Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Good dehydrogenation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Noble-metal-modified aluminum alloy material and preparation method thereof

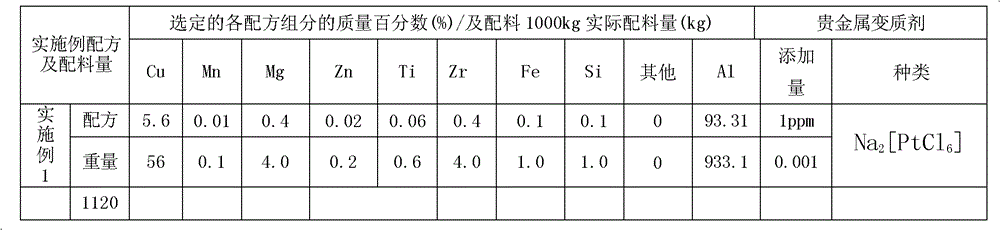

The invention discloses a noble-metal-modified aluminum alloy material and a preparation method thereof. The alloy comprises the following components in percentage by weight: 5.0-6.5% of Cu, at most 0.1% of Mn, at most 0.5% of Mg, at most 0.15% of Zn, at most 0.2% of Ti, at most 0.5% of Zr, at most 0.6% of Bi, at most 0.6% of Pb, and the balance of Al and inevitable trace impurities; the noble metal modifier accounts for 1ppm-0.1% of the total amount; and the content of any single impurity element is at most 0.05%, and the total content of the impurity elements is at most 0.1%. The invention can effectively reduce the generation of pinholes, and has the effect of high modification efficiency.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

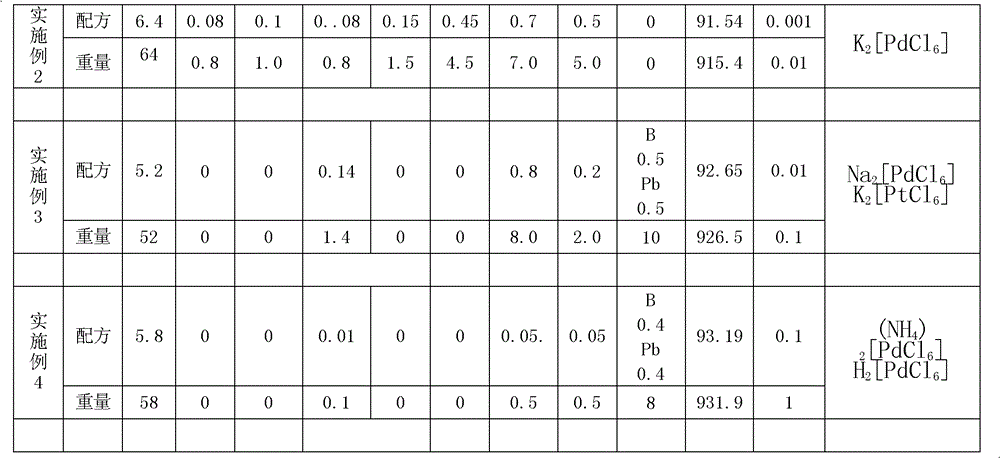

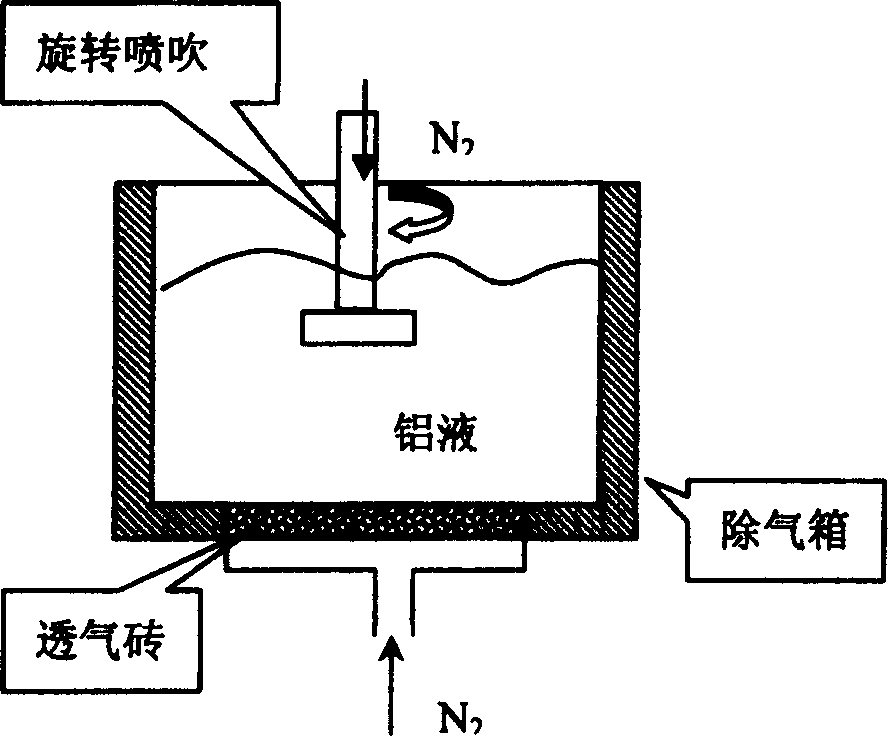

Method of purifying aluminium alloy melt

A process for cleaning the molten Al-alloy by removing hydrogen features that the inertial gas is sprayed onto top surface of molten Al-alloy contained in a degassing case via rotating nozzle while onto the bottom of the molten Al-alloy via the air-permeable bricks on the bottom of the degassing case.

