Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

184results about How to "Promote recrystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

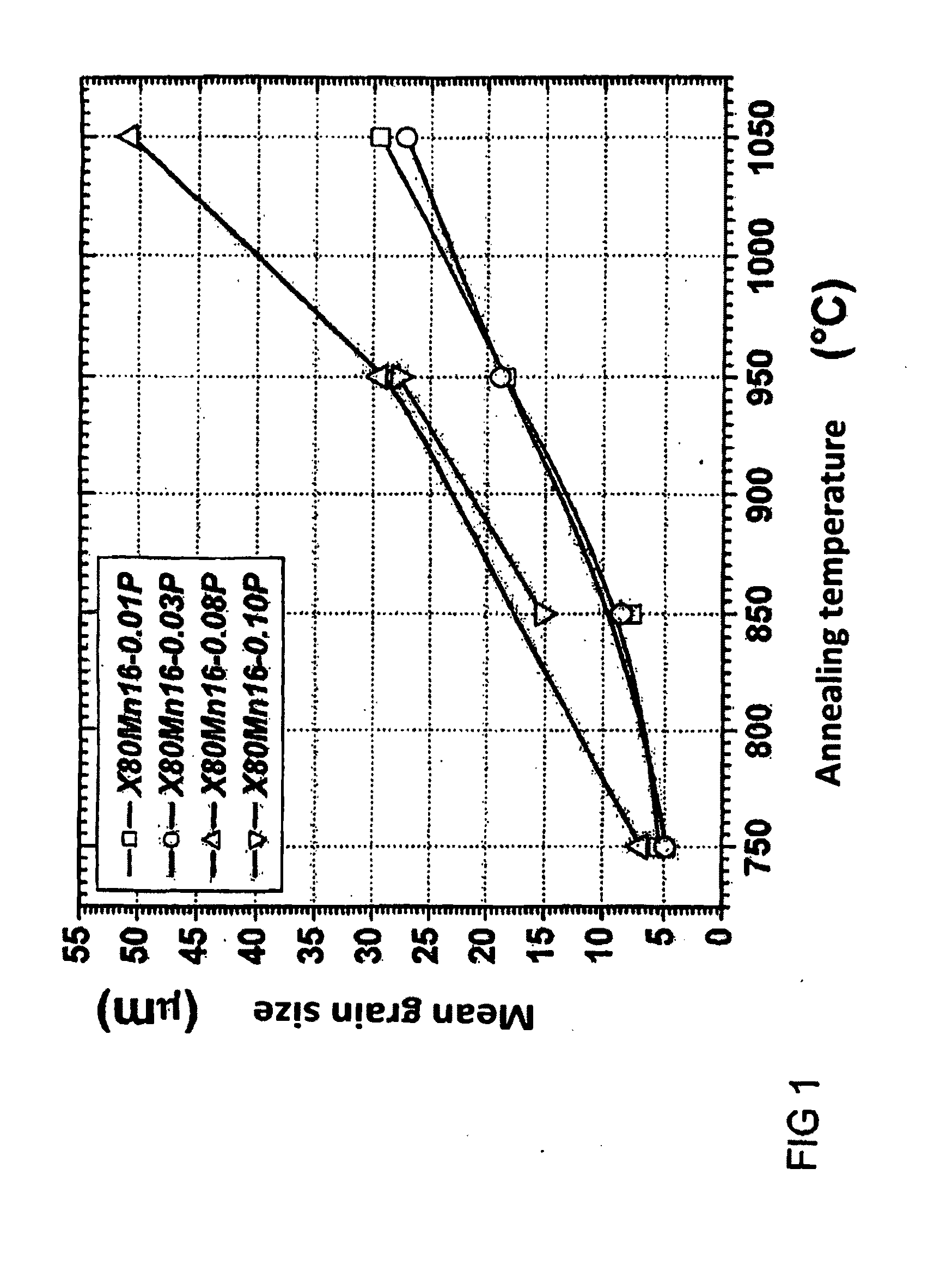

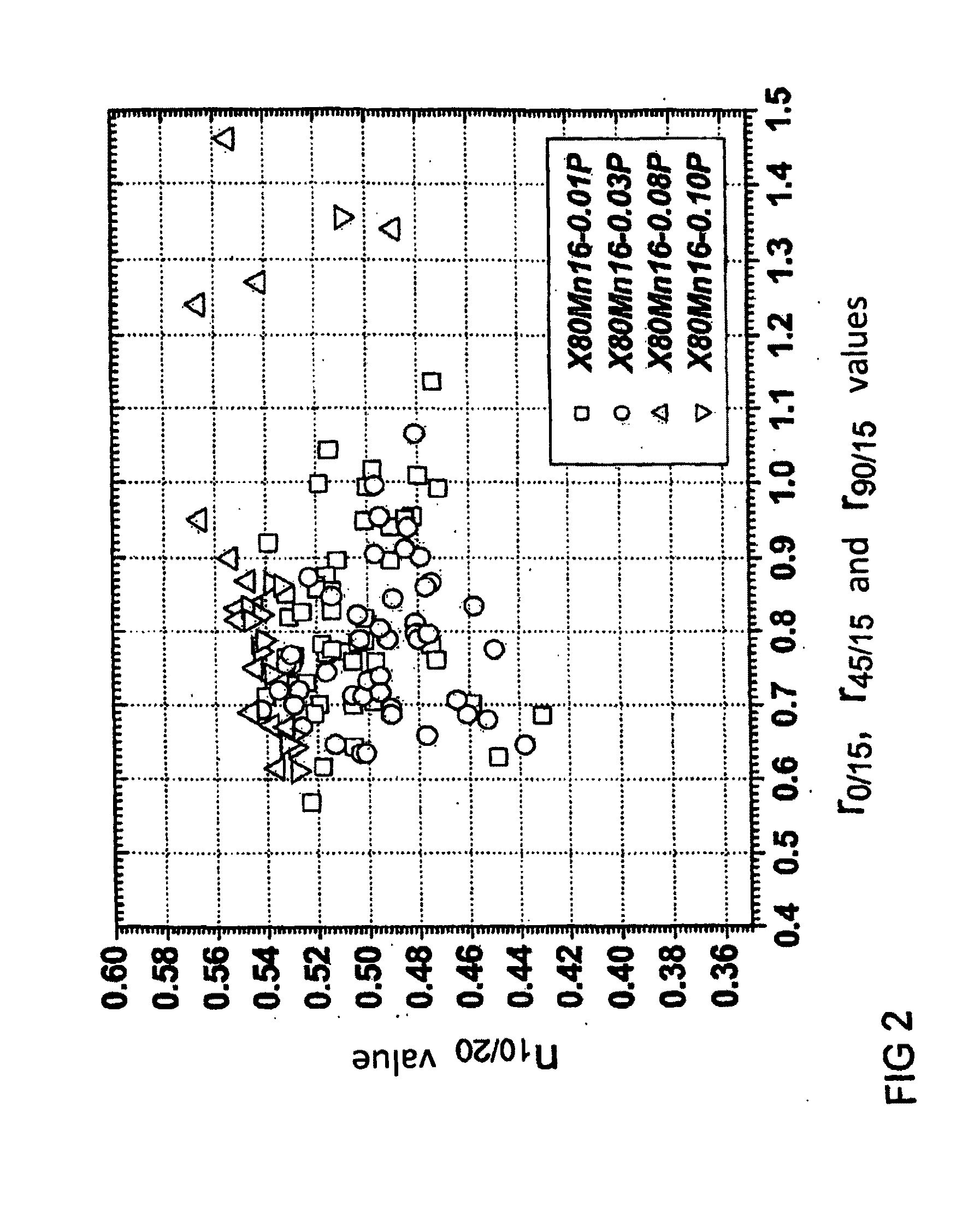

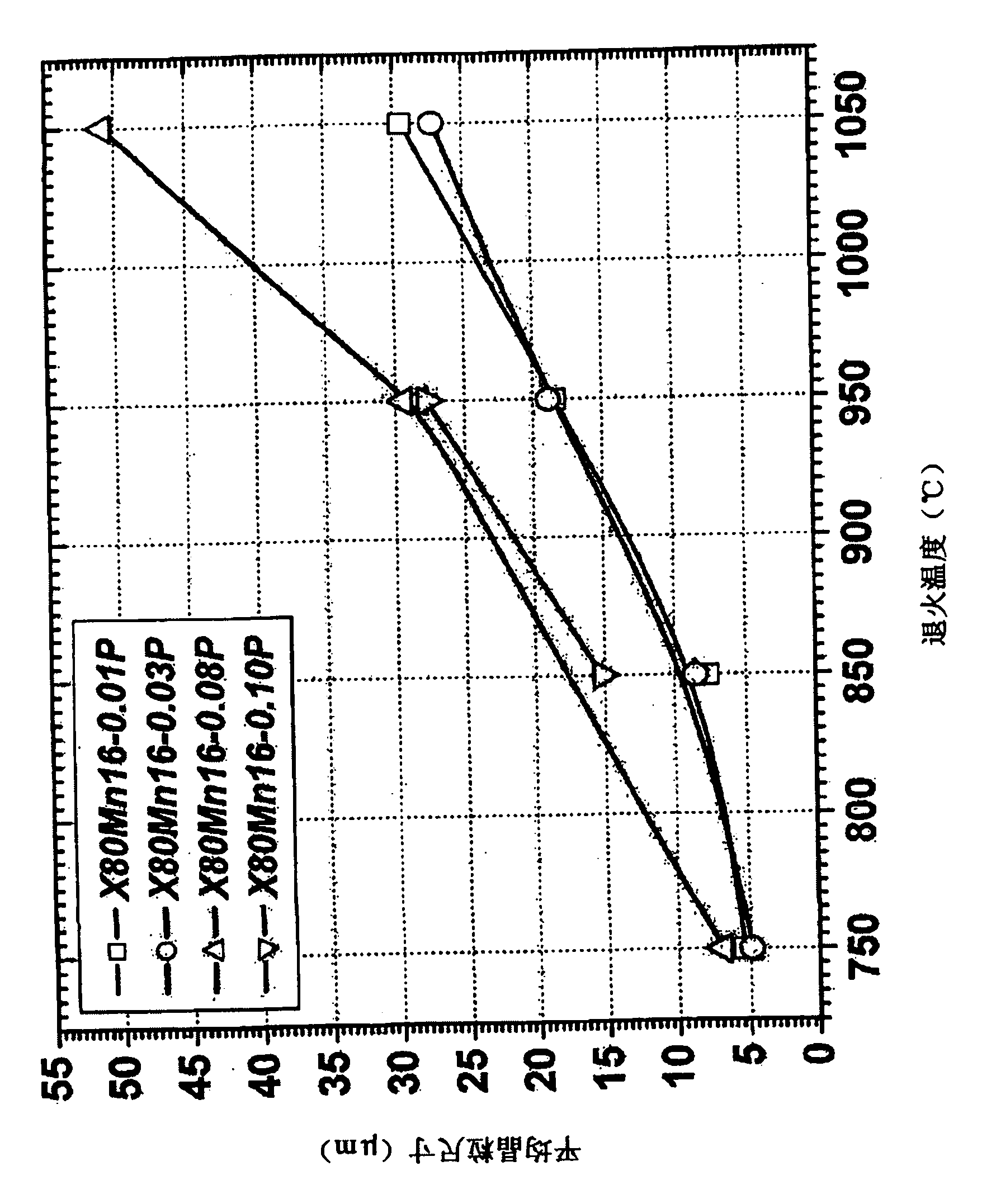

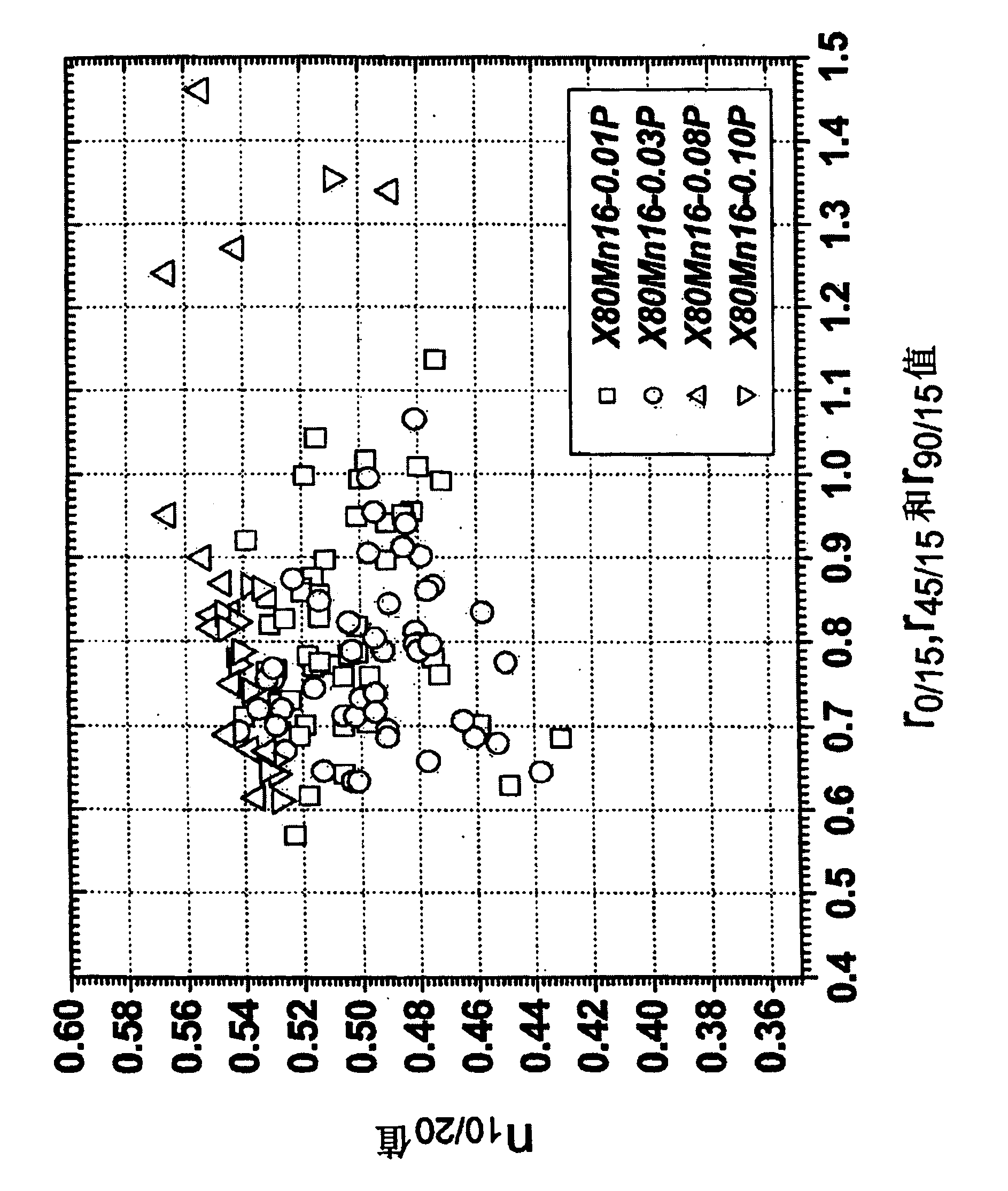

Manganese steel strip having an increased phosphorous content and process for producing the same

InactiveUS20110308673A1Improve solid solubilityImprove solubilityFurnace typesHeat treatment furnacesChemical compositionManganese

A hot-rolled austenitic manganese steel strip having a chemical composition in percent by weight of 0.4%≦C≦1.2%, 12.0%≦Mn≦25.0%, P≧0.01% and Al≦0.05% has a product of elongation at break in % and tensile strength in MPa of above 65,000 MPa %, in particular above 70,000 MPa %. A cold-rolled austenitic manganese steel strip having the same chemical composition achieves a product of elongation at break in % and tensile strength in MPa of above 75,000 MPa %, in particular above 80,000 MPa %.

