Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

414 results about "Mannich base" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

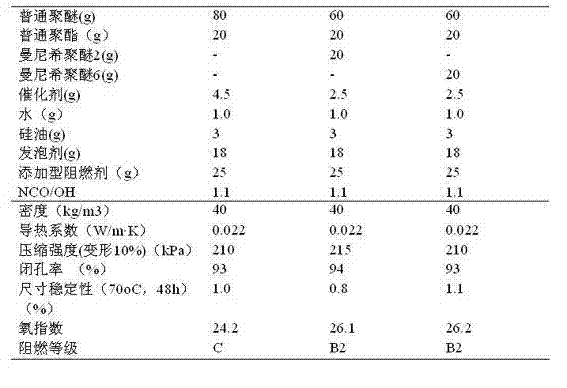

A Mannich base is a beta-amino-ketone, which is formed in the reaction of an amine, formaldehyde (or an aldehyde) and a carbon acid. The Mannich base is an endproduct in the Mannich reaction, which is nucleophilic addition reaction of a non-enolizable aldehyde and any primary or secondary amine to produce resonance stabilized imine (iminium ion or imine salt). The addition of a carbanion from a CH acidic compound (any enolizable carbonyl compound, amide, carbamate, hydantoin or urea) to the imine gives the Mannich base.

High temperature acidified corrosion inhibitor for oil passageway containing Cr

The invention relates to a high-temperature acidizing inhibiter containing a Cr oil pipe. A main agent A comprises the following compositions by weight portion: 25 to 35 portions of quinoline quaternary ammonium salt or quinoline derivate quaternary ammonium salt, 5 to 10 portions of potassium iodide, and 40 to 60 portions of organic solvent methanol or formaldehyde. An addition agent B comprises the following compositions by weight portion: 30 to 50 portions of Mannich base, 15 to 35 portions of propiolic alcohol, 5 to 15 portions of chromic chloride, and 20 to 35 portions of formaldehyde. During use, the proportion of A to B is 2-1.5:1 according to the weight portions, in an environment of 15 percent HCl+3 percent HF mud acid and 20 percent hydrochloric acid, inhibitions to super 13Cr at 100 DEG C, 120 DEG C and 140 DEG C all accord with acidizing standard requirement; and according to SY / T5405-1996 acidizing inhibiter performance test method and evaluating indicator, corrosion velocity of the inhibiter is lower than 40g / m<2>h at 140 DEG C. The inhibiter achieves the requirement of primary standard, and solves the problem of acidizing corrosion of Cr-contained steel in a high-temperature oil well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Benzylated mannich base curing agents, compositions, and methods

ActiveUS20170240691A1Improve compatibilityFaster amine-epoxy reaction rateAmino preparation from aminesEpoxy resin coatingsEpoxyHydrogen

Compositions and curing agents comprising a benzylated Mannich base composition. The benzylated Mannich base composition includes a reaction product of (a) a substituted phenolic compound having at least one substituent of formula (I):wherein R1 is each independently a linear or branched alkyl group having 1 to 4 carbon atoms, and R2 is hydrogen, methyl, ethyl or phenyl, with (b) a benzylated polyalkylene polyamine (II):wherein RA is substituted or unsubstituted benzyl; RB is each independently RA, or a hydrogen atom, or a group selected from C1-C16 linear, cyclic, and branched alkyl, alkenyl, and alkaryl groups; X, Y, and Z are independently selected from C2-C10 alkylene, and cycloalkylene groups; y is an integer from 0 to 7, and z is an integer from 0 to 4; and, optionally, (c) a multifunctional amine. Amine-epoxy compositions and articles produced from these compositions are also disclosed.

Owner:EVONIK OPERATIONS GMBH

Preparation method and applications of reaction type Mannich polyether polyol with permanent flame retardant effect

The invention provides a preparation method of reaction type Mannich polyether polyol with permanent flame retardant effect. The preparation method of reaction type Mannich polyether polyol with permanent flame retardant effect comprises the following steps: reacting paraformaldehyde or formaldehyde solution with diethanol amine to obtain 3-ethoxyl-1,3-oxazolidine reaction liquid, and then carrying out reduced pressure distillation to obtain the product 3-ethoxyl-1,3-oxazolidine; reacting aromatic phenol compounds or / and melamine compounds with 3-ethoxyl-1,3-oxazolidine to obtain Mannich base as intermediate; and carrying out polymerization reaction between the intermediate Mannich base and epoxy compound to obtain crude product of reaction type Mannich polyether polyol with permanent flame retardant effect, then carrying out reduced pressure distillation to remove impurities with low boiling points, and thus obtaining finished product. The reaction type Mannich polyether polyol simultaneously has the high stability and thermal stability of rigid polyurethane foam and the flame resistance of phenolic foam, is applied to foaming rigid polyurethane foam, and has wide application prospect.

Owner:JIANGSU YOKE TECH

High temperature acidizing corrosion inhibitor and preparation method thereof

ActiveCN101892042AReduce dosageGood corrosion inhibitionDrilling compositionBorehole/well accessoriesStructural formulaPhenyl group

The invention relates to a high temperature acidizing corrosion inhibitor. The corrosion inhibitor consists of 45 to 60 weight parts of mannich base quaternary ammonium salt, 15 to 30 weight parts of dimethylformamide and 20 to 35 weight parts of isopropanol, wherein the mannich base quaternary ammonium salt has a structural formula shown as a formula (I); n is an integer of 0 to 3; R is a low alkyl group substituted phenyl group, a low alkyl group substituted carboxyl group and low alkyl group substituted hydroxyl group; and R1 and R2 are the low alkyl group and the low phenyl group respectively. The invention also relates to a method for preparing the high temperature acidizing corrosion inhibitor. The high temperature acidizing corrosion inhibitor is used as a corrosion inhibitor in oil field exploitation.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method of improving the acrylic rubber sealant compatibility in an internal combustion engine

InactiveUS20070184992A1Improve compatibilityAdditivesFoam dispersion/preventionSimple Organic CompoundsAcrylic rubber

