Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Reduce system viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extraction system for extracting lithium isotope

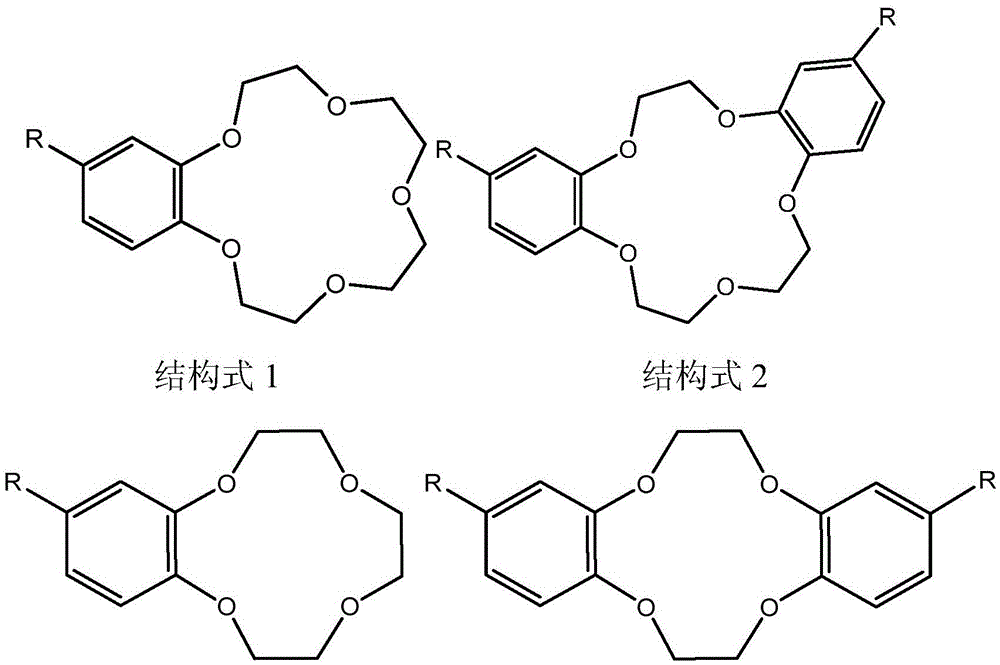

ActiveCN105536536ALow costStrong adaptability to industrial operationsIsotope separationChemistryBenzene

The invention provides an extraction system for extracting lithium isotope. The system comprises an extracting agent, a hydrophobic ionic liquid and a diluent. The hydrophobic ionic liquid and the diluent are in the volume ratio of 1-15:1-10; the extracting agent has concentration in an extraction organic phase of 0.05-2.5mol / L; the extracting agent is at least one of benzo-15-crown-5 and a derivative thereof, or benzo-14-crown-4 and a derivative thereof. Compared with the crown ethers and pure ionic liquid system of the prior art, the system has the advantages of low operating costs and strong industry adaptability.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Preparation method of oxidized bacterial cellulose solution

The invention discloses a preparation method of an oxidized bacterial cellulose solution, and belongs to the field of dissolution of bacterial cellulose. The preparation method comprises the followingsteps: purifying, crushing, homogenizing and performing ultrasonic treatment to bacterial cellulose, then oxidizing by a mixed oxidizing system of TEMPO / NaBr / NaClO, then washing, performing dry crushing or dewatering to obtain oxidized bacterial cellulose powder or an oxidized bacterial cellulose slurry, dissolving the oxidized bacterial cellulose powder or the oxidized bacterial cellulose slurryby using an aqueous alkaline dissolving agent solution, then standing at a low temperature for freezing, and thawing to obtain the transparent oxidized bacterial cellulose solution. The preparation method is simple and easy to implement, a technology is easy to control, the reagent dosage is relatively low, and the cost is saved; by the preparation method, the cellulose can be effectively dissolved to directly obtain the oxidized bacterial cellulose solution; the oxidized bacterial cellulose solution can be widely applied to the field of packaging, biomedical materials, intelligent hydrogels,membrane preparation, preparation of specially-shaped hydrogels and the like, so that the application field of the bacterial cellulose is widened.

Owner:TIANJIN UNIV OF SCI & TECH

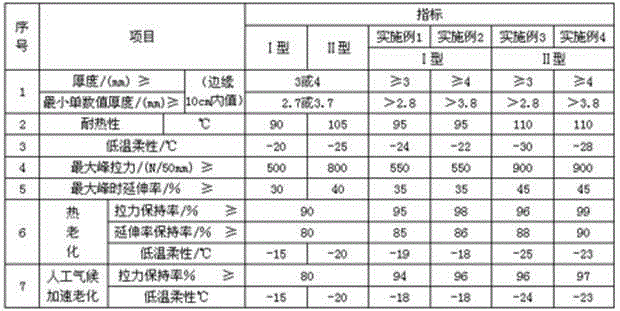

Epoxy resin system for casting process of wind electricity generation vanes

InactiveCN101585956ALong operating timeReduce system viscosityFinal product manufactureMachines/enginesEpoxyFiber

The invention discloses an epoxy resin system for casting process of wind electricity generation vanes. The epoxy resin system is composed of epoxy resin and active diluent that match. Weight ratio of epoxy resin and active diluent is 55:45 to 85:15. The epoxy resin system is mixed with curing agent according to weight ratio of epoxy resin: curing agent=100:20 to 40. Curing difficulty is 60 DEG C / 15h or 80 DEG C / 8h to obtain casting bodies of wind electricity generation vanes. The epoxy resin system of the invention has longer operation time, low system viscosity and great fiber leachability. Each of performances of the cured casting bodies satisfies use standard of nationally regulated wind electricity generation vane, which is adapted to large composite material of wind vanes.

Owner:株洲时代工程塑料制品有限责任公司

Stereo-lithography rapid-prototyping polysiloxane photosensitive resin composition and preparation method and application thereof

InactiveCN105278239AFast curing rateReduce system viscosityPhotosensitive materials for photomechanical apparatusLithographic artistHeat resistance

The invention relates to a stereo-lithography rapid-prototyping polysiloxane photosensitive resin composition and its preparation method and application. The stereo-lithography rapid-prototyping polysiloxane photosensitive resin composition mainly comprises the following raw materials (by weight): 10-85% of double-side acrylate polysiloxane, 3-21% of polyacrylate polysiloxane, 10-60% of an acrylate polysiloxane diluent, 10-60% of an acrylate diluents and 1.0-4.0% of a radical initiator. The raw materials are mixed according to the above ratio and the mixed raw materials are stirred and heated to obtain a transparent liquid, namely the stereo-lithography rapid-prototyping polysiloxane photosensitive resin. After stereo-lithography prototyping, the stereo-lithography rapid-prototyping polysiloxane photosensitive resin composition has rapid-prototyping characteristic of photosensitive resin and also has polysiloxane characteristic of high and low temperature resistance. A component molded by the use of the photosensitive resin has advantages of high precision, good heat resistance and the like.

Owner:QINGDAO UNIV OF SCI & TECH

Solvent-free epoxy heavy anti-corrosion paint extruded and coated to inner wall of crude oil gathering pipeline

InactiveCN109181477AGood chemical resistanceAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

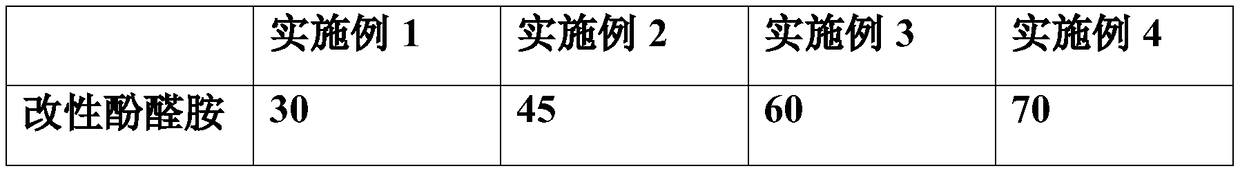

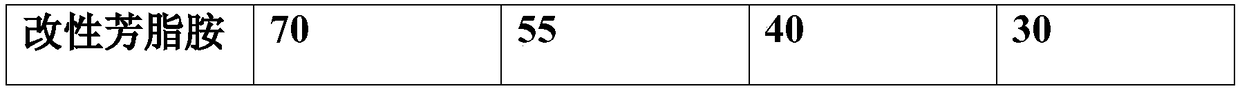

The invention discloses a solvent-free epoxy heavy anti-corrosion paint which is extruded and coated to the inner wall of a crude oil gathering pipeline. The paint comprises a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 10-25 parts of E-51 epoxy resin, 12-30 parts of F-51 epoxy resin, 10-15 parts of titanium dioxide, 1-2 parts of phthalocyanine green, 1-2 parts of organic yellow, 1.5-3 parts of a thixotropic agent, 0.3-0.5 part of a wetting dispersant, 5-8 parts of inert liquid resin, 3-5 parts of an active diluting agent, 3-5 parts of a hyperbranched toughening agent, 15-20 parts of precipitated barium sulfate, 8-15 parts of anti-rust pigment, 0.3-0.5 part of a defoaming agent, 0.2-0.4 part of a flatting agent; the component B is prepared from 30-70 parts of modified phenolic amine curing agent and 70-30 parts of modified aromatic amine curing agent; and the mass ratio of the component A to the component B is(5-7):1. The solvent-free epoxy heavy anti-corrosion paint is applicable to gathering pipeline extruding and coating processes, the pipeline inner wall coating has excellent corrosion resistance and physical performance, the coating process can be reduced, the construction time can be saved, and the work efficiency can be improved.

