Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1539 results about "Interfacial polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

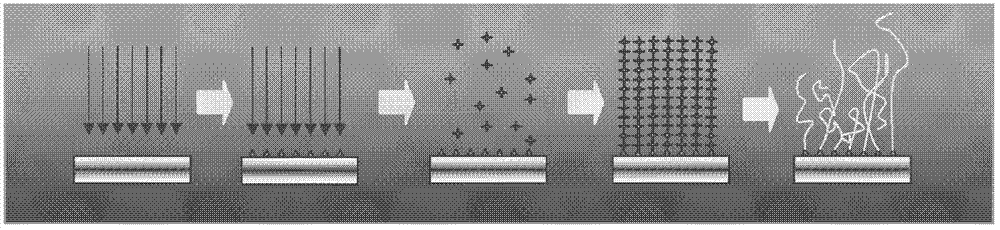

Interfacial polymerization is a type of step-growth polymerization in which polymerization occurs at the interface between two immiscible phases (generally two liquids), resulting in a polymer that is constrained to the interface. There are several variations of interfacial polymerization, which result in several types of polymer topologies, such as ultra-thin films, nanocapsules, and nanofibers, to name just a few.

Systems and methods of forming particles

InactiveUS20070054119A1Synthetic resin layered productsChemical/physical/physico-chemical microreactorsChemical reactionMicrometer

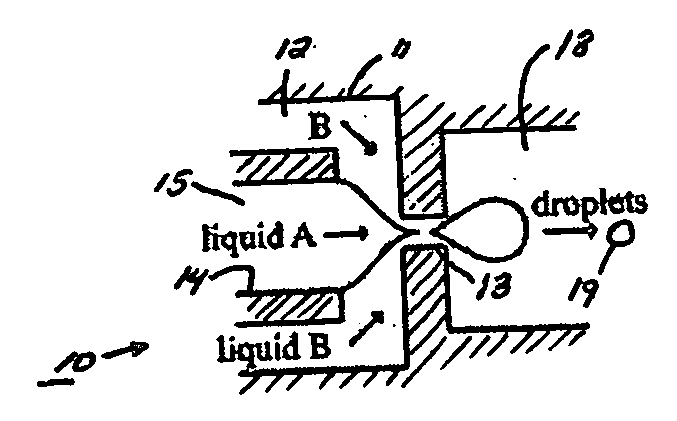

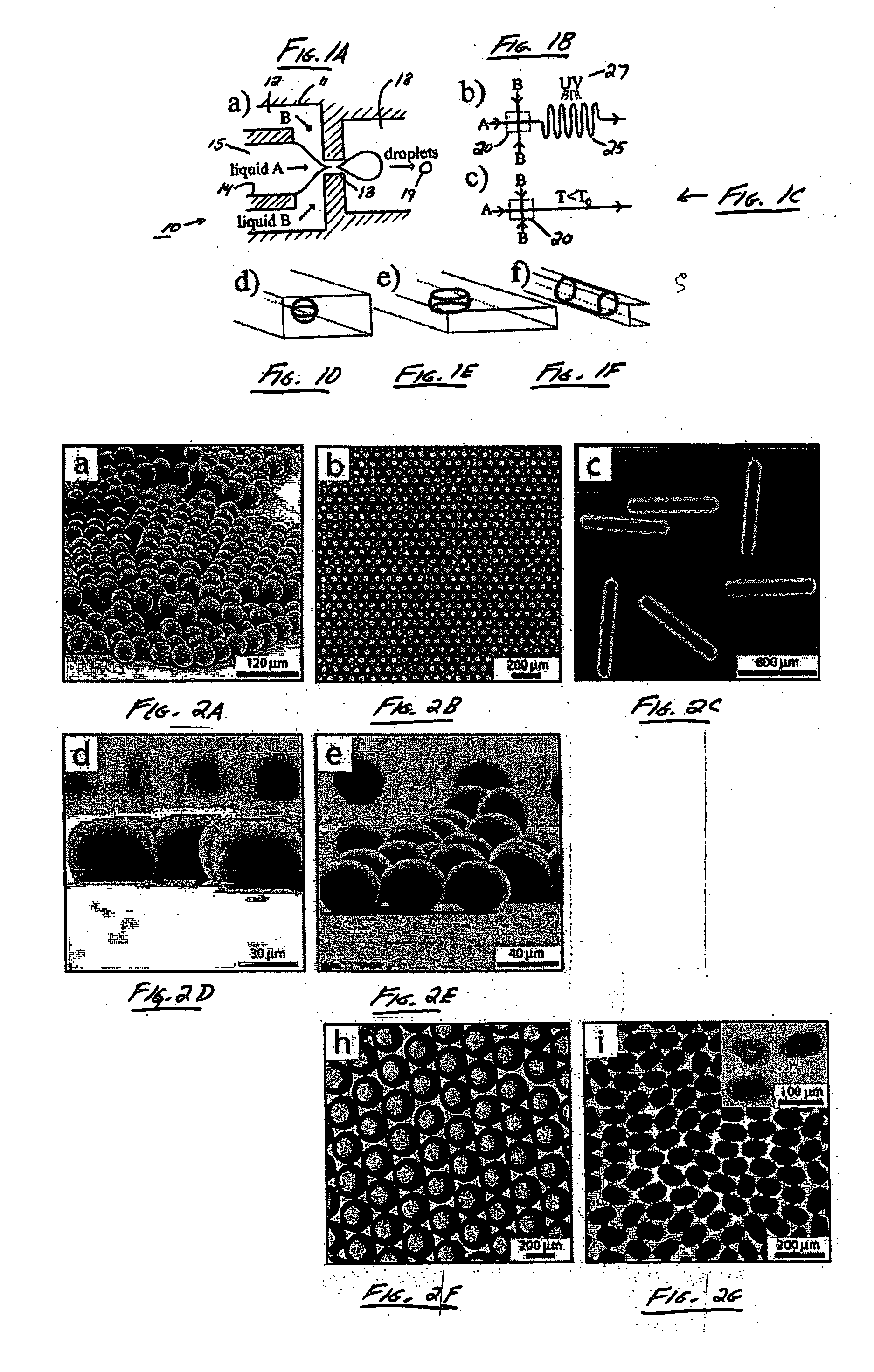

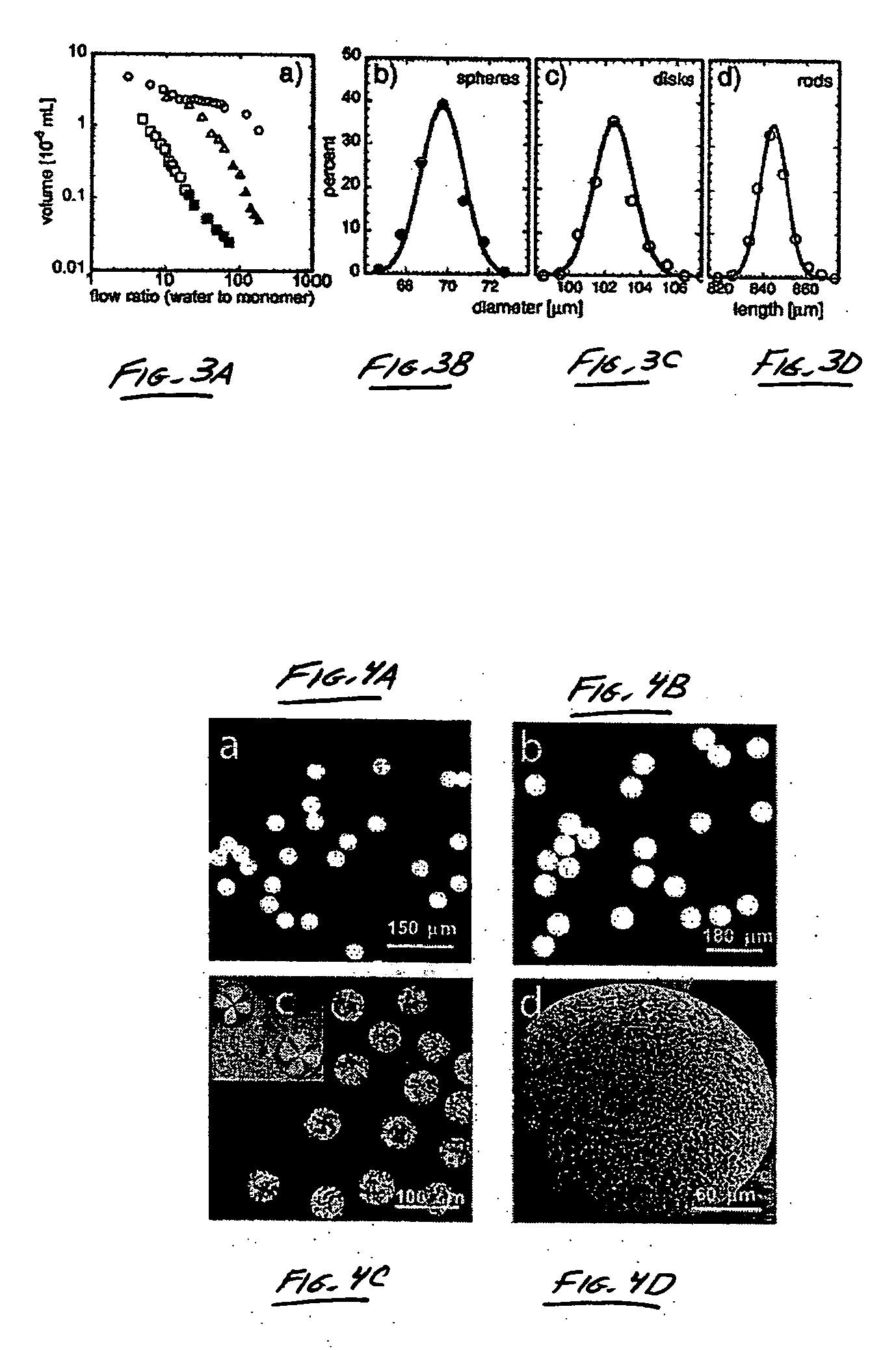

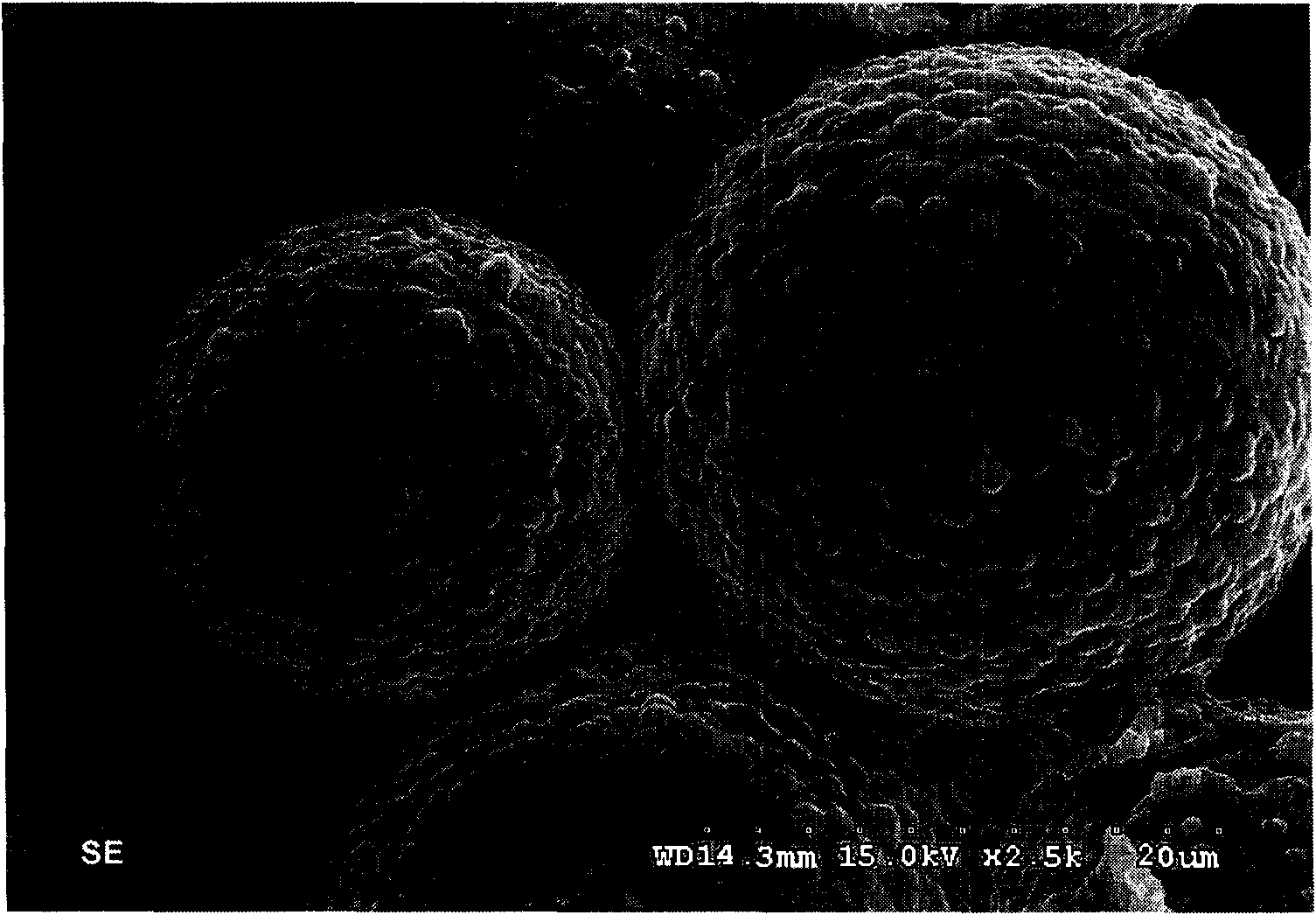

The present invention generally relates to systems and methods of forming particles and, in certain aspects, to systems and methods of forming particles that are substantially monodisperse. Microfluidic systems and techniques for forming such particles are provided, for instance, particles may be formed using gellation, solidification, and / or chemical reactions such as cross-linking, polymerization, and / or interfacial polymerization reactions. In one aspect, the present invention is directed to a plurality of particles having an average dimension of less than about 500 micrometers and a distribution of dimensions such that no more than about 5% of the particles have a dimension greater than about 10% of the average dimension, which can be made via microfluidic systems. In one set of embodiments, at least some of the particles may comprise a metal, and in certain embodiments, at least some of the particles may comprise a magnetizable material. In another set of embodiments, at least some of the particles may be porous. In some embodiments, the invention includes non-spherical particles. Non-spherical particles may be formed, for example, by urging a fluidic droplet into a channel having a smallest dimension that is smaller than the diameter of a perfect mathematical sphere having a volume of the droplet, and solidifying the droplet, and / or by exposing at least a portion of a plurality of particles to an agent able to remove at least a portion of the particles.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Microcapsule of organic phase change energy storage material and preparation method thereof

ActiveCN101555401AHas infrared reflective propertiesHas infrared absorption propertiesEnergy storageHeat-exchange elementsChemistryIn situ polymerization

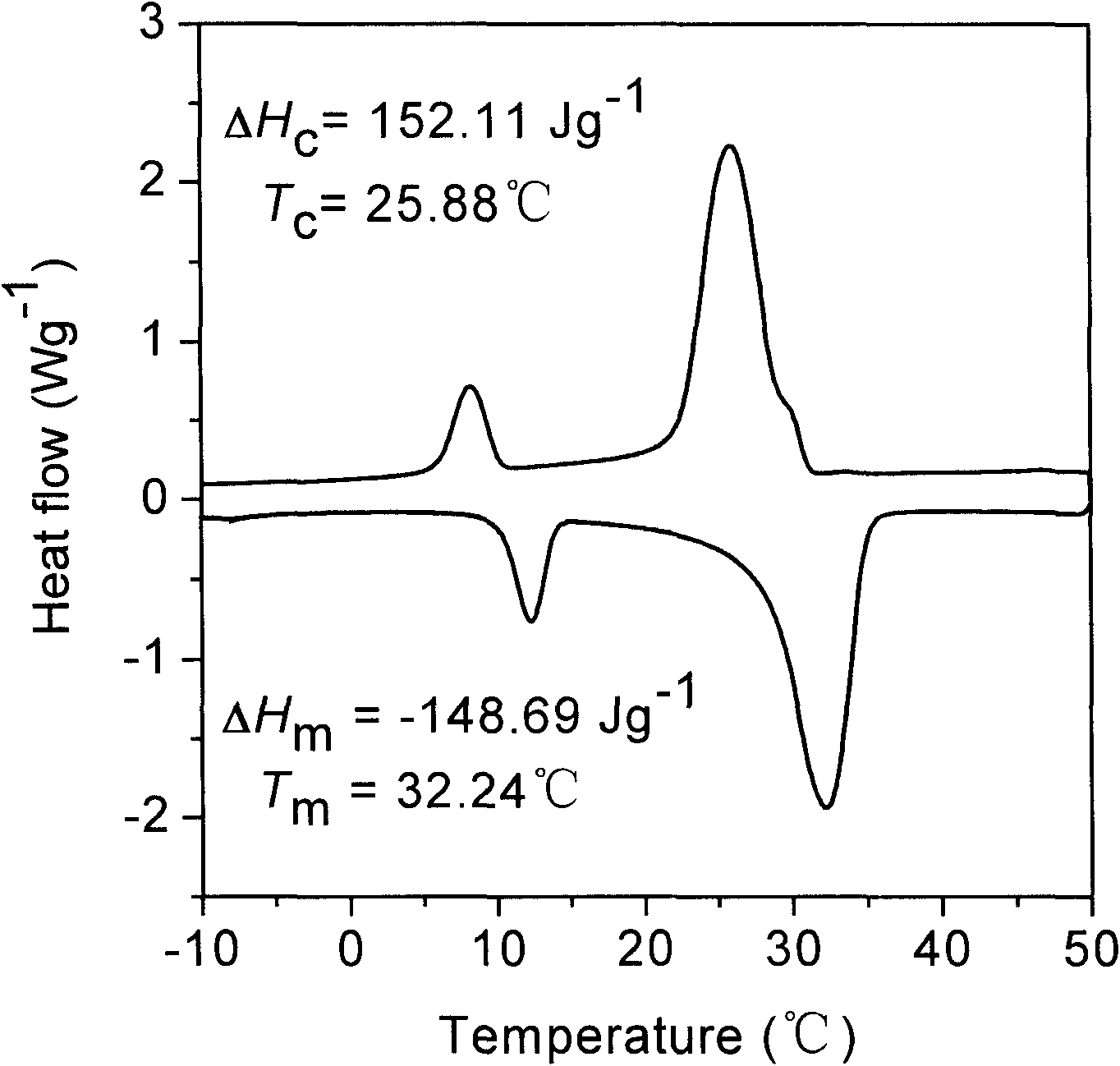

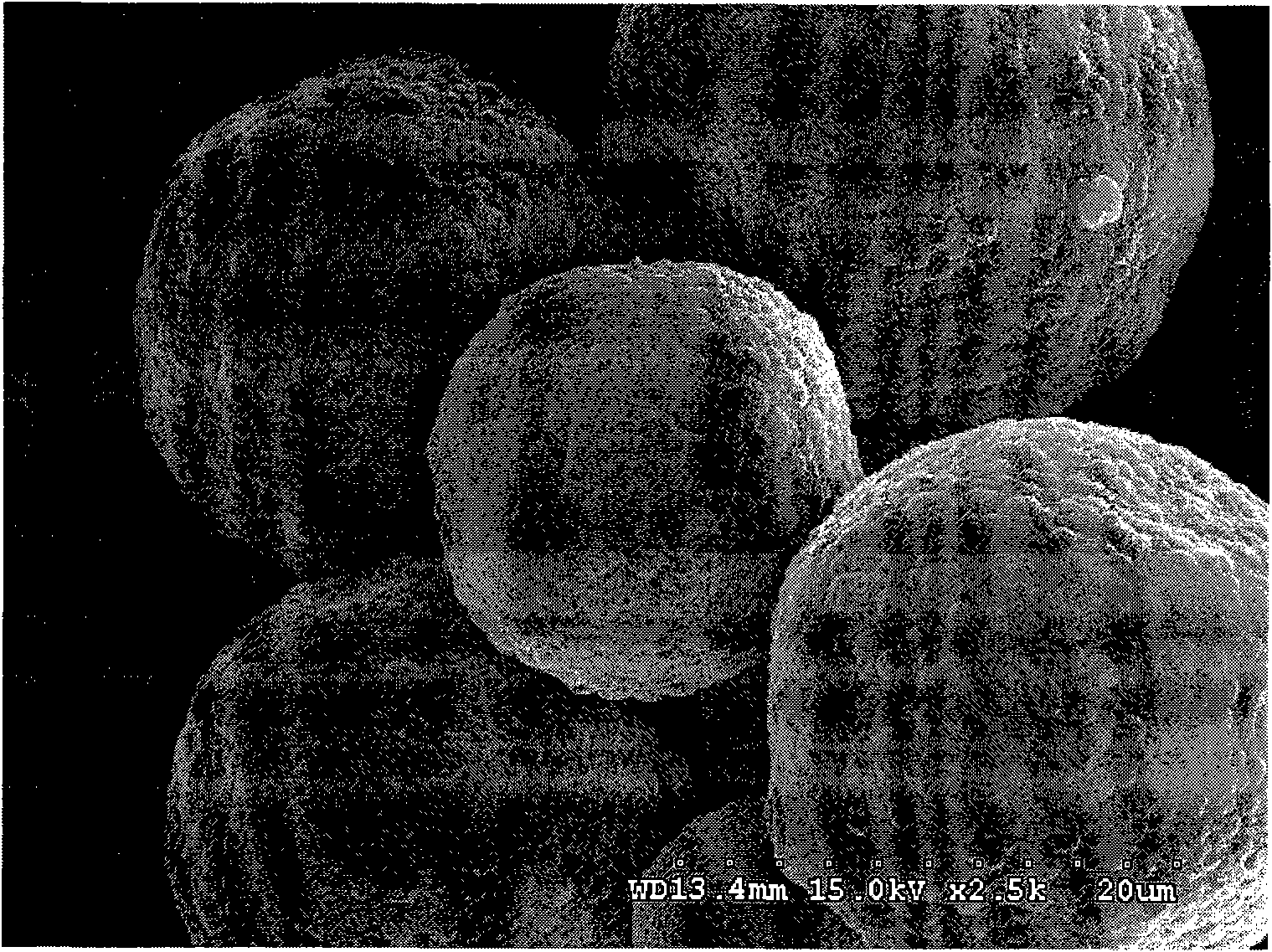

The invention discloses a microcapsule of an organic phase change energy storage material and a preparation method thereof. The microcapsule of an organic phase change energy storage material comprises a core and a nucleocapsid, wherein the material of the core comprises the organic phase change energy storage material; the nucleocapsid at least comprises an inner layer and an outer layer, the inner layer is packaged by any one of an in situ polymerization method, an interface polymerization method, a reaction phase separating method, a double agglomeration method and a sol-gal process, and the outer layer is packaged by any one of an in situ polymerization method, a reaction phase separating method, a sol-gal process and a double agglomeration method. The microcapsule has adjustable size, nucleocapsid composition and shell thickness, favorable flexibility, mechanical strength, penetrability resistance and dispersibility and can be widely applied to the fields of energy sources, materials, aero-space, textile, electric power, medical apparatus, architecture, and the like, such as solar utilization, industrial afterheat and waste heat recovery, architecture energy storage, dress with constant temperature, air conditioners for cool and heat accumulation, constant temperature of electric appliances, and the like.

