Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1939results about How to "Fast dissolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

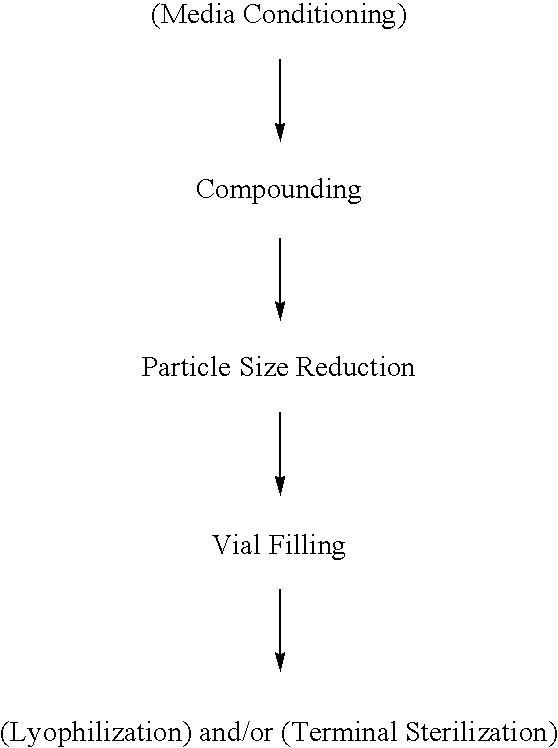

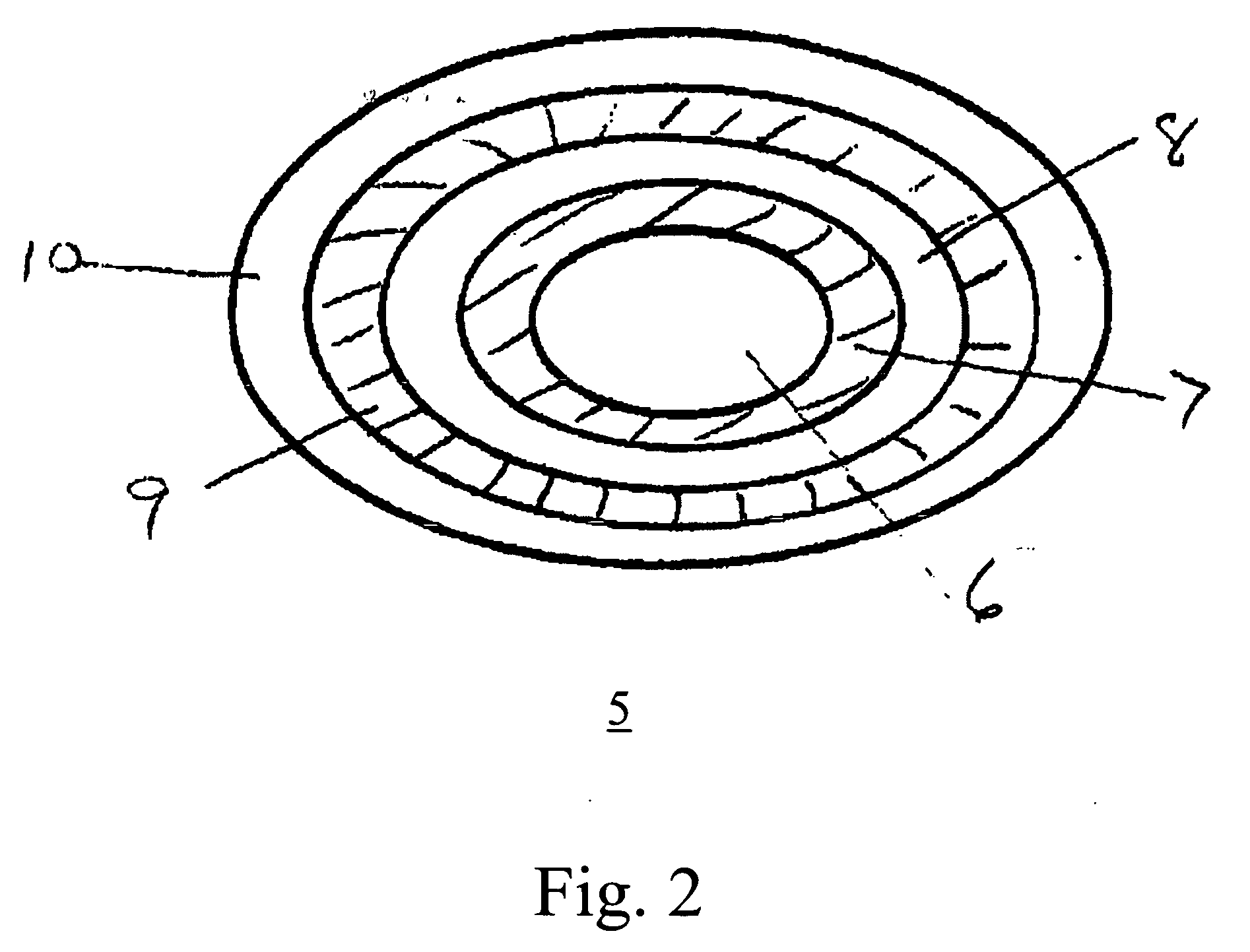

Porous drug matrices and methods of manufacture thereof

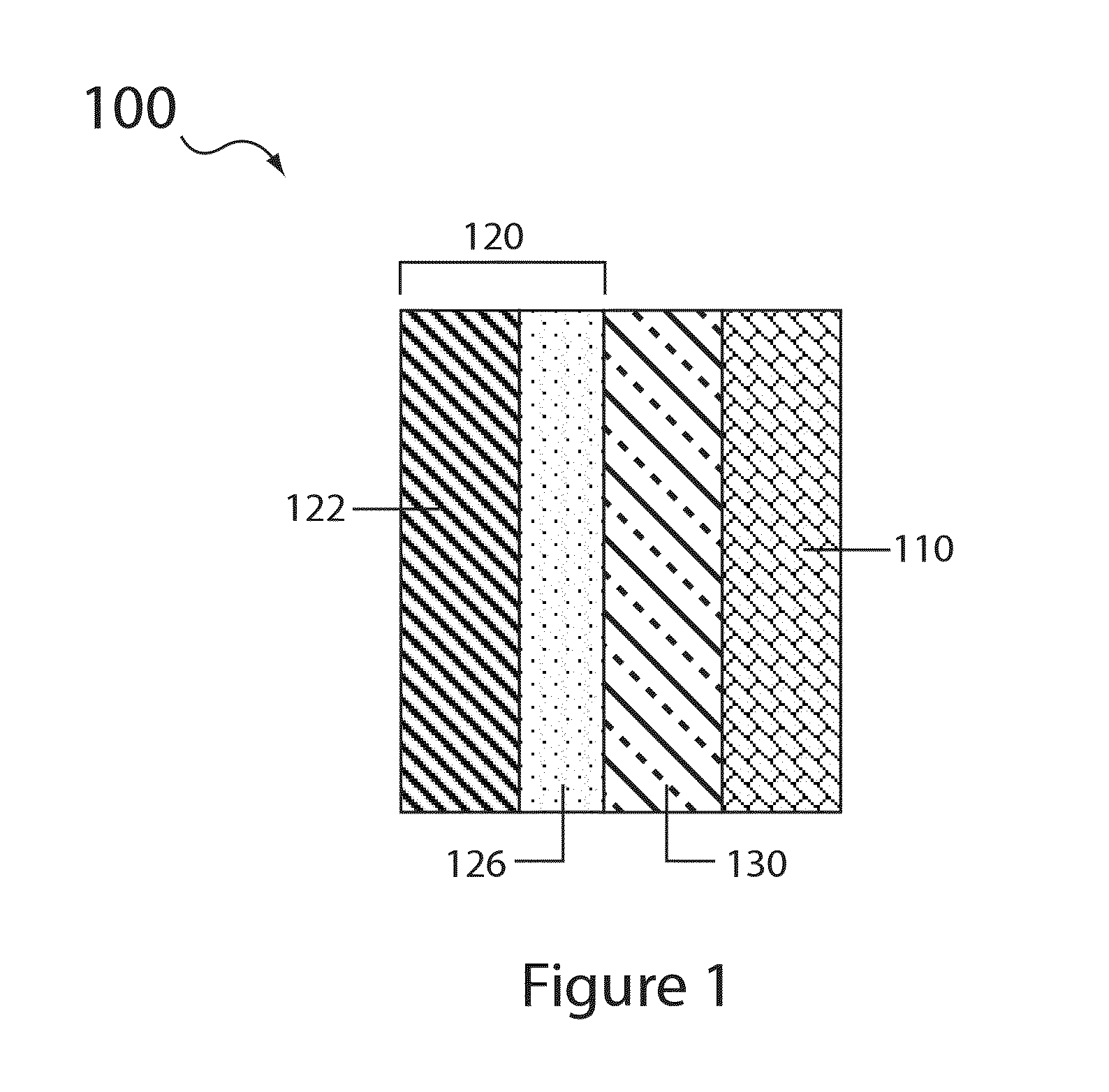

InactiveUS20050048116A1Fast dissolutionHigh dissolution ratePowder deliveryGranular deliveryDrugs solutionMicroparticle

