Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

370 results about "5005 aluminium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

5005 aluminium alloy is an aluminium alloy with good resistance to atmospheric corrosion. It is used in decorative and architectural applications. It is a member of the 5000 series of aluminum-magnesium wrought alloys. As such, it is not used in casting. It can attain moderate to high strength by cold working, and has relatively high welded strength compared to other aluminum alloy families. Tempers H116 and H321 can be used in fresh and salt water.

6063 aluminium alloy with high strength and elongation coefficient an dproduction thereof

The invention opened a high strength and high extensibility 6063 Al alloy which contain the Cu, Mn, chrome, Fe, Zn, Ti, Al. The process is: a, founding: adding the material to the furnace melting stir ring and skimming coving refining skimming and refining thermal retardation casting ingot. b extruding and heat processing: isotroping air cooling, heating extruding quenching cutting cooling stretching straightening aging treatment product. The process has improved the mechanics of the alloy, also the elongation percentage (60%) and the intensity (40%). The tensile strength has been improved to 280-300 MPa, the elongation percentage is improved to 13%. So it satisfy the windows and the curtain wall's need.

Owner:CENT SOUTH UNIV +1

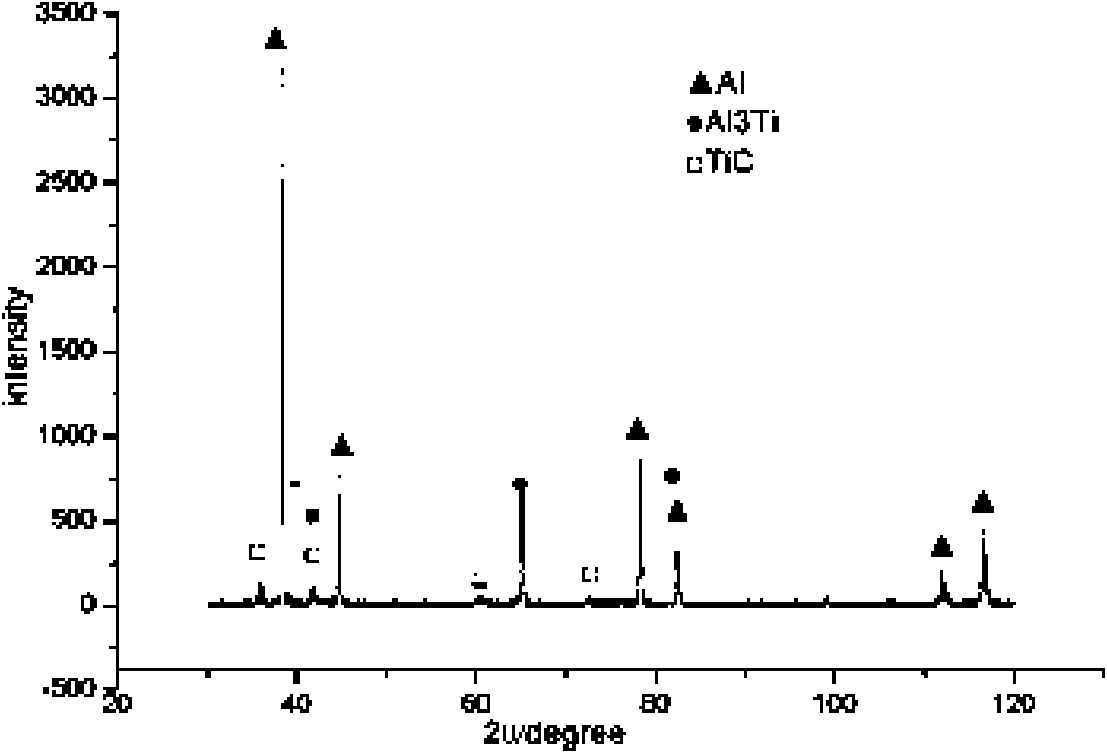

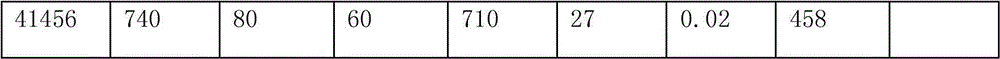

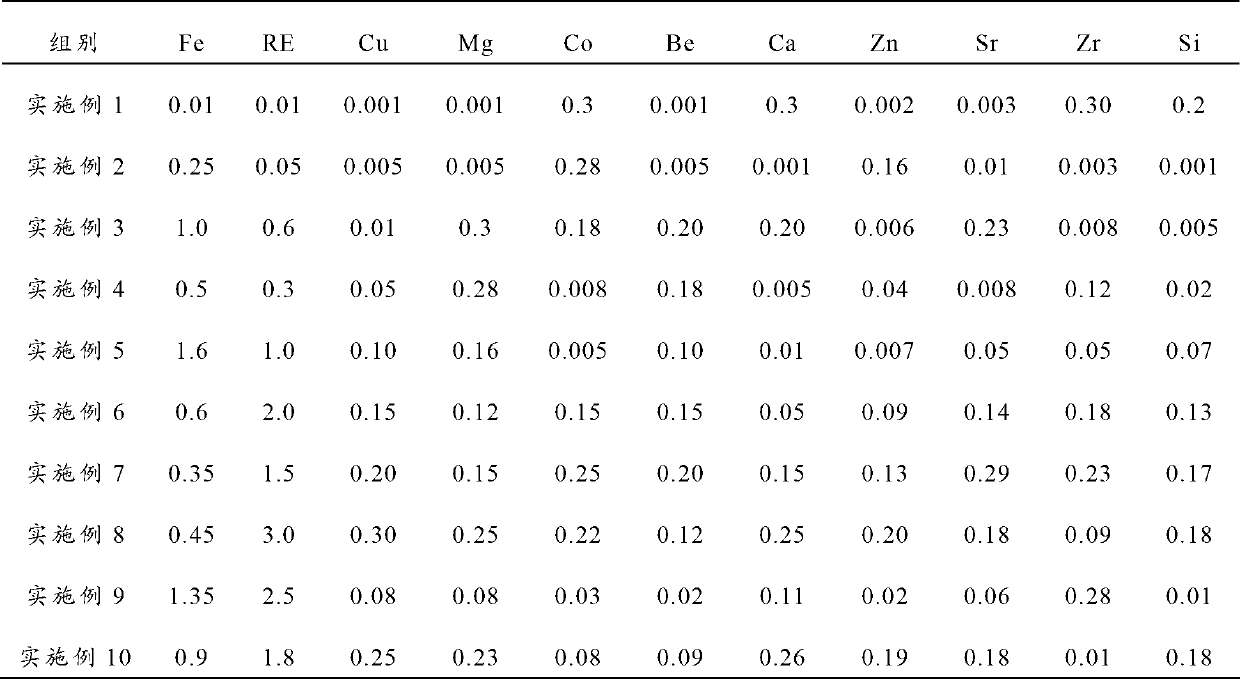

Refiner of aluminium and aluminium alloy with high efficiency and low cost and preparation method thereof

The invention provides a refiner of aluminium and aluminium alloy with high efficiency and low cost and a preparation method thereof, belonging to the technical field of a refiner of aluminium and aluminium alloy and solving the problems that in the prior art, the refiner of the aluminium and aluminium alloy has higher requirements for technique equipment, trivial and complex technique, excessive cost, poor product performance and the like. The refiner of aluminium and aluminium alloy with high efficiency and low cost is aluminium-titanium-carbon-rare earth master alloy; the master alloy contains 3% to 10wt% of Ti, 0.02 to 1wt% of C, 0.02 to 1wt% of RE, aluminium and impurity elements; and the preparation method comprises the following steps of: adopting the rare earth compound as a reacting promoter, casting after smelting reaction and obtaining the refiner. The preparation method has low cost, high efficiency and easy industrialization; the raw material has low price and wide source; the preparation can be carried out in a well-type resistance furnace, does not need extra stirring equipment, and has simple technique; and the refiner has the advantages of capability of being used with a modifier simultaneously, stable organization, refining effect and the like.

Owner:FUZHOU UNIV

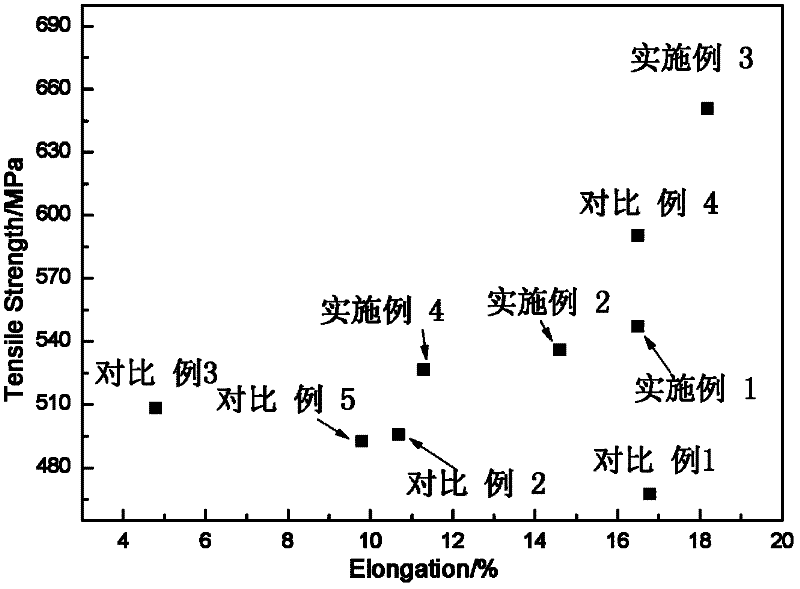

Heat treatment technology for markedly raising comprehensive performance of aluminium alloy

InactiveCN102242325AMeet the requirements of large structural partsPractical application value of large industry5005 aluminium alloySolid solution

A heat treatment technology for markedly raising comprehensive performance of aluminium alloy is accomplished by the adoption of the following scheme: carrying out a solid solution treatment on the aluminium alloy, taking the aluminium alloy out of a furnace and carrying out water quenching, and carrying out a pre-aging treatment, cold deformation and a secondary aging treatment. Nanometer-level aging precipitation strengthening phase is formed by the pre-aging treatment, and dislocation configuration generated from the subsequent cold deformation can be changed, so as to improve the strength, ductility and toughness of the alloy; during the cold deformation, nanometer-level atomic clusters will precipitate out from solute atoms precipitated during the pre-aging treatment, or ''pinning'' air mass is formed around the dislocation structure, thus further raising the strength of the alloy. The precipitated precipitation strengthening phase is nanometer level, thus raising the ductility and toughness of the alloy and markedly enhancing the strength of the alloy on the basis of guaranteeing good plasticity. The technological process provided by the invention is simple, is convenient to operate, can be adopted to markedly raise comprehensive performance such as the strength and plasticity of the aluminium alloy and improve the corrosion resistant performance and fatigue resistant performance of the aluminium alloy, and is suitable for industrial application.

Owner:CENT SOUTH UNIV

Refining agent for aluminium and aluminium alloy melting

InactiveCN102312104AReduce dosageGood effect of removing impuritiesProcess efficiency improvementSlagHydrogen content

The invention provides a refining agent for melting processing of aluminium and aluminium alloy, and the refining agent comprises the following six components of KCl, NaCl, CaF2, Na2SiF6, Na3AlF6, C2Cl6. When the refining agent of the invention is used for melting of aluminium and aluminium alloy, the degassing and impurity-removing effect is better; the hydrogen content in aluminium alloy melt is lower; the burning loss of the metal can be reduced effectively; meanwhile the refining agent has certain heating effect, so the hot slag recovery is more convenient and the recovery rate is higher.