Owner:BEIJING NEW BUILDING MATERIAL

Reverse Osmosis Membranes

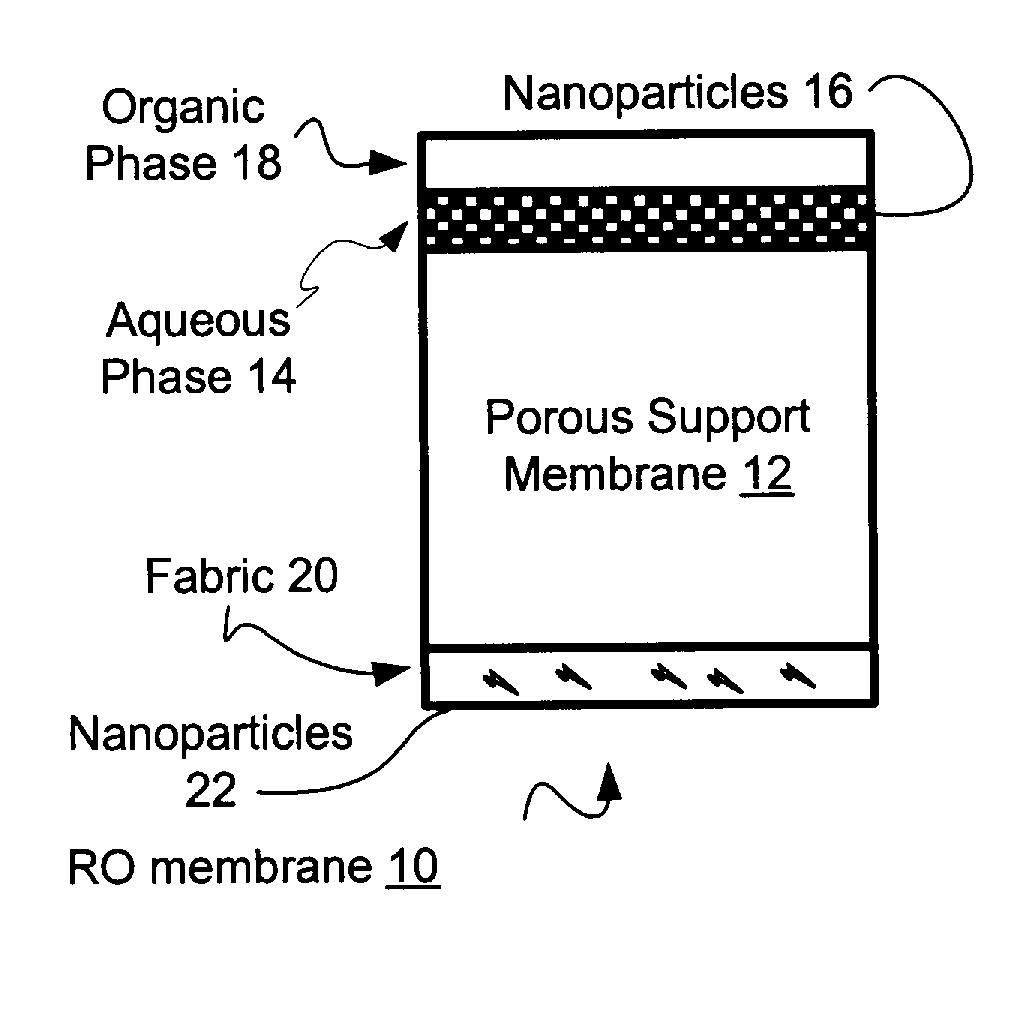

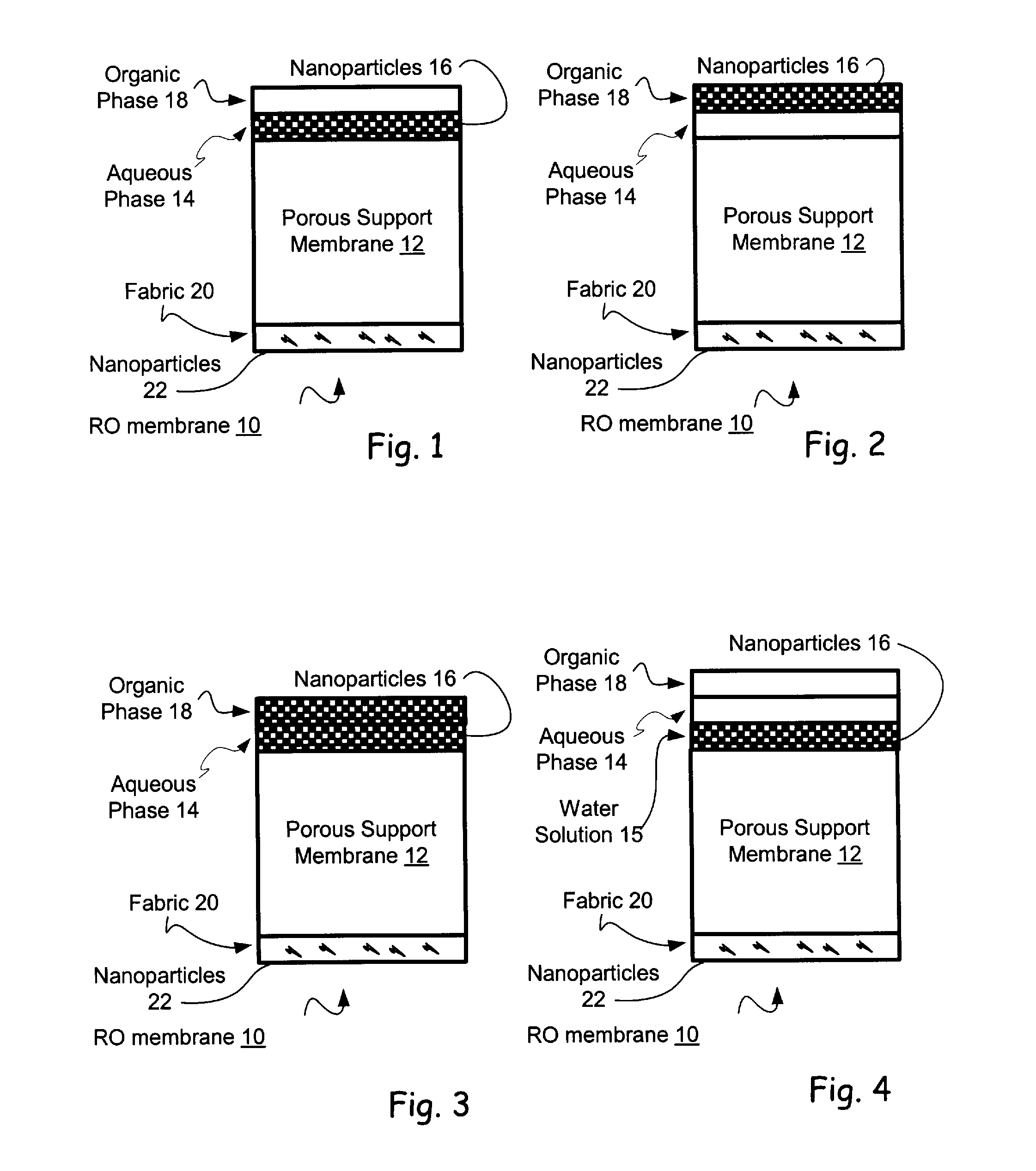

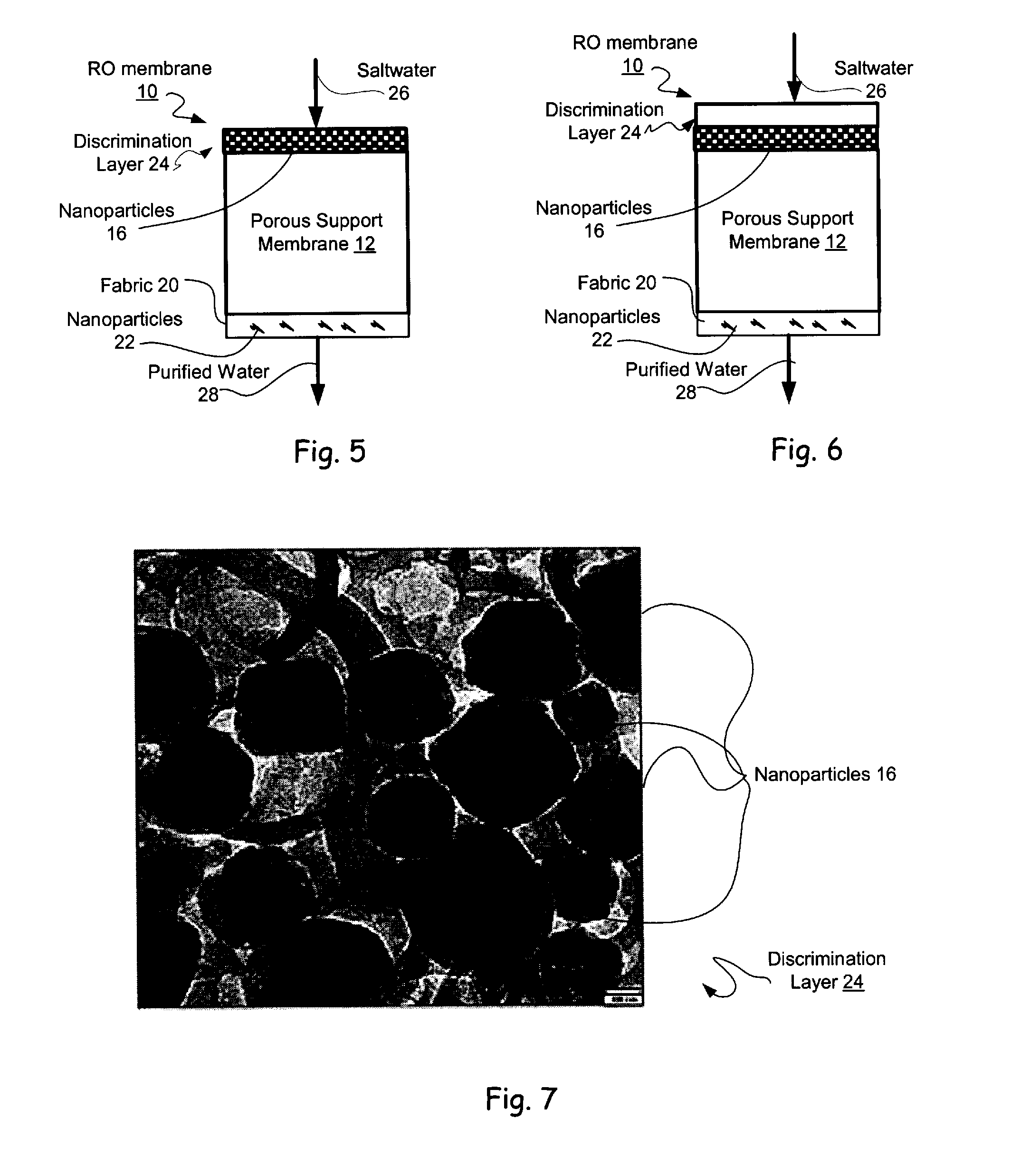

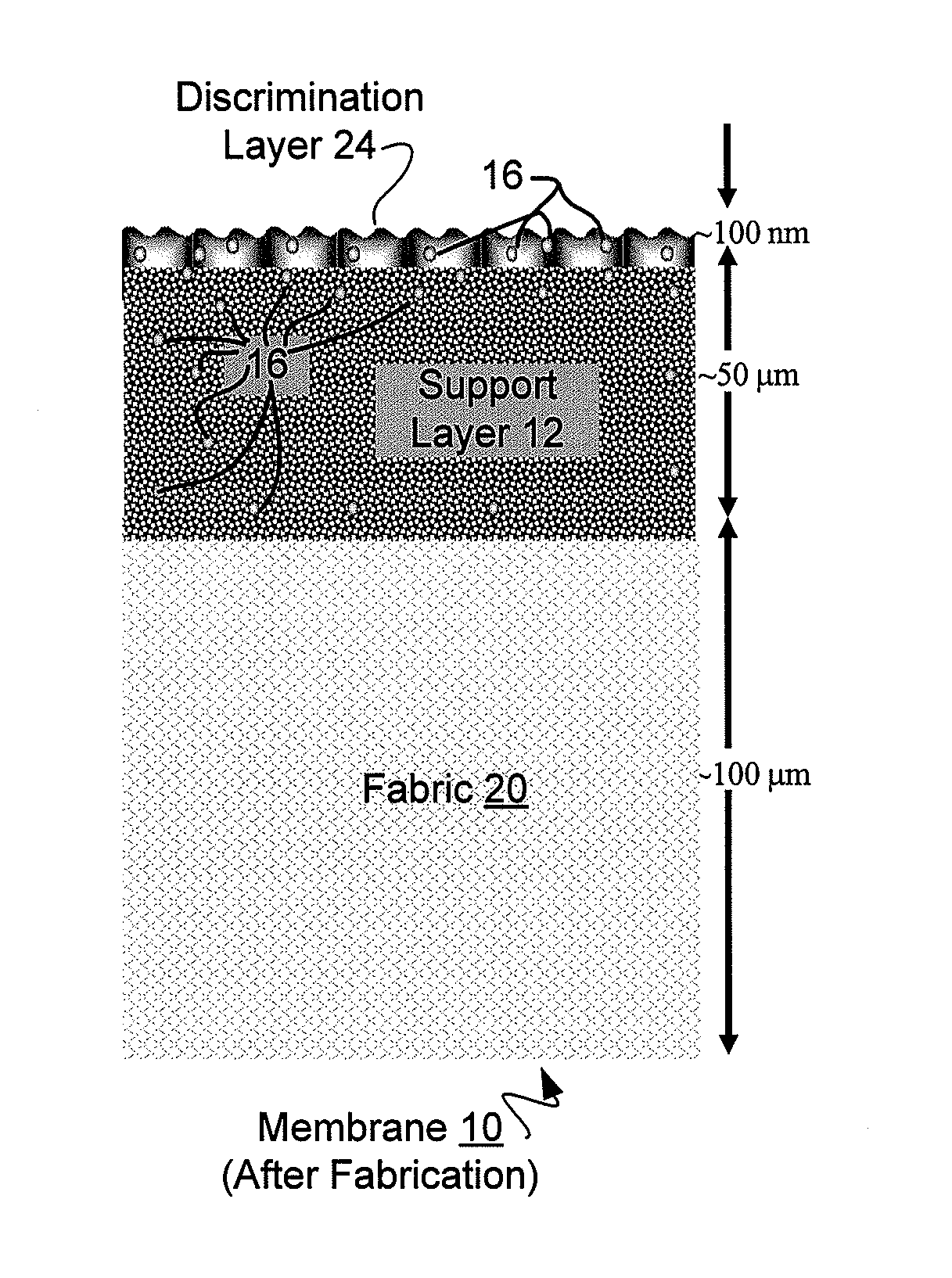

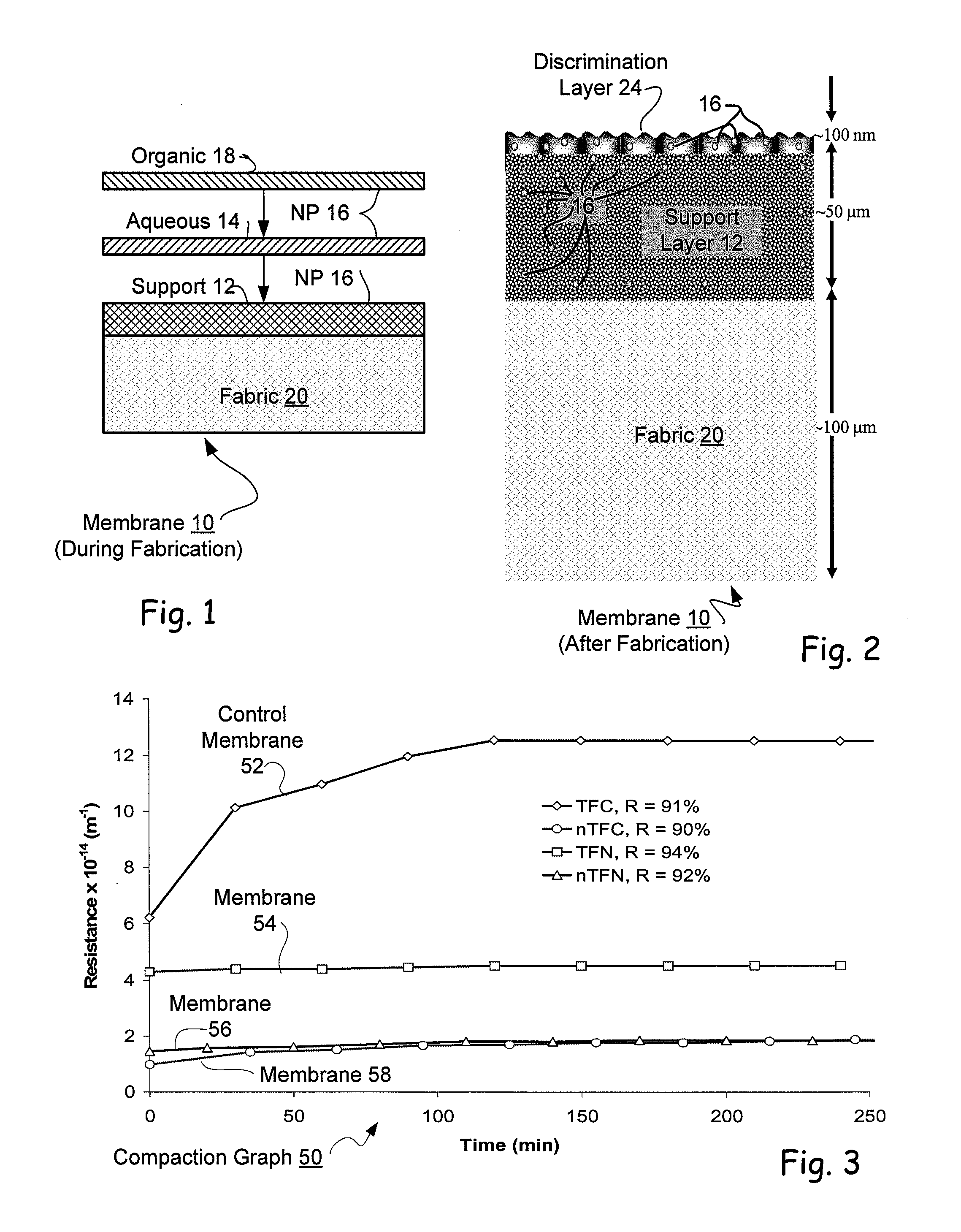

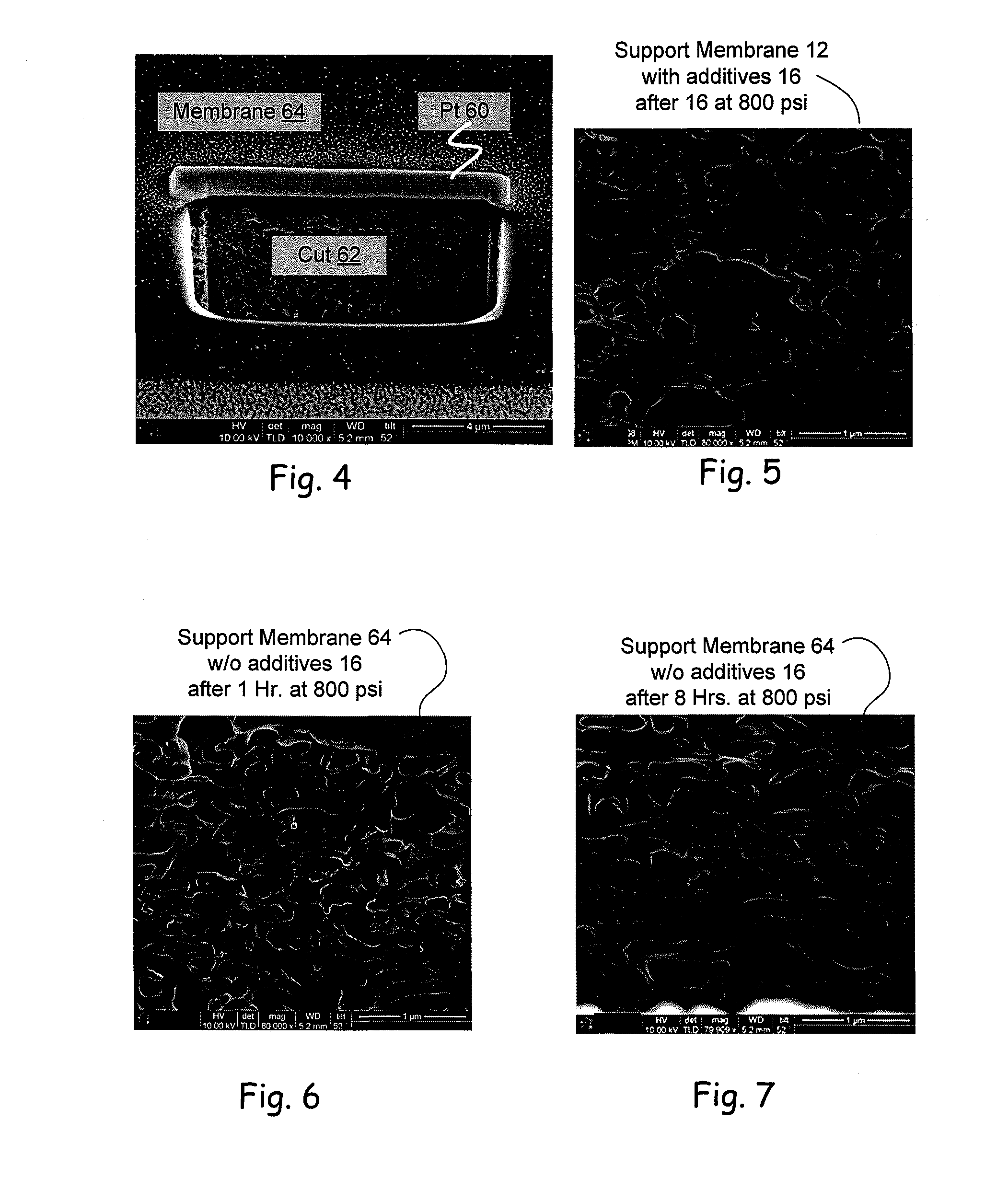

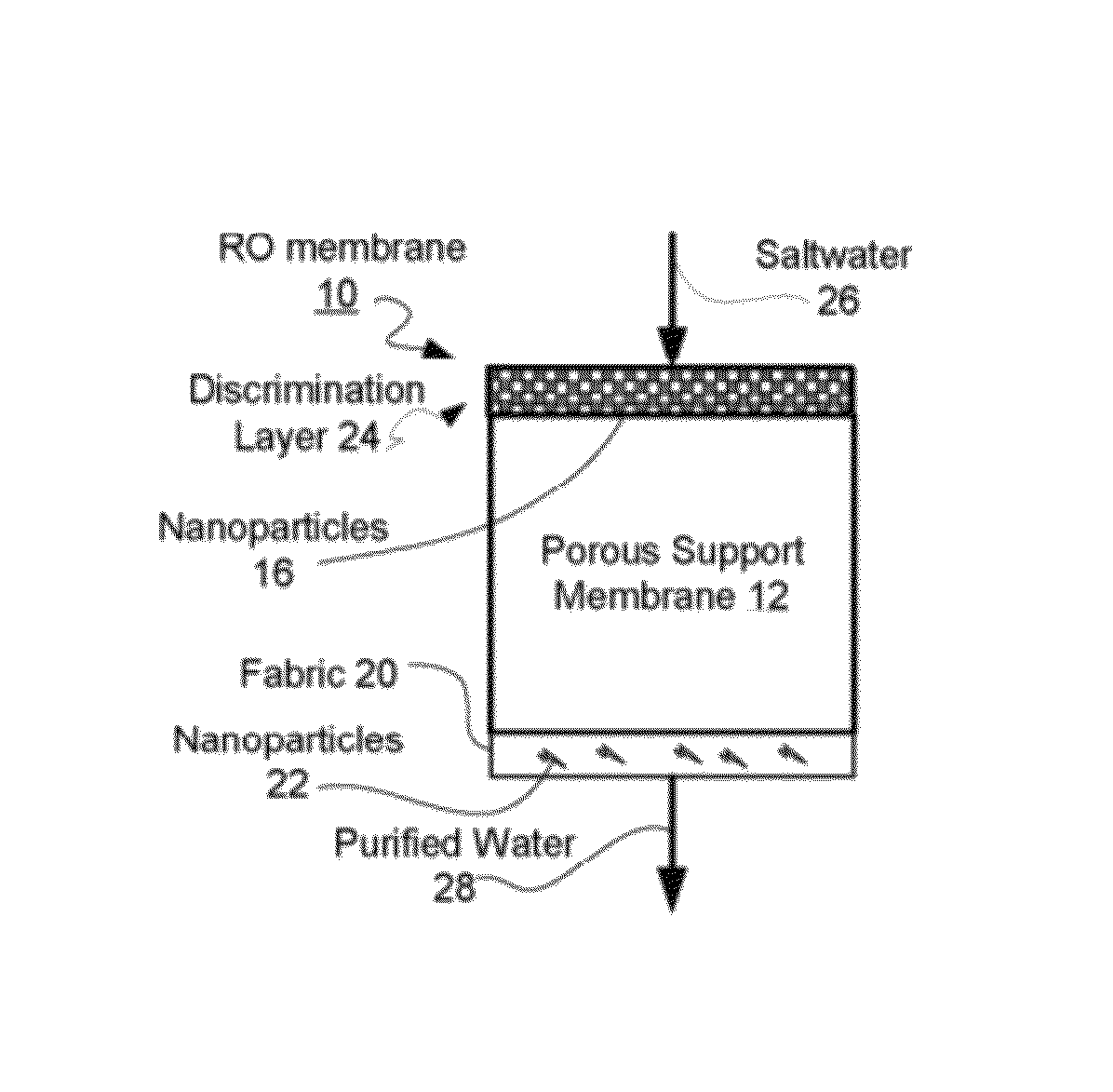

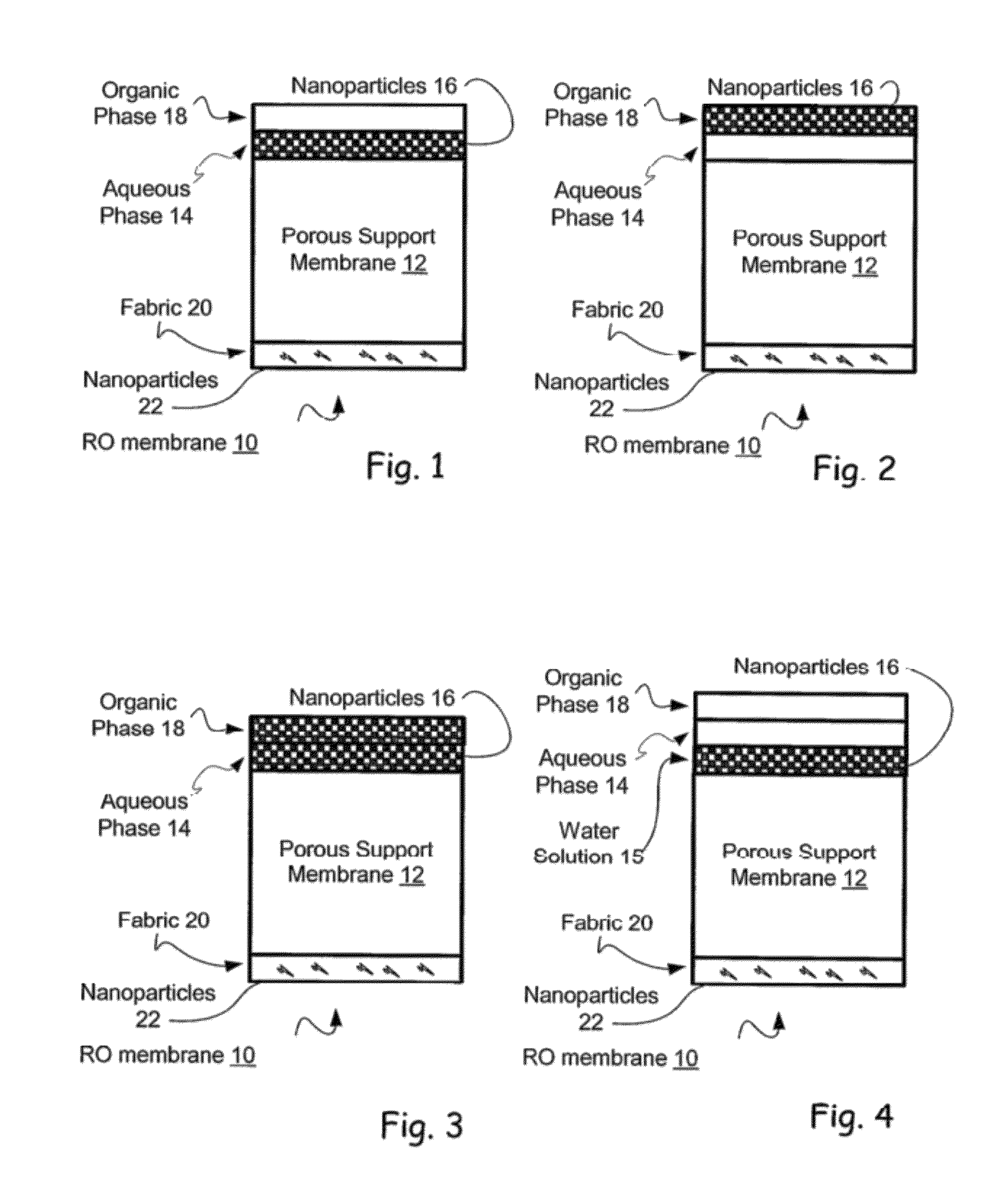

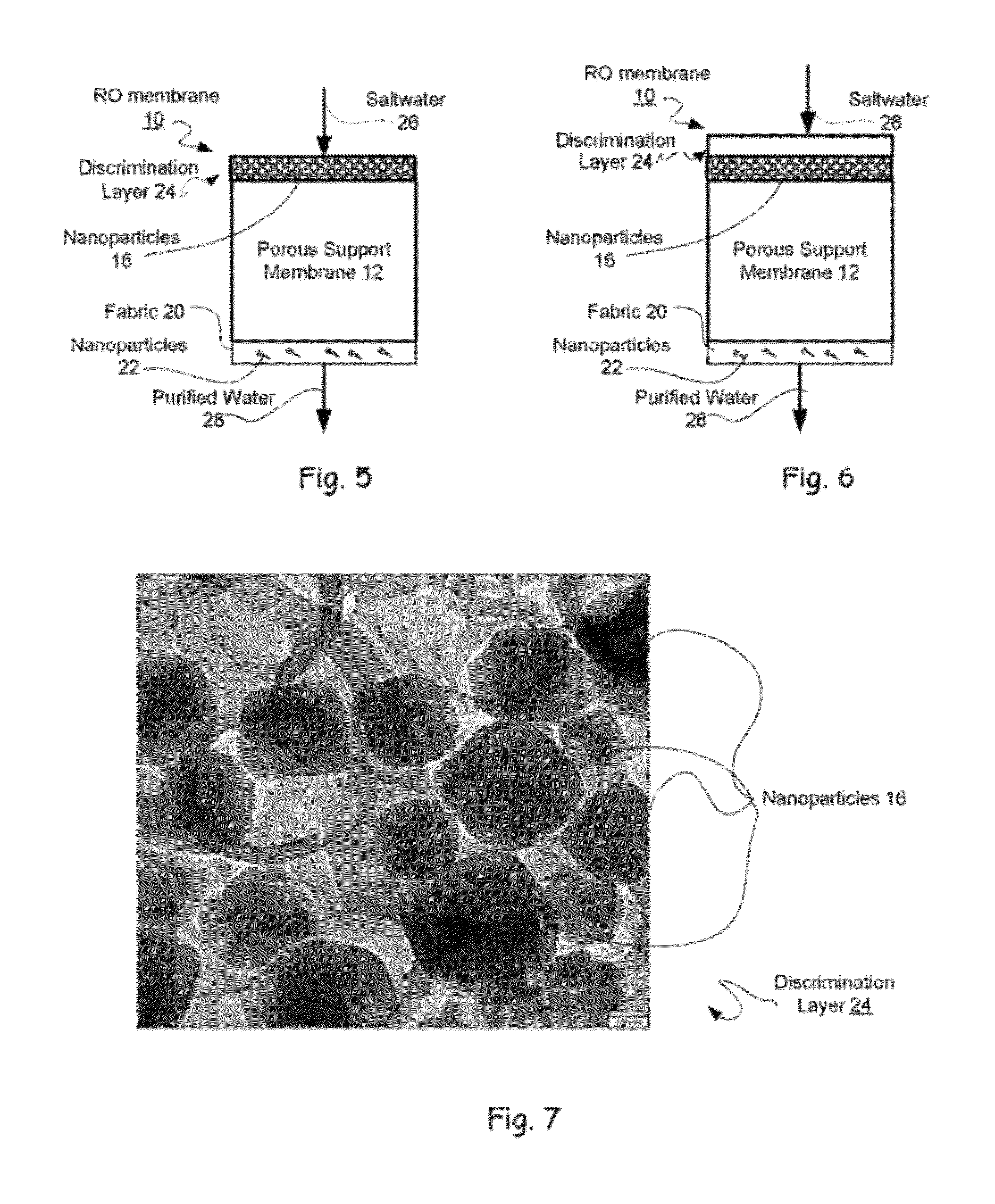

Reverse osmosis membranes made by interfacial polymerization of a monomer in a nonpolar (e.g. organic) phase together with a monomer in a polar (e.g. aqueous) phase on a porous support membrane. Interfacial polymerization process is disclosed for preparing a highly permeable RO membrane, comprising: contacting on a porous support membrane, a) a first solution containing 1,3-diaminobenzene, and b) a second solution containing trimesoyl chloride, wherein at least one of solutions a) and b) contains nanoparticles when said solutions are first contacted, and recovering a highly permeable RO membrane.

Owner:NANOH2O

Thin film membranes with additives for forward and pressure retarded osmosis

InactiveUS20090272692A1Reduce pressureMembranesGeneral water supply conservationNanoparticleUltimate tensile strength

A thin film composite or TFC membrane formed by interfacial polymerization of an organic and aqueous phase on a support membrane with nanoparticles in the discrimination layer and / or the support membrane, optimized by the selection of nanoparticles for membrane flux, hydrophilicity and to minimize thickness of the support membrane while maintaining the strength and ruggedness characteristics required for forward osmosis (FO) and / or pressure retarded osmosis (PRO) so that the flux flow paths are less tortuous than conventional support membranes and thereby provide increased flux flow.

