, in which a specific tackifier is compounded, and tackiness and various physical properties are improved, compared with compounding a petroleum resin or a terpene resin, is provided. The rubber composition for a tire comprising an alkyd resin and a pneumatic tire using the same. It is preferable that a material derived from a resource other than petroleum, particularly, a material derived from animal and / or vegetable, and more particularly, a material derived from an animal oil and / or a vegetable oil is contained in the alkyd resin, and it is preferable that unsaturated polybasic acid is contained in the alkyd resin.

Owner:SUMITOMO RUBBER IND LTD

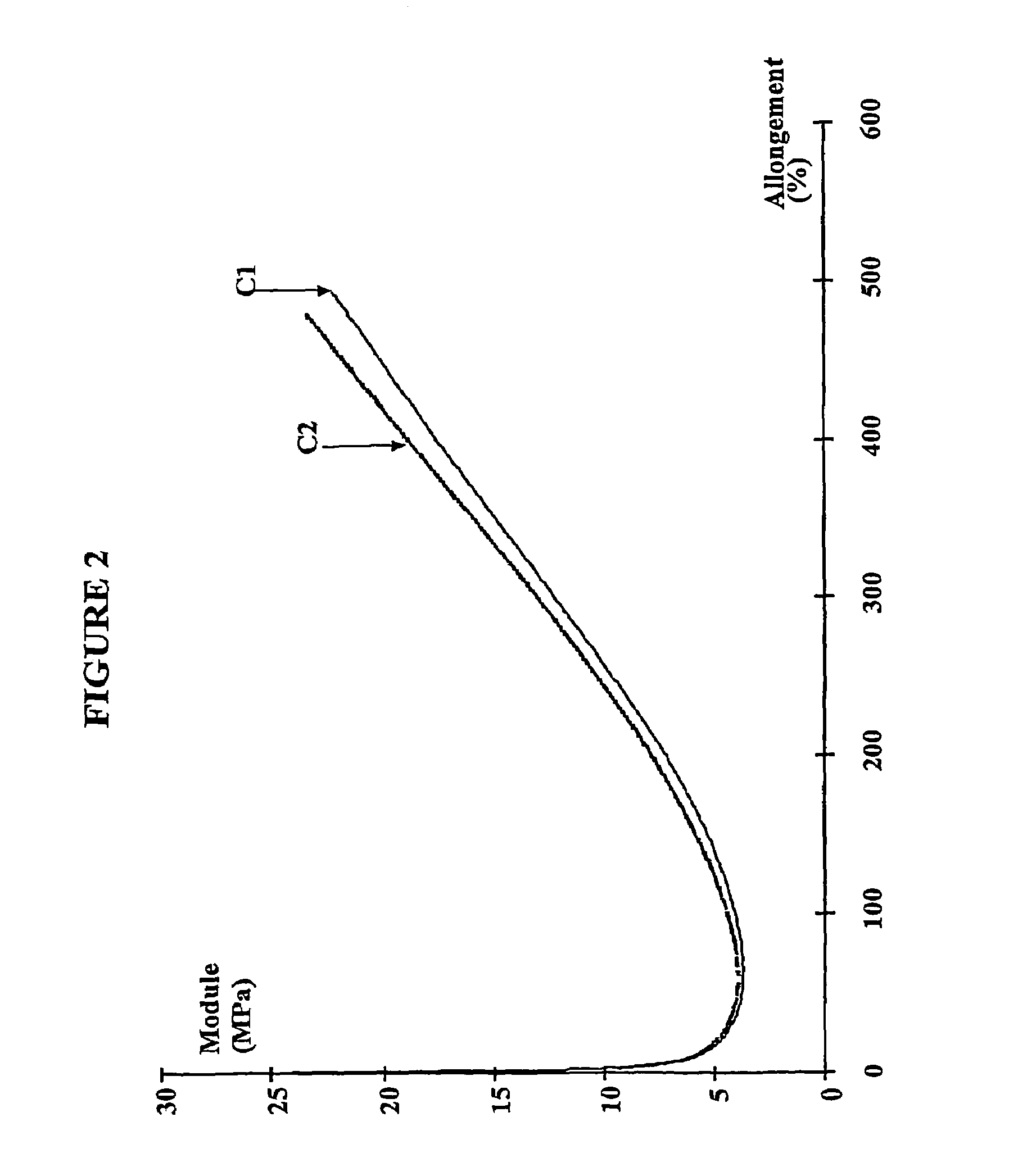

Rubber composition usable as a tire tread

InactiveUS20020183436A1Improved hysteresis propertiesReduce rolling resistanceSpecial tyresTyre tread bands/patternsElastomerCross-link

The present invention relates to a cross-linkable or cross-linked rubber composition having improved hysteresis properties in the cross-linked state which is useful for constituting a tire tread, to a process for preparation of such a cross-linkable composition, to a tread of this type and to a tire having reduced rolling resistance. The rubber composition according to the invention is based on: an elastomeric matrix comprising at least one diene elastomer which comprises a carboxylic acid function at one or at each of its two chain ends, and a reinforcing filler comprising a reinforcing inorganic filler, wherein said diene elastomer has a molecular weight which is greater than 80,000 g / mol, and it is present in a majority quantity in said elastomeric matrix.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Rubber composition for a tire comprising a multifunctional polyorganosiloxane as coupling agent

InactiveUS6878768B2Reduce rolling resistanceImprove wear resistanceSpecial tyresDyeing processElastomerDouble bond

The present invention relates to a sulfur-cross-linkable elastomeric composition that is useful for the manufacture of tires. This elastomeric composition is based on at least one isoprene elastomer (in particular natural rubber), a reinforcing inorganic filler (in particular, silica), and an (inorganic filler / isoprene elastomer) coupling agent. The coupling agent is a multifunctional polyorganosiloxane (POS), which comprises functions denoted as “Y” and “X”, wherein the Y function is at least one hydroxyl or hydrolyzable function grafted to the silicon atoms of the coupling agent and the X function is a group bearing at least one activated ethylene double bond and is grafted to the silicon atoms of the coupling agent. This POS is, in particular, a POS having an imide, acid or ester function, the ethylene double bond of which is activated by at least one adjacent carbonyl group (—C═O). The present invention further relates to a tire comprising the composition described above as well as semi-finished products for tires, in particular, treads, where the tires comprise a rubber composition according to the present invention.

Owner:MICHELIN RECH & TECH SA

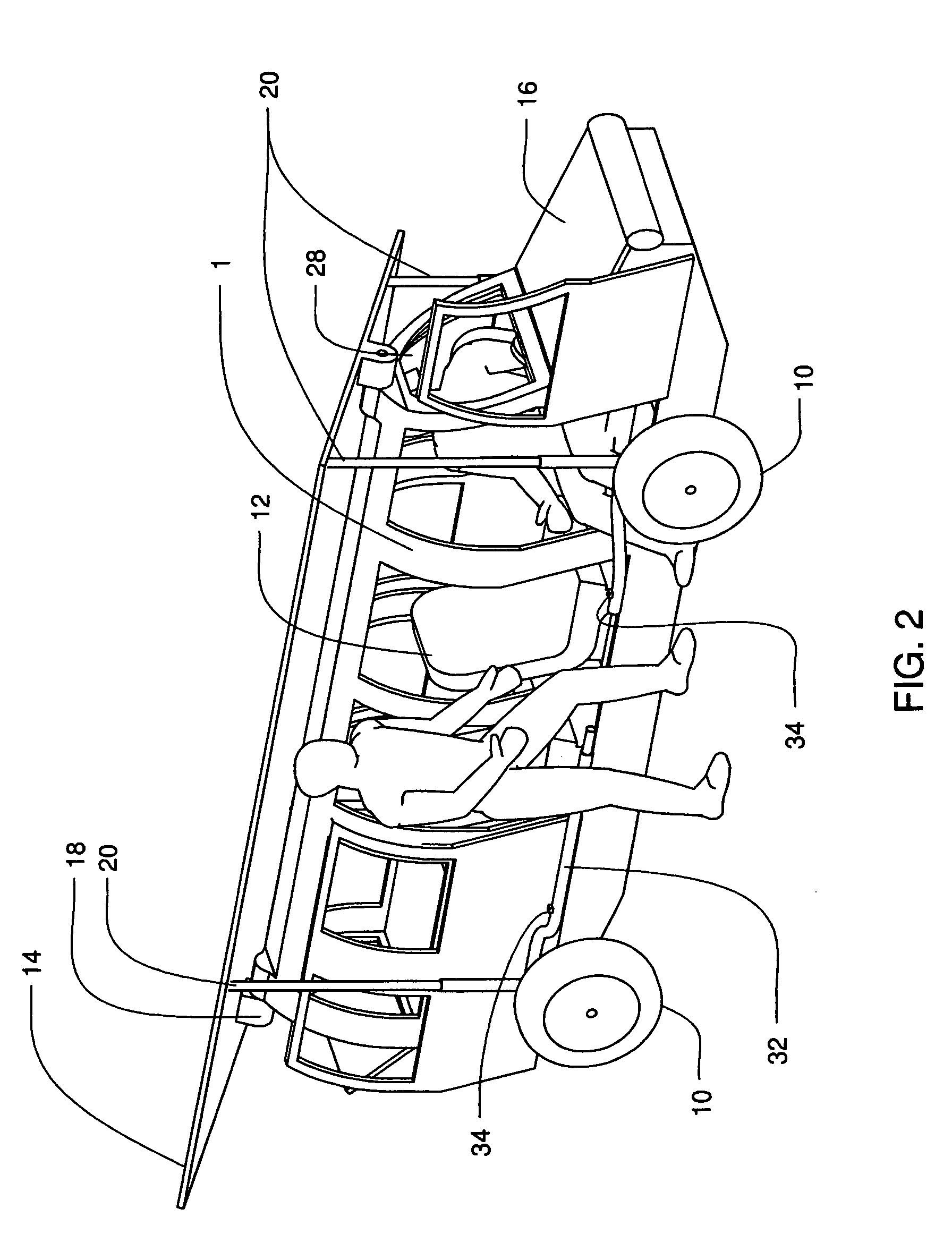

Electric car with maximized solar assist

InactiveUS20100193260A1Eliminate emissionsReduce threatAuxillary drivesVehicular energy storageElectricityContinuous flow

The present invention is an electric car with a maximized solar panel assist. Since batteries are normally charged at night while solar energy is created during the day, this system creates an almost continuous flow of electricity to the batteries. Since the weight and cost of the batteries are the main handicap for electric cars and a continuous flow of electricity minimizes the need for a large and expensive battery system, this is the most logical way to build a viable electric car.