Owner:ALNAN ALUMINIUM CO LTD

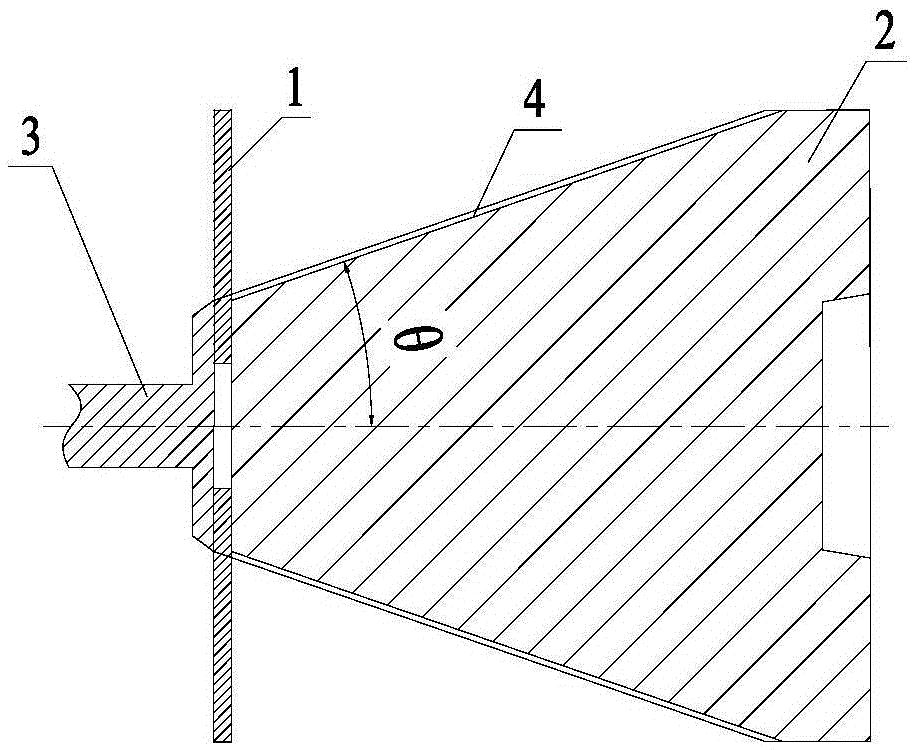

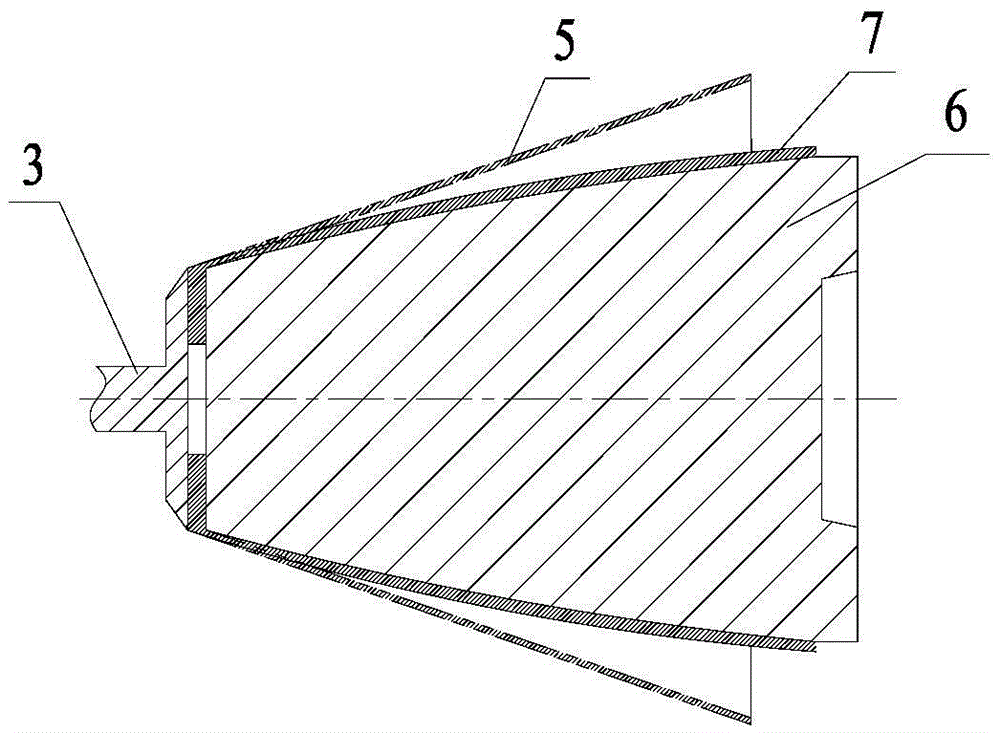

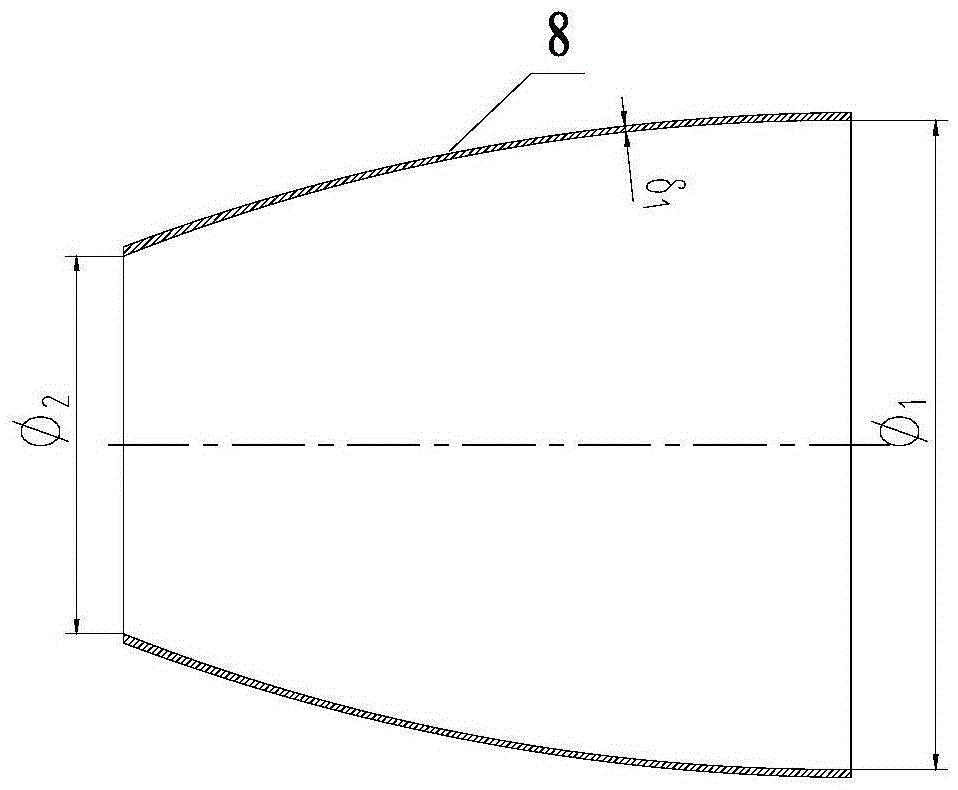

Spinning machining method for aluminium alloy thin-walled revolution body

ActiveCN105537449AMeet sizeFulfil requirementsHollow articles5005 aluminium alloy5052 aluminium alloy

The invention discloses a spinning machining method for an aluminium alloy thin-walled revolution body. The spinning machining method comprises the following steps: producing an aluminium alloy spun blank with required dimensions, and carrying out annealing treatment on the aluminium alloy spun blank; carrying out shearing spinning on the aluminium alloy spun blank to obtain a primary conical barrel; carrying out annealing treatment on the primary conical barrel, and cutting a process allowance at a large end to form a secondary conical barrel; carrying out common spinning on the secondary conical barrel on a spinning machine to obtain a pre-spun aluminium alloy thin-walled revolution body; and carrying out annealing treatment and surface polishing treatment on the pre-spun blank, and then cutting process allowances at the two ends of a spun part by using a plasma cutting machine, so as to obtain the aluminium alloy thin-walled revolution body meeting process requirements. According to the invention, the aluminium alloy thin-walled revolution body is machined by virtue of the technologies of shearing spinning and common spinning; the dimension and structural performance requirements of a bullet shell are met; a machining method and a stamping-welding method can be replaced; and a low-cost and efficient machining method is provided for machining for an aluminium alloy shell of a bullet.

Owner:湖北三江航天江北机械工程有限公司

Process of making oil cylinder body and cover with aluminium alloy

The process of making oil cylinder body and cover of aluminum alloy includes the following steps: heating in a smelting furnace the materials comprising Zn 1-8.0 wt%, Mg 1.0-5.0 wt%, Cu 0.8-2.5 wt%, Mn 0.2-1.0 wt%, Cr 0.1-0.3 wt% and Al for the rest; refining; casting in extruding and casting mold through fast closing mold, slowly applying pressure and maintaining pressure for the aluminum alloy to solidify and crystallize; and final solid solution ageing T6 heat treatment on the cast blank to obtain oil cylinder body and cover casting. The process has high material utilizing rate, high production efficiency and low production cost, and the product blank has light weight, compact and homogeneous structure and less faults.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

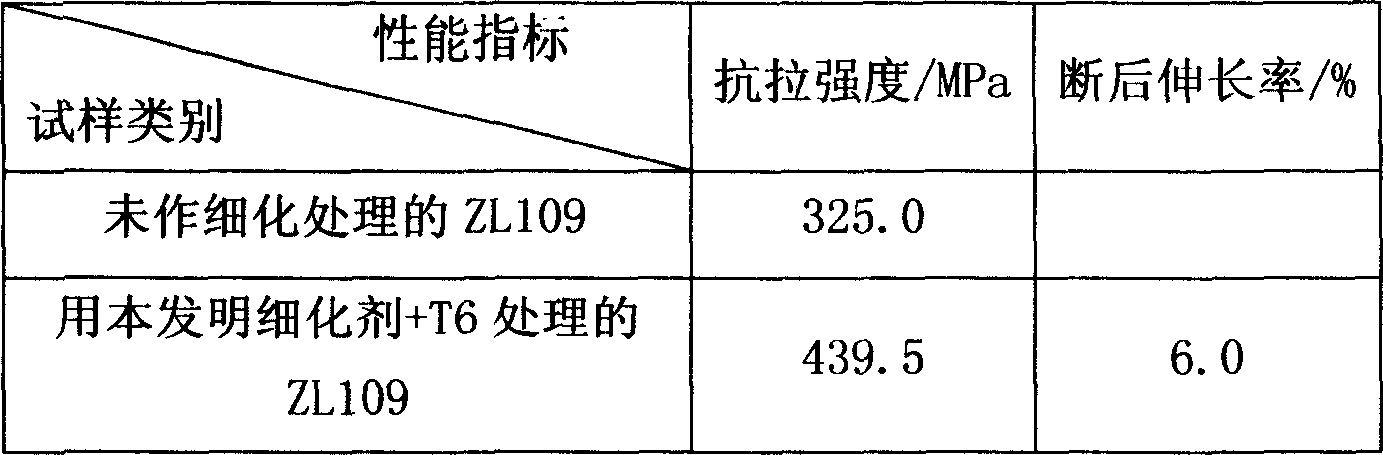

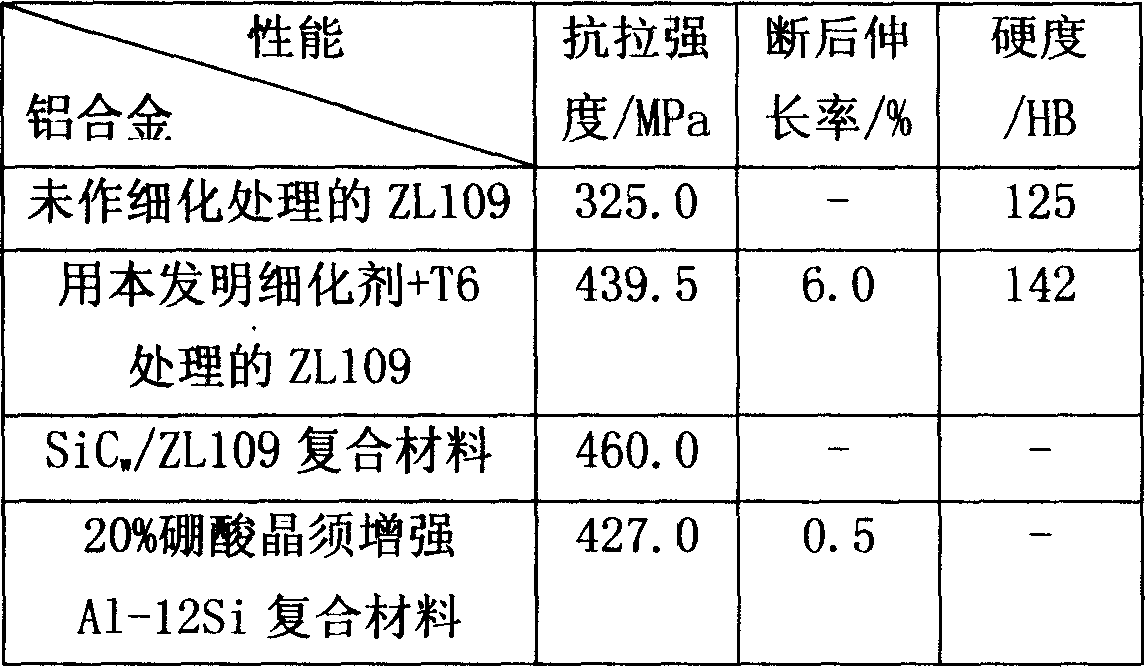

Grain fining agent for casting aluminium alloy, preparation process and application thereof

This invention relates to the crystal grain refining agent which is used to produce aluminium alloy and the method of preparation and application thereof. It is composed of intermediate alloy Cu-P and Al-Ti-B and the crystal grain refine reagent has nanometer crystal band, the weight ratio of the alloy Cu-P to alloy Al-Ti-B is 0.35-0.45:0.65-0.55, the average thickness of bank is 0.3-0.6mm, and the average width is 0.4-1.2mm. The bank is made by quickly quenching flailing. It can be applied to the plunger of the combustion engine by melting metal casting. During the production of aluminium alloy by melting metal, the primary crystal silicon and eutectic silicon can be refined by adding into the crystal grain refine reagent, this increases the energy of interface, so it can decrease the flaw of casting, the over-all properties of the aluminium alloy can be increased. At last, the mechanical property of plunger which is made of aluminium alloy, the abrasion of it and the lifetime of it can improve distinctly.

