Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

200results about How to "Improve adhesion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

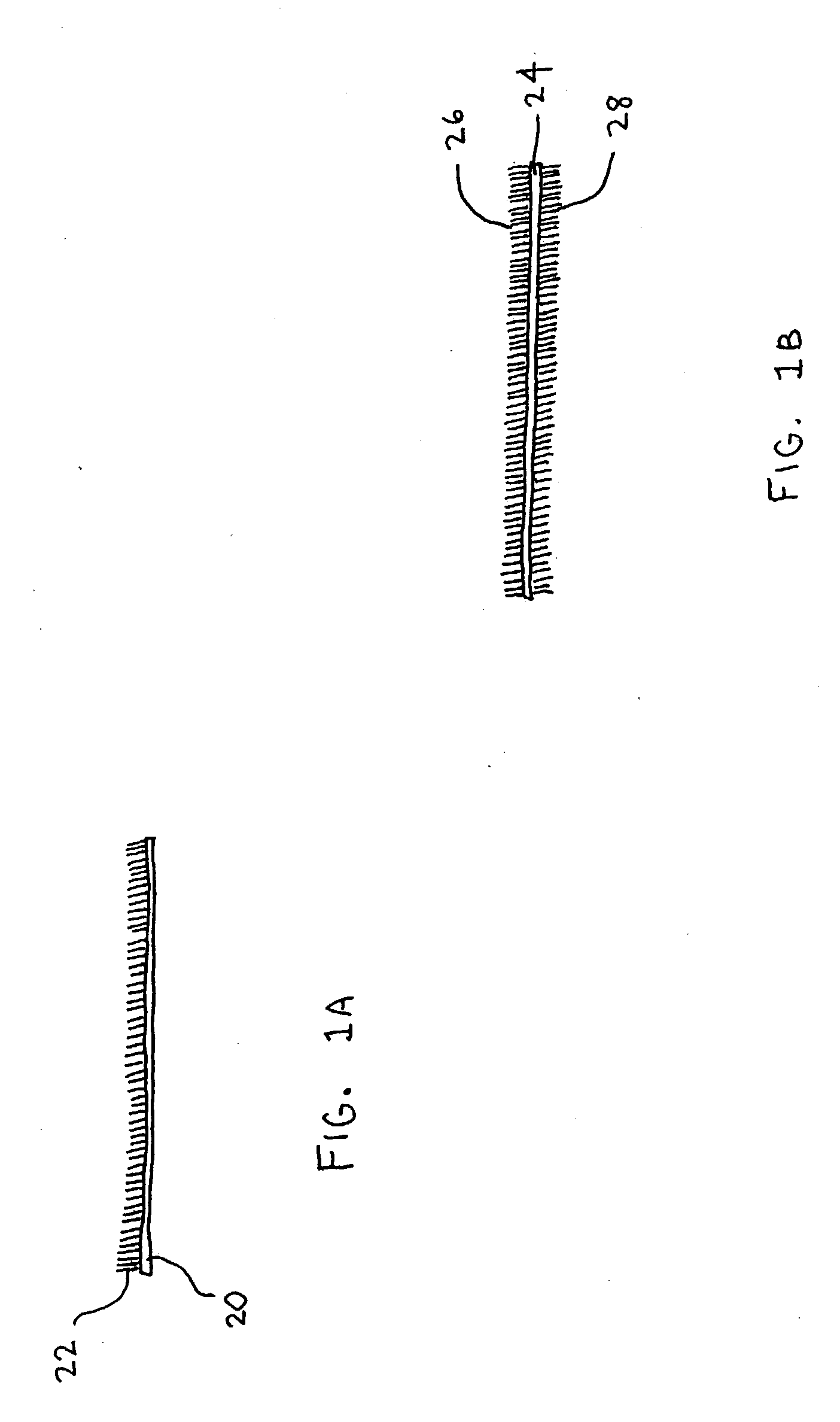

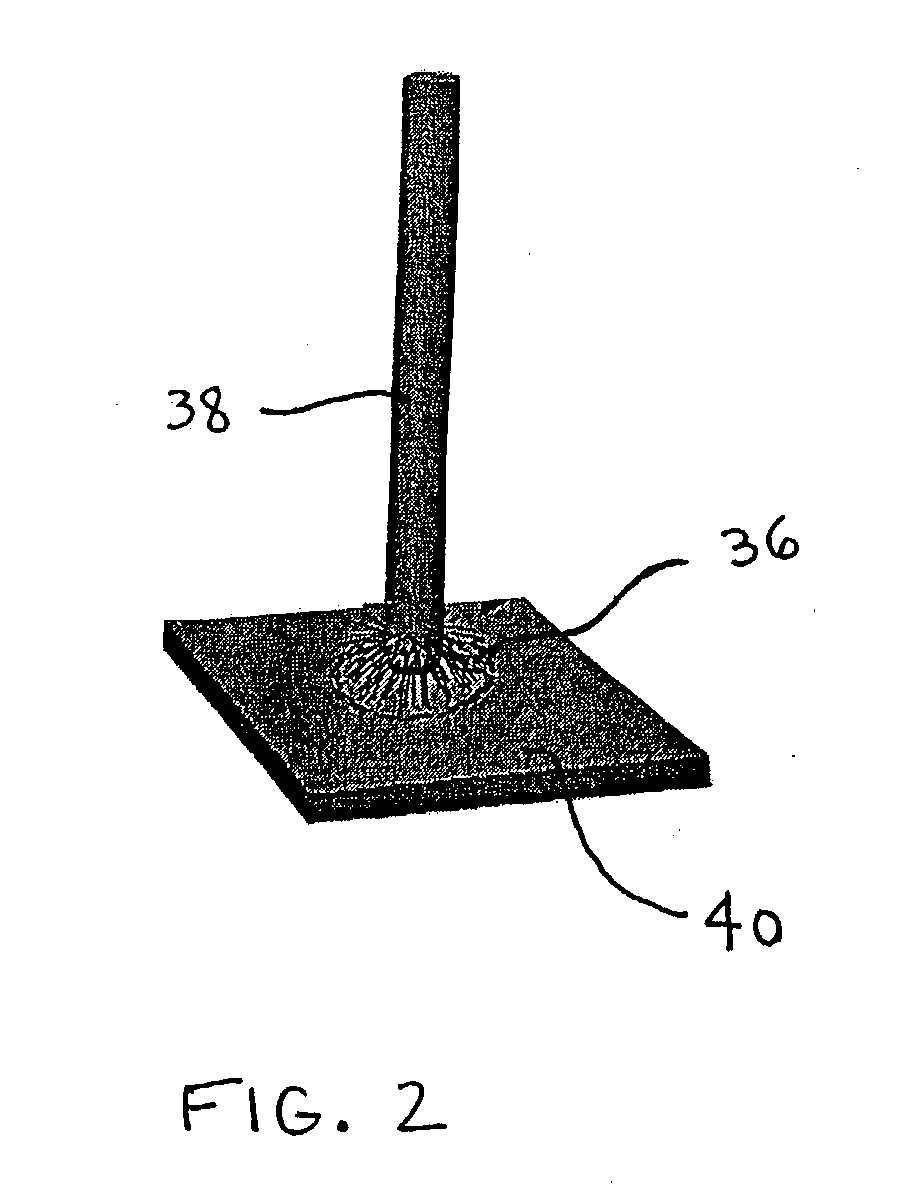

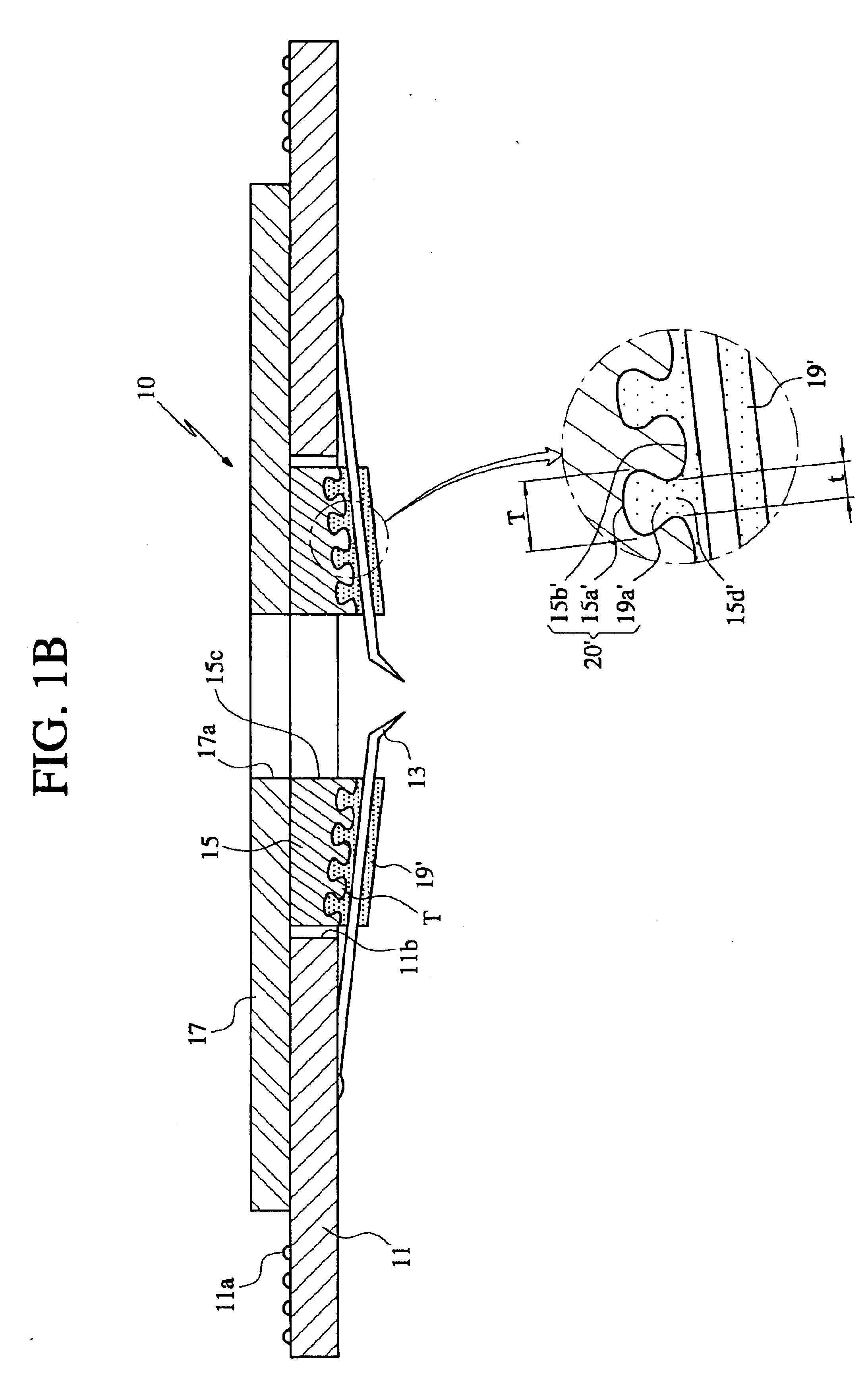

Fiber adhesive material

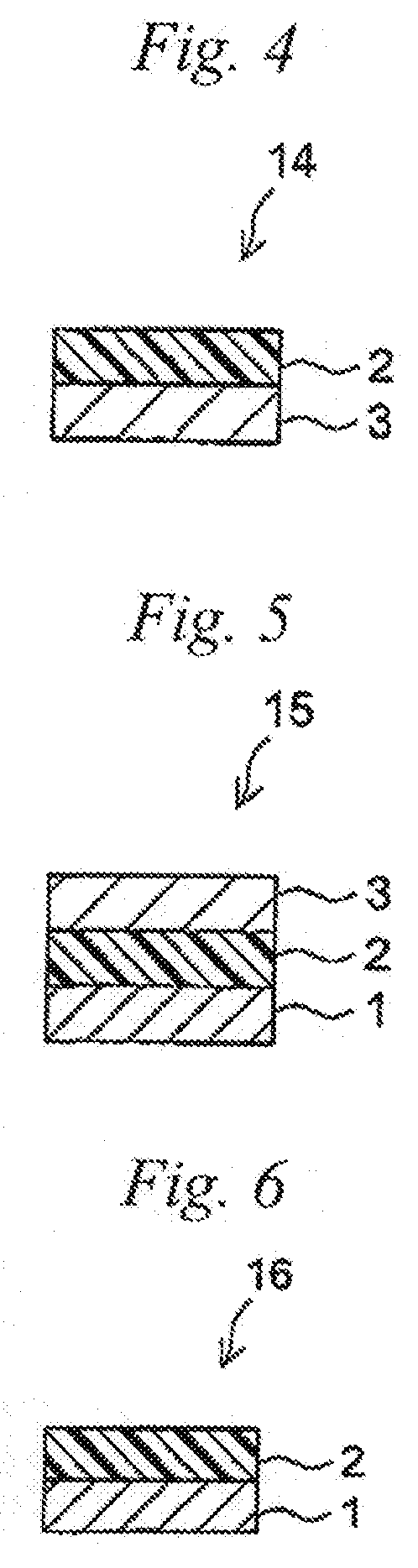

InactiveUS20040071870A1Improve adhesion performanceMaterial nanotechnologySemiconductor/solid-state device detailsDielectricFiber

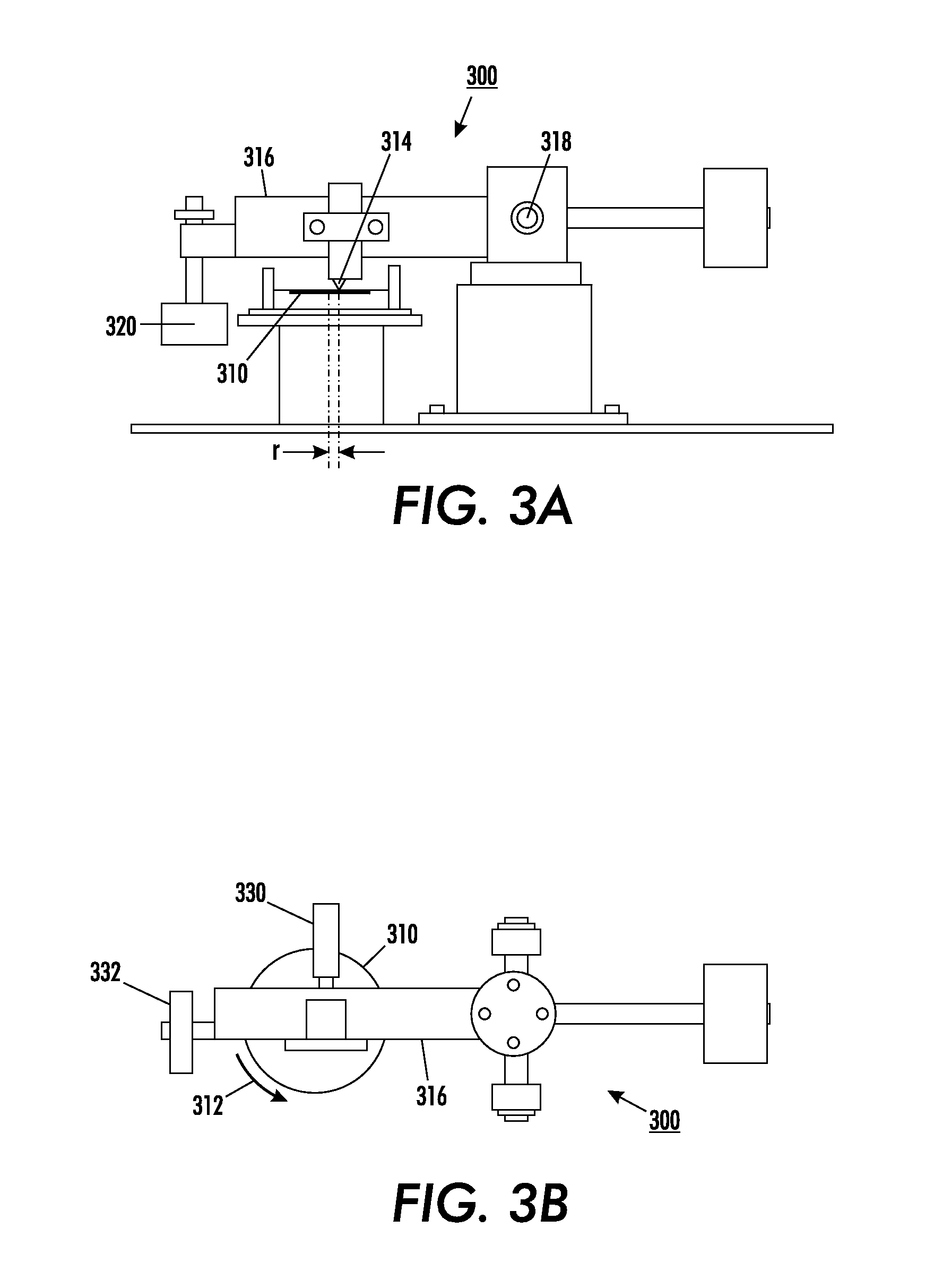

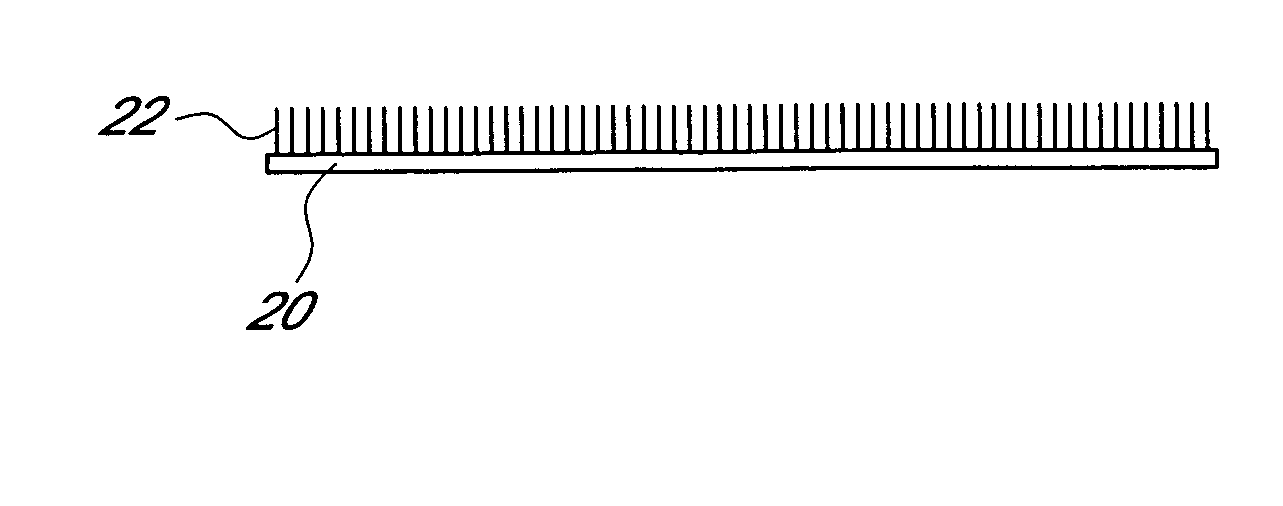

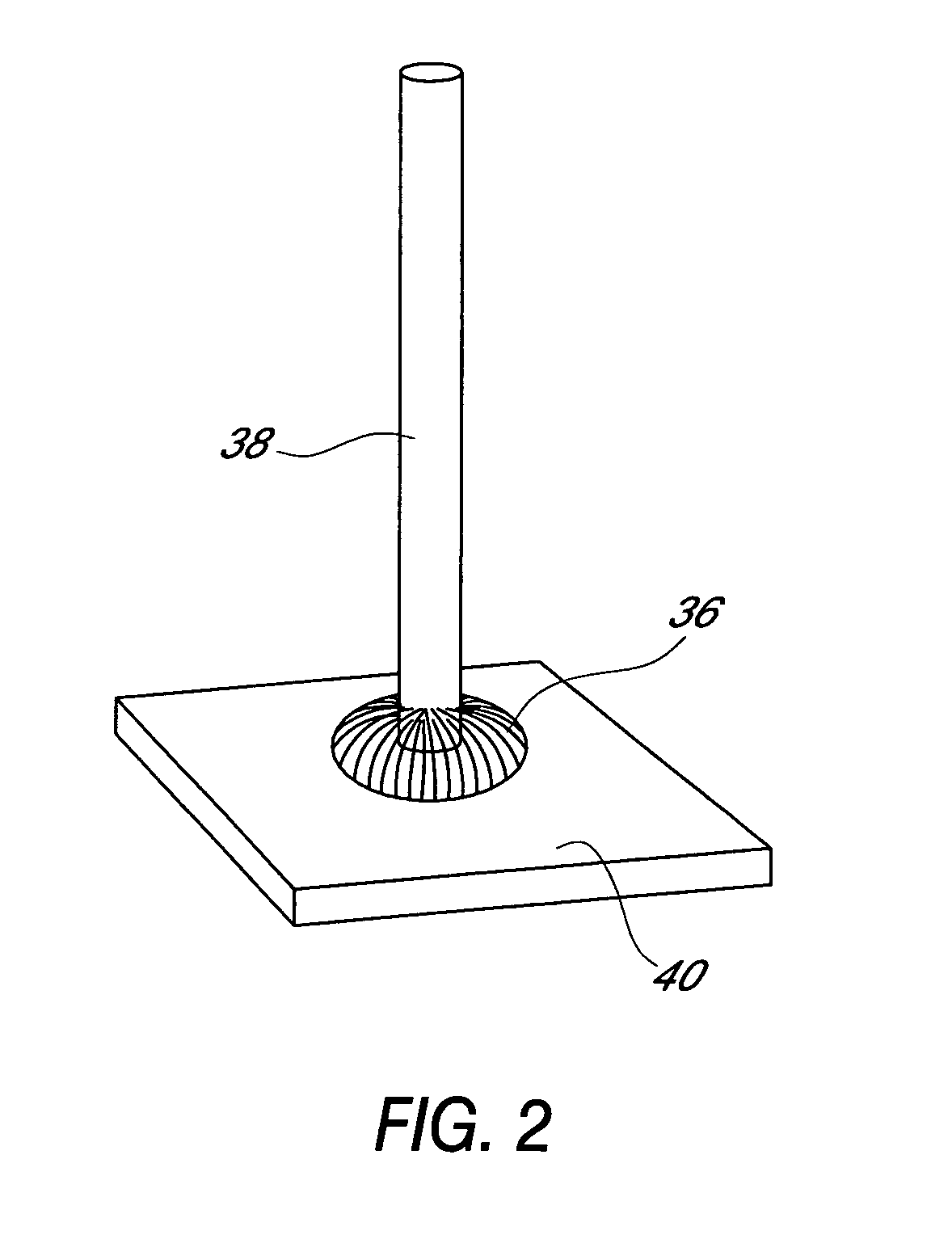

A fiber velvet comprising nano-size fibers or nanofibrils attached to micro-size fibers is disclosed. Methods of manufacturing the velvet as well as various uses of the velvet are also described. For example, the fiber velvet can be used as a thermal interface or as an adhesive material. The nanofibrils may be attached to a flat base or membrane, or may be attached to the tip portions of the micro-size or larger diameter fibers. Various attributes of the micro-size fibers and of the nano-size fibers, for example, geometry (e.g. size, length, packing density) material type (e.g. carbon, metal, polymer, or ceramic) and properties (e.g. conductivity, modulus, surface energy, dielectric constant, surface roughness) can be selected depending on the desired attributes of the fiber velvet. The nanofibrils have a diameter of less than about 1 micron, and may advantageously be formed from single walled and / or multi-walled carbon nanotubes.

