Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about How to "Composite firm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chinese medicinal herb antimicrobial hand cleanser and preparation method thereof

ActiveCN101185621AGood effectImprove the bactericidal effectCosmetic preparationsToilet preparationsHand sanitizerDissolution

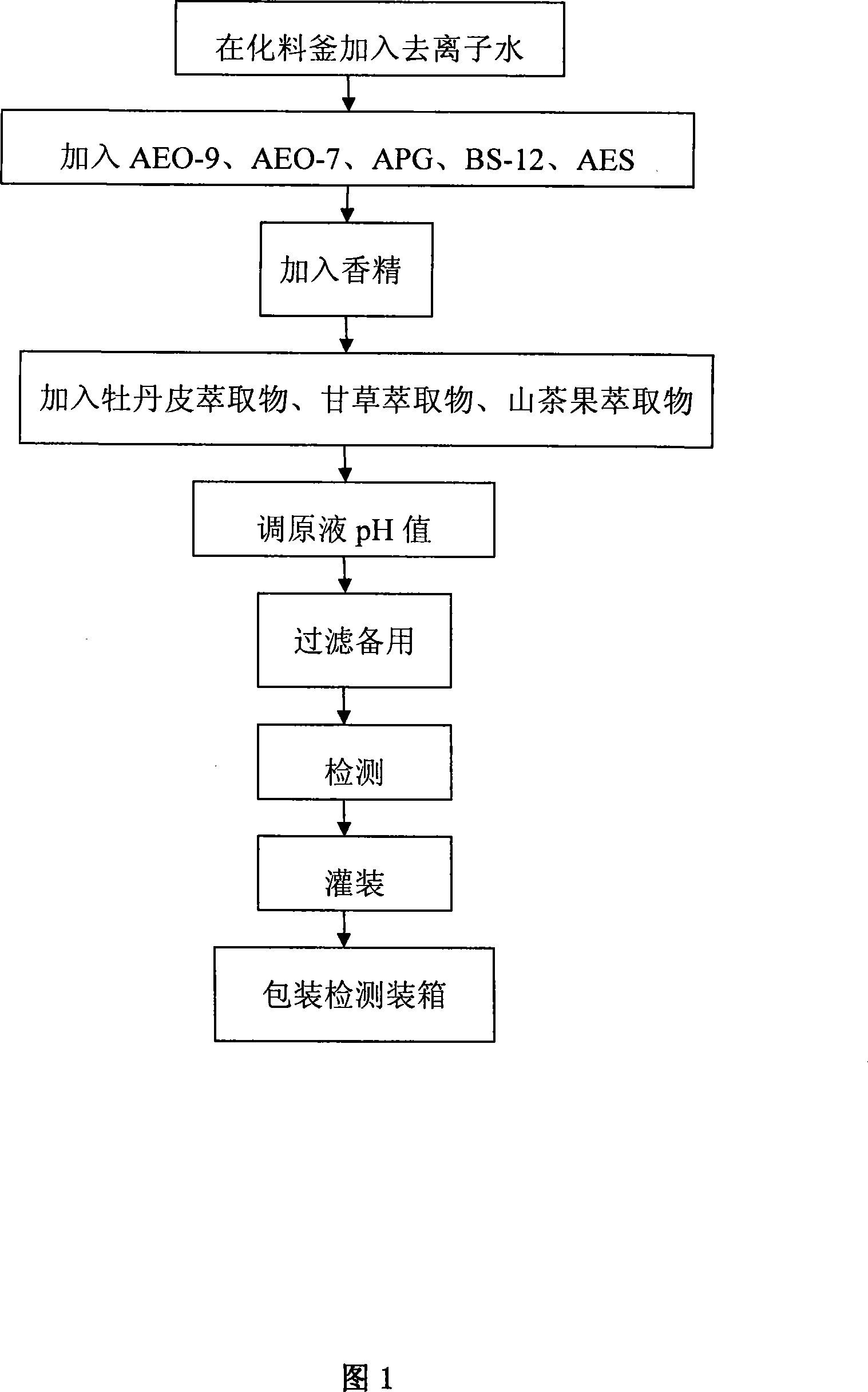

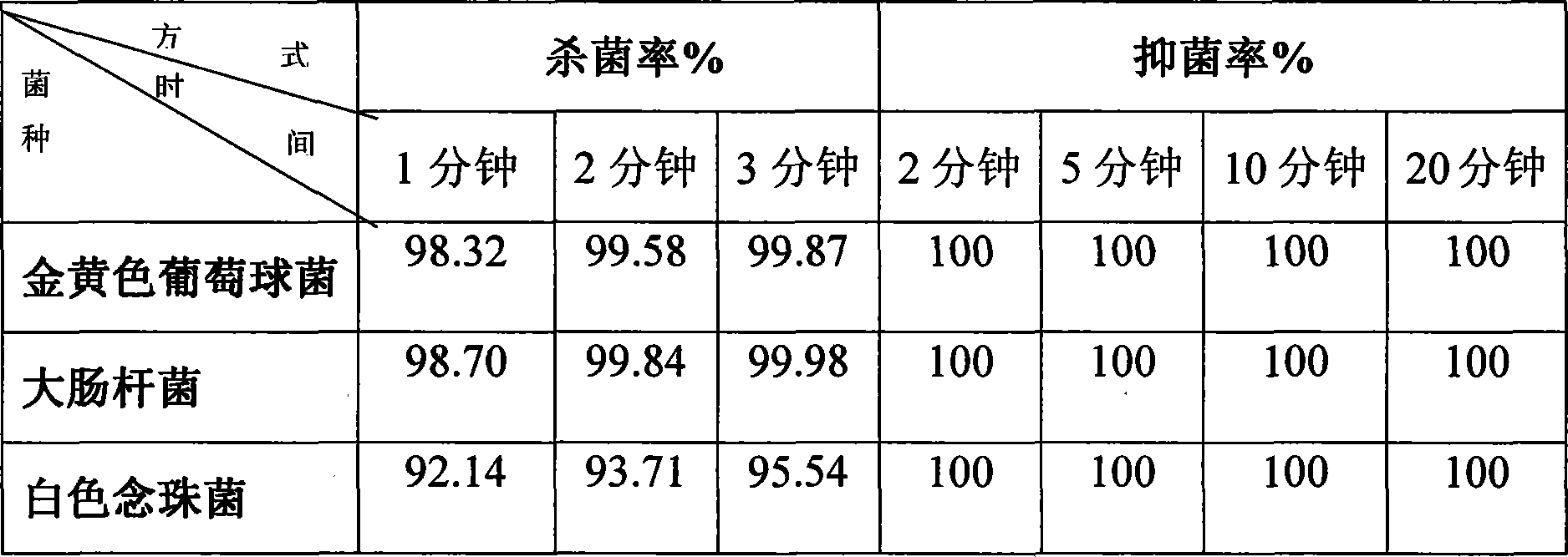

The invention provides a Chinese herbal medicine antibiotic hand washing and a preparation method thereof and relates to detergent field. The Chinese herbal medicine antibiotic hand washing is made of the mixture of Chinese herb liquorice, peony bark, camellia fruit extract liquid and synergistic agent and eradicator and can decontaminate and disinfect under the condition that the actual washing of the customers are met. The Chinese herbal medicine antibiotic hand washing is prepared by APG, AEO-9, AEO-7, BS-12, AES, peony bark extractive matter, liquorice extractive matter and camellia fruit extractive matter, etc. The preparation method is that deionized water and the materials are added to a dissolution kettle for dissolution, then obtaining the product. The invention adopts Chinese herbal extracts, surfactant and other effective components for optimization and combination, enhances sterilization effect, functions to decontaminate, moisten and protect hands and has low production cost.

Owner:北京绿伞科技股份有限公司

Thermal spraying self-bonding metal alloy powder with coated composite structure

ActiveCN105642885AIncrease temperatureComposite firmMolten spray coatingTransportation and packagingThermal sprayingMetal alloy

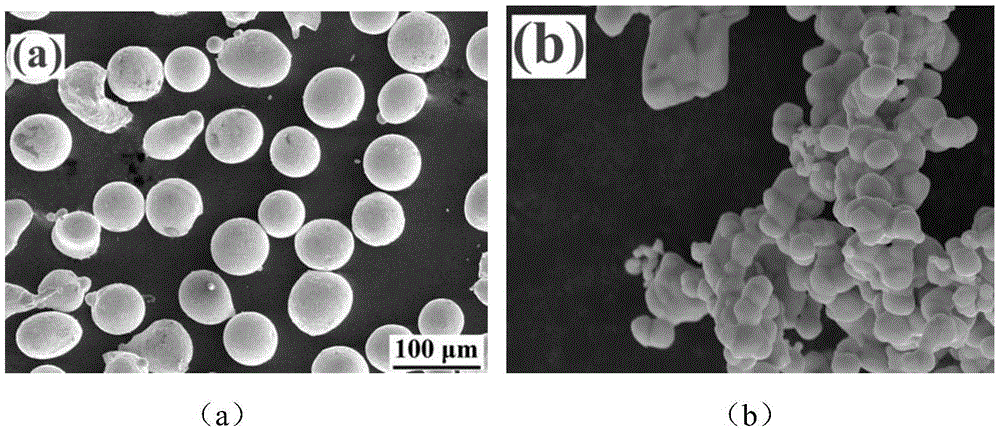

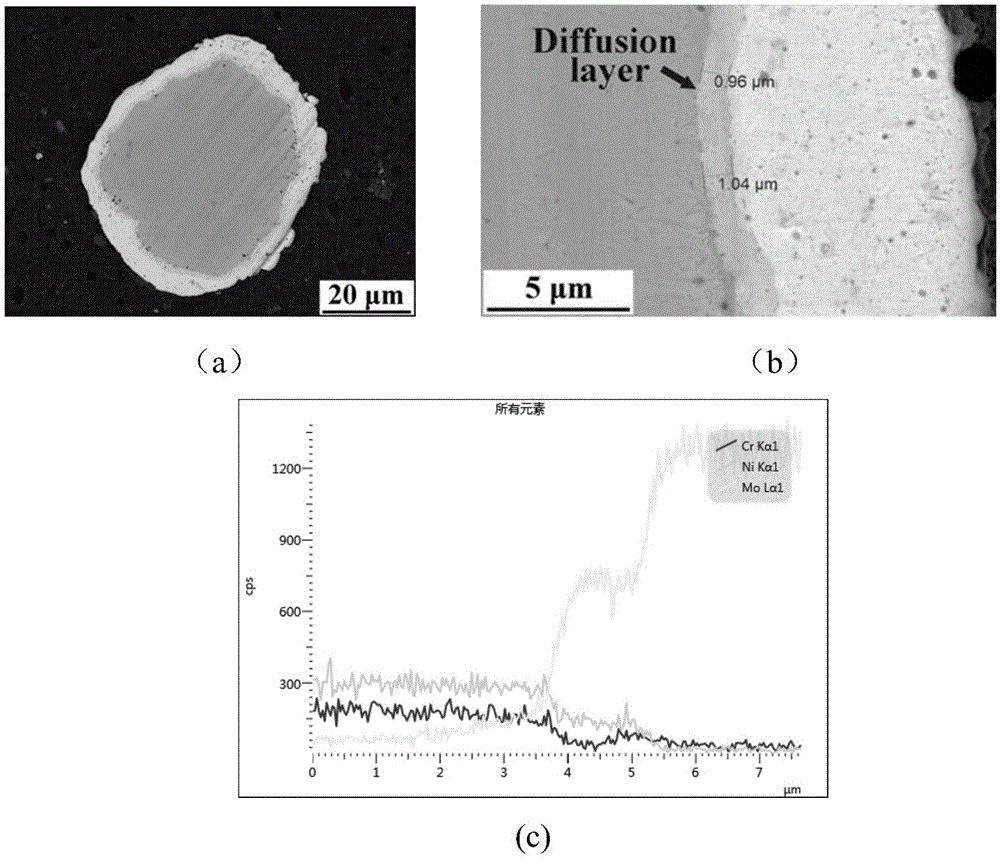

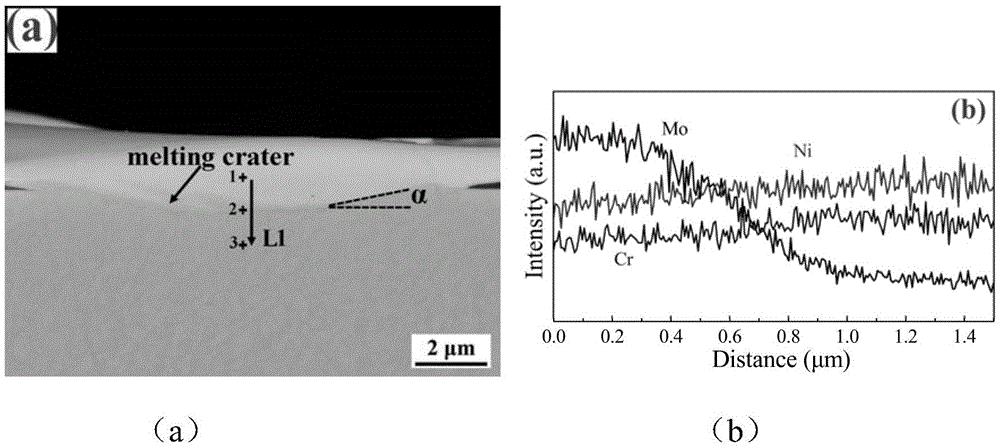

The invention discloses a thermal spraying self-bonding metal alloy powder with a coated composite structure and belongs to the technical field of material processing. The metal alloy powder is composite structural powder formed by coating outer-layer metal and coated metal particles, the surfaces of the coated metal particles are uniformly coated with the coating outer-layer metal, a melting point of the coating outer-layer metal is higher than a melting point of the coated metal particles, the coating layer and the coated metal particles are metallurgically bonded to form the composite structural powder. When a metal alloy coating prepared by the composite structural powder is adopted, due to the fact that metallurgical bonding reaction occurs between the coating and a substrate and also occurs among particle layer interfaces in the coating, the interface bonding can be firm, accordingly the bonding strength between the coating and the substrate and the cohesion bonding strength of the particle layers in the coating are remarkably improved, and the long-term usage stability of the coating is ensured. The metal alloy coating prepared by the metal alloy powder has excellent corrosion resistance properties.

