Preparation method of positively charged composite nanofiltration membrane

A composite nanofiltration membrane, positively charged technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high retention rate of divalent salts and low efficiency of divalent salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1: Preparation of aqueous monomer solution

[0039] (1) Add polyethyleneimine, sodium carbonate and sodium dodecylsulfonate to deionized water, heat and stir until sodium dodecylsulfonate dissolves;

[0040] (2) Add 2-hydroxypropyltrimethylammonium chloride chitosan to the solution described in (1), heat and stir until 2-hydroxypropyltrimethylammonium chloride dissolves;

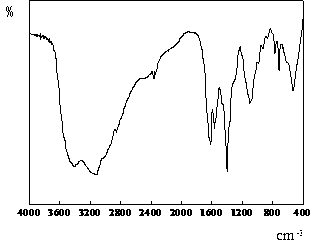

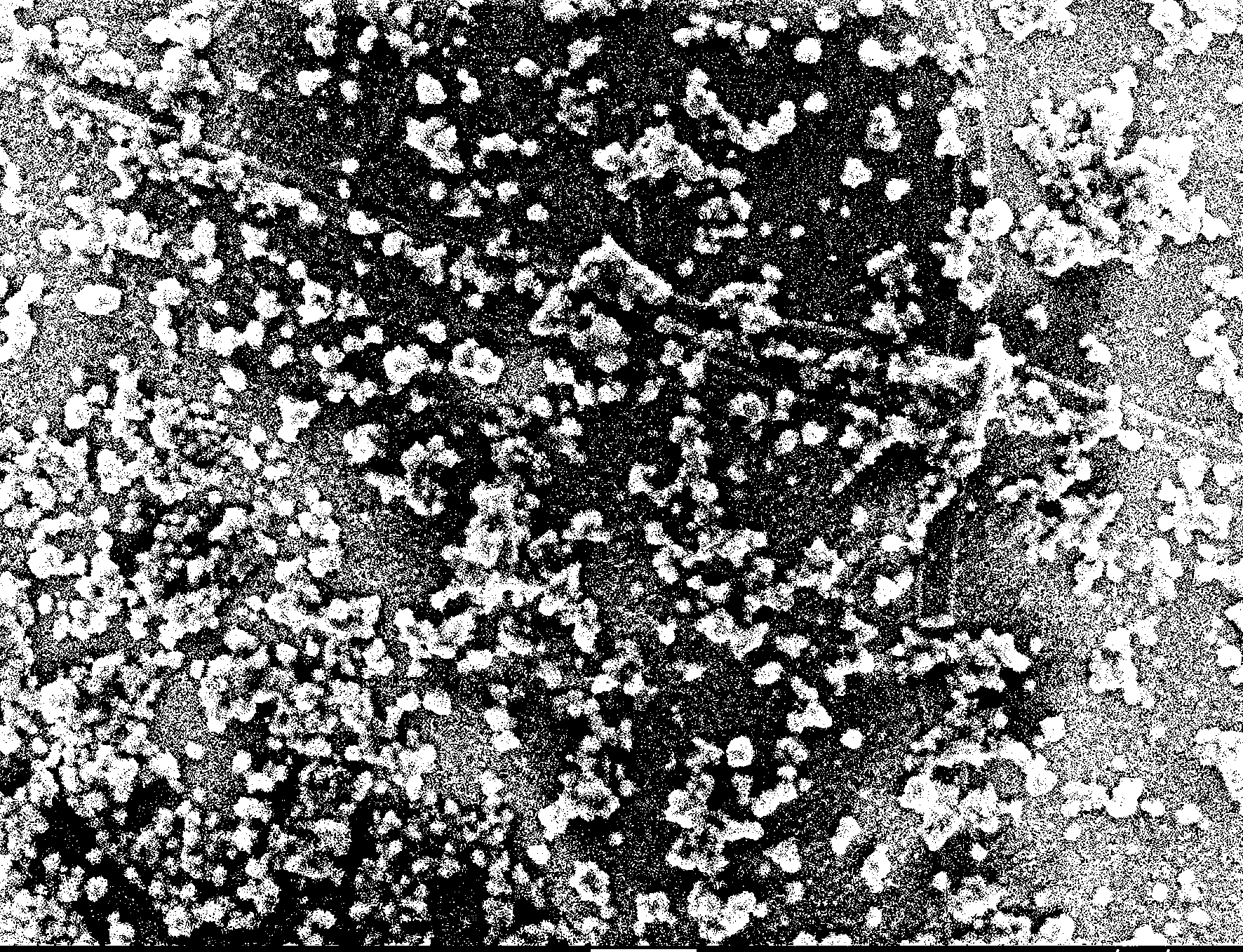

[0041] (3) Add nano-titanium dioxide powder into the solution described in (2), stir to disperse nano-titanium dioxide into a suspension, and ultrasonically oscillate the suspension to obtain a uniform and stable dispersion of nano-titanium dioxide, which is the aqueous phase for interfacial polymerization monomer solution.

[0042] The mass percentage composition of polyethyleneimine in the above-mentioned aqueous phase monomer solution is 3%, the mass percentage composition of sodium carbonate is 0.2%, the mass percentage composition of sodium lauryl sulfonate is 0.2%, chitosan The mass perce...

Embodiment 2

[0056] Step 1: Preparation of aqueous monomer solution

[0057] (1) Add polyethyleneimine, sodium carbonate, and sodium dodecylsulfonate to ionized water, heat and stir until sodium dodecylsulfonate dissolves;

[0058] (2) Add N, N, N-trimethyl chitosan quaternary ammonium salt to the solution described in (1), heat and stir until N, N, N-trimethyl chitosan quaternary ammonium salt dissolves;

[0059] (3) Add nano-titanium dioxide powder into the solution described in (2), stir to disperse nano-titanium dioxide into a suspension, and ultrasonically oscillate the suspension to obtain a uniform and stable dispersion of nano-titanium dioxide, which is the aqueous phase for interfacial polymerization monomer solution.

[0060] The mass percentage composition of polyethyleneimine in the above-mentioned aqueous phase monomer solution is 4%, the mass percentage composition of sodium carbonate is 0.3%, the mass percentage composition of sodium lauryl sulfonate is 0.3%, chitosan The ...

Embodiment 3

[0074] Step 1: Preparation of aqueous monomer solution

[0075] (1) Add polyethyleneimine, sodium carbonate and sodium dodecylsulfonate in deionized water, heat and stir until sodium dodecylsulfonate dissolves;

[0076] (2) Add O-carboxymethyl-N-trimethyl chitosan quaternary ammonium salt to the solution described in (1), heat and stir O-carboxymethyl-N-trimethyl chitosan quaternary ammonium salt to dissolve ;

[0077] (3) Add nano-titanium dioxide powder into the solution described in (2), stir to disperse the nano-titanium dioxide into a suspension, and ultrasonically oscillate the suspension to obtain a uniform and stable dispersion of nano-titanium dioxide, which is the aqueous phase for interfacial polymerization monomer solution.

[0078] The mass percentage composition of polyethyleneimine in the above-mentioned aqueous phase monomer solution is 5%, the mass percentage composition of sodium carbonate is 0.4%, the mass percentage composition of sodium lauryl sulfonate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com