Owner:KULR TECH

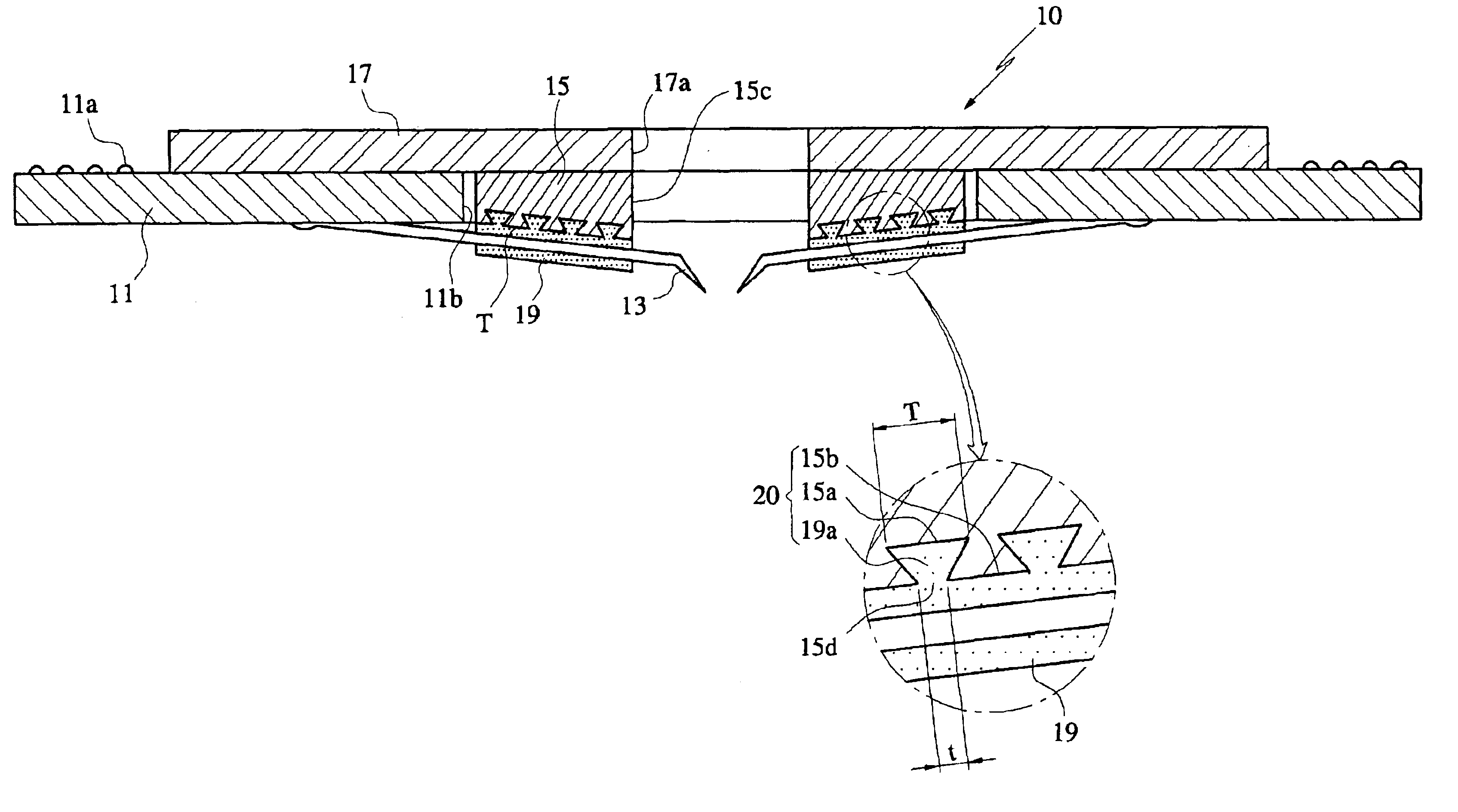

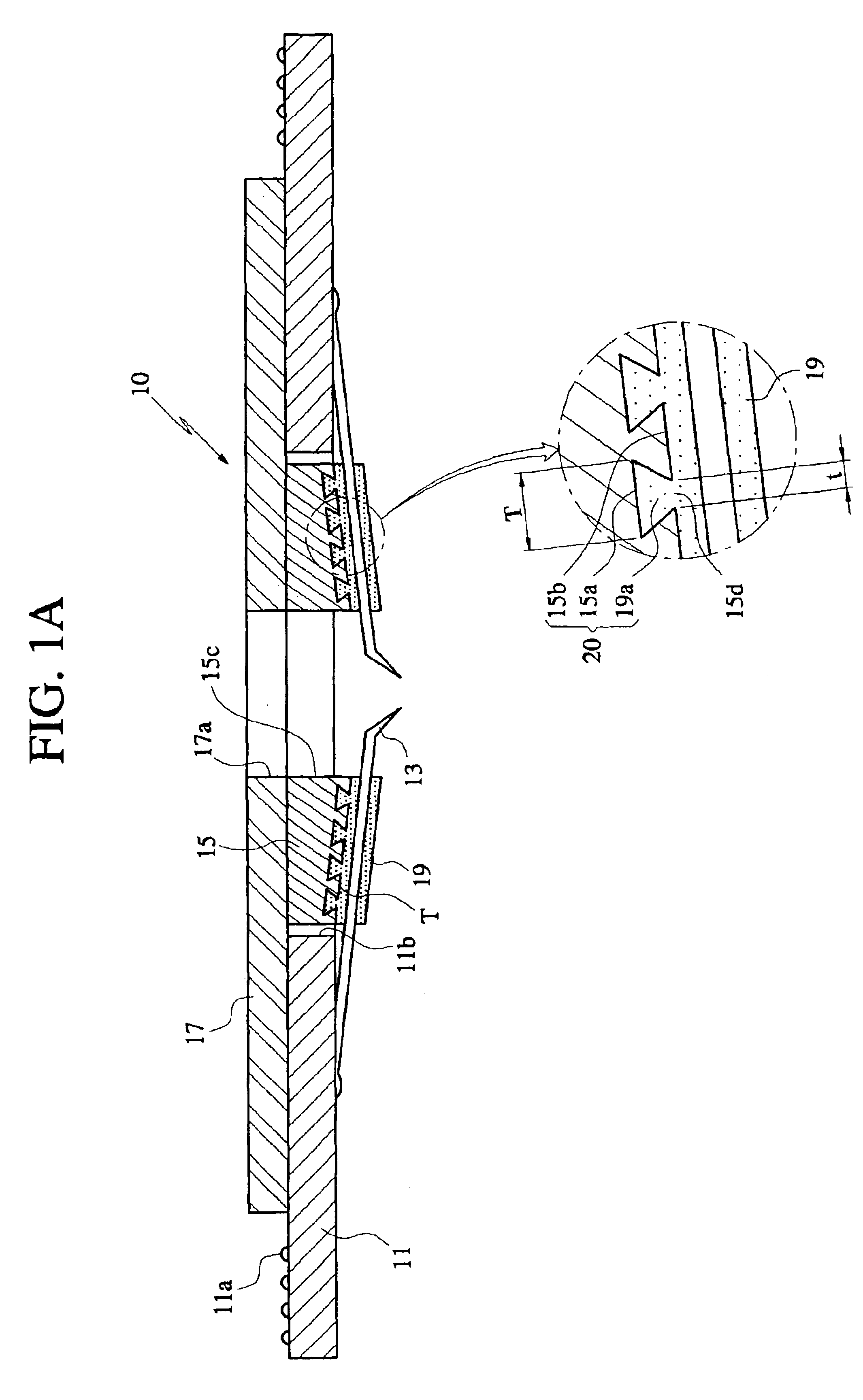

Needle fixture of a probe card in semiconductor inspection equipment and needle fixing method thereof

InactiveUS6900653B2Improve adhesion performanceAvoid crackingSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardAdhesive

A needle fixture of a probe card and a needle fixing method in semiconductor inspection equipment include a needle fixture of a probe card in semiconductor inspection equipment including a printed circuit board; a needle fixture installed in the printed circuit board; a resin unit affixing a probe needle to the needle fixture using an adhesive; and a separation preventer for preventing separation of the resin unit from the needle fixture, wherein the separation preventer includes: a plurality of notches formed along a bottom surface of the needle fixture; and the adhesive filling the plurality of notches.

Owner:SAMSUNG ELECTRONICS CO LTD

Polymeric adhesive including nanoparticle filler

InactiveUS20080249221A1Increase potential for homogeneous dispersionReduce load levelMaterial nanotechnologyNon-macromolecular adhesive additivesHalloysiteAdhesive

Disclosed is a novel polymeric nanoparticle adhesive composite including a nanoparticle filler and method for the production thereof. More particularly, the disclosure describes the use of nanoparticle fillers, including a novel halloysite nanoparticle filler which utilizes generally cylindrical or tubular nanoparticles (e.g. rolled scroll-like shape). The filler is effectively employed in a polymer nanoparticle adhesive composite, containing the halloysite nanoparticle or other equivalent naturally occurring nanotubular filler, in which the advantages of the nanoparticle filler are provided (e.g., reinforcement, flame retardant, etc.) while maintaining or improving mechanical performance of the adhesive composite (e.g., adhesive strength and tack)

Owner:NATURALNANO RES

Fiber adhesive material

InactiveUS20060213599A1Improve adhesion performanceMaterial nanotechnologySemiconductor/solid-state device detailsFiberDielectric

A fiber velvet comprising nano-size fibers or nanofibrils attached to micro-size fibers is disclosed. Methods of manufacturing the velvet as well as various uses of the velvet are also described. For example, the fiber velvet can be used as a thermal interface or as an adhesive material. The nanofibrils may be attached to a flat base or membrane, or may be attached to the tip portions of the micro-size or larger diameter fibers. Various attributes of the micro-size fibers and of the nano-size fibers, for example, geometry (e.g. size, length, packing density) material type (e.g. carbon, metal, polymer, or ceramic) and properties (e.g. conductivity, modulus, surface energy, dielectric constant, surface roughness) can be selected depending on the desired attributes of the fiber velvet. The nanofibrils have a diameter of less than about 1 micron, and may advantageously be formed from single walled and / or multi-walled carbon nanotubes.

Owner:KNOWLES TIMOTHY R +1

Water borne epoxy intermediate paint

ActiveCN102093805AImprove mechanical propertiesImprove salt spray resistanceEpoxy resin coatingsEpoxyCompound a

The invention discloses water borne epoxy intermediate paint. The intermediate paint comprises a component A and a component B, and the weight ratio of the component A to the component B is between 0.5 and 10, wherein the component A comprises the following ingredients in percentage by weight: 23-55 percent of water borne epoxy resin curing agent, 0.1-1 percent of wetting dispersant, 1-5 percent of antirust pigment, 5-10 percent of tinting pigment, 1-5 percent of filler, 1-2 percent of film forming auxiliary, 0.1-1 percent of defoaming agent, 0.1-0.5 percent of flatting agent, 0.01-0.5 percent of antiseptic, 0.5-2 percent of rust inhibitor, 0.01-0.1 percent of rheology modifier and 36.09-49.9 percent of softened water; and the component B comprises the following ingredients in percentage by weight: 10-30 percent of self-emulsified water borne epoxy resin and 70-90 percent of softened water. By compounding a self-emulsified epoxy resin emulsion and a self-emulsified water borne epoxy resin curing agent, the mechanical performance and the salt mist resistance of the paint can be improved, and the environmentally friendly requirement can be fulfilled.

Owner:武汉海源九天新材料有限公司 +2

High-performance and single-component white waterborne adhesion primer and preparation method thereof

ActiveCN105505166AImprove adhesionGood strength and flexibilityPolyurea/polyurethane coatingsOrganosolvAcrylic acid

The invention belongs to the field of coatings and particularly relates to single-component white waterborne adhesion primer and a preparation method thereof. The high-performance and single-component white waterborne adhesion primer comprises a part A and water, wherein the part A comprises components in percentage by weight as follows: 25%-30% of waterborne single-component polyurethane, 8%-10% of a waterborne acrylic emulsion, 5%-10% of waterborne silica sol, 0.5%-1.0% of an adhesion promoter, 3.9%-6.3% of a function auxiliary, 31%-45% of filler and 10%-15% of water. The problems of hot sticking, cold shortness, high probability of cracking through thick coating and difficulty in adhesion of an oily substrate of conventional single-component white primer are solved, and the high-performance and single-component white waterborne adhesion primer contains few volatile organic solvents and meets the environment-friendly requirement.

Owner:AODA KOALA PAINT HUIZHOU

Torpedo can spouting material and spouting method thereof

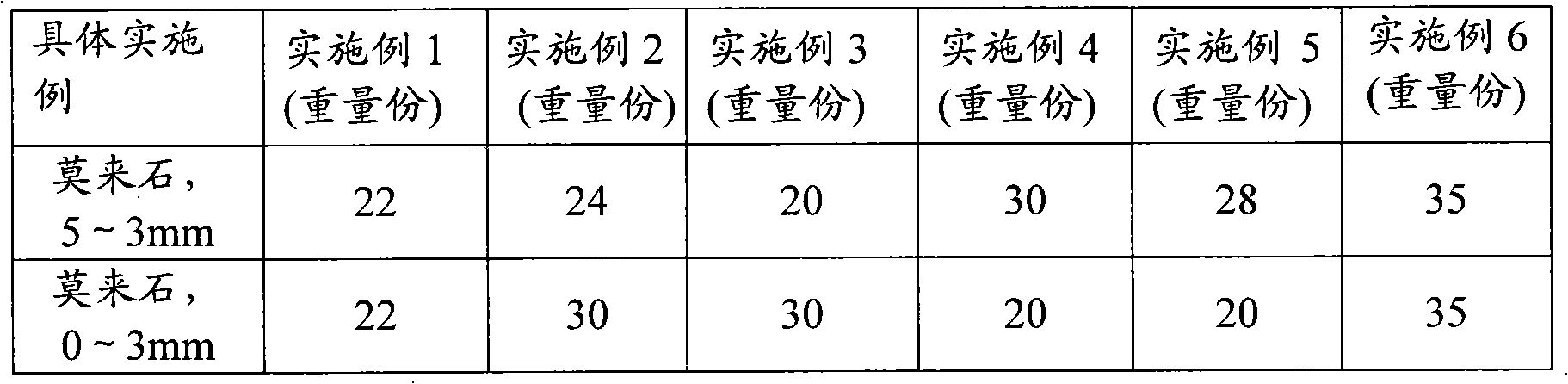

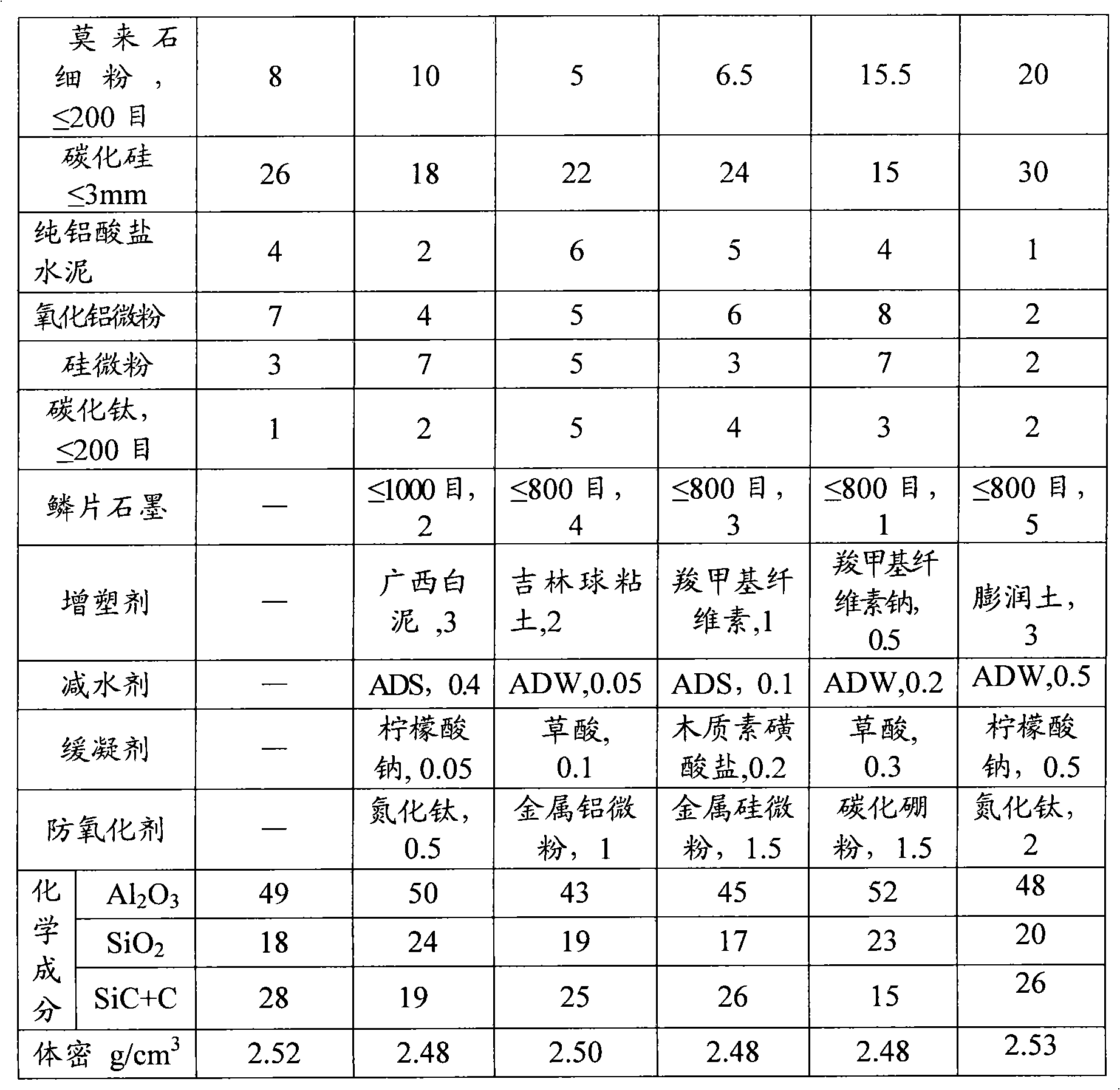

ActiveCN102040386AImprove adhesion performanceImproved density and plasticityMelt-holding vesselsTitanium carbideChemical composition

The invention provides a torpedo can spouting material and a spouting method thereof. The torpedo can spouting material comprises the following components in parts by weight: 20-35 parts of mullite particles with the particle size of 3-5mm, 20-35 parts of mullite particles with the particle size of 0-3mm, 5-20 parts of mullite fine powder not greater than 200 meshes, 15-30 parts of silicon carbide with the particle size not greater than 3mm, 1-6 parts of pure aluminate cement, 2-8 parts of aluminum oxide micro powder not greater than 320 meshes, 2-7 parts of silicon micro powder and 1-5 parts of titanium carbide not greater than 200 meshes; and the torpedo can spouting material mainly comprises the following chemical components in percentage by weight: 40-65% of Al2O3, 15-25% of SiO2 and 15-30% of SiC+C. The invention also further provides the spouting method of the spouting material. The torpedo can spouting material provided by the invention has favorable corrosive resistance and antioxidation.

