Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1860 results about "Suspension polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

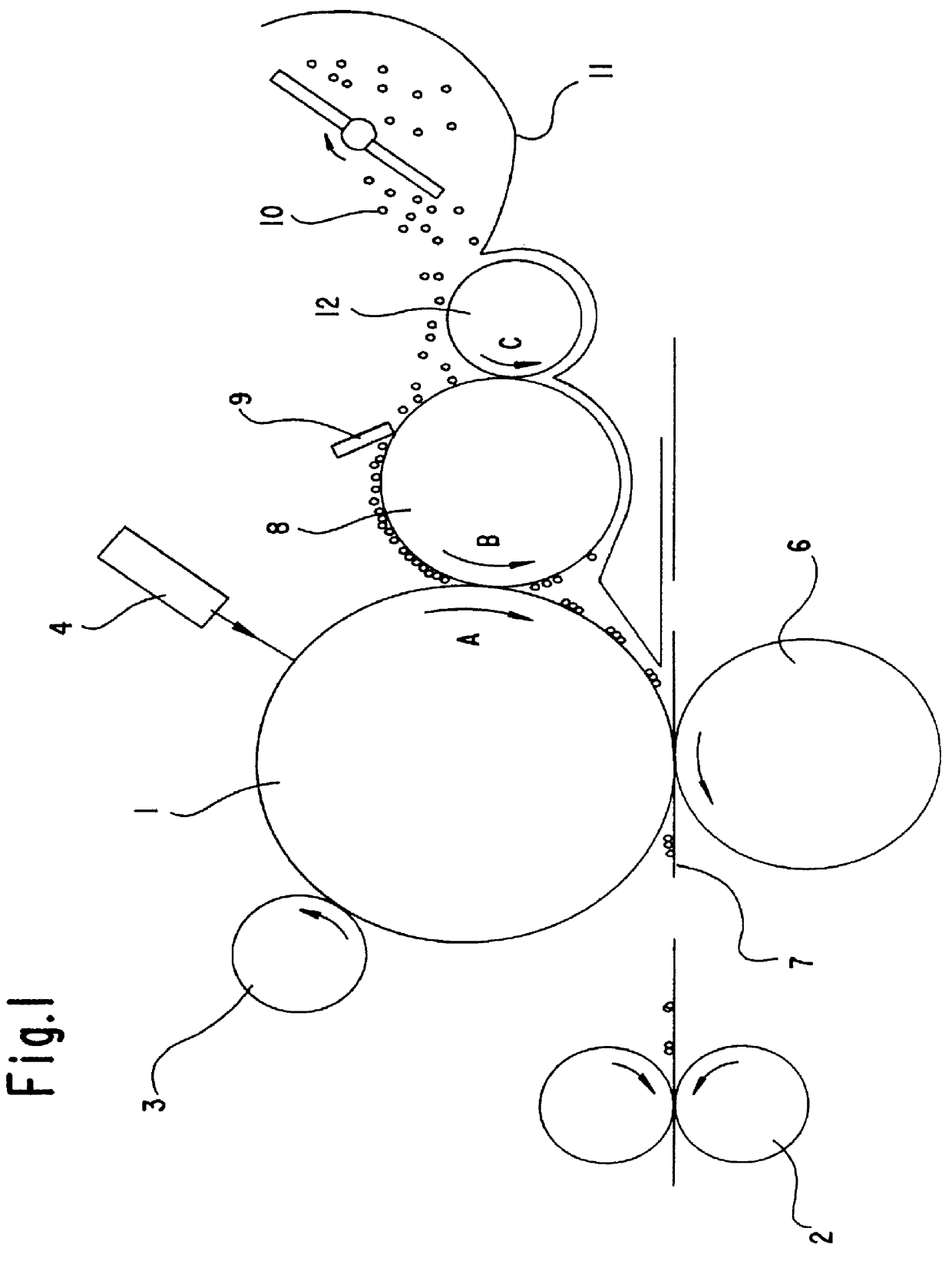

Suspension polymerization is a heterogeneous radical polymerization process that uses mechanical agitation to mix a monomer or mixture of monomers in a liquid phase, such as water, while the monomers polymerize, forming spheres of polymer.

Cleaning compositions comprising a multi-polymer system comprising at least one alkoxylated grease cleaning polymer

ActiveUS20090124528A1Easy to cleanOrganic detergent compounding agentsOrganic/inorganic per-compounds compounding agentsPolymer scienceAlkoxyl radicals

Owner:THE PROCTER & GAMBLE COMPANY

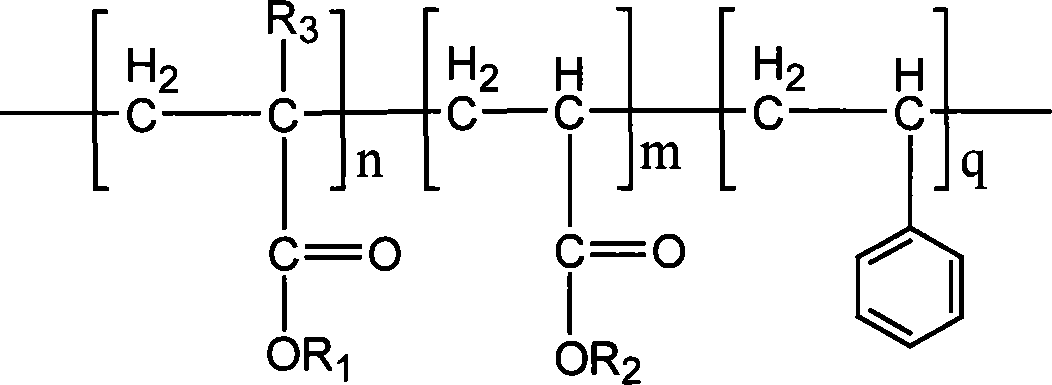

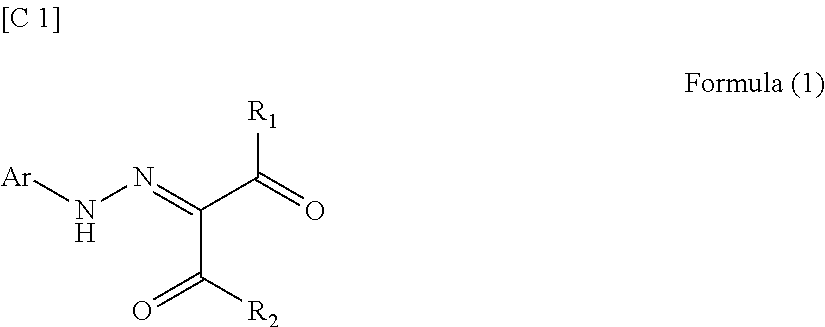

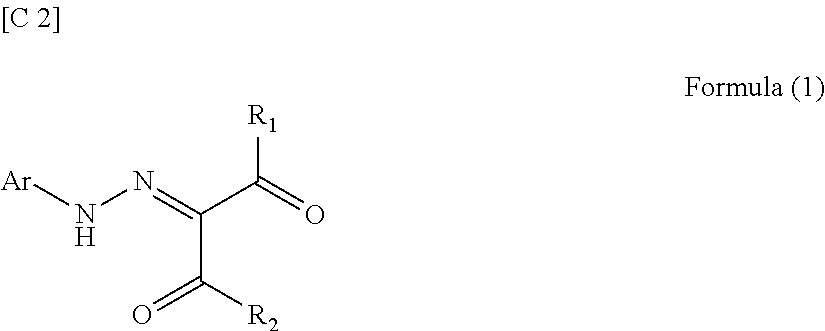

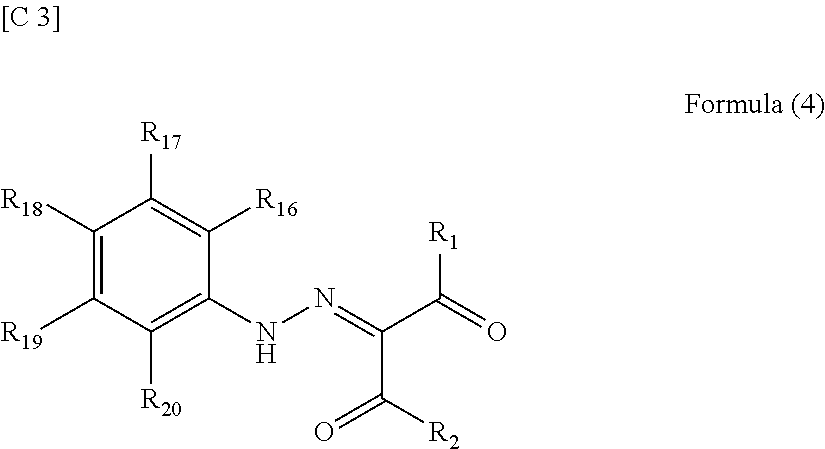

Polymerized toner

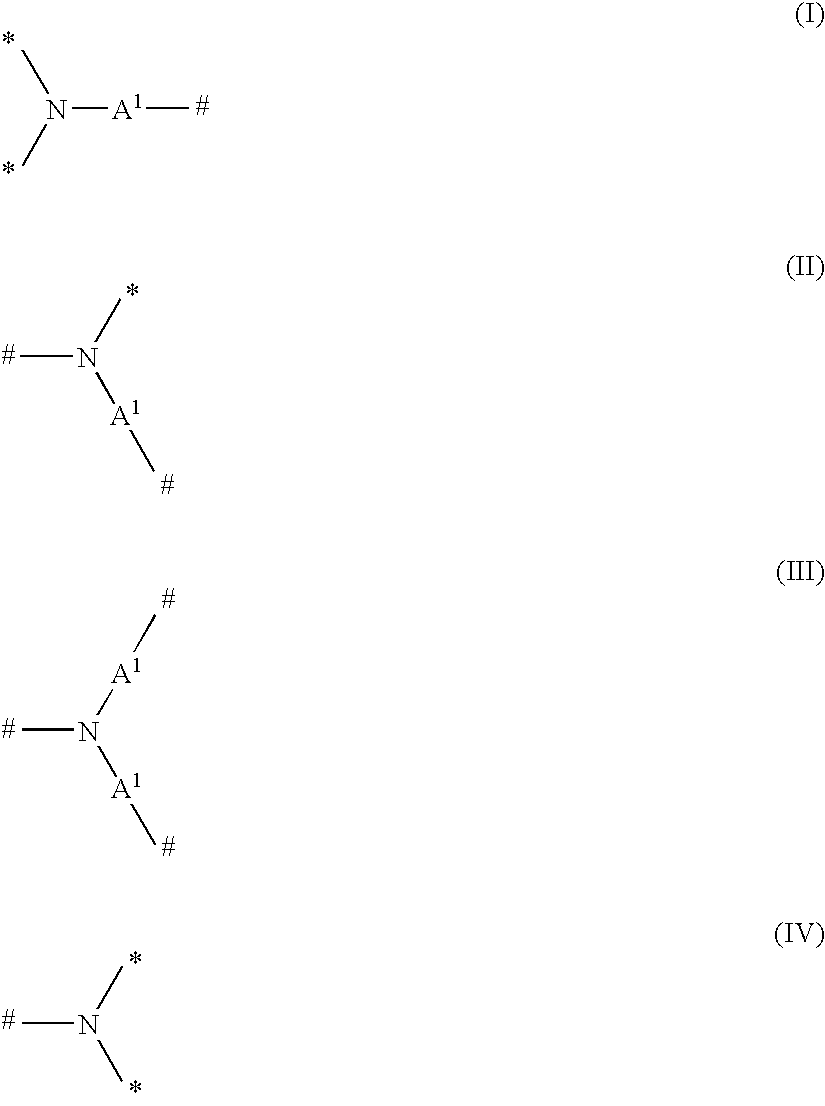

A monomer for a shell or a mixture of at least two monomers for a shell was suspension polymerized in the presence of core particles and a polymerization initiator to obtain polymer particles, wherein said core particles are formed of a polymer obtained by polymerization of a monomer for a core or a mixture of at least two monomers for a core and containing a colorant, wherein said monomer for a shell or mixture of monomers for a shell is one which gives upon polymerization a polymer having a glass transition temperature higher than that of the polymer forming the core particle, and wherein said polymerization initiator is represented by the following formula 1: wherein X1, X2, X3 and X4 independently represent oxygen atom, sulfur atom, >NR (wherein R is hydrogen atom, alkyl group, or group); R1, R2, R3, R4, R5 and R6 independently represent alkyl group, aryl group, or alkyl or aryl group having at least one substituent which is -OR, -OH, -NHR, or -NR2(wherein R is alkyl group or aryl group), and n and m independently represent an integer of 1 to 10. An outer additive was applied on the polymer particle to obtain a polymerized toner. This polymerized toner has low fixing temperature, excellent overhead projector transparency, good shelf stability, and exhibiting a less pronounced reduction in electric charge under conditions of high humidity and high temperature.

