Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

355results about How to "Reduce casting defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

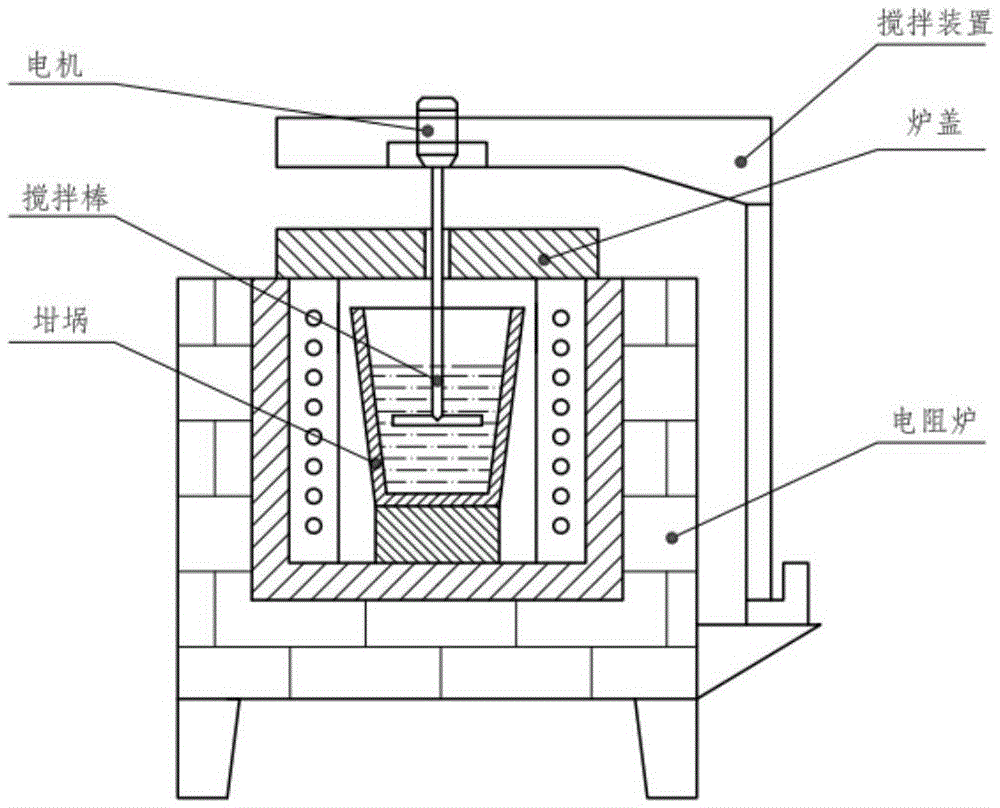

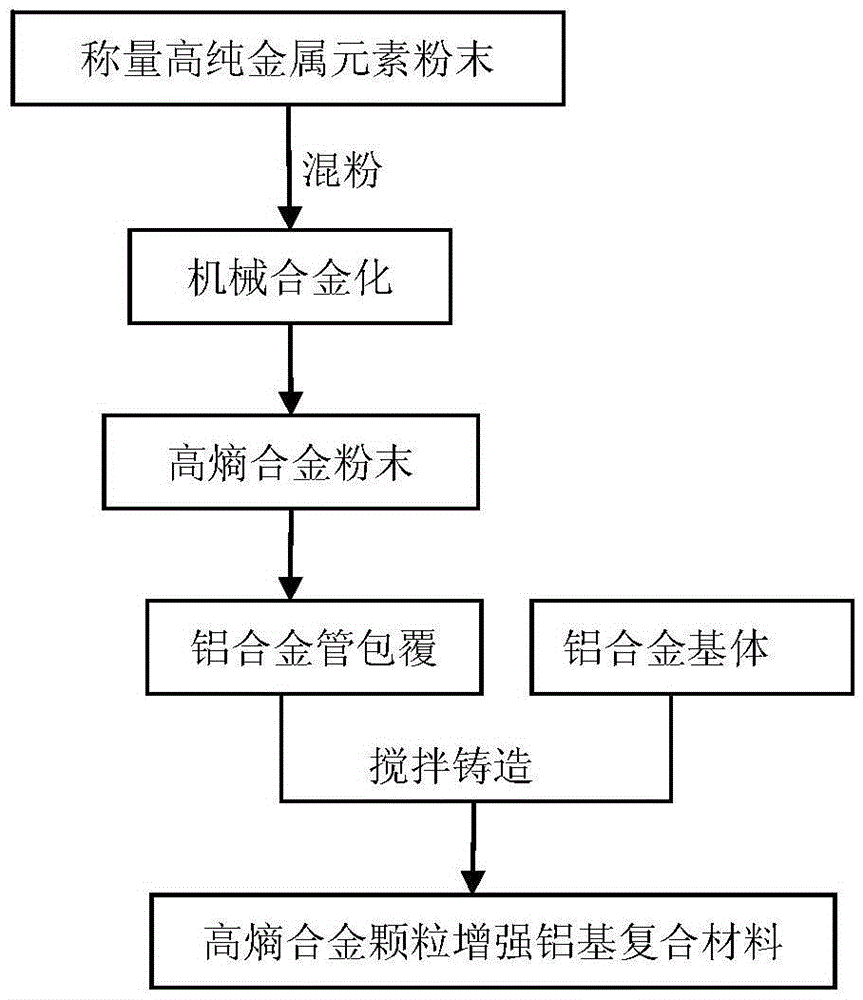

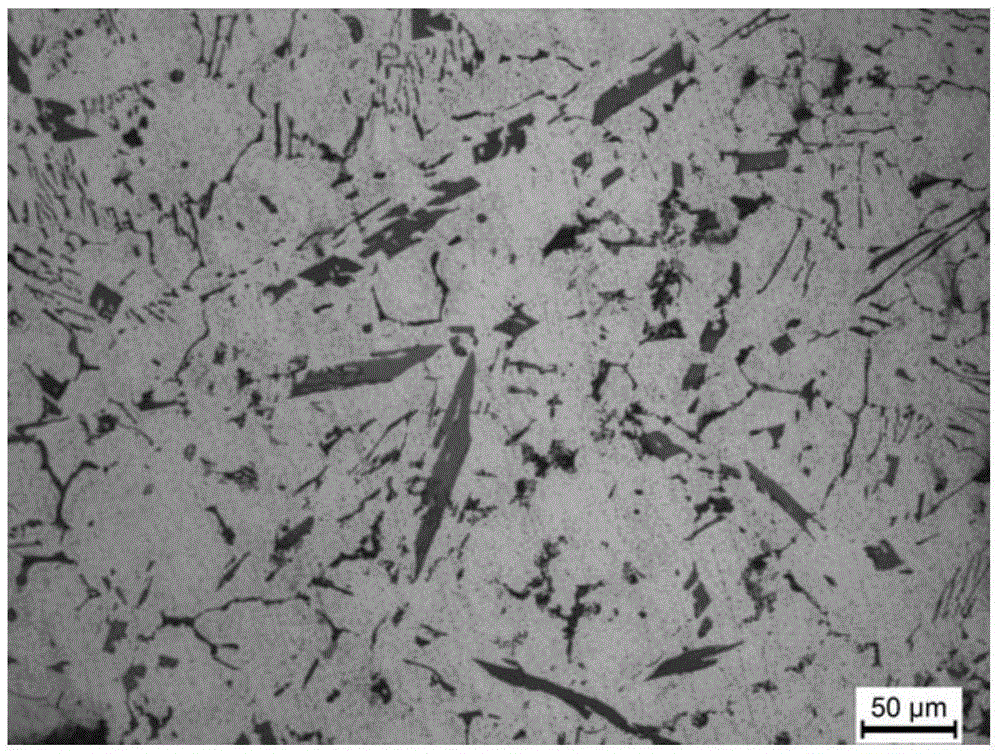

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

Low-cost non-rare-earth type high-strength magnesium alloy and preparing method thereof

The invention relates to low-cost non-rare-earth type high-strength magnesium alloy and a preparing method thereof. The alloy is Mg-Bi-Ca-Mn magnesium alloy, and is prepared from, by mass, 2-10% of Bi, 0.1-1.5% of Ca, 0.1-1.0% of Mn and the balance magnesium. The novel magnesium alloy is based on a Mg-Bi binary metal series, the element Bi serves as the main alloy element, and the Mg3Bi2 phase with high melting point is contained in the magnesium alloy. Furthermore, the magnesium alloy is evenly dispersed and distributed on a matrix through a simple alloying means, the metamorphism to a second phase by the element Ca and the element Mn and the combination of a plastic deformation processing means so that crystal boundary migration can be effectively pinned in the deformation process to hinder dislocated movement, grains are obviously refined, the strength of the alloy is greatly improved, and thus the ultra-high-strength magnesium alloy is developed in the alloy series.

Owner:HEBEI UNIV OF TECH

Method for manufacturing blank of pipe clamp

InactiveCN105728648AAchieve productionSave materialFoundry mouldsFoundry coresMolding machineCasting defect

The invention discloses a method for manufacturing a blank of a pipe clamp and belongs to the field of construction. The method comprises the following steps that 1, a pipe clamp precoated sand mold is designed and manufactured according to a design drawing of the pipe clamp; 2, the precoated sand mold of the pipe clamp is placed on an automatic molding machine, and a precoated sand pouring sand shell model and a sand core model are manufactured; 3, pouring is carried out; and 4, a casting is taken out and cleaned. The method has the beneficial effects that production of the blank of the pipe clamp can be efficiently achieved, materials and manpower can be saved, and the mechanical machining amount can be reduced; and casting defects can be reduced, the yield is increased, and automatic production can be easily achieved.

Owner:YUZHOU KUNLUN MOLD CO LTD

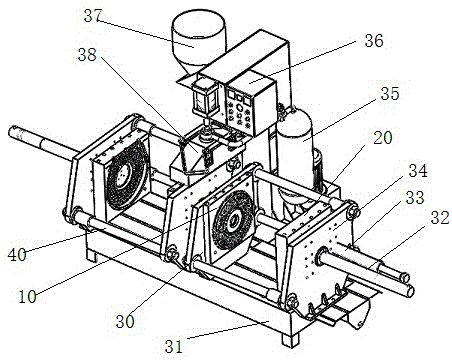

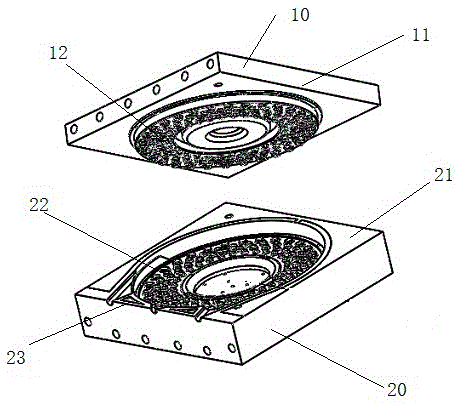

Preparation method for active element sintered ZTA (Zirconia Toughened Alumina) particulate reinforced steel based compound grinding roller and grinding disk

The invention discloses a preparation method for an active element sintered ZTA (Zirconia Toughened Alumina) particulate reinforced steel based compound grinding roller and a grinding disk. The preparation method comprises the following steps: 1) uniformly mixing multiple active element powder, and then adding a defined amount of binding agents and fully mixing with ZTA particulates so as to uniformly cover the active element powder on the surfaces of the particulates, filling into a graphite mould, pressing, and then drying; 2) sintering, thereby obtaining a porous precast block; 3) fixing the precast block on a specific casting position and pouring molten metal, cooling and de-molding, thereby obtaining the compound grinding roller or grinding disk. According to the preparation method, the shape and size of the ZTA particulate precast block can be controlled through the mould and the technique is simple and has higher production efficiency, yield and practicability. Besides, the active element introduced into the interface can increase the wettability and binding strength of the interface and a compound layer structure with interactive distributed enhanced phase and base can ensure the longer service life of the grinding roller and the grinding disk under high stress effect.