Owner:江西金达通新材料科技有限公司

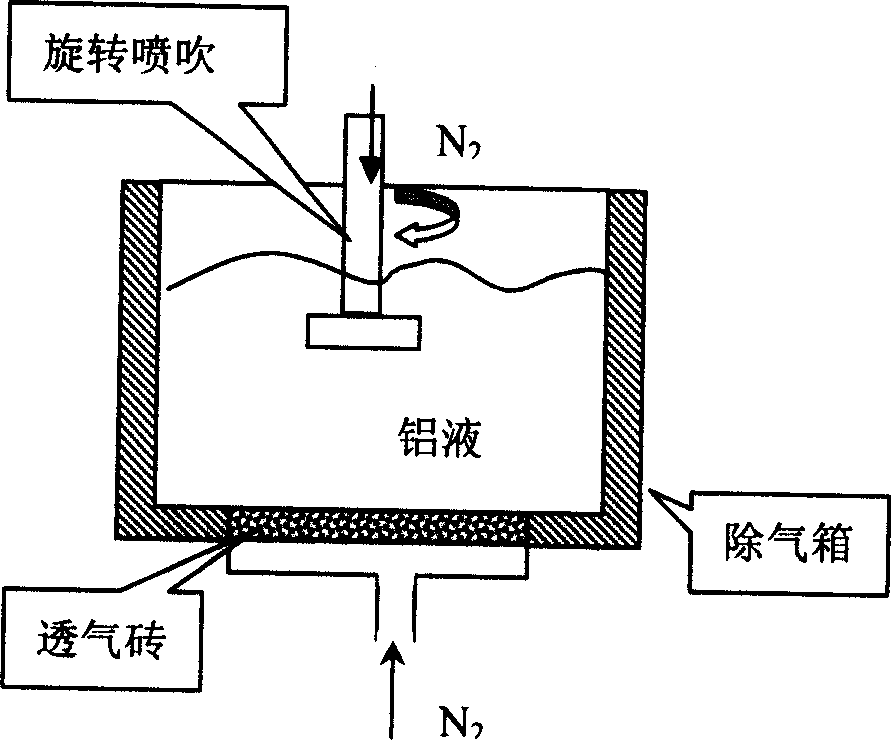

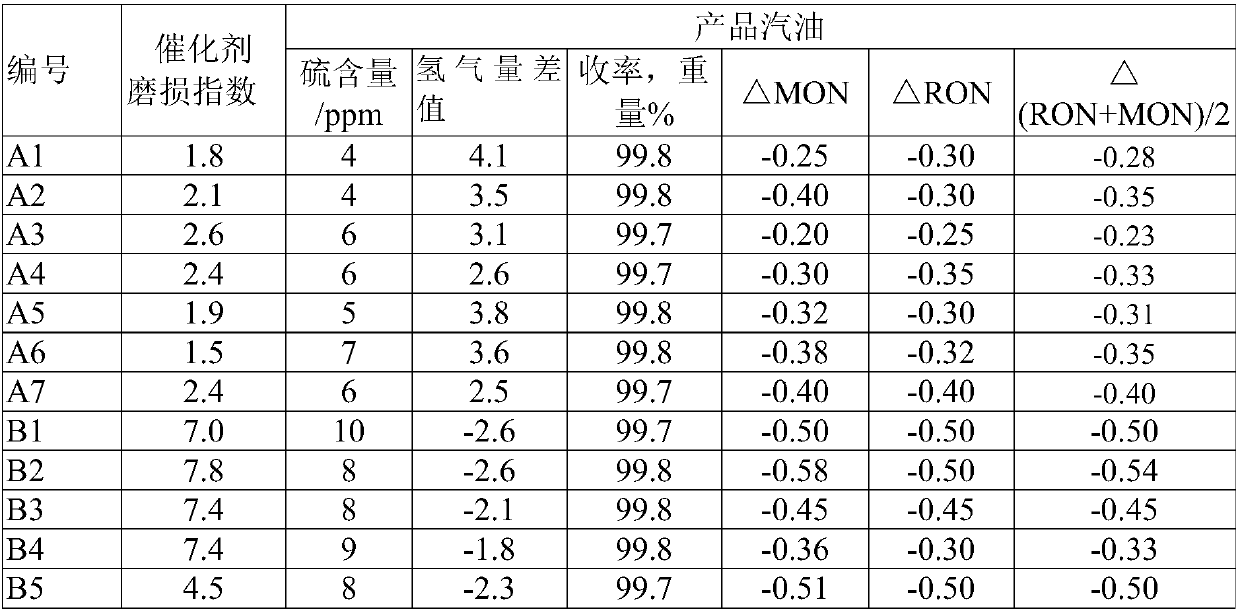

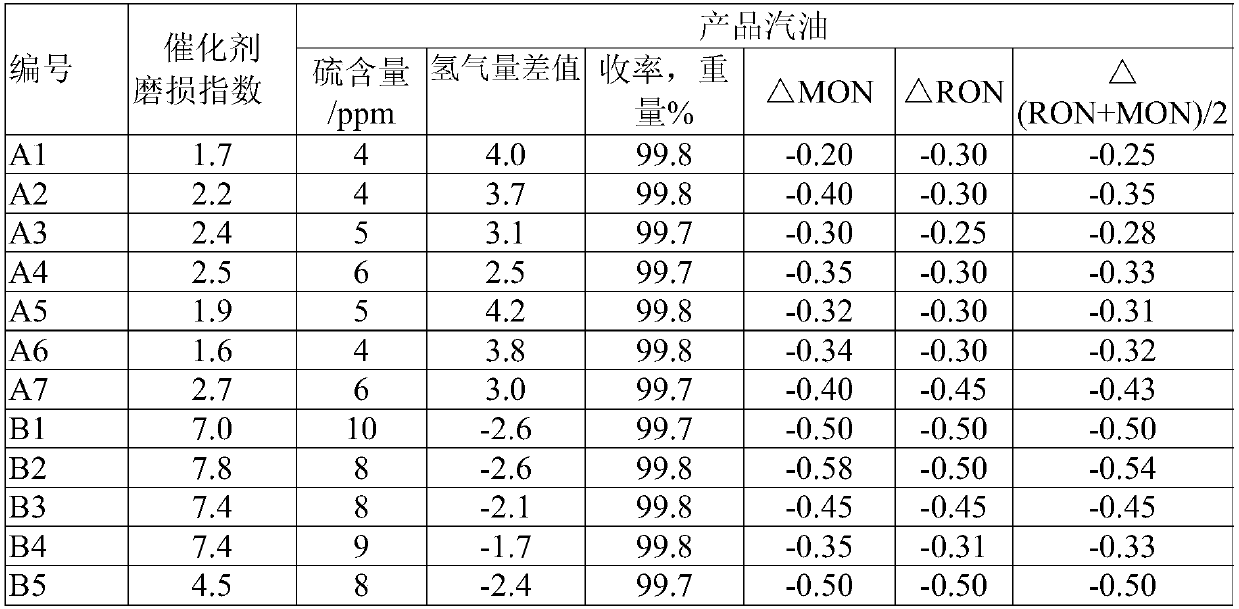

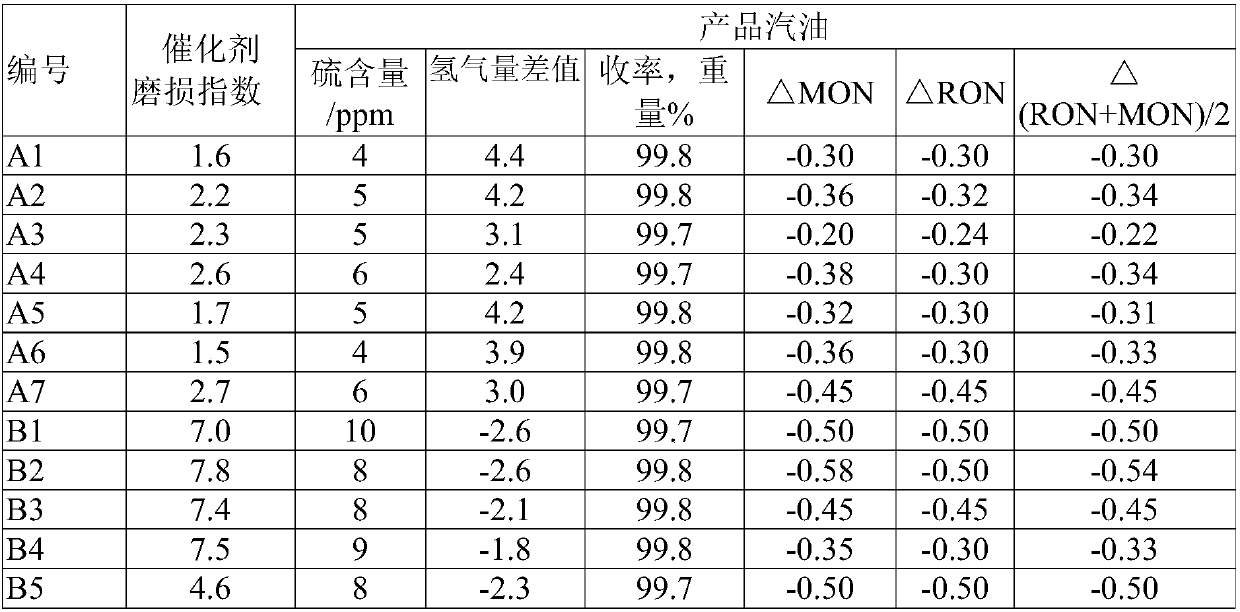

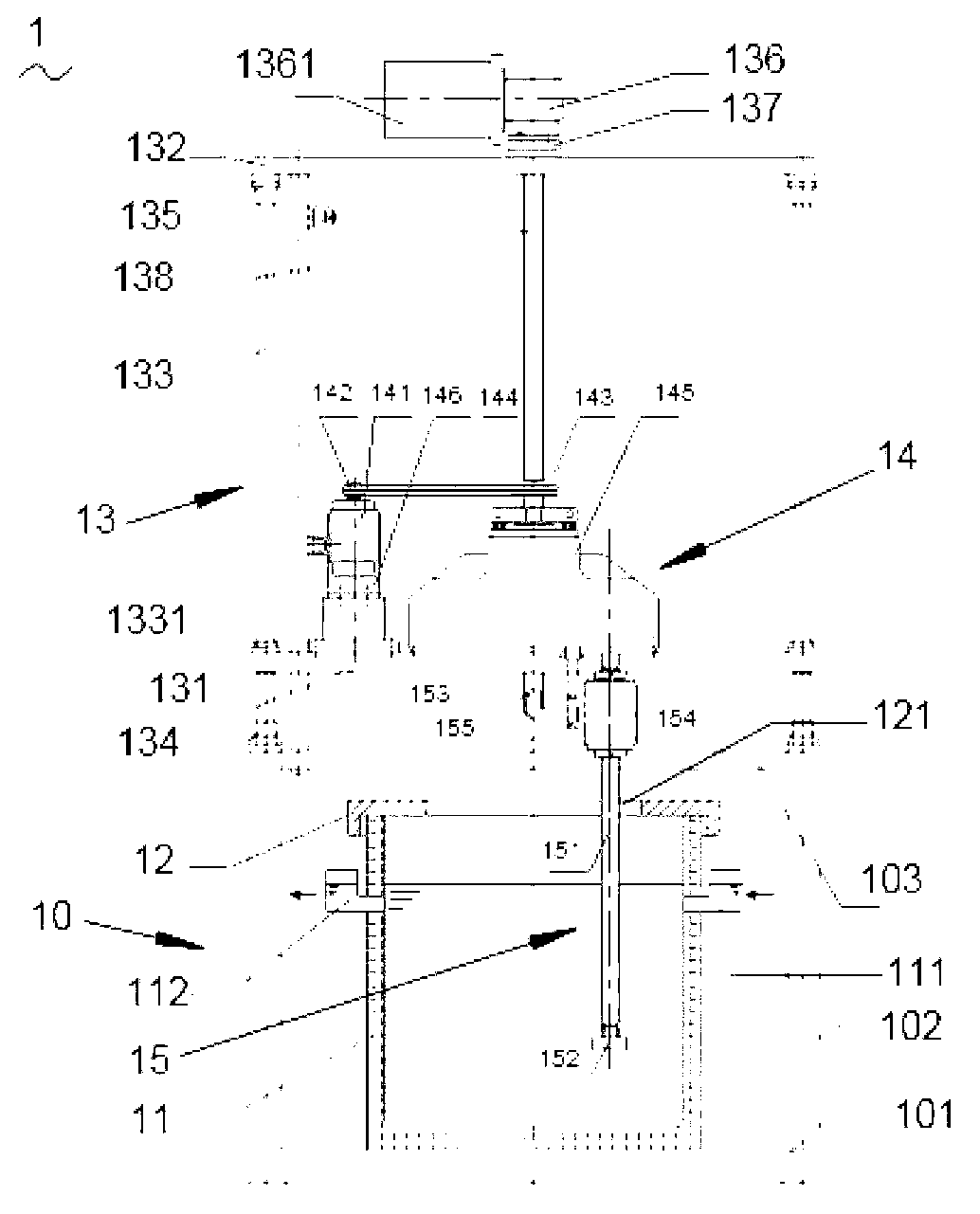

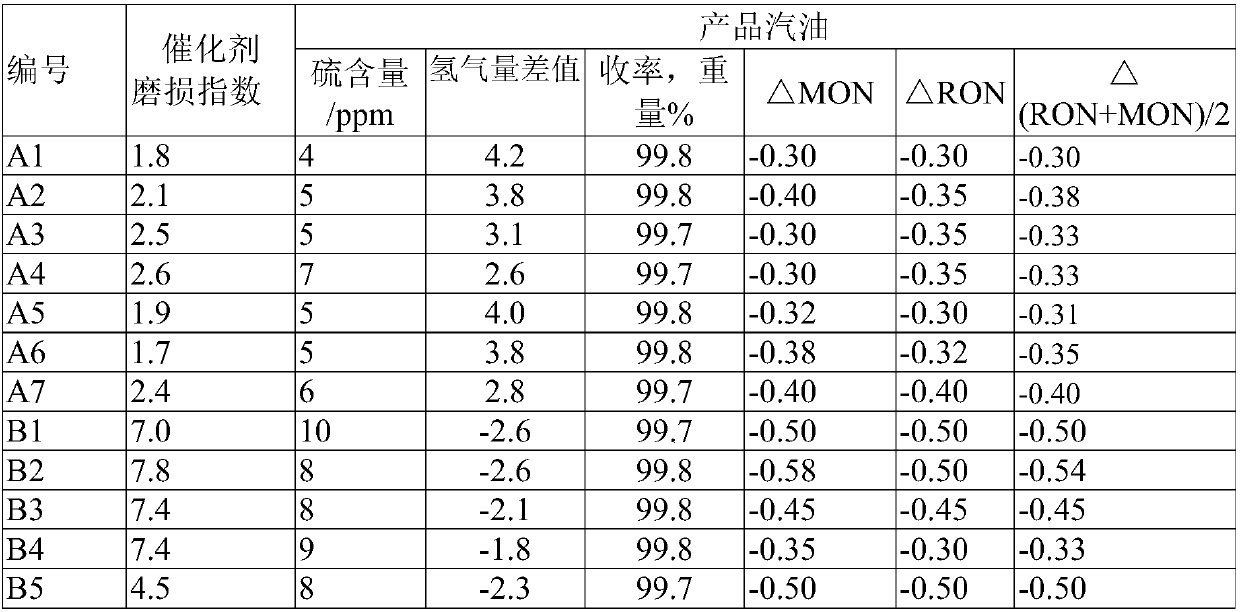

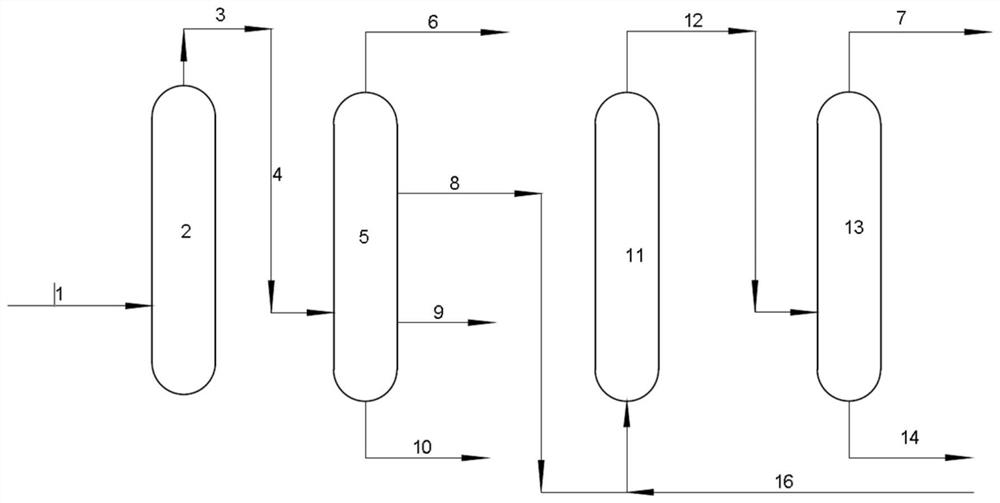

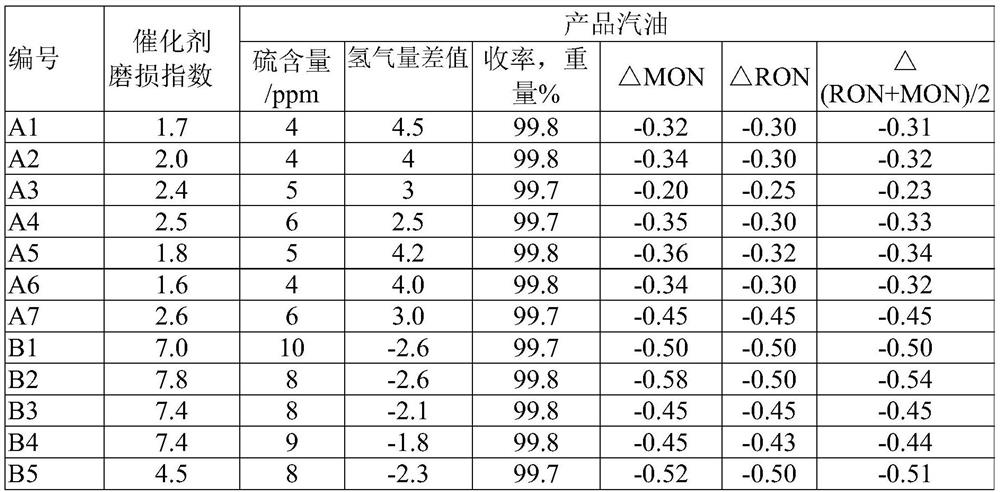

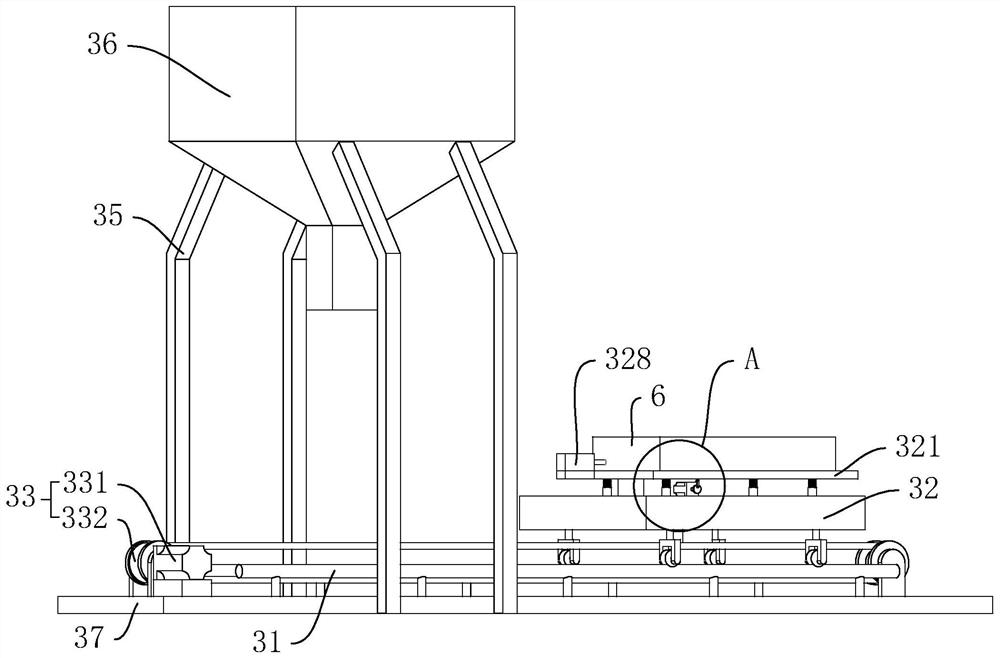

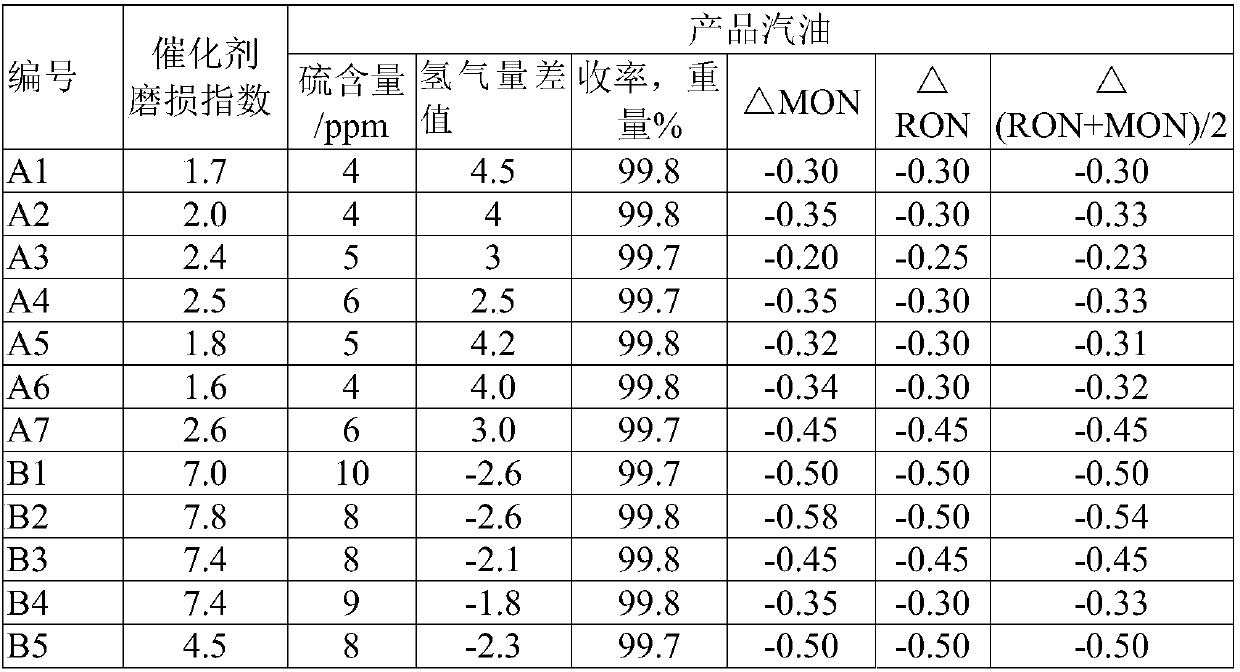

Combined method and device for cracking and desulfurization and combined process of catalytic cracking and adsorptive desulfurization

ActiveCN109722302AReduce usageLow costTreatment with hydrotreatment processesCombined methodFuel oil

The invention relates to a combined method and device for cracking and desulfurization and a combined process of catalytic cracking and adsorptive desulfurization. The method comprises the steps: (1)performing contact of heavy oil with a catalytic cracking catalyst so as to obtain a cracking product, (2) performing separation on the cracking product so as to obtain light fractions with final boiling points of 215-365 DEG C, (3) performing contact of the light fractions with a desulfurization catalyst at a hydrogen-oil volume ratio of 50-250 so as to obtain a desulfurized product, wherein thecomposition of the desulfurization catalyst comprises at least one sulfur-storing metal oxide, and (4) performing separation on the desulfurization product so as to obtain a liquefied petroleum gas fraction, a gasoline fraction and an optional light diesel fraction. Adsorptive desulfurization is performed directly on the liquefied gas and / or the gasoline and / or the diesel oil without separation, and separation is conducted on the LPG and the gasoline and / or the diesel oil after desulfurization is performed, so that the separation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aluminum alloy sodium-free refining agent containing rare earth

The invention discloses an aluminum alloy sodium-free refining agent containing rare earth. The aluminum alloy sodium-free refining agent comprises, by weight, 50-60 parts of KCl, 30-35 parts of K2CO3, 10-15 parts of LiCl, 30-35 parts of AlF3, 10-12 parts of potassium fluoroaluminate, 5-10 parts of CaF2, 5-10 parts of carbon powder, 15-25 parts of light calcium carbonate, 2-8 parts of CaO, 2-5 parts of fluorite and 5-10 parts of rare earth. By means of the refining agent, no impurity sodium is introduced into the aluminum alloy refining process, rare earth metal is added, and therefore the mechanical performance of alloy can be effectively improved.

