Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Improve tackiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

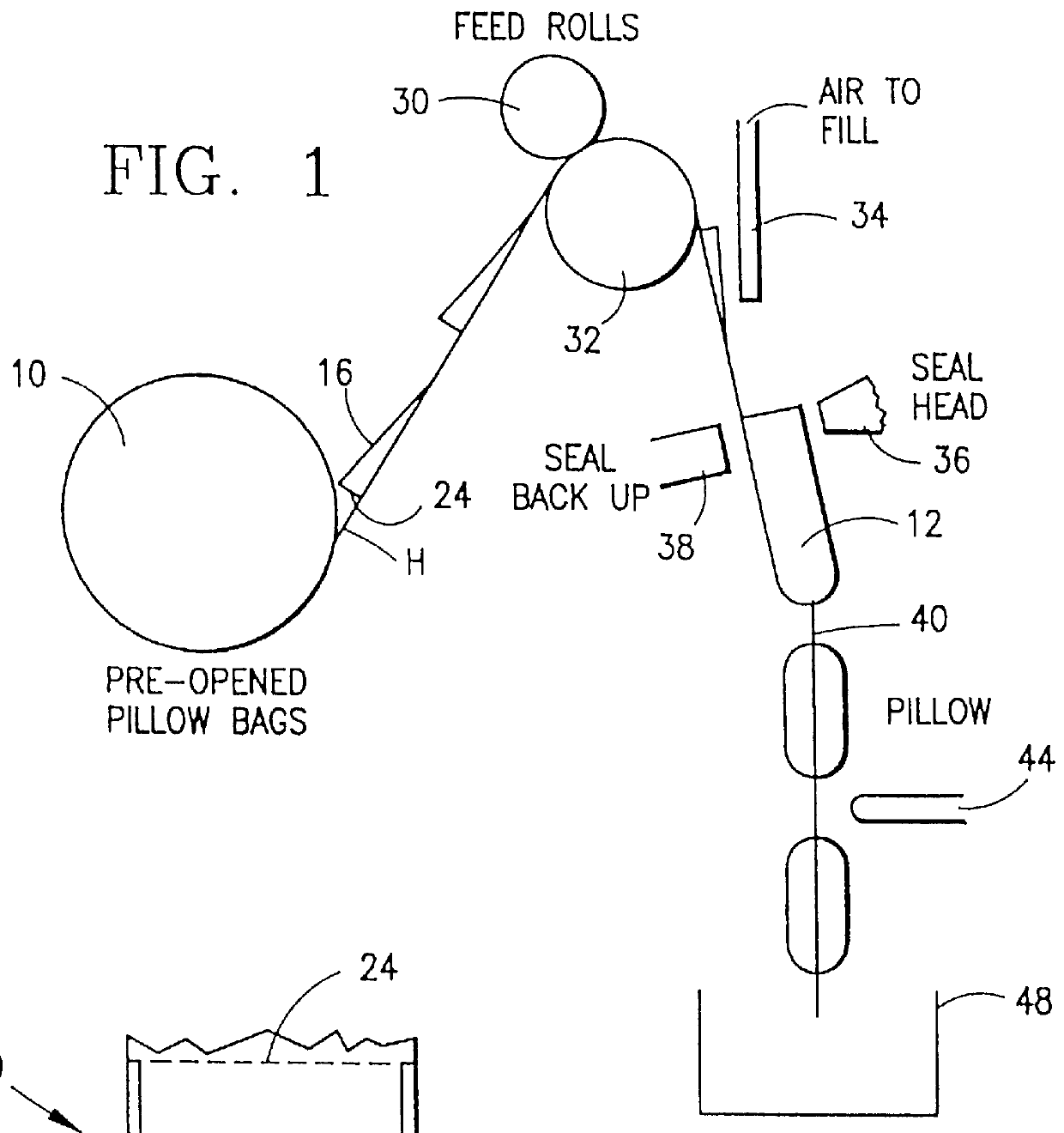

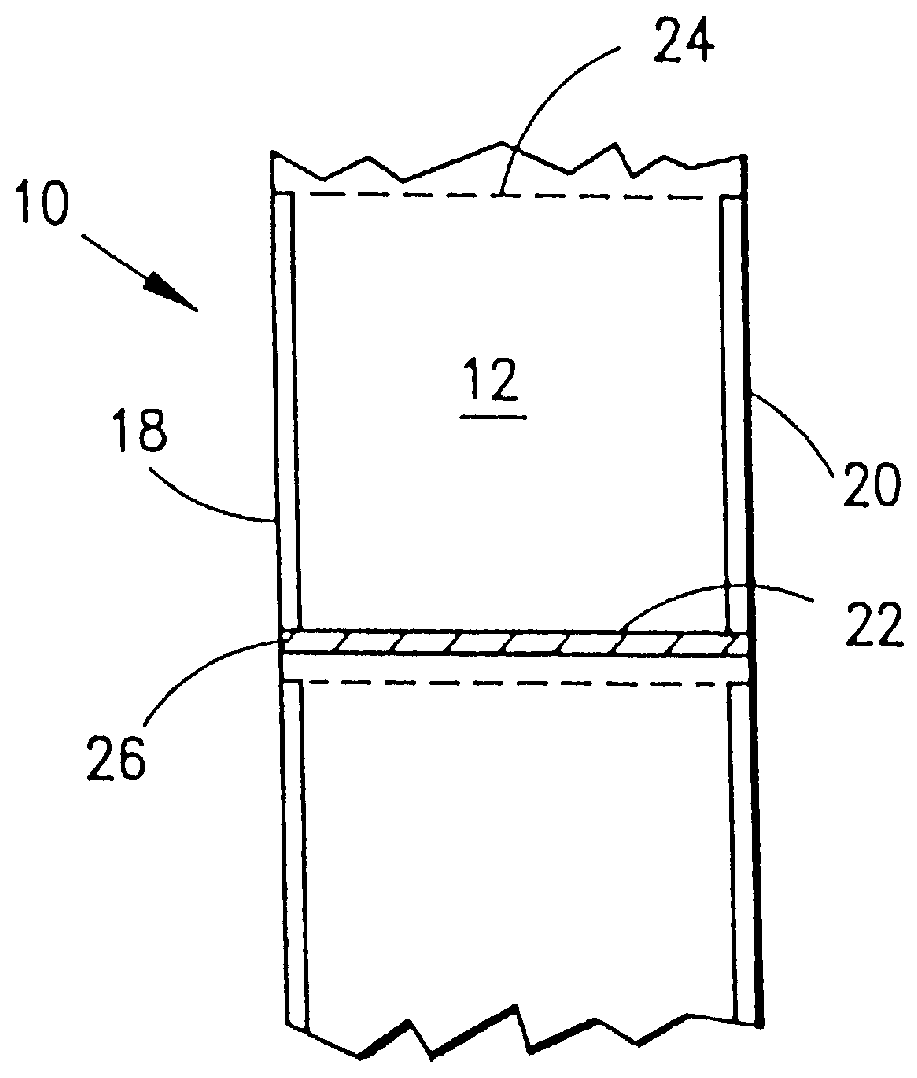

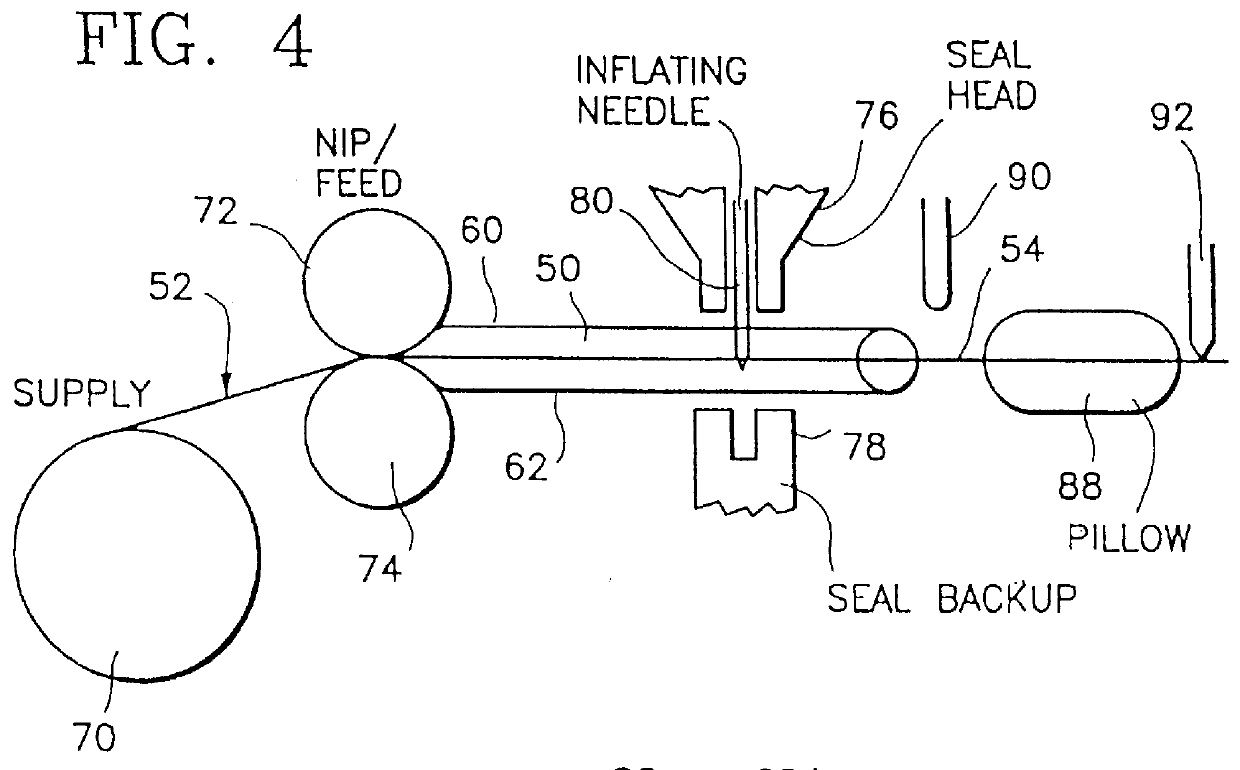

Method for producing inflated dunnage

InactiveUSRE36501E1Easy disposalEasy to reusePreventing unwanted cargo movementLabelling non-rigid containersDunnageCarton

A method for producing inflated dunnage on the site of use, comprising providing, in rolled form, a plurality of preformed plastic bags, each of the bags comprising two plastic sheets in facing relationship and sealed along three edges with one edge remaining open. Air is blown toward each of the open edges in sequence, causing each bag to inflate, and the fourth edge of each inflated bag is sealed, the bag being empty except for the air. At least one sealed inflated bag is separated from the roll and placed in a carton to serve as dunnage. In an alternate embodiment, the stock material is provided in a continuous tubular form, and an air inflation needle is used to puncture a surface of the tube for inflation purposes.

Owner:AUTOMATED PACKAGING SYST

Rubber composition for tire and pneumatic tire using the same

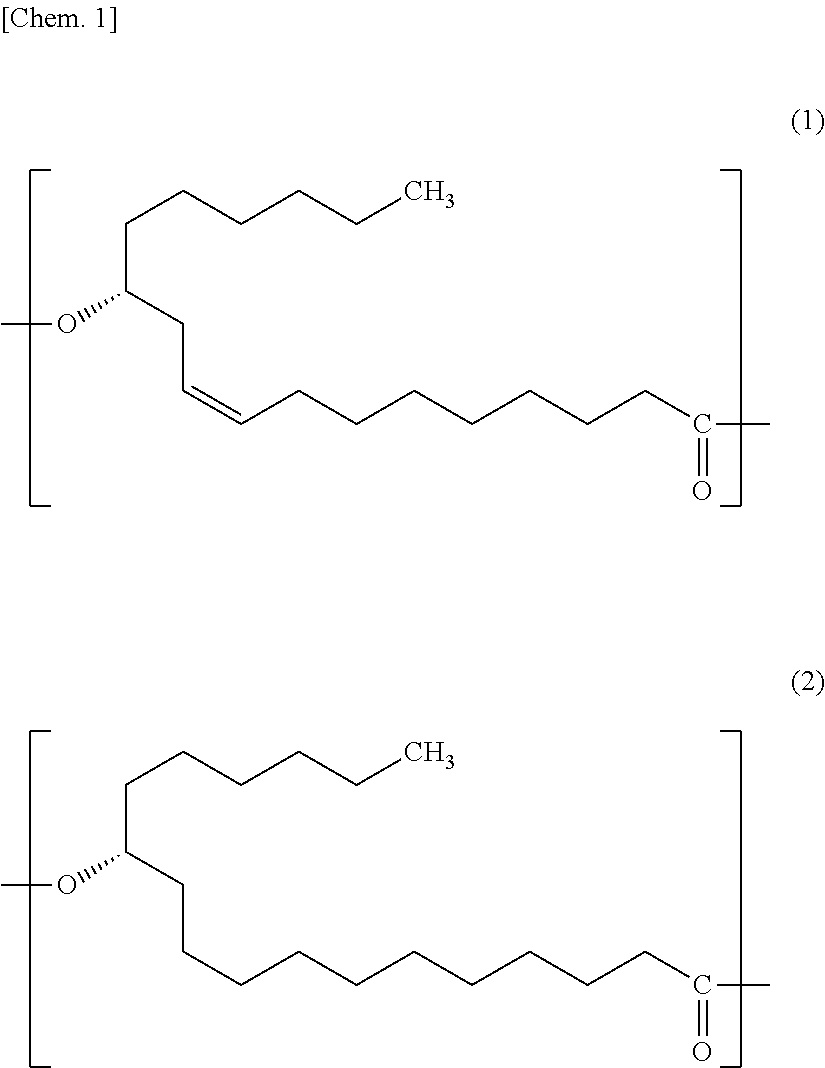

A rubber composition for a tire, in which a specific tackifier is compounded, and tackiness and various physical properties are improved, compared with compounding a petroleum resin or a terpene resin, is provided. The rubber composition for a tire comprising an alkyd resin and a pneumatic tire using the same. It is preferable that a material derived from a resource other than petroleum, particularly, a material derived from animal and / or vegetable, and more particularly, a material derived from an animal oil and / or a vegetable oil is contained in the alkyd resin, and it is preferable that unsaturated polybasic acid is contained in the alkyd resin.

