Low-friction gelled acid and preparation method thereof

A technology of gelled acid and low friction, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of increasing the cost of fracturing and acidification, high pressure of high-pressure pump trucks, and large frictional resistance, etc., to save acidification Cost, reduction of frictional resistance, effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] In the second aspect, the embodiment of the present invention also provides a preparation method of low-friction gelling acid, the preparation method comprising the following steps:

[0051] According to the ratio of each component in the gelling acid, add hydrochloric acid, corrosion inhibitor, corrosion inhibitor synergist, and iron ion stabilizer to the liquid mixing container in sequence, stir evenly, then add water and gelling agent, and stir for 15- After 25 minutes, add drainage aid and mix evenly to obtain low-friction gelling acid.

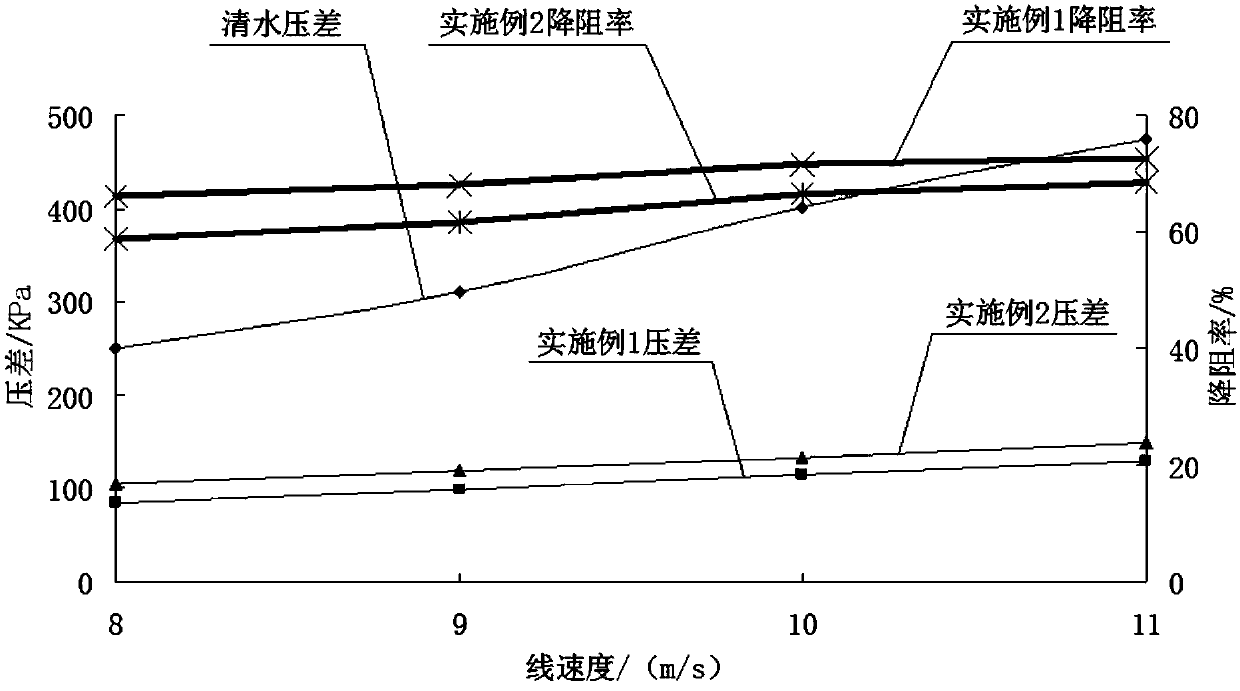

Embodiment 1

[0067] This embodiment provides a low-friction gelled acid, which comprises the following components in weight percent:

[0068] Gelling agent: 0.2%; Corrosion inhibitor: 2.5%; Corrosion synergist: 0.2%; Iron ion stabilizer: 1.3%; Drainage aid: 1.8%; Hydrochloric acid: 15%; The balance is water.

[0069] Wherein, the gelling agent is composed of a homopolymer of methacryloyloxyethyltrimethylammonium chloride and polyethylene glycol diacrylate, and polyethylene glycol diacrylate is used as a chain extender in the gelling agent The mass fraction of the gelling agent is 0.001%, and the viscosity-average molecular weight of the gelling agent is greater than 10 million. The corrosion inhibitor is quinoline quaternary ammonium salt, the corrosion inhibitor synergist is propynyl alcohol, and the iron ion stabilizer is citric acid and sodium erythorbate. The drainage aid comprises the following components in weight percentage: 65% of polyoxyethylene ether, 10% of ethylene glycol mono...

Embodiment 2

[0074] This embodiment provides a low-friction gelled acid, which comprises the following components in weight percent:

[0075] Gelling agent: 0.5%; Corrosion inhibitor: 2.5%; Corrosion synergist: 1.0%; Iron ion stabilizer: 1.5%; Drainage aid: 1.5%; Hydrochloric acid: 20%; The balance is water.

[0076] Wherein, the gelling agent is composed of a homopolymer of methacryloyloxyethyltrimethylammonium chloride and polyethylene glycol diacrylate, and polyethylene glycol diacrylate is used as a chain extender in the gelling agent The mass fraction of the gelling agent is 0.005%, and the viscosity-average molecular weight of the gelling agent is greater than 10 million. The corrosion inhibitor is Mannich base quaternary ammonium salt, the corrosion synergist is pyroantimonate, and the iron ion stabilizer is sodium nitrilotriacetate and sodium erythorbate. The drainage aid comprises the following components in weight percentage: 75% of polyoxyethylene ether, 10% of ethylene glycol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com