Owner:PUYANG REFRACTORIES GRP CO LTD

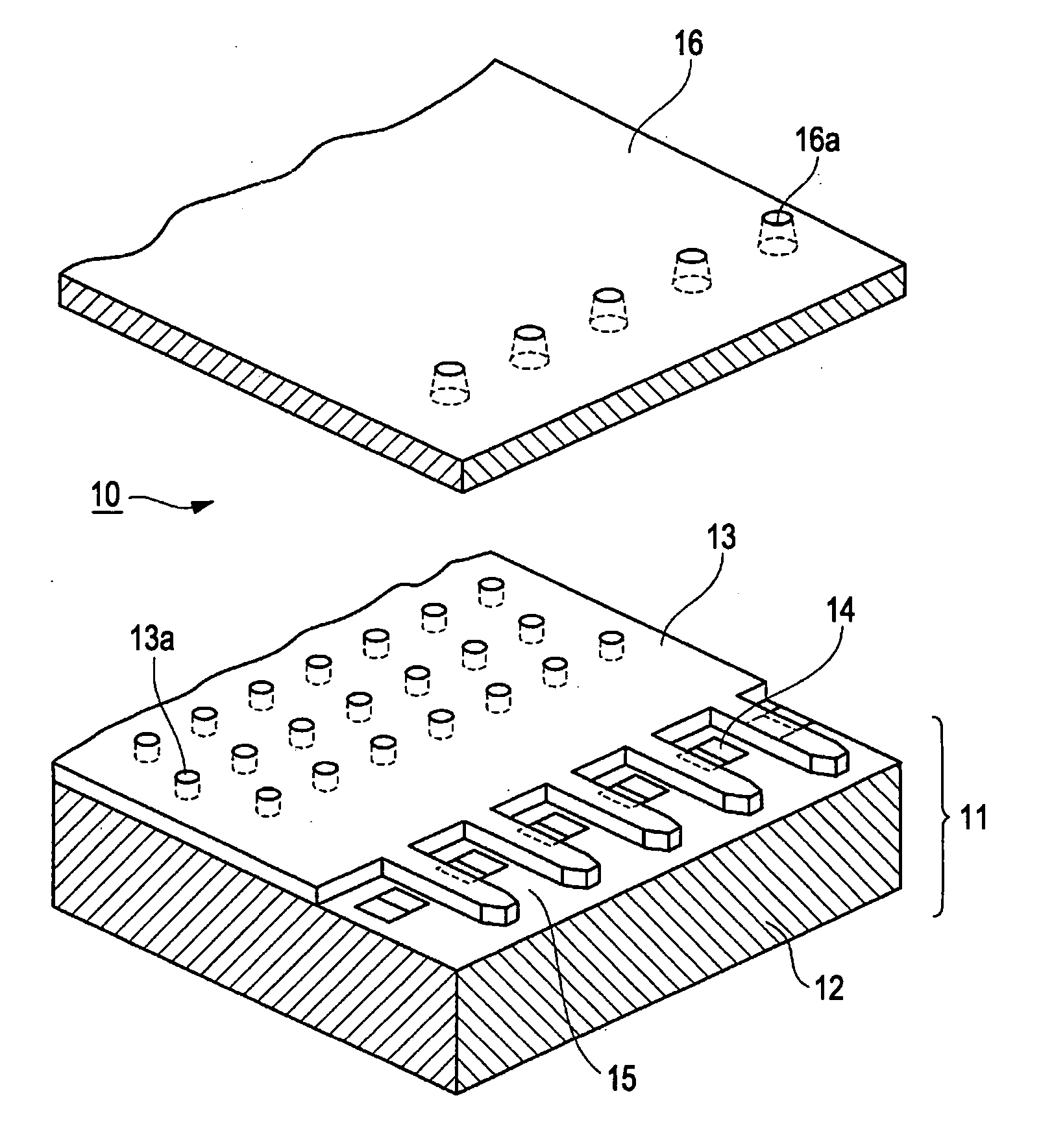

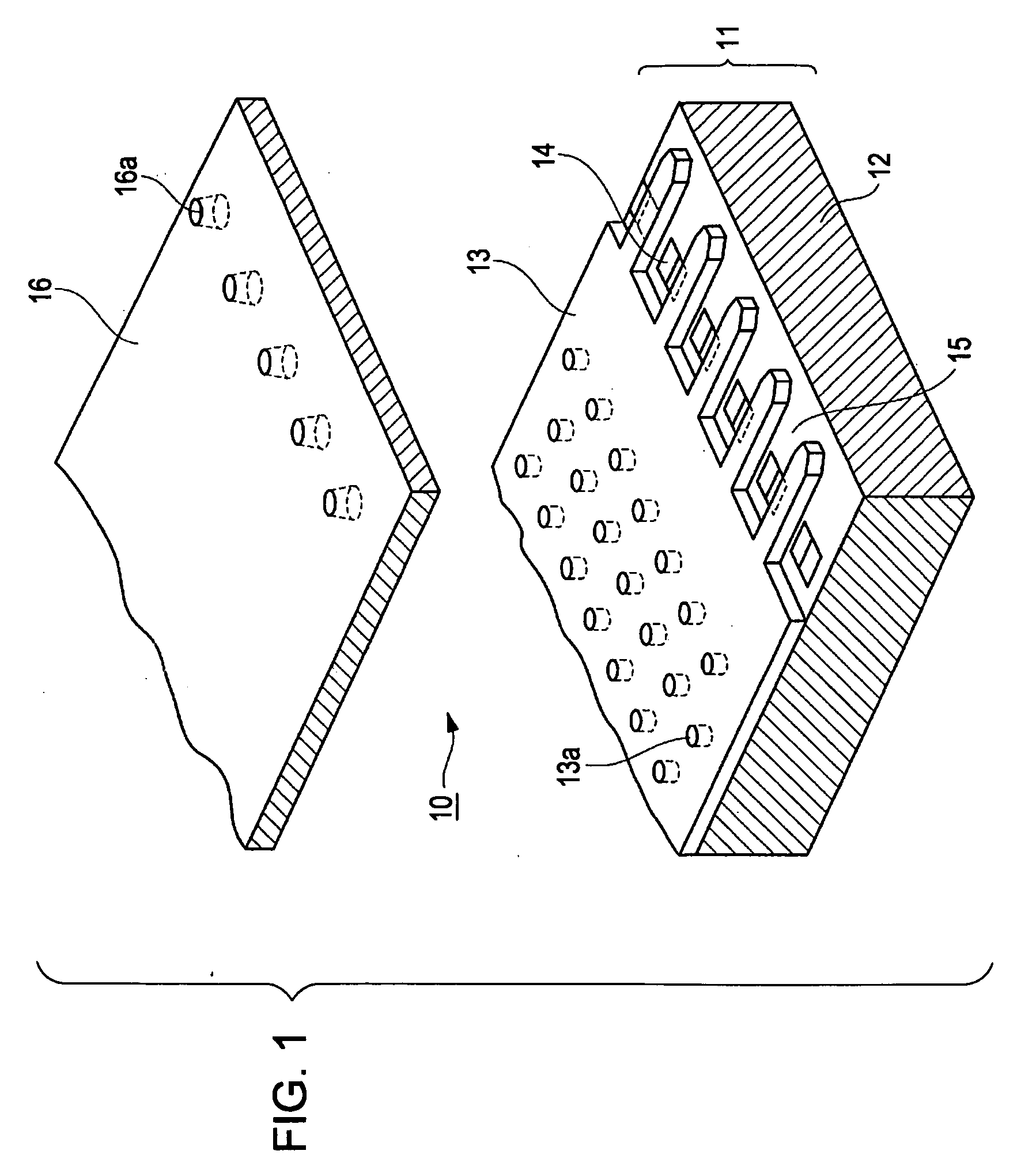

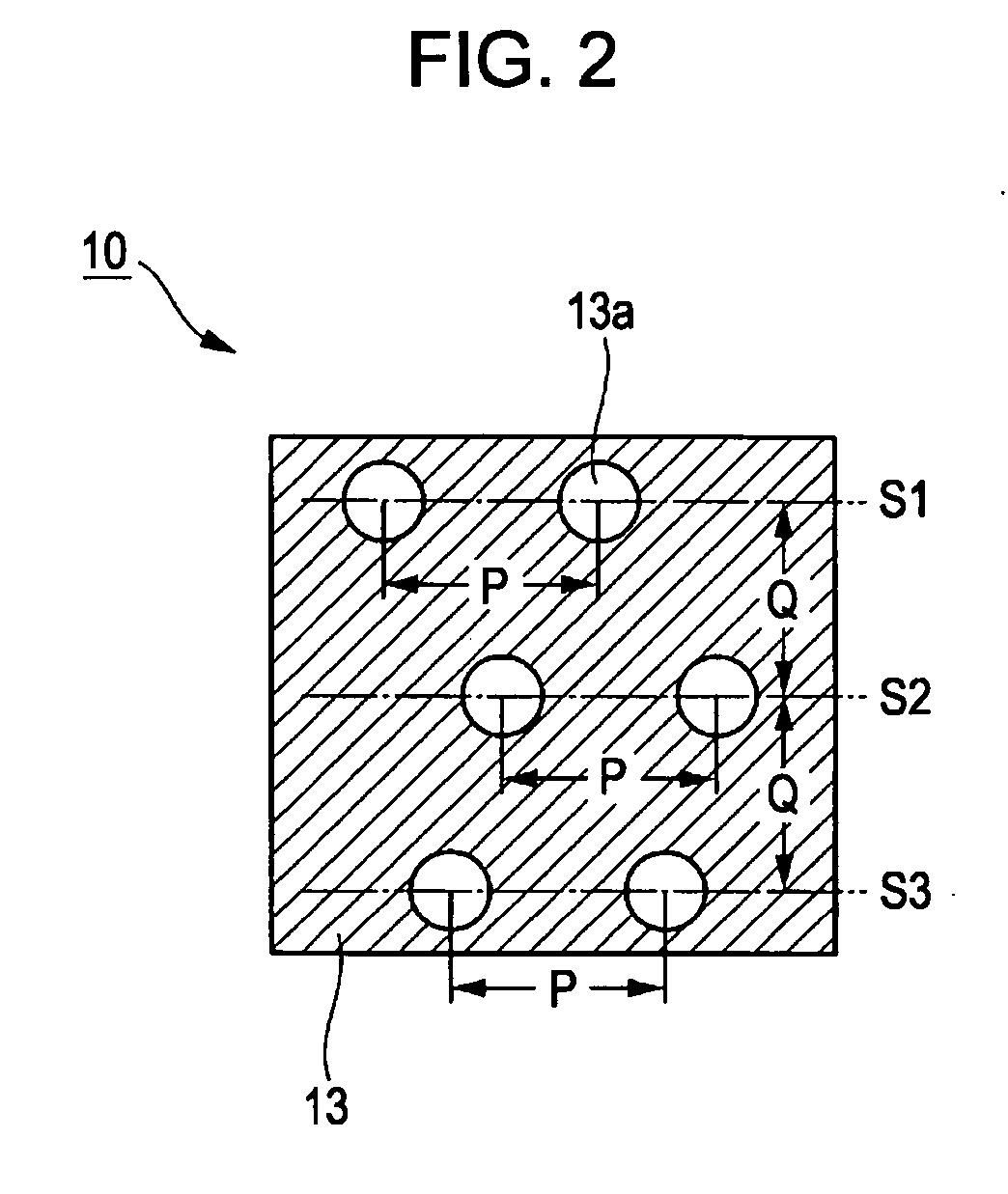

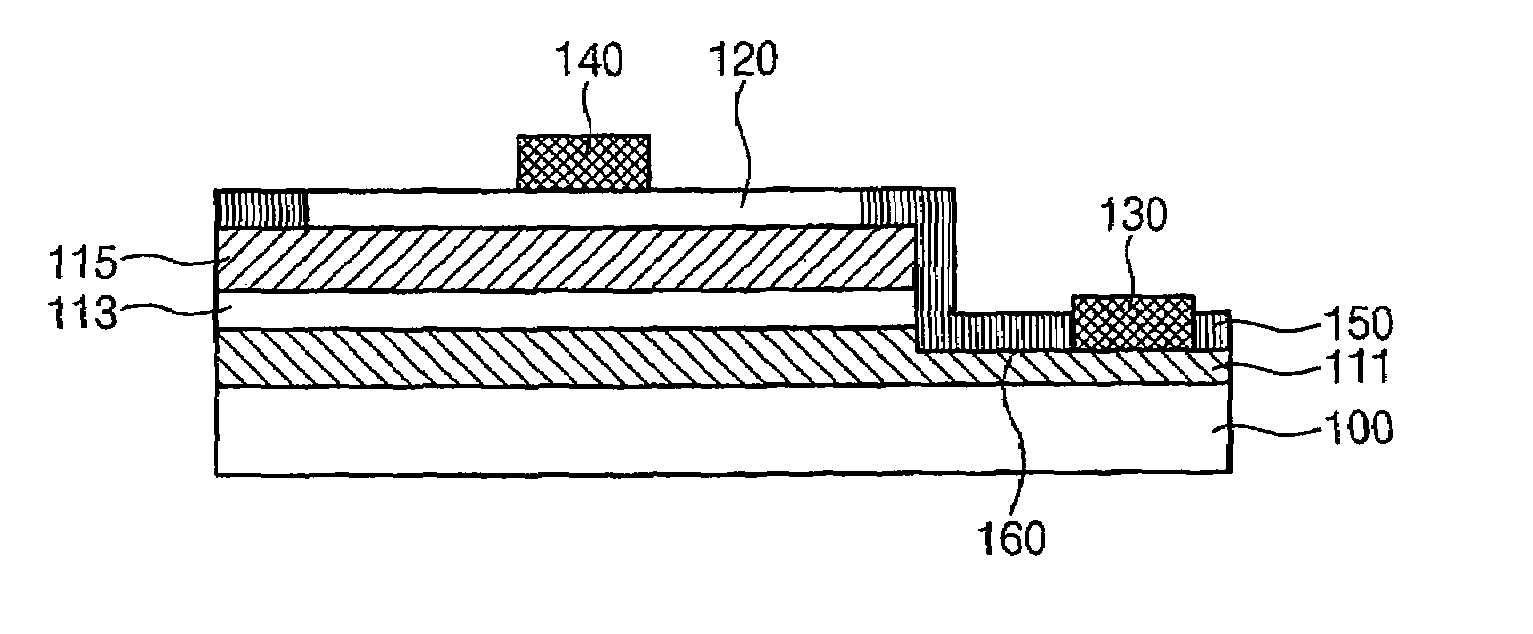

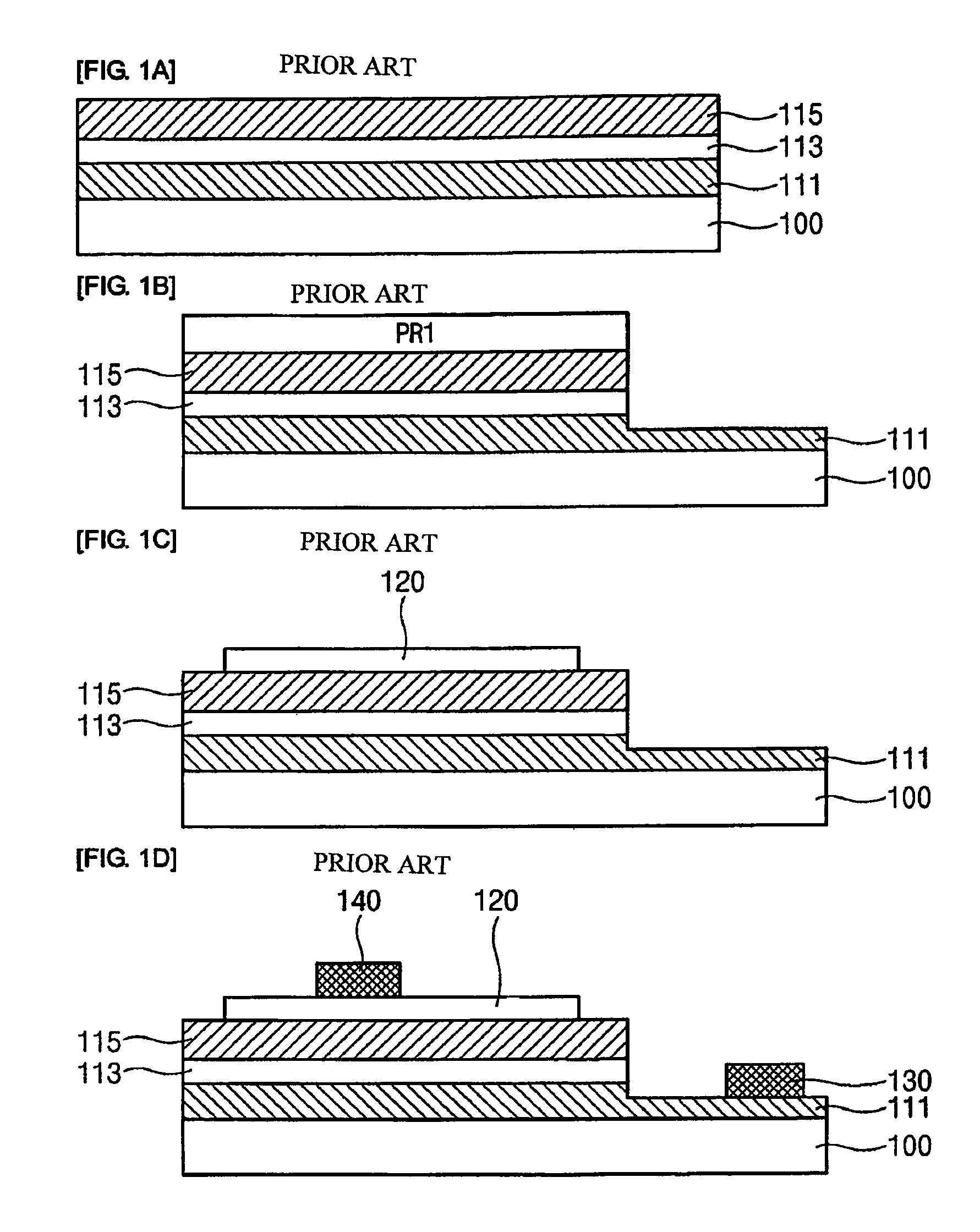

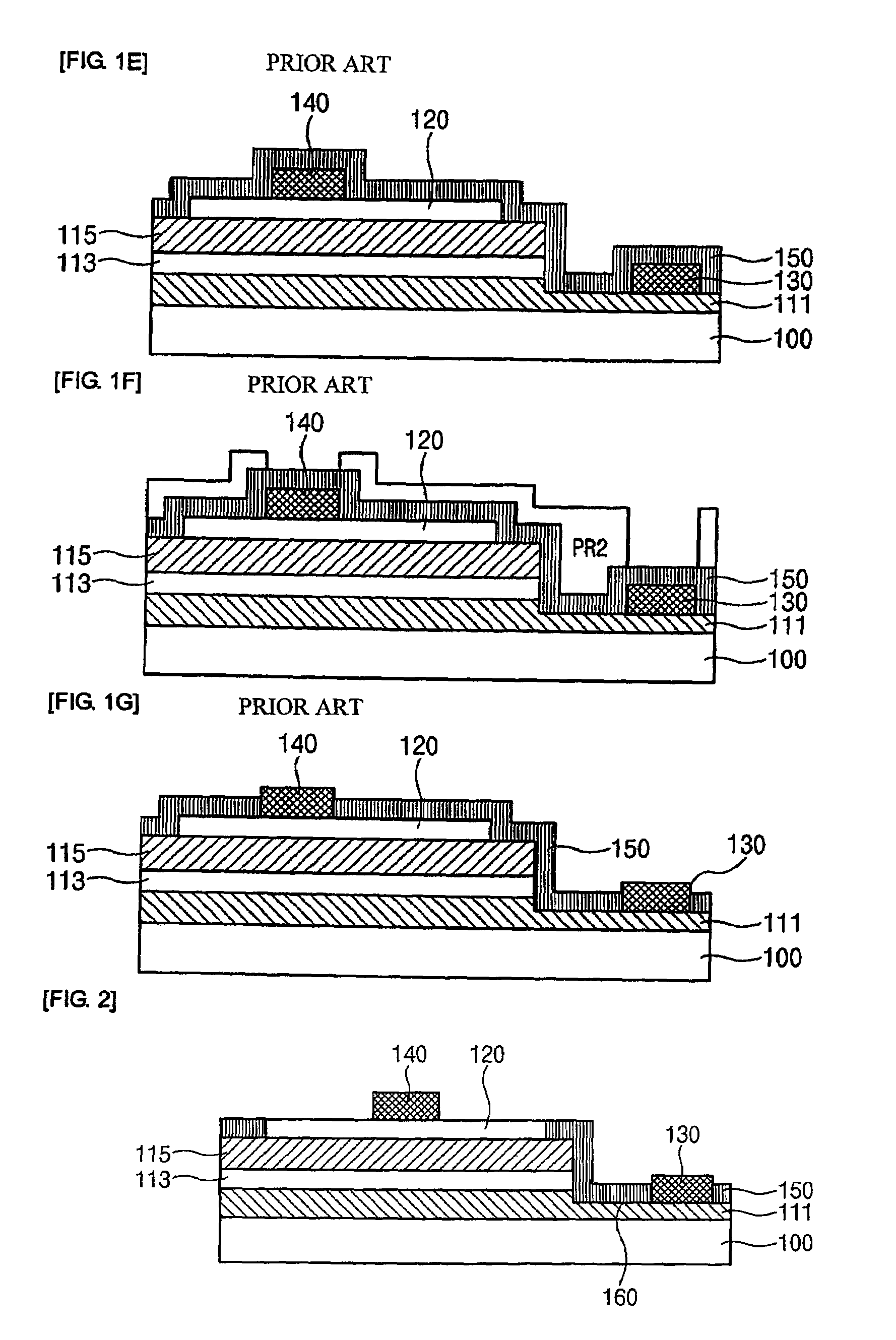

Liquid ejection head, liquid ejection apparatus, and manufacturing method of liquid ejection head

InactiveUS20060283974A1Improve image qualityIncrease production capacityMovable spraying apparatusSpray nozzlesEngineeringSemiconductor

A liquid ejection head includes an energy-generating element arranged on a semiconductor substrate, a barrier layer deposited on the semiconductor substrate for forming a liquid chamber in the periphery of the energy-generating element, and a nozzle sheet bonded on the barrier layer and having a nozzle formed at a position opposing the energy-generating element, in which the liquid ejection head ejects liquid contained in the liquid chamber from the nozzle as liquid droplets by the energy-generating element, and the barrier layer is provided with a plurality of depressions, each having an independent contour, arranged within a range, which is separated from the border of the barrier layer, on an adhesive region adhering to the nozzle sheet.

Owner:SONY CORP

Dental Compositions with Surface-Treated Filler for Shelf Stability

ActiveUS20080293846A1Simple methodImprove adhesion performanceImpression capsDentistry preparationsStrong acidsSurface preparation

The invention features dental compositions containing a basic filler that has been surface-treated with a strong acid to increase the shelf life of the composition.

Owner:3M INNOVATIVE PROPERTIES CO

Gallium nitride based light emitting diode

ActiveUS7687821B2Avoid stickingSimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingTectorial membraneGallium nitride

Owner:SAMSUNG ELECTRONICS CO LTD

Alkyl lubricating grease used for surface protection of steel wire rope and preparation method thereof

InactiveCN102994198AImprove adhesion performanceGood anti-corrosion performanceLubricant compositionAmmonium polyphosphatePetroleum

The invention relates to alkyl lubricating grease used for surface protection of a steel wire rope and a preparation method thereof. The alkyl lubricating grease comprises the following components by weight: 52.0-78.0% of base oil, 10.0-35.0% of microcrystalline wax, 8.0-30.0% of thickener, 0.25-0.6% of alkyl diphenylamine, 1.5-3.0% of petroleum barium sulfonate and 1.5%-3.0% of lanolin calcium soap. The sum of the weight percentages is 100%. The moving viscosity of the base oil under 100 DEG C is 10.0-40.0 mm2 / s, the thickener is ammonium polyphosphate (APP) or amorphous poly alpha olefin (APAO), and the dropping melting point of the microcrystalline wax is 65-85 DEG C. The APP or the APAO is utilized as the thickener, dropping point of the alkyl lubricating grease is improved, adhesion performance of the alkyl lubricating grease is improved, and antirust performance and anti-corrosion performance of the alkyl lubricating grease are excellent.

Owner:天津市津冠润滑脂有限公司

Olefin polymer, composition thereof and adhesive resin comprising the composition

InactiveUS20090280318A1Improve adhesion performanceMonocarboxylic acid ester polymer adhesivesSynthetic resin layered productsPolymer scienceAddition polymer

Provided is a new adhesive polyolefin resin composition, containing 1 to 100% by weight of a high polymer structure, that has good heat resistance and excellent adhesion performance to polyolefins and various polar materials, wherein a polyolefin segment (A) is bonded with an addition polymer segment (B) of a non-olefinic vinyl monomer and a reactive group is introduced into the addition polymer segment (B) and an adhesive or dispersion obtained therefrom.