Owner:VOESTALPINE STAHL GMBH

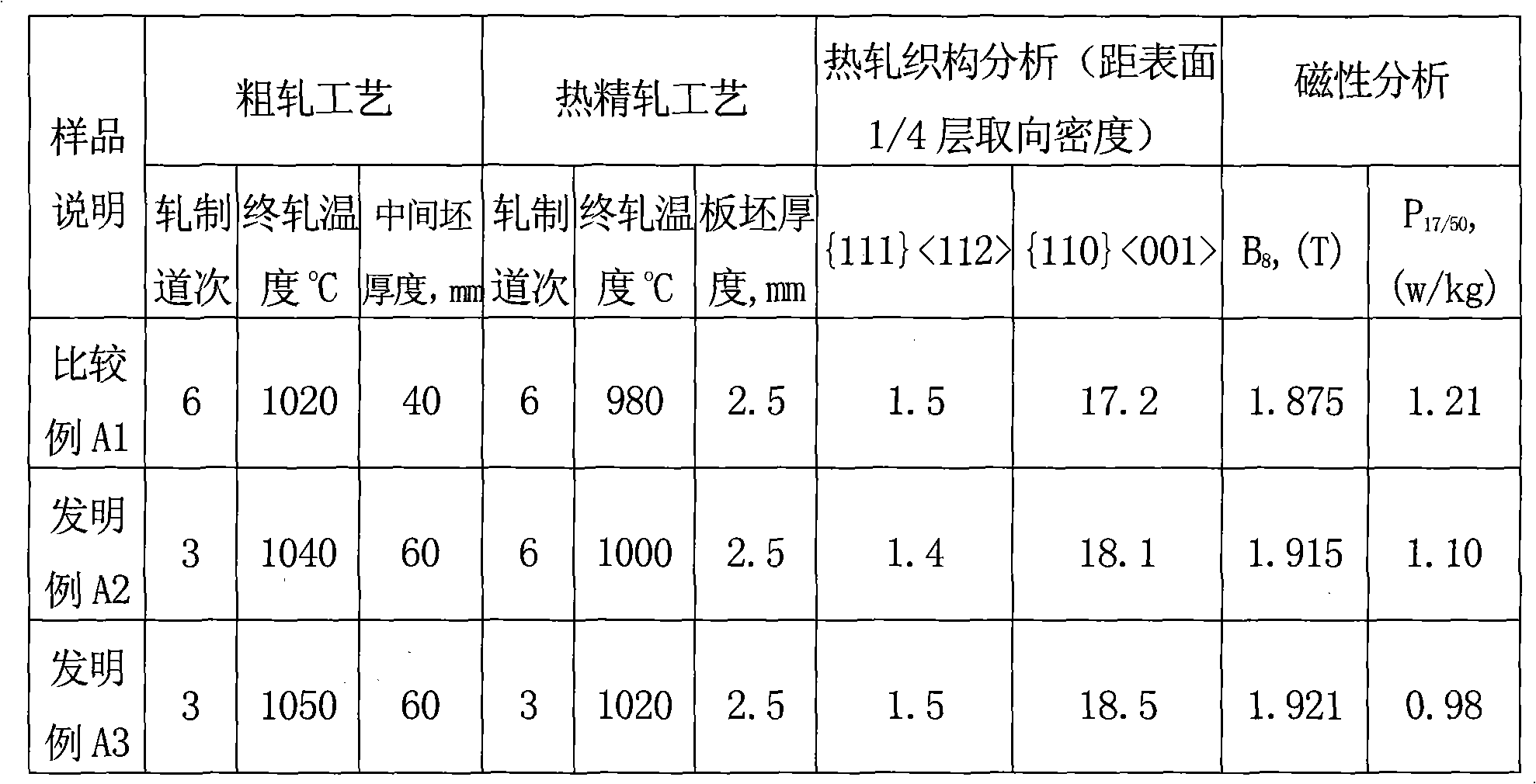

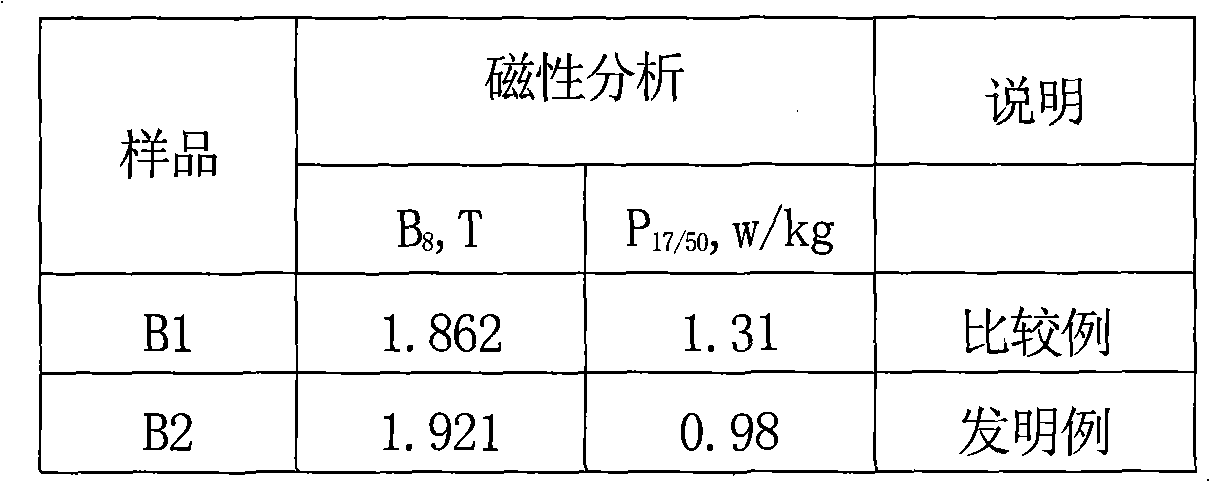

High magnetic induction grain-oriented silicon steel and production method thereof

ActiveCN101353760AReduce contentInhibition formationRoll mill control devicesMetal rolling arrangementsChemical compositionSilicon

The invention discloses a high magnetic induction oriented silicon steel and a production method thereof. The silicon steel comprises the following chemical composition: 0.055wt percent to 0.080wt percent of C, 2.9wt percent to 3.5wt percent of Si, 0.01wt percent to 0.02wt percent of Mn, 0.005wt percent to 0.010wt percent of Als, 0.0050wt percent to 0.0090wt percent of N, 0.25wt percent to 0.55wt percent of Sn, 0.010wt percent to 0.030wt percent of P, 0.10wt percent to 0.20wt percent of Cu, and the rest are Fe and unavoidable impurities. The production method comprises the following steps of: smelting, continuous casting, hot rolling, reeling, cold rolling, decarburizing annealing and high-temperature annealing. The production method effectively overcomes the shortcoming of poor producibility of the prior art and improves the production efficiency as well as the magnetism of the silicon steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for producing ferritic stainless steel

ActiveCN101008043APromote recrystallizationGood recrystallized structureRoll force/gap control deviceTemperature control deviceAcid washingStrip steel

The invention relates to a modified method for preparing ferrite non-corrodible steel, comprising heating casting blank, phosphorus removing, roughing down, phosphorus removing, fine rolling, cooling, spiraling, acid washing and cold reducing. The heating temperature is controlled between 1000- 1200 Deg. C; the outlet for roughing down is controlled between 900- 1100 Deg. C, and the relative pressing rate for roughing down is distributed backwards to increase break deformation energy restoration and promote break recrystallization; increase swing steel of middle roller way of 10- 100s between roughing down and fine rolling to ensure the time and condition for middle blank recrystallization; the temperature for fine rolling inlet is controlled between 850- 1050 Deg. C, for outlet the temperature is controlled between 750- 950 Deg. C, the relative pressing rate for fine rolling is distributed backwards to increase break deformation energy restoration and promote break recrystallization; the break after rolling is cooled to 600- 800 Deg. C for batching.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

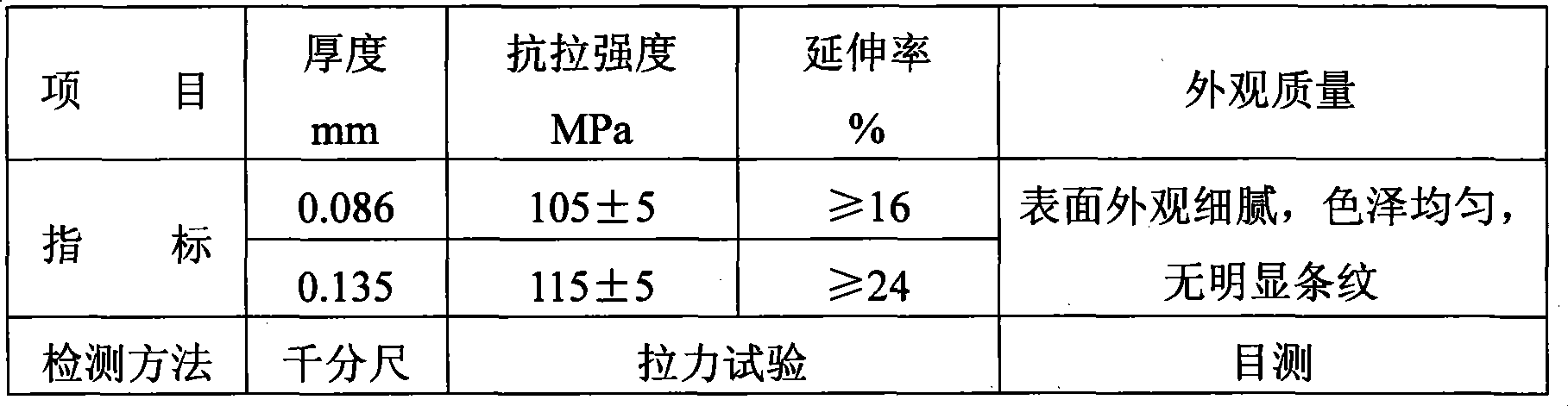

Aluminium alloy foil material for container and method for producing the same

ActiveCN101397622AReduce the influence of plasticityHigh elongationRoll mill control devicesMetal rolling arrangementsManganeseTitanium

The invention discloses an aluminum alloy foil used for containers, which is characterized in that: the components and the weight ratios are: 0.42 to 0.52 percent of iron, 0.05 to 0.20 percent of silicon, 0.04 to 0.13 percent of copper, 1.10 to 1.30 percent of manganese, 0.020-0.040 percent of titanium and the residual quantity of aluminum. The manufacturing method of the aluminum alloy foil used for containers comprises slab casting and rolling, pre-annealing, plank cold rolling, intermediate annealing, cold rolling, finished product annealing, greasing and cutting. Compared with the prior art, the aluminum alloy foil has the remarkable advantages: higher tensile strength and elongation; good deep-drawing performance, formability and stiff and smooth degree, beautiful appearance, uniform color and luster without defect, thus meeting the requirement of the users.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

Aluminum oxide carrier and preparation method thereof

The invention discloses a preparation method of an aluminum oxide carrier. The preparation method comprises the following steps: firstly, performing neutralization reaction on an alkaline aqueous precipitator solution and an acidic aqueous aluminium salt solution to obtain precipitate slurry; secondly, adding water-soluble resin into the precipitate slurry, and performing aging treatment through microwave heating; finally, filtering, washing, drying and shaping the aged mixed material to obtain the final aluminum oxide carrier. The aluminum oxide carrier prepared by adopting the preparation method has a relatively large aperture and concentrated pore distribution, especially 10-20nm pores account for a large proportion of the total pore volume; the aluminum oxide carrier is suitable for being used as the carrier for a heavy oil hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

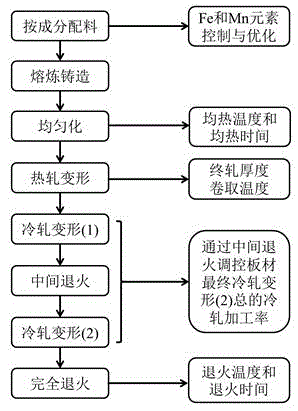

Aluminum alloy sheet material for vehicles and preparation method thereof

InactiveCN104894442AUniform recrystallized structureImprove formabilityChemical compositionAluminium alloy

The invention discloses an aluminum alloy sheet material for vehicles and a preparation method thereof. The aluminum alloy sheet material comprises 4.5-5.5wt% of Mg, 0.15-0.35wt% of Mn, 0.10-0.30wt% of Fe, less than or equal to 0.15wt% of Si, less than or equal to 0.10wt% of Ti, less than or equal to 0.10wt% of Cu, less than or equal to 0.10wt% of Zn, less than or equal to 0.10wt% of Cr and the balance Al and unavoidable impurities. The preparation method orderly comprises material blending, melting casting, uniformization, hot rolling deformation, primary cold rolling deformation, intermediate annealing, secondary cold rolling deformation and complete annealing. Through the design and optimization of alloy components and preparation processes, the 5XXX-series aluminum alloy sheet material with high formability and a low cost is prepared by the existing conventional plate and strip production line.

Owner:SHANDONG NANSHAN ALUMINUM

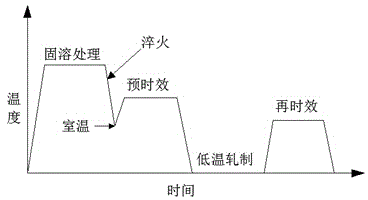

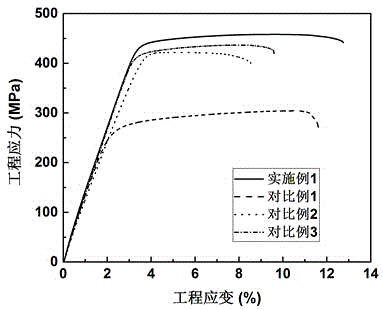

Strain aging method for improving mechanical properties of aluminum alloy

The invention discloses a strain aging method for improving the mechanical properties of aluminum alloy. The strain aging method comprises the following steps: the aluminum alloy is subjected to the solution treatment for 20-60 min at 520-560 DEG C; the aluminum alloy material after the solution treatment is water-cooled and quenched to room temperature; the aluminum alloy is subjected to the pre-aging treatment for 10-30 min at 150-180 DEG C so that the aluminum alloy material is in an underaged state; the aluminum alloy material after the pre-aging treatment is immersed in liquid nitrogen for 20-30 min and then is subjected to the multi-pass low-temperature rolling; finally, the rolled aluminum alloy material is subjected to the low-temperature reaging treatment for 85-100 hours at 100-130 DEG C so as to further strengthen the aluminum alloy. According to the invention, the strain aging method effectively improves the tensile strength and yield strength of aluminum alloy, is simple in process, easy to operate and low in cost, and has good generalizability.