Owner:XI AN JIAOTONG UNIV

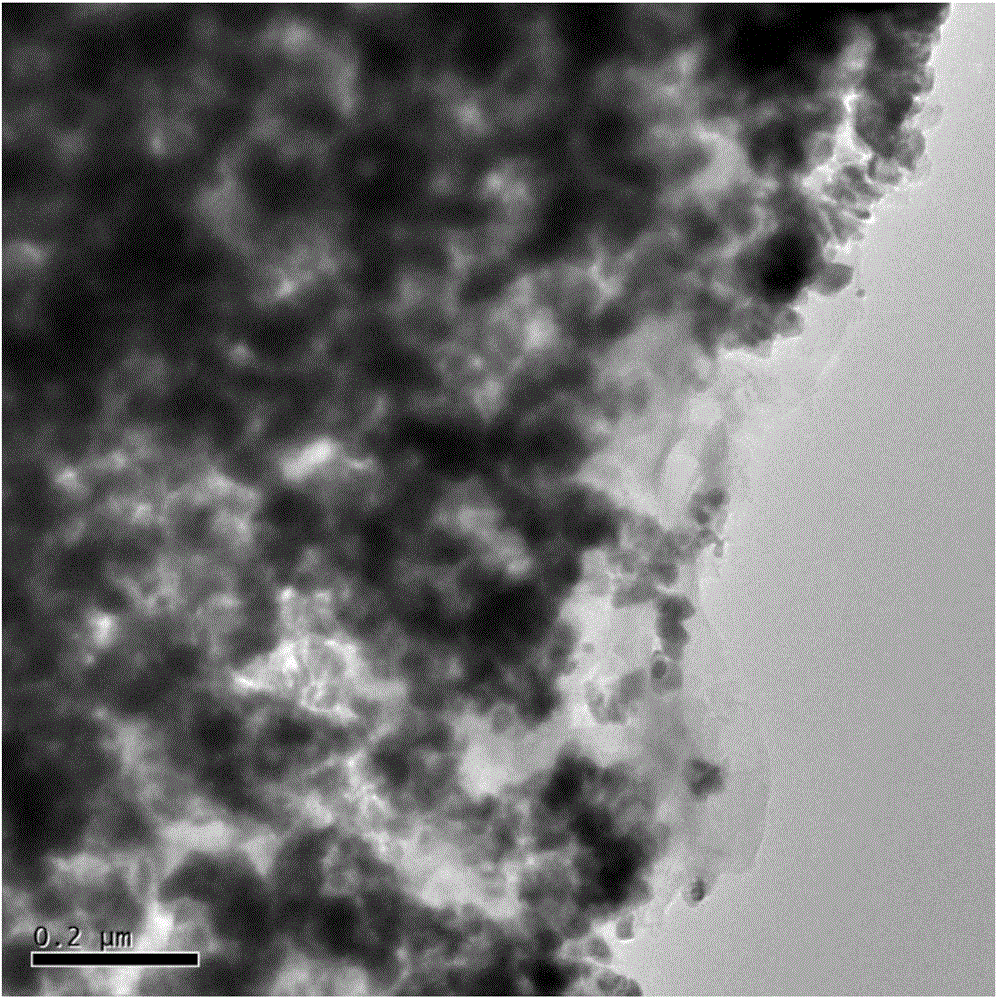

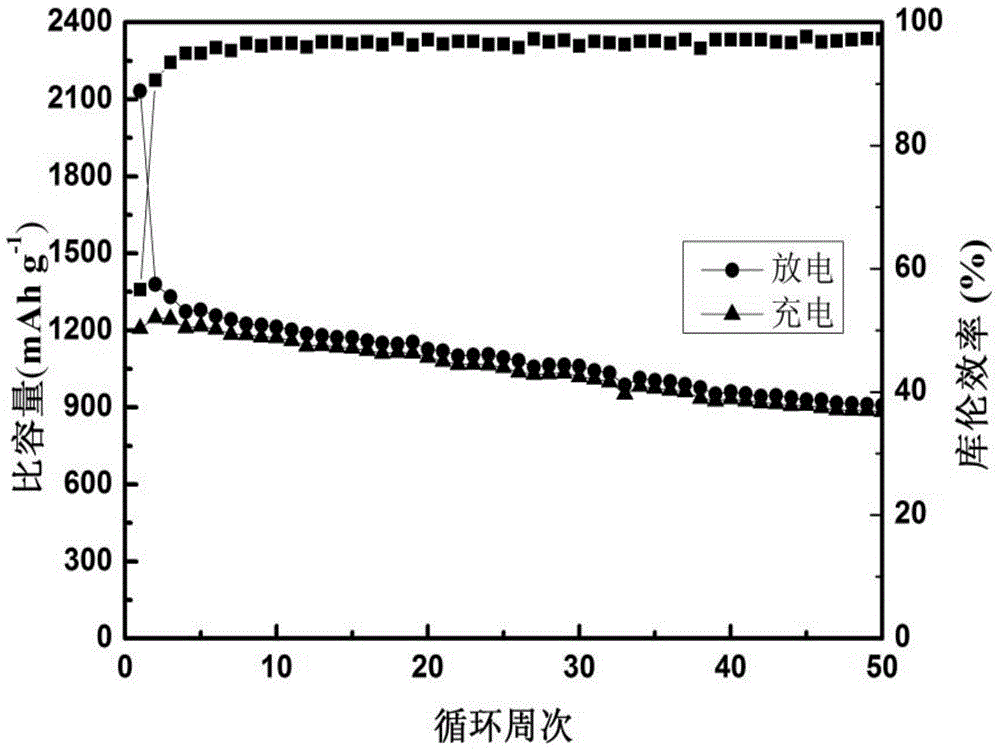

Tin oxide and porous carbon composite lithium ion battery anode materials

Disclosed is a production method of tin oxide and porous carbon composite lithium ion battery anode materials. The production method comprises the following steps of step 1, producing HKUST-1; step 2, activating HKUST-1, removing an organic solvent, adding a tin chloride solution by an injection method under the condition that the air is isolated and fully impregnating a pore passage, wherein the pore passage is occupied by the organic solvent; step 3, removing the solvent to obtain a precursor, performing 600 DEG C of firing of a muffle furnace under the protection of the argon gas, performing trimesic acid ligand carbonization, performing copper and tin reduction and alloying and obtaining a high dispersion of copper and tin alloy and carbon compound; step 4, selectively removing copper through nitric acid, converting tin oxide into tin dioxide to be stored in the pore passage in the form of nanocrystallization and obtaining the high performance composite materials. The tin oxide and porous carbon composite materials produced by the production method are firm in compositing, simple in operation and uniform in product; the tin oxide and porous carbon composite materials are large in capacity, high in current density, high in coulomb efficiency and high in rate performance current density when being applied to the lithium ion battery anode materials; the mass production can be achieved and the production cost is low.

Owner:NANKAI UNIV

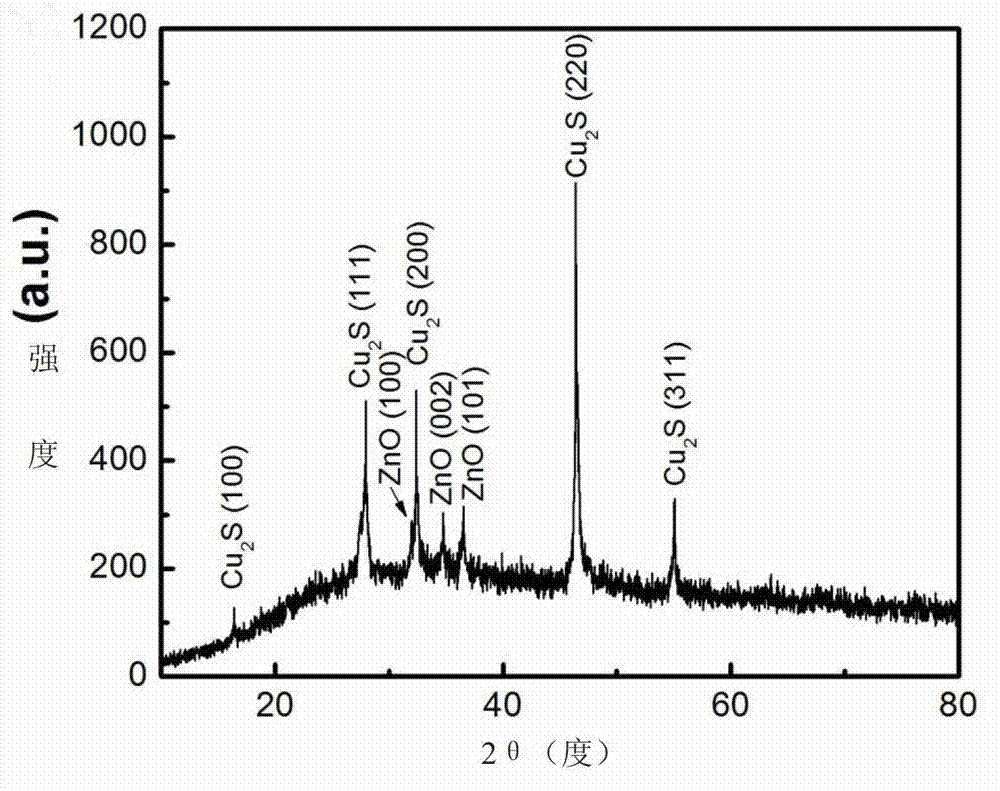

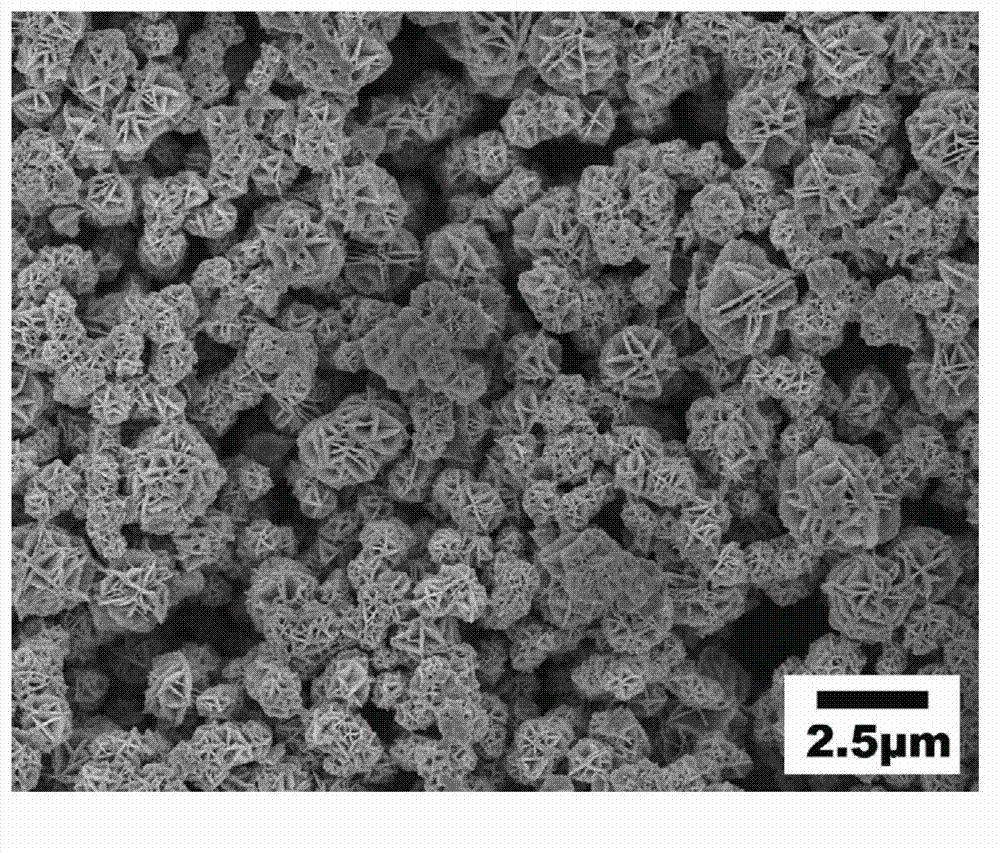

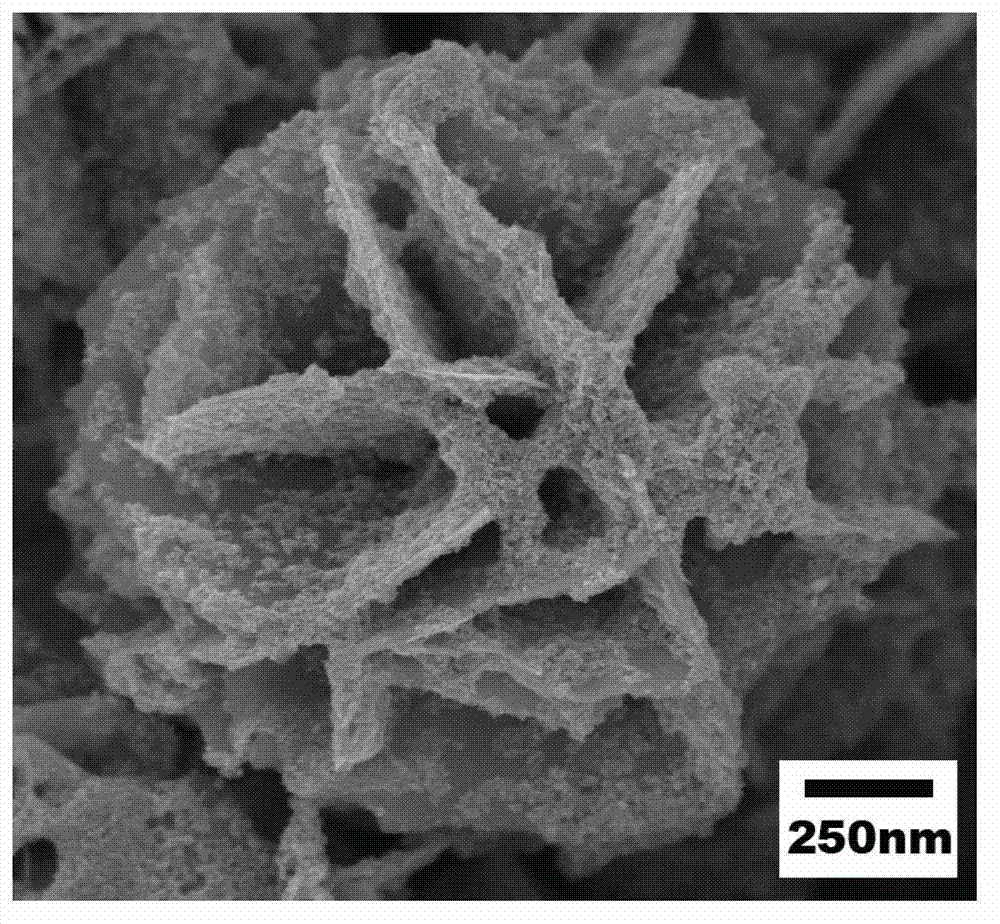

Three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material and preparation method thereof

InactiveCN103204536ARapid annealingPromote recrystallizationMaterial nanotechnologyPhysical/chemical process catalystsImideSemiconductor materials

The invention discloses a three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material. The three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material comprises ZnO nanometer-particle crystals and a CU2S nanometer-flower structure substrate material, wherein the ZnO nanometer-particle crystals are uniformly covered on the CU2S nanometer-flower structure substrate material; the CU2S nanometer-flower structure substrate material consists of Cu2S nanometer-sheets; and a P-N junction is formed at the interface of the ZnO nanometer-particle crystals and the Cu2S nanometer-flower structure. The invention further discloses a preparation method of the three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material. The preparation method comprises the following steps of: synthesizing the Cu2S nanometer-flower crystals and ZnO nanometer-particle crystals by adopting a hydrothermal synthesis method, respectively; and uniformly compounding the ZnO nanometer particles on the Cu2S nanometer-sheets by using PEI (Polyether Imide) as an auxiliary material to obtain the three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material. The three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material has the advantages of being low in cost, low in growth temperature, high in repeatability and the like, and also has great development application potential in the on-spot emission field and the photo-catalysis field.