Owner:SUMITOMO RUBBER IND LTD

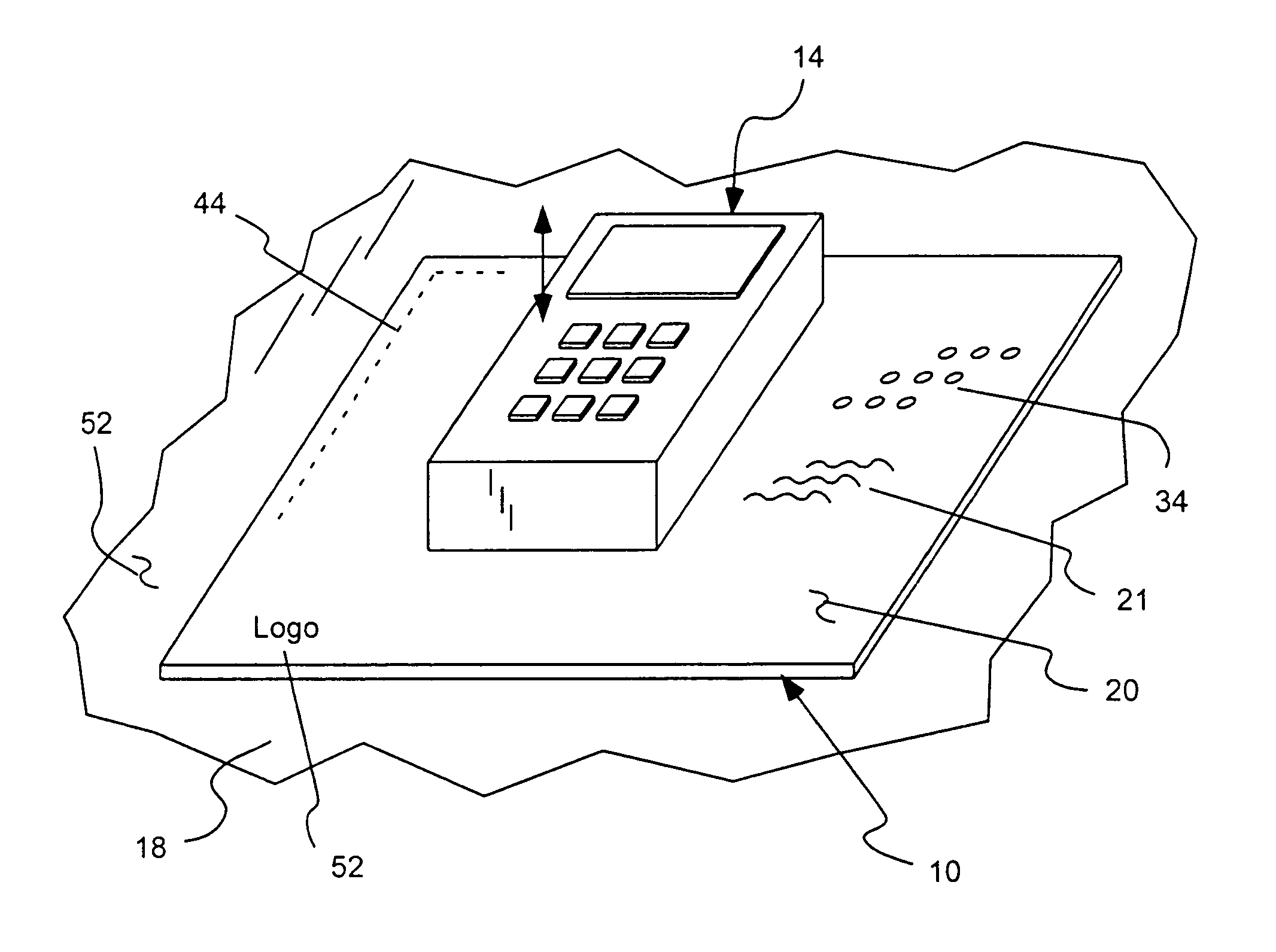

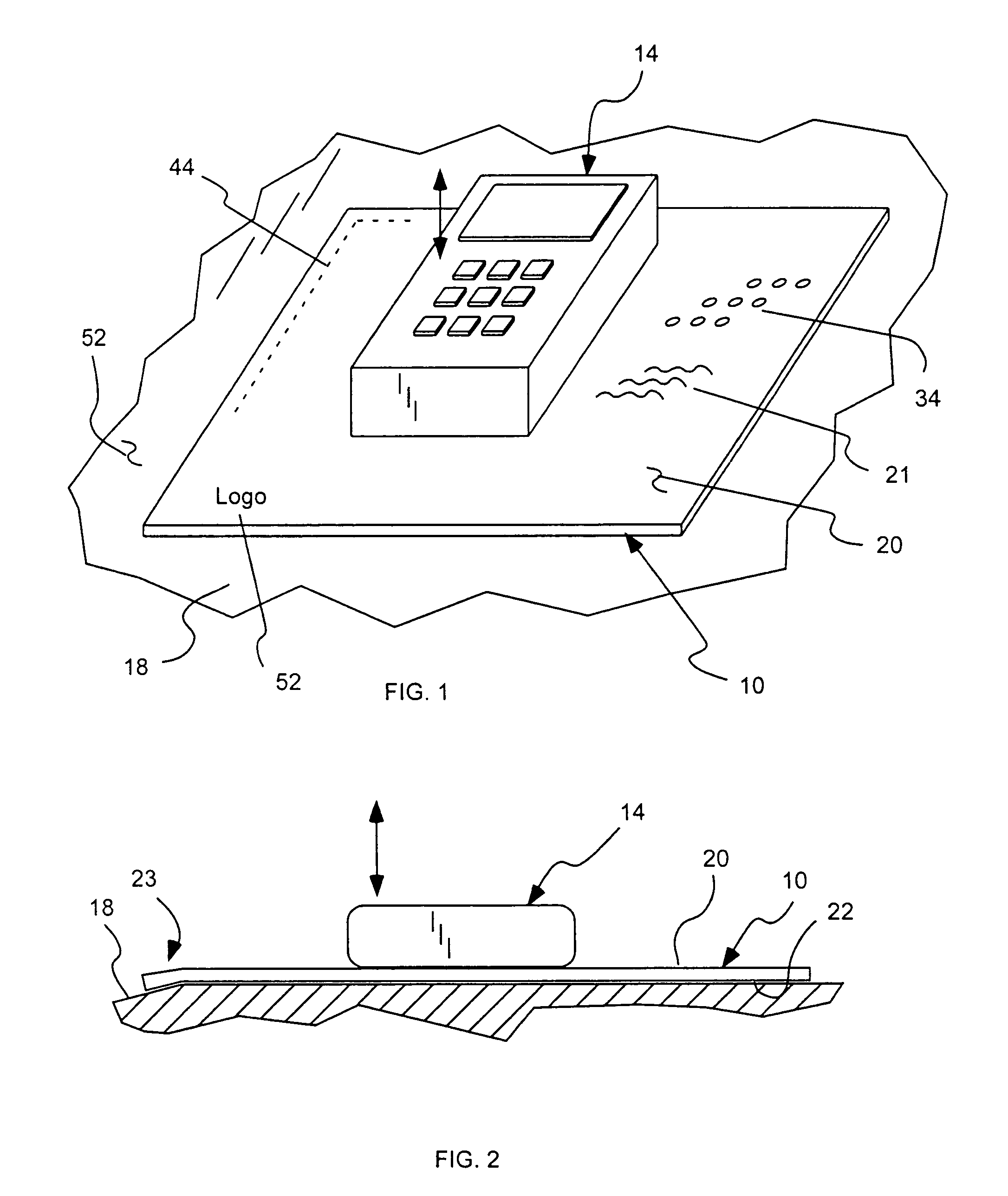

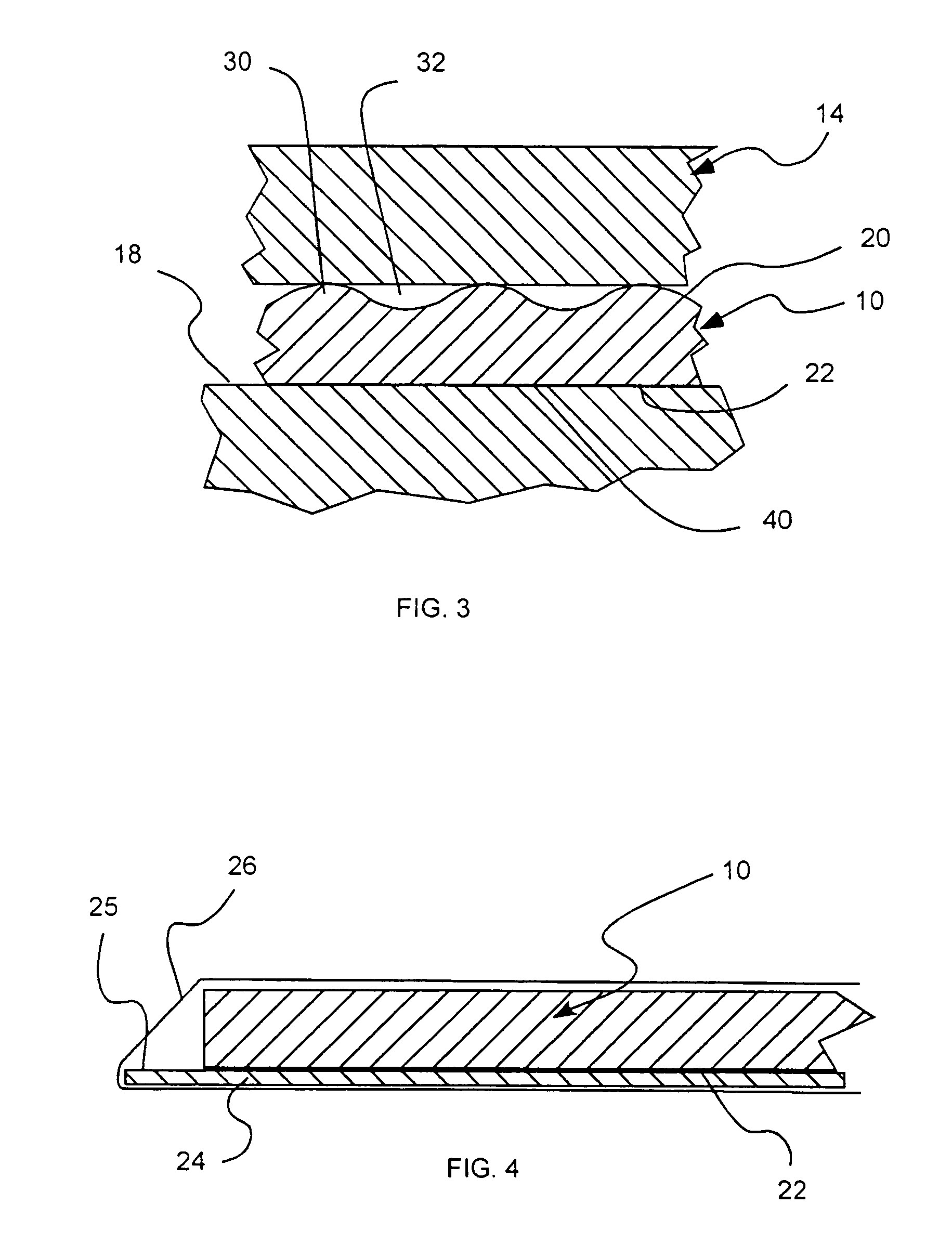

Frictional holding pad

InactiveUS7125602B2Easy retrievalImprove tackinessLuggage compartmentPassenger spaceEngineeringSupport surface

A frictional holding pad for removably attaching items, such as a cell phone, to a surface, such as a dash, to allow storage of items on the pad to prevent the items from shifting or sliding due to the movement of the support surface. A bottom surface of the pad is tacky to cling to the surface and a top surface is tacky to cling to the item. A lowermost contact surface of the pad can have a greater surface area than an uppermost contact surface. Indicia can be formed on the pad. The pad can be translucent or transparent. The pad can include an expanded vinyl material or a polyurethane material.