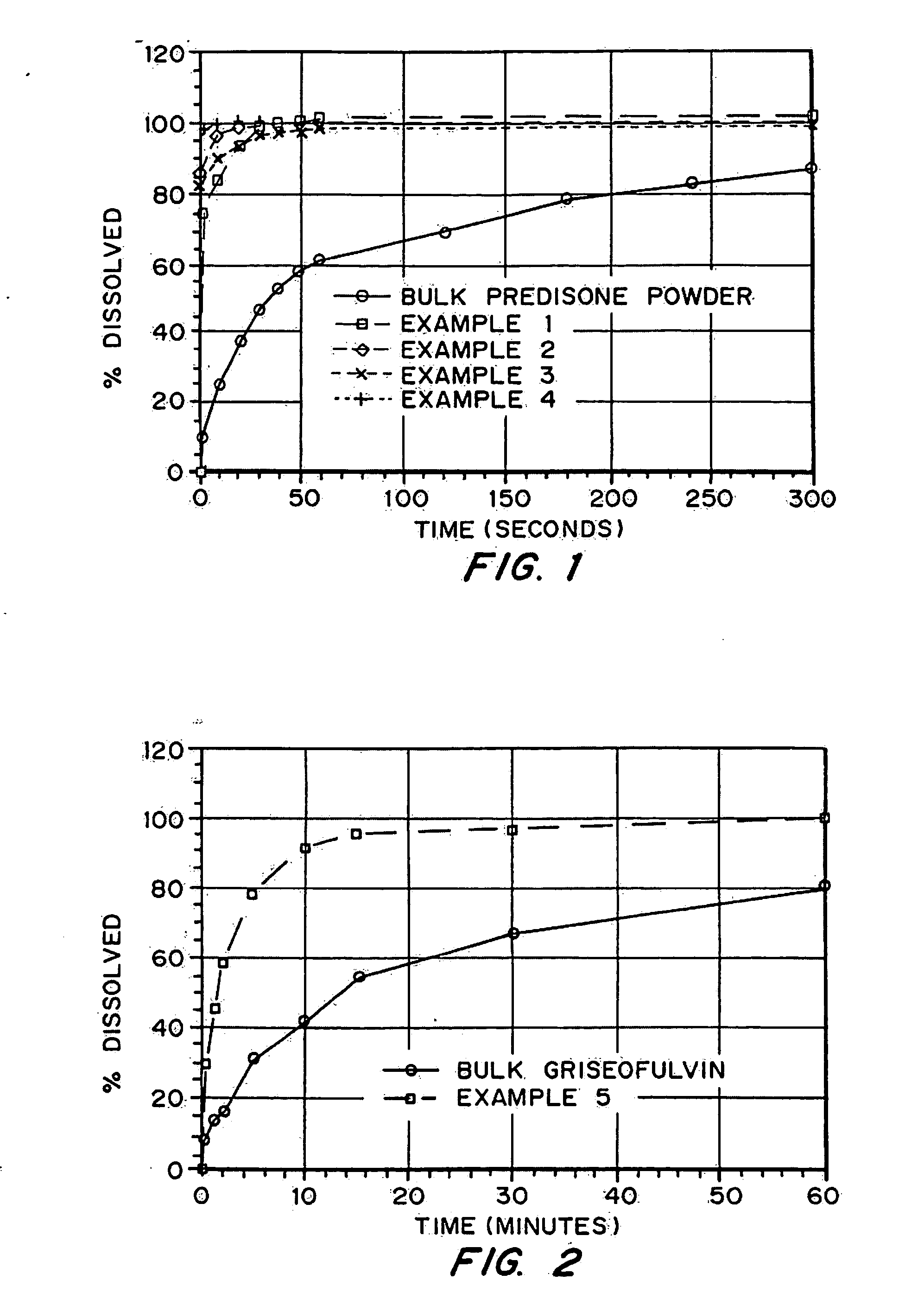

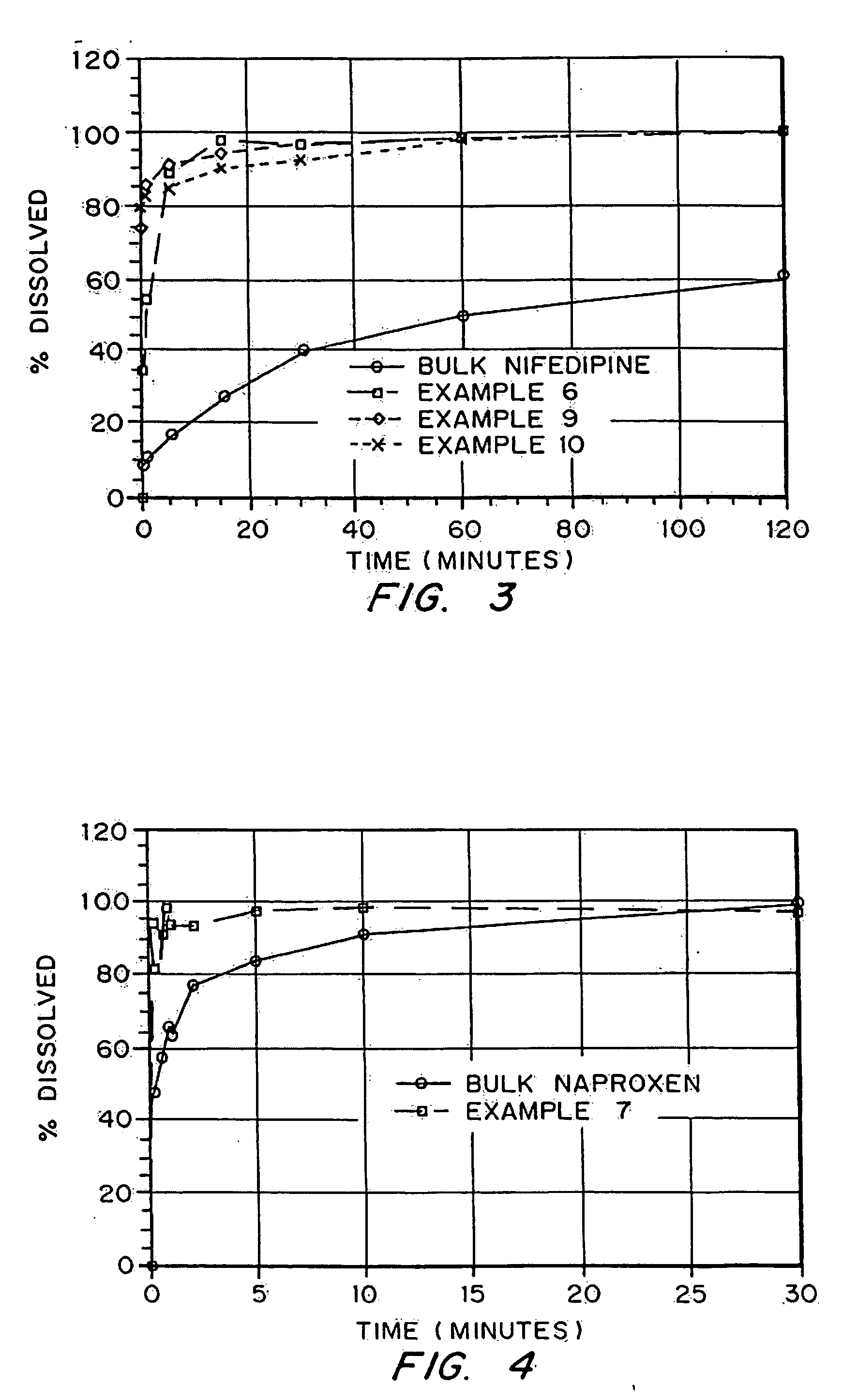

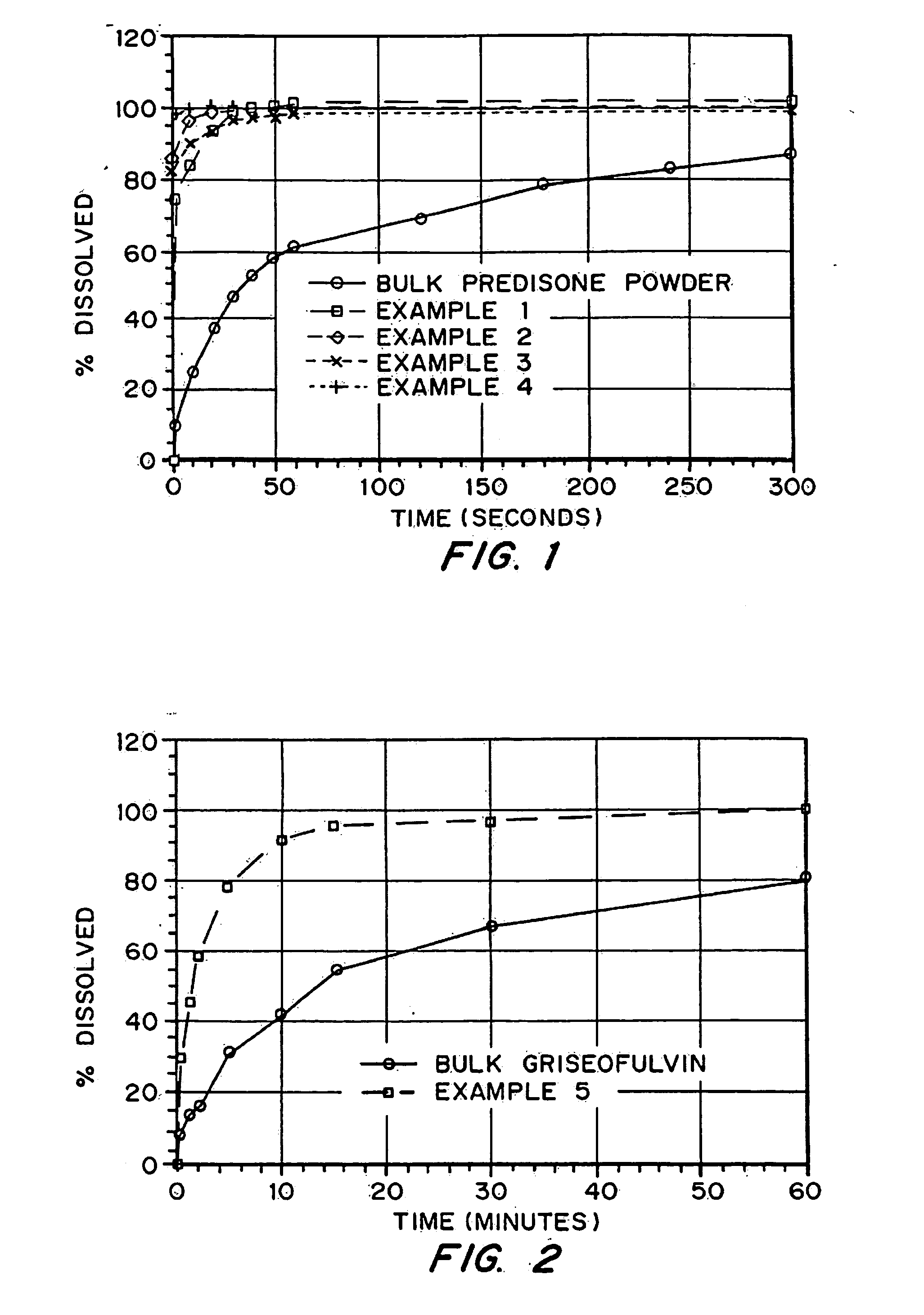

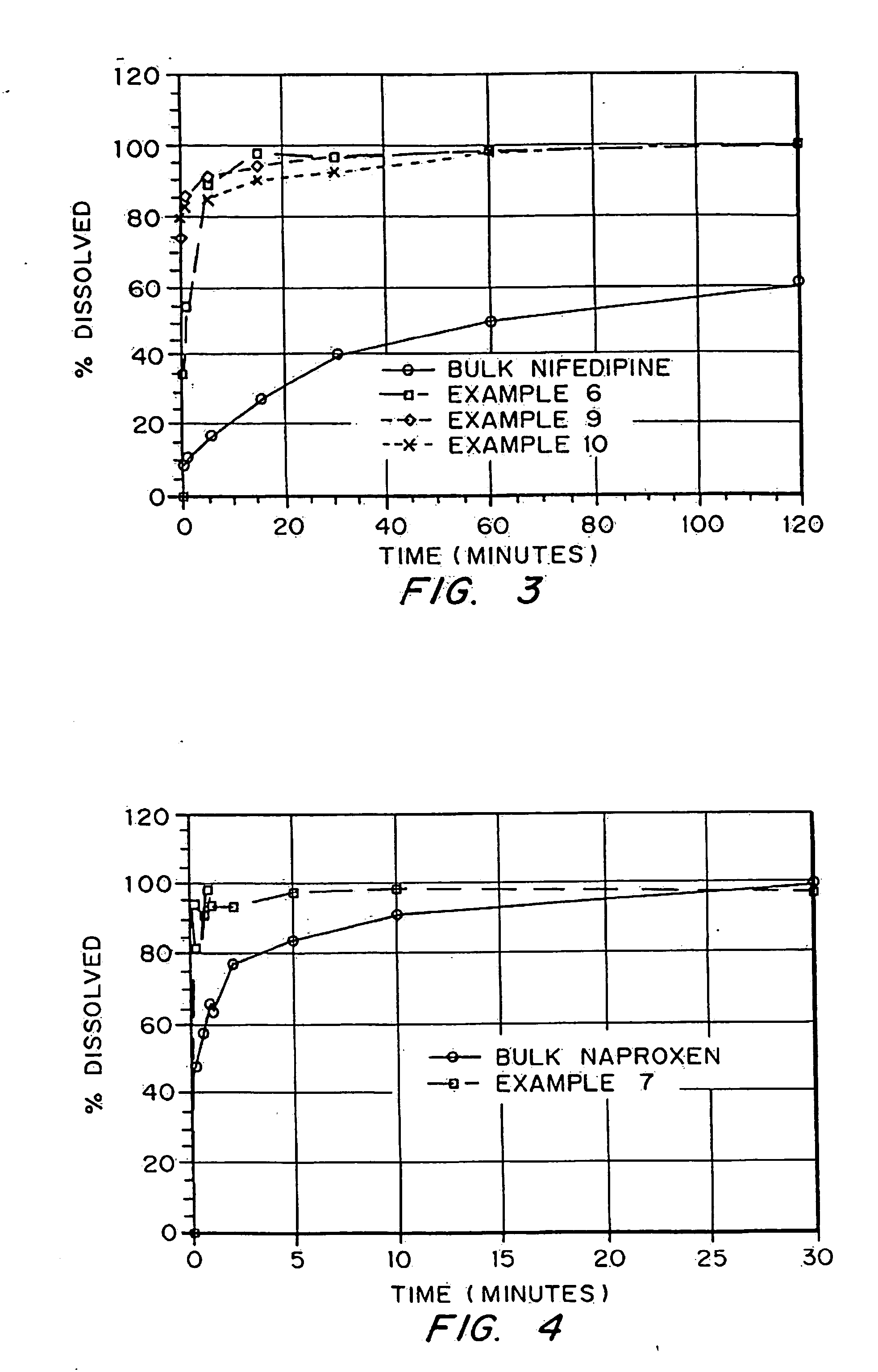

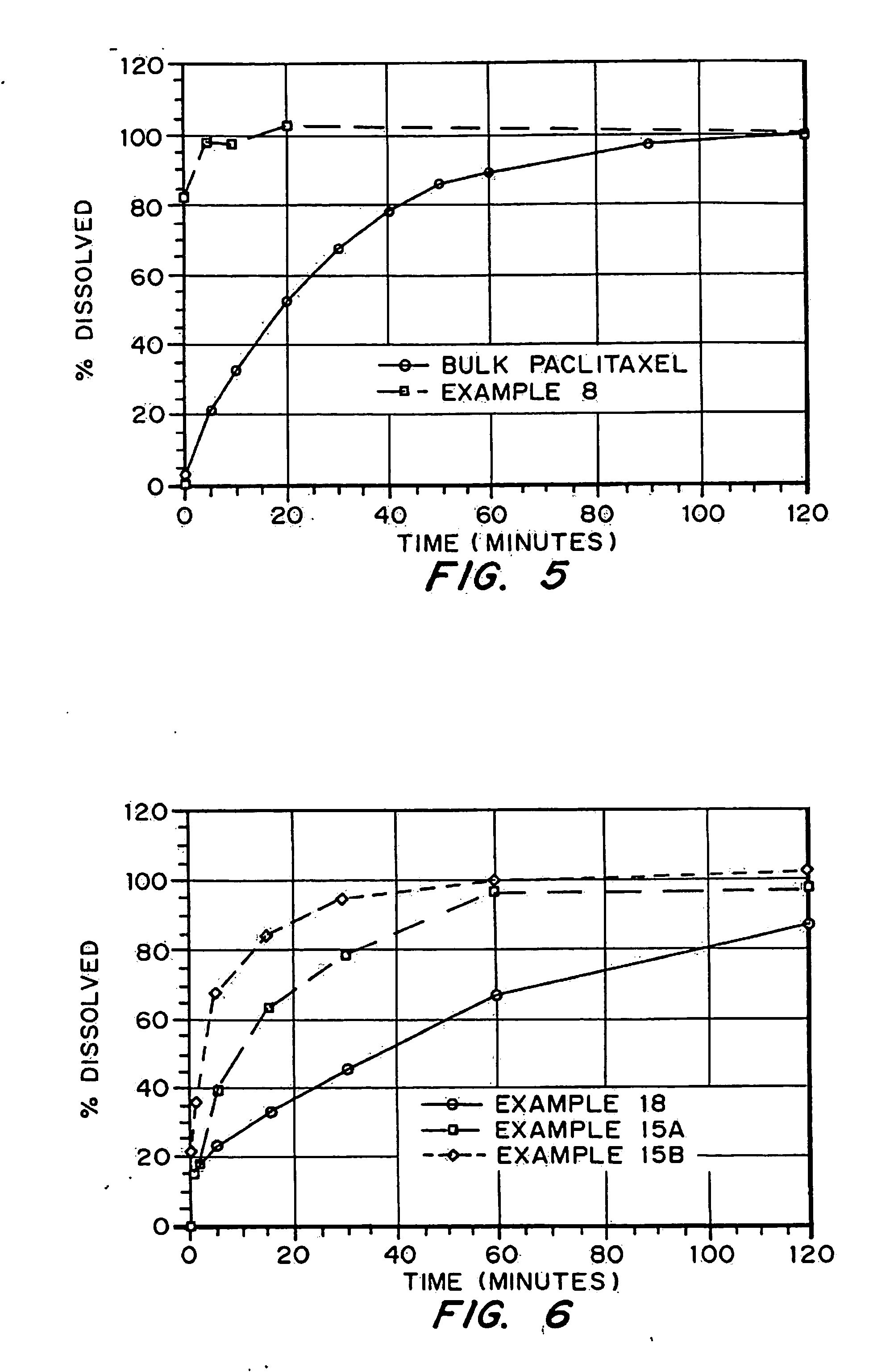

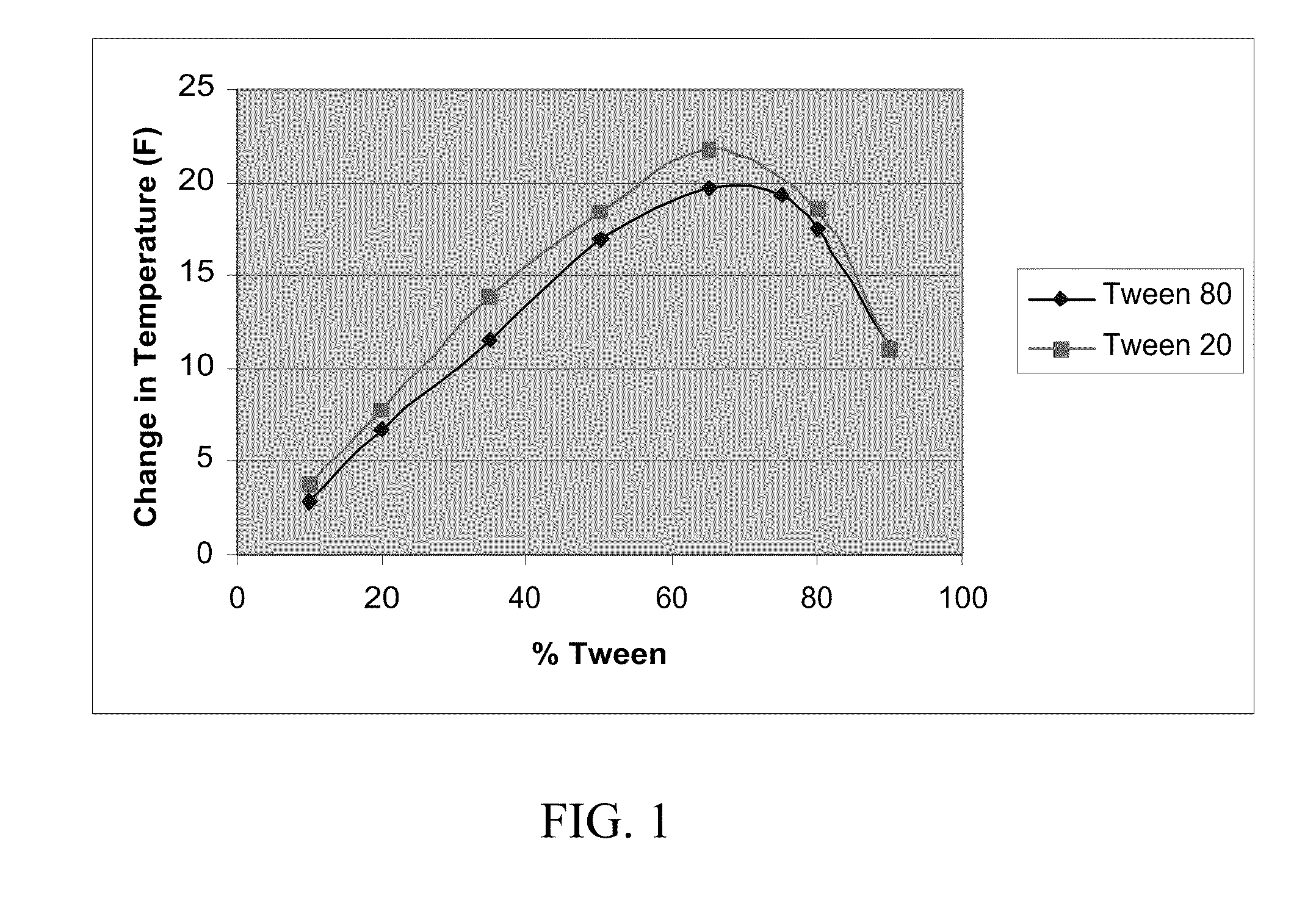

Drugs, especially low aqueous solubility drugs, are provided in a porous matrix form, preferably microparticles, which enhances dissolution of the drug in aqueous media. The drug matrices preferably are made using a process that includes (i) dissolving a drug, preferably a drug having low aqueous solubility, in a volatile solvent to form a drug solution, (ii) combining at least one pore forming agent with the drug solution to form an emulsion, suspension, or second solution and hydrophilic or hydrophobic excipients that stabilize the drug and inhibit crystallization, and (iii) removing the volatile solvent and pore forming agent from the emulsion, suspension, or second solution to yield the porous matrix of drug. Hydrophobic or hydrophilic excipients may be selected to stabilize the drug in crystalline form by inhibiting crystal growth or to stabilize the drug in amorphous form by preventing crystallization. The pore forming agent can be either a volatile liquid that is immiscible with the drug solvent or a volatile solid-compound, preferably a volatile salt. In a preferred embodiment, spray drying is used to remove the solvents and the pore forming agent. The resulting porous matrix has a faster rate of dissolution following administration to a patient, as compared to non-porous matrix forms of the drug. In a preferred embodiment, microparticles of the porous drug matrix are reconstituted with an aqueous medium and administered parenterally, or processed using standard techniques into tablets or capsules for oral administration.

Owner:ACUSPHERE INC

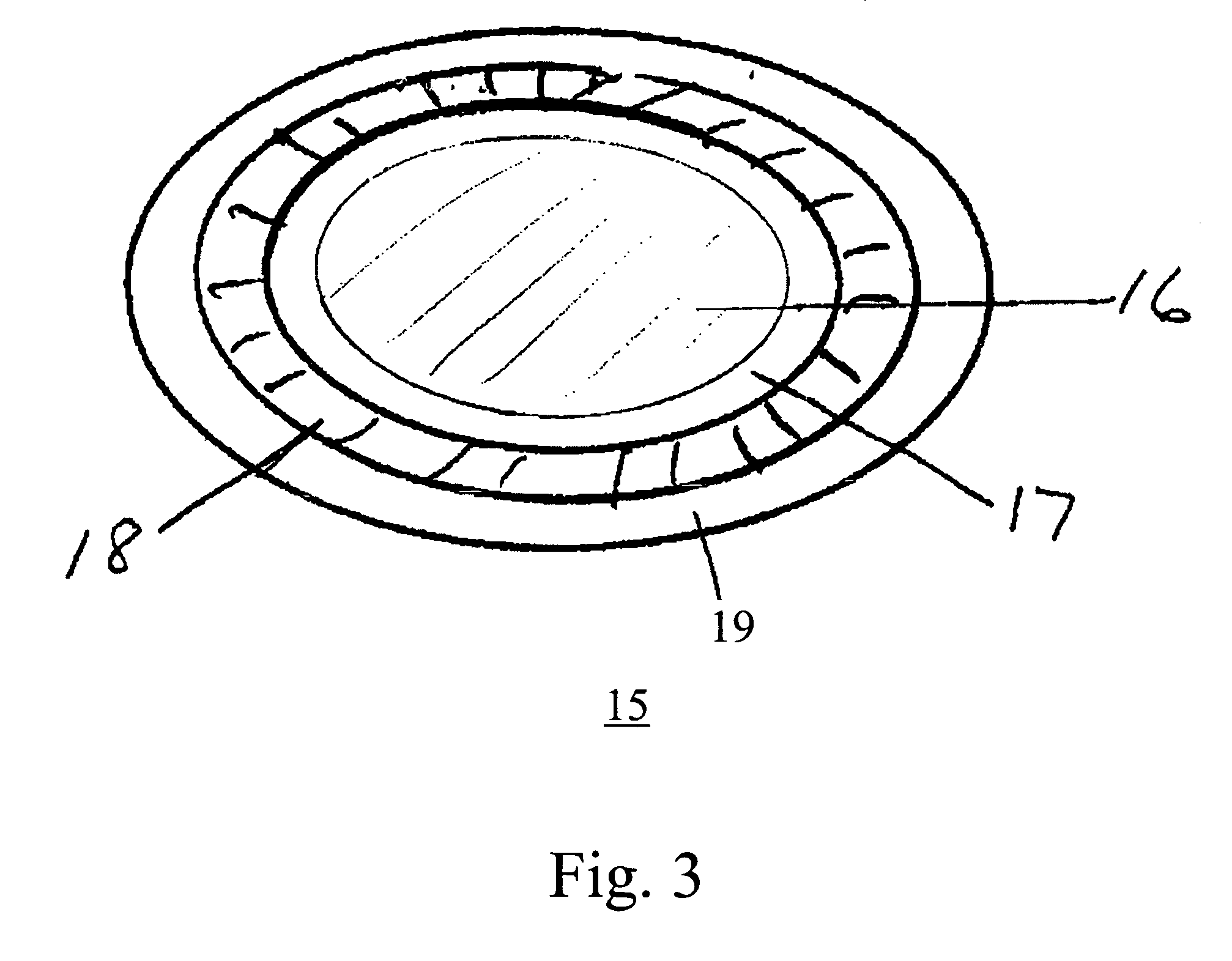

Porous drug matrices and methods of manufacture thereof

InactiveUS20050058710A1Fast dissolutionExtended half-lifePowder deliveryGranular deliveryDrugs solutionMicroparticle

Drugs, especially low aqueous solubility drugs, are provided in a porous matrix form, preferably microparticles, which enhances dissolution of the drug in aqueous media. The drug matrices preferably are made using a process that includes (i) dissolving a drug, preferably a drug having low aqueous solubility, in a volatile solvent to form a drug solution, (ii) combining at least one pore forming agent with the drug solution to form an emulsion, suspension, or second solution and hydrophilic or hydrophobic excipients that stabilize the drug and inhibit crystallization, and (iii) removing the volatile solvent and pore forming agent from the emulsion, suspension, or second solution to yield the porous matrix of drug. Hydrophobic or hydrophilic excipients may be selected to stabilize the drug in crystalline form by inhibiting crystal growth or to stabilize the drug in amorphous form by preventing crystallization. The pore forming agent can be either a volatile liquid that is immiscible with the drug solvent or a volatile solid compound, preferably a volatile salt. In a preferred embodiment, spray drying is used to remove the solvents and the pore forming agent. The resulting porous matrix has a faster rate of dissolution following administration to a patient, as compared to non-porous matrix forms of the drug. In a preferred embodiment, microparticles of the porous drug matrix are reconstituted with an aqueous medium and administered parenterally, or processed using standard techniques into tablets or capsules for oral administration.

Owner:ACUSPHERE INC

Gelling compositions and methods

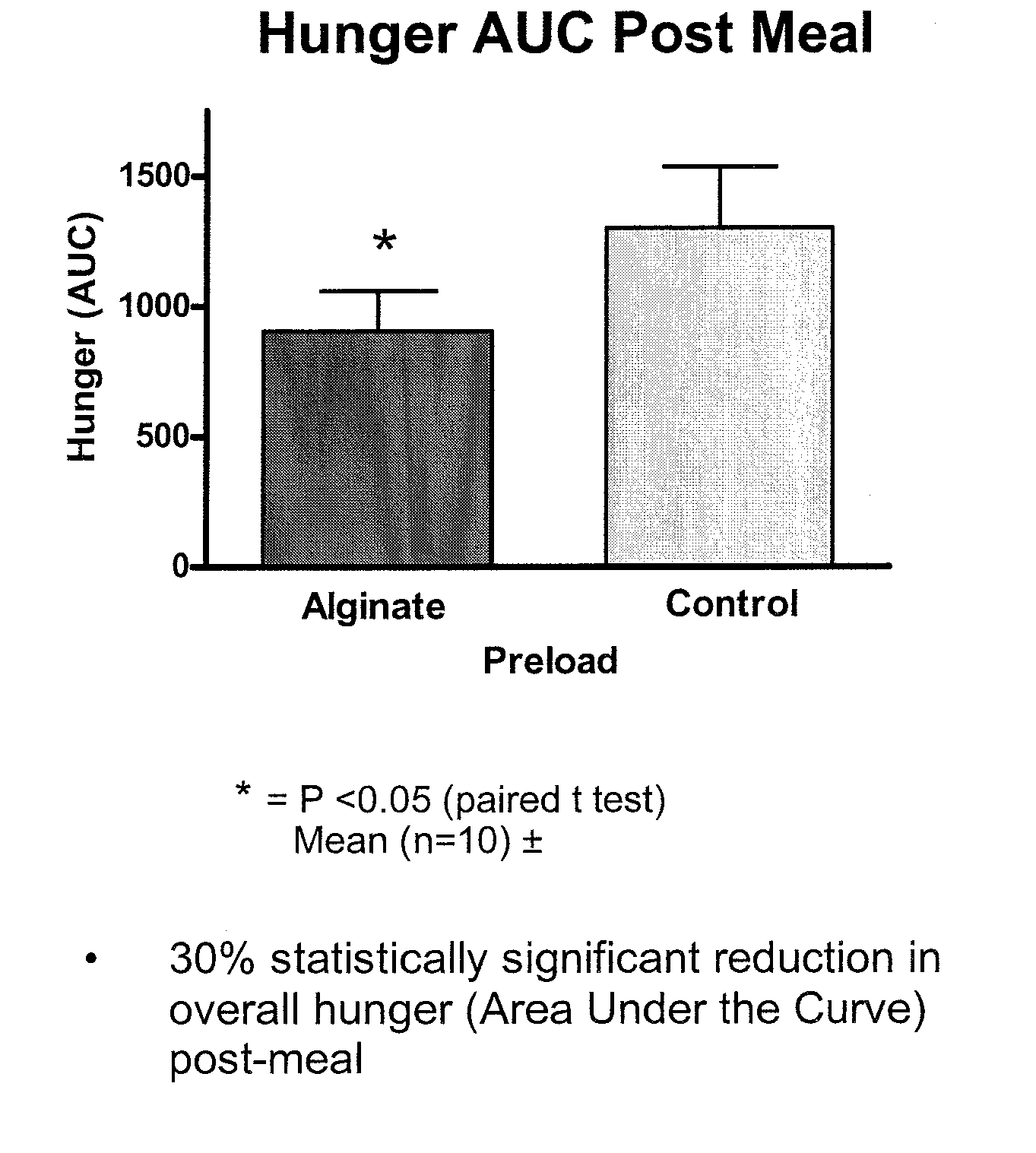

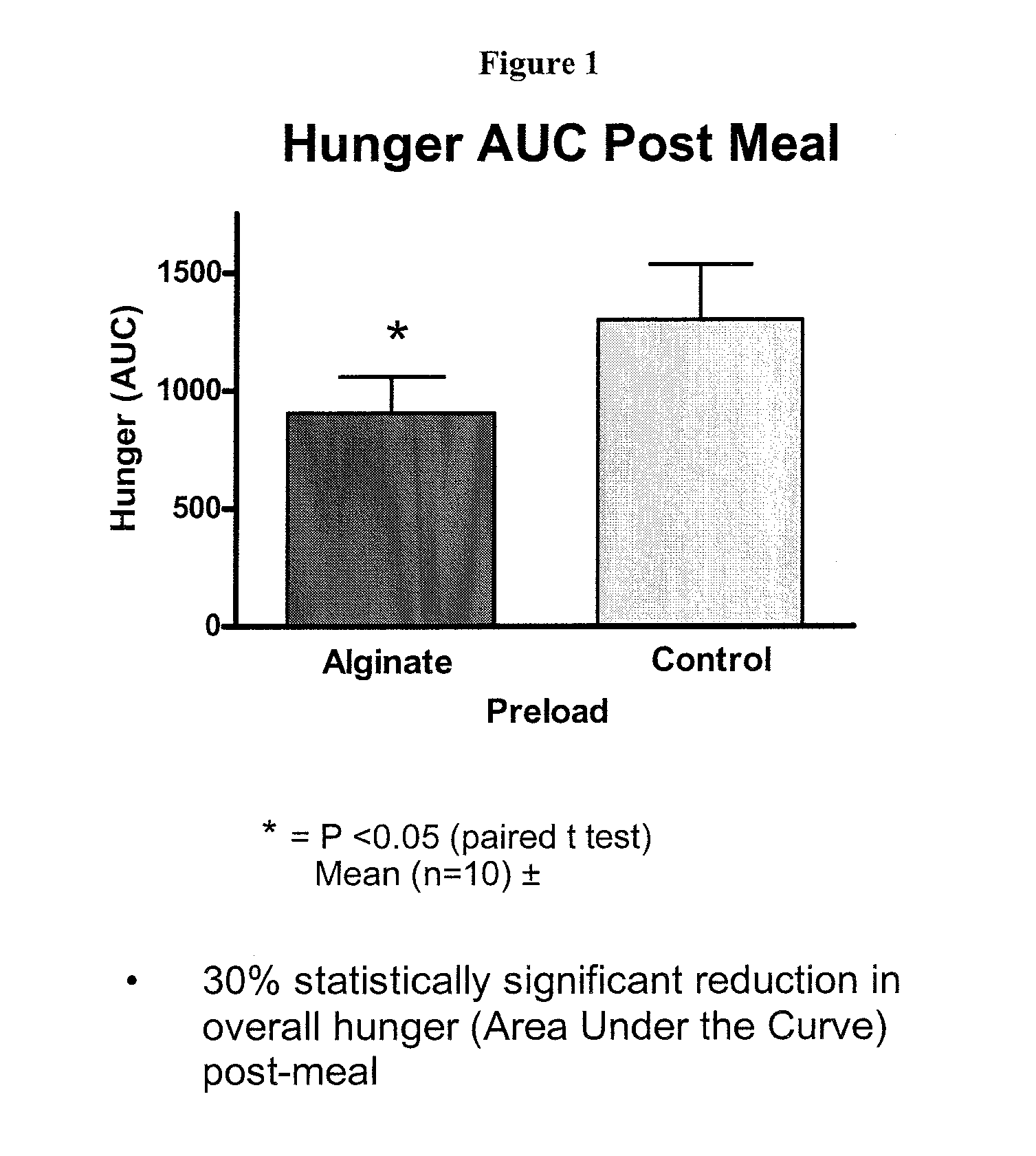

InactiveUS20070087038A1Facilitate cross-linkingIncrease gel volumeOrganic active ingredientsDispersion deliveryChemistryExtended time

