Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Efficient gluing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

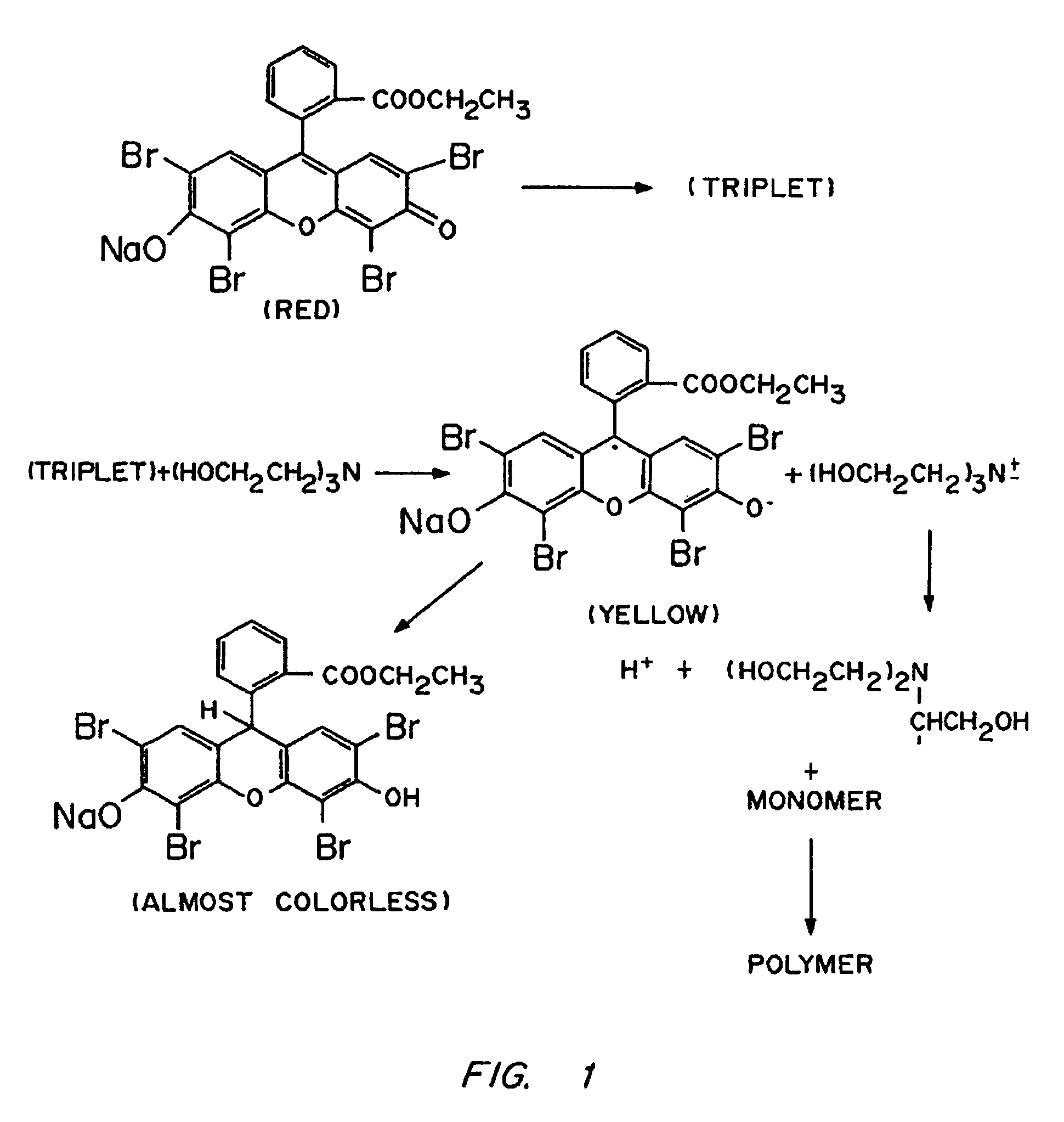

Gels for encapsulation of biological materials

InactiveUS7413781B2Facilitated DiffusionGood flexibilitySurgical adhesivesPeptide/protein ingredientsActive matterWater soluble

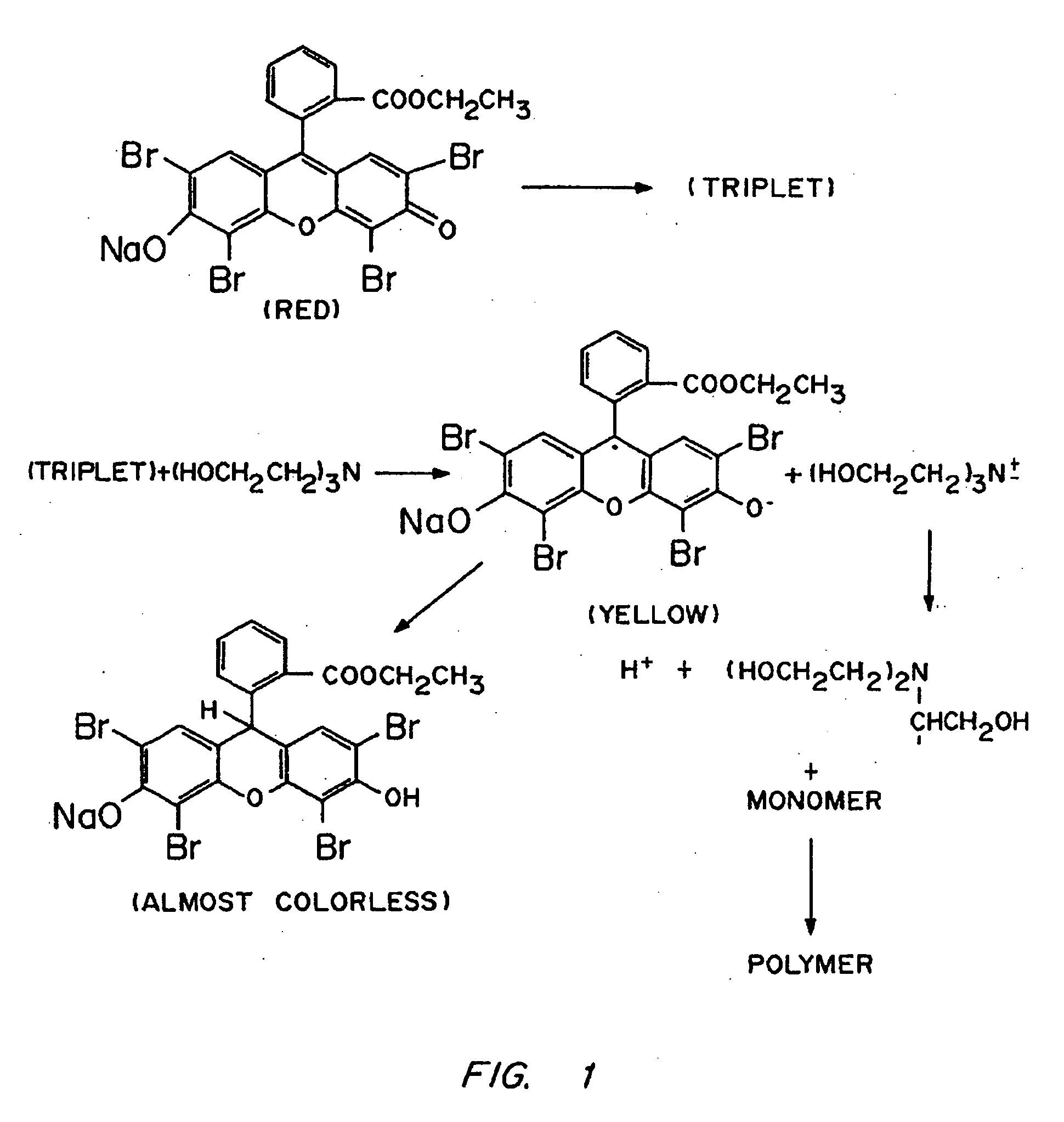

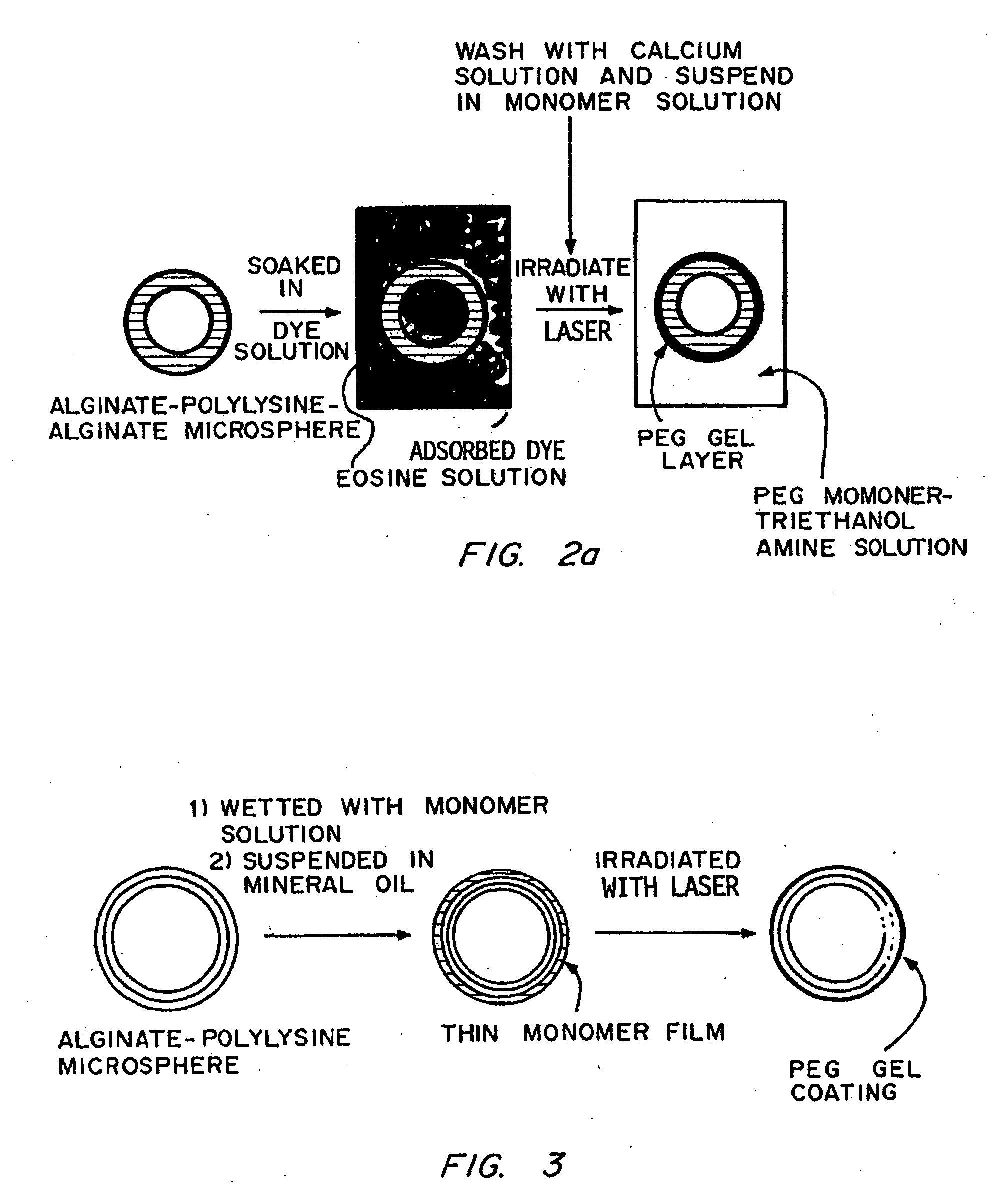

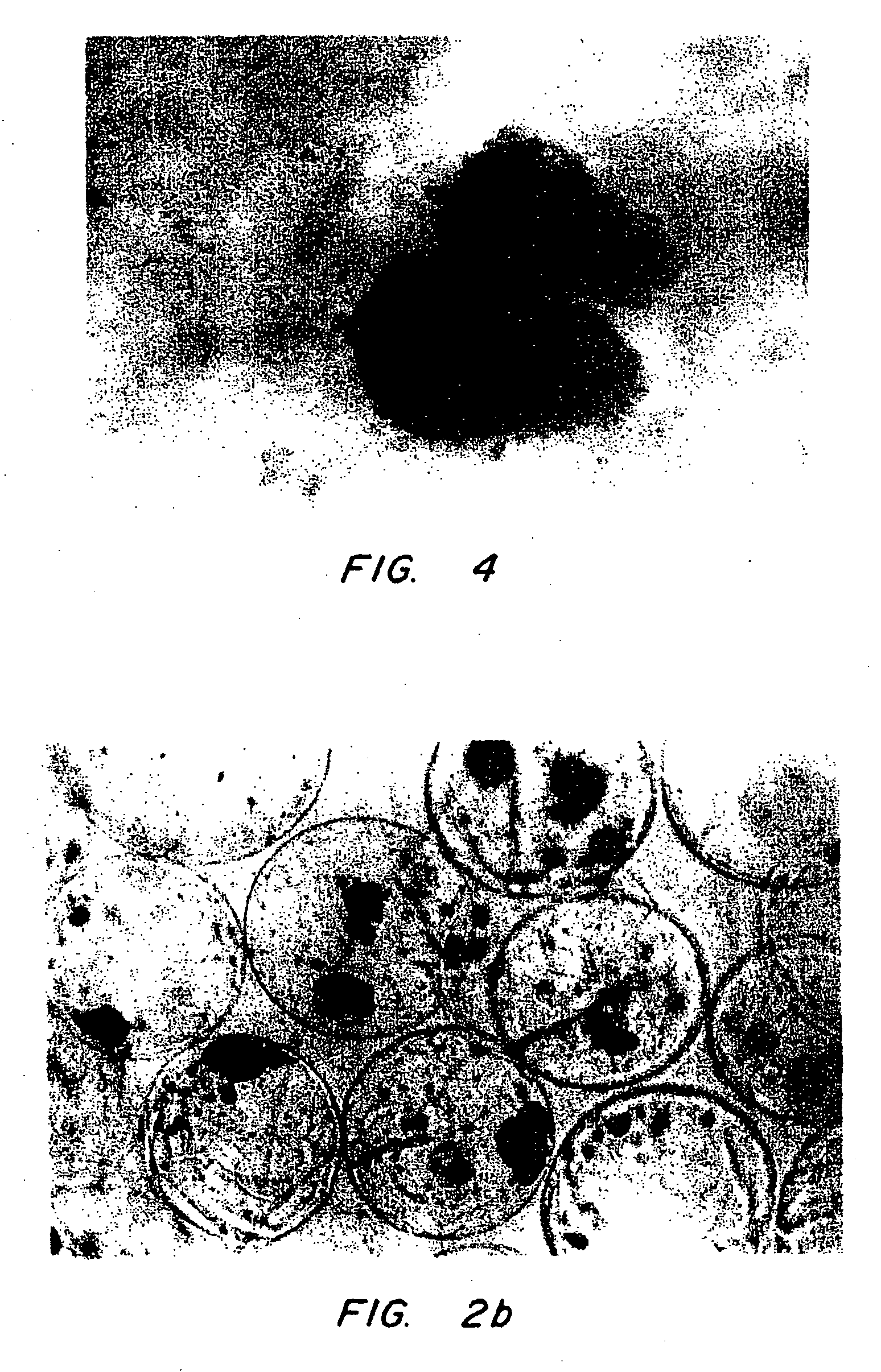

This invention provides novel methods for the formation of biocompatible membranes around biological materials using photopolymerization of water soluble molecules. The membranes can be used as a covering to encapsulate biological materials or biomedical devices, as a “glue” to cause more than one biological substance to adhere together, or as carriers for biologically active species. Several methods for forming these membranes are provided. Each of these methods utilizes a polymerization system containing water-soluble macromers, species, which are at once polymers and macromolecules capable of further polymerization. The macromers are polymerized using a photoinitiator (such as a dye), optionally a cocatalyst, optionally an accelerator, and radiation in the form of visible or long wavelength UV light. The reaction occurs either by suspension polymerization or by interfacial polymerization. The polymer membrane can be formed directly on the surface of the biological material, or it can be formed on material, which is already encapsulated.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