Owner:广西平果铝合金精密铸件有限公司

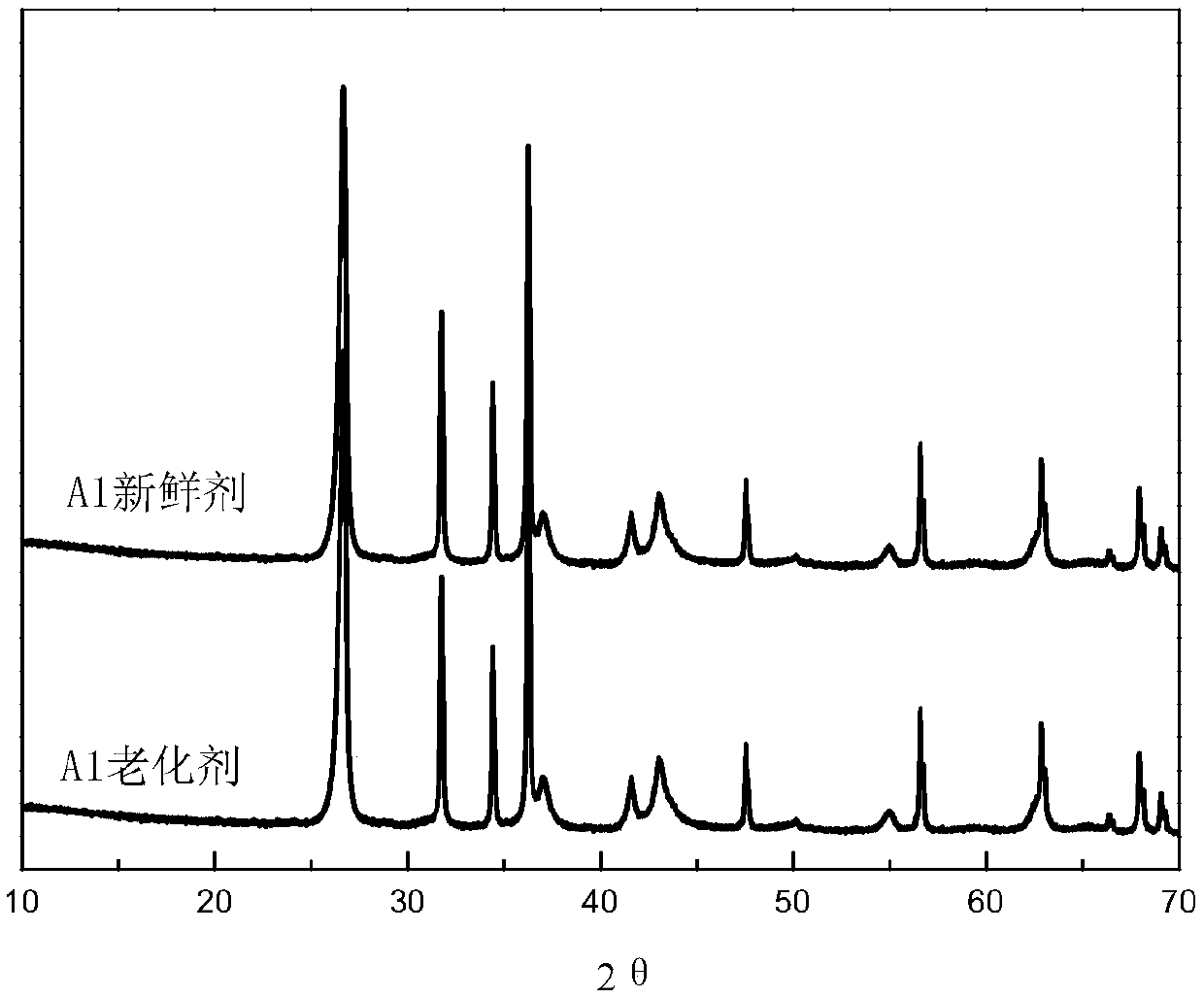

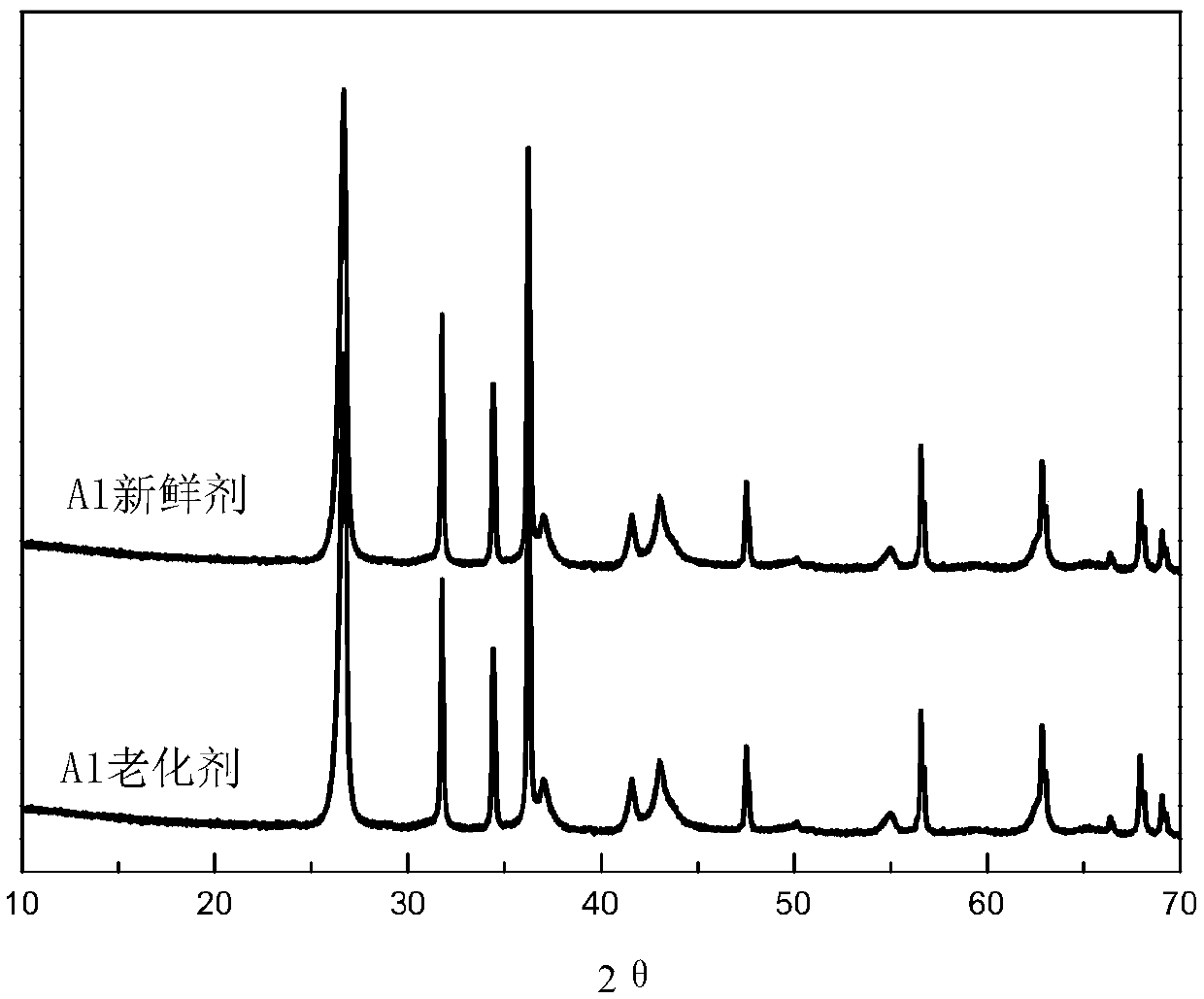

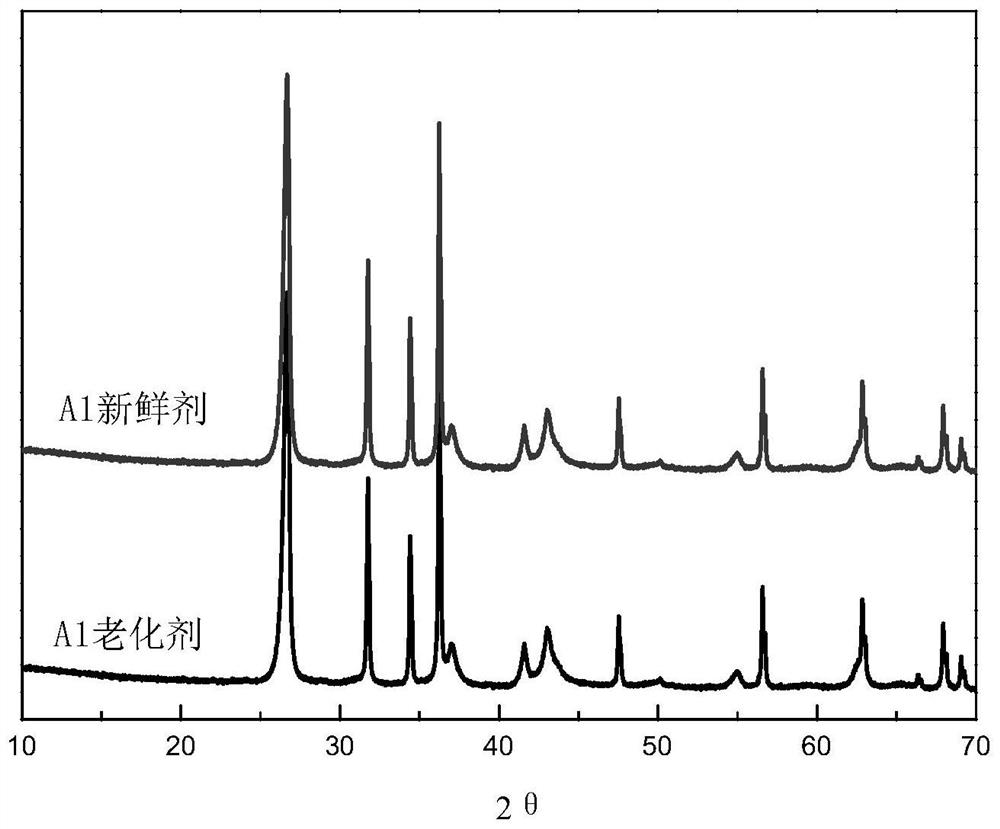

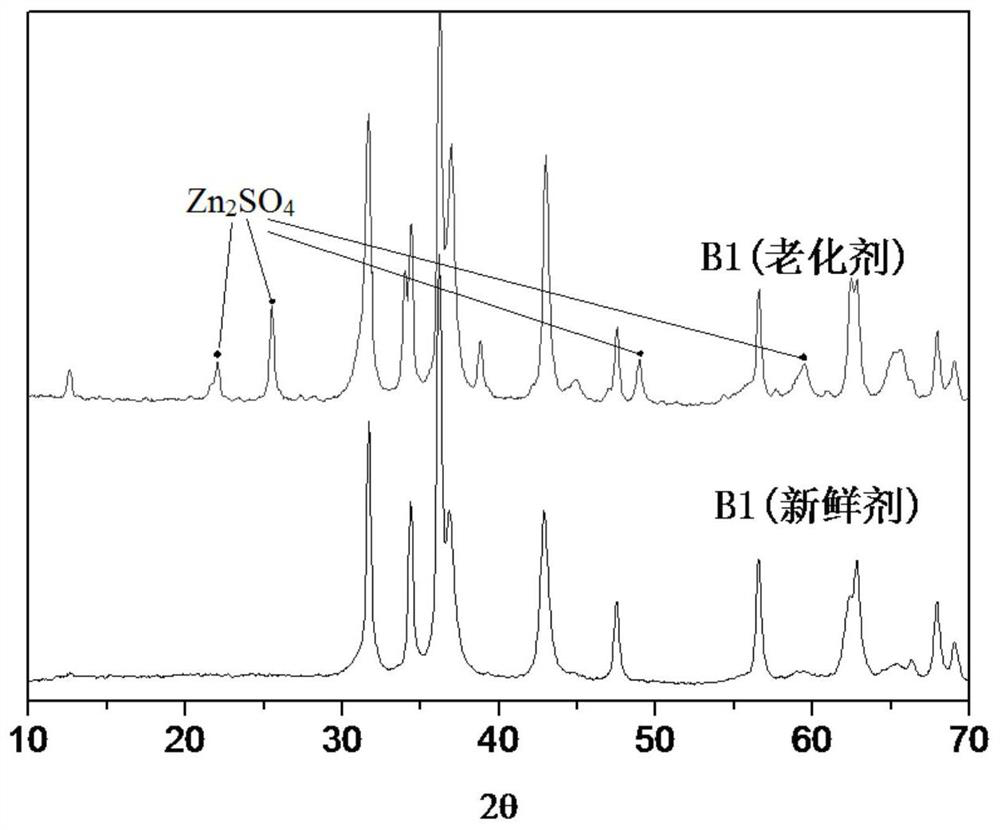

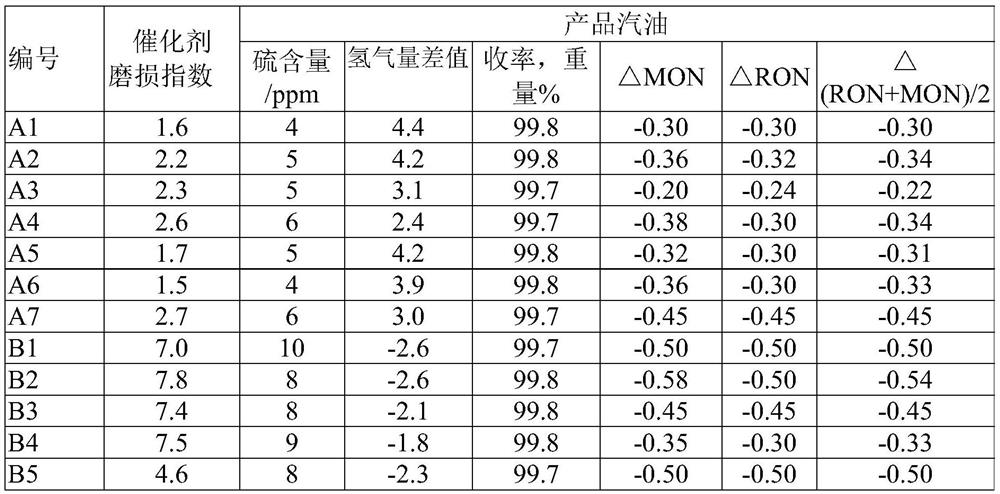

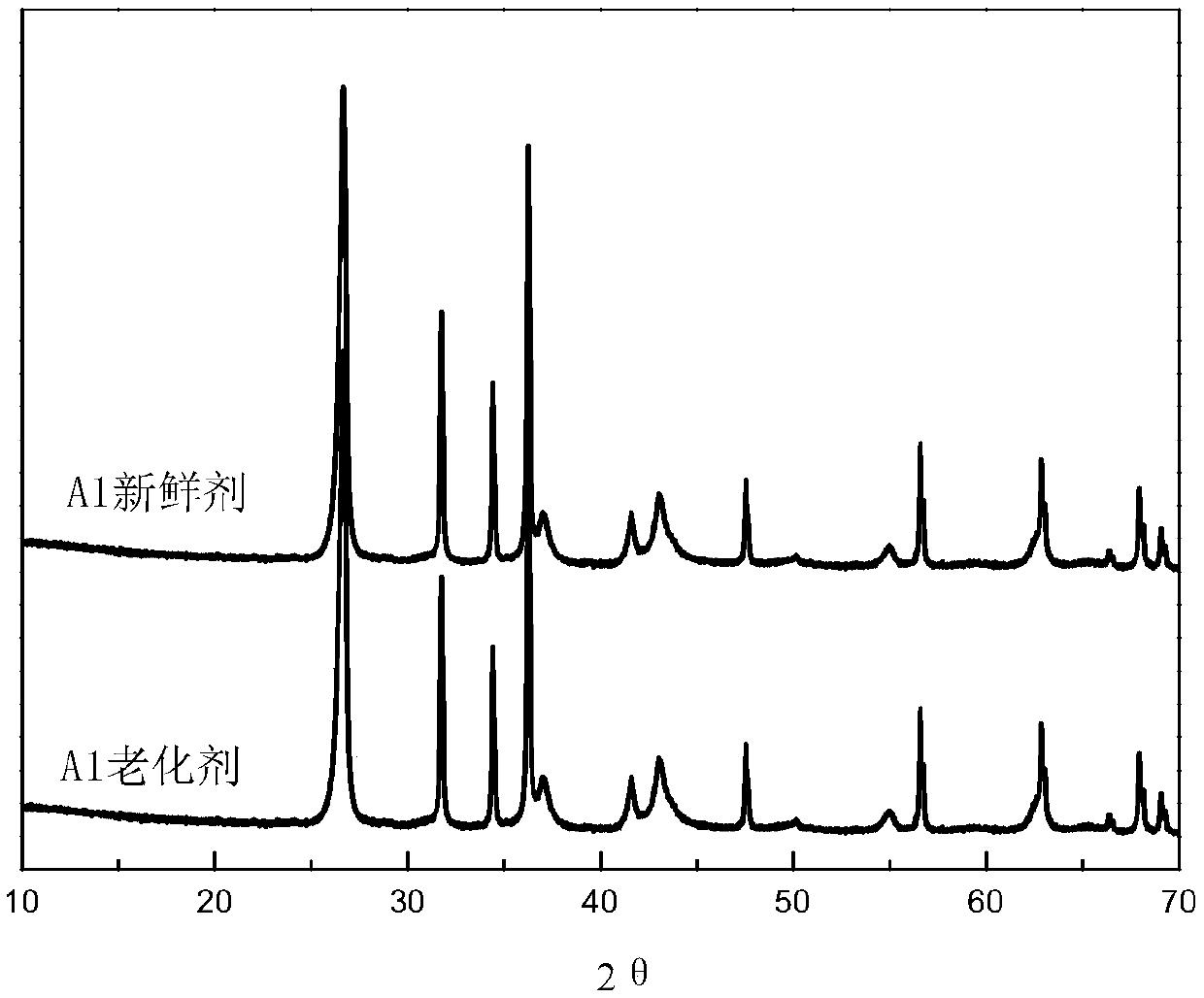

Hydrocarbon oil desulfurization catalyst containing FAU structural molecular sieve, preparation method of hydrocarbon oil desulfurization catalyst and hydrocarbon oil desulfurization process

ActiveCN109718829AWith desulfurizationWith dehydrogenation propertiesMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSulfur

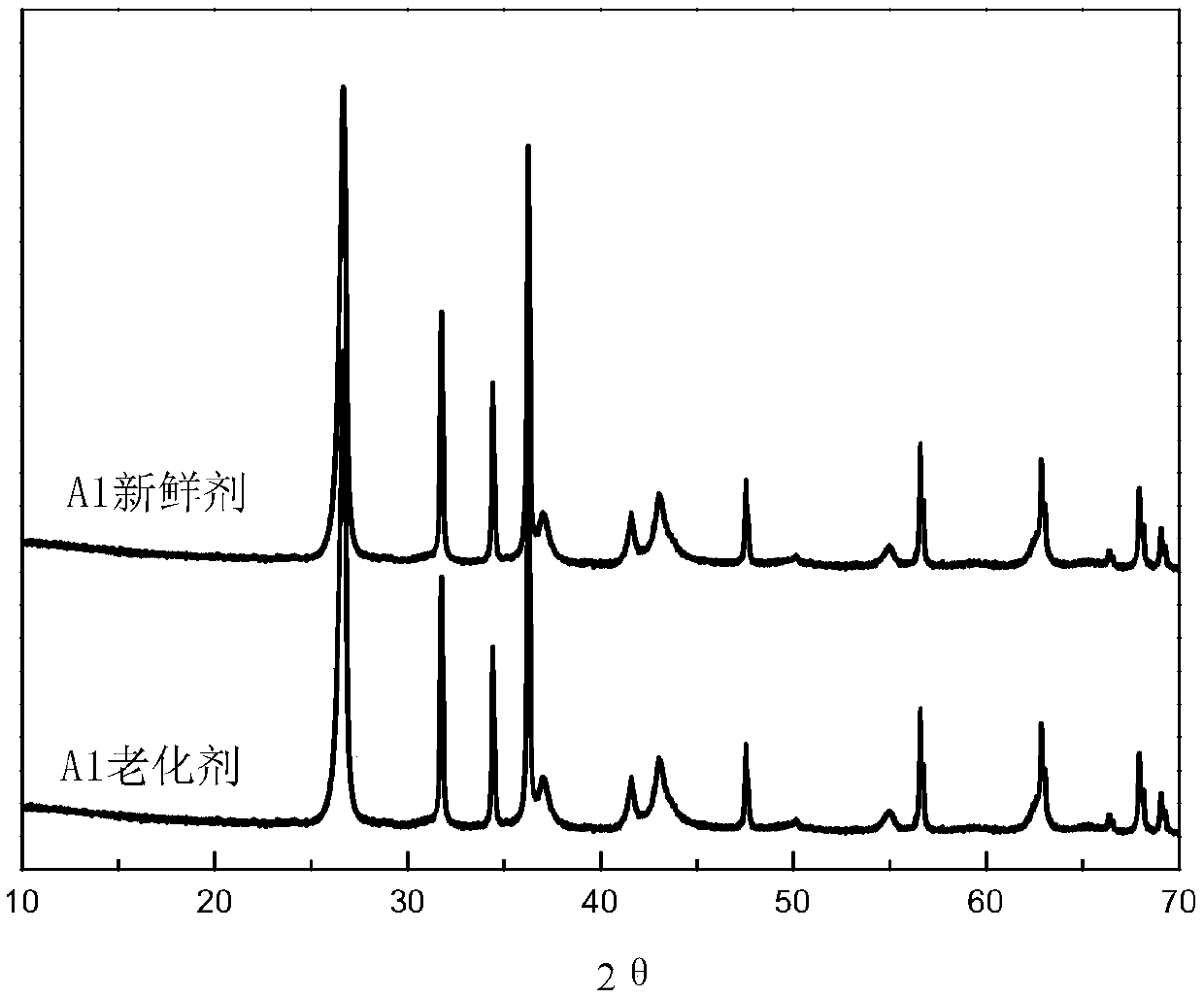

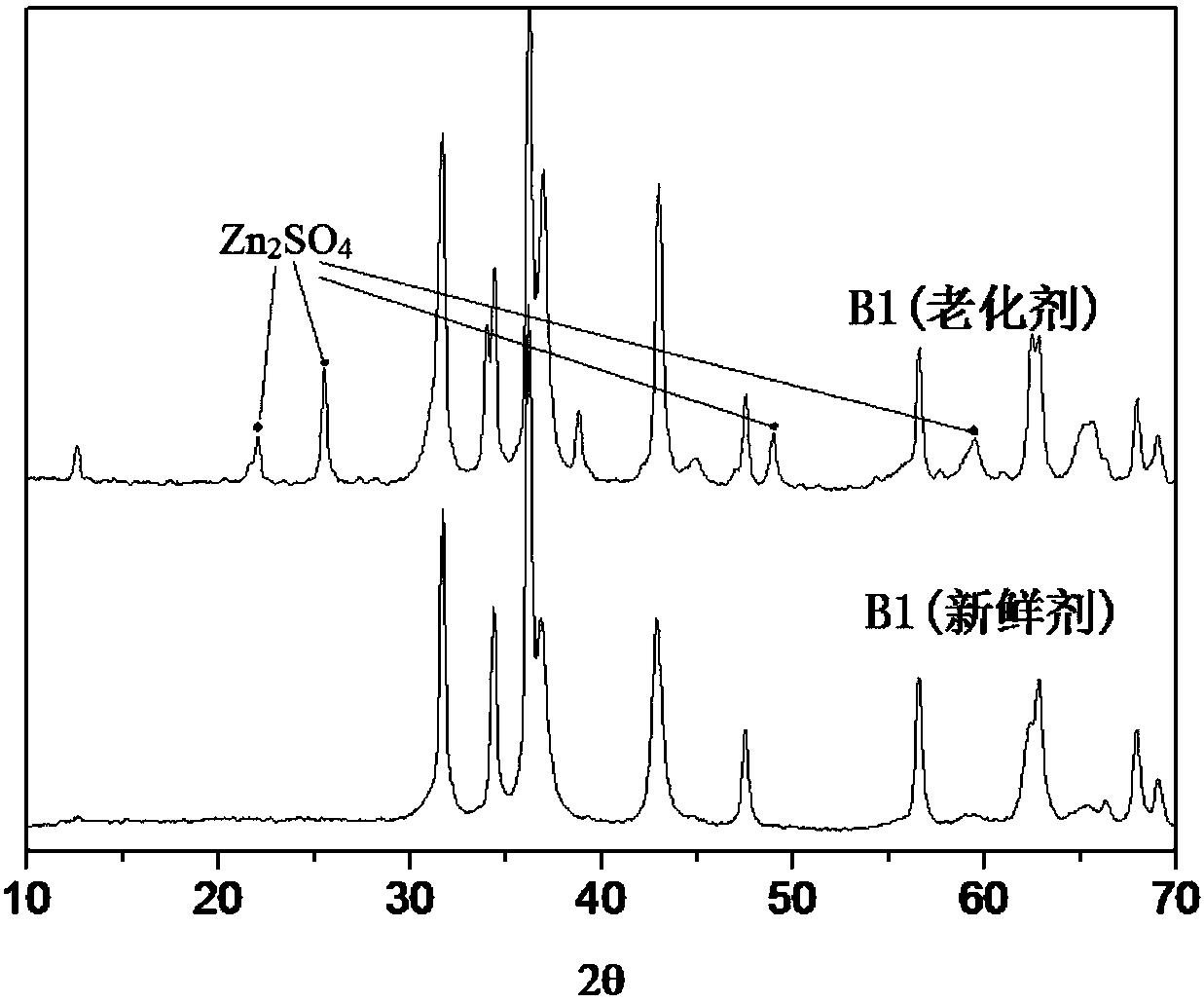

The invention relates to a hydrocarbon oil desulfurization catalyst containing an FAU structural molecular sieve, a preparation method of the hydrocarbon oil desulfurization catalyst and a hydrocarbonoil desulfurization process. Based on the weight of the hydrocarbon oil desulfurization catalyst or the total weight of a sulfur storage metal oxide, an inorganic oxide binder, boron nitride, the FAUstructural molecular sieve and a metal accelerant, the hydrocarbon oil desulfurization catalyst contains 10-80wt% (calculated by oxides) of sulfur storage metal oxide, 3-35wt% (calculated by oxides)of inorganic oxide binder, 5-40wt% of boron nitride, 1-20wt% (calculated by dry bases) of FAU structural molecular sieve and 5-30wt% (calculated by metal elements) of metal accelerant. When being applied to the hydrocarbon oil desulfurization process, the hydrocarbon oil desulfurization catalyst provided by the invention has the advantages of high stability, good desulfurization activity and goodwear resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

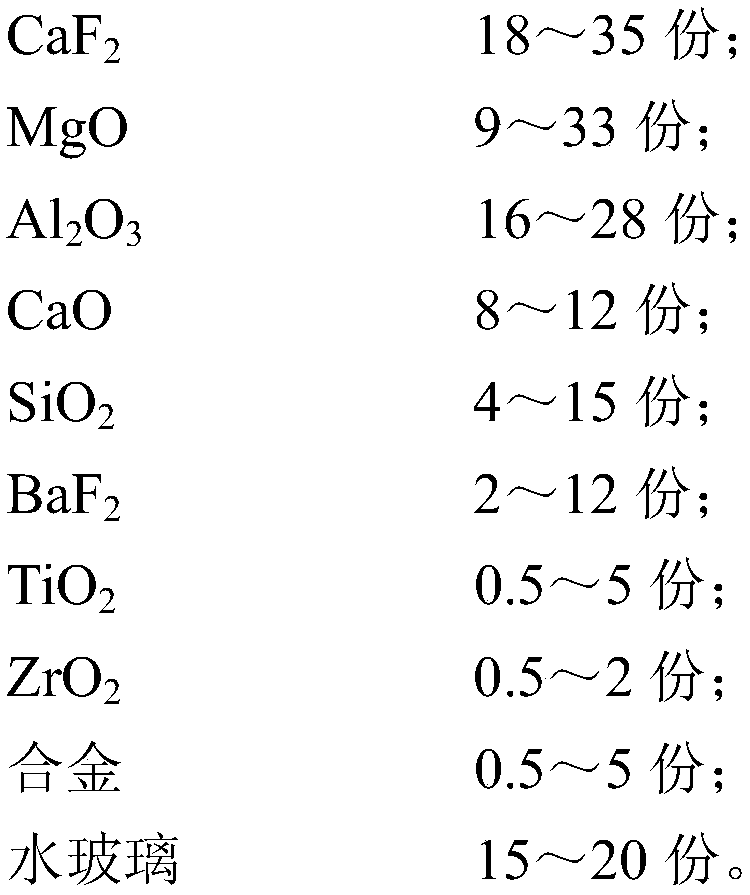

Nickel base alloy submerged arc welding sintered flux and preparation method and application thereof

InactiveCN108015453ADelay transitionImprove purityArc welding apparatusWelding/cutting media/materialsHydrogenSlag

The invention belongs to the technical field of welding materials, and particularly relates to a nickel base alloy submerged arc welding sintered flux and a preparation method and application thereof.According to the nickel base alloy submerged arc welding sintered flux, a main slag system is mainly composed of a CaF2-MgO-Al2O3-CaO-BaF2-SiO2 system, and specifically comprises the following components of, by mass, 18-35 parts of CaF2, 9-33 parts of MgO, 16-28 parts of Al2O3, 8-12 parts of CaO, 4-15 parts of SiO2, 2-12 parts of BaF2, 0.5-5 parts of TiO2, 0.5-2 parts of ZrO2, 0.5-5 parts of alloy and 15-20 parts of sodium silicate. The flux provided by the invention is good in performance and low in diffusible hydrogen, is matched with a solid welding wire ERNiCrMo-4, and is good in manufacturability, and the weld metal mechanical performance is good.