Owner:AMERICAN COVERS

Tacky resin composition and pressure-sensitive adhesive film or sheet

InactiveUS20100317802A1Exact rangeHigh transparencyLayered productsThin material handlingElastomerOlefin polymerization

A tacky resin composition which has proper initial tackiness, is sufficiently inhibited from rising in tackiness with time, can keep tackiness at a proper range even when it receives a slight heat history or is stored for a long time, has very small dependence on peeling speed, and can provide high transparency to a pressure-sensitive adhesive film or sheet as required, and a pressure-sensitive adhesive film or sheet for the surface protection of an article, which is obtained form the tacky resin composition.The tacky resin composition comprises (A) 5 to 80 parts by weight of an olefin polymer (component A), (B) 5 to 80 parts by weight of an ethylene / unsaturated ester copolymer (component B) and (C) 1 to 60 parts by weight of a styrene-based elastomer and / or an olefin-based elastomer (component C) based on 100 parts by weight of the total of the components A, B and C.

Owner:MITSUI LTD

Resin-additive masterbatch

The present invention provides a resin additive masterbatch which not only is capable of containing a resin additive having a low melting point at a high concentration, but also can be continuously produced without strand breakage and has an improved surface tackiness.The resin additive masterbatch comprises, with respect to 100 parts by mass of (A) a crystalline resin, 100 to 900 parts by mass of (B) a resin additive, 0.1 to 10 parts by mass of (C) a metal salt of an organic acid other than fatty acid and 0.1 to 10 parts by mass of (D) a gelling agent,the resin additive masterbatch being characterized in that the above-described (B) resin additive retains a liquid state when melted with heating to 250° C. and then cooled to 80° C. and kept for 30 minutes.

Owner:ADEKA CORP

Rubber composition for tire and pneumatic tire using the same

InactiveUS20070100061A1Reduce rolling resistanceIncrease stickinessSpecial tyresInksCompound aPetroleum resin

A rubber composition for a tire, in which a specific tackifier is compounded, and tackiness and various physical properties are improved, compared with compounding a petroleum resin or a terpene resin, is provided. The rubber composition for a tire comprising an alkyd resin and a pneumatic tire using the same. It is preferable that a material derived from a resource other than petroleum, particularly, a material derived from animal and / or vegetable, and more particularly, a material derived from an animal oil and / or a vegetable oil is contained in the alkyd resin, and it is preferable that unsaturated polybasic acid is contained in the alkyd resin.

Owner:SUMITOMO RUBBER IND LTD

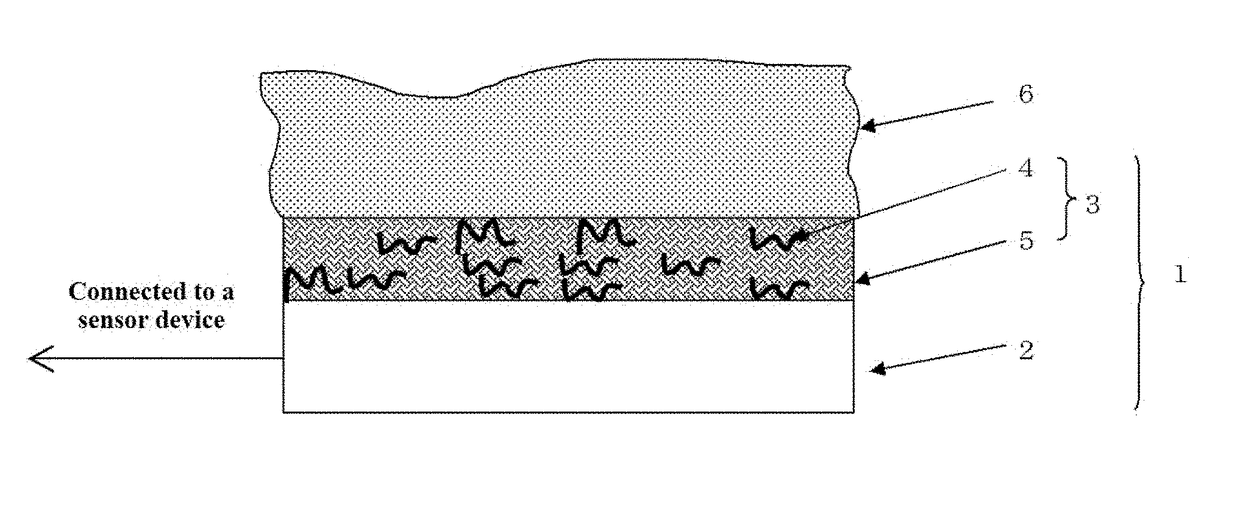

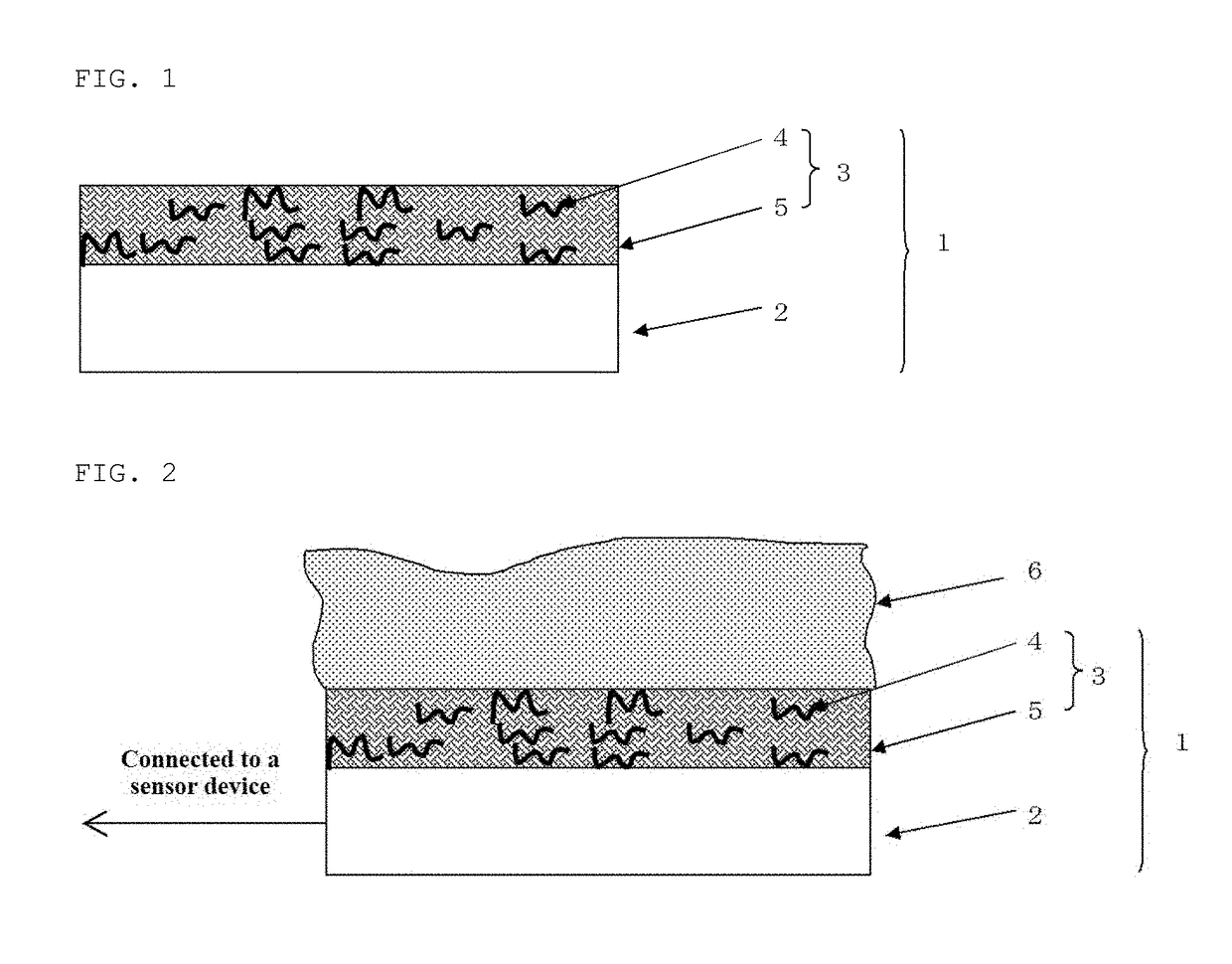

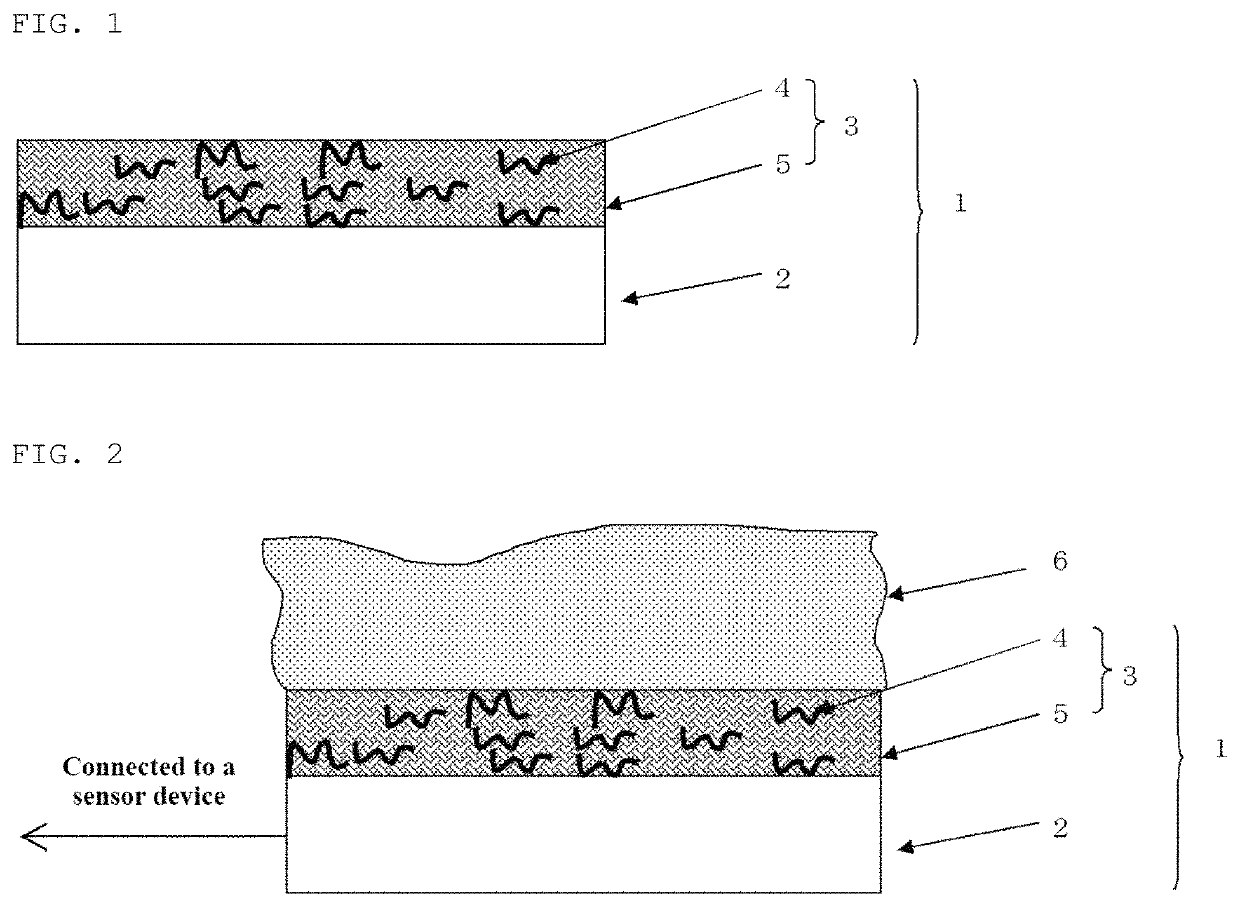

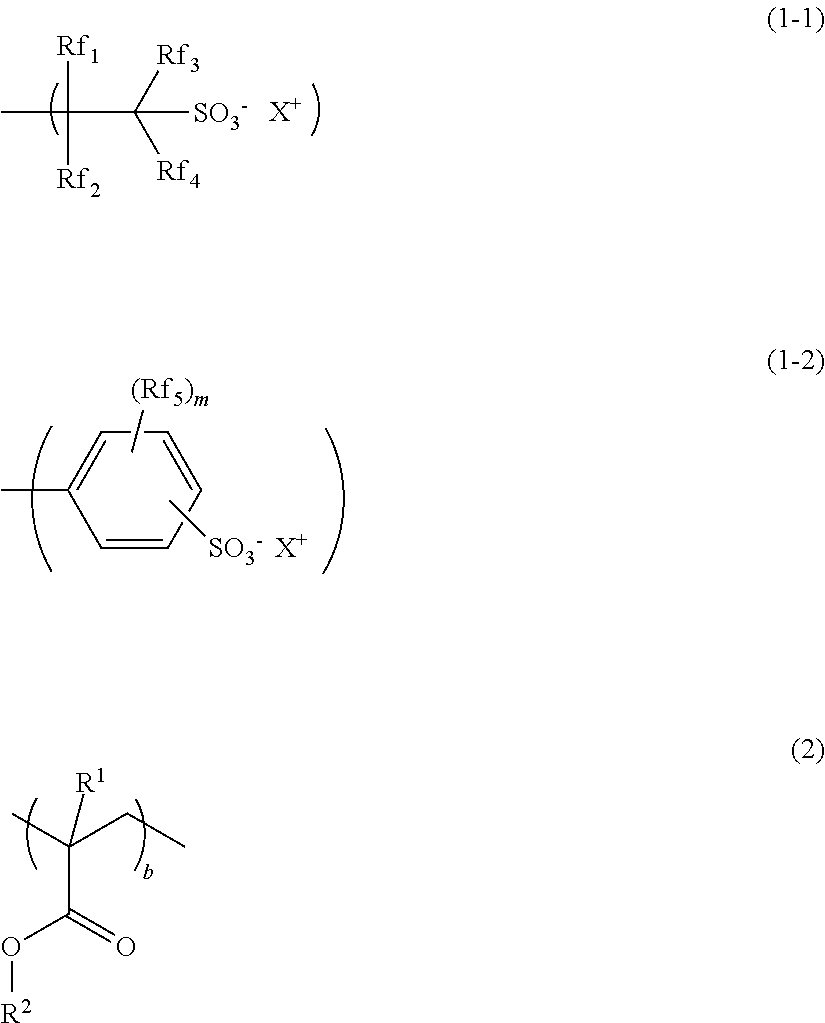

Bio-electrode composition, bio-electrode, and method for manufacturing bio-electrode

ActiveUS20180168470A1High tackiness and elasticityExcellent electrical conductivityCation exchanger materialsElectrocardiographyElectrically conductiveRepeat unit

The present invention provides a bio-electrode composition including a polymer compound having both an ionic repeating unit A and a (meth)acrylate repeating unit B, wherein the ionic repeating unit A is a repeating unit selected from the group consisting of sodium salt, potassium salt, and ammonium salt having either or both partial structures shown by the following general formulae (1-1) and (1-2), and the (meth)acrylate repeating unit B is a repeating unit shown by the following general formula (2).This can form a living body contact layer for a bio-electrode with excellent electric conductivity, biocompatibility, and light weight, which can be manufactured at low cost and does not cause large lowering of the electric conductivity even when it is wetted with water or dried.