Owner:ZEON CORP

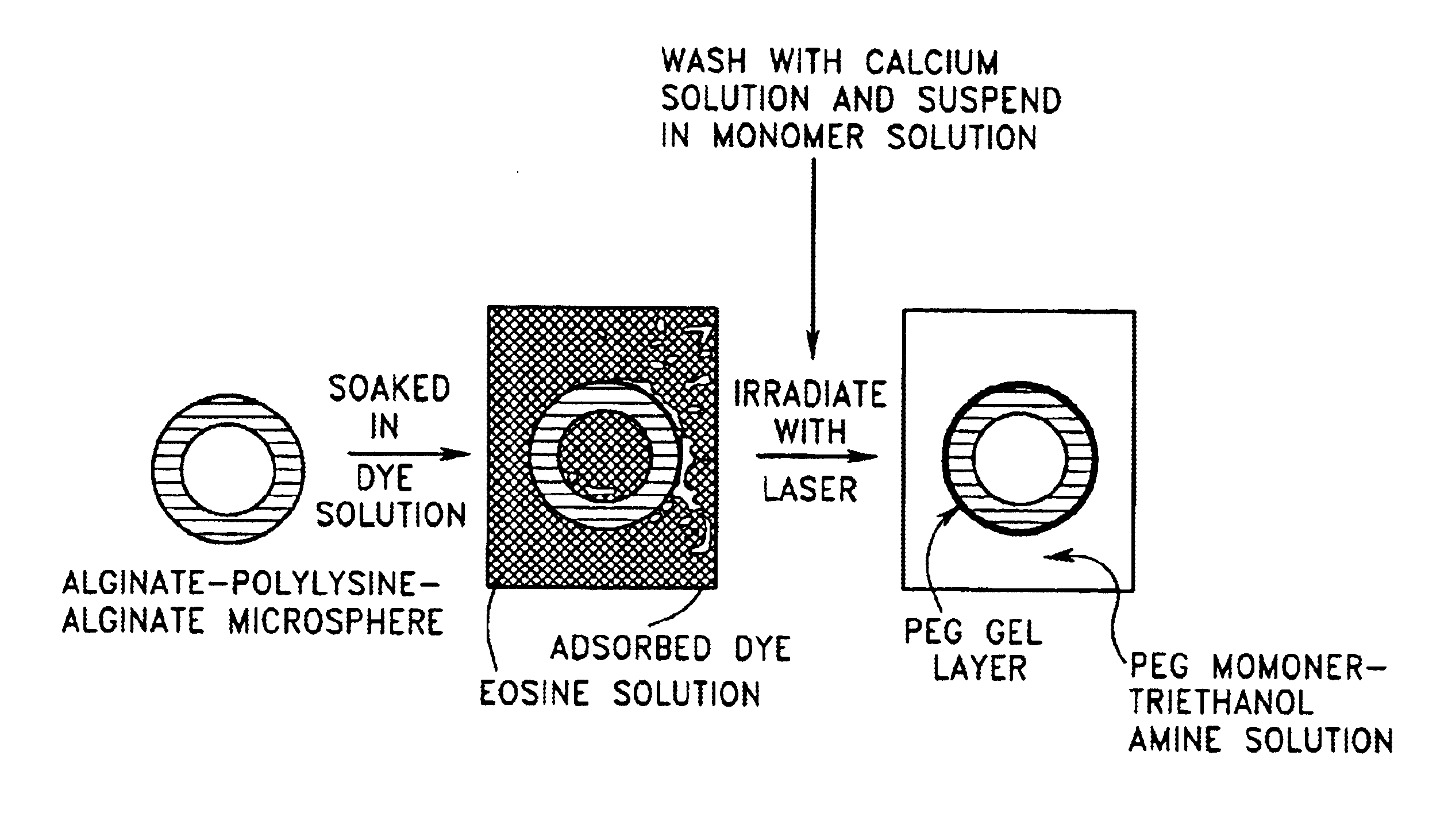

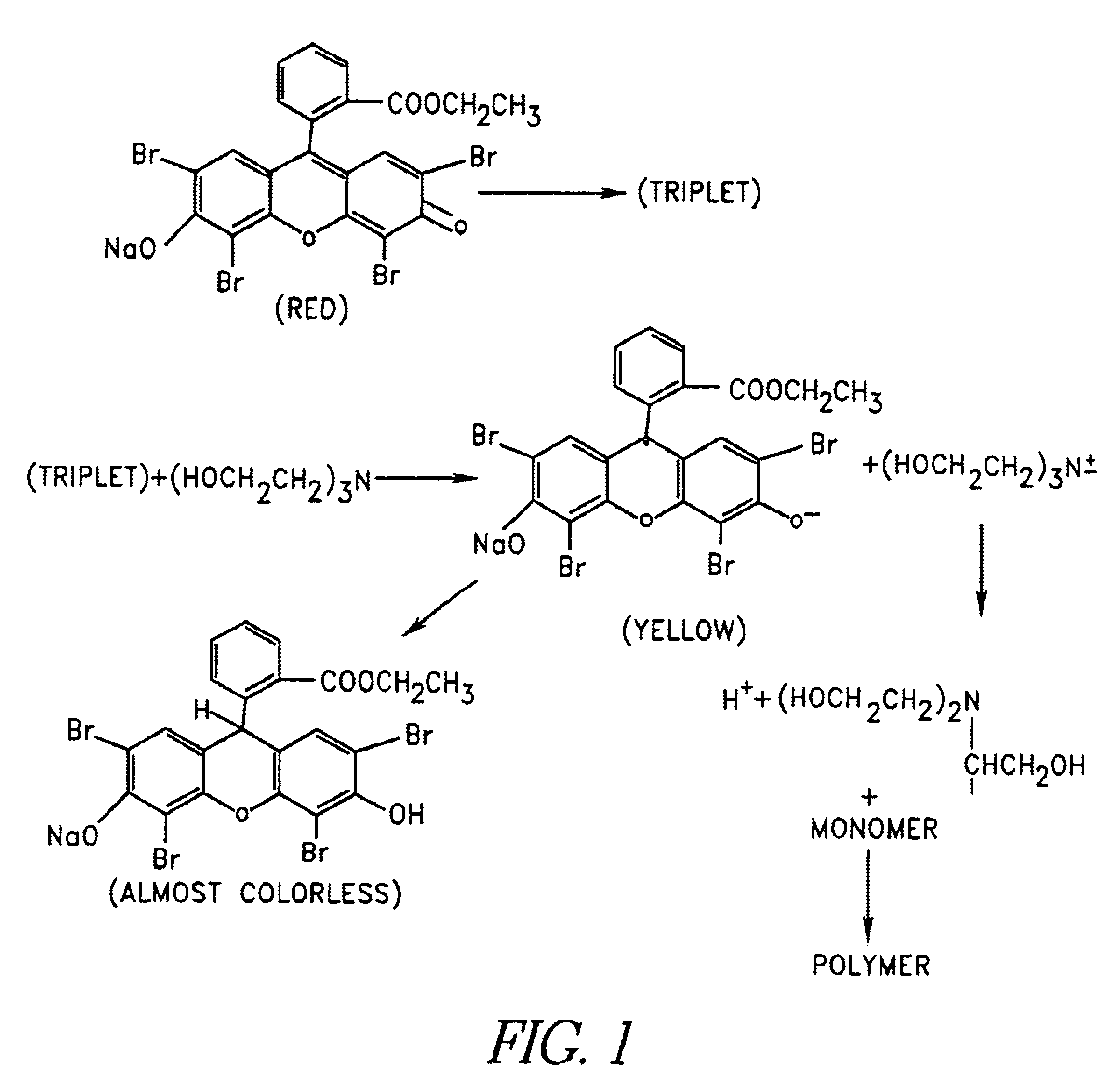

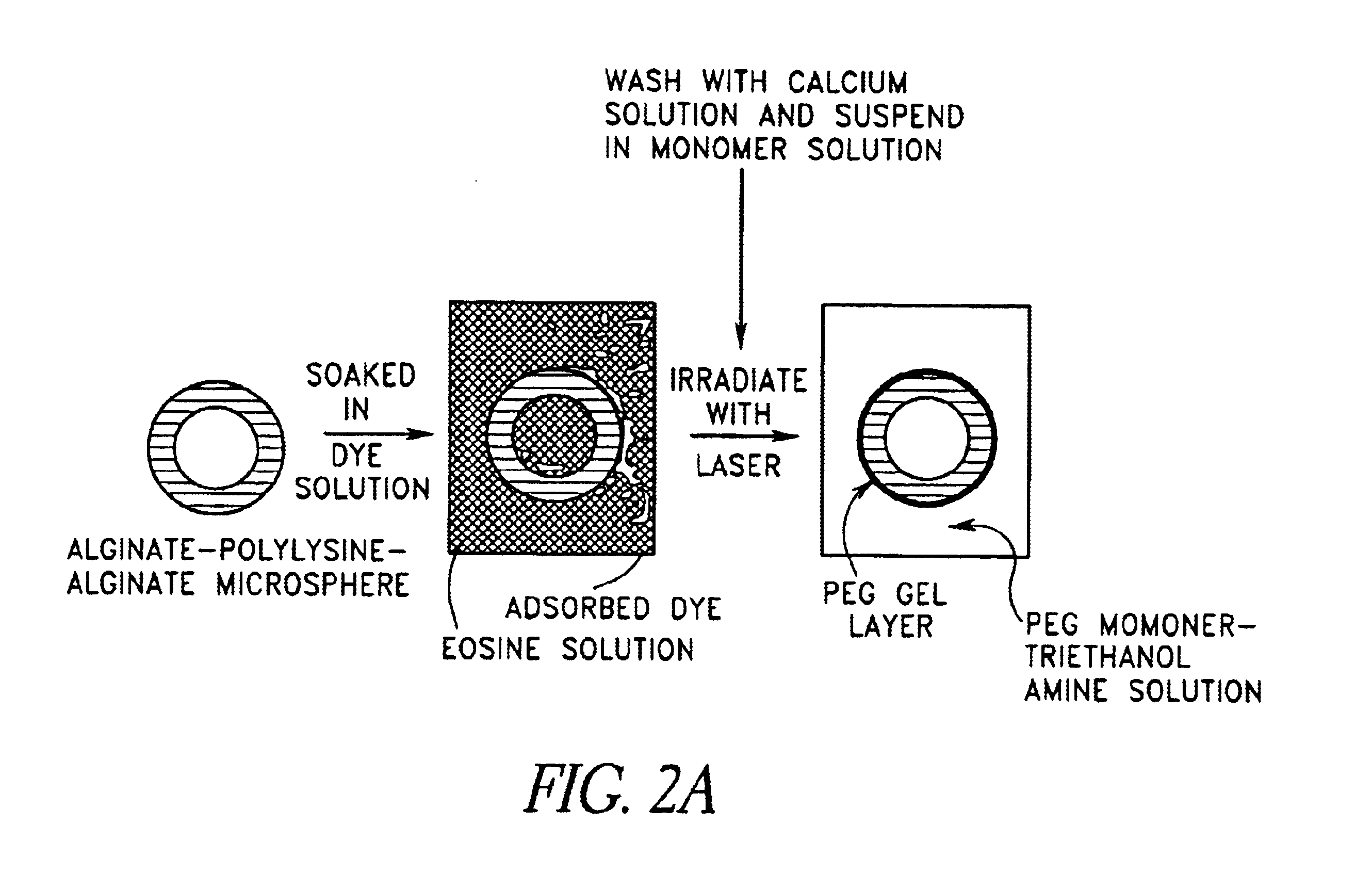

Gels for encapsulation of biological materials

InactiveUS6911227B2Efficient gluingFacilitated DiffusionImmobilised enzymesSurgical adhesivesActive matterWater soluble

This invention provides novel methods for the formation of biocompatible membranes around biological materials using photopolymerization of water soluble molecules. The membranes can be used as a covering to encapsulate biological materials or biomedical devices, as a “glue” to cause more than one biological substance to adhere together, or as carriers for biologically active species. Several methods for forming these membranes are provided. Each of these methods utilizes a polymerization system containing water-soluble macromers, species, which are at once polymers and macromolecules capable of further polymerization. The macromers are polymerized using a photoinitiator (such as a dye), optionally a cocatalyst, optionally an accelerator, and radiation in the form of visible or long wavelength UV light. The reaction occurs either by suspension polymerization or by interfacial polymerization. The polymer membrane can be formed directly on the surface of the biological material, or it can be formed on material, which is already encapsulated.

Owner:NOVOCELL

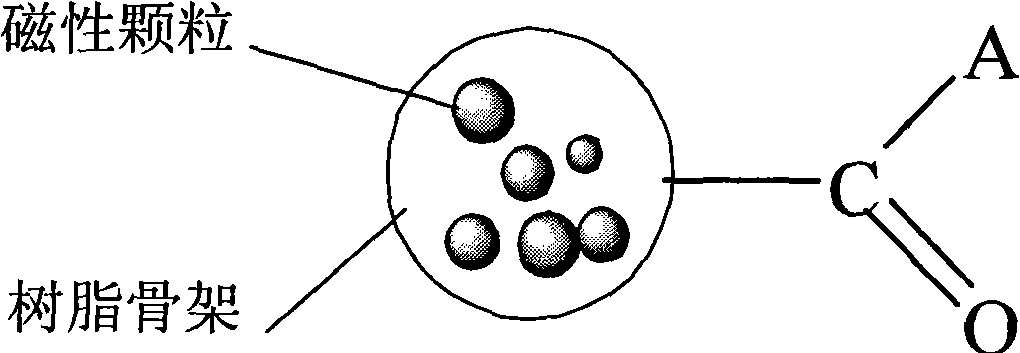

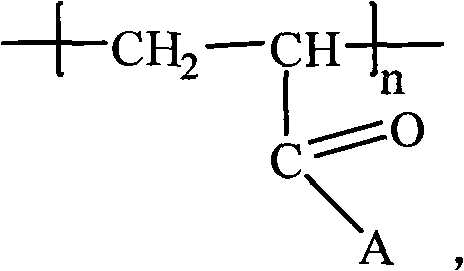

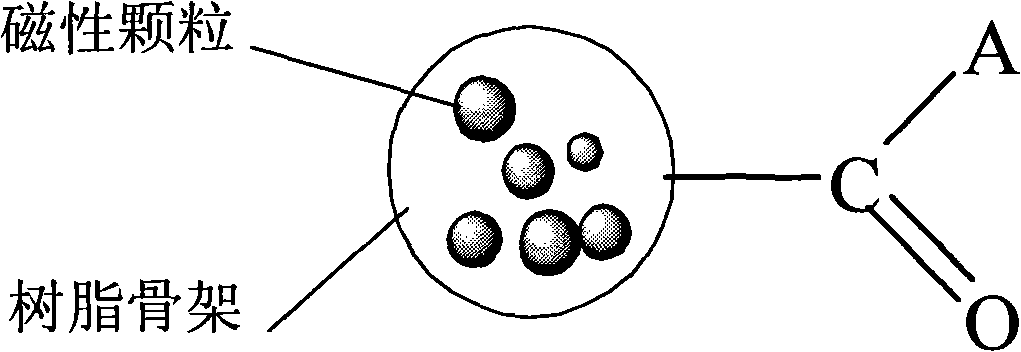

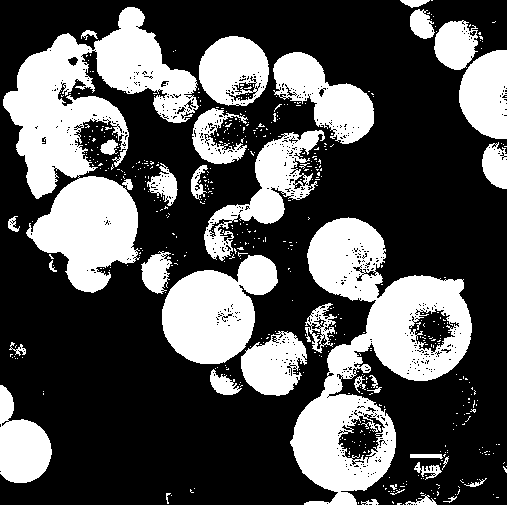

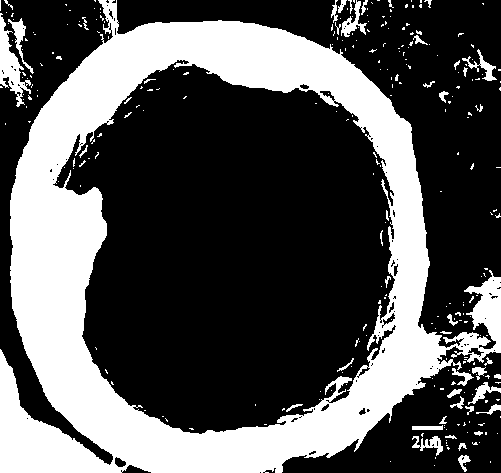

Magnetic acrylic acid series strongly basic anion exchange microballoon resin and preparation method thereof

ActiveCN101781437AIncrease switching capacityHigh base exchange capacityInorganic material magnetismAnion exchangersCross-linkIon exchange

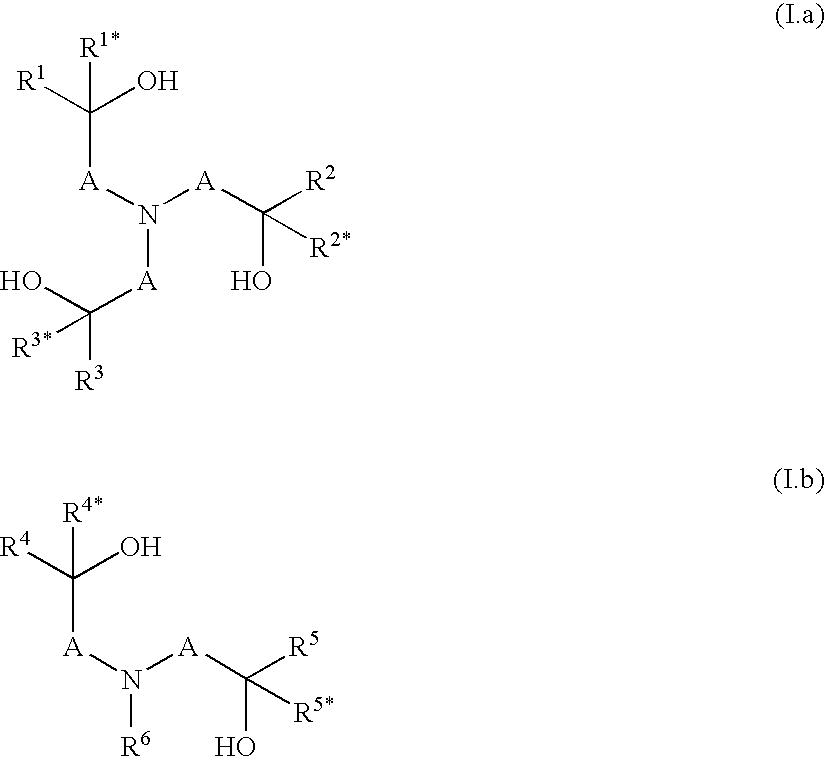

The invention discloses a magnetic acrylic acid series strongly basic anion exchange microballoon resin and a preparation method thereof. The microballoon resin has the following structure: the resin skeleton is internally provided with magnetic particles, wherein A stands for a radical containing quaternary ammonium salt. The preparation method comprises the following steps: acrylic acid series substances serve as a monomer, the monomer is mixed with cross-linking agent and pore-forming agent to form oil phase; the oil phase is uniformly mixed with the magnetic particles and then suspension polymerization is carried out on the mixture; after going through amination and alkylation reaction, the polymerized magnetic polymer particles form the quaternary ammonium salt, namely the magnetic acrylic acid series strongly basic anion exchange microballoon resin. Exchange capacity of the resin is higher than any magnetic acrylic acid series strongly basic anion exchange microballoon resin ever found in existing literatures and reports and domestic market as well as foreign markets and can replace the traditional strongly basic anion exchange resin, thus being capable of being used for separating and removing soluble organisms in various water bodies, especially disinfection by-product precursor and multiple negative ions such as nitrate and phosphate.