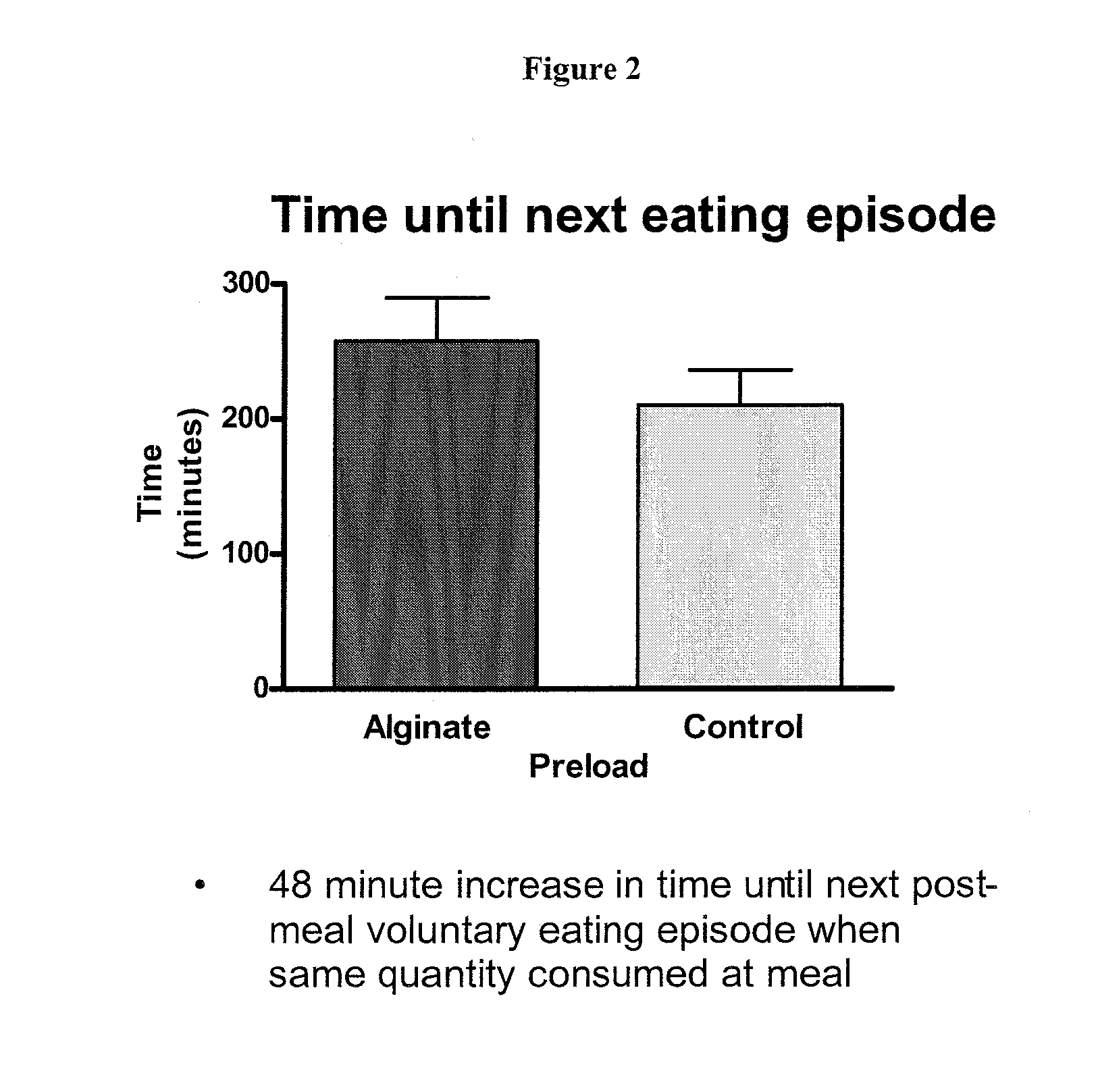

A method for the administration of a composition that augments the acidity of gastric fluid such that intra-gastric gelation of the polysaccharide:acid soluble multivalent cation formulation is initiated independent of endogenous acid secretion. The composition includes:(a) at least one of a polysaccharide, modified polysaccharide, or polysaccharide salt, each capable of ionotropic gelation, (b) at least one source of multivalent cations capable of solubilization at an acidic pH, and (c) at least one acid component capable of providing a controlled release of protons sufficient to solubilize the multivalent cations. The composition is capable of hydrating in aqueous media and subsequently forming a gel in a stomach when ingested, which gel resists peristaltic forces and remains in the stomach for an extended time. Also disclosed are edible compositions including this composition, as well as methods of inducing a satiety effect and providing controlled release of various components employing the composition of the invention.

Owner:FMC BIOPOLYMER AS

Concentrated film delivery systems

ActiveUS20110301070A1Fast degradationFast dissolutionInorganic/elemental detergent compounding agentsGas/heat producing compositionsWater soluble polymersWater soluble

A water soluble strip that includes a carrier film that include water soluble polymer, one or more actives and one or more agents such as heat forming agent and / or degrading accelerator. The water soluble strip can optionally include other additives. The actives includes antimicrobial agent, cleaning agent and / or surfactant. The water soluble strip can include other materials. The heat forming agent and / or degrading accelerator, when used, are designed facilitate in degrading or dissolving the water soluble strip and / or increase the activity of the one or more actives. The water soluble film can be used for a variety of applications such as a hard surface cleaning strip, dishwashing strip, laundry cleaning strip, stop removing strip, drain unclogging strip, toilet bowl cleaning strip and the like. The water soluble strip eliminates the need to purchase and store numerous containers and / or heavy containers of cleaner that take up large amounts of shelf space.

Owner:THE CLOROX CO

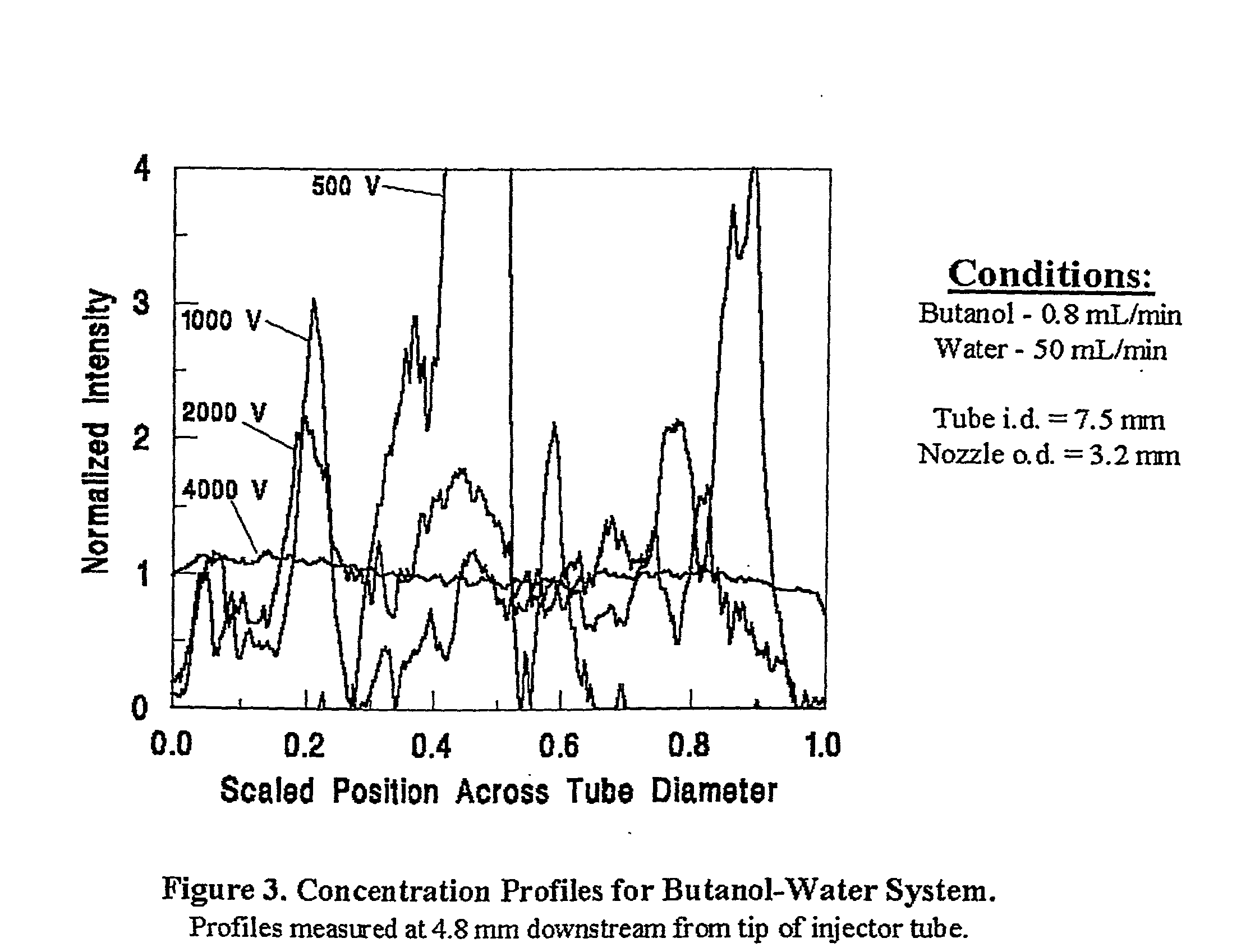

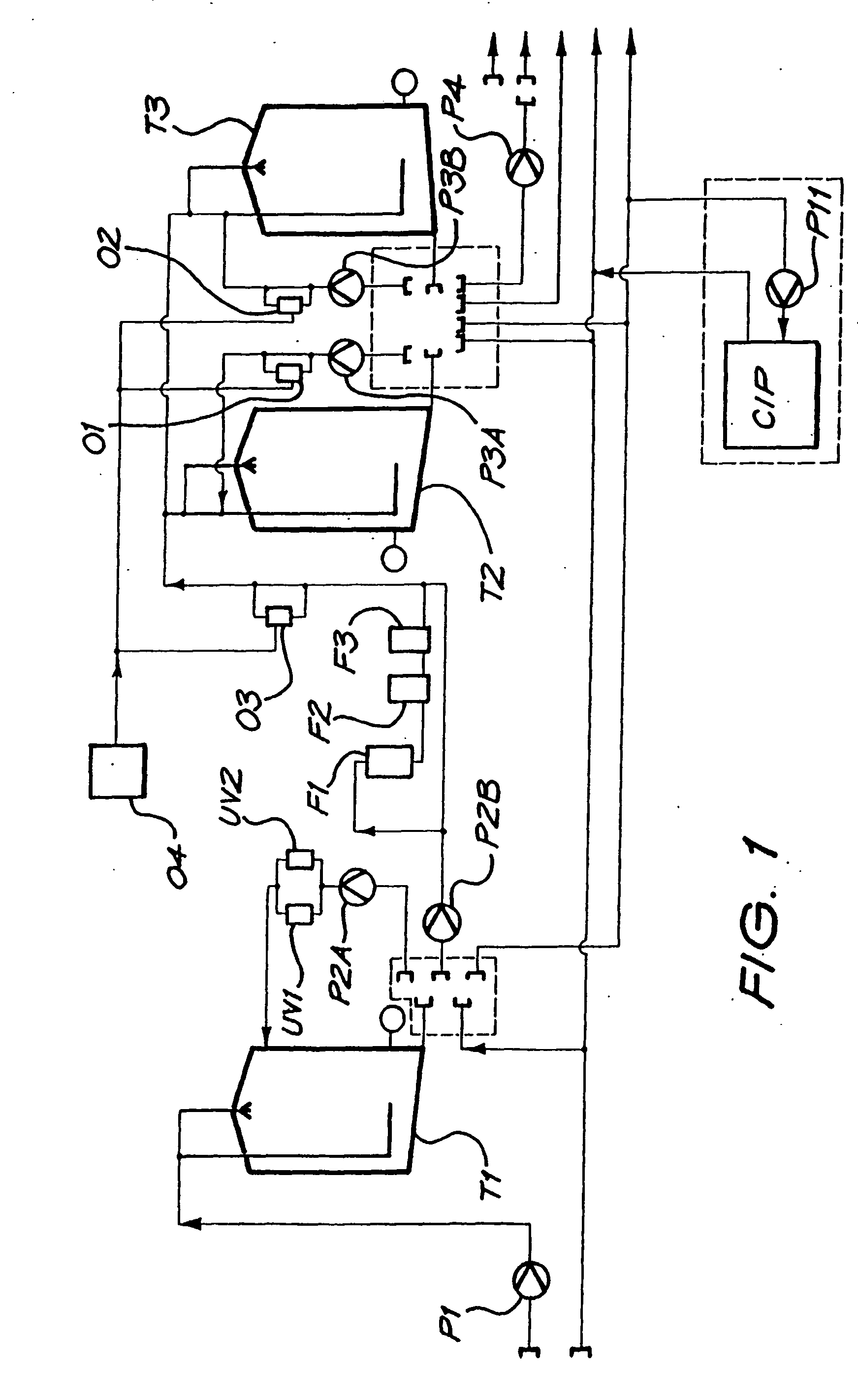

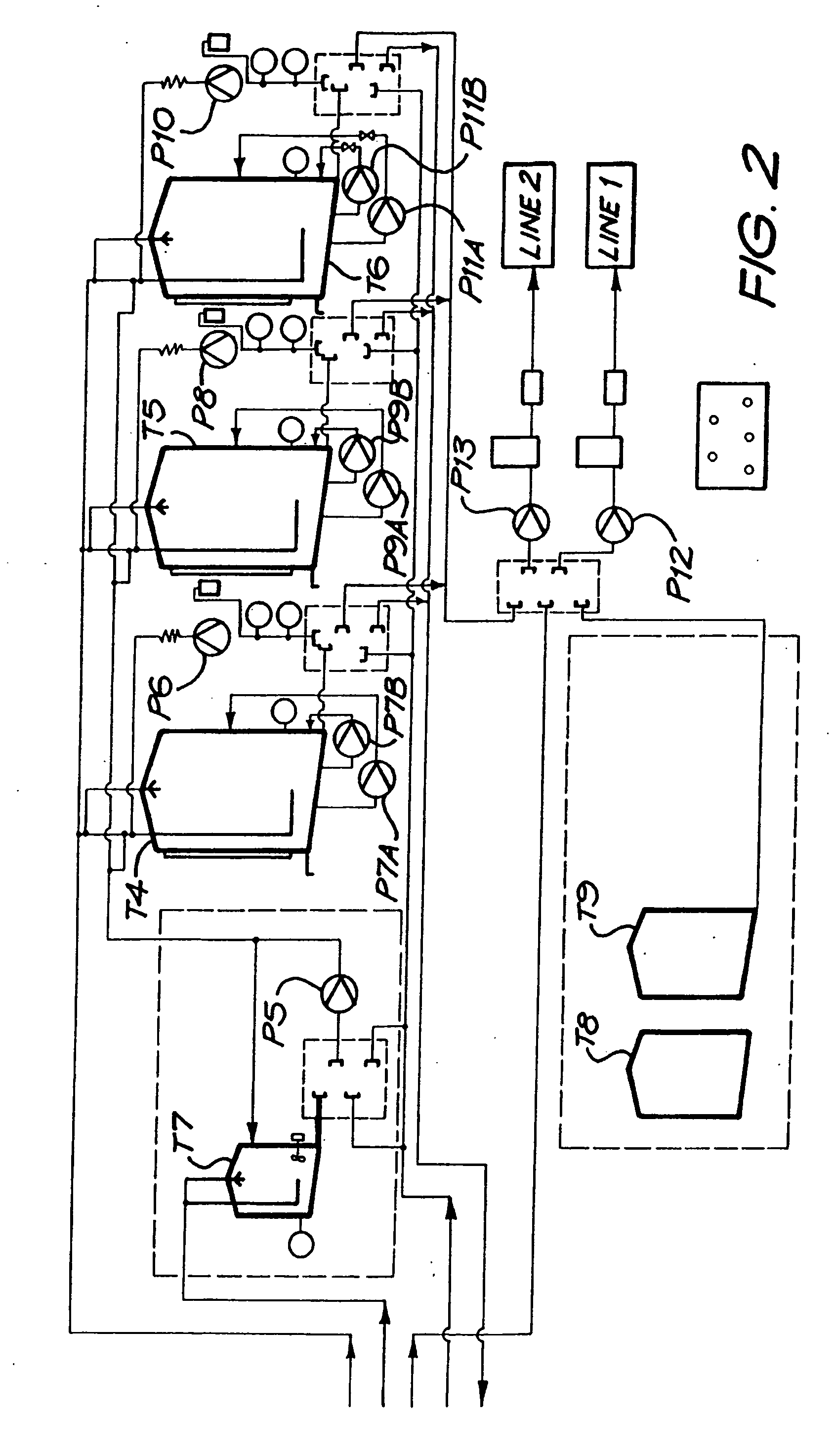

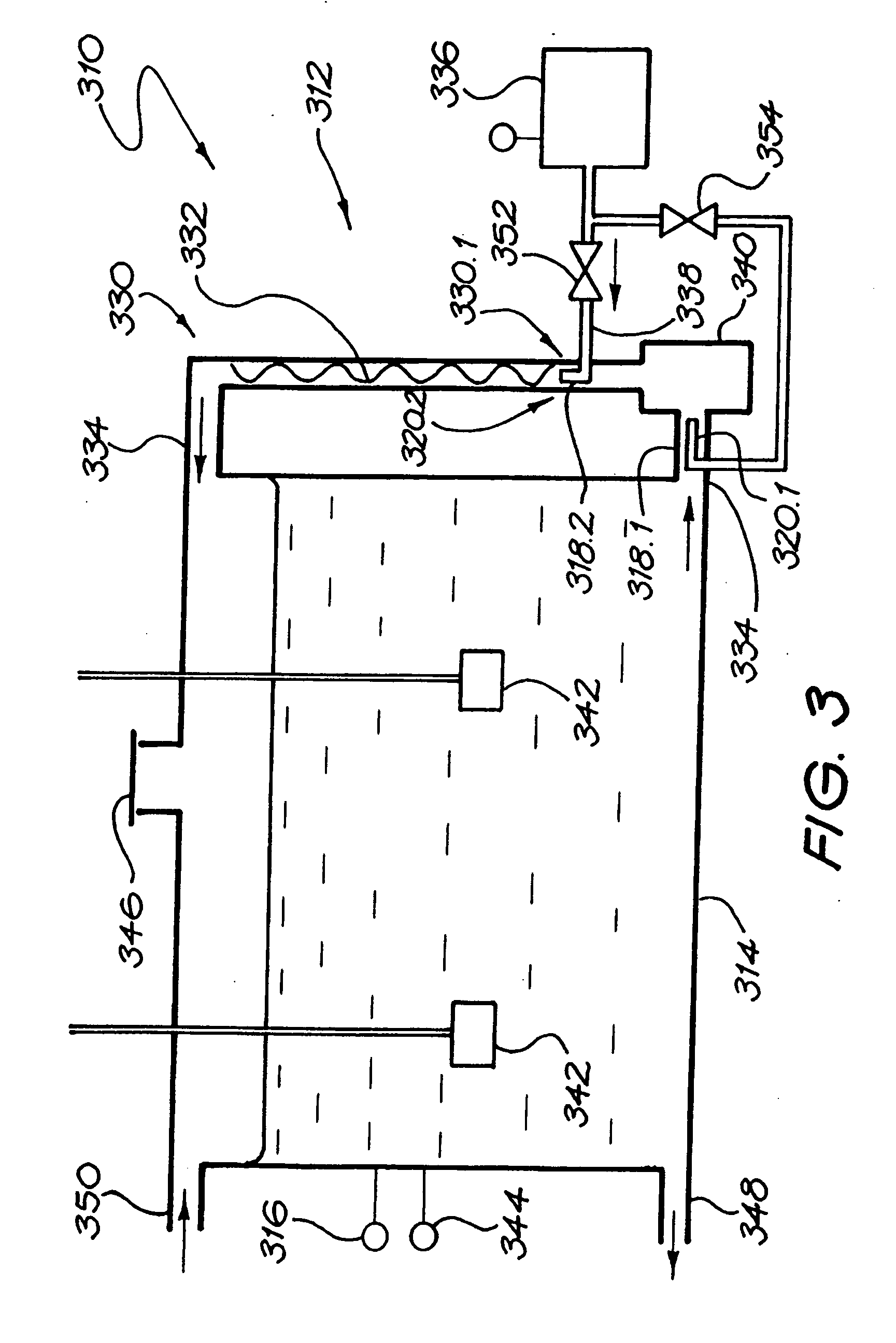

Continuous flow, electrohydrodynamic micromixing apparatus and methods

InactiveUS20010050881A1Increase chanceRapid and thorough mixing of fluidElectrostatic separatorsLiquid separation by electricityHigh rateDissolution