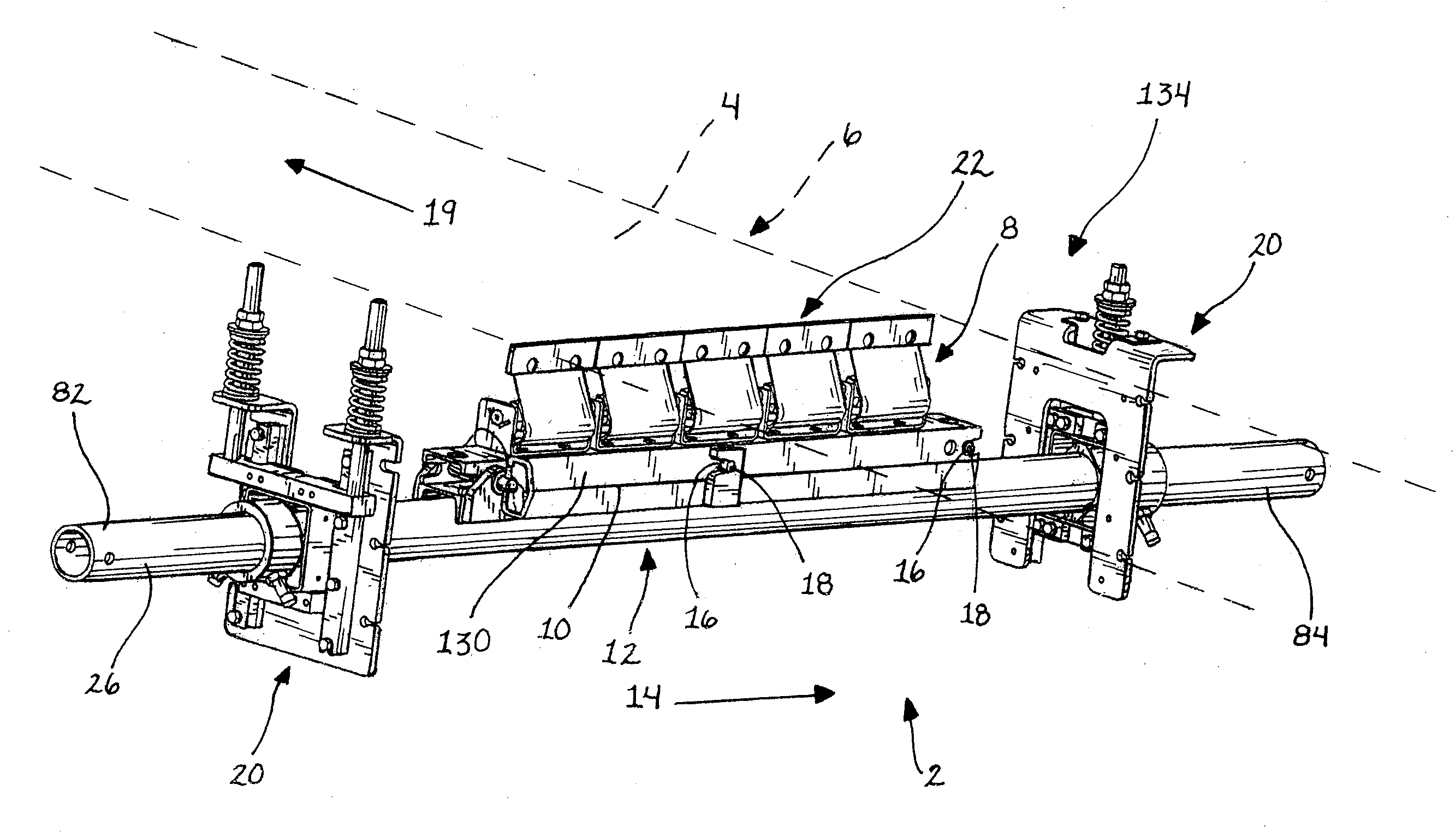

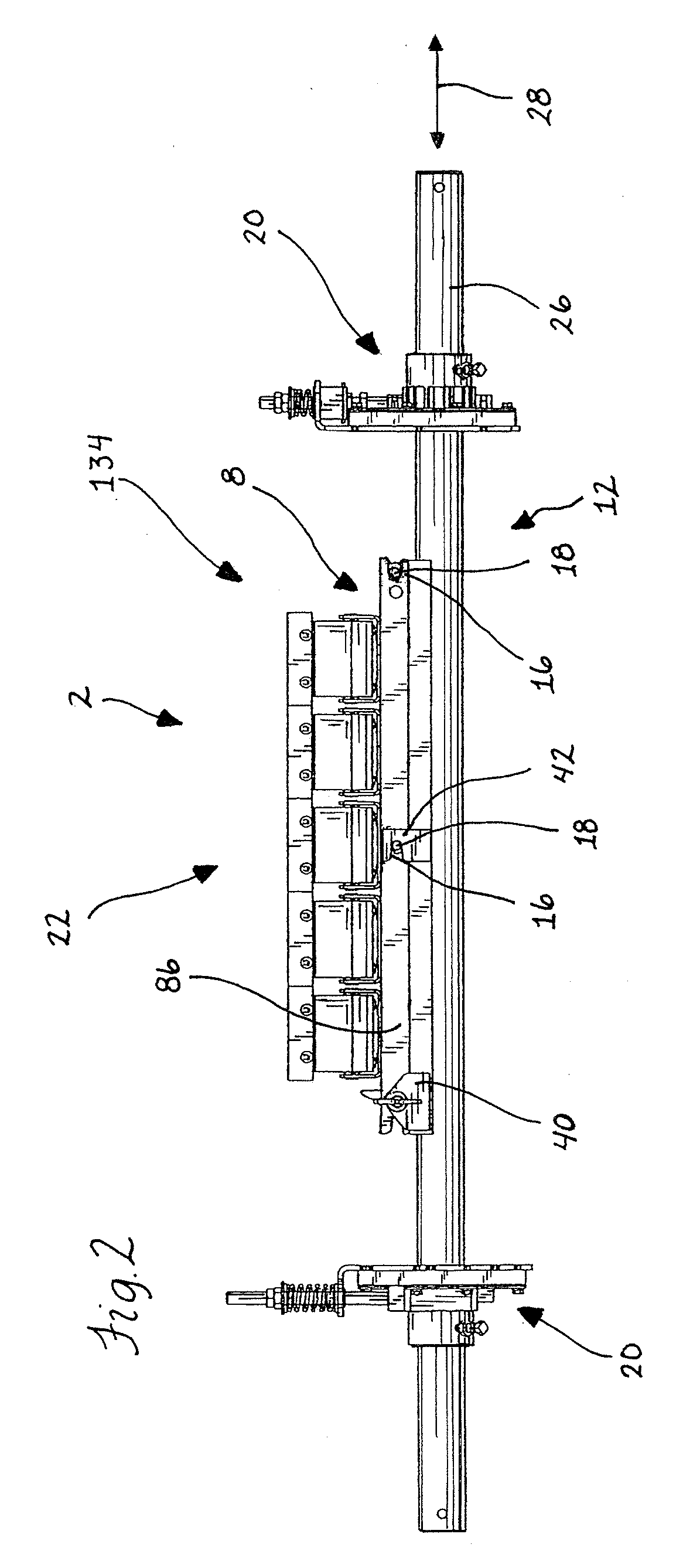

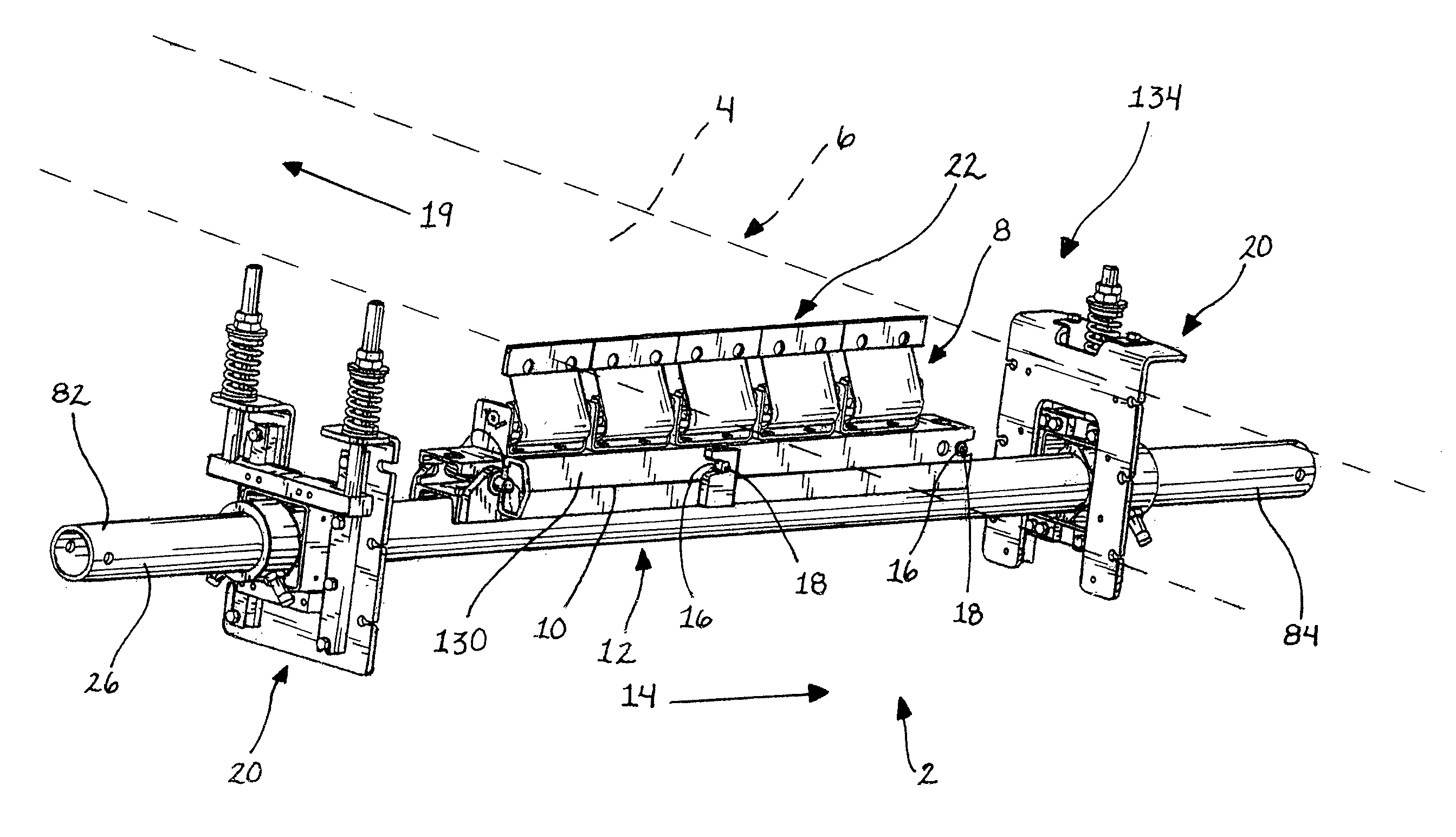

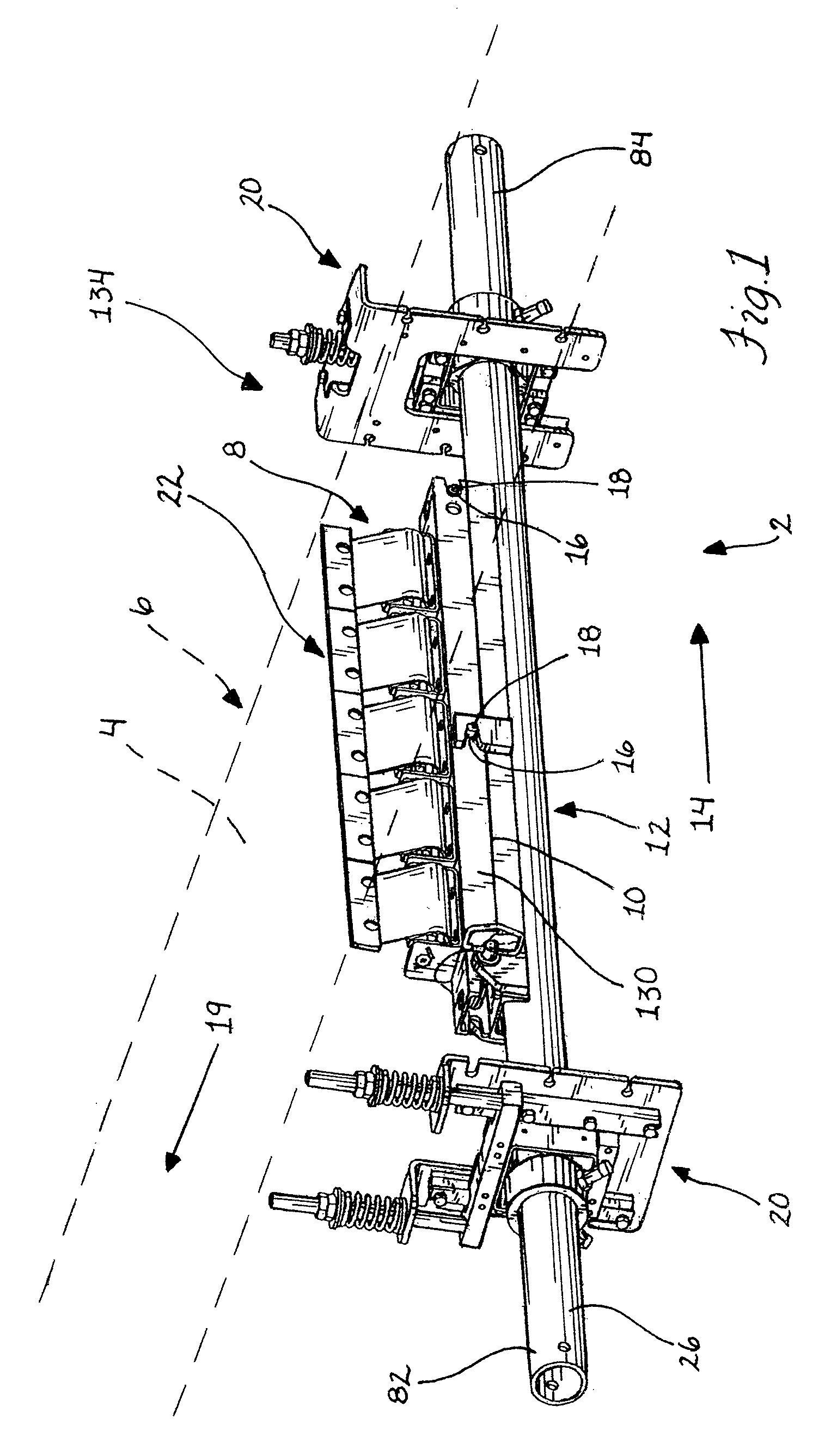

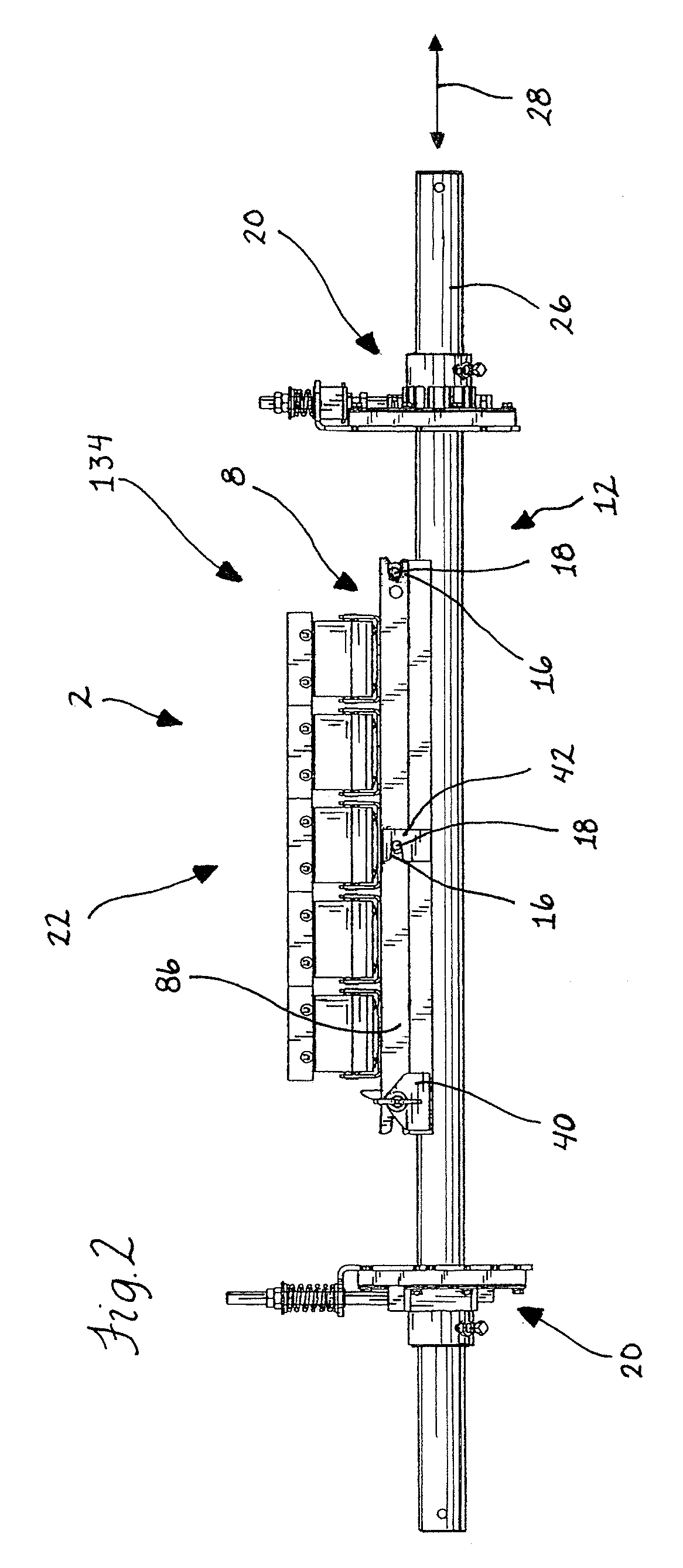

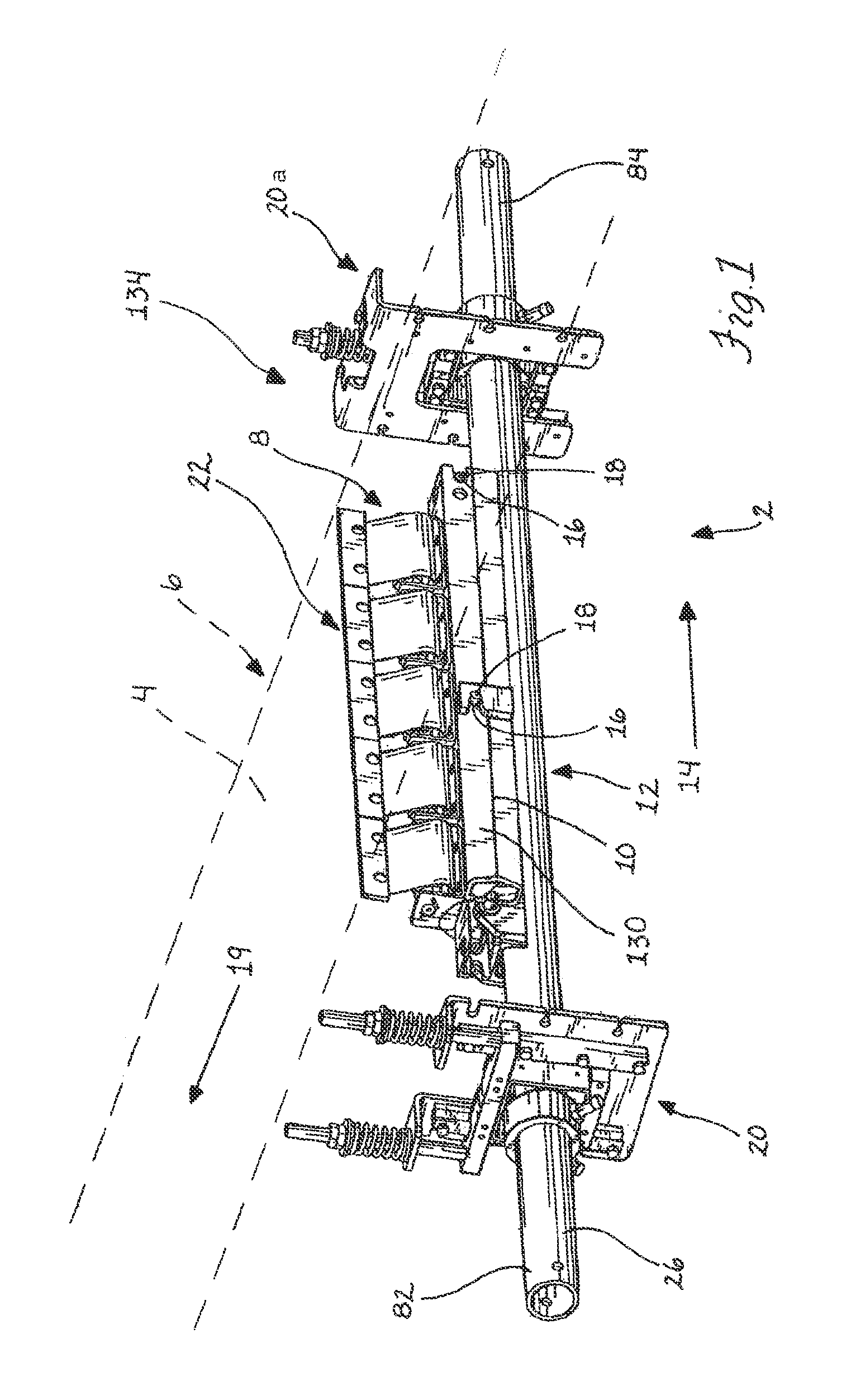

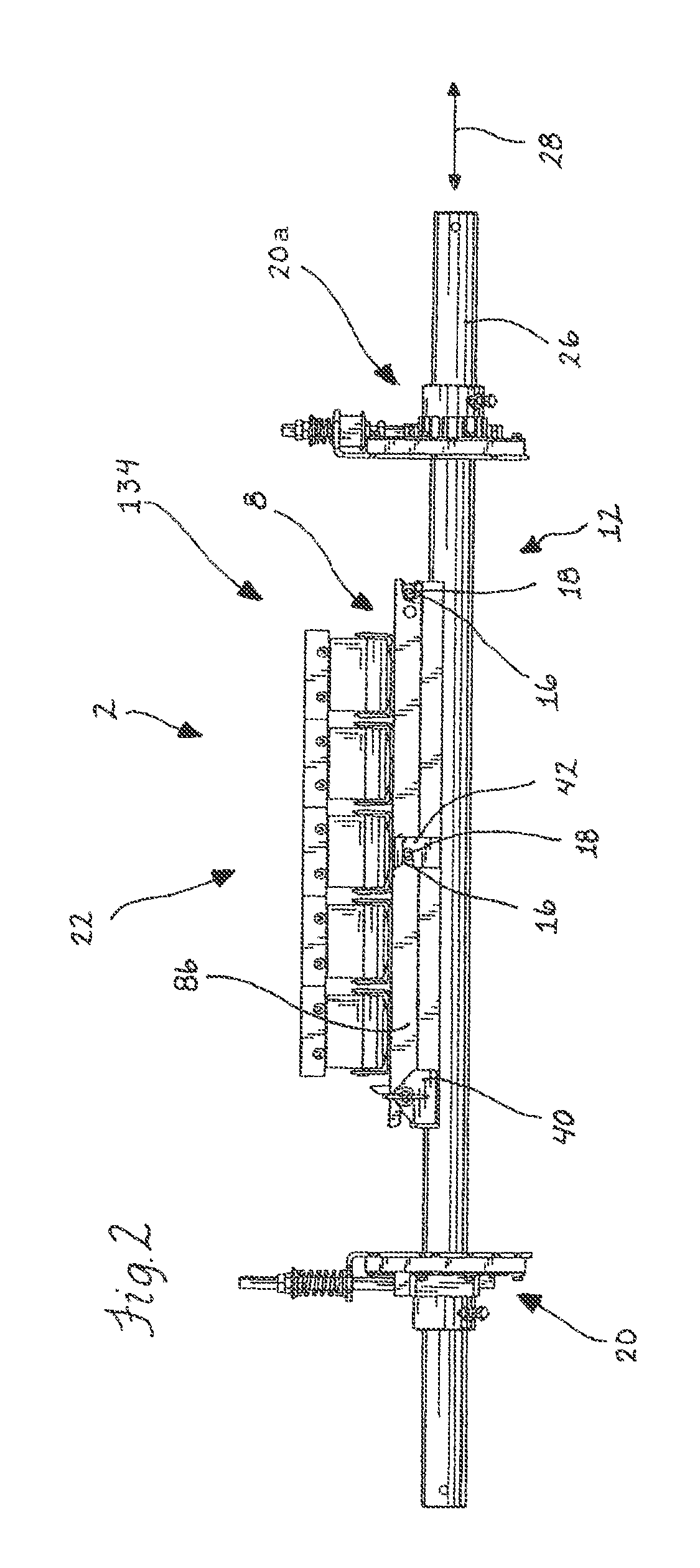

Removable Cartridge Cleaner

ActiveUS20100000842A1Faster and easy removalEfficient gluingConveyorsCleaningEngineeringMechanical engineering

A removable cartridge cleaner assembly is provided that allows for faster and easier removal of the belt cleaner blades out from under a conveyor belt. In one aspect the assembly includes a biasing surface of one of an elongate support assembly and a channel member configured to be engaged by a securing member and urge distal ends of legs of the channel member into tight engagement with the elongate support assembly and minimize debris accumulation therebetween. In another aspect, the elongate base member and rail member each include lateral portions configured to slidably engage corresponding wedge portions to urge the rail member toward the base member. A method of installing a belt cleaner assembly is also provided which includes camming a rail member downwardly toward the support member upper surface.

Owner:FLEXIBLE STEEL LACING

Removable cartridge cleaner

ActiveUS7987966B2Faster and easy removalEfficient gluingConveyorsCleaningEngineeringMechanical engineering

A removable cartridge cleaner assembly is provided that allows for faster and easier removal of the belt cleaner blades out from under a conveyor belt. In one aspect the assembly includes a biasing surface of one of an elongate support assembly and a channel member configured to be engaged by a securing member and urge distal ends of legs of the channel member into tight engagement with the elongate support assembly and minimize debris accumulation therebetween. In another aspect, the elongate base member and rail member each include lateral portions configured to slidably engage corresponding wedge portions to urge the rail member toward the base member. A method of installing a belt cleaner assembly is also provided which includes camming a rail member downwardly toward the support member upper surface.

