Preparation method of acidizing corrosion inhibitor in high-temperature and concentrated acid environment

An acidified corrosion inhibitor, high temperature technology, applied in the field of acidified corrosion inhibitor preparation, can solve the problems of poor dispersibility, easy coking and other problems, achieve excellent corrosion inhibition effect, reduce side reactions, good solubility and dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Example 1: A kind of preparation, dissolution dispersibility and storage performance measurement of acidification corrosion inhibitor used in high temperature concentrated acid environment, its specific steps are as follows:

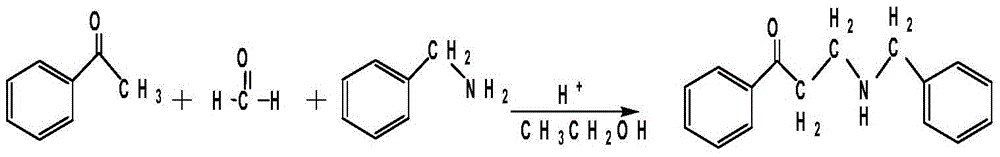

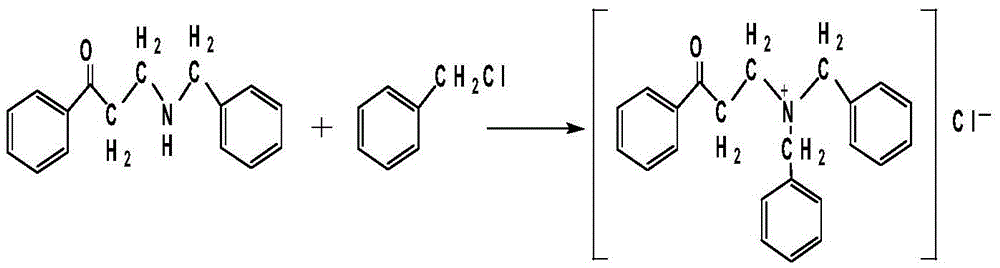

[0018] The first step "two-step method" synthesizes the Mannich base intermediate, using formaldehyde, benzylamine, and acetophenone as raw materials, wherein the molar ratio of the monomer raw materials used is: formaldehyde: benzylamine: acetophenone=1 ~1.2:1~1.2:1. First add 7.20g of formaldehyde, 25.68g of benzylamine, 20ml of absolute ethanol as a solvent, 6ml of concentrated hydrochloric acid as a catalyst, in a three-necked flask equipped with a thermometer, a serpentine condenser and a stirrer and an oil bath at 110°C React in the pot, the reaction time is 2h, then add 24.00g of acetophenone, slowly add concentrated hydrochloric acid dropwise to adjust the pH value of the system to 4, react at the same temperature and stirring speed for 4h...

example 2

[0023] Example 2: a kind of preparation method and corrosion inhibition performance measurement of the acidification corrosion inhibitor used in high temperature concentrated acid environment, its concrete steps are as follows:

[0024] The first step "two-step method" synthesizes the Mannich base intermediate: take formaldehyde, benzylamine and acetophenone as raw materials, wherein the molar ratio of the monomer raw materials used is: formaldehyde: benzylamine: acetophenone=1 ~1.2:1~1.2:1. First add 6.90g of formaldehyde, 24.61g of benzylamine, 20ml of absolute ethanol as a solvent, 6ml of concentrated hydrochloric acid as a catalyst, in a three-necked flask equipped with a thermometer, a serpentine condenser and a stirrer and an oil bath at 110°C React in the pot, the reaction time is 2h, then add 24.00g of acetophenone, slowly add concentrated hydrochloric acid dropwise to adjust the pH value of the system to 4, react at the same temperature and stirring speed for 4h, and ...

example 3

[0034] Example 3: A kind of preparation method and the morphology observation of the acidification corrosion inhibitor used in the high temperature concentrated acid environment, its concrete steps are as follows:

[0035] The first step "two-step method" synthesizes the Mannich base intermediate: formaldehyde, benzylamine and acetophenone are used as raw materials, and the molar ratio of the monomer raw materials used is: formaldehyde: benzylamine: acetophenone=1~ 1.2:1~1.2:1. First add 6.00g of formaldehyde, 21.40g of benzylamine, 20ml of absolute ethanol as a solvent, 6ml of concentrated hydrochloric acid as a catalyst, in a three-necked flask equipped with a thermometer, a serpentine condenser and a stirrer and an oil bath at 110°C React in the pot, the reaction time is 2h, then add 24.00g of acetophenone, slowly add concentrated hydrochloric acid dropwise to adjust the reaction pH value to 4, react at the same temperature and stirring speed for 4h, and obtain the crude Ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com