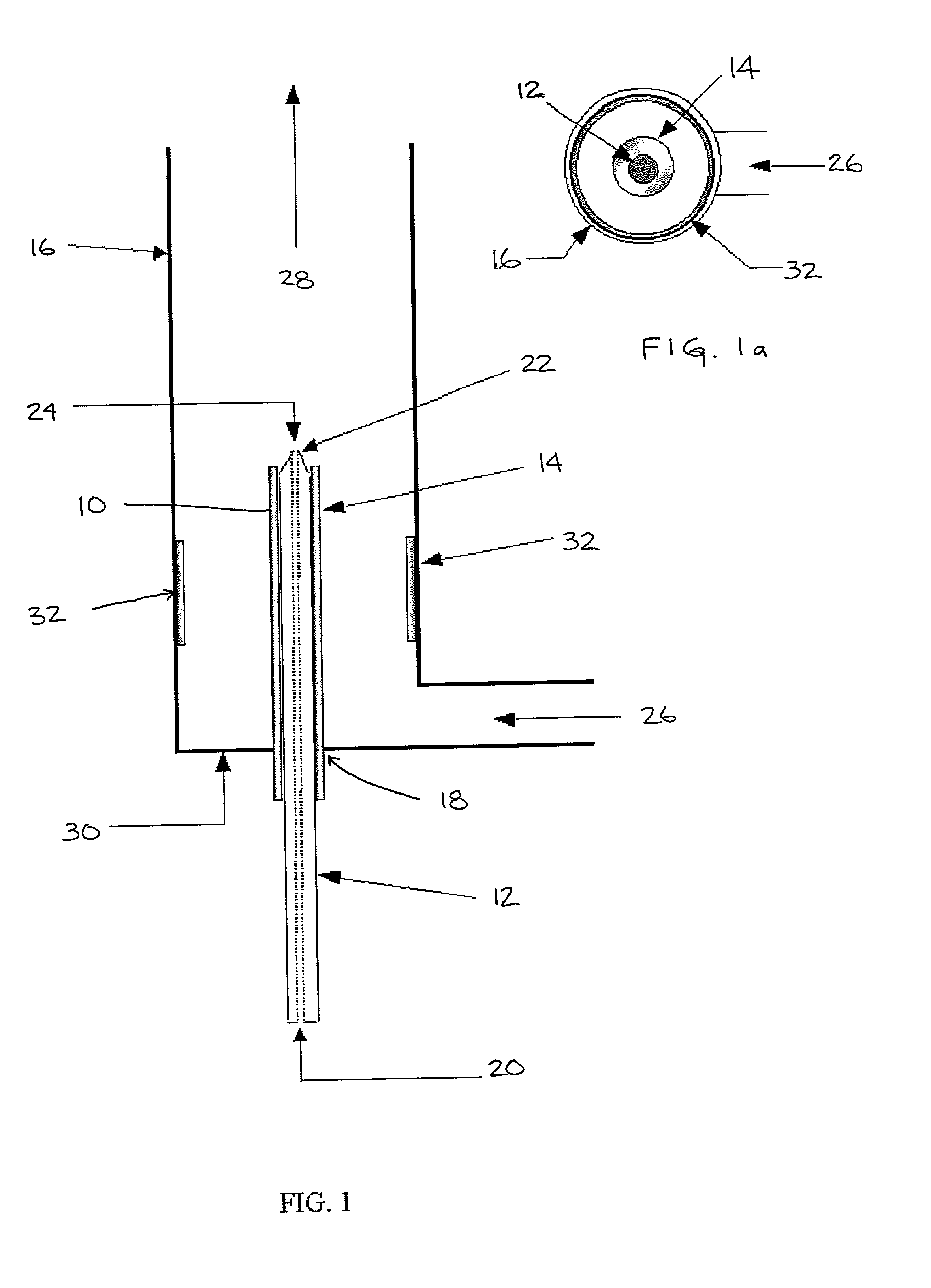

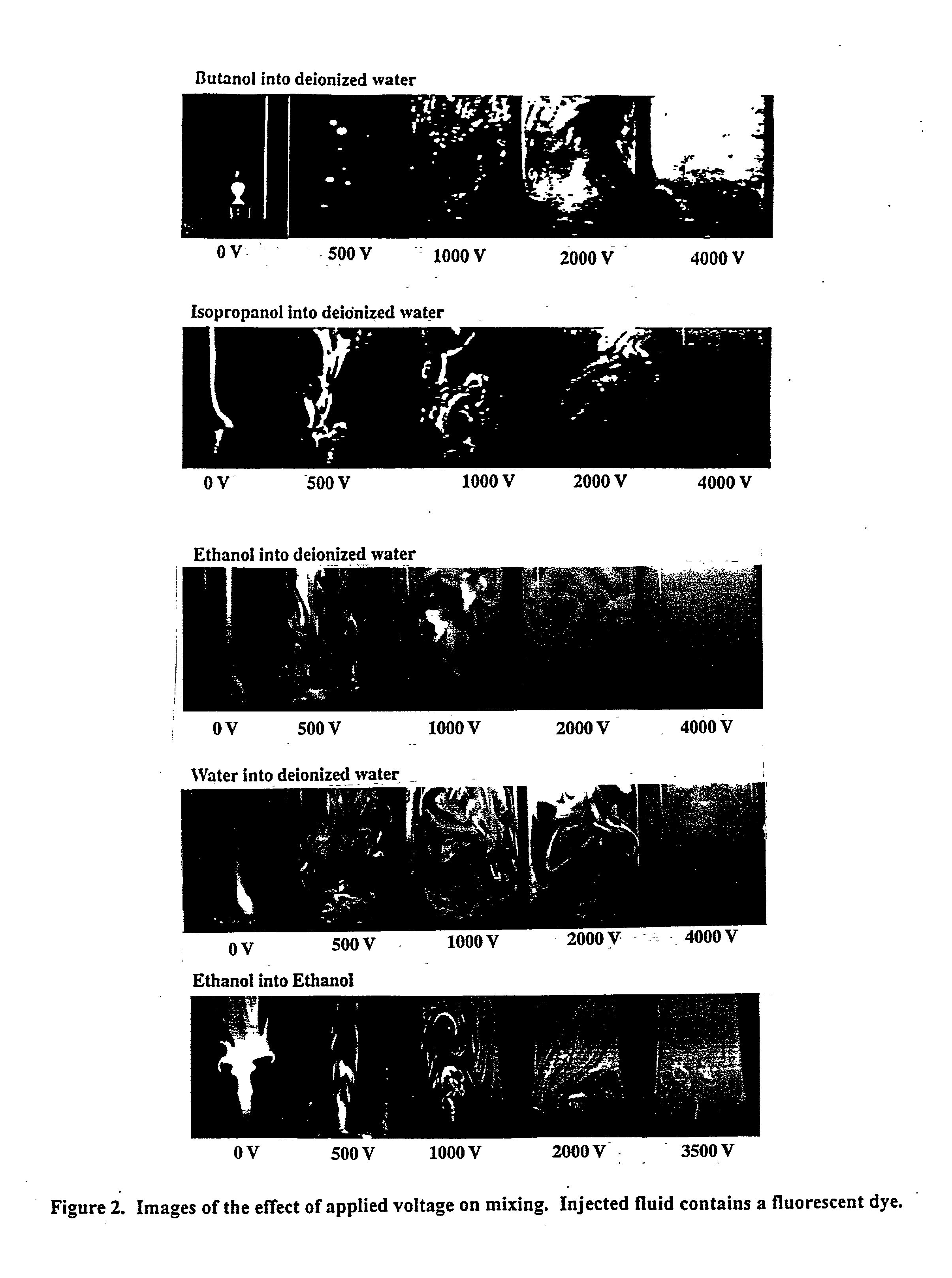

The present invention relates to methods and apparatus that employ electrohydrodynamic flows in miscible, partially miscible and immiscible multiphase systems to induce mixing for dissolution and / or reaction processes. The apparatus and methods of the present invention allow micromixing of two or more components and can advantageously be used to conduct liquid-phase reactions uniformly and at high rates

Owner:LOCKHEED MARTIN ENERGY SYST INC

Aerosol and injectable formulations of nanoparticulate benzodiazepine

InactiveUS20060198896A1Easy doseReduce injection volumeBiocidePowder deliveryBenzodiazepinePolyethylene glycol

Described are nanoparticulate formulations of a benzodiazepine, such as lorazepam, that does not require the presence of polyethylene glycol and propylene glycol as stabilizers, and methods of making and using such formulations. The formulations are particularly useful in aerosol and injectable dosage forms, and comprise nanoparticulate benzodiazepine, such as lorazepam, and at least one surface stabilizer. The formulations are useful in the treatment of status epilepticus, treatment of irritable bowel syndrome, sleep induction, acute psychosis, and as a pre-anesthesia medication.

Owner:ELAN PHRMA INT LTD

Process and appratus for use in preparing an aqueous magnesium bicarbonate solution

InactiveUS20050255174A1Rate of dissolutionFast dissolutionBiocideMagnesium carbonatesDissolutionMagnesium bicarbonate

A method and an apparatus for preparing a substantially clear aqueous solution containing magnesium bicarbonate are disclosed. One method of preparing a substantially clear aqueous solution containing magnesium bicarbonate, includes contacting, with species resulting from the dissolution of carbon dioxide in water, an aqueous suspension of magnesium carbonate, at suitable conditions of pressure and temperature, so as to obtain an aqueous solution of magnesium bicarbonate and controlling the pH of the said solution so that, after reaction of the said species with the magnesium carbonate, the final pH falls within a range of from about 8.0 to about 8.8. One apparatus suitable for preparing an aqueous solution of magnesium bicarbonate, comprises means for contacting, with species resulting from the dissolution of carbon dioxide in water, a suspension of powdered magnesium carbonate in water so as to form an aqueous solution of magnesium bicarbonate and means for controlling the pH of the solution between about 7 and about 9 by adjusting the amount of at least one of the said species and said powdered magnesium carbonate that is contacted with the other.

Owner:SHELLEY ARTHUR +2

Quick disintegrating tablet in buccal cavity and manufacturing method thereof

InactiveUS6656492B2Good effectDisintegrates quicklyPowder deliveryLiquid surface applicatorsHigh concentrationLow speed

The present invention pertains to a quick disintegrating tablet in buccal cavity, characterized in that drug-containing particles with a mean particle diameter of approximately 50~approximately 250 mum and an apparent specific gravity of approximately 0.5~approximately 1.2 consisting of a bitter tasting drug and / or drug of inferior fluidity and a pharmaceutical preparation carrier and obtained by spray drying are added to a quick disintegrating tablet in buccal cavity comprising a drug and saccharide. Moreover, the present invention pertains to a method for manufacturing drug-containing particles having a specific mean particle diameter and specific apparent gravity by dissolving and suspending a bitter tasting drug and / or drug of inferior fluidity and a pharmaceutical preparation carrier (preferably containing water-insoluble polymer, particularly at least aqueous ethyl cellulose suspension (preferably containing plasticizer)) to a high concentration in terms of solid concentration in a solvent that is pharmaceutically acceptable and then spray drying this liquid using a rotating disk-type spray dryer, with the disk operating at low speed, and a method for manufacturing a quick disintegrating tablet in buccal cavity comprising said particles.

Owner:ASTELLAS PHARMA INC

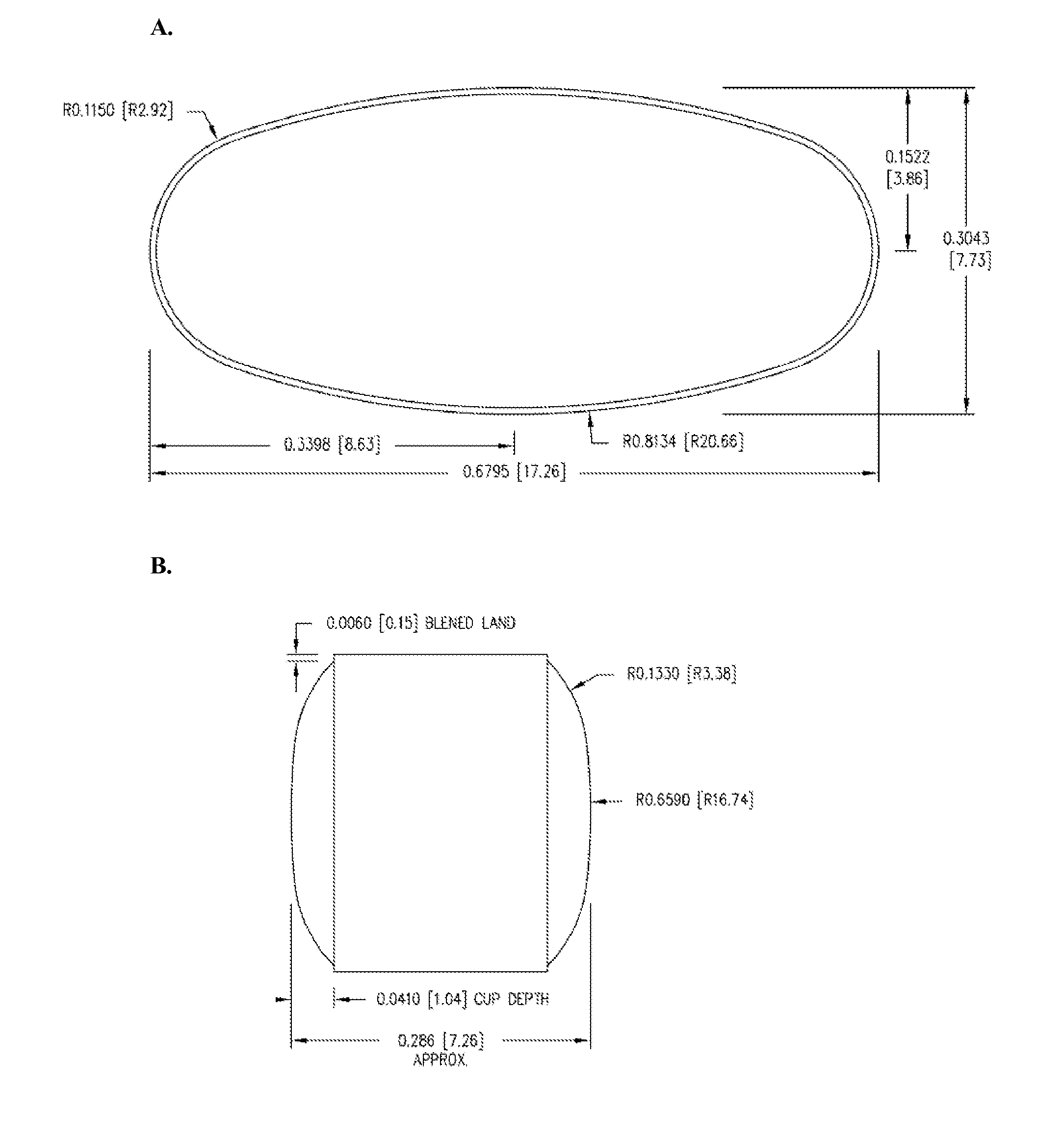

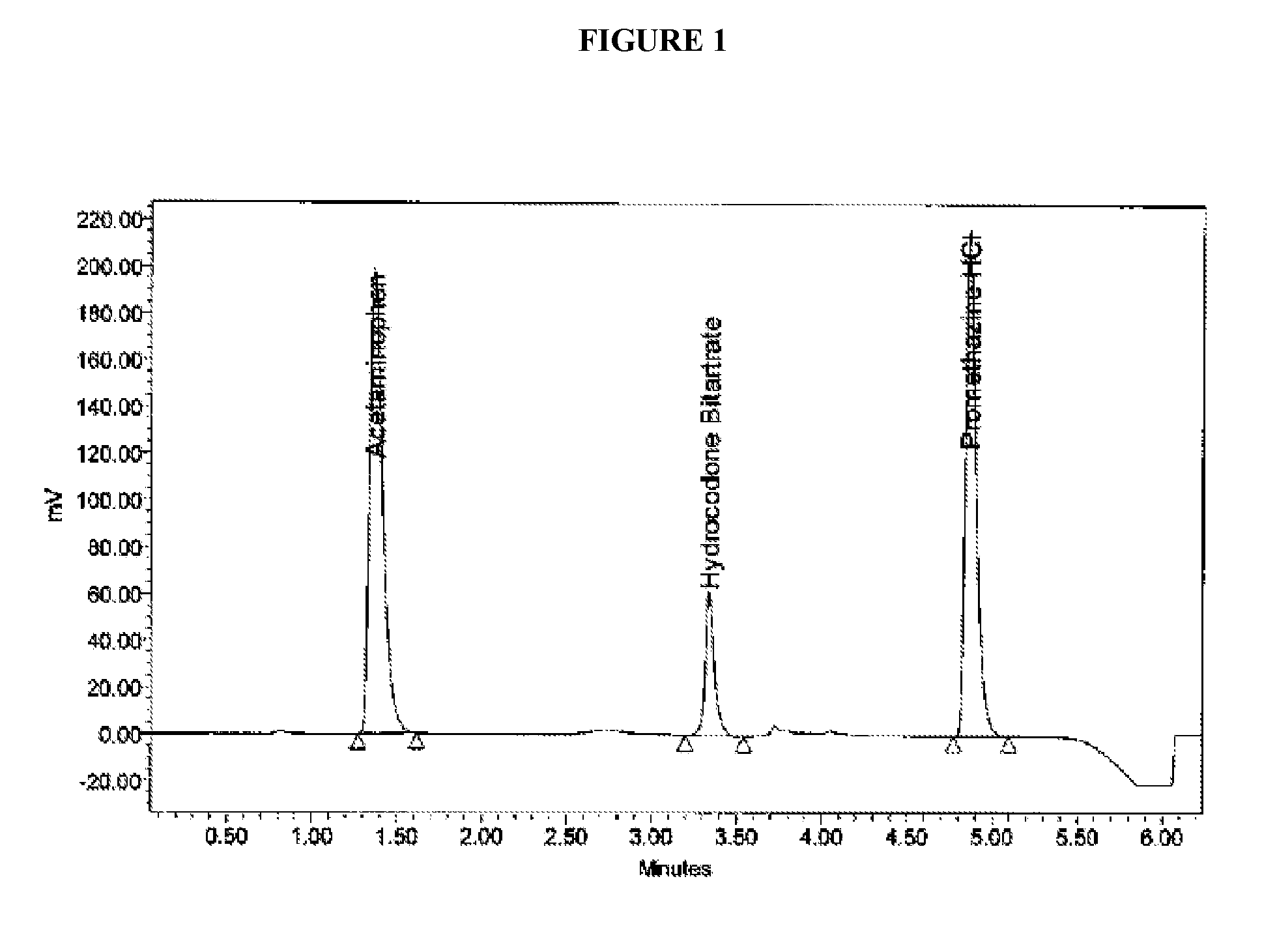

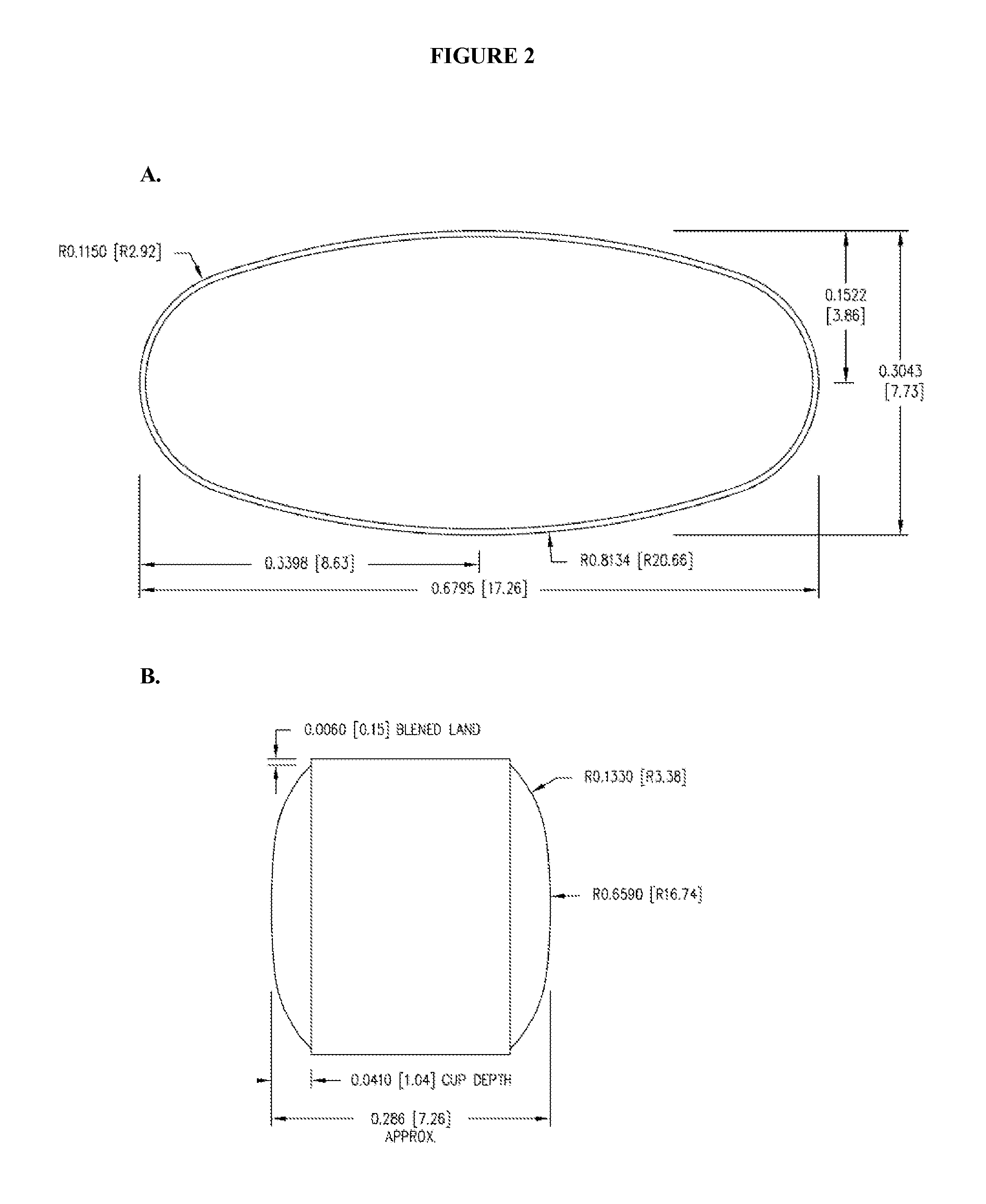

Pharmaceutical compositions

ActiveUS20110262539A1Fast dissolutionTreating and preventing painNervous disorderAntipyreticAdverse effectComposition methods

Methods and compositions are provided which comprise effective amounts of analgesic to treat a subject, including reducing or eliminating an adverse effect associated with the analgesic.

