Preparation method of high-strength dissolublealuminum alloy material

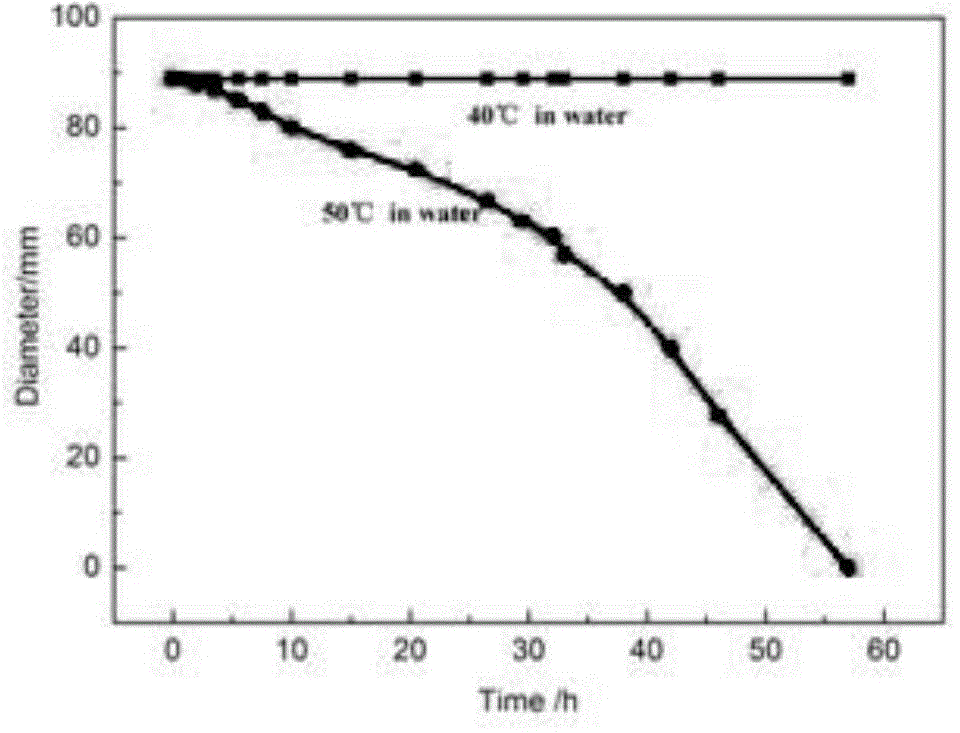

An aluminum alloy material and high-strength technology, applied in the field of preparation of high-strength soluble aluminum alloy materials, can solve problems such as lack of product components, difficult control of sintering temperature, complicated production process, etc., to achieve improved solubility, fast dissolution speed, and The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1, high temperature burning

[0026] Put the aluminum ingot into the melting furnace and raise the temperature to 760°C to melt it into molten aluminum;

