Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

316 results about "Hydroxypropyl guar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Galactasol™ carboxymethyl hydroxypropyl guar (CMHPG) is an anionic guar derivative used as a gelling agent for oil and gas hydraulic fracturing fluids to suspend proppant.

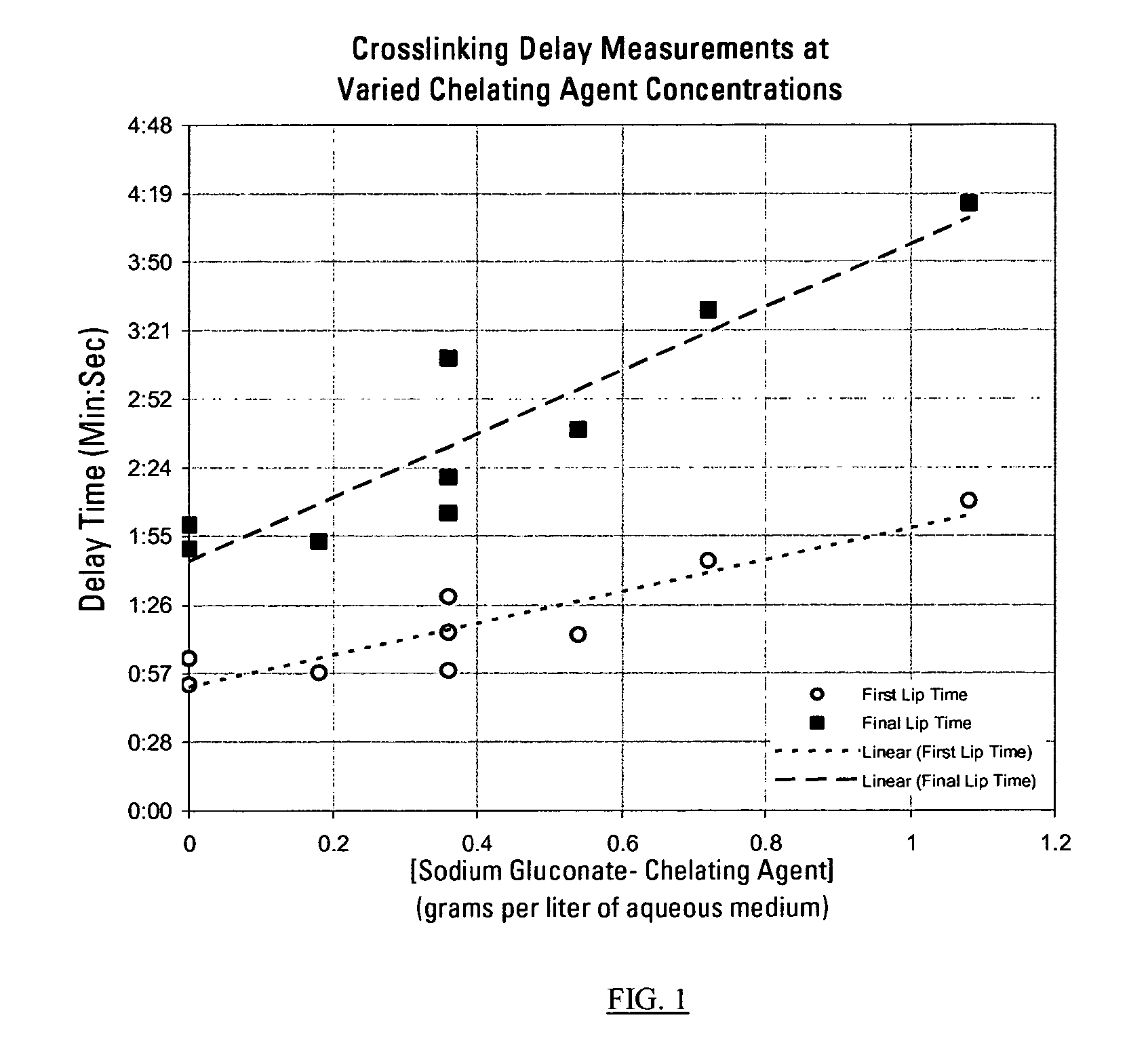

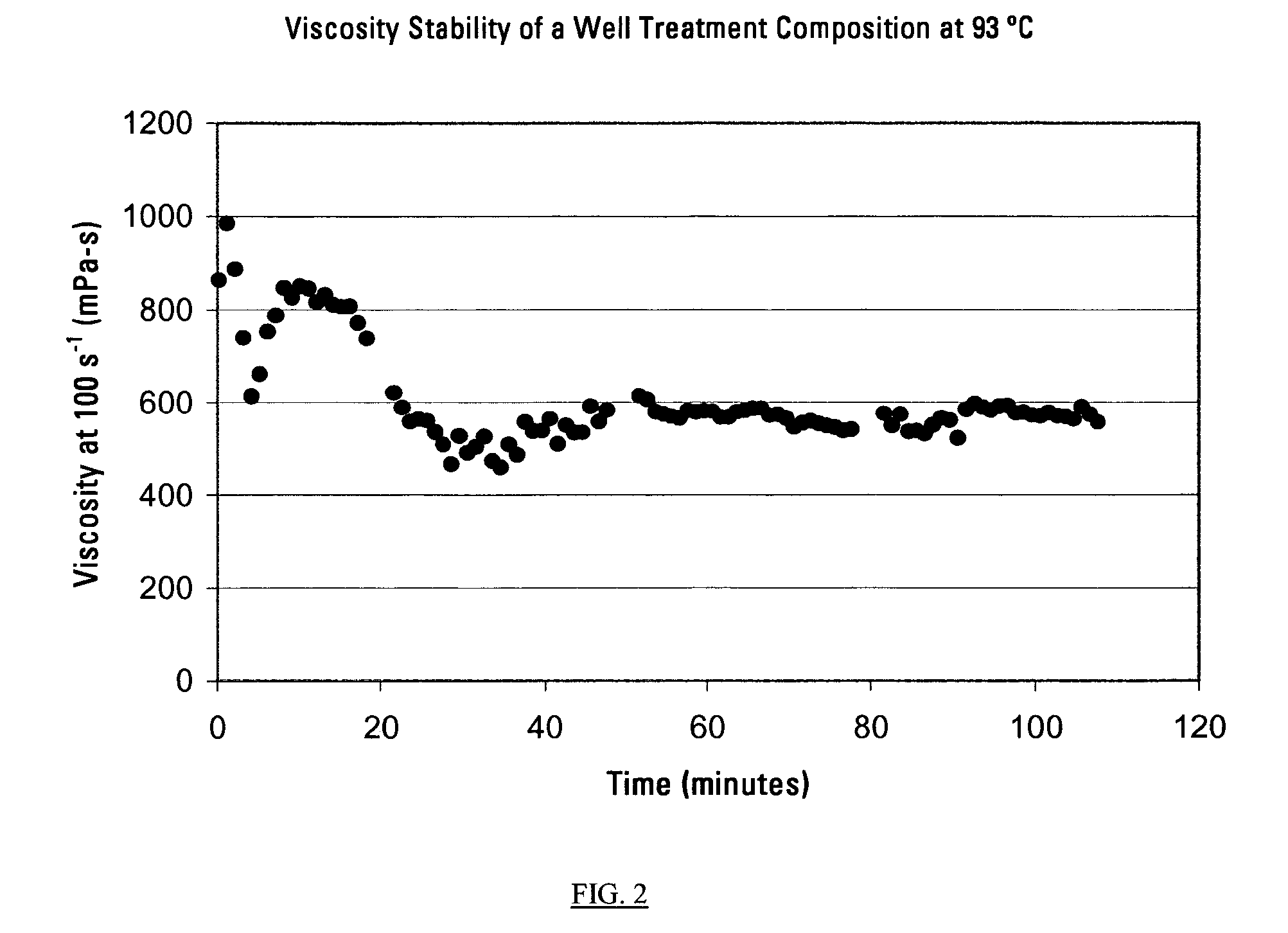

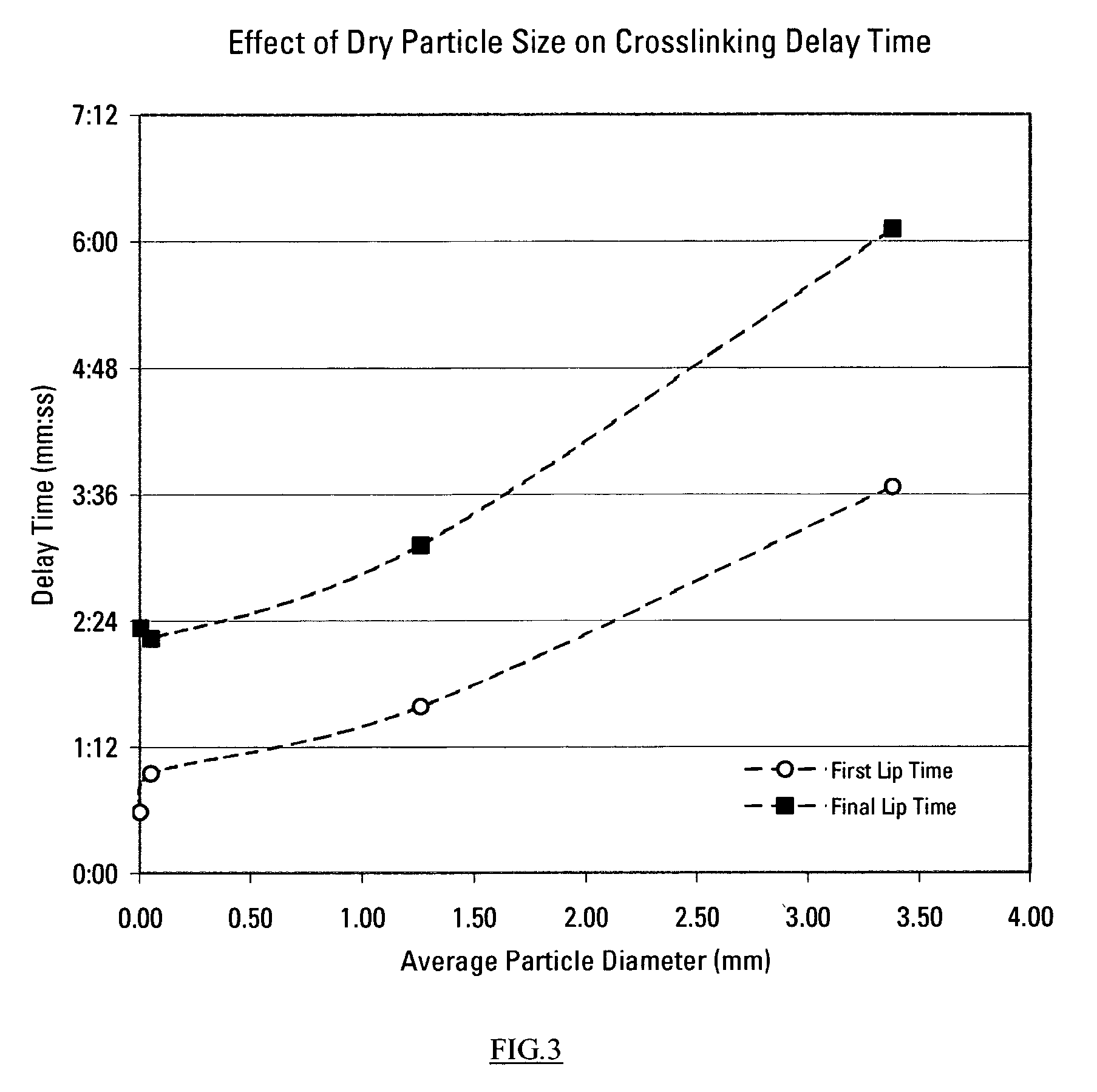

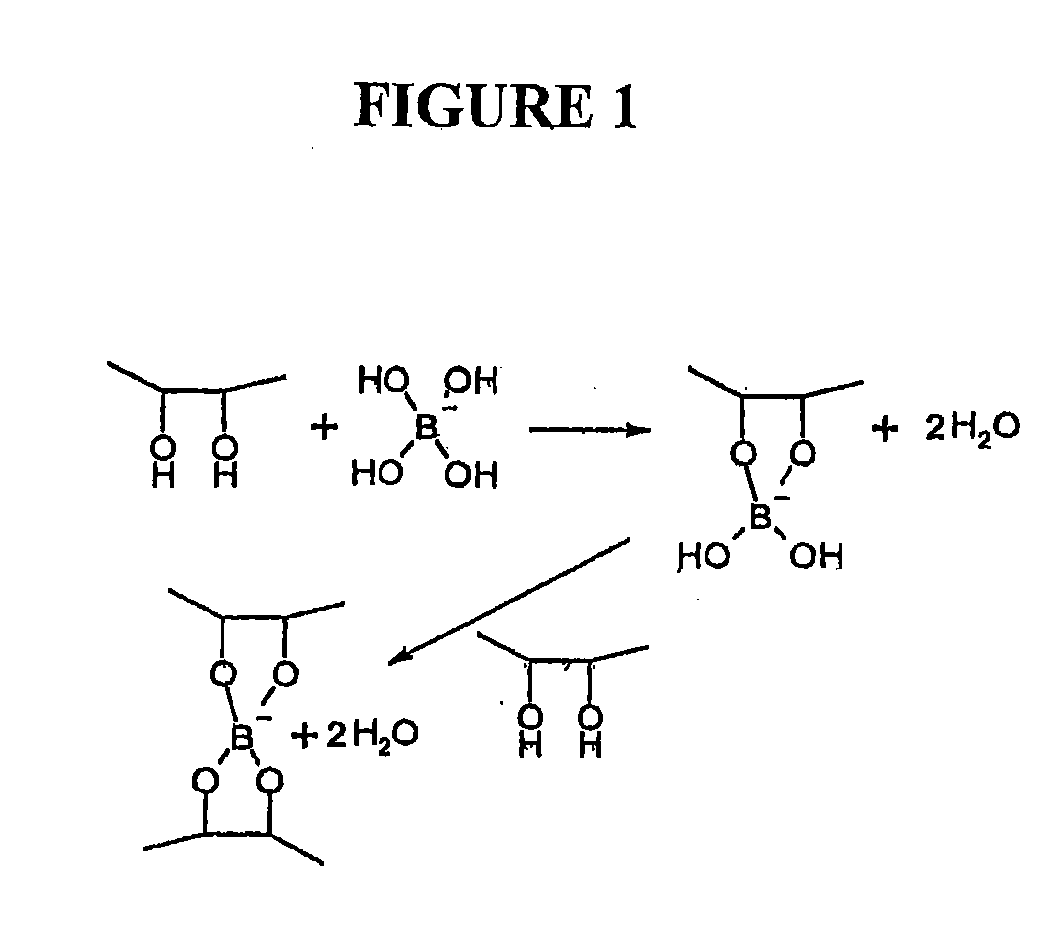

Well treatment composition crosslinkers and uses thereof

This invention relates to compositions used in treating subterranean formations, which include a hydrated polymer, and a dry blended multi-functional component. The hydrated polymer and dry blended multi-functional component are mixed at the ground surface of a wellsite, and subsequently injected into the formation providing controlled delay in crosslinking to achieve targeted fluid viscosity properties. The hydrated polymer may be a guar, hydroxypropyl guar, carboxymethyl guar, carboxymethylhydroxypropyl guar, synthetic polymers, and guar-containing compounds. The dry blended multi-functional component may include a crosslinker and a chelating agent, and the well treatment fluid may further include an activator mixed with the hydratable polymer. The chelating agent may be a polyols, gluconate, sorbitol, mannitol, carbonate, or any mixtures thereof. The crosslinker may be any source of boron, alkaline earth metal borates, alkali metal borates, zirconium compounds, titanium compounds, or any combination thereof, while the activator may be a caustic soda or magnesium oxide compound. The invention further provides methods for producing a well treatment composition including providing a hydrated polymer, and providing a dry blended multi-functional component. Also, methods of hydraulically fracturing a subterranean formation, as well as cleanup operations and gravel packing a wellbore are provided as well.