Owner:LOCL PHARMA

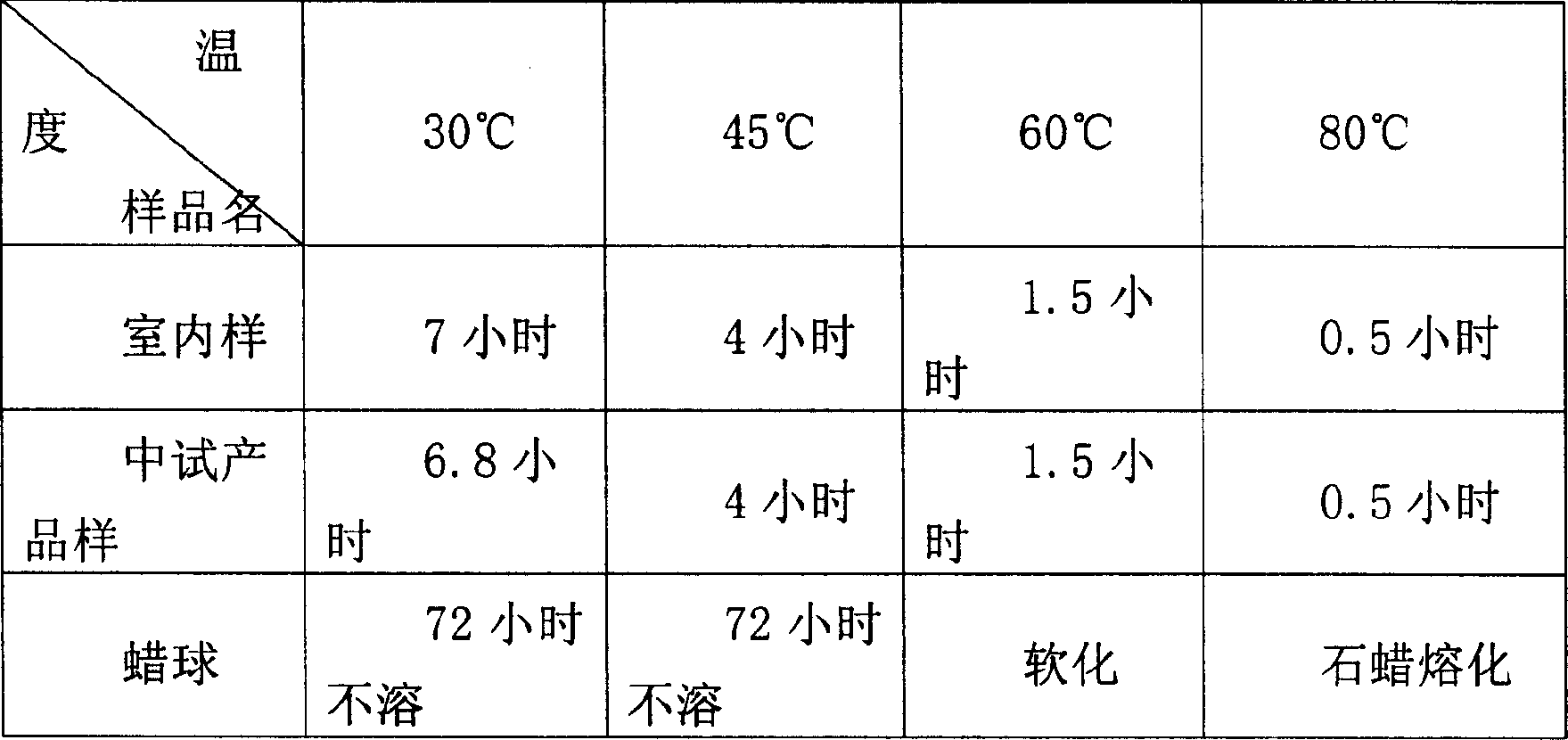

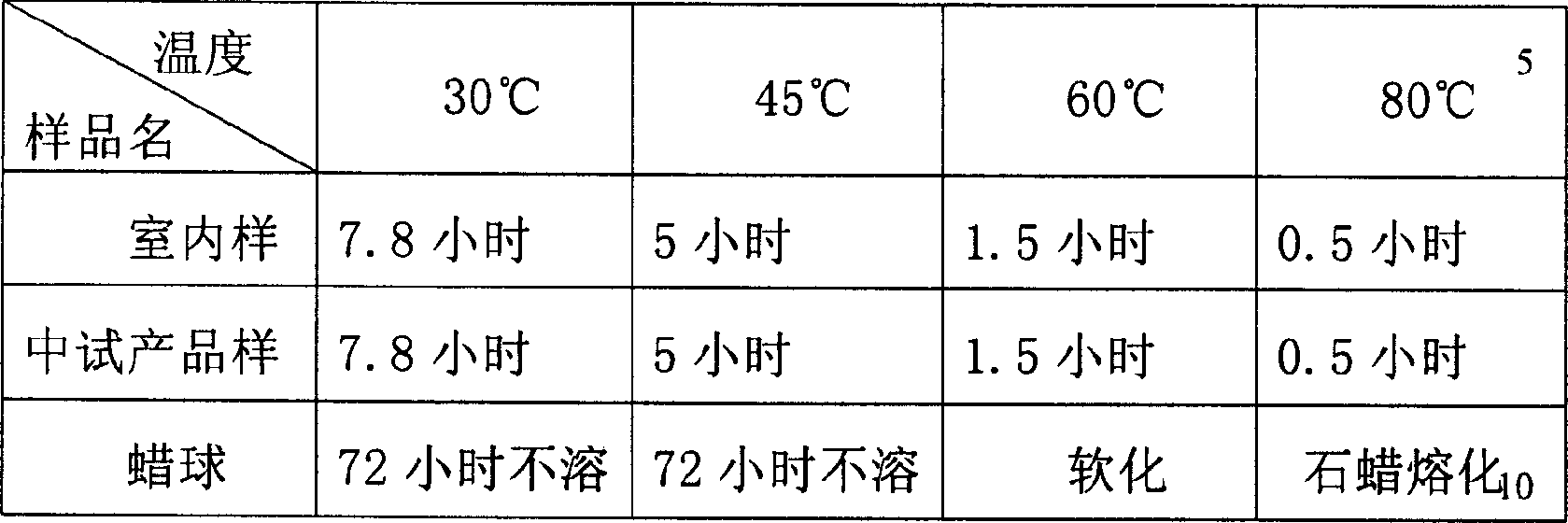

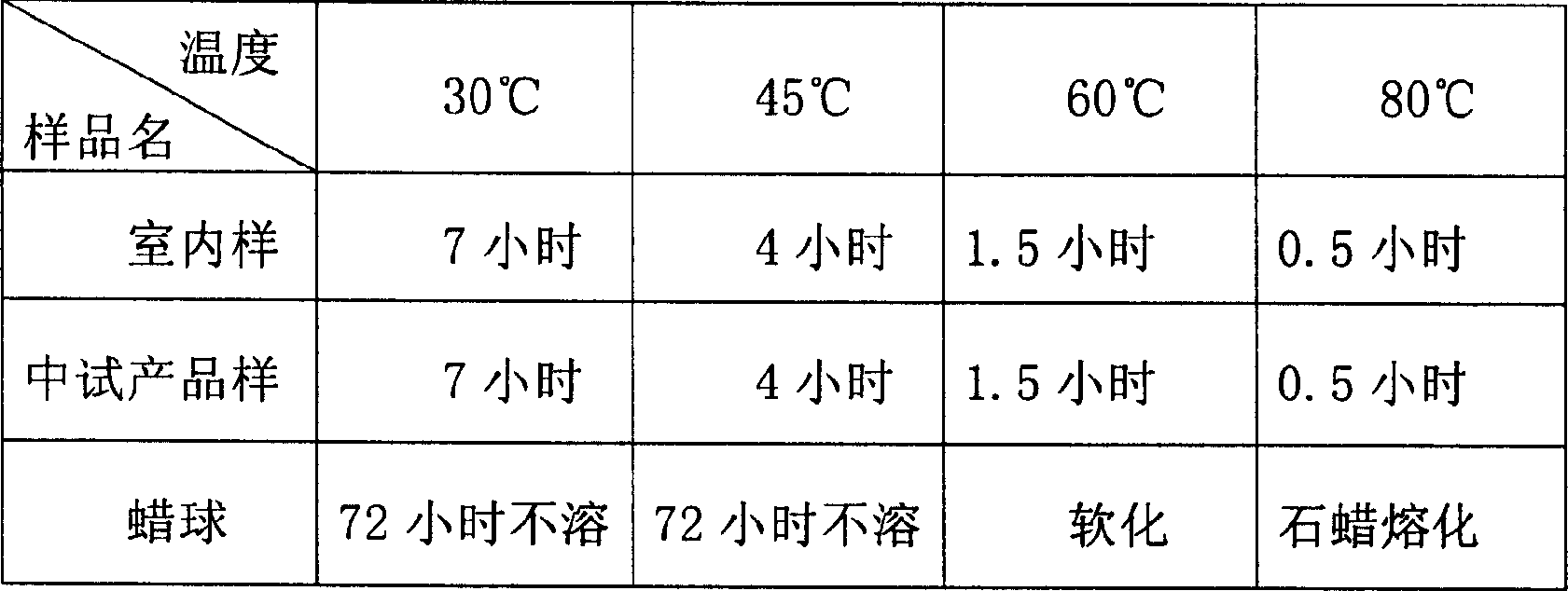

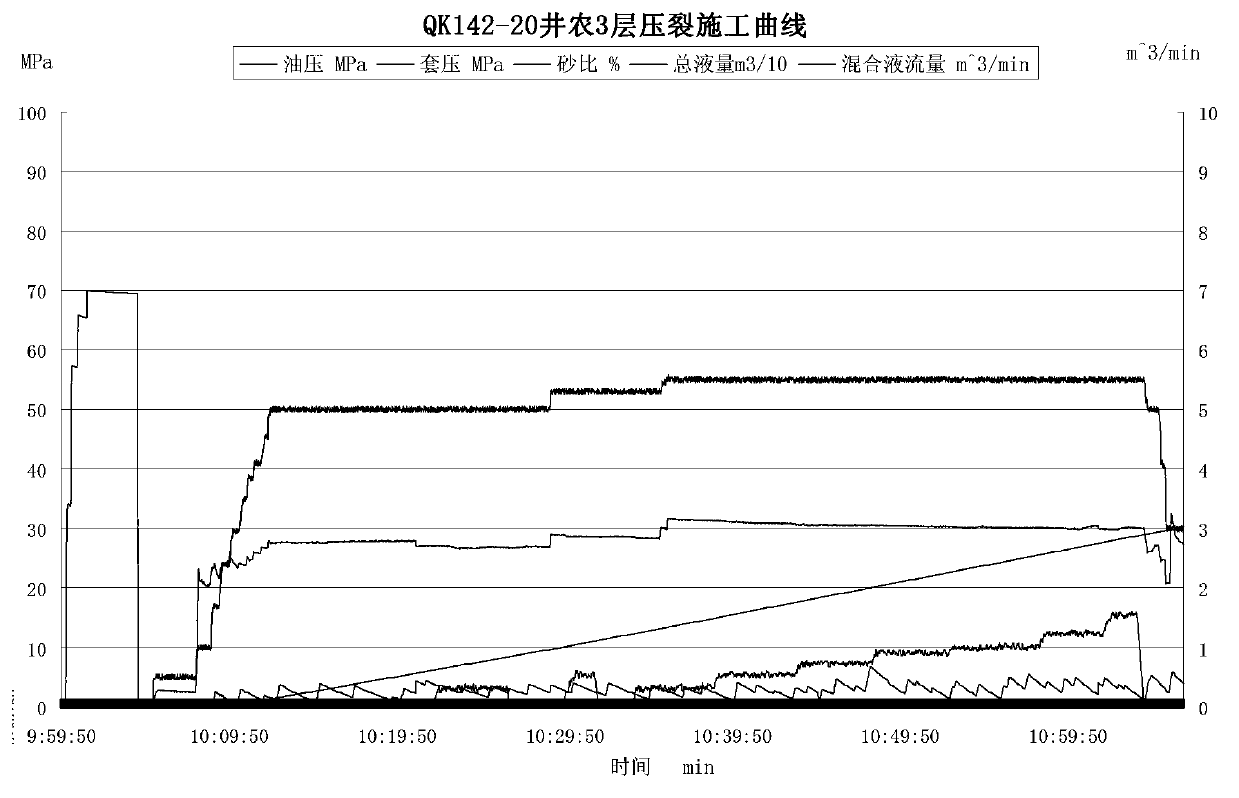

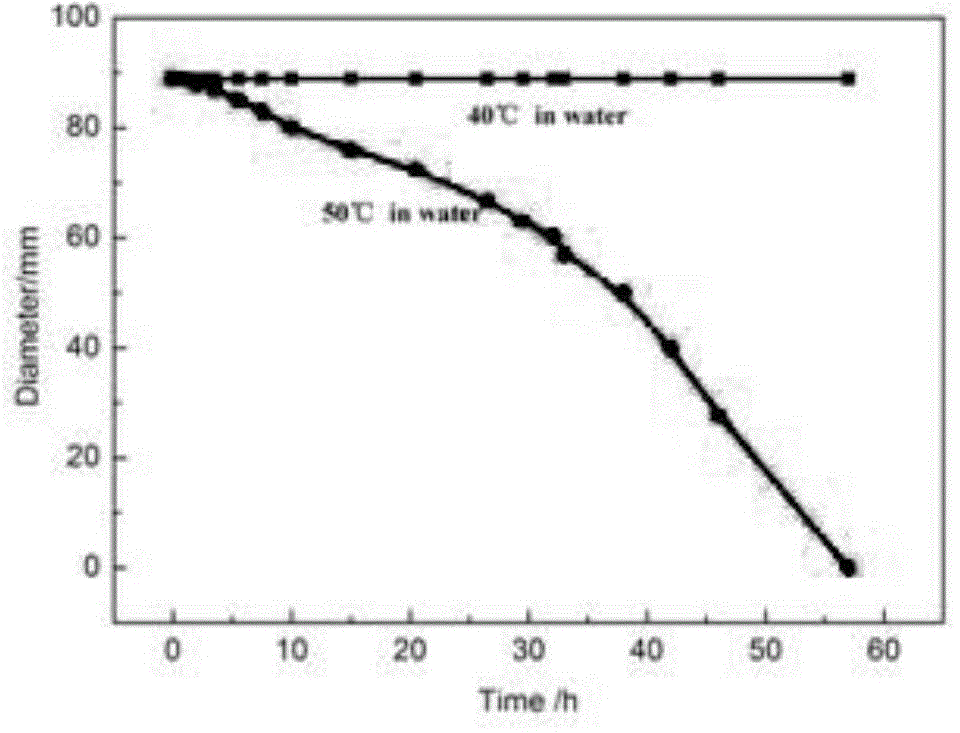

Water-solubility acidity temporary plugging agent for press cracking

The invention relates to a water-soluble fracturing-acidifying temporary-stopping agent, used in temporary- stopping bed of oil water well in the course of selecting fracturing and multi-crack fracturing. It is comprised of bone glue, sulfonated pitch and guargum in the weight ratio of 5.5-6.5 to 1.5-3.5 to 1-2. Its preparing method is taking a certain amount of water to heat and keep the temperature at 70-80 deg.C, adding in bone glue and stirring, dissolving; when the temperature is lowered to 40-50 deg.C, adding in sulfonated pitch and stirring uniformly; adding in guargum and strongly stirring uniformly; pouring into a special container, spreading out into an about 3mm-thick cake in shape, and naturally drying; crushing and then screening, and selecting the particles with 3-6 mm diameter as the finished product. It is fast to dissolve, low-cost and strongly-stopping.

Owner:北京卓辰基业技术开发有限公司

Unitary solid chlorine dioxide effervescent tablet and preparation method thereof

InactiveCN101228868AFast dissolutionImprove chemical yieldBiocideDisinfectantsEffervescent tabletChlorine dioxide

The invention discloses a one-variable solid effervescent tablet and a preparation method for the tablet. The material system of the effervescent tablet comprises chlorite, solid acid source, free halogen source, activated Promoter, desiccant, bond, release agent, effervescent and surfactant. The preparation technique includes: after the coating processing with chlorite grains, drying and mixing well with other raw materials according to a specific proportion and technique requirements to prepare compound raw materials, and then pressing into tablets with different specification and shaping on the tablet machine to fit for application in various occasions. The effervescent tablet can quickly release chlorine dioxide and acquire pellucid water solution of chlorine dioxide while dissolving in the water, which is high in stability, rapid in dissolving rapid and strong in bactericidal ability.

Owner:石家庄卫科生物科技有限公司

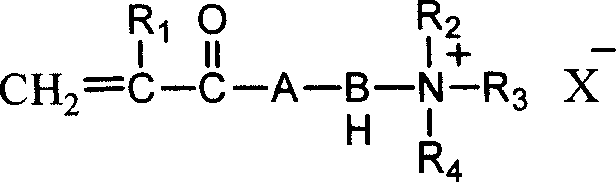

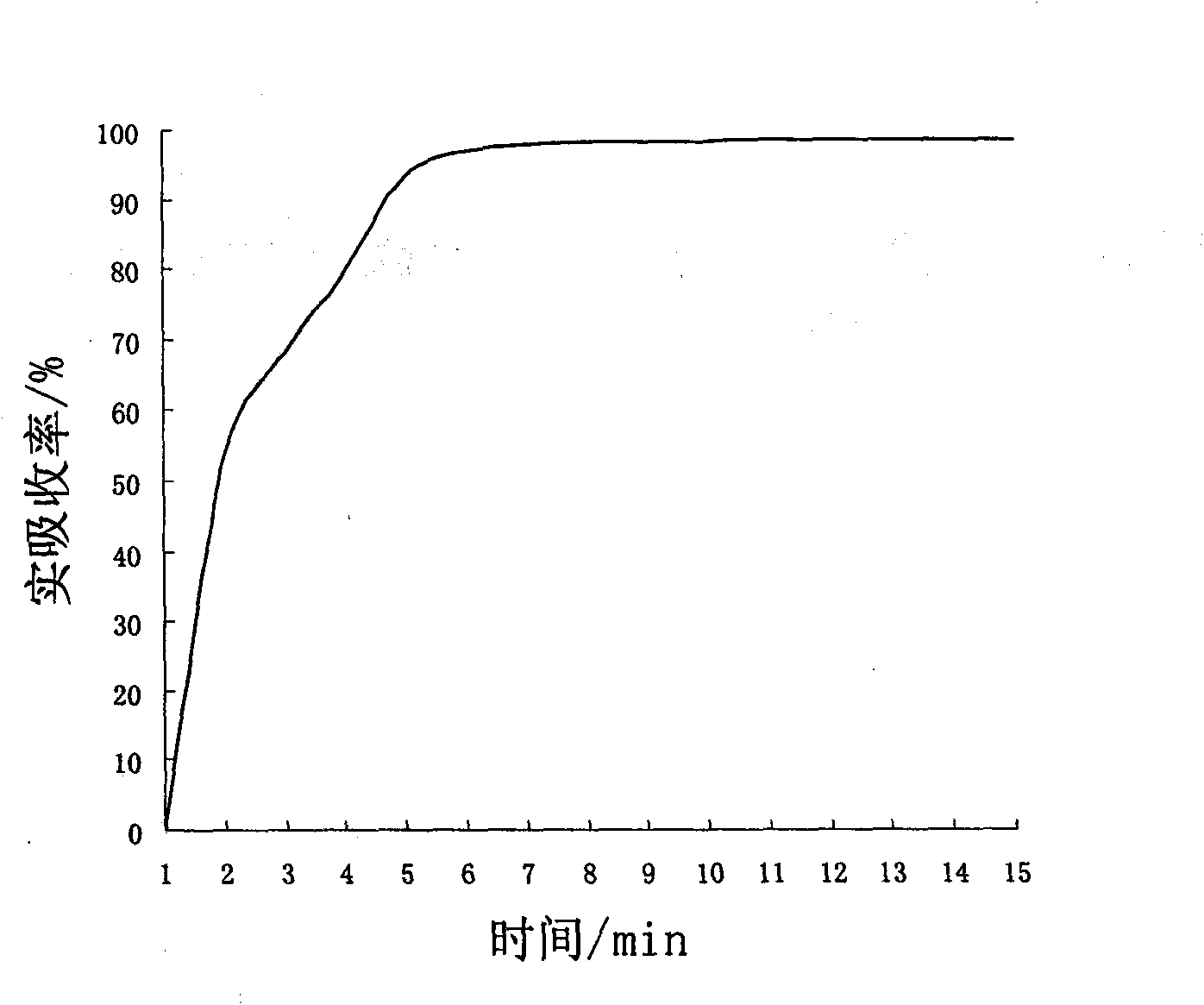

Method of synthesizing cation polyacrylamide water-in-water emulsion

The invention discloses a synthesizing method of cationic polyacrylamide 'water-in-water' emulsion, which is characterized by the following: adopting inorganic solution as dielectric with specific viscosity number is 30-90ml / g low-molecular cationic polymer solution as stabilizer; copolymerizing free radical of cationic monomer with double bond and non-ion monomer to form the product with grain size less than 1um; fitting for disposing urban effluent, oil-field effluent and paper-making domain.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

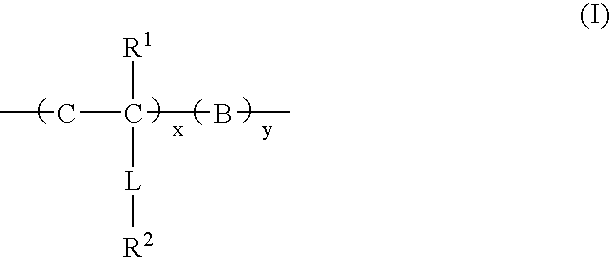

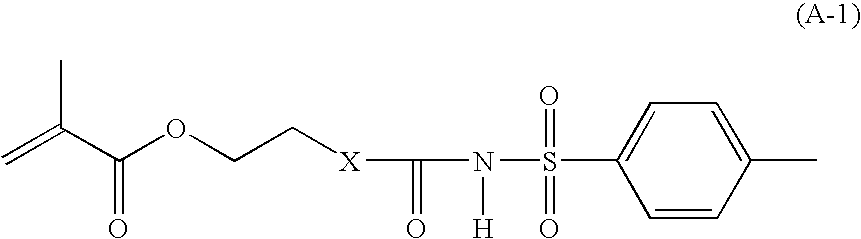

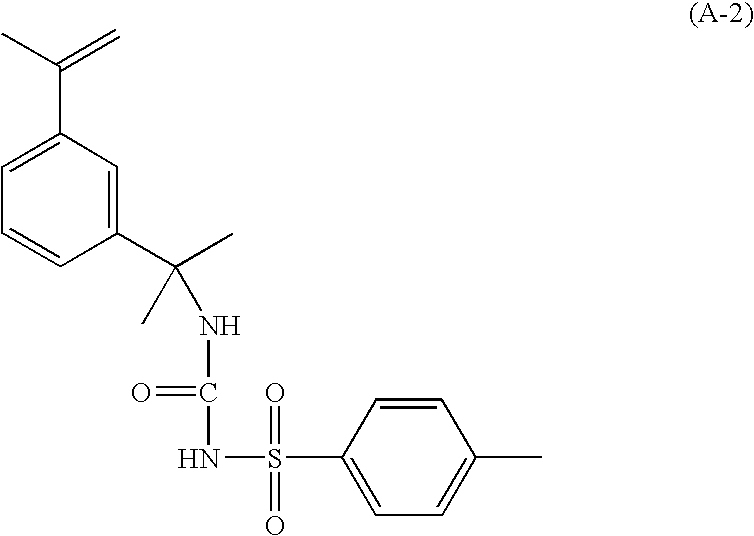

Multilayer imageable element containing sulfonamido resin

InactiveUS7163770B1Reduces sludge formationSlow down the dissolution ratePhotosensitive materialsRadiation applicationsHydrogenChemical compound

A positive-working imageable element comprises inner and outer layers and a radiation absorbing compound such as an IR absorbing dye. The inner layer includes a first polymeric material. The ink receptive outer layer includes a second polymeric binder comprising a polymer backbone and an —X—C(═T)—NR—S(═O)2— moiety that is attached to the polymer backbone, wherein —X— is an oxy or —NR′— group, T is O or S, R and R′ are independently hydrogen, halo, or an alkyl group having 1 to 6 carbon atoms. After thermal imaging, the element can be developed using an alkaline developer. Use of the particular second polymeric binder reduces sludging in the developer. Its dissolution rate in the developer is slow enough to resist developer attack in the non-imaged areas of the outer layer but rapid enough for the second polymeric binder to be quickly loosened from imaged areas and kept suspended or dissolved for a considerable time.

Owner:EASTMAN KODAK CO

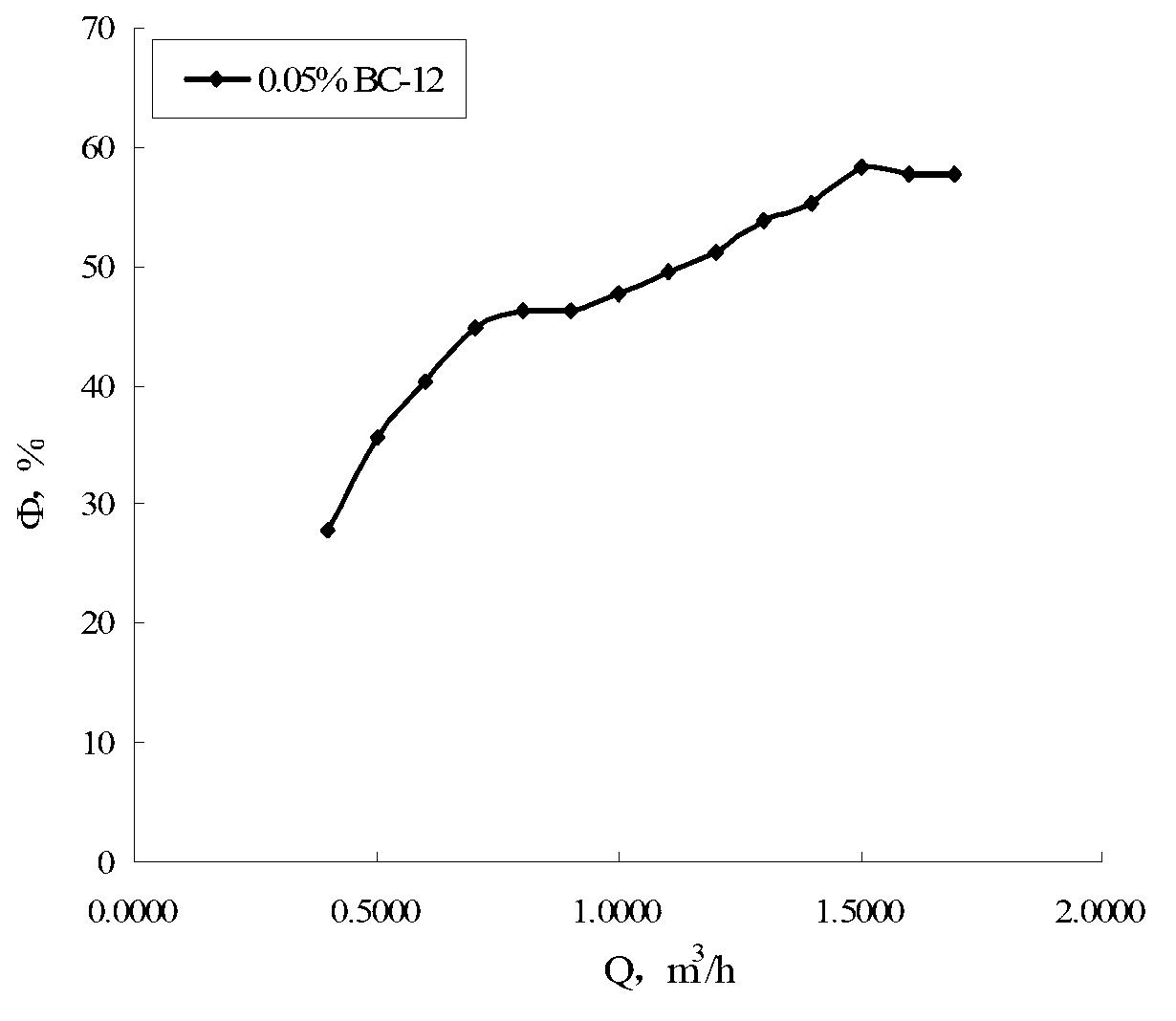

Slickwater fracturing fluid drag reducer and preparation method thereof

ActiveCN103013488AImprove stabilityReduce system complexity indexDrilling compositionFunctional monomerFracturing fluid

The invention discloses drag reducer which can be applied to slickwater fracturing fluid and a method for preparing drag reducer. The method includes: adding organic salt into acrylamide and functional monomer aqueous solution to prepare an aqueous phase, adding the aqueous phase into an oil phase system consisting of surfactant and base oil under the condition of high-speed stirring to form a stable W / O (water in oil) type microemulsion system, feeding nitrogen for dispersing oxygen, and adding initiator for polymerization to form a branchless long chain structure. The polymer microemulsion is a transparent or semitransparent thermodynamic stable system, can be quickly swelled into water and is directly usable. Adding a small quantity of the drag reducer during fluid transport can improve flow quantity and reduce energy consumption to some extent, and the drag reduction effect can reach 30%-65% when the drag reducer is compared with clear water. The drag reducer has the advantages of high stability, dissolving speed and dissolving performance, convenience in use, remarkable drag reduction effects and the like and is applicable to the slickwater fracturing technology, and excellent yield increasing effects are obtained after the drag reducer is applied to field fracturing operations.