Owner:SHIN ETSU CHEM CO LTD

Method for inhibiting corrosion in an aqueous aerosol or foam hair styling composition

InactiveUS6368575B2Improve corrosion resistanceNegatively affecting performanceCosmetic preparationsHair removalEmulsionEmulsion polymerization

A method for improving the corrosion resistance of aerosol or foam hair spray formulations in metal containers is disclosed. In particular, the present invention involves the use of phosphate ester emulsifiers in the preparation of the emulsion polymer hair fixative resins to provide corrosion resistance of the hair styling composition in metal containers without negatively affecting the performance of the hair styling product itself. Use of the selected emulsifiers is particularly useful in non-corrosive aqueous hair styling compositions containing low (80% or less) volatile organic compound (VOC) concentrations.

Owner:ROHM & HAAS CO

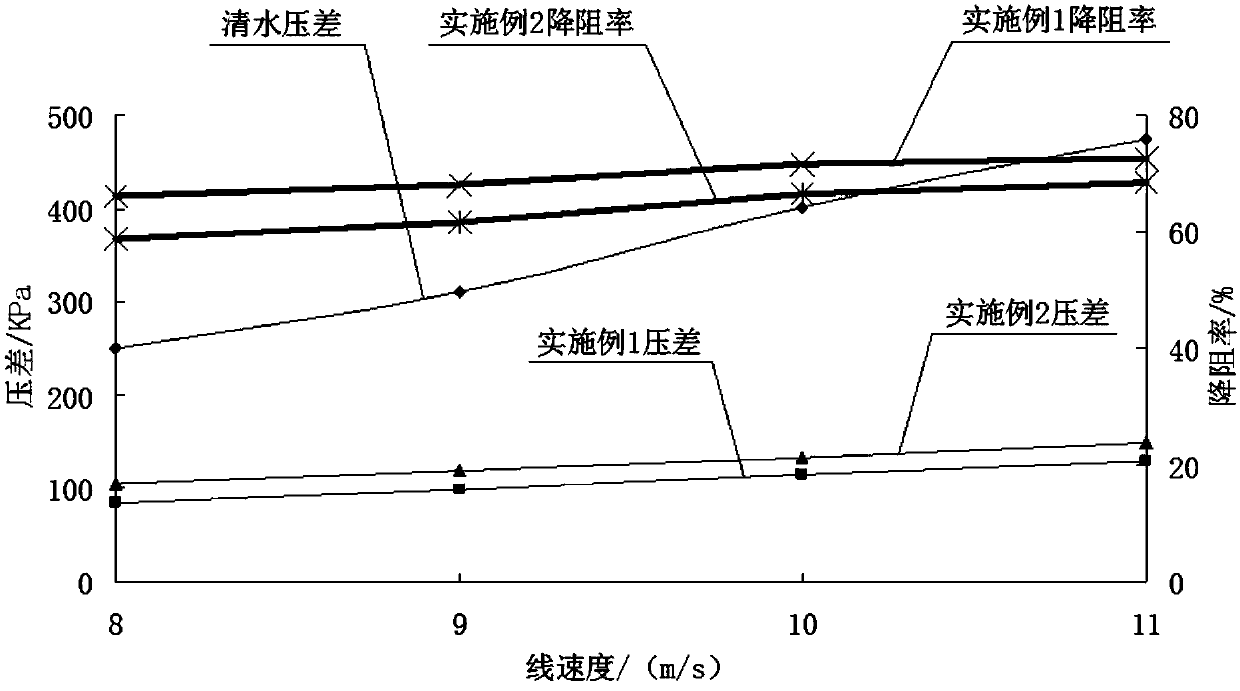

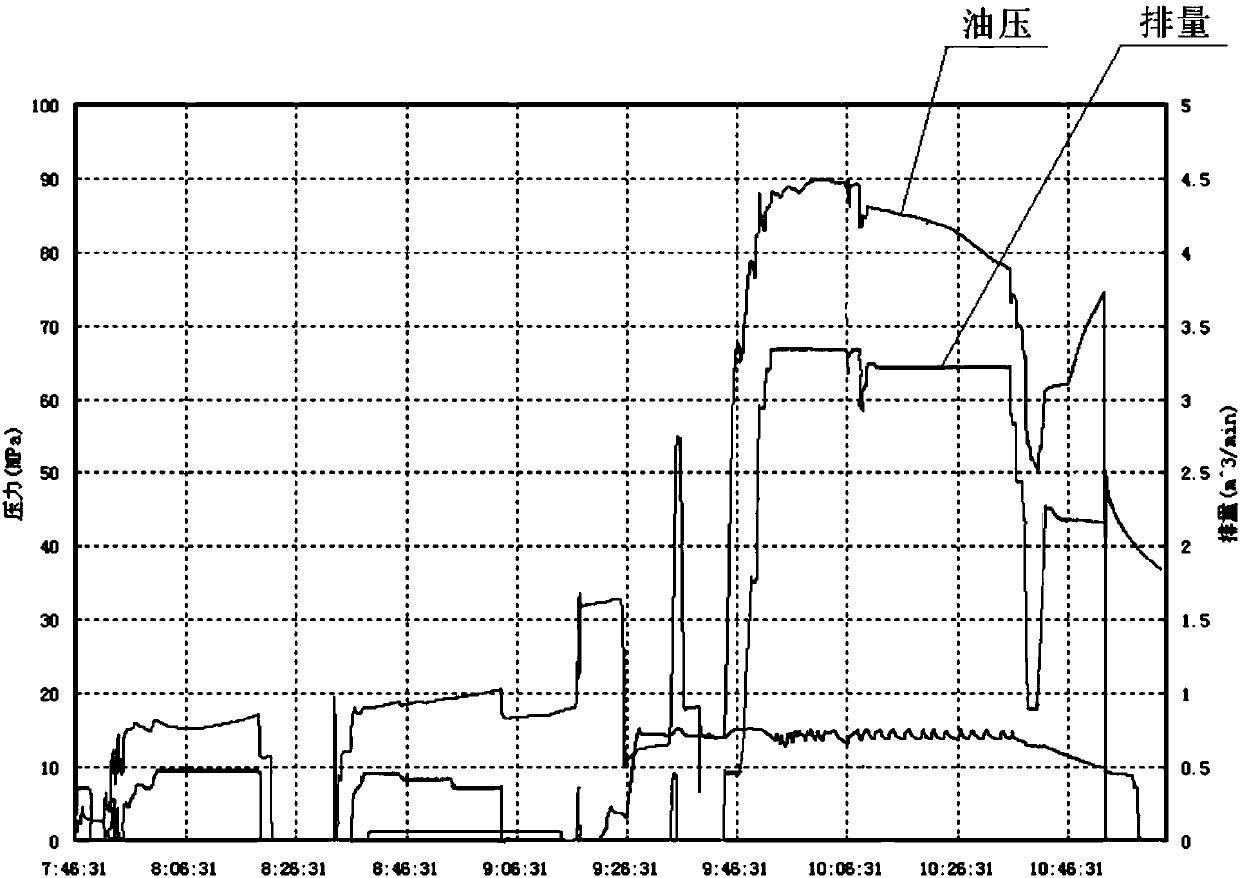

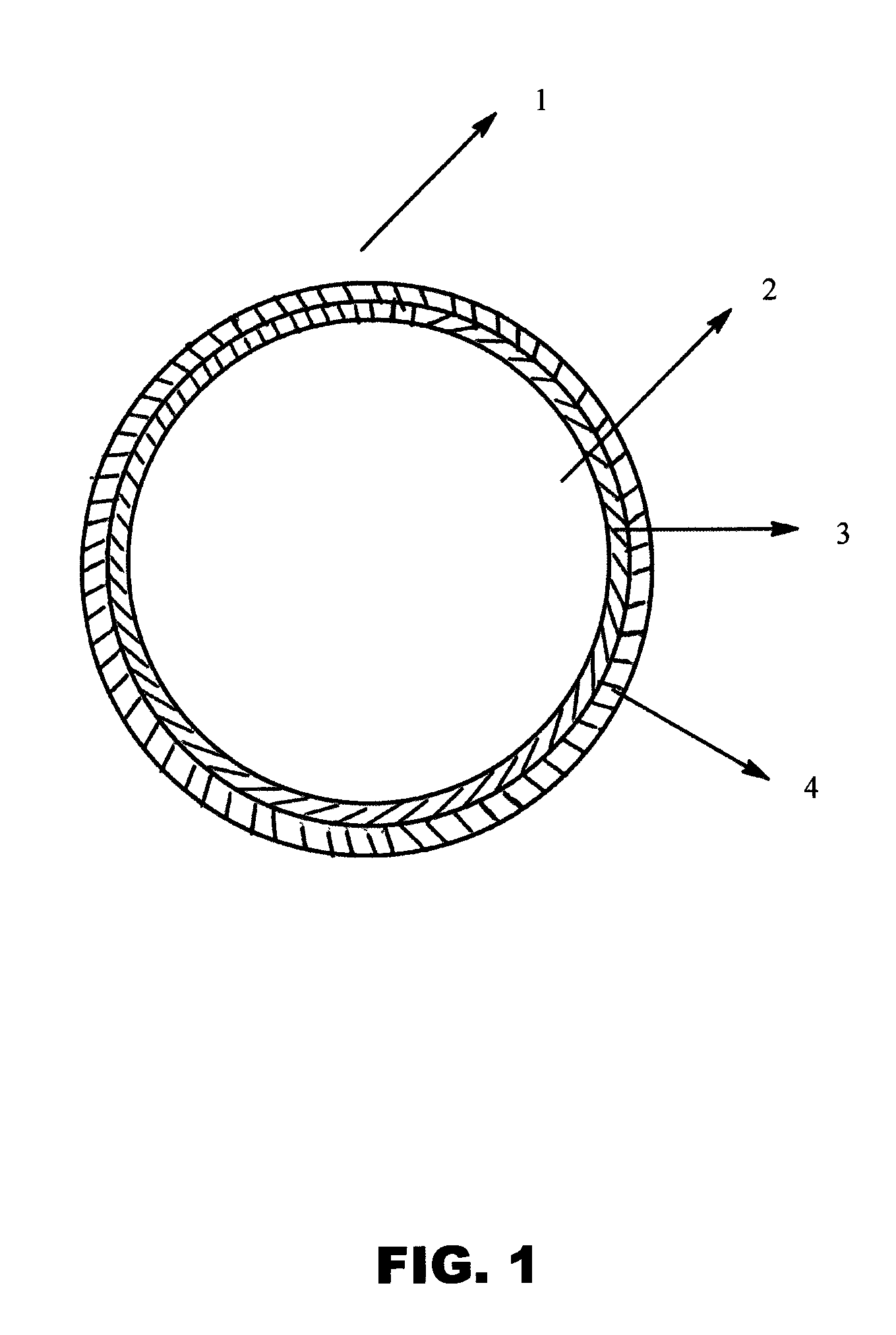

Low-friction gelled acid and preparation method thereof

The invention discloses a low-friction gelled acid and a preparation method thereof, and belongs to the field of acidification of oil wells. The low-friction gelled acid is prepared from: by weight, 0.2-0.5% of a gelling agent, 1-4% of a corrosion inhibitor, 0.1-1% of corrosion inhibition synergist, 1-2 % of an iron ion stabilizer, 1-2% of a cleanup additive, 15-23% of hydrochloric acid and the balance water, wherein the gelling agent is composed of a homopolymer of methacryloxyethyl trimethyl ammonium chloride and a chain extender, and the mass fraction of the chain extender in the gelling agent is 0.001-0.005%. According to the low-friction gelled acid provided in the embodiment of the invention, the molecular weight of the homopolymer in the gelling agent is effectively increased by adding the chain extender, so that the tackifying capability and resistance reduction performance of the gelling agent are improved; therefore, the friction of the gelled acid is reduced, the pressure required by a high-pressure pump truck during fracture acidizing is reduced, and energy and the cost of fracture acidizing are saved; meanwhile, by forming a chemical adsorption layer on the surface ofmetal through the cooperation of the corrosion inhibitor and the corrosion inhibition synergist, the corrosion to metal is slowed down.