Owner:FLEXIBLE STEEL LACING

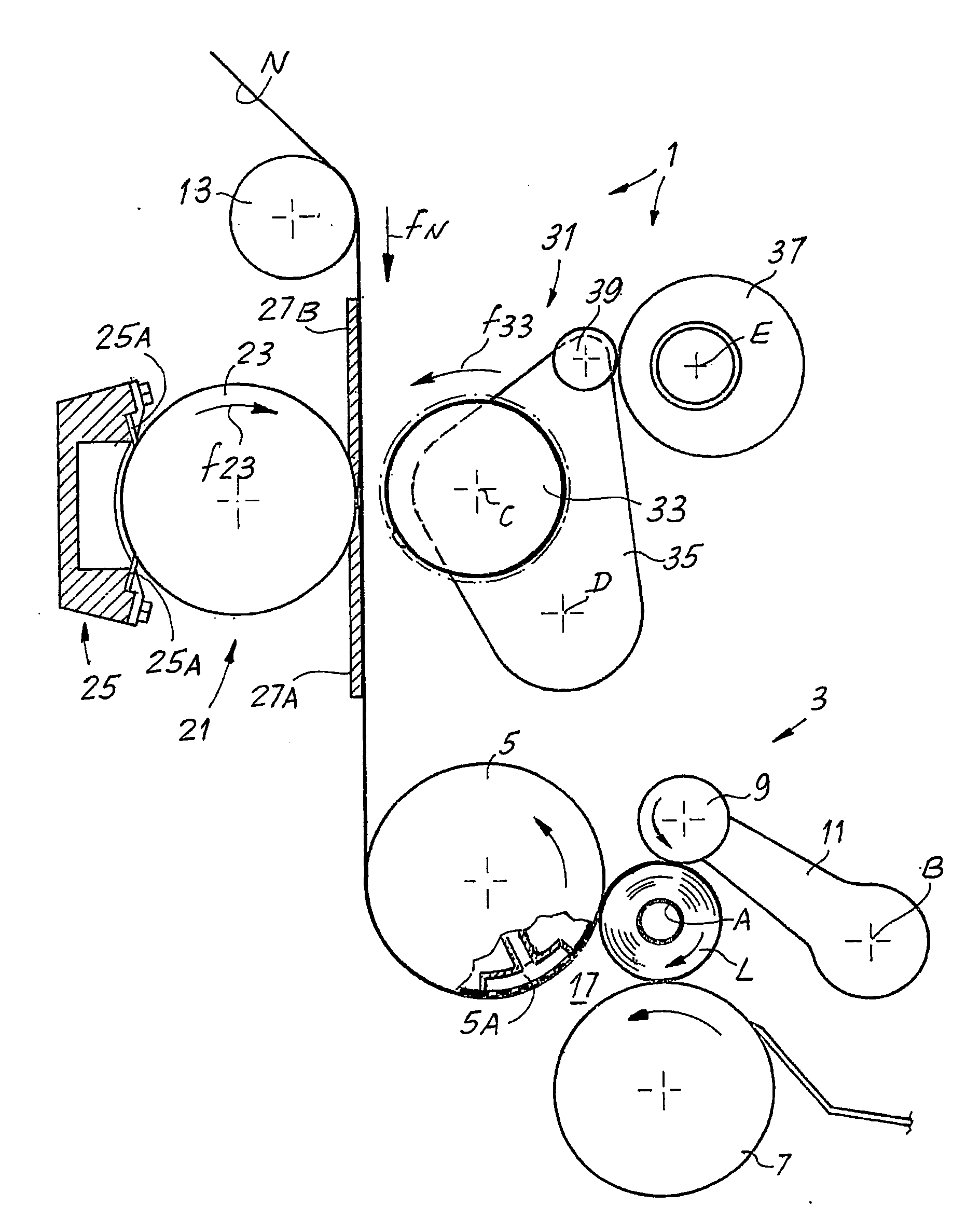

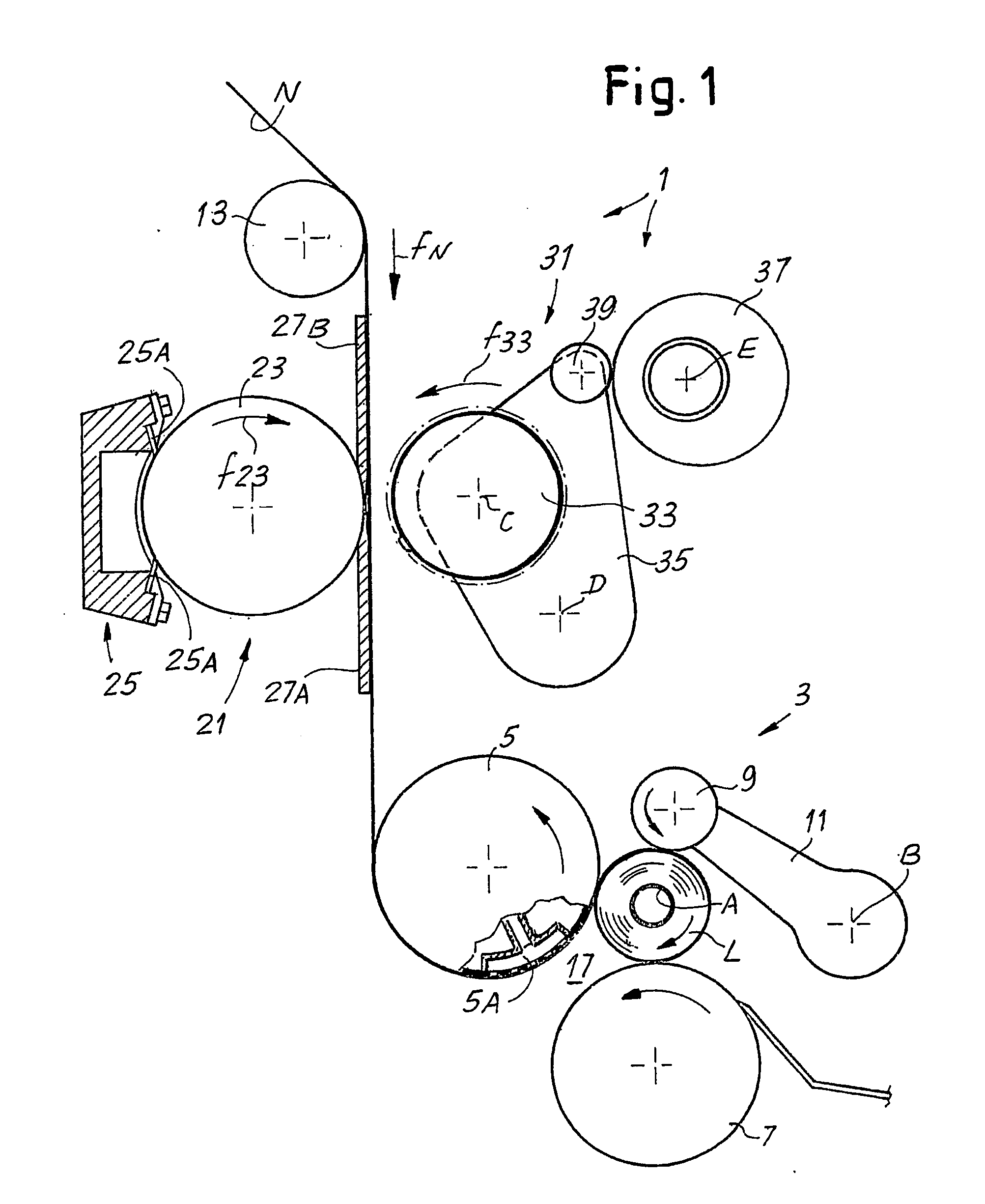

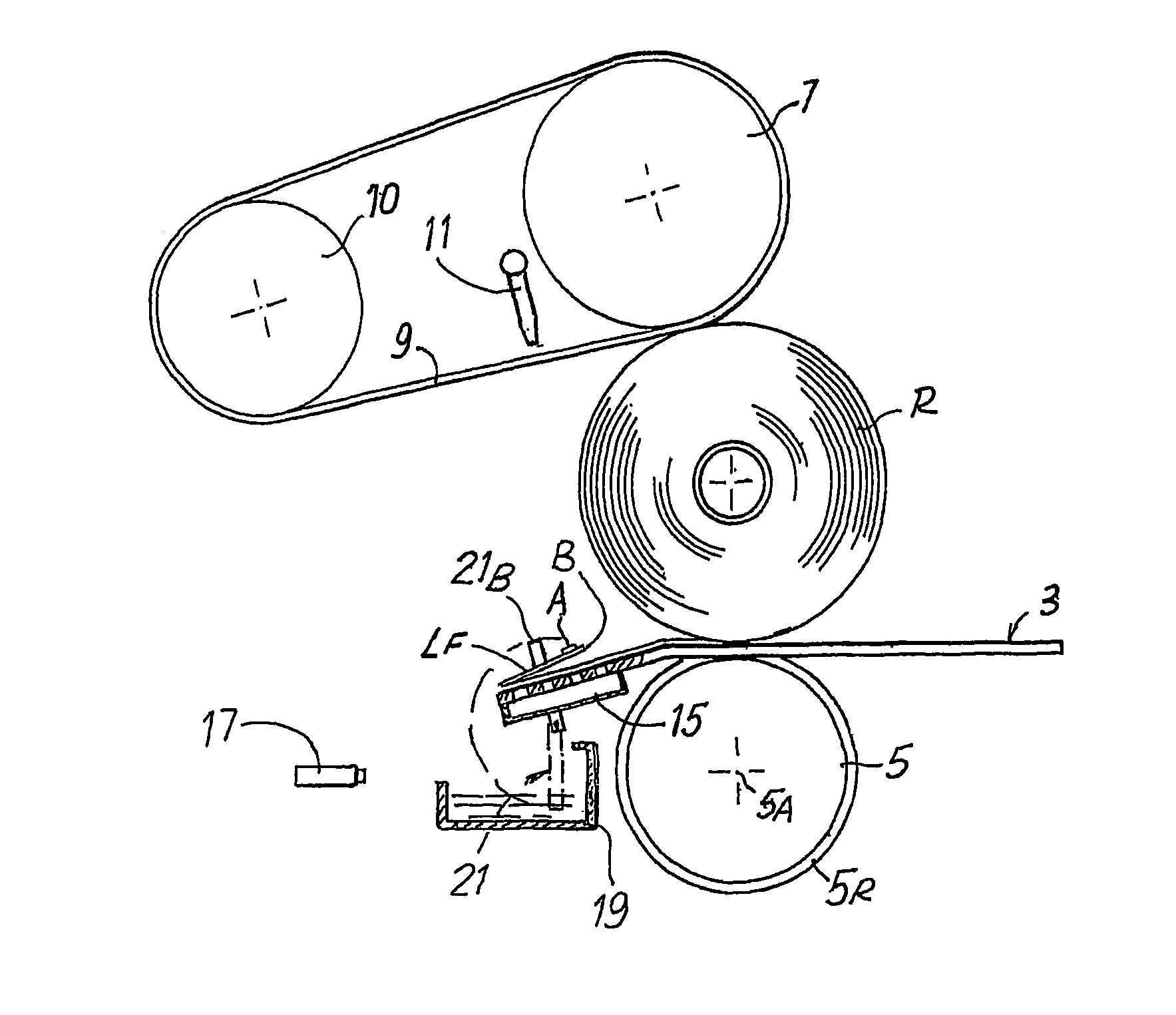

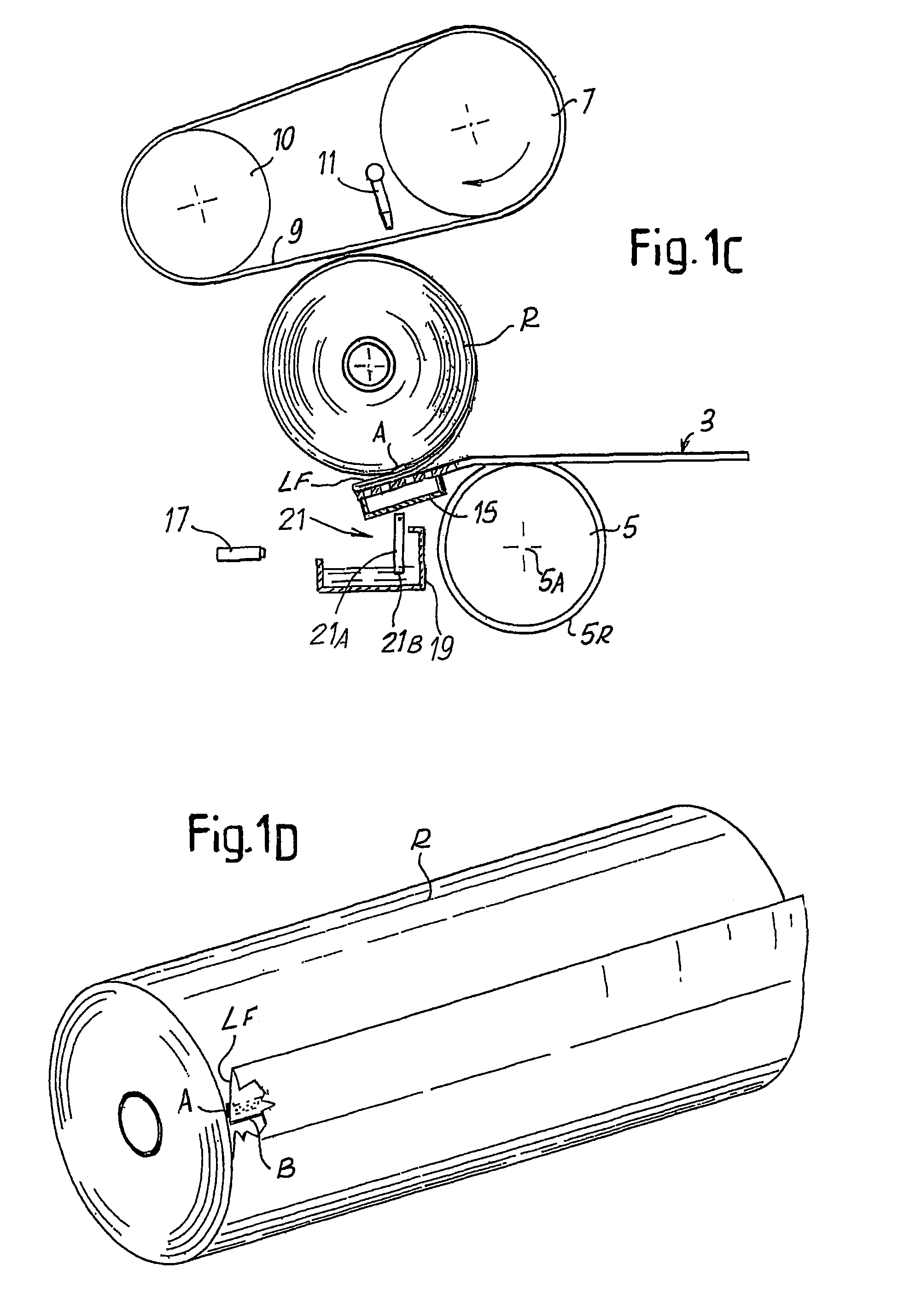

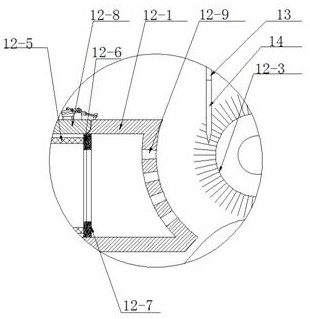

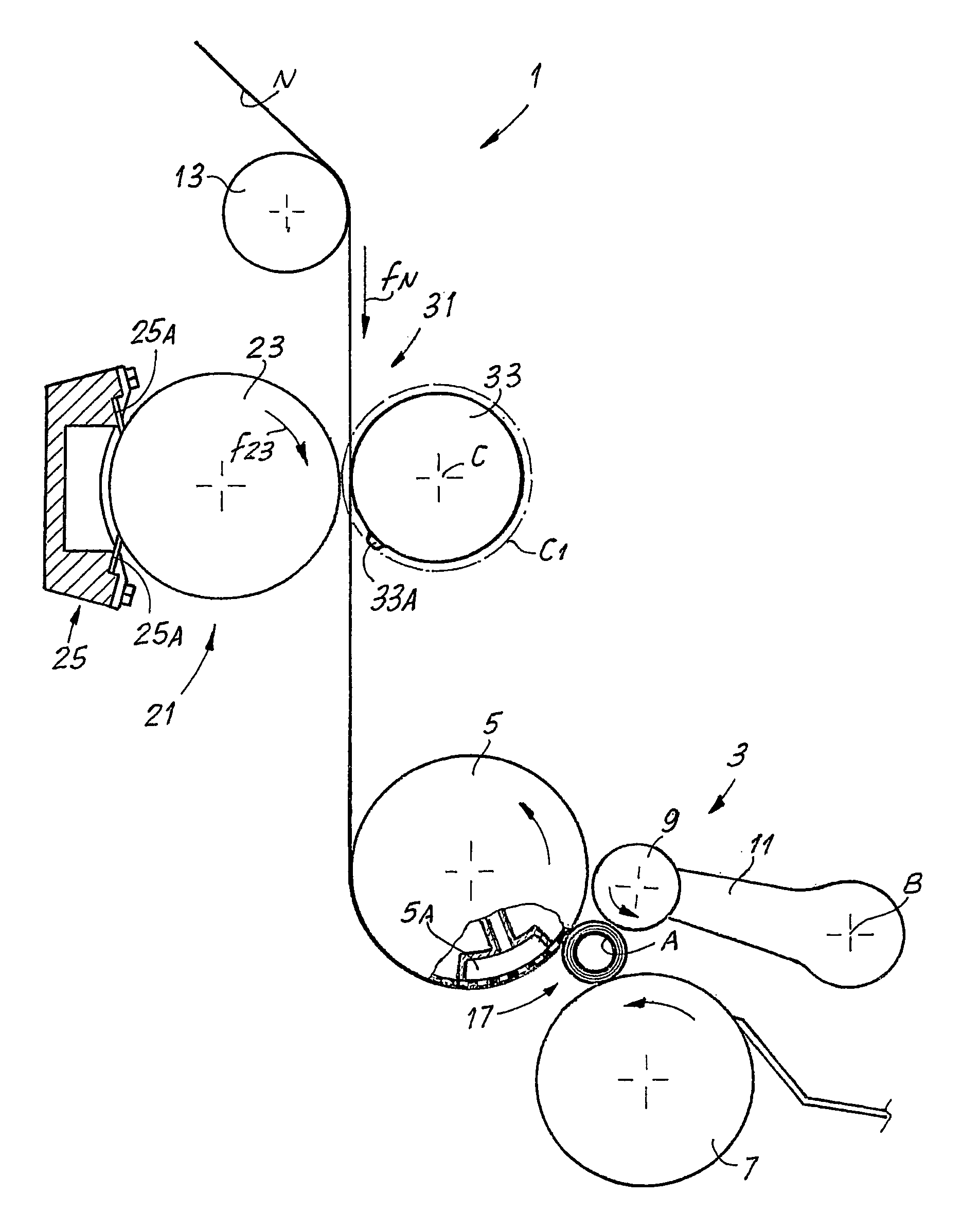

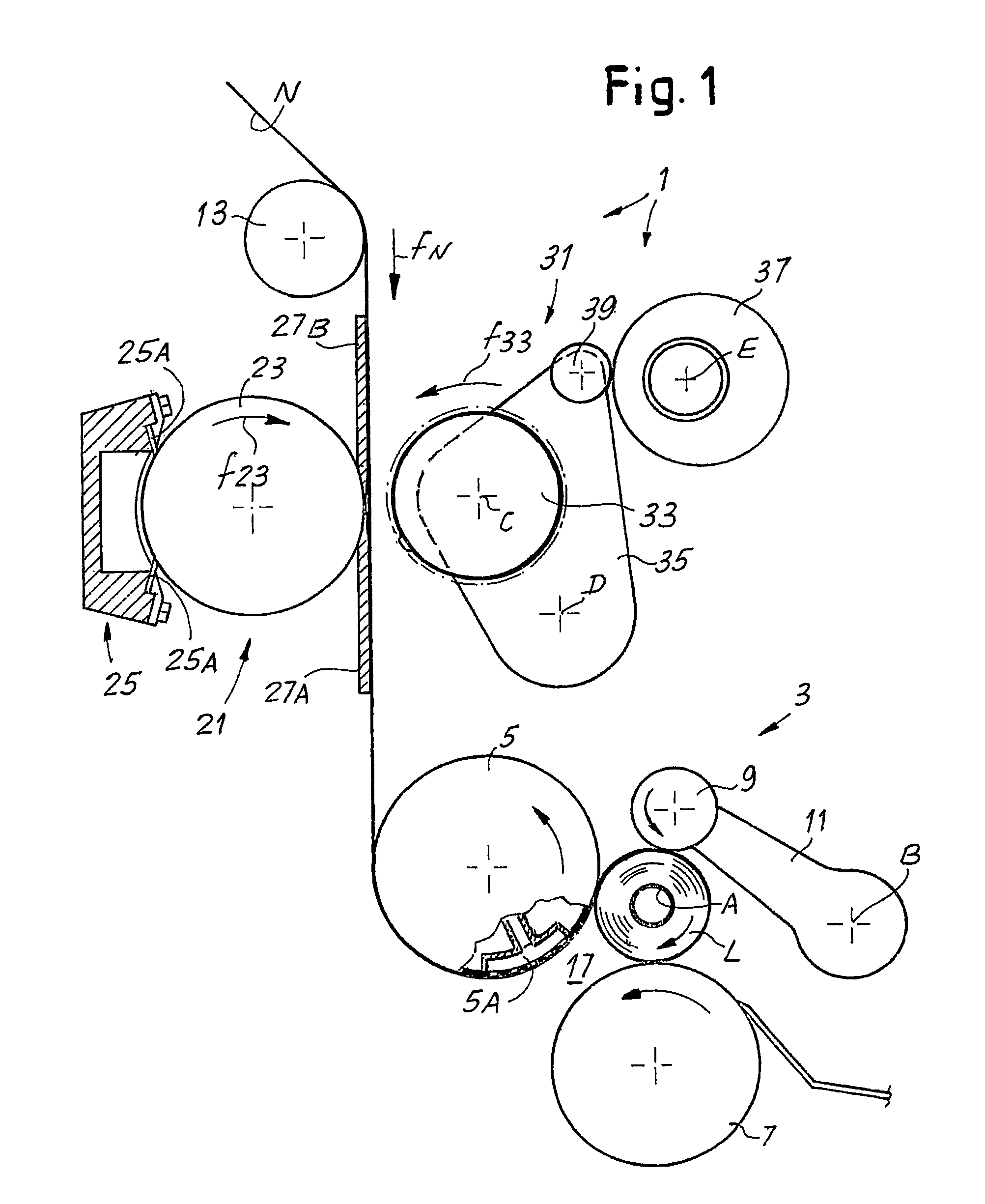

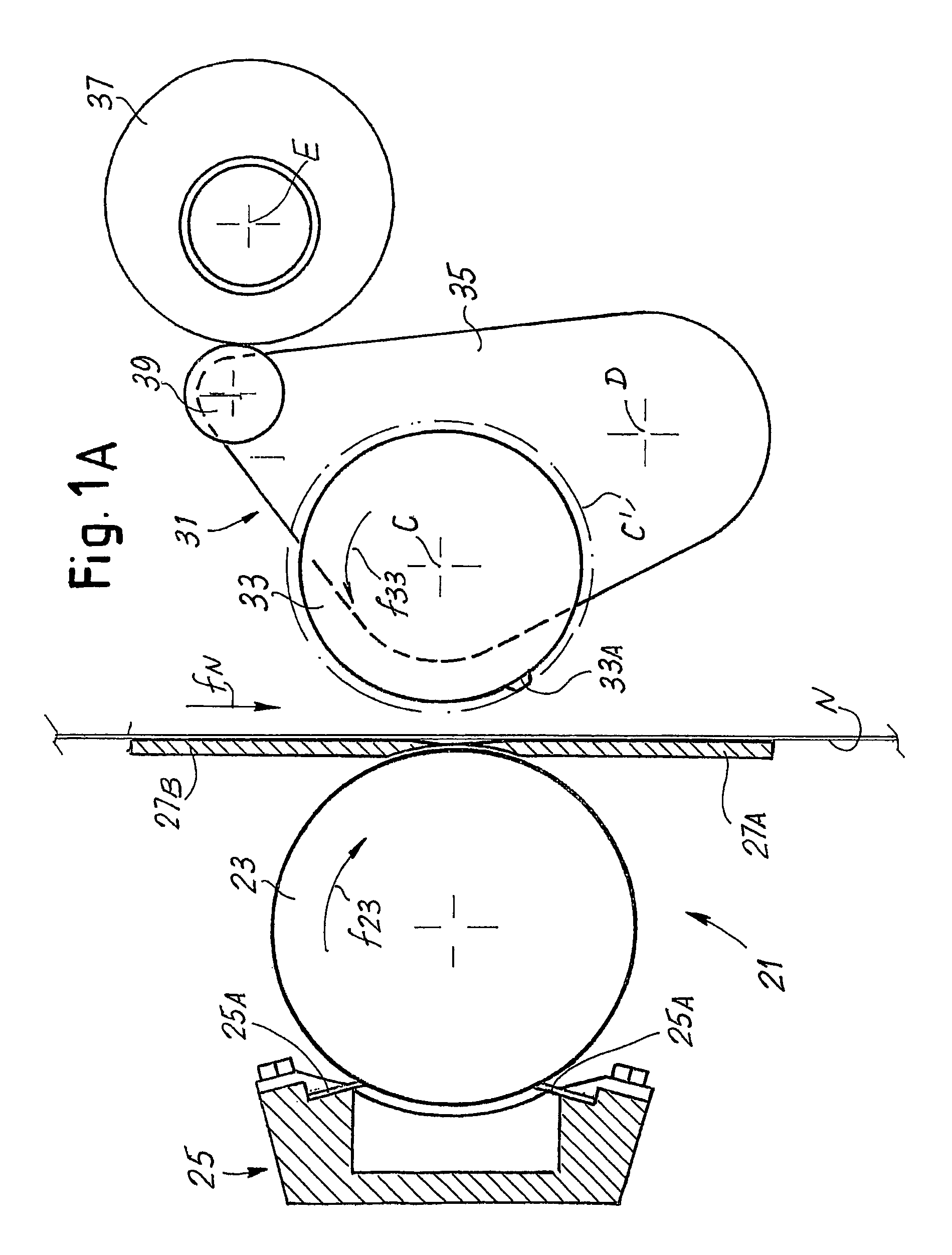

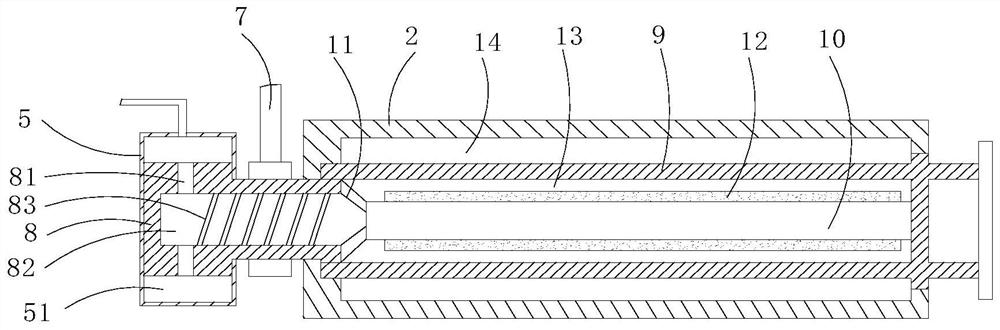

Method and device for gluing the free edge of a log of web material in a rewinding machine

InactiveUS20100025515A1Efficient gluingEffective meanArticle deliveryWebs handlingEngineeringFree edge

A rewinding machine for producing logs of web material is described which includes a winding unit; a feed path of the web material towards the winding unit; a severing device to sever the web material upon completion of winding each log; and a glue dispenser to apply a glue to the web material. The machine also includes a diverter member disposed and controlled to temporarily divert the web material towards the glue dispenser.

Owner:FABIO PERINI SPA

Removable cartridge cleaner

ActiveUS8757360B2Faster and easy removalEfficient gluingCleaningMetal working apparatusLocking mechanismEngineering

A removable cartridge cleaner assembly is provided that has an insertion device for ease in installing an elongate cartridge assembly carrying belt cleaner assemblies onto an elongate support extending across a conveyor belt in an operative position thereon. In one form, an elongate lever handle pivotally connected to the elongate cartridge assembly can be used to generate a leveraged insertion force, preferably by an operator that does not need to reach into the operating envelope of the conveyor system, e.g. beyond tensioning mechanisms or under the belt. The handle and the cartridge assembly can have an over center locking mechanism therebetween for providing the operator tactile feedback as to when pivoting of the lever handle has caused the cartridge assembly to be shifted to its operative position on the support.

Owner:FLEXIBLE STEEL LACING

Device and method for closing the tail end of logs of web material and relative logs obtained therewith

InactiveUS7846286B2Facilitate subsequent stepEfficient gluingPaper/cardboard wound articlesLaminationAdhesiveEngineering

Owner:FABIO PERINI SPA

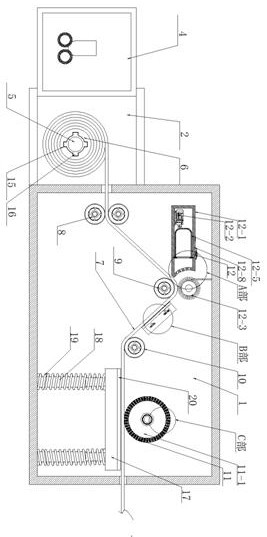

Gluing device capable of cleaning dust on surface of adhesive tape for adhesive tape production

ActiveCN111659580AViscous effectReduce exposure timeLiquid surface applicatorsCleaning using toolsAdhesive beltStructural engineering

The invention discloses a gluing device capable of cleaning dust on the surface of an adhesive tape for adhesive tape production, and relates to the technical field of adhesive tape production equipment. A discharging roller movably sleeves a rotating shaft, and an adhesive tape base material is wound on the outer side wall of the discharging roller; first guide rollers are symmetrically arrangedon the upper side and the lower side of the left side in a first box body, a second guide roller is arranged on the upper portion of the right side of first guide rollers, a third guide roller is arranged on the lower portion of the right side of the second guide roller, and the height of the second guide roller is higher than that of the first guide rollers and the third guide roller; and the right end of the adhesive tape base materials sequentially passes through the left side wall of the first box body, the first guide rollers on the upper and lower sides, the upper side surface of the second guide roller, the lower side surface of the third guide roller and the right side wall of the first box body, and the adhesive tape base materials are connected to an outer adhesive tape winding mechanism. The dust on the surface of the adhesive tape can be cleaned before the adhesive tape is glued; and meanwhile, the exposure time of the base materials in the air is reduced, the influence ofthe dust on the adhesion of the later adhesive tape is prevented, and the quality of the finished products is improved.

Owner:常州都铂高分子有限公司

Gumming machine for aluminum plate film coating

InactiveCN107812663AEfficient gluingRaise the liquid levelLiquid surface applicatorsCoatingsEngineeringBrush

The invention discloses a gumming machine for aluminum plate film coating. The gumming machine for aluminum plate film coating comprises a workbench, an installing plate, conveying rollers, brush rollers, supporting legs, a glue box, an installing frame, first gumming rollers, first sponge sleeves, second gumming rollers, second sponge sleeves, a piston block, an adjusting bolt and a support; thevertically arranged installing plate is fixedly arranged on the rear side of the upper portion of the workbench; the plurality of conveying rollers arranged at intervals are arranged on the front sideof the installing plate, and are located at the same horizontal height; the two brush rollers are arranged on the front side of the installing plate from top to bottom, and are located between any two adjacent conveying rollers; the upper portion the brush roller on the lower side and the upper portions of the conveying rollers are located at the same horizontal height; and the brush roller on the upper side is tangential with the brush roller on the lower side. Compared with the prior art, gumming can be efficiently and fast performed on an aluminum plate, the efficiency and the effect of gumming are improved, the labor intensity of a worker is lowered, the machining efficiency is improved, and great convenience is brought to film coating of the aluminum plate.