[0027] Step 2, mass ratio stirring

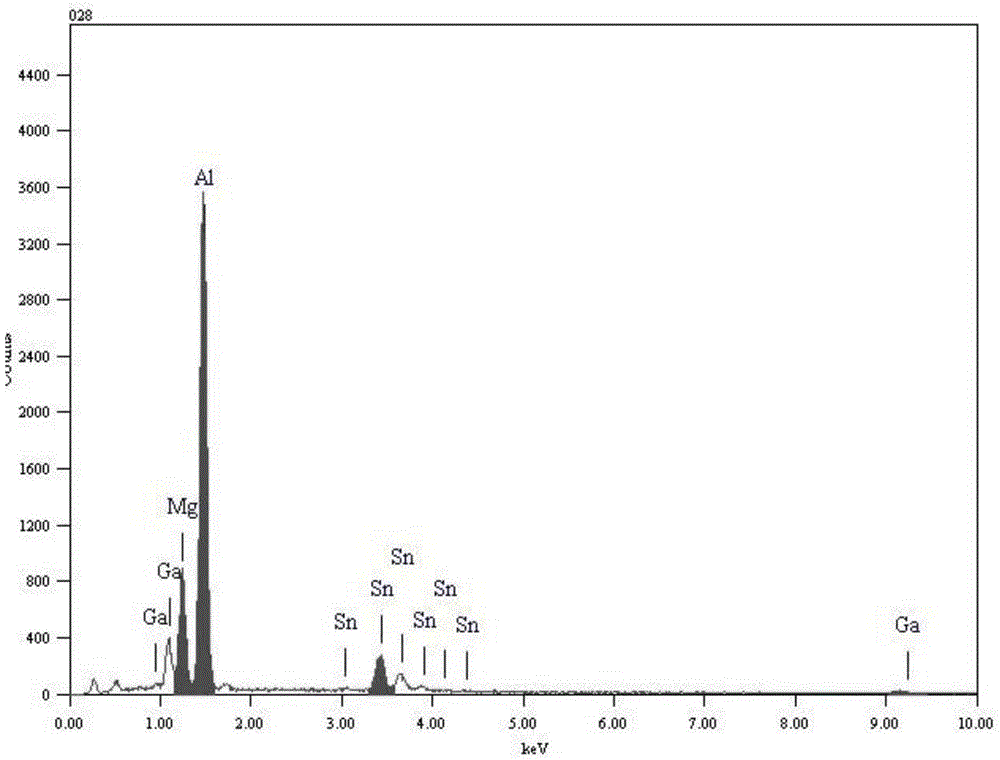

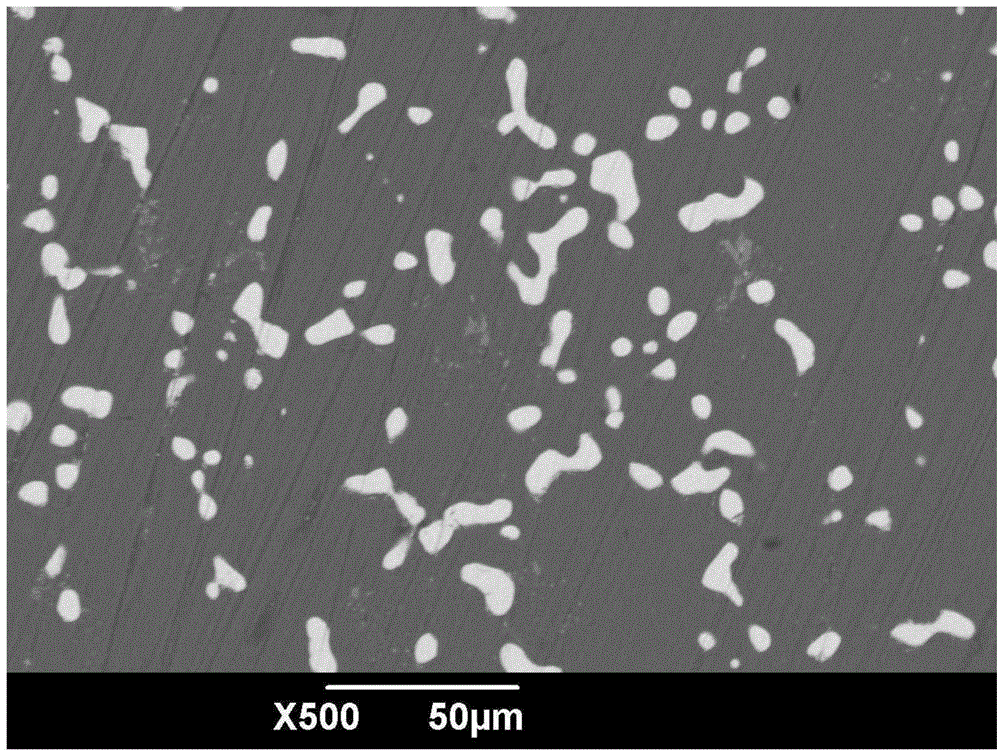

[0028] The aluminum liquid obtained in step 1 is weighed according to the formula and the mass percentage is Al: 71.0%, Sn: 12.0%, Si: 2.0%, Mn: 1.0%, Mg: 4.0%, Ga: 8.0%, In: 0.5%, Zn: 1.5%, fully stirred, and kept at 760°C for 0.5 hours to make it a macroscopically uniform melt;

[0029] Step 3, slag removal and cooling

[0030] Add 0.2%wt defoamer to the melt obtained in step 2 to remove slag, and pour it into a preheated mold; after cooling the obtained casting to room temperature, perform heat treatment in a muffle furnace at 350°C for 2 hours , to produce high-strength soluble aluminum alloy materials.

Embodiment 2

[0032] Step 1, high temperature burning

[0033] Put the aluminum ingot into the melting furnace and raise the temperature to 710°C to melt it into molten aluminum;

[0034] Step 2, mass ratio stirring

[0035] The aluminum liquid obtained in step 1 is weighed according to the formula and the mass percentage is Al: 62.0%, Sn:

[0036] 17.5%, Si: 2.0%, Mn: 1.5%, Mg: 4.0%, Ga: 11.0%, In: 1.0%, Zn: 1.0%, fully stirred, and kept at 710°C for 2 hours to make it macroscopically uniform The nature of the melt;

[0037] Step 3, slag removal and cooling

[0038] Add 0.5%wt defoamer to the melt obtained in step 2 and carry out the slag removal process, and pour it into a preheated mold; after cooling the obtained casting to room temperature, heat treatment is carried out in a muffle furnace at 350°C, and the heat treatment time is For 2h, a high-strength dissolvable aluminum alloy material is obtained.

Embodiment 3

[0040] Step 1, high temperature burning

[0041] Put the aluminum ingot into the melting furnace and raise the temperature to 760°C to melt it into molten aluminum;

[0042] Step 2, mass ratio stirring

[0043] The aluminum liquid obtained in step 1 is weighed according to the formula and the mass percentage is Al: 90.0%, Sn: 8.0%, Si: 0.1%, Mn: 0.2%, Mg: 1.0%, Ga: 0.1%, In: 0.3%, Zn: 0.3%, fully stirred, and kept at 760°C for 0.5 hours to make it a macroscopically uniform melt;

[0044] Step 3, slag removal and cooling

[0045] Add 0.2%wt defoamer to the melt obtained in step 2 and carry out the slag removal process, and pour it into a preheated mold; after cooling the obtained casting to room temperature, heat treatment is carried out in a muffle furnace at 350°C, and the heat treatment time is For 2h, a high-strength dissolvable aluminum alloy material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com