Owner:PETROCHINA CO LTD

Method for Manufacturing Inks, and Inks, Printed Matter and Shaped Products Based on Method Thereof

InactiveUS20090041991A1Improve featuresGood adhesivenessLiquid surface applicatorsDecorative surface effectsOligomerUV curing

Provided is a method for manufacturing inkjet system ultraviolet curable inks which are improved in formability, adhesiveness and tackiness by selecting a combination of a monofunctional radical polymerization monomer as a major component with other polyfunctional radical polymerization oligomers and / or monofunctional radical polymerization monomers.Also, obtained is a method for manufacturing inkjet system ultraviolet curable inks in which phenoxyethylacrylate is a basic composition used as a photo polymerization reactive composition and other monofunctional radical polymerization monomers and / or polyfunctional radical polymerization oligomers are mixed within a predetermined relative quantity, if necessary, thereby realizing results in which at least two of the above-described characteristics are favorable and the remaining one is far from poor, inks according to the method, decorating printed matter and decorating sheet shaped articles using the inks, and insert molding shaped products using the decorating printed matter and the decorating sheet shaped articles.

Owner:TEIKOKU PRINTING INKS MFG CO LTD

Low temperature curable proppant

InactiveUS20160075940A1Enhances natural tackinessReduce viscosityLiquid surface applicatorsFluid removalSURFACTANT BLENDPolyresin

Owner:DUREZ CORP

Polyurethane dispersions and coatings made therefrom

A polyurethane having enhanced properties is made from an aqueous polyurethane dispersion having therein a nonvolatile, non-reactive, property enhancing water-soluble (NNPEW) compound such as urea. Even though the NNPEW is soluble in water, the NNPEW remains in the polyurethane after being exposed to water. In another embodiment, the NNPEW may react with a compound present in the dispersion other than the polyurethane particles of the dispersion when removing the water of the dispersion to form the polyurethane or upon subsequent heating.

Owner:KOONCE WILLIAM A +2

Tocopheryl polyethylene glycol succinate articles and process for preparing TPGS articles

InactiveUS20050163828A1Improved surface tackinessExcellent hardness propertiesOrganic active ingredientsOrganic chemistryPolymer scienceGram

The present invention relates to a TPGS article having a weight no greater than 1 gram and a tackiness no greater than about 1550 grams. In addition, the present invention relates to a process for producing said TPGS articles.

Owner:EASTMAN CHEM CO

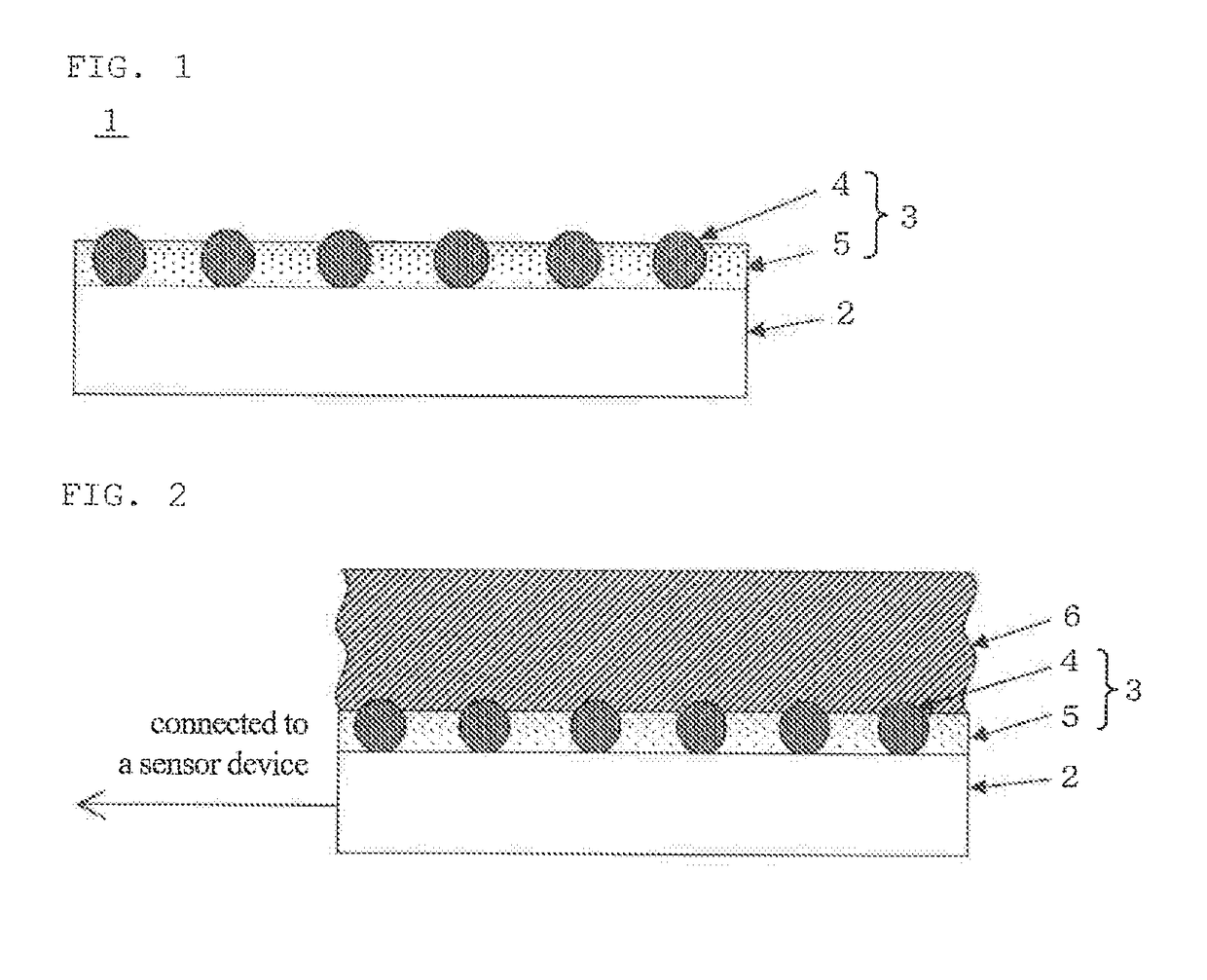

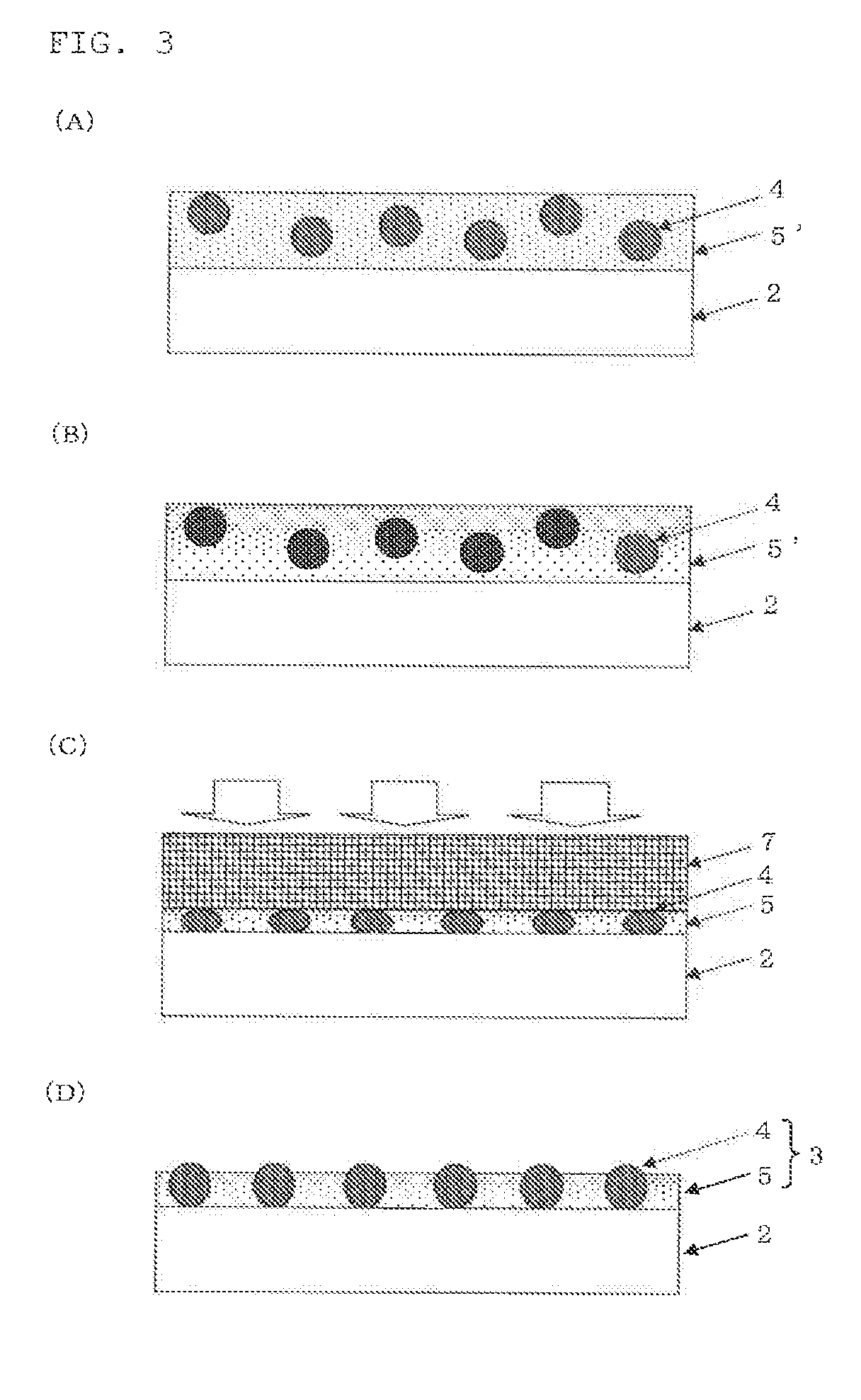

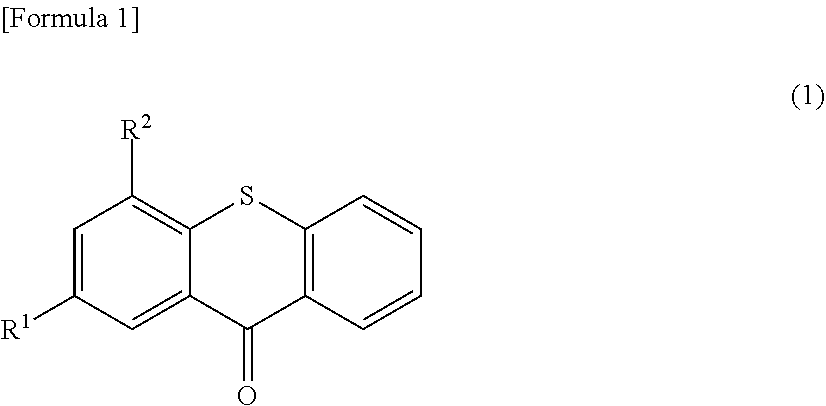

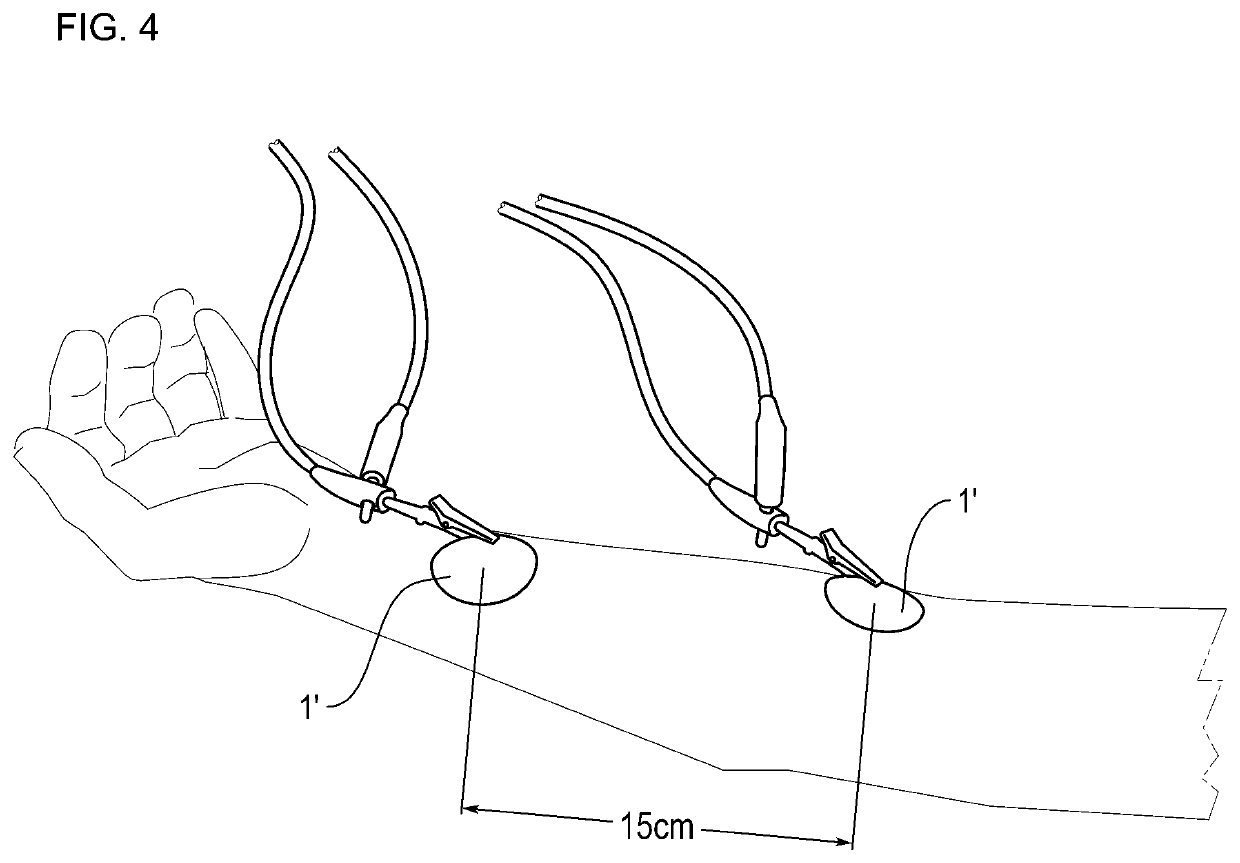

Bio-electrode and method for manufacturing the same

ActiveUS20170323698A1Efficiently conductedIncreased repellencyPlastic/resin/waxes insulatorsNon-conductive material with dispersed conductive materialPlatinumBiological body