Owner:FORD GLOBAL TECH LLC +1

Reverse osmosis membranes

Owner:NANOH2O

Gels for encapsulation of biological materials

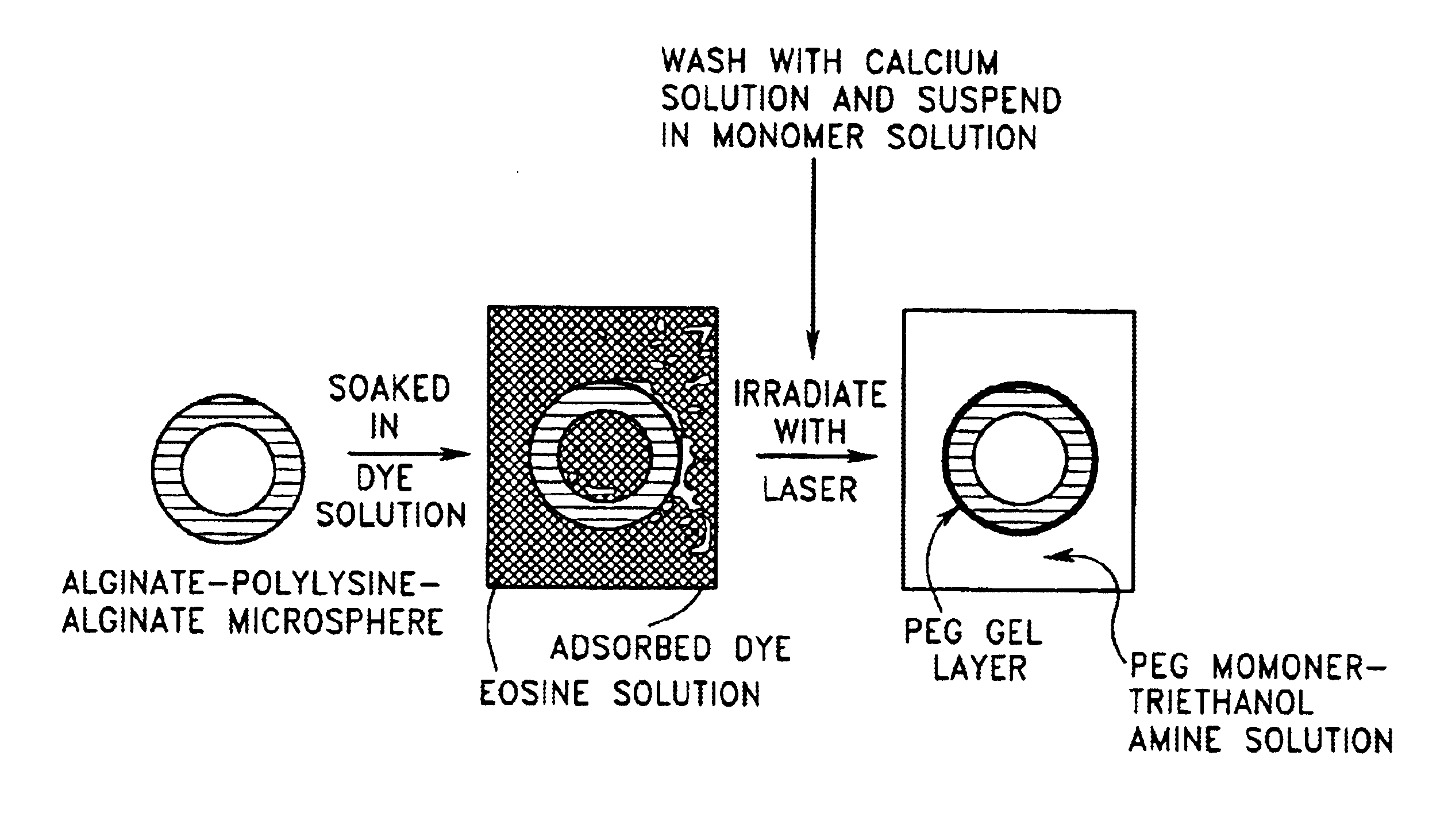

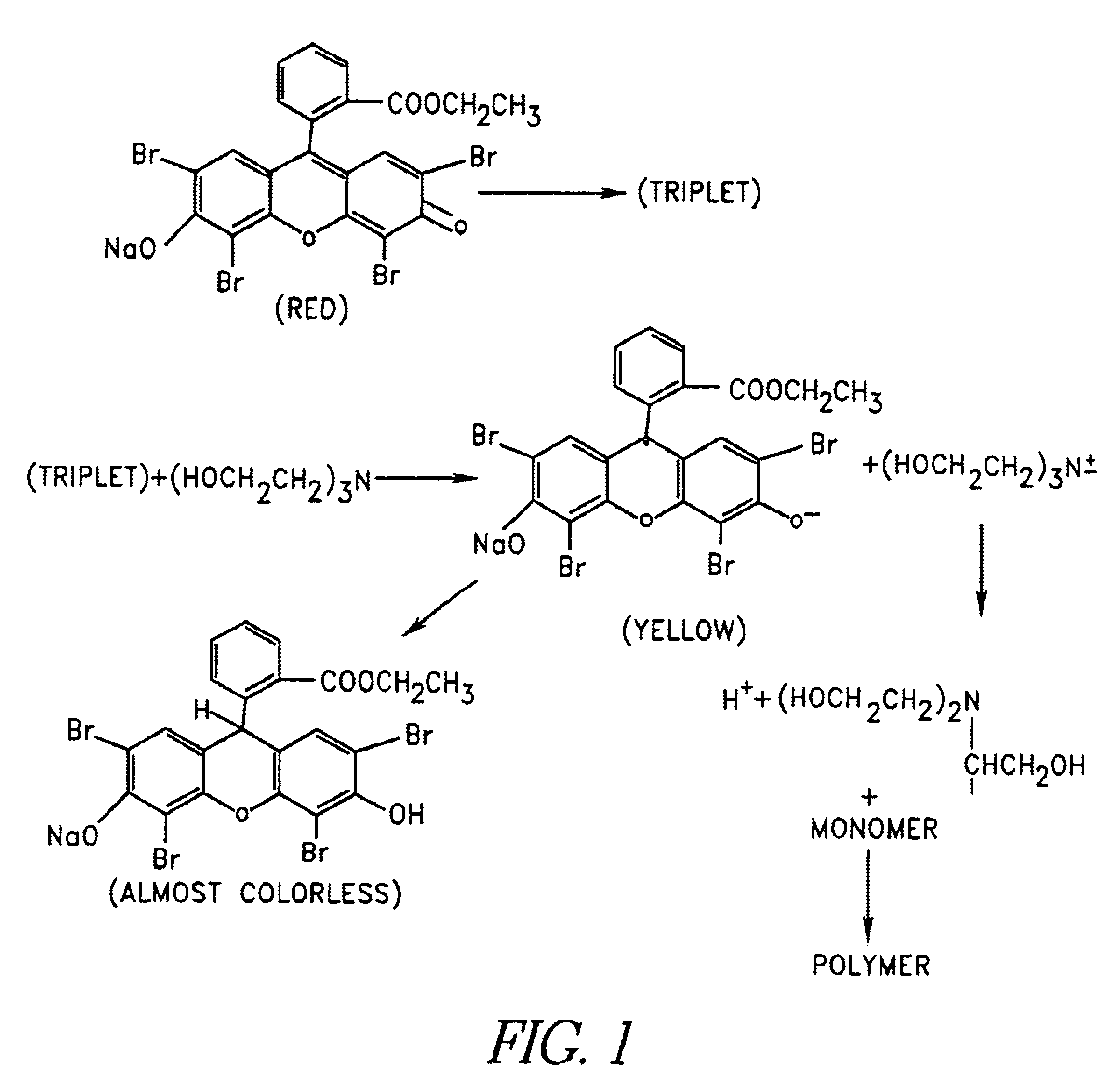

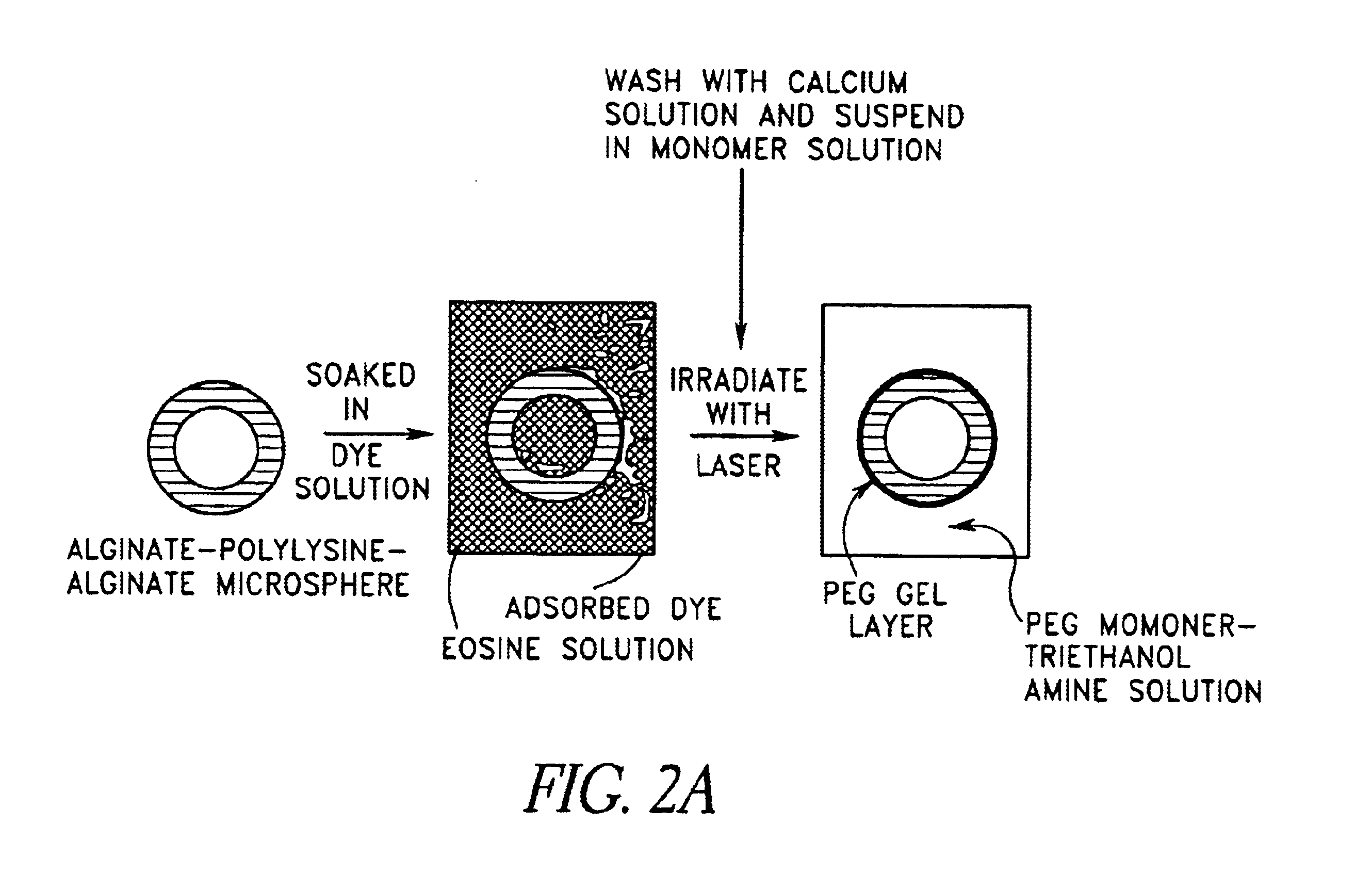

InactiveUS6911227B2Efficient gluingFacilitated DiffusionImmobilised enzymesSurgical adhesivesActive matterWater soluble

This invention provides novel methods for the formation of biocompatible membranes around biological materials using photopolymerization of water soluble molecules. The membranes can be used as a covering to encapsulate biological materials or biomedical devices, as a “glue” to cause more than one biological substance to adhere together, or as carriers for biologically active species. Several methods for forming these membranes are provided. Each of these methods utilizes a polymerization system containing water-soluble macromers, species, which are at once polymers and macromolecules capable of further polymerization. The macromers are polymerized using a photoinitiator (such as a dye), optionally a cocatalyst, optionally an accelerator, and radiation in the form of visible or long wavelength UV light. The reaction occurs either by suspension polymerization or by interfacial polymerization. The polymer membrane can be formed directly on the surface of the biological material, or it can be formed on material, which is already encapsulated.