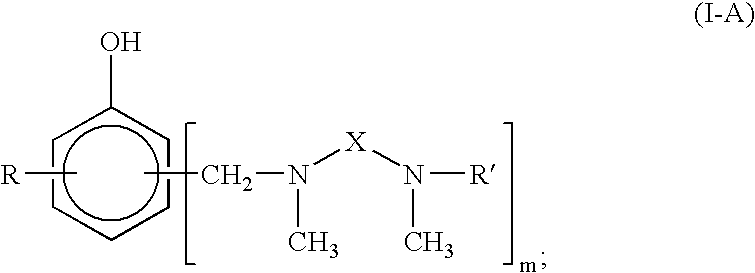

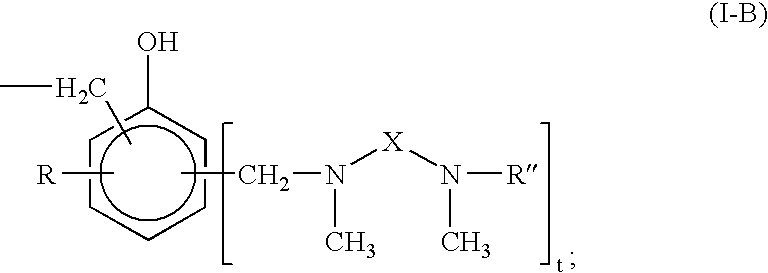

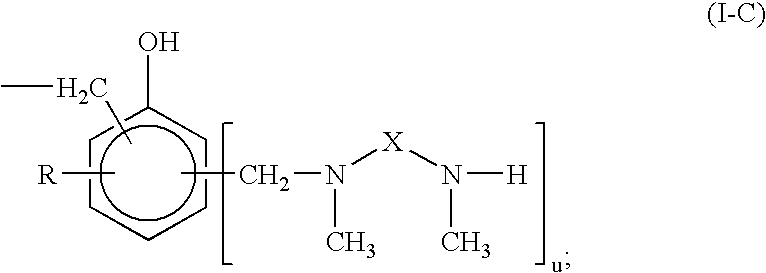

It has been discovered that a lubricating oil composition containing a certain combination of a nitrogen-containing dispersant and a metal-containing detergent of an alkali metal salt of alkylphenol derivative having a Mannich base structure, together with a phosphorus-containing organic compound, can be effectively employed in a method for improving the acrylic rubber sealant compatibility in an internal combustion engine, if the ratio of the nitrogen-containing dispersant and a metal-containing detergent of an alkali metal salt of alkylphenol derivative having a Mannich base structure is adjusted to a specific range, i.e., in the range of from 1:0.005 to 1:2 in terms of the nitrogen contents.

Owner:CHEVRON JAPAN

Non-ionic self-emulsifying epoxy resin curing agent and preparation method thereof

The invention discloses a non-ionic self-emulsifying epoxy resin curing agent and a preparation method thereof. The method comprises that polyethylene glycol and epoxy resin of low molecular weight are adopted to pre-prepare a water-based chain segment under the function of a catalytic agent, the water-based segment is reacted with a mannich base which is prepared from cardanol, formaldehyde and polymine, and at the same time, organosilicone is added to conduct partial end blocking, compatibility of a system on an inorganic component is increased, and the non-ionic cashew phenol amine epoxy curing agent with the self-emulsifying capacity is obtained. The natural cardanol and the polyethylene glycol in the main raw materials of the curing agent have no adverse effect on environment. The prepared curing agent integrates the advantages of non-ionic emulsion and cashew phenol amine.

Owner:GUANGDONG UNIV OF TECH

Activated arylamine-based polybenzoxazines

InactiveUS6160079AFacilitate ring openingLow polymerization temperatureSilicon organic compoundsGlass transitionElectron

Arylamines with electron donating groups such as alkyl and alkoxy groups in the meta position on the aromatic ring change the polymerization temperature of the benzoxazine prepared therefrom and offer an opportunity for an additional crosslinking site (the para position on the aromatic amine can couple to a Mannich base generated by the opening of the oxazine ring of the benzoxazine or a methylene bridge generated by a degradation reaction). Naphthenic amines with an alkyl or alkoxy substituent on the 5th through the 8th carbon atom on the naphthalene ring can function similarly. The polymers for benzoxazines prepared from at least 10% substituted aromatic or naphthenic amines are useful due to low polymerization temperatures and higher Tg (glass transition temperature).

Owner:EDISON POLYMER INNOVATION EPIC

Low-sulfur diesel oil multi-effect additive composition

A multi-effect additive composition for low-sulfur diesel includes: components A and B at weight ratio of (A):(B) = 1:0.1-10, wherein, component A consisting of reacted product or mixture of Mannich base, which is prepared from polyolefin phenol, C1-C6 aldehyde and polyenoic polyamines, and phenol acid; and component B consisting of reacted product or mixture of natural oil fat and amine and / or alcohol. The additive achieves additive amount 50-2000ppm as diesel wear resisting agent, stabilizing agent and dispersing agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of acidizing corrosion inhibitor in high-temperature and concentrated acid environment

InactiveCN105419774AImprove high temperature resistanceImprove solubilityDrilling compositionSolubilityAlcohol