Owner:CHONGQING UNIV

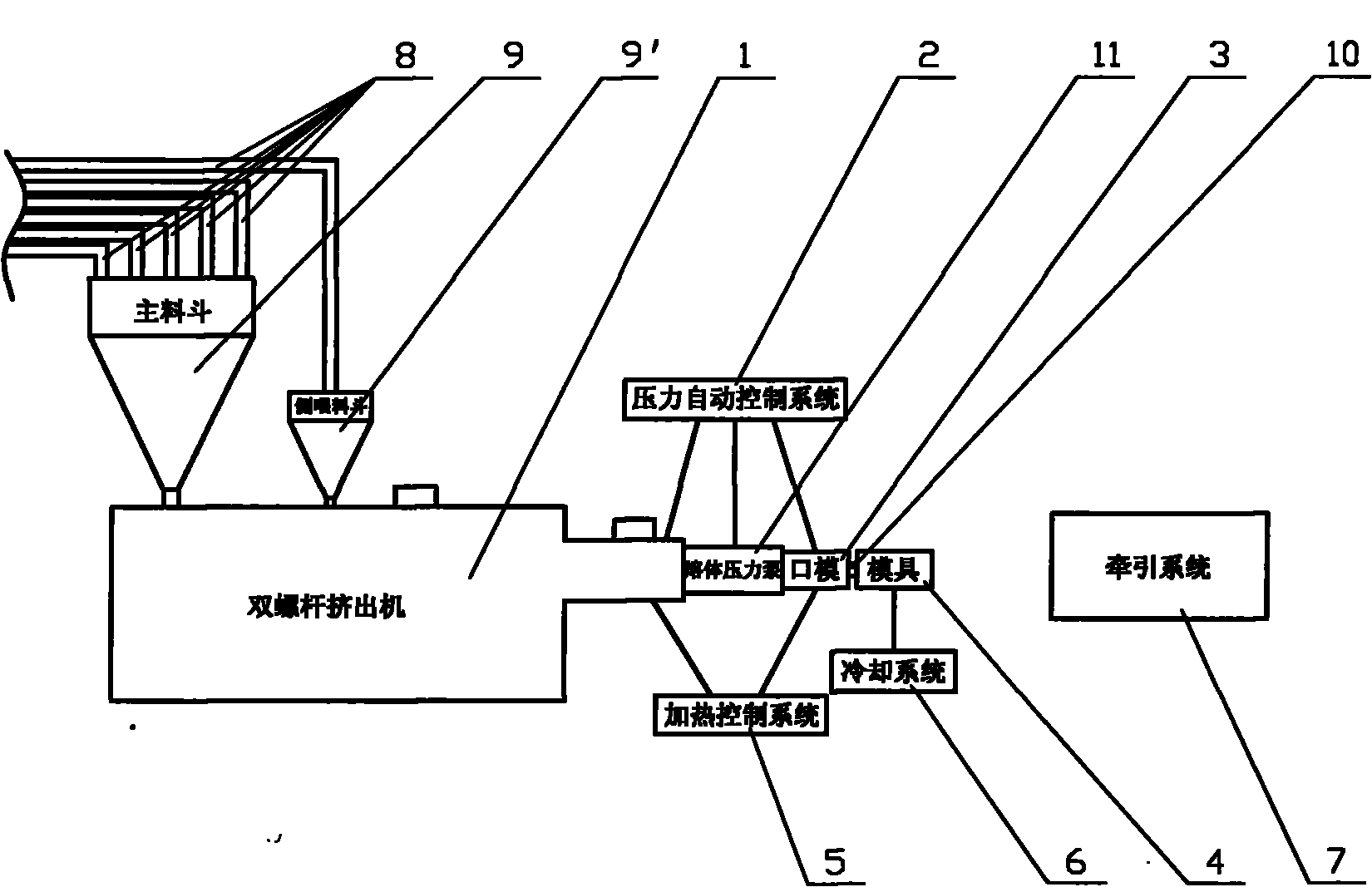

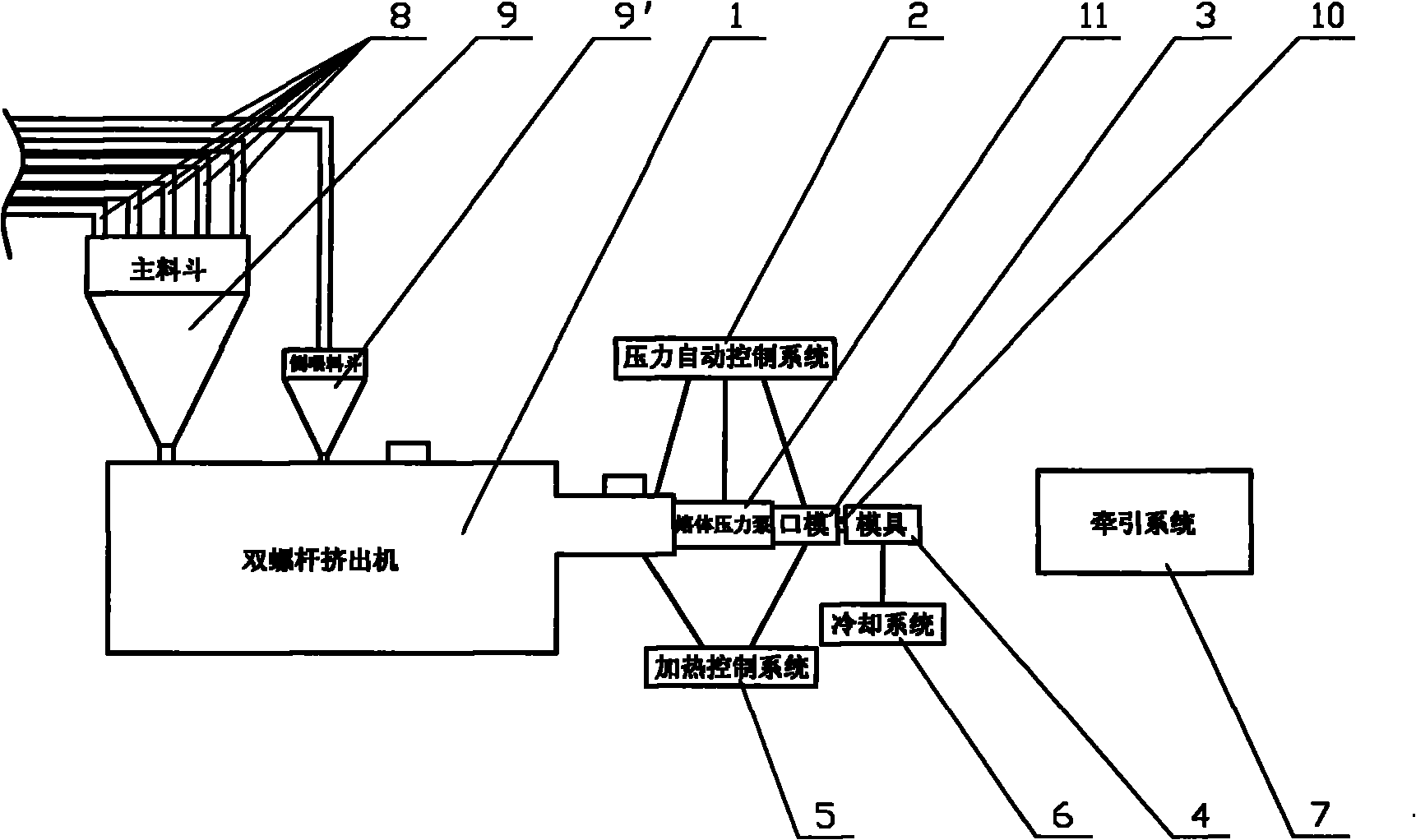

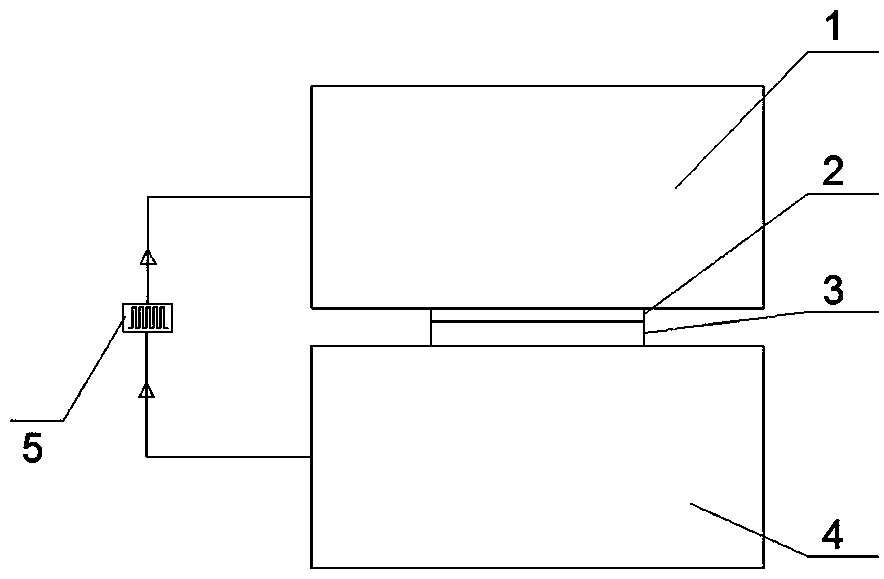

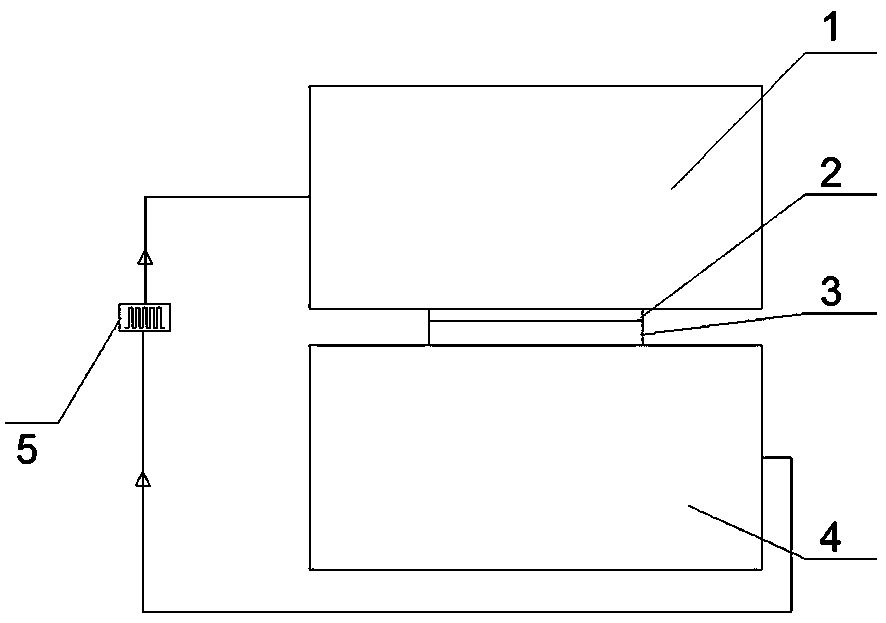

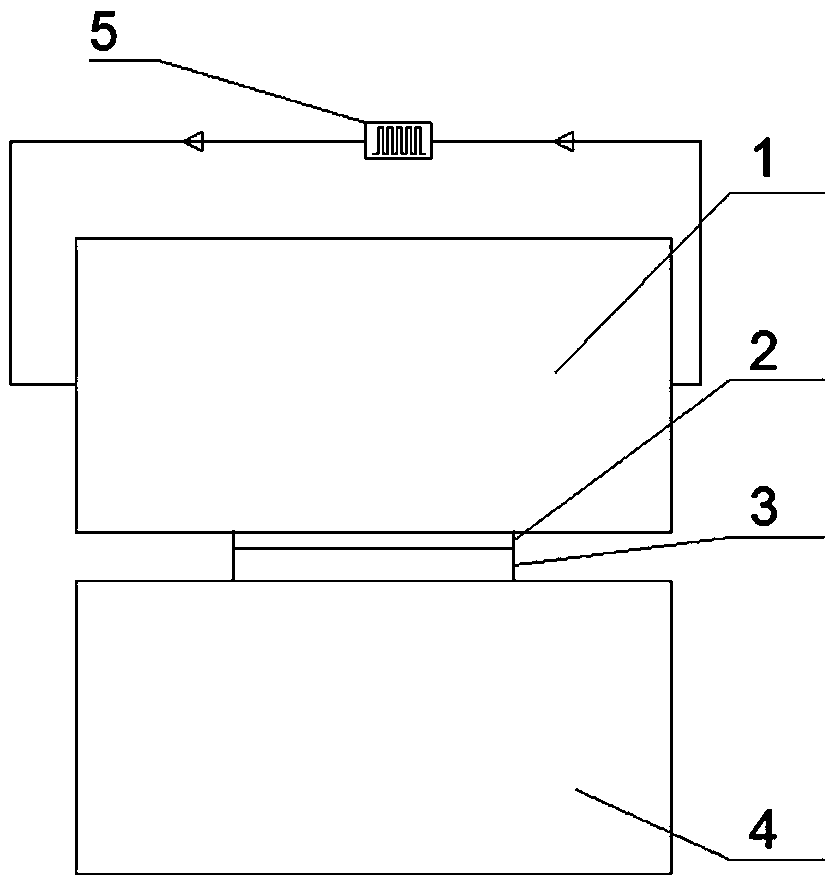

Device and method for manufacturing glass fibre reinforced nylon 66 heat-insulating strips

InactiveCN101791844AImprove product performanceEasy to recrystallizeNylon 66Manufacturing engineering

The invention discloses a device for manufacturing glass fibre reinforced nylon 66 heat-insulating strips, which comprises a feeding system, an extruder, a pressure control system, a die, a shaping die, a heating control system, a cooling system and a pull system. The feeding system comprises conveying pipelines and a hopper and each conveying pipeline conveys a single component of raw materials to the hopper and then feeds the material to the extruder; and the extruder is a double-screw extruder. The invention also discloses a method for manufacturing the glass fibre reinforced nylon 66 heat-insulating strips on the basis of the manufacturing device. In the device and the method, each component of the raw materials does not need to be mixed for pelletizing in advance, and a mode of conveying the single component of the raw materials with each conveying pipeline is adopted, so a pelletizing process and a melting and plasticizing process of the materials are reduced; the heat-insulating strip product with high performance and stable quality can be obtained to meet using requirements; and the application and development of the heat-insulating strip product and the manufacturing process technology are promoted.

Owner:FOSHAN NANHAI YILE ENG PLASTICS

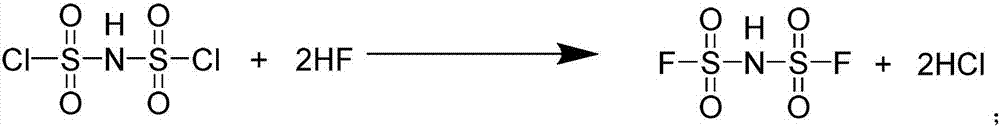

Lithium bis(fluorosulfonyl)imide preparation method

The invention discloses a lithium bis(fluorosulfonyl)imide preparation method. The method comprises the following steps that 1, BCSA is introduced into anhydrous hydrogen fluoride gas, and bis(fluorosulfonyl)imide is obtained; 2, bis(fluorosulfonyl)imide is mixed with a first organic solvent, a water removal agent is added, the mixture is mixed to be uniform, lithium salt is added, a reaction is conducted, after the reaction is completed, filtration is conducted, and a crude lithium bis(fluorosulfonyl)imide product is obtained; 3, the crude lithium bis(fluorosulfonyl)imide product is cleaned with a second organic solvent, the first organic solvent is added, purification is conducted, and lithium bis(fluorosulfonyl)imide granules are obtained. Accordingly, when a fluorination reaction is conducted, hydrogen fluoride serves as a fluorinated reagent and a solvent, the solvent cost and steps of recycling and the like are omitted, the method has the advantages that the cost is low, raw materials are easy to obtain, HCl gas generated through the reaction can only need to be absorbed with alkali liquor, and after the reaction is completed, the high-purity bis(fluorosulfonyl)imide can be obtained in a reduced pressure distillation mode.