Owner:MITSUI CHEM INC

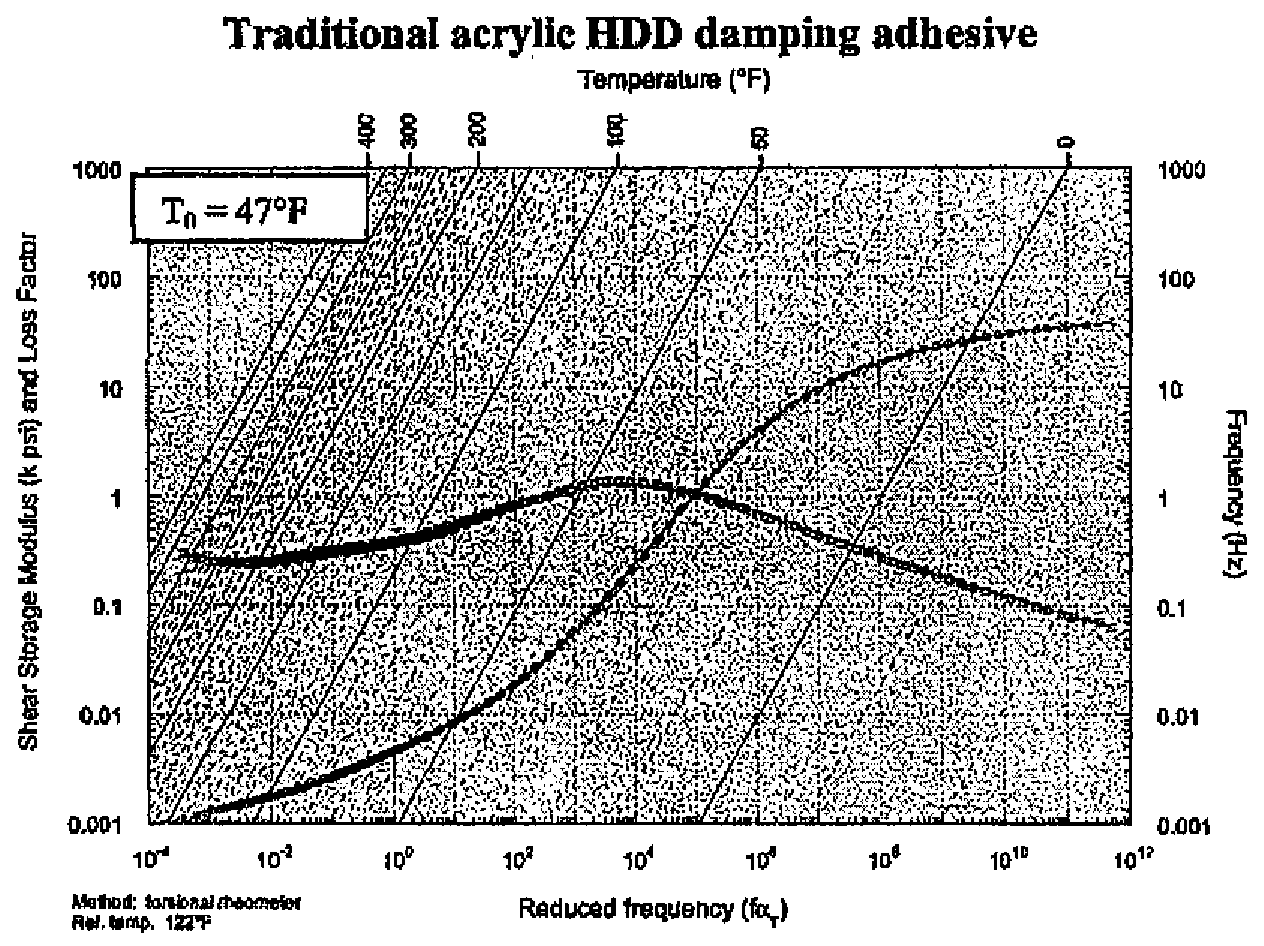

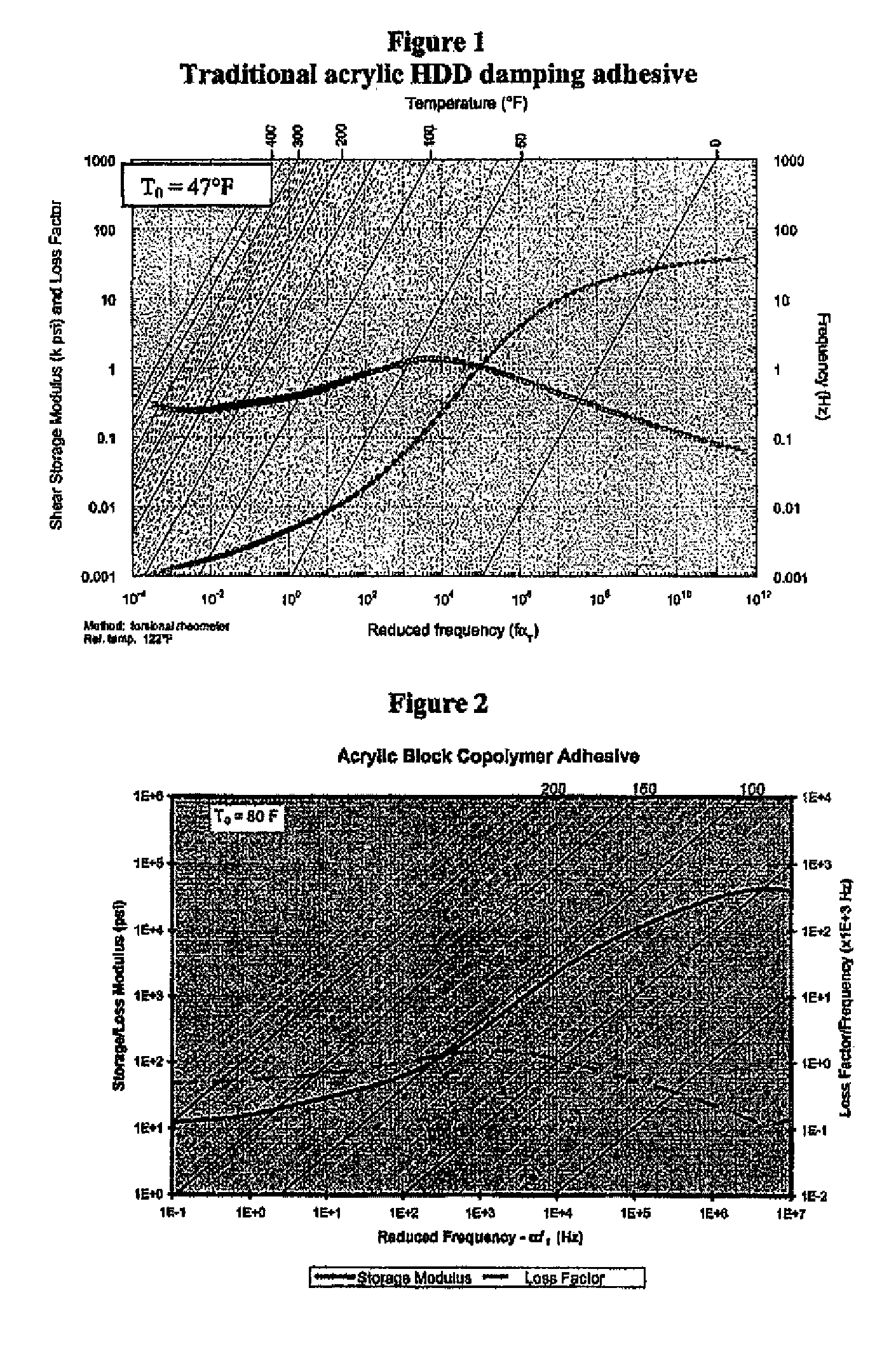

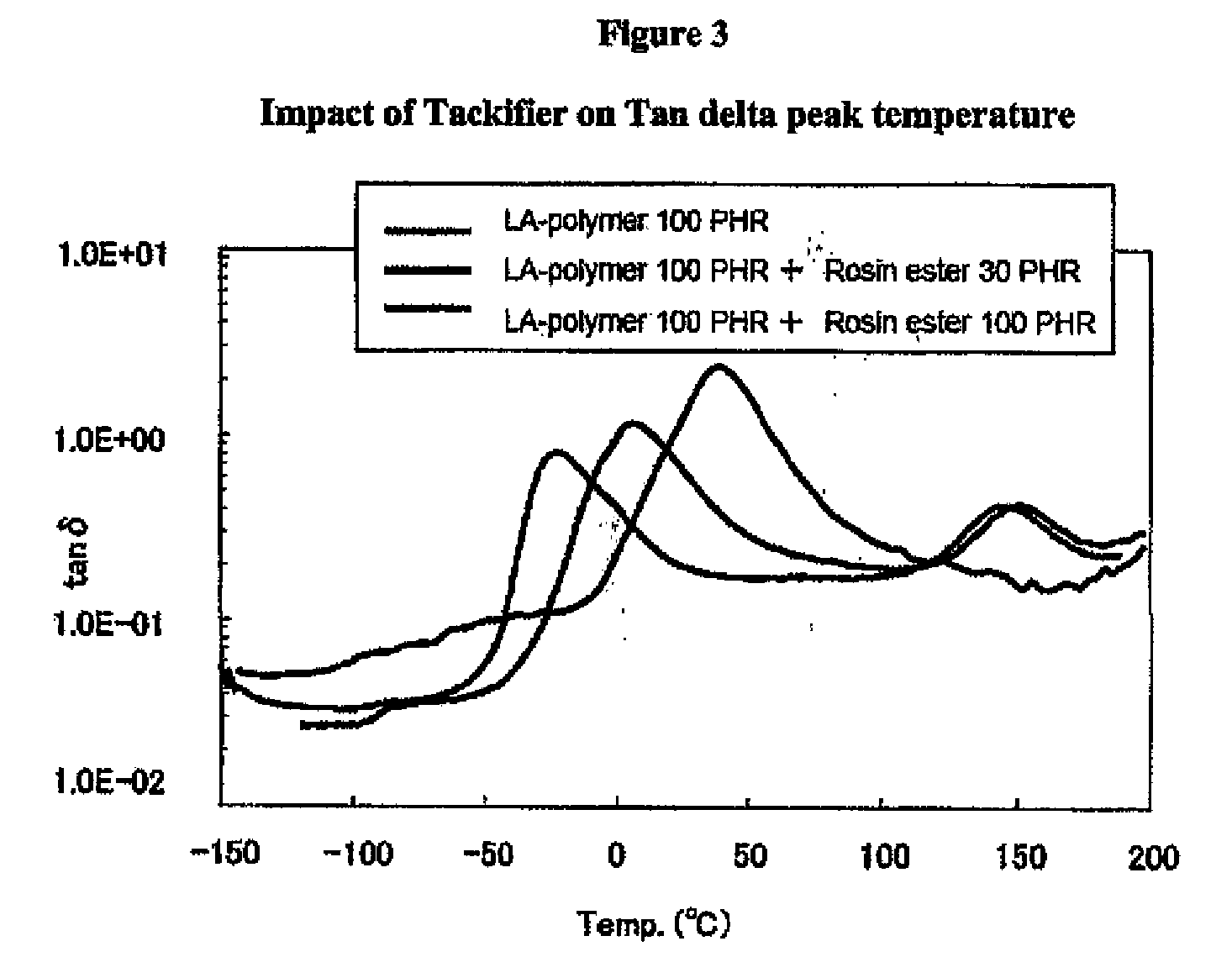

Acrylic Block Copolymers as Acoustical and Vibrational Dampening Material for Use in Electronic Devices

InactiveUS20080194759A1Improve adhesion performanceImproved acoustical and vibrational damping performanceEmulsion paintsAdhesivesPolymer scienceMeth-

An electronic device comprises a pressure sensitive adhesive comprising a block copolymer comprising at least one block of a poly(alkyl(meth)acrylate), e.g., poly(methyl(meth)acrylate), and at least one block of a poly(alkylacrylate), e.g., poly(butylacrylate). The adhesive can further comprise a tackifier, e.g., a rosin ester.

Owner:BRADY WORLDWIDE INC

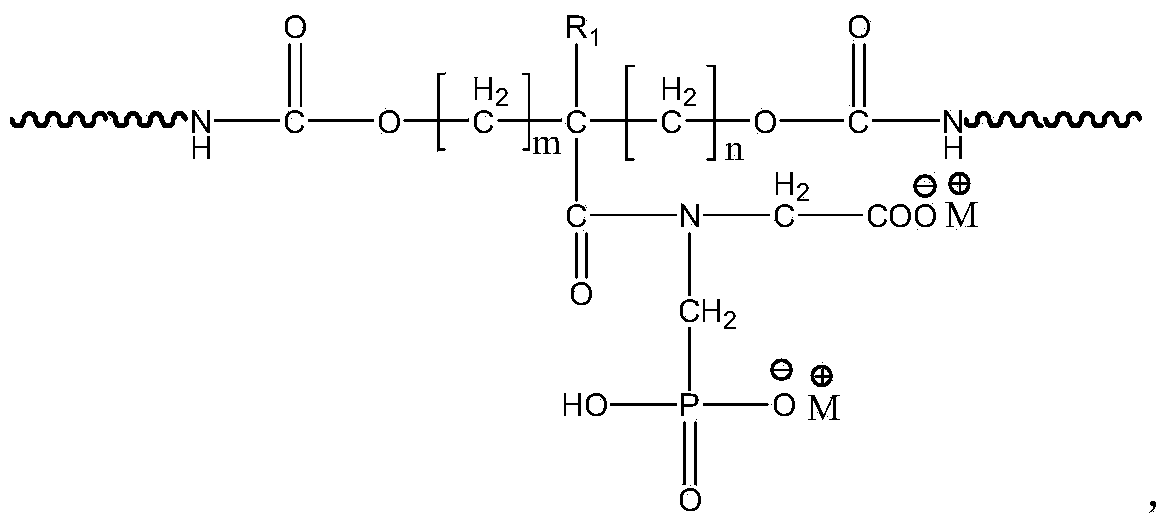

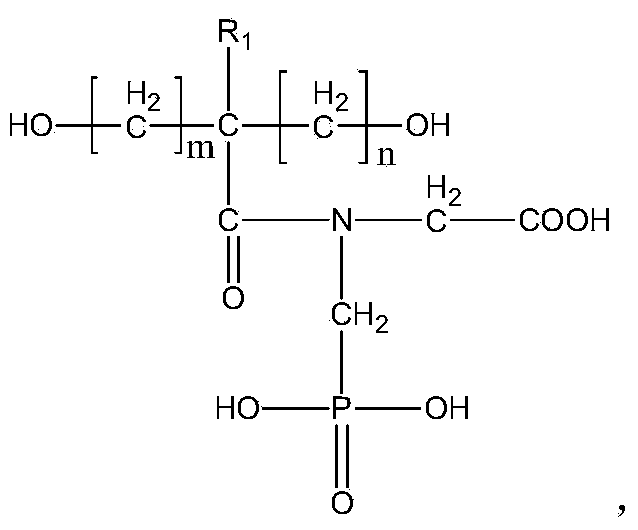

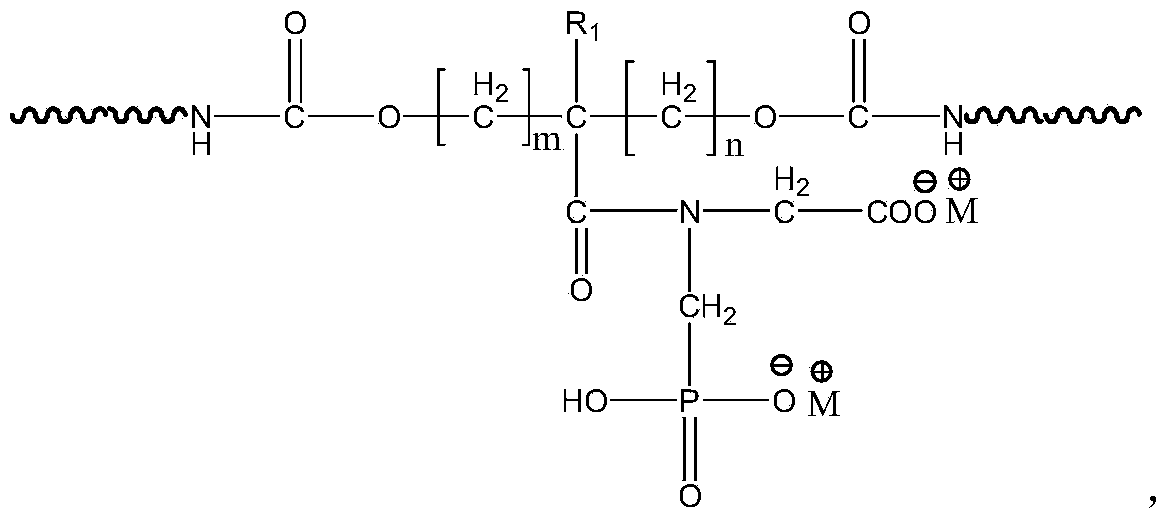

Waterborne polyurethane emulsion and preparation method thereof

The invention relates to a waterborne polyurethane polymerization monomer, and relates to a waterborne polyurethane emulsion which is obtained by polymerizing the waterborne polyurethane polymerization monomer. The waterborne polyurethane emulsion is prepared by the following raw materials in percentage by weight: 5-20% of oligomer polyols, 0-5% of micromolecule chain extender, 5-14% of diisocyanate, 1-5% of hydrophilic chain extender, 1-5% of saltifying reagent, 0.1-0.5% of catalyst and 50-70% of deionized water. The invention also relates to a preparation method of the waterborne polyurethane emulsion. The waterborne polyurethane emulsion provided by the invention has strong chemical stability, good water tolerance and solvent resistance, excellent adhesive force and favorable flame retardance, so that the research gap of waterborne polyurethane products simultaneously containing phosphoric acid hydrophilic group and carboxylic acid hydrophilic group in the prior art is filled.

Owner:FUJIAN POLYTECH TECH CO LTD

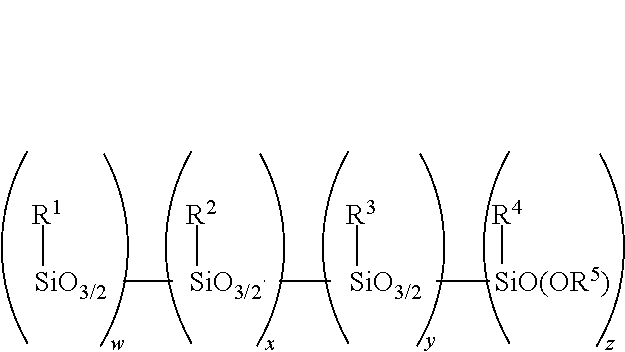

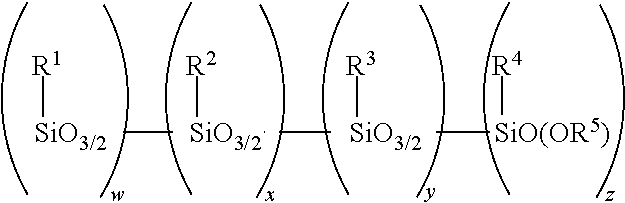

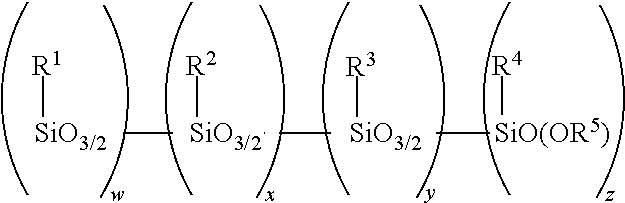

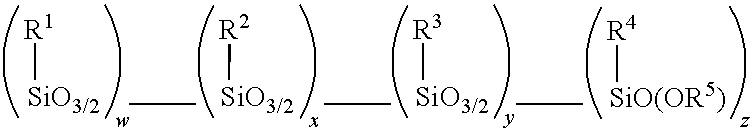

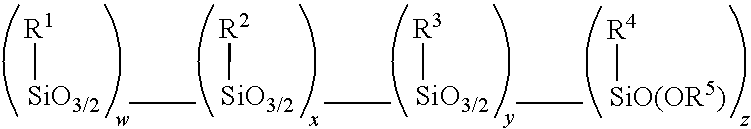

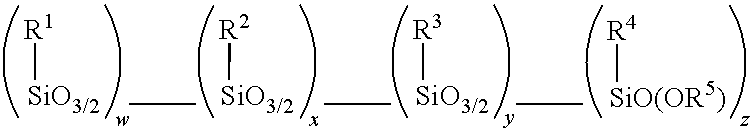

Amino alkoxy-modified silsesquioxane adhesives for improved metal adhesion and metal adhesion retention to cured rubber

InactiveUS8642691B2Improve environmental conditionsLess alcoholConductive materialSpecial tyresEndcappingThiol

Amino alkoxy-modified silsesquioxanes (amino AMS), and / or amino co-AMS compounds that also comprise a mercaptosilane or a blocked mercaptosilane, are excellent adhesives for coating plated or unplated metal wire for adherence of the wire to a rubber stock. The amino AMS and / or the amino / mercaptan co-AMS adhesives can be used with all types of rubber and there is no requirement for the use of special adhesive additives to the rubber vulcanizates, such as, but not limited to, cobalt, resins and high sulfur levels. In particular, the use of amino AMS and / or amino / mercaptan co-AMS compounds as adhesives for bonding wire to rubber also improves the adherence performance of the reinforcements to obtain sufficient bonding that is resistant to degradation over the course of time, especially resistance to thermal aging and / or thermo-oxidizing aging, in particular corrosion in the presence of water. Vulcanized rubber compositions that contain an amino AMS and / or amino / mercaptan co-AMS compound also have improved adhesion to embedded uncoated steel after humidity aging compared with vulcanized rubber compositions not containing the amino alkoxy-modified silsesquioxane.

Owner:BRIDGESTONE CORP

Easy-sprayed polypropylene composition and preparation method therefor

The invention discloses an easy-sprayed polypropylene composition and a preparation method therefor. The composition comprises the following ingredients in parts by weight: 33-77.6 parts of polypropylene resin, 10-15 parts of POE, 10-30 parts of mineral filler, 1-5 parts of grafts, 1-15 parts of cycloolefin copolymer, 0.2-1 part of stabilizer and 0.2-1 part of colorant. According to the easy-sprayed polypropylene composition and the preparation method therefor, by using mutual coordination of the grafts and the cycloolefin copolymer, the surface tension of a material is improved, and the adhesive power of paint is improved; and the adhesive power performance of the paint during high-pressure water flush experimentation is improved.