Owner:石家庄市油漆厂

Polyaspartic ester urea adhesive and construction technology thereof

ActiveCN107522845AGood physical propertiesGood weather resistancePolyurea/polyurethane coatingsPolyurethane adhesiveEquivalence ratio

The invention discloses a polyaspartic ester urea adhesive and a construction technology thereof. The adhesive comprises a main agent and a curing agent in an equivalence ratio being 1:(0.9-1.1), and the main agent is prepared from 80-90 parts by weight of polyaspartic ester resin, 2-5 parts by weight of an oxazolidine absorbent, 8-12 parts by weight of a molecular sieve, 0.1-0.5 parts by weight of a defoaming agent and 0.1-0.5 parts by weight of a base material wetting agent. The adhesive contains no toxic substances such as free TDI (toluene diisocyanate) and the like, contains no organic solvents, phthalate plasticizers and heavy metal, belongs to a solvent-free system, is environmentally friendly, non-toxic and harmless, further has good physical performance and is good in weather fastness, high in tensile strength and elongation at break, good in rebound resilience and not prone to discoloration, construction is easy, operability and physical performance of the adhesive are equivalent to those of a conventional polyurethane adhesive, and excellent environment-friendly safety and physical characteristics are integrated. The technological process of preparation is simple, conditions are mild, construction performance is good, coating is easy, and therefore, the adhesive is suitable for industrial batch production.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

Purification method for coal tar soft pitch

InactiveCN102839008AImprove solubilityHigh yieldWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionPurification methodsCentrifugation

The present invention relates to a purification method for coal tar soft pitch. The method is characterized by comprising: stirring and uniformly mixing coal tar soft pitch with a softening point of 30-60 DEG C and a solvent according to a mass ratio of 1:0.5-1.5 at a temperature of 120-300 DEG C; carrying out thermal and adding the resulting material to a continuous centrifuge; carrying out continuous centrifugation separation at the same temperature to obtain a supernatant and residue; carrying out vacuum distillation on the supernatant; removing the solvent to obtain the purified pitch; and recovering the solvent to reuse. The method of the present invention has the following advantages and effects that a dissolution property of the soft pitch in the solvent and a process yield can be significantly improved, difficulties of mixing and separation are significantly decreased, and operation and maintenance are convenient.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

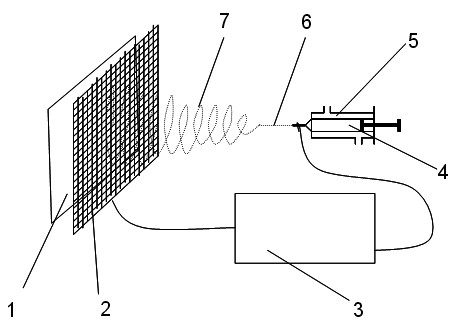

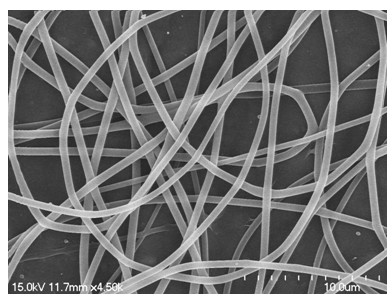

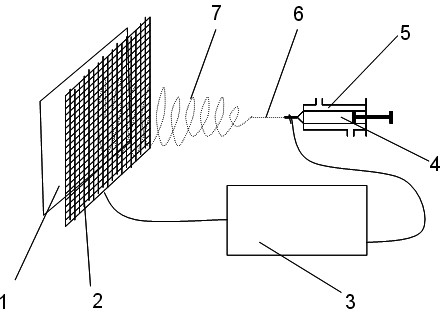

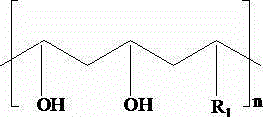

Polyvinyl alcohol nanofiber, and preparation method and device thereof

ActiveCN102586928ALow viscosityImprove spinnabilityFilament/thread formingMonocomponent synthetic polymer artificial filamentNonwoven fabricHydroxy compound

The invention discloses polyvinyl alcohol (PVA) fiber, and a preparation method and a preparation device thereof. The method comprises the following steps: dissolving polyvinyl alcohol into distilled water; adding 1 to 5 weight percent of water soluble hydroxyl terminated hyperbranched polyester; placing the obtained mixed liquor at the temperature of between -20 and -70 DEG C and freezing for 8 to 24 hours; defreezing and heating at room temperature to prepare spinning liquor with the viscosity of 180 to 550 mpa.s; and obtaining high strength polyvinyl alcohol nano-fiber nonwoven fabric with the strength of 1,045 to 1,800 N / m<2> on a receiving screen by an electrostatic spinning process. The PVA liquor is frozen and defrozen, so the intermolecular chain entanglement is improved, more intermolecular hydrogen bonds are formed, and the tensile strength of the obtained nano-fiber can be obviously improved. The invention has a simple process, is pollution free in the production process and contributes to quick development and popularization application of the PVA nano-fiber.

Owner:仙桃市茂盛塑料制品有限公司

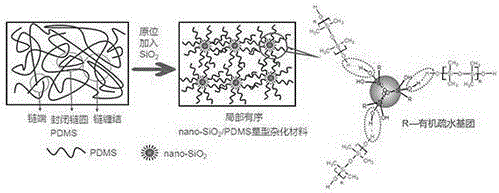

Method for in-situ preparing nano-silicon dioxide/hydroxy terminated polydimethylsiloxane hybrid material

The invention discloses a method for in-situ preparing a nano-silicon dioxide / hydroxy terminated polydimethylsiloxane hybrid material. The method comprises the following steps: heating cyclosiloxane and a catalyst to 95-105 DEG C under a stirring state, stirring for 30-120 minutes to open loop of cyclosiloxane and perform prepolymerization reaction; then, adding nano-silicon dioxide, and stirring at the constant temperature of 95-105 DEG C until no fraction is distilled out; and stirring under a condition that the vacuum degree is negative 0.02MPa-negative 0.09MPa until no fraction is distilled out, wherein the mass ratio of cyclosiloxane monomer to the catalyst to nano-silicon dioxide is 100:5*10<4>-2*10<4>:(2-18). According to the hybrid material prepared by the method, the rheological property of the hybrid material is improved, nano-silicon dioxide and PDMS are bonded through chemical bonds, and the bonding mode of inorganic filler and polymer matrix is changed.

Owner:河南海博瑞硅材料科技有限公司

Stereo-lithography rapid-prototyping cationic polysiloxane photosensitive resin composition and preparation method and application thereof

The invention relates to a stereo-lithography rapid-prototyping cationic polysiloxane photosensitive resin composition and its preparation method and application. The stereo-lithography rapid-prototyping cationic polysiloxane photosensitive resin composition mainly comprises the following raw materials (by weight): 10-85% of double-side polysiloxane containing an epoxide group, 3-21% of polyepoxy polysiloxane, 10-60% of a polysiloxane diluents containing an epoxy group and 1.0-4.0% of a cationic initiator. The raw materials are mixed according to the above ratio and the mixed raw materials are stirred and heated to obtain a transparent liquid, namely the stereo-lithography rapid-prototyping polysiloxane photosensitive resin. After stereo-lithography prototyping, the stereo-lithography rapid-prototyping polysiloxane photosensitive resin has rapid-prototyping characteristic of photosensitive resin and also has polysiloxane characteristic of high and low temperature resistance. A component molded by the use of the photosensitive resin has advantages of low shrinkage, high product precision, good heat resistance and the like.