Owner:XI AN JIAOTONG UNIV +1

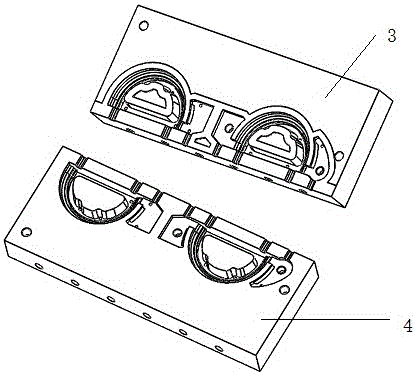

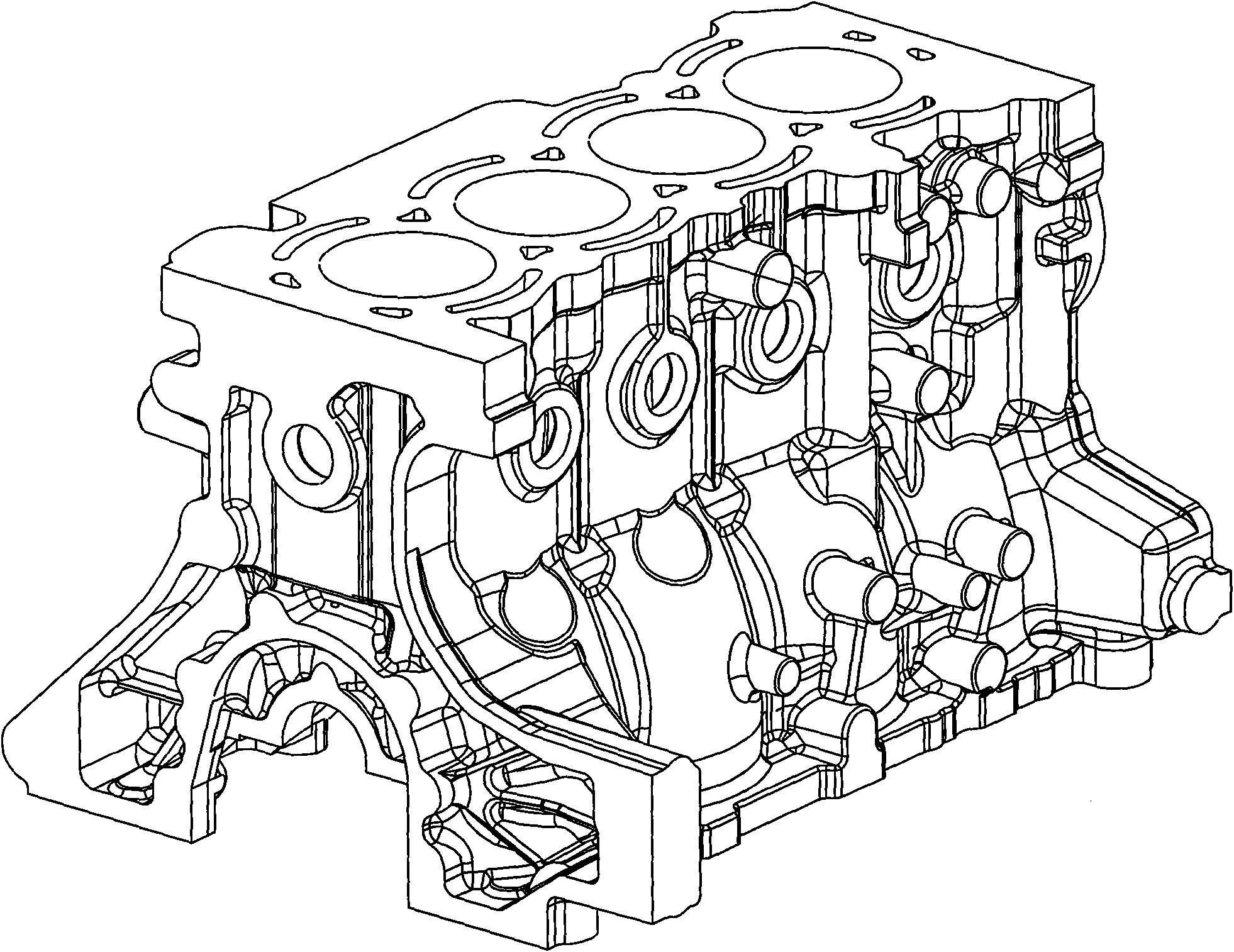

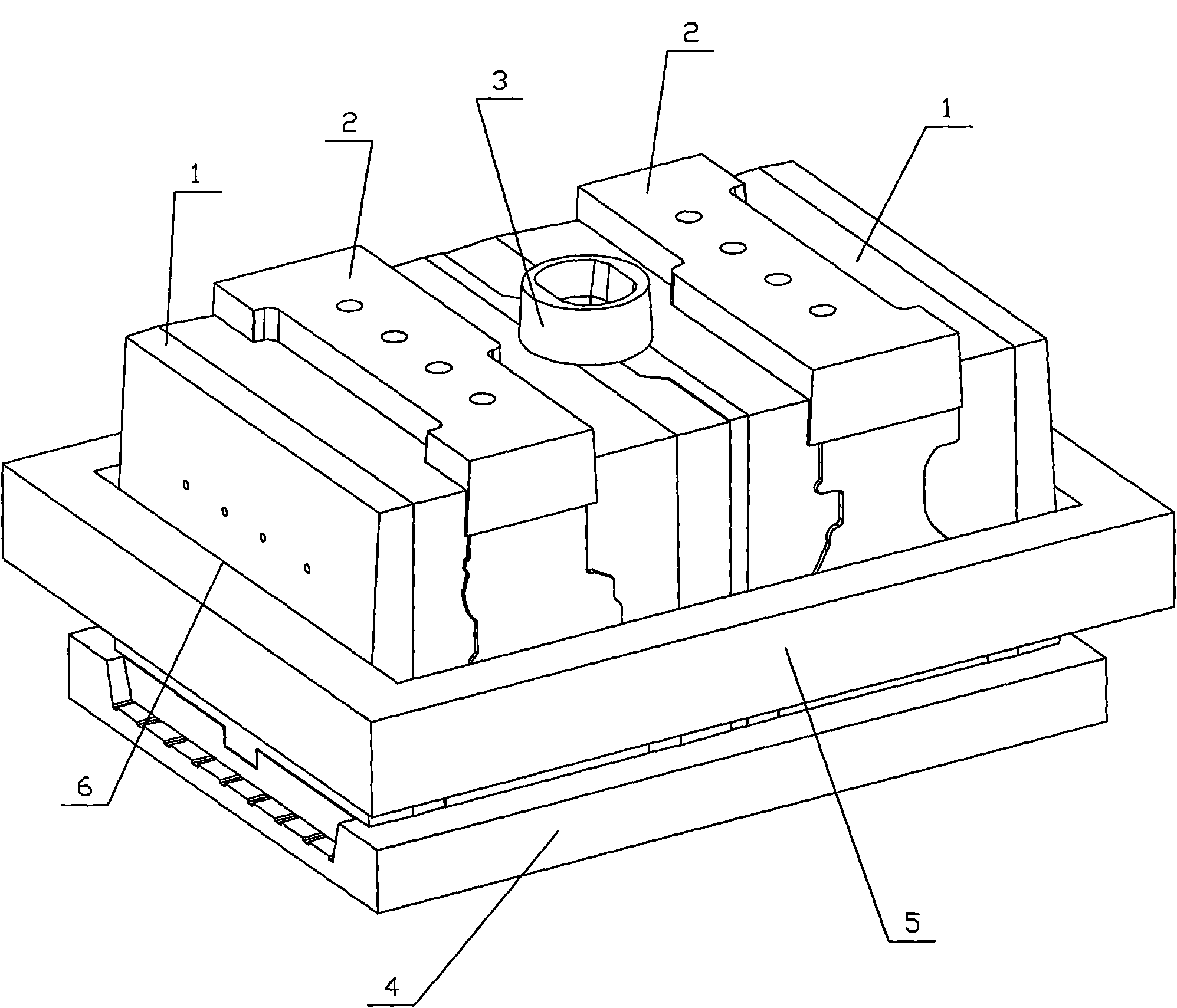

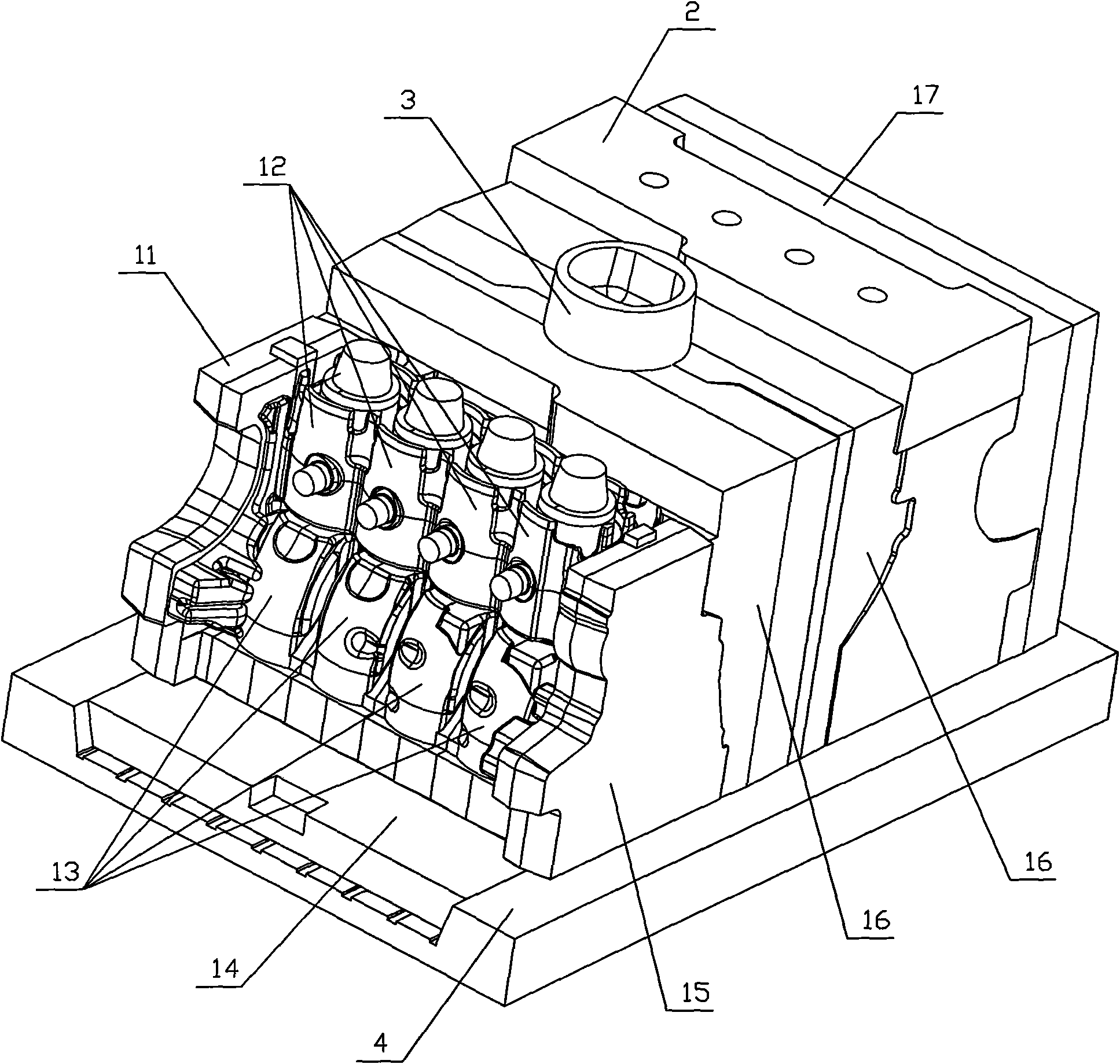

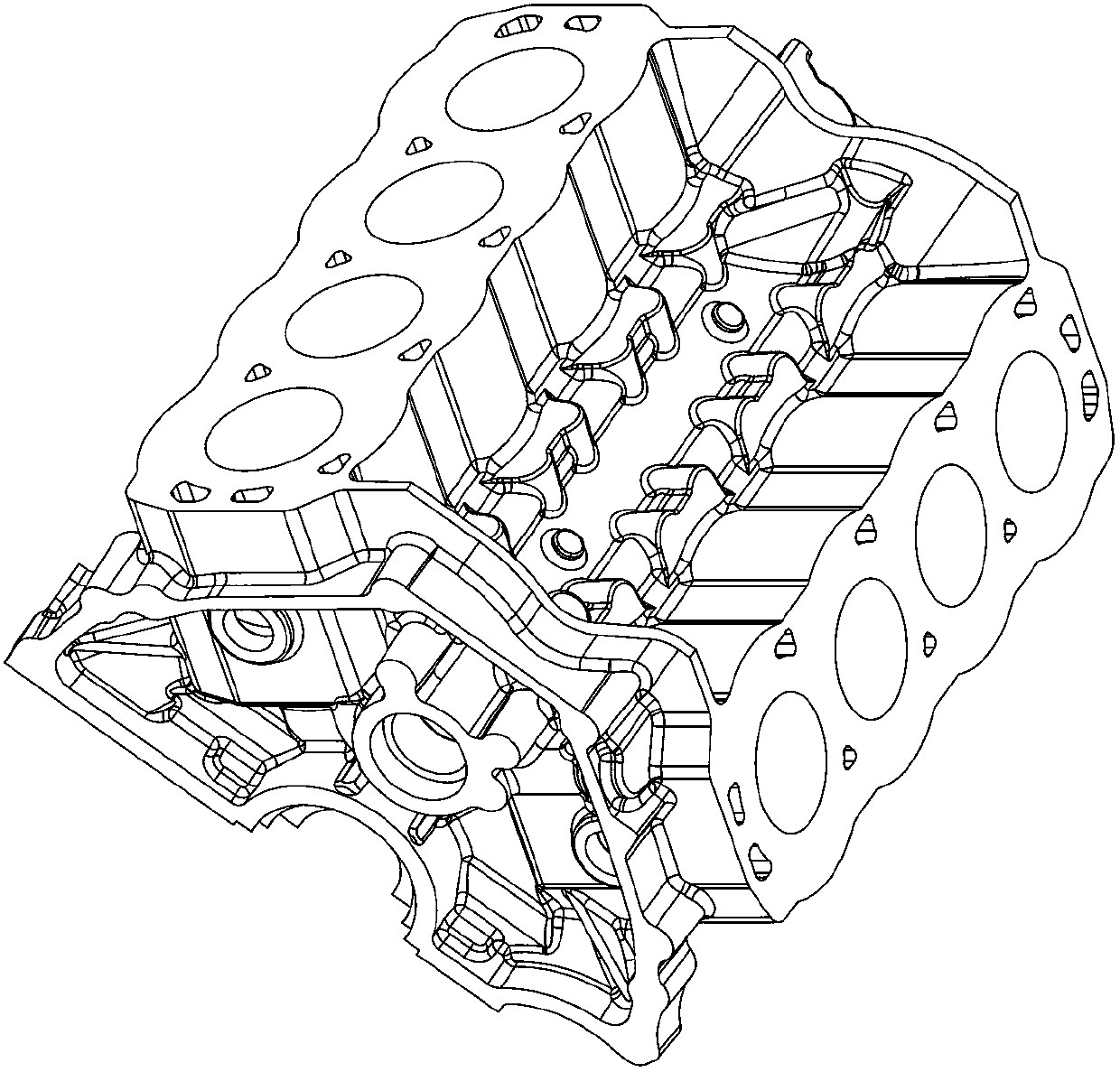

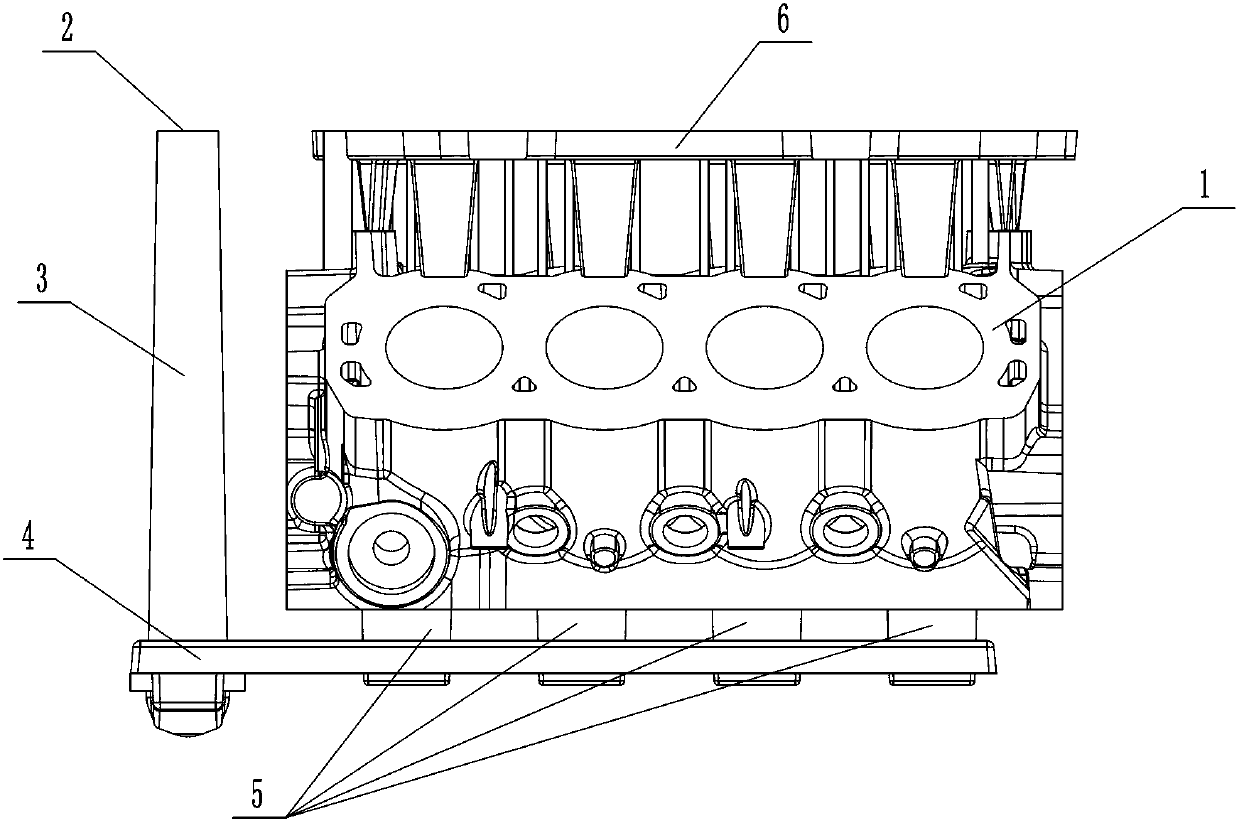

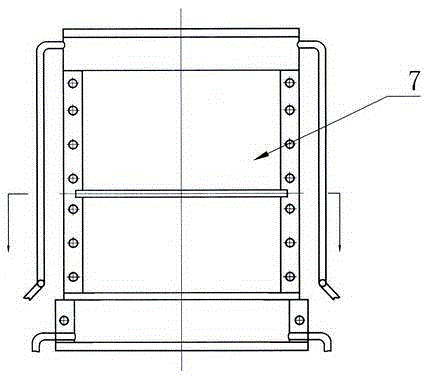

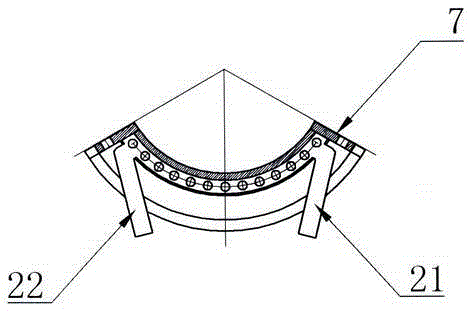

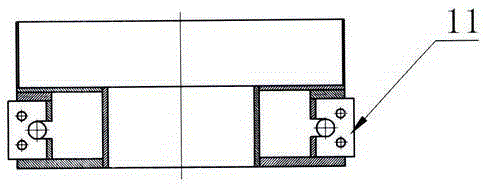

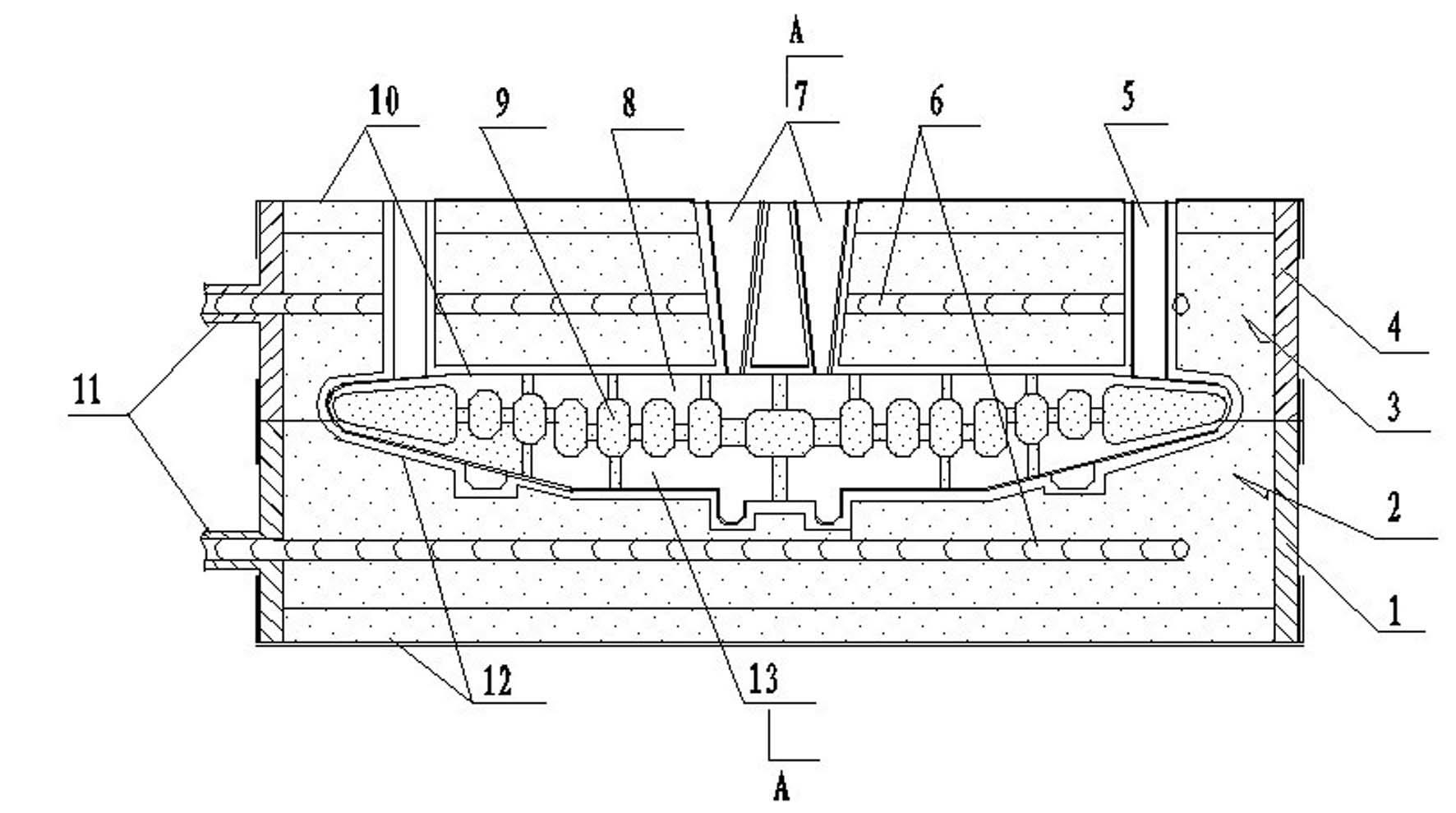

Core assembly pouring device for cylinder block casting in automobile engine

InactiveCN101817060ASolve the deformationReduce in quantityFoundry mouldsFoundry coresEngineeringCylinder block

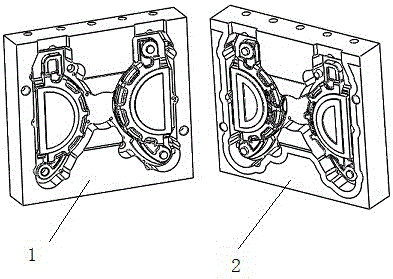

The invention discloses a core assembly pouring device for a cylinder body casting in an automobile engine, comprising a base plate (4), two raiser cores (2), a sprue core (3), sand core assemblies (1) and a locking device (5), wherein the sand core assemblies (1) are connected on the base plate (4) and are locked by the locking device (5), the raiser core (2) and the sprue core (3) are located on the two adjacent sand core assemblies (1) which are clamped on the base plate (4), and the locking device (5) is sleeved and pressed outside the two sand core assemblies (1). By adopting the structure, the sand core of the cylinder body consists of a plurality of sand cores, and each sand core is composed of a plurality of small sand cores, thus reducing the size of each sand core, being beneficial to the forming of the sand cores and reducing casting defects of castings; and meanwhile, the number of the sand core assemblies is two, e.g. one die generates two castings, thus greatly improving production efficiency.

Owner:宁波强盛机械模具有限公司

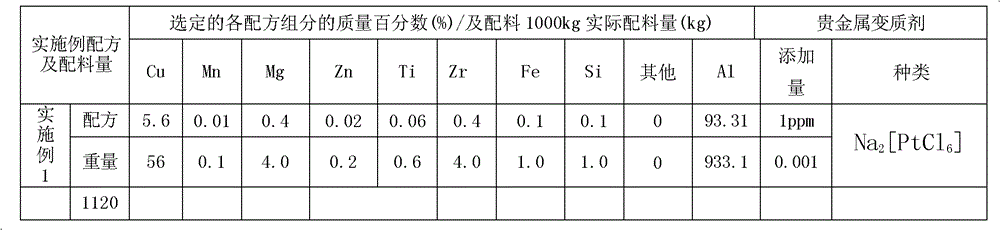

Noble-metal-modified aluminum alloy material and preparation method thereof

The invention discloses a noble-metal-modified aluminum alloy material and a preparation method thereof. The alloy comprises the following components in percentage by weight: 5.0-6.5% of Cu, at most 0.1% of Mn, at most 0.5% of Mg, at most 0.15% of Zn, at most 0.2% of Ti, at most 0.5% of Zr, at most 0.6% of Bi, at most 0.6% of Pb, and the balance of Al and inevitable trace impurities; the noble metal modifier accounts for 1ppm-0.1% of the total amount; and the content of any single impurity element is at most 0.05%, and the total content of the impurity elements is at most 0.1%. The invention can effectively reduce the generation of pinholes, and has the effect of high modification efficiency.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

High-chromium cast iron composite inoculant, preparation method and application thereof

The invention relates to a high-chromium cast iron composite inoculant, a preparation method and an application thereof, in particular to cast iron alloy containing chromium. The high-chromium cast iron composite inoculant is a nanocrystalline high-chromium cast iron composite inoculant containing rare-earth ferrosilicon and ferroboron. The high-chromium cast iron composite inoculant comprises Fe-Ce-Si-Ca intermediate alloy and Fe-B intermediate alloy, wherein the weight ratio between the Fe-Ce-Si-Ca intermediate alloy and the Fe-B intermediate alloy is 1:0.07-0.13. The nanocrystalline crystal grains of the inoculant are less than 100nm, the inoculant is a flaky inoculant obtained by carrying out melt fast-quenching processing on raw materials which comprise commercially purchased rare-earth ferrosilicon and commercially purchased ferroboron, the inoculant is used for carrying out crystal grain and tissue refining processing on the tissue of the high-chromium cast iron alloy of high-chromium cast iron wear parts used for engineering machinery, the processing method is a metal melt casting method, the casting defect of the existing casting technology of the high-chromium cast iron alloy is overcame, and matrix crystal grains and cementite phases are obviously refined, so that the overall mechanical properties of the high-chromium cast iron alloy are obviously improved.

Owner:TIANJIN LIXINSHENG ADVANCED CASTING

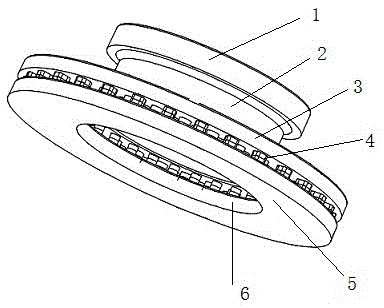

Workblank manufacturing method of automobile brake disc

