Extracting and separating method of high-temperature coal tar

A high-temperature coal tar and separation method technology, which is applied in tar processing, tar processing through selective solvent extraction, petroleum industry, etc., can solve the problems of coal tar separation and utilization rate limitation, waste of energy, large investment, etc. And the effect of remarkable energy saving of equipment, low equipment investment and short payback period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

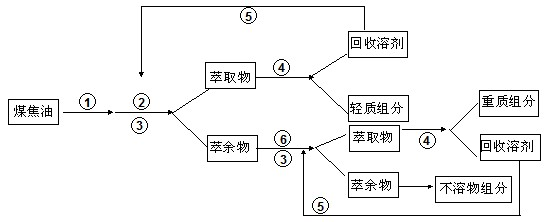

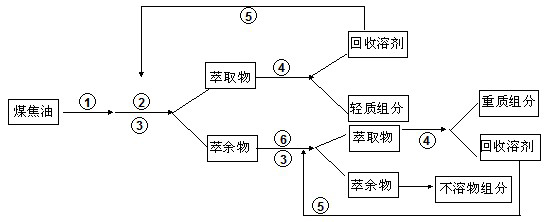

Image

Examples

Embodiment 1

[0024] Example 1: After fully stirring and heating at 50-60 degrees, the raw material of coal tar and the mixed solvent of petroleum ether and light oil of equal volume were mixed and extracted for 4 hours according to the volume ratio of 1:2. After the system reached equilibrium, the equal volume of petroleum ether and The mixed solvent of light oil and the light components of coal tar are in the upper layer, and the heavy pitch components in the raw coal tar are in the lower layer. The extract and raffinate are separated by filtration, and the extract is distilled to recover an equal volume of petroleum ether and light oil mixed solvent for recycling. The extract is rich in coal tar light components; the raffinate contains coal powder, coal tar heavy asphalt of QI insoluble matter of coke powder.

[0025] After fully stirring and heating at 80-90 degrees, the raffinate of the above-mentioned coal tar mixed solvent and the mixed solvent of equal volume carbon disulfide and ac...

Embodiment 2

[0026] Example 2: After fully stirring and heating at 70-80 degrees, the raw material of coal tar and the mixed solvent of 3 parts of n-hexane and 1 part of naphthalene oil were mixed and extracted for 2 hours according to the volume ratio of 1:4. After the system reached equilibrium, n-hexane and naphthalene oil The mixed solvent and the light components of coal tar are in the upper layer, and the heavy pitch components in the raw coal tar are in the lower layer. The extract and raffinate are separated by filtration, the extract is distilled and the mixed solvent of n-hexane and naphthalene oil is recovered and recycled. The extract is rich in coal tar light components; the raffinate contains coal powder, coal tar heavy asphalt of QI insoluble matter of coke powder.

[0027] After fully stirring and heating at 90-100 degrees, the raffinate of the above-mentioned coal tar mixed solvent and the mixed solvent of 3 parts of toluene and 1 part of tetrahydrofuran were mixed and ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com