Owner:FREEMAN BENJAMIN

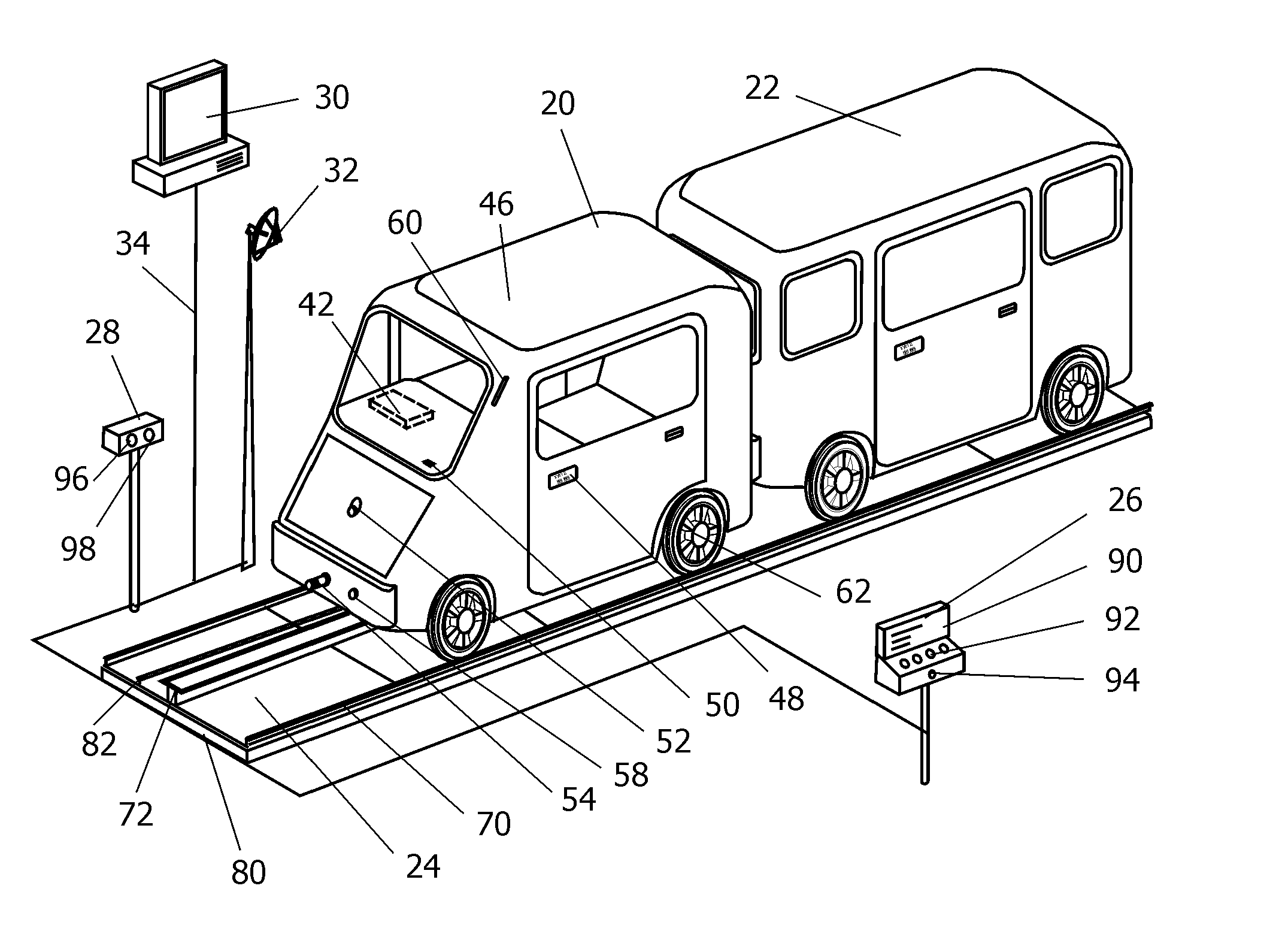

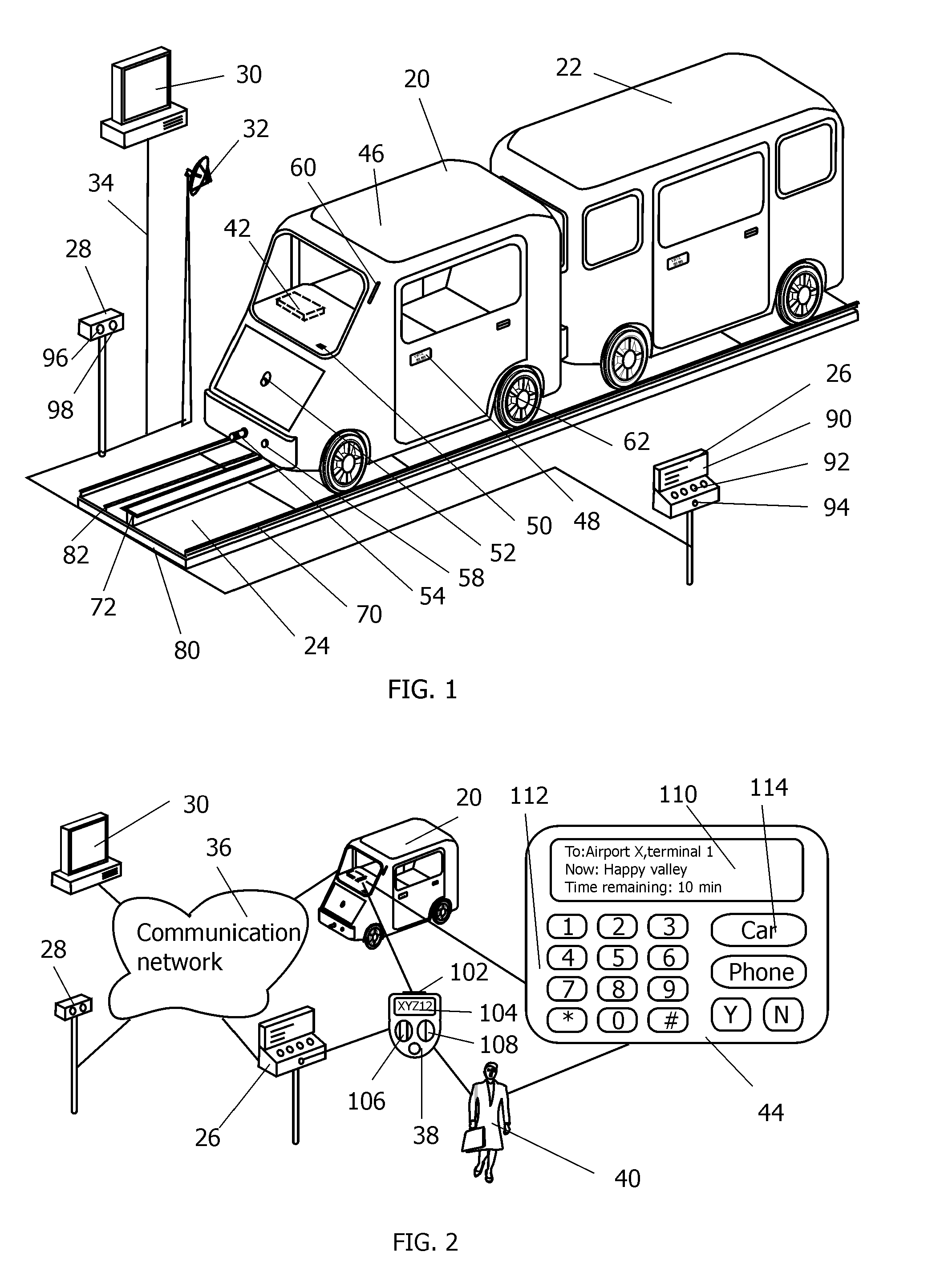

Personal Transportation System

InactiveUS20050038575A1Increase speedTransportation is highRefuge islandsAutomatic systemsThree levelControl system

An autonomous personal transportation system for moving passengers and light freights is constructed with a track network and small vehicles on the track network. There are a number of stations and stops for loading and unloading on side tracks off the mainline of the track network. The vehicle width is limited to a dimension for one seat. The vehicles can be coupled statically or dynamically to form a train. The track has side rails for the rigid wheels of the vehicle and a central rail for centering the vehicle on the guideway and providing additional acceleration and braking capability. The control system for the movement of vehicles is divided into three levels: the central control system, the wayside control system and the vehicle control system.

Owner:WU HENGNING

Tyre crown rubber material and mixing method thereof

InactiveCN102604170AGood physical and mechanical propertiesIncrease elasticitySpecial tyresRolling resistance optimizationRubber materialPolymer science

The invention discloses a tyre crown rubber material. The tyre crown rubber material comprises the following raw materials in parts by weight: 60-80 of natural rubber, 20-40 of butadiene rubber BR9000, 0-0.4 of peptizer, 10-30 of intermediate super abrasion furnace black, 25-45 of white carbon black, 3-7 of silane coupling agent, 3-5 of zinc oxide, 1-4 of stearic acid, 1-3 of antiager 6PPD, 0-2 of antiager RD, 1-3 of microcrystalline paraffin, 1-3 of sulfur, 1.5-2.5 of accelerator, 4-6 of fatty acid salt processing agent, 0-1 of anti-reversion agent, 2-5 of environment-friendly arene oil TDAE (Treated Distillate Aromatic Extract), 1-3 of octyl phenolic aldehyde tackifying resin and 0-0.3 of scorch retarder. When mixing is carried out in three sections, partial formula raw materials are subjected to rubber material mixing, and then other formula materials are added for rubber material mixing. The tyre crown rubber material produced by using the tyre crown rubber material formula is good in comprehensive processing property, has the characteristics of low thermogenesis, ageing resistance and tearing resistance and is environment-friendly and can be used for producing green full-steel radial tyre crown.