InactiveCN105458184AAchieve productionSave materialFoundry mouldsMoulding machinesSand castingCasting defect

The invention discloses a workblank manufacturing method of an automobile brake disc, and belongs to the field of automobile accessory manufacturing. The method comprises the following steps that firstly, according to design paper of the brake disc, and a precoated sand shell mold and a sand core mold are designed and manufactured; secondly, the sand shell mold or sand core mold is placed on a sand shell or sand core automatic forming machine to manufacture a precoated sand casting sand shell model and a sand core model; thirdly, pouring is carried out; and fourthly, a casting is taken out and cleaned. The beneficial effects that production of the brake disc workblank can be efficiently achieved, materials and manpower are saved, mechanical allowance is reduced, casting defects are reduced, the yield is improved, and automation production is easily achieved are achieved.

Owner:YUZHOU KUNLUN MOLD CO LTD

V8 type gray cast iron cylinder body casting pouring method

ActiveCN103121082AStable flow rateSmall structureFoundry mouldsFoundry coresAssembly structureMaterials science

The invention discloses a V8 type gray cast iron cylinder body casting pouring method which is carried out by adopting a core assembly pouring mode. The V8 type gray cast iron cylinder body casting pouring method comprises the following steps of: 1, setting a pouring position of a casting; 2, arranging a pouring system; 3, assembling a core assembly; and 4 pouring. Compared with the prior art, the V8 type gray cast iron cylinder body casting pouring method has the characteristics of relatively simple core assembly structure, high yield and low production cost.

Owner:宁波亿泰来模具有限公司

Manufacturing method of spheroidal graphite cast iron casting of wind power yaw variable-pitch device

The invention discloses a manufacturing process of a spheroidal graphite cast iron casting of a wind power yaw variable-pitch device. The process comprises the following processes of mould making, foaming and moulding, paint brushing, boxing and shaping, electric furnace smelting, tundish-covering nodulizing treatment, vacuum-assist pouring and three-time inoculation treatment, wherein the boxing and shaping process is a layered assembling process, so that the production efficiency can be improved and the process yield can be increased; cold iron is vibrated and reasonably arranged, so that the compactness of tissues in the casting can be improved and the defect of shrinkage porosity can be avoided; by virtue of the processes of electric furnace smelting and tundish-covering nodulizing treatment, the nodulizing rate of the casting can be stabilized and increased and the mechanical properties of the casting can meet the technical quality requirements of wind power castings; the spheroidal graphite cast iron casting manufactured by the process is compact and uniform in tissue, hardly has defects, has good surface quality and high size precision; the casting forming of multiple layers of castings can be realized; and the production efficiency and the process product yield are improved.

Owner:CHTC HEAVY IND

Manufacturing method of vermicular cast iron piston ring

InactiveCN103451510AMeet performance needsHigh tensile strengthPiston ringsFoundry mouldsWear resistanceToughness

The invention discloses a manufacturing method of a vermicular cast iron piston ring. The material of the vermicular cast iron piston ring comprises the following chemical components in percentage by weight: 3.4-4.0% of C, 2.4-3.2% of Si, not more than 0.3% of Mn, 0.2-0.4% of Cr, 0.2-0.6% of Mo, 0.5-1.0% of Cu, 0.05-0.15% of Ti, not more than 0.1% of P, not more than 0.05% of S, 0.009-0.02% of Mg and the balance of Fe and inevitable impurities. The manufacturing method of the vermicular cast iron piston ring comprises the following technical steps of moulding, smelting, casting, shaking out, shot blasting, mechanical processing, surface treatment and the like. By adopting the manufacturing method disclosed by the invention, the thinning of the piston ring is achieved, the production process is relatively simple, and the manufactured vermicular cast iron piston ring is high in elasticity, strength, toughness and wear resistance.