Owner:EAST CHINA NORMAL UNIV

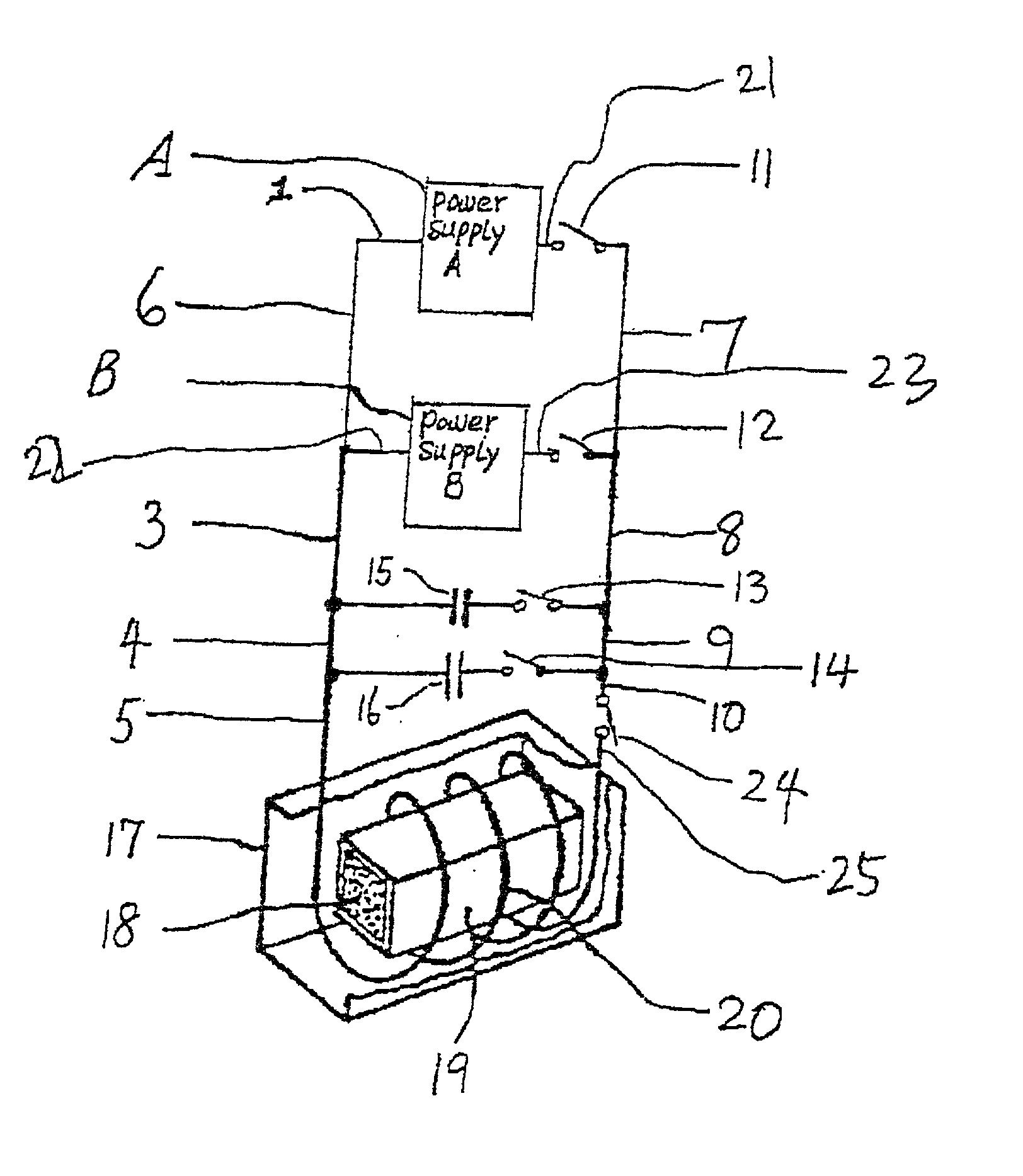

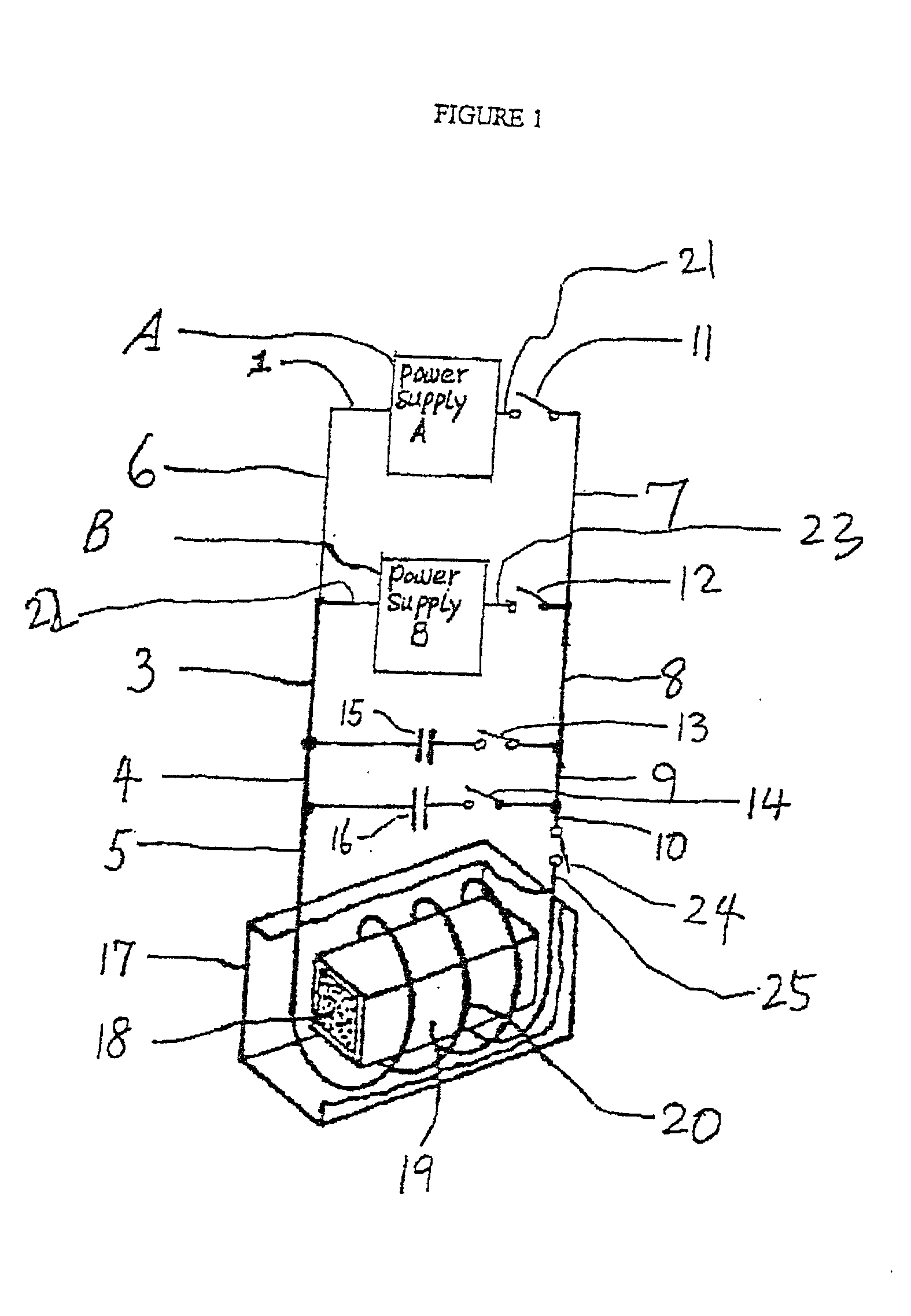

Method for producing & manufacturing density enhanced, DMC, bonded permanent magnets

InactiveUS20020036367A1Improve compatibilityHigh mechanical strengthElectrotherapyInorganic material magnetismParticulatesVoid ratio

Disclosed is a method of manufacturing density enhanced, bonded permanent magnets having the following properties: a. maximum energy product (BH)max up to 40% greater than that of traditional, mechanical, compacted, bonded permanent magnets, b. (BH)max up to 99% of theoretical, c. void ratio approaching 0 volume %, and d. use temperature from room temperature up to about 550° C., said method comprising the step of compacting a mixture of permanent magnet particulates and a binder using pulsed electromagnetic forces, where each pulse has a pulse time less than the thermal time constant of the permanent magnet particulate, and wherein said compaction is achieved without adversely affecting the binder or the structure of the permanent magnet particulates.

Owner:ELECTRON ENERGY CORP

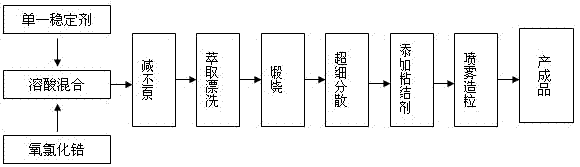

Composite stable microcrystal zirconium oxide ceramic mixed powder and manufacturing process

The invention provides composite stable microcrystal zirconium oxide ceramic mixed powder and a manufacturing process. Industrial-grade zirconium oxide powder is used as a main material and a suitable amount of cerium oxide (CeO), yttrium oxide (Y2O3), aluminum oxide and calcium carbonate (CaCO3) are used as stabilizing agents; all the components are prepared according to the following percentage by weight: 10-12% of the cerium oxide (CeO), 1-2% of the yttrium oxide (Y2O3), 3-8% of the aluminum oxide (Al2O3), 1-2% of the calcium carbonate (CaCO3) and the balance of the industrial-grade zirconium oxide powder; and the powder materials are mixed according to the proportion and the composite stable microcrystal zirconium oxide ceramic mixed powder is prepared by the steps of physically mixing, super-thinning, calcining, dispersing and granulating. With the adoption of a plurality of the stabilizing agents, the stable composition of zirconium oxide is realized, and zirconium oxide ceramic which is stably composited has better physiochemical performances.

Owner:株洲市创锐高强陶瓷有限公司

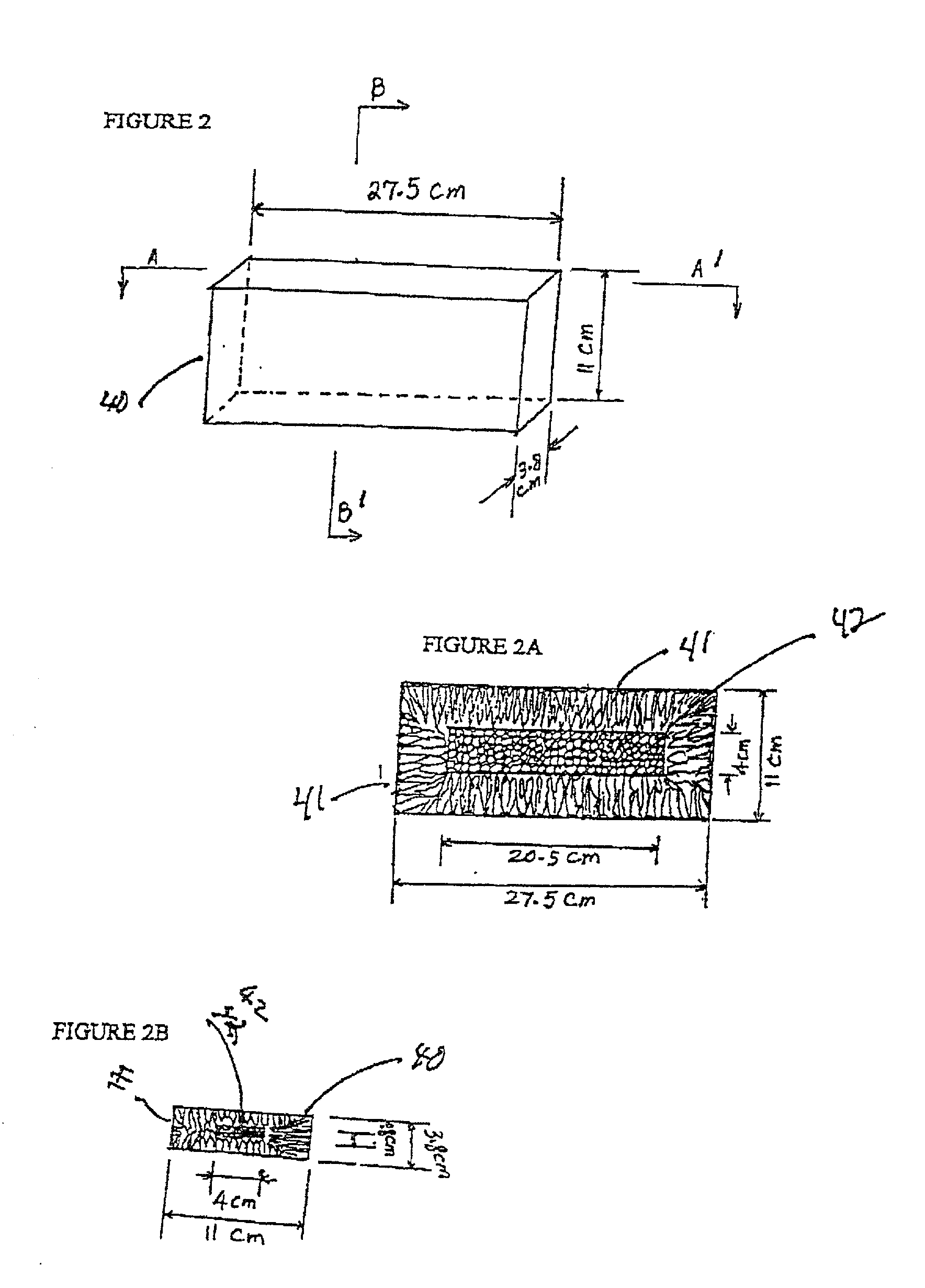

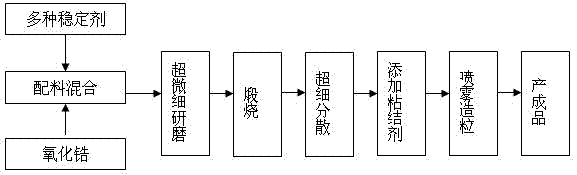

Composite intermediate layer sliding plate with filled polytetrafluoroethylene and method for preparing the same

ActiveCN101492906AComposite firmReduce coefficient of frictionBridge structural detailsComposite structureFrictional coefficient

The invention belongs to the technical field of composite modification of high molecular materials, and provides a filling polyfluortetraethylene composite interlayer slide board for a bridge support and a preparation method thereof. The filling polyfluortetraethylene composite interlayer slide board adopts a three-layer composite structure, wherein, the middle layer is a filling modified polyfluortetraethylene layer, the upper surface layer and the lower surface layer are pure polyfluortetraethylene layers, namely, the integral bearing capacity of the slide board is improved by mainly utilizing the filling modified polyfluortetraethylene layer in the middle layer with the characteristics of high bearing capacity and small creepage; and the surface layers are the pure polyfluortetraethylene layers, so that the slide board keeps the low frictional coefficient property of the pure polyfluortetraethylene. The filling polyfluortetraethylene composite interlayer slide board has the characteristics of low frictional coefficient, high bearing capacity, small creepage and small compressive deformation, can meet the requirement of high-speed railway bridge supports on frictional pair materials, can be widely applied to the frictional pair materials used as bridge support products, and can also be applied to other fields such as pipeline supports and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

PVC card matrix material

InactiveCN101348591AImprove permeabilityImprove printing effectRecord carriers used with machinesDynePrinting ink

The invention relates to a PVC card matrix material. The constituents in portion by weight of the card matrix material are: 80 to 20 portions of PVC resin, 80 to 20 portions of chloride-vinyl acetate resin, 1 to 6 portions of modified PVC resin, 1 to 2 portions of heat stabilizer, 1 to 2.5 portions of processing additive, 5 to 15 portions of titanium dioxide, 0 to 10 portions of nanometer calcium carbonate, 0.7 to 2.3 portions of lubricant, 3 to 12 portions of anti-impact modifier and 0.1 to 0.6 portions of bonding accelerator. The PVC card matrix material has a high dyne characteristic, and in printing process, the PVC card matrix material is strong in printing ink adsorption force and permeability, good in printing effect, printing color fastness as well as compounding fastness and difficult to peel.

Owner:CHANGZHOU BAIJIA NIANDAI FILM TECH CO LTD

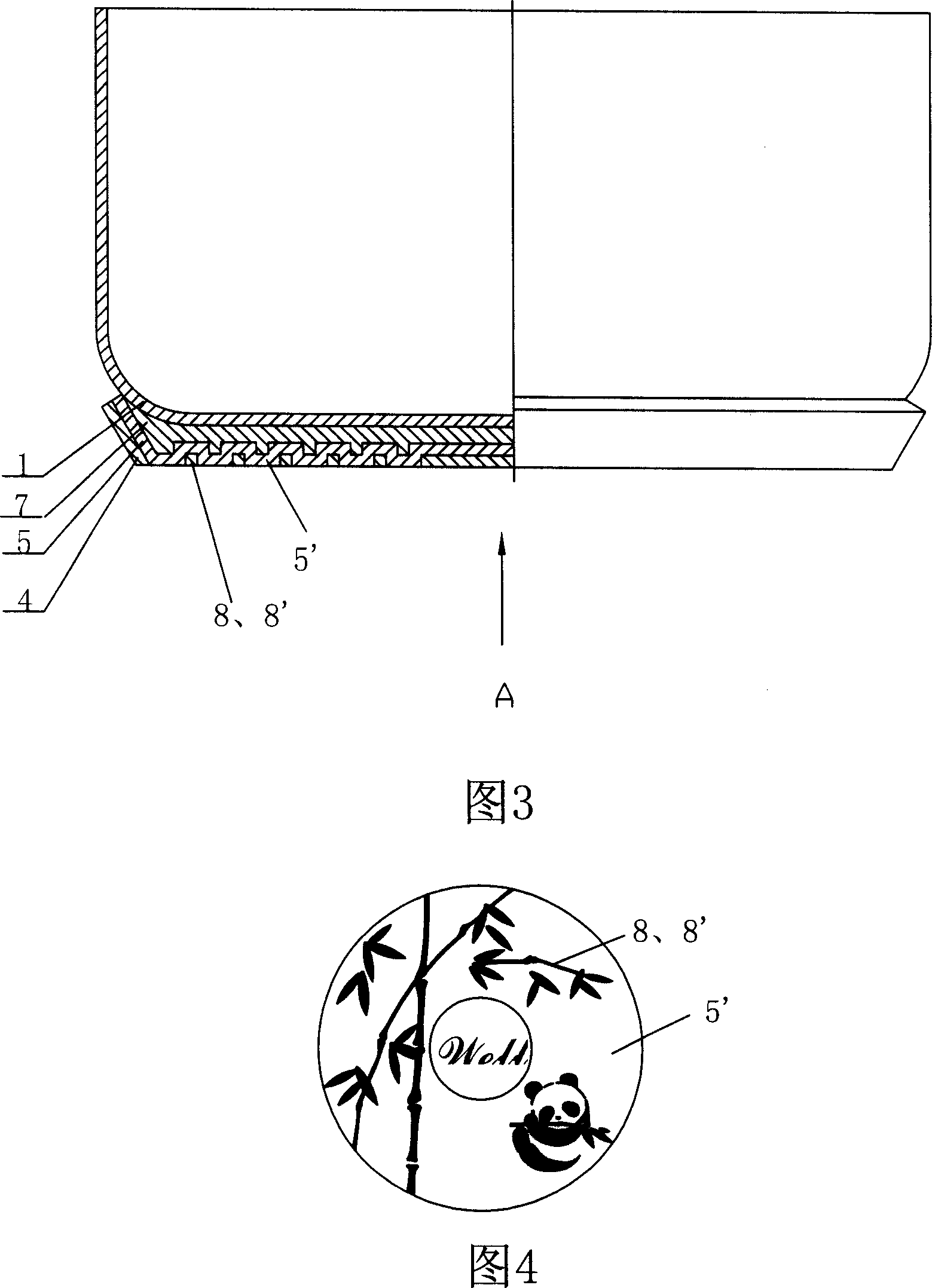

A cooking utensil having double bottoms and its processing method

The composite metal sheet, pure aluminum plate material, and the cooker bottom is compagination, the shape of the composite metal sheet is corresponding to the shape of the cooker bottom. The invention discloses a cooker with composite bottom and its production method. The cooker comprises cooker body made of stainless steel 304, and composite metal bottom. The composite metal bottom includes composite metal sheet made of composite metal plate materials composed of pure copper (T2) and stainless steel 409 or stainless steel 430 ; and pure aluminum (1050) plate material arranged between the composite metal sheet and cooker bottom of the cooker body. The composite metal sheet, pure aluminum plate material, and the cooker bottom is compagination connected, the shape of the composite metal sheet is corresponding to the shape of the cooker bottom. The method comprises selecting composite metal plate materials; punch-forming to obtain the composite metal sheet; punching the T2 layer to form concave patterned grooves; bonding the composite metal sheet, the 1050 plate material and the cooker bottom while heating; removing the T2 pure copper on the composite metal sheet bottom; and polishing the composite metal bottom to form pattern of stainless steel and T2. The cooker has good appearance and wide application.

