Preparation method and applications of reaction type Mannich polyether polyol with permanent flame retardant effect

A Mannich polyether and reactive technology, which is applied in the field of preparation of reactive Mannich polyether polyols, can solve problems such as difficulty in use, high brittleness, powder drop, etc., and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

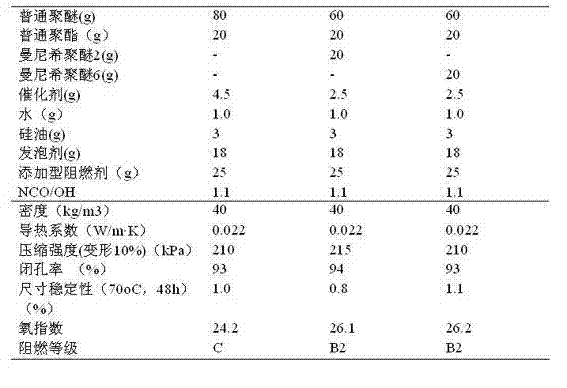

Examples

Embodiment 1

[0033] 1. Add 105g of diethanolamine and 30g of paraformaldehyde into a three-necked flask equipped with a mechanical stirrer, a thermometer and a condenser, raise the temperature to 70°C and keep it warm for 3 hours; then collect the fractions at 125-130°C / 8000Pa by vacuum distillation The product 3-hydroxyethyl-1,3-oxazolidine.

[0034] 2. Add 47g of phenol into a three-necked flask with mechanical stirring, thermometer and condenser and heat it to 70°C, stir and add 117g of 3-hydroxyethyl-1,3-oxazolidine dropwise, and keep warm for 5h after the dropwise addition. The intermediate Mannich base is obtained.

[0035] 3. Take 164g of the intermediate Mannich base and add it to the autoclave, add 3.3g of KOH, raise the temperature to 80°C and depressurize for 1h, replace the nitrogen for 3 times and then depressurize to -0.1MPa; feed ethylene oxide and raise the temperature React at 110°C, keep the reaction pressure at 0.4MPa, until the amount of ethylene oxide added reaches 8...

Embodiment 2

[0037] 1. Add 105g of diethanolamine and 83g of formaldehyde aqueous solution (37%) into a three-necked flask equipped with mechanical stirring, a thermometer and a condenser, raise the temperature to 80°C and keep it warm for 2h; then collect under reduced pressure distillation at 125-130°C / 8000Pa The fractions gave the product 3-hydroxyethyl-1,3-oxazolidine.

[0038] 2. Add 55g of hydroquinone to a three-necked flask equipped with a mechanical stirrer, a thermometer and a condenser and heat it to 90°C, stir and add 117g of 3-hydroxyethyl-1,3-oxazolidine dropwise, and the dropwise addition ends Incubate for 2h to obtain the intermediate Mannich base.

[0039] 3. Take 172g of the intermediate Mannich base and add it to the autoclave, add 1.3g of DMC catalyst, raise the temperature to 90°C and depressurize for 1h, replace the nitrogen for 3 times and then depressurize to -0.1MPa; feed propylene oxide and raise the temperature React at 120°C, keep the reaction pressure at 1MPa...

Embodiment 3

[0041] 1. Add 105g of diethanolamine and 30g of paraformaldehyde into a three-necked flask equipped with a mechanical stirrer, a thermometer and a condenser, raise the temperature to 60°C and keep it warm for 4 hours; then collect the fractions at 125-130°C / 8000Pa by vacuum distillation to obtain The product 3-hydroxyethyl-1,3-oxazolidine.

[0042] 2. Add 42g of melamine and 42g of deionized water into a three-necked flask equipped with mechanical stirring, a thermometer and a condenser, stir and heat to 60°C, add 117g of 3-hydroxyethyl-1,3-oxazolidine dropwise, drop After the addition, the temperature was kept for 7 hours, and the intermediate Mannich base was obtained after removing water under reduced pressure.

[0043] 3. Take 159g of the intermediate Mannich base and add it to the reactor, add 0.16g of Et2O·BF3 catalyst, 153g of epichlorohydrin (the molar ratio of the epoxy compound to the intermediate Mannich base is 3.3:1), and then Raise the temperature to 80°C and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com