Owner:SCHLUMBERGER TECH CORP

Polymeric artificial tear system

InactiveUS20090270345A1Facilitate cross-linkingIncreased formationBiocideSenses disorderDiolBoric acid

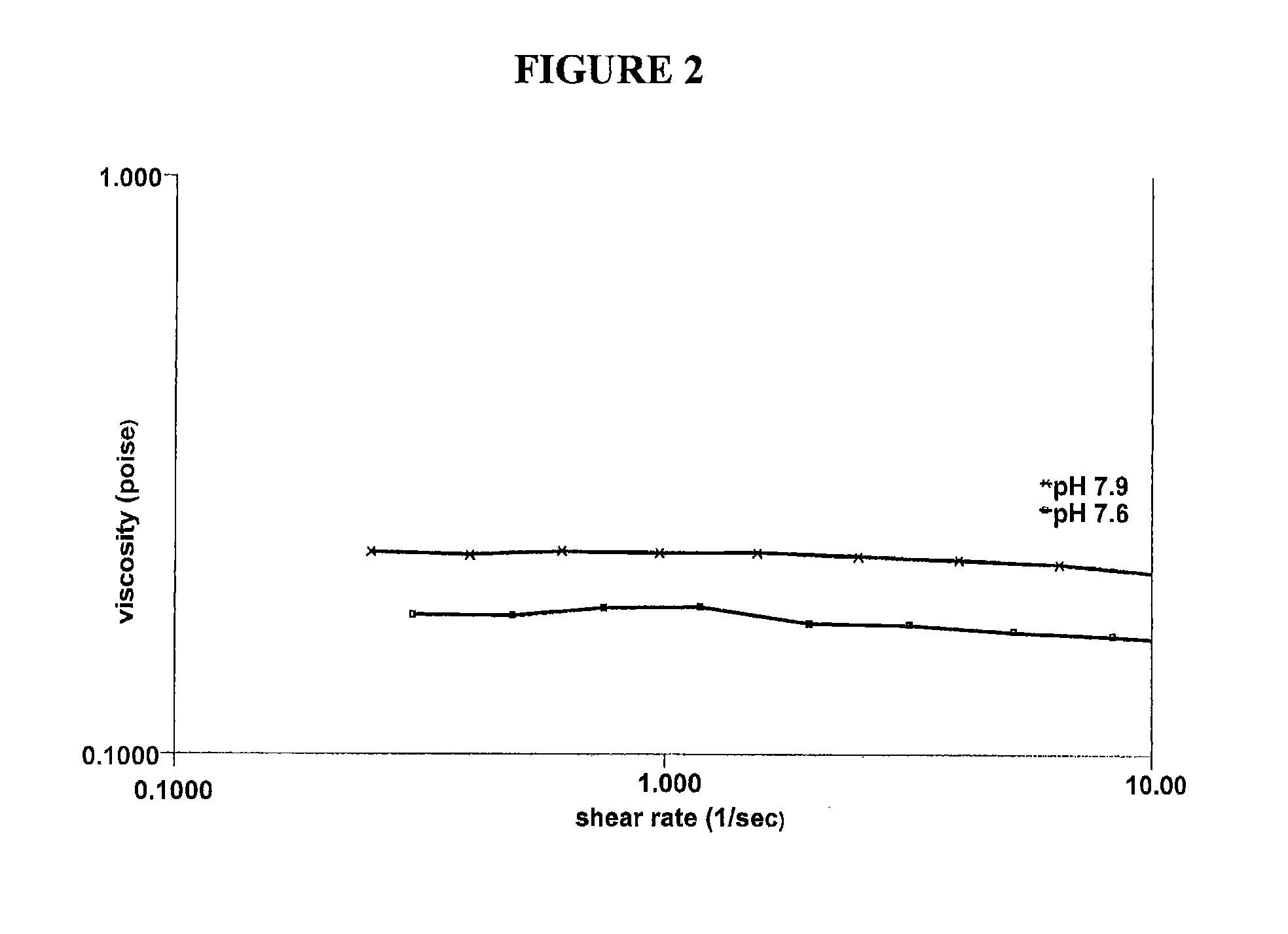

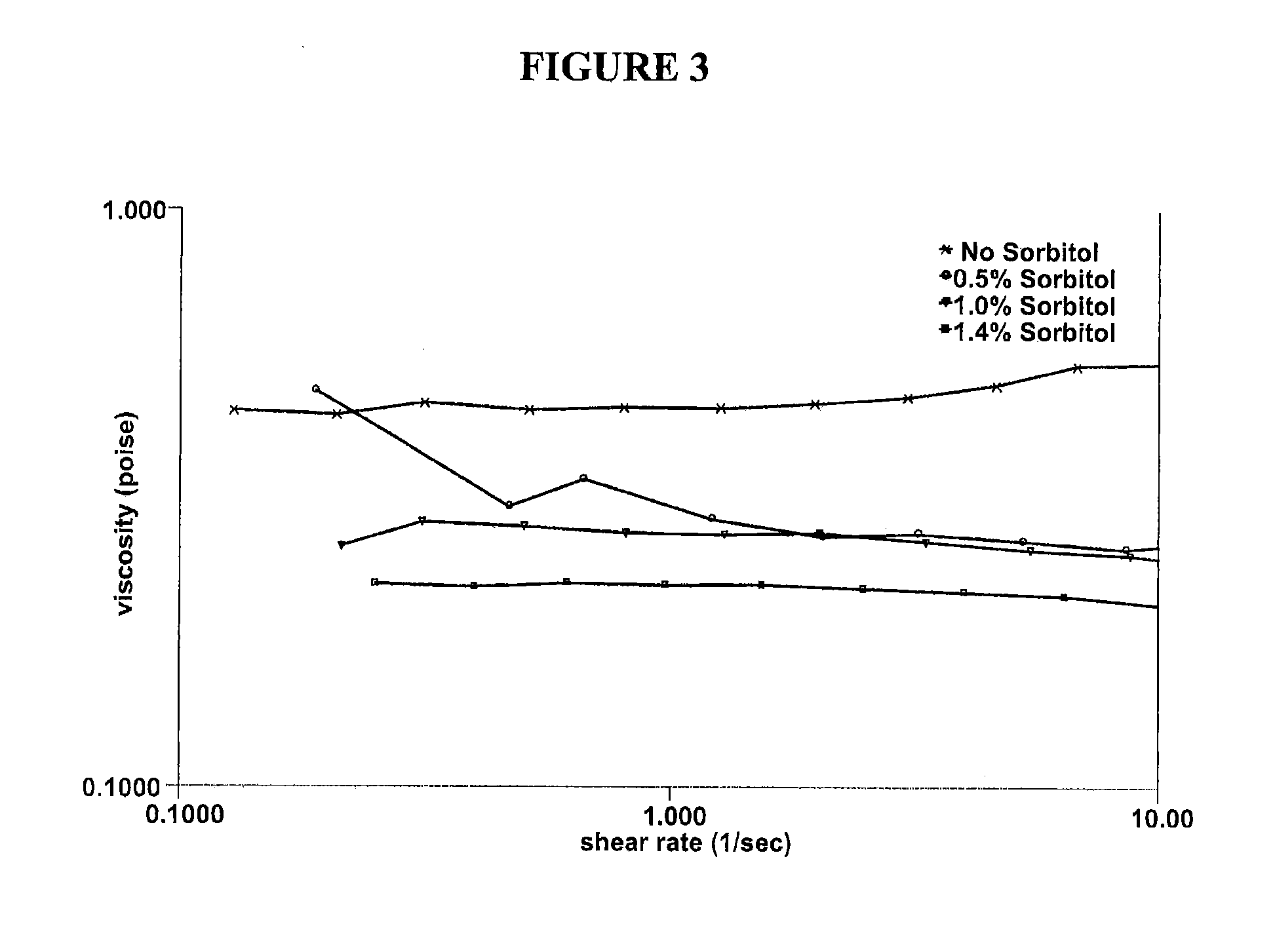

The present invention relates to artificial tear formulations and ophthalmic formulations suitable for drug delivery. The formulations comprise galactomannans such as guar or hydroxypropyl guar and a borate source such as boric acid. The formulations further comprise a cis-diol such as sorbitol that interferes with the cross-linking of galactomannan and borate. Optionally, the formulations are substantially free of divalent cations.

Owner:ALCON RES LTD

Non-damaging fracturing fluids and methods for their use

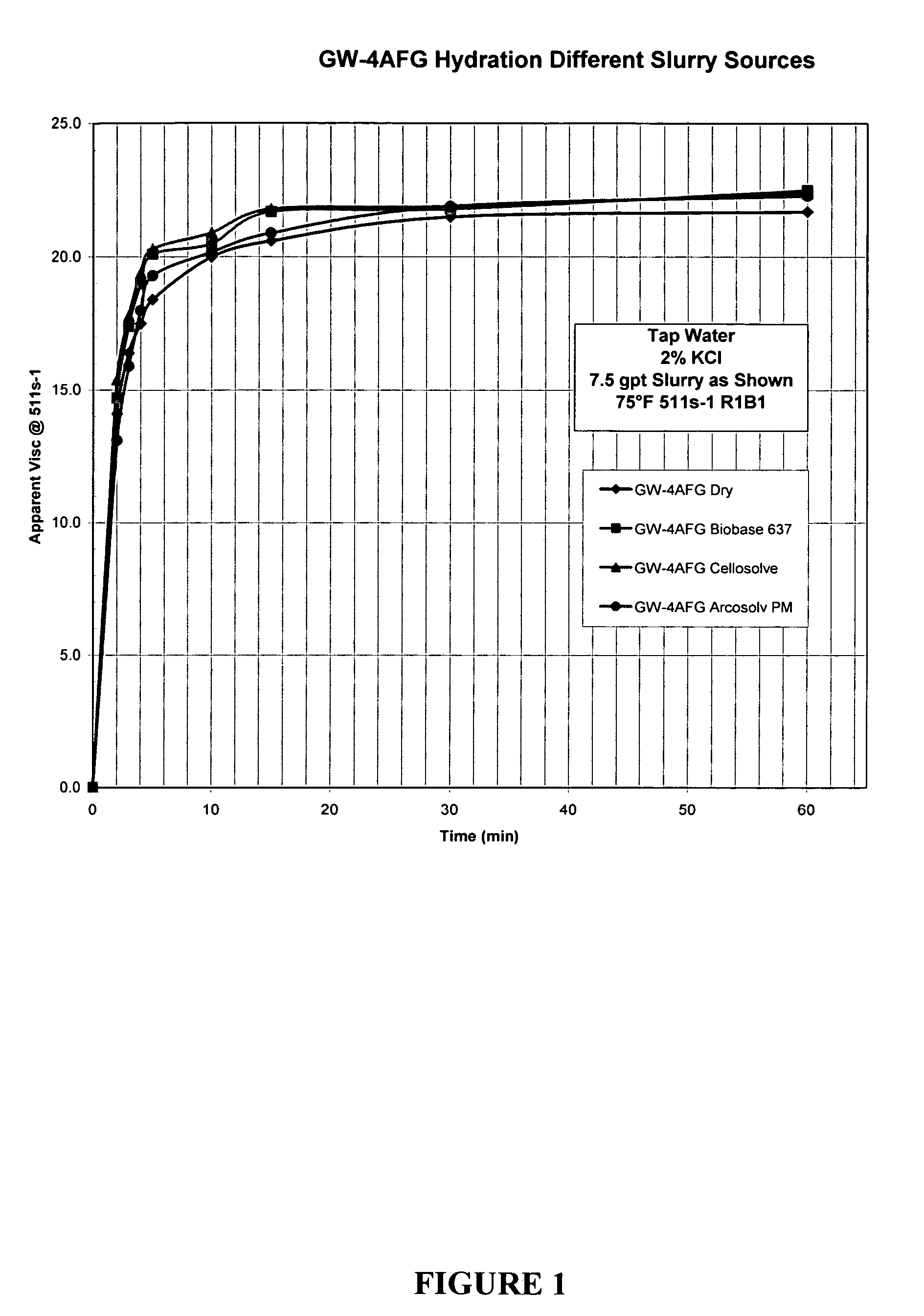

A non-aqueous well treatment fluid is provided containing a glycol-soluble polymer such as highly substituted hydroxypropyl guar in an alkylene glycol or alkylene glycol ether solvent. A non-aqueous slurry composition for use in preparing water-based well treatment fluids is also provided, having a glycol-soluble polymer such as highly substituted hydroxypropyl guar in an alkylene glycol or alkylene glycol ether solvent. A method is provided for utilizing such a slurry to prepare a water-based well treatment fluid, the method including loading a water-soluble polymer into the slurry, then metering the loaded slurry into water.