Owner:胡志明

Glass fibre reinforcement and surface modification method

ActiveCN104947410AImprove interface performanceIncreased flexural modulusPhysical treatmentPolyesterSilanes

The present invention discloses a glass fibre reinforcement and surface modification method in the material manufacturing field of the automotive upholstery. According to the method, firstly, a modified polyurethane waterborne emulsion is prepared. Secondly, a water-soluble polyester, the modified polyurethane waterborne emulsion, the gamma-propyl-trimethoxy-silane, the gamma-propyl tri-methoxy silane, the deionized water, an ammonium salt and a fatty acid amide are adopted as raw materials and are mixed up to prepare a dipping solution. After that, a continuous glass fiber mat is immersed in the dipping solution and is taken out of the dipping solution after being subjected to supersonic vibration and impregnation. The obtained continuous glass fiber mat is dried while being kept out of the sun, and then a reinforced and surface-modified continuous glass fiber mat. According to the invention, the gamma-propyl-trimethoxy-silane and the gamma-propyl tri-methoxy silane are adopted as coupling agents to react with polyurethane to generate a copolymer. In this way, the interface performance of the fiber mat with a resin matrix is improved. Products obtained through the above method can be used for manufacturing the automotive upholstery and automotive structural parts, which have the advantages of light weight, small thickness and low cost under the same intensity.

Owner:扬州市邗江扬子汽车内饰件有限公司

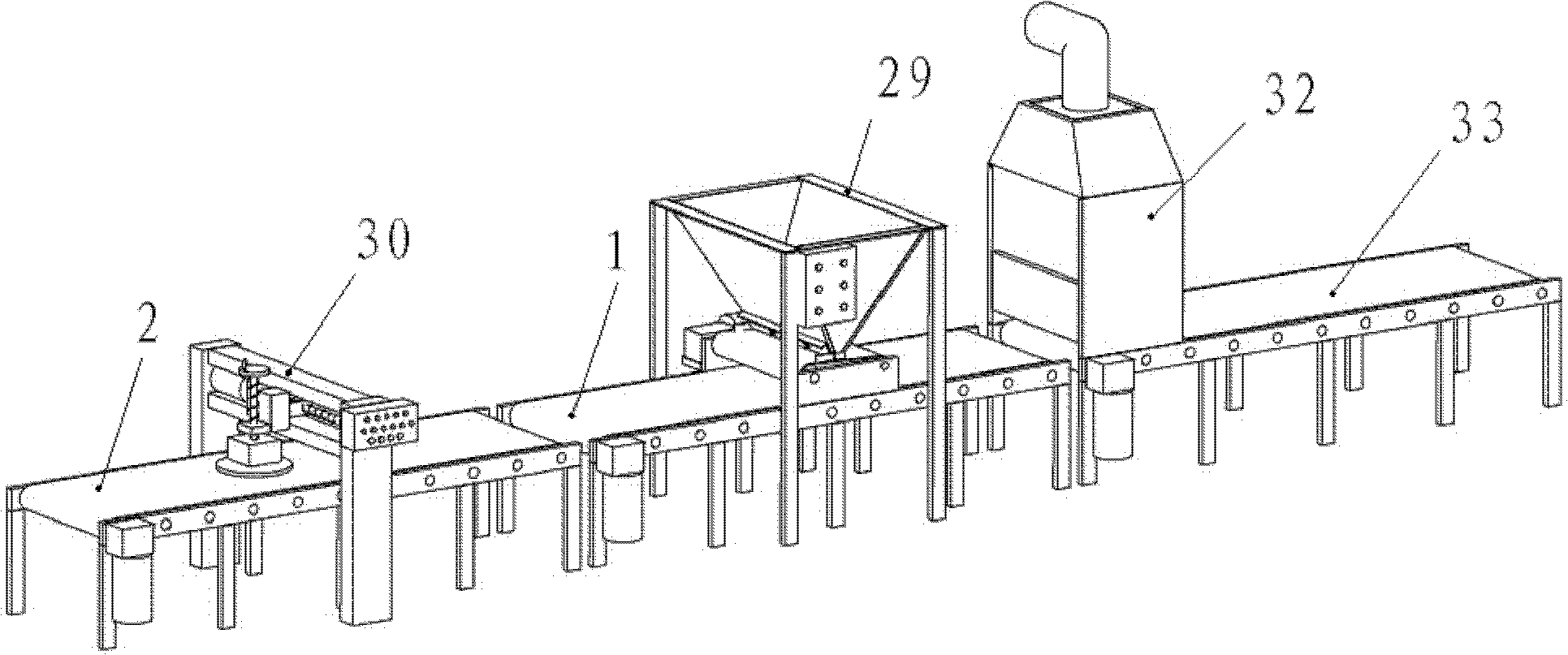

System and method for producing colored sand plate

ActiveCN102615919AAdjustable thicknessGuaranteed permeabilityLaminationLamination apparatusDistribution systemEngineering

The invention relates to a device for producing a decorative plate and particularly discloses a system and a method for producing a colored sand plate. The system comprises a glue-spaying sand-distribution system and a pressing and polishing system which are sequentially arranged, wherein the glue-spaying sand-distribution system is arranged in front of the pressing and polishing system; the glue-spaying sand-distribution system comprises one or more glue-spraying subsystems and sand-distribution subsystems which are arranged in a staggered way, and the glue-spraying subsystems are arranged in front of the sand-distribution subsystems; each glue-spraying subsystem comprises a glue-spraying device and a first base material board conveying device which is arranged below the glue-spraying device; each sand-distribution subsystem comprises a sand leakage device and a second base material board conveying device which is arranged below the sand leakage device; and the pressing and polishing system comprises a pressing and polishing device and a third base material board conveying device which is arranged below the pressing and polishing device. By the system for producing the colored sand plate, the continuous operation of glue spraying, sand distribution, and pressing and polishing can be realized, colored sand plates with different thicknesses of colored sand layers can be produced, and colored sand and base material boards of the produced colored sand plates are stably compounded.

Owner:北京宝莲纳新材料技术有限公司

Nano alumina-containing modified wood production method

InactiveCN104859011AHigh surface hardnessEfficient processingWood treatment detailsPretreatment apparatusPolyethylene glycolNano al2o3

The invention discloses a nano alumina-containing modified wood production method including five steps of wood pretreatment, preparation of a wood modification agent, preparation of a wood modification fluid, dipping treatment and post drying treatment, the wood modification agent comprises nano alumina, polyethylene glycol (peg), aluminum and titanium compound coupling agent OL-AT1618, distilled water, sodium octaborate, diammonium phosphate, boric acid, carbendazim, dodecyl dimethyl benzyl ammonium chloride, sodium dodecyl benzene sulfonate and silicon sol, and the particle size of the nano alumina is in the 1-100 nm range. The beneficial effect is that the nano alumina-containing modified wood has the advantages of simple process, high efficiency, environmental protection, strong permeability, stable performance, even composite and the like, and the surface hardness, smoothness, wear resistance, cold and hot fatigue, fracture toughness, good processing properties, dimension stability, anti-corrosion flame retardant properties and the like of the treated wood are improved obviously.

Owner:王玉燕

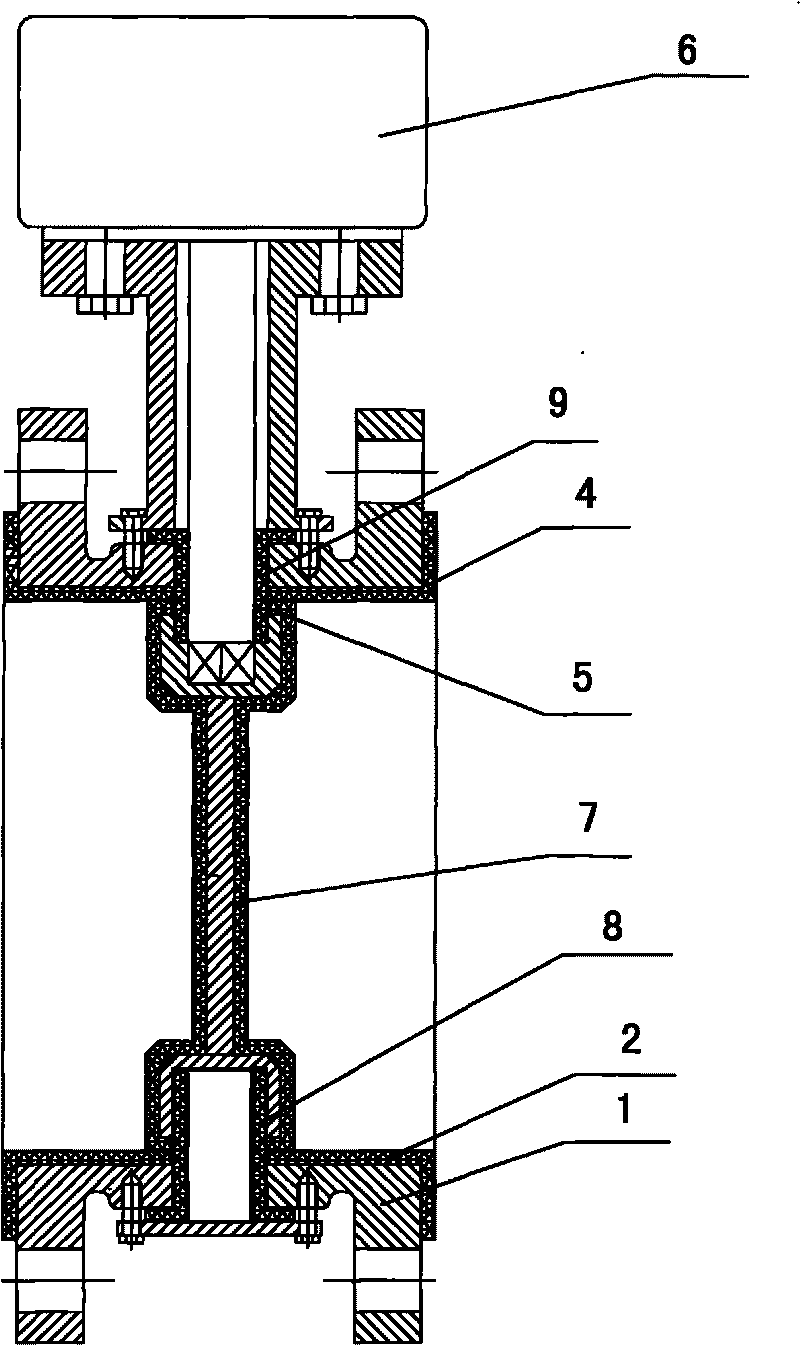

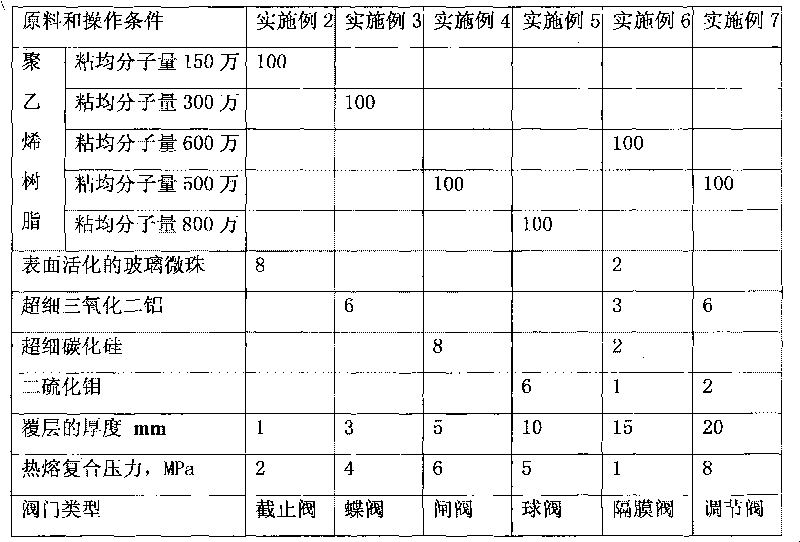

Ultrahigh molecular weight polyethylene steel-plastic composite valve and preparation method thereof

The invention relates to an ultrahigh molecular weight polyethylene steel-plastic composite valve and a preparation method thereof. The ultrahigh molecular weight polyethylene steel-plastic composite valve belongs to a valve for transporting liquid material, in particular to an ultrahigh molecular weight polyethylene steel-plastic composite valve with special properties of corrosion resistance, abrasiveness resistance and hard adhesion. The ultrahigh molecular weight polyethylene steel modeling composite valve comprises a metal valve body and a valve core and is characterized in that a layer of ultrahigh molecular weight polyethylene material cladding is adhered to all the element surfaces contacting with the liquid material on the outer surface of the valve core and the inner cavity surface of the valve body; the ultrahigh molecular weight polyethylene material cladding adopts ultrahigh molecular weight polyethylene and is added with one or more than one auxiliary agent component from organic silicon, surface active glass bead, ultra-fine aluminum oxide, ultra-fine carborundum and molybdenum disulfide, wherein the viscosity-average molecular weight of the ultrahigh molecular polyethylene is larger than or equal to 1.5 millions. The invention solves the problems of high production cost caused by higher-price fluoroplastics in the prior art and less firm fastening of a liner and steel valve body materials.

