Double-layer composite hollow fiber nano-filtration membrane and preparation method and special tool thereof

A double-layer composite, nanofiltration membrane technology, applied in the field of membrane separation, can solve the problems of thin coating affecting separation performance, reducing membrane flux, etc., achieving good chemical and thermal stability, reducing manufacturing costs, and increasing pore size and pore size. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

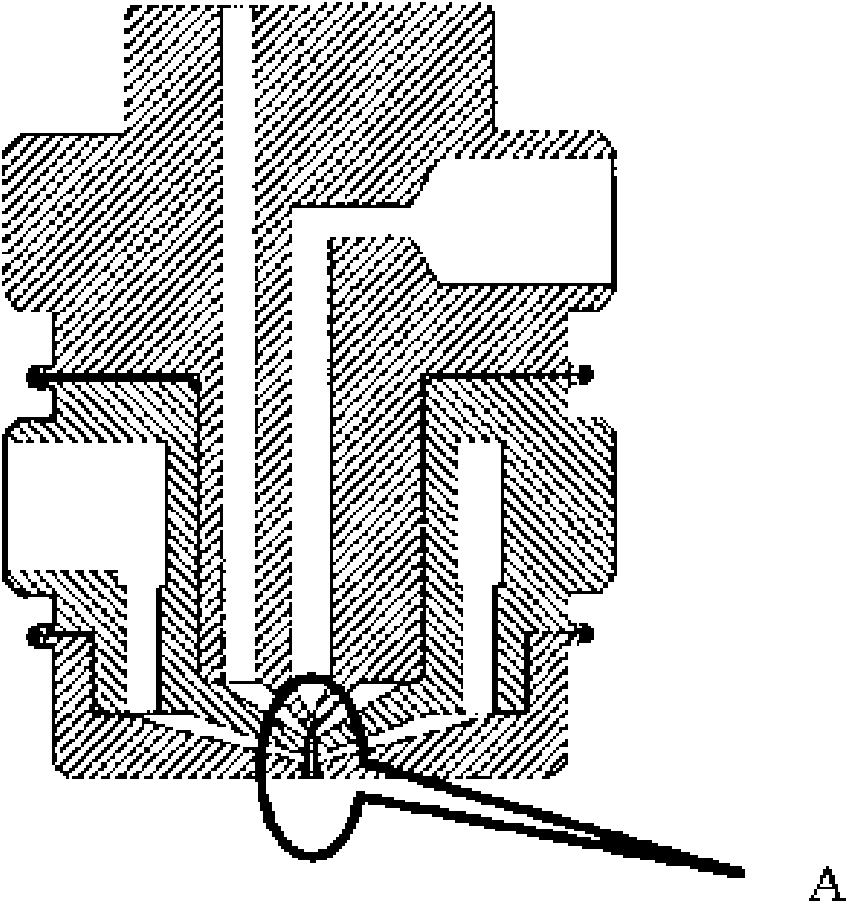

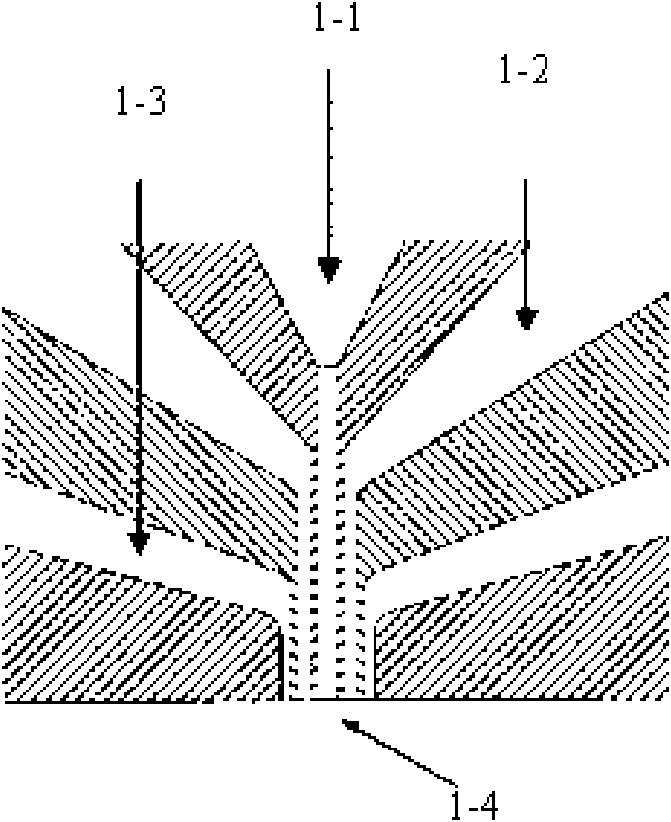

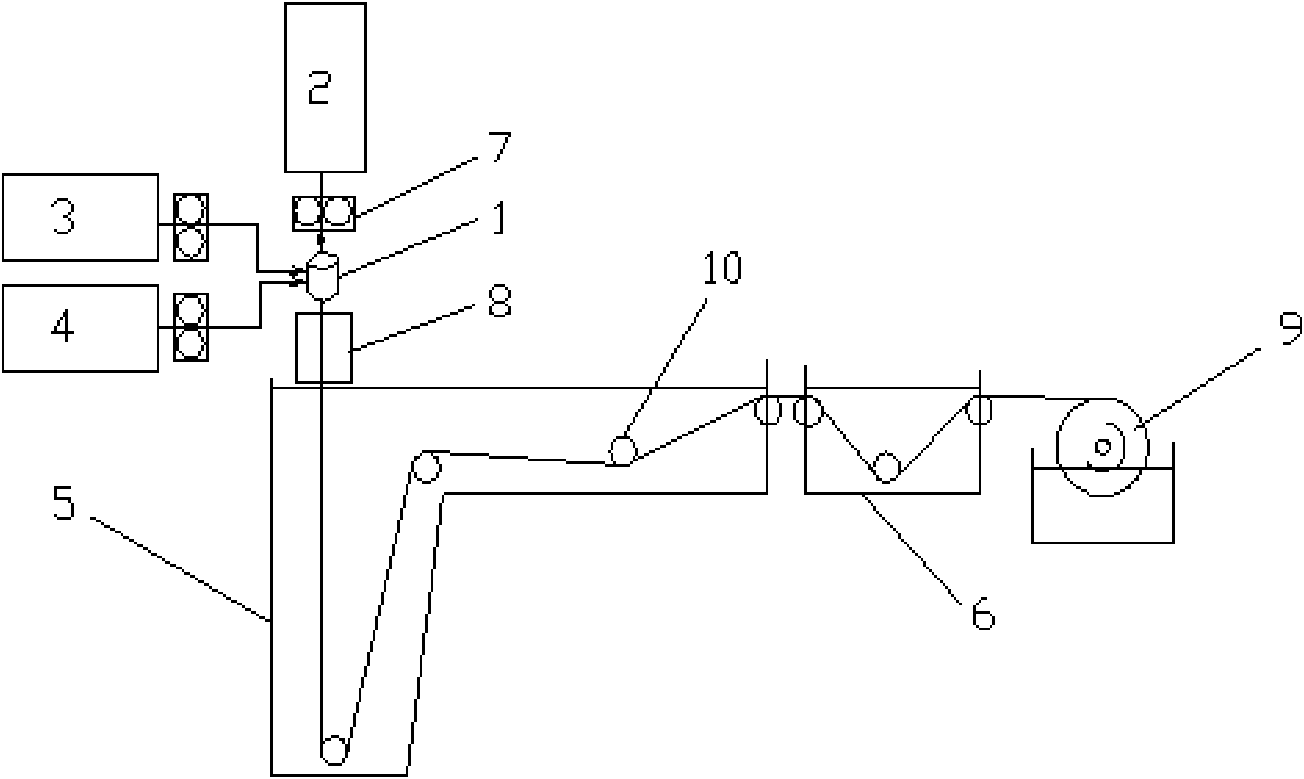

[0042] see Figure 4 , The middle of the figure is the double-layer composite hollow fiber nanofiltration membrane of this embodiment, including the selective separation of the outer skin layer and the mechanical support inner layer; among them, the upper left is the outer surface of the selective separation of the outer skin, and the upper right is the selective separation of the outer skin The lower left position mechanically supports the outer surface of the inner layer, and the lower right position mechanically supports the inner surface of the inner layer. There are membrane pores on the selective separation skin layer, the membrane pore diameter is 0.5-2 nanometers; the thickness of the selective separation skin layer is 10-10000 nanometers; the thickness of the mechanical support inner layer is 1-3 mm; the double-layer composite hollow fiber nanofiltration membrane The selective separation of the outer skin layer and the mechanical support inner layer are respectively di...

Embodiment 2

