Full-automatic gold stamping machine

A fully automatic hot stamping machine and frame technology, which is applied to printing machines, rotary printing machines, general parts of printing machinery, etc., can solve the problems of low production efficiency, unstable quality, expensive hot stamping plates, etc., and achieve full surface, peeling off, etc. High strength and excellent adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

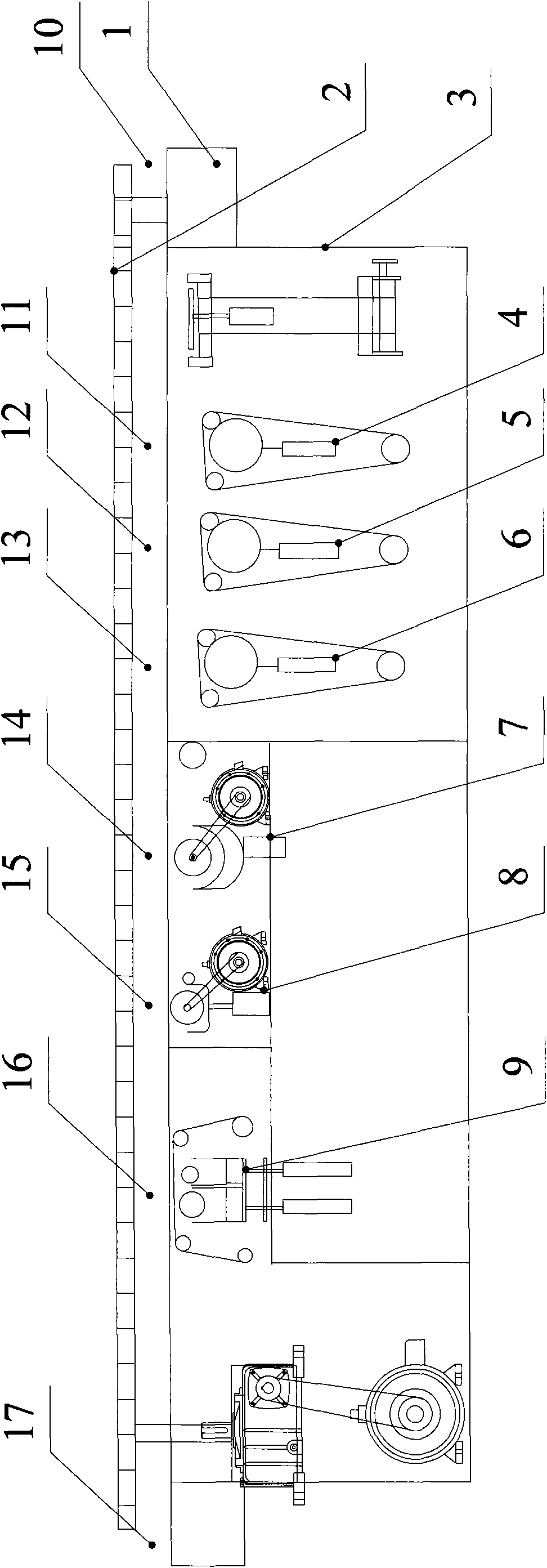

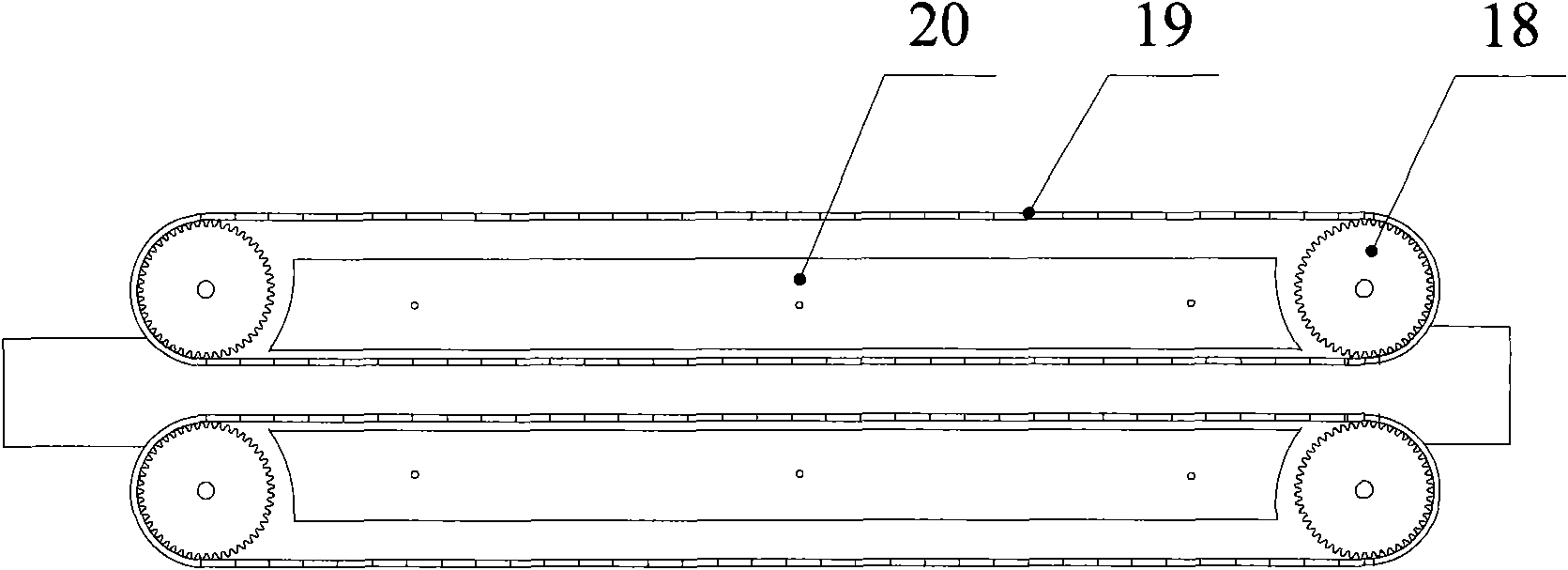

[0052] Such as figure 1 , figure 2 As shown, the fully automatic hot stamping machine includes a console, a frame 3, a worktable 1 is provided on the frame 3, and a chain drive 2 for clamping and conveying paper, the chain drive 2 Set above the worktable 1, the chain transmission