Owner:QINGDAO UNIV OF SCI & TECH

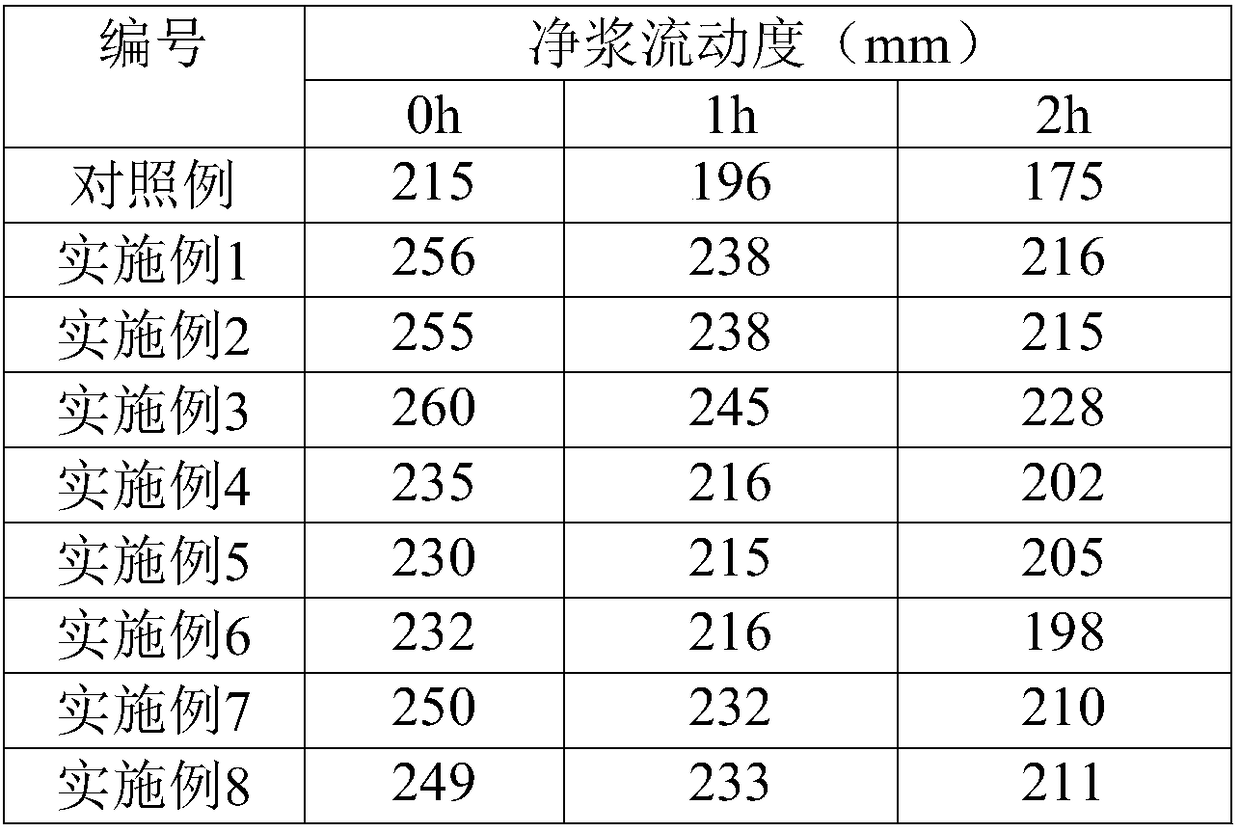

Solid polycarboxylate superplasticizer as well as preparation method and application thereof

The invention relates to the technical field of concrete additives, in particular to a solid polycarboxylate superplasticizer as well as a preparation method and application thereof. According to thepreparation method, an unsaturated carboxylic acid and a liquid polyether monomer are subjected to direct free radical polymerization reactions in a solvent-free environment, and then the solid polycarboxylate superplasticizer which is excellent in property is prepared. By adopting the preparation method, a body polymerization mode is implemented, no solvent or medium is used in the whole process,and a common method that water or an organic solvent is added at an early stage and is removed at a later stage is effectively improved; the obtained solid polycarboxylate superplasticizer not only is convenient to transport, but also has properties superior to those of solid polycarboxylate superplasticizers in the market.

Owner:联泓(江苏)新材料研究院有限公司

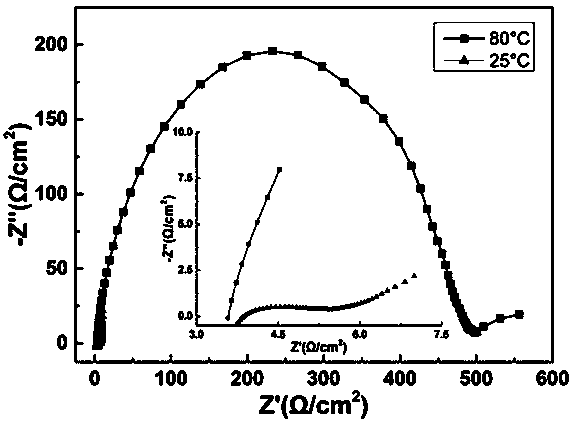

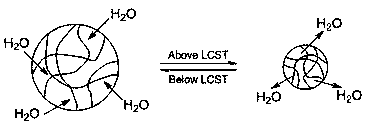

Temperature-sensitive polymer electrolyte as well as preparation method and application thereof

ActiveCN107759726AMild conditionsReduce system viscosityHybrid capacitor electrolytesOil phaseElectrochemistry

The invention relates to a temperature-sensitive polymer electrolyte as well as a preparation method and application thereof. The preparation method of the temperature-sensitive polymer electrolyte comprises the following steps: stably dispersing an aqueous phase component containing an electrolyte in an oil phase component to form an emulsion under the condition of strong stirring, and then raising the temperature to carry out a reversed phase suspension polymerization reaction under the condition of continuous strong stirring and inert gas filling, so as to obtain the temperature-sensitive polymer electrolyte, wherein the volume ratio of the aqueous phase component to the oil phase component is (0.1-1.0):1. The temperature-sensitive polymer electrolyte is obtained through a reaction of areversed phase suspension polymerization method, and the electrolyte is green and environmentally-friendly and can be cycled reversibly; and the application of the electrolyte in an electrochemical energy storage device can effectively solve the safety problem hindering the wide application of high specific energy density and high-power energy storage devices in commercialization.

Owner:SUN YAT SEN UNIV +1

Adhesive with high electrical and thermal conductivity and preparation method thereof

InactiveCN113265210AEasy dischargeImprove densification performanceMacromolecular adhesive additivesEpoxynovolac adhesivesAdhesive cementPolymer science

The invention discloses an adhesive with high electrical and thermal conductivity and a preparation method thereof. The conductive adhesive comprises the following components in parts by weight: 5-10 parts of epoxy resin, 0.5-2 parts of a toughening agent, 3-5 parts of a curing agent, 0.03-0.06 part of a curing accelerator, 0.05-0.2 part of a coupling agent, 0.1-0.5 part of a thixotropic agent, 3-8 parts of a solvent and 82-96 parts of a conductive filler, the conductive filler is silver powder, the tap density is 3-6g / cc, and the average particle size is 2-5 microns. According to the technical scheme, the formula is based on epoxy resin, silver powder with different particle sizes is used as conductive filler to prepare the high-thermal-conductivity and high-electric-conductivity adhesive, and meanwhile, the high-thermal-conductivity and high-electric-conductivity adhesive has good electric conductivity and mechanical property; the heat conductivity is greater than 10W / m.k, and the heat conductivity coefficient is more than four times that of the conventional conductive adhesive; the volume resistivity is lower than 9 * 10 <-5 > omega.cm; and the shearing force is greater than 10Kgf.