Owner:HEBEI UNIV OF TECH

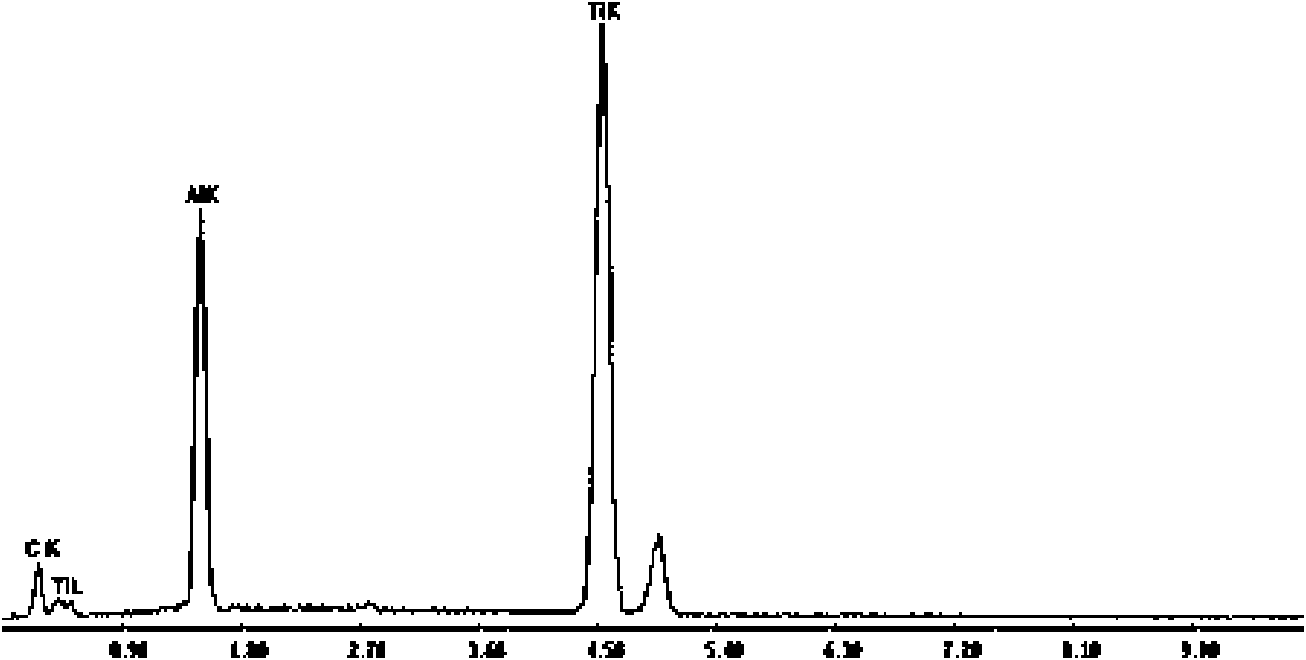

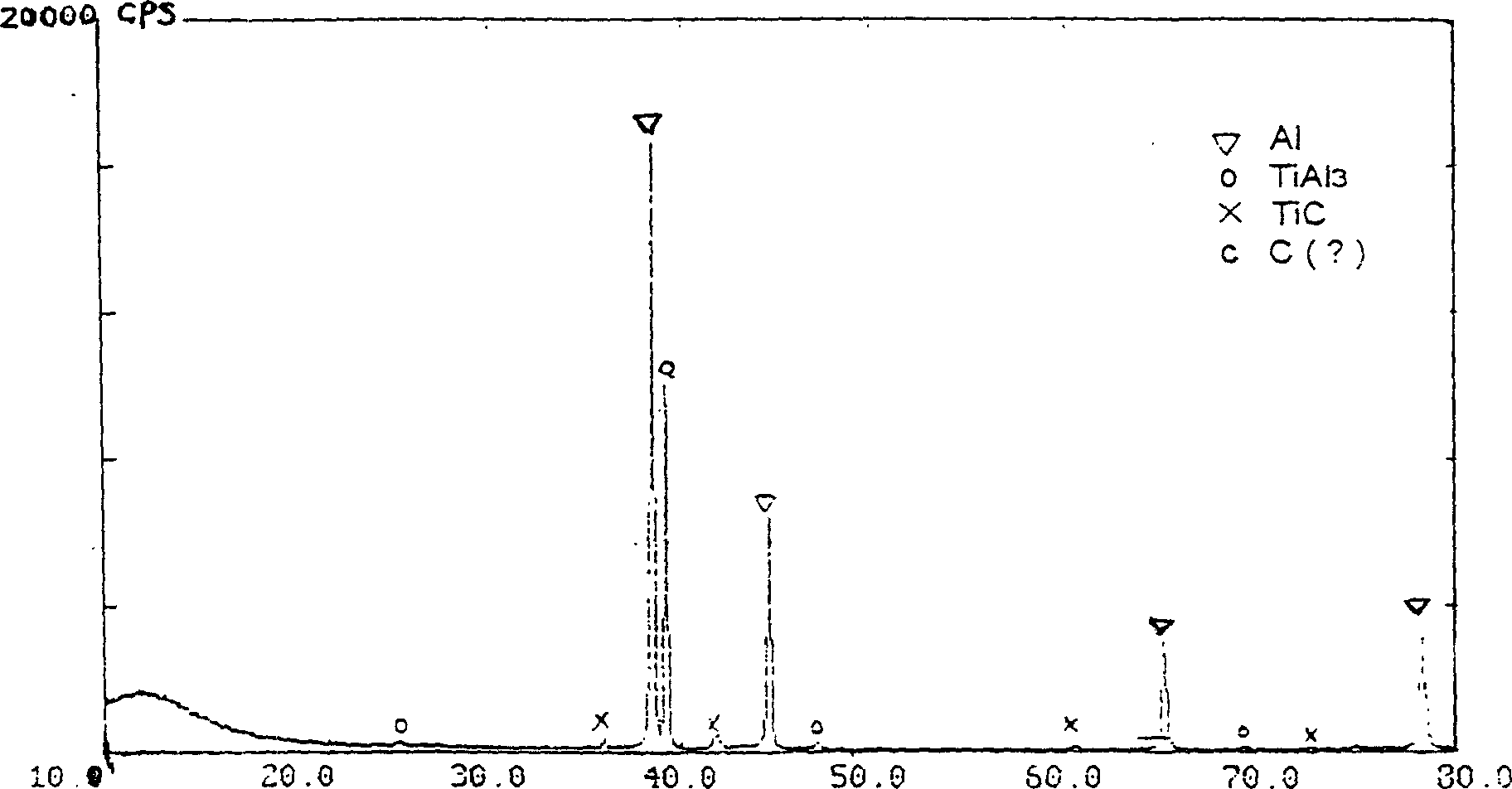

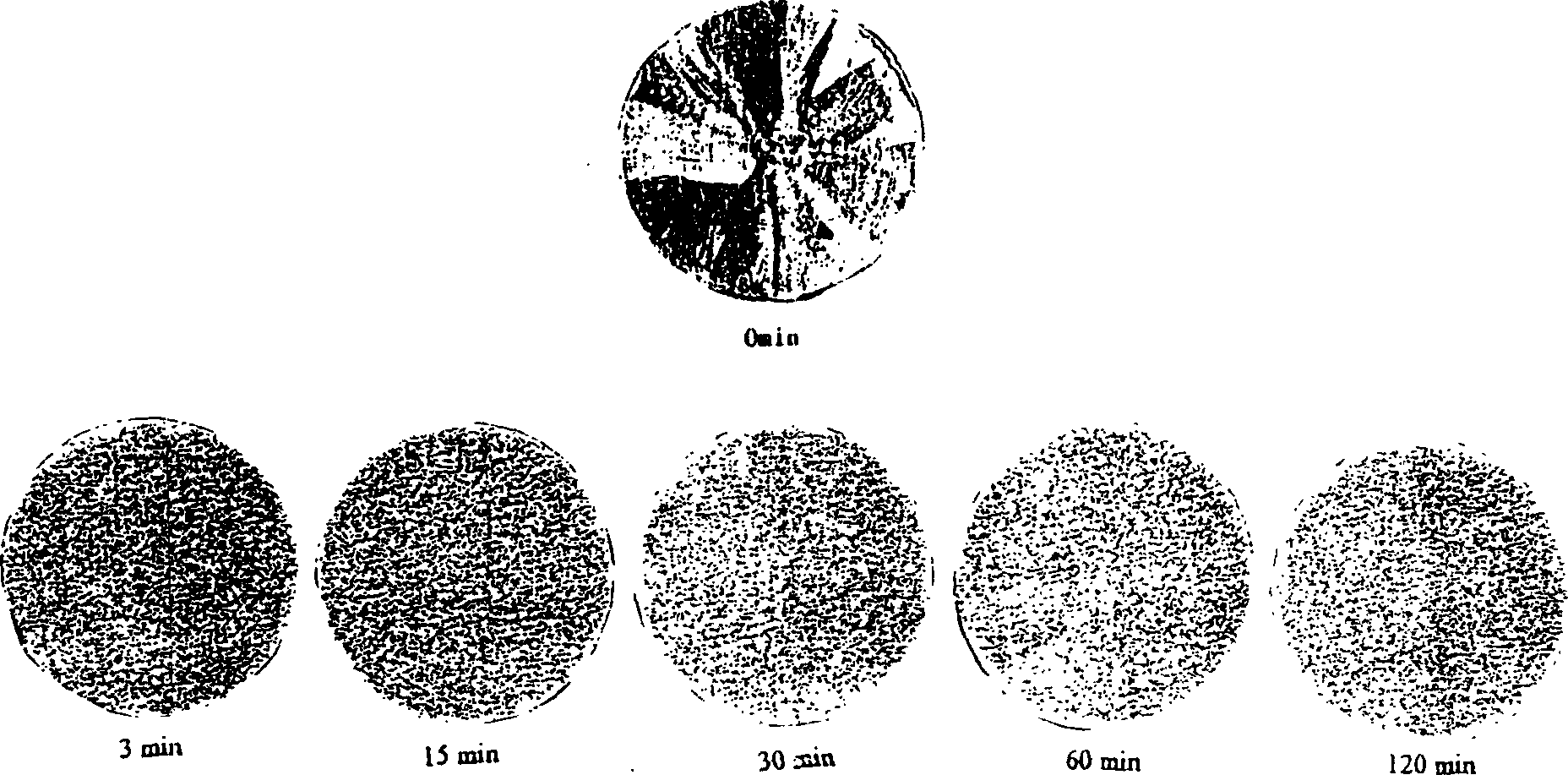

Refining agent for crystalline grain of aluminium titanium carbon intermediate alloy

The aluminium titanium carbon intermediate alloy grain thinning agent relates to a AlTiC grain thining agent containing TiC granules for thinning aluminium and aluminium alloy and its preparation method. It is characterized by that said alloy composition contains (wt%) 3%-6% of Ti anjd 0.02%-0.5% of C, the reset is aluminium and inevitable impurity, in which the ratio of Ti:C is 25:1. Its preparation method is characterized by that the carbon powder prepared by using one selected from industrial graphite, natural graphite, amorphous graphite, active carbon and carbon black carbon is introduced into aluminium melt by means of graphite rotor of rotary refining equipment and stirred until the aluminium melt contains no monomer carbon.