Owner:SHANDONG KELI NEW MATERIAL CO LTD

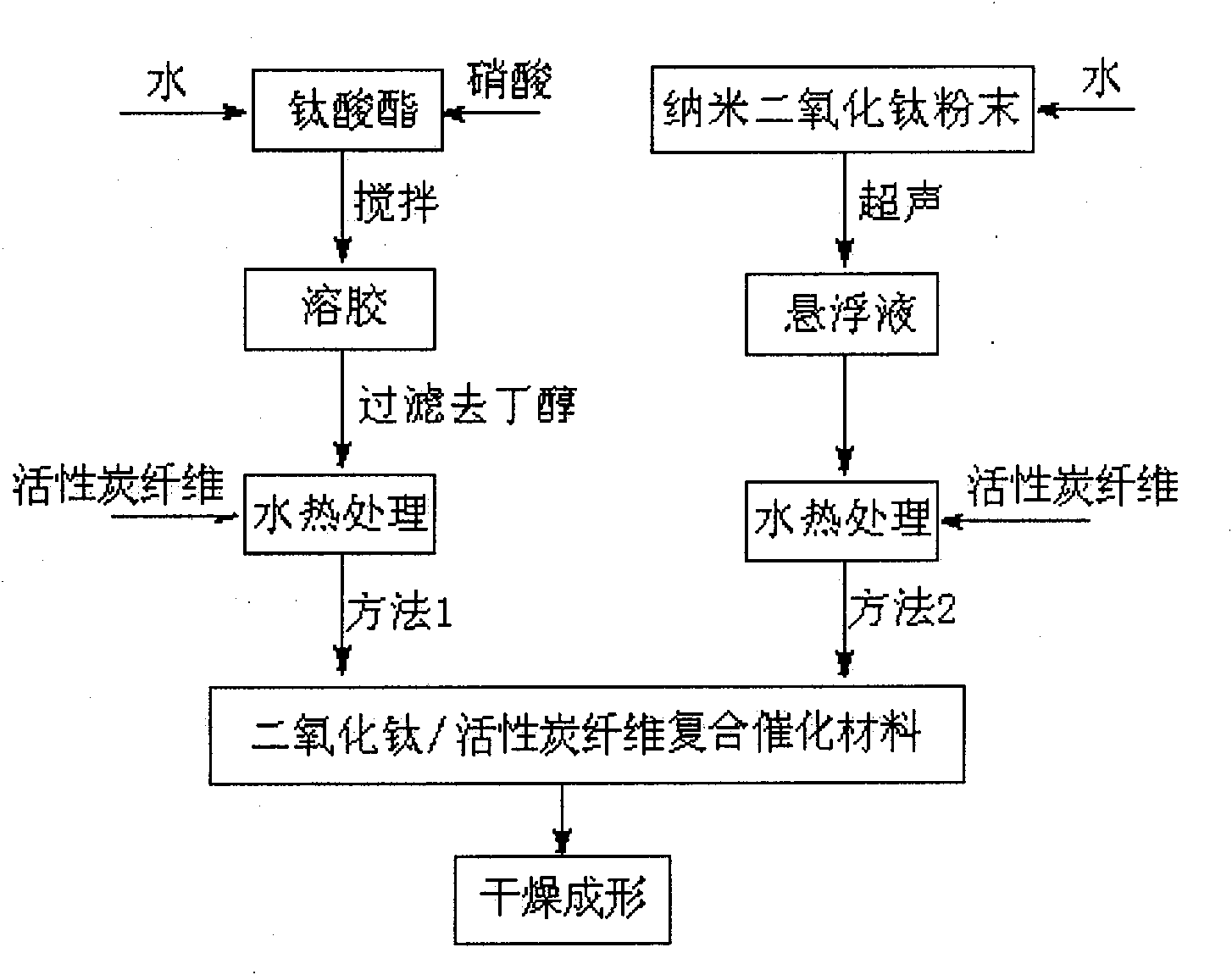

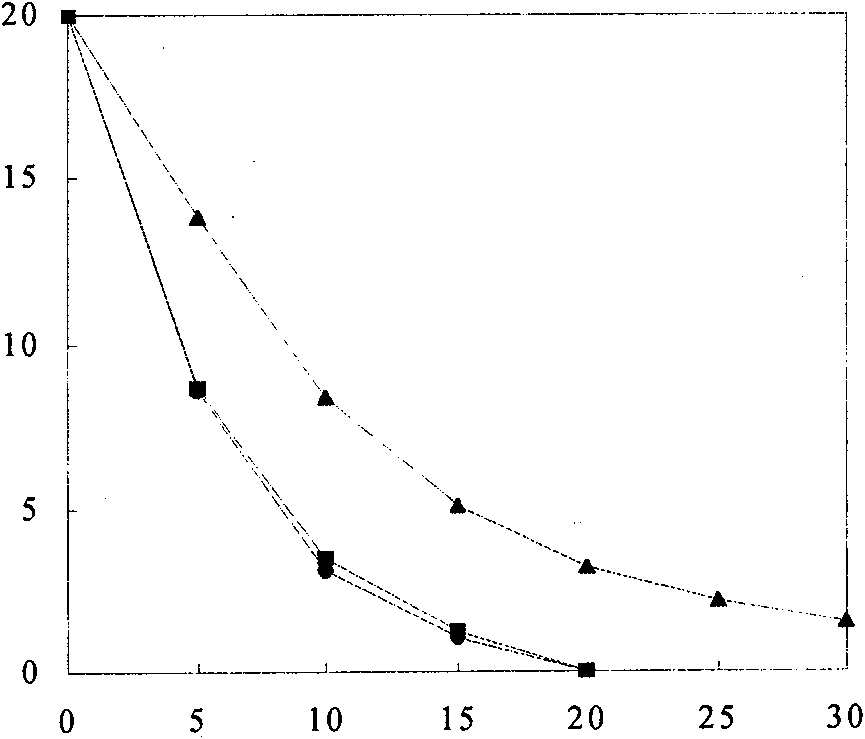

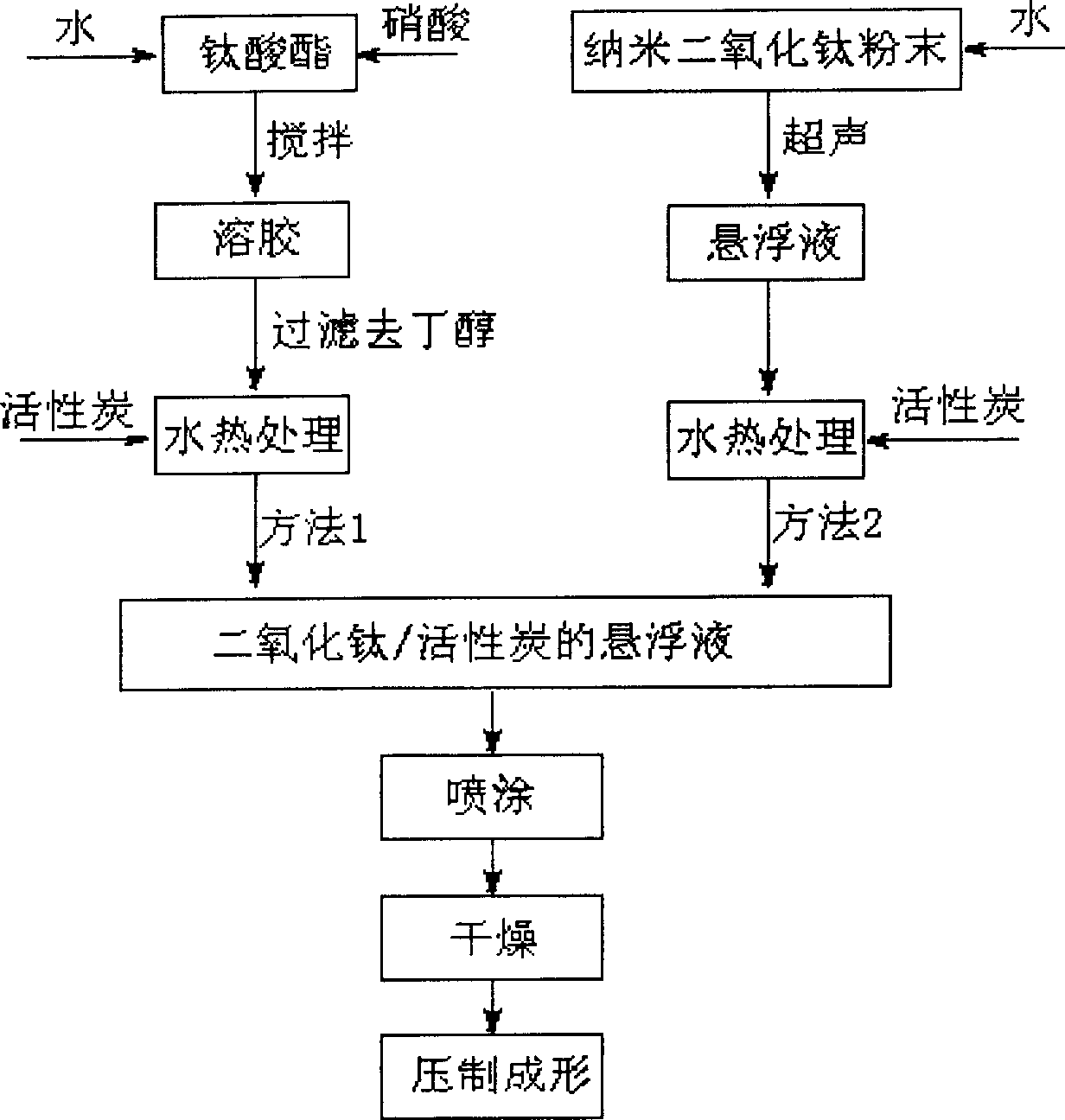

Preparation method of composite photocatalytic material for fresh-keeping of fruit and vegetable

InactiveCN101766996ANotable featuresSignificant progressPhysical/chemical process catalystsFood preservationFiberPhotocatalytic reaction

The invention discloses a preparation method of a composite photocatalytic material for fresh-keeping of fruits and vegetables and a process thereof, comprising preparation of sol through acidic hydrolysis with titanium ester as a raw material, or preparation of absorption type composite photocatalytic material through ultrasonic dispersion of nano titanium dioxide in water and water heating treatment after adding activated carbon fiber, wherein the titanium dioxide is the main catalyst of the absorption type composite photocatalytic material, and the activated carbon fiber is the carrier and the supporting mass thereof. The prepared material can transform ethylene, ethanol, acetaldehyde and the like generated in breathing of fruits and vegetables in processing plants and refrigerators for the fruits and vegetables, and hydrogen sulfide, ammonia and other common volatile contaminants generated in rotting of the fruits and vegetables into harmless materials through photocatalytic reaction under the ultraviolet irradiation. Simultaneously, the invention has the function of killing bacteria and microbes, thereby ensuring that the fruits and vegetables are fresh and safe to eat.

Owner:乔维汉 +2

Hot-melt glue film for combining polypropylene cellular boards and preparing method of hot-melt glue film

ActiveCN105647434AMeet compoundComposite firmNon-macromolecular adhesive additivesAntioxidantPliability

The invention discloses a hot-melt glue film for combining polypropylene cellular boards and a preparing method of the hot-melt glue film. The preparing method comprises the steps that ternary co-polypropylene with a low melting point, an ethylene-propylene copolymer or an ethylene-butylene copolymer, C5 / C9 copolymerization resin, high-molecular-weight PP wax and an antioxidant are put into a kneading machine according to a certain proportion for smelting treatment, after the system is smelted, a closure silane adhesion promoter is added multiple times, kneading treatment is carried out, then water ring granulation is carried out, the materials are extruded and then subjected to curtain coating treatment, and the hot-melt glue film is prepared. In the matrix, ternary co-polypropylene is adopted for blending modification, and thus the requirement of consumers for carrying out combination under the situation without softening deformation of PP cellular boards can be met; the low-temperature flexibility of hot-melt glue can be improved with the ethylene-propylene copolymer or the ethylene-butylene copolymer; the adhesion strength can be improved through the closure silane adhesion promoter; the hot-melt glue film prepared from the formula system is good in film forming performance and fast in crystallization, and thus can be easily prepared with the curtain coating process technology, lining paper is not needed, cost is reduced, and popularization is facilitated.

Owner:PINGHU ZHANPENG HOT MELT ADHESIVE WEB & FILM

Unsaturated cationic lipid derivative, preparation method, and application in plasmid delivery system

ActiveCN111087317AFacilitated releaseGood biocompatibilityOrganic compound preparationPeptidesAlkaneViral vector

The invention relates to the field of chemistry and preparations, in particular to an unsaturated cationic lipid derivative, a preparation method thereof, and application in a plasmid delivery system.The cationic lipid takes electropositive lysine as a hydrophilic head group, amino acid as a skeleton and an unsaturated alkane chain as a hydrophobic tail chain, so that the cationic lipid has the advantages of good biocompatibility, high safety and the like. The synthesis method is simple and quick, low in synthesis cost and beneficial to large-scale production. The cationic liposome constructed on the basis of the unsaturated cationic lipid designed by the invention can stabilize the load plasmid without leakage, has better gene transfection efficiency on various tumor cells and primary cells than positive control Liponectamine2000, and has no obvious cytotoxic effect on cells. The invention provides a safe and efficient cationic lipid and non-viral vector platform for plasmid delivery.

Owner:CHINA PHARM UNIV

Coconut fiber plate for mattress

ActiveCN102669989AComposite firmEffective compoundStuffed mattressesSynthetic resin layered productsPolyesterFiber

The invention relates to a coconut fiber plate, in particular to a coconut fiber plate for a mattress, which comprises an upper layer, a middle layer and a lower layer which are compounded together through a hot air penetrating technology, wherein the upper layer and the lower layer comprise dual-component sheath core fibers and polyester hollow fibers, and the middle layer comprises dual-component sheath core fibers and coconut fibers. The coconut fiber plate for the mattress has the advantages of no formaldehyde release, no glue smell, difficulty in dampness and mildew, flat surface and uniformity in thickness.