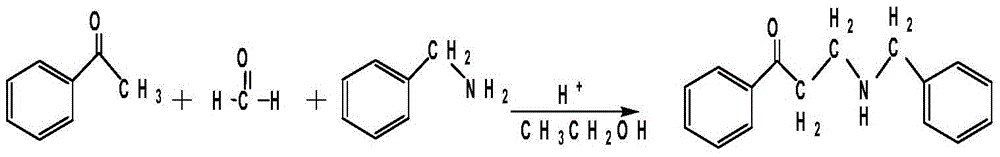

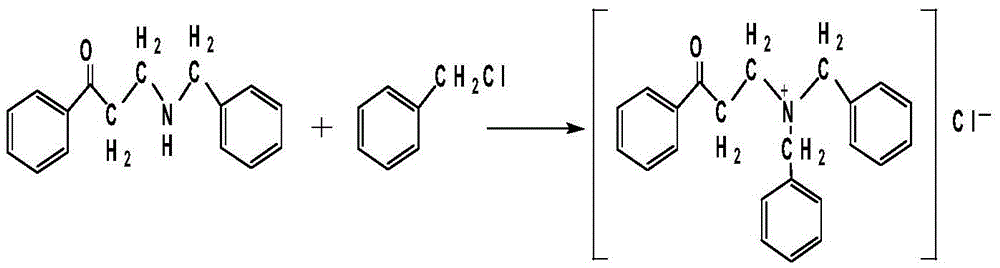

The invention relates to a preparation method of acidizing corrosion inhibitor in a high-temperature and concentrated acid environment. The preparation method is used for an acidification technology in carbonate oil reservoir exploration and overcomes the problem that existing high-temperature acidification corrosion inhibitor is poor in solubility and dispersion in use and prone to coking. According to the technical scheme, firstly, formaldehyde, benzene methanamine, absolute ethyl alcohol and concentrated hydrochloric acid are added into a three-necked flask, and then the three-necked flask is placed into an oil bath pan with the temperature being 110 DEG C for conducting a reaction for 2 hours; then, acetophenone is added, the pH is adjusted to 4 through concentrated hydrochloric acid, a reaction is conducted for 4 hours, and a coarse mannich base is obtained; thirdly, a vacuum rotary evaporation instrument is utilized for purification, separation is conducted, and a mannich base intermediate is obtained; fourthly, after the intermediate obtained in step 3 is washed, benzyl chloride is added, a reaction is conducted for 6 hours at the temperature of 110 DEG C, evaporation and separation are conducted through the vacuum rotary evaporation instrument, and mannich base quaternary ammonium salt is obtained; finally, potassium iodide is added in the mannich base quaternary ammonium salt stirring process for conducting mixed distribution, and the high-temperature acidizing corrosion inhibitor is obtained. The acidizing corrosion inhibitor has good solubility and dispersion, can further improve corrosion inhibition efficiency and is good in stability.

Owner:SOUTHWEST PETROLEUM UNIV

Diesel fuel additive

ActiveUS20110302828A1Improve stabilityReduce and prevent visible depositCombustion enginesLiquid carbonaceous fuelsPolystyreneSuccinic acid

A diesel fuel additive composition, a fuel containing the fuel additive, a method for improving diesel engine performance using the additive and a method for making the additive for diesel engines having a high pressure fuel injection system. The fuel additive has a number average molecular weight (Mn) of from about 500 to about 10,000 and is selected from a hydrocarbyl-substituted succinic acid or anhydride or derivative thereof and a hydrocarbyl-substituted Mannich base. The additive has a molecular weight distribution such that less than about 25 wt. % of the additive has a molecular weight of 400 or less as measured by gel permeation chromatography (GPC) based on a polystyrene calibration curve.

Owner:AFTON CHEMICAL

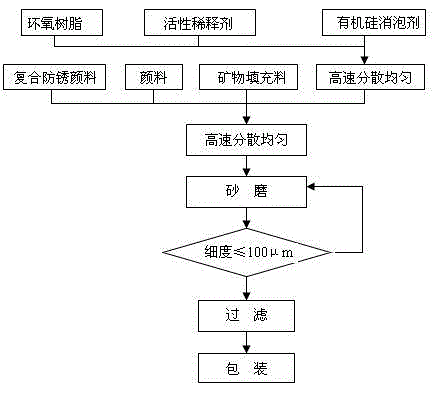

Solvent-free epoxy weight anticorrosion paint used for coated joints of steel buried pipeline

ActiveCN102719171AModerate viscosityEasy constructionAnti-corrosive paintsEpoxy resin coatingsSolvent freePolyamide

The invention introduces a solvent-free epoxy weight anticorrosion paint used for coated joints of a steel buried pipeline, which comprises a component A and a component B; wherein the mass percentage of each raw material in the component A comprises: 30-45% of epoxy resin, 5-15% of glycidyl ether active diluent, 0.05%-1% of silicone defoamer, 20-35% of compound anti-rust pigment, 3-10% of other pigments, 5-15% of barium sulfate mineral filler, 10-20% of other mineral fillers and 0.3-1.5% of polyamide wax; the mass part of each raw material in the component B comprises: 10-25 parts of polyamide curing agent, 5-15 parts of Mannich base and 0.5%-2 parts of curing accelerator; and the mass ratio of the component A to the component B is 100 to 15-35. The paint provided by the present invention has the advantages of pure epoxy, environmental friendly performance and saved resource due to solvent-free property; and is capable of raising the anti-corrosive property, chemical resistance property and insulating property; and is capable of raising the toughness resistance, wear resistance and impact resistance of the coating by employing the mineral fillers.

Owner:XIAMEN SUNRUI SHIP COATING

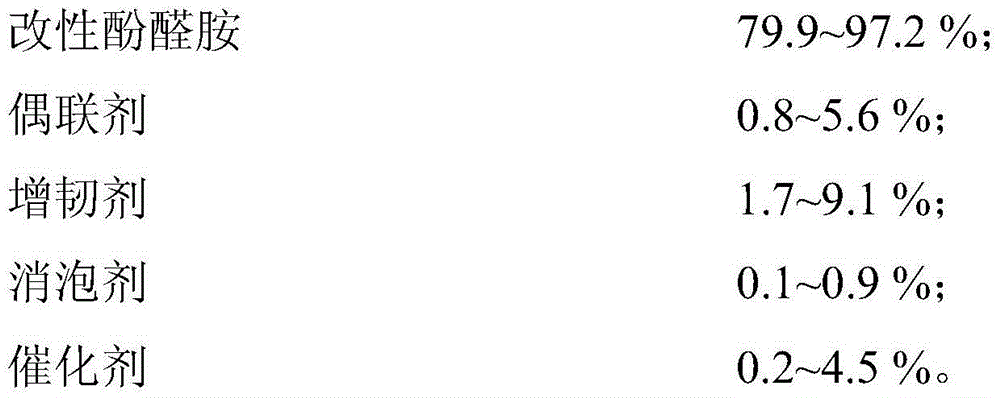

Epoxy resin solvent-free low temperature curing agent, preparation method and application thereof