Owner:JIAXING BOLONG ALUMINUM DECORATIVE BOARD

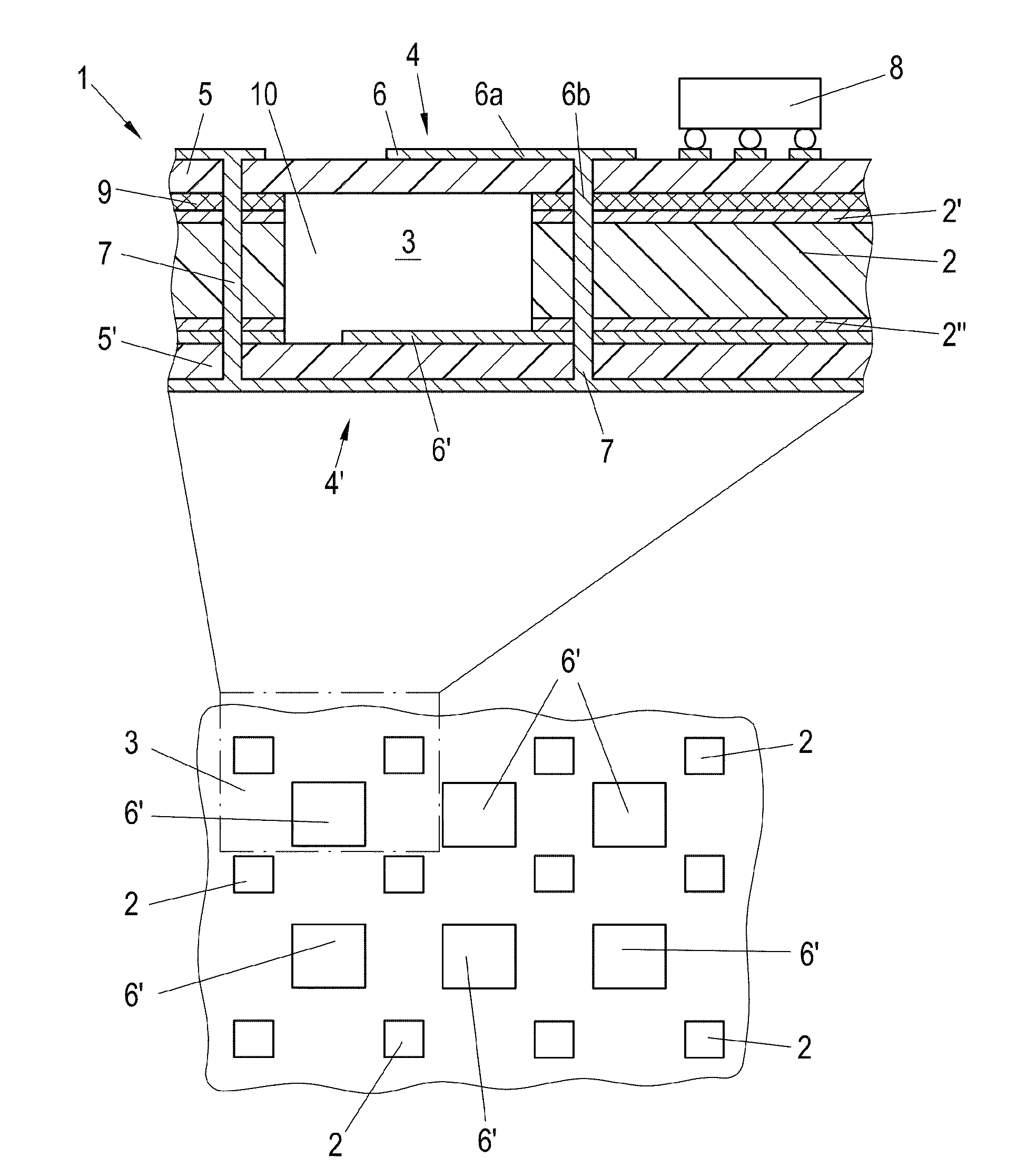

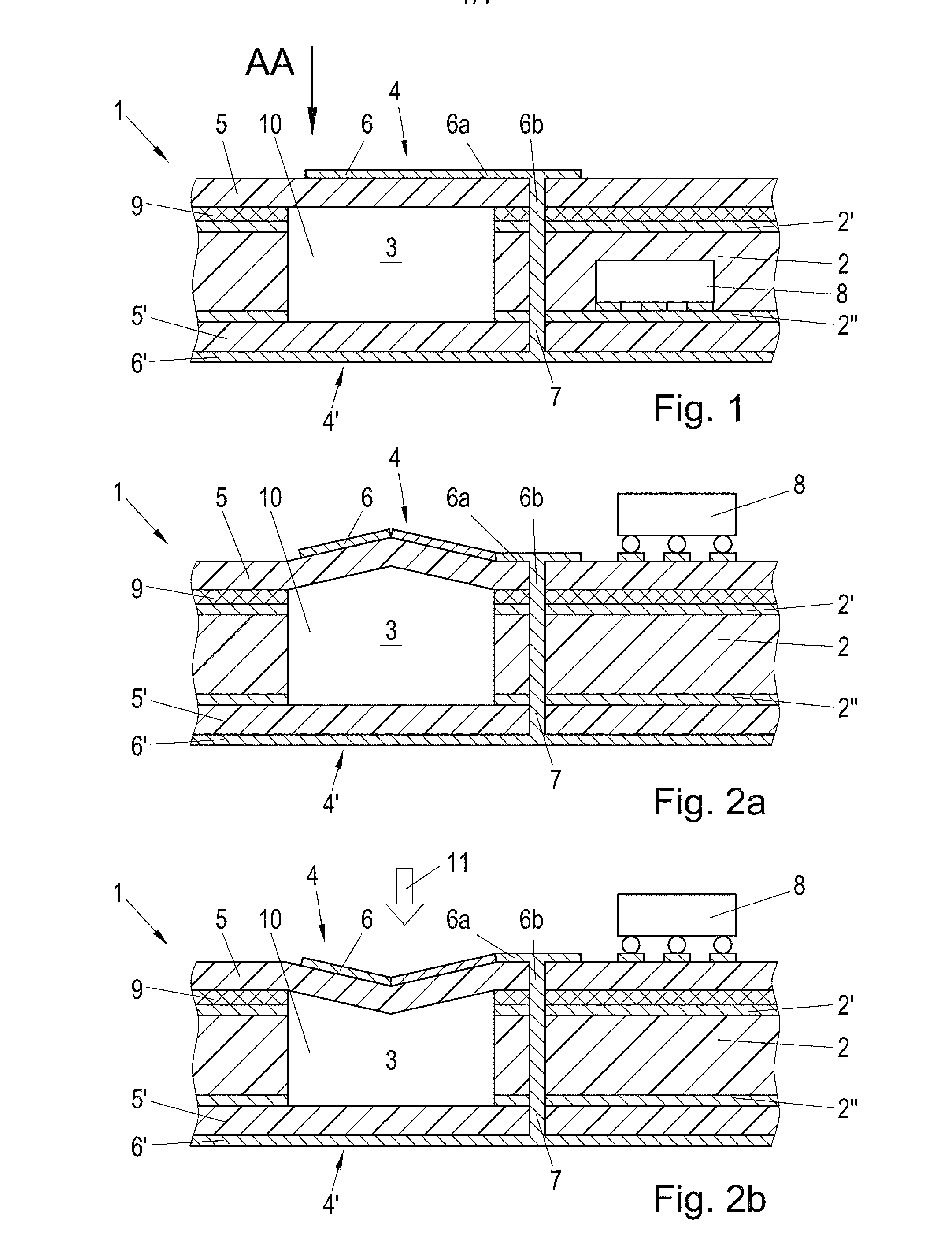

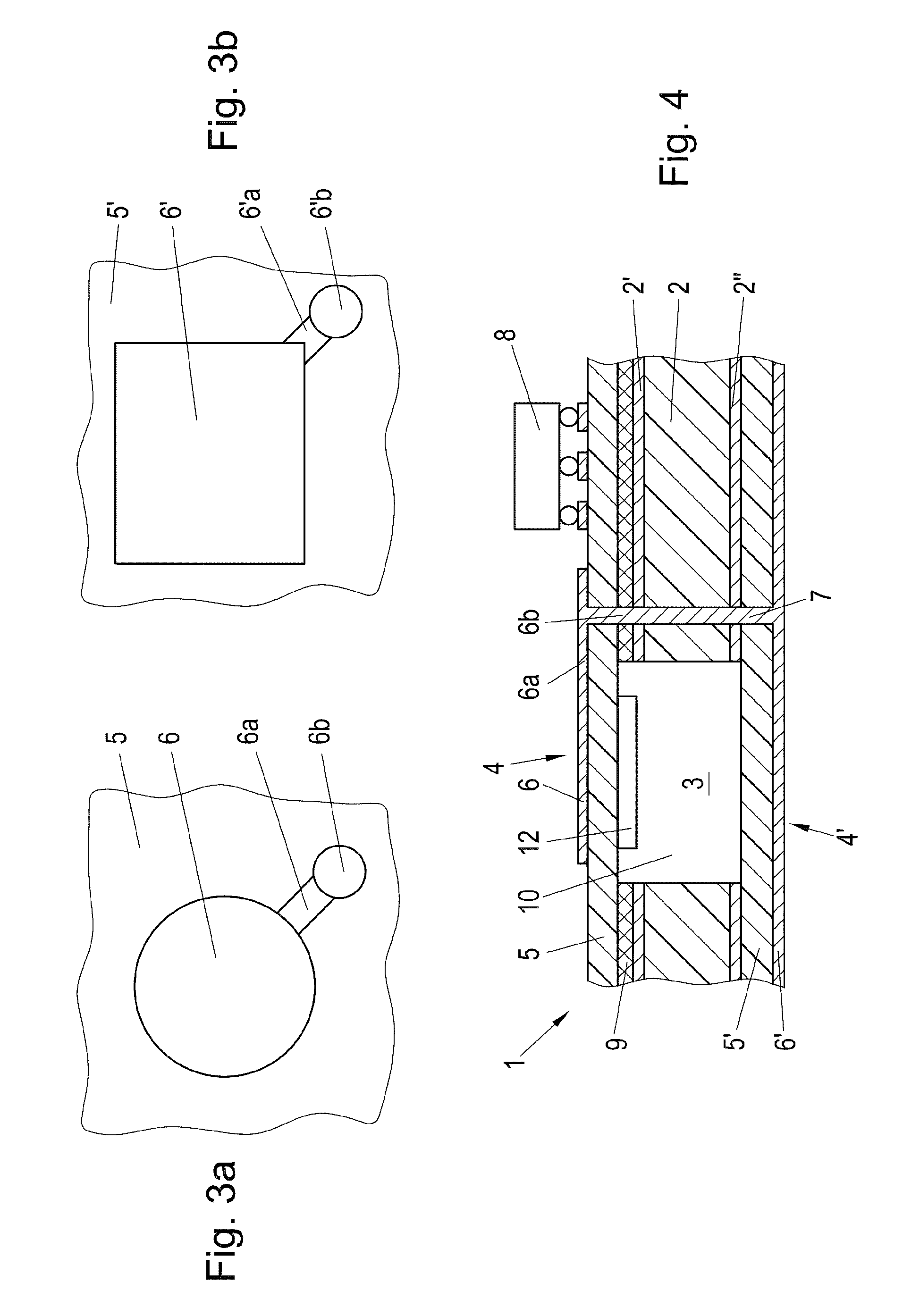

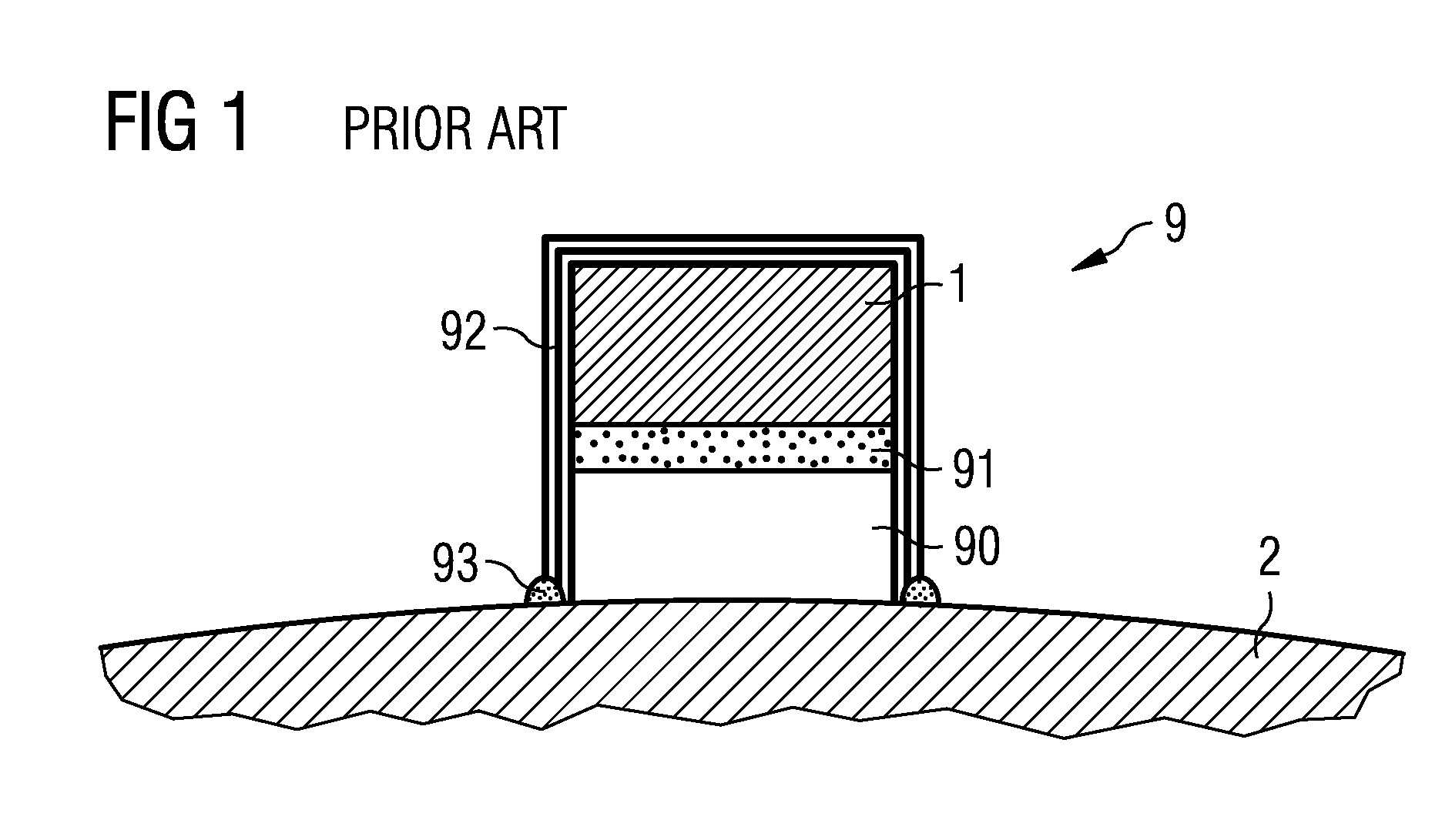

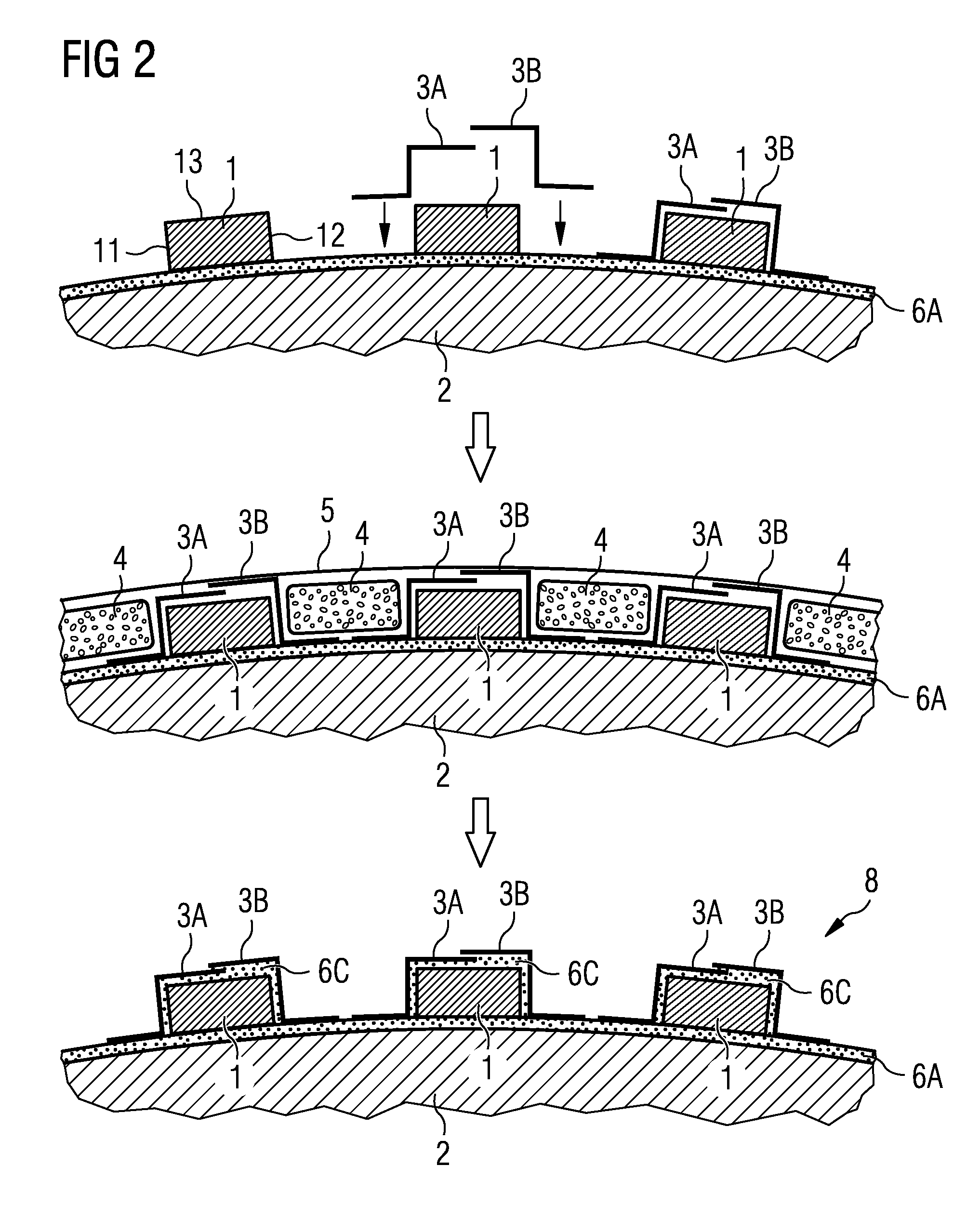

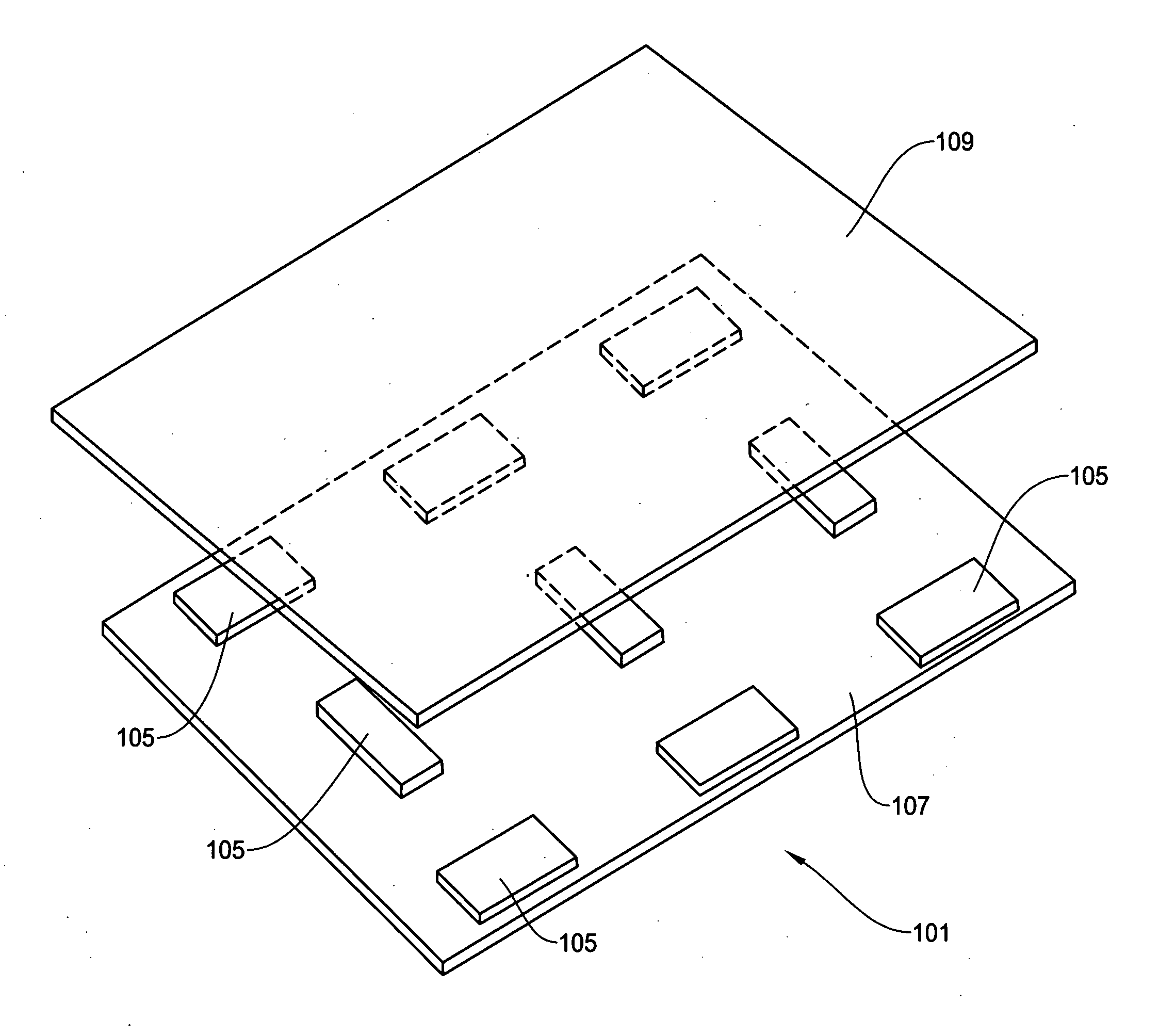

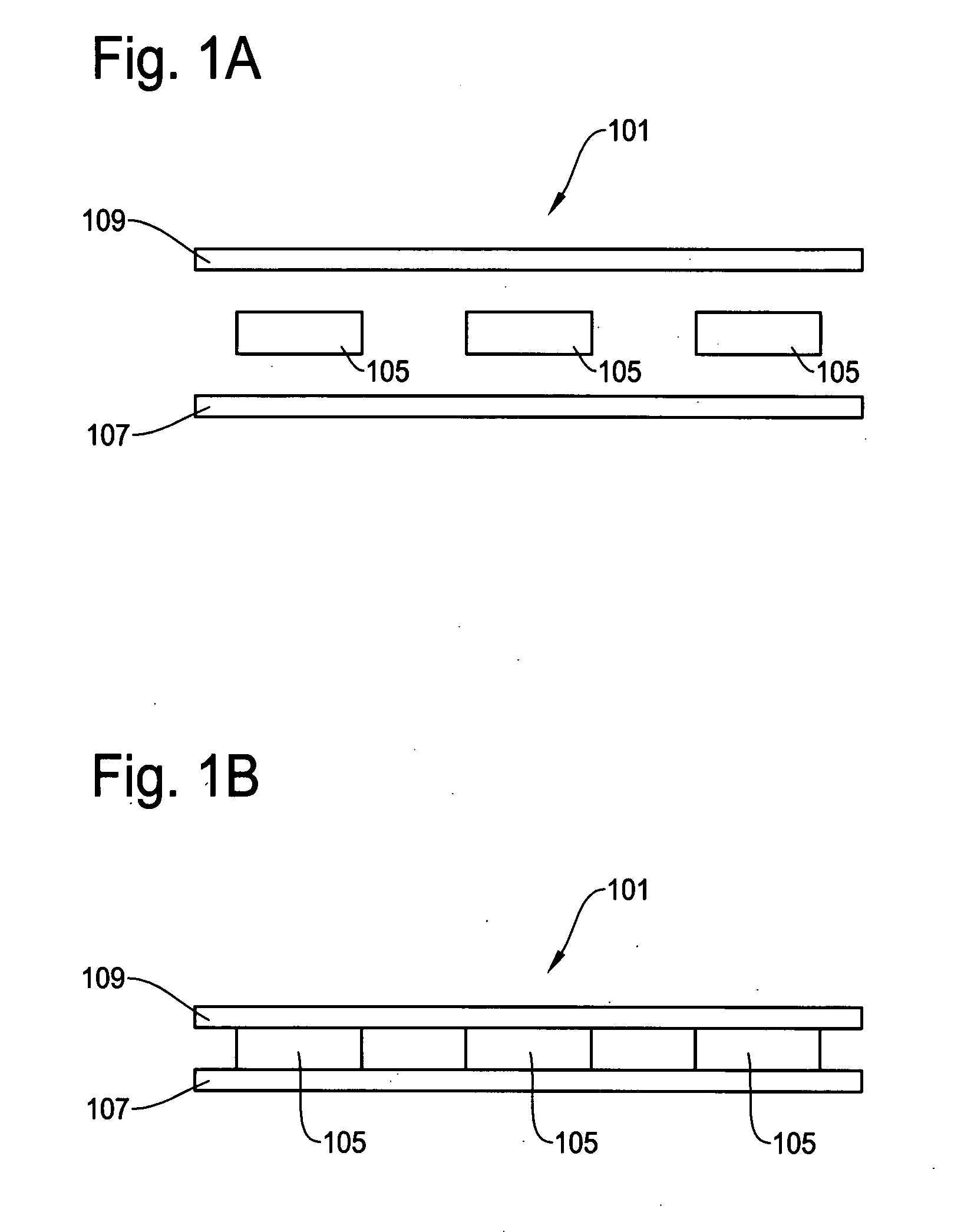

Printed Circuit Board

InactiveUS20160330840A1Highly integratedImprove protectionCapacitance measurementsSemiconductor electrostatic transducersCapacitanceElectronic component

In a connection system for electronic components comprising a plurality of insulating layers and conductive layers, and having at least one cavity, the at least one cavity is covered on both sides thereof at least by an electrode-group of an insulating layer followed by a conductive layer, the electrode-groups forming electrodes of a capacitor. A method for detecting failure of a connection system for electronic components comprises the steps of continuously measuring the capacitance of the at least one capacitor formed by the electrode groups and generating a failure message when detecting a discontinuity in the progression of capacitance of the at least one capacitor.

Owner:AT & S AUSTRIA TECH & SYSTTECHN AG

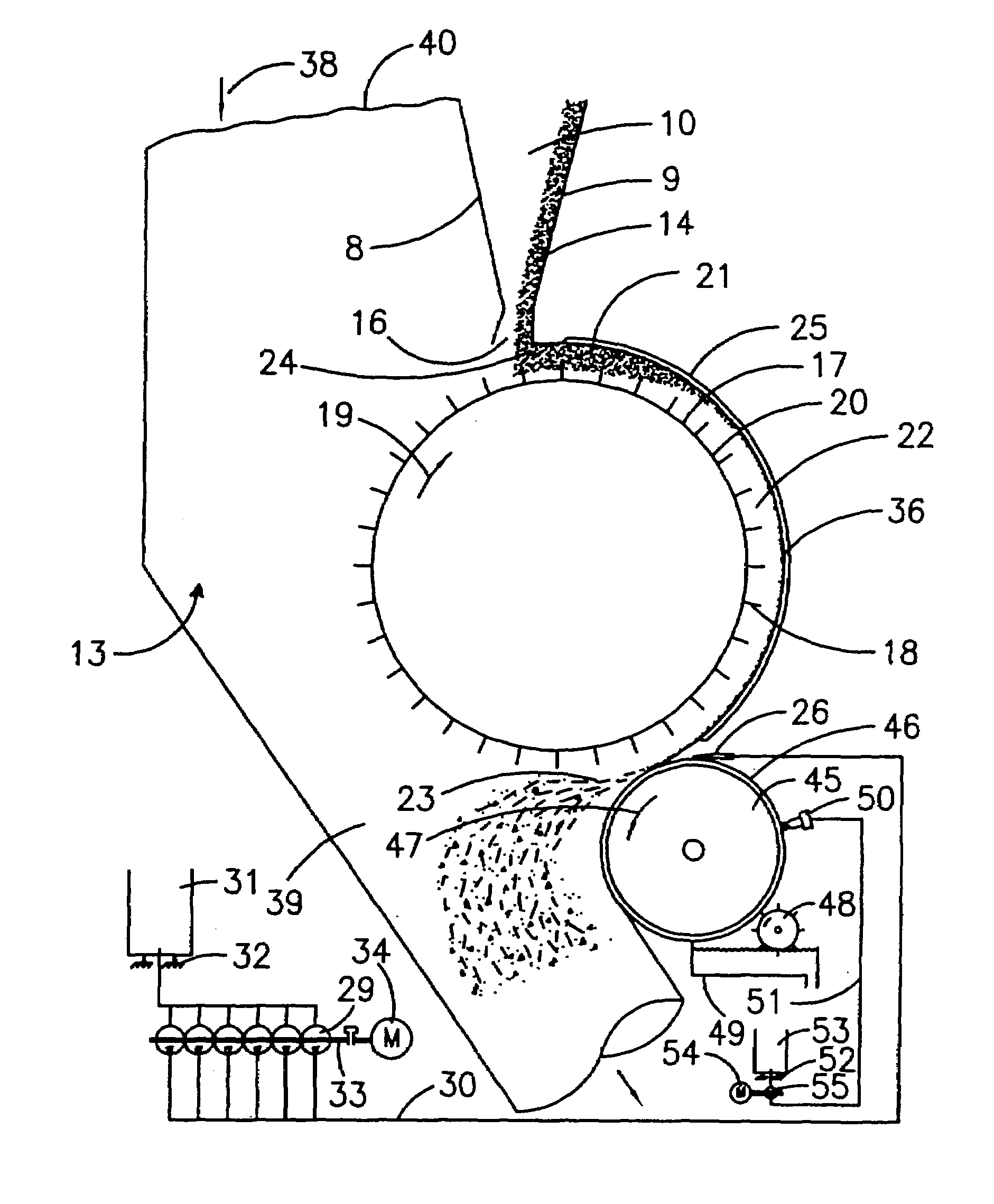

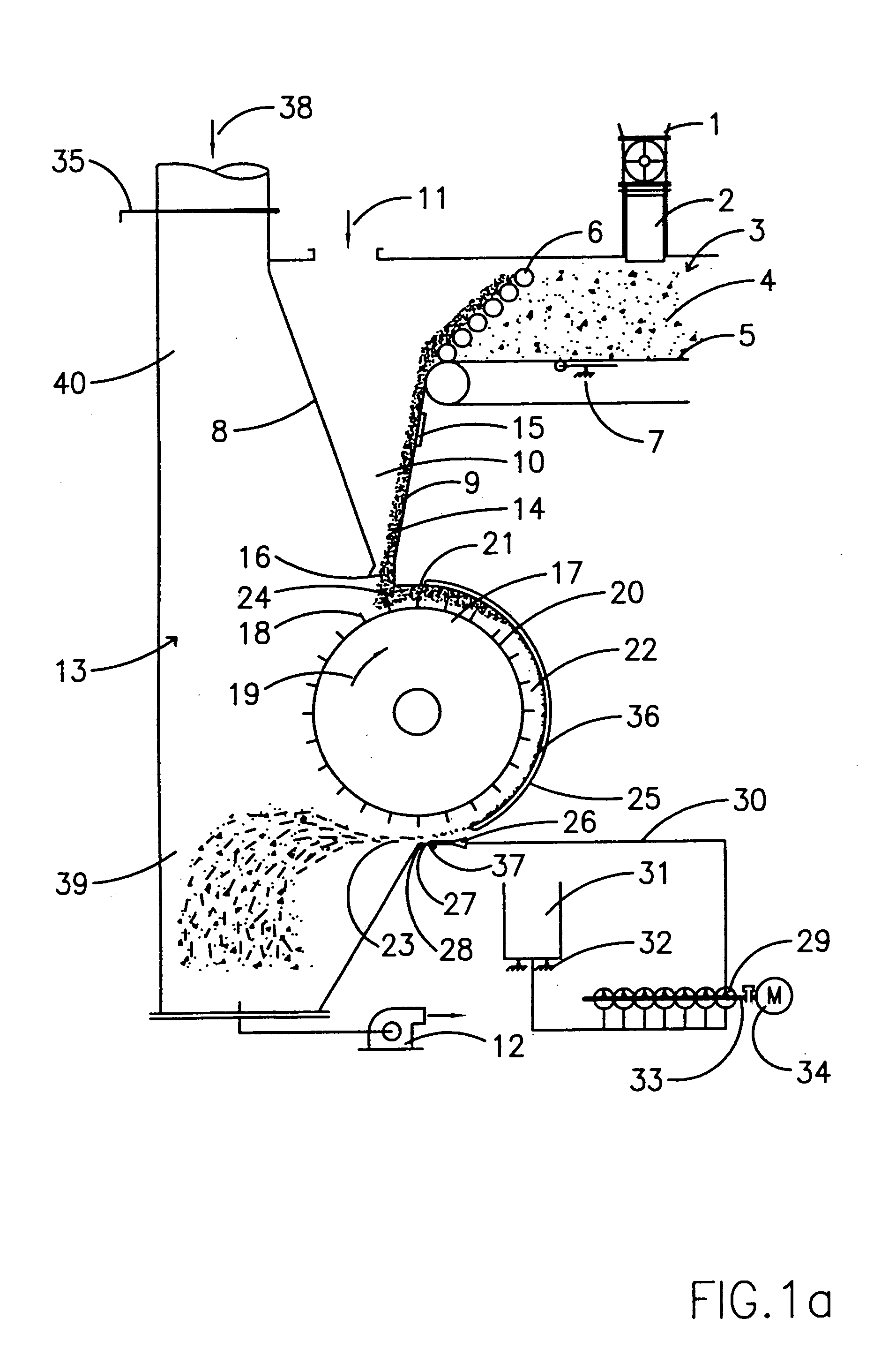

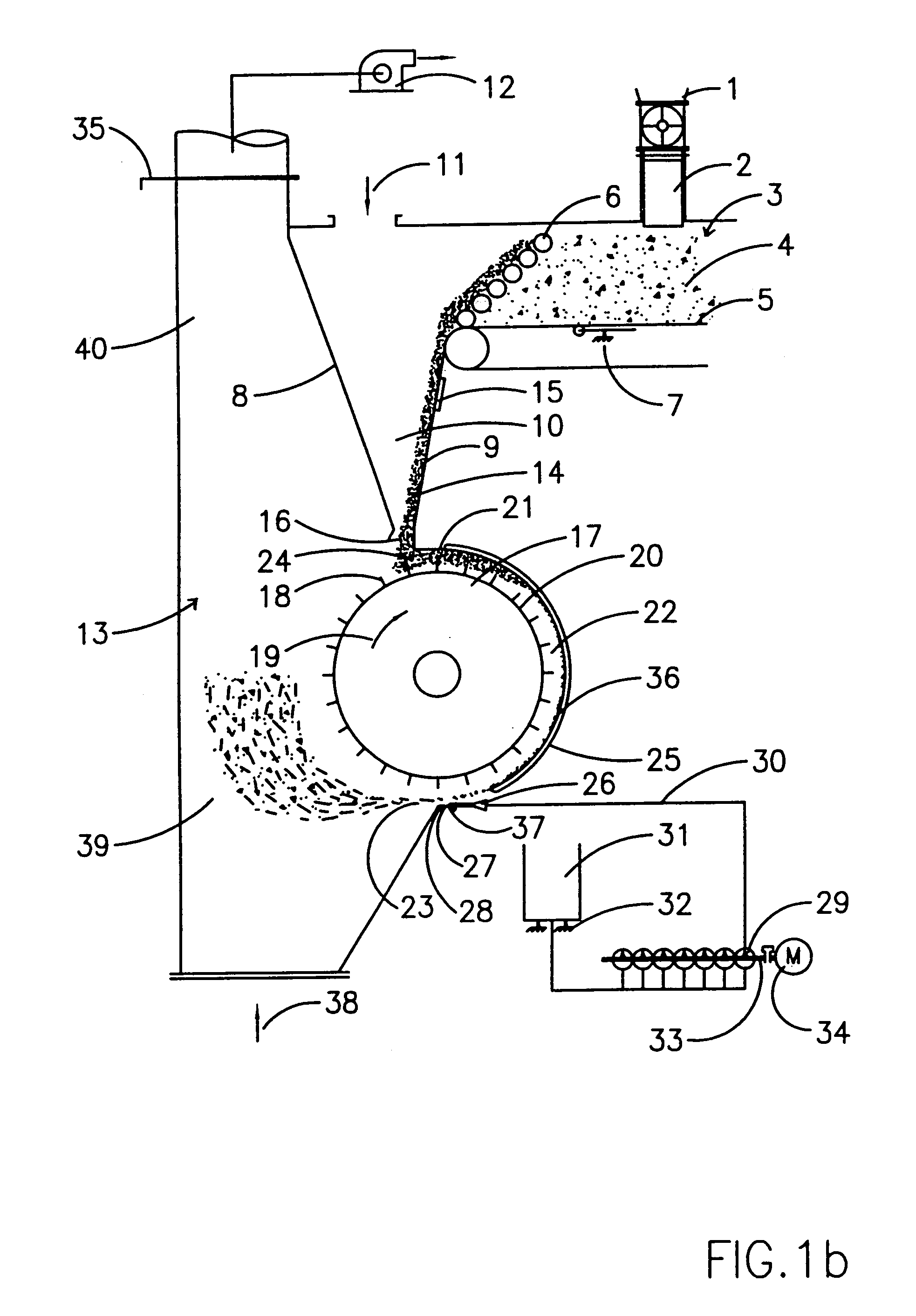

Process and device for gluing dried fibers designated for the production of fiberboards

Dried fibers which are designated for the production of fiber boards are supplied to a fiber roller (17) from a metering device through a feed chute (10) which is subjected to negative pressure, which fiber roller is provided on its surface with a plurality of pins (18) and rotates in such a manner that the fibers (14) are deflected by the pins (18), are directed along a chute section (22) defined by means of a partial section (20) of the periphery of the fiber roller (17) and an opposite-lying wall (21) and gluing means and said fibers are accelerated to approximately the peripheral speed of the fiber roller (17) by means of the pins (18) and an air flow generated by said pins. The fibers (36) lie against a section of the wall and are glued in the region of or adjacent to one end of the wall section and exit at an outlet orifice (23) of the chute section (22). In the case of an alternative process, after exiting the chute section substantially horizontally the fibers are deflected in an upward or downward direction and are glued in this region by means of at least one spray nozzle.

Owner:FLAKEBOARD

Gels for encapsulation of biological meterials

InactiveUS20070100015A1Facilitated DiffusionGood flexibilitySurgical adhesivesPeptide/protein ingredientsLong wavelengthPhotoinitiator

This invention provides novel methods for the formation of biocompatible membranes around biological materials using photopolymerization of water soluble molecules. The membranes can be used as a covering to encapsulate biological materials or biomedical devices, as a “glue” to cause more than one biological substance to adhere together, or as carriers for biologically active species. Several methods for forming these membranes are provided. Each of these methods utilizes a polymerization system containing water-soluble macromers, species, which are at once polymers and macromolecules capable of further polymerization. The macromers are polymerized using a photoinitiator (such as a dye), optionally a cocatalyst, optionally an accelerator, and radiation in the form of visible or long wavelength UV light. The reaction occurs either by suspension polymerization or by interfacial polymerization. The polymer membrane can be formed directly on the surface of the biological material, or it can be formed on material, which is already encapsulated.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Removable cartridge cleaner

ActiveUS20110203904A1Faster and easy removalEfficient gluingCleaningMetal working apparatusLocking mechanismEngineering

A removable cartridge cleaner assembly is provided that has an insertion device for ease in installing an elongate cartridge assembly carrying belt cleaner assemblies onto an elongate support extending across a conveyor belt in an operative position thereon. In one form, an elongate lever handle pivotally connected to the elongate cartridge assembly can be used to generate a leveraged insertion force, preferably by an operator that does not need to reach into the operating envelope of the conveyor system, e.g, beyond tensioning mechanisms or under the belt. The handle and the cartridge assembly can have an over center locking mechanism therebetween for providing the operator tactile feedback as to when pivoting of the lever handle has caused the cartridge assembly to be shifted to its operative position on the support.

Owner:FLEXIBLE STEEL LACING

Method and device for gluing the free edge of a log of web material in a rewinding machine