Owner:NANJING INNOVATION CENT FOR ENVIRONMENTAL PROTECTION IND

Hydrophobically modified clay polymer nanocomposites

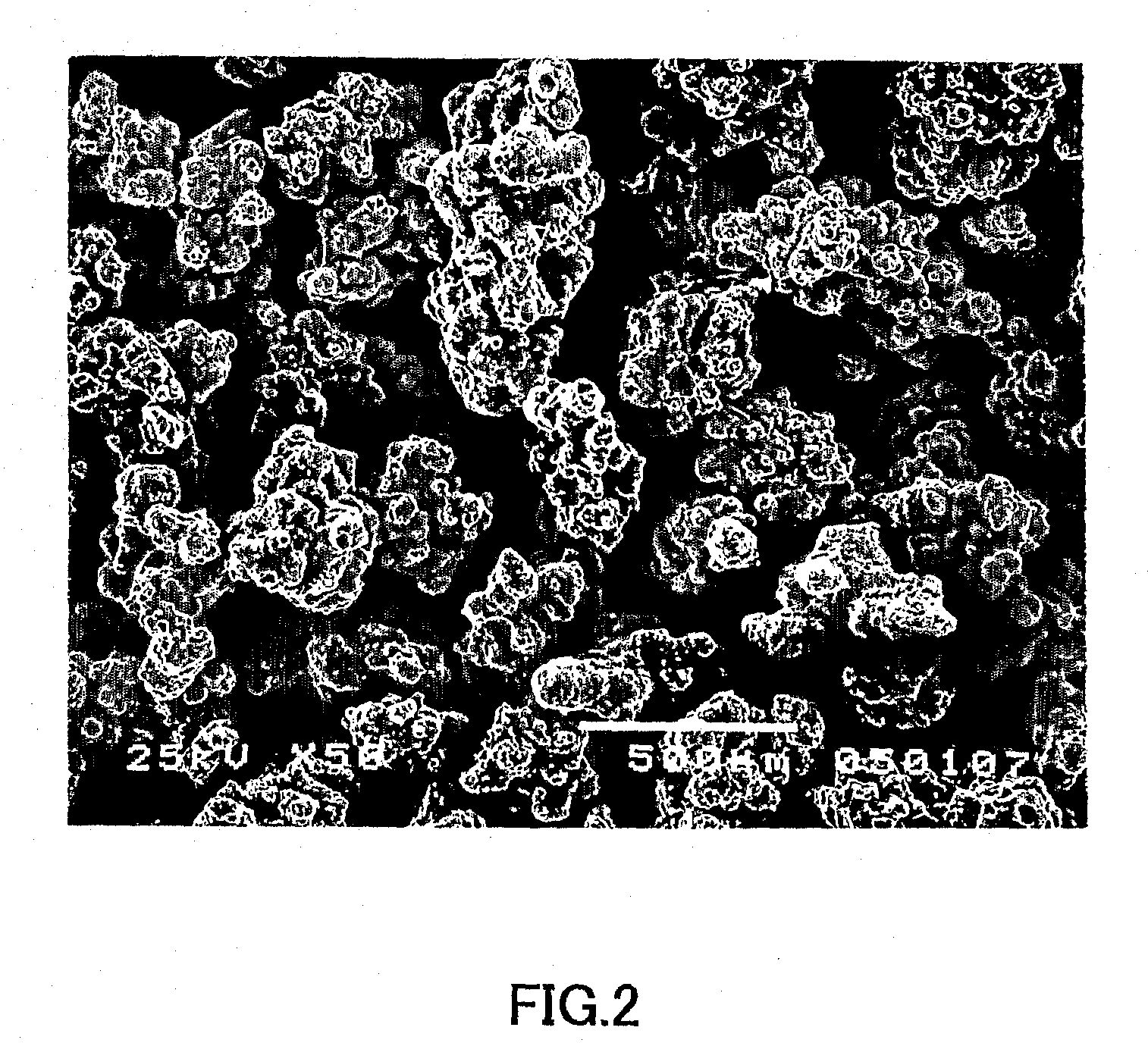

InactiveUS20020058739A1Control of particle sizeReduced stabilityMaterial nanotechnologyLayered productsColloidSolution polymerization

The present invention is directed, in part, to improved nanocomposite compositions and processes for preparing same. Specifically, in one embodiment, there is provided a process for preparing an aqueous nanocomposite dispersion, wherein the process comprises: polymerizing via suspension polymerization a suspension comprising at least one ethylenically unsaturated monomer and a hydrophobically modified clay to form the nanocomposite dispersion after polymerization, wherein the hydrophobically modified clay is dispersed in the monomer. Other embodiments include processes for preparing aqueous nanocomposite particles, colloids, and dispersions using hydrophobically modified clays in aqueous systems and compositions comprising same.

Owner:ROHM & HAAS CO

Method for producing expandable polystyrene particles

A process for preparing expandable particulate styrene polymers wherein from 5 to 50% by weight of expanded graphite and also, if desired, from 2 to 20% by weight of a phosphorus compound, are present as flame retardants, by suspension polymerization of styrene in the presence of the flame retardants.

Owner:BASF AG

Method for preparing hollow polymer microsphere coated with phase change material

ActiveCN103285793ASmall particle sizeIncrease coverageHeat-exchange elementsMicroballoon preparationPolymer scienceMicrosphere

The invention belongs to the technical field of preparation of phase change materials and microcapsules, and specifically relates to a method for preparing a hollow polymer microsphere coated with a phase change material. The method comprises the following steps of: performing surface modification on hydrophilic inorganic nanoparticles by an ionic surfactant, and adding the phase change material and monomers to the modified inorganic nanoparticles, which are taken as a stabilizer, to prepare the hollow polymer microsphere coated with the phase change material through a Pickering suspension polymerization method. The preparation process is simple, the raw materials are cheap and easily available, the inner wall of the prepared hollow polymer microsphere is made from polymers, the outer layer of the prepared hollow polymer microsphere is made from the inorganic nanoparticles, and the organic phase change material is coated inside the prepared hollow polymer microsphere. The prepared microsphere has a small size, the coating rate of the phase change material is high, and the outer inorganic nanoparticle layer enhances thermal stability, heat transfer efficiency, sealing performance and mechanical properties of the microsphere.

