Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1323 results about "Galactose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

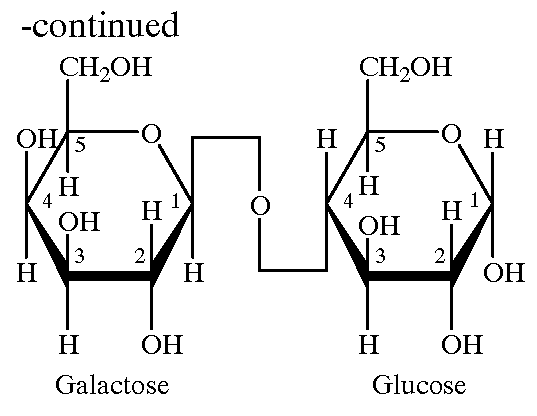

Galactose (/ɡəˈlæktoʊs/, galacto- + -ose, "milk sugar"), sometimes abbreviated Gal, is a monosaccharide sugar that is about as sweet as glucose, and about 65% as sweet as sucrose. It is a C-4 epimer of glucose.

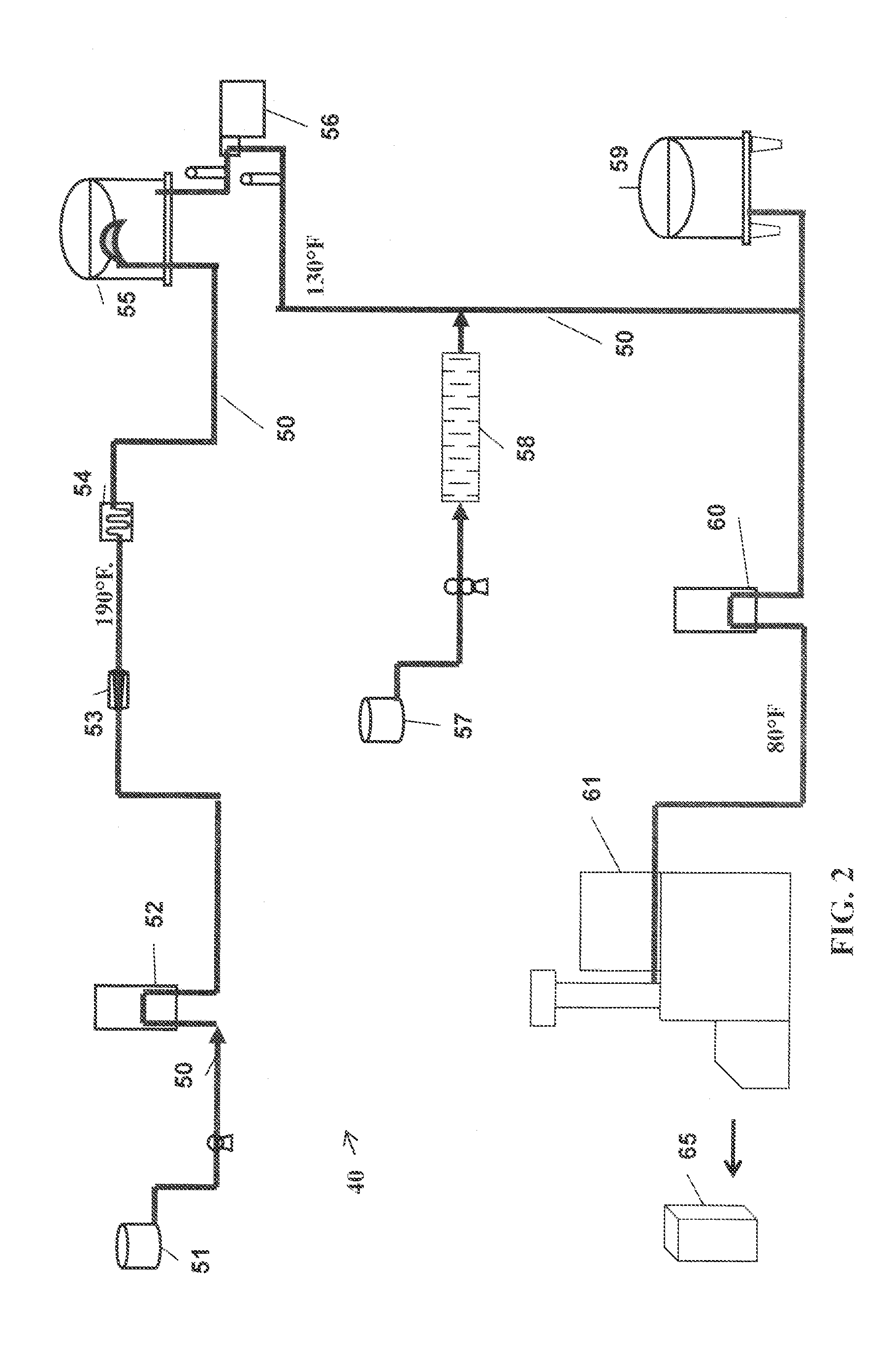

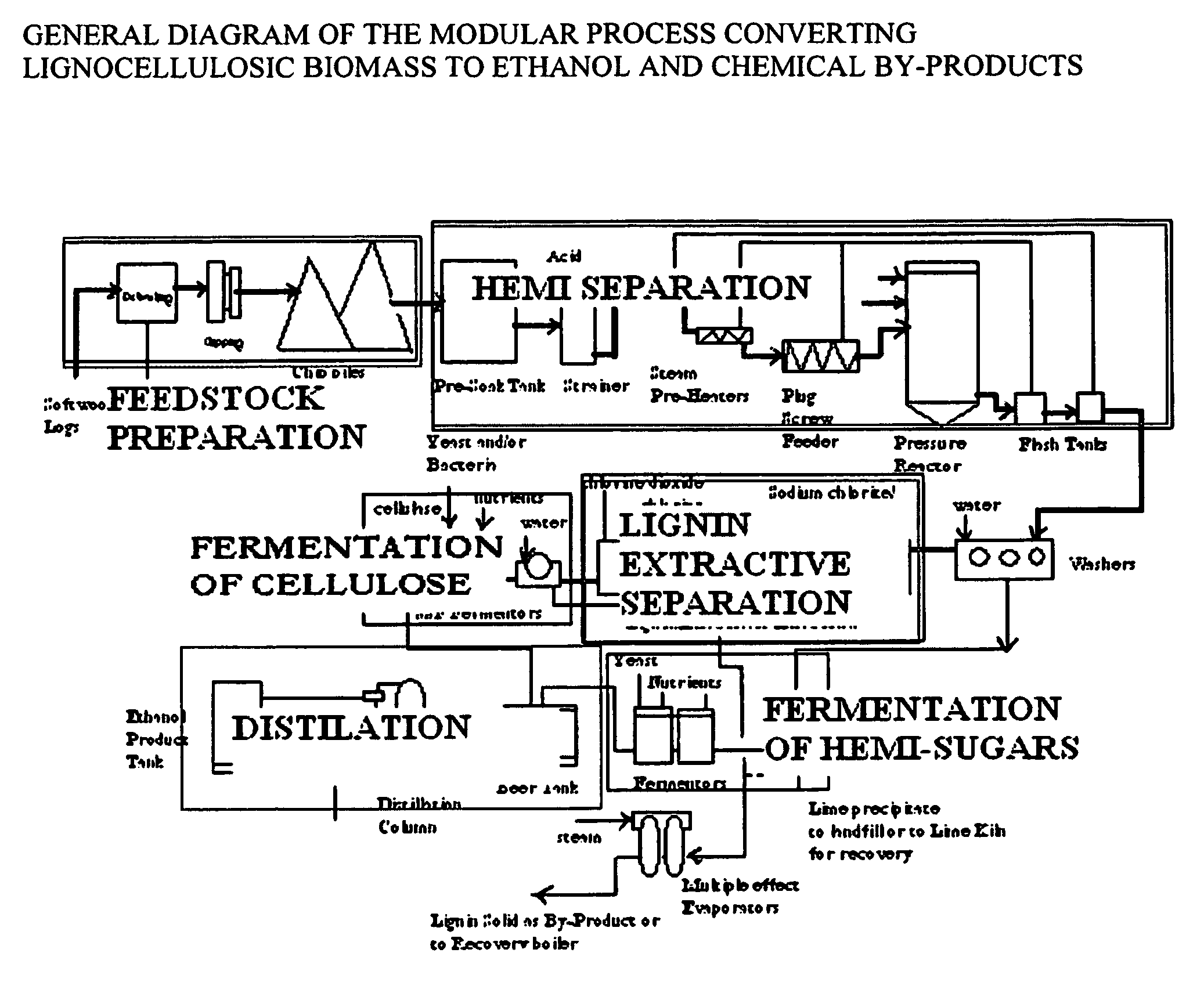

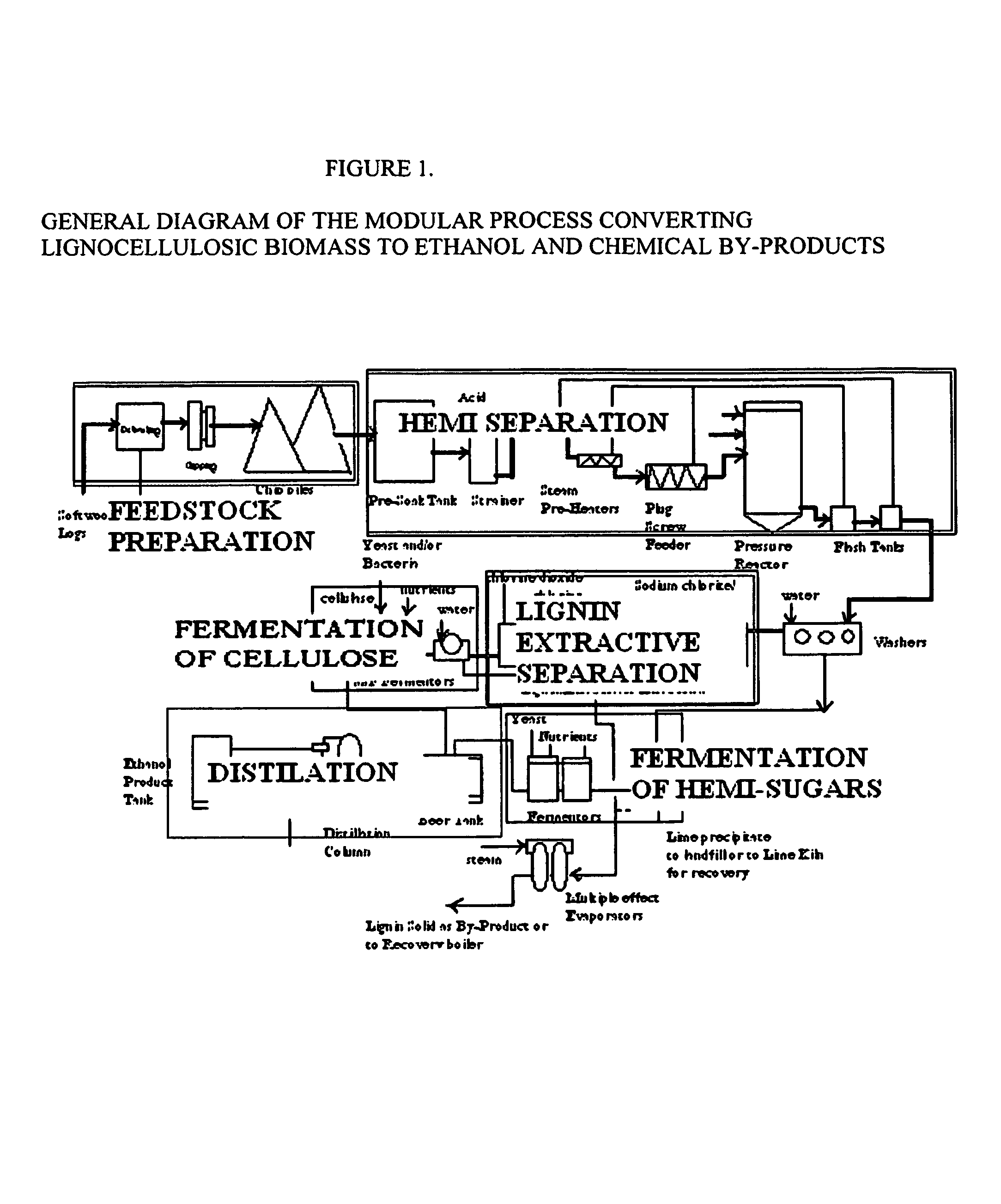

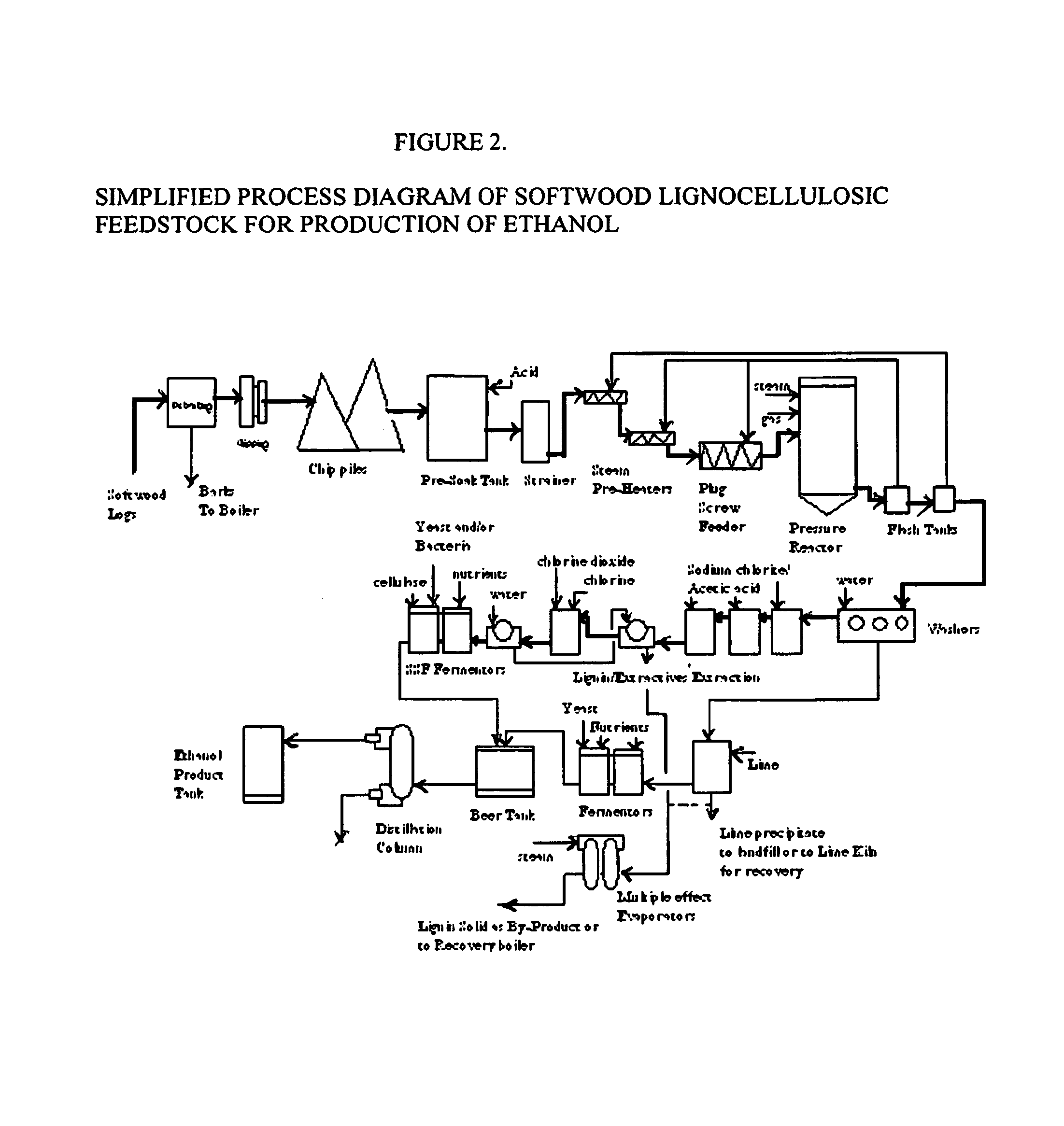

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

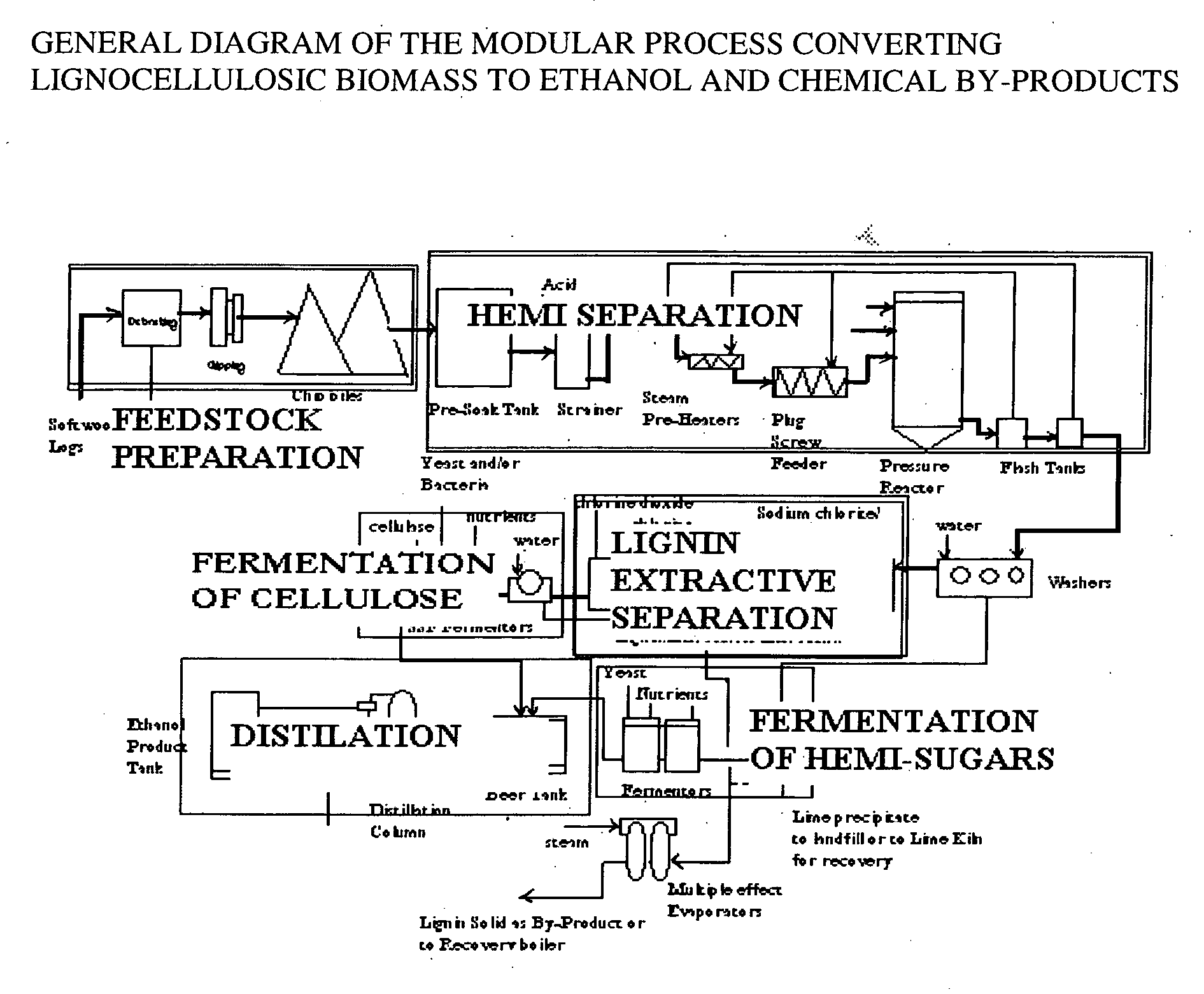

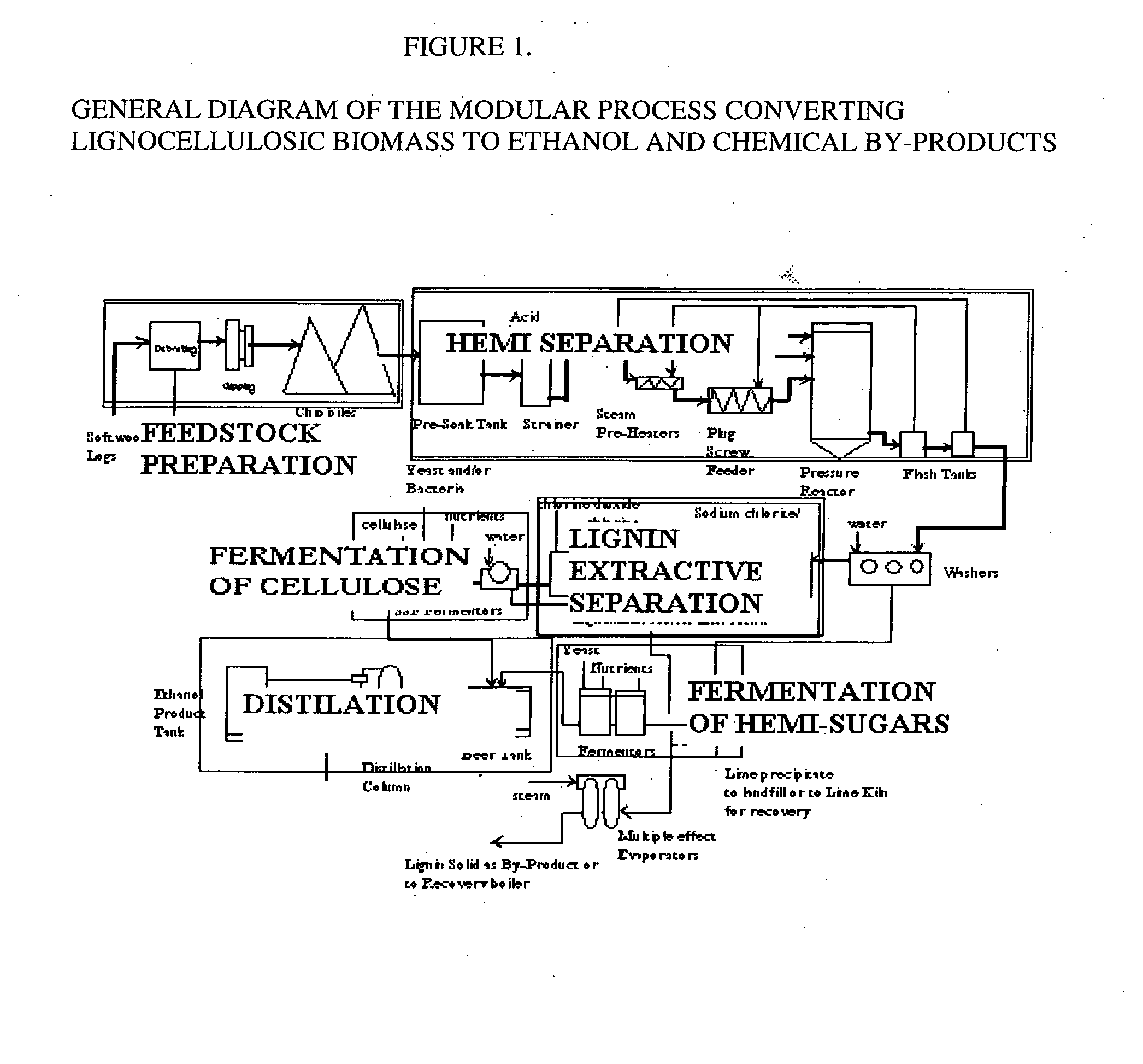

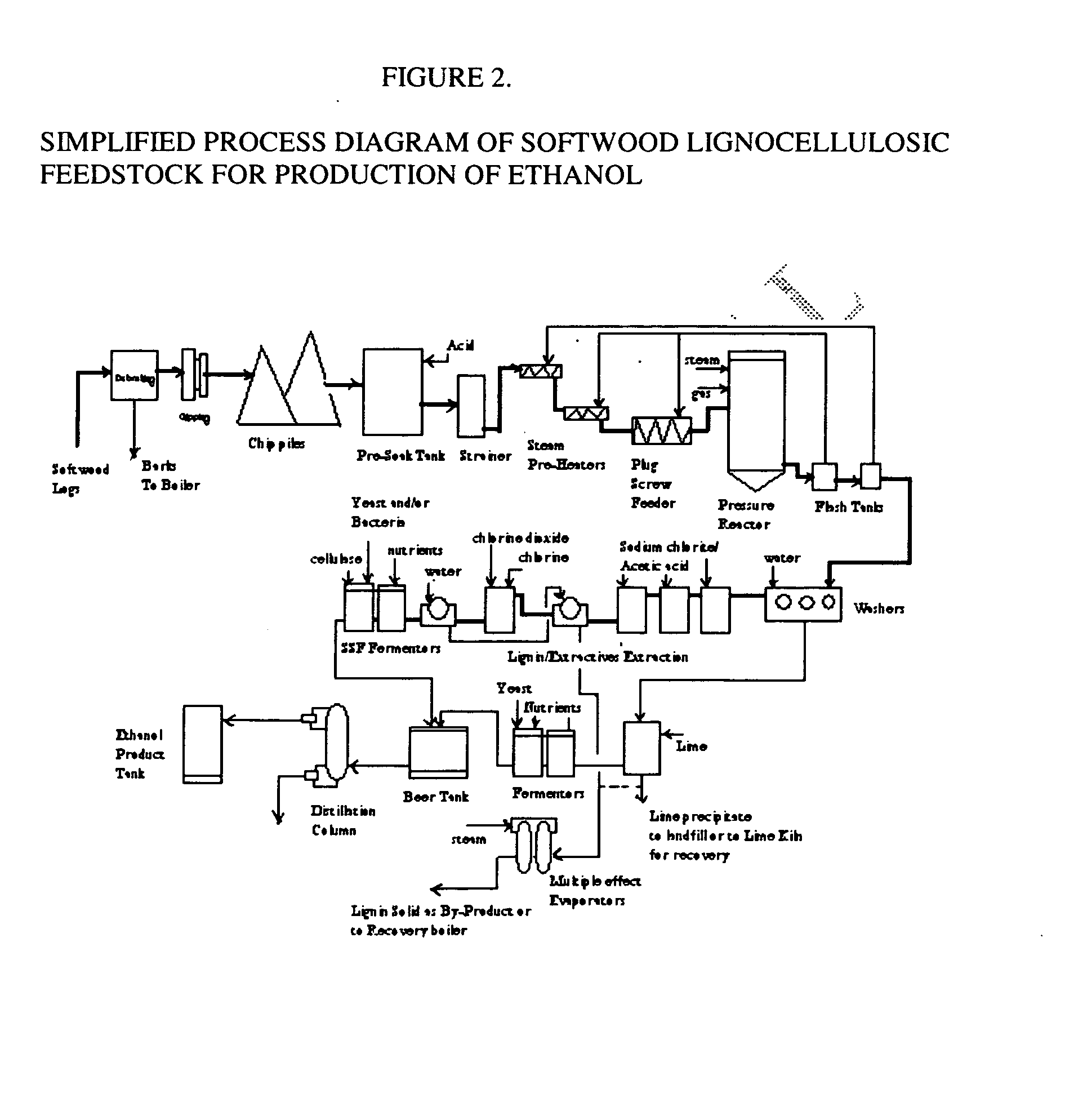

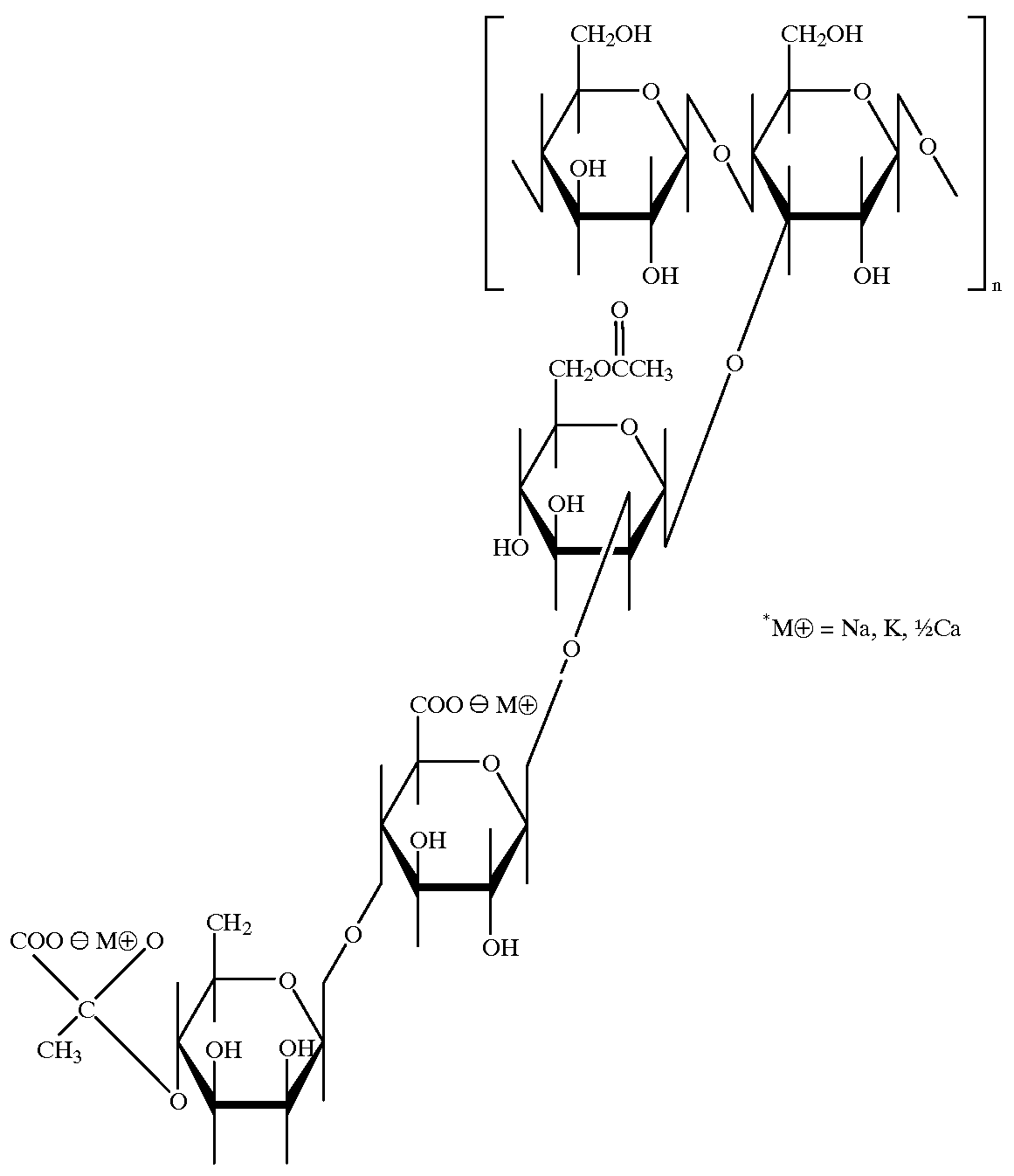

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

Product quality enhancement in mammalian cell culture processes for protein production