Owner:北京中天鹏宇科技发展有限公司

Three-dimensional photoetching rapidly-formed hybrid polysiloxane-based photosensitive resin composition and preparation method and application thereof

InactiveCN105223777AFast curing rateReduce system viscosityPhotomechanical apparatusEpoxyHeat resistance

The invention relates to a three-dimensional photoetching rapidly-formed hybrid polysiloxane-based photosensitive resin composition and a preparation method and application thereof. The three-dimensional photoetching rapidly-formed hybrid polysiloxane-based photosensitive resin composition mainly comprises the following raw materials based on mass ratio: 20-70% of polysiloxane epoxy resin, 10-45% of polysiloxane acrylic ester, 1.0-4.0% of radical initiator, 1.0-6.0% of cationic initiator and 10-60% of polysiloxane diluents. The three-dimensional photoetching rapidly-formed hybrid polysiloxane-based photosensitive resin composition is obtained by mixing the raw materials and heating the mixture into a transparent liquid under stirring according to the above proportions. The three-dimensional photoetching rapidly-formed hybrid polysiloxane-based photosensitive resin composition disclosed by the invention can develop the characteristic of rapid forming of photosensitive resin and also has the characteristic of high- and low-temperature resistance of polysiloxane after three-dimensional photoetching forming. The part formed by using the photosensitive resin has the advantages of high accuracy, favorable heat resistance and the like.

Owner:QINGDAO UNIV OF SCI & TECH

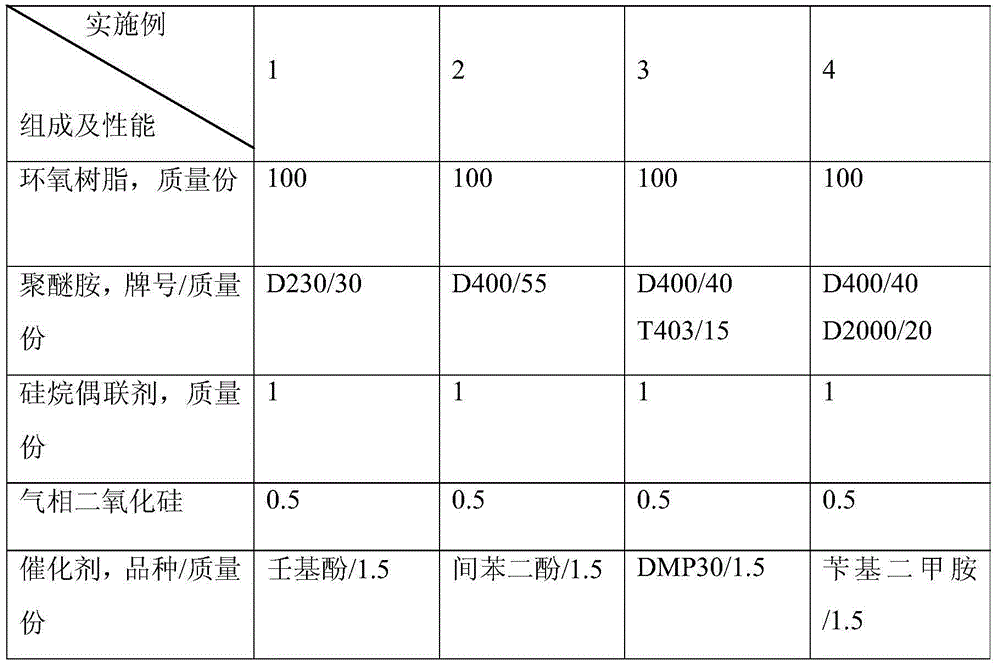

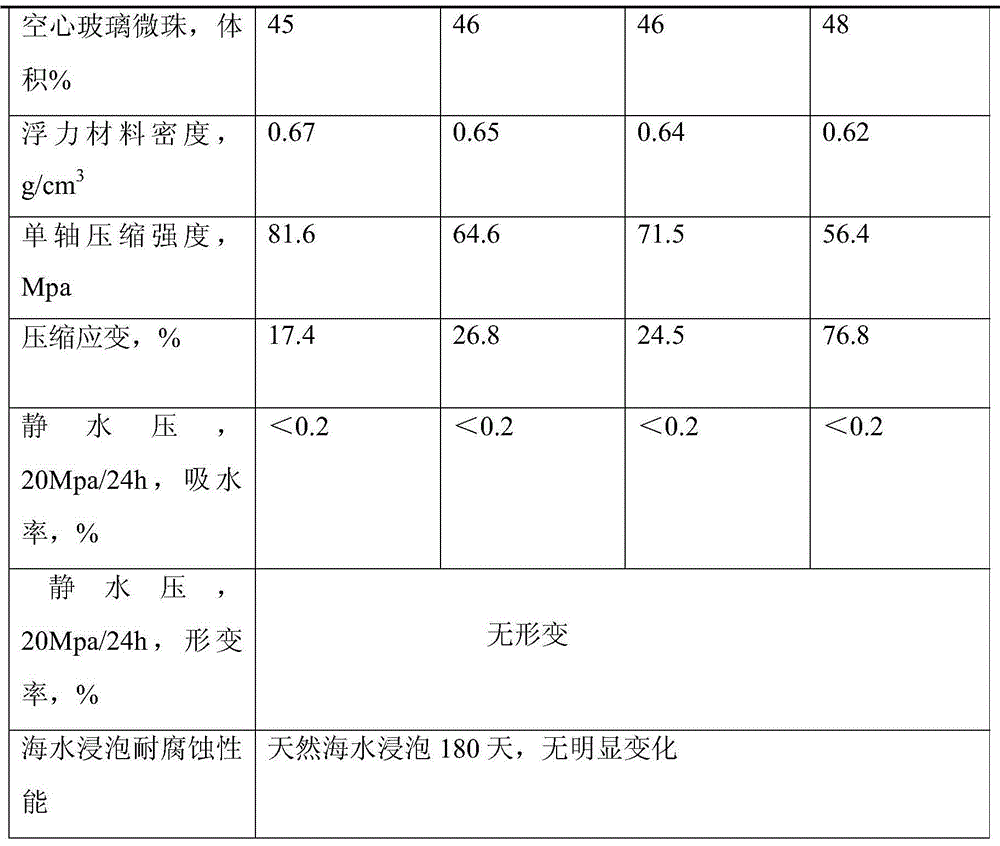

Submersible vehicle encapsulation composite foam filling materials and preparation method thereof

The invention discloses submersible vehicle encapsulation composite foam filling materials and a preparation method of the submersible vehicle encapsulation composite foam filling materials. The filling materials are composed of epoxy resin, polyether amine curing agents, silane coupling agents, polysiloxane defoamer, catalysts, thixotropic agents and hollow micro glass beads. The preparation method includes the steps of (1) pre-mixing of liquid materials, (2) preparation of slurry, (3) high-pressure air-free pouring, and (4) curing and performance test. The composite foam filling materials are low in system viscosity, good in flowing levelling property, long in construction period and suitable for a pouring encapsulation process, and can be cured at room temperature, the curing reaction heat release temperature peak is low, and condensate is tenacious, high in strength, small in contracting rate and good in adhesive property with steel and other materials. The composite foam filling materials are resistant to sea water soaking corrosion, good in effect after being tried, and suitable for encapsulation filling and water insulation sealing of a submarine non-water-sealing structure, a buoy, a subsurface buoy and other marine submersible vehicles.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

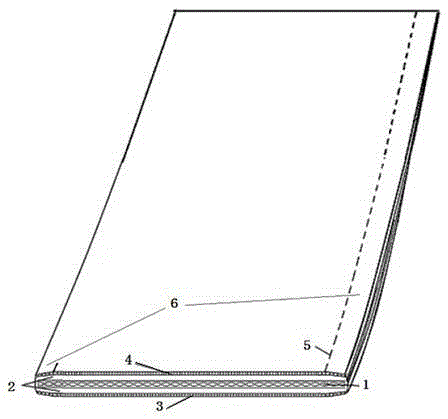

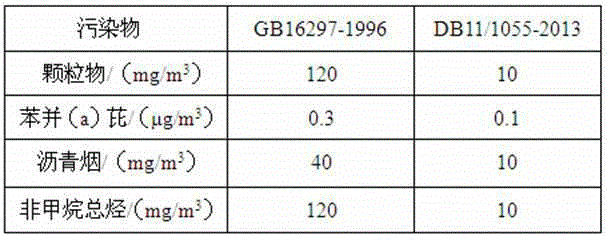

Environment-friendly type elastomer modified asphalt waterproof roll

InactiveCN105386525AReduce generationEmission reductionRoof covering using flexible materialsBuilding insulationsFiberPolyester

The invention relates to an environment-friendly type elastomer modified asphalt waterproof roll which is a multi-layer composite structure. A long fiber polyester base material reinforcing layer is arranged in the middle of an environment-friendly type elastomer modified asphalt layer; and the environment-friendly type elastomer modified asphalt layer consists of the following components in parts by mass: 45-55 parts of low-smoke asphalt, 4-12 parts of SBS (styrene butadiene styrene) thermoplastic rubber, 1-4 parts of powdered butadiene styrene rubber, 5-10 parts of natural asphalt master patch, 0-3 parts of polybutylene elastomer, 5-10 parts of rubber processing oil, 0-2 parts of polyolefin auxiliaries, 0-2 parts of amide wax, and 20-30 parts of 180-mesh talcum powder. The environment-friendly type elastomer modified asphalt waterproof roll has the beneficial effects that: by optimizing and applying environment-friendly raw materials such as the low-smoke asphalt and the like, a low-temperature production process of the modified asphalt is realized, so that generation and discharge of atmospheric contaminant such as non-methane hydrocarbon, particulate matters and the like in a production process of the elastomer modified asphalt waterproof roll are effectively reduced, and therefore, the pollution problem in the production process of the elastomer modified asphalt waterproof roll is completely solved.