Owner:安徽大瑞橡胶有限公司

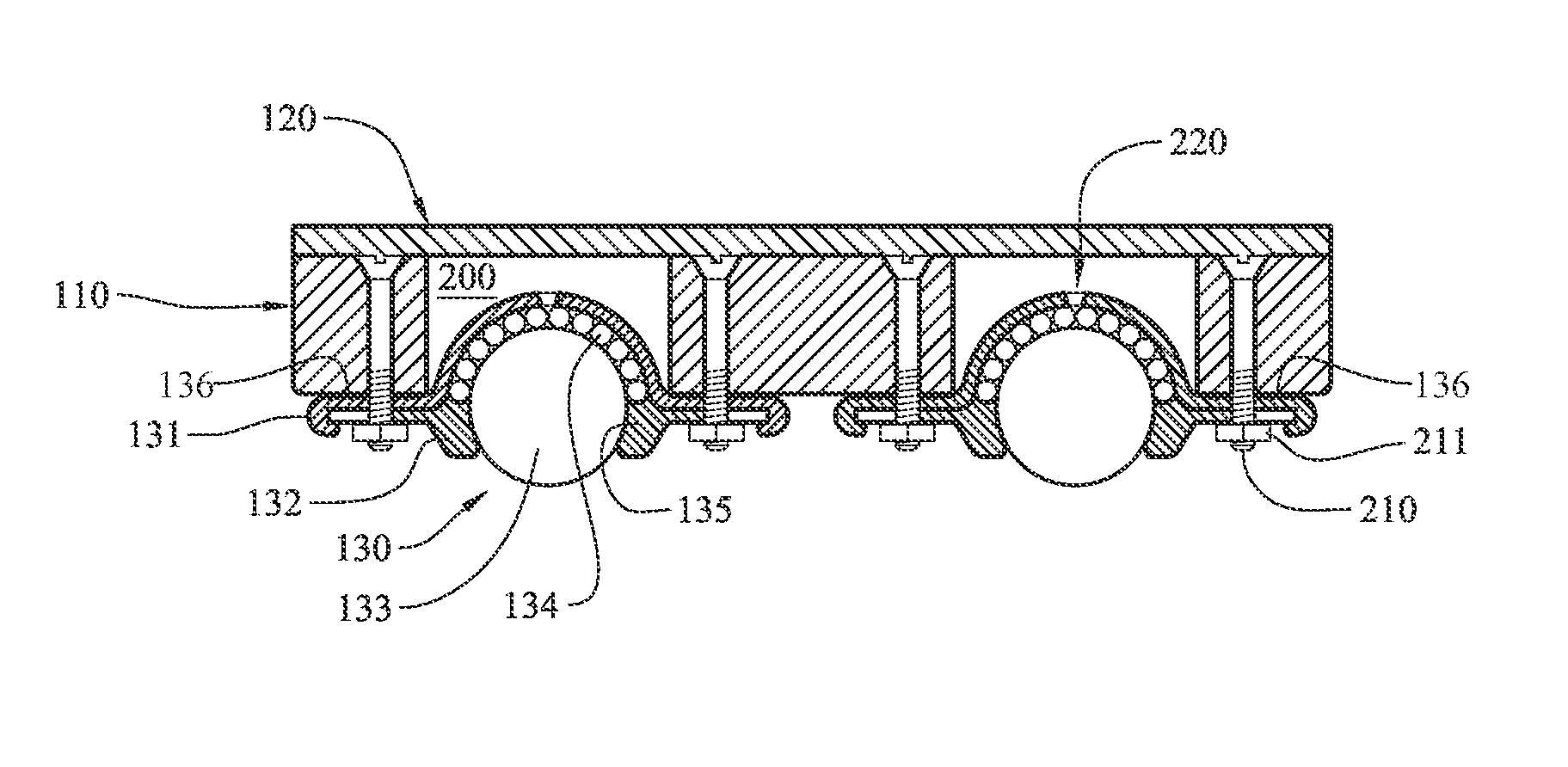

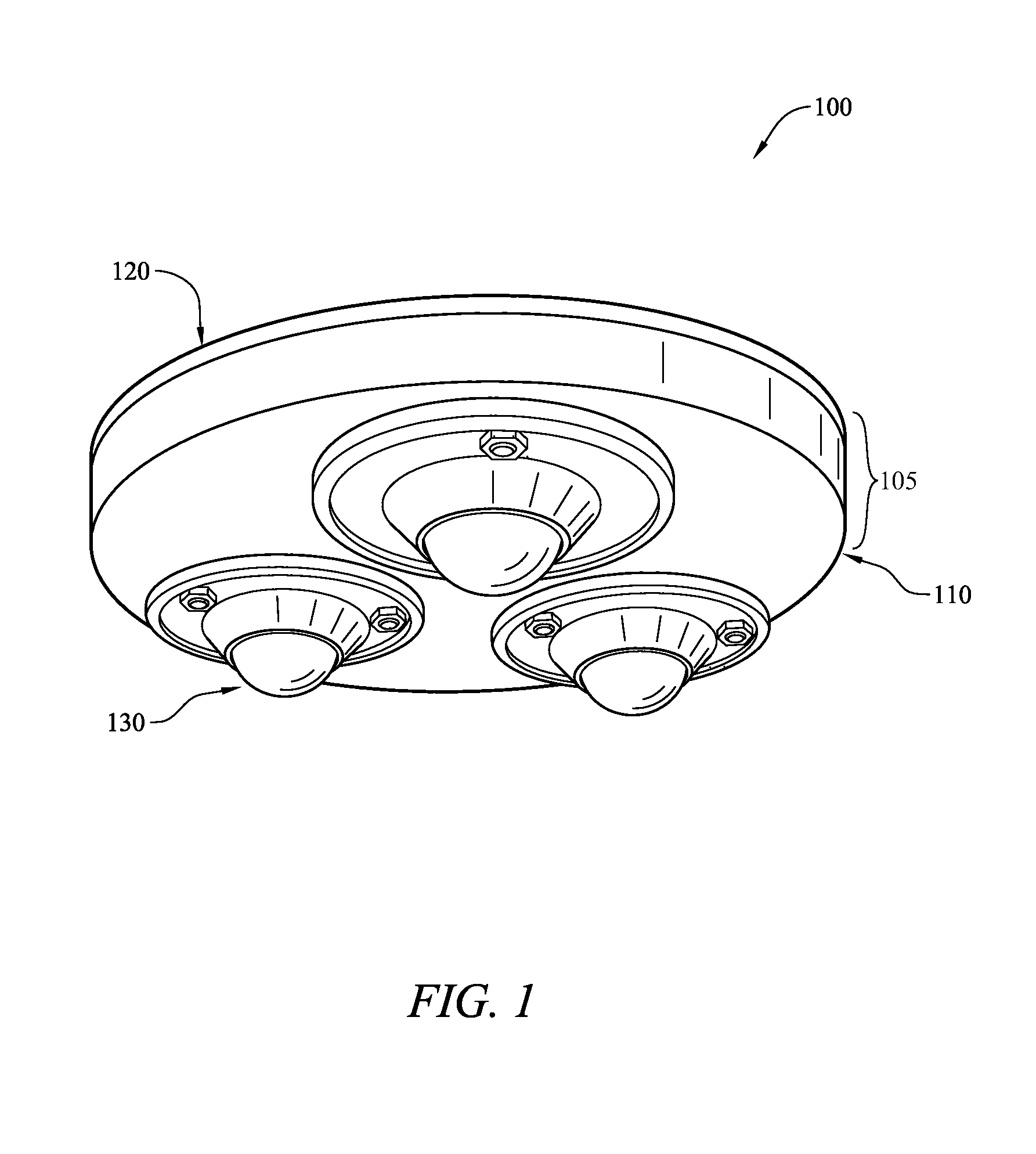

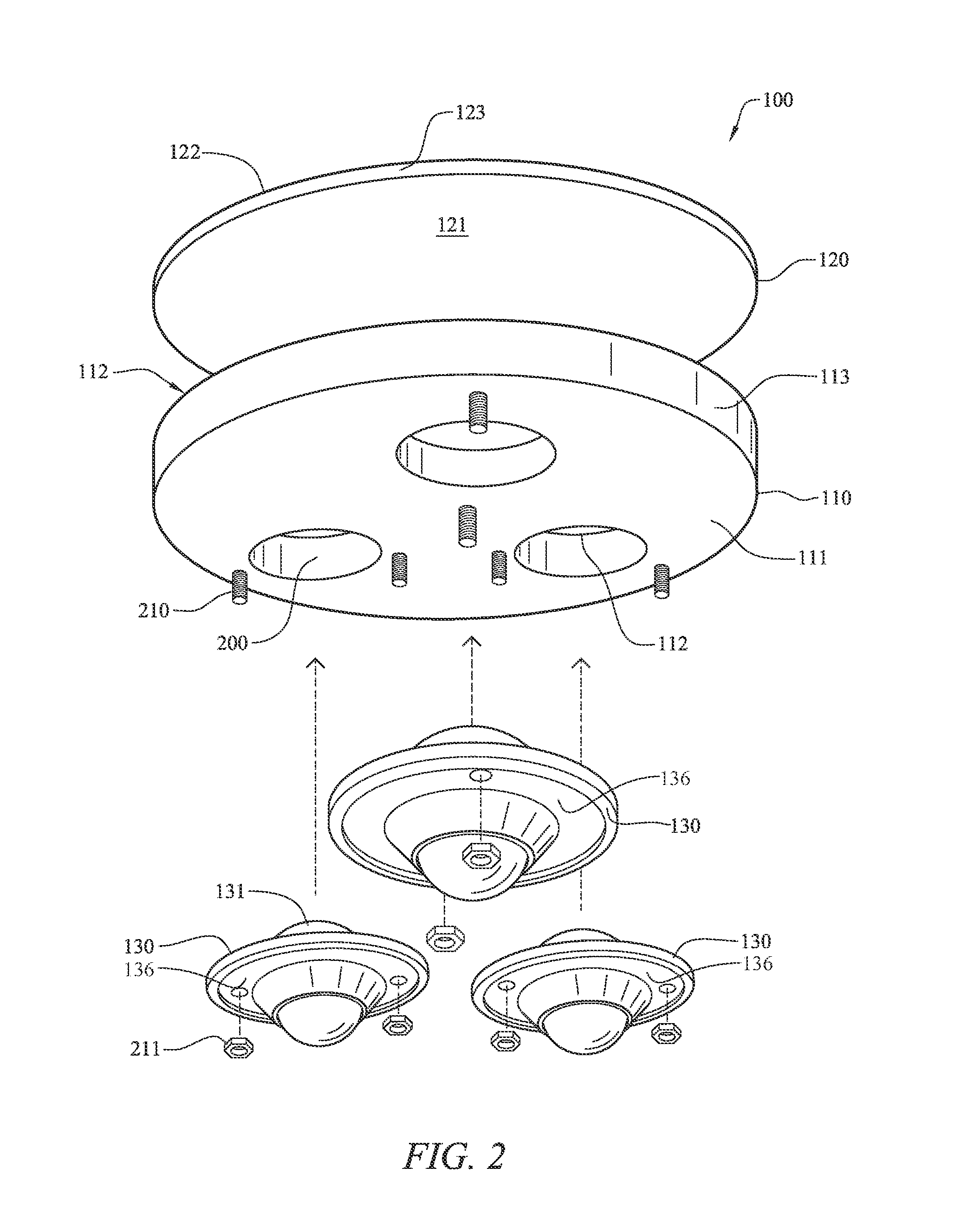

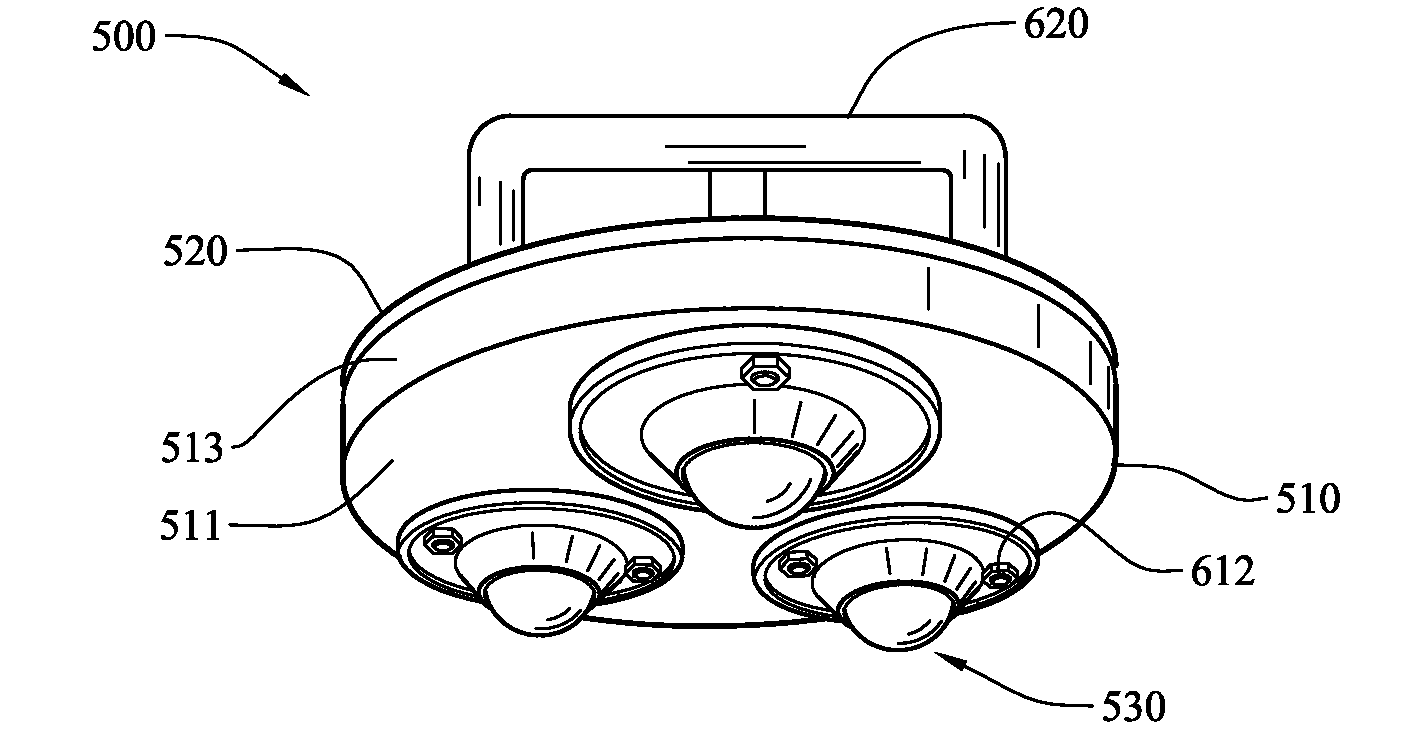

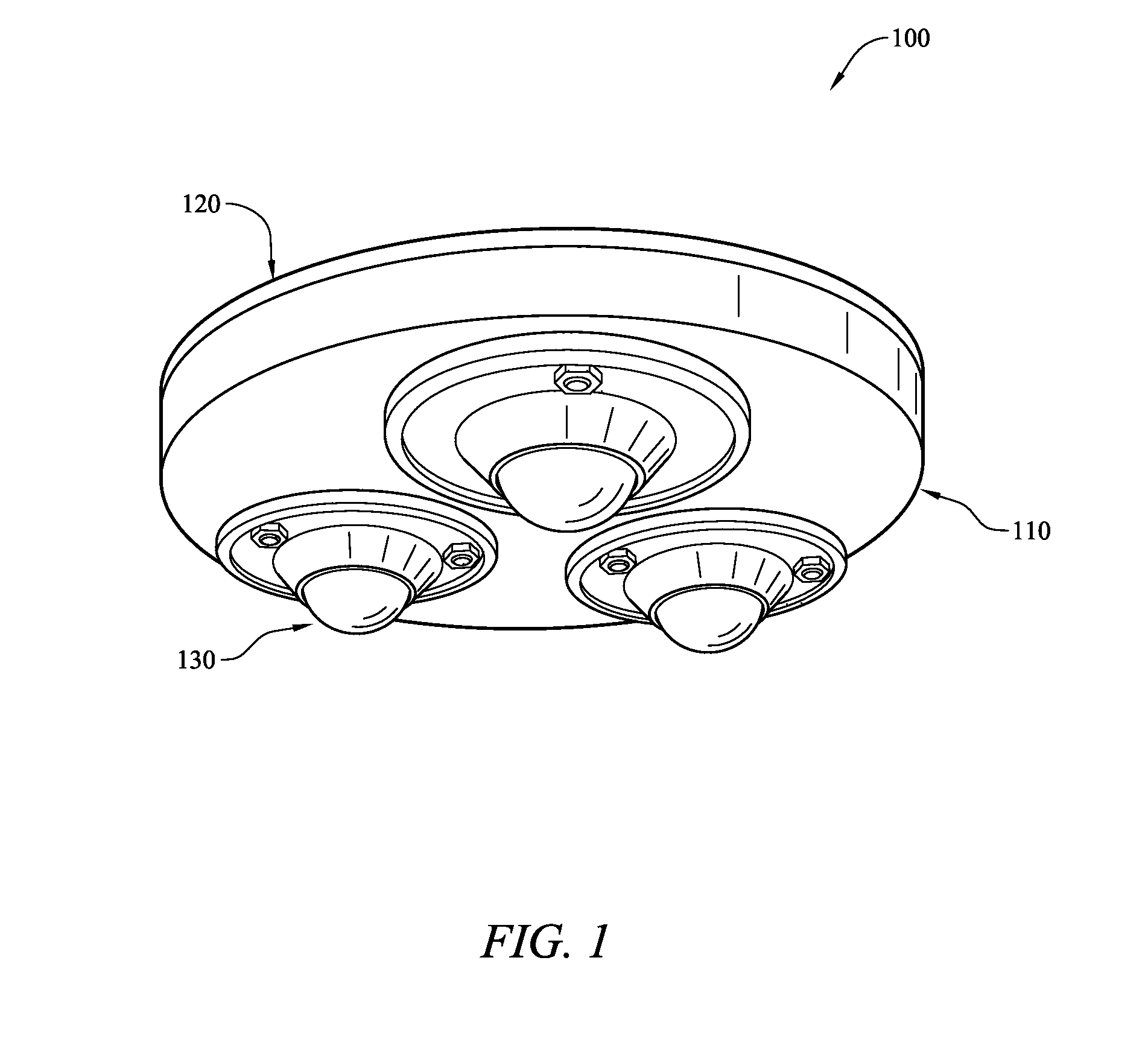

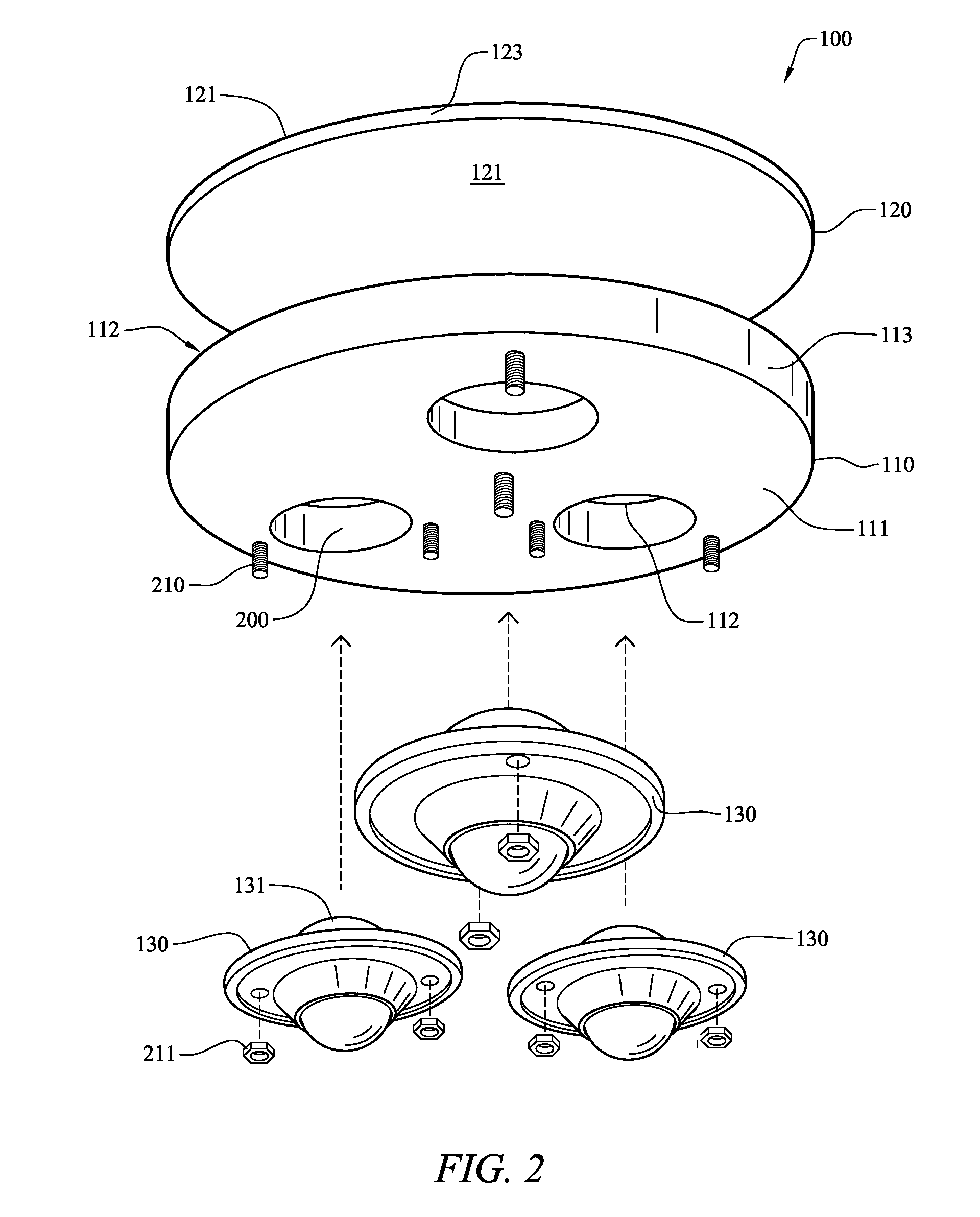

Omnidirectional exercise platform

ActiveUS8827879B2Permit some movementEasy to trainStiltsMuscle exercising devicesEngineeringMechanical engineering

An omnidirectional exercise platform is disclosed which includes a base member, a pad member and a plurality of ball transfer units. The pad member is coupled to a top surface of the base member. The plurality of ball transfer units is coupled to a bottom surface of the base member. An angular offset is provided between the plurality of ball transfer units to stabilize the omnidirectional exercise platform during use. The ball transfer units each comprise a hemispherical housing, a primary ball member and a plurality of secondary ball members disposed between an inner surface of the hemispherical housing and the primary ball member. The housing further includes an aperture located and sized to facilitate cleaning and maintenance procedures of the ball transfer unit. A handle is releasably coupled to the top surface of the base member to thereby provide a user with a variety of hand placement positions.