Owner:SHIJIAZHUANG JINGANG KAIYUAN POWER SCI & TECH

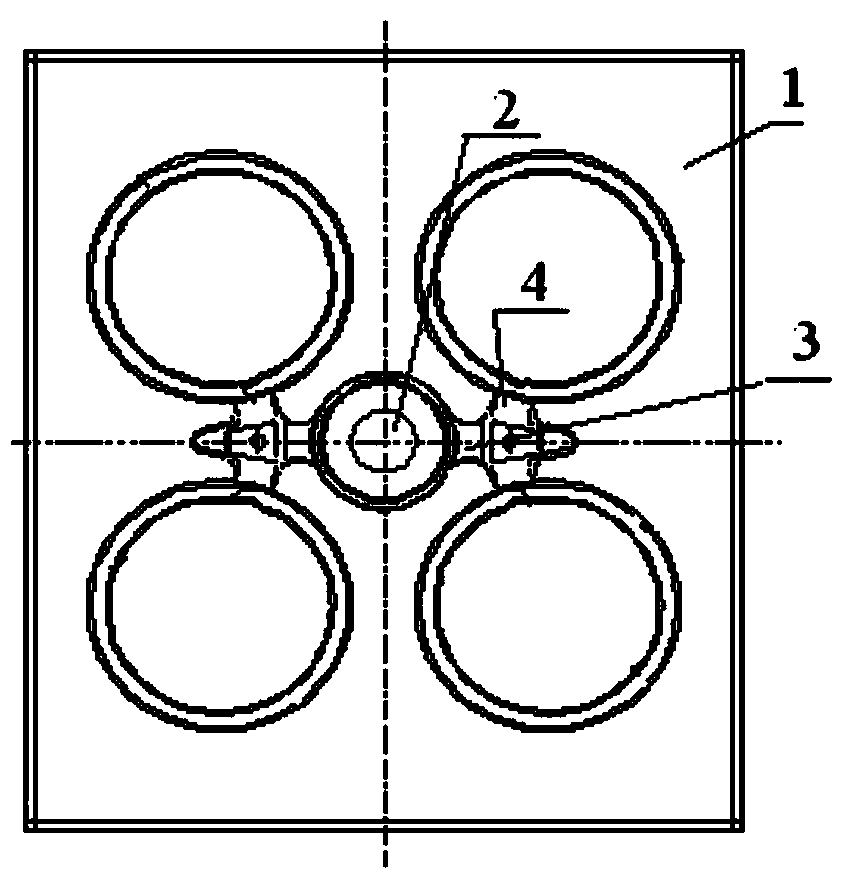

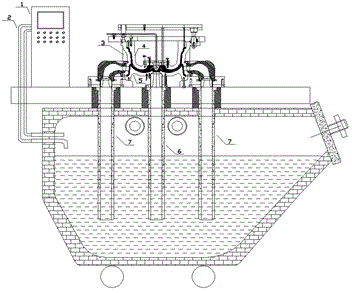

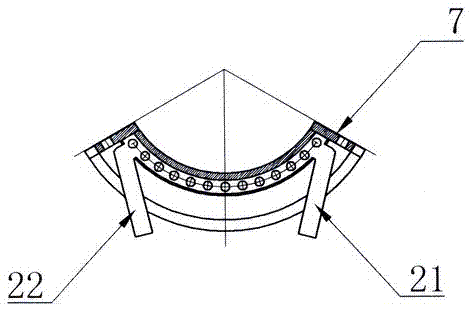

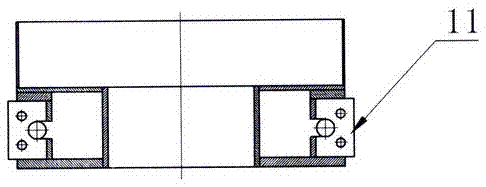

Combined pouring and purifying system for automobile aluminium alloy wheel with big diameter being more than 26 inches

The invention discloses a combined pouring and purifying system for automobile aluminium alloy wheels with big diameter being more than 26 inches; the system is composed of a control cabinet, compression and decompression pipes, side dies, a top die, a bottom die, one central pouring system and two lateral pouring system; the central pouring system is composed of a circular arc filter screen, an iron pouring gate, a ceramic vacuum cup and a ceramic liquid-rising pipe; each lateral pouring system is composed of a lateral pouring feeding inlet, a cap-shaped filter screen, another iron pouring gate, another ceramic vacuum cup, a ring-shaped sealing gasket and another ceramic liquid-rising pipe; the feeding interface of each lateral pouring system is assembled at the die assembly place of two side dies and a Lip middle-upper part area; the volume of each lateral pouring feeding inlet is 100-200cm<3>; the width of the section thereof is 2.0-4.0mm, and the height thereof is 25.0-50.0mm; the invention has the characteristics that the mould filling time is short; the casting period is short; the casting defect is less; the interior quality of a casting is excellent; the casting process is convenient to control, and the like.

Owner:JIANGSU KAITE AUTO PARTS

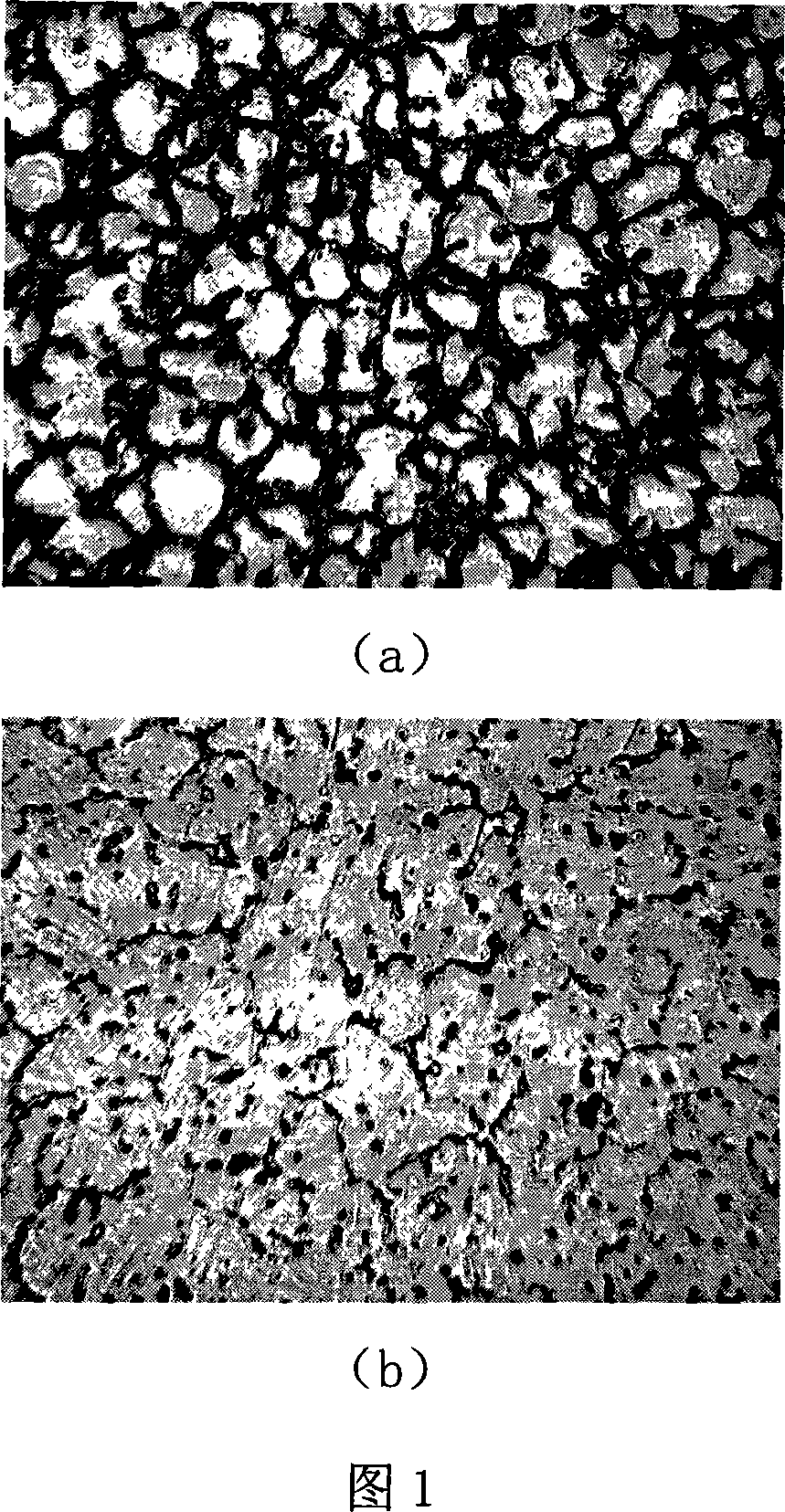

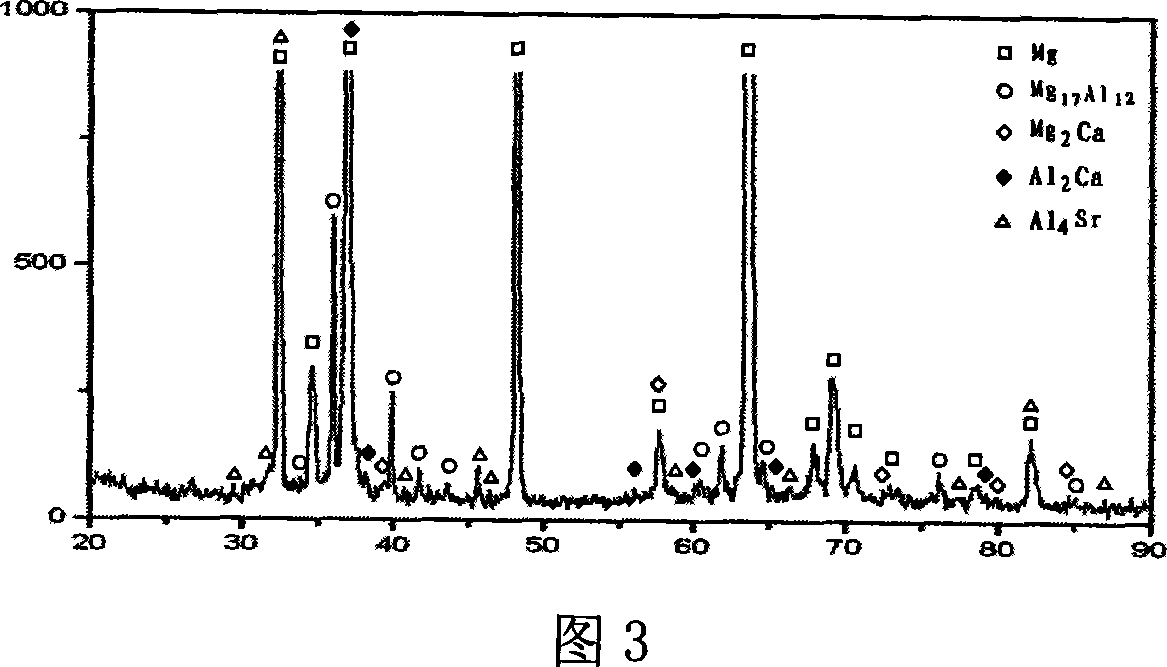

Alkaline-earth heat insulating magnesium alloy for vehicle use and producing method thereof

InactiveCN101067178AImprove performanceImprove flame retardant performanceRoom temperatureSolid solution

The heat resistant magnesium alloy for use in automobile has the components including Al 7-10 wt%, Zn 0.8-1.2 wt%, Mn 0.1-0.8 wt%, Ca 0.1-1.5 wt%, Sr 0.05-0.15 wt%, and Mg 88-91 wt%. During smelting, intermediate alloys Al-Ca and Al-Sr are added into magnesium alloy melt to increase Ca and Sr contents; and after smelting, the magnesium alloy is solid solution treated at 410 deg.c for 16-24 r and ageing treated at 180 deg.c for 16-40 hr to raise the strength. The heat resistant magnesium alloy is one kind of cast alloy with room temperature strength higher than that of AZ91 alloy, relatively high creep property at high temperature, high fire retarding performance, less interdendritic shrinkage and other casting faults and low cost, and is suitable for use in producing high temperature automobile parts.