Owner:XIAMEN UNIV

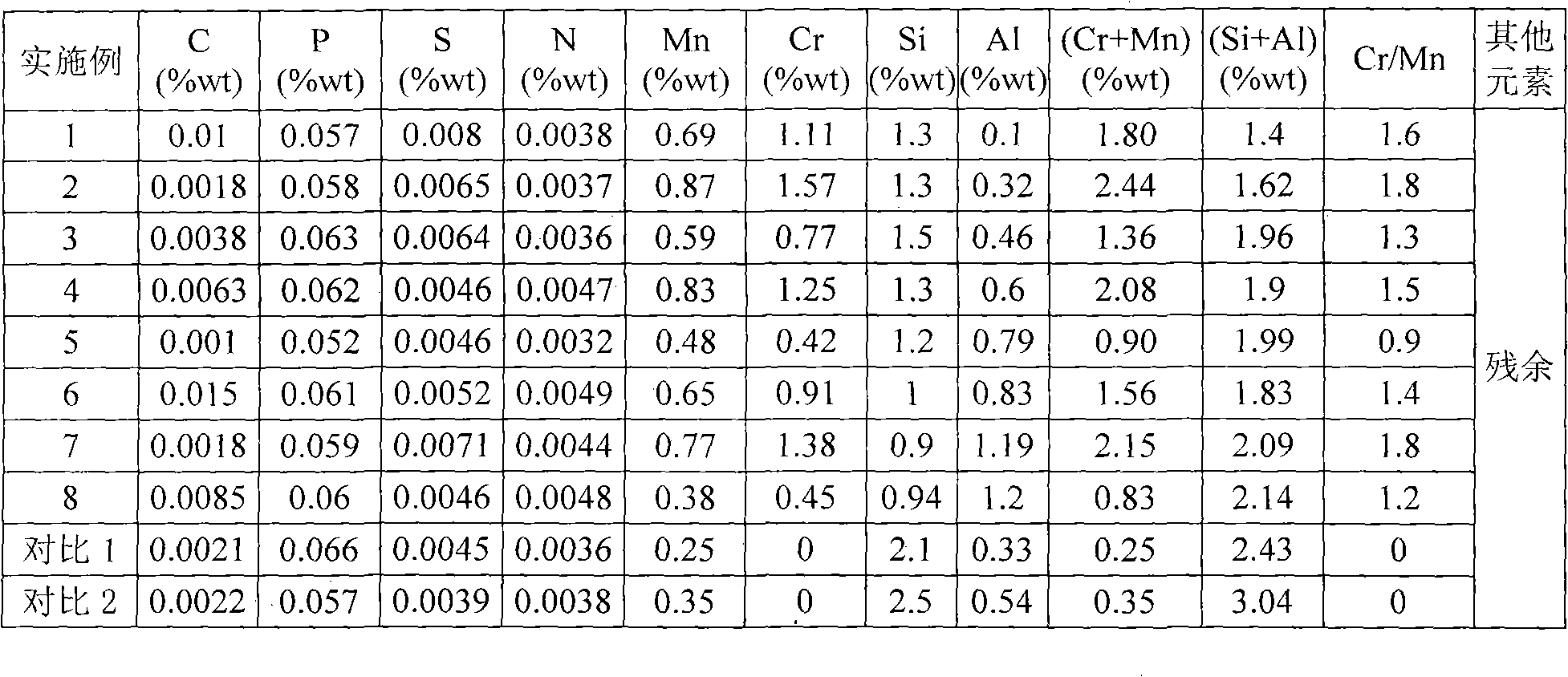

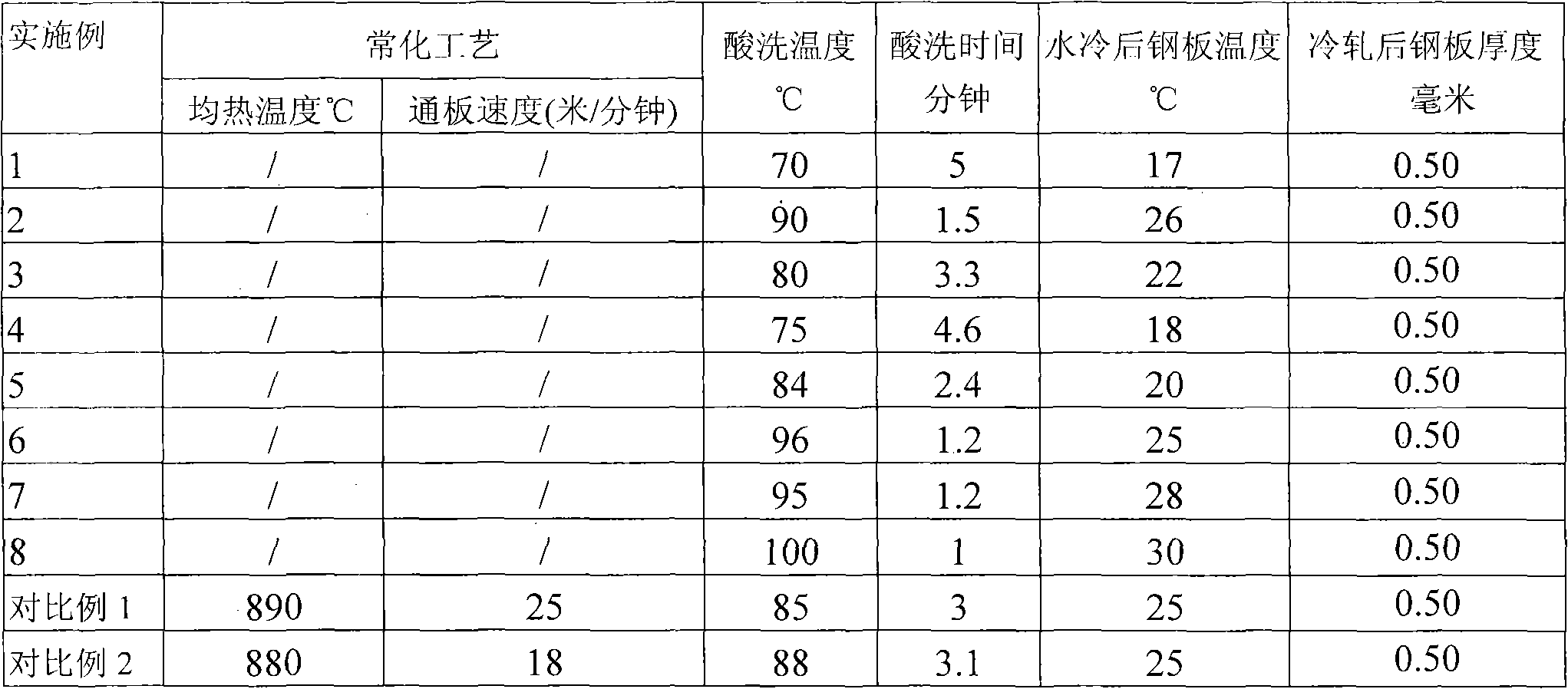

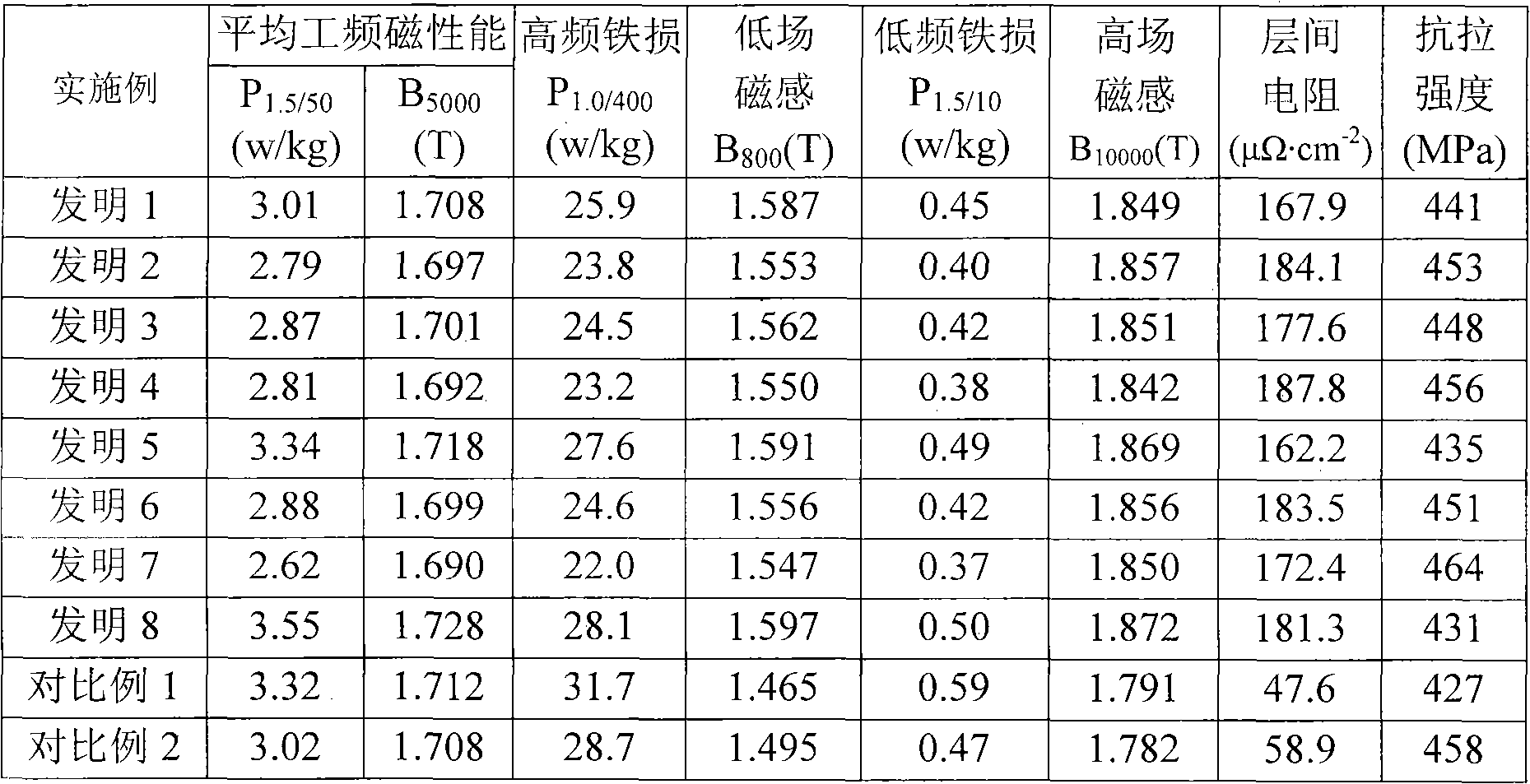

Non-oriented electrical steel for variable frequency motor and production method thereof

InactiveCN101876028AStorage capacity declineRich in componentsManufacturing stator/rotor bodiesElectrical steelFree cooling

The invention relates to non-oriented electrical steel for a variable frequency motor and a production method thereof, aiming to overcome the defects of traditional non-oriented electrical steel which has high strength and poor toughness and can not meet the requirement of the variable frequency motor and complex process. The non-oriented electrical steel comprises the flowing chemical components in percentage by weight: 0.001-0.015 percent of C, 0.3-0.9 percent of Mn, 0.4-1.6 percent of Cr, 0.1-1.2 percent of Al, 0.9-1.6 percent of Si, no more than 0.08 percent of P, no more than 0.015 percent of S, no more than 0.008 percent of N and the balance of Fe and residue, wherein the sum of the weight percent of Si and Al is 1.4-2.2 percent, the sum of the weight percent of Cr and Mn is 0.7-2.5 percent, and Cr / Mn is 0.9-2.0. The production method comprises the following steps of: smelting by using a clean steel process and continuously casting to form a billet; heating the billet; roughly rolling; finish rolling, and controlling the accumulated percentage of reduction of former four passes to be 80-95 percent; reeling; naturally cooling to the room temperature; washing with acid; cold rolling; decarbonizing; soaking; cooling according to conventional method, coating and finishing. The invention has the advantages of simple process, low iron loss at low frequency and power frequency, lower iron loss at high frequency, higher magnetic induction as well as good corrosion resistance and stamping property.

Owner:WUHAN IRON & STEEL (GROUP) CORP

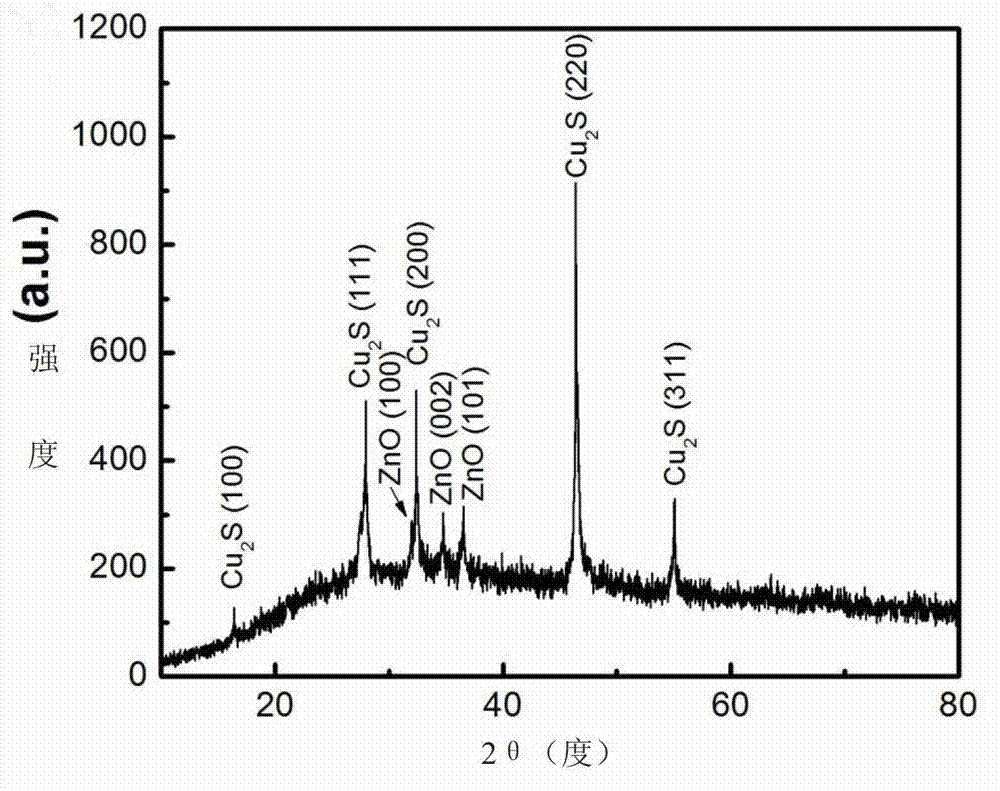

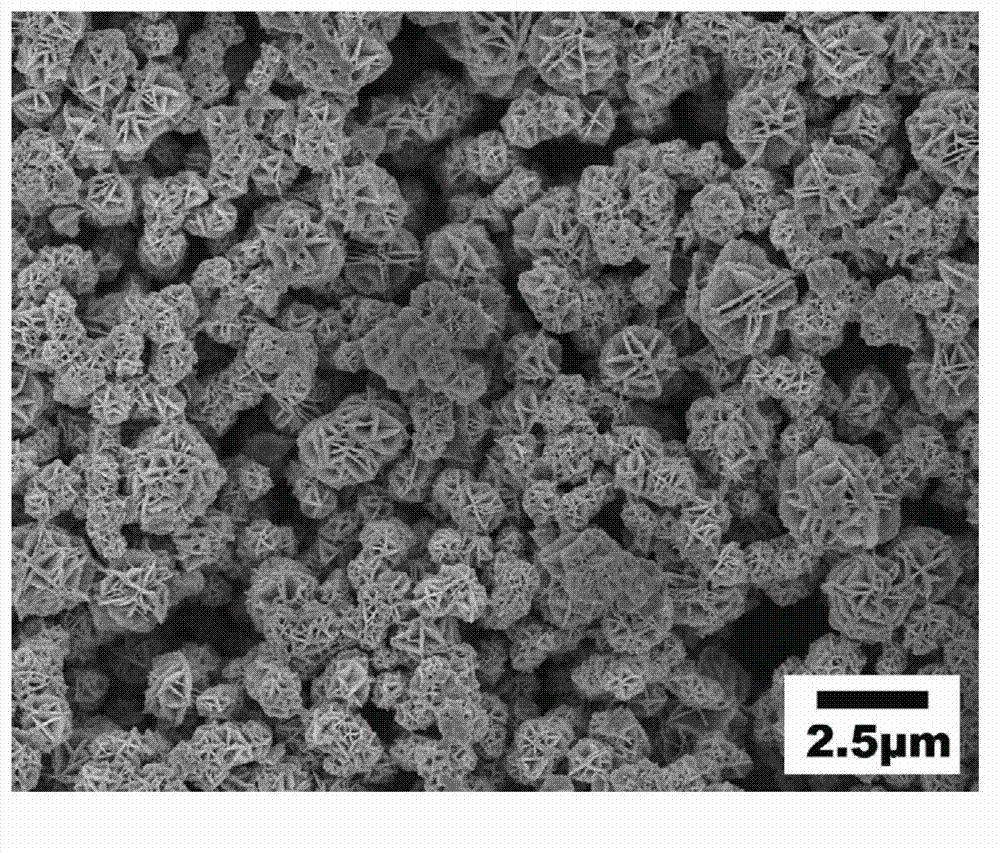

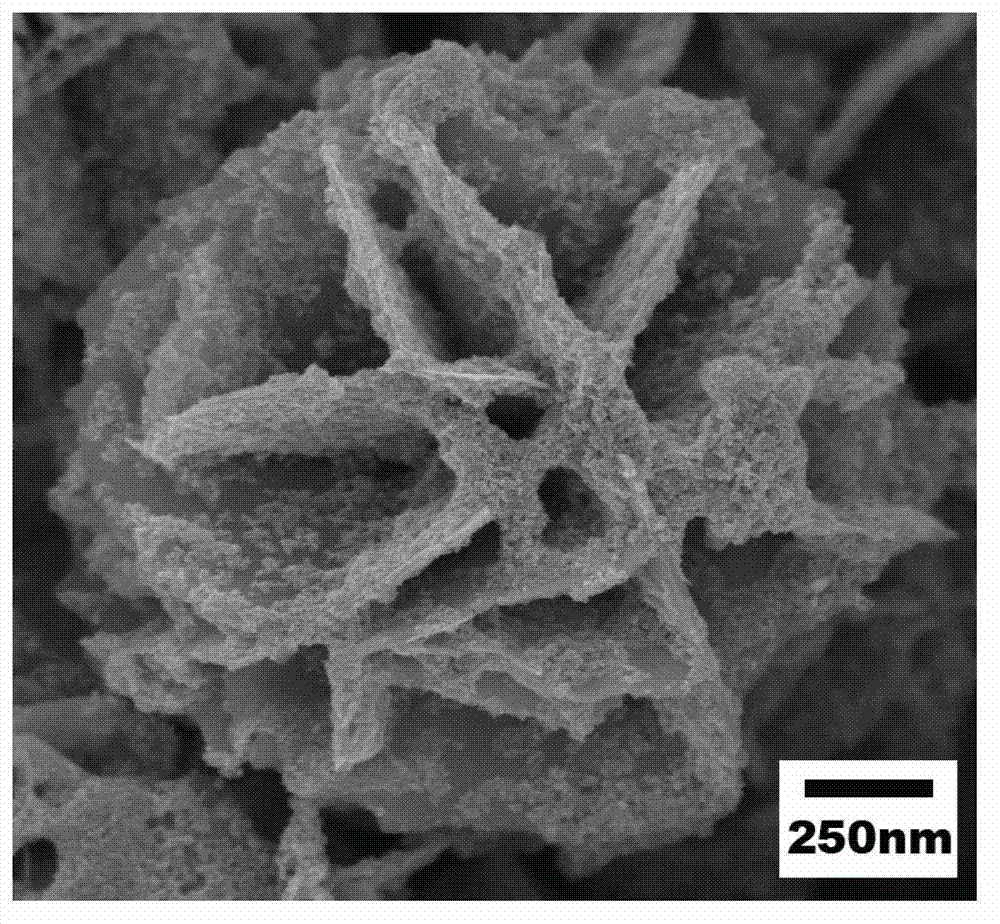

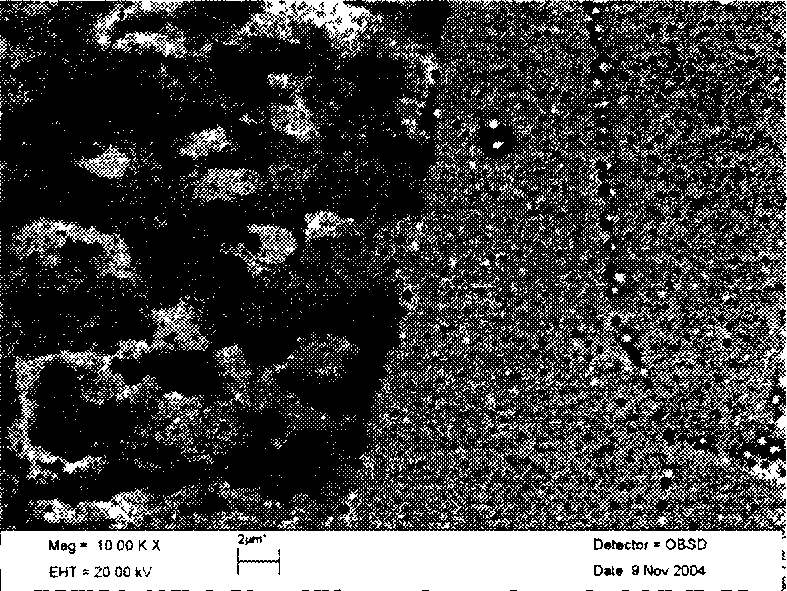

Three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material and preparation method thereof

InactiveCN103204536ARapid annealingPromote recrystallizationMaterial nanotechnologyPhysical/chemical process catalystsImideSemiconductor materials

The invention discloses a three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material. The three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material comprises ZnO nanometer-particle crystals and a CU2S nanometer-flower structure substrate material, wherein the ZnO nanometer-particle crystals are uniformly covered on the CU2S nanometer-flower structure substrate material; the CU2S nanometer-flower structure substrate material consists of Cu2S nanometer-sheets; and a P-N junction is formed at the interface of the ZnO nanometer-particle crystals and the Cu2S nanometer-flower structure. The invention further discloses a preparation method of the three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material. The preparation method comprises the following steps of: synthesizing the Cu2S nanometer-flower crystals and ZnO nanometer-particle crystals by adopting a hydrothermal synthesis method, respectively; and uniformly compounding the ZnO nanometer particles on the Cu2S nanometer-sheets by using PEI (Polyether Imide) as an auxiliary material to obtain the three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material. The three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material has the advantages of being low in cost, low in growth temperature, high in repeatability and the like, and also has great development application potential in the on-spot emission field and the photo-catalysis field.