Owner:NOVOCELL

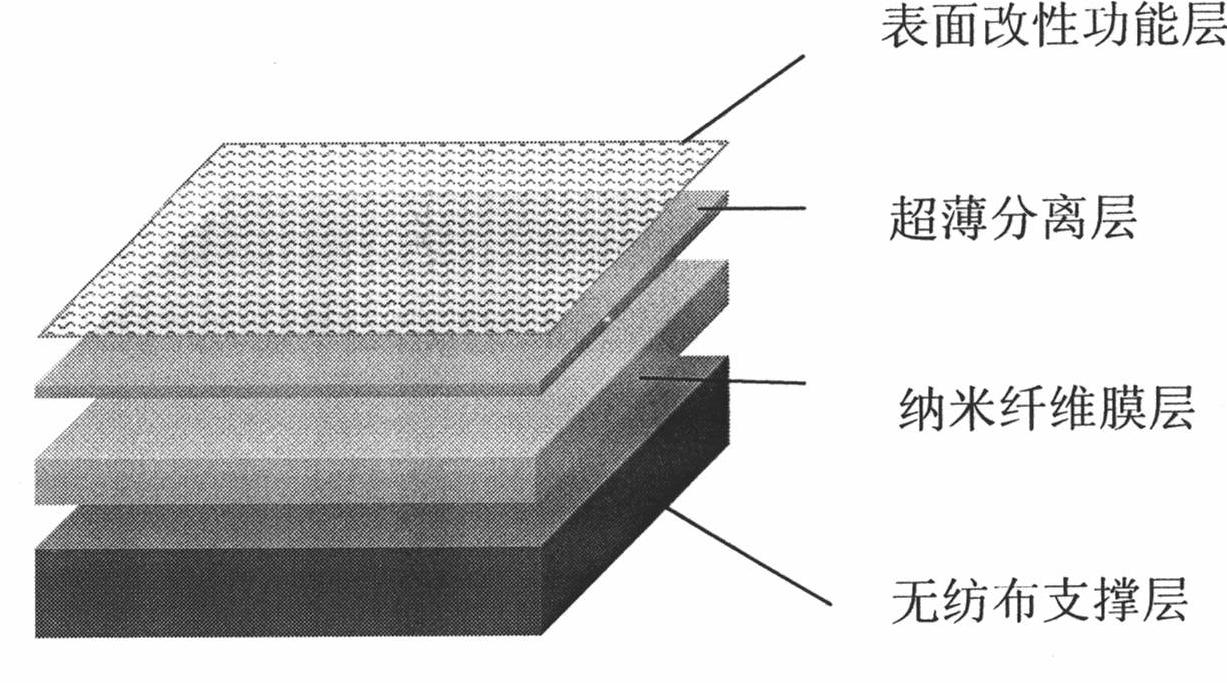

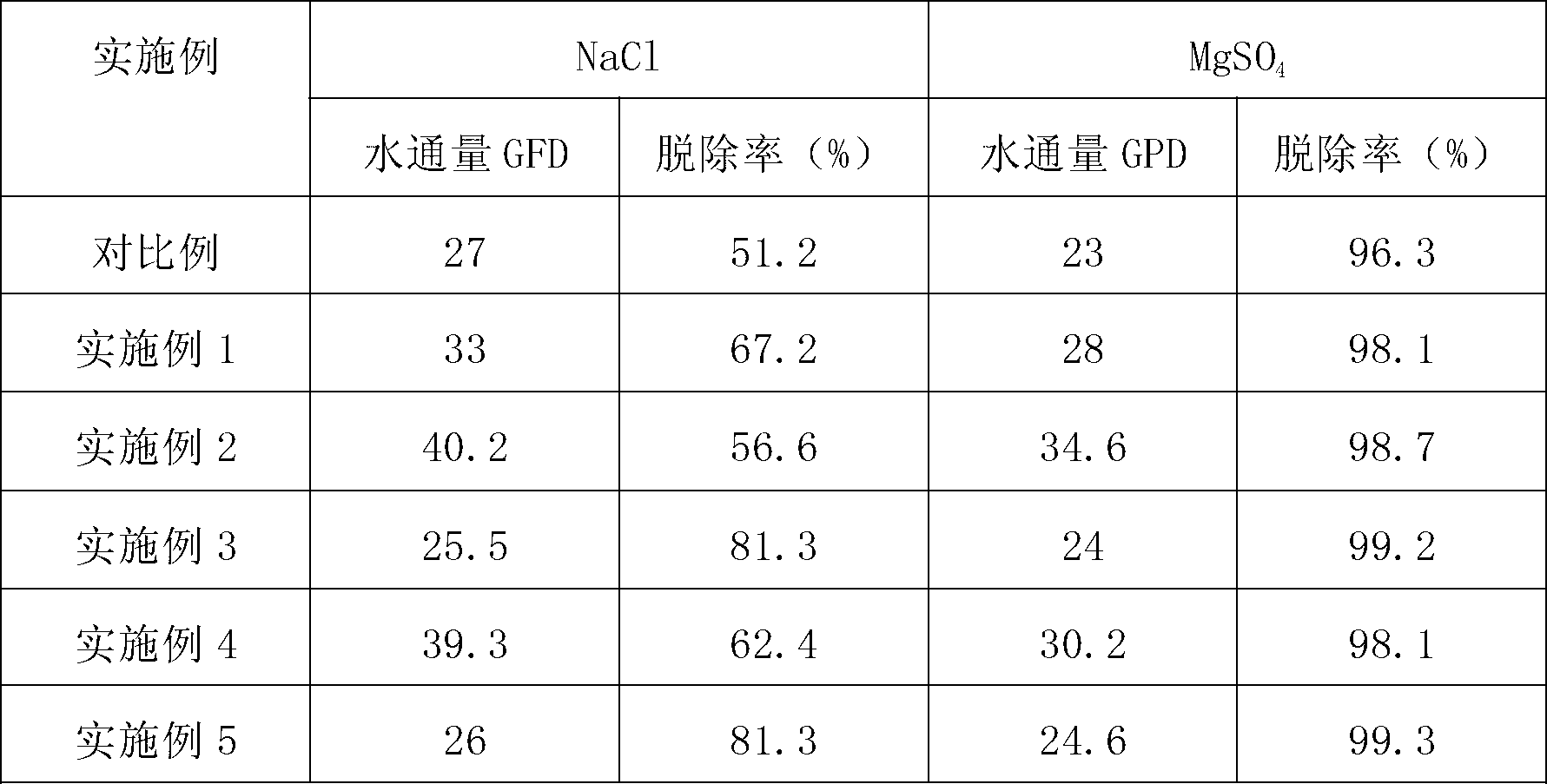

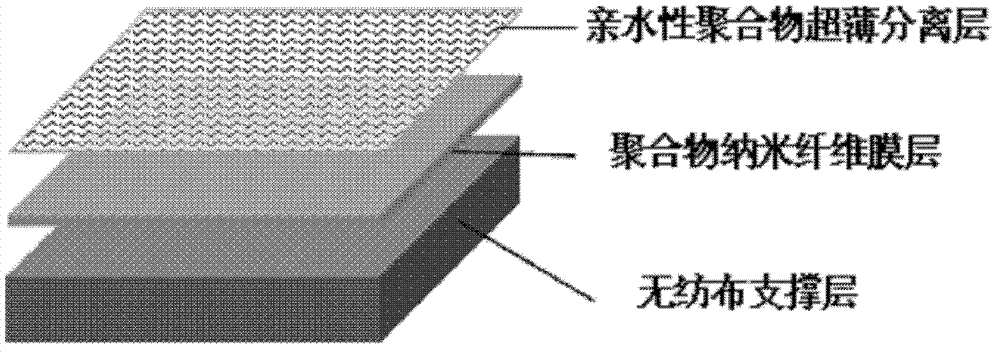

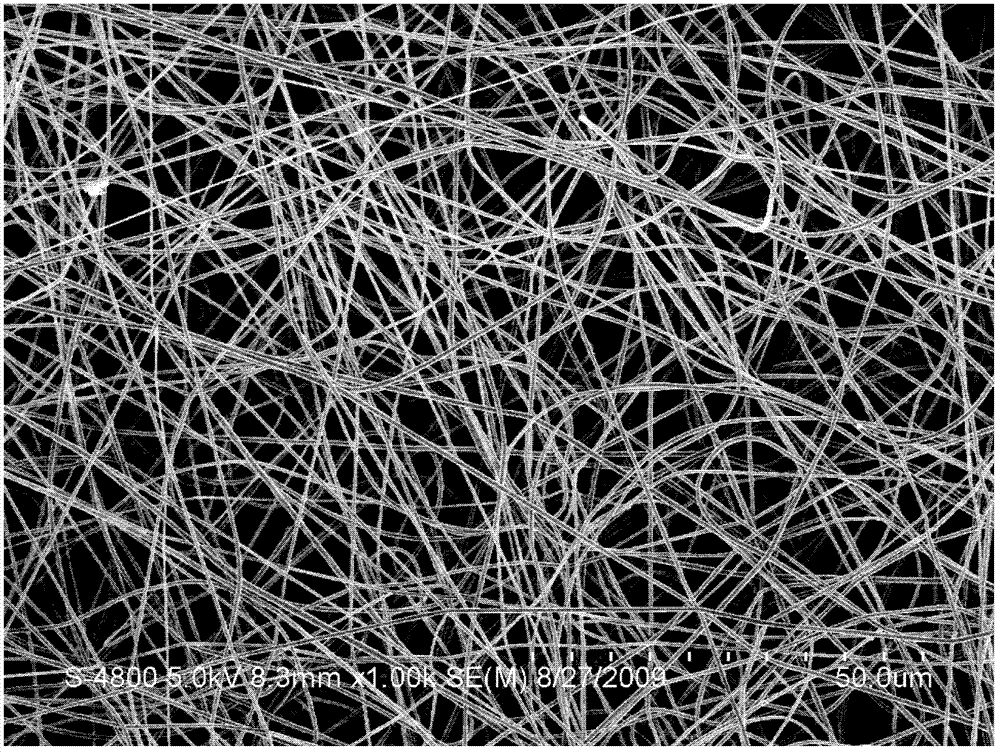

Hyperfiltration membrane or nanofiltration membrane with multi-layered composite structure and preparation method thereof

InactiveCN102139187AIncrease water fluxHigh retention rateSemi-permeable membranesEnvironmental resistanceHydrophilic polymers

The invention relates to a hyperfiltration membrane or nanofiltration membrane with a multi-layered composite structure and a preparation method thereof. The hyperfiltration membrane or nanofiltration membrane is a polymer electrostatic spinning nanofiber membrane layer characterized in strong chemical resistance prepared through an electrostatic spinning method, a hydrophilic polymer ultra-thin separation layer obtained through interfacial polymerization, and a functional group surface modification functional layer formed through the grafting reaction of reactant gases on the surfaces of hydrophilic polymers, or a long-chain polymer surface modification functional layer formed through the grafting reaction of the reaction gases on the surfaces of the hydrophilic polymers, or a functionalgroup-containing long-chain polymer surface modification functional layer through the grafting reaction of the reaction gases with the functional groups on the surfaces of the hydrophilic polymers. The hyperfiltration membrane or nanofiltration membrane with the multi-layered composite structure has the advantages of high water flux, high cutting rate and stable chemical performances. The filtration membrane can be used for the production of domestic water, drinking water or water in special conditions, and is suitable for the medical field, food field, environmental protection field and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Membranes for separation

ActiveUS20140251897A1Stable in organic solventControl freedomSemi-permeable membranesMembranesOrganic solventProtic solvent

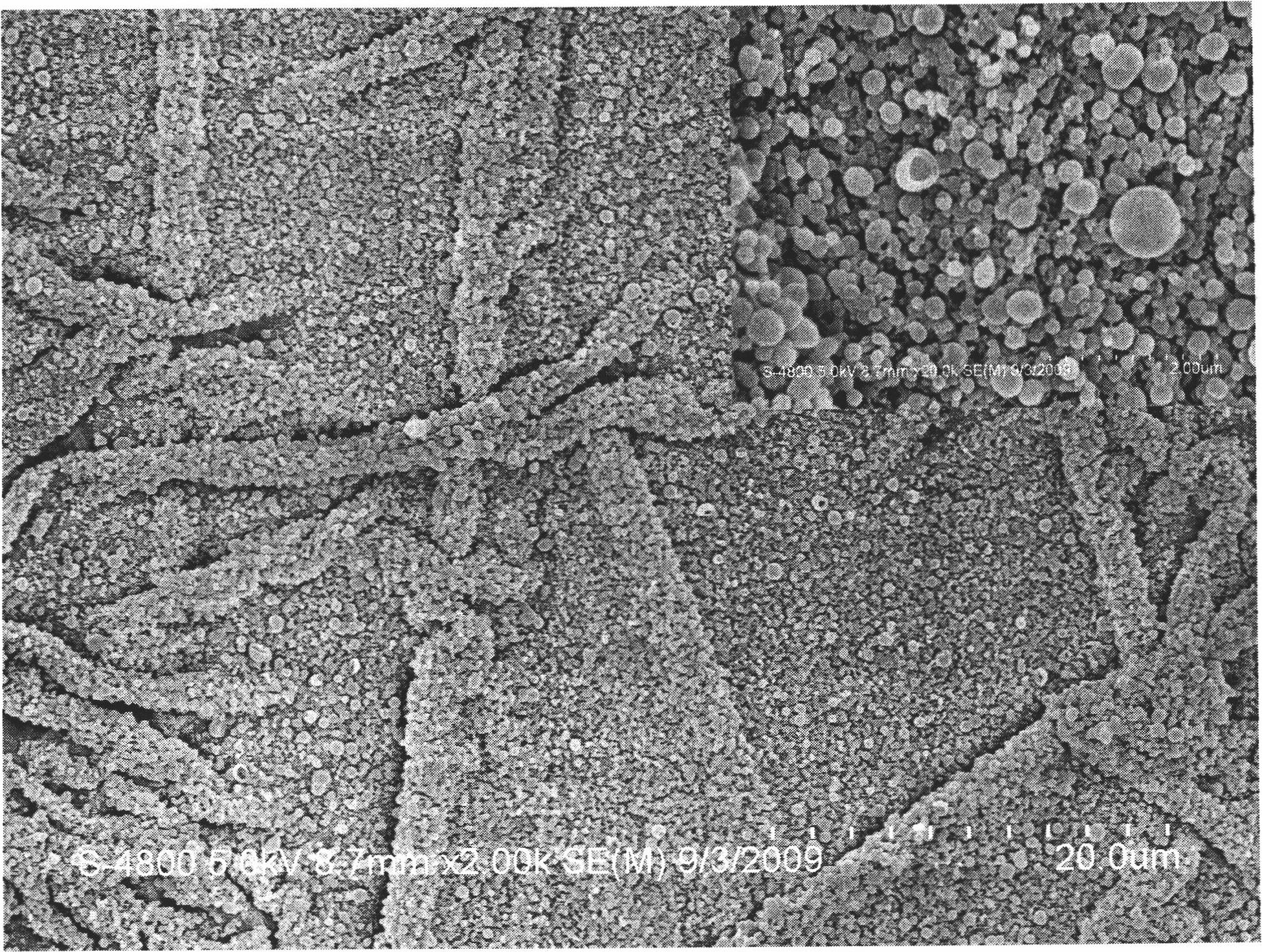

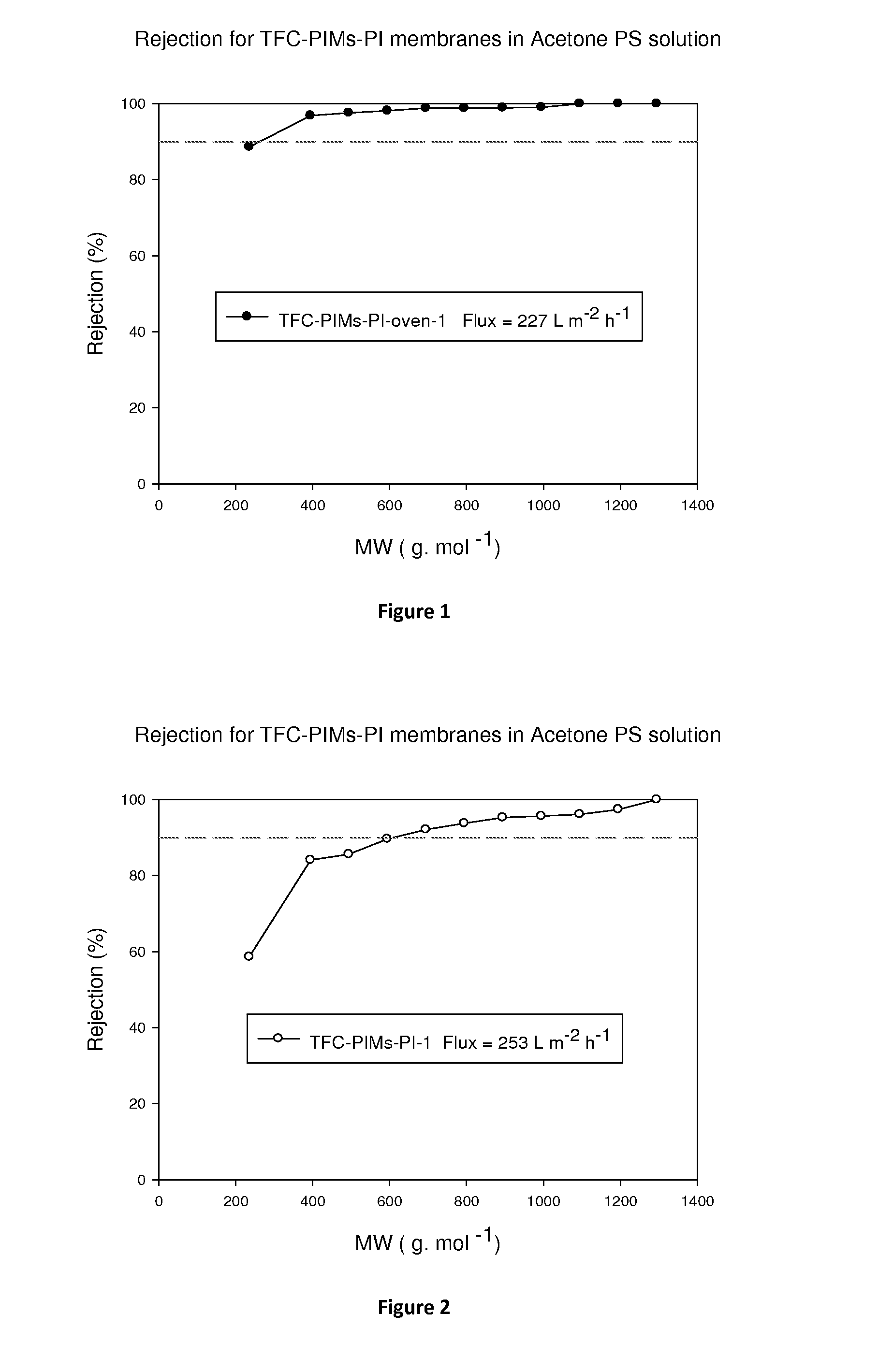

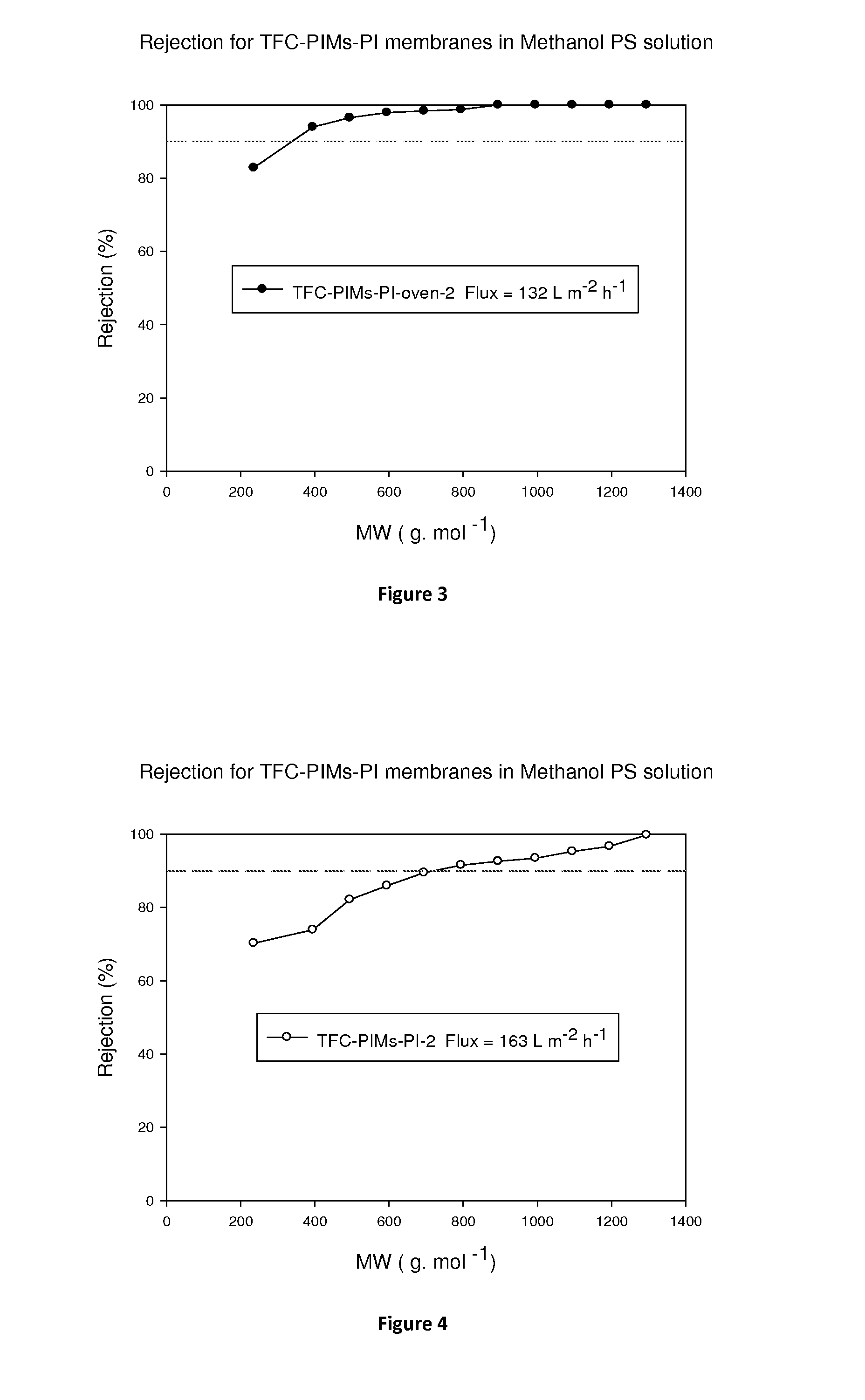

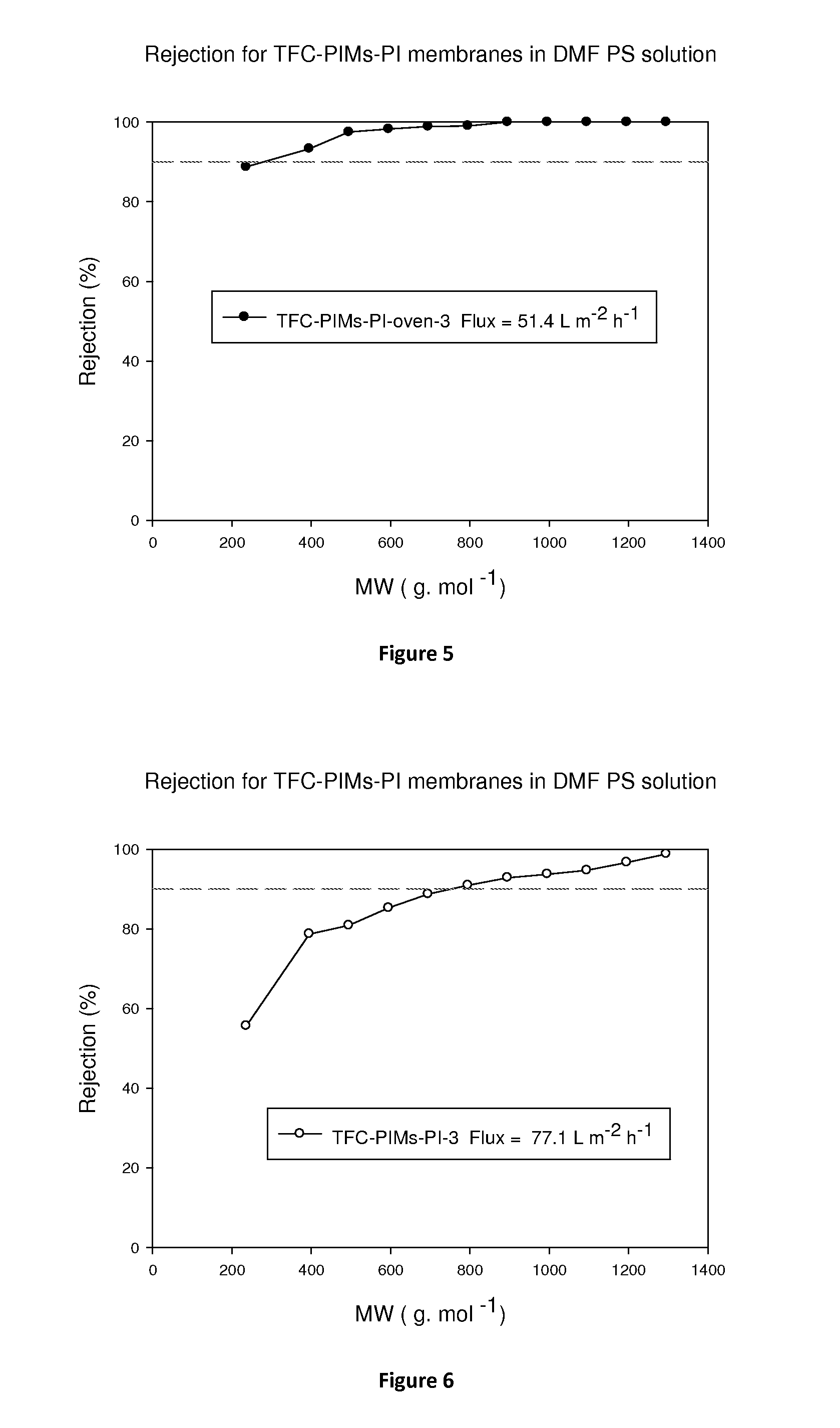

The present invention relates to a composite membrane for gas separation and / or nanofiltration of a feed stream solution comprising a solvent and dissolved solutes and showing preferential rejection of the solutes. The composite membrane comprises a separating layer with intrinsic microporosity. The separating layer is suitably formed by interfacial polymerisation on a support membrane. Suitably, at least one of the monomers used in the interfacial polymerisation reaction should possess concavity, resulting in a network polymer with interconnected nanopores and a membrane with enhanced permeability. The support membrane may be optionally impregnated with a conditioning agent and may be optionally stable in organic solvents, particularly in polar aprotic solvents. The top layer of the composite membrane is optionally capped with functional groups to change the surface chemistry. The composite membrane may be cured in the oven to enhance rejection. Finally, the composite membrane may be treated with an activating solvent prior to nanofiltration.

Owner:IP2IPO INNOVATIONS LTD

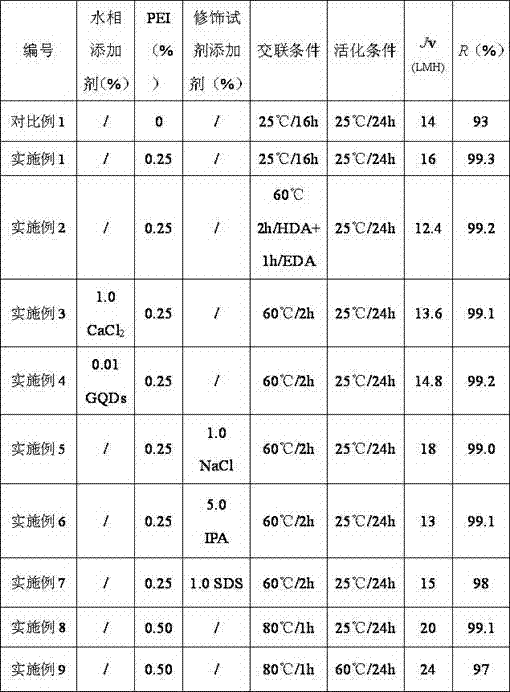

High-selectivity composite nanofiltration membrane and preparation method thereof

InactiveCN101934201AIncreasing the thicknessImproves stain resistanceSemi-permeable membranesPolyamideOxidation resistant

The invention discloses a high-selectivity composite nanofiltration membrane and a preparation method thereof. The high-selectivity composite nanofiltration membrane comprises a nonwoven layer and a polymer porous supporting layer; and the porous supporting layer is provided with one or two polyamide surface layers prepared by reacting polyamine and / or amine polyalcohol with chlorine polyacyl. Compared with the prior art, by forming one or two polyamide surface layers on the porous supporting layer through an interfacial polymerization method, the nanofiltration membrane has increased thickness of a surface layer, has more smooth, hydrolysis-resistant, oxidation-resistant and scratch-resistant surface, and improves pollution resistance; and the surface of the membrane can carry negative or positive charges, so that the composite nanofiltration membrane has a high-selectively functional desalting layer; besides, the method for preparing the composite nanofiltration membrane is simple to operate, high water flux and desalination rate are ensured under low pressure, and the service life of the membrane component is prolonged.

Owner:北京时代沃顿科技有限公司

Encapsulated essential oils

The invention provides a process for the preparation of essential oil microcapsules comprising dissolving a di- or polyisocyanate into an essential oil, emulsifying the resulting mixture in an aqueous solution containing a di- or polyamine, and / or a di or polyhydroxy compound to effect encapsulation of said essential oil through interfacial polymerization, whereby there is formed a polyurea and / or polyurethane film around the essential oil droplets which film enhances the stability of said essential oil, reduces its evaporation rate and controls its release rate when applied to a substrate.