ActiveUS7332303B2Low production costQuality improvementAnimal cellsCell receptors/surface-antigens/surface-determinantsHigh cellBiotechnology

Owner:BRISTOL MYERS SQUIBB CO

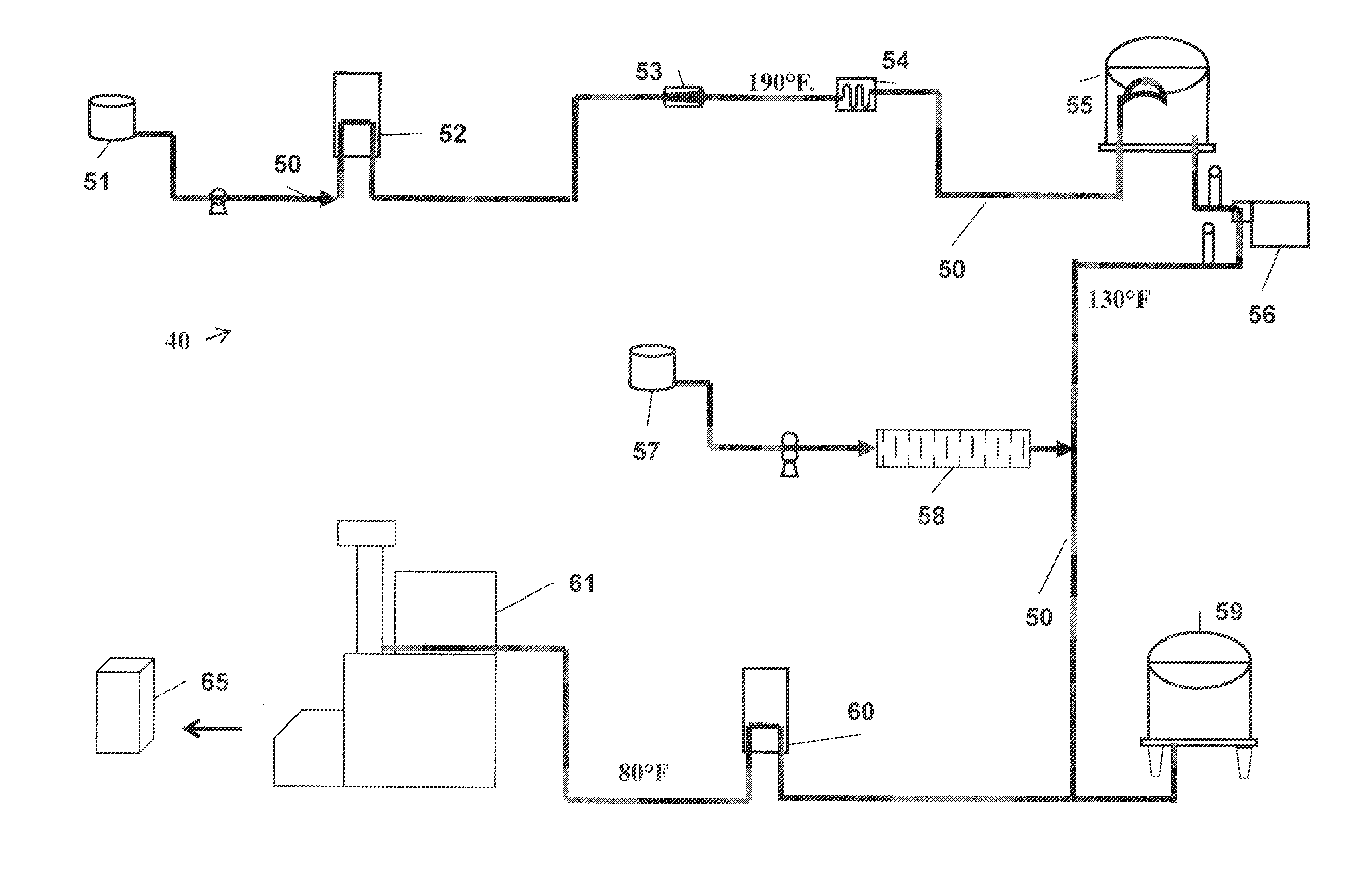

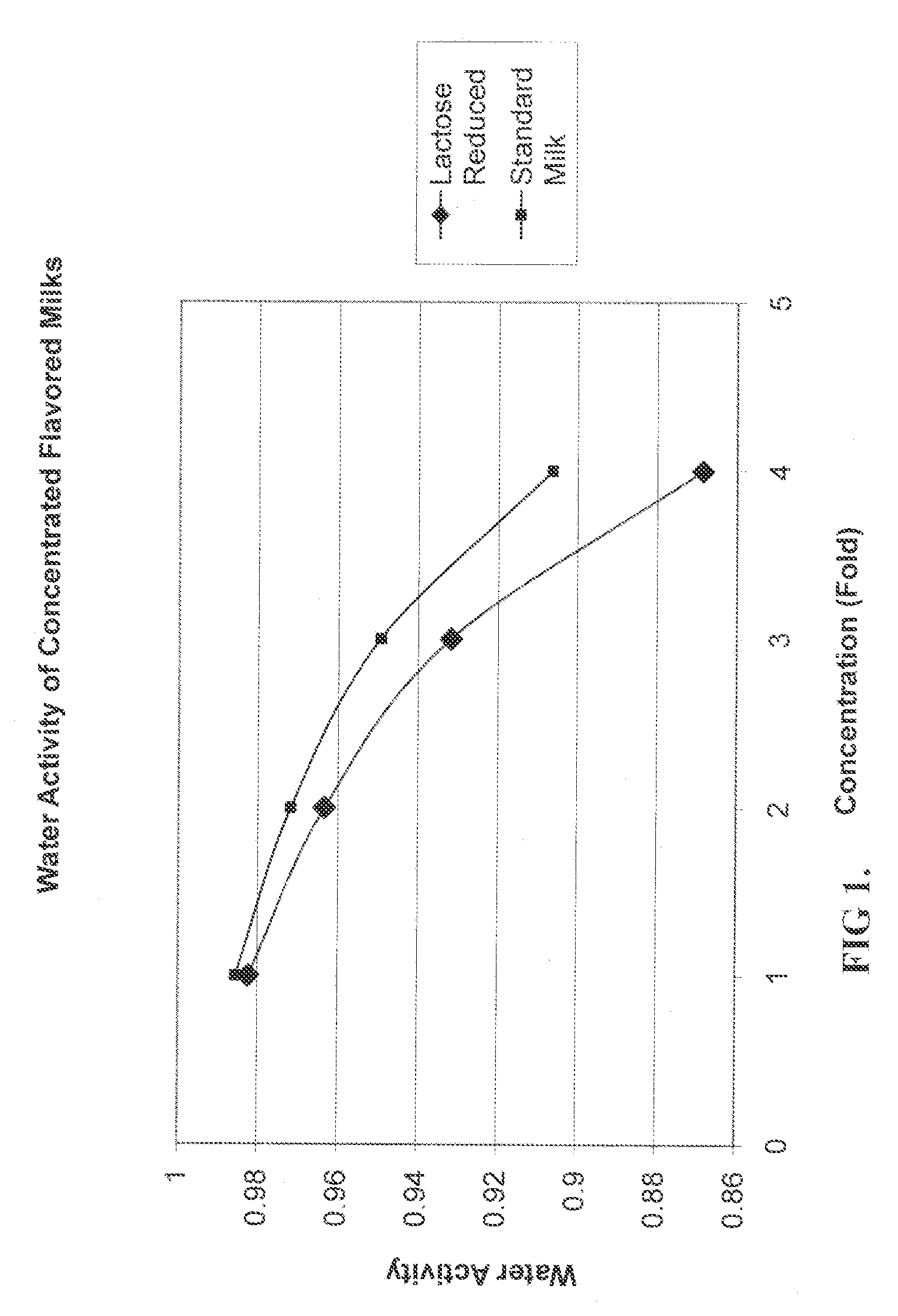

Process For Making A Shelf-Stable Milk Based Beverage Concentrate

InactiveUS20090317514A1Minimizes thermal exposureLower water activityMilk preparationMilk preservationLactaseWater activity

A concentrate, system and low-temperature process for preparing a shelf-stable milk concentrate that does not require ultra-high temperature thermal processing for control of the microbiology of the product is disclosed herein. The method preferably incorporates aseptic technology and the enzymatic reduction of lactose to control water activity. The method preferably includes the enzymatic conversion of the lactose in the milk to its component sugars glucose and galactose, which preferably changes the colligative properties of the concentrate, decreases the amount of free water, and reduces the osmolarity.

Owner:DAIRYVATIVE TECH

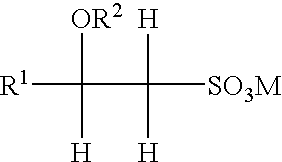

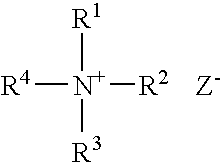

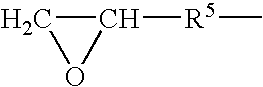

Personal care composition containing a non-guar galactomannan polymer derivative

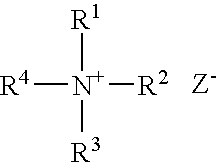

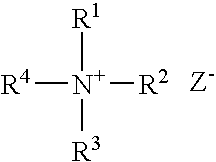

Personal care compositions comprise (a) from about from about 5 wt. % to about 35 wt. % of a detersive surfactant; (b) at least about 0.05 wt. % of a galactomannan polymer derivative having a mannose to galactose ratio of greater than 2:1 on a monomer to monomer basis, the galactomannan polymer derivative selected from a cationic galactomannan polymer derivative and an amphoteric galactomannan polymer derivative having a net positive charge, the galactomannan polymer derivative having a molecular weight from about 1,000 to about 10,000,000 and a cationic charge density from about 0.9 meq / g to about 7 meq / g; and (c) at least about 20 wt. % of an aqueous carrier. Methods of treating hair or skin comprise applying the personal care composition as described above to the hair or skin and rinsing the hair or skin.

Owner:THE PROCTER & GAMBLE COMPANY

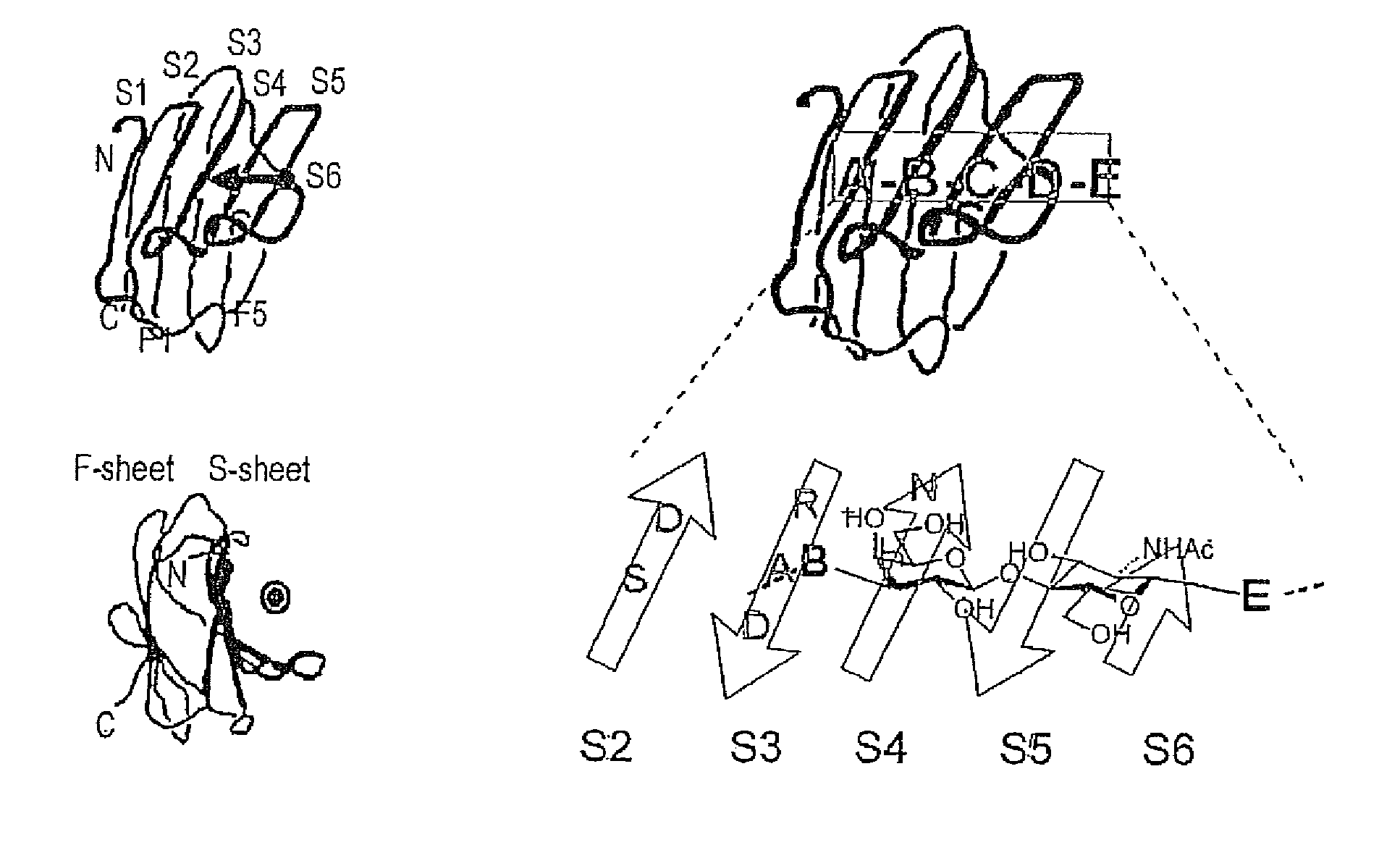

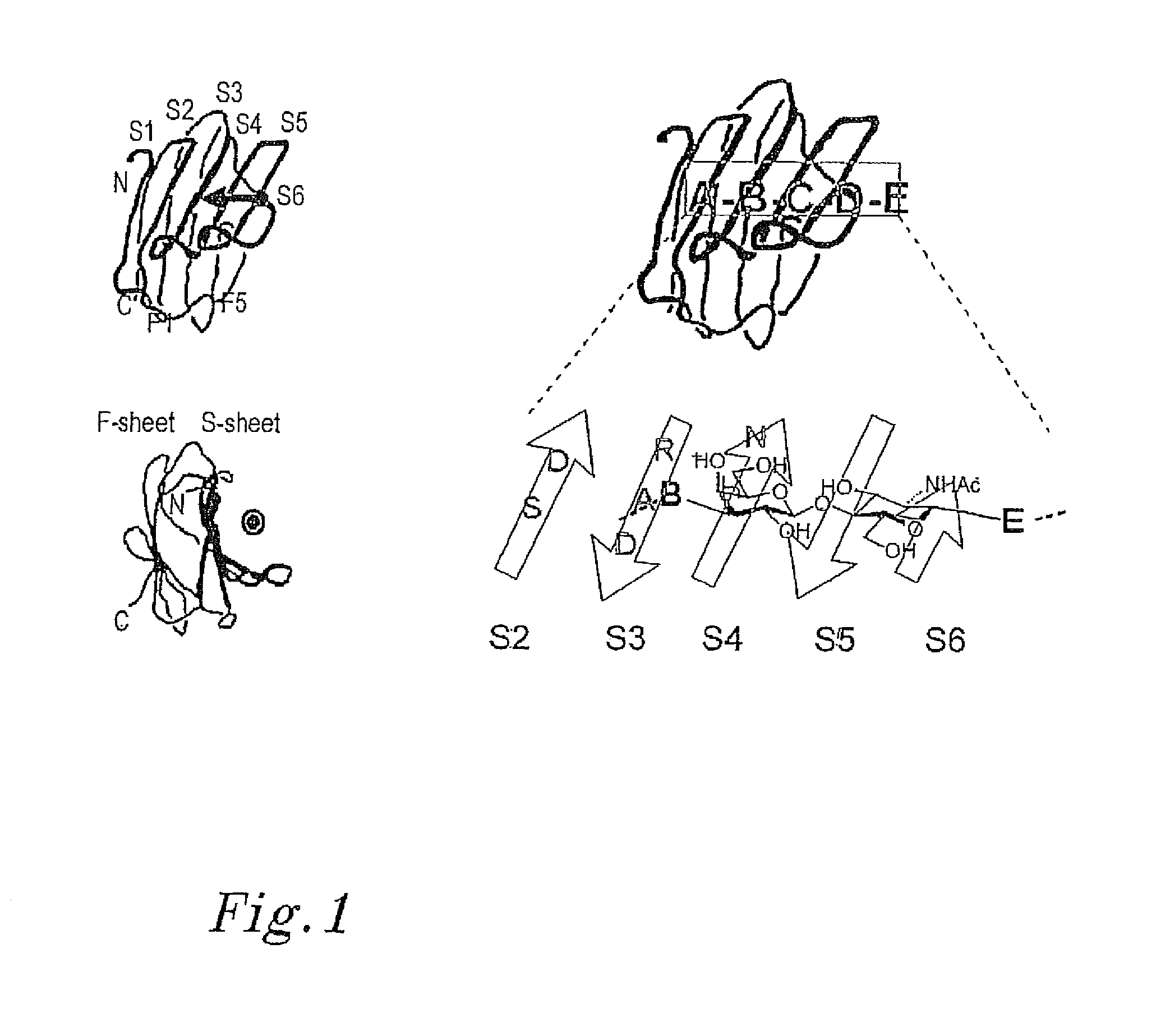

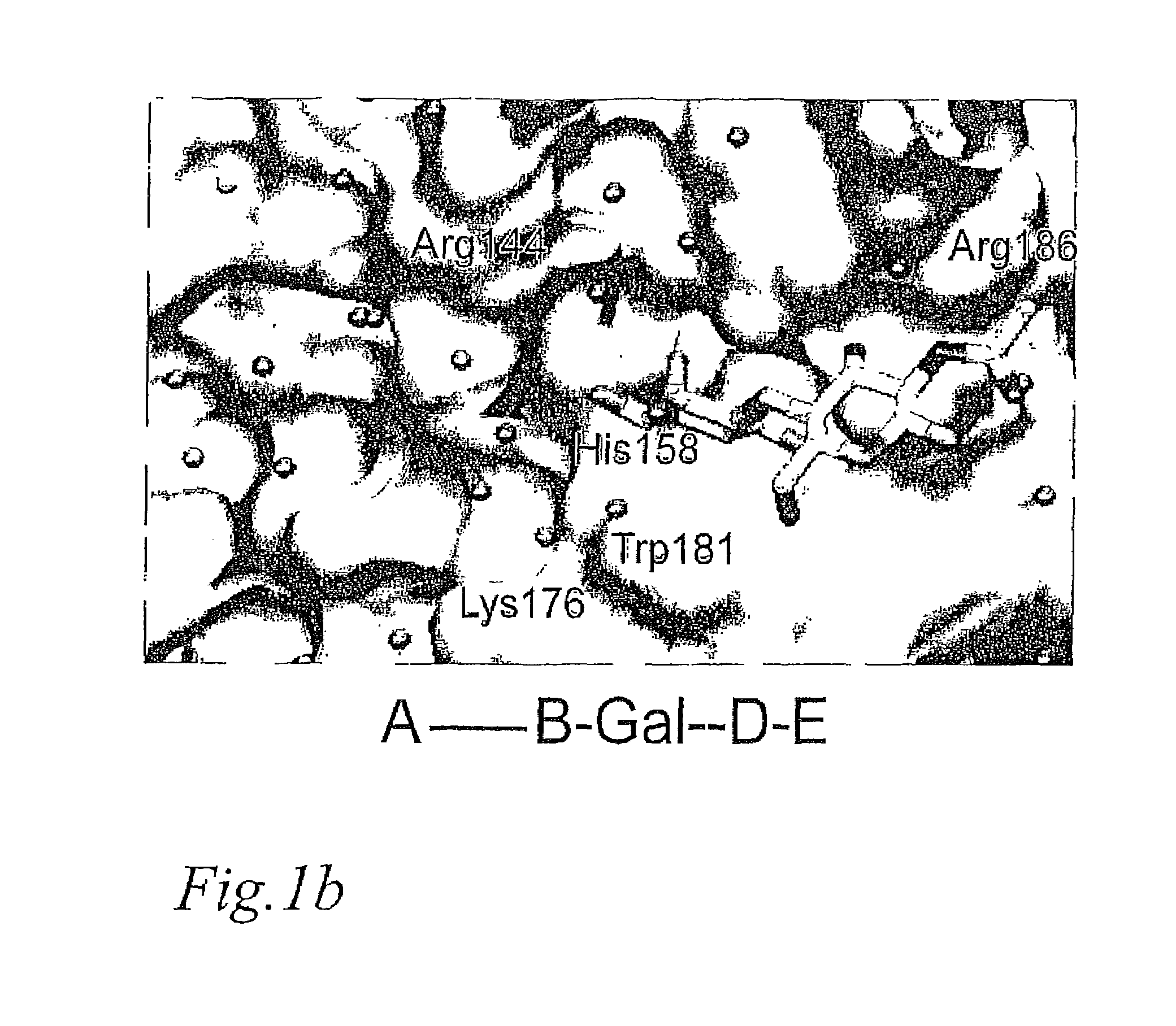

Galactoside inhibitors of galectins

InactiveUS7638623B2Process economyHigh affinityEsterified saccharide compoundsOrganic active ingredientsDiseaseMedicine

Owner:GALECTO BIOTECH

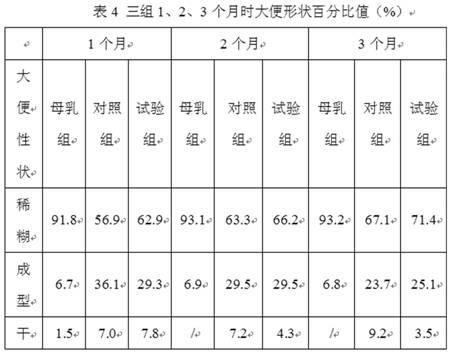

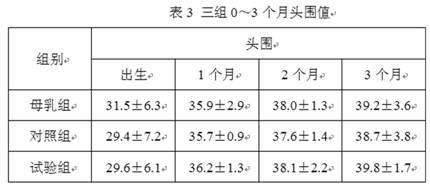

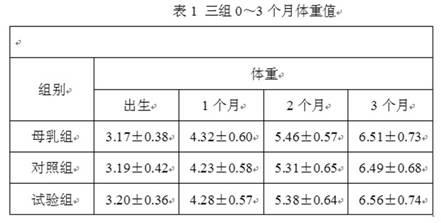

A kind of infant formula milk powder that does not get angry and its preparation process

ActiveCN102283289ANot ediblePromote digestion and absorptionMilk preparationVegetable oilFructooligosaccharide

The invention relates to an anti-inflaming infant formula milk powder and a preparation process thereof. The anti-inflaming infant formula milk powder comprises the following components in percentage by weight: 22%-50% of lactose, 10%-20% of goat milk whey protein concentrate, 9.8%-20% of structural grease 1,3-dioleoyl 2-palmitoyl triglyceride, 10%-13.5% of non-fat goat milk powder, 8%-10% of vegetable oil, 2%-8% of beta-casein, 0.8%-1.6% of fructooligosaccharides, 0.5%-1.5% of mineral premix, 0.3%-1% of galactooligosaccharide, 0.2%-1% of immunoglobulin G, 0.2%-0.5% of lactulose, 0.10%-0.45% of arachidonic acid, 0.1%-0.6% of docosahexaenoic acid, 0.06%-0.12% of vitamin premix, 0.04%-0.06% of lactoferrin, and 0.01%-0.06% of nucleotide. The invention also includes the preparation process ofthe infant formula milk powder. The nutrition constituents and the functions of the infant formula milk powder are close to those of breast milk, the infant formula milk powder is easy to assimilate,and infants do not get inflamed after eating the milk powder.

Owner:AUSNUTRIA DAIRY CHINA

Galactose-pronged carbohydrate compounds for the treatment of diabetic nephropathy and associated disorders

Methods and compositions of the invention relate to the treatment of diabetic nephropathy and associated disorders. In particular, the methods and compositions use a pharmaceutical-grade galactose-pronged carbohydrate or pharmaceutical compositions thereof alone or in combination with other therapeutic agents.