Owner:胜利油田大明新型建筑防水材料有限责任公司

Kettle-type method for preparing needle coke

InactiveCN103045278AReduced mosaic structureReduce system viscosityCoking carbonaceous materialsChemistrySystem pressure

The invention discloses a kettle-type method for preparing needle coke, which comprises the following steps: (1) adding raw oil into a coking kettle, heating to 430-480 DEG C, keeping the constant temperature for 2-6 hours while controlling the pressure of 0.5-2.0 MPa, collecting the discharged oil gas, and separating out 200-400 DEG C fraction; (2) after finishing keeping the constant temperature, closing the exhaust port, cooling the system to 200-400 DEG C, adding the 200-400 DEG C fraction collected in the step (1), and keeping the constant temperature for 1-4 hours; (3) after finishing keeping the constant temperature, and slowly heating the system to 430-500 DEG C, wherein the heating speed is controlled to control the exhaust amount at 0.01-1h<-1> and the system pressure at 0.5-2.0 MPa; and (4) heating the system to 520-550 DEG C, and coking for 1-4 hours, wherein the needle coke generated by reaction is deposited on the coking tower bottom. The method can be used for producing high-quality needle coke; and the operational process is easy to control, is simple and feasible, and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

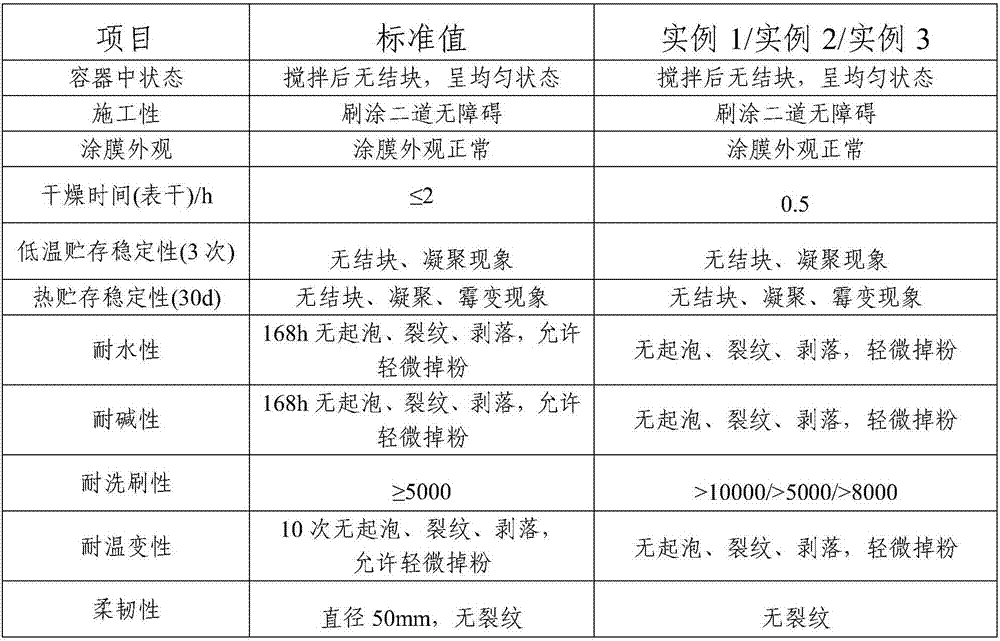

Composite paint with good storage stability and preparation method of composite paint

ActiveCN107459880AGood storage stabilityWith wetting and dispersing effectAlkali metal silicate coatingsEmulsionPotassium silicate

The invention discloses composite paint with good storage stability and a preparation method of the composite paint. The composite paint is prepared from the following components in parts by weight: 25 to 32 parts of water, 0.3 to 0.5 part of hydroxyethyl cellulose, 0.5 to 0.8 part of defoaming agent, 10 to 15 parts of titanium dioxide, 5 to 8 parts of talcum powder, 22 to 30 parts of heavy calcium powder, 0.5 to 0.8 part of stabilizer LOPON ST, 15 to 20 parts of potassium silicate solution, 5 to 8 parts of emulsion and 0.5 to 1 part of reinforcing agent. The test verifies that the storage stable period of the composite paint is about 6 months, so that the storage stability is greatly improved compared with that of the paint in the prior art.

Owner:澳汉盛川化工(北京)有限公司

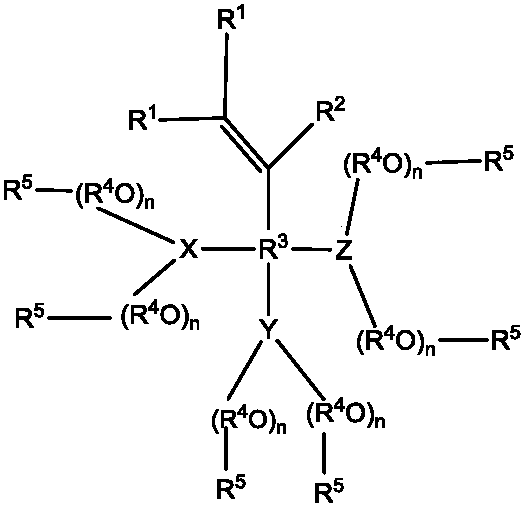

Preparation method of polyurethane modified acrylate polymeric dispersant for coatings

The invention relates to a preparation method of a polyurethane modified acrylate polymeric dispersant for coatings. The preparation method comprises the following steps: preparing polyhydroxy acrylate, synthesizing polymeric polyurethane of mono-isocyanate, and modifying acrylate by virtue of polyurethane. The preparation method has the advantages that the preparation process is simple, products are easily available, and the generation of by-products is avoided; prepared polyurethane modified acrylate has various different polar segments and wide consistency, is applicable to various polar systems, does not influence the consistency of the systems, includes multiple pigment wetting groups and is capable of well dispersing various pigments, so that the tinting strength of the pigments is effectively improved, the viscosity of the systems is effectively decreased, and the pigment slurry has good storage stability and excellent surface dyeing resistance and floating performance.

Owner:KITO CHEM CO LTD

Sprayable inorganic foamed heat preservation mortar

The invention discloses sprayable inorganic foamed heat preservation mortar. The sprayable inorganic foamed heat preservation mortar is prepared from the following components in percentage by weight:20 to 30 percent of a cementing material, 12 to 23 percent of glass beads, 3.5 to 5.5 percent of fine aggregate, 1.5 to 2.5 percent of bentonite, 0.5 to 1 percent of rubber powder, 0.06 to 0.11 percent of cellulose ether, 0.05 to 0.11 percent of staple fiber, 0.02 to 0.04 percent of starch ether, 0 to 0.1 percent of a foaming agent or 0 to 0.04 percent of an air entraining agent, 0 to 0.2 percentof a water repellent and 45 to 55 percent of water. According to the sprayable inorganic foamed heat preservation mortar disclosed by the invention, the volume weight of the sprayable inorganic foamedheat preservation mortar is reduced by adopting a mode that lightweight aggregate and the glass beads are combined with foaming; on one hand, high-performance heat preservation mortar can also be prepared by adopting lower-quality glass beads of which the water absorption rate per volume is 45 to 90 percent, a heat preservation effect is increased, and materials and energy are saved; on the otherhand, small bubbles introduced by the foaming agent (or the air entraining agent) can play a lubricating role and is capable of reducing the system viscosity and increasing the flowability, and pumped heat preservation mortar is enabled not to be in segregation; meanwhile, the volume weight of heat preservation mortar is reduced, and the spraying resilience rate of the heat preservation mortar during spraying construction is smaller than 15 percent.