Owner:FUDAN UNIV

Thermoexpandable thermoplastic microspheres

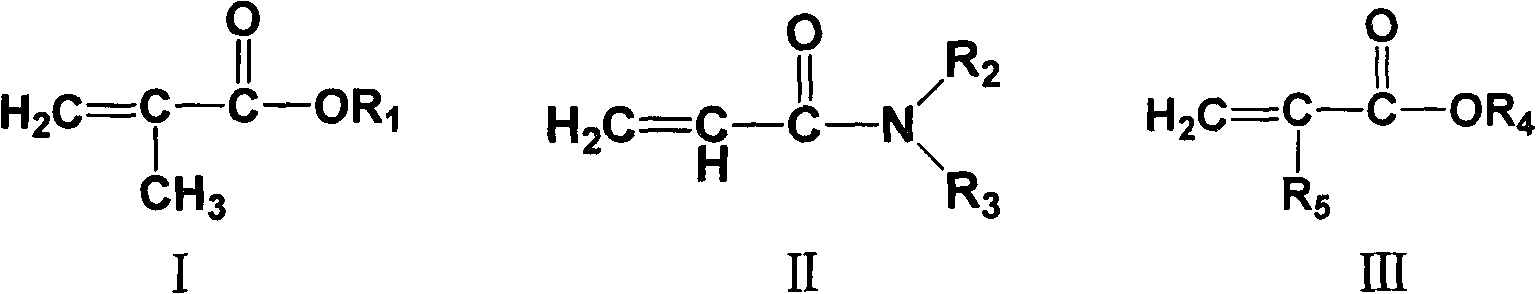

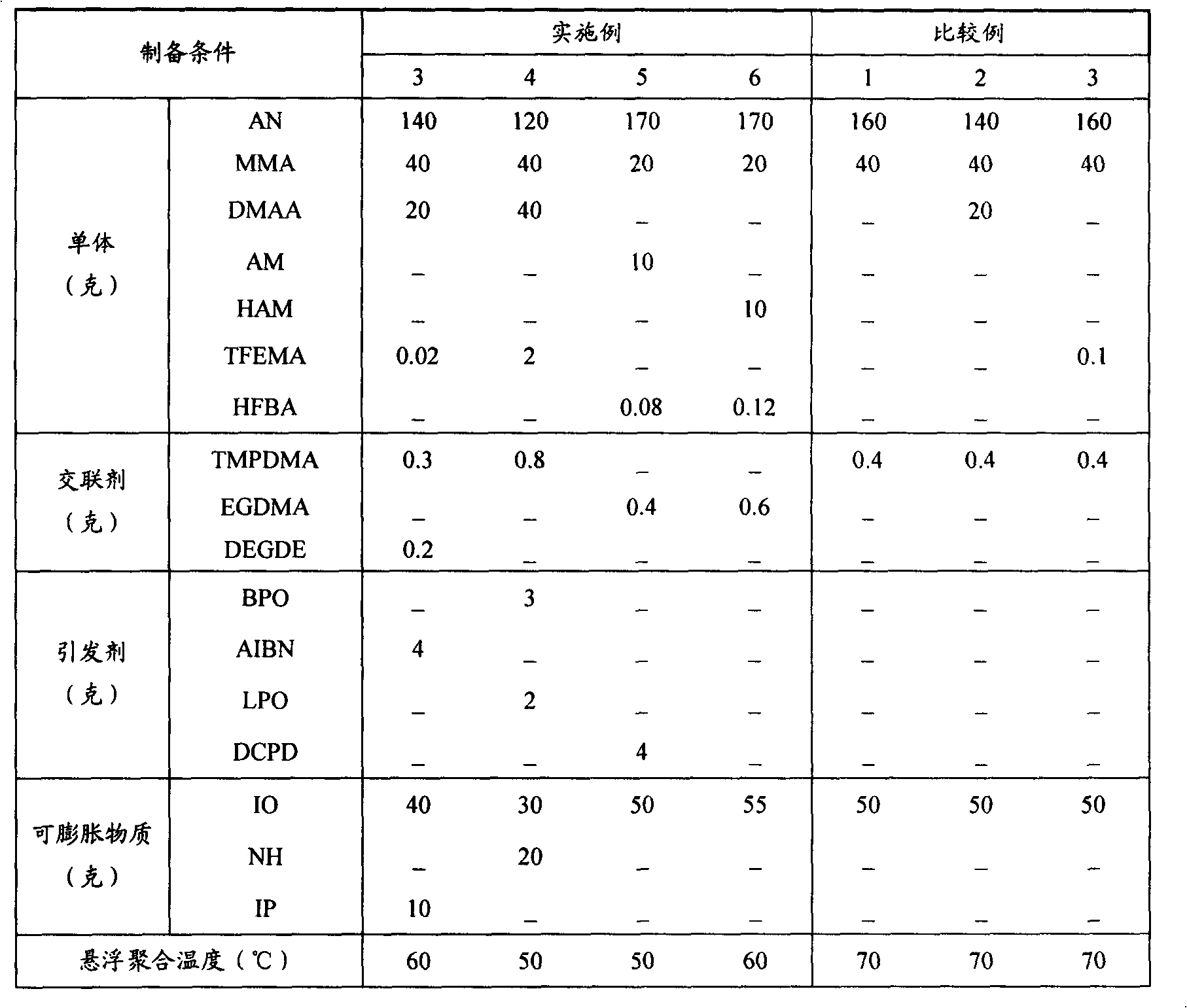

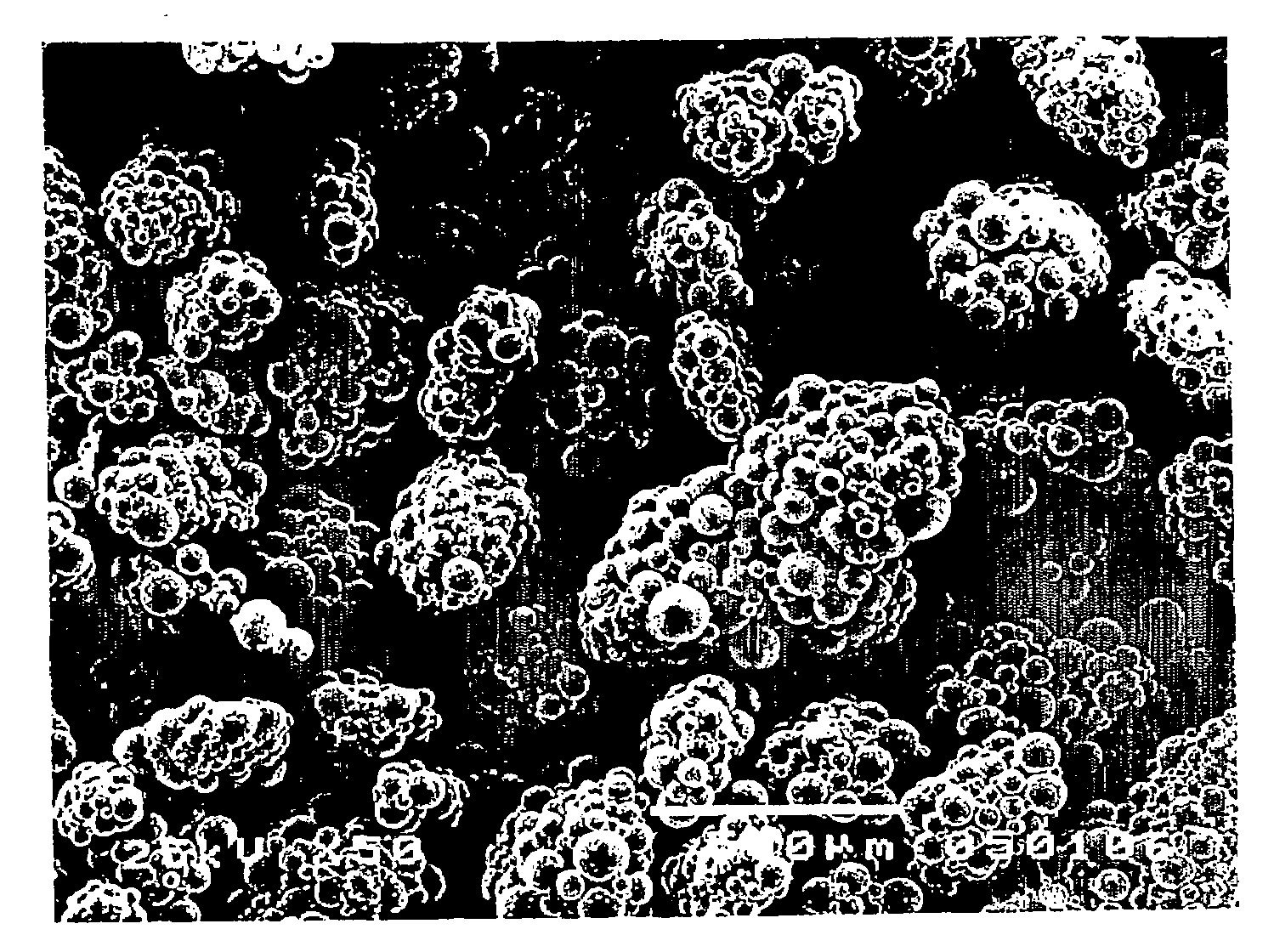

The invention relates to thermoexpandable thermoplastic microspheres which are mainly prepared by carrying out suspension polymerization on olefine polymerizable monomers and expandable substances. The thermoexpandable thermoplastic microspheres have a core-shell structure which uses the thermoplastic polymers as the shell and the expandable substances as the cure. The invention is characterized in that on the basis of 100 wt% as the total weight of the olefine polymerizable monomers, the olefine polymerizable monomers are composed of 30-90 wt% of acrylonitrile, 5-50 wt% of methacrylate monomers, 1-20 wt% of acrylamide monomers, 0.01-1.0 wt% of fluorine-containing acrylate monomers and 0-40 wt% of acrylic monomers. The start T of the thermoexpandable thermoplastic microspheres is 160-200 DEG C.

Owner:NANOSPHERE SHANGHAI

Particulate water-absorbing agent with water-absorbing resin as main component, method for production of the same, and absorbing article

InactiveUS20090036855A1Promote absorptionComfortable to useOther chemical processesBaby linensHigh concentrationCross-link

Reversed phase suspension polymerization is allowed while controlling content of minor components in monomer, particularly controlling a content of acetic acid and propionic acid being not higher than 500 ppm, controlling a content of acrylic acid dimer being not higher than 1000 ppm, in acrylic acid. Cross-linked polymer obtained by the polymerization is subjected to a surface crosslinking treatment without substantially using an organic solvent, and under heating at high temperature (150° C. or higher and 250° C. or lower). Thereafter, agglomeration is carried out without substantially using an organic solvent. Accordingly, a particulate water-absorbing agent including a water-absorbing resin having superior property, and being suited for practical applications at high concentrations in absorbing cores such as a diaper and the like without generation of any odor of the organic solvent can be obtained because no volatile organic compound is included.

Owner:NIPPON SHOKUBAI CO LTD

Water-absorbent resin and production prcess therefor

InactiveUS20040110913A1Solve problemsHigh propertyAbsorbent padsEmulsion paintsWater solubleAqueous solution

To provide: a process in which a coarse gel itself is made not to form in the case of applying the aqueous solution polymerization; and a process in which the polymerization is mildly controlled and the production is stably carried out in the case of applying the reversed-phase suspension polymerization or static polymerization, in a production of a water-absorbent resin. In a production process for a water-absorbent resin, which comprises a polymerization step that includes the steps of carrying out polymerization, involving crosslinking, of an aqueous solution of a water-soluble unsaturated monomer including acrylic acid(salt);and at the same time carrying out fine division of the resultant hydrogel, or in a production process for a water-absorbent resin, which comprises the steps of carrying out polymerization, involving crosslinking, of an aqueous solution of a water-soluble unsaturated monomer including acrylic acid(salt);and carrying out fine division of the resultant hydrogel, or in a production process for a water-absorbent resin, which comprises a polymerization step that includes the steps of carrying out polymerization, involving crosslinking, of an aqueous solution of a water-soluble unsaturated monomer including acrylic acid(salt); and at the same time obtaining a finely divided hydrogel, the water-soluble unsaturated monomer is adjusted in order to contain furfural in an amount of 11 to 1,000 weight ppm (relative to the monomer).

Owner:NIPPON SHOKUBAI CO LTD

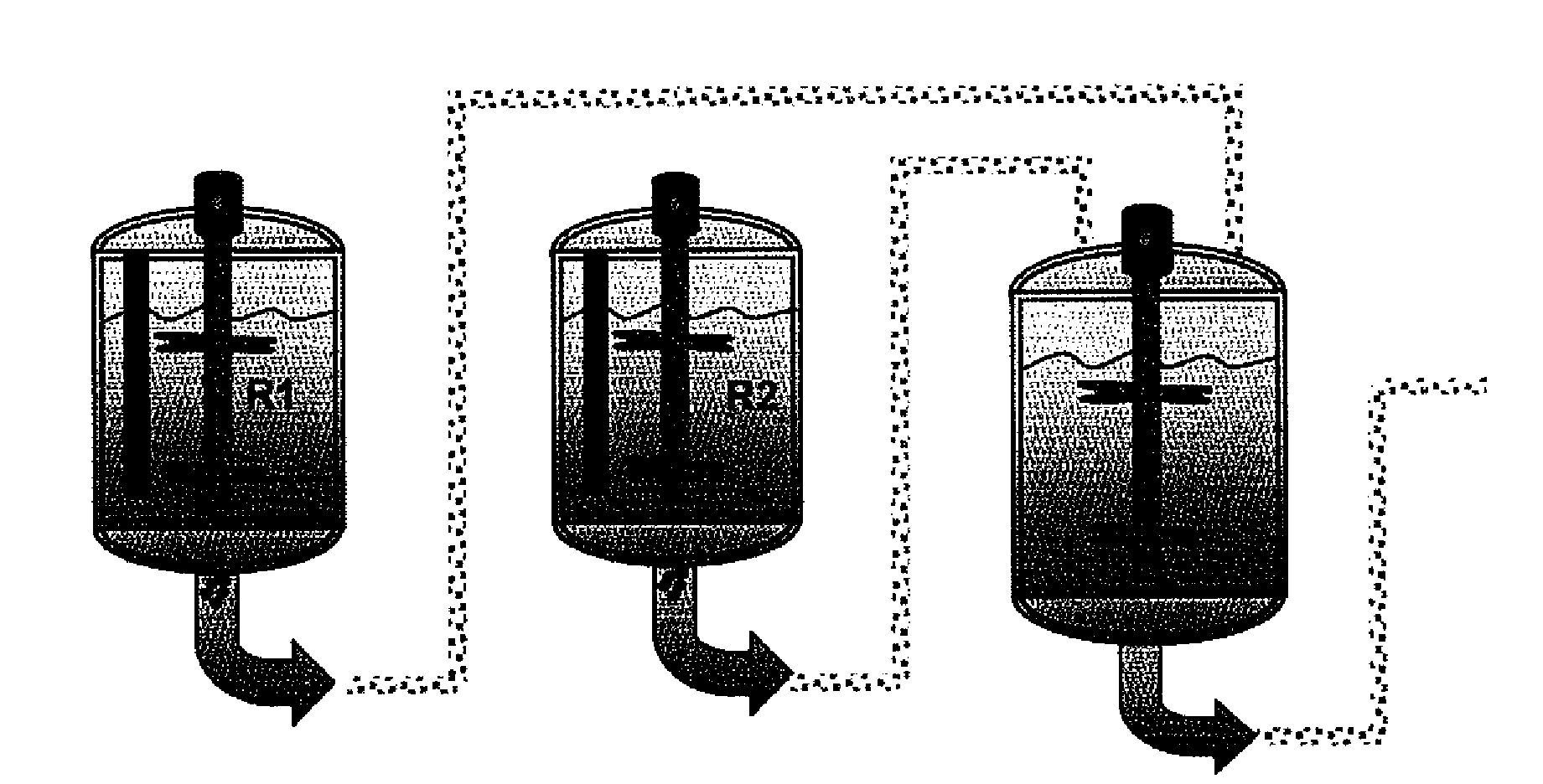

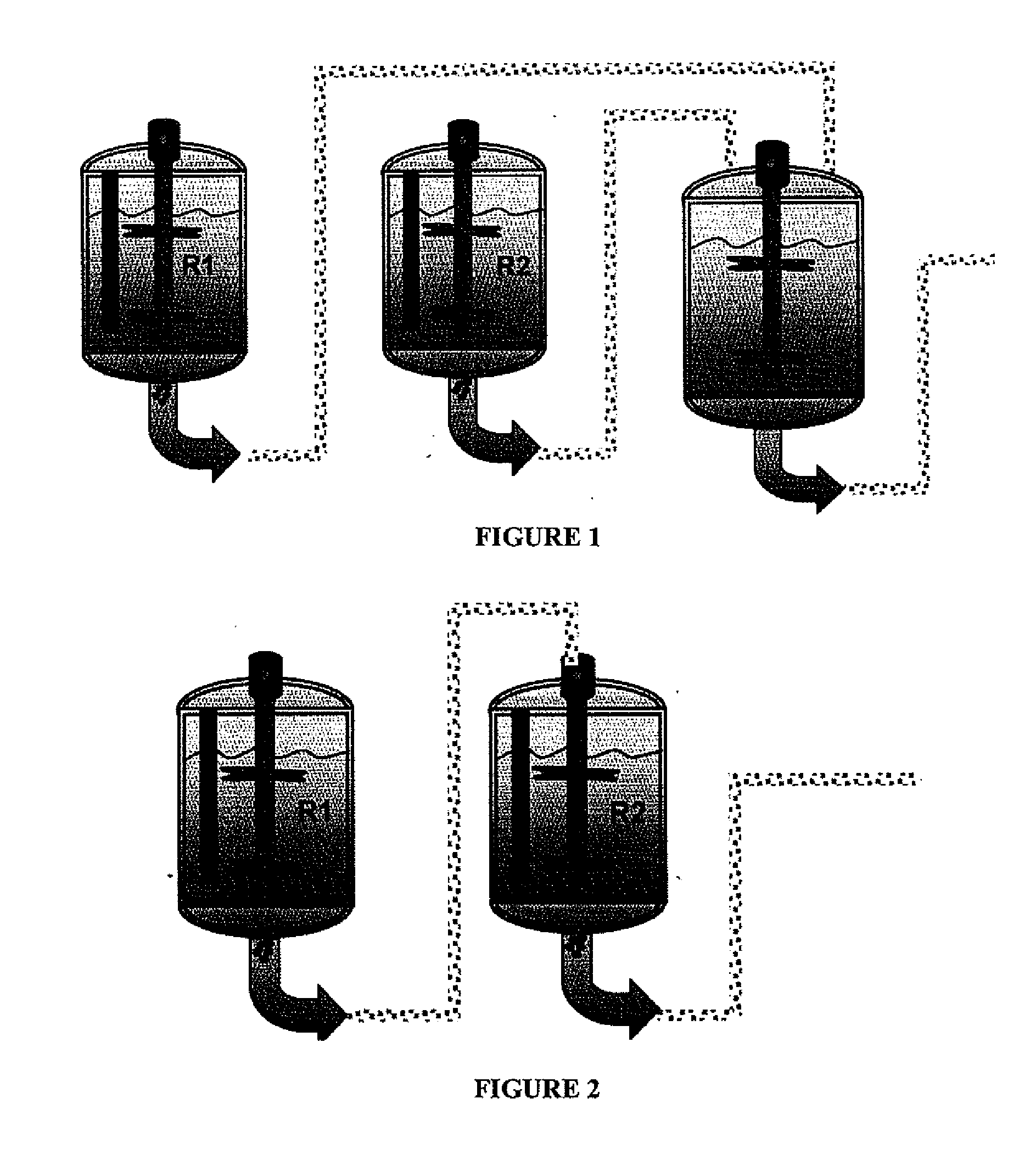

Suspension polymerization process for manufacturing ultra high molecular weight polyethylene, a multimodal ultra high molecular weight polyethylene homopolymeric or copolymeric composition, a ultra high molecular weight polyethylene, and their uses

InactiveUS20090163679A1Easy to processHigh molecular weightMonocomponent polyolefin artificial filamentFluidized bed dryingPolymer science

The present invention relates to a suspension polymerization process for the production of ultra high molecular weight polyethylene, wherein the operation is carried out in at least two reactors of the CSTR type (continuous stirring tank reactor), in a serial configuration, wherein the first reactor is fed with solvent, monomer and, optionally, comonomer; Ziegler-Natta type catalyst, said catalyst composition having a chloride concentration of at least 55%, based on its composition, and preferably more than 76%, chlorinated cocatalyst and chain growth regulator, said continuous stirring tank reactor being kept under a pressure between 0.1 to 2.0 MPa and temperature from 40° C. to 100° C., which contents of the first reactor are transferred to the subsequent reactor, by means of a pressure differential or through pumping, wherein said subsequent reactors are kept under a pressure between 0.1 to 2.0 MPa and temperature from 40° C. to 100° C., and fed with solvent, monomer, and, optionally, comonomer, catalyst, cocatalyst and chain growth regulator, the pressure and temperature in each of the reactors being different from one another up to the “nth” reactor, the number of reactors “n” varying from 2 to 4; the suspension thus obtained in reactor “n” being centrifugated for the removal of solvent and dried in a fluidized bed drier; thereby resulting in an ultra high molecular weight polyethylene homopolymeric or copolymeric composition with polydispersity greater than or equal to 6.