Owner:GALECTIN THERAPEUTICS

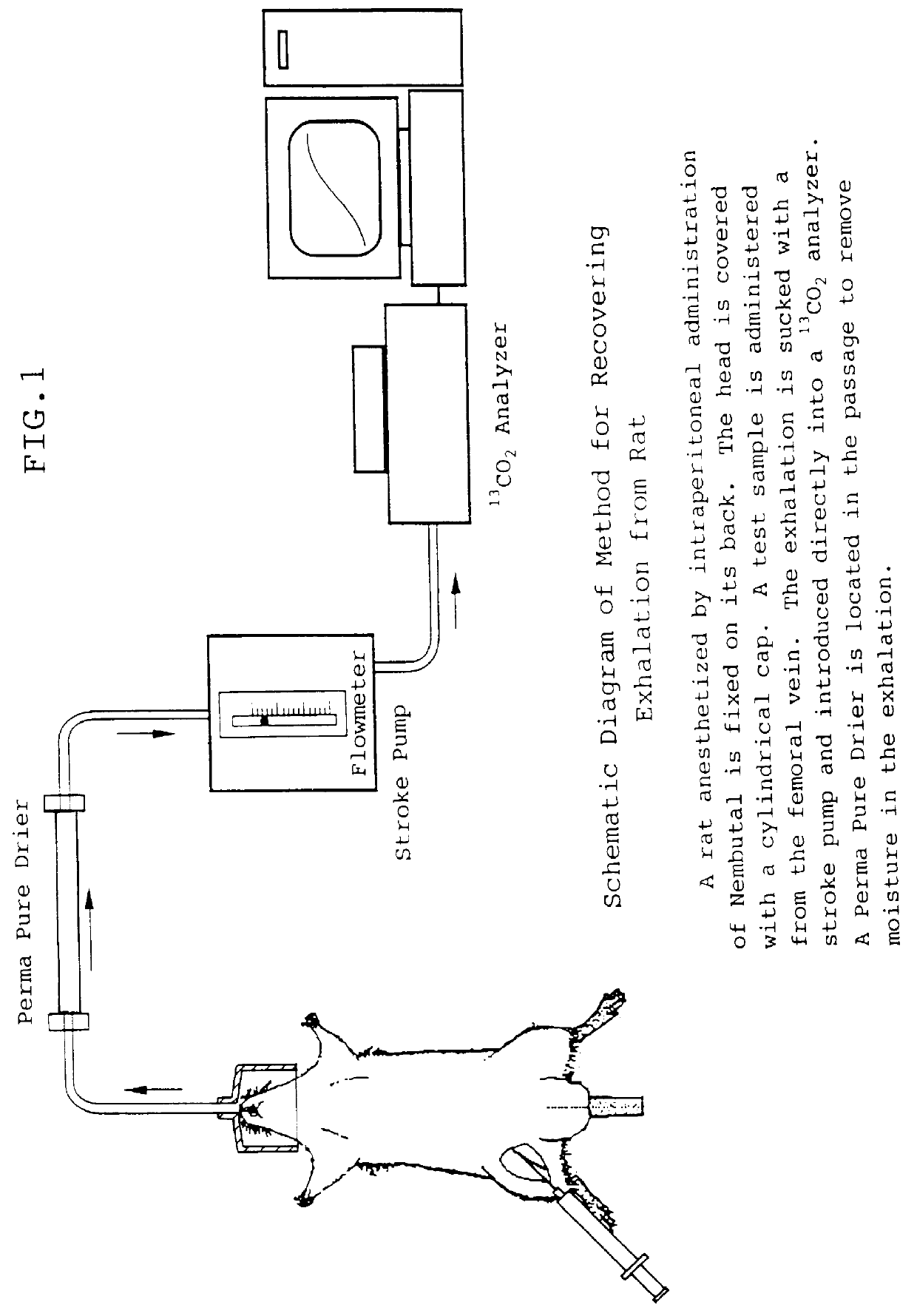

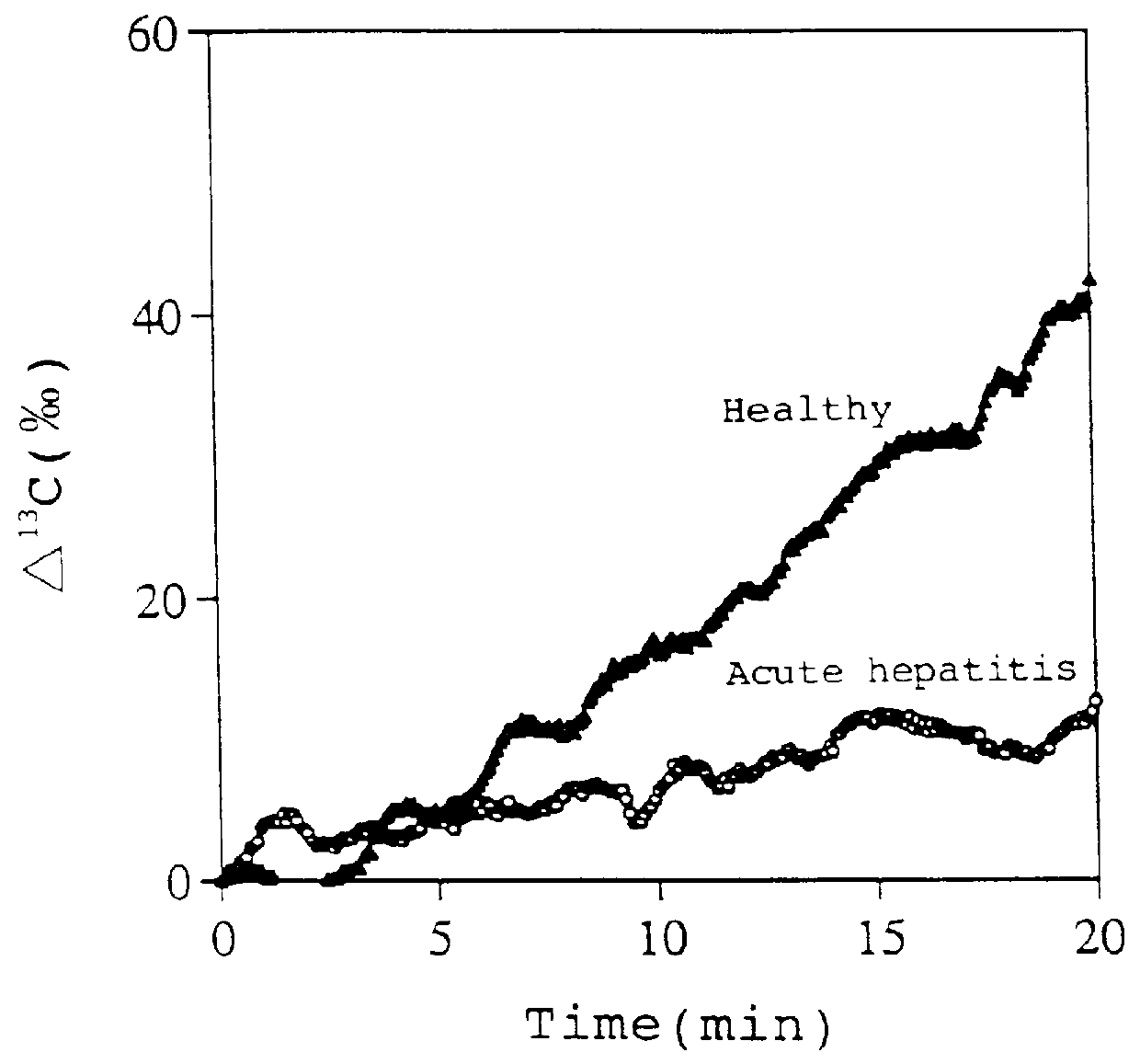

Diagnostic agent for liver function

InactiveUS6071245ALessen the burden on the bodyEasy to useRadioactive preparation carriersRespiratory organ evaluationSide effectGlycerol

The present invention relates to a diagnostic agent for liver function, comprising a compound labelled with 13C at least at one specific position selected from the group consisting of the following (a) to (f): (a) galactose, glucose or xylose labelled with 13C at least at one specific position or a starch composed of glucose units labelled with 13C at least at one specific position; (b) a polar amino acid, heterocyclic amino acid, isoleucine or valine labelled with 13C at least at one specific position; (c) a carboxylic acid constituting the glycolytic pathway or the citric acid cycle, labelled with 13C at least at one specific position; (d) a fatty acid labelled with 13C at least at one specific position; (e) a glyceride labelled with 13C at least at one specific position; and (f) glycerol labelled with 13C at least at one specific position. According to the present invention, a diagnostic agent for liver function which imposes less physical burden on a subject, can give accurate test result immediately, and can be used safely without side effects is provided. The diagnostic agent of the invention is useful for evaluating the liver function of a subject at the time when the test is carried out.

Owner:TOKYO GAS CO LTD

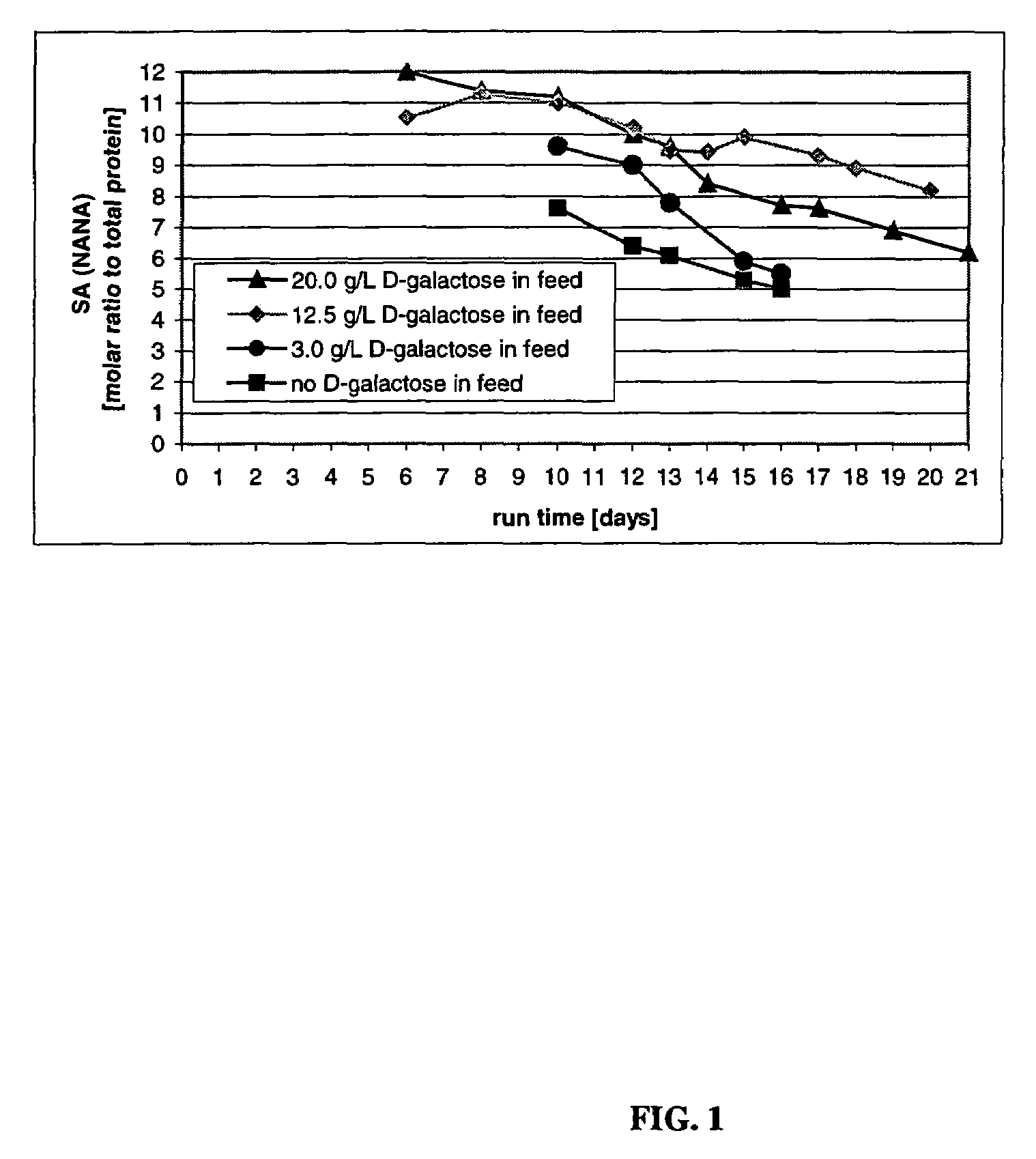

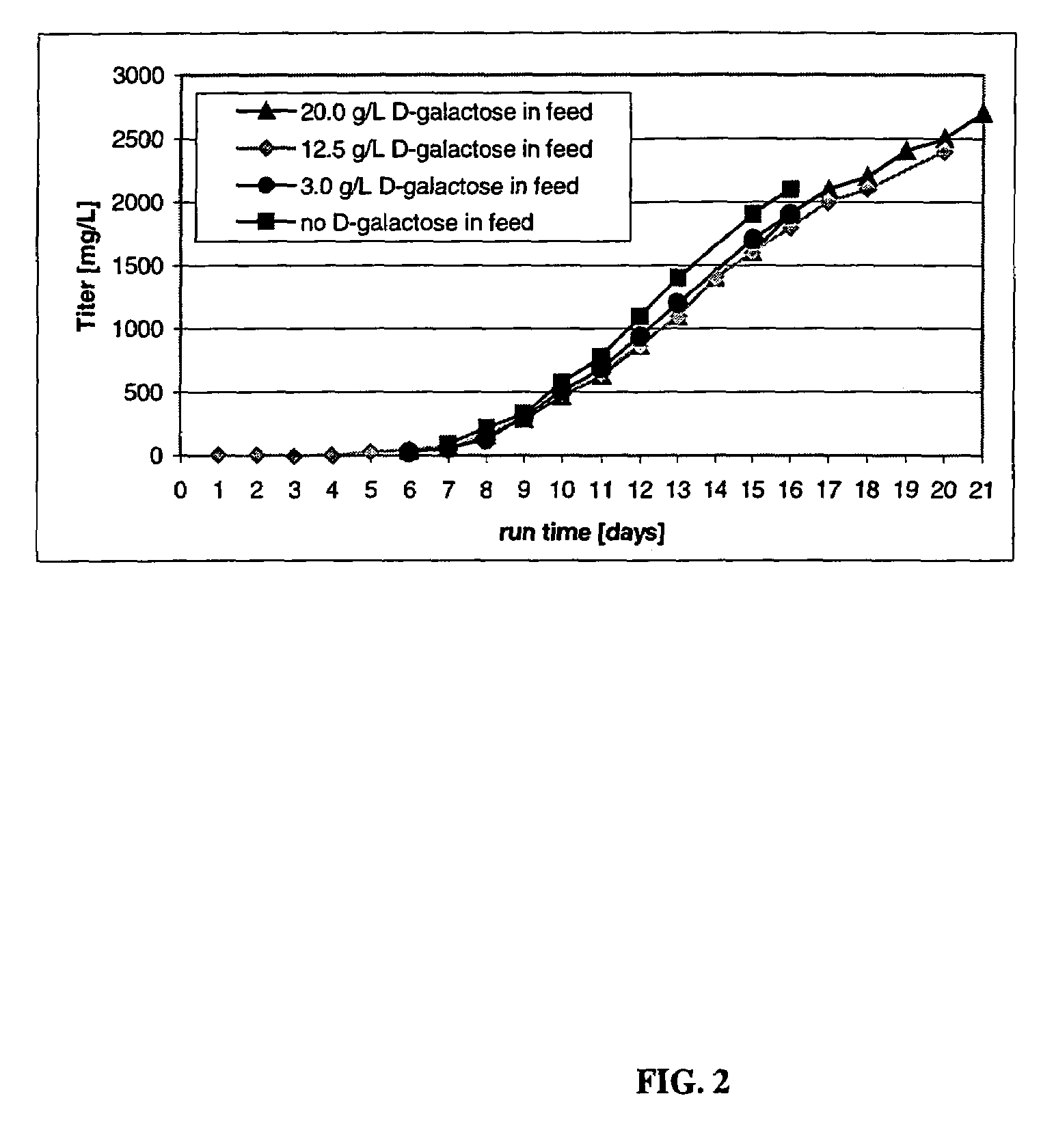

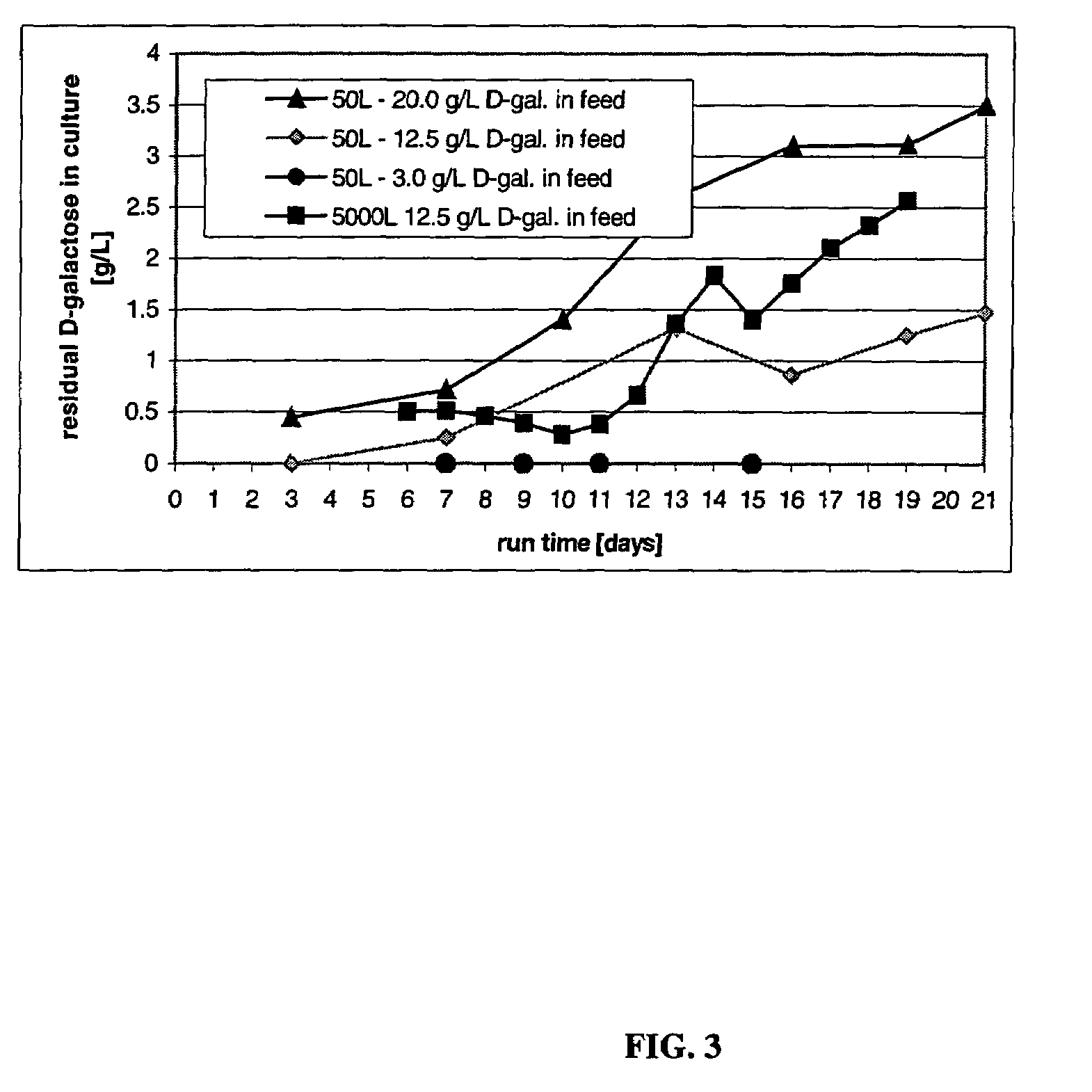

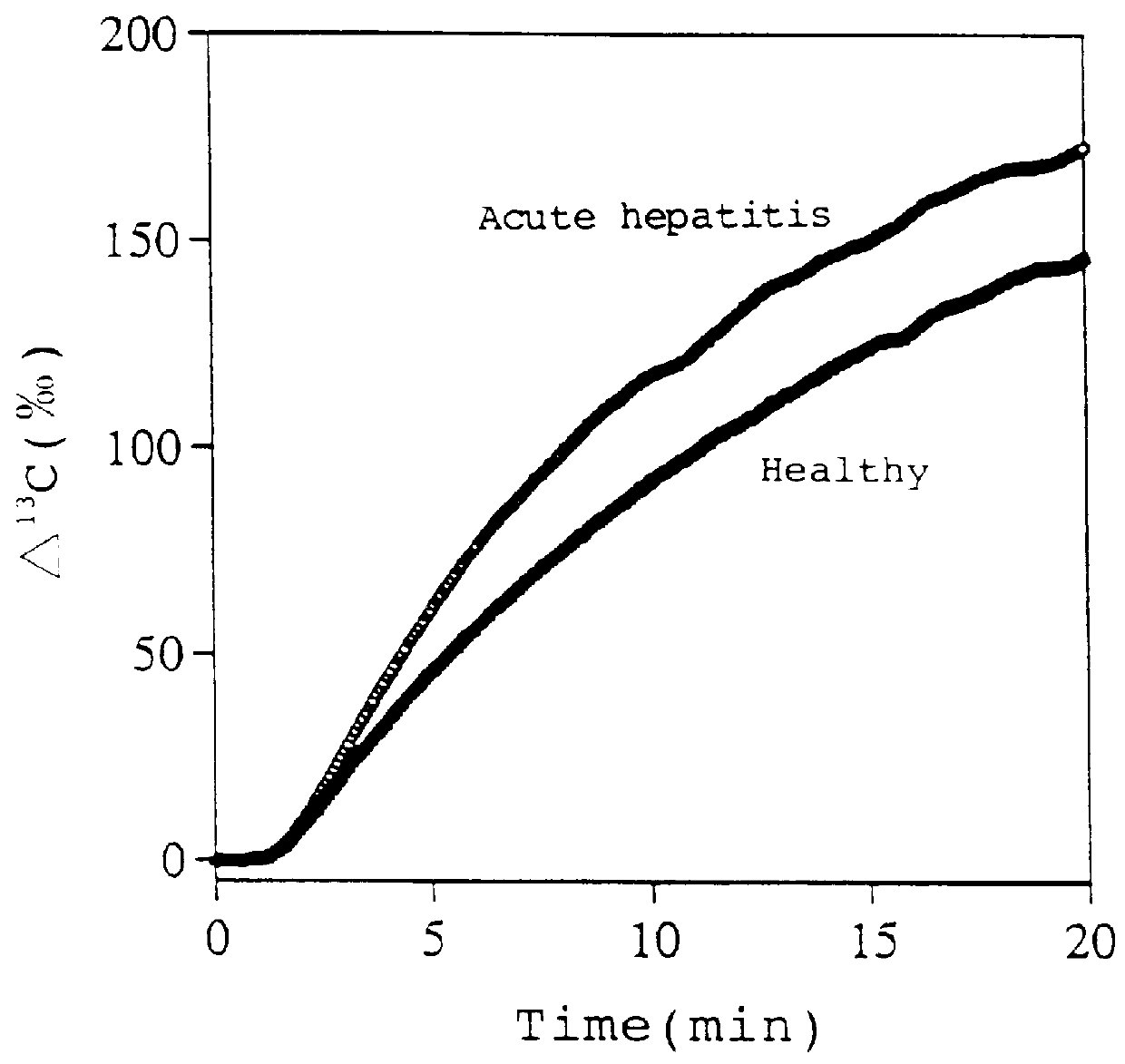

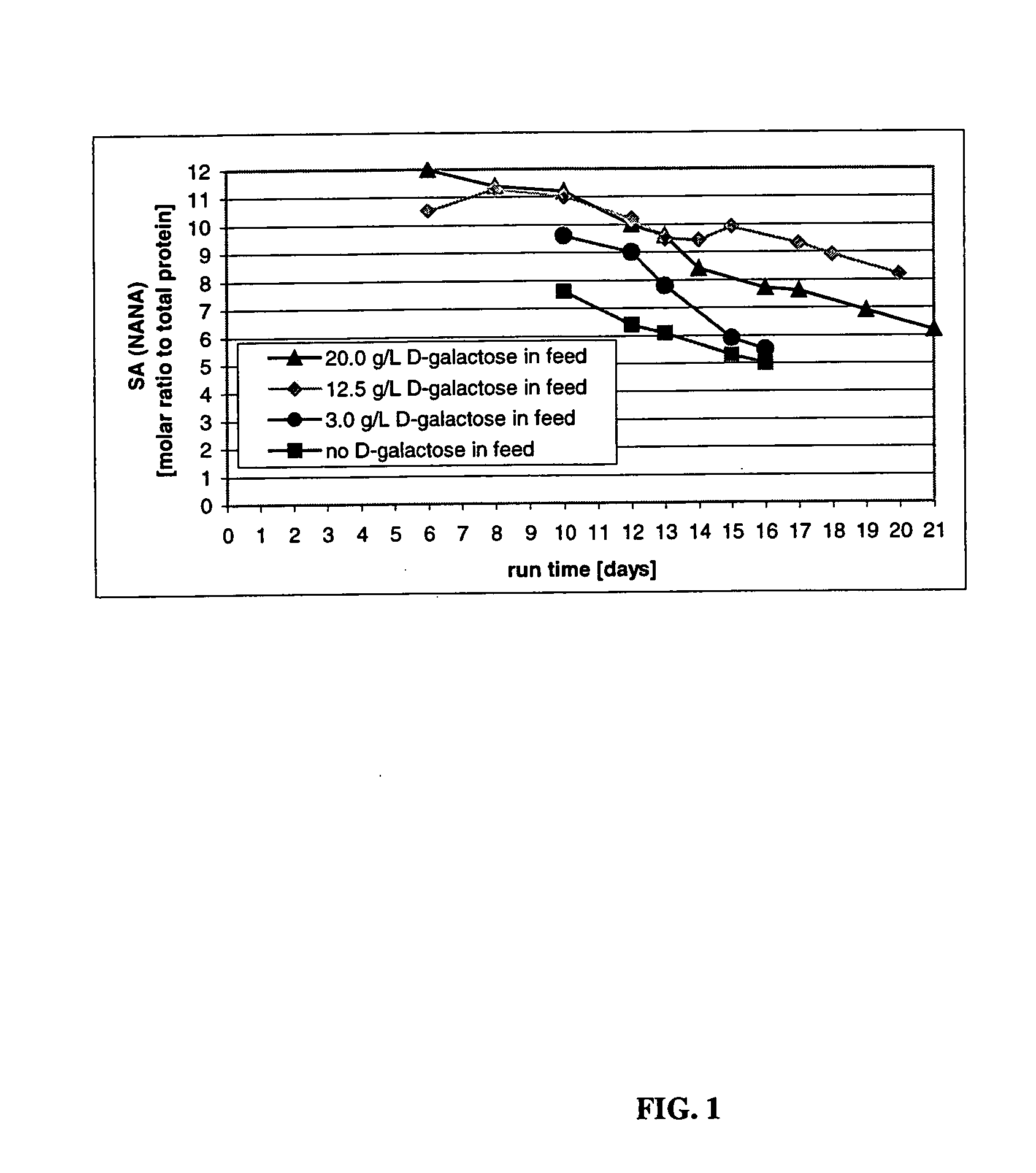

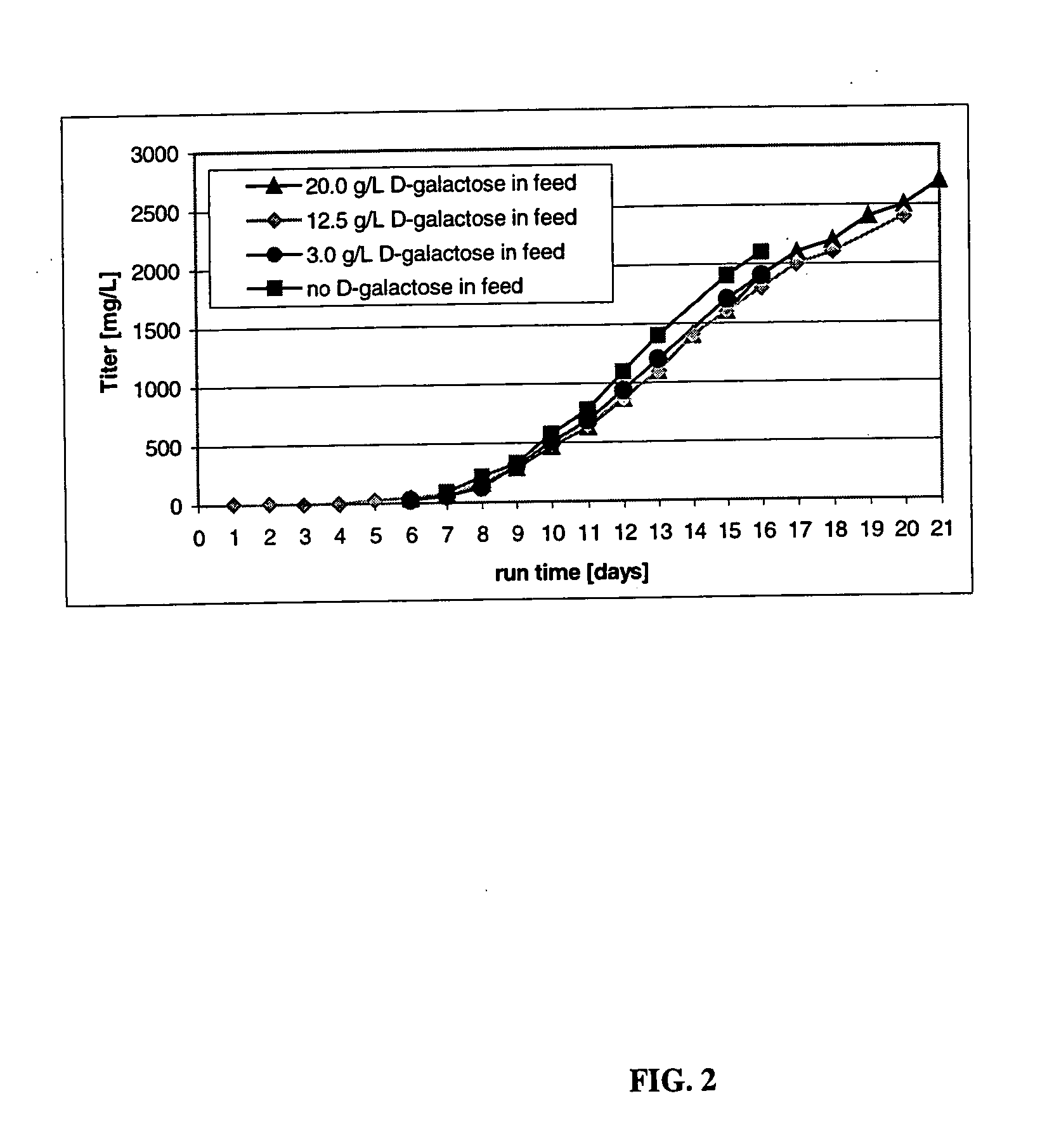

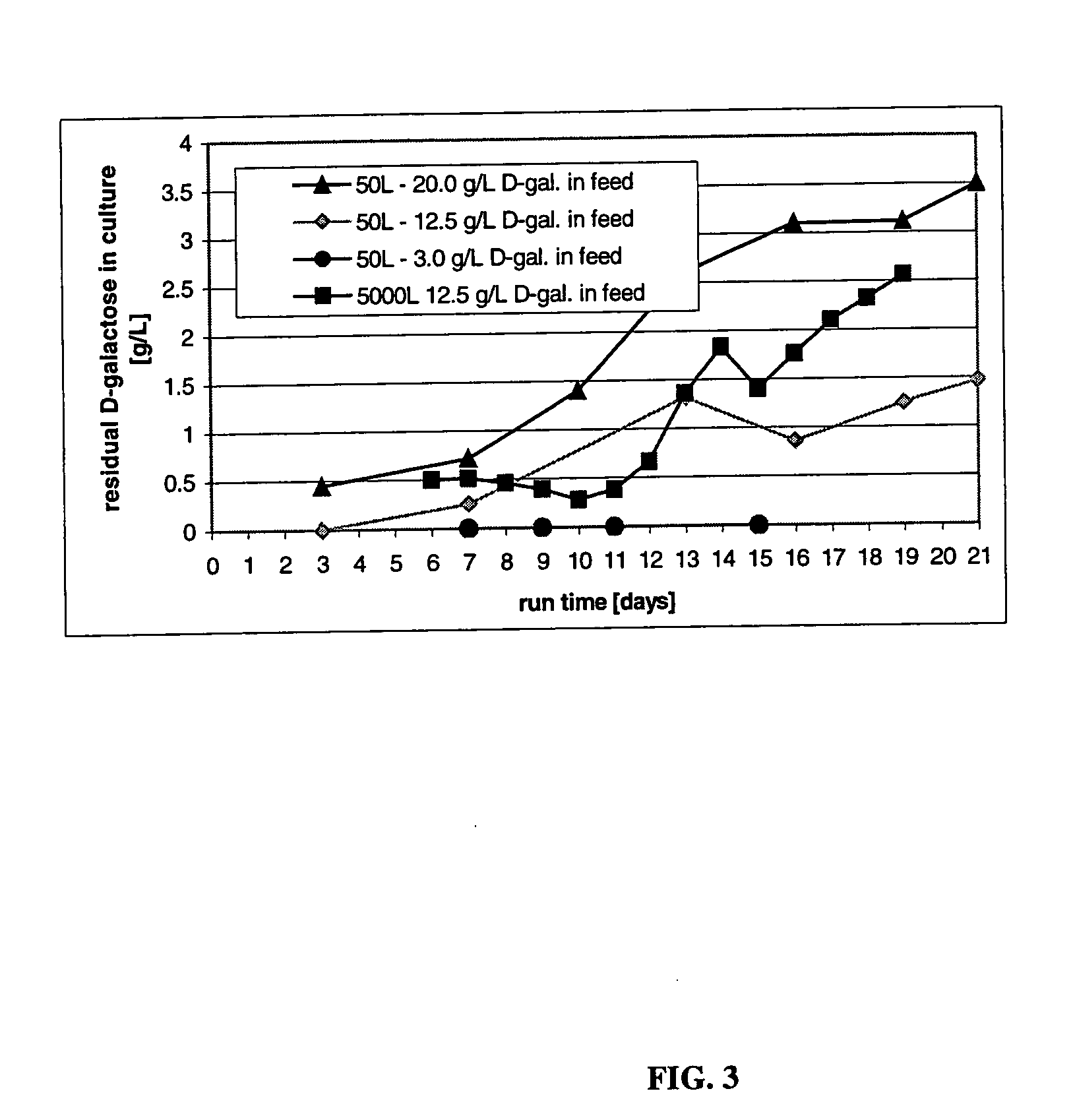

Product quality enhancement in mammalian cell culture processes for protein production