Owner:HUNAN UNIV

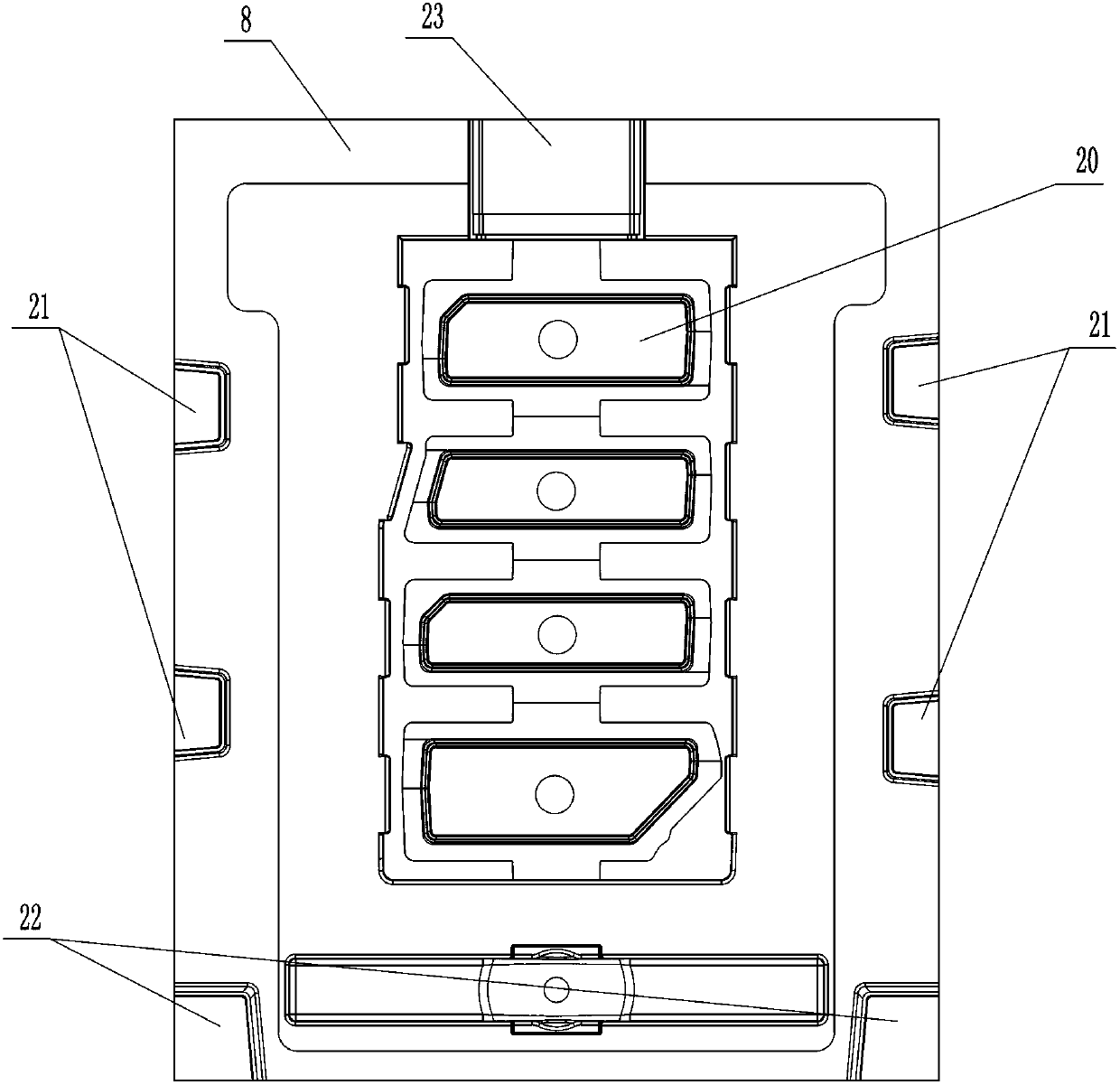

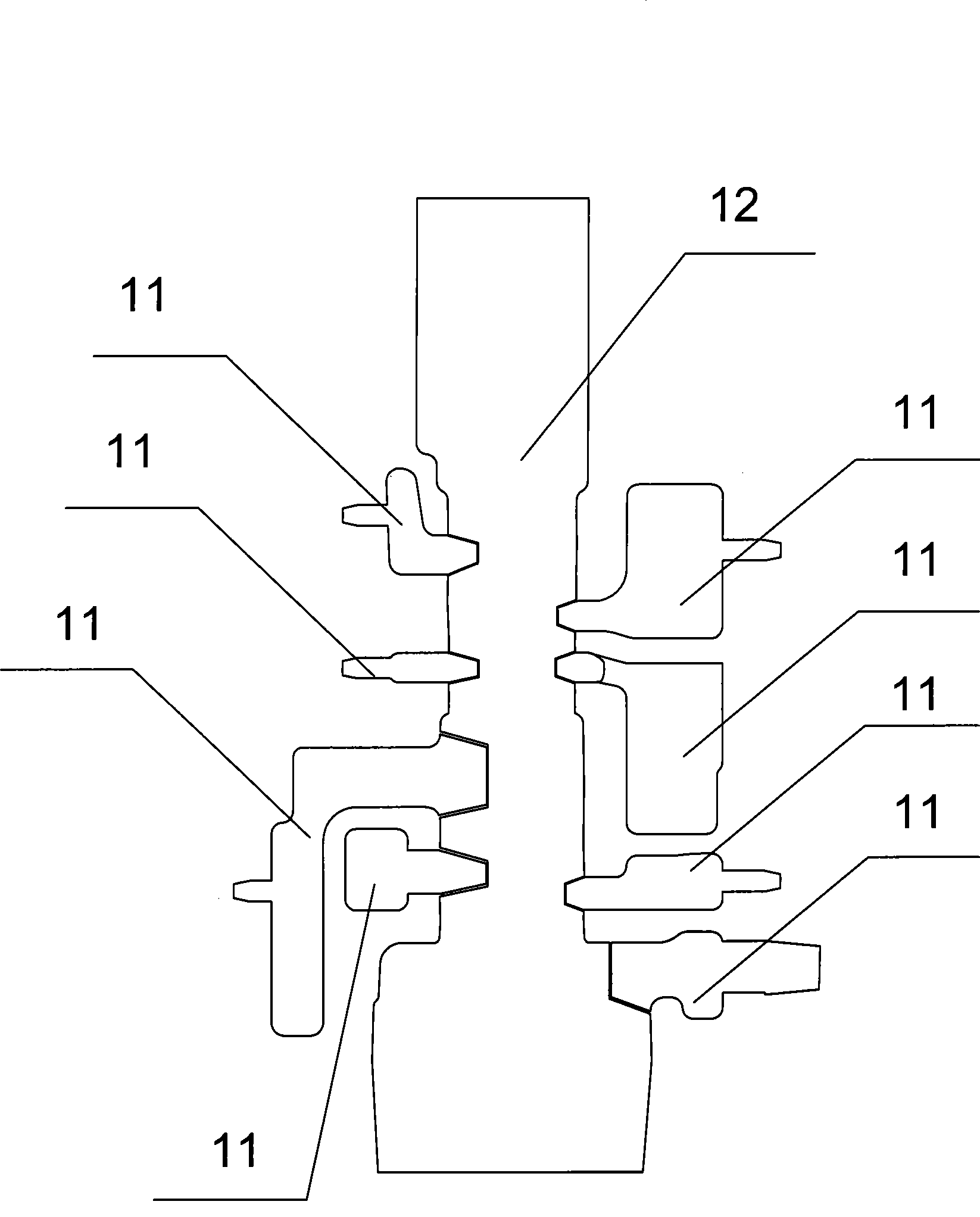

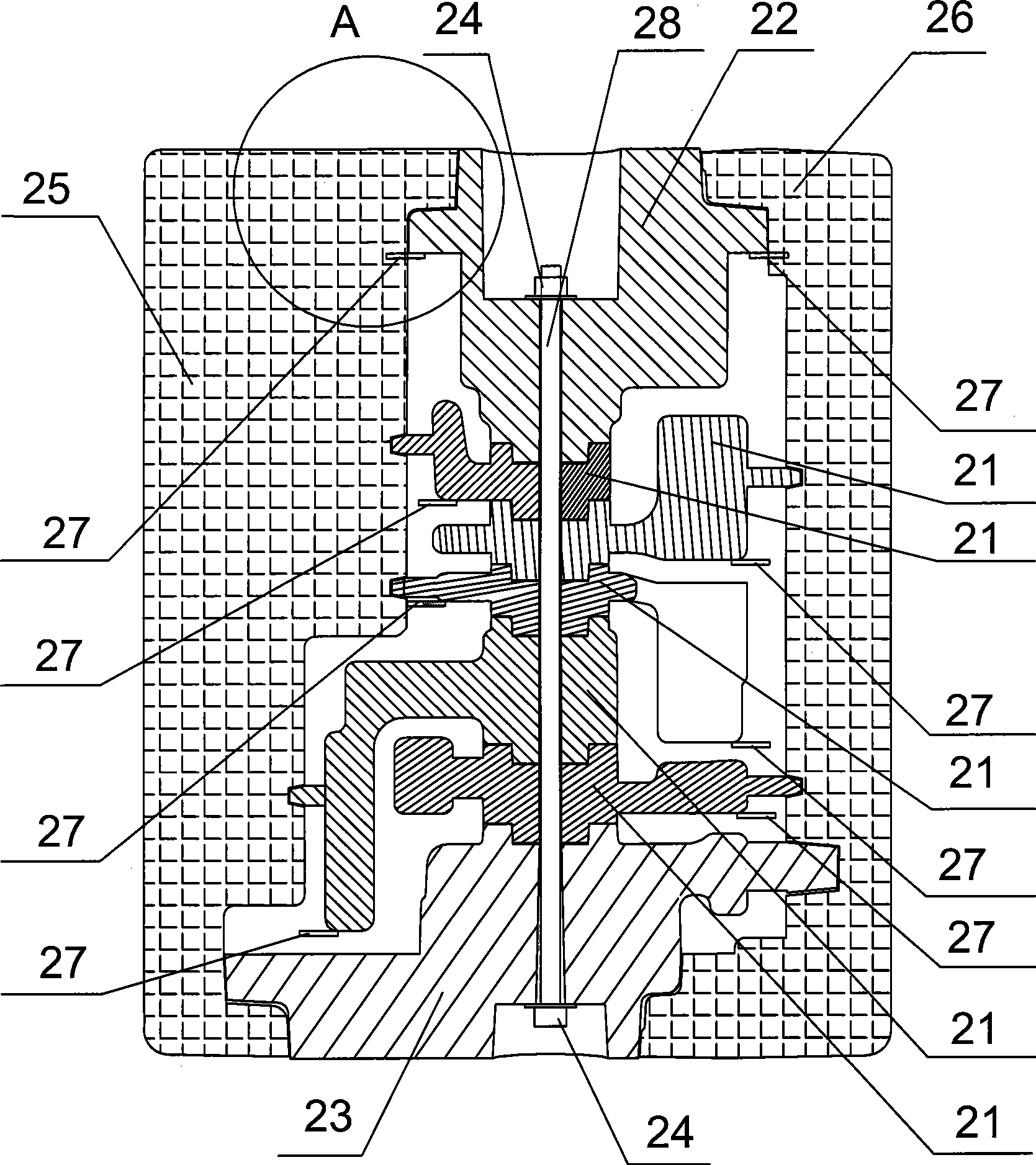

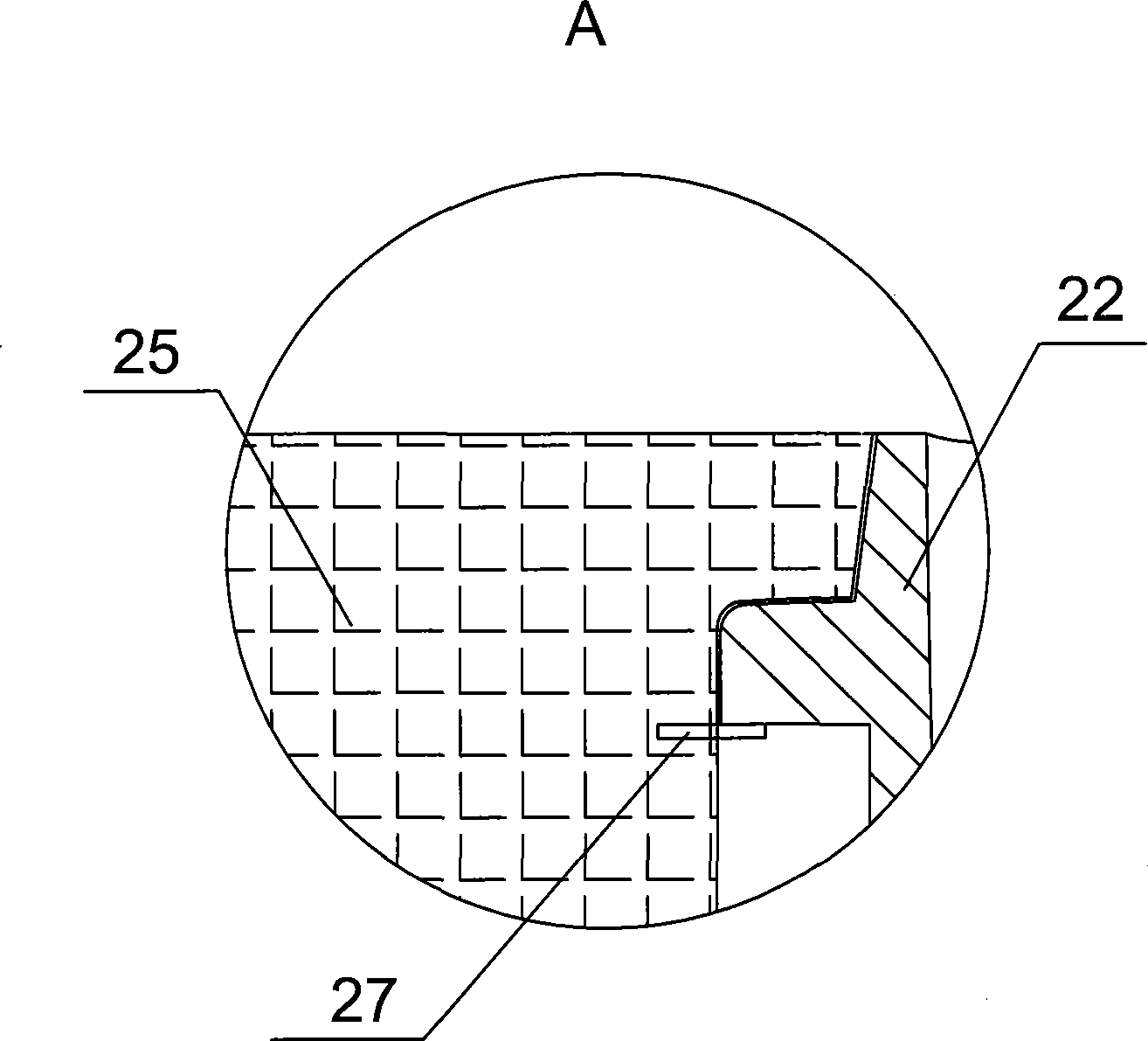

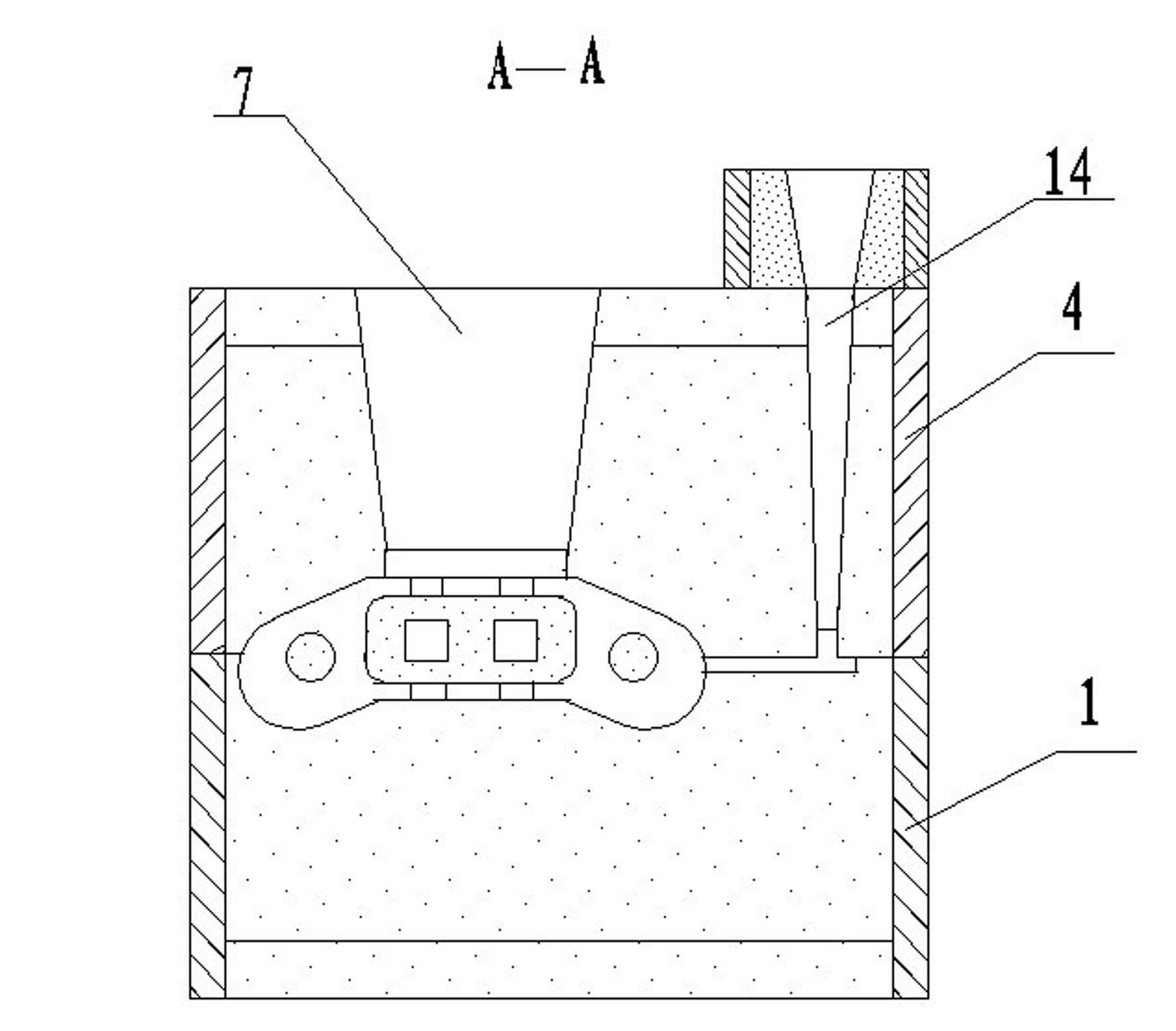

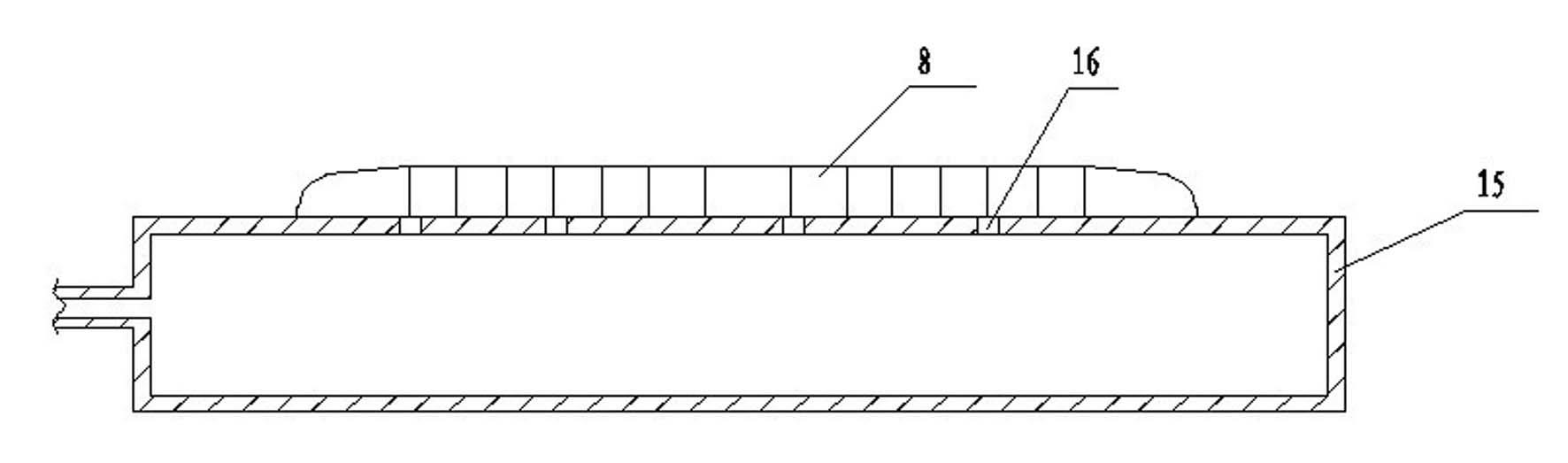

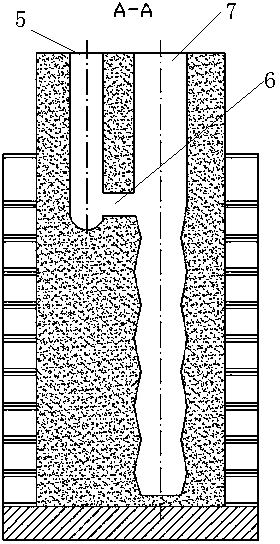

Core assembly and core assembling technique thereof

InactiveCN101456062AHigh dimensional accuracyReduce casting defectsFoundry mouldsFoundry coresNuclear engineeringCasting defect

The invention relates to a core assembly, which comprises a plurality of cavity cores which are orderly connected in series by cascading holes on the cavity cores, an upper outline core and a lower outline core arranged at two ends of the plurality of the serial cavity cores respectively, a cascading piece passing through the upper outline core, the plurality of the cavity cores and the lower outline core in turn, and a left side core and a right side core arranged at two sides of the upper outline core, the plurality of the cavity cores and the lower outline core respectively, wherein a sealed cavity for accommodating pouring liquid is formed among the upper outline core, the right side core, the lower outline core, the left side core and the plurality of the cavity cores. The invention also relates to core assembling technology. The core assembly and the core assembling technology make a casting have higher size accuracy, reduce the casting defect caused by sticking, and increase operability of the core assembling process at the same time.

Owner:SUZHOU MINGZHI TECH

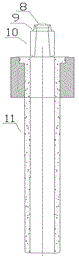

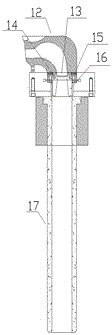

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Novel modeling method for casting large-sized and ultra large-sized alloy steel track shoes

InactiveCN102554122AImprove the working environmentExtended service lifeFoundry mouldsFoundry coresPlastic filmAlloy steel

The invention provides a novel modeling method for casting large-sized and ultra large-sized alloy steel track shoes. The method comprises the following steps of: placing a model on a shaping plate with a gas extracting box; covering a heated plastic film on a model form and the shaping plate; attaching the plastic film to each part of the form and the shaping plate through vacuum suction force; brushing a high temperature resistant costing on the model form attached with the plastic film; placing a sand box mounted with a gas extracting device on a model plate; forming a casting head and a gas outlet in an upper casting sand box; filling dry quartz sand into the sand box; ramming the casting sand by using a vibration table; scraping the sand model; covering an upper sealing sand box of the sand model by using a plastic film; pumping loose sand in the sand box to negative pressure so that the sand model is hardened; pulling out the hardened sand model to obtain the model form; making upper and lower sand models; setting a core; and closing the box for casting. Compared with the traditional sand model, the novel modeling method for casting the large-sized and ultra large-sized alloy steel track shoes, provided by the invention, has the following advantages that: the working environment is largely improved, the size accuracy and surface roughness of the cast are improved, long service life of the mold is obtained, the consumption of the casting sand and auxiliary materials is saved, energy is saved and emission is reduced.

Owner:姜玉飞

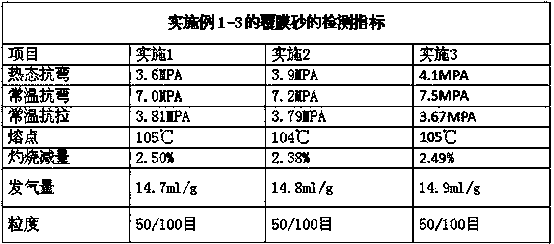

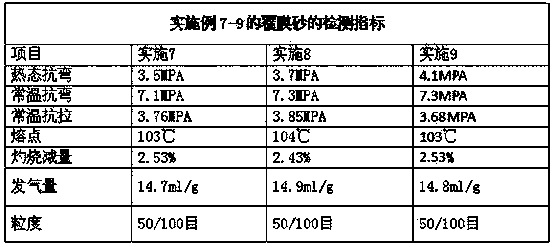

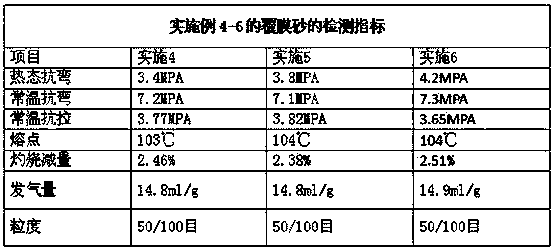

Special precoated sand for cast of high alloy material

The invention discloses special precoated sand for cast of high alloy material. The sand comprises roughing sand, a lubricant, an adhesive, a curing agent and a coupling agent. The adhesive is 1.7-1.9 % of the total weight of the roughing sand. The curing agent is 9-11 % of the weight of the adhesive. The lubricant is 6-8 % of the weight of the adhesive. The coupling agent is 1-2 % of the weight of the adhesive. The roughing sand comprises reclaimed sand, cerabeads, and magnetic sand. The reclaimed sand is 50-65 % of the total weight of the roughing sand. The cerabeads are 25-35 % of the total weight of the roughing sand. The magnetic sand is 10-15 % of the total weight of the roughing sand. The sand has various superior properties of high temperature resistance, high strength, low expansion, low gas release and easy collapse. The sand can guarantee that the process of cast of high alloy material can be smoothly performed, and the production efficiency is improved.

Owner:西峡飞龙特种铸造有限公司

Smelting method for Al-Mg-Mn-Cu-Ti aluminum alloy

The invention discloses a smelting method for an Al-Mg-Mn-Cu-Ti aluminum alloy. The smelting method comprises the following steps of (1) preparing before smelting; (2) batching; (3) smelting, namely preheating a cast iron crucible furnace, and adding a covering agent; adding partial raw materials into a cast iron crucible after the covering agent is completely dissolved, and increasing the temperature and adding pure Mn ingots after the raw materials are completely smelted; continuously stirring and gradually increasing the temperature after the pure Mn ingots are smelted, slagging off, transferring melt to a graphite crucible heat preserving furnace, sampling and performing stokehole chemical component analysis; (4) preserving the heat and refining; namely adjusting the components of the melt, controlling the temperature of the furnace, pressing a refining agent into an aluminum alloy melt, degassing and refining; and (5) casting, namely covering a coating agent without magnesium on the surface of the aluminum alloy melt, slagging off after standing, and finally casting. The Al-Mg-Mn-Cu-Ti aluminum alloy produced by the smelting method has the advantages of less casting defects, high yield, low content of impurities of produced products, and good mechanical performance.