Owner:BRASKEM SA

Method for producing toner particles

Owner:CANON KK

Toner, toner production process and image forming method

InactiveUS6569589B2Improve charging effectSlightly affectedDevelopersElectrographic process apparatusMonomer compositionEngineering

Owner:CANON KK

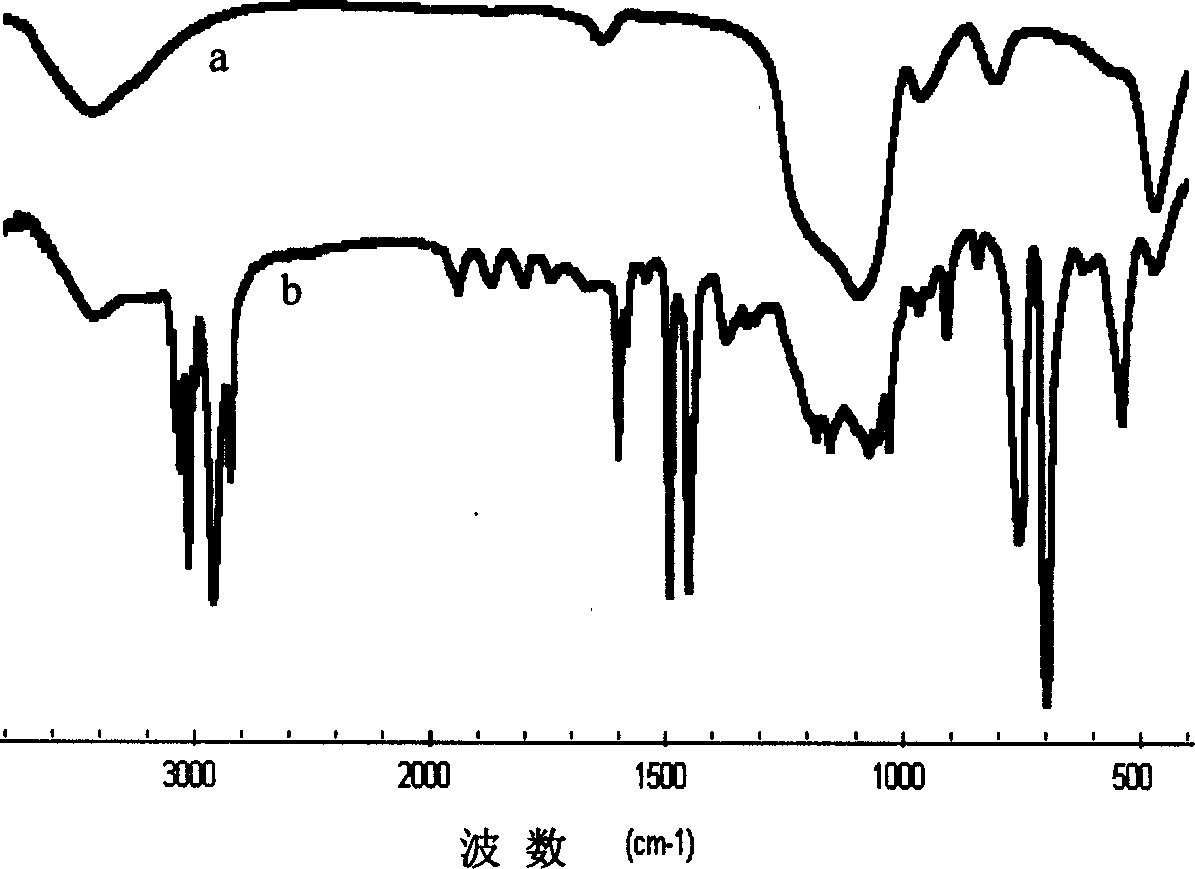

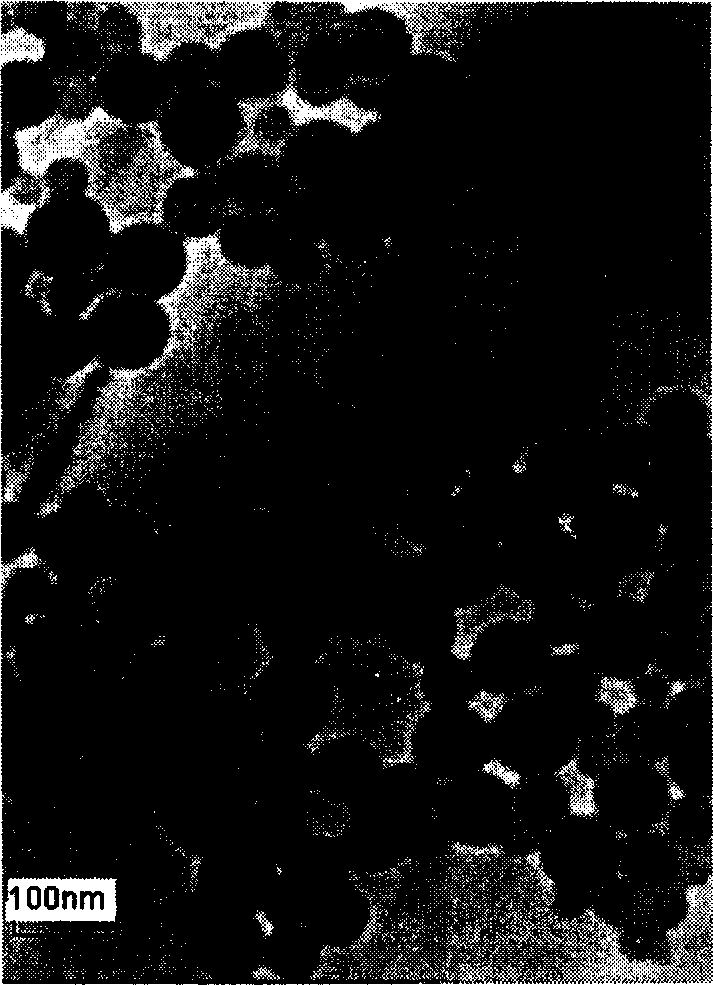

Composite polyolefin/sio2 nano particle and its prepn

The present invention belongs to the field of polymer material technology. Inorganic nano Sio2 partticle, organic olefin monomer and coupler as raw materials are subjected to emulsion polymerization or suspension polymerization in water as medium in the presence of various emulsifiers and initiator, so that the olefine polymer is grafted to the surface of inorganic nano SiO2 particle to form inorganic nano SiO2 particle core-organic olefin polymer shell structure. The composite particle is spherical, has homogeneous particle size smaller than 100 nm, and has high grafting rate and high grafting efficiency. The prepared compoisite olefin polymer / SiO2 particle material has wide application in the development of nano technology.

Owner:TSINGHUA UNIV

Thermoplastic roofing membranes

InactiveUS20100167013A1Well mixedPrevent scalingRoof covering using flexible materialsSynthetic resin layered productsThermoplasticPolymer science

The present invention provides thermoplastic roofing membranes comprising particles of crosslinked rubber and an aqueous (co)polymer dispersion. The thermoplastic roofing membranes are formed by combining particles of crosslinked rubber and a suspension polymer dispersion, or a coagulated aqueous latex (co)polymer dispersion, to form a mixture in aqueous dispersion, which aqueous dispersion mixture is subjected to solid state shear pulverization to form materials that can be processed as thermoplastics at crosslinked rubber concentrations of from 10 wt.% to as high as 95 wt.%, based on the total solids of the material. The method may further comprise kneading the pulverized product, followed by extrusion to form roofing membranes.

Owner:CRUZ CARLOS A +2

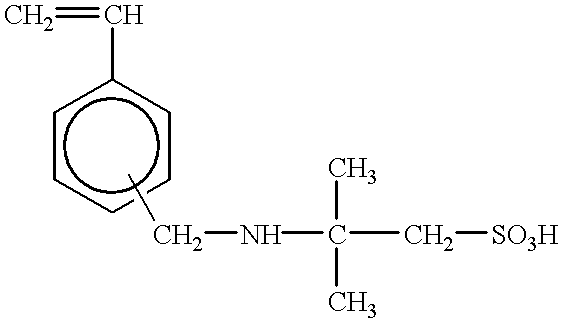

Microsphere type embolic agent and preparation technology thereof

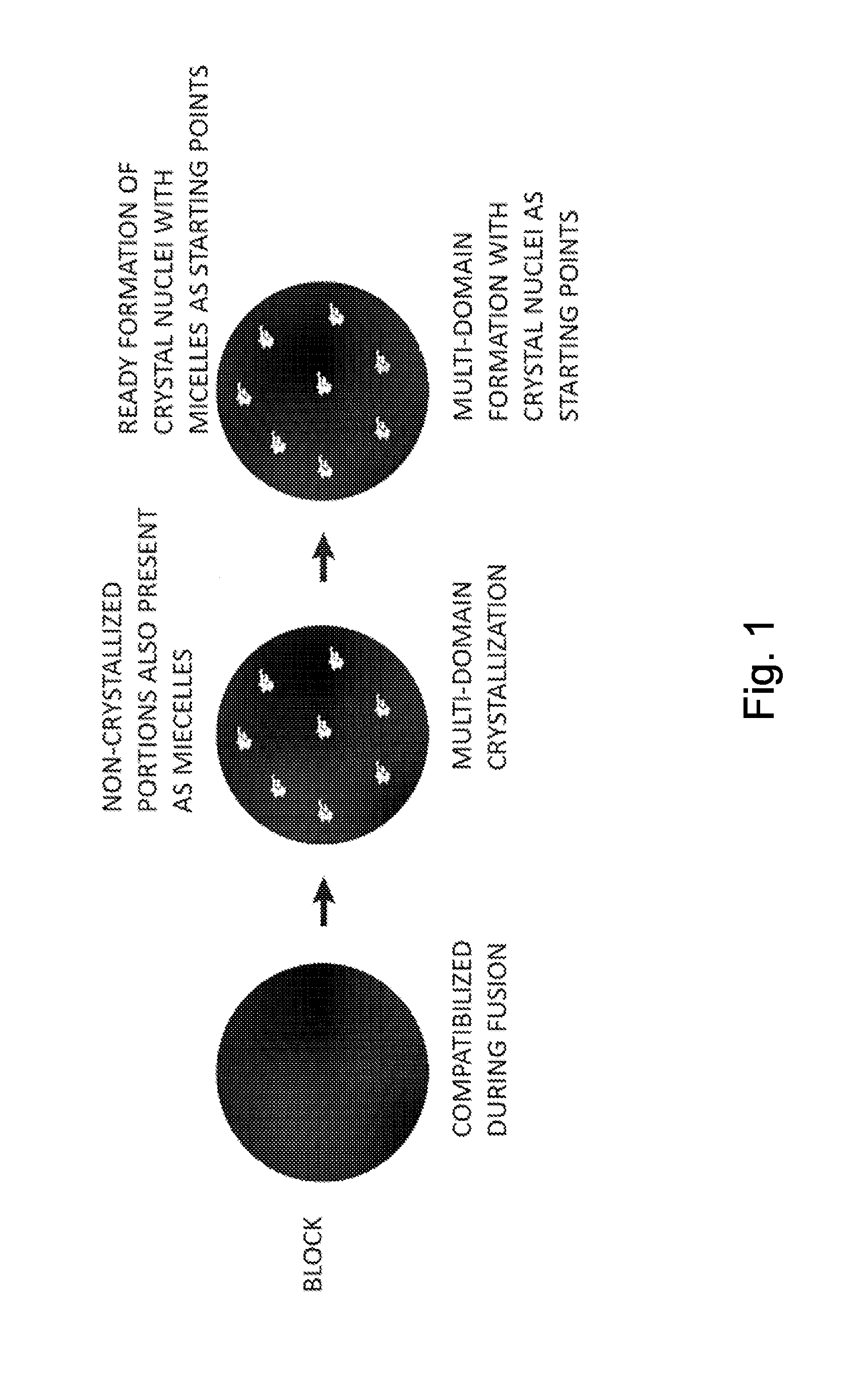

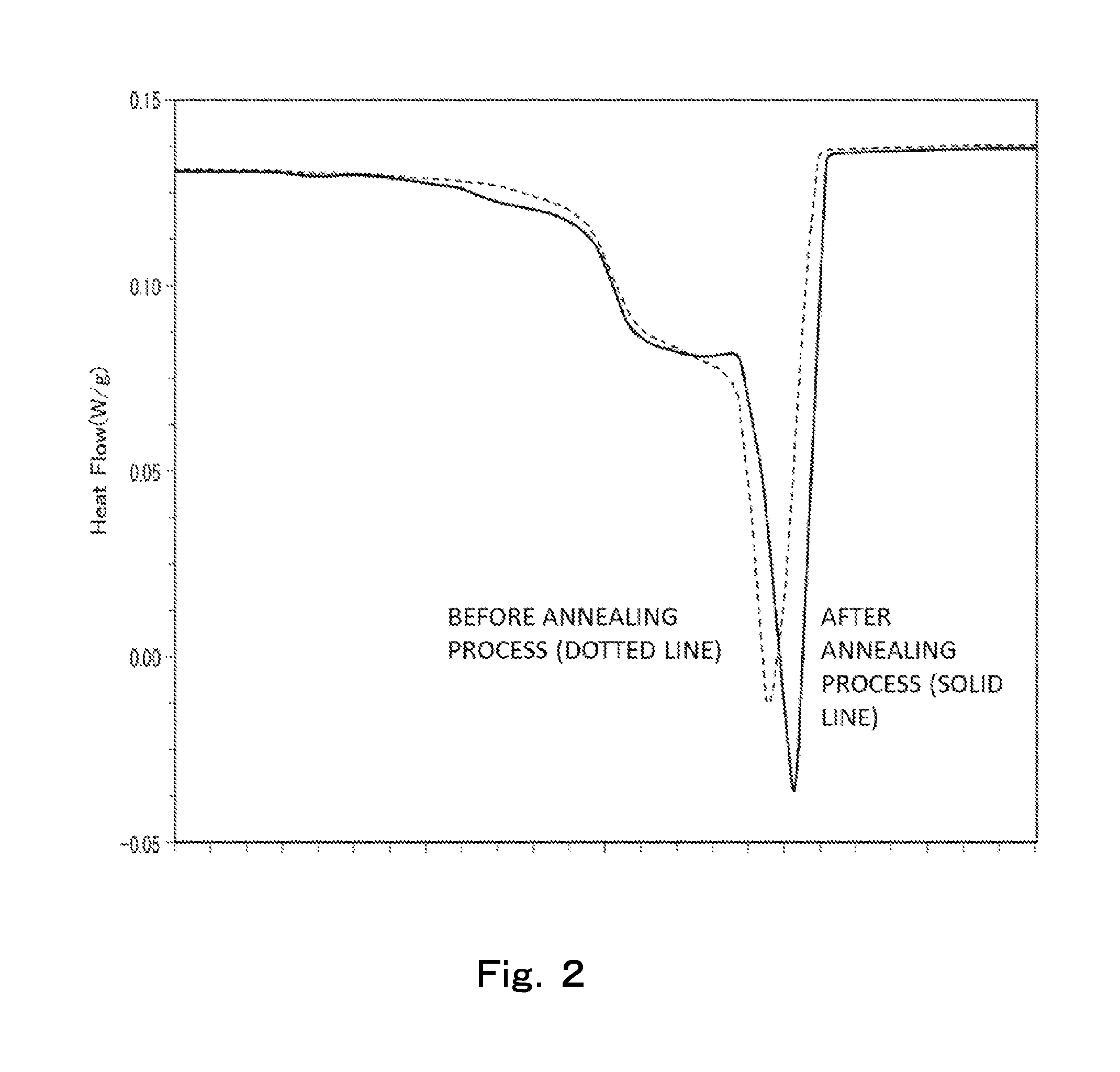

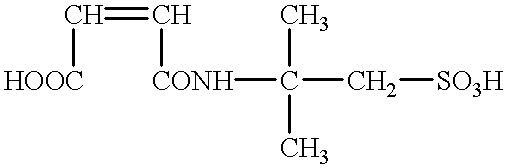

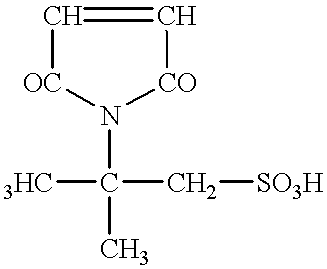

The invention provides a microsphere embolic agent, which is an elastic microsphere formed by the crosslink polymer of the functionalized macromolecules with the biocompatibility, and the particle size of the microsphere ranges from 1 Mum to 1500 Mum. The preparing technology includes the steps as follows: in a covalent link, linking a crosslinkable micromolecules with an acrylic acid structure on the polyvinyl alcohol, polyethylene glycol or polysaccharide macromolecules, forming the functionalized macromolecules; after that, the functionalized macromolecules and the monomer of the 2- acrylamide-2-methyl propanesulfonic acid undertakes opposite suspension polymerization, obtaining the crosslink polymeric microsphere embolic agent. The embolic agent has comparatively large retractility and elasticity, whose particle size is controllable and has perfect dispersiveness; moreover, the raw material is non-toxic and at the same time has good biocompatibility and stability. The preparing technology is a real chemosynthesis technology, whose material and preparing process does not produce any virus pollution, according with various requirements of the international embolic agent, which can replace various import and domestic expensive embolic agent products and is extensively applicable to various surgeries in the interventional radiology field.