Owner:中冶武汉冶金建筑研究院有限公司

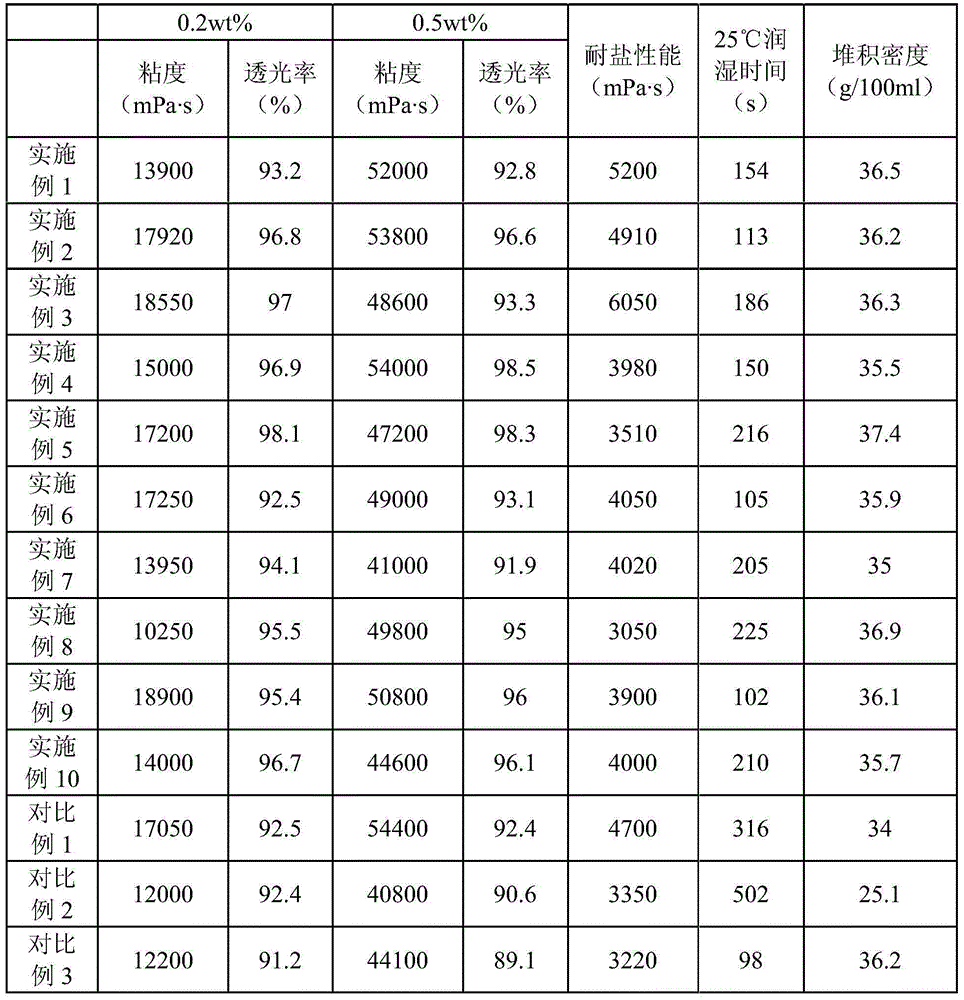

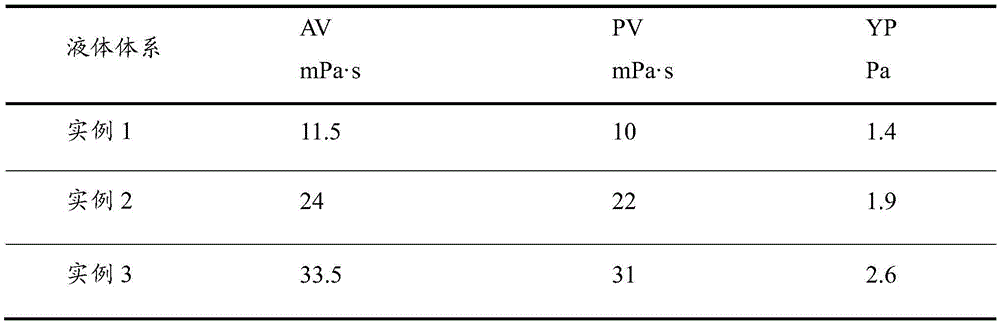

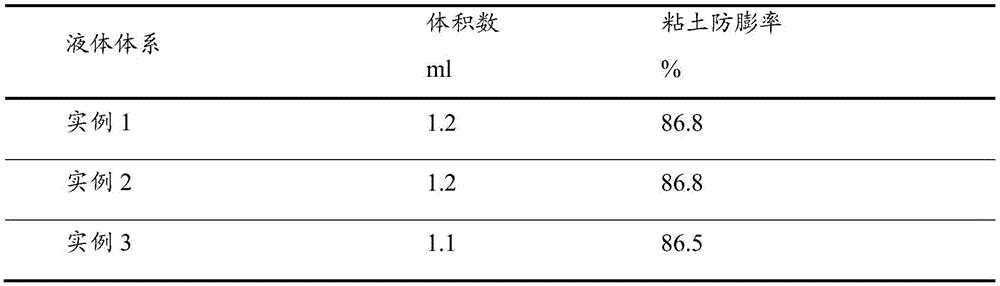

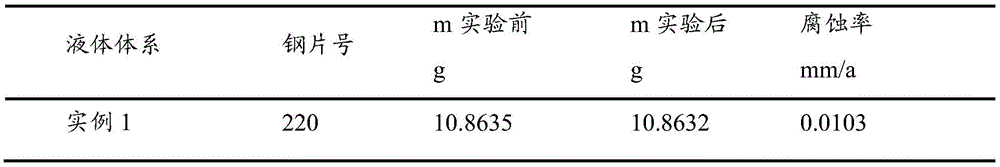

Quick-wetting carboxylic acid copolymer thickening agent and preparation method thereof

ActiveCN104861104AShort wetting timeSmall particle size distribution rangeCross-linkHydrocarbon solvents

The invention provides a preparation method of a quick-wetting carboxylic acid copolymer thickening agent, which comprises the following steps: adding an organic inert solvent containing at least 55wt% of a hydrocarbon solvent, 15wt%-20wt% of a monomer as well as an initiator, a dispersant and a cross-linking agent which are required by reaction into a reaction vessel, and performing reaction at 45-55DEG C for 30-60min; mixing an organic inert solvent containing at least 55wt% of an ester solvent, the rest of the monomer and the initiator, the dispersant and the cross-linking agent which are required by reaction, and adding the mixture into the reaction vessel within 3-6h and reacting under the same reaction temperature; and after all the reactant is dropwise added, raising the temperature to 55-75DEG C, adding the initiator again, performing heat preservation for 1-4h so that the monomer in the reaction system is reacted completely, ending the reaction, and discharging a product. The invention aims to provide the quick-wetting carboxylic acid copolymer thickening agent with quick wetting and dispersing properties and high bulk density, and meanwhile the invention further provides the preparation method of the quick-wetting carboxylic acid copolymer thickening agent.

Owner:GUANGZHOU TINCI MATERIALS TECH

Solid-phase-free high density well killing fluid

InactiveCN105647491AReduce system viscosityImprove corrosion resistanceDrilling compositionWell killAlkylphenol

The invention discloses a solid-phase-free high density well killing fluid, which comprises the following components in percentage by weight: 0.1 to 0.5% of deoxidant, 0.5 to 3.0% of corrosion inhibitor, 40 to 70% of composite salt weighting agent, 5 to 15% of crystallization inhibitor, 0.1 to 1.5% of water locking resistant agent, and the balance being water, wherein the water locking resistant agent is prepared by compounding perfluoro octyl carboxylic acid polyoxyethylene ether, alkylphenol polyoxyethylene ether, and methanol / ethanol. The provided solid-phase-free high density well killing fluid has the advantages of no solid phase, low system viscosity, strong anticorrosion performance, little biological toxicity, good reservoir compatibility, and simple and convenient onsite preparation, and solves the problems that conventional well killing fluids have bad reservoir compatibility and thermal stability; crystallization and agglomeration happen when the density of well killing fluid is adjusted for a second time, and solid phase in the well killing fluid damages the reservoir that is next to the well for a second time. The comprehensive performance of well killing fluid is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Preparation method of one-component solvent-free polyurethane waterproof coating

The invention relates to a preparation method of a one-component solvent-free polyurethane waterproof coating. The preparation method is mainly characterized by comprising the following steps: adding mixed polyhydric alcohols of polyether diol and polyfunctional polyether polyol, which are mixed according to a certain mass ratio, into a reaction vessel; adding isocyanate after dehydrating and reacting at 50-80 DEG C for 1-4 h; cooling to room temperature; and adding pre-dried plasticizer, antifoaming agent, anti-oxidant and ultraviolet ray absorber and uniformly mixing to prepare the polyurethane waterproof coating. The preparation method has the following advantages: 1) the raw materials used are cheap and easily available, and a synthetic method is simple, efficient and low-cost and is easy for amplification of the operation process and realization of industrial production; and 2) water is used as a curing agent of polyurethane resin; and a compact polyurethane elastomer film can be formed after addition of 50-80% of water, uniform stirring and solidification during the construction, is nontoxic and environmentally friendly and has high safety. As a polyfunctional active group is introduced, a compact cross-linked network structure can be formed after the coating encounters water and is solidified. The coating has excellent mechanical properties (tensile strength of the film is greater than 4MPa and elongation at break is greater than 1000%), can be used as an excellent waterproof material, and has a wide application prospect.