ActiveUS20050084933A1Increased and enhanced sialic acid contentLow production costAnimal cellsCell receptors/surface-antigens/surface-determinantsBiotechnologyHigh cell

The present invention describes methods and processes for the production of proteins, particularly glycoproteins, by animal cell or mammalian cell culture, illustratively, but not limited to, fed-batch cell cultures. The methods comprise feeding the cells with D-galactose, preferably with feed medium containing D-galactose, preferably daily, to sustain a sialylation effective level of D-galactose in the culture for its duration, thus increasing sialylation of the produced proteins. The methods can also comprise at least two temperature shifts performed during the culturing period, in which the temperature is lower at the end of the culturing period than at the time of initial cell culture. The cell culture processes of the invention involving two or more temperature shifts sustain a high cell viability, and can allow for an extended protein production phase. The methods can also comprise the delayed addition of polyanionic compound at a time after innoculation. Supplementation of the cultures with D-galactose, preferably in a feed medium, to sustain galactose at sialylation effective levels in the cultures until the end of a culture run reverses a decline in sialylation that accompanies culture scale up, and is advantageous for large scale culturing processes.

Owner:BRISTOL MYERS SQUIBB CO

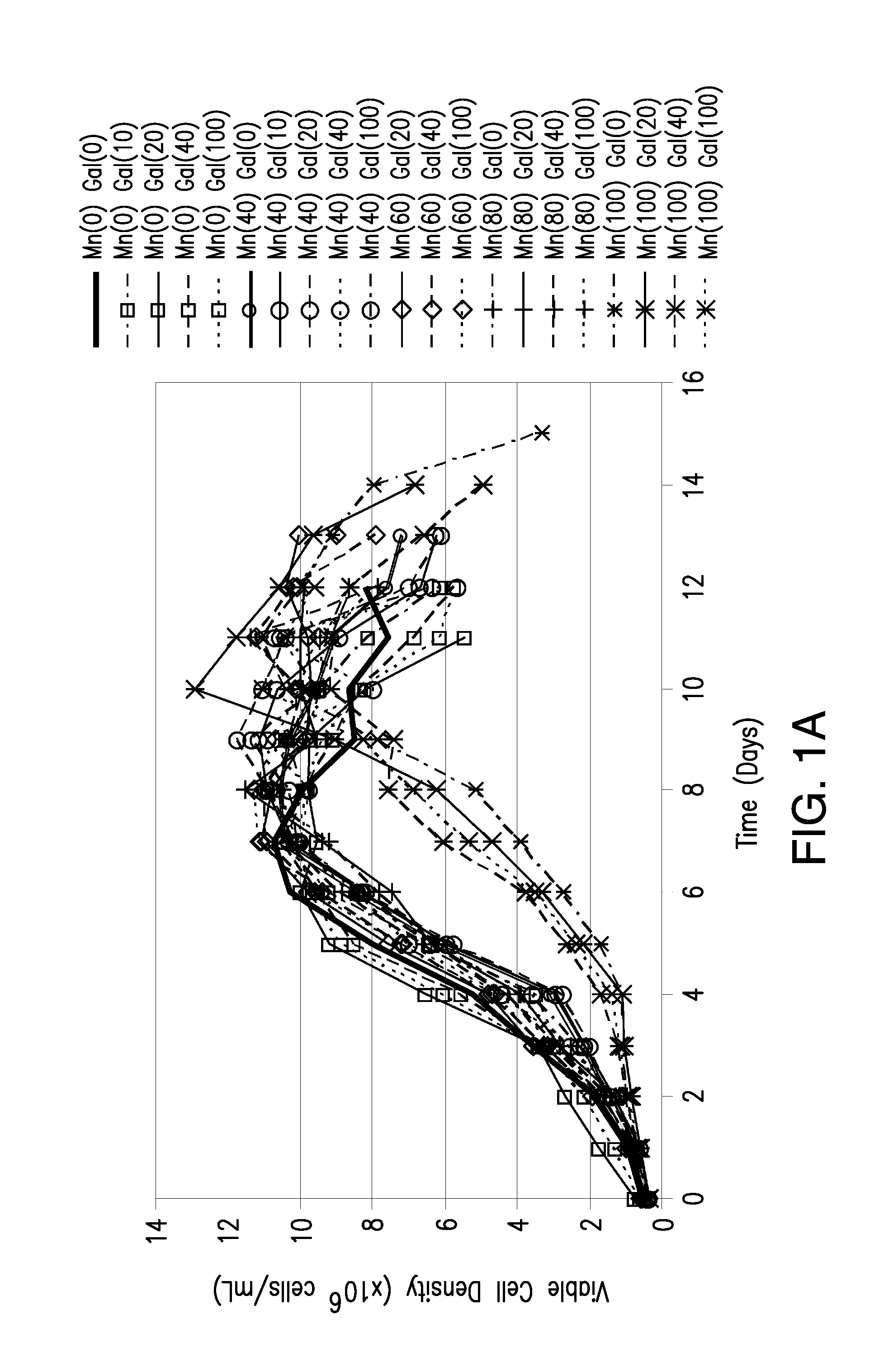

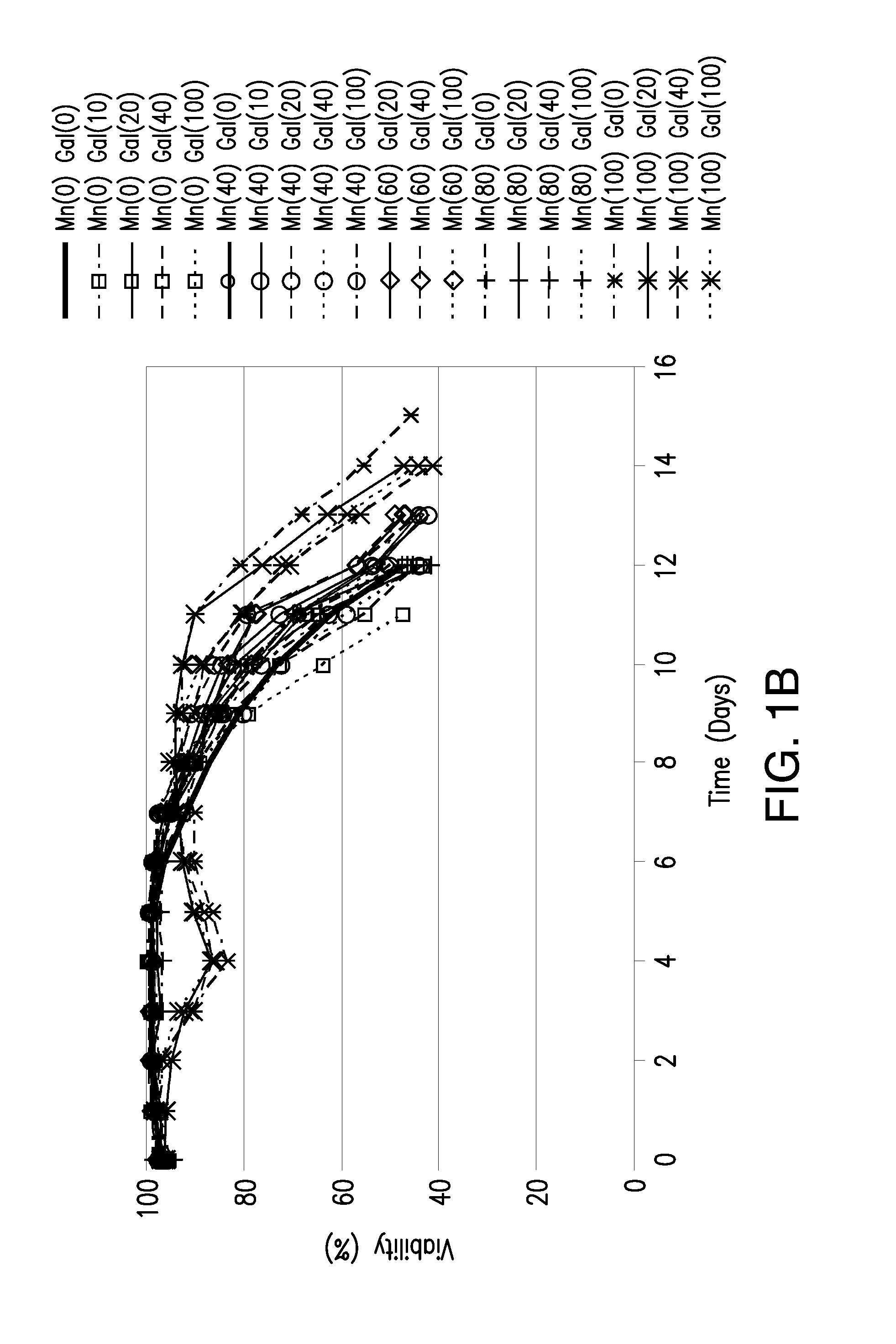

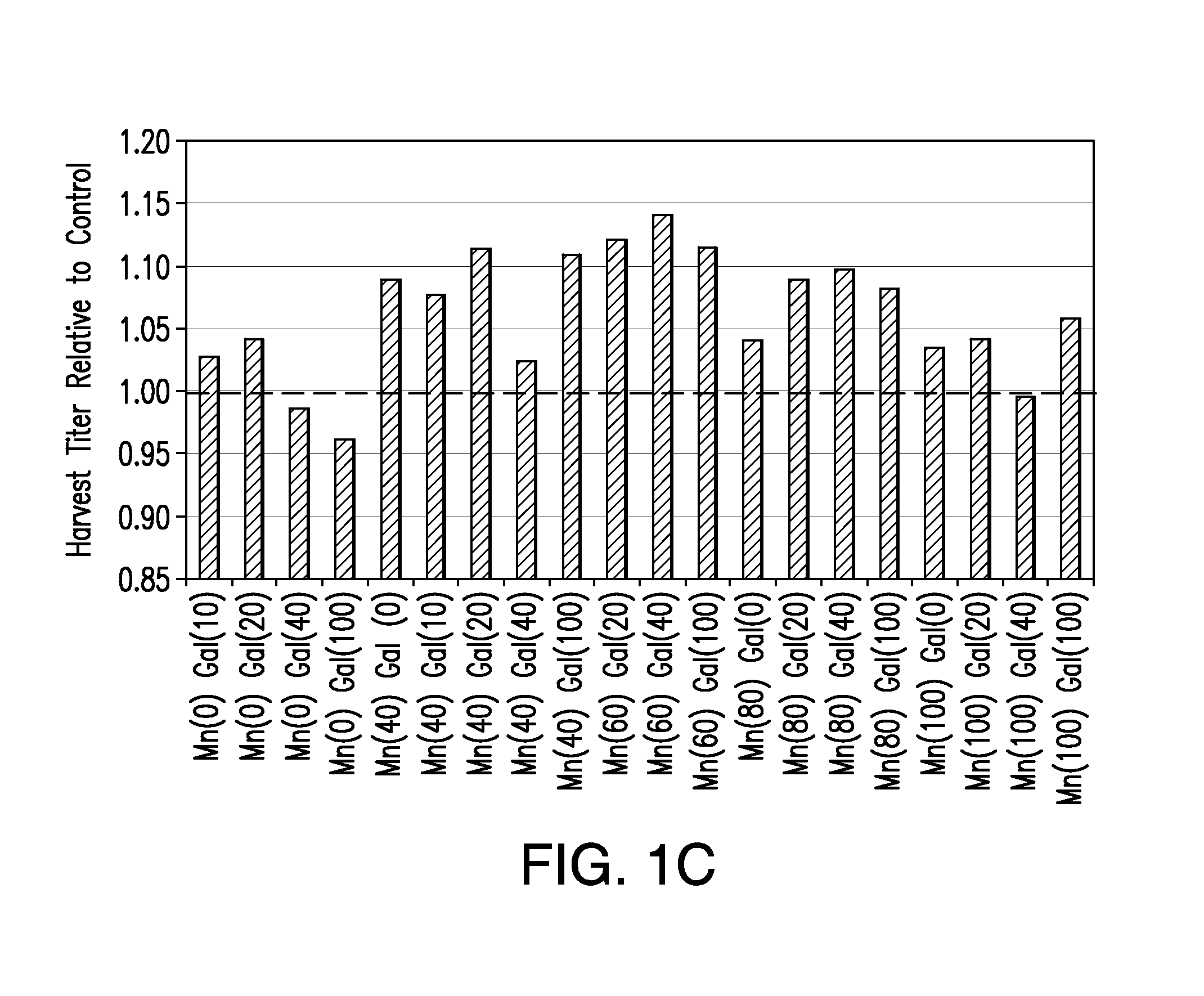

Methods for controlling the galactosylation profile of recombinantly-expressed proteins

The present invention relates to methods for modulating the glycosylation profile of recombinantly-expressed proteins. In particular, the present invention relates to methods of controlling the galactosylation profile of recombinantly-expressed proteins by supplementing production medium, e.g., a hydrolysate-based or a chemically defined medium, with manganese and / or D-galactose.

Owner:ABBVIE INC

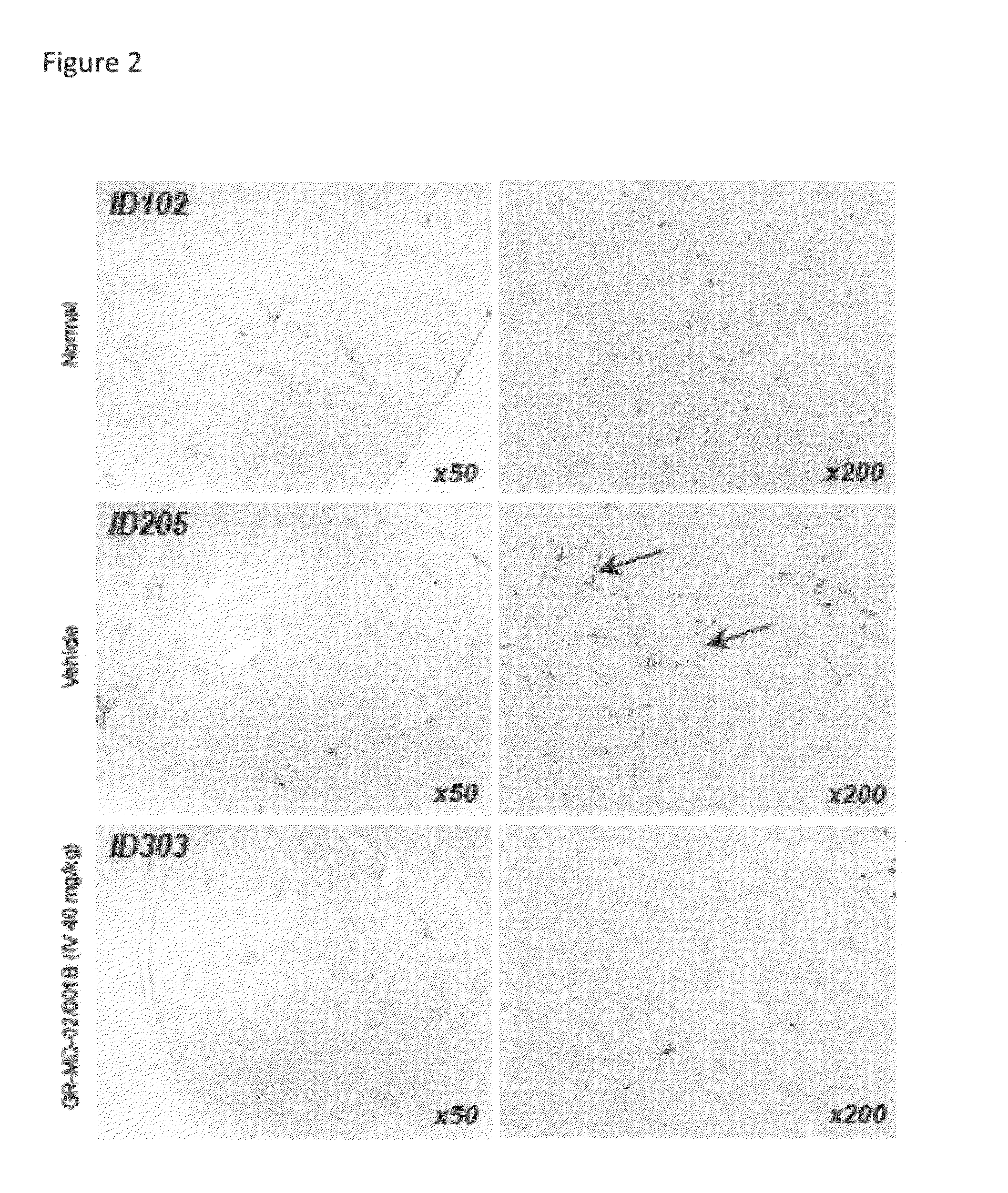

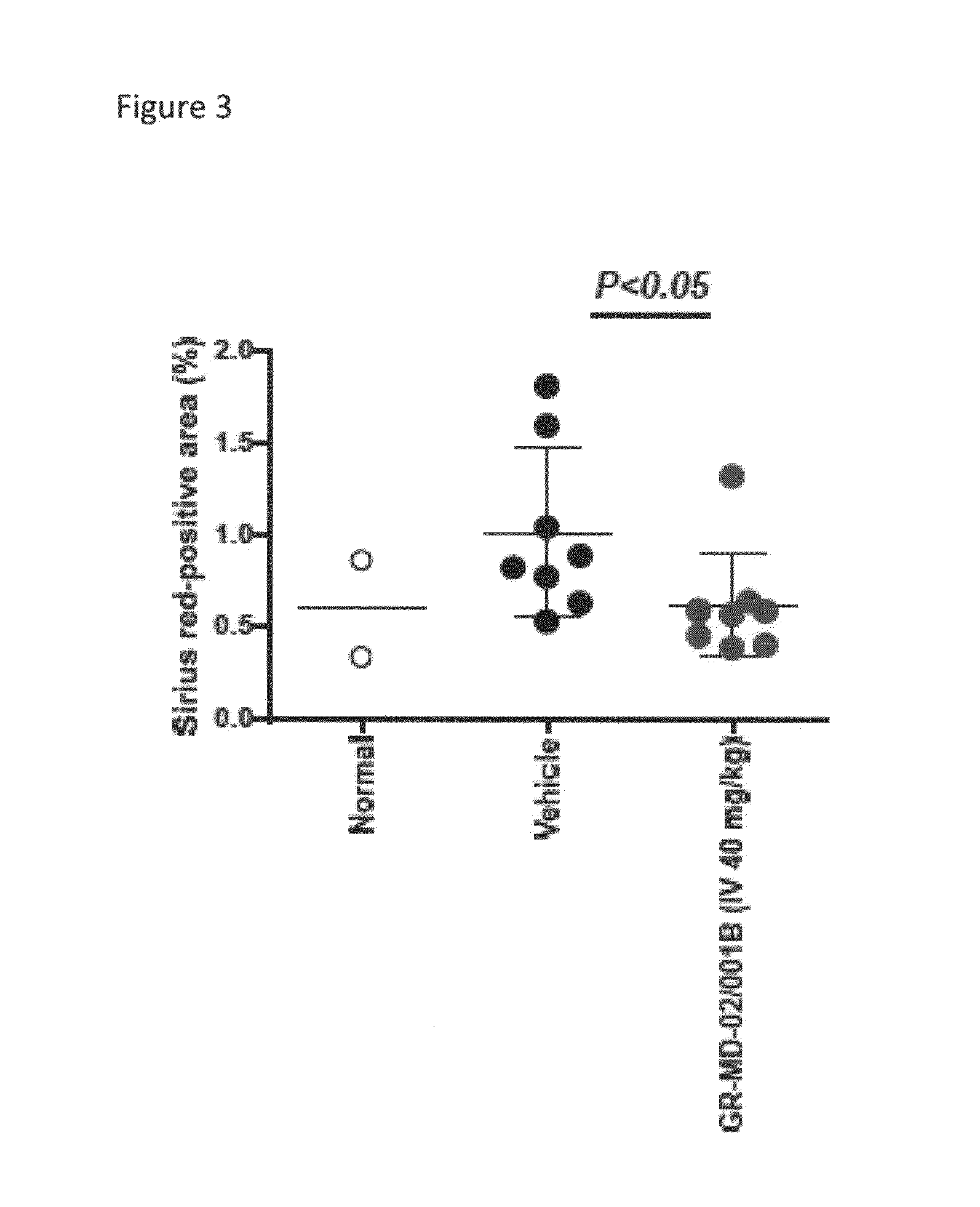

Galactose-pronged polysaccharides in a formulation for antifibrotic therapies

Methods and compositions for reducing fibrosis and cirrhosis are provided in which an effective dose of an admixture of a polysaccharide compound and, for example, a compound selected from the group consisting of antibodies specific to intracellular or cell-surface: (i) beta-PDGF receptors; (ii) synaptophysin; (iii) zvegf3; (iv) CCR1 receptors; (v) connective tissue growth factor; (vi) alpha 1-smooth muscle actin; (vii) matrix metalloproteinases MMP 2 and MMP9; (viii) matrix metalloproteinase inhibitors TIMP1 and TMP2; (ix) integrins; (x) TFG-β1; (xi) endothelin receptor antagonists; and (xii) collagen synthesis and degradation modulating compounds; (xiii) actin synthesis and degradation modulating compounds; and (xiv) tyrosine kinases is administered to an animal in order to treat fibrosis.

Owner:GALECTIN THERAPEUTICS

Shampoo containing a gel network and a non-guar galactomannan polymer derivative

ActiveUS20060269502A1Cosmetic preparationsCationic surface-active compoundsAmphiphileSURFACTANT BLEND

Shampoo compositions comprise (a) from about 5% to about 50% of one or more detersive surfactants; (b) a dispersed gel network phase comprising: (i) at least about 0.05% of one or more fatty amphiphiles; (ii) at least about 0.01% of one or more secondary surfactants; and (iii) water; (c) at least about 0.05% of a galactomannan polymer derivative with a net positive charge and having a mannose to galactose ratio of greater than 2 : 1 on a monomer to monomer basis, wherein the galactomannan polymer derivative has: (i) a molecular weight from about 1,000 to about 10,000,000; and (ii) a cationic charge density from about 0.7 meq / g to about 7 meq / g; and (d) at least about 20% of an aqueous carrier; all by weight of the shampoo composition.

Owner:THE PROCTER & GAMBLE COMPANY

Hair conditioning composition containing a non-guar galactomannan polymer derivative

A hair conditioning composition comprising:a) from about 0.01 wt. % to about 10 wt. % of a non-guar galactomannan polymer derivative having a mannose to galactose ratio of greater than 2:1 on a monomer to monomer basis, said non-guar galactomannan polymer derivative selected from the group consisting of a cationic non-guar galactomannan polymer derivative and an amphoteric non-guar galactomannan polymer derivative having a net positive charge;i. wherein said non-guar galactomannan polymer derivative has a molecular weight from about 1,000 to about 10,000,000; andii. wherein said non-guar galactomannan polymer derivative has a cationic charge density from about 0.7 meq / g to about 7 meq / g;b) a conditioning agent selected from the group consisting of cationic surfactants, cationic polymers, nonvolatile silicones, nonvolatile hydrocarbons, saturated C14 to C22 straight chain fatty alcohols, nonvolatile hydrocarbon esters, and mixtures thereof; andc) wherein said hair conditioning composition is substantially free of an anionic surfactant.