Owner:昆山吉美川纤维科技有限公司

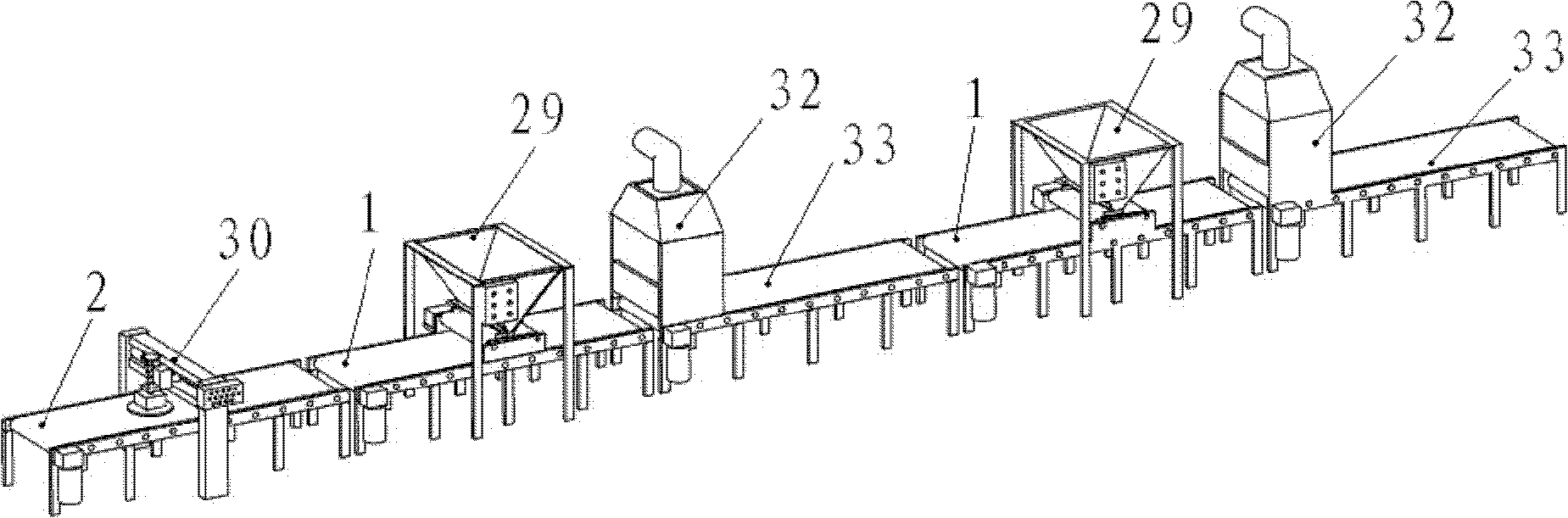

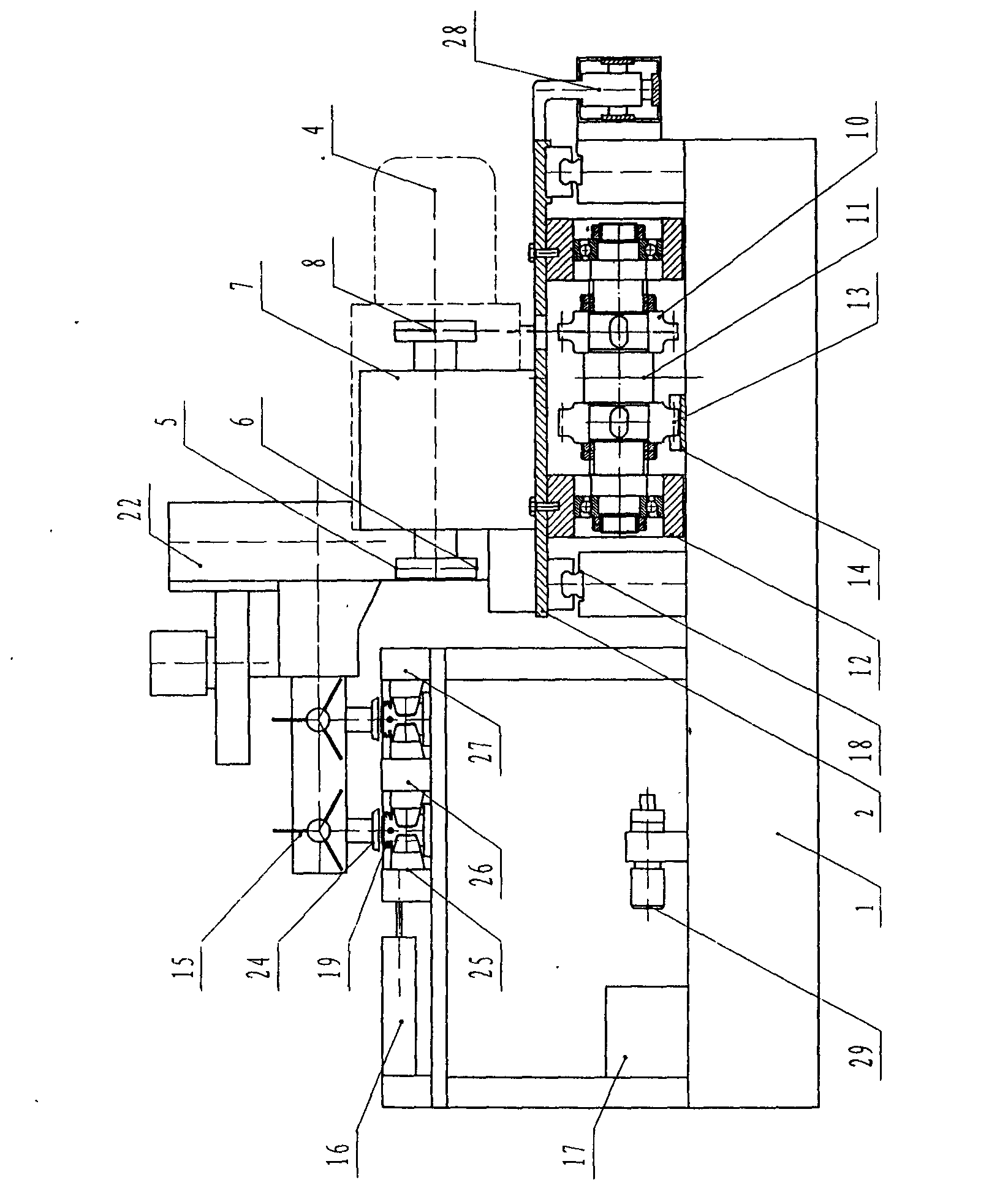

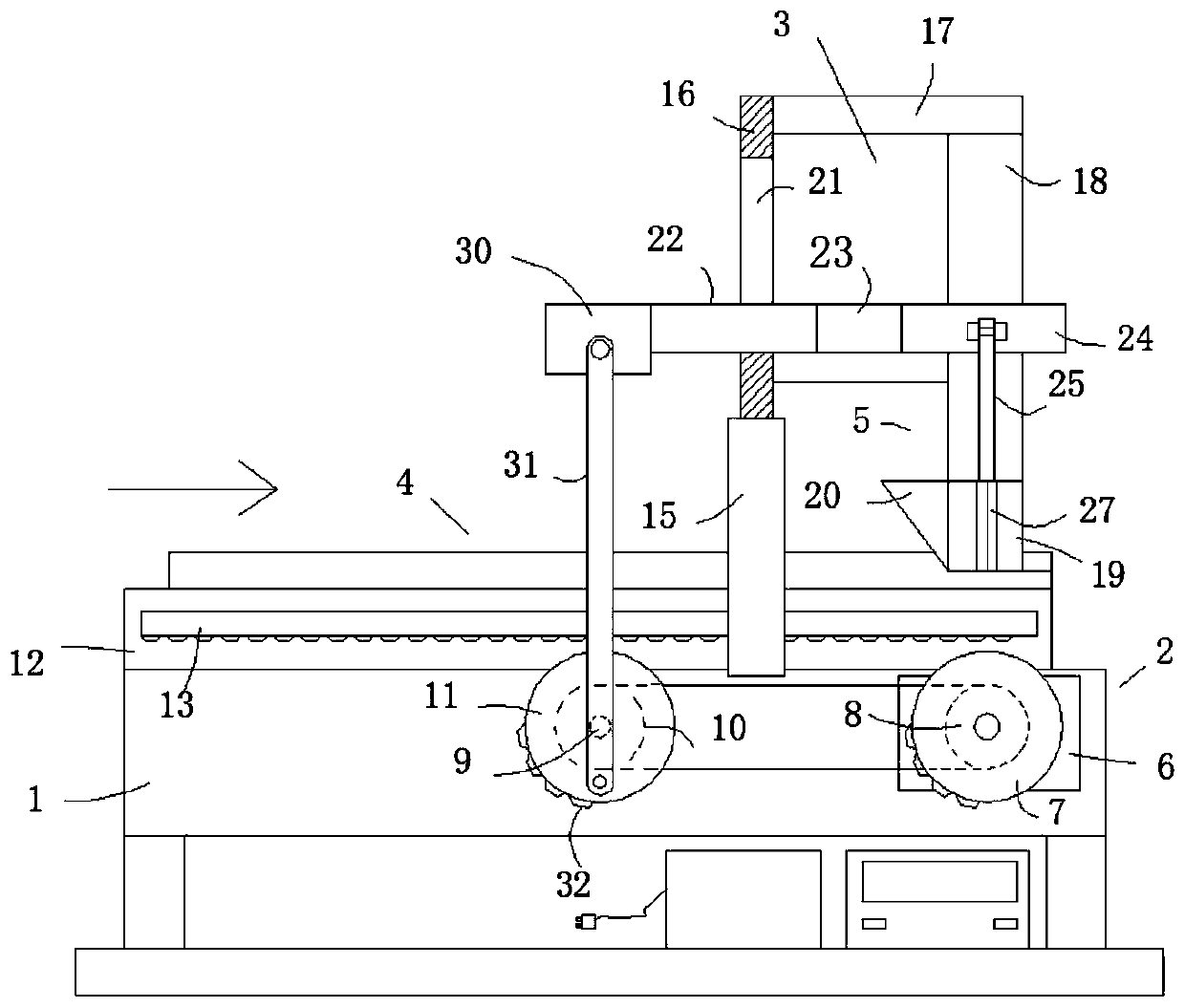

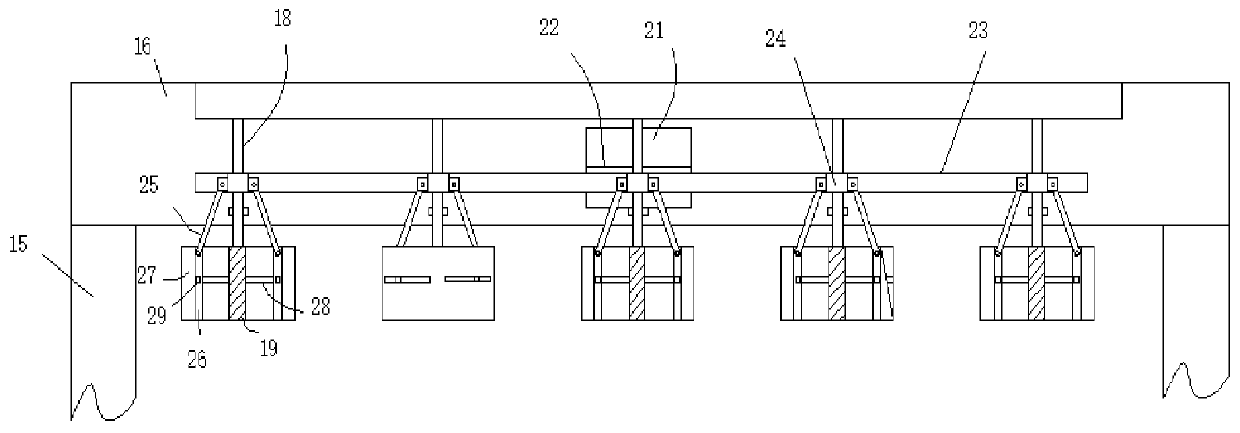

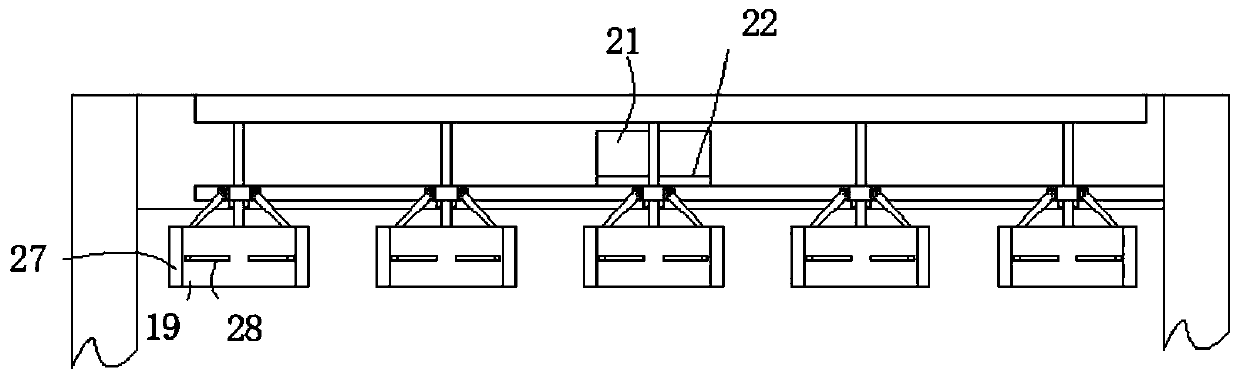

Double-head welding and milling machine for steel aluminum composite rails

InactiveCN103056666AIncrease productivityComposite firmArc welding apparatusOther manufacturing equipments/toolsMilling cutterSlide plate

The invention relates to a double-head welding and milling machine for steel aluminum composite rails, and belongs to special processing equipment for steel aluminum composite conductor rails of third rail ladle aluminum of an urban rail transit power supply system. The double-head welding and milling machine for the steel aluminum composite rails mainly comprises a base 1 with a rolling guide rail pair 18, a sliding plate 2 provided with a double-head welder 3 and a double-head milling machine 15 and a clamping device 32 with a cylinder 16, the sliding plate 2 moves by the aid of a power device 33 composed of a speeding regulating motor 4, a reduction gearbox 7 and the like. Two J-shaped or L-shaped stainless steel bars 31 are transversely fastened on the upper portion of each of two H-shaped aluminum sections 30 with the length of 15m or 18m, then the stainless steel bars 31 and the H-shaped aluminum sections 30 are transversely clamped by the clamping device 32, the sliding plate 2 is started to horizontally move from end to end, and the double-head welder 3 on the sliding plate 2 starts automatic MiG gas shielded welding to enable each J-shaped or L-shaped stainless steel bar to form a C-shaped whole. Two milling cutters 24 on the double-head milling machine 15 in the rear of the sliding plate 2 rotate coordinately to flatly mill weld joints 34 on the stainless steel bars so as to composite the stainless steel bars 31 and the aluminum sections 30, and accordingly steel aluminum composite conductor rails of ladle aluminum 19 are formed. The two working procedures of welding and milling are combined to be completed on the same complete machine, two steel aluminum composite rails can be welded and milled simultaneously, production efficiency is high, and steel and aluminum composite quality is good.

Owner:山东伟盛铝业有限公司

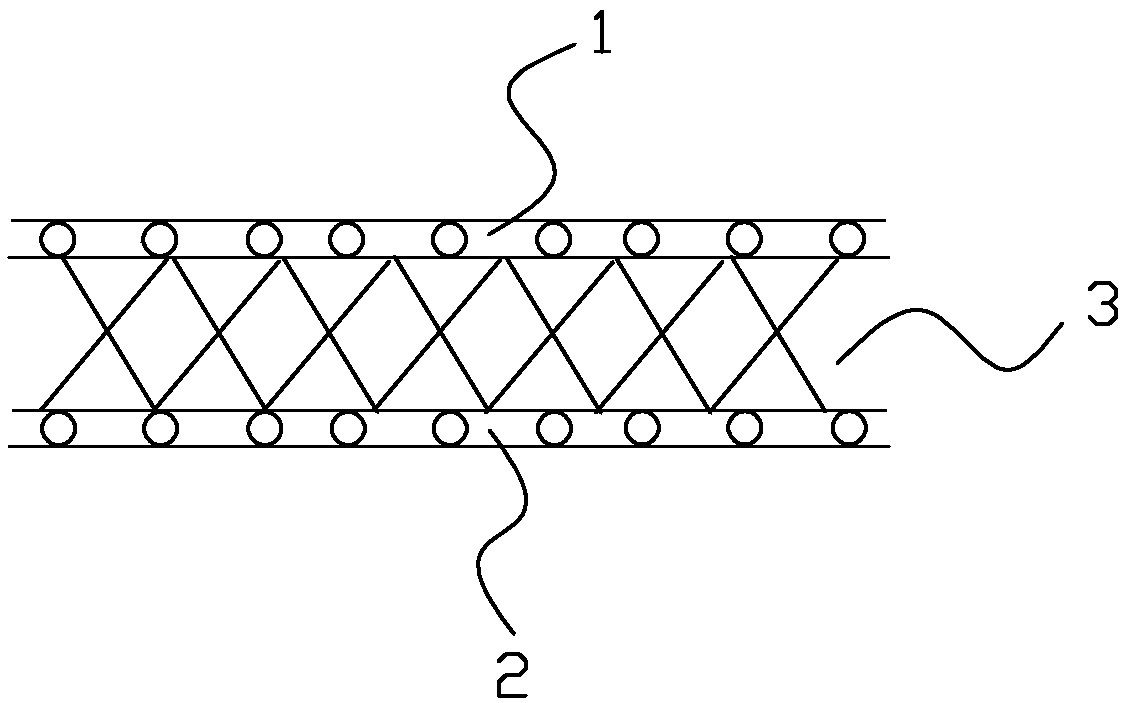

Sandwich screen cloth for composite plate

InactiveCN108162514AThree-dimensional network structureStable structureSynthetic resin layered productsConjugated synthetic polymer artificial filamentsPolyesterYarn

The invention relates to the technical field of spinning production and provides sandwich screen cloth for a composite plate. The sandwich screen cloth can be compounded with a plate and is good in high temperature resistance, the strength, the impact resistance and the shearing stress of the plate can be effectively improved, and the sandwich screen cloth consists of a surface layer, a bottom layer and support yarns between the surface layer and the bottom layer; the surface layer, the bottom layer and the support yarns form the sandwich screen cloth of a three-dimensional manner; the surfacelayer is made of a thermal resistant spandex fiber and a carbon fiber which are woven together to form a parallel structure; the bottom layer is made of the thermal resistant spandex fiber and a polyester fiber which are woven together to form a parallel structure; the support yarns are thermal resistant spandex fiber woven single yarns.