The present invention provides a bio-electrode including an electro-conductive base material and a living body contact layer formed on the electro-conductive base material; wherein the living body contact layer contains a resin layer and particles dispersed in the resin layer, the particles being coated with gold, platinum, silver, or alloy of these metals; a thickness of the resin layer is equal to or thinner than an average particle size of the particles; the resin layer contains a silicon-containing resin and a non-silicon-containing resin; and the silicon-containing resin is localized in the direction of a surface of the resin layer. The bio-electrode of the present invention is superior in electric conductivity and biocompatibility, light in weight, can be manufactured at low cost, and can combine repellency of the resin layer surface and adhesion properties of the resin layer to particles.

Owner:SHIN ETSU CHEM IND CO LTD

Polarized film, optical film, and image display device

InactiveUS20150049380A1Resists change in resistanceReduce penetrationLamination ancillary operationsOptical filtersWater vapor permeabilityPolarizer

A polarizing film, comprising a polarizer; transparent protective films with a water-vapor permeability of 150 g / m2 / 24 hours or less provided on both sides of the polarizer; and adhesive layers each interposed between the polarizer and one of the transparent protective films, wherein the adhesive layers are formed by applying an active energy ray to an active energy ray-curable adhesive composition containing a radically polymerizable compound, and the transparent protective films are bonded to the polarizer with the adhesive layers.

Owner:NITTO DENKO CORP

Radial multi-block copolymer containing tapered block, and preparation method and usage thereof

InactiveUS20050197463A1Easy to processImprove propertiesAdhesivesTooth cleaningCouplingPolystyrene-block-polyisoprene

A radial multi-block copolymer contains a tapered block as represented by the following formula 1. The radial multi-block copolymer, which includes a polystyrene block, a poly(isoprene-styrene)tapered block, a polyisoprene block, and a polybutadiene block, can be used as an excellent pressure-sensitive adhesive material. (pA-pT-pB)m-X-n(pC-pB-pT-pA) Formula 1: where pA is the polyvinyl aromatic block; pT is the poly(isoprene-styrene)tapered block; pB is the polyisoprene block; pC is the polybutadiene block; X is the residue of a multi-functional coupling agent used in preparation of the radial multi-block copolymer; m and n are integers equal to or greater than 1, representing the number of branches associated with X; and pT=pTA+pTB, where pTA is the pA component of pT, and pTB is the pB component of pT.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Method for inhibiting corrosion in an aqueous aerosol or foam hair styling composition

InactiveUS20010003581A1Avoid corrosionImprove corrosion resistanceCosmetic preparationsHair removalEmulsionEmulsion polymerization

A method for improving the corrosion resistance of aerosol or foam hair spray formulations in metal containers is disclosed. In particular, the present invention involves the use of phosphate ester emulsifiers in the preparation of the emulsion polymer hair fixative resins to provide corrosion resistance of the hair styling composition in metal containers without negatively affecting the performance of the hair styling product itself. Use of the selected emulsifiers is particularly useful in non-corrosive aqueous hair styling compositions containing low (80% or less) volatile organic compound (VOC) concentrations.

Owner:ROHM & HAAS CO

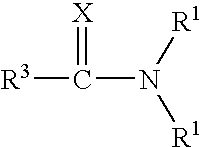

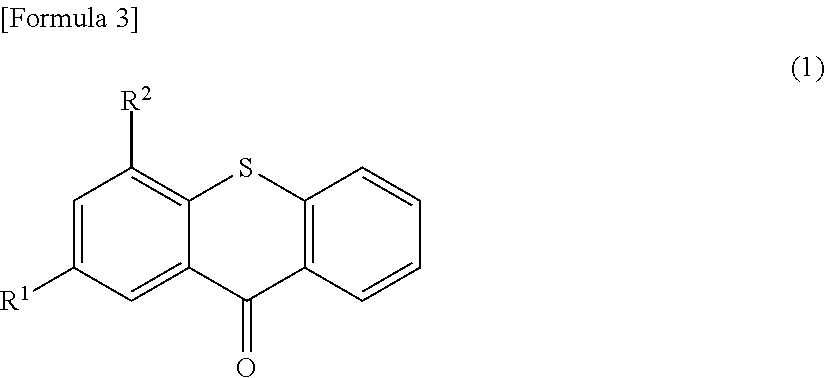

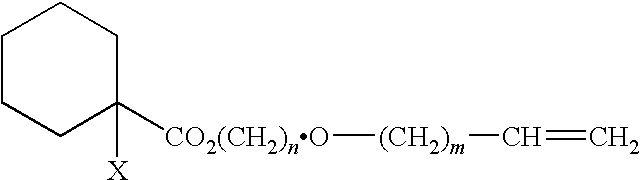

Curable composition, adhesive composition containing such curable composition, and adhesive

InactiveUS20090082488A1Improve propertiesImprove retentionEster polymer adhesivesOrganic non-macromolecular adhesiveWeather resistanceMeth-

The present invention has its object to provide an acrylic curable composition which is improved in tackiness, retention and other adhesive properties without reducing the thermal stability and weather resistance. The above-mentioned object can be solved bya curable compositionwhich comprises, as an essential component, polymer (I), which is a (meth)acrylic acid ester copolymer having, in each molecule, at least one group represented by the general formula 1:—OC(O)C(Ra)═CH2 (1) (wherein Ra represents a hydrogen atom or a hydrocarbon group containing 1 to 20 carbon atoms) at a terminus of the molecular chain and is obtained by (co)polymerizing an (meth)acrylic acid alkyl ester the alkyl moiety of which contains 7 to 20 carbon atoms.

Owner:KANEKA CORP

Removable pressure sensitive adhesive compositions and sheets

InactiveUS7374815B2Easy to disassembleSolve the lack of cohesionPolyureas/polyurethane adhesivesSynthetic resin layered productsPeel forceMelamine

A removable pressure sensitive adhesive composition includes at least (A) a hydroxyl-group-containing acrylic polymer, (B) an amine compound containing plural hydroxyl groups, and (C) a polyisocyanate compound and has a gel fraction of equal to or more than 70% by weight after drying or curing. A removable pressure sensitive adhesive sheet has a removable pressure sensitive adhesive layer including the removable pressure sensitive adhesive composition formed on one or both sides of a base material. The sheet may have a 180° peel force with respect to a melamine-faced steel sheet of 5 N / 20-mm or less and may have a 180 ° peel force after adhesion at 50° C. for 48 hours of 1.2 times or less the initial adhesion (after adhesion at 23° C. for 20 minutes), as determined at a pulling rate of 300 mm / minute, 23° C. and 50% relative humidity.

Owner:NITTO DENKO CORP

Copolymer and lubricating oil composition

InactiveUS20180201864A1Heat suppressionMaintain adhesionAdditivesBase-materialsChemical compositionHeat resistance

The present invention addresses the problem of providing a lubricating oil composition having excellent heat resistance (suppression of discoloration in heating) and tackiness while maintaining excellent viscosity properties of a lubricating oil composition using a ricinolic acid polymer. The present invention provides a copolymer (B) containing structural units (a) derived from ricinolic acid, structural units (b) derived from an aliphatic dicarboxylic acid and structural units (c) derived from a diol having 2 to 10 carbon atoms in a specific ratio and having a specific intrinsic viscosity, and provides a lubricating oil composition containing a base oil and the copolymer (B) and having a mass ratio (mass of (A) / mass of (B)) of the base oil (A) to the copolymer (B) of 60 / 40 to 99.5 / 0.5.