Owner:EAST CHINA NORMAL UNIV

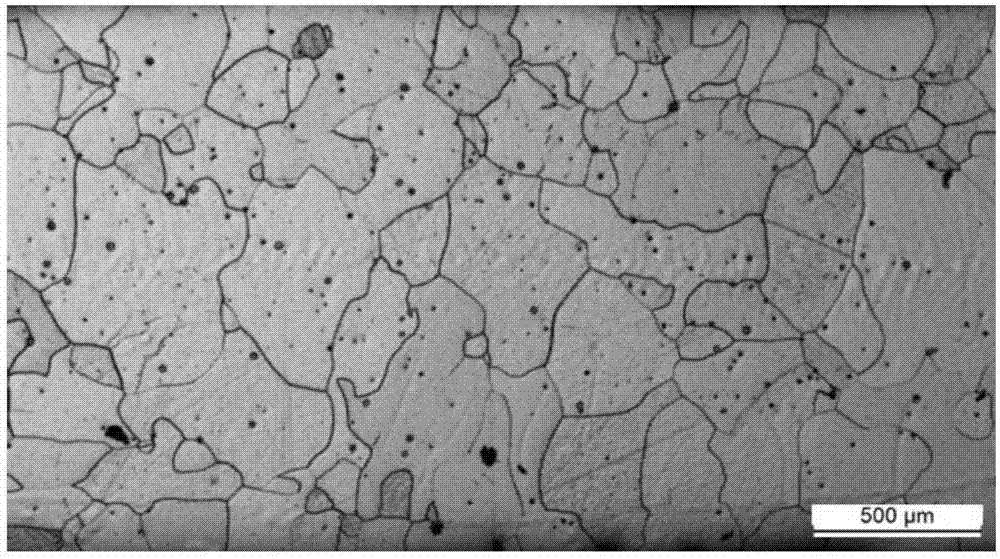

Manganese steel strip having an increased phosphorus content and process for producing the same

InactiveCN102216474AHigh and uniform solid solubilityPromote recrystallizationChemical compositionManganese

A hot-rolled austenitic manganese steel strip having a chemical composition in percent by weight of 0.4% = C = 1.2%, 12.0% = Mn = 25.0%, P = 0.01% and Al = 0.05% has a product of elongation at break in % and tensile strength in MPa of above 65 000 MPa%, in particular above 70 000 MPa%. A cold-rolled austenitic manganese steel strip having the same chemical composition achieves a product of elongation at break in % and tensile strength in MPa of above 75 000 MPa%, in particular above 80 000 MPa%.

Owner:FOSTER ALPINE STEEL LTD

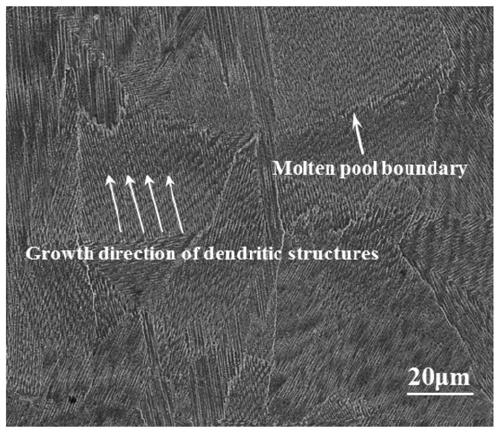

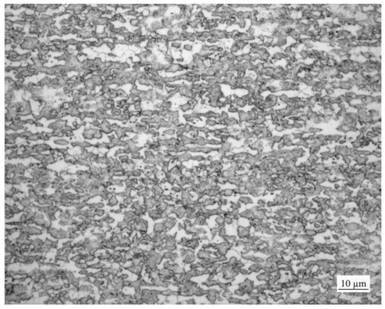

Selective laser melting forming Inconel718 alloy and heat treatment method thereof

InactiveCN111360266AHigh strengthPromote precipitationAdditive manufacturing apparatusIncreasing energy efficiencyHot isostatic pressingHeat conservation

Owner:SOUTH CHINA UNIV OF TECH +1

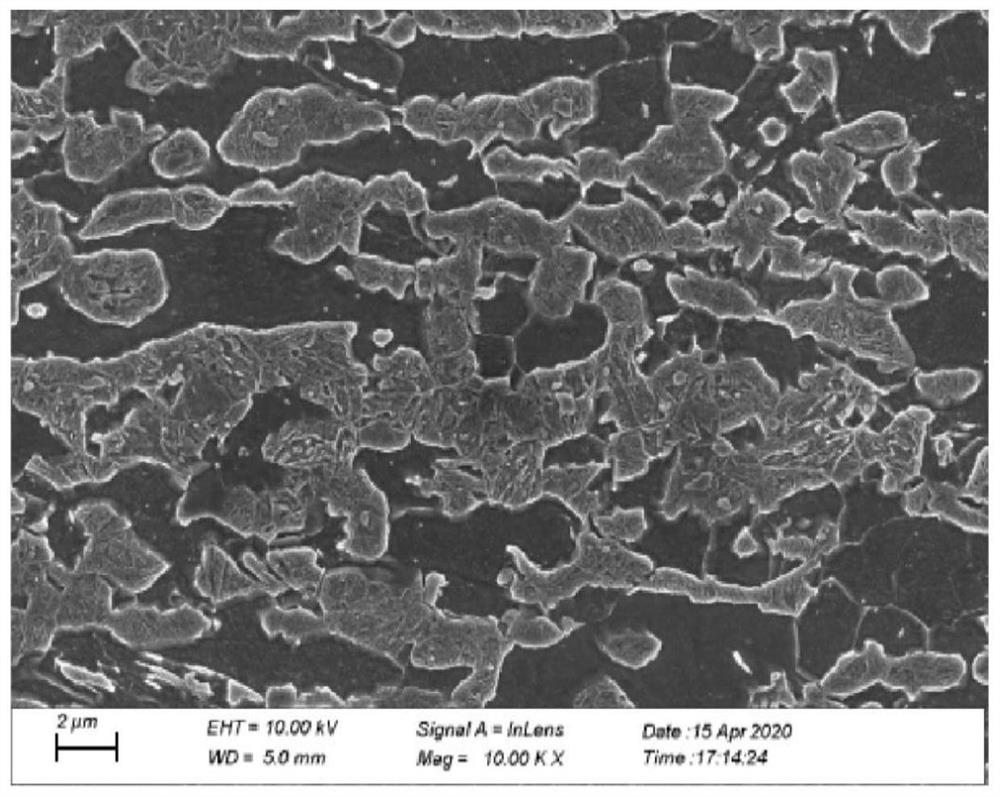

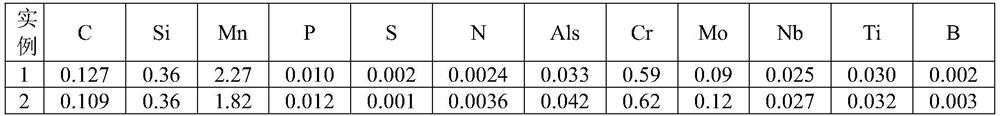

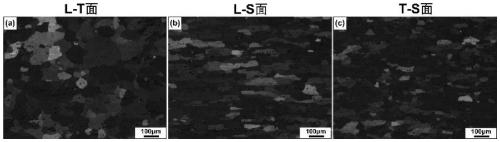

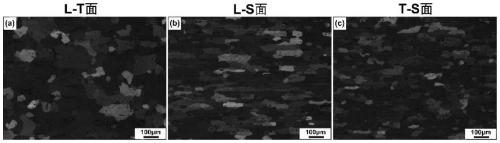

Low-carbon-equivalent 1180 MPa-grade hot galvanizing dual-phase steel and production method thereof

ActiveCN112522623AReduce contentImprove hardenabilityHot-dipping/immersion processesUltimate tensile strengthMechanical properties of carbon nanotubes

The invention discloses low-carbon-equivalent 1180 MPa-grade hot galvanizing dual-phase steel and a production method thereof, and belongs to the technical field of cold-rolled plate strip production.The low-carbon-equivalent 1180 MPa-grade hot galvanizing dual-phase steel comprises the following chemical components including, by mass percent, 0.05-0.14% of C, 0.05-0.40% of Si, 1.20-2.50% of Mn,less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.015-0.070% of Als, less than or equal to 0.0060% of N, 0.006-0.20% of Mo, 0.010-0.040% of Nb, 0.010-0.040% of Ti, 0.20-0.67% ofCr, larger than 0 and less than 0.005% of B, and the balance Fe and inevitable impurities. The production method comprises the processes of smelting, hot rolling, acid rolling, hot galvanizing and thelike. According to the low-carbon-equivalent 1180 MPa-grade hot galvanizing dual-phase steel and the production method thereof, the steel has excellent mechanical properties, the yield strength is 880-960 MPa, the tensile strength is 1193-1276 MPa, the elongation A80 is 6.0-10.0%, and the problem that the steel cannot meet the requirements of high strength, high yield strength and low cost at thesame time can be effectively solved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Rolling process for improving surface corrosion resistance of 6061 aluminum alloy

ActiveCN111334677AImprove corrosion resistanceImprove mechanical propertiesAnodisationTemperature controlThick plate

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a rolling process for improving surface corrosion resistance of 6061 aluminum alloy. The aluminum alloy comprises, by weight, 0.50%-0.65% of Si, less than or equal to 0.2% of Fe, 0.25%-0.35% of Cu, less than or equal to 0.10% of Mn, 0.9%-1.1% of Mg, 0.13%-0.26% of Cr, less than or equal to 0.05% of Ni, less than or equal to 0.04% of Zn, less than or equal to 0.15% of Ti, less than or equal to 0.05% of single impurities while less than or equal to 0.15% of the total impurities, and the balance Al. In the hot rolling procedure, the hot rolling process combining large-deformation rolling and small-deformation temperature control rolling is adopted, a 6061-T651 alloy thick plate with the excellent corrosion resistance is prepared, the grain structure of the plate is fine and uniform, and under the condition that the mechanical property is not lost, the corrosion resistance of the plate in the acidenvironment is greatly improved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Aluminum alloy profile for high-corrosion-resistance curtain wall and preparation method of aluminum alloy profile

InactiveCN106399778AHigh strengthGood repeatabilityAnodisationElectrophoretic coatingsElectrophoresisIngot

The invention discloses a preparation method of an aluminum alloy profile for a high-corrosion-resistance curtain wall. The preparation method of the aluminum alloy profile for the high-corrosion-resistance curtain wall comprises the following steps that molten aluminum comprising 3%-5% of Zn, 0.9%-1.3% of Mg, 0.6%-1.2% of Cu, 0.05%-0.15% of Mn, 0.06%-0.12% of Cr, 0.07%-0.12% of Re, 0.06%-0.12% of Zr, 0.03%-0.06% of Sc, 0.15%-0.35% of Fe, 0.15%-0.35% of Si, 0.02%-0.06% of Ti and the balance Al is cast into a cast ingot, and then homogenizing treatment and extrusion forming are conducted; degreasing, alkali washing and anodic oxidation treatment are conducted after stretching and straightening; and finally, electrophoresis treatment is conducted, so that the aluminum alloy profile is obtained. According to the aluminum alloy profile for the high-corrosion-resistance curtain wall and the preparation method of the aluminum alloy profile, the curtain wall made of the aluminum alloy profile is good in corrosion resistance, high in strength, not prone to deformation or color changing, and long in service life.

Owner:安徽省煜灿新型材料科技有限公司

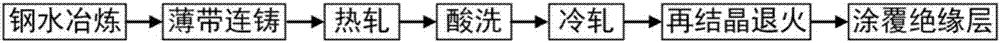

Method for preparing high-magnetic-strength non-oriented silicon steel thin products on basis of thin-strip casting

The invention belongs to the technical field of metallurgy, and particularly relates to a method for preparing high-magnetic-strength non-oriented silicon steel thin products on the basis of thin-strip casting. The method comprises the following steps: (1) smelting molten steel according to set ingredients, wherein the molten steel comprises the following ingredients in percentages by mass: less than or equal to 0.003% of C, 2.0-3.5% of Si, less than or equal to 0.01% of Mn, less than or equal to 0.003% of Al, 0.02-0.06% of P, less than or equal to 0.003% of S, and the balance of Fe and inevitable impurities; (2) carrying out thin-strip casting to obtain a cast strip; (3) carrying out hot rolling under the condition of an inert atmosphere; (4) reeling the cast strip after the cast strip is cooled to the temperature of 650 DEG C, removing iron oxide scale and then carrying out single-stage multi-pass cold rolling; and (5) carrying out continuous annealing on the cold rolled strip, coating the cold rolled strip with an insulating layer and then drying the insulating layer to obtain the high-performance non-oriented silicon steel thin products. The method is based on a thin-strip casting technology, the process is simplified, the production cost is reduced, and the magnetic performance of the non-oriented silicon steel thin finished products is improved.

Owner:NORTHEASTERN UNIV

Composite additive for preparing hematite concentrate pellet and application thereof

A composite additive for preparing hematite concentrate pellets comprises the following components: humic acid, calcium peroxide, and paigeite. During application, the composite additive is added which has a mass percent of 0.5%-1.6% of the total mass of the hematite concentrates, and the finished product pellets are obtained by pelletization, preheating, and roasting. Compared with pellets prepared by traditional technology, the hematite pellets prepared by the composite additive of the invention have improved falling strength of the green pellets, and compression strength of the finished product pellets; the preheating temperature and roasting temperature suitable for the pellets are reduced; both the preheating time and roasting time are shortened; the TFe grade is increased by 0.8%-1.2%. The composite additive of the invention has reasonable component ratios, is easy to process and manufacture, has a low using amount and a low residual amount, can significantly improve the pelletability of hematite concentrates which are difficult to be palletized, can improve the green pellet quality, has good heat stability, and can effectively reduce the preheating and roasting temperatures and shorten the preheating and roasting time of hematite concentrates. The composite additive of the invention is applicable to the production of oxidized pellets by hematites, and is especially applicable to the production of oxidized pellets by specularites. The composite additive of the invention is applicable to large-scale industrial production.

Owner:CENT SOUTH UNIV

Process for improving the extrudability of high-strength aluminum alloys

A high-strength aluminum alloy having good porthole extrudability is provided. It has a Vickers hardness Hv of not less than 40 as measured in a homogenized state created by heat treatment before extrusion and a Vickers hardness Hv of not less than 20 imparted by plastic working after the heat treatment.