Owner:惠安县大林鞋服有限公司

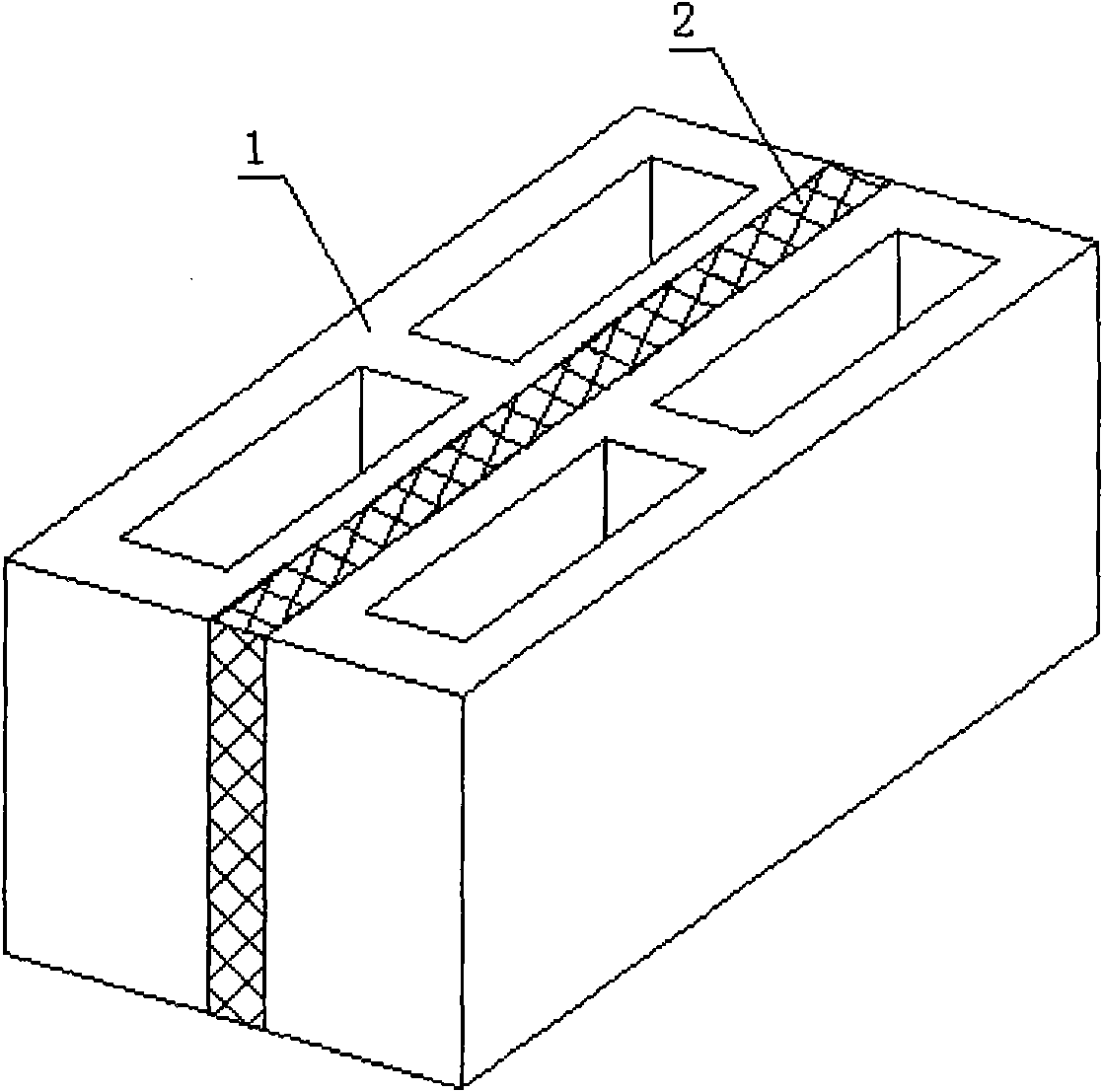

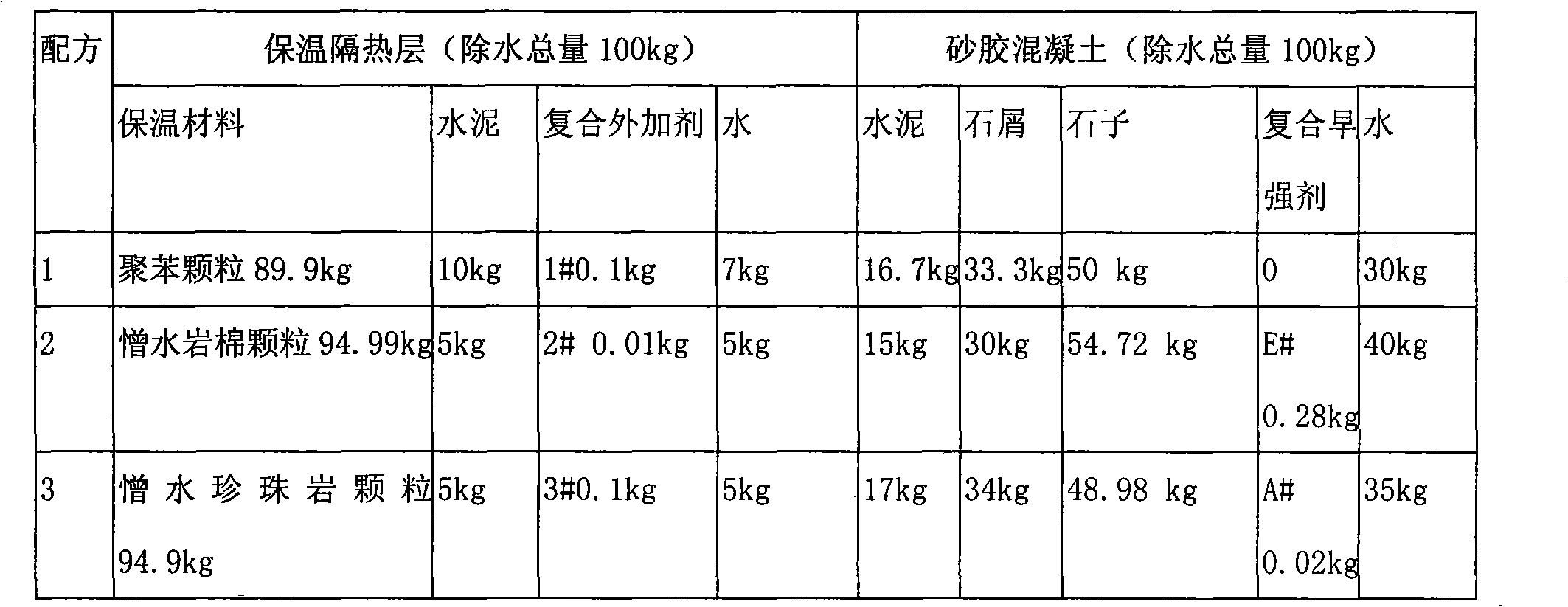

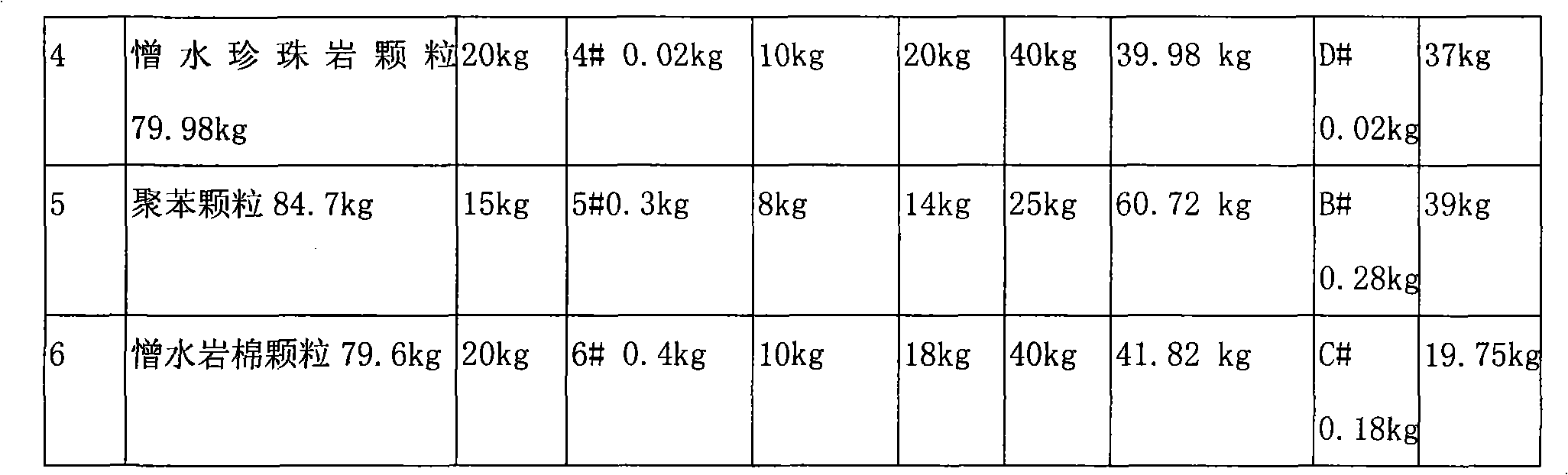

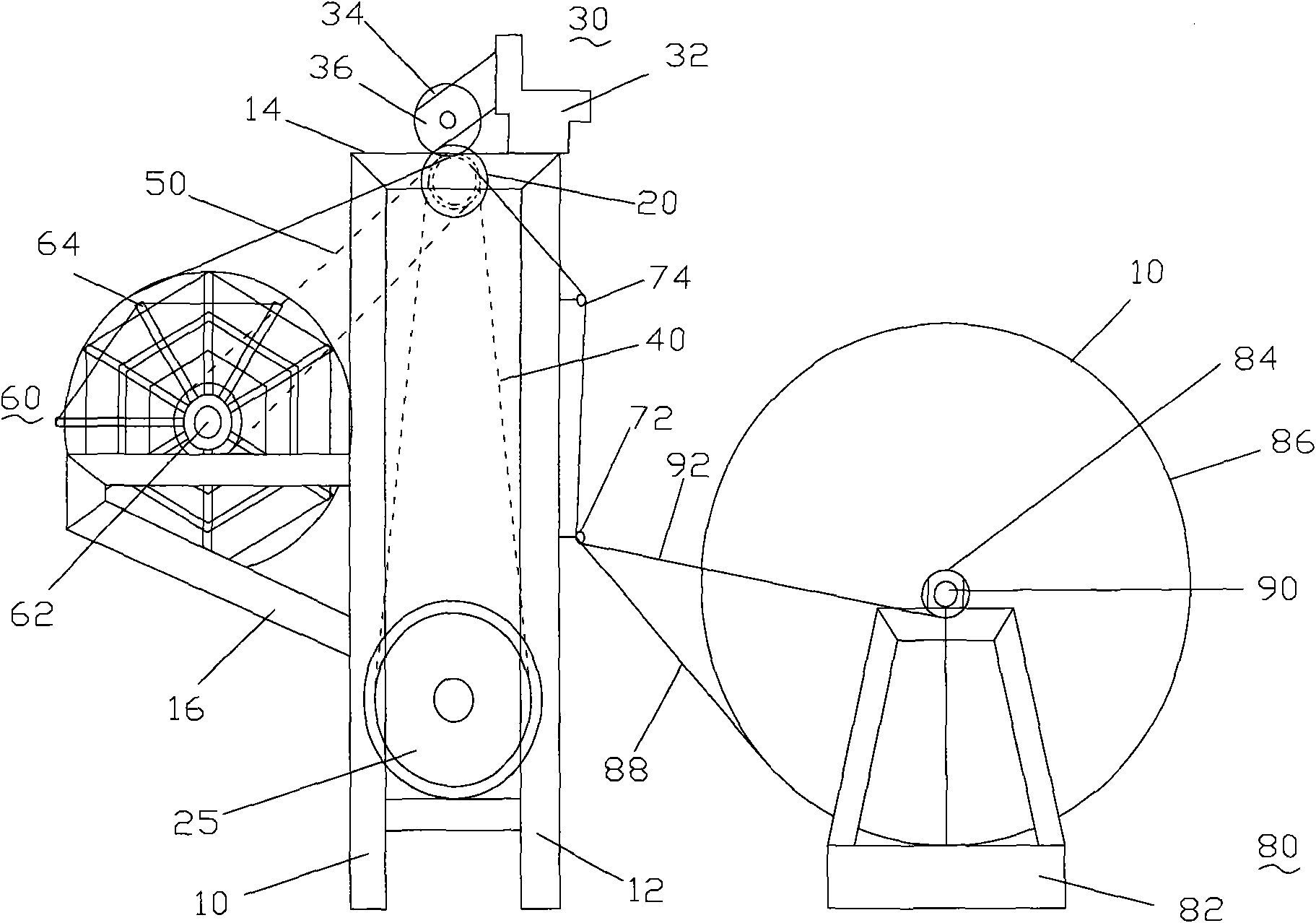

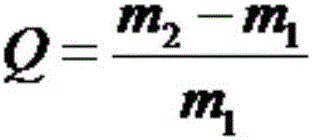

Sandwiched mortar heat-insulating/warm-keeping block, preparation and application thereof

InactiveCN102051946AComposite firmNot easy to fall offConstruction materialClimate change adaptationExtrusionMaterials science

The invention discloses a sandwiched mortar heat-insulating / warm-keeping block which is a novel functional wall block having multiple building functions of energy saving, environment protection, heat insulation, warm keeping, fire prevention and noise absorption. The invention further discloses preparation and application of the sandwiched mortar heat-insulating / warm-keeping block. A warm-keeping / heat-insulating layer is arranged in the middle of the sandwiched mortar heat-insulating / warm-keeping block, mortar concrete is arranged at both sides of the warm-keeping / heat-insulating layer, and the sandwiched mortar heat-insulating / warm-keeping block is formed by carrying out vibration and extrusion forming on the warm-keeping / heat-insulating layer and the mortar concrete. The heat-insulatinglayer of the mortar warm-keeping block provided by the invention has stable structure, and the heat-insulating / warm-keeping layer is combined with the block into a whole and can not fall off easily. Thus, the prepared block is durable, thereby being a favorable novel wall material having the functions of heat insulation, warm keeping, fire prevention, energy saving, emission reduction and environment protection.

Owner:SHANGHAI YUNER INDAL

X-ray development material compound device, method and dressing

The invention discloses an X-ray development material compound device; comprising a working table, and a motor arranged on the working table; two sides of the working table are respectively provided with a coil handling apparatus and a rolling device driven by a motor, dressing and X-ray development material which are axially wound on the coil handling apparatus commonly wind around a compound compression roller on the working table through a cloth guider and are rolled by the rolling device. At least one ultrasonic wave compound head which can compound the dressing and X-ray development material which pass through the compound compression roller in a high-frequency way is arranged on the working table. The invention also relates to a relative compound method and medical dressing. The invention adopts an ultrasonic wave compound way, the compound head vibrate in a high-frequency way, so as to effectively heat and pressurize to the X-ray development material and the dressing, the compound is firm and the development material is not easy to fall off; the development material which takes PVC plastics as a carrier can be compounded, or the fiber linear development material mixed with permanent white can be compounded; in addition, the energy consumption is low and the invention is environmental-protection.

Owner:稳健医疗(天门)有限公司 +1

Preparation method for antibacterial hemostatic microspheres based on cellulose

ActiveCN106421877AKeep hydrophilicMaintain hemostatic effectSurgical adhesivesPharmaceutical delivery mechanismMicrosphereHemostatics

The invention relates to a preparation method for antibacterial hemostatic microspheres based on cellulose, and belongs to the field of functional polymer materials. The preparation method for the antibacterial hemostatic microspheres comprises the steps: firstly, dissolving amphiphilic cellulose derivatives in an organic solvent, dissolving alginate in water, and mixing the two solutions; then adding an oil-in-water type emulsifier and tea tree oil into the mixed solution, and then carrying out heating and stirring reaction for 1-10 h under a condition of the temperature of 30-80 DEG C; and finally, separating microspheres by centrifugation, washing with a washing auxiliary agent, and filtering and drying to obtain the microsphere product. The method avoids toxic effects generated from microsphere crosslinking with a chemical crosslinking agent, and the obtained microspheres have certain hydrophilicity and have good hemostatic and antibacterial effects.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

(Ti,W)Cp/Fe in-situ composite bimetal positioning fusion process and product

The invention discloses a (Ti,W)Cp / Fe in-situ composite bimetal positioning fusion process. The (Ti,W)Cp / Fe in-situ composite bimetal positioning fusion process comprises the steps that a hard phase particle (Ti,W)C and active element particles Cr, Mo, Cu are mixed with cold glue to form pellets which are then pressed into a pre-formed block to be placed at a designated position; in a negative pressure environment, base material molten steel after smelting treatment is poured into the pre-formed block, and the pouring temperature is 1600-1650DEG C; and the pouring is completed, and a (Ti,W)Cp / Fe in-situ composite is formed by quenching after solidification. The mass ratio of the hard phase particle (Ti,W)C to the base material alloy molten steel is 5 to 30%, and the density ratio of the hard phase particle (Ti,W)C to iron-based metal liquid is 0.9 to 1.1. The (Ti,W)Cp / Fe in-situ composite bimetal positioning fusion process strengthens the metallurgical bond between the hard phase and the base material through the in-situ fusion of the (Ti,W)C particle, the active elements and the base material, avoids the falling and separation of the hard phase, enhances the uniform distribution of the particles, enhances the strength, toughness and wear resistance of a product in a positioning enhancement zone, improves the product adaptation range and prolongs the service life, and reduces the process difficulty and production cost.

Owner:山东恒森特种装备有限公司

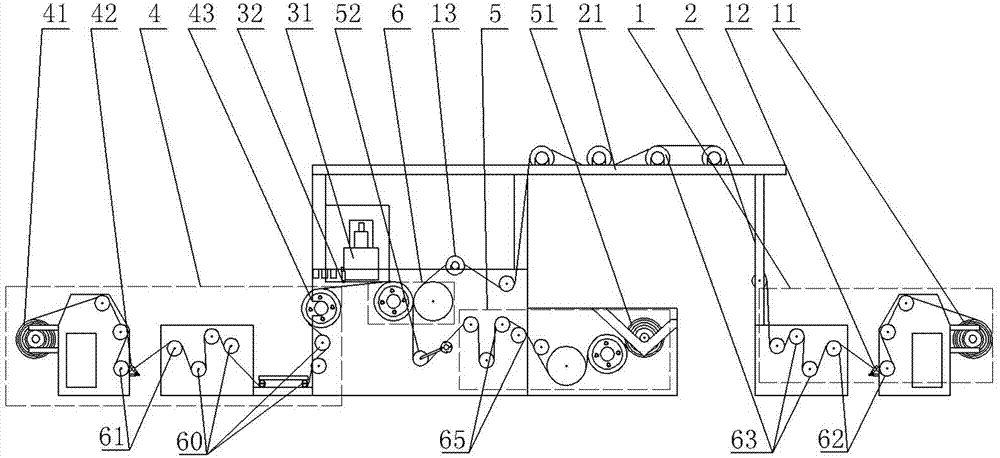

Automatic production system for glue spraying type gas-permeable membrane composite cloth

The invention relates to an automatic production system for glue spraying type gas-permeable membrane composite cloth. The automatic production system comprises a frame body, wherein a gas-permeable membrane conveyer is arranged at the left side of the frame body, a non-woven cloth conveyer is arranged at the right side of the frame body, composite paired rollers are arranged on the frame body, a material receiving device is arranged at the right sides of the composite paired rollers, and a wide-range glue spraying nozzle covering a gas-permeable membrane is arranged between the gas-permeable membrane conveyer and the composite paired rollers; and the material receiving device comprises a material receiving roll, and a plurality of traction rollers are arranged between the material receiving roll and the composite paired rollers. The automatic production system has the characteristics that the covering is uniform, the compositing is firm, the product percent of pass is high and the like. According to the automatic production system, the glue melting, glue spraying, compositing and rolling can be automatically realized due to the integrated structural design; and as the glue spraying is carried out by the fixed glue spraying nozzle, the fixed glue spraying nozzle and the gas-permeable membrane conveyer are organically integrated, the large-area and wide-coverage glue spraying can be carried out on a gas-permeable membrane, and glue spraying face is changed from a point into a surface, so that the glue joint area and the viscosity of hot melting glue are substantially improved, furthermore, the coverage of the hot melting glue is uniform, and the glue dosage is little.