Owner:HENAN UNIV OF SCI & TECH

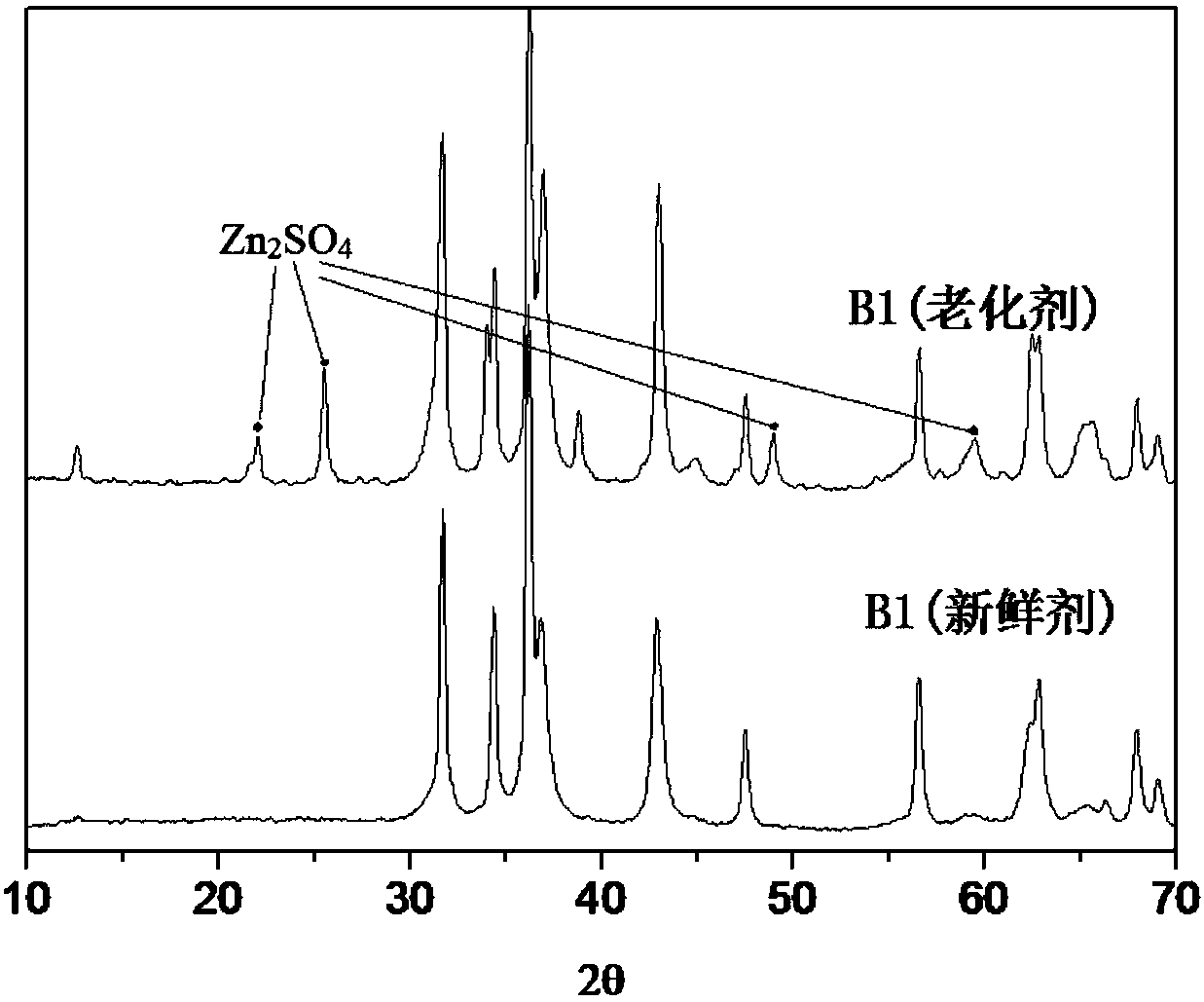

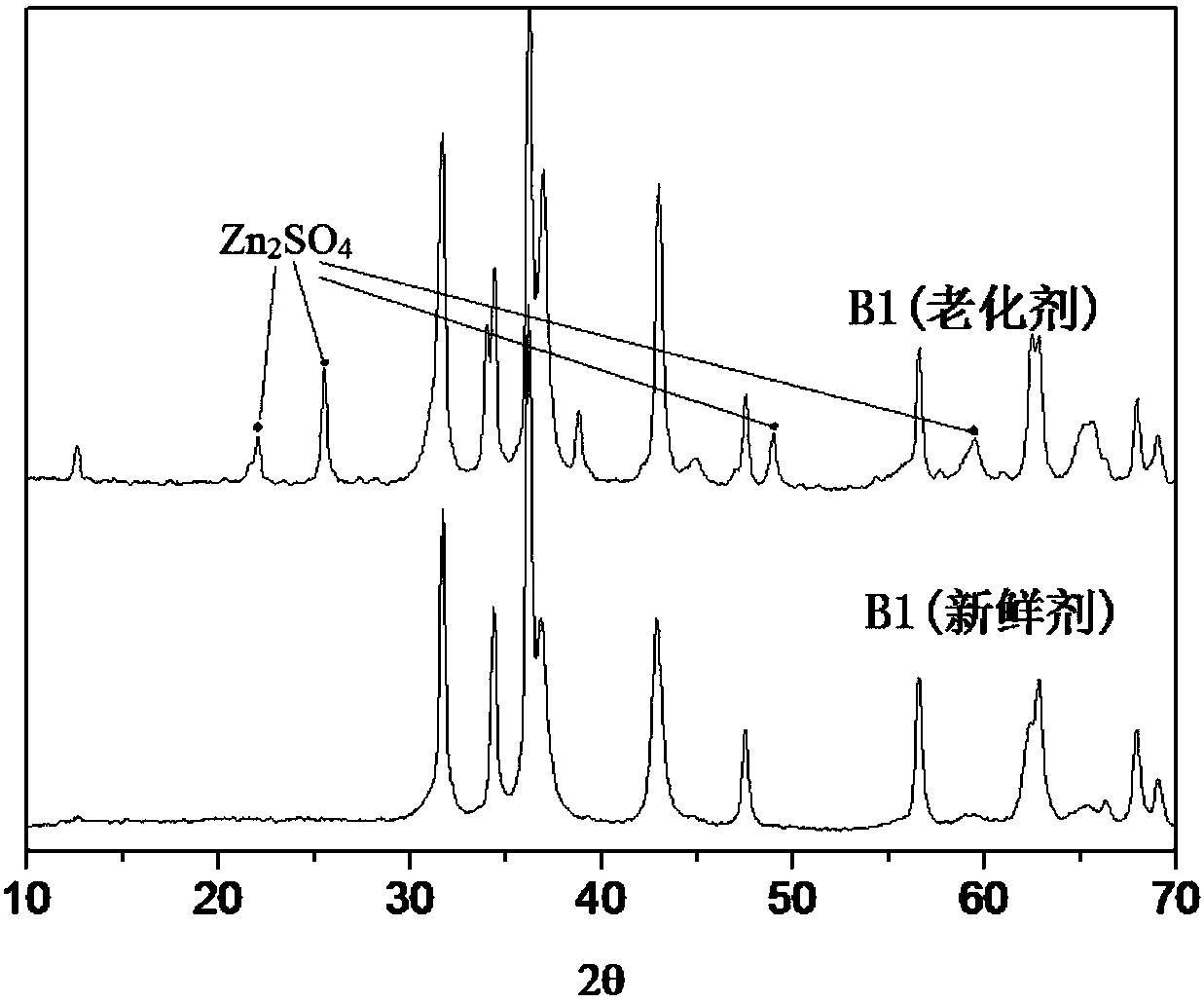

Hydrocarbon oil desulfurization catalyst containing IMF-structure molecular sieve, preparation method of hydrocarbon oil desulfurization catalyst and process for hydrocarbon oil desulfurization

ActiveCN109718842AReduce usageLow costMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSulfur

The invention relates to a hydrocarbon oil desulfurization catalyst containing an IMF-structure molecular sieve, a preparation method of the hydrocarbon oil desulfurization catalyst and a process forhydrocarbon oil desulfurization. Through adoption of the weight of the hydrocarbon oil desulfurization catalyst or the total weight of sulfur-storing metal oxide, an inorganic oxide binder, boron nitride, the IMF-structure molecular sieve and a metal promoter as a standard, the hydrocarbon oil desulfurization catalyst contains, by weight, 10-80% of the sulfur-storing metal oxide on the basis of oxide, 3-35% of the inorganic oxide binder on the basis of oxide, 5-40% of boron nitride, 1-20% of the IMF-structure molecular sieve based on a dry basis and 5-30% of the metal promoter on the basis ofmetal elements. The hydrocarbon oil desulfurization catalyst has the advantages of high stability, good desulfurization activity and good wear resistance when applied to the process for hydrocarbon oil desulfurization.

Owner:CHINA PETROLEUM & CHEM CORP +1

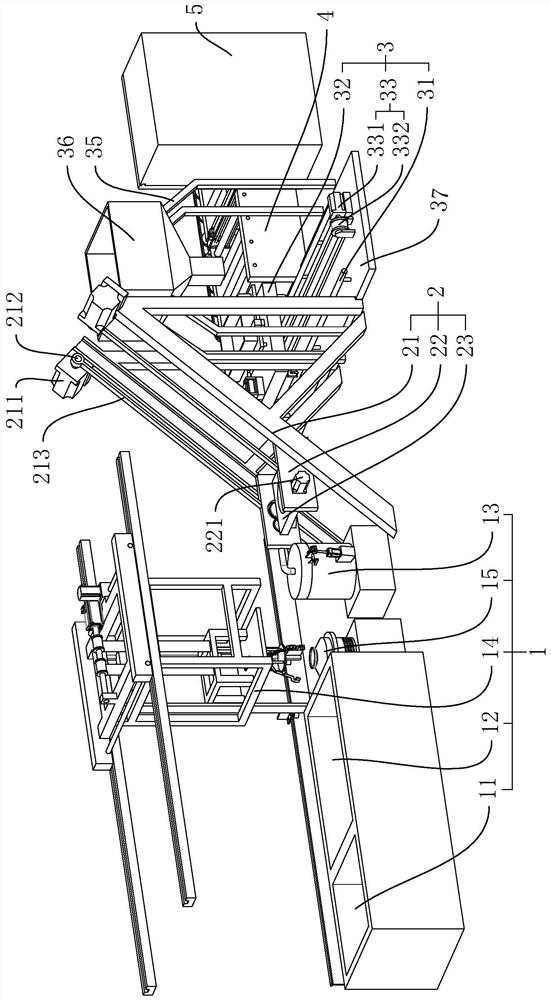

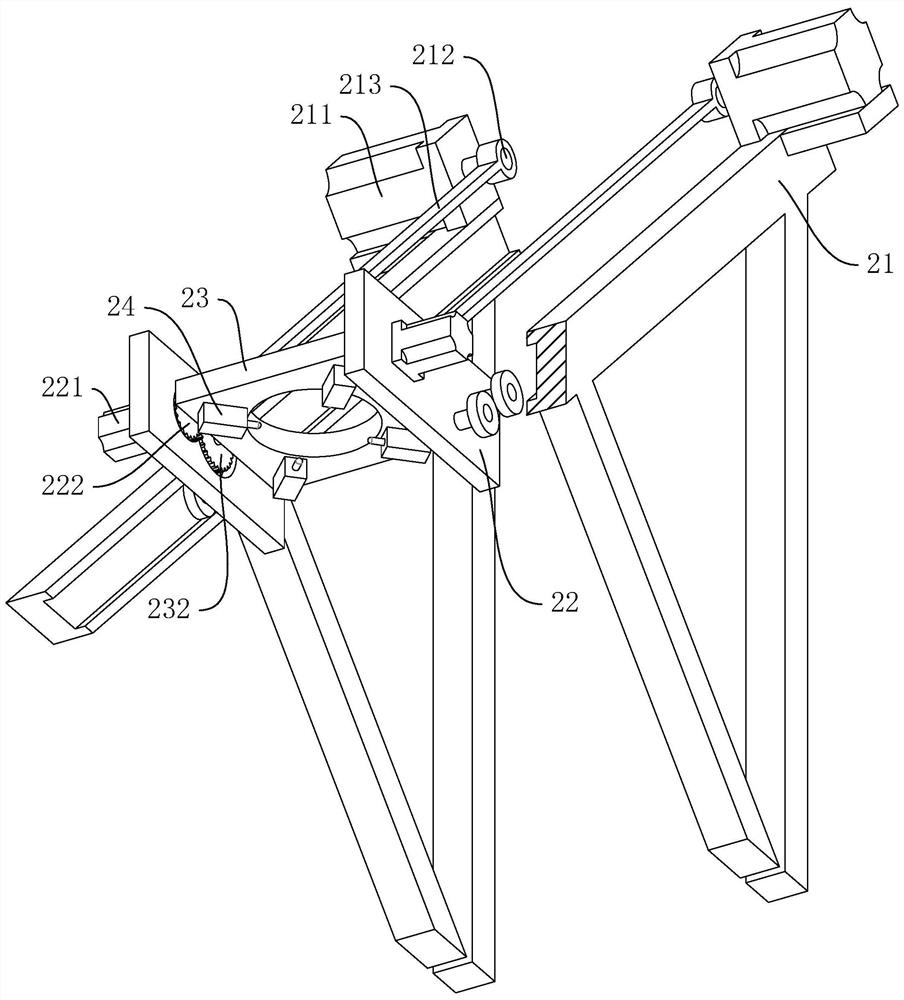

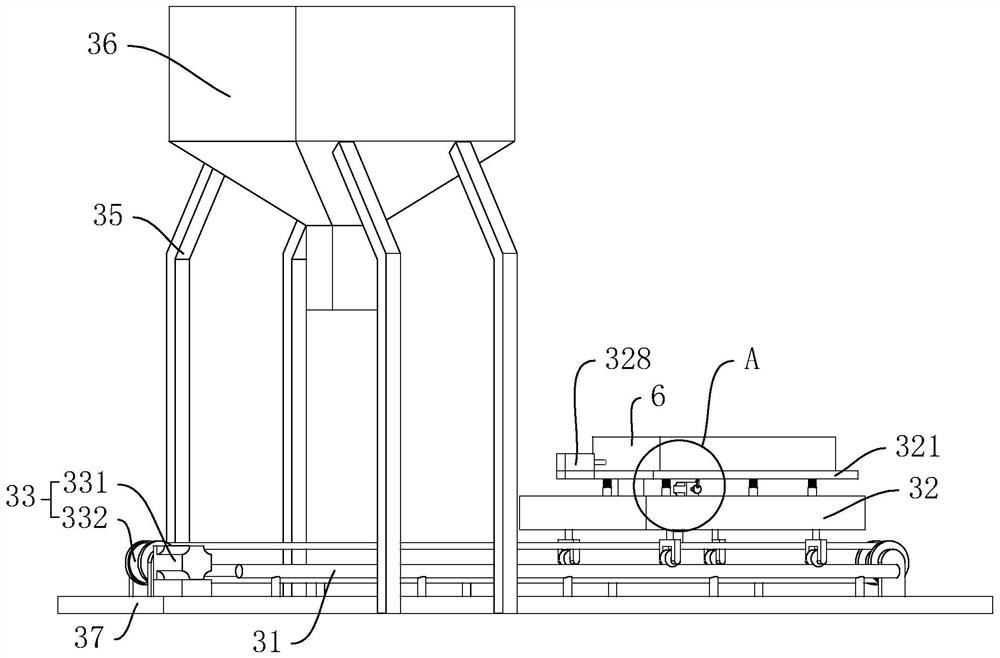

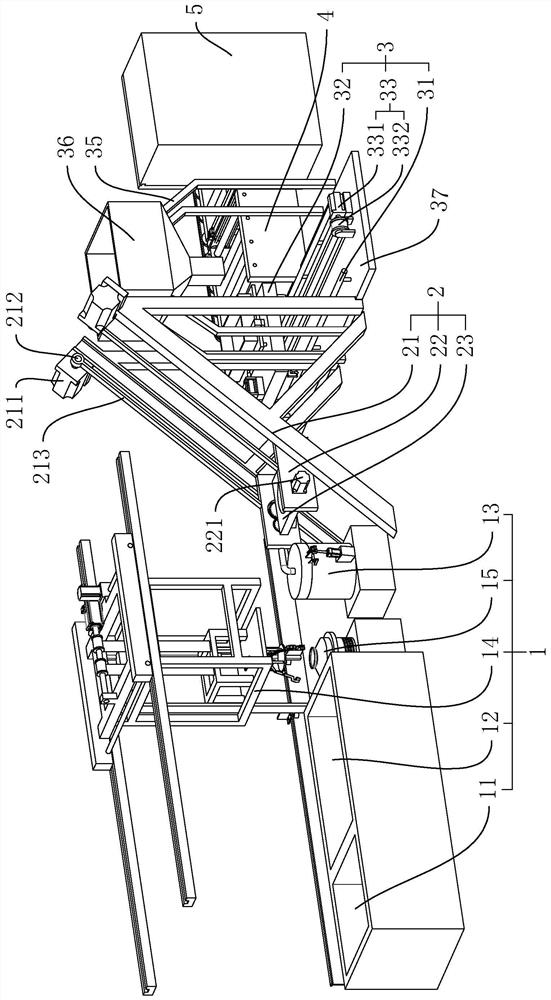

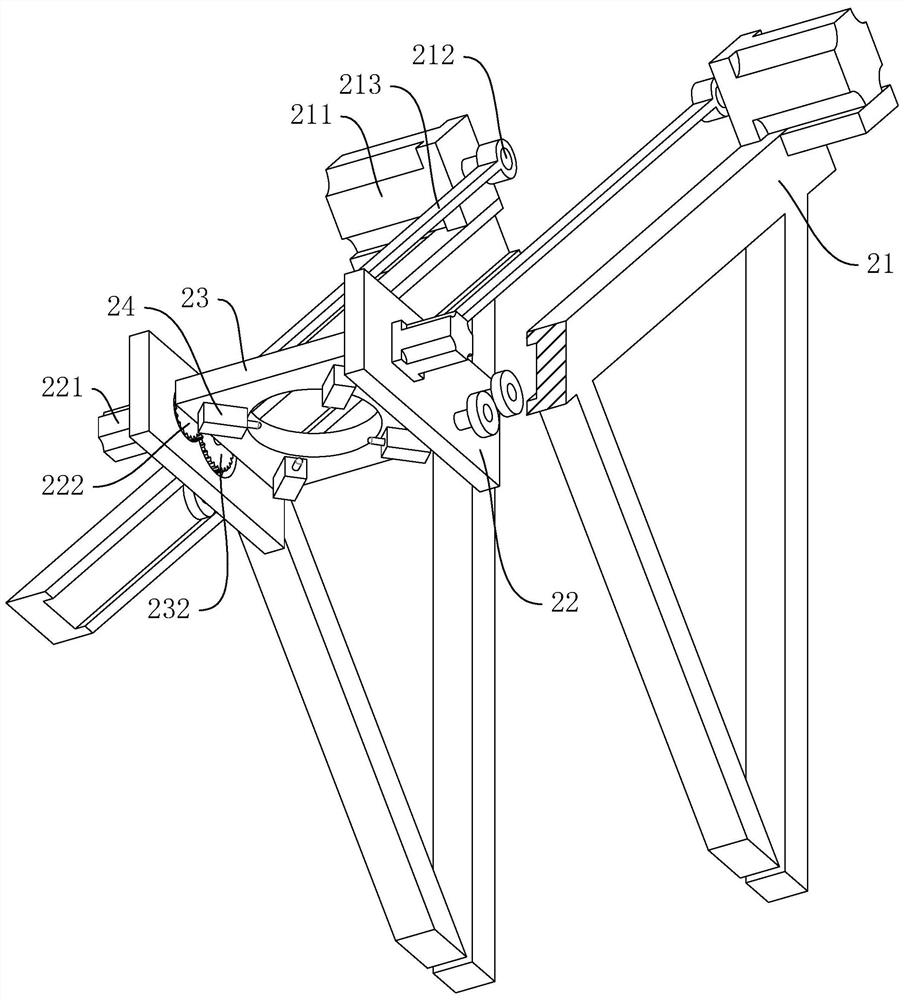

Automatic barrel plating production line

ActiveCN111647934AHigh degree of automationImprove work efficiencyElectrolysis componentsConveyor partsAutomatic controlControl system

The invention relates to the technical field of barrel plating production lines, in particular to an automatic barrel plating production line. The production line includes a barrel plating system, a material transferring system, a hydrogen removal system and an automatic control system. The barrel plating system includes an electroplating device, a cleaning device, a drying device, a drying drum and a moving hanging frame. The material transferring system includes a material transferring device, the material transferring device includes a hoisting frame, a supporting seat and a fixing frame, afirst motor is arranged at the upper end of the hoisting frame, an output end of the first motor is fixedly connected with a driving roll, and a hoisting belt for hoisting the supporting seat is arranged on the driving roll in a winding mode. The hydrogen removal system includes a stove and a material receiving device, the material receiving device includes a transmission frame, a material basketand a transmission mechanism, and a first push mechanism is arranged on the transmission frame. Parts in the drying drum can be automatically poured into the material basket through the material transferring device, the transmission mechanism can drive the material basket to move to the stove, and the automatic degree of the barrel plating production line can be effectively improved.

Owner:太仓市海峰电镀有限公司

Method of purifying aluminium alloy melt

A process for cleaning the molten Al-alloy by removing hydrogen features that the inertial gas is sprayed onto top surface of molten Al-alloy contained in a degassing case via rotating nozzle while onto the bottom of the molten Al-alloy via the air-permeable bricks on the bottom of the degassing case.