Owner:BJ SERVICES CO

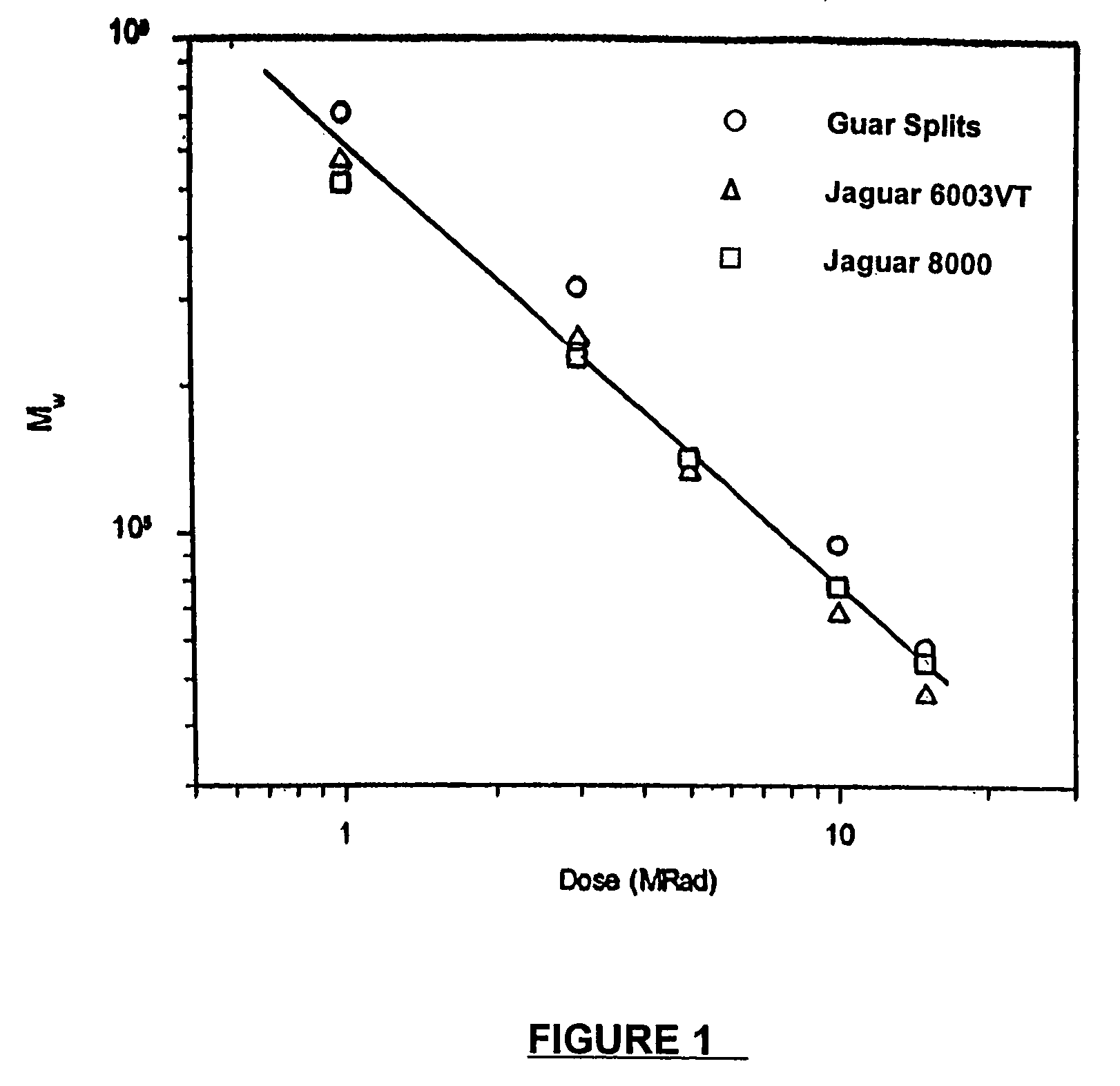

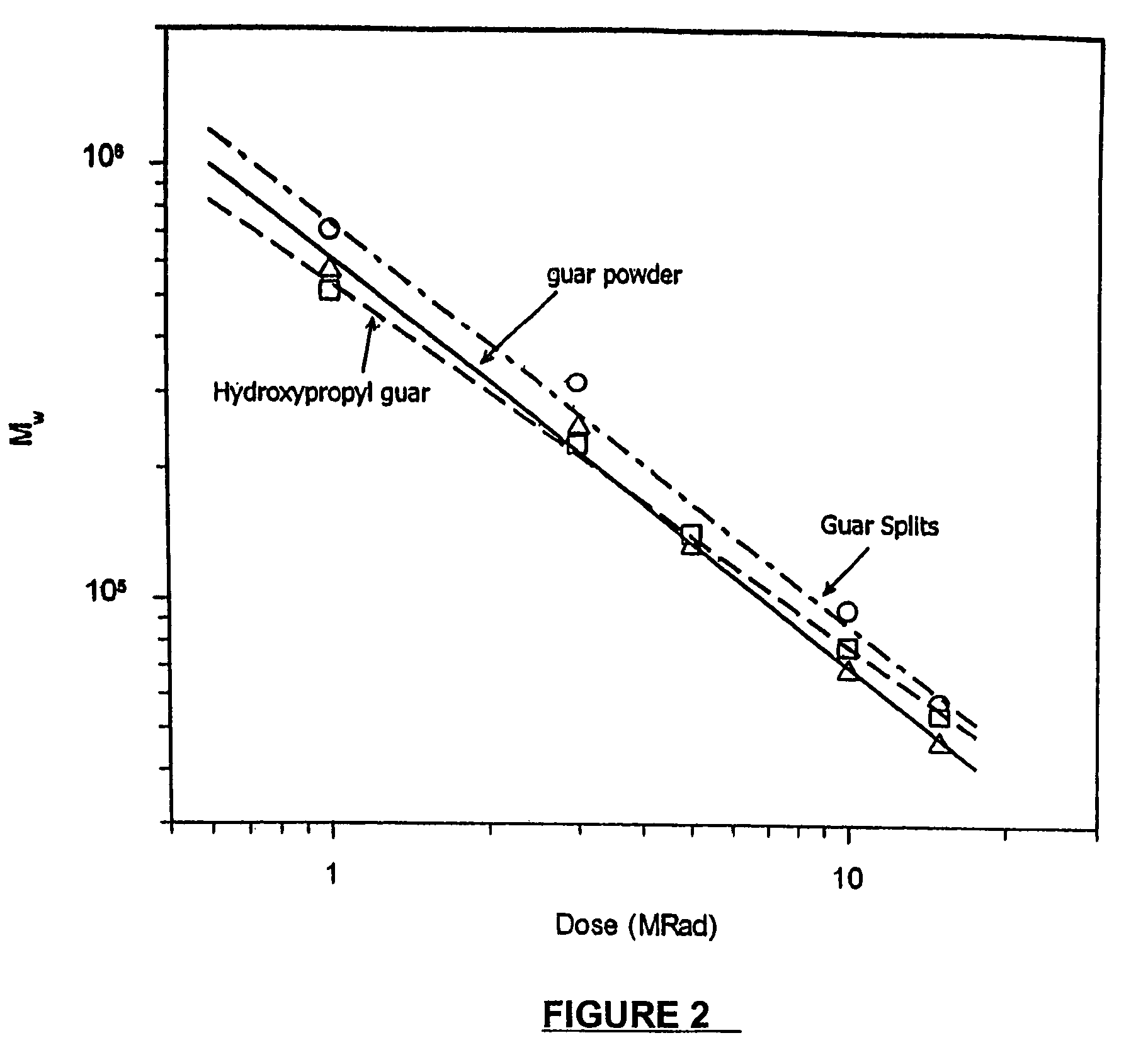

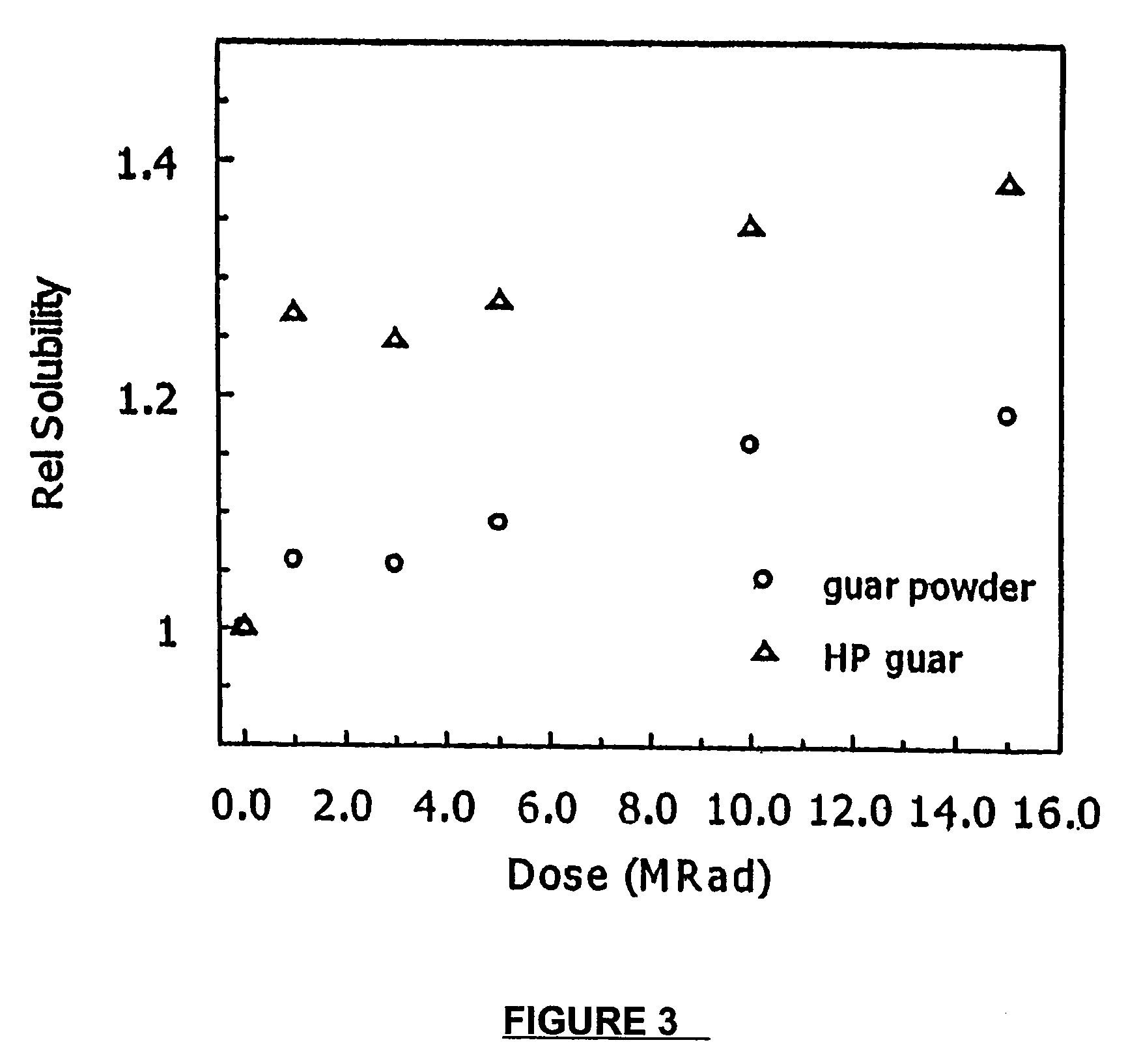

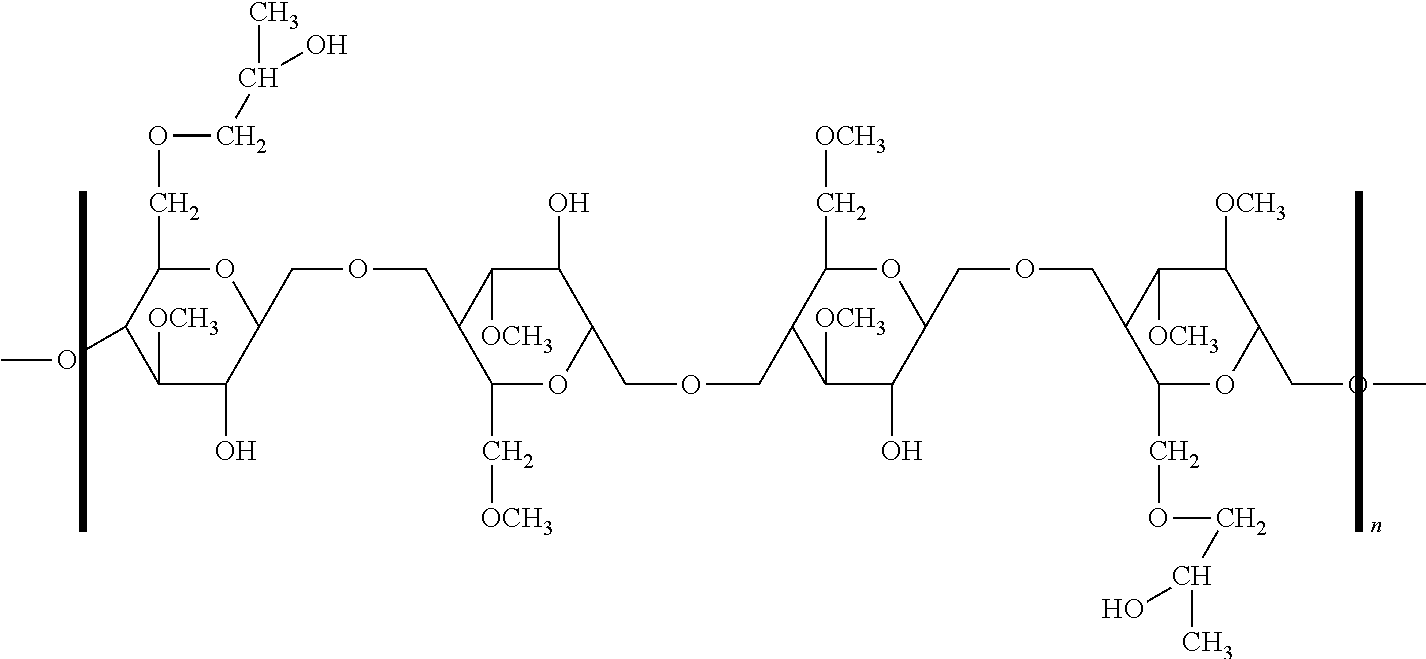

Molecular weight reduction of polysaccharides by electron beams

ActiveUS7259192B2Promote recoveryEasy to useOther chemical processesFibre treatmentHigh energyOil production

A method of depolymerizing galactomannan-type polysaccharide polymers and xanthan, preferably galactomannans, to a pre-selected lower molecular weight by irradiation with high energy electron beams. The preferred galactomannans for treatment according to this method are guar gum, guar splits and hydroxypropyl guar. In a preferred embodiment the guar gum is depolymerized preferably to a molecular weight of about 150,000 Daltons to about 200,000 Daltons. The depolymerized guar has a polydispersity of less than about 3.0 and is useful in oil well fracturing to enhance oil production.

Owner:RHODIA OPERATIONS SAS

Benefit agent delivery particles comprising non-ionic polysaccharides

InactiveUS20140206587A1High affinityCosmetic preparationsHair cosmeticsHydroxyethyl ethylcelluloseEmulsion polymerization

The invention provides a composition comprising a benefit agent delivery particle comprising at least one of hydroxylpropyl methyl cellulose, hydroxylethyl methyl cellulose, hydroxylpropyl guar, hydroxylethyl ethyl cellulose or methyl cellulose. The benefit agent delivery particle may further comprise a non-polysaccharide polymer, preferably an aminoplast polymer. The benefit agent delivery particle may comprise a perfume. The invention also provides a process for the manufacture of the particles in which perfume oil is encapsulated using emulsion polymerization to form core-shell particles, (in the alternative the perfume may be adsorbed later) and, a further polymer layer is formed on the outer surface of the core shell-particles in the presence of the delivery aid.