Owner:SUZHOU HENGRUI CALLISYN BIOLOGICAL MEDICINE TECH CO LTD

Moisture-retention sustained and controlled release fertilizer and method of preparing the same

InactiveCN101508616AThe synthesis process is simpleUniform thicknessFertilizer mixturesHigh absorptionDouble coating

The invention discloses a water holding slow-controlled releasing fertilizer and a preparation method thereof, belonging to the technical field of agricultural fertilizers and preparation thereof. Macromolecule coating fertilizer is taken as an inner core and a water holding layer is taken as an outside layer to form a double-coating water holding slow-controlled releasing fertilizer; an inner coating is macromolecule protective layer coating material with nutrition controlling and releasing property; an outside coating is the water holding layer with excellent water holding property. Water retention agent suspension liquid is sprayed to the surface of macromolecule coating fertilizer grains for outside coating; wherein the water retention agent is prepared by taking cyclohexane, emulsifier, acrylic acid, acrylamide, sodium hydroxide, cross linker and evocating agent and adopting the method of opposite phase suspension polymerization. The fertilizer has the function of controlled releasing, drought resistance, water saving, water holding and soil improving and the advantages of high absorption percentage, wear resistance, difficult falling and the like; utilization ratio of liquid manure is improved and the fertilizer can be widely used to desert control, lawn plant, soil improvement, gardening, agriculture and forestry and the like.

Owner:CHINA AGRI UNIV

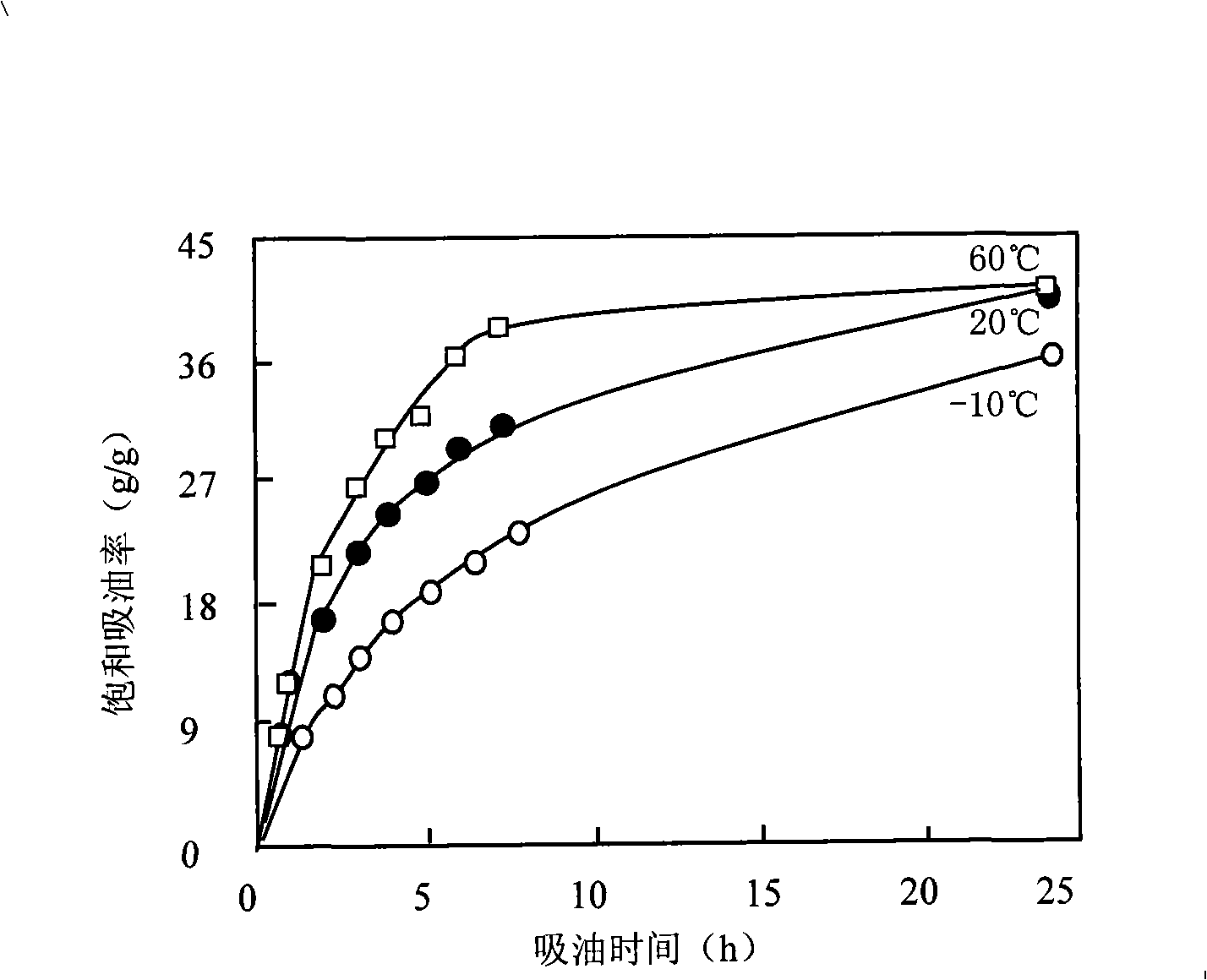

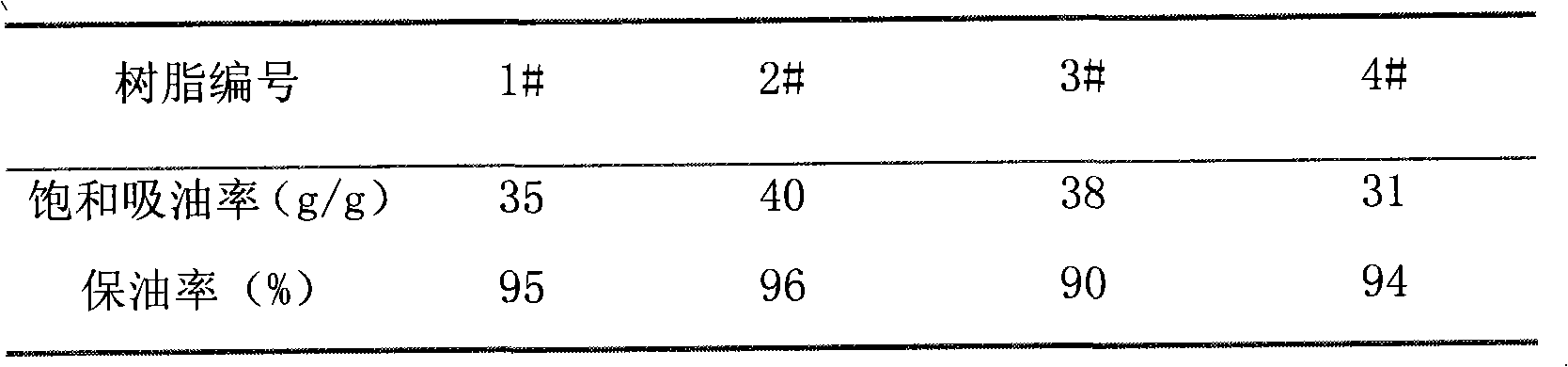

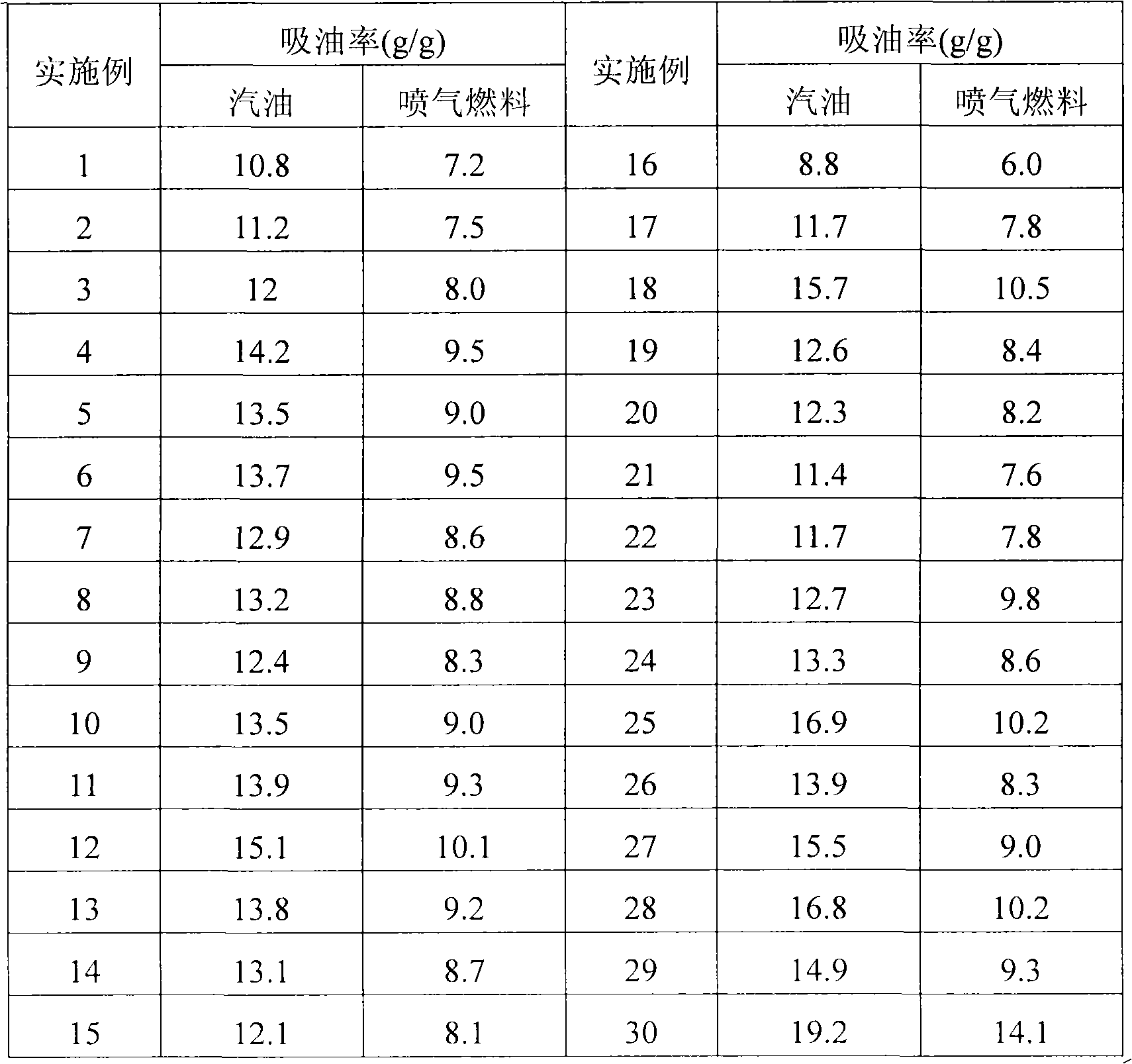

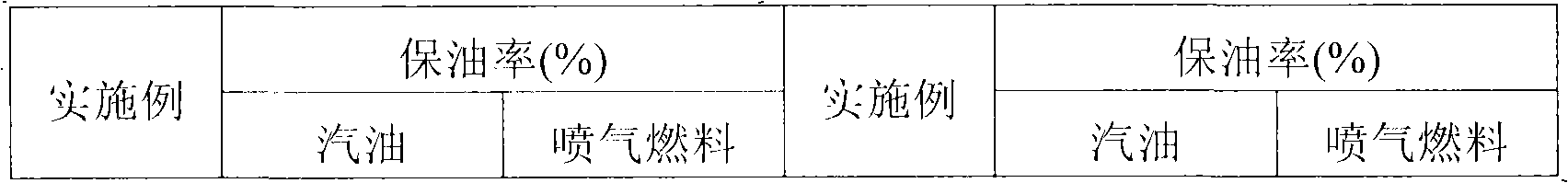

High oil suction resin and uses thereof

InactiveCN101314624AHigh saturated oil absorptionFast oil absorptionFatty/oily/floating substances removal devicesOther chemical processesDistillationWastewater

The invention a high oil-absorbing resin, which is prepared from monomer, cross-linking agent, pore forming agent, initiator and dispersant at a ratio of 100:(1.2-2.8):(10-50):(0.2-2):(0.1-0.5) by initiating suspension polymerization in a nitrogen gas protective atmosphere via free-radical. The high oil-absorbing resin is adopted as an adsorbent in abandoned oil recovery treatment, for example, the high oil-absorbing resin which accounts for 2.5wt%-10wt% of the oil amount of a waste transformer is added to an oil water mixture of the waste transformer, and the waste transformer oil in waste water can be absorbed by resin and condensed into gel blocks, so as to separate from the water. The gel blocks containing the waste transformer oil is removed by filtering with a filter screen. The tank water can be discharged in a pollution-free manner. The oil product is recovered from the gel blocks containing the oil by distillation. The resin can be utilized repeatedly. The abandoned oil recovery treatment method adopting the high oil-absorbing resin has the advantages of simple process and low processing cost, and conforms to the environmental requirements.

Owner:HEFEI POWER SUPPLY COMPANY OF STATE GRID ANHUI ELECTRIC POWER +1

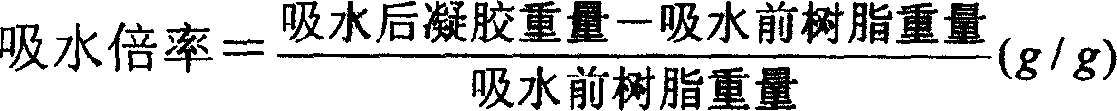

Process for preparing high water absorption resin

The preparation process of high water absorption resin includes following steps: neutralizing acrylic acid monomer with alkali solution to 60-90 % neutralizing degree, adding functional monomer in 0.5-50 % of total monomer weight, water soluble initiator or oxidation-reduction system in 0.05-0.5 % and water soluble cross-linking agent in 0.005-0.2 %; feeding the said mixed liquid into reactor, adding non-polar organic solvent in 2-10 times the volume of the mixed liquid and containing non-ionic surfactant, stirring to form inverse suspended polymerizing system; heating to 35-80 deg.c for free radical cross-linking copolymerization while adding oil soluble cross-linking agent in 0.005-0.3 % total monomer weight; dewatering after finishing polymerization, separation and drying to obtain the high water absorption resin. The obtained polyacrylate resin has the advantages of powerful water absorption, high salt tolerance, high gel strength and fast water absorption speed.

Owner:ZHEJIANG UNIV

Organic solvent absorbing agent and preparation method thereof

InactiveCN103752289AWide absorption rangeHigh absorption rateOther chemical processesAlkali metal oxides/hydroxidesCross-linkMethacrylate

The invention discloses an organic solvent absorbing agent and a preparation method thereof. The organic solvent absorbing agent is prepared by carrying out suspension polymerization reaction on acrylics, methacrylates, styrene, a cross-linking agent and an initiating agent in the environment that water and a dispersing agent exist. The organic solvent absorbing agent disclosed by the invention has the advantages of wide absorbing range, high absorption rate, high absorption speed and the like; an absorbed surface has small viscosity and a certain jelly strength, the organic solvent absorbing agent is convenient to recover and recycle and good in industrial applicability. The organic solvent absorbing agent disclosed by the invention can be reused more than ten times, the problem of poor reusability of a conventional absorbing material is solved, the secondary pollution caused by emission of a used absorbing agent as a waste is effectively reduced, and meanwhile the effects that the resource utilization rate is improved and the cost is reduced are achieved. The organic solvent absorbing agent can be used for treatment of industrial solvent-containing wastewater, and leakage and emergent absorption of an organic solvent in chemical production and is high in practicability and has a broad development prospect.