Owner:内盖夫研发局属本古里昂大学

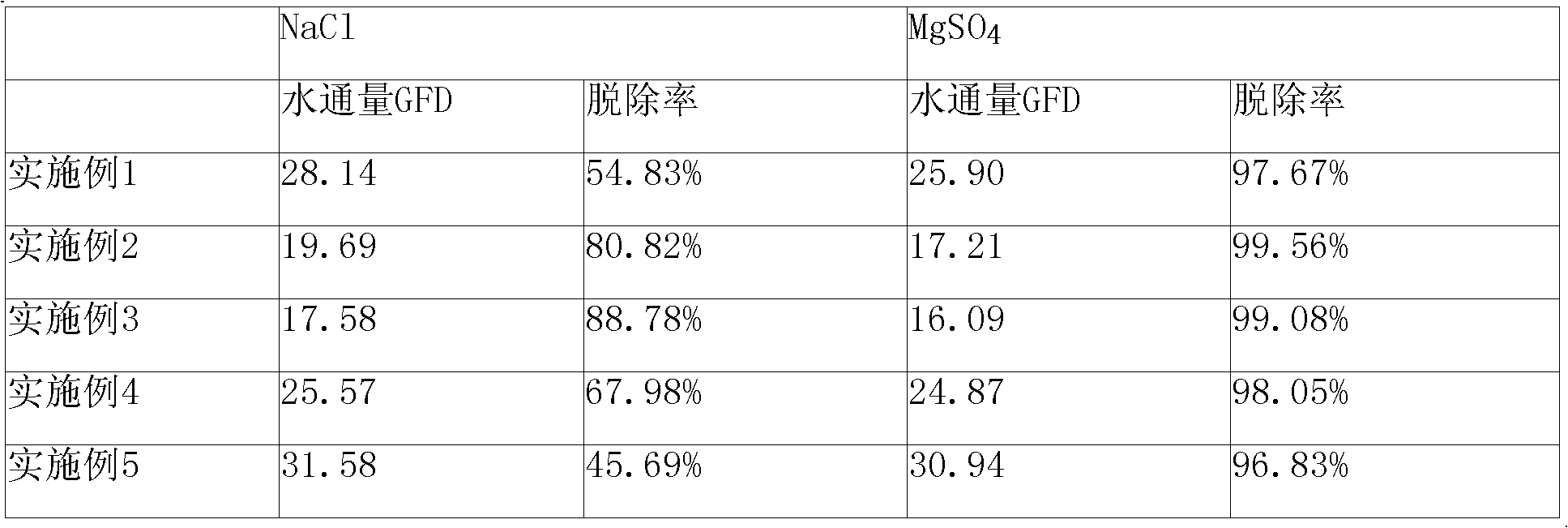

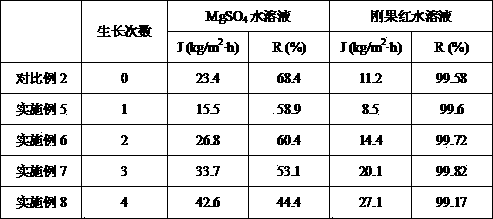

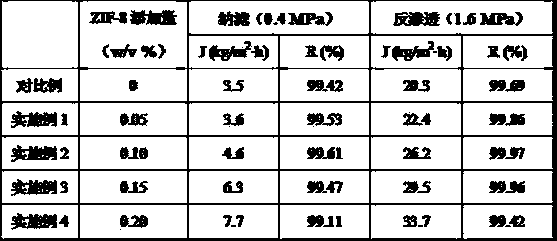

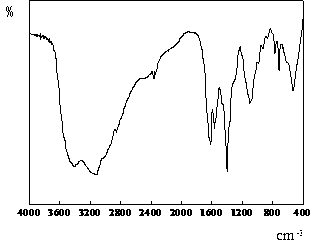

High-flux polyamide/ZIF-8 nanofiltration composite film and preparation method thereof

InactiveCN104209022ASolve the problem of fragmentationImprove permeabilitySemi-permeable membranesInorganic saltsPolymer science

The invention discloses a preparation method of a high-flux polyamide / ZIF-8 nanofiltration composite film. The preparation method comprises the following steps of (1) growing a ZIF-8 type metal-organic framework material on an ultrafiltration bottom film in situ; (2) preparing a polyamide skin layer on the bottom film with ZIF-8 particles through interfacial polymerization; and (3) post-treating a primary composite film to obtain the polyamide / ZIF-8 nanofiltration composite film. A dense skin layer of the nanofiltration film consists of ZIF-8 and polyamide; by virtue of single or multiple in-situ growth, the ZIF-8 particles grow on the surface of the bottom film, and the polyamide skin layer is formed through interfacial polymerization, and the ZIF-8 particles on the surface of the bottom film are embedded into the polyamide layer. By use of a ZIF-8 multi-hole structure and a nano-grade channel size, the nanofiltration separation performance of the polyamide film of the prepared polyamide / ZIF-8 nanofiltration composite film can be improved. On the basis of the in-situ growth method, the operation of firstly synthesizing ZIF-8 and then adding into film preparation liquid is eliminated, so that the film preparation technology is simple; the performance of the polyamide / ZIF-8 film prepared by in-situ growth for multiple times is high; when the nanofiltration composite film is used for separating an inorganic salt aqueous solution system, the permeation flux can be increased; when the nanofiltration composite film is used for separating a congo red aqueous solution, the permeation flux and the retention rate can be increased at the same time.

Owner:BEIJING FORESTRY UNIVERSITY

Crosslinked hyperbranched polyalcohol composite nano filter membrance and method of preparing the same

InactiveCN101254417AImprove throughputHigh retention rateSemi-permeable membranesFood additiveUltrafiltration

The invention discloses a crosslinking hyper branched polymer composite nanofiltration membrane as well as the preparation method thereof. The crosslinking hyper branched polymer composite nanofiltration membrane is prepared by taking an ultrafiltration membrane as a basement membrane and crosslinking hyper branched polymer as a selecting layer through hyper branched polymer and the interfacial polymerization of polybasic acid, polybasic acyl chloride, polybasic anhydride and polybasic amine; and the interfacial polymerization takes the mixed solution of water and ethanol as the water phase and n-hexane, n-heptane or n-octane as the organic phase. As the hyper branched polymer has the spheroidal structure, a plurality of nano-voids exist in the interior of the molecule, so as to enable the selecting layer of the crosslinking hyper branched polymer composite nanofiltration membrane to be looser, and leads the nanofiltration membrane to maintain high flux and retention rate under the lower operating pressure. The nanofiltration membrane can be used in the fields of medicament, foodstuff, environmental protection, etc. The composite nanofiltration membrane is applicable to the separation and the condensation of high valence ions, low valence ions, neutral particles, drugs, food additives, etc.

Owner:ZHEJIANG UNIV

Microencapsulated compositions and methods for tissue mineralization

ActiveUS20100272764A1Increase contentHigh densityCosmetic preparationsImpression capsActive agentP phosphate

The present invention is directed to compositions, products and methods useful for bone and tooth mineralization. The compositions comprise polymer microcapsules containing aqueous salt solutions. The shells of the microcapsules can be semi-permeable or impermeable. Solutions of calcium, fluoride and phosphate salts are particularly useful in the compositions of the invention. The microcapsules are preferably prepared by surfactant free inverse emulsion interfacial polymerization. Bone products include cements, scaffolds and bioactive glass. Dental products include pastes, gels, rinses and many other dental materials.

Owner:PREMIER DENTAL PRODS

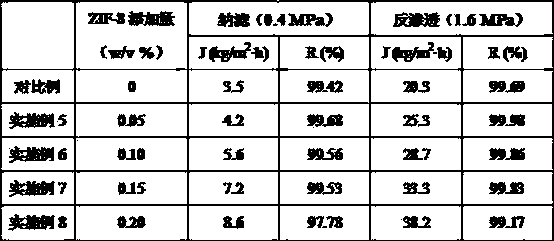

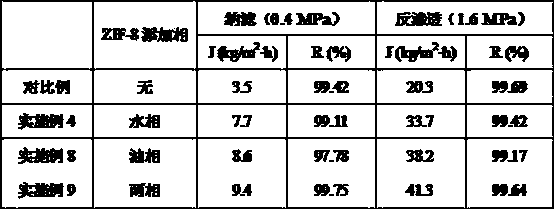

Preparation method of aromatic polyamide film modified by ZIF-8 type metal-organic framework material

InactiveCN104209021AIncrease fluid channelFacilitate water permeation membraneSemi-permeable membranesPolymer scienceMetal-organic framework

The invention discloses a preparation method of an aromatic polyamide film modified by a ZIF-8 type metal-organic framework material. A ZIF-8 filling polyamide composite film is prepared on an ultrafiltration bottom film by an interfacial polymerization method, wherein nano-grade ZIF-8 particles are added into an m-phenylenediamine aqueous solution and / or a trimesoyl hexane solution; a polyamide ultrathin skin layer, to which ZIF-8 is added, is formed through interfacial polymerization. The preparation method has the advantages that by the use of a ZIF-8 nano-grade aperture and a three-dimensional multi-hole structure, the selectivity or the permeability of the aromatic polyamide film is improved; the prepared ZIF-8 filling polyamide composite film can serve as a nanofiltration or reverse osmosis film for removing organic matters from the aqueous solution; when the adding ratio of an organic phase or water phase solution, to which ZIF-8 is added, is 0.05-0.15% (w / v), the performance of the film is the highest, and the permeation flux and the retention rate can be increased at the same time; furthermore, the nanofiltration or reverse osmosis performance of the two-phase adding film is higher than that of a single-phase adding film.

Owner:BEIJING FORESTRY UNIVERSITY

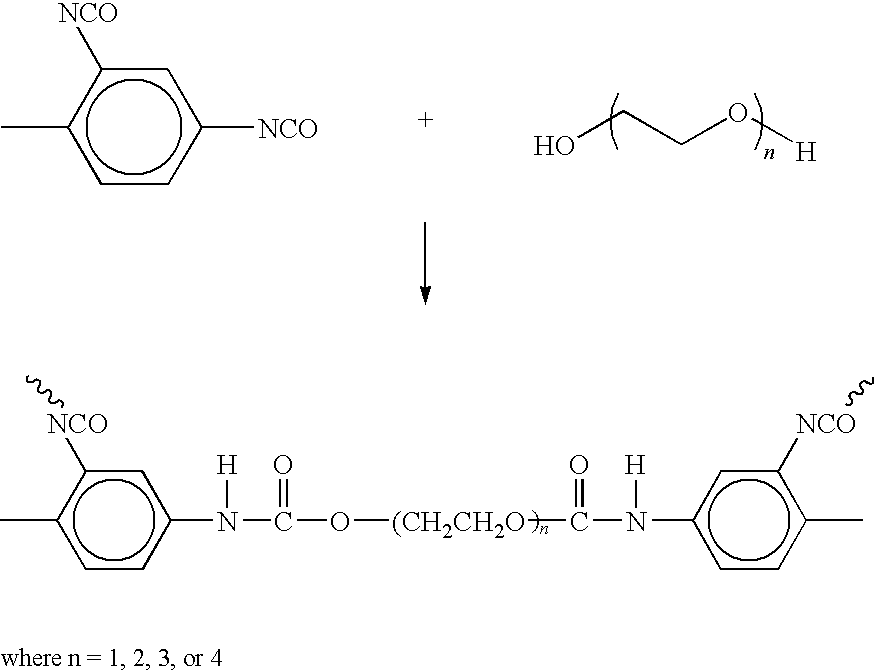

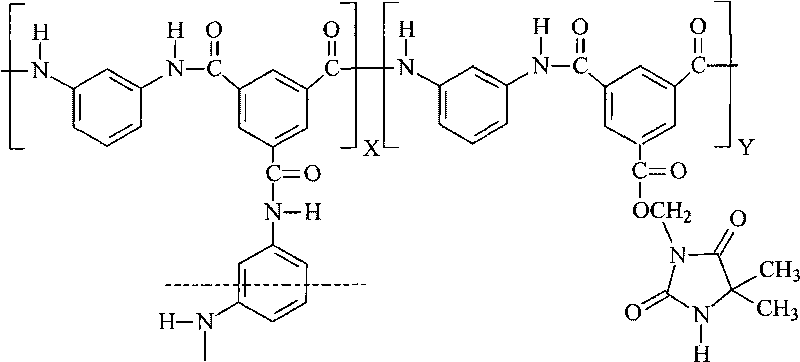

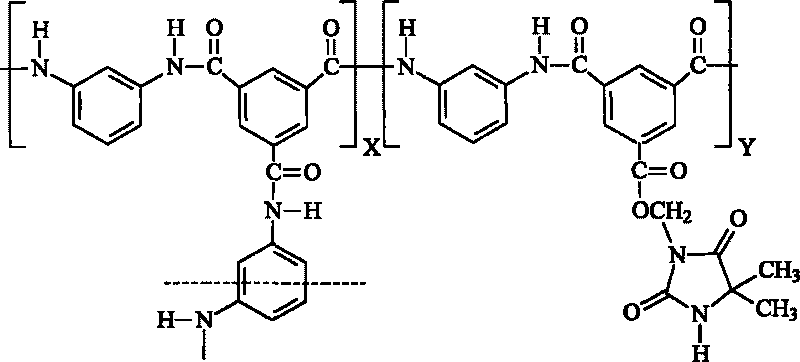

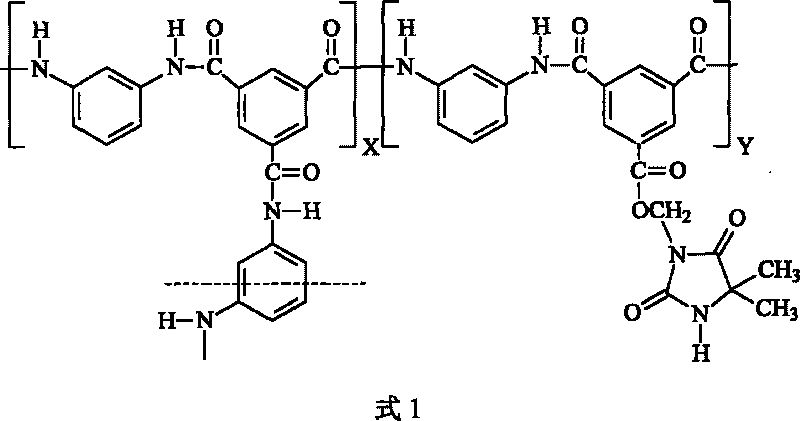

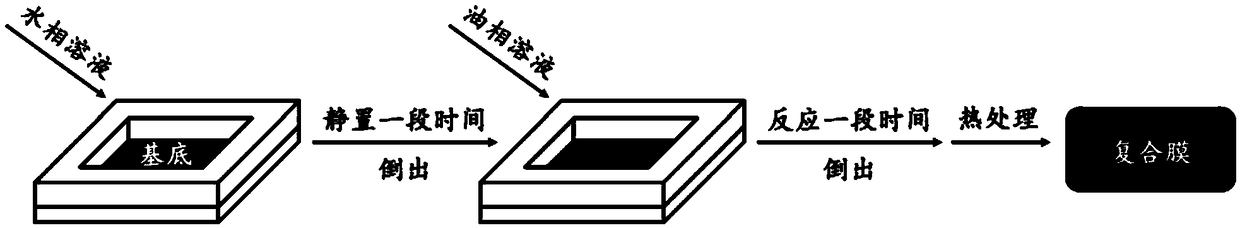

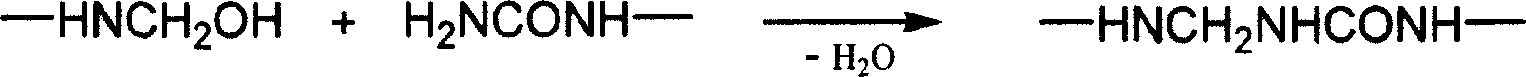

Grafted modified aromatic polyamide composite reverse osmosis membrane and preparation method thereof

ActiveCN101695636AImprove chlorine resistanceSimple methodSemi-permeable membranesHydantoin derivativesPolysulfone membrane

The invention discloses a grafted modified aromatic polyamide composite reverse osmosis membrane and a preparation method thereof, belonging to preparation technology of composite reverse osmosis membranes. The structural formula of the membrane is shown as follow. The preparation process comprises the following steps: taking a polysulphone membrane as a support membrane, preparing an aromatic polyamide composite reverse osmosis membrane to be grafted by an interfacial polymerization; enabling a graft modified solution containing 3-hydroxymethyl-5,5-dimethylhydantoin to contact the surface of the membrane to be grafted quickly for reacting, and conducting heat treatment to obtain the modified aromatic polyamide composite reverse osmosis membrane grafted with hydantoin derivatives. The invention has simple process, and the prepared membrane has the characteristics of good chlorine resistance and good microbial contamination resistance.

Owner:TIANJIN UNIV

Preparation method of high-throughput cross-linked polyimide solvent-resistant agent nanofiltration membrane and application thereof

ActiveCN107469651AGood solvent resistanceEasy to separateSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCross-linkOrganic solvent

The invention discloses a preparation method of a high-throughput cross-linked polyimide solvent-resistant agent nanofiltration membrane. The preparation method comprises the following steps: interface polymerization, polyamines modification, chemical cross-linking and solvent activation. According to the preparation method disclosed by the invention, the polyamines modification on the surface of an original ecological membrane is carried out after the interface polymerization is carried out, so that the separation performance and the solvent-resistant agent performance of the membrane are obviously improved. The polyamines have more free amino groups, so that the cross-linking degree of an interface separation layer is greatly enhanced, and the solvent-resistant agent performance of the membrane is effectively improved; polyamines modified reagents containing different additives are adopted, so that the separation performance of the membrane can be improved. The preparation process disclosed by the invention is simple, and has good application prospects in the fields of separation of organic solvent systems and treatment on water containing organic solvents.

Owner:OCEAN UNIV OF CHINA

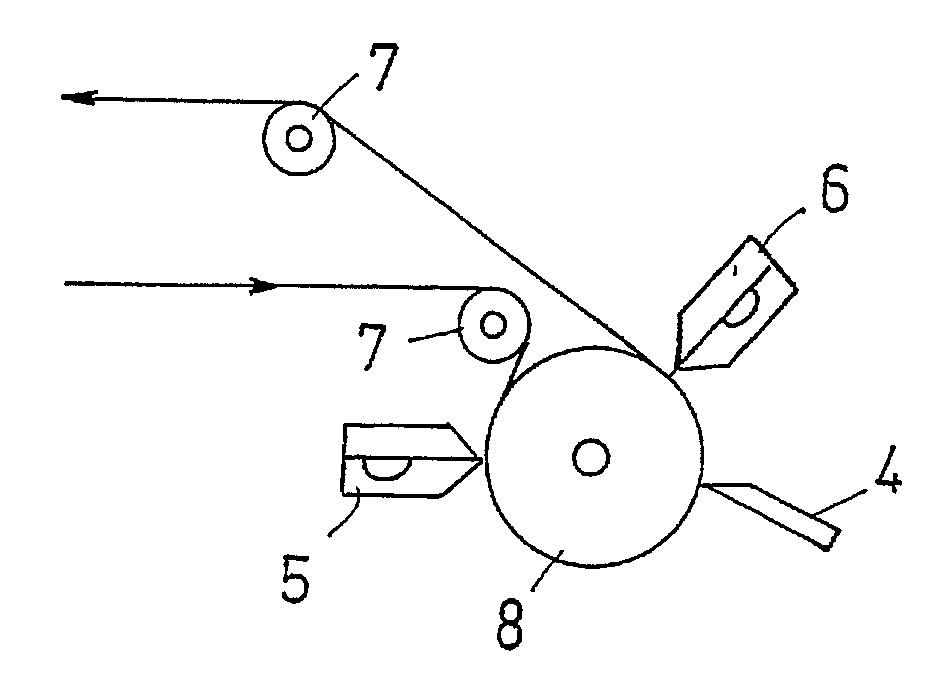

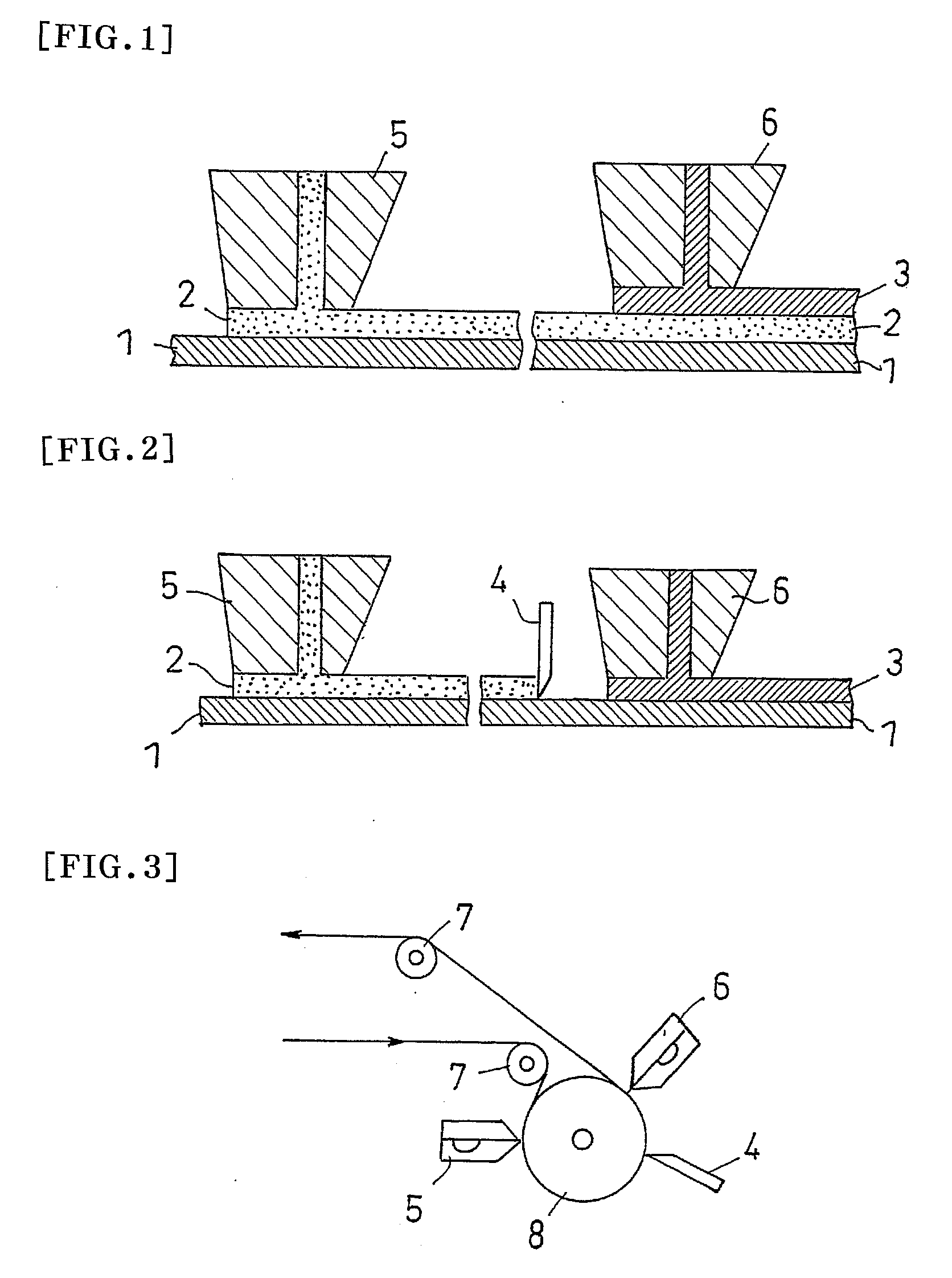

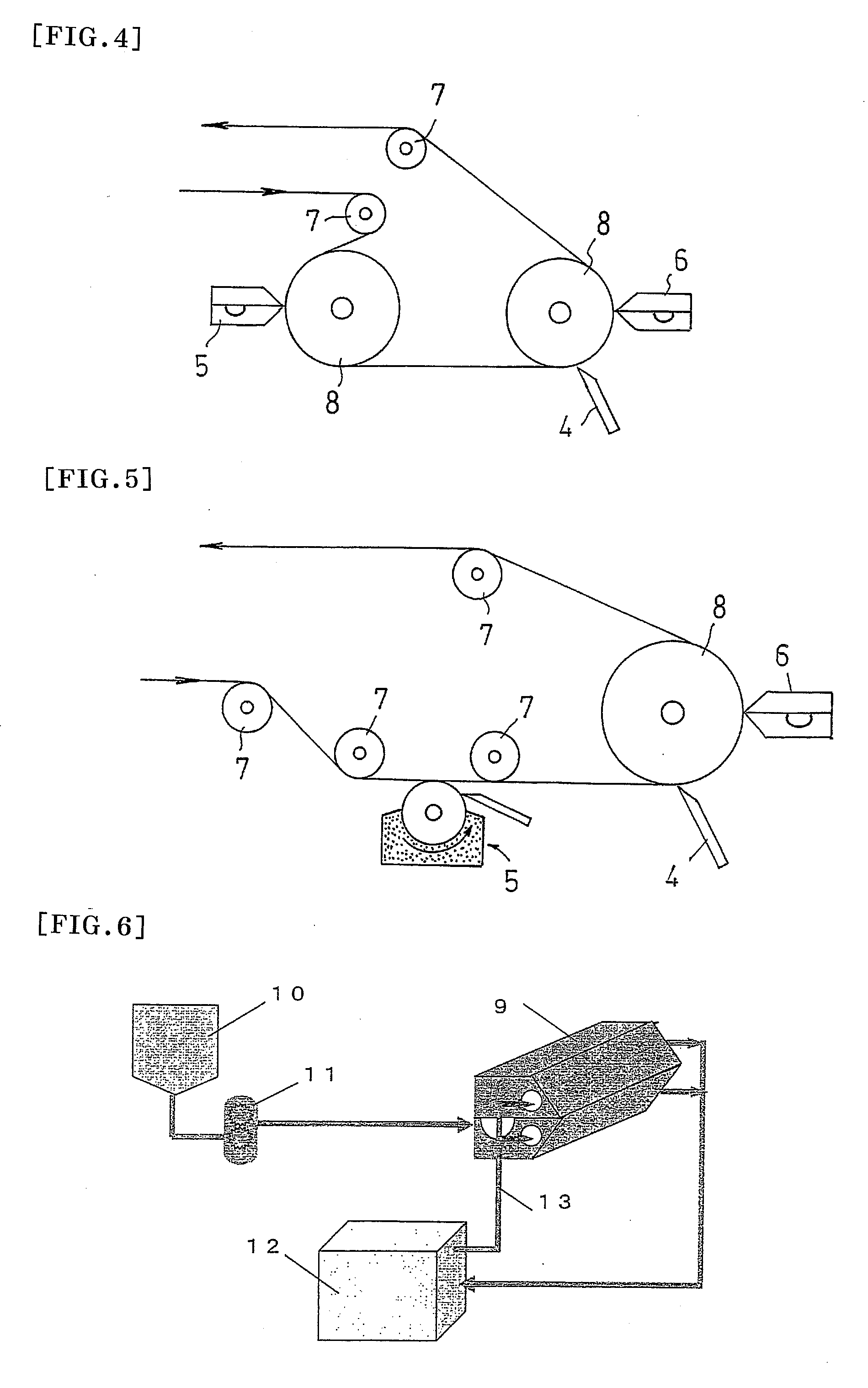

Process for producing composite reverse osmosis membrane

InactiveUS20090050558A1Reduce the amount of solutionEasy to operateMembranesPretreated surfacesReverse osmosisPolyamide

Provided is a process for continuously producing a composite reverse osmosis membrane comprising a polyamide skin layer and a porous support for supporting the polyamide skin layer, the method comprising: A) applying an aqueous solution α containing a compound having two or more reactive amino groups to form a covering layer of an aqueous solution on the porous support while moving the porous support; B) permeating the aqueous solution α in micro pores of the porous support by holding the covering layer on the porous support for 0.2 to 15 seconds; C) removing the covering layer while holding the aqueous solution α within the micro pores of the porous support; and D) forming the polyamide skin layer by applying an organic solution β containing a polyfunctional acid halide onto the surface of the porous support to make the aqueous solution α contact the organic solution β for interfacial polymerization.