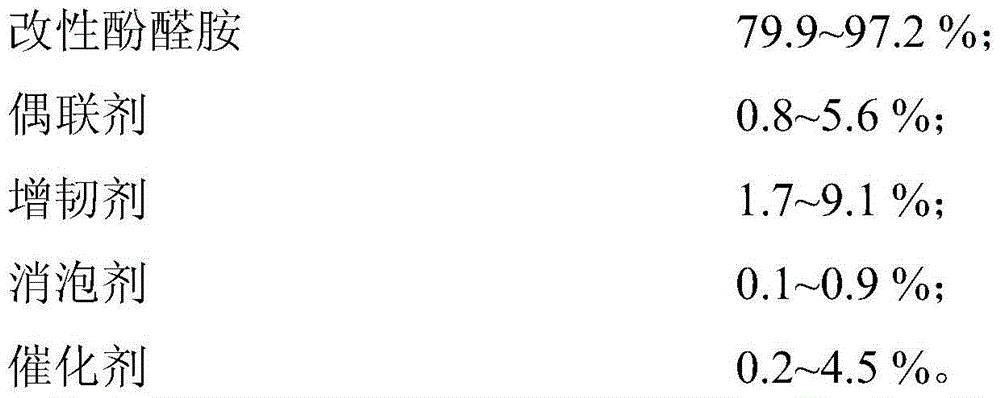

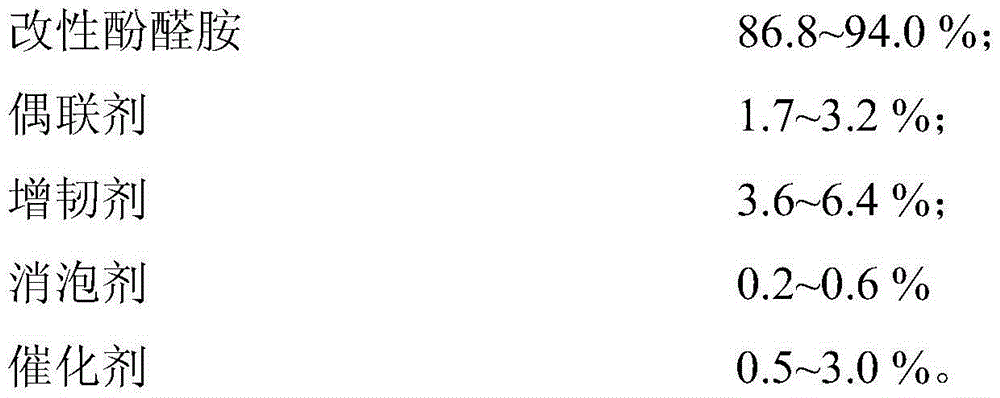

The invention belongs to the technical field of epoxy resin curing agent preparation technology, and discloses an epoxy resin solvent-free low temperature curing agent, a preparation method and an application. The curing agent can be better used in cement mortar and used for preparing epoxy grouting material under low temperature in water environment. The curing agent comprises the following components by mass percentage: 79.9-97.2% of modified phenolic amine, 0.8-5.6% of coupling agent, 1.7-9.1% of flexibilizer, 0.1-0.9% of antifoaming agent and 0.2-4.5% of catalyst. According to the invention, thiourea group is introduced, thiourea modified amine, polyamine, long chain alkylphenol and paraformaldehyde are performed a Mannich reaction to synthesize novel thioureido-containing Mannich base, so that solidification rate under low temperature environment is increased, disadvantage of poor solidification efficiency under wet surface and water can be overcome, and a silane coupling agent is added for improving surface tension of system contact surface and increasing the solidification efficiency under water environment.

Owner:国科广化(南雄)新材料研究院有限公司

Compound corrosion inhibitor suitable for seawater corrosion medium and preparation method of compound corrosion inhibitor

ActiveCN103993321AGood water solubilitySimple production processZINC SULFATE HEPTAHYDRATESodium gluconate

The invention discloses a compound corrosion inhibitor suitable for a seawater corrosion medium and a preparation method of the compound corrosion inhibitor. The compound corrosion inhibitor is composed of the following components in percentage by mass: 40-60% of linseed oil Mannich base quaternary ammonium salt, 1-5% of sodium gluconate, 2-10% of zinc sulfate heptahydrate, 5-10% of sodium molybdate and 20-40% of isopropanol, wherein the percentage sum of all the components is equal to 100%. The compound corrosion inhibitor has the beneficial effects of low cost, environment friendliness and good corrosion inhibiting effect.

Owner:江苏德威涂料有限公司

High-solid surface-tolerant epoxy zinc-rich primer and preparation method and application thereof

ActiveCN110144160AIncrease crosslink densityImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsChemical industryEpoxy

The invention relates to a high-solid surface-tolerant epoxy zinc-rich primer. The primer is prepared from a component A and a component B according to a weight ratio of (16-20):1; the component A comprises the following components in parts by weight: 5-9 parts of liquid phenolic epoxy resin, 6-15 parts of E20 solid epoxy resin, 0.5-1.5 parts of an active diluent, 0.1-0.3 part of a dispersing agent, 70-80 parts of main rust-proof pigment, 2-6 parts of chemical anti-rust pigment, 1.5-2.5 parts of an anti-settling agent and 3-4 parts of an organic mixed solvent; and the component B comprises thefollowing components in parts by weight: 1.5-2.5 parts of a polyamide curing agent, 2-3 parts of a Mannich base curing agent, 0.3-0.6 part of a silane coupling agent and 0.2-0.6 part of an organic mixed solvent. The invention also relates to a preparation method of the primer and a coating film. The primer is high in solid content and low in VOC content, is resistant to corrosion, has a long effect, has good adhesive force and salt fog resistance, and is particularly suitable for repairing and maintaining equipment in industries such as chemical industry, thermoelectricity, machinery and thelike.

Owner:江阴市大阪涂料有限公司

Low-surface treatment solvent-free epoxy weight anticorrosion paint capable of painting under water

InactiveCN101492586ADense coatingStrong adhesionAntifouling/underwater paintsPaints with biocidesSolvent freeFirming agent

A solventfree epoxy heavy-duty coating which can be treated on the lower surface and coated underwater is divided into first division distribution ratio and second division distribution ratio; wherein, the first division distribution ratio comprises the ingredients based on the parts by weight: 20-50 parts of epoxide resin, 4-7 parts of reactive diluent, 0.06-1 part of defoaming agent, 4-7 parts of special fatty acid soap, 0.5-2 parts of aerosol, 5-10 parts of mineral water absorber, 20-50 parts of packing material and 5-10 parts of pigment; the second division distribution ratio comprises the ingredients based on the parts by weight: 65-85 parts of mannich base firming agent and 15-35 parts of organic nitrogen base. As the epoxide resin with low molecular weight, the special fatty acid soap, the organic nitrogen base and the mineral water absorber are adopted, the heavy-duty coating can be coated in the wet underwater environment with rust, the coating is dense, and the adhesive force is strong. Therefore, the solventfree epoxy heavy-duty coating reduces the number of coating channels, improves the efficiency of construction, lowers the construction cost and prolongs the service life of corrosion resistance; when being solidified underwater, the coating has no problem of solvent volatilization, and can plays the role of protection effectively for a long time, thus overcoming the defect that solvent based coating brings pollution to the water environment due to solvent volatilization, and having absolute cost performance.