Owner:THE PROCTER & GAMBLE COMPANY

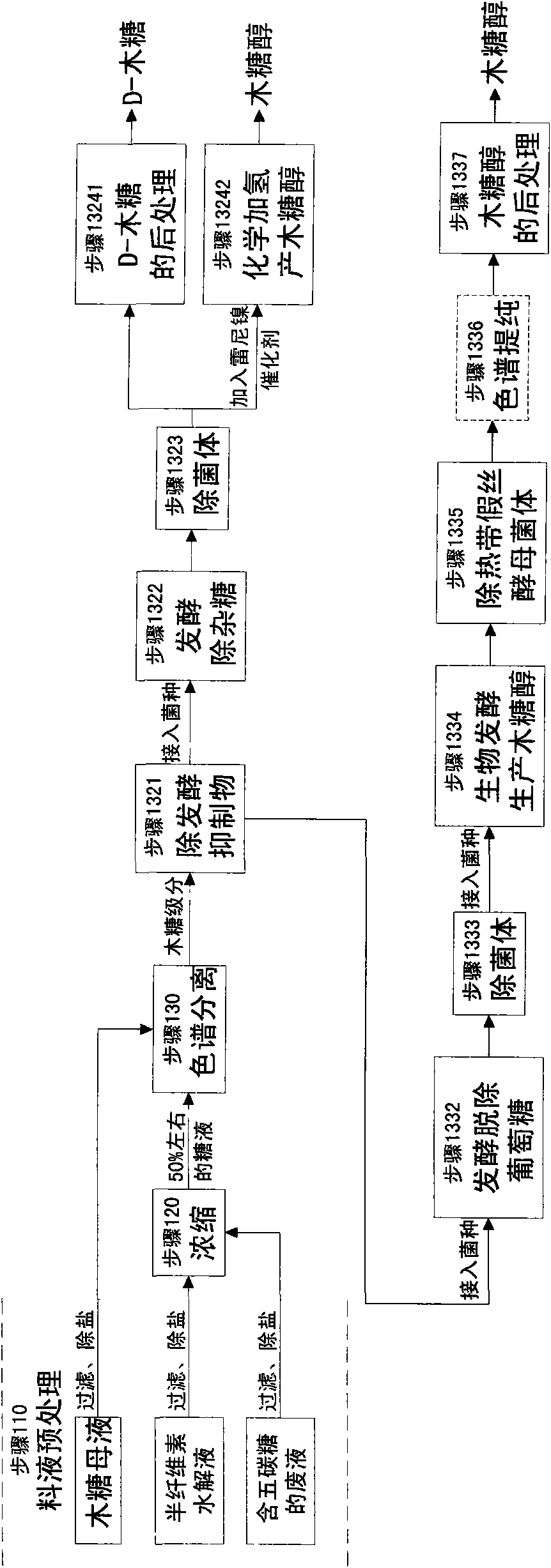

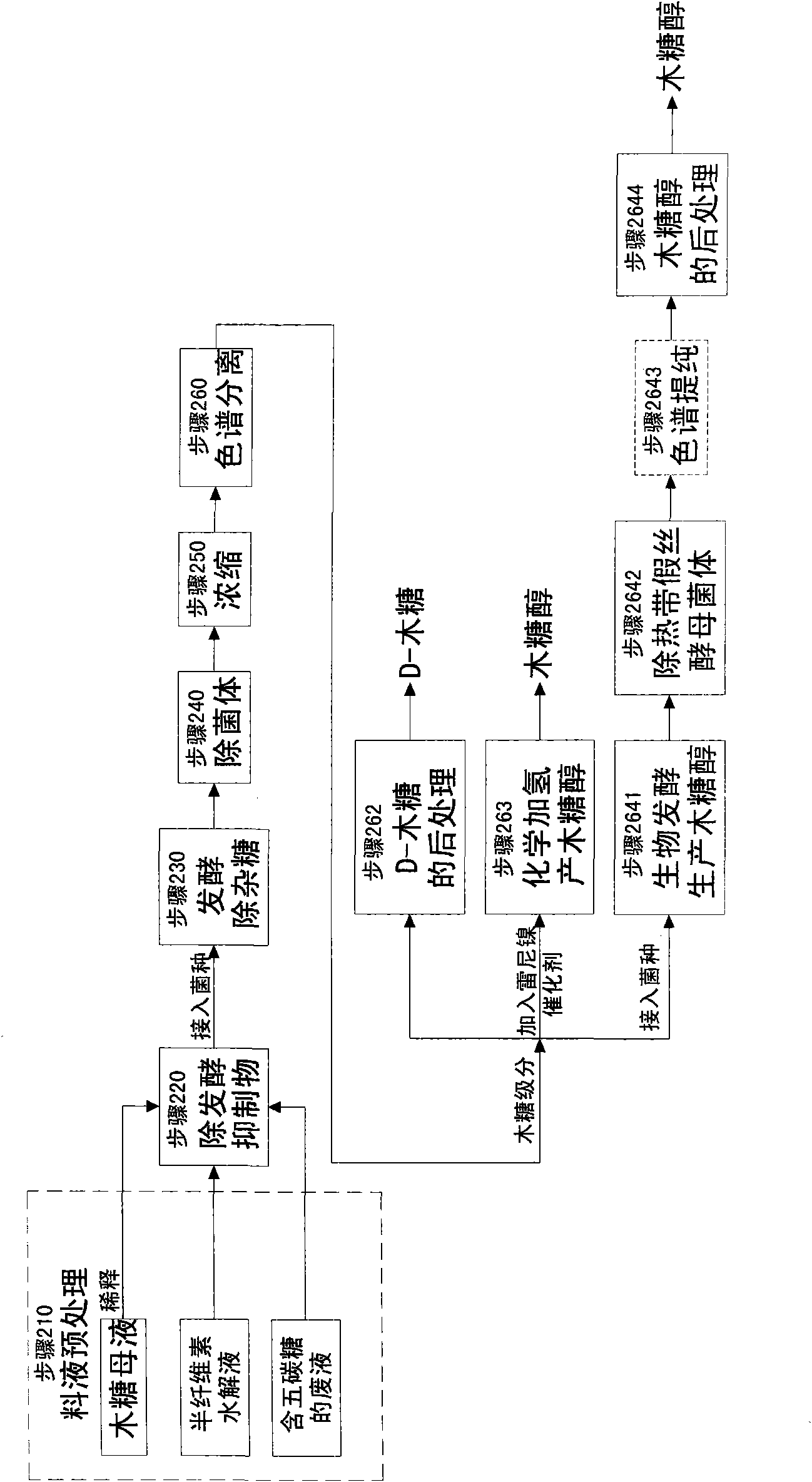

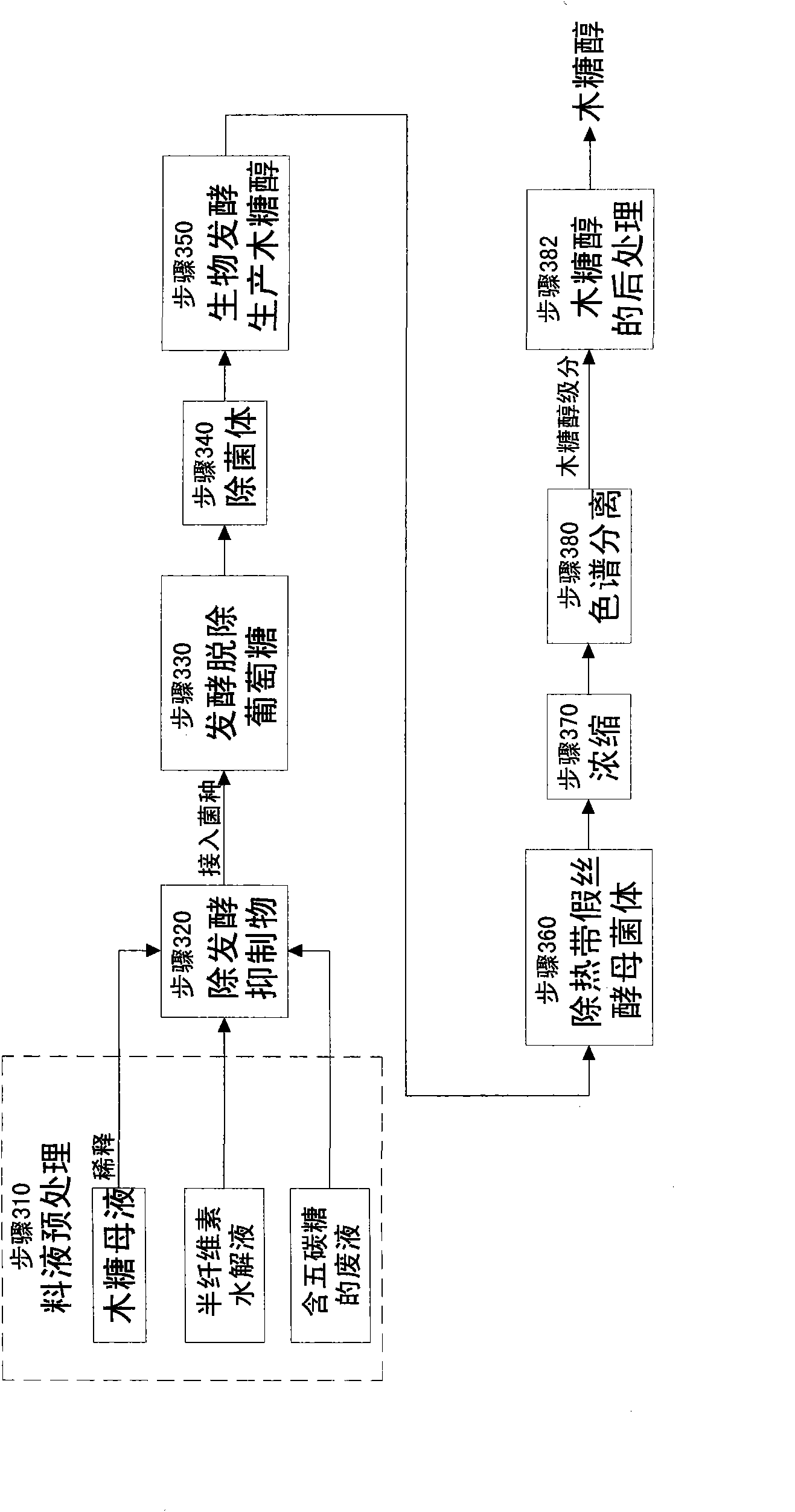

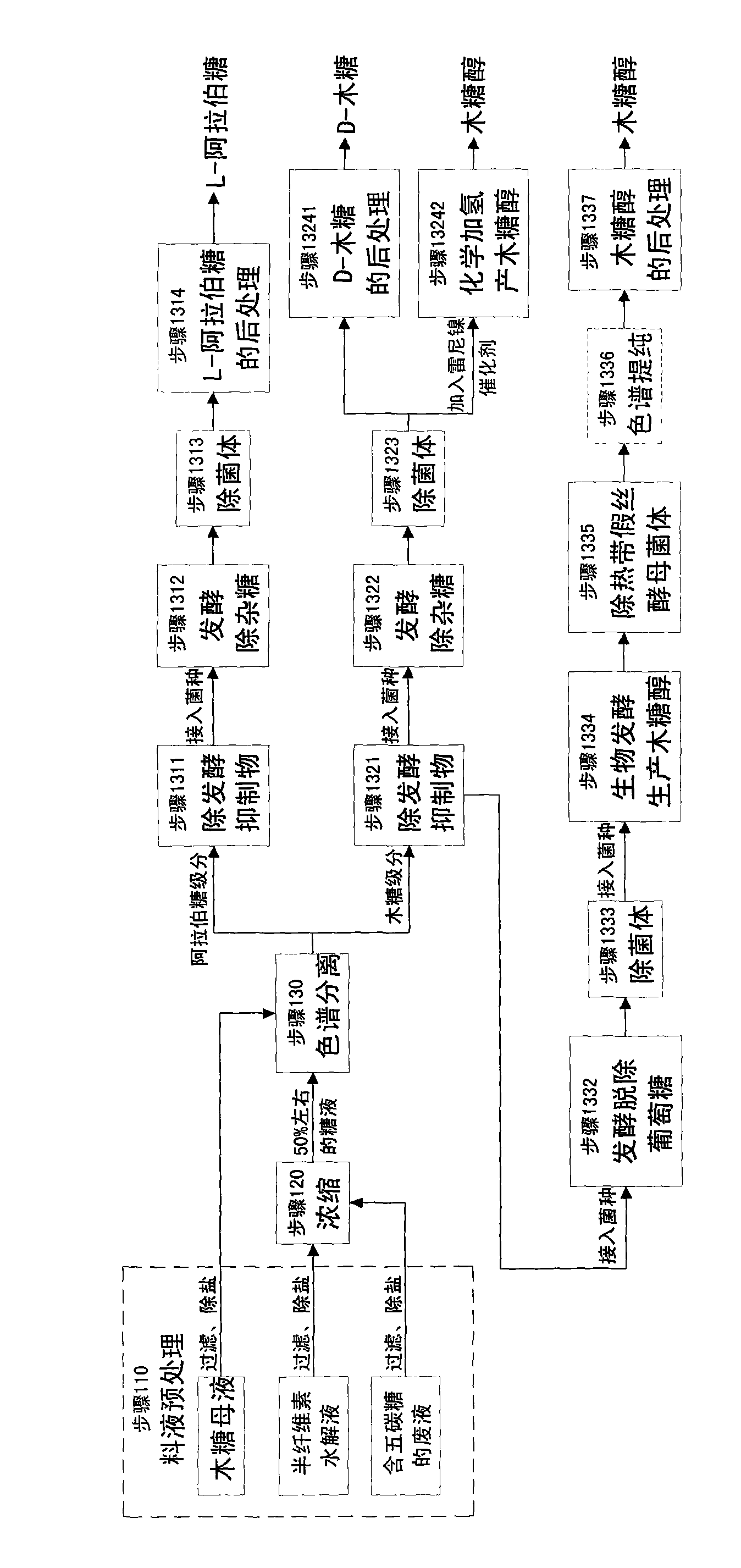

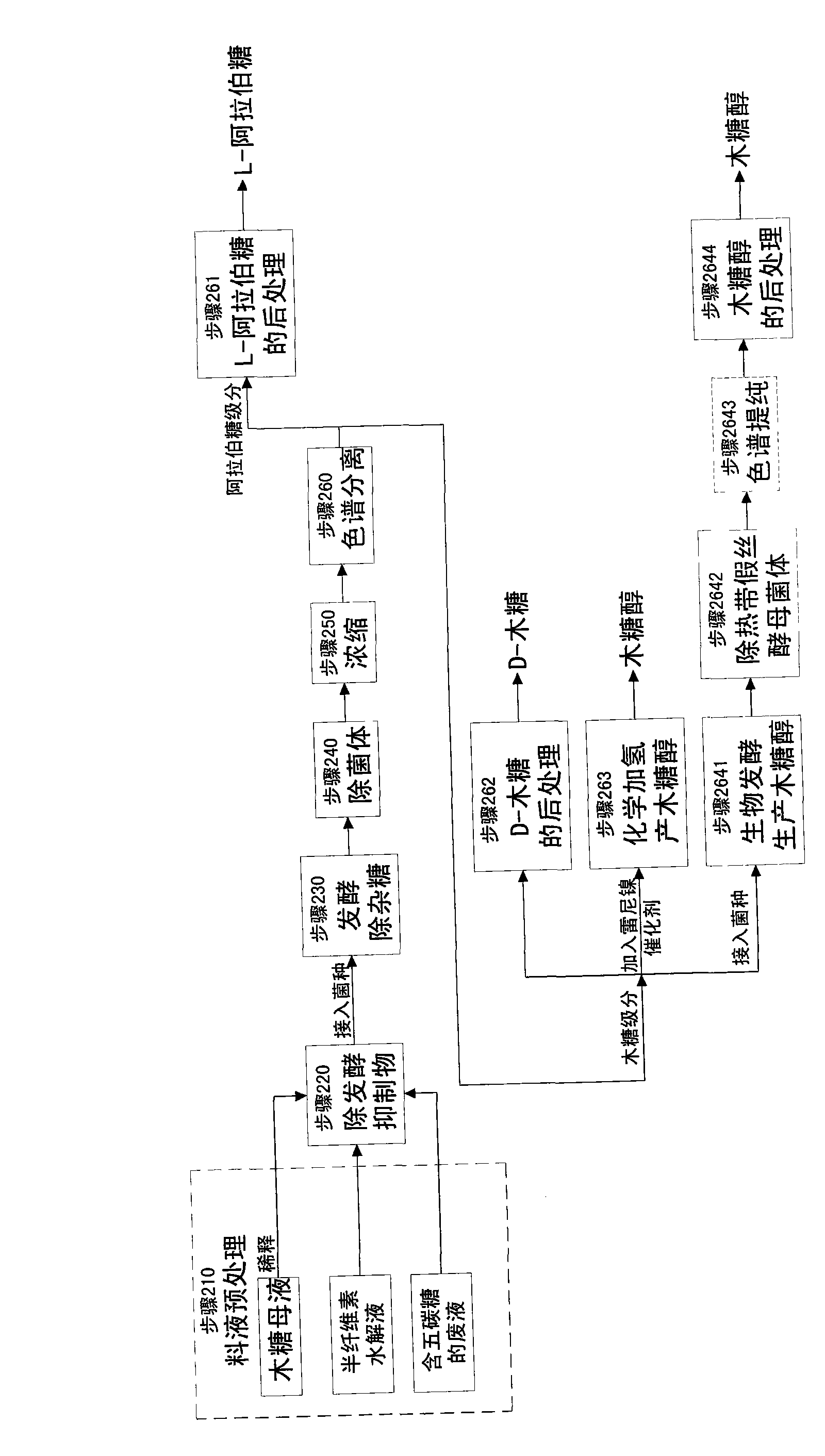

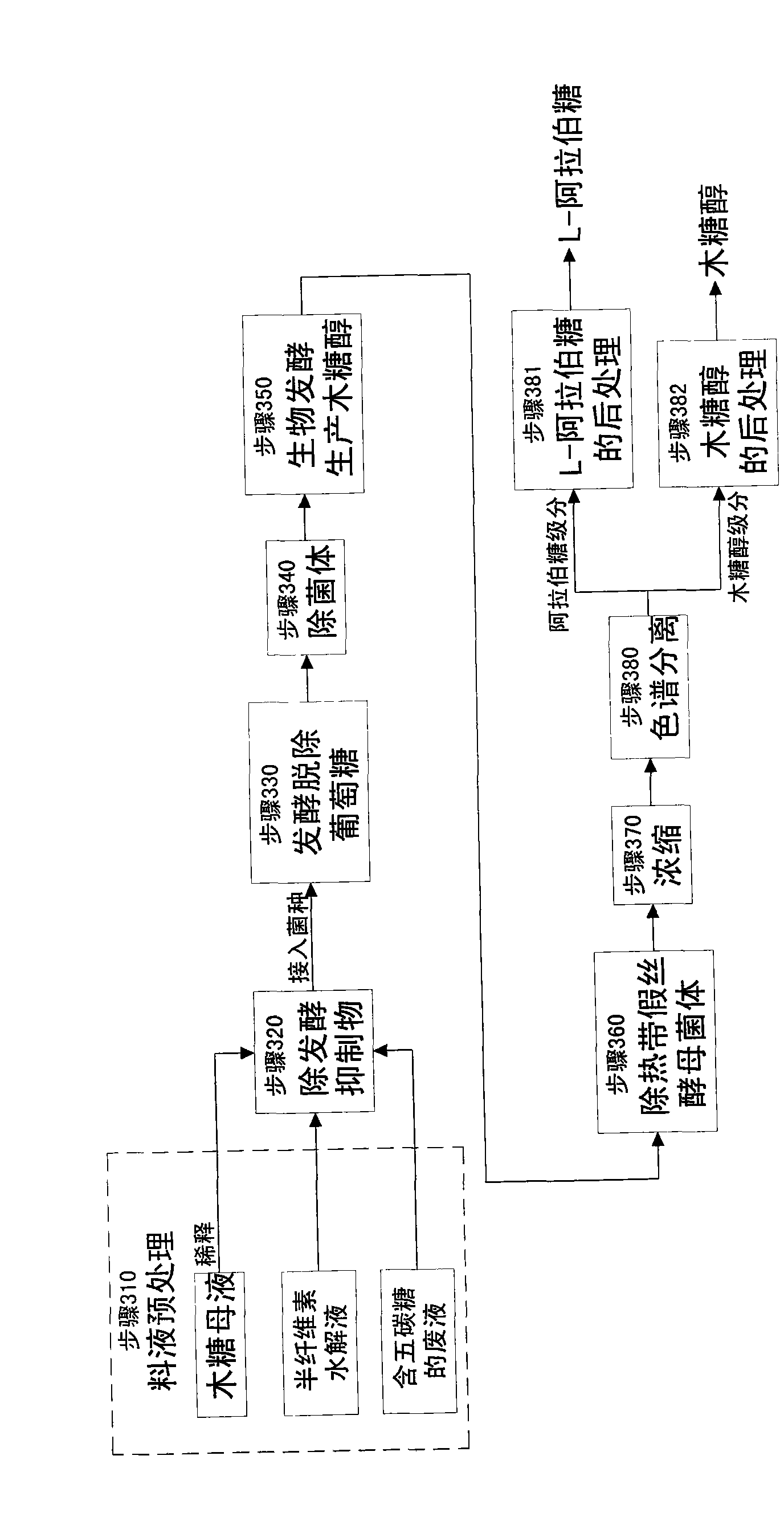

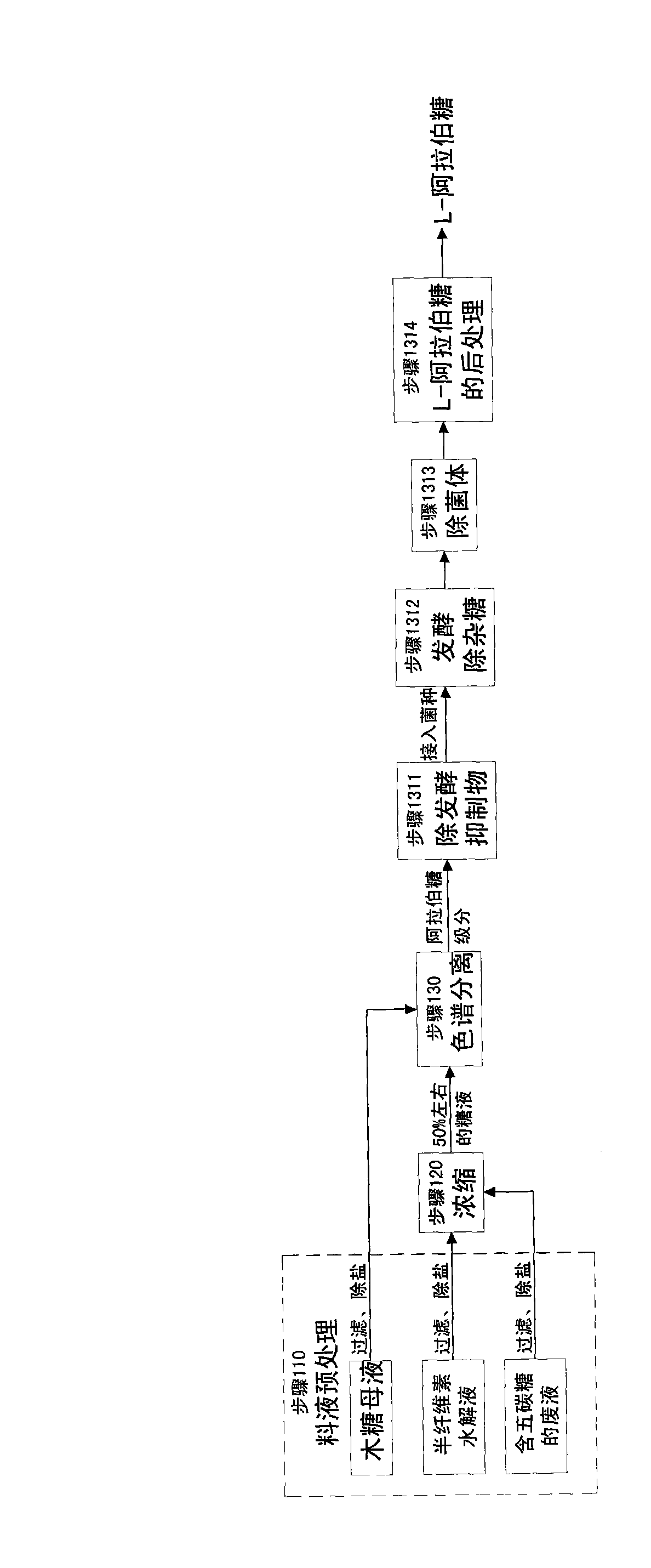

Method for producing wood sugar product

ActiveCN101659681AHigh purityFermentation went wellIon-exchange process apparatusSugar derivativesChromatographic separationHydrolysis

The invention relates to a method for producing a wood sugar product and a byproduct of ethanol or D-ribose or citric acid. The method takes hydrolysis liquid, wood sugar mother liquor and / or production waste liquid containing pentose of agricultural or forestry waste as the raw materials, comprising the following steps: (a) preprocessing feed liquid; (b) colour spectrum separation: separating thefeed liquid into arabinose fraction feed liquid and wood sugar fraction feed liquid; (c) removing mixed sugar at least containing glucose and galactolipin; and (d) carrying out aftertreatment on thewood sugar fraction feed liquid to obtain the wood sugar product. The wood sugar product comprises xylitol and D-wood sugar. The invention has low production cost and high efficiency and is suitable for large-scale industrial production.