Owner:CONOPCO INC D B A UNILEVER

Well Treatment Composition Crosslinkers and Uses Thereof

This invention relates to compositions used in treating subterranean formations, which include a hydrated polymer, and a dry blended multi-functional component. The hydrated polymer and dry blended multi-functional component are mixed at the ground surface of a wellsite, and subsequently injected into the formation providing controlled delay in crosslinking to achieve targeted fluid viscosity properties. The hydrated polymer may be a guar, hydroxypropyl guar, carboxymethyl guar, carboxymethylhydroxypropyl guar, synthetic polymers, and guar-containing compounds. The dry blended multi-functional component may include a crosslinker and a chelating agent, and the well treatment fluid may further include an activator mixed with the hydratable polymer. The chelating agent may be a polyols, gluconate, sorbitol, mannitol, carbonate, or any mixtures thereof. The crosslinker may be any source of boron, alkaline earth metal borates, alkali metal borates, zirconium compounds, titanium compounds, or any combination thereof, while the activator may be a caustic soda or magnesium oxide compound. The invention further provides methods for producing a well treatment composition including providing a hydrated polymer, and providing a dry blended multi-functional component. Also, methods of hydraulically fracturing a subterranean formation, as well as cleanup operations and gravel packing a wellbore are provided as well.

Owner:DESSINGES MARIE NOELLE +1

High temperature resistant well-cementing spacer fluid and preparation method thereof

ActiveCN104449606AGood thickeningGood suspensionDrilling compositionSodium BentoniteSuspending Agents

The invention relates to a high temperature resistant well-cementing spacer fluid and a preparation method thereof. The spacer fluid consists of: 100 parts by weight of fresh water, 2-8 parts by weight of a suspending agent, 2-10 parts by weight of a diluents, 25-400 parts by weight of a weighting agent, and 1-15 parts by weight of a flushing agent. Specifically, the suspending agent is composed of 100 parts by weight of OCMA bentonite, 2 parts by weight of hydroxypropyl guar gum and 8 parts by weight of xanthan gum; the diluent is composed of 100 parts by weight of sodium lignin sulfonate and 20 parts by weight of sulfonated tannin; the flushing agent consists of 40 parts by weight of fatty alcohol-polyoxyethylene ether, 40 parts by weight of triethanolamine oleate and 20 parts by weight of sodium tripolyphosphate; and the weighting material is barite. The spacer fluid has stable performance under 180DEG C high temperature condition, still has good rheological performance under the premise of ensuring the system good suspension stability, is compatible with conventional cement slurry and drilling fluid systems, improves the rheological properties of drilling fluid, enhances the displacement efficiency, and reinforces the cementation quality of a cement ring with a well cementation first interface and a second interface.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

Formula for preparing fracturing liquid by utilizing biological enzyme preparation

The invention relates to a formula for preparing fracturing liquid by utilizing a biological enzyme preparation, and the biological enzyme is prepared by 0.2-0.5 percent of biological enzyme de-plugging agent by weight, a thickening agent, i.e. hydroxypropyl guar, a cross linking agent, i.e. borax, or an organic boron cross linking agent and a biological gel breaker, wherein the cross linking ratio of the cross linking agent is 100:5 or 100:0.25. The preparation has the advantages of good environment protection property, super activity and catalytic force, small usage amount, convenient use, enhanced efficiency, no residue after gel breaking, long action time under a stratum, good recovery and stability function on stratum rock cores, water-solubility, good wetting effect, simple and convenient operation, simple field construction equipment, and the like, is suitable for an oil well with a pH value from 4 to 10, and is favorable to accelerating the movement of water molecules.

Owner:SUNCOO PETROLEUM TECH

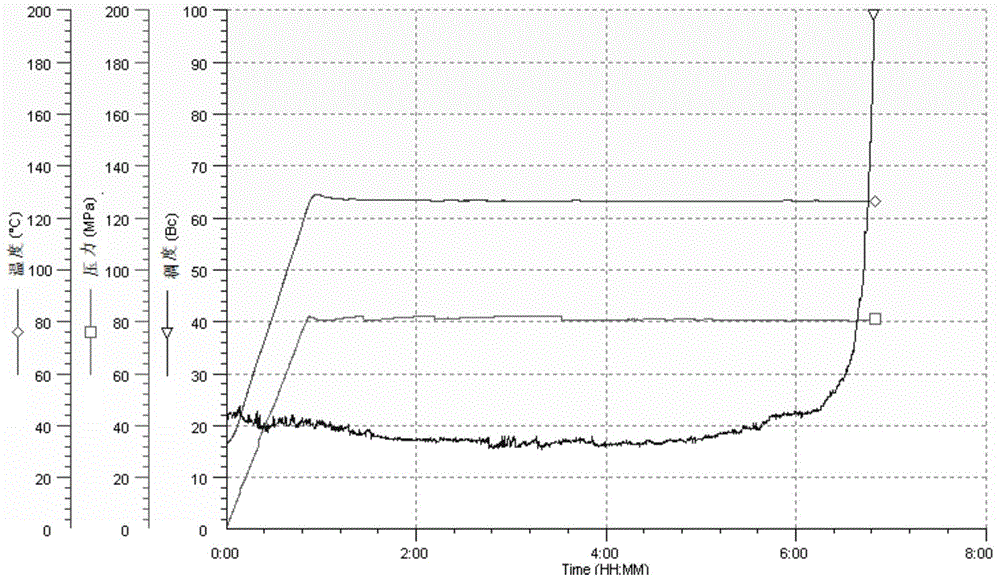

Seawater-based fracturing fluid for fracturing sea high-temperature oil-gas reservoir

ActiveCN103215024AFulfil requirementsControllable delay timeDrilling compositionCross-linkFracturing fluid

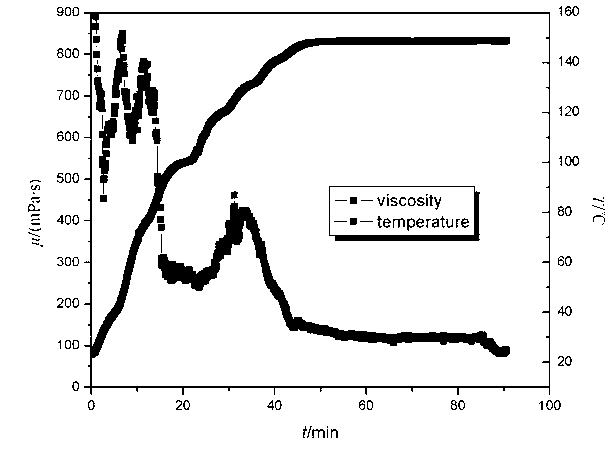

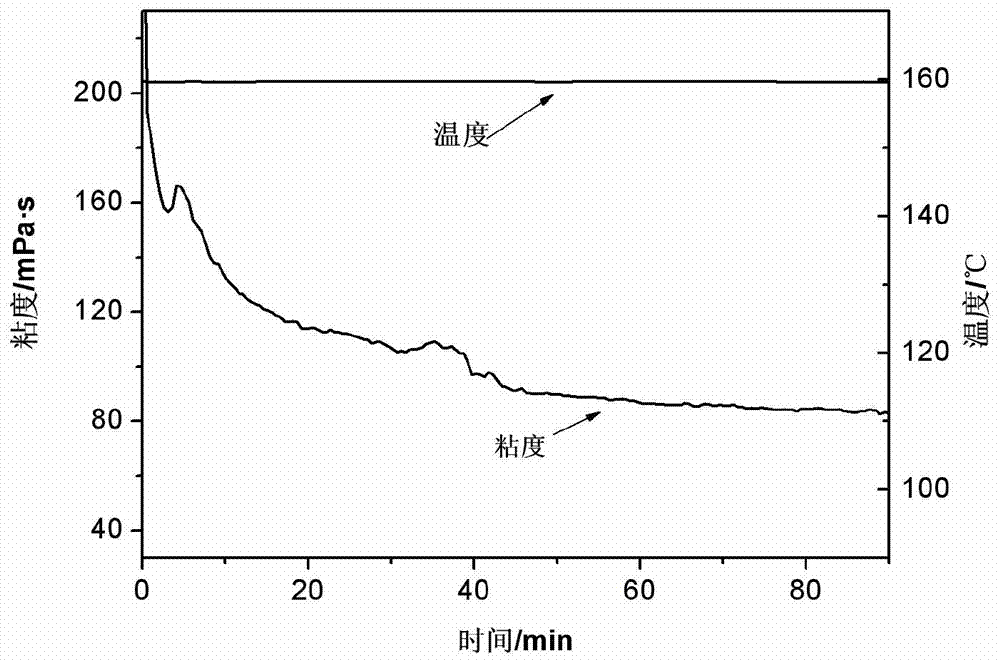

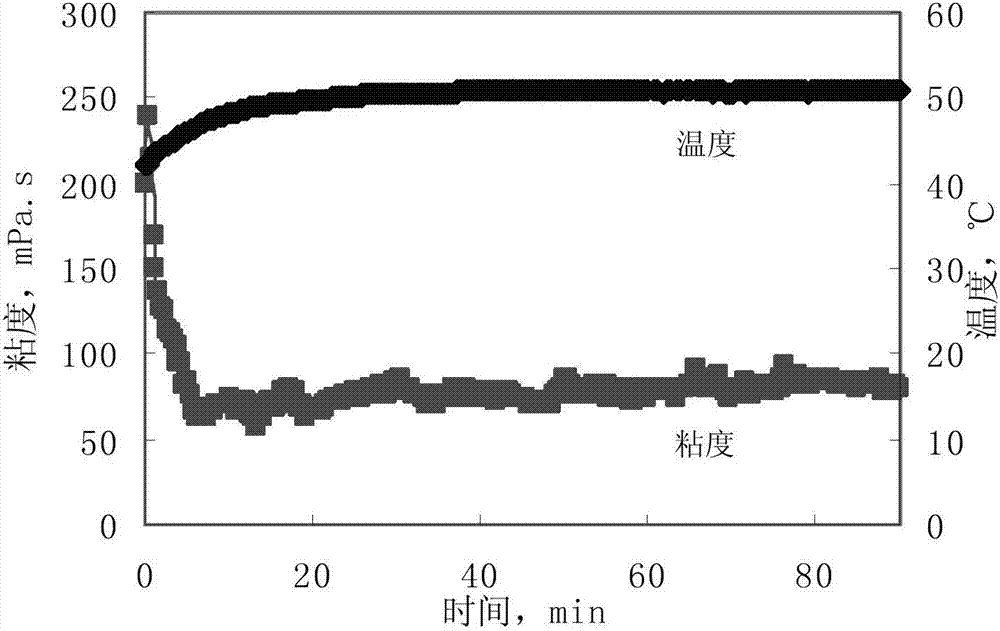

The invention discloses a seawater-based fracturing fluid for fracturing a sea high-temperature oil-gas reservoir and relates to the technical field of cross-linked gel fracturing fluid. The seawater-based fracturing fluid comprises a base solution, a cross-linking agent and a thickening agent, wherein the base solution comprises the components (in percentage by weight) in terms of the weight of the prepared seawater-based fracturing fluid total solution as follows: 0.3%-0.8% of thickening agent, 0.1%-0.3% of pH regulating agent, 0.1%-0.5% of discharge aiding agent and the balance being seawater; relative to the mass fraction of the base solution, the cross-linking agent is 0.4%-0.6%; and the thickening agent refers to guar gum, carboxy-methyl hydroxypropyl guar gum, hydroxypropyl guar gum, fenugreek gum or sesbania gum. The seawater-based fracturing fluid is adopted, so that the dissolving speed of the thickening agent is quick, and therefore, direct mixing and continuous constructing can be realized, and therefore, the seawater-based fracturing fluid is in particular suitable for the fracturing construction of the sea high-temperature oil-gas reservoir. Meanwhile, the fracturing fluid can be continuously sheared for 90 minutes under the conditions of 150 DEG C and 170s<-1>, so that the viscosity is kept to be 70mPa.s or more.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

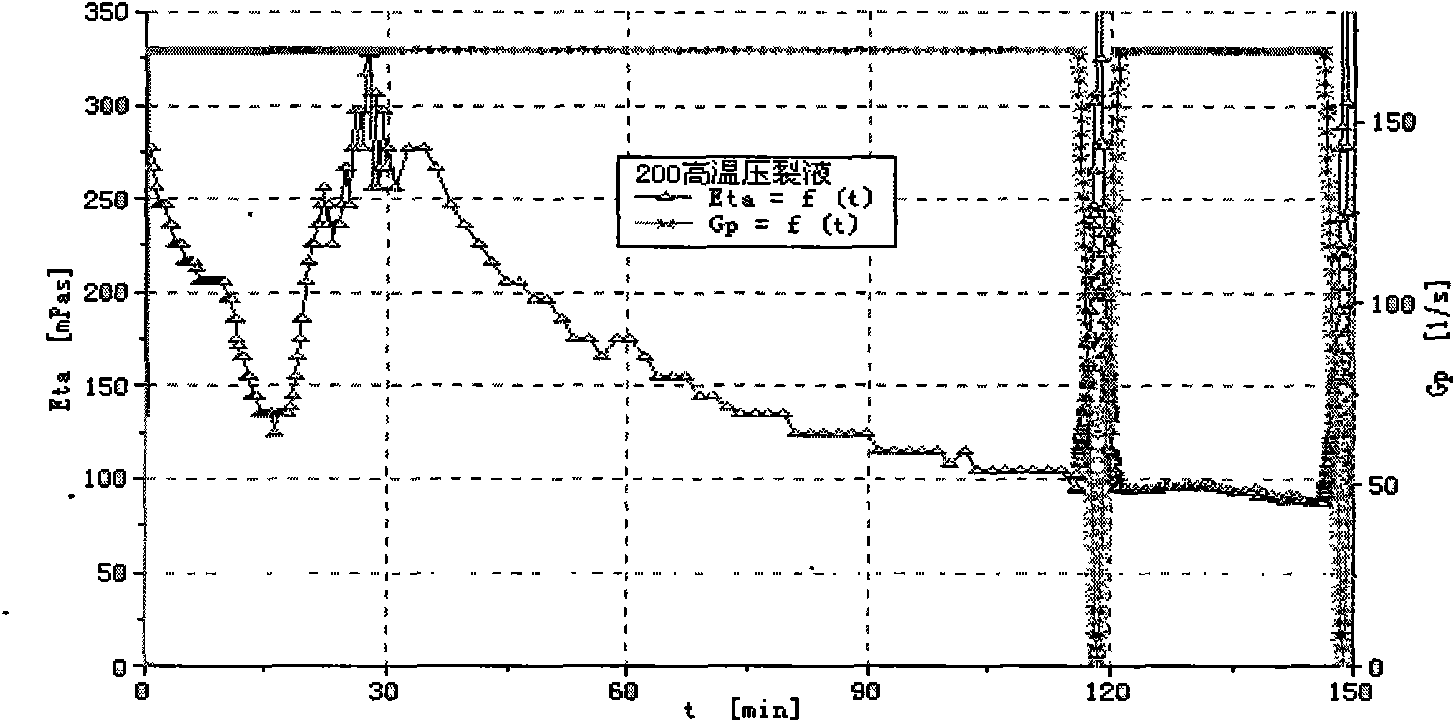

200-DEG C super-high temperature fracturing fluid

InactiveCN101633839AReduce broken linksReduce the possibility of broken linksDrilling compositionPersulfateFracturing fluid

The invention relates to a 200-DEG C super-high temperature fracturing fluid. The fracturing fluid comprises the following components in terms of mass percentage: 0.60% of carboxymethyl hydroxypropyl guar gum, 0.35% of polyacrylamide, 0.18% of organosilicon polyether, 0.09% of polyoxypropylene polyoxyethylene polyoxypropylene octadecanol ether, 0.24% of dodecyl ammonium chloride, 0.12% of cation long chain polymer, 0.33% of organo-metallic crosslinker, 0.00027% of persulfate, 0.0001% of high-valence oxysalt and the balance of water. The fracturing fluid is high-temperature-resistant and shear-resistant and has complete gel breaking property.