Owner:FUZHOU UNIV

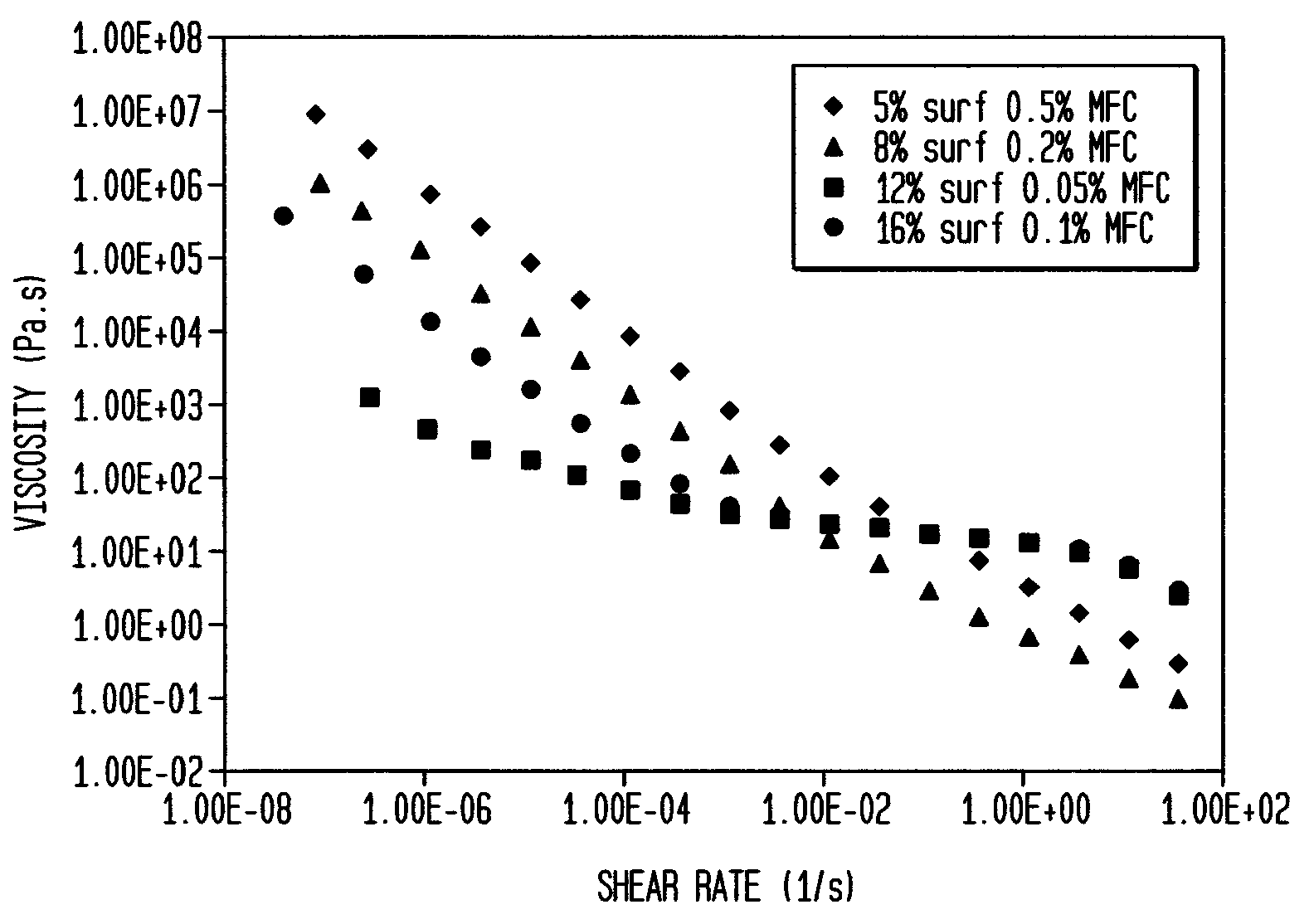

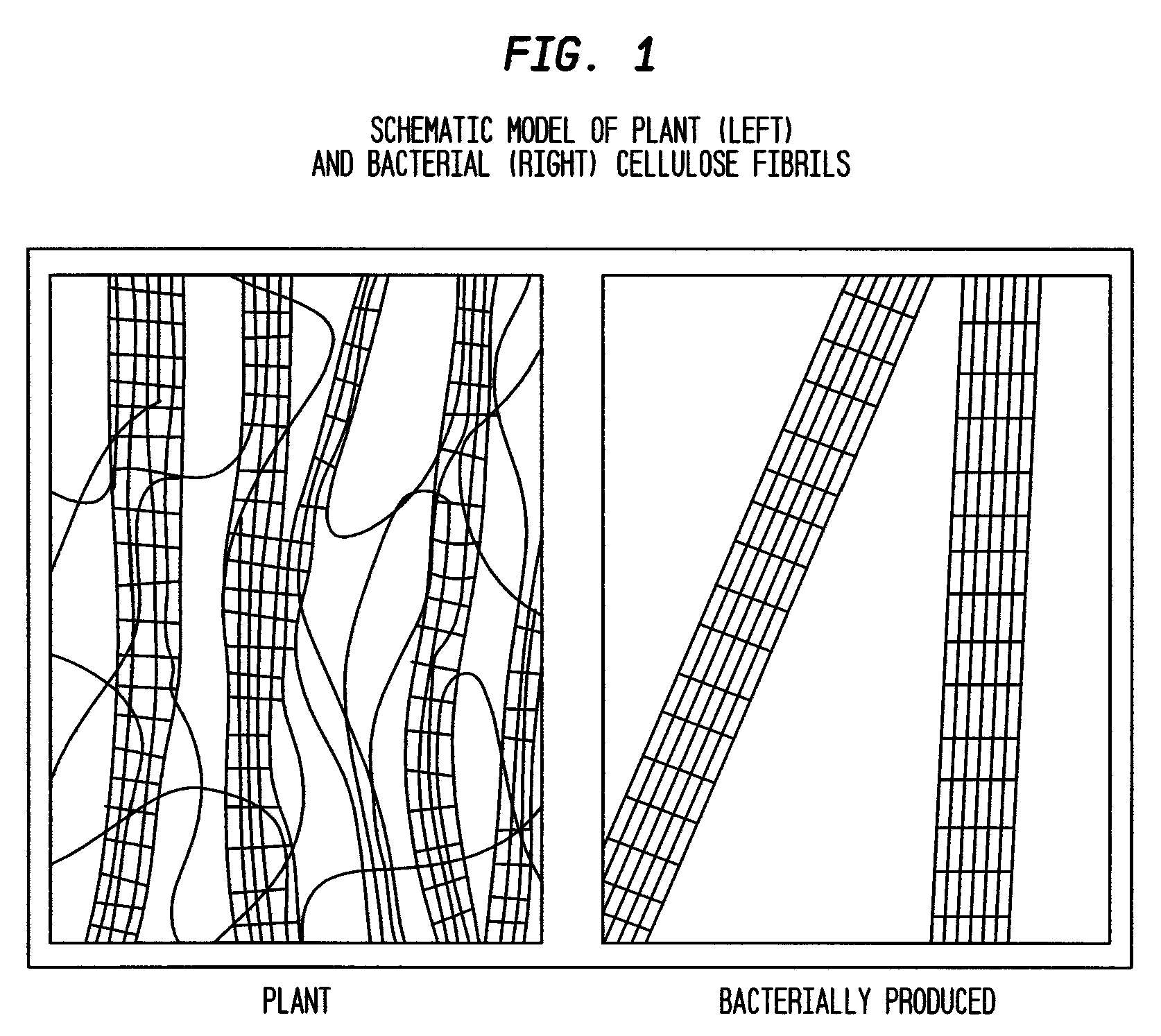

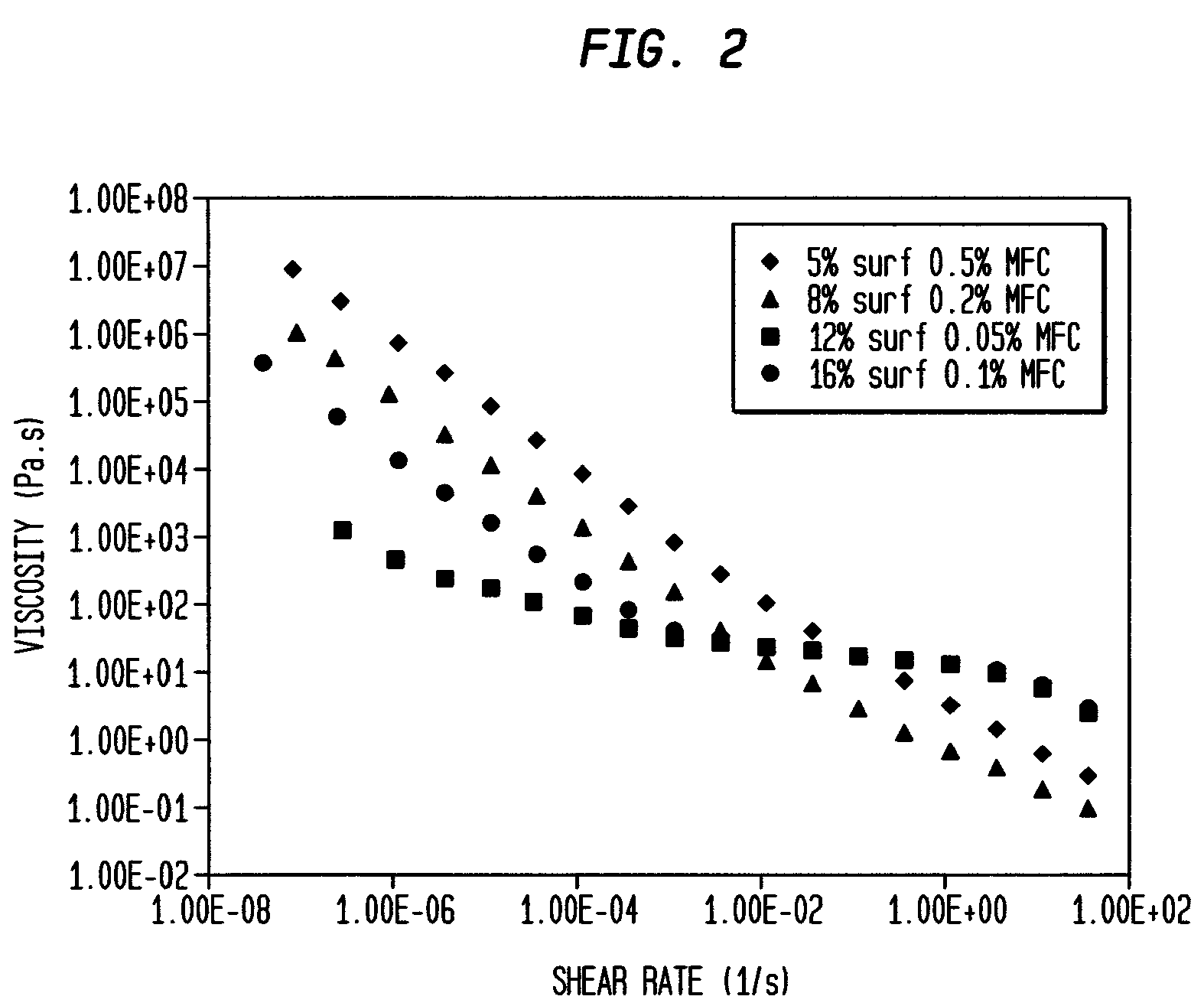

Liquid cleansing compositions comprising microfibrous cellulose suspending polymers

The present invention relates to personal care liquid cleansing compositions comprising bacterially produced microfibrous cellulose (MFC) suspending polymers which have not previously been used in personal care compositions.

Owner:CONOPCO INC D B A UNILEVER

Method for the fracture stimulation of a subterranean formation having a wellbore by using impact-modified thermoset polymer nanocomposite particles as proppants

ActiveUS20130045901A1High elastic modulusHigh glass transition temperatureMaterial nanotechnologySynthetic resin layered productsLiquid mediumOligomer

A method for fracture stimulation of a subterranean formation includes providing a thermoset polymer nanocomposite particle precursor composition comprising a polymer precursor mixture, dispersed within a liquid medium, containing at least one of an initiator; at least one of a monomer, an oligomer or combinations thereof, said monomer and oligomer having three or more reactive functionalities capable of creating crosslinks between polymer chains; at least one of an impact modifier; and nanofiller particles substantially dispersed within the liquid medium; subjecting the nanocomposite particle precursor composition to suspension polymerizing conditions; subjecting the resulting nanocomposite particles to heat treatment; forming a slurry comprising a fluid and a proppant that includes the heat-treated nanocomposite particles; injecting the slurry into a wellbore; and emplacing the proppant within a fracture network in the formation.

Owner:SUN DRILLING PRODS

High oil absorption resin and synthetic method thereof

The invention discloses a high oil absorbing resin, and a process for preparation comprises utilizing short-chain ester of (metyl group) acrylic acid, long-chain ester of acrylic acid and styrene monomer to be monomers, adding dispersing agent and surface active agent, and getting through suspension polymerization and random copolymerization under the condition of the existence of cross linker and initiating agent. The process for synthesizing has lithe time consumption, which can be industrialized, and high oil absorbing resin which is got has high oil absorbing efficiency, fast oil absorbing speed, and which can be recycled to be repeatedly used.

Owner:SUZHOU TIMELYBLUE ENVIRONMENTAL TECH

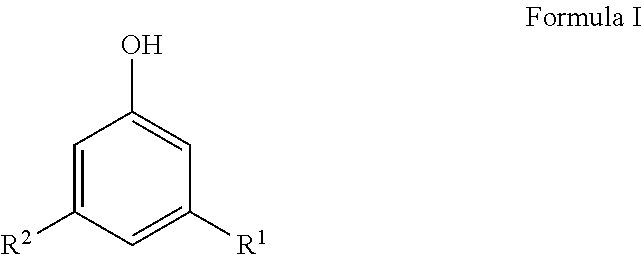

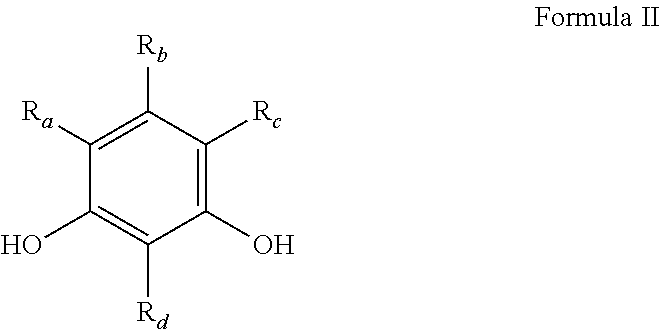

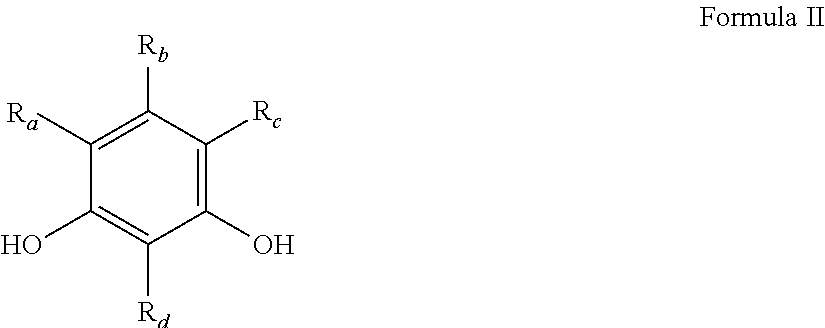

Preparation of phenol-formaldehyde resin beads using suspension or emulsion polymerization

Methods for making polymer particles in gel form via an emulsion and / or suspension polymerization are provided. In at least one specific embodiment, the method can include reacting a first reaction mixture comprising a phenolic monomer, an aldehyde monomer, and a first catalyst to produce a prepolymer. The method can also include combining the prepolymer with a carrier fluid and a second catalyst to produce a second reaction mixture. The second catalyst can include a dicarboxylic acid, an anhydride, a dihydroxybenzene, or any mixture thereof. The method can also include polymerizing the prepolymer to form polymer particles in gel form.