Owner:SHANGHAI KINGFA SCI & TECH +1

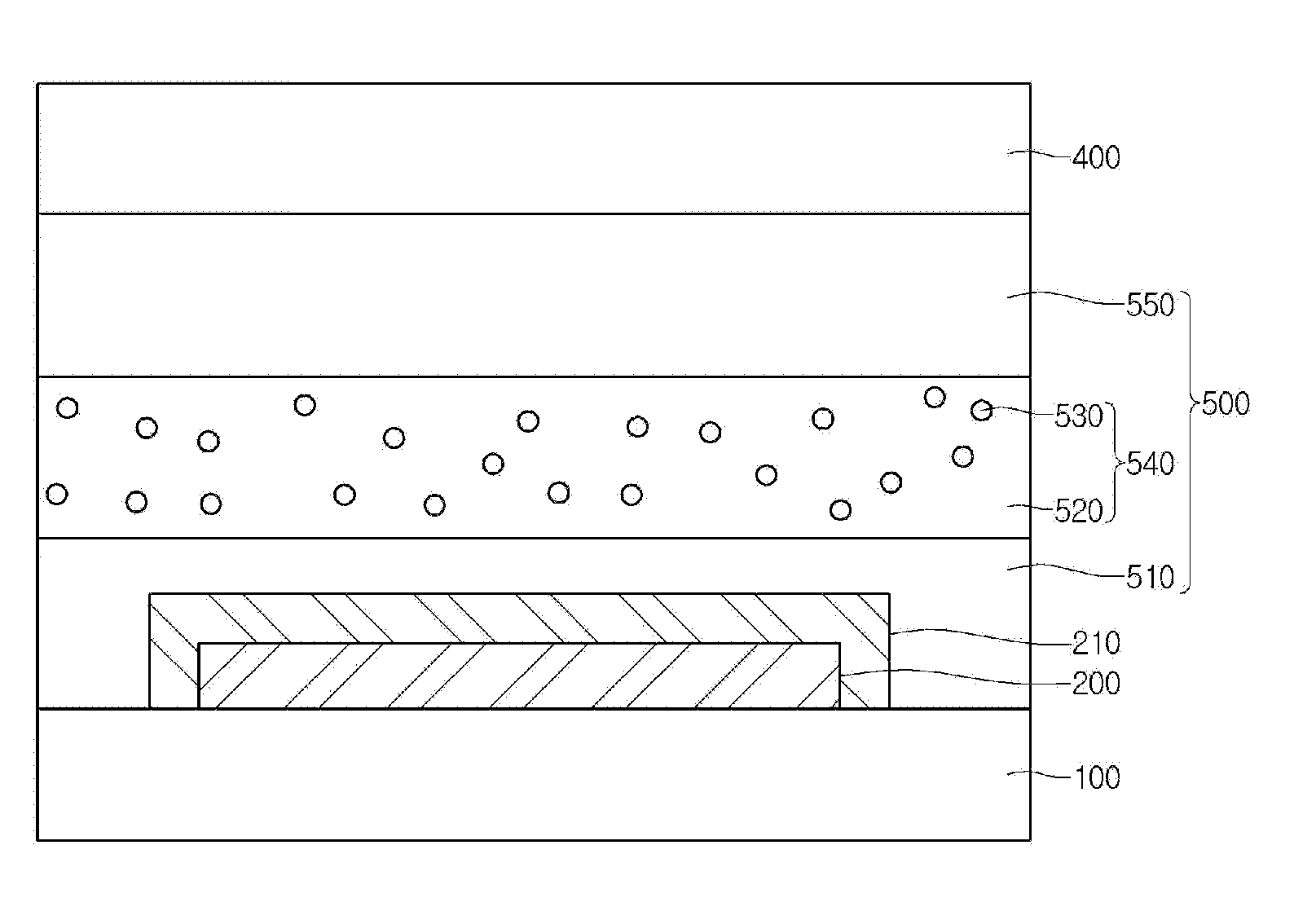

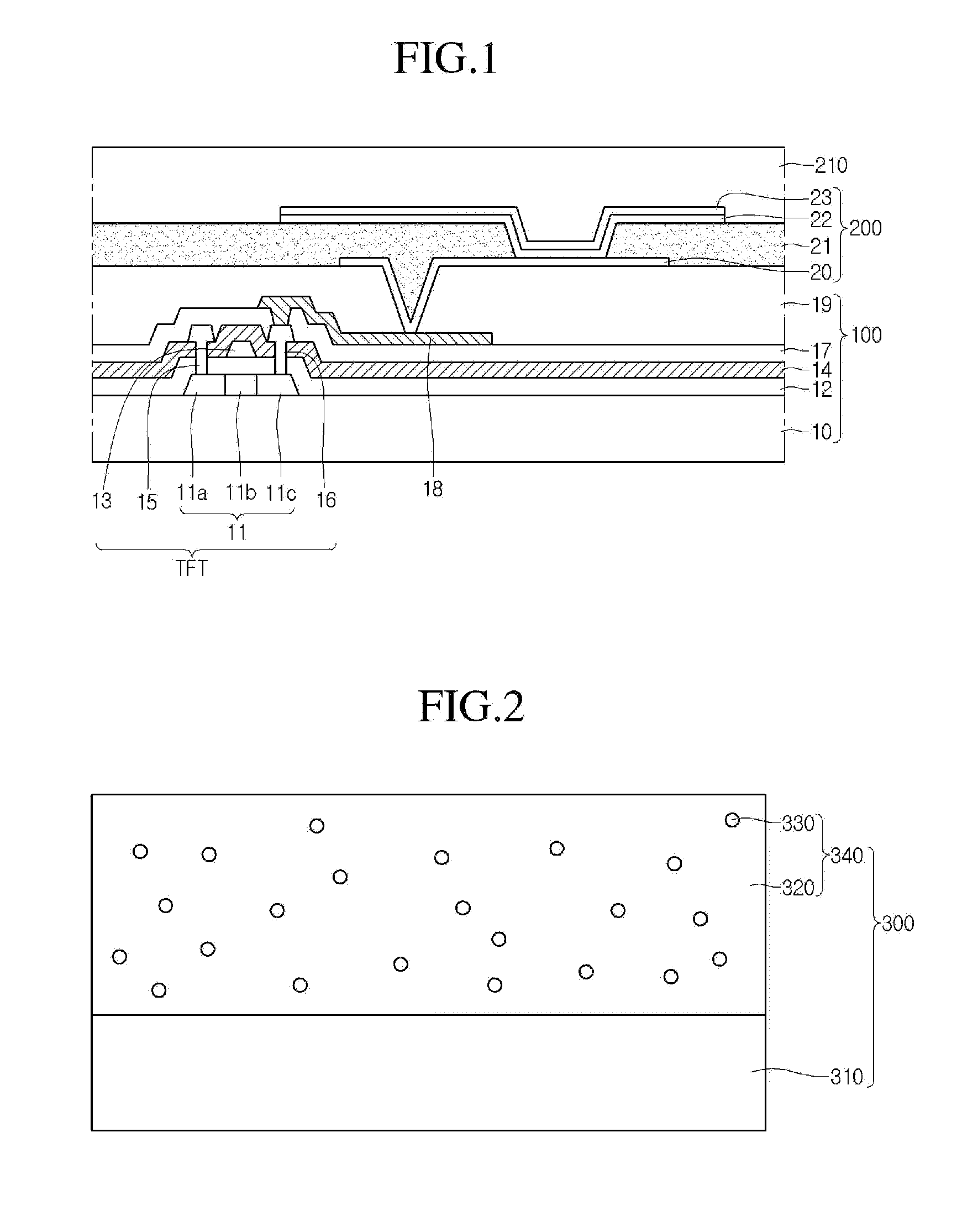

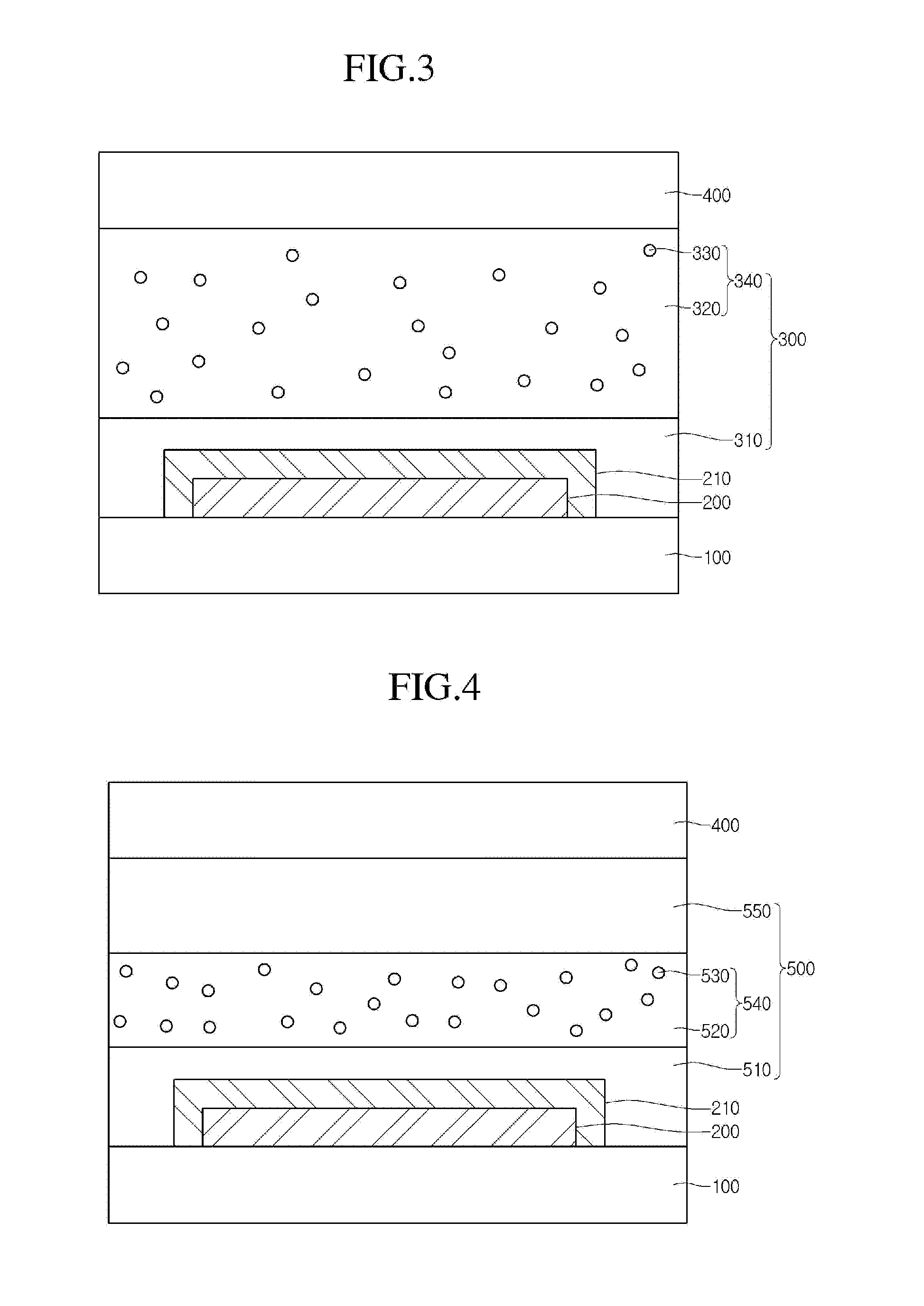

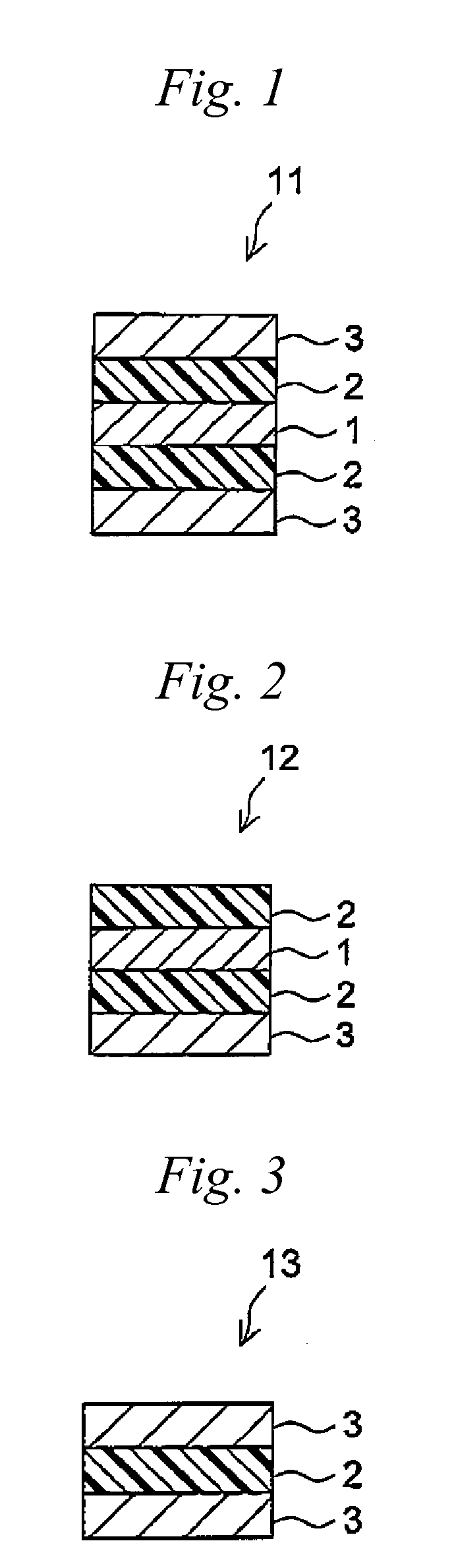

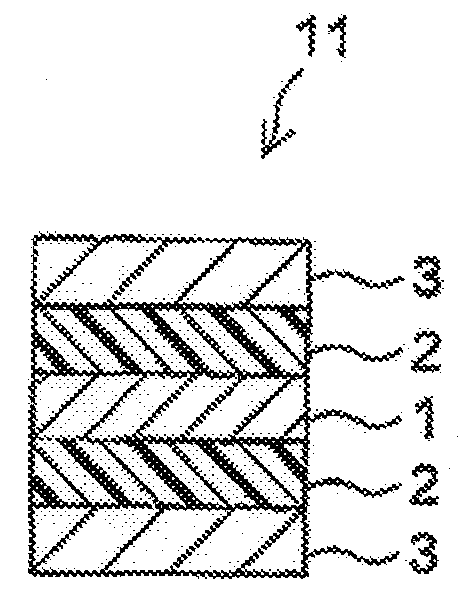

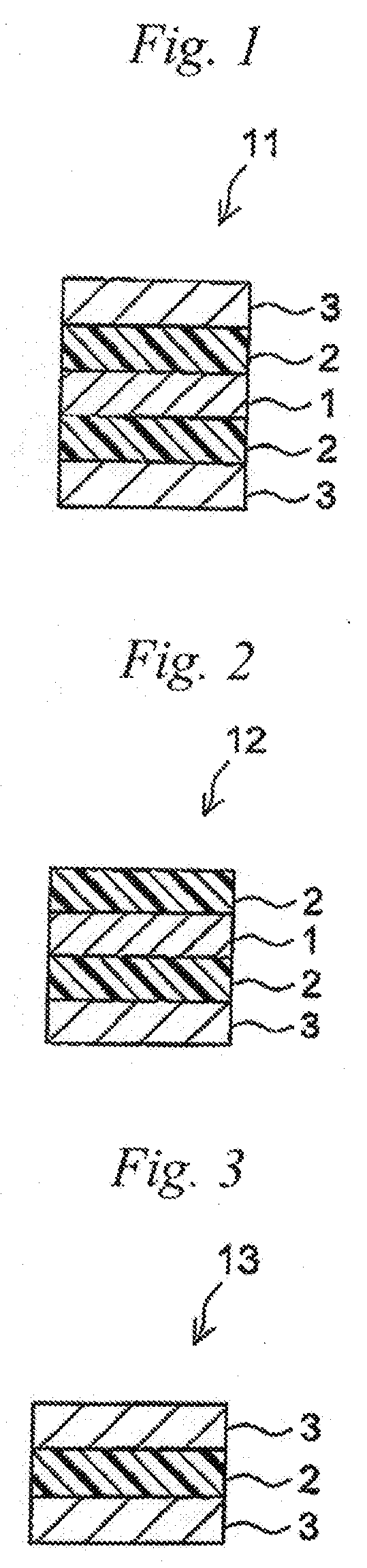

Organic light emitting display device

ActiveUS20150155522A1Relax strengthPrevent peelingSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsDisplay device

An organic light emitting display device is disclosed which includes: an element substrate provided with a thin film transistor; an organic light emitting element electrically connected to the thin film transistor and formed on the element substrate; a protective layer formed on the organic light emitting element; an adhesive film configured to include a first adhesive layer and a second adhesive layer which are sequentially stacked on the protective layer, the first adhesive layer including a resin layer and the second adhesive layer including another resin layer and a filler; and a sealing substrate disposed on the second adhesive layer and combined with the element substrate, which is provided with the organic light emitting element, by the adhesive film. One of the resin layers of the first and second adhesive layers within the adhesive film is formed from a non-hardening resin layer.

Owner:LG DISPLAY CO LTD

Adhesive and its application

InactiveUS20110003146A1Facilitate speedFacilitate strengthLayered productsFilm/foil adhesivesChemistryIsocyanate compound

The invention provides a tri-component adhesive composition comprising a first component containing one or more polyols, a second component containing one or more isocyanates and a third component containing one or more all-purpose polyurethane catalysts or modified catalysts thereof. According to different applications, the additive proportion of the third component is adjusted to achieve desired curing speed and adhesive strength of the adhesive under a wide range of temperature.

Owner:HENKEL KGAA

Pressure-sensitive adhesive composition and use thereof

InactiveUS20090291301A1Improve adhesionEfficient preparationFilm/foil adhesivesSynthetic resin layered productsPolymer scienceCarboxyl radical

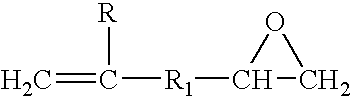

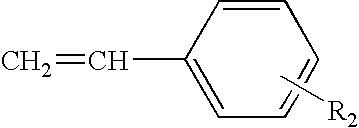

The present invention relates to a pressure-sensitive adhesive composition used for a pressure-sensitive adhesive sheet to be directly attached to a metal surface, the composition including, a monomer mixture or an acrylic copolymer material obtained by at least partially polymerizing the monomer mixture, the monomer mixture including: at least one monomer (monomer m1) selected from alkyl(meth)acrylates represented by the following formula (I): CH2═C(R1)COOR2 in which R1 is a hydrogen atom or a methyl group, and R2 is an alkyl group having 1 to 20 carbon atoms, and N-methylol (meth)acrylamide (monomer m2); in which the monomer m1 and the monomer m2 are contained in a total amount of 60% by weight or more based on the total amount of the monomer mixture, and the monomer mixture includes substantially no carboxyl group-containing monomer.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive composition, pressure-sensitive adhesive sheet, and method for producing the same

InactiveUS20090291227A1Improve adhesion performanceGood adhesionMixing methodsFilm/foil adhesivesCarboxyl radicalMethyl group

The present invention relates to a pressure-sensitive adhesive composition including, as a main ingredient, a monomer mixture or an acrylic copolymer material obtained by at least partially polymerizing the monomer mixture, the monomer mixture including: at least one monomer (monomer ml) selected from alkyl (meth)acrylates represented by the following formula (I) CH2═C(R1)COOR2 in which R1 is a hydrogen atom or a methyl group, and R2 is an alkyl group having 1 to 20 carbon atoms: at least one monomer (monomer m2) selected from N-hydroxyalkyl (meth)acrylamides represented by the following formula (II) CH2═C(R1)CONHR4 in which R3 is a hydrogen atom or a methyl group, and R4 is a hydroxyalkyl group having 2 to 4 carbon atoms: and at least one monomer (monomer m3) selected from N-vinyl cyclic amides and (meth)acrylamides that may have an N-alkyl group; and the monomer mixture including substantially no carboxyl group-containing monomer.

Owner:NITTO DENKO CORP

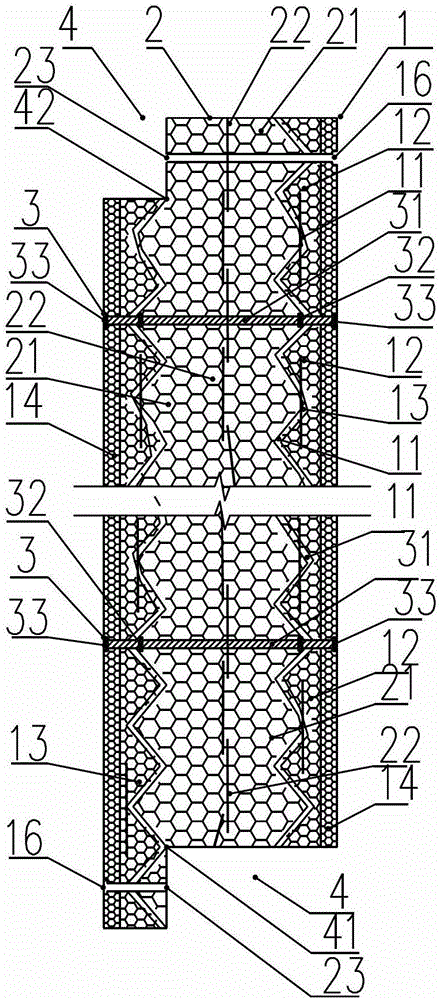

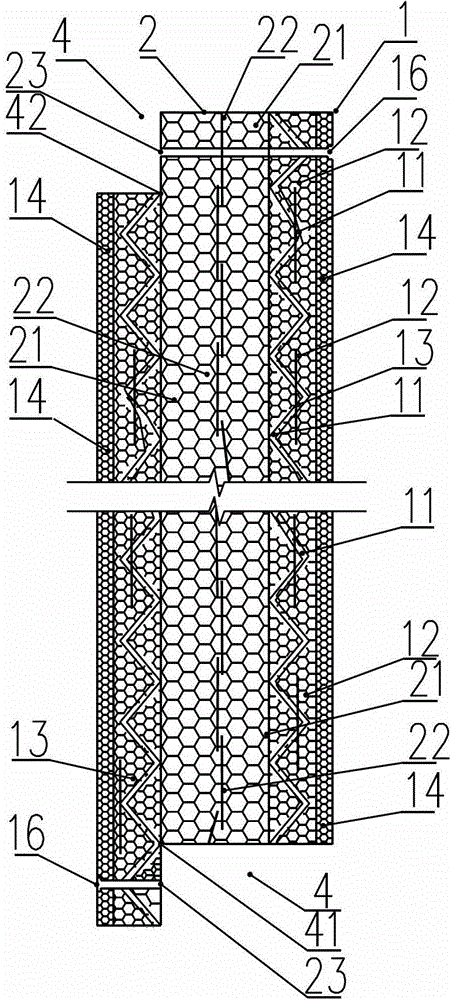

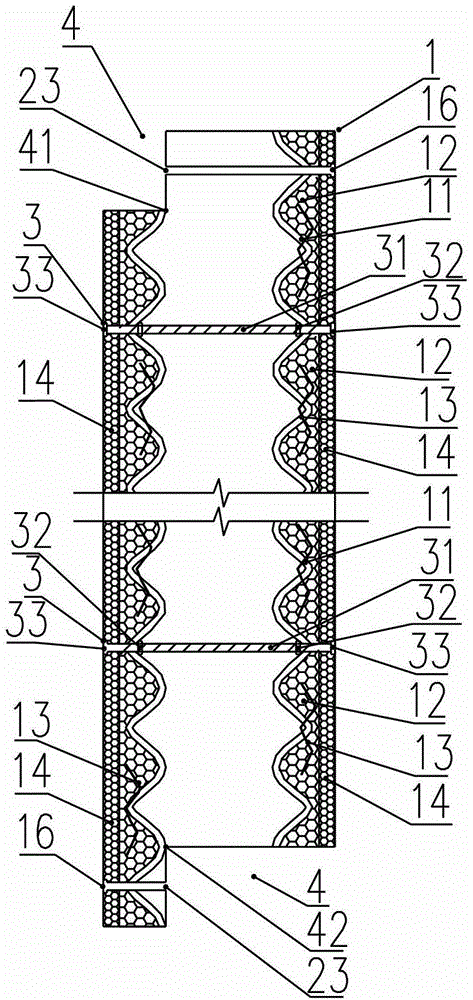

High-strength composite corrugated fiber foam cement heat insulation material

InactiveCN103334504AImprove sound insulation and noise reductionImprove thermal insulation performanceHeat proofingWater-setting substance layered productEnvironmental resistanceFiber

The invention discloses a high-strength composite corrugated fiber foam cement heat insulation material. Aiming at the defects that organic materials such as polyphenyl, extruded sheet and polyurethane, belonging to petroleum extractant, are complicated in structure, easy to age, inflammable, easy to crack, easy to seep and are short in service life, and inorganic materials such as a foam cement heat insulation board cannot reach the use strength of a wall body, the invention designs the high-strength composite corrugated fiber foam cement heat insulation material. The heat insulation material comprises corrugated fiber cement heat insulation material, composite foam cement heat insulation material, a fixed connecting support component, and concave-convex or male-female connecting mortise and tenon joints. The design purposes of meeting the use strength of a building outer wall and reducing the cost are realized by utilizing the performances of low heat conductivity coefficient, non-inflammability, high compression resistance and breaking strength of the foam cement, foamed ceramics and corrugated fiber cement plate and a pouring extrusion and foam technique. The high-strength composite corrugated fiber foam cement heat insulation material has the characteristics that the performances of heat preservation and insulation, non-inflammability and fireproofing, sound insulation and noise reduction, lightweight earthquake and acid rain resistance can be improved, and the material has the advantages on performance that the structure is simple, the material is saved, the mounting and dismounting are convenient, the construction efficiency is high, the service life is long, the cost is low, the material can be used as a finished wall body and recycled, and is energy-saving and environmental-protection.

Owner:BENXI NATURAL ICE PREPARATION ENG

Amino alkoxy-modified silsesquioxane adhesives for improved metal adhesion and metal adhesion retention to cured rubber

Amino alkoxy-modified silsesquioxanes (amino AMS), and / or amino co-AMS compounds that also comprise a mercaptosilane or a blocked mercaptosilane, are excellent adhesives for coating plated or unplated metal wire for adherence of the wire to a rubber stock. The amino AMS and / or the amino / mercaptan co-AMS adhesives can be used with all types of rubber and there is no requirement for the use of special adhesive additives to the rubber vulcanizates, such as, but not limited to, cobalt, resins and high sulfur levels. In particular, the use of amino AMS and / or amino / mercaptan co-AMS compounds as adhesives for bonding wire to rubber also improves the adherence performance of the reinforcements to obtain sufficient bonding that is resistant to degradation over the course of time, especially resistance to thermal aging and / or thermo-oxidizing aging, in particular corrosion in the presence of water.