Owner:DAQING OILFIELD CO LTD

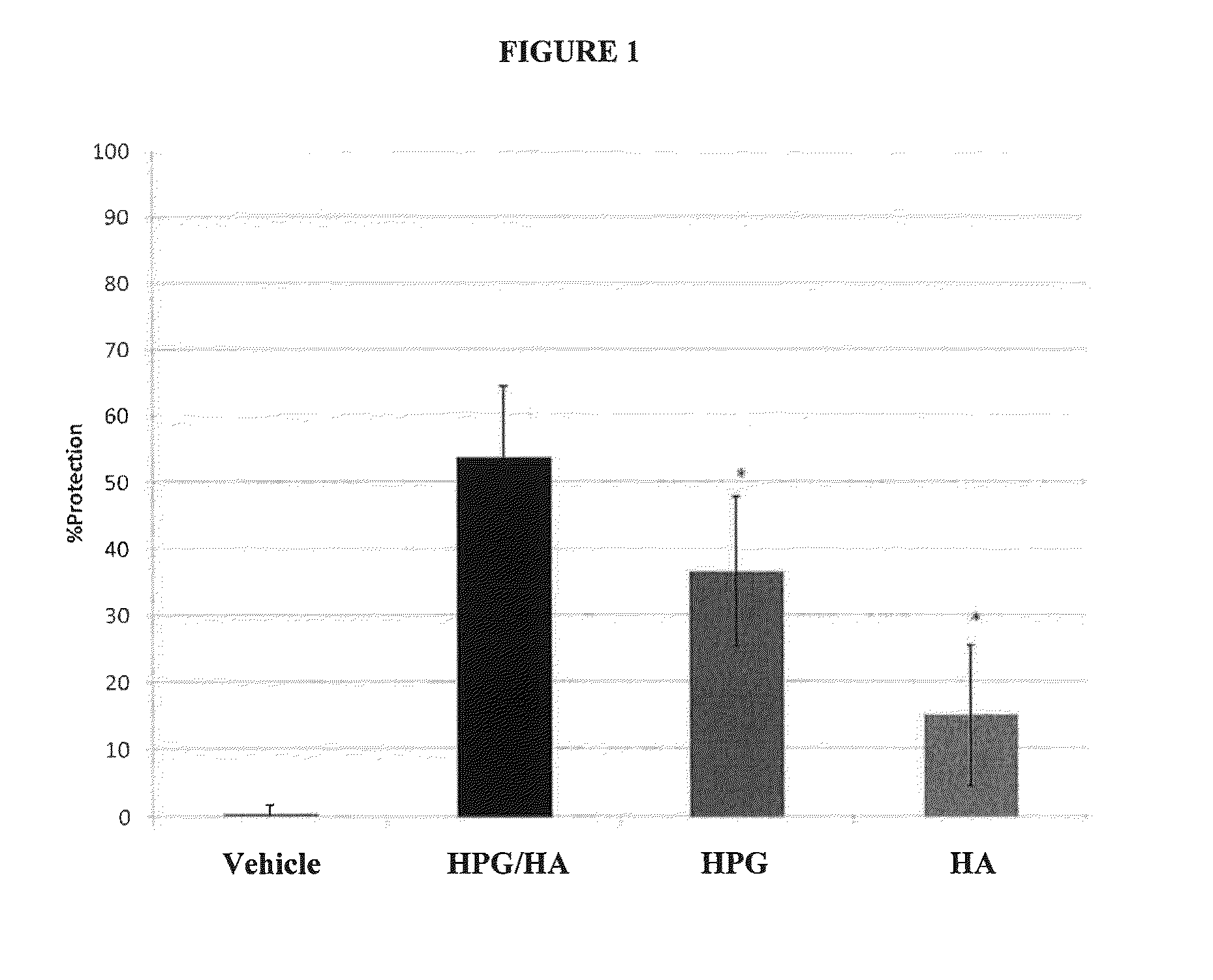

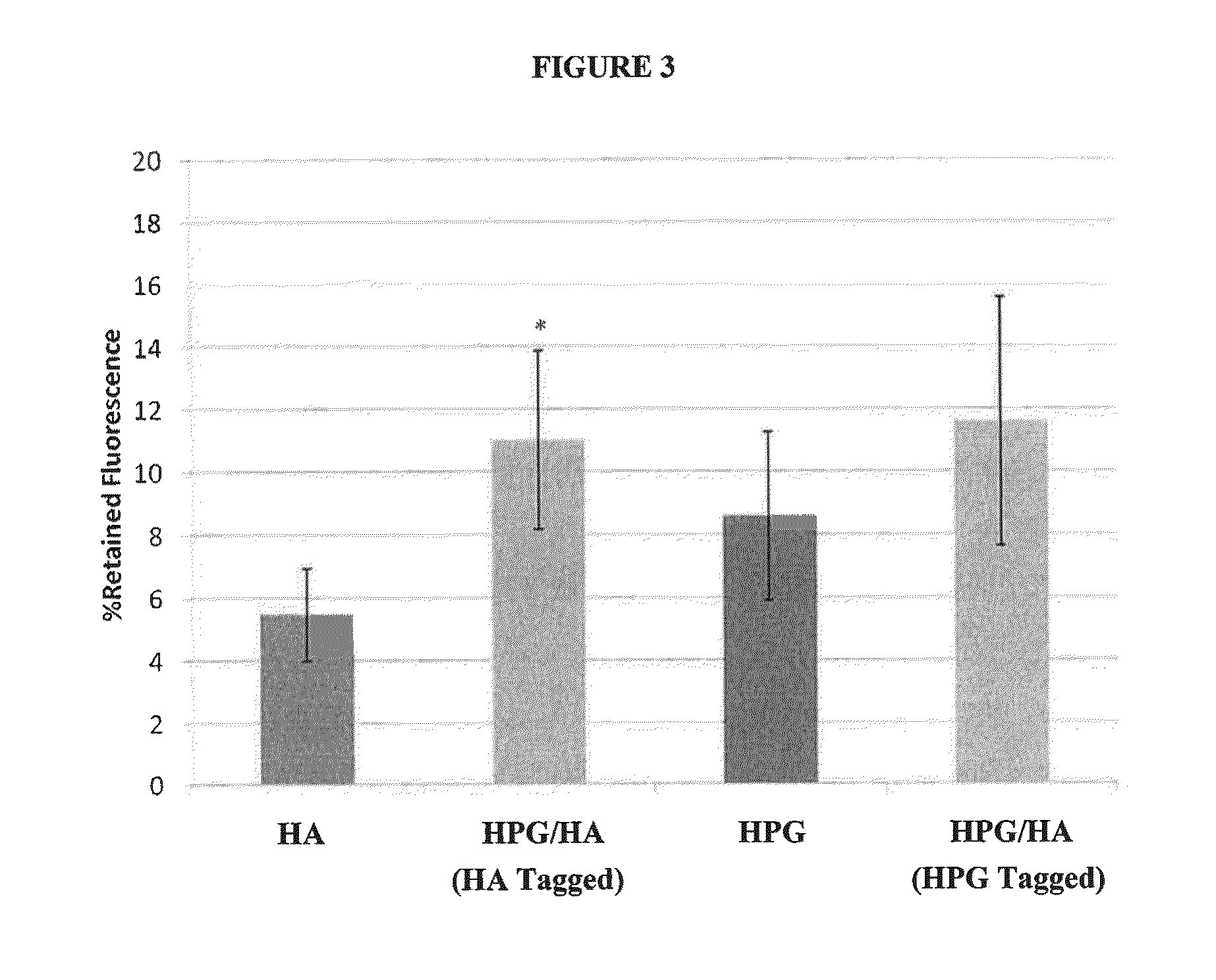

Ophthalmic compositions with improved dessication protection and retention

InactiveUS20130296264A1Improved desiccation protectionImprove retention characteristicsBiocideSenses disorderDiolHyaluronic acid

The present invention relates to artificial tear compositions and ophthalmic compositions suitable for drug delivery. In one embodiment of the present invention, the compositions comprise a galactomannan polymer such as guar or hydroxypropyl guar, hyaluronic acid, and a cis-diol such as sorbitol. In a preferred embodiment, the compositions also comprise a borate compound.

Owner:ALCON RES LTD

Ultralow-temperature guanidine gum fracturing fluid

InactiveCN103484092AEasy to useReduce pollutionDrilling compositionFracturing fluidHydroxypropyl guar

The invention relates to an ultralow-temperature guanidine gum fracturing fluid comprising 0.3%-0.45% of hydroxypropyl guar gum, 1-15% of KCl, 1-3% of a discharge aiding agent, 0.5-2% of a demulsifying agent, 0.5-2%% of a clay stabilizer, 0.1-0.5% of a fungicide, 0.01-0.03% of a pH value regulator, 0.002-0.008% of an activator, 0.1-0.3% of a crosslinking agent, 0.04-0.1% of a gel breaker, and the balance being water. The using effect of the fracturing fluid can be improved to a great extent, and the fracturing fluid can completely break gel and flow back at a low temperature of 15 DEG C-35 DEG C.

Owner:PETROCHINA CO LTD

High-temperature hyper-salinity water-base fracturing fluid

ActiveCN103497754AShorten crosslinking timeDisperse completelyDrilling compositionWater basedCross-link

The invention discloses high-temperature hyper-salinity water-base fracturing fluid consisting of thickening liquid, a cross-linking agent and a gel breaker, wherein the thickening liquid comprises the following components in percentage by weight: 0.4-0.7% of a thickening agent, 0.1-0.8% of a cleanup additive, 0.01-0.1% of a sterilizing agent, 0.1-0.3% of a temperature stabilizing agent, and the balance of hyper-salinity seawater or stratum produced water; the thickening agent is sulfonyl hydroxypropyl guar gum, sulfonyl betaine amphoteric guar gum or sulfonyl carboxymethyl guar gum; the cross-linking agent is a stable complex formed from reaction of 9-18% of a zirconium compound, 3-40% of a boron compound, 9-18% of a chelating ligand and 5-19% of a bridging ligand by mass; the gel breaker is either ammonium persulfate or sodium persulfate. The fracturing fluid is directly prepared from hyper-salinity water and realizes effective utilization of seawater and hyper-salinity produced water from land, and is applicable to seaborne and terrestrial high-temperature oil-gas wells.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method and application of hydroxypropyl guar gum/nanocellulose cross-linked adsorption film

ActiveCN106345424AGood adsorption/desorption performanceImprove mechanical propertiesSemi-permeable membranesOther chemical processesCross-linkMethyl violet

The invention discloses s preparation method of a hydroxypropyl guar gum / nanocellulose cross-linked adsorption film. The method takes hydroxypropyl guar gum and microcrystalline cellulose as main raw materials, and comprises the steps: thinning the microcrystalline cellulose in a nano grinder and a high-strength ultrasonic wave generator successively to prepare nanocellulose, then respectively dispersing and dissolving the nanocellulose and hydroxypropyl guar gum in maleic acid, then adding maleic anhydride and sodium hypophosphite, stepwise heating to carry out esterification and cross-linking reaction, centrifuging and defoaming the reactant, shaping the reactant in a mold, forming a film by drying, and cleaning and freeze-drying the film to obtain the adsorption film. The film prepared by the method is light yellow and transparent, has good adsorptive capacity on copper ions, zinc ions, led ions, methylene blue and methyl violet, and simultaneously has higher mechanical properties.

Owner:KUNMING UNIV OF SCI & TECH

Anion healthy paint

InactiveCN101684221ASustained releaseAntifouling/underwater paintsPaints with biocidesPropanediolSodium hydroxide

The invention relates to an anion healthy paint which comprises the following combination raw materials in parts by weight: 300 parts of purified water, 1.5 parts of hydroxypropyl guar gum, 2 parts ofhydroxyethylcellulose, 1 part of waterborne pigment wetting agent, 4 parts of water soluble dispersant, 3 parts of defoamer, 200 parts of titanium dioxide, 72 parts of anion coating additive, 50 parts of micro calcined kaolin, 10 parts of aluminosilicate, 10 parts of wollastonite, 10 parts of barite, 8 parts of propanediol, 1 part of sodium hydroxide diluent, 2 parts of bactericide, 50 parts of talcum powder, 60 parts of fine heavy calcium carbonate, 13 parts of mildewproof powder, 200 parts of styrene-acrylic emulsion and 2.5 parts of thickener. A preparation method comprises the following steps: putting the purified water into a dispersion reactor; respectively adding the hydroxypropyl guar gum and cellulose into the dispersion reactor; then adding the diluent, the wetting agent, the dispersant, the bactericide, the defoamer, the aluminosilicate, the talcum powder, the kaolin, the titanium dioxide, the heavy calcium, the wollastonite, the barite and the mildewproof powder; sand grinding the mixture; adding the defoamer, the propanediol, the styrene-acrylic emulsion, the anion additive, the thickener and the purified water into a paint mixing reactor; and finally adding sodium hydroxide and filtering and packing to obtain the anion healthy paint.

Owner:杨录真

Leakage-proof type temporary blockage additive for low-pressure thin oil well

The invention discloses a leakage-proof type temporary blockage additive for a low-pressure thin oil well, which belongs to the field of workover treatment for a thin oil well in petroleum industry. The temporary blockage additive comprise the following raw materials in weight percentage: 0.4-0.6% of hydroxypropyl guar gum, 0.2-0.4% of organic titanium, 5-10% of petroleum resin, 0.3-0.5% of dodecyl dimethyl betaine, 0.1% of sodium sulfite, 0.02-0.04% of ammonium persulfate and 88.5-93.5% of water. The leakage-proof type temporary blockage additive of the invention crosslinks the hydroxypropyl guar gum with the organic titanium to form a gel system, and at the same time adds a certain amount of petroleum resin to form a compound temporary blockage system. The temporary blockage system can immediately break gel without blocking off the oil well, and avoids the accident of stuck pump caused by broken gel fragment. In addition, the leakage-proof type temporary blockage additive has the advantages of no pollution, no harm to a reservoir and low cost.