Owner:CHENGDU BAICHUN PETROLEUM TECH +1

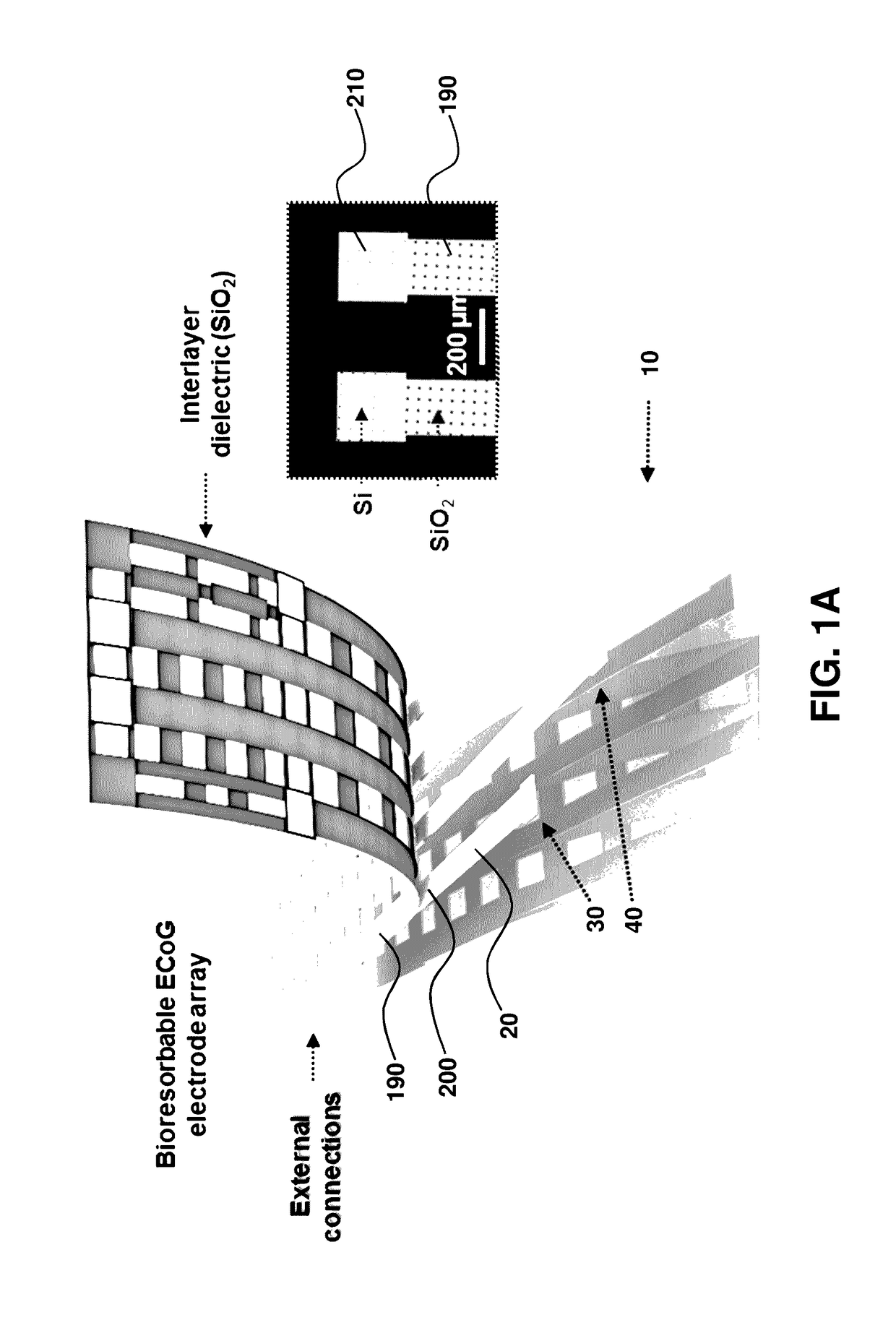

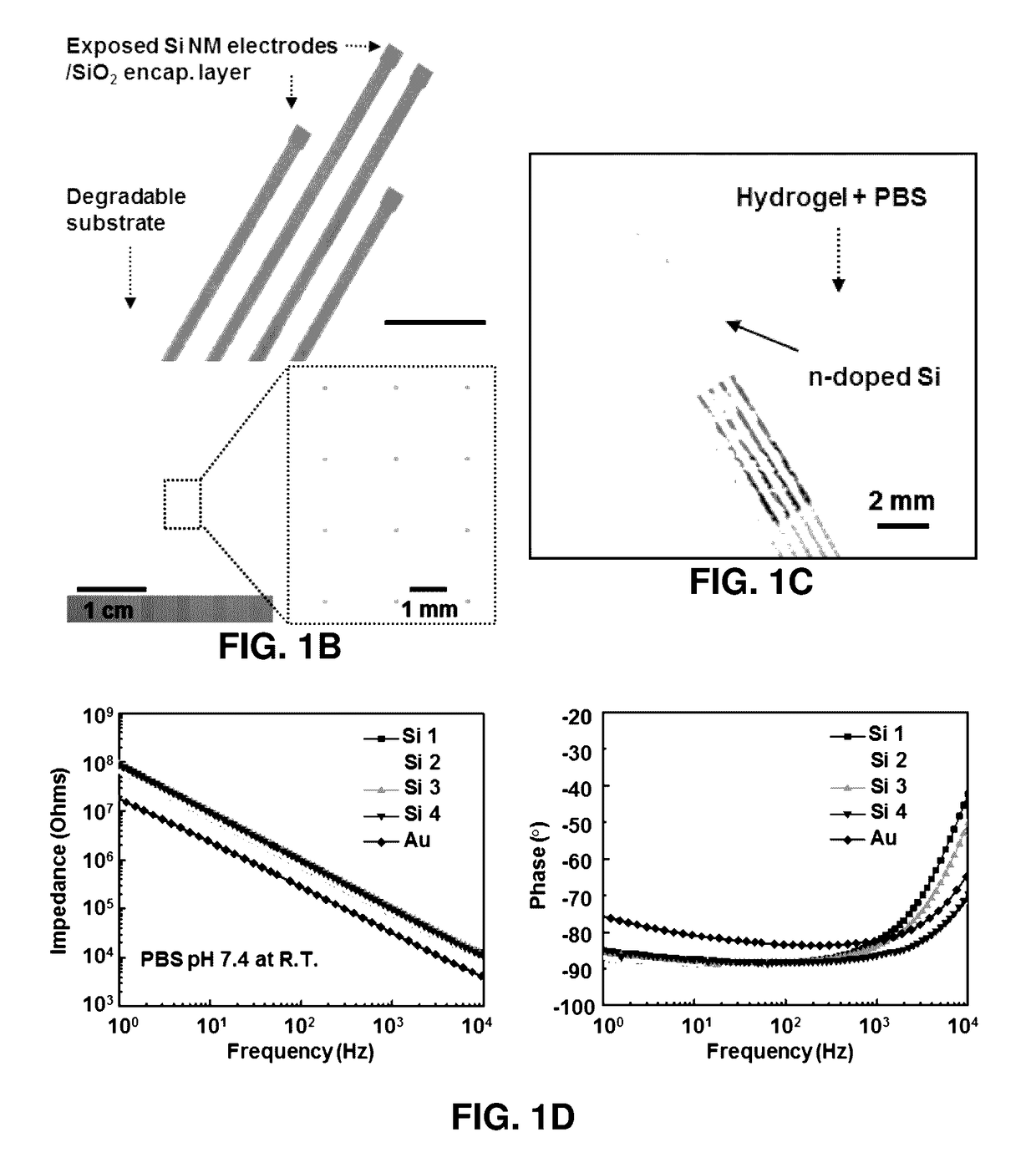

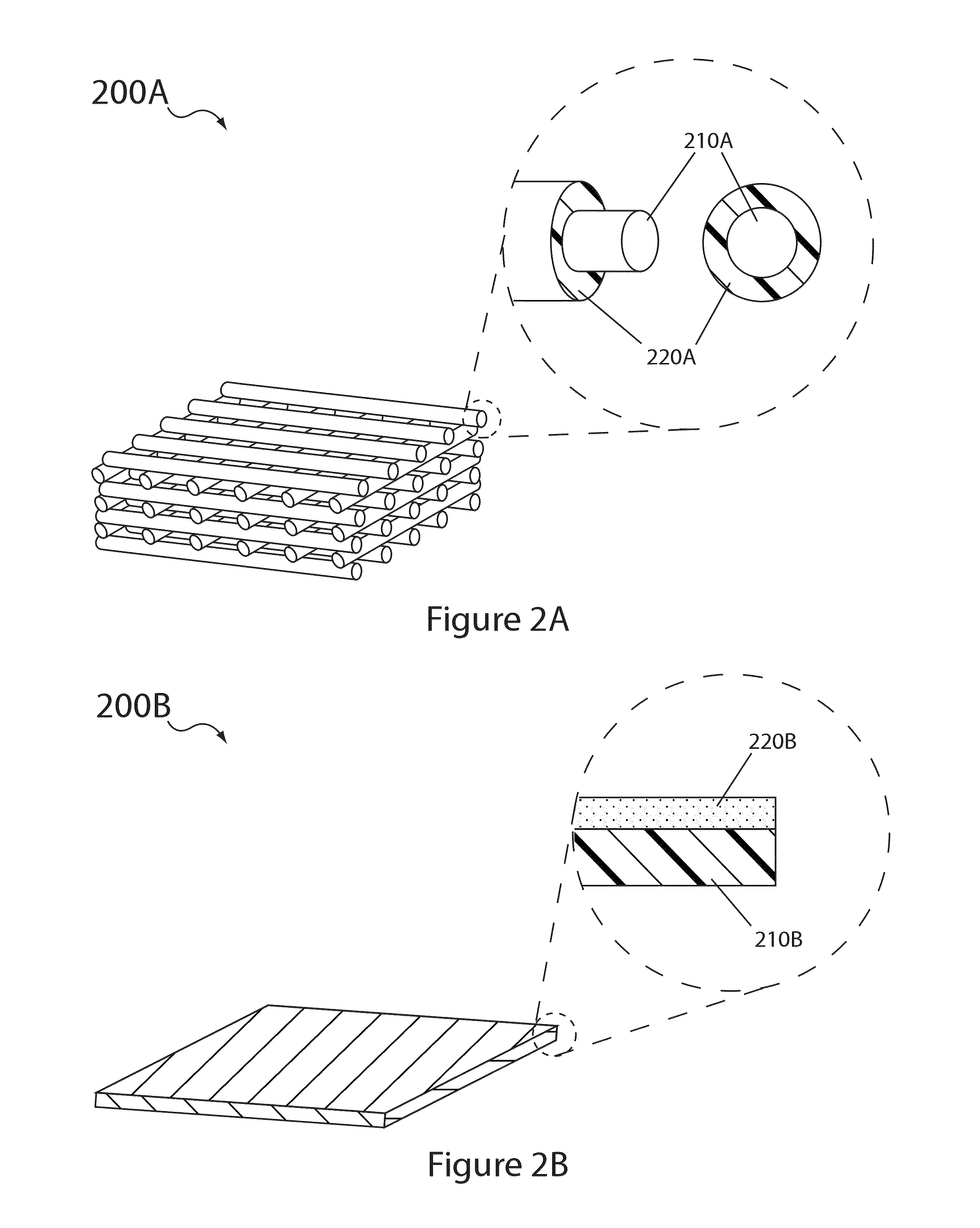

Bioresorbable Silicon Electronics for Transient Implants

ActiveUS20170128015A1Fast dissolution kineticsEasy to controlElectroencephalographyHead electrodesElectrode arrayMedical device

Provided are implantable and bioresorbable medical devices comprising a bioresorbable substrate and an electronic circuit supported by the bioresorbable substrate. The electronic circuit comprises a membrane of silicon having a thickness less than or equal to 5 μm and an array of dissolvable electrodes, wherein the dissolvable electrodes are formed from the membrane of silicon. The electronic circuit is configured to conformally contact a biological tissue and electrically interface with biological tissue during use. The silicon may be highly doped to provide the requisite characteristics for electrically interfacing with biological tissue, and may be further used to form other components of the electronic circuit, including back-plane transistors electrically connected to the electrode array.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