Owner:ZHUOZHOU JINGYING ALUMINUM ALLOY MATERIAL

Low pressure casting aluminium alloy for cylinder cap of minicar engine

The present invention relates to a minicar engine cylinder cap low-pressure casting aluminium alloy, and its main chemical components are Si, Cu and Mg, in particular Cu and Mg control is better, and its harmful impurity element control is serious, and after said alloy is undergone the processes of modification treatment by means of modification agent and (T6) heat treatment, its tensile strength QbMPa is greater than or equal to 300, HB is about 110, and said alloy has enough strength and rigidity and good size stability, and said alloy can meet the requirements for miniature car engine cylinder cap low-pressure casting process and mechanical working process.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Preparation method of high-quality 6061 aluminium alloy forging for semiconductor equipment

ActiveCN102644039AImprove qualityEasy to operateMetal-working apparatus5005 aluminium alloyHeat treated

A preparation method of a high-quality 6061 aluminium alloy forging for semiconductor equipment comprises the following steps of: (1) blank making by a common semicontinuous casting method; (2) homogenization heat treatment of 6061 aluminium alloy by two-stage homogenization technology, wherein a first-stage temperature range is 540-570 DEG C, heat preservation time is selected to be 12-24 hours, a second-stage temperature range is 570-620 DEG C, and heat preservation time is selected to be 18-24 hours; (3) forging technology, wherein a preheating temperature of a press chopping block is 300-350 DEG C, the maximal forging heating time is not more than 3 when multi-heating forging is employed, an upsetting forging ratio for each heating is controlled to be 4-6 when forging with 2-3 heating times is employed, the forging ratio is controlled to be 7-9 when forging with one heating time is employed, and the final forging temperature is controlled to be 320-360 DEG C; (4) solid solution aging technology, wherein a solid solution temperature is 520-540 DEG C, heat preservation time is on a basis of 45 min, the heat preservation time increases by 1 min when the thickness of the forging increases by 1 mm, an aging temperature is 160-180 DEG C, and heat preservation time is between 16-25 hours. The invention provides the preparation method of a high-quality 6061 aluminium alloy forging for semiconductor equipment, and the method has the advantages of strong operability, high yield, stable product performance, high product added value, and the like, is applicable to production for small-lot supply, and has significant economic benefits.

Owner:GRIMAT ENG INST CO LTD

Preparation method of 7B04 aluminium alloy section

InactiveCN101760679AGood mechanical propertiesMeet the indicator requirements5005 aluminium alloyIngot

The invention relates to a preparation method of a 7B04 aluminium alloy section, which solves the problems that a large-sized round cast ingot is difficult to form and mechanical property and electrical conductivity can not meet index requirements at the same time in the traditional preparation process of the 7B04 aluminium alloy section. The preparation method comprises the following steps of: 1, smelting the round cast ingot of a casting alloy; 2, uniformly annealing; 3, extruding into the section; 4, quenching; and 5, aging to obtain the 7B04 aluminium alloy section. The 7B04 aluminium alloy section has properties meeting the index requirements, and achieves the finished product ratio more than 80 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Method for casting aluminium alloy

ActiveCN101474668AQuality improvementReduced mobilityFoundry mouldsFoundry cores5005 aluminium alloy6005 aluminium alloy

The invention provides a casting method of aluminum alloys. The method comprises four steps of smelting, refining, moulding and pouring. The casting method is characterized by adding specific additive in the casting process and strictly controlling standing time and casting temperature after refining of aluminum pad to enhance purity of aluminum melt and product quality of the aluminum alloys. The tensile strength, pinhole and the like of the castings which are made by the method are obviously enhanced, and defective index of large aluminum alloy castings made by the method is obviously reduced, and the method is applicable to casting of large aluminum castings with high requirements.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD +1

Nouel high-strength wear-resisting and corrosion-resisting aluminium alloy

InactiveCN1775979ASolve the technical problems of coarse tissue, composition segregation, and unstable performanceSolve the technical problems of coarseness, composition segregation, and unstable performanceMolten metal pouring equipmentsPortable lifting5005 aluminium alloyIngot

The invention relates to a new type strong antifriction anticorrosion aluminum alloy and the method to manufacture that belongs to metal material field. The weight ratio of the constituents is Si 1.0-50%, Fe 0.5-10.0%, Cu 0.1-5.0%, Mg 0.01-5.0%, La 0.01-3.0%, Ce 0.01-3.0% and the rest is Al. The manufacturing method is that: mixing the simple metal substance Al, Si, Fe, Cu, Mg, La, Ce according to the ratio, spraying settling to AlSiFeCuMgLaCe alloy rotundity ingot on the spraying molding device. The alloy rotundity could be processed to molding mechanism components. It could be widely used in motorcar, mechanism, metallurgy, and electric. The combination property is improved.

Owner:KUNMING INST OF PRECIOUS METALS

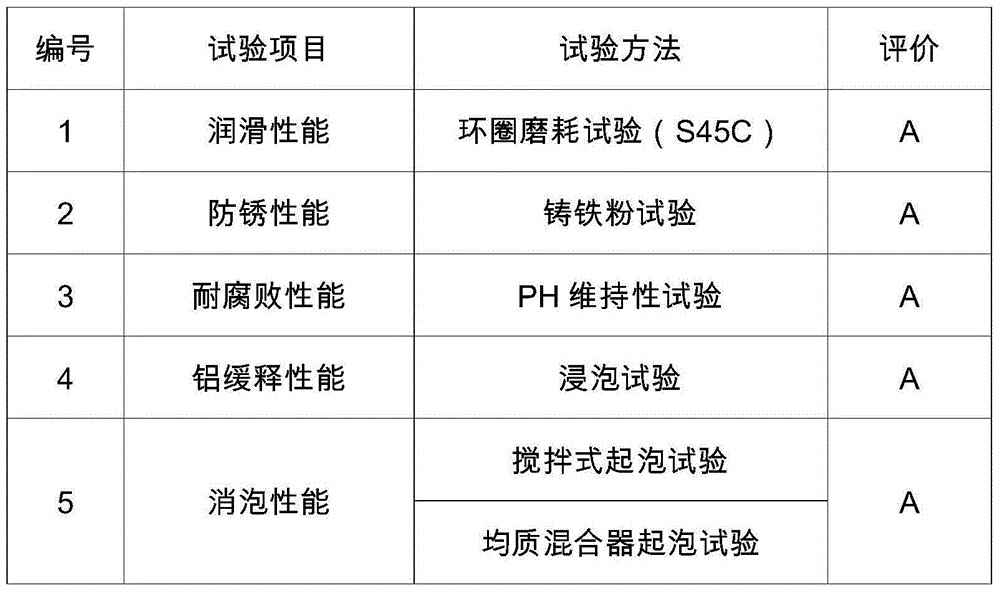

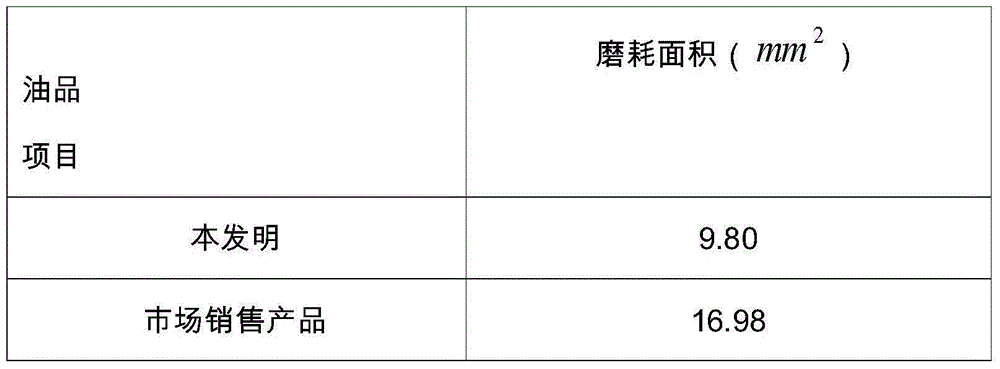

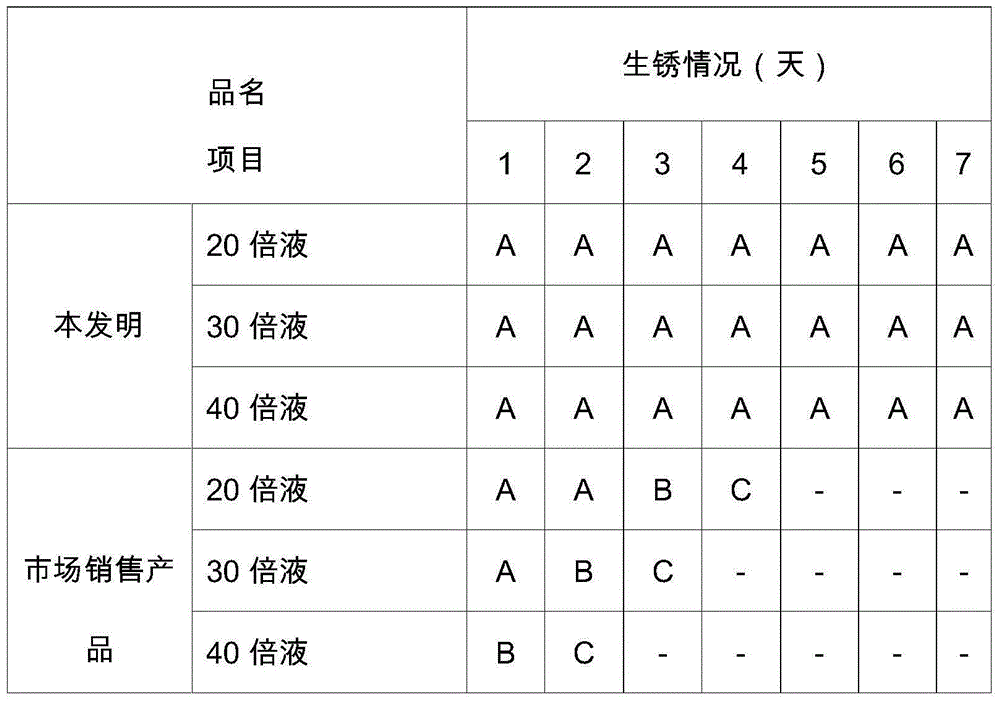

Microemulsified cutting fluid

InactiveCN105001964AImprove rust resistanceImprove the lubrication effectLubricant composition5005 aluminium alloyToxic chemical

The invention provides a microemulsified cutting fluid. The microemulsified cutting fluid comprises following ingredients, by weight, 3.00 to 21.00% of a pH value conditioning agent, 0.50 to 4.00% of an antirust agent, 0.50 to 2.00% of a bacteriostatic agent, 6.00 to 18.00% of an anionic surfactant, 1.00 to 5.00% of a nonionic surfactant, 1.00 to 4.00% of a corrosion inhibitor, 4.00 to 15.00% of a base oil, and 40 to 50% of water. The microemulsified cutting fluid possesses excellent rust resistance, lubricating properties, and especially excellent corrosion resistance on aluminium alloy, so that a problem that corrosion resistance of conventional microemulsified cutting fluid on different aluminium alloy processing is poor is solved. The microemulsified cutting fluid is suitable for processing of metal such as aluminium parts and steel parts. The microemulsified cutting fluid contains no toxic chemicals, such as nitrite and hydrozybenzene, which are harmful for human body or the environment, is friendly to the environment, and is high in efficiency.

