Epoxy resin solvent-free low temperature curing agent, preparation method and application thereof

An epoxy resin and solvent-free technology, which is applied in the field of epoxy resin curing agent preparation, can solve the problems of low-molecular-weight thiol compounds with strong odor, respiratory system damage, and polyamine volatilization, so as to improve curing efficiency and improve Surface tension, effect of increasing curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

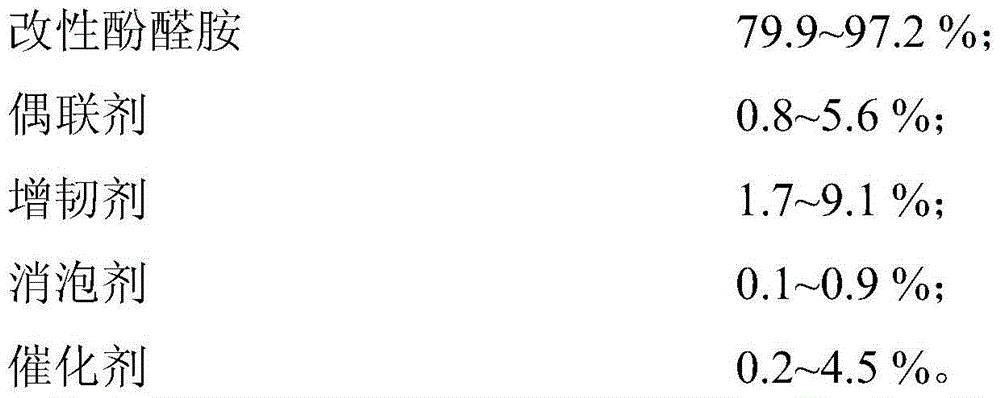

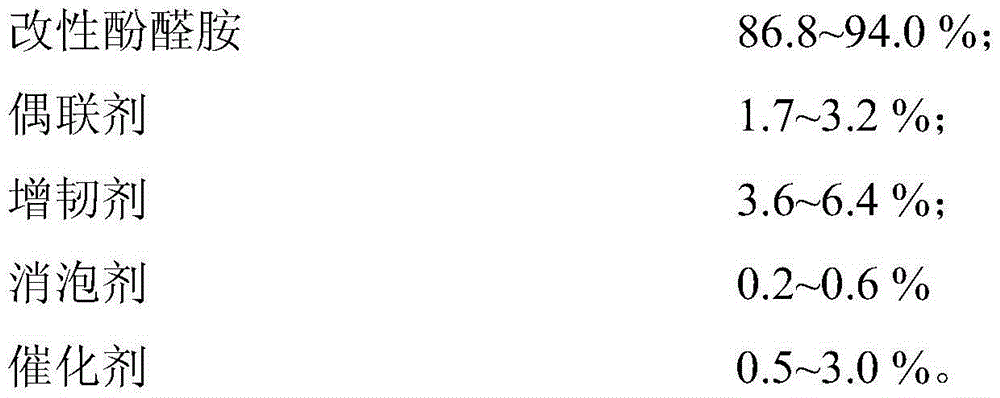

[0045] Embodiment 1: Preparation of epoxy resin solvent-free low-temperature curing agent

[0046] (1) Preparation of thiourea modified amine

[0047] Mix 44.6g of diethylenetriamine, 39.1g of m-phenylenediamine and 42.9g of thiourea, pass in an inert gas, heat at 60°C under mechanical stirring, and raise the temperature after the thiourea is completely melted to 140°C, reflux for 4 hours, lower the temperature to 55°C, continue the reaction for 1 hour, and cool to obtain 118.1 g of dark yellow thiourea-modified amine;

[0048] (2) Preparation of modified phenalkamine

[0049] Mix 113.5g of isophorone diamine with 118.1g of thiourea-modified amine and 80.7g of cardanol, heat at 50°C while stirring, add 24.5g of paraformaldehyde powder in batches, and raise the temperature to 95°C Reflux for 3 hours, cool, wash with warm water to remove unreacted polyamine and formaldehyde, distill off the water generated during the reaction at 110°C under reduced pressure, and cool to obtain...

Embodiment 2

[0052] Embodiment 2: Preparation of epoxy resin solvent-free low-temperature curing agent

[0053] (1) Preparation of thiourea modified amine

[0054] Mix 49.7g of diethylenetriamine, 35.7g of m-phenylenediamine and 39.1g of thiourea, pass in an inert gas, heat at 60°C under mechanical stirring, and raise the temperature after the thiourea is completely melted to 140°C, reflux for 4 hours, lower the temperature to 55°C, continue the reaction for 1 hour, and cool to obtain 116.5g of dark yellow thiourea modified amine;

[0055] (2) Preparation of modified phenalkamine

[0056] Mix 117.3g of isophoronediamine with 116.5g of thiourea-modified amine and 81.4g of cardanol, heat at 50°C while stirring, add 23.7g of paraformaldehyde powder in batches, and heat up to 95°C Reflux for 3 hours, cool, wash with warm water to remove unreacted polyamine and formaldehyde, distill off the water generated during the reaction at 110°C under reduced pressure, and cool to obtain 327.1 g of modi...

Embodiment 3

[0059] Embodiment 3: Preparation of epoxy resin solvent-free low-temperature curing agent

[0060] (1) Preparation of thiourea modified amine

[0061] Mix 45.4g of diethylenetriamine, 38.9g of m-phenylenediamine and 40.2g of thiourea, pass in an inert gas, heat at 60°C under mechanical stirring, and raise the temperature after the thiourea is completely melted to 140°C, reflux for 4 hours, lower the temperature to 55°C, continue the reaction for 1 hour, and cool to obtain 115.9g of dark yellow thiourea modified amine;

[0062] (2) Preparation of modified phenalkamine

[0063] Mix 115.9g of isophorone diamine with 117.4g of thiourea-modified amine and 79.6g of cardanol, heat at 50°C while stirring, add 23.2g of paraformaldehyde powder in batches, and raise the temperature to 95°C Reflux for 3 hours, cool, wash with warm water to remove unreacted polyamine and formaldehyde, distill off the water generated during the reaction at 110°C under reduced pressure, and cool to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com