Combined pouring and purifying system for automobile aluminium alloy wheel with big diameter being more than 26 inches

A technology of purification system and casting system is applied in the casting field of automobile aluminum alloy wheels, which can solve the problems of long casting cycle of wheel filling distance, coarse metallographic structure α dendrite, low structural strength of wheels, etc., and achieves convenient casting process control. , The effect of less casting defects and short filling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

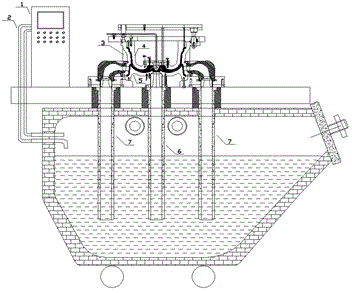

[0009] 010-2610 Low pressure gating system.

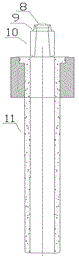

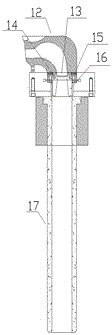

[0010] Such as figure 1 , 2 , 3, a combined casting system for aluminum alloy wheels of automobiles with a diameter of more than 26 inches, which consists of a control cabinet 1, a pressurization and pressure relief pipeline 2, a side mold 3, a top mold 4, a bottom mold 5, and a central casting system 6 Composed with lateral casting system 7. The central casting system 6 is composed of an arc-shaped filter screen 8 with a diameter of 65 mm, an iron gate 9, a ceramic thermos cup 10 and a ceramic liquid riser 11, and its feeding port is a circle with a diameter of 65 mm; It consists of a casting inlet port 12, a hat-shaped filter screen 13 with a diameter of 50mm, an iron gate 14, a ceramic insulation cup 16, an annular sealing gasket 15 and a ceramic liquid riser 17. The pressurization and pressure relief pipeline 2 is connected with the holding furnace of the low pressure machine and the control cabinet 1; the side mold 3 adopts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com