Owner:WUHAN SPACEFLIGHT SCI & TECH PETROCHEM CO LTD

Die-casting aluminium alloy

InactiveCN1607261AMake up for the disadvantage of about 45% higher densitySave electricityMold fillingManganese

A aluminium alloy for press casting very thin parts (0.7-1.2 mm) is composed of (by weight) 10.0-14.0 % of silicon, 2.5-4.5 % of copper, 0-2.0 % of nickel, 0-1.5 % of manganese, the total content of nickel and manganese keeps in 0.5-2.0 %. The alloy castability (mold filling ability) increases by more than 20 %. Under high pressure press casting, 0.7-1.2 mm wall casting can be made and can be used as casing of 3C products, also the cost is reduced by more than 20-30 % compared with magnesium alloy.

Owner:ALLOY MATERIALS LAB

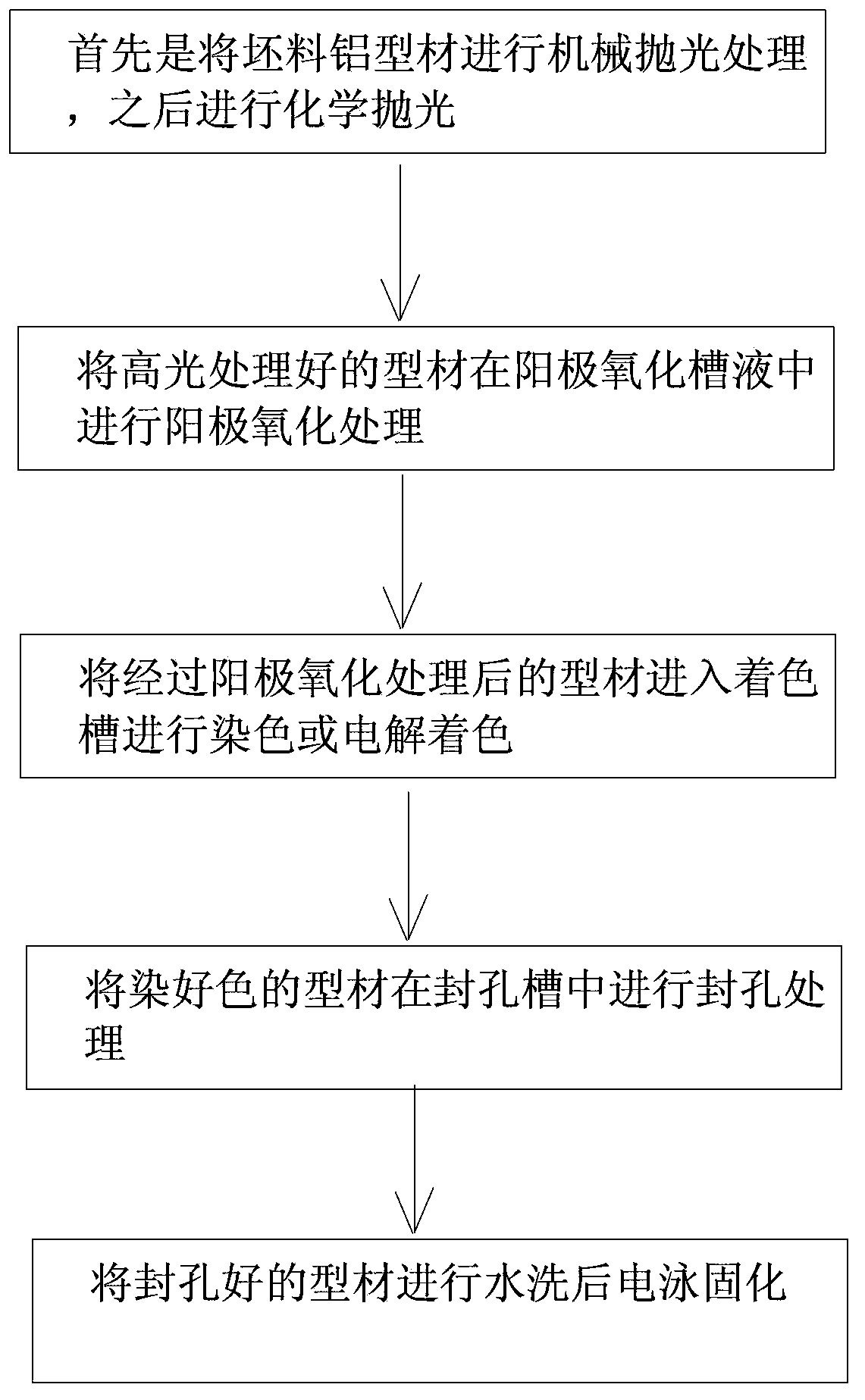

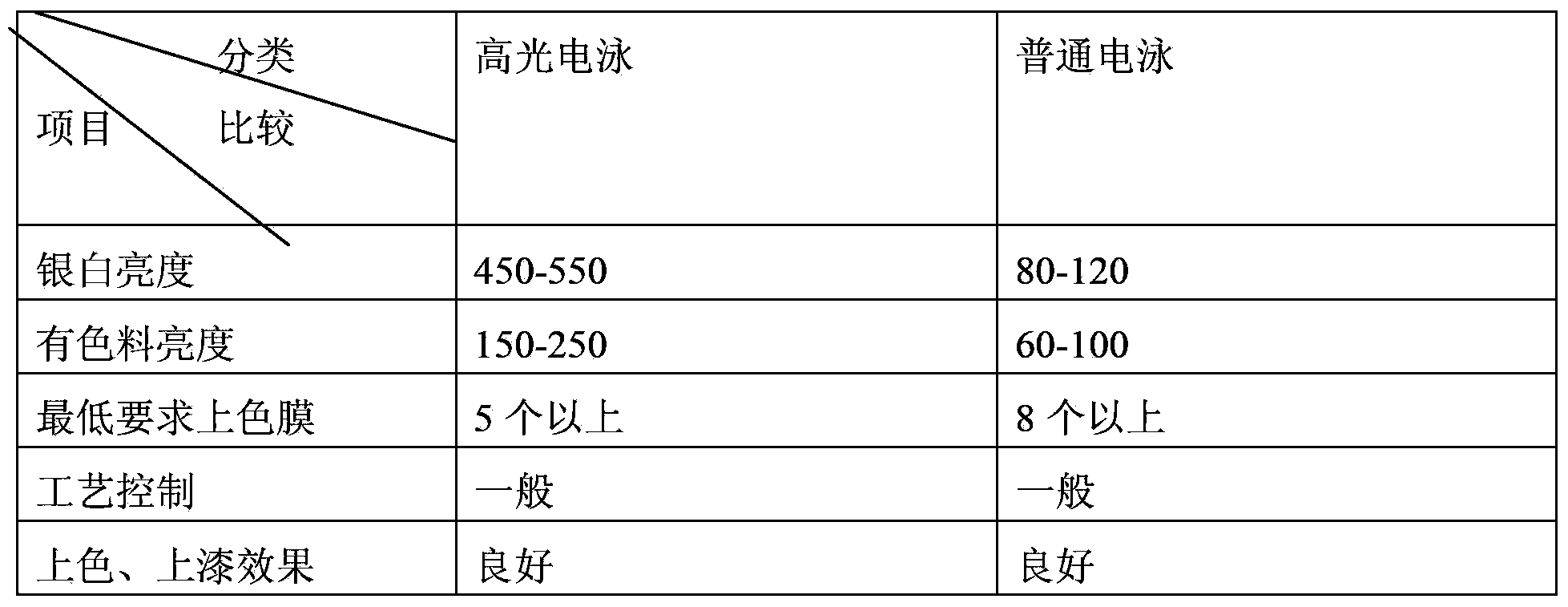

High-light anode oxidation and electrophoresis process of aluminium alloy

ActiveCN103352244AStrong acid and alkali resistanceChange tint colorAnodisationElectrophoretic coatingsWeather resistanceElectrophoresis

The invention discloses a high-light anode oxidation and electrophoresis process of aluminium alloy, which is rarely used in the industry of all aluminum material factories and is most suitable for batch production. The high-light anode oxidation and electrophoresis process comprises the following procedures of: (1) high-light treatment of the aluminium alloy; (2) generation of an oxidation film by anode oxidation; (3) coloring; (4) high-temperature hole sealing; and (5) electrophoresis and curing procedures. The high-light anode oxidation and electrophoresis process disclosed by the invention has the advantages that for the aluminium treated by the process, the color is bright without large change, a layer of electrophoresis paint film is coated on the surface, the glossiness is bright, the corrosion resistance and the weather resistance are optimal, the decorative effect is optimal, the aluminum alloy can be arranged outdoors for sunning, the acid and alkali resistance is high, and the process control is easy in the production process.

Owner:GUANGDONG YAOYINSHAN ALUMINUM

Grain refinement machining process of hard aluminium alloy cast ingot

ActiveCN102943193AEliminate the external conditions that ariseRefining as-cast grain5005 aluminium alloyIngot