Owner:PETROCHINA CO LTD

High-density low-friction fracturing fluid

InactiveCN102676148AGood compatibilityDelayed cross-linking propertiesDrilling compositionPolymer scienceFracturing fluid

The invention relates to high-density low-friction fracturing fluid. The high-density low-friction fracturing fluid is made of, by weight, 20-46.5% of weighting agent sodium nitrate, 0.4-0.6% of thickener hydroxypropyl guar gum, 0.4-1.0% of cleanup additive Gemini surfactant, 0.1-0.3% of pH (potential of hydrogen) modifier, 0.1-0.3% of bactericide lauryltrimethylammonium chloride or dodecyl dimethyl benzyl ammonium bromide, 0.5-1.0% of clay stabilizer quaternary ammonium salt, 0.5-1.0% of temperature stabilizer organic amine composite, and the balance water. Sodium nitrate is used for increasing weight, the density at the normal temperature can reach 1.35g / cm<3>, and the high-density low-friction fracturing fluid is long in delayed crosslinking time, low in friction, low in filter loss, high in high-temperature rheological property, and especially applicable to fracture modification of ultradeep compact reservoirs under unusual high pressure, wellhead construction pressure can be reduced remarkably. Further, the high-density low-friction fracturing fluid is applicable to massive popularization and application to mine fields, low in cost and low in stratum damage, and has wide market prospect.

Owner:SOUTHWEST PETROLEUM UNIV +1

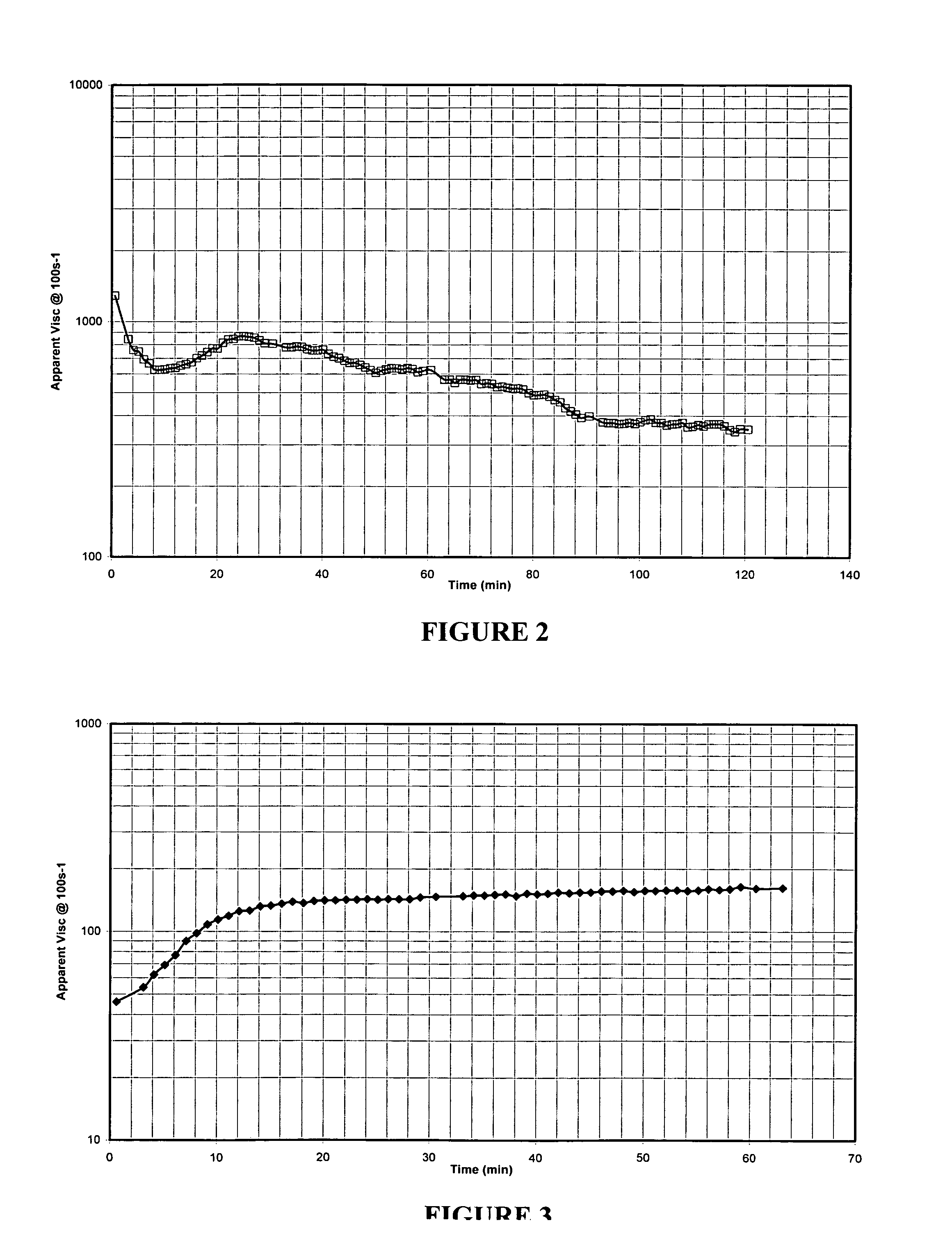

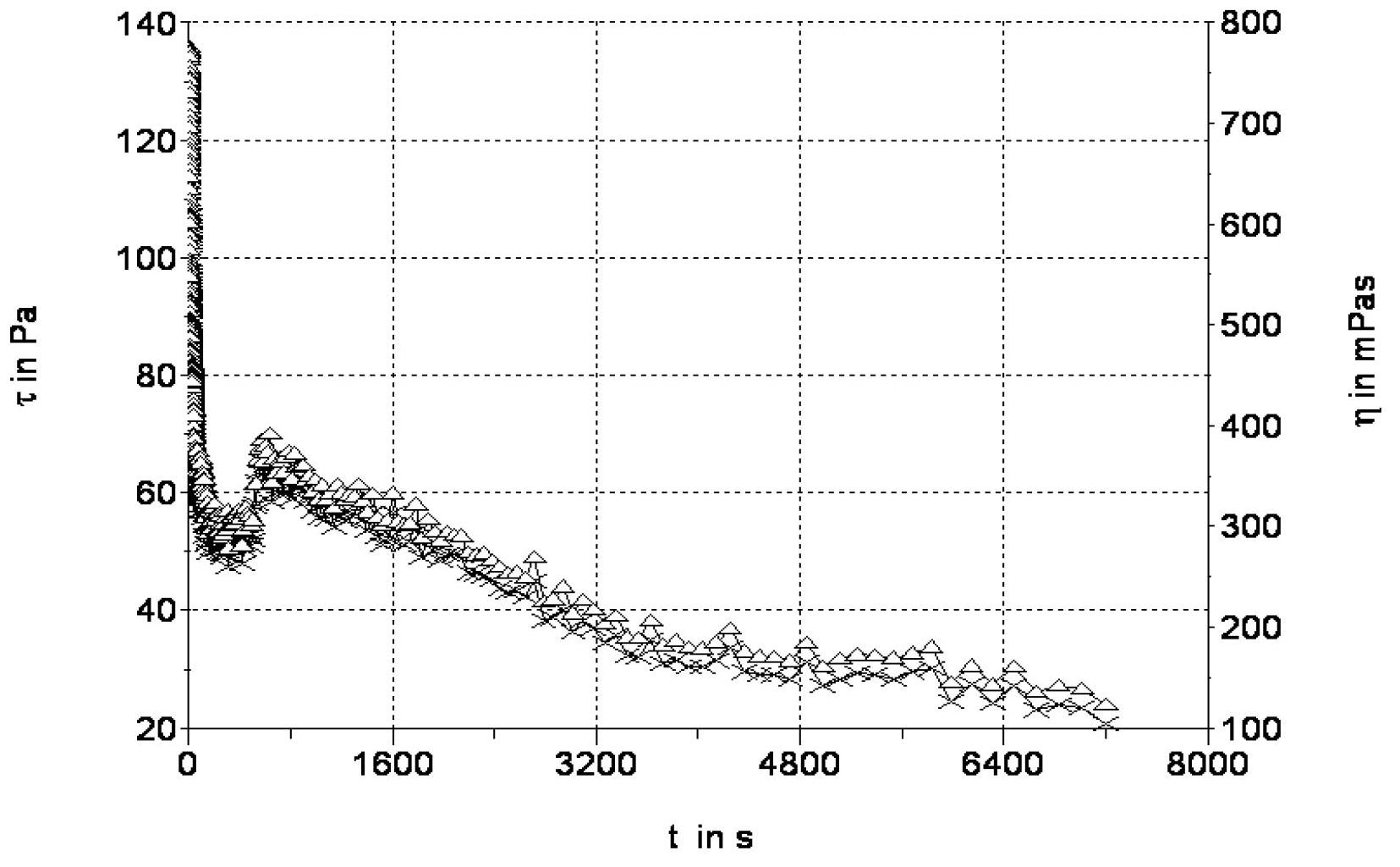

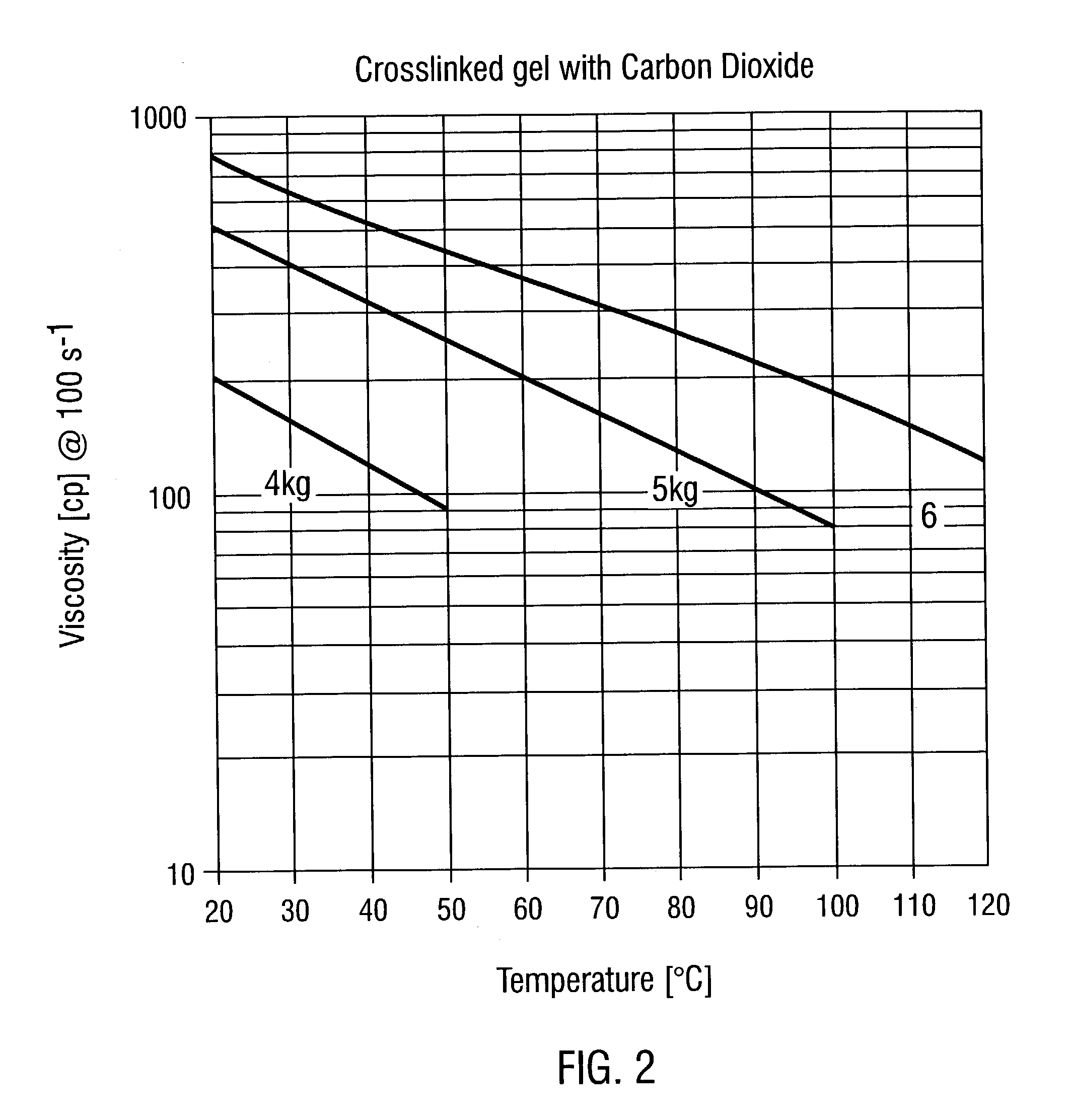

Carbon dioxide compatible non-aqueous crosslinked fracturing fluids and methods for their use

Alcohol based hydraulic fracturing fluids useful for treating oil and gas wells are disclosed. The fluids are compatible with carbon dioxide, and comprise an alcohol, a polymer, a crosslinking agent, and a breaker. Hydroxypropyl guar with a molar substitution of about 1.2 to about 2.2 is identified as a presently preferred polymer.

Owner:BAKER HUGHES INC

High performance acidizing fracturing fluid and preparation method thereof

The invention relates to an acidizing fracturing fluid added thickening acid liquid and a preparation method thereof. The thickening acid liquid provided by the invention is composed of an acid liquor, a thickening agent and additives in a mass ratio of 5:3:2. Specifically, the acid liquor is formed by mixing of hydrochloric acid, hydrofluoric acid and acetic acid. The thickening agent is formed by compounding of N-vinyl lactam, ethoxylated fatty amine and carboxymethyl hydroxypropyl guar gum. The additives mainly include an antiswelling agent, a corrosion inhibitor, a ferric ion stabilizer and a discharge aiding agent. The thickening acid liquid provided by the invention has the advantages of good high temperature resistance and shear resistance, etc. The thickening acid liquid provided by the invention can be added into a water-based fracturing fluid, a foam fracturing fluid or a mixture of the two to undergo crosslinking through a cross-linking agent so as to form the compound acidizing fracturing fluid. The obtained compound acidizing fracturing fluid integrates acidizing and fracturing, so that the diapiric fracturing fluid can form a multi-component foam system and release heat and gas, thus achieving the triple functions of acidizing, fracturing and foaming.

Owner:CHANGZHOU UNIV +1

Ultralow-concentration fracturing fluid and preparation method thereof

The invention relates to an ultralow-concentration fracturing fluid and a preparation method thereof. Currently, a reservoir is reconstructed by adopting a hydraulic fracturing method with the following shortcomings: (1) the rubber crushing residue content in the fracturing fluid is high and is generally 500-600 mg / L; and (2) the using amount of the rubber crushing agent is larger during reconstructing the reservoir and the average using amount is up to about 0.03%. The ultralow-concentration fracturing fluid provided by the invention comprises 93.35-97.4 parts of water, 0.25-0.35 part of hydroxypropyl guar, 1.0-2.0 parts of cross-linking agent, 0.40-2.0 parts of surfactant, 0.20-1.0 part of clay stabilizer, 0.05-0.5 part of bacteriacide and 0.2-0.8 part of temperature resistant reinforcing agent; and the preparation method comprises the following steps of: preparing a solution A in a container; and mixing the solution A and the cross-linking agent according to a volume ratio of 100:1-100:2 so as to form the fracturing fluid. In the fracturing fluid provided by the invention, the concentration of the hydroxypropyl guar as a thickening agent is up to 0.25-0.35%.