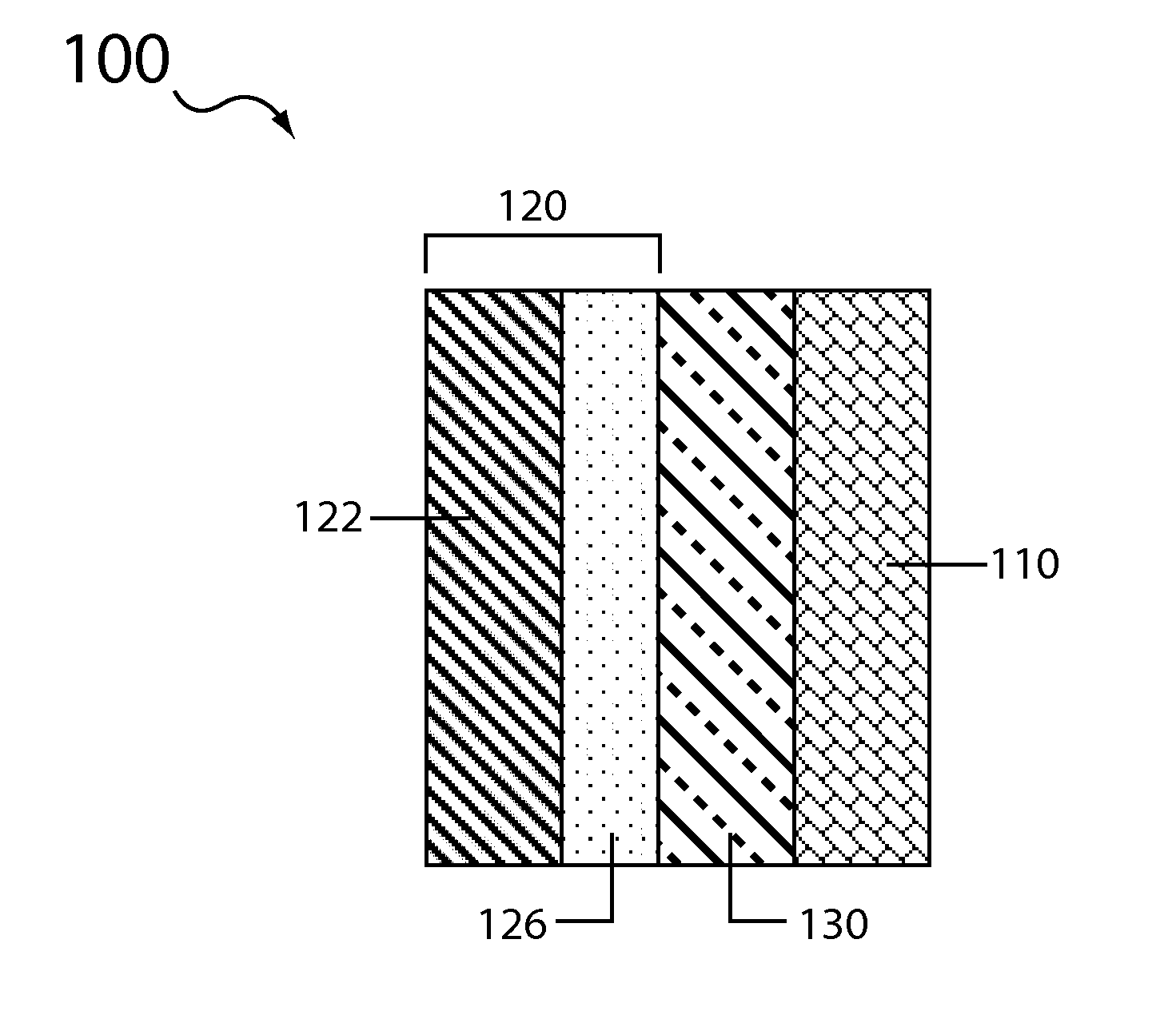

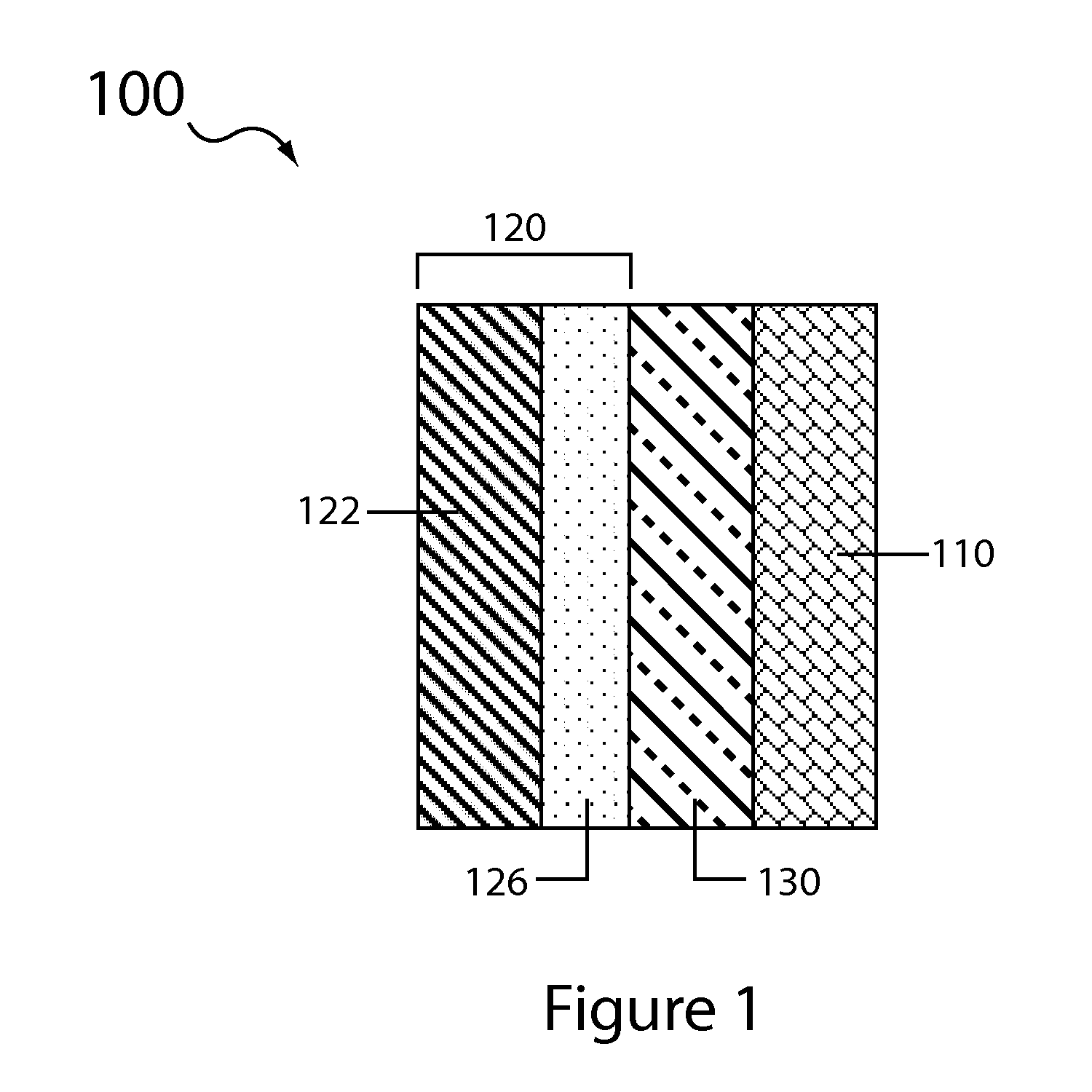

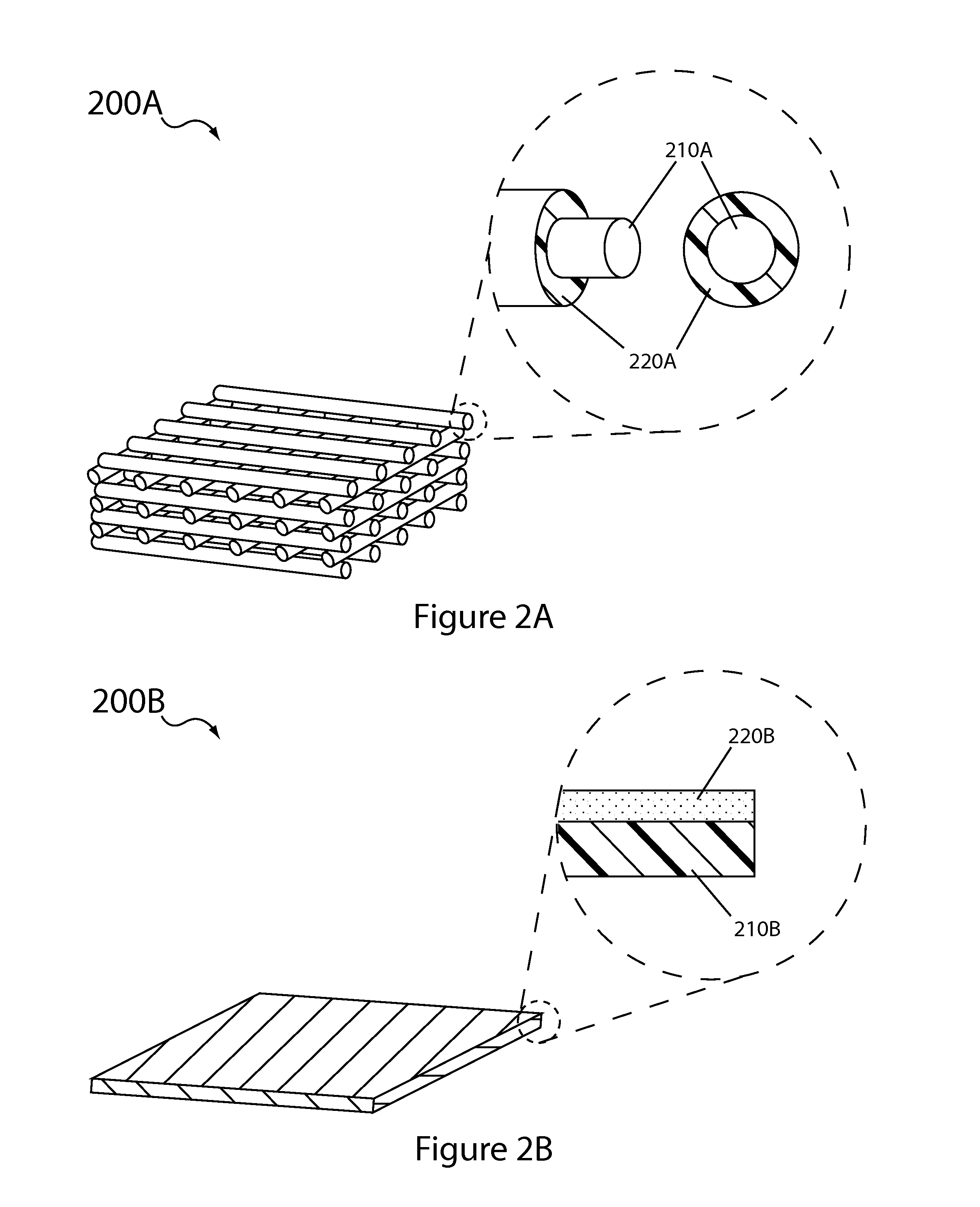

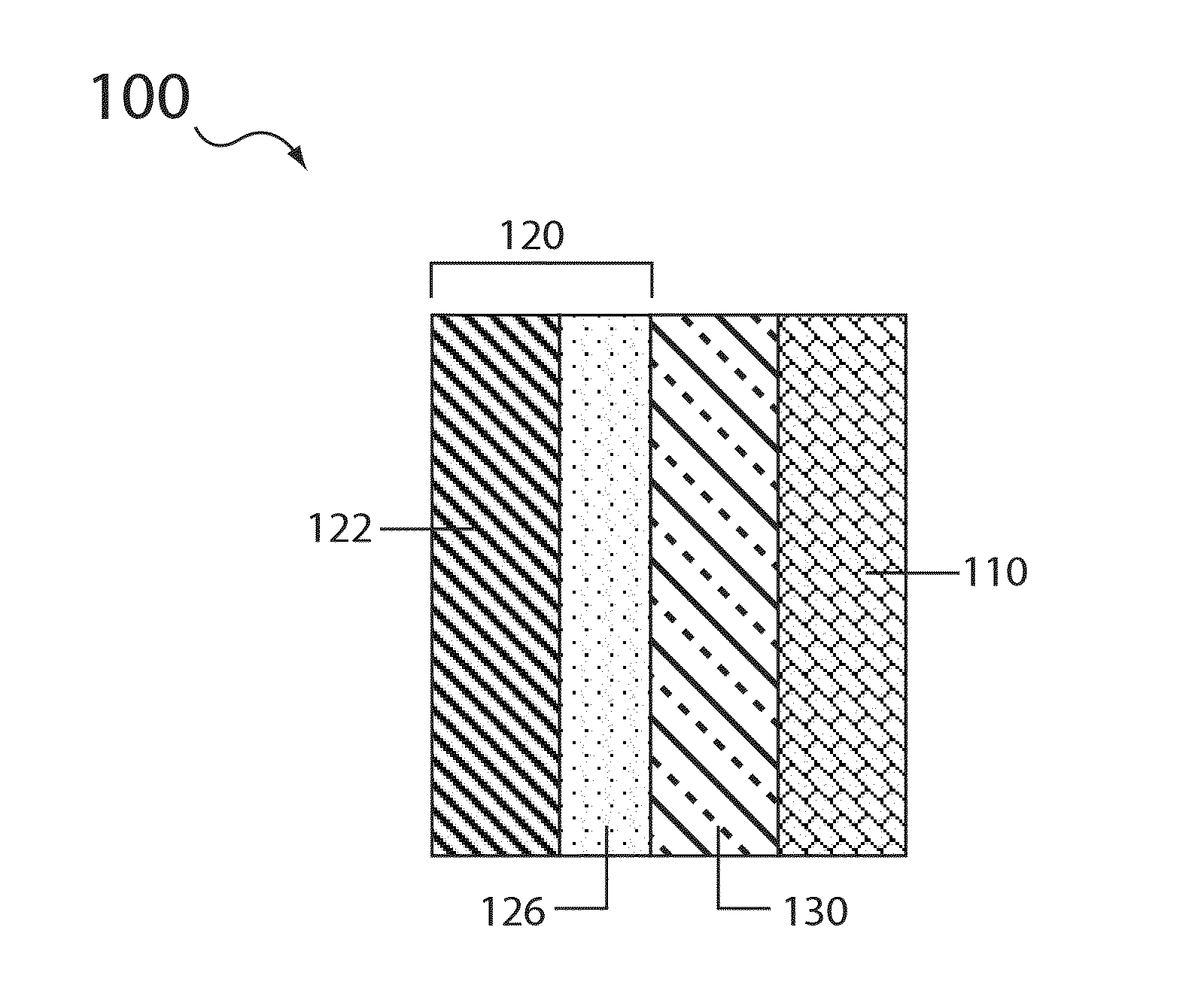

Aqueous electrolyte lithium sulfur batteries

InactiveUS20130141050A1Maintain cell integrityMaintain securityBatteries circuit arrangementsFuel and secondary cellsLithium sulfurAqueous electrolyte

Provided are lithium sulfur battery cells that use water as an electrolyte solvent. In various embodiments the water solvent enhances one or more of the following cell attributes: energy density, power density and cycle life. Significant cost reduction can also be realized by using an aqueous electrolyte in combination with a sulfur cathode. For instance, in applications where cost per Watt-Hour (Wh) is paramount, such as grid storage and traction applications, the use of an aqueous electrolyte in combination with inexpensive sulfur as the cathode active material can be a key enabler for the utility and automotive industries, providing a cost effective and compact solution for load leveling, electric vehicles and renewable energy storage.

Owner:POLYPLUS BATTERY CO INC

Electrolyte compositions for aqueous electrolyte lithium sulfur batteries

ActiveUS8828574B2Improve solubilityImprove ionic conductivityElectrode carriers/collectorsSolid electrolyte cellsLithium sulfurAqueous electrolyte

Provided are lithium sulfur battery cells that use water as an electrolyte solvent. In various embodiments the water solvent enhances one or more of the following cell attributes: energy density, power density and cycle life. Significant cost reduction can also be realized by using an aqueous electrolyte in combination with a sulfur cathode. For instance, in applications where cost per Watt-Hour (Wh) is paramount, such as grid storage and traction applications, the use of an aqueous electrolyte in combination with inexpensive sulfur as the cathode active material can be a key enabler for the utility and automotive industries, providing a cost effective and compact solution for load leveling, electric vehicles and renewable energy storage.

Owner:POLYPLUS BATTERY CO INC

Preparation of high molecular weight instant cation polyacrylamide

The invention relates to a preparation method for instant cation polyacrylamide with a high molecular weight. The monomer of acrylamide and a cation type monomer are used as the main materials, firstly, the acrylamide and a comonomer are dissolved into deionized water; then a photoinitiator and / or a photosensitizer additive and a redox initiator are added in the solution to form a compound initiating system; the materials of the components are uniformly mixed in a viscous state, poured on a plane and paved into a sheet shape, introduced with high purity nitrogen, then ultraviolet light illumination is carried out to the materials paved into the sheet shape; after the materials of the viscous state are in a gel block, the materials are dried, broken, granulated and cracked to obtain a product of a dry powder shape. In the invention, the heat release and temperature rising of bulk adiabatic polymerization are avoided, while the polymerization and drying are carried out under a lower temperature; therefore, the reaction process is stable; the product has the advantages of higher molecular weight, better solubility, faster dissolving speed, simple technique and low cost; in addition, the processing after polymerization reduces the working procedure of breaking of bulk gel.

Owner:朱定洋

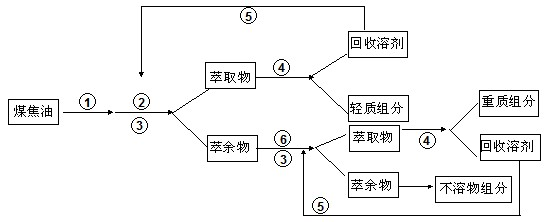

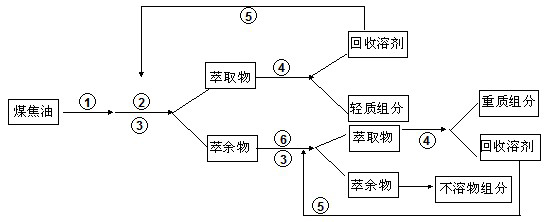

Extracting and separating method of high-temperature coal tar

InactiveCN102492451AHigh purityEfficient separationTar working-up by solvent extractionTime rangeDistillation

An extracting and separating method of high-temperature coal tar belongs to a coal tar separation method. The extracting and separating method includes the step of adding No.1 or No.2 solvent into the coal tar at the ordinary pressure for secondary extraction and separation. Extraction processes are carried out under the pretreatment condition of sufficiently mixing and heating, heating temperature is lower than 150 DEG C, raw materials of the coal tar are respectively mixed with the No.1 or No.2 solvent according to the volume proportion of 1:2 to 4, extraction time ranges from 1 to four hours, extracts and raffinate are obtained after the No.1 solvent and the coal tar are filtered and separated when the system is balanced, and the No.1 solvent is recovered by distillation and recycled. The extracting and separating method has the advantages that energy saving effect of equipment is evident, process is simple and convenient, operation conditions are moderate, manufacturing cost and investment of the equipment are low and benefits are evident. Adding quantity of the solvent and extraction operation parameters are changed, separation depth and process capacity of the coal tar can be flexibly mastered and selectively controlled.

Owner:CHINA UNIV OF MINING & TECH

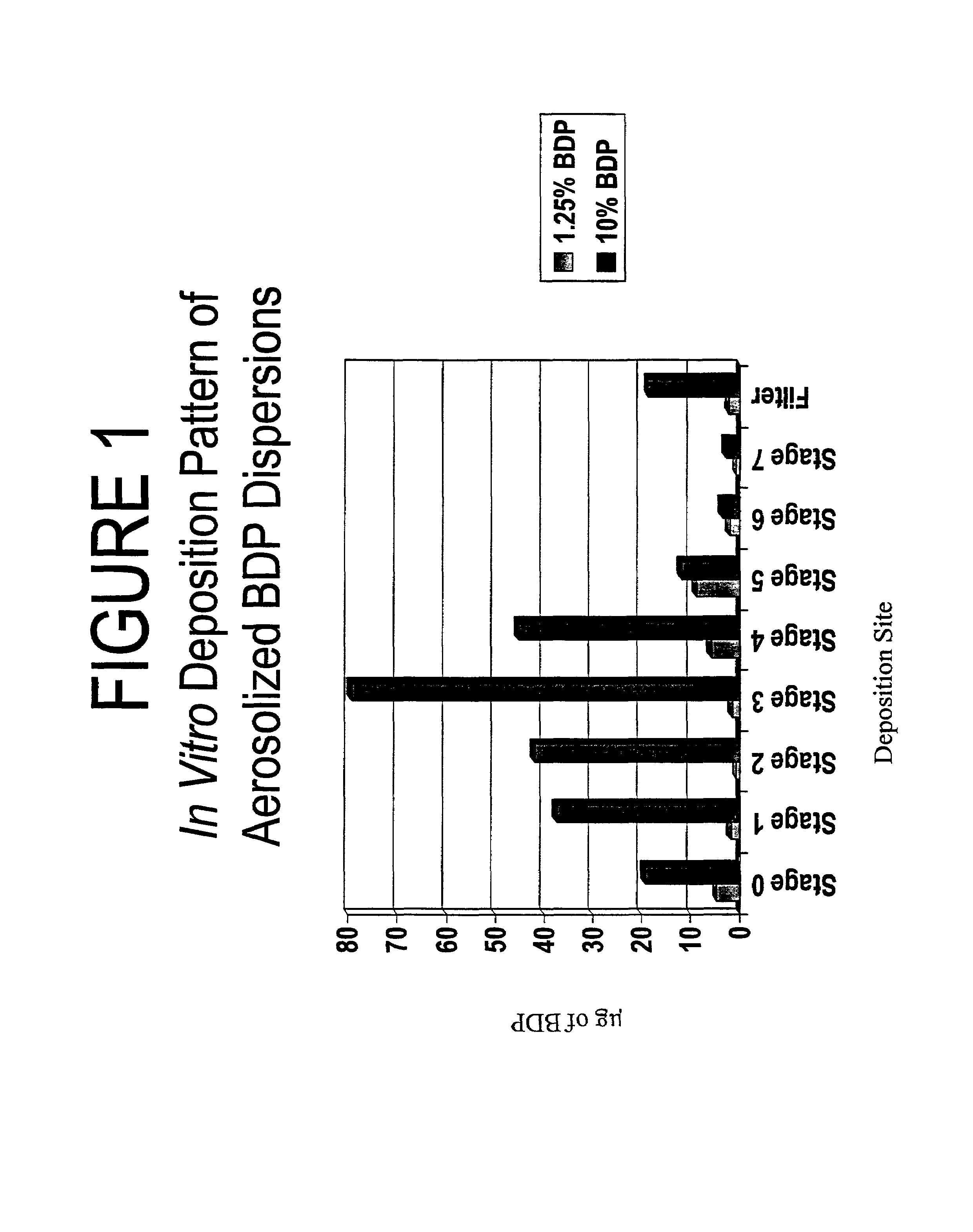

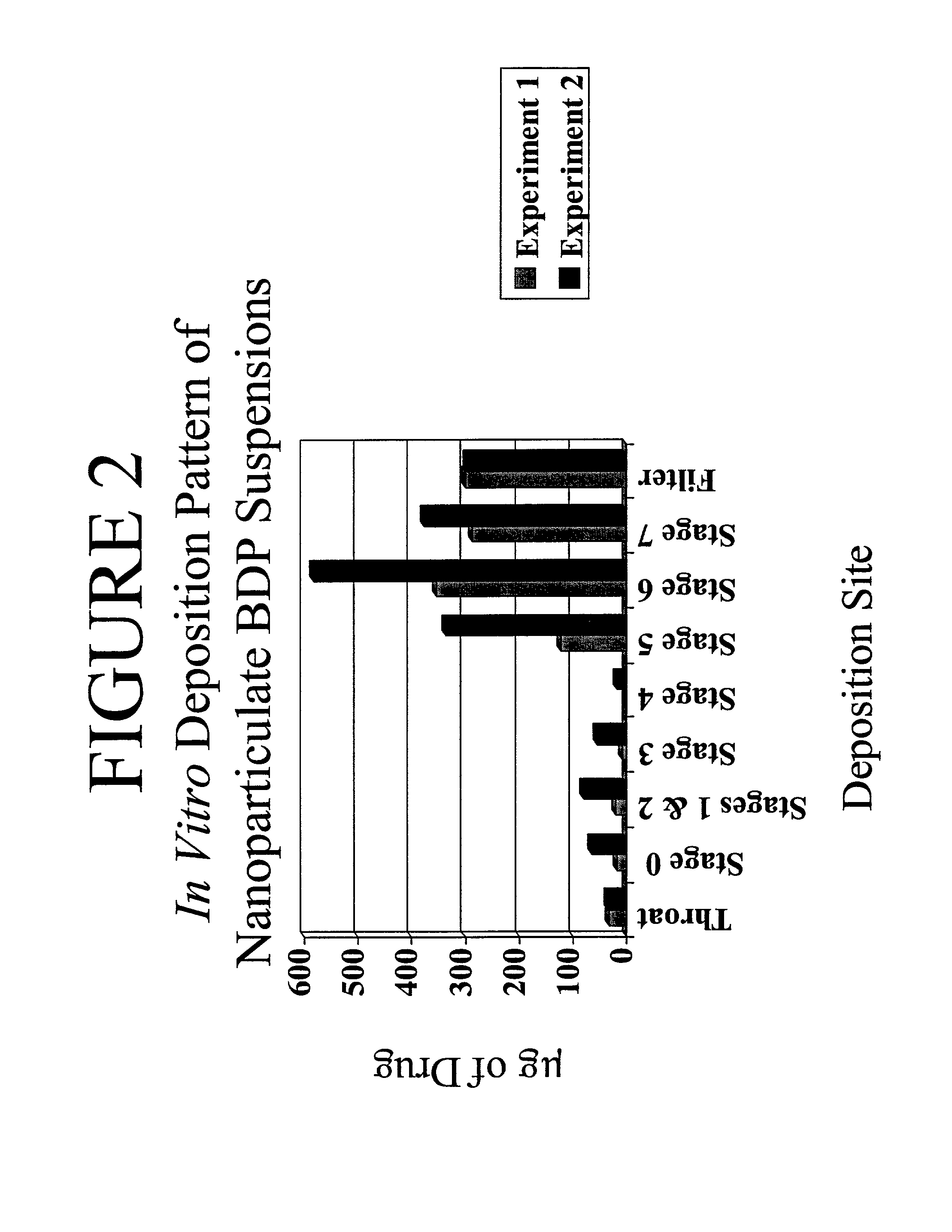

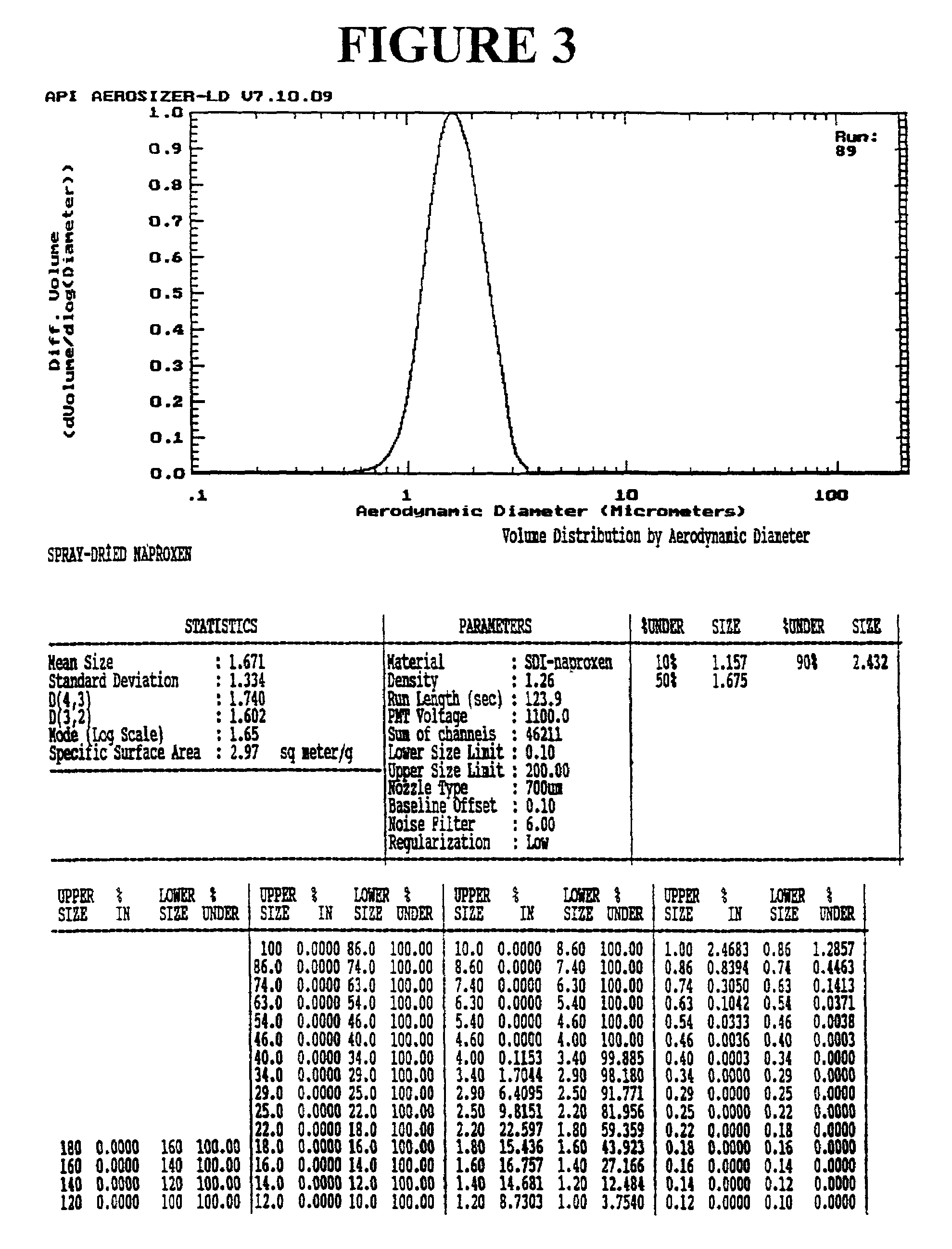

Dry powder aerosols of nanoparticulate drugs

InactiveUS7521068B2Permit deliveryEasy to atomizeAntibacterial agentsOrganic active ingredientsNanoparticleAerosol delivery

There invention discloses aqueous dispersions of nanoparticulate aerosol formulations, dry powder nanoparticulate aerosol formulation, propellant-based aerosol formulations, methods of using the formulations in aerosol delivery devices, and methods of making such formulations. The nanoparticles of the aqueous dispersions or dry powder formulations comprise insoluble drug particles having a surface modifier on the surface thereof.