Owner:MITSUI CHEM INC

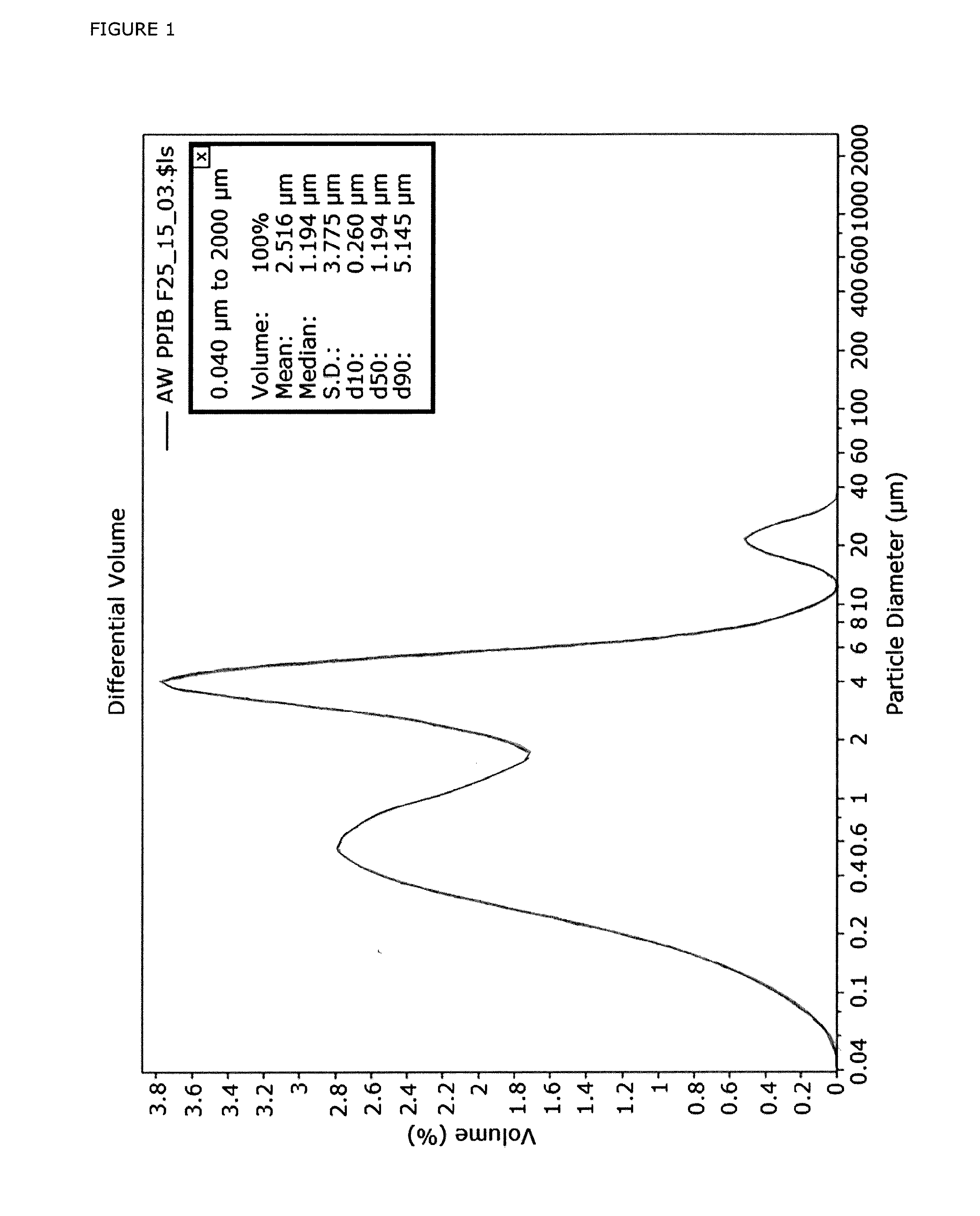

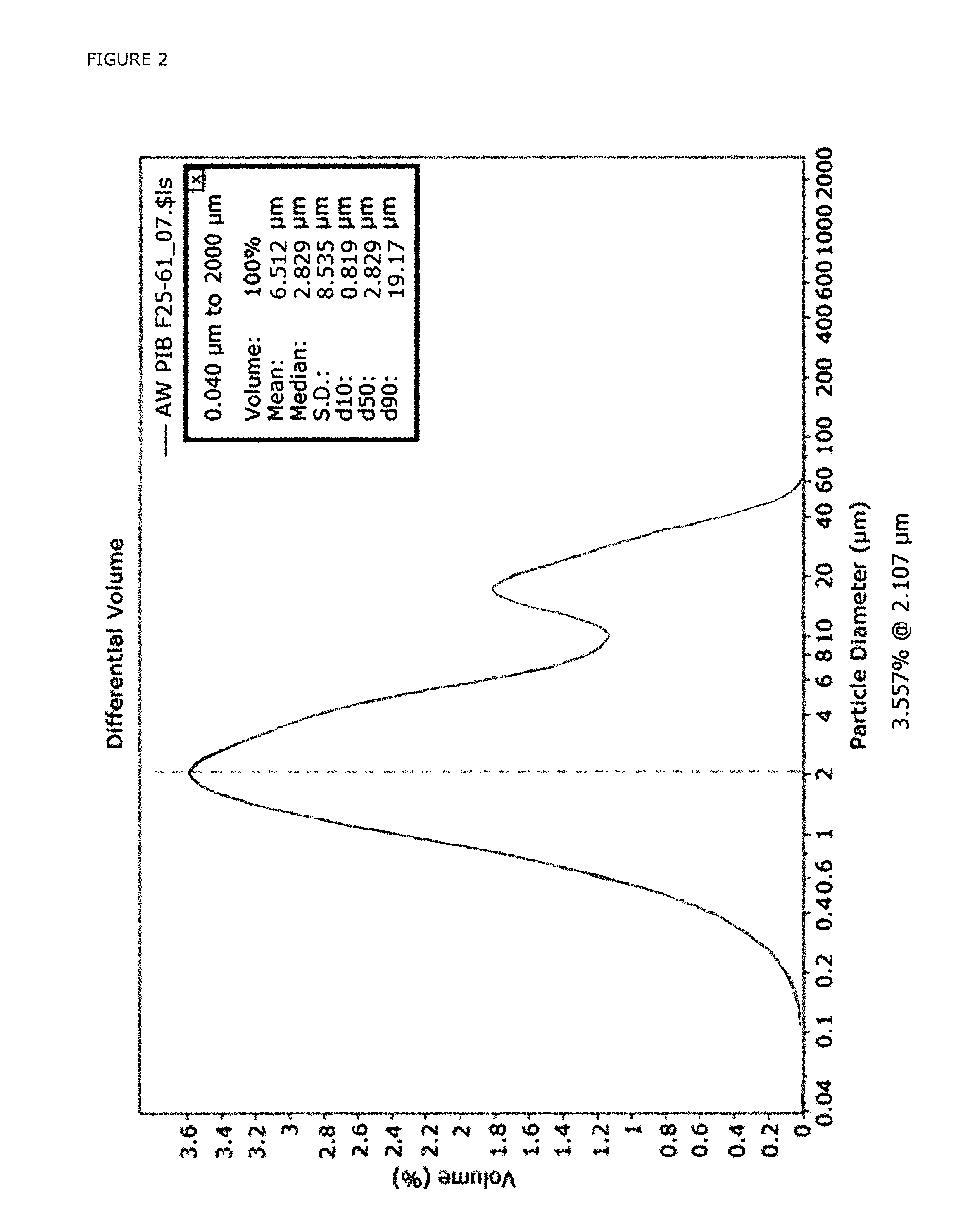

Method for the preparation of stable emulsions of polyisobutene

ActiveUS20150203637A1Improve tackinessReduce viscosityAntifouling/underwater paintsPaints with biocidesWaxEmulsion

The invention relates to a method for preparing a stable and thin liquid polyisobutene emulsion comprising the steps of i) heating a polyisobutene polymer, optionally mixing said polyisobutene polymer with a wax and / or oil, thereby obtaining a pre-mix, ii) mixing said pre-mix in water containing one or more surfactants in a concentration of the surfactant of maximum 5% wt. at a controlled flow rate, which flow rate is sufficiently slow to form particles of the pre-mix, thereby obtaining a pre-emulsion, and iii) homogenising said pre-emulsion, thereby obtaining said polyisobutene emulsion with an average particle size of at maximum 100 μm.

Owner:EMULCO LAB C V B A

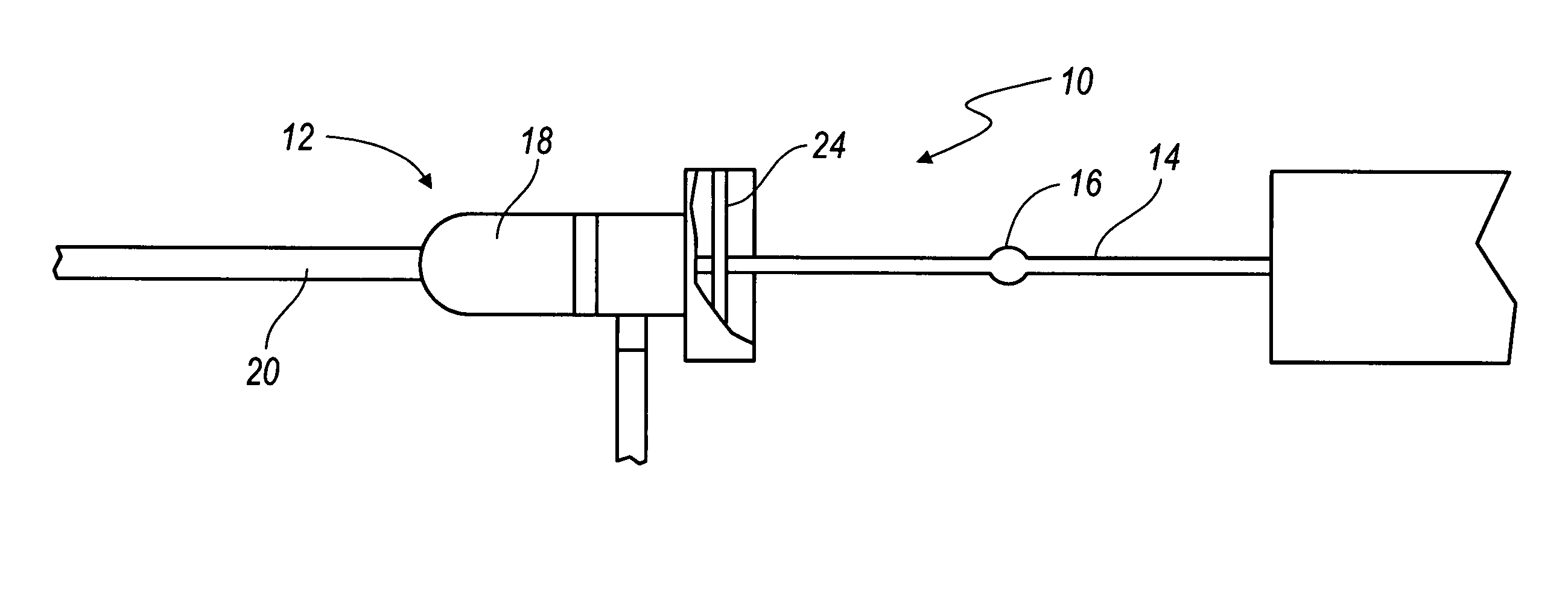

Introducer tactile feature

InactiveUS20060190005A1Improve the immunityImprove surface roughnessStentsEar treatmentRelative motionAdded resistance

An introduction system and method of use is provided. The introduction system includes a catheter assembly, a member, and a tactile indicator. The member is configured to be introduced through the catheter assembly and the tactile indicator is configured to provide a tactile sensory input when the member reaches a predetermined position relative to the catheter assembly. As such, the tactile indicator provides increased resistance to the relative motion between the member and catheter assembly when the member reaches the predetermined position.

Owner:COOK INC

Method for producing terpene-phenolic resins

The invention provides a method for producing terpene-phenolic resins. The terpene-phenolic resins with high tackifying property are obtained, so that the performance of the terpene-phenolic resins is improved. The method for producing the terpene-phenolic resins comprises the following steps of: A, dipping a-pinene with the purity of not less than 98 percent into a mixed liquid of phenol and methylbenzene under a temperature condition of 30-50 DEG C; adding boron trichloride serving as a catalyst into the mixed liquid to stir at least for one hour; and standing for 3-4 hours under a temperature condition of 40-60 DEG C to obtain a primary reactant; B, putting the primary reactant into hot water with the temperature of 90-100 DEG C to wash away boron trichloride to obtain the resin liquid of the terpene-phenolic resins; and C, clearing the water of the resin liquid of the terpene-phenolic resins; and putting the liquid into a distilled pot to distill and heat to 180 DEG C to obtain methylbenzene serving as a solvent; vacuumizing, distilling and heating methylbenzene; heating methylbenzene to 260 DEG C under a vacuum degree ranging from -0.08Mpa to -0.1Mpa; reducing the temperature to 240 DEG C after the vacuum is destroyed to package so as to obtain the solid terpene-phenolic resins.

Owner:XINYI SONGYUAN CHEM CO LTD

Resin-additive masterbatch

Owner:ADEKA CORP

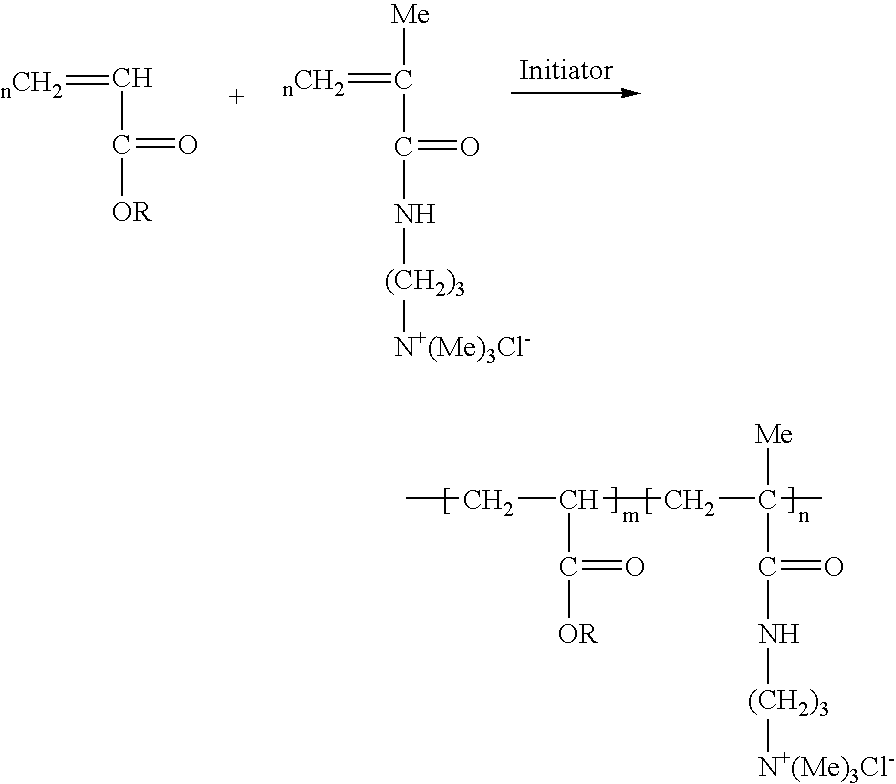

Water soluble/dispersible and easy removable cationic adhesives and coating for paper recycling

InactiveUS6969752B1Improve adhesionGood cohesion propertyAmide/imide polymer adhesivesCyclic processFiber

The present invention is an adhesive or coating composition that is dispersible or dissolvable in water, making it useful in as a coating or adhesive in paper intended for recycling. The composition of the present invention is cationically charged thereby binding with the fibers of the paper slurry and thus, resulting in reduced deposition of adhesives on equipment during the recycling process. The presence of the composition of the present invention results in stronger interfiber bonding in products produced from the recycled fibers.