Owner:西安长庆化工集团有限公司

Instant guar gum and preparation method thereof

The invention belongs to instant guar gum and a preparation method thereof. The instant guar gum is prepared from the following raw materials in parts by weight: 20-80 parts of guar gum raw powder, 10-25 parts of propylene oxide, 4-10 parts of chloroacetic acid, 5-10 parts of hydrochloric acid with mass concentration of 20 percent, 150-200 parts of solvent alcohol, 8-20 parts of alkali liquor with concentration of 10 percent, 150-200 parts of water, 20-50 parts of hydrophobic modification material and 1000 parts of washing medium, wherein the solvent alcohol is any one of methanol, ethanol, ethylene glycol or isopropyl alcohol; the hydrophobic modification material is any one of bromododecane, bromohexadecane or bromooctadecane; the washing medium is any one of isopropyl alcohol, methanol or ethanol. According to the instant guar gum and the preparation method thereof, a step of taking hydroxypropyl guar gum out in oil field fracturing construction is not needed, a reaction process is saved, and pollution and waste caused by post-treatment of the reaction process are reduced.

Owner:张春雨

High temperature aqueous-based zirconium crosslinking composition and use

A fracturing fluid or crosslinking composition suitable for use at high temperature (275-340° F., 135-171° C.) comprising (a) an aqueous liquid, (b) brine, (c) a thermal stabilizer, (d) a non-delaying alkaline buffer sufficient to provide a pH less than 9, (e) an organic acid, (f) hydroxypropyl guar and (g) a zirconium crosslinking agent. The composition is useful as a fracturing fluid in oil field applications, for example, for hydraulically fracturing a subterranean formation or selectively plugging a permeable zone or leak in a subterranean formation.

Owner:DORF KETAL SPECIALITY CATALYSTS

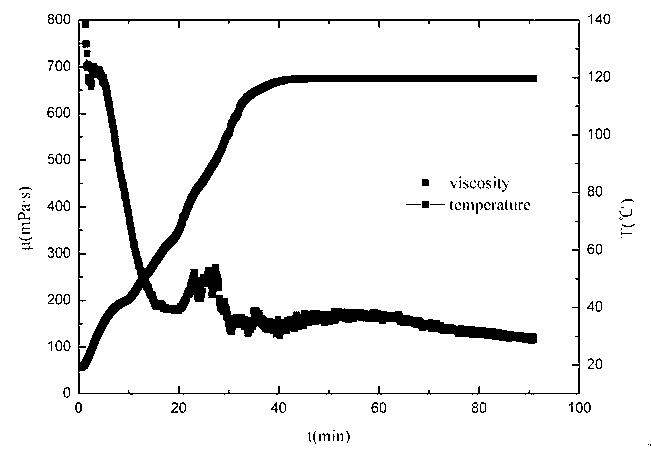

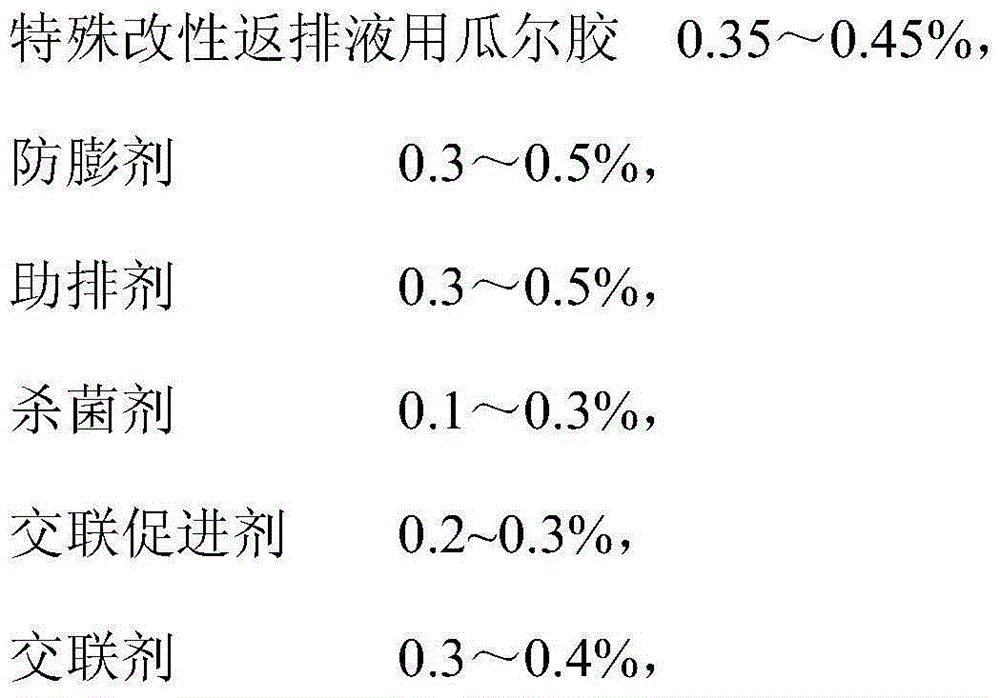

Fracturing fluid prepared by utilizing fracturing flow-back fluid and preparation method thereof

InactiveCN105131932ACompletely broken glueAchieve recyclingDrilling compositionPolymer scienceFracturing fluid

The invention provides a fracturing fluid prepared by utilizing a fracturing flow-back fluid and a preparation method thereof. The fracturing flow-back fluid is not processed or subjected to simple processing and then is directly used to prepare the fracturing fluid. The fracturing fluid is composed of a thickening agent and other auxiliary agents, and employs a crosslinking agent compatible with a guar gum thickening agent used for the flow-back fluid and a crosslinking promoter. The formula crosslinking time 1-3 min is adjustable, the temperature resistance is 120 DEG C or more, and the system frictional resistance is reduced by 20% or more compared with a common hydroxypropyl guar gum fracturing liquid. The fracturing liquid preparation method realizes cyclic utilization of the fracturing flow-back fluid, and the prepared fracturing liquid possesses good performances.

Owner:昆山京昆油田化学科技有限公司

Cross-linking agent for fracturing fluid with ultralow hydroxypropyl guar concentration and fracturing fluid prepared from cross-linking agent

The invention relates to a cross-linking agent for fracturing fluid and preparation method of the cross-linking agent. The cross-linking agent comprises the following components in parts by mass: 450 to 650 parts of water, 150 to 250 parts of salt of organic acid, 100 to 250 parts of boron compound, 50 to 150 parts of polylol and 10 to 50 parts of sodium hydroxide. The method for preparing the cross-linking agent comprises the following steps of: mixing the salt of organic acid and water and adding the mixture into the boron compound, and reacting at the temperature of 70 to 80 DEG C for 2 hours; adding the sodium hydroxide to regulate the pH value to 6 to 8, and reacting at the temperature of 70 to 80 DEG C for 3 hours; adding the polylol, reacting at the temperature of 70 to 80 DEG C for 1 hour, and preparing the cross-linking agent. The invention also relates to fracturing fluid with ultralow hydroxypropyl guar concentration. The fracturing fluid mainly comprises the following components in parts by volume: 96.1 to 98.2 parts of aqueous solution of hydroxypropyl guar and 0.25 to 0.4 part of the cross-linking agent. According to the fracturing fluid, the amount of thickening agent can be reduced, so that the damage and cost are reduced.

Owner:PETROCHINA CO LTD

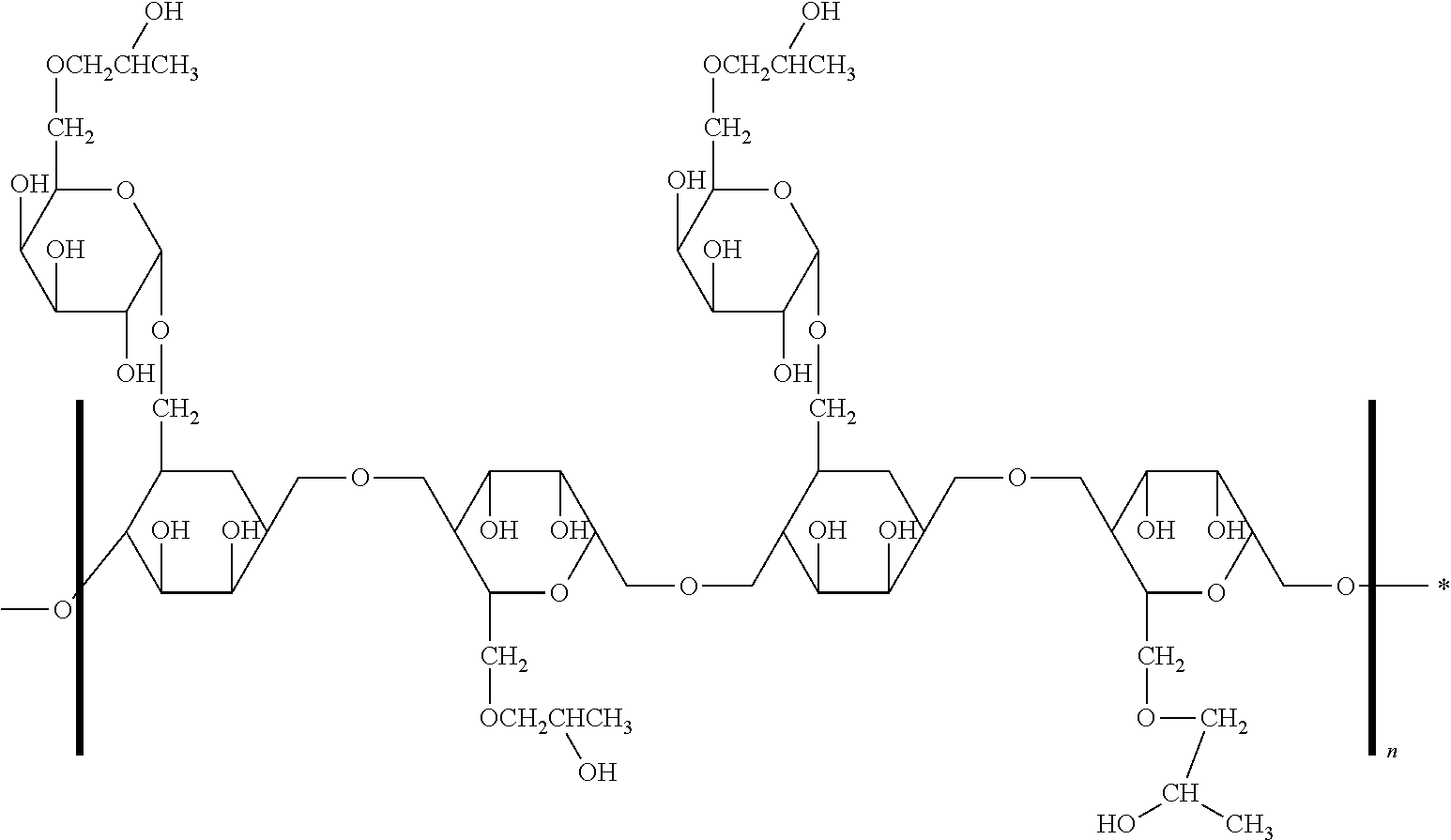

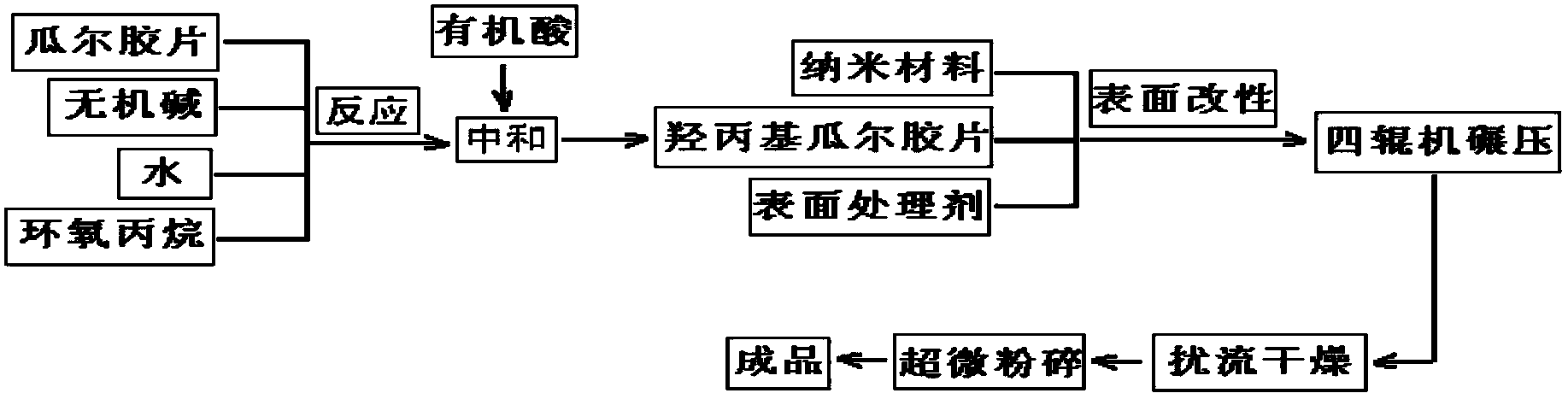

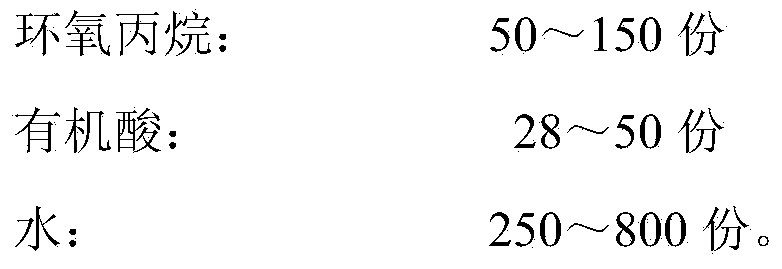

Method for preparing instant guar gum applicable to continuous blending under low temperature condition

ActiveCN103641927ARapid dispersion and thickeningFast dissolutionDrilling compositionSolubilityEnvironmental resistance

The invention relates to a method for preparing instant guar gum applicable to continuous blending under a low temperature condition. The method comprises the following steps: performing chemical modification and neutral reaction on guar gum pieces in a kneading machine so as to prepare hydroxypropyl guar gum pieces, adding a nano material and a surfactant to perform surface modification so as to obtain a surface modification material, subsequently performing a grinding technique based on a four-roller machine, a succeeding stretch and tackifying technique, a turbulent flow drying technique and an airflow vortex micro powder crushing and separation technique on the surface modification material so as to obtain the instant guar gum applicable to continuous blending under the low temperature condition. By adopting the method, the difficult problem of construction in winter and autumn in northern areas can be solved, the complex separation and purification processes of washing in alcohol and water are omitted, and the method has the characteristics of freedom of wastewater and waste gas discharge in the reaction process, safety, environment friendliness, simple process, low cost, high reaction efficiency and good guar gum instant solubility.

