Preparation method for high energy saving environmental protection type phthalocyanine green pigment

An energy-saving and environmentally friendly, phthalocyanine green technology, applied in the direction of organic dyes, optical filters, etc., can solve the problems of recycling, environmental pollution, and high risk, and achieve improved product dispersion, improved gloss and color strength, and high brightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] a. A reaction kettle with a volume of 5 cubic meters, put 500 kilograms of phthalocyanine green pigment crude product and 1500 kilograms of 100% sulfuric acid, keep stirring for 8 hours, the temperature is 65 ℃ ~ 110 ℃, add 25 kilograms of ammonium salt and 25DMF; put the obtained acid mixture into 30 tons of water, the water temperature is 30 ℃ ~ 90 ℃, stir evenly; then filter and wash until the pH value is neutral, dry to obtain a block pigment, or crush to obtain a powder pigment, and obtain the pigment derivatives of 250 kg;

[0024] b. Mix 20 kilograms of the derivative of the pigment with 180 kilograms of untreated crude phthalocyanine green pigment, and mix evenly to obtain 200 kilograms of high-energy-saving and environment-friendly phthalocyanine green pigment.

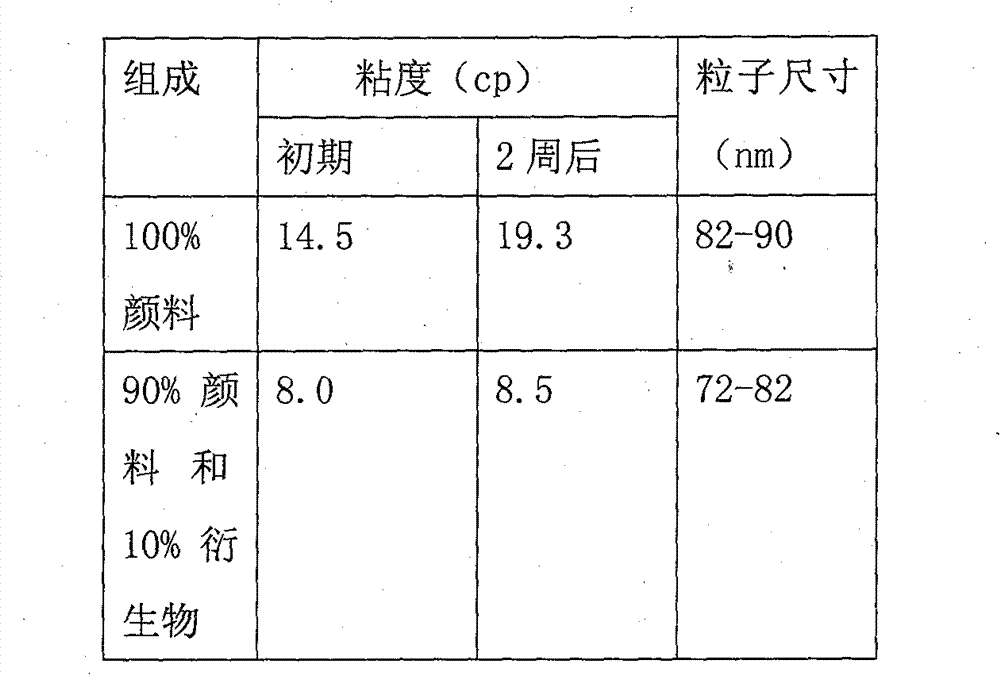

[0025] Compare the high-energy-saving and environment-friendly phthalocyanine green pigment with the untreated crude phthalocyanine green pigment, as shown in Table 1:

[0026]

[0027] Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com