Owner:SHENGQUAN HEALTANG

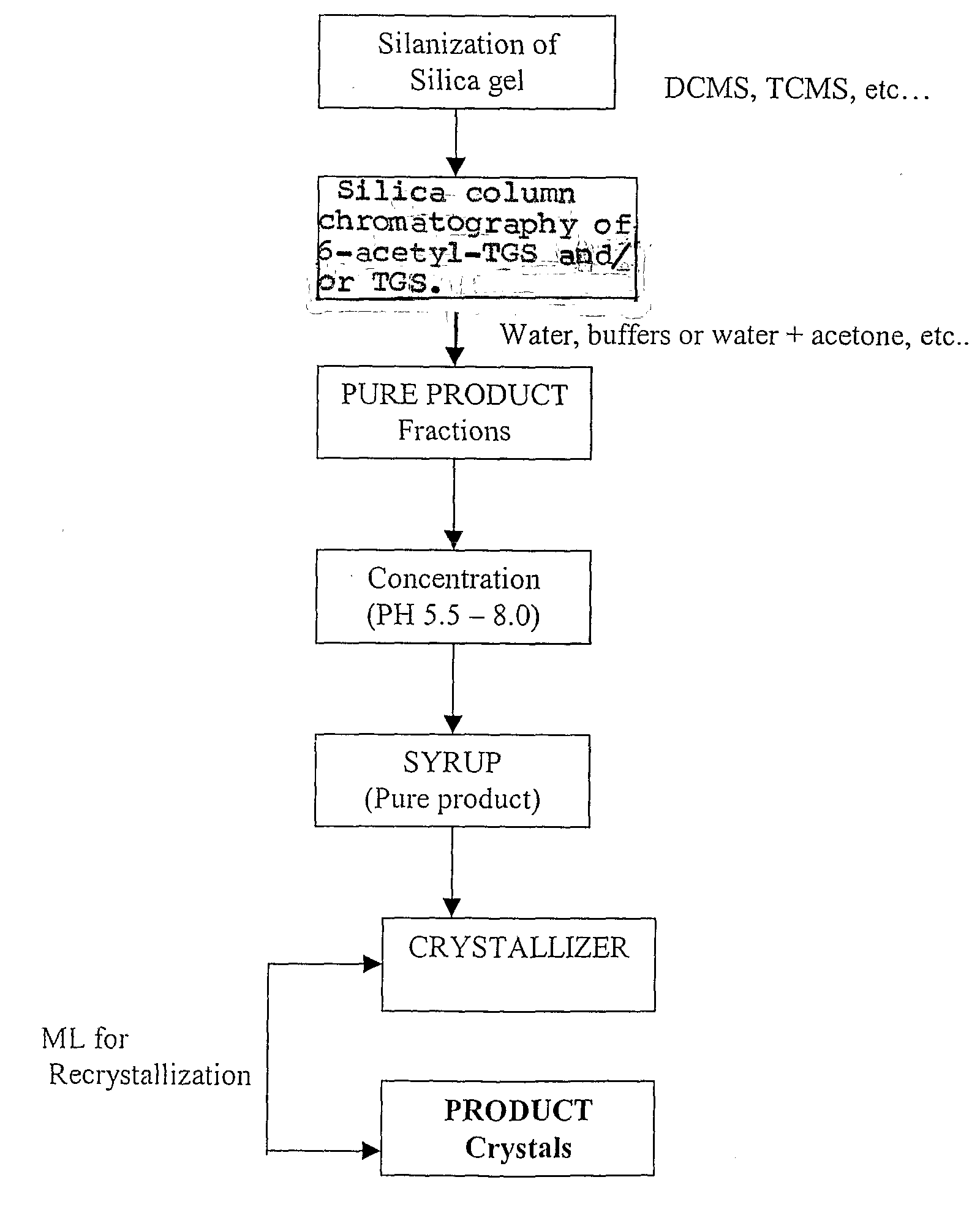

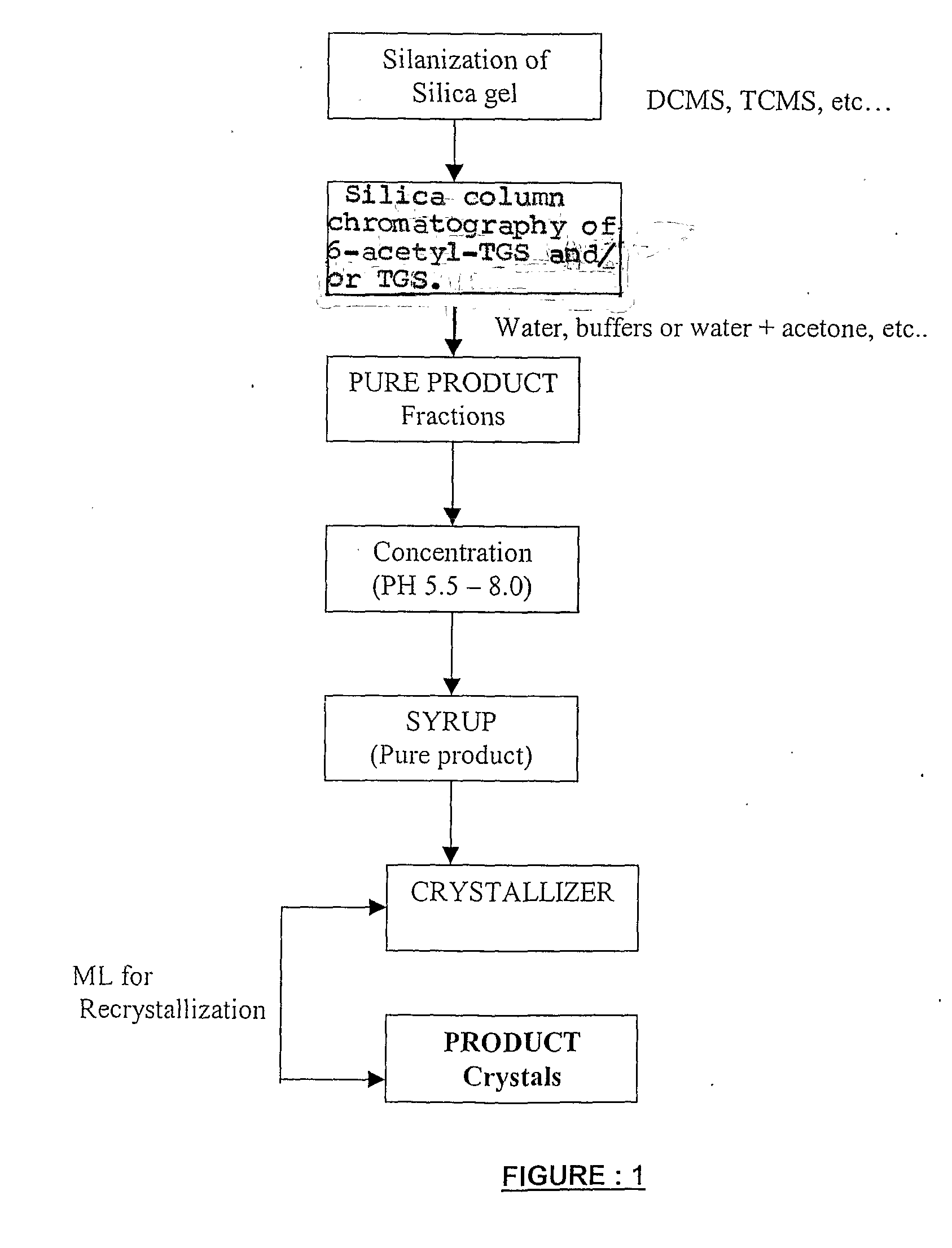

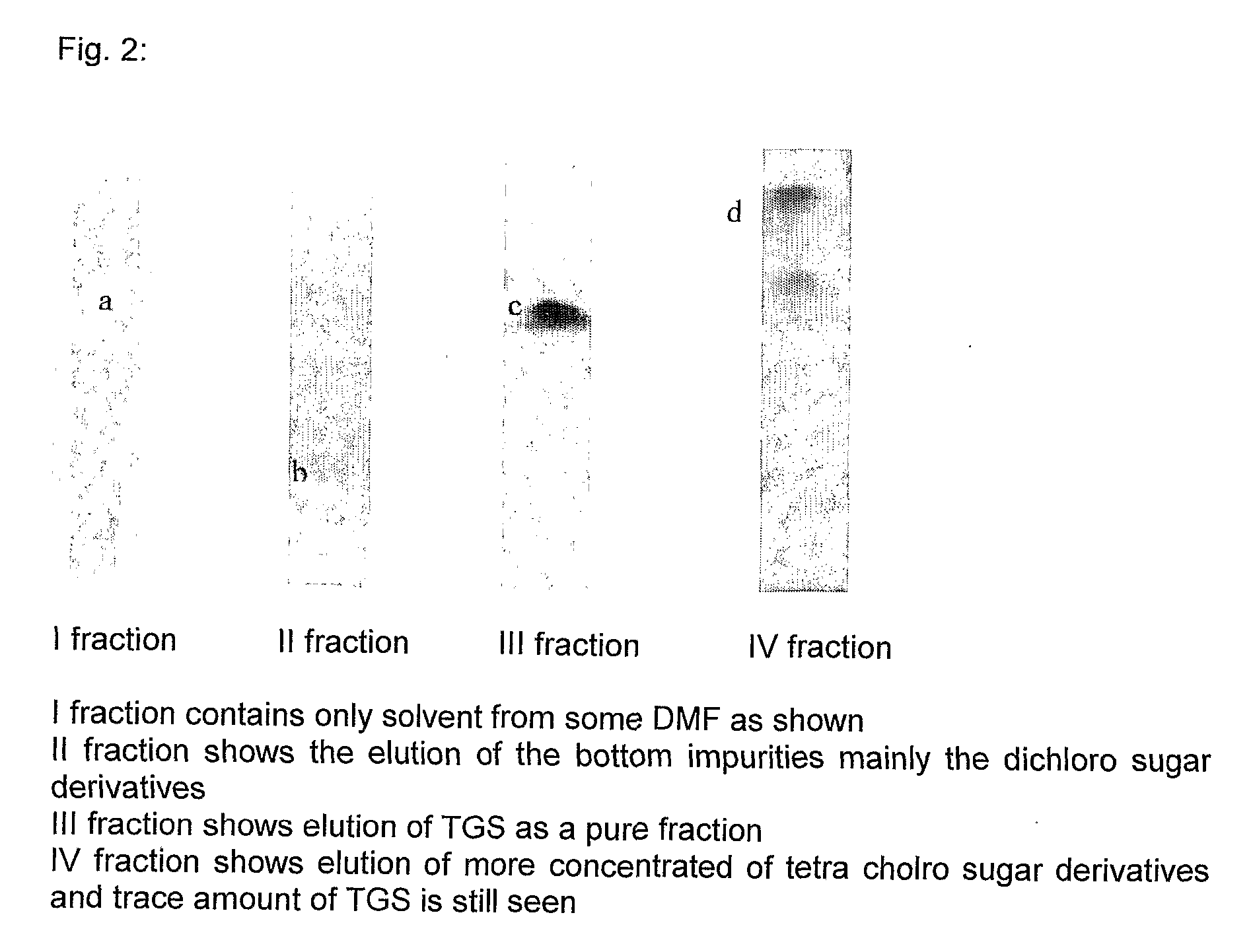

Process for Purification of 6 Acetyl 4,1', 6' Trichlorogalactosucrose and 4,1', 6' Trichlorogalactosucrose by Chromatography on Silanized Silica Gel

InactiveUS20070270583A1Purification using adsorption agentsSugar derivativesStationary phaseOrganic solvent

A reverse phase column chromatographic process of purification of 6-acetyl-4,1′,6′trichlorogalactose and 4,1′,6′trichlorogalactose is described which uses silanized silica as stationary phase and water or predominatly aqeous mixture derived from water and small proportion of organic solvents as a mobile phase.

Owner:V B MEDICARE PVT LTD

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS7666637B2Robust and cost-effectiveImproving biological reactivity of celluloseChemical industryBiofuelsChemical treatmentHydrolysate

The invented process separates main components in lignocellulosic biomass, specifically hardwoods, softwoods into lignin and fractions of high purity sugars which are used for ethanol production. The invented process comprises of treatment stages at high temperature and high pressure with hydrochloric acid or sulfuric acid. Residual lignin and extractives in the cellulosic solid fraction are selectively removed by chemical treatments of sodium chlorite, anhydrous acetic acid, chlorine and chlorine dioxide to enhance the purity and biological conversion of cellulose to ethanol. The pre-hydrolysate generated from the acid treatment stage, containing xylose, arabinose, galactose, glucose and the purified cellulosic fraction are enzymatically hydrolyzed and fermented to produce ethanol. Significant amount of lignin from the process is recovered as a by-product.

Owner:NGUYEN XUAN NGHINH

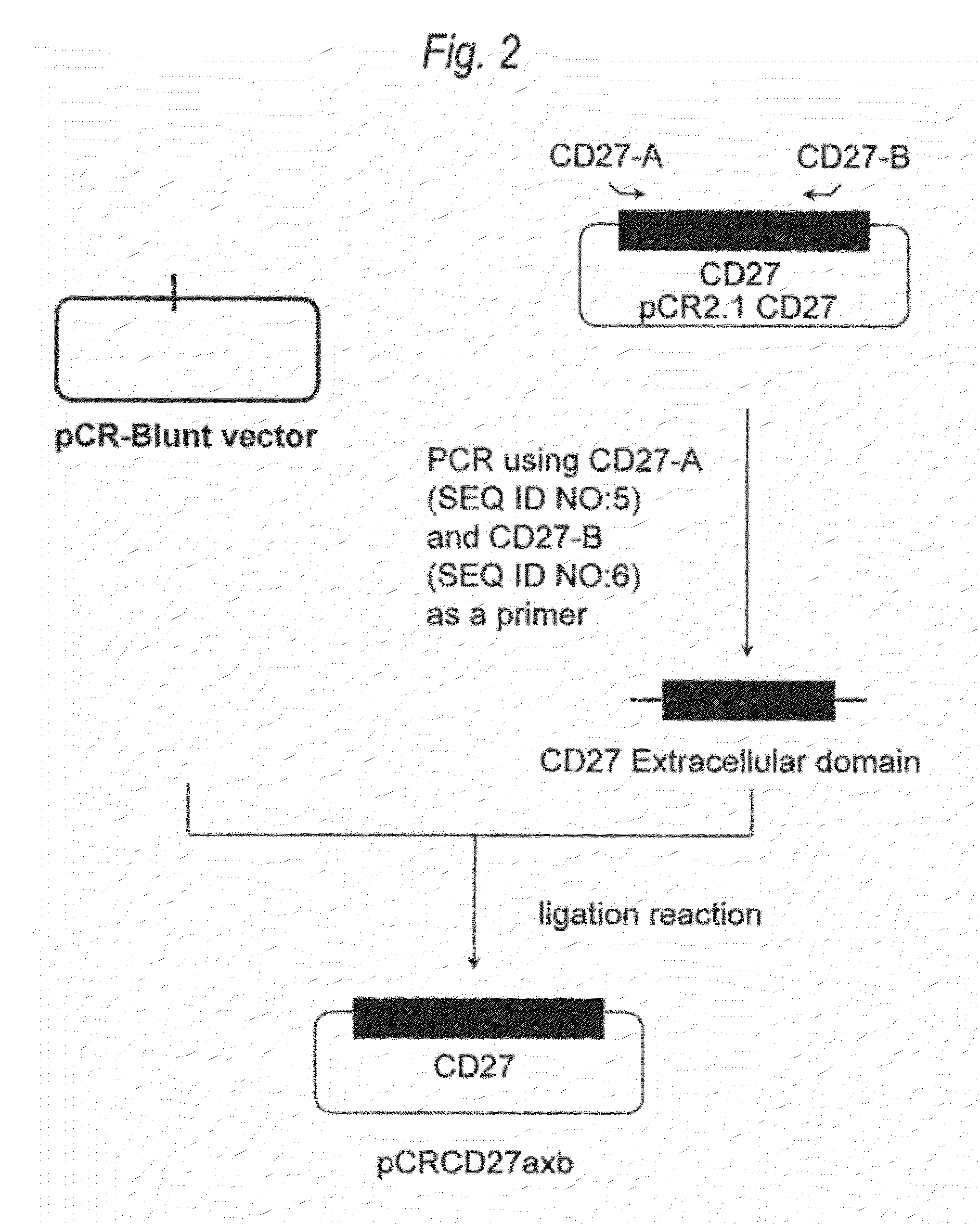

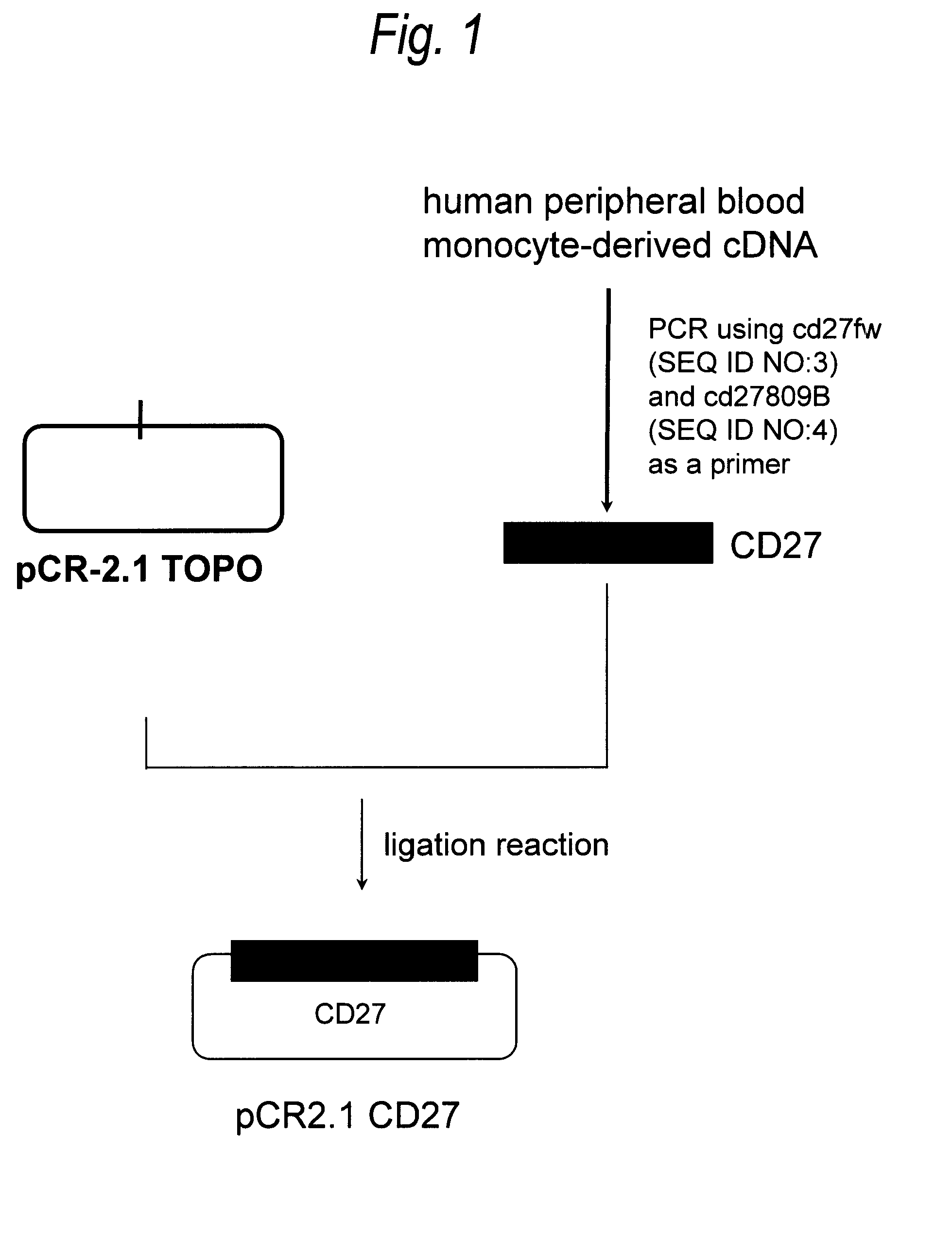

Anti-cd27 humanized monoclonal antibody

The present invention provides a monoclonal antibody which specifically recognizes CD27 containing an O-linked sugar chain to which galactose is not bound and binds to its extracellular region, or a method for using the same. The present invention can provide a monoclonal antibody or an antibody fragment thereof, which specifically recognizes a polypeptide encoded by CD27 gene containing an O-linked sugar chain to which galactose is not bound, and binds to its extracellular region; a hybridoma which produces the antibody; a DNA which encodes the antibody; a vector which comprises the DNA; a transformant obtainable by transforming the vector; a process for producing an antibody or an antibody fragment thereof using the hybridoma or the transformant; and a diagnostic agent or a therapeutic agent comprising the antibody or the antibody fragment thereof as an active ingredient.

Owner:KYOWA HAKKO KIRIN CO LTD

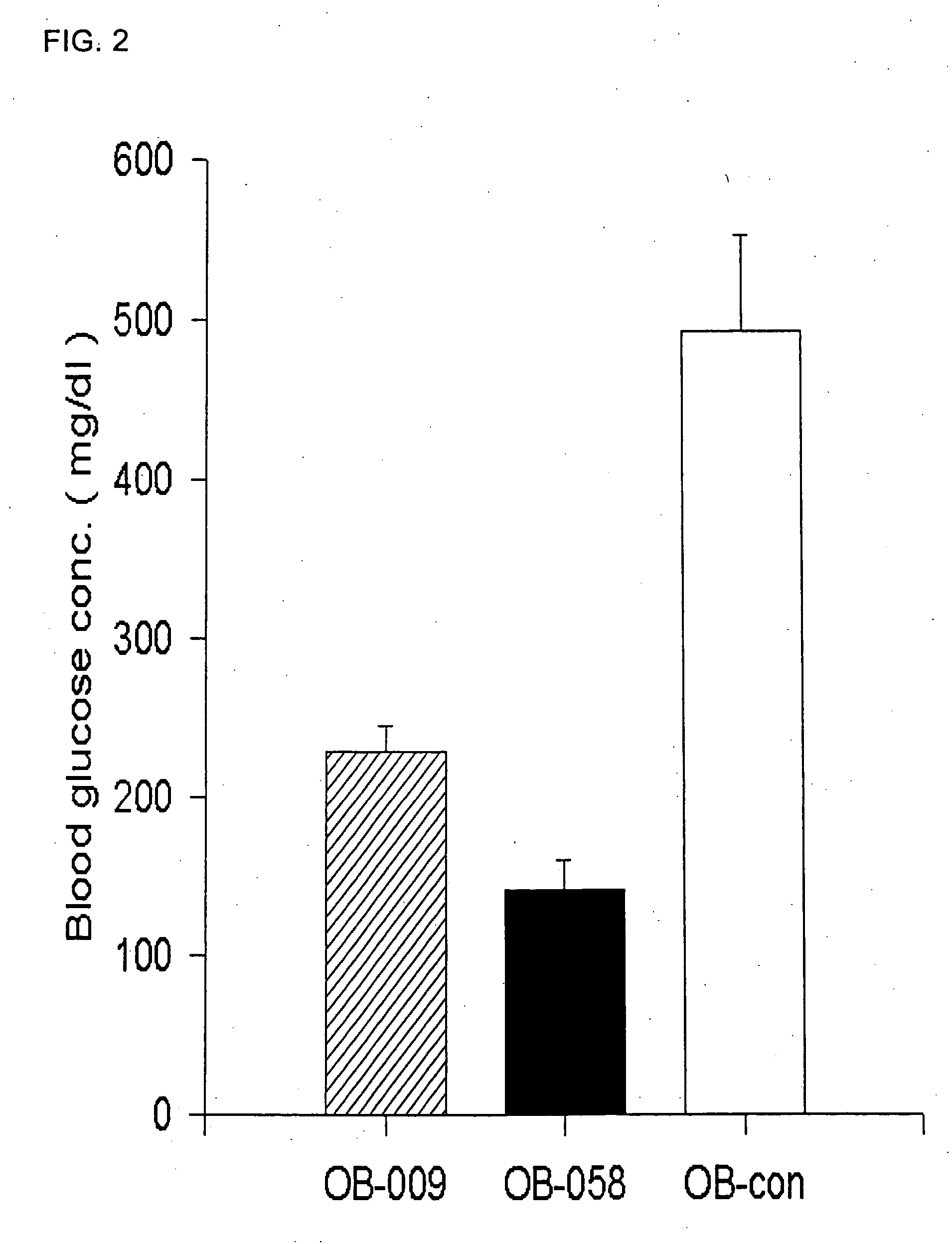

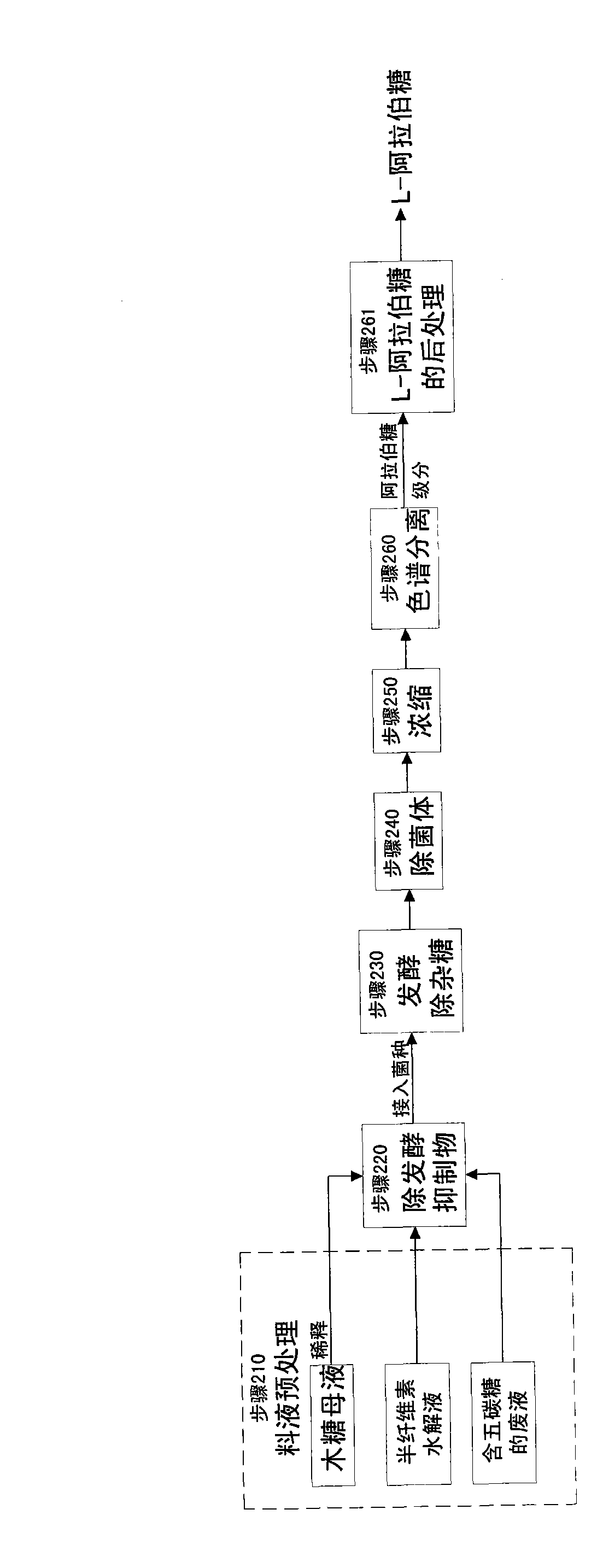

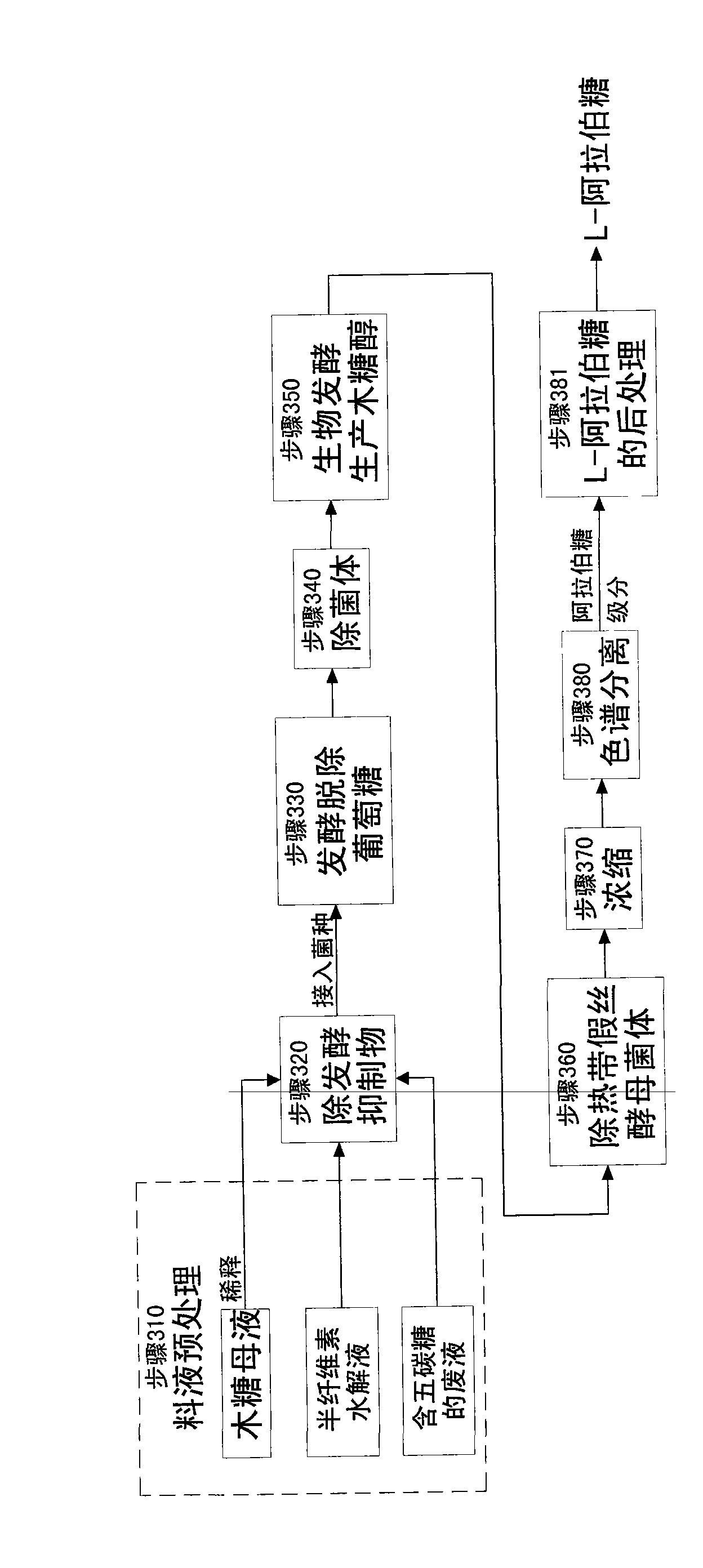

Method for producing L-arabinose and D-xylose

ActiveCN101665523AHigh purityFermentation went wellIon-exchange process apparatusSugar derivativesBiotechnologyChromatographic separation

The invention relates to a method for producing L-arabinose and D-xylose, which can simultaneously produce ethanol or D-ribose or citric acid as a byproduct. The method utilizes a hydrolyzate of agricultural waste, a xylose mother liquor and / or a production waste liquor containing pentose as the raw materials and comprises the following steps: (1) pretreating the raw materials; (b) carrying out the chromatographic resolution to separate the raw materials into an arabinose-stage liquor and a xylose-stage liquor; (c1) removing fermentation inhibitors which are impurities and unwanted bacteria, which have an inhibiting effect on the fermentation; (c2) fermenting to remove unwanted saccharides at least comprising glucose and galactose; (d) and finally, respectively carrying out the post treatment on the arabinose-stage liquor and the xylose-stage liquor to obtain the L-arabinose and the D-xylose. Steps (c1) and (c2) are arranged before the chromatographic resolution in step (b) or after step (b). The method has the advantages of low production cost and high efficiency, and is suitable for large-scale industrial production.