Owner:ALKERMES PHARMA IRELAND LTD

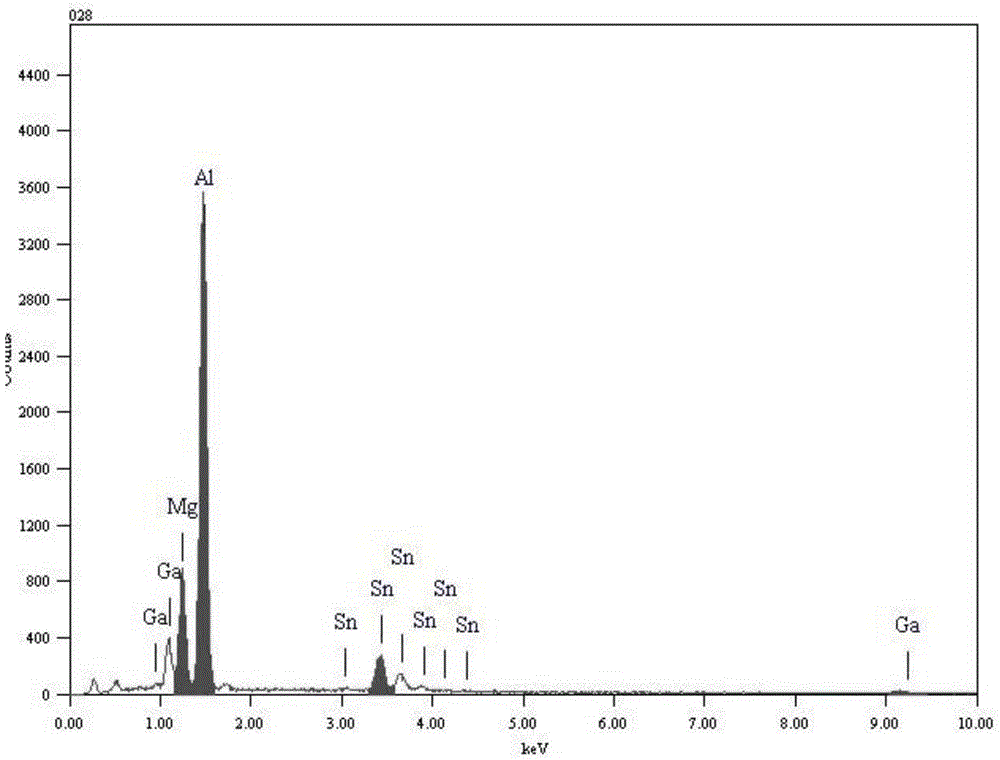

Preparation method of high-strength dissolublealuminum alloy material

A preparation method of a high-strength dissolublealuminum alloy material comprises high-temperature firing, stirring at the mass ratio, deslagging, cooling and thermal treatment. A high-strength aluminum alloypreparation principle and an electrochemical corrosion principle are combined, the product composition stability is successfully controlled, the Al-based alloy material with dissolubility, high strength, good shock resistance, high-temperature resistance, high-pressure resistance, high probability of processing, higher thermodynamic property and excellent dissolving property is prepared, and the overall performance of the material is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of water-in-water cationic polyacylamide emulsion

The invention relates to a synthetic method of water-in-water cationic polyacylamide emulsion. The synthetic method is characterized by mixing inorganic salt, non-ionic hydrophilic monomers, anionic monomers, hydrophobic monomers, functional monomers having surface activity, a stabilizing agent, a chelating agent and deionized water, adjusting the pH value to be between 6.5 and 7.5, uniformly emulsifying the mixture by an emulsifying machine, introducing nitrogen for protection, adding an evocating agent at twice at the temperature of 18 to 50 DEG C, carrying out second polymerization reactionfor 1 to 3 hours after 4 to 7 hours of the time of first polymerization reaction and making the emulsion product.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Medicinal preparation containing 5-methyl-1-phenyl-2-(1h)-pyridone as active ingredient

ActiveUS20040048902A1Oral convenienceImprove complianceBiocideOrganic chemistryBULK ACTIVE INGREDIENTTraditional medicine

A tablet characterized by comprising 5-methyl-1-phenyl-2-(1H)-pyridone as the main ingredient and, based on the main ingredient, 10 to 50 wt. % excipient, 5 to 40 wt. % disintegrator, 1 to 10 wt. % binder, 0.5 to 5 wt. % lubricant, 2 to 6 wt. % coating basis, and 0.05 to 3 wt. % light-shielding agent, wherein the odor or bitterness of the 5-methyl-1-phenyl-2-(1H)-pyridone is masked and the light stability is improved.

Owner:INTERMUNE INC

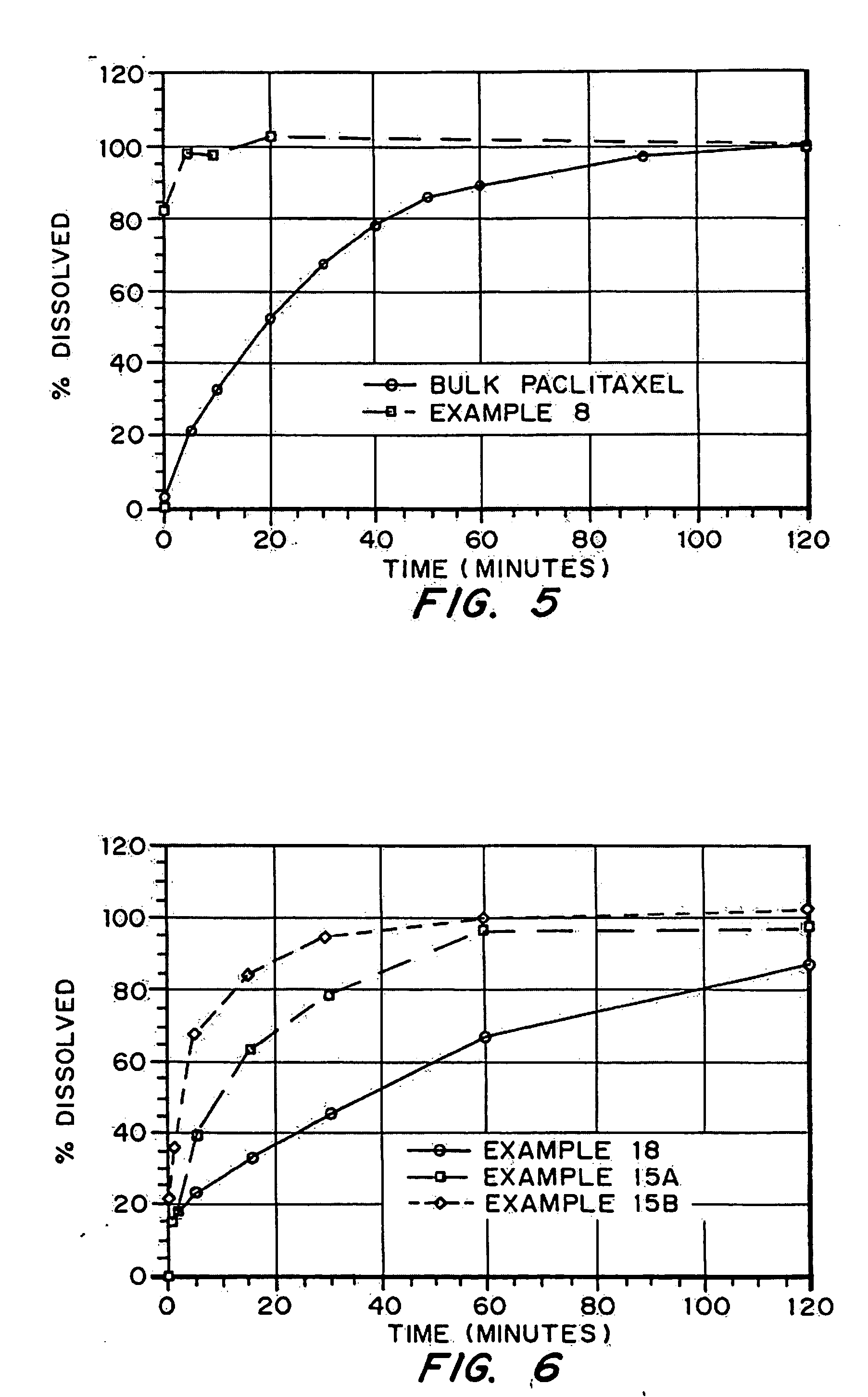

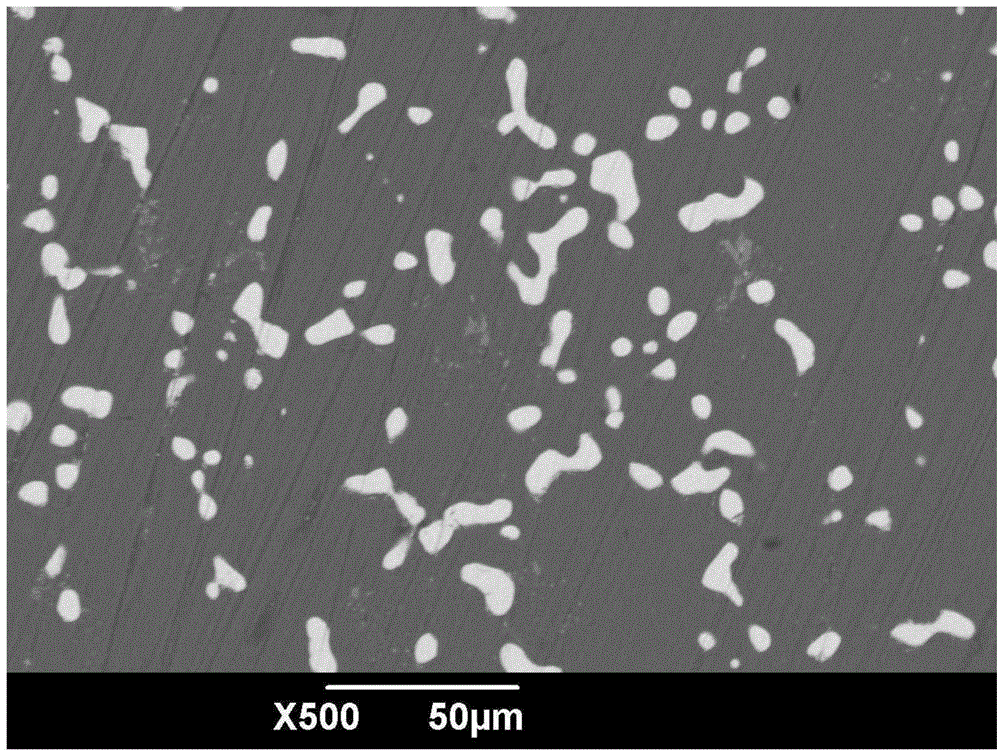

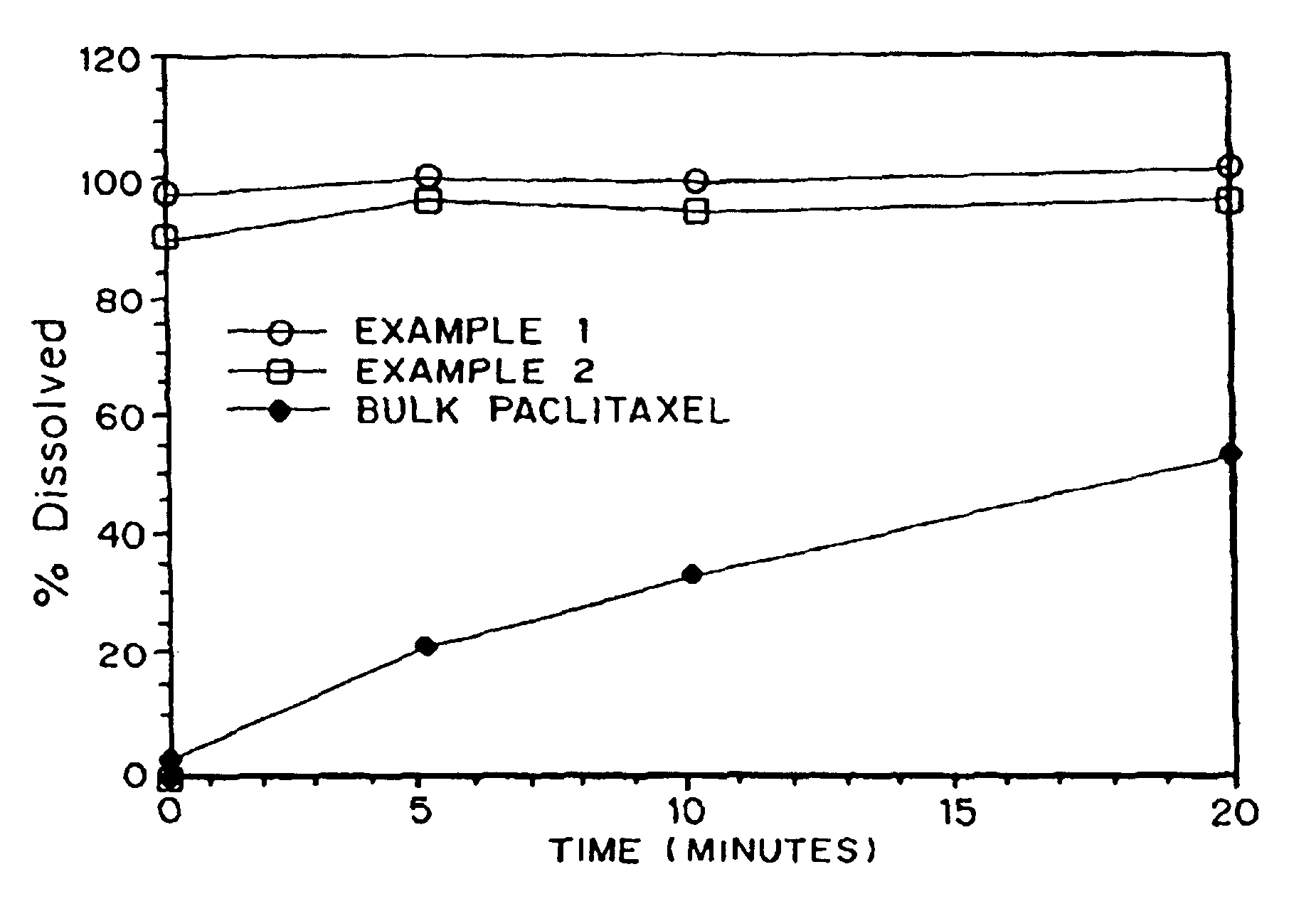

Porous paclitaxel matrices and methods of manufacture thereof

InactiveUSRE40493E1Fast dissolutionLower the volumeBiocideOrganic active ingredientsCaplet Dosage FormEngineering

Paclitaxel is provided in a porous matrix form, which allows the drug to be formulated without Cremophor and administered as a bolus. The paclitaxel matrices preferably are made using a process that includes (i) dissolving paclitaxel in a volatile solvent to form a paclitaxel solution, (ii) combining at least one pore forming agent with the paclitaxel solution to form an emulsion, suspension, or second solution, and (iii) removing the volatile solvent and pore forming agent from the emulsion, suspension, or second solution to yield the porous matrix of paclitaxel. The pore forming agent can be either a volatile liquid that is immiscible with the paclitaxel solvent or a volatile solid compound, preferably a volatile salt. In a preferred embodiment, spray drying is used to remove the solvents and the pore forming agent. In a preferred embodiment, microparticles of the porous paclitaxel matrix are reconstituted with an aqueous medium and administered parenterally, or processed using standard techniques into tablets or capsules for oral administration.

Owner:ACUSPHERE INC

Additive for smelting aluminium alloy and preparation method and application method thereof

The invention relates to an additive for smelting aluminium alloy and a preparation method and an application method thereof, relating to the technical field of nonferrous alloy manufacturing with a special additive. The additive is composed of metal powder, cosolvent, heat-generating agent, detonating agent and moisture proof agent. The preparation method comprises the following steps: raw materials comprising the following by mass percentage, 70-81.5% of metal powder, 15-20% of cosolvent, 2-5% of heat-generating agent, 1-3% of detonating agent and 0.5-2% of moisture proof agent, are fully mixed evenly into compound powder with a ball mill, and the mixture is put into a mould, and is performed with cold pressing by a hydraulic pressure machine so as to obtain the additive for smelting aluminium alloy. The application method of the invention comprises the following steps: a graphite crucible filled with a pure aluminium pig is arranged in a resistance furnace to be heated until the aluminium pig is melted into aluminium liquid, and then the additive is added to react with the aluminium liquid so as to obtain aluminium alloy. Under the condition that the quality of aluminium alloy is not lowered, the additive solves the problems of high dissolving temperature, low absorptivity and unstable absorptivity of the additive.

Owner:HEBEI UNIV OF TECH

Shale gas reservoir pre-fracture composite acid solution, preparation method and application thereof

InactiveCN105086989APrevent collapseCore dissolution rate maintenanceDrilling compositionAcetic acidHydrofluoric acid

The invention belongs to the field of petroleum engineering and relates to a shale gas reservoir pre-fracture composite acid solution and its preparation method and application. The composite acid solution comprises the following components: Component a) at least one component of hydrochloric acid, hydrofluoric acid, fluorboric acid, phosphoric acid, formic acid and acetic acid; and Component b) a corrosion inhibitor, a discharge aiding agent, a ferric iron stabilizer and a clay stabilizer. The composite acid solution containing different acids is selected for different reservoirs. Rock core corrosion ratio is 25-30%. A certain rock core corrosion ratio is maintained, and borehole wall collapse caused by too high corrosion ratio is also prevented. The corrosion inhibitor, the discharge aiding agent, the ferric iron stabilizer and the clay stabilizer which are used as additives have good compatibility with acid. The composite acid solution provided by the invention has advantages of fast dissolving speed, uniform mixing, high corrosion inhibition efficiency, high surface activity, good clay stabilizing effect and wide range. Applicable temperature of the composite acid solution is 20-180 DEG C. by the use of the composite acid solution, normal construction of large-scale fracturing of long horizontal-section shale gas wells can be guaranteed under the condition of existing equipment capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

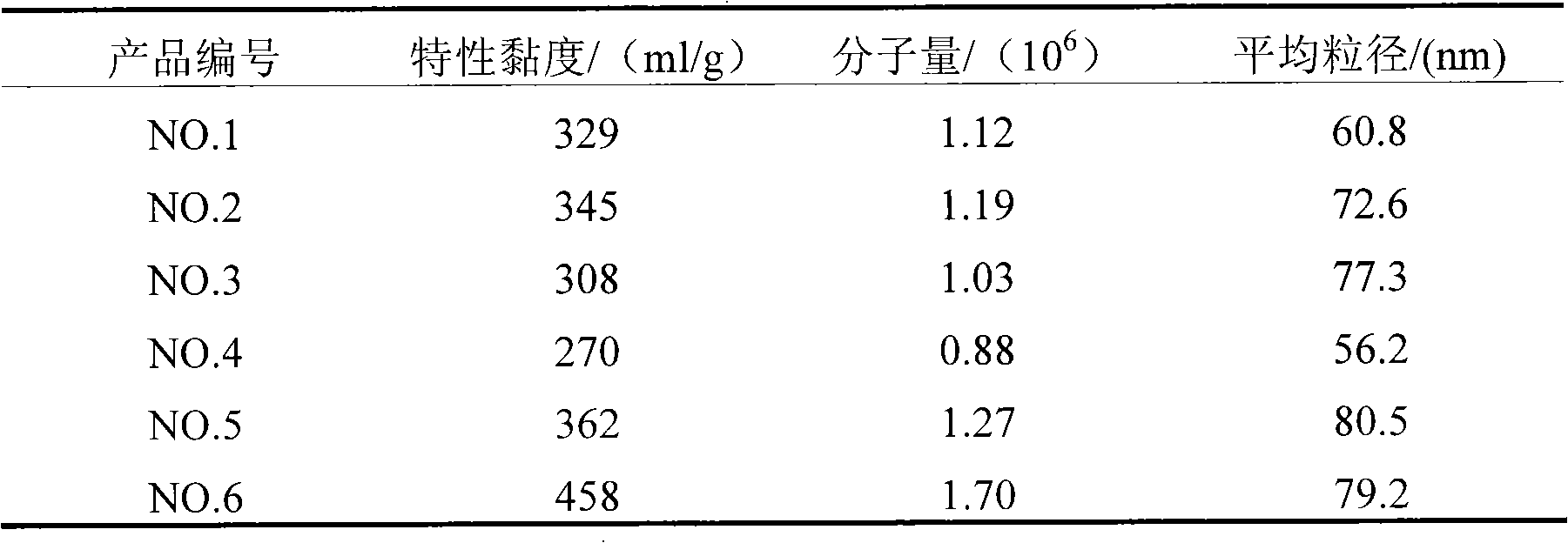

Preparation of cationic polyacrylamide reverse microemulsion

InactiveCN101298488AFast aggregationPolymerization temperature is easy to controlChemical industryIndustrial water treatment

The invention relates to a preparation method for cationic-type polyacrylamide reverse micro emulsion. The appearance of the micro emulsion is transparent or translucent low-viscosity micro latex and the mean particle diameter is 50 to 80 nm. The micro emulsion can be placed for a long time without delaminating. After routine extraction with alcohol and acetone, the micro emulsion becomes white powdered solids with the intrinsic viscosity of 200-600 ml / g. The preparation method is to take acrylamide and diallyl dimethyl ammonium chloride as comonomer, apply compounded emulsifying agent and redox initiation system, add sodium formate as reagent and additive in polymerization, and then apply the method of stepwise polymerization to the reverse micro emulsion polymerization. The cationic-type polyacrylamide of the invention has the advantages of moderate molecular weight, stable emulsion, rapid dissolution and narrow particle size distribution, thus being able to be widely applied to fields such as oil exploitation, paper making, textile dying, daily chemical industry and industrial water treatment.

Owner:SHANDONG UNIV

Preparation method of amphoteric polyacrylamide dispersion liquid

The invention discloses a preparation method of amphoteric polyacrylamide dispersion liquid. The preparation method comprises the following steps: putting a main functional monomer into a mixed system comprising an amphoteric dispersion stabilizer, a chelating agent, a pH regulator and inorganic salt deionized water solution; initiating a reaction by virtue of an initiating agent; and preparing the amphoteric polyacrylamide dispersion liquid by virtue of a dispersion polymerization method. The dispersion liquid prepared by adopting a novel amphoteric polymer dispersion stabilizer has the characteristics of good stability, high molecular weight, high dissolution rate and the like, and a synthetic process of the dispersion liquid is environment-friendly and pollution-free and is low in energy consumption, and the product is nontoxic and noncorrosive, cannot generate secondary pollution and accords with the development direction of green and environment-friendly chemical assistants. The amphoteric polyacrylamide dispersion liquid has an application prospect in the fields of water treatment, papermaking, printing and dyeing, oil fields, mining, daily chemicals and the like.

Owner:JIANGSU FEYMER TECH

Lansoprazole orally disintegrating tablets

InactiveUS20070141151A1Dissolve fastPrevent degradationBiocidePill deliveryLansoprazoleOrally disintegrating tablet

The invention provides orally disintegrating tablets that readily disintegrates in the mouth, releasing enteric coated drug sub-tablets.

Owner:TEVA PHARM USA INC

Additive for strengthening wet flue gas desulfurization technology

InactiveCN102580514AImprove qualityAchieve reuseCalcium/strontium/barium sulfatesDispersed particle separationOrganic acidAdipic acid

The invention belongs to the technical field of a limestone / gypsum wet flue gas desulfurization technology, and particularly relates to an additive for strengthening a wet flue gas desulfurization technology, which comprises the following components in percentage by mass: 35-45% of mixed organic acid, 5-10% of organic acid salt, 6-9% of surfactant, 1-6% of heavy metal salt and 35-45% of dirt dispersion agent; and the mixed organic acid comprises adipic acid, wherein the percentage of mass of the adipic acid in the mixed organic acid is not less than 50%. The additive can be added and used for strengthening the wet flue gas desulfurization technology, improve the desulfurization efficiency of a system, reduce the energy consumption, strengthen oxidization, improve the limestone quality and restrain system scaling, and accordingly, the purposes of energy conservation, consumption reduction and waste recycling are realized.

Owner:SCI GREEN SHANDONG ENVIRONMENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com