Owner:BRIDGESTONE CORP

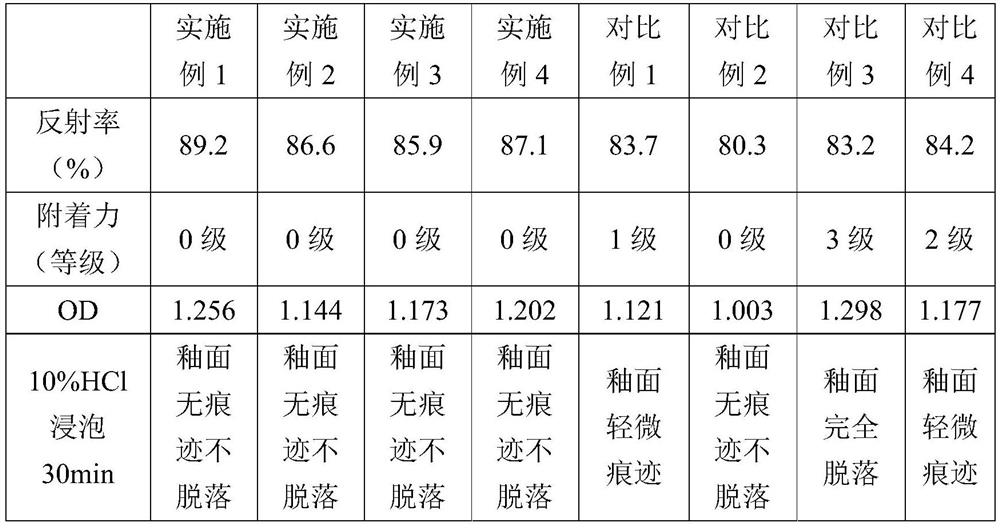

High-reflection glass slurry for photovoltaic module glass backboard and preparation method thereof

ActiveCN112724716AImprove reflectivityImproved low reflectivityPhotovoltaic energy generationReflecting/signal paintsPhysical chemistrySlurry

The invention belongs to the technical field of glass slurry, and particularly relates to high-reflection glass slurry for a photovoltaic module glass backboard and a preparation method of the high-reflection glass slurry, the high-reflection glass slurry for the photovoltaic module glass backboard is high in reflectivity, and the slurry comprises titanium dioxide, low-melting-point glass powder, erbium oxide and water-based varnish; wherein the low-melting-point glass powder is prepared from ZnS and TiO2. The high-reflection glass slurry for the glass backboard of the photovoltaic module, provided by the invention, has high adhesive force, chemical stability, use safety and relatively high reflectivity, and is suitable for the glass back plate of the photovoltaic module.

Owner:黄山市晶特美新材料有限公司

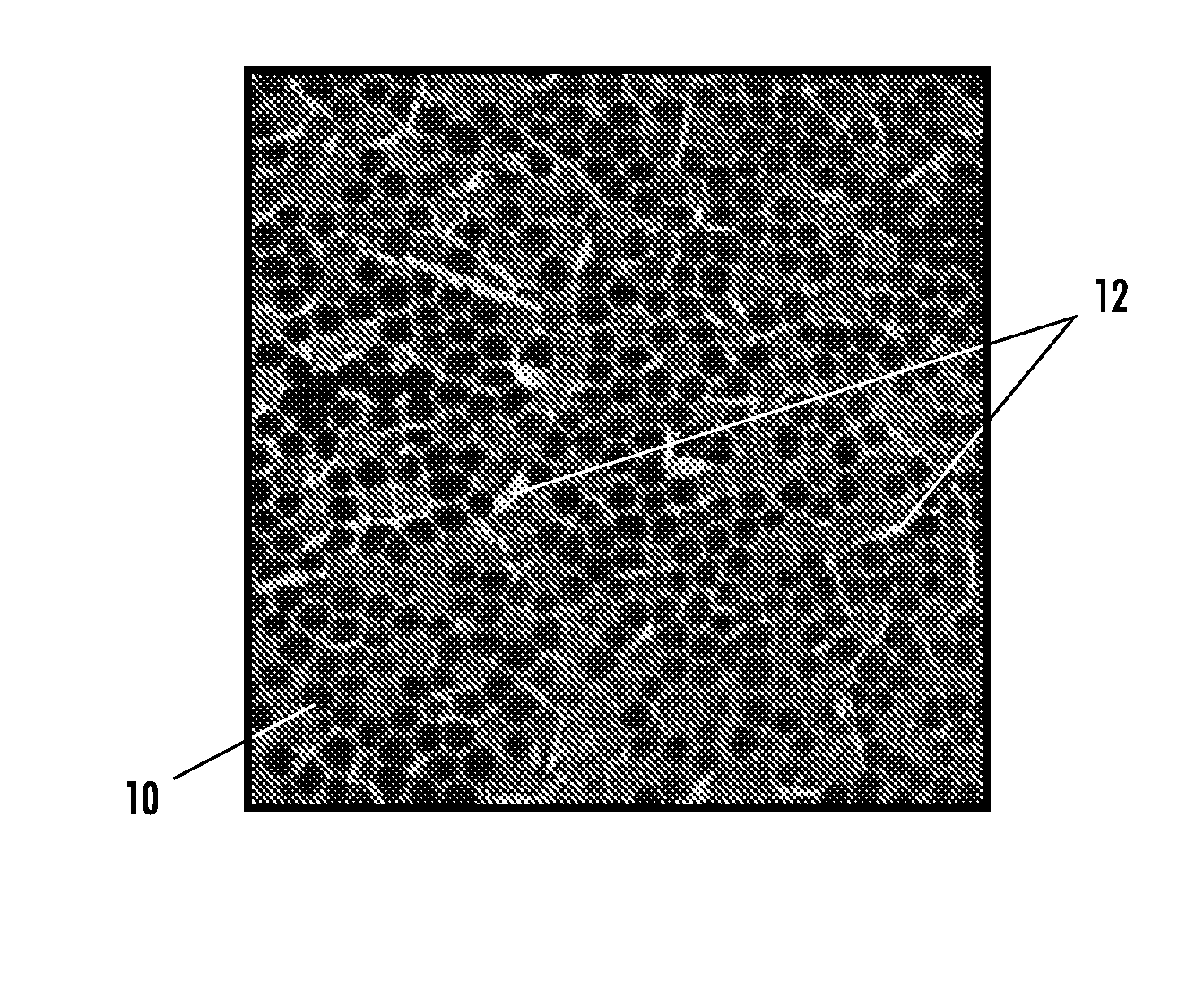

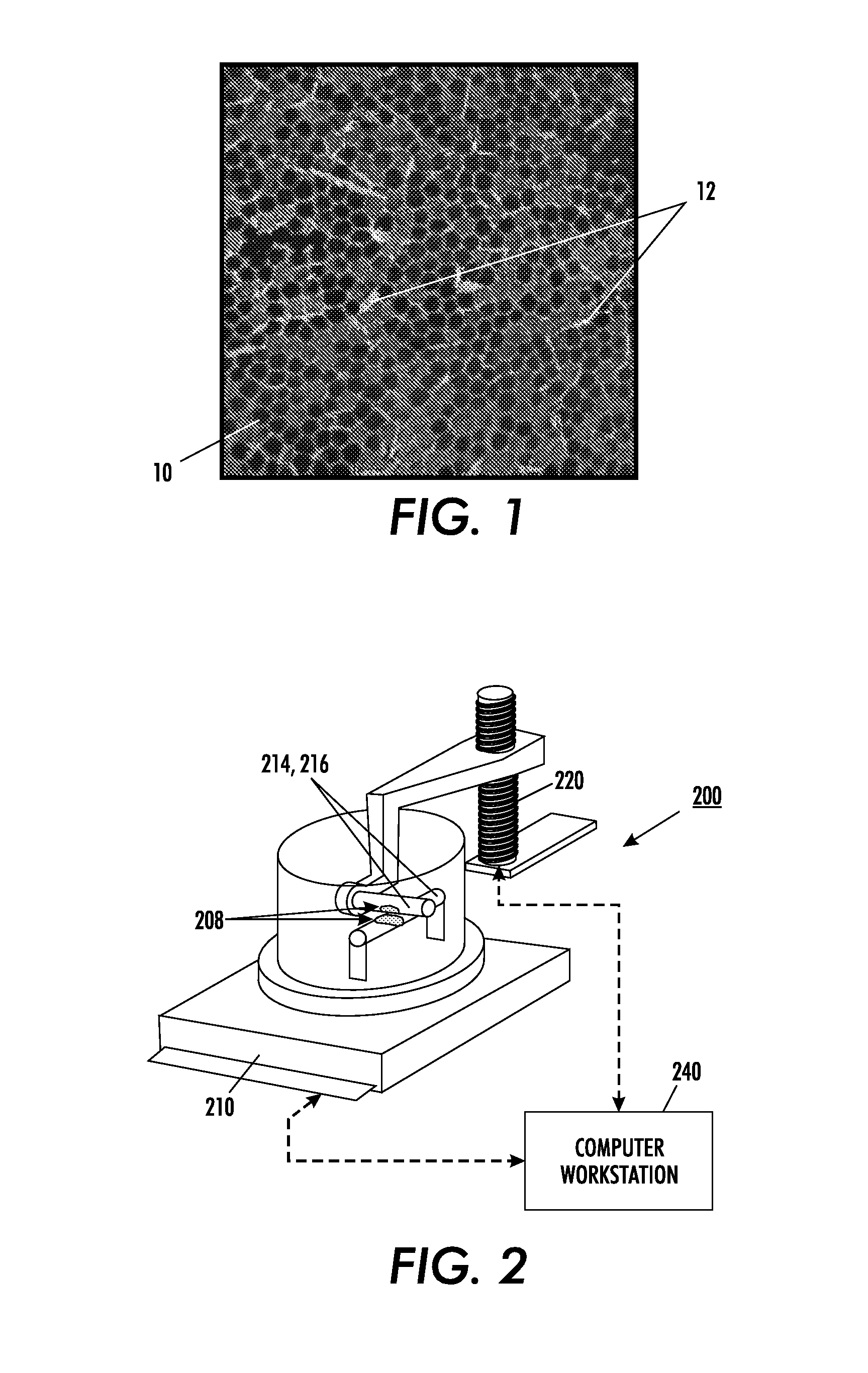

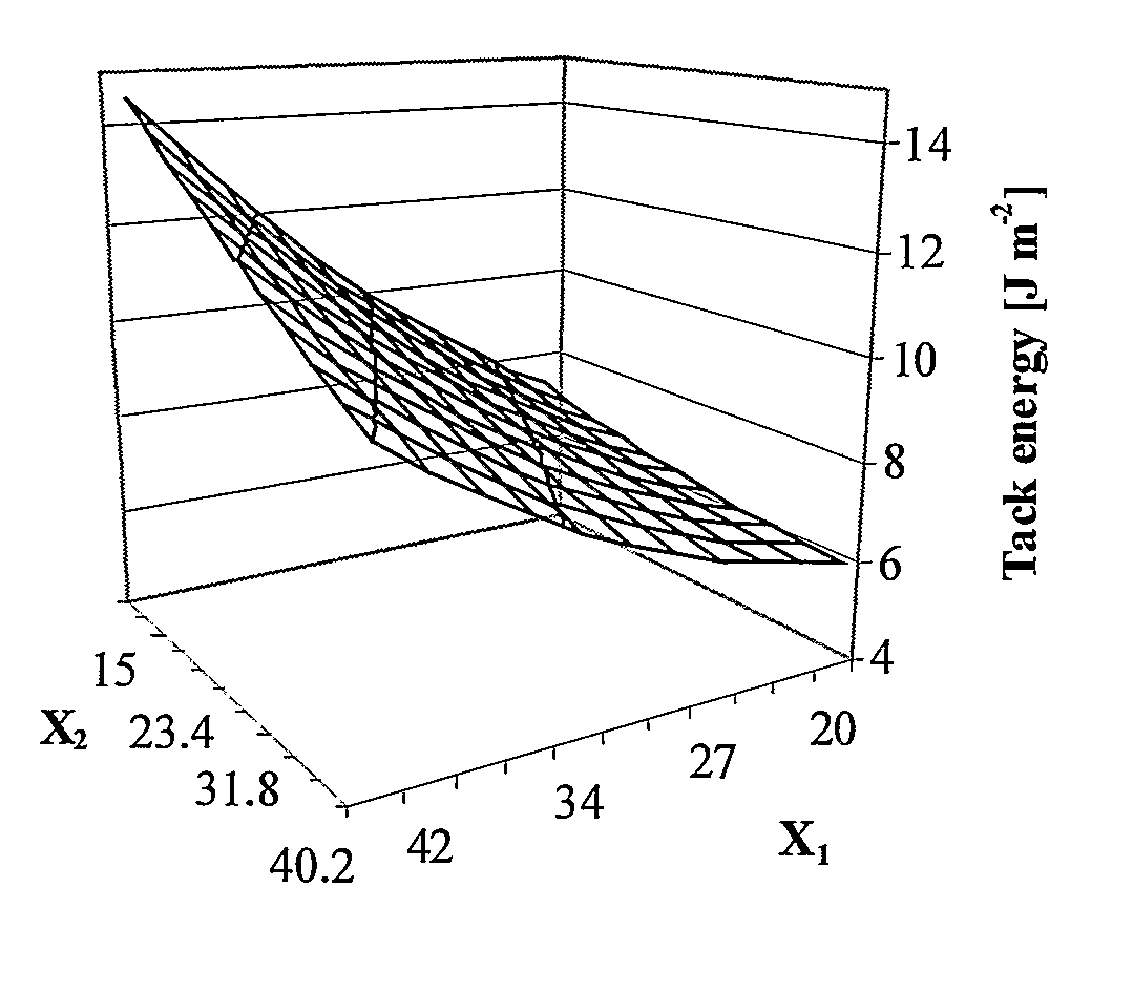

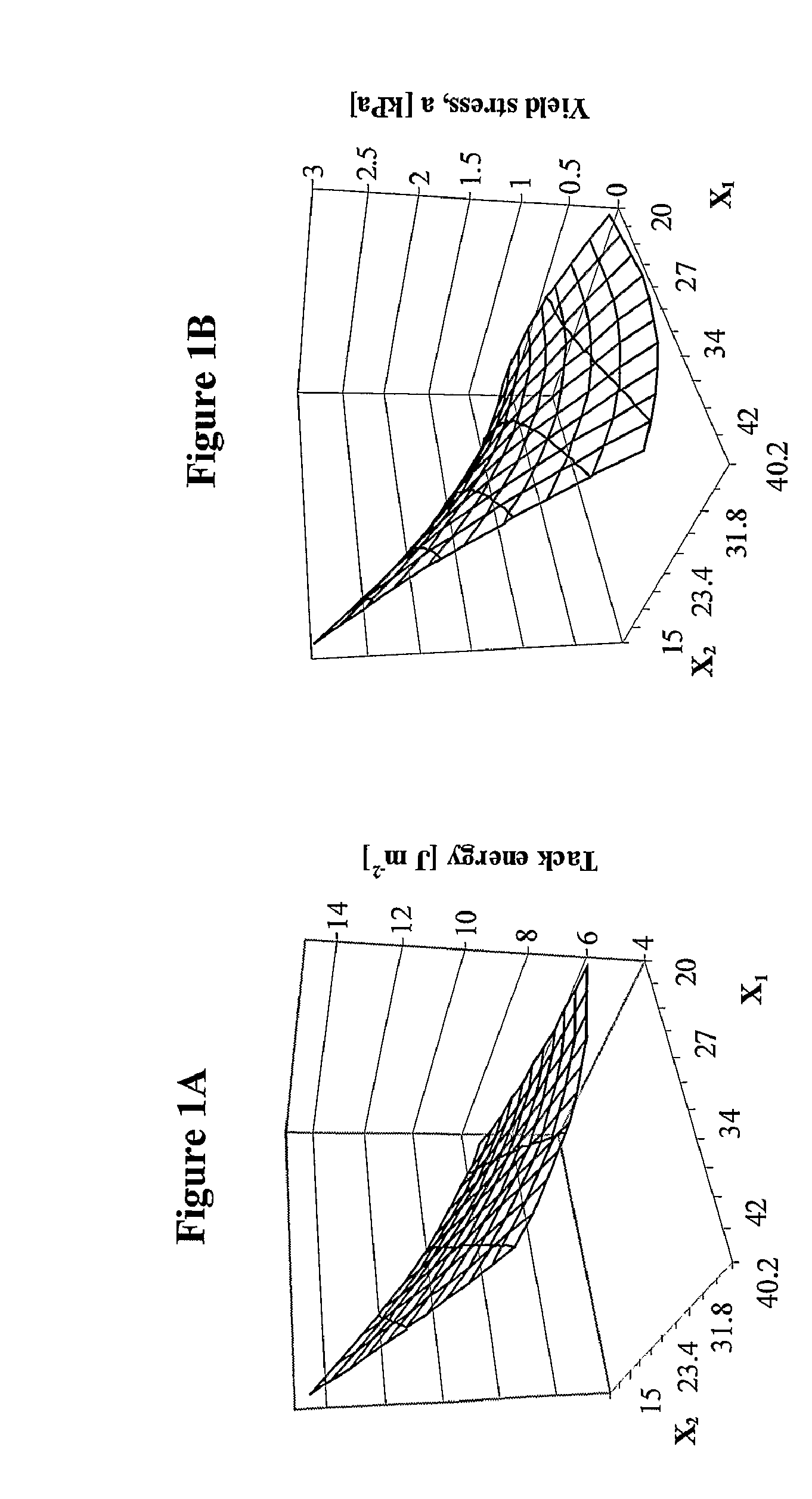

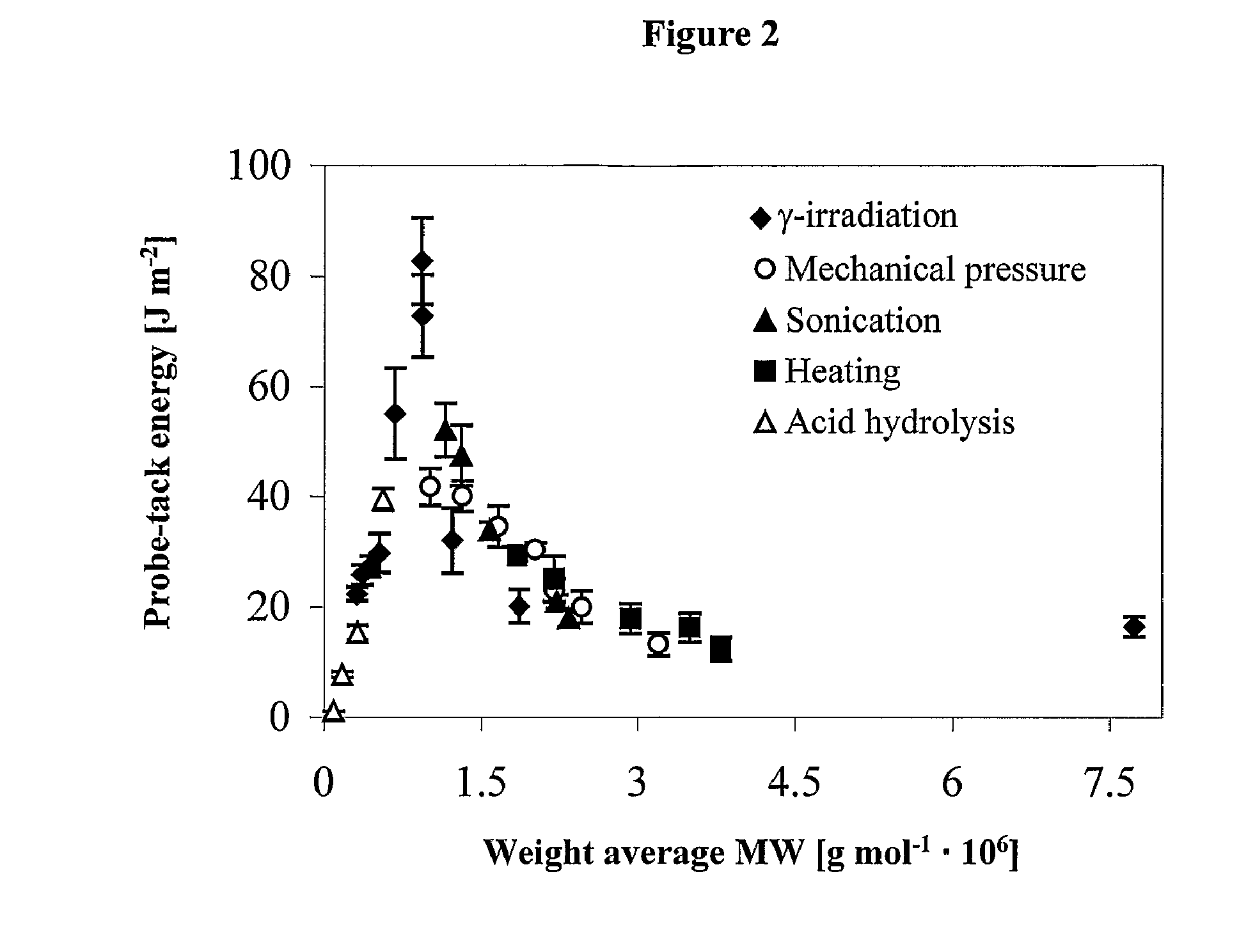

Depolymerized polysaccharide-based hydrogel adhesive and methods of use thereof

InactiveUS20080081056A1Simple and cost-effective manufacturing processMaintain good propertiesCosmetic preparationsPowder deliveryWound healingAdhesive

The present invention provides novel polysaccharide-based adhesive hydrogel compositions useful for wound healing and topical and transdermal delivery of therapeutic and cosmetic agents, methods of preparation and uses thereof. The hydrogel includes modified polysaccharides which bestow superior cohesion and adhesiveness to the hydrogel. The present invention further provides methods and a device useful for the testing the adhesive properties of hydrogels.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