Owner:TOYOTA JIDOSHA KK +1

Method for indirect-electrification-type continuous electrolytic etching of metal strip and apparatus for indirect-electrification-type continuous electrolytic etching

ActiveUS7063780B2Shape stableImprove processing efficiencyElectrolysis componentsElectrochemical machining apparatusA-series and B-seriesEtching

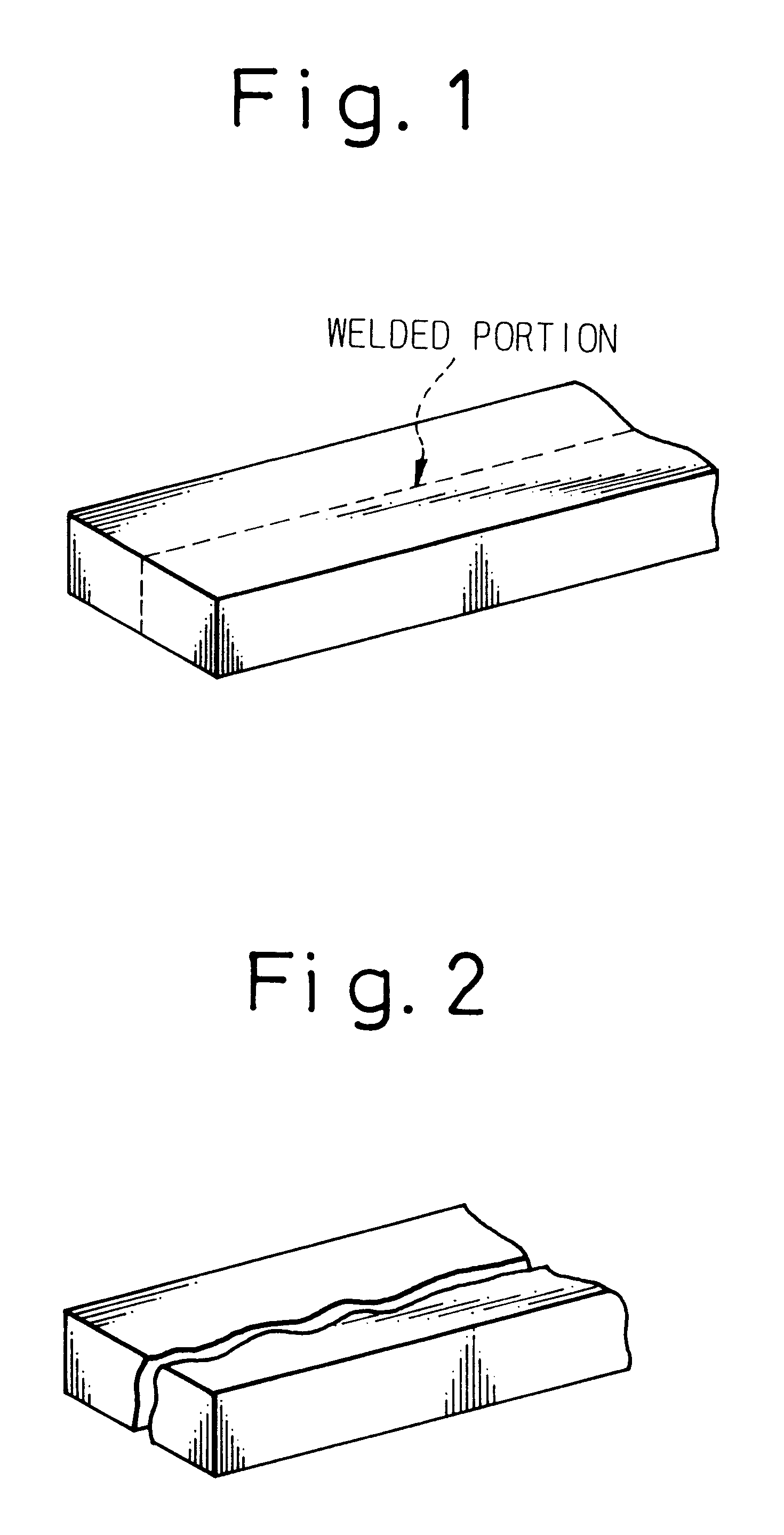

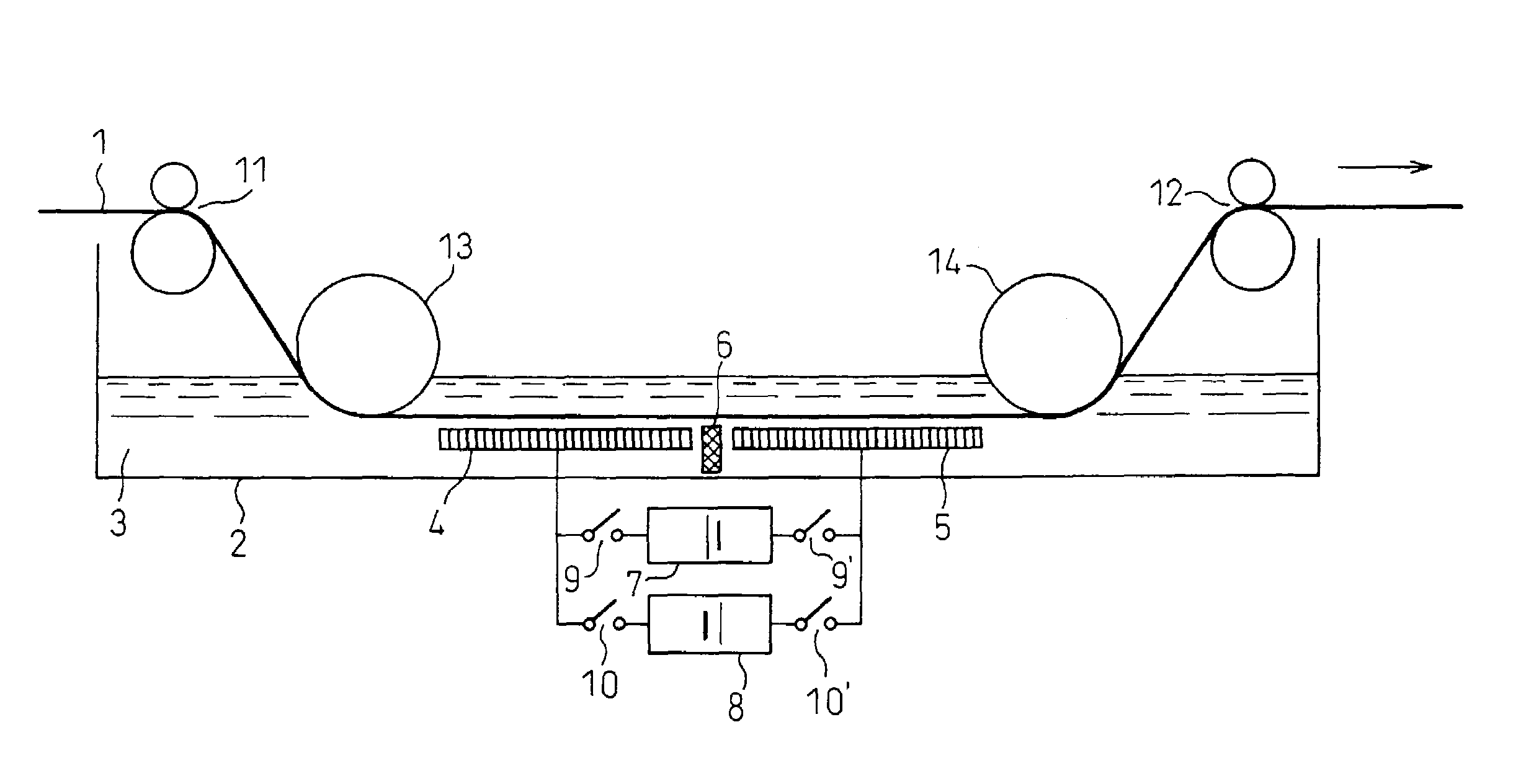

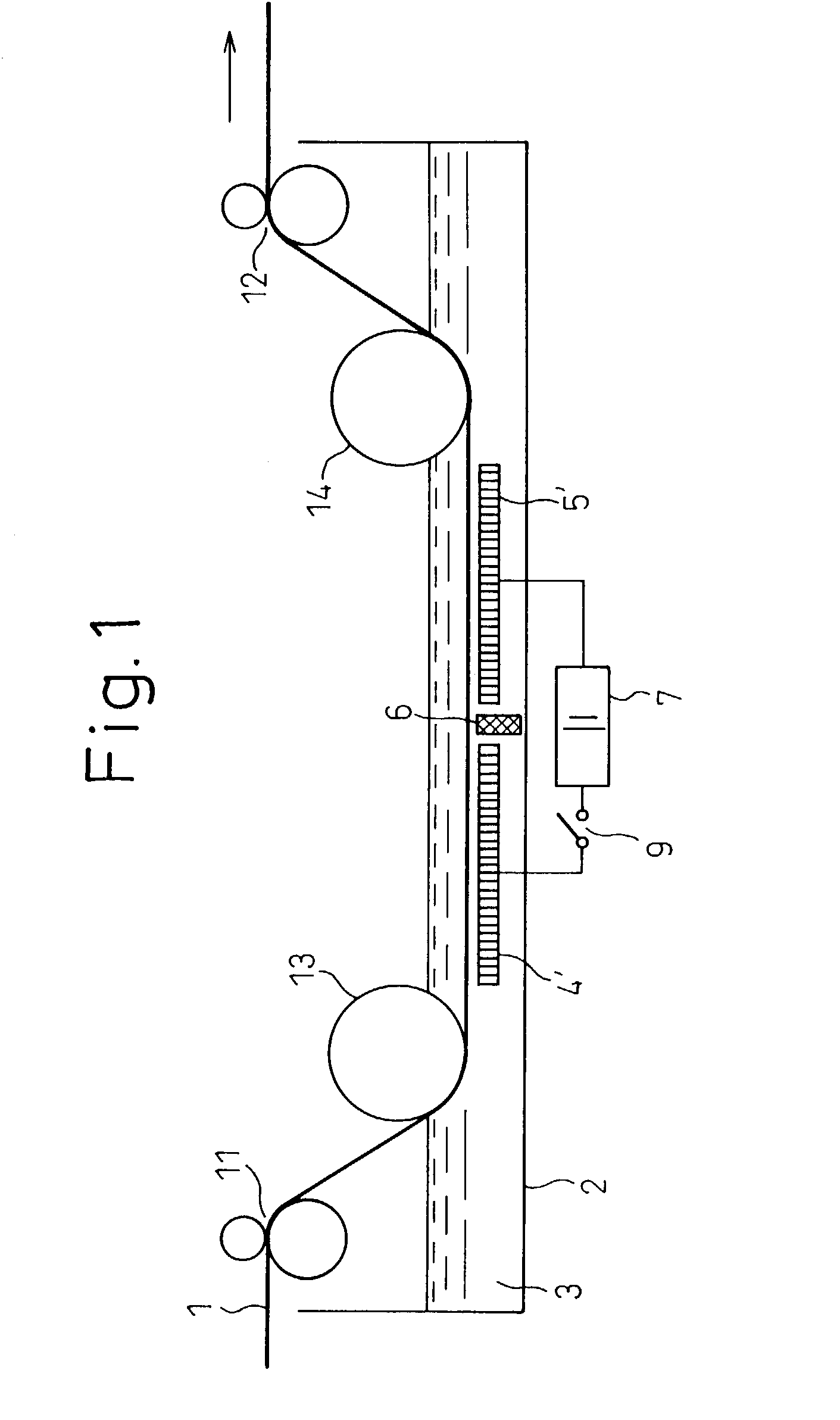

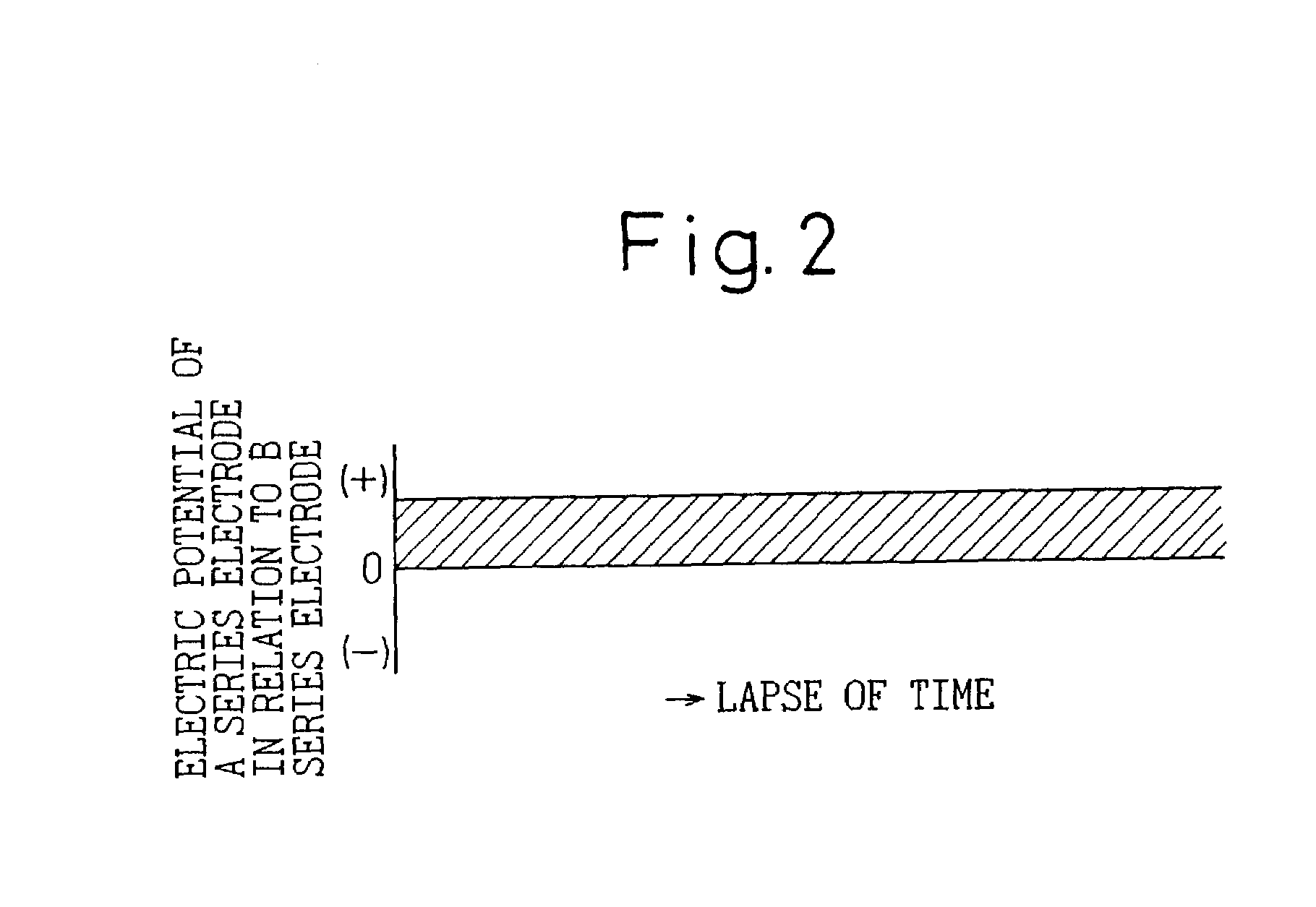

The present invention provides a method for indirect-electrification-type continuous electrolytic etching of a metal strip suitable for producing a low-core-loss, grain-oriented silicon steel sheet not susceptible to the deterioration of core loss after stress-relief annealing, and an apparatus for the indirect-electrification-type continuous electrolytic etching. It is a method for indirect-electrification-type continuous electrolytic etching of a metal strip and an apparatus for the same for continuously forming grooves by indirect-electrification-type electrolytic etching on a metal strip on which an etching mask is formed in etching patterns on one or both surfaces, wherein: plural electrodes of an A series and a B series are arranged alternatively, at least in a pair, in said order in the travelling direction of the metal strip so that they face the surface to be etched of the metal strip on which the etching patterns are formed; the space between the metal strip and the group of the electrodes is filled with an electrolyte; and voltage is applied across the A series and B series electrodes.