Owner:FABIO PERINI SPA

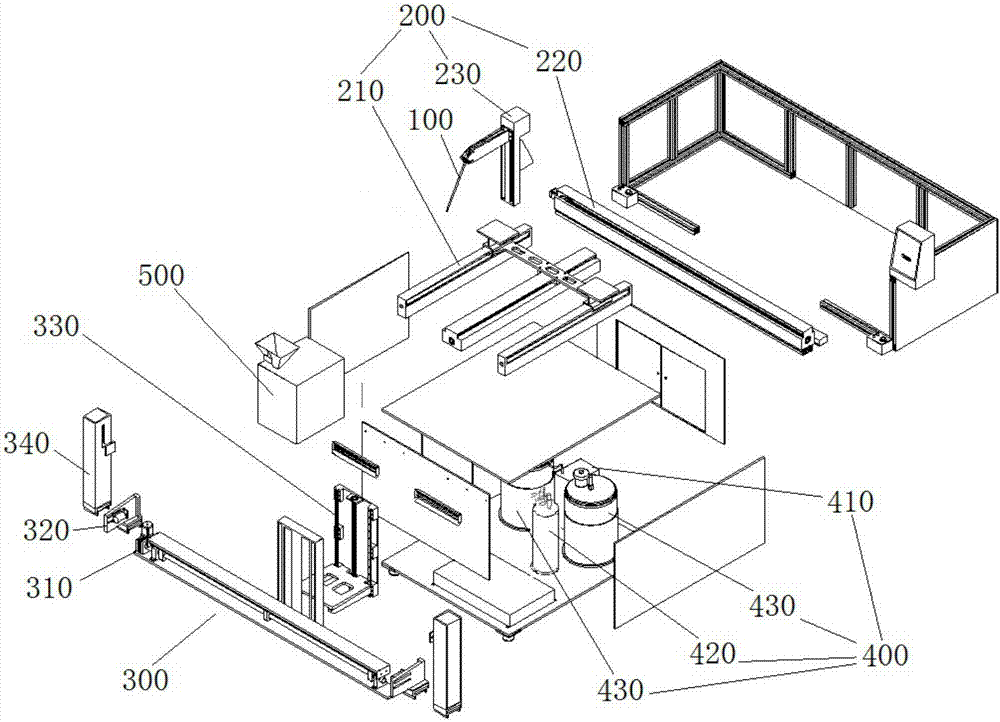

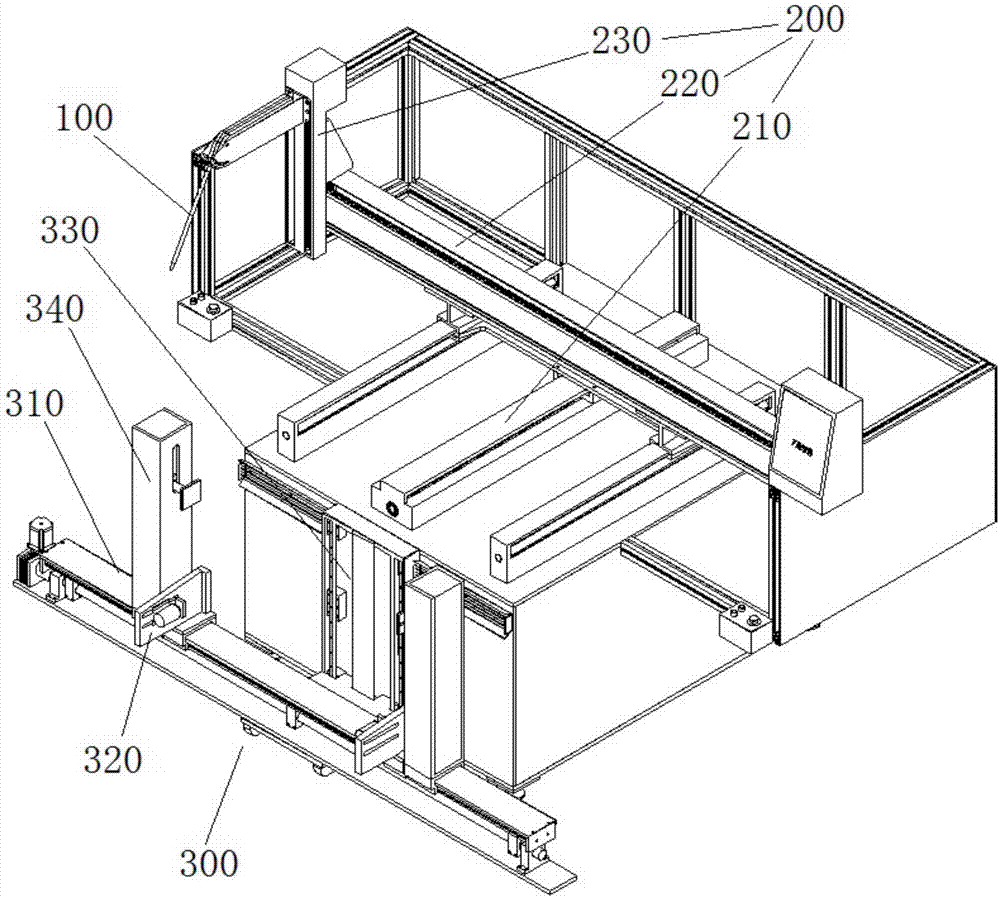

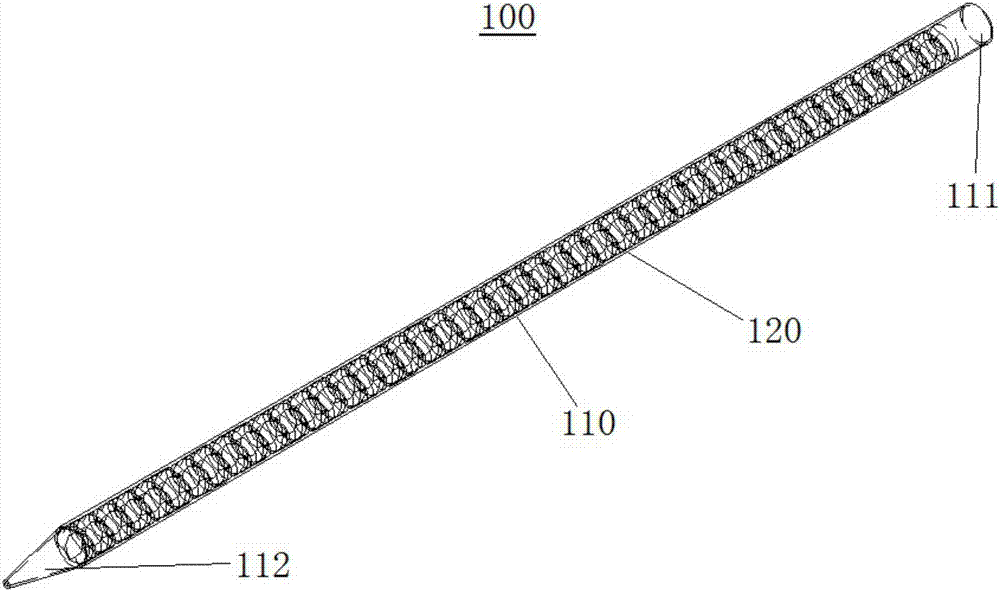

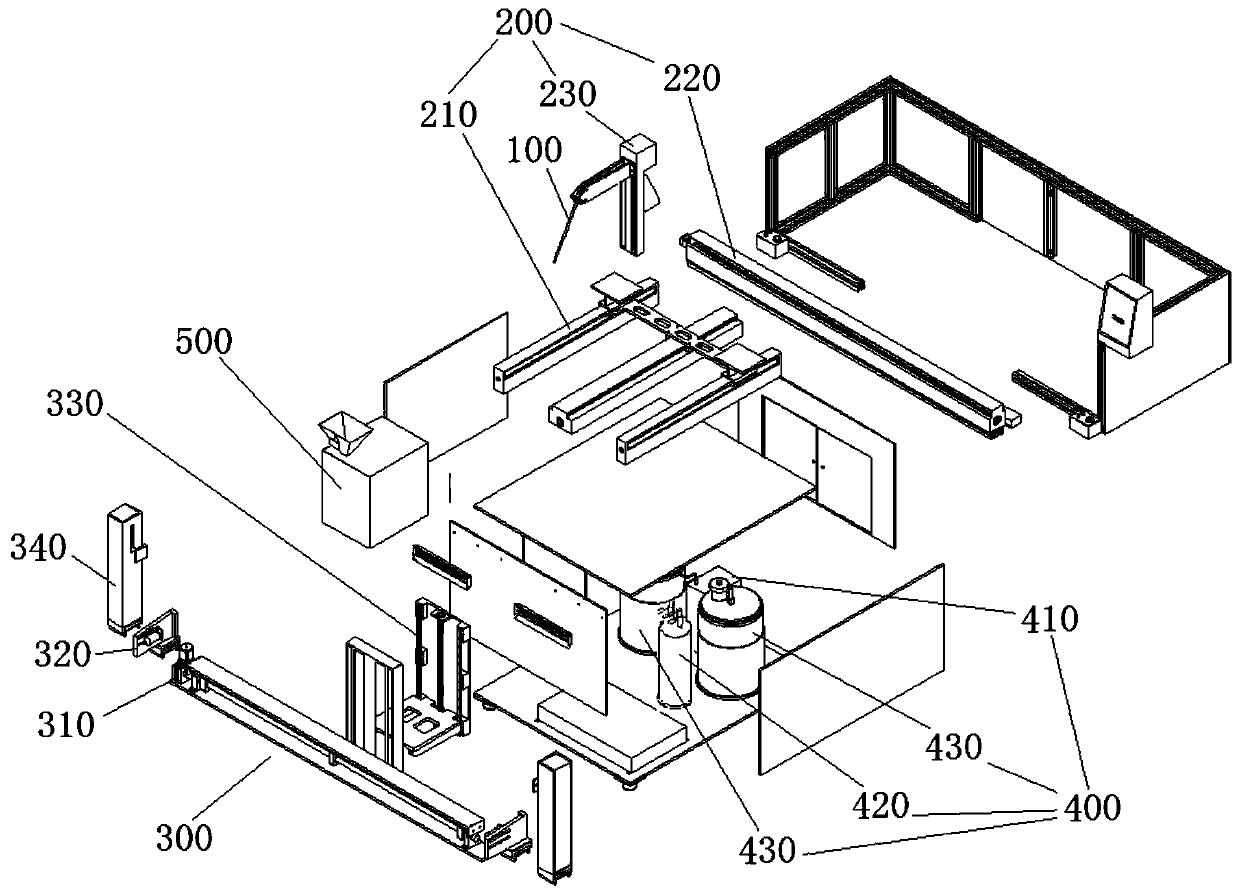

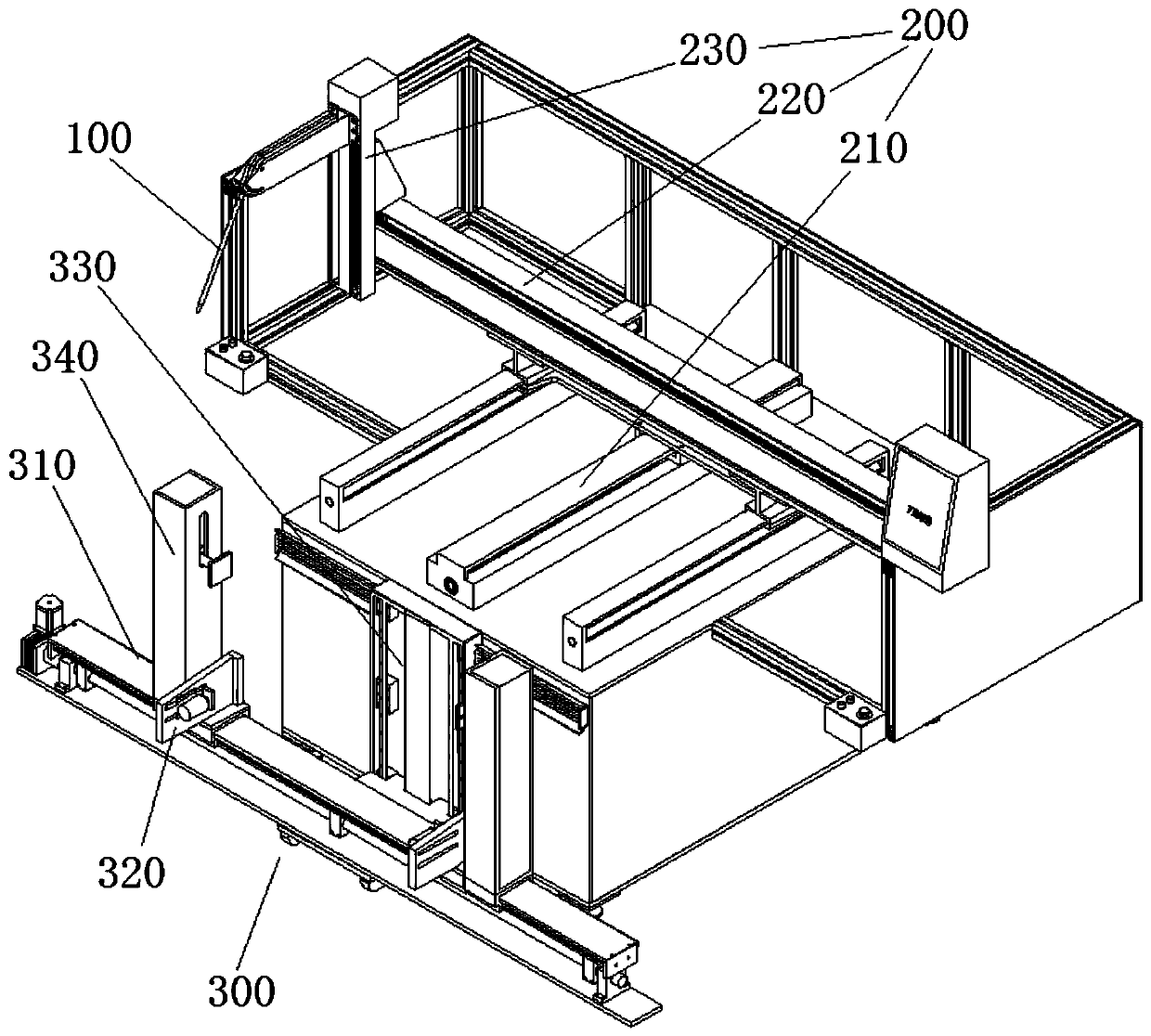

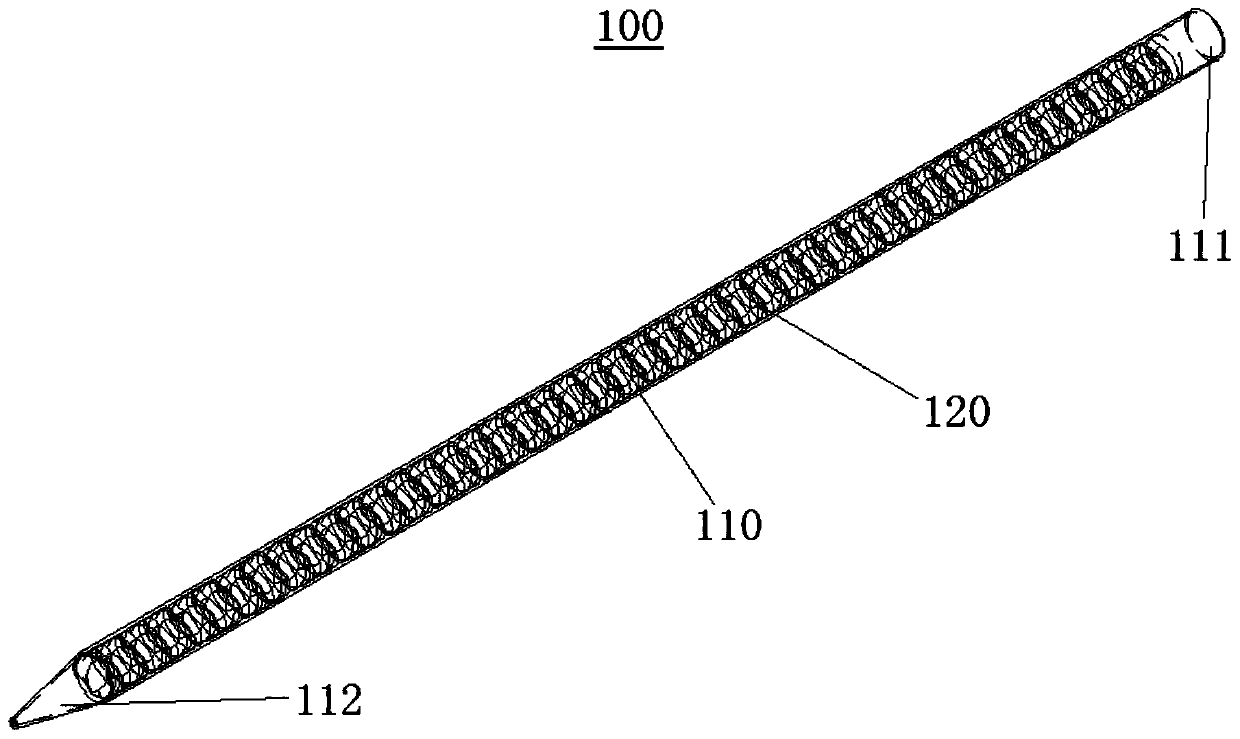

Multi-dimensional frame gluing equipment

ActiveCN106862014AControl the amount of glue injectedControl movement speedLiquid surface applicatorsCoatingsEngineeringMulti dimensional

The invention provides multi-dimensional frame gluing equipment which comprises a gluing gun, a three-dimensional movement device, a frame adjustment device and a material feeding device. The gluing gun is installed on the three-dimensional movement device, and the three-dimensional movement device can drive the gluing gun to move forwards and backwards, leftwards and rightwards and up and down; the frame adjustment device is installed on the front side of the three-dimensional movement device, and the frame adjustment device can fix a frame and adjust the angle of the frame relative to the gluing gun; the material feeding device is connected with the gluing gun through a pipe and can convey glue to the gluing gun to perform gluing on the frame. By the adoption of the multi-dimensional frame gluing equipment, gluing action can be completed rapidly and efficiently, the gluing process of a frame filter can be mechanized, manpower and materials are greatly reduced, product quality is guaranteed, and gluing efficiency of the frame filter is improved.

Owner:广州金田瑞麟环境科技有限公司

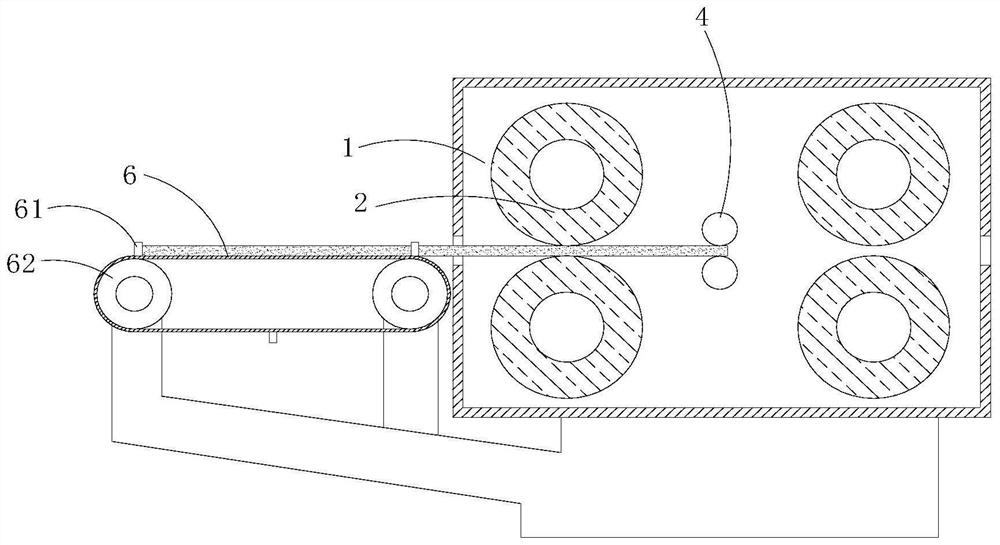

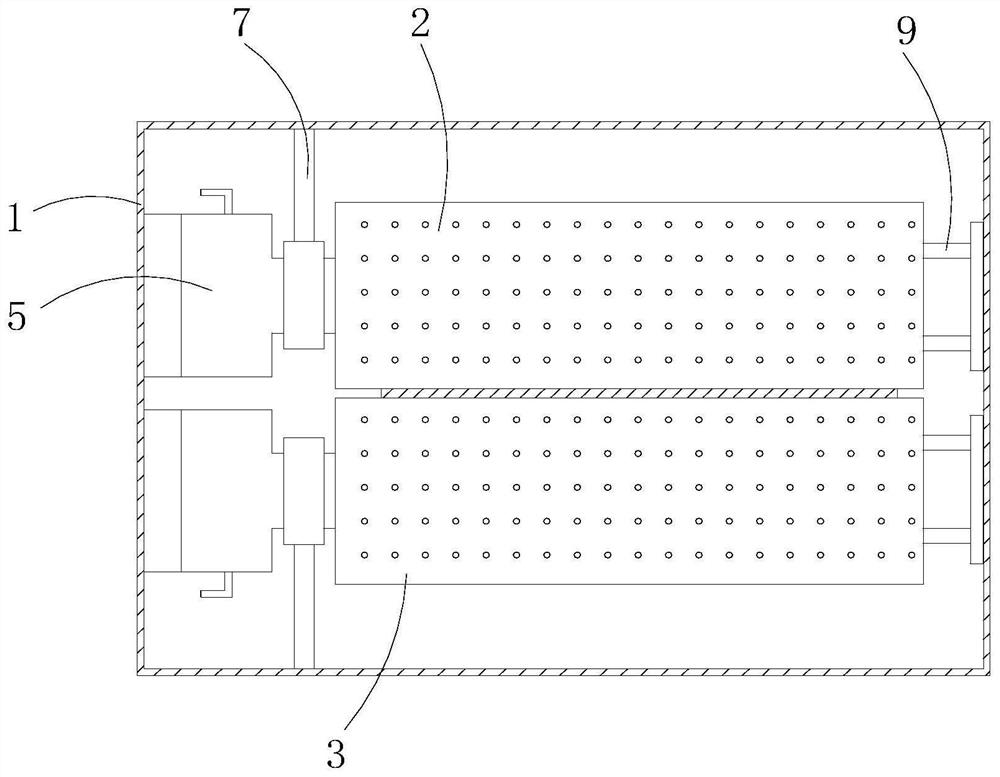

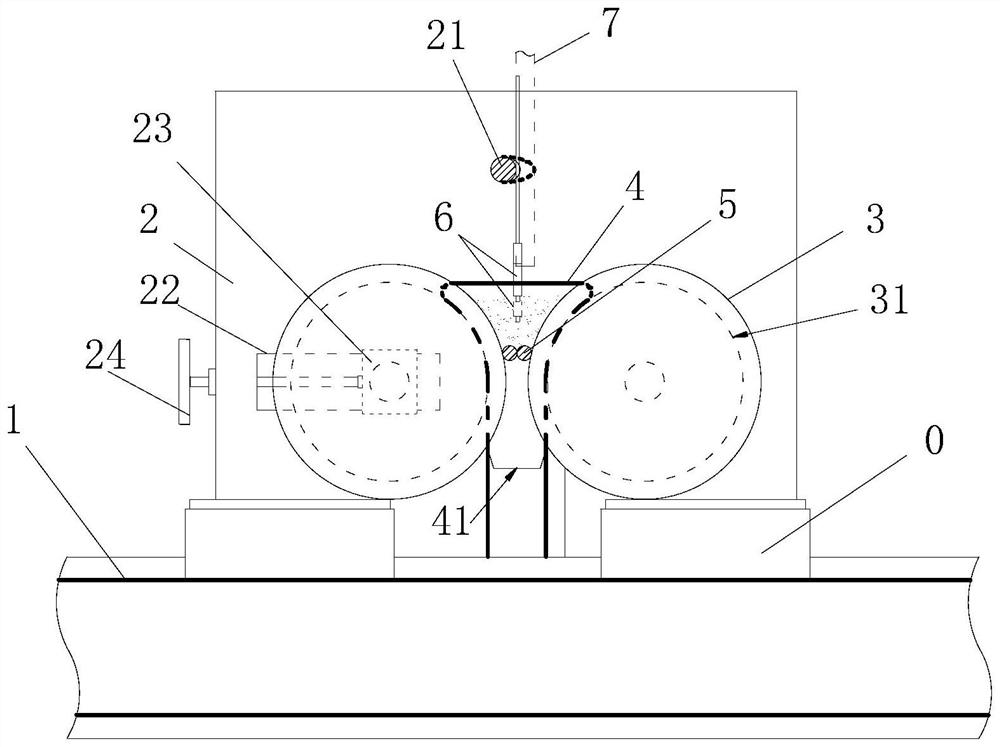

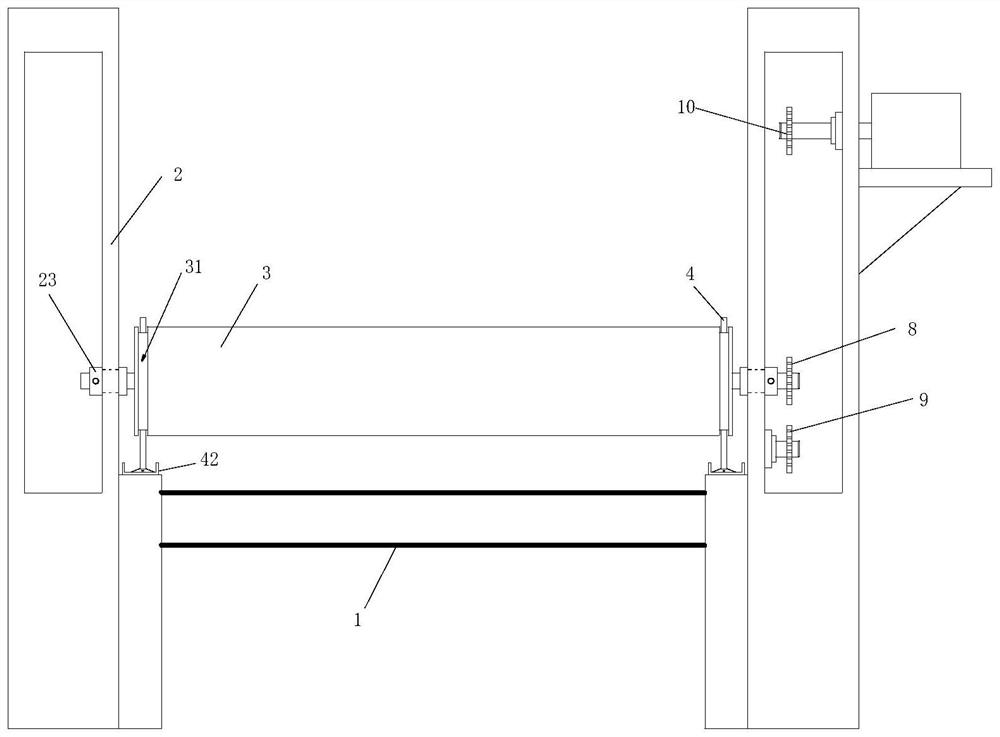

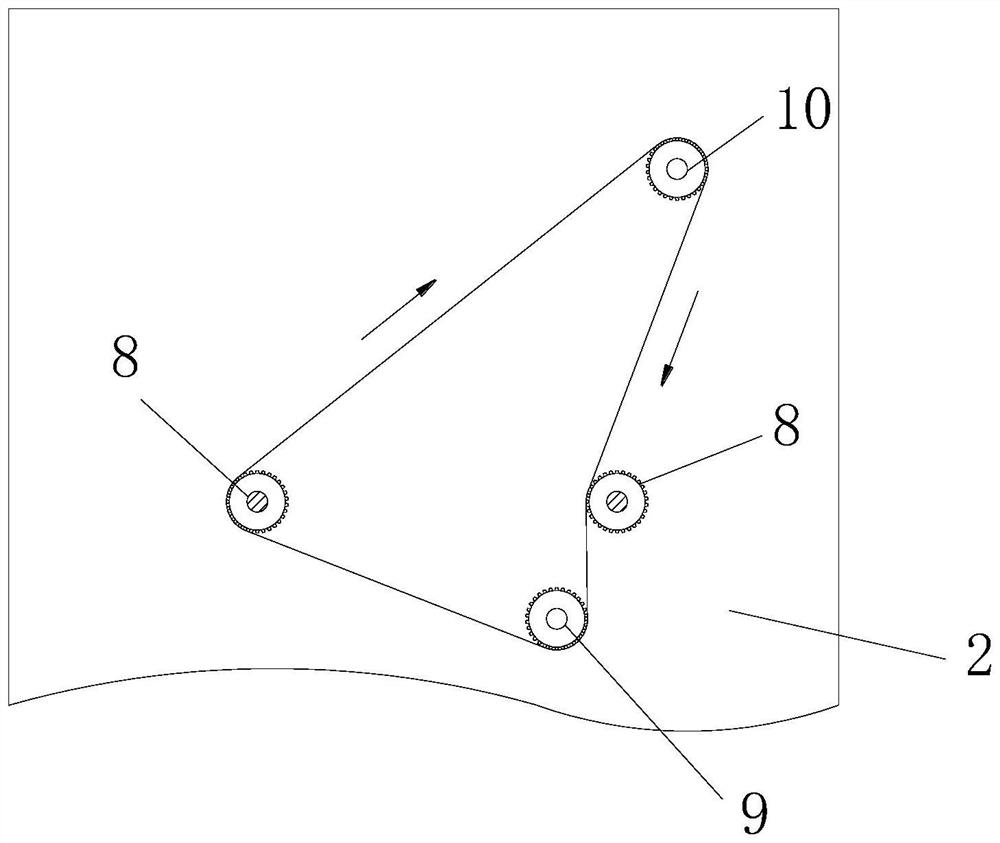

Glue storage type plywood gluing system

InactiveCN112264249ASave force stepsSave energyLiquid surface applicatorsCoatingsStructural engineeringCentrifugal force

The invention discloses a glue storage type plywood gluing system. The system comprises a gluing box, a material pushing conveying belt, an upper glue wheel and a lower glue wheel; the material pushing conveying belt is located outside the gluing box; the upper glue wheel and the lower glue wheel are located in the gluing box and are grouped; a coaxial fixed eccentric cylinder is arranged in the upper glue wheel; a corresponding upper glue storage box is arranged on one side of the upper glue wheel; and a glue feeding roller is arranged inside the upper glue storage box. According to the gluestorage type plywood gluing system, an existing gluing roller surface gluing mode is changed, gluing is conducted through glue storage in the glue wheels and the centrifugal force effect, gluing is efficient, meanwhile, gluing power comes from the moving force of a plywood, power sharing is achieved, the gluing and force applying steps can be effectively saved, and energy consumed by gluing is saved.