[0057] The tools used in this example are the same as those in Example 1. The selected ratio and process conditions are shown in Table 2. The SPSF-PVC double-layer composite hollow fiber nanofiltration membrane was prepared.

[0058] Table 2 Preparation of SPSF-PVC double-layer composite hollow fiber nanofiltration membrane

[0059] Selective separation of outer skin layer casting film (wt%)

[0060] The hollow fiber nanofiltration membrane module made of these filaments has a rejection rate of 15% for 1 mM / L sodium chloride under an operating pressure of 1 kg and an external pressure operation mode, and a rejection rate of 80% for 1 mM / L magnesium chloride; The rejection rates for methyl green and sunset yellow dyes are 85% and 95%; the pure water permeability is 0.8L / (m 2 ·Hr·atm).

Embodiment 3

[0062] The tools used in this example are the same as those in Example 1. The selected ratio and process conditions are shown in Table 3. The SPES-PAN double-layer composite hollow fiber nanofiltration membrane was prepared.

[0063] Table 3 Preparation of SPES-PAN double-layer composite hollow fiber nanofiltration membrane

[0064] Selective separation of outer skin layer casting film (wt%)

[0065] Outer skin layer casting film flow rate (ml / min)

[0066] The hollow fiber nanofiltration membrane module made of these filaments has a rejection rate of 10% for 1 mM / L sodium chloride and 82% for 1 mM / L magnesium chloride under 1 kg operating pressure and external pressure operation mode; The rejection rates for methyl green and sunset yellow dyes are 89% and 95%; the pure water permeability is 1.8L / (m 2 ·Hr·atm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com