Owner:NIPPON STEEL CORP

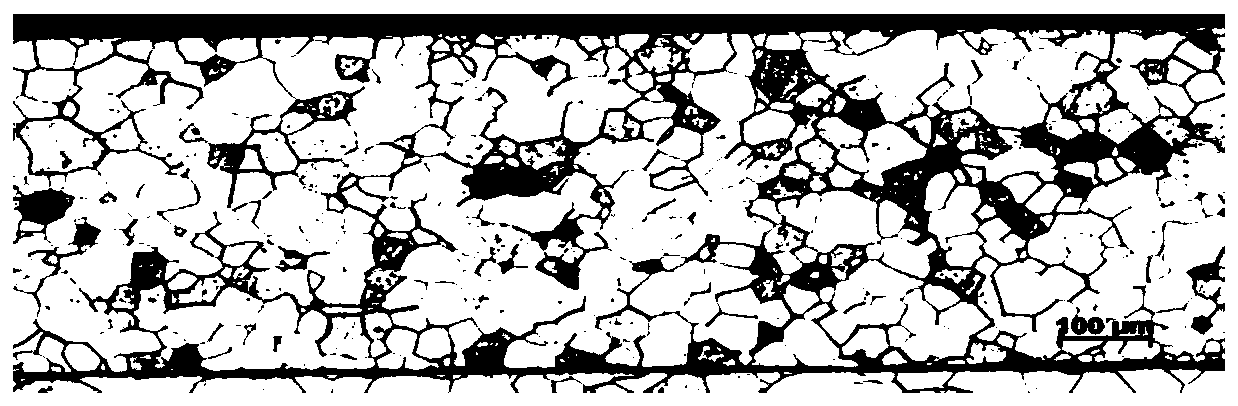

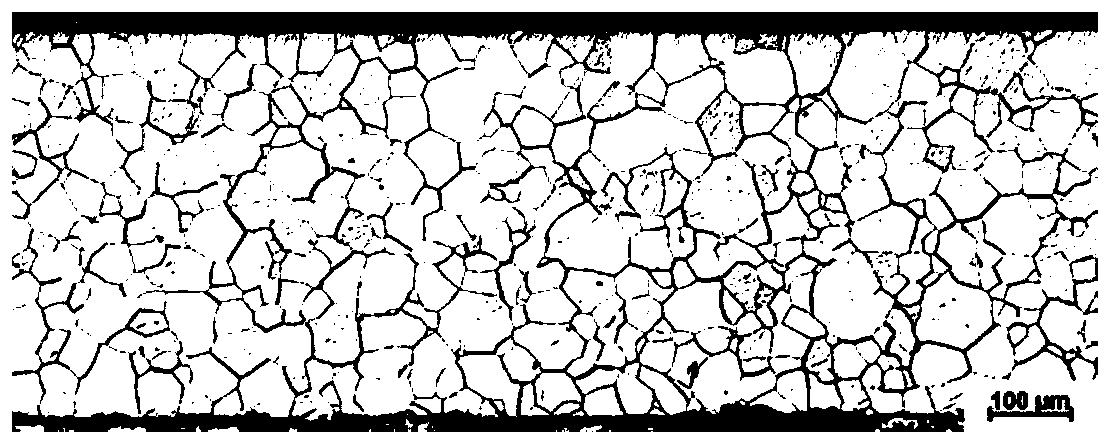

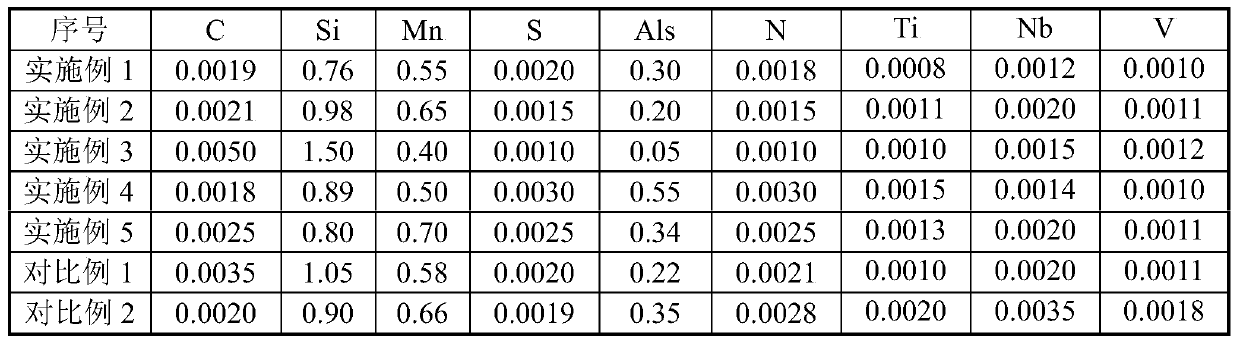

Non-oriented silicon steel for sheet billet production and manufacturing method thereof

The invention discloses non-oriented silicon steel for sheet billet production and a manufacturing method thereof and belongs to the technical field of production of non-oriented silicon steel. The non-oriented silicon steel comprises the chemical components in percent by weight: less than or equal to 0.005% of C, less than or equal to 1.50% of Si, greater than or equal to 0.40% but less than or equal to 0.70% of Mn, greater than or equal to 0.050% but less than or equal to 0.55% of Als, greater than or equal to 0.0010% but less than or equal to 0.0030% of S, greater than or equal to 0.0010% but less than or equal to 0.0030% of N, less than or equal to 0.0015% of Ti and the balance Fe and inevitable impurities. By carrying out process treatment such as smelting, continuous casting, heating, hot continuous rolling, rolling, pickling, cold rolling, product annealing, straightening and withdrawing, insulating layer coating and stress-relief annealing on the raw materials of the componentsby adopting a sheet billet production flow, the non-oriented silicon steel which is low in iron loss and high in magnetic polarization with the Si content of being less than 1.5% and the Al content of being within 0.05-0.5% is obtained under a condition of not adding noble metals. After stress-relief annealing, the decreasing proportion of the iron loss is relatively high, so that the electromagnetic property of the non-oriented silicon steel can be further improved.

Owner:MAANSHAN IRON & STEEL CO LTD

Ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method thereof

ActiveCN1827824AExcellent long-lasting antibacterial effectLow content of alloying elementsTemperature control deviceHeat treatment process controlPre treatmentChromium

Disclosed is a ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method, wherein the stainless steel matrix comprises (by wt%) Cr 12.0-14.0%, Cu 0.70-2.20%, C <=0.08-0.15, the preparing process comprises pre-processing melted iron, passing through composite revolving furnace, vacuum oxygen decarbonization furnace, refined-smelting ladle furnace, continuous plate blank casting, casting blank annealing, tandem rolling, and annealing in a bell-type furnace.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

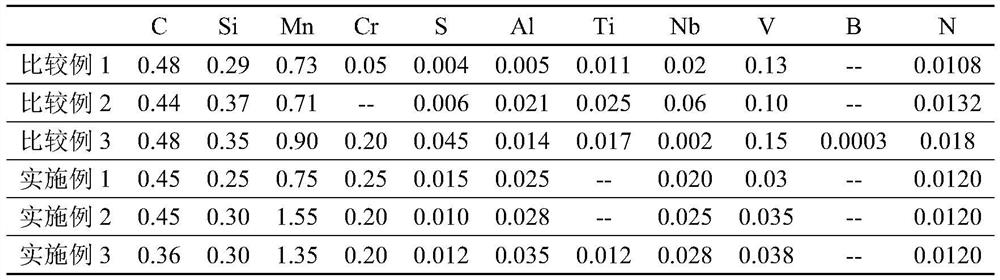

High-strength and high-toughness hot-rolled round steel capable of being directly cut and preparation method thereof

ActiveCN111647799ASolid solubility product is smallReduce addFurnace typesHeat treatment furnacesAlloyPearlite

The invention relates to high-strength and high-toughness hot-rolled round steel capable of being directly cut and a preparation method thereof. Elements of the round steel contain Nb, V and other microalloys, so that grain refinement and strength improvement are facilitated. Two-stage rolling of cogging and continuous rolling is adopted, air cooling temperature holding is carried out before two times of rolling, a steel billet is overturned by 180 degrees through a cogging mill during first-time air cooling temperature holding, and after first-time temperature holding, the steel billet is roughly rolled into an intermediate square billet through the cogging mill; second-time air cooling temperature holding is performed before continuous rolling of the intermediate square billet, the temperature of the intermediate billet is held to the initial temperature of continuous rolling of 800-950 DEG C, the intermediate billet is continuously rolled into the round steel by using a continuous rolling machine after the second-time temperature holding, and the final rolling temperature is 780-900 DEG C; and when the temperature of the round steel subjected to hot rolling is held to be lower than Ar3, the round steel is comprehensively cooled through spraying and air cooling, after being cooled to 600 DEG C, the round steel is subjected to stack cooling to obtain a microstructure of lamellar pearlite and a small amount of ferrite.

Owner:JIANGSU VALIN XIGANG SPECIAL STEEL +1

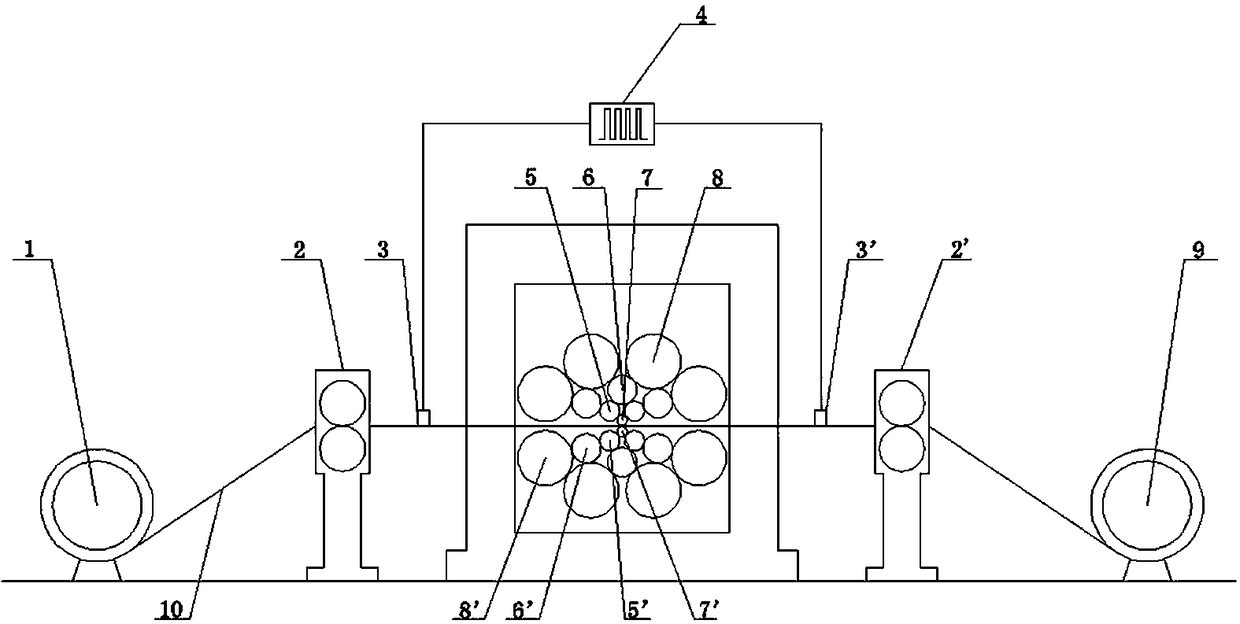

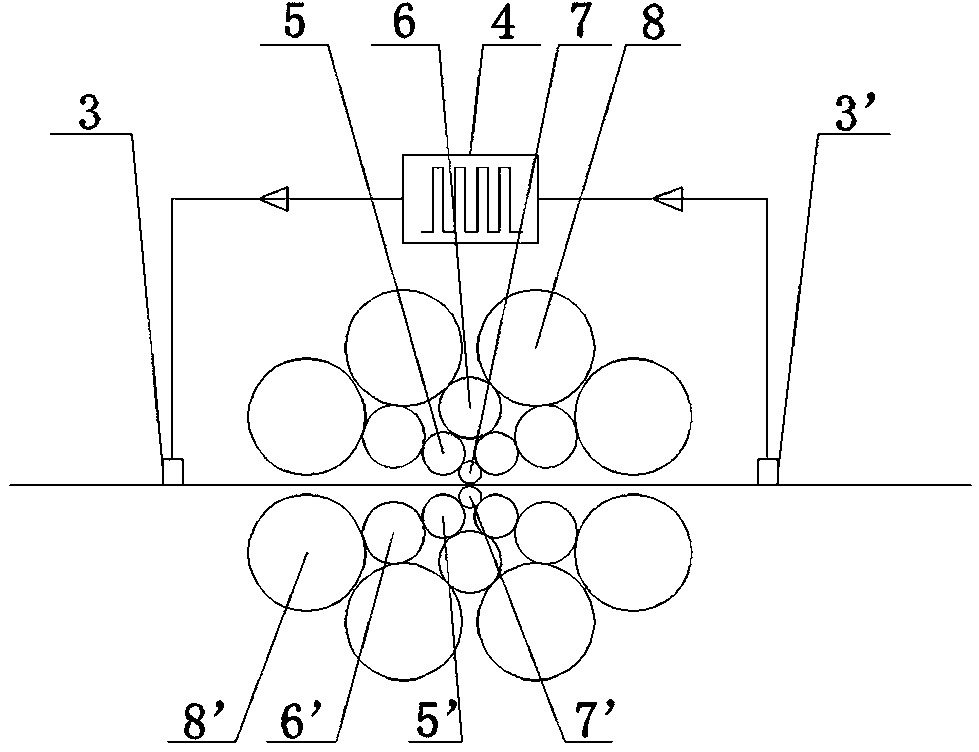

Method for rolling ultrathin foil through multi-roll mill under auxiliary of pulse currents

ActiveCN108144964AImprove plastic deformation abilityThe overall thickness is thinMetal rolling arrangementsPulse power supplySialon

The invention belongs to the technical field of ultrathin strip rolling, and particularly relates to a method for obtaining foil which is smaller in thickness, higher in size precision, more stable inperformance and smaller in grain size by applying pulse currents in the process that the ultrathin foil is rolled with a multi-roll mill. Equipment used in the method comprises the multi-roll mill, an electric brush and a pulse power supply. Sialon ceramic rolls are adopted as an upper working roll and a lower working roll of the multi-roll mill, the insulating problem of the mill equipment can be solved through the mill rolls, the condition that heat energy is generated when the pulse currents pass through the mill rolls is avoided, wear of the mill rolls is reduced, and electric energy is saved. The pulse currents output by the pulse power supply form a closed circuit through the electric brush and an ultrathin strip, and electroplastic rolling is achieved. By adding the pulse currentsin the multi-roll rolling process of the ultrathin strip, the plastic deformation capability of the ultrathin strip is improved, crack propagation is inhibited, the ultrathin strip with the bright surface is rolled, the production efficiency is improved, and the ultrathin strip which is smaller in thickness, higher in size precision, more stable in performance and smaller in grain size is obtained.

Owner:TAIYUAN UNIV OF TECH

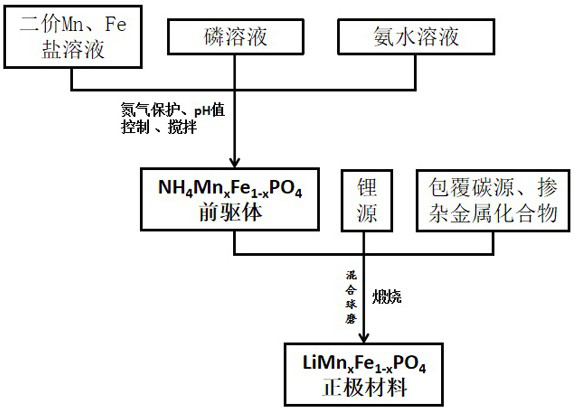

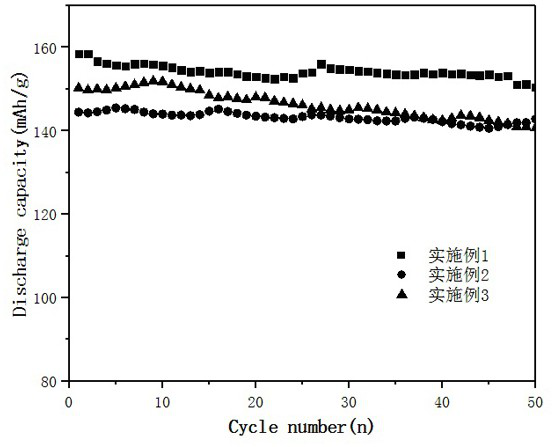

Preparation method of carbon-coated lithium iron manganese phosphate positive electrode material

ActiveCN111900344AShape is easy to controlPromote recrystallizationPhosphatesCell electrodesCarbon coatingPhysical chemistry

The invention relates to a preparation method of a carbon-coated lithium iron manganese phosphate positive electrode material, which comprises the following steps: preparing a transition metal salt solution A, a phosphorus solution B and an ammonia water solution C according to the molar ratio of Mn to Fe, and simultaneously dropwise adding the solutions into a reaction kettle to prepare a lithiumiron manganese phosphate positive electrode material precursor; and preparing a lithium source from the precursor according to a molar ratio, adding a coating carbon source and a doped metal compound, and calcining under the protection of an inert atmosphere to obtain the carbon-coated lithium iron manganese phosphate positive electrode material. According to the preparation method of the carbon-coated lithium iron manganese phosphate positive electrode material, the formation of an impurity phase is effectively reduced, and the oxidation phenomenon possibly generated in the reaction is greatly inhibited; the material is modified by adopting conductive carbon coating and ion doping, so that the electronic conductivity of the material is improved, the Jahn-Teller effect of Mn < 3 + > is weakened, the cycling stability of the material is improved, and the practical application of the carbon-coated lithium iron manganese phosphate positive electrode material is greatly promoted.