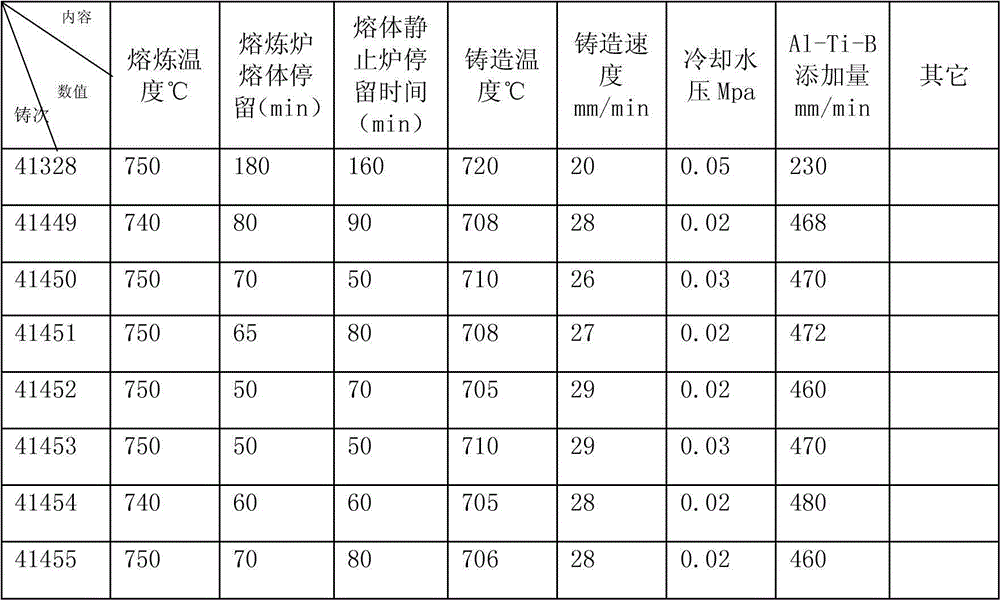

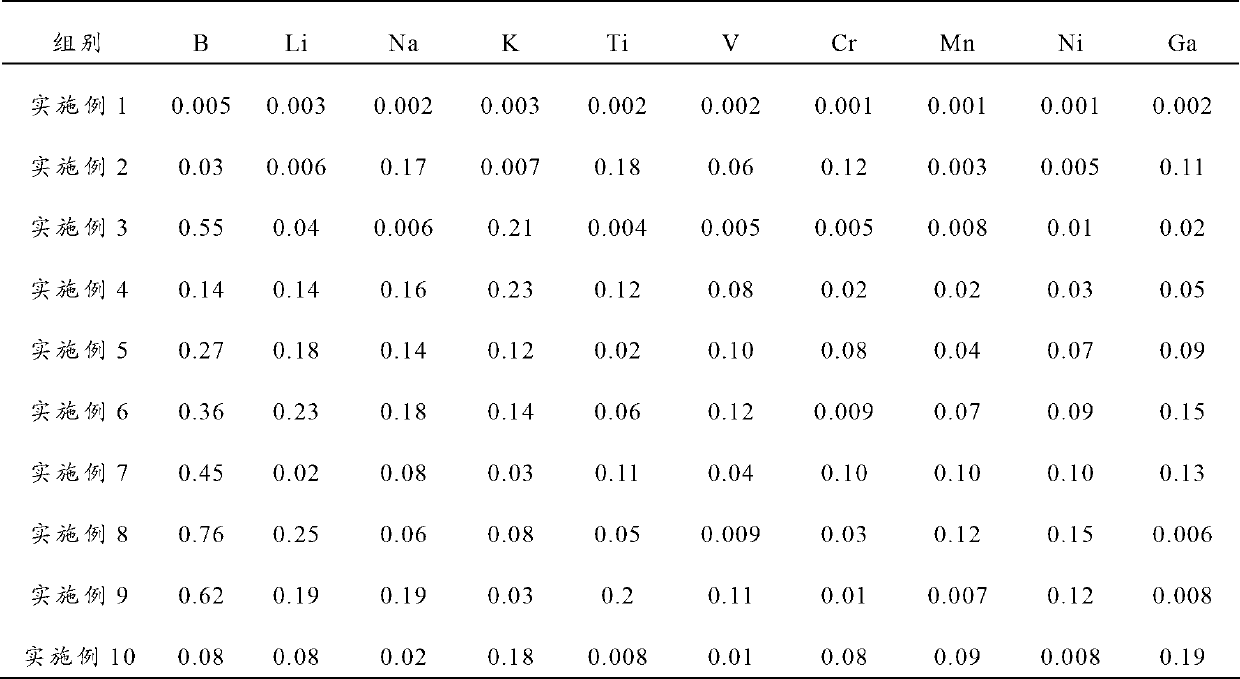

The invention provides a grain refinement machining process of a hard aluminium alloy cast ingot, belonging to the technical field of aluminum alloy machining. The grain refinement machining process comprises the following steps of: blending, smelting, stirring, temperature measuring, sampling, component and temperature regulating, turning down, refining (namely primary purifying), standing, online adding of Al-Ti-B wires, online degassing and deslagging (namely secondary purifying), two-stage filtering, hot-top casting at a same level, and homogenizing of the cast ingot, thus completing grain refinement machining of the hard aluminium alloy cast ingot. The hard aluminium alloy cast ingot machined by the machining process has a better heat deformation property, is high in strength through online quenching during extruding, has better welding and corrosion resistance properties and a certain stress corrosion resistance property, and especially has a high shock absorption capacity as well as a good folding resistance property.

Owner:丛林铝业科技(山东)有限责任公司

Production process of aluminium alloy specially used for automobile hubs in salt damage regions

A production process of aluminium alloy specially used for automobile hubs in salt damage regions. The aluminium alloy comprises the following components by weight: 6.8-7.4% of Si, 0.32-0.40% of Mg, 0.08-0.13% of Ti, not more than 0.13% of Fe, not more than 0.01% of Zn, not more than 0.03% of Ca, not more than 0.01% of Cu, not more than 0.05% of Mn, not more than 0.01% of P, not more than 0.05% of Ni, not more than 0.05% of Cr, not more than 0.01% of Sn, not more than 0.05% of Pb, and the balance of raw aluminum ingots. The process comprises the following steps: melting the components of Si, Ti, Fe, Zn, Ca, Cu, Mn, P, Ni, Cr, Sn, Pb, and raw aluminum ingots in a melting furnace according to the weight ratios, when the temperature reaches 750-820 DEG C, uniformly stirring the melt, adding Mg according to the weight ratio, uniformly stirring, removing slag to obtain aluminium alloy melt; introducing the aluminium alloy melt into a standing furnace, spraying a refining agent with argon or nitrogen into the aluminium alloy melt for refining; when the refining process completes, removing slag, allowing the aluminium alloy melt to stand in the standing furnace for 30 min; performing casting molding of the aluminium alloy melt after standing by an automatic casting machine, stacking and packaging to obtain the aluminium alloy specially used for automobile hubs in salt damage regions.

Owner:秦皇岛开发区美铝合金有限公司

Al-Fe-Os-RE aluminium alloy, preparation method thereof and power cable

ActiveCN103103384AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsPower cable5005 aluminium alloy

The invention provides an Al-Fe-Os-RE aluminium alloy and a preparation method thereof. The preparation method comprises the following steps of: a) casting an aluminium alloy cast ingot; b) homogenizing the aluminium alloy cast ingot and rolling the homogenized aluminium alloy cast ingot to obtain an aluminium alloy rod material; c) intermittently annealing the aluminium alloy rod material obtained in the step b); and d) aging the aluminium alloy rod material obtained in the step c), thus obtaining the aluminium alloy. The invention also provides a power cable. The aluminium alloy has better overall performances by selecting and controlling the added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

Aluminium alloy with high strength and excellent cutting property and preparation method thereof

The invention relates to an aluminium alloy with high strength and excellent cutting property and a preparation method thereof, and belongs to the technical field of alloys. The product, namely the aluminium alloy with high strength and excellent cutting property, is obtained through slagging-off, alloy preparing, refining, standing, casting, homogenizing, extruding and carrying out artificial aging after melting an aluminium ingot. According to the invention, by means of proportioning alloy composition, controlling a production process and the like, the alloy bar can achieve the tensile strength of greater than or equal to 280MPa, the regulated non-proportional extension strength of greater than or equal to 250MPa, the elongation A of greater than or equal to 10 percent and the HV hardness of 98 to 108; the cutting property of the material is greatly improved.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

Low porosity closed cell foam aluminum alloy and its preparation method

The invention discloses a low porosity closed cell foam aluminum alloy preparation method comprising the steps of, (1) heating aluminium alloy to melting, (2) charging 0.5-5% thickener, stirring the aluminium alloy to increase thickness, (3) charging foaming agent 0.2-5.0 wt% of aluminium alloy, stirring homogeneously, (4) stirring 10s-180s again, (5) extracting the stirring paddle, (6) subjecting the thermal insulated foam aluminium alloy flux to simultaneous cooling. The invention also discloses a closed cell foam aluminium alloy with low factor of porosity.

Owner:SOUTHEAST UNIV

Al-Fe-Rh-RE aluminium alloy, preparation method thereof and power cable

ActiveCN103103382AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsPower cable5005 aluminium alloy

The invention provides an Al-Fe-Rh-RE aluminium alloy and a preparation method thereof. The preparation method comprises the following steps of: a) casting an aluminium alloy cast ingot; b) homogenizing the aluminium alloy cast ingot and rolling the homogenized aluminium alloy cast ingot to obtain an aluminium alloy rod material; c) intermittently annealing the aluminium alloy rod material obtained in the step b); and d) aging the aluminium alloy rod material obtained in the step c), thus obtaining the aluminium alloy. The invention also provides a power cable. The aluminium alloy has better overall performances by selecting and controlling the added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

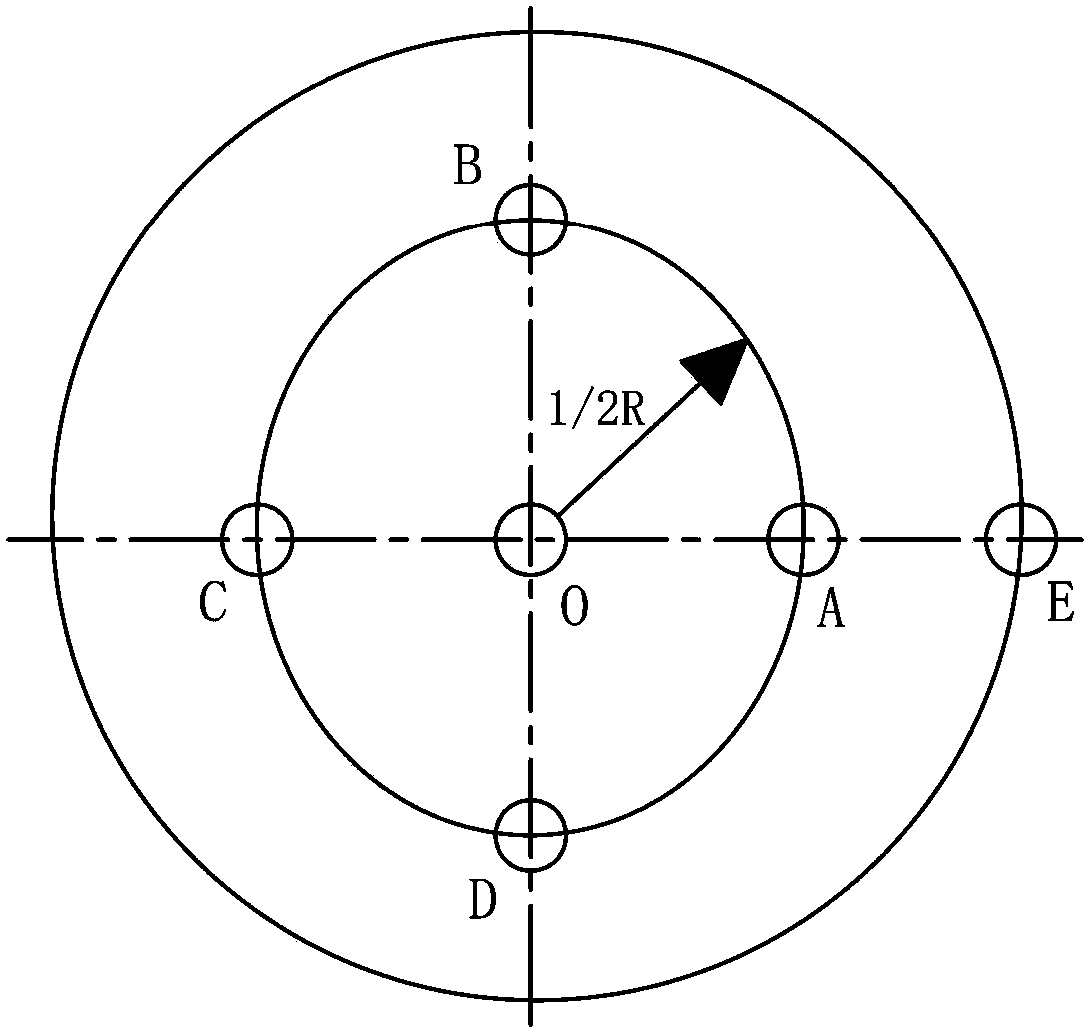

Method for preparing aerospace-level vanadium-aluminium alloy

The invention provides a method for preparing an aerospace-level vanadium-aluminium alloy. The method comprises the following steps: uniformly mixing vanadium pentoxide, metallic aluminium and a coolant, putting into a smelting furnace, igniting and smelting to obtain a vanadium-aluminium alloy with the vanadium content of 75-85wt% and slag; adding the vanadium-aluminium alloy obtained through the smelting into a vacuum induction furnace, adding aluminum, remelting and refining to obtain the aerospace-level vanadium-aluminium alloy with the vanadium content of 45-55wt%, wherein the mass ratio of the added aluminum to the added vanadium-aluminium alloy is 0.45-0.77. The method provided by the invention has the advantages that the aerospace-level vanadium-aluminium alloy can be obtained; the smelting furnace does not need to be knotted and only simple filling is carried out by using corundum fine powder with the particle size less than 5mm, the furnace body can be protected and the requirements for smelting the vanadium-aluminium alloy through aluminothermy are satisfied, so that the production cost is reduced and the method is simple in operation.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Shape memory alloy particle reinforced light metal-based composite material and preparation method thereof

The invention provides a shape memory alloy particle reinforced light metal-based composite material and a preparation method thereof. The composite material comprises a substrate and shape memory alloy particles, wherein the volume content of the shape memory alloy particles is 5-40% and the thickness of the composite material is 2-20 millimeters. The method is characterized by prearranging the shape memory alloy particles in an aluminium alloy or magnesium alloy plate by adopting the dot matrix porous particle prearranging mode to prepare the shape memory alloy particle reinforced light metal-based composite material through the friction stir processing technology. The composite material has the following advantages: the particles in the composite material are uniformly distributed; the interface between the particles and the substrate is clean and no reactants are generated on the interface; and the composite material has the shape memory effect and excellent damping property.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