Owner:威瑞泰科技发展(宁波)有限公司

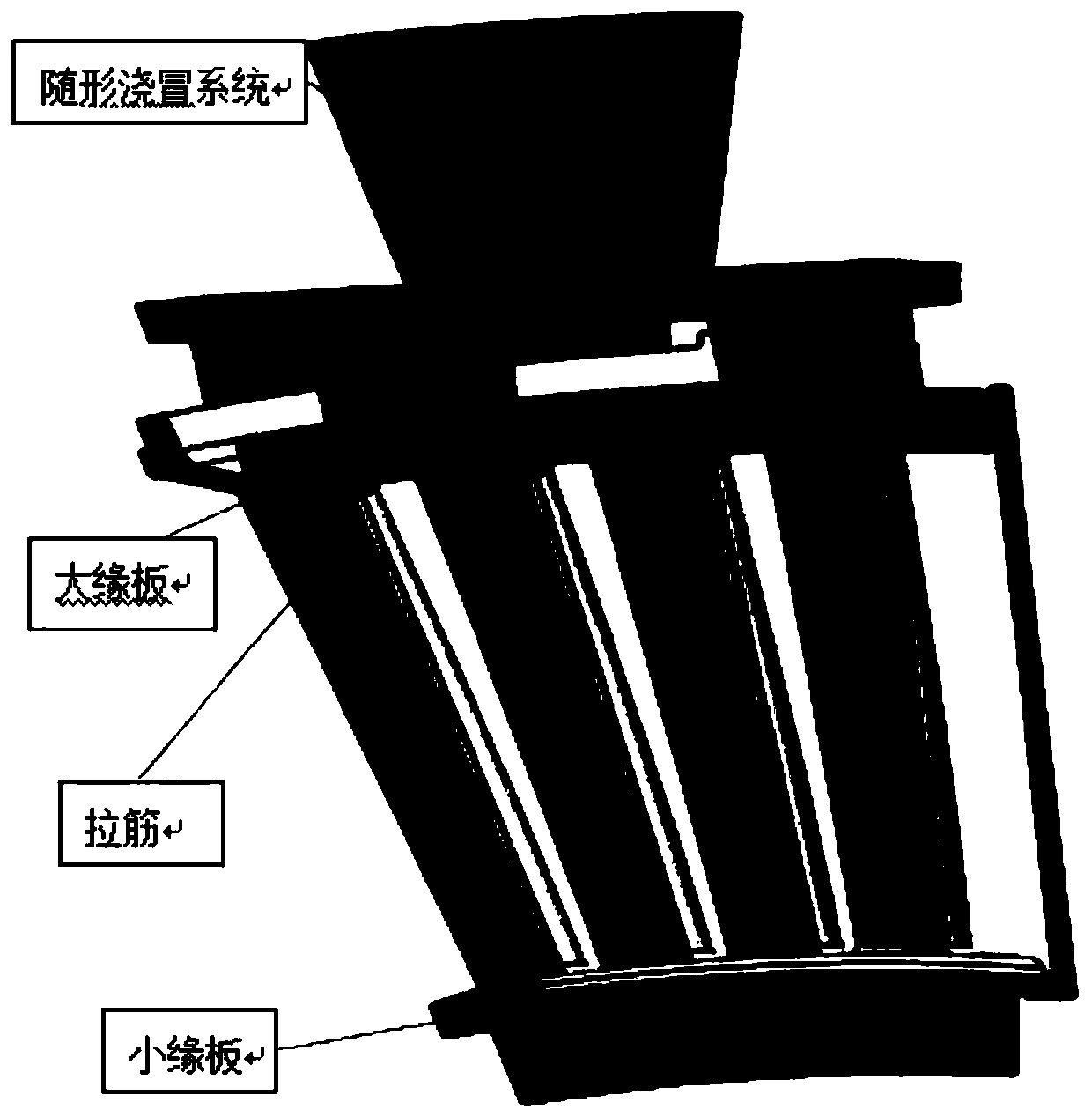

Casting forming process of complex high temperature alloy multi-union guide vane casting

The invention discloses a casting forming process of a complex high temperature alloy multi-union guide vane casting, and belongs to the technical field of precision casting. The process is characterized in that a casting body wax mold is prepared, and the casting body wax mold and a rigging system are assembled into a module; the module is coated with refractory coating layer by layer, is sent into a dewaxing kettle for dewaxing, and is sent into a baking furnace for high temperature pre-baking; the exterior of a shell is wrapped in a step type and is tied with refractory insulation cotton; ahigh temperature alloy rod is remelted and smelted to obtain high temperature alloy metal liquid; before pouring, the shell is sent into the baking furnace again, and then is sent into a vacuum induction casting furnace, and the high temperature alloy metal liquid is poured into the shell; and after pouring is completed, heat preservation is carried out, and shell removal, cutting, sand blastingand polishing are carried out after furnace exiting. The casting forming process effectively reduces or eliminates casting defects such as looseness and cracking easily generated at the connecting positions of hot joint vanes and small edge plates, the yield is improved to 75% to 80%, and the process is suitable for complex high temperature alloy multi-union guide vane casting.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

Method for improving deformability of oxide ceramic shells precisely cast by titanium-aluminum alloy

ActiveCN105290313AGood collapsibilityReduce intensityFoundry mouldsFoundry coresOxide ceramicCombustion

The invention discloses a method for improving the deformability of oxide ceramic shells precisely cast by titanium-aluminum alloy. The method comprises the steps that polypropylene fiber and graphite powder are added in the preparing process of precisely casting the shells, and combustion is achieved through high-temperature roasting of the polypropylene fiber and the graphite powder so as to form pores in the shells and improve the deformability. Particularly, in the steps of slurry preparation and slurry coating on the shells in the preparation process of precisely casting the shells, the polypropylene fiber is wound on the surfaces of the oxide shells, and back-layer slurry containing graphite powder is adopted for coating. By the adoption of polypropylene fiber winding during shell preparation and preparation of the back-layer slurry containing the graphite powder in the method, the deformability of the shells is effectively improved, accordingly the cold and hot cracking tendency occurred in the solidification process of castings is effectively reduced, and the qualified rate of the castings is improved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Grate bar material and production method thereof as well as combined pouring unit of sintering machine

ActiveCN103849819AReduce contentHigh hardnessFoundry mouldsFurnace typesChemical compositionBar product

The invention relates to a production method of a grate bar material of a sintering machine. The production method mainly solves the problems that a high-alloy grate bar is complex in production process, relatively high in production cost, difficult in casting flaw control, non-uniform in performance and the like in the prior art. The technical scheme of the invention is as follows: the grate bar material of the sintering machine comprises the following chemical components in percentage by mass: 1-1.5% of C, 1.5-2.5% of Si, 1.2-2.2% of Al, 2.5-3% of Mn, 11-15% of Cr, 0.3-0.8% of Mo, 0.01-0.03% of Nb, 0.01-0.03% of Ti, 0.03-0.1% of Re, less than or equal to 0.06% of P, less than or equal to 0.06% of S, and the balance of Fe and inevitable impurity elements. A sand casting process of 'one pouring with more molds' is applied, so that the aluminum content and the casting flaws of a silicon grate bar are reduced, and the production cost is reduced. A heat treatment furnace provided with a flow guide circulating fan is applied to low-temperature uniform heat treatment on a cast so as to improve the performance uniformity of casts of the same batch. By adopting the production method disclosed by the invention, a grate bar product of the sintering machine, which is good in process stability, good in performance and relatively low in production cost, can be obtained.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Modified manufacturing process for high-chromium cast iron composite roll through forged steel roll neck and equipment

The invention discloses a modified manufacturing process for a high-chromium cast iron composite roll through a forged steel roll neck and equipment. The material comprises, by mass, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, 0%-0.05% of P, 0%-0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable microelements. Yttrium-based rare earth nodulizing and compound inoculating of Ba, Ca and silicon iron are adopted, and modification treatment is conducted by adding Nb, Ti, V, B, and Sb, so that the mechanical property of the roll is improved. The strength of the roll is improved through the forged steel roll neck. Overall in-mold heating and fusion casting are conducted on a core rod through an induction heater. Forming is conducted through a water cooled crystallizer. A composite layer interface can be dynamically controlled. The process is simple, the efficiency is high, power consumption is small, the cost is low, composition segregation is avoided, and the service life of the roll is long.