Owner:江苏海基新能源股份有限公司

Homogenization heat treatment method of aluminum alloy ingot casting for pop-top can body

The invention discloses an aluminum alloy cast ingot uniform heat treatment method of tin pot body, which comprises the following steps: (1)making mass percent of alloy as 0.20 Si, 0.52 Fe, 0.18 Cu, 1.02 Mn and 1.23 Mg; setting the other single element not bigger than 0.05 and major total not bigger than 0.15; making the surplus as Al; casting the tin pot body with aluminum alloy; proceeding high-temperature uniform treatment in propulsion heating furnace with cooling device; controlling the temperature at 550-620 deg.c and keeping temperature time at 12-24h; forced-cooling to 460-500 deg.c with cooling speed at 20-60 deg.c / h; (2) controlling heat treatment of evolution phase in the same heating furnace; controlling the temperature at 450-500 deg.c and time at 6-12 h. This invention provides support for high quality production of AA3104 aluminum alloy sheet.

Owner:中铝西南铝板带有限公司

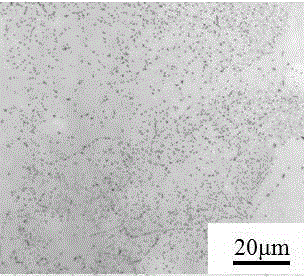

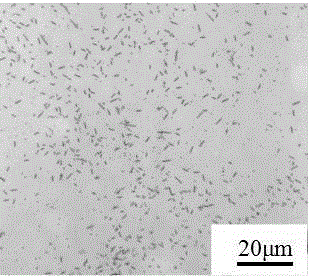

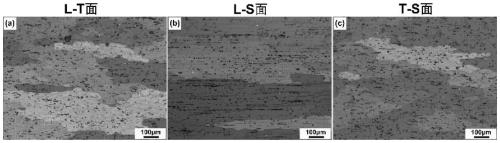

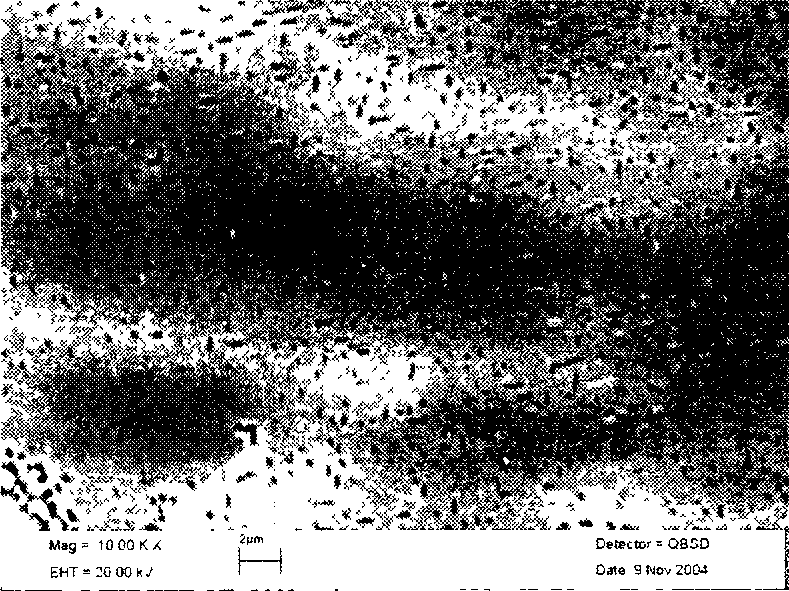

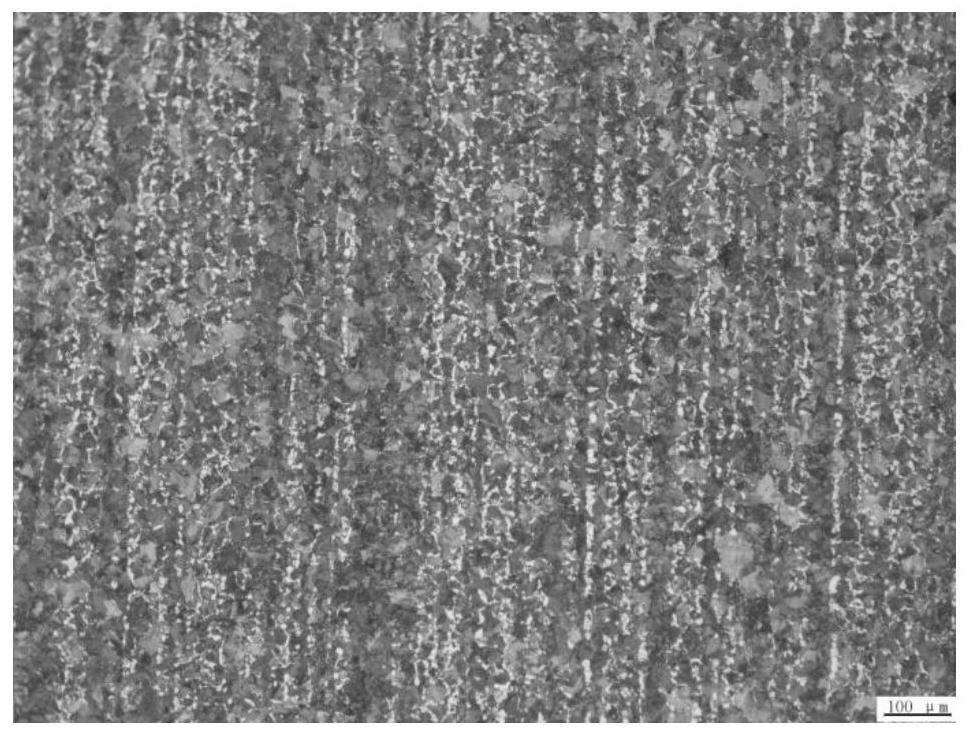

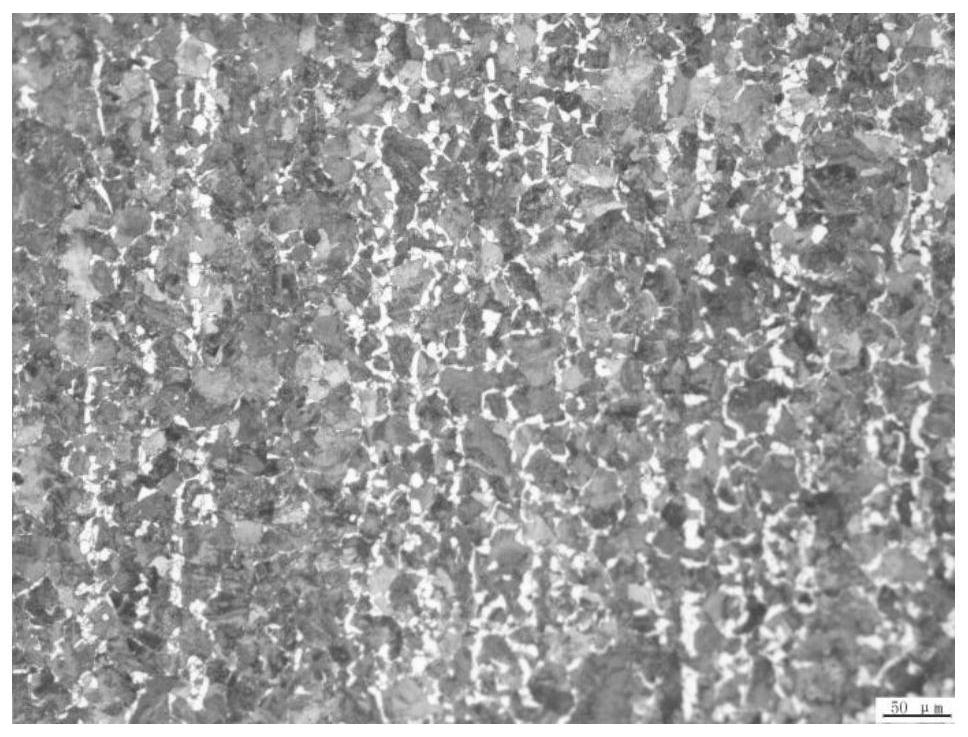

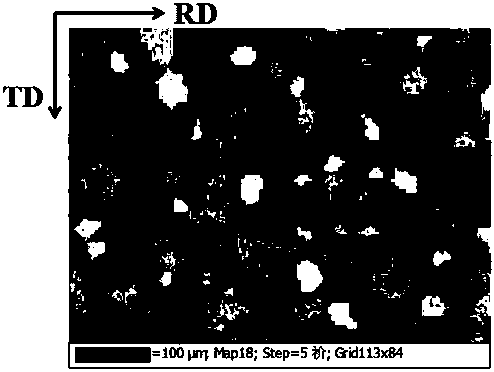

Method for producing ultra-pure ferritic stainless steel for decoration by adopting Steckel mill

ActiveCN110819877AEliminate Oriented Grain ClustersReduce defectsSS - Stainless steelHeating furnace

The invention discloses a method for producing ultra-pure ferritic stainless steel for decoration by adopting a Steckel mill, and belongs to the field of stainless steel production. The problem of surface plate pattern defects existing in the ultra-pure ferritic stainless steel rolled by the Steckel mill is solved. The method comprises the following steps of smelting and continuous casting; grinding; heating by a heating furnace; hot rough rolling; hot finishing rolling; hot rolling coiling; hot annealing acid washing; cold rolling; cold annealing acid washing; and flattening. According to themethod, aiming at the characteristics of the Steckel mill, a reasonable rolling temperature and rolling schedule and a suitably low thermal annealing temperature are adopted, oriented grain clustersin the microstructure of the cold rolled product produced through a traditional process are eliminated, the microstructure that grains is in a randomly dispersed distribution is obtained, and then plate pattern defects, in the rolling direction, of the macroscopic surface of a cold rolled 2B product is effectively eliminated, so that the product grinding and drawing process is guaranteed to be qualified at a time.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

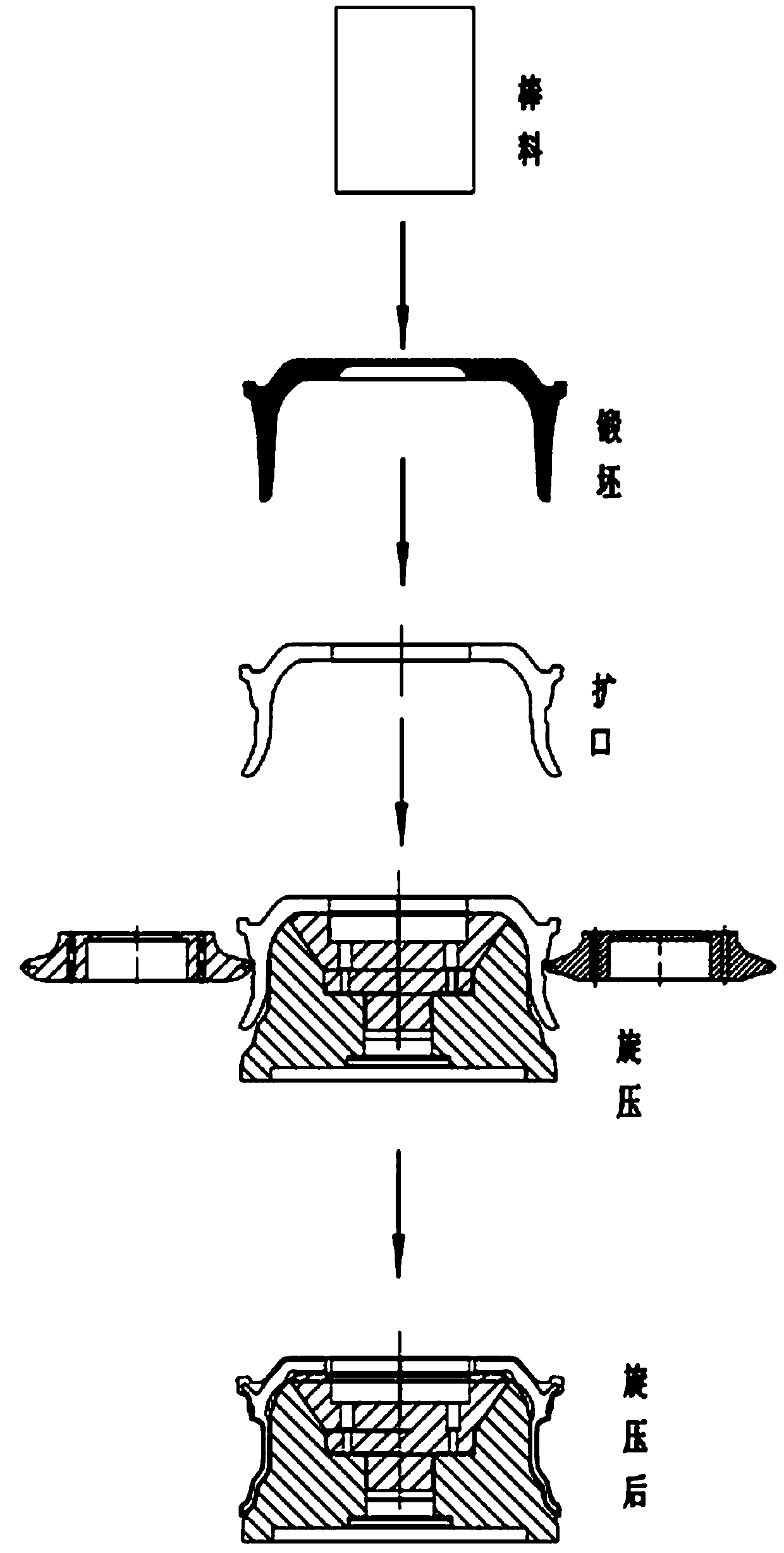

Magnesium alloy wheel forging-spinning composite forming method

InactiveCN104191181AHigh strengthReduce casting defectsDisc wheelsUltimate tensile strengthMachining

The invention relates to a casting method of magnesium alloy wheels, in particular to a magnesium alloy wheel forging-spinning composite forming method. The method includes feeding, heating, forging, flaring, pre-machining, preheating, spinning, performing heat treatment, finishing and performing surface treatment. The method has the advantages that material is saved, the bar material can be saved above 10%, and the cost of raw material of magnesium alloy during wheel production is saved; the producing efficiency is high, the forming steps are reduced, and the producing efficiency can be improved greatly; since the machining allowance is reduced, when the subsequent forming and finishing are performed, the machining amount is reduced, and the producing efficiency is improved; the waste quality is reduced, in the processing of machining wheels through a wheel blank machine, since the machining allowance is reduced, and the amount of magnesium chips can be reduced after machining; the strength of the wheel is high, in the process of spinning, effects can be applied to positions of the wheel intermediate-product rim portion more evenly through a spinning wheel, and the strength of the wheel is improved.

Owner:山西银光华盛镁业股份有限公司

Rolling method for applying pulse current to rollers

InactiveCN108339852AExtended service lifeHigh bonding strengthMetal rolling arrangementsClosed loopPulse power supply

The invention belongs to the technical field of double metal composite material rolling, and in particular to a method for improving the bonding strength of double metal composite boards through applying pulse current to upper and lower rollers in the rolling process. The method comprises the main steps of treatment of coating layer metal and base layer metal before rolling, communication of the pulse current to the upper roller or the lower roller and startup of a rolling mill for rolling. The rolling method for applying the pulse current to the rollers is to add a pulse power supply in the rolling process; and the pulse current output by positive and negative poles of the pulse power supply flows through the rollers and the boards through different modes to form a closed loop. The rolling method has the beneficial effects of acceleration of the element dispersion of the coating layer metal and the base layer metal, improvement of the dispersion efficiency, reduction of the rolling force, improvement of the bonding strength and improvement of the rolling production efficiency.

Owner:TAIYUAN UNIV OF TECH

Preparation method of phosphogypsum recrystallized wall material

The invention provides a preparation method of an ardealite recrystallization wall material. The method comprises steps of: mixing ardealite and additives in a mass ratio of 1:0.02-0.15; grinding the mixture to -200 mesh to realize intimate mixing of the ardealite and the additives; mixing the ground mixture and water in a mass ratio of 1:0.15-0.25, blending well, moulding and maintaining under normal temperature and normal pressure to obtain an ardealite wall finished product. According to the method, cost of binder is saved, and a calcination process and corresponding pollution are avoided. More importantly, the recrystallization solidified wall material has more stable performance and overcomes a problem of expansion and cracking of a current similar burn-free ardealite brick during usage, because a phenomenon of an unstable long-term wall material endurance, caused by expansion of sulphate aluminium after addition of cement, is avoided.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com