device 2 is composed of two groups of leaf chain devices arranged in parallel, a transmission channel is formed between the two groups of leaf chain devices, and the leaf chain devices are fixed on the frame The sprocket 18 on the end, the plate chain 19 that is wound on the sprocket 18 and the guide rail 20 that is arranged on the plate chain 19 inner sides form. The transmission channel is located between the chain transmission device 2 and the worktable 1 , one end of the transmission channel is provided with a paper entry station 10 , and the other end of the transmission channel is provided with a paper exit station 17 .

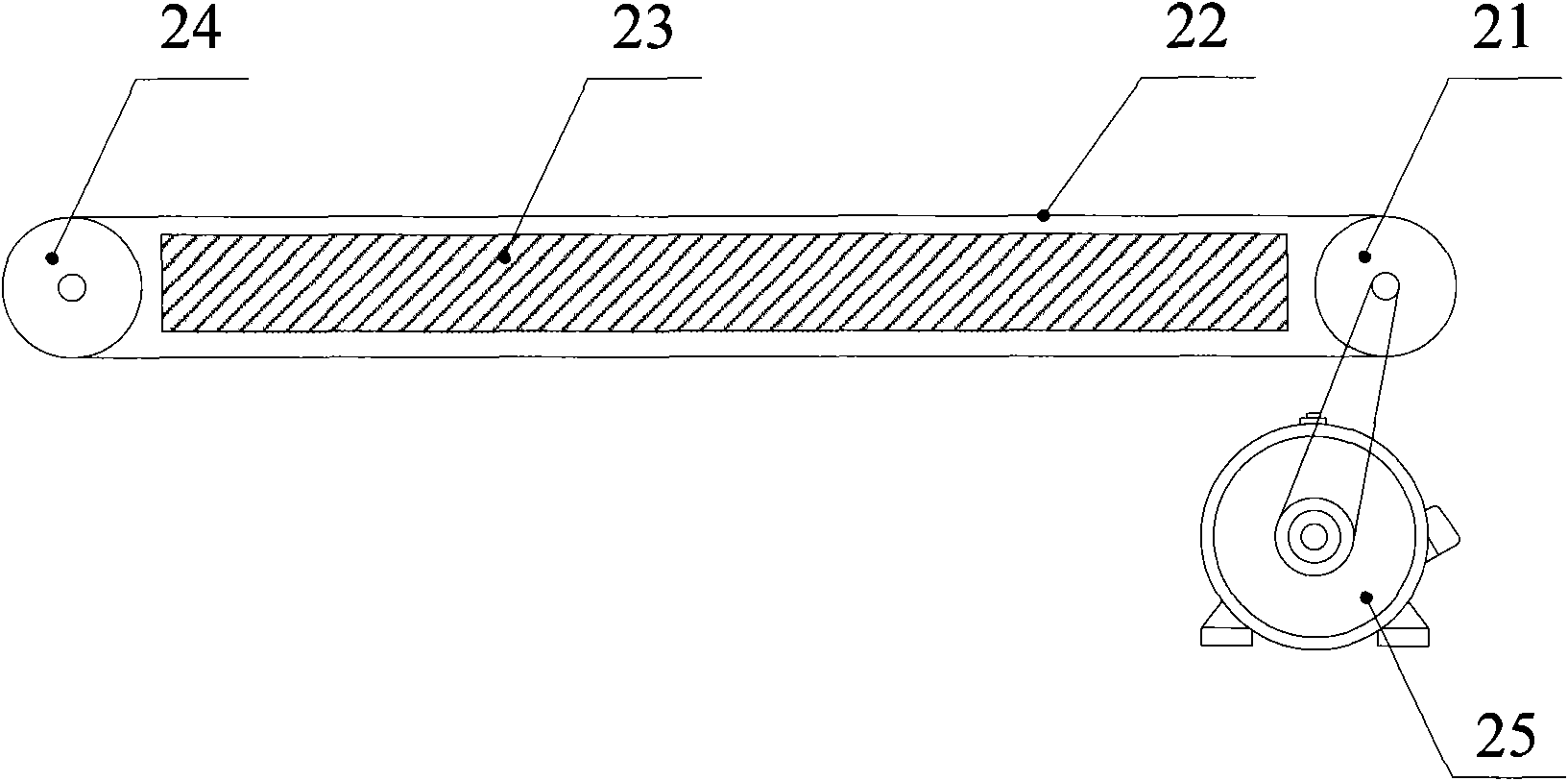

[0053] Such as Figure 4 , Figure 5 As shown, a grinding device is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com