Owner:GEORGIA TECH RES CORP

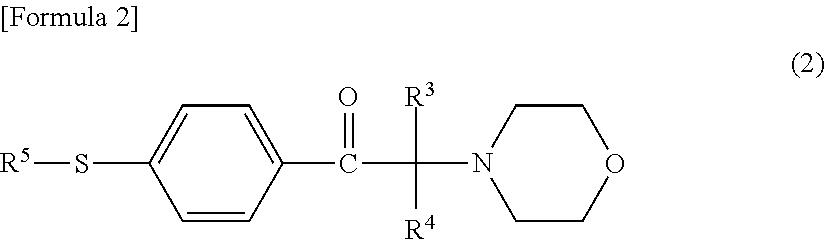

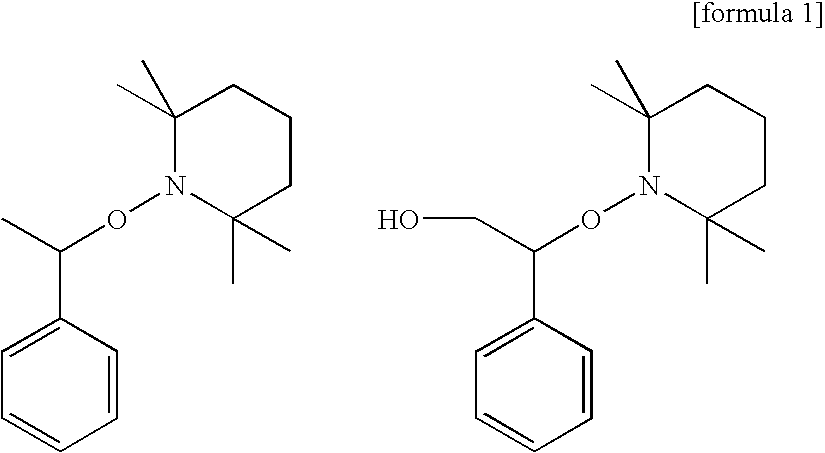

Bio-electrode composition, bio-electrode, and method for manufacturing bio-electrode

ActiveUS11071485B2Efficiently conductedImprove conductivityCation exchanger materialsSurgeryMethacrylateMeth-

The present invention provides a bio-electrode composition including a polymer compound having both an ionic repeating unit A and a (meth)acrylate repeating unit B, wherein the ionic repeating unit A is a repeating unit selected from the group consisting of sodium salt, potassium salt, and ammonium salt having either or both partial structures shown by the following general formulae (1-1) and (1-2), and the (meth)acrylate repeating unit B is a repeating unit shown by the following general formula (2).This can form a living body contact layer for a bio-electrode with excellent electric conductivity, biocompatibility, and light weight, which can be manufactured at low cost and does not cause large lowering of the electric conductivity even when it is wetted with water or dried.

Owner:SHIN ETSU CHEM IND CO LTD

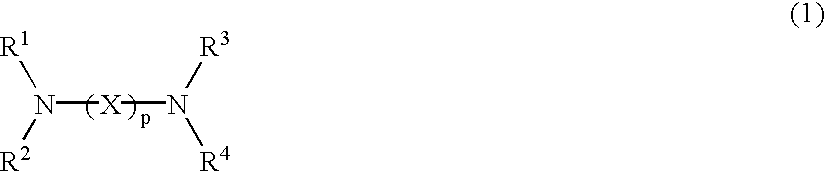

Adhesive composition, bio-electrode, method for manufacturing a bio-electrode, and salt

ActiveUS10808148B2Efficiently conductedImprove conductivityElectroencephalographyElectrocardiographyEngineeringConductive materials

An adhesive composition including a resin and electro-conductive material, wherein the electro-conductive material is an ammonium salt of fluorosulfonic acid having 5 or more carbon atoms shown by the general formula (1): (R1—X—Z—SO3−)n Mn+ (1), wherein, R1 represents a monovalent hydrocarbon group having 1 to 40 carbon atoms and optionally substituted by a heteroatom or optionally interposed by heteroatom; X represents any of a single bond, ether group, ester group, and amide group; Z represents an alkylene group having 2 to 4 carbon atoms, containing 1 to 6 fluorine atoms, and optionally containing a carbonyl group; Mn+ represents a cation having one or two ammonium cation structures. This can form a living body contact layer for a bio-electrode with excellent electric conductivity, biocompatibility, and light weight, which manufactures at low cost and does not cause large lowering of the electric conductivity even when it is wetted with water or dried.

Owner:SHIN ETSU CHEM IND CO LTD

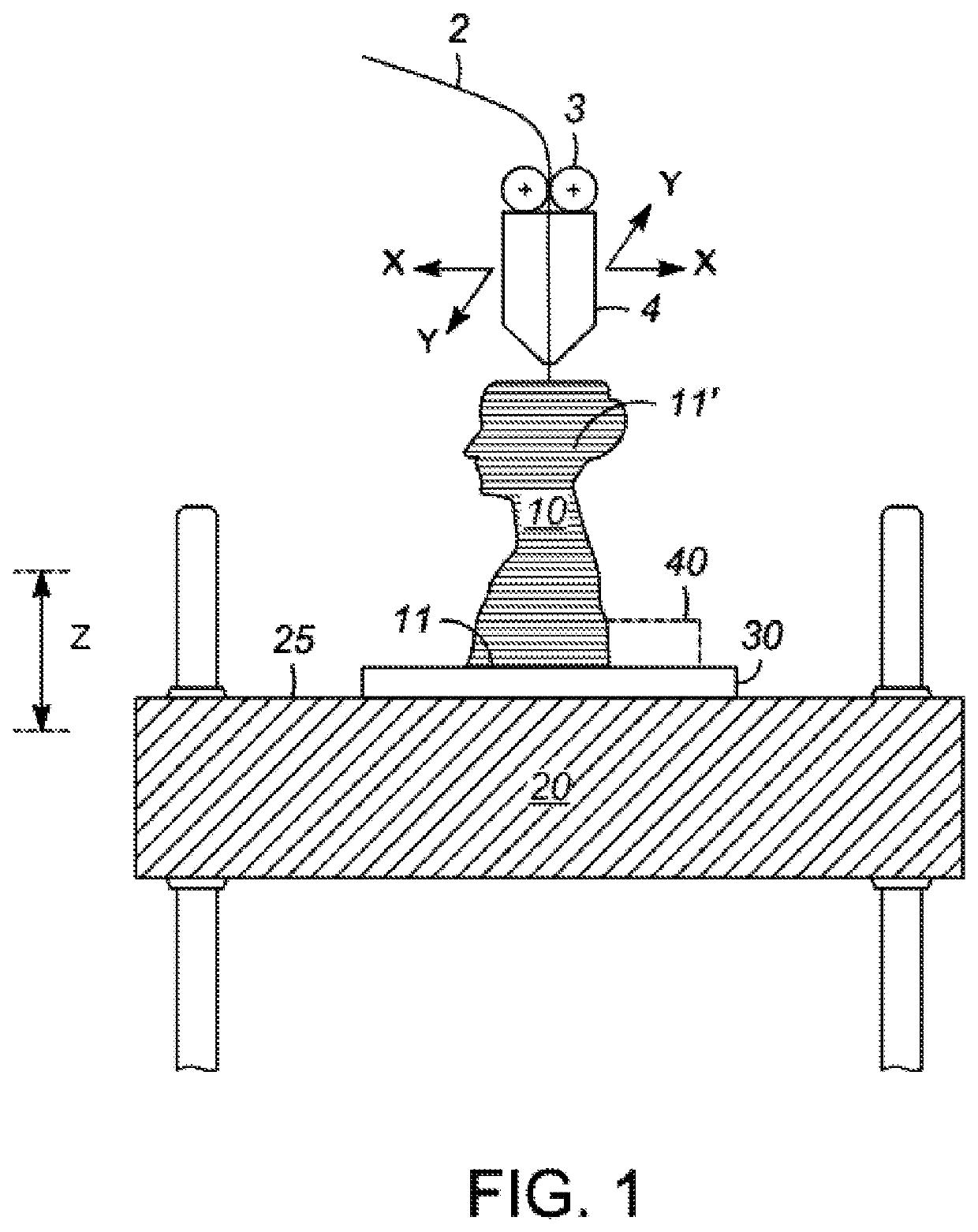

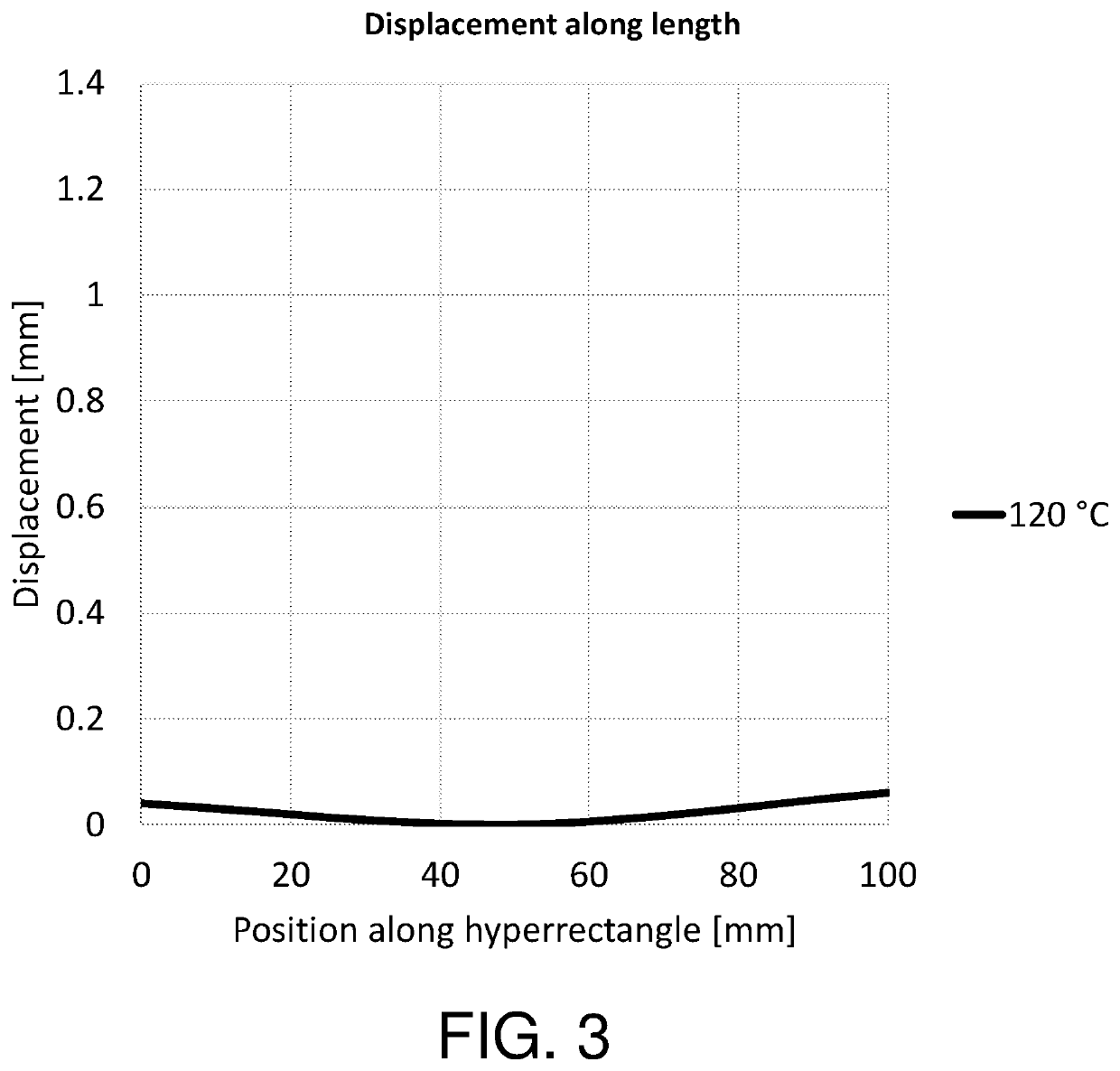

Adhesive compositions and their use in 3D printing

PendingUS20200377769A1Improve adhesionParticular applicabilityAdditive manufacturing apparatusAcid polymer adhesivesFused filament fabricationPolymer science

Adhesive compositions comprising an aqueous dispersion of an acrylic polymer are disclosed, with such compositions having particular applicability in additive manufacturing processes, such as three-dimensional (3D) printing, including Fused Filament Fabrication (FFF). In particular, the compositions address drawbacks associated with an improper degree of adhesion between a thermoplastic build material and build plate, which decrease the quality of printed objects. In representative aqueous dispersions, the solids content of at least about 5 wt. % and also most about 95 wt. % of the acrylic polymer is solubilized, with the balance of this polymer comprising dispersed solid particles.

Owner:COVESTRO NETHERLANDS BV

Hydrogenated copolymer composition, adhesive material composition, and adhesive film

PendingUS20220049137A1Improve balanceSuppression of increase in tackinessMacromolecular adhesive additivesPressure sensitive film/foil adhesivesPolymer chemistryConjugated diene

An object of the present invention is to provide a hydrogenated copolymer composition and the like having an excellent balance among initial tack strength, suppression of increase in tackiness, and suppression of uneven thicknesses of a tacky layer. The object can be achieved with the following hydrogenated copolymer composition.A hydrogenated copolymer composition comprising:a component (a) comprising a polymer block comprising a vinyl aromatic monomer unit as a main component and a polymer block comprising a conjugated diene monomer unit as a main component; anda component (b) comprising a polymer block comprising a vinyl aromatic monomer unit as a main component and a polymer block comprising a conjugated diene monomer unit as a main component.

Owner:ASAHI KASEI KK

Radial multi-block copolymer containing tapered block, and preparation method and usage thereof

InactiveUS20070129499A1Easy to processImproved propertyAdhesivesTooth cleaningCouplingPolystyrene-block-polyisoprene

A radial multi-block copolymer contains a tapered block as represented by the following formula 1. The radial multi-block copolymer, which includes a polystyrene block, a poly(isoprene-styrene)tapered block, a polyisoprene block, and a polybutadiene block, can be used as an excellent pressure-sensitive adhesive material. (pA-pT-pB)m-X-n(pC-pB-pT-pA) Formula 1: where pA is the polyvinyl aromatic block; pT is the poly(isoprene-styrene)tapered block; pB is the polyisoprene block; pC is the polybutadiene block; X is the residue of a multi-functional coupling agent used in preparation of the radial multi-block copolymer; m and n are integers equal to or greater than 1, representing the number of branches associated with X; and pT=pTA+pTB, where pTA is the pA component of pT, and pTB is the pB component of pT.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com