Owner:SHENGQUAN HEALTANG

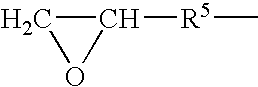

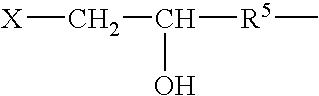

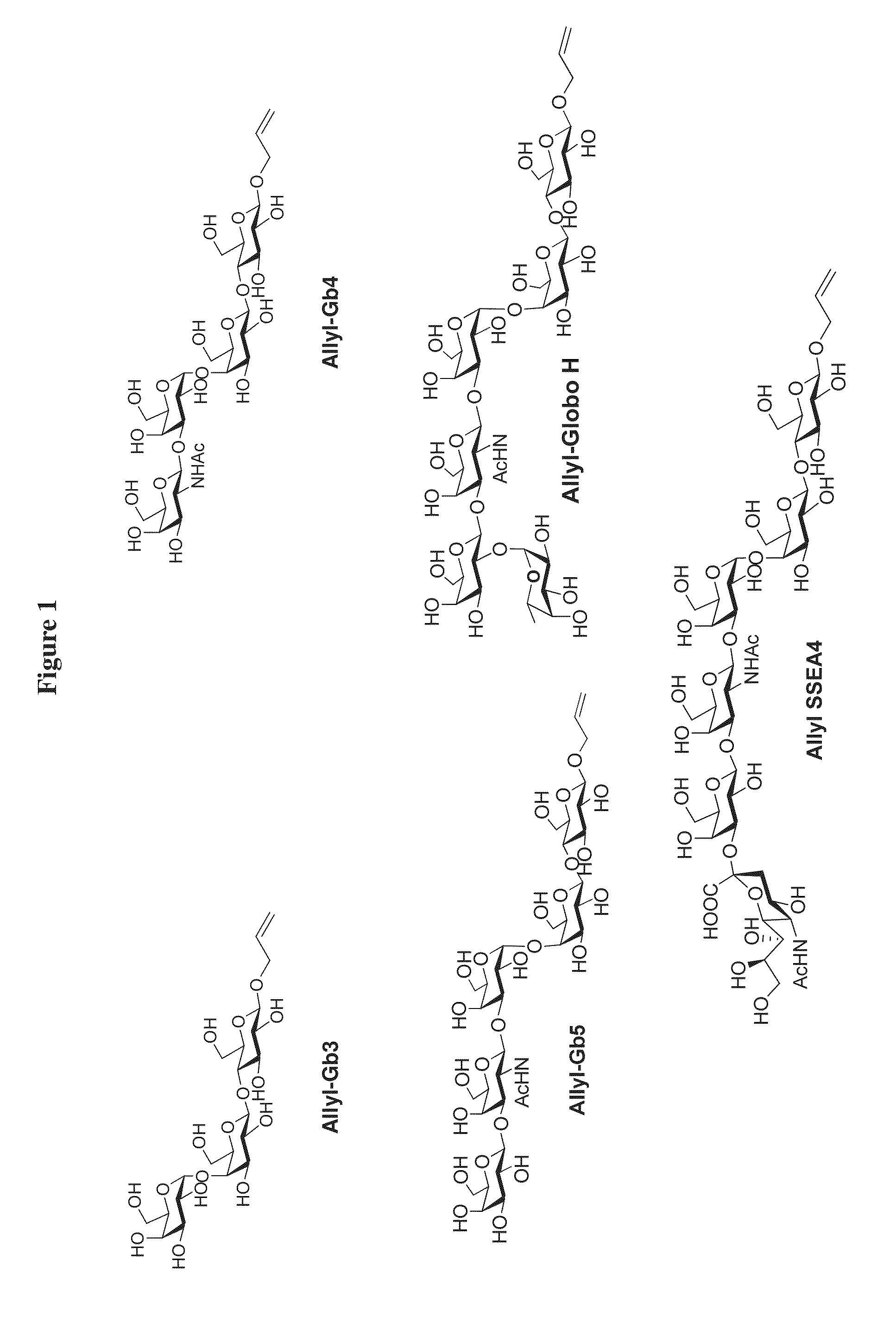

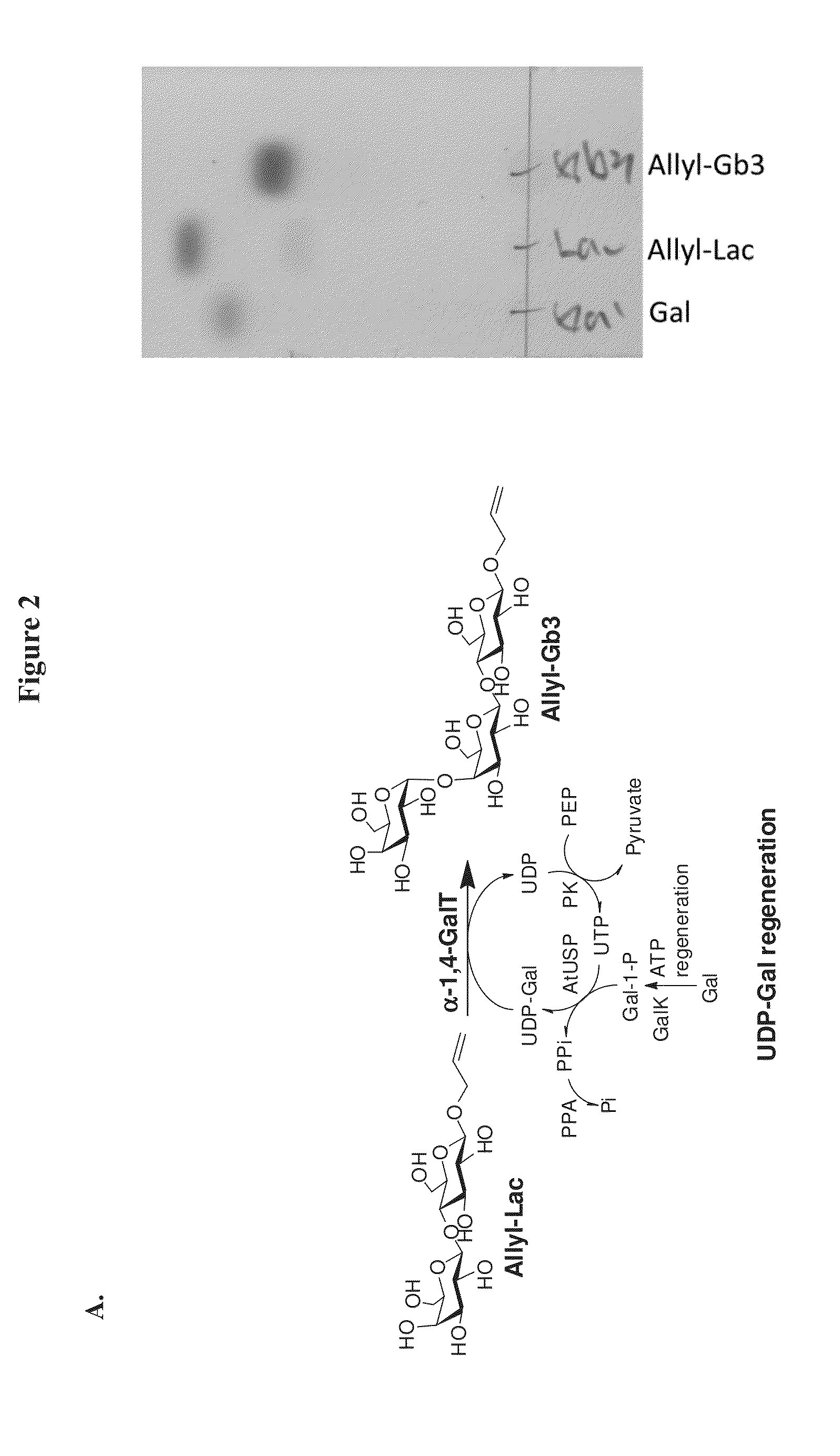

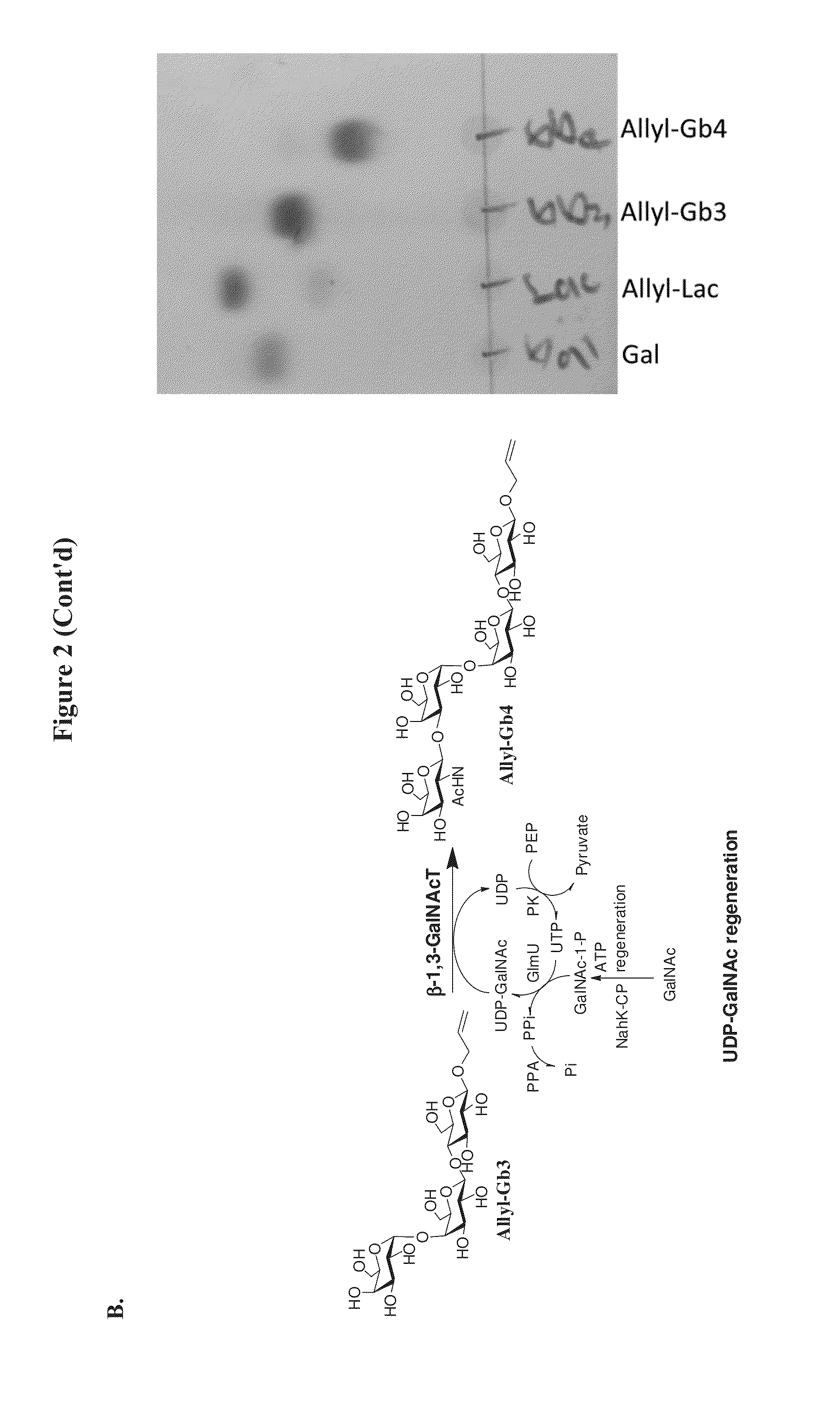

Large scale enzymatic synthesis of oligosaccharides

ActiveUS20140051127A1Bioreactor/fermenter combinationsBiological substance pretreatmentsEnzymatic synthesisNucleotide

A novel UDP-Gal regeneration process and its combined use with a galactosyltransferase to add galactose to a suitable acceptor substrate. Also described herein are synthetic methods for generating Globo-series oligosaccharides in large scale, wherein the methods may involve the combination of a glycosyltransferase reaction and a nucleotide sugar regeneration process.

Owner:ACAD SINIC

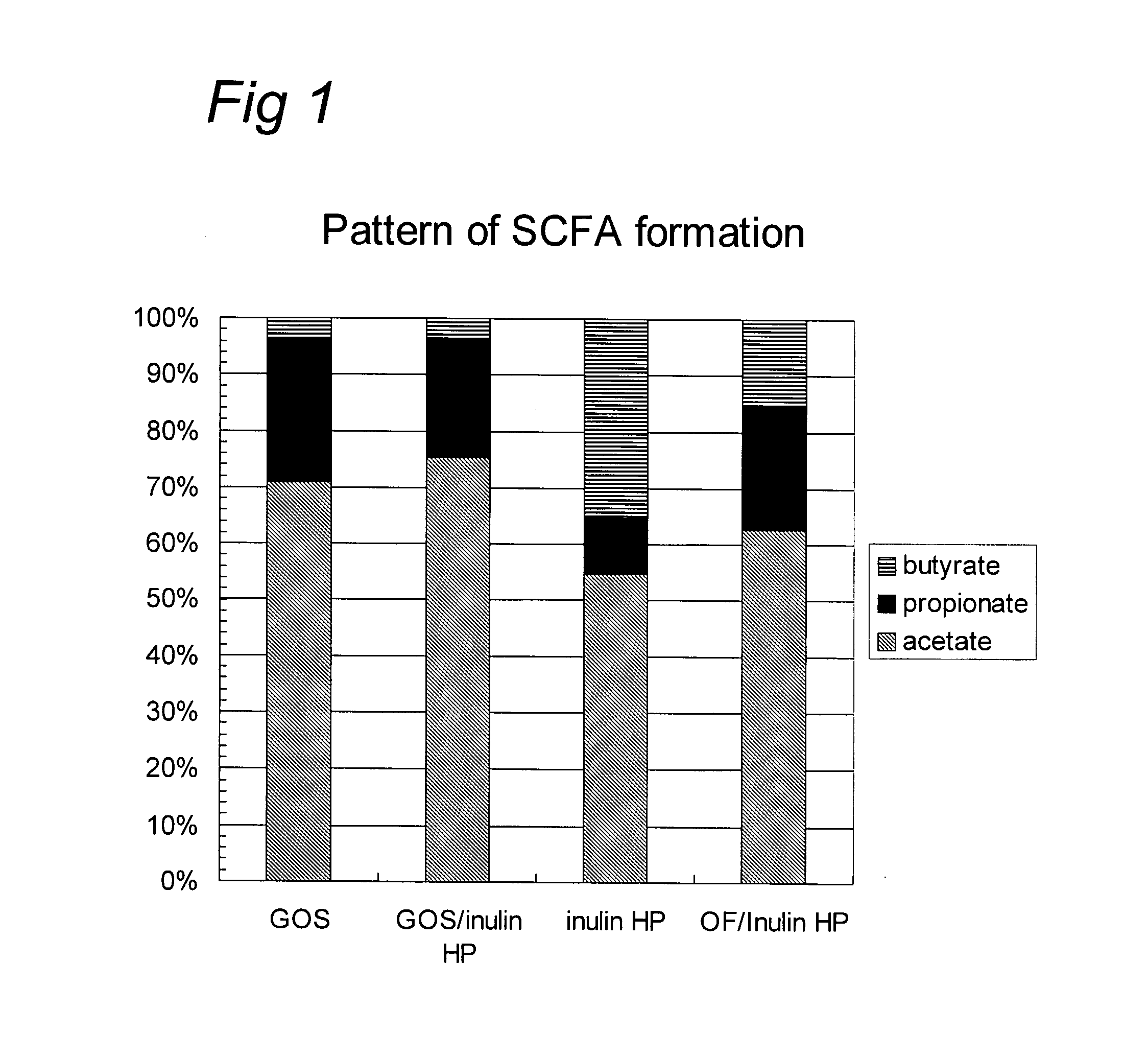

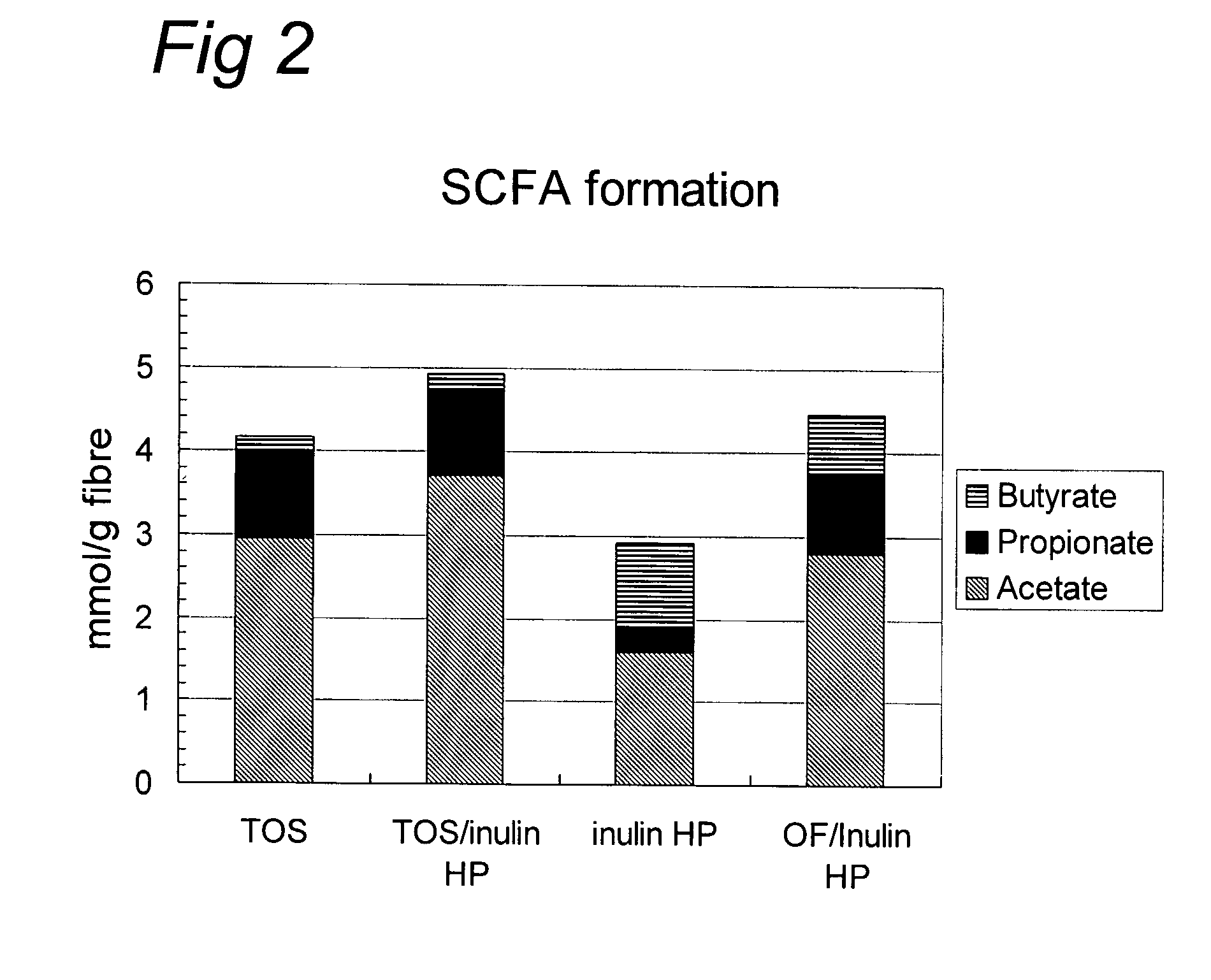

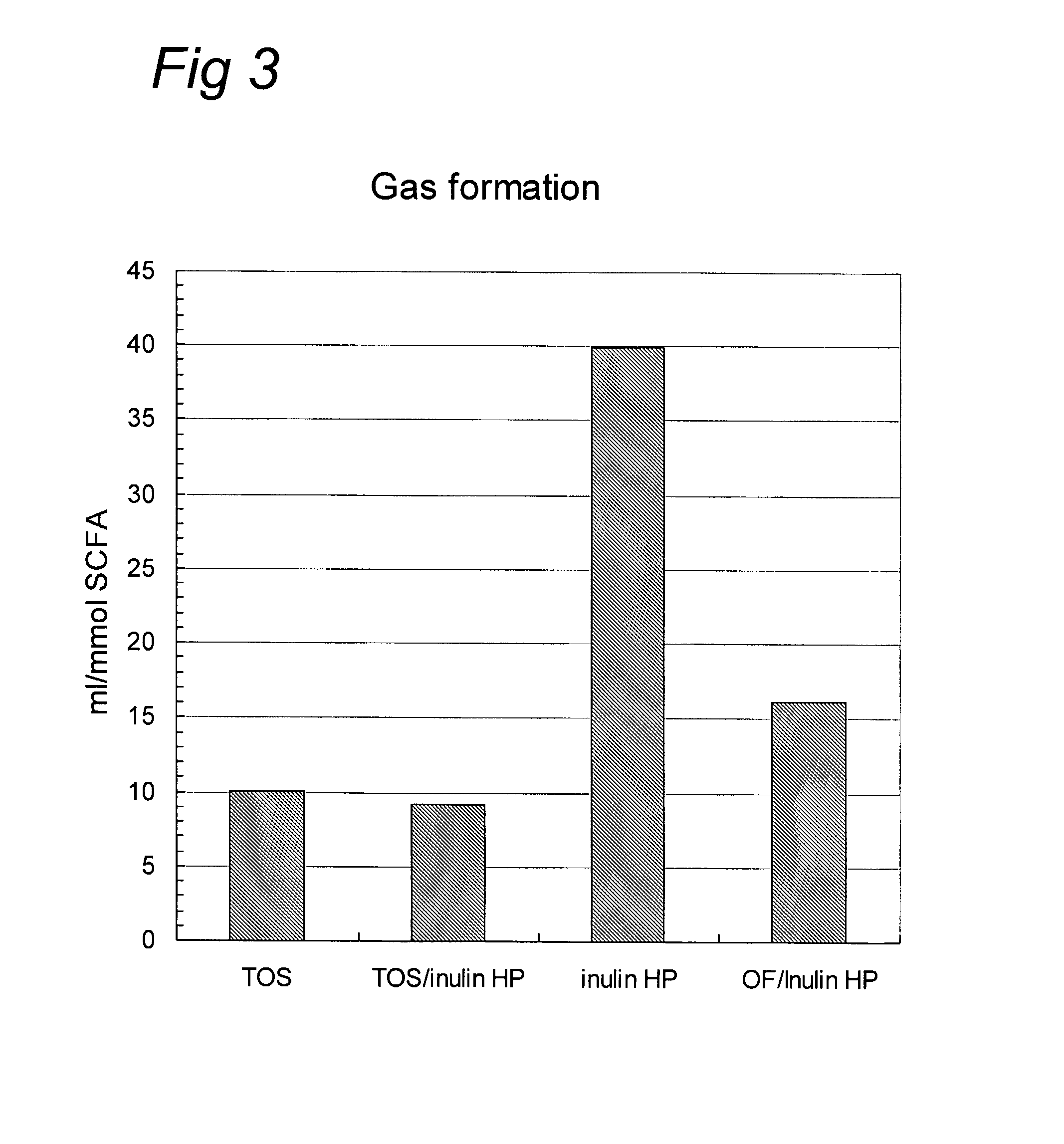

Synergism of gos and polyfructose

InactiveUS20100069320A1Increase the amount addedDecrease in faecal pHBiocideHydrocarbon active ingredientsPolyfructoseMedicine

The present invention relates to the filed of prebiotics. Provided are uses for compositions comprising synergistically effective amounts of polyfructose and galactooligosaccharides (GOS).

Owner:NUTRICIA

Anti-CD27 antibody

ActiveUS9023999B2MicroorganismsImmunoglobulins against cell receptors/antigens/surface-determinantsDiagnostic agentAntibody fragments

The present invention provides a monoclonal antibody which specifically recognizes CD27 containing an O-linked sugar chain to which galactose is not bound and binds to its extracellular region, or a method for using the same.The present invention can provide a monoclonal antibody or an antibody fragment thereof, which specifically recognizes a polypeptide encoded by CD27 gene containing an O-linked sugar chain to which galactose is not bound, and binds to its extracellular region; a hybridoma which produces the antibody; a DNA which encodes the antibody; a vector which comprises the DNA; a transformant obtainable by transforming the vector; a process for producing an antibody or an antibody fragment thereof using the hybridoma or the transformant; and a diagnostic agent or a therapeutic agent comprising the antibody or the antibody fragment thereof as an active ingredient.

Owner:KYOWA HAKKO KIRIN CO LTD

Composition and method for reducing the colonization of animal intestines by salmonella and other bacterial pathogens

InactiveUS6126961AReducing human pathogen colonizationSafe and economical reductionBiocideAnimal feeding stuffIntestinal structureBacteroides

An animal feed composition for reducing colonization of animal intestines by Salmonella and other bacterial pathogens, includes a polysaccharide containing cis-hydroxy sugar units or a derivative thereof, or the monosaccharide ribose or rhamnose, or a derivative thereof, and an animal feed. The polysaccharide cis-hydroxy sugar units may be one or more of mannose, a mannose derivative, galactose, a galactose derivative, galactomannans, galactosamine, fucose and arabinose. The polysaccharides may be incorporated into an animal feed in the form of a food gum or other biolpolymer.

