Submersible vehicle encapsulation composite foam filling materials and preparation method thereof

A composite foam and filling material technology, which is applied in the field of marine solid buoyancy materials and composite foam filling materials, can solve problems such as unseen manufacturing methods, and achieve good effects, good bonding performance, and good flow and leveling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0023] The present invention will be further elaborated below in conjunction with specific embodiments, but the present invention is not limited.

[0024] The embodiment of the present invention further specifically illustrates the reliability and feasibility of the composite foam filling material for submersible potting. However, the present invention is not limited to the following examples, and the present invention will be further described in detail below in conjunction with the examples.

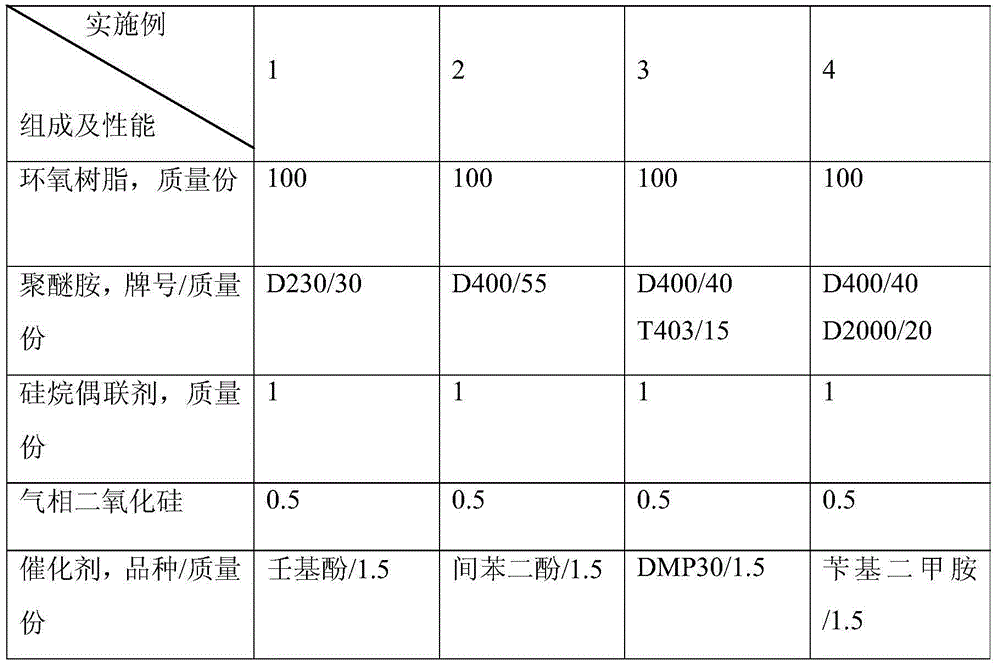

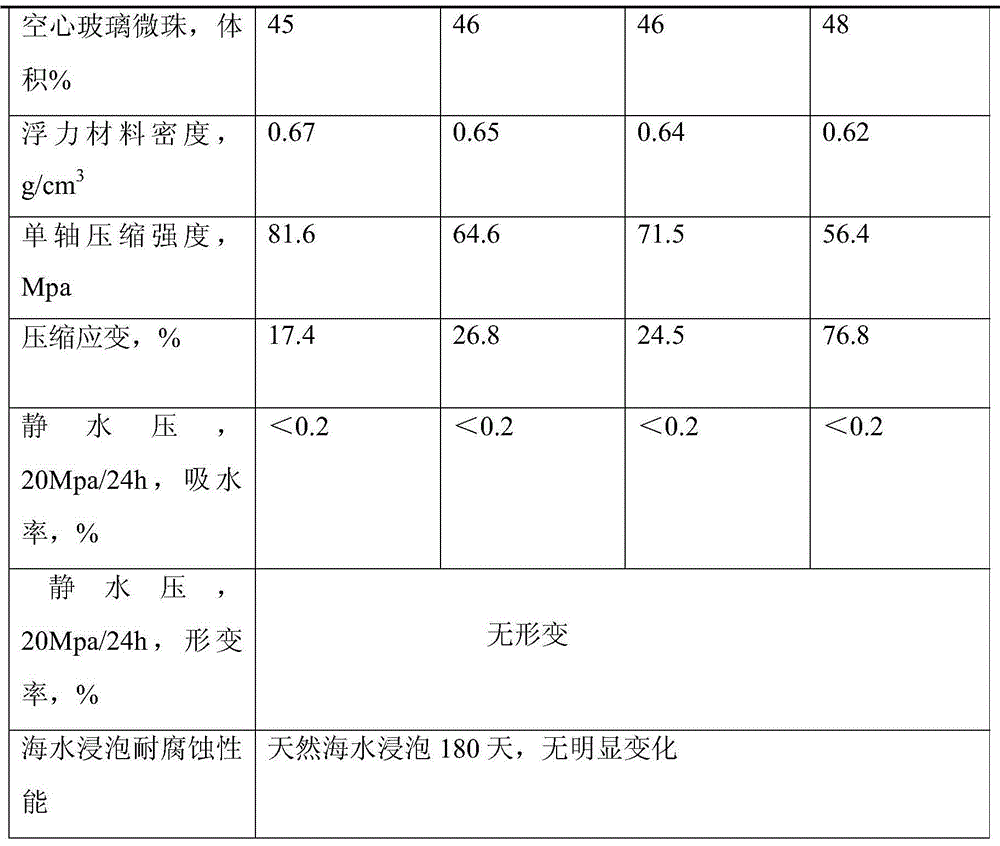

[0025] Embodiment 1-4 Composite foam filling material proportion and performance are listed in the table.

[0026] For potting composite foam filling materials, the polyether amine cured epoxy resin system has low viscosity, good flow and leveling properties, can be cured at room temperature, and is suitable for pouring and potting processes. The operation time is long and the construction period is long, the exothermic temperature peak of the curing reaction is low, the cured product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com