Owner:NITTO DENKO CORP

High-water-flux forward-osmosis composite membrane and preparation method thereof

ActiveCN103977718AHigh selectivityImprove hydrophilicitySemi-permeable membranesConcentration polarizationPolysulfone membrane

The invention relates to a high-water-flux forward-osmosis composite membrane and a preparation method thereof. The forward-osmosis composite membrane is a polysulfone-sulfonated polysulfone-inorganic filler blended / polyamide composite membrane. A traditional osmosis membrane is generally applied to a reverse-osmosis system, and if the traditional osmosis membrane is used in a forward-osmosis process, the water flux of osmosis is far lower than a theoretical value since the traditional osmosis composite membrane is large in thickness, the hydrophilicity of a supporting layer of a polyamide layer is poor so as to cause serious inner concentration polarization. The preparation method comprises the following steps: blending a polymer with a modifier to form film casting liquid; after scraping or leveling, performing non-solvent coagulating bath with water; by a phase-inversion method, preparing a polysulfone ultrafiltration membrane with good hydrophilicity, high porosity, uniform surface pore structure and narrow pore diameter distribution; and in a clean environment and at room temperature, airing the polysulfone membrane till the surface is dry, and growing a polyamide active layer on the surface of the polysulfone membrane by an interfacial polymerization method, thereby obtaining the forward-osmosis composite membrane with good hydrophilicity, high porosity, low thickness and high mechanical strength. The high-water-flux forward-osmosis composite membrane disclosed by the invention has the advantages that not only the osmosis flux is high, but also the reverse leakage of an extraction medium is low, and the selective permeability is good.

Owner:UNIV OF SCI & TECH OF CHINA

Composite Membranes and Membrane Systems and Methods For Production and Utilization Thereof

InactiveUS20080197070A1Easy to useImprove foulingSemi-permeable membranesMembranesHydrophilizationPolymer science

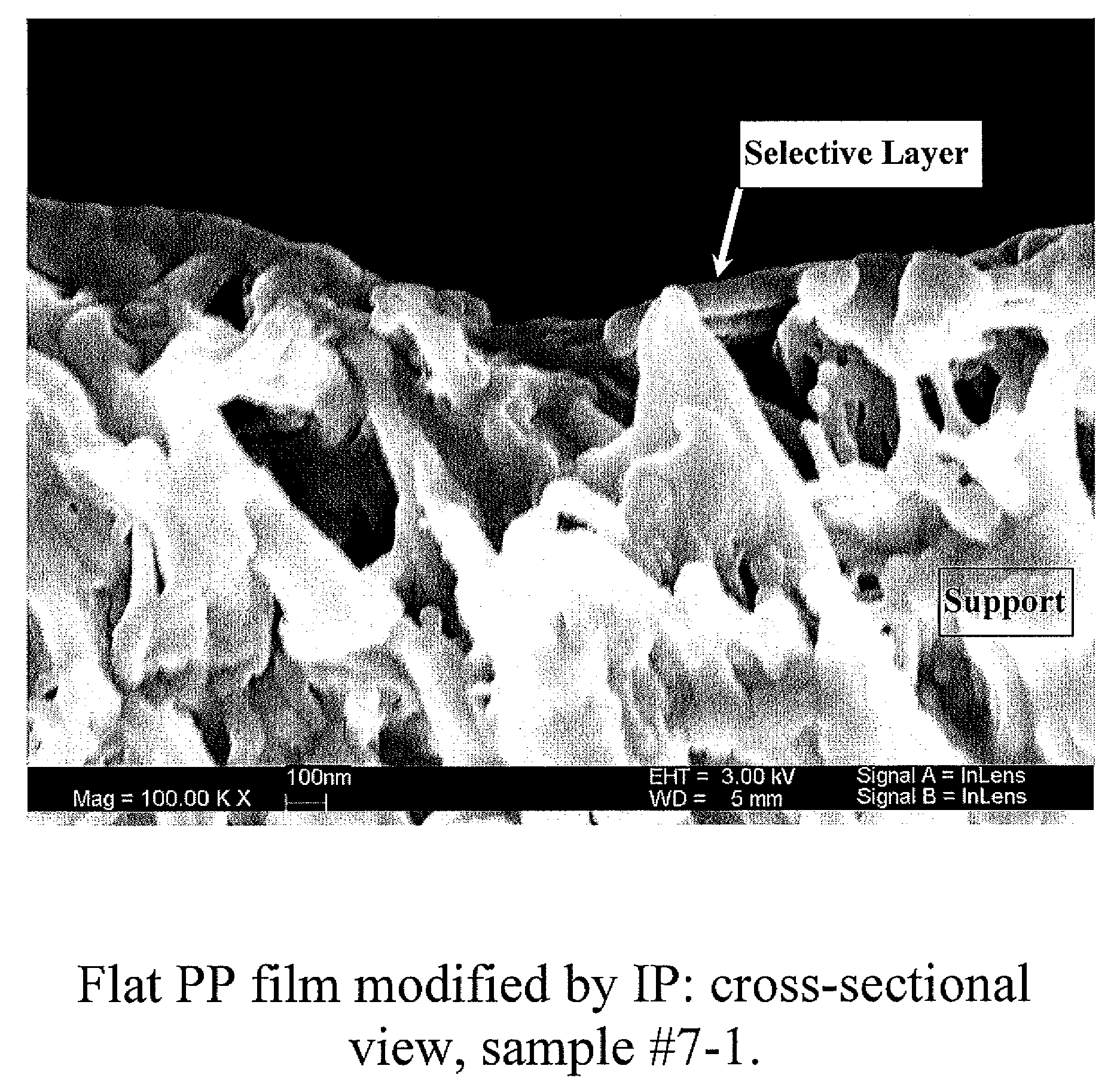

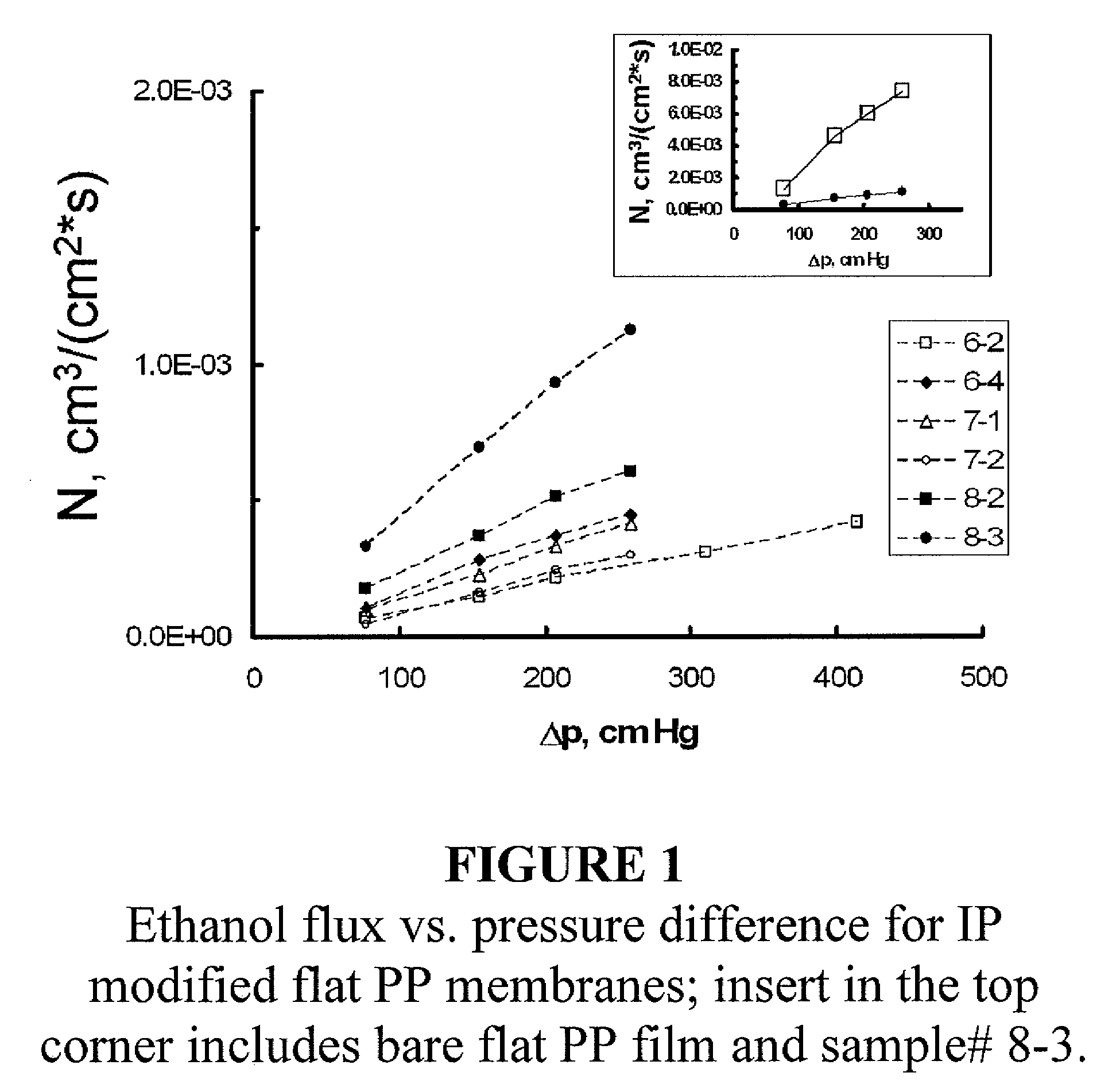

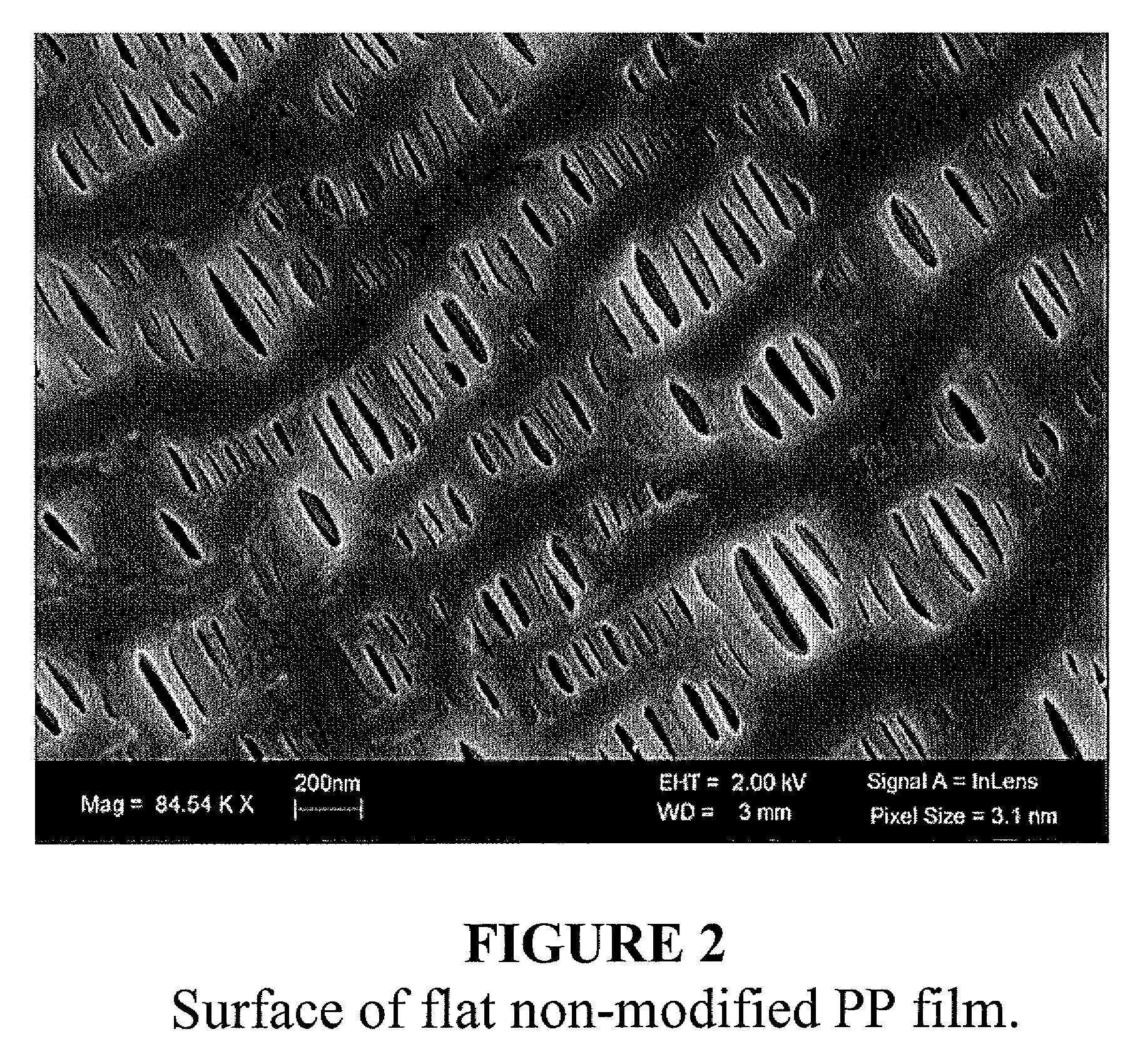

Thin film composite membranes on polyolefin structures may be prepared by interfacial polymerization on a polyolefin support. Polyolefin structures may have hollow and / or solid portions. The polyolefin structure may be hydrophilized prior to interfacial polymerization. The hydrophilized structure may also be treated with an aqueous monomer containing solution first, followed by the organic monomer containing solution. Alternatively, an organic monomer solution may be introduced first, followed by the aqueous monomer containing solution when treating a hydrophilized structure. The formed membrane may possess advantageous characteristics, including stability, hydrophilicity, predetermined pore sizes and / or solvent resistance.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Preparation method of positively charged composite nanofiltration membrane

The invention discloses a preparation method of a positively charged composite nanofiltration membrane, belonging to the technical field of the membrane. The key technology comprises the processes of utilizing polyethyleneimine (PEI), chitosan quaternary ammonium salt, and nano TiO2 as water-phase film-forming materials; taking trimesoyl chloride (TMC) as an organic-phase film-forming material; taking ultrafiltration membranes such as polysulfone, polyether sulfone and sulfonated polyethersulfone as supported base membranes, and preparing the PEI / chitosan quaternary ammonium salt / TiO2 / TMC composite nano-filtration membranes by an interfacial polymerization method. The membrane has the advantages of high flux, high dye intercept rate, and low intercept rate of inorganic salt such as sodium sulfate and sodium chloride, can generate negative intercept phenomenon of salt when dye / salt system is separated, is high in dye and inorganic salt separating efficiency, and is suitable for desalination and purification of coarse liquid dye, especially the preparation of high-purity liquid dye for digital ink-jet printing.

Owner:ZHENGZHOU UNIV

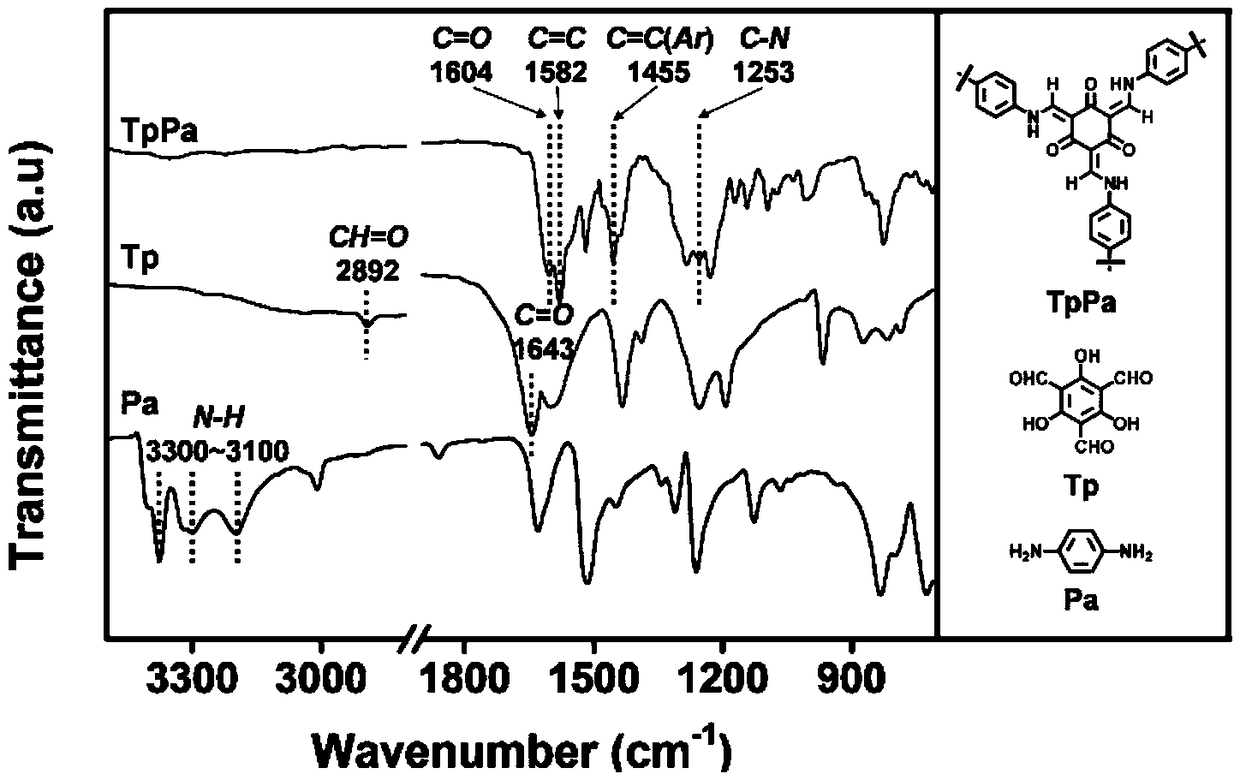

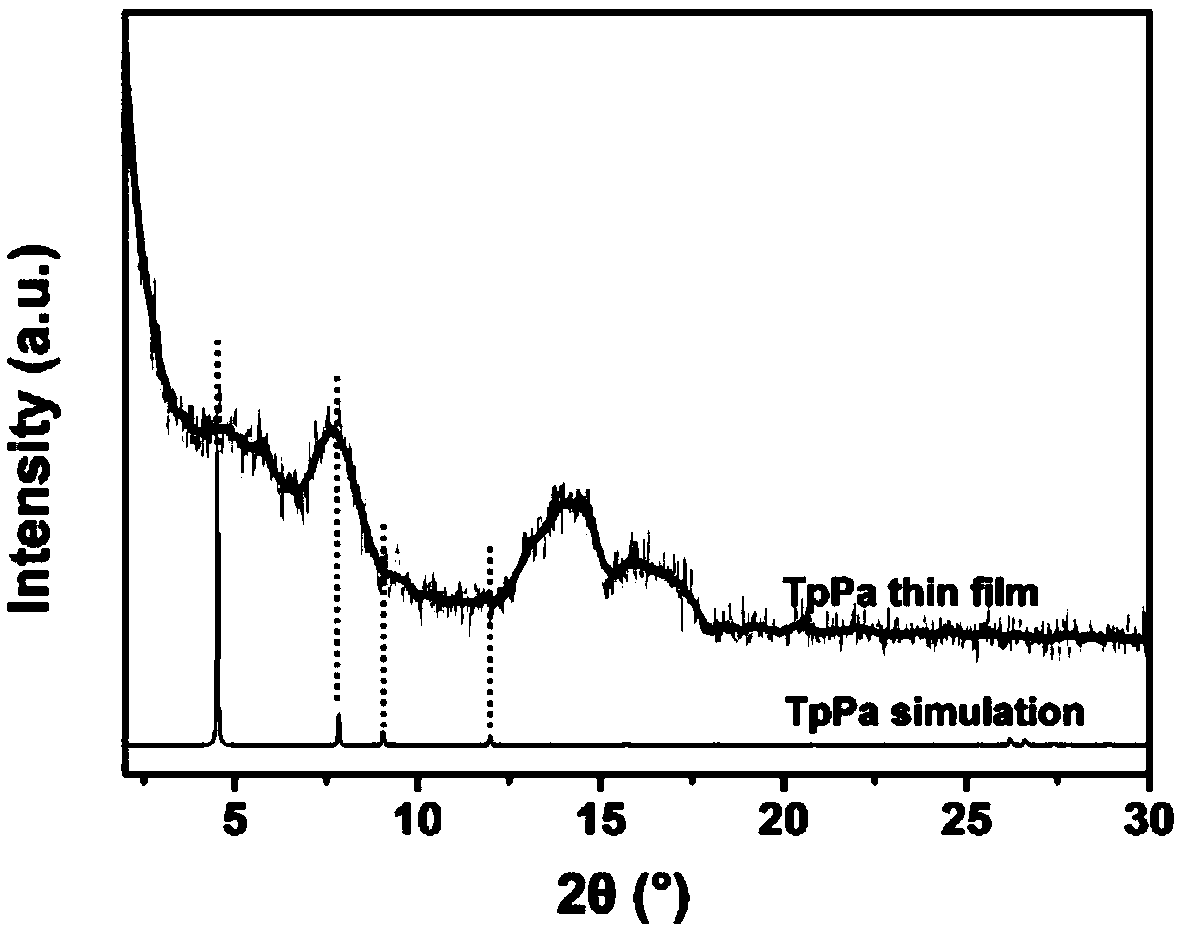

Method for preparing high-throughput covalent organic framework nano-filtration membrane on basis of interfacial polymerization

ActiveCN108889139AGood chemical stabilityHigh permeation fluxSemi-permeable membranesFiltration membraneBinding force

The invention provides a method for effectively preparing a high-throughput covalent organic framework (COFs) nano-filtration membrane on the basis of interfacial polymerization. The method comprisesthe following steps: sequentially applying an aqueous phase solution dissolved with polyamine monomers and an organic phase solution dissolved with polyaldehyde / polyketones monomers to the surface ofa porous carrier to carry out interfacial polymerization; diffusing the polyamine monomers in the aqueous phase solution saturated porous carrier to a water / oil interface to carry out schiff base reaction with polyaldehyde / polyketones in an organic phase, and gradually forming a covalent organic framework separating layer on the surface of the porous carrier by a conformal growth manner; and thencarrying out heat treatment on a composite membrane consisting of the separating layer and the porous carrier to enhance the binding force of the covalent organic framework separating layer and the porous carrier, and promoting crystallization and conversion of the covalent organic framework. The method not only is simple and convenient to operate and short in technological process, but also is well compatible with an existing process, thus, continuous product becomes possible, and the prepared composite membrane has high flux.