Owner:OMNI EXERCISE

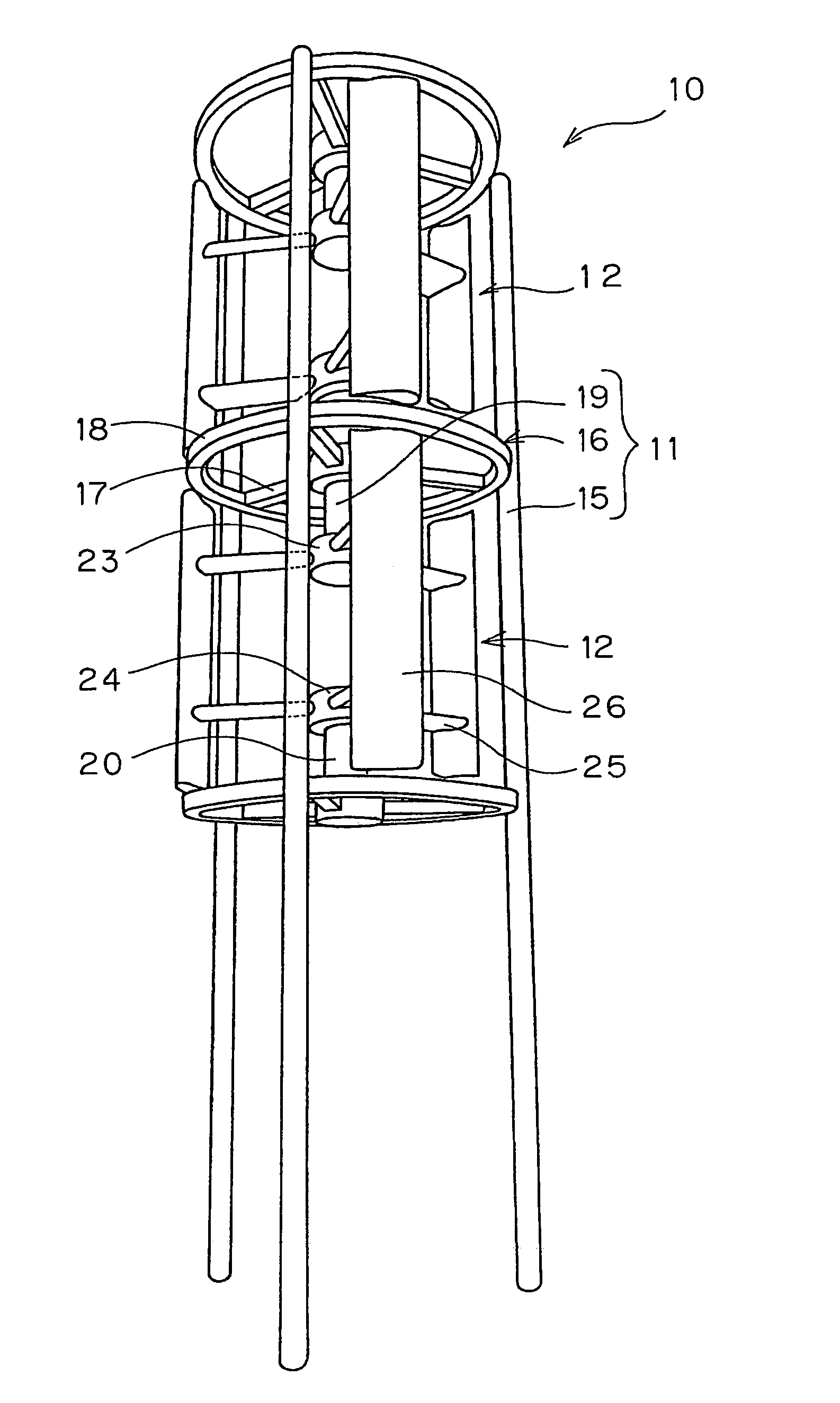

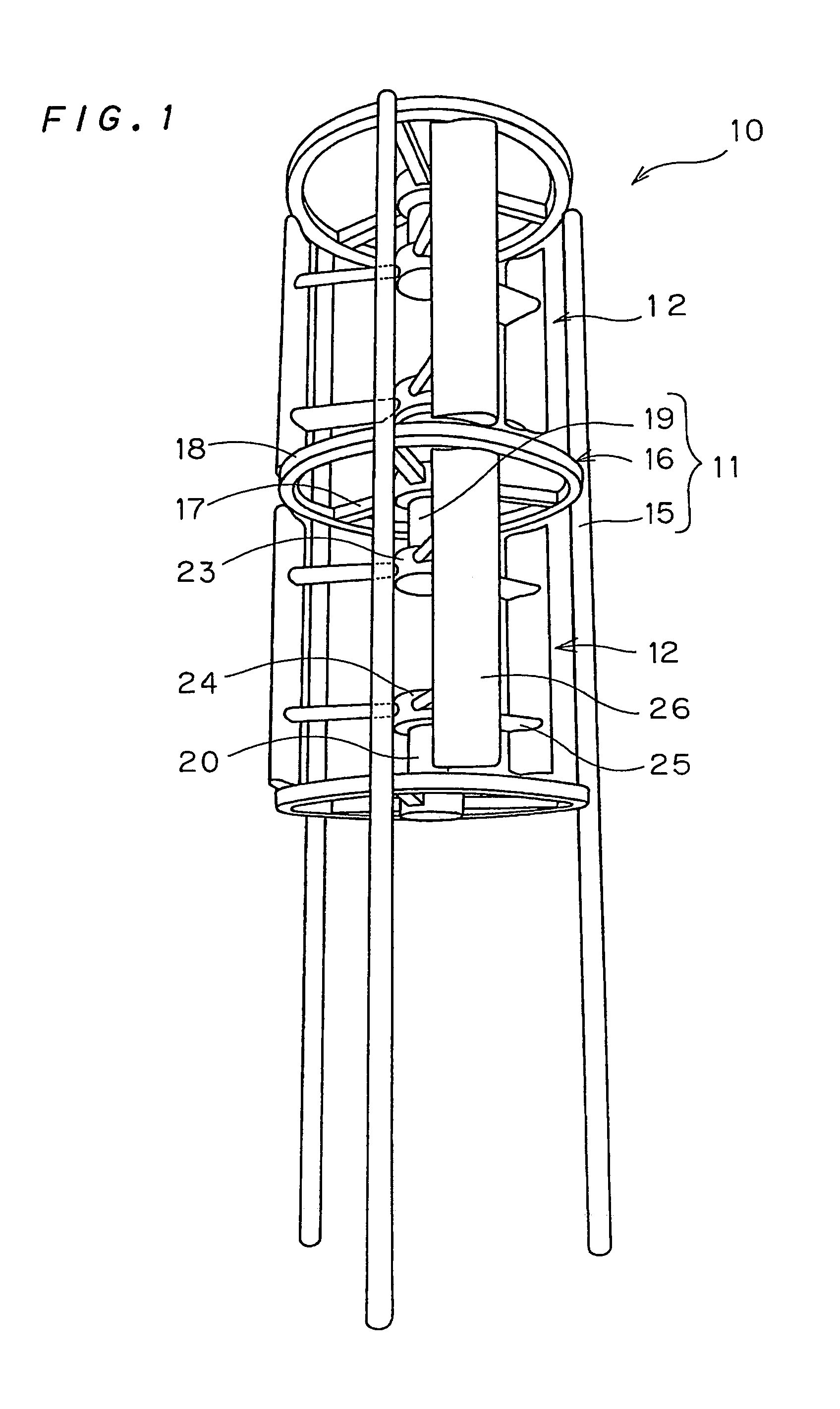

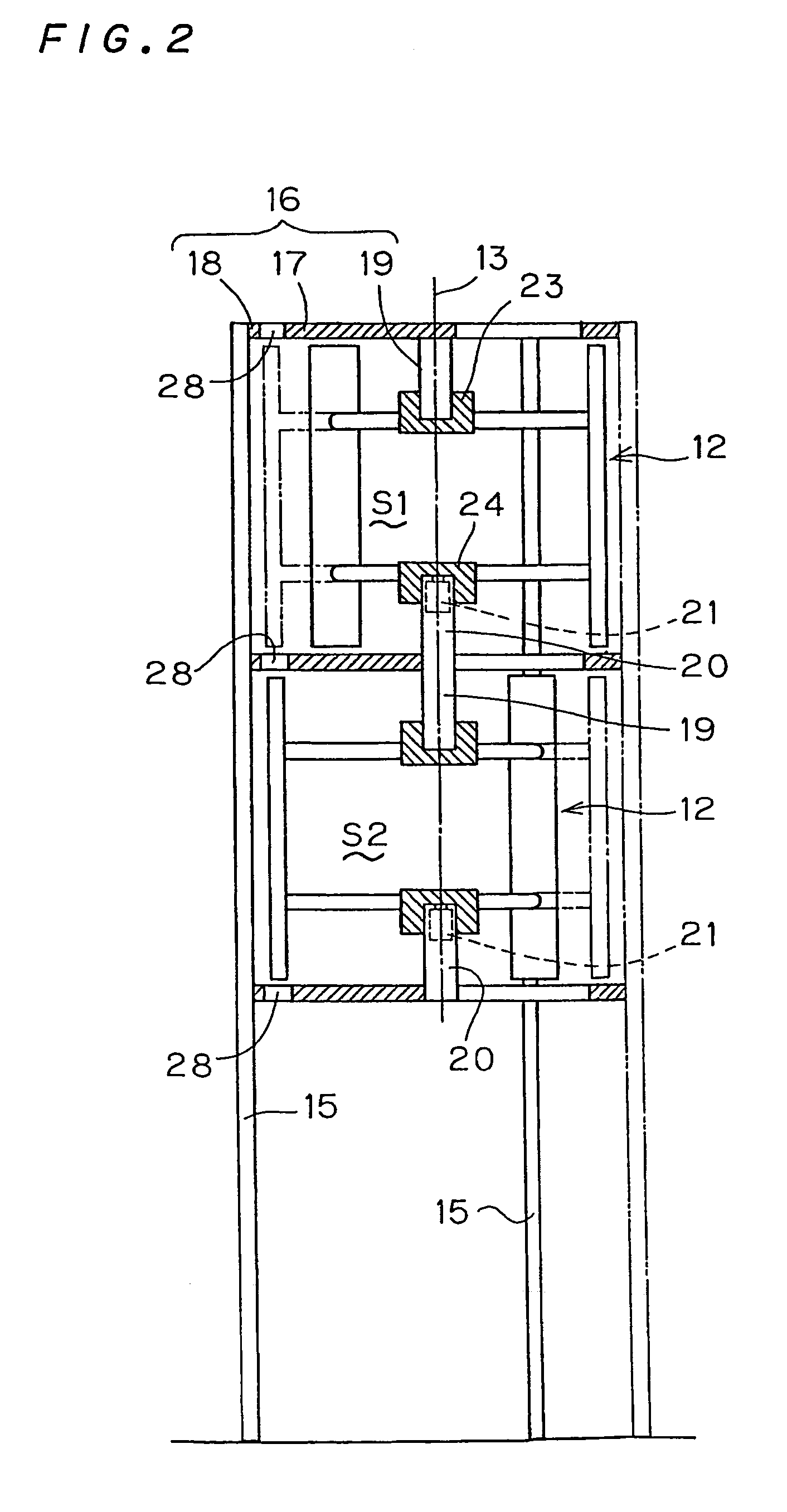

Rotor supporting structure of windmill for power generation

Owner:KINPARA SHIRO

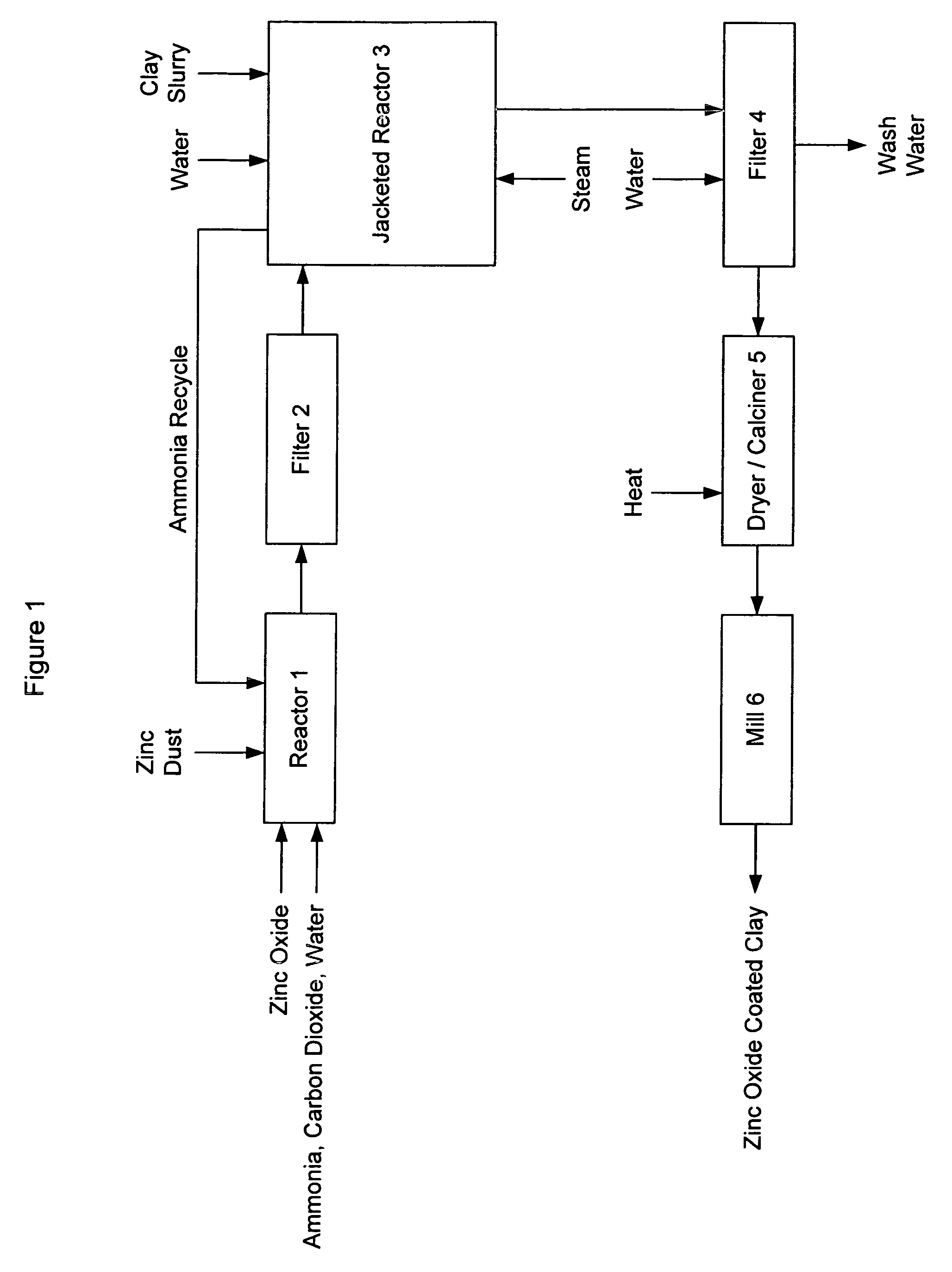

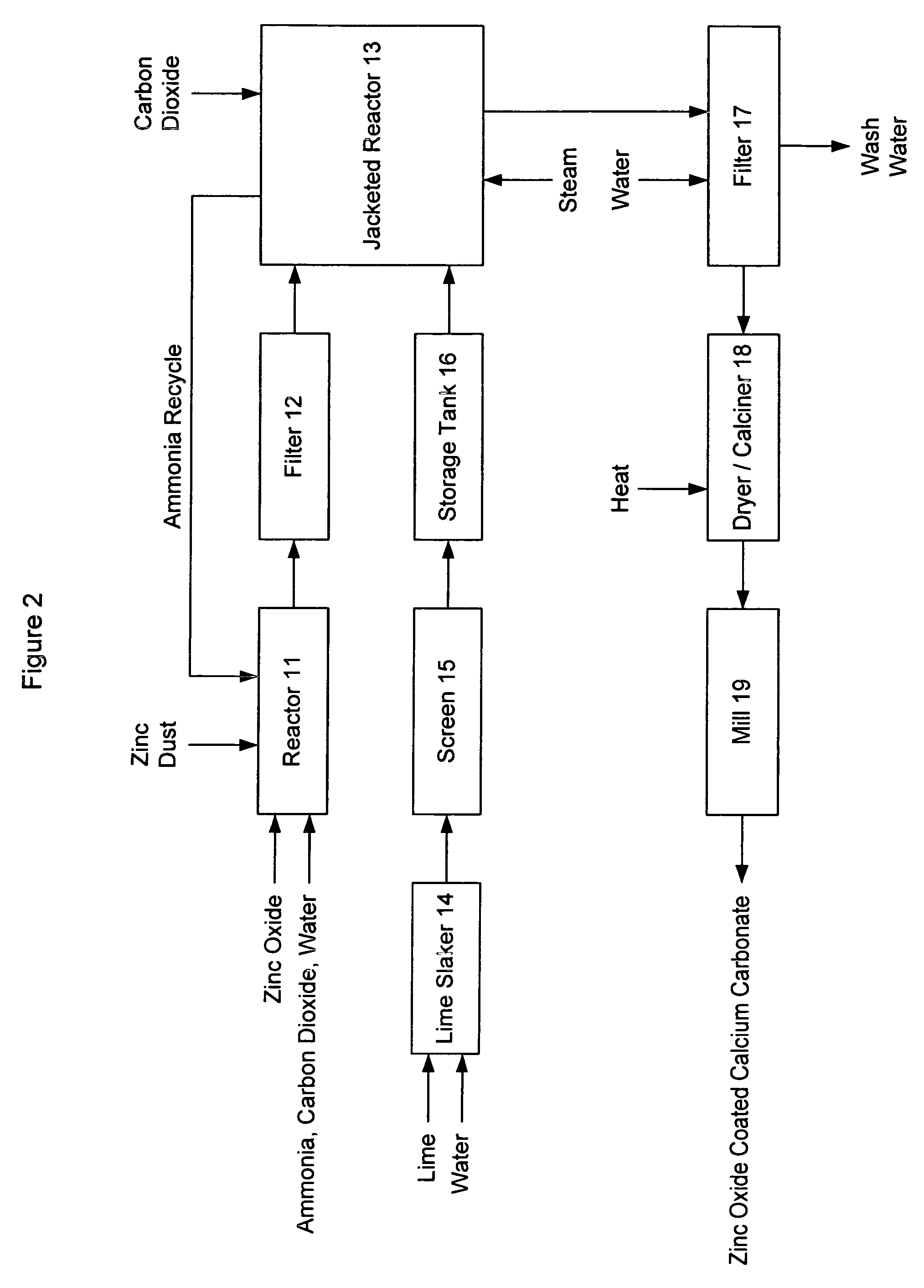

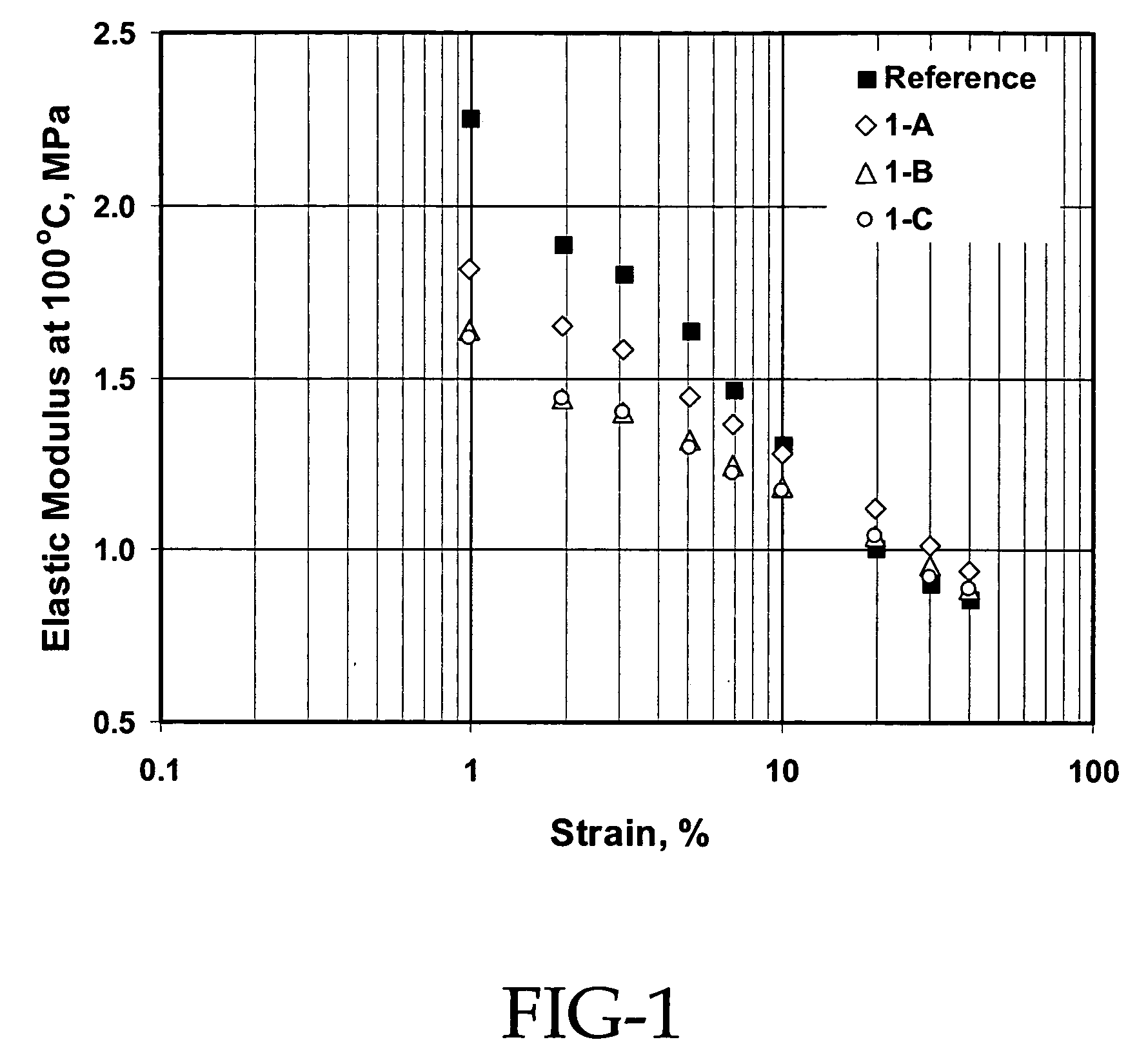

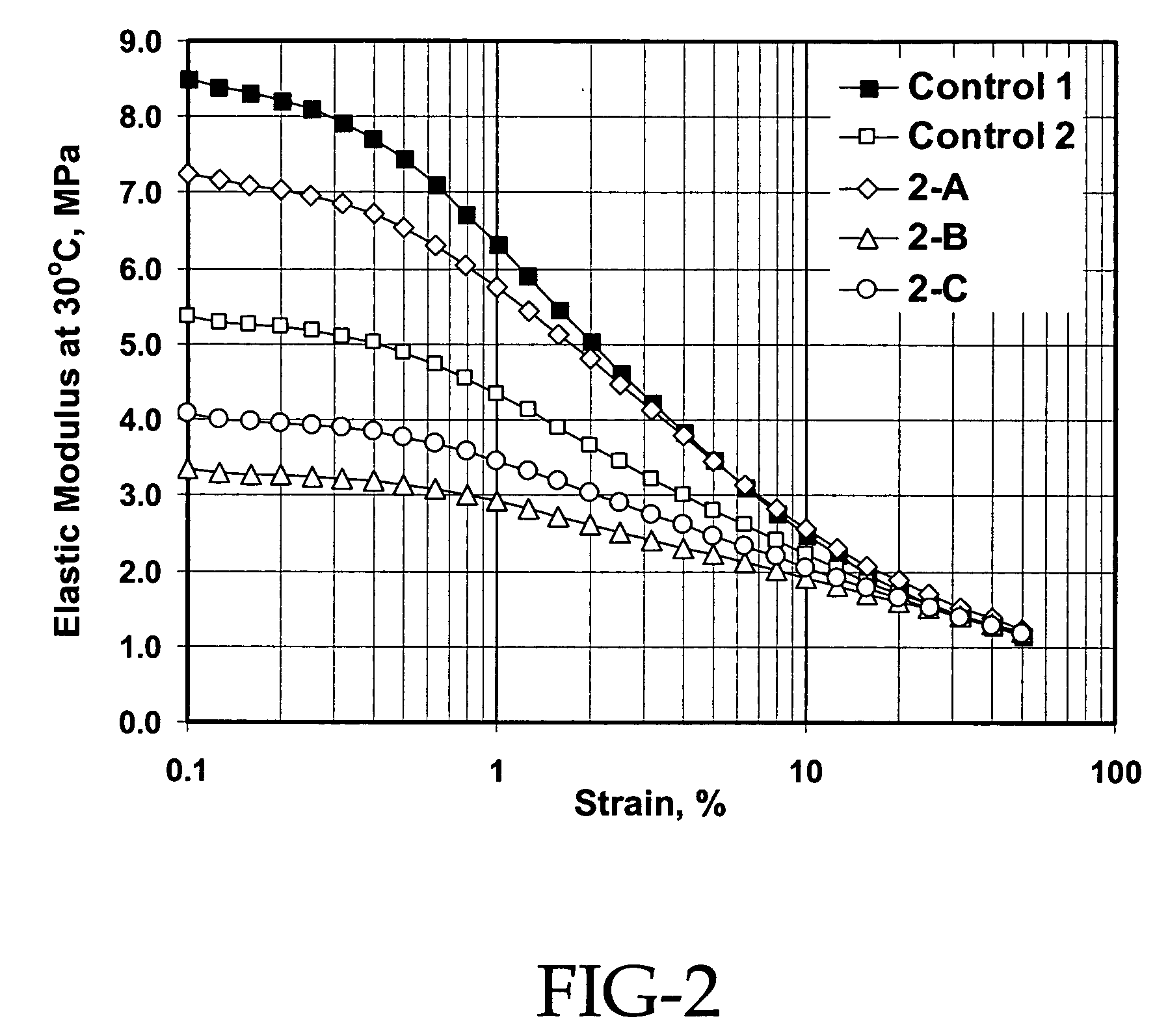

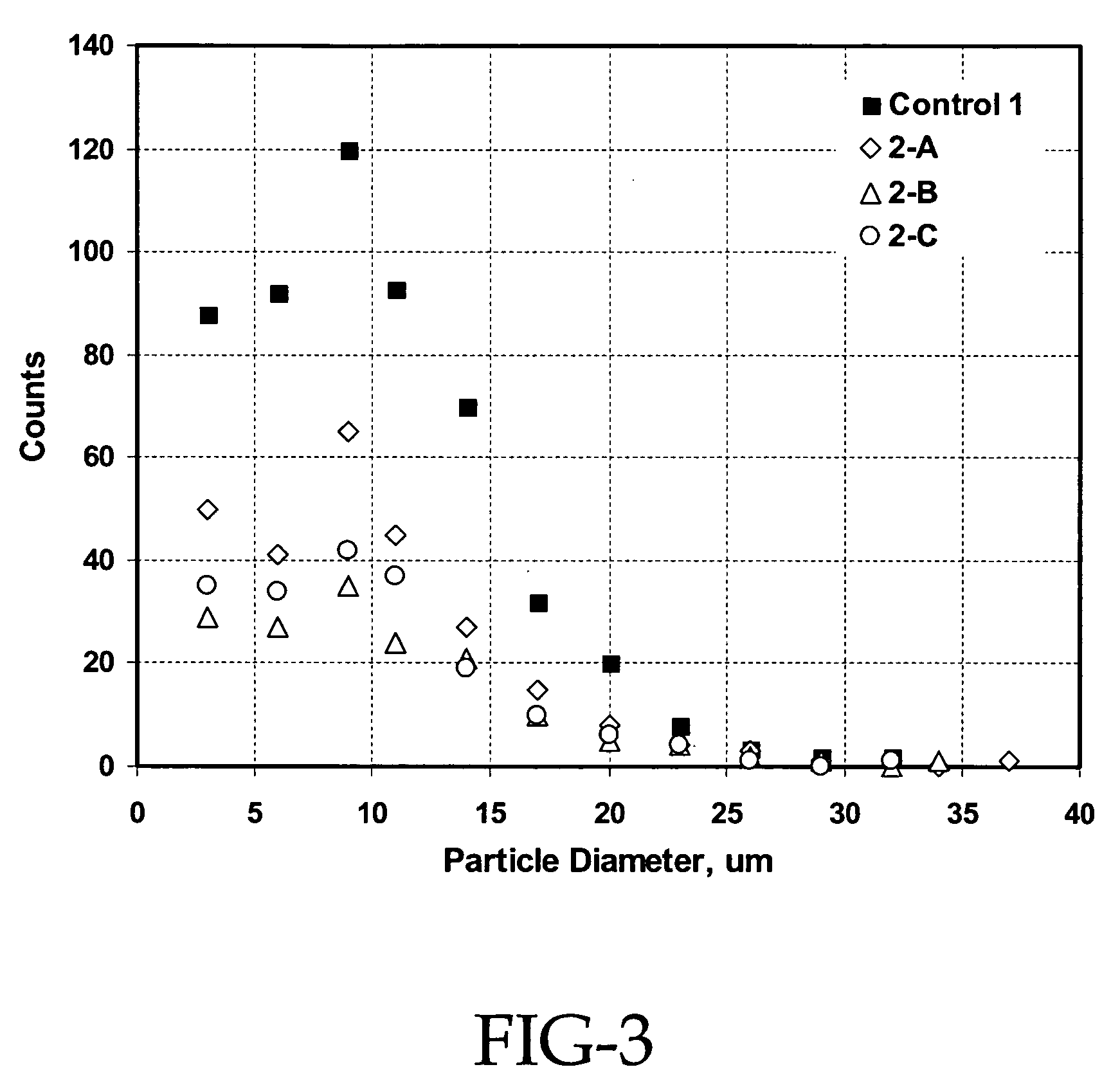

Zinc oxide coated particles, compositions containing the same, and methods for making the same

ActiveUS20070072959A1High modulusHigh tensile strengthInorganic pigment treatmentSynthetic resin layered productsCost savingsZinc

Zinc oxide and / or zinc carbonate coated particles, methods of coating particles with zinc oxide and / or zinc carbonate, and various applications of such coated particles, including applications in cosmetics, rubber, and other polymer materials, are disclosed. As compared to rubber formulations with zinc oxide and core materials added separately, formulations including the present coated particles may have a higher transparency, lower Mooney viscosity and lower minimum torque, improved dispersability, a higher modulus at 100% and / or at 300% elongation, a higher tensile strength, better aging resistance, better abrasion resistance, lower density, and / or lower heat build up. Thus, products containing the present coated particles may enjoy similar or better properties than comparative products that include a conventional filler and / or zinc oxide per se, and the present coated particles may result in cost savings for the corresponding product formulations.