Owner:青岛中科润唐新材料科技有限公司

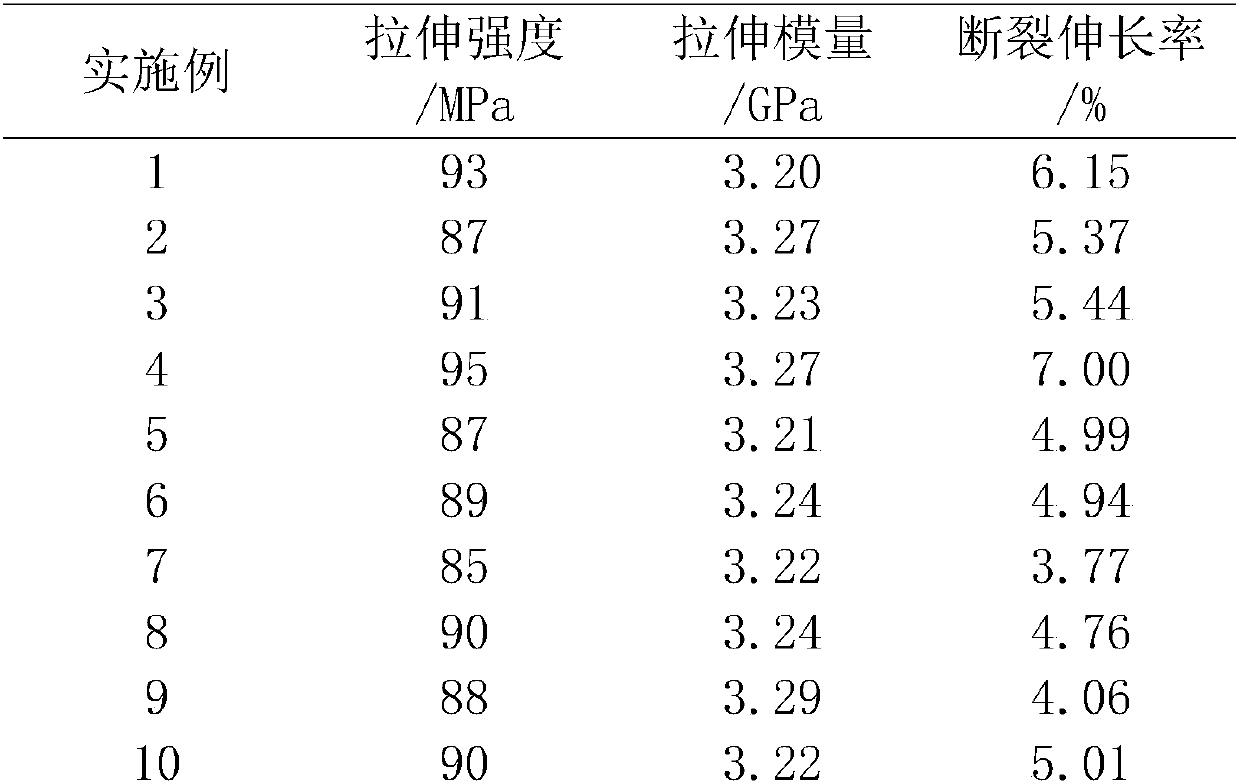

High-strength and high-toughness epoxy resin

The present invention discloses high-strength and high-toughness epoxy resin. The high-strength and high-toughness epoxy resin is obtained by curing of the following raw materials: 38wt%-59wt% of substrate resin, 38wt%-59wt% of a curing agent and 0.1wt%-3wt% of an accelerator; the substrate resin is a mixture of epoxy resin and a reactive diluent; the reactive diluent is a weakly-polar epoxy compound with side chains. The epoxy resin cured material with high tensile strength, high tensile modulus and good toughness is obtained by adding a proper amount of weakly-polar and low-viscosity epoxy resin to obtain a low-viscosity epoxy resin component, mixing the obtained epoxy resin component, the curing agent and the accelerator, and performing a curing reaction. According to the invention, various epoxy resin is suitable for preparing the epoxy resin cured material provided by the invention, and the method is simple.

Owner:BEIJING UNIV OF CHEM TECH

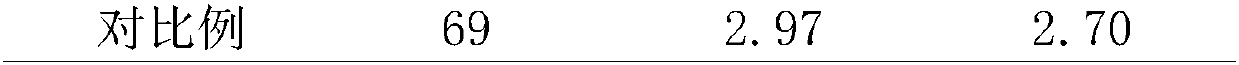

Low VOC waterborne epoxy zinc-rich primer and preparation method thereof

InactiveCN110128917AIncrease the viscosity of the aqueous phaseGood storage stabilityAnti-corrosive paintsEpoxy resin coatingsEmulsionZinc

The invention provides a low VOC waterborne epoxy zinc-rich primer and a preparation method thereof. The primer comprises an A component and a B component, and the weight ratio of the A component to the B component is 2.5-3:1. The A component comprises the following raw materials in parts by weight: 0.5-2.5 parts of a wetting dispersing agent, 2.5-5.5 parts of a thickening agent, 80-100 parts of afilm-forming auxiliary agent, 8-12 parts of a leveling agent, 40-80 parts of an anti-settling agent, 16-24 parts of talc powder, 1500-1700 parts of zinc powder, 50-70 parts of an epoxy curing agent resin, 10-14 parts of an adhesion promoter, and 1-10 parts of a catalyst. The B component comprises the following raw materials in parts by weight: 3-5 parts of a thickening agent, 1-3 parts of a wetting dispersing agent, 280-320 parts of a modified bisphenol A type epoxy emulsion, 0.5-1.5 parts of a defoaming agent, and the like. The storage stability of the prepared low VOC waterborne epoxy zinc-rich primer is significantly improved, and the VOC content is remarkably lowered.

Owner:绵阳麦思威尔科技有限公司

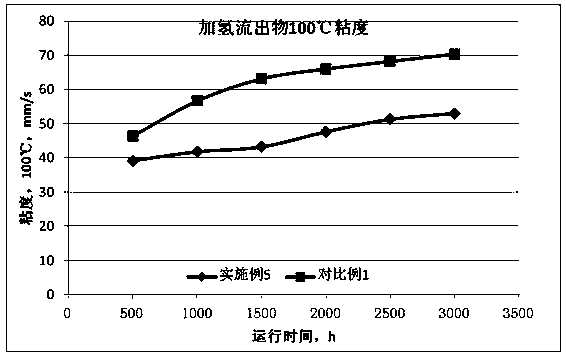

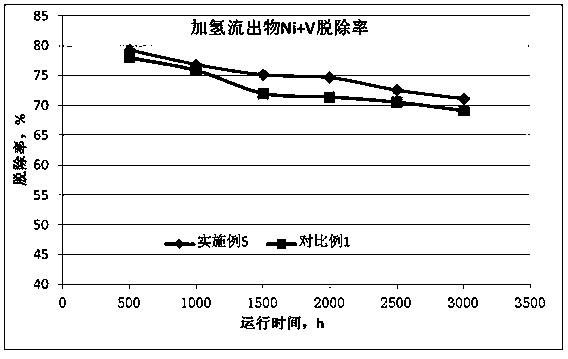

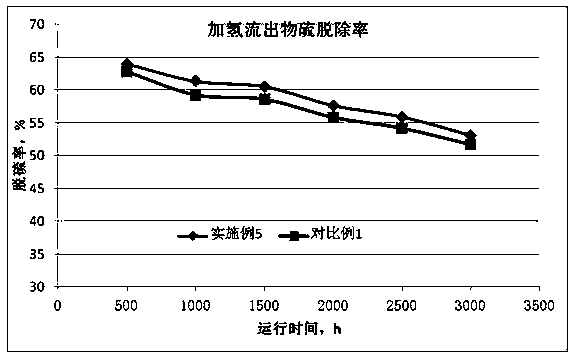

Method for removing metal impurities in residual oil through hydrogenation

ActiveCN111378471ARapid responseImprove responseTreatment with hydrotreatment processesRefining to eliminate hetero atomsPtru catalystMetal impurities