Owner:HUBEI HONGYUE NEW MATERIAL

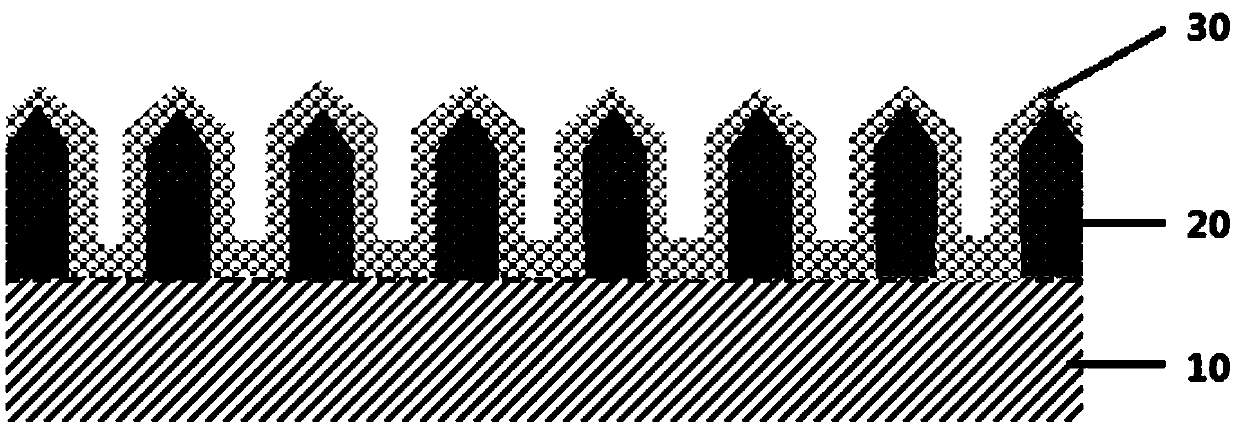

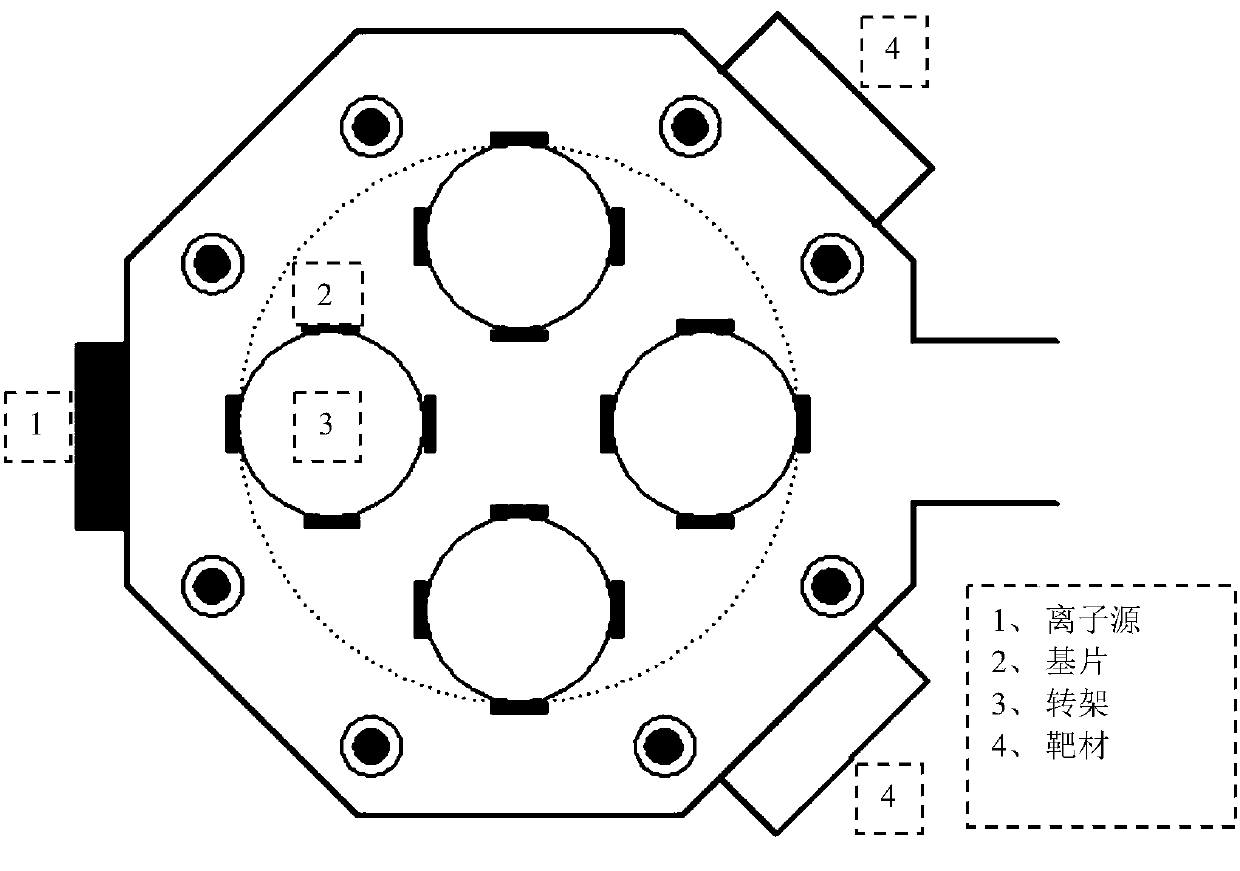

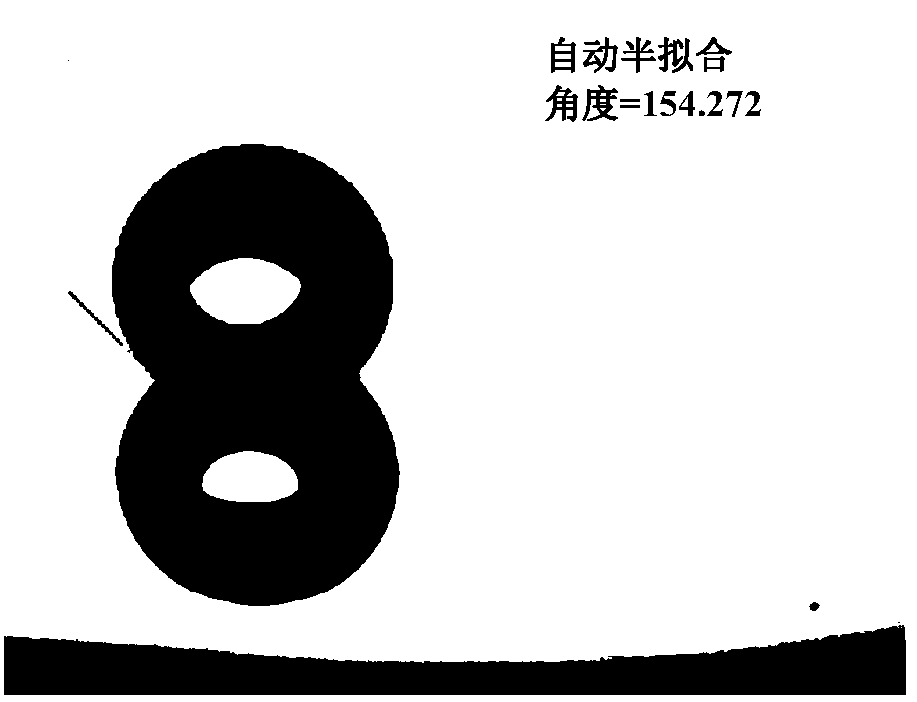

Super-hydrophobic diamond-like carbon composite layer structure and preparation method thereof

ActiveCN111304602AComposite firmImprove adhesionVacuum evaporation coatingSputtering coatingCarbon compositesNano structuring

The invention provides a preparation method of a diamond-like carbon composite layer structure. The preparation method comprises the following steps of providing a substrate, and sequentially carryingout pretreatment, glow cleaning and ion etching cleaning on the substrate; placing the cleaned substrate in a deposition chamber, introducing argon gas, adjusting the pressure intensity of a vacuum chamber to 0.2-1.3 Pa, starting a first target material and a second target material, controlling the target power of the first target material to 30-70W, controlling the target power of the second target material to 30-70W, and depositing a prefabricated transition layer under the condition that the bias voltage of the substrate is 100-300V; taking out the sample deposited with the prefabricated transition layer, placing the sample in a container containing an etching solution, carrying out ultrasonic treatment, etching the prefabricated transition layer to form a transition layer with a micro-nano structure array on the surface so as to obtain an etched sample; and after cleaning the surface of the etched sample, placing the etched sample in the deposition chamber, and depositing a diamond-like layer on the surface of the transition layer of the etched sample.

Owner:SHENZHEN INST OF ADVANCED TECH

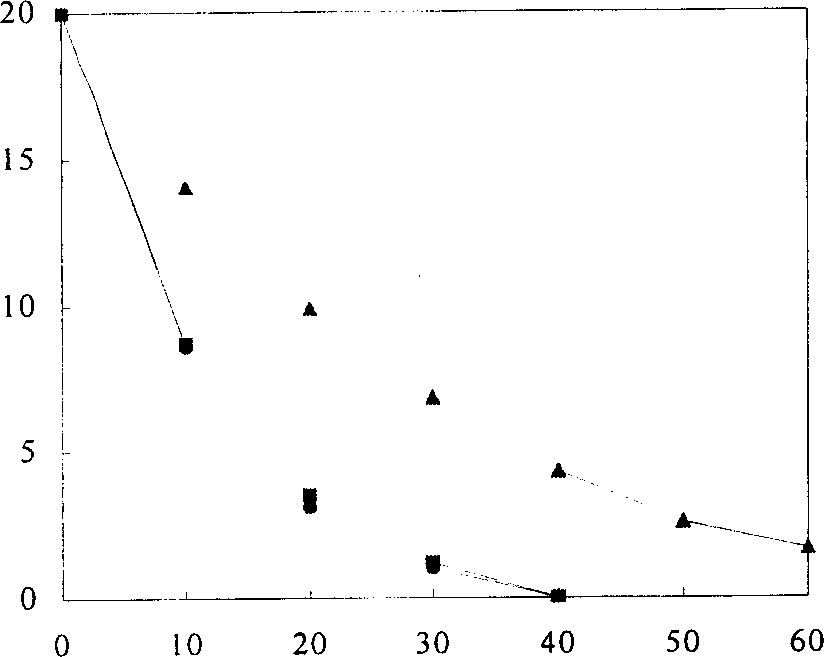

Method of preparing composite photocatalytic material for air purification

InactiveCN1283355CSmall volume shrinkageComposite uniformCatalyst activation/preparationPhotocatalytic reactionPapermaking

The invention discloses a preparation method of a photocatalytic purification composite material for purifying air. The method uses titanate as raw material to prepare titanium dioxide sol by sol-gel method, or ultrasonically disperses nano titanium dioxide powder in water to prepare titanium dioxide suspension, and then adds activated carbon for hydrothermal treatment to prepare a suspension containing titanium dioxide / activated carbon composite catalyst; and then Combined with the papermaking process, it is sprayed on the paper before the paper drying section, dried, and pressed into a corrugated shape to prepare an adsorption-type composite photocatalytic purification material with titanium dioxide as the main catalyst, activated carbon as the carrier, and paper as the support. The material of the present invention converts common volatile organic pollutants in the air into harmless products through photocatalytic reaction in a closed or semi-closed space, irradiated by ultraviolet light.

Owner:NO 63971 TROOPS PLA

Cold-resistant and pressure-resistant PVC (polyvinyl chloride) profiled bar

InactiveCN102660086AImprove cold resistanceImprove bending resistanceCyclohexanonePolyvinyl chloride

The invention relates to a cold-resistant and pressure-resistant PVC (polyvinyl chloride) profiled bar which comprises a PVC base material, a processing reinforcing agent and a PVC modifying agent. The content of the PVC base material ranges from 60% to 85%, the content of the processing reinforcing agent ranges from 3% to 7%, and the content of the PVC modifying agent ranges from 10% to 35%. The PVC base material is composed of, by weight, 100 parts of polyvinyl chloride, 2 parts of antioxidants, 15-20 parts of flame retardants, 2 parts of heat stabilizers, 5-7 parts of epoxidized soybean oil, 0.5 part of zinc stearate, 0.5 part of stearic acid, 2 parts of processing agents and 10 parts of titanium dioxide. The PVC modifying agent is composed of, by weight, 2-5 parts of ethylene-ethylene vinyl acetate copolymer, 2.5-4 parts of di-n octyl phthalate, 4 parts of cyclohexanone and 5 parts of dimethylbenzene. The cold resistance and the pressure resistance of the cold-resistant and pressure-resistant PVC profiled bar are greatly improved, the preparation process is simple, and materials are easily obtained.

Owner:新疆蓝山屯河型材有限公司 +1

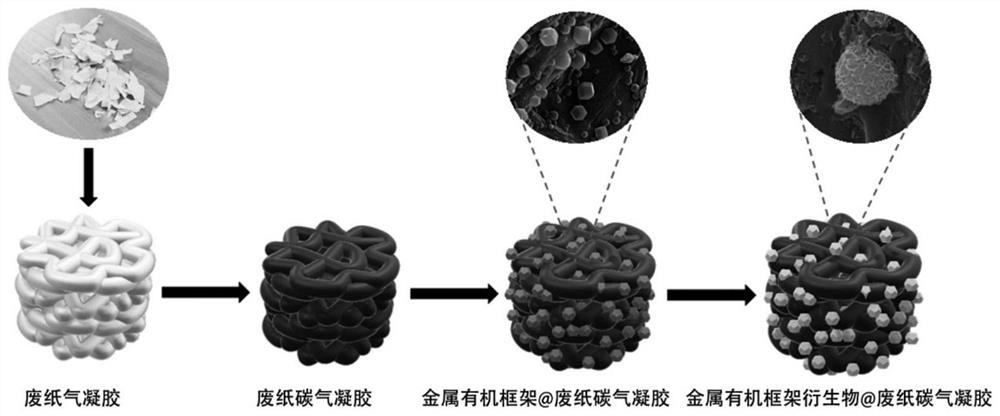

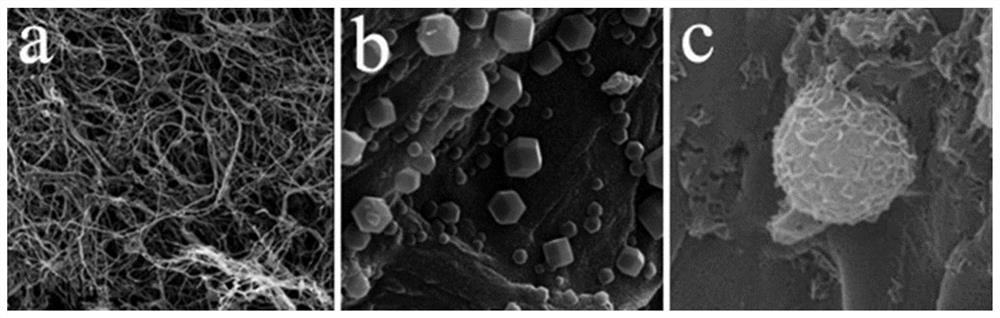

Waste paper aerogel, aerogel derivative and preparation method thereof

PendingCN112591728AEasy to makeShort cycleCarbon preparation/purificationPhosphidesSodium chlorateMetal-organic framework

The invention relates to waste paper aerogel, an aerogel derivative and a preparation method thereof, and belongs to the technical field of aerogel materials. The method comprises the following steps:soaking the waste paper, deinking, carrying out surface functionalization treatment, carrying out suction filtration, molding and drying to obtain waste paper aerogel, and calcining at 400-1000 DEG Cto obtain waste paper carbon aerogel; wherein the surface functionalization treatment is as follows: a compound A solution is used for treating the waste paper, the pH value of the treatment is 4-4.5, the treatment temperature is 70-80 DEG C, the treatment time is 2-6 hours, and the compound A is one of hydrogen peroxide, sodium hypochlorite, sodium chlorite and sodium periodate. The method for preparing aerogel from waste paper has the advantages of simple preparation process, short period, small secondary pollution and the like. The prepared aerogel is more stable. The metal organic framework derivative-coated waste paper-based composite carbon aerogel can load a large number of electrocatalytic active substances, is light in weight and high in conductivity, and can be widely applied tocommercial electrocatalytic materials.

Owner:SICHUAN UNIV

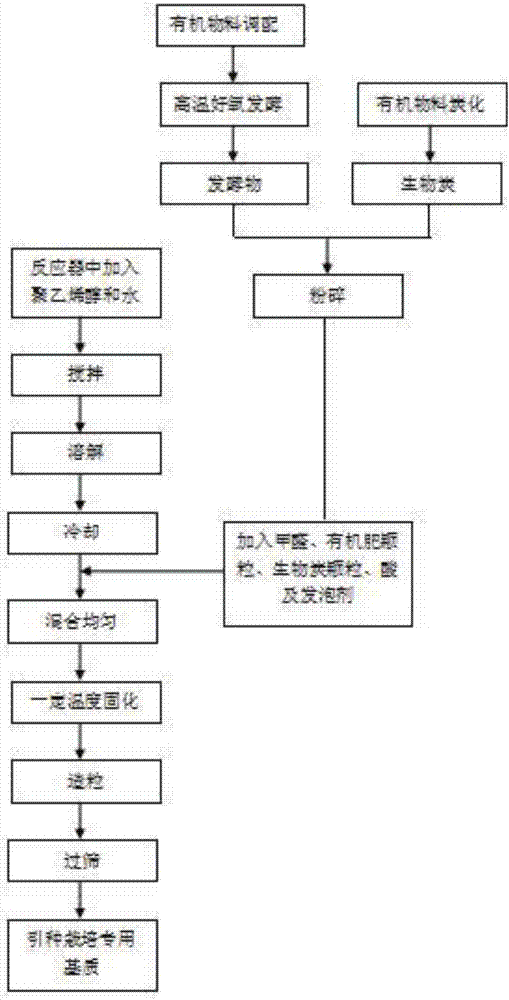

Introduction and cultivation matrix for garden plants and preparation thereof

InactiveCN107285851AImprove breathabilityGood water and fertilizer retentionBio-organic fraction processingExcrement fertilisersPolyvinyl alcoholGarden plants

The invention discloses an introduction and cultivation matrix for garden plants. The introduction and cultivation matrix contains a polyvinyl formal carrier, charcoal and a composted material, wherein the charcoal and the composted material are compounded in situ to the surface and / or pores of the polyvinyl formal carrier. Besides, the invention further provides an in-situ compounding method of the matrix. Polyvinyl formal in-situ compounded with the charcoal and the composted material is taken as the matrix and has the characteristics of light weight, excellent water-retaining property and air permeability and the like. A preparation method of the matrix is simple, and the prepared matrix has stable and excellent performance.

Owner:HUNAN XISI ECOLOGY TECH

Automatic feeding and roughening device for composite board processing

ActiveCN111070394ARealize automatic feedingImproved ability to resist sideways movementAuxillary shaping apparatusElectric machineryDrive motor

The invention discloses an automatic feeding and roughening device for composite board processing, and relates to the field of composite board processing. The automatic feeding and roughening device comprises a working table fixed to a base; a driving assembly, a main cutting assembly, a feeding assembly and an assistant cutting assembly are installed on the working table, the assistant cutting assembly is installed on the main cutting assembly and located above the feeding assembly, the driving assembly is in transmission connection with the feeding assembly, and the driving assembly is in linkage connection with the assistant cutting assembly; and the driving assembly comprises a driving motor fixed to the front side of the working table. According to the scheme, main roughening groovesand assistant roughening grooves formed after roughening are perpendicular to each other to form zigzag roughening grooves, which is beneficial to enhancing the attachment effect in subsequent composite board processing, so that the lateral sway resistance of boards is high, and the boards are composited more firmly; and besides, processing of the roughening grooves is automatically completed, manual roughening processing is not needed, the roughening forming effect is good, and the roughening efficiency is high.

Owner:湖州互融新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com