Owner:桃江县德聚人和中小企业公共服务平台有限公司

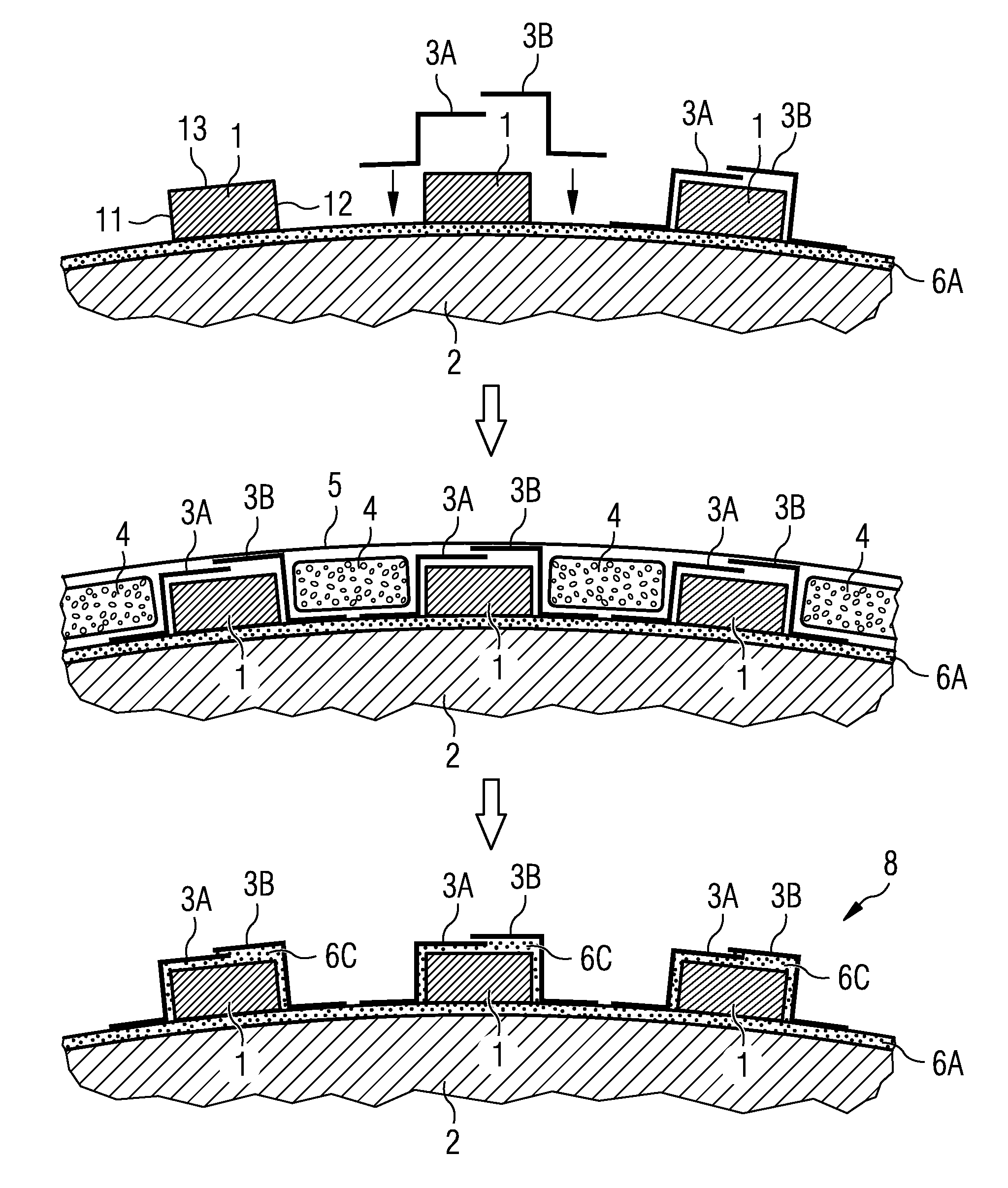

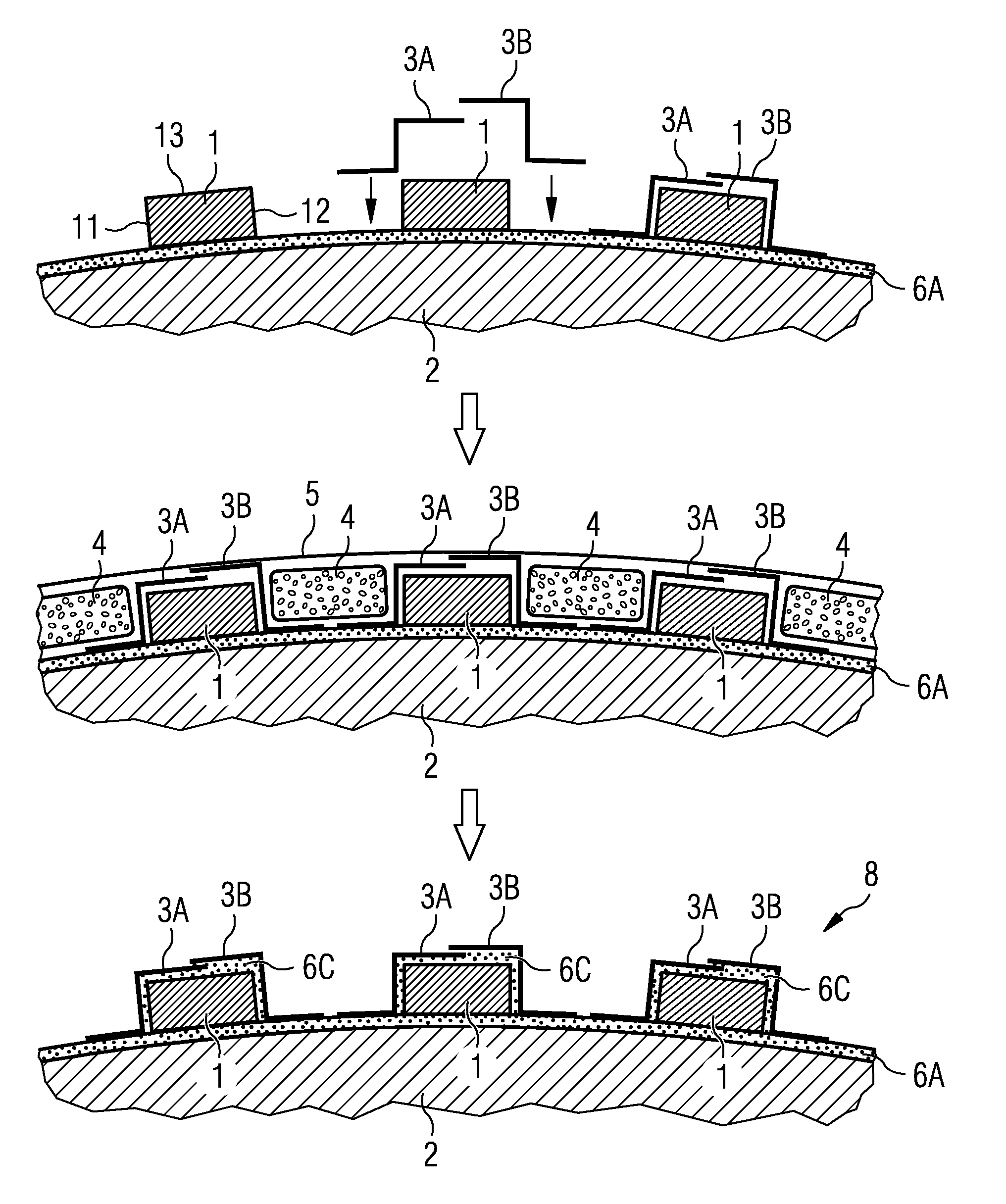

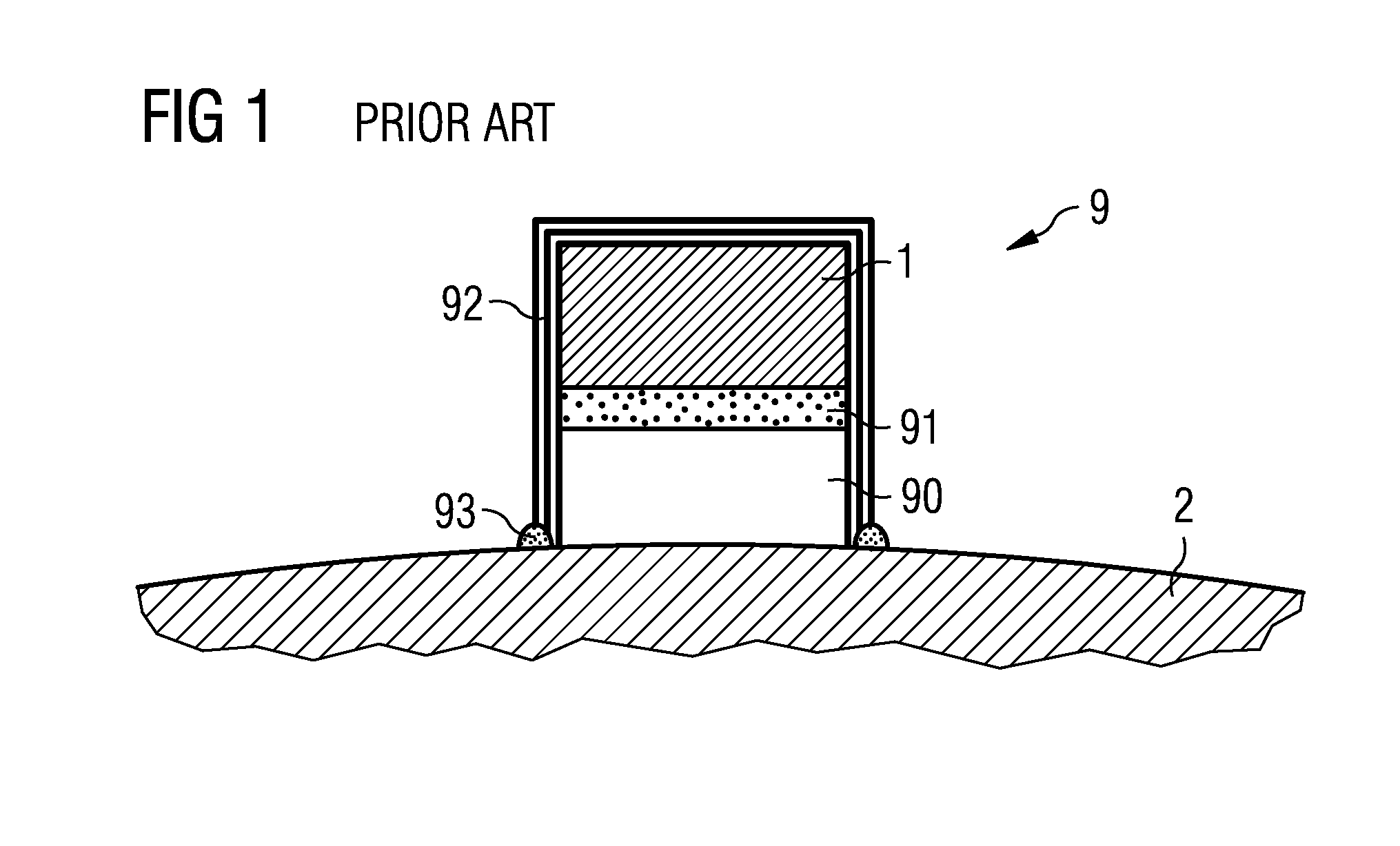

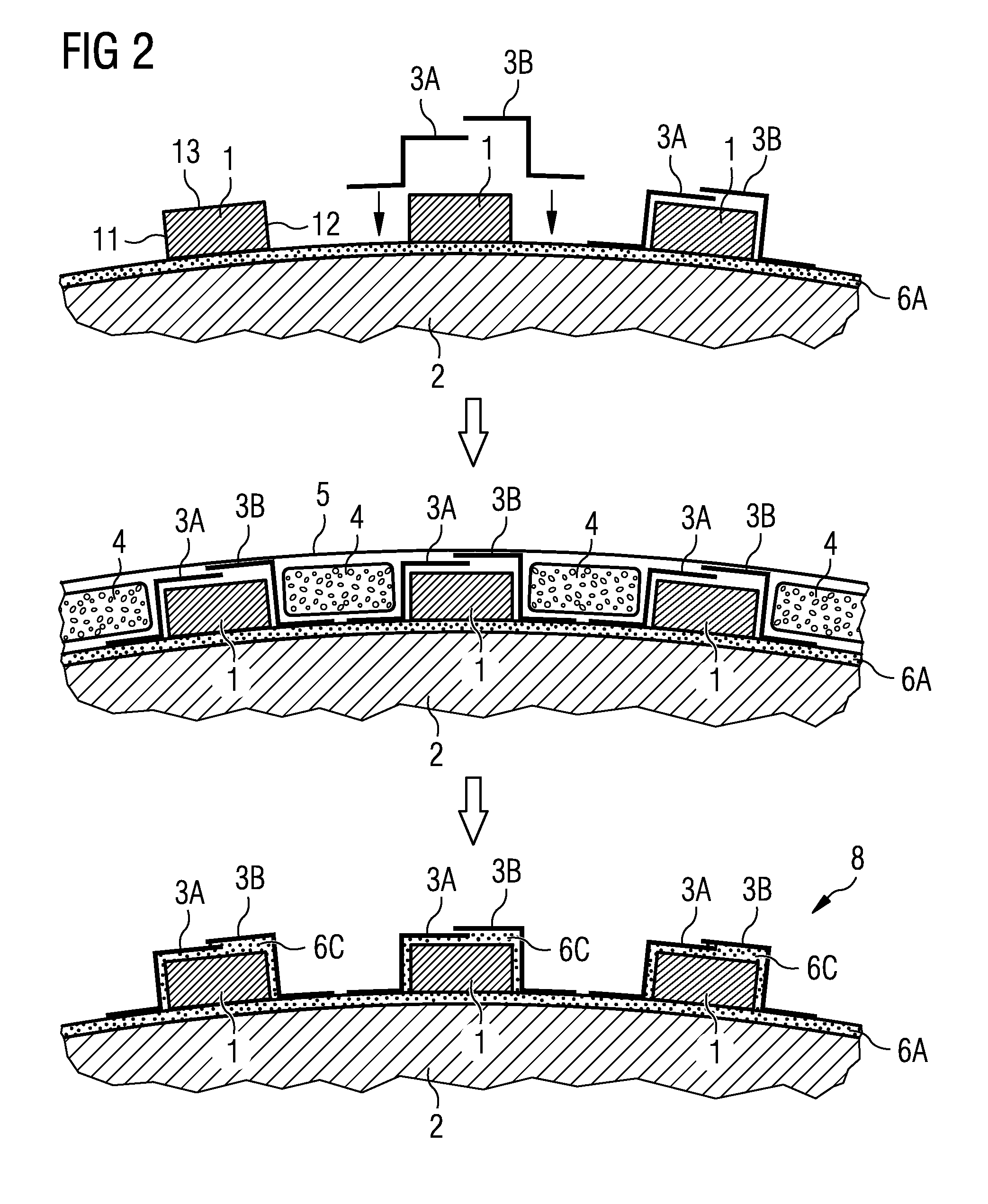

Method of attaching a magnet to a rotor or a stator of an electrical machine

InactiveUS20120326545A1Efficient gluingNot leaving too much leewayMagnetic circuit rotating partsSynchronous machinesAdhesiveElectric machine

A method of attaching a magnet to a rotor or a stator of an electrical machine is provided. The method includes arranging a magnet along a surface of the rotor or stator; arranging a pair of retainers, one on each side of the magnet; enclosing the rotor or stator, magnet and retainers in a vacuum bag; and performing vacuum evacuation to consolidate the magnet to the retainers by means of adhesive. A magnet mounting arrangement for a rotor or a stator of an electrical machine and a wind turbine with a generator including a rotor and a stator and such a magnet mounting arrangement are also provided.

Owner:SIEMENS AG

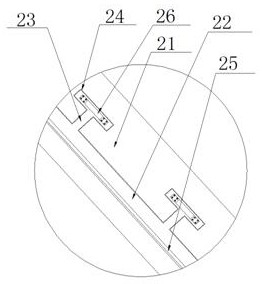

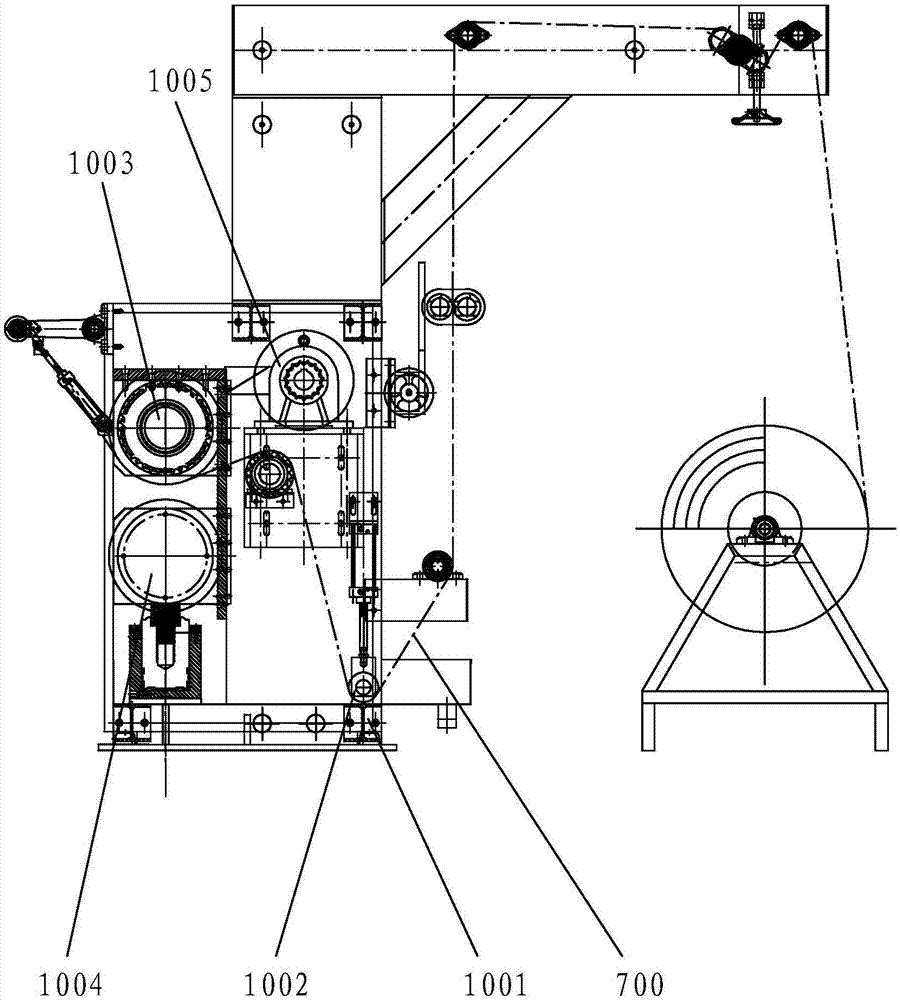

Cloth printing assembly line

PendingCN107053834AAchieve corrective effectEasy to printPrinting press partsAssembly lineEngineering

The invention provides a cloth printing assembly line. The cloth printing assembly line sequentially comprises a cloth feeding section, a first drying section, a printing section, a second drying section, a cooling section and a cloth collecting section in the cloth flowing direction. By means of the cloth printing assembly line, cloth can be effectively prepared before printing, and printing is facilitated; efficient correction of the cloth is achieved, ink can be added to a printing roller efficiently, the working state of a printing part can be switched conveniently, operation is flexible, and maintenance is convenient; and the printing roller can be driven independently in all directions, printing deviation in all the directions is overcome, efficient and uniform pulp ink scraping is conducted on the printing roller, the cloth is efficiently and fully dried before printing, a conveying belt is evenly glued, oil stains on the conveying belt are efficiently scrubbed, the conveying belt is efficiently cleaned, the printed cloth achieves effective drying and back face printing, the overall attractiveness effect and quality of the cloth are improved, the cloth is made more flat through cooling and extrusion, the whole assembly line is smooth and efficient in printing, the printing quality is greatly improved and practicability is high.

Owner:泉州市西格玛智能工业机械有限公司

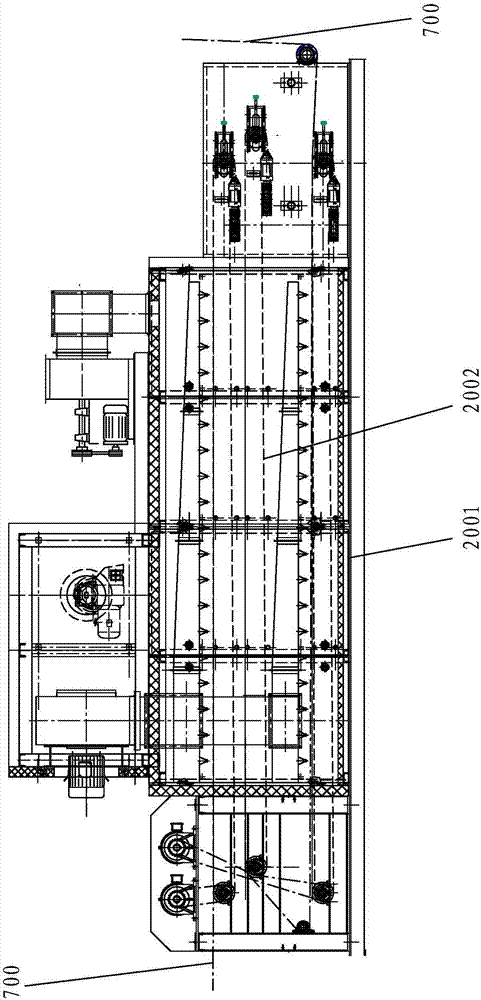

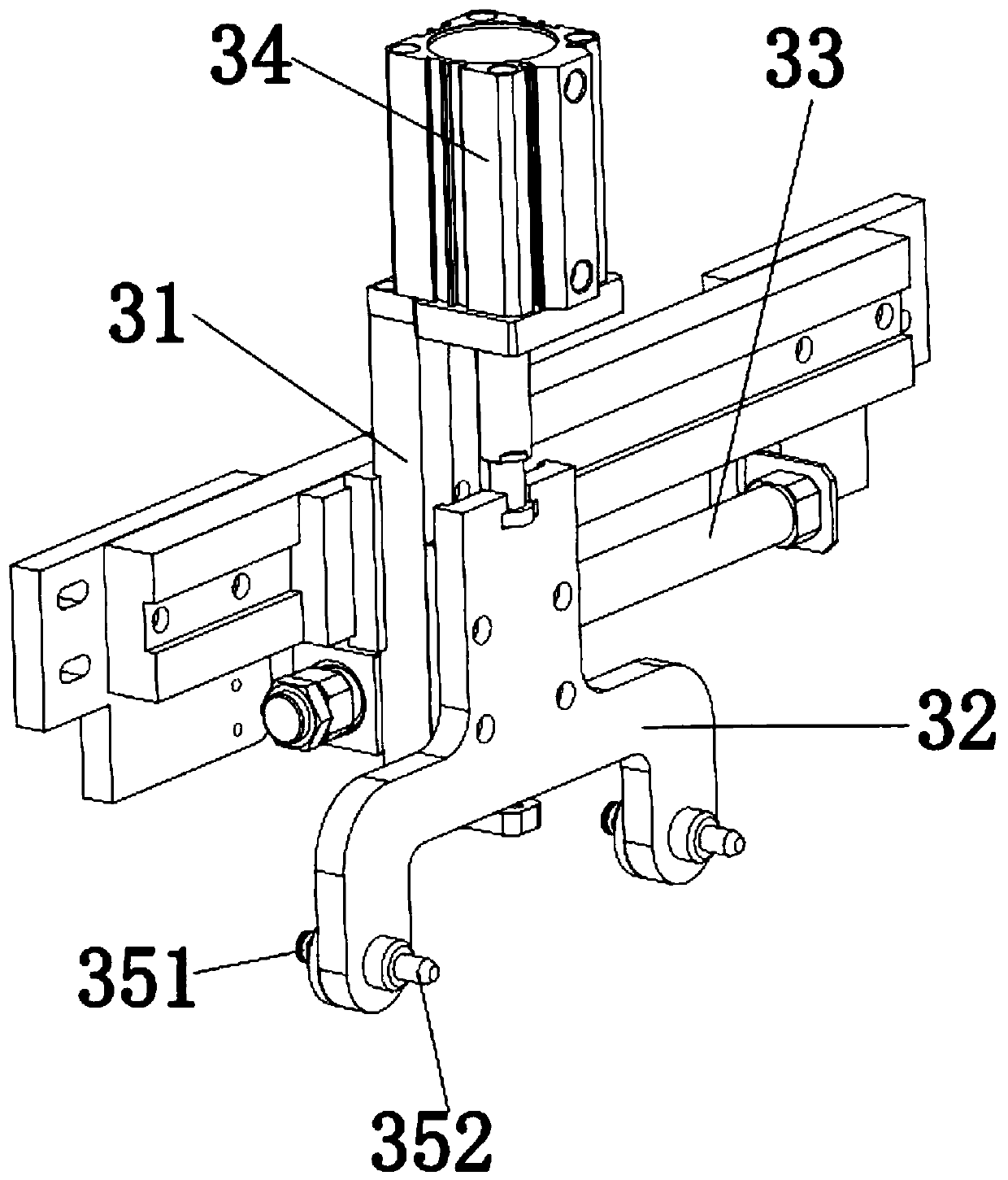

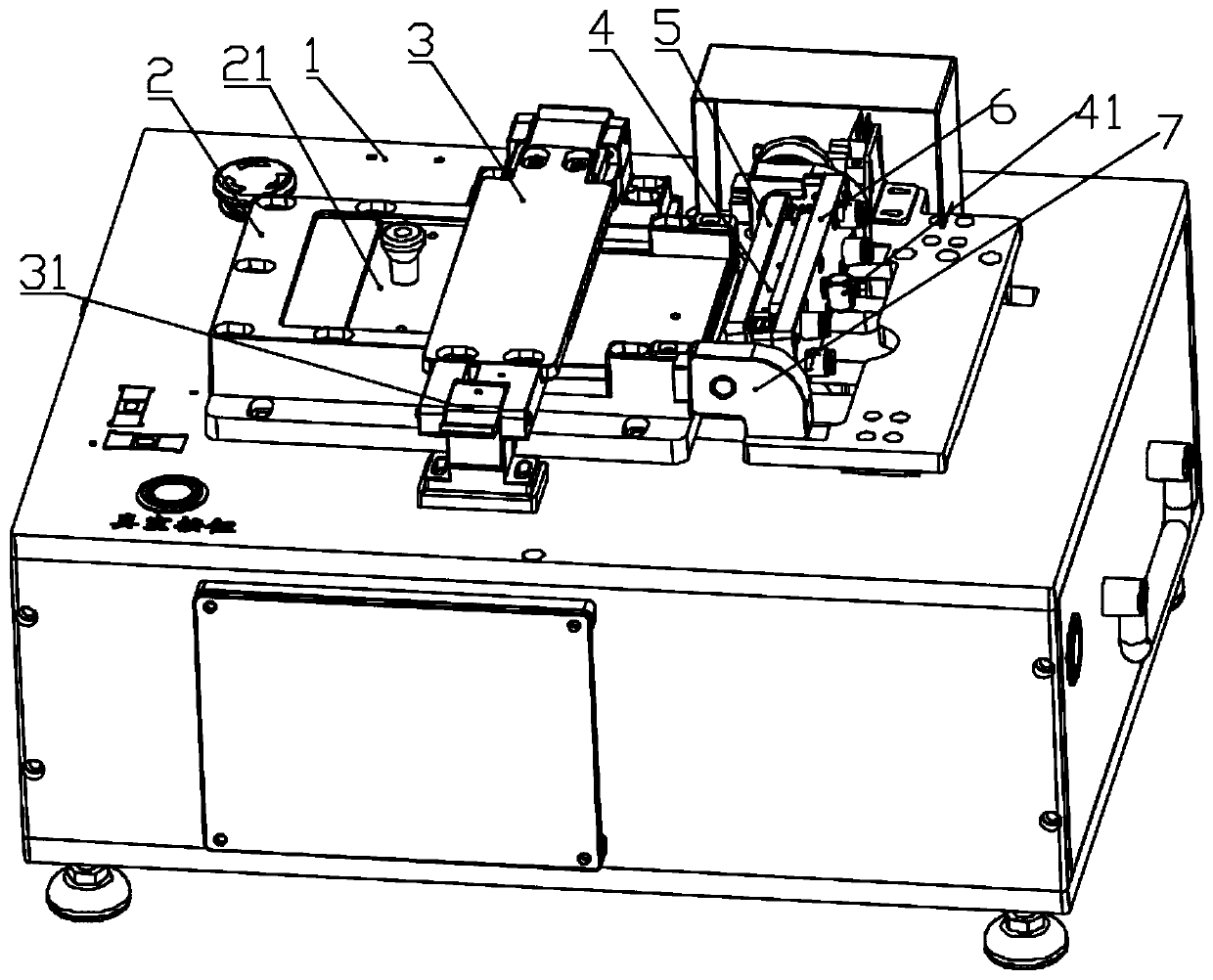

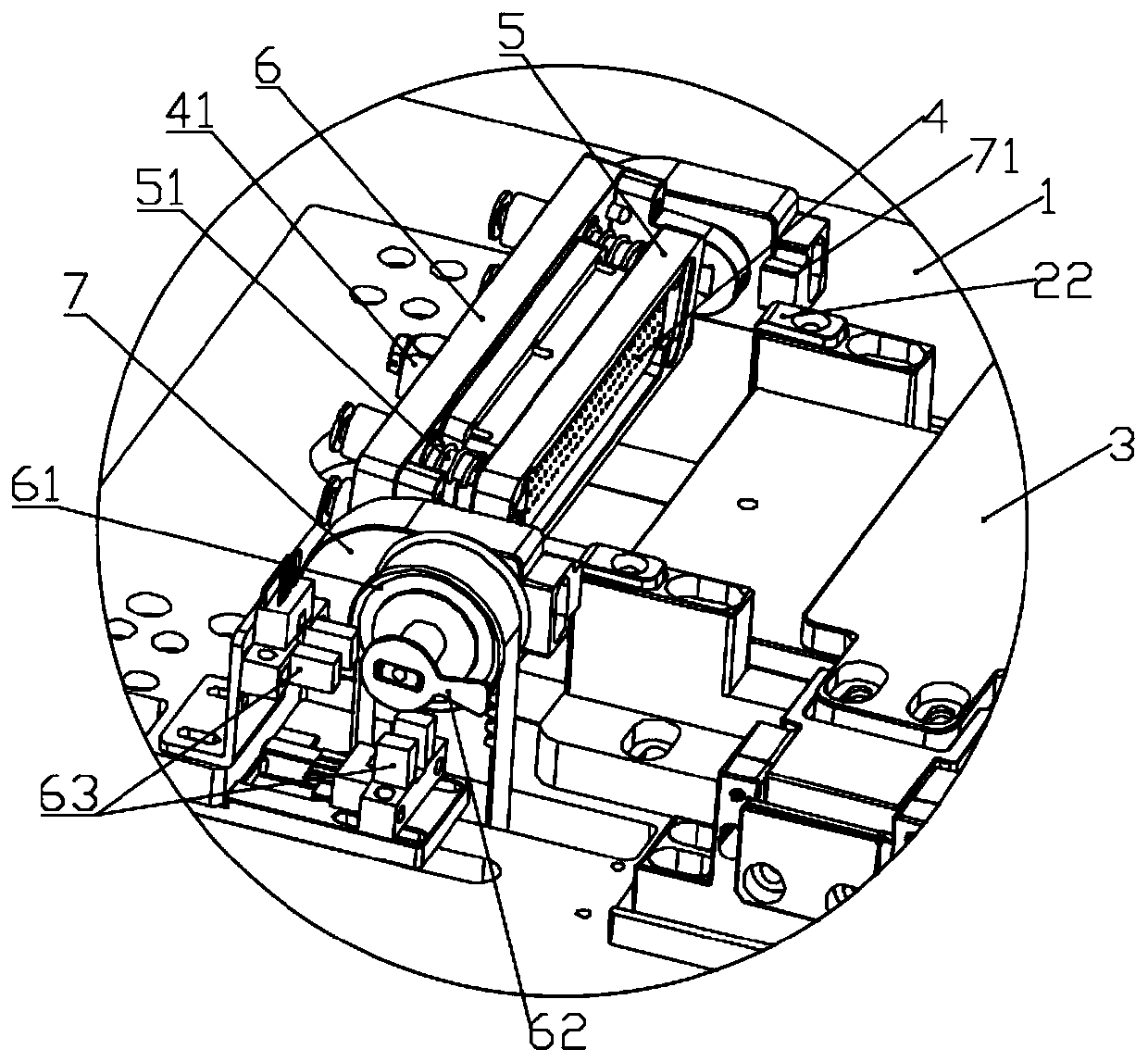

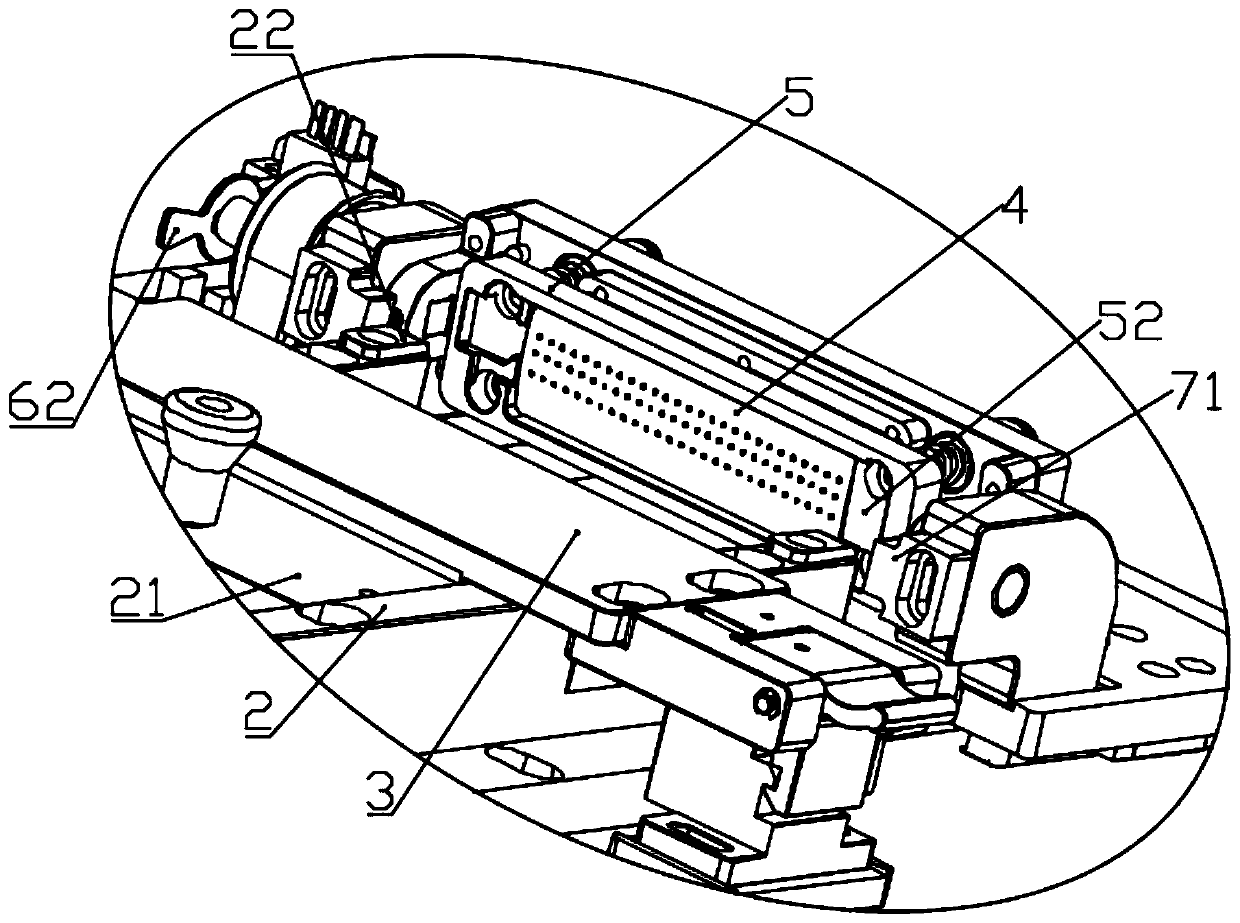

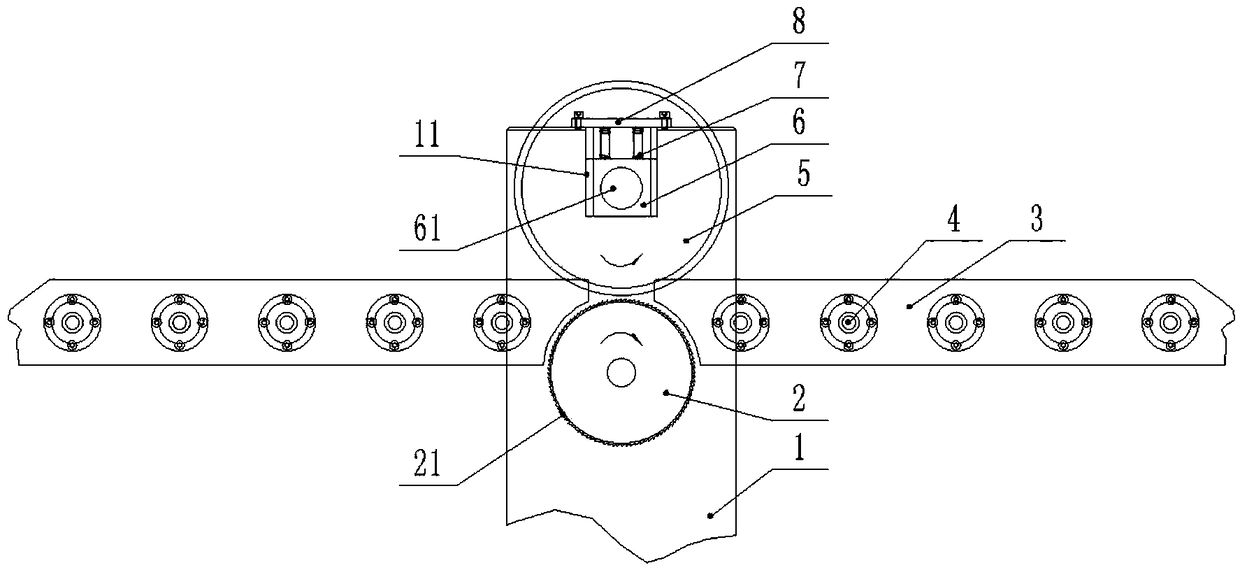

Automatic adhesive tape pasting module

The invention provides an automatic adhesive tape pasting module comprising a rack, and an adhesive tape stripping mechanism, an adhesive tape suction mechanism and a pasting mechanism which are arranged on the rack. The adhesive tape stripping mechanism comprises a tape dispenser, a pressing block arranged on the tape dispenser, a feeding shaft, a receiving shaft, an adhesive tape stripping motorused for driving the receiving shaft to rotate, and an adjusting knob component used for regulating the levelness of the receiving shaft. The adhesive tape stripping mechanism is used for stripping single-sided adhesive tapes, and the adhesive tape suction mechanism is used for sucking the single-sided adhesive tape; the pasting mechanism is used for pasting the single-sided adhesive tape on a product; the single-sided adhesive tape can comprise two rows; in this way, automatic adhesive tape stripping and pasting are achieved, and the adhesive tape pasting efficiency is high; backing paper ofa double-sided adhesive tape is pressed by the pressing block, and the receiving shaft is driven by the adhesive tape stripping motor to rotate so that the single-sided adhesive tape can be stripped,thereby facilitating adsorption of the adhesive tape suction mechanism; and the adjusting knob component is used for regulating the levelness of the feeding shaft and the receiving shaft and keepingthe single-sided adhesive tape horizontal.