Owner:丹阳恒庆复合材料科技有限公司

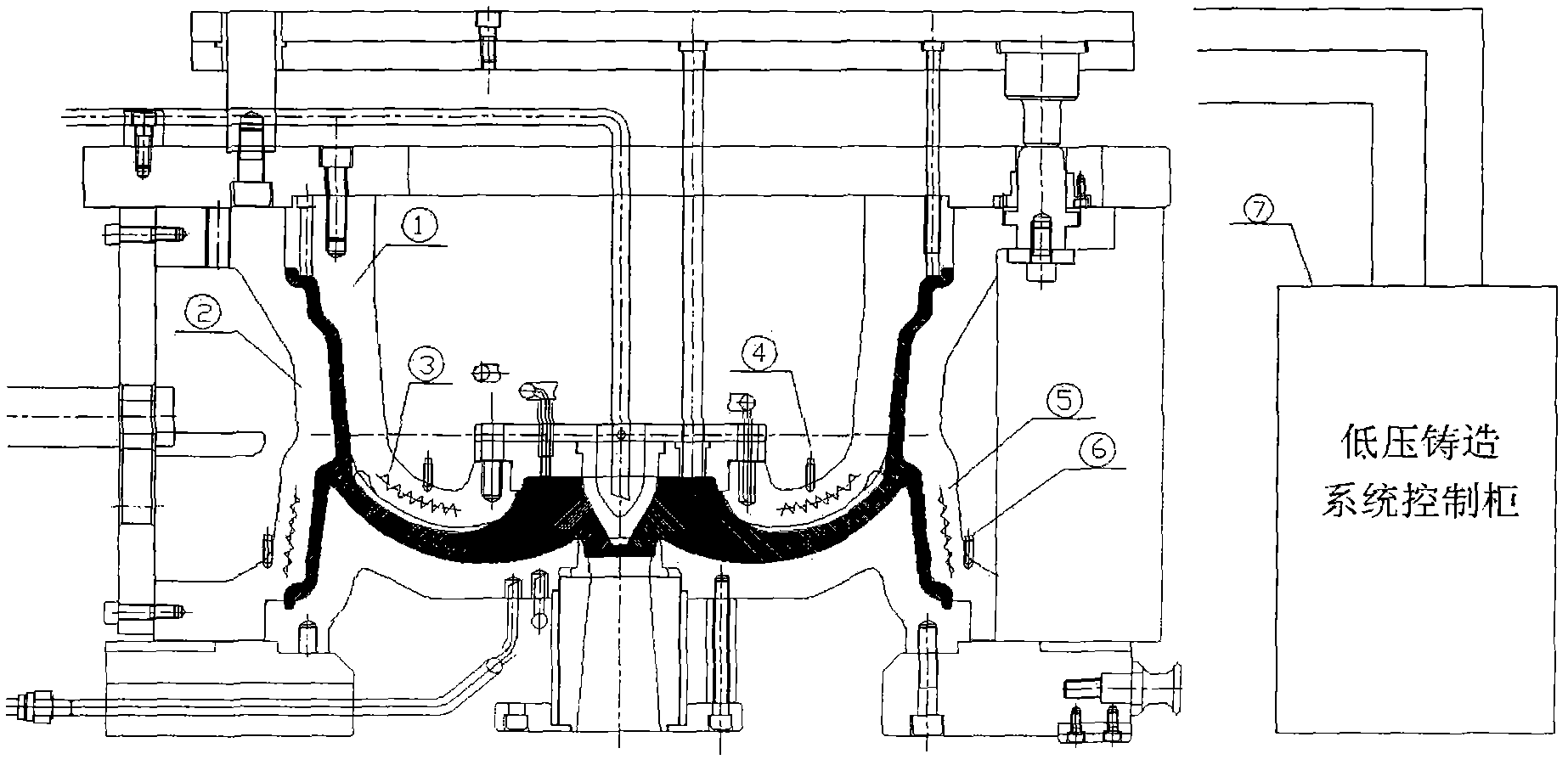

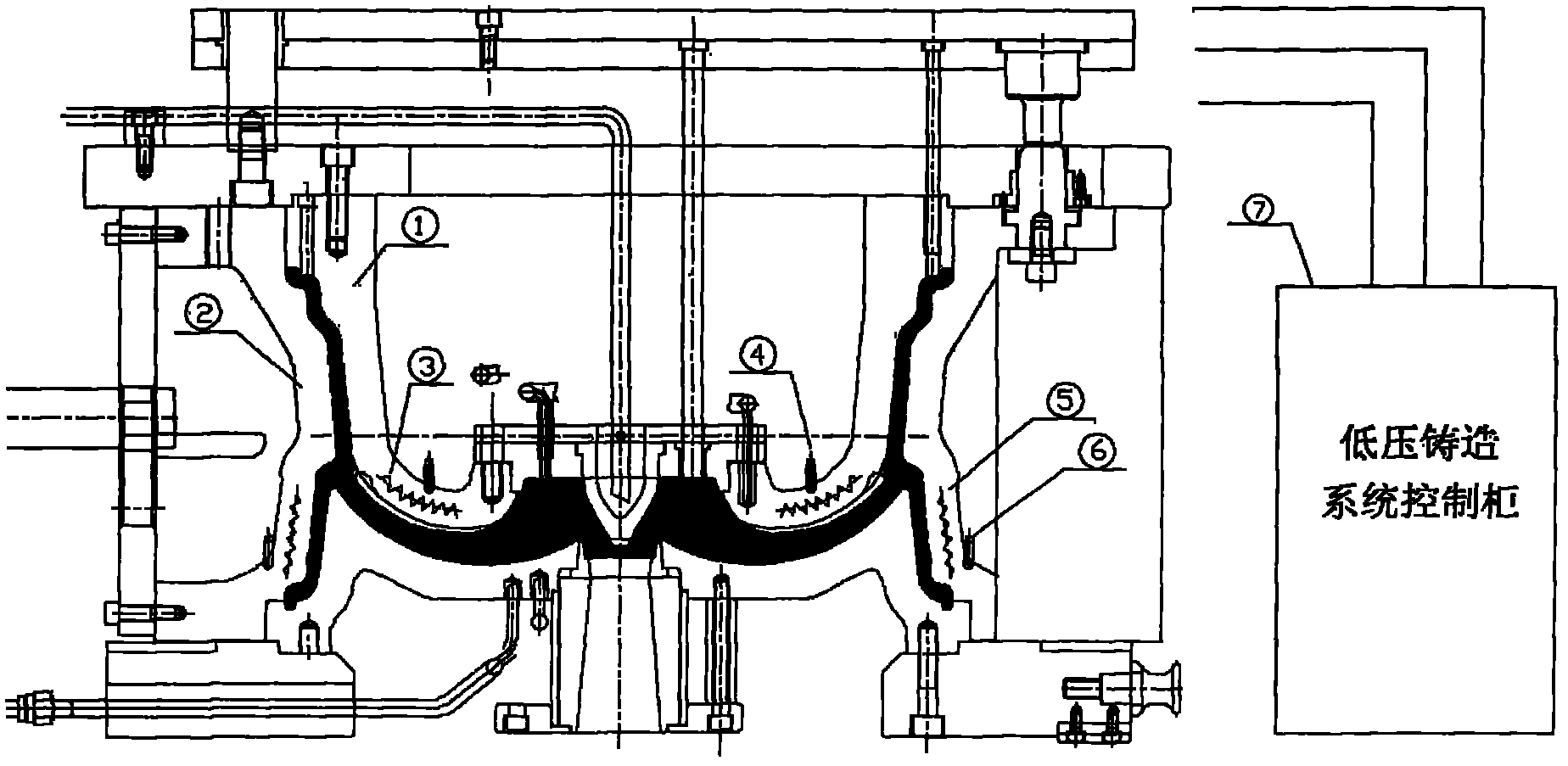

Low-pressure cast aluminum-alloy wheel-casting sequential-solidification temperature-field compensating method

InactiveCN102463344AGuaranteed sequential solidificationReduce casting defectsResistance wireCasting defect

The invention relates to a low-pressure cast aluminum-alloy wheel-casting sequential-solidification temperature-field compensating method, wherein the areas of a mould needing temperature compensation are found out by simulating solidification for casting before product casting, the areas are generally positioned at a top mould and a side mould according to the casting characteristics of an aluminum-alloy wheel, a heating resistance wire and a thermocouple are installed at the top mould and the side mould when the mould is developed, the heating resistance wire and the thermocouple are connected with a low-pressure casting-system control cabinet, the mould temperature is set according to the technical requirements of casting processes, and when the mould temperature reaches the technical requirements, the heating resistance wire stops working; and when the temperature is insufficient, the heating resistance wire begins to work, thereby the temperatures of the side mould and the top mould which are after-cooled are guaranteed to be balanced, the sequential solidification of molten aluminum is guaranteed, casting defects are reduced, and compared with a traditional process, the method is a more economical and practical method for guaranteeing casting sequential solidification.

Owner:JIANGSU KAITE AUTO PARTS

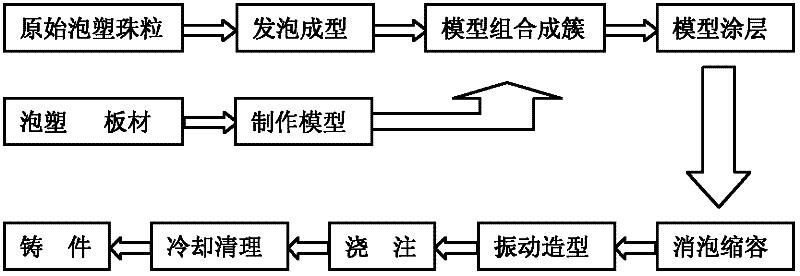

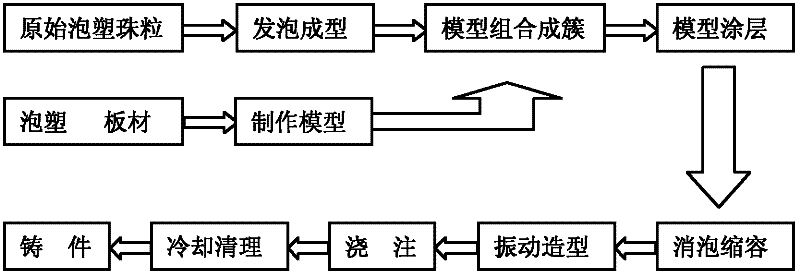

Green lost foam casting technology

InactiveCN102366821AReduce casting defectsReduce carbon contentFoundry mouldsFoundry coresDry sandProduct gas

The invention relates to a novel green lost foam casting technology. The core is not to let a foaming mold be gasified and disappear during the casting process but to let it defoam for recovery, utilization and discharge of polluted gases so as to reach the purpose of green environmental protection. Without the gasification of the foaming mold, casting defects (such as pore defect) can be substantially eliminated, alloy carburetting can be avoided and the casting quality can be improved. After coating the foaming mold with paint, the surface of the foaming mold is coated with a binder and sand to produce a shell with a certain thickness. After the shell is completely hardened, the foaming mold is heated for defoaming, and casting is carried out in allusion to different shapes. By a corresponding method, the defoamed residual mold is taken out to complete the shell making. Finally, direct shell casting, sand burying (common dry sand, iron shot and the like), magnetic casting and vacuum casting the like are chosen according to the tension force of a casted molten metal. The technology is green and environmentally friendly with no pollution, can be used to substantially improve the quality of the lost foam casting, and can be widely applied in the industrial production.

Owner:DALIAN JIAOTONG UNIVERSITY

Casting method of ZL101 thin-wall aluminium alloy part

The invention discloses a casting method of a ZL101 thin-wall aluminium alloy part. The method includes steps of: 1) preparing moulding sand raw materials; 2) preparing binder slurry, wherein the binder slurry comprises 36-40% by weight of starch, 6-8% by weight of furan resin, 14-16% by weight of calcium bentonite, 3-5% by weight of bagasse cellulose powder having a size of -100 meshes, 1-2% by weight of zinc stearate and 2-3% by weight of sodium tripolyphosphate, with the balance being water; 3) preparing moulding sand; 4) manufacturing a casting and gating system; 5) smelting a ZL101 alloy, wherein 0.035% of Sr is added for modification, argon is fed after slag removal, gas removal is performed by rotation, smelting is performed when the temperature is 735-745 DEG C, and the alloy is allowed to stand for 10-12 min after smelting; 6) casting, wherein the aluminum alloy casting temperature is controlled to e 720-730 DEG C, and the casting speed is controlled in a manner that the former two fifth of the total casting amount adopts a speed of 6-8 kg / s, the middle two fifth adopts a speed of 4-5 kg / s, and the last one fifth adopts a speed of 6-8 kg / s; and 7) cooling with the mould, opening the mould, cleaning and performing thermal processing.