Owner:NANJING UNIV OF TECH

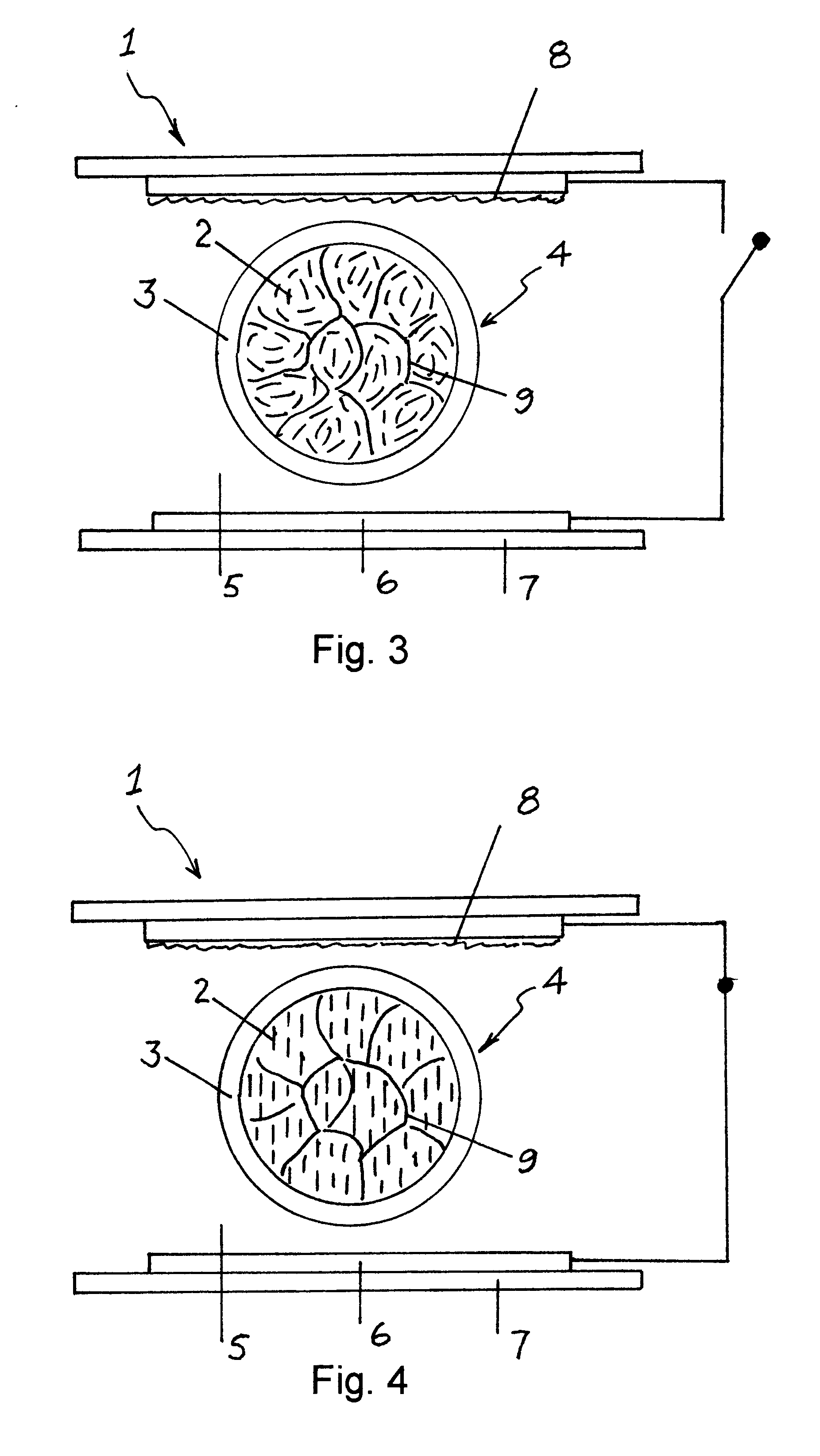

Microencapsulated liquid crystal having multidomains induced by the polymer network and method

A liquid crystal material containing polymer network forming material is microencapsulated by a method utilizing an interfacial polymerization which creates a combination of polyurethane and polyurea polymers or melamine fromaldehyde or urea formaldehyde polymer which form the capsule walls surrounding the discrete liquid crystal droplets. The prepolymer of urethane acrylate and acrylate within the liquid crystal capsules is cured under UV light irradiation to form a web-like structure and induce the formation of polydomain configuration of nematic director. This allows to produce the display having faster switching property and showing significant lower threshold voltage.

Owner:HSU YING YEN

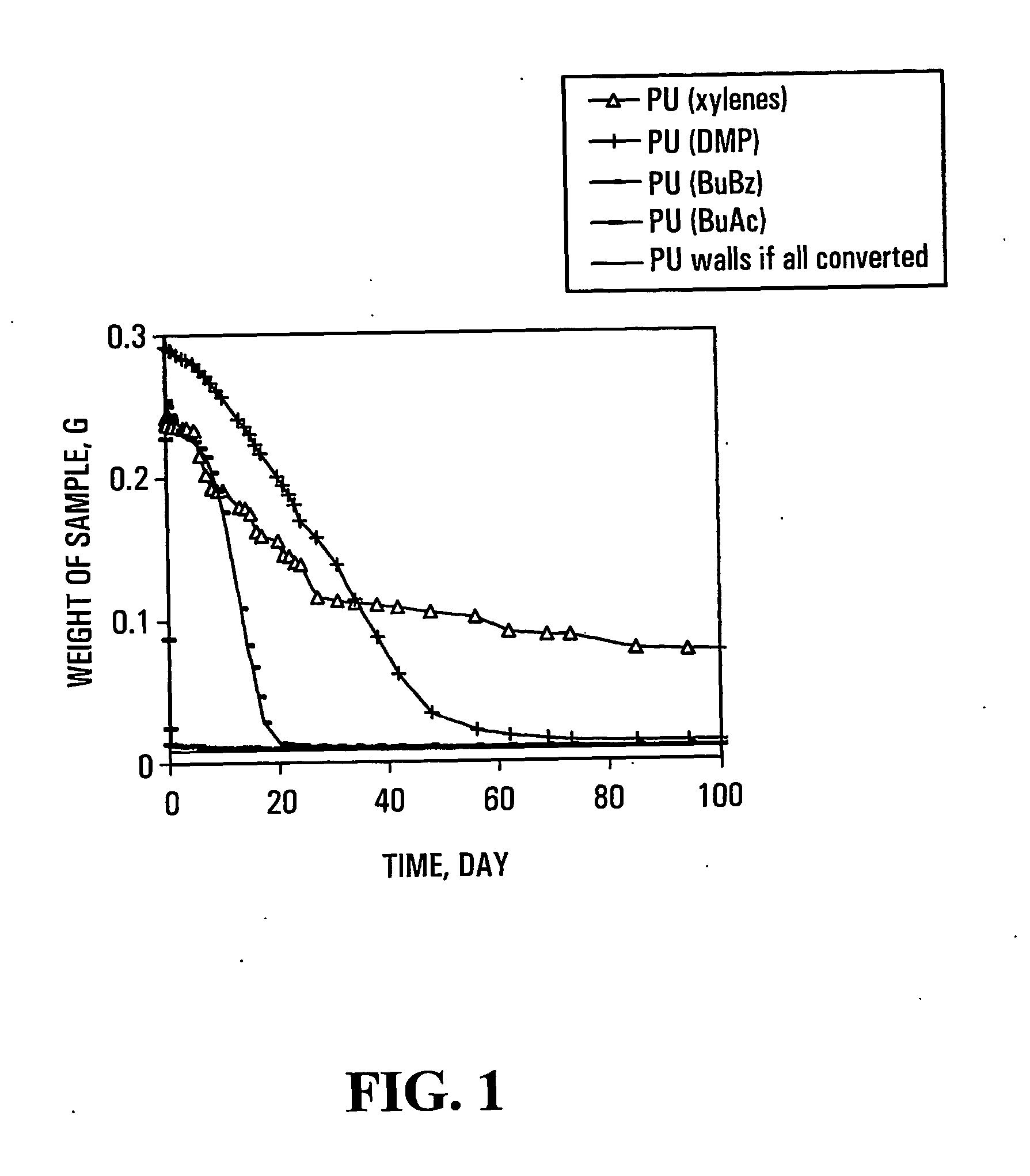

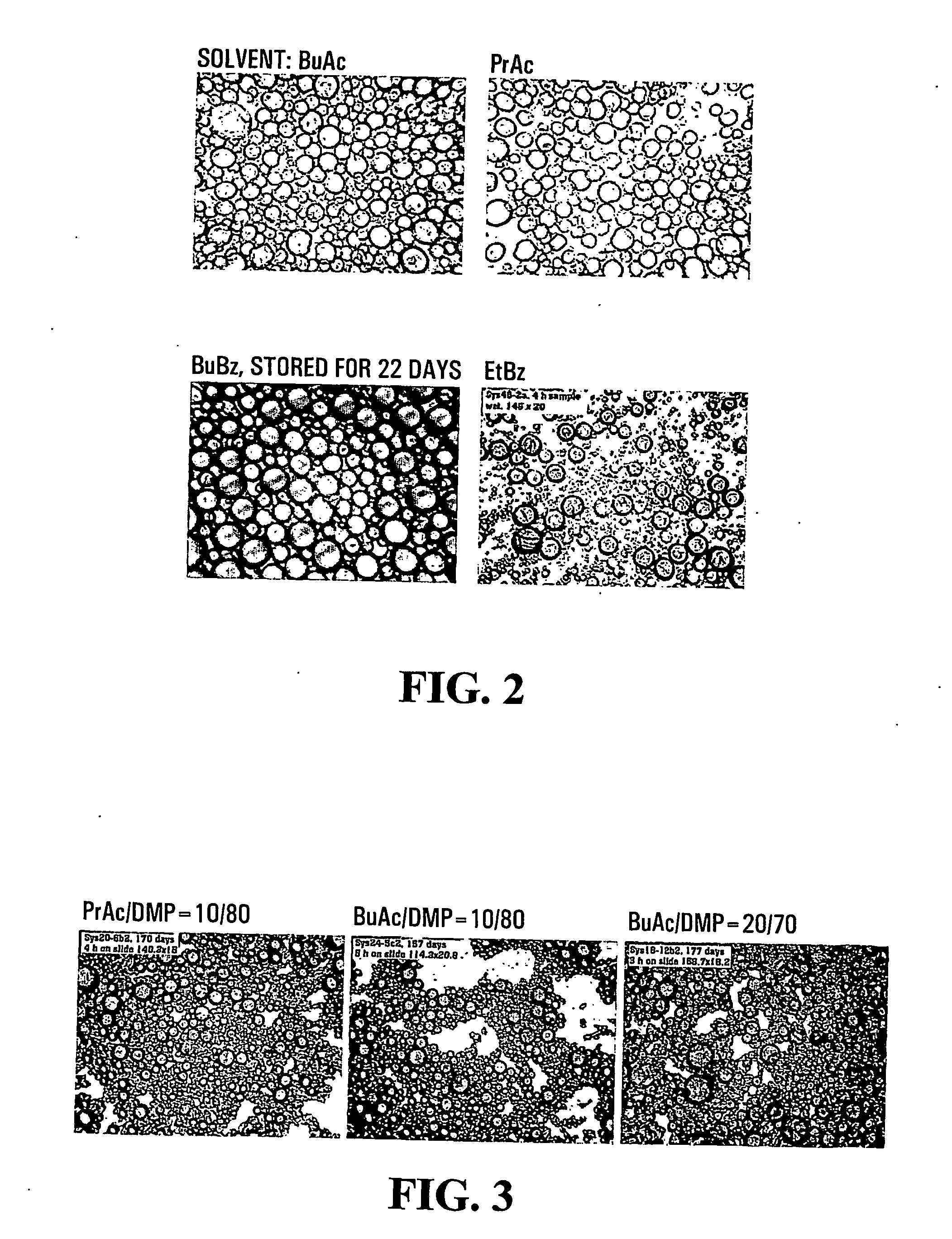

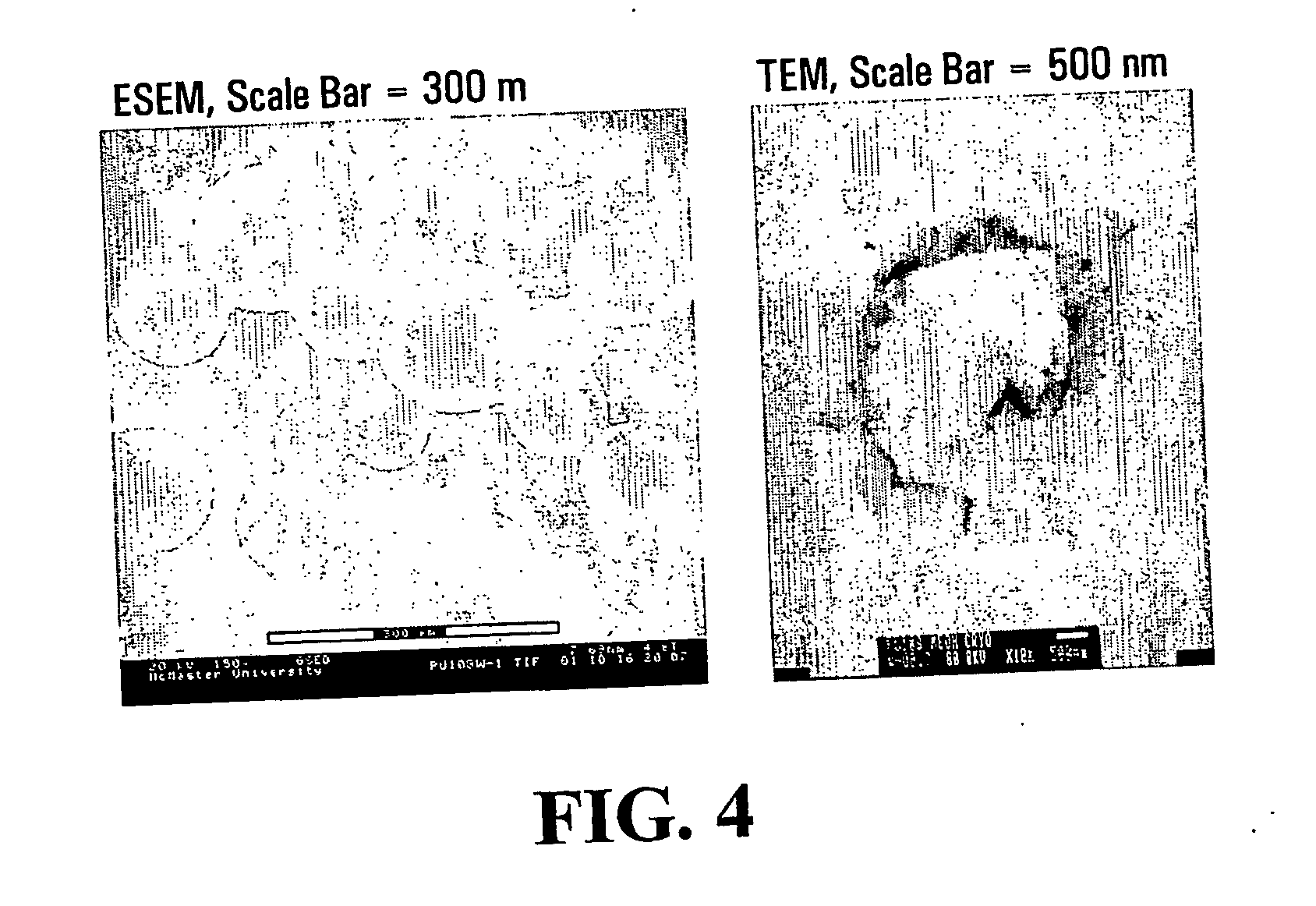

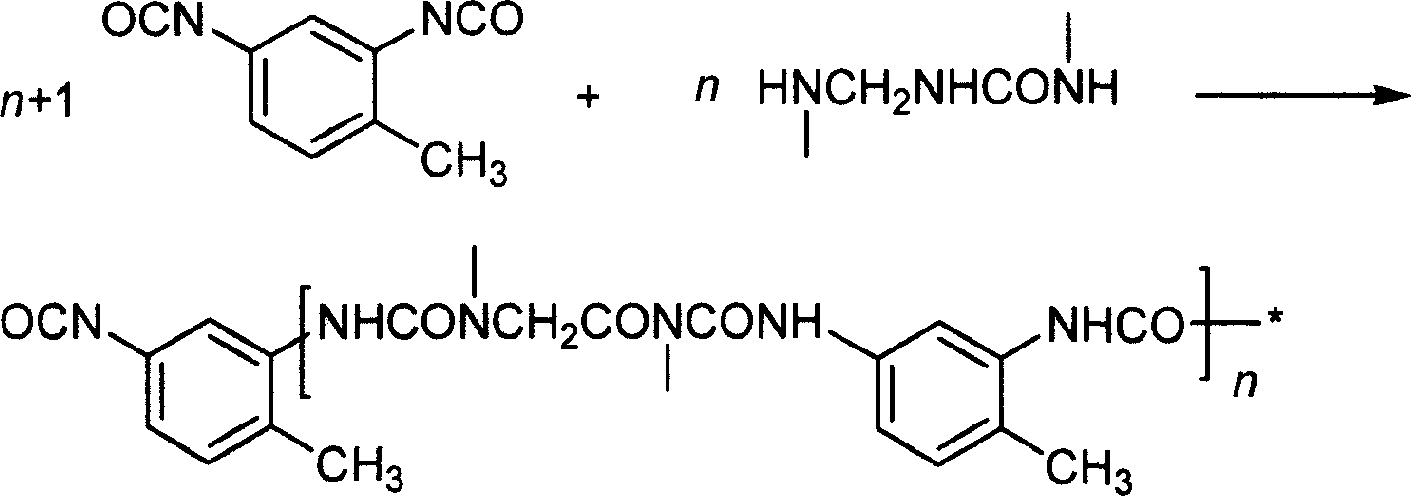

Method of encapsulating hydrophobic organic molecules in polyurea capsules

InactiveUS20050271735A1Rapid and quantitative formationFacilitated releaseBiocideCosmetic preparationsControlled releaseSolubility

It is known to encapsulate various materials in polyurea microcapsules, but obtaining satisfactory microcapsules incorporating alcoholic materials has proven difficult. A process has now been found where polyurea microcapsules are formed by interfacial polymerization between an aqueous phase and a water-immiscible phase, and properties, particularly the solubility parameters, of the water immiscible phase are closely matched to corresponding properties of the polyurea. Microcapsules prepared by this process have improved stability, mechanical strength and controlled release properties.

Owner:MCMASTER UNIV

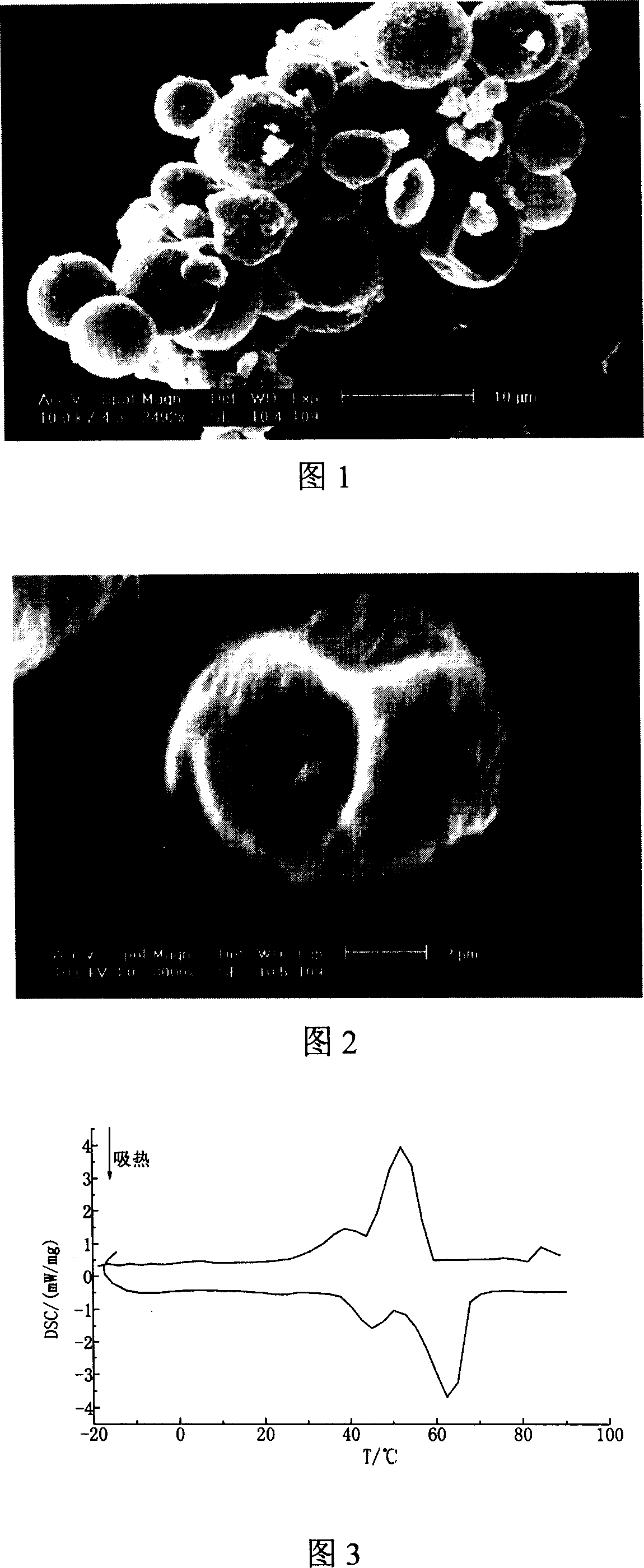

Preparation method of phase transformation material microcupsule

InactiveCN101045857AHigh mechanical strengthRaw materials are easy to getHeat-exchange elementsMicroballoon preparationParaffin waxToluene diisocyanate

This invention relates to preparation method of a facies change stuff microcapsule. It takes paraffin as phase-change material, takes toluene diisocyanate and urea-formaldehyde resin as cyst wall stuff, by interfacial polymerization and in situ polymeric method to carry out microencapsulate, to prepare double deck, microcapsule packed paraffin phase-change material. This method could prepare microcapsule phase-change material that contain any specification paraffin from 1% to 70%. Transformation temperature of this phase-change material is adjustable from 0 to 70 deg.C. This compound phase-change material can directly apply to construction region, textile region, and martial region and so on.