Owner:XIAMEN SUNRUI SHIP COATING

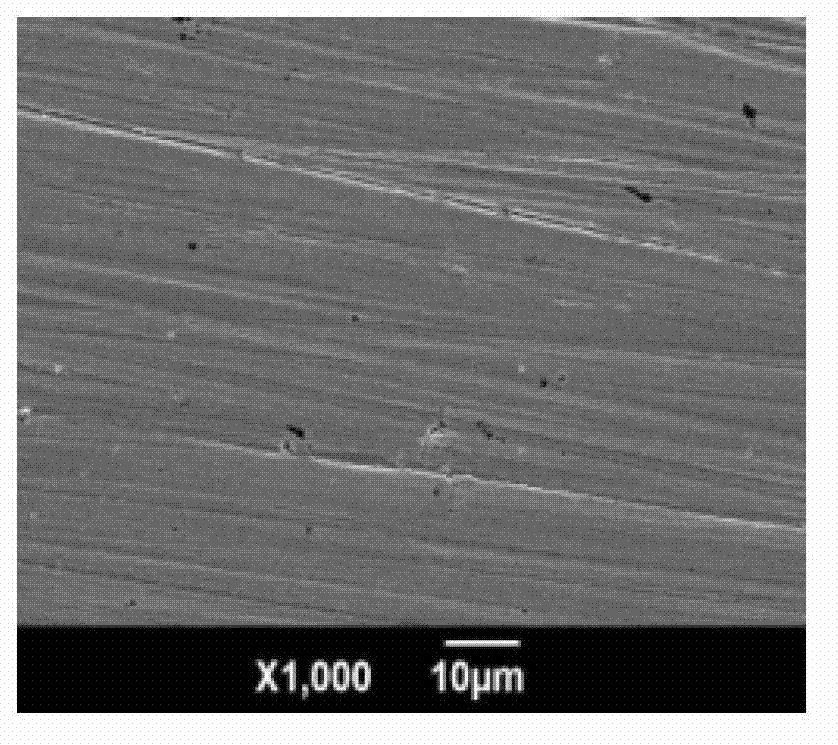

Solvent-free epoxy heavy-duty anticorrosive coating for automatic spraying for online repairing of petroleum pipelines

InactiveCN101638546AImprove anti-corrosion performanceGood chemical resistancePipe elementsAnti-corrosive paintsLow speedLacquer

The invention relates to a solvent-free epoxy heavy-duty anticorrosive coating for automatic spraying for online repairing of petroleum pipelines, which consists of a first component coating containing a paint vehicle and a second component coating containing a curing agent, wherein the first component comprises the following materials in portion by weight: 30 to 60 portions of epoxy resin, 5 to 15 portions of glycidyl ether reactive diluent, 0.05 to 1 portion of silicone antifoaming agent, 20 to 35 portions of nano anticorrosive pigment, 7 to 25 portions of silicon dioxide mineral filler, and3 to 10 portions of pigment. The second component comprises the following materials in portion by weight: 15 to 35 portions of mannich base, 15 to 35 portions of cardanol curing agent, 3 to 10 portions of polyamide wax, and 30 to 55 portions of silicon dioxide mineral filler. The first component and the second component are dispersed evenly at a high speed and a low speed respectively, and then packaged after being filtered by an 80-mesh filter screen. The solvent-free epoxy heavy-duty anticorrosive coating can realize the automatic spraying for the online repairing, can be applied to the automatic spraying for corrosion protection of a newly-built pipework, and can also be applied to the corrosion protection of other steel structure and reinforced concrete works.

Owner:XIAMEN SUNRUI SHIP COATING

High-temperature acidifying inhibiter and preparation method thereof

InactiveCN101643642AReduce moisture contentAvoid hydrolysisDrilling compositionBenzyl chlorideAcetophenone

The invention relates to a high-temperature acidifying inhibiter and a preparation method thereof. The high-temperature acidifying inhibiter comprises the following materials in parts by weight: 79.33-87.68 of ethanol, 19-21 of methanoic acid, 22.33-24.68 of aniline, 31.11-34.39 of acetophenone, 26.13-28.88 of methanal, 31.54-34.86 of benzyl chloride and 8.55-9.45 of propiolic alcohol, wherein theethanol, the methanoic acid and the aniline are placed into a reaction kettle to be stirred; then the acetophenone is added into the reaction kettle; then a methanal solution is dripped into the reaction kettle; the benzyl chloride is added into the reaction kettle after the methanal solution is dripped into the reaction kettle; the temperature of the reaction kettle is reduced to room temperature, and then the propiolic alcohol is added into the reaction kettle to be stirred. The water content inside the reaction kettle is low without adding an aqueous hydrochloric acid solution so as to prevent the benzyl chloride from hydrolyzing and be beneficial to reducing the unit consumption of the benzyl chloride in the quaterisation reaction process; before the methanal is completely dripped, the amount of the methanal dripped into the reaction kettle is less than the reaction mole ratio of synthetic Mannich base, the methanal is in an insufficient state so as to reduce the volatilization ofthe methanal, ensure the health of operators and be safer.

