200-DEG C super-high temperature fracturing fluid

A fracturing fluid and ultra-high temperature technology, applied in the field of fracturing fluid, can solve the problems of poor shear resistance of fracturing fluid, reduced activity of crosslinking agent, oxidative degradation, etc., to improve viscosity and sand-carrying performance, shear resistance Good cutting performance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

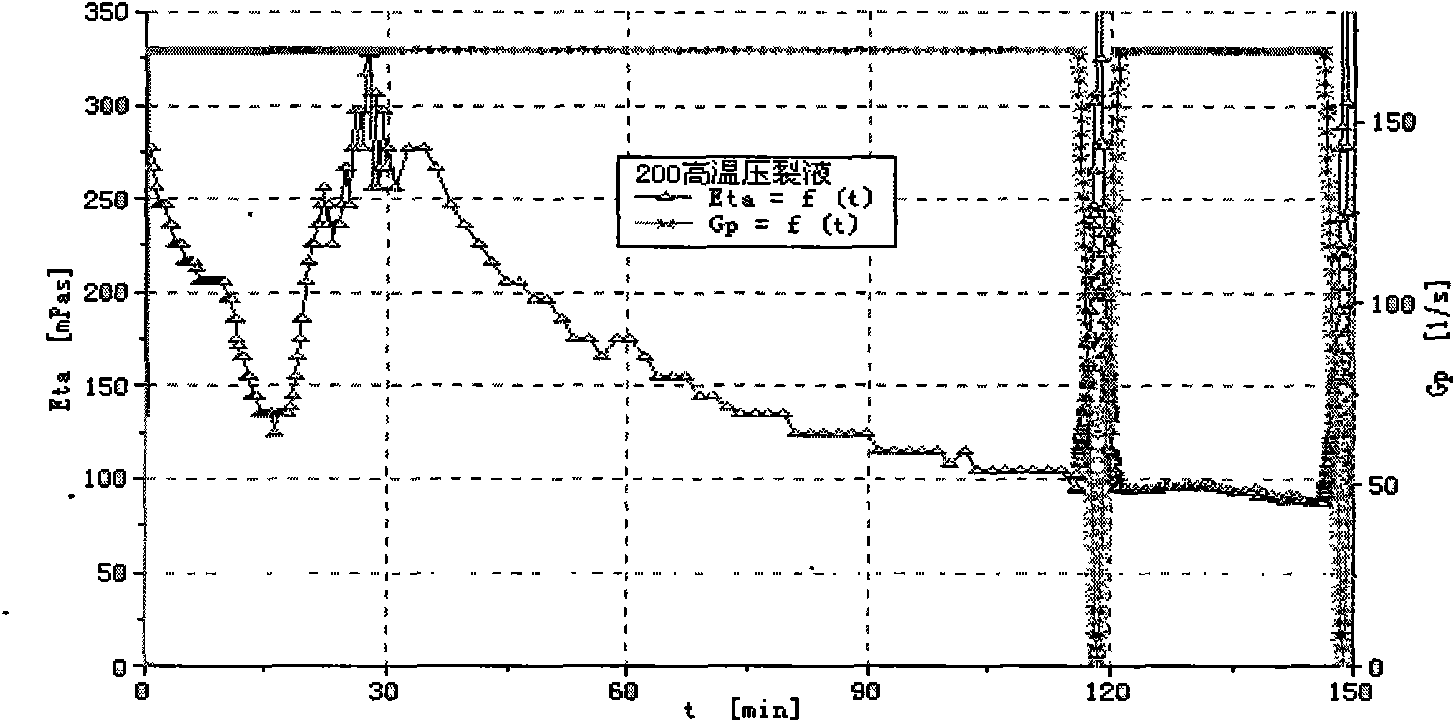

[0011] The present invention will be further described below in conjunction with embodiment: carboxymethyl hydroxypropyl guar gum 0.60%, polyacrylamide 0.35%, organosilicon polyether 0.18%, demulsifier SP169 0.09%, lauryl ammonium chloride 0.24 %, 0.12% of cationic long-chain polymer, 0.33% of organic zirconium crosslinking agent, 0.00027% of potassium persulfate, 0.0001% of sodium nitrite and the rest of water are mixed to obtain the fracturing fluid of the present invention, and the fracturing fluid is carried out Performance evaluation, the method used for performance evaluation refers to the standard ST / Y 5107-2005, the results are shown in Table 1, and the rheological properties of fracturing fluid are shown in figure 1 .

[0012] Performance evaluation results of fracturing fluid of the present invention Table 1

[0013]

[0014] Table 1 and figure 1 The evaluation results are: 200°C ultra-high temperature fracturing fluid has a viscosity of 88.1mPa.s at a temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com