Owner:山东金明新材料有限公司 +1

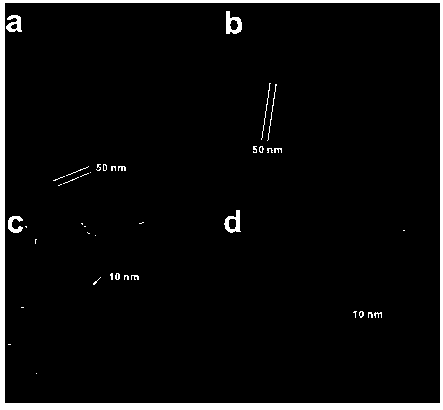

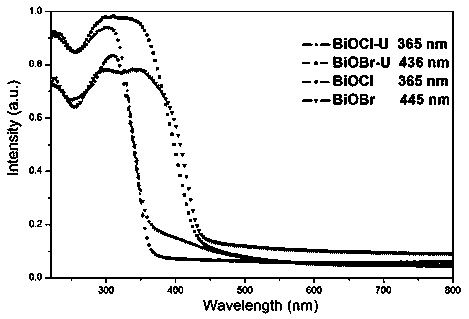

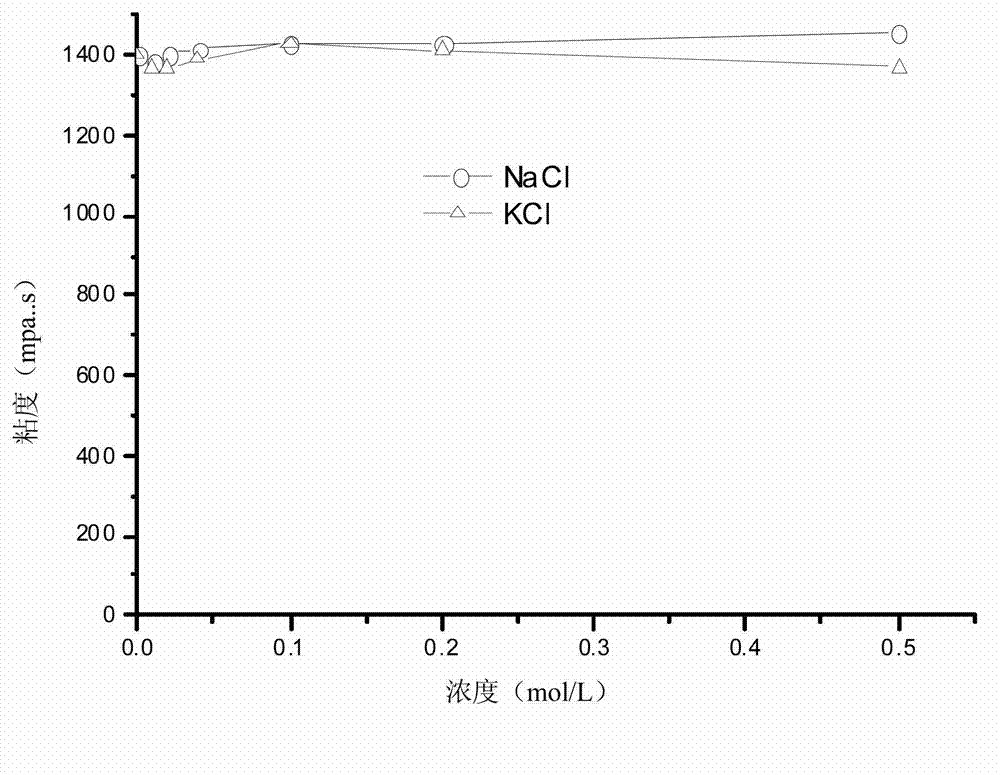

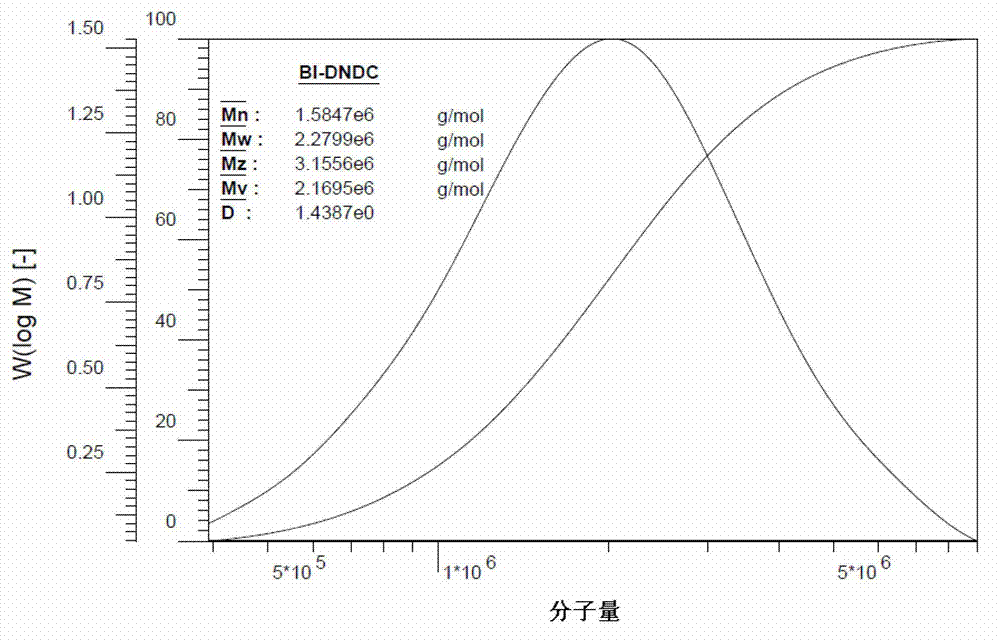

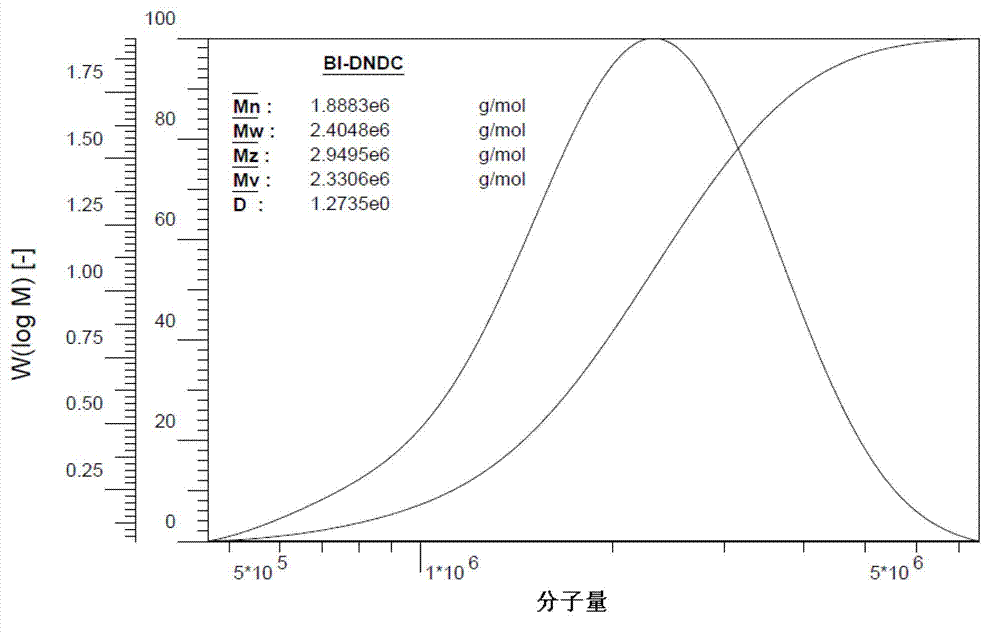

Ultra-thin bismuth oxyhalide nanosheet as well as preparation and application thereof

InactiveCN108380226AImprove stabilityHigh catalytic efficiencyHydrocarbon from carbon oxidesGaseous fuelsPotassiumHydrolysis

The invention discloses an ultra-thin bismuth oxyhalide nanosheet as well as preparation and application thereof. The ultra-thin bismuth oxyhalide nanosheet is prepared by using bismuth nitrate pentahydrate, potassium chloride or potassium bromide as raw materials, and hydroxypropyl guar gum as a thickening agent, and adopting a hydrolysis method at low temperature. The preparation method providedby the invention has a simple process and low costs, and is green, environmentally friendly and easy to control and produce in a large scale; the guar gum is added as the thickening agent in the preparation process, various raw materials are mixed more uniformly, so that an occurrence of agglomeration of macromolecular particles in the preparation process is avoided, and preparation of a more ultra-thin bismuth oxyhalide photocatalyst with a larger specific surface area is facilitated; and the prepared ultra-thin bismuth oxyhalide nanosheet is a nano-scale layered structure, can respond in avisible light range, has stronger stability, higher catalytic efficiency, and a significant effect and huge application space in the field of photocatalytic reduction of CO2.

Owner:NANYANG NORMAL UNIV

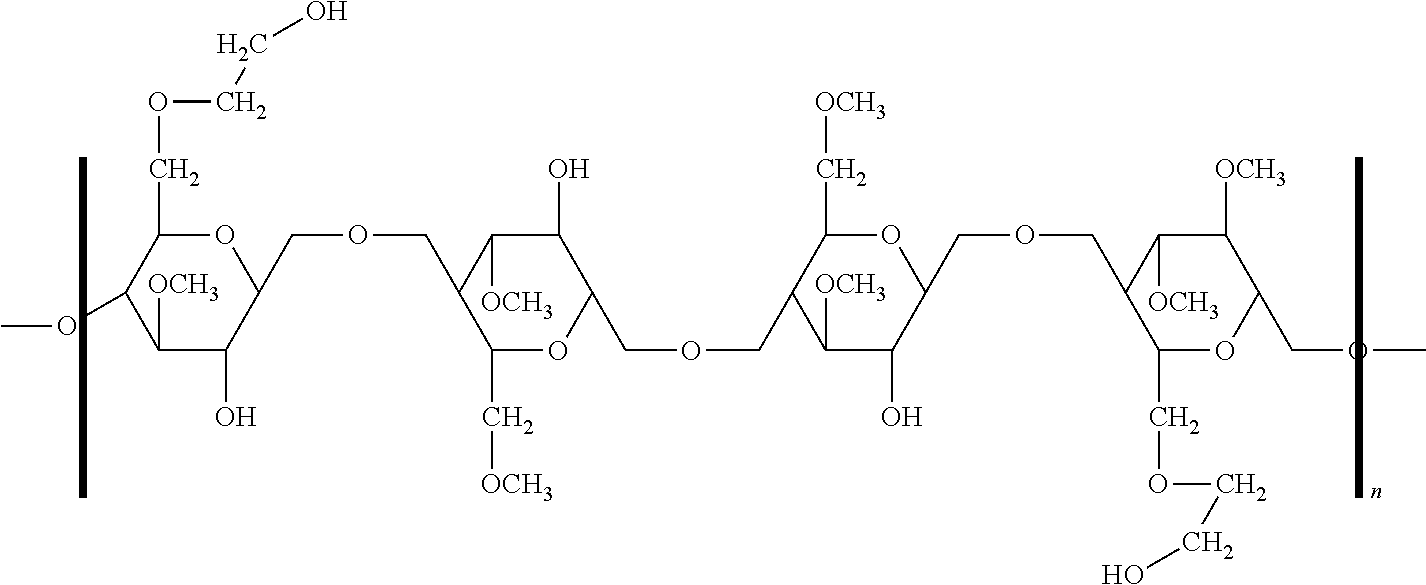

Sulfonic acid modified carboxymethyl hydroxypropyl guar gum, and preparation method and application thereof

ActiveCN103113486AImprove surface activityReduce surface activityDrilling compositionAlcoholAqueous sodium hydroxide

The invention relates to sulfonic acid modified carboxymethyl hydroxypropyl guar gum, and a preparation method and application thereof. The structural formula of the sulfonic acid modified carboxymethyl hydroxypropyl guar gum is shown in the specification, wherein R is H, and n is 0, 1, 2 or 3; or R is OH, and n is 0-6. The preparation method comprises the following steps: adding carboxymethyl hydroxypropyl guar gum into a reaction vessel, and adding an alcohol water solution; in a nitrogen atmosphere, dropwisely adding a sodium hydroxide water solution, heating to 65-80 DEG C while stirring, dropwisely adding a sulfonating agent, and reacting for 3-10 hours; and regulating the pH value of the solution to 7 with acid, filtering, collecting solids, and drying to obtain light yellow powder, namely the sulfonic acid modified carboxymethyl hydroxypropyl guar gum. The prepared sulfonic acid modified carboxymethyl hydroxypropyl guar gum is high in thickening efficiency, low in surface / interface tension, easy to realize viscosity break and beneficial to flowback.

Owner:PETROCHINA CO LTD

Oil well sand washing plugging agent and plugging method

The oil well sand washing and plugging agent is re-compounded with component A of polymer and component B of cross-linking agent. The first recipe includes component A comprising guar gum powder, hydroxyl propyl guar gum powder, tonka bean gum powder, sesbania powder, hydroxyl propyl-hydroxyl methyl sesbania powder or hydroxyl propyl sesbania powder 10-70%, expansion preventing agent 0-10%, emulsifier 0.5-10% and industrial oil 20-60%; and component B comprising organoboron 30-70% and biological enzyme 10-60%. The second recipe includes component A of polyacrylamide latex 30-90% and component B of organoboron 10-70%. The present invention is used for oil well sand washing and plugging, and has simple construction, good operability, and high plugging effect.

Owner:SUNCOO PETROLEUM TECH

Method for preparing high-curing modified-guar-gum contained aqueous solution

ActiveCN1936179AHigh solid contentLow viscosityWater-repelling agents additionPaper/cardboardAqueous solutionViscosity

The invention discloses a high content modified guar gum solution manufacture method. The modified guar gum powder could be hydroxide propyl guar gum, positive ion guar gum or the mixture. It includes the following steps: adding positive ion oxidation guar gum powder into water to make the viscosity over 3000mpa.s, adding mannose enzyme solution, adding galactose oxidase solution, heating to 40-60 degree centigrade and reacting for 4-8 hours to gain modified guar gum solution that has viscosity at about 200-500mpa.s, content is 10-25%. The invention could be used to make paper making sizing agent. Comparing to simply using AKD, the sheet and the Cobb value after aging is obviously decreased.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

Preparation method for amphoteric hydroxypropyl guar gum derivative

The invention discloses a preparation method for an amphoteric hydroxypropyl guar gum derivative. The preparation method is characterized by comprising the following steps: (1) performing esterification reaction on hydroxypropyl guar gum and toluene sulfochloride to obtain hydroxypropyl guar gum tosylate; (2) employing an amination reagent to perform nucleophilic substitution on hydroxypropyl guar gum tosylate, removing tosylate group, so as to obtain an amino guar gum derivative; and (3) reacting the amino guar gum derivative under the catalysis of an acid, so as to obtain an amphoteric polymer containing both amino and carboxyl. The preparation method is a new method for preparing the amphoteric guar gum derivative in the field, and the method is simple and practicable, and the reactions are easy to control.

Owner:昆山京昆油田化学科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com