Owner:HUILIN SHENGDA ENERGY MATERIAL SCI & TECH DEV BEIJING

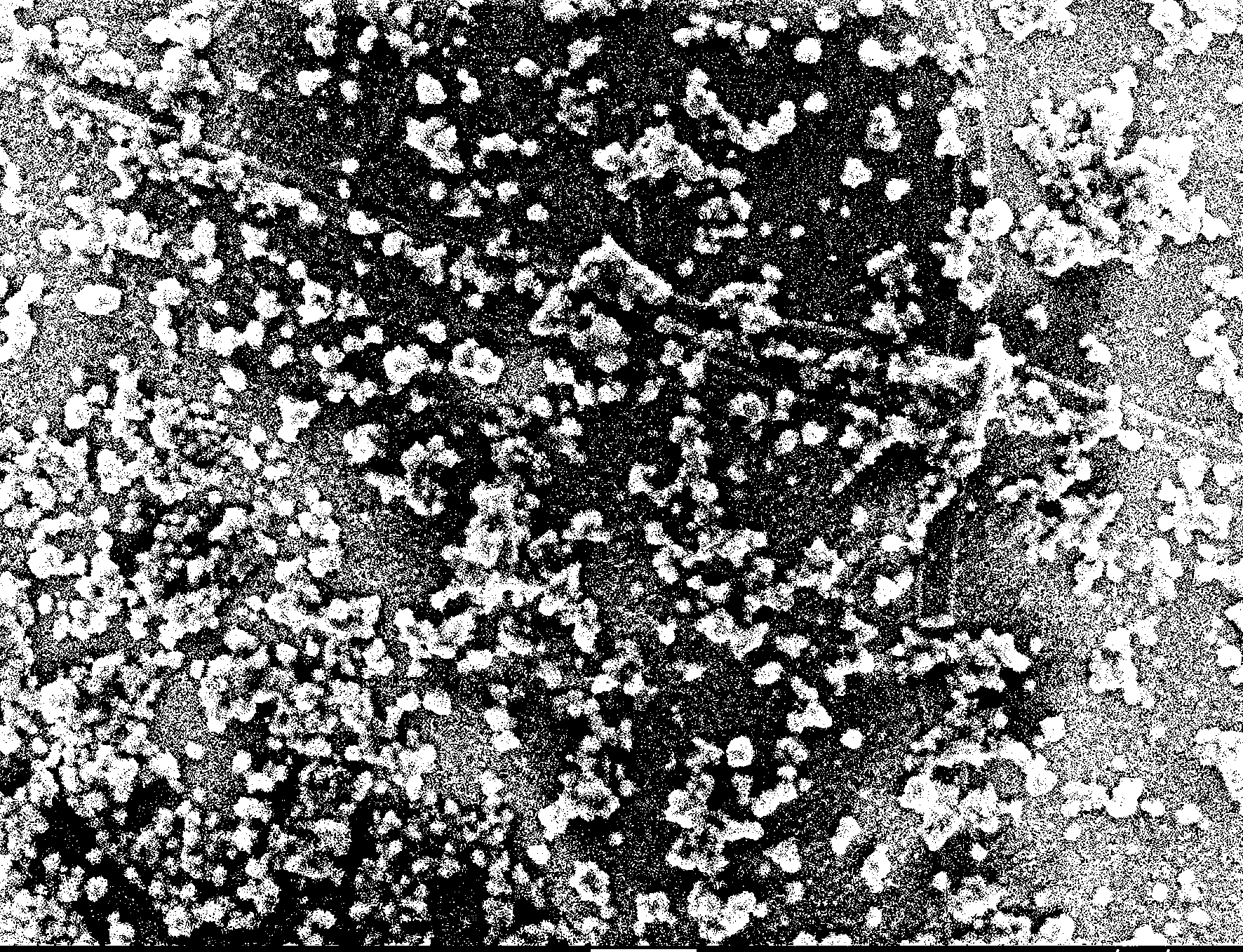

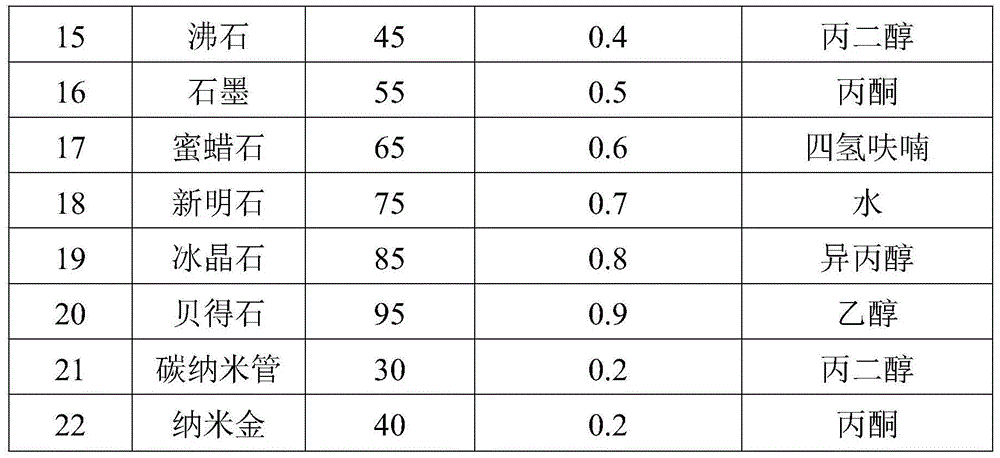

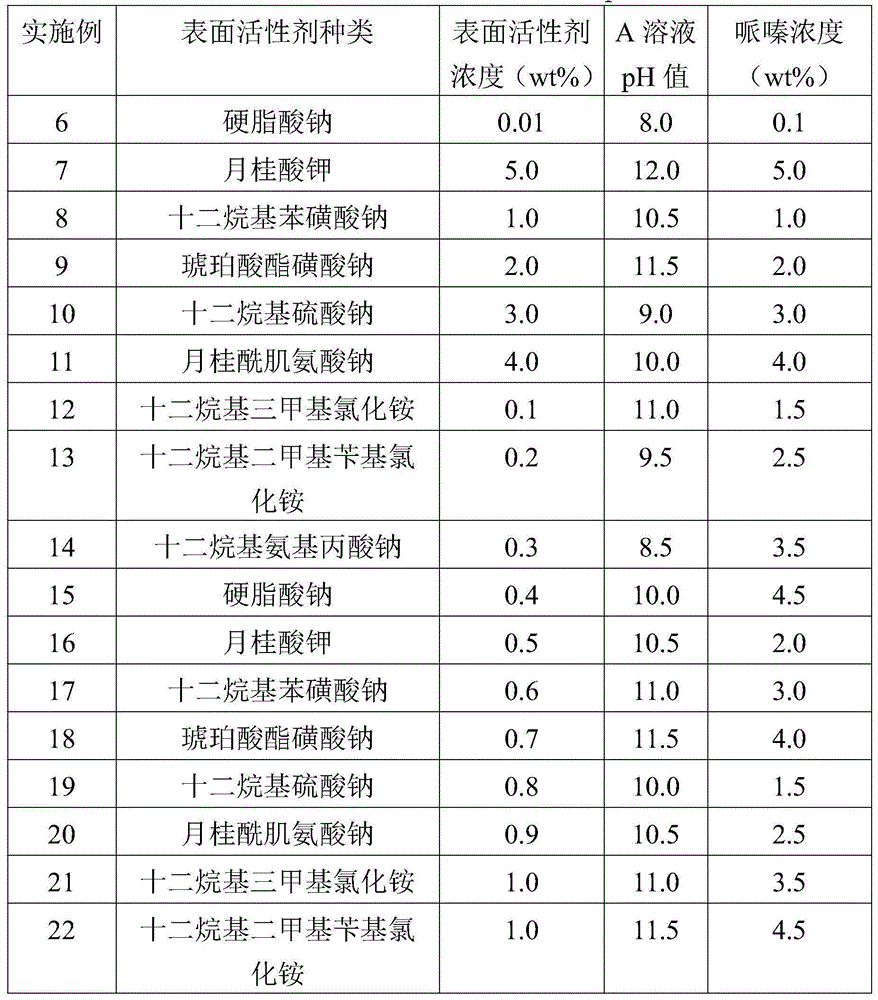

Preparation method of high-throughput anti-pollution composite nanofiltration membrane

ActiveCN104667759AImprove performanceImprove throughputSemi-permeable membranesGlycerolSurface-active agents

The invention discloses a preparation method of a high-throughput anti-pollution composite nanofiltration membrane. The preparation method comprises the following steps: inorganic nanoparticles are uniformly dispersed in a porous polymer supporting layer, a surface active agent is added in solution A, a polyamide layer is prepared on the porous polymer supporting layer through interfacial polymerization, hot water soaking treatment and glycerol moisturization treatment are adopted, and then drying is performed, and thus, the high-throughput anti-pollution composite nanofiltration membrane is prepared. According to the method, the porous supporting layer microstructure is changed by inorganic nano particles, the surface active agent is added in the solution A, and the flux and the antifouling property of the composite nanofiltration membrane are improved. The preparation method is easy, the raw material is cheap, the preparation process is simple and the method has good industrial applicability.

Owner:VONTRON TECH CO LTD

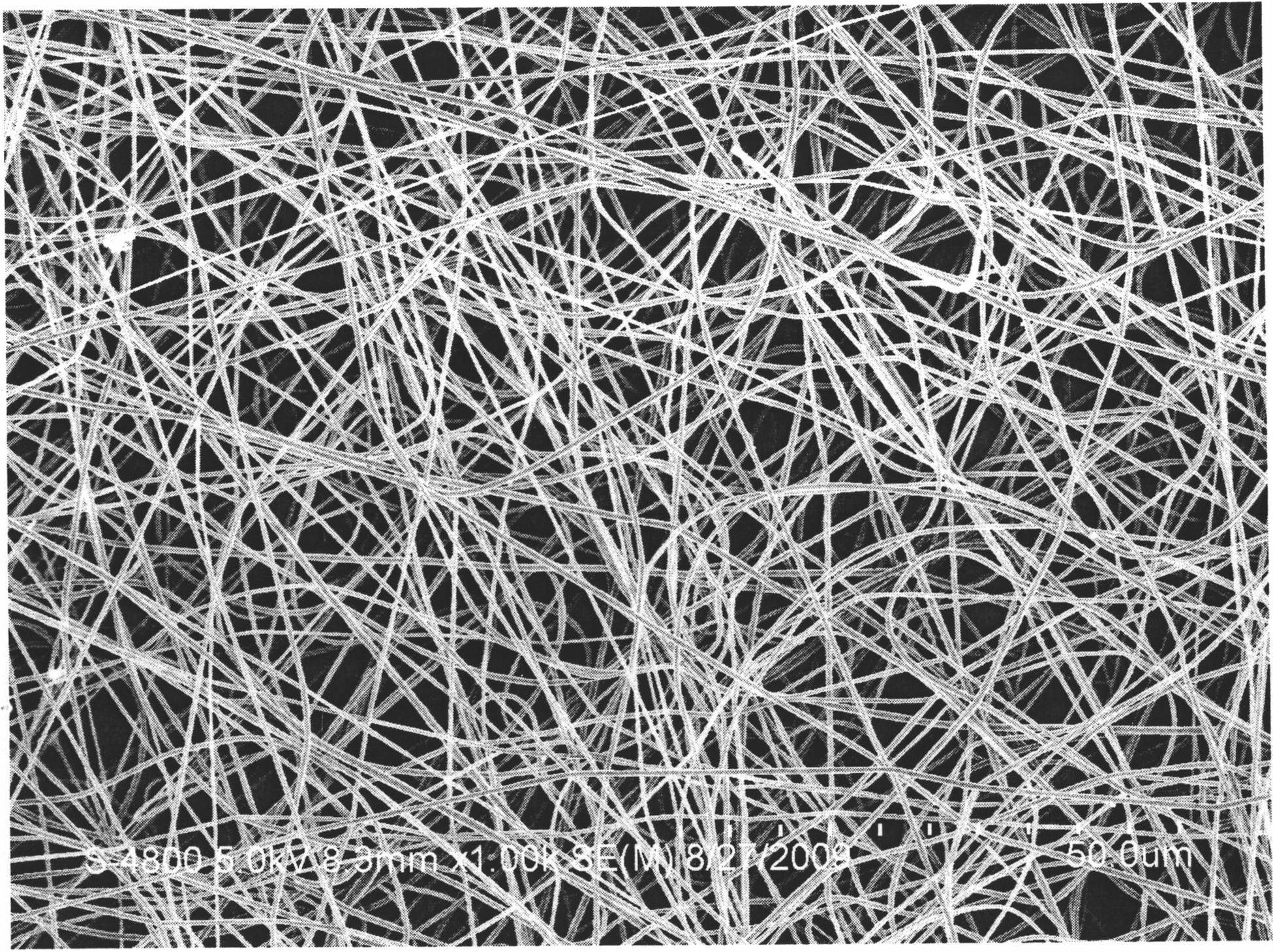

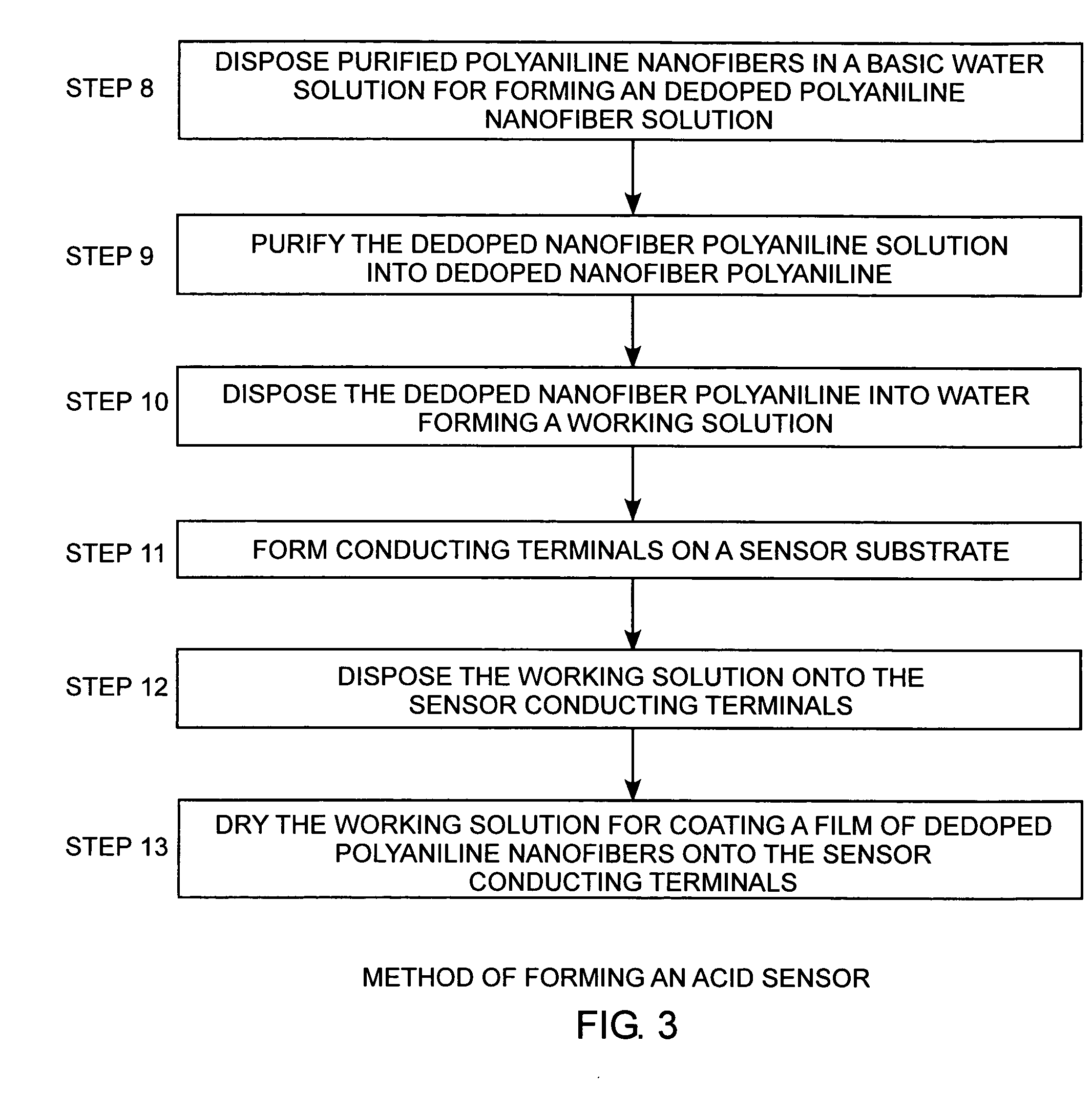

Synthetic method for conducting polymer nanofibers

ActiveUS20050131139A1High sensitivityFaster chemical time responseMaterial nanotechnologySynthetic resin layered productsFiberTime response

Polymer nanofibers, such as polyaniline nanofibers, with uniform diameters less than 500 nm can be made in bulk quantities through a facile aqueous and organic interfacial polymerization method at ambient conditions. The nanofibers have lengths varying from 500 nm to 10 μm and form interconnected networks in a thin film. Thin film nanofiber sensors can be made of the polyaniline nanofibers having superior performance in both sensitivity and time response to a variety of gas vapors including, acids, bases, redox active vapors, alcohols and volatile organic chemicals.

Owner:THE AEROSPACE CORPORATION +1

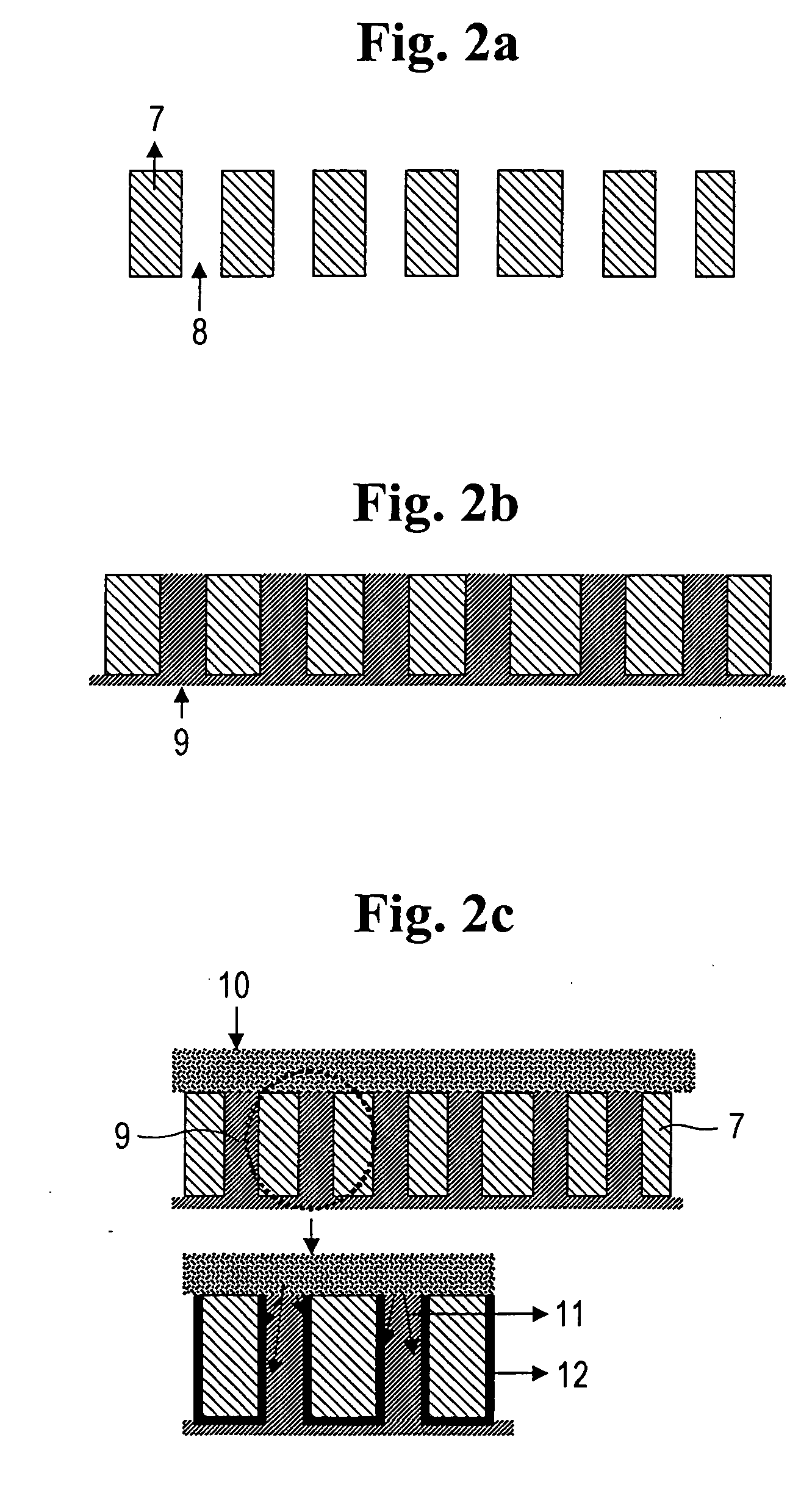

Method of fabricating a three-dimensional nanostructure

InactiveUS20070100086A1Rapid and reliable mannerManufactured rapidly and reliablyMaterial nanotechnologyNanostructure manufactureInterfacial reactionMicrometer

There is provided a rapid and reliable method of fabricating a three-dimensional organic / inorganic nanostructure of a well-arranged shape wherein tubes or fibers of several nanometer to several micrometer size have horizontal and vertical orientations. The method of the present invention comprises the following steps: A) forming a tube- or fiber-type structure of an organic or inorganic nanometer / micrometer size by an interfacial polymerization method or interfacial reaction method; and B) obtaining the organic / inorganic composite three-dimensional nanostructure.

Owner:KOREA INST OF SCI & TECH

Nanofiltration membrane with nanometer hybridized desalination layer

The invention discloses a nanofiltration membrane with a nanometer hybridized desalination layer. The desalination layer formed through interphase hybridization of an inorganic nanoparticle with a particle size of 1 to 1000 nm and polyamide or polyimide is arranged on a porous supporting layer of the membrane. A preparation method for the nanofiltration membrane mainly comprises the following steps: pre-dispersion of the nanoparticle, preparation of a solution A, preparation of a solution B, interfacial polymerization, surface polishing and roller squeezing, rinsing with deionized water, moisture retention with glycerin and drying, wherein air drying and sulfonation can be carried out after surface polishing and roller squeezing. According to the invention, nanometer hybridization effects of a high polymer nano-material in the nanofiltration membrane are made full use of, so hydrophilic performance, antioxidation performance and anti-pollution performance of the nanofiltration membrane are improved, and the nanofiltration membrane has the advantages of low pollution, great flux and a high removal rate. The preparation method is scientific and reasonable, enables the nanometer composite nanofiltration membrane with a specific nanoparticle and polyamide hybridized desalination layer to be prepared and has higher ion selectivity, low pollution capability and temperature stability.

Owner:VONTRON TECH CO LTD

Preparation method of multi-layer composite-structure filter membrane

InactiveCN102949938AIncrease water fluxHigh retention rateUltrafiltrationReverse osmosisWater useFiber

The invention relates to a method for preparing a multi-layer composite-structure filter membrane with a plasma pretreatment method. According to the filter membrane, a polymer nano-grade fiber film layer prepared through an electrostatic spinning method, and a hydrophilic polymer ultra-thin separation layer are sequentially arranged on a non-woven fabric support layer substrate. Before the hydrophilic polymer ultra-thin separation layer is prepared through an interfacial polymerization reaction, the plasma pretreatment is carried out on the surface of the polymer nano-grade fiber film layer, such that functional groups are grafted on the surface of the polymer nano-grade fiber. Therefore, polymer nano-grade fiber film surface property is improved, such that the polymer ultra-thin separation layer can be better compounded, and the filtering performance of the multi-layer composite-structure filter membrane is comprehensively improved. The multi-layer composite-structure filter membrane provided by the invention has the characteristics of high water flux, high retention rate, and stable chemical property. The film can be used in productions of water used in special conditions, such as domestic water and drinking water. The film is suitable to be used in fields such as medicines, foodstuffs, environment protection, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

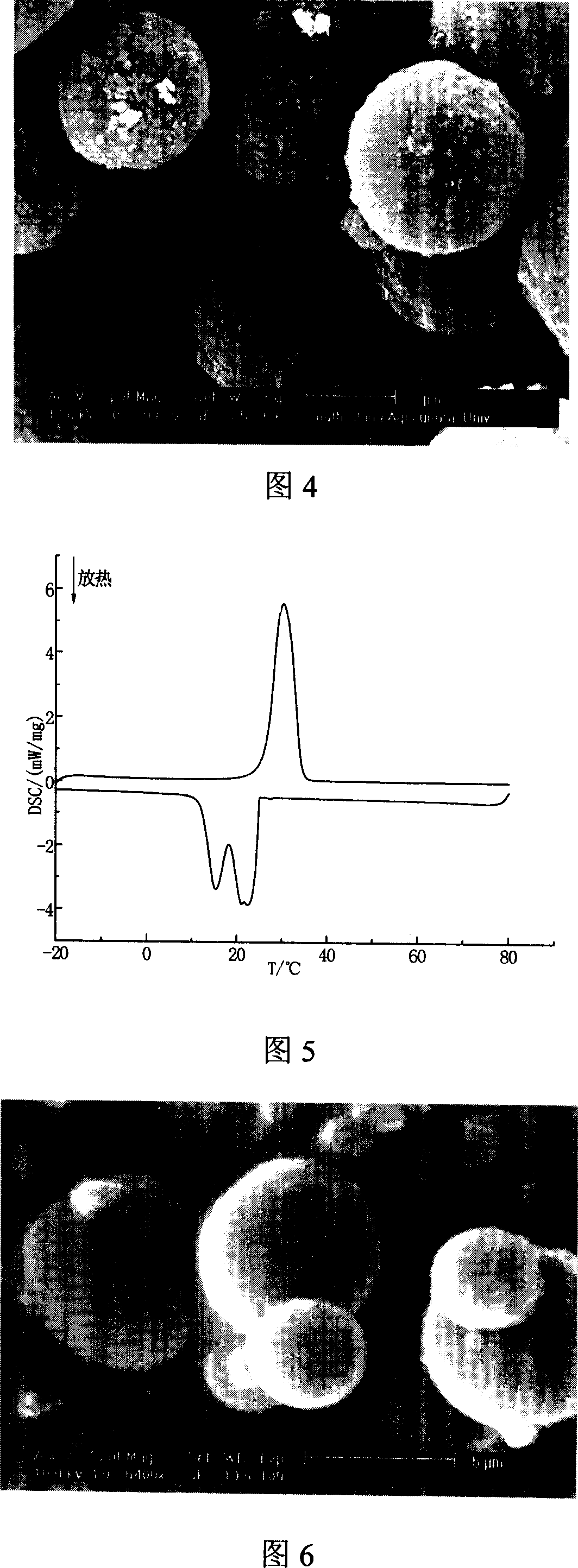

Double shell microcapsule phase change material with paraffin compound as core and its preparing process

InactiveCN1986721ATightly packedHigh strengthHeat-exchange elementsMicroballoon preparationParaffin waxChemistry

The present invention discloses double shell microcapsule phase change material with paraffin compound as core and its preparation process. The double shell microcapsule phase change material has core of phase change material paraffin or paraffin mixture with phase change temperature 20-70 deg.c and double polymer shell, including one inner shell of polyurea material formed through polymerizing polybasic amine, polyol and isocyanate or acyl chloride, and one outer shell formed through polymerizing melamine and formaldehyde. The double shell microcapsule phase change material has complete coating, low permeation and capacity of being used repeatedly, and may be used widely in textile, electronic industry and other fields.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com