Owner:SUZHOU WANXIANG TECH CO LTD

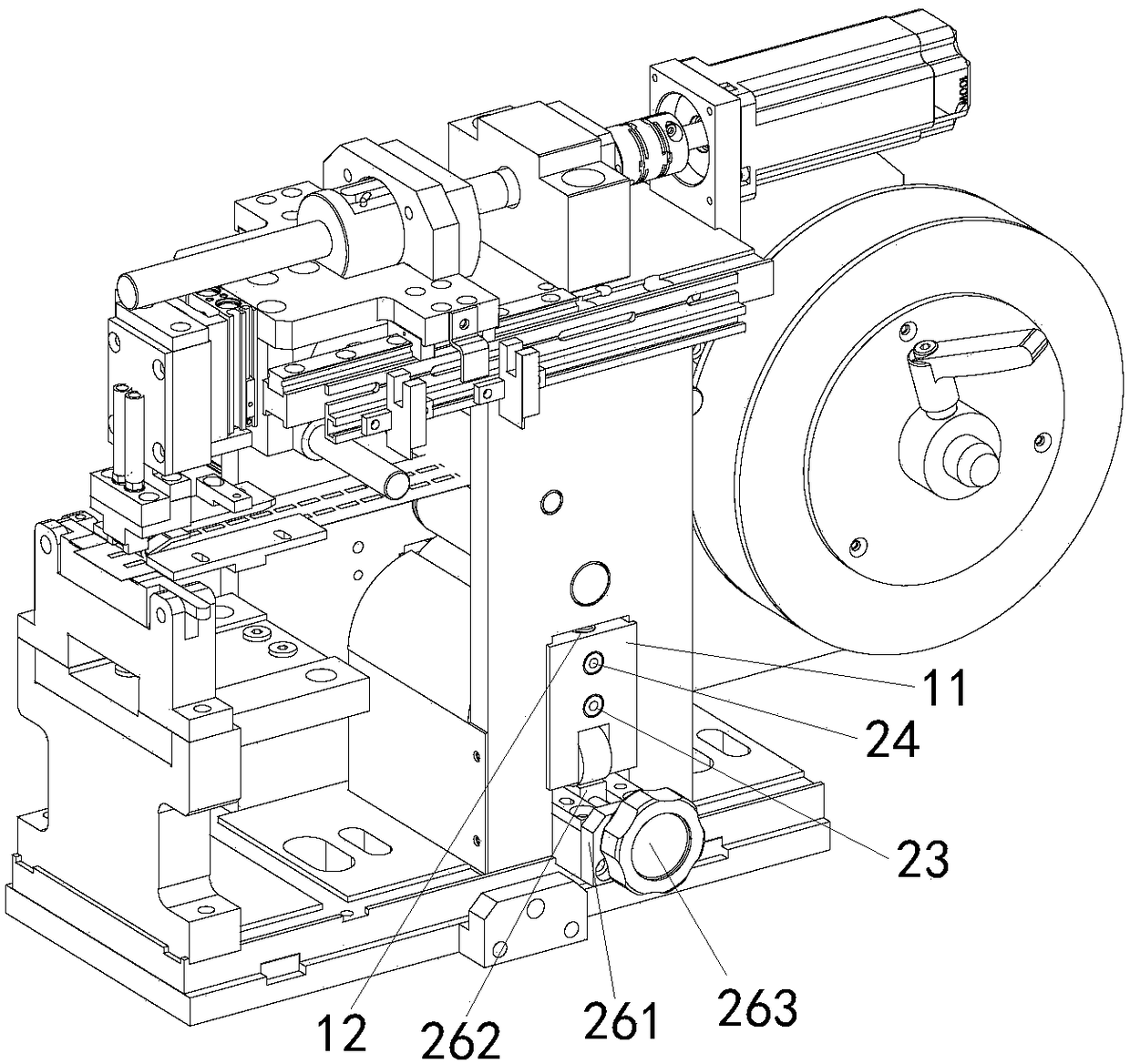

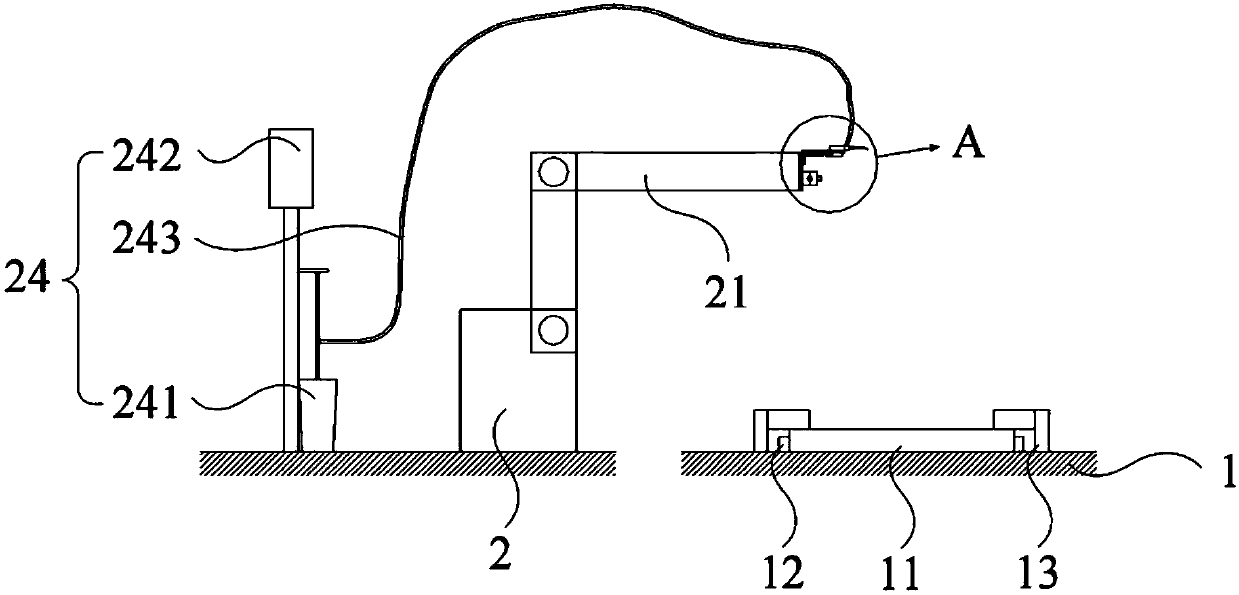

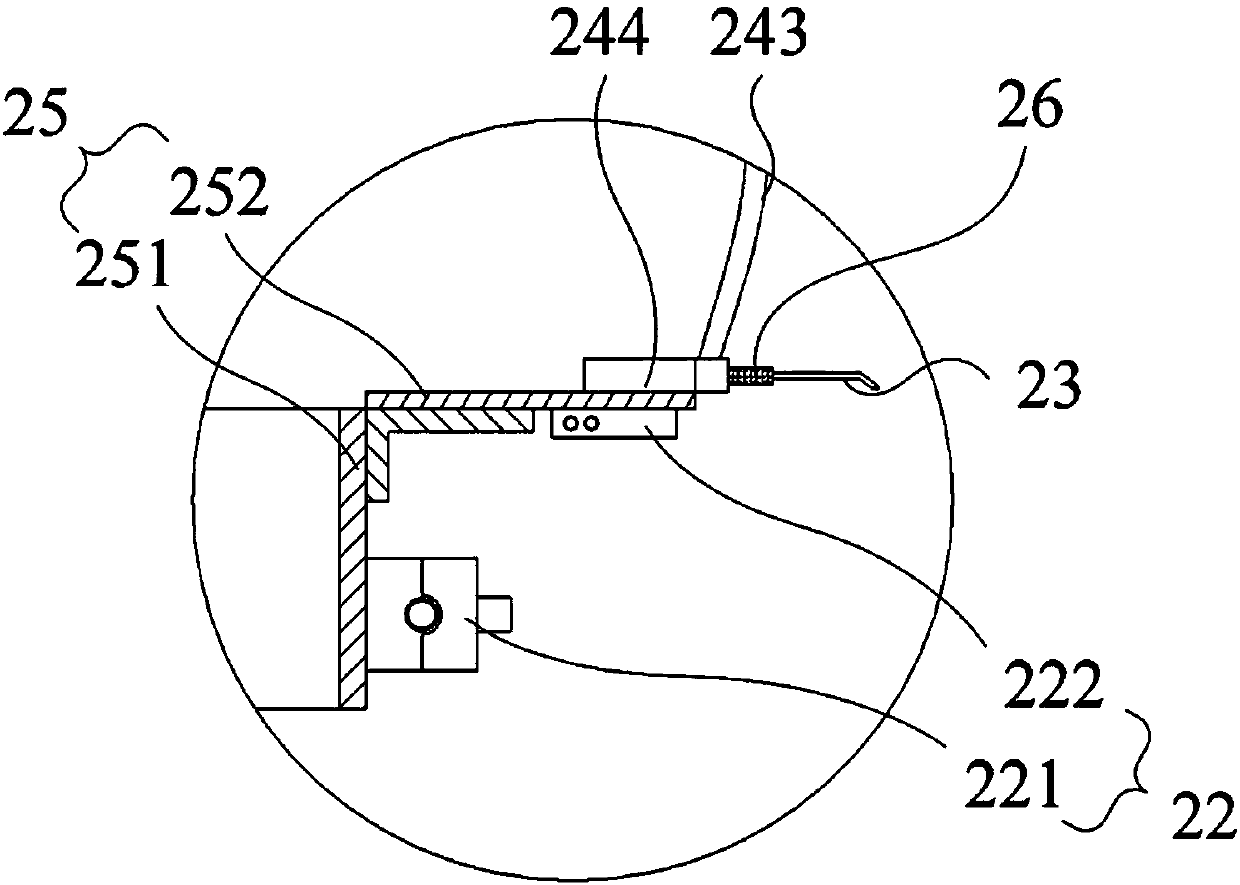

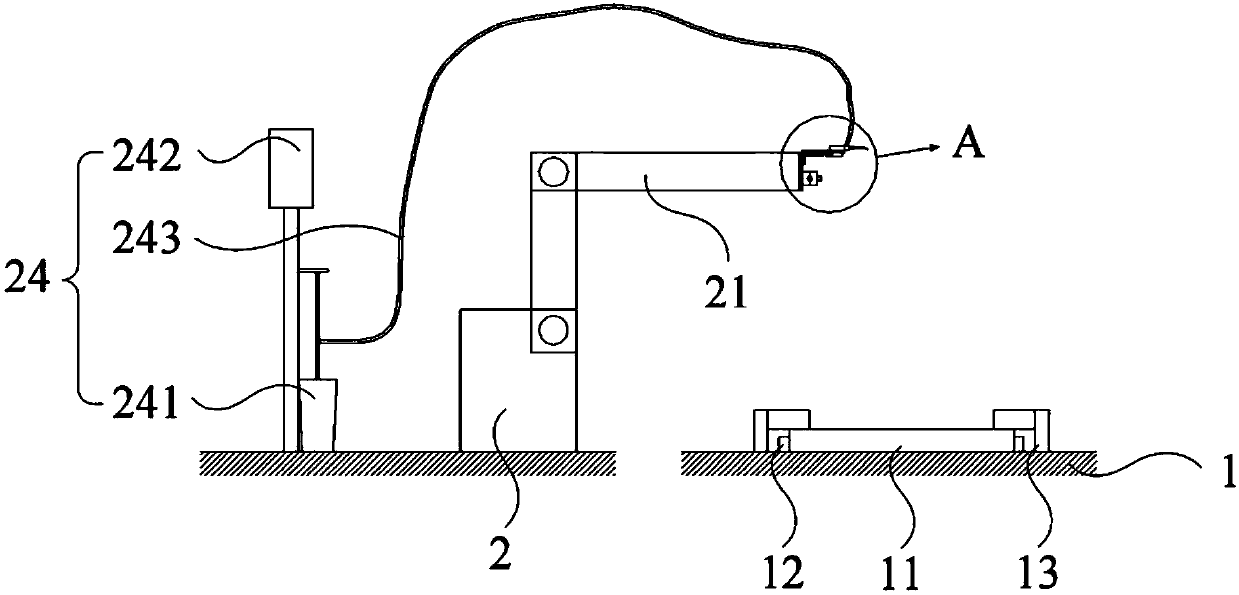

Robot gluing system and method

InactiveCN109985769AMore efficient and more reliable glue applicationSave the link of scraping glueLiquid surface applicatorsCoatingsEngineeringScratching

The invention provides a robot gluing system and method. The system comprises a workbench and a robot. A work station for loading a workpiece is arranged on the workbench. The robot is arranged on oneside of the workbench and is provided with a mechanical arm, and a control part and a glue gun head are arranged on the mechanical arm. The glue gun head is connected with a glue supply part, and thecontrol part is electrically connected with the glue supply part and used for controlling the glue supply part to supply glue to the glue gun head so that the glue gun head can output the glue. The control part is electrically connected with the mechanical arm and used for controlling the mechanical arm to move to the position over the work station to glue the workpiece. The method comprises thesteps that the workpiece is fixed to the work station of the workbench; the robot is operated to enable the mechanical arm to glue the workpiece at the position over the work station; and after gluingis finished, fireproof cloth is pasted on the surface, coated with a glue layer, of the workpiece. According to the robot gluing system and method, regular, quantitative and fixed-route gluing can beachieved precisely, a glue scratching link is omitted, and therefore gluing is efficient and reliable.

Owner:AULTON NEW ENERGY AUTOMOTIVE TECHNOLOGY GROUP +1

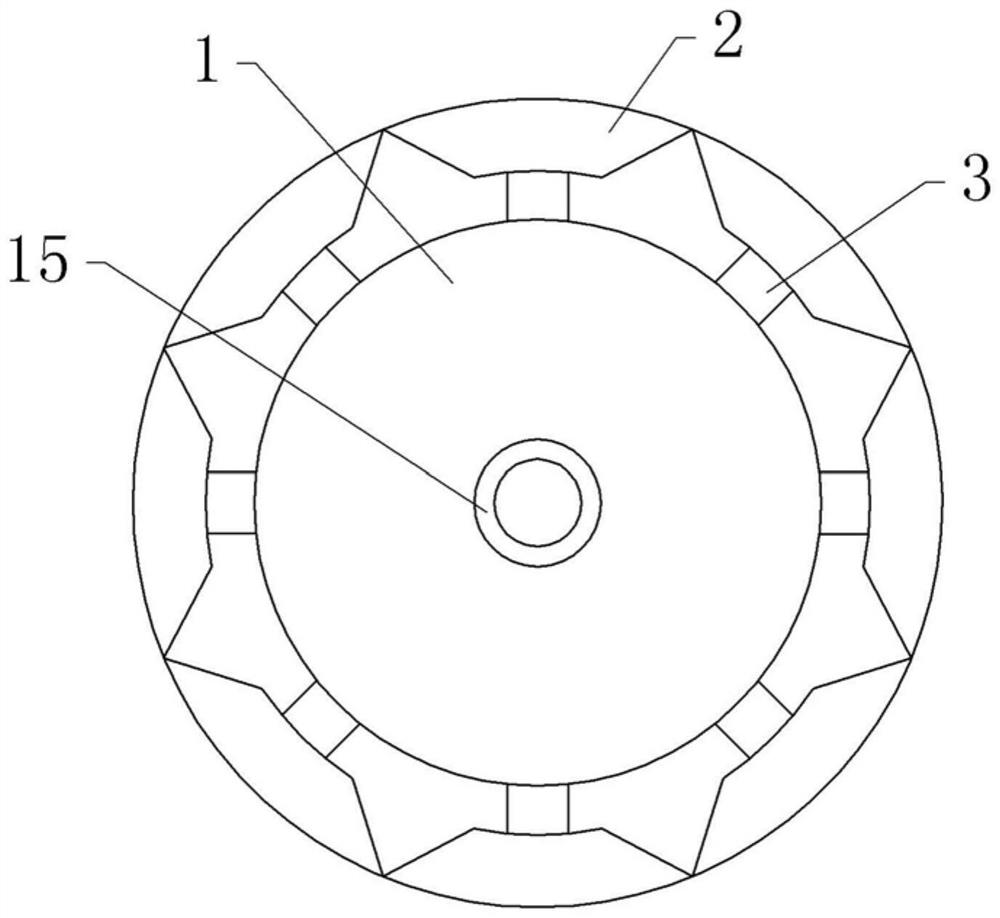

Method of attaching a magnet to a rotor or a stator of an electrical machine

InactiveUS9071104B2Not leaving too much leewayEfficient gluingMagnetic circuit rotating partsManufacturing stator/rotor bodiesAdhesiveEngineering

A method of attaching a magnet to a rotor or a stator of an electrical machine is provided. The method includes arranging a magnet along a surface of the rotor or stator; arranging a pair of retainers, one on each side of the magnet; enclosing the rotor or stator, magnet and retainers in a vacuum bag; and performing vacuum evacuation to consolidate the magnet to the retainers by means of adhesive. A magnet mounting arrangement for a rotor or a stator of an electrical machine and a wind turbine with a generator including a rotor and a stator and such a magnet mounting arrangement are also provided.

Owner:SIEMENS AG

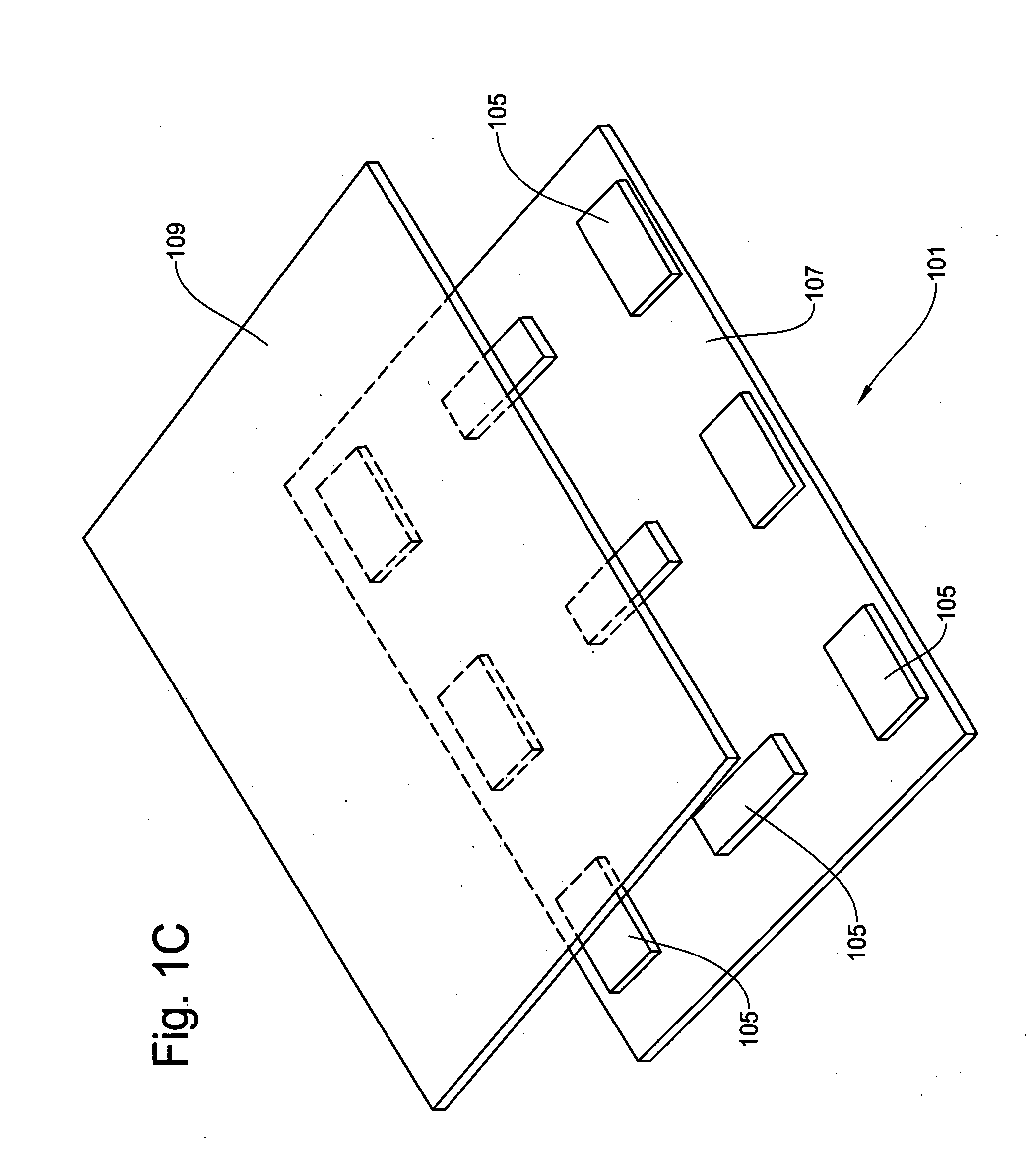

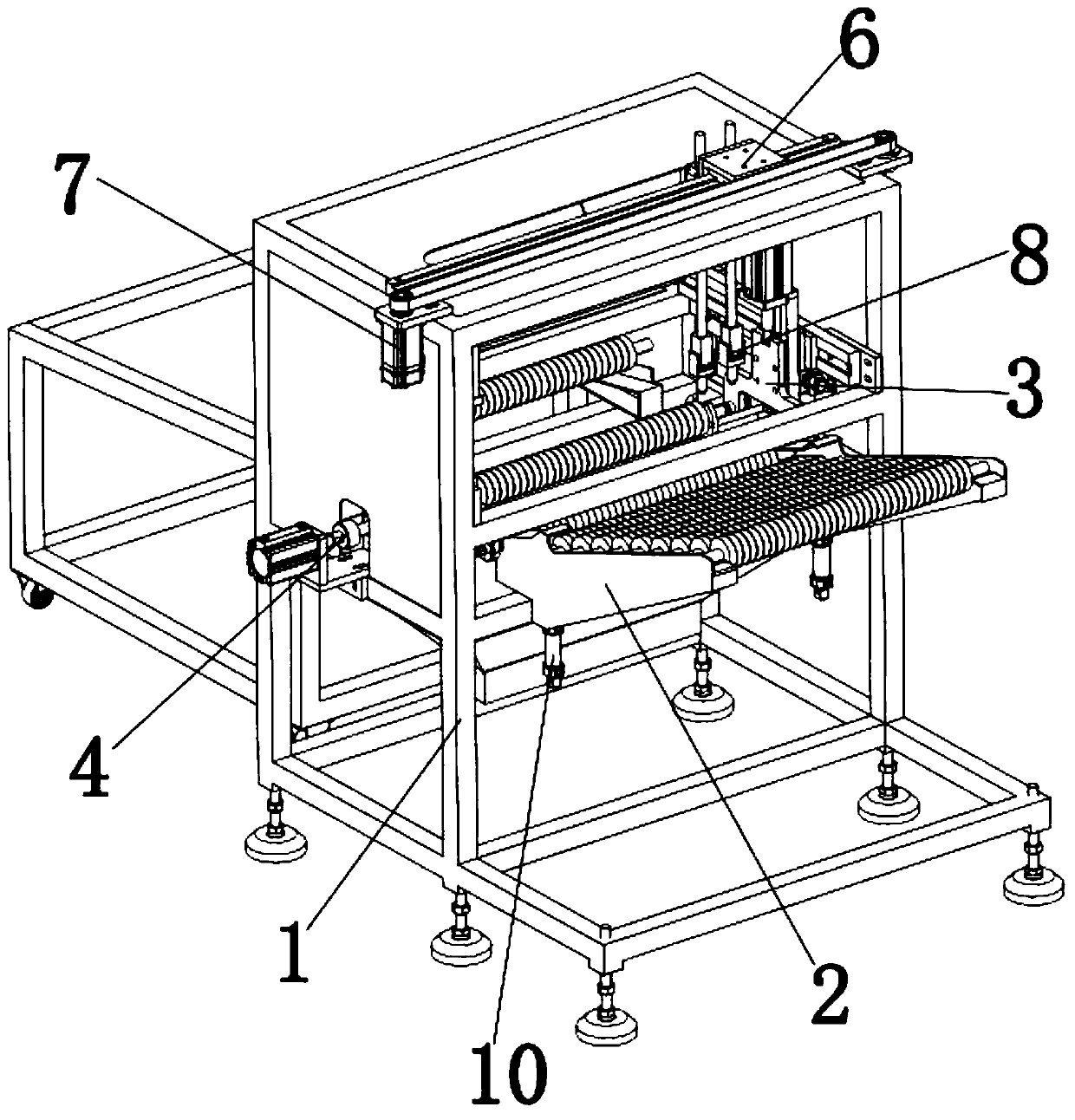

Loading pallet manufacturing apparatus

InactiveUS20080202696A1Increase production efficiencyDecrease production costManual label dispensersPaper/cardboard articlesMachine pressEngineering

A loading pallet manufacturing apparatus produces loading pallets made of recyclable material with high efficiency where the loading pallet is configured by a top plate, a bottom plate, and a plurality of beams. The loading pallet manufacturing apparatus includes beam cassettes having the beams therein, chucks that retrieve and transfer the beams and place the beams on the surface of the bottom plate, plate feed rollers for transferring the top and bottom plates, glue application rollers for applying the glue to the top and bottom plates, a press for pressing the top plate and the bottom plate with the beams therebetween, thereby bonding the top plate, beams, and the bottom plate to one another.

Owner:SHIMADA YUKO

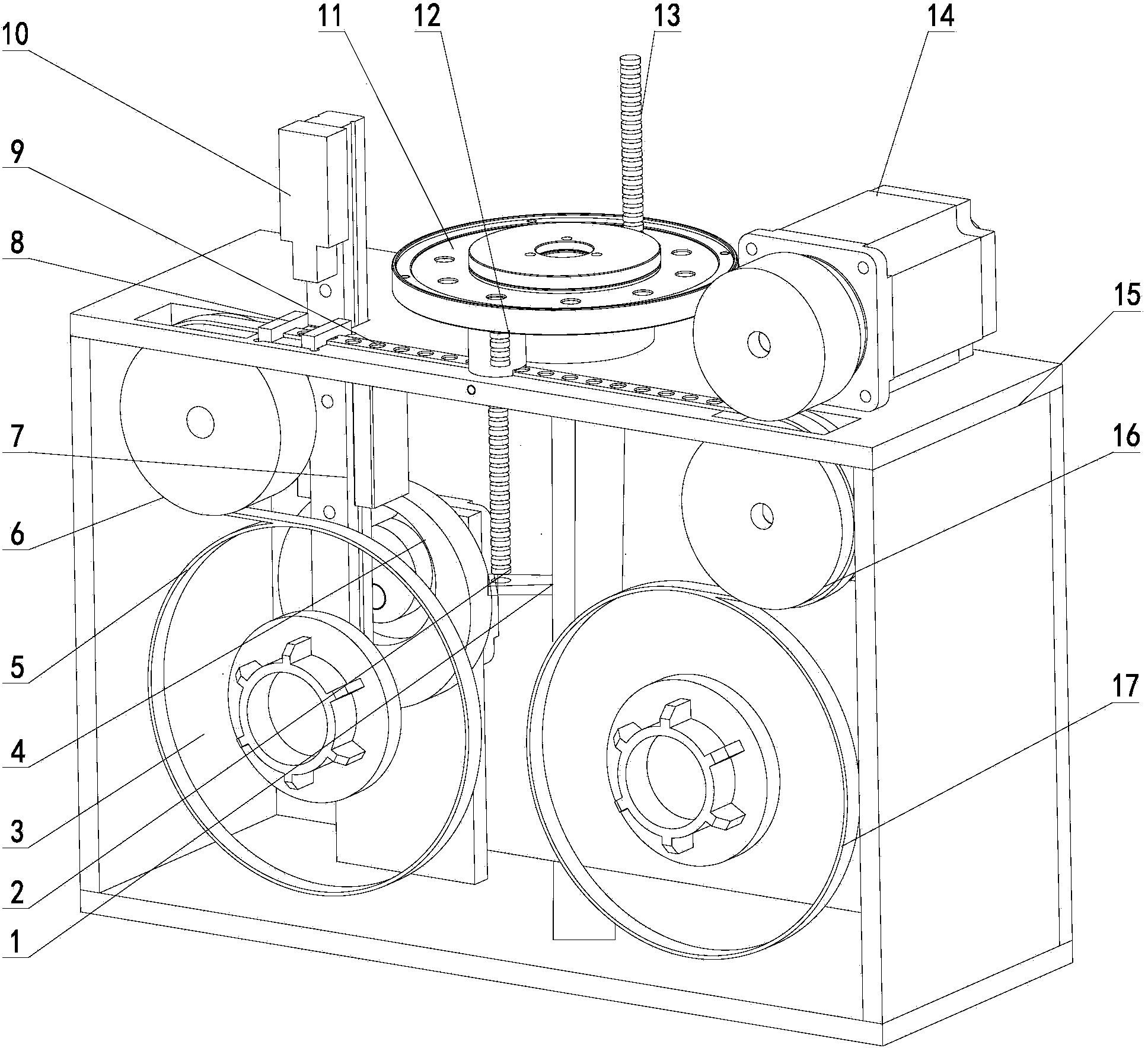

Glue spraying device for rollers

The invention relates to a glue spraying device for rollers. The device comprises a rack, a material placing seat, a transferring assembly, a rotary driving assembly, a glue spraying assembly and a receiving seat, wherein the rotary driving assembly is installed on the rack, the material placing seat and the receiving seat are arranged on the two sides of the rotary driving assembly, the transferring assembly is installed between the material placing seat and the receiving seat in a sliding mode, the glue spraying assembly is installed on the rack in a sliding mode, and the glue spraying assembly is located above the rotary driving assembly. By the adoption of the scheme, glue can be conveniently sprayed to the rollers, and production efficiency is high.