The invention discloses a method for removing metal impurities in residual oil through hydrogenation. According to the method, fed materials comprise a residual oil raw material, hydrogen and a material viscosity adjusting auxiliary agent, the material viscosity adjusting auxiliary agent comprises ethylene tar, and the fed materials are subjected to a hydrotreatment reaction in a hydrodemetallization reaction zone to obtain a hydrogenation effluent; the hydrodemetallization reaction zone is at least filled with a first hydrodemetallization catalyst, wherein the first hydrodemetallization catalyst comprises a carrier component and a hydrogenation active metal component, and the carrier component comprises carbon and alumina. According to the method disclosed by the invention, the ethylene tar is added into the residual oil raw material as a material viscosity adjusting aid, so that the system viscosity under the reaction condition can be effectively reduced, the hydrodemetallization ofthe residual oil is promoted, and the improvement of the reaction performances such as subsequent desulfurization, carbon residue removal and the like is facilitated through the synergistic effect ofall the components under the hydrodemetallization reaction condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solvent-resistant polyurethane elastomer and preparation method therefor

The invention belongs to the technical field of application of polyurethane and particularly relates to a solvent-resistant polyurethane elastomer and a preparation method therefor. The solvent-resistant polyurethane elastomer is prepared from a component A, a component B and a component C according to the mass ratio of 100: (20 to 30): (3 to 15), wherein the component A is prepared from polyesterpolyol through vacuum dehydration at the temperature of 100 DEG C to 120 DEG C, the polyester polyol is polysuccinate polyester polyol containing ethylene glycol and diethylene glycol, the ethylene glycol accounts for 50% to 80% (mole percent) of the total amount of the ethylene glycol and the diethylene glycol, the component B is isocyanate, and the component C is a curing agent ingredient and is obtained through dehydrating an alcohol type chain extender and then mixing the dehydrated alcohol type chain extender with a catalyst. The solvent-resistant polyurethane elastomer disclosed by theinvention is low in system viscosity, good in operability, good in solvent resistance and superior and environment-friendly in comprehensive performance, and compared with the ordinary polyurethane elastomers, the solvent resistance is improved to certain extent; and the invention simultaneously provides the easy and feasible preparation method.

Owner:SHANDONG INOV POLYURETHANE

Slump retaining type high-performance solid polycarboxylic acid water reducing agent as well as preparation method and application thereof

ActiveCN107987229AReduce manufacturing costReduce production energy consumptionBulk polymerizationAcid water

The invention relates to the technical field of concrete additives and specifically relates to a slump retaining type high-performance solid polycarboxylic acid water reducing agent as well as a preparation method and application thereof. By adopting a bulk polymerization way, no solvent or medium is applied in the whole process; the reaction is carried out in a room-temperature condition, therebyovercoming the shortcoming that high-temperature melting and high-temperature polymerization are performed in traditional synthesis process of solid polycarboxylic acid; the synthesis technology is simple and efficient, easy to control, safe, environment-friendly and pollution-free; the production cost and energy consumption are low; the product is convenient for transportation, and the performance of the product is better than that of the slump retaining type solid polycarboxylic acid water reducing agent available on the market, and thus the product has a remarkable prospect in market application.

Owner:联泓(江苏)新材料研究院有限公司

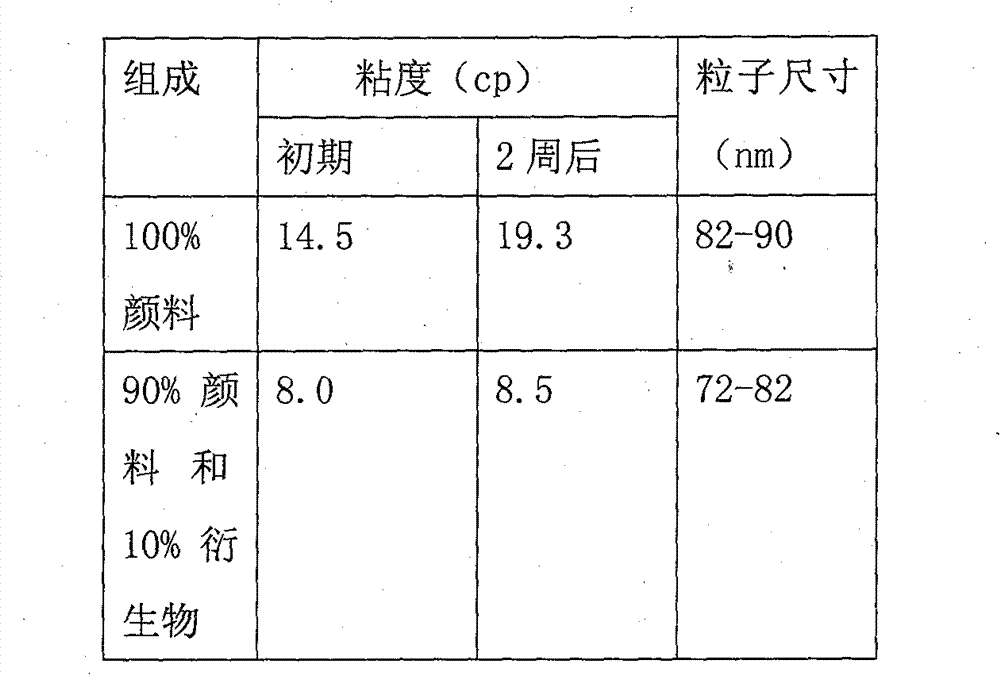

Preparation method for high energy saving environmental protection type phthalocyanine green pigment

InactiveCN102786814AFull color developmentIncrease brightnessOptical filtersOrganic dyesHigh energyFiltration

The present invention provides a preparation method for a high energy saving environmental protection type phthalocyanine green pigment, wherein a crystallization stabilizer and a solvent are added in a preparation process. The concrete process comprises: adding a phthalocyanine green pigment crude product and an acid in a reaction kettle, stirring, and adding a crystallization stabilizer, an organic solvent and the like during an acid treatment process; adding the resulting acid mixture to water, and uniformly stirring; carrying out filtration water washing until the pH value is close to a neutral pH value, and drying to obtain a bulk pigment, or crushing to obtain a powder pigment, wherein a derivative of the pigment is obtained; adding the derivative to a untreated phthalocyanine green pigment crude product according to a certain proportion to carry out mixing, wherein a high energy saving environmental protection type phthalocyanine green pigment composition is obtained after carrying out uniform mixing. The high energy saving environmental protection type phthalocyanine green pigment prepared by the method of the present invention has high brightness and high contrast, can meet applications in traditional industries, and can further be used for color filters of liquid crystal photoresists.

Owner:南通乐彩颜料化工有限公司

Hydrophobic polyquaternary-ammonium-salt antistatic agent for oil products and preparation method of hydrophobic polyquaternary-ammonium-salt antistatic agent

ActiveCN106190369AGood antistatic propertiesReduce system viscosityLiquid carbonaceous fuelsChemistryAntistatic agent

The invention relates to a hydrophobic polyquaternary-ammonium-salt antistatic agent for oil products and a preparation method of the hydrophobic polyquaternary-ammonium-salt antistatic agent. The preparation method includes the steps of firstly, dissolving methyl acrylyl oxyethyl trimethyl ammonium chloride, long chain alkyl acrylate and initiator azodiisobutyronitrile into a low-molecular-weight alcohol solvent to form a monomer solution; secondly, adding a hydrocarbon solvent into a container, stirring, heating, and dropwisely adding the monomer solution obtained in the first step after the heating; thirdly, heating after the dropwise adding, and then preserving the heat; fourthly, washing the solution after the reaction in cold water, and stirring fast to obtain a crude product; fifthly, subjecting the crude product to vacuumizing filtration, and then performing vacuum drying to obtain the hydrophobic polyquaternary-ammonium-salt antistatic agent. The testing results obtained by using distilled aviation kerosene and standard base oil as testing oil show that the novel antistatic agent prepared by the method is excellent in antistatic performance and can be used as the antistatic agent for the oil products.

Owner:NORTHWEST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com