Owner:AURUM CERTUS

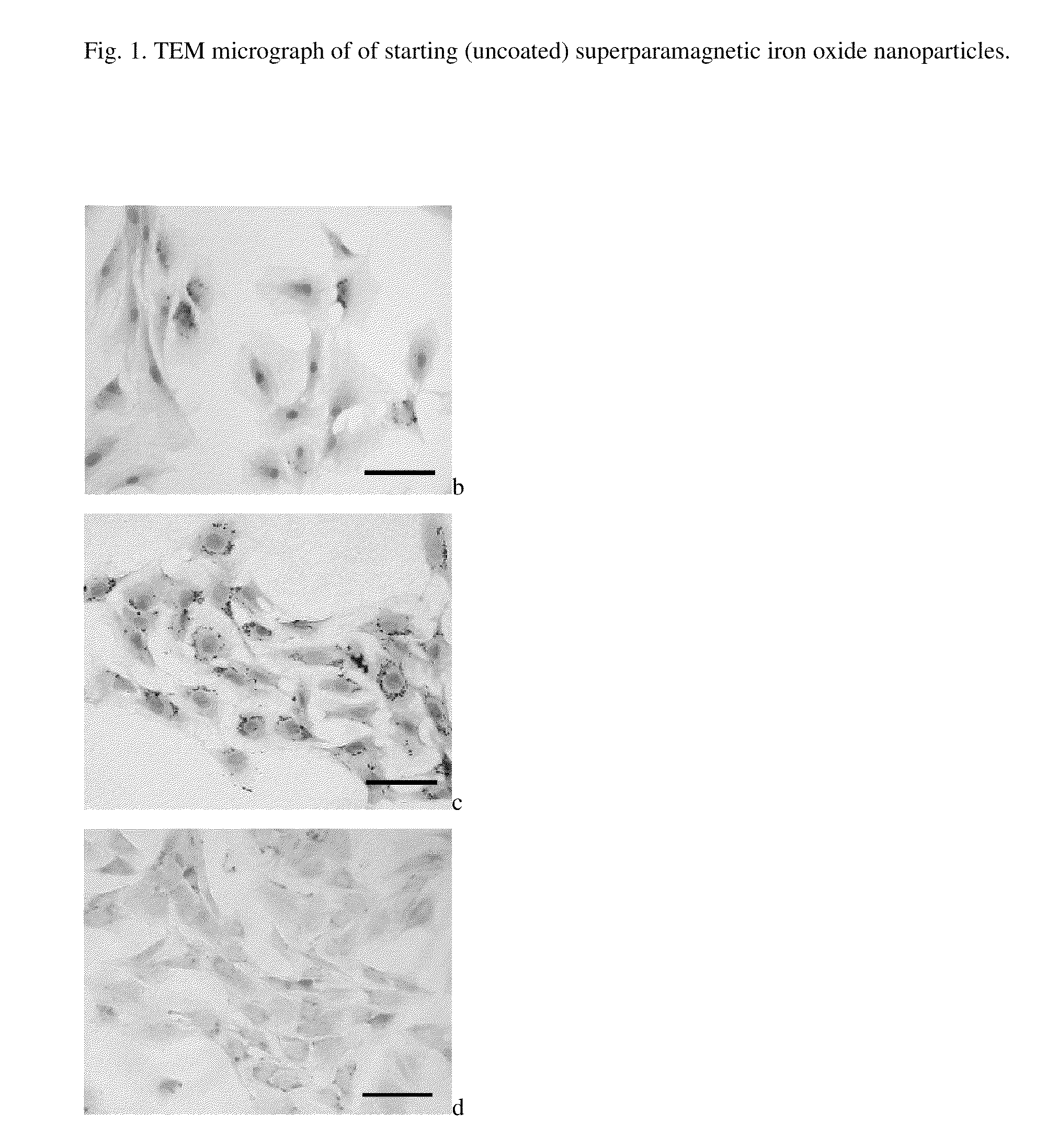

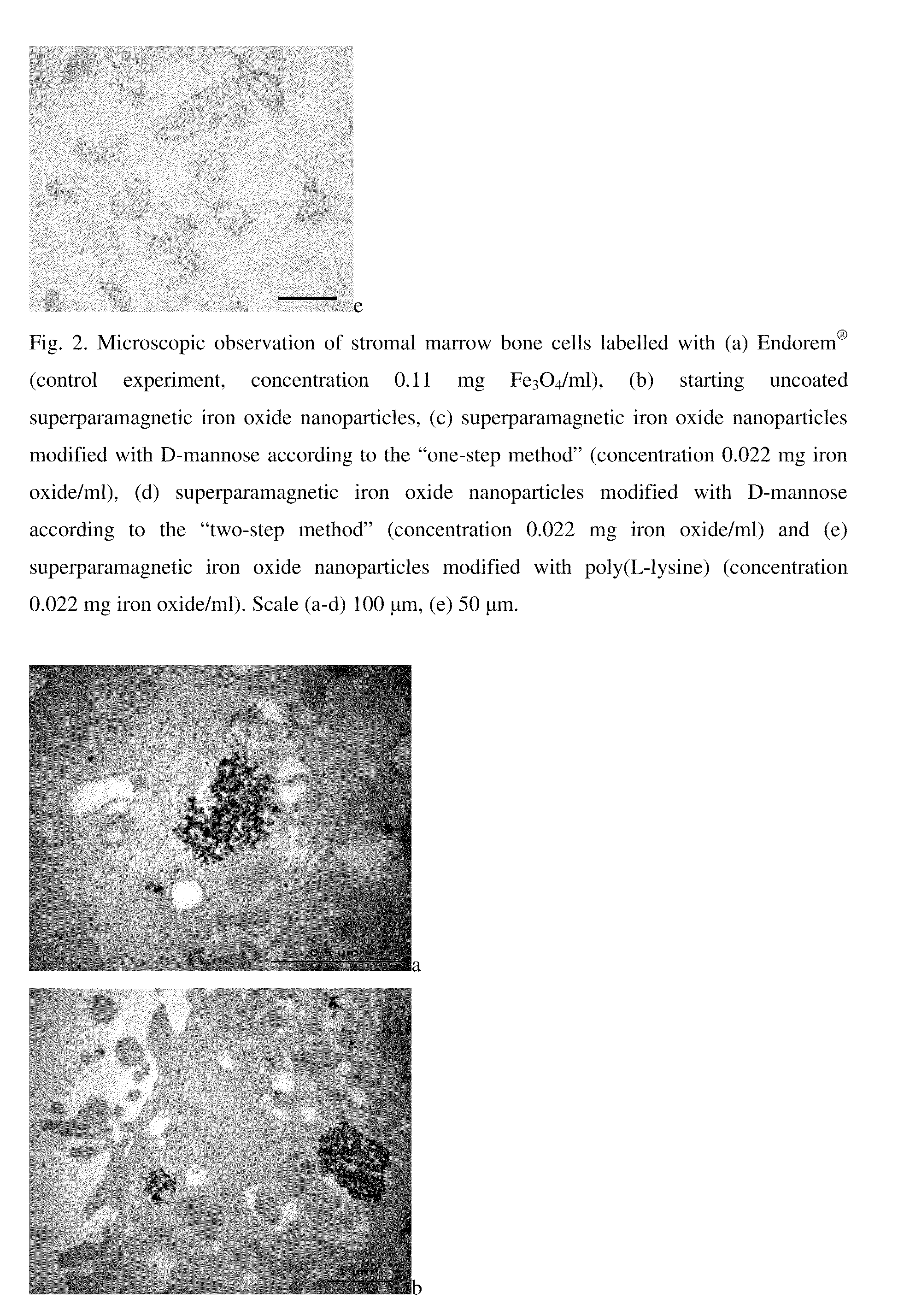

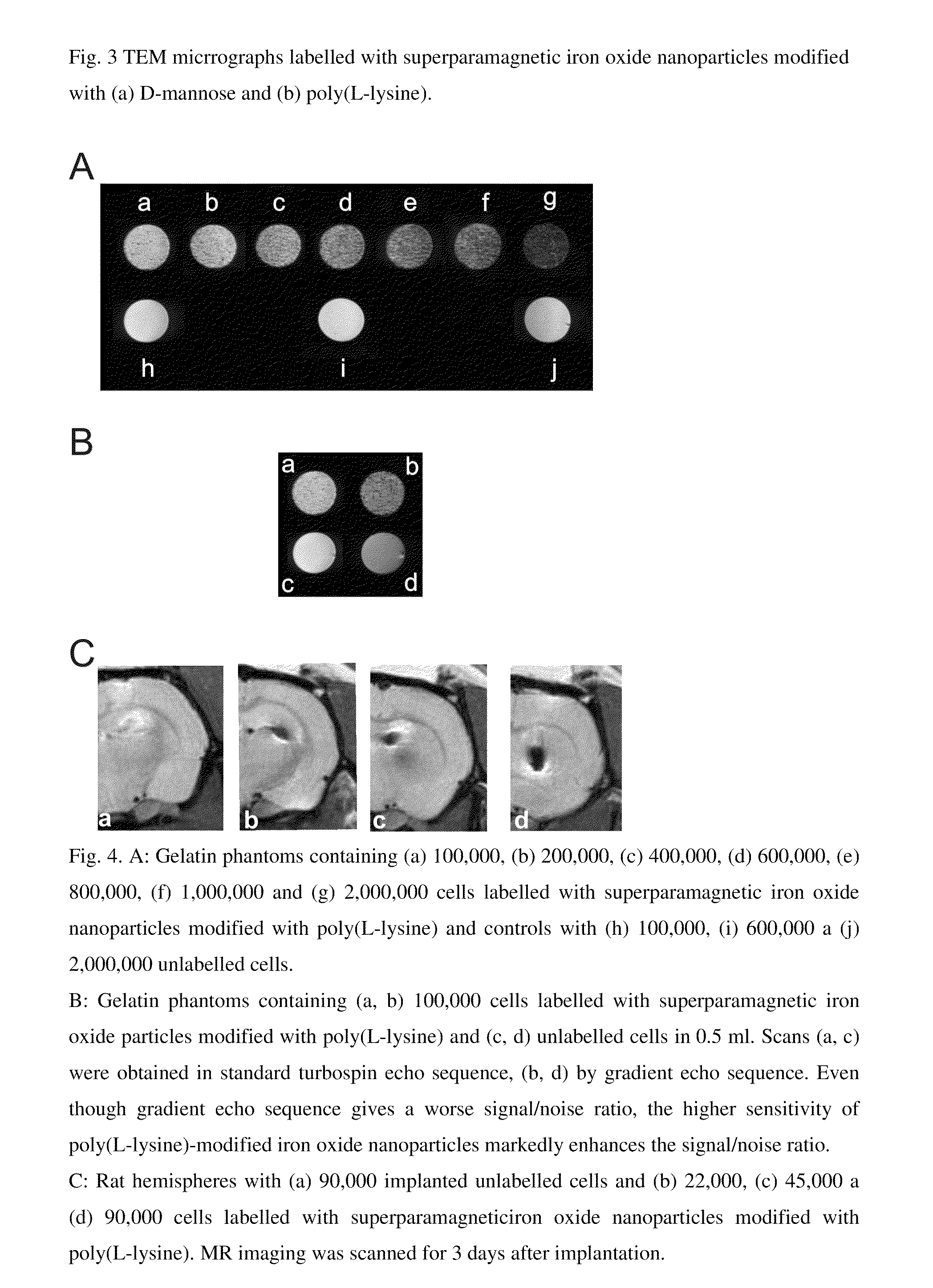

Superparamagnetic Nanoparticles Based on Iron Oxides with Modified Surface, Method of Their Preparation and Application

InactiveUS20090309597A1Less loadImprove abilitiesPigmenting treatmentMaterial nanotechnologyArginineDextran

The subject of the invention is superparamagnetic nanoparticle probes based on iron oxides, to advantage magnetite or maghemite, with modified surface, coated with mono-, di- or polysaccharides from the group including D-arabinose, D-glucose, D-galactose, D-mannose, lactose, maltose, dextrans and dextrins, or with amino acids or poly(amino acid)s from the group including alanine, glycine, glutamine, asparagine, histidine, arginine, L-lysine, aspartic and glutamic acid or with synthetic polymers based on (meth)acrylic acid and their derivatives selected from the group containing poly(N,N-dimethylacrylamide), poly(N,N-dimethylmethacrylamide), poly(N,N-diethylacrylamide), poly(N,N-diethylmethacrylamide), poly(N-isopropylacrylamide), poly(N-isopropylmethacrylamide), which form a colloid consisting of particles with narrow distribution with polydispersity index smaller than 1.3, the average size of which amounts to 0.5-30 nm, to advantage 1-10 nm, the iron content is 70-99.9 wt. %, to advantage 90 wt. %, the modification agent content 0.1-30 wt. %, to advantage 10 wt. %.The particles of size smaller than 2 nm with polydispersity index smaller than 1.1 can be obtained by a modified method of preparation.Superparamagnetic nanoparticle probes according to the invention are prepared by pre-precipitation of colloidal Fe(OH)3 by the treatment of aqueous 0.1-0.2M solution of Fe(III) salt, to advantage FeCl3, with less than an equimolar amount of NH4OH, at 21° C., under sonication, to which a solution of a Fe(II) salt, to advantage FeCl2, is added in the mole ratio Fe(III) / Fe(II)=2 under sonication and the mixture is poured into five- to tenfold, to advantage eightfold, molar excess of 0.5M NH4OH. The mixture is left aging for 0-30 min, to advantage 15 min, and then the precipitate is repeatedly, to advantage 7-10 times, magnetically separated and washed with deionized water. Then 1-3 fold amount, to advantage 1.5 fold amount, relative to the amount of magnetite, of 0.1 M aqueous solution of sodium citrate is added and then, dropwise, 1-3 fold amount, to advantage 1.5 fold amount, relative to the amount of magnetite, of 0.7 M aqueous solution of sodium hypochlorite. The precipitate is repeatedly, to advantage 7-10 times, washed with deionized water under the formation of colloidal maghemite to which, after dilution, is added dropwise, to advantage under 5-min sonication, an aqueous solution of a modification agent, in the weight ratio modification agent / iron oxide=0.1-10, to advantage 0.2 for amino acids and poly(amino acid)s and 5 for saccharides.The particles smaller than 2 nm with polydispersity index smaller than 1.1 are prepared by mixing at 21° C. 1 volume part of 10-60 wt. %, to advantage 50 wt. %, of an aqueous solution of a saccharide, disaccharide or polysaccharide, such as D-arabinose, D-glucose, D-galactose, D-mannose, lactose, maltose, dextran and dextrins, and 1 volume part of aqueous solution of a Fe(II) and Fe(III) salt, to advantage FeCl2 and FeCl3, where the molar ratio Fe(III) / Fe(II)=2. A 5-15%, to advantage 7.5%, solution of NH4OH is added until pH 12 is attained and the mixture is heated at 60° C. for 15 min. The mixture is then sonicated at 350 W for 5 min and then washed for 24 h by dialysis in water using a membrane with molecular weight cut-off 14,000 until pH 7 is reached. The volume of solution is reduced by evaporation so that the final dry matter content is 50-100 mg / ml, to advantage 80 mg per 1 ml.Superparamagnetic nanoparticle probes according to the invention can be used for labelling cells used in magnetic resonance imaging for monitoring their movement, localization, survival and differentiation especially in detection of pathologies with cell dysfunction and of tissue regeneration and also for labelling and monitoring cells administered for cell therapy purposes, in particular embryonal stem cells, fetal stem cells, stem cells of an adult human including bone marrow stem cells, olfactory glial cells, fat tissue cells, in the recipient organism by magnetic resonance.The preparation of labelled cells proceeds by adding to the complete culture medium 5-20 μl, to advantage 10 μl, of a colloid containing 0.05-45 mg iron oxide per ml, to advantage 1-5 mg iron oxide per ml of the medium, and culturing the cells for a period of 1-7 days, to advantage for 1-3 days, at 37° C. and 5% of CO2.

Owner:INST OF MACROMOLECULAR CHEM ASCR V V I +1

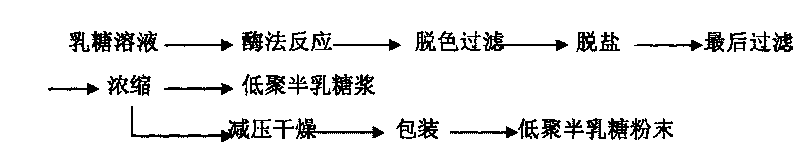

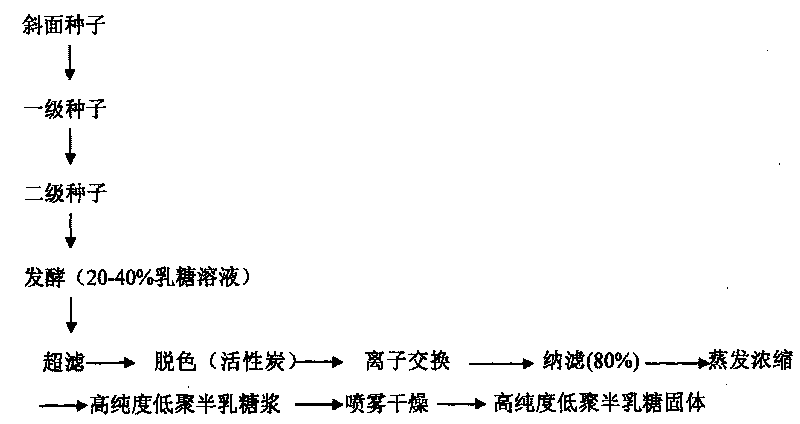

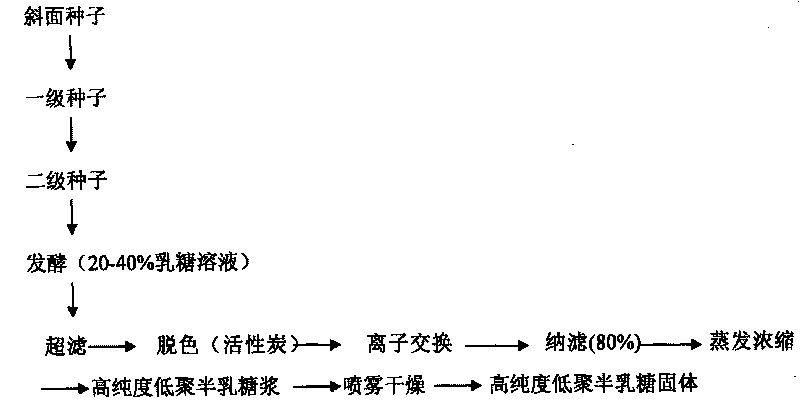

Aspergillus oryzae and method for preparing high purity galacto-oligosaccharides by using same

ActiveCN101691538ASimple processEase of industrial productionFungiMicroorganism based processesHigh concentrationUltrafiltration

The invention relates to a method for preparing high purity galacto-oligosaccharides, comprising the following product separation and purification steps: Aspergillus oryzae fermentation, ceramic membrane ultrafiltration, nanofiltration separation and the like. In the method, the Aspergillus oryzae separated from the soil is adopted as an original strain and the Aspergillus oryzae BLB-21 (with preservation number of CGMCC No.2951), a high efficiency transformed strain obtained through mutation screening in the laboratory, is directly used to ferment high concentration lactose solution, thus avoiding the steps of enzyme purification and the like in the process of preparing the galacto-oligosaccharides by an enzyme method and saving time and labor. The high purity galacto-oligosaccharides are obtained by ultrafiltration and nanofiltration separation, the process is ideal, the conditions are mild and the method has extensive industrial production prospect.

Owner:BAOLINGBAO BIOLOGY

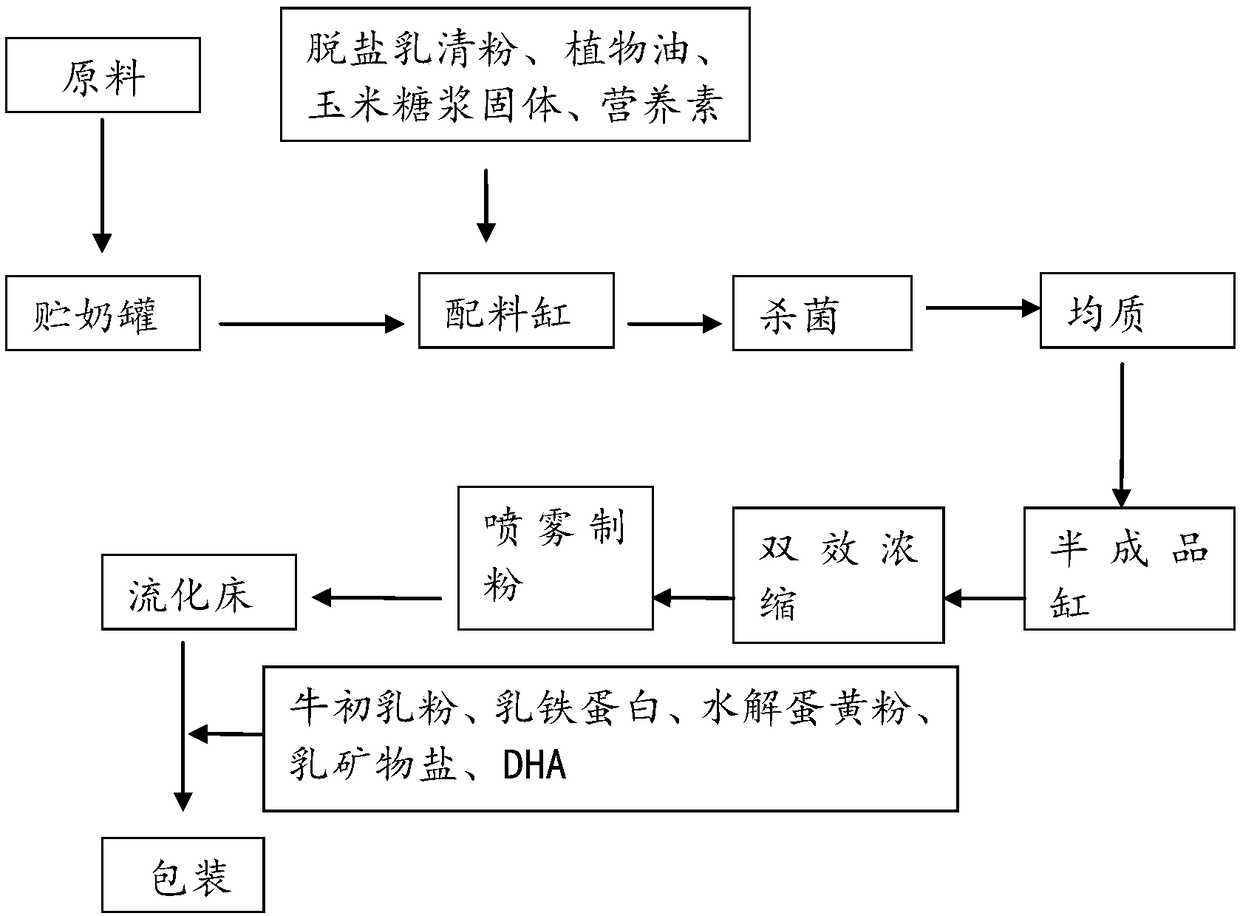

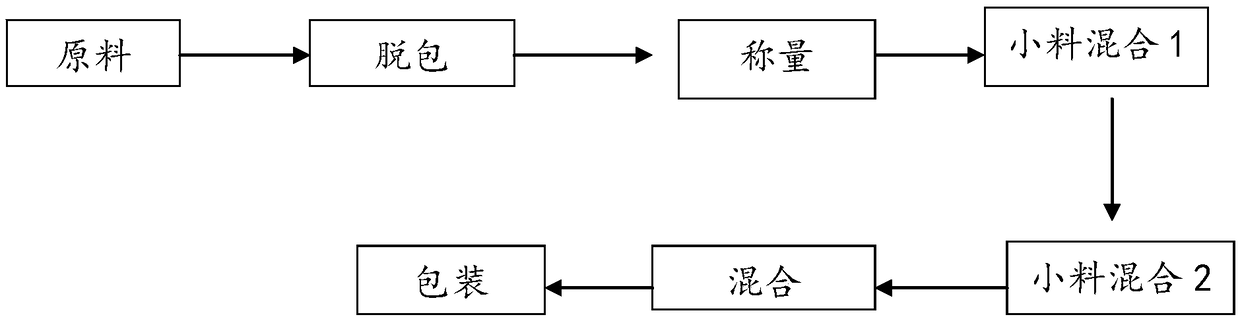

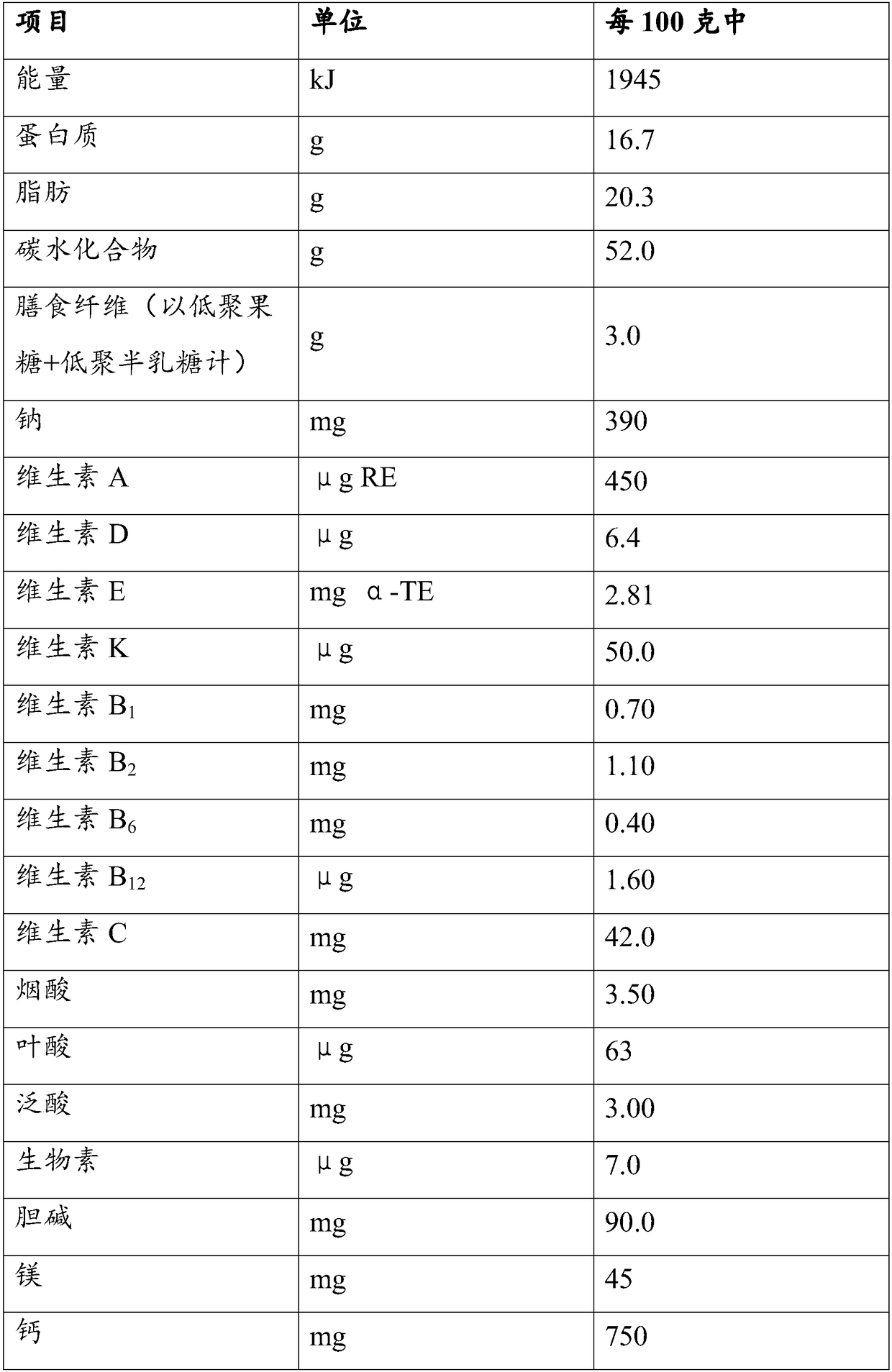

Formula milk powder assisting development of height of children and production method

The invention discloses formula milk powder assisting development of height of children. The formula milk powder consists of the following components of raw milk or whole milk powder, desalinated wheypowder, skimmed milk powder, solid corn syrup ( or maltodextrin ), whey protein powder, crystallized fructose, vegetable oil, fructo-oligosaccharide, anhydrous butter, galactooligosaccharide, docosa-hexaenoic, bovine coloctrum powder, milk mineral salt, hydrolyzed dried egg yolk, lactoferrin, phosphatide, vitamin A, vitamin D, vitamin E, vitamin K, vitamin B1, vitamin B2, vitamin B6, vitamin B12,vitamin C, magnesium, calcium, iron, zinc, selenium and the like. According to the formula milk powder assisting the development of the height of the children and a production method disclosed by theinvention, the products have the characteristics of ''supplementing, promoting and improving'', namely supplementing nutrition required by growth and development of Chinese children, promoting absorption of key nutrition for the development of the height, and improving immunity of the children, so that the height of the Chinese children is assisted to quickly grow.

Owner:上海育博营养食品有限公司

Infant formula milk powder added with secretory immunoglobulin A and preparation method thereof

ActiveCN101953403AMeet the needs of healthy growth and developmentRich in nutrientsWhey manufactureBiotechnologyImmunologic substance

The invention discloses infant formula milk powder added with secretory immunoglobulin A and a preparation method thereof. The infant formula milk powder consists of demineralized whey powder, defatted milk powder, mixed vegetable oil, milk sugar, mineral substance premix, lecithin, arachidonic acid, lactulose, fructooligosaccharides, oligosaccharide, water soluble vitamin premix, secretory immunoglobulin A, calcium hydroxide, citric acid, docosahexenoic acid, milk phosphatide, lactoferrin, soyabean lecithin, liposoluble vitamin premix, nucleotide and L-carnitine. The invention also discloses a method for preparing the infant formula milk powder. The infant formula milk powder has important effects of improving infant immunologic function, preventing allergy and preventing mucous membrane infection. The provided secretory immunoglobulin A fluidized bed low-temperature addition technology contributes to effectively guaranteeing the activity of immunity substances.

Owner:AUSNUTRIA DAIRY CHINA

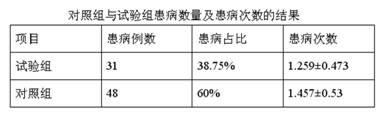

Microorganism for treatment or prevention of corpulence and diabetes mellitus, and pharmaceutical composition containing the same

InactiveUS20050112112A1Reduce the amount requiredLess weight gainBiocideBacteriaIntestinal structureDiabetes mellitus

The present invention relates to microorganisms for the treatment or the prevention of obesity or diabetes mellitus, which reduce the amount of monosaccharide or disaccharide which may be absorbed into human body by converting monosaccharides such as glucose, fructose, galactose et al. and disaccharides into polymeric materials which cannot be absorbed by the intestine, and relates to a pharmaceutical composition containing the said microorganisms.

Owner:BIONEER

Method for producing L-arabinose

ActiveCN101665524AHigh purityFermentation went wellIon-exchange process apparatusSugar derivativesChromatographic separationImpurity

The invention relates to a method for producing L-arabinose, which can simultaneously produce ethanol, D-ribose and citric acid as byproducts. The method utilizes a hydrolyzate of agricultural waste, a xylose mother liquor and / or a production waste liquor containing pentose as the raw materials and comprises the following steps: (a) pretreating the raw materials; (b) carrying out the chromatographic resolution to separate the raw materials into an arabinose-stage liquor and a xylose-stage liquor; (c) removing impurities and unwanted bacteria, which have an inhibiting effect on fermentation, as well as unwanted saccharides at least comprising glucose and galactose; (d) and carrying out the post treatment on the arabinose-stage liquor to obtain the L-arabinose. Steps (c1) and (c2) are arranged before the chromatographic resolution in step (b) or after step (b). The invention has the advantages of low production cost and high efficiency, and is suitable for large-scale industrial production.

Owner:SHENGQUAN HEALTANG

Amino acid humanized infant formula milk powder and preparation method thereof

ActiveCN104012657APromote absorptionPromote growth and developmentMilk preparationVegetable oilTyrosine

The present invention relates to amino acid humanized infant formula milk powder and a preparation method thereof. The amino acid humanized infant formula milk powder comprises the following materials by a certain weight percent: lactose, demineralised whey powder, vegetable oil, skimmed milk powder, hydrolyzed whey protein, galactooligosaccharides, fructo oligosaccharide, a mineral premix, ARA, casein hydrolysate, whey protein concentrate, soybean phospholipids, DHA, a water-soluble vitamin premix, casein phosphopeptides, lactoferrin, L-tyrosine, nucleotide, a lipid soluble vitamin premix, L-tryptophan, L-methionine and taurine. The present invention also includes a method for preparing the amino acid humanized infant formula milk powder. The present invention can effectively solve the problem of pool protein absorption and digestion effect and the low protein utilization rate of infants during infant period.

Owner:AUSNUTRIA DAIRY CHINA

Preparation method for low-lactose fermented dairy product

The invention discloses a preparation method for a low-lactose fermented dairy product. The preparation method has two modes; in one of the modes, lactase is added into milk and ferment is inoculated at the same time, so that the low-lactose fermented dairy product is prepared; in the other mode, lactase is first added into fresh milk, so that lactose is hydrolyzed into glucose and galactose, and ferment is then inoculated, so that the fermented dairy product is prepared. The low-lactose fermented dairy product prepared by the preparation method not only has the characteristics of low lactose content and high viable count, but also has the specific flavor and taste of fermented milk, the change of acidity is little in the process of later storage, and the taste is good. The preparation method is applicable to the preparation of low-lactose fermented dairy products.

Owner:JUNLEBAO DAIRY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com