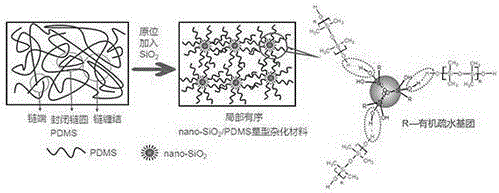

Method for in-situ preparing nano-silicon dioxide/hydroxy terminated polydimethylsiloxane hybrid material

A technology of hydroxyl-terminated polydimethylsiloxane and nano-silica, which is applied in the field of in-situ preparation of nano-silica/hydroxyl-terminated polydimethylsiloxane hybrid materials, which can solve agglomeration and polymer rheology Poor, nano-silica specific surface area and other problems, to achieve the effect of viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

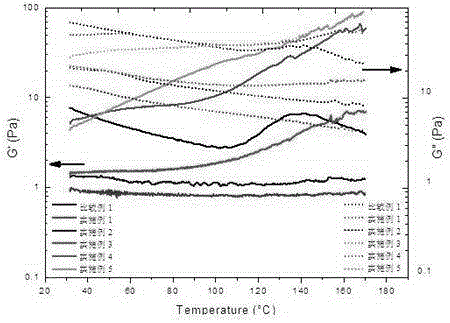

Embodiment 1

[0027] A method for in-situ preparation of nano-silica / hydroxy-terminated polydimethylsiloxane hybrid material includes the following steps: DMC and tetramethylammonium hydroxide are added to a three-necked flask equipped with a reflux condenser, and Under stirring, the temperature was raised to 100°C and stirred at constant temperature for 50 min to make DMC ring open and pre-polymerization reaction occurred; then nano-silica was added and stirred at 100°C for 60 min without fractions distilled out; and the vacuum degree was -0.02 MPa Under the condition of ~-0.04 MPa, stir at a constant temperature of 100°C until no fractions are distilled out; cool to room temperature to obtain; wherein the mass ratio of DMC ring body, tetramethylammonium hydroxide and nano silica is 100: 2× 10 -4 :2.

Embodiment 2

[0029] A method for in-situ preparation of nano-silica / hydroxy-terminated polydimethylsiloxane hybrid material includes the following steps: DMC and tetramethylammonium hydroxide are added to a three-necked flask equipped with a reflux condenser, and Under stirring, the temperature was raised to 105℃, and stirred at constant temperature for 50 min to make DMC ring open and prepolymerization reaction occurred; then nano silica was added and stirred at 100℃ constant temperature for 60 min, and no fractions were distilled out; and the vacuum degree was -0.02 MPa Under the condition of ~-0.04 MPa, stir at 105℃ until no fractions are distilled out; cool to room temperature to get it; among them, the mass ratio of DMC monomer, tetramethylammonium hydroxide and nano silica is 100: 2× 10 -4 : 4.

Embodiment 3

[0031] A method for in-situ preparation of nano-silica / hydroxy-terminated polydimethylsiloxane hybrid material includes the following steps: DMC and tetramethylammonium hydroxide are added to a three-necked flask equipped with a reflux condenser, and Under stirring, the temperature was raised to 100°C and stirred at constant temperature for 50 min to make DMC ring open and pre-polymerization reaction occurred; then nano-silica was added and stirred at 100°C for 60 min without fractions distilled out; and the vacuum degree was -0.02 MPa Under the condition of ~-0.04 MPa, stir at a constant temperature of 100°C until no fractions are distilled out; cool to room temperature to obtain; wherein the mass ratio of DMC ring body, tetramethylammonium hydroxide and nano silica is 100: 2× 10 -4 : 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com