Owner:DAYE HONGTAI ALUMINUM IND CO LTD

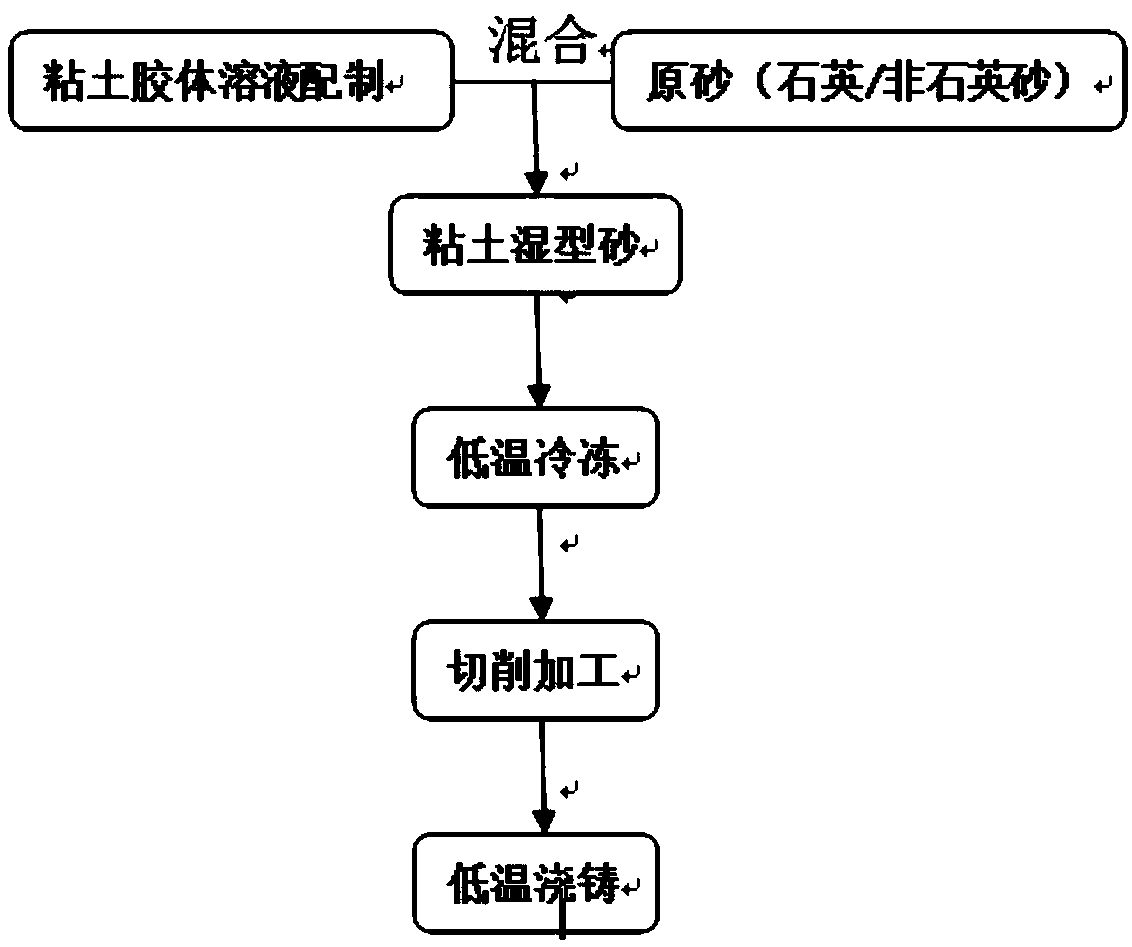

Mouldless cast forming method of frozen clay sand

InactiveCN109332578AImprove surface accuracyImprove working conditionsFoundry mouldsFoundry coresHardnessUltimate tensile strength

The invention belongs to the field of sand mould casting, and discloses a mouldless cast forming method of frozen clay sand. The mouldless cast forming method comprises the steps: crude sand and a clay binder are evenly mixed, moulding sand is manufactured and placed into a sand box to be compacted, a clay sand blank is manufactured and then placed into a low-temperature environment of minus 15-minus 40 DEG C to be sufficiently frozen, and after the strength and the surface hardness of the clay sand reach the index, a standby sand blank is manufactured; and a machining program is generated through a part model, a mouldless forming machine is driven to enable the frozen sand blank to be cut and assembled into a sand mould, and then the sand mould is cast under a normal-temperature or low-temperature environment. After the clay sand mould is frozen, air permeability is good, and the air hole defect in the metal liquid solidifying process is reduced; the compression-resisting (tensile) strength of the sand mould is high, the surface hardness is high, and the mouldless cast forming method is suitable for mouldless cutting forming; compared with traditional manual moulding, a mouldlessmanufacturing process of the frozen clay sand is high in efficiency and high in sand mould precision; and meanwhile, during casting, a high-temperature metal liquid melt is high in supercooling degree, thus in the metal solidifying process, the temperature gradient is large, a metal cast is compact in structure, and the mechanical property is good.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Two-fluid bimetal compound poured crushing hammer manufacturing method

InactiveCN106521328AHigh bonding strengthPrevent oxidationFurnace typesHeat treatment furnacesWork in processUltimate tensile strength

The invention relates to a two-fluid bimetal compound poured crushing hammer manufacturing method. The method comprises the steps that casting is conducted, specifically, a hammer handle pouring system and a hammer pouring system are arranged on a sand mold; high-chromium cast iron and low-carbon alloy steel are smelted, a hammer handle part adopts a low-carbon alloy steel material, and a hammer part adopts a high-chromium cast iron material; a hammer handle is poured at first, according to the weight of the hammer, after 3-15 seconds, a binding agent is added to the low alloy steel liquid surface of a sand mold cavity, and then high-chromium alloy is started to be poured; after pouring is completed, still standing is conducted, after molten steel is cooled and solidified, a semi-finished compound hammer can be obtained; and the semi-finished compound hammer is subjected to heat treatment, and the compound hammer product is obtained finally. By adding the binging agent in the process, a fusion layer which is compact in structure, free of shrinkage cavities, loose and high in strength is formed on an interface of two metals, and the binding strength of the two metals is improved.

Owner:哈德托普华亨(山西)耐磨铸业有限公司

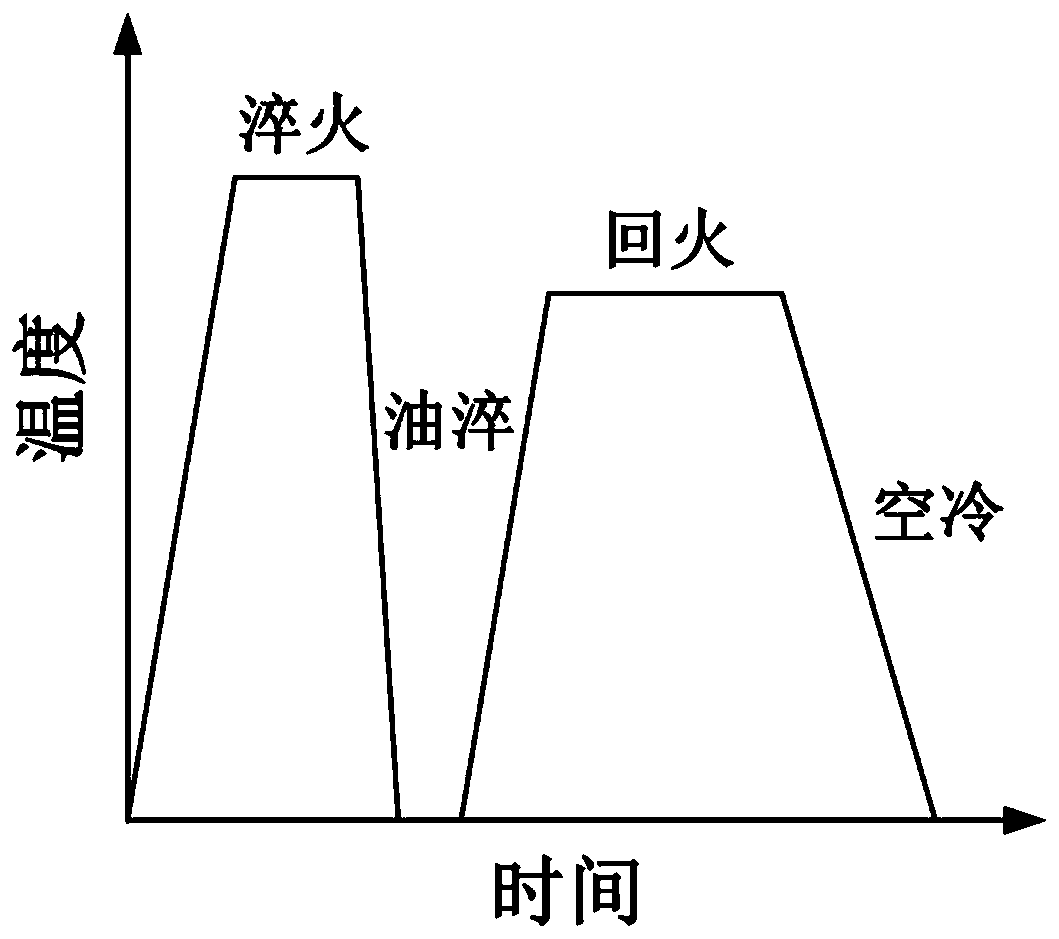

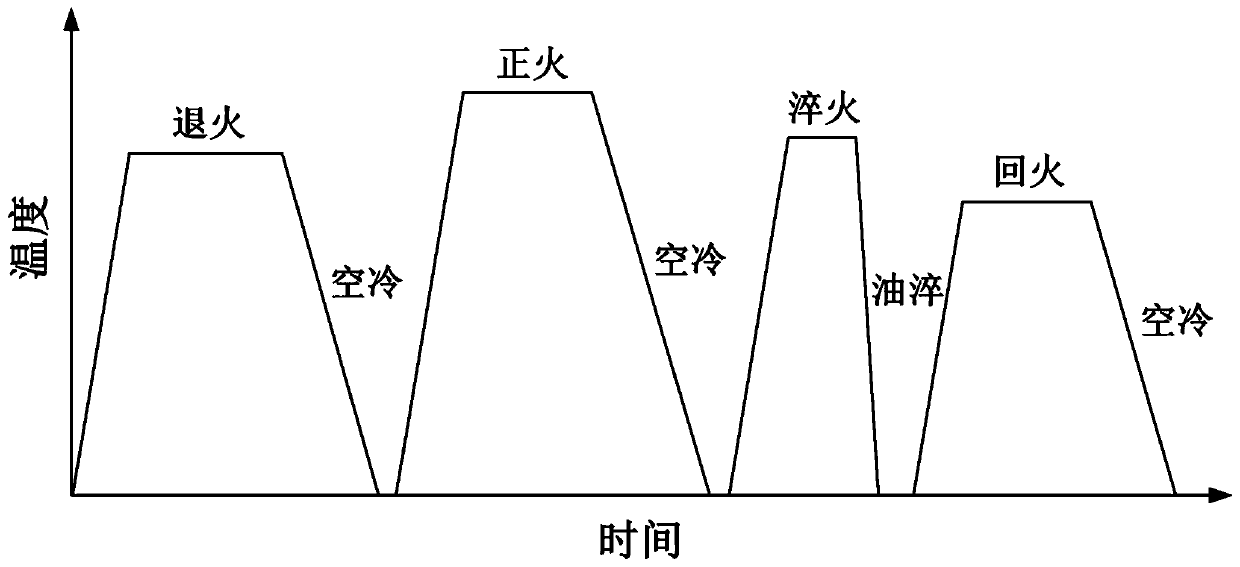

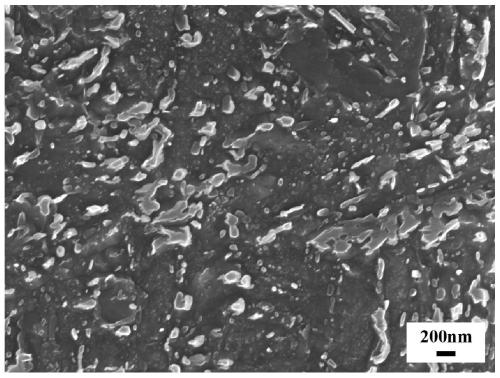

High-toughness cold-hot-fatigue-resistant cast steel for high-speed train brake disc and preparation method thereof

ActiveCN111360198AMatch mechanicsMatching cold and heat fatigue resistanceFoundry mouldsFurnace typesBrakeMetallic materials

The invention relates to high-toughness cold-hot-fatigue-resistant cast steel for a high-speed train brake disc and a preparation method thereof, belongs to the field of metal materials and preparation thereof, and solves the problem of matching of room-temperature toughness, high-temperature mechanical properties and cold and hot fatigue failure resistance of the cast steel for the high-speed train brake disc in the prior art. The high-toughness cold-hot-fatigue-resistant cast steel for the high-speed train brake disc comprises the following chemical components, in percentage by mass, of 0.20%-0.40% of C, 0.30%-0.70% of Si, 0.50%-2.00% of Mn, 0.50%-2.00% of Cr, 0.50%-2.00% of Ni, 0.40%-1.80% of Mo, 0.01%-0.30% of V, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% ofS, smaller than or equal to 0.010% of O, smaller than or equal to 0.015% of N, and the balance Fe and inevitable impurities, wherein the total content of the Mn, the Cr and the Ni is 2.00%-6.00%, andthe total content of the Mo and the V is 0.41%-2.00%. Through reasonable composition, organization structure and preparation process regulation and control, excellent room-temperature toughness, high-temperature mechanical property and cold and hot fatigue failure resistance of the cast steel are matched, the requirements for comprehensive mechanical property and long service life of the cast steel brake disc of a high-speed train are met, and the cast steel is suitable for being used as a material for the cast steel brake disc of the high-speed train.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Investment casting method

InactiveCN103861998AHigh dimensional accuracyPrecise DimensionsFoundry mouldsFoundry coresInvestment castingTurpentine

The invention discloses an investment casting method. The investment casting method mainly comprises the following steps: configuring pattern materials; pressing the pattern materials: painting a compression surface with a layer of turpentine oil and pouring the mixed pattern materials obtained in the step A so as to press the pattern materials; drying a fired mold; combining the fired mold with a gating system so as to manufacture a shell; roasting the shell. According to the method provided by the invention, a prepared fired mold product is high in dimensional accuracy, small in number of casting flaws and reliable in product quality, castings obtained through pouring by utilizing the method are precious in sizes and high in surface quality, and the method is even suitable for casting fired molds and castings which are complicated in casting shapes, resistant to high temperature and not easy to process. According to the method provided by the invention, the production cycle is shortened, the production efficiency is improved, the production cost is reduced, and the method has the guiding significance on practical production.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

Auxiliary technique capable of increasing graphite mould titanium alloy casting quality

InactiveCN101456061AImprove thermal conductivityLow thermal conductivityFoundry mouldsFoundry coresGraphiteSlurry

The invention relates to an auxiliary process for improving quality of a graphite type titanium alloy casting, which comprises the following steps: before pouring, using Y2O3, adhesive and deionized water to prepare surface slurry for accurately casting titanium according to a ratio of 85:10:5, using a thin brush to evenly coat the surface slurry on the surface of a graphite type core for forming the casting during pouring till fully covering, roasting the graphite type core in vacuum at a temperature of between 900 and 1,000 DEG C after the graphite type core is placed for 1 hour, preserving heat for 2 to 4 hours at a vacuum degree of less than or equal to 10Pa, cooling the graphite type core to be below 300 DEG C along with cooling of a furnace, discharging the graphite type core and then preserving heat at a temperature of between 100 and 200 DEG C in a baking oven, and taking out the graphite type core for standby during pouring. The auxiliary process can use the special surface slurry to fill pores on the surface of graphite, prevents the graphite from attaching to the surface of the casting after pouring, reduces the defects of cold lap, flow mark and the like generated on the surface of the casting, and increases tendency to forming gross shrinkage by the casting.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com