Owner:SHOUGUANG YUXIN CHEM IND

Mannich base as well as preparation method and uses thereof

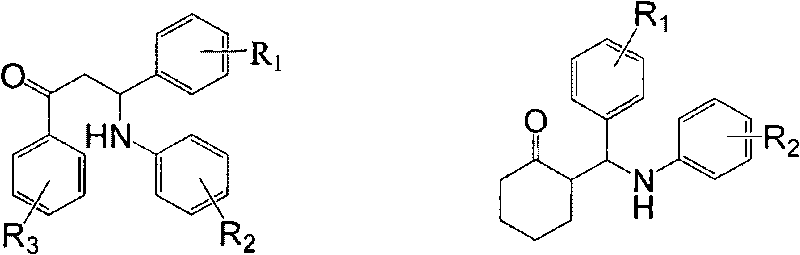

The present invention relates to a mannich base which is synthesized by the mannich reaction of dimeric cyclohexanone and formaldehyde with at least one kind of polyamine, wherein, the dimeric cyclohexanone is the dimer of the cyclohexanone, comprising the single or mixed form of 2-(1-cyclohexenyl) cyclohexanone, 2-(1-cyclohexyl) cyclohexanone and 2-(1-cyclohexylidene) cyclohexanone. The concrete preparation method of the product of the present invention is characterized in that by-product containing dimeric cyclohexanone autoclave liquid during the process of the cyclohexanone production is processed for the saponification treatment to collect the dimeric cyclohexanone by distilling (or obtain the dimeric cyclohexanone product directly), the dimeric cyclohexanone and the formaldehyde react with at least one kind of the polyamine for one to ten hours under 10 DEG C to 100 DEG C to be dehydrated to obtain the product. The product of the present invention is mainly used as curing agent to be applied in an epoxy system or a polyurethane system.

Owner:YUEYANG CHANGDE CHEM IND

Method for preparing cold-recycling asphalt emulsification additive

ActiveCN103113618AGood emulsifying effectImprove stabilityOrganic compound preparationBuilding insulationsEthylene oxideAlkylphenol

The invention relates to a method for preparing a cold-recycling asphalt emulsification additive. The method comprises the following steps of: (1) adding polyamine to aldehyde solution, and carrying out reaction so as to produce aldimine solution; (2) cooling down, and reacting produced aldimine with alkylphenol so as to produce mannich base solution; and (3) adding an epoxy ethane derivative, and carrying out reaction, thereby obtaining the cold-recycling asphalt emulsification additive. The method has the advantages that the synthesis process is simple, the reaction conditions are mild, the yield is high, and the industrialization is easily realized. The emulsifying property and normal-temperature storage stability of emulsified asphalt prepared through the cold-recycling asphalt emulsification additive are good; and a cold-recycling asphalt mixture prepared from the emulsified asphalt is better in road performance, various strengths are obviously increased, and various other properties all meet the cationic emulsified asphalt standard established by the Ministry of Communications and the technical indicator on mixing performance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

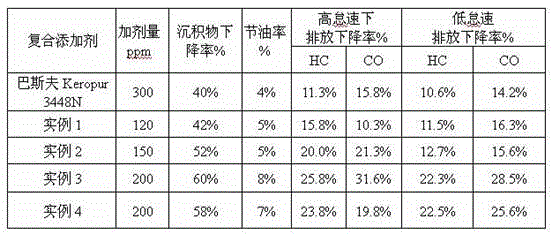

Composite high-cleanness fuel oil additive and preparation method thereof

ActiveCN105647600AImprove detergencyReduce wearLiquid carbonaceous fuelsFuel additivesCombustion chamberHazardous substance

The invention relates to the field of oil product additives, in particular to a composite high-cleanness fuel oil additive and aims at providing a composite high-cleanness fuel oil additive for improving the dynamic properties, cleanness and corrosion and abrasion resistance of fuel oil and a preparation method thereof. The composite high-cleanness fuel oil additive is prepared from, by mass, a detergent main agent 10-60%, an anti-abrasion agent 0-10%, a corrosion inhibitor 0-10%, an antioxidant 0-5%, carrier oil 15-40% and the balance a thinner, wherein the detergent main agent is one or more of polyisobutylene phenol mannich base, PEA polyether amine and polyisobutylene amide. The fuel oil adopting the composite additive has good cleanness, the colloid, carbon deposition and coking at automobile jet nozzles, throttle valves, combustion chambers and other parts can be obviously reduced, the abrasion of components of a fuel system can be reduced, the oxidative deterioration of the fuel oil and the additive can be inhibited, and the harmful substances in engine tail gas emissions can be reduced.

Owner:SHAANXI YANCHANG PETROLEUM ENERGY TECH CO LTD

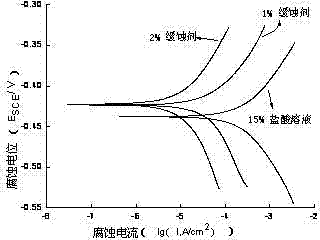

Preparation method and application of low toxicity acidizing corrosion inhibitor

InactiveCN103289663AEasy to degradeProduction operation safetyOrganic chemistryOrganic compound preparationAcid fracturingCarcinogen

The invention discloses a preparation method and application of a low toxicity acidizing corrosion inhibitor. The preparation method mainly includes two steps: 1. synthesizing a Mannich base quaternary ammonium salt; and 2. diluting the Mannich base quaternary ammonium salt to 15-20% (mass percentage) with a solvent. The corrosion inhibitor disclosed in the invention is a typical adsorption type corrosion inhibitor, can rapidly form a compact and firm hydrophobic protective membrane on the surface of a P110 steel test piece, thus effectively preventing an acid solution from corroding P110 steel. The corrosion inhibitor prepared in the invention belongs to a mixed corrosion inhibit inhibitor. The inhibitor employs cinnamic aldehyde with the advantages of the green, low toxicity, easy degradation and the like to replace the cancerogenic substance formaldehyde, is not added with iodide, alkynol or other synergists polluting the environment, has the advantages of simple synthesis process, small dosage, low toxicity, etc., and is suitable to oil and gas well acidizing, acid fracturing stimulation and other operations.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Curing Agent For Low Temperature Cure Applications

ActiveUS20090259003A1Improved “ walk-on ” dry timeRapid hardness developmentIsocyanic acid derivatives preparationOther chemical processesEpoxyEndcapping

The present invention provides Mannich base derivatives of N,N′-dimethyl secondary diamine polymers including Mannich base derivatives of methylamine-terminated poly-(N-methylazetidine) and Mannich base derivatives of methylamine-terminated poly-(N-methylazacycloheptane). Amine curing agent compositions and amine-epoxy compositions containing Mannich base derivatives of N,N′-dimethyl secondary diamine polymers are also disclosed.