Owner:NIP RAYMOND LEE

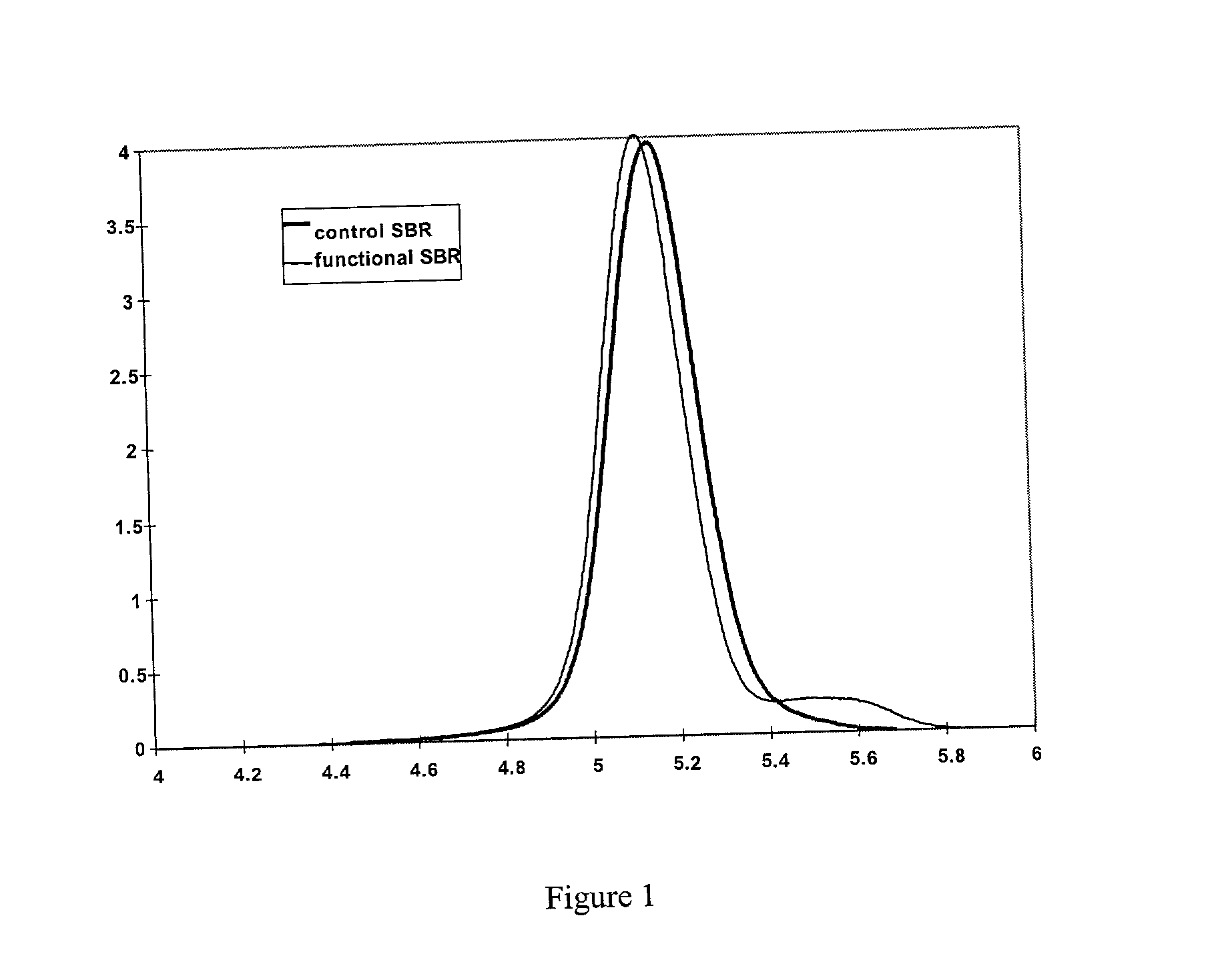

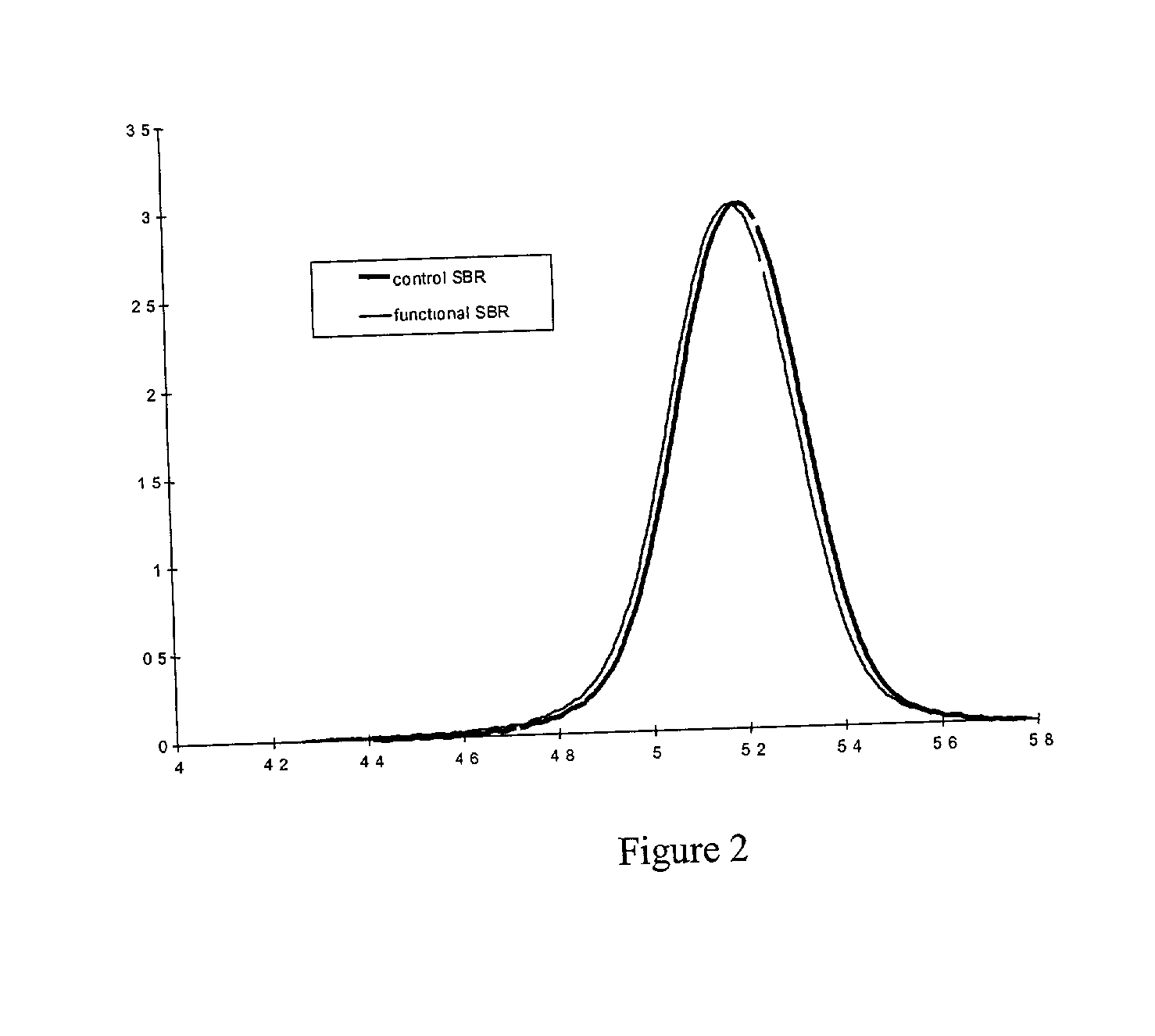

Silica containing rubber composition

InactiveUS20050209370A1Enhanced snow/ice tractionReduce rolling resistanceSpecial tyresOrganic dyesElastomerHydrocarbon solvents

This invention discloses a method for preparing rubber compositions that exhibit unique combinations of properties that are desirable for tire tread applications for enhanced snow / ice and wet traction, low rolling resistance and increased treadwear performance in comparison with conventional silica compounds. Specifically, a high reactively silane coupling agent, such as a mercaptosilane, is used in combination with a silane coupling typically used for silica tread compounds such as bis(triethoxylsilylpropyl)disulfide to treat silica pellets in a hydrocarbon solvent at elevated temperatures. The treated silica is then blended with solution elastomer cement in a hydrocarbon solvent. The deposited reactive silanes partially react with the elastomer molecules forming a layer of polymer grafted on the silica surfaced. This structure significantly improves the silica retention during the steam stripping operation. Almost 100% (99+%) silica retention has been achieved by this invention. After solvent removal from steam stripping, the treated silica / elastomer mixer is dewatered and dried using conventional equipment such as shaker screens, expellers and expanders to form a well-dispersed silica masterbatch. This technique results in silica compounds with excellent silica dispersion and increased filler-polymer interaction, hence enhanced compound performance such as better physical properties, more desirable dynamic properties (low hysteresis at high temperatures and high hysteresis at low temperatures) and increased abrasion resistance.

Owner:THE GOODYEAR TIRE & RUBBER CO

Compounding silica-reinforced rubber with low volatile organic compound (VOC) emission

ActiveUS7799870B2Improve reinforcementGreat tractionSilicon organic compoundsSynthetic resin layered productsPolymer scienceAlkoxy group

Alkoxy-modified silsesquioxane compounds are described. The alkoxy-modified silsesquioxane compounds contain an alkoxysilane group that participates in an alkoxysilane-silica reaction as a silica dispersing agent in rubber, with the release of zero to about 0.1% by weight of the rubber of volatile organic compounds (VOC), especially alcohol, during compounding and further processing. Further described are methods for making alkoxy-modified silsesquioxanes, methods for making vulcanizable rubber compounds containing alkoxy-modified silsesquioxanes, vulcanizable rubber compounds containing alkoxy-modified silsesquioxanes, and pneumatic tires comprising a component that contains alkoxy-modified silsesquioxanes.

Owner:BRIDGESTONE CORP

Omnidirectional exercise platform

ActiveUS20130023391A1Permit some movementEasy to trainMovement coordination devicesMuscle exercising devicesEngineeringMechanical engineering

An omnidirectional exercise platform is disclosed which includes a base member, a pad member and a plurality of ball transfer units. The pad member is coupled to a top surface of the base member. The plurality of ball transfer units is coupled to a bottom surface of the base member. An angular offset is provided between the plurality of ball transfer units to stabilize the omnidirectional exercise platform during use. The ball transfer units each comprise a hemispherical housing, a primary ball member and a plurality of secondary ball members disposed between an inner surface of the hemispherical housing and the primary ball member. The housing further includes an aperture located and sized to facilitate cleaning and maintenance procedures of the ball transfer unit. A handle is releasably coupled to the top surface of the base member to thereby provide a user with a variety of hand placement positions.

Owner:OMNI EXERCISE

Rubber composition for use in tires

ActiveUS20110226395A1Low in roll resistanceHigh wet grip performanceSpecial tyresTyre tread bands/patternsFuel efficiencyViscosity

A rubber composition for use in tires is described which provides increased fuel efficiency and improved wet grip performance. The rubber composition includes from 5 to 70 parts by mass of silica having a BET specific surface area from 50 to 200 m2 / g per 100 parts by mass of a diene rubber. The rubber composition includes from 1 to 25 parts by mass of an aromatic modified terpene resin and at least one terpene per 100 parts by mass of a diene rubber. The rubber composition further includes from 1 to 70 parts by mass of a naphthenic oil per 100 parts by mass of a diene rubber, where a CN % proportion of a CA %·CP %·CN % ratio calculated according to ASTM D2140 / ASTM D3238 is the greatest and the CA % proportion is less than 15%, and a dynamic viscosity at 40° C. is from 17 to 30 mm2 / sec.

Owner:YOKOHAMA RUBBER CO LTD

Natural rubber and method for producing the same, rubber composition and pneumatic tire using the same, modified natural rubber and method for producing the same, and rubber composition for tread or for covering carcass cord and pneumatic tire using the same

InactiveUS20110253285A1Easy to processImprove fuel economySpecial tyresPneumatic tyre reinforcementsEngineeringTread

Owner:SUMITOMO RUBBER IND LTD

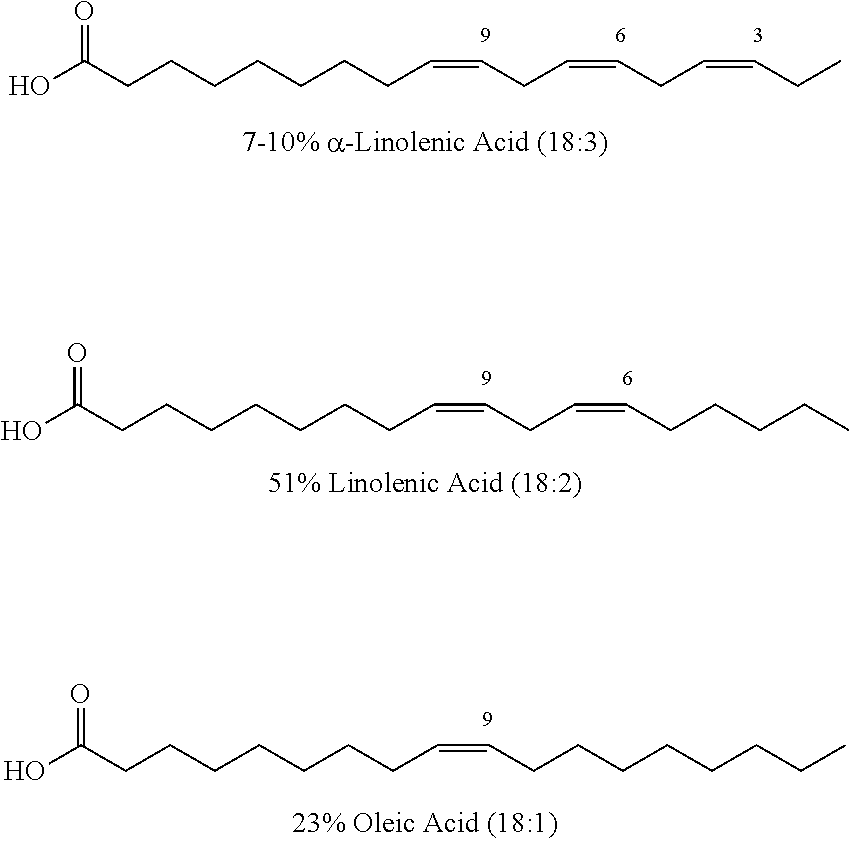

Triglyceride containing solution polymerization prepared styrene/butadiene elastomer and tire with component

InactiveUS20130289183A1High Mooney viscosityHigh molecular weightSpecial tyresInksElastomerTriglyceride

This invention relates to vegetable oil extended rubber containing soy oil and tire with a component of such oil extended rubber.

Owner:KERNS MICHAEL LESTER +3

Diene rubber, process for producing the rubber and rubber composition containing the same

InactiveUS6147178AReduce heat buildupReduce rolling resistanceOrganic-compounds/hydrides/coordination-complexes catalystsSpecial tyresRolling resistancePolymer science

PCT No. PCT / JP97 / 00519 Sec. 371 Date Aug. 24, 1998 Sec. 102(e) Date Aug. 24, 1998 PCT Filed Feb. 24, 1997 PCT Pub. No. WO97 / 31028 PCT Pub. Date Aug. 28, 1997A diene rubber comprised of a conjugated diene homopolymer or a conjugated diene / aromatic vinyl copolymer; the homopolymer or copolymer having on at least one end of its polymer chain a quaternary ammonium group to which four carbon atoms have been bound; at least 10% of the bound conjugated diene units being a vinyl bond; and the homopolymer or copolymer further having a weight average molecular weight (Mw) of 100,000 to 2,000,000. This rubber exhibits well reduced heat build-up, which is an index of a well reduced rolling resistance, and having tensile strength and abrasion resistance.

Owner:ZEON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com