Owner:GEORGIA PACIFIC CHEM LLC

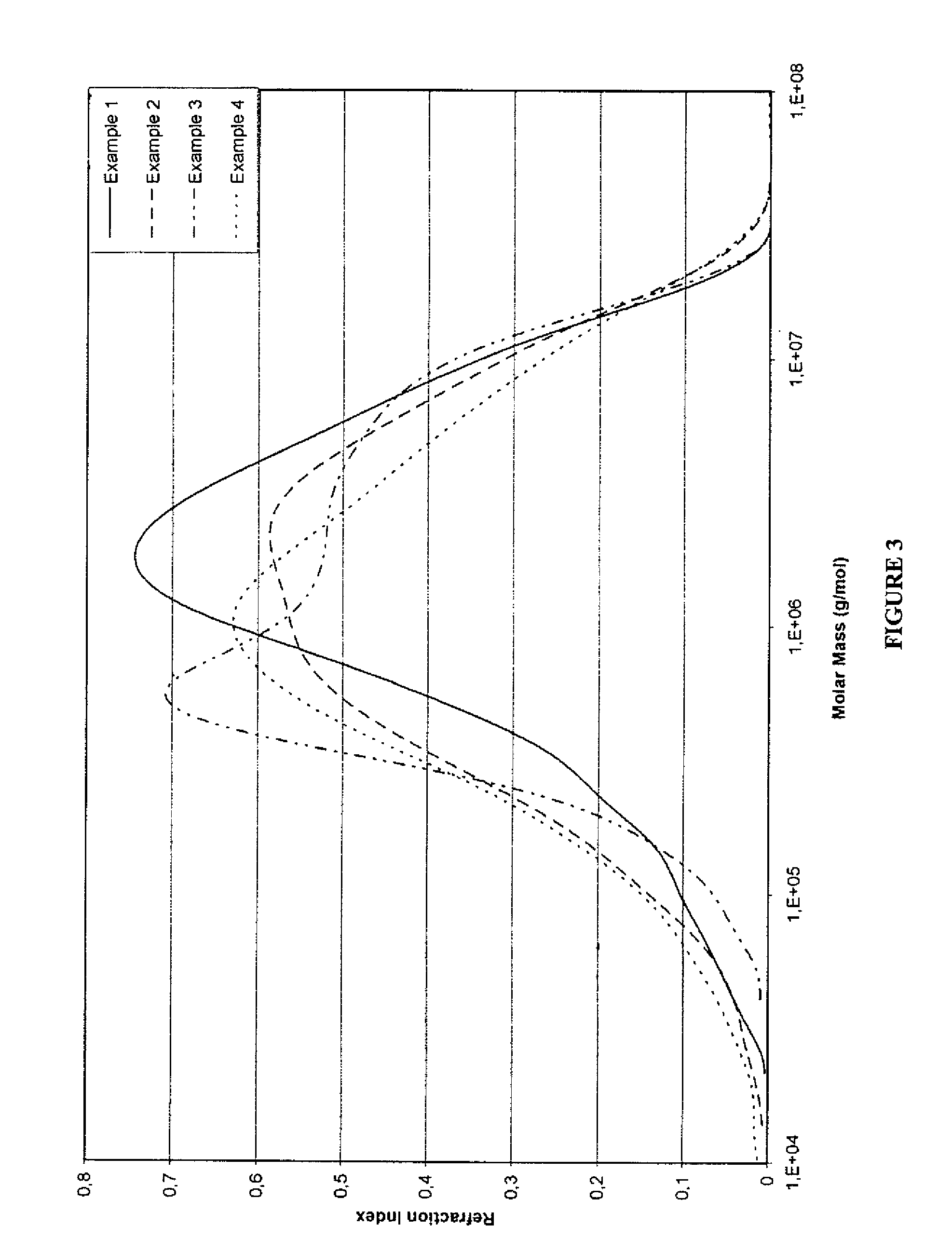

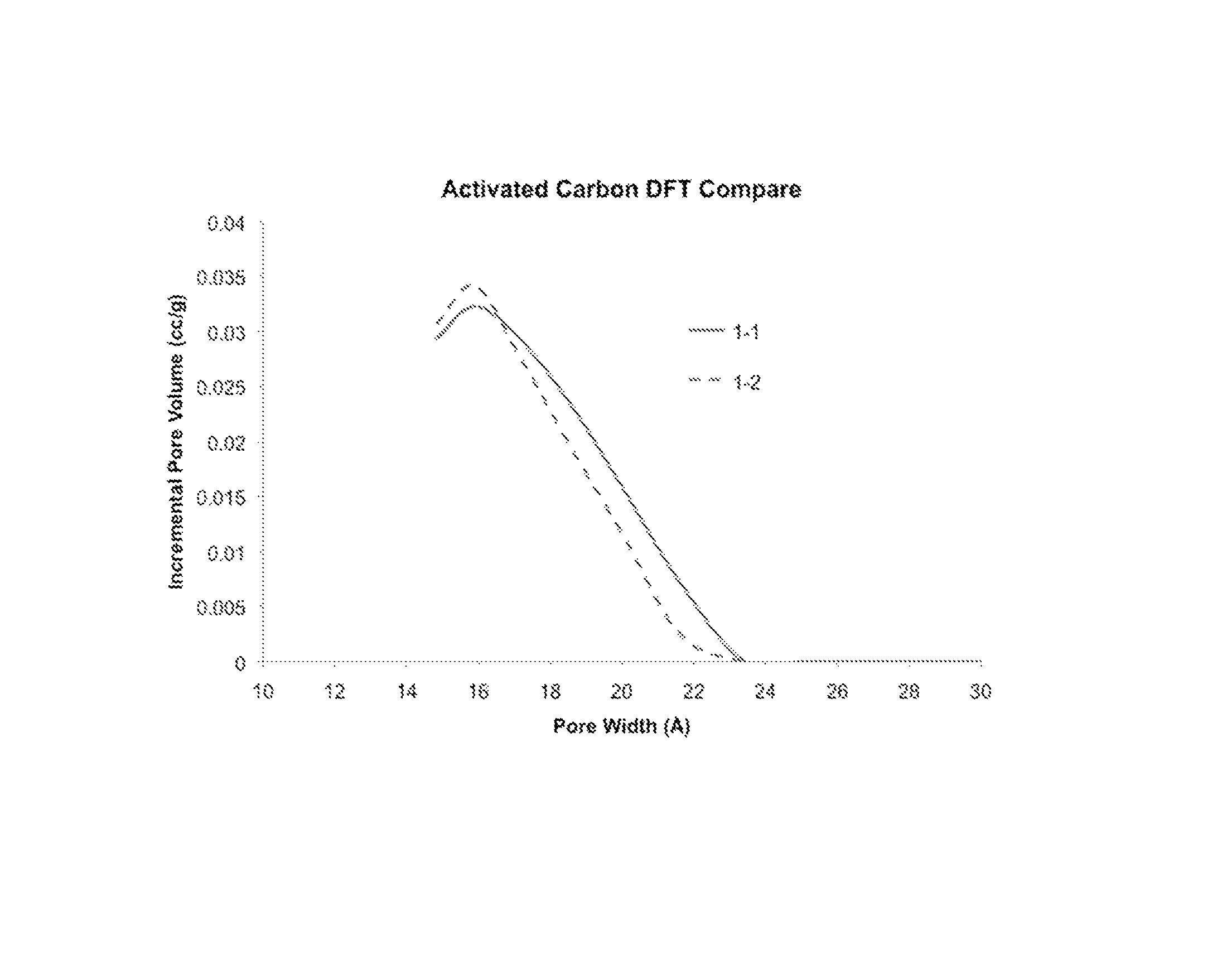

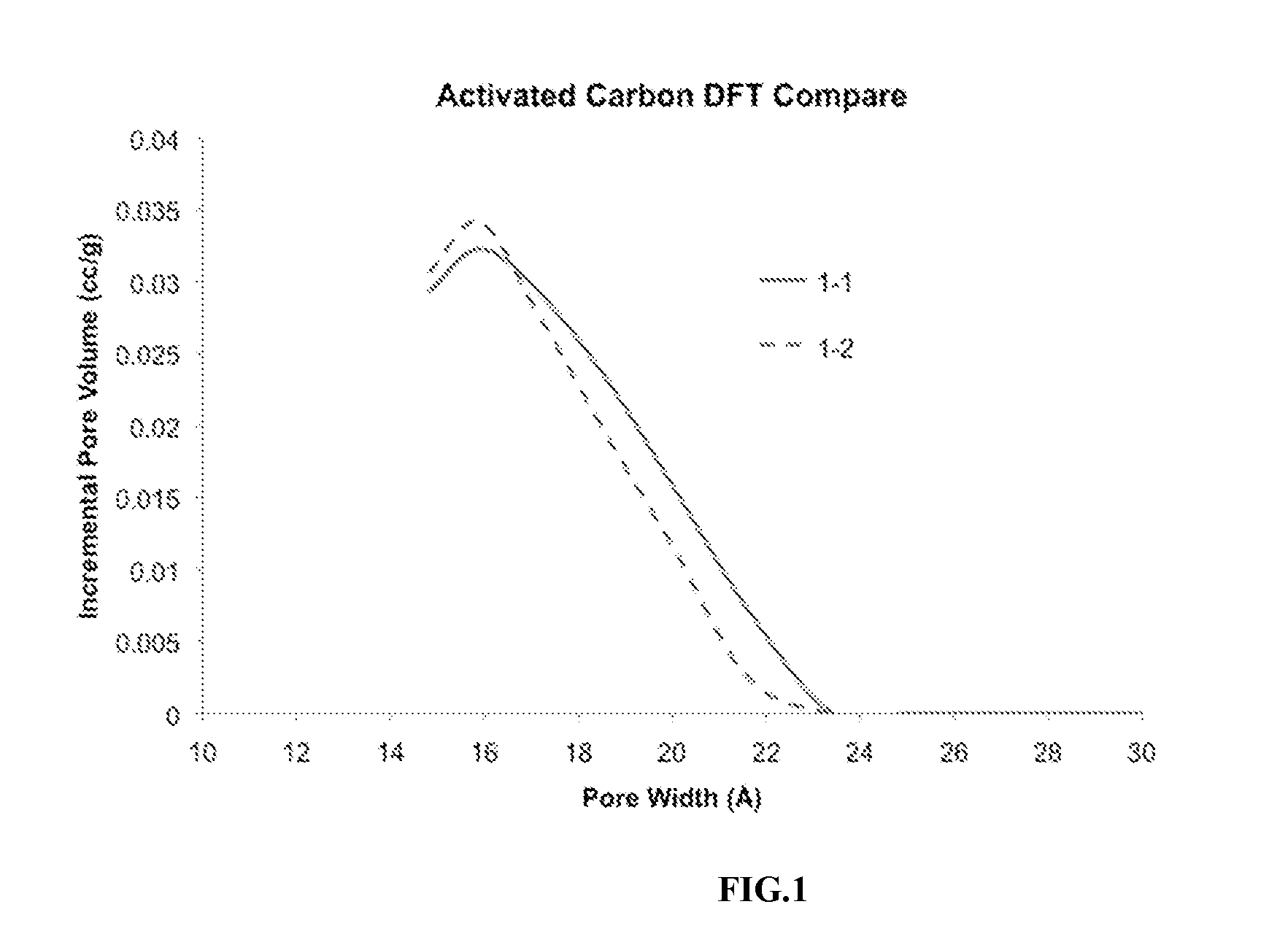

Emulsion and suspension polymerization processes, and improved electrochemical performance for carbon derived from same

The present application is directed to methods for preparation of polymer particles in gel form and carbon materials made therefrom. The carbon materials comprise enhanced electrochemical properties and find utility in any number of electrical devices, for example, as electrode material in ultracapacitors or batteries. The methods herein can also be employed generally to improve emulsion and / or suspension polymerization processes by improved control of diffusion of acidic and basic species between the polymer and secondary phases.

Owner:GEORGIA PACIFIC CHEM LLC

Improved emulsion and suspension polymerization processes, and improved electrochemical performance for carbon derived from same

The present application is directed to methods for preparation of polymer particles in gel form and carbon materials made therefrom. The carbon materials comprise enhanced electrochemical properties and find utility in any number of electrical devices, for example, as electrode material in ultracapacitors or batteries. The methods herein can also be employed generally to improve emulsion and / or suspension polymerization processes by improved control of diffusion of acidic and basic species between the polymer and secondary phases.

Owner:GEORGIA PACIFIC CHEM LLC

Dispersion stabilizer for suspension polymerization of vinyl compound and method of producing the same

ActiveUS7070731B2Less polymer scale adhesionHigh bulk densityColloidal chemistry detailsAcetic acidPolymer science

The present invention provides a new dispersion stabilizer that satisfies, at a high level, the performances required for a dispersion stabilizer used for suspension polymerization. A method of producing a dispersion stabilizer that is useable for suspension polymerization of a vinyl compound and contains a vinyl alcohol polymer (A) includes producing the vinyl alcohol polymer (A) by heat-treating a vinyl alcohol polymer (B) at a temperature of 90 to 180° C. for 0.5 to 20 hours in an atmosphere in which an oxygen concentration is 8000 ppm or lower. The vinyl alcohol polymer (B) has a saponification degree of at least 60 mol % and contains a residual acetic acid group whose block character is in the range of 0.3 to 0.6.

Owner:KURARAY CO LTD

Toner

ActiveUS8916319B2Satisfactory image densityLower Level RequirementsDevelopersZeta potentialDissolution

Owner:CANON KK

Porous high oil absorption resin and preparation method thereof

InactiveCN101891860AOther chemical processesAlkali metal oxides/hydroxidesSolution polymerizationJet fuel

The invention relates to a porous high oil absorption resin and a preparation method thereof. The preparation method reasonably proportions raw materials and performs suspension polymerization on the proportioned raw materials to prepare the porous high oil absorption resin, and comprises steps of dispersing, mixing, charging, suspension polymerization, extracting and conventional post-processing. The porous high oil absorption resin has high oil absorptivity, particularly for jet fuel.

Owner:PLA AIR FORCE OIL MATERIAL RES INST

High oil absorption resin and its synthesis method

InactiveCN1442438AHigh oil absorptionCompliance with emission requirementsCalcium biphosphateSynthesis methods

A high-oil-absorbency resin is prepared from acrylate as monomer, ethanediol acrylate as cross-linking agent, gel or cellulose as disperser, active calcium phosphate as co-disperser, and azo or oganic peroxide as trigger through suspension polymerizing. Its granularity is 0.3-2 mm and has high oil absorbency (up to 37 times).

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com