Owner:浙江智菱科技有限公司

Sealing glue pasting device

PendingCN111169729APlay a buffer roleAvoid damageWrapper twisting/gatheringRotational axisEngineering

The invention discloses a sealing glue pasting device. The sealing glue pasting device comprises a glue pasting assembly and a product fixing assembly. The glue pasting assembly comprises a glue pasting head, an overturning plate and a support, the glue pasting head is connected to the overturning plate, and the overturning plate is rotationally connected to the support; the glue pasting head is provided with a plurality of air holes which are communicated with a vacuum generating device and are used for adsorbing sealing glue; and the product fixing assembly comprises a product carrying plateand a cover plate used for fixing a product, the product carrying plate is provided with a product groove used for containing the product, and the support is connected with a turnover driving devicewhich is used for driving the support to slide relative to the product carrying plate. In the glue pasting process, a certain contact point of the glue pasting head and the product serves as the axis,the glue pasting head is rotated relative to the product, and deviation of the sealing glue from the product is avoided; moreover, as the sealing glue connecting surface of the glue pasting head is an arc of which the arc surface is parallel to the rotating axis of the overturning plate, air between the sealing glue and the product can be sequentially extruded from the central position of the sealing glue to the two sides through the arc surface, and bubbles are prevented from being generated.

Owner:昆山铭世特智能科技有限公司

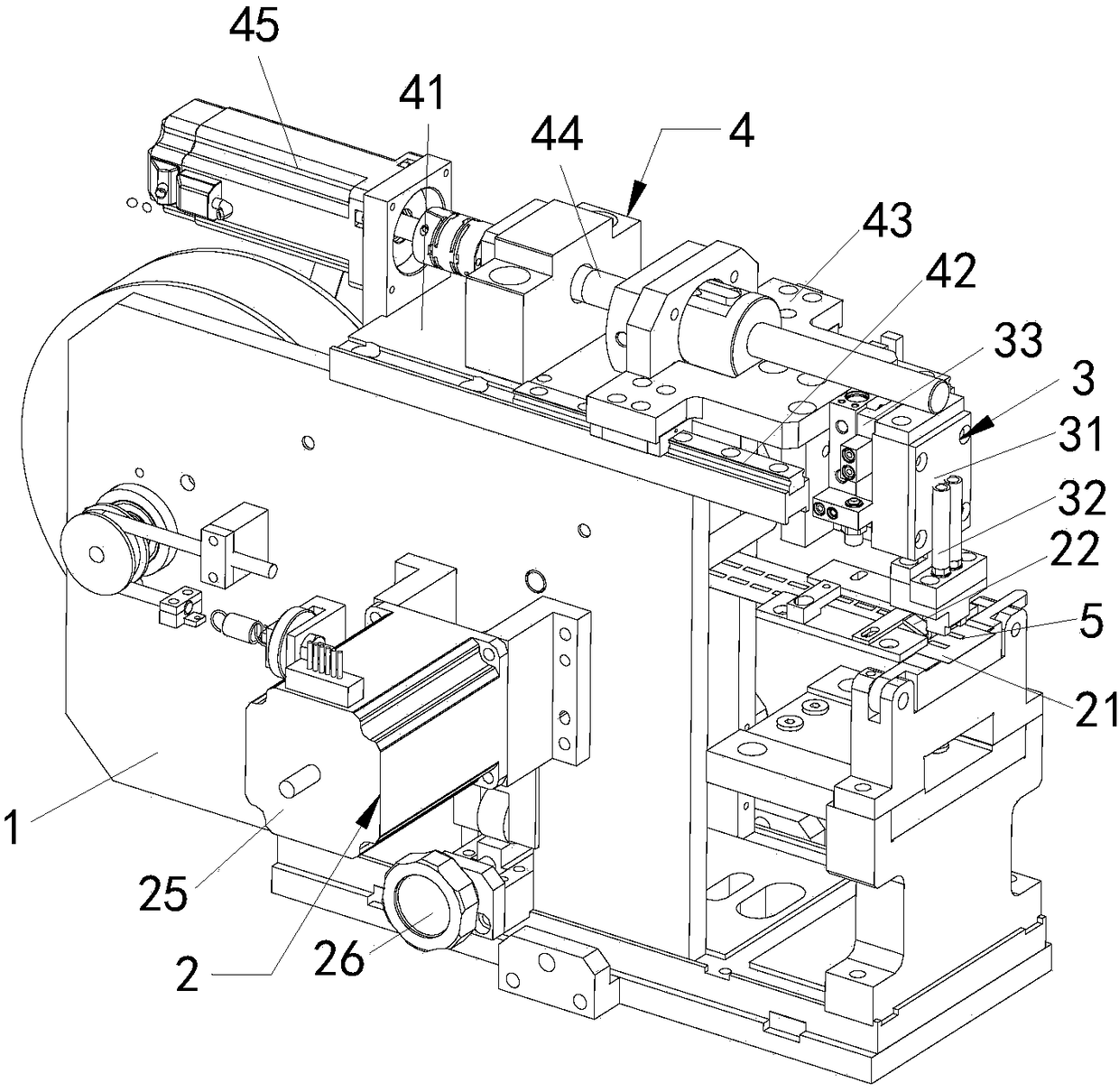

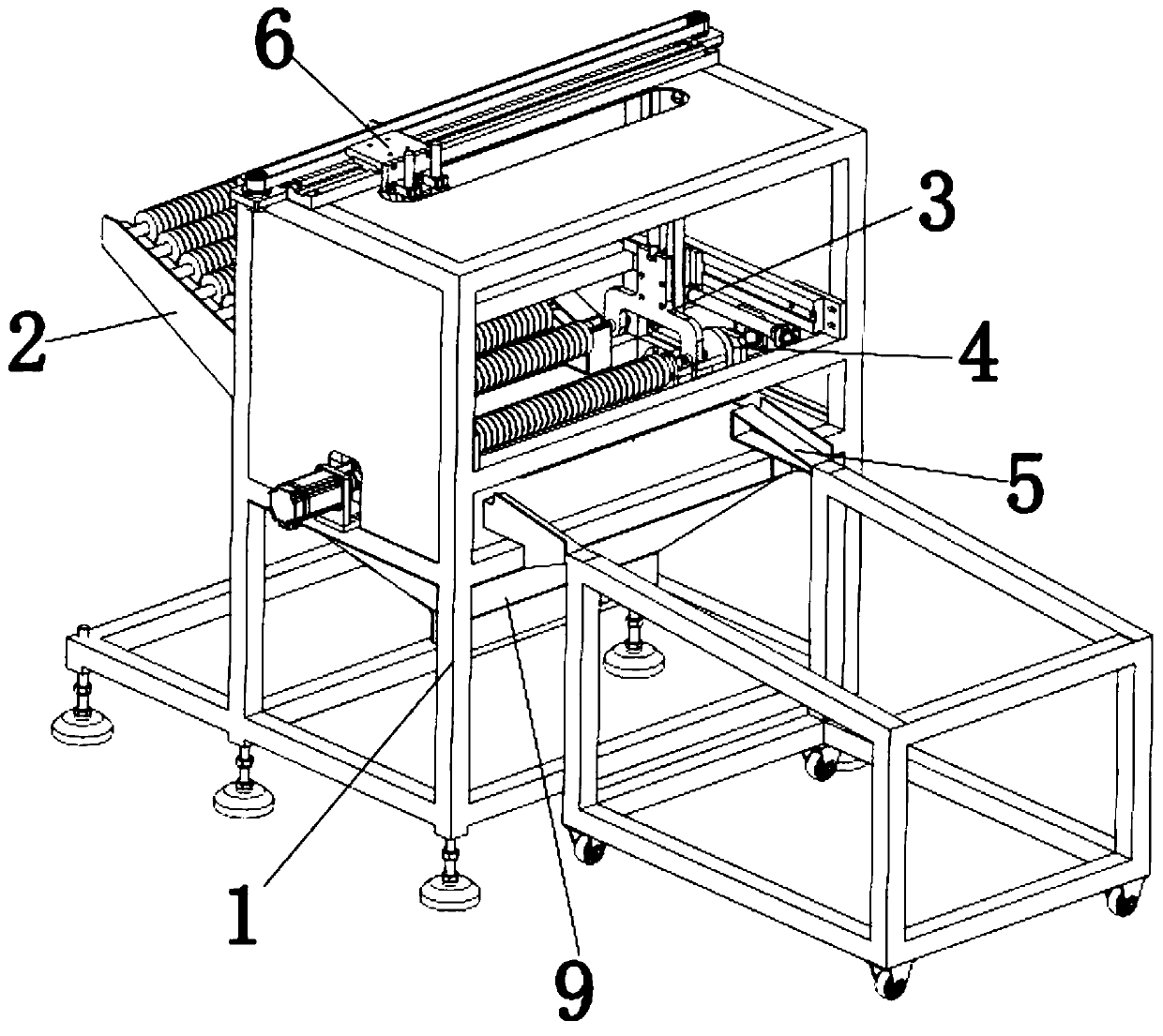

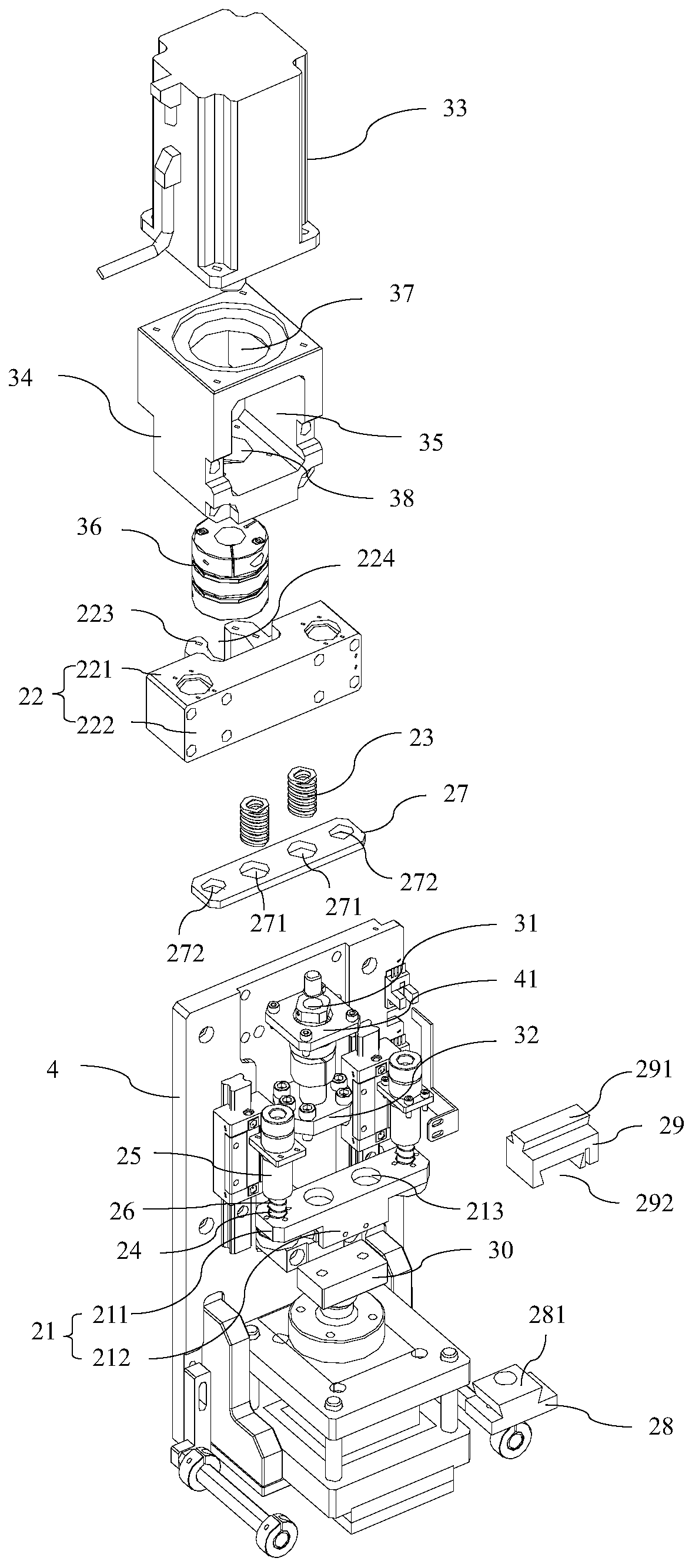

A multi-dimensional frame gluing equipment

ActiveCN106862014BImprove gluing efficiencyApply glue evenlyLiquid surface applicatorsCoatingsFixed frameAdhesive glue

The invention provides multi-dimensional frame gluing equipment which comprises a gluing gun, a three-dimensional movement device, a frame adjustment device and a material feeding device. The gluing gun is installed on the three-dimensional movement device, and the three-dimensional movement device can drive the gluing gun to move forwards and backwards, leftwards and rightwards and up and down; the frame adjustment device is installed on the front side of the three-dimensional movement device, and the frame adjustment device can fix a frame and adjust the angle of the frame relative to the gluing gun; the material feeding device is connected with the gluing gun through a pipe and can convey glue to the gluing gun to perform gluing on the frame. By the adoption of the multi-dimensional frame gluing equipment, gluing action can be completed rapidly and efficiently, the gluing process of a frame filter can be mechanized, manpower and materials are greatly reduced, product quality is guaranteed, and gluing efficiency of the frame filter is improved.

Owner:广州金田瑞麟环境科技有限公司

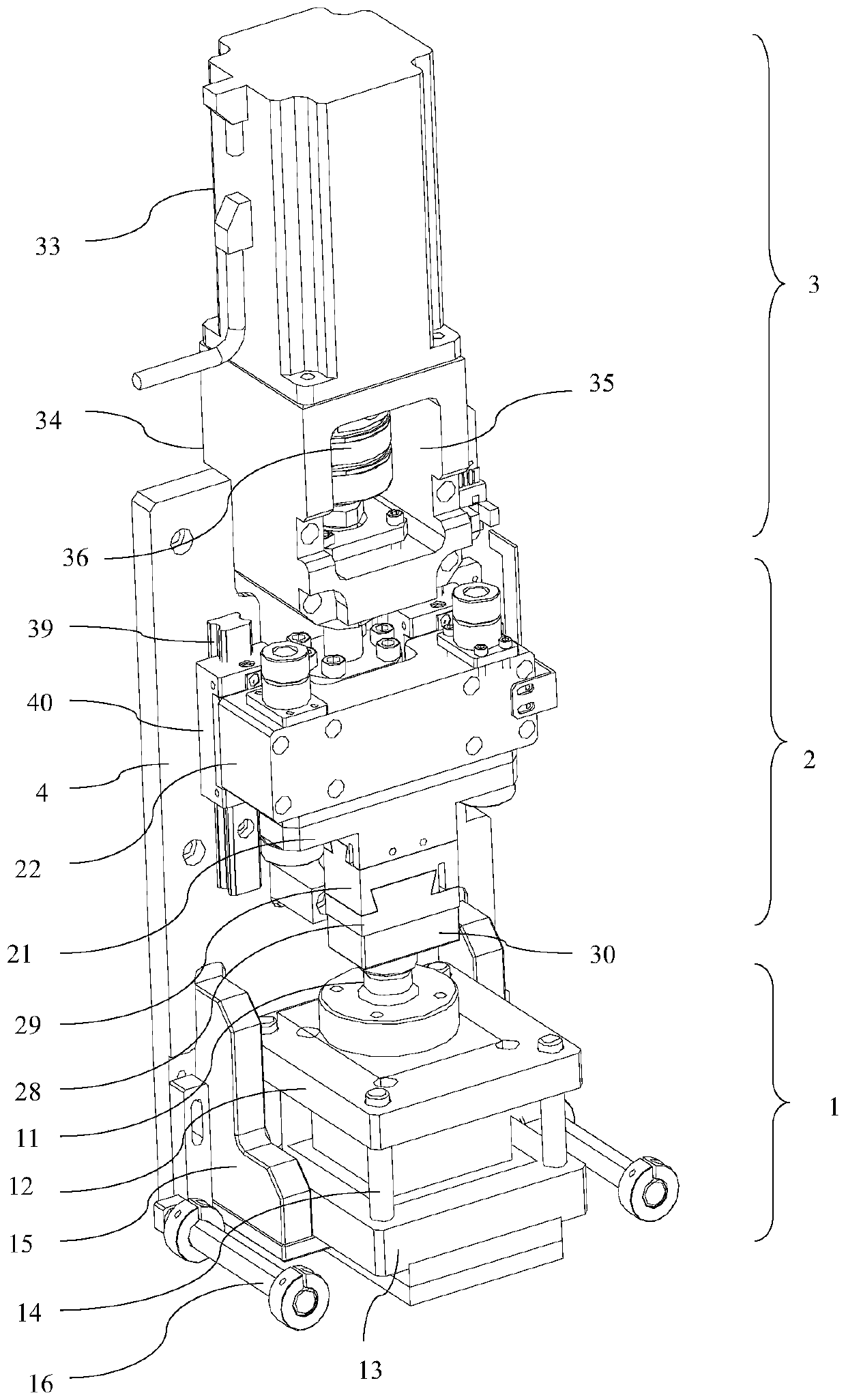

Magnet back adhesive tape bonding machine

InactiveCN104291146AAccurate locationHigh degree of automationLabelling flat rigid surfacesArticle deliveryAdhesive beltButt joint

The invention discloses a magnet back adhesive tape bonding machine. The magnet back adhesive tape bonding machine comprises a base, a material distribution disk fixed to the top of the base and used for material distribution of magnets, adhesive tape installing disks fixed to the base and used for storing adhesive tape, adhesive tape uncoiling guide wheels used for pushing and guiding the adhesive tape, an adhesive tape die cutting device and an adhesive tape pulling device, wherein the adhesive tape die cutting device and the adhesive tape pulling device are fixed to the top of the base, a plurality of material distribution holes are formed in the material distribution disk, a material falling hole can be in butt joint with the material distribution holes and adhesive tape die cutting pieces is formed in the upper portion of the base, and a lifting mechanism used for pressing and separating the magnets from the adhesive tape die cutting pieces is arranged below the material falling hole. The magnet back adhesive tape bonding machine further comprises a driving device used for driving the adhesive tape die cutting device, the material distribution disk, the lifting mechanism and the adhesive tape pulling device. The magnet back adhesive tape bonding machine can automatically complete die cutting, feeding, magnet separation and magnet adhesive tape bonding of double-sided adhesive tape, is high in automation degree, efficient in adhesive tape bonding and accurate in position, and avoids pollution caused by manual operation so that product quality can be guaranteed.

Owner:SHENZHEN CIYAN MAGNET TECH

Gluing device for paper tray feet

PendingCN114472051APrevent overflowEfficient gluingLiquid surface applicatorsCoatingsEngineeringLiquid level sensor

The invention discloses a gluing device for paper tray feet, which comprises a conveying device for conveying the tray feet and a mounting rack fixed on two sides of the conveying device, the inner side of the mounting rack is connected with two glue rollers which rotate oppositely through a driving mechanism, the two glue rollers are arranged in an attached manner and form a cavity for containing glue liquid, a gluing pipe is arranged above the cavity, and the gluing pipe is connected with the conveying device. The gluing pipe is connected with the pump body and is used for pumping glue; and two vertically arranged liquid level sensors with different heights are also arranged in the cavity, and are matched with the control panel to control the gluing work of the pump body. According to the gluing device for the paper tray feet, the two gluing rollers attached to each other are adopted for gluing the tray feet conveyed at the bottom, and glue can be supplied automatically.

Owner:海宁市华升包装有限公司

Sign board gluing process

ActiveCN112827774AGood effectImprove uniformityLiquid surface applicatorsCoatingsMechanical engineeringIndustrial engineering

The invention belongs to the technical field of methods for coating a surface with liquid or fluid, and discloses a sign board gluing process. The sign board gluing process comprises the following steps of 1, primary coating is conducted, specifically, a gluing roller is attached with glue and rolls on the surface of a sign board to complete primary gluing on the sign board; and 2, secondary coating is conducted, specifically, the gluing roller attached with the glue is utilized to roll along the surface, coated with the glue, of the sign board to complete secondary gluing on the sign board, so that gluing on the sign board is completed. The problem that in the prior art, a gluing machine is adopted for completing gluing of the sign board, and thus the cost is too high is solved.

Owner:CHONGQING PINGAN SCUTCHEON FACTURE

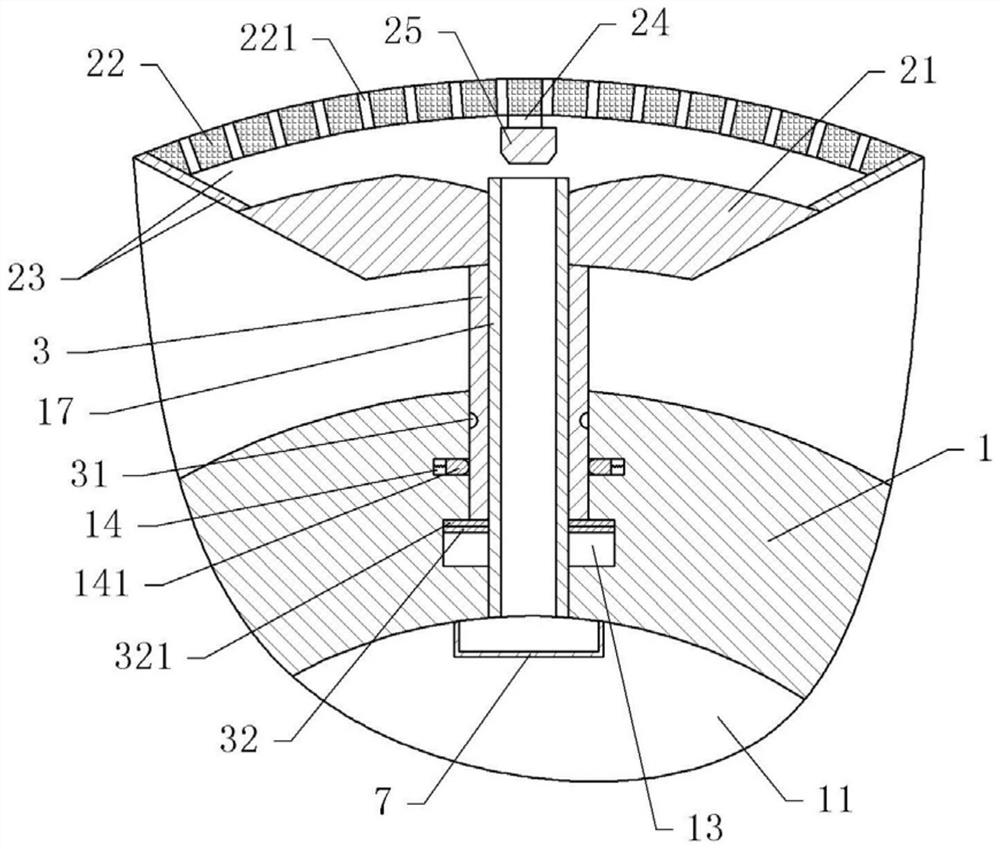

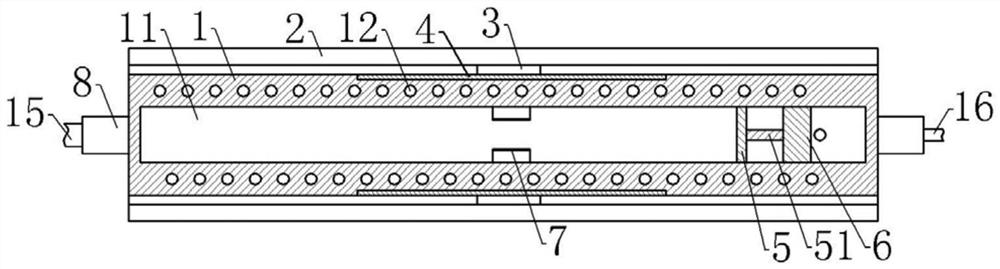

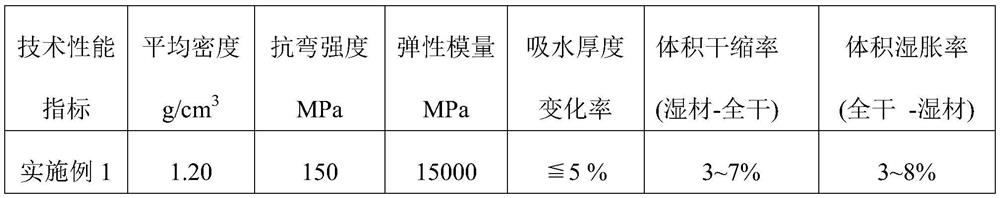

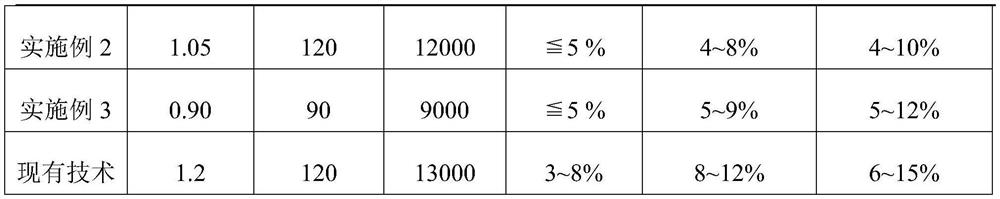

Preparation method of efficient special-shaped bamboo scrimber

InactiveCN111805664AEfficient gluingHigh mechanical strengthReed/straw treatmentWood impregnation detailsPolymer scienceMoisture resistance

The invention discloses a preparation method of an efficient special-shaped bamboo scrimber. Alkali liquor dipping, cooking, softening and high-frequency heating processes are adopted; the method comprises the following steps: soaking and cooking bamboo wood by using an alkali liquor, rinsing, soaking in a thermosetting resin and drying, carrying out recombining high-frequency heating treatment onbamboos; wherein the structure and characteristics of the high-efficiency special-shaped bamboo scrimber product are obviously optimized and improved, the average density of the high-efficiency special-shaped bamboo scrimber product can be controlled to be 0.90-1.20 g / cm < 3 >, the bending strength of the high-efficiency special-shaped bamboo scrimber product is 90-150 MPa, the elastic modulus ofthe high-efficiency special-shaped bamboo scrimber product is 9000-15000 MPa, and the water-absorbing thickness change rate is less than 5%. The prepared efficient special-shaped bamboo scrimber is good in mechanical property and machining property, and has high weather resistance, moisture resistance and dimensional stability.

Owner:LONGYAN UNIV +1

A fixed-point gluing device for wooden boards at equal intervals

ActiveCN107138320BRealize online gluingImprove work efficiencySpray nozzlesEngineeringControl valves

An equal-spacing fixed point gluing device for a wood board includes two side plates. The tops of the two side plates are provided with slide ways by processing, sliders are installed in the slide ways and locked tightly through compressed springs and cover plates, the middles of the sliders are provided with installation holes by machining, a glue injection barrel is movably installed between the sliders, the glue injection barrel includes a barrel body, an inner cover and an outer cover, the inner cover is connected with a solid shaft, the outer cover is connected with a hollow pipe, the hollow pipe stretches into the barrel body, air holes are formed in the wall of the pipe by machining, a glue injection hole and an air vent are formed in the diameter direction of the outer cover by machining, a roller is installed below the glue injection barrel and between the two side plates, sawteeth are arranged on the periphery of the roller by machining, the left side and the right side of the roller are provided with feeding rails, and free rolling shafts are installed on the feeding rails; the wood board is placed horizontally on the free rolling shafts, the roller rotates and drives the wood board to move to the right and drives the glue injection barrel to rotate anticlockwise, when a travel switch makes contact with the wood board, a stroke control valve is switched on, glue in the glue injection barrel is sprayed out from a spray hole, equal-spacing fixed point gluing of the wood board is achieved, the device is compact in structure, and on-line gluing can be achieved.

Owner:舟山市敏瑞科技咨询有限公司

Full-automatic gluing machine head, full-automatic gluing machine and stamping and gluing method thereof

ActiveCN108207079BLow priceEasy to replaceLaminating printed circuit boardsManufacturing cost reductionStamping

The invention relates to a full automatic adhesive pasting paper machine head, a full automatic adhesive pasting paper machine, and a stamping and adhesive pasting method. The full automatic adhesivepasting paper machine head comprises a stamping and pasting die, a pushing and pressing assembly used for pressing the stamping and pasting die, and a driving assembly for providing driving force which are connected in sequence from the bottom up; the pushing and pressing assembly comprises a first pressing part used for pushing and pressing the stamping and pasting die, and a second pressing partused for pushing and pressing the first pressing part and is driven by the driving assembly; the first pressing part is mounted below the second pressing part; and at least one first elastic part used for buffering stamping and pasting pressure is arranged between the second pressing part and the first pressing part. The full automatic adhesive pasting paper machine head is light and convenient,basically adopts standard mechanisms, and is low in cost, convenient to change, high in universality, and capable of lowering manufacturing cost; efficient, accurate and quick adhesive pasting on an FPC board can be realized, so that production efficiency is improved; in addition, the full automatic adhesive pasting paper machine head is safe and free of oil dirt; and by virtue of the buffering elastic part, the stamping and pasting pressure can be controlled, and damage to the FPC board by a punching head can be prevented.

Owner:深圳市鼎晖伟业自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com