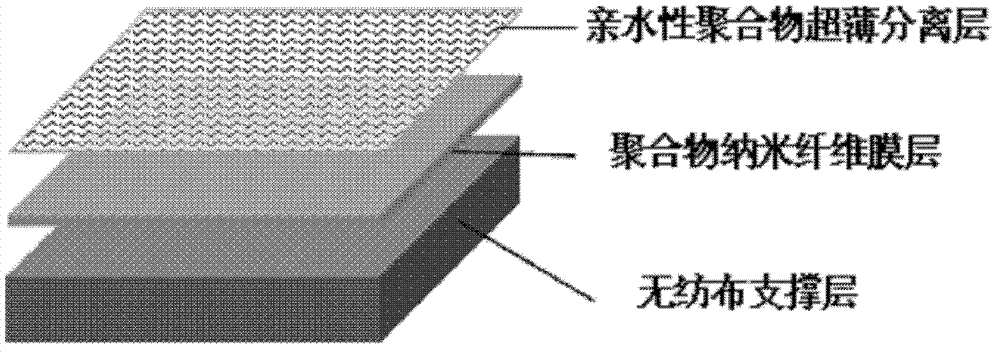

Preparation method of multi-layer composite-structure filter membrane

A multi-layer composite and composite membrane technology, applied in chemical instruments and methods, ultrafiltration, membrane technology, etc., can solve the problems of maximum water flux limitation and low porosity, and achieve high water flux, high porosity, The effect of increased water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

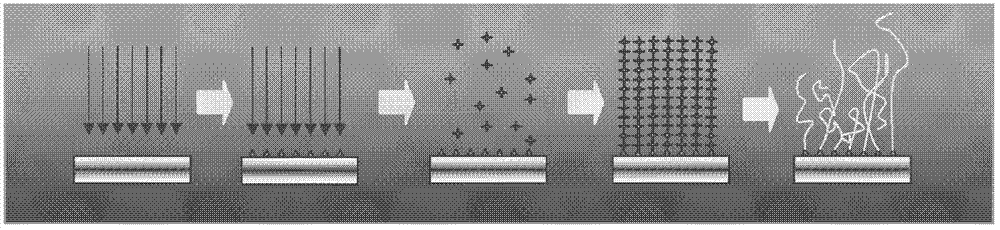

Method used

Image

Examples

Embodiment 1

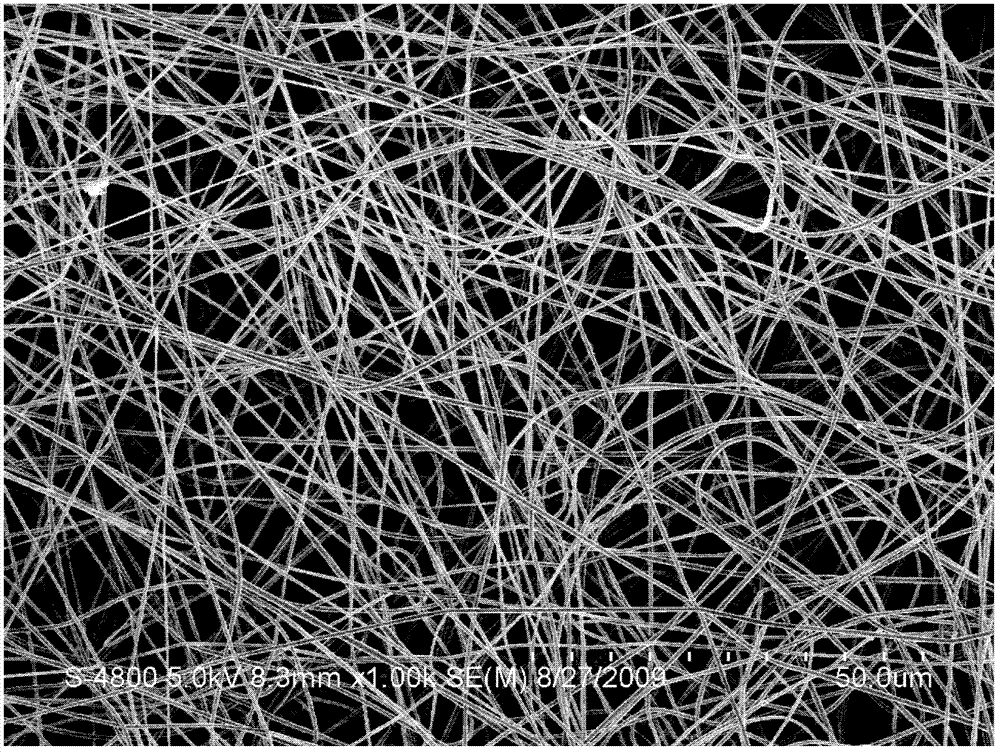

[0053] 1). Dissolve polyvinylidene fluoride in N,N-dimethylformamide at 50°C, stir for 6 hours to mix evenly, and obtain polyvinylidene fluoride electrospinning solution, wherein polyvinylidene fluoride is in The volume concentration in the electrospinning solution was 15%.

[0054] 2). Put the polyvinylidene fluoride electrospinning solution prepared in step 1) into the liquid storage device of the electrospinning equipment at a temperature of 50°C. The piston of the liquid storage device is connected to the syringe pump, and the liquid storage device passes through the The tetrafluoroethylene tube is connected to the spinneret, the spinneret is fixed, and the non-woven fabric is placed on the metal plate as a collector. Adjust the distance between the spinneret and the collector to be 15cm; the ambient temperature of spinning is 50°C, including the temperature of the electrospinning solution in the liquid storage device and the temperature of the collector are both 50°C; tur...

Embodiment 2

[0063] 1). Dissolve polyvinylidene fluoride in N,N-dimethylformamide at 50°C, stir for 6 hours to mix evenly, and obtain polyvinylidene fluoride electrospinning solution, wherein polyvinylidene fluoride is in The volume concentration in the electrospinning solution was 15%.

[0064]2). Put the polyvinylidene fluoride electrospinning solution prepared in step 1) into the liquid storage device of the electrospinning equipment at a temperature of 50°C. The piston of the liquid storage device is connected to the syringe pump, and the liquid storage device passes through the The tetrafluoroethylene tube is connected to the spinneret, the spinneret is fixed, and the non-woven fabric is placed on the metal plate as a collector. Adjust the distance between the spinneret and the collector to be 15cm; the ambient temperature of spinning is 50°C, including the temperature of the electrospinning solution in the liquid storage device and the temperature of the collector are both 50°C; turn...

Embodiment 3

[0072] 1). Dissolve polyvinylidene fluoride in N,N-dimethylformamide at 50°C, stir for 6 hours to mix evenly, and obtain polyvinylidene fluoride electrospinning solution, wherein polyvinylidene fluoride is in The volume concentration in the electrospinning solution was 15%.

[0073] 2). Put the polyvinylidene fluoride electrospinning solution prepared in step 1) into the liquid storage device of the electrospinning equipment at a temperature of 50°C. The piston of the liquid storage device is connected to the syringe pump, and the liquid storage device passes through the The tetrafluoroethylene tube is connected to the spinneret, the spinneret is fixed, and the non-woven fabric is placed on the metal plate as a collector. Adjust the distance between the spinneret and the collector to be 15cm; the ambient temperature of spinning is 50°C, including the temperature of the electrospinning solution in the liquid storage device and the temperature of the collector are both 50°C; tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com