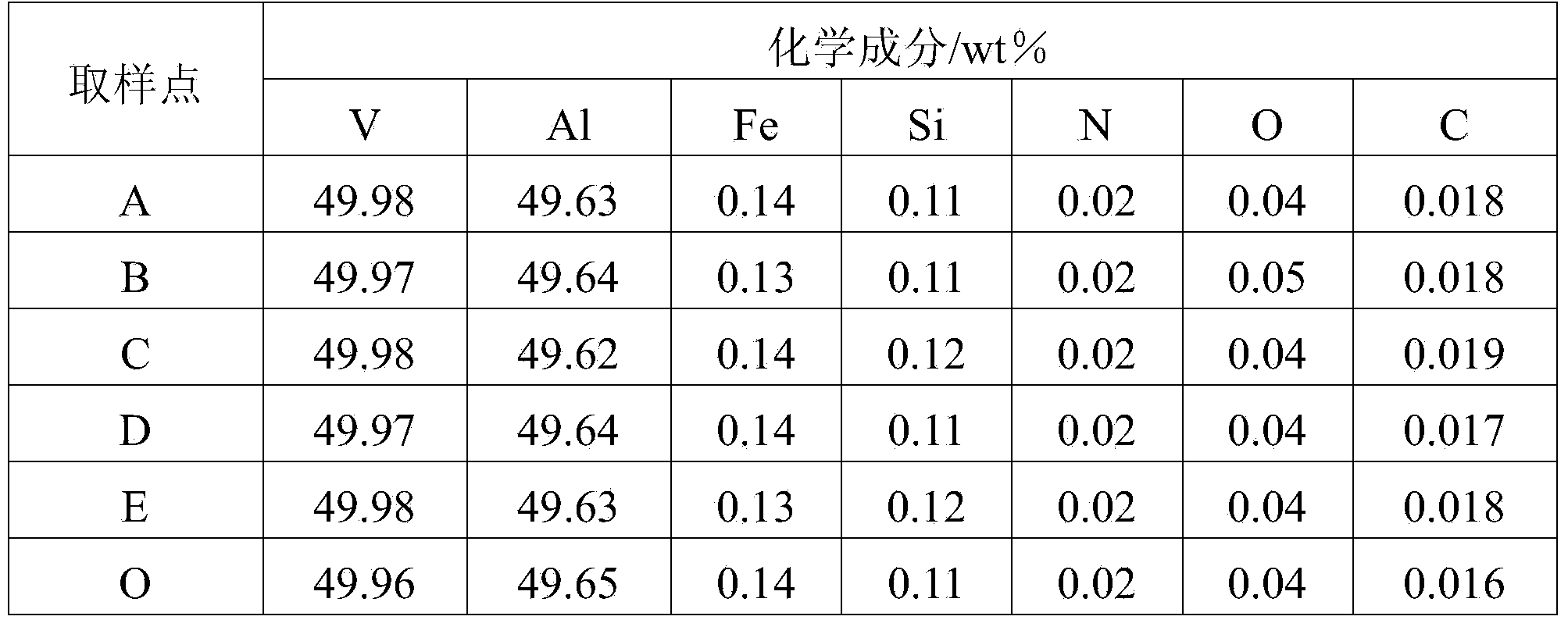

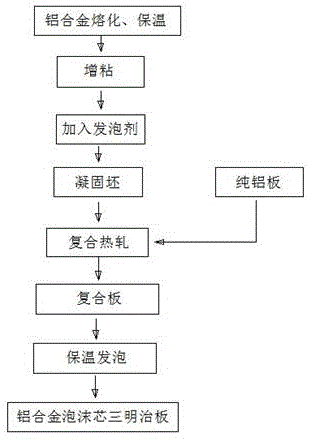

Preparation method of sandwich board with aluminium alloy foam core

InactiveCN105642671ASimple processProcess is easy to controlMetal rolling arrangementsFoaming agentSandwich board

The invention provides a preparation method of a sandwich board with an aluminium alloy foam core and belongs to the field of porous metal materials. According to the method, an aluminium alloy is melted, kept at the temperature and tackified, a foaming agent TiH2 subjected to pre-oxidation treatment is added to tackified aluminium alloy melt for stirring dispersion, after TiH2-containing tackified aluminium alloy melt is cooled and solidified, a solidified blank is obtained, a pure aluminium board and the solidified blank are subjected to composite hot-rolling, a composite board with the surface being a pure aluminium layer and the core being an aluminium alloy foamable precursor is obtained, then the composite board is heated to the temperature 10-30 DEG C higher than that of an aluminium alloy liquid phase line for heat-insulating foaming, and the sandwich board with the surface being a pure aluminium layer and the core being aluminium alloy foam is obtained after a foamed body is cooled.