Owner:EVONIK OPERATIONS GMBH

Mannich base metal iodide corrosion inhibitor and preparation method thereof

ActiveCN102533245AProtection is in progressSolve the shortcomings of easy decompositionCopper organic compoundsPotassium organic compoundsIodideStrong acids

The invention discloses a Mannich base metal iodide corrosion inhibitor and a preparation method thereof. The Mannich base metal iodide corrosion inhibitor comprises components of the following mass percentage: 15 to 30 percent of the metal iodide of a condensate of ketone, aldehyde and amine, and 70 to 85 percent of complex, wherein the complex is made up of following materials with mass percentof: 5 to 15 percent of cetylpyridinium chloride, 5 to 20 percent of emulsifier, and 65 to 80 percent of solvent. The metal iodide of a condensate of ketone, aldehyde and amine can be obtained by reaction of the metal iodide and the condensate of ketone, aldehyde and amine synthesized with 1-naphthy lamine, paraformaldehyde, and ethyl phenyl ketone. The problem that other corrosion inhibitors can be easily decomposed at high temperature can be solved, the inconvenience in production caused by toxic material can be reduced, acidification and corrosion of hydrochloric acid at high temperature can be inhibited, the problem of corrosion by strong acid during the acidification fracturing of petroleum exploitation can be solved, and the goal of protecting oil pipes can be achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Mixed Detergent Composition for Intake Valve Deposit Control

ActiveUS20160289584A1Improve performanceImprove economyLiquid carbonaceous fuelsFuel additivesGasoline fuelInlet valve

A detergent additive package, fuel additive concentrate, fuel composition and method for operating an engine on an unleaded gasoline fuel. The additive package includes a Mannich base detergent mixture, wherein the mixture contains a first Mannich base detergent component derived from a di- or polyamine and a second Mannich base detergent component derived from a monoamine. A weight ratio of the first Mannich base detergent to the second Mannich base detergent in the mixture ranges from about 1:6 to about 3:1.

Owner:AFTON CHEMICAL

Mannich base type acidizing corrosion inhibitor and preparation method thereof

InactiveCN104560005ABarrier to osmosisRaise the reaction energy barrierDrilling compositionBorehole/well accessoriesEnvironmental resistanceSynthesis methods

The invention relates to a mannich base type acidizing corrosion inhibitor and a preparation method thereof. The mannich base type acidizing corrosion inhibitor is characterized by being prepared from the following components in percentage by mass: 25-30% of a host corrosion inhibitor, 30-45% of an organic solvent and 30-40% of water. The preparation method comprises the following steps: (1) adding 2-mercaptobenzothiazole and benzaldehyde, or 2-mercaptobenzothiazole and furfural or 2-mercaptobenzothiazole and cinnamyl aldehyde in a mole ratio of 1.0:(1.0-1.8) as a host corrosion inhibitor raw material into ethanol, mechanically stirring, slowly dropping adding phenylamine, adjusting the pH value of the solution to be 2-4, implementing reaction for 4-10 hours at 75-90 DEG C, and cooling to be the room temperature, thereby synthesizing a host corrosion inhibitor mannich base compound; and (2) dissolving the host corrosion inhibitor in an organic solvent according to a ratio, and uniformly mixing and stirring with water, thereby obtaining the mannich base type acidizing corrosion inhibitor. As synthesized raw materials which are environment-friendly, low in toxicity and easy to degrade are adopted, the acidizing corrosion inhibitor provided by the invention can effectively prevent corrosion of an acid liquid to metal, and has the characteristics of simple synthesis method, safe production and operation, stable and remarkable corrosion inhibition property, low cost and environment friendliness.

Owner:YANGTZE UNIVERSITY

High-temperature O2/CO2 corrosion inhibitor for coiled tubing and preparation method of agent B of high-temperature O2/CO2 corrosion inhibitor

ActiveCN102627955AEnsure safe operationAvoid corrosionBorehole/well accessoriesSulfite saltMannich reaction