Owner:江西金达通新材料科技有限公司

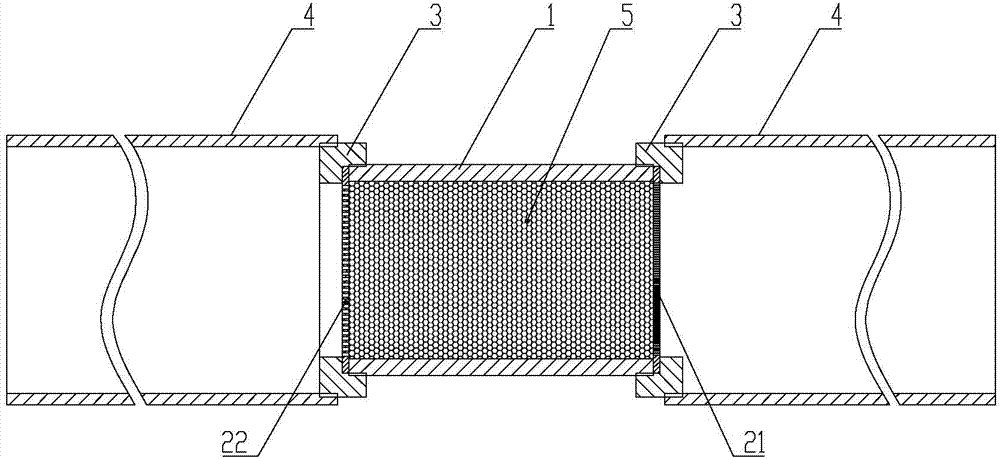

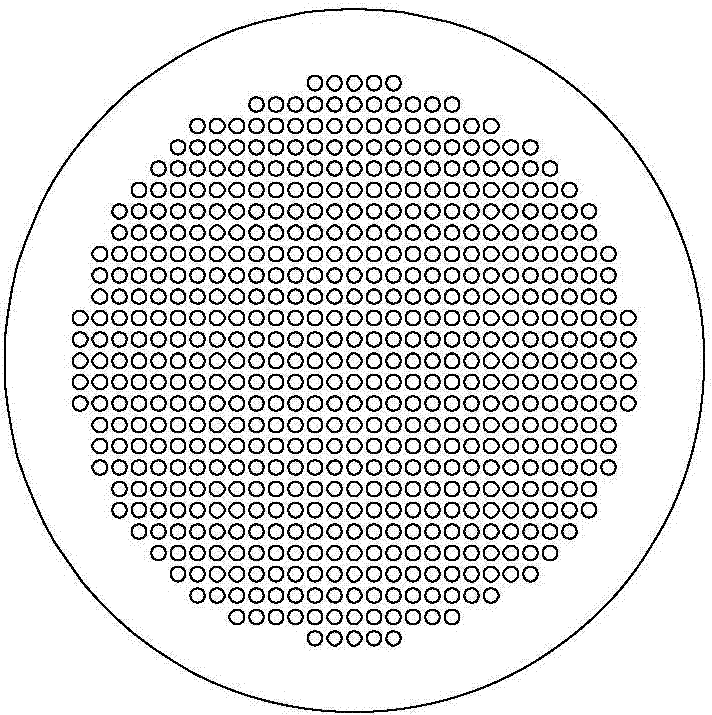

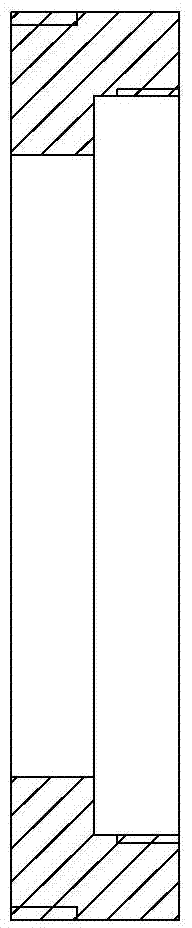

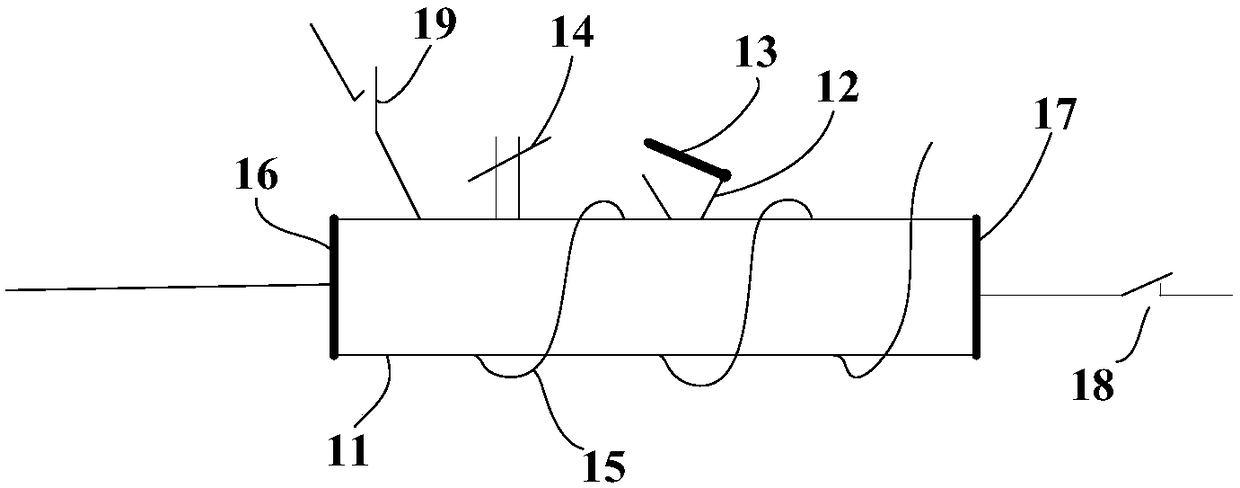

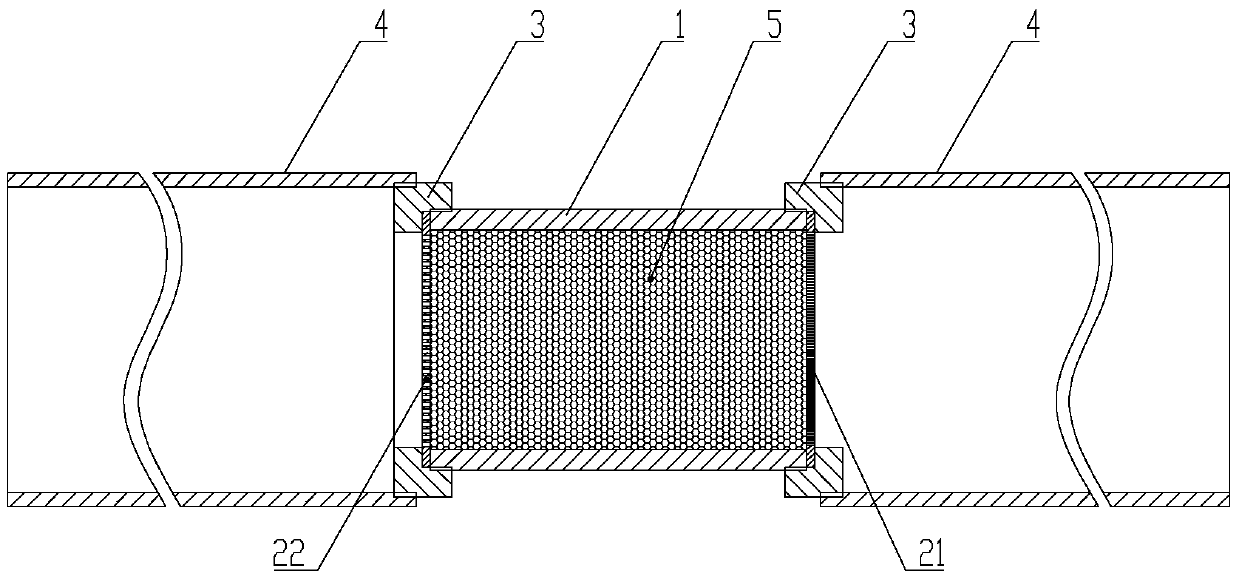

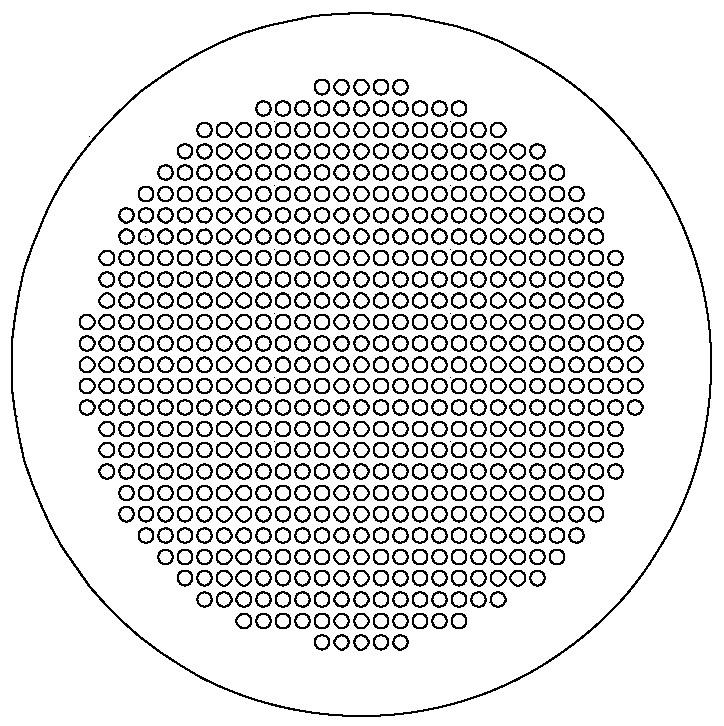

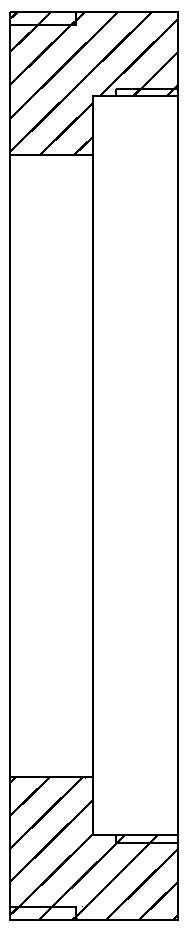

Alloy melt hydrogen removal device and online hydrogen removal method thereof

The invention discloses an alloy melt hydrogen removal device and an online hydrogen removal method thereof. The device comprises a purifying tube which comprises an alloy melt inflow end and an alloy melt outflow end, Ti-Mo alloy particles are evenly placed into the purifying tube, and the alloy melt outflow end is provided with a first sealing plate used for filtering the Ti-Mo alloy particles. The alloy melt hydrogen removal device is simple in structure, convenient to install and replace, low in hydrogen removal cost, good in hydrogen removal effect and easy to apply to industrial production. Besides, the online hydrogen removal method based on the alloy melt hydrogen removal device is few in process procedure, equipment is convenient to install and replace, and the hydrogen removal effect is good. A magnesium alloy melt prepared by means of the device and the method can remarkably reduce the content of hydrogen in the melt, metallurgical quality of castings is improved, and the device and the method have good application prospect in industrial production.

Owner:CHONGQING UNIV

Refining furnace dehydrogenation method

InactiveCN102094110AHigh dehydrogenation rateGood dehydrogenation effectHydrogen contentDehydrogenation

The invention relates to a refining furnace dehydrogenation method. The method comprises the following steps: 1) a ladle is opened to a hydraulic lifting position, the ladle is jacked, an insertion tube is inserted, bottom blowing argon is performed, the stirring intensity is 3-5L / (min.t), vacuumizing is performed to ensure that the vacuum degree is reduced to less than 2mbar in 3-5 minutes, molten steel is sucked in the vacuum chamber of a single-burner refining furnace; 2) vacuumizing is completed in 3-5 minutes to ensure that the vacuum degree is no more than 2mbar; 3) before the dehydrogenation of molten steel, alloying is performed according to the component requirements of different steels, and alloy is added to ensure that the component weight percentages of molten steel meet the requirements of the steel finished product; 4) dehydrogenation is performed, wherein the vacuum degree remains no more than 2mbar in no less than 15min; and 5) bottom blowing argon is stopped, and when molten steel is in a rest state after 2min, the vacuum valve is opened to break vacuum. The refining furnace dehydrogenation method has high dehydrogenation rate and the hydrogen content of molten steel can be reduced to 0ppm-1.5ppm. Therefore, the dehydrogenation rate is 70%-90%.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

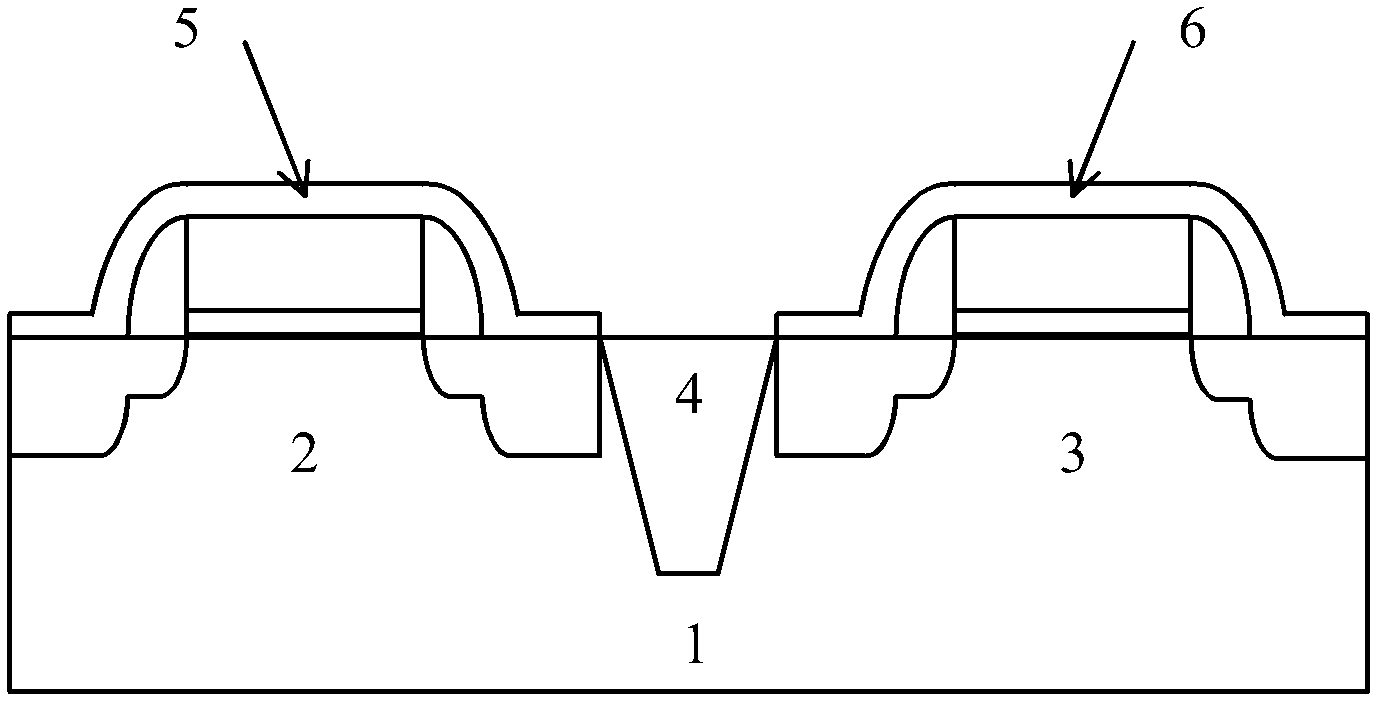

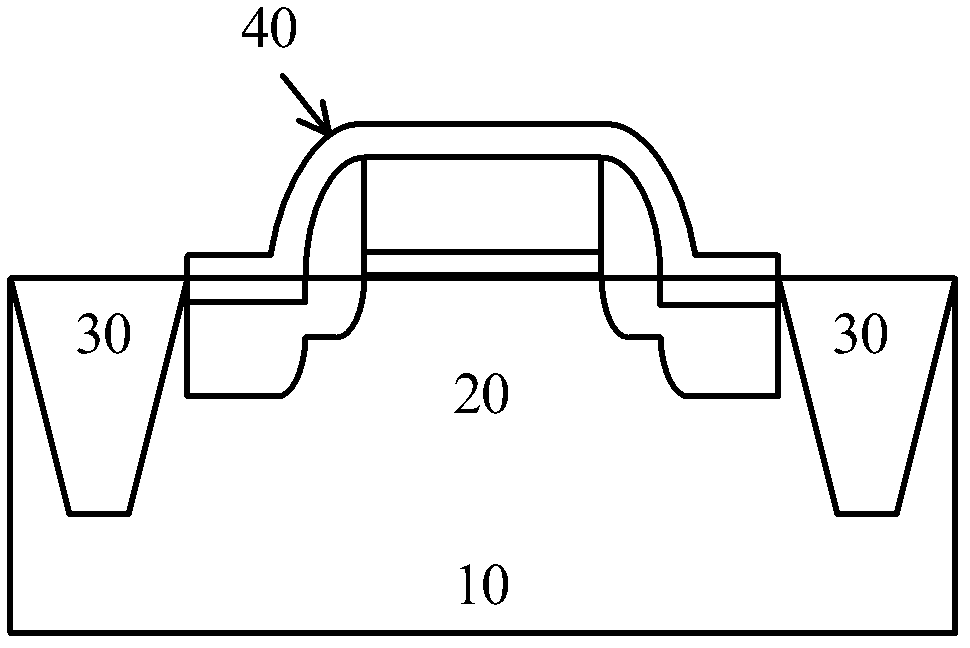

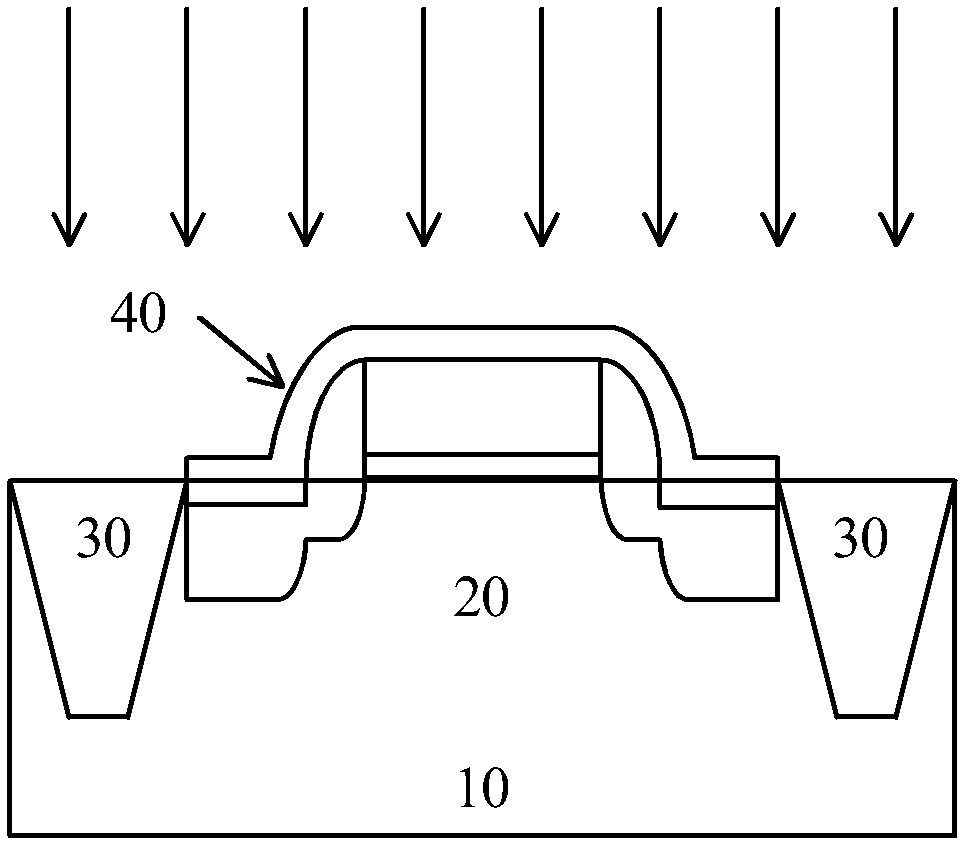

Semiconductor device and production method thereof

ActiveCN103035524AHigh absorption coefficientIncrease the tensile stressSemiconductor/solid-state device manufacturingSemiconductor devicesDehydrogenationUltraviolet lights

Disclosed is a semiconductor device and a production method thereof. An N-channel metal oxide semiconductor (NMOS) device is covered by a silicon nitride film of a high ultraviolet light absorption coefficient through a Plasma Enhanced Chemical Vapor Deposition (PECVD), the silicon nitride film can absorb ultraviolet light well when the silicon nitride film is subjected to annealing on the laser surface, the dehydrogenation effect is good, the silicon nitride film has high tensile stress after dehydrogenation, a substrate is not required to be heated due to the high ultraviolet light absorption coefficient of the silicon nitride film, the bad effect on the device, which is caused by the facts that the substrate is heated and the dehydrogenation is conducted, can be avoided, and the heat budget brought by a PECVD process.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

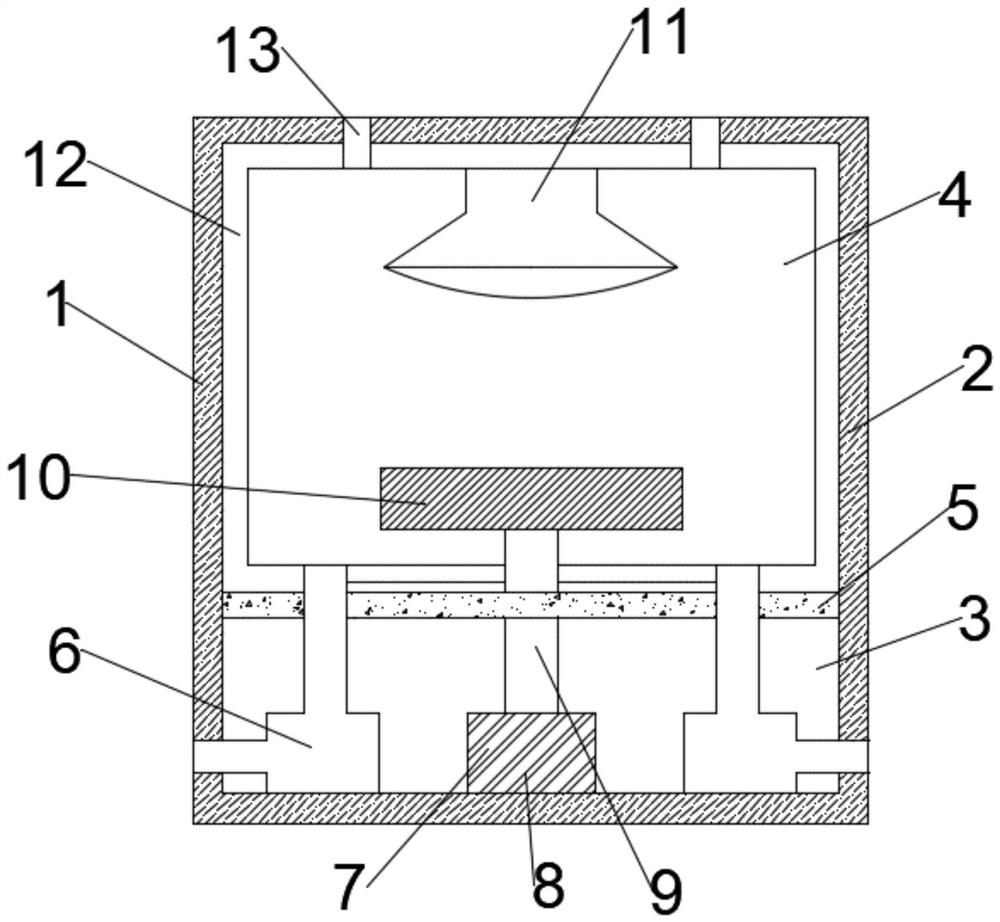

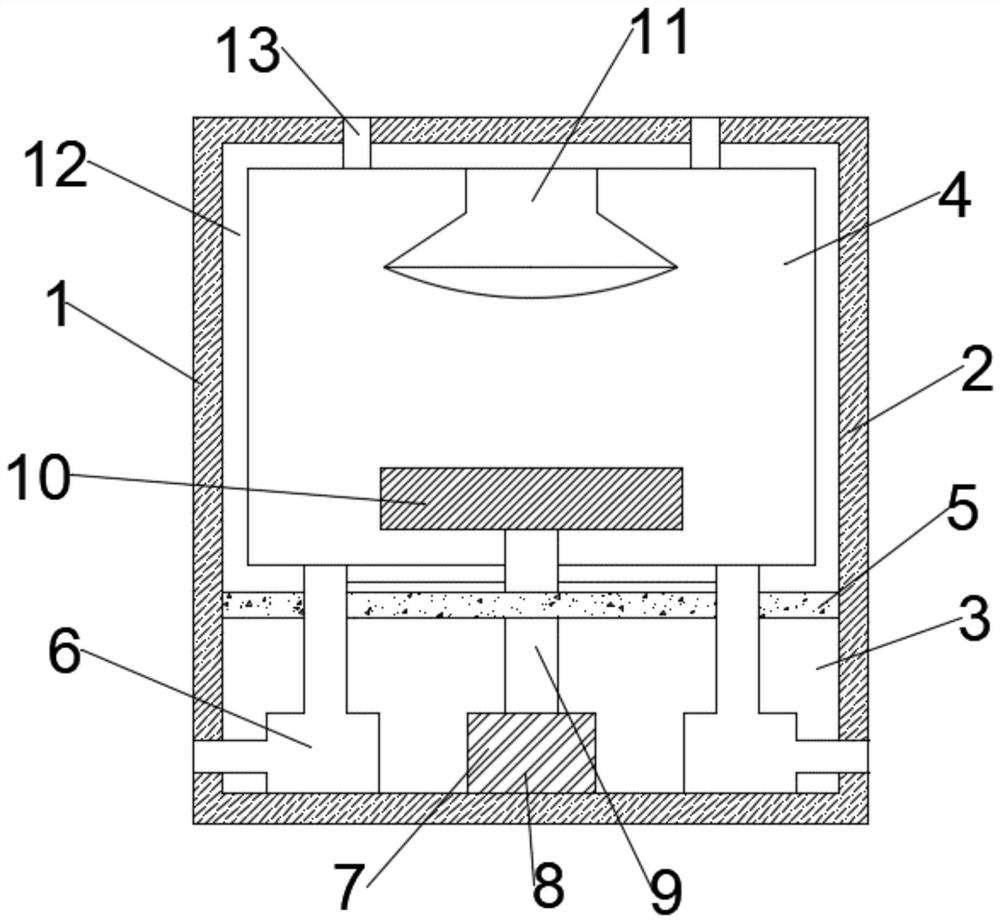

Uniform drying device for electroplated parts

ActiveCN113293419AMaximize utilizationEasy to remove waterMaterial nanotechnologyDrying gas arrangementsThermodynamicsWater vapor

The invention discloses a uniform drying device for electroplated parts, which comprises a drying device body, an inner cavity of the drying device body is separated by a heat insulation interlayer to form a heating cavity and a constant-temperature cavity, and the heating cavity and the constant-temperature cavity are separated through the heat insulation interlayer; blowing devices and a rotating device are arranged in the heating cavity, the rotating device is fixed to the bottom of the heating cavity, and the blowing devices are arranged on the two sides of the rotating device; and an infrared heating lamp is arranged at the top of the constant-temperature cavity, and a heat preservation lining is arranged on the inner wall of the constant-temperature cavity and is made of a nanometer aerogel material. On the basis of an existing drying device, a heating plate is arranged in the constant-temperature cavity, and the heat preservation lining is additionally arranged, so that heat can be utilized to the maximum extent, the temperature in the drying device is isolated from the outside world, water molecules and hydrogen molecules can be adsorbed, therefore, the electroplated parts can obtain better water removal and hydrogen removal effects, and separated water vapor or hydrogen cannot be adsorbed to the electroplated parts again.

Owner:柳州市荣鑫金属表面处理有限公司

Hydrocarbon oil desulfurization catalyst containing FAU-structure and/or BEA-structure molecular sieve, preparation method of hydrocarbon oil desulfurization catalyst and process for hydrocarbon oil desulfurization

ActiveCN109718830AWith desulfurizationWith dehydrogenation propertiesMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSulfur

The invention relates to a hydrocarbon oil desulfurization catalyst containing an FAU-structure and / or BEA-structure molecular sieve, a preparation method of the hydrocarbon oil desulfurization catalyst and a process for hydrocarbon oil desulfurization. Through adoption of the weight of the hydrocarbon oil desulfurization catalyst or the total weight of sulfur-storing metal oxide, a zirconia binder, boron nitride, the FAU-structure and / or BEA-structure molecular sieve and a metal promoter as a standard, the hydrocarbon oil desulfurization catalyst contains, by weight, 10-80% of the sulfur-storing metal oxide on the basis of oxide, 3-35% of the zirconia binder on the basis of oxide, 5-40% of boron nitride, 1-20% of the FAU-structure and / or BEA-structure molecular sieve based on a dry basisand 5-30% of the metal promoter on the basis of metal elements. The hydrocarbon oil desulfurization catalyst has the advantages of high stability, good desulfurization activity and good wear resistance when applied to the process for hydrocarbon oil desulfurization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Planetary rotary blowing aluminum melt purifying device

The invention discloses a planetary rotary blowing aluminum melt purifying device, which comprises a frame, a degassing box, a top cover, an elevating mechanism, a planetary driving mechanism, a rotary blowing device, a rotary spray head and an air inlet pipe, wherein the elevating mechanism is arranged on the upper part of the frame; the planetary driving mechanism is arranged on an installation seat; the rotary blowing device further comprises a rotating lever; the upper end of the rotating lever is connected with an output shaft of a planetary driver; the rotary spray head is arranged at one end of the rotating lever which is different from the output shaft of the planetary driver, and is positioned in the degassing box; and the air inlet pipe is connected with the rotary spray head. According to the planetary rotary blowing aluminum melt purifying device disclosed by the invention, the rotary spray head has high-speed auto-rotation and low-speed revolution functions simultaneously, bubbles are distributed uniformly in the degassing box, easily reach the corner regions of the degassing box, are dispersed and float uniformly in the degassing box, and are mixed fully with an aluminum melt, the liquid level of the aluminum melt is stable, the diffusion course of hydrogen in the aluminum melt is shortened, gas-liquid contact is strengthened, and the hydrogen removing effect is improved.

Owner:SHENYA AUTOMATION EQUIP LAIZHOU CO LTD

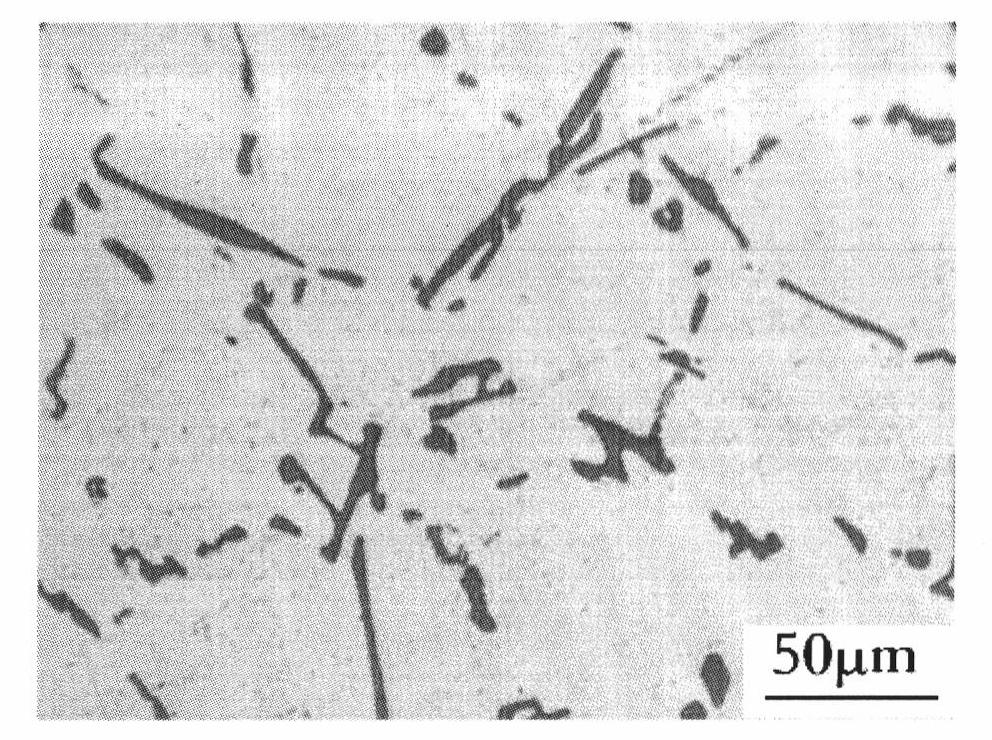

Rare earth element containing aluminum material for explosion-proof membrane and manufacturing method of rare earth element containing aluminum material

ActiveCN111500899AExcellent hydrogen removalGood dehydrogenation effectRare-earth elementElectrically conductive

The invention discloses a rare earth element containing aluminum material for an explosion-proof membrane. The rare earth element containing aluminum material comprises, by mass percent, 1.0%-1.4% ofFe, not larger than 0.25% of Si, not larger than 0.1% of Cu, 0.4%-0.8% of Mn, not larger than 0.5% of Mg, 0.05%-0.07% of RE and the balance Al, wherein Fe+Mn<=2.0%, and Fe / Si is 1.5-4.0. The inventionfurther discloses a manufacturing method of the rare earth element containing aluminum material for the explosion-proof membrane. Composite rare earth is added into a standing furnace, an Al-RE-B intermediate alloy is used as a refining agent to refine the aluminum alloy structure, and homogenizing treatment is carried out before hot rolling. By means of the rare earth element containing aluminummaterial, the mechanical property of the explosion-proof membrane for a lithium battery is effectively improved, excellent electric conductivity is kept, the microstructure is refined, the yield strength of a finished product of the explosion-proof membrane is larger than or equal to 50 MPa, meanwhile, ductility can reach 40% or above, and electric conductivity is 53.5%IACS or above.

Owner:JIANGSU ALCHA ALUMINUM +1

Hydrocarbon oil desulfurization catalyst containing MFI structural molecular sieve as well as preparation method of catalyst and hydrocarbon oil desulfurization process

ActiveCN109718838AWith desulfurizationWith dehydrogenation propertiesMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSulfur

The invention relates to a hydrocarbon oil desulfurization catalyst containing an MFI structural molecular sieve as well as a preparation method of the catalyst and a hydrocarbon oil desulfurization process. Based on a weight of the hydrocarbon oil desulfurization catalyst or a total weight of a sulfur storage metal oxide, an inorganic oxide bonding agent, boron nitride, the MFI structural molecular sieve and a metal promoter, the hydrocarbon oil desulfurization catalyst contains the following components: 10-80% by weight of the sulfur storage metal oxide based on an oxide, 3-35% weight by weight of the inorganic oxide bonding agent based on an oxide, 5-40% by weight of the boron nitride, 1-20% by weight of the MFI structural molecular sieve on a dry basis and 5-30% by weight of the metalpromoter based on a metal element. The hydrocarbon oil desulfurization catalyst provided by the invention has the advantages of high stability, good desulfurization activity and good wear resistance when applied to the hydrocarbon oil desulfurization process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sodium-free refining agent used for smelting aluminum alloy

The invention discloses a sodium-free refining agent used for smelting an aluminum alloy. The refining agent is prepared from the following raw materials including, by weight, 10-16 parts of calcium fluoride, 10-14 parts of potassium fluorosilicate, 10-14 parts of potassium fluotitanate, 8-12 parts of potassium chloride, 8-14 parts of lithium chloride, 8-14 parts of magnesium chloride, 6-10 partsof titanium dioxide and 3-5 parts of carbon powder. According to the refining agent, in the refining process, the hydrogen removing effect is remarkable, oxide impurities in melt can be removed fully,hot slag is recovered more conveniently, and the recovery rate is higher. Due to containing of titanium, a certain effect of refining the alloy is achieved. The refining agent does not contain sodiumsalt ingredients and has a good refining effect.

Owner:徐州轩辕铝业有限公司

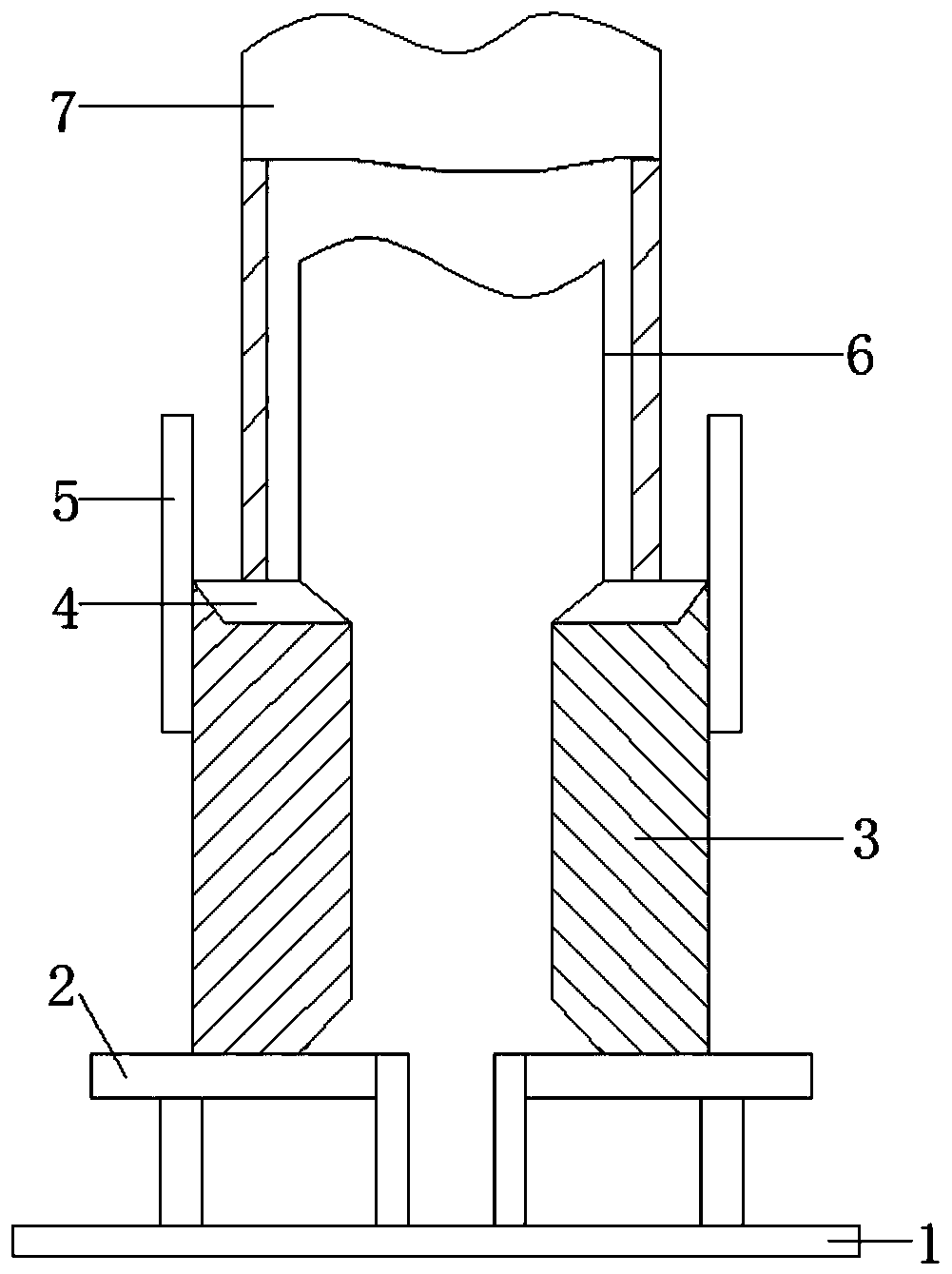

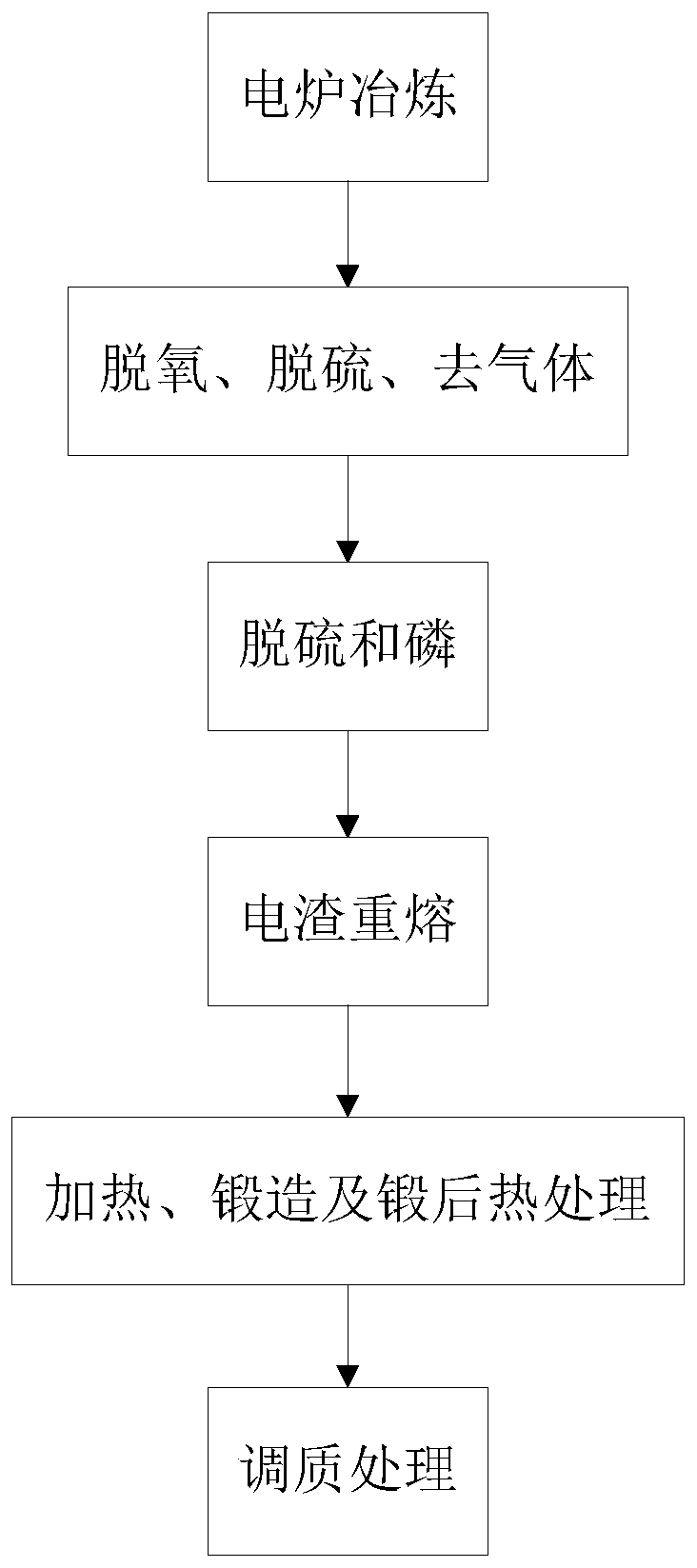

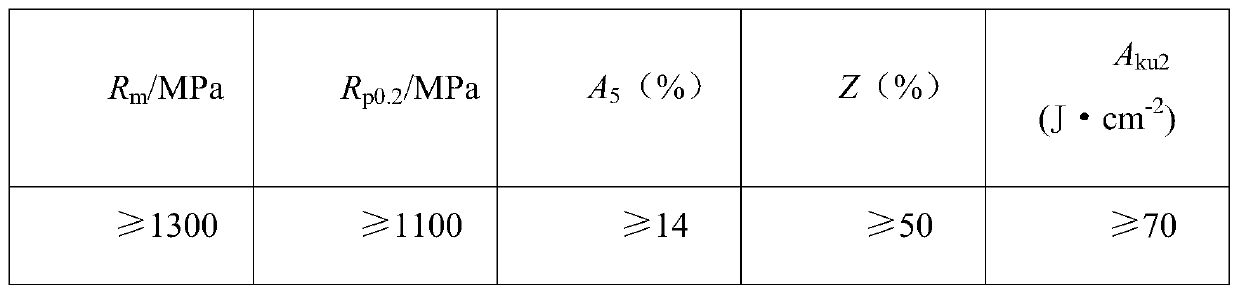

Melting device of 32Cr3Mo1V steel casting roller sleeve and process of producing steel casting roller sleeve through melting device

PendingCN110699593AImprove impact toughnessIncrease contact areaElectric furnaceProcess efficiency improvementStress relievingCarbide

The invention discloses a melting device of a 32Cr3Mo1V steel casting roller sleeve and a process of producing the steel casting roller sleeve through the melting device. By means of the proper temperature at the last phase of melting and the primary phase of oxidizing, high-alkalinity, high-oxidizability and good-flowability slag is created; metal is supplemented between a first electrode and a second electrode through a step-by-step power-reduction and current-reduction and on-off-combined mode, so the minimum shrinkage depth is ensured, and the yield of an electroslag ingot is increased; bymeans of normalizing, the aims of uniform formation and refined grain are realized; since hydrogen is low in solubility, high in diffusing coefficient and good in dehydrogenating effect at the temperature and a forging is subjected to heat preserving and then water quenching and oil cooling, quenching cracks are effectively avoided, the aims of performance stabilizing and stress eliminating are realized, and the purposes of realizing the minimum shrinkage depth and minimum size, increasing the yield of the electroslag ingot, reducing the quenching cracks and improving the poor stability are realized since the performance of the high-speed steel casting roller is not only related to the matrix structure of the roller and carbides, but also has an important effect in the production process.

Owner:江苏环宇冶金科技有限公司

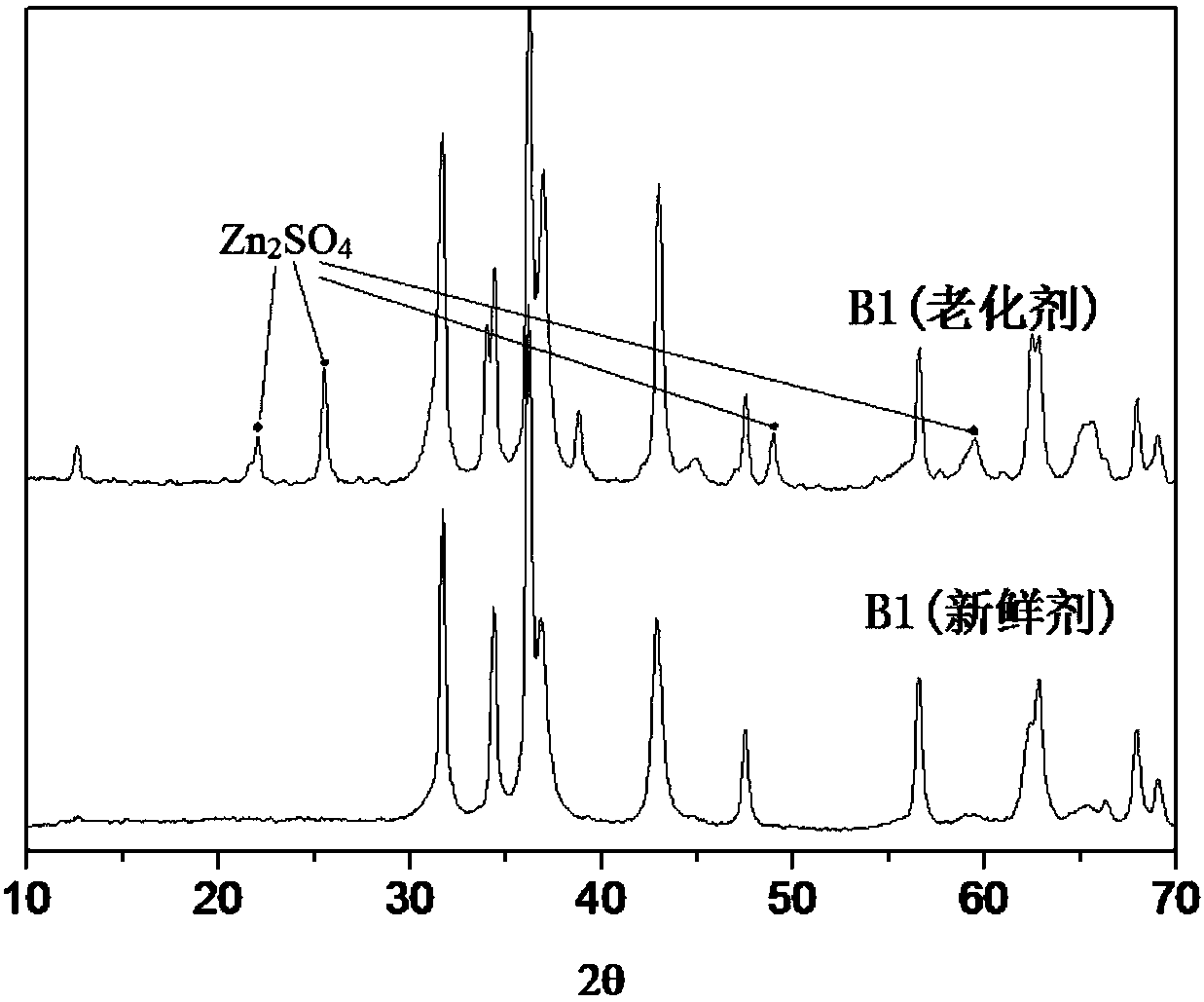

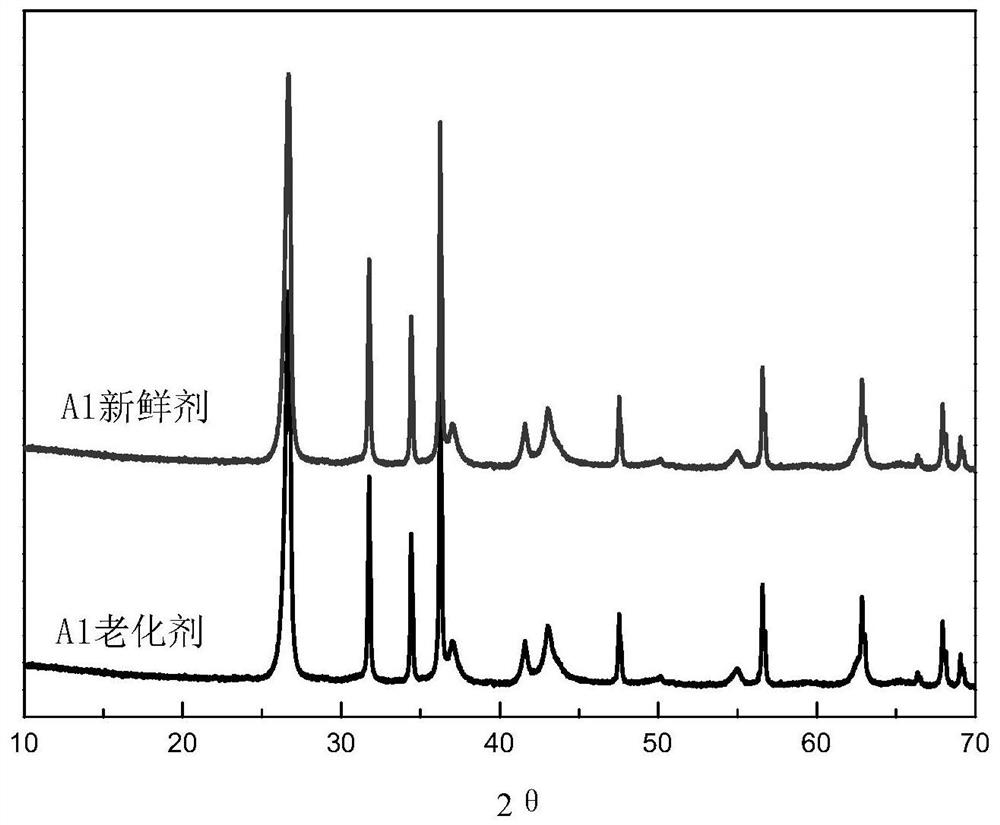

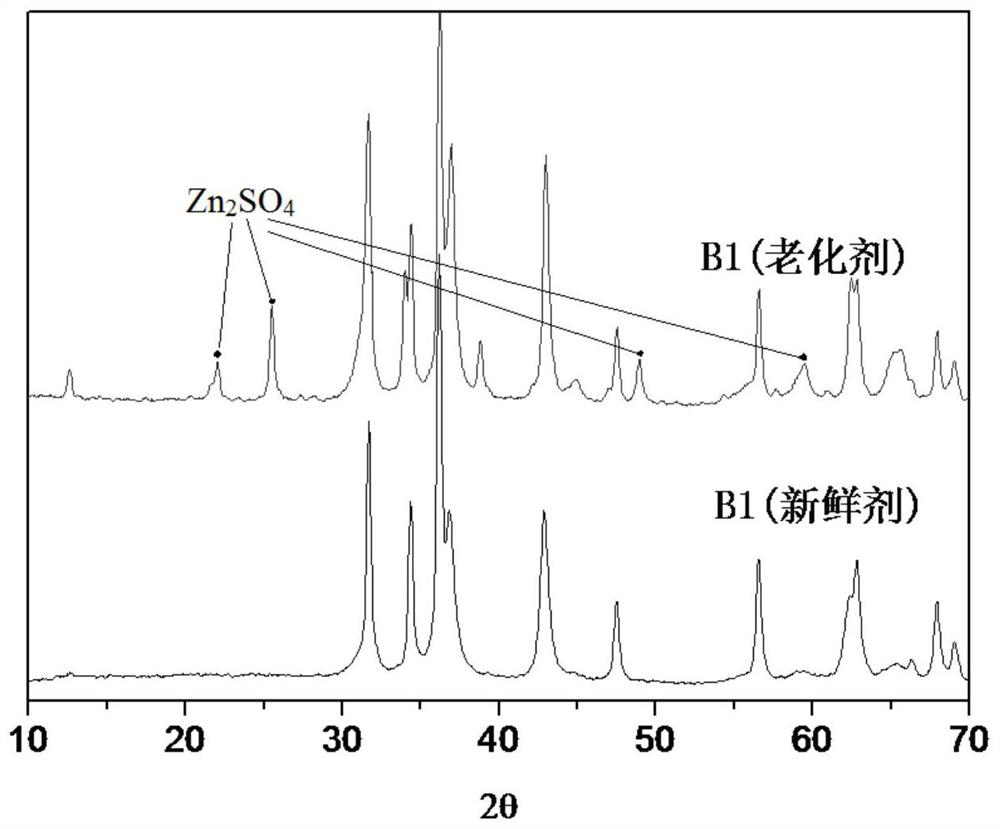

A cracking and desulfurization combined method and device and combined process of catalytic cracking and adsorption desulfurization

The invention relates to a cracking and desulfurization combined method and device and a combined process of catalytic cracking and adsorption desulfurization. The method comprises: (1) contacting heavy oil with a catalytic cracking catalyst to obtain a cracked product; (2) separating the cracked product, the step of obtaining a light fraction with an end boiling point of 215-365°C, (3) contacting the light fraction with a desulfurization catalyst under the condition that the volume ratio of hydrogen to oil is 50-250, and obtaining a desulfurization product , wherein the composition of the desulfurization catalyst includes at least one sulfur-storing metal oxide, and (4) the step of separating the desulfurization product to obtain a liquefied petroleum gas fraction, a gasoline fraction and an optional gas oil fraction. The invention directly performs adsorption desulfurization on liquefied gas and gasoline and / or diesel oil without separation, and separates LPG from gasoline and / or diesel oil after desulfurization, thereby reducing separation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

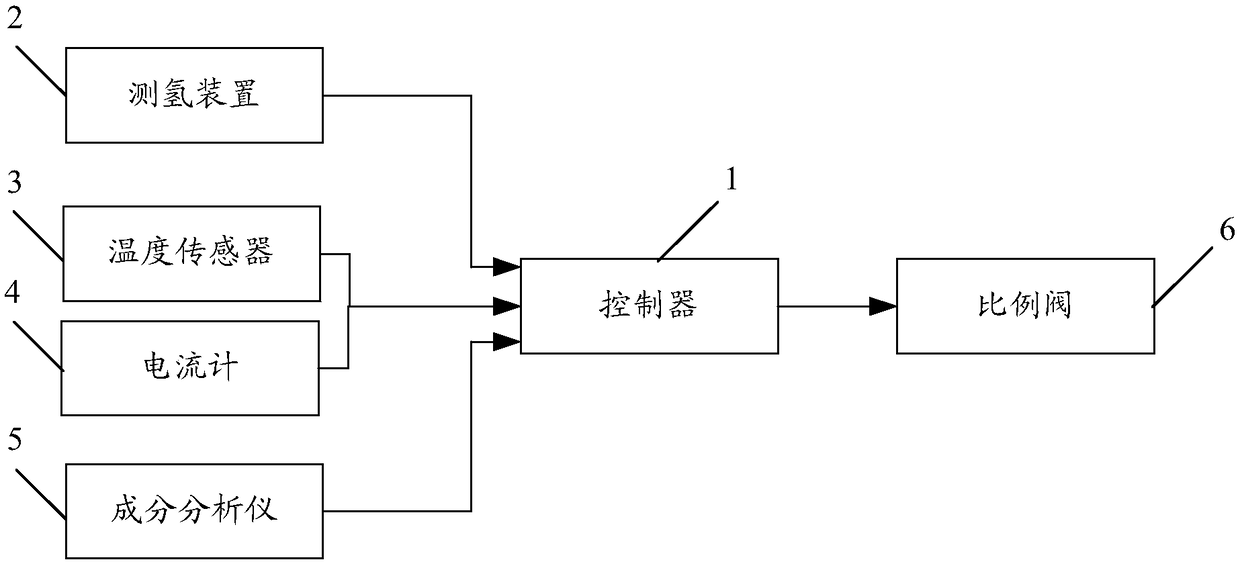

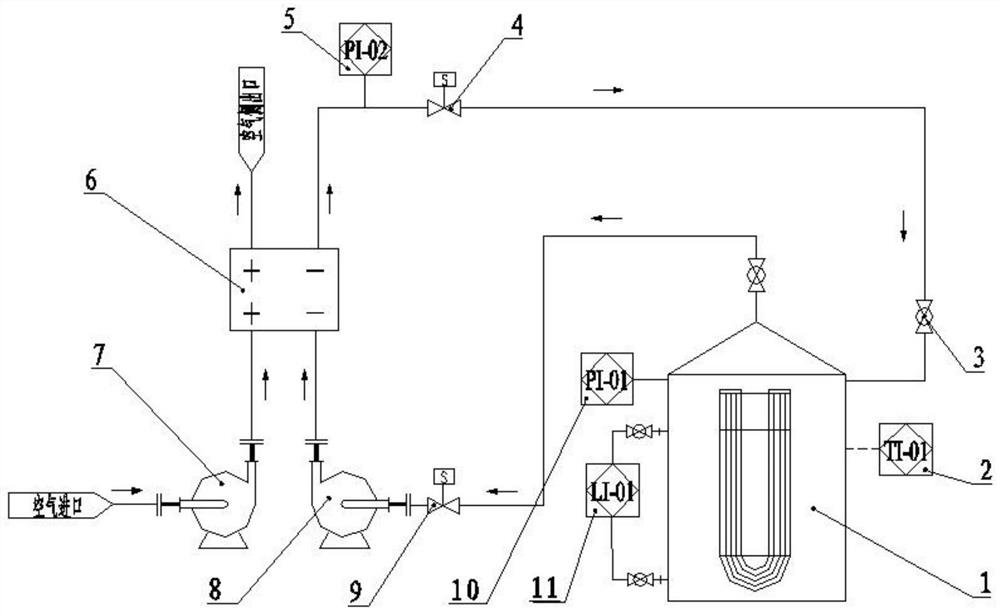

Molten aluminum gas-removing and gas-supplying control method, device, system and computer storage medium

The invention provides a molten aluminum gas-removing and gas-supplying control method. The method comprises the following steps: collecting an X-ray emitted from molten aluminum through an X-ray receiver, performing spectral analysis on the X-ray, and determining major metal components contained in the molten aluminum; according to the major metal components, determining types of inert gases which need to be fed into a molten aluminum tank; according to a first difference value of hydrogen content in the molten aluminum in a cylindrical container and setting standard hydrogen content, controlling an opening degree of a proportional valve so as to control an input quantity of the inert gas, wherein while the first difference value is greater than a first setting threshold, controlling an opening of the proportional valve to be enlarged so as to increase input of the inert gas; and while the first difference value is smaller than the first setting threshold, controlling the opening of the proportional valve to be reduced so as to decrease the input of the inert gas. The provided method is capable of acquiring the hydrogen content in the molten aluminum and determining the componentsof the molten aluminum, and based on the hydrogen content and the components of the molten aluminum, automatically controlling the selection and the precision input quantity of the inert gases. The hydrogen removing effect is good and the inert gases can be saved.

Owner:LUOYANG XINYUANDA METALLURGICAL COMPLETE EQUIP CO LTD

Method for casting aluminium alloy

ActiveCN101474668BImprove product qualityHigh purityFoundry mouldsFoundry cores5005 aluminium alloy6005 aluminium alloy

The invention provides a casting method of aluminum alloys. The method comprises four steps of smelting, refining, moulding and pouring. The casting method is characterized by adding specific additive in the casting process and strictly controlling standing time and casting temperature after refining of aluminum pad to enhance purity of aluminum melt and product quality of the aluminum alloys. The tensile strength, pinhole and the like of the castings which are made by the method are obviously enhanced, and defective index of large aluminum alloy castings made by the method is obviously reduced, and the method is applicable to casting of large aluminum castings with high requirements.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD +1

Magnesium alloy melt dehydrogenation device and online dehydrogenation method

The invention discloses an alloy melt hydrogen removal device and an online hydrogen removal method thereof. The device comprises a purifying tube which comprises an alloy melt inflow end and an alloy melt outflow end, Ti-Mo alloy particles are evenly placed into the purifying tube, and the alloy melt outflow end is provided with a first sealing plate used for filtering the Ti-Mo alloy particles. The alloy melt hydrogen removal device is simple in structure, convenient to install and replace, low in hydrogen removal cost, good in hydrogen removal effect and easy to apply to industrial production. Besides, the online hydrogen removal method based on the alloy melt hydrogen removal device is few in process procedure, equipment is convenient to install and replace, and the hydrogen removal effect is good. A magnesium alloy melt prepared by means of the device and the method can remarkably reduce the content of hydrogen in the melt, metallurgical quality of castings is improved, and the device and the method have good application prospect in industrial production.

Owner:CHONGQING UNIV

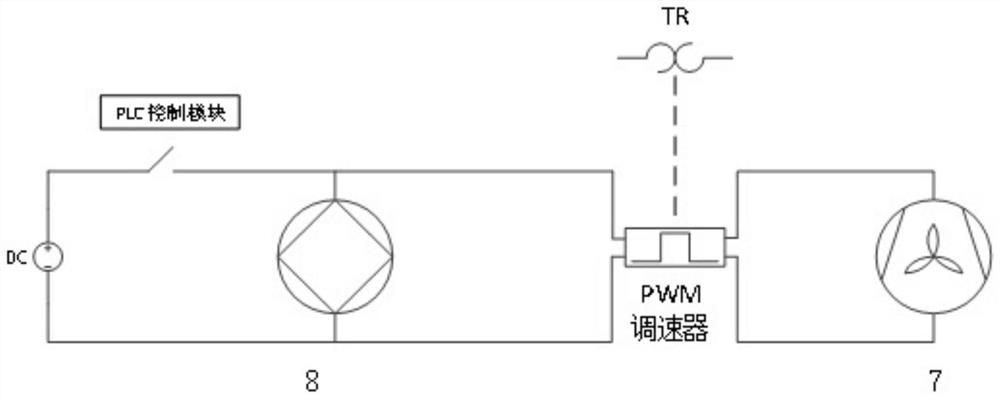

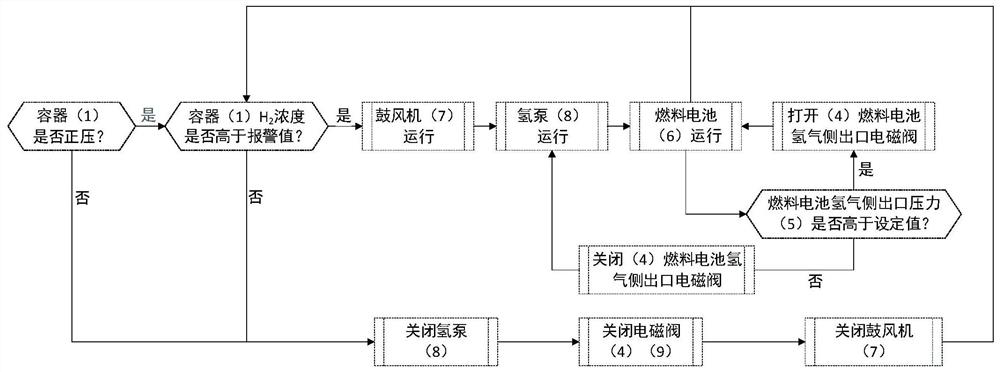

Hydrogen removal system of closed container

ActiveCN111799490AImprove securityMinor changesFinal product manufactureFuel cellsHydrogen concentrationControl system

The invention relates to a hydrogen removal system of a closed container, and belongs to the technical field of safety production. The system comprises a closed container, a fuel cell hydrogen side outlet electromagnetic valve, a fuel cell hydrogen side outlet pressure sensor, a hydrogen fuel cell, an air blower, a hydrogen pump, a fuel cell hydrogen side inlet electromagnetic valve, a closed container pressure sensor and an electrical control system. The hydrogen removal system for solving the hydrogen accumulation problem of the closed system is designed by utilizing the hydrogen reaction capacity of the hydrogen fuel cell. According to the invention, according to change of the hydrogen concentration in the closed container, the operation state of the hydrogen removal system is adjustedin real time, the system can be opened to remove hydrogen as long as the concentration exceeds a warning value until the concentration of hydrogen in the container is reduced to a safe range, the safety risk caused by hydrogen accumulation in the container is effectively reduced, and safe and stable operation of a closed electrochemical system is facilitated.

Owner:SHANGHAI POWER EQUIP RES INST

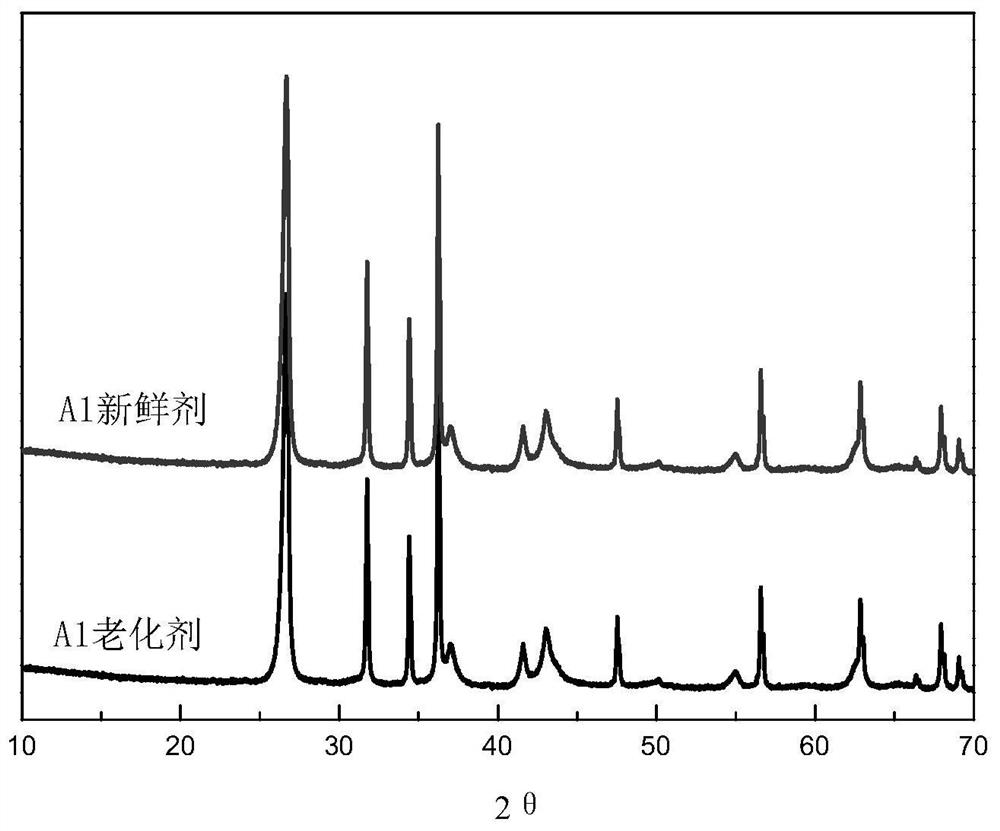

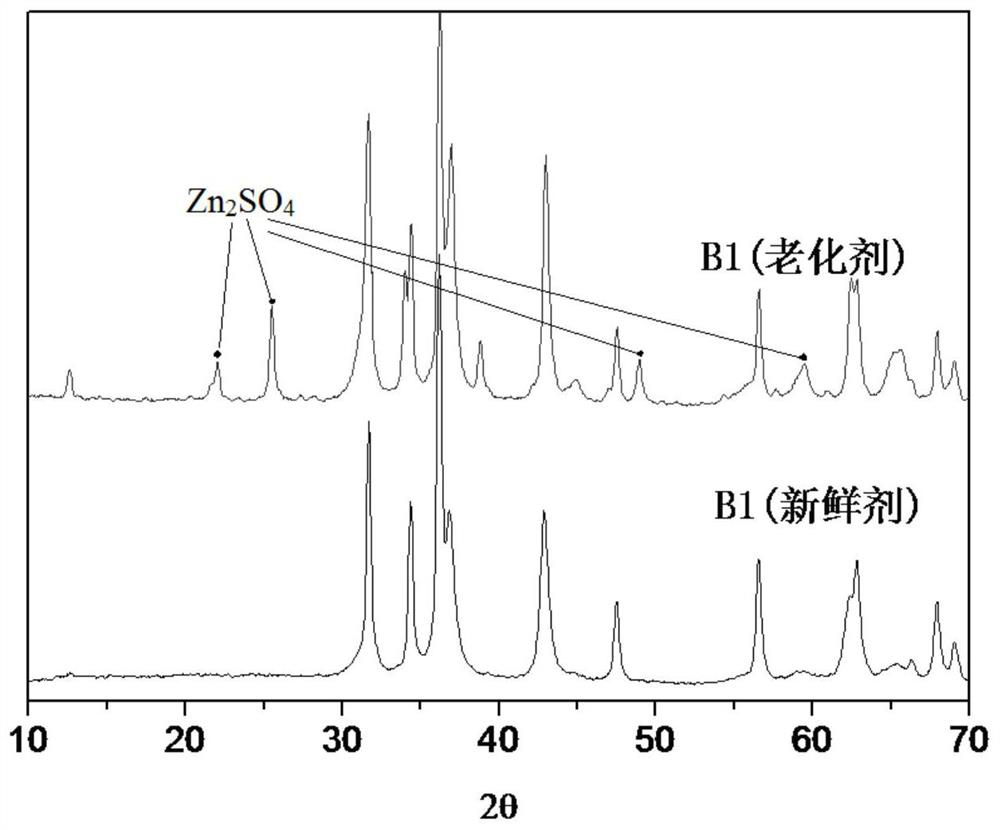

A hydrocarbon oil desulfurization catalyst and its preparation method and hydrocarbon oil desulfurization process

ActiveCN109718841BReduce usageLow costMolecular sieve catalystsHydrocarbon oils refiningMolecular sievePtru catalyst

The present invention relates to a hydrocarbon oil desulfurization catalyst containing IMF structural molecular sieve and zirconia binder, its preparation method and the process of hydrocarbon oil desulfurization. , zirconia binder, boron nitride, IMF structural molecular sieve and metal accelerator as a basis, the hydrocarbon oil desulfurization catalyst contains 10-80% by weight of sulfur-storing metal oxides in terms of oxides, and in terms of oxides 3-35% by weight of zirconia binder, 5-40% by weight of boron nitride, 1-20% by weight of IMF structure molecular sieve in terms of dry basis and 5-30% by weight of metal promoter in terms of metal elements . When the hydrocarbon oil desulfurization catalyst provided by the invention is used in a hydrocarbon oil desulfurization process, it has the advantages of high stability, good desulfurization activity and good wear resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A uniform drying device for electroplating parts

ActiveCN113293419BMaximize utilizationEasy to remove waterMaterial nanotechnologyDrying gas arrangementsThermal insulationWater vapor

The invention discloses a uniform drying device for electroplating parts, which comprises a drying device body. The inner cavity of the drying device body is separated by an insulating layer to form a heating cavity and a constant temperature cavity. The compartments are separated; the heating chamber is equipped with a blowing device and a rotating device, the rotating device is fixed at the bottom of the heating chamber, and the blowing device is arranged on both sides of the rotating device; the top of the constant temperature chamber is provided with an infrared heating lamp, The inner wall is provided with a thermal insulation lining, and the material of the thermal insulation lining is nano airgel material. On the basis of the existing drying device, the present invention sets the heating plate in the constant temperature chamber and adds a thermal insulation lining. The thermal insulation lining of the present invention can not only maximize the utilization of heat, but also make the temperature in the drying device It is isolated from the outside world and can absorb water molecules and hydrogen molecules, so that the electroplated parts can get better water and hydrogen removal effects, and the precipitated water vapor or hydrogen will not be adsorbed on the electroplated parts again.

Owner:柳州市荣鑫金属表面处理有限公司

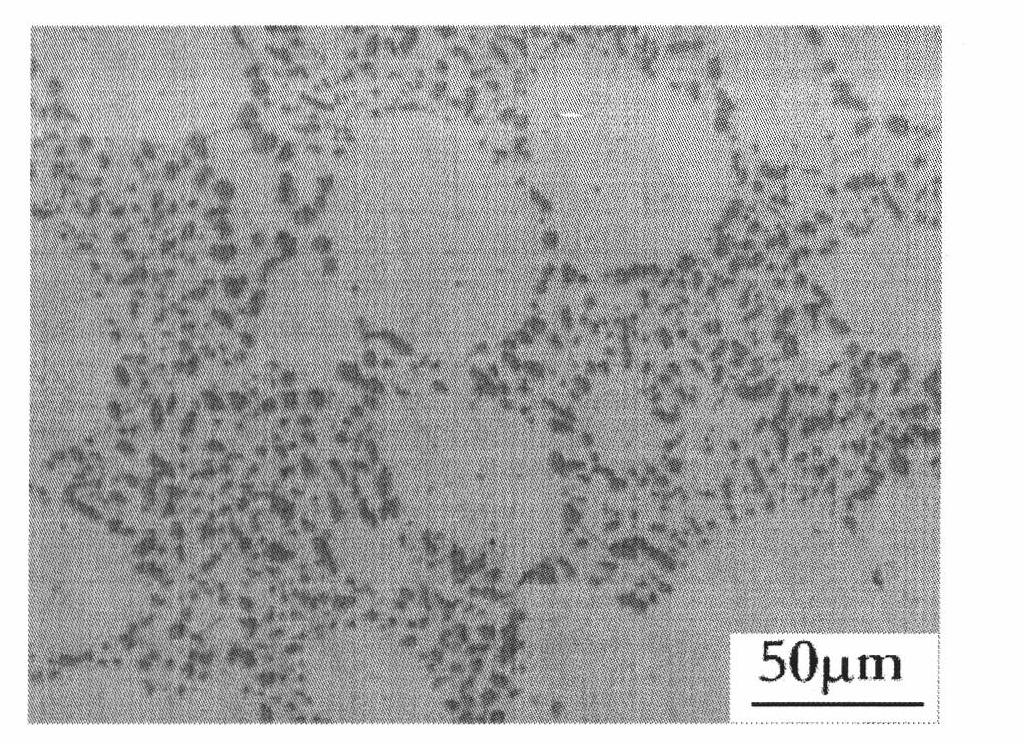

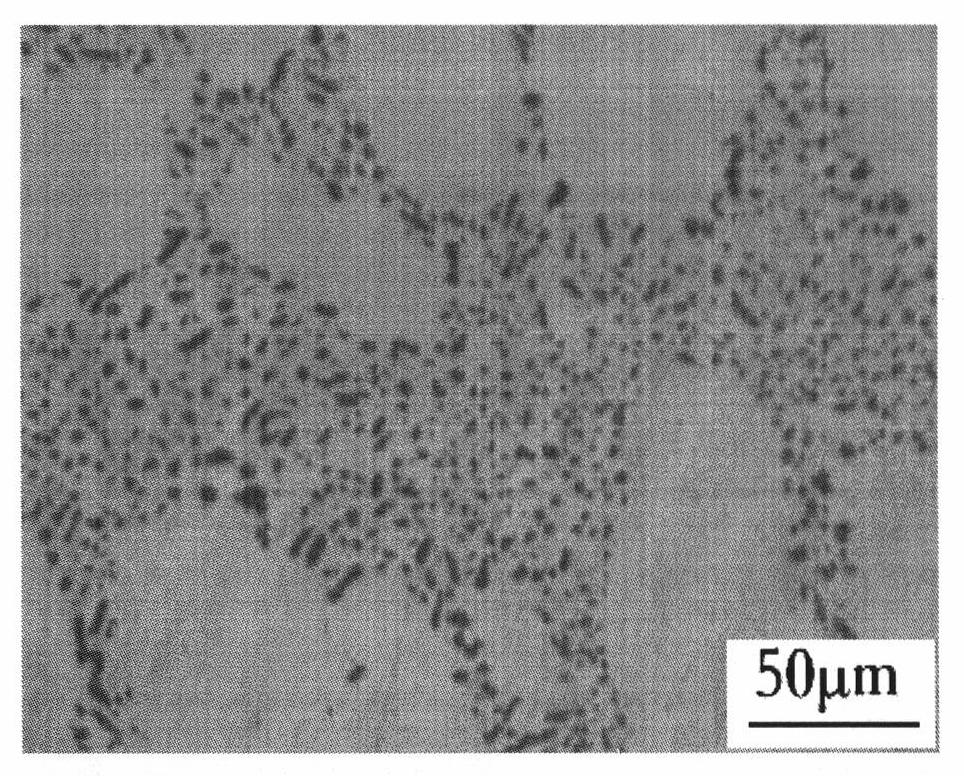

A kind of aluminum alloy refining agent containing lanthanum, erbium and zirconium

ActiveCN105316507BGood dehydrogenation effectImprove mechanical propertiesLanthanumSodium hexafluoroaluminate

The invention discloses an aluminum alloy refining agent containing lanthanum, erbium and zirconium. The refining agent includes material A and material B, wherein the material A includes the following raw materials in parts by weight: 70-80 parts of NaCl, 50-56 parts of KCl, 12-18 parts of LiCl, 30-36 parts of NaF, 10-12 parts of AlF3, 10-12 parts of sodium fluoroaluminate, 12-18 parts of carbon powder, 20-28 parts of light calcium carbonate, 5-10 parts of CaO; the B material It is composed of C2Cl6, TiO2 and metal in a weight ratio of 5:1.5~2:1~1.5, and the metal is a mixed metal containing Mg, La, Er and Zr; A material and B material are used together, and the weight ratio is 2~4 :1. Using the refining agent of the present invention in the process of refining aluminum alloy can not only realize the removal of hydrogen and oxide inclusions, but also play a role in modifying and refining the structure of aluminum alloy.

Owner:广西平果铝合金精密铸件有限公司

An automated barrel plating production line

ActiveCN111647934BHigh degree of automationImprove work efficiencyElectrolysis componentsConveyor partsAutomatic controlControl system

The present invention relates to the technical field of a barrel plating production line, in particular to an automated barrel plating production line, including a barrel plating system, a material transfer system, a hydrogen removal system and an automatic control system. The barrel plating system includes an electroplating device, a cleaning device, a drying device, The drying cylinder and the mobile hanger, the material transfer system includes a material transfer device; the material transfer device includes a lifting frame, a support seat and a fixed frame; the upper end of the lifting frame is provided with a first motor, and the output end of the first motor is fixedly connected to a driving roller. The driving roller is wound with a lifting belt for lifting the support seat. The hydrogen removal system includes an oven and a material receiving device; the material receiving device includes a transmission frame, a material basket and a transmission mechanism. The transmission frame is provided with a first pushing mechanism. The parts in the drying cylinder can be automatically poured into the material basket through the material transfer device, and the transmission mechanism will drive the material basket to move to the oven, which effectively improves the automation of the rack plating production line.

Owner:太仓市海峰电镀有限公司

Hydrocarbon oil desulfurization catalyst containing Fau structure and/or Bea structure molecular sieve and preparation method and process

ActiveCN109718830BReduce usageLow costMolecular sieve catalystsHydrocarbon oils refiningMolecular sievePtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbon oil desulfurization catalyst containing SAPO molecular sieve as well as preparation method of catalyst and hydrocarbon oil desulfurization process

ActiveCN109718847AWith desulfurizationWith dehydrogenation propertiesMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSulfur

The invention relates to a hydrocarbon oil desulfurization catalyst containing an SAPO molecular sieve as well as a preparation method of the catalyst and a hydrocarbon oil desulfurization process. Based on a weight of the hydrocarbon oil desulfurization catalyst, or a total weight of a sulfur storage metal oxide, an inorganic oxide binding agent, boron nitride, the SAPO molecular sieve and a metal promoter, the hydrocarbon oil desulfurization catalyst contains the following components: 10-80% by weight of the sulfur storage metal oxide based on an oxide, 3-35% by weight of the inorganic oxidebinding agent based on an oxide, 5-40% by weight of the boron nitride, 1-20% by weight of the SAPO molecular sieve on a dry basis and 5-30% by weight of the metal promoter based on a metal element. The hydrocarbon oil desulfurization catalyst provided by the invention has the advantages of high stability, good desulfurization activity and good wear resistance when applied to the hydrocarbon oil desulfurization process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com