Owner:KUNMING UNIV OF SCI & TECH

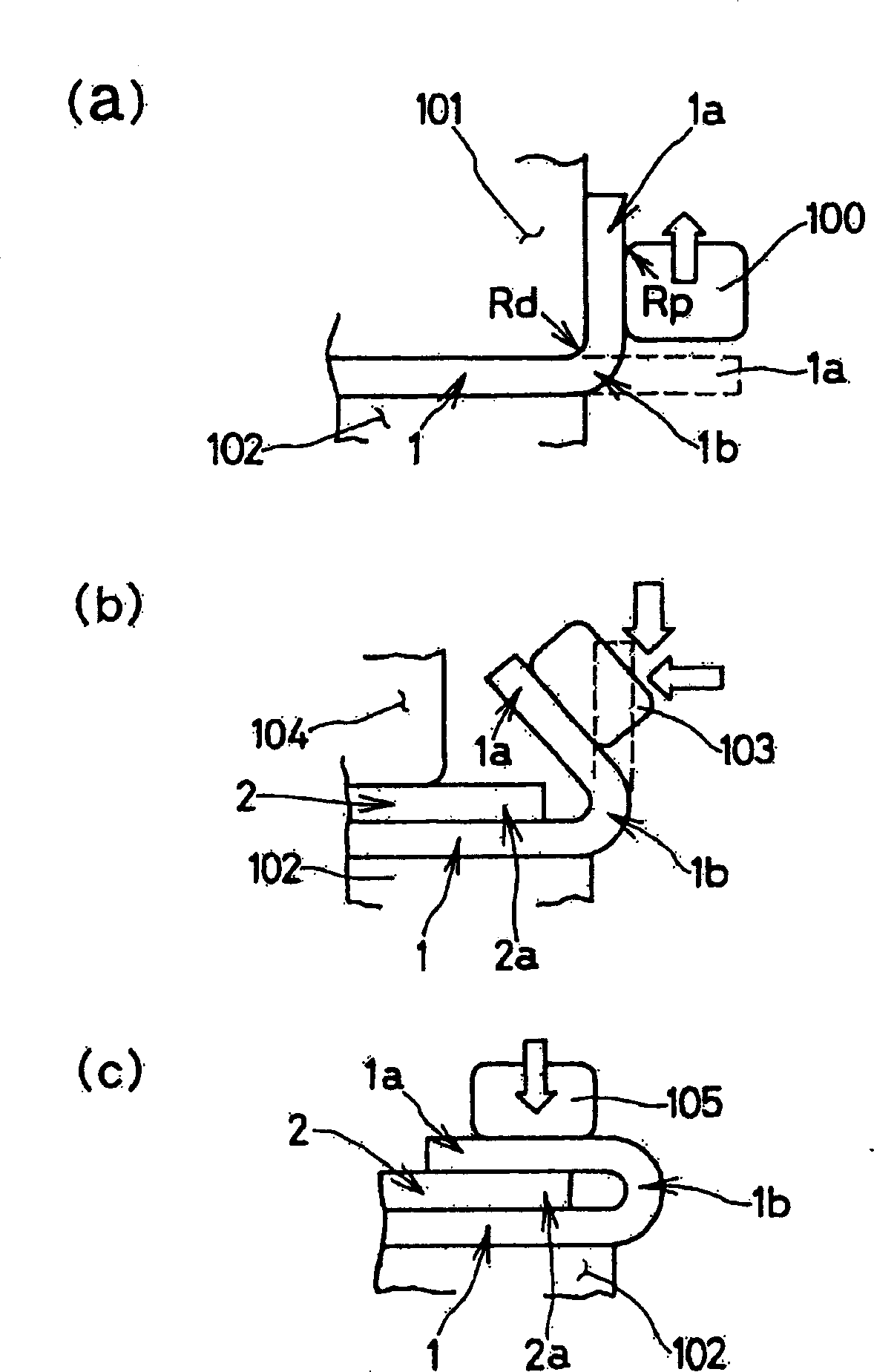

Thermal bend actuator comprising aluminium alloy

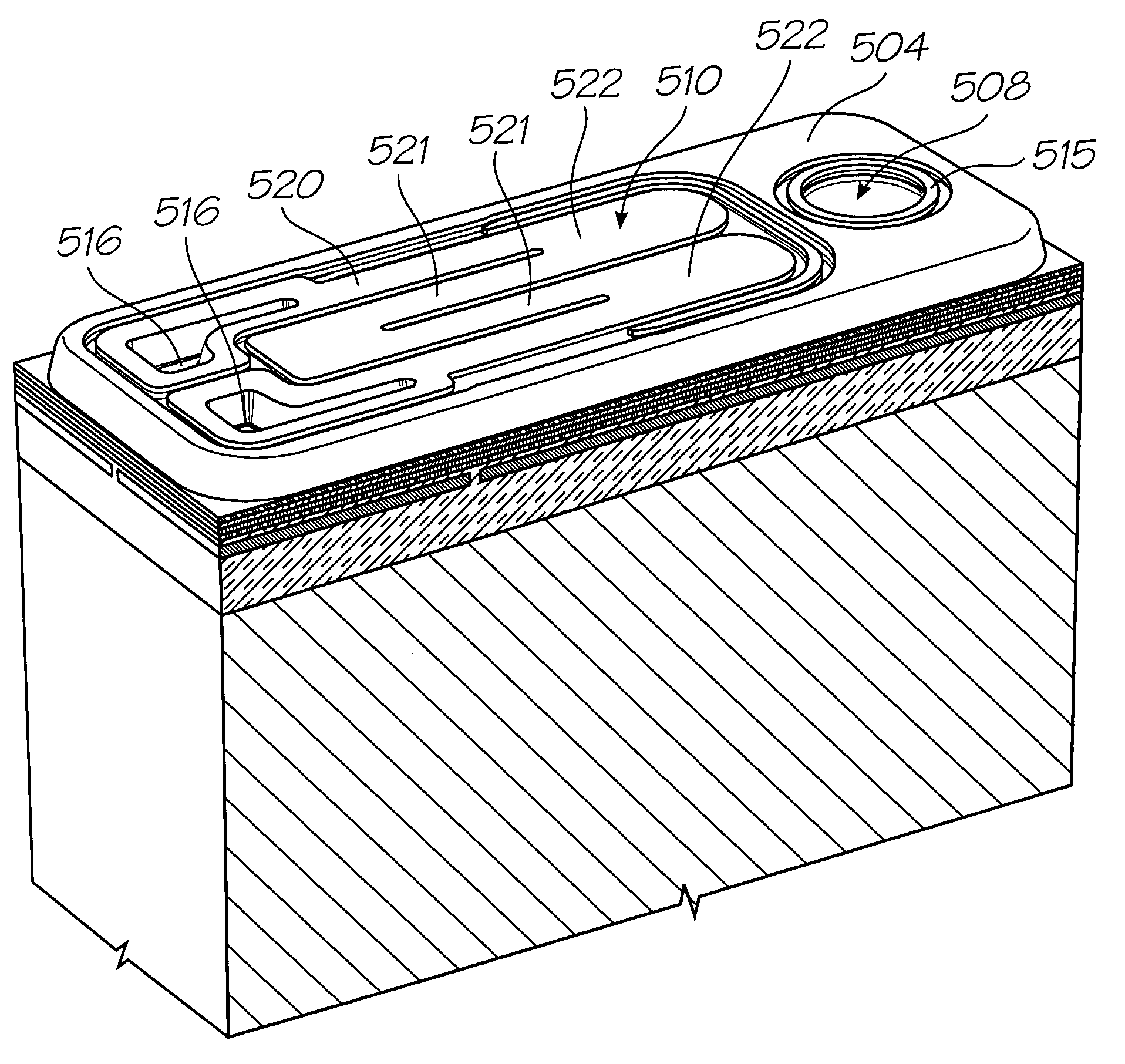

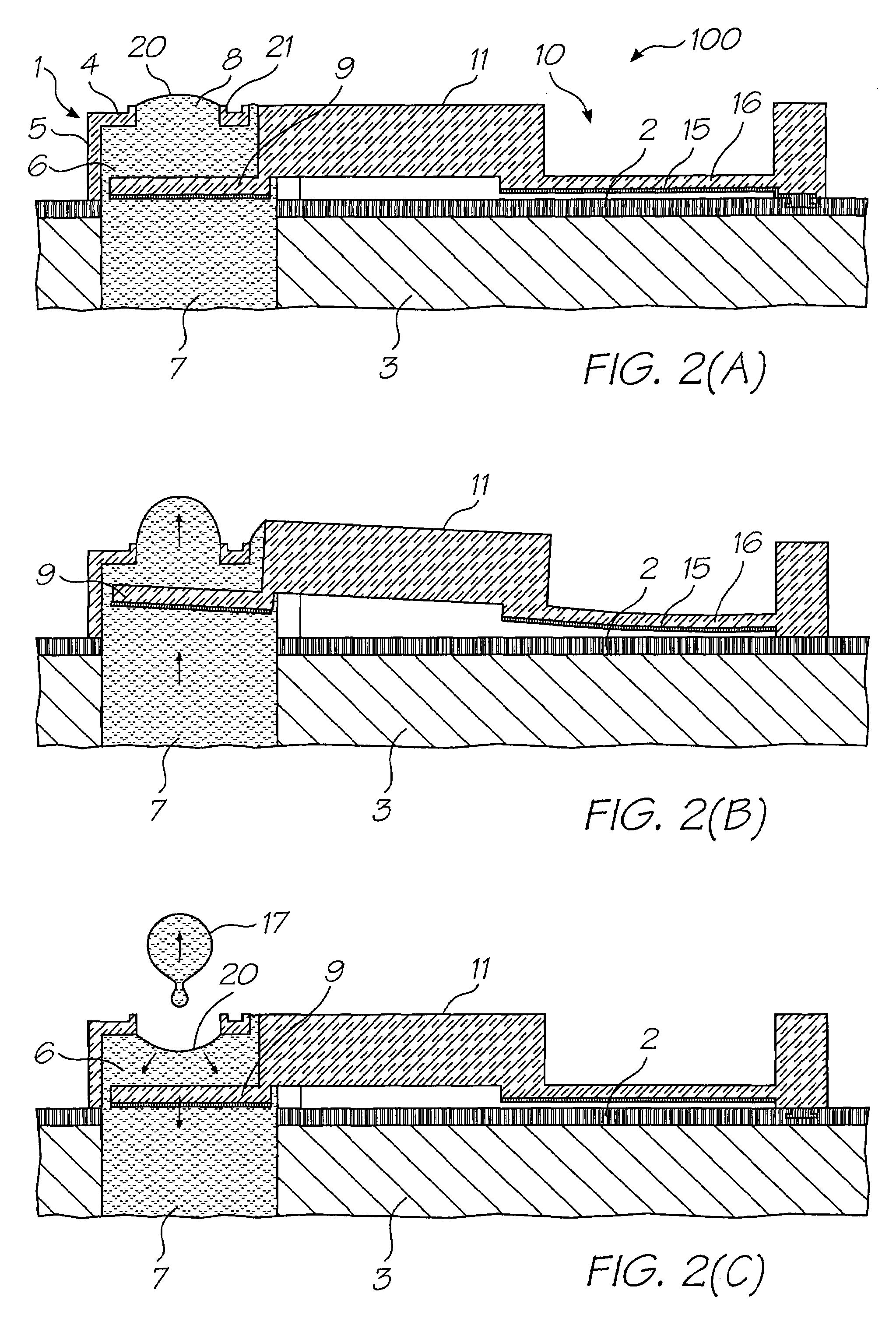

A thermal bend actuator, having a plurality of elongate cantilever beams, is provided. The actuator comprises: a first active beam for connection to drive circuitry, the first beam being defined by a tortuous beam element, the tortuous beam element having a plurality of contiguous beam members; and a second passive beam mechanically cooperating with the first beam. When a current is passed through the first beam, the first beam expands relative to the second beam, resulting in bending of the actuator. The plurality of contiguous beam members comprises a plurality of longer beam members extending along a longitudinal axis of the first beam, and at least one shorter beam member extending across a transverse axis of the first beam and interconnecting longer beam members.

Owner:MEMJET TECH LTD +1

Aluminium alloy for use in a brazed assembly

InactiveUS6413331B1Obtain long-life corrosion performanceHigh strengthWelding/cutting media/materialsSoldering media5005 aluminium alloy5052 aluminium alloy

Owner:CORUS ALUMINUM WALPROD

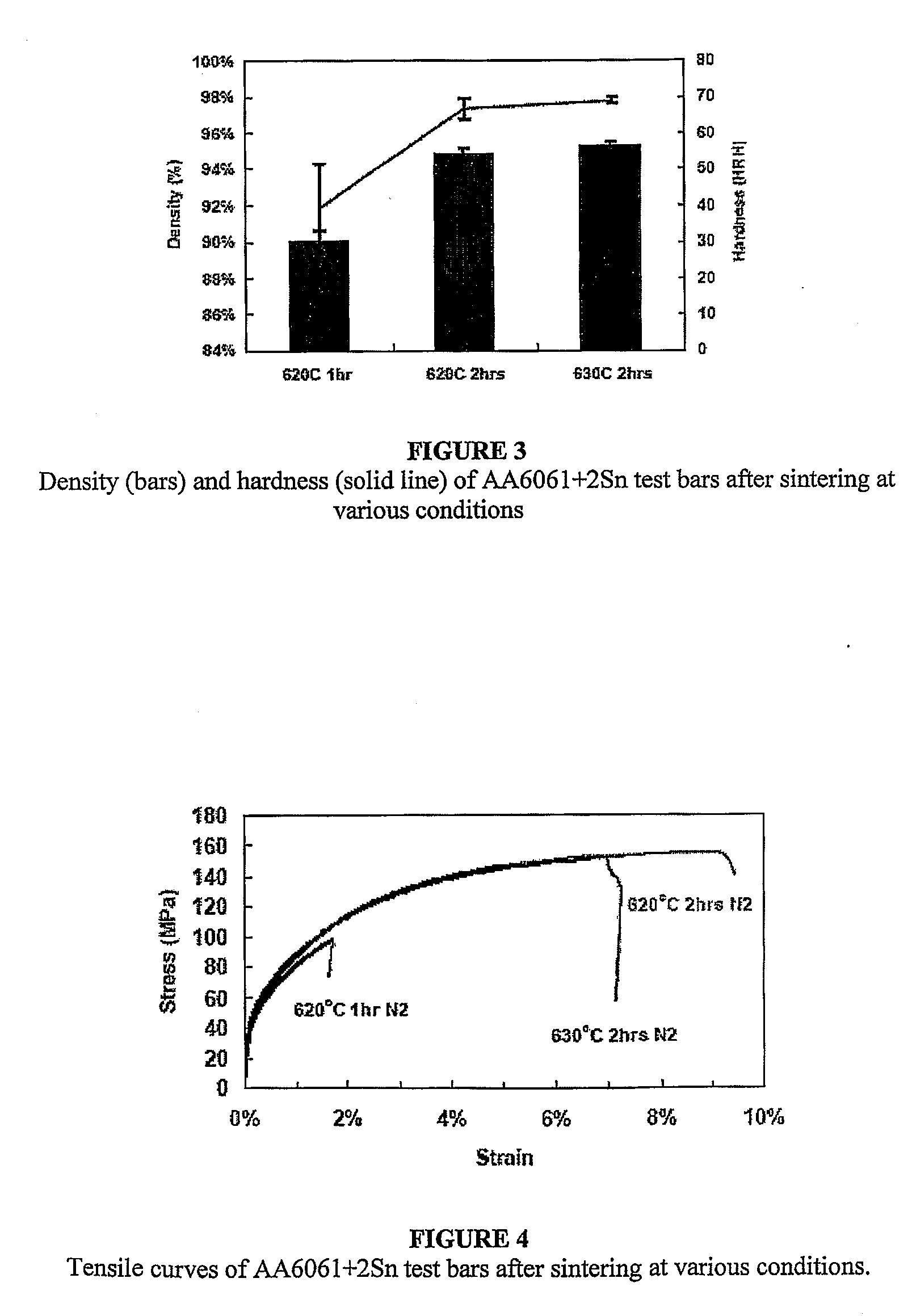

Metal injection moulding method

InactiveUS20100183471A1Improve wetting characteristicImprove sintering behaviourCoatings5005 aluminium alloyNitrogen gas

A method for forming an article by metal injection moudling of aluminium or an aluminium alloy. The method comprises the steps of forming a mixture containing an aluminium powder or an aluminum alloy powder or both and optionally ceramic particles, a binder, and a sintering aid comprising a low melting point metal. The mixture is injection moulded and the binder is removed to form a green body. The green body is sintered. The sintering is conducted in an atmosphere containing nitrogen and in the presence of an oxygen getter.

Owner:QUEENSLAND THE UNIV OF

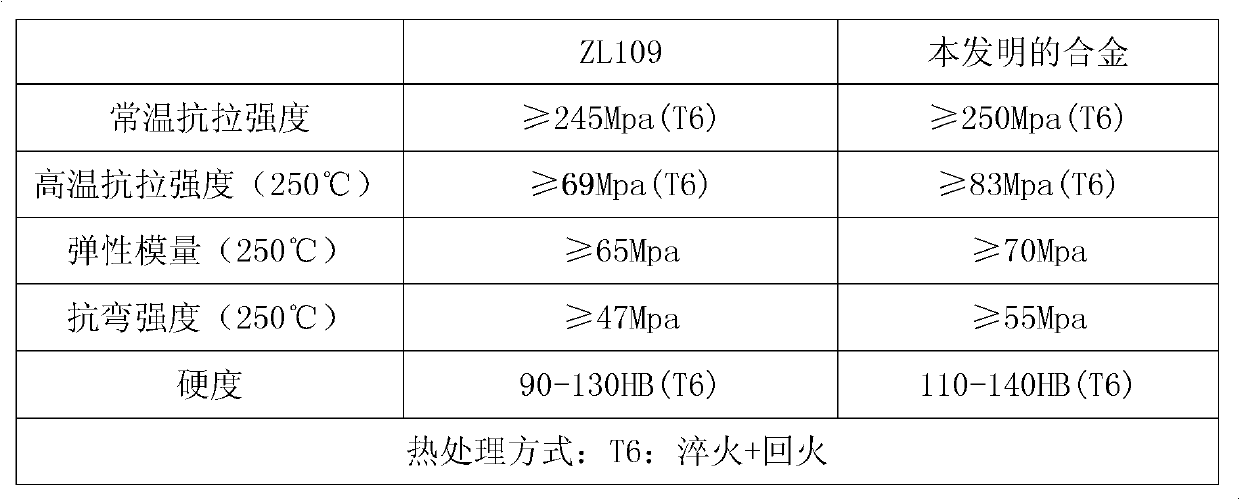

Novel casting aluminium alloy and preparation method thereof

The invention discloses a casting aluminium alloy and a preparation method thereof. The casting aluminium alloy comprises the following components in percentage by weight: 11-13wt% of Si, 2-4wt% of Cu, 0.5-1.2wt% of Mg, 2-3.5wt% of Ni, 0.08-0.18wt% of Ti, 0.1-0.2wt% of V and the balance of aluminium ingot, wherein the mark of the aluminium ingot is Al99.50. Compared with the existing casting aluminium alloy ZL109, the casting aluminium alloy has the advantages that comprehensive mechanical property is greatly improved, and high-temperature thermal fatigue strength is improved by 10%. Each index of the obtained aluminium alloy is far beyond the national criterion of acceptability after the aluminium alloy is tested by the aluminium alloy tensile property experiment of the environment experiment center of the China Academy of Engineering Physics. The casting aluminium alloy is used for manufacturing engine pistons, the working performance of the engine piston can be greatly improved, and the service life of the piston can be greatly prolonged.

Owner:四川渝邻汽车零部件有限公司

Shaping method of aluminium alloy section

This invention provides a method for molding aluminum alloy. The method comprises: applying more than 1% processing tension on 6000 series aluminum alloy, and heating at 50-150 deg.C for aging and hardening reclamation treatment. Since the moldability of aluminum alloy is reclaimed, thus the aluminum alloy can be molded at ambient conditions. By using this method, the moldability of 6000 series aluminum alloy after aging and hardening at room temperature can be reclaimed.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com