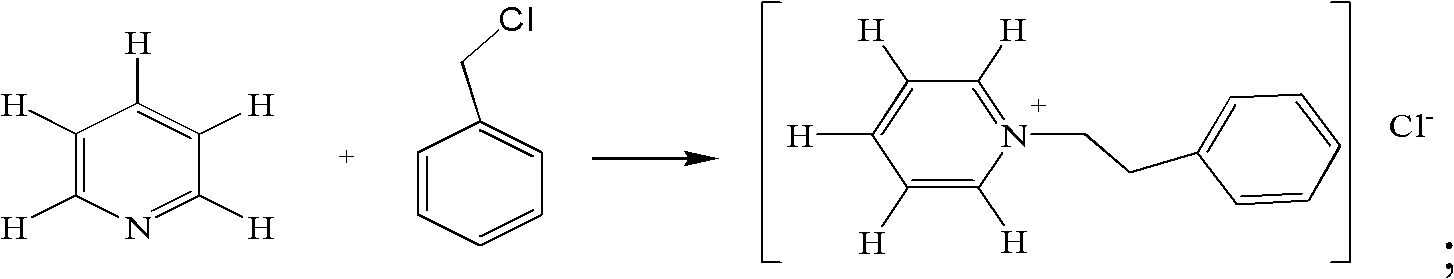

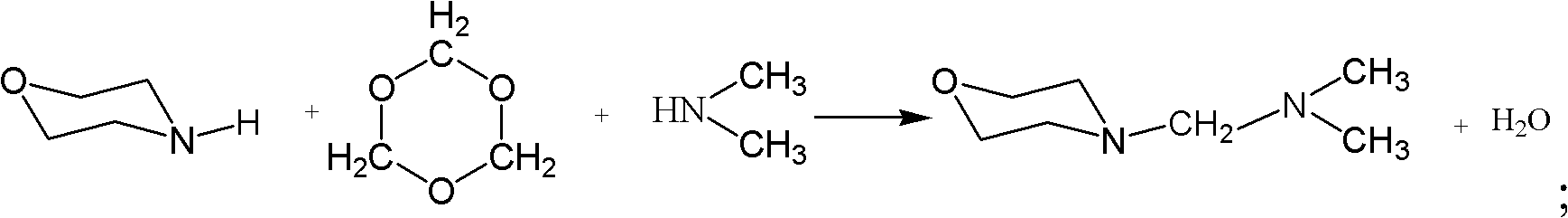

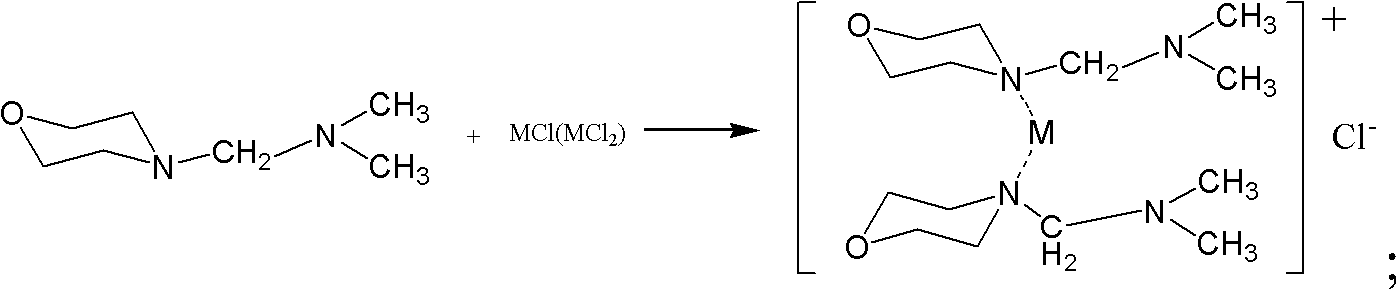

The invention discloses a high-temperature O2 / CO2 corrosion inhibitor for coiled tubing. The high-temperature O2 / CO2 corrosion inhibitor for the coiled tubing is used by matching an agent A mainly used for deoxidizing and an agent B mainly used for resisting corrosion of carbon dioxide, wherein the agent A is acetone oxime, D-ascorbic acid, sodium sulfite or ferrous sulphate; and the agent B is formed by mixing the components in percentage by weight: 20-30 percent of quaternary pyridine salt, 10-15 percent of mannich base chelate, 3-7 percent of surfactant and 48-67 percent of solvent. The quaternary pyridine salt is obtained by reacting pyridine with benzyl chloride; and the mannich base chelate is obtained by aldehyde ketone amine condensate generated by morpholine, trioxymethylene and dimethylamine through a mannich reaction with metal chloride. The corrosion inhibitor provided by the invention has use temperature up to 170DEG C, is suitable for a water-corrosive medium in which oxygen and carbon dioxde coexist and can be used for effectively inhibiting the corrosion of media such as the oxygen and the carbon dioxide and ensuring safe operation of the coiled tubing in the production process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparing method of mannich base

InactiveCN101717320ALow costImprove securityOrganic compound preparationAmino group formation/introductionRoom temperatureKetone

The invention provides a preparing method of mannich base. The method takes three components of aldehyde, amine, ketone or naphthol as a raw material, takes water as a solvent, and takes liquid superacid as a catalyst, the raw material, the solvent and the catalyst are reacted at normal pressure and room temperature, and then recrystallized and dried to obtain the product of mannich base. The method has the advantages of mild condition, convenient operation, environment protection, high efficiency, good selectivity, high productivity and easy realization.

Owner:ANYANG NORMAL UNIV

Diesel composition

ActiveCN101768484AImprove Oxidation StabilityImprove detergencyLiquid carbonaceous fuelsCarbon numberBiodiesel

The invention provides a diesel composition which contains base diesel and an additive, wherein the base diesel contains biodiesel and the additive contains a component a and a component b. The component a is prepared by the following method: mixing Mannich base generated by reaction of polyolefin-based phenol, aldehyde with carbon number being 1-6 and polyethylene polyamine with organic acid containing phenolic groups according to the molar ratio of the polyethylene polyamine in the Mannich base to the organic acid containing phenolic groups to react at 50-200 DEG C for 0.5-20h in the presence of solvents, wherein the molar ratio is 1:0.5-5. The component b is an arylamine antioxidant and / or a hindered phenol antioxidant. When taking the pure biodiesel as the base diesel, the diesel composition of the invention has better oxidation stability and detergency, and when taking the blended fuel containing biodiesel as the base diesel, the diesel composition has better stability, detergency and dispersancy.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of phenolic emulsifier, emulsified bitumen and its application

ActiveCN102516097AGood emulsificationThe synthesis process is simpleOrganic compound preparationBuilding insulationsAlkylphenolStructural formula

The invention relates to a preparation method of a phenolic emulsifier. The preparation method has advantages of simple synthesis technology, mild reaction condition and high yield, and is easy to realize industrialization. The invention also relates to emulsified bitumen emulsified by the phenolic emulsifier obtained by the above preparation method and an application thereof. The preparation method of the phenolic emulsifier contains the following steps of: performing a reaction between polyamines and aldehyde to generate aldimine, adding alkylphenol, performing a reaction to generate Mannich base, and acquiring the phenolic emulsifier, wherein the mol ratio of alkylphenol to aldehyde to polyamines is 1: (1-1.5): (1-1.5); alkylphenol is a compound as shown in the structural formula II; aldehyde is a compound as shown in the structural formula III; and polyamines is a compound as shown in the structural formula IV. The preparation method has advantages of simple synthesis technology, mild reaction condition and high yield, and is easy to realize industrialization. The emulsifier obtained by the preparation method has good emulsifying property. Each performance of the prepared emulsified bitumen meets the cationic emulsified bitumen standard and agitation performance technical indexes which are set by the Ministry of Communications.

Owner:JIANGSU SOBUTE NEW MATERIALS

Diverting acid for carrying out acidification and transformation on high-temperature oil and gas well with long well segment

InactiveCN102585797AUniform transformationHigh viscoelasticityDrilling compositionBetaineTemperature resistance

The invention relates to diverting acid for carrying out acidification and transformation on a high-temperature oil and gas well with a long well segment, which comprises the following components: 4.5 to 5.0 percent by mass of diverter octadecanoyl amido ethyl dimethylamine betaine, 1.0 to 2.0 percent by mass of corrosion inhibitor Mannich base, 1.0 to 2.0 percent by mass of ferric ion stabilizererythorbic acid or sodium erythorbate, 20 percent by mass of hydrochloric acid and the balance water. According to the invention, the characteristic that the diverting acid has different molecule aggregation morphologies and aggregation numbers under different pH values is utilized; the high temperature resistance diverting acid with viscoelasticity is prepared by adding the corrosion inhibitor Mannich base and the ferric ion stabilizer erythorbic acid or sodium erythorbate; and after the diverting acid is injected into a formation, the viscosity of the acid is rapidly improved along with theconsumption of the acid and the injection pressure at the bottom of the well also rises along with the consumption of the acid, so that the acid is forced to permeate and divert toward the formation,a reservoir is uniformly acidified and the acidification effect is obviously improved.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com