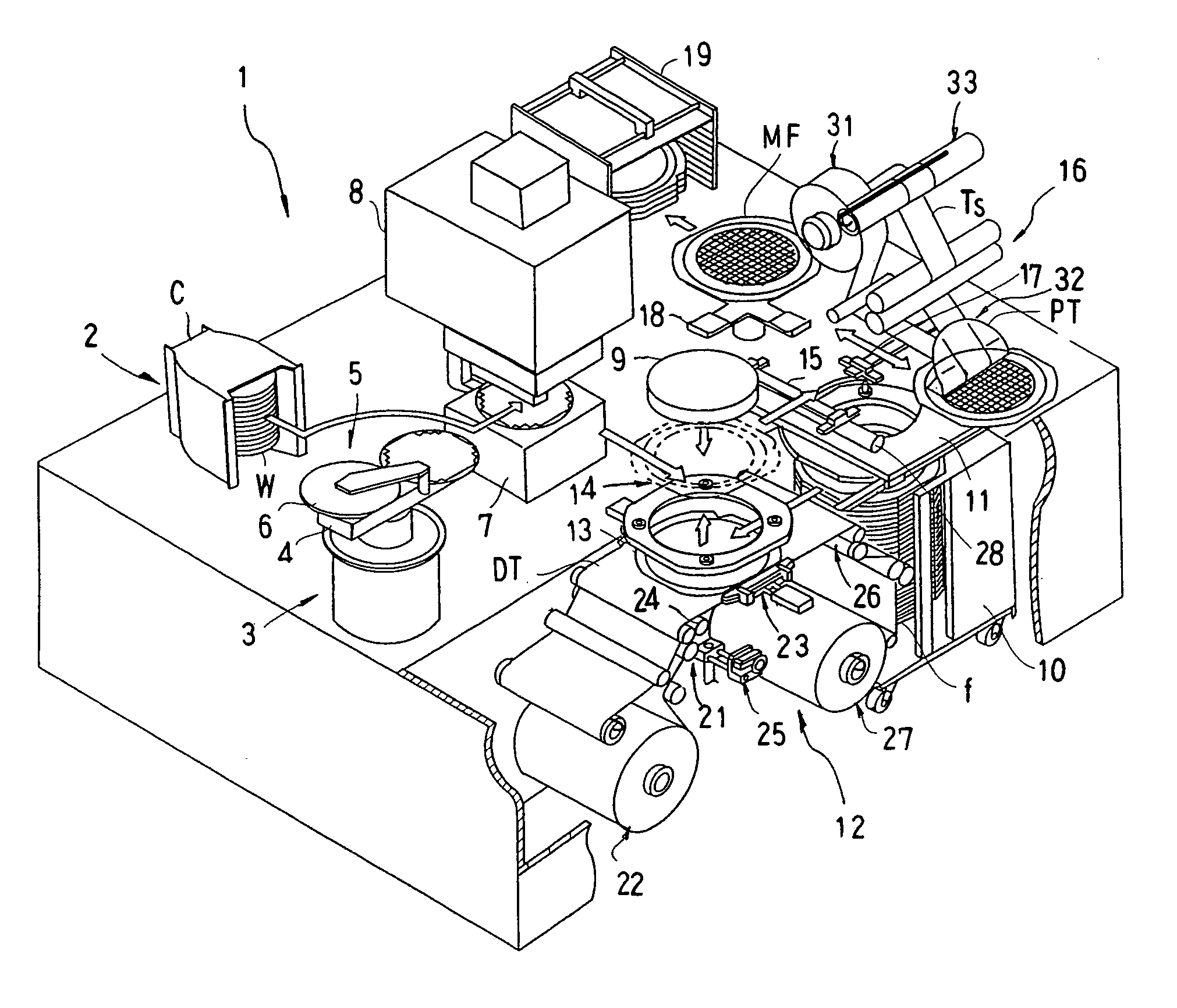

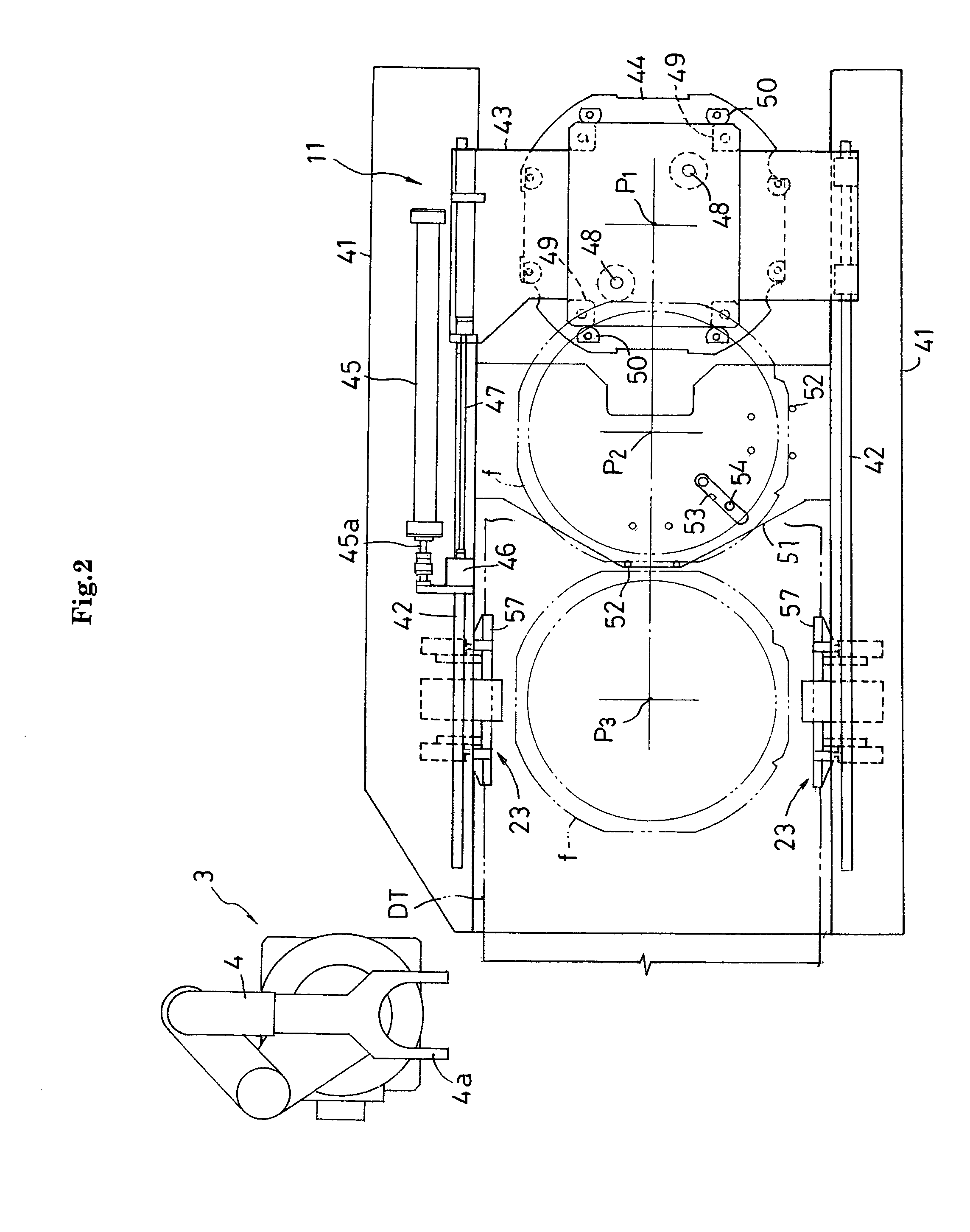

Work bonding and supporting method and work bonding and supporting apparatus using the same

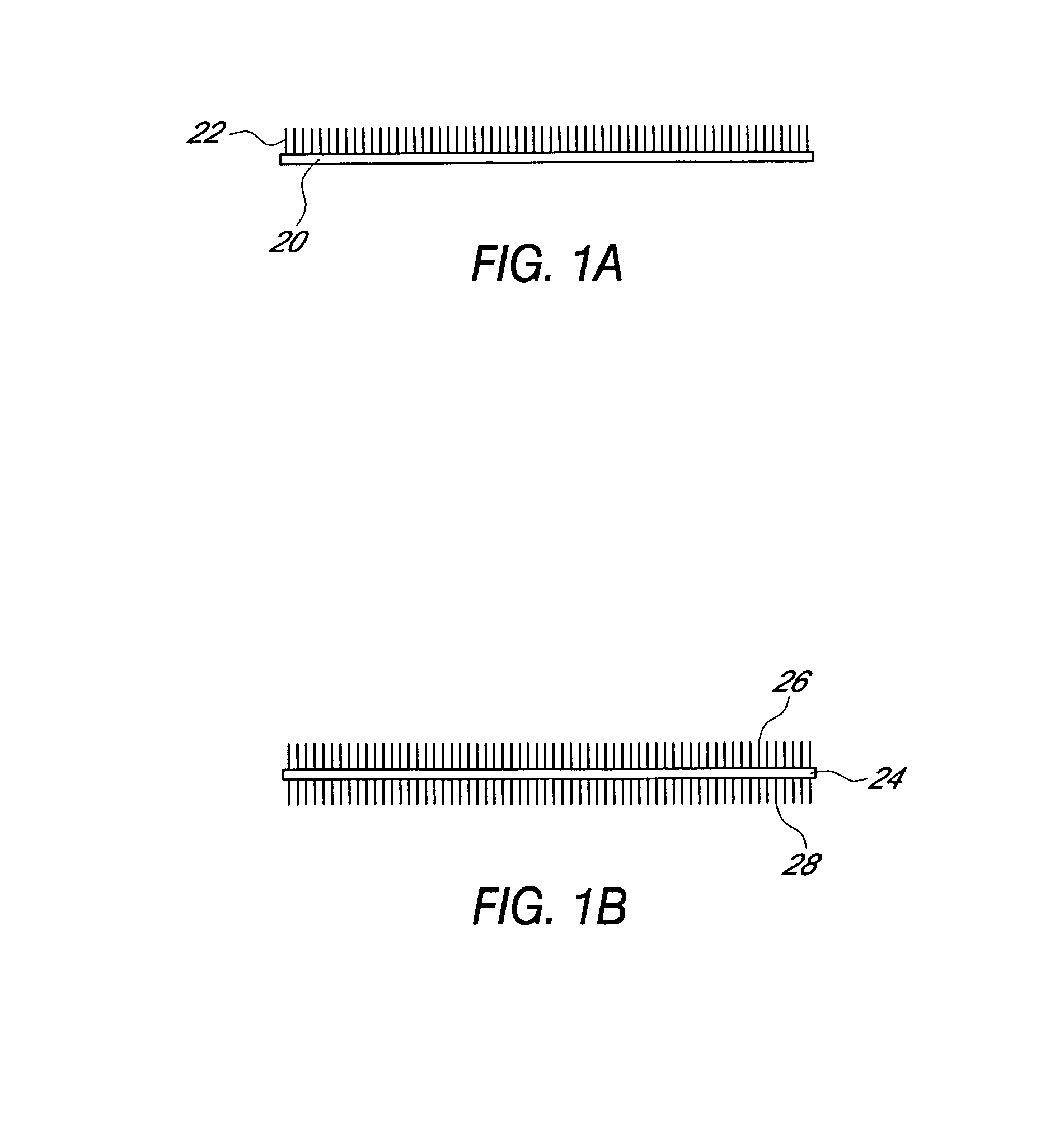

InactiveUS8110058B2Suitable for bondingImprove adhesion performanceLamination ancillary operationsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Tape heating means is allowed to come close to an adhesive tape for support and, in a heating state, the adhesive tape for support is stretched and tensioned with proper tension in a tape width direction and a transport direction. A heated work is bonded to an adhesive face of the tensioned adhesive tape for support, thereby supporting the work.

Owner:NITTO DENKO CORP

Alkyd resin coating for industrial outer wall and preparation method thereof

InactiveCN105038543AImprove adhesion performanceImprove adhesionAnti-corrosive paintsPolyester coatingsResin coatingDimethyl siloxane

The invention discloses an alkyd resin coating for an industrial outer wall. The alkyd resin coating comprises, by weight parts, 60-68 parts of drying oil alkyd resin, 20-50 parts of epoxy modified alkyd resin, 15-30 parts of acyclic acid modified alkyd resin, 2-4 parts of propylene glycol monomethyl ether acetic ester, 5-10 parts of propylene glycol, 5-10 parts of alcohol etherification melamine resin, 2-8 parts of urea resin, 1-3 parts of 2-amino-2-methyl-1-propanol, 20-25 parts of carboxymethyl cellulose, 1-3 parts of silane coupling agent, 1-4 parts of sodium dodecylbenzene sulfonate, 1-3 parts of polyoxyethylene polyoxypropylene ether, 1-2 parts of wetting agent, 1-3 parts of solydimethyl siloxane, 0.5-1.5 parts of preservative, 1-2 parts of hydroxypropyl guar gum, 40-60 parts of water, 5-20 parts of amyl acetate, 5-10 parts of super fine calcium carbonate, 2-8 parts of magnesium silicate, 6-10 parts of kaolin and 2-8 parts of china clay. The invention further discloses a method for preparing the alkyd resin coating for the industrial outer wall. The alkyd resin coating for the industrial outer wall is good in adhesive force and excellent in corrosion resistance.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

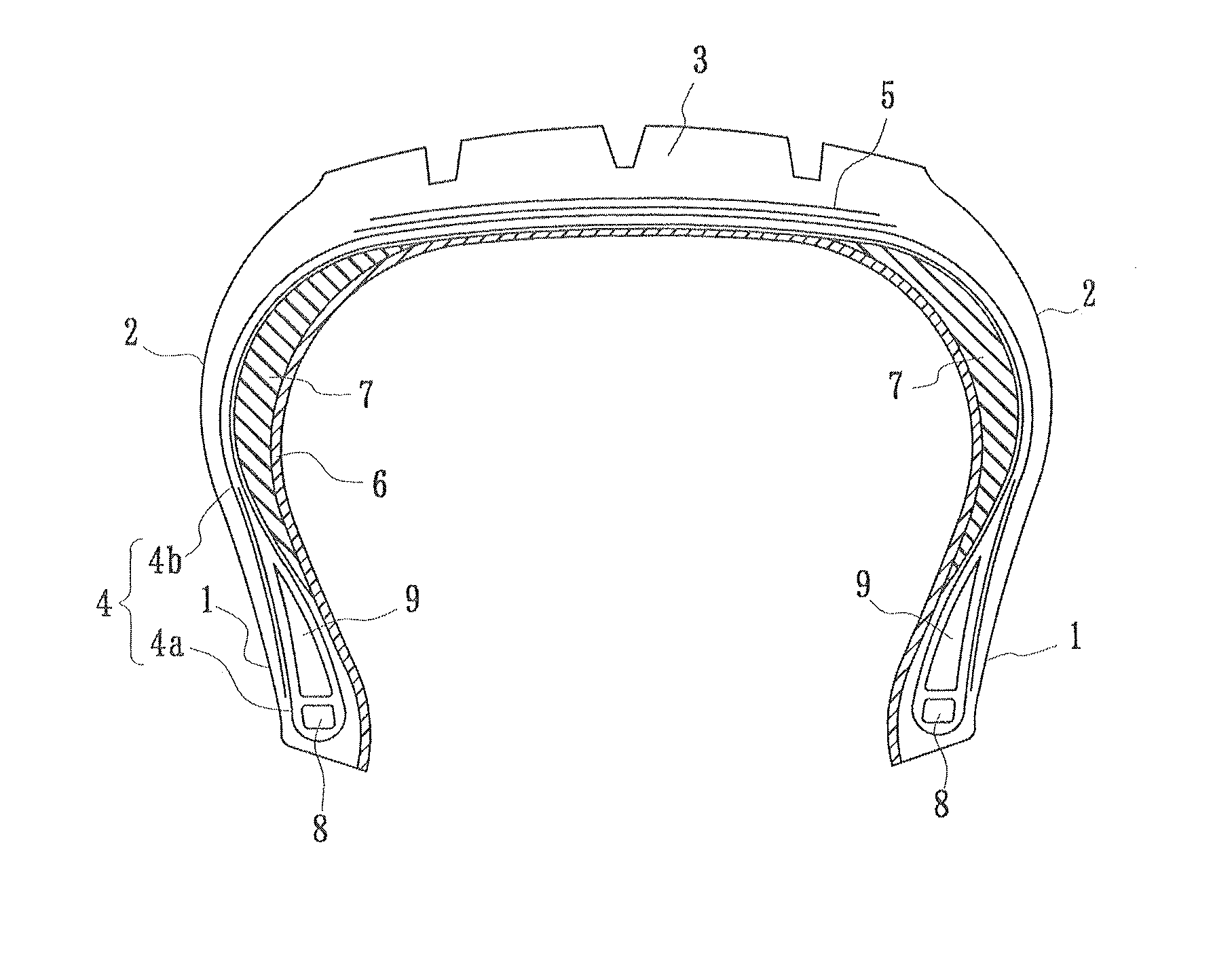

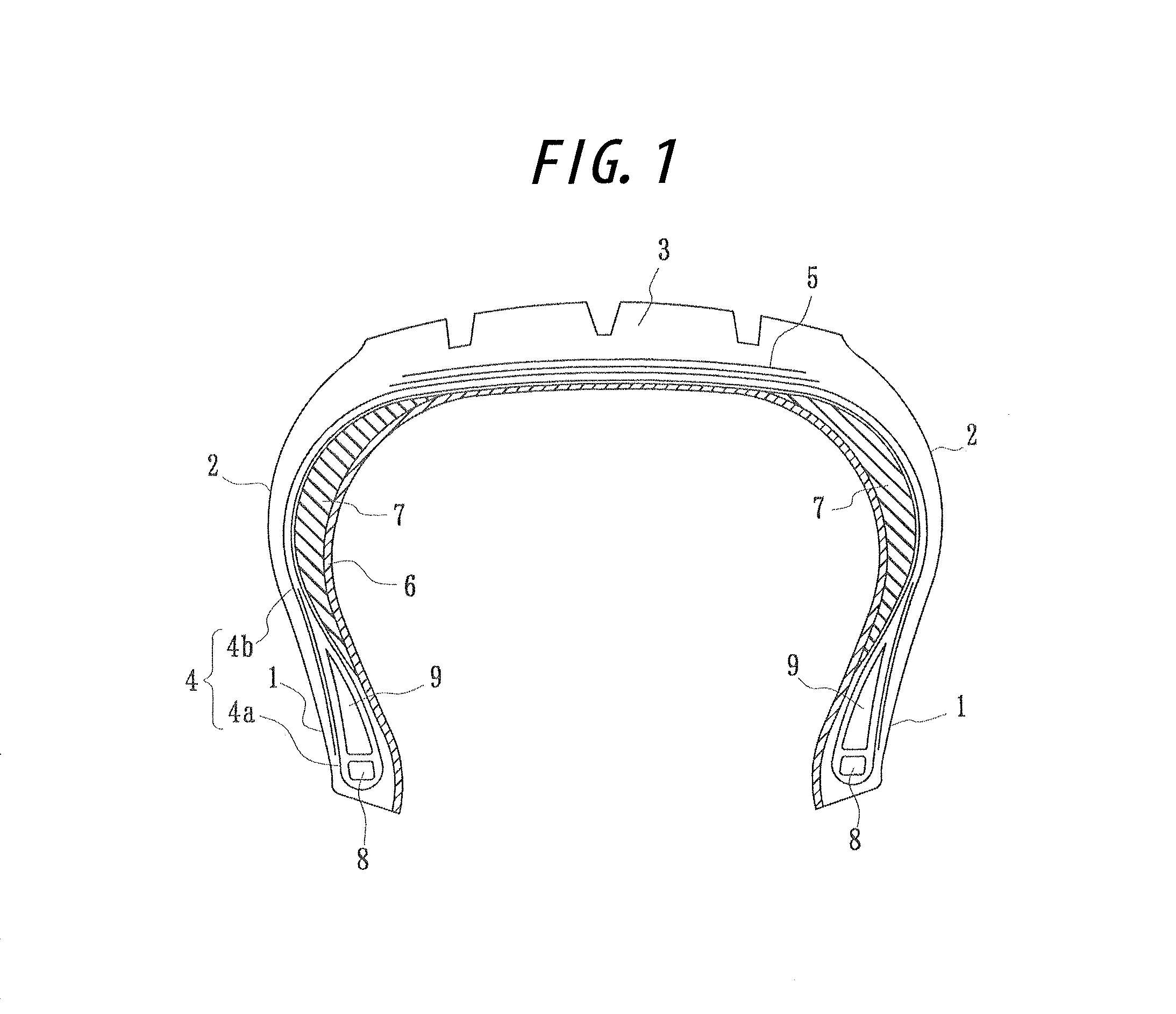

Rubber laminate, run-flat tire, and pneumatic tire

InactiveUS20130312890A1Improve adhesionImproved run-flat durabilityWithout separate inflatable insertsSynthetic resin layered productsVulcanizationEngineering

Provided are: a rubber laminate having high adhesion between a rubber member including a non-diene rubber and a rubber member including a diene rubber; a run-flat tire obtained by using the rubber laminate, having high adhesion between a side-reinforcing rubber layer and an inner liner, with excellent run-flat durability; and a pneumatic tire including a color layer having high adhesion force to a side rubber while being excellent in stain resistance. The rubber laminate is obtained by laminating a rubber member A including a non-diene rubber and a rubber member B including a diene rubber on each other, the rubber member A and the rubber member B containing a vulcanization accelerator of the same type.

Owner:BRIDGESTONE CORP

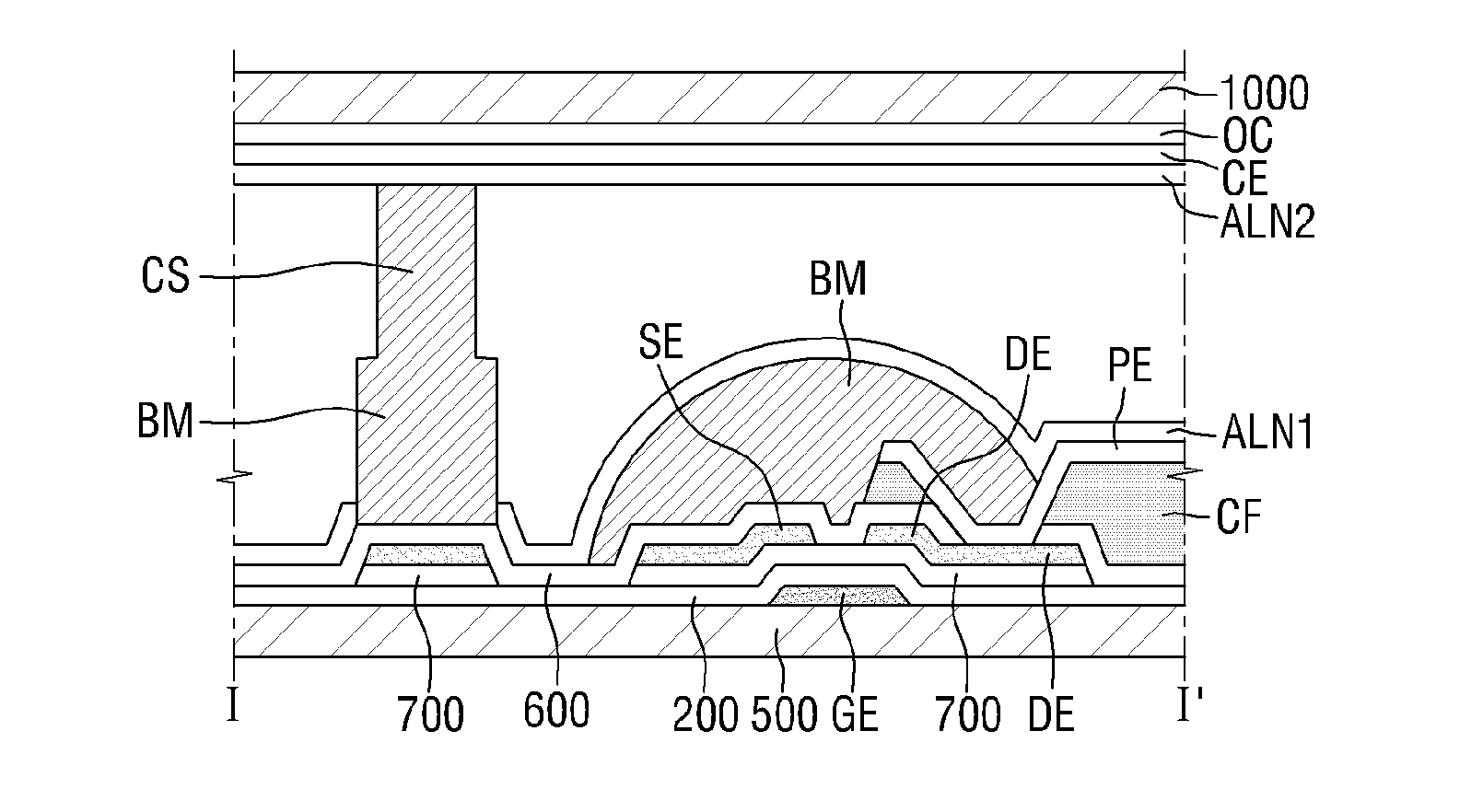

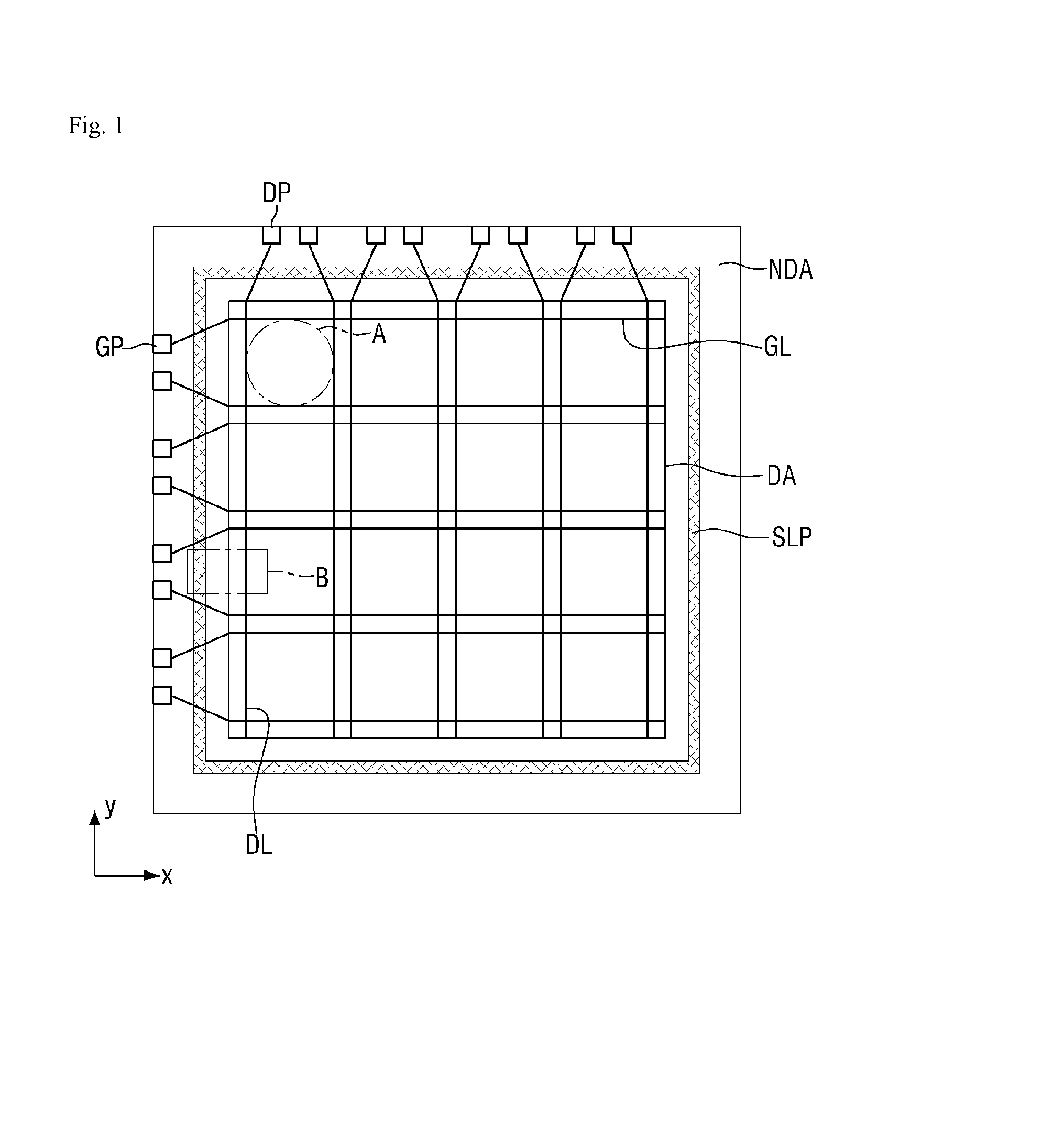

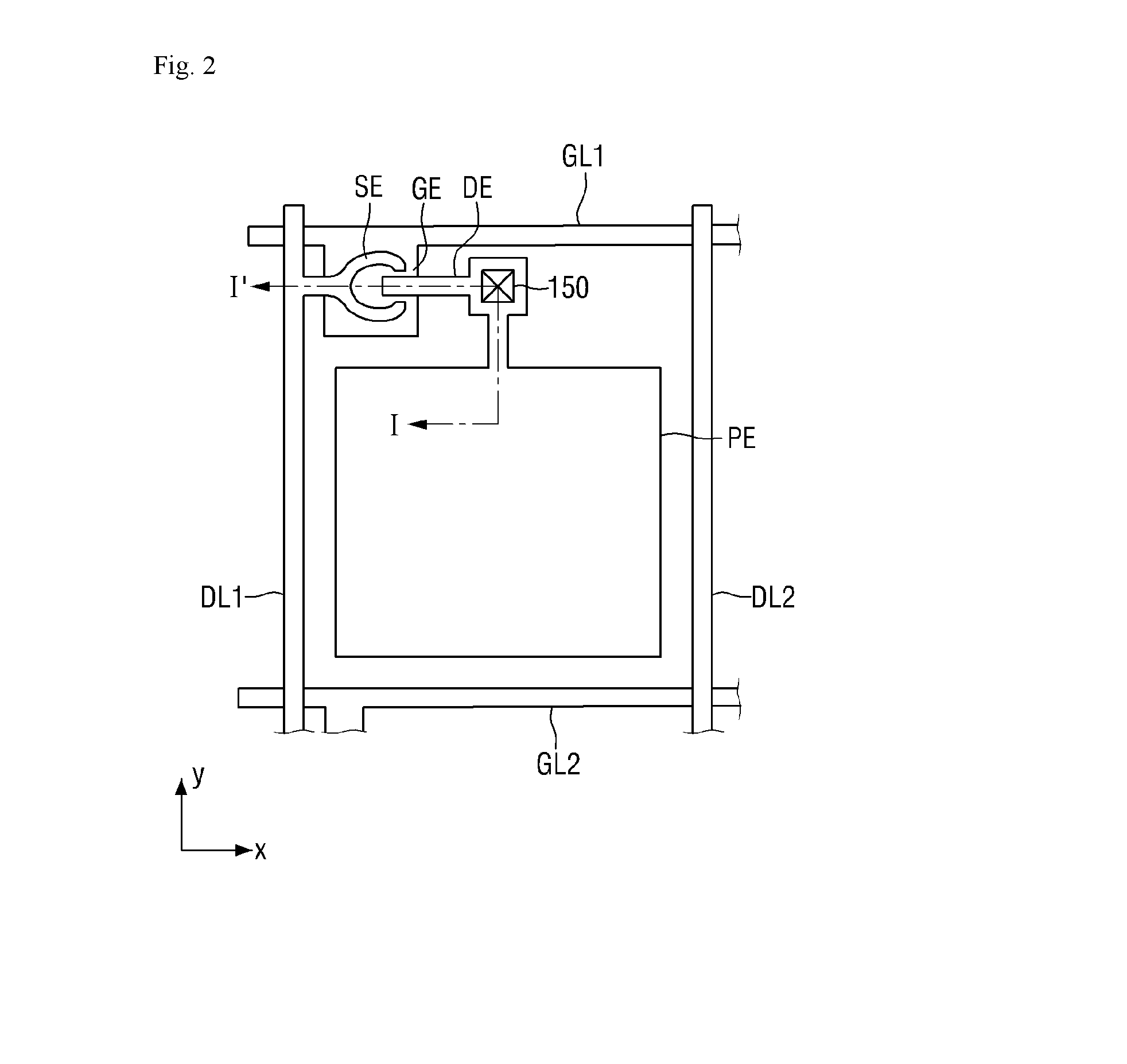

Liquid crystal display and method of manufacturing the same

InactiveUS20170045782A1Improve adhesion performanceNon-linear opticsLiquid-crystal displayEngineering

Provided are a liquid crystal display and a method of manufacturing a liquid crystal display. According to an aspect of the present inventive concept, there is provided a liquid crystal display which includes a first substrate which includes a display area and a non-display area disposed outside the display area, a second substrate which is located opposite the first substrate, a light-blocking pattern which is disposed on the non-display area, and a plurality of alignment layer barrier patterns which protrude from the black matrix toward the second substrate and are formed integrally with the light-blocking pattern in the non-display area.

Owner:SAMSUNG DISPLAY CO LTD

Method for the modification of polyolefins

A process for obtaining a polyolefin composition endowed with improved adhesion performance, especially paintability, comprising premixing a high-flow polyolefin resin with one or more grafting monomers and initiator, possibly also one or more comonomers, feeding the obtained premix and a low-flow polyolefin resin into a mixing device, and gradually heating the components to above their melting points while being subjected to mixing forces. The process may be carried out in an extruder, and polyether amine may optionally be introduced into the extruding mass downstream of the feeding point.

Owner:BOREALIS TECH OY

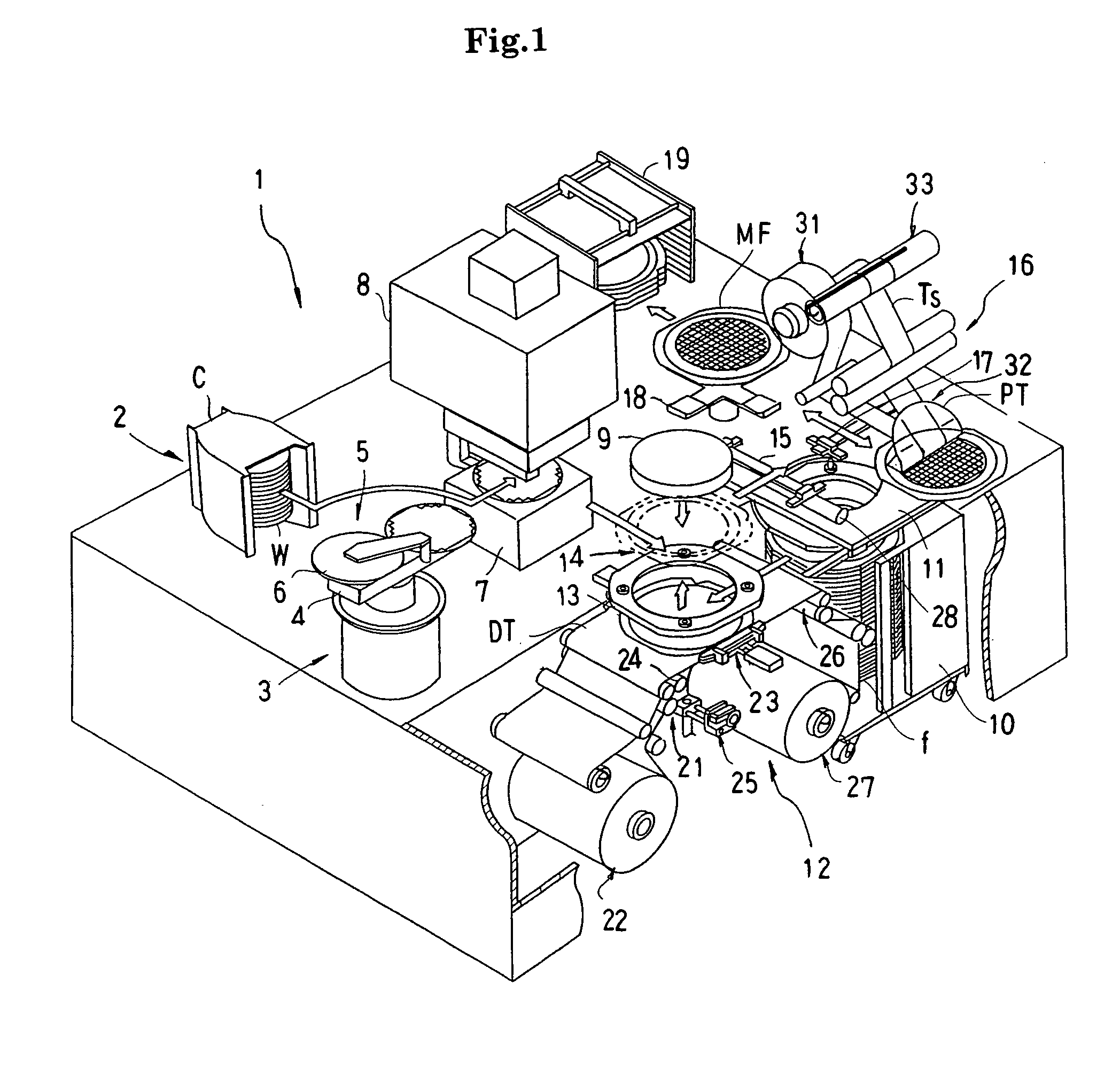

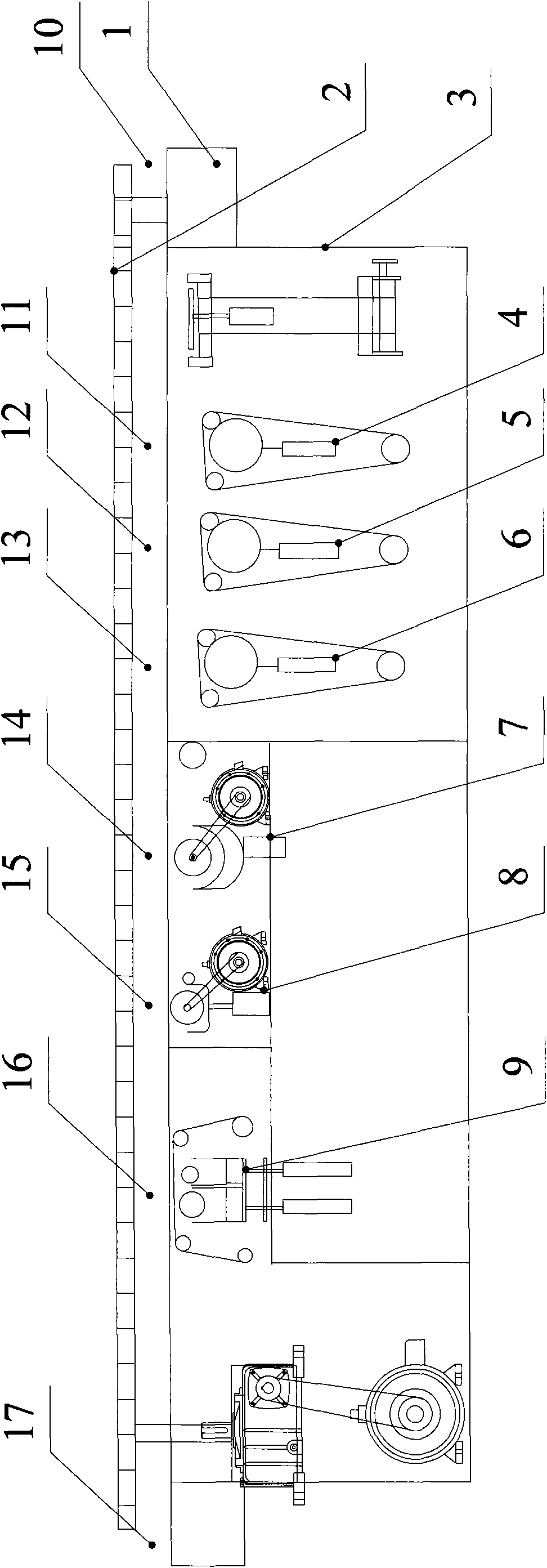

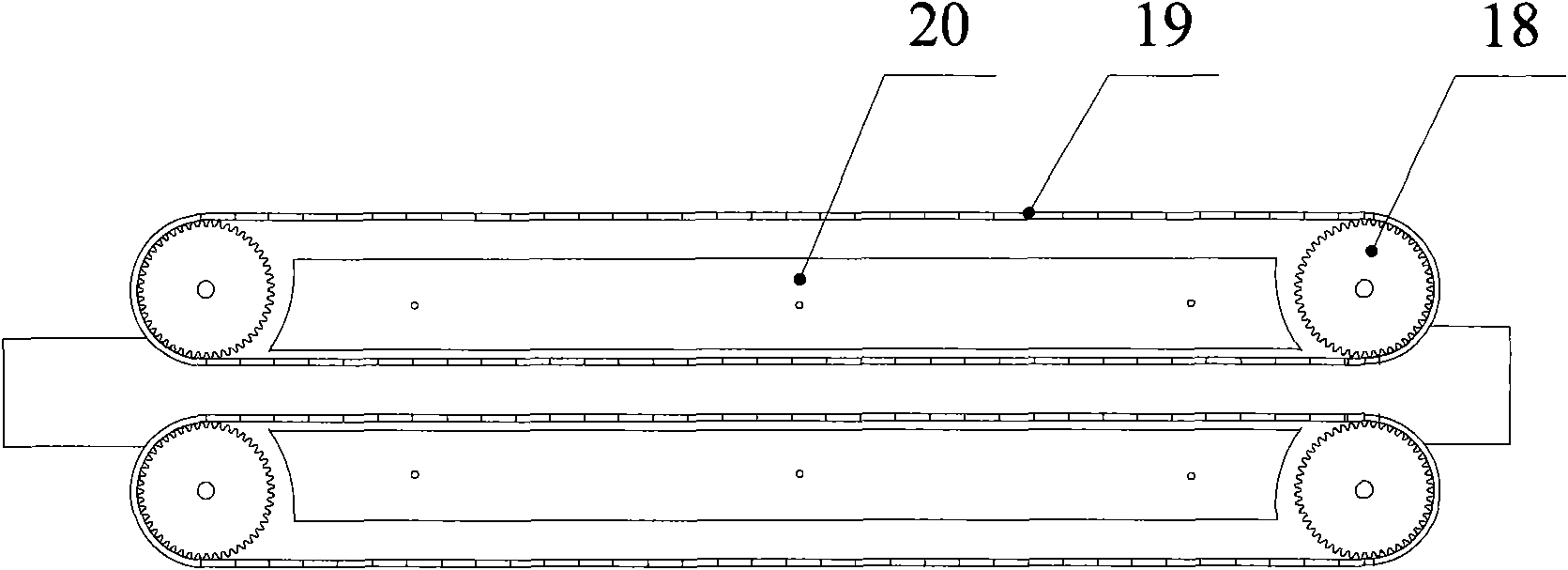

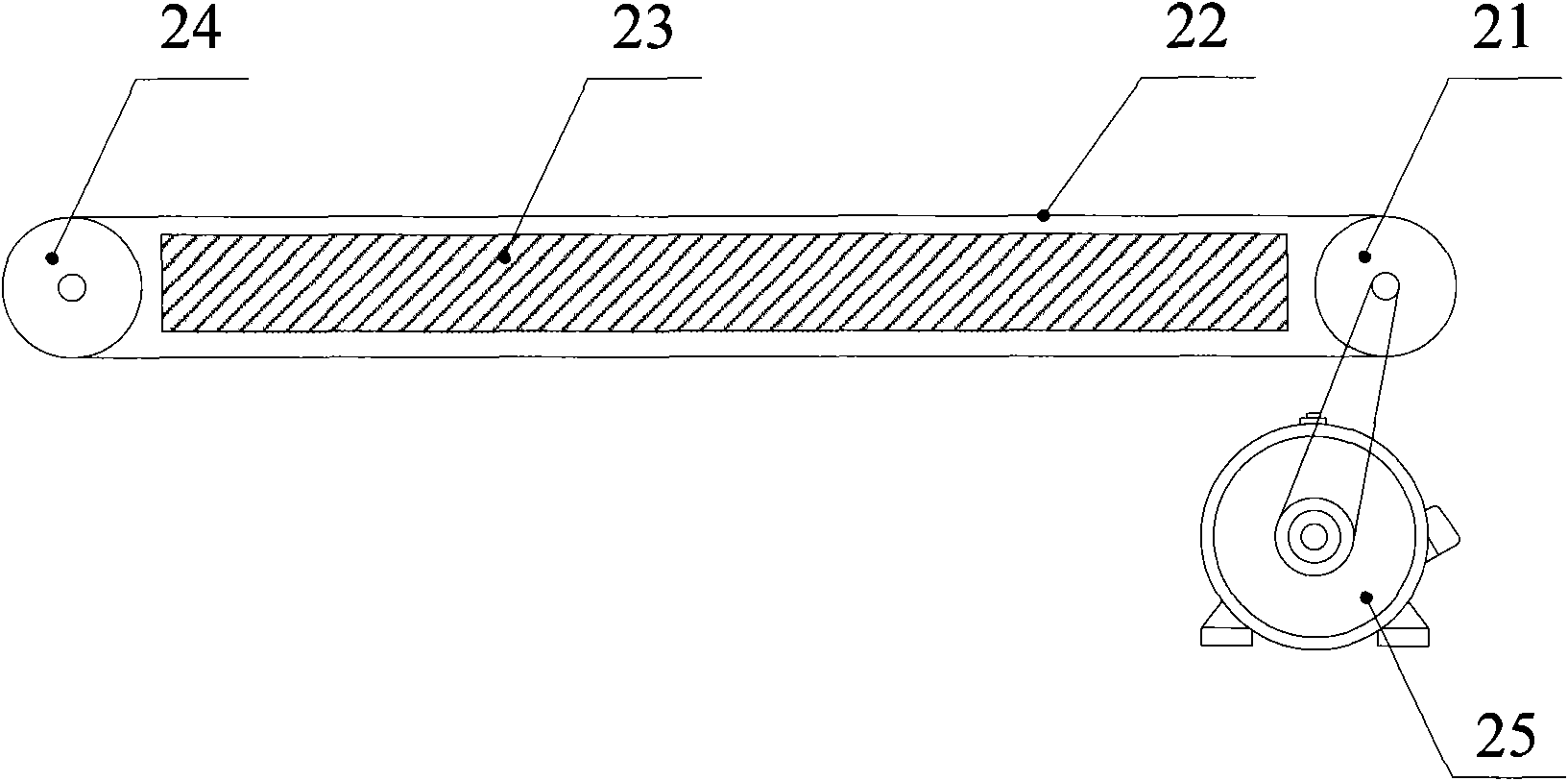

Full-automatic gold stamping machine

InactiveCN101676103AMeet environmental protection requirementsAvoid labor intensityTransfer printingPrinting press partsFailure rateBusiness card

The invention relates to the field of paper product processing machinery, in particular to a full-automatic gold stamping machine used for paper end surface side. The full-automatic gold stamping machine comprises a control console and a stander, wherein the stander is provided with a working platform; the gold stamping machine also comprises a chain transmission device used for clamping and conveying paper; the chain transmission device is arranged above the working platform, and a transmission channel is arranged between the chain transmission device and the working platform; one end of thetransmission channel is provided with a paper feeding station, and the other end thereof is provided with a paper exiting station; meanwhile, the gold stamping machine also comprises a grinding device, a deashing device, a sizing device and a gold stamping device. The device has the advantages of stable running, high production efficiency, full-automatic control, low failure rate, safety and reliability as well as convenient operation, and can be widely used for gold stamping (or silver stamping, coloring) of end surfaces of high quality books, notebooks, business cards, identification cards,bank cards and products made